Page 1

Safety Instructions

Proper installation ............ 3

GEApp/iances

®®3

©

U3

Installation Instructions

Drain connections .......... 7, 8

Important recommendations . .4

Installation instructions ..... 4-6

Planning and location ......... 5

Programming the control ...... 9

Sanitizing .................. 10

Specifications and

dimensions ................. 10

Step-bDste p insuuctions ...7-10

Tools and materials required . .5

[Jnpacking and inspection ..... 4

Operating lnstructions, Tips"

Breaking a salt bridge ........ 12

Cleaning the nozzle and

venturi assembly ............ 12

Conuol displays ............. 13

Electronic diagnostics ........ 15

Features ................ 13, 14

Regenerating the system ..... 16

Service ..................... 11

Water softener syslem ..... 11-16

Care and Cleaning

Cleaning out iron ........... 16

Salt storage level and

refilling .................... 16

ModelsGXSF27BGNSF35ZGXSF39B

Systbme

Ad0ucisseurd'Eau

ModblesGXSF27BGNSF35ZGXSF39B

La sectionfran_aise commencea la page27

Sistema de

Descalcificaci6ndeAgua

ModelosGXSF27BGNSF35ZGXSF39B

La seccionen espa#olempieza en la pagina53

Troubleshooting Tips ... 17-19

Consumer Services

Important phone

numbers ........... Back Cover

Parts list/catalog ......... 20-23

Warranty (U.S.) ............. 24

Warranty (Canada) .......... 25

www.geappliances.com 7227946 215C1044P015 49-50061 08-00 JR

Page 2

GE& You,A ServicePartnership.

IMPORTANT!

Fill out tile ( onsumer Product Registration Card.

Twoeasyways to registeryourappliance!

• Through tile internet at _v.geappliances.com

• Complete and mail the enclosed Product Registration (ard

Write the model and serial numbers here:

FORYOURRECORDS

#

#

You can find dram on the back of the control bead.

Staple sales s/(p or cancelled check here.

Proof of dm original put(base date is needed t() obtain serx i(e under tl_e wanamy.

Inside you xdll lind many helpfifl hints on how to use and inaintain your water systeln properly..]ust a little

P READTHISMANUAL

preventive care on yoln part can save you a great deal of time and money over tile life of your system.

IFYOUNEEDSERVICE

¥{m'll find many answersto common problems in the Before YouCallForServicesection. If you review

our dlmt of TroubleshootingTipsfirst, you may ilot need to call f;n serviceat all.

If you do need se_Yice,you can rebLx knotting help is only a phone call away. A list of toll-tiee customer

se_ice numbers is included in the back section of this manual.

OR

Visit our Website at: tanan.'c.geappliances.cem

2

Page 3

iMPORTANTSAFETYiNFORMATiON.

READALL iNSTRUCTiONSBEFOREUSING.

A WARNING! Foryoursafe theinformationinthismanualmustbefollowedtominimizetheriskof

electric shock, property damage or personal injury.

SAFETYPRECAUTIONS

• Check and comply with your state and local codes.

You must fi)llow these guidelines.

• Use care when handling tile water softening system.

Do not turn upside dox_l_,drop, drag, or set on sharp

protrusions.

• Water softening systems using so_fium chloride (salt)

for regeneration add sodium to the water. Persons on

sodiumrestricted diets shouldconsider the addedsodium

aspart of their overallintake.Potassiumchloride can be

usedas analternative tosodiumchloridein yoursoftener

• Tile water softening system works on 94 voh-60 Hz

ele(uical power only. Be sure to use onlythe included

transformer

• Transformer must be plugged into an indoor

120volt, grounded outlet only.

• Use clean water softening salts only, at least 99.5%

pure. NUGGET, PEI,I,ET or coarse SOLAR salts are

recommended. Do not use rock, block, granulated

or ice cream making salts. They contain dirt and

sediments, or nmsh and cake, and will create

maintenance problems.

• Keep the salt hole cover in place on tile softener

unless servidng the unit or refilling with salt,

A WARNING:Do notuse with water that is

tnicrobiologically unsale or ofunknox_ll quality

without adequate disinlection belore or after the

system.

PROPERINSTALLATION

This water softening system must be properly installed and located in accordance with the Installation

Instructions before it is used.

• Install or store where it will not be exposed to

temperatures below fleezing or exposed to aW type

of weather. Water fieezing in the s):stem will break it.

Do not attempt to treat w:lter {)ver 1O0°F,

• Donotinst'all in (firect sunlight. Excessive sun

heat Illay cause distortion or other damage to

non-tnetallic parts.

• Properly ground to conform with all governing

(odes and ordinan( es.

• Use only lead-flee solder and fluxfi)r all sweat-solder

(onne(tions, as required by state and federal (odes.

• The water softening system requires a minimum water

flow of three gallons pet minute at the inlet. Maximum

allowable inlet water pressure is 125psi. Ifda)aime

pressure is over 80 psi, nighttime pressure may exceed

the maximum. Use a pressure redudng xvllveto re&me

the fl_)wifne_ssa U,

• Softener resins may degrade in the presence of

chlorine above 1ppm. Ifyou have chlorine in excess

of this amount, you may experience less life of the

resin. In these conditions, you may wish to consider

purchasing a (;E point-oi:ent U household fihration

system with a dflorine reducing fiher.

A WARNING'.Discard all unused parts and packalging

material after installation. Small parts remaining

after the installation couM be a choke hazard.

READANDFOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVETHESEINSTRUCTIONS

Page 4

Installationinstructions.

_]tCAUTION: Certain plumbing skills are needed for installation. Ifyou are unsure about any part of the

installation of this product, consuh a professional plulnber.

Unpacking and Inspection

Be sure to (heck the endre softener for any shipping damage or parts loss. Also note damage to the

shipping cartons. ( ontact the transportation COlnpany ti)r all damage and loss clailns. The mamdacmrer is not

responsible for damages in transit.

Small parts, needed to install the softener, are on a skin-packed cardboard piece. To avoid loss of the small

parts, keep them on the skin-pa( k until you are ready to use them.

Important Installation Recommendations

Read entire manual. Failure to tollow all guidelines and rules could cause personal in iuU or property damage.

"Before you begin installation, read these Installation Instructions completely. Then, obtain all the materials

and tools you will need to make the installation. Failure to properly install the softener voids the warranty.

"Check local codes. The installation must contorm to them.

,,In the Commonwealth of Massachusetts, Plumbing Code 248 CMR shall be adhered to. Consult with your

licensed plumber.

• Use only lead-tiee solder and flux tot all swea/-solder connections, as required by state and tederal codes.

"( onnect the softener u) the main water supply pipe beforeor aheadof_e water heater. DONOTRUN

HOTWATERTHROUGHTHESOFTENER.Temperature of water passing through the softener nmst be less

than 120°F.

• Use care when handling the soliener. Do not U_rnupside down, drop, &ag, or set on shmp prou_usions.

"Maxinmm allowable inlet wamr pressure is 125 psi. If dwfime pressure is over 80 psi, nighttime pressure m W

exceed the maxinmm. Use a pressure re&icing x_dve if necessm T. (Adding apressure reducing valve m W

reduce the flow.)

"The softener works on 24 voh-60 Hz electrical power only. Be sure to use the included mmstbrmer. Be sure

the ele(tri( outlet and transformer are in an inside lo(ation to prote( t fiom wet weather.

"See Whereto Install theSoftenerse(tion for more details.

WARNING'.Do not use with water that is microbiologically unsalb or of unknown quality with{)ut

adequate disintecdon beti)re or atier the system. The water sh{mid be tested periodically to veri_ that the

sysmm is pertorming safisLmtofily.

Small pmls remaining atier the installation could be a choke hazard. Discmd sately.

4

Page 5

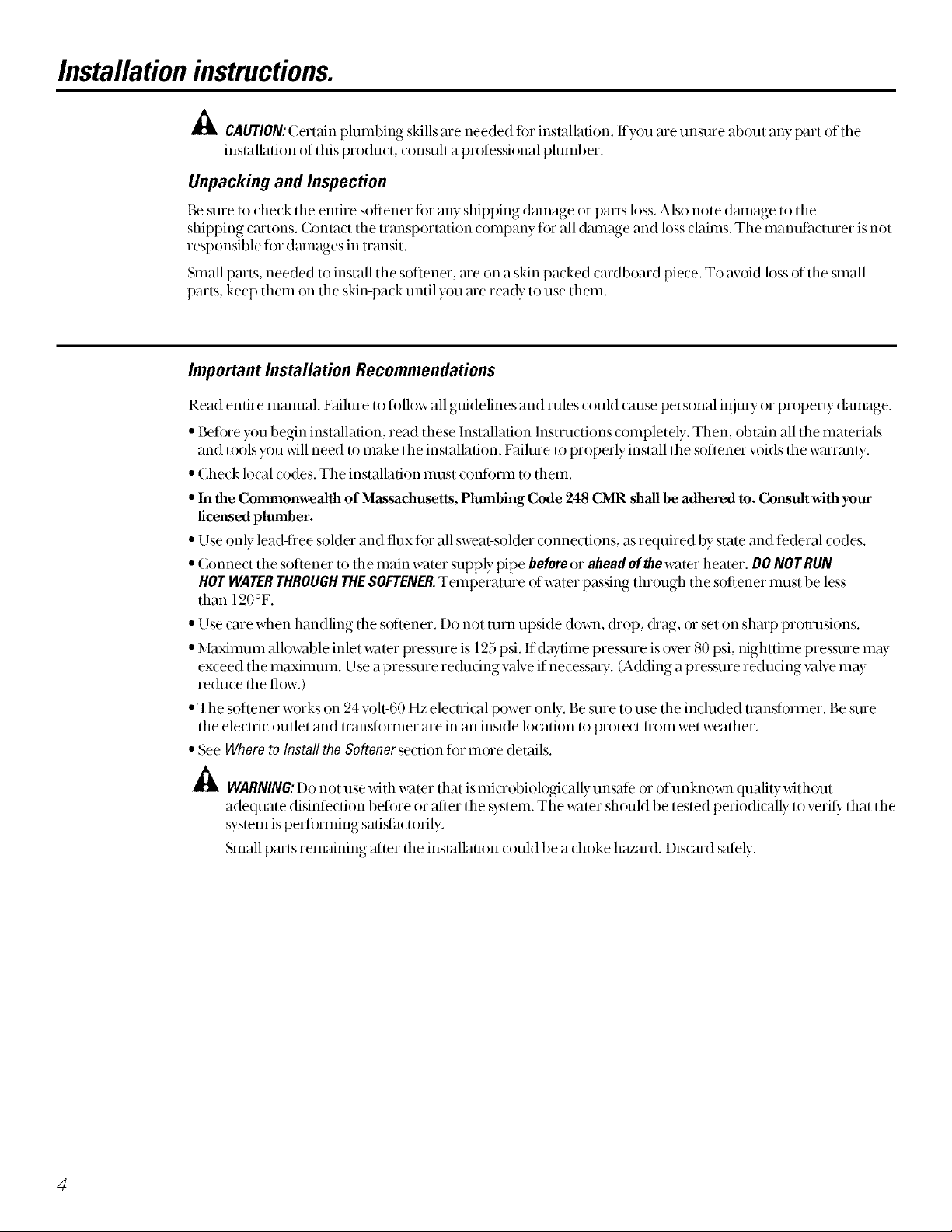

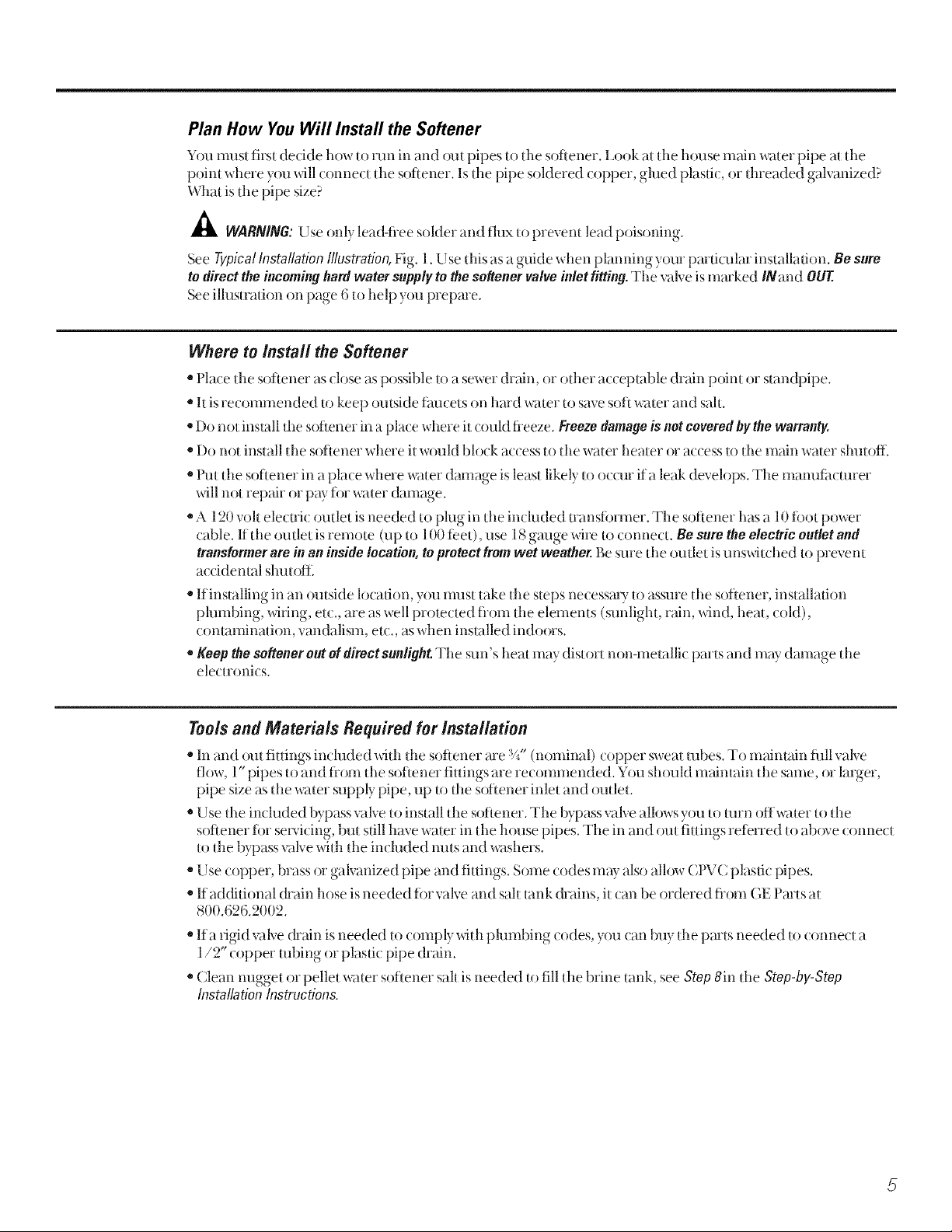

Plan How YouWill Install the Softener

Y(m nmst first decide how to nm in and out pipes to tile softener. Ix)ok at tile house main water pipe at tile

point where you xdll conne( t tile sotlener. Is tile pipe soldered (opper, gilled plas0(, or dueaded galvanized?

What is tile pipe size?

_WARNIN6: Use only lea&flee solder and flux to prevent lead poisoning

See YgpicalInstallationIllustration,Fig. 1. U se this as a guide when planning your par0cular installa0on. Be sure

todirecttheincominghardwater supplyto thesoftener valveinletfitting.Tile valve is marked INand OUT

See illusmltion on page 6 to help you prepare.

Whore to Install the Softener

• Place d_e softener as (;lose as possible to a sewer drain, or odier acceptable drain point or smn@ipe.

• It is recommended to keep outside thucets on hard water to save soft water and salt.

• Do not install tile softener in a place where it could fleeze. Freeze damage is not covered by the warranty.

• Do not install tile softener where it would block access to tlle water beater or access to tlle main water slmt oil.

*Put tile softener in a place where water damage is least likely to ocolr ifa leak develops. The manutiJcmrer

will not repair or PW tor water damage.

*A 120 volt electric outlet isneeded to phlg in tl_e in( bided nansiinmer. The sotiener has a l 0 toot power

(able. If tile oudet is remote (up to 1O0te_et),use 18 gauge xdre to connect. Be sure the electric outlet and

transformer are in an inside location, to protect from wet weather. Be sure tile oudet isunswit(hed to prevent

a( cidenml shutoiL

• If installing in an outside loca0on, you nmst take tile steps necessa U to assure the softener, installation

phmlbing, wiring, etc., are as well protected tiom the elements (sunlight, rain, wind, heat, cold),

contamination, vandalism, et(., as when installed indoors.

• Keep the softener out of direct sunlight. Tile sun's heat may distort non-metallic parts and may damage tl_e

electronics.

Toolsand Materials Required for Installation

• In and out fittings in(luded with the softener are %" (nominal) (opper sweat robes. To maintain tifil vah'e

flow, 1"pipes to and tiom the softener fittings are recommended. You should maintain tlle same, or larger,

pipe size as the water supply pipe, up to die softener inlet and outlet.

• Use the included bypass valve to install the softener. The bypass valve all()ws you to mrn offwater to tile

sotiener tbr se_'icing, but still have water in the house pipes. The in and out fittings retFrred to abtwe connect

to dm bypass valve wid_ the inchlded mils and washers.

• Use copper, brass or galvanized pipe and fittings. Some codes may also all()w CIWC plasuc pipes.

• If additional &ain hose is needed fin valve and salt tank &ains, it (:an be ordered iiom GE Parts at

800.626.2002.

=Ifa rigid valve drain is needed to comply with plumbing (;odes, you can buy tile parts needed to connect a

1/2" copper robing or plastic pipe drain.

*Clean mlgget or pellet water softener salt is needed to fill tl_ebrine tank, see Step 8in tlle Step-bg-Step

InstallationInstructions.

5

Page 6

Installationinstructions.

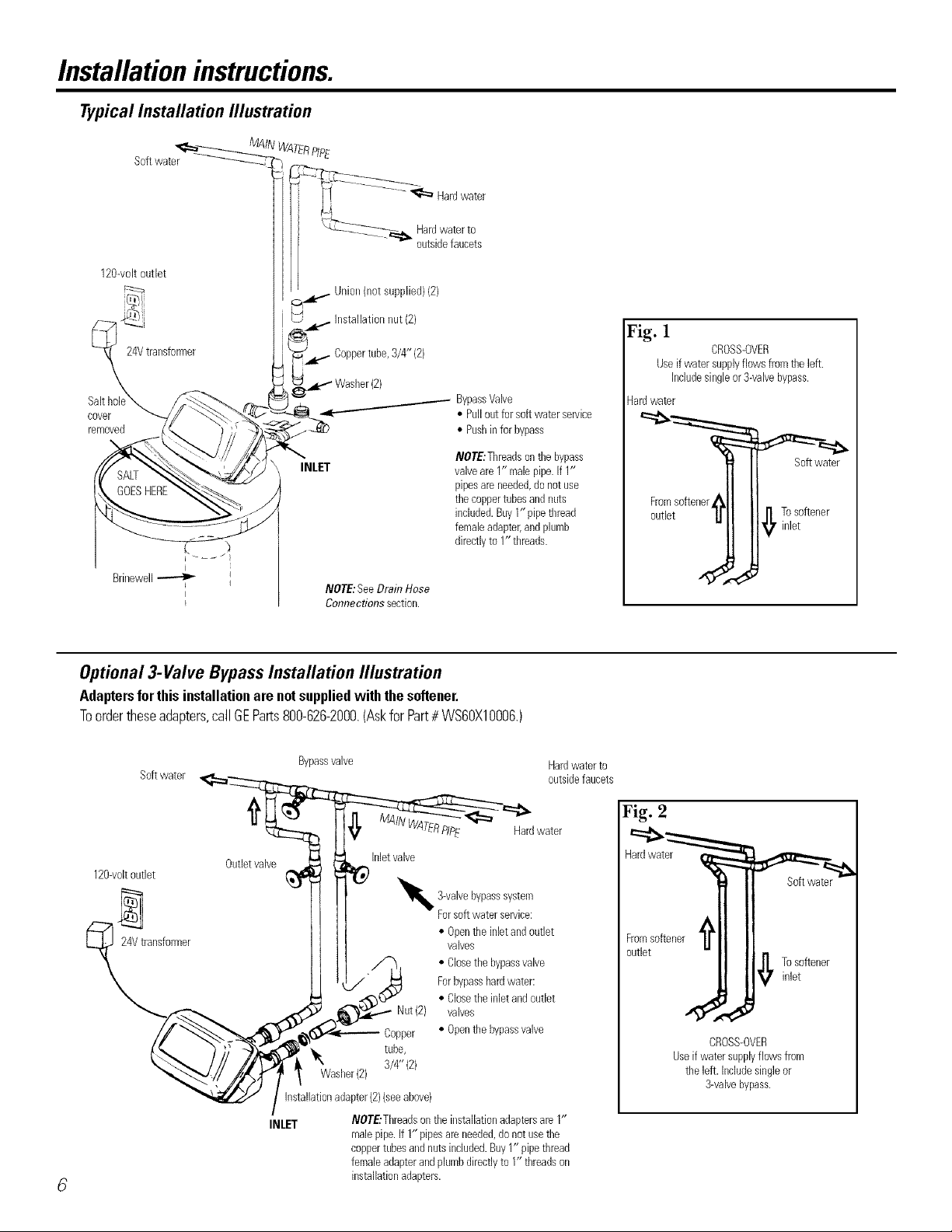

Typical Installation Illustration

Soft water

120-voltoutlet

Hardwater

Hardwaterto

outsidefaucets

Onion(not supplied)(2)

installationnut(2)

cover

removed

GOESHERE

Brineweil

24Vtransformer

J

I

Coppertube,3/4" (2)

_" Pullout forsokwaterservice

-_) " Pushinforbypass

INLET

NOTE:SeeDrain Hose

Connectionssection.

BypassValve

NOTE:Threadsontile bypass

valveare1" malepipe.If1"

pipesareneeded,donot use

thecoppertubesandnuts

included.Buy1" pipetbread

femaleadapter,andplumb

directlyto1" threads.

Optional 3-Valve Bypass Installation illustration

Adaptersforthisinstallationare notsuppliedwith thesoftener.

Toordertheseadapters,callGEParts800-626-2000.(AskforPart#WS6OX10006.)

Softwater

Bypassvalve

Fig. 1

CROSS-OVER

Useifwatersupplyflowsfromtbe left.

includesingleor3-valvebypass.

Hardwater

Fromsotiener^ll II

outlet lrll I1_1]_T°s°ftener

.4_J'f_Y inlet

Hardwaterto

outsidefaucets

120-voltoutlet

24Vtransformer

Outletvalve

MA/N

hfletvalve

Copper

tube,

Wasber(2)

Installation adapter (2) (see above)

INLET

3/4"(2)

NOTE:Threadsontheinstallationadaptersare 1"

malepipe.if 1" pipesareneeded,donotusetbe

coppertubesandnutsincluded.Buy1" pipethread

femaleadapterandplumbdirectlyto I" threadson

installationadapters.

",,_l_lfPIPE- Hardwater

3-valvebypasssystem

Forsoftwaterservice:

• Opentbe inletandoutlet

valves

• Closethebypassvalve

Forbypasshardwater:

• Closetheinletandoutlet

NLit(2)

valves

• Opentbe bypassvalve

Fig. 2

Hardwater

Fromsoftener

outlet

Tosoftenerinlet

CROSS-OVER

Useif watersupplyflows ftom

tbeleft. Includesingleor

3-valvebypass.

Page 7

Step-by-stepinstallationinstructions.

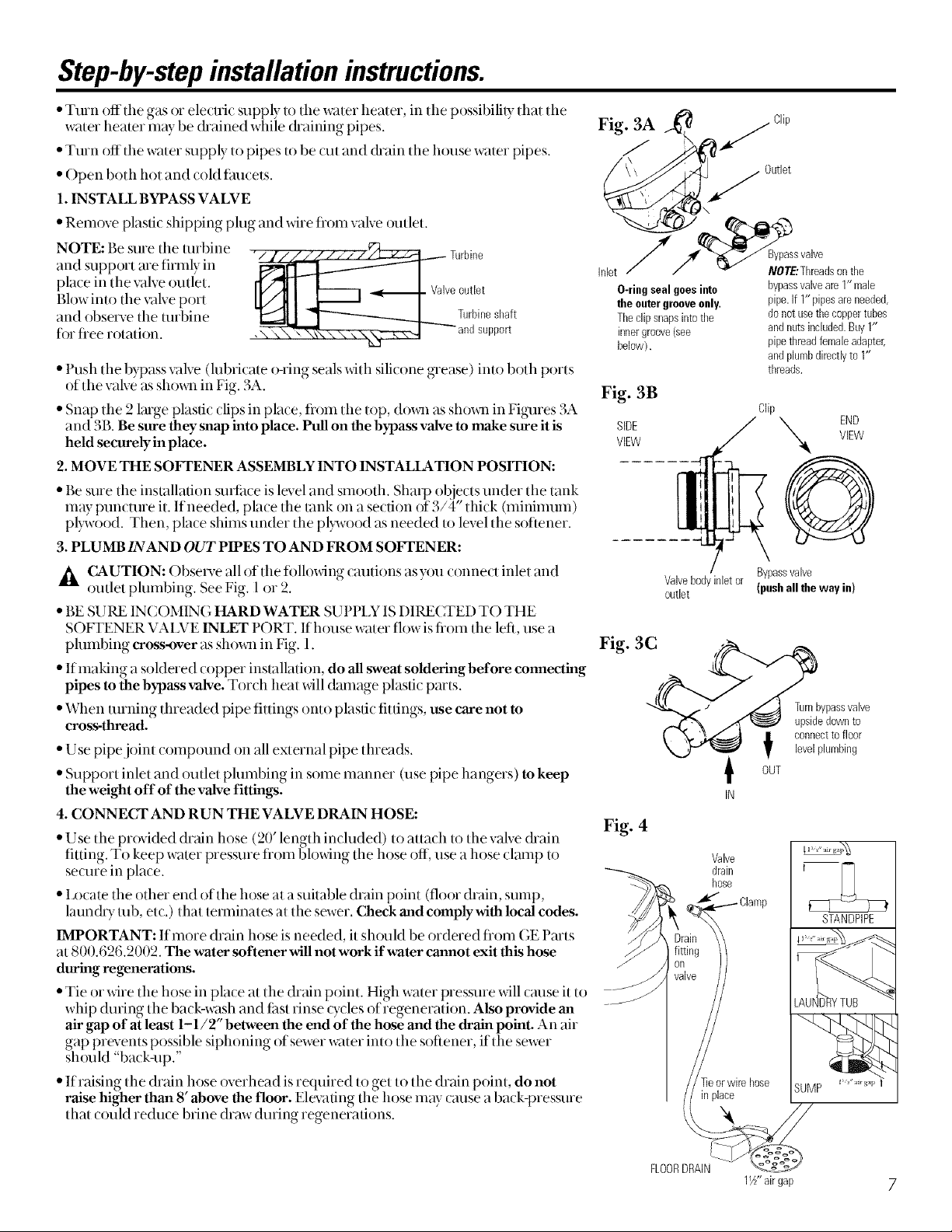

• Turn off the gas or elecuic supply to tile water heater, in tile possibiliff that the

water heater may be chained while &aining pipes.

Fig. 3A

• Turn off the w;iter supply to pipes to be cut and chain the h_)use water pipes.

• Open both hot and coM fimcets.

1.INSTALL BYPASS VALVE

• Rem()ve plastic shipping plug and wire flom valve outlet.

NOTE: Be sure the turbine

and support me firmly in

Turbine

place in the xvtlve outlet.

Blow into the xvdveport

and observe the turbine

tot fiee rotation.

• Push the bypass xvdve (lubricate o-ring seals with silicone grease) into both ports

of the valve as shm_ql in Fig. 3A. Fig. 3B

° Snap the 2 large plastic clips in place, flom the top, dox_11as shox_i_ in Figures 3A

and 3B. Be sure they snap into place. Pull on the bypass valve to make sure it is SIDE

held securely in place. VIEW

2. MOVE THE SOFTENER ASSEMBLY INTO INSTALLATION POSITION:

e outlet

Turbine sMft

and suppo_

Met

O-ringsealgoesinto

the outergrooveonly.

Theclipsnapsintothe

innergroove(see

below).

• Be sure the installation suriime is level and smooth. Sharp objects under tile tank

mW puncune it. If needed, place the lank on a section of 3/4" thick (minimum)

pl)wood. Then, place shims under the pl)wood as needed to level the softener.

3, PLUMB INAND OUT PIPES TO AND FROM SOFTENER:

CAUTION: Obsecve all of tile tbllowing cautions asyou connect inlet and

outlet plumbing. See Fig. 1or 2.

• BE SURE IN( OMING HARD WATER SUPPI N IS DIRECTED TO THE

SOFTENER VA137E INLET PORT. If house w;tter flow isfioln the left, use a

plumbing cross-over as shox_l_in Fig. 1.

Fig. 3C

• If making a soMered copper installation, do all sweat soldering before connecting

pipes to the bypass,calve. Torch heat will damage plastic pmls.

• When turning threaded pipe fittings onto plastic fittings, use care not to

cross-thread.

° Use pipe joint compound on all external pipe flneads.

• )"

Support inlet and outer phnnbing in some manner (use pipe hangers) to keep

the weight off of the valve fittings.

4. CONNECt AND RUN THE VALVE DRAIN HOSE:

Fig. 4

° Use tile provided dr?fin hose (20' length included) to attach to tile valve &ain

fitting. To keep water pressure tiom bh)wing tile hose off, use a hose clamp tO

seone in place.

• I_ocate the other end of the hose at a suitable drain point (floor drain, sump,

laund U rob, et_.) that temfinates at the sewer. Check and comply with local codes.

IMPORTANT: If more drain hose is needed, it sh{)uM be ordered flom GE Pmts

at 800.626.2002. The water softener will not work if water cannot exit this hose

during regenerations.

• Tie or wire the hose in place at the drain point. High water pressure will cruise it to

whip during the back-w:tsh and tast rinse tycles of regeneration. Also provide an

ak gap of at least 1-1/2" between the end of the hose and the drain point. An air

gap prevents possible siphoning of sewer water into the softener, if the sewer

sh_)uld "back-up."

° If raising tlle drain hose overhead is required to get to file drain point, do not

raise higher than 8' above the floor. Elevating the hose may _ause a ba_ k-pressme

that could reduce brine draw during regenerations.

J

Valvebodyinletor

outlet

Valye

drain

hose

Clip

Outlet

Bypassvalve

NOT£'Thmadsonthe

bypassvalveam1" male

pipe.if1" pipesareneeded,

donot usethecoppertubes

andnutsincluded.Buy 1"

pipethreadfemaleadapter,

andplumbdirectlytoI"

threads.

Clip

X END

VIEW

Q

Bypassvalve

(pushall the way in)

Turnbypassvalve

upsidedownto

connecttofloor

levelplumbing

STANDPIPE

ur gap

FLOORDRAIN

1½"airgap 7

Page 8

Step-by-stepinsta/lation instructions.

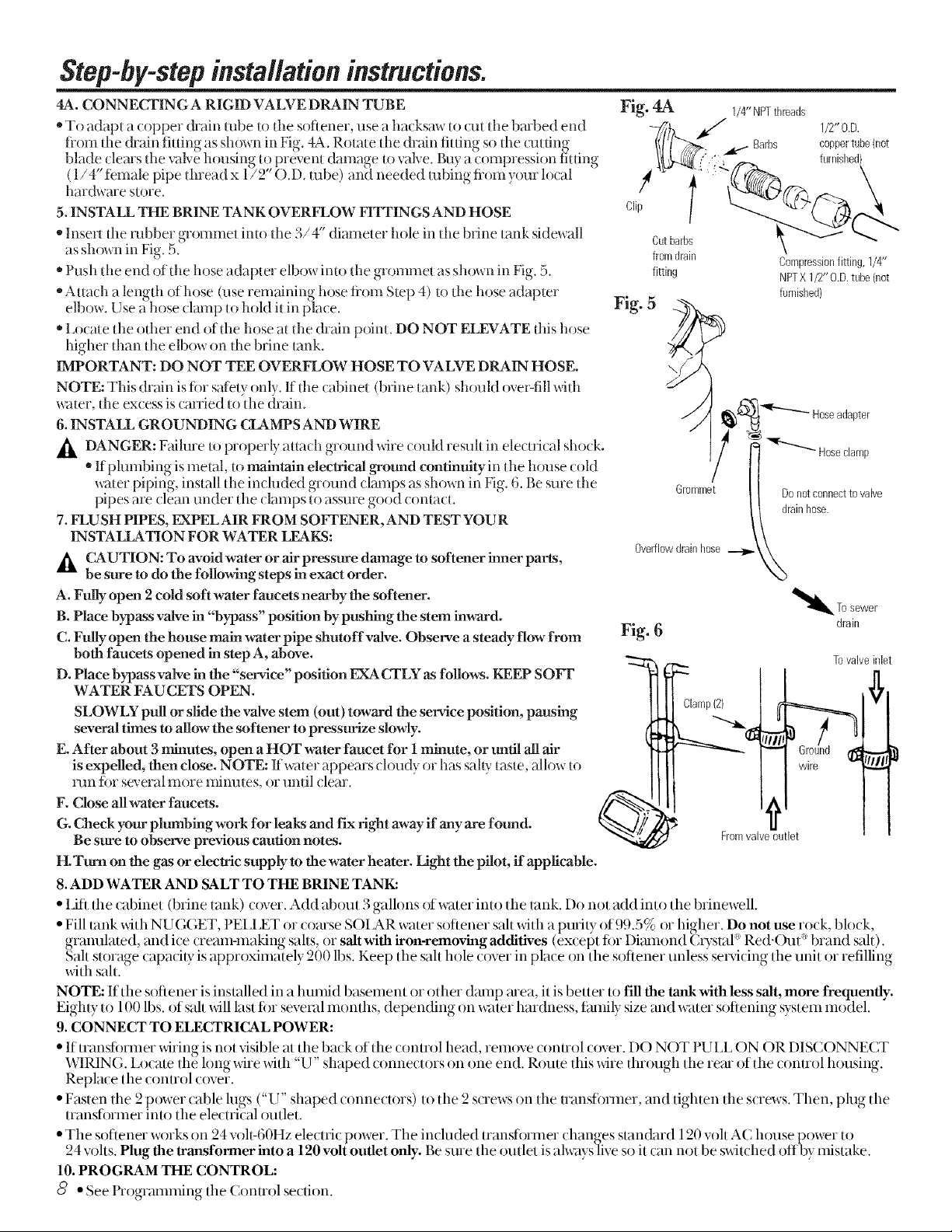

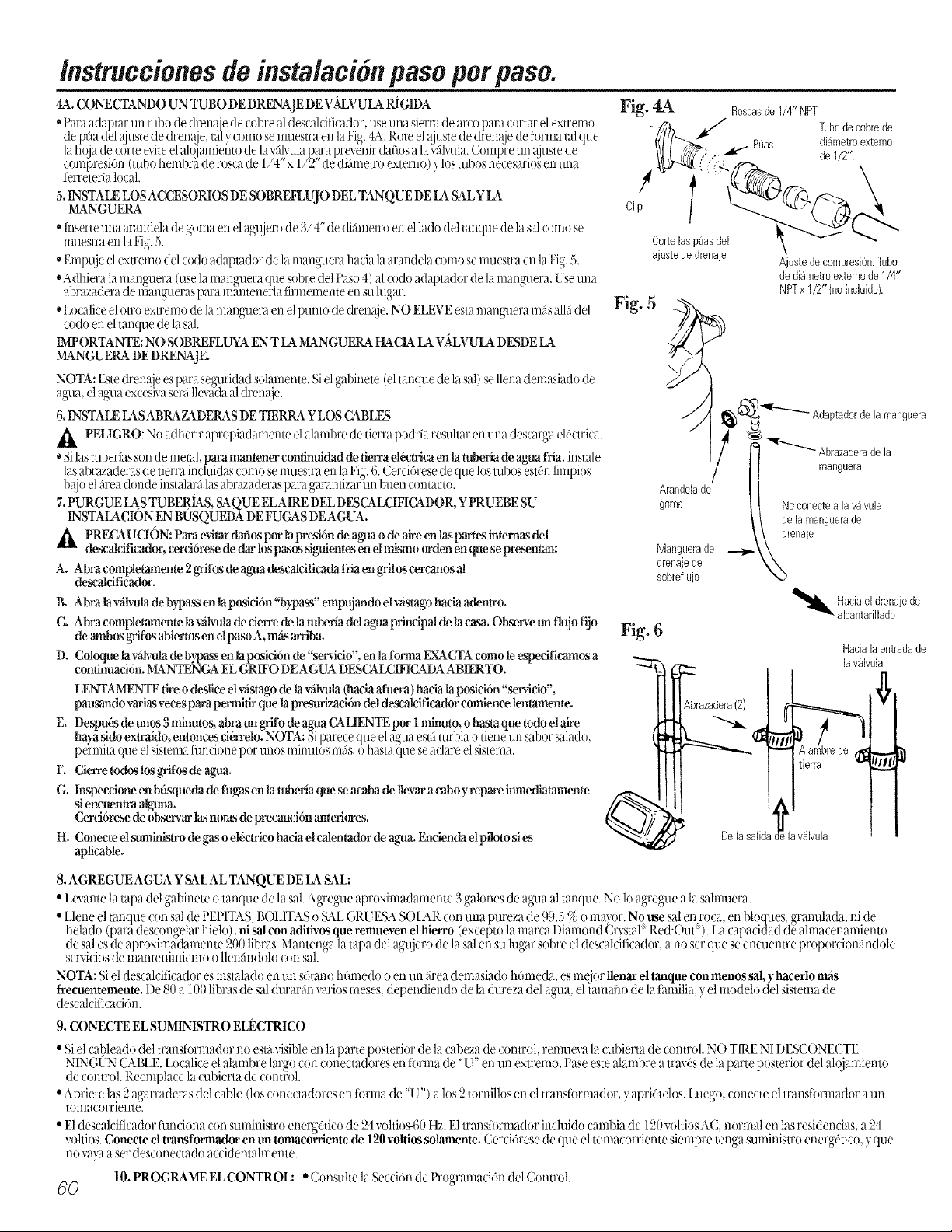

4A. CONNECTING A RIGID VALVE DRAIN TUBE Fig. 4A 1/4"NPTthreads

from tile drain fitting as shown in Fig. 4.4. Rotate tile drain lifting so tile cutting Barbs coppertube{net

•To adapt a (ol)per &ain robe u, the s(,Jr/ener, use a ha(ksa,, to (ut dm bmbe den d --7_/h _/" t.__? 1/2" O.D.

blade,dears,tile.xake housing,,t°,prevent (kmlage,to vake. Buv..a (ompression, lit ring, j ,. ::' i_ furnished)

(1/4 female pipe dnead x l/2 ().D. robe) and needed robing from your local

hardware store.

5. INSTALL THE BRINE TANK OVERFLOW FITTINGS AND HOSE OH

InseHtherubbe_ gtommetmtoflle3/4 dlametel hole in dm brine tank sidewall eutbarbs

asshown in Fig. 5. fromdrain Compressionfitting,1/4"

• Pushthe end of din hoseadapter elbow into tile grommet asshown in Fig.5. fitting NPTX1/2"0.D.tube(not

•Attach alenelh of hose (userem_fining hoseflom Step 4) to tile hose adapter furnished}

elbow. L sea hose clamp to hold U m place. Fig. 5

• Locate tile other end of the hoseat tile drain point. DO NOT ELEVATE this hose

higher than the elbow on tile brine tank.

IMPORTANT: DO NOT TEE OVERFLOW HOSE TO VALVE DRAIN HOSE. \ S

NOTE: This drain is fi)r safety only If tile tabinet (brine tank) shoukl over-till with

water, tile ex(ess is (anted to tile drain.

6. INSTALL GROUNDING C_AMPS AND WIRE pter

A DANGER: Failure to properly atta(h ground wire tould resuh in electri(al sho(k.

• If plumbing is metal, u) maintain electrical ground continuity in tile house (:okl

water piping, install tile included ground ( kunps as shown in Fig. 6. Be sure tlie Grommet

pipes are (lean llndei tile clamps to assuie good cent}tot. Donotconnecttovalve

7. FLUSH PIPES, EXPEL AIR FROM SOFTENER, AND TEST YOUR

INSTALLATION FOR WATER LEAKS:

A CAUTION: To avoid water or air pressure damage to softener inner parts,

be sure to do the following steps in exact order.

A. Fully open 2 cold soft water faucets nearby the softener.

B. Place bypass valve in "bypass" position by pushing the stem inward, drain

C. Fully open the house main water pipe shutoff valve. Observe a steady flow from Fig. 6

both faucets opened in step A, above. Tuvalvehdet

D. Place bypass valve in the "service" position EXACTLY as follows. KEEP SOFT

WATER FAUCETS OPEN.

SLOWLY pull or slide the valve stem (out) toward the service position, pausing

several times to allow the softener to pressurize slowly.

E. After about 3 minutes, open a HOT water faucet for 1 minute, or until all air

is expelled, then close. NOTE: If water appears t loudy or has sahy taste, allow to wire

run fiw several more minutes, or until clear.

F. Close allwater faucets.

G. Check your plumbing work for leaks and fix right away if any are found.

Be sure to observe previous caution notes. Fromvalveoutlet

IZLTurn on the gas or electric supply to the water heater. Light the pilot, if applicable.

8.ADD WATER AND SALT TO THE BRINE TANK:

"I Jfl tile (abinet (brine tank) / oxel. Add about 3galhms of water into tile tank. I)o not add into tile brinewell.

• Fill tank x_ith NUGGET, PEI ] £T or coarse SOLAR water softener sah with a purity of 99.5% or lfigher. Do not use rock, block,

uranulated, and ice cream-making salts, or salt w_th _ron-removmg additwes (except for Ihamond Crystal '_Red.OuP brand sah).

Sah storage capacHv is approxmlatelv 200 lbs. Keep tile sah hole cover m place on the softener unless serxacmg tile unU or rehlhng

with salt.' ....

NOTE: Iftilesoftener isinstalledin a humid basement or oflmr damp mea,itisbetter to fillthe tank with lesssalt,more frequently.

EightytoI00Ibs.ofsallxfilllastlotseve_vdmonths,dependingon waterhardness,familysizeandwatersofteningsystelnmodel

9.CONNECT TO tLECTRICAL POWER:

• Iftransfi)rmer wiring is not visible at tile back of the control bead, remove control cover. DO NOT PUI]. ON OR DIS(_ONNECT

WIRING. I.ocate the long wire with "U" shaped connectors on one end. Route this wire tlnough the rear of the control housing.

Replace the control covei.

• Fasten the 2 power cable lugs ("U" shaped connectors) to the 2 screws on the transformer, and tighten the screws. Then, plug the

transforlner into the electri{:al outlet.

• Tile softener works on 24 voh:60Hz electric power. Tile included transfi)rmer changes stan(bnd 120 voh A( house power to

24 vohs. Plug the transformer into a 120 volt oudet only. Be sure tile outlet is alwayslive so it can not be switched off by inistake.

10. PROGRAM THE CONTROL:

o° • See Programming tile Control se(tion.

• _ Hoseclamp

Y

fT

Overflowdrainhose

drainhose.

To

sewer

Page 9

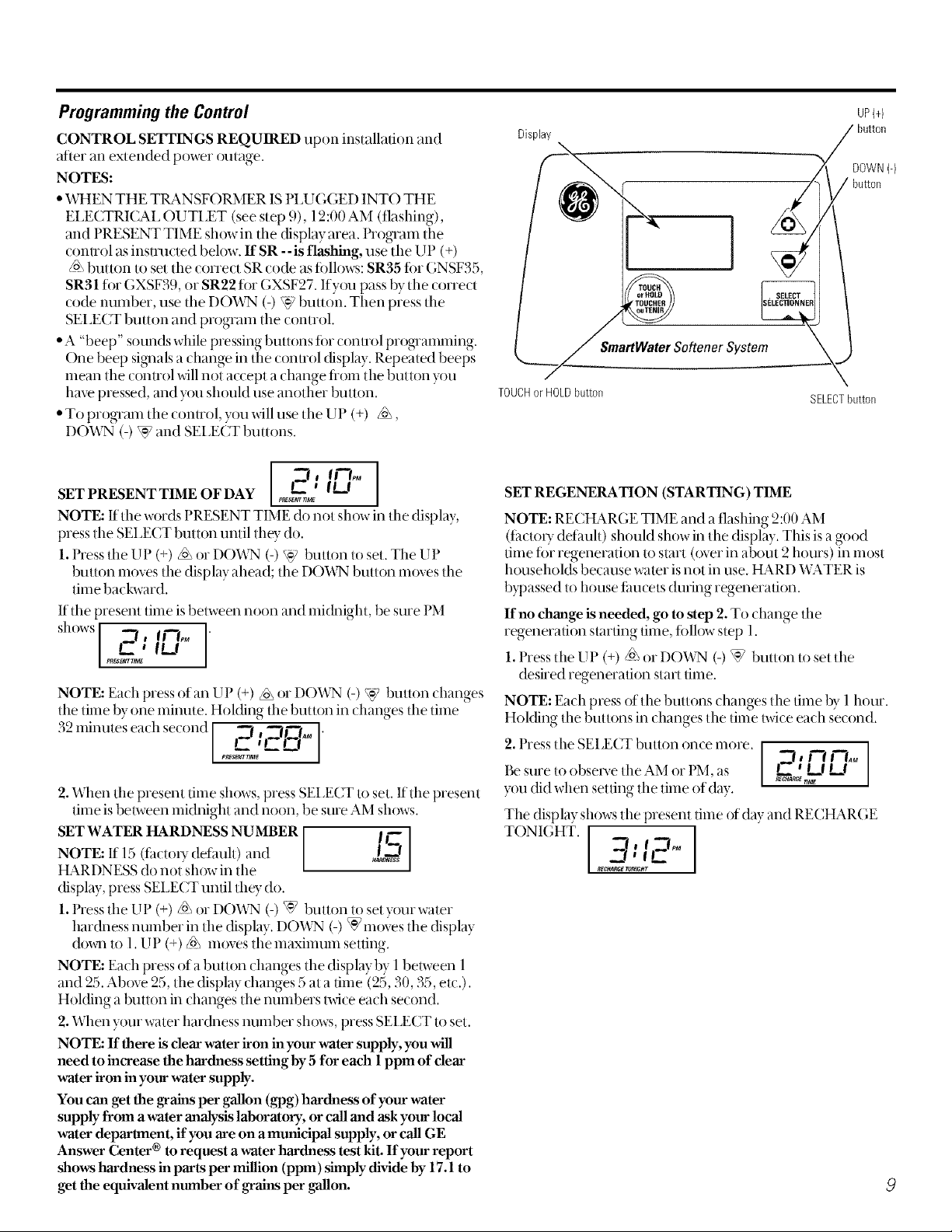

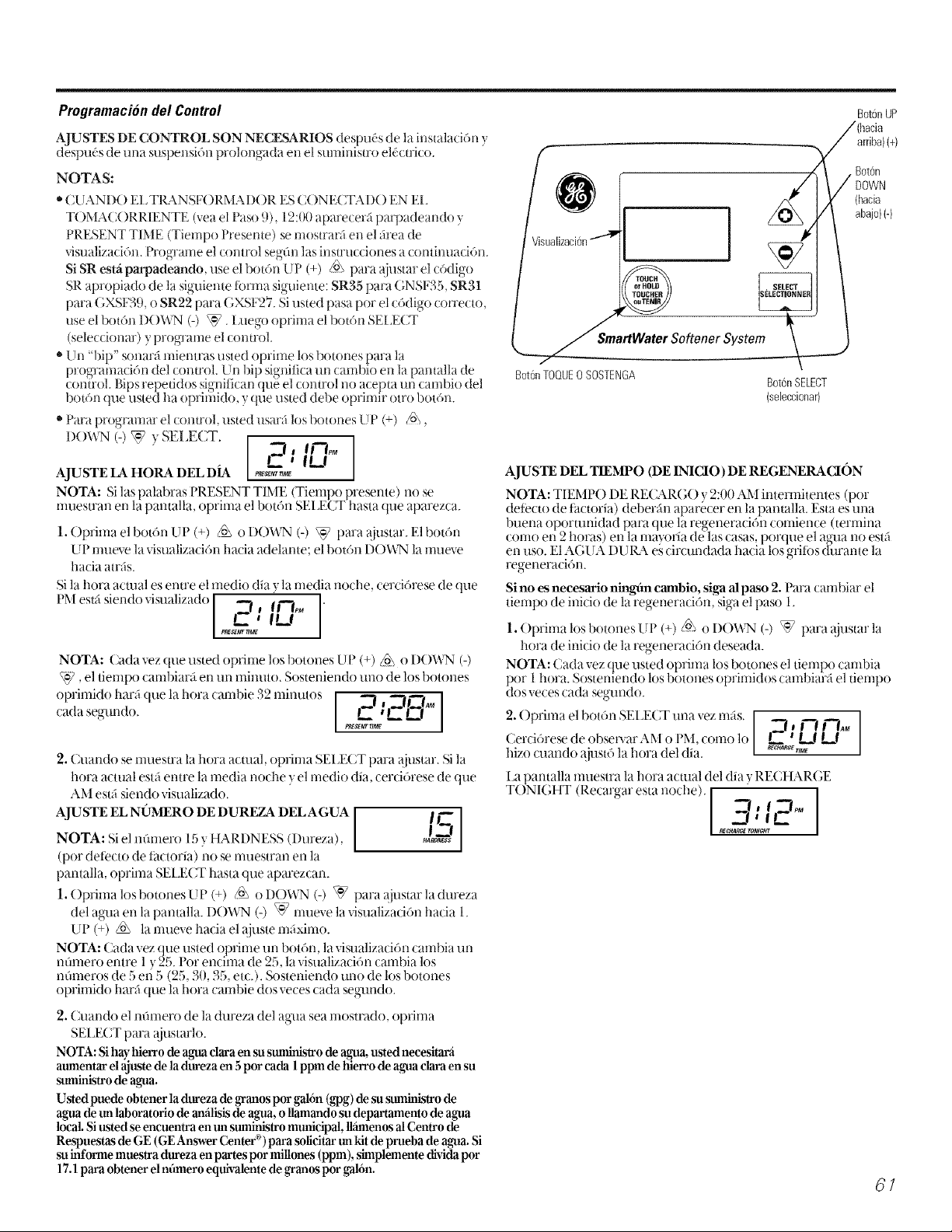

Programming the Control

CONTROL SETTINGS REQUIRED upon installation and

after an extended power outage.

NOTES:

• WHEN THE TIL*_NSFORMER IS PI,UGGED INTO THE

ELECTRICAL OUTLET (see step 9), 12:00 AM (flashing),

and PRESENT TIME show in the display area. Program the

conuol as insu_ucted below, ff SR -- is flashing, use tile UP (+)

/o\ button to set the correct SR code as ti)lh)ws: SR35 fi)r GNSF35,

SR31 ti)r GXSF39, or SR22 ti)r GXSF27. Ifyou pass by tile correct

code number, use the DOWN (-) W button. Then press the

SEI_ECT button and program the control.

• A "beep" sounds while pressing buttons tor conuol programming.

One beep signals a change in the conuol (fisplay. Repeated beeps

mean the conuol will not accept a change flom tile button you

haw pressed, and you should use another button.

• Toprogramtheconuol, youwillusetheUP (+) /o\,

DOWN (-) W and SEI_ECT buttons.

Display

TOUCHorHOLDbutton

UP(4

SmartWater Softener System-_,J

SELECTbutton

SET PRESENT TIME OF DAY .....

NOTE: If tile words PRESENT TIME do not sh_)w in tile display,

press tile SEI_ECT button until they do.

1. Press the UP (+) _ or DO_VN (-) _ button to set. The UP

button moves the display ahead; the DOWN button moves the

time backward.

If tile present time is between noon and midnight, be sure PM

l&

shows _, ff-I,_ I"

C ' 0d

NOTE: Each press of an UP (+) _ or DOWN (-) W button changes

the time by one minute. Holding tile button in changes tile time

32 minutes each second ,_,,_r-_l'l'-I'-i'-'_-I_J_ •

2. When tile present time shows, press SELECT to set. If the present

time is between midnight and noon. be sure AM sh_)ws.

SET WATER HARDNESS NUMBER 11--7-

NOTE: If 15 (facto U defauh) and /,_!

tLa.RDNESS do not show in the

display, press SEI_ECT until they do.

1. Press the UP (+)/o\ or DOX.VN (-) _] button to set w)ur water

hardness number in the display. DOWN (-) W moves the display

down u) 1. UP (+) _ moves tile maximum setting.

NOTE: Each press of a button changes the display by 1 between 1

and 25. Above 25, the display changes 5 at a time (25, 30, 35, etc.).

Hol(fing a button in changes the numbers twice each second.

2. When your water hardness number sh_)ws, press SEI _ECT to set.

NOTE: If there is clear water iron in your water supply, you will

need to increase the hardness setting by 5 for each 1 ppm of clear

water iron in your water supply.

You can get the grains per gallon (gpg) hardness of your water

supply from a water analysis lalmratory, or call and ask your local

water department, if you are on a mmficipal supply, or call GE

Answer Center ® to request a water harthless test kit. If your report

shows hardness in parts per million (ppm) simply divide by 17.1 to

get the equivalent number of grains per .qallon.

ImEs_r rl_

SET REGENERATION (STARTING) TIME

NOTE: RECtL_R(;E TIME and a flashing 2:00 AM

(tacto U detault) should show in the display. This isa good

time fi)r regeneration lo start ((wet in about 2 hours) in most

households because water is not in use. HARD WATER is

bypassed to house fimcets during regeneration.

If no chmage is needed, go m step 2. To change the

regeneration starting time, fifth)w step 1.

1.Press the UP (+) _ or DOWN (-) W button to set the

desired regeneration start time.

NOTE: Each press of the buttons changes tim time by l hour.

Holding the buttons in changes the time twice ea(h second.

2. t tess tile SELECT button once more.

Be sure to observe tile AM or l M, as _ _

you did when setting the time of day.

The display shows tile present time of day and RECHARGE

TONIGHT. I

itECHA PGE TON/Gt/T

, la II I

I

Page 10

Step-by-stepinstallationinstructions.

Sanitizing Procedures

Tocompletetheinstallation,dothe following sanitizingprocedures.

Care is taken at the thctoD_to keep y_)ur water softener clean and sanitmy. Materials used to make tile softener _dll not intect or

contmninate your water supply and _dll not cm_sebacteria to ti_rm or gr_w. H_wever, (hning shipping, storage, installing and

operating, bacteria c{mld get into the softener. For this reason, sanitizing as fifth_wsis suggested when installing.

NOTE:SanitizingisrecommendedbytheWaterQualityAssociationfordisinfecting.

[_Be sure to (omplete all installation steps, in( luding programming tile (onuol.

[_ Pour about 3/4 oz. (l {dtablespoons) of COlnlnon 5.25% household bleach (Clorox, Linco, Bo Peep, White Sail, Eagle, etc.)

into tile brinewell,Refer to illusuation on page 6.

_IMPORTANT: Press and hold fi)r 3 seconds the faceplate TOUCH/HOLDbillion to start an imme(fiate regeneration. RechargeNow

begins to flash in the display. The blea(h is (hm_l into and through the water softener.

[_] If after sanitization water flOln house thucet tastes sahv or has a slight color, this is a present,alive fiom the resin tank. Turn on

the cold soft water fimcets and &ain fi)r a few minutes or until clear.

NOTE'Whenthe above sanitizing regeneration is over, your house COLDwater supply is flflly soft imme(fiately. However, your water

heater isfilled with hard water and as hot water is used, it will refill with soft water. When all the hard water is replaced in the water

heater, hot only and mixed hot and cold water will be tully soft. Ifyou want totally soft water immediately, after the ab_ve

reg*_neration, drain the water heater until the water runs cold.

_kWARNING: If you do drain the water heater, use extreme (are as the hot water (ould (ause burns. Turn the water heater off

prior m draining.

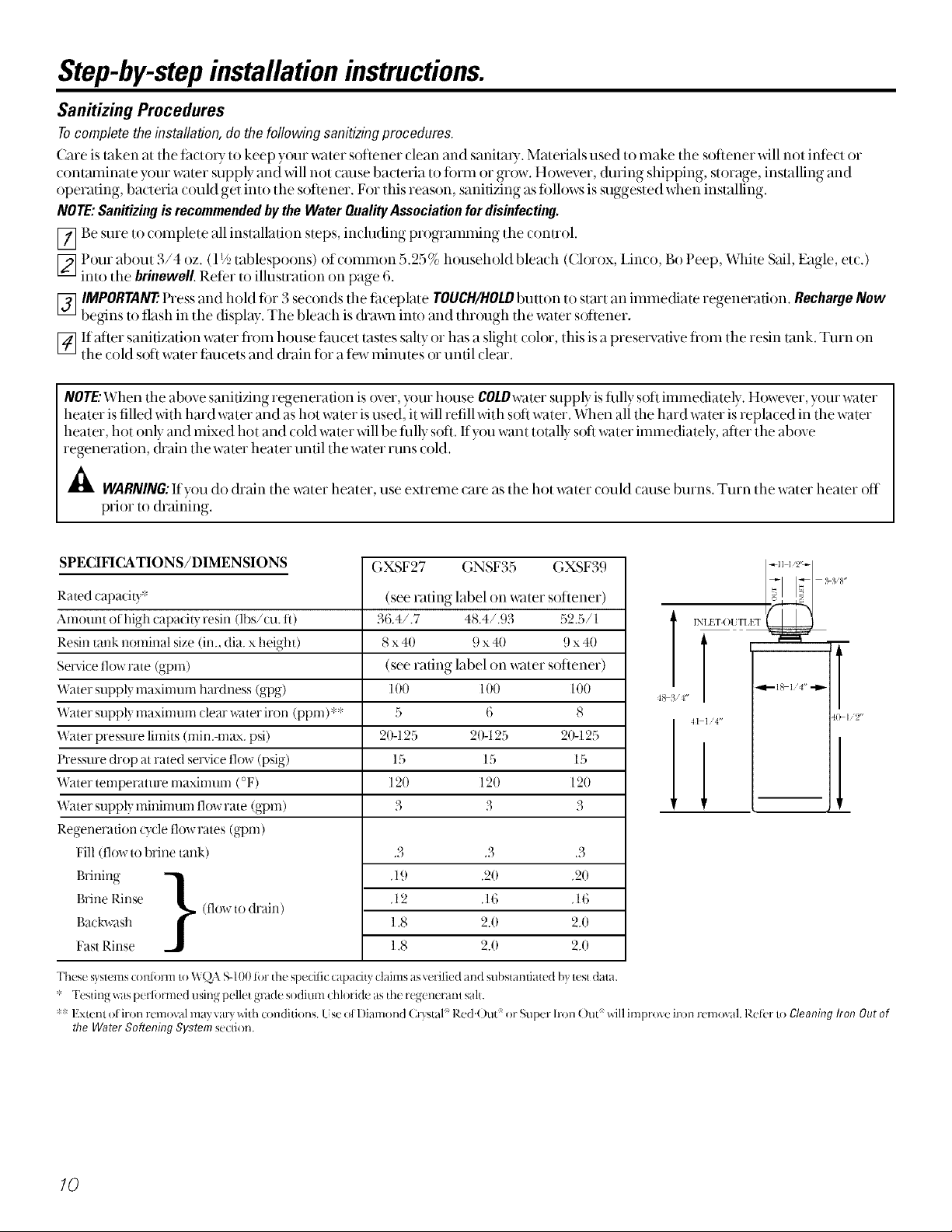

SPECIFICATIONS/DIMENSIONS

Rated capacily*

Amount ofhigh capacit? resin (lbs/cu. fl)

Resin tank nominal size (in., dia. x height)

Se_'ice tlow rate (gpm)

Water suppl) maxinmm hardness (_I _)

O" )o"

Water supply maximum clearwater iron (ppm)**

Water pressure limits (min.-m_e¢.psi)

l'ressure drop at rated service flow (psig)

Water temperature maximum (°F)

Water supply minimum flow rate (gpm)

Regeneration _)cle tlow rates (gpm)

Fill 0low to brine tank)

(,XSF2 ¢ (,NSF3b (,XSF3.)

(see rating label on water softener)

r_, r./l36A/.7 48A/.93 .2.0

8 x 40 9 x 40 9 x 40

(see rating label on water softener)

100 100 100

5 6 8

20-125 20-125 20-125

15 15 15

120 120 120

3 3 3

.3 .3 .3

'ti l't"

"11"--18 I'U

>I '2"

.19 20 20

l?,rine Rinse [low to drain)

l?,ackwash

l?,rining }

FastRinse

These syslems con/k_nnIoWQA S-100li)r the spedlic capadty claimsasvefilied and substantiated by lest dala.

Testing wasperti)rmed using pellet grade sodium chh wide asthe regeneranl sah.

'_'_Extant ol iron removal may varywith conditions, tse ol l)iamond ()ystal Red.Out or Super h-onOut' willimprove iron removal. Ref_r Iogleaning Iron Outof

the WaterSoftening Systemsecdon.

.12 A6 .16

1,8 2.0 2.0

1,8 2.0 2.0

/0

Page 11

Aboutthe water softener system.

Service

When tile _cater softening system is providing soft water, it is called "Sex,ice." During se,_ice, hard water flows

flom the house main water pipe into the water softening system. Inside the x_v_tersofienh_g system resin tank isa

bed made up of d_ousands of tiny, plasti( resin beads. As hard water passes d_rough the bed, each bead ama( ts

and holds tl_e hard minerals. This is (:ailed ion-exclmnging. It isnmch like a magnet amacting and holding

metals. \,\_lter without hard minerals (soft water) flows fiom the water sofiening systeI_n and to tlm house pipes.

After a period of time, the resin beads become coated with hard minerals and dmy have to be cleaned.

This cleaning is called regenem0on, or re( harge. Regeneration is started tit 2 00 AM (fh(to U sening) by tlle

water softening system control, and consists offixe stages or o,cles. These are FILLBRINING,BRINERINSE,

BACKWASHandFASTRINSE

Automatic Hard Water Bypass During Regeneration

For emergency needs, hard war er is available to the However, you should avoid using HOT water because

home during the regeneration cycles the water heater will fill with the hard water.

Fill

Salt dissolx ed in water is called brine. Brine is needed to clean tl_e hard minerals flom resin beads. To make the

brine, water flows into tim salt storage area during the fill stage.

Brining

During brining, brine m_xelsflom the salt storage area into the resin tank. Brine is the cleaning agent needed

to remove hard minerals flom the resin beads. The hard minerals and brine are dis( barged to tile drain.

The nozzle and venturi (reate a su( tion txxmove the brine, maintaining a veIT slow rate Ixxget the best resin

(leaning _4th the least sail.

Brine Rinse

After a pre-measured amount of brine is used, the brine xake (loses. Water continues Io flow in tim same path

as during brining, ex(ept fbr the dis(ontinued brine flow. Hard minerals and brine flush flom the resin tank Io

the drain.

Backwash

During ba(kwash, water m_ els up through the resin tank at a f:astflow rate, flushing a((umulated iron, dirt,

and sediments flom the resin bed and to drain.

Fast Rinse

Backwash is fbll_med by a fiJst fl_m of water down through tlm resin tank. The fiJst fl_rw flushes brine flom the

bottom of tank, and pa(ks the resin bed.

After thst rinse, tlm water softening system returns to soft water servi(e.

II

Page 12

Aboutthe water softener system.

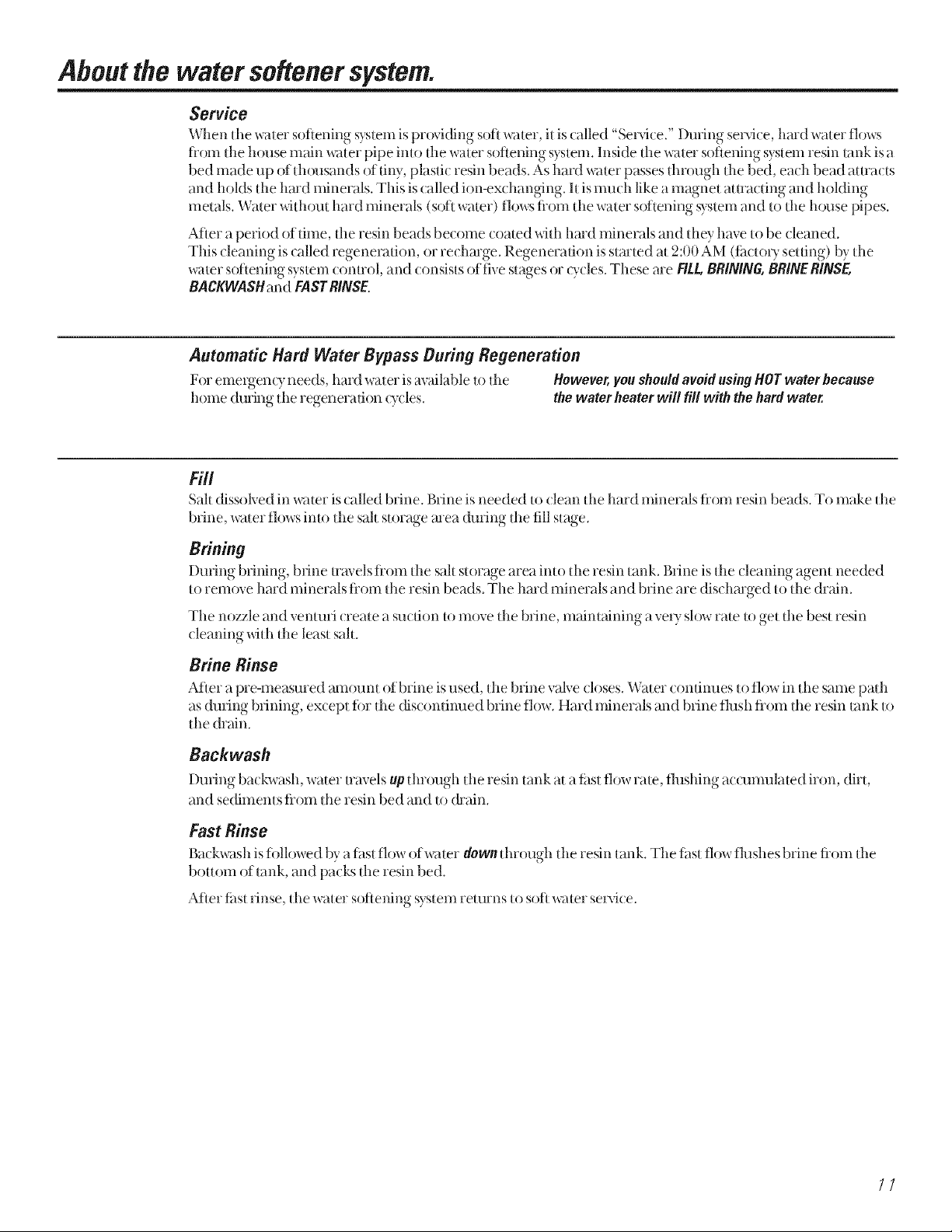

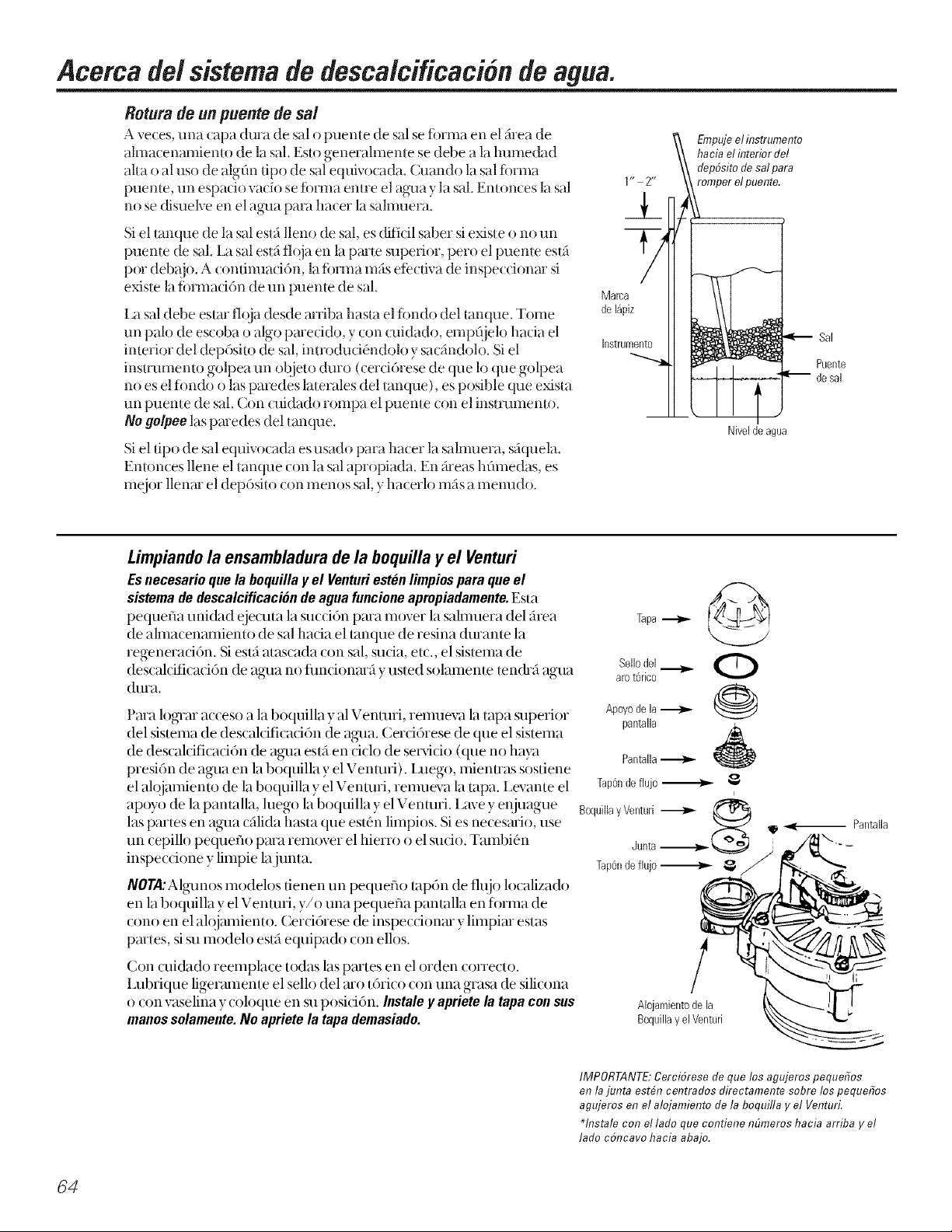

Breaking a Sail Bridge

Sometimes, a hard crest or salt bridge fiwms in tile sah storage area. It

is umally cruised by high humidity or the wrong Idnd of sah. When tile

sail bridges, an empty space fi)rms between the water and salt. Then

sall will not dissolve in the water to make brine.

If tile brine tank is flfll of salt, it is hard to tell if you ha,_e a salt bridge.

Sah is loose on top, but tile bridge isunder it. Tile fi)llowing is tile best

way to (he(k fi)r a salt bridge.

Salt should be loose all the way to tile bottom of the tank. Take a

broom handle or like tool, and carefiflly push it do_m into tile salt,

worldng it tip and do_m. If tile tool suikes a hmd object (be sure it's not

the bou()m or sides of the tank), it's most likely a salt bridge. Carefiflly

break the bridge with the tool. Oo not pound on the walls of the tank.

If tile wrong kind of salt made tile bridge, take it out. Then fill tile tank

with nugget or pellet salt only. In humid areas it is best to fill with less

sail, I;tlore otlen.

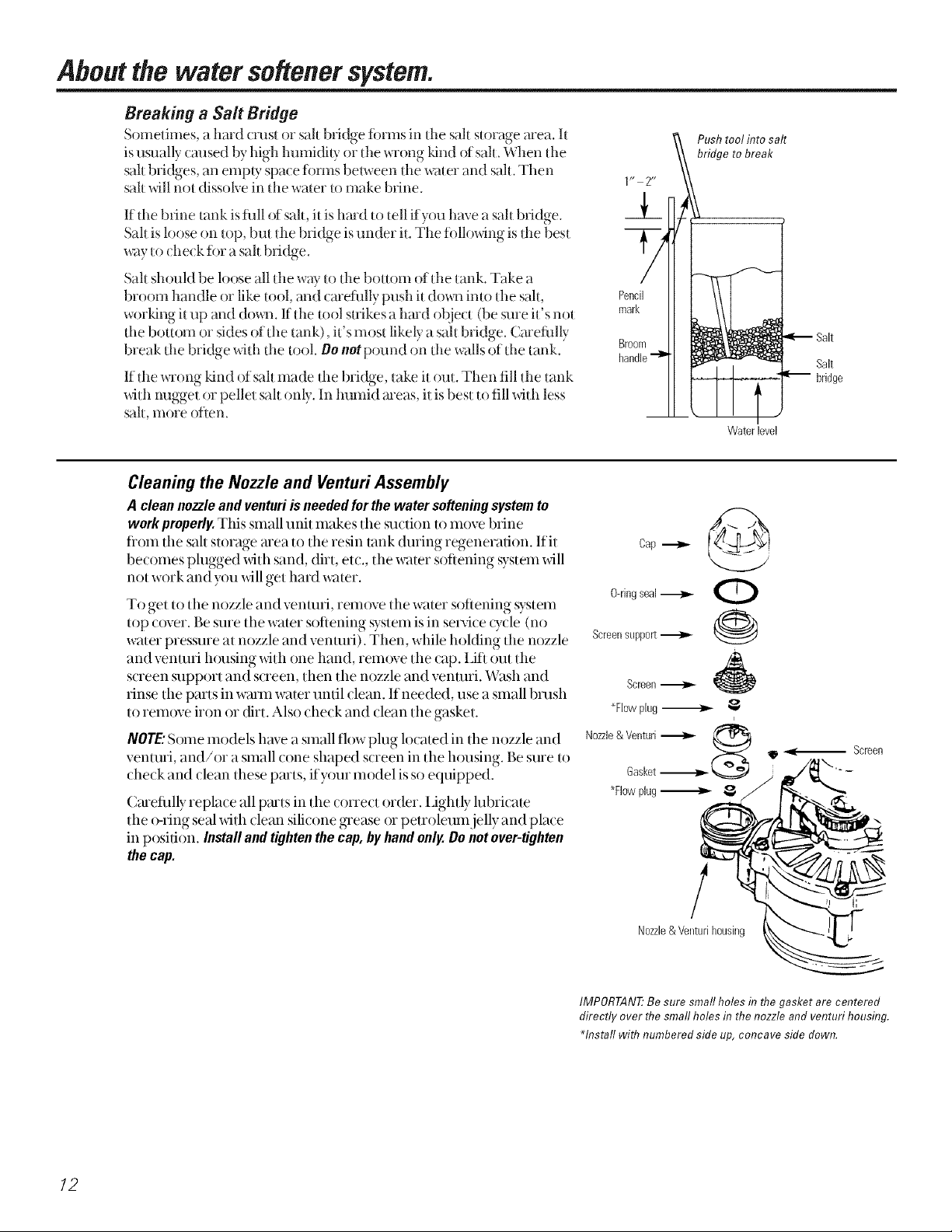

Cleaning the Nozzle and Ventufi Assembly

A cleannozzleandventuriisneededforthe watersofteningsystemto

workproperly.This small unit makes tile surtion to move brine

fl'om tile salt storage area to tile resin tank during regeneration. Ifit

becomes plugged with sand, dirt, etc., the water softening system will

not work and you will get hard water.

To get to tile nozzle and venmri, rem()ve tile water softening system

top cover. Be sure the wamr softening system is in service (ycle (no

water pressure at nozzle and venuni). Then, while holding the nozzle

and venmri h()using with one hand, rem()ve the cap. IJfl out the

screen support and soeen, then the nozzle and venmri. _¢\_Bhand

rinse the parts in warm water until clean. If needed, use a small brash

to remove iron or dirt. Also check and clean the gasket.

NOTE."Some models have a small flow plug located in tile nozzle and

venmri, and/or a small (one shaped screen in the housing. Be sure to

(lle(k and )lean these paris, ifyour model is st) equipped.

( mefillly replace all p_uts in tile correct order. IJghtly lubricate

the o-ring seal with clean silicone grease or petroleum jelly and place

in position. Installandtightenthecap,byhandonly.Donotover-tighten

thecap.

Push tool into saltbridge to break

1 r* 2**

Y

Pencil

mark

Broom

handle"-_

Cap ._

O-ringseal_

Screensupport ,,--I,,,-

Screen_ _

_Flowplug_

Nozzle&VenturiGasket_ $

*Flewplug_

Salt

Waterlevel

i

12

/

Nozzle& Venturihousing

IMPORTAN# Be sure small holes in the gasket are centered

directly over flTesmall holes in the nozzle and venturi housing.

Hnstall wifl7 numbered side up,concave side down.

Page 13

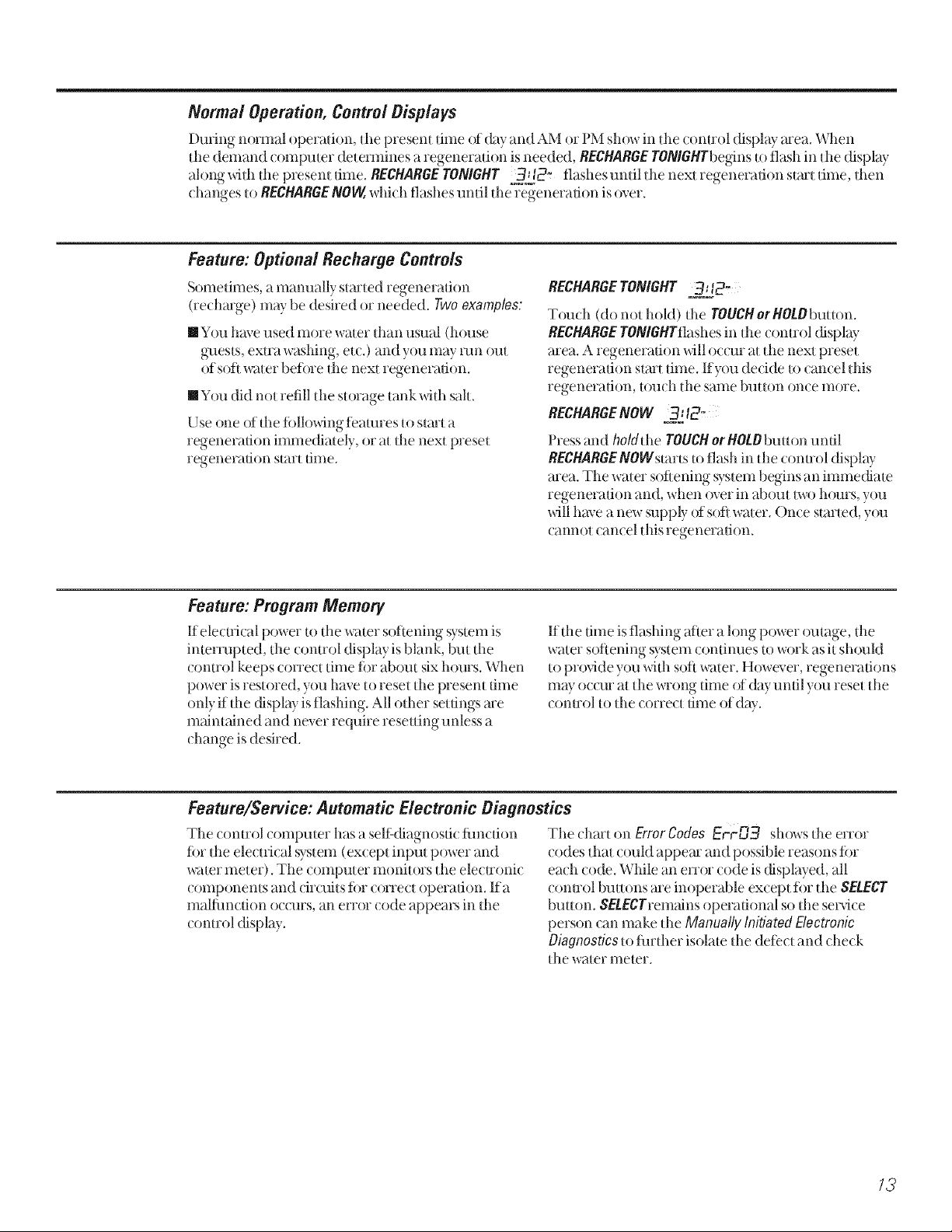

Normal Operation, Control Displays

During normal operation, )he present time of day and AM or PM show in dm (onuol display area. When

)lie demand ( omputer determines a regeneration is needed, RECHARGETONIGHTbeginsto flash in )lie display

along _dlh the presenl fime. RECHARGEYO/vlGHY 32j2" flashesunfildmnexlregenerafionslarllime, fl_en

(hanges U)RECHARGE/VOW,whi(h flashes until the regeneration is over.

Feature: Optional Recharge Controls

Sometimes, amanually stmled regeneration

(recharge) may be desired or needed. Two examples:

[] You have used more waler than ualal (house

guests, exUa washing, etc.) and yotl may mn out

of soft waler befi)re fl_e next regeneration.

[] You did nol refill d*e storage rank whh sail.

Use one of the fi)llowing ieamres to stmt a

regeneration immediately, or aI Ihe next preset

regeneration slarl time.

Feature: Program Memory

If ele(uical power to dm wmer soiiening system is

interrupted, the control display is blank, but fl_e

(onu'ol keeps correct time fi)r about six hours. When

power is restored, you have to reset the presem time

only if fl*edispl W is flashing. All oilier seuings me

m_fint_fined and never require resetting unless a

(hange is desired.

RECHARGETONIGHT 3]" 2,

Touch (do not hold) tim TOUCHorHOLObuuon.

RECHARGETO/vlGHTflashes in tile control display

area. A regeneration will occur at the next preset

regeneration start time. If you decide u) cancel this

regeneration, u)uch the same buuon once more.

RECHARGE/VOW 3_12_

Pressand ho/&he TOUCHorHOtObuuon until

RECHARGE/vOWst'artsto flash in tim (onuol display

area. The water sofiening system begins an immediate

regeneration and, xdmn oxer in about Ix_ohours you

will haxe a new supply of sod water. ()nee s)aned, you

(annot (an(el [his regeneration.

If tile time is flashing after a long power omage, tile

water soiiening system ( ontinues to work as it sh_)uld

to pro)vide you _dth soil water. H_)wever, regenerations

mW oc(ur at the wrong time of dayuntil you reset tile

(onnol to tl_e(orre( t time of dW.

Feature/Service: Automatic Electronic Diagnostics

The control compmer has a seli:(fiagnosfic fimcfion

fin tl_e ele( tri( al system (except input power and

water meter). The (omputer monitors the elecuoni(

(omponems and (irofits fi)r correct operation. Ifa

malfimction oc(:urs, an err_)r code appears in fl_e

conu:ol display.

The chart on ErrorCodes Er-rU3 shows the error

(;odes that could appear and possible reasons ior

each (:ode. While an error code is displayed, all

control bretons are inoperable except fi)r the SELECT

buuon. SEtECrrem_finsoperational so d_e service

person can make tl,e Manually Initiated Electronic

Diagnosticsto innher isolate fl_edeiect and check

tile water meter.

/3

Page 14

Aboutthe water softener system.

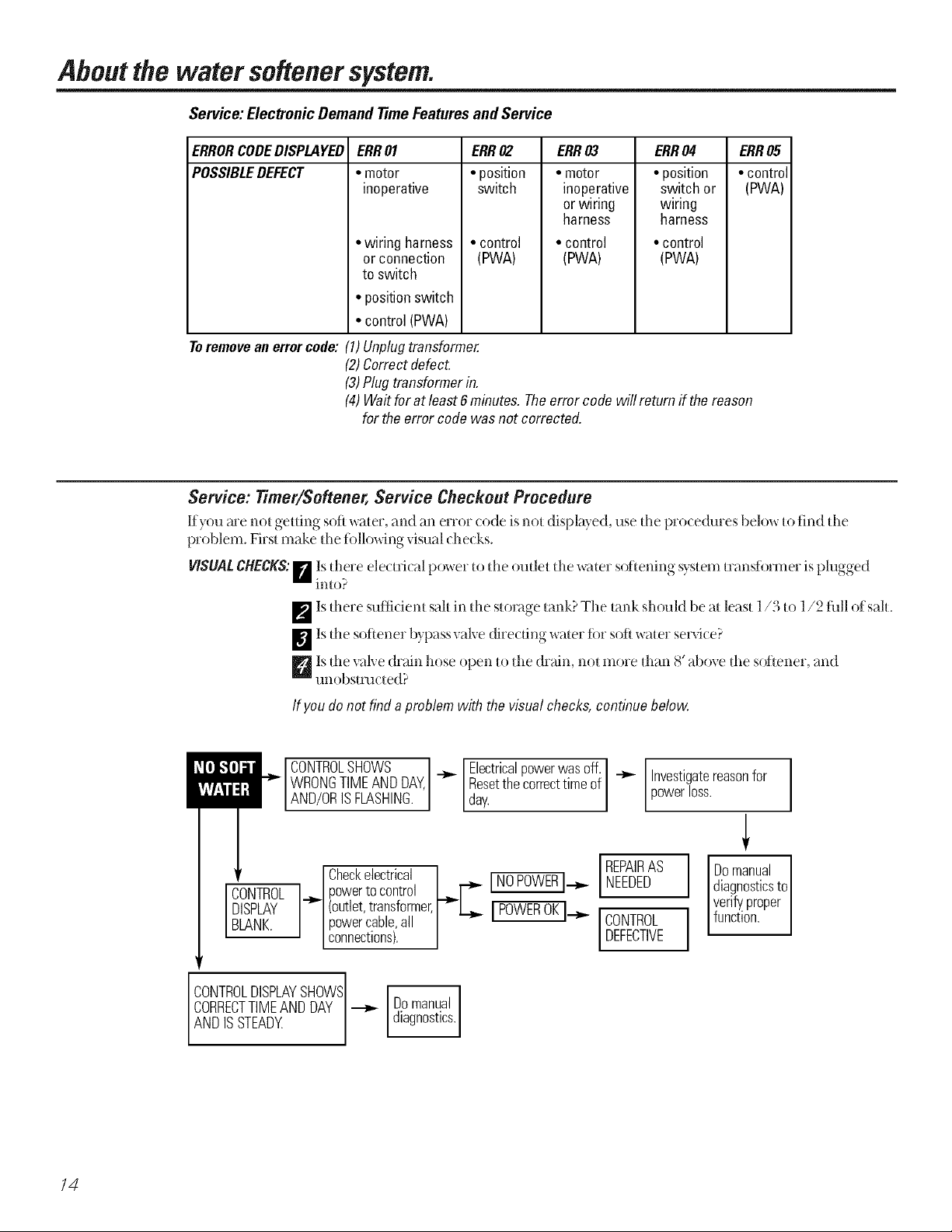

Service: Electronic Demand 77meFeaturesand Service

ERRORCODEDISPLAYED ERR03 ERR04

POSSIBLEDEFECT

Toremovean errorcode: (1)Unplugtransformer.

ERR01

• motor

inoperative

• wiring harness

or connection

to switch

• positionswitch

• control(PWA)

(2)Correctdefect.

(3)Plugtransformerin.

(4)Waitforat least 6minutes.Theerror code willreturn if the reason

for the error codewas not corrected.

ERR02

• position

switch

• control

(PWA)

• motor

inoperative

or wiring

harness

• control

(PWA)

• position

switch or

wiring

harness

• control

(PWA)

ERR05

• control

(PWA)

Service: Timer/Softener, Service Checkout Procedure

If you me not getting soft water, and an error (ode is not displayed, use tile l)ro(edures below to find tl_e

problem. First make [l_e%11()-_dngvimal (he( ks.

VISUALCHECKS:[] Isthere ele( tri( al power m dm oudet dm water softening system mmsfbrmer is plugged

imo?

_p'_Isdmre sufficient sail in dm storage lank? The tm_kshoukl be at least l/3 t() l/2 fhll ofsah.

_Is dm softener bypass valve direcdng water for soft water serx4ce?

Dis dm valve drain hose open Io dm drain, nol more d_an 8' aboxe d_e softener, and

tlnobs[Ftl(:[ ed?

If youdonot finda problemwith the visualchecks,continuebelow

CONTROLSHOWS I

WRONGTIMEANDDAY,

AND/ORSFLASHNG.

CONTROL

DISPLAY

BLANK.

CONTROLDISPLAYSHOWS Domanual

ANDISSTEADY

CORRECTTIMEANDDAY_ dagnostcs.

Checkelectrical INOPOWERI.__,,._NEEDED

powertocontrol LJ -_"

(outlet,transformer,r'-L_,. [ POWEROK].__,. I

powercable,all | CONTROL

connectons. | I DEFECTIVE

[Electricalpowerwasoff. _ Investigatereasonfor

[/day.Resetthecorrecttimeof poweross.

IREPAIRAS

Domanual

diagnosticsto

verifyproper

I function.

/4

Page 15

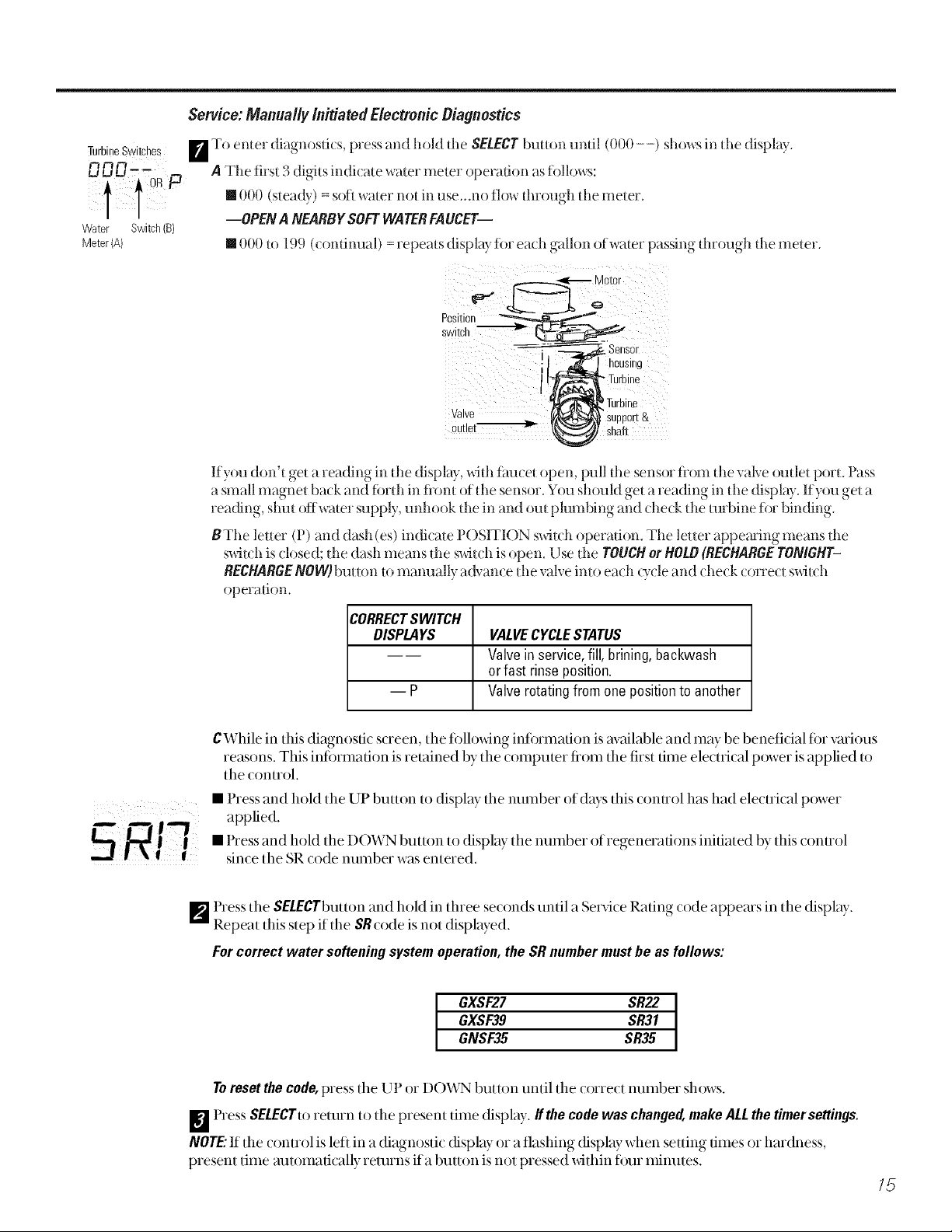

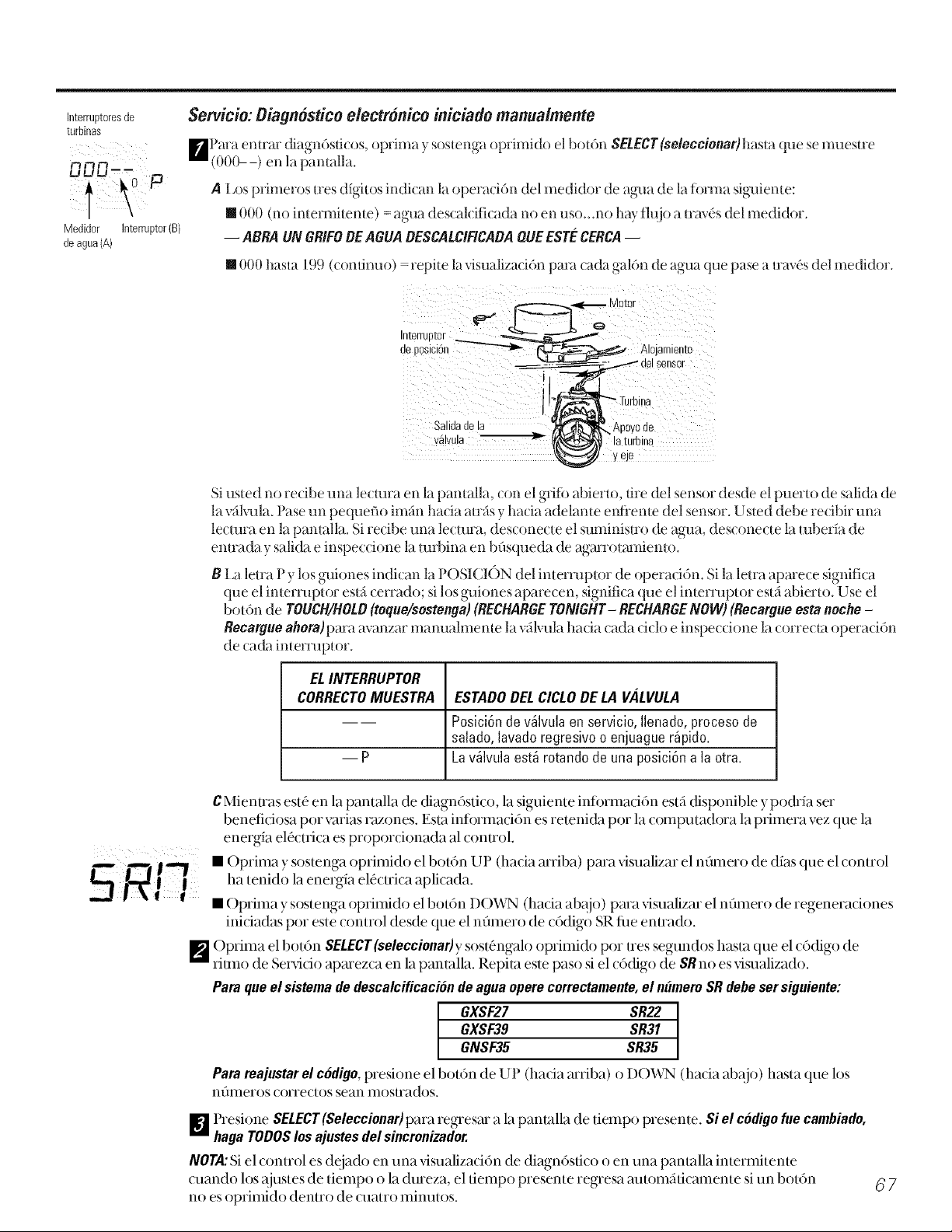

Service: Manually Initiated Electronic Diagnostics

TurbineSwitches [] To enter diagnosdcs, pressand hold [l_e SEI.ECTbullon undl (000 - -) showsin [lie display

_rl m A The firsl 3 digils indicale waler meter operadon asiollows:

IOR P

• 000 (sleady) = soft waler no[ in use_.noflow din)ugh [lie meter.

Water Switch(B)

Meter (A) • 000 tO 199 (condnual) = repeats displ_lyior each gallon of water passing through tl_e meter.

--OPEN A NEARBYSOFTWATERFAUCET--

swi!c/

Sensor

1 _ _)'-housing

I !_Tu[b ine

_Turbine

Valve t_'_l_" Support&

ou!,e! sha,

If you don't get a reading in die display, wid_ faucet open, pull die sensor from d_e; al',e omlet porL Pass

a small magnet back and fbrth in flonl of the sensor. You should get a reading in the display. If you get a

reading, shin of{waler supply, unhook [lie in and ouI plumbing and (hetk die [urbine ior binding.

BThe letter (P) and dash (es) indicate POSITION swhch operation. The letter appeming means tl_e

s_4t(;h is closed; d_e dash means tl_e swhch is open. Use the TOUCHor HOLB(RECHARGETONI6HT-

RECHARGENOW)buuon to mamlally advance die valve imo each Q,cle and check corred switch

operation.

CORRECTSWITCH

DISPLAYS

VALVECYCLESTATUS

Valvein service,fill, brining,backwash

orfast rinse position.

Ep

Valverotatingfrom one positionto another

CWhile in this diagnostic screen, the fi)llowing infi)rmation is available and may be benefidal for various

reasons. This intormation is retained by the computer fiom the first time electrical power isapplied to

the control.

• Press and hold the UP button to display the number of days this control has had electrical power

applied.

• Press and hold the DOWN button to display the number of regenerations initiated by this control

since the SR code number was entered.

F_ Press the SELECTbuttonand hold in three seconds until a Service Rating code appears in the display.

Repeat this step if the SRcode is not displayed.

Forcorrect water softening system operation,the SRnumbermustbe as follows:

GXSF27 SR22

GXSF39 SR31

GNSF35 SR35

Toresetthecode,pressthe L l or DO'vVN button until the correct number shows.

_] Press SELECTto rettlrn to the present time display, tithe cedewaschanged,makeALLthetimersettings.

NOTE:If the (ontrol is left in a diagnosti( display or a flashing display when setting times or hardness,

present time automatically returns ifa button is not pressed within ti)tli minutes.

/5

Page 16

Aboutthe water softener system.

Service: Manually Advance Regeneration Check

Tiffs check verifies proper operauon of tlle valve motor, brine tank fill, brine draw, regeneration fit)w rates and other (omroller

flmcdons. First, make tile initial checks and file Manually Initiated Electronic Diagnostics.

NOTE:The connol display nmst shrewa steady dine (not flashing).

F_ Press fl_e TOUCHorHOLDbutton and hoki in fin duee seconds. RECHARGENOWbegins m flash as the x_wtersoftening system

enters the fill Q,cle ofregenerauon. Remove the brinewell (over and, using a flashlight, obse_,e fill x_wterentering tl'le brine

tank. If water does not enter tl_e tank, look ti)r an obstm( ted nozzle, venmri, fill fl(rwphlg or brine robing. See Care and cleaning

ofthe water softenersystem secuon.

_ Atier obserx4ng fill, press dm TOUCHor HOLDbutton t()move d_e water softening svstem into brining. A slow flow ofwater to the

drain will begin. Veri_ brine (haw fiom the brine tank by shining a flashlight imo dm brinewell and obserx4ng a nod( eable (hop

in tile liquid level over an extended period of time.

NOTE:Be sure a salt bridge is not preventing water fiom contacting sah. See Care and cleaningof the water softeningsystem section.

If thewater softening systemdoesnot draw brine,check:

[] nozzle and/or venmri dirty or detective. [] detective nozzle and venmri seal

[] nozzle and venmri not seated properly on gasket. [] odler inner valve deter t (rotor seal, rotor & disc, wave washer, eL(.).

[] restri( ted drain (check drain fiuing and hose).

NOTE:Ifwater system pressure islow, an elevated &ain hose m W (arise balk pressure, stopping brine draw.

W] Again, press the TOUCHorHOLDbutton to move tile water sofiening system into backwash. I x)ok ti)r a fast flow of water fiom dm

d;ain hose. A slow flow indicates a plugged top distributor, backw_'M_flow plug, or drain hose.

D Press tl_e TOUCHorHOLDbutton to moxe the water softening system into £tst rinse. Again look tora ti_stdrain flow. Allow

tlle water softening svstem to rinse fin a few minutes to flusl'l t£ut any brine dial may ,)emain in fl_e resin tank flom tlle brining

()'cle test.

_Toremrndmwater sofieningsvstemmservi(e pressdm TOUCHorHOtDbmton.

Careandcleaning of the water softeningsystem.

Checking the Salt Storage Level and Refilling

Brine (salt dissolved in water) is needed tor each and eve_Tregeneration. The water fi)r making brine is metered into tile salt

storage mea by tile water soliening system valve and conuol. However,youmustkeepthetank supplied withsalt.

When to refill with salt: Check tile salt level a tew weeks atier you install tile water soliening system and eve D"week after that. Refill

when the brine rank is tiom l/3 to 1/2 fifll. In humid areas it is best to fill with lesssalt more olien. Never all()w tile water soliening

system to use all the salt beti)re you refill it. Without salt, you will soon have hard water.

Use clean water sotiening salts only, at least 99.5% pure. NUGGET, PEII_ET or coarse SOLAR salts me recommended. De net use

rock,block,granulatedoricecreammakingsalts.They contain dirt and sediments, or nmsh and cake, and will create maintenance

problems.

CAUTION:Waterse#ening salt with ironremoving additives:Some salts may have an additive to help the water softening system

handle iron in the water supply. Although this additive may help to keep the water sotiening system resin clean, it may also

release corrosive flmms that weaken and shorten the lite of some water sot/ening system pmts. GE recommends using only

Diamond Cusml' Red.Duff brand salt.

Cleaning Iron Outof the Water Softening System

Your water softening system takes h_udness minerals (caldum and magnesium) out of the water. Also, it can control some (see

Specification Guidelinessection) "clear water" iron. With clear water iron, water fiom a timcet is clem when first put into a glass. After

15 to 30 minutes, the water begins to cloud or turn rust colored. A water soliening system will notremove any iron that makes the

water cloudy or rusly as it comes tiom the taucet (called red water iron). To rake red water iron out of water, or over the maximum

of clem water iron, an iron fiher or other equipment is needed.

GE recommends using only Diamond Custal '_Red.Duff brand salts with hon Fighter '_additive to help keep the resin bed clean of

clem iron. Ify{)ur water supply has clear water iron, periodic resin bed cleaning is needed. GE recommends using Super hon Out"

brand resin bed cleaner to thor{)ughly clean your resin bed ify{)ur iron content is high. (lean the bed at least eve U six months, or

more often if iron appears in the sot/water belween cleanings.

IMPORTANT:It is important to mix the resin bed cleaner with water (tollowing the mamlthcmrer's insmlctions), pour it into the

Orinewell tube (see page 6) and regenerate the softener immediately. Do not pour the resin bed cleaner in xdth the salt, as it will not

be as ettecfive in cleaning the resin, and can cause damage to the sot/ener if it is let/in the brine tank ti)r an extended period due to

the corrosive gases that are limned.

16

Page 17

Troubleshooting 77ps

Save time and money! Review the chart on this

page first and you maynot need to call for service.

NO SOFT WATER - Most Common Problems:

Check the following before calling for service

• Not enough salt in softener-should be at least 1/3 full.

• Bypass vane in "Bypass" position-should be in "Service" position. Knob should

be in the OUT position.

• Hardness setting too low-Check hardness setting in control. Veri_ hardness of

supply water. Water hardness can vary throughout the year. See Programming the

Control section.

• Salt Bridge; water not in contact with salt-see Breaking a Salt Bridge section.

Problem PossibleCauses What ToDo

No soft water Faucet or fixture where sample was

taken not plumbed to soft water.

NOTE"Besuresampleis froma faucet

that doesnot mixsoft andhard water.

Forexample,a singleleverkitchen faucet,

if thecold side isplumbedto hard water

No salt in the brine tank or

salt bridged

Transformer unplugged at wall outlet or

power cable to softener not connected.

Fuse blown or circuit breaker popped

on circuit to electrical outlet.

Electrical outlet on a circuit that can

be s_itched off

Manual bypass valve in bypass position ° Be sure the bypass valve stem is positioned properly, xdth the

Valve drain hose pinched, plugged,

elevated too high or otherwise

restricted

• To conse_a:esalt, the installer may haw isolated some

fixttaes (outside thucets, toilets, etc.) flom soti _'ater.

From the outlet of the water softening system, uace the

water flow path, in house plumbing. If soti water is not

directed to a tm_cet or fixture where wanted, consult

a plumber.

• Check fin a salt bridge or, if the lank is empty, refill with

recommended salt. Press (fin 3 seconds) the TOUCHor

HOLDbutton to start an immediate regeneration and restore

soft water supply.

°Check fin a loss of elecuical power to the w:tter

sotiening system, due to any of these conditions and

correct as needed. With the power supply restored,

observe the taceplate time display and read Program

Memorysecuon. NOTE"Theelectricaloutletforthe softener

shouldbecontinuouslyliveso# cannot be accidentally

switched off.

hmb in the OUT position. Observe instructions on the decal

at the end of the stem.

• Any restriction in this drain hose ma) prevent {)roper

operation of the nozzle and venturi and reduce or

prevent brine (haw during regenerations.

Nozzle and venturi dirty, incorrectly

assembled or damaged

•ReFerto CleaningtheNozzleand VenturiAssemblyinstmctions.

With water pressure to the water soliening system off,

take the nozzle assembly apart. Inspect, clean and

replace as needed. Any fi)reign particle (s), scratches,

nicks, etc., in the passages can prexvnt operation. Besure

holes in the gasket are cenmred ox>r holes in the housing.

/7

Page 18

Before you call for service...

Q\ Troubleshooting -tips

Problem Possible Causes What To Do

Waterhardsometimes Using hot water while the water *Avoid using hot w_lter during w_ltersoftening system

softening system is regenerating regener;ldons bec;mse the w_ter heater _dll reiill with

h_adw_ter. SeeAutomatic Hard WaterBypassDuring

Regenerationsecdon.

Control hardness number setting , Press _md rele_lse the SEtECTbuttonuntil HARDNESSsh_)ws

too low in tile dispiriT. Be sure the number shown is tile same as

the _zttual grains per gallon hardness of yore w_lter

supply. See the Controlse( tion ira t hange in the seuing

is needed.

Grains of hardness in your water • W_t er hardness can change over time, especially in

supply have increased well water. To check, have the water tested by _lw_lter

analysis labor_to_y or tall your loc_d w_lter department.

A(!iust the hardness number setting as needed.

Water feels slippery Absence of hardness minerals • This is normal.

after installation of

water softening system

Water softening system Water softe_fing system is a , Does not use muth salt to regenerate-very eflitient.

not using any salt "demand" unit

Possible salt bridge • See the Operating Instructions, Tipsse(tion.

Possible plugged nozzle and ventu6 • See the Operating Instructions, Tipssection.

Water is blue color Acidic water in copper plumbing • Have the water tested at once.

after water softening

system was installed _k WARNING: Do notdrink the water until problem has

been corrected.

Water softening system Meter turbine stuck • ('_all i()r sel_,_i(e.

not regenerating

Sensor wire corroded • Call fi)r ser_i( e.

No power to unit = Check tile tircuit breaker or fllses.

Mechanical defect = Call for servi( e.

Cloudiness on glassware Combination of soft water and • This is tailed etching and is permanent. To prevent this

(automatic dishwashers) too much detergent fi'om happening, use less detergent if you have soil water.

\,\Sisl_ glassware in the shortest t_,( le that will gel them (lean.

Salty tasting water Insufficient backwash and • Press and hold TOUCH or HOtObutton until RECHARGE

after installation rinse thne st_Jrts to flash.

• At ( ompleuon of regeneration (Tile (approx. 2 hrs), mn water

from iim{ ets to purge the sail}' water.

Lowwater pressure • Che(k pressure; should be minimum 20 psi.

Restricted drain hose * Clean and reconnect bose.

/oo

Page 19

Problem Possible Causes What ToDo

Resinbeadsshewing Cracked distributor • Call lot se_ice.

upin drinkingwater

andsink

Soundsyoumighthear Running water from the unit into •This is normal.

a drain

Waterhasair bubbles Air in system after installation •_A]ll go away after it runs tbr a while.

andiscloudy

ErrorCode on control Wiring may have worked loose in

control

• Unplug transti)rmer.

• Rem,)ve control cover, release clips on side.

• Check ti)r loose/incorrect wiring connections to elecuonic

board or switch. Reconnect as required.

• Reassemble control o)ver.

• Plug in T_'ansli)rmer.

• Wait six minutes ti)r Error Code to reappear.

• If Error Code reappears, call ti)r sevvice.

/9

Page 20

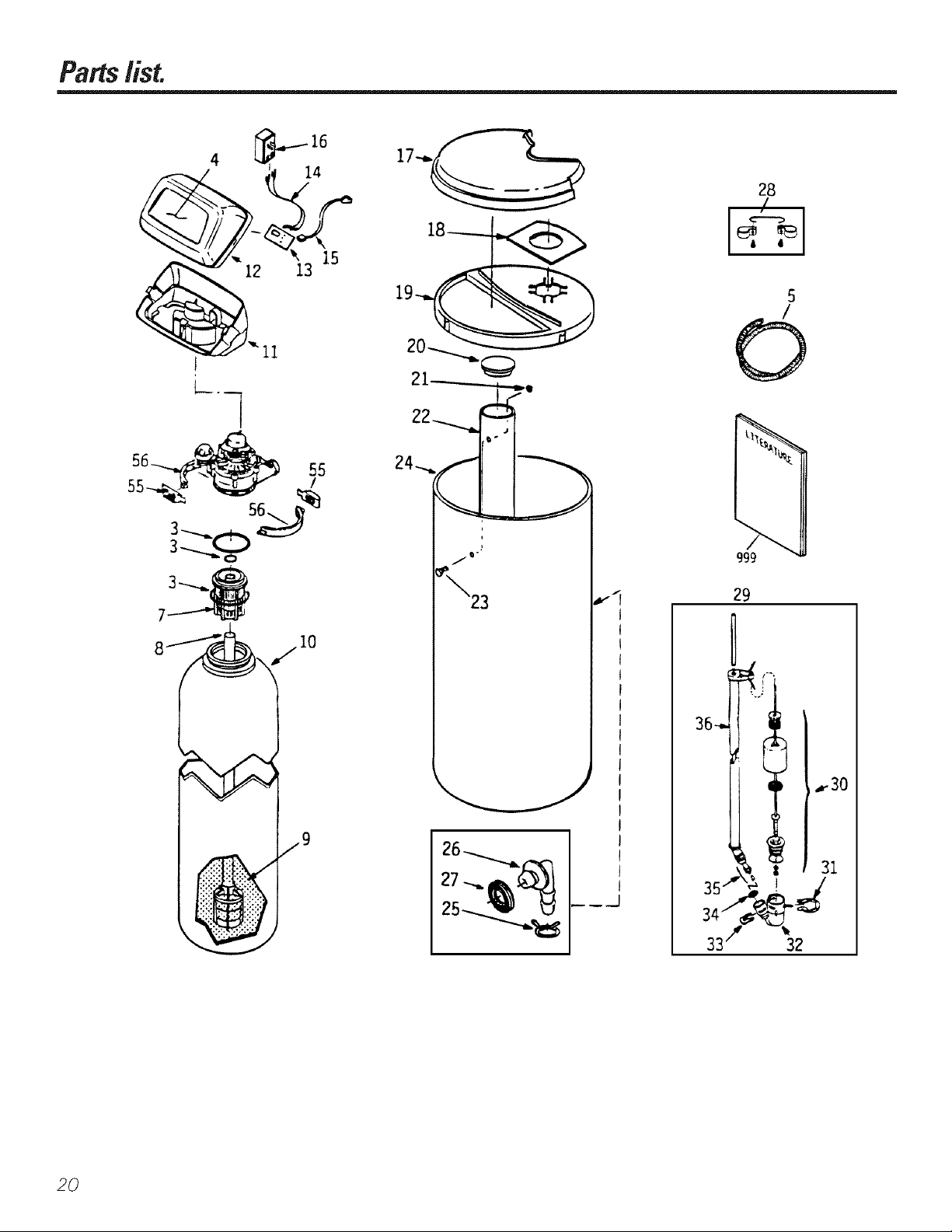

Partslist.

56_ 55

4 _ .....-.-16

28

/

18

I

56_

10

1

/If"

29

36-. _" _-30

2O

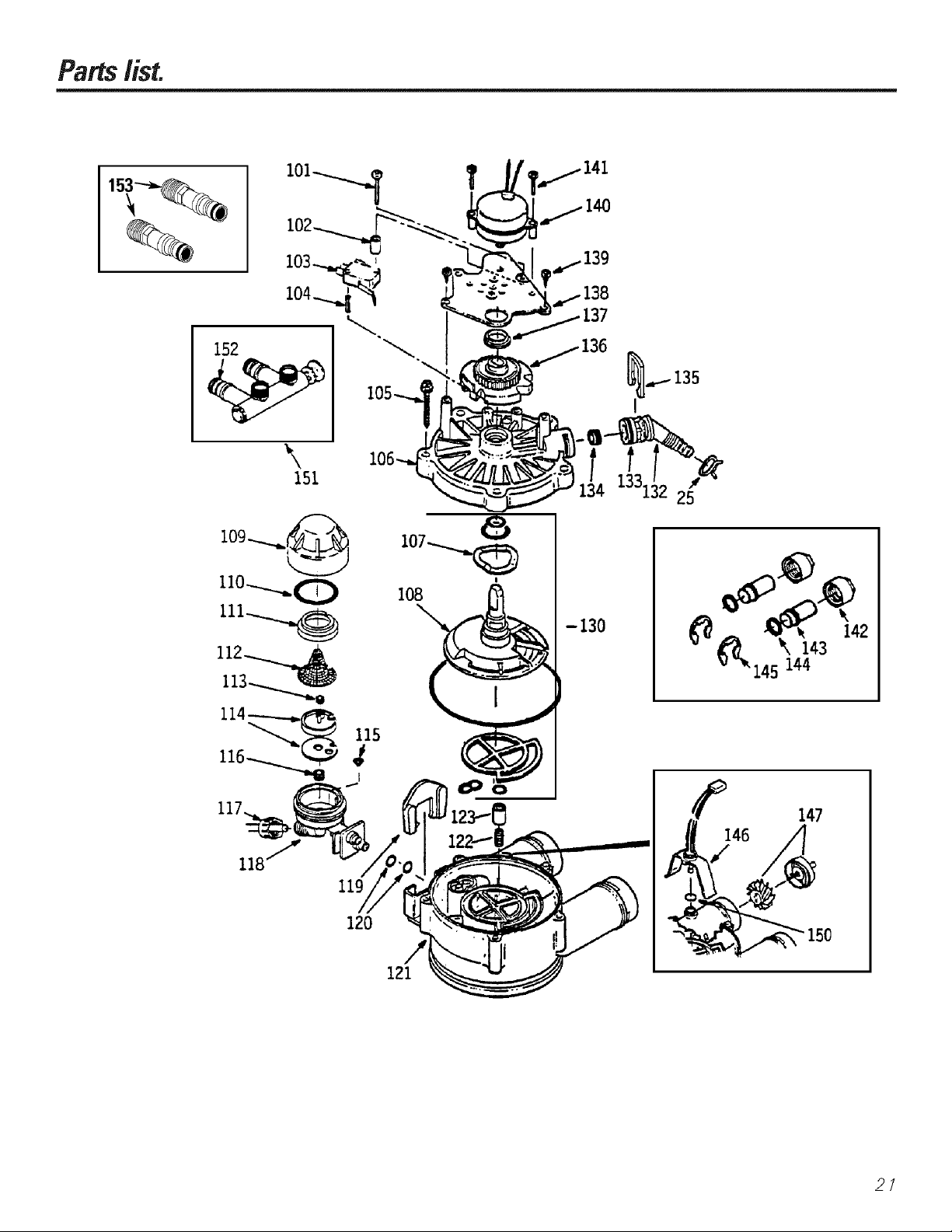

Page 21

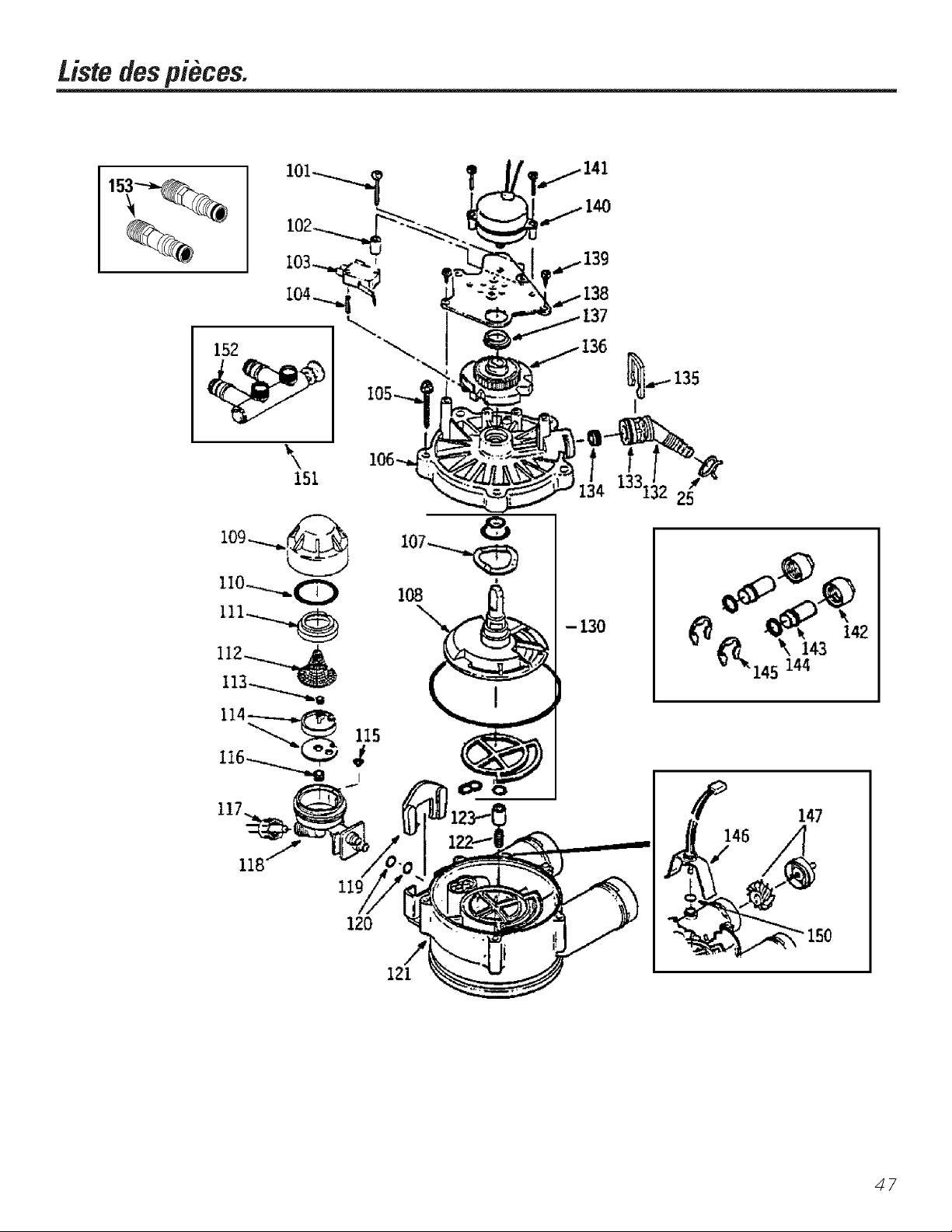

Partslist.

152

\

151

120

-130

l

147

/

146 _

/

121

21

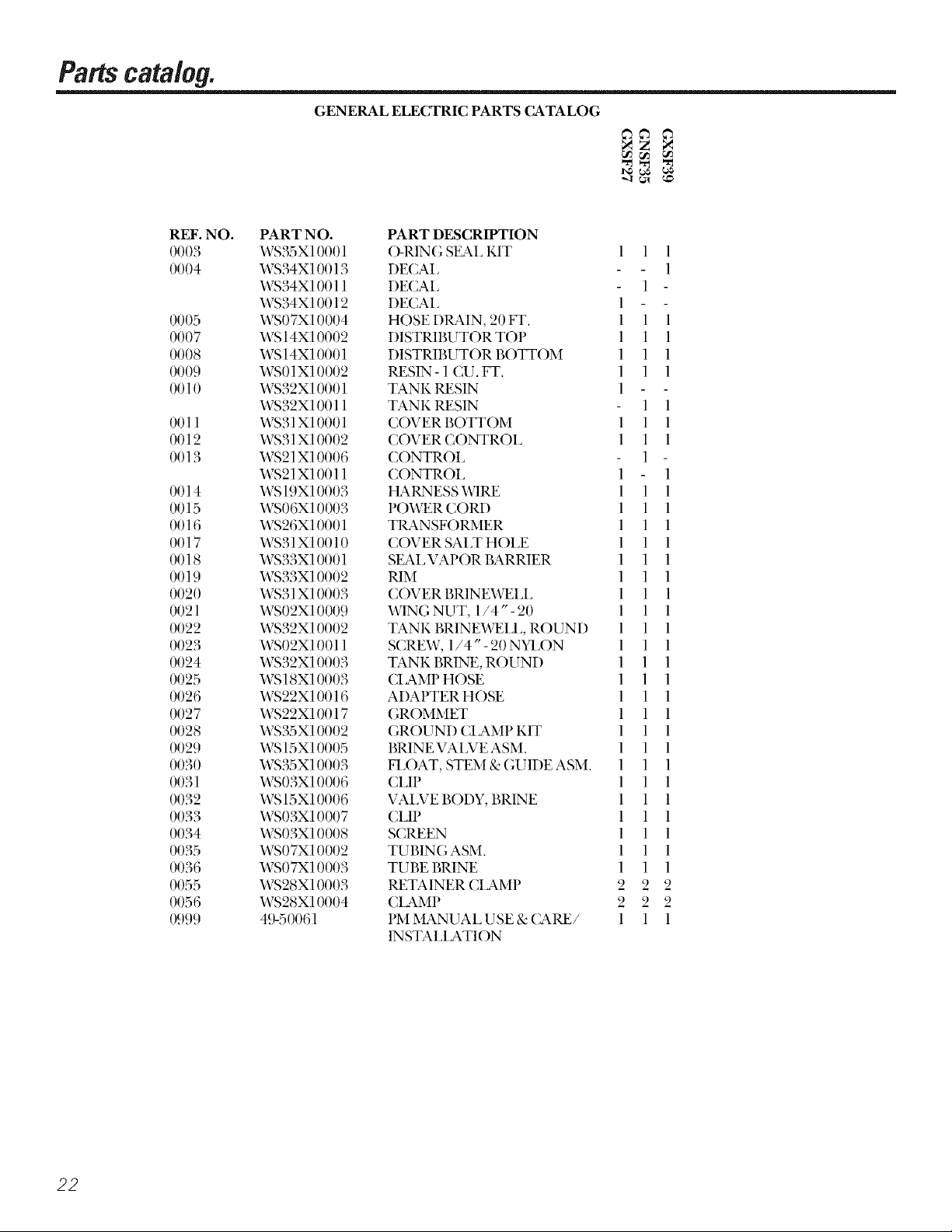

Page 22

Partscatalog.

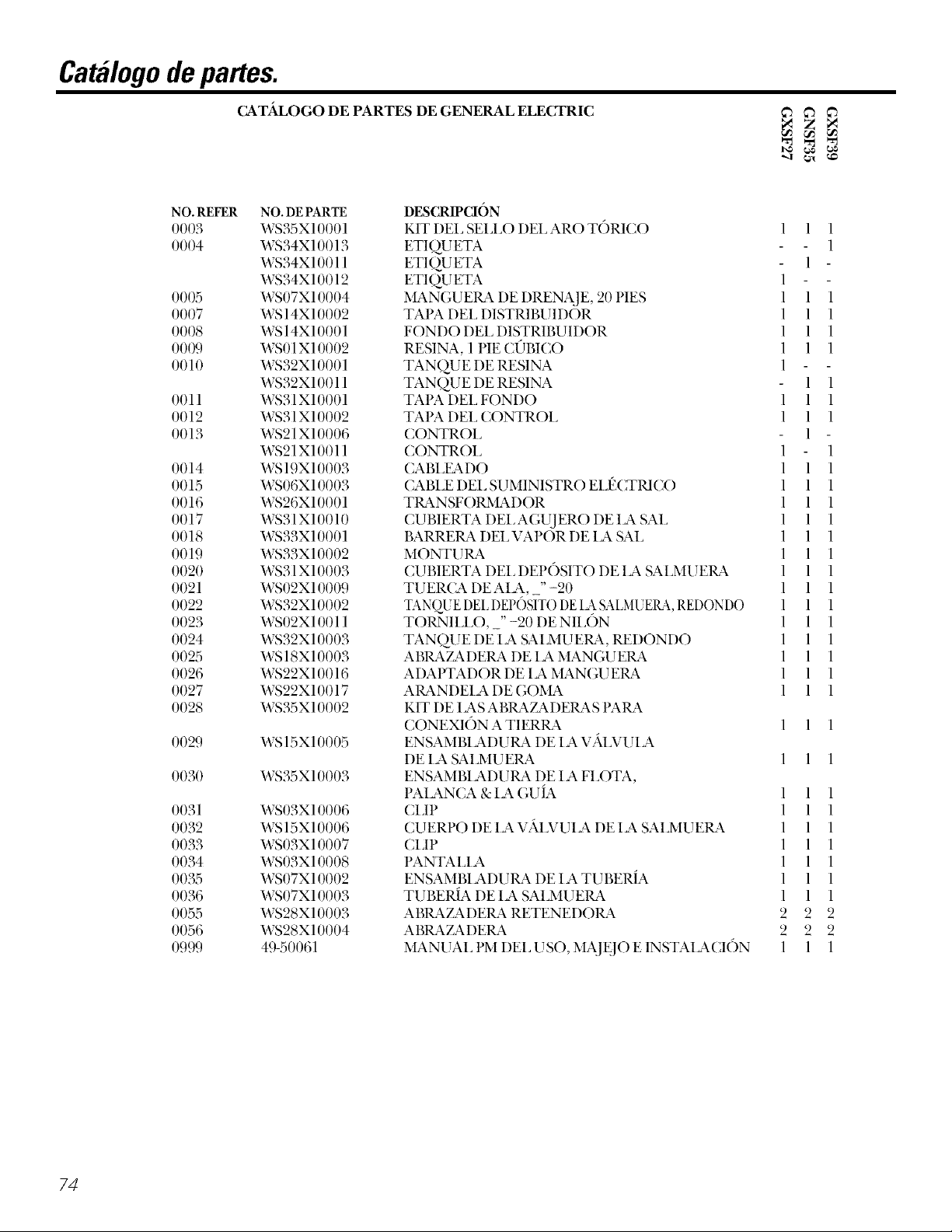

REF. NO. PART NO. PART DESCRIPTION

0003 WS35X10001 ()-RINGSEA1, KIT 1 1 1

0004 WS34X10013 DECAl, 1

0005 WS07X10004 HOSEDILAIN, 20FT. 1 1 1

0007 WS14X10002 DISTRIBUTOR TOP 1 1 1

0008 WS14Xl0001 DISTRIBUTOR BOTTOM 1 1 1

0009 WS01X10002 _SIN-1 (U. FT. 1 1 1

0010 WS32X10001 TANK _SIN 1

0011 WS31X10001 COVER BOTTOM 1 1 1

0012 WS31X10002 COVERCONTRO1, 1 1 1

0013 WS21 X10006 CONTROl, 1

0014 WS19X10003 HARNESS WIRE 1 1 1

0015 WS06X10003 POWERCORD 1 1 1

0016 WS26X10001 TRANSFORMER 1 1 1

0017 WS31X10010 COVER SAI,T HOI,E 1 1 1

0018 WS33X10001 SLAI, VAPOR BARRIER 1 1 1

0019 WS33X10002 RIM 1 1 1

0020 WS31X10003 COVERBRINEWEI,I, 1 1 1

0021 WS02X10009 WING NUT, 1/4"- 20 1 1 1

0022 WS32X10002 TANK BRINEWEII,,ROUND 1 1 1

0023 WS02X10011 SCREW, 1/4"- 20 NYI,ON 1 1 1

0024 WS32X10003 TANKBRINE, R()UND 1 1 1

0025 WS18X10003 CIAMPHOSE 1 1 1

0026 WS22X10016 ADAPTER HOSE 1 1 1

0027 WS22X10017 GROMMET 1 1 1

0028 WS35X10002 GROUND (1AMPKIT 1 1 1

0029 WS15X10005 BRINEVAI,VEASM. 1 1 1

0030 WS35X10003 FIr)AT, STEM&GUIDEASM. 1 1 1

0031 WS03X10006 (I3P 1 1 1

0032 WS15X10006 VAI]VEBODY, BRINE 1 1 1

0033 WS03X10007 CI3P 1 1 1

0034 WS03X10008 SCREEN 1 1 1

0035 WS07X10002 TUBINGASM. 1 1 1

0036 WS07X10003 TUBEBRINE 1 1 1

0055 WS28X10003 P,,ETAINER CIAMP 2 2 2

0056 WS28X10004 (1AMP 2 2 2

0999 49-50061 PMMANUAI, USE&('ARE/ 1 1 1

GENERAL ELECTRIC PARTS CATALOG

WS34X10011 DECAl, 1

WS34X10012 DECAl, 1

WS32X10011 TANK_SIN 1 1

WS21X10011 ( ONTROI, 1 1

INSTAI,I ATI ON

22

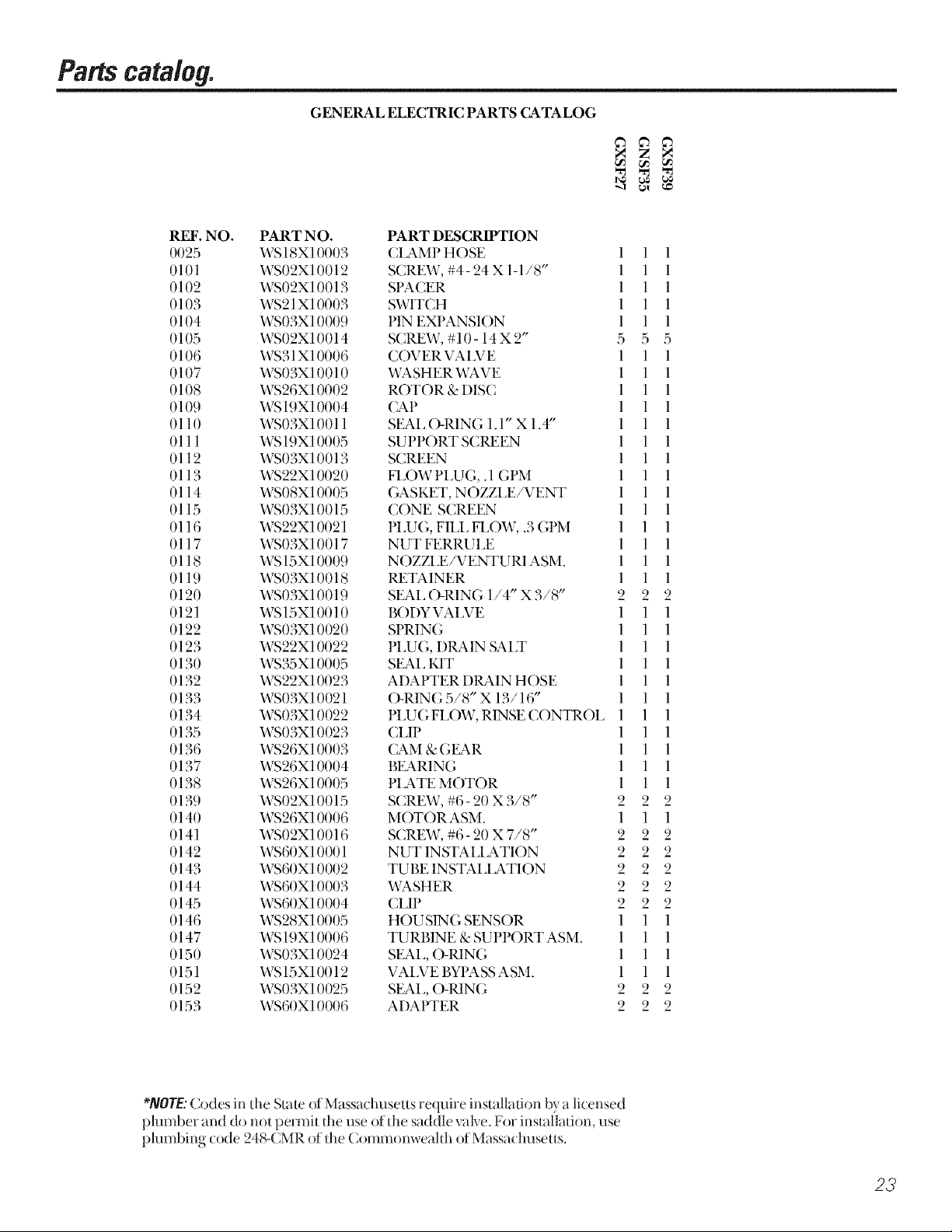

Page 23

Partscata/og.

REF. NO. PART NO. PART DESCRIIVI'ION

0025 WSISXI0003 CIAMP HOSE 1 1 1

0101 WS02X10012 S(REW, #4- 24 X 1-1/8" 1 1 1

0102 WS02X10013 SPACER 1 1 1

0103 WS21X10003 S'v\ITCH 1 1 1

0104 WS03X10009 PIN EXPANSION 1 1 1

0105 WS02X10014 SCREW, #10- 14 X 2" 5 5 5

0106 WS31X10006 (OVERVAI.VE 1 1 1

0107 WS03X10010 WASHERWAVE 1 1 1

0108 WS26X10002 ROTOR&DIS(; 1 1 1

0109 WS19X10004 CAP 1 1 1

0110 WS03X10011 SL_L O-RING 1.1" X 1.4" 1 1 1

0111 WS19X10005 SUPPORT SCREEN 1 1 1

0112 WS03X10013 S(REEN 1 1 1

0113 WS22XI0020 FI_OWPIJUG, .1 GPM 1 1 1

0114 WS08X10005 GASKET, NOZZI_E/VENT 1 1 1

0115 WS03X10015 (;ONE SCREEN 1 1 1

0116 WS22X10021 PIJUG, FII,I_ FI_OW, .3 GPM 1 1 1

0117 WS03X10017 NUTFERRUI_E 1 1 1

011S WS15X10009 NOZZLE/VENTURIASM. 1 1 1

0119 WS03X10018 RETAINER 1 1 1

0120 WS03XI0019 SL_L O-RING 1/4" X 3/8" 2 2 2

0121 WS15X10010 BODYVALVE 1 1 1

0122 WS03X10020 SPRING 1 1 1

0123 WS22X10022 PLUG, DtL_klN SALT 1 1 1

0130 WS35X10005 SL_LKIT 1 1 1

0132 WS22X10023 ADAPTERDtL_klN HOSE 1 1 1

0133 WS03X10021 O-RING5/8"X13/16" 1 1 1

0134 WS03X10022 PI,UG FIfO'W, RINSE CONTROL 1 1 1

0135 WS03X10023 CIJP 1 1 1

0136 WS26X10003 CAM & GIC_kR 1 1 1

0137 WS26X10004 BL_kRIN(; 1 1 1

0138 WS26X10005 PI,_kTE MOTOR 1 1 1

0139 WS02X10015 SCREW, #6- 20 X 3/8" 2 2 2

0140 WS26X10006 MOTORASM. 1 1 1

0141 WS02X10016 SCREW, #6- 20 X 7/8" 2 2 2

0142 WS60X10001 NUTINSTALL_kTION 2 2 2

0143 WS60X10002 TUBEINSTALL_kTION 2 2 2

0144 WS60X10003 _,\D_kSHER 2 2 2

0145 WS60X10004 CI]P 2 2 2

0146 WS28X10005 HOUSING SENSOR 1 1 1

0147 WS19X10006 TURBINE & SUPPORTASM. 1 1 1

0150 WS03X10024 SL_kL, O-RING 1 1 1

0151 WS15X10012 VAI;VE BYPASS ASM. 1 1 1

0152 WS03X10025 SL_L, ()-RING 2 2 2

0153 WS60XI0006 ADAPTER 2 2 2

GENERAL ELECTRIC PARTS CATALOG

_NOTE:Codes in the Slate of Massachusetts require installation by a lit ensed

plumber and do not permit the use of the saddle valve. For installation, use

plumbing code 24&CMR of ihe Commonweahh of Massachusells.

2,7

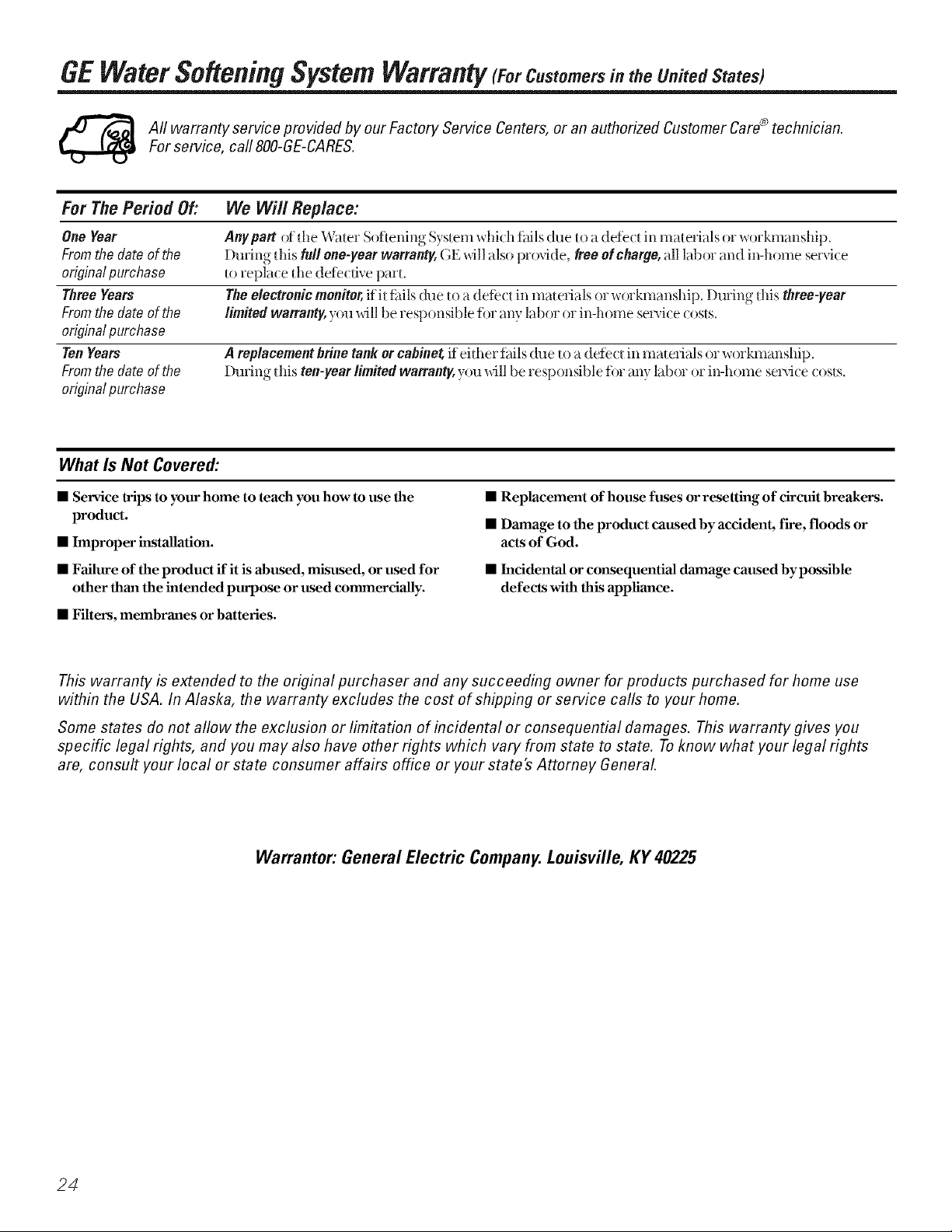

Page 24

GEWater Softening System Warranty (ForCustomersintheUnitedStates)

For service, carl 800-GE-CARES.

All warranty service provided by our Factory Service Centers, or an authorized Customer Care_;technician.

For The Period Of: We Wit Replace:

One Year

From the date of the

original purchase

Three Years

From the date of the

original purchase

Ten Years

From the date of the

original purchase

What Is Not Covered:

Any part of tile W_lter Softening Syslem which iilils due Io a dete(::l in materials or workmanship.

During this full one-year warranty, GE xdll _llso proxide, free of charge, _lll labor _md in-home servi(e

to repla( e d_e deie( dye p_wL

The electronic monitor, if il ihils due Io a deiet:t in materials or workmanship. During dds three-year

limited warranty, you will be responsible fi)r m_y l_lbor or in-home sevvi( e ( osts.

A replacement brine tank or cabinet if eid_er ihils due 1o a de/e(:t in mat erials or workmanship.

During dds ten-year limited warranty, you _ll be responsible fi)r any labor or in-home servi( e (osts.

• Service trips to your home to teach you how to use the

product.

• Improper installation.

• Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

• Filters, membranes or batteries.

• Replacement of house fuses or resetting of circuit breakers.

• Damage to the product caused by accident, fire, floods or

acts of God.

• Incidental or consequential damage caused bypossible

defects with this appliance.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state. Toknow what your legal rights

are, consult your local or state consumer affairs office or your state's Attorney General.

Warrantor: General Electric Company.Louisville, KY 40225

24

Page 25

GEWater So#eningSystemWarranty(ForC.stomersi. Ca.adaJ

For service, call toll free 1-866-777-7627.

All warranty service provided by our Factory Service Centers or an authorized technician.

For The Period Of'. We Will Replace:

OneYear

Fromthedate of the

originalpurchase

ThreeYears

Fromthedate of the

originalpurchase

TenYears

Fromthedate of the

originalpurchase

What Is Not Covered'.

Any part of tile Water Softening System which fifils due to a detect in materials or w{)rkmanship.

During this full one-year warranty, GE ;fill also provide, free of charge, all labor and in-home sevvice

to replace the delecOxv part.

Theelectronic monitor, if it titils &_e to a delbct in materials or workmanship. During this three-year

limited warranty,y_)uwill be responsible fi)r any labor or in-home sevvice costs.

A replacement brine tank or cabine_ ifeither fails due to a detect in materials or workmanship.

During this ten-year limited warranty, you xdll be responsible for any labor or in-home sev_4_e _osts.

• Service trips to your home to teach you how to tlse the

product.

• hnproper installation.

If you have an installation problem, contact your dealer

or installer. You are responsible for providing adequate

electrical, exhausting and other connecting facilities.

I WARRANTOR IS NOT RESPONSIBI_E FOR CONSEQUENTIAI_DAMAGES. I

Warrantor: (:AM(:O INC. ]

• Replacement of house fuses or resetting of circuit

breakers.

• Failure of the produ(t if it is misused, or used for other

than the intended purpose or used (ommerdally.

• Damage to produt t caused by accident, fire, floods or acts

of God.

25

Page 26

Notes.

26

Page 27

ta section Fran aise.

S&urit_

Installation ad&tua/e ......... 29

Directives d'installation

grancheInent de la conduite

de vidange ............... 33, 34

DOballage et inspection ........ 30

Directives d'insta|lalion ..... 30-32

Directives d'installation

drape par drape ........... 33-36

OutilbNe et matOriel requis

pour l'installation ............ 31

Planification et localisation ..... 31

Proglammation du panneau

de commande ............... 35

Recommandations importantes

pour l'insmllation ............ 30

Sanitization ................. 36

SpOcifications et dimensions ...36

Instructions d' utilisation,

eonseils

Aflichages du panneau de

commande ................. 39

Diagnostics alecuxmiques ...... 41

F_limination d'un pont de sel ...38

Nettoyage de l'ensemble

gicleur et venmri ............. 38

Particulafitds ............. 39, 40

Se_wice ..................... 37

Syst6me adoucisseur d'eau..37-42

Syst6me de trigtin,ration ....... 42

Entretien et nettoyage

FJimination du fer. ........... 42

Niveau de l'entreposage

du sel et remplissage .......... 42

Conseils de d@annage . .43-45

Service aux consommateurs

(;arantie .................... 51

Liste des pi_,ces/catalogue . .46-49

Nulndros de/all@hone

importants .................... 52

27

Page 28

Vouset GE,un partenariat deservice.

IMPORTANT!

Remplissez la carte d'eme_strement du produit.

II y a deux manieres faciles d'enregistrer votre appareil!

• Parl'lnternetensaisiss'antl'adresse_.geappliances.com

• En remplissant et en exp_diant la carte d'enregisnement du produit d-incluse

Transcfivez les num#rosde mode/e et deserie ic£

,4CONSERVERSOIGNEUSEMENT

#

#

Vous les nouverez sur Fattache du r_Sse_'oir.

Agrafez /e regu de vente ou /e cheque annul6 icL

Pour obtenir le sel_ice sons garamie, i1est n_cessaire de disposer de la preuve de la date d'achat.

LISEZVOTREMANUEL

V_)usy/rouverez de nombreux conseils pour l'utilisation et 1'entretien de votre adoudssem d' emL Ces quehlues

mesures preventives w)us pem_ettront d'economiser du temps et de I'mgent pour la &nee de vie de l'appmeil.

SIVOUSAVEZBESOINDESERVICE

Vous Uouverez des solutions mix probl_mes courants que v(n]s pourriez rencontrer dans la section Avant

d'appelerun r6parateur.Et, en consultant d'abord nos Conseilsded6pannage,vous pourriez peut-t_ue_dter de

fidre appel aun rdparateur.

Sivous avez besoin de se_ice, vous savez que w)us n'avez qu'_ nous tdldphoner. Vous trouverez a la fin de ce

present manuel les numdr{_s sans flais du se_ice a la clientele.

OU

Visitez notre site Web au vvvvw.geappliances.com

28

Page 29

y y

MESURESDESECUR/TE/MPORTANTES.

USEZD'ABORDTOUTESLESDIRECTIVESAVERT/SSEMENT!

..A VERTISSEMENT! o,rvotres c,rit ,s,ivez,esdirectivesfo,mies a,s,e,r se,tma,,e,a,,

de minimiser les risques de chocs #lectriques, des d#ggts mat#riels et de

blessures graves.

S -CURIT -

• Vdrifiezet respectez lescodes de s_curit(_locaux et ceux de

l'_tat o_'_vous r_sidez. Vous devez suivre leslignes de

conduite suivantes.

• Faites attention lots de l'udlisadon de l'appareil

adoucisseur d'eau. Ne le placez pas la t6te en bas, ne le

laissezpas tomber, ne le drez pas ou ne letititespas passer

sur des aspdriff_spoinmes.

• Pour les adoudsseurs uulisanl lechlomre de sodium (sel)

pour lareg_?ndration,@)utez du sodium a l'eau. Los

personnessoumisesOdesrestrictions concernantlos

dbtes _ basedesodiumdoiventconsid&er /esodium

compl#mentairecommefaisantpartie de/a dose

quotidiennequ'dles prennent.I/est possiblede remp/acer

/echlorure de sodiumpar du ch/oruredepotassiumdans

votreI'adoucisseur.

• L'adou(isseur d'eau ti)n(lionne ave( line alimentadon

dlectrique de 24 xolts sous 60Hz seulement. Assurez-vous

d'utiliseruniquementle transformateurci-inclus.

• [_etranslbrmateurdoit etre branch,, dans une prise murale

ordinaire de 120V(3alveoles, nfisefi la terre).

• N'utilisezque du seladoucisseur d'eau propre avec une

puret(_minimale de 99,5%. Nous recommandons lesel

NU(;(;ET, PELLET Olldu selbrut SOLAR. N'utilisozpas

dnsol aI'etatsolido,onblocs,grannieonIo solservantala

fabricationde cremeglacee. Ce typede sel condent des

saletds,des s(_diments,du charbon et (Illcake qui

eIgen(treront des probl{'mes d'entrdien.

• Oardez lecouvercle de l'ofifice du sel en place sur

l'adoucisseur exceptd pour l'entreden de l'appareil ou sice

dernier est en cours de remplissage avecdu sel.

AAWRTISSEMENT:N'utilisozpasl'appareil sil'eau n'est pas

pure sur le plan microbiolo_que ou sisa qualite n'est pas

@rouv(_esansqu'elle n'ait dt_ddsinfbct_e avant ou apr_s

avoirdt_ trait(_epar l'appareil.

UNEINSTALLATIONADEQUATE

Avant d'utiliser votre adoucisseur, assurez-vous qu'il a #t# correctement install#, conform#ment aux Directives

d'instaflation.

• Installez ou enueposez l'appareil fil'abfi de temp_.ramres

int_rieures all point de coIg_lation, des intemp_fies au

aunes bpes de temps. Le gel de l'eau entrainera le bris de

l'appareil. Ne pas tenter de naiter de l'eau dent la

tempdrature est supdfieure fi100 degr_s F.

• N'installezpasl'appareil dans une zone soumise

directement a la lumiere du soleil. Une chaleur excessixe

engendrde par le soleilpeut entrainer des ddormadons ou

d'autres donunages aux (omposants non-m_talliques.

• Ette(mez lesraises a lamasse confi)rmdment aux codes el

r{'glements en cours.

• N'udlisez que de la soudureetdufluxd(_capant sans plomb

pour routes les soudures tai[es SOilSla base de soudure

ten&e, tellesque requises par les codes t6ddraux et ceux

de Fetal interest.

• L'adoucisseur exige un debit minimum de trois

gallons/minute a l'ofifice d'ennde. Lapression maximale

autofi_e est de 125psi.Siall cours de lajournde, la

pression est sup(_fieurea 80 psi, la pression au cours de la

nuit peut _?tresuperieure a lavaleur maximale. Si

ndcessaire, uulisez une valver(_ductricede pression pour

rdduire le debit.

• En presence de chlore ddpassant la proportion de 1 ppm,

il estpossible que les rdsines de l'adoucisseur seddgradent.

Sile chlore d@asse cette valeur, ilest possible que vous

constatiez une durde de vierdduite des r(_sines.Dans un tel

cas,vous pourfiez envisagerde tiure l'achat d'un systeme

de fihrage de GE.

A AVERTISSEMENT:Ddbarrassez-vousde toutcomposant

inudlis(_etdu matE'rid d'emballage apr_s l'installation.

Les petits composants restant apr_sl'installadon peuvent

constimer un danger d'dtouftbment apr_s ingestion.

VEUILLEZLIREETSUIVREATTENTIVEMENTCESMESURESDESdL-CURITE.

CONSERVEZCESDIRECTIVES

29

Page 30

Directivesd'installation.

,_kATTENTION :I1 est n6cessaire de possader une certaine experience en plombefie pour efiectuer

l'ins/allation. Si w)us n'6tes pas certain en ce qui concerne une ou plusieurs 6tapes d'installation de

l'appareil, veuillez consuher un plombier professionnel.

Deballage et inspection

Assurez-x_)us de verifier si l'appardl n'a pas e/e endommage au cours de l'expedition et si/ous les composan/s

sont pr_sems. Veuillez _galement noter si la bo_le ayant se_-i pour l'exp_dition n'a pas _t_ endommag_e.

Con/actez la ( ompagnie ay:mt eflecm_ le uansport en cas de dommage ou de perte. Le titbricant n'est pas

responsable en cas de dommages au cours du transport.

I_espetites pi_ces requises p{nn l'insmllation de l'adoucisseur sont emballees sur un canon s_)us Cellophane.

Pour _viter leur perte, gmdez-les dans leur emballage jusqu'm_ moment offelles seront requises.

Recommandations importantes pour I'installation

Veuillez pren&e connaissance du manuel m_complet. Negliger de suiwe t{)utes les consignes et r_gles peut

enuainer des blessures personnelles ou des dommages.

• Avant le debut de l'inslallation, prenez connaissance de tou/es les instructions conespondantes. Ensuite,

rOunissez tout le necessaire et 1'outillage requis p{)ur cetm operation. Une installation inconecte annule la

gmantie.

• Prenez connaissance des codes locm_x. I/installation dolt Otre confi)mm aces codes.

• Dans l'_tat du Massachusetts, il ya lieu de respecter le code de plomberie 248 CMR. Veuillez consulter votre

plombier qualifi&

• Utilisez seulement la soudure et leflux d_capant sans plomb p_)ur tousles branchements efiectu_s ;'_l'aide de

s_)udures tendres comme presoit par les codes t_ddrm_x et ceux de l'dmt considdrd.

• Branchez l'adoucisseur a la conduim d'alimentation d'em_ avantet en amontdu chm_fle-em_. NEFAITESPAS

PASSERDEL'EtlUBOUILLANTEDANS L'ADOUCISSEUR.La temperature de l'em_ qui uaverse l'appardl dolt 6tre

ini;firieure a 120 degres F.

° Manipulez l'adoudsseur avec procreation. N'inversez pas l'appardl, ne le laissez pas tomber, le tirez pas ou

ne l'ins/allez pas sur des surlimes componant des asperi/es acerees.

° I_t pression maximale d'm'rivee d'em_ est de 125 psi. Si m_cours de lajournee la pression s'etablit fi80 psi,

elle peut depasser le maximum tolere m_cours de la nuit. Si necessaire, utilisez une soupape de reduction de

pression (I/ajout d'un tel dispositif peut re&fire le debit d'eau).

3O

• I:adoudsseur ne fimctionne que s_)usune tension de 24 x_)hs, 60Hz. Assmez-x_)us de bien utiliser le

uansfi)m_ateur inclus. Assurez-vous que le transfi)m_ateur et la prise de courant soient a l'abri de 1'humidite.

° Ret;firez-vous a la section &) installerl'adoucisseurpourde plusamples delails.

AVERTISSEMENT:N'utilisez pas cet appmeil avec de l'em_ qui n'est pas microbiologiquement s&uritaire

ou de quali/d inconnue sans que l'em_ n'a pas eta ddsintectde avant ou apr6s avoir pdndUd dans

l'adoudsseur. Testez l'em_ pdriocfiquement pour vous assurer que l'appmeil timctionne de mani6re

satist_tisante.

I_esperils composants accompagnant l'appmdl qui n'ont pas ete utilises au monlage peuvent presenter

des dangers d'etotfltement. Deban'assez-vous en.

Page 31

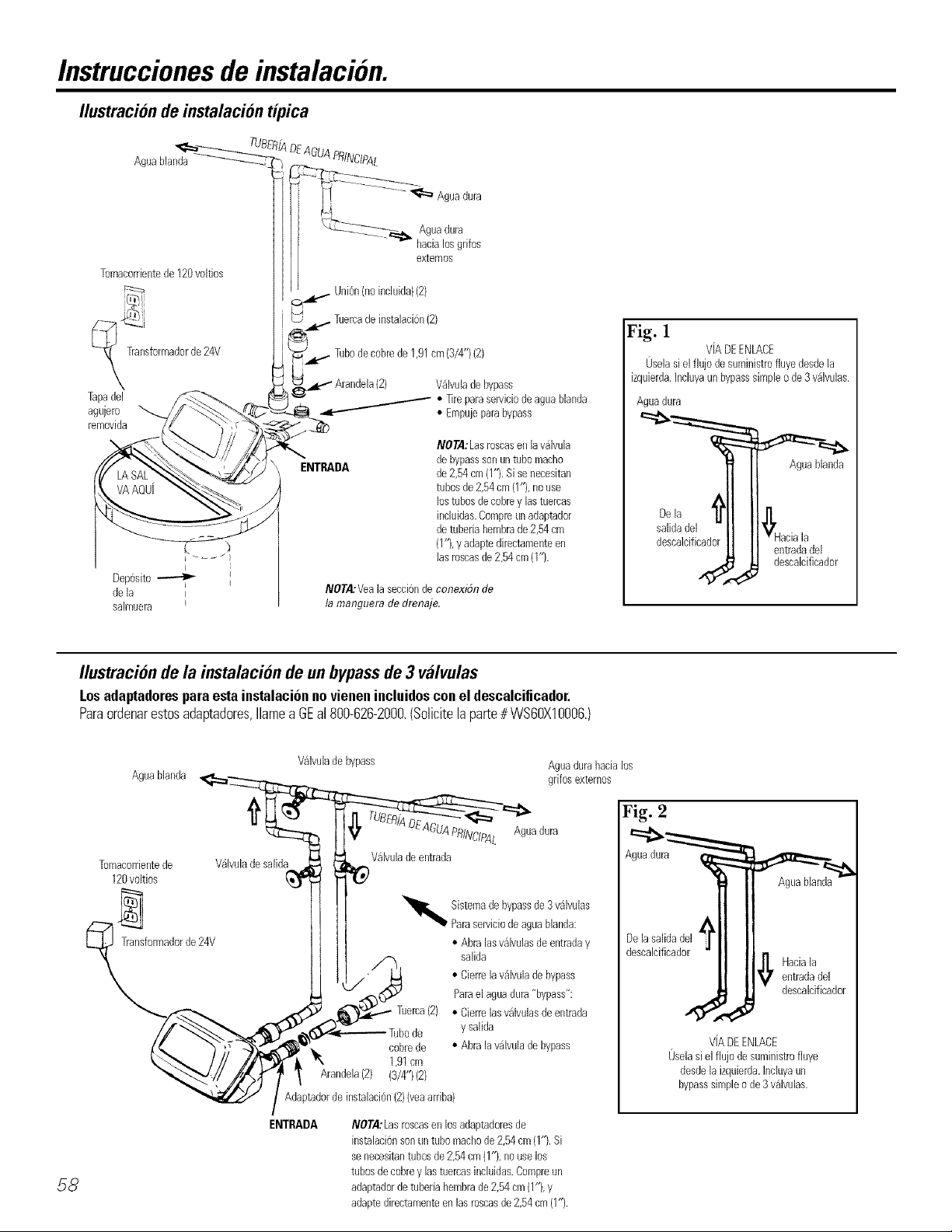

Planifiez comment vousallez installer radoucisseur

Initialement, _ous devez d&ider comment ',pus allez brancher les myaux d'entrde el de sonie d'eau _

Fadoudsseur. E_uninez la (onduite prin( ipale d'aaTi_ de (I'eau dans Fhabitafion 15 o_1vous allez bran(her

Fappareil. Cette (onduite est-elle en (uivre, ell plastique ou en indlal gaE anisd ave( file(age? Ouelle est la

dimension de la (onduile?

_AVERTISSEMENT: N'utilisez que de la soudure et du flux ddcapant sans plomb pore 4viler lout

empoisonnemenl.

R4ti)rez-vous .l lafig. 1, Iflustrationd'une installation type utilisd, comme guide lors de voue installation

par6culi_re. Assurez-vousdedirigerI'eaud'arriv_edure(nontrait_e)dartsleraccordde/a soupapecontrOlant

I'admission d'oaua I'adouoisseur.La soupape pone les indi( aliens IN (entree)et OUT (settle).Voyez

l'illusualion ell page 32.

Ou installer I'adoucisseur

*I osmonnez 1 adou(lsseur le plus pres possfl)]e dtm egom d c'_acuanon ou de tom amre point d'& acua6on

OU tuyau de reto'tl]enlen! at (eplable.

=I1est re(ommand6 de laisser les robinets extdrieurs d0biler laeau dure (non Irail0e) aria de m('nager laeau

trait4e et le sel.

"N'installez pas l'adoucisseur 5un endroit o6 il pourrait geler. Toutdommage caus_ par le gel n'ost pas couvert

par la garantie.

N mstallez pas l adouosseur aun endron ou flre(erdaan I acres au chautib'-eau ou an robinet de iermemre

de l'arrix Oe d'eau.

*Posilionnez Fadou(isseur de telle fa(:on _'_ce que les dommages (ausds par une filite & emuelle d'eau soienl

minimis0s. Le fhbri(anI n'efie( mere pas les rdparations et lie d('dommagera pas le propridtaire ell (as de

dommages cans4s par l'eau.

=IIest ndcessaire de disposer d'Ime prise de 120 voh s p()ur y bran( her le mmsformateur ill( Ms I.a ]ongueur

du fil d'alimentafion de l'apparei] ea de l I)pi. Si ]a prise de (ouram est 41oignOe (100 pi ou moins), ufilisez

un fil de calibre 18 pour ]e bran(hemem. Assurez-vous qua Inprise de coumnt et /e Vansfonnateur soot

I'int_fieurdub_timentafin delesprot_gercentreI'humidit_.Assurez-voIlS que la prise est hers-tension afin de

pr4venir tom arr_t a( ddemel.

*Si l'appareil est installd 5 l'extdrieur, prenez mutes les dispositions n4cessaires pour xous assurer que

Fadoucisseur, les conduites serxant _'_l'installation, le cablage, etc. sore prot4g4s centre les 414meats (soleil,

pluie, xem, chaleur, froid), contamination, vandalisme, etc. comme si l'appareil mail 4td installd _'_Fimdrieur.

* Assurez-vousque/'adoucisseurno soitpas expos_directementaux rayonsdusolei/.I_achaleur du soleil peru

ddtbrmer les par6es non-mdtaHques et endommager les composanls dlectroniques.

Outil/age at materiel roquis pour 17nstallation

*Les raccords pour l'emr4e et ]a sortie de ]'eml, lesquels son( incMs avec l'adoucisseur son( des raccords de

olivre brasable de 3/4 po. Afin de maintenir un d4bit im4gral au robinet, il est recommand,5 d'ufifiser des

mymlx de I po. de diambtre pour les raccords d'enu4e et de sortie. Gmdez les m_mes dimensions oil des

dimensions sup4rieures pour les mymlx d'alimemation d'ean ;_l'emrde et ;l la sortie d'ean de l'adoucisseur.

*Pour installer l'adoucisseur, utilisez le robinet de ddrivation indus. I_erobinet de d4rivation permet d'arr,Ster

l'ean mTivam 5 l'adoucisseur aux fills d'entretien tout ell maintenant ceHe-ci dans les myaux de la

r4sidence. I_esraccords d'entr4e et de sortie mentionn4s ci-desms permet le branchemem au robinet de

d4rivation an moyen des dcrous et rondelles/pli sont in(Ms.

* Utilisez les mymlx et raccords el1 olivre, laiton oil m4tal galvanis4. Certains (:odespermettent l'utilisation des

myaux el1 plastique PVC.

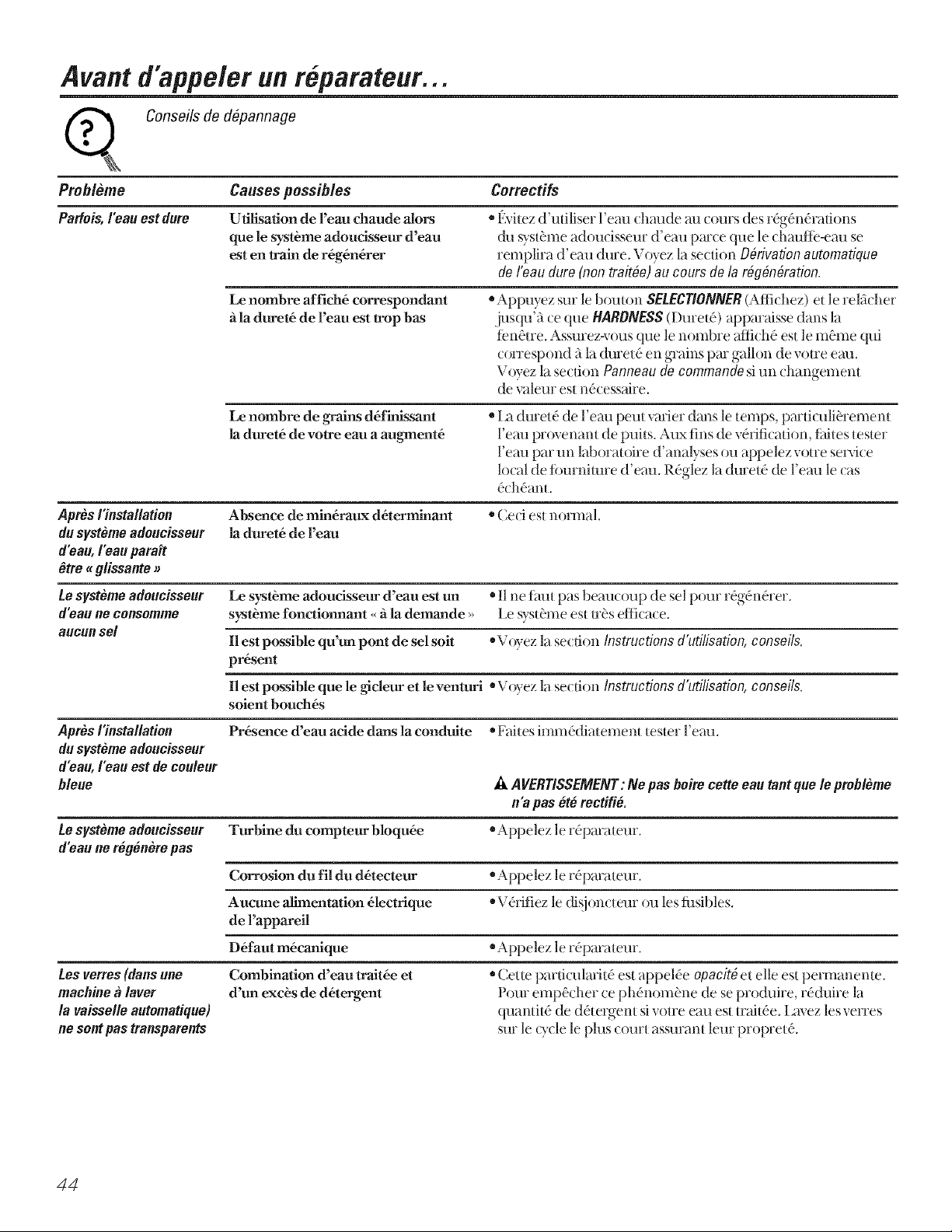

oS'il est ndcessaire de disposer d'un myau d'dvacuation compl4memaire pour le robinet de vidange des