Page 1

0

Safetg information ............. 2

installation Instructions ...s-12

Step-bg-step instructions ....... 6-12

Operating Instructions

Breaking a salt bridge ............. 1/4

Cleaning the nozzle and

venturi assemblg ................. 14

Features ......................... !5

Service .................... 13, 16-18

Water softener sgstem ........ 16-18

Care and Cleaning ............ 19

Troubleshooting Tips ...... 20-22

ge.com

Water Softening

Sgstem

Model GXSF30H

Sistema Suavizante

de Agua

Consumer Support

Consumer Support ....... Back Cover

Parts list/catalog .............. 23-26

Warrantg (U.S.) ................... 27

Warrantg (Canada) ............... 28

Sgstem tested and certified bg NSF International against NSF/ANSI Standard 44 for the

chemical reduction claims specified on the performance data sheet.

Sistema probado g certificado par NSF International contra norma 44 de NSF!ANSI para las

afirmaciones de reducci6n de los productos quimicos especificadas en la hoja de datos de

funcionamiento.

Mode!o GXSFgOH

La secci6n en espafiol empieza en la p_gina 29

Write the model and serial

numbers here:

Model #

Serial #

To find these numbers, lift the

cover and look on the rim

below the control panel.

7283918 215Cl173P021

49-50177 06-06 JR

Page 2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

;i WARNING!

For your safety, the information in this manual must be followed to minimize the risk of electric

shock, property damage or personal injurg.

SAFETYPRECAUTIONS

::Ji::Check and complg with gour state and local codes.

You must follow these guidelines.

::Ji::Use care when handling the water softening

sgstem. Do not turn upside down, drop, drag

or set on sharp protrusions.

?_:Water softening sgstems using sodium chloride

(salt) for recharge add sodium to the water.

Persons on sodium restricted diets should consider

the added sodium as part of their overall intake.

Potassium chloride can be used as on alternative

to sodium chloride in your softener.

?_:The water softening sgstem works on 24 volt-60 Hz

electrical power onlg. Be sure to use only the

included transformer.

iJi::Transformer must be plugged into an indoor

120 volt, grounded outlet onlg.

::Ji::Use clean water softening salts onlg, at least 99.5%

pure. NUGGET,PELLETor coarse SOLARsalts are

recommended. Do not use rock, block, granulated

or ice cream making salts. Theg contain dirt and

sediments, or mush and cake, and will create

maintenance problems.

::J_::Keep the salt hole cover in place on the softener

unless servicing the unit or refilling with salt.

WARN ING: DOnot usewith water that

is microbiologicallg unsafe or of unknown qualitg

without adequate disinfection before or after the

sgstem.

PROPERINSTALLATION

This water softening system must be properlg installed and located in accordance with the

Installation Instructions before it is used.

?_:Install or store where it will not be exposed to

temperatures below freezing or exposed to ang

tgpe of weather. Water freezing in the sgstem will

break it. Do not attempt to treat water over 100°R

::Ji::Do not install in direct sunlight. Excessive sun or

heat mag cause distortion or other damage to

non-metallic parts.

?_:Properlg ground to conform with all governing

codes and ordinances.

!;_:Use onlg lead-free solder and flux for all

sweat-solder connections, as required bg

state and federal codes.

?_:Softener resins mag degrade in the presence of

chlorine above 2 ppm. If gou have chlorine in excess

of this amount, gou mag experience reduced life

of the resin. In these conditions, gou mag wish to

consider purchasing a GEpoint-of-entrg household

filtration sgstem with a chlorine reducing filter.

A WARNING: Discard all unused parts

and packaging material after installation. Small

parts remaining after the installation could be

a choke hazard.

Thewater softening sgstem requires a minimum

water flow of three gallons per minute at the inlet.

Maximum allowable inlet water pressure is 125 psi.

If dagtime pressure is over 80 psi, nighttime pressure

mag exceed the maximum. Usea pressure reducing

valve to reduce the flow if necessarg.

READAND FOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVETHESEINSTRUCTIONS

Page 3

nstructlons Model G×SF30H

iJns'a"a:ionIwaterso'tenin0systemI

I [_ Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: ge.com I

WARNING: Read entire manual. Failure to follow all guides and rules could cause personal

injurg or propertg damage.

• Check with gour state and/or local public works department for plumbing codes. You must follow their

guides as gou install the Water Softening sgstem.

NOTE: Failure to complg with these installation instructions will void the product warrantg, and the

installer will be responsible for ang service, repair or damages caused therebg.

BEFORE BEGINNING INSTALLATION

Read these instructions completelg and carefullg.

• IMPORTANT - savetheseinstructions

for local inspector's use.

• IN PORTANT - Observeallgoverning

codes and ordinances.

• Note to Installer- Besure to leave these

instructions with the Consumer.

• Note to Consumer- Keep these instructions

for future reference.

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation

is not covered under the Warranty.

• A shutoff valve must be available or added near

the installation point.

IMPORTANT INSTALLATION

RECOMMENDATIONS

• In the Commonwealth of Massachusetts,

Plumbing Code 248 CMR shall be adhered to.

Consult with your licensed plumber.

• Useonlg lead-free solder and flux for all sweat-

solder connections, as required bg state and

federal codes.

IMPORTANT INSTALLATION

RECOMMENDATIONS (CONT.)

• Use care when handling the softener. Do not

turn upside down, drop, drag or set on sharp

protrusions.

Maximum allowable inlet water pressure is 125

psi. If daytime pressure is over 80 psi, nighttime

pressure may exceed the maximum. Use a

pressure reducing valve if necessary. (Adding a

pressure reducing valve may reduce the flow.)

The softener works on 24 volt-60 Hz electrical

power onlg. Be sure to use the included

transformer. Be sure the electric outlet and

transformer are in an inside location to protect

from moisture.

• See Where to Install the Softener section

for more details.

AWARNI NG:Do not use with water

that is microbiologicall9 unsafe or of unknown

qualitg without adequate disinfection before or

after the system. The water should be tested

periodicallg to verify that the system is

performing satisfactorily.

• Small parts remaining after the installation could

be a choke hazard. Discard safelg.

• Connect the softener to the main water supplg

pipe before or ahead of the water heater.

DO NOT RUN HOT WATER THROUGH THE

SOFTENER. Temperature of water passing

through the softener must be less than 120°R

Page 4

Installation Instructions

UNPACKING AND INSPECTION

Be sure to check the entire softener for ang

shipping damage or parts loss. Also note damage

to the shipping cartons. Contact the transportation

compang for all damage and loss claims. The

manufacturer is not responsible for damages

in transiL

Small parts needed to install the softener are

packaged either in a bag or on a cardboard

sheet. To avoid loss of the small parts, keep them

packaged until gou are readg to use them. Be sure

not to discard components hidden in packaging.

TOOLS AND MATERIALS REQUIRED

FOR INSTALLATION

• Pliers

Screwdriver

• Teflon tape

• Razor knife

o

Two adjustable wrenches

o

Additional tools may be required if modification

to home plumbing is necessarg.

In and out fittings included with the softener

are !" NPT male adapters. You should maintain

the same, or larger, pipe size as the water supplg

pipe, up to the softener inlet and outlet. Then,

use the necessarg adapters to connect the

water supplg to the !" NPT male adapters.

Use the included bgpass valve to install the

softener. The bgpass valve allows gou to turn off

water to the softener for servicing, but still have

water in the house pipes. The NPT male adapters

referred to above connect to the bgpass valve

with the included plastic clips.

WHERE TO INSTALL THE SOFTENER

Place the softener as close as possible to a

sewer drain, or other acceptable drain point

or standpipe.

It is recommended to keep outside faucets

on hard water to save soft water and salt.

Do not install the softener in a place where it

could freeze. Freeze damage is not covered bg

the warrantg.

Do not install the softener where it would block

access to the water heater or access to the main

water shutoff.

Putthe softener in a place where water damage

is least likelg to occur if a leak develops. The

manufacturer will not repair or pag for water

damage.

A &20-volt electric outlet is needed to plug in the

included transformer. The softener has a !0-foot

power cable. If the outlet is remote (up to !00

feet), use 18 gauge wire to connect. Be sure the

electric outlet and transformer are in an inside

location, to protect from wet weather. Be sure

the outlet is unswitched to prevent accidental

shutoff.

If installing in an outside location, gou must

take the steps necessarg to assure the softener,

installation plumbing, wiring, etc., are as well

protected from the elements (sunlight, rain, wind,

heat, cold), contamination, vandalism, etc., as

when installed indoors. Outdoor installation is

not recommended, and voids the warrantg.

Keep the softener out of direct sunlight.

The sun's heat mag distort non-metallic

parts and mag damage the electronics.

Use appropriate fitting/pipe material (i.e., copper,

brass, galvanized or CPVC) to connect the !" NTP

plastic adapters to the house plumbing.

If additional drain hose is needed for valve and

salt tank drains, it can be ordered from GE Parts

at 800.626.2002, part number WS07X!0004.

If a rigid valve drain is needed to complg with

plumbing codes, gou can bug the parts needed

to connect a 1/2" copper tubing or plastic pipe

drain. See Step 4.

Clean nugget or pellet water softener salt is

needed to fill the brine tank. See Step 8.

Page 5

Installation Instructions

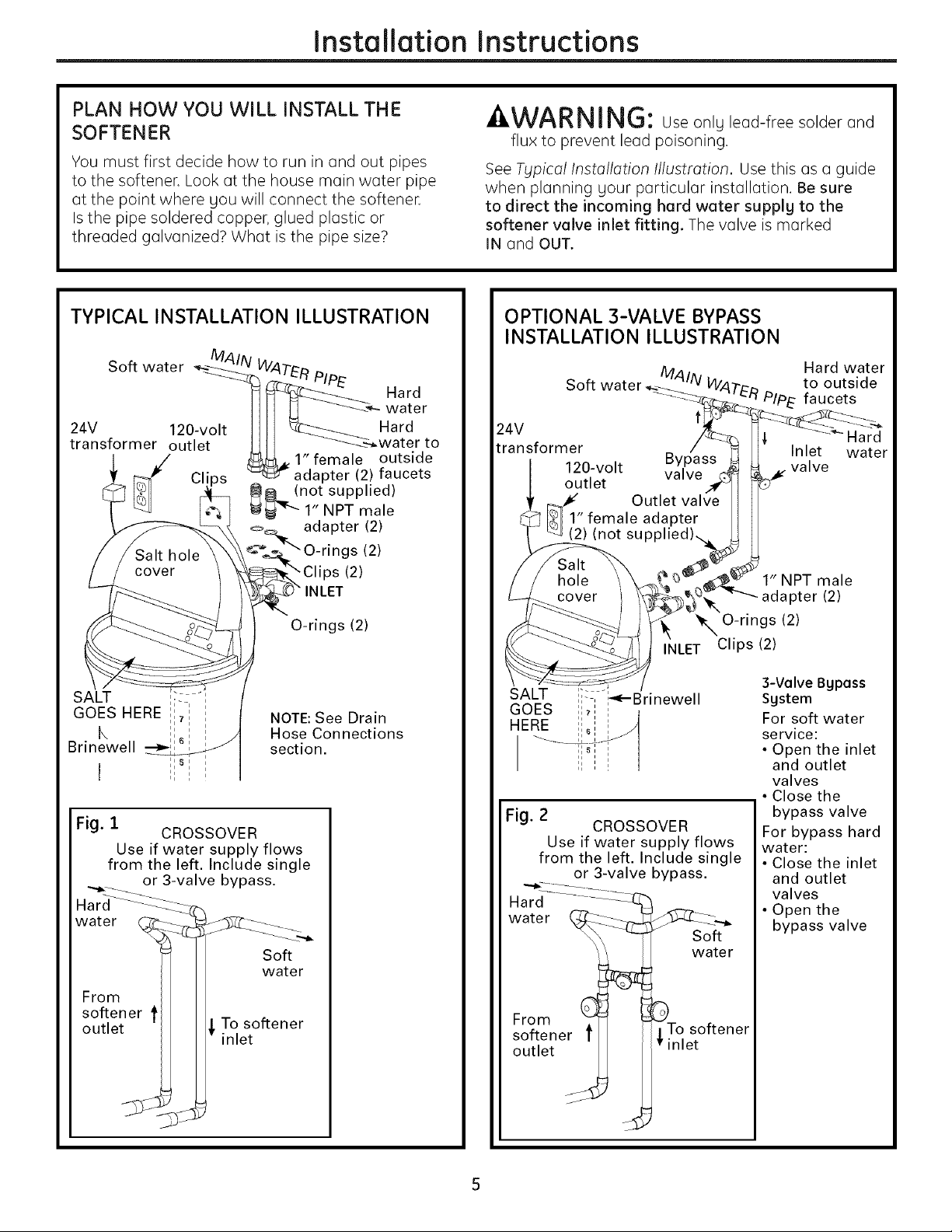

PLAN HOW YOU WILL INSTALL THE

SOFTENER

You must first decide how to run in and out pipes

to the softener. Look at the house main water pipe

at the point where gou will connect the softener.

Is the pipe soldered copper, glued plastic or

threaded galvanized2 What is the pipe size2

TYPICAL INSTALLATION ILLUSTRATION

-&WARNING: Use onlg lead-free solder and

flux to prevent lead poisoning.

See Typical Installation Illustration. Use this as a guide

when planning gour particular installation. Be sure

to direct the incoming hard water supplg to the

softener valve inlet fitting. The valve is marked

IN and OUT.

OPTIONAL 3-VALVE BYPASS

INSTALLATION ILLUSTRATION

Hard water

Soft water

24V Hard

transformer Inlet water

120-volt valve

outlet

to outside

Pip E faucets

Fig. 1

from the left. Include single

water

From

softener t

outlet

CROSSOVER

Use if water supply flows

or 3-valve bypass.

To softener

inlet

Soft

water

Fig. 2

from the left. Include single

Hard--.................::i-_-T.

water

From

softener t

outlet

CROSSOVER

Use if water supply flows

or 3-valve bypass.

?Tn_e_°ft ener

1" NPT male

"q_"'--add pter (2)

_, O-rings (2)

INLET Clips (2)

3-Valve Bgpass

Sgstem

For soft water

service:

• Open the inlet

For bypass hard

water:

• Close the inlet

• Open the

Soft

water

and outlet

valves

Close the

bypass valve

and outlet

valves

bypass valve

S

Page 6

Installation Instructions

BEFORE YOU BEGIN

• Turn off the gas or electric supplg to the water

heater, in the possibilitg that the water heater

mag be drained while draining pipes.

• Turn off the water supplg to pipes to be cut and

drain the house water pipes.

• Open both hot and cold faucets at the lowest

location possible.

NOTE: For easier installation, remove the top cover.

Release 2 clips at rear of cover. Rotate cover

forward and lift up.

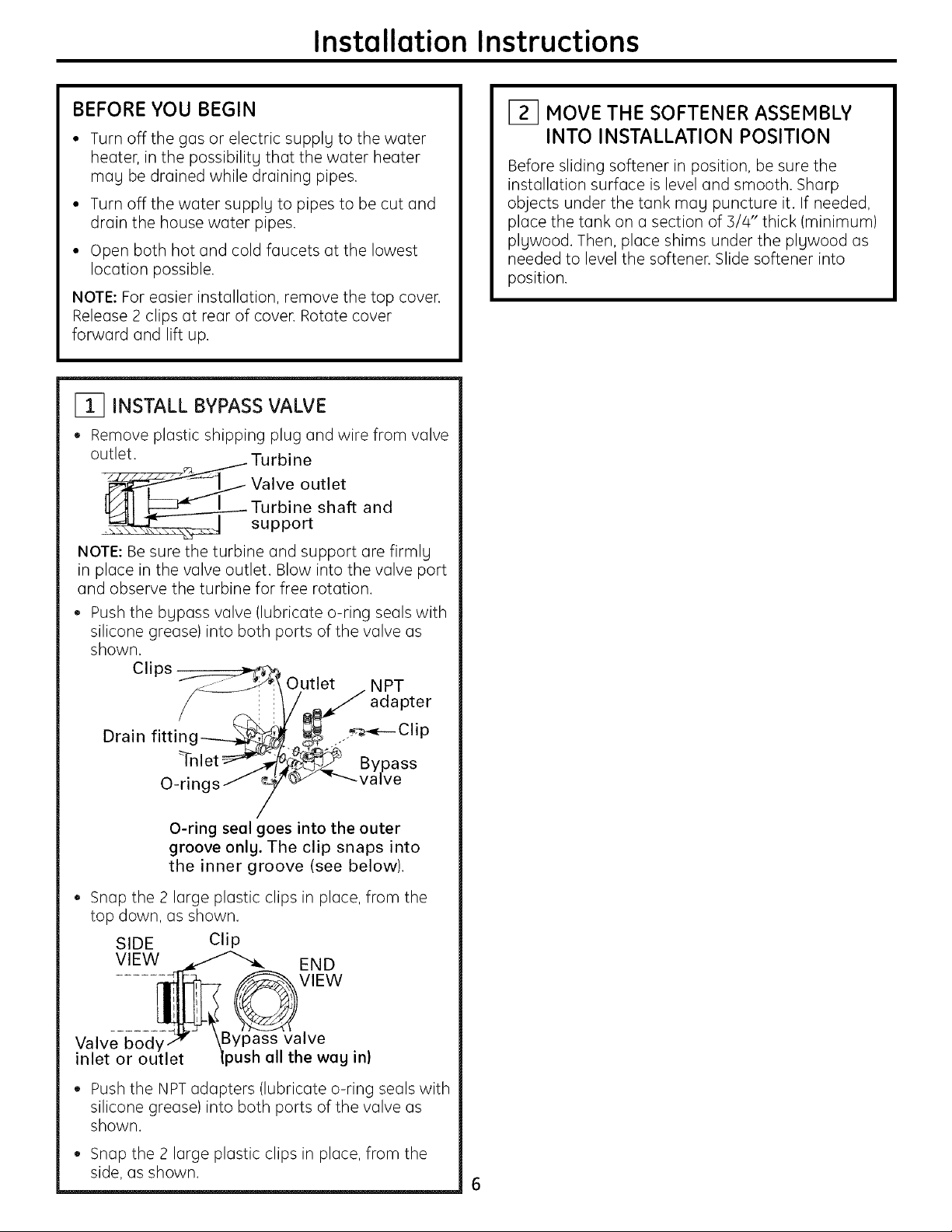

I_1 INSTALL BYPASS VALVE

• Remove plastic shipping plug and wire from valve

outlet.

"'_ Valve outlet

• _J support

NOTE: Be sure the turbine and support are firmlg

in place in the valve outlet. Blow into the valve port

and observe the turbine for free rotation.

• Push the bgpass valve (lubricate o-ring seals with

silicone grease) into both ports of the valve as

shown.

Clips __

Turbine

Turbine shaft and

:! Outlet . NPT

[_ MOVE THE SOFTENER ASSEMBLY

INTO INSTALLATION POSITION

Before sliding softener in position, be sure the

installation surface is level and smooth. Sharp

objects under the tank mag puncture it. If needed,

place the tank on a section of 5/4" thick (minimum)

plgwood. Then, place shims under the plgwood as

needed to level the softener. Slide softener into

position.

Drain fitti K_ _clip

n_g_ I/ _ adapter

_nlet --_-, _._ Bypass

O-rings_ '_ "'---valve

/

O-ring seal goes into the outer

groove only. The clip snaps into

the inner groove (see below).

• Snap the 2 large plastic clips in place, from the

top down, as shown.

SIDE Clip

VIEW END

VlEW

Valve bod, Bypass valve

inlet or )ush all the wag in)

• Push the NPT adapters (lubricate o-ring seals with

silicone grease) into both ports of the valve as

shown.

• Snap the 2 large plastic clips in place, from the

side, as shown. 6

Page 7

Installation Instructions

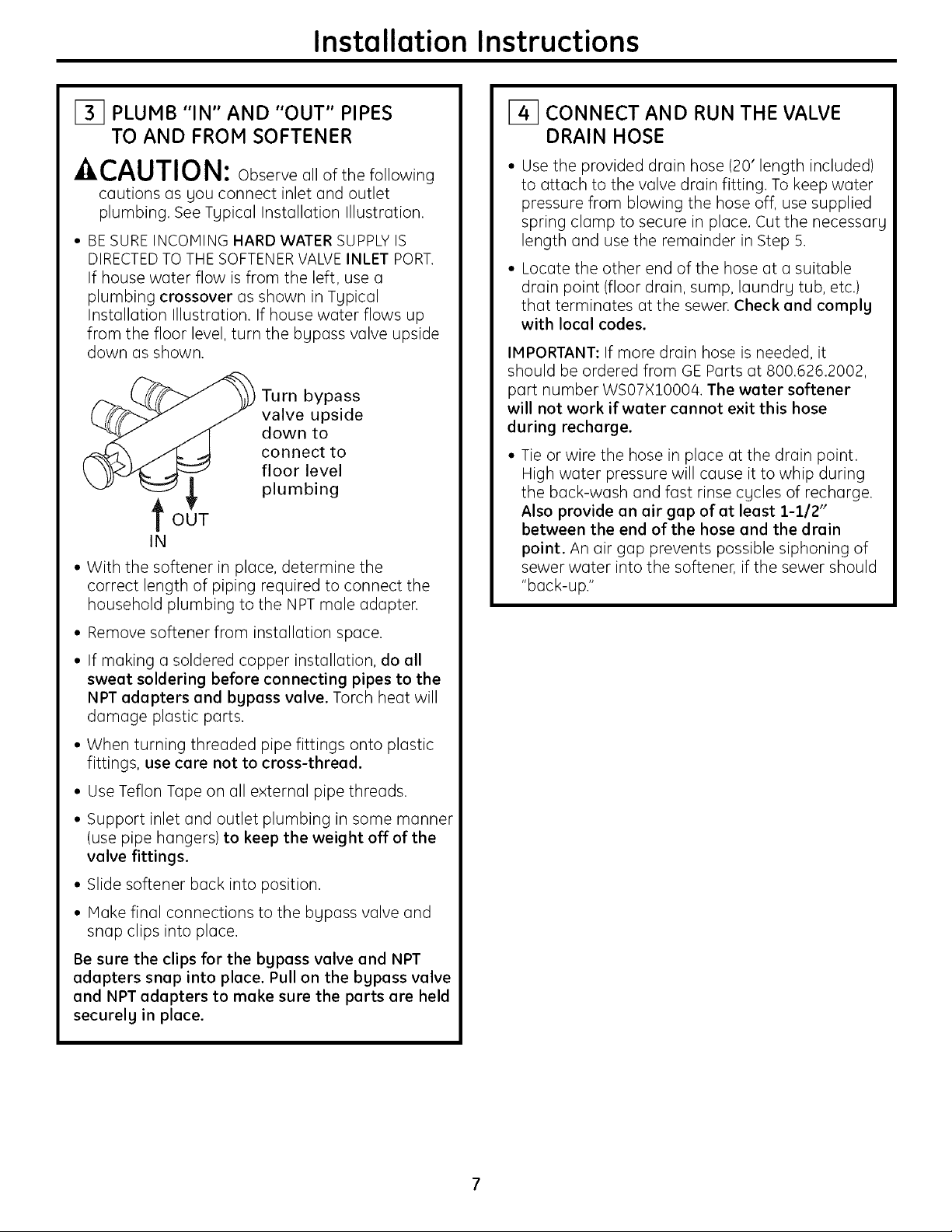

131 PLUMB "IN" AND "OUT" PIPES

TO AND FROM SOFTENER

,CAUTION: Observe all of the following

cautions as gou connect inlet and outlet

plumbing. See Typical Installation Illustration.

• BE SUREINCOMING HARD WATER SUPPLY IS

DIRECTEDTO THE SOFTENER VALVE INLET PORT.

If house water flow is from the left, use a

plumbing crossover as shown in Tgpical

Installation Illustration. If house water flows up

from the floor level, turn the bgpass valve upside

down as shown.

Turn bypass

valve upside

down to

connect to

floor level

plumbing

tOUT

IN

• With the softener in place, determine the

correct length of piping required to connect the

household plumbing to the NPT male adapter.

141 CONNECT AND RUN THE VALVE

DRAIN HOSE

Use the provided drain hose (20' length included)

to attach to the valve drain fitting. To keep water

pressure from blowing the hose off, use supplied

spring clamp to secure in place. Cut the necessarg

length and use the remainder in Step 5.

Locate the other end of the hose at a suitable

drain point (floor drain, sump, laundrg tub, etc.)

that terminates at the sewer. Check and complg

with local codes.

IMPORTANT: If more drain hose is needed, it

should be ordered from GE Parts at 800.626,2002,

part number WS07X10004, The water softener

will not work if water cannot exit this hose

during recharge.

• Tie or wire the hose in place at the drain point,

High water pressure will cause it to whip during

the back-wash and fast rinse cgcles of recharge.

Also provide an air gap of at least 1-112"

between the end of the hose and the drain

point. An air gap prevents possible siphoning of

sewer water into the softener, if the sewer should

"back-up."

• Remove softener from installation space.

• If making a soldered copper installation, do all

sweat soldering before connecting pipes to the

NPT adapters and bypass valve. Torch heat will

damage plastic parts.

• When turning threaded pipe fittings onto plastic

fittings, use care not to cross-thread.

• Use Teflon Tape on all external pipe threads.

• Support inlet and outlet plumbing in some manner

(use pipe hangers) to keep the weight off of the

valve fittings.

• Slide softener back into position.

• Make final connections to the bgpass valve and

snap clips into place.

Be sure the clips for the bypass valve and NPT

adapters snap into place. Pull on the bypass valve

and NPT adapters to make sure the parts are held

securely in place.

Page 8

Installation Instructions

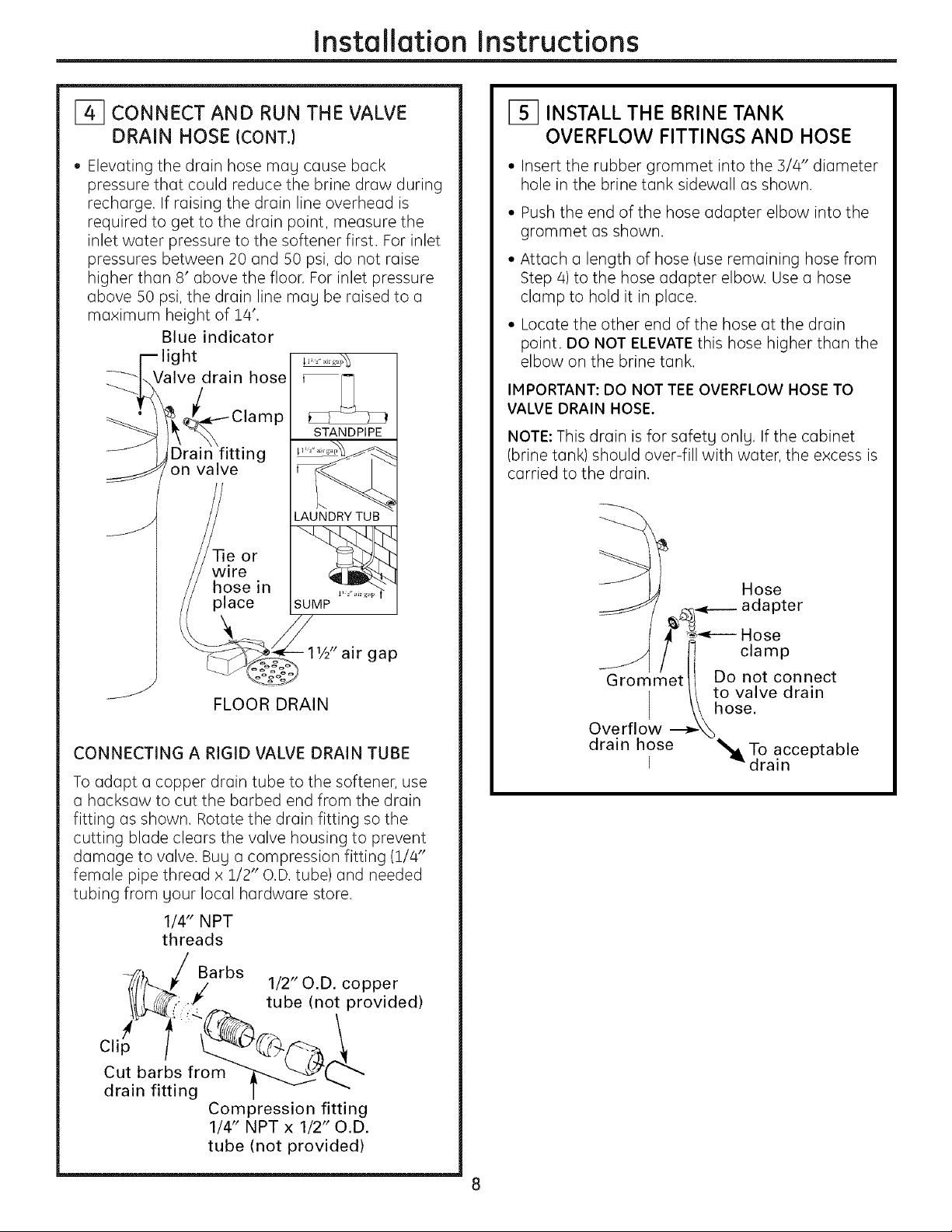

F_ CONNECT AND RUN THE VALVE

DRAIN HOSE (CONTJ

• Elevating the drain hose may cause back

pressure that could reduce the brine draw during

recharge. If raising the drain line overhead is

required to get to the drain point, measure the

inlet water pressure to the softener first. For inlet

pressures between 20 and 50 psi, do not raise

higher than 8' above the floor. For inlet pressure

above 50 psi, the drain line may be raised to a

maximum height of 14'.

Blue indicator

light

[_ INSTALL THE BRINE TANK

OVERFLOW FITTINGS AND HOSE

• Insert the rubber grommet into the 3/4" diameter

hole in the brine tank sidewall as shown.

• Push the end of the hose adapter elbow into the

grommet us shown.

• Attach a length of hose (use remaining hose from

Step 4) to the hose adapter elbow. Use a hose

clamp to hold it in place.

• Locate the other end of the hose at the drain

point. DO NOT ELEVATEthis hose higher than the

elbow on the brine tank.

IMPORTANT: DO NOT TEE OVERFLOW HOSE TO

VALVE DRAIN HOSE,

NOTE: This drain is for safety only. If the cabinet

(brine tank) should over-fill with water, the excess is

carried to the drain.

11½" air gap

FLOOR DRAIN

CONNECTING A RIGID VALVE DRAIN TUBE

To adapt a copper drain tube to the softener, use

a hacksaw to cut the barbed end from the drain

fitting as shown. Rotate the drain fitting so the

cutting blade clears the valve housing to prevent

damage to valve. Bug a compression fitting (1/4"

female pipe thread x 1/2" O.D. tube) and needed

tubing from your local hardware store.

1/4" NPT

threads

/

7_t_/,,,_./ Barbs 1/2" O.D. copper

J

jj Hose

_y _----- adapter

___i Hose

_ t i clamp

Grommet II Do not connect

/I to valve drain

I \\hose.

Overflow ---_

drain hose _To acceptable

I "_drain

Cli_:-/€'p / tube (not provided)

Cut barbs from

drain fitting

Compression fitting

1/4" NPT x 1/2" O.D.

tube (not provided)

8

Page 9

Installation Instructions

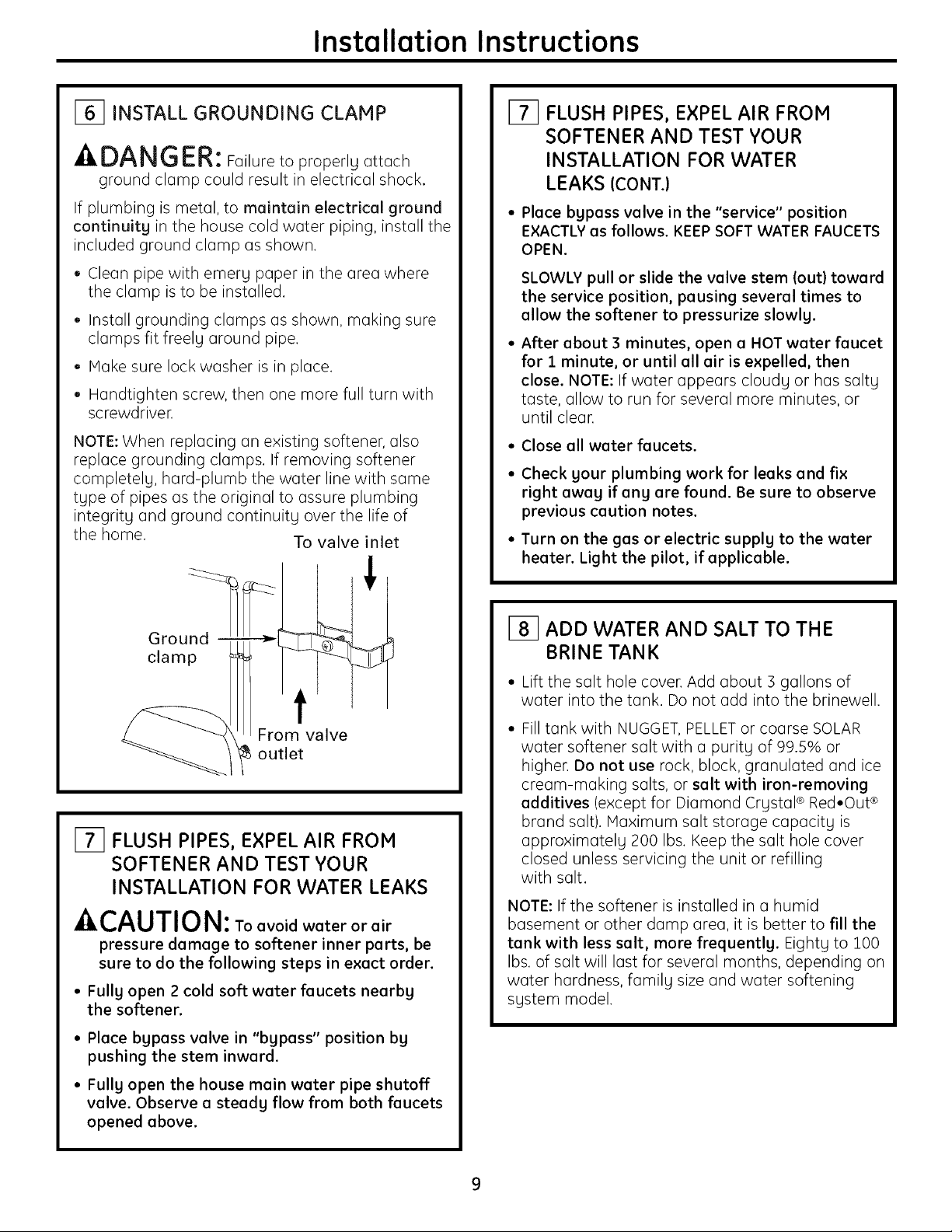

16] INSTALL GROUNDING CLAMP

-ADANGER: Failure to properly attach

ground clamp could result in electrical shock.

If plumbing is metal, to maintain electrical ground

continuity in the house cold water piping, install the

included ground clamp as shown.

• Clean pipe with emery paper in the area where

the clamp is to be installed.

Install grounding clumps us shown, making sure

clamps fit freely around pipe.

Make sure lock washer is in place.

Hundtighten screw, then one more full turn with

screwdriver.

NOTE: When replacing an existing softener, also

replace grounding clamps. If removing softener

completely, hard-plumb the water line with same

type of pipes as the original to assure plumbing

integrity and ground continuity over the life of

the home. To valve inlet

171 FLUSH PIPES, EXPEL AIR FROM

SOFTENER AND TEST YOUR

INSTALLATION FOR WATER

LEAKS ICONT.)

• Place bypass valve in the "service" position

EXACTLY as follows. KEEP SOFT WATER FAUCETS

OPEN.

SLOWLY pull or slide the valve stem tout) toward

the service position, pausing several times to

allow the softener to pressurize slowly.

After about 3 minutes, open a HOT water faucet

for 1 minute, or until all air is expelled, then

close. NOTE: If water appears cloudy or has salty

taste, allow to run for several more minutes, or

until clear.

• Close all water faucets.

Check your plumbing work for leaks and fix

right away if any are found. Be sure to observe

previous caution notes.

Turn on the gas or electric supply to the water

heater. Light the pilot, if applicable.

Ground i

clamp

i

From valve

outlet

171 FLUSH PIPES, EXPEL AIR FROM

SOFTENER AND TEST YOUR

INSTALLATION FOR WATER LEAKS

-4,CAUTION: Toavoidwateror air

pressure damage to softener inner parts, be

sure to do the following steps in exact order.

• Fully open 2 cold soft water faucets nearby

the softener.

• Place bypass valve in "bypass" position by

pushing the stem inward.

I_ ADD WATER AND SALT TO THE

BRINE TANK

• Lift the salt hole cover. Add about 3 gallons of

water into the tank. Do not add into the brinewell.

Fill tank with NUGGET, PELLET or coarse SOLAR

water softener salt with a purity of 99.5% or

higher. Do not use rock, block, granulated and ice

cream-making salts, or salt with iron-removing

additives (except for Diamond Crystal ®Red•Out ®

brand salt). Maximum salt storage capacity is

approximately 200 Ibs. Keep the salt hole cover

closed unless servicing the unit or refilling

with salt.

NOTE: If the softener is installed in a humid

basement or other damp area, it is better to fill the

tank with less salt, more frequently. Eighty to 100

Ibs. of salt will last for several months, depending on

water hardness, family size and water softening

system model.

• Fully open the house main water pipe shutoff

valve. Observe a steady flow from both faucets

opened above.

Page 10

Installation Instructions

_] CONNECT TO ELECTRICAL POWER

To gain access to the transformer/power cord

assemblg, remove the salt hole cover from the

softener. Unclip the tabs on the rear of the top cover

and rotate the cover upward to remove. DO NOT

PULL OR DISCONNECT WIRING.

• The softener works on 24 volt-60Hz electric

power. The included transformer changes

standard !20-volt AC house power to 24 volts.

Plug the transformer into a 120-volt outlet onlg.

Be sure the outlet is alwags live so it can not be

switched off bg mistake.

• Replace the top cover.

Replace the salt hole cover.

PROGRAMMING THE CONTROL

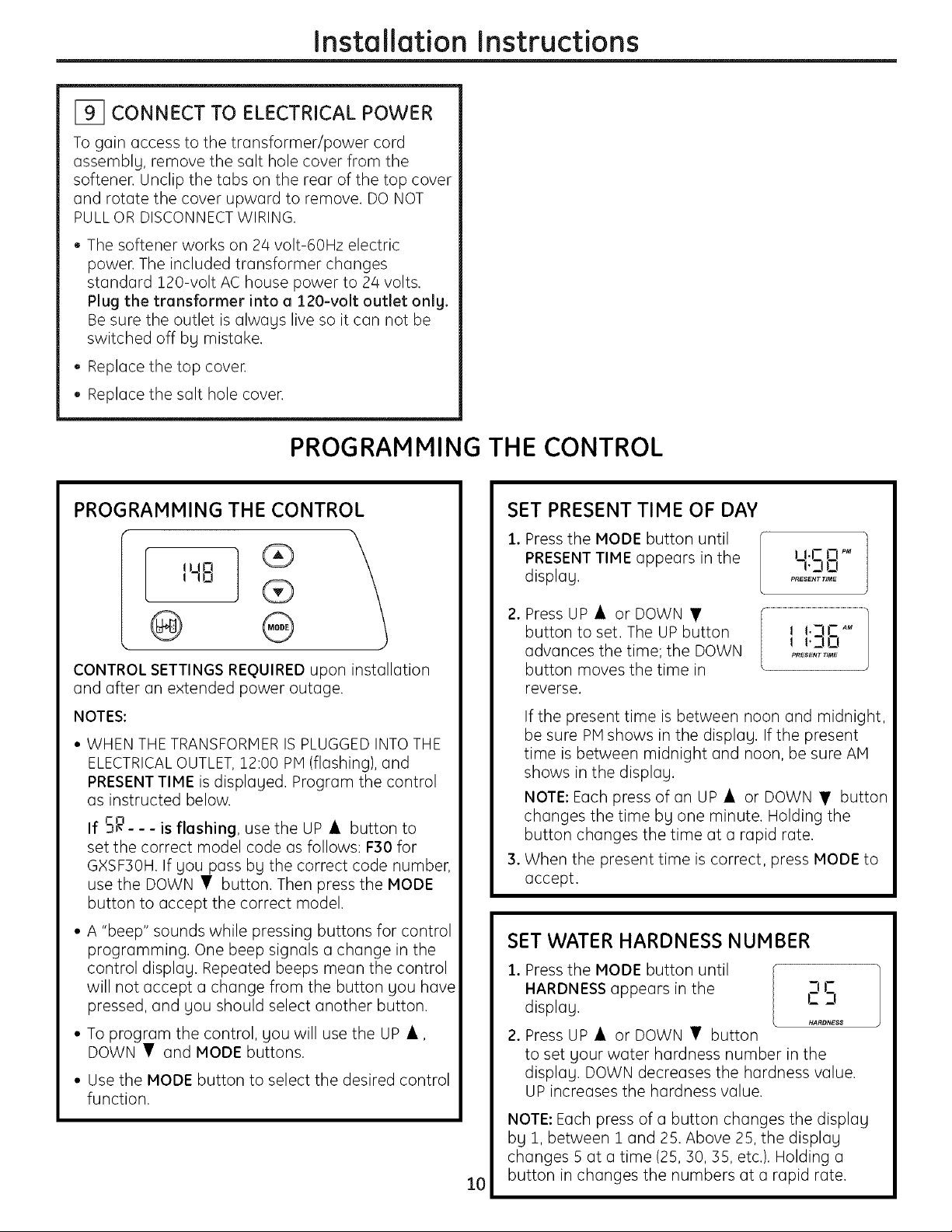

PROGRAMMING THE CONTROL

CONTROL SETTINGS REQUIRED upon installation

and after an extended power outage.

NOTES:

• WHEN THE TRANSFORMER IS PLUGGED INTO THE

ELECTRICALOUTLET, 12:00 PM (flashing), and

PRESENT TIME is displaged. Program the control

as instructed below.

If -_ - - - ,s flashing, use the UP • button to

set the correct model code as follows: F30 for

GXSF30H. If gou pass bg the correct code number,

use the DOWN • button. Then press the MODE

button to accept the correct model.

• A "beep" sounds while pressing buttons for control

programming. One beep signals a change in the

control displag. Repeated beeps mean the control

will not accept a change from the button gou have

pressed, and gou should select another button.

• To program the control, gou will use the UP •,

DOWN • and MODE buttons.

• Use the MODE button to select the desired control

function.

SET PRESENT TIME OF DAY

Press the MODE button until

,

PRESENTTIME appears in the

displag.

,

Press UP • or DOWN •

button to set. The UP button

I I 1.3C A_

advances the time; the DOWN

button moves the time in

L PRESENT TIME

reverse.

If the present time is between noon and midnight,

be sure PMshows in the displag. If the present

time is between midnight and noon, be sure AM

shows in the displag.

NOTE: Each press of an UP • or DOWN • button

changes the time bg one minute. Holding the

button changes the time at a rapid rate.

,

When the present time is correct, press MODE to

accept.

SET WATER HARDNESS NUMBER

1. Press the MODE button until

HARDNESS appears in the CIS

displag.

2. Press UP • or DOWN • button

to set gour water hardness number in the

displag. DOWN decreases the hardness value.

UP increases the hardness value.

NOTE: Each press of a button changes the displag

bg 1, between 1 and 25. Above 25, the displag

changes 5 at a time (25, 30, 35, etc.). Holding a

button in changes the numbers at a rapid rate.

10

1.1 tl

n.DO

PRESENT _ME

HARDNESS

Page 11

Installation Instructions

SET WATER HARDNESS NUMBER (CONT.)

3. When the displag shows gour water hardness

(in grains per gallon), press MODE to accept.

NOTE: If there is clear water iron in your water

supply, you will need to increase the hardness

setting bg 5 for each 1 ppm ofclearwater iron

in your water supply.

You can get the grains per gallon (gpg} hardness

of your water supply from a water analysis

laboratory. If you are on a municipal supply,

call your local water department. Or call Legend

Technical Services, an independent laboratory,

to request a water hardness test kit at

1.800.949.8220, option 4. If your report shows

hardness in parts per million (ppm) or milligrams

per liter (rag/I), simply divide by 17.1 to get the

equivalent number of grains per gallon.

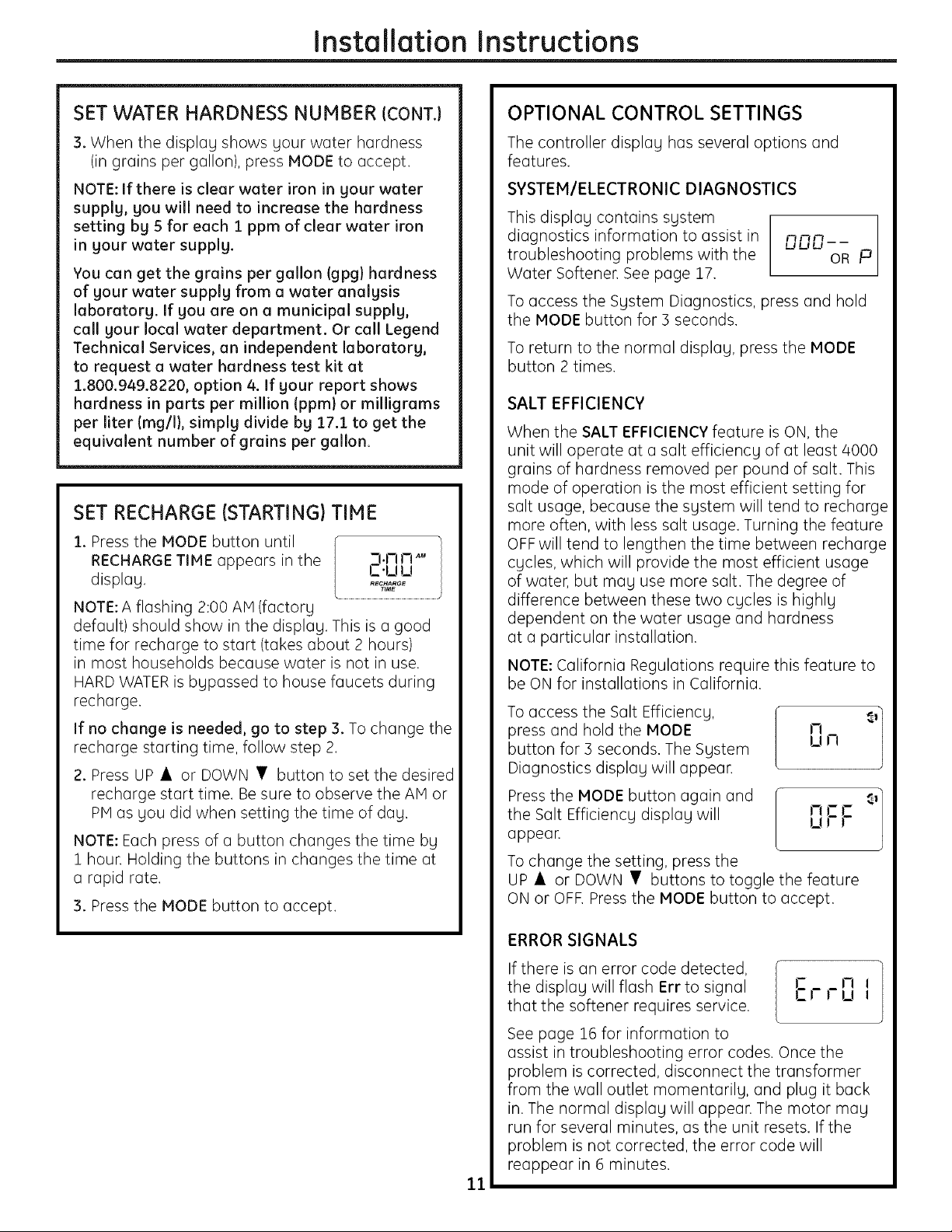

SET RECHARGE (STARTING) TIME

1.Press the MODE button until r

RECHARGE TIME appears in the / _-I.rll-I "M

d isplag, k................................._°;_i:u.............................

NOTE: A flashing 2:00 AM (factorg

default) should show in the displag. This is a good

time for recharge to start (takes about 2 hours)

in most households because water is not in use.

HARD WATER is bgpassed to house faucets during

recharge.

If no change is needed, go to step 3. To change the

recharge starting time, follow step 2.

2. Press UP • or DOWN • button to set the desired

recharge start time. Be sure to observe the AM or

PM as gou did when setting the time of dag.

NOTE: Each press of a button changes the time bg

1 hour. Holding the buttons in changes the time at

a rapid rate.

3. Press the MODE button to accept.

OPTIONAL CONTROL SETTINGS

The controller displag has several options and

features.

SYSTEM/ELECTRONIC DIAGNOSTICS

This display contains system

diagnostics information to assist in

troubleshooting problems with the

Water Softener. See page 17.

To access the Sgstem Diagnostics, press and hold

the MODE button for 3 seconds.

To return to the normal displag, press the MODE

button 2 times.

SALT EFFICIENCY

When the SALT EFFICIENCY feature is ON, the

unit will operate at a salt efficiencg of at least 4000

grains of hardness removed per pound of salt. This

mode of operation is the most efficient setting for

salt usage, because the sgstem will tend to recharge

more often, with less salt usage. Turning the feature

OFF will tend to lengthen the time between recharge

cgcles, which will provide the most efficient usage

of water, but nag use more salt. The degree of

difference between these two cgcles is highlg

dependent on the water usage and hardness

at a particular installation.

NOTE: California Regulations require this feature to

be ON for installations in California.

To access the Salt Efficiencg,

press and hold the MODE

button for 3 seconds. The Sgstem

Diagnostics displag will appear.

Press the MODE button again and

the Salt Efficiencg displag will

appear.

To change the setting, press the

UP • or DOWN • buttons to toggle the feature

ON or OFK Press the MODE button to accept.

!_1 IJ LJ --

nnn P

OR

LT,-,

NCC

urr

ERROR SIGNALS

If there is an error code detected,

the displag will flash Err to signal

that the softener requires service.

See page Z6 for information to

assist in troubleshooting error codes. Once the

problem is corrected, disconnect the transformer

from the wall outlet momentarilg, and plug it back

in. The normal displag will appear. The motor mag

run for several minutes, as the unit resets. If the

problem is not corrected, the error code will

reappear in 6 minutes.

11

Er rl] I

Page 12

SANITIZING PROCEDURES

Installation Instructions

To complete the installation, do the following

sanitizing procedures.

Care is taken at the factory to keep your water

softener clean and sanitary. Materials used to make

the softener will not infect or contaminate your water

supplg and will not cause bacteria to form or grow.

However, during shipping, storage, installation and

operation, bacteria could get into the softener. For

this reason, sanitizing as follows is suggested when

installing.

NOTE: Sanitizing is recommended bg the

Water Oualitg Association for disinfecting.

1. Be sure to complete all installation steps, including

programming the control.

2. Pour about 3/4 oz. (lY_ tablespoons) of common

5.25% unscented household bleach (Clorox, Linco,

Bo Peep, White Sail, Eagle, etc.) into the brinewell.

Refer to illustration on page 5.

3. IMPORTANT: Press and hold for 3 seconds

the faceplate RECHARGE @ button to start an

immediate recharge. RECHARGE begins to flash in

the display. The bleach will be drawn through the

water softener, and out the drain. This process

takes approximatelg 2 hours.

4. If, after sanitization, water from the house

faucet tastes salty or has a slight color, this is a

preservative from the resin tank. Turn on the cold

soft water faucets and drain for a few minutes or

until clean

NOTE: When the sanitizing recharge is over, all

remaining bleach is flushed from the conditioner

and your house COLD water supply is fully soft

immediatelg. However, your water heater is filled

with hard water and as hot water is used, it will refill

with soft water. When all the hard water is replaced

in the water heater, hot only and mixed hot and cold

water will be fullg soft. If you want totallg soft water

immediatelg, after the above recharge, drain the

water heater until the water runs cold.

ZI,WARNING:,fyoudodrainthewater

heater, use extreme care as the hot water could

cause burns. Turn the water heater off prior to

draining.

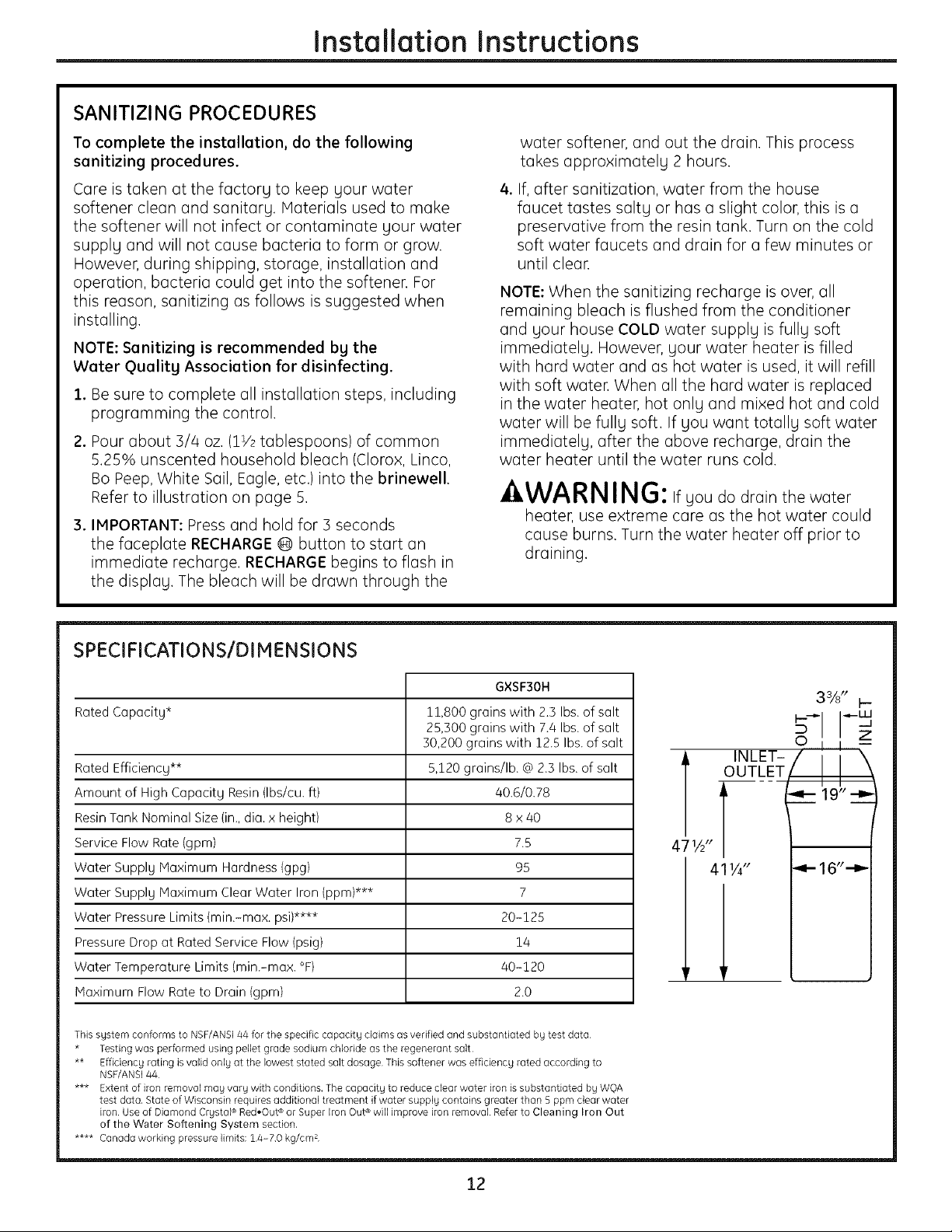

SPECIFICATIONS/DIMENSIONS

GXSF30H

Rated Capacity* 11,800 grains with 2.3 Ibs. of salt

25,300 grains with 7.4 Ibs. of salt

50,200 grains with 12.5 Ibs. of salt

Rated Efficiency** 5,120 grains/lb. @ 2.3 Ibs. of salt

Amount of High Capacity Resin (Ibs/cu. ft) 40.6/0.78

Resin Tank Nominal Size {in., dia. x height) 8 x 40

Service Flow Rate (gpm) 7.5

Water Supply Haximum Hardness (gpg) 95

Water Supply Maximum Clear Water Iron (ppm)*** 7

Water Pressure Limits (min.-max. psi)**** 20-125

Pressure Drop at Rated Service Flow (psig) 14

Water Temperature Limits (min.-max. °F) 40-120

Haximum Flow Rate to Drain (gpm) 2.0

This system conforms to NSF/ANS144 for the specific capacity claims as verified and substantiated bg test data

* Testing was performed using pellet grade sodium chloride as the regenerant salt

** Effidencg rating is valid only at the lowest stated salt dosage This softener was effidencg rated according to

NSF/ANS144

*** Extent of iron removal may vary with conditions, The capadtg to reduce clear water iron is substantiated by WOA

test data, State of Wisconsin requires additional treatment if water supply contains greater than 5 ppm clear water

iron Use of Diamond Crystal ® Red,Out ® or Super Iron Out ®will improve iron removal Refer to Cleaning Iron Out

of the Water Softening System section,

**** Canada working pressure limits: 14-70 kg/cm 2

3%" I--

i..__ i I_u..I

INLET-

OUTLET

471A"

41 I/4"

12

Page 13

About the water softener system, ge.com

Service

When the water softening system is providing

soft water, it is called "Service." During service,

hard water flows from the house main water pipe

into the water softening system. Inside the water

softening system resin tank is a bed made up of

thousands of tiny, plastic resin beads. As hard

water passes through the bed, each bead

attracts and holds the hard minerals. This is

called ion-exchanging. It is much like a magnet

attracting and holding metals. Water without

hard minerals (soft water) flows from the water

softening system and to the house pipes.

After a period of time, the resin beads become

coated with hard minerals and theg have to be

cleaned. This cleaning is called recharge.

Recharge is started at 2:00 AH (factory setting)

by the water softening system control, and

consists of five stages or cgcles. These are FILL,

BRINING, BRINE RINSE, BACKWASH and FAST

RINSE.

Automatic Hard Water Bgpass During Recharge

For emergencg needs, hard water is available

to the home during the recharge cgcles.

Fill

Salt dissolved in water is called brine. Brine is

needed to clean the hard minerals from resin

beads. To make the brine, water flows into the

salt storage area during the fill stage.

However, gou should avoid using HOT water

because the water heater will fill with the hard

water.

Backwash

During backwash, water travels up through

the resin tank at a fast flow rate, flushing

accumulated iron, dirt and sediments

from the resin bed and to the drain.

Brining

During brining, brine travels from the salt storage

area into the resin tank. Brine is the cleaning

agent needed to remove hard minerals from the

resin beads. The hard minerals and brine are

discharged to the drain.

The nozzle and venturi create a suction to move

the brine, maintaining a very slow rate to get the

best resin cleaning with the least salt.

Brine Rinse

After a pre-measured amount of brine is used,

the brine valve closes. Water continues to flow in

the same path as during brining, except for the

discontinued brine flow. Hard minerals and brine

flush from the resin tank to the drain.

Fast Rinse

Backwash isfollowed by a fast flow of water

dawn through the resin tank. The fast flow

flushes brine from the bottom of the tank,

and packs the resin bed.

After fast rinse, the water softening system

returns to soft water service.

15

Page 14

About the water softener sgstem.

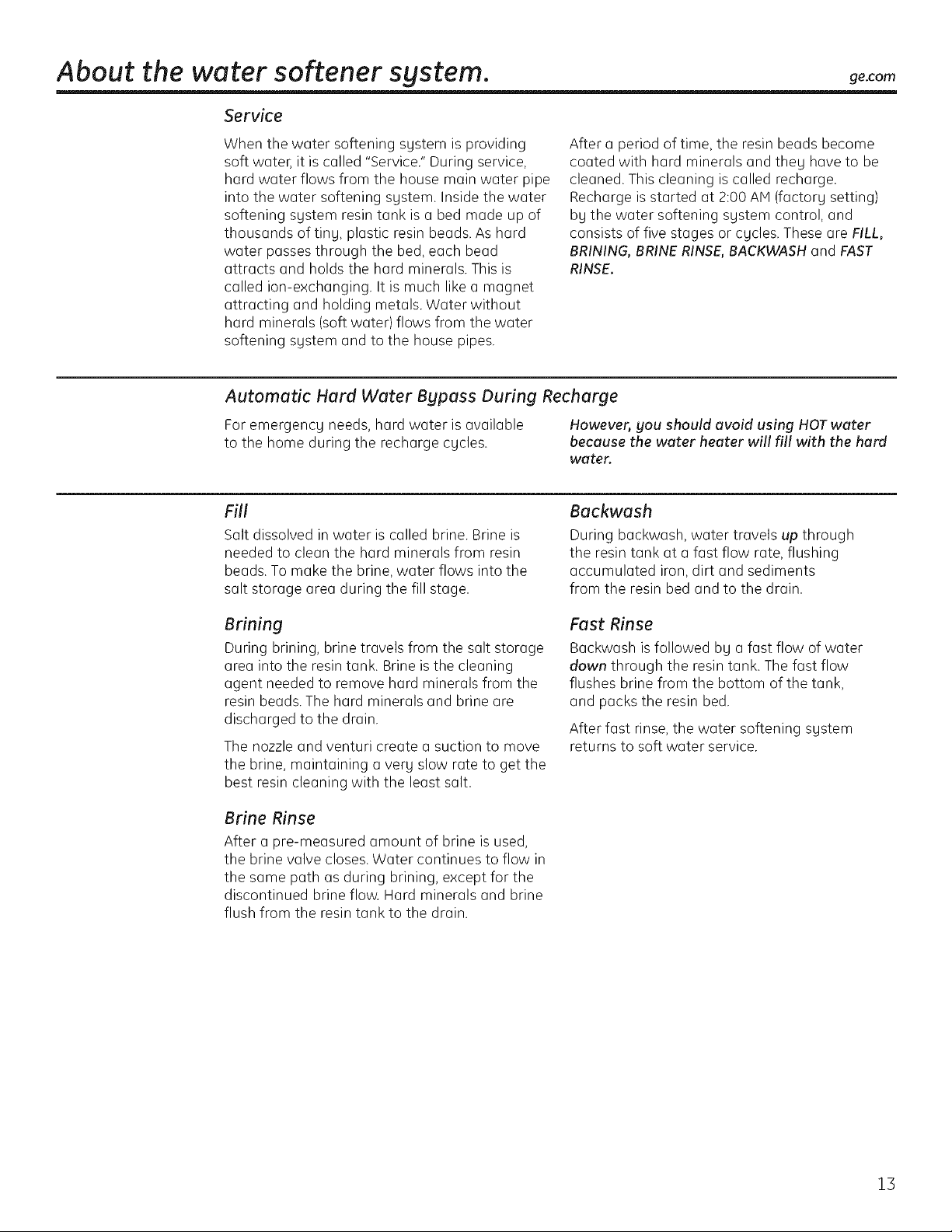

Breaking a Salt Bridge

Sometimes, a hard crust or salt bridge forms in

the salt storage area. It is usuallu caused bu high

humidity or the wrong kind of salt. When the salt

bridges, an empt Uspace forms between the

water and salt. Then salt will not dissolve in the

water to make brine.

If the brine tank is full of salt, it is hard to tell

if Uou have a salt bridge. Salt is loose on top, but

the bridge is under it. The following isthe best

wag to check for a salt bridge.

Salt should be loose all the wag to the bottom of

the tank. Takea broom handle or like tool, and

carefullu push it down into the salt, working it up

and down. If the tool strikes a hard object (be

sure it's not the bottom or sides of the tank), it's

most likelu a salt bridge. Carefullu break the

bridge with the tool. Do not pound on the walls

of the tank.

If the wrong kind of salt made the bridge, take it

out. Then fill the tank with nugget or pellet salt

only. In humid areas, itis best to fill with less salt,

more often to prevent a salt bridge from forming.

Push tool into salt

bridge to break

/

Pencil

mark

Broom

handle

bridge

Water level

14

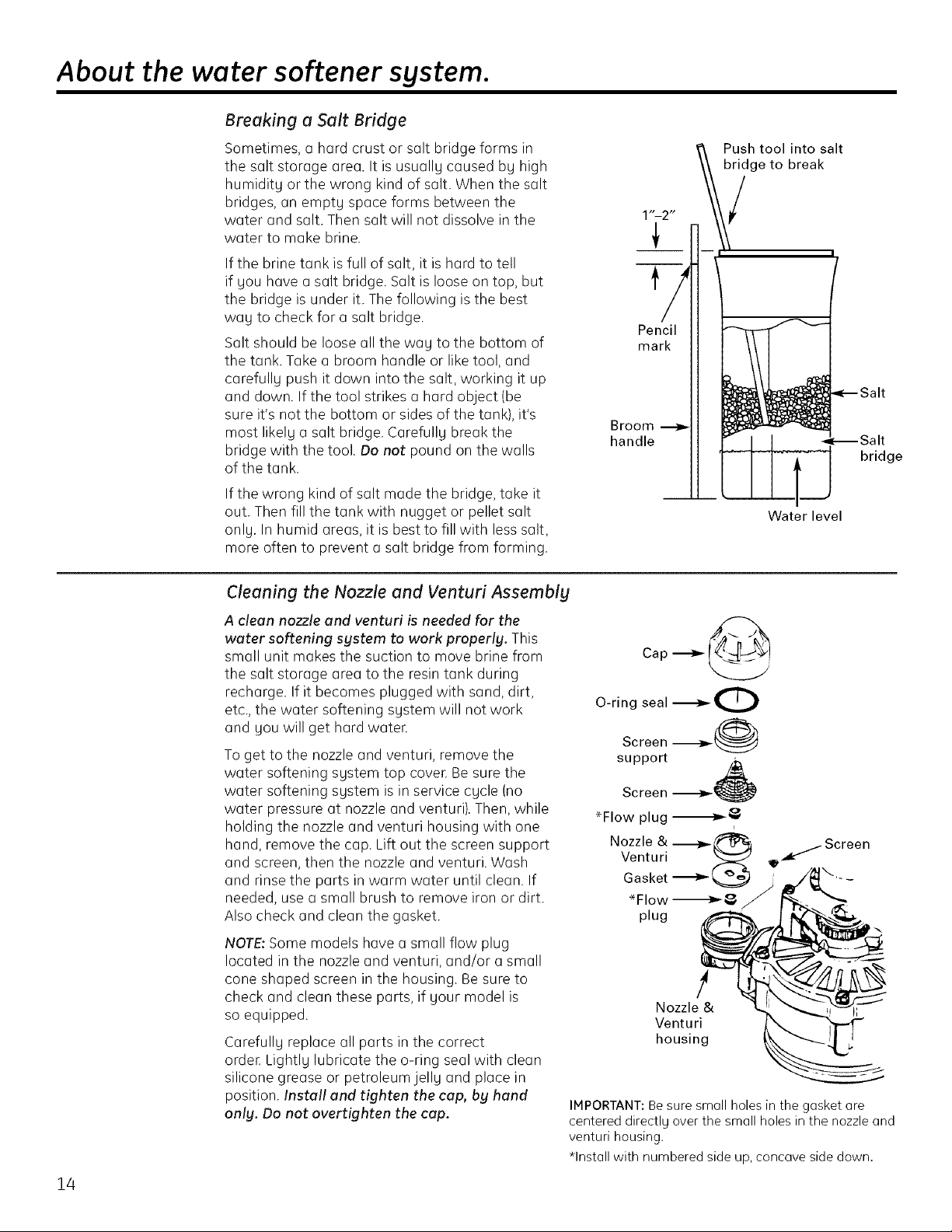

Cleaning the Nozzle and Venturi Assemblg

A clean nozzle and venturi is needed for the

water softening system to work properly. This

small unit makes the suction to move brine from

the salt storage area to the resin tank during

recharge. If it becomes plugged with sand, dirt,

etc., the water softening sustem will not work

and Uouwill get hard water.

To get to the nozzle and venturi, remove the

water softening sustem top cover. Be sure the

water softening sustem is in service cgcle (no

water pressure at nozzle and venturi). Then, while

holding the nozzle and venturi housing with one

hand, remove the cap. Lift out the screen support

and screen, then the nozzle and venturi. Wash

and rinse the parts in warm water until clean. If

needed, use a small brush to remove iron or dirt.

Also check and clean the gasket.

NOTE;Some models have a small flow plug

located in the nozzle and venturi, and/or a small

cone shaped screen in the housing. Be sure to

check and clean these parts, if uour model is

so equipped.

Carefullu replace all parts in the correct

ordeE Lightlu lubricate the o-ring seal with clean

silicone grease or petroleum jellu and place in

position. Install and tighten the cap, by hand

only. Do not overtighten the cap.

Cap -_

O-ring seal _0

Screen --_._ @

support

Screen

*Flow plug _

Nozzle & __ _ Screen

Venturi _ _--

Gasket _v=_

plug

*Flow -_l__

Nozzle &

Venturi

housing

IMPORTANT: Be sure smoll holes in the gasket are

centered directlg over the small holes in the nozzle and

venturi housing.

*Install with numbered side up, concove side down.

i

Page 15

Normal Operation, Control Displays

During normal operation, the present time of day

and AM or PM show in the control display area.

When the demand computer determines a

recharge is needed, RECHARGE TONIGHT begins

to flash in the display along with the present

time. RECHARGE TONIGHT flashes until the next

recharge start time, then changes to RECHARGE,

which flashes until the recharge is over.

Feature: Optional Recharge Controls

Sometimes, a manually started recharge may

be desired or needed. Two examples:

::Ji::You have used more water than usual (house

guests, extra washing, etc.) and you mag run

out of soft water before the next recharge.

!i::iThe sgstem ran out of salt.

Use one of the following features to start a

recharge immediately, or at the next preset

recharge start time.

ge.com

RECHARGE TONIGHT

Touch (do not hold) the RECHARGE 0 button.

RECHARGE TONIGHT flashes in the control

display area. A recharge will occur at the next

preset recharge start time. If you decide to cancel

this recharge, touch the same button once more.

RECHARGE NOW

Press and hold the RECHARGE _ button until

RECHARGE NOW starts to flash in the control

display area. The water softening system begins

an immediate recharge and, when over in about

two hours, you will have a new supply of soft

water Once started, you cannot cancel this

recharge.

Feature: Memory

If electrical power to the water softening system

is interrupted, the control display is blank, and

the blue indicator light is off, but the control

keeps correct time for about 6 hours. When

power is restored, you have to reset the present

time only if the display and blue indicator light

are flashing. All other settings are maintained

and never require resetting unless a change is

desired.

If the time isflashing after a long power outage,

the water softening sgstem continues to work as

it should to provide you with soft water. However,

recharge may occur at the wrong time of day

until you reset the control to the correct time

of day.

Feature/Service: Automatic Electronic Diagnostics

The control computer has a self-diagnostic

function for the electrical system (except input

power and water meter). The computer monitors

the electronic components and circuits for

correct operation. If a malfunction occurs,

an error code appears in the control display.

The chart on Error Codes shows the error

codes that could appear and possible reasons

for each code. See Monuollbl Initiated Electronics

Diognostics to further isolate the defect.

15

Page 16

About the water softener system.

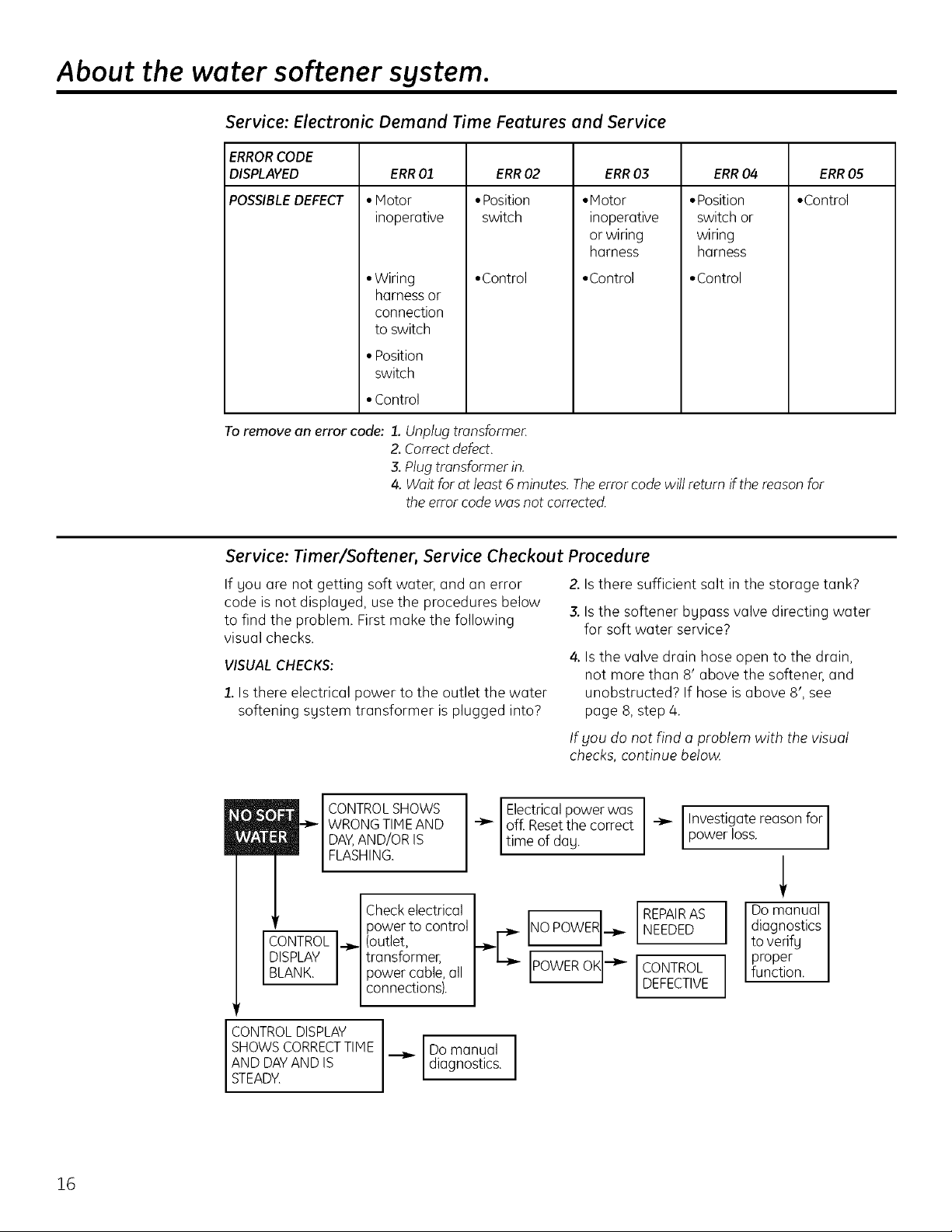

Service: Electronic Demand Time Features and Service

ERRORCODE

DISPLAYED ERR03 ERR04 ERR05

POSSIBLEDEFECT • Control

Toremove an error code: 1. Unplugtransformer.

ERR01

• Motor

inoperative

• Wiring

harness or

connection

to switch

• Position

switch

• Control

Z Correctdefect.

& Plug transformer in.

4. Wait for ot leost 5 minutes. The error code will return if the reasonfor

theerror code was not corrected.

ERR02

•Position

switch

•Control

•Motor

inoperative

or wiring

harness

•Control

•Position

switch or

wiring

harness

• Control

Service: Timer/Softener, Service Checkout Procedure

If gou are not getting soft water, and an error

code is not displaced, usethe procedures below

to find the problem. First make the following

visual checks.

VISUAL CHECKS:

1.Is there electrical power to the outlet the water

softening sgstem transformer is plugged into?

CONTROL SHOWS

WRONG TIME AND

DAY,AND/OR IS

FLASHING.

Electricalpower was I Investigate reason for

off. Resetthe correct _ Ipower oss.

time of dag.

Checkelectrical

power to control

CONTROL

DISPLAY

BLANK.

transformer,

.._ (outlet,

power cable,all

connections).

"-_"C POWEROK--_- I CONTROL

Z Isthere sufficient salt in the storage tank?

3. Isthe softener bypass valve directing water

for soft water service?

4. Is the valve drain hose open to the drain,

not more than 8' above the softener, and

unobstructed? If hose is above 8', see

page 8, step 4.

tf bloudo not find a problem with the visual

checks, continue below.

INO POWERI.__. REPAIRAS

NEEDED

DEFECTIVE

diagnostics

Domanual

to verifg

function.

i proper

16

CONTROL DISPLAY

SHOWS CORRECTTIME

AND DAYAND IS

STEADY.

Domanual

diagnostics.

Page 17

Service: Manually Initiated Electronics Diagnostics

ge.com

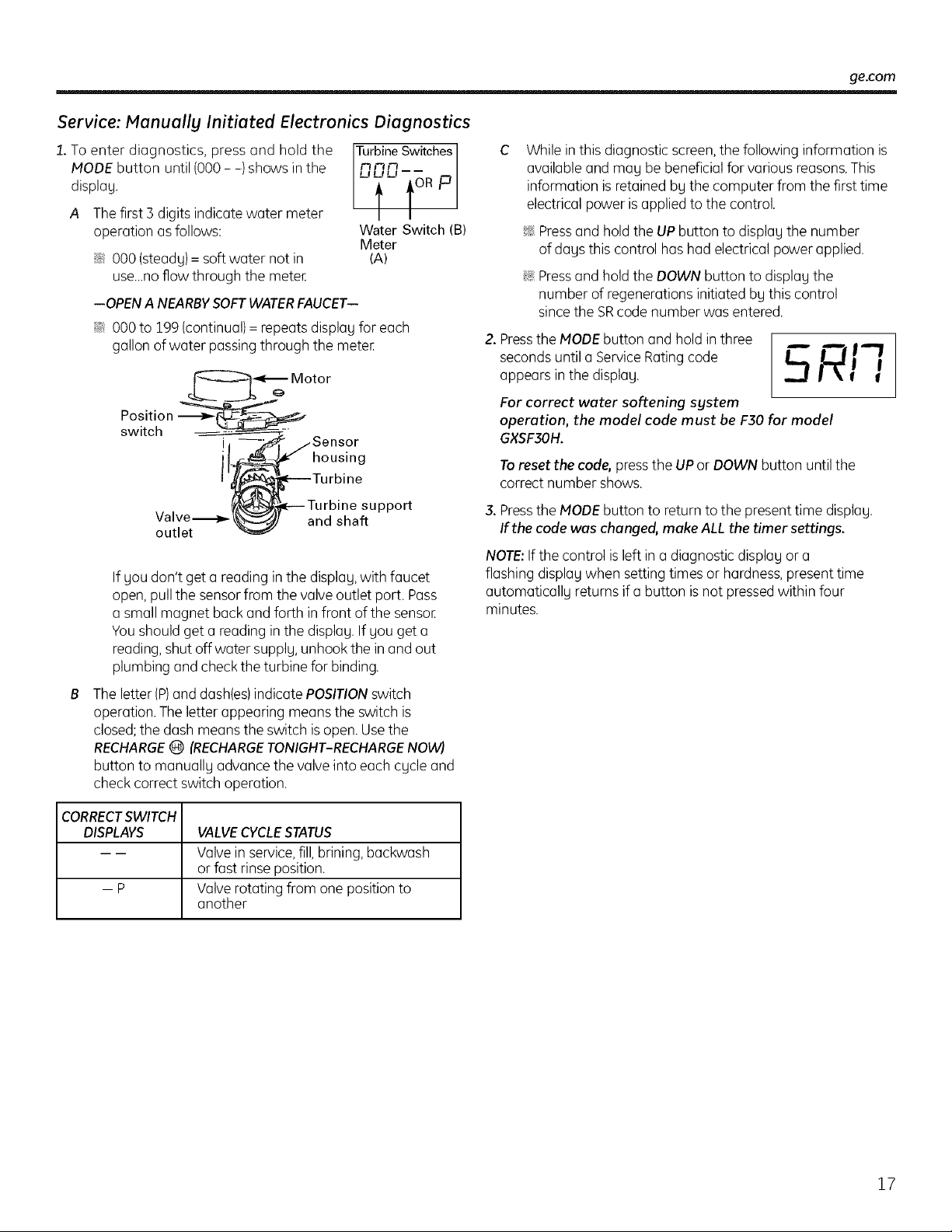

1.To enter diagnostics, press and hold the

MODE button until (000 - -) shows in the

Turbine Szjtches 1

displag.

A The first ] digits indicate water meter

operation asfollows:

Water Switch (B)

Meter

::J_::000 (steady)= soft water not in

use_.noflow through the meter.

--OPEN A NEARBY SOFT WATER FAUCET--

::J_::000 to 199 (continual)=repeats display for each

gallon of water passing through the meter.

switch

Valve-_-

outlet

..Sensor

housing

and shaft

If you don't get a reading in the display, with faucet

open, pullthe sensorfrom the valve outlet port. Pass

a small magnet back and forth in front of the sensor.

Youshould get a reading in the display. If you get a

reading,shut off water supply,unhook the in and out

plumbing and check the turbine for binding.

The letter (P)and dash(es)indicate POSITIONswitch

operation. Theletter appearing means the switch is

closed;the dash means the switch isopen.Usethe

RECHARGE0 (RECHARGETONIGHT-RECHARGENOW)

button to manually advance the valve into each cycle and

check correct switch operation.

(A)

pport

While in this diagnostic screen,the following information is

available and may be beneficial for various reasons.This

information is retained by the computer from the first time

electrical power isapplied to the control.

?_:Pressand hold the UP button to display the number

of days this control hashad electrical power applied.

?_:Pressand hold the DOWN button to display the

number of regenerations initiatedby this control

sincethe SRcode number was entered.

2. Press the MODE button and hold in three

seconds until a Service Rating code

appears in the displag,

For correct water softening system

operation, the model code must be F30 for model

GXSF3OH,

To reset the code, press the UP or DOWN button until the

correct number shows.

3, Press the MODE button to return to the present time displag,

If the code was changed, make ALL the timer settings.

NOTE: If the control is left in a diagnostic display or a

flashing display when setting times or hardness, present time

automatically returns if a button is not pressed within four

minutes.

5 i'--EI-"/

I I

CORRECTSWITCH

DISPLAYS

-p

VALVECYCLESTATUS

Valvein service,fill,brining,backwash

or fast rinse position.

Valverotating from one position to

another

!7

Page 18

About the water softener system.

Service: Manuallg Advance Recharge Check

NOTE:The control display must show a steady

time (not flashing).

1. Pressthe RECHARGE@ button and hold in for

three seconds. RECHARGENOW begins to 3.

flash as the water softening system enters the

fill cycle of recharge. Remove the brinewell

cover and, using a flashlight, observe fill water

entering the brine tank. If water does not enter

the tank, look for an obstructed nozzle, venturi, 4.

fill flow plug or brine tubing. See Coreand

Cleaning of the Water Softener System section.

2. After observing fill, press the RECHARGE@

button to move the water softening system

into brining. A slow flow of water to the drain

will begin. Verify brine draw from the brine

tank by shining a flashlight into the brinewell

and observing a noticeable drop in the liquid

level over an extended period of time.

NOTE:Be sure a salt bridge is not preventing

water from contacting salt. SeeCore and

cleoning of the water softening system section.

If the water softening system does not draw

brine, check:

::Ji::nozzle and/or venturi dirty or defective.

::J_::defective nozzle and venturi seal.

::Ji::nozzle and venturi not seated properly

on gasket.

::Ji::other inner valve defect {rotor seal, rotor and

disc, wave washer, etc.).

?_:restricted drain {check drain fitting and

hose).

NOTE:If water sgstem pressure is low, an

elevated drain hose mag cause back pressure,

stopping brine draw.

Again, press the RECHARGE0 button to move

the water softening sgstem into backwash.

Look for a fast flow of water from the drain

hose. A slow flow indicates a plugged top

distributor, backwash flow plug or drain hose.

Press the RECHARGE0 button to move the

water softening sgstem into fast rinse. Again

look for a fast drain flow. Allow the water

softening sgstem to rinse for a few minutes

to flush out ang brine that mag remain in

the resin tank from the brining cgcle test.

5.

To return the water softening sgstem to

service, press the RECHARGE_ button.

18

Page 19

Care and cleaning of the water softening system, geeom

Checking the Salt Storage Level and Refilling

Brine (salt dissolved inwater)is needed for each

and every recharge. The water for making brine

is metered into the salt storage area by the

water softening system valve and control.

However, gou must keep the tank supplied

with salt.

When to refill with salt: Check the salt level a

few weeks after you install the water softening

system and periodically after that. Refill when

the tank gets lessthan !/3 full. In humid areas it

is best to refill with less salt and more often, to

avoid forming a salt bridge (see page 14).Never

allow the softening system to use all the salt

before you refill it. Without salt, you will soon

have hard water.

Cleaning Iron Out of the Water Softening Sgstem

Use clean water softening salts only, at least

99.5% pure. NUGGET,PELLETor coarse SOLAR

salts are recommended. Do not use rock, block,

granulated or ice cream making salts. They

contain dirt and sediments, or mush and cake,

and will create maintenance problems.

CAUTION: Wotersoftening salt

with iron removing additives: Some salts

may have an additive to help the water

softening system handle iron in the water

supply. Although this additive may help to

keep the water softening system resin clean,

it may also release corrosive fumes that

weaken and shorten the life of some water

softening system parts. GE recommends

using only Diamond Crystal®Red,Out®

brand salt.

Your water softening system takes hardness

minerals (calcium and magnesium) out of

the water. Also, it can control some (see the

Specification Guidelines section) "clear water"

iron. With clear water iron, water from a faucet

is clear when first put into a glass. After 15 to 30

minutes, the water begins to cloud or turn rust

colored. A water softening system will not

remove any iron that makes the water cloudy

or rusty as it comes from the faucet (called red

water iron).To take red water iron out of water,

or over the maximum of clear water iron,

an iron filter or other equipment is needed.

GErecommends using only Diamond Crystal®

Red.Out ®brand salts with Iron Fighter®additive

to help keep the resin bed clean of clear iron. If

your water supply has clear water iron, periodic

resin bed cleaning is needed. GErecommends

using Super Iron Out®brand resin bed cleaner

to thoroughly clean your resin bed if your iron

content is high. Clean the bed at least every six

months, or more often if iron appears in the soft

water between cleanings.

IMPORTANT:It isimportant to mix the resin bed

cleaner with water (following the manufacturer's

instructions), pour it into the brinewell tube

(seepage 5) and recharge the softener

immediately. Do not pour the resin bed cleaner

in with the salt, as it will not be as effective in

cleaning the resin, and can cause damage to

the softener if it is left in the brine tank for an

extended period due to the corrosive gases

that are formed.

19

Page 20

Before you call for service...

Save time and moneg! Review the chart on the following

pages first and gou mag not need to call for service.

Troubleshooting Tips

NO SOFTWATER- Most Common Problems:

Check the following before coiling for service:

• Not enough saltishould be at least 1/3 full.

• Bypass valve in "Bypass" positioniknob should be in the "OUT" (service)position.

• Hardness setting too low. Check hardness setting and adjust. Verify hardness of supply

water--from local water company, water test or call the GEAnswer Center.

• Salt Bridgeisalt solidifies above water level so that brine water is not in contact with

salt. See the Breaking a Salt Bridge section.

Problem Possible Causes What To Do

No soft water Faucet or fixture where sample was •

taken not plumbed to soft water.

NOTE:Be sure sample is from a faucet

that does not mix soft and hard waten

For example, o single lever kitchen faucet,

if the cold side is plumbed to hard woten

Nosalt inthe brine tank or

salt bridged

Transformer unplugged at wall outlet or

power cableto softener not connected.

Fuseblown or circuit breaker popped

on circuit to electrical outlet.

Electrical outlet on a circuit that can

continuously be switched off

Manual bypass valve in bypass position • Be surethe bypass valve stem ispositionedproperly, with the

Valve drain hose pinched, plugged,

elevated too high or otherwise

restricted

Toconservesalt,the installermay haveisolatedsomefixtures

(outsidefaucets, toilets,etc.)from softwater.Fromthe outlet

of the water softening system, trace the water flow path,

in house plumbing. If soft water isnot directed to a faucet

or fixture where wanted,consult a plumber

Checkfor a salt bridge or,ifthe tank isempty, refill with

recommended salt. Press(for3 seconds)the RECHARGE@

button to start an immediate recharge and restore

soft water supply.

Checkfor a lossof electrical power to the water softening

system, due to any of these conditions and correct as needed.

With the power supply restored, observethe faceplate time

display and read Programming the Controlsection.

NOTE:Theelectricaloutlet forthe softenershouldbe

liveso it cannot be accidentally switched off

knob in the OUTposition.Observeinstructions on the decal

at the end of the stem.

• Any restriction inthis drain hosemay preventproper

operationof the nozzle andventuri and reduce or prevent

brine draw during recharge.

20

Nozzleand venturi dirty, incorrectly

assembled or damaged

Referto Cleaningthe Nozzle and VenturiAssemblg instructions.

With water pressureto the water softening system off,take the

nozzleassembly apart. Inspect, clean and replace asneeded.

Any foreign particle(s),scratches, nicks,etc.,in the passagescan

preventoperation.Besureholesin thegasket are centeredover

holesinthe housing.

Page 21

Problem Possible Causes What To Do

Water hard sometimes Using hot water while the water , Avoid usinghot water during water softening sgstem

softening sgstem is regenerating recharge because the water heater will refill with hard wateE

SeeAutomatic Hard Water BypassDuringRechargesection,

page !3.

Control HARDNESSnumber setting oPressthe MODEbutton until arrow pointsto HARDNESS.

too low Be surethe number shown isthe same asthe actual grains per

gallon hardness of your water supplg Seethe Programming

the Control section ifa change in the setting is needed.

Grains of hardness in gout water o Water hardnesscan change over time, especiallg in wellwateE

supplg have increased To check, havethe water tested bg a water analgsis laboratorg

or call gour localwater department. Adjust the HARDNESS

number setting as needed.

Water feels slippery Absenceof hardness minerals , This is normal. Hardnessin water gives it the abrasive feel

after installation of gou mag have been accustomed to. The slipperg feelisthe

water softening system clean feelof soft wateE

Water softening system Water softening sgstem isa , Does not use much salt to regenerate-verg efficient.

not using any salt "demand" unit

Possible salt bridge , Seethe About the Water SoftenerSgstem section,page 14.

ge.eom

Possible plugged nozzle and venturi _ Seethe About the Water SoftenerSystem section,page 14.

Water is blue color Acidic water in copper plumbing o Have the water tested at once.

after water softening

system was installed

Water softening system Meter turbine stuck , Seethe Service:Manually Initiated ElectronicsDiagnostics

not regenerating section for troubleshooting procedures,page 17.

, Callfor service.

Sensorwire not plugged into , Seethe Service:Manually Initiated ElectronicsDiagnostics

the control section for troubleshooting procedures,page 17.

, Callfor service.

No power to unit , Checkthe circuit breakeror fuses.

Mechanical defect , Callfor service.

Cloudiness on glassware Combination of soft water and , This is called etching and is permanent. To prevent this

(automatic dishwashers) too much detergent from happening, uselessdetergent if gou havesoft wateE

Wash glassware in the shortest cgcle that will get them clean.

Excessive/high level Valve drain hose pinched, , Ang restriction in this drain hosemag prevent proper

of water in brine tank plugged, elevated too high operation of the nozzleand venturi and reduceor prevent

or otherwise restricted brine draw during recharge.

Nozzleand ventud dirtg, incorrectlg

assembled or damaged

See the Cleaning the Nozzle and Venturi Assembly section,

page !4. With water pressure to the water softening sgstem

off, take the nozzle assemblg apart. Inspect, clean and

replace as needed. Ang foreign particle(s), scratches, nicks,

etc., in the passages can prevent operation. Be sure holes

in the gasket are centered over holes in the housing.

21

Page 22

Before you call for service...

Troubleshooting Tips

Problem Possible Causes What To Do

Salty tasting or Unit not sanitized * Complete theSanitization Procedureson page 12.

brown/yellow colored • At completion of recharge cucle (approx.2 hrs),run water

water after installation from faucets to purge the salty water.

Lowwater pressure Checkpressure.

• Drain height 8' or less,pressureshouldbe minimum of 20 psi.

• Drain height above8', pressureshouldbe minimum of 50 psi.

Restricted drain hose • Clean and reconnect hose.

• Check for kinksin drain line.

Brown/yellow Unit was idle for a period of time • Complete the Sonitizotion Procedureson page 12.

colored water

Resinbeads showing Cracked distributor • Callfor service,

up in drinking water

and sink

Soundsgou might hear Running water from the unit • Thisisnormal.

into a drain during recharge

Water has air bubbles Air in sgstem after installation • Will go away after it runs for a while.

and is cloudy

Error Code on control Wiring mag have worked loose • Seepage 16for details.

in the control

• Unplug transformer,

• Removecontrol cover,releaseclips on side.

• Checkfor loose/incorrect wiring connections to electronic

board or switch. Reconnect asrequired.

• Reassemblecontrol cover.

• Plugin Transformer,

• Wait six minutes for Error Codeto reappear,

• If ErrorCodereappears,call for service.

22

Page 23

Parts list. g_._om

11

4

\

28

16

55 / 55

3_

\

12

13

22

ggg

2g

/

24

36

33 32

_- 3O

$ 31

23

Page 24

Parts list.

_135

,_¢-25

124-- 115

,/

134 133

-- 130

132

145

J

146 147

24

117

118

119

120

121

150

S

Page 25

Parts catalog, go. o

GENERAL ELECTRIC PARTS CATALOG

G

X

S

F

3

0

H

REF. NO. PART NO. PART DESCRIPTION (02)

0003 WS35XlO001 O-RING SEAL KIT 1

0004 WS34XlO015 DECAL, FACEPLATE 1

0005 WSO7XlO004 HOSE, DRAIN, 20 FT. i

0007 WS14XlO002 DISTRIBUTOR, TOP i

0008 WS14XlO001 DISTRIBUTOR, BOTTOM i

0009 WSO1XIO002 RESIN, i CU. FT. i

0010 WS32XlO011 RESIN TANK, 9 X 40 i

0011 WS31XlO022 COVER, TOP W/LENS i

0012 WS31XlO023 FACEPLATE 1

0013 WS21XlO017 CONTROL 1

0016 WS26XlO013 TRANSFORMER WITH

POWER CORD i

0017 WS31XlO021 COVER, SALT HOLE,

WITH LABELS 1

0018 WS33XlO001 VAPOR BARRIER i

0019 WS33XIO007 RIM 1

0020 WS31XlO024 COVER, BRINEWELL W/DECAL 1

0021 WSO2XlO009 NUT 1

0022 WS32XlO017 BRINEWELL W/DECAL 1

0023 WSO2XlO027 SCREW 1

0024 WS32XlO016 TANK, BRINE, ROUND 1

0025 WS18XIO003 CLAMP, HOSE 2

0026 WS22XlO016 ADAPTER, HOSE 1

0027 WS22XlO017 GROMMET 1

0028 WS35XlO035 GROUND CLAMP KIT 1

0029 WS15XlO035 BRINE VALVE ASM. 1

0030 WS35XlO036 FLOAT, STEM & GUIDE 1

0031 WSO3XIO006 CLIP 1

0032 WS15XIO006 VALVE BODY, BRINE 1

0033 WSO3XIO007 CLIP 1

0034 WSO3XIO008 SCREEN 1

0035 WSO7XIO002 TUBING ASM. 1

0036 WSO7XIO015 BRINE TUBE ASM. 1

0037 WS31XIO018 BACK COVER, ELECTRONICS 1

0038 WSO2XlO029 SPACER 1

0039 WSO2XIO030 FACEPLATE SUPPORT 1

0055 WS28XlO003 RETAINER CLAMP 2

0056 WS28XlO004 CLAMP 2

0101 WSO2XIO012 SCREW 1

0102 WSO2XIO013 SPACER 1

0103 WS21XIO003 SWITCH 1

0104 WSO3XIO009 PIN, EXPANSION 1

0105 WSO2XIO014 SCREW 5

0106 WS31X10006 COVER, VALVE 1

0107 WS03X10010 WAVE SPRING 1

0108 WS26X10002 ROTOR & DISC ASM. 1

0109 WS19X10004 CAP, VENTURI 1

0110 WS03X10011 SEAL, O-RING 1

NOTE: Codes in the State ofMassachusetts require installation bg a licensed

plumber and do not permit the use of the saddle valve. For installation, use

plumbing code 248-CMR of the Commonwealth of Massachusetts.

25

Page 26

Parts catalog.

GENERAL ELECTRIC PARTS CATALOG

REF. NO. PART NO. PART DESCRIPTION (02)

0111 WSI9XIO005 SUPPORT SCREEN 1

0112 WSO3XIO013 SCREEN 1

0113 WS22X10020 FLOW PLUG, .10 GPM 1

0114 WS08X10005 GASKET & ASPIRATOR 1

0115 WSO3X10015 CONE SCREEN 1

0116 WS22X10021 PLUG, FILL FLOW, .30 GPM 1

0117 WS03XI0017 FERRULE NUT 1

0118 WS15X10034 NOZZLE/VENTU RI BODY 1

0119 WSO3X10018 RETAINER 1

0120 WSO3XlO019 SEAL, O-RING, 1/4" X 3/8" 2

0121 WSI5XIO010 BODY, VALVE 1

0122 WS03X10020 SPRING 1

0123 WS22X10022 PLUG, DRAIN SEAL 1

0124 WS15X10009 NOZZLE/VENTU RI ASM. 1

0130 WS35X10005 SEAL KIT,3/4" 1

0132 WS22X10023 ADAPTER, DRAIN HOSE 1

0133 WS03X10021 O-RING, 5/8"X 13/16" 1

0134 WS03X10022 PLUG, FLOW, RINSE CONTROL 1

0135 WS03X10023 CLIP 1

0136 WS26X10003 CAM & GEAR 1

0137 WS26X10004 BEARING 1

0138 WS26X10005 PLATE, MOTOR, 3/4" 1

0139 WS02X10015 SCREW, #6-20 X 3/8" 2

0140 WS26X10011 MOTOR ASM. 1

0141 WS02X10016 SCREW, #6-20 X 7/8" 2

0143 WS60X10013 ADAPTER-NPT THREADED-STD VALVE 2

0145 WS60X10004 CLIP 4

0146 WS28X10017 HARNESS WIRE, SENSOR ASS?'.,3/4" 1

0147 WS19X10006 TURBINE & SUPPORT ASM, 1

0150 WS03X10024 SEAL, O-RING 4

0151 WS15X10053 BYPASS VALVE ASM, 1

0152 WS03X10025 SEAL, O-RING 4

0999 49-50177 OWNER'S MANUAL 1

G

X

S

F

3

0

H

WS60X10014 INSTALLATION KIT 1

26

NOTE: Codes in the State of Massachusetts require installation by a licensed

plumber and do not permit the use of the saddle valve. For installation, use

plumbing code 248-CMR of the Commonwealth of Massachusetts.

Page 27

GEWater Softening System Warranty. (For Customers in the United States)

All warrants service provided by our 5martWater T"Authorized Servicer

Network. To schedule service, call 800.952.5039 M.&) or 866.777.7627

(Canada). Please hove serial number and model number available when

calling for service.

Staple your receipt here.

Proof o1:the original purchase

dote is needed to obtain service

under the warranty.

For The Period Of: We Will Replace:

OneYear Any part of the Water Softening Sustemwhich fails due to a defect in materials or workmanship.

From thedate of the During this limited one-year warranty, GEwill also provide,free of charge, all labor and related

original purchase serviceto replacethe defective par[.

ThreeYears Theelectronic monitor, if it fails due to a defect in materials or workmanship. Duringthis

From thedate of the three-year limited warranty, Sou will be responsiblefor ang labor or related service costs.

original purchase

TenYears A replacement brine tank or cabinet, if eitherfails due to a defect in materials or workmanship.

From thedate of the During this ten-year limited warranty, Souwill be responsiblefor ang labor or relatedservicecosts.

original purchase

What Is Not Covered:

[] Service trips to sour home to teach Sou how to use

the product.

[] Improper installation, delivers or maintenance.

[] Failure of the product if it is abused, misused, altered, used

commercially or used for other than the intended purpose.

[] Use of this product where water is microbiologically unsafe

or of unknown quality, without adequate disinfection before

or after the system. Systems certified for cyst reduction may

be used on disinfected water that may contain filterable

cysts.

[] Replacement of house fuses or resetting of circuit breakers.

[] Damage to the product caused bg accident, fire, floods or

acts of God.

[] Incidental or consequentialdamage causedbg possible

defects with this appliance, its installation or repair.

[] Product not accessible to provide required service.

Limited Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for

I EXCLUSION OF IMPLIED WARRANTIES--Your sole and exclusive remedy is product repair as provided in this I

a particular purpose, are limited to one gear or the shortest period allowed by law.

This warranty is extended to the original purchaser and an;] succeeding owner for products purchased for home use within

the USA. If the product is located in on area where service bbla GEAuthorized Servicer is not available, Sou may be

responsible for a trip charge or blOUma_j be required to bring the product to an Authorized GEService location for service.

InAlaska, the warranty excludes the cost of shipping or service ca!ls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warrants gives you

specific legal rights, and you mog also have other rights which vary from state to state. To know what your legal

rights are, consult your local or state consumer affairs office or your state's AttorneLj General.

Warrantor: General Electric Company. Louisville, KY40225

I

I

27

Page 28

GEWater Softening System Warranty. (For Customers in Canada)

All warranty service provided by our Factory Service Centers or an authorized technician. For service,

call toll free 1.866. 777.7627. Please hove serial number and model number available when coiling for service.

For The Period Of: We Will Replace:

One Year Any part ofthe Water Softening System which fails due to a defect in materials or workmanship.

From the date ofthe During this limited one-year warranty, GEwill also provide,free of charge, all labor and related

on_ginalpurchase service to replace the defective part.

ThreeYears Theelectronicmonitor, ifit fails due to a defect in materials or workmanship. During this

From the date ofthe three-year limited warranty, you will beresponsible for any labor or related service costs.

anginal purchase

TenYears Areplacement brine tank or cabinet, if either fails due to a defect in materials or workmanship.

From the date ofthe During this ten-year limited warranty, you will be responsiblefor any labor or related servicecosts.

anginal purchase

What Is Not Covered:

• Service tripsto your home to teach you how to use

the product.

• Improper installation, delivery or maintenance.

• Failure of the product if it is abused, misused, altered, used

commercially or used for other than the intended purpose.

• Useof this product where water is microbiologicallg unsafe

or of unknown quality, without adequate disinfection before

or after the system. Systemscertified for cyst reduction may

be used on disinfected water that may contain filterable

cysts.

EXCLUSION OF IMPLIED WARRANTIES--Your sole and exclusive remedy is product repair as provided in this

Limited Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for

a particular purpose, are limited to one year or the shortest period allowed by law.

This warranty isextended to the original purchaser and any succeeding owner for products purchased for home use within

Canada. In-home warranty service will be prodded in areas where it is available and deemed reasonable by Mabe to provide.

WARRANTOR IS NOT RESPONSIBLE FOR CONSEQUENTIAL DAMAGES. ]

• Replacement of house fuses or resetting of circuit breakers.

• Damage to the product caused by accident, fire, floods or

acts of God.

• Incidental orconsequential damage caused by possible

defects with this appliance, its installation or repair.

• Product not accessible to provide required service.

II

28

I Warrantor: MABE CANADA INC. I

Page 29

Informaci6n de seguridad .... so

Instrucciones

de instalaci6n .............. ] t-4o

Instrucciones paso por paso .... 34-40

Instrucciones de operaci6n

C6mo limpiar la ensambladura

de la boquilla g el Venturi .......... 43

C6mo romper un puente de sal ..... 42

Funciones ........................ 44

Servicio ................... 41, 44-47

Sistema de descalcificaci6n

de agua ...................... 41-47

Cuidado g limpieza ............ 48

Consejos para la soluci6n

de avenas .................. 49-5!

Soporte al diente

Garant[a ......................... 58

Lista de partesicat61ogo ....... 54-57

Soporte al consumidor ............ 59

Escriba aqui los n_meros de modelo

y de la serie:

Modelo No.

Serie No.

Para encontrar estos nOmeros,

levante la cubierta g mire en el borde,

debajo del panel del control.

29

Page 30

INFORMACION INIPORTANTE DE SEGURIDAD.

LEA TODAS LAS INSTRUCCIONES ANTES DEL USO.

ADVERTENCIA

Par su seguridad, se debe seguir la informaci6n en este manual con el fin de reducir el riesgo de

una descarga eldctrica, dahos a la propiedad o dahos personales.

PRECAUCIONESDE SEGURIDAD

?_:Revisey cumpla con todos losc6digos estatales y

locales.Observelas pautas aqui presentadas.

::Ji::Tengacuidado al manipular el sistema de

descalcificaci6n de agua. NoIo voltee,deje caer,

arrastre o coloque en protuberancias extremas.

::Ji::Lossistemas de descalcificaci6n de agua que utilicen

cloruro de sodio (sadpara la recarga agregan sodio al

agua. Lospersonasque siguendietos conrestricciones

de sodiodeben considerar d sodio odicionalcoma

porte de su consumogeneral.Eldoruro depotosio

puede servir coma uno oltemotivo poro el cloruro de

sodiode su descolcificodor.

Elsistemade descalcificaci6nde agua funciona

solamente con 28voltios-60 Hz.Cerci6resede usar

exclusivomenteel tronsformodor incluido.

!b Eltransformador se debe conectar 0nicamente

a un tomacorriente interior con conexi6n a tierra

de 120 voltios.

?(:Utilice0nicamente salespara descalcificaci6n

del agua, al menos con 99,5%de pureza. Se

recomiendan las salesen PEPITAS,BOLITAS

o SALGRUESASOLAR.No utilice salesen roca,

bloque,granuladas o sales para la elaboraci6n

de helados. Estaspueden contener suciedad g

sedimentos,o pasta g masa g podrian crear

problemas de mantenimiento.

?(:Mantenga la tapa del orificio de la salen su lugar

en el descalcificador a menos que est6 realizando

mantenimiento o reponiendo la sal.

,ADVERTENCIA: No,, econagua

que sea microbiol6gicamente insegura o de calidad

desconocida sin Ilevara cabola desinfecci6n

adecuada antes o despu6s del sistema.

INSTALACION CORRECTA

Este sistema de descalcificaci6n de agua debe instalarse correctamente y colocarse de acuerdo o los

instrucciones de instalaci6n antes de su usa.

?_:Instale o almacene donde no quede expuesto a

temperaturas par debajo del punto de congelaci6n

ni est6 expuesto a ning0n tipo de indemencias

atmosf6ricas. Siel agua Ilegaacongelarse dentro

del sistema,@stepodria romperse. No intente dar

tratamiento al agua sise encuentra a una

temperatura par encima de B8°C (100°F).

?_:No instale expuesto a los ragas directos del sol.

Exposici6nal solacalor excesivos podrian causar

distorsi6n u otros da_os alas partes no met61icas.

::J_::Conectea tierra de manera apropiada seg0n los

c6digos g ordenanzas aplicables.

::Ji::Usesolamente fundente blsoldodum sinplomo para

todas las conexiones de condensaci6n soldadas,

seg0n losc6digos estatales g federales aplicables.

::Ji::Elsistema de descalcificaci6nde agua requiereun

flujo de agua minima de tres galonespar minuto en la

entrada. La presi6nde entrada m6xima permitida es de

125psi.Sila presi6ndurante el dia espor encima

de 80 psi,la presi6nnocturna podria exceder el

m6ximo. Useuna v61vulareductorade presi6n

para reducir el flujo si esnecesario.

_: Lasresinasde descalcificaci6npodrian degradarse

ante la presenciade cloro porencima de2 ppm.

Siusted tieneuna cantidadde cloro magor a 6sta,

quiz6sexperimente una vida menor de laresina.

Enestascondiciones,es posibleque quiera

considerar la compra de un sistema defiltraci6n

del punto de admisi6n para casas GEcon un filtro

reductor de cloro.

ADVERTENCIA:Desechetodaslas

partes g losmateriales de embalaje no utilizados

despu6s de la instalaci6n. Partespequer_as

restantes despu6sde la instalaci6n podrian

representar un peligro de asfixia.

LEAYSIGAESTAINFORMACIONDESEGURIDADCUIDADOSAMENTE.

GUARDE ESTASINSTRUCCIONES

30

Page 31

Instrucciones

Sistema Suavizante de Agua

de instalaci6n

r_ zPreguntas? Llame 800.GE.CARES (800.432.2737) o Visite nuestra p6gina en la red en: ge.com

Modelo G×SF30H

ADVERTENCIA: Lea este manual en su totalidad. No seguir todas las pautas g normas

podria causar lesiones personales o daSos a la propiedad.

• Consulte con la autoridad de obras pSblicas estatal/Iocal para los c6digos de plomeria. Deber6 seguir

estas pautas para instalar el sistema de filtraci6n de agua.

NOTA: No cumplir con estas instrucciones de instalaci6n invalidar6 la garantia del producto, g el instalador

ser6 responsable par cualquier servicio, reparaci6n o daSos causados.

ANTES DE EMPEZARLA INSTALACI6N

Lea estas instrucciones completa g

cuidadosamente.

•IMPORTANTE - Guardeestas

instrucciones puru usa del inspector local.

• IMPORTANTE - Observetodoslos

c6digos Y ordenanzas vigentes.

• Nota al instalador - Aseg0rese de dejar estas

instrucciones al consumidor.

• Nota al consumidor- Conserve estas

instrucciones para consultas poster(ores.

• La instalaci6n apropiada es la responsabilidad

del instalador.

• Las averfas del producto causadas por una

instalaci6n inadecuada no est6n cubiertas por

la garantia.