Page 1

GE

g

READ THOROUGHLY BEFORE INSTALLING

GENERAL

This luminaire is designed for application in hazardous

location environments.

Lighting Solutions

WARNING

Risk of electric shock

• Turn power off before servicing

– see instructions

GEH-5850

INSTRUCTIONS

POWR•GARD® LUMINAIRE

Make all electrical connections in accordance with

the National Electrical Code and any applicable

local code requirements.

THE OPERATING TEMPERATURE “T-CODE”

LISTED FOR THIS LUMINAIRE IS BASED ON THE

FOLLOWING BULB SIZES. USE OF OTHER THAN

THESE MAY RESULT IN A HIGHER OPERATING

TEMPERATURE AND COULD RESULT IN A HAZARDOUS CONDITION.

LAMP TYPE WATTAGE BULB SIZE

HIGH PRESSURE SODIUM 70,100,150 ED 23 1/2

HIGH PRESSURE SODIUM 250, 400 ED 18

METAL HALIDE/MERCURY 175, 250 ED 28

METAL HALIDE/MERCURY 400 ED 37

CAUTION: Check the operating temperature limits

marked on the ballast assembly prior to installation to be sure it conforms to the environmental

temperature restrictions and NEC classifications.

WARNING: TO PREVENT IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE SUPPLY

CIRCUIT FROM THE LUMINAIRE BEFORE RELAMPING, REMOVING, OR PERFORMING ANY MAINTENANCE.

INSTALLATION

CAUTION

Unit will fall if not installed properly

• Follow installation instructions

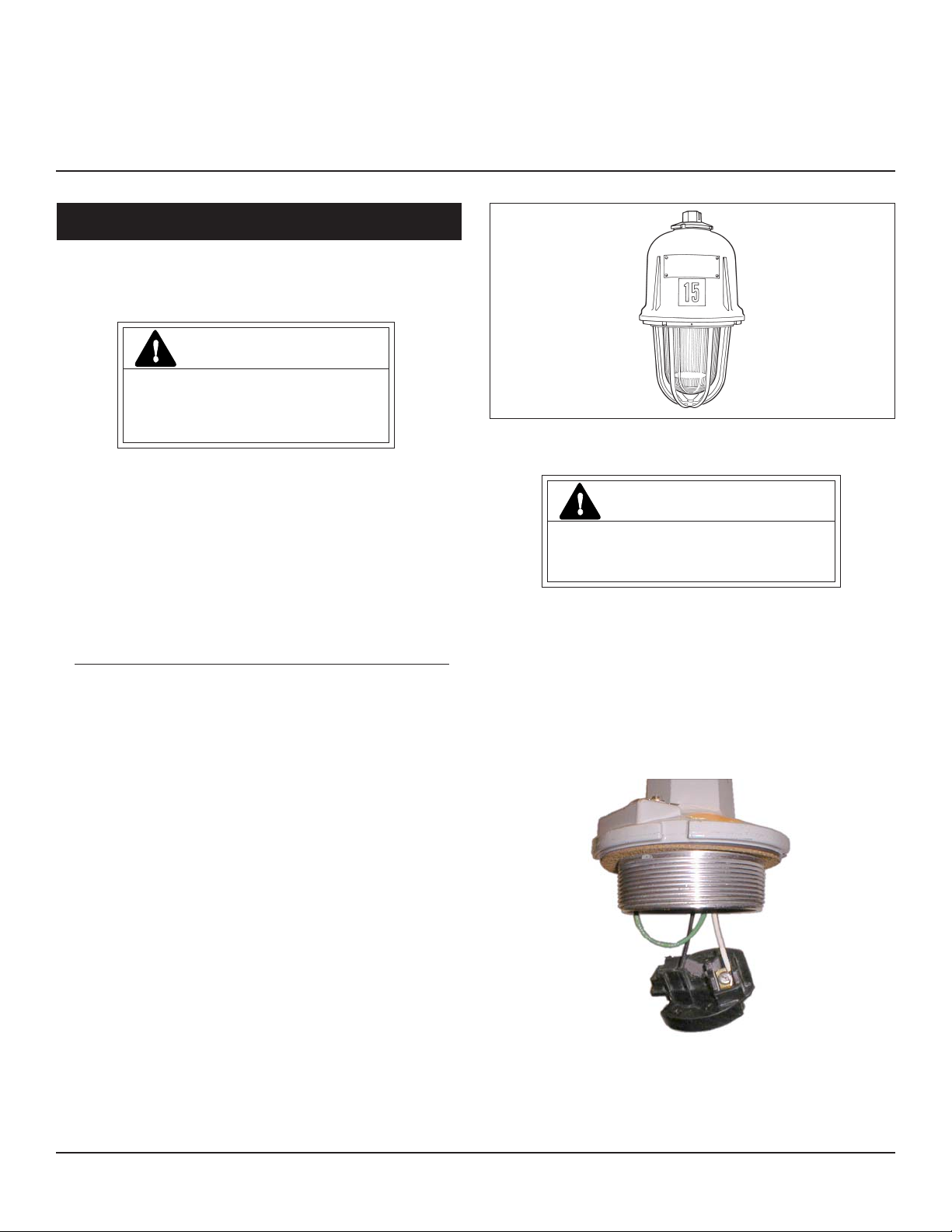

MOUNTING CONDUIT

Take the mounting hub and remove the electrical

disconnect from it. Thread the mounting hub onto the

conduit five threads minimum and tighten the set screw.

Connect the ground lead to the screw provided in the

mounting hub.

Connect the supply wires to the electrical disconnect

according to the color coding labels if applicable. Refasten

the disconnect into the mounting hub. See Figure A.

UNPACKING

The ballast assembly and mounting fittings have been

properly packed in separate cartons so that no parts should

have been damaged during transit. Remove packing

materials used to protect threads and inspect. Do not

attempt to assemble or use parts with damaged threads.

Verify that supply voltage is correct by comparing it

to nameplate.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

Figure A

MOUNTING STANCHION

AND WALL BRACKET

For the stanchion arm, mount arm onto the conduit five

threads minimum and tighten the set screw. For the wall

bracket, attach bracket to the support surface through the

Page 2

four clearance holes provided. Remove the electrical

disconnect from the mounting hub and connect electrically

as stated for conduit mounting.

EXTERNAL REFLECTORS

A reflector, if used, is attached to the bottom of the globe

ring with the three screws provided.

MOUNTING SURFACE

Attach the surface mounting box to the support surface

through the four clearance holes provided. Remove the

electrical disconnect from the mounting hub and connect

electrically as stated for conduit mounting.

NOTE: Threads on the ballast housing to ac-

cept the above mountings are factory

lubricated with General Electric Versalube

G322L. Additional lubricant of the same type

may be applied if necessary.

BALLAST HOUSING

Thread the ballast housing onto the hub. The electrical

disconnect will automatically mate after five threads have

engaged. Continue engaging until the housing is tightly

threaded onto the hub and then tighten the set screw at the

bottom of the hub.

LAMP INSTALLATION

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

If a globe guard is on the unit, the reflector is attached

using the same screws that hold the guard. These screws

need only be loosened since the reflector is provided with

keyhole slots.

If an angle reflector is used, orient the reflector with

respect to the three screws so that the main light output is

near the desired direction. After loosening the set screw the

globe ring can then be slightly rotated to complete the

reflector orientation. Then retighten the set screw.

MAINTENANCE

It will occasionally be necessary to clean the optical

assembly in order to maintain the light level. Frequency of

cleaning will depend on the dirt level in the user’s facility

and the minimum light level which is acceptable to him.

The reflector should be cleaned with any suitable nonabrasive solution of water and soap or detergent. Residual

cleanser should be removed by clean water rinsing. The

glassware may be cleaned with any conventional glass

cleanser.

Disconnect the power supply circuit before relamping.

Loosen the set screw near the bottom edge of the ballast

housing. Unthread the glass globe support ring which

threads into the ballast housing. To assist in removing this

globe ring, a screw driver can be inserted in the pry slots, or

the globe ring can be loosened by lightly tapping on the

globe ring ribs.

Use only lamps specified on nameplate. Observe

lamp manufacturer’s recommendations and restric-

tions on lamp operation, particularly ballast type,

burning position, etc.

Damage may occur to the fixture if the lamp is inserted

while power is on, or if the lamp is not tight in the socket

when power is applied.

LAMP TIGHTNESS: The lamp should be securely

inserted to the NEMA-EEI specified torque of 35 inchpounds, which is best achieved by very firmly tightening to

insure application of sufficient torque. Tightening must be

sufficient to fully depress and load the center contact of the

socket.

After lamp is installed, rethread globe ring into ballast

housing until it firmly seats. Tighten set screw.

WARNING: GLOBE IS TEMPERED

GLASS. DO NOT SCRATCH OR CHIP.

Page 3

GE

g

À LIRE AVEC SOIN AVANT D’INSTALLER

PRÉSENTATION

Ce luminaire estconçu pour une application dans les

environnements dangereux.

Lighting Solutions

DANGER

Risque d’électrocution

• Mettre hors tension avant d’intervenir

– Suivez les instructions

Effectuez tous les raccordements en conformité avec les

normes nationales et les éventuels règlements locaux

applicables.

LA TEMPÉRATURE NOMINALE“T-CODE” LISTÉE POUR CE

LUMINAIRE EST BASÉE SUR LES TAILLES D’AMPOULES

SUIVANTES. SI VOUS EN UTILISIEZ DE DIFFÉRENTES,

CELA POURRAIT AMENER UNE TEMPÉRATURE DE

FONCTIONNEMENT PLUS ÉLEVÉE ET PROVOQUER UNE

SITUATION DANGEREUSE.

TYPE DE LAMPE PUISSANCE TAILLE

SODIUM HAUTE PRESSION 70,100,150 ED 23 1/2

SODIUM HAUTE PRESSION 250, 400 ED 18

HALOGÈNURE/MERCURE 175, 250 ED 28

HALOGÈNURE/MERCURE 400 ED 37

ATTENTION: Vérifiez la température limite de

fonctionnement avant de l’installer pour vérifier qu’il

compatible avec les restrictions de température de

l’environnement et les normes NEC.

GEH-5850

INSTRUCTIONS

®

LUMINAIRE POWR•GARD

INSTALLATION

ATTENTION

Risque de chute en cas de mauvais

montage • Suivez les instructions

MONTAGE SUR CONDUITE

Prenez le raccord de montage et débranchez-en la déconnexion

électrique rapide. Vissez-le sur la conduite sur au moins cinq filets et

serrez la vis de blocage. Raccordez le fil de terre sur la vis disponible

dans le raccord de montage.

Connectez les fils d’alimentation sur la prise de déconnexion

électrique en fonction de leurs marquages de couleur s’il y a lieu.

Rebranchez la prise à déconnexion rapide dans le raccord de

montage (voir schéma A).

AVERTISSEMENT : POUR ÉVITER UNE INFLAMMATION

EN ATMOSPHÈRE DANGEREUSE, DÉBRANCHEZ

L’ALIMENTATION DU LUMINAIRE AVANT DE CHANGER

SA LAMPE, DE LE DÉMONTER OU D’OPÉRER TOUT

ENTRETIEN DESSUS.

DÉBALLAGE

L’ensemble de ballast et les dispositifs de montage ont été

correctement emballés dans des cartons séparés de façon à ce

qu’aucune pièce ne soit détériorée durant le transport. Enlevez les

matériaux d’emballage utilisés pour protéger les filetages et

inspectez. N’essayez pas d’assembler ou d’utiliser des pièces avec

des filets endommagés.

Schéma A

MONTAGE AVEC MONTANT

Vérifiez que la tension secteur disponible est la bonne en

comparant avec l'indication de tension sur la plaque

d'identification.

Ces instructions n'ont pas pour destination de couvrir tous les détails ou variantes de l'équipement, ni de répondre à toutes les éventualités que vous pourriez rencontrer pendant l'installation,

le fonctionnement ou l'entretien. Si vous souhaitez des informations complémentaires, ou si vous rencontrez un problème particulier qui ne soit pas adressé de votre point de vue d'acheteur,

le sujet doit être remonté jusqu'à la société GE Lighting Solutions

ET SUPPORT MURAL

Pour le bras de montant, montez le bras sur la conduite sur cinq

filets au minimum et serrez la vis de blocage. Pour le support mural,

fixez-le sur la surface de support en utilisant les quatre orifices de

dégagement disponibles.

Page 4

Débranchez la prise électrique à déconnexion rapide du raccord

de montage et faites le raccordement électrique comme expliqué

pour le montage sur conduite.

MONTAGE EN SURFACE

Fixez la boîte de montage en surface sur la surface d’accueil en

utilisant les quatre trous de dégagement disponibles. Débranchez la

prise électrique à déconnexion rapide du raccord de montage et

faites le raccordement électrique comme expliqué pour le montage

sur conduite.

NOTE : Les filets sur le caisson de ballast compatible avec

les types de montages précédents sont lubrifiés avec du

Versalube G322L de General Electric. Appliquez un

supplément de lubrifiant du même type si nécessaire.

Une fois la lampe installée, revissez à fond l’anneau de

globe sur le caisson de ballast. Serrez la vis de blocage.

AVERTISSEMENT : LE GLOBE EST EN VERRE

TREMPÉ, ÉVITEZ LES RAYURES ET COUPS.

RÉFLECTEURS EXTERNES

Un réflecteur, s’il est utilisé, est fixé sur le bas de l’anneau

de globe avec les trois vis fournies.

S’il y a une protection de globe sur le luminaire, le

réflecteur est fixé en utilisant les mêmes vis qui maintiennent

la protection. Ces vis n’ont seulement qu’à être desserrées

pour ce montage puisque le réflecteur est pourvus d’orifices de

montage en trous de serrure.

CAISSON DE BALLAST

Vissez le caisson de ballast sur le raccord de montage. La prise

électrique à déconnexion rapide va automatiquement se brancher

après que cinq filets aient été engagés. Continuez de visser jusqu’à ce

que le caisson soit bien serré sur le raccord de montage, puis serrez

la vis de blocage sur le bas du raccord.

INSTALLATION DE LAMPE

ATTENTION

Risque de brûlure

Laissez le bloc d’ampoule refroidir

avant d'y toucher

Débranchez l’alimentation électrique avant de remettre une

lampe. Desserrez la vis de blocage près du bord inférieur du caisson

de ballast. Dévissez le support du globe en verre qui est fixé sur le

caisson de ballast. Pour aider à enlever l’anneau de globe, une lame

de tournevis peut être insérée dans les fentes de levier, ou l’anneau

de globe peut être desserré en tapotant légèrement sur ses nervures.

N’utilisez que le type de lampe spécifié sur la plaque

d’identification. Observez les recommandations et restrictions

du fabricant sur le fonctionnement de la lampe, en particulier

pour le type de ballast, la position d’utilisation, etc.

Si un réflecteur coudé est utilisé, orientez-le en fonction

des trois vis de façon à ce que la sortie lumineuse principale

soit près de la direction voulue. Après desserrage de la vis de

blocage, l’anneau de globe peut alors être légèrement tourné

pour parfaire l’orientation du réflecteur. La vis de blocage est

ensuite resserrée.

ENTRETIEN

Il sera nécessaire à l'occasion de nettoyer l’ensemble optique pour

maintenir le niveau d'éclairage. La fréquence de ces nettoyages

dépend du niveau d'empoussièrage local et du seuil minimum de

luminosité acceptable pour l'utilisateur. Le réflecteur doit être lavé

avec une solution d'eau et de n'importe quel détergent ménager

doux et non abrasif, rincez à l'eau claire pour enlever les résidus de

nettoyant. Le vitrage peut être nettoyé avec un produit pour vitres

classique.

Des dommages peuvent se produire dans le luminaire si la lampe

est insérée quand il est encore sous tension, ou si la lampe était mal

serrée au moment de sa mise sous tension.

SERRAGE DE LAMPE : La lampe doit être insérée de façon

sûre avec un couple de serrage NEMA-EEI spécifié à 4,4 mkg (35

livre-pouce), ce qui est le mieux réalisé en serrant fortement à la

main pour mettre un couple suffisant. Le serrage doit complètement

appuyer et charger le contact central de la douille avec le culot de la

lampe.

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

16943533----888

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

g

35-201578-6N (1/01)

Loading...

Loading...