Page 1

IN

ST

RU

CT

ION

S

GEK-65573

TIME

IAC6OT,

OVERCURRENT

IAC8OT,

RELAYS

IAC9OT

GENERAL

ELECTRIC

Page 2

GEK-65573

DESCRIPTION

APPLICATION

CONSTRUCTION

RATINGS

TIME

OVERCURRENT

INSTANTANEOUS

AUXILIARY

CONTACTS

BURDENS

TIME

OVERCURRENT

INSTANTANEOUS

AUXILIARY

CHARACTERISTICS

TIME

OVERCURRENT

INSTANTANEOUS

RECEIVING,

ACCEPTANCE

VISUAL

HANDLING

TESTS

INSPECTION

MECHANICAL

TIME

INSTANTANEOUS

CAUTION

DRAWOUT

POWER

TIME

REQUIREMENTS

OVERCURRENT

TIME

PICKUP

TIME

INSTANTANEOUS

PICKUP

AUXILIARY

INSTALLATION

INSTALLATION

TIME

INSTANTANEOUS

AUXILIARY

TIME

CHECKS

OVERCURRENT

PERIODIC

INSTANTANEOUS

AUXILIARY

CONTACT

SYSTEM

TEST

SERVICING

MECHANICAL

TIME

INSTANTANEOUS

ELECTRICAL

TIME

INSTANTANEOUS

OF

PARTS

FIGURES

RENEWAL

LIST

OVERCURRENT

UNIT

OVERCURRENT

UNIT

OVERCURRENT

AND

INSPECTION

OVERCURRENT

RELAY

TESTING

SETTING

TEST

TEST

UNiT

AND

RESET

UNIT

TESTS

OVERCURRENT

UNIT

ROUTINE

AND

UNIT

UNIT

CLEANING

ADJUSTMENTS

OVERCURRENT

ADJUSTMENTS

OVERCURRENT

UNIT

UNIT

UNIT

STORAGE

UNIT

OVERCURRENT

GENERAL

UNIT

UNIT

UNIT

MAINTENANCE

UNIT

UNIT

UNIT

UNIT

UNIT

CONTENTS

UNIT

UNIT

UNIT

UNIT

PAGE

3

3

4

5

5

7

8

P

8

8

9

9

10

10

10

10

11

11

11

11

11

11

11

12

12

12

13

13

13

13

13

14

14

14

14

14

15

15

15

15

15

15

16

16

16

16

17

17

17

18

19

2

Page 3

GEK—65573

The

overcurrent

instantaneous

drawout

overcurrent

extremely

this

feature

The

instantaneous

amperes

continuous

The

Fig.

15.

IAC0T,

case.

inverse

time

of

and

outline

units

overcurrent

unit,

is

provided

overcurrent

units

both

short

IAC8OT

with

The

which

in

have

the

and

wound

three

is

the

IAC9OT.

by

time

time

mounting

TIME

IAC6OT,

and

units

models

inverse

the

units

an

adjustment

and

ratings,

OVERCLJRRENT

IAC8OT,

DESCR

IAC9OT

shading

and

one

relays

coils

dc

differ

in

The

relays

associated

are

range

instantaneous

are

provided

dimensions

APPI

IPTION

auxiliary

only

the

IAC6OT,

do

distance

adjustable

units,

of

the

ICAT

ION

RELAYS

IAC9OT

consist

for

in

not

of

25

in

L2

torque

unit,

the

very

include

relays.

over

to

as

the

size

of

two

control,

all

characteristic

inverse

a

tarciet

range

a

1.

The

well

section

drawout

induction

mounted

as

information

on

two

in

in

the

seal-in

of

8

available

RATINGS.

case

disk

plunger-type

the

L2

of

the

IAC8OT

unit

to

1;

ranges

on

are

shown

timer

size

time

and

since

the

in

their

in

The

conjunction

of

the

distance

supply.

coils

the

and

auxiliary

operation

This

arrangement

zone

tripping

At

the

protection

The

covered

mho-type

The

CEY51A

contacts

directional

control

CEY52A

IAC6OT,

with

instantaneous

relay

The

time

contacts

unit,

of

the

same

time

and

elementary

by

this

distance

is

a

of

the

mho

the

time

contacts.

These

cvii-y

pcesibZ

turthe

the

our

chaser’s

T

hat

no

such

I1C80T

two

trip

circuit

overcurrent

of

which

time

provides

and

overcurrent

the

scheme

backup.

diagram

instruction

relays

first-zone

instantaneous

relay

overcurrent

ntructiuns

contingency

information

purposos,

the

xtcnt

rssuranee

and

zones

overcurrent

the

dc

in

overcurrent

the

to

directional

that

operates

not

do

to

b

desi

red

the

required

isg;yen

the

IAC9OT

of

step—distance

to

prevent

units

auxiliary

turn

completes

means

relays

provides

in

Fig.

book

may

provide

units

unit.

purport

met

be

n

or

houid

mat

ter

ullauirt

urnjucts

C;

th

respet

units

are

units

for

or

a

10

be

two—zone

of

the

The

to

cover

cnneetion

partJ

be

descrl,ed

to

relays

are

incorrect

torque

unit.

the

provides

obtaining

fuses

definite

illustrates

used

mho

relay

the

dc

auxiliary

time

details

all

with

cular

problerro

referred

herein

lonol

codes

are

relays.

connected

tripping

controlled

The

second

wound

the

installed

second

in

conjunction

protection

that

IAC

relay.

overcurrent

or

variations

installation,

arise

to

the

General

r,ieet

applicable

and

ordinances

specifically

In

this

to

zone

shading

second

close

coordination

at

zone

how

any

against

trips

The

unit

unit

in

operation

which

arm

Tiectric

aSsr.

because

application

supervise

on

loss

by

distance

coil

zone

tapped

reach

one

of

with

without

CEY52A

in

the

trips

equipment

or

not

covered

Company.

1555

they

designed

of

means

circuit.

time-delay

loads

for

the

the

CEV51A

multi—phase

time

is

JAC

the

nor

,rintenance.

sufficiently

and

NEM4

vary

of

the

three

to

•

greatly.

the

the

relay

provide

for

the

the

ac

wound

relays

between

on

overall

delay

second

breaker

Should

standards;

use

contacts

first

zone

potential

shading

operate

Subsequent

tripping.

second

the

line.

line

IAC

relays

and

CEY52A

faults.

through

zone

to

torque

via

for

for

in

the

3

Page 4

GEK-65573

It

not

are

these

units

contacts

contacts,

fault

current.

The

accomodate

fuses

with

The

Separate

faults.

The

operating

are

coil

pickup

the

contact

The

portion

magnetic

points

with

lower

the

resistor

a

legs

auxiliary

is

important

designed

of

it

range

the

and

scheme

ground

inverse

coil

connected

point.

of

the

extremely

of

circuit.

on

a

of

must

these

is

the

tap

the

for

he

obvious

and

desired

relays

shown

relays

and

wound

auxiliary

iron

block.

(and

magnetic

unit

note

to

continuous

set

units

that

above

are

that

characteristics

pickup

at

other

Fig.

in

must

inverse

very

on

a

U—magnet

to

The

points

tap

U-magnet

unit

inverse

time

structure

of

One

these

The

capacitor

circuit.

hA.H

the

they

setting

be

“A.”

other

on

the

operation

maximum

to

he

must

of

points

10

provides

used

time

iron

on

a

includes

overcurrent

two

has

a

is

is

the

This

instantaneous

in

the

picked-up

expected

connected

operate

the

time

at

and

the

on

to

reliably

overcurrent

the

system.

protection

protection

for

CONSTRUCTION

overcurrent

structure.

tap

block

wound

to

shadinci

unit

concentric

tapped

a

extremely

operating

floating

winding

inverse

floating

overcurrent

load

full

supervise

time

same

against

units

The

provide

coils

is

the

windings

current

units)

circuit

units

position.

current.

on

the

units

permit

against

consist

several

a

ready

which

watt-metric

on

winding

which

and

connected

is

For

the

IAC

this

relays

reason

in

However,

first

the

minimum

must

time

multi—phase

zone

internal

he

coordination

CEY51A

selected

faults.

single-phase-to—ground

a

on

means

are

type.

middle

tapped

operating

the

of

selecting

connected

The

leg

current

of

of

taps

the

connected

coils

contact

a

in

is

connected

two

the

to

if

line

to

upper

to

series

on

the

to

a

the

tap

the

of

In

moving

The

contact

shaft

depending

the

on

acts

shaft

assembly

sapphire

an

adjustable

projects

The

compensated

driving

travel

of

Each

adjustable

The

carries

upward

into

cylindrical

both

is

on

jewel,

into

variable

force

of

of

the

types

which

restrained

tap

disk

consists

spring

pivot

bronze

a

the

by

as

the

the

armature

moving

the

pole

time

of

completes

by

setting,

produce

to

mounted

assembly

guide

retarding

spiral

spring

the

moving

contact,

instantaneous

contacts

coil

piece

by

inside

overcurrent

spiral

a

and

the

of

a

ring

force

shape

winds

is

mounted

upward

the

trip

the

motion

its

desired

polished

a

in

mounted

located

resulting

of

up.

thus

overcurrent

as

flux

coil.

the

units

circuit

spring

is

time

pin

screw-type

the

on

induction

the

A

calibrated

controlling

on

the

armature

the

created

Guides

the

when

give

to

retarded

characteristic.

driven

assembly.

frame

the

from

top

the

is

at

units

threaded

in

the

for

4

disk

it

the

by

into

and

of

gradient

disk.

time

the

of

portion

operated.

is

rectangular

the

and

touches

proper

an

the

The

having

the

This

dial

pickup

the

plunger

the

assembly

stationary

shaft

contact

Plnico

The

drag

lower

shaft

upper

bearing

polished

a

shaft.

the

of

results

determines

time.

plunger-type

of

a

The

magnet

rod

are

closing

macnet,

bearing

and

spiral

in

construction.

plunger

armature

provided

carry

riding

consists

pin

an

the

rod

frame

contact.

current

which

for

on

which

spring

increased

distance

which

drawn

is

and

at

the

the

a

of

is

a

the

Page 5

top

by

a

carrier

allow

inside

access

The

telephone-type

The

removed

top

are

inserted

cover

prevents

TIME

from

and

bottom.

completed

is

OVERCURRENT

hole

in

the

to

auxiliary

relay

components

the

through

in

place

attached

the

cover

the

the

relay

The

of

UNIT

pole

calibration

armature

unit

to

from

is

of

each

case.

electrical

removable

the

the

‘A”

shown

connection

being

piece,

is

relay

The

case

and

Lube.

to

adjust

a

telephone—type

in

Fig.

are

cradle

connections

connection

plugs

from

replaced

GEK—65573

at

the

Openings

pickup.

11.

mounted

is

locked

between

to

permit

the

front

until

RATINGS

bottom

relay.

on

plugs.

and

the

by

in

the

a

cradle

in

the

the

Separate

testing

includes

connection

the

sides

The

assembly

case

case

fit

of

of

the

construction

by

means

blocks

testing

the

relay

an

interlock

plug

has

the

calibration

which

of

and

in

been

molded

of

can

latches

cradle

plugs

its

inserted.

a

be

case.

arm

contact

tube

typical

easily

at

blocks

can

which

the

be

The

Ratings

Available

RANGE

AMPERES

0.5

of

the

RELAY

IAC6OT

IAC8OT

IAC9OT

taps

-

4.0

time

overcurrent

FREQUENCY

CYCLES

________

for

time

0.5,

60

60

overcurrent

0.6,

0.7,

unit

TABLE

MAIN

UNIT

0.5

2.0

0.5

1.5

units

TABLE

0.8,

are

I

PICKUP

(TIME)

-

4.0

-

16.0

-

4.0

-

12.0

II

TAPS

1.0,

given

in

RANGE,

are

shown

AVAILABLE

1.?,

1.5,

Table

I.

AMPERES

INSTANTANEOUS

J

on

2—50

Table

(AMPERES)

2.0,

2.5,

UNIT

LI

3.0,

4.0

1.5

—

12

2.0

-

16

1.5,

2.0,

2.0,

2.5,

2.5,

3.0,

3.0,

4.0,

4.0,

5.0,

6.0,

7.0,

8.0,

5.0,

6.0,

7.0,

8.0,

10.0,

10.0,

12.0,

12.0

16.0

5

Page 6

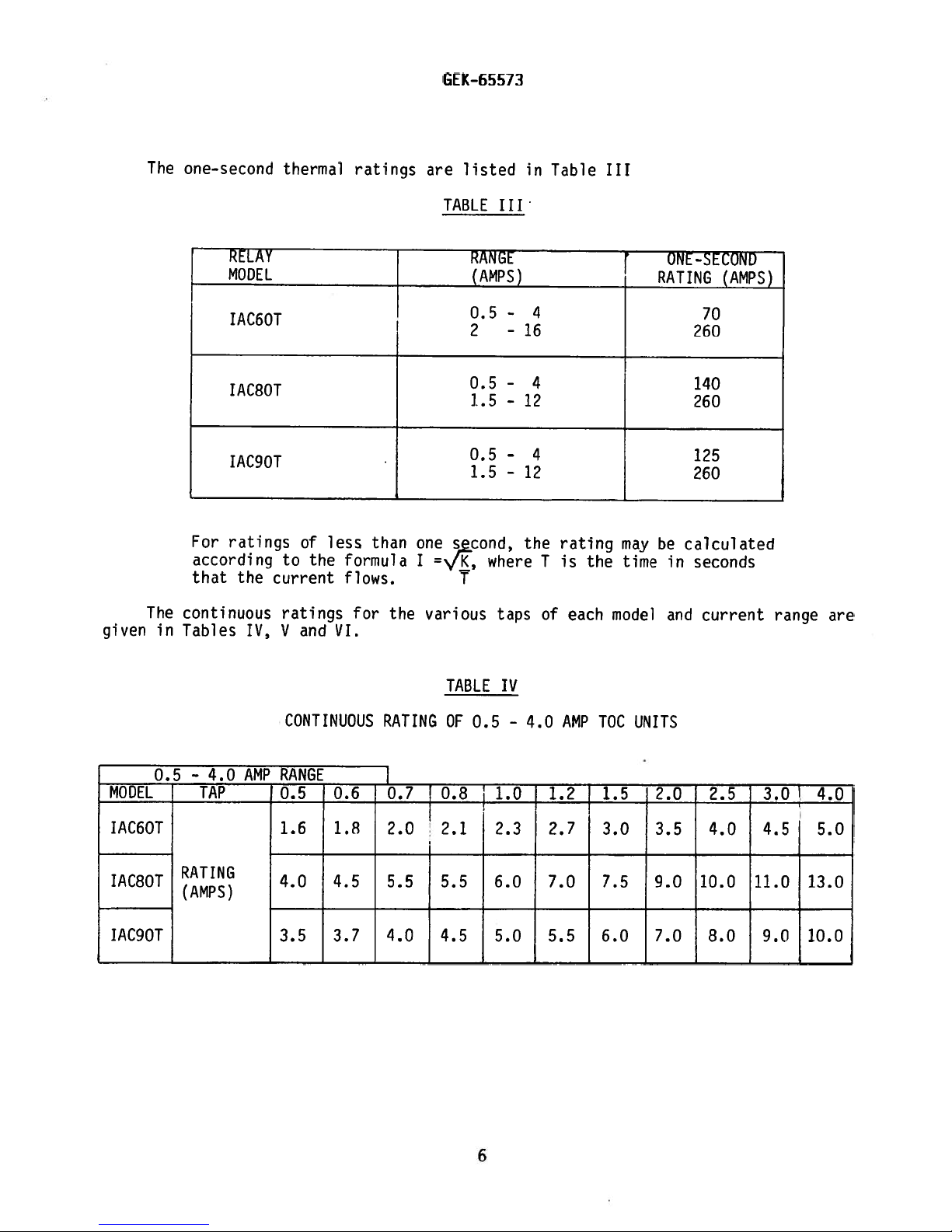

The

one—second

thermal

ratinqs

SEK-65573

are

listed

in

Table

III

given

The

in

RELAY

MODEL

IAC6OT

IAC8OT

IAC9OT

For

ratings

according

that

the

continuous

Tables

IV,

of

to

current

ratings

V

and

the

less

formula

flows.

VI.

for

than

the

TABLE

one

I

=./i,

various

RANGE

(AMPS)

0.5

2

0.5

1.5-12

0.5

1.5

second,

where

T

III

-

-

-

-

-

taps

16

12

the

ONE-SECOND

RATING

4

(AMPS)

70

260

4

140

260

4

125

260

T

of

rating

is

each

the

may

time

model

be

in

and

calculated

seconds

current

range

are

0.5

MODEL

IAC6OT

IAC8OT

IAC9OT

-

TAP

4.0

CONTINUOUS

AMP

RANGE

0.5

1.6

4.0

3.5

0.6

1.8

4.5

3.7

RATING

0.7

2.0

5.5

4.0

TABLE

OF

0.5

0.8

2.1

5.5

4.5

IV

1.0

2.3

6.0

5.0

-

4.0

AMP

TOC

UNITS

1.2

2.7

7.0

5.5

1.5

3.0

7.5

6.0

2.0

3.5

9.0

7.0

2.5

4.0

10.0

8.0

3.01

4.5

11.0

9.0

4.0

5.0

13.0

10.0

6

Page 7

GEK—65573

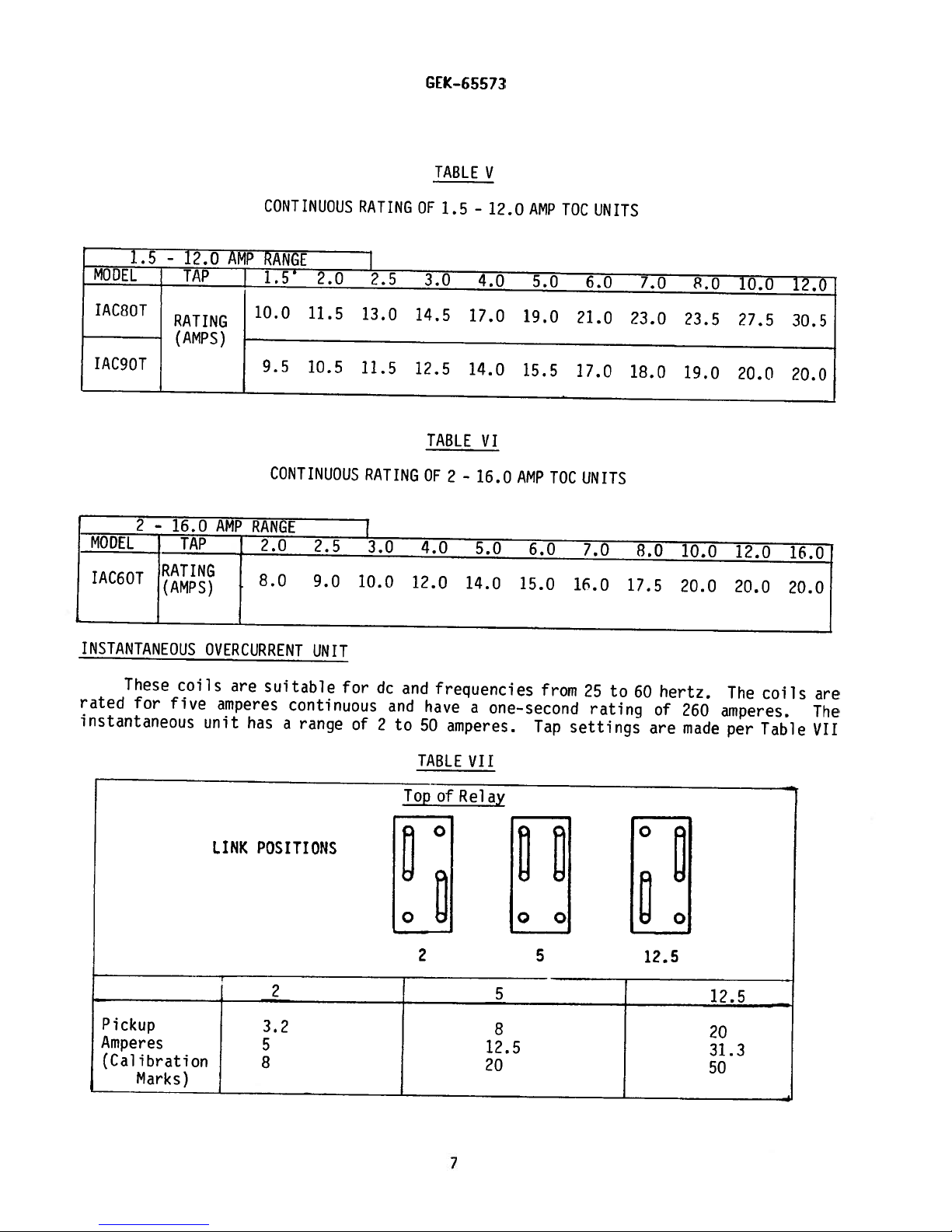

1.5

-1?.O

MODEL

IACBOT

IAC9OT

2

-

MODEL

IAC60(AMps)

RATING

TAP

RATING

(AMPS)

16.0

AMP

TAP

CONTINUOUS

AMU

RANGE

1.5

10.0

9.5

CONTINUOUS

RANGE

2.0

8.0

2.0

11.5

10.5

2.5

9.0

RATING

2.5

13.0

11.5

RATING

3.0

10.0

TABLE

OF

3.0

14.5

12.5

TABLE

OF

4.0

12.0

1.5-

2

17.0

14.0

-

16.0

5.0

14.0

V

4.0

VI

12.0

AMP

5.0

19.0

15.5

AMP

6.0

15.0

TOC

TOC

UNITS

6.0

21.0

17.0

UNITS

7.0

16.0

7.0

23.0

18.0

8.0

17.5

8.0

23.5

19.0

10.0

20.0

10.0

27.5

20.0

12.0

20.0

12.0

30.5

20.0

16.0

20.O

INSTANTANEOUS

These

rated

instantaneous

Pickup

Amperes

(Calibration

for

coils

five

Marks)

OVERCURRENT

are

suitable

amperes

unit

LINK

continuous

has

a

range

POSITIONS

3.?

5

8

UNIT

for

of

dc

and

2

and

to

Topof

frequencies

have

50

amperes.

TABLE

Relay

2

one-second

a

VII

12.5

20

from

25

to

rating

Tap

settings

8

60

hertz.

of

are

12.5

260

made

The

amperes.

per

12.5

20

31.3

50

coils

Table

j__________________________

are

The

VII

7

Page 8

GEK-65573

AUXILIARY

The

CONTACTS

The

carry

less.

breaker

30

The

auxiliary

amperes,

TIME

OVERCURRENT

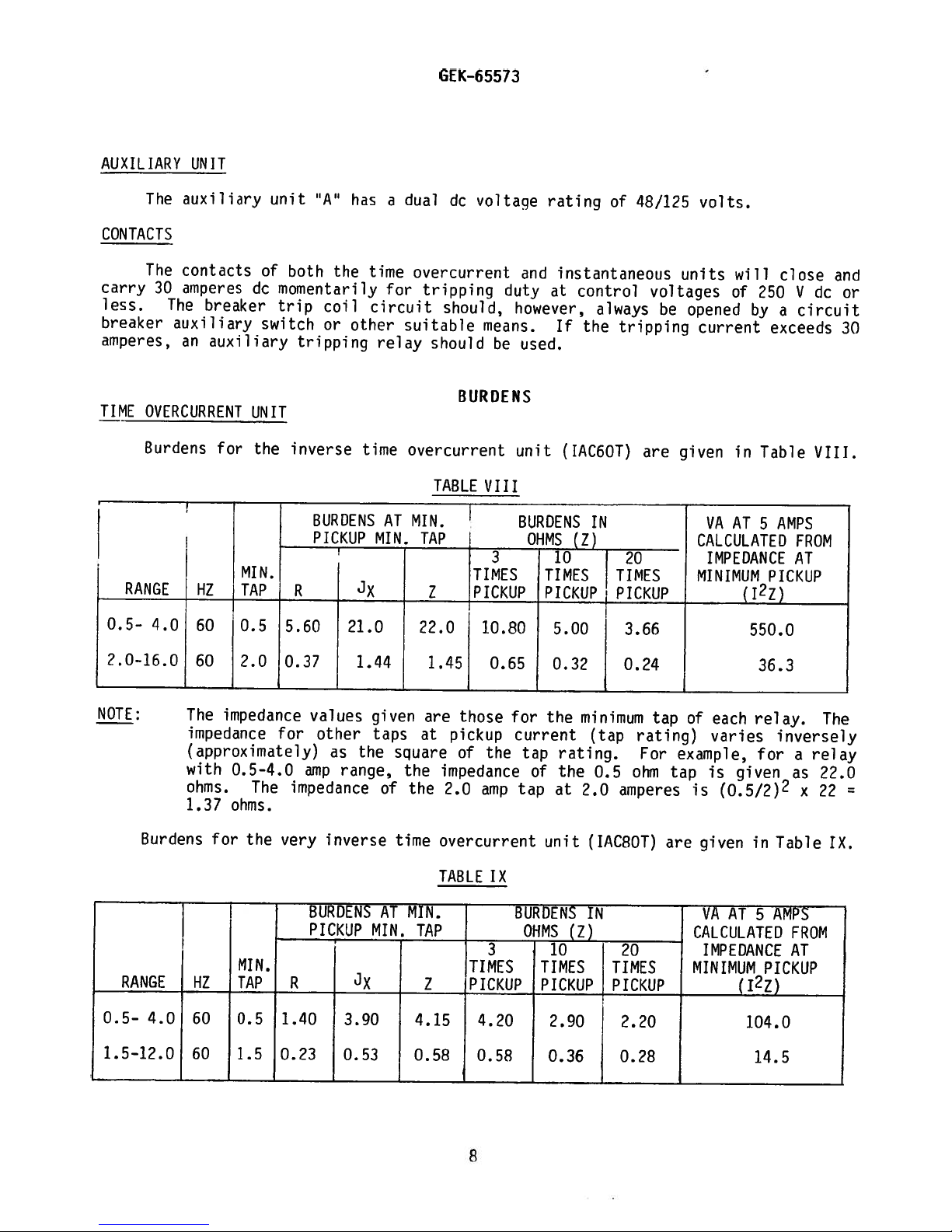

Burdens

RANGE

UNIT

auxiliary

contacts

amperes

breaker

an

auxiliary

for

HZ

unit

of

dc

switch

UNIT

the

MIN.

TAP

“A”

both

the

momentarily

trip

coil

or

other

tripping

inverse

BURDENS

PICKUP

R

has

time

circuit

relay

time

AT

MIN.

a

dual

overcurrent

for

tripping

suitable

overcurrent

MIN.

TAP

Z

dc

should,

should

B

TABLE

voltaqe

duty

means.

be

(JR

DENS

VIII

3

TIMES

PICKUP

rating

and

instantaneous

at

however,

If

used.

unit

(IAC6OT)

BURDENS

OHMS

(7)

10

TIMES

PICKUP

of

control

always

the

IN

48/125

voltages

be

tripping

are

20

TIMES

PICKUP

volts.

units

opened

will

of

250

by

current

given

VA

in

AT

Table

5

CALCULATED

IMPEDANCE

MINIMUM

(127)

close

V

circuit

a

exceeds

VIII.

AMPS

FROM

AT

PICKUP

dc

and

or

30

0.5-

.O-16.O

NOTE:

RANGE

0.5-

1.5—12.0

4.0

The

impedance

(approximately)

with

ohms.

1.37

Burdens

4.0

60

60

for

HZ

60

60

0.5

2.0

impedance

for

0.5-4.0

The

ohms.

very

the

MIN.

TAP

0.5

1.40

1.5

0.23

5.60

21.0

0.37

values

other

as

range,

amp

impedance

inverse

BURDENS

PICKUP_MIN.

R

3.90

0.53

1.44

given

taps

the

square

of

time

AT

22.0

1.45

are

at

the

the

MIN.

TAP

7

4.15

0.58

10.80

0.65

those

pickup

of

the

impedance

2.0

amp

overcurrent

TABLE

IX

3

TIMES

PICKUP

4.20

0.58

5.00

0.32

for

the

current

tap

rating.

of

the

tap

at

unit

BURDENS

OHMS

(7)

10

TIMES

PICKUP

2.90

0.36

3.66

0.24

minimum

(tap

0.5

2.0

amperes

(IAC8OT)

IN

20

TIMES

PICKUP

2.20

O.?8

tap

rating)

For

ohm

of

each

varies

example,

tap

is

given

(0.5/2)2

is

given

are

VA

AT5AMPS

CALCULATED

IMPEDANCE

MINIMUM

550.0

36.3

relay.

for

in

(12Z)

104.0

14.5

inversely

a

as

x

Table

FROM

AT

PICKUP

The

relay

22.0

22

IX.

=

8

Page 9

GEK—65573

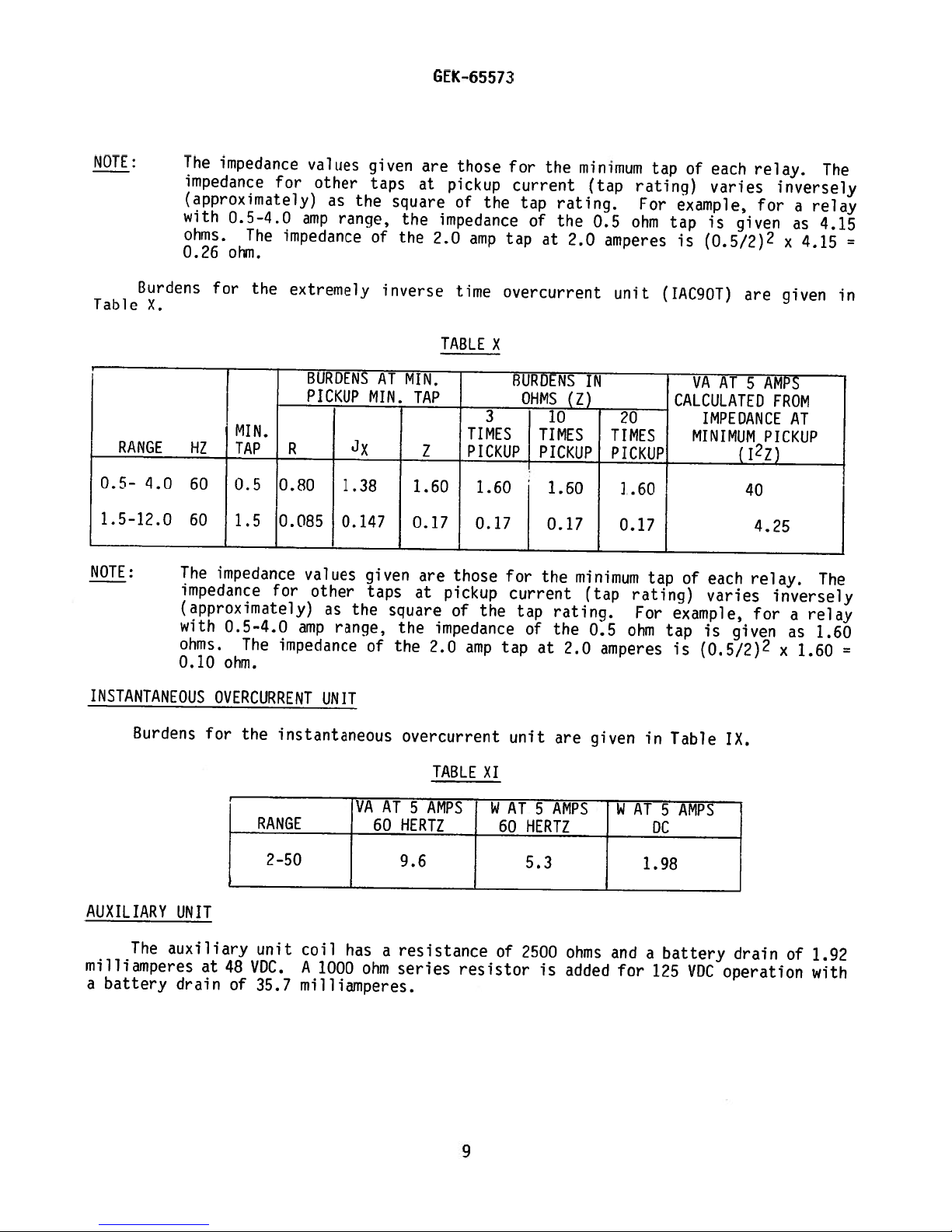

NOTE:

Table

RANGE

0.5-

1.5-12.0

NOTE:

The

impedance

(approximately)

with

ohms.

0.26

Burdens

X.

4.0

The

impedance

(approximately)

with

ohms.

0.10

impedance

for

HZ

60

60

impedance

0.5-4.0

The

ohm.

the

M1N.

TAP

0.5

1.5

0.5-4.0

The

ohm.

values

for

other

amp

rnpedance

extremely

BURDENS

PICKUP

R

0.80

0.085

values

for

other

as

amp

impedance

as

ranqe,

1.38

0.147

range,

the

the

given

taps

of

inverse

AT

MIN.

given

taps

square

of

are

at

square

the

the

MIN.

TAP

Z

1.60

0.17

are

at

the

the

those

pickup

of

impedance

2.0

amp

time

TABLE

TIMES

PICKUP

1.60

0.17

those

pickup

of

the

impedance

2.0

amp

for

current

the

tap

tap

overcurrent

X

BURDENS

OHMS

3

for

current

tap

of

tap

the

rating.

of

the

at

10

TIMES

PICKUP

1.60

0.17

the

rating.

the

at

2.0

minimum

(tap

0.5

2.0

amperes

IN

(Z)

TIMES

PICKUP

minimum

(tap

0.5

amperes

unit

20

1.60

0.17

ohm

tap

rating)

For

example,

ohm

tap

is

(IAC9OT)

CALCULATED

tap

of

rating)

For

example,

tap

is

of

each

relay.

varies

is

given

(0.5/2)2

are

AT

VA

5

IMPEDANCE

MINIMUM

(12Z)

40

4.25

each

relay.

varies

for

is

given

(0.5/2)2

inversely

for

a

as

x

given

AMPS

FROM

AT

PICKUP

inversely

a

as

x

relay

4.15

relay

1.60

The

4.15

in

The

1.60

=

INSTANTANEOUS

Burdens

AUXILIARY

The

milliamperes

battery

a

for

UNIT

auxiliary

at

drain

OVERCURRENT

the

unit

VDC.

48

of

35.7

UNIT

instantaneous

coil

A

1000

milliamperes.

has

a

ohm

overcurrent

TABLE

resistance

series

XI

resistor

of

unit

2500

is

are

ohms

added

given

and

for

in

a

125

Table

battery

VDC

IX.

drain

operation

of

1.92

with

9

Page 10

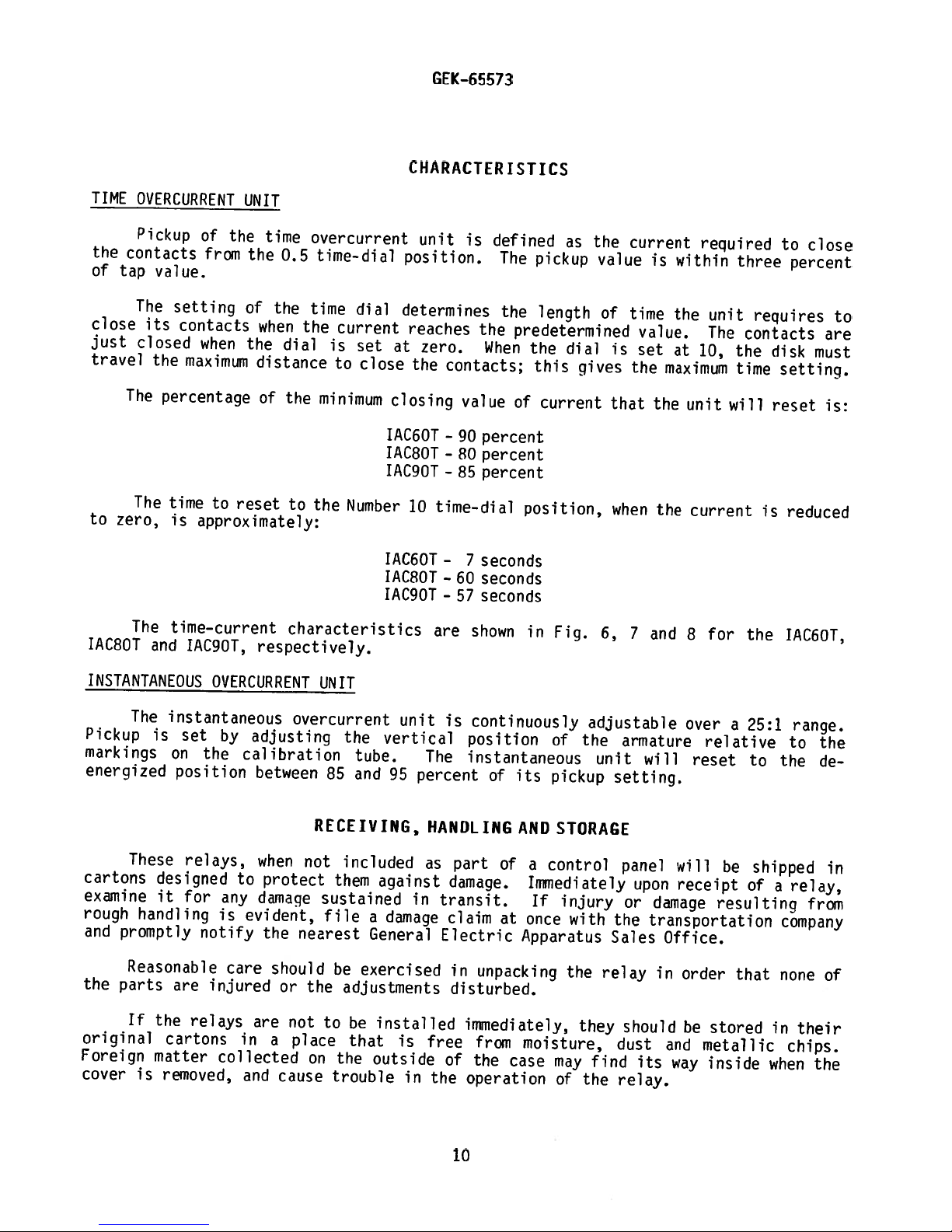

TIME

OVERCURRENT

GEK-65573

CHARACTERISTICS

UNIT

Pickup

the

contacts

of

tap

The

close

just

travel

its

closed

the

The

The

to

zero,

The

IAC8OT

and

INSTANTANEOUS

of

from

value.

setting

contacts

when

maximum

percentage

time

is

approximately:

time-current

IAC9OT,

to

OVERCURRENT

the

time

the

of

when

the

distance

of

reset

respectively.

overcurrent

time-dial

0.5

the

time

the

current

dial

is

to

the

minimum

to

the

characteristics

UNIT

dial

set

close

IAC6OT

IAC8OT

IAC9OT

Number

IAC6OT

IAC8OT

IAC9OT

unit

position.

determines

reaches

at

zero.

the

closing

10

time-dial

are

is

the

When

contacts;

value

-

percent

90

-

80

percent

-

85

percent

-

7

seconds

-

60

seconds

-

57

seconds

shown

defined

The

pickup

the

length

predetermined

the

this

of

current

position,

in

Fig.

as

dial

gives

the

value

of

is

that

when

6,

current

is

time

value.

set

the

the

the

7

and

required

within

the

unit

The

at

10,

maximum

unit

current

8

for

three

contacts

the

time

will

the

to

percent

requires

disk

setting.

reset

is

reduced

IAC6OT,

close

to

are

must

is:

Pickup

markings

energized

These

cartons

examine

rough

and

promptly

Reasonable

the

parts

If

original

Foreign

cover

The

instantaneous

is

on

designed

it

handling

the

cartons

matter

is

removed,

set

the

position

relays,

for

notify

are

injured

relays

by

adjusting

calibration

between

when

to

protect

any

damage

is

evident,

the

care

are

in

collected

and

overcurrent

not

nearest

should

or

the

not

place

a

on

cause

the

vertical

tube.

85

and

95

RECEIVING,

included

them

against

sustained

file

damage

a

General

be

exercised

adjustments

to

be

installed

that

the

outside

trouble

unit

is

The

percent

HANDLING

as

in

transit.

Electric

is

free

of

in

the

continuously

position

instantaneous

of

part

of

damage.

claim

in

at

unpacking

disturbed.

immediately,

from

the

operation

10

of

its

pickup

AND

STORAGE

a

control

Immediately

If

injury

once

Apparatus

moisture,

case

may

of

adjustable

the

unit

with

the

they

find

the

armature

setting.

panel

or

the

Sales

relay

should

dust

relay.

over

will

reset

will

upon

receipt

damage

transportation

Office.

in

order

be

and

its

way

a

relative

be

resulting

that

stored

metallic

inside

25:1

to

the

shipped

of

a

company

none

in

when

range.

to

relay,

from

their

chips.

the

de—

in

of

the

Page 11

GEK—65573

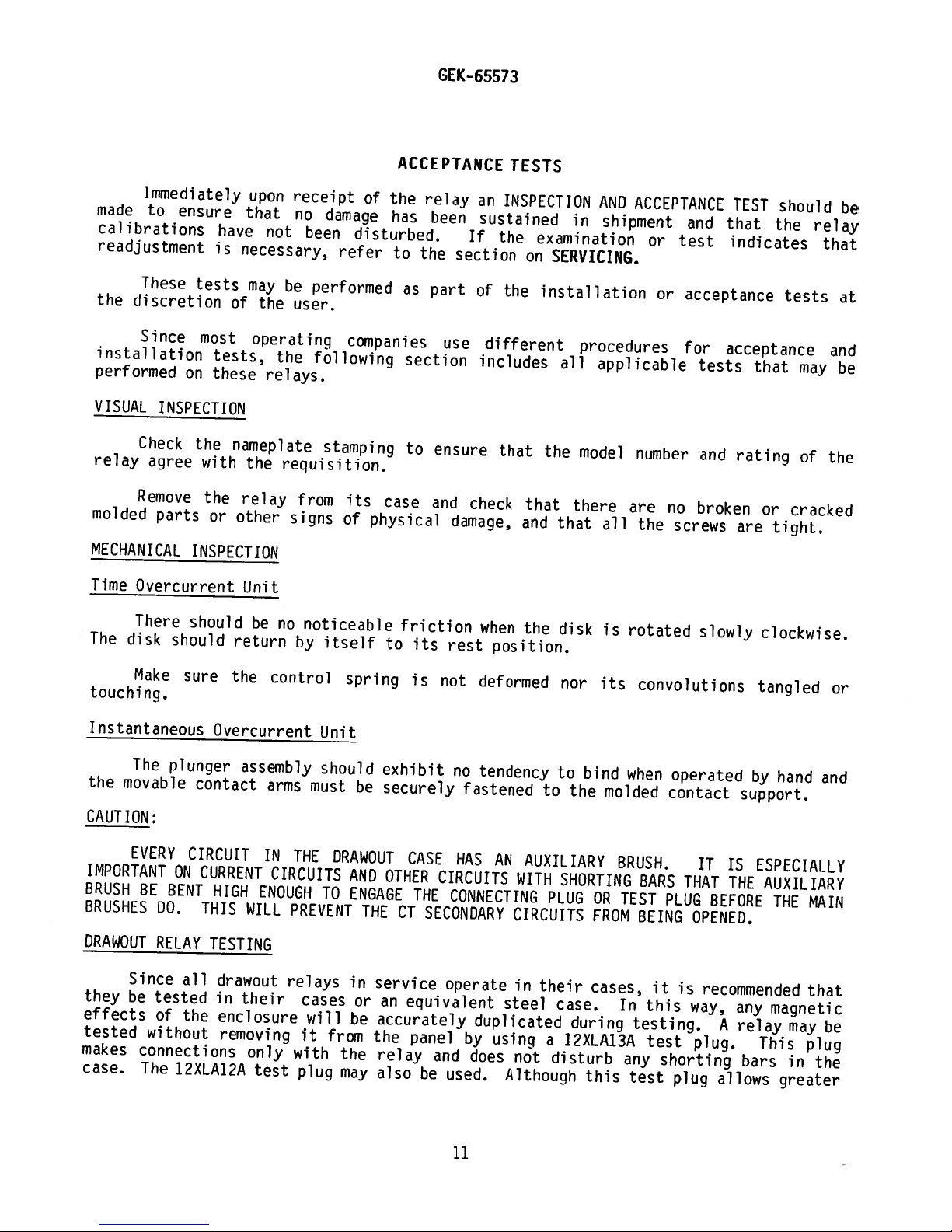

Immediately

made

to

ensure

calibrations

readjustment

These

the

discretion

Since

installation

perlormed

VISUAL

on

INSPECTION

Check

relay

agree

Remove

molded

parts

MECHANICAL

Time

Overcurrent

upon

that

have

is

tests

most

not

necessary,

may

of

the

operating

tests,

these

the

with

the

or

relays.

nameplate

the

relay

other

INSPECTION

Unit

receipt

no

damage

been

be

performed

user.

the

following

stamping

requisition.

from

signs

of

disturbed.

refer

companies

its

case

of

physical

ACCEPTANCE

the

relay

has

been

If

to

the

section

as

part

of

use

section

to

ensure

and

check

damage,

TESTS

an

INSPECTION

sustained

the

on

the

different

includes

that

that

and

AND

in

shipment

examination

SERVICING.

installation

procedures

all

applicable

the

model

there

that

all

ACCEPTANCE

and

or

test

or

acceptance

for

tests

number

are

the

no

screws

and

broken

TEST

should

that

the

indicates

tests

acceptance

that

rating

or

are

tight.

relay

that

may

of

the

cracked

be

at

and

be

There

The

disk

Make

touching.

Instantaneous

The

the

movable

CAUTION:

EVERY

IMPORTANT

BRUSH

BRUSHES

DRAWOUT

BE

DO.

RELAY

Since

they

be

tested

effects

tested

makes

case.

of

without

connections

The

should

should

sure

Overcurrent

plunger

contact

CIRCUIT

ON

CURRENT

BENT

HIGH

THIS

TESTING

all

drawout

in

the

enclosure

removing

12XLA12A

be

return

the

assembly

arms

IN

ENOUGH

WILL

their

only

test

no

noticeable

by

itself

control

Unit

should

must

THE

DRAWOUT

CIRCUITS

TO

PREVENT

relays

cases

will

it

from

with

plug

spring

exhibit

be

securely

AND

OTHER

ENGAGE

THE

in

service

or

an

be

accurately

the

the

relay

may

also

friction

to

its

is

CASE

THE

CT

SECONDARY

equivalent

panel

and

be

when

rest

position.

not

deformed

no

tendency

fastened

HAS

AN

CIRCUITS

WITH

CONNECTING

CIRCUITS

operate

in

steel

duplicated

by

using

does

not

used.

Although

the

disk

is

nor

its

to

bind

to

the

AUXILIARY

SHORTING

PLUG

OR

FROM

their

cases,

case.

during

a

12XLA13A

disturb

this

rotated

convolutions

when

molded

BRUSH.

BARS

TEST

BEING

In

testing.

any

test

operated

contact

PLUG

it

this

test

shorting

slowly

IT

THAT

BEFORE

OPENED.

is

recommended

way,

A

plug.

plug

allows

clockwise.

tangled

by

hand

support.

IS

ESPECIALLY

THE

AUXILIARY

THE

any

magnetic

relay

This

bars

greater

may

in

or

and

MAIN

that

be

plug

the

11

Page 12

GEK-65573

testing

since

POWER

flexibility,

connections

REQUIREMENTS

All

alternating

sinusoidal

fundamental

affected

by

Therefore,

to

use

freedom

relay;

sine

a

from

however,

electromagnets

sinusoidal

TIME

OVERCURRENT

Rotate

close

at

the

Where

brush

its

in

or

support.

waveforms

frequency,

the

applied

in

wave

harmonics)

any

(such

waveforms.

UNIT

the

time

zero

time

the

contacts

out

by

it

requires

are

made

GENERAL

current

can

it

waveform.

order

of

current

relay

as

time

dial

dial

just

means

of

to

he

analyzed

follows

to

properly

cannot

using

slowly

setting.

its

CT

shortinq

both

the

operated

that

and/or

be

tuned

overcurrent

and

close

can

adjusting

relay

devices

as

a

alternating

test

voltage.

expressed

circuits,

relays)

check

be

screw.

jumpers

and

the

are

fundamental

alternating

The

as

a

would

by

means

adjusted

This

and

external

affected

frequency

current

purity

finite

R—L

of

by

screw

the

current

or

RC

be

essentially

a

running

exercise

by

devices

of

the

number

lamp

should

circuitry.

frequency.

plus

relays,

sine

for

networks,

that

the

stationary

be

of

greater

harmonics

(relays)

it

is

wave

any

or

affected

the

contacts

held

Since

of

will

essential

(i.e.,

particular

saturating

by

contact

securely

care,

non-

the

he

its

non-

just

in

With

between

gap

approximately

The

position

When

connection

screws

tap

plug.

The

adjusting

notches

brought

around

into

adjustment

intermediate

the

factory

within

minimum

Time

five

closing

Setting

The

close

its

the

contacts

the

1/32

minimum

of

the tap

changing

plug

into

pickup

ring.

agreement

has

between

to

percent

setting

contacts

stationary

current

to

the

of

See

the

been

close

value.

of

inch

screw

the

short

tap

the

Fig.

edge.

disturbed.

the

of

the

when

just

wipe.

current

marked

unit

with

various

its

the

time

the

closing

at

in

the

2.

By

turning

contacts

tap—plug

current

contact

which

the

current

for

for

The

the

dial

at

the

tap

setting

the

any

ring

the

tap

This

tap

settings

from

determines

reaches

No.0time

brush

contacts

of

at

the

block

transformer

desired

current

may

be

ring,

setting

adjustment

any

setting.

setting,

and

its

will

the

top

relay

secondary

current

tap

is

turned

the

operating

employed,

to

be

obtained.

time-dial

The

the

length

a

predetermined

just

by

also

unit

metal

the

of

while

and

adjusted

inserting

permits

position

resets

of

there

backing

close

circuit.

then

current

if

time

value.

relay.

in

replace

by

for

The

should

is

determined

the

case,

means

a

screwdriver

of

some

any

unit

at

a

at

90

the

The

be

strip

Next,

the

of

the

reason,

desired

is

minimum

percent

unit

requires

contacts

sufficient

to

ensure

by

remove

screw

connection

spring-

a

in

unit

may

setting

adjusted

current

of

the

the

the

the

be

this

at

the

to

are

1?

Page 13

just

closed

travel

maximum

The

the

tiiiie

along

while

moving

the

time

its

when

maximum

setting.

primary

dial.

supporting

it

the

dial

amount

adjustment

However,

shelf;

away

increases

is

to

for

further

moving

set

close

the

adjustment

the

on

the

time.

GEK-65573

zero.

the

contacts

time

of

magnet

When

operation

is

obtained

toward

the

and

dial

therefore

of

by

the

disk

is

the

moving

set

unit

shaft

on

this

the

10,

setting

is

made

permanent

decreases

the

by

disk

gives

means

magnet

the

must

the

of

time,

Pickup

connections

two

Time

test

The

INSTANTANEOUS

Test

Set

the

percent

Test

Set

the

connection

relay

relay

in

of

relay

will

UNIT

Fig.

tap

in

Fig.

operate

at

13,

value

to

the

the

and

0.5

the

current.

No.

13,

RELAY

IAC6OT

IAC8OT

IAC9OT

main

apply

the

time-dial

unit

5

time—dial

five

timing

position

should

position

times

should

TABLE

XII

close

tap

be

TIME

and

and

current

within

1.73

1.27

0.89

2.0

its

contacts

the

the

IN

SECONDS

-

-

0.95

(10.0

1.83

1.35

ampere

2.0

limits

tap.

within

ampere

amperes)

in

Using

tap.

Table

plus

to

Using

the

XII.

the

or

test

minus

the

relay.

Pickup

aligned

pickup

unit

operating

continuous

gradually

95

AUXILIARY

connected

percent

picks

The

at

percent

The

up

and

units

with

settinq

this

coil

decreased

UNIT

relays

for

of

and

Reset

are

the

on

setting,

motion,

of

pickup.

the

the

lower

wipes

the

are

normally

top

the

unit

at

until

normally

lower

voltage

in

mark

on

nameplate.

see

should

the

calibration

the

value

with

one

supplied

the

Fiq.

contacts

shipped

of

rating

from

calibration

It

should

14.

pick

up,

from

the

dc

across

continuous

With

closing

current

reset.

the

voltage

motion

13

the

factory

tube.

be

gradually

level.

The

factory

rating

terminals

sufficient

its

reset

9

of

the

with

This

increasing

normally

The

value

with

shown

and

armature.

the

bottom

corresponds

to

check

open

test

current

should

the

coil

on

the

10

and

of

to

the

pickup

test

current

contacts

should

be

between

circuit

nameplate.

check

that

the

the

of

armature

minimum

of

each

in

with

then

85

unit

Apply

unit

the

one

be

and

HAN

60

“A”

Page 14

GEK—65573

INSTALLATION

The

relay

lighted

is

Typical

The

shown

The

to

facilitate

relay

in

internal

external

INSTALLATION

The

following

Time

Overcurrent

1.

Set

approximatley

until

current

Check

2.

tap

the

user.

Instantaneous

should

Fig.

TESTS

tap

value

relay

Unit

should

15.

connection

connections

tests

Unit

screw

light

the

is

the

operating

may

must

installed

be

inspection

be

mounted

are

on

twice

defined

be

coordinate.

in

five

diagrams

are

to

be

desired

tap

series

as

pickup

time

times

in

and

on

a

shown

performed

value

with

at

a

clean,

testinq.

vertical

for

in

tap.

until

and

some

tap

The

Fig.

Using

the

should

multiple

rating

value

dry

surface.

the

10.

the

at

contacts

contacts

or

used

location,

relays

time

the

be

of

the

The

are

of

test

just

begins

within

the

maximum

is

left

free

outline

shown

installation:

circuit

close.

to

flicker.

two

tap

value.

fault

to

from

and

in

in

Reduce

percent

the

dust,

panel

Fig.

Fig.

This

of

This

current

discretion

and

drilling

4

13,

the

current

value

tap

multiple

for

well

and

apply

value.

which

of

5.

of

of

the

1.

2.

3.

4.

Auxiliary

The

the

on

the

of

voltage,

Ri

is

diagrams,

Set

Set

approximate

pickup

Gradually

pickup

Check

Unit

operating

relay

two

the

in

series

Fig.

the

the

that

nameplate.

voltage

dc

leads

4

desired

pickup

setting.

apply

(see

coil

to

with

and

position

Fig.

the

instantaneous

circuit

As

ratings.

terminal

the

6.

tap

by

current

14).

shipped

auxiliary

range.

turning

in

of

If

points

the

and

the

from

it

the

calibration

adjust

unit

auxiliary

the

is

desired

and

9

unit

bottom

the

resets

factory

should

9A

coil.

of

tube

armature

between

unit

the

to

operate

Refer

the

corresponding

as

85

“A”

has

unit

be

interchanged

to

knurled

required

and

a

dual

is

connected

the

the

95

unit

internal

armature

to

for

percent

rating

dc

at

so

the

the

of

for

the

that

connection

to

desired

correct

pickup.

as

the

higher

resistor

the

shown

lower

dc

14

Page 15

GEK—65573

In

view

it

is

important

interval

and

the

experience

is

sugqested

of

between

user’s

to

that

years.

These

original

serviced

TIME

OVERCURRENT

1.

tests

settings.

as

described

Perform

setting

2.

Perform

INSTANTANEOUS

Check

outlined

in

that

the

PERIODIC

the

vital

that

a

periodic

periodic

experience

select

the

are

the

points

intended

If

in

UNIT

pickup

in

service.

the

time

UNIT

the

instantaneous

INSTALLATION

role

of

checks

with

test

interval

listed

deviations

this

manual.

tests

tests

section.

CHECKS

protective

test

will

periodic

to

insure

as

described

as

AND

program

vary

testing.

best

below

that

are

encountered,

described

unit

ROUTINE

relays

depending

suited

he

checked

in

picks

be

the

the

in

up

MAINTENANCE

in

the

operation

followed.

upon

Until

to

relays

at

the

the

his

an

have

relay

INSTALLATION

the

INSTALLATION

at

the

It

is

environment,

user

has

individual

interval

not

must

section

section.

desired

of

power

a

recognized

type

accumulated

requirements,

of

from

deviated

be

retested

current

for

one

from

level,

system,

that

of

relay

enough

to

their

the

the

it

two

and

tap

as

AUXILIARY

Check

UNIT

that

INSTALLATION

CONTACT

consists

effect

left,

the

files,

SYSTEM

For

a

yet

tool

abrasive

TEST

CLEANING

cleaning

of

superfine

it

insures

Although

relay,

intervals

overall

based

section.

flexible

a

will

this

the

auxiliary

relay

file.

clean

the

paper

instruction

functional

on

the

contacts,

strip

The

off

cleaning

or

cloth

tests

customer’s

unit

of

any

operates

a

metal

polishing

corrosion

of

the

of

any

book

to

experience.

flexible

with

actual

kind

is

check

when

an

etched—roughened

action

thoroughly

points

to

clean

primarily

the

voltage

burnishing

is

so

and

of

relay

written

system

is

applied,

tool

delicate

rapidly.

contact.

contacts.

to

operation

should

surface,

that

Do

check

are

as

outlined

be

resembling

no

scratches

The

flexibility

not

and

recommended

used.

use

set

in

knives,

the

the

This

in

are

of

TAC

at

15

Page 16

sections

restoring

IF

any

are

of

them.

the

found

mechanical

to

be

out

or

of

GEK-65573

electrical

limits,

SERVICING

check

the

followino

points

described

points

should

in

be

the

previous

observed

in

MECHANICAL

Time

Overcurrent

1.

Contact

The

contacts

contact

travel.

which

When

the

time-dial

correctly

position

Loosen

shaft

The

leaf

inch

1/64

thin

screwdriver

Shaft

2.

End

play

upper

the

is

pivot.

die-cast

approximately

magnet.

inch

1/32

adjustment

ADJUSTMENTS

Unit

Adjustment

should

tip

should

The

contact

scale

the

dial

should

regulate

time

adjusted,

of

the

arm

the

until

screw

spring

the

which

contacts

on

deflection.

blade

End

Play

is

determined

Both

supporting

centered

upper

The

play.

end

is

completed.

have

be

wipe

position

is

regulate

attached

the

The

bearing

pivot

Be

aprroximately

deflected

is

of

moved

indicate

clamps

just

stop

deflection

between

by

the

and

frame.

in

should

sure

that

adjusted

the

to

the

the

to

the

the

make

arm

should

the

relative

pivot

The

the

then

both

about

zero.

dial

arm

air

by

brush

position

to

shaft,

to

for

can

leaf

are

lower

be

set

1/3?

1/32

turning

relative

If

read

which

the

zero

be

so

be

spring

positions

held

jewel

gaps

located

screws

inch

inch

the

where

it

does

zero.

is

shaft

time—dial

formed

increased,

and

in

position

must

of

the

so

are

wipe.

when

to

and

the

of

that

screws

the

the

contacts

not

This

located

turn

setting.

that

if

stop

the

be

driving

the

securely

That

the

in

brush

and

is

done

below

the

there

necessary,

arm.

lower

means

by

located

magnet

shaft

is,

the

disk

the

stop.

just

the

by

the

arm

relative

is

jewel

of

so

has

tightened

stationary

completes

contact

brush

close,

brushes

changing

time

dial.

to

approximately

by

forcing

bearing

set

screws

that

the

the

and

inch

1/64

after

its

the

are

the

the

a

and

in

disk

drag

to

the

Friction

3.

to

gaps

any

slot,

tube.

to

bind

the

disk

can

tendency

contact

and

If

a

tendency

obstructions

drag

magnet

Instantaneous

1.

Friction

If

there

that

guide

the

plate

Unit

is

moving

calibrating

travel.

interfere

to

guide

that

or

no

excessive

with

bind

pin

foreign

Dirt

or

is

friction

or

the

motion

excessive

centered

matter

16

metallic

is

is

evident,

particles

of

the

disk.

friction

and moves

present

in

is

present,

freely

between

first

the

in

the

check

wattmetric

check

U-shaped

the

armature

to

for

or

see

and

Page 17

Moving

2.

The

flexible

assembly

should

straight

degree

and

the

ELECTRICAL

Time

Overcurrent

1.

Pickup

The

current

tap

screw

firmly

the

relay

connection

Contact

Leads

moving

centrally

be

reshaped

back

to

the

bend

in

the

bare

lead

ADJUSTMENTS

Unit

Adjustments

at

which

in

the

tap

into

the

tap

is

in

plugs

have

contact

located.

as

slot

lead

should

the

block

position

service

follows:

at

project

contacts

at

been

leads

If

these

in

the

a

point

the

marked

the

tap

withdrawn.

GEK-65573

should

moving

the

insulated

compound

just

either

operate

top

of

the

with

screw

be

contact

mounting

beyond

up

or

is

unit.

the

desired

must

formed

portion

the

down

normally

The

not

to

leads

plate.

end

to

the

controlled

tap

pickup

be

keep

have

of

the

There

of

the

terminal

screw

current.

removed

the

moving

been

deformed,

lead

should

insulating

by

should

until

should

screw.

means

be

Note

the

contact

extend

be

a

sleeve,

of

screwed

that

relay

they

90—

the

if

2.

The

pickup

adjusting

around

brought

adjustment

setting

close

percent

In

making

Note

that

Pickup

Normally

unit.

is

found

CHECKS,

supporting

moving

towards

on

the

moved

of

the

the

between

its

of

Time

If

it

it

the

disk

away

disk

of

ring.

edge.

into

has

contacts

the

pickup

the

Adjustments

pickup

the

to

be

can

shelf.

away

shaft,

for

from

at

the

The

By

agrenent

been

the

tap

checks,

“A”

unit

time

pickup

outside

be

restored

from

all

the

the

smallest

unit

ring

turning

disturbed.

various

from

plug

contacts

is

time

Moving

the

be

sure

positions

shaft,

for

may

with

tap

any

time—dial

setting.

use

controlled

for

the

by

the

shaft

that

its

radius

any

be

turned

the

the

This

settings.

the

connections

must

a

particular

limits

changing

magnet

increases

in

of

the

outer

current

ring,

tap

by

mentioned

its

disk

edge

of

tap

by

inserting

the

setting

adjustment

The

position

be

closed

means

the

towards

the

final

and

must

the

disk.

is

adjusted

operating

employed,

also

unit

at

of

Fig.

during

of

the

time—dial

in

position

the

time.

position

shaft

be

at

by

a

screwdriver

current

if

for

makes

is

adjusted

a

minimum

13.

tests.

time

dial

setting

ACCEPTANCE

of

the

shaft

If

is

decreases

the

drag

clears

assembly.

least

1/8

means

of

some

possible

at

current

at

and

TESTS

drag

magnet

the

If

inch

of

a

in

the

the

unit

reason

any

the

factory

within

the

top

pickup

and

multiple

PERIODIC

magnet

the

time

is

counterweight

the

magnet

from

the

spring—

notches

may

this

desired

five

of

the

its

on

while

moved

is

edge

be

to

Instantaneous

Refer

to

Unit

the

INSTA[LATION

section

for

current

17

pickup

adjustments.

Page 18

GEK-65573

to

enable

Electric

model

it

When

number

is

recommended

the

prompt

ordering

Company,

of

specify

the

that

replacement

renewal

quantity

relay

sufficient

parts,

for

of

which

RENEWAL

quantities

any

that

address

required,

the

part

PARTS

are

the

name

is

of

renewal

worn,

nearest

of

the

required.

broken

Sales

part

parts

or

Office

wanted,

carried

be

damacjed.

of

and

the

give

in

stock

General

complete

18

Page 19

GEK—65573

LIST

OF

FIGURES

PAGE

Fiq.

Fig.

Fig.

Fju.

Fig.

FiQ.

Fig.

Fig.

Fig.

Fig.

Fig.

Fig.

Fig.

1

JAC6OT

IAC6OT

2

3

IAC9OT

4

JAC6OT

5

IAC9OT

6

Inverse

7

Very

Extremely

8

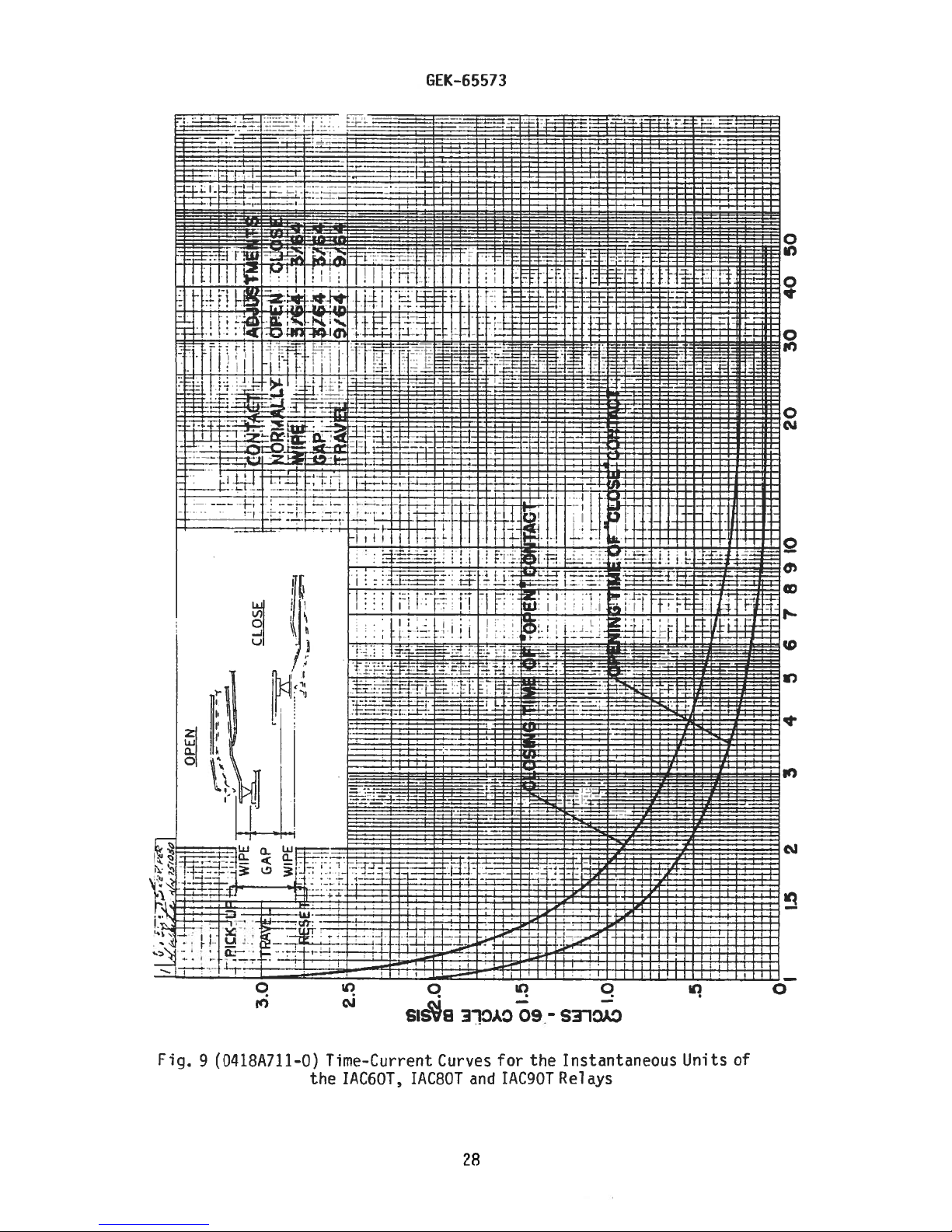

Instantaneous

9

10

External

11

Auxiliary

12

Cross

Test

13

Relay,

Relay,

Relay,

and

TAC80T

Internal

60

Hertz

Inverse

Inverse

Connections

Unit

Section

Connections

Front

Rear

Rear

Connections

Time

60

Hertz

Unit

of

Drawout

-

View

View

View

Internal

Curves

Hertz

60

Time

Time

Connections

Time

Curves

Time

Curves

Case

Overcurrent

Curves

Connections

Unit

19

20

21

22

23

24

25

26

27

28

29

30

31

Fig.

14

Test

Connections

Fig.

15

Outline

and

Panel

-

Instantaneous

Drilling

19

Unit

32

33

Page 20

GEK—65573

Fig.

1

(Later)

IAC6OT

Relay,

Removed

20

from

Case,

Front

View

Page 21

GEK—65573

Fig.?

(Later)

IAC6OT

Relay,

Removedfrom

21

Case,

Rear

View

Page 22

GEK—65573

Fiq.

3

(Later)

Type

IAC9OT

Relay,

Removed

22

from

Case,

Rear

View

Page 23

GEK-65573

II

13

i*

15

TOC

WOUND

SHADING

17

Is

lOC.

02

COILS

A

CONNECTIONS

SHOWN

LOWER

HIGHER

AIER(HANGE

LEADS

2

=

SHORT

*

Fig.

4

FINGER

(0275A4595—O)

Internal

Connections

for

B

Relay—Types

ID

IAC6OT

and

IAC8OT

FOR

RE

RATING.

RATING

FOR

THESE

23

Page 24

GEK—65573

Tio

clio

ç

TOC TOC

*

02

5

17

c

TOC

SHADING

R

bC’

WOUND

COILS

A

C4

CONNECTION

SHOWN

LOWER

HIGHER

INTERCHANGE

A

RATING.

THESE

ARE FOR

RATING

LEADS

S

FOP

=SHORT

FINGER

Fig.

5

(0275A4596—O)

Internal

8

Connections

24

for

Relay-Type

I0

IAC9OT

Page 25

a,

L7

C-fl

c-i)

SECONDS

IN

-

‘a

-

rn

0,

1

-,

‘a,

700

40

0))

1.a

‘cc

000

100

I00

00O

0)00

4000

.

V

—

-

—

0000

—

0000

—

0000

-

-

00:7

,c,00

—

88888k

8

-

0

-

0

-

0

—

--

0

o

00

o

-:

-

-“

0

‘

0

0

—

.i’

0

0

Ni

0

-,

0

—

-i

0

0

0

•

000

O0Ni

00..00

0

0

0

•

—0

Ni

a,

Lfl

=

0

0

0—

>0

C-4

8

3

H

-+

-

——--

:

I-

-

31(IL

NI

———--

———-—-

---

-----

————-

——--——-

—-

—-

--

——.——--

h———

uNO3

L772;

--

---

--

:1:

-

,‘;I___

Settings

Dial

---I

———--

—--

——--

-

--

:-

—-

——--

———-

-——--

-——--

:

—

--

--

:::::

-—-

C

I

—I

-U

r

(I)

1

0

—

—

Time

—

-

-

88•-

-

3

-

8

--

-

-

-

-

-

-

8

II

m

I

-<

-

:

-U

LI)

-1

z

-I

m

6)

——

—-

loot—-

—

1I

m

0,

Co

Co

0,

(J

=

-5

0,

C

-

-

C-,

-S

T

r\)

,

-S

CD

-S

C-)

Di

Di

Li,

C-,

-

C-)

Li,

-5

0

CD

-

Di

CD

C-)

C

a,

Page 26

2

I

LtJ

I

I

I

Oto

:0—

toO

.1.00

0

C

0

—

to

tO

z

to

to

o

(0

.1.000

0

C-

to

—

0=

to

0

-

o

(0

0

c

-

0

0

—

-

cc.”-,

0

—

-

C

-.

NI

2

I

o

—

L.

=

—

t_-t

(C

to

c-to—

-

C

Lt

—

‘—C

C

-,

-o

to

=

I—

—

to

cc

>-

—O

II!!!!

I

I

1

III

I

I

£GNO3c

NI

U

H

H

EEEE

EEE

HEEE

EE’

,

EE

rE’E—’

—

—

-

::

-

-

:::

—

—

—

-

::

-

- -

::::z

---

--

--———

-————

--

--————

---———

---

.-—

sujsoIQeuIIj

-————

--———

-

-

--——

.

---—

-.--

---

-——

--

-

--——

---—

—

--

--——

-

--

——

---—

—

--

----——

-

.—-——

--

---——

--

--

-

---——

--——

-

-

-

-

——

--

——

--

I

liME

---—

---—

--

-——

IN

*a

H

‘

E

—

:

EEEE:

- -

—

—

—

—

S

-

-

----

——NI

—

—

_“•

--

ci

-

-

-

-

-

—

a)

----—a.

c

-

-

-

-

-

---—

---—

---—.——

——

—

1

I-.

C,

z

—

C

03

S.

Q-)

>

I

I

I

I

Page 27

.0

.0

.7

.4

100

410

040

I04

00

IC

70

10-

I.-

44-

00-

,-

RAT

I

TIME

0.5-9.0

1.5—12.0

2-5

————-

——-——-

————-

—

I

0

BOO

UNIT

INST.

0.

2—16

I

0-661

20-60

IJNIT

-Ll.

—--

—--

411

7

0

--

--

--

--

--

GEK-65573

I

III

————-

————-

————-

———--

———--

00

00

40

00

10101010.—

EXTE

t

CEID

0.5,0.6,0.7,O.8,,.U.l.2,l.5,2.0,2.S,3.0,4.0

.5,2.0,2.5,3.0,4.0,5.

2.0,2.5,3.0,

RM’IC-E

TIME

LI.

0,5.0,6.0,7.0,

UNIT

--

(80C

TAPS

0,6.0,7.

--

--

--

--

H

I

H

I

I

I

I

II

I

SERIES)

ADJ

ml

US

INST

UNIT

CONT

I

0,6.0,

10,

8.0.

——

———

——

——

——

2.

0.0,

5

12,

—-C---

—

--

—

-

-

.

----

—--

—--

—--

—-—

-——-—

---

--

——

——

——

NIJOUSLY

ADJUSTABLE

—

—

-

-

F

NT

S

-

-

-

-

-

III

HI

100

—--

—--

—--

---

---

I.

II

II

JO

1)

I’-

z

0

C.)

L.2

—

!th\r::

\__

--

—----

--

—---

EEE

--

—---

EZEEEE:

.4

0”

2

Lfl

0

2

.7.

a

-I

I

-7

Fig.

8

(0888B0274-.5)

0

7

4

I

1

I

I

III

III

MULTIPLES

60

Hertz

20

20

Time-Current

JO

JO

OF

40

40

IO7II0II

IO7IId4,

00

00

RELAY

Characteristics

27

TAP

g

s

SETTING