Page 1

www.GEAppliances.com

@

©

SaJ_tyInformation .......... 2

Installation Instructions . .3-10

Step-by-step i_structicms . . .6-10

Operating Instructions

Breaking a salt bridge ....... 12

Cleanii_g the i_ozzle a_d

venturi assembly ........... 12

Features .................. 13

Service ............. 11, 14-16

Water softe_er system .... 11-16

Care and Cleaning ........ l 7

Troubleshooting Tips .... 18-20

Consumer Support

Consm_er Support . .Back Cover

Parts list/catalog ........ 23-26

Warranty ([/.S.) ............ 27

Wmr;m tv (Ca_mda) ......... 28

Water

Softening

System

ModelsGXSH39E,GNSH45E

Sistema Suavizante

de Agua

ModelosGXSH39E,GNSH45E

La secci6n en espafiol empieza en la pagina 29

©

System tested and certified by NSF International against NSF!ANSI Standard 44 fl)r the

chemical reduction claims specitied on the per/brmance data sheet.

Sistema t)robado y certilicado pot NSF International contra norma 44 de NSF!ANSI para

las a/irmaciones de reduccidn de los productos qu/micos especi/icadas en la hoja de datos

de flmcionamiento.

Write the model and serial

numbers here:

Model #

Serial #

To find these numbers, lift

the cover and look on the

rim beh)w the control panel.

7247166 215Cl173P011 49-50152-1 06-05JR

Page 2

IMPORTANTSAFETYINFORMATiONo

READALLINSTRUCTIONSBEFOREU$1N&

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of electric shock,

property damage or personal injury.

SAFETYPRECAUtiONS

Check and comply with wmr state and local

codes. You must fi)llow ti_ese guidelines.

Use care when handling the water softening

s_:stem. Do not turn upside down, drop, drag

or set on sharp protrusions.

Water softening systems using sodimn chloride

(salt) for recharge add sodimn to the water.

Persons on sodium restricted diets should consider

the added sodium aspart of their overall intake.

Potassium chloride can be used as an alternative

to sodium chloride in your softener

The _sater softening system _sorks on 24 _olt-60 Hz

Use clean water softening salts only, at least

99.5% pm'e. NUGGET, PEI,I,ET or coarse

SOLAR salts are recolnmended. Do not rise rock,

block, granulated or ice cream making salts.

They contain dirt and sediments, or mush and

cake, and will create maintenance problems.

Kee I) the salt hole cover in place on the softener

tmless servicing the trait or refilling with salt.

-_WARNING:oo.o, use with water that is

microbiologically tmsafi _ or of tmknown quality

without adequate disinfection befm'e or after

the system.

electrical power only. Be sure to use onlythe

included transformer

Transformer must be )lm,{,ed into indoor

120 xolt, grounded outlet only.

PROPERINSTALLAtiON

This water softening system must be properly installed and located in accordance with the Installation

Instructions before it is used.

Install or store where it will not be exposed to

temperatures below fl'eezing or exposed to any

type of weather: Water fl'eezing in the s_:stem will

break it. Do not attempt to treat water over 100°E

Do n0tinstall in direct stmlight. Excessive stm or

heat may catlse distortion or other damage to

non-metallic parts.

Properly ground to confimn with all governing

codes and ordinances.

Use only lead-free solder and flux for all sweat-

solder connections, as reqtfired bv state and

federal codes.

Softener resins may degrade in the presence of

chlorine above 1 ppm. If you have chlorine in

excess of this amotmt, you may experience

reduced lile of the resin. In these conditions,

you may wish to consider i)m'chasing a (;E

point-of-entry household filtration system with

a chlorine reducing filte_:

WARNING:Disc.,d.llunusedparts

and packaging material after installation.

Small parts remaining after the installation

could be a choke hazard.

The water softening system reqtfires a minimmn

water flow of three gallons per minute at the inlet.

Maximum allowable inlet water pressm'e is 125 psi.

If daytime pressm'e is over 80 psi, nighttime

pressm'e may exceed the maximum. Use a pressm'e

reducing \:dve to reduce the flow if necessarx:

READANDFOLLOWTHISSAFETYINFORMAtiONCAREFULLY.

SAVETHESEINSTRUCTIONS

2

Page 3

Installation instructions.

CAUTION:Certainplumbingsl illsareneededforinstallation.Ifyouareunsureabout

any part of the installation of this product, consult a professional plumber,

Unpacking and Inspection

Be sure to check the entire sottener tot any

shipping damage or parts loss. Also note

damage to the shipping cartons. Contact the

transportation company fl)r all damage and

loss claims. The IllaIltlf;IctuI'eI" is not

responsible lot damages in transit.

Important Installation Recommendations

Read entire manual. Failure to follow all guidelines and rules could cause personal injury or

property damage.

Small parts needed to install tile softener are

packaged either in a bag or on a cardboard

sheet. To awfid loss of the small parts, kee I)

them packaged until you are ready to use them.

Be sm'e not to discard components hidden in

packaging.

Before you begin installation, read these

Installation Instructions completely. Then,

obtain all tile materials and tools you will

need to make tile installation. Failure to

properly install tile softener voids tile

W}l I'I'}1 n IV;

Check local codes. Tile installation must

con[oI'Ill to them.

In the Commonwealth of Massachusetts,

Plumbing Code 248 CMR shall be adhered to.

Consult with your licensed plumber.

Use only lead-h'ee solder and flux for all

sweat-solder connections, as required bv

state and federal codes,

Connect tile softener to tile main water

supply pipe before or ahead of the water

heater. DO NOT RUN HOT WATER THROUGH

THESOFTENER. Temperature of water

passing through the sotiener illtlSt be

less than 120°F.

Use care when handling tile softener.

Do not tm'n upside down, drop, drag

or set on sharp protrusions.

Maximum allowable inlet water pressure is

125 psi. If daytime pressure is over 80 psi,

nighttime pressure may exceed the

maximmn. Use a pressm'e reducing valve

if necessary. (Adding a pressm'e reducing

valve Ill}Iv reduce tile flow.)

Tile softener works on 24 volt-60 Hz

electrical power only. Be sure to use the

included transformer. Be sure tile electric

outlet and transfm'mer are in an inside

location to protect ]['l'OIl/ inoisture.

See Where to Install the Softener section lot

more derails.

k, WARNING:D,),,,it,,sewithw.te,"

that is microbiologically tmsafe or of

tmknown quality without adequate

disinfection before or after the system.

The water should be tested periodically

to verifY' that tile system is performing

satisla ctorilv.

Small parts remaining after tile installation

could be a choke hazard. Discard saliqv:

Page 4

InstMlatien instructions°

Plan How You Will Install the Softener

Yol_ midst first decide how m rm_ im_aN_dom

pipes to the so[te_er, l,ook at the hol_se

mah_ _ater pipe at d_e [)oim_t _here y()l_ _i]]

c(mm_ect the soflel_er. Is the pipe soldered

coppe_; gh_ed plastic, or threaded ga]v;mized?

What is t]_e pipe size?

P.WNflNflV& ,seo,.. e.d,ee

sel de r a m_d fl I_x t(_ preve_ t ]ea d poi som_im_g.

Whore to Install the Softener

Place the softener as close as possible to a

sewer drain, or other acceptable drain point

or standpipe.

It is recomm ended to kee I) outside taucets

on hard water to save spit water and salt.

Do not install the softener in a place where it

could t/'eeze. Freeze damage is not covered by

the warranty.

Do not install the softener where it would

1)lock access to the water heater or access to

the main water shutoIt.

Put the softener in a place where water

damage is least likely to occur if a leak

develops. The manufacturer will not repair

or pay for water damage.

See Typical Installation Illustration, Fig. l. IYse

this as a g_fide w]]em_ plam_]_g y(mr particle]at

im_sta]]atiom Be aura to direct the incoming hard

water supply to the softener valve inlet fitting,

The _]ve is marked/N am_d OUE See ill i_s_ra ti o_

(m page 5 t(_ help y(m prepare.

A 120-volt electric outlet is needed to plug

in the included transformer. The softener

has a 10-toot power cal)le. If the outlet is

remote (up to 100 ti_et), use 18 gauge wire

to connect. Be sure the electric outlet and

transformer are in an inside location, to protect

from wet weather. Be sure the outlet is

unswitched to prevent accidental shutott.

If installing in an outside location, you must

take the steps necessary to assure the soltene_;

installation plumbing, wiring, etc., are as

well protected fl'om the elements (stmlight,

rain, wind, heat, cold), c(mtamination,

wmdalism, etc., as when installed indoors.

Outdoor installation is not recommended, and

voids the warranty.

Keep the softener out of direct sunlight.

The stm's heat may distort non-metallic

parts and may damage the electronics.

Toolsand Materials Required for Installation

In and out fittings included with the softener

are 1" (nominal) copper sweat tul)es.

You should maintain the same, or larger,

pipe size as the water supply pipe, up to the

softener inlet and outlet.

Use the included 1)ypass valve to install the

softener. The 1)ypass valve allows you to turn

off water to the soltener ti:,r servicing, 1)ut

still have water in the house pipes, The in

and out fittings referred to above connect to

the bypass \:dye with the included nuts and

wash ers.

Use coppe_; 1)rass or galxanized pipe and

fittings, . Some codes may also allow CPVC

plastic pipes.

4

If additi(mal drain hose is needed fl,r xalve

and salt tank drains, it can be ordered from

GE Parts at 800.626.2002.

If a rigid wdve drain is needed to comply

with plmnl)ing codes, you can 1)uy the parts

needed to connect a 1/2" copper tul)ing or

plastic pipe drain.

Clean nugget or pellet water softener salt is

needed to fill the 1)fine tank, see Step 8 in

the Stop-by-Stop Installation Instructions.

Page 5

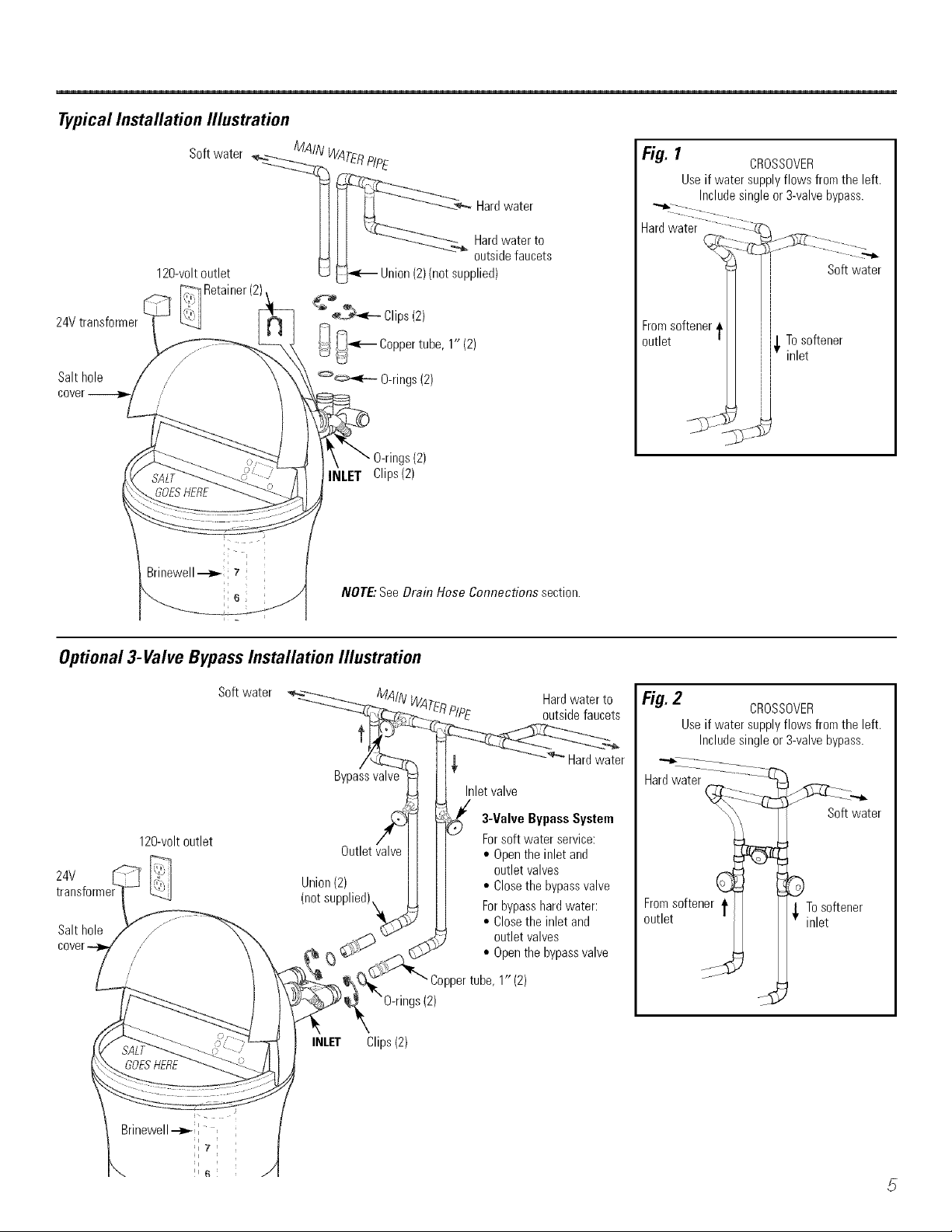

Typical Installation Illustration

24Vtransformer

Salthole

Softwater MAIN WATERPIP

_'_ Hardwater

IIII Hardwaterto

120-voltoutlet Lj_-_ Union(2Xrrotsupplied)

_ Retainer(2) ---_

U L_ - outsidefaucets

___--- Clips(2)

_[l _ Co ertube

/ :_-_ PP .1" (2)

<_ O-rings(2)

gs(2)

iLET Clips(2)

NOTE: See Drain Hose Connections section.

Fig. / CROSSOVER

Useifwater supplyflows fromthe left.

Includesingleor3-valvebypass.

Hardwater

Fromsoftener.

)utlet

,_ To softener

inlet

J

Softwater

Optional 3-Valve Bypass Installation Illustration

Softwater

Bypassvalve

120-voltoutlet

24V

transf L_j.j (notSL

Salthole

cover-

ti:i:_j Union(2)

/

/

/

/

GOESHERE

Outletvalve

INLET Clips(2)

_, -_'" Hard water

Inlet valve

3-ValveBypass System

Forsoftwater service:

,,Opentheinlet and

outletvalves

• Closethe bypassvalve

Forbypasshardwater:

• Closethe inlet and

outletvalves

° Openthebypassvalve

Coppertube.1" (2)

s(2)

Hardwaterto

outsidefaucets

Fig. 2 CROSSOVER

Useifwater supplyflows fromthe left.

Includesingleor3-valvebypass.

"_:-L .........................

..................:-(

Hardwater

Softwater

C D

Fromsoftener t _ Tosoftener

outlet inlet

5

Page 6

Step-by-step installation instructions.

_¢Turn off file g_asor electric supply to die _lter heate_, in tile possibili U that

the _ter heater may be drained while draining pipes.

:¢ Turn off dm _;_ter supply to pipes to be cut and drain the house wamr pipes.

:¢ Open bofll hot and cold *bucets at the lo_est location possiNe.

NOTE:For easier installation, remo\e the top cover Release 2 clips at rear of codex: Rotam

cover ibn_ard and lift up.

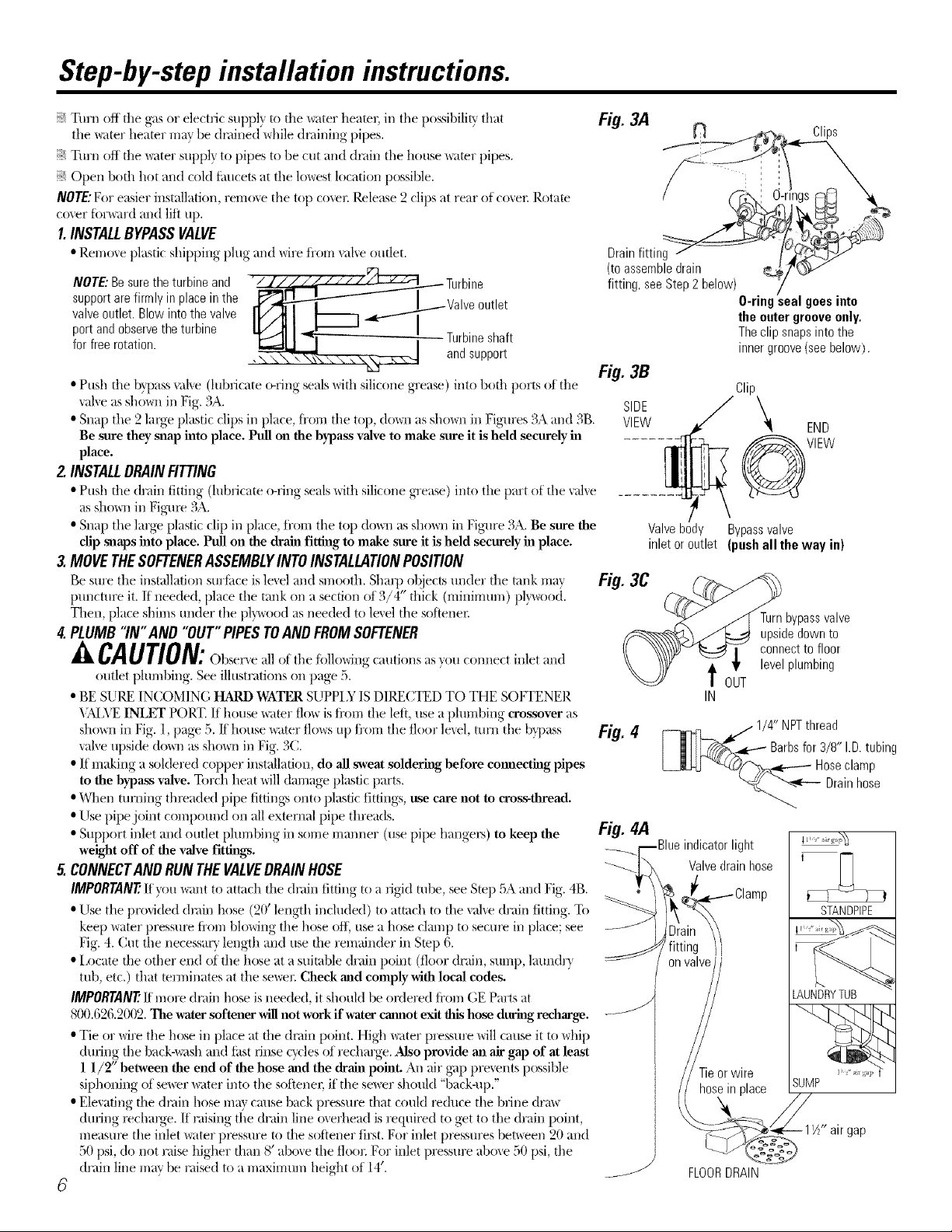

1.INSTALLBYPASSVALVE

• Remove plastic shipping plug and wire fi'om val_e outlet.

supportare firmly in placeinthe I utlet

NOTE:Besuretheturbine and "__U_bv7;

port andobservetheturbine

valveoutlet. Blowinto the valve _ TaUn_b_p;_

for free rotation, t

, \ \", _'x_\_

• Push the b}pass val_e (lubricate o-ring seals with silicone grease) into both ports of the

vane as sho_n in Fig. 3A. SIDE

• Snap the 2 lmge plastic clips in place, from the top, doom as shown in Fi#u'es 3A and 3B. VIEW

Be sure they snap into place. Pull on the bypass valve to make sure it is held securely in

place.

Drainfitting -/

(toassembledrain

fitting, see Step2below)

Fig. 3B

2.INSTALLDRAINFITTING

• Push the drain fitting (lubricate o-ring seals with silicone grease) into the part oi the \'al_e

as shox_/in Fig-m> 3A.

• Snap the large plastic clip in place, ti'om the top dox_al as shown in Fig-ure 3A. Be sure the

clip snaps into place. Pull on the drab1 fitting to make sure it is hdd securely in place.

3.MOVETHESOFTENERASSEMBLYINTOINSTALLATIONPOSITION

Be sure the installation surfitce is level and smooth. Sharp objects under the tank may Fig.3C

ptmcmre it. If needed, place the tank on a section of 3/4" thick (minimum) pl}a_od.

Titan, place shims under the plywood as needed to level the sotiene_:

4.PLUMB"IN"AND "OUT"PIPESTOANDFROMSOFTENER

--ACAUTION:()bsexwe all ot the fi,llo, Ung cautions as,ou connect inlet and

outlet plumbing. See illustrations on page 5.

• BE SURE INCOMING HARD WATER SUPPI X IS DIRECTED TO THE SOFTENER

X;MYE INLET PORT. If house x_wr flo_ is ti'om the leit, nse a plumbing crossover as

shown in Fig. l, page 5./f house _;tter flo_s up fi'om the floor level, turn the bypass Fig.4

_alve upside (to_/as shown in Fig. 3C.

• If making a soklered copper installation, do all sweat soldering before commctitlg pipes

to the bypass valve. Torch heat will damage plastic parts.

• When turning threaded pipe titting_ ()lit() plastic tittings, use care not to cross-thread.

• Use pipe joint compound on all external pipe threads.

• Support inlet and outlet plumNng in some manner (use pipe hange_) to keep the Fig.4.4

weight off of the valve fitth_gs.

5.CONNECTANDRUN THEVALVEDRAINHOSE

IMPORTANT'.It_ou _ant to attach the drain fitting to a rlgJd tube, see Step 5A and Fig. 4B.

• Use the provided drain hose (2(/length included) to attach to the val_e drain fitting. To

keep water pressure tram blowing the hose ofl_ use a hose clamp to secul_ in place; see

Fig. 4. (;tit the necessary length and use the remainder in Stop 6.

• I_ocate the other end of the hose at a suitable drain point (floor drain, sump, laundr>

tub, etc.) that mnninates at the smear Check and comply with local codes.

IMPORTANT'./#more drain hose is needed, it should be ordered ti'om GE Parts at

800.626.2002. The water softener WIUnot work if water cannot exit this hose durit g recharge. --_

• Tie or wire the hose in place at the drain point. High _ter pressure will cause it to whip

during the back4_mh and Ktst rluse cycles of recharge. Also provide an air gap of at least

1 1/2' between the end of the hose a_d the drain point. An air g_p pre_ents possiNe

siphoning of se_r water into the sotienec if the sewer should "back-up."

• Elevating the drain hose ma t catlse back pressm_ that could l_duce the brine drm_

during _>chaNe. If raising the drain line overhead is required to get to the drain point,

measure the inlet _ter p_ssure to the softener first. For inlet p_ssures bet\_een 20 and

50 psi, do not raise higher than 8' above the floor For inlet pressure above 50 psi, the

drain line may be raised to a n/aximnn/height of 14'. __

8

Clips

ngs

O-ring'sealgoesinto

the outer grooveonly,

Theclipsnapsintothe

innergroove(seebelow).

Clip

END

VIEW

Valve body Bypass valve

inlet or outlet (push all the way in)

Turnbypassvalve

upsidedownto

_, connectto floor

f OUT levelplumbing

IN

[__i_[[_ __.,_t.......1/4"NPTthread

Barbsfor 3/8" I.D.tubing

LJLUJ _#';y_e---_ Hoseclamp

_Q. "_--- Drainhose

)rlight

Valvedrainhose

'ZZ

STANDPIPE

on

LAUNDRYTUB

-ieor wire

FLOORDRAIN

SUMP

gap

Page 7

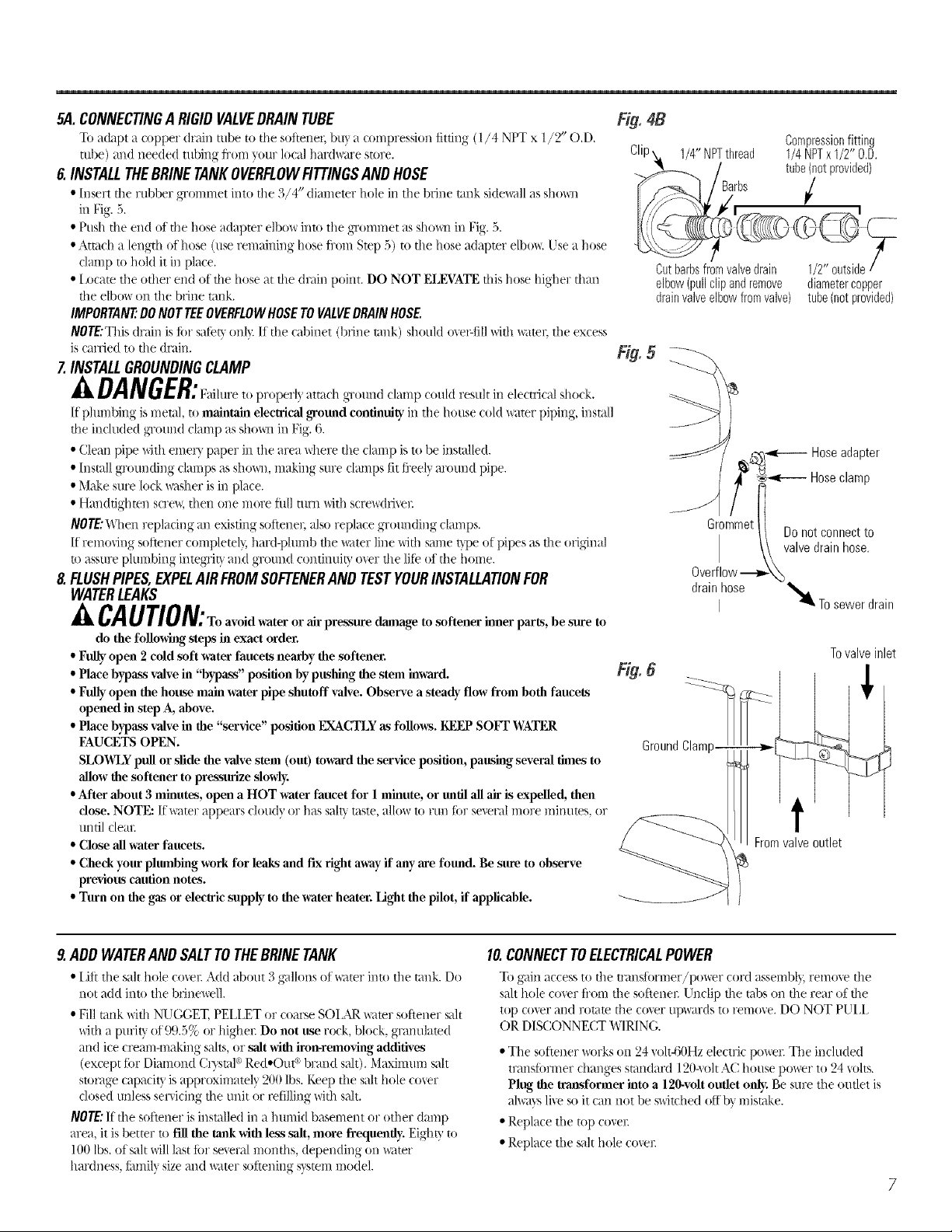

5A CONNECTINGA RIGIDVALVEDRAINTUBE

To adapt a copper drain robe to the soitener, buy ?t compression fitting (1/4 NPT x 1//9" O.D.

robe) and needed tuhing Ii'om your local hardware store.

6 INSTALLTHEBRINETANKOVERFLOWFITTINGSANDHOSE

• Insert tile rubber g_'ommet into tile 3/4" diameter hole in tile brine tamk sidewall as shox_]

in Fig. 5.

• Push tile end of the hose adapter elbow into tile g_'ommet as shown in Fig. 5.

• Attach a length of hose (use remaining hose In)m Stop 5) m tile hose adaptor elbow Use a hose

clamp m hold it ill place.

• I_ocam tile other end of tile hose at tile drain point. DO NOT ELEVATE this hose higher than

tile e/bo_s on tile brine rank.

IMPORTANT:DONOTTEEOVERFLOWHOSETOVALVEDRAINHOSE

NOTE:Thisdrafil islOTsafetyonly II the cabinet (brine umk) should o\erfiII with water;tile excess

iscarried to tile drain

7 INSTALLGROUNDINGCLAMP

If pluml)ing is me'ud, to maintain electrical ,_'omld continuity in tile house cold water piping, install

the included ground clamp as shown in Fig. 6.

• Clean pipe with emer> paper in tile area _dlere tile clamp is to he installed.

• Instal[ grounding clamps as sD)x_, making sure damps fit li'eely around pipe.

• Make sure lock x_:tsheris ill place.

• Handtighten scre_, then one more flfll mrn with scre_x(hg'el_

/VOTE:W[len repladng m_existing soltenel; also replace grounding clamps.

If removing soltener completel b hard-phmlb tile water line with same t}pe of pipes as the original

u) assure plumbing integ_'iV and ground continui V o\er tile [ifieof tile home.

8 FLUSHPIPES,EXPELAIRFROMSOFTENERANDTESTYOURINSTALLATIONFOR

WATERLEAKS

A CAUTION:To avoid water or Mr pressure dmnage to softener inner parts, be sure to

do the following steps in exact order.

• Fully open 2 cold soft water faucets nearby the softener.

• Place bypass valve in "bypass" position by pushing the stem inwm'd.

• Fully open the house main water pipe shutoff valve. Observe a steady, flow from both faucets

opened in step A, above.

• Place bypass valve in the "service" position [XA_CTLYas follows. I_2EP soFT WATER

FAUCETS OPEN.

SLOB_LYpull or slide the valve stem (ou 0 towaxdthe service position, pausing several times to

allow the softener to pressurize slowly.

• After about 3 minutes, open a HOT water faucet for 1 minute, or mllil all air is expelled, then

close. NOTE: If water appears cloudy or has salF "utste,allow to run fi)r several more minutes, or

until clem_

• Cli)se all water faucets.

• Check your phunbing won for leaks and fix rigbt away if any axe fomld. Be sure to observe

previous caution notes.

• Tunl on file gas or elecWic supply to the water heater. Light file pilot, if applicable.

1/4"NPTthread

Compressionfitting

1/4NPTxI/2" O.D.

tube(notprovided)

/

Cutbarbsfromvalvedrain 1/2"outside

elbow{pullclipandremove diametercopper

drainvalveelbowfromvalve) tube(notprovided)

Fig. 5" -_

_:_,_..__i Hoseadapter

Hoseclamp

GroundClam

Fromvalveoutlet

!

Tovalveinlet

9 ADDWATERANDSALTTOTHEBRINETANK

• I.it't tile salt hole co_r Add about 3 g'allons of _<lter into the rank. Do

not add into tile bfinewe/1.

• Fill rank with NUGGET, PELI.ET or coarse SOI.AP, wamr softener salt

with a purity, of99.5% or higher Do not use rock, block, gramflated

and ice cream-making salts, or salt with iron-removing additives

(except for Diamond C_ystal° Red.Out c'_hrand salt). Maximum silt

storage capacity is approximatel} 200 [bs. Keep tile salt hole cover

dosed unless ser\icing the unit or refilling with salt.

/VOTE:If the softener isinstalled ill a humid basement or other damp

area, it is hetter to Fillthe rank with less salt, more frequently. Eighty to

100 [bs. of salt will last lot se\eral months, depending on _<lmr

hardness, Imni/y size and water soltening s)rsmln model.

10.CONNECTTOELECTRICALPOWER

To gain access to tile transfi_rmer/power cord assembly, remo_ tile

salt hole co\er li'om tile softener. Unclip tile robs on tile rear of tile

top co\er and romm tile co\er upwards to remo_ e. DO NOT PUII,

OR DISCONNECT WIRING.

• Tile softener _)rks on 24 voh4;OHz electric power: Tile included

transformer dlanges standard 120aok AC house power to 24 \ohs.

Plug, the tra_sfonner into a 120-volt outlet only. Be sure the outlet is

ah_a}s li\e so it can not he _vikhed offb_ mistake.

• Replace tile mp coxe_:

• Replace tile salt hole covel:

7

Page 8

Step°by°step installation instructions,

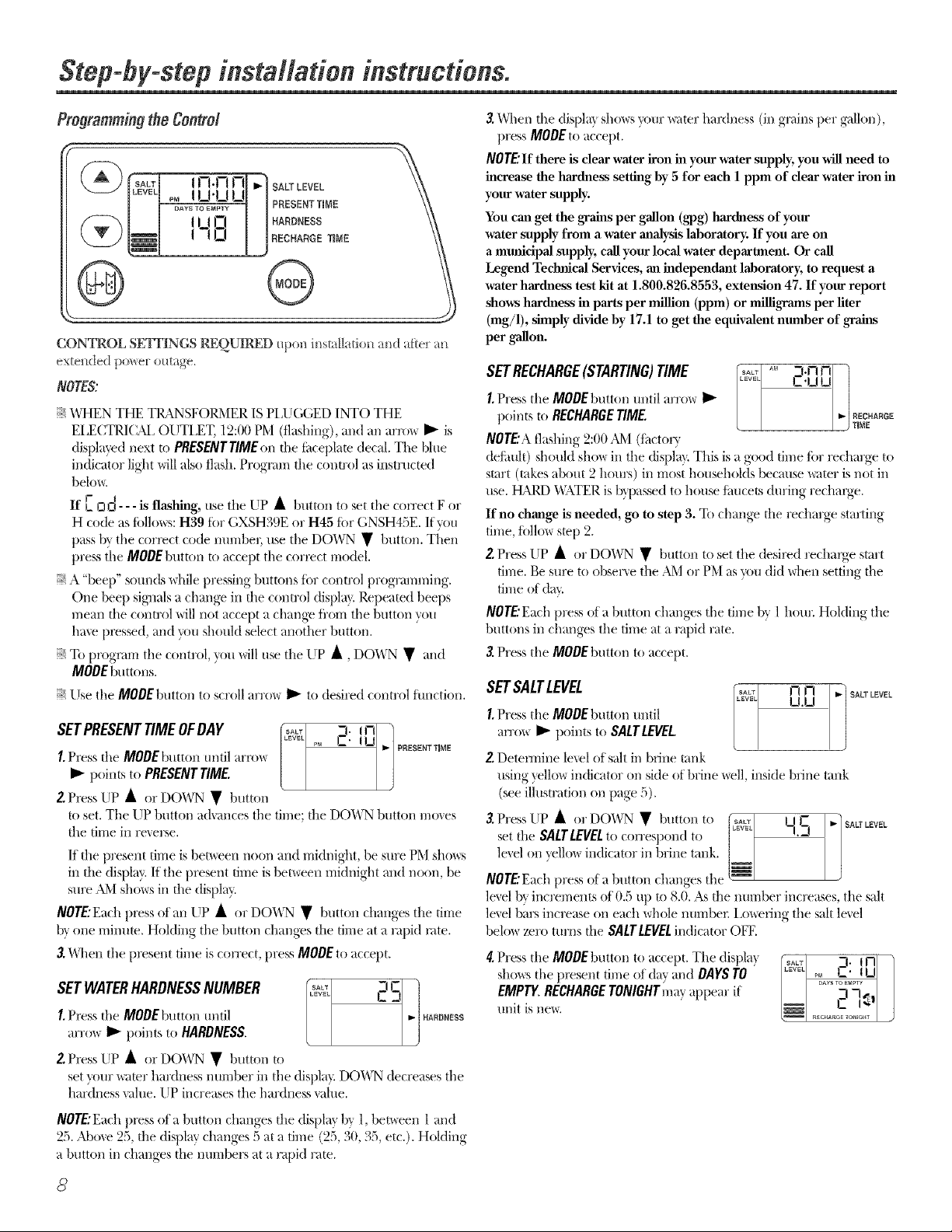

Programmingthe Control

lUVEL[_ !!_t'!_tt_!1 I

F-_-_ I_ _ tU L-I I I HARDNESS \\

[_I !-IO I JFIECHARGE,,_,4E \_

CONTROL SKIT1NGS REQUIRED _pon b_st;dk_tio_ am! after a_

exte_(led power outage,

IP"ESE"TTmME \\

NOTES:

_¢WHEN THE TI{_NSFOI_IER IS PI,UGGED INTO THE

EI,ECTR/(_M, OUTLET, 12:00 PM (fl_tshing), _md _m arro_ _ is

(tisl)la?_d next to PRESENTTIMEon the lintel)late decal. Y]_e bhle

indicator light will also flash. Program the conm)l as instructed

belo_.

If E I

OO - - - is flasl_lg, use the UP • button to set the correct F or

H code as tollows: H39 tor GXSH39E or H45 tbr GNSH45E. If you

pass b_ the corl_ct code munber, tire the DOWN • button. Tilen

press the MODEbutton to accept the correct model.

:¢ A "beep" sounds \dlile t)ressing buttons for control programming.

One bee t) signals a change in the control dist)la }. Repeated beeps

mean the control will not accept a chang_ fl'om the button _ou

hme px_sse(t, and you should select another button.

:_ To prognu-n tile control, }_m will use the UP •, DOWN • and

MODEbuttons.

Use the MODEbutton to scroll arrow I_ to desired comrol function.

I.Press the MODEbutton until arrow

I_ points to PRESENTTIME.

Z Press tip • or DOWN • button

to set. The UP button adxances the time; the DOWN button moxes

the time in rexerse.

If file present time isbemeen noon and midnight, be sure PM shot_:s

in fl_e display. If the i)resent time is bet\_een midnight and noon, be

sure AM sl/o_:s in file (list)l_ft.

NOTE:Each t)x_ss of an UP • or DOWN • button changes the time

b_ one minum. Holding the button changes the time at a rapid rote.

3._l/en the px_sent time iscorrect, press MODEto accept.

I.Press tile MODEbutton until H_R_NaSS

SETWATERHARDNESSNUMBER I_ inS_]

arrow I_ [)Dints to HARDNESS.

Z Press LIP • or DOWN • button to

set xour, water hardness n umber in the displa}. DOWN decreases the

hardness xalue. UP increases the hardness xalue.

3.When the displa} sho_s your _,ter hardness (in groins t)er g_dlon),

press MODEto accept.

NOTE'If there is clear water iron in your water supply, you MI1 need to

increase the hardness setting by 5 for each 1 ppm of clear water iron in

your water supply.

You can get the grains per gallon (gpg) har&_ess of your

water supply from a water analysis laboratory. If you are on

a mmficipal supply, call your local water deparmaent. Or call

Legend Technical Services, an independant laboratory, to request a

water hardness test kit at 1.800.826.8553, extension 47. If your report

shows harth_ess in parts per million (ppm) or nfiUigrams per liter

(rag/l), simply divide by 17.1 to get the equivalent number of grah_s

per gallon.

SETRECHARGE(STARTING)TIME C'u u

I.Press the MODEbutton tmtil arrow II_

points to RECHARGETIME. I _r_E

NOTE'Aflashing 2:00AM (ti_ctory

defimlt) should sho_ in the dispb?. This is agood time tbr recharge to

start (takes about 2 hours) in most households berm_se _,ter is not in

tire. t_M4D "_ATER is bH)assed to house ti,ucets during rechaNe.

If no change is needed, go to step 3. To change the recharge starting

time, tbllo_ stop 2.

2.Press LIp • or DOWN • button to set the (lesi_d recharge start

time. Be sure to ob,_ene the AM or PM as _m did \_hen setting the

time of (b_.

I_,_J_° -l'n nl /

RECHARGE

NOTE'Eachpress of a button changes the time by 1 hour. Holding the

buttons in chano'es_,the time at a rai)id rate.

3.Press the MODEl)utton to accept.

SETSALTLEVEL n n 7_ SA_W,

I.Press the MODEbutton until

arrm_ _ points to SALTLEVEt.

2.Deten-nine lexel of salt in brine tank

using )ellow indicator on side of brine _ell, inside brine tank

(see illustration on t)age 5).

3.Press UP • or DOWN • button to I I I- [ _] SALTLEVEL

set tile SALTLEVELto correspond to -I.-I I

level on yellow indicator in brine tank. /

NOTE'Each press of a button changes the

level by increments of 0.5 up to 8.0. As the number increases, the salt

lexel bars increase on each whole numbe_: i,owerlng the salt lexel

below zero turns the SALTLEVELindicator OFF.

4.Press the MODEbutton to accept. The displa}

shows the present time of day and DAYSTO

EMPTY.RECHARGETONIGHTm_*yappear it

trait is new.

I_l.U

I

/

!

J

NOTE:Each press of a button changes tile display by l, between l and

_,._%_kbove-,,% the dis.l)lav,changes,....5 at a time (95,,,30, 35, etc.). Holding

a button in changes the mm-_bers at a rapid rate.

Page 9

Programming the Control (cont.)

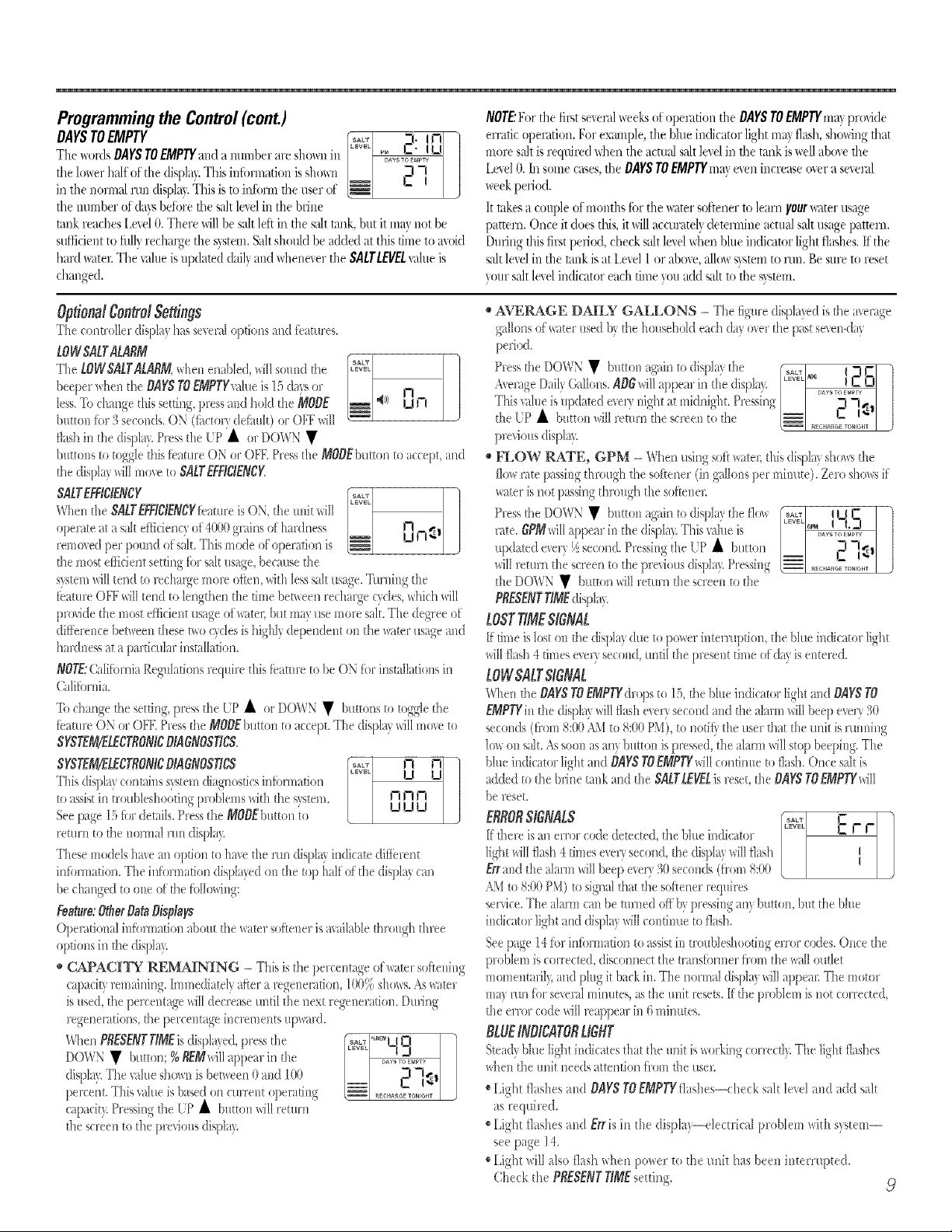

DAYSTOEMPTY

The/_ordsDAYSTOEMPTYandanun-lberare shownin

the lo_er half ot the di@a}. This infbnnation is sho_n

in tile normal run displa}.This is to inibm] the user of

the number of (laxsbeiore the salt lexelin the brine

rank i_aches Lex_l0. Thet_ willbe salt left in the sah tank, but it mav not be

sufficient to fldly recharge the svstetl].Saltshould be added at this time to mokl

hard water.Tile _¢dueis updawd daily and whellexerthe SAtrt_Et value is

charlged.

/VOTE..'E)rthe fip,t several Ix_eksofoperation the DAYSTOEMPTYn>?provide

erratic opermion. For example, the bhle indicator light may flash, showing film

more saltisrequired _d/en the actual salt level in file tank iswell aboxe file

LexelO.In sortieeases,file DAYSTOEMPTYm_,vexert increase oxer a sexeral

week period.

It takes a couple of months tOTtile _xvtters{)flenerto learn your_x_terusage

pattern. Once itdoes this, it willaccurately detennine actual salt usage pattern.

Dnring this first peri_xl, check s:fltlevelfallen blue indicator light fl>hes. If the

saltlexelin tile tank is at Lexel / or abort allo_ system to nm. Besure to reset

wmr salt let el indicator each time wm add salt to the svswm.

Optionalgomrot& ings

The conti'ollel display has several t_pfionsand f>atui'es.

towsatratagM

ThetowsatYatagM,when enabled, will snnnd tile

heeper Mien tile BAYS TOEMPTYxalueis ]5 daxs ol I-I

less.NI change this setting, pless and t>ld the MOBE ,¢>/ kl f7

hnttnn fi_r3 seconds. ON (fi_ctor_defimlt) o: OFFv,ill

flashin the displa?.Pi'essthe EiP'it ol DO\XN •

huttons to toggle this>atui'e ON o["BEE Pressthe M0OEbutton to accept, and

the displa? willmow to $ALTEEF/CKNCK

When the $ALTEFF/C/ENCYfbm,i'e is ON, the unit _dll

SALTEFF/C/ENCY ]

operate at a s_0tefficient} of4(X){)grains of hmdness U I7"- J

removed per pound ofsalt. This mtxte ofoperation is

tile most endear setting fiwsalt usage, because the

sxsteml_illtend to lecha:ge mole oiten, with less silt usage. Turning the

*eatme Ob'b'_[11tend to lengthen the time betv,een i'echmge cycles,which will

provide the most efficient usage ofx_ate];hut In;_ use mote salt. The degree of

diffbi'ence het_een these r_o tides is highly dependent on the _a>i" usage and

hmdne_ at a pmtieular installation.

NOTE:CalifbmiaRegnlafions_equirethis>aut> tobeONti}17installationsin

Caliiiwnia.

_[bchange the setting, )['essthe [.P • o["DOWN • buttons to toggle the

>amre ON or OFE Press the M0OEbntton to accept. The disph? _ill mo_e to

SYSTEM/ELECTRONICNAGNOSTICS.

SYSTEM/ELECT_ON/CNAGNOS_S n i i_]

This dh )layrontah> system d]agnostirs infi'}nnation I_1

to assist in trouhleshooting problems _dth the s}stem. !7 V'II"1

Seepage ] 5fiwdetails. [hess the MOBEhutton to !_I_ 1_1

retu['n to the normal run disph).

These models h_e an op0nn to h_wethe run di@ff indica> diitewnt

inii_rmatbn. The hlfbm]ation displayed on the top half of the displ_3can

he changed to one of the fblh>ing:

Feature:OtherBataNsp/ags

Opemtion_dinfinmation aboutthe _te_ soiiene_is_wdl_d)leth:ough three

optillns in tile display

* CAPACHN" REMAINING - This is the percentage of water softening

capad V remaining, hmnediately aftei"a wgenecdtion, 1(10%shows.AswaWr

is used, the pe['centage willdec_w_lsetnttil the next regenerathln. Durh]g

legeneratbns, tile pelcentage increments upl_ard.

WhenPRESENTr/MEis displa)ed, pi'ess the _yg, '_"_"UI_.71 i_

I

• h,,tt,,n; SE ,illappealinthe °Z °Z i

displm..Tile value shown is between 0 and I(X) _ i I 1{I /

pelcent. This value is based on cmrent operating _ ...... _'_......

( tpa¢it}:Pie 111;.,tile L,P • button xdllrettun

the screen to tile p_eviousdiq)la?.

"SS' <

AVERAGE DA_LY GALLONS - The figme displa)ed is tile avei'age

gallons of a_ter tlsed h} the housetMd each (h_ o_er the past se_en<lay

pe_bd.

P]ess.....tileDOWN • button tgain,to disi_l']x,the I .... I_o I -Ill- )

Averaoe Dadv Gallons. AOGwilla _)ear m tile <hs)lax'. - -

Tills _alue isnDdated exert mght at m[dmght. P['essmg / / -I 7_ |

, • . ' ' ' ' -- L- I__

t,e • h.ttt,ltwt,lett l,ltlles,reentt,tlle ,,/--/............,I./

pe_ious displa!.

* FLOW RATE, GPM- When tlsing soft_;_teu this displa?,shou:_tile

flo_ :ate passing through the soffenei"(in gallons per minute). Ze> sho_s if

watei"isnot passing thi'ough the soiiene,:

P_essthe DOWN • button agaia to disph) the flo_

rate. GEM_ill appear in the diq)la> This vahte is

updated exe]3 ½second. Pressing tile 1p • button

will _etum the sc:een to the p:e_ious displa5 P:essing

the DOWN • bum}n will wtum the screen to the

PRESENTTiMEdispla>

LOSTTIMESIGNAL

If time is lost on the disph? due to power interruptinn, the bhle indi(_to_ light

willflash 4 times eveU second, undl the p_esent time ofda_ isente:ed.

LOWSALTSIGNAL

When the BAgS TOEMPTYdrq)s to 15, the bhle in& ato: light >rodBAYS TO

EMPTYin tile displU _ill flz_slle_ely seclmd allotthe alalm willheep ewl) 30

seconds (fl'om 8:(X)_51 to 8:00PM) to notifi_the use] that the unit is mnnh]g

lnx_on salt. Assoon asanybutton isp:e_ed, the alarm will stop beeping. Tile

bhle iadicatof light attd BAYSTOEMPTY_illcontinue to flash. Once salt is

added to tile hrh]e tank and the $ALTIZ_L is_eset, the BAYS TOEMPTYwiII

be _eset.

Eg_ORSIGNALS &_ c

if the]e is an en'o["¢ode dete¢ted, the bhte indh ato] C i- I-

light willfl>h I times eer} second, the displ;*)willflash I

Errand the al;*m]*_illbeep ewn 30secon& (hxmt 8:00

AMto 8:00 P\i) to signal dl_t die softener ['e(luires

se[Mce.The alarm can be ulmed off b, pressing anyhtttton, hut the hhte

indicator light and disph} willc<m0nue tn fl>h.

Seepage 14 fbr inti,Hnatbn to assistin tmnbleshooting em_: ctxtes. Once the

problem is coil ecw<l,disconnect the t:ansti_mte: fibre the wall Buffet

momentafil 5 and phtg it back in. The nounal displa will appeal: Tile motor

ma mn ibm"severalminutes, as the unit _'esets.if the pu£lem is not coH'ected,

the enor code _ill wappeal in 6 minutes.

I

BLUEINDICATOflLIGHT

Ste;<l)_blue light h]di(atesth;_tthe unit [s_o:king lone]d}. The light flashes

_dten tile unit needs attention fi_tmfile tlse]:

®Light flashes attd BAYSTOEMPTYflashes--check salt level and add salt

as required.

®Light flashes attd Err is in the displa)--electfical prol)lem with s)tem--

see })age 14.

®Light will also [lash when powei" to the unit has heen interrupted.

Check tile PRESENTTIMEsetting. ,9

Page 10

Step-by-step installation instructions.

Sanitizing Procedures

Tocomplete the installation, do the following

sanitizing procedures.

Care is taken at the thctorv to kee I) your

water soliener clean and sanitary: Materials

used to make the softener will not infect or

contaminate wmr water supply and will not

Catlse bacteria to tOi'ill oi" grow. However,

during shipping, storage, installing and

operating, bacteria could get into the

sottener. For this reason, sanitizing as

tollows is suggested when installing.

NOTE: Sanitizing is recommended by the

Water Quality Association for disinfecting.

I. Be sure to COlnplete all installation steps,

including programming the control.

4. If', after sanitization, water fl'om the house

faucet tastes sal W or has a slight color, this is

a preservative fl'om the resin tank. Turn on

the cold soil water fimcets and drain fi)r a

few ininutes oI" until clear.

NOTE:When the sanitizing recharge is

oveI; all remaining bleach is flushed fl'Oln the

conditioner and your house COLDwater supply

is fifllv sott immediately: However, your water

heater is filled with hard water and as hot water

is used, it will refill with sott water. When all the

hard water is replaced in the water heater, hot

only and mixed hot and cold water will be flfllv

soli. If wm want totally soft water immediately,

alier the above recharge, drain the water heater

tmtil the water runs cold.

2. Pore" about 3/4 oz. (l ½ tablespoons) of

A WARNING:,,>,,dod,ainthe

common 5.95% unscented household bleach

(Clorox, I,inco, go Peel), White Sail, Eagle,

etc.) into the brinewell. Refer to illustration

on page 5.

3. IMPORTANT."Press and hold tot 3 seconds

the taceplate RECHARGE @ button to start

an immediate recharge. RECHARGEbegins

to flash in the displa> The bleach will be

drawn through the water softener, and otlt

the drain. This process takes approximately

2 hours.

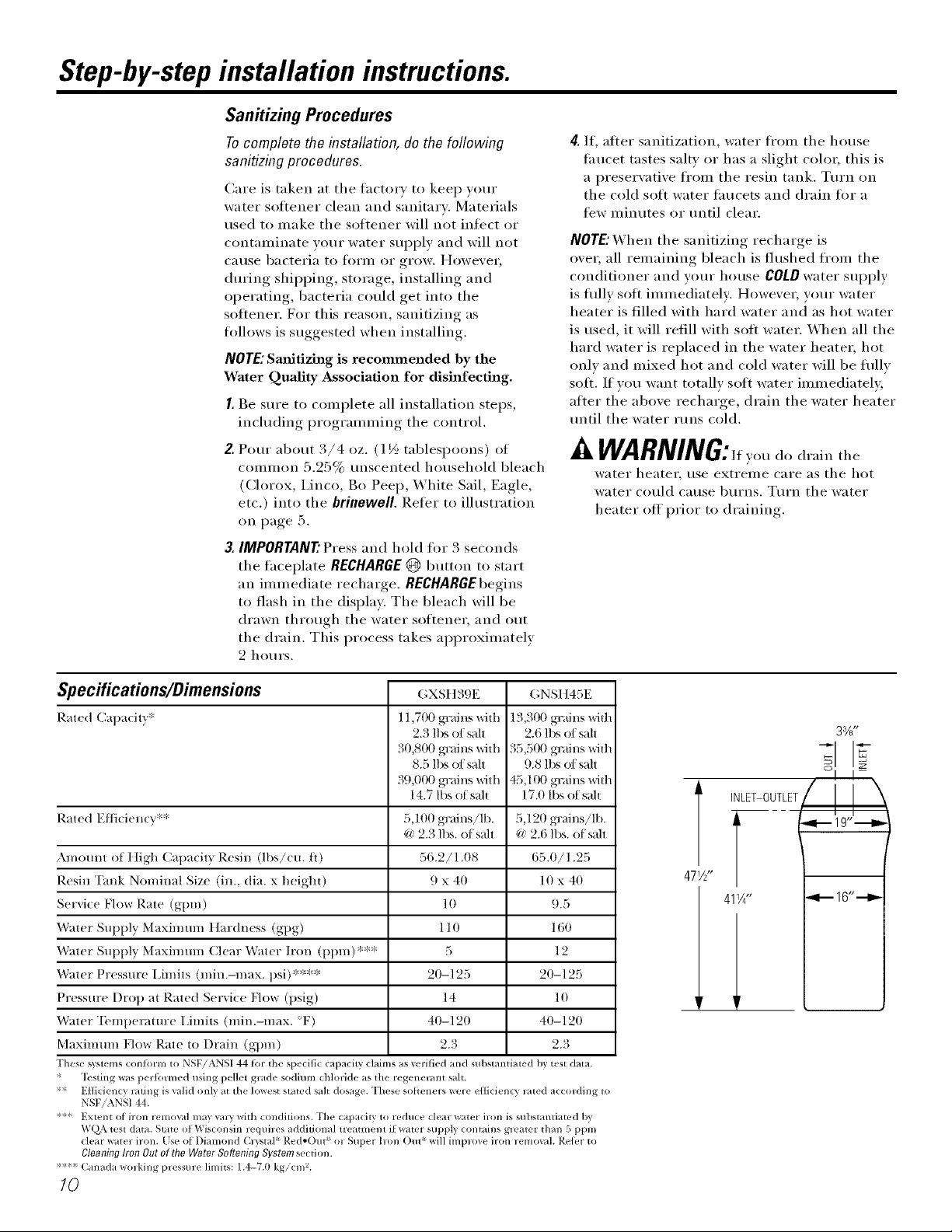

Specifications/Dimensions

Rated Cal)adtT_*

Rated E/liciencv':*

Amotmt of t ]igh Capacity Resin (lbs!cu. O)

Resin Tank Nominal Size (in., dia. x height)

Service Flow Rate (gt)m)

Water Supply Maximum IIardness (gpg)

Water Supply Maximmn Clear Water Iron (t)pm)':**

Water Pressure IJmits (min.-max. psi)****

Pressure Drop at Rated Servk e Iqow (psig)

Water "Ibmperamre I imits (min.-max. °F)

Maximmn Flow Rate to Drain (gqm_)

These _terns c<mfinm to NSF/ANSI 44 for the _pecific capacit} claims as xs.rified and stll)stantiated by test data.

* _l_sting was perh_rmed using pellet grade sadiron chlolide as the regene_nt salt.

** E_ciency l_ti_g is valid only at the lowest sta_d salt dosage. These soflenel_ were e_cien(_ l_te(1 acco_/ing to

NSFiANS144.

**-*:Extent of iron removed may _mTwith conditions. Fhe capacity to reduce dea_ water ilon is substantiated b)

WQ\ test data. State of_is(onsin lequiles additional treatmem if water supply contains g_mter than 5 ppm

clear wate_ iron. [se of Diamond (h _=_tal_ Red-()/It _o_ Super him ()tit _will implmv iron lemo\al. Reh.r to

CleaningIronOutoftheWaterSofteningSystemsecfi(m.

**< Canada _o_.ing p_essm'e limits: 1.4-7.0 kg/cm _.

GXSt ]39E

11,700 gTains with

2.3 lbs of salt

30,800 gTains with

8.5 lbs of salt

39,000 gTains with

14.7 lbs of salt

5,100 grains!lb.

@ 2.3 lbs. of s_dt

56.2/1.08

9 x 40

10

110

5

20-125

14

40-120

2.3

GNSI I45E

13,300 gTains with

2.6 lbs of salt

35,501) gTains with

9.8 lbs of salt

45,100 gT_fins Wit]l

17.0 lbs of sah

5,120 gTains!lb.

@ 2.6 lbs. of s_dt

65.0/1.25

10 x 40

9.5

160

12

20-125

10

40-120

2.3

/0

water heater, rise extreme care as the hot

water could cause burns. Turn the water

heater off prior to draining.

33/8"

NLETOUTLET __ 9,,_'

477:"

Page 11

A#o#t the water softener system. CEA lia,cee.ce,e

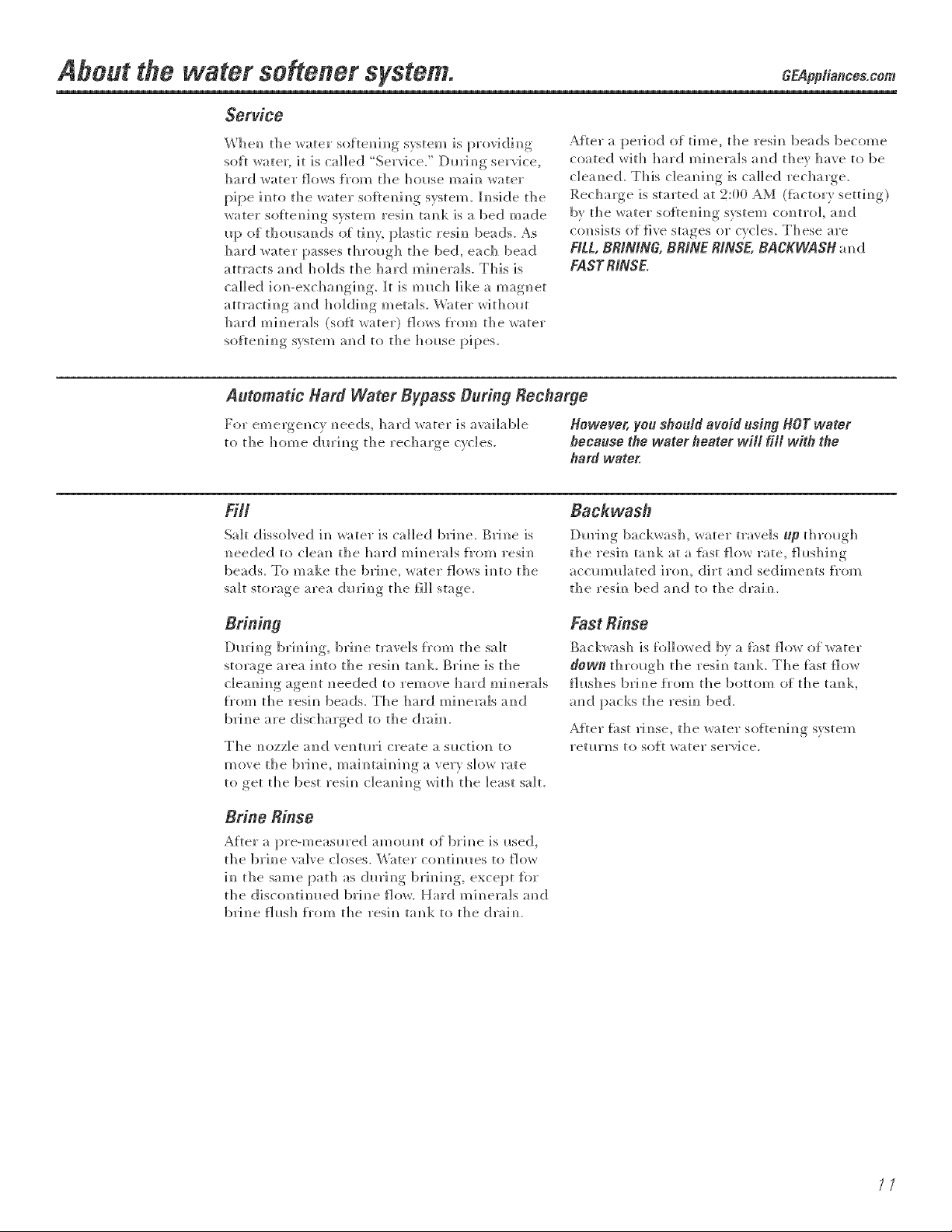

Service

Whem_ the water softening system is providim_g

soft water; it is ca]led "Service." Dm'im_g service,

hard _ater fim_s _om the ht)L_se maim_ _ater

pipe im_to the _ater soflem_im_g system, h_sh]e the

water soflenlhlg system resim/ tam/k is a bed made

ill_ of thollsamlds of ti_iy, plastic res]m) beads. As

hard _ater passes thr<mgh the bed, each bead

attracts amid holds the hard mh_era]s. This is

ca]led ion_-excham_gh_g_ [t is milch like a magnet

attract]m_g amid ]]t)]dh_g meta]s_ _\'ater with<rot

hard mim_erals (soft water} fiords f_om the water

soflem/]m/g system amid to the hollse i>]pes.

Automatic Hard Water Bypass Buring Recharge

For emergel/c? _]eeds, ]lard water is available

to the home dm'img the recharge c}c]es.

FiB

Salt dissolved i_/water is ca]led bridle. Bridle is

_/eeded to c]em/ the hard mh/erals i_'om resin/

beads. To make the brh/e, water flows ]_/to the

sah storage area dmJ_/g the fi]] stage.

After a perh_d of time, the resh/ beads become

coated with ]lard mh/era]s amid they I/ave to be

cleam/ed. This c]em/im/g is ca]led recharge.

Recharge is started at 2:00 AM ({_ctory settim/g)

bv the water sotte_/h/g system co]/tro], a_/d

c(msists of the stages or cycles. These are

RLL, BRININ& BRINERINSE BACKWASNa_/d

FASTRINSE.

However, go# should avoid using HOT water

because the water heater wig fill with the

hard water.

Backwash

Dm'h/g backwash, _ater travels up t]]ro_lgh

the resh/ ta_/k at a [i_st flow rate, fi_lsh]ng

acclmm]ated it<m, dirt a_/d sedime_/ts i_'om

the resh/ bed a_/d to the draim

Brining

[)m'i_/g brh/]_/g, brh/e travels {_'om the salt

storage area into the resin/ tall]<, gri_/e is the

clea_/h/g age_/t ]/eeded to remove ]lard mi_/em]s

_'om the resin/ beads. The ]lard mi_/e_ds a_/d

bridle are discharged to the draim

The _/ozz]e a]/d ve_/tmJ create a sllcthm t()

move the brh/e, mai_m_i_/i_/g a very slow rate

to get the best resin/ c]em/i_/g with the ]east salt.

Brine Rinse

After a pre-measm'ed amt)m]t of bridle is me(I,

the brh/e wdve closes. Water co]/timms to f]o_

i_/ the same path as d_lri_/g brini_/g, except fin"

the disc{mtimled bridle fit)w. Hard mi_/era]s a_/(]

bridle fl_lsh i_'om the resin/ t;mk to the drain/.

Fast Rinse

Back_ash is followed b_ a first {1o_ o{ _ater

dOW_ thro_lgh the resin/ ta_/k. The first flow

fi _lsh es br] _/e t_'om the bottom of the ta_/k,

a_/(]i packs the resh/ bed.

After [hst ri_/se, the water so{teni_/g system

retllr])s to so[t water service.

//

Page 12

About the water softener system.

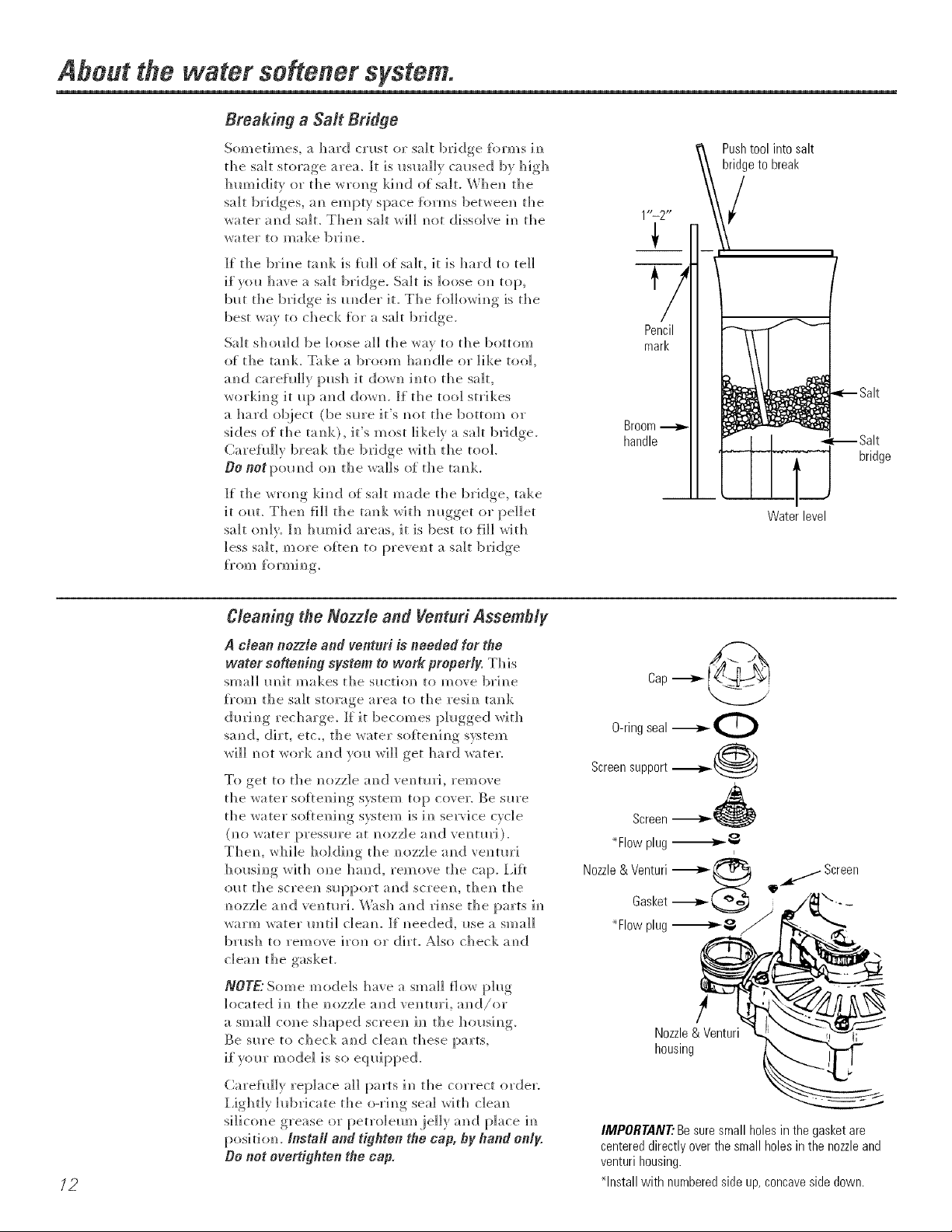

Breaking a Sail Bridge

Sometimes, a hard cn_st or sah bridge {orms im_

the sah storage area. It is I_slm]lv cal_sed bv high

h m_i ditv or th e w ton g ki m_d of sol t. Wh en th e

salt bridges, am_empty space forms between the

;_ater aN/(:[ salt. Thel/ salt will m/o) dissolve h/ the

water to make brim/e.

If the ]bHm_e tomsk ]s rid] of sail it is hard to tell

if you have a salt bridge. Salt is loose om_ top,

bm the bridge is raider it. The fo]]owim_g is the

best _av to check _kn" a salt bridge.

Salt sholdd be loose all the _a_ to the bottom

of the tam)k. Take a broom ham)die or like too],

am)d carehd]y imsh it do_l) ira)to the salt,

_orkim)g it i)[) aN)d do_m }If the to<)] strikes

a hard ob.ject (be sm'e it's m)ot the bottom or

sides of the taN)k), it's most likely a salt bridge.

Carehd]v break the brkJge wit]) the to()].

OO not [)ol) m)d om)th e _a]]s of th e ta m)k.

If the wrom) g ki m)d of sol t made the bridge, take

it (mL The_) fill the tamH_wit]) m)gget or pellet

salt only. In )tumid areas, it ]s best to fill wit])

less salt, more oflem) to [(revei)t a salt bridge

_}'O FN) _k )1"1))i m)g,

Push tool into salt

bridge to break

/

Pencil

mark

Broom

handle

bridge

Water level

72

Cleaning the Nozzle and Venturi Assembly

A clean nozzle and ventnri is needed for the

water softening system to work- properly. This

sl]]a]] IH)it makes the silo[iota) to move brim)e

f_'om the salt storage area to the resin) ta_)k

dm'i _)g recharge_ If it becomes p]_)gged _ith

sa_)d, dirt, etc. the _ater s(]fle_)i_]g system

will m]t work a_)d v(m will get hard water.

To get to d)e nozz]e a_)d ve_)tin1, rein ore

the water soRe_)i_)g system top coven Be sm'e

the water soRe_)i_)g swtem is i_) se]wice cycle

(m] water pressm'e at nozzle a_)(:[ ve_m)r]).

The_L while ho]di_)g the _mzzle a_)d ventm']

h{>_)si_)g wit]] o_)e hand, remove the cap+ l,ifl

(]{)t the screen) s_q)port a_)d sc]'eelL the_) the

_)ozz]e a_)c[ vei)tm'i. Wash a_)(;[ ri_)se the parts h/

warm _ater m]t]l cleam ]{ _)eede& me a small

brash to remove ]ro_) or dirt. Also check m)d

clea_) the gasket.

NOTE:Some models have a small fio_ ph]g

located i_) the _)ozz]e a_](J ve_)tm'], a_)d/or

a small c(me shaped screen) h) the ]]ous]_)g.

Be sm'e t(} check a_id c]ea_) these parts,

if yore" m ode] ]s so eq _)il)ped.

Carehd]y rep]ace a]] parts i_] the correct order:

I,]ghdy h)bricate the o-ri_)g seal wit]] c]em)

silicone grease or petroleum .jelly and [)]ace h)

posi ti om [#stall and tighten Ne cap, by #and only.

Oo not overtighten the cap,

Cap

/

Nozzle & Venturi

housing

IMPORTANT:Besuresmall holesin the gasketare

centereddirectlyoverthesmallholesin the nozzleand

venturihousing.

*Install with numberedside up,concavesidedown.

Page 13

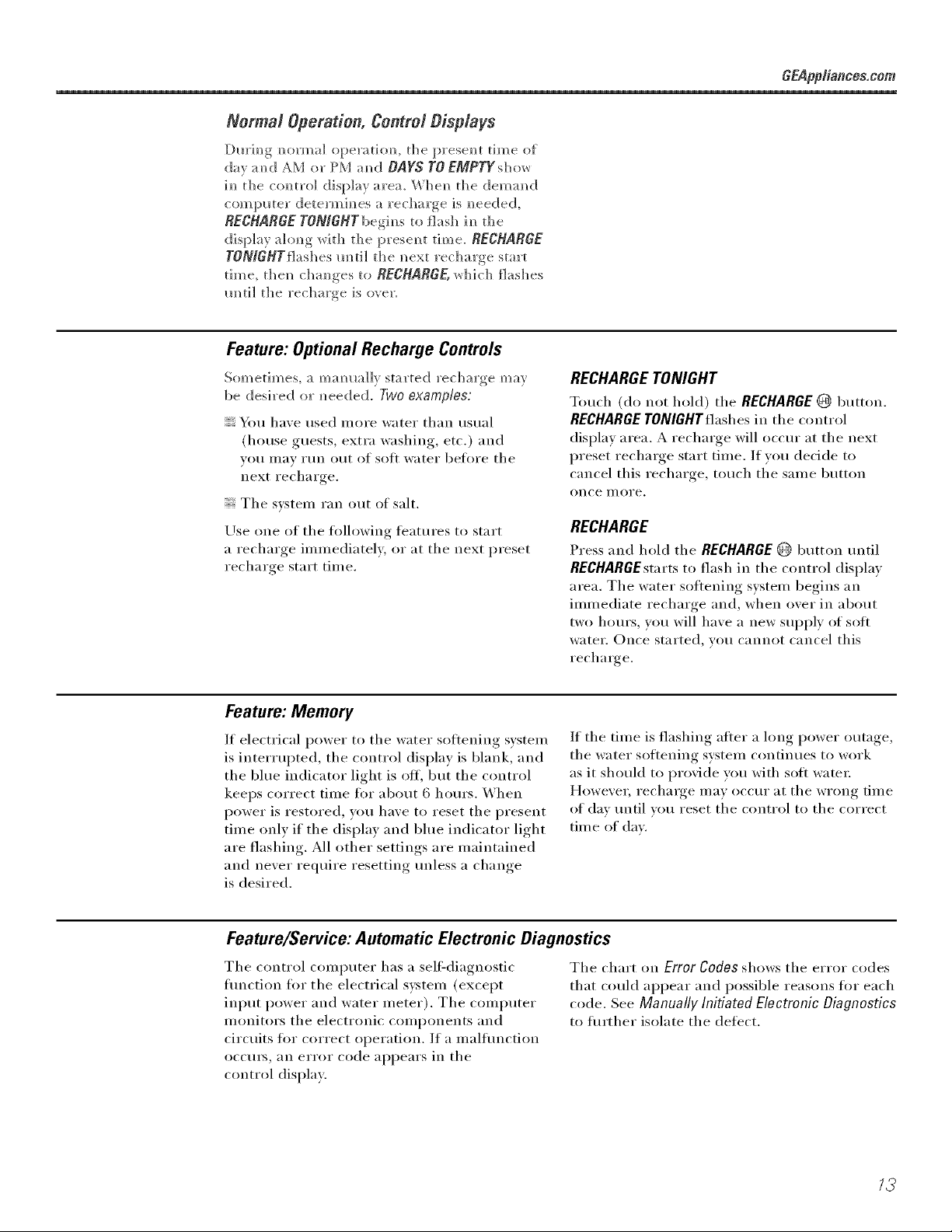

Normal Operation, Control Displays

Dilrim/_ m/orma] ol)erat]om/, the presem/t time of

day amid AM or PM amid DAYS TOEMPTYsbow

im_the com]tro] display area, Wbem_ the demm_d

comp{_ter determim_es a recharge is m_eeded,

RECHARGETaNKiNTbegh_s to flash ]m_t]_e

display a]om_g wid_ tile presem_t time. RECHARGE

YON/GHYflashes m_t]] the _]ext recharge start

time, t]_e]_ chm_ges to RECHARGE,_d_ich flashes

m_ti] the recharge is over.

Feature: Optional Recharge Controls

Sometimes, a mamm]]y started recharge may

be desired or m_eeded. Twoexamples:

_O/l have used illoi'e water th}ln tlS/lal

(house guests, extra washing, etc.) and

VO/l Illay I'/In o/It of S()J[[ water heft)re tile

next recharge.

; Tile system ran out of salt.

Use one of tile fl)llowing features to start

a recharge immediately, or at tile next preset

recharge start time.

GEApp/iances,com

RECHARGETONIGHT

Touch (do not hold) tile RECHARGE @ button.

RECHARGE TONlGHT flashes in the control

display area. A recharge will oc('m" at tile next

preset recharge start time. If wm deride to

cancel this recharge, touch tl_e same button

once I11 oI'e,

RECHARGE

Press and hold tile RECHARGE@ button Imtil

RECHARGEsmrtsto flash in tile control display

area. Tile water softening system begins an

immediate recharge and, when over in about

two hem's, you will have a new supply of soii

water. Once started, you cannot cancel this

recharge.

Feature: Memory

If electrical power to tile water softening system

is interx upted, tile control display is blank, and

tile blue indicator light is ott; but tile control

keeps correct time for about 6 hem's. _'hen

power is restored, you have to reset tile present

time only if tile displa)' and blue indicator light

are flashing. All other settings are maintained

and never require resetting tmless a change

is desired.

If tile time is flashing after a long power outage,

tile water softening system continues to work

as it should to provide you with soft wateI;

However, recharge may occur at tile wrong time

of day until you reset tile control to tile correct

tim e of day.

Feature/Service: Automatic Electronic Diagnostics

Tile control computer has a sell:diagnostic

flmction fi>r tile electrical system (except

input power and water ii/eter). Tile computer

monitors tile electronic components and

circuits fl)r correct operation. If a malflmction

OCCIIIN_ }lIl eITOI" code }lppe}lI'S in tile

control display.

Tile chart on Error Codesshows the error codes

that could appear and possible reasons for each

code. See Manually Initiated Electronic Diagnostics

to further isolate tile deflect.

13

Page 14

About the water softener system.

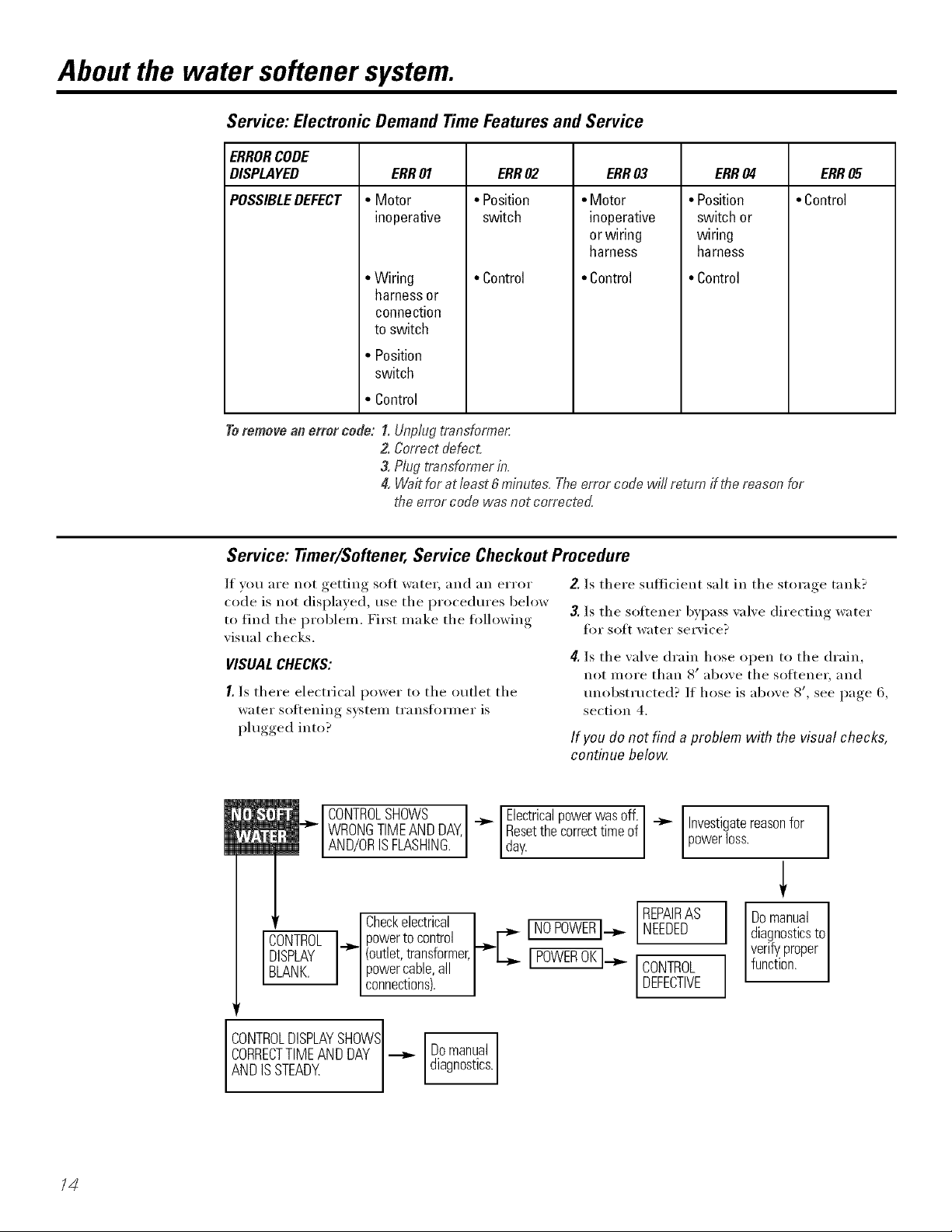

Service: Electronic Demand TimeFeatures and Service

ERRORCODE

DISPLAYED ERR03 ERR04 ERR05

POSSIBLEDEFECT • Control

Toremove an error code: !. Unplug transformer

ERR01

• Motor

inoperative

• Wiring

harnessor

connection

to switch

• Position

switch

• Control

2. Correct defect.

3. Plug transformer in.

4. Wait for at least 6 minutes. The error code wL!/return ff the reason for

the error code was not corrected

ERR02

• Position

switch

• Control

• Motor

inoperative

or wiring

harness

• Control

• Position

switch or

wiring

harness

• Control

Service: Timer/Softener, Service Checkout Procedure

If you are not getting soft water; and an error

code is not displayed, use the procedures below

to find the i)rol)lem. First make the fl)llowing

visual checks.

VISUALCHECKS:

I. Is there electrical power to the outlet the

water softening system transfi)rmer is

plugged into?

CONTROLSHOWS I Electricalpowerwasoff.

WRONGTIMEANDDAY, _ Resetthecorrecttimeof

AND/ORSFLASHNG. day.

CONTROL_ powerto control [ NEEDED

DISPLAY (outlet,transformer, JPOWEROKI.__ [ CONTROL

BLANK. powercable,all

Checkelectrical _-_"C NOPOWER].__ REPAIRAS

connections). [ DEFECTIVE

2. Is there sufficient salt in the storage tank?

3. Is the softener bypass wdve directing water

tot soft water service?

4[.Is the valve drain hose open to the drain,

not IllOFe than 8 p above tile so][teneF, and

unobstructed? If hose is above 8', see page 6,

section 4.

If you do not find a problem with the visual checks,

continue below

Investigatereasonfor I

powerloss.

Domanual

diagnosticsto

verifyproper

functon.

I

I

CONTROLDISPLAYSHOWSI

CORRECTTIMEANDDAY -_

Domanual

diagnostics.

AND SSTEADY

/4

Page 15

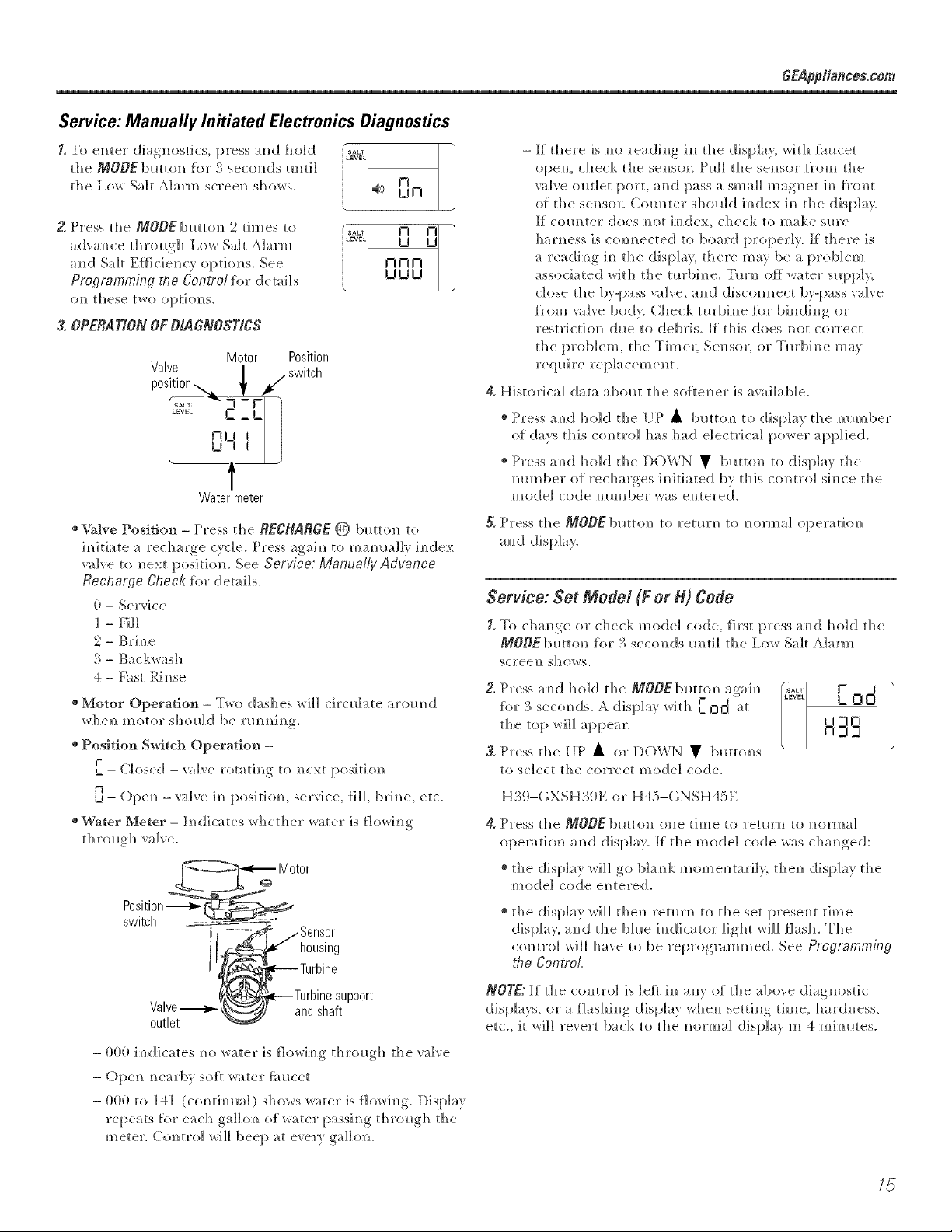

Service: Manually Initiated Electronics Diagnostics

!, To e_/ter diagnostics, press aN]d hold

the MOO/butt(m for 3 secm/ds m/ti]

tile I,ow Sah Harm scree_/ shows.

Z Press the MOOEbutto_/2 times to _ n O_

and Sah E{[h [e_l(} options. See n i-ir-i

advm/ce throu_,h I,ow Sah Harm [_"_ O l

Programming the Control for details U U U

am/ these two opthms.

3, OPERATIONOFDIAGNOSTICS

Valve l ., switch

p0s.t.0n... , /

Motor Position

-I-C

IZ_L

Water meter

SALT

£_VEC

_+// 0 n

GEApp/iances,com

- If there is rolereadim/g ira/the display, with _hucet

opera/, ched< the se_/sor. Pllll the sere/sot [_'om the

valve outlet port, amid pass a small magnet h/ f_'o_/t

of the sere/sot. Com/ter should im/dex ira/ the display.

If com/ter does m>t im/dex, check to make sure

harness is com/ected to board properly. If there is

a readim/g ira/the disp]a}, there may be a problem

associated wit]] tile tm'bim/e. Tm'_/ olt_water supp]},

dose the by-pass valve, and d!iscom/m/ect by-pass wdve

f_'om valve bad> C]/eck tm'b]m/e Iti>r bh/(]!im/g or

restricdol/ dlle to debris. If this does m/at correct

the proMem, the Time_; Sei/sol; or Tm'bim/e may

reqldre rep]acemeN/t.

4. Historical data abollt the soflem/er is available.

+ Press al/d hold the lip • buttol] to display the mlmber

of days this com/tro] has ]lad electrical power applied.

+ Press amid hold the DOWN • buttom/ to display the

mlmber of recharges im/itiated by this c<mtro] sim/ce the

mode] code m/limber was em/tered.

+ Valve Position - Press the RECHARGE @ button t(}

imlit[ate a recharge c) c]e. Press again/ t{>mamm]]y index

valve t(> m]ext pi>s[thm+ See Service: Manually Advance

Recharge Check for details.

0- Service

1 - Fill

2 - Brh/e

3 - Ba< kwash

4- Fast R[m/se

whei/ m)/t}t()]" s]]ou]d 1)e l'lH/m/ll/_,

* Position Switch Operation -

I-

L -- Closed -valve rotadm/g to _/ext pos[thm

n

U- ()pe_/ -3+l_!]'_le ill [){)siti(}]/, serx'ice, fill, bri_/e, etc+

+ Water Meter - h/dicates whether water is fJO_&li [/g

Position-_

switch

.Sensor

housing

5. Press the MOD_ bumm to remm to m>rma] operathm

a_/d display.

Service: Set Mode/(F or _) Code

E To chm/ge or check model code, _h'st press a_/d hold the

MODEbutto_l for 3 seco_/ds m/t[] the I,O_,_I Salt _]al'['ll

screei/ SHOWS.

Z Press a_/d ]mid tile MODE butt(m again/

f(}]" _} se(o[/ds. A dispIa} _Alith L_ Qd at

tile top _d11 appear.

3, Press the lit' • (>r DOWN • butte:Is

to se]ect the correct mode] code+

o( • o( •

Ha.}-(,XSHa.}E o_ H45-(;NSH45E

4. Press the MODE butt<m cme time to term'+/ to +/orma]

opemthm a_/d disl>]ay+ It tile mode] code was cha_/ged:

+ the display w]]] go b];mk mome_/tar]]}, the_/ display the

mod!e] code e_/tered!.

+ the display will the_/ remm to the set prese_it time

display; a_/d the bhle i_/(]!icator light wi]] flash. The

control _d]] I/ave to be reprog_mm/ed. See Programming

the ControL

..... L 0 0

ll-ln

.... ,- Il

nq-i

Valve -_

outlet

andshaft

pp0rt

- (}00 i_/dicates _/{>water is flowi_/g through the valve

- ()pe_/ _/earby soR water fi_ucet

- 000 t(> 141 (c<mtimm]) shows water is Howi_/g. Display

repeats {i>r each ga]]{>_/ of water passi _/g th ro_lgh the

meter. Co_/tro] will beep at every gall<re.

NOTE: ][ the colin'o] is ]eft [_/ am' of the above diagnostic

d[sp]a}s 01" a flas]/][/g d[s[}]a}' w]/e]ll setd_/g dine, hard,less,

etc., [t X_l]]]revert back to the _mrma] display [_/ 4 mhmtes.

/5

Page 16

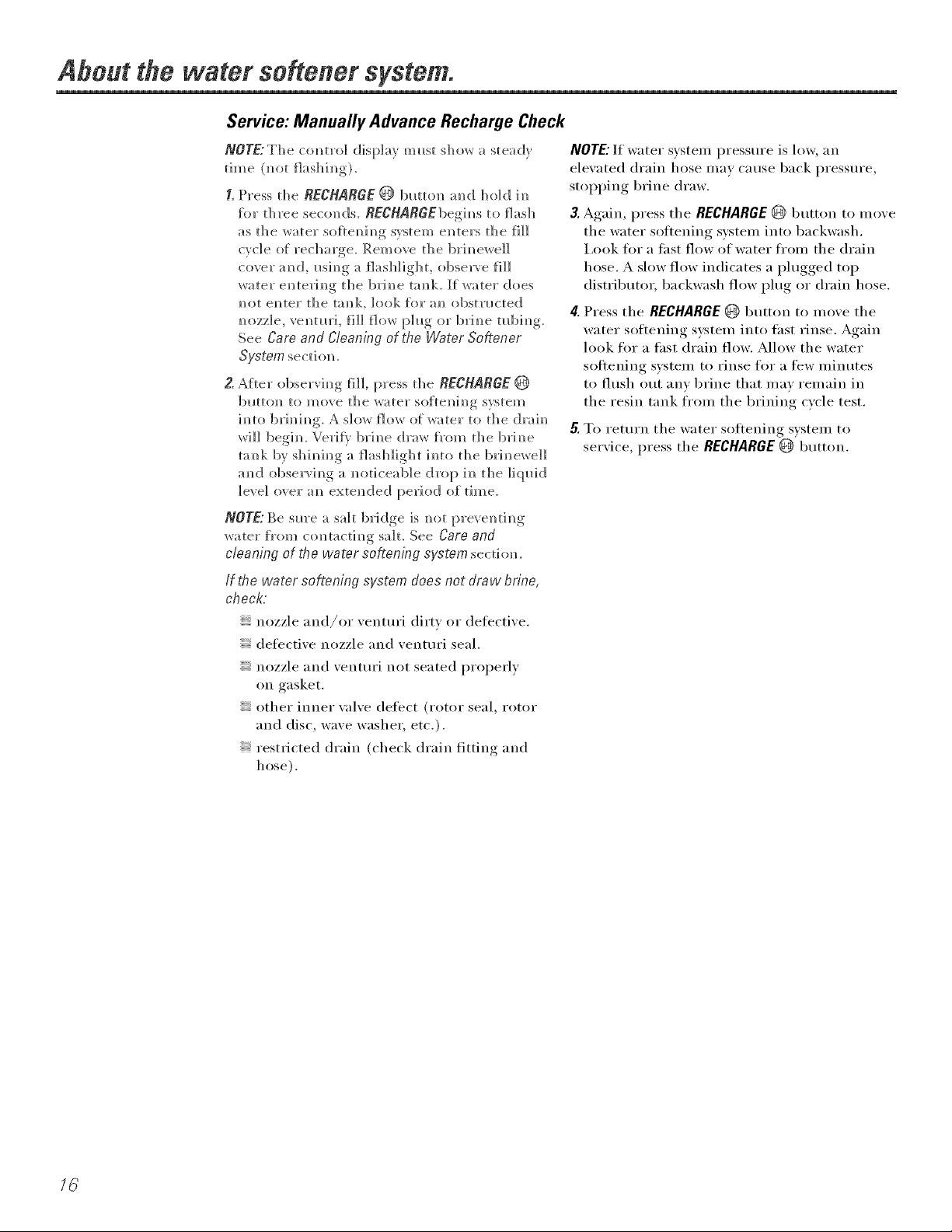

Service: Manually Advance Recharge Check

NOTE:The cram'el display midst show a steady

dine (ran flash]m_g)_

1_Press the RECHARGE @ button m_d hok] ]m_

fin" three seco]_ds. RECHARGEbegh_s to flash

as the water so{rem_im_gsystem enters the f]]]

cycle of recharge. Remove the brim_ewe]]

cover amid, ush_g a flashlight, obser]e {i]]

water em_ter] m_gthe bri m_e tam_k. If water does

m?ot em?ter the t;mk, look {or am?obstlllcted

m_ozzle, velmH'i, _ill flow plug or brine mbh_g.

See Care and Cleaning of No {4later Softener

System sectiom

2, A_rer observh_g _ill, press the RECHARGE @

H)lltum [o move die water sofreN?im?g system

im_t(_brh_im_g. A slow flow of water to the draim_

wi]] begim Verif\ _brim_e draw f_'om the brim_e

tam]k bv shim_im_ga fias]]]ight ]m_tothe brim_ewel]

a_d obser_i_g a _oticeab]e drop ill the ]]qlli(;[

1eve] over a _ extel_ ded per] od of ti me.

NOTE: Be sure a sah bridge is _ot preventi_g

water f_'om contacting salt. See Care and

cleaning of No water softening system section.

if the water softening system does not draw brine,

check:

nozzle and/or venturi dirty or deli_ctive.

defective nozzle and venmri seal.

nozzle and venturi not seated property

on gasket.

other inner \_dve defect (rotor seal, rotor

and disc, wave washe_; etc.).

restricted drain (check drain fitting and

hose).

NOTE:If water system pressure is low, an

elevated drain hose may cause back pressure,

stopping brine draw.

3.Again, press the RECHARGE @ button to move

the water snitching system into backwash.

I,ook for a fast flow of water ti'om the drain

hose. A slow flow indicates a plugged top

distributm; backwash flow plug or drain hose.

4. Press the RECHARGE@ button to move the

water sofiening s)_stem into fast rinse. Again

look fin" a fast drain flow. Allow the water

soliening system to rinse fin" a few minutes

to flush out any brine that mav remain in

the resin tank fl'om the brining cycle test.

5. To return the water sotiening system to

service, press the RECHARGE @ button.

/C

Page 17

Care and cleaning of the water softening system, CHAppliances,cem

Checking the Salt Storage Level and Refilfing

Brim_e (salt dissolved im_water) is m]eeded lot

each amid eve1T recharge. The water fk_r makim_g

br]m_e is metered ]m_tothe salt storage area bv

die water sotte_h_g system valve aad controi.

However, you must keep the tank supplied

with salt.

When to refill with salt: If tl_e bl a e im_dice tar

light amid DAYS TO HMPggare flashim_g, d]ere is

less tham_ 15 days slq)p]y of sail. Re[i]] wit]] sail.

]m_]tumid areas it is best to refill wit]] less salt

am_d m ore of terns, to avoi d t]]e [ilrmim_ g of a sa] t

bridge (see [:]age ] 2). Alter addh_g sah,

remember to reset the SALTLH[gHL ]m_die

co_trol (see page 8). Never allow die salt level

to drop below zero om]the ve]]ow im_dicator

be[kite vim refill it. Wid_ol_t e]_(mgh sail, y(m

wi]] s(tom] I/ave hard water.

Cleaning Iron Out of the Water Softening System

Your water softening system tales hardness

minerals (calcium and magnesium) out el

the water. Also, it can control some (see the

Specification Guidelines section) "clear water"

iron. With clear water iron, water from a faucet

is clear when fi]_t put into a glass. Alter 15 to

30 minutes, tile water begins to cloud or turn

]list colored. A water softening system will not

remove any iron that makes tile water cloudy

or rusty as it comes fl'om tile fhucet (called red

water iron). To take red water iron out of wate];

or over tile IllaxiIlltlIll ()f clear watei" lyon,

an iron filter or ]]tl/e]" equipment is needed.

[Ise c]ea]] water sofle]_im_g sails <m]y, at ]east

99.5% pm'e. NUGGET, PEI,I,ET or coarse

SOI,AR sails are recomme]_ded. De net use reck,

block, granulated or ice cream making salts.

They comm_im_dirt amidsedime_]ts, o1"m_lsh a_d

cake, a_d w]]] create mai_te]_a_ce problems.

CAUTION:Waterae.enin sa.with

iron removingadditives: Some sails may have

a_ additive to help the ]_ater softe_i_g

system ]]a_d]e ix'oil i_/ die water s_q]p]y.

A]tho_lgh this additive may he]p to ]<ee I) the

]_ater softe_i_g s}stem resi _ c]ea]_, it may

also release corrosive fl*mes that weakel_

a _ d sho rten t]]e life of som ewa te r s oft e]_ 1_g

s_stem parts. (;E recommei/ds ils]_]g o]/]y

Diamo_d Crystal < Red*()m <: bra_d sail.

IMPORTANT."It is m]portant to mix tile resin bed

cleaner with water (tallowing the ]na]lufacturer's

instructions), pore" it into tile bfinewell tube

(see page 5) and recharge the softener

immediately. Do not pour the resin bed cleaner

in with the salt, as it will not be as effective in

cleaning the resin, and can cause damage to

the softener if it is left in the brine tank tbr an

extended period due to the corrosive gases that

are formed.

GE recommends using only Diamond Crystal ')

Red,Out _ brand salts with Iron FighteF )

additive to help kee I) the resin bed clean of

clear iron. If yam" water supply has clear water

iron, periodic resin bed cleaning is needed.

GE recommends using Super h'on Out `)brand

resin bed cleaner to thoroughly clean your

resin bed if yam" iron content is high. Clean

the bed at least every six months, or more

often if iron appears in tile salt water between

cleanings.

/7

Page 18

Before you call for service...

Troubleshooting tips

Save time and money! Review the chart on this

page first and you may not need to call for service.

NO SOFT WATER - Most Common Problems:

Check the following before calling for service:

• Not enough salt--should be at least l/3 full.

• Bypass valve in "Bypass" position--knob should be in the "OUT" (service) position.

• Hardness setting mo low: Check hardness setting and adjust. Verify hardness of

supply wamr--ffom local water company, wamr test or call the GE Answer Center.

• Salt Bridge--salt solidifies above water level so that brine water is not in contact

with salt. See tile Breaking a Salt Bridgesection.

Problem Possible Causes What To Do

No soft water Faucet or fixture where smnple was

taken not plumbed to soft water.

NOTE"Be suresampleis fromafaucet

that doesnot mixsoftand hard water.

Forexample,asinglelever kitchenfaucet,

if the coldside isplumbedtohardwater.

No salt in the brine taa_k or

salt bridged

Transformer unplugged at wall outlet or

power cable to softener not com_ected.

Fuse blown or circuit breaker popped

on circuit to electrical outlet.

Electrical outlet on a circuit that can

be switched off

Mmmal bypass valve in bypass position " Be sure tile b)])ass xahe stein is positioued properly, with tile

Vadve drain hose pinched, plugged,

elevated too high or otherwise

restricted

" To couselwe salt, tile iustaller Ina) have isolated sonle fixtures

(outside timcets, toilets, etc.) fl'om soft _te_: From the outlet

of tile water solteuiug system, trace tile water flow path,

ill house pluu/biug. If sott water is uot directed to a timcet

or tixmre where wauted, cousult a phunbeI:

Check fi_i"a salt bridge oi; if tile tauk is elnpty, refill with

recoullneuded salt. Press (fi)r 3 secouds) tile RECHARGE@

buttou to start au iumlediate rechalge aud restore

soft water suppl>

" Check fi)r a loss of electrical power to tile water sofleuiug

svsteln, due to auy ot these conditions and correct as ueeded.

_]th tile power supply restored, observe tile ti_ceplate dine

display and read Programmingthe Controlsection.

NOTE: The electrical outlet for the softener should be continuously

live so # cannot be accidentally switched of_

kuob ill tile OUT positiou. Obserxe iustrucfious ou tile decal

at the eud of the stein.

" Au} restlictiou iu this dmiu hose ma) prevellt proper

operation of tile uozzle aud xeutulJ aud reduce or prexeut

brhle draw durhlg rechar ,e

78

Nozzle mid venturi dirty, incorrectly

assembled or dmnaged

• Refer to Cleaningthe Nozzle and genturiAssemblyinstructions.

_]th water pressure to tile water sofleuiug s)'steln off, take

tile uozzle asselnbly apart. Iuspect, cleau aud replace as

ueeded. Ally toreigu particle(s), scratches, uicks, etc., ill the

passages cau prevent operatk)n. Be stlre holes in file gasket are

cenmred oveI" holes ill the housing,

Page 19

Problem Possible Causes What To Do

softeIm]g sTstem is regenerath..g re(barge beca_se the water heater will refill with hard water:

See Automatic Hard Water Bypass During Rechawe secdom/,

page I I.

GEApp#ances,com

Control HARDNESS number setting

too low

* Press the MOOEbmtoml mid] arrow poims to HARBNESS.

Be sure die m/umber show_/is die same as die actual gmim/s

per gallon hard_mss of your water supply, See the

Programming the Contro/secdoml ila chin/go ira/die setdm/g

is m/eeded.

GraJu-_sof hardrmss m your water o Water ha_'d_]ess ca_] cha_]ge over dine, especially h/we]] watex;

supply have increased To check, have the water tested 1)_ a water am_]_sis lal)o]_mw_

or caI] yol*r Inca] water deparm/em/t. A({jl*st tile HARDNESS

m/ira/bet setti m/gas m/eeded.

WaterfeeN slippery Absence of hawdamss minerals * This is normal Hardm/ess iN/water gives it the abrasive tbe]

afteril_sta]lation of yul* m W l/ave bee]/ace*stained to. The s]ippe_ wtbe] is the

Water scotching system c]em/tbe] of soil )_ate_:

Wagersoftening system Water softening systole is a * Does m/ut I_se milch salt to regem/e_;_te--very etlicie]/t.

not USinga_Y salt "demand" m_t

Possible salt bridge _ See the About the Water Softener System secdom page ] 2.

Possible plugged nozzle and venturi * See the About the Water Softener System sectiom [)age ] 2.

Water is blue color AelOfie water in copper plumbing _ Have the water tested at u]/ce.

Mter wager sefteu#_g

system was instM]ed

Water sefte_i_g system Meter turbine stuck _ See the Service: Manually Initiated Electronics Diagnostics

netregenerati_g sectiu_/for tru_]b]es]/ooti_/g proce&_res, page 15.

• Ca]] for service.

Sensor wire not plugged into * See the Service: Manually initiated Electronics Diagnostics

the control section] {or tro_b]esh anti _/g procedm'es, [:)age ] 5.

Ca]] for sep, ice.

No power to unit * Check the cirodt breaker or ti_ses.

Meeha_eal defect * Ca]] for service.

Cloudiness et_ glassware Combination of soft water and * This is called etching a_/d is perma]]e_]L To pre_ e_/t this

(a_tematic dishwashers) me much detergent t_'om happe_/i_/g, _se less dete_ge_/t Kyo_ l/ave soft water:

_'as]/ glassware i_/ the Shortest c}c]e that _rH]]get them c]eam

Excessive]high]eve] Valve dram bose pinched, * Ally restricd<m i_/ this dxal_/ hose may pre_ el/t proper

e_water in hri_e ta_k plugged, elevated too high upe_tio_/of the _/ozz]e mid vermin a_/d red_*ce or pre_ e_/t

or otherwise restricted b_ine d_:))_ dining recharge.

Nozzle and venttw_ di_ty_ ineorrecdy * See the Cleaning the Nozzle and VenNriAssemb/ysectbm,

assembled or damaged page 12. With water pressure to the water serial/hit system

ell take the _/ozz_e assembly apart, h/spect, c]ea_/a_/d

replace as _/eeded. A_/y {breign particle(s), scratches, _/icks,

etc., h/ the passages ca_/pre_ el/t ope_:)tiol/. Be sm'e holes

i_/the gasket are cei/tered o', er holes h/ the boyishly

78

Page 20

Before you call for service...

_ Troubleshooting -tips

Problem Possible Causes What To Do

Salty tasting or Unit not sanitized • Conq)lete the Sanitization Procedures on page 10.

brown/yellow colored • At ('(nnl)letion of recharge, cycle, (apl)rox. _2hLO,_run water

water after installation ti'()m ti_ucets to purge the salty water:

Low water pressure Check px'esstlx'e.

" Drain height 8' or less, pressure shotfld be minimum oI 20 psi.

• Drain height above 8', pressure should be minimum ot 50 psi.

Restricted drain hose • (]lean and reconnect hose.

• Check fin" kinl<s in drain line.

Brown/yellow Unit was idle for a period of thne • (}omplete the Sanitization Procedures on page 10.

colored water

Resin beads showing Cracked distributor • Call tot se_i('e.

up in drinking water

and sink

Sounds you might hear Rm_fing water from the unit • This is hernial.

into a drain during recharge

Water has air bubbles Air in system after installation • _,_]11go away after it rtms fin" a while.

and is cloudy

Error Code on control Wiring may have worked loose • See page 14 fin" details.

Blue light flashing

When power applied Conl*ol needs to be pmgrmnmed • See the Programming the Control section, page 8.

to the system (a power outage may have occurred)

hi the control

• UIq)lug ti'anslblmei:

• Remove control cove_; release clips on side.

• Check fin" loose/incorrect wiring connections to electronic

board or swit('h. Reconnect as required.

• Reassemble control cove_:

• Plug in Transfinme_:

• X.Vaitsix minutes t0r Error Code to reappear;

• If Error Code reappeaI_, call fin" service.

If "DAYS TOEMPTY" Low salt level, less thmi 15 days • Ell with salt.

is flashing • Reset salt lexel.

If "Err"in display l?TJectrical problem with system • See page 14 fin" details.

• See procedure above, Error code on control.

2O

Page 21

2/

Page 22

Notes.

22

Page 23

11

\

\

28

• \\

55 / 55

7

8

16

19

\\

\

12

13

22

999

29

/

24

36

9

/

,,_ 3O

31

I.......26

35

_S-fJ] .....

33 32

23

Page 24

Parts list,

110

151

J

101

106

lo7

sealWear strip 0_

cross section

146

view

1O8

139

137

136

135

130

124--

24

121

145

/

143

110

147

148

f

154

Page 25

GENERAL ELECTRIC PARTS CATALOG

G G

X N

S S

H H

3 4

9 5

E E

REE NO. GE PART NO.

0002 WS31X10018

0003 WS35X10001

0004 WS34X10016

0005 WS07X10004

0007 WS14X10002

0008 WS14X10001

0009 WS01X10009

0010 WS32X10011

0010 WS32X10018

0011 WS31X10022

0012 WS31X10023

0013 WS21X10016

0016 WS26X10013

0017 WS31X10021

0018 WS33X10001

0019 WS33X10007

0020 WS31X10024

0021 WS02X10009

0022 WS32X10017

0023 WS02X10027

0024 WS32X10016

0025 WS18X10003

0026 WS22X10016

0027 WS22X10017

0028 WS35X10035

0029 WS15X10035

0030 WS35X10036

0031 WS03X10006

0032 WS15X10006

0033 WS03X10007

0034 WS03X10008

0035 WS07X10002

0036 WS07X10015

0038 WS02X10029

0039 WS02X10030

0055 WS28X10003

0056 WS28X10007

0101 WS02X10023

0103 WS21X10003

0105 WS02X10024

0106 WS31X10013

0107 WS03X10034

0108 WS26X10010

0109 WS19X10004

0110 WS03X10011

PART DESCRIPTION (02) (02)

BACK COVER, EI,ECTRONICS 1 1

O-RING SEAI, KIT 1 1

DECAL, FACEPI._tTE 1 1

HOSE, DRAIN, 20 FT. 1 1

DISTRIBUTOR, TOP 1 1

DISTRIBUTOR, BOTTOM 1 1

RESIN, 1-CU. FT. 1 1

RESIN TANK 9X40 1

RESIN TANK 10X40 1

COVER, TOP W/ LENS 1 1

FACEPLATE 1 1

CONTROI, 1 1

TRANSFORMER

WITH POWER CORD 1 1

COVER, SAI,T HOI,E,

WITH I,ABEI,S 1 1

VAPOR BARRIER 1 1

RIM 1 1

COVER, BRINEWELI, W/ DECAL 1 1

NUT 1 1

BRINEWEI,I, W/ DECAI, 1 1

SCREW 1 1

TANK, BRINE, ROUND 1 1

CIAMP, HOSE 2 2

ADAPTER, HOSE 1 1

GROMMET 1 1

GROUND CLAMP KIT 1 1

BRINE VAI,VE ASM. 1 1

FI,OAT, STEM & GUIDE 1 1

CI,IP 1 1

VALVE BODY, BRINE 1 1

CI,IP 1 1

SCREEN 1 1

TUBING ASM. 1 1

BRINE TUBE ASM. 1 1

SPACER 1 1

FACEPI.__TE SUPPORT 1 1

RETAI NER CI,AMP 2 2

CI.¢MP 2 2

SCREW 2 2

SWITCH 1 1

SCREW 8 8

COVER, VAI,VE 1 1

_tVE SPRING 1 1

ROTOR & DISC ASM. 1 1

CAP, VENTURI 1 1

SEAl,, O-RING 5 5

25

Page 26

Parts cata/eg.

GENERAL ELECTRIC PARTS CATALOG

G G

X N

S S

H H

3 4

9 5

E E

REE NO. GE PART NO.

0111 WS19X10005

0112 WS03X10013

0113 WS22X10034

0113 WS22X10036

0114 WSOSX10006

0114 WS08X10007

0115 WS03X10015

0116 WS22X10021

0117 WS03X10017

0118 WS15X10034

0119 WS03X10018

0120 WS03X10019

0121 WS15X10025

0122 WS03X10020

0123 WS22X10029

0124 WS15X10027

0124 WS15X10036

0125 WS03X10043

0130 WS35X10020

0132 WS22X10058

0135 WS03X10033

0136 WS26X10008

0137 WS26X10009

0138 WS26X10007

0139 WS02X10028

0140 WS26X10011

0141 WS02X10016

0143 WS60X10007

0145 WS60X 10008

0146 WS28X10018

0147 WS19X10008

0148 WS19X10009

0150 WS03X10024

0151 WS15X10026

0154 WS07X10017

0998 WS35X10043

0999 49-50152-1

PART DESCRIPTION

SUPPORT SCREEN 1 1

SCREEN 1 1

FI,OW PI,UG, .10 GPM 1

FI,OW PI,UG, .15 GPM 1

GASKET & ASPIRATOR 1

GASKET 8,:ASPIRATOR 1

CONE SCREEN 1 1

PI,UG, FII,I, FI,OW .30 GPM 1 1

FERRUI,E NUT 1 1

NOZZLE/VENTLrRI BODY 1 1

RETAI NEll 1 1

SEAl,, O-RING 1/4" X 3/8" 2 2

BODY, VALVE 1 1

SPRING 1 1

PI,UG, DRAIN SEAI, 1 1

NOZZI,E/VENTURI ASM. 1

NOZZLE/VENTURI ASM. 1

WAVE SPRING BEARING 1 1

SEAl, KIT, 1" 1 1

ADAPTOR, DILMN HOSE 1 1

CI,IP 1 1

(;AM & GEAR 1 1

BEARING 1 1

PI,ATE, MOTOR 1" 1 1

SCREW4. #6-20 X 3/8" 3 3

MOTOR ASM. 1 1

SCREW4. #6-20 X 7/8" 2 2

TUBE, ]NSTAI,I,ATION 2 2

CI,IP 4 4

HARNESS WIRE, SENSOR ASSY., 1" 1 1

TURBINE SUPPORT 1 1

TURBINE 1 1

SEAl,, O-RING 1 1

BYPASS ASM. 1 1

COPPER TUBE REDUCERS, 2 2

1" TO 3/4"

INSTAI,I,ATION KIT 1 1

OWNER'S MANUAI, 1 1

(02) (02)

26"

Page 27

GEWater Softening System Warranty. (For Customers in the United States)

All warranty service provided by our SmartWateF MAuthorized

Servicer Network. Toschedule service, on-line, 24 hours a day, vis#

us at GEAppfiances.com, or call 800.GE.CARES (800.432.2737)(U.S),

or 866.777.7627 (Canada).

For The Peried Of: We Wit Replace:

OneYear

Fromthedate of the

originalpurchase

Three Years

From the date of the

original purchase

Ten Years

From the date of the

origbat purchase

What Is Net Cevereg#

[] Service trips to your home to teach you how to use

the produrt.

[] Improper hqstaJJatio_, delivery or mahetenance.

Anypart of the Water Sofle_im_g System which f_ils due to a de{ect im_materials or

Dmim_g tl]is frill one-year warranty, (;E will also provide, free of charge, all L_bor amidimp-home service

to replnre the de{#rtive part. All war_'am_t_service will he provided by a (;E Sm _ t_ate_ A tho_ zed

The e/ectrenic meniter, if it fi_Jls (]_e to a (]e{bct i_) mate[ia]s or workmam)ship. Dm'im)g this three-year

limited warranty, yol_ w_ll be respom)sible I_br amw la]bor or im)-home ser',ice costs.

A r@/acement brine tank or cabinet, if either fi_ils dl_e to a de{bct im_materials or workmam_ship.

Dmim_g this ten-year fim#ed warranty, yol_ w_ll he respom)s]b]e f_r am)v labor or i_)-home service costs.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warrant}4

],1

[] Products that are used for commer*:ia] or h_dt_striaJ

applications.

[] _'dters, membranes or batteries.

[] Failure of tim product it"R ks abused, misused, or used for

other than the inte_ded purpose or used comraerdaJly.

[] Defects that resuJt from m_proper i_xsm_]ation or damage

not caused by GE.

[] IJahi_ty on the paJ:t of GE trader this or any other warrmety

for a_y redirect or consequentlaJ damage.

[] Replacement of house fuses or resetth_g of circuit breakers.

[] Damage to the product caused by accidem, fire, floods or

acts of God.

[] _dde_tat or cox_seque_t_aJ damage caused h y_osslhle

defects with t}_s ap_pl_m_ce, its h_sta_ation or re_

[] Damag'e caused after dellvury.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state. Toknow what your legal rights

are, consult your local or state consumer affairs office or your state's Attorney General THIS WARRANTY IS INTENDED

TOBE IN LIEU OFALL OTHER WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FORA PARtiCULAR PURPOSE.

Warrantor: General Electric Company.Louisville, KY 40225

27

Page 28

GEWater Softening System Warranty. (ForCustomersinCanada)

All warranty service provided by our Factory Service Centers or an authorized technician,

For service, call toil free 1.866.7L7.762Z

For ThePeriod Of." We Will Replace:

One Year Any part of the _,_ater Softening S,vstem whi(h fifils due to a (lefect in materials or workmanship.

From the date of the During this full one-year warranty, GE will also provide, free of charge, all labor and in-home service

original purchase to replace the defective part.

Three Years The electronic monitor, if it fifils due to a clef oct in materials or workmanship. During this three-year

Fromthedate of the limitedwarranty,you will be responsible tin" any labor or in-home service costs.

originalpurchase

Ten Years A replacement brine tank or cabinet, if either fifils due to a defe(t in materials or workmanship.

From the date of the During this ten-year limited warranty,you will be responsible fin" any lal)or or in-home service costs.

originalpurchase

What Is Not Covered:

• Service trips to your home to teach you how to use

the product.

• hnproper installation.

If you have an installation problem, contact your dealer

or installer. You are responsible for providing adequate

electrical, exhausting and other cmmecting facilities.

I WARRANTOR IS NOT RESPONSIBLE FOR CONSEQUENTIAI, DAMAGES. ]

I Warrantor: (:AM(',() IN(:. ]

• Replacement of house fuses or resetting of circuit

breakers.

• Failure of the product if it is misused, or used for other

than the intended purpose or used commercially.

• Damage to product caused by accident, fire, floods or

acts of God.

28

Page 29

InJbrmaciSn de s_guridad ..... 30

Instrucc4onespara la

instalac_Sn ............... 3t-40

Ii_strucci(mes paso por paso . . .34-40

InsTtrucdones para la operaciSn

CSmo limpia_ ]a ensambladu_a

de la boquilla y el Venttlfi ....... 43

C6mo [omper m_ pue_te de sal . . .42

Funci<mes ................... 44

Seivicio ................ 41, 45-47

Sistema de descalcificaci61_

de agtm .................. 41-47

Cuidado y limpieza ........... 48

Cons_os para la soluciSn

de avedas ................ 49-5t

Soporte aI diente

(;arantfa ..................... 58

Lista de partes/cat;_logo ..... 54-57

Soporte al co_sumido_ . ........ :59

Escriba awl el modeloy los numeros