Page 1

GEAppliances.com

om

0

(./3

Safety Information .................... 2

Specifications and Dimensions ........ 3

About the Softener .................... 6

Before you Start ....................... 7

Installation Requirements .......... 8-10

Installation Instructions ........... 11-15

U3

Programming the Softener ........ 16-21

Care and Cleaning ................. 22, 23

g3

Routine Maintenance ................. 24

Before you call for Service ......... 25-28

Exploded ViewlParts List .......... 31-34

Warranty (U.S.)....................... 35

Warranty (Canada) ................... 36

Systems tested and certified by NSFInternational against

NSF/ANS!Standard 44 for the chemical reduction claims

specified on page 3.

Water Softening

System

Models GXSH4OV,GXSH45V

Write the model ond seriol

numbers here:

Model #

Seriol #

Tofind these numbers, lift

the cover and look on the rim

below the control panel.

SystemsTested and Certified by the Water Quality Association

against CSAB483.1.

Ifyou have any questions or concerns when installing or maintaining your

water softener, call our toll free number at 800-952-5039 (US)or 866-777-7627

(Canada}, or visit www.geappliances.com When you call, please be prepared

to provide the model and serial number of your product. This information can

befound on the rating decal located on the rim under the salt cover.

7329201 49-50283-101-12GE

Page 2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

SAFETYPRECAUTIONS

_k WARNING! Foryoursdety,theinformationinthismanualmustbe_ollo_edtominimize

the risk of electric shock, property damage or personal injury.

&DANGER:

Electric Shock Hazard:

Install metal ground clamp to metal house

water supply pipe before beginning

installation. Securely tighten connection in

center of metal ground clamp. Failure to do

so can result in death or electric shock.

Check and comply with your state and local

codes. You must follow these guidelines.

_: Use care when handling the water softening

system. Do not turn upside down, drop, drag or

set on sharp protrusions.

Water softening systems using sodium chloride

(salt)for recharge add sodium to the water.

Persons on sodium restricted diets should

consider the added sodium as part of their

overall intake. Potassium chloride can be used

as an alternative to sodium chloride in your

softener.

Use only lead-free solder and flux for all sweat-

solder connections, as required by state and

federal codes.

This water softening system must be properly

installed and located in accordance with the

installation instructions before it is used.

A WARNING:oonot use with water

that is microbiologically unsafe or of unknown

quality without adequate disinfection before

or after the system.

WARNING: Discard all unused

parts and packaging material after

installation. Small parts remaining after the

installation could be a choke hazard.

The water softening system works on 2/4volt-

60 Hz electrical power only. Besure to use the

included external power supply.

iiiiiii_

External power supply must be plugged into an

indoor 120 volt, grounded outlet only.

iiiiiii_

Use clean water softening salts only, at least

99.5% pure. NUGGET,PELLETor coarse SOLAR

salts are recommended. Do not use rock, block,

granulated or ice cream making salts. They

contain dirt and sediments, or mush and cake,

and will create maintenance problems.

Keep the salt hole cover in place on the softener

unless servicing the unit or refilling with salt.

In the state of California: You must turn the

Salt Efficiency Feature setting to ON. This may

initiate more frequent recharges. However it

will operate at 4,000 grains per pound of salt or

higher. To turn on the Salt Efficiency Feature,

follow the instructions in the "Salt Saver"

section of this manual

_'1__ _ READ AND FOLLOW THI_ _FET_ INFORMATION C_REFULL_.

In the Commonwealth of Massachusetts,

Plumbing Code 248 CMR shall be adhered to.

Consult with your licensed plumber.

/_F-_ SAVE THESE INSTRUCTIONS

Page 3

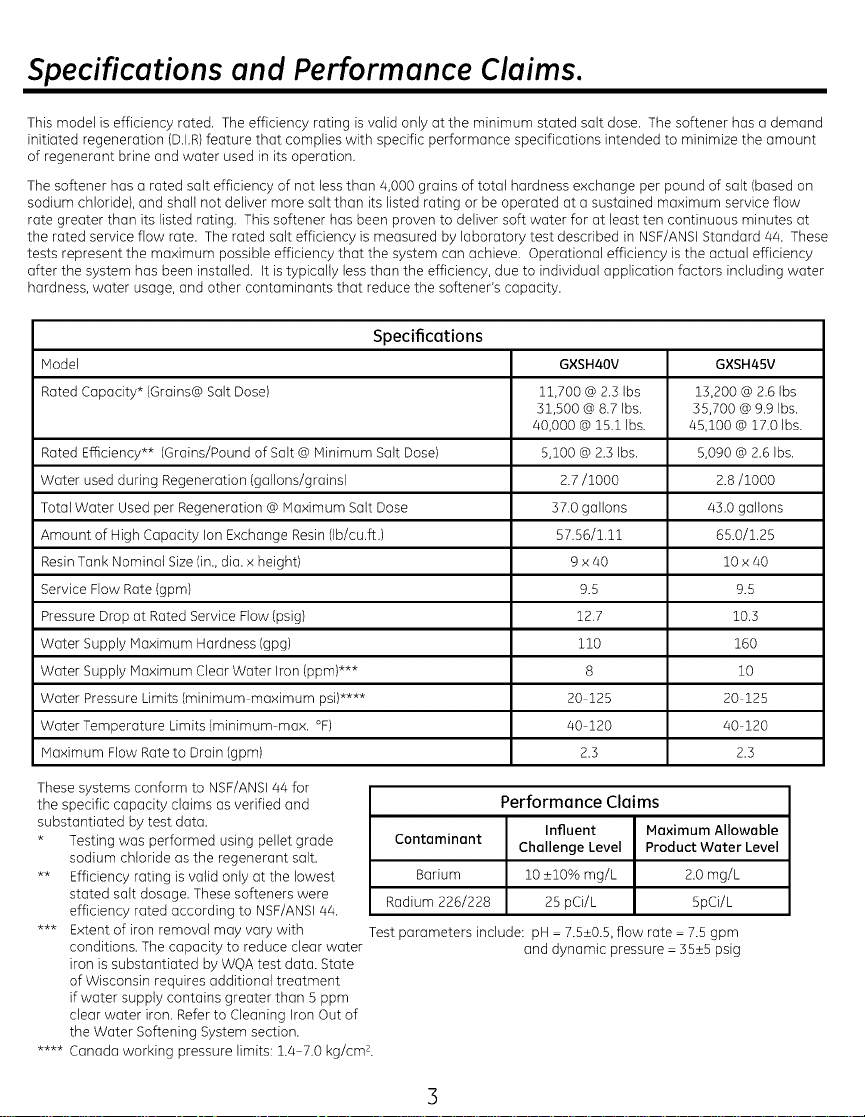

Specifications and Performance Claims.

This model is efficiency rated, The efficiency rating is valid only at the minimum stated salt dose, The softener has a demand

initiated regeneration (D,I,R)feature that complies with specific performance specifications intended to minimize the amount

of regenerant brine and water used in its operation.

The softener has a rated salt efficiency of not less than 4,000 grains of total hardness exchange per pound of salt (based on

sodium chloride), and shall not deliver more salt than its listed rating or be operated at a sustained maximum service flow

rate greater than its listed rating, This softener has been proven to deliver soft water for at least ten continuous minutes at

the rated service flow rate. The rated salt efficiency is measured by laboratory test described in NSF/ANSI Standard/44. These

tests represent the maximum possible efficiency that the system can achieve, Operational efficiency is the actual efficiency

after the system has been installed, It is typically less than the efficiency, due to individual application factors including water

hardness, water usage, and other contaminants that reduce the softener's capacity.

Specifications

Model

Rated Capacity* (Grains@ Salt Dose)

Rated Efficiency** (Grains/Pound of Salt @ Minimum Salt Dose)

Water used during Regeneration (gallons/grains)

Total Water Used per Regeneration @ Maximum Salt Dose

Amount of High Capacity Ion Exchange Resin (Ib/cu,ft,)

Resin Tank Nominal Size (in., dia. x height)

Service Flow Rate (gpm)

Pressure Drop at Rated Service Flow (psig)

Water Supply Maximum Hardness (gpg)

Water Supply Maximum Clear Water Iron (ppm)***

Water Pressure Limits (minimum maximum psi)****

Water Temperature Limits (minimum max. °F)

Maximum Flow Rate to Drain (gpm)

GXSH40V

11,700 @ 2,3 Ibs

31,500 @ 8.7 Ibs,

40,000 @ 15,1 Ibs.

5,100 @ 2.3 Ibs.

2.7/1000

37,0 gallons

57,56/i,ii

9 Ha0

9.5

12,7

110

8

20 125

40 120

2.3

GXSH45V

13,200 @ 2,6 Ibs

55,700 @ 9,9 Ibs,

45,100 @ 17,0 Ibs.

5,090 @ 2.6 Ibs,

2.8/1000

43,0 gallons

65.0/125

10 x 40

9.5

10S

160

10

20 125

40 120

2.3

These systems conform to NSF/ANSI 44 for

the specific capacity claims as verified and

substantiated by test data.

* Testing was performed using pellet grade

sodium chloride as the regenerant salt.

** Efficiency rating is valid only at the lowest

stated salt dosage, These softeners were

efficiency rated according to NSF/ANSI 44,

*** Extent of iron removal may vary with

conditions. The capacity to reduce clear water

iron is substantiated by WOA test data. State

of Wisconsin requires additional treatment

if water supply contains greater than S ppm

clear water iron. Refer to Cleaning Iron Out of

the Water Softening System section.

.... Canada working pressure limits: 1.a 7.o kg/cm%

Performance Claims

Contaminant

Barium 10 _+10% mg/L 2.0 mg/L

Radium 226/228 25 pCi/L SpCi/L

Test parameters include: pH - 7.5_+0.5,flow rate - 7.5 gpm

Influent Maximum Allowable

Challenge Level Product Water Level

and dynamic pressure - 55_+5 psig

Page 4

About the water softener system.

SERVICE

When the water softening system is providing

soft water, it is called "Service." During service,

hard water flows from the house main water pipe

into the water softening system. Inside the water

softening system resin tank is a bed made up of

thousands of tiny, plastic resin beads. As hard

water passes through the bed, each bead attracts

and holds the hard minerals. This is called ion-

exchanging. It is much like a magnet attracting

and holding metals. Water without hard minerals

(soft water) flows from the water softening system

and to the house pipes.

AUTOMATIC HARD WATER BYPASSDURING

RECHARGE

During recharge the water softener is

automatically put in bypass mode allowing hard

water to be available to the home. Oncethe

softener is recharged water is directed back

through the softener to be conditioned.

After a period of time, the resin beads become

coated with hard minerals and they have to

be cleaned. This cleaning is called recharge.

Recharge is started at 2:00 AM (factory setting) by

the water softening system control, and consists

of five stages or cycles. These are FILL, BRINING,

BRINERINSE,BACKWASH and FASTRINSE.

However, you should avoid using HOT water

because the water heater will fill with the hard

water.

FILL

Salt dissolved inwater is called brine. Brine is

needed to clean the hard minerals from resin

beads. To make the brine, water flows into the salt

storage area during the fill stage.

BRINING

During brining, brine travels from the salt storage

area into the resin tank. Brine isthe cleaning agent

needed to remove hard minerals from the resin

beads. The hard minerals and brine are discharged

to the drain.

The nozzle and venturi create a suction to move

the brine, maintaining a very slow rate to get the

best resin cleaning with the least salt.

BRINE RINSE

After a pre-measured amount of brine is used,

the brine valve closes. Water continues to flow in

the same path as during brining, except for the

discontinued brine flow. Hard minerals and brine

flush from the resin tank to the drain.

BACKWASH

During backwash, water travels up through

the resin tank at a fast flow rate, flushing

accumulated iron, dirt and sediments

from the resin bed and to the drain.

FAST RINSE

Backwash is followed by a fast flow of water down

through the resin tank. The fast flow flushes brine

from the bottom of the tank,

and packs the resin bed.

After fast rinse, the water softening system returns

to soft water service.

Page 5

About the water softener system.

NORMAL OPERATION, CONTROL DISPLAYS

During normal operation, the present time of

day and AM or PMand DAYSTO EMPTYshow

in the control display area.

The system will automatically recharge at the

preset recharge time as needed.

FEATURE: OPTIONAL RECHARGE CONTROLS

Sometimes, a manually started recharge may

be desired or needed. Two examples:

You have used more water than usual (house

guests, extra washing, etc.) and you may run

out of soft water before the next recharge.

The system ran out of salt.

Use one of the following features to start a

recharge immediately, or at the next preset

recharge start time.

FEATURE: MEMORY

If electrical power to the water softening system is

interrupted, the control display is blank, and the blue

indicator light is off, but the control keeps correct

time for 24 hours. When power is restored, you have

to reset the present time only if the display and blue

indicator light are flashing. All other settings are

maintained and never require resetting unless a

change is desired.

FEATURE/SERVICE: AUTOMATIC

ELECTRONIC DIAGNOSIS

The control computer has a self-diagnostic

function for the electrical system (except input

power and water meter). The computer monitors

the electronic components and circuits for correct

operation. If a malfunction occurs, an error code

appears in the control display.

RECHARGE TONIGHT

Touch (do not hold) the RECHARGE button.

RECHARGE TONIGHT flashes in the control display

area. A recharge will occur at the next preset

recharge start time. If you decide to cancel this

recharge, touch the same button once more.

RECHARGE NOW

Press and hold the RECHARGE button until

RECHARGE NOW starts to flash in the control

display area. The water softening system begins

an immediate recharge and, when over in about

two hours, you will have a new supply of soft

water. Once started, you cannot cancel this

recharge.

If the time is flashing after a long power outage,

the water softening system continues to work as

it should to provide you with soft water. However,

recharge may occur at the wrong time of day until

you reset the control to the correct time

of day.

Page 6

About the water softener system.

WATER CONDITION INFORMATION

IRON

Iron inwater can cause stains on clothing and

plumbing fixtures. It can negatively affect the

taste of food,drinking water, and other beverages.

Iron inwater is measured in parts per million

(ppm). The total* ppm of iron, and type or types*,

is determined by chemical analysis. Four different

types of iron in water are:

Ferrous (clear water)iron

Ferric (red water)iron

Bacterial and organically bound iron

Colloidal and inorganically bound iron (ferrous

or ferric)

Ferrous (clear water)iron is soluble and dissolves

in water. This water softener will reduce

moderate amounts of this type of iron (see

specifications).**Ferrous (clear water)iron is

usually detected by taking a sample of water in

a clear bottle or glass. Immediately after taking,

the sample is clear. Asthe water sample stands,

it gradually clouds and turns slightly yellow or

brown as air oxidizes the iron. This usually occurs

in 15 to 30 minutes.

When using the softener to reduce Ferrous (clear

water) iron, add 5 grains to the hardness setting

fore very 1ppm of Ferrous (clear water)iron. See

"Set Water Hardness Number" section.

Ferric (red water), and bacterial and organically

bound irons are insoluble. This water softener

will not remove ferric or bacterial iron. This iron

is visible immediately when drawn from a faucet

because it has oxidized before reaching the

home. It appears as small cloudy yellow, orange,

or reddish suspended particles. After the water

stands for a period of time,the particles settle to

the bottom of the container. Generally these irons

are removed from water by filtration. Chlorination

is also recommended for bacterial iron.

Colloidal and inorganically bound iron is of ferric

or ferrous form that will not filter or exchange

out of water. This water softener will not remove

colloidal iron. In some instances, treatment

may improve colloidal iron water. Colloidal iron

water usually has a yellow appearance when

drawn. After standing for several hours, the color

persists and the iron does not settle, but remains

suspended in the water.

SEDIMENT

Sediment is fine, foreign material particles

suspended in water. This water softener will not

remove sediment. This material is most often clay

or silt. Extreme amounts of sediment may give

the water a cloudy appearance. A sediment filter

installed upstream of the water softener normally

corrects this situation.

* Water may contain one or more of the four

types of iron and any combination of these. Total

iron is the sum of the contents.

** Capacity to reduce clear water iron is

substantiated by WOA test data.

CHLORINE

Softener resins may degrade in the presence

of chlorine above 2 ppm. If you have chlorine

in excess of this amount, you may experience

reduced life of the resin. In these conditions, you

may wish to consider purchasing a GE point-of-

entry household filtration system with a chlorine

reducing filter.

Page 7

Before you start.

BEFORE YOU START

The water softener requires a minimum water flow of 3 gallons per minute at the inlet. Maximum

allowable inlet water pressure is 125 psi. If daytime pressure is over 80 psi, nighttime pressure may

exceed the maximum. Use a pressure reducing valve if necessary (Adding o pressure reducing valve

may reduce the flow). If your home is equipped with a back flow preventer, on expansion tank must

be installed in accordance with local codes and lows.

The water softener uses o direct plug-in external power supply (included). Be sure to use the included

power supply and plug itinto o nominal 120V, 60 cycle household outlet that is in o dry location only,

grounded and properly protected by an over current device such as o circuit breaker or fuse.

Do not use this system to treat water that is microbiologicully unsafe or of unknown quality without

adequate disinfection upstream or downstream of the system.

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

Screwdriver

Teflon tape

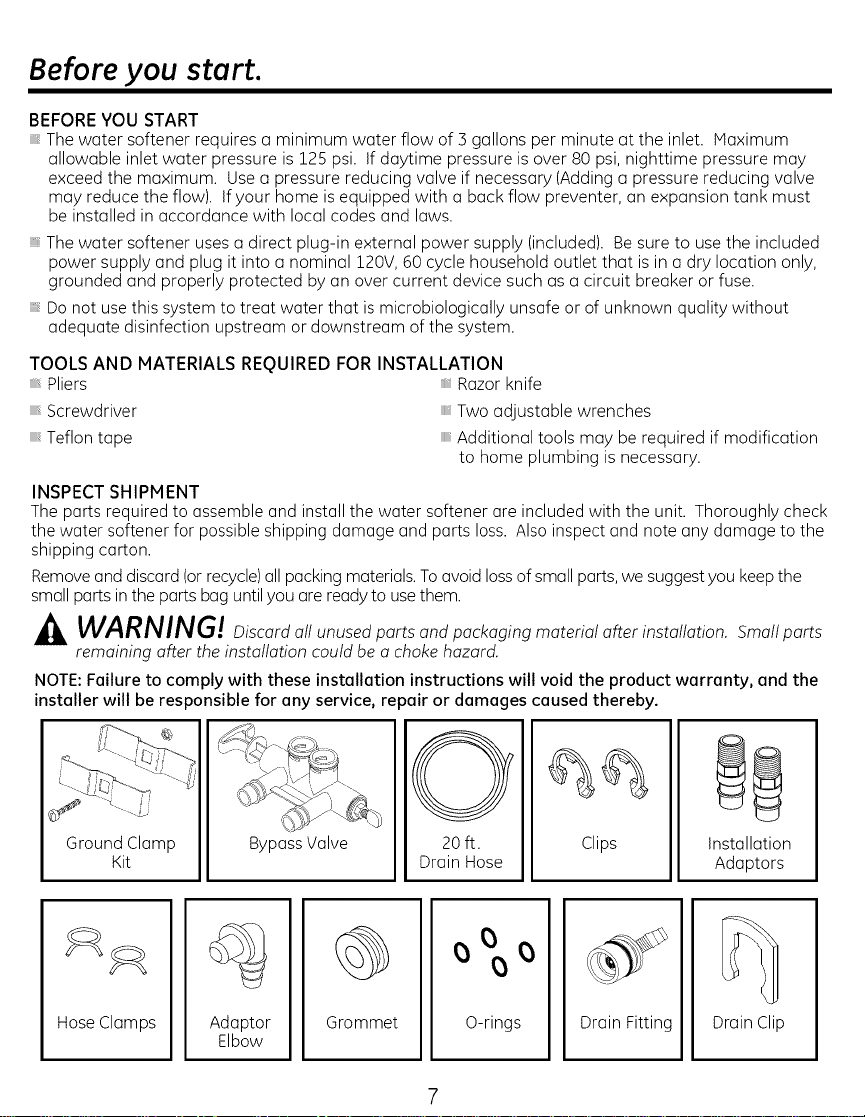

INSPECT SHIPMENT

The ports required to assemble and install the water softener ore included with the unit. Thoroughly check

the water softener for possible shipping damage and ports loss. Also inspect and note any damage to the

shipping carton.

Removeand discord (or recycle)all packing materials. Toovoid loss of small ports, we suggest you keepthe

small ports in the ports bug until you are ready to usethem.

Razor knifePliers

Two adjustable wrenches

Additional tools may be required if modification

to home plumbing is necessary.

WARNING! Discord oil unused ports ond pockoging material after installation. Small ports

remaining after the installation could be o choke hazard.

NOTE: Failure to comply with these installation instructions will void the product warranty, and the

installer will be responsible for any service, re _air or damages caused thereby.

Ground Clamp

Kit

Bypass Valve

20 ft. Clips

Drain Hose

Installation

Adaptors

Hose Clamps Adaptor

Elbow

Grommet

O-rings Drain Fitting Drain Clip

Page 8

Installation Requirements.

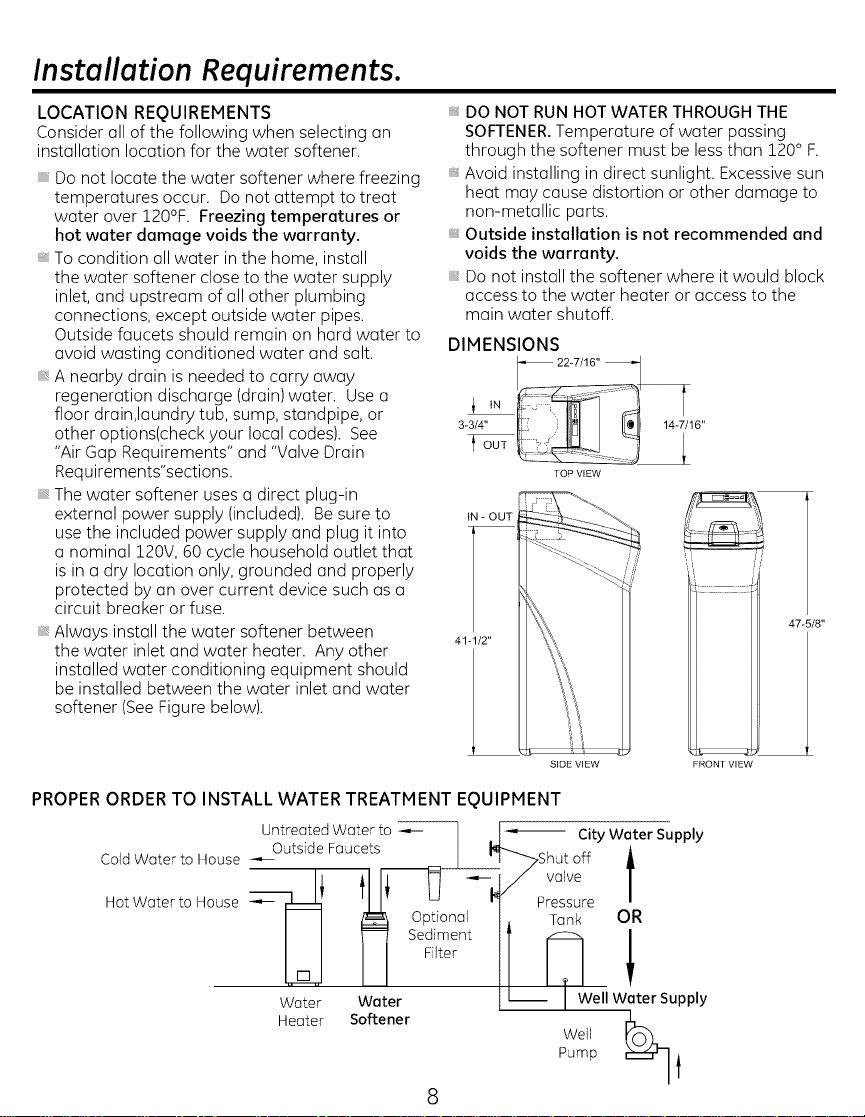

LOCATION REQUIREMENTS

Consider all of the following when selecting an

installation location for the water softener.

Do not locate the water softener where freezing

temperatures occur. Do not attempt to treat

water over 120°F. Freezing temperatures or

hot water damage voids the warranty.

To condition all water in the home, install

the water softener close to the water supply

inlet, and upstream of all other plumbing

connections, except outside water pipes.

Outside faucets should remain on hard water to

avoid wasting conditioned water and salt.

A nearby drain is needed to carry away

regeneration discharge (drain) water. Use a

floor drain,laundry tub, sump, standpipe, or

other options(check your local codes). See

"Air Gap Requirements" and "Valve Drain

Requirements"sections.

The water softener uses a direct plug-in

external power supply (included). Besure to

use the included power supply and plug it into

a nominal 120V, 60 cycle household outlet that

is ina dry location only, grounded and properly

protected by an over current device such as a

circuit breaker or fuse.

Always install the water softener between

the water inlet and water heater. Any other

installed water conditioning equipment should

be installed between the water inlet and water

softener (See Figure below).

DO NOT RUN HOT WATER THROUGH THE

SOFTENER. Temperature of water passing

through the softener must be less than 120° F.

Avoid installing in direct sunlight. Excessive sun

heat may cause distortion or other damage to

non-metallic parts.

Outside installation is not recommended and

voids the warranty.

Do not install the softener where it would block

access to the water heater or access to the

main water shutoff.

DIMENSIONS

_ 22-7/16"

3-3/4" _{t: IIMI IL° I 14-7/16"

TOP VIEW

IN - OUT

47-5/8"

41-1/2"

PROPER ORDER TO INSTALL WATER TREATMENT EQUIPMENT

UntreatedWaterto --.-- I . I_'_ City Water Supply

.,_Outside Faucets_l_shut off i

ColdWater to House _ "--I_ valve

/_ Optional I, Tank OR

I I _=I Sediment If _ I

Wo_er ;aJer Filter U I !ell 2ter Supply

Heater Softener PumpWell _

8

SIDE VIEW FRONT VIEW

Page 9

Installation Requirements.

PLUMBING CODES

All plumbing must be completed in accordance

with national, state and local plumbing codes.

In the state of Massachusetts: TheCommonwealth

of Massachusetts plumbing code 2¢8-CMR shall be

adhered to. A licensed plumber shall be used for

this installation.

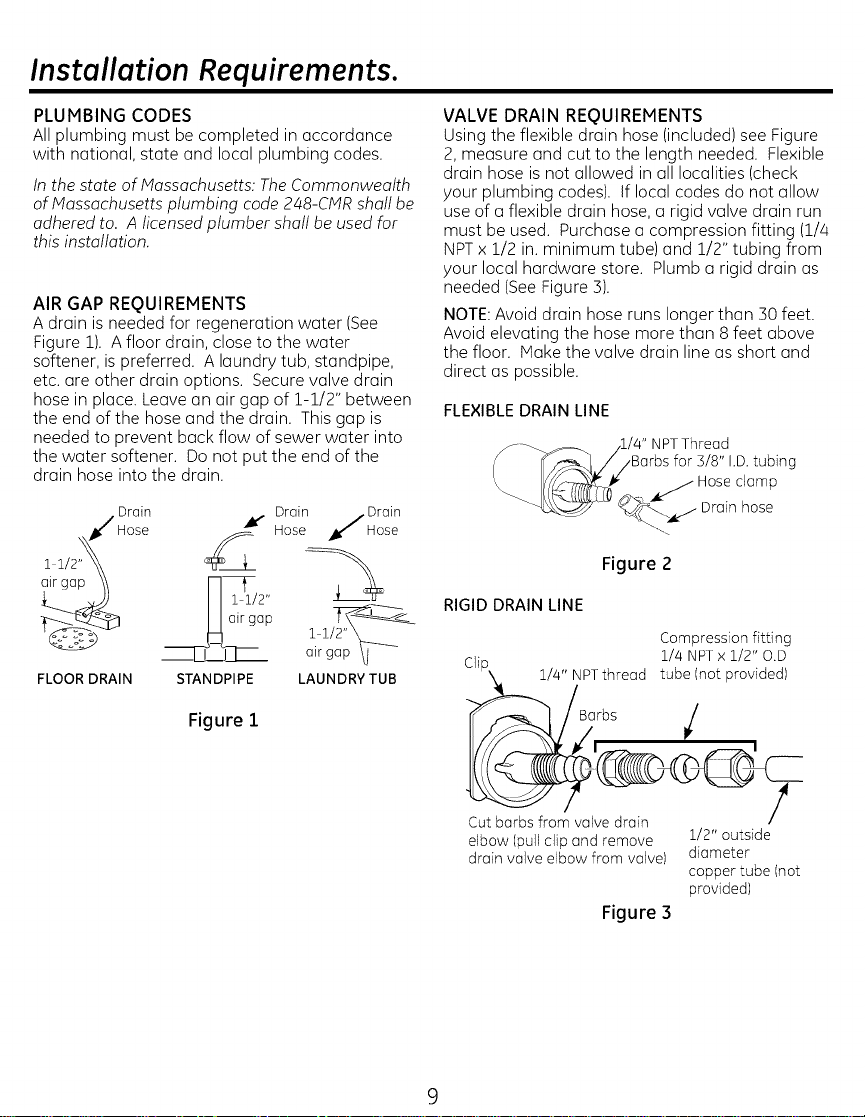

AIR GAP REQUIREMENTS

A drain is needed for regeneration water (See

Figure 1). A floor drain, close to the water

softener, is preferred. Alaundry tub, standpipe,

etc. are other drain options. Secure valve drain

hose in place. Leave an air gap of 1-1/2" between

the end of the hose and the drain. This gap is

needed to prevent back flow of sewer water into

the water softener. Do not put the end of the

drain hose into the drain.

Drain

1 1/2"_ Hose

Hose / Drain

Drain ,_/ Hose

M air

__. I_ airgap \l

FLOOR DRAIN

STANDPIPE LAUNDRY TUB

VALVE DRAIN REQUIREMENTS

Using the flexible drain hose (included) see Figure

2,measure and cut to the length needed. Flexible

drain hose is not allowed in all localities (check

your plumbing codes). )f local codes do not allow

use of a flexible drain hose, a rigid valve drain run

must be used. Purchase a compression fitting (1//4

NPTx 1/2 in. minimum tube) and 1/2" tubing from

your local hardware store. Plumb a rigid drain as

needed (SeeFigure 3).

NOTE:Avoid drain hose runs longer than 30 feet.

Avoid elevating the hose more than 8 feet above

the floor. Make the valve drain line as short and

direct as possible.

FLEXIBLE DRAIN LINE

NPTThread

,Barbsfor 3/8" I.D.tubing

clamp

hose

Figure 2

RIGID DRAIN LINE

Compressionfitting

Cli- 1//4 NPT× 1/2" O.D

_u_\. l/a," NPTthread tube (notprovided)

Figure 1

B_lrbs

Cutbarbsfrom valvedrain

elbow(pullclipand remove 1/2" outside

drainvalve elbowfrom valve) diameter

coppertube (not

provided)

Figure 3

Page 10

Installation Requirements.

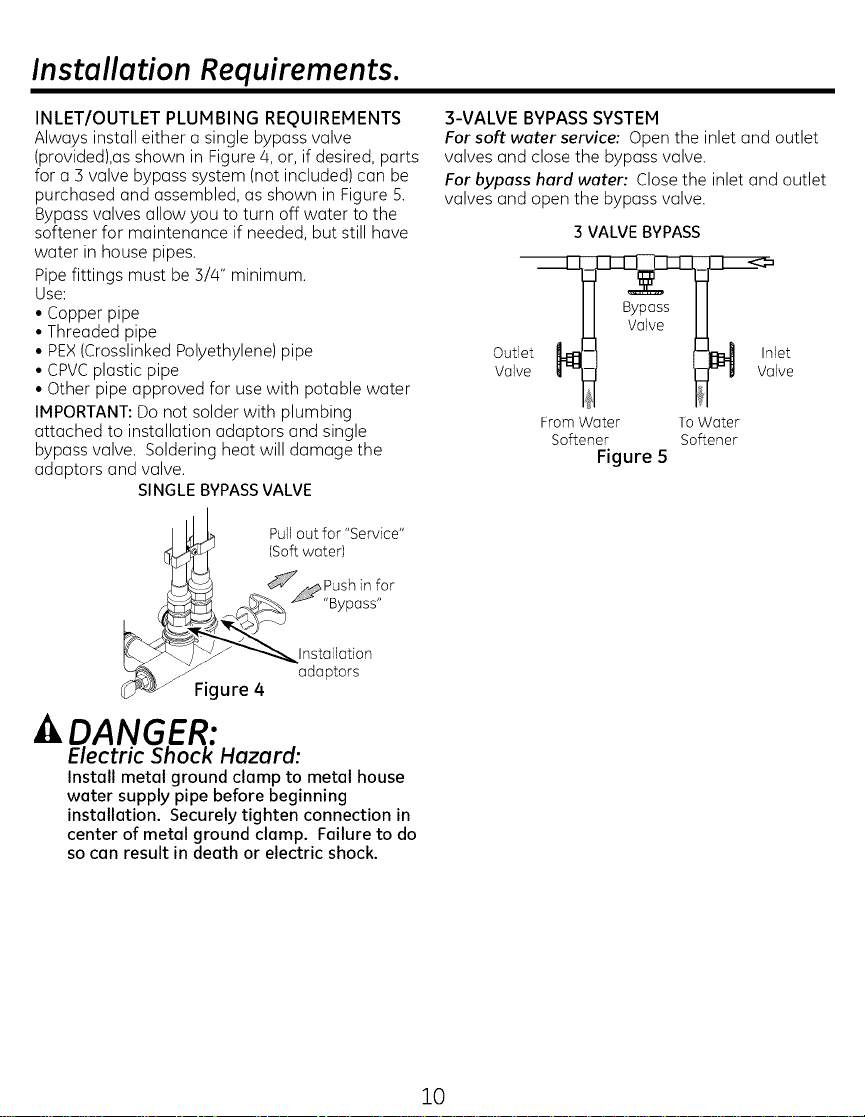

INLET/OUTLET PLUMBING REQUIREMENTS

Always install either a single bypass valve

(provided),as shown in Figure 4, or, if desired, parts

for a 3 valve bypass system (not included) can be

purchased and assembled, as shown in Figure 5.

Bypass valves allow you to turn off water to the

softener for maintenance if needed, but still have

water in house pipes.

Pipe fittings must be 3/4" minimum.

Use:

• Copper pipe

• Threaded pipe

• PEX(Crosslinked Polyethylene) pipe

• CPVCplastic pipe

• Other pipe approved for use with potable water

IMPORTANT:Do not solder with plumbing

attached to installation adaptors and single

bypass valve. Soldering heat will damage the

adaptors and valve.

SINGLEBYPASSVALVE

Pullout for "Service"

(Softwater)

Ca 2s!°r

Installation

adaptors

Figure 4

3-VALVE BYPASS SYSTEM

For soft water service: Open the inlet and outlet

valves and close the bypass valve.

For bypass hard water: Closethe inlet and outlet

valves and open the bypass valve.

3 VALVE BYPASS

let

Outlet

Valve

alve

FromWater ToWater

Softener Softener

Figure 5

DANGER:

Electric Shock Hazard:

Install metal ground clamp to metal house

water supply pipe before beginning

installation. Securely tighten connection in

center of metal ground clamp. Failure to do

so can result in death or electric shock.

10

Page 11

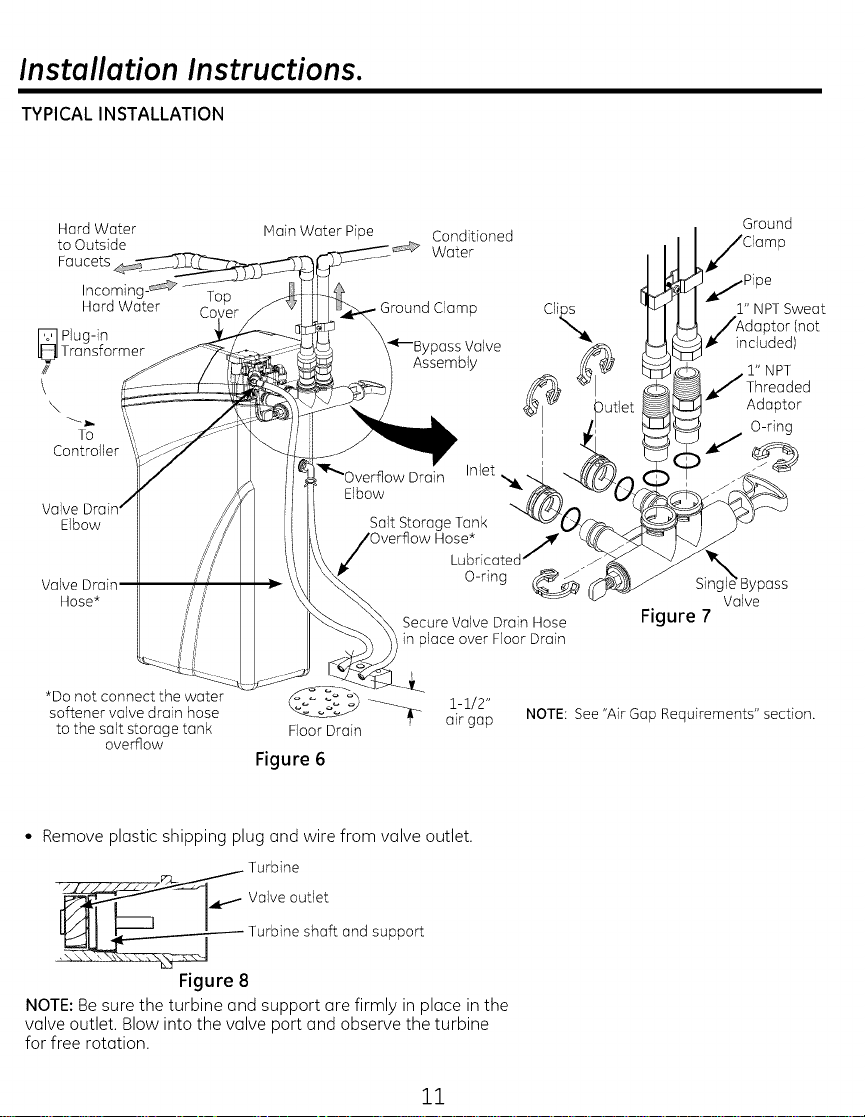

Installation Instructions.

TYPICAL INSTALLATION

Hard Water

to Outside

Faucets

Incoming- _

Hard Water

_ Plug-in

Transformer

/I

\

k

To

Controller

Cc

Top

Main Water Pipe

)verflow Drain InJet _,_£q

Conditioned

Water

Ground Clamp Clip.s

Assembly

)ass Valve

Elbow ._/_

Elbow

Valve

Hose*

*Do not connect the water

softener valve drain hose

to the salt storage tank Floor Drain air gap

overflow

Figure 6

Salt Storage Tank "-_¢L(.__(_

Secure Valve Drain Hose

in place over Floor Drain

H°Lue;ricatedJ

O-ring _"

1-1/2"

Ground

Clamp

1 /Pipe

2" NPTSweat

JAdaptor (not

t_included)

l" NPT

Threaded

Adaptor

O-ring

)ass

Valve

Figure 7

NOTE: See "Air Gap Requirements" section.

• Remove plastic shipping plug and wire from valve outlet.

_-_2_j_ Turbine

Valve outlet

_ Turbine shaft and support

Figure 8

NOTE: Be sure the turbine and support are firmly in place in the

valve outlet. Blow into the valve port and observe the turbine

for free rotation.

11

Page 12

Installation Instructions.

TURN OFF WATER SUPPLY

1.Close the main water supply valve, located near

the well pump or water meter. Salt

2. Open all faucets to drain all water from house

pipes.

NOTE:Be sure not to drain water from the water

heater, as damage to the water heater elements Brinewell

could result.

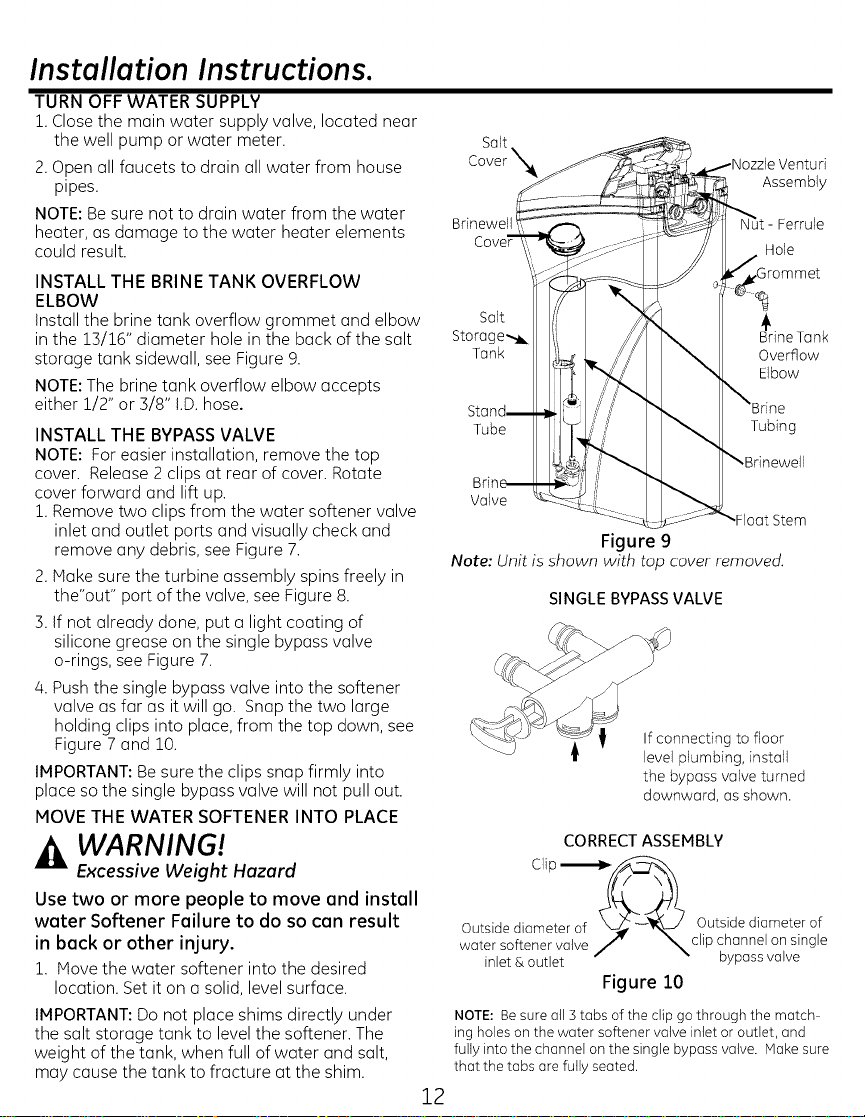

INSTALL THE BRINE TANK OVERFLOW

ELBOW

Install the brine tank overflow grommet and elbow

in the 13/16" diameter hole in the back of the salt

storage tank sidewall, see Figure 9.

NOTE:The brine tank overflow elbow accepts

either 1/2" or 3/8" !.D.hose.

INSTALL THE BYPASS VALVE

NOTE: For easier installation, remove the top

cover. Release 2 clips at rear of cover. Rotate

cover forward and lift up.

1.Remove two clips from the water softener valve

inlet and outlet ports and visually check and

remove any debris, see Figure 7.

2. Hake sure the turbine assembly spins freely in

the"out" port of the valve, see Figure 8.

3. If not already done, put a light coating of

silicone grease on the single bypass valve

o-rings, see Figure 7.

4. Push the single bypass valve into the softener

valve as far as it will go. Snap the two large

holding clips into place, from the top down, see

Figure 7 and 10.

IMPORTANT:Be sure the clips snap firmly into

place so the single bypass valve will not pull out.

HOVE THE WATER SOFTENER INTO PLACE

WARNING!

Excessive Weight Hazard

Use two or more people to move end install

weter Softener Feilure to do so con result

in beck or other injury.

1. Hove the water softener into the desired

location. Set it on a solid, level surface.

IMPORTANT:Do not place shims directly under

the salt storage tank to level the softener. The

weight of the tank, when full of water and salt,

may cause the tank to fracture at the shim.

Salt

Storage-,_ B_rineTank

Tank Overflow

Tube Tubing

Valve

Note: Unit is shown with top cover removed.

Outside diameter of _ --_,,_ Outside diameter of

water softener valve J _clip channel on single

inlet & outlet bypass valve

NOTE: Be sure all 3 tabs of the clip go through the match

ing holes on the water softener valve inlet or outlet, and

fully into the channel on the single bypass valve. Hake sure

that the tabs are fully seated.

12

Jri

Assembly

Ferrule

Hole

Elbow

Stem

Figure 9

SINGLE BYPASS VALVE

If connecting to floor

level plumbing, install

the bypass valve turned

downward, as shown.

CORRECT ASSEMBLY

Figure 10

Page 13

Installation Instructions.

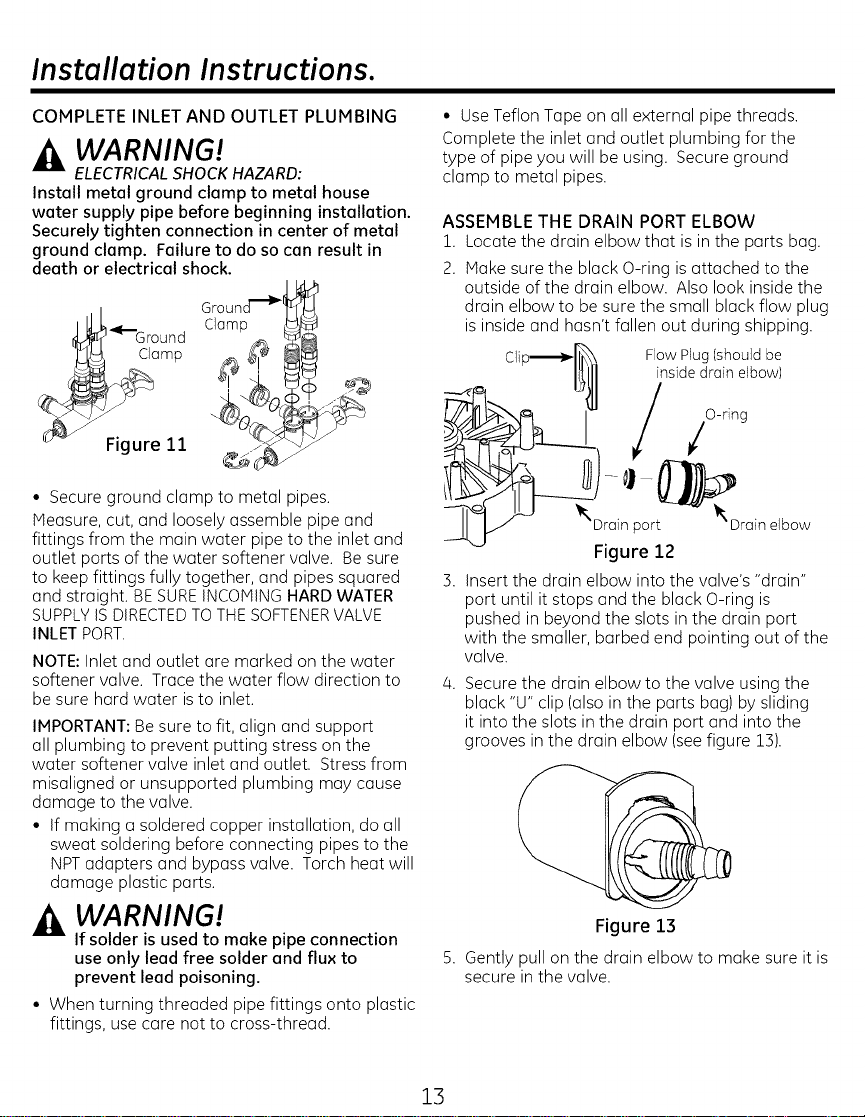

COMPLETE INLET AND OUTLET PLUMBING

WARNING!

ELECTRICALSHOCKHAZARD:

Install metal ground clamp to metal house

water supply pipe before beginning installation.

Securely tighten connection in center of metal

ground clamp. Failure to do so can result in

death or electrical shock.

I_I_G round Clamp

Gr°un !

• Secure ground clamp to metal pipes.

Measure, cut, and loosely assemble pipe and

fittings from the main water pipe to the inlet and

outlet ports of the water softener valve. Be sure

to keep fittings fully together, and pipes squared

and straight. BESUREINCOMING HARD WATER

SUPPLYISDIRECTEDTO THESOFTENERVALVE

INLET PORT.

NOTE:Inlet and outlet are marked on the water

softener valve. Trace the water flow direction to

be sure hard water is to inlet.

IMPORTANT:Be sure to fit, align and support

all plumbing to prevent putting stress on the

water softener valve inlet and outlet. Stress from

misaligned or unsupported plumbing may cause

damage to the valve.

• If making a soldered copper installation, do all

sweat soldering before connecting pipes to the

NPTadapters and bypass valve. Torch heat will

damage plastic parts.

• UseTeflon Tape on all external pipe threads.

Complete the inlet and outlet plumbing for the

type of pipe you will be using. Secure ground

clamp to metal pipes.

ASSEMBLE THE DRAIN PORT ELBOW

1. Locate the drain elbow that is in the parts bag.

2. Make sure the black O-ring is attached to the

outside of the drain elbow. Also look inside the

drain elbow to be sure the small black flow plug

is inside and hasn't fallen out during shipping.

CI Flow Plug (should be

inside drain elbow)

O-ring

/

_"Di[-in por_Drain elbow

Figure 12

3. Insert the drain elbow into the valve's "drain"

port until it stops and the black O-ring is

pushed in beyond the slots in the drain port

with the smaller, barbed end pointing out of the

valve.

4. Secure the drain elbow to the valve using the

black "U" clip (also in the parts bag) by sliding

it into the slots in the drain port and into the

grooves in the drain elbow (seefigure 13).

%

WARNING!

If solder is used to make pipe connection

use only lead free solder and flux to

prevent lead poisoning.

• When turning threaded pipe fittings onto plastic

fittings, use care not to cross-thread.

Figure 13

B. Gently pull on the drain elbow to make sure it is

secure in the valve.

13

Page 14

Installation Instructions.

INSTALL VALVE DRAIN HOSE

1.Measure and connect the 3/8"drain line

(provided) to the water softener valve drain

fitting. Use a hose clamp to hold the hose in

place.

NOTE:Avoid drain hose runs longer than 30 feet.

Avoid elevating the hose more than 8 feet above

the floor. Make the valve drain line as short and

direct as possible.

IMPORTANT:If codes require a rigid drain line

see"Valve Drain requirements" section.

2. Route the drain hose or copper tubing to the

floor drain or other suitable drain point. Secure

drain hose. This will prevent "whipping" during

regenerations. See "Air Gap Requirements"

section (Figure 1).

3. Cut and secure the hose.

NOTE: The softener will not work if the water

cannot exit the drain hose during recharge.

INSTALL SALT STORAGE TANK OVERFLOW

HOSE

1.Measure, cut to needed length and connect the

3/8"drain line (provided) to the salt storage tank

overflow elbow and secure in place with a hose

clamp.

2. Route the hose to the floor drain, or other

suitable drain point no higher than the drain

fitting on the salt storage tank (This is a gravity

drain). If the tank overfills with water, the

excess water flows to the drain point. Cut the

drain line to the desired length and route it

neatly out of the way.

IMPORTANT:Forproper operation of the water

softener, do not connect thewater softener valve

drain tubing to the salt storage tank overflow hose.

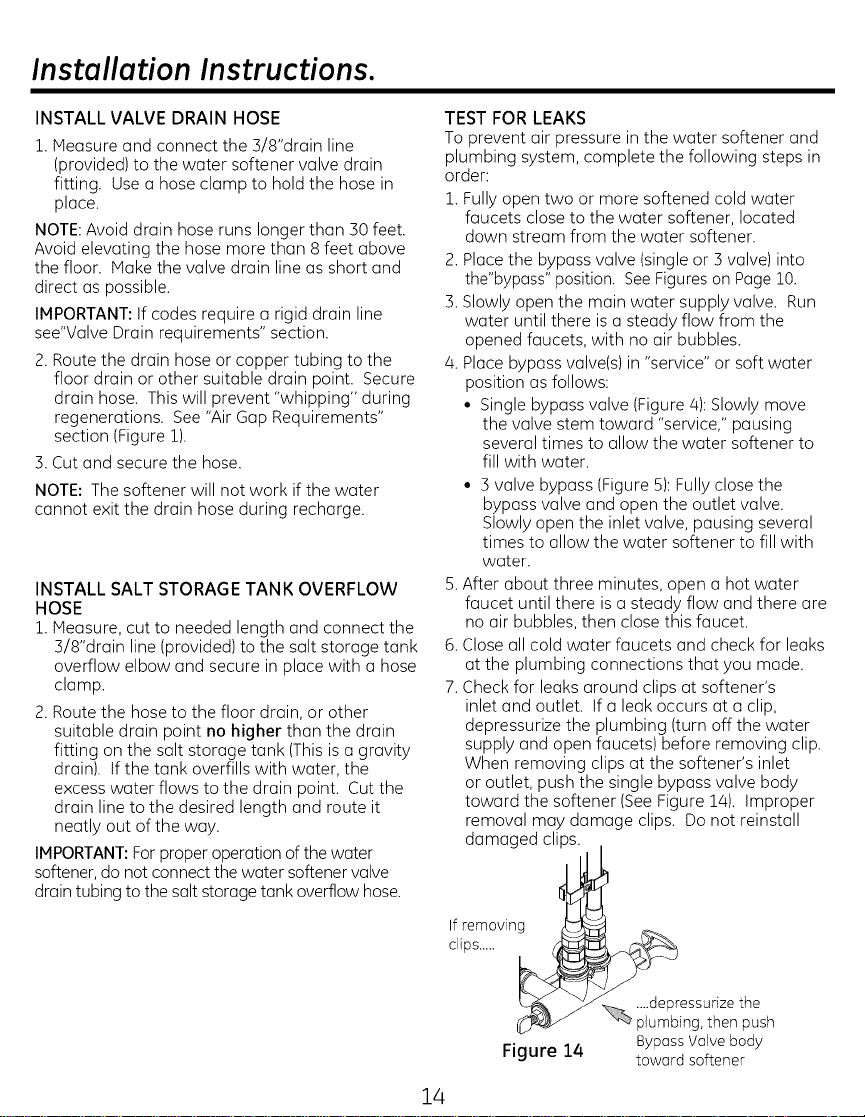

TEST FOR LEAKS

To prevent air pressure in the water softener and

plumbing system, complete the following steps in

order:

1. Fully open two or more softened cold water

faucets close to the water softener, located

down stream from the water softener.

2. Place the bypass valve (single or 3 valve)into

the'bypass" position. SeeFigureson Page Z0.

3. Slowly open the main water supply valve. Run

water until there is a steady flow from the

opened faucets, with no air bubbles.

/4.Place bypass valve(s)in "service" or soft water

position as follows:

• Single bypass valve (Figure/4): Slowly move

the valve stem toward "service," pausing

several times to allow the water softener to

fill with water.

• 3 valve bypass (Figure 5): Fully close the

bypass valve and open the outlet valve.

Slowly open the inlet valve, pausing several

times to allow the water softener to fill with

water.

5. After about three minutes, open a hot water

faucet until there is a steady flow and there are

no air bubbles, then close this faucet.

6. Close all cold water faucets and check for leaks

at the plumbing connections that you made.

7. Check for leaks around clips at softener's

inlet and outlet. If a leak occurs at a clip,

depressurize the plumbing (turn off the water

supply and open faucets) before removing clip.

When removing clips at the softener's inlet

or outlet, push the single bypass valve body

toward the softener (SeeFigure 1/4). Improper

removal may damage clips. Do not reinstall

damaged clips.

If removing

clips.....

14

Figure 14

....depressurize the

plumbing, then push

Bypass Valve body

toward softener

Page 15

Installation Instructions.

ADD WATER AND SALT TO THE SALT

STORAGE TANK

WARNING!

EXCESSIVEWEIGHT HAZARD:

Use two or more people to move end lift

solt bogs. Failure to do so con result in

beck or other injuries.

1. Using a container, add about three gallons of

clean water into the salt storage tank.

2.Add salt to the storage tank. Use nugget,

pellet or coarse solar salts with lessthan 1%

impurities.

PLUG IN THE WATER SOFTENER

1. Plug the water softener into an electrical outlet

that is not controlled by a switch.

2. Replace the top cover.

3. Replace the salt hole cover.

NOTE: The water heater is filled with hard

water and,as hot water is used, it will refill

with conditioned water. In a few days, the hot

water will be fully conditioned. To have fully

conditioned hot water immediately, wait until

the initial recharge is over. Then, drain the water

heater(following instructions for water heater) until

water runs cold.

-- WARNING! Discard all unused parts

and packaging material after installation.

Small parts remaining after the installation

could be a choke hazard.

SANITIZE THE WATER SOFTENER/SANITIZE

AFTER SERVICE

1.Open salt hole cover, remove the brinewell cover

and pour about 3 oz.(6tablespoons) of household

bleach into the softener brinewell. Replace the

brinewell cover.

2.Hake sure the bypass valve(s)isin the

"service"(open)position.

3.Start a recharge (regeneration). See"Start a

Recharge'on Page 13.

4.After the recharge has completed, fully open a

cold water faucet, downstream from the softener,

and allow 50 gallons of water to passthrough

the system. Thisshould take at least 20 minutes.

Closethe faucet.

15

Page 16

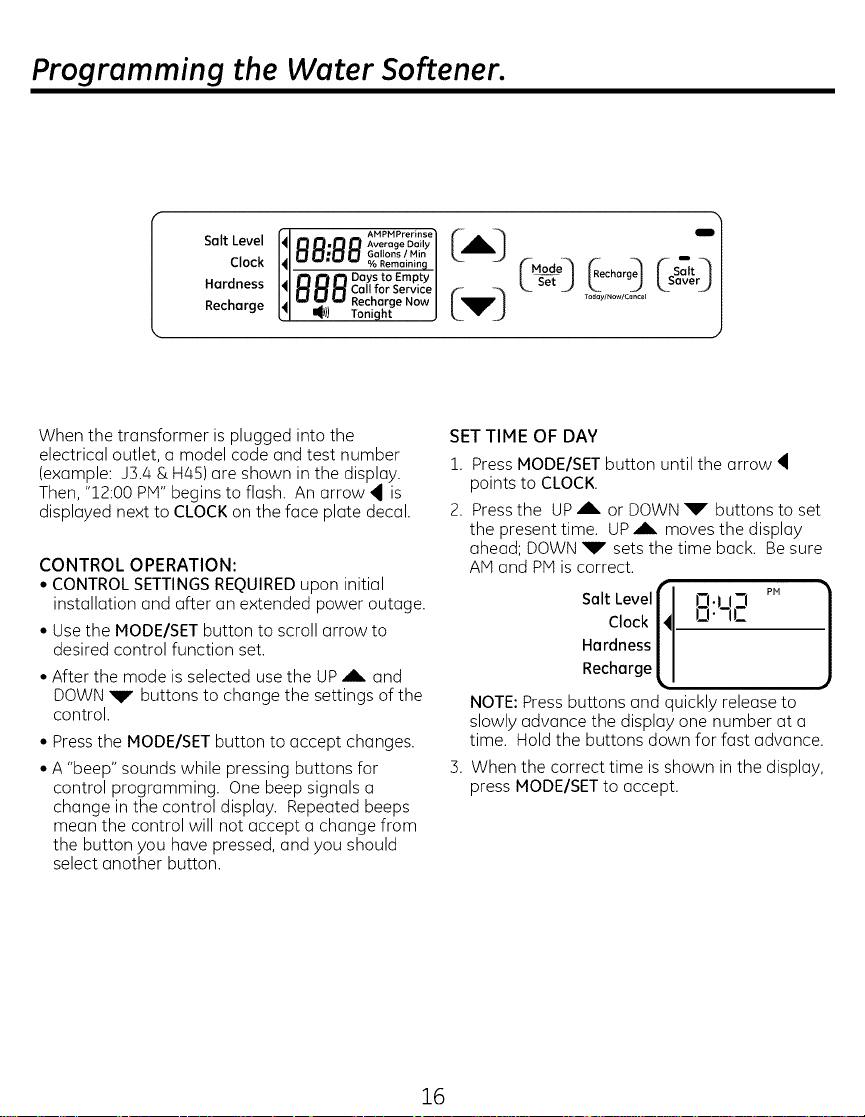

Programming the Water Softener.

Salt Level

Hardness

Recharge

When the transformer is plugged into the

electrical outlet, a model code and test number

(example: J3.a & Has) are shown in the display.

Then, "12:00 PM" begins to flash. An arrow _ is

displayed next to CLOCKon the face plate decal.

CONTROL OPERATION:

•CONTROLSETTINGSREQUIREDupon initial

installation and after an extended power outage.

° Use the MODE/SET button to scroll arrow to

desired control function set.

•After the mode is selected use the UP ,_- and

DOWN_V buttons to change the settings of the

control.

• Pressthe MODE/SET button to accept changes.

• A"beep" sounds while pressing buttons for

control programming. One beep signals a

change in the control display. Repeated beeps

mean the control will not accept a change from

the button you have pressed, and you should

select another button.

Clock

1orlmll-lr] GollonslMin I

I .... % Remainin_t I

I _ _ r'_ Days to Empty /

IHHH Ca,,to,Service/

, ,,,,oo,0 ,,

I_ _ _ Recharge Now / _

|. Set ..) char

SET TIME OF DAY

1. PressMODEISET button until the arrow

points to CLOCK.

2. Pressthe UPAIL or DOWN_W"buttons to set

the present time. UP ,A, moves the display

ahead; DOWN _W"sets the time back. Be sure

AN and PiVtis correct.

NOTE:Pressbuttons and quickly release to

slowly advance the display one number at a

time. Hold the buttons down for fast advance.

3. When the correct time isshown in the display,

press MODE/SET to accept.

i!) "

Today/Now/Cancel

Salt Levelf J-I.I I-1

Clock I' o.-,c

Hardness /

RechargeL

PH

16

Page 17

Programming the Water Softener.

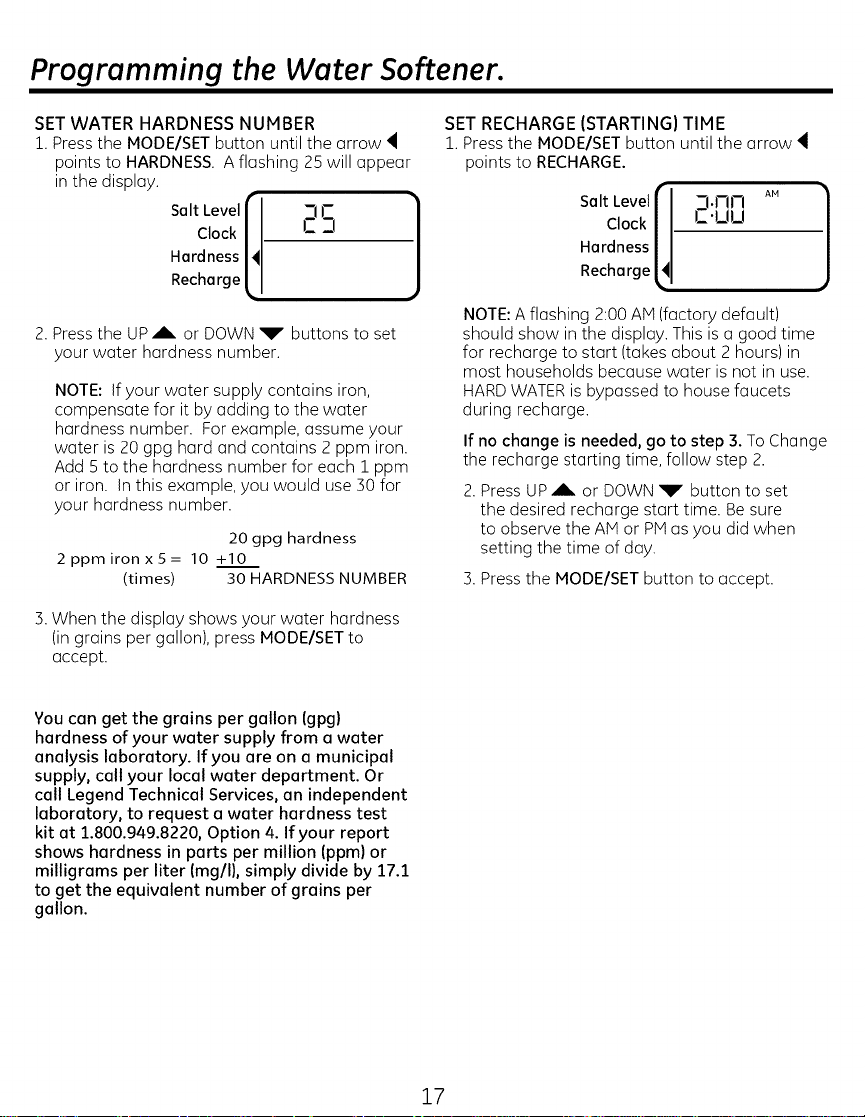

SET WATER HARDNESS NUMBER

1.Press the MODE/SET button until the arrow

points to HARDNESS.A flashing 25 will appear

in the display.

Clock /

Hardness I'

Salt Level r ]

Recharge l -

2. Press the UP_b. or DOWN_r" buttons to set

your water hardness number.

NOTE: Ifyour water supply contains iron,

compensate for it by adding to the water

hardness number. For example, assume your

water is 20 gpg hard and contains 2 ppm iron.

Add 5 to the hardness number for each lppm

or iron. Inthis example, you would use 30 for

your hardness number.

20 gpg hardness

2ppmironx5= 10 +10

5. When the display shows your water hardness

(in grains per gallon), press PIODE/SETto

accept.

(times) 30 HARDNESS NUMBER

SET RECHARGE (STARTING} TIME

1. Press the MODE/SET button until the arrow

points to RECHARGE.

Salt Levellr __,i-lt-I A.

Hardness

Clock [4 IZ'UU

Recharge

NOTE:Aflashing 2:00 AM (factory default)

should show inthe display. Thisis a good time

for recharge to start (takes about 2 hours)in

most households because water is not in use.

HARDWATERis bypassed to house faucets

during recharge.

If no change is needed, go to step 3. To Change

the recharge starting time, follow step 2.

2. Press UP_b, or DOWN V button to set

the desired recharge start time. Be sure

to observe the AM or PMas you did when

setting the time of day.

3. Press the PIODE/SET button to accept.

You can get the grains per gallon (gpg)

hardness of your water supply from a water

analysis laboratory. If you are on a municipal

supply, call your local water department. Or

call Legend Technical Services, an independent

laboratory, to request a water hardness test

kit at 1.800.949.8220, Option 4. If your report

shows hardness in parts per million (ppm) or

milligrams per liter (mg/I), simply divide by 17.1

to get the equivalent number of grains per

gallon.

17

Page 18

Programming the Water Softener.

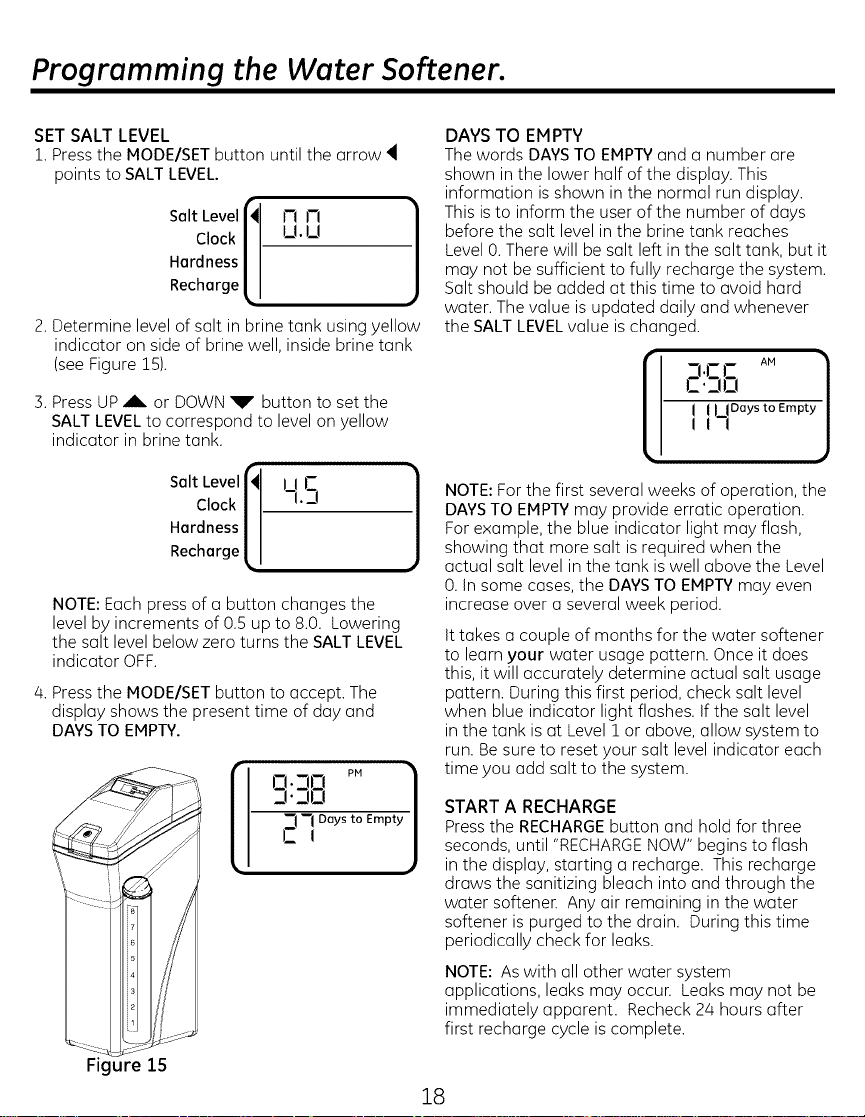

SET SALT LEVEL

1. Press the MODE/SET button until the arrow 4

points to SALT LEVEL.

Solt Level

Clock

Hordness

Rechorge

2. Determine level of salt in brine tank using yellow

indicator on side of brine well, inside brine tank

(see Figure 15).

3. Press UP _b, or DOWN_P" button to set the

SALT LEVELto correspond to level on yellow

indicator in brine tank.

Solt Level

Clock |

Hordness |

Rechorge [.

NOTE:Each press of a button changes the

level by increments of 0.5 up to 8.0. Lowering

the salt level below zero turns the SALT LEVEL

indicator OFF.

4. Press the MODE/SET button to accept. The

display shows the present time of day and

DAYS TO EMPTY.

111_'2

-!.D

3.]0

"7 "7 Days to Empty

CI

[iD.70 P. 1

DAYS TO EMPTY

The words DAYSTO EMPTYand a number are

shown in the lower half of the display. This

information isshown in the normal run display.

This isto inform the user of the number of days

before the salt level in the brine tank reaches

Level 0. There will be salt left in the salt tank, but it

may not be sufficient to fully recharge the system.

Salt should be added at this time to avoid hard

water. The value is updated daily and whenever

the SALT LEVELvalue is changed.

,:_.n,n_ _1

7.1-1- A.

1l,_,,oo ,o m0j

NOTE:For the first several weeks of operation, the

DAYSTO EMPTY may provide erratic operation.

For example, the blue indicator light may flash,

showing that more salt is required when the

actual salt level in the tank is well above the Level

0. In some cases, the DAYSTO EMPTYmay even

increase over a several week period.

It takes a couple of months for the water softener

to learn your water usage pattern. Once it does

this, it will accurately determine actual salt usage

pattern. During this first period, check salt level

when blue indicator light flashes. If the salt level

in the tank is at Level 1 or above, allow system to

run. Be sure to reset your salt level indicator each

time you add salt to the system.

START A RECHARGE

Press the RECHARGE button and hold for three

seconds, until "RECHARGE NOW" begins to flash

in the display, starting a recharge. This recharge

draws the sanitizing bleach into and through the

water softenen Any air remaining in the water

softener is purged to the drain. During this time

periodically check for leaks.

NOTE: As with all other water system

applications, leaks may occun Leaks may not be

immediately apparent. Recheck 24 hours after

first recharge cycle is complete.

Figure 15

18

Page 19

Programming the Water Softener.

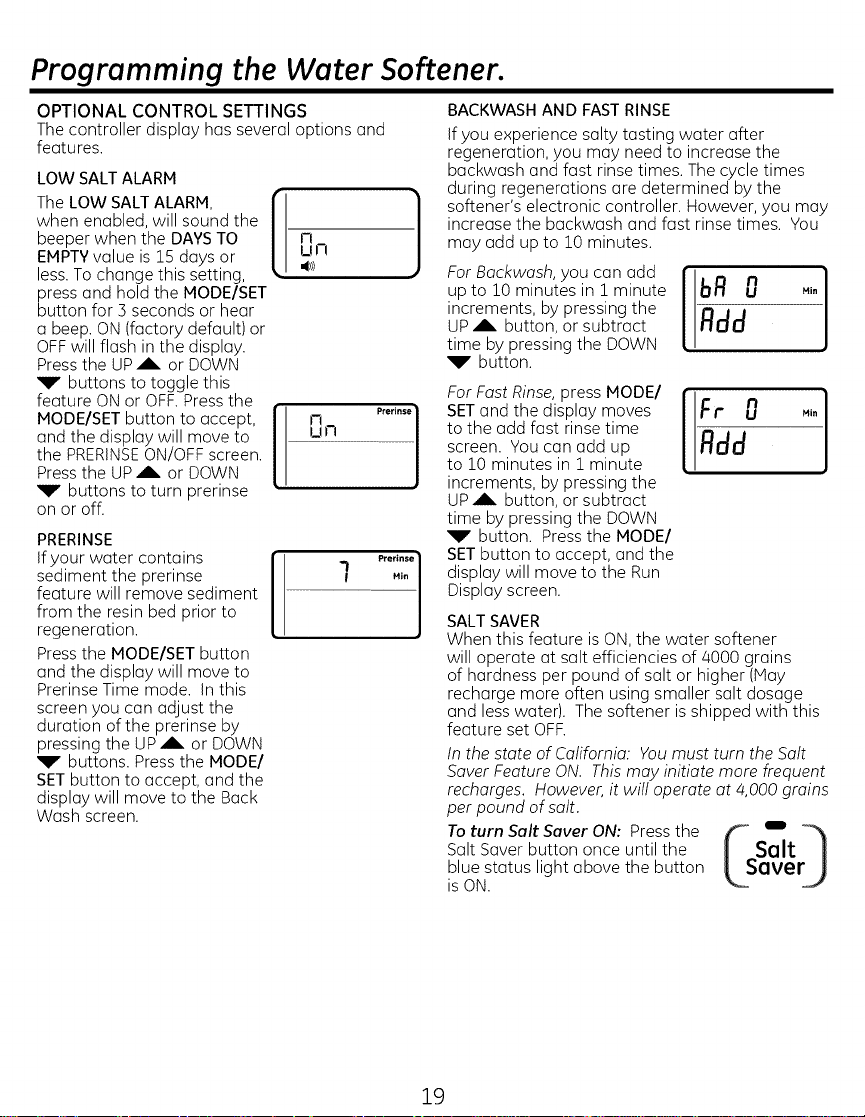

OPTIONAL CONTROL SETTINGS

The controller display has several options and

features.

LOW SALTALARM

The LOW SALT ALARM,

when enabled, will sound the

beeper when the DAYSTO

EMPTYvalue is 15 days or

less.To change this setting,

press and hold the MODE/SET

button for 3 seconds or hear

a beep. ON (factory default) or

OFFwill flash in the display.

Press the UP_b. or DOWN

V' buttons to toggle this

feature ON or OFF.Press the

MODE/SET button to accept,

and the display will move to

Dn

the PRERINSEON/OFF screen.

Pressthe UP _b. or DOWN

_r buttons to turn prerinse

on or off.

PRERINSE

If your water contains

sediment the prerinse

feature will remove sediment

from the resin bed prior to

regeneration.

Press the MODE/SET button

and the display will move to

Prerinse Time mode. In this

screen you can adjust the

duration of the prerinse by

pressing the UP,b. or DOWN

_r" buttons. Press the MODEl

SET button to accept, and the

display will move to the Back

Wash screen.

Prerinse]

BACKWASH AND FAST RINSE

If you experience salty tasting water after

regeneration, you may need to increase the

backwash and fast rinse times. The cycle times

during regenerations are determined by the

softener's electronic controller. However, you may

increase the backwash and fast rinse times. You

may add up to 10 minutes.

For Backwash, you can add

up to 10 minutes in 1minute

increments, by pressing the

UP Ab. button, or subtract

time by pressing the DOWN

_T button.

For Fast Rinse, press MODEl

SETand the display moves

to the add fast rinse time

screen. You can add up

to 10 minutes in 1minute

increments, by pressing the

UP _ button, or subtract

time by pressing the DOWN

_T" button. Press the MODE/

SETbutton to accept, and the

display will move to the Run

Display screen.

SALTSAVER

When this feature isON,the water softener

will operate at salt efficiencies of 4000 grains

of hardness per pound of salt or higher (May

recharge more often using smaller salt dosage

and less water). The softener is shipped with this

feature set OFF.

In the state of California: You must turn the Salt

Saver Feature ON. Thismay initiate more frequent

recharges. However, it will operate at 4,000 grains

per pound of salt.

To turn Salt Saver ON: Press the

Salt Saver button once until the

blue status light above the button

is ON.

Rdd

19

Page 20

Programming the Water Softener.

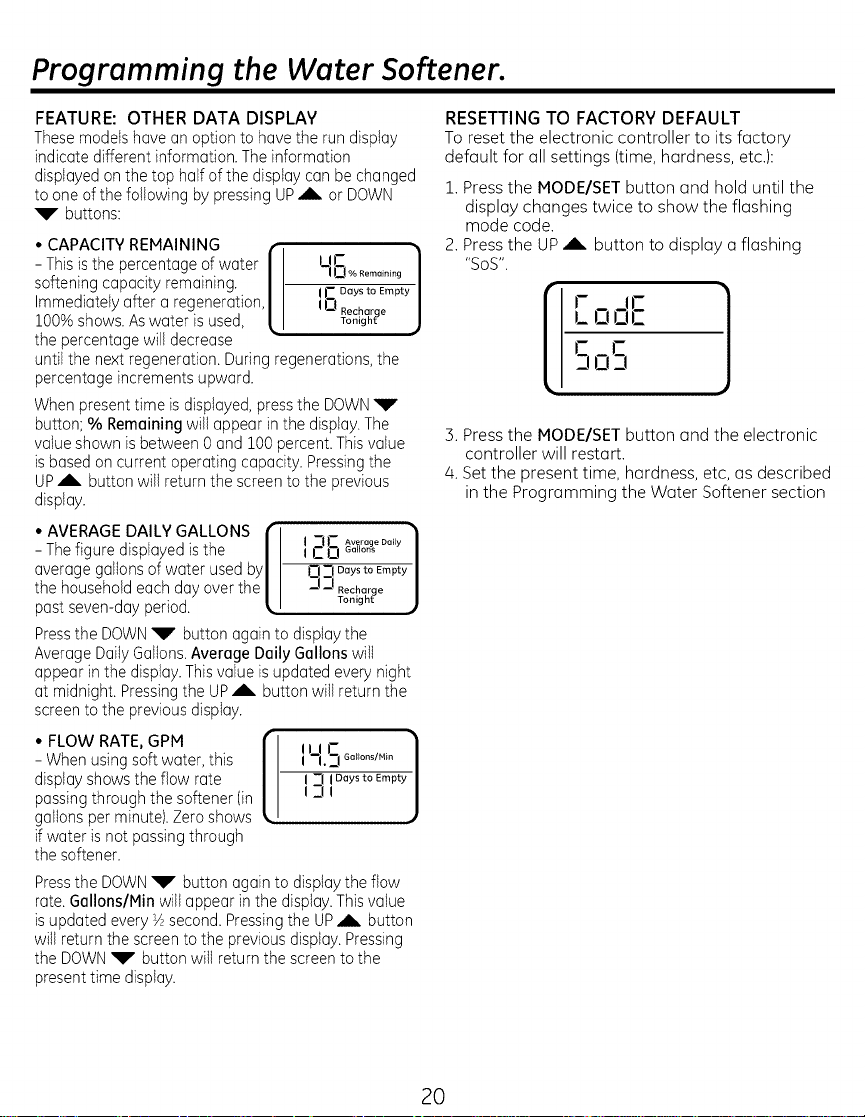

FEATURE: OTHER DATA DISPLAY

Thesemodelshave an option to havethe run display

indicatedifferent information.The information

displayedonthe top half of the displaycan be changed

to one of the followingby pressingUP,A, orDOWN

_V buttons:

° CAPACITYREMAINING .,--

- Thisisthe percentageof water II I II-

softeningcapacity remaining. II ICDays to Empty J

Immediatelyafter a regeneration,II

lO0%shows.Aswater is used, _1 lU_g_ih_h_?eJ

the percentagewiii decrease

untiI the next regeneration.Duringregenerations,the

percentageincrements upward.

Whenpresenttime is displayed,pressthe DOWN_r'

button:% Remainingwill appear in the dispIay.The

valueshown is between0 and 100percent.Thisvalue

isbasedon current operatingcapacity.Pressingthe

UP_b. button will return the screento the previous

display.

• AVERAGEDALLYGALLONS

- Thefigure displayedisthe

averagegallons ofwater usedby

the householdeach day overthe

past seven-dayperiod.

Pressthe DOWN_r' button againto disptaythe

AverageDailyGallons.Average Daily Gallonswill

appear in the dispiay.Thisvalue isupdated everynight

at midnight. Pressingthe UP_b. button will return the

screento the previousdisplay.

• FLOWRATE,GPM

- Whenusing softwater, this

displayshowsthe flow rate

passingthrough the softener(in

gallonsperminute).Zeroshows

if water is not passingthrough

the softener.

Pressthe DOWN_Y button againto displaythe flow

rate. Gallons/Min wilt appear in the display.Thisvalue

isupdated everyVzsecond.Pressingthe UP,A, button

wili return the screento the previousdispiay.Pressing

the DOWN_F" button will returnthe screento the

presenttime display.

--I 0 °/°Remaining /

C0 Go,o..

Cl =l Days to Empty

I _-- Average Daily 1

__I__IRecharge

Tonight

--I I Days to Empty

-i!

I LI.S Go,o.s/._.

, ,_

RESETTING TO FACTORY DEFAULT

To reset the electronic controller to its factory

default for all settings (time, hardness, etc.):

1. Press the MODE/SET button and hold until the

display changes twice to show the flashing

mode code.

2. Press the UP _k, button to display a flashing

"SOS".

OOC

)

,

3. Press the MODE/SET button and the electronic

controller will restart.

/4.Set the present time, hardness, etc, as described

in the Programming the Water Softener section

20

Page 21

Programming the Water Softener.

POWER OUTAGE MEMORY

If electrical power to the water softener is lost,

"memory" built into the timer circuitry will keep

all settings for up to 24 hours. While the power

is out, the display is blank and the water softener

will not regenerate. When electrical power is

restored, the following will occur:

Reset the present time only if the display is

flashing. The HARDNESSand RECHARGETIME

never require resetting unless a change is desired.

Even if the clock is incorrect after a long power

outage, the softener operates as it should to keep

your water soft. However, regenerations may

occur at the wrong time of day until you reset the

clock to the correct time of day.

NOTE:If the water softener was regenerating

when power was lost, it will now finish the cycle.

BLUE INDICATOR LIGHT

Steady blue light indicates that the unit isworking

correctly. The light flashes when the unit needs

attention from the user.

• Light will also flash when power to until has

been interrupted. Check the PRESENTTIME

setting.

• Light flashes and DAYSTO EMPTYflashes -

check salt level and add salt as required.

• Light flashes and Err is in the display - electrical

problem with system.

LOW SALT SIGNAL

When the DAYSTO EMPTYdrops to 15, the blue

indicator light and DAYSTO EMPTYin the display

will flash every second and the alarm will beep

every 50 seconds (from 8:00 AM to 8:00 PM),to

notify the user that the unit is running low on

salt. As soon as any button is pressed, the alarm

will stop beeping. The blue indicator light and

DAYSTO EMPTYwill continue to flush. Once salt

is added to the brine tank and the SALT LEVELis

reset, the DAYSTO EMPTYwill be reset.

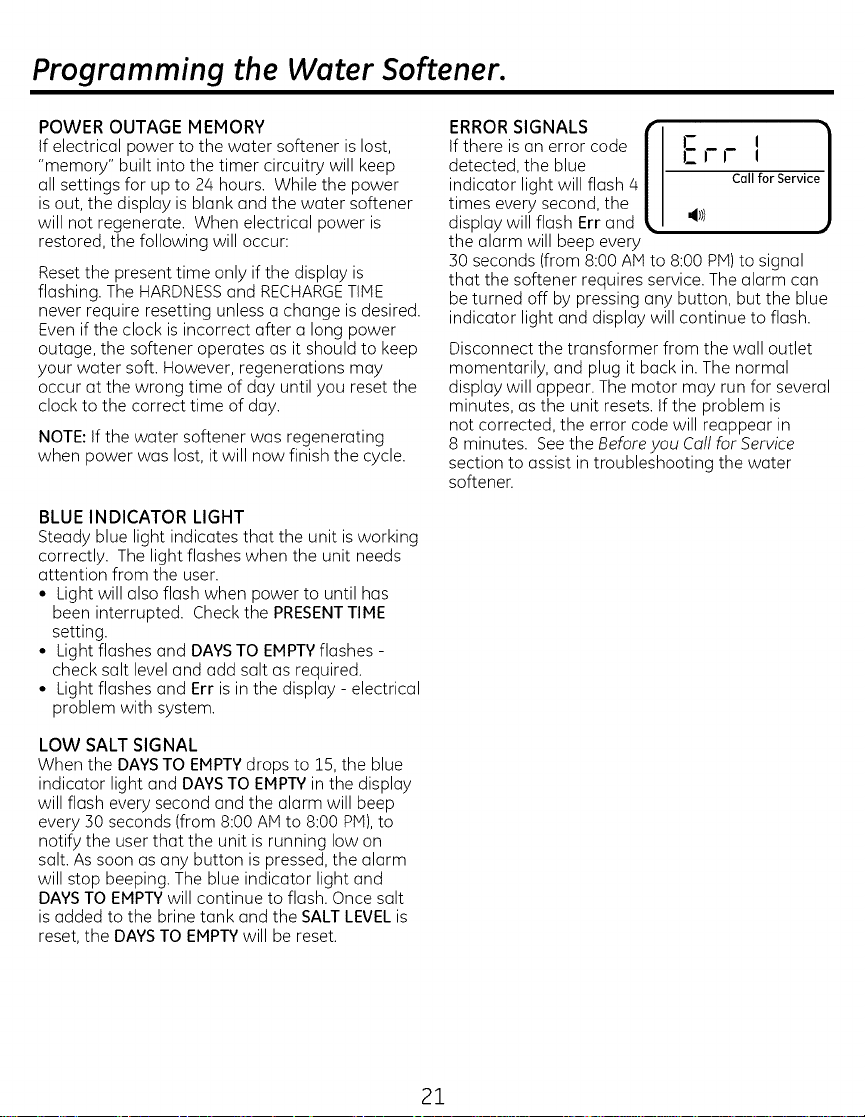

If there is an error code I- I 1

detected, the blue IZ I- !-

indicator light will flash 4 Call forServic

ERROR SIGNALS [ J/

times every second, the

display will flash Err and . 4t))

the alarm will beep every

50 seconds (from 8:00 AM to 8:00 PM)to signal

that the softener requires service. The alarm can

be turned off by pressing any button, but the blue

indicator light and display will continue to flash.

Disconnect the transformer from the wall outlet

momentarily, and plug it back in. The normal

display will appear. The motor may run for several

minutes, as the unit resets. Ifthe problem is

not corrected, the error code will reappear in

8 minutes. See the Before you Coil for Service

section to assist in troubleshooting the water

softener.

21

Page 22

Care and cleaning.

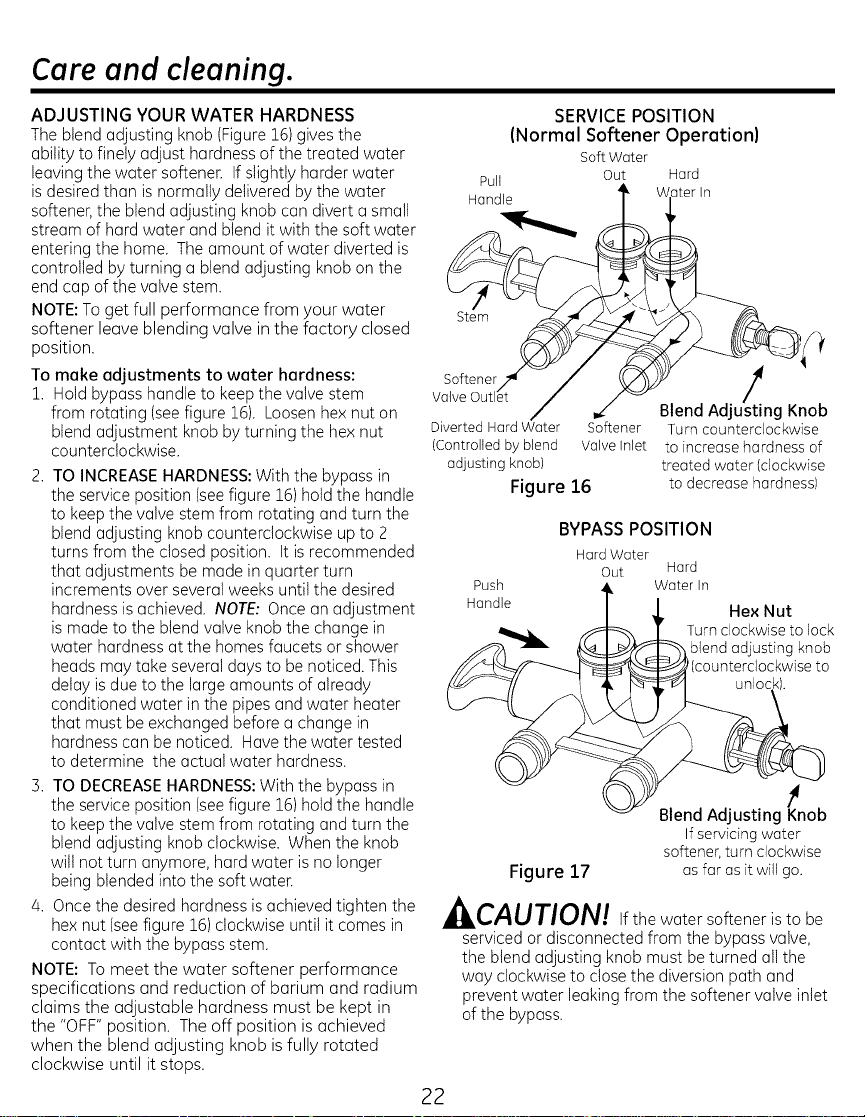

ADJUSTING YOUR WATER HARDNESS

The blend adjusting knob(Figure16)gives the

ability to finely adjust hardness of the treated water

leavingthe water softener. Ifslightly harder water

is desired than is normally delivered by the water

softener, the blend adjusting knob can divert asmall

stream of hard water and blend it with the soft water

entering the home. The amount of water diverted is

controlled byturning a blend adjusting knobon the

end cap of the valve stem.

NOTE:To get full performance from your water

softener leave blending valve in the factory closed

position.

To make adjustments to water hardness:

1. Holdbypass handle to keep the valve stem

from rotating (see figure 16). Loosen hex nut on

blend adjustment knob by turning the hex nut

counterclockwise.

2. TO INCREASE HARDNESS: With the bypass in

the service position (see figure 16) hold the handle

to keep the valve stem from rotating and turn the

blend adjusting knob counterclockwise up to 2

turns from the closed position. It is recommended

that adjustments be made in quarter turn

increments over several weeks until the desired

hardness is achieved. NOTE: Once an adjustment

is made to the blend valve knob the change in

water hardness at the homes faucets or shower

heads may take several days to be noticed. This

delay is due to the large amounts of already

conditioned water in the pipes and water heater

that must be exchanged before a change in

hardness can be noticed. Have the water tested

to determine the actual water hardness.

3. TO DECREASE HARDNESS: With the bypass in

the service position (see figure 16) hold the handle

to keep the valve stem from rotating and turn the

blend adjusting knob clockwise. When the knob

will not turn anymore, hard water is no longer

being blended into the soft water.

/4. Once the desired hardness is achieved tighten the

hex nut (see figure 16) clockwise until it comes in

contact with the bypass stem.

NOTE: To meet the water softener performance

specifications and reduction of barium and radium

claims the adjustable hardness must be kept in

the "OFF" position. The off position is achieved

when the blend adjusting knob is fully rotated

clockwise until it stops.

SERVICE POSITION

(Normal Softener Operation)

Soft Water

Pult Out Hard

Handle ]ter In

Stem

Softener./_

Valve Outlet /

Diverted Hard Water

(Controlled by blend

adjusting knob)

Figure 16

Softener

Valve Inlet

Blend Adjus/_ting Knob

Turn counterdockw)se

to increase hardness of

treated water (clockwise

to decrease hardness)

BYPASS POSITION

Hard Water

Push

Handle

Figure 17

Out Hard

Water In

Turn clockwise to lock

blend adjusting knob

(counterclockwise to

Blend Adjusting K_nob

If serv)c)ng water

softener, turn dockw)se

as for as it will go.

Hex Nut

unlock).

,i I,CAUTION! If the water softener isto be

serviced or disconnected from the bypass valve,

the blend adjusting knob must be turned all the

way clockwise to close the diversion path and

prevent water leaking from the softener valve inlet

of the bypass.

22

Page 23

Care and cleaning.

CHECKING THE SALT STORAGE LEVEL end

REFILL

Brine (salt dissolved in water)is needed for each

and every recharge. The water for making brine

is metered into the gait storage area by the water

softening system valve and control. However, you

must keep the tank supplied with salt.

ADDING SALT

Lift the salt hole cover and check the salt storage

level frequently. If the water softener uses all

the salt before you refill it, you will experience

hard water. Until you have established a refilling

routine, check the salt every two or three weeks.

Always add if lessthan 1/4 full. Be sure the

brinewell cover is on.

NOTE: if using potassium chloride (KCI),do not fill

above level 4 on the brinewell decal.

NOTE: In humid areas, it is best to keep the salt

storage level lower, and to refill more often to

avoid salt "bridging".

Recommended Salt: Nugget, pellet or coarse

solar salts with less than 1% impurities.

Salt Not Recommended: Rock salt, high in

impurities, block, grandulated table, ice melting,

ice cream making salts, etc.

_CAUTION:

Water softening salt with iron removing

additives:

Some suits mey hove on odditive to help the

woter softening system hendle iron in the

water supply. Although this additive may

help to keep the woter softening system

resin cleon, it may olso release corrosive

fumes thet weoken end shorten the life of

some water softening system parts.

CLEANING IRON OUT OF THE WATER

SOFTENI NG SYSTEM

Your water softening system takes hardness

minerals (calcium and magnesium) out of

the water. Also, it can control some (see the

Specification Guidelines section) "clear water" iron.

With clear water iron, water from a faucet

is clear when first put into a glass. After 15 to 30

minutes, the water begins to cloud or turn rust

colored. A water softening system will not remove

any iron that makes the water cloudy

or rusty as it comes from the faucet (called red

water iron). To take red water iron out of water,

or over the maximum of clear water iron,

an iron filter or other equipment is needed.

If your water supply has clear water iron, periodic

resin bed cleaning is needed. GErecommends

using Super Iron Out_'brand resin bed cleaner

to thoroughly clean your resin bed if your iron

content is high. Clean the bed at least every six

months, or more often if iron appears in the soft

water between cleanings.

IMPORTANT:It is important to mix the resin bed

cleaner with water (following the manufacturer's

instructions), pour it into the brinewell (seeFigure

9)and recharge the softener immediately. Do not

pour the resin bed cleaner

in with the salt, as it will not be as effective in

cleaning the resin, and can cause damage to

the softener if it isleft in the brine tank for an

extended period due to the corrosive gases

that are formed.

23

Page 24

Routine Maintenance.

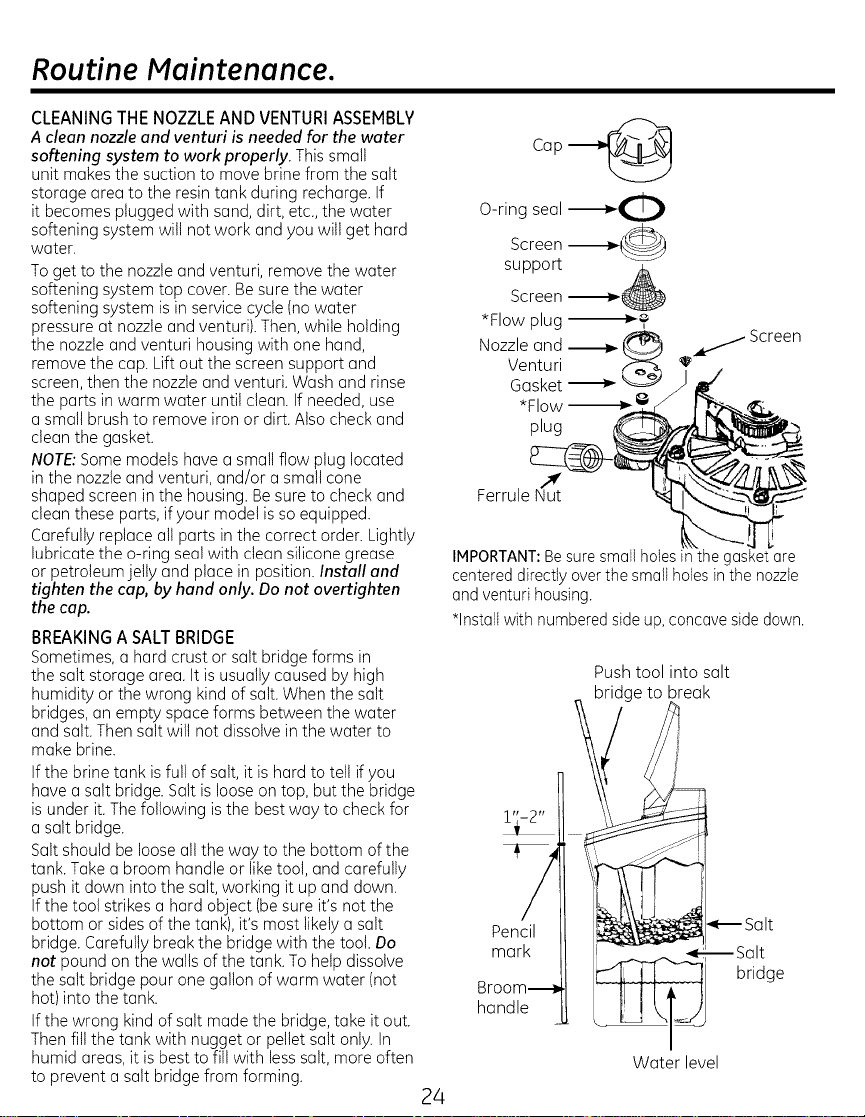

CLEANING THE NOZZLEAND VENTURI ASSEMBLY

Aclean nozzle and venturi is needed for the water

softening system to work properly. This small

unit makes the suction to move brine from the salt

storage area to the resin tank during recharge. If

it becomes plugged with sand, dirt, etc., the water

softening system wilt not work and you will get hard

water.

Toget to the nozzleand venturi, remove the water

softening system top cover. Besure the water

softening system is in service cycle (no water

pressure at nozzleand venturi). Then,while holding

the nozzleand venturi housing with one hand,

remove the cap. Lift out the screen support and

screen, then the nozzle and venturi. Wash and rinse

the parts in warm water until clean. If needed, use

a small brush to remove iron or dirt. Alsocheck and

clean the gasket.

NOTE:Some models have a small flow plug located

in the nozzleand venturi, and/or a small cone

shaped screen inthe housing. Be sure to check and

clean these parts, if your model is so equipped.

Carefully replace all parts in the correct order. Lightly

lubricate the o-ring sealwith clean silicone grease

or petroleum jelly and place in position. Install and

tighten the cap, by hand only. Do not overtighten

the cap.

BREAKINGA SALTBRIDGE

Sometimes, a hard crust or salt bridge forms in

the salt storage area. It is usually caused by high

humidity or the wrong kind of salt.When the salt

bridges,an empty space forms between the water

and salt. Then salt will not dissolve in the water to

make brine.

Ifthe brine tank isfull of salt,it is hard to tell if you

havea salt bridge. Salt is loose on top, but the bridge

is under it.The following is the best way to check for

a salt bridge.

Salt should be loose all the way to the bottom of the

tank. Takea broom handle or like tool, and carefully

pushit down into the salt, working it up and down.

Ifthe tool strikes a hard object (besure it's not the

bottom or sides of the tank), it's most likely a salt

bridge.Carefully break the bridge with the tool. Do

not pound on the walls of the tank. To help dissolve

the salt bridge pour one gallon of warm water (not

hot)into the tank.

Ifthe wrong kind of salt made the bridge, take it out.

Then fill the tank with nugget or pellet salt only. In

humid areas,it is best to fill with less salt, more often

to prevent a salt bridge from forming.

Screen _i

*Flow plug "--_

Nozzle and _._ _I _ Screen

Venturi

plug

Ferrule N_tut

IMPORTANT:Besuresmall holesin the gasket are

centereddirectly overthe small holesin the nozzle

andventuri housing.

*Installwith numberedside up, concavesidedown.

Push tool into salt

bridge to break

i

7

Pencil

mark

Broom--

handle

24

_ _Salt

--Salt

Water level

bridge

Page 25

Before you call for service.

Troubleshooting Tips

Save time and money! Review the chart on this page first and you may not

need to call for service.

NO SOFT WATER - Most Common Problems:

Check the following before calling for service:

• Not enough salt-should be at least 1/3 full.

• Bypass valve in "Bypass" position-handle should be inthe "OUT" (service) position.

• Hardness setting too low. Check hardness setting and adjust. Verify hardness of supply water-

from local water company, water test or call the GEAnswer Center (800-952-5039 in US).

• Salt Bridge-salt solidifies above water level so that brine water is not in contact with salt. See

the Breaking a Salt Bridge section.

Possible Cause What to do

Foucet or fixture where somple wos

token not plumbed to soft woter.

NOTE: Be sure sample is from a faucet

that does not mix soft and hard water.

For example, a single lever kitchen

faucet, if the cold side is plumbed to

hard water.

• To conserve salt, the installer may have isolated

some fixtures (outside faucets, toilets, etc.) from

soft water. From the outlet of the water soften-

ing system, trace the water flow path, in house

plumbing. Ifsoft water is not directed to a faucet

or fixture where wanted, consult a plumber.

• Check for asalt bridge or, if the tank is empty, refill

with recommended salt. Press (for 3 secondsl

the RECHARGEbutton to start an immediate

recharge and restore soft water supply.

• Check for a loss of electrical power to the water

softening system, due to any of these conditions

and correct as needed. With the power supply

restored, observe the faceplate time display and

read Programming the Control section. NOTE:

the electrical outlet for the softener should be live

so it cannot be accidentally switched off.

• Be sure the bypass valve stem is positioned prop-

erly, with the handle in the OUT position.

• Turn blending valve clockwise to closed position.

• Any restriction in the drain hose may prevent

proper operation of the nozzle and venturi and

reduce or prevent brine draw during recharge..

• Refer to Cleaning the Nozzle and Venturi Assembly

instructions. With water pressure to the water

softening system off, take the nozzle assembly

apart. Inspect, clean and replace as needed.

Any foreign particle(s), scratches, nicks, etc. in the

passages con prevent operation. Be sure holes in

the gasket are centred over holes in the housing.

25

Page 26

Before you call for service.

Possible Cause What to do

Using hot water while the water • Avoid using hot water during water softening

softening system is regenerating system recharge because the water heater will

Control HARDNESSnumber setting • Press MODE/SETbutton until arrow points to

too low HARDNESS. Be sure the number shown is the

Grains of hardness in your water • Water hardness can change over time, especially

supply have increased in well water. To check, hove the water tested

Absence of hardness minerals • This is normal. Hardness in water gives it the

Water softening system is a • Doesnot use much salt to regenerate - very

"demand" unit el_cient.

Possible salt bridge • See the Breaking a Salt Bridge section.

Possible plugged nozzle and venturi • See the Cleaning the Nozzle and Venturi Assembly

Acidic water in copper plumbing • Hove the water tested at once.

refill with hard water. SeeAutomatic Hard Water

Bypass During Recharge section.

same astheactualgrainspergallonhardnessof

yourwatersupply.See Programming theControl

sectionifo change insettingisneeded.

by o water analysis laboratory or call your local

water deportment. Adjust the Hardness number

setting as needed.

abrasive feel you may hove been accustomed to.

The slippery feel is the clean feel of soft water.

• See the Adjusting your Water Hardness section.

section.

Meter turbine stuck

Sensorwire not plugged into the • See the Manually Initiated Electronics Diagnostics

control section for troubleshooting procedures.

No power to unit • Check the circuit breaker or fuses.

Mechanical defect • Coil for service.

Combination of soft water and too • This is called etching and is permanent. To

much detergent prevent this from happening, use less detergent

• See the Manually Initiated Electronics Diagnostics

section for troubleshooting procedures.

• Call for service.

• Coil for service

if you hove soft water. Wash glassware inthe

shortest cycle that will get them cleon..

26

Page 27

Before you call for service.

Possible Cause What to do

Valve drain hose pinched, plugged,

elevated too high or otherwise

restricted

Nozzle and venturi dirty, incorrectly

assembled or damaged.

Unit not sanitized

Lowwaterpressure

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

Restricted drain hose

Unit was idle for a period of time • Complete the Sanitization Procedures.

• A restriction in this drain hose may prevent proper

operation of the nozzle and ventufi and reduce or

prevent brine draw during recharge.

• Refer to Cleaning the Nozzle and Venturi Assembly

instructions. With water pressure to the water

softening system off, take the nozzle assembly

aport. Inspect, cleon and replace as needed.

Any foreign particle(s), scratches, nicks, etc. inthe

passages con prevent operation. Be sure holes in

the gasket ore centred over holes in the housing

• Complete Sonitizotion Procedures.

• At completion of recharge cycle (approx. 2 hours),

run water from faucets to purge the salty water.

Check pressure:

• Drain height 8' or less, pressure should be mini-

mum 20 psi.

• Drain height above 8',pressure should be mini-

mum 50 psi.

• Cleon and reconnect hose.

• Check for kinks in drain line

Cracked distributor • Check softener "IN & OUT" plumbing is correct.

Running water from the unit into a • This is normal.

drain during recharge

Air in system after installation • Will go away after it runs for o while.

Control needs to be programmed {a

iiiiii_i_i!_i_ii!ii!ii!__!_Ji%_!_i!_i_!iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_i_i_ilil_l_i

power outage may have occurred)

Low salt level, less than 15 days

• Coilfor service.

• Seethe Programming the Control section.

• Fillwith salt.

• Reset salt level.

27

Page 28

Before you call for service.

Possible Cause

Wiring may hove worked loose in

the control

i_'Ei_di_ay Electrical problem with system • Call for service.

What to do

• Unplug external power supply.

• Remove control cover, release clips on side.

• Check for loose/incorrect wiring connections

to electronic board or switch. Reconnect as

required.

• Reassemble control cover.

• Plug in Transformer.

• Wait 8 minutes for Error Code to reappear.

• If error Code reappears, call for service.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

28

Page 29

Advanced troubleshooting for service.

AUTOMATIC ELECTRONIC DIAGNOSTICS

Thiswater softener hasa f

self-diagnosticfunction

forthe electricalsystem

(exceptinto powerand/

or water meter). Thewater

softener monitors electronic .

componentsand circuits

forcorrect operation. If

a malfunctionoccurs,an error codeappears in the

display.

Whilean error codeappears in the display,all buttons

areinoperable exceptthe MODE/SETbutton.

MODE/SETremainsoperationalso the service person

can perform the ManualAdvancedDiagnostics,see

below,to further isolatethe problem.

Procedure for removing error code from display:

1. Unplugtransformer from electrical outlet.

2. Correctproblem.

3. Hug in transformer.

4. Wait 8 minutes. Theerror codewill return if the

problemwas not corrected.

MANUAL INITIATED ELECTRONICDIAGNOSTICS

Usethe following proceduresto advancethe water

softenerthrough the regenerationcyclesto check

operation.

Liftoff the Salt HoleCover,removethe top coverby

unlockingthe tabs in the back androckingforward,

to observecam and switch operationduringvalve

rotation.

1. Pressand holdMODE/SETfor3 secondsuntil the

Setlowsalt alarm displayappears,next pressthe

MODE/SETbutton five addition times until "000"

showsin the display,then retease,seeFigure 19.

2. The 3 digitsindicated water meter operation as

follows: Ifyou don't get a readingonthe display,

with faucet open,pullthe sensorfrom thevalve

outtet port. Passa smallmagnet backandforth

in front of the

sensor. You

shouldget a

readingin the

display. If you

get a reading,

shut off water

supply,unhook

the in and

out plumbing

andcheckthe

turbinefor

binding.

outlet

Err l ]

[

Figure 18

Call for service/

Turbine

support end

short

3. Symbolsin the displayindicate POSITIONswitch

operation,see Figure19

Switchis open

Switchi_closed

2 ,_,

J

rl rl rl rl rl rl

, U U U'r',%-- , f ,_

\Water Meter/ Figure 19

4 UseRECHARGEbutton to manuallyadvancethe

valveinto each cycleand checkcorrect switch

operation. NOTE:Besurewater isin contact with

salt,and notseparated by a saltbridge (seeBreaking

aSaltBridgesection).

5. Whilein this diagnosticscreen,the following

information isavailable and may be beneficialfor

variousreasons. Thisinformation is retained by

the computer from thefirst time electrical power is

appliedto the electronic controller.

a. Pressthe_b.UP button to display the number

of days thiselectronic control hashad electrical

power applied.

b. Pressthe_VDOWN buttonto display the

number of regenerationsinitiated bythe

electroniccontrol sincethe code numberwas

entered.

6. Pressand holdthe NODE/SETbuttonuntilthe mode

code(H40for GXSH40Vor H45for GXSH45V)shows

in the display. This codeidentifies the softener

mode. If an incorrectmodelcodeis displayed,the

softenerwill operate on incorrectconfigurations

data.

LooE

lln

H- u

It, ]

Tochange the code number,pressthe Ab.UP or _V'

DOWNbutton untilthe correctcode shows.

Toreturn to the present time display,pressthe

NODE/SETbutton.

PresstheNODE/SETbuttonto returnto the present

time display. If the codewas changed, makeall

the timer setting. NOTE:If the controlisleft in a

diagnosticdisplayor a flashingdisplaywhen setting

timesor hardness,presenttime automaticallyreturns

if a button is not pressedwithin four minutes.

UUU

,_--'llr

Page 30

Advanced troubleshooting for service.

Service: Manually Advance Recharge Check

NOTE: The control display must show a steady time (not

flashing).

1.Press the RECHARGEbutton and hold in for three

seconds. RECHARGEbegins to flash as the water

softening system enters the fill cycle of recharge.

Remove the brinewell cover and, using a flashlight,

observe fill water entering the brine tank. If water

does not enter the tank, look for an obstructed nozzle,

venturi, fill flow plug or brine tubing. See Care and

Cleaning of the Water Softener System section.

2.After observing fill, press the RECHARGEbutton to

move the water softening system into brining. A

slow flow of water to the drain will begin. Verify brine

draw from the brine tank byshining a flashlight into

the brinewell and observing a noticeable drop in the

liquid level over an extended period of time (is to 20

minutes).

NOTE: Besure a salt bridge is not preventing water from

contacting salt. See Care and cleaning of the water

softening system section.

If the water softening system does not draw brine, check:

, nozzle and/or venturi dirty or defective.

, defective nozzle and venturi seal.

, nozzle and venturi not seated properly

on gasket.

, other inner valve defect (rotor seal, rotor and disc,

wave washer, etc.).

, restricted drain (check drain fitting and hose).

NOTE: If water system pressure is low, an elevated drain

hose may cause back pressure, stopping brine draw.

5. Again, press the RECHARGEbutton to move the water

softening system into backwash. Look for a fast flow

of water from the drain hose. A slow flow indicates a

plugged top distributor, backwash flow plug or drain

hose.

4. Press the RECHARGEbutton to move the water

softening system into fast rinse. Again look for a fast

drain flow. Allow the water softening system to rinse

for a few minutes to flush out any brine that may

remain in the resin tank from the brining cycle test.

5.To return the water softening system to service, press

the RECHARGEbutton.

30

Page 31

Exploded View.

4

ii

m19

(_o

29

23

55

24m

36m

{

}

31

25

Page 32

Exploded View.

139

109--

I

1i0---------0

113

118

124

Cross-section

View

132

134 133

148

147

--152

152

32

Page 33

Parts List.

REF. NO.

O0O2

0003

0004

0005

0006

0007

0008

0009

0010

0010

0011

0012

0013

0016

0017

0019

0020

0021

0022

0023

0024

0025

0026

0027

0028

0029

0030

0031

0032

0033

0034

0035

0036

0055

0056

0101

0103

0105

0106

0107

0108

0109

0110

GE PART NO.

WS31XlO051

WS35XlO001

WS34XlO023

WSO7XIO004

WS31XlO044

WSI4XlO002

WS14XIO005

WSO1XIO002

WS32XlO011

WS32XlO018

WS31XlO052

WS34XlO021

WS21XlO054

WS26XlO013

WS31XlO053

WS33XlO010

WS31XlO024

WSO2XlO009

WS34XlO025

WSO2XlO027

WS32XlO032

WS18XlO003

WS22XlO016

WS22XlO017

WS35XlO035

WS15XlO077

WS35XZO063

WS6OXIO004

WS15XIO006

WSO3XlO023

WSO3XIO008

WSO7XIOO30

WSO7XIO015

WS28XlO003

WS28XZO007

WSO2XZO023

WS2ZXZO003

WSO2XZO024

WS31XlO013

WSO3XlO034

WS26XlO010

WSI9XIO010

WSO3XIO011

PART DESCRIPTION

BACK COVER, ELECTRONICS

O-RING SEAL KIT

DECAL, FACEPLATE

HOSE, DRAIN, 20 FT.

FILTER SCREEN

DISTRIBUTOR, TOP

DISTRIBUTOR, BOTTOM

RESIN, 1-CU. FT.

TANK, RESIN 9X40

TANK, RESIN lOX40

COVER, TOP

FACEPLATE

CONTROL

EXTERNAL POWER SUPPLY

WITH POWER CORD

COVER, SALT HOLE,

WITH LABELS

RIM

COVER, BRINEWELL W/DECAL

WING NUT, 1/4 - 20