GE IBCG51M*Y1A Series, IBCG53M*Y1A Series, IBCG78M, IBCG52M, IBCG54M Instruction Manual

...Page 1

INSTRUCTIONS

GEK-49822E

GROUND

DIRECTIONAL

TYPES

IBCG51M

IBCG51M(.-)Y1A

I

BCG52M

IBCG53M

IBCG53M(—)Y1A

IBCG54M

IBCG77M

I

BCG78M

OVERCURRENT

RELAYS

GE

Protection

Great

205

Malvern,

and

Valley

PA

19355-1337

Control

Parkway

Page 2

GEK-4

9822

CONTENTS

DESCRIPTION

APPLICATION

RATINGS

OVERCURRENT

TIME

DIRECTIONAL

UNIT

INSTANTANEOUS

TARGET

AND

SEAL-IN

CONTACTS

CHARACTERISTICS

PICKUP

RESET

OPERATING

(TIME

OVERCURRENT

TIME

BURDENS

CONSTRUCTION

DIRECTIONAL

UNIT

CONTACTS

TIME

OVERCURRENT

TARGET

SEAL-IN

INSTANTANEOUS

RECEIVING,

HANDLING

STORAGE

ACCEPTANCE

VISUAL

MECHANICAL

TOP

BOTTOM

TARGET

TESTS

INSPECTION

INSPECTION

UNIT

(TOC)

UNIT

AND

SEAL-IN

INSTANTANEOUS

DRAWOUT

POWER

TARGET

PICKUP

TIME

CURRENT

TIME

PICKUP

TIME

RELAYS,

REQUIREMENTS,

AND

SEAL-IN

AND

DROPOUT

OVERCURRENT

SETTING

SETTING

TEST

TEST

UNIT

UNIT

UNIT

UNIT

UNIT

UNIT

AND

(DIR)

UNIT

GENERAL

UNIT

UNIT

UNIT)...

UNIT!

GENERAL

TEST

PAGE

3

4

5

6

7

7

8

8

8

8

9

9

9

11

11

11

11

12

12

12

13

13

13

13

13

13

14

14

14

14

15

15

16

16

16

DIRECTIONAL

CURRENT

POTENTIAL

INSTANTANEOUS

INSTALLATION

LOCATION

MOUNTING

CONNECTIONS

INSPECTION

CAUTION

OPERATION

TARGET

TIME

AND

OVERCURRENT

DIRECTIONAL

CURRENT

POTENTIAL

INSTANTANEOUS

PERIODIC

CHECKS

MAINTENANCE

TARGET

TIME

AND

OVERCURRENT

DIRECTIONAL

INSTANTANEOUS

SERVICING

TARGET

TIME

AND

OVERCURRENT

DISK

AND

CONTACT

CHARACTERISTICS

AND

ADJUSTMENTS

DIRECTIONAL

BEARINGS

CUP

AND

CONTACT

BIAS

TORQUE

CLUTCH

ADJUSTMENT

INSTANTANEOUS

CONTACT

RENEWAL

PARTS

UNIT

POLARIZATION

POLARIZATION

UNIT

SEAL-IN

UNIT

UNIT

UNIT

POLARIZATION

POLARIZATION

UNIT

AND

ROUTINE

SEAL-IN

UNIT

UNIT

UNIT

UNIT

SEAL-IN

UNIT

UNIT

BEARINGS

ADJUSTMENT

CHECK

UNIT

STATOR

ADJUSTMENTS

ADJUSTMENT

UNIT

CLEANING

PAGE

17

17

17

17

17

17

18

18

18

18

18

18

18

19

19

19

ig

19

19

19

19

20

20

20

20

20

20

20

21

21

21

21

22

22

23

23

23

2

Page 3

GEK—49822

The

Type

the

protection

inverse,

All

the

an

instantaneous

can

be

controls

A

target

this

that

the

seal-in

unit

unit

it

to

IBCG

very

IBCG

potential

the

seal-in

is

will

unit

provide

IBCG51M

IBC

G

IBCG52M

relays

of

inverse

relays

directional

operation

unit

connected

pick

are

protection

GROUND

Fl

5

1

(

-

are

feeders

or

contain

polarized,

of

is

in

up

whenever

connected

DIRECTIONAL

Y

1

A

)

ground

and

extremely

a

unit

or

the

time

provided

series

for

them

I

BC

DESCRIPTION

directional

transmission

inverse

time

overcurrent

of

the

current

overcurrent

in

with

time

the

in

parallel

and

OVERCURRENT

TYPES

IBCG53M

3M

G

5

(

-)

IBCG54M

overcurrent

lines.

time

induction

polarized,

each

the

of

contacts

overcurrent

with

their

associated

YIA

They

characteristics.

unit

of

cup

or

unit.

the

relays.

of

unit

the

contacts

RELAYS

relays

the

type.

both,

the

operates.

control

are

induction

The

time

of

IBCG77M

678

IBC

used

available

The

directional

and

it

operating

overcurrent

The

the

time

springs.

M

primarily

with

disk

directionally

contacts

overcurrent

type

coil

unit

for

either

and

unit

for

so

of

Those

relays

Hi—Seismic

The

IBCG52M,

IBCG51M,

All

the

panel

for

are

Table

drilling

the

shown

I

instantaneous

53M

and

IBCG

relays

by

Figures

lists

These

every

possible

further

the

purchaser’s

To

but

no

such

having

54M

the

relays

dimensions

are

the

various

instructions

conttngency

infornation

the

extent

assurance

and

are

given

purposes,

the

77M

10,

be

required

the

desired

is

designation

overcurrent

78M

relay

mounted

for

in

Figure

11

and

models

do

purport

not

eet

to

be

or

the

matter

products

the

with

given

relay

models

in

which

12.

and

to

In

should

should

respect

Y1A

unit

models

respectively.

standard

are

5,

ranges

cover

connection

particular

referred

be

described

local

to

following

of

given

6,

7,

details

all

with

problem

herein

3

that

codes

the

are

Ml

in

8

and

or

installation,

arise

the

to

meet

and

hinged

the

size

Figure

are

variations

General

applicable

ordinances

the

model

armature

two-contact

drawout

9.

Typical

available.

operation

which

are

£I.ctrC

in

ANSI,

because

26.

.quipaient

or

covered

not

Conça,29.

IEZ’E

number

construction.

cases,

Internal

external

nor

,aint.nanc..

sufficxantly

and

vary

they

versions

the

to

provide

RXNA

greatly.

also

outline

connections

5hould

standards,

contain

of

connections

for

for

a

the

and

Page 4

GEK—49822

I

The

ground

•

Relay

Model

IBCG51M(-)A

IBCG52M(-)A

II3CG51M(-)Y1A

IBCG53M(-)A

IBCG54M(-)A

IBCG53M(—)Y1A

IBCG77M(-)A

IBCG78M(—)A

Type

fault

IBCG

relays

detectors

EXTENDED

Time

Characteristic

Inverse

Inverse

Inverse

Inverse

Very

Inverse

Very

Inverse

Very

Extremely

Extremely

ground

are

a

transmission

in

Inverse

Inverse

APPLICATION

directional

TABLE

RANGE

Inst

Unit

No

No

Yes

No

No

Yes

No

No

line

I

RELAYS

IBCG

Inst.

-

-

6-150

-

-

6-150

-

—

overcurrent

protective

Pickup

0.5-4,

0.5—4,

0.5—4,

0.5-4,

0.5-4,

0.5-4,

0.5-4,

0.5—4,

Range

Time

relays

relaying

2-16

2-16

2-16

1.5-12

1.5-12

1.5-12

1.5-12

1.5—12

that

scheme.

may

mt

Conn.

Fig.

Fig.

Fig.

Fig.

Fig.

Fig.

Fig.

Fig.

be

5

7

6

5

7

6

8

9

used

as

relays

The

instantaneous

a

unit.

source

from

the

conditions

voltage

of

current

The

shown

current

polarization

using

alone.

differences

in

flowing

capacity

the

upon

to

value,

should

be

is

relays

upon

all

set

this

there

circuit-current

may

inverse

The

tap

exceedingly

be

time

operating

setting

proportional

contain

It

may

dual

Table

the

at

location

the

selective

the

wide

a

relays.

is

to

directional

of

potential,

is

advantageous

cause

polarization

between

I.

through

time

used

be

of

system

operating

range

with

long

time

of

determined

the

time

a

current

might

the

Inverse

given

a

the

of

in

cases

the

fault

generating

with

maximum

in

fault

with very

such

For

the

current

overcurrent

overcurrent

current,

or

polarization

favored

be

compared

as

various

time

relay

fault.

where

in

setup.

time

generating

position,

cases,

time

overcurrent

by

the

magnitude

to

use

relays

is

Very

the

relation

fault

becomes

the

inverse

the

time-dial

unit.

or

dual

others.

at

to

models

should

influenced

fault

to

The

current

greater

capacity,

operating

time

inverse

as

illustrated

unit

that

The

sources

both

polarization

be

to

polarization

covered

be

inverse

current

the

relay,

reason

flowing.

as

together

relays

time

unit

for

setting.

is

directional

may

favored

Figure

from

by

used

largely

time

magnitude

this

for

the

time

and

relay

any

The

by

torque

controlled

unit

used

be

because

some

at

illustrates

13

source

a

this instruction

systems

on

by

the

and

extremely

is

only

and

For

current

with

with

even

is

given

slightly

is

that

fault

variation

minimum

longer

more

value

is

operating

the

time

curves

be

may

dual

to

changing

times

of

where

system

inverse

dependent

relays

currents

decreased.

fault

with

applicable.

current

of

time

is

by

polarized

polarize

system

whereas

effect

the

voltage

book

the

fault

generating

mainly

not

or

must

below

short-

in

current

extremely

inversely

in

Figures

an

or

are

time

at

be

If

and

4

Page 5

15,

of

same

in

16

the

both

for

and

tap

cases

80

17.

setting.

amperes

the

Note

current

on

that

That

the

the

8

is

current

is,

ampere

10

for

times

G[K-49822

values

a

given

tap

as

setting.

on

time-dial

for

50

these

amperes

curves

setting,

on

are

the

the

given

5

time

ampere

as

will

multiples

be

tap,

the

since

If

selective

possible

relay

the

opening

The

be

set

In

determining

directly

that

several

ViA

high

short-circuit

each

relays

behind

non-directional.

maximum

in

The

external

Figure

IBCG

models.

the

800

series

(see

circuits

since

coil

entire

Table

of

all

ratings

operating

action

differs

circuit

breaker

to

19,

should

relays

The

TOC

I),

the

operating

of

contain

trip

the

the

The

fault

described

(time

IAC

have

TOC,

all

circuit.

of

two

current

sufficiently

breakers.

after

Hi-Seismic

a

directly

setting

relay

unit

current.

be

also

overcurrent)

relays.

extended

JOC

and

current

units

the

for

as

should

taken

in

the

circuits

should

or

more

of

to

Allowance

relay

for

faults

this

well

be

The

into

this

IOC

The

(25—to-i)

directional

relays

line

the

insure

contacts

instantaneous

unit,

at

as

set

effects

account

RATINGS

instruction

units

(instantaneous

are

considered

be

is

required,

and

then

choose

the

must

proper

be

sequence

made

close.

overcurrent

some

with

the

it

have

distance

will

remote

a

of

in

be

terminal,

suitable

transient

determining

are

available

extended

necessary

overcurrent)

range.

units

Ratings

are

shown

normally connected

in

determining

for

down

amount

overreach,

(8-to—i)

of

determine

time

a

in

the

unit.

the

transmission

to

because

of

setting.

the

in

operating

the

individually.

series,

in

the

value

the

time

consider

margin

as

50

range

units,

the

operation

involved

This

the

illustrated

and

similar

the

rating

maximum

for

unit

line.

faults

unit

above

hertz

60

when

current

However,

operating

of

each

of

in

may

is

the

to

used

the

Relay

Model

IBCG51M

IBCG51M(—

IBCG52M

IBCG53M

IBCG53M(IBCG54M

IBCG77M

IBCG78M

)V1A

)Y1A

ONE

SECOND

Range

(Amps)

0.5-4.0

2.0-16

0.5—4.0

1.5-12

0.5-4.0

1.5-12

5

TABLE

RATING

H

OF

TOC

UNITS

One

Rating

Second

(Amps)

70

260

140

260

125

260

Page 6

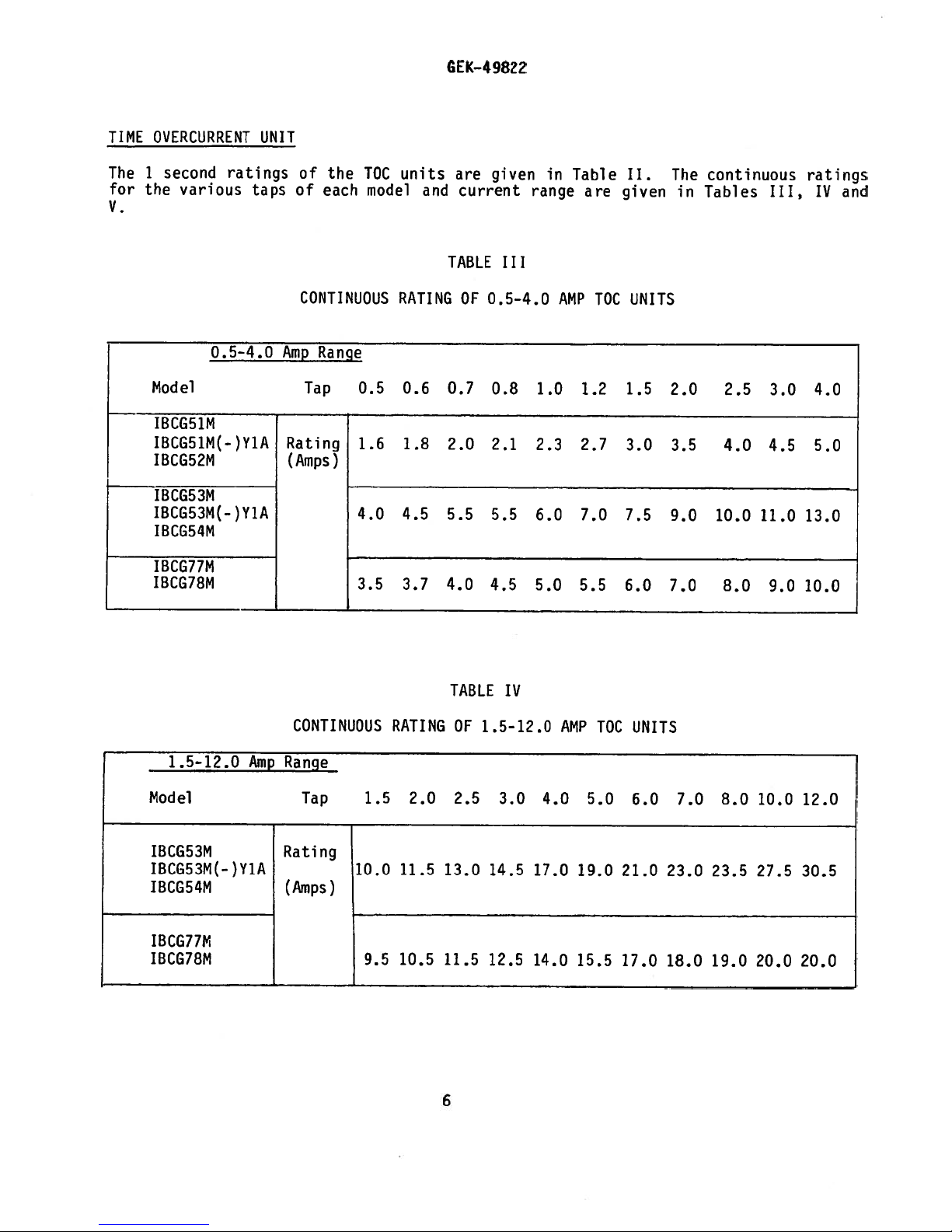

TIME

OVERCURRENT

GEK—49822

UNIT

1

The

for

V.

second

the

Model

IBCG51M

IBCG51M(-)Y1A

IBCG5?M

IBCG53M

IBCG53M(—)Y1A

IBCG54M

IBCG77M

IBCG78M

various

0.5-4.0

ratings

taps

of

the

of

each

CONTINUOUS

Range

Amp

Tap

Rating

(Amps)

TOC

model

0.5

1.6

4.0

3.5

units

and

RATING

0.6

1.8

4.5

3.7

4.0

are

current

TABLE

OF

0.7

2.0

5.5

given

III

0.5-4.0

0.8

2.1

5.5

4.5

in

range

1.0

2.3

6.0

5.0

Table

AMP

2.7

7.0

5.5

are

1.2

TOC

II.

given

UNITS

1.5

3.0

7.5

6.0

The

in

2.0

3.5

9.0

7.0

continuous

Tables

2.5

4.0

10.0

8.0

III,

3.0

4.5

11.0

9.0

ratings

IV

4.0

5.0

13.0

10.0

and

1.5-12.0

Model

IBCG53M

IBCG53M(-)Y1A

IBCG54M

IBCG77M

IBCG78M

Amp

CONTINUOUS

Range

Tap

Rating

(Amps)

1.5

10.0

r

9.5

RATING

2.0

11.5

10.5

TABLE

OF

2.5

13.0

11.5

6

IV

1.5-12.0

3.0

14.5

12.5

4.0

17.0

14.0

AMP

19.0

15.5

5.0

TOC

UNITS

6.0

21.0

17.0

7.0

23.0

18.0

8.0

23.5

19.0

10.0

27.5

20.0

12.0

30.5

20.0

Page 7

GEK-49822

2-16.0

Amp

Model

IBCG51M

IBCG51M(-)Y1A

IBCG52M

DIRECTIONAL

directional

The

of

5

amperes

The

potential

for

60

UNIT

seconds.

INSTANTANEOUS

Range

unit

anda1

polarizing

UNIT

CONTINUOUS

Tap

2.0

Rating

8.0

(Amps)

9.5

current

second

rating

coils

RATING

2.5

9.0

10.5

polarizing

of

will

TABLE

OF

3.0

10.0

11.5

150

withstand

V

2-16.0

4.0

12.0

12.5

and

amperes.

AMP

5.0

14.0

14.0

operating

120

TOC

6.0

15.0

15.5

volts

UNITS

7.0

16.0

17.0

coils

continuously

8.0

17.5

18.0

have

10.0 12.0

20.0

20.0

19.0 20.0

continuous

a

and

360

16.0

20.0

20.0

rating

volts

instantaneous

The

operation

is

accomplished

the

applicable

range,

mounted

on

either

connect

on

terminal

Instantaneous

Unit

6-150

**

The

28-150.

the

be

sure

rat

i

unit

one

by

the

internal

lead

T

6.

CONTINUOUS

(Amps)

range

There

maximum

to

n

g.

coil

of

positioning

connections

terminal

to

For

approximate,

is

will

setting

L

select

is

two

range

the

the

of

ranges

6

L,

AND

Range

always

and

higher

hinged

(H

of

leads

diagrams

and

reverse

TABLE

SECOND

ONE

L

H

which

be

the

or

L).

T

lead

VI

Range

(Amps)

-

6

-

30

means

least

at

minimum

range,

armature

Selection

and

E

referred

the

to

E

leads

RATINGS

30

150

that

1

H

since

construction

at

terminal

to

auxiliary

and

T

OF

Continuous

Rating

(Amps)

6-30,

ampere

setting.

it

has

in

E.

lOG

10.2

19.6

of

the

Table

UNIT

30-150

overlap

Whenever

the

and

high

See

6.

I.

terminal

One

Second

Rating

(Amps)

may

between

higher

is

or

Table

For

that

260

be

possible,

continuous

tapped

low

the

6—29,

range

VI

H

is

for

and

7

Page 8

GEK-49822

TARGET

The

in

Table

coil.

The

0.2

0.2

up

trip

of

7

tripped.

AND

rating

VII.

DC

RESISTANCE

MIN

OPERATING

CARRY

CARRY

CARRY

60

Hz

ampere

to

coils

ohms

will

SEAL-IN

and

UNIT

impedance

The

+10%

(AMPERES)

CONT.

30

10

(AMPERES)

AMPS

AMPS

FOR

FOR

IMPEDANCE

tap

2.0

is

amperes,

requiring

reduce

tap

(OHMS)

(SEC.)

(sEC.)

(OHMS)

for

at

more

the

of

setting

use

the

than

current

the

seal-in

used

SEAL-IN

+0-25%

with

minimum

2

amperes,

trip

to

unit

will

TABLE

UNIT

coils

control

there

so

low

for

depend

VII

RATINGS

which

voltage.

is

a

value

the

on

0.2

8.3

0.2

0.37

0.05

0.45

50.0

operate

a

possibility

0.2

the

that

and

current

on

If

the

2

ampere

TAP

—

currents

this

that

breaker

drawn

tap

the

taps

by

2.0

0.24

2.0

2.3

2.2

20

0.65

ranging

is

used

resistance

will

are

the

not

given

trip

from

with

be

The

2.0

minimum

maximum

tions

ary

it

relay

should

relay,

may

coil

CONTACTS

The

current-closing

exceeding

the

seal—in

PICKUP

When

the

it

potential

maximum

will

connected

potential

ampere

control

control

be

which

be

necessary

to

250

unit.

torque

pick

up

in

series.

polarization

tap

voltage,

voltage.

arranged

in

allow

volts.

polarized,

angle

at

should

be

provided

If

so

that

turn

energizes

to

connect

enough

rating

Their

current

of

current-carrying

the

of

60°

approximately

The

performance

is

typified

used

with

the

the

tripping

the

induction

the

a

loading

to

operate

the

induction

CHARACTERISTI

directional

lag

(current

0.5

ampere

in

Figure

8

current

trip

of

trip

unit

the

coils

current

unit

coil

resistor

the

unit

rating

Cs

will

lags

with

unit

13.

that

does

exceeds

contacts

or

coils.

in

target

is

is

pick

voltage).

the

with

take

not

exceed

parallel

seal-in

30

amperes

limited

up

operating

simultaneous

30

will

On

by

at

When

and

2

amperes

30

amperes,

operate

such

with

unit.

for

the

3.6

volts-amperes

current

polarizing

amperes

the

an

application,

the

voltages

tap

polarized,

current

or

more

connec

an

auxili

auxiliary

rating

at

coils

at

the

not

of

at

and

Page 9

The

of

current

the

tap

required

screw

setting.

to

close

the

GEK—49822

overcurrent

time

unit

contacts

will

be

within

5%

RESET

(TIME

Inverse

inverse

When

to

relays,

the

time

the

number

and

OPERATING

The

time

The

time

respectively

operating

same

same

time.

The

time-current

Figure

The

60

the

18

capacitive

cycles

current

OVERCURRENT

time

overcurrent

units

relay

is

10

60

seconds

TIME

curve

curves

for

of

for

conditions,

and

its

burden

and

120

circuit

UNIT)

at

80%,

de-energized,

time

dial

for

the

directional

time

the

inverse,

characteristic

transient

of

the

volts

is

burdens

units

and

position

very

overcurrent

very

the

overreach

potential

10

of

reset

extremely

the

inverse

unit

inverse

relay

of

volt

the

amperes

directional

at

90%

inverse

time

required

is

approximately

time

is

shown

unit

and

will operate

the

Hi-Seismic

characteristic

BURDENS

polarizing

of

time

and

extremely

in

are

extremely

at

0.86

unit.

the

minimum

units

for

the

Figure

shown

inverse

repeatedly

instantaneous

is

shown

circuit

power

6

in

of

at

disk

seconds

inverse

14.

Figures

within

by

the

factor.

pickup

85%.

to

time

Figure

directional

completely

for

time

15,

relays.

1

unit

Table

current,

inverse

relays.

16

or

2%

is

shown

19.

VIII

and

For

of

unit

very

reset

time

17,

the

the

by

at

gives

Table

IX

Ordinarily

transformers

transformers.

fault

of

and

the

instantaneous

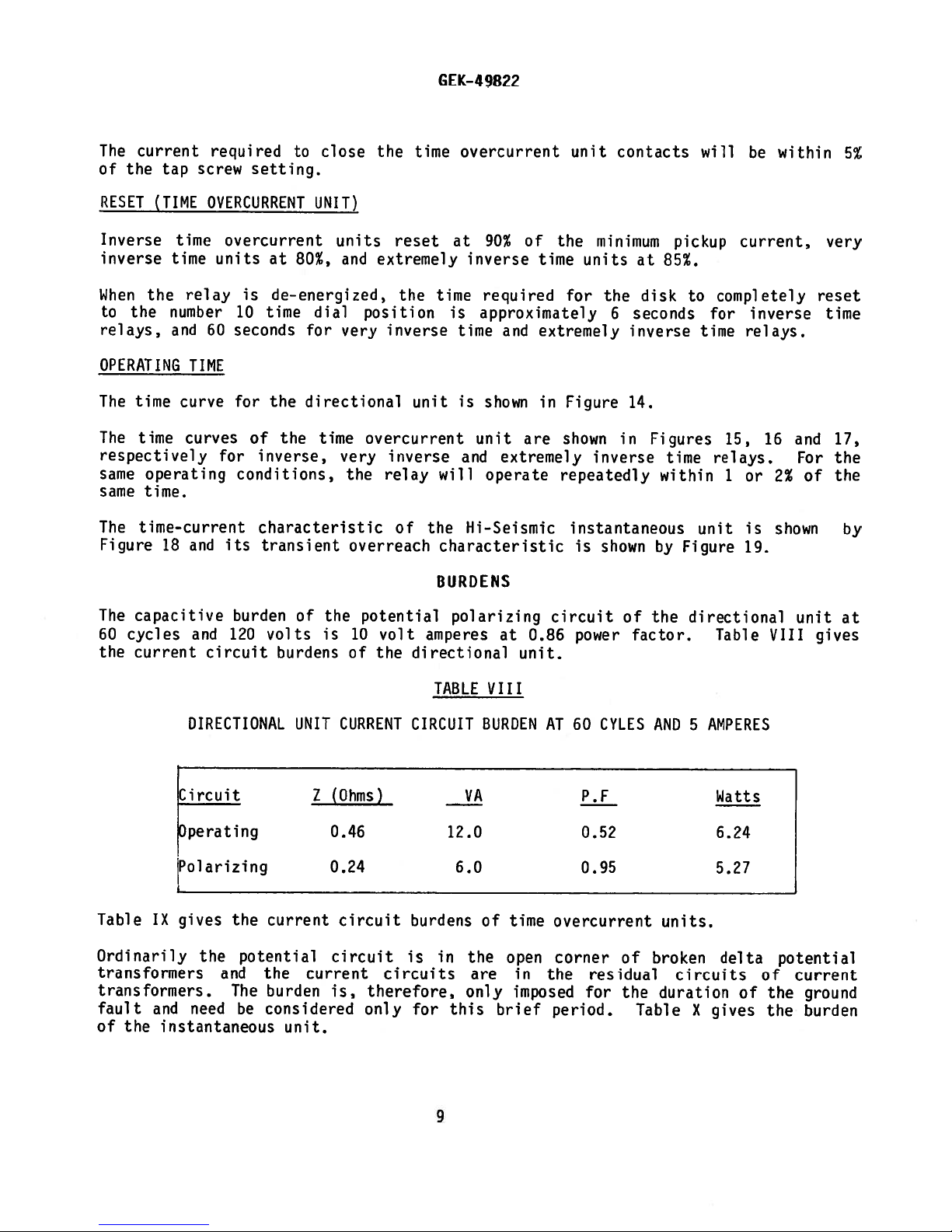

DIRECTIONAL

Circuit

perating

Polarizing

gives

the

the

potential

and

the

The

need

be

considered

UNIT

current

burden

unit.

(Ohms)

Z

0.46

0.24

circuit

circuit

current

is,

CURRENT

circuits

therefore,

only

TABLE

CIRCUIT

12.0

burdens

is

in

for

this

9

VIII

BURDENAT60

VA

6.0

of

time

the

open

are

in

only

imposed

brief

CYLES

P.F

0.52

0.95

overcurrent

corner

the

residual

for

period.

of

the

AND

broken

duration

Table

units.

circuits

AMPERES

5

Watts

6.24

5.27

delta potential

of

X

gives

of

the

the

current

ground

burden

Page 10

GEK-49822

Time

Characteristic

Inverse

Inverse

Very

Inverse

Inverse

Very

Extr.

Extr.

Inverse

Inverse

**The

The

inversely

for

tap

approximately

+

Some

operate

can

a

CT

purpose.

Calculated

4

impedance

impedance

the

Type

is

22

companies

at

be

made.

secondary

CURRENT

CIRCUIT

Tap

Range

Eff.Res.

(Amps) (Ohms)

0.5/4

2/16

0.5/4

1.5/12

0.5/4

1.5/12

5.60

0.37

1.40

0.23 0.53 0.58

0.80

0.005

values

for

other

approximately

IBCG51M

ohms.

relay,

The

(0.5/1)2

list

minimum

It

pickup.

should

circuit,

from

burden

BURDENS

Burdens

given

taps,

as

impedance

x

22

=

relay

not

since

minimum

at

React.

(Ohms)

21.0

1.44

3.90

1.38

0.147

are

the

0.5/4

5.5

burdens

This

be

TABLE

at

those

at

square

amperes,

ohms.

column

used

the

IX

60

AT

Minimum

**Imped

(Ohms)

22.0

1.49

4.15

1.60

0.17

for

pickup

of

of

the

only

is

in

calculating

burden

pickup.

CYCLESOFTHE

Pickup

+Volt

5.5

5.8

1.0

1.3

0.4

0.4

minimum

P.F.

0.25 10.80

0.25

0.33

0.40

0.50

0.50

Amps

the

current

the

current

the

impedance

ampere

1

as

included

tap,

the

so

volt—ampere

5

amperes

at

UNIT

TOC

Impedance

Ohms

Times

3

Mm

P.U.

0.65

4.20 2.90

0.58 0.36

1.60 1.60

0.17 0.17

tap

of

(tap

rating),

rating.

of

the

at

volt-ampere

direct

a

is

10

Mm

5.00

0.32

each

0.5

ampere,

1

comparison

burdens

used

at

Times

P.U.

relay.

varies

Example:

ampere

input

for

*VA

At

Amperes

555.0

36.3

104.0

14.5

40.0

4.25

is

to

in

this

Fivc

Inst.

Unit

Amps

6-150

Hz

Range

60

Range

Amps

L

H

6-30

30-150

BURDENOFTHE

Mm.

Pickup

Amps

6

30

10

TABLE

X

INSTANTANEOUS

Burden

Pickup

R

0.110

0.022

0.078

0.005

UNIT

Mm

at

(Ohms)

Z

0.135

0.023

3

0.095

0.022

Burden

Times

Pickup

10

0.081

0.022 0.222

Ohms

20

0.079

(Z)

Page 11

GEK-49822

IBCG

type,

of

relays

The

and

directional

its

The

disk

type.

means

overcurrent

The

IBCG

relays

by

Table

The

IBCG

I,

relays

DIRECTIONAL

directional

The

stator

stationary

the

having

central

annular

current-operating,

The

principle

relay

like

higher

resulting

with

a

split-phase

torque

in

CONTACTS

an

closing

unit.

have

UNIT

eight

air

by

wattmetric

a

faster

a

consist

of

instantaneous

unit

contacts,

have

a

target

hinged-armature

a

mounted

are

unit

is

poles

core.

gap

between

current—polarizing

which

torque

element,

induction

and

lower

and

two

is

in

of

projecting

The

rotor

more

CONSTRU

units,

a

power

either

potential

directionally

seal—in

type

the

single-ended

the

induction—cylinder

cuplike

the

poles

and

is

developed

although,

motor.

inertia

sensitive

CTI

ON

overcurrent

time

directional

or

controls

and

unit

models

instantaneous

Mi

inward

aluminum

and

and

induction

the

potential—polarizing

is

the

in

arrangement

The

induction-cylinder

than

unit.

unit

current

drawout

arranged

core.

same

the

unit

(bottom)

polarized

the

with

the

overcurrent

case.

construction

rotor

The

as

that

of

induction-disk

(top)

of

of

the

or

operation

suffix,

ViA

unit.

with

symmetrically

is

free

poles

are

coils.

of

an

parts,

the

construction

the

induction

induction

both

of

the

as

laminated

a

around

to

operate

fitted

induction

unit

provides

construction,

and,

is

cup

by

time

shown

a

in

with

disk

more

The

directional

Figure

effects

low

another,

The

conical

brush

contact

20.

of

gradient

hence,

contact

contact

(E)

brush

Similarly,

the

stationary

contact

contact

dial,

brush

contact.

together

TIME

The

by

OVERCURRENT

inverse

current-operating

coil

coils

flow

coils

operating

is

which

is

act

connected

in

to

disk.

They

vibration.

material

dial

which

on

bears

the

end

functions

retainer

The

stationary

means

time

are

such

produce

unit

of

are

they

resist

(A)

supports

tip

is

against

of

contact

of

a

UNIT

and

coil

to

connected

a

direction

contacts

the

Both

which,

(C).

mounted

the

brush

to

after

mounting

very

wound

taps

a

split-phase

that

low

the

contact

the

The

the

stationary

retainer

stop

the

the

contact

screw

inverse

on

on

the

in

series

as

control

gradient

stationary

when

separation.

stationary

moving

button

a

inner

motion

moving

support

U-magnet

a

tap

to

close

subjected

contact

face

contact

(H).

CL)

time

block.

with

field

the

type,

and

contact

contact

of

of

and

(K)

and

two

overcurrent

iron

a

directional

the

which,

time

specially

moving

to

arm

tip

the

moving

brush

The

the

contact

stationary

and

locknuts

structure.

The

directional

in

overcurrent

constructed

contact

vibration,

brush

supports

(D)

(F).

contact

bears

stop

the

screw

contact

units consist

U-magnet

turn,

(B)

against

arm

contact

(M).

unit

unit

develops

brushes

tend

on

The

(J),

striking

by

dial

The

contains

contact.

contacts,

unit

to

which

the

end

brush

the

mounted

members

tapped

are

minimize

are

to

follow

is

moving

of

the

retainer

inner

are

of

wound

When

the

torque

shown

made

mounted

contact

moving

face

on

the

moving

have

assembled

tapped

a

operating

shading

power

shading

on

in

the

of

one

a

(G).

of

the

made

the

11

Page 12

The

extremely

that

used

structure

One

of

other

is

contacts,

magnetic

unit

contact,

The

disk

touches

spring

to

permanent

variable

compensated

driving

force

in

has

these

a

a

circuit.

shaft

the

give

magnet

retarding

inverse

watthour

two

is

floating

resistor,

the

carries

stationary

the

by

the

as

the

concentric

a

tapped

winding

When

unit

proper

acting

force

spiral

spring

time

overcurrent

meters

current

which

a

capacitor

power

develops

the

moving

contact

contact-closing

on

the

resulting

shape

winds

except

windings

winding

is

flow

is

torque

contact

or

contacts.

disk

of

the

up.

GEK-49822

unit

as

on

connected

and

in

such

on

the

to

produce

from

induction

follows:

the

connected

the

operating

which

current,

the

is

of

middle

in

two

a

direction

completes

The

the

gradient

disk,

the

the

to

series

coils

shaft

and

desired

wattmetric

upper

leg

taps

with

on

as

disk.

is

its

of

which

of

on

the

to

the

restrained

motion

time

the

results

type

portion

the

magnetic

the

the

directional

lower

close

trip

circuit

is

characteristic.

spiral

in

of

tap

legs

a

directional

by

retarded

an

similar

the

circuit.

block;

of

when

a

spiral

spring

increased

iron

unit

by

to

the

the

it

a

The

is

TARGET

A

seal-in

has

its

overcurrent

seal-in

operates,

manually

cover.

INSTANTANEOUS

The

IOC

the

right

obtained

range;

a

predetermined

circuit

until

releases

These

designed

it

handling

promptly

for

relays,

to

any

is

notify

Reasonable

parts

are

SEAL-IN

coil

unit

released

unit

side

by

this

and

it

is

the

protect

damage

evident,

care

injured

UNIT

unit

is

in

unit,

picks

it

raises

UNIT

is

a

of

using

combination

raising

released.

target

when

not

them

sustained

the

nearest

should

or

mounted

series

arranged

up

by

small

the

a

value,

its

of

included

file

be

the

on

the

and

its

in

and

seals—in

a

target

into

pressing

hinged-armature-type

TOC

unit.

tapped

coil

provides

the

instantaneous

target

The

the

into

same

instantaneous

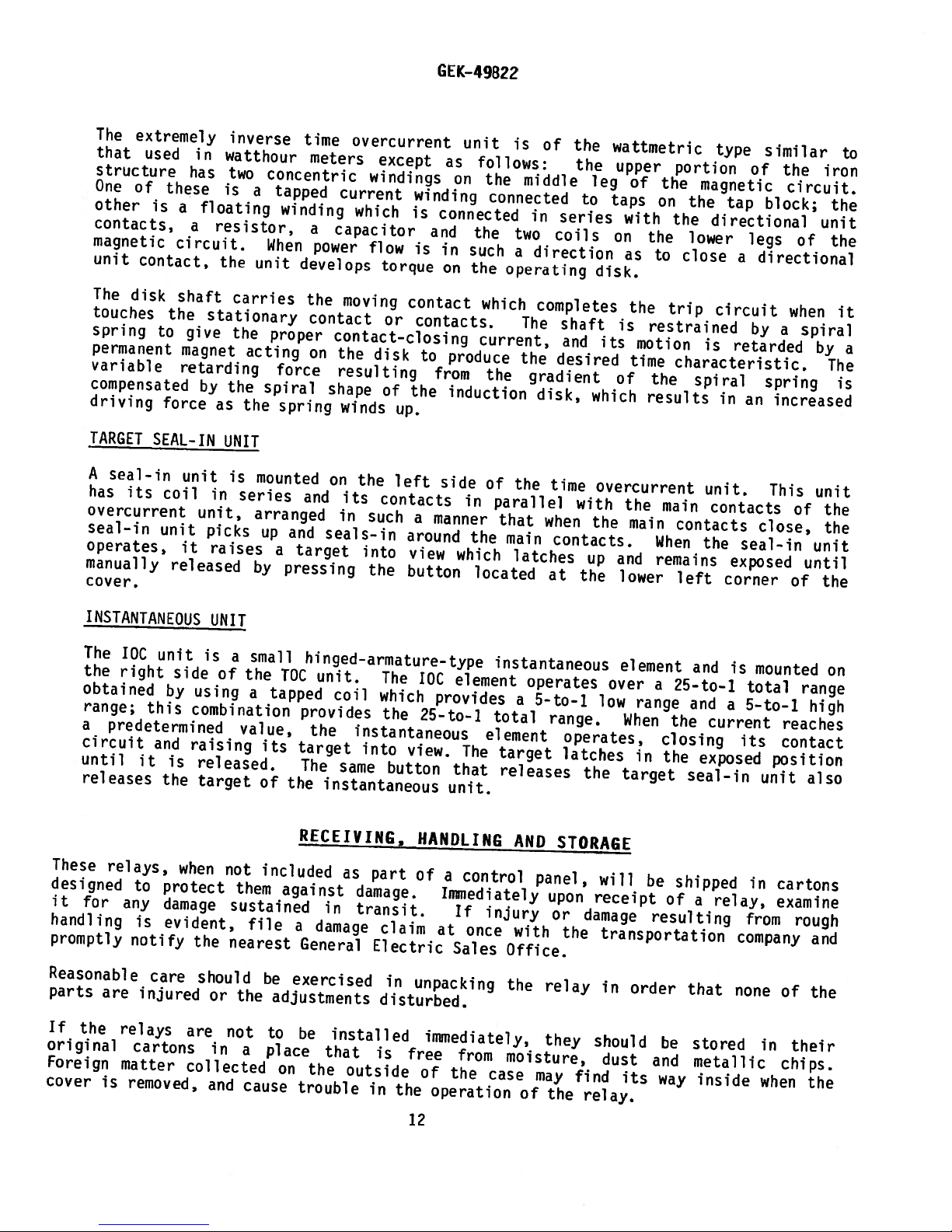

RECEIVING.

as

against

a

in

damage

damage.

transit.

General

exercised

adjustments

left

contacts

such

around

view

the

button

The

which

the

view.

button

part

claim

Electric

in

disturbed.

side

in

a

manner

the

which

located

bC

element

provides

25-to-i

The

that

unit.

HANDLING

of

a

control

Inmiediately

If

at

once

Sales

unpacking

of

the

time

parallel

that

when

main

contacts.

latches

at

instantaneous

operates

a

5-to-i

total

range.

element

target

releases

AND

panel,

upon

injury

or

with

Office.

the

relay

overcurrent

with

the

up

and

the

over

low

operates,

latches

the

STORAGE

will

receipt

damage

the

transportation

in

the

main

When

remains

lower

element

a

range

When

in

target

be

resulting

order

main

contacts

left

and

25-to-i

and

the

closing

the

seal—in

shipped

of

a

that

unit.

contacts

the

seal—in

exposed

corner

is

a

current

its

exposed

relay,

company

none

This

close,

mounted

total

5-to-i

position

unit

in

cartons

examine

from

unit

of

unit

until

of

range

high

reaches

contact

also

rough

and

of

the

the

the

the

on

If

the

original

Foreign

cover

matter

is

cartons

removed,

relays

are

not

in

collected

and

a

cause

to

place

on

be

the

trouble

installed

that

outside

in

immediately,

is

free

the

from

of

the

operation

case

they

moisture,

may

of

the

find

relay.

should

dust

its

be

and

way

stored

metallic

inside

in

chips.

when

their

the

12

Page 13

GEK-49822

Immediately

made

to

ensure

calibrations

readjustment

Since

tests,

these

operating

the

relays.

acceptance

VISUAL

Check

agree

Remove

parts

the

tions

formed

INSPECTION

the

with

the

or

other

shorting

diagrams,

to

nameplate

contact

MECHANICAL

Top

Unit

(TOC)

upon

receipt

that

not

have

is

necessary,

conipanies

following

These

tests,

the

relay

at

requisition.

from

signs

bars

are

Figures

the

INSPECTION

no

damage

been

section

tests

the

discretion

stamping

its

of

physical

in

the

5

shorting

of

the

disturbed.

refer

use

includes

to

case

proper

to

ACCEPTANCE

relay

been

has

to

the

different

be

may

of

ensure

and

check

damage

location(s)

inclusive,

9,

bar.

an

INSPECTION

sustained

the

If

section

procedures

all

applicable

performed

the

user.

that

that

and

TESTS

in

examination

on SERVICING.

for

as

the

model

there

that

all

shown

as

that

and

AND

tests

part

number

are

screws

ACCEPTANCE

shipment

the

or

acceptance

that

the

of

and

broken

no

are

the

main

internal

by

the

and

test

may

rating

or

tight.

brush

TEST

that

indicates

and

installation

performed

be

installation

of

cracked

connec

is

should

the

the

Check

properly

be

relay

that

on

or

relay

molded

that

1.

2.

3.

4.

5.

Bottom

1.

2.

Target

1.

2.

3.

4.

disk

The

disk

The

magnet.

Both

The

position.

The

moving

is

at

Unit

rotating

The

The

contact

and

The

armature

Both

The

target

when

The

contacts

shaft

air

gaps

disk

the

(DIR)

Seal-in

contacts

the

target

end

should

be

should

should

contact

time

0

dial

shaft

should

gap

Unit/Instantaneous

and

contacts

should

should

release

should

play

centered

be

rotate

should

end

make

latch

have

should

free

freely

just

position.

should

play

be

0.015—0.025

should

at

into

button

approximately

be

0.005—0.015

the

foreign

air

in

of

and

touch

be

Unit

move

approximately

view

is

just

operated.

inch.

gaps

of

matter.

should

the

stationary

0.015—0.020

inch

on

the

freely

when

the

as

the

0.030

inch

both

return

inch.

low

operated

same

contacts

wipe.

the

contact

gradient

time.

electromagnet

itself

by

by

make

when

contact.

hand.

and

to

the

should

the

time

and

unlatch

drag

reset

dial

13

Page 14

GEK-49822

DRAWOUT

Since

they

magnetic

relay

plug.

shorting

test

the

external

POWER

All

sinusoidal

the

will

Therefore,

use

freedom

relay;

RELAYS,

all

drawout

tested

be

effects

may

be

tested

This

plug

exercise

bars

allows

plug

in

of

circuitry.

REQUIREMENTS,

alternating—current-operated

waveforms

fundamental

be

affected

in

order

sine

from

wave

harmonics)

a

however,

electromagnets

waveforms.

GENERAL

relays

in

their

of

the

without

makes

the

case.

greater

greater

GENERAL

can

frequency,

by

the

to

of

current

any

relay

(such

as

in

service

cases

or

enclosure will

removing

connections

The

12XLA12A

testing

care,

applied

test

analyzed

be

it

alternating

since

follows

waveform.

and/or

cannot

using

time

be

tuned

overcurrent

operate

an

it

only

flexibility,

connections

devices

as

that

voltage.

expressed

in

equivalent

be

accurately

from

with

plug

test

affected

are

fundamental

a

alternating-current

current

The

as

circuits,

relays)

their

the

the

it

are

relays

purity

a

steel

may

requires

finite

R-L

cases,

duplicated

panel

relay

made

or

is

case.

by

and

also

be

CT

to

by

frequency.

frequency

properly,

of

the

number

RC

networks,

affected

it

using

does

both

(AC)

is

In

during

used.

shorting

the

plus

it

sine

for

by

recommended

this

way,

testing.

12XLA13A

a

not

disturb

Although

jumpers

relay

Since

harmonics

devices

is

wave

any

or

(relays)

essential

(i.e.,

particular

saturating

non—sinusoidal

and

that

any

A

test

any

this

and

the

non—

of

to

its

TARGET

target

The

When

the

0.2

used

minimum

ampere

minimum

The

seal-in

seal-in

take

a

There

will

(undesired)

necessary

adjustment.

time.

Pickup

1.

Connect

ammeter

to

2.

Close

3.

Increase

4.

Open

the

5.

Decrease

AND

control

unit.

screw

and

2.0

picked

SEAL-IN

and

with

control

tap.

tap

from

now

tap

to

Tap

Dropout

relay

and

amperes.

or

jumper

the

the

parallel

the

seal-in

trip

When

voltage,

screw

To

the

be

and

prevent

screws

load

current

up

current

UNIT

unit

coils

voltage,

is

change

left-hand

screws

place

Test

studs

box

the

contact

position.

has

operating

the

trip

the

tap

the

the

in

it

the

should

1

and

so

contact(s)

slowly

slowly

operating

an

the

target

coil

screw

screw

tap

holding

setting,

stationary

both

back

right—hand

never

2

(see

the

that

that

until

circuit

until

on

taps.

in

be

current

the

the

14

currents

and

current

should

the

stationary

allowed

internal

parallel

seal-in

of

seal—in

coil

seal-in

be

the

first

contact

Next,

left—hand

can

step

tapped

ranging

tap

ranges

placed

right-hand

remove

and

remove

contact

remain

to

connections

be

controlled

the

seal-in

unit

2;

the

unit

at

from

screw

from

in

the

place

contact.

picks

seal-in

drops

and

0.2

0.2

2

to

the

2.0

stationary

connecting

it

the

screw

from

in

both

diagram)

unit

up.

unit

out.

to

should

30

ampere

in

This

over

contact.

See

2.0

amperes

the

from

getting

taps

to

should

See

amperes.

2.0

be

tap.

contact

plug.

desired

procedure

at

a

range

a

Table

Table

amperes

in

set

at

of

the

out

the

source,

DC

of

XI.

remain

XI.

at

the

the

the

Then

tap.

other

is

of

same

0.1

in

Page 15

GEK-49822

TIME

Rotate

close

Where

brush

in

its

With

sufficient

ensure

Current

OVERCURRENT

the

time

at

the

0

time—dial

the

contacts

in

or

out

by

support.

the

contacts

gap

between

approximately

Setting

UNIT

dial

means

TARGET

TAP

0.2

2.0

slowly

just

just

the

1/32

setting.

close

of

its

closing

stationary

inch

AND

and

wipe.

SEAL-IN

PICKUP

CURRENT

0.115

1.15

check

can

be

adjusting

at

TABLE

UNIT

-

0.195

-

1.95

by

adjusted

screw.

No.

contact

XI

OPERATING

means

of

by

This

0

time—dial

brush

CURRENTS

DROPOUT

CURRENT

0.05

0.55

a

running

screw

and

OR

OR

lamp

its

MORE

MORE

that

the

should

setting,

metal

the

contacts

stationary

be

held

there

backing

contact

securely

should

strip

just

be

to

The

minimum

determined

block

When

the

procedure

relay

screw

the

connecting

The

minimum

should

time

dial

means

driver

current

This

adjustment

between

Pickup

IBCG53/54

IBCG77/78

means

of

permits

obtained.

closed.

is

marked

tap

must

and

shorts

and

place

be

within

position.

of

the

blade

of

the

adjustment

relays.

relays,

the

any

The

Further

current

by

the

setting

be

plug.

current

spring

in

the

unit

available

variable

desired

control

at

position

in

amperes,

is

followed:

the

it

in

required

5%

of

If

adjusting

the

notches

can

also

tap

by

means

A

different

the

pickup

resistor

setting

spring

adjustment

which

changed

current

the

the

this

be

permits

settings.

the

of

the

as

shown

with

(1)

transformer

tap

marked

to

value

adjustment

ring.

around

brought

any

of

the

procedure

of

the

in

intermediate

is

prewound

of

this

time

plug

in

the

Remove

rotate

marked

the

into

desired

control

unit

the

phase-shifting

setting

15

overcurrent

in

Tables

relay

the

secondary

for

the

the

on

has

The

ring

edge.

agreement

applies

for

between

approximately

the

tap

III,

energized

connecting

desired

disk

the

been

can

By

setting

spring

to

any

current

is

seldom

unit

block.

IV

slowly

tap

disturbed,

be

turning

with

to

applies

the

circuit.

the

will

and

in

plug;

winding.

pickup

and

plate

turned

the

be

IBCG77/78

tap

various

6600

required;

V.

its

for

the

obtained

setting

with

close

The

case,

this

(2)

current.

to

any

it

by

ring,

tap

to

This

tap

if

its

tap

de-energizes

Remove

close

tap

can

be

inserting

setting

intermediately

the

relays.

is

adjustment

settings

the

contacts

it

contacts

plate

the

following

the

(3)

the

contacts

setting

restored

a

the

operating

employed.

IBCG51/52

For

adjusted

is

required,

on

this

the

tap

Replace

and

screw

and

the

also

to

be

just

is

by

by

Page 16

9822

GEK—4

because

necessary

more

it

Test

Connections

shown

and

form

employed

form.

connection

time

the

Setting

Time

setting

The

close

just

closed

travel

maximum

primary

The

time

dial.

along

time,

beyond

of

than

in

The

its

the

time

its

while

the

the

wind

to

900

Figures

constant

testing

in

contact

diagram,

test.

of

contacts

when

maximum

setting.

adjustment

However,

supporting

moving

cutout

insufficient

up

the

notches)

(3

for

making

and

22

frequency.

induction

in

must

time

the

when

dial

the

amount

further

shelf;

it

away

the

in

the

for

control

pickup

23.

the

blocked

be

dial

current

is

to

the

increases

disk.

range

spring

the

from

Use

Stepdown

relays

wound

determines

set

close

time

adjustment

moving

of

and

a

closed

reaches

on

the

of

the

adjuster

factory

time

source

transformers

since

shading

0.

contacts

operation

is

magnet

the

time.

the

variable

setting.

checks

of

their

coil

jumpered

or

the

predetermined

a

When

obtained

more

120

length

the

and

of

toward

Be

resistor,

the

on

volts

or

use

circuit

of

dial

therefore

the

by

sure

than

time

or

phantom

may

for

time

is

unit

moving

the

the

300

over-current

greater

cause

marked

both

the

value.

set

this

is

disk

magnet

it

(1

loads

the

on

made

the

shaft

should

notch)

with

should

distorted

a

see

D,

pickup

unit

The

the

10,

setting

by

permanent

decreases

never

never

or

unit

good

internal

test

requires

contacts

disk

gives

means

extends

unwind

are

wave

not

wave

and

are

must

the

the

of

magnet

the

out

be

be

to

Pickup

rated

Use

contact

the

Set

connection

value

tap

Test

Time

the

Set

connection

relay

should

Test

must

frequency

relay

in

current

relay

in

for

the

to

0.5

22,

be

Figure

closed

at

(1.96—2.04

No.

at

Figure

operate

Relay

IBCG51-IBCG52

23,

within

Type

IBCG53-IBCGS4

both

perform

time-dial

the

time—dial

5

apply

amps).

the

TOC

the

main

limits

UNIT

pickup

the

unit

setting

times

5

OPERATING

Mm.

1.72

1.27

pickup

position

should

tap

given

TABLE

Time

and

and

and

current

in

XII

in

time

time

and

close

the

Table

TIME

Seconds

Midpoint

1.78

1.31

tests.

tests.

ampere

2.0

its

2.0

(10.0

XII.

LIMITS

contacts

amp

amp)

The

tap.

tap.

directional

within

the

to

Max

1.83

1.35

Using

Using

+

relay.

the

2.0%

the

unit

test

of

test

The

18CG77-IBCG78

0.89

16

0.92

0.95

Page 17

GEK-49822

DIRECTIONAL

Current

a.

b.

Polarization

Connect

The

unit

slip

I

This

level

for

too

Potential

a.

Connect

b.

With

between

INSTANTANEOUS

Make

operate.

Whenever

continuous

The

set

core.

counterclockwise

picks

value

sure

instantaneous

the

up.

is

Polarization

V

that

See

possible,

rating.

instantaneous

Turning

obtained.

UNIT

per

between

long

per

set

0.75-1.75

UNIT

the

It

may

Figure

should

8-18

of

a

Figure

for

the

internal

unit

the

increases

be

Once

24

test

close

amperes.

current

period

5

instantaneous

use

unit

necessary

25

volts

amps.

the

has

core

the

of

test

connections

an

to

the

desired

connections.

its

contacts

can

overheat

time.

connections.

at

terminals

higher

adjustable

a

desired

clockwise

pickup.

to

unit

repeat

pickup

within

CAUTION

the

9

is

diagram

range

core

pickup,

decreases

Bring

this

value

to

in

since

5%

coil

10.

the

and

located

loosen

up

the

operation,

is

of

if

the

correct

Table

the

the

current

reached,

0.5

applied

unit

VI.

higher

at

the

pickup;

ampere.

should

range

the

locknut

slowly

until

tighten

too

range

top

The

frequently

close

in

which

of

and

turning

until

the

desired

the

clutch

has

the

locknut.

its

a

unit.

adjust

the

the

or

contacts

it

is

higher

pickup

should

to

To

the

core

unit

F

Refer

instantaneous

the

The

range

position

the

full-clockwise

LOCATION

The

location

well

lighted

to

Table

instantaneous

of

the

of

1/8

of

should

to

facilitate

VI

(p.7)

unit.

unit.

instantaneous

a

turn

position.

be

clean

inspection

Do

of

not

and

for

the

exceed

unit

“full

(see

clockwise”,

INSTALLATION

dry,

and

17

CAUTION

continuous

these

Table

free

from

testing.

and

ratings

VI)

and

dust

must

20

1

second

when

be

turns

and

ratings

applying

obtained

counterclockwise

excessive

of

current

between

vibration

the

to

a

core

from

and

Page 18

MOUNTING

The

relay

diagram

is

should

shown

CONNECTIONS

The

internal

Typical

external

be

mounted

in

connection

wiring

Figure

on

26.

diagrams

diagrams

a

vertical

are

for

GEK-49822

surface.

the

various

shown

by

relays

Figures

The

outline

10,

are

11

and

shown

and

12.

panel

in

drilling

Figures

to

5

9.

Unless

mounted

recomended

conductor

INSPECTION

At

the

time

loose

screws,

corrected

Every

especially

bars

plug

secondary

Before

factory

the

the

adjustments

relay

necessary

contacts.

not

in

circuit

that

or

relay

leaves

to

The

on

that

less

of

or

the

important

the

test

circuits

change

following

a

steel

the

case

than

installation,

other

manner

in

auxiliary

plug

is

put

have

the

factory.

this

panel

be

B&S

1/12

the

imperfections.

described

the

drawout

on

current

brush

before

from

being

into

service,

not

been

setting

tests

are

which

grounded

gage

copper

relay

in

the

be

the

main

opened.

OPERATION

disturbed.

If

the

in

suggested:

adequately

through

should

If

section

CAUTION

case

circuits

bent

high

brushes

it

should

setting

order

wire

has

Refer

a

or

be

any

on

an

and

enough

to Figure

be

The

has

to

grounds

mounting

its

equivalent.

inspected

trouble

SERVICING.

auxiliary

other

do.

time

open

to

given

not

circuits

engage

This

a

dial

been

the

the

for

is

21.

check

will

time

stud

tarnished

found,

brush.

the

will

changed,

relay

or

screw

it

with

be

shorting

connecting

prevent

determine

to

set

overcurrent

case,

It

at

it

it

with

contacts,

should

is

CT

before

0

will

is

a

be

that

be

unit

TARGET

1.

2.

TIME

1.

2.

AND

SEAL-IN

Make

sure

that

Perform

OVERCURRENT

Set

tap

pickup

UNIT

screw

approximately

the

current

This

Check

value

relay

Use

value

the

the

may

must

test

of

operating

be

coordinate.

UNIT

the

and

on

twice

until

current

5

circuit

tap

dropout

desired

tap

the

times

screw

light

should

time

tap

shown

tests

value

at

The

in

is

tap.

be

some

rating

value

Figure

in

as

current

in

within

18

the

outlined

Using

series

multiple

or

the

used

23.

desired

the

until

with

5%

of

maximum

is

of

left

in

test

tap

the

tap.

the

ACCEPTANCE

circuit

contacts

the

contacts

value.

tap

value.

fault

to

the

in

just

begins

This

current

discretion

TEST

Figure

close.

multiple

for

section.

22,

to

which

of

the

apply

Reduce

flicker.

of

user.

tap

the

Page 19

GEK—49822

DIRECTIONAL

Current

a.

Connect

b.

Adjust

UNIT

Polarization

per

the

polarized.

Potential

c.

d.

If

potential

Adjust

from

values

Polarization

the

the

for

INSTANTANEOUS

1.

Select

relay

the

2.

Set

the

(see

higher

the

ACCEPTANCE

Figure

control

polarized,

control

angle

this

of

test.

UNIT

desired

internal

range

since

instantaneous

TEST

section.

24

test

spring

connect

spring

maximum

range

connections

it

unit

PERIODIC

connections.

for

0.5

per

or

7.2

torque.

by

making

diagram).

has

a

higher

to

pick

CHECKS

ampere

Figure

volt

volts

10

the proper

continuous

at

up

ROUTINE

AND

pickup

25

amperes

Whenever

the

if

current

connections.

test

and

(±10%)

0.72

since

amperes