Page 1

GE MDS

Reference Manual

Part # 05-4811A01, Rev. A

Intrepid-HC HP

Wireless Broadband Transceiver

Version 1.x

Page 2

Page 3

Table of Contents

Chapter 1 Installation.................................................................................... 1-1

General......................................................................................................................................1-1

1+0/1 + 1 Instal la t ion .................................................................................................................1-4

2+2 XPIC Installat ion.............................................................................................................1-12

N+1 Sp lit Moun t Insta llation ................................................................................................1-16

Insta llatio n C o n figura tion Illust ra t ions..............................................................................1-18

Chapter 2 Initial System Setup..................................................................... 2-1

General......................................................................................................................................2-1

Initial Setup using the Craft Terminal..................................................................................2-2

Additional Setup using the NMS........................................................................................... 2-5

Initial Setup for GE MDS Intrepid-HC HP/T .......................................................................2-14

Connecting Line Interfaces .................................................................................................2-32

Chapter 3 Acceptance & Commissioning Procedures............................... 3-1

Site Acceptance Procedure................................................................................................... 3-2

1+0 Commissioning Procedure ............................................................................................3-7

1+1 Commissioning Procedure ............................................................................................3-9

2+0 XPIC Co mmissi o ning Pr o c e dure................................................................................. 3-12

GE MDS Intrepid-HC HP Commissioning Log..................................................................3-15

Appendix A—Connector Pin-Outs...............................................................A-1

General......................................................................................................................................A-1

External Alarms Connector Pin-Out.....................................................................................A-2

Protection Connector Pin-Out...............................................................................................A-3

Modem-PPP Cr oss Cable Pin-Outs......................................................................................A-4

Wayside Channel Connector Pin-Outs................................................................................A-5

Appendix B—PPP/SLIP Driver Installation..................................................B-1

Appendix C—Frequency Information ..........................................................C-1

Page 4

Safety Precautions & Declared Material

Fiber Optic Line Precautions

Before tur ning on the equipment, m ak e s ure that the f iber optic cable is intact an d is

connected t o t he trans mitt er.

!!

!!

Do not use broken or non-terminated fiber optic cables/connectors or look

!!

ATTENTION: The laser beam is invisible!

The use of optical devices with the equipment will increase eye hazard.

Do not attempt to adjust the laser drive current.

straight at the laser beam.

!!

CLASS 1 LASER PRODUCT

Complies with IEC 60 825-1:1993 + A1:1997 + A2:2001, and EN 60825-1:1994

+ A1:1996 + A2:2001

General Equipment Precautions

Use of controls, adjustments, or performing procedures other than those

!!

When working with an IDU, note the following risk of electric shock and

!!

!!

specified herein, may result in hazardous radiation exposure.

energy hazard: Disconnecting one power supply disconnects only one power

supply module. To isolate the unit completely, disconnect all power supplies.

Machine noise information order - 3. GPSGV, the highest sound pressure

level amounts to 70 dB (A) or less, in accordance with ISO EN 7779.

Page 5

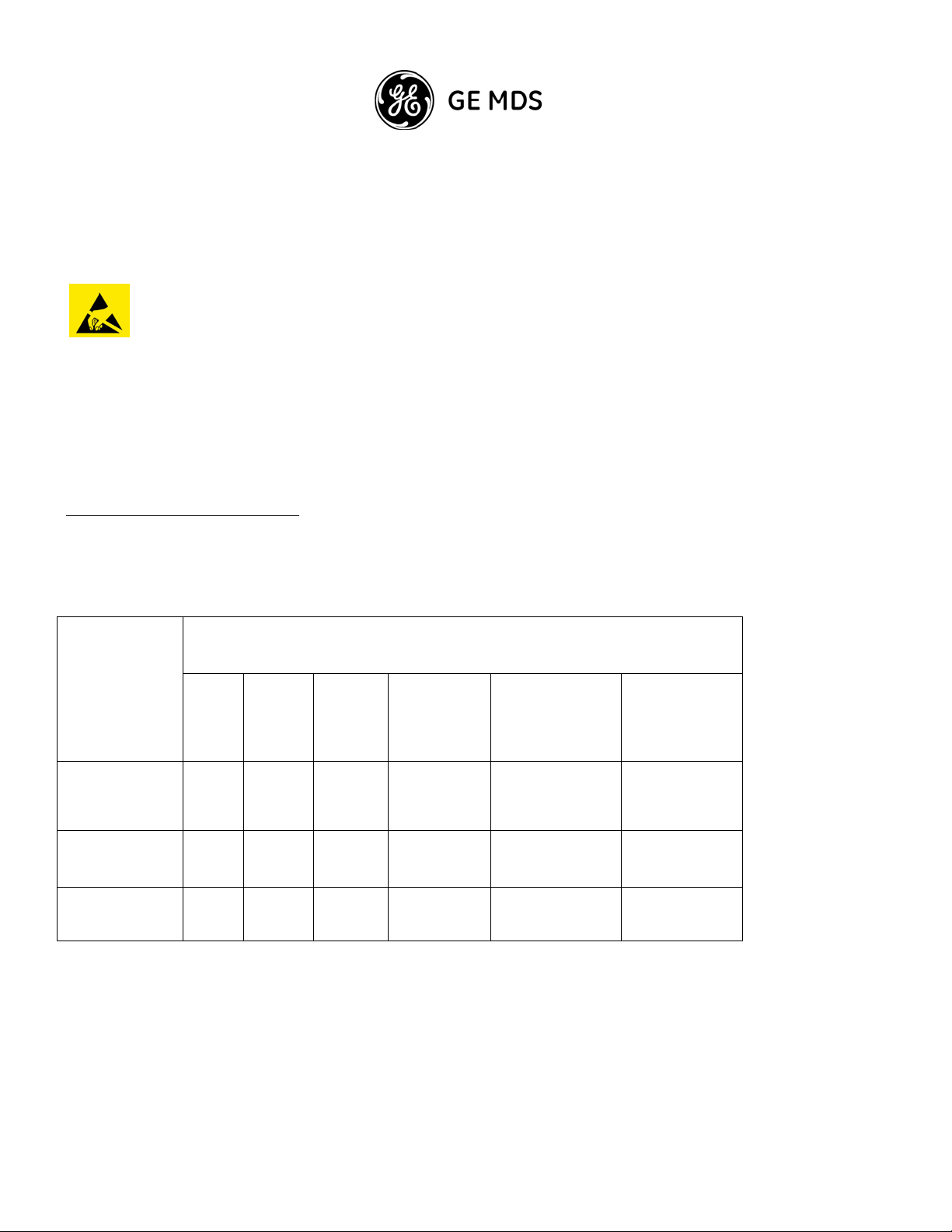

Safety Precautions & Declared Material (continued)

Static electricity may cause bodily harm, as well as harm to electronic components

inside the device.

Anyone responsible for the installation or maintenance of the IDU must use an

ESD Wrist Strap.

ESD protection measures must be observed when touching the IDU.

To prevent damage, before touching components inside the device, all electrostatic

must be discharged from both personnel and tools.

RoHS Compliance Declaration

子信息品有毒有害物申明

Component

/

PCB/Circuit

Modules

Mechanica l Par t s

Cabl es

Electronic Info r mation Pro duct s Decl arati on of Haz ardous /Toxic Substanc es

Hazardous Substance

Lead

(Pb)

Comply Comply Comply Comply Comply Comply

Comply Comply Comply Comply Comply Comply

Comply Comply Comply Comply Comply Comply

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium (Cr

VI)

Polybrominated

Biphenyls (PBB)

Polybrominated

Diphenyl Ethers

(PBDE)

Page 6

Page 7

Chapter 1: Installation

General

This guide provides insta llation procedures for the following GE MDS Intrepid-HC HP systems:

GE MDS Intrepid-HC HP 1+0/1+1 configuration

GE MDS Intrepid-HC HP 2+2 XPIC configuration

GE MDS Intrepid-HC HP N+1 configuration

Abou t GE MDS Intrepid-HC HP

The GE MDS Intrepid-HC HP supports multiple capacities, frequencies, modulation sc hemes, and configurations

for various network re quirements. Its RF transceiver units operate in the fr equency range of 6-11 GHz.

GE MDS Intrepid-HC HP capacities can be upgraded from 45 Mbps up to N x 155 Mbps.

For long distance links and bac kbone requirements, GE MDS Intrepid-HC HP offers Space Diversity functionality.

Each transceiver can contains two receivers and one transmitter, which enable built-in diversity capa bility.

Built in Diversity in each transceiver increases the reliability of the link. In a 1+1/2+2 Hot Standby or N+1

configuration w ith Space Diversity, if a hardware failure occurs, the Diversity will not be affected.

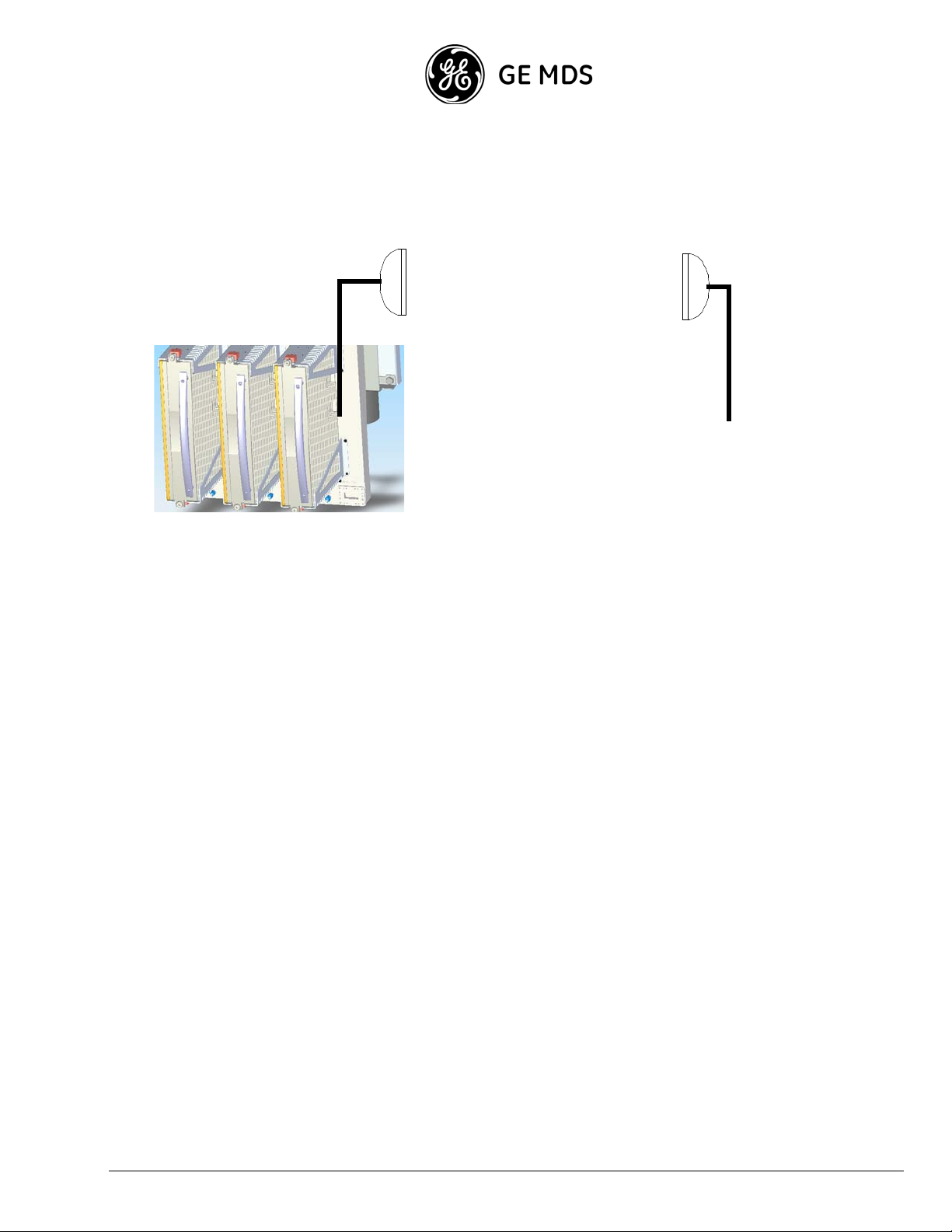

GE MDS Intrepid-HC HP is installed in a Split-Mount configura tion, as shown in the following example

illustration.

GE MDS Intrepid-HC HP Installation Guide 1-1

Page 8

2+0 Confi gurati on

The GE MDS Intrepid-HC HP RFU works together with Intrepid-HC, Intrepid-HC HP/T, and Intrepid-HC 64P,

which are modular network connec tivity IDUs designed to meet growing market demands for increased spectralefficient systems.

GE MDS Intrepid-HC is designed to deliver double the ca pacity using a single 28 MHz wide channel. The system

is easy to install, offers a variety of interface possibilities, and represents a cost-effective alternative to fiber.

GE MDS Intrepid-HC HP/T (all indoor, trunked unit) is a high capacity N+1 trunk radio system that was designed

to support multiple capacitie s, frequencies, modulation schemes, and configurations for various network

requirements.

GE MDS Intrepid-HC 64P is a high capacity PDH radio designed for seamless upgra de from medium to high

capacity, with a built-in Fast Ethernet port and switch.

GE MDS Intrepid-HC HP RFUs together with the different GE MDS IDUs provide a powerful, reliable, a nd

comprehensive solution for a variety of wireless network scenarios and requirements.

GE MDS Intrepid-HC HP RFU

GE M D S Intre pi d -HC I D U

GE MDS Intrepid-HC 64P IDU GE MDS Intrepid-HC HP/T IDU

1-2

GE MDS Intrepid-HC HP Installation Guide

Page 9

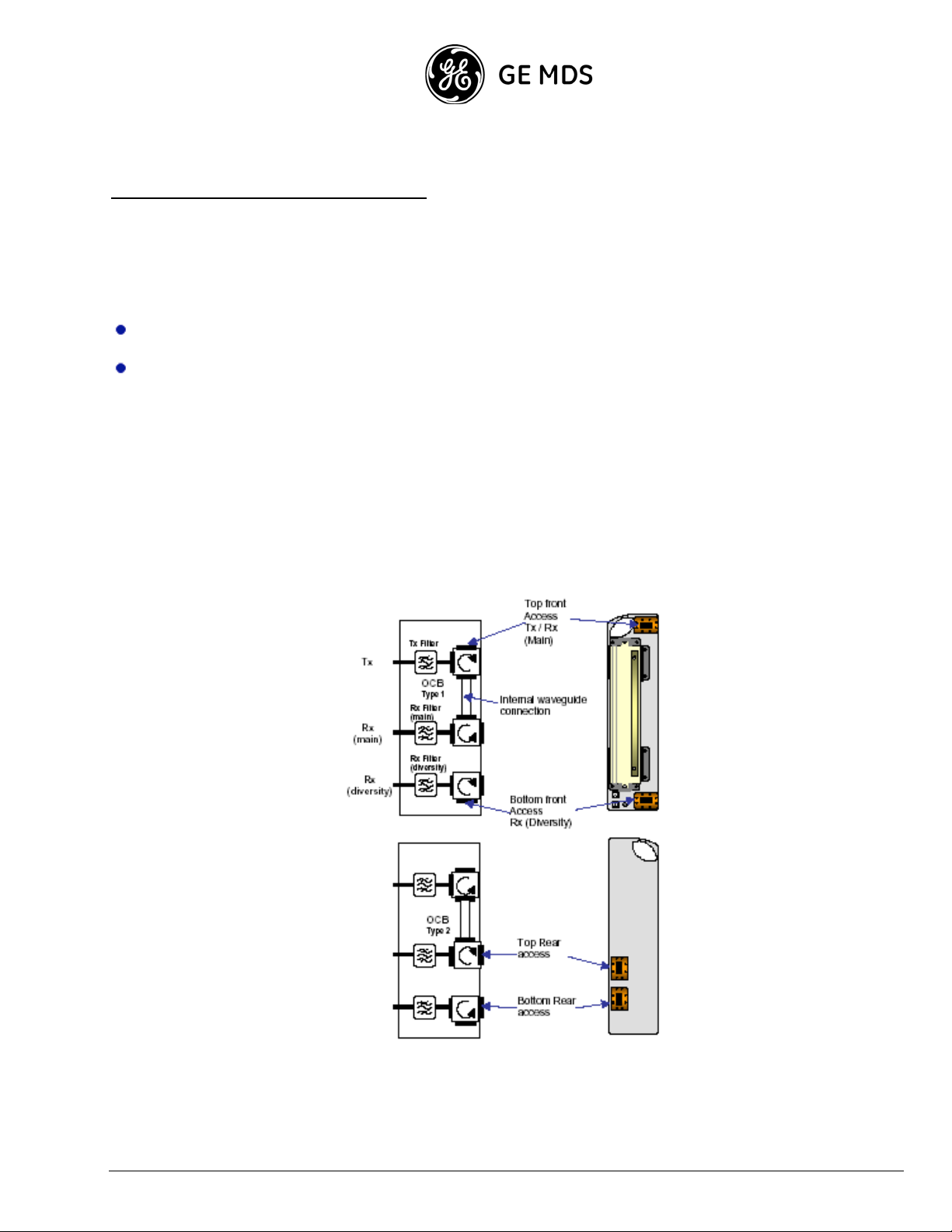

About the GE MDS Intrepid-HC HP OCBs

GE MDS Intrepid-HC HP RFUs and OCBs (Outdoor Circulator Blocks) can be chained in different ways for

different configurations.

Two types of OCBs can be used:

Type1 OCB

Type2 OCB

The main difference between the tw o types are the cir culator directions. Depending on the configur ation, OCB Type

1 or Type 2 are used together with waveguide shorts, waveguide loads, U Bends, C Bends, or couplers.

Each OCB has four waveguide access points: two in the front, and two at the rear. The diversity access point is

optional.

If the system is not configured f or diversity, all the relevant access points on the OCB must be terminated using

waveguide shorts

.

Type 1 OCB

Type 2 OCB

GE MDS Intrepid-HC HP Installation Guide 1-3

Page 10

s

1+0/1+1 Installation

This section describe s the installation procedure for GE MDS Intrepid-HC HP in a 1+0 or 1+1 configuration.

The components involved in this proce dure include the following:

RFU

OCB

Hang e r Ki t

Pole Mount Kit

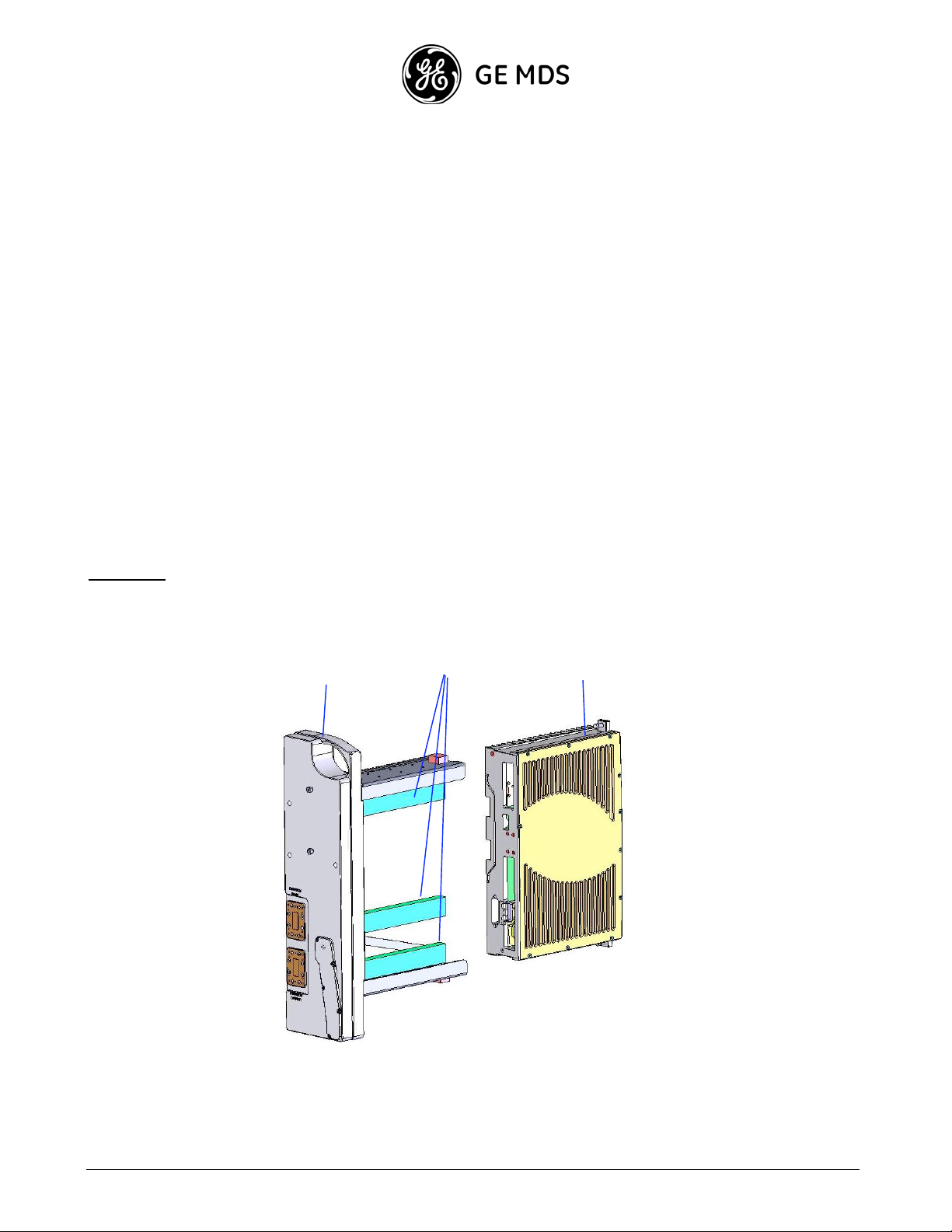

Assembling the RFU and OCB

The RFU is generally assembled in the factor y with the OCB, and de livered as a single unit.

If the RFU is delivered separate ly with the OCB, do the follow ing:

Important:

1. Remove the RFU and the OCB from the box.

The instructions in this guide should be performed indoors.

OCB

Filter

RFU

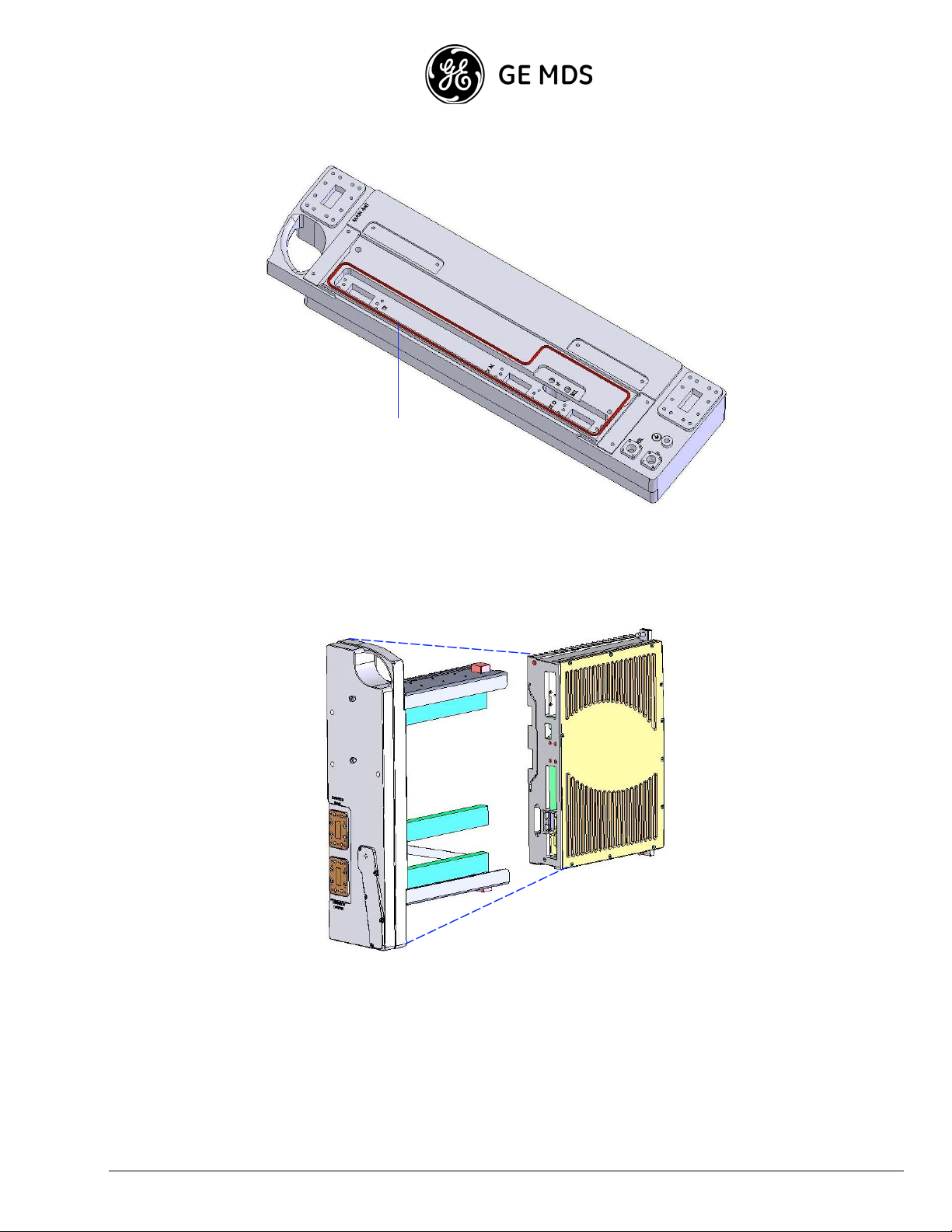

2. Make sure that the OCB sealing gasket is in place.

1-4

GE MDS Intrepid-HC HP Installation Guide

Page 11

OCB

Sealing

Gasket

3. Gently slide the RFU in the OCB, making sure that the two empty spaces in the RFU correspond to the filte r

positions on the OCB.

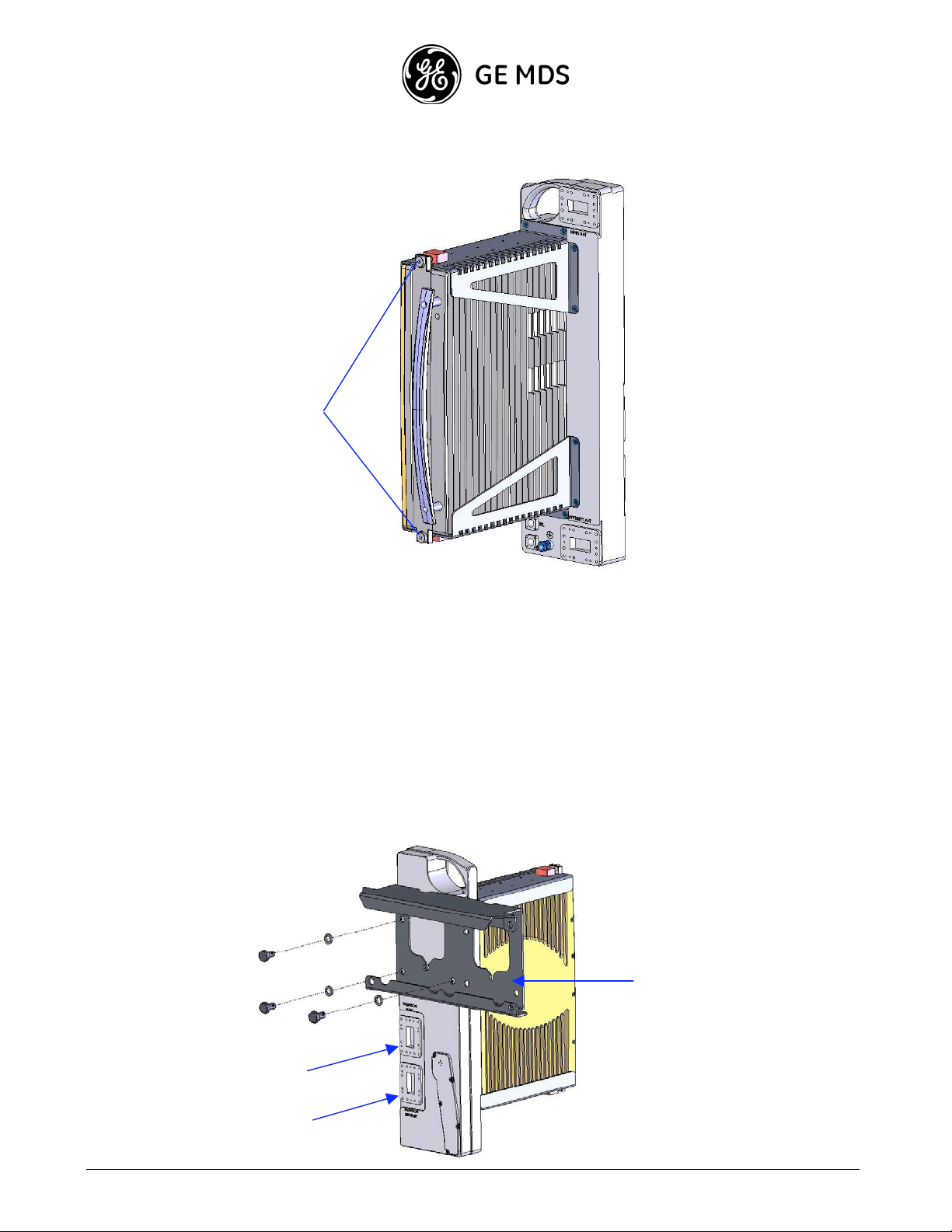

4. Tighte n the Allen Head screws to the OCB using an Allen wrench.

GE MDS Intrepid-HC HP Installation Guide 1-5

Page 12

)

Allen

Head

Screws

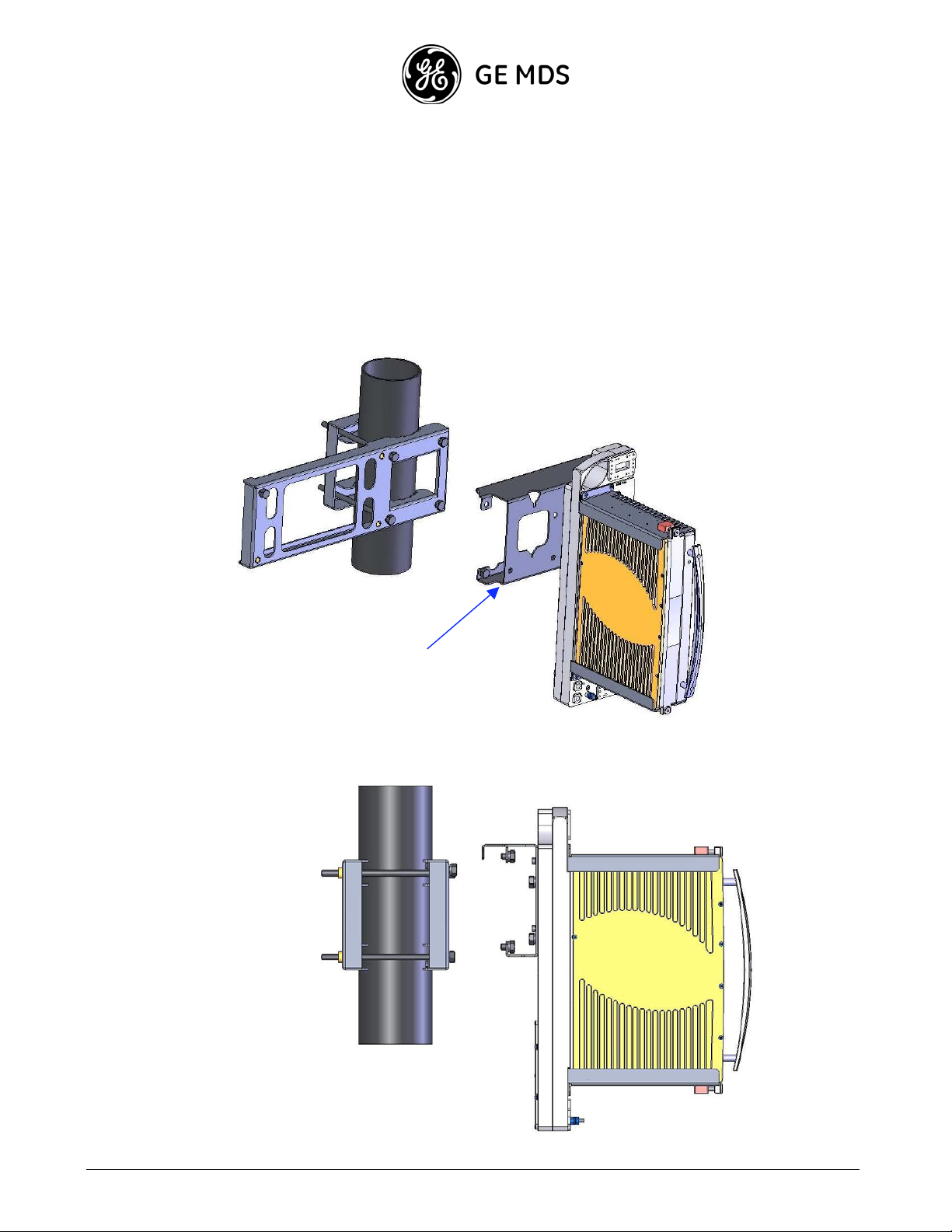

Assembling the Hanger Kit

The Hanger Kit is used to connect two RFUs and OCBs to the Pole Mount Kit. It consists of a single metal plate.

To assemble the Hanger Kit together with the RFU and OCB:

1. Place the RFU on the floor and hold it upright, as shown in the photo below.

2. Place the Hanger Kit in line with the OCB, as shown in the illustration below , a nd fasten the Kit to the OCB

using 3 large (M-10 type) screws.

Three Screws

1-6

Fas teni ng the

Hanger Kit to

the

OCB

Main

Extension

Diversity

GE MDS Intrepid-HC HP Installation Guide

Hanger Bend

(to place on

the

Pole Kit

Page 13

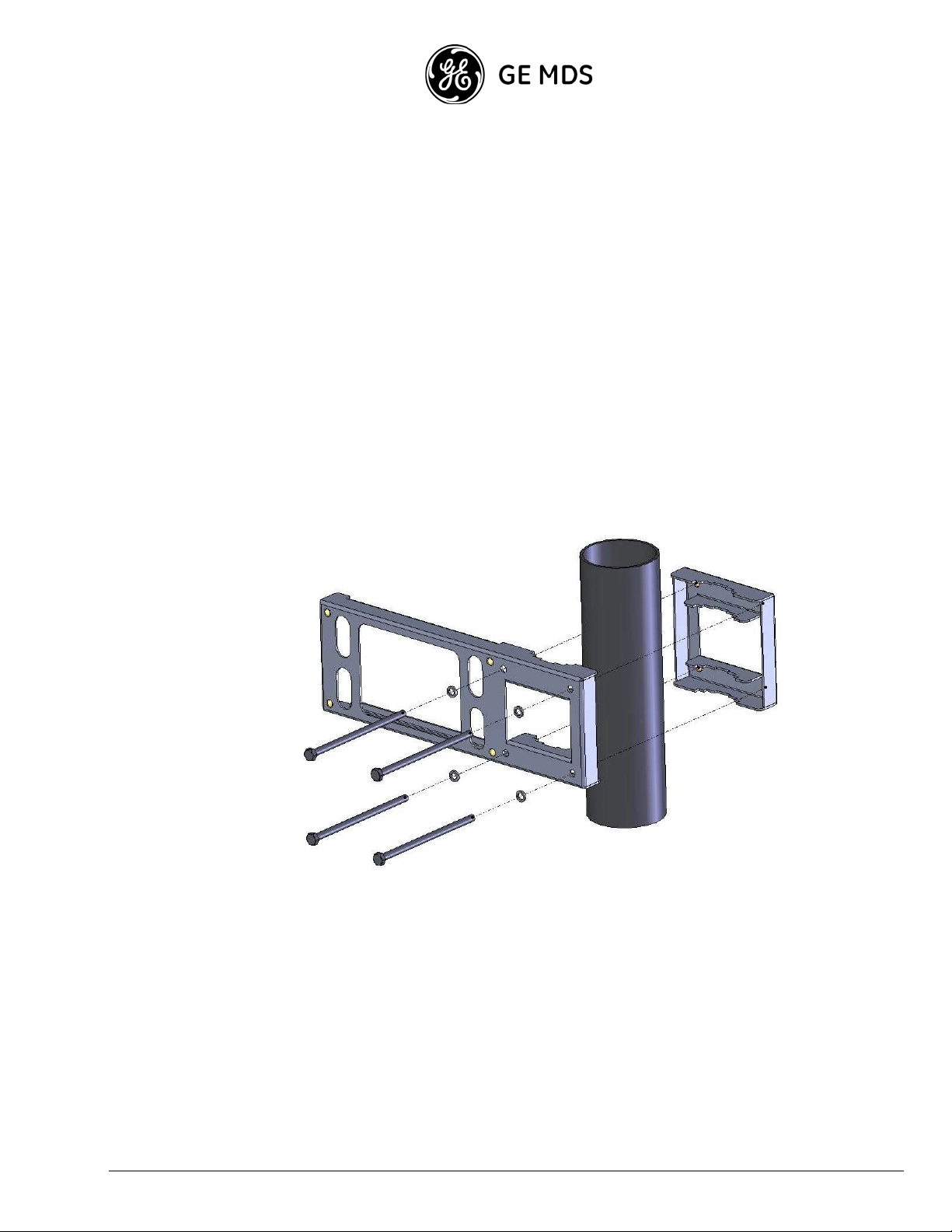

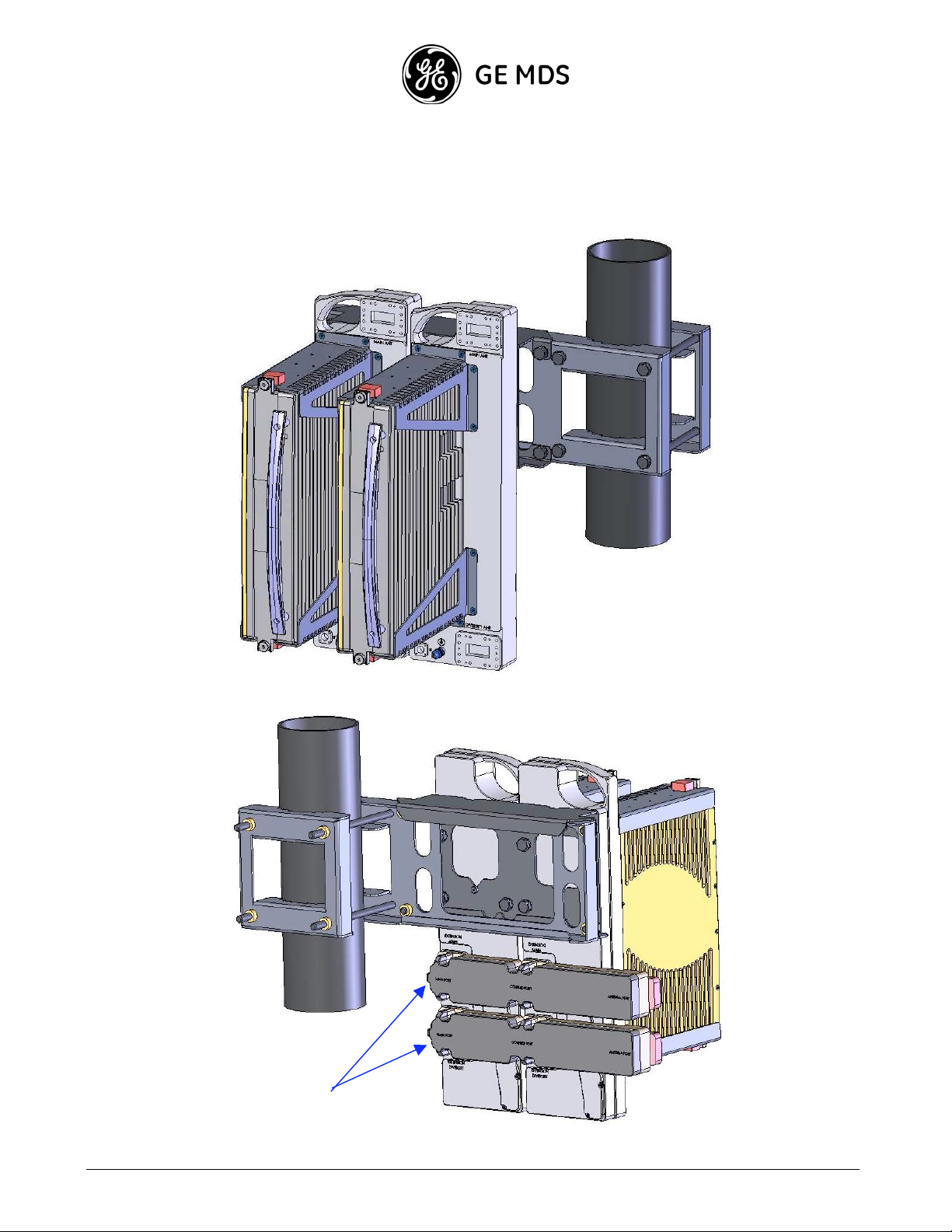

Assembling the Pole Mount Kit

The Pole Mount Kit is used to connect the Hanger Kit (together with the RFU and OCB) to the pole.

The kit consists of a single metal plate with a clamp assem bly.

Important: The diameter of the pole upon whic h the kit is mounted must be between 50 mm (2") and

125 mm (5").

To assemble the Pole Mount Kit on the pole:

1. Open the Pole Mount Kit clamp, and assemble the kit on the pole, as shown in the following illustration.

Four Screws

Fas teni ng the

Pole Mo unt Kit

to the Po l e

2. Fasten the kit to the pole using the 4 screws, as shown in the photo above.

GE MDS Intrepid-HC HP Installation Guide 1-7

Page 14

Assembling the Hanger Kit (with RFU and OCB) and Pole Mount Kit

To assemble the Hanger Kit and the Pole Mount Kit:

1. Lift the Hanger Kit with the fastene d RFU and OCB, and hang it, using the Hanger Bend, on the Pole Mount

Kit, as shown in the following illustrations.

Hanger

Bend

Side view

showing how

the Hanger

Kit is hung on

the Pole

Mount Kit.

1-8

GE MDS Intrepid-HC HP Installation Guide

Page 15

Mount Kit.

Side view of

the Hanger

Kit assembled

on the Pole

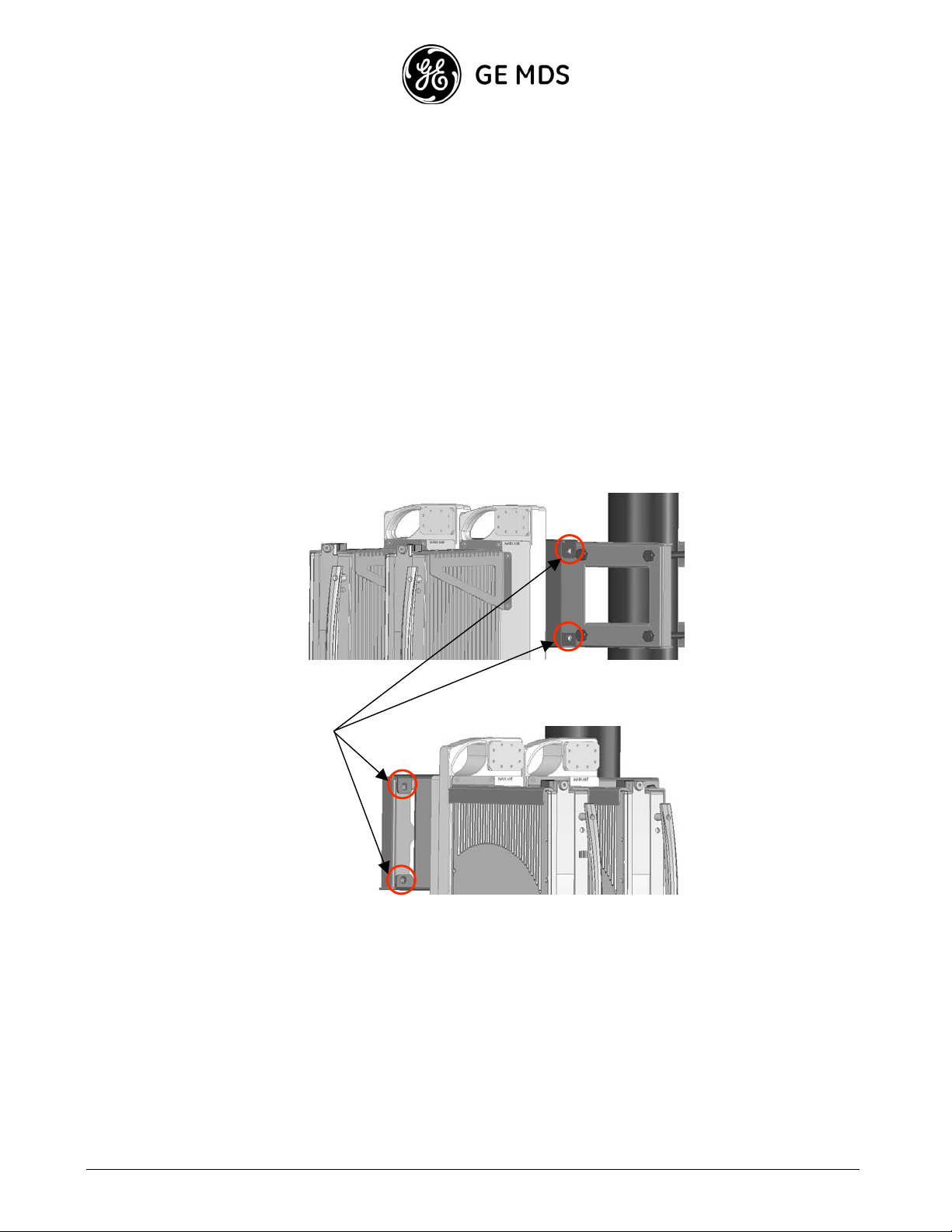

2. Faste n the Hanger Kit to the Pole Mount Kit using 4 large (M-10 type) screws, as shown in the following

illustration.

Screws

fastening

the Hanger

Kit to the

GE MDS Intrepid-HC HP Installation Guide 1-9

Page 16

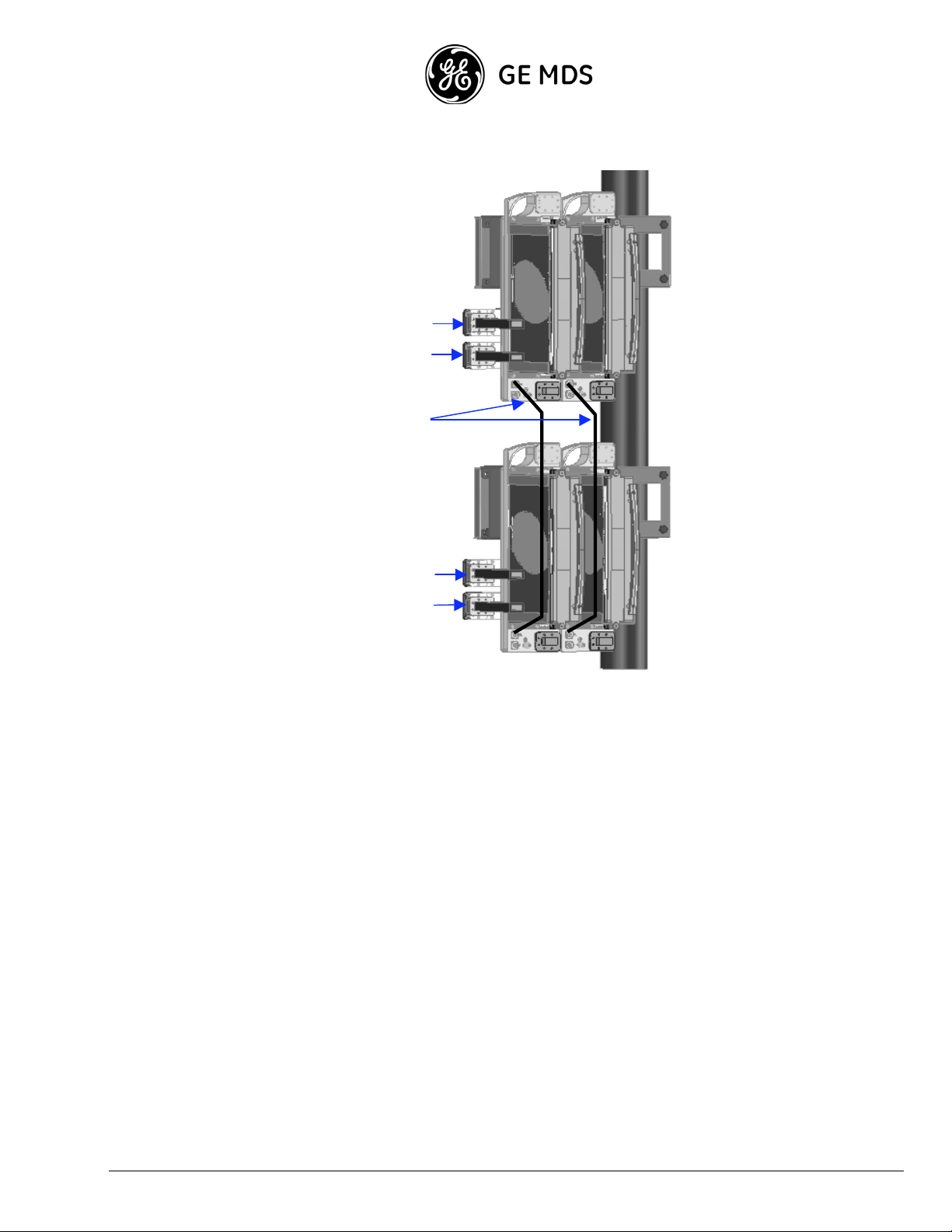

Each Pole Mount Kit can accommodate two RFUs and OCB units, as shown in the following illustration.

Couplers

1-10

GE MDS Intrepid-HC HP Installation Guide

Page 17

RFU Cable Connections

The RFU cable connectors are located on the bottom of the RFU, as shown in the following photo:

XPIC/RSL

IF

Ground

Waveguide

The connections include the following:

XPIC/RSL For XPIC functionality and radio signa l monitoring.

IF Connects the RFU to the IDU.

Ground Used for electrical gr ound.

Flexible Waveguide Connects the RFU to the antenna.

GE MDS Intrepid-HC HP Installation Guide 1-11

Page 18

2+2 XPIC Installation

This section describe s the installation procedure for GE MDS Intrepid-HC HP in a 2+2 XPIC configuration.

Flexible Waveguide

Connection to Main

Horizontal and

Vertical Antenna

Ports

Elliptical Waveguide

/ Waveguide-toCoax Connection to

Diversity Horizontal

and Vertical

Antenna Ports

1-12

GE MDS Intrepid-HC HP Installation Guide

Page 19

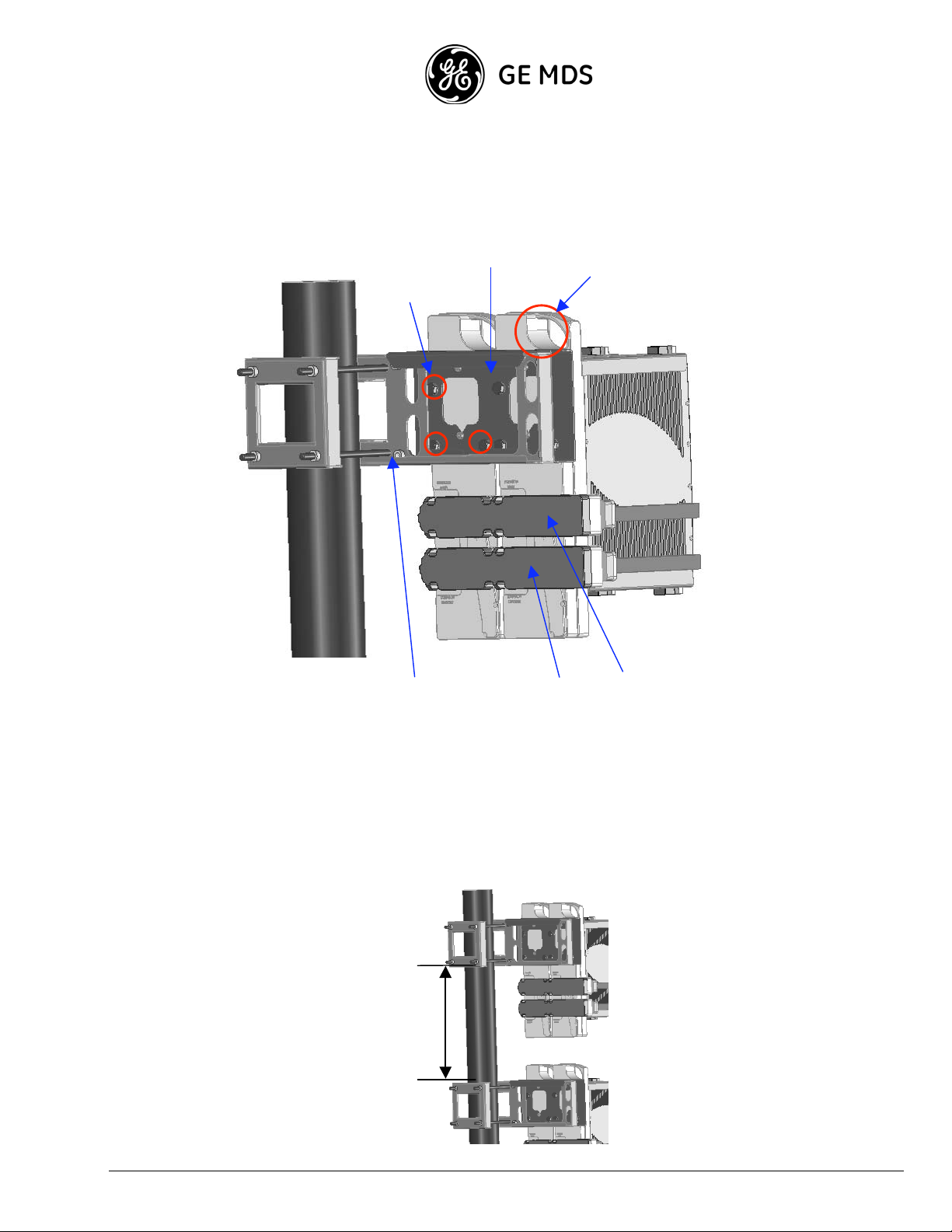

Installation Components

M10 Scre ws

Fastening

the OCB to

the Hanging

Bracket

Hanging

Bracket

Lifting

Handle

Pole Mount

Kit with Cl amp

Bracket

Diversity

Coupler

Main

Coupler

Installation Procedure

1. Connect both pole mount kits to the pole.

If the RFUs are to be assembled one above the other, there should be a minimum distanc e of 40 cm between

the two pole mount kits, as shown in the following illustration.

40 cm

GE MDS Intrepid-HC HP Installation Guide 1-13

Page 20

Important: The diameter of the pole upon which the kit is mounted must be between 50 mm (2") and

125 mm (5").

2. Connect shorts and 50 ohm terminations on all OCBs (shorts on main antenna ports, 50 ohm terminations on

diversity antenna por ts).

3. Assemble both couplers on the OCBs.

4. Attach the hanging bracke t to the OCBs and tighten the screw s that fasten the OCB to the hanging-bracket.

5. Gently lift the assembled unit to the pole using the lifting handle.

6. Place the assembled units on the pole mount clamp bracket and fasten the M10 screws, as shown in the

following illustration.

M10 Scre ws used

to Fasten the Units

to the Pole M ount

Clamp

7. Connect the XPIC cables between the units, as shown in the following illustration.

1-14

GE MDS Intrepid-HC HP Installation Guide

Page 21

Main Antenna H Pole Port

Diver s i ty Antenn a H Po l e Port

XPIC Cables

Main Antenna V Pole Port

Diver s i ty Antenn a V Pole Port

8. Connect the flexible wa veguides to the antennas, as shown in the illustration above (V and H poles are

selected as requir ed - in the illustration above they are selected arbitrar ily).

GE MDS Intrepid-HC HP Installation Guide 1-15

Page 22

g

(

)

N+1 Split Mount Installation

This section describe s the installation procedure for GE MDS Intrepid-HC HP in an N+1 split mount configuration,

where N is less than or equal to 5.

A split mount N+1 configuration is achieved using Type-1 and Type-2 OCBs alternatively.

Two Type 1 a nd Type 2 OCBs are interconnected via U bends at the rear extension ports. The third OCB is chained to

the second OC B through the main and diversity ports, using a flexible waveguide.

Each OCB is conne cted to the relevant IF ca ble from the Intrepid-HC HP /T Baseband Indoor.

The following example shows a 4+1 space diversity dual pole configuration.

Flexible

Wave

uide

To Main V

Antenna

Flexible

Waveguide

Termination

U Bend

To Diversity V

Antenna

To Main H

Antenna

U Bend

To Diversity H

Antenna

4+1 SD Dual Pole

Split Mount

(OCB Front View)

1-16

GE MDS Intrepid-HC HP Installation Guide

4+1 SD Dual Pole

Split Mount

OCB Rear View

Page 23

Note: When installing an N+1 configuration, a ssemble the OCBs in an inverted order, to maintain the same

branching loss betwee n the carriers, as shown in the following illustration.

Site A

C1

C2

C3

Site B

C3

C2

C1

GE MDS Intrepid-HC HP Installation Guide 1-17

Page 24

Installation Configuration Illustrations

This section provide s illustrations of different GE MDS Intrepid-HC HP installation conf igurations.

Note that in this section, the following abbreviations are used:

HSB - Hot Standby

FD - Frequency Diversity

SD - Space Diversity

DP - Dual Pole

MP - Main Path

SP - Secondary Path

MA - Main Antenna

DA - Diversity Antenna

N/A - Not Applicable

WG - Waveguide

X/Y dB: X refers to 6-8 GHz, Y refers to 11 GHz

1-18

GE MDS Intrepid-HC HP Installation Guide

Page 25

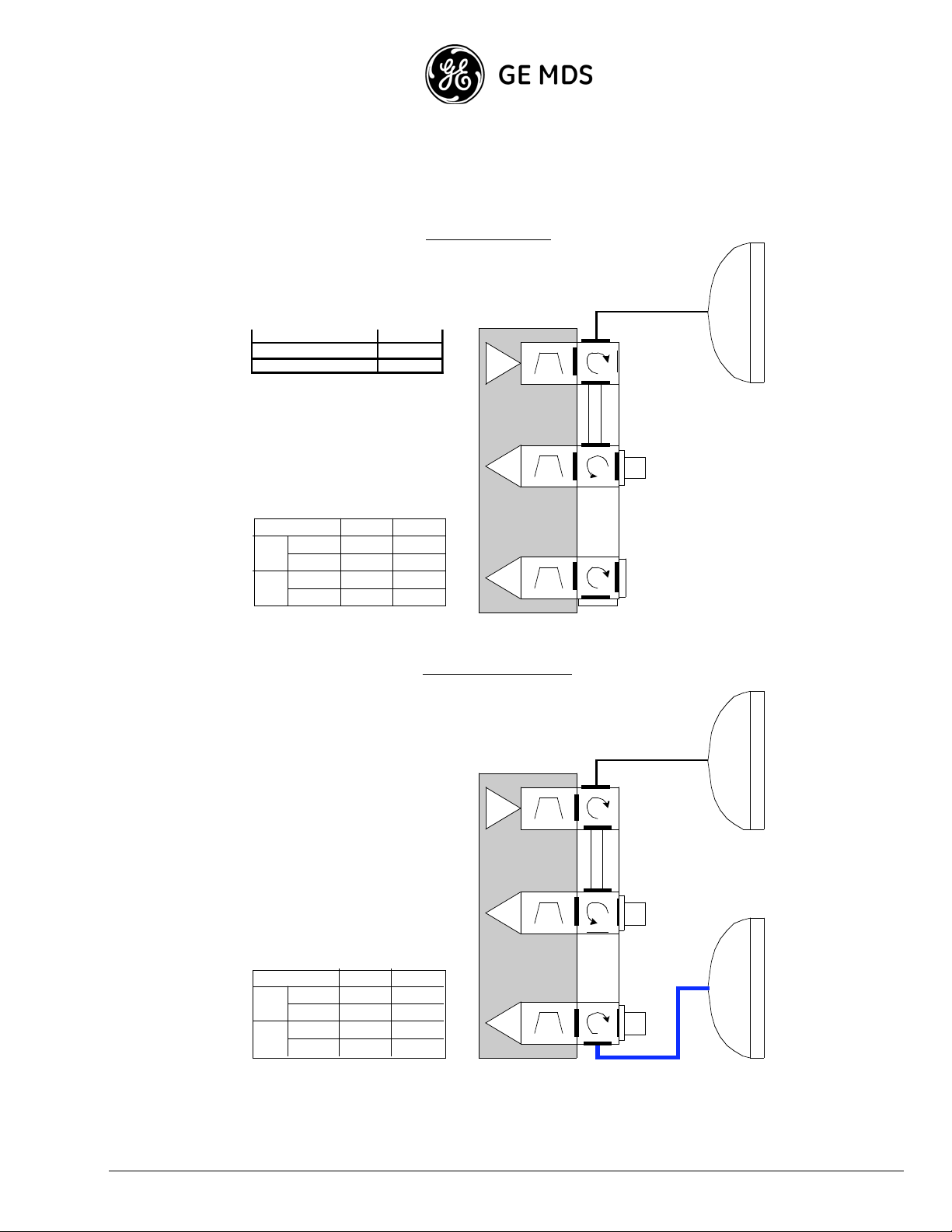

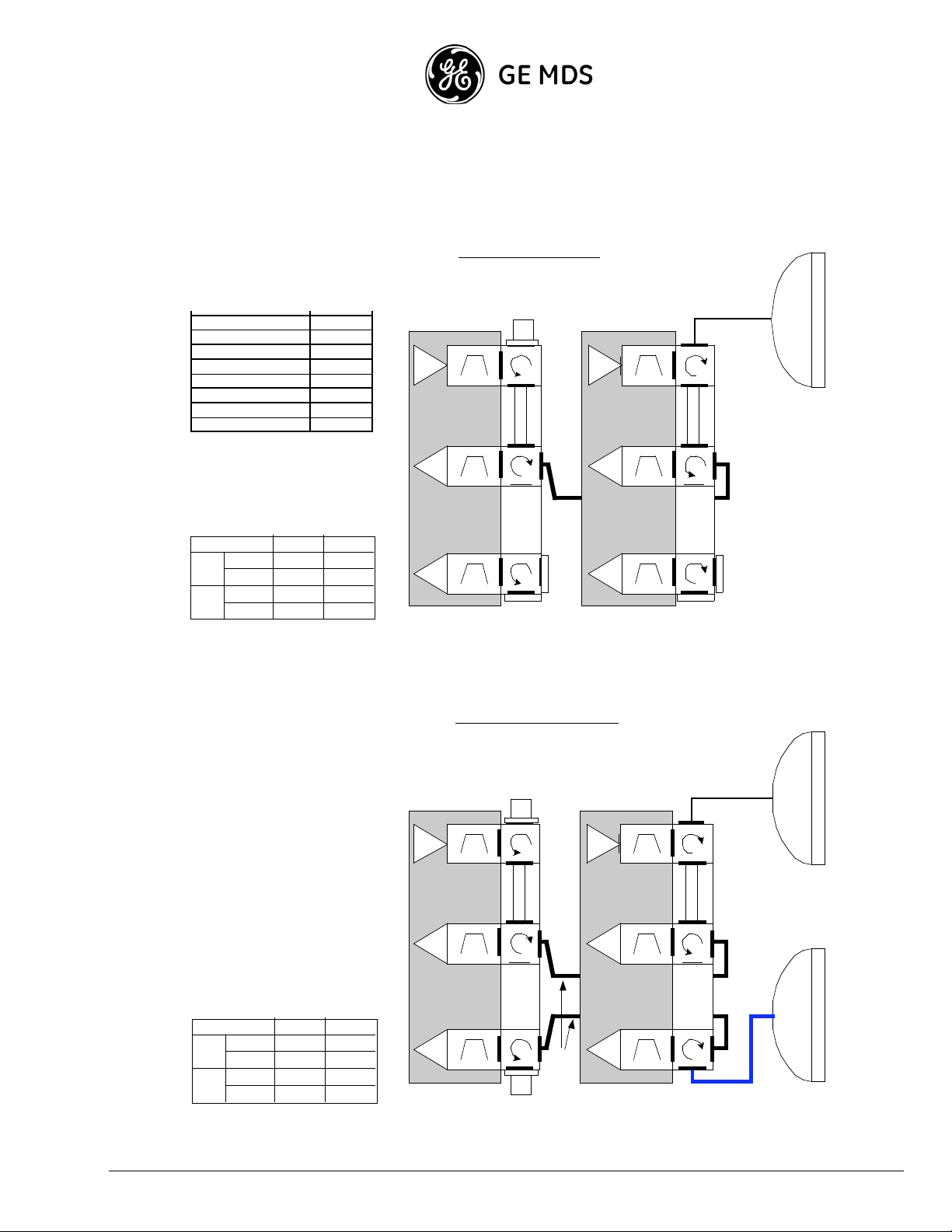

1+0 & 1+0 Space Diversity

SP Ant

1

ID M-155 1

enna

IDC + Ch as s i s 1

1+0 Configuration

TX

RFU

Flexible WG

TX f1

TX Filter

1+0

M.A

M.P

D.A

M.A

S.P

D.A

1+0 SD

M.A

M.P

D.A

M.A

S.P

D.A

* Coax Cabl e 3.5/ 5dB

B.L W.G

0dB 0.5dB

N/A N/A

N/A

N/A

N/A

N/A

B.L W.G

N/A

N/A

0.5dB

1.5/2.5dB*

N/A

N/A

0dB

0dB

RX f1

RX M

RX Fi lte r

RX f1

RX D

RX Fi lte r

1+0 SD Configuration

TX

TX f1

TX Filter

RFU

RX M

RX f1

RX Fi lte r

RX f1

RX D

RX Fi lte r

OCB

typ e 1

OCB

typ e 1

50

ohm

Flexible WG

50

ohm

50

ohm

Eliptical W G

or Coax Cable

GE MDS Intrepid-HC HP Installation Guide 1-19

Page 26

Pole Mount 1

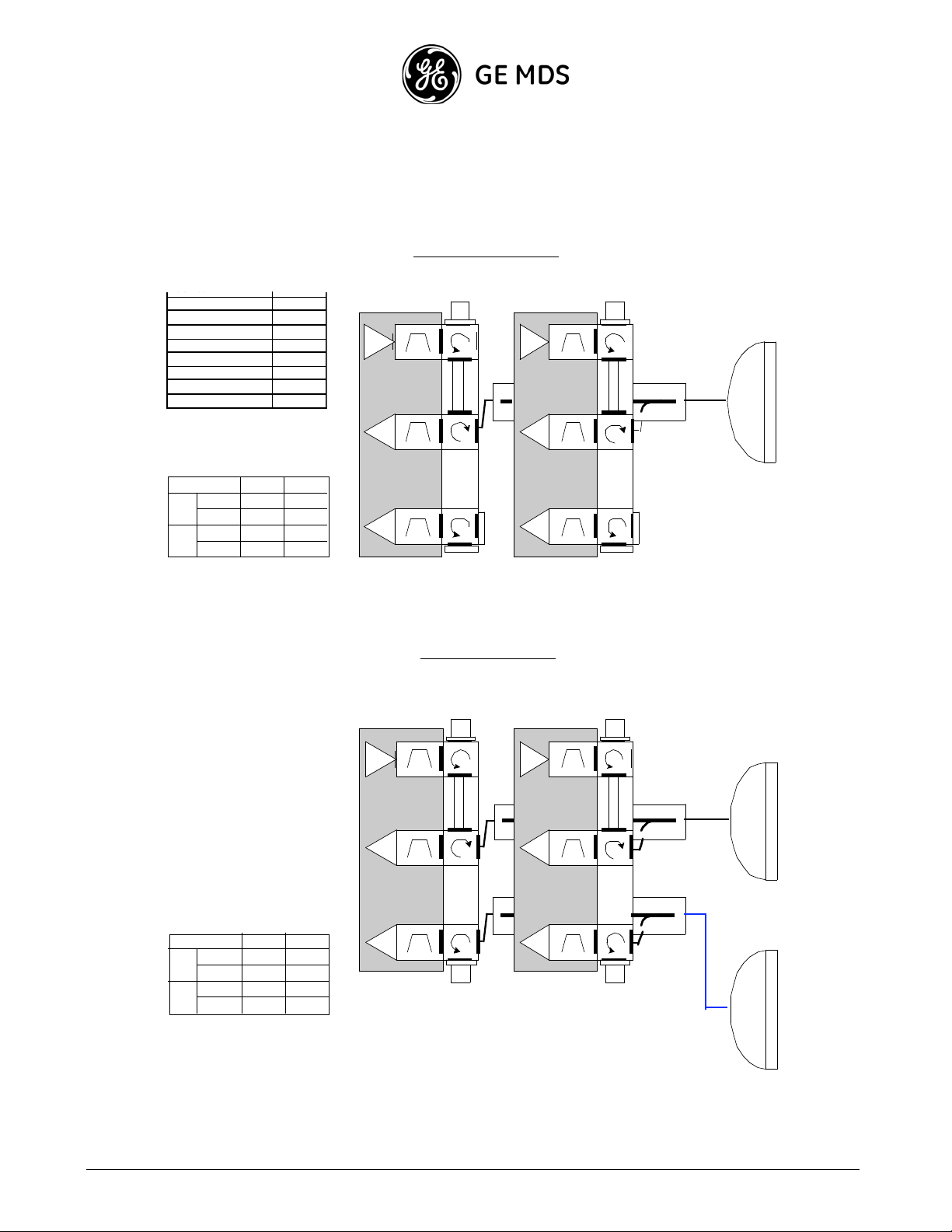

1+1 Hot Standby & 1+1 Hot Standby Space Diversity

1+1 HSB Configuration

50ohm Termination 2

Short 4

Coupler Ty pe 1 1

Flex WG 1. 2m 1

SP Antenna 1

IDC + Chassis 1

IDM-155 2

Protection Kit 1

M.A

D.A

M.A

D.A

B.L W.G

1.6/1.8dB 0.5dB

N/A

7/7.4dB

N/A

1+1 HSB

M.P

S.P

N/A

0.5dB

N/A

50

oh

m

TX

TX

f1

TX Filter

RFU

RX f1

RX M

RX Fi lte r

OCB

type

2

RX f1

RX D

RX Fi lte r

TX

TX Filter

RFU

RX M

RX Fi lte r

RX D

RX Fi lte r

RX f1

RX f1

50

oh

m

TX

f1

F le xible WG

OCB

type

2

1+1 SD Configuration

50

oh

m

TX

TX f1

TX Filter

RFU

TX

TX Filter

RFU

50

oh

m

TX

f1

F le xible WG

1-20

GE MDS Intrepid-HC HP Installation Guide

1+1 SD

M.A

M.P

D.A

M.A

S.P

D.A

* Coax Cabl e 3.5/ 5dB

B.L W.G

1.6/1.8dB

1.6/1.8dB

7/7.4dB

0.5dB

1.5/2.5dB*

0.5dB

1.6/1.8dB 1.5/2.5dB*

RX f1

RX M

RX Fi lte r

OCB

typ e 2

RX f1

RX D

RX Fi lte r

50

oh

m

RX f1

RX M

RX Fi lte r

OCB

typ e 2

RX f1

RX D

RX Fi lte r

50

oh

m

Eliptical W G

or Coax Cable

Page 27

1+1 Frequency Diversity & 1+1 Frequency Diversity + Space Diversity

1+1 FD Configuration

50ohm Termination 1

Short 4

U Bend WG Type 1 1

Flex WG 1.2m 1

SP Antenna 1

IDC + Ch ass is 1

IDM-155 2

Protection Kit 1

M.P

S.P

1+0 FD

M.A

D.A

M.A

D.A

B.L W.G

0.25dB

N/A

N/A

N/A

0.5dB

N/A

N/A

N/A

50

ohm

TX

TX f3

TX Filter

RFU

RX f3

RX M

RX Fi lte r

OCB

typ e 2

RX f3

RX D

RX Fi lte r

1+1 FD/SD Configurati on

Flexible WG

TX

TX f1

TX Filter

RFU

RX f1

RX M

RX Fi lte r

OCB

typ e 1

RX f1

RX D

RX Fi lte r

Flexible WG

50

ohm

TX

TX f3

TX Filter

8GHz RFU

RX f3

RX M

RX Fi lte r

OCB

typ e 2

1+0 SD

M.A

M.P

D.A

M.A

S.P

D.A

B.L W.G

1.5/2.5dB*

0.25dB

N/A

N/A

0.5dB0.25dB

N/A

N/A

RX f3

RX D

RX Fi lte r

U bends

50

ohm

* Coax Cabl e 3.5/ 5dB

TX

TX f1

TX Filter

8GHz RFU

RX f1

RX M

RX Fi lte r

OCB

typ e 1

RX f1

RX D

WG

RX Fi lte r

Eliptical W G or

Coax Cable

GE MDS Intrepid-HC HP Installation Guide 1-21

Page 28

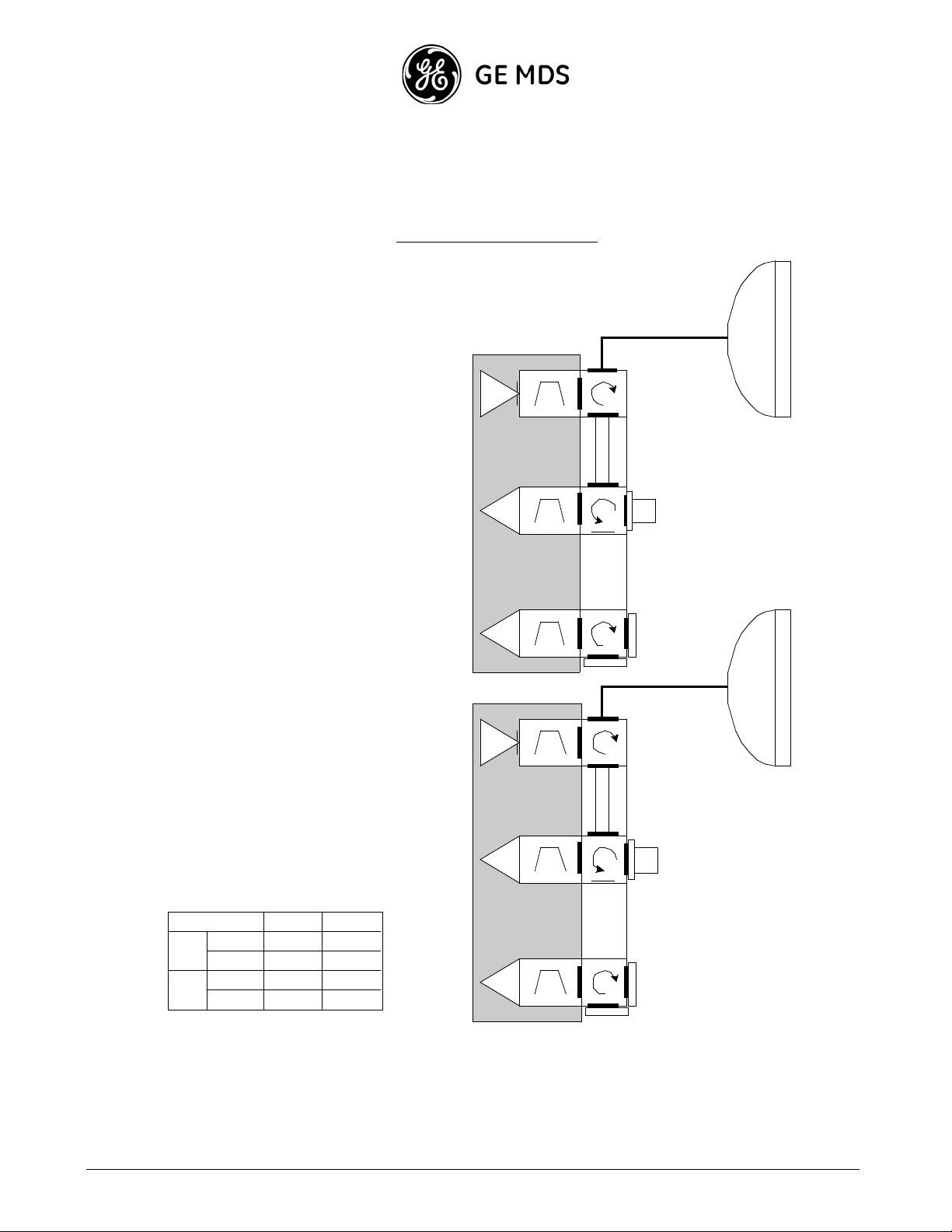

1+1 Space Diversity BBS

1 +1 S D BBS Configura tion

TX

TX f1

TX Filter

RFU

Flexible WG

Main

antenna

1+0 SD BBS

M.P

S.P

M.A

D.A

M.A

D.A

B.L W.G

0dB 0 .5 dB

0dB 0 .5 dB

N/A

N/A

N/A

N/A

RX M

RX D

RX M

RX D

RX f1

RX F i lte r

OCB

typ e 1

RX f1

RX F i lte r

ohm

50

Flexible WG

TX

TX f1

TX Filter

Diversity

RFU

RX f1

RX F i lte r

RX f1

RX F i lte r

OCB

typ e 1

ohm

50

antenna

1-22

GE MDS Intrepid-HC HP Installation Guide

Page 29

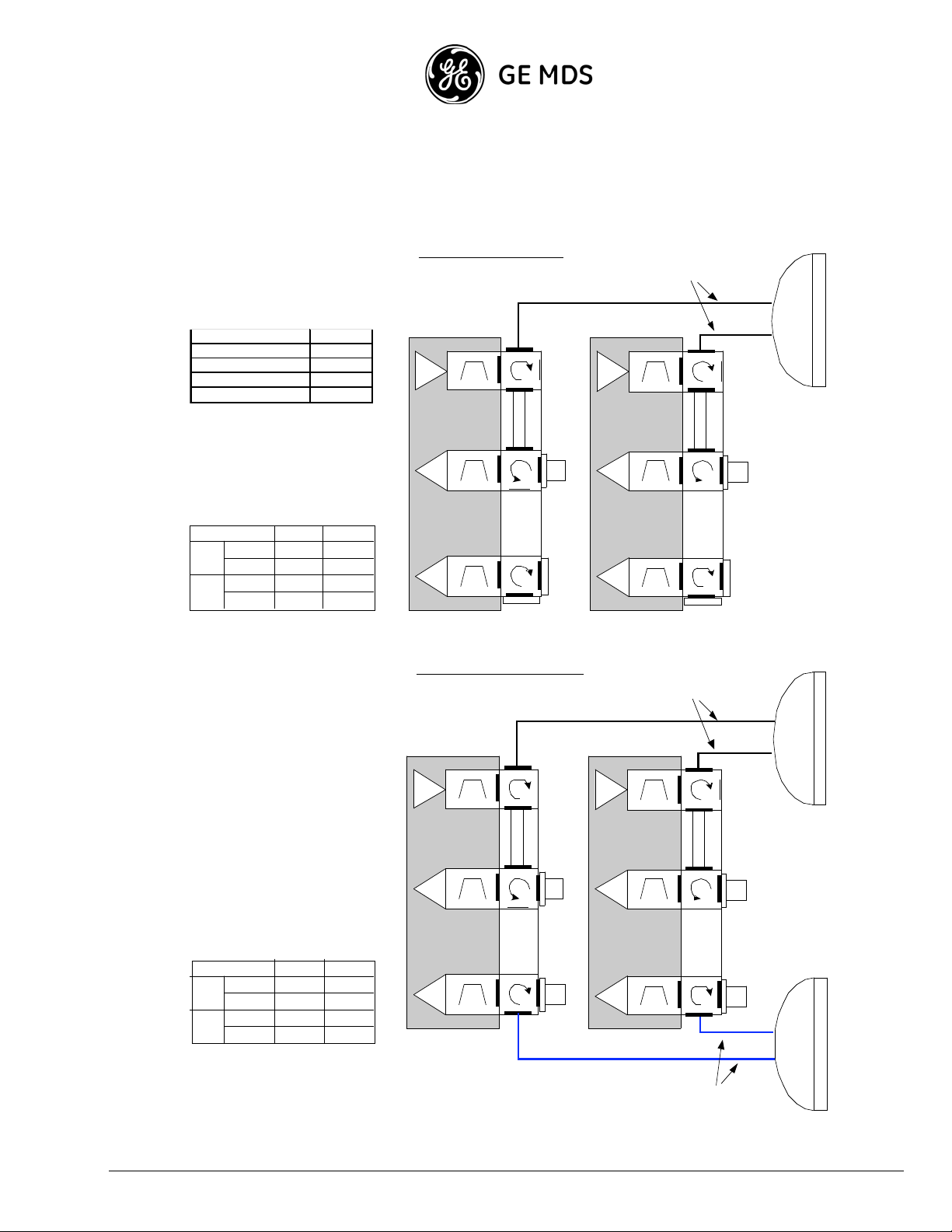

2+0 Dual Pole & 2+0 Space Diversity Dual Pole

2+0 DP Configura tion

Flex WG 1.2m 2

DP Antenna 1

XPIC cable 3m long 1

IDC + Ch ass is 1

IDM-155 2

TX

TX f1

TX Filter

RFU

Flexible WG

TX

TX f1

TX Filter

RFU

2+0 DPA

M.A

M.P

D.A

M.A

S.P

D.A

2+0 SD DP A

M.A

M.P

D.A

M.A

S.P

D.A

* Coax Cabl e 3.5/ 5dB

B.L W.G

0dB 0.5 dB

N/A

N/A

N/A

N/A

N/A

N/A

B.L W.G

N/A

N/A

0.5dB

1.5/2.5dB*

N/A

N/A

0.B

0dB

OCB

type

50

ohm

1

RX M

RX f1

RX Fi lte r

RX f1

RX D

RX Fi lte r

2+0 S D DP Configura tion

TX

TX f1

TX Filter

RFU

OCB

typ e 1

50

ohm

50

ohm

RX M

RX f1

RX Fi lte r

RX f1

RX D

RX Fi lte r

OCB

type

50

ohm

1

RX f1

RX M

RX Fi lte r

RX f1

RX D

RX Fi lte r

Flexible WG

TX

TX f1

TX Filter

RFU

OCB

typ e 1

50

ohm

50

ohm

RX f1

RX M

RX Fi lte r

RX f1

RX D

RX Fi lte r

Eliptical W G or

Coax Cable

GE MDS Intrepid-HC HP Installation Guide 1-23

Page 30

2+0 Single Pole & 2+0 Space Diversity Single Pole

2+0 S P Configuration

Pole Mount 1

50ohm Termination 1

Short 4

U Bend W G Type 1 1

Flex W G 1.2m 1

SP Antenna 1

IDC + Ch ass is 1

IDM-155 2

2+0 SPA

M.P

S.P

M.A

D.A

M.A

D.A

B.L W.G

0.25dB 0.5dB

N/A

N/A

N/A

N/A

N/A

N/A

50

ohm

TX f2

TX

TX Filter

RFU

RX f2

RX M

RX Fi lte r

OCB

typ e 2

RX f2

RX D

RX Fi lte r

2+0 S D S P Configuration

50

ohm

Flexible WG

TX f1

TX

TX Filter

RFU

RX f1

RX M

RX Fi lte r

OCB

typ e 1

RX f1

RX D

RX Fi lte r

Flexible WG

2+0 SD SPA

M.P

S.P

M.A

D.A

M.A

D.A

B.L W.G

0.25dB

1.5/2.5dB*

0.25dB

N/A

N/A

0.5dB

N/A

N/A

TX

RX M

RX D

8GHz RFU

TX f1'

TX Filter

RX f1

RX Fi lte r

RX f1

RX Fi lte r

OCB

typ e 2

ohm

U bends

WG

50

TX

RX M

RX D

8GHz RFU

TX f0'

TX Filter

RX f0

RX Fi lte r

RX f0

RX Fi lte r

OCB

typ e 1

Eliptical W G or

Coax Cable

* Coax Cabl e 3.5/ 5dB

1-24

GE MDS Intrepid-HC HP Installation Guide

Page 31

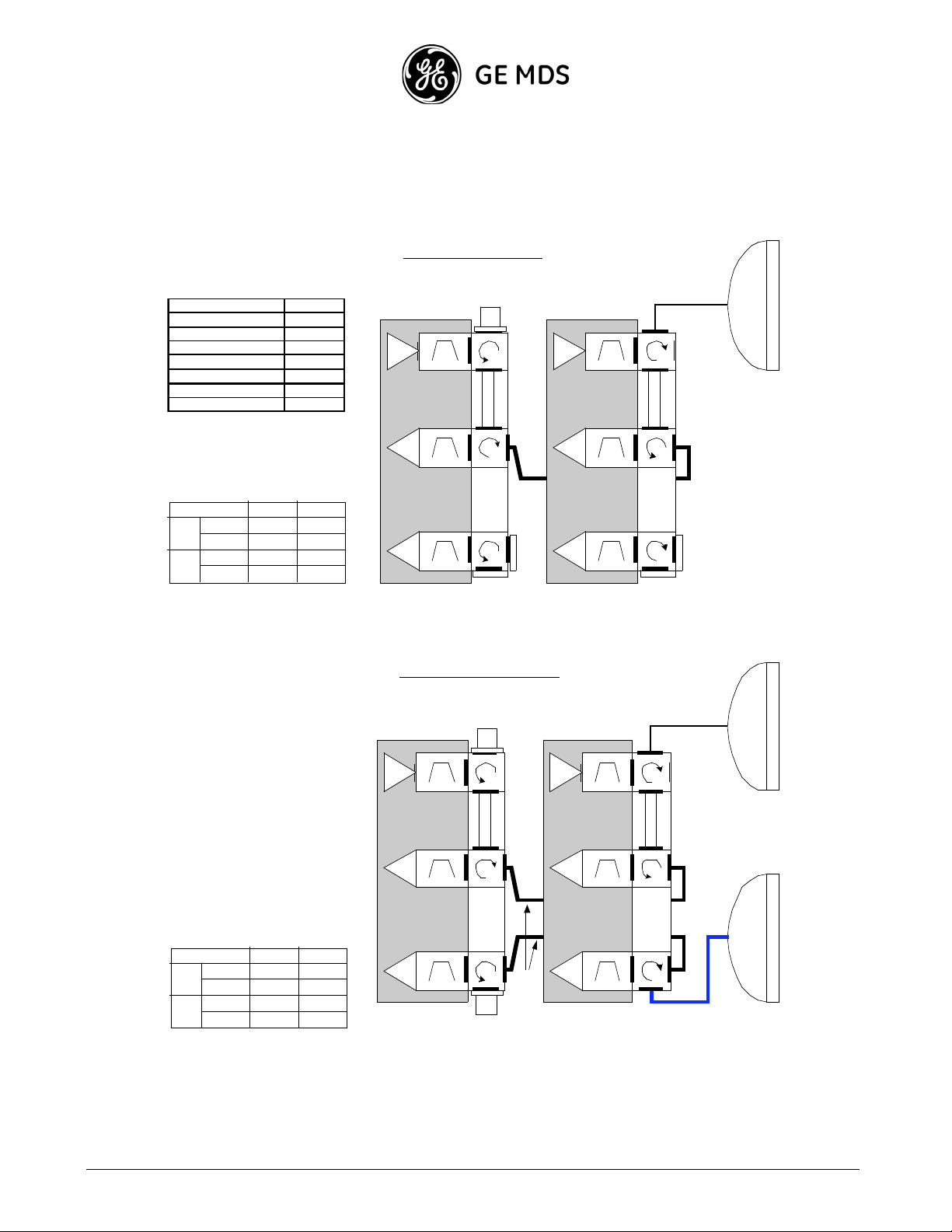

2+2 Hot Standby Dual Pole

2 +2 HSB DP Configur ati o n

RX M

RX D

50

ohm

TX f1

TX

TX Filter

TX f1

TX

TX Filter

50

ohm

Flexible WG

RFU

RX f1

RX Fi lte r

OCB

typ e 2

RX f1

RX Fi lte r

50

ohm

TX f1'

TX

TX Filter

RFU

RX M

RX D

RFU

RX f1

RX Fi lte r

OCB

typ e 2

RX f1

RX Fi lte r

50

ohm

TX f1'

TX

TX Filter

RFU

RX M

RX D

RX f1'

RX Fi lte r

RX f1'

RX Fi lte r

OCB

typ e 2

2+2 HSB DPA

M.A

M.P

D.A

M.A

S.P

D.A

RX f1'

RX M

RX Fi lte r

RX f1'

RX D

RX Fi lte r

B.L W.G

1.6/1.8dB 0.5dB

N/A

7/7.4dB

N/A

typ e 2

N/A

0.5dB

N/A

OCB

GE MDS Intrepid-HC HP Installation Guide 1-25

Page 32

C

21

2+2 Hot Standby Single Pole

2+2 HSB SP Configura tion

50

ohm

Flexible WG

RX M

RX D

TX

TX f2

TX Filter

RFU

TX

TX f1

TX Filter

RFU

Flexible WG

RX f2

RX Fi lt e r

RX f2

RX Fi lt e r

OCB

typ e 2

ohm

50

RX M

RX D

RX f1

RX Fi lt e r

OCB

typ e 1

RX f1

RX Fi lt e r

oupler Type

Flex W G 1.2m 2

TX

TX f2

TX

TX f1

SP Ant e nn a 1

IDC + Ch as s i s 2

TX Filter

RFU

RFU

TX Filter

IDM-155 4

Protection Kit 2

RX M

RX D

1-26

GE MDS Intrepid-HC HP Installation Guide

RX f2

RX Fi lt e r

RX f2

RX Fi lt e r

OCB

typ e 2

RX M

RX D

RX f1

RX Fi lt e r

RX f1

RX Fi lt e r

OCB

typ e 1

2+2 HSB SPA

M.A

M.P

D.A

M.A

S.P

D.A

B.L W.G

1.9/2.1dB

N/A

7.3/7.7dB

N/A

0.5dB

N/A

1dB

N/A

Page 33

2+2 Space Diversity Dual Pole

2+2 S D DP Configura tion

50

ohm

TX

TX f1

TX Filter

RFU

RX M

RX f1

RX Fi lte r

OCB

typ e 2

RX f1

RX D

RX Fi lte r

TX

TX f1

TX Filter

50

ohm

50

ohm

RFU

TX

TX f1

TX Filter

RFU

RX M

RX f1

RX Fi lte r

RX f1

RX D

RX Fi lte r

TX

TX f1

TX Filter

RFU

ohm

OCB

typ e 2

ohm

ohm

50

Flexible WG

50

50

RX M

RX D

RX f1

RX Fi lte r

RX f1

RX Fi lte r

2+2 SD DP A

M.P

S.P

typ e 2

M.A

D.A

M.A

D.A

OCB

50

ohm

B.L W .G

1.6/1.8dB

1.6/1.8dB

7/7.4dB 0.5dB

7/7.4dB 1.5/2.5dB*

0.5dB

1.5/2.5dB*

RX f1

RX M

RX Fi lte r

OCB

typ e 2

RX f1

RX D

RX Fi lte r

50

ohm

Eliptical W G or

Coax Cable

* Coax Cabl e 3.5/ 5dB

GE MDS Intrepid-HC HP Installation Guide 1-27

Page 34

2+2 Space Diversity Single Pole

50

ohm

2+2 S D S P Configurati on

Flexible WG

TX

TX f2

TX Filter

RFU

RX f2

RX M

RX Fi lte r

OCB

typ e 2

RX f2

RX D

RX Fi lte r

TX

TX f2

TX Filter

RFU

RX f2

RX M

RX Fi lte r

OCB

typ e 2

50

ohm

50

ohm

TX

TX f1

TX Filter

RFU

RX f1

RX M

RX Fi lte r

OCB

typ e 1

RX f1

RX D

RX Fi lte r

TX

TX f1

TX Filter

RFU

RX f1

RX M

RX Fi lte r

OCB

typ e 1

Flexible WG

Flexible WG

Eliptical W G or

Coax Cable

RX f2

RX D

RX Fi lte r

50

ohm

2+2 SD SPA

M.P

S.P

M.A

D.A

M.A

D.A

B.L W.G

1.9/2.1dB

1.9/2.1dB 1.5/2.5dB*

7.3/7.7dB

7.3/7.7dB 2/3dB**

RX f1

RX D

RX Fi lte r

0.5dB

1dB

* Coax Cabl e 3.5/ 5dB

** Coax Cabl e 4/5. 5dB

1-28

GE MDS Intrepid-HC HP Installation Guide

Page 35

2+2 Frequency Diversity Single Pole

2+2 FD S P Configur ation

Flexible WG

TX

RFU

RX M

RX D

Flexible WG

TX

RFU

TX

TX Filter

RX

RX Fi lte r

RX

RX Fi lte r

TX

TX Filter

TX

f3

TX

f1

TX Filter

RFU

RX

f3

OCB

typ e 2

f3

50

oh

m

f4

RX M

RX D

f1

RX Fi lte r

OCB

typ e 1

RX

f1

RX Fi lte r

TX

TX

f2

TX Filter

RFU

RX M

RX D

RX

RX Fi lte r

RX

RX Fi lte r

f2

OCB

typ e 1

f2

2+2 FD SP A

M.P

S.P

M.A

D.A

M.A

D.A

RX M

RX D

RX

f4

RX Fi lte r

OCB

typ e 2

RX

f4

RX Fi lte r

B.L W.G

0.75dB

N/A

N/A

N/A

1dB

N/A

N/A

N/A

GE MDS Intrepid-HC HP Installation Guide 1-29

Page 36

2+2 Hot Standby Frequency Diversity Dual Pole

2+2 HSB FD DP Configura tion

m

50

oh

RX M

RX D

TX

TX f3

TX Filter

RFU

RX f3

RX Fi lt e r

OCB

type

2

RX f3

RX Fi lt e r

RX M

RX D

TX

TX f1

TX Filter

RFU

RX f1

RX Fi lt e r

OCB

type

1

RX f1

RX Fi lt e r

Flexible WG

m

50

oh

TX

TX

f3'

TX Filter

RFU

TX

TX

f1'

TX Filter

RFU

RX M

RX D

2+2 FD DPA

M.P

S.P

M.A

D.A

M.A

D.A

RX f3'

RX Fi lt e r

RX f3'

RX Fi lt e r

OCB

type

2

B.L W.G

0.25dB 0.5dB

N/A

N/A

N/A

N/A

N/A

N/A

RX M

RX D

RX f1'

RX Fi lt e r

OCB

type

1

RX f1'

RX Fi lt e r

1-30

GE MDS Intrepid-HC HP Installation Guide

Page 37

2+2 Frequency Diversity / Space Diversity Dual Pole

2+ 2 S D/FD DP Configuration

50

ohm

Flexible WG

TX f3

TX

TX Filter

RFU

RX M

RX f3

RX Fi lte r

OCB

typ e 2

RX f3

RX D

ohm

RX Fi lte r

TX

TX f3'

TX Filter

RFU

50

50

ohm

TX f1

TX

TX Filter

RFU

RX M

RX f1

RX Fi lte r

OCB

typ e 1

RX f1

RX D

RX Fi lte r

TX

TX f1'

TX Filter

RFU

Flexible WG

Eliptical WG or

Coax Cable

RX M

RX f3'

RX Fi lte r

RX f3'

RX D

RX Fi lte r

3+3 SD DP A

M.A

M.P

D.A

M.A

S.P

D.A

* Coax Cabl e 3.5/ 5dB

OCB

typ e 2

ohm

50

B.L W.G

0.25dB

1.5/2.5dB*

0.25dB

N/A

N/A

0.5dB

N/A

N/A

RX M

RX f1'

RX Fi lte r

OCB

typ e 1

RX f1'

RX D

RX Fi lte r

Eliptical W G or

Coax Cable

GE MDS Intrepid-HC HP Installation Guide 1-31

Page 38

N+1 Systems

4+1 FD DP Configuration

U bends W G

TX f5

TX

TX Filter

RFU

OCB

typ e 1

50

oh

m

RX f5

RX M

RX Fi lte r

RX f5

RX D

RX Fi lte r

TX f3

TX

TX Filter

RFU

RX f3

RX M

RX Fi lte r

OCB

type

2

RX f3

RX D

RX Fi lte r

TX f1

TX

TX Filter

Flexible WG

RFU

RX f1

RX M

RX Fi lte r

OCB

type

1

RX f1

RX D

RX Fi lte r

U bends W G

TX f3'

TX

TX Filter

RFU

RX f3'

RX M

RX Fi lte r

OCB

type

2

TX

TX

f1'

TX Filter

RFU

RX f1'

RX M

RX Fi lte r

OCB

type

1

RX f3'

RX D

RX Fi lte r

N MS & WAYSID E POWER

IDC

IDC

IDC

STM-1

STM-1

STM-1

IDM

IDM

RX f1'

RX D

RX Fi lte r

IF

IF

IDM

STM-1

Switch card (XC)

STM-1

IF

IF

IF

IDM

IDM

1-32

GE MDS Intrepid-HC HP Installation Guide

Page 39

5+1 FD DP Configuration

U bends W G

TX f5

TX

TX Filter

RFU

OCB

typ e 1

50

oh

m

RX f5

RX M

RX Fi lte r

RX f5

RX D

RX Fi lte r

TX f3

TX

TX Filter

RFU

RX f3

RX M

RX Fi lte r

RX D

RX f3

RX Fi lte r

OCB

type

2

TX f1

TX

TX Filter

Flexible WG

RFU

RX f1

RX M

RX Fi lte r

RX D

RX f1

RX Fi lte r

OCB

type

1

U bends W G

TX f3'

TX f5

TX

TX Filter

RFU

RX f5

RX M

RX Fi lte r

OCB

typ e 1

TX

TX Filter

RFU

RX f3'

RX M

RX Fi lte r

OCB

type

2

TX

TX

f1'

TX Filter

RFU

RX f1'

RX M

RX Fi lte r

OCB

type

1

RX D

RX f5

RX Fi lte r

N MS & WAYSID E POWER

IDC

IDC

IDC

N MS & WAYSID E POWER

IDC

IDC

RX D

RX f3'

RX Fi lte r

STM-1

STM-1

STM-1

IDM

IDM

IDM

RX D

IF

IF

STM-1

Switch card (XC)

STM-1

IF

IF

STM-1

Switch Card (XC)

RX f1'

RX Fi lte r

IF

IF

IF

IF

IDM

IDM

IF

IF

IDM

Inter- she lf

XC cable

GE MDS Intrepid-HC HP Installation Guide 1-33

Page 40

4+1 FD S D DP Configura tion

U bends W G

RX M

RX D

RX M

RX D

TX f3

TX

TX Filter

RFU

RX f3

RX Fi lte r

RX Fi lte r

RX f3

OCB

type

2

TX f5

TX

TX Filter

RFU

OCB

typ e 1

50

oh

m

RX f5

RX Fi lte r

RX f5

RX Fi lte r

RX M

RX D

TX f1

TX

TX Filter

Flexible WG

RFU

RX f1

RX Fi lte r

RX f1

RX Fi lte r

OCB

type

1

U bends W G

RX M

TX f3'

TX

TX Filter

RFU

RX f3'

RX Fi lte r

OCB

type

2

RX M

TX

TX

f1'

TX Filter

RFU

RX f1'

RX Fi lte r

OCB

type

1

Flexible WG

RX f3'

RX D

RX Fi lte r

N MS & WAYSID E POWER

IDC

IDC

IDC

STM-1

STM-1

STM-1

IDM

IDM

IDM

RX f1'

RX D

RX Fi lte r

IF

IF

STM-1

Switch card (XC)

STM-1

IF

IF

IF

IDM

IDM

1-34

GE MDS Intrepid-HC HP Installation Guide

Page 41

5+1 FD S D DP Configuration

U bends W G

TX f5

TX

TX Filter

RFU

OCB

typ e 1

50

oh

m

RX f5

RX M

RX Fi lte r

RX f5

RX D

RX Fi lte r

TX f3

TX

TX Filter

RFU

RX f3

RX M

RX Fi lte r

OCB

type

2

RX f3

RX D

RX Fi lte r

TX f1

TX

TX Filter

Flexible WG

RFU

RX f1

RX M

RX Fi lte r

OCB

type

1

RX f1

RX D

RX Fi lte r

U bends W G

TX f3'

TX f5

TX

TX Filter

RFU

RX f5

RX M

RX Fi lte r

OCB

typ e 1

TX

TX Filter

RFU

RX f3'

RX M

RX Fi lte r

OCB

type

2

TX

TX

f1'

TX Filter

RFU

RX f1'

RX M

RX Fi lte r

OCB

type

1

RX D

RX f5

RX Fi lte r

N MS & WAYSID E PO WER

IDC

IDC

IDC

N MS & WAYSID E PO WER

IDC

IDC

RX D

RX f3'

RX Fi lte r

STM-1

STM-1

STM-1

IDM

IDM

IDM

RX D

IF

IF

STM-1

Switch card (XC)

STM-1

IF

IF

STM-1

Switch Card (XC)

RX f1'

RX Fi lte r

IF

IF

IF

IF

IDM

IDM

IF

IF

IDM

Inter- she lf

XC cable

GE MDS Intrepid-HC HP Installation Guide 1-35

Page 42

1-36

GE MDS Intrepid-HC HP Installation Guide

Page 43

Chapter 2: Initial System Setup

General

After the system is installe d and tested, and antenna alignment is performed, the next step is initial IDU setup and

configuration.

Initial setup proce dures are performed on a craft terminal via a serial port connection.

Note:

Configuration proc edures are generally performed using the NMS software supplied with MDS Intrepid-HC HP.

A description of the NMS and how to use it is provided in the NMS User Guide.

The craft terminal should be used only to perform the initial setup procedures describe d in this chapter. Once the

system is up and running, use NMS to maintain and operate the system on a regular basis.

Initial Setup Steps

The initial MDS Intrepid-HC HP setup proce dure includes the following steps:

Procedures Performed using a Craft Terminal:

- Connecting to the IDU via the terminal port

- Defining IP addresses

- Setup Options

Procedur es Perfo r m ed using th e N M S:

- Connecting to the Ethernet port

- Installing the software

- Setting the local TX frequency channe l

- Specifying system information

- Configuring the local/rem ote transport

- Configuring trap forwarding

MDS Intrepid-HC HP Installation and Operation 2-1

Page 44

- Setting up external alarms

Connecting the Line Interfaces

Initial Setup using the Craft Terminal

The following procedures a re performed after the RFU and antenna are installed.

Con necting to the ID U via Serial Port

Turn the IDU power switch ON.

On the front panel of the IDU, the DRWR LED should be lit green.

To set up the HyperTerminal connection:

1. Connect the RS-232 port of your computer to the RS-232 (9-pin) port on the IDU front panel. This port is

labeled “Termina l”.

2. Select Start, Prog rams, Accesso ries , Co m m unica ti on, HyperTer minal.

3. Double-click the HyperTerminal application icon.

4. For Conne ctio n Description , type Terminal, and click OK.

5. In the Connect Using field (Pho n e Number), select Direct t o Com 1, and click OK.

6. In the Port Settings tab (Com 1 Properties), specify the following settings:

Bits per second - 19,200

Data bits - 8

Parity - None

Stop bits - 1

Flow control - Hardware

7. Click OK.

8. After you connect to the terminal, to enter the terminal setup program, press Enter.

9. For password, use admin.

2-2 MDS Intrepid-HC HP Installation and Operation

Page 45

Defining IP Addresses

Before you can configure the MDS Intrepid-HC HP system, you need to define IP addresse s using the craft

terminal.

The MDS Intrepid-HC HP includes two IP interfaces: an Ethernet interface, and a serial interface. Each interface

has its own IP address and IP mask.

The IP address is a four digit number separa ted by decimal points. Each IP address is a pair netid,hostid, where

netid identifies a ne twork, and hostid identifies a host on the network. The IP mask separates between the netid and

hostid.

For example, if the IP address is 192. 114.35.12 (11000000 01110010 00100011 00001100), and the IP mask is

255.255.255.0 (11111111 11111111 11111111 00000000), the netid is 192.114.35, and the hostid is 12.

An IP interface can only communicate with hosts that are on the same net (have the same netid). In the example

above, the interface ca n communicate only with hosts that have netid 192.114.35 (for 1 to 255).

If The transceiver ha s a frame to send to a host that is not on the Etherne t IP netid or the ser ial IP netid, the frame

should be sent to an intelligent de vice (usually a gateway) on the network. Such a device, known as a "default

router", will know how to send the frame over the internet. The default gateway should be a host on one of the

Transceiver inter face netids.

The following figure shows how the tra nsceiver is integrated in the local network.

GE MDS Intrepid-HC HP Installation Guide 2-3

Page 46

To define IP Addresses:

1. In the main terminal program menu, select Configuration.

2. Select IDC.

3. Select Basic.

4. Select IP and define the addresses as described above.

Important

After you set up IP addresses, restart the IDU to activate the m.

Setup Options in the Terminal Pr ogr am

The main menu in the terminal setup program includes the following options:

Configuration (1) - the main setup section in whic h you can configure the IDC, the right and left drawers,

protection, SNMP management, in- band routing, and other such parameters.

System Stat us (2) - used to obtain information about the different software versions currently used in the system.

Maintenance (3) - used to perform software upload, download, and reset.

Diagnostics (4) - used to perf orm loopbacks a nd obtain system information.

Logs (5) - used to view alarm and configuration log reports.

2-4 MDS Intrepid-HC HP Installation and Operation

Page 47

Additional Setup Using the NMS

Some of the initial setup proce dures require the use of The NMS.

Once initial setup is complete , use The NMS to run the system on a daily basis.

Connecting to the Ethernet Port

1. Connect a crossed Ethernet cable from your PC to the Ethernet Port. If the connection is to a LAN (wall

connection) use the standa rd Ethernet cable.

2. Make sure the IP address on your PC is on the same sub-net as you defined in the MDS Intrepid-HC HP indoor

unit (in most cases, the first three numbers of the IP address must be identical, depending on the sub-net mask).

NMS PC Requirements

Before you install the NMS software, verify that your PC has the following minimum requirements:

For Windows

Processor: Pentium 4, 2.8 GHz (minimum)

Memory (RAM): 256 MB minimum

Operating System: Windows 2000 or above

Serial Port: RS-232 (Hyper-Terminal)

For UNIX

Processor: Blade 100 Ultra 5 (minimum)

Memory (RAM): 256 MB minimum

Operating System: Solaris 8 or 10

Installing the Network Management Software (NMS)

Note: More detailed information about the NMS installation is provide d in Chapter 5 - Operation.

1. Insert the NMS CD in the CD drive.

2. In Windows Explorer, double- click the setup.exe file.

The installation progra m begins.

3. Follow the instructions displayed.

GE MDS Intrepid-HC HP Installation Guide 2-5

Page 48

Starting the NMS

1. Select Star t , Progr ams, N MS, NMS El e me nt Ma na ger.

The NMS Login window appears.

NMS Login Window

2. Enter the IP address of the IDU, and the SNMP community (for SNMP protocol access).

3. For User Name use admin and for Password use admin (default settings).

4. Select Save Password if you want the NMS to remember the password you entered.

Note that there are two types of passwor ds, eac h with a different security level for authorized activitie s:Read

Only - user is permitted to perform monitoring a ctivities only. Read/Write - user is permitted to change system

configuration and syste m administrator parameters, and perform monitoring a ctivities.

After you log in, the Main NMS window appears.

Main NMS Window

2-6 MDS Intrepid-HC HP Installation and Operation

Page 49

Setting the Local TX Frequency Channel

If the TX frequency was previously defined using the HyperTerminal, use this screen only to verify that the correct

frequency was s et.

1. Select Configuration, RFU Left/Right, RFU Configuration, or click the RFU icon in the tool bar.

At the top of the window, the system displays TX/Rx ranges, the gap between them, and the channel

bandwidth.

RFU Configuration Window

Note: In the window shown above, the RFU illustration shows two antennas. Only one antenna appears in the

illustration if the IF C (IF Combiner) is not supported.

2. The RFU Pa rameters area is read-only. The Duplex Frequency value changes in accordance with the TX/RX

frequency values.

3. You can change the TX and RX frequencies of the ODU in one of the following ways:

Manually enter the TX frequenc y and/or RX frequency (6, 7, 8, 10, 11 GHz only) in the respective fields.

GE MDS Intrepid-HC HP Installation Guide 2-7

Page 50

Or click the up/down arrows in the TX Channel field to selec t the channel (the frequency will be updated

accordingly).

For the Frequency Control area, note the following:

Only one standard is generally show n, pr edetermined by the ODU parameters. When the standard is unknown,

the TX Channel field will be disabled.

TX Channel se lection is possible only when a predefined standard file was installed. In some cases, you may

be able to select more than one standar d.

The Rx Freque ncy field is read-only for systems other than 6, 7, 8, 10, and 11 GHz.

The arrow on the right side in the Frequency Control area is green when communication exists between the

local and remote units. If there is no communication between the units, the arrow is red.

4. Select the XPIC Enabled option if you want to activate the XPIC mechanism.

With The transceiver opera ting in co-channel dual polarization (CCDP) mode, using the cross polariz ation

interfere nce canceller (XPIC) algorithm, two STM-1 signals can be transmitted ove r a single 28 MHz channel,

using vertical and hor izontal polarization. This enables double capacity in the same spectrum bandwidth.

Note: Setting XPIC for the right drawer will effect the left drawer as well, and vice versa.

5. Select Local Only if you want to frequency changes to affect only the local unit. Select Local + Remote if you

want frequency changes to affec t the remote unit as well.

Note: If there is a communication failure between the local and remote units, the Local + Remote option will be

disabled.

6. In the Tra nsmitter Con fi g urati o n area, select TX Mute to block transmission to the remote unit. By default,

this option is not selected.

Select ATPC to activate the Automatic Transmit Power Control feature.

For Set TX Level, enter or select the designated signal level. Possible range is -10 to max power level. By

default, the transmit signal level is set to the maximum power level.

The Monitored TX Level field (read-only) displays the system 's transmitted power level.

7. In the R ecei ver Configurati o n area, the Set Reference Rx Lev el field should be set to the Rx level to which

the actual level will be compare d. This field is active only if ATPC is enabled.

Receiver Mode is the Rx path, which can be set to Main, Diversity, or Combined. This field appears only if

IFC (IF Combiner) is supported.

RSL Connec to r So ur ce can be Diversity or Main. This field appears only if XPIC is not supported and IFC is

supported.

The Monitored Rx Lev el (Main) field is read-only and displays the received power level.

Monitored Rx Level (Diversity) is a read- only field that displays the received power level of the Diver sity

channel.

8. Click Apply to save the settings.

9. Click Close.

2-8 MDS Intrepid-HC HP Installation and Operation

Page 51

Specifying System Information

To specify system information:

1. Select File, Local/Remote, System Information., or click the S ystem Information icon

.

System Information Window

2. In the Current Time area, click Da t e/Time Con f i g ura t i o n and set the date and time (in the format

HH:MM:SS).

3. The read-only Description field provides information about the Transce iver system.

4. (Optional) In the Name field, enter a name for this link. By convention, this is the node ’s fully-qualified

domain name.

5. (Optional) In the Contact field, enter the name of the person to be contacted when a problem with the system

occurs. Include information on how to contact the designated person.

6. (Optional) In the Location field, enter the actual physical loc ation of the node or agent.

7. The Up Time field, S oftware Versi o ns area, and Serial Numbers area are read-only.

8. Click Apply. The settings are saved.

9. Click Close.

GE MDS Intrepid-HC HP Installation Guide 2-9

Page 52

Local/Re m ote Tr ansport Confi gur ation

The Local/Remote Transpor t Configuration window allows you to change threshold levels for the radio and alarms,

and to configure specia l transm ission parameters. This is recommended for advanced users only.

Note: You will need to restart the NMS if you change the transport protocol.

1. Select Configuration, Local/R emote, IDU, Tran sport.

The Transport Configuration window appears.

Transport Configuration Window

2. The Protocol field displays the curre nt data transfer protocol. To change the protocol, clic k the drop down list

and select SDH, SONET, or SONET-C.

3. Click Apply to save the settings.

4. Click Close.

Trap Forwarding Configuration

This section explains how to set up a trap forwar ding plan. If your application does not require trap forwarding, you

can skip the following procedur e.

1. Select Configuration, Local/Remote, Management System, Tra ps Configuration, or click the Traps

Configuration icon.

The Trap Forwarding Configuration window appears.

2-10 MDS Intrepid-HC HP Installation and Operation

Page 53

Trap Forwarding Configuration Window

2. In the Managers IP Address area, specify the IP addresses of the managers to which you want traps to be sent.

For each manager IP you specify, specify the Trap Port, and for Send Trap for Ala r ms wit h Sev e ri ty , select

the severity filte r to determine which types of alarms will be forwarded.

3. In the Send Trap for Alarms of Group section, you determine which alarms will be sent as SNMP traps to

each manager. In each manager column, select the alarm types you want to include for that manager.

4. In the Trap Options area, select Standard traps include serial num ber if you want trap messages to include

the IDU serial number.

Select Report local traps of far end IDU if you want remote IDU trap messages to be reported locally.

Select Use different ID for each alarm type if you want each type of alarm to receive a unique ID.

Select Send “clear” traps with zero severity if you want a trap with a “clear” severity (instead of the alarm's

original severity) to be sent to the IP addresses you specified.

5. For CLLI (Common Language Location Identifie r), enter up to 18 characters that will represent your system

ID when traps are sent.

6. For Heartbeat Period, a heartbeat signal will be generated every x minutes (the number you enter) to tell your

system that the tr ap mechanism is wo rk ing.

7. Click Apply to save the settings.

GE MDS Intrepid-HC HP Installation Guide 2-11

Page 54

Extern al Alarms Setup

The procedure detailed in this se ction is required only if alarms generated by external equipme nt are connected to

the IDU, or if the IDU alarm outputs are connected to other equipm ent (using the alarms I/O connector).

1. Select Configuration, Local/Remote, IDU, Exter na l Ala r ms, or click the Local/Re mo te Ex te rna l Alarms

icon.

The Input/Output External Alarms window appears.

Input/Output External Alarms Window

Follow the steps below for both the Local and Remote sides.

The microcontroller in the IDU reads ala rm inputs (dry contact) and transmits them to the management system.

This allows The transce iver to report external alarms that are not related to its own system.

For each alarm on the left side of the window, do the following:

2. Click on the box next to the alarm number to enable/disable the alarm.

3. If you enable an alarm, enter a description of the alarm in the text field.

4. Select the alarm’s severity level from the drop-down list (Major, Minor, Warning, or Event).

5. The transceiver provides three alarm outputs that can be used by other systems to sense alarms. The outputs are

configured on the right side of the window.

2-12 MDS Intrepid-HC HP Installation and Operation

Page 55

The alarm outputs are Form C Relays. Each output relay provides thr ee pins, as follows:

Normally Open (NO)

Normally Closed (NC)

Common (C)

Output alarms can be defined as any of the following:

Major

Minor

Warning

External

Power

BER

Line

Loopback

LOF

IDU

ODU

Cable

Remote

The default alarm output setting f or each relay is “Power”.

The relays may be connected to customer- specific applications. Refer to Appendix B for details concerning the

alarm connector pin assignm ents.

6. After you complete the configuration, click Apply to save the settings.

7. Click Close.

Exiting the NMS

To exit the NMS, select File, Exit in the main window.

GE MDS Intrepid-HC HP Installation Guide 2-13

Page 56

Initial Setup for Intrepid-HC HP/T IDU

Initia l Setup Steps for up to 9 + 1 Conf iguration

Cascading two Intrepid-HC HP/T IDUs at each site enables a configuration of up to 9+1 (10 carriers), or XPIC 7+1

with two additional carr iers.

The setup steps for a configura tion of up to 9+1, are identical to those of the configuration of up to 4+1 (see above)

except for the following dif ferences:

You must configure all six IDCs using the HyperTerminal.

You must specify if you are using cascading mode, using the HyperTermina l

You must specify in which IDU the protected link will be defined.

To set the cascading mode:

1. In the main terminal program menu, select Configuration.

2. Select System configuration.

3. Select Cluster configuration.

Specify the number of sub-racks in the system . 1 f or stand alone, or 2 for cascading mode.

Specify either 1 or 2 for the sub-rack number. The protecte d carrier will be in sub-rack 1.

2-14 MDS Intrepid-HC HP Installation and Operation

Page 57

Defining IP Addresses

Before you can configure the Intr epid-HC HP/T system, you need to define four IP addresses using the craft

terminal.

The Intrepid-HC HP/T includes thr ee levels of two IP interfaces: an Ethernet interface, and a serial interface. Each

interface has its own IP addre ss and IP mask.

You must configure an IP address for each of the three IDCs - a unique shelf number for each she lf in the cluster.

In addition, you must define same base IP address for every Intrepid-HC HP/T IDC. The address is a four digit

number separated by decimal points. Each IP address is a pair netid-hostid, where netid identifies a network, and

hostid identifies a host on the ne twork. The IP mask separates between the netid and hostid.

For example, if the IP address is 192. 114.35.12 (11000000 01110010 00100011 00001100), and the IP mask is

255.255.255.0 (11111111 11111111 11111111 00000000), the netid is 192.114.35, and the hostid is 12.

An IP interface can only communicate with hosts that are on the same net (have the same netid). In the example

above, the interface ca n communicate only with hosts that have netid 192.114.35 (for 1 to 255).

If Intrepid-HC HP/T has a frame to send to a host that is not on the Ethernet IP netid or the serial IP netid, the frame

should be sent to an intelligent de vice (usually a gateway) on the network. Such a device, known as a "default

router", will know how to send the frame over the internet. The default gateway should be a host on one of the

Intrepid-HC HP/T interface netids.

The Intrepid-HC HP/T cluster is manage d as a single Network Element (NE) by the EMS.

GE MDS Intrepid-HC HP Installation Guide 2-15

Page 58

The following figure illustr ates an Intrepid-HC HP/T management model from an EMS/NMS point of view.

Each IDC calculates its own IP address, considering cascade shelf# and floor#:

where:

##*3 floorshelfIPbaseIP ++=

IPbase is dividable by 8 (i.e. = IPbase & 0xfffffff8),

shelf# = 0, which is the cascade master (the one with the pr otected carrier), or 1 for cascade slave,

floor# = 1, 2, or 3 (the number of the floor within the Intrepid-HC HP/T shelf).

In-band Management

In-band management of the Intrepid-HC HP/T link chain must be configured carefully due to a large number of

public IP address alloc ations. In addition, it should be noted that in-band mana gement becomes a limiting factor for

chain length when only the Class C DCN is used.

The figure below illustrate s the largest Class C in-band subnet (with CIDR = 26 bits, i.e. subnet mask

255.255.255.192).

The DCN shown in the figure makes use of the 192.168.1.64 in-band subnet. This subnet allows 62 nodes

192.168.1.65 - 192.168.1.126, and has a broadcast address of 192.168.1.127.

It is assumed that the Intrepid-H C HP/T at site A has a single GNE 1 assigned to one of the IDCs.

All three IDCs at site A have direct out-of - band IP connectivity with remote management applications (NMS,

SNMP Agent, Telnet). The remaining Intrepid-HC HP/T chain IP addresses are accessed via the GNE IDC.

2-16 MDS Intrepid-HC HP Installation and Operation

Page 59

Note that the Inband bytes run through the uppe r level of the cluster.

The Ethernet interfa ce of every Ne twork Element (NE) is assigned the CIDR=/29 subnet, i.e. subnet mask

255.255.255.248. This allows 6 elements to be communicated over the interface. These addresse s can be fully

utilized when two Intre pid-HC HP/T shelves are cascaded for 7+1 group protection.

The figure above shows “back-to-back” connected Intrepid-HC HP/T shelves at the same sites: B, C, and D, for

East/West chaining. Two NE IDCs (NE 2 and NE 3), at the same site, are connected over a PPPoE link.

This scheme allows four links of up to 7+1 (eight Intrepid-HC HP/T shelves, as shown, or sixteen shelves cascade d

in pairs) chaine d through the same NMS/SNMP Agent management, when IP addresses are allocated as described

above.

Notes:

1. The CIDR=/29 subnet allows externa l element communication (such as a laptop connected to the site B LAN)

only if there are less than six IDCs opera ting on two cascade d Intrepid-HC HP/T

sufficient for three Intr epid-HC HP/T

cascading shelves. Three cascaded shelves require CIDR=/28 nodes

shelves. The subnet is not

(subnet mask 255.255.255.240). This reduces the available number of chained links to 50%.

GE MDS Intrepid-HC HP Installation Guide 2-17

Page 60

2. High protocol timing constraints (SNMP/TFTP) are expected in Intrepid-HC HP/T link chains due to the large

number of hops (each East/West site adds two in-band routing hops), and a large number of managed IDC

nodes.

The following slight optimiz ation may be useful for a chain topology (but not for a ring):

One of the in-band NE management channels is configure d as a Default GNE Direction, assuming the channel

leads to the nearest GNE under normal conditions. Then, in-band routing chooses this channel as a first prior ity

for every “in-band packet” generated internally, or received fr om the Ethernet interface.

To define IP Addresses:

1. In the main terminal program menu, select Configuration.

2. Select System configuration.

3. Select IDC configuration.

4. Select IDC Basic configuration.

5. Select IP.

6. Define the addresses as described above: e lement IP and basic IP of the units.

2-18 MDS Intrepid-HC HP Installation and Operation

Page 61

Important

7. Repeat the steps above for the remaining IDCs in the Intrepid-HC HP/T IDU.

: After you set up IP addresses, restart the IDUs to activate them.

Setup Options in the Terminal Pr ogr am

The main menu in the terminal setup program includes the following options:

Configuration (1) - the main setup section in whic h you can configure the IDC, the right and left drawers,

protection, SNMP management, in- band routing, and other such parameters.

System Stat us (2) - used to obtain information about the different software versions currently used in the system.

Maintenance (3) - used to perform software upload, download, and reset.

Diagnostics (4) - used to perf orm loopbacks a nd obtain system information.

Logs (5) - used to view alarm and configuration log reports.

GE MDS Intrepid-HC HP Installation Guide 2-19

Page 62

Additional Setup Using the NMS

After you perform initial se tup via the terminal, some additional procedures should be perf ormed via the NMS

software.

Note: The information in this section is provided only for basic initial setup. More detailed inf ormation about the

NMS is provided in the NMS User Guide.

Connecting to the Ethernet Port

1. Connect a crossed Ethernet cable from your PC to the Ethernet Port. If the connection is to a LAN (wall

connection), use the standard Ethernet cable.

2. Make sure the IP address on your PC is on the same sub-net as the one you defined for the IDU (in most cases,

the first three numbers of the IP addre ss must be identica l, depending on the sub-net mask).

NMS PC Requirements

Before you install the NMS software, verify that your PC has the following minimum requirements:

For Windows

Processor: Pentium 4, 2.8 GHz (minimum)

Memory (RAM): 256 MB minimum

Operating System: Windows 2000 or above

Serial Port: RS-232 (Hyper-Terminal)

For UNIX

Processor: Blade 100 Ultra 5 (minimum)

Memory (RAM): 256 MB minimum

Operating System: Solaris 8 or 10

Installing the Network Management Software (NMS)

Note: More detailed information about NMS installation is pr ovided in the NMS User Guide.

1. Insert the NMS CD in the CD drive.

2. In Windows Explorer, double- click the setup.exe file.

The installation progra m begins.

3. Follow the instructions displayed.

2-20 MDS Intrepid-HC HP Installation and Operation

Page 63

Starting the NMS

1. Select Star t , Progr ams, N MS, NMS El e me nt Ma na ger.

The NMS Login window appears.

NMS Login Window

2. Enter the IP address of the second IDC, and the SNMP community (for SNMP protocol access). If you are

working in cascading mode, select the IP address of the second IDC in the master unit.

3. For User Name use admin and for Password use admin (default settings)

4. Select Save Password if you want NMS to remember the password you entere d.

Note that there are two types of passwor ds, eac h with a different security level for authorized activitie s: Read

Only - user can perform monitoring activitie s only.

Read/Write - user can change system configuration and system administrator parameters, and perform

monitoring activities.

After you log in, the Main NMS window appears.

GE MDS Intrepid-HC HP Installation Guide 2-21

Page 64

Main NMS Window for Intrepid-HC HP/T

Setting the Local TX Frequency Channel

If the TX frequency was previously define d using the HyperTerminal, use the frequency window in the NMS only

to verify that the correc t frequency was set.

Note that the concept of N+1 system configuration is to first configure all the carriers separ ately to work as a stand

alone system. After all the carriers are set up as an N+0 configuration, including the XPIC links, then the protection

type is configured.

1. Select Configuration, RFU, RFU Configuration, or click the RFU icon in the tool bar.

At the top of the window, the system displays TX/Rx ranges, the gap between them, and the channel

bandwidth.

2-22 MDS Intrepid-HC HP Installation and Operation

Page 65

RFU Configuration Window

2. In the Frequency Control section, set the TX Channel to the required channel. By default, it is set to the first

channel. If you are unsure of the required channel, refer to the System Descriptions guide for channel

allocations.

The frequency of the selected TX channel appears in the TX Frequency field.

3. If you prefer, you can set the TX frequenc y by entering a fre quency, in MHz, in the TX Frequency section. If

the frequency is not available , a warning message will appear to enable the entered frequency, or to change it

to the nearest available channel.

4. Select the XPIC option (which appears under the RFU illustration) to activate the XPIC mechanism. Th e

mechanism is used to cancel cross polar interference in a dual polarization system.

5. Select the Local Only option. B y default, the Local + Remote option is selected. However, since there is no

connection to the remote unit at this tim e, the Local + Remote option is not available.

6. Click Apply to save the settings.

7. Click Close.

GE MDS Intrepid-HC HP Installation Guide 2-23

Page 66

Setting up the N+1 Configuration

1. Select Protection, H/W protection, H/W protection type.

H/W Protection Type Window

2. Click the Protection Topology drop-down list and select the required configur ation, as follows:

HSB 1+1 - the upper level is activated with two drawers that protect each other, while the standby drawer is

muted.

HSB 2+2 - levels one and three of the IDU are activated. Each level protec ts the other when the standby IDU is

muted. Each level operates in XPIC mode. Exter nal protection cables need to be connected between levels one

and three.

1+1 - the +1 algorithm is activated. The upper level includes two carriers, whereby the left one is protected.

2+1 - three separate carriers with one protected.

3+1 - four separate carr iers with one prote cted.

4+1 - five separate carriers with one protected.

5+1 - cascade mode, six separate carr iers with one protected.

6+1 - cascade mode, seven separate carriers with one protected.

7+1 - cascade mode, eight separate car riers with one protected.

8+1 - cascade mode, nine separate carrie rs with one protected.

2-24 MDS Intrepid-HC HP Installation and Operation

Page 67

9+1 - cascade mode, ten separate carrie rs with one protected.

3. Select Protection, H/W protection, H/W protection configuration.

The following window will appear if the prote ction type you selected was between 1+1 and 9+1.

H/W Protection Configuration Window

4. Select Protectio n E na bl ed .

5. Select Switch On Earl y Warning if you want the switch to occur when the system reaches an MSE of -28.

6. For Revertive Link, select the carrier that will be connected to the +1 modem. Your selection will be used in

cases where a switch occurs and then the system re turns to normal operation.

Examples

Revertive = Extra Traffic

If a major alarm occurs at site A, a request is sent to site B to transmit through the Extra Traffic channel. The

switch that is performe d is Hitless (up to 10 ms), a nd the Extra Traffic channel will no longer exist on both

sides by definition (gene rally, the system can protect up to two faults at different sides). The moment the alarm

is cleared, the +1 (Extra Traff ic) modem will refer to the input from the +1 MUX.

Revertive = None

Each carrier MUX will receive two inputs: its own modem, and the +1 modem. The Extra Traffic channel will

not exist. Data to the MUX (for each of the defined carriers) will be received from its own modem until the

GE MDS Intrepid-HC HP Installation Guide 2-25

Page 68

first hitless fault. When the fault is cleared, the MUX will receive data from two sources: the +1 modem, and

its own modem, meaning the next fault in this channel will be errorless (if other carriers will fail, the da ta will

be hitless).

Revertive = Carrier#X

MUX number X will always receive two sources: the +1, and its own, unless there is a fault in another carrier.

If MUX number X receives two sources, and a fault occurs, the switch is errorle ss. I n all the other cases, the

switch is hitless.

7. For Revertive Switch Timeout, specify the period (in seconds) after which the revertive mode will be

activated.

8. For High Pri ori ty Thr es hol d , click the drop-down list and select the criteria upon which the system will

perform a switch to the channel you chose as high priority.

The options include: Base band Loss of Frame, Baseband Excessive BER, Baseband Signal Degrade, and Early

Warning

9. In the priority table, designate the high priority channel(s) . A high priority channel will be switched first when

the criteria chose n for the threshold is met, even if a major fault occurs in a different channel.

The Priority Level options include :

Normal - regular operation acc ording to the N+1 mechanism

High Priority

Not Protected – stand-a lone channel without protection

Specifying System Information

Note: To specify system information, you must perform the follow ing steps in all three IDCs in the Intrepid-HC

HP/T IDU:

1. Select File, System, Information., or click the System Information icon

.

2-26 MDS Intrepid-HC HP Installation and Operation

Page 69

System Information Window

2. In the Current Time area, click Da t e/Time Con f i g ura t i o n and set the date and time (in the format

HH:MM:SS).

3. The read-only Description field provides information about the GE MDS Intrepid-HC HP system.

4. (Optional) In the Name field, enter a name for this link. By convention, this is the node ’s fully-qualified

domain name.

5. (Optional) In the Contact field, enter the name of the person to be contacted when a problem with the system

occurs. Include information on how to contact the designated person.

6. (Optional) In the Location field, enter the actual physical loc ation of the node or agent.

7. The Up Time field is read-only and shows how long the system has been operating continuously.

8. For Left/Right Carrier Na me , specify the name you want to give the carrier for identification purposes.

9. Click Apply. The settings are saved.

10. Click Close.

GE MDS Intrepid-HC HP Installation Guide 2-27

Page 70

Local/Re m ote Tr ansport Confi gur ation

The Local/Remote Transpor t Configuration window allows you to change threshold levels for the radio and alarms,

and to configure specia l transm ission parameters. This is recommended for advanced users only and should be done

in all of the three IDCs in the Intrepid-HC HP/T IDU.

Note: You will need to restart the NMS if you change the transport protocol.

1. Select Configuration, IDU, Transport.

The Transport Configuration window appears.

Transport Configuration Window

2. The Protocol field displays the current data transfer protocol. To change the protocol, c lick the drop down list

and select SDH, SONET, or SONET-C.

3. Click Apply to save the settings.

4. Click Close.

2-28 MDS Intrepid-HC HP Installation and Operation

Page 71

Trap Forwarding Configuration

This section explains how to set up a trap forwar ding plan. If your application does not require trap forwarding, you

can skip the following procedur e.

1. Select Configuration, Management Syste m, Traps Co nfi gura ti on, or click the Traps Configuration icon.

The Trap Forwarding Configuration window appears.

Trap Forwarding Configuration Window

2. In the Managers IP Address area, specify the IP addresses of the managers to which you want traps to be sent.

For each manager IP you specify, specify the Trap Port, and for Send Trap for Ala r ms with Severity, select

the severity filte r to determine which types of alarms will be forwarded.

GE MDS Intrepid-HC HP Installation Guide 2-29

Page 72

3. In the Send Trap for Alarms of Group section, you determine which alarms will be sent as SNMP traps to

each manager. In each manager column, select the alarm types you want to include for that manager.

4. In the Trap Options area, select Standard traps include serial number if you want trap messages to include

the IDU serial number.

Select Report local traps of far end IDU if you want remote IDU trap messages to be reported locally.

Select Use different ID for each alarm type if you want each type of alarm to receive a unique ID.

Select Send “clear” traps with zero severity if you want a trap with a “clear” severity (instead of the alarm's

original severity) to be sent to the IP addresses you specified.

5. For CLLI (Common Language Location Identifie r), enter up to 18 characters that will represent your system

ID when traps are sent.

6. For Heartbeat Period, a heartbeat signal will be generated every x minutes (the number you enter) to tell your

system that the tr ap mechanism is wo rk ing.

7. Click Apply to save the settings.

Extern al Alarms Setup

The procedure detailed in this se ction is required only if alarms generated by external equipme nt are connected to

the IDU, or if the IDU alarm outputs are connected to other equipm ent (using the alarms I/O connector).

The IDU has eight external alarm inputs and five external alarm outputs. Since each of the three levels support five

outputs, the system uses the OR function between the outputs of each floor, and accordingly generates the alarm.

1. Select the middle floor of the IDU, and se lect Configuration, IDU, External Alarms.

Or, click the External Alarms icon

Or, click the EXT ALARM IN icon on the IDU front panel

.