Page 1

GE

g

Lighting Solutions

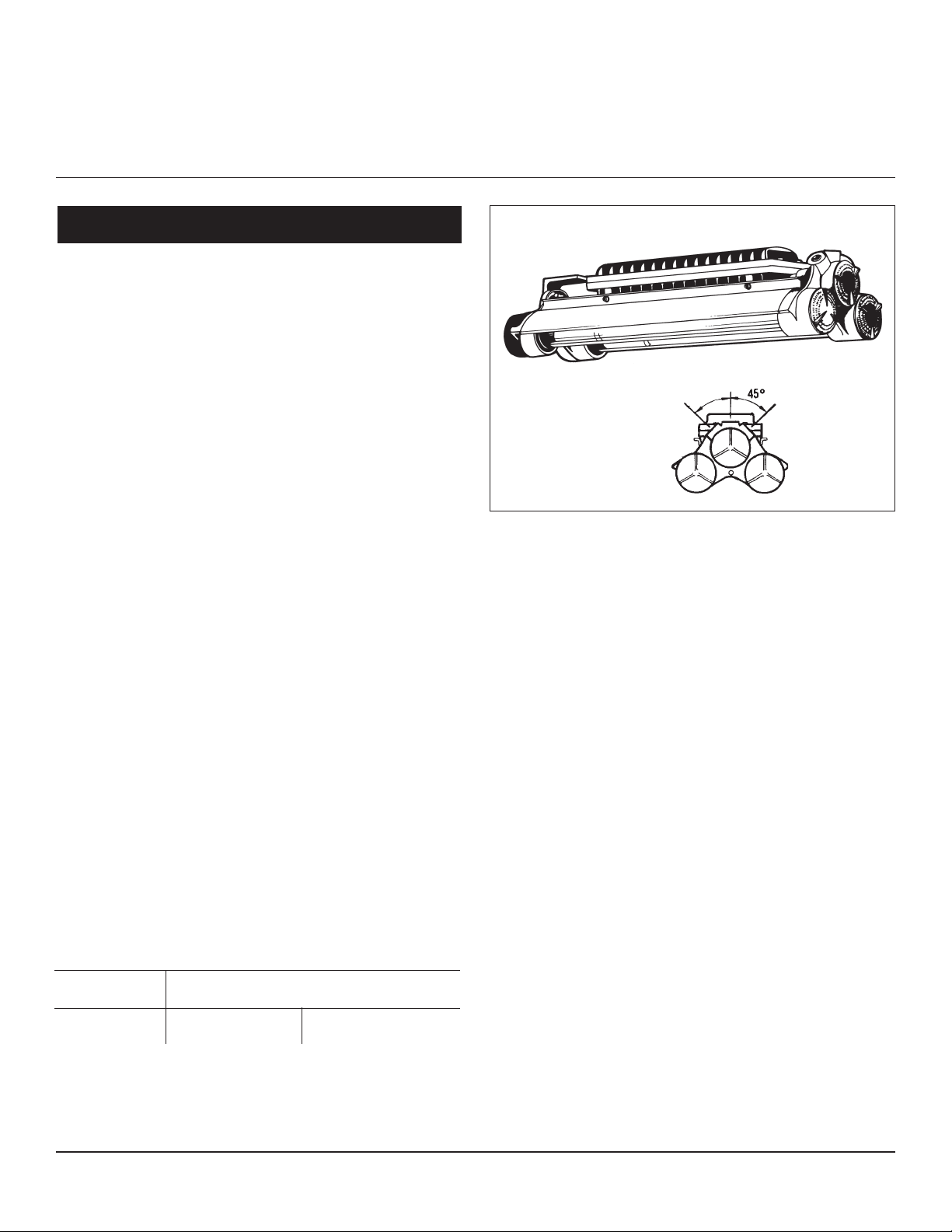

H4 Hazardous Location Luminaire

READ THOROUGHLY BEFORE INSTALLING

WARNING: DANGEROUS VOLTAGES EXIST

WITHIN THESE UNITS AND ALL PRECAUTIONS

USUALLY OBSERVED IN HANDLING HIGH

VOLTAGE EQUIPMENT SHOULD BE OBSERVED.

MAKE CERTAIN POWER IS OFF BEFORE

STARTING INSTALLATION PROCEDURE OR

BEFORE SERVICING.

Caution: When installing the luminaire in hazardous

locations, check the operating temperature limits prior to

installation to be sure it conforms to the environmental

temperature restrictions and NEC classifications.

GEH-5734B

INSTRUCTIONS

THIS FIXTURE SHOULD BE INSTALLED BY QUALIFIED

TECHNICIANS IN STRICT ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE AND ANY LOCAL REQUIREMENTS.

INSTALLATION

Caution: To avoid electrical shock hazard.

1. Before installation or service of this fixture,

make sure that the circuit is deactivated.

2. This unit is furnished completely assembled.

Before installing, check the fixture label to

insure correct voltage and frequency.

3. Typical fixture installations are shown on

back of page.

OPERATIONAL DATA

Operate this fixture at its rated voltage. See fixture label for

data. To receive full benefit of rated lamp output and to

prolong ballast life, it is essential that voltage supply to the

fixture be maintained within the following limits:

NOMINAL APPLIED VOLTAGE RANGE

VOLTAGE MINIMUM MAXIMUM

120 110 125

277 255 290

MAINTENANCE DATA

1. Although no routine maintenance is required to keep this

fixture functional, it should be checked perodically to ensure

that it is working properly and to look for any external

damage.

2. For optimum performance, keep light transimissions parts of

the fixture clean. Any commercial glass cleaner can be used

to clean the glass tubes.

3. Relamping Procedure:

A. Biaxial Lamp — Disconnect supply circuit. Remove the

lamp access cover (opposite conduit entrance side).

Using the relamp support, remove the lamp from the

fixture. Remove the lamp support and install on new

lamp. Install lamp and lamp access cover.

B. T8/T5 Lamp — Disconnect supply circuit. Remove

lamp access cover (either end of lamp). Loosen

lampholder bracket screws. Twist and remove

lampholder bracket. Remove lamp and install new lamp,

seating lamp in opposite lampholder. Replace

lampholder into position on the lamp. Twist slightly to

place lampholder bracket under screw heads, and tighten

screws. Reattach lamp access cover.

4. In the event of glass tube breakage, it will be necessary to

replace the damaged unit with a factory sealed housing

assembly, in order to maintain the integrity of the fixture.

See the fixture parts list for ordering.

5. When replacing Ballast, it should be of Class-P, thermallyprotected type.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

Page 2

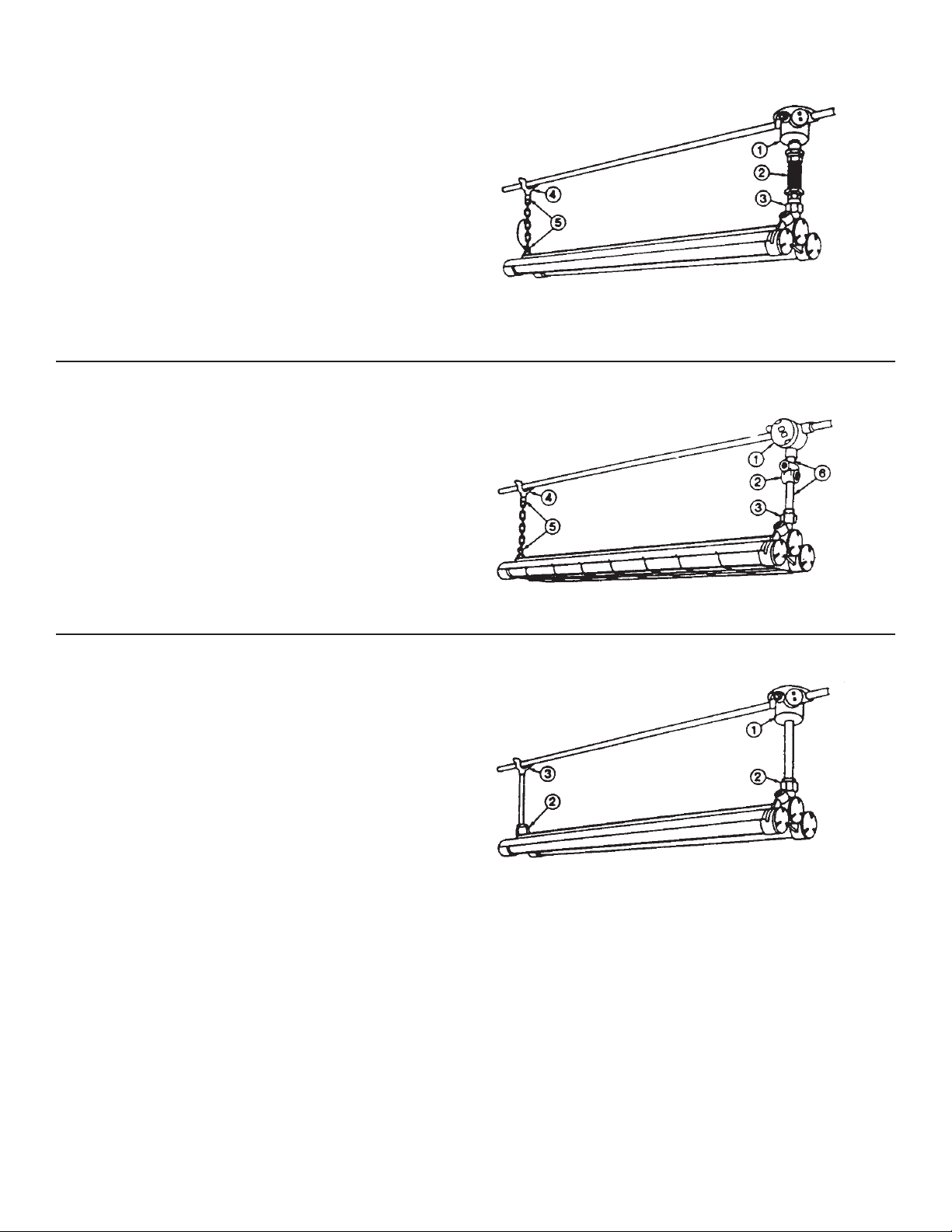

TYPICAL INSTALLATIONS

(Mounting Hardware/Supports by others)

Dummy (non-powered) end lowers for relamping clearance

which is required when fixtures are mounted in close

proximity. Flexible mounting provides free swing and impact

protection.

1. Splice Box/Fixture Hanger

2. Flexible Pendant Hanger

3. Union

4. Rigid Support

5. Support Hook

NOTE: Leave extra links to support fixture in relamping

positions.

Dummy (non-powered) end lowers for relamping clearance

which is required when fixtures are mounted in close

proximity.

1. Splice Box/Fixture Hanger

2. Swivel Hanger

3. Union

4. Rigid Support

5. Support Hook

6. Conduit Nipple

NOTE:Leave extra links to support fixture in relamping

position.

Rigid mounted for installations where relamping can be

accomplished without lowering dummy end.

1. Splice Box/Fixture Hanger

2. Union

3. Rigid Support

g

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

16943533----888

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

35-201578-P9 (11/08)

Loading...

Loading...