Page 1

www.GEAppliances.com

Safety Information ........... 2

Installation Instructions ...3-1 o

Step-by-step instructions .... 6-10

Operating Instructions

Breaking a salt bridg_ ........ 19

Cleaning the nozzle and

venturi assembly ............ 19

Features ................... 13

Service .............. 11, 14-16

V(ater softener system ..... 11-16

Care and Cleaning ......... 17

Troubleshooting Tips ..... 18-20

Consumer Support

Consumer Support . . .Back Cover

Parts list/catalog ......... 92-25

V_'arranty (U.S.) ............. 96

_'arrantv (Canada) .......... 97

Water

Sistema

La secci6n en espa#ol empieza en la pagioa 29

Softening

System

ModelGXSF27£

Suavizante

de Agua

Modelo GXSF27E

©

System tested and certified by NSF International against NSF!ANSI Standard 44 fl)r the

chemical reduction (laims specitied on the per/brmance data sheet.

Sistema probado y certiticado pot NSF International contra norma 44 de NSF/ANSI para

las afirmaciones de reduccidn de los productos qufmi(os especi/icadas en la hoja de datos

de flmcionamiento.

Write themodelandserial

numbers here:

Model #

Serial #

To find these numbers, lift

the cover and look on the

rim below the control panel.

7247182 215Cl173P009 49-50150 02-05Jfl

Page 2

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of electric shock,

property damage or personal injury.

SAFETYPRECAUtiONS

_: Check and cmnl)ly with vour state and local

codes. You must tollow ti/ese guidelines.

::Ji::Use care when handling the water softening

s_:stem. Do not turn upside down, drop, drag

or set on sharp protrusions.

?_:Water softening systems using sodimn chloride

(salt) for recharge add sodium to the water:

Persons on sodium restricted diets should consider

the added sodium as part of their overafl intake.

Potassium chloride can be used as an alternative

to sodium chloride in your softener

The _ater softening system _orks on 24 xolt-60 Hz

electrical power only. Be sure to use only the

included transformer

iJi::Transformer must be )luo,_ed into indoor

120 xolt, grotmded outlet only.

_: Use clean water softening salts only, at least

99.5% pm'e. NUGGET, PEI,I,ET or coarse

SOLAR salts are recommended. Do not use rock,

block, granulated or ice cream making salts.

They contain dirt and sediments, or mush and

cake, and will create maintenance problems.

::Ji::Keep the salt hole cover in place on the softener

tmless servicing the trait or refilling with salt.

A WARNING:oo.o, use with water that is

microbiologically unsati _ or of unknown quality

without adequate disinfection befi)re or after

the system.

PROPERINSTALLAtiON

This water softening system must be properly installed and located in accordance with the Installation

Instructions before it is used.

_: Install or store where it will not be exposed to

temperatures beh)w fl'eezing or exposed to any

type of weather: Water fi'eezing in the system will

break it. Do not attempt to treat water over 100°E

::Ji::Do n0tinstall in direct sunlight. Excessive sun or

heat may cause distortion or other damage to

non-metallic parts.

Properly ground to cent)tin with all governing

codes and ordinances.

Use only lead-free solder and flux for all sweat-

solder connections, as required by state and

federal codes.

_: Softener resins may degrade in the presence

of chlorine above 1 ppm. If you have chlorine

in excess of this ainount, you inay experience

reduced life of the resin. In these conditions,

you may wish to consider pro'chasing a (;E

point-ofent_ T household filtration system with

a chlorine reducing filte_:

A WARNING:Disc.,-d.lluilusedpax'ts

and packaging material alter installation.

Small parts remaining after the installation

could be a choke hazard.

Tile water softening s}:stem requires a minimum

water flow of three galhms per minute at the inlet.

Maximum allowable inlet water pressm'e is 125 psi.

]f daytime pressm'e is over 80 psi, nighttime

pressm'e may exceed the maximmn. Use a pressm'e

reducing \:dye to reduce the flow if necessarx:

READANDFOLLOWTHISSAFETYINFORMAtiONCAREFULLY.

SAVETHESEINSTRUCTIONS

2

Page 3

Installation instructions.

A_ CAUTION: Certain plumbing skills are needed for installation. If you are unsure about

any part of the installation of this product, consult a professional plumber.

Unpacking and Inspection

Be sure to check the entire softener for any

shii)ping damage or parts loss. Also note

(lamage to tile shii)ping cartons. Contact the

transportation company for all damage and

loss claims. The ii/antlf_lCttli'ei" is not

responsible fl)r damages in transit.

Important Installation Recommendations

Read entire manual. Failure to follow all guidelines and rules could cause personal injury or

property damage.

_: Before you 1)egin installation, read these

Installation Instructions completely. Then,

obtain all tile materials and tools you will

need to make the installation. Failm'e to

properly install the softener voids the

W[I IT[I n IV.

::Ji::Check local codes. Tile installation m ust

conform to them.

::Ji::In the Commonwealth of Massachusetts,

Plumbing Code 248 CMR shall be adhered to.

Consult with your licensed plumber.

::J?::Use only lead-h'ee solder and flux for all

sweat-solder connections, as required bv

state and federal codes.

_: Connect tile soliener to tile main water

supply pipe before or ahead of the water

heater. DO NOT RUN HOT WATER THROUGH

THESOFTENER.Temperature of water

passing through tile softener illtlst be

less than 120°F.

Small parts needed to install tile softener are

packaged either in a bag or on a cardboard

sheet. To avoid loss of the small parts, kee I)

them packaged tmtil you are ready to use them.

Be StlYe not to discard components hidden in

packaging.

Maximum allowable inlet water pressm'e is

195 psi. If daytime pressure is over 80 psi,

nighttime pressure may exceed tile

maximmn. Use a pressure reducing wflve

if necessary: (Adding a pressure reducing

wflve may reduce tile flow.)

::Ji::Tile softener works on 24 volt-60 Hz

electrical power only. Be sure to use tile

included transformer. Be sure tile electric

outlet and transformer are in an inside

location to protect ['l'OlIl i/loisttlre.

_: See Where to Install the Softener section fl)r

more derails.

A WARNING:Do use with water

that is microbiologically tmsafe or of

tmknown quali W without adequate

disinfection befi)re or atier the system,

The water should be tested periodically

to verif)' that tile system is peril)truing

satistactorilv.

_: Use care when handling tile softener.

Do not ttlFn upside down, drop, drag

OI" set on shay l) l)I'otI'/Isions.

_: Small parts remaining after tile installation

could be a choke hazard. Discard safely.

Page 4

Installation instructions.

Plan How You Will Install the Softener

You must first decide how to mm in and out

pipes to the softener. I,ook at the house

main water pipe at the point where you will

connect the soiiener. Is the pipe soldered

coppe_; glued plastic or threaded galwmized?

What is the pipe size?

.4,WARNING:Use..l, le,,d.,ee

solder and flux to prevent lead poisoning.

Where to Install the Softener

::Ji::Place the sottener as close as possible to a

sewer drain, or other acceptable drain point

or standpipe.

::Ji::It is recommended to kee I) outside thucets

on hard water to save sott water and salt.

_: Do not install the softener in a place \_here it

could fi'eeze. Freeze damage is not covered by

the warranty.

_: Do not install the softener where it would

block access to the water heater or access to

the main water shutott.

Put the softener in a place where water

damage is least likely to occur if a leak

develops. The manufacturer will not repair

or pay for water damage.

See Yypical Installation Illustration, Fig. 1. Use

this as a guide when planning yore" particular

installation. Be sure to direct the incoming hard

water supply to the softener valve inlet fitting.

The valve is marked IN and OUT See illustration

on page 5 to help you prepare.

_: A 120-volt electric outlet is needed to plug

in the included transtormer. The sottener

has a 10 toot power cable. If the outlet is

remote (up to 100 filet), use 18 gauge wire

to connect. Be sure the electric outlet and

transformer are in an inside location, to protect

from wet weather. Be sure the outlet is

unswit('hed to prevent accidental shutolt.

_: If installing in an outside location, you must

take the steps necessary to assure the sotiene_;

installation plumbing, wiring, etc., are as

well protected ti'om the elements (stmlight,

rain, wind, heat, cold), contamination,

wmdalism, etc., as when installed indoors.

Outdoor installation is not recommended, and

voids the warranty.

_: Keep the softener out of direct sunlight.

The sun's heat may distort non-metallic

parts and may damage the electronics.

Toolsand Materials Required for Installation

_: In and out fittings included with the softener

are 3/4" (nominal) Col)per sweat tubes.

You should maintain the same, or larger,

pipe size as the water supply pipe, up to the

sottener inlet and outlet.

Use the included bypass valve to install the

sottener. The bypass wflve allows you to turn

off water to the soltener fin" servicing, but

still have water in the house pipes. The in

and out fittings referred to above connect to

the bypass valve with the included nuts and

wash ers.

::Ji::Use coI)pet; brass or galwmized pipe and

fittings. Some codes may also allow CPVC

plastic pipes.

4

If additi(mal drain hose is needed tot wove

and salt tank drains, it can be ordered from

GE Parts at 800.626.2002.

::Ji::If a rigid wdve drain is needed to comply

with plmnbing codes, you can buy the parts

needed to connect a 1/2" coI)per tubing or

plastic pipe drain.

::Ji::Clean nugget or pellet water sottener salt is

needed to fill the brine tank, see Step 8 in

the Step-by-Step Installation Instructions.

Page 5

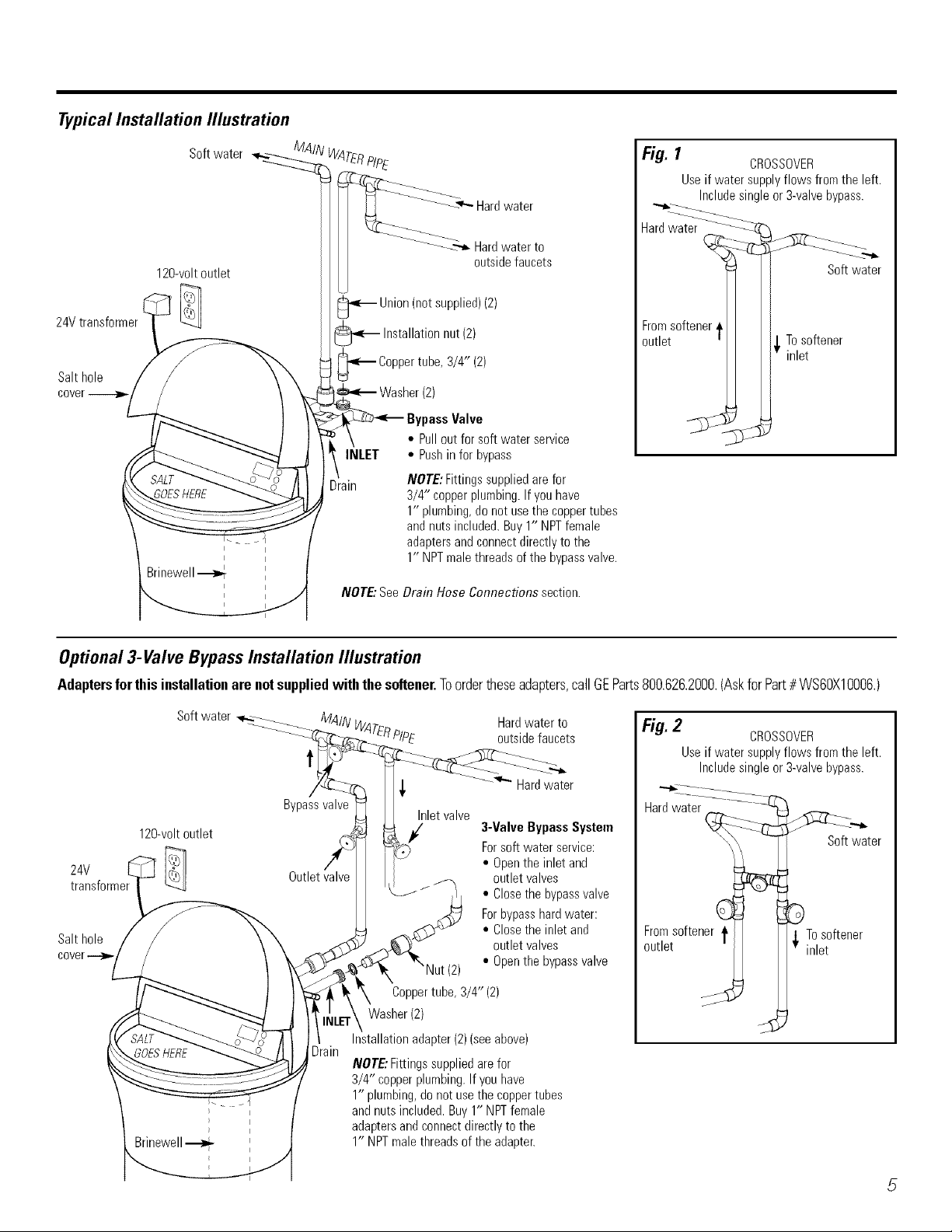

Typical Installation Illustration

24V transf(

Salt hole

cover

Softwater

120-voltoutlet

Brinewell

,_. HAl

/V47_RP/PE

-_ "_'---Hardwater

"_-__...._L Hardwaterto

outsidefaucets

_ Union (not supplied) (2)

(_-_ Installation nut (2)

_ opper tube, 3/4" (2)

Washer (2)

_assValve

• Pulloutfor softwater service

INLET

Drain

NOTE: See Drain Hose Connections section.

• Pushin for bypass

NOTE:Fittingssuppliedare for

3/4" copperplumbing.If youhave

1" plumbing,do notusethe coppertubes

andnutsincluded.Buy1" NPTfemale

adaptersandconnectdirectlytothe

1" NPTmalethreadsof the bypassvalve.

Fig. 1 CROSSOVER

Useifwater supplyflows fromthe left.

Includesingleor3-valvebypass.

Hard water

Fromsoftener,

)utlet

,_ To softener

inlet

Softwater

Optional 3-Valve Bypass Installation Illustration

Adapters for this installation are not supplied with the softener. Toorderthese adapters,call GEParts800.626.2000.(Askfor Part# WS6OX10006.)

Softwater ,_..,_ ...... MAIN

Bypassvalve

120-voltoutlet ¢4

P_

24V I_l! Outletvalve

transformer

Salthole

Drain

I_RPIPE outsidefaucets

_-___-_ ____

Inlet valve

(2) • Openthebypassvalve

Coppertube,3/4" (2)

Washer(2)

Installation adapter (2)(see above)

NOTE:Fittingssuppliedarefor

3/4" copperplumbing.If youhave

1" plumbing,donot usethecoppertubes

andnutsincluded.Buy1" NPTfemale

adaptersandconnectdirectlytothe

1" NPTmalethreadsof the adapter.

Hardwaterto

.... _ Hardwater

3-Valve BypassSystem

Forsoft water service:

• Opentheinlet and

outletvalves

• Closethebypassvalve

Forbypasshardwater:

• Closetheinlet and

outletvalves

Fig. 2 CROSSOVER

Useifwater supplyflows fromthe left.

Includesingleor3-valvebypass.

Hardwater (_

C

Fromsoftener1'

outlet

_, Tosoftener

inlet

Softwater

5

Page 6

Step-by-step installation instructions.

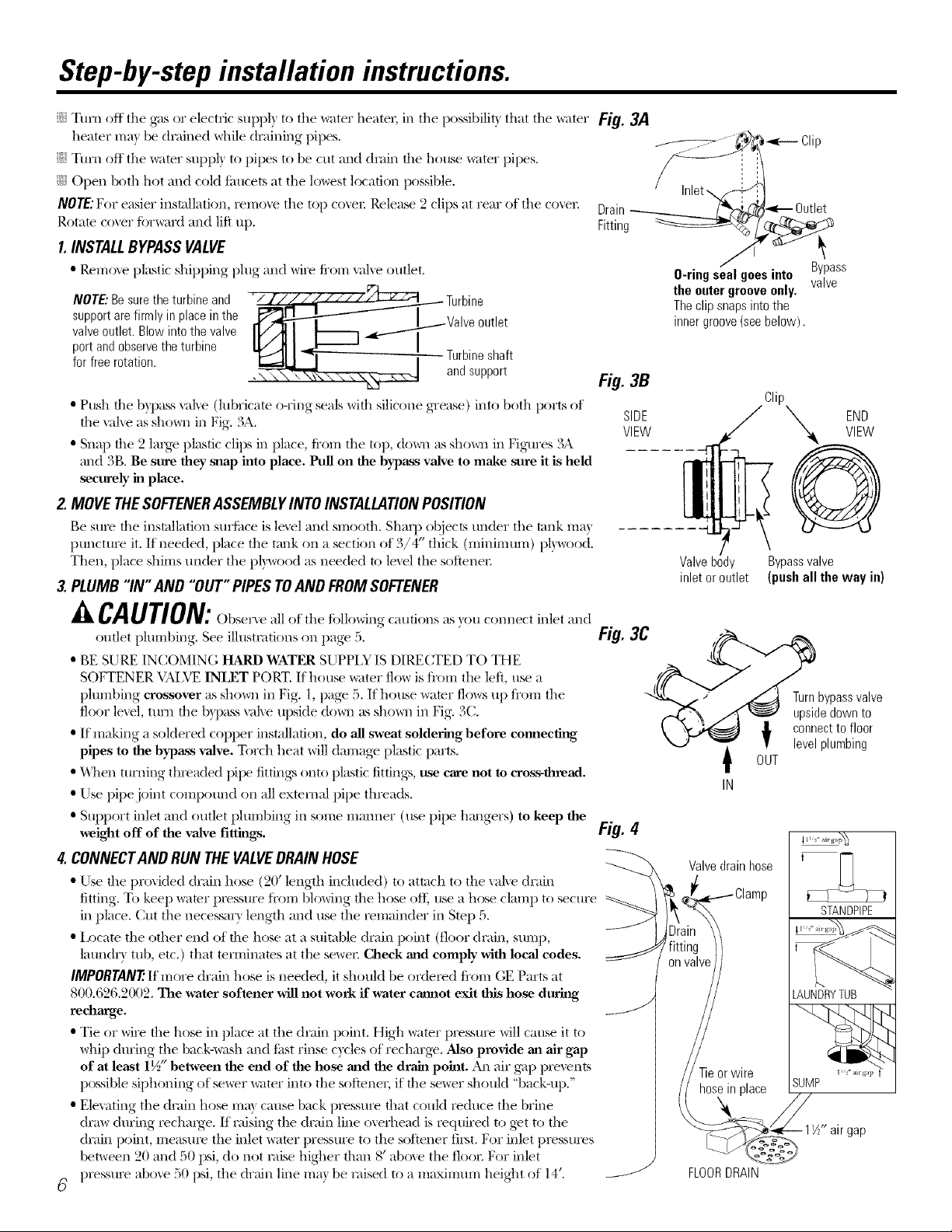

i_g:Turn off the gas or electric suppl) to the water heateL in the possibilit} that the water _i_. 3A

heater ma} be drained while draining pipes.

i:g:Turn off the water supp]) to pipes to be cut and drain tile house water pipes,

i:g:Open both hot and cold timcets at tile lo_vst location possible.

NOTE:For easier installation, remove file top covei; Release 9 clips at rear of tile cove_:

Rotate coxvr ti)rward and lift up.

1.INSTALLBYPASSVALVE

• Remo_v plastic shipping plug and wire fi'om valve outlet.

supportare firmly in placeinthe I utlet

NOTE:Besuretheturbineand ' __;_;

port and observe the turbine

valveoutlet. Blowinto the valve _ Ta_blsn:p;_[

for free rotation, t

• Push the b}pass vane (lubricate o4"ing seals with silicone g_'ease) into both ports of

the valve as shown in Fig. 3%

• Snap the 2 lm'ge plasdc clips in place, fi'om the top, down as sho_m in Figures 3A

ml(t 3B, Be sure they snap into place. Pull on the bypass valve to make sure it is held

securely in place.

Z MOVETHESOFTENERASSEMBLYINTOINSTALLATIONPOSITION

Be sure file installation suriiJce is lexel and smoofll. Sharp objects under the rank ma)

ptxxlcttxre it. If needed, place tile tmlk on a section of 3/4" thick (minimum) pb'_)od.

Then, place shims under the pl)'_)od as needed to level the softener

3.PLUMB "IN" AND "OUT" PIPESTOAND FROMSOFTENER

Drain

Fitting

Hg3B

SIDE

VIEW

i-c--- Clip

O-ringseal goesinto

the outer grooveonly.

Theclip snapsintothe

innergroove(seebelow).

Clip

Valvebody

inletor outlet

Bypassvalve

(pushall the way in)

Bypass

valve

END

,&CAUTION:Obser.eall tle ca,.,,,lsas,o. o,nle.,lle anal

outlet phmlbing'. See illustrations on page 5. Fig.3C

• BE SURE INCOMING HARD WATER SUPPIX IS DIRECTED TO THE

SOFTENER VA[YE INLET PORT. If house water flow is from the left, use a

plumbing crossover as sho_m in Fig. 1, pag> 5. If house water flows up from tile

floor lexvl, ttxrn tile bypass valxe upside ctoxm as shoxm in Fig. 3C.

• If making a soldered copper installation, do all sweat soldering before connecting

pipes to the bypass valve. Torch heat will dmnage plastic pm'ts.

• _'\]len turning threaded pipe fittings onto plastic fittings, use care not to cross-thread.

• Use piI)ejoint compound on all exmrnal pipe threads,

• Supl)ort inlet and outlet phmlbing in some manner (txse pipe hangers) to keep the

weight off of the valve fittings. Fig. 4[

4 CONNECTANDRUN THEVALVEDRAINHOSE

• Use file In'ovided drain hose (20' length included) to attach to the valxe drain

fitting. To keep wamr presstxre ti'om blowing the hose oft; use a hose clamp to secure

in place. Cut the necessm? length and use the remainder in Step 5.

• i z)cate the other end of the hose at a stfitable chain point (floor chain, sump,

launch 3 tub, etc,) that mrminams at the sewex: Check and comply with local codes.

IMPORTANT'.If more drain h()se is needed, it should be orctexed from GE Parts at

800.626,2002, The water softener will not work if water cannot exit this hose during

recharge.

• Tie or wire the hose in place at the chain point. High water pressure will cause it to

whip during the back-wash and thst rinse cycles of rechargv. Also provide an air gap

of at least 1½" between the end of the hose and the drain point. An air gap pre_vnts

possible siphoning of sewer water into the soflenex; if the sewer should "back-up."

• Elevating the chain hose ma) cause back pressure that could reduce the brine

draw during rechaxge. If raising the chain line overhead is reqtfired to get to the

drain point, measure the inlet water pressure to the softener first. For inlet pressures

between 20 and 50 psi, do not raise higher dlan 8' abo_e the floox: For inlet

6' presstxre above 50 psi, the drain line ma) be raised to a maximmn height of 14'.

O_U connectto floor

IN

Valvedrainhose

FLOORDRAIN

Turnbypassvalve

upsidedownto

T

levelplumbing

gap

Page 7

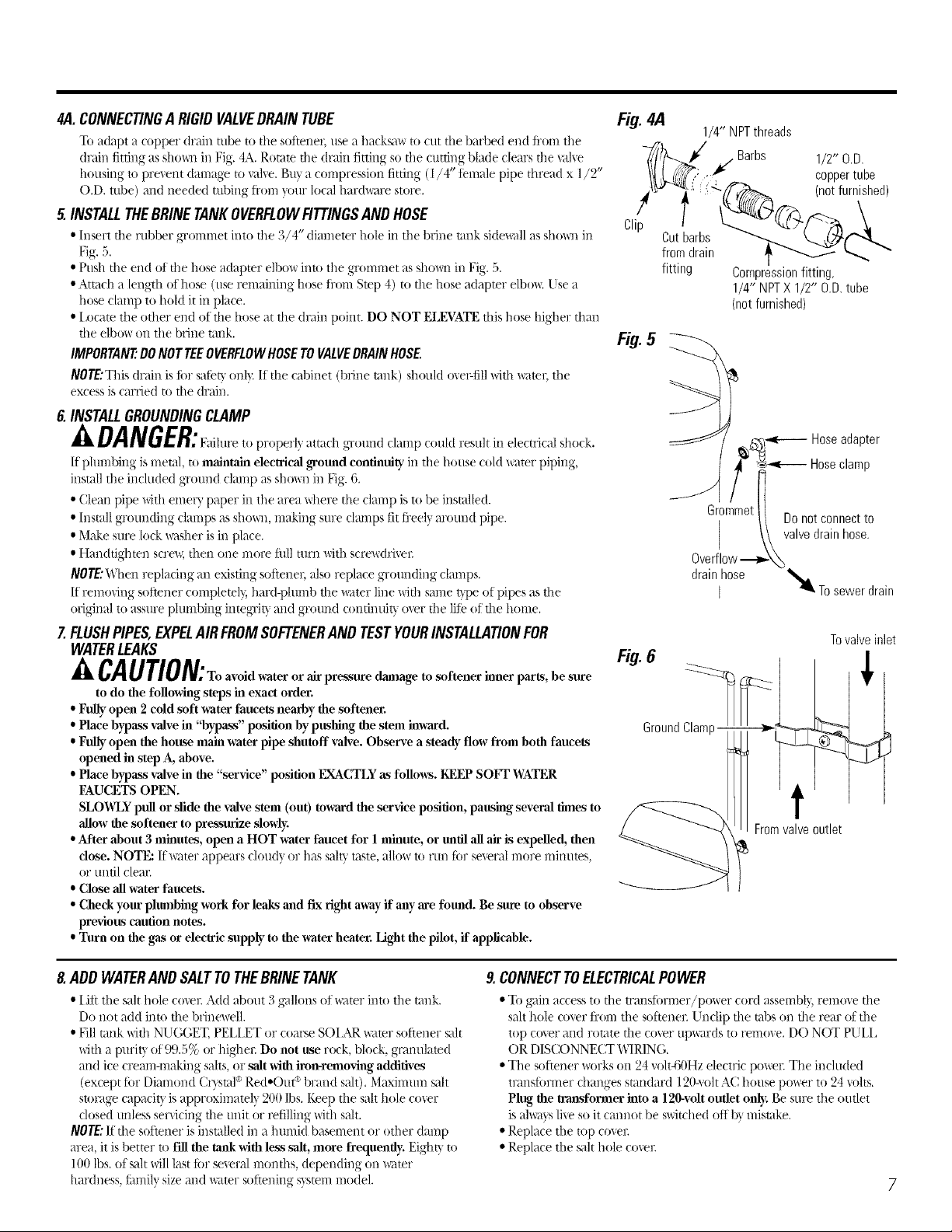

#,4.CONNECTINGA RIGIDVALVEDRAINTUBE

To adapt a copper drain tube to the soiteneL use a hack_m to cut the barbed end fl'om the

drain fitting as shown in Fig. 4A. Rotale file drain fitting st) file cutting blade clears file xahe

housing u) pre\ent damage to valve. But a compression fitting (1/4" fi:male pipe thread x l/2"

O.D. robe) and needed tubing fi'om p)ur It)cadhardware store.

5.INSTALLTHEBRINETANKOVERFLOWRT"I'INGSANDHOSE

• Insert tt/e rubber gxommet into tile 3/4" diameter hole in tile brine tank sidewall as sho_ql in

Fig. 5.

• Push the end of tile hose adapter elbow into tile gxonm/et as shown in Fig. 5.

• Attach a length of hose (use remaining hose Ii'om Stop 4) to the hose adapter e/bo_. Use a

hose clamp to hold it in place.

• I_ocam tile other end of the hose at the drain point. DO NOT ELEVATE this hose higher than

the elbowson tile bdne rank.

IMPORTANT:DONOTTEEOVERFLOWHOSETOVALVEDRAINHOSE.

NOTE:This drain is %I" safieff only. If the cabinet (brine rank) should o\er-Iill with watel; tile

excess is carried m the drain.

6.INSTALLGROUNDINGCLAMP

If plumbing is metal, to maintain electrical gromld continuity in tile house cold water piping,

iusmll tile included gTotmd clamp as sho_n ill Fig. 6.

• (;lean pipe with emery paper in the area _dmre the clamp is to be iusmlled.

• Install grounding clamps as shoxnl, making sure damps fit li'eely arotmd pipe.

• Make sure lock x<@mr is ill place.

• Handtighten scre_, then one more fll[Imrn with scre_ddver

NOTE:When repladng ml existing soltenel; also replace grounding clamps.

If removing soltener completel b hard-plumb the water line with same t_pe of pipes as the

original to assure plumbing inmgrit} and ground confimlit_ over the lile of the home.

Z FLUSHPIPES,EXPELAIRFROMSOftENERANDTESTYOURINSTALLATIONFOR

WATERLEAKS

CAUTION:To avoid water or air pressure damage to softener inner parts, be sure

to do the following steps in exact order.

• Fully open 2 cold soft water faucets nearby the softener.

• Place bypass valve in "bypass" position by puslfing the stem inwaxd.

• Fully open the house main water pipe shutoff valve. Observe a steady flow from both faucets

opened in step A, above.

• Place bypass valve in the "service" position I_NACTLYas follows. I@'EP SO_3" WATER

FAUCETS OPFN.

SLOWLY pull or slide the valve stem (out) towaxd the service position, pausing several times to

allow the softener to pressurize slowly.

• After about 3 minutes, open a HOT water faucet for 1 minute, or mlfil all air is expelled, then

dose. NOTE: If water appears cloudy or has salt}'"u_ste,allow to run for several more minutes,

or until cleaI:

• Close all water faucets.

• Check your plumbing won for leaks and fix rigbt awayif any axe fomld. Be sure to observe

previous caution notes.

• Tunl on the gas or eledric supply to the water beater. Light the pilot, if applicable.

Fig4A

Bg5_

1/4" NPTthreads

1/2" O.D.

coppertuhe

(notfurnished

Cutbarbs

fromdrain

fitting

J

-_@°mmet/i Donotconnectto

Compressionfitting,

1/4" NPTX 1/2" O.D.tube

(notfurnished)

££_,,-_ Hoseadapter

e--- Hoseclamp

] \\valve drainhose.

Overflow.i_&_

drainhose

I _ Tosewerdrain

Tovalveinlet

Fromvalveoutlet

7

8.ADD WATERANDSALTTOTHEBRINETANK

• LiR tile salt hole cove£ Add about 3 g'4llons of _<_terinto tile rank.

Do not add into the brineweg.

• Fig rank wifll NUGGET, PELI.ET or coarse SOI.AR wamr softener salt

with a purit_ of 99.5% or hi0_er Do not use rock, block, gramdated

and ice cream-making salts, or salt with iron-removing additives

(except for Diamond (2I')rS_] _ Red"Out c'>brand salt). Maximum sdt

su)rage capacity is approximatel} 200 Ibs. Keep the salt hole co\er

closed unless set\icing the unit or refilling with salt.

NOTE:Ifthe softener is installed ill a humid basement or other damp

area, it is bettor m flUthe tank with less salt, more frequently. Eight} to

100 Ibs. of salt will last tor se\eral months, depending on _<_mr

hardness, fiunily size and water softening S}rSml_ modeh

9.CONNECTTOELECTRICALPOWER

• To gain access to the U'ausfbrmer/po_er cord assemb(v, remo_e the

salt hole co\er fi'om tile softener. Undip the mt)s on the rear of tile

top co\er and rotate the cover 11pwaYdstOremox e. DO NOT PUI 1_

OR DISCONNECT WIRING.

• The softener works on 94 xolta;(lHz electric powei: The included

transf6rmer dmnges standard 120-xoltAC house power to 24 \oiLs.

Plug, the transformer into a 120-volt outlet only. Be sure tile outlet

is alwa}s/i\e so it cannot be switched offb} mistake.

• Replace tile top cmer

• Replace tile salt hole cover

7

Page 8

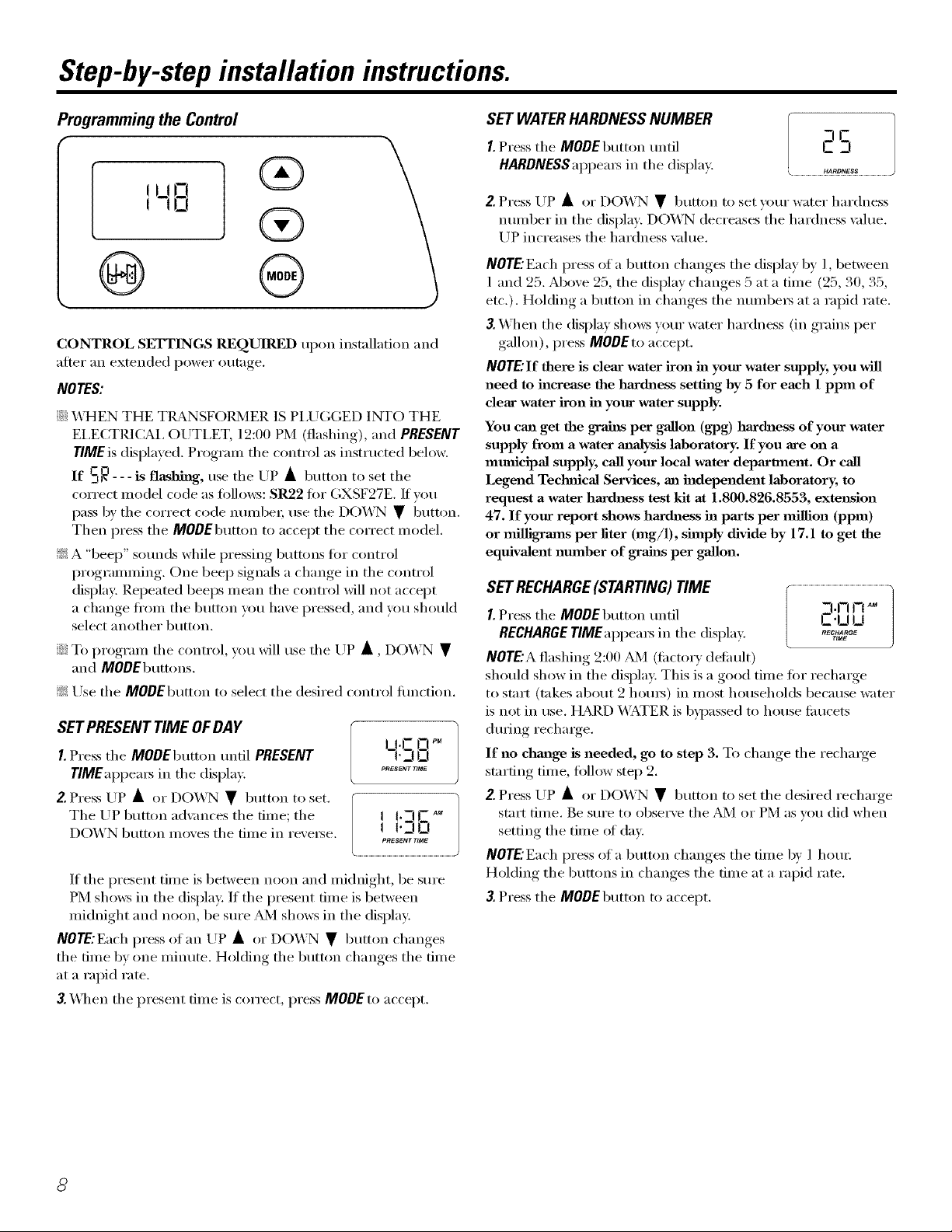

Step-by-step installation instructions.

Programming the Control

CONTROL SETTINGS REQUIRED upon installation and

alter an extended power outage.

NOTES:

::Ji::X4_HEN THE T1L_tNSFORMER IS PI,UGGED INTO THE

EI,ECTRI(:AI, OUTI,ET, 12:00 PM (flashing), and PRESENT

TIME is displayed. Program tile control as instructed bel_m'.

If __--I_-- -is flashing, use tile Up • button to set tile

correct model code as fi)llo_vs: S1_2 fin" GXSF27E. If wm

pass by tile correct code nmnbe_; use tile DOWN • i)utton.

Then press the MODEbutton to accept the correct model.

_: A "beep" sounds while pressing buttons tor control

programming. One beep signals a change in the control

display: Repeated beeps mean tile control will not accept

a change ti'om tile button you have pressed, and you should

select another button.

::Ji::To program tile control, p)/i will tlse tile UP •, DOWN •

and MOOEbuttons.

_: Use the MODEbutton to select the desired control fimction.

SETPRESENT TIME OFDAY

I. Press tile MODEbutton until PRESENT

TIMEappeax_ in tile display.

2.Press Lrp • or DOWN • button to set.

The UP button ad\m_ces tile time; tile

DOWN button inoves tile time in i'eveiNe.

If tile present time is between noon and midnight, be sure

PM sho_vs in the display. If the present time is between

midnight and noon, be sure _] shows in tile display:

NOTE:Each press of an UP • or DOWN • button changes

the time bv one minute. Holding the button changes the time

at a rapid rate.

3. \_]/en the present time is correct, press MODE to accept.

_PM

U.CO

I'JO

PRESeNT'ME

I !.-IF'_

v30

PRESENT_M_

SET WATERHARDNESS NUMBER

I. Pressthe MODEbutton until

HARDNESSappeax_in the display.

2. Press UP • or DO_VN • button to set your water hardness

nmnber in tile display. DOWN decreases tile hardness xdue.

UP increases tile hardness xdue.

NOTE'Each press of a button changes tile display by 1, between

1 and 25. Above 25, the display changes 5 at a time (25, 30, 35,

etc.). Holding a button in changes tile nulnbei_ at a rapid rate.

3. When the display sho_vs yore" water hardness (in grains per

gallon), press MODEm accept.

NOTE."If there is dear water iron in your water supply, you will

need to increase the haacd_mss setting by 5 for each 1 ppm of

clear water iron in your water supply.

You cm_ get the grains per gallon (gpg) haacd_mss of your water

supply from a water m_aJysis laboratory. If you are on a

municipal supply, call your local water department. Or call

Legend Tecl_fical Services, an independent laboratory, to

request a water haaxlness test kit at 1.800.826.8553, extension

47. If your report shows hamd_mss in parts per million (ppm)

or milligrmns per liter (rag/l), shnply divide by 17.1 to get the

equivalent nmnber of grains per gallon.

SETRECHARGE(STARTING)TIME

I

I. Press the MODE button until l _£_E!IjRECHARGETIMEappea_ in tile display.

NOTE.'A flashing 2:00 _/I (ii_cto_y delimit)

shouM show in the display: This is a good time tot recharge

to start (takes about 2 houi_) in most households because water

is not in use. HARD X_;_TER is b}passed to house tinlcets

dm-ing rechmge.

If no chm_ge is needed, go to step 3. To change the rechmge

starting time, tollow step 2.

2.Press UP • or DOX4'N • button to set tile desired rechaxge

start time. Be sure to observe tile f_dVIor PM as w)u did when

setfng the time ot day,

NOTE.'Each press of a button changes tile time by l horn;

Holding tile buttons in changes tile time at a rapid rate.

3. Press the MODE button to accept.

-_Hn

AM

I-t

8

Page 9

Optional Control Settings

The controller display has several options and teatures.

SYSTEM/ELECTRONICDIAGNOSTICS

This display contains s?'stem diagnostics

infimnation to assist in troubleshooting n r-tr'f

problems with the _Ailtei" Sot_tenei: See 0B P

page 15.

To access the Sysmm Diagnostics, press and hold the MODE

b/itton li)i" 3 seconds.

To return to the nomml displa 5 press the MODEbutton 2 times.

' blUU----

SALTEFFICIENCY

X._]mn the SALT EFFICIENCYflmmre is ON, the unit will operate

at a salt efficiency ot at least 4000 grains of hardness removed

per l)otmd of salt. This mode of operation is the most efficient

setting tot salt usage, because the system will tend to rechmge

more olten, with less salt usage. Turning the feature OFF will

tend to lengthen the time between recharge cycles, which will

provide the most eftident usage of water; but may use more

salt. The degree ot difli_rence between these two cycles is highly

dependent on the water usage and hardness at a particular

insmllation.

NOTE: Califi)rnia Regulations require this teature to be ON for

installations in Califiwnia.

To access the Salt Eflicienc}; press and hold

the MODEbutton fin" 3 seconds. The System

Diagnostics display will al)l)ea_:

Press the MODEbutton again and the Salt

Efficiency display will ai)i)em:

To change the setting, press the UP • or

DOWN • buttons to toggle the leature

ON or OFF. Press the MODE bumm to

accept.

On

i.................................OFF°']

ERRORSIGNALS

I r- n

]f there is an error code detected, the displa_ ] I-.7.I- I- U I

will flash Err to signal that the sottener L.............................................................................................................

requires se_Ti('e.

See page 14 ti)r inflmnation m assist in troubleshooting

error codes. Once the problem is corrected, disconnect the

transfom_er fi'om the wall outlet momentarily, and plug it back

in. The nomml display will apl)ea_: The motor may rim fin"

several minutes, as the unit resets. If the problem is not

corrected, the error code will reappear in 6 minutes.

Page 10

Step-by-step installation instructions.

Sanitizing Procedures

Tocomplete the installation, do the following

sanitizing procedures.

Care is taken at the factory to kee I) your

water sotiener clean and sanitary: Materials

used to make the sotiener will not infect or

contaminate vour water supply and will not

cause bacteria to t()i'ill OI" gI'oW, However,

during shipping, storage, installing and

operating, bacteria could get into the

softeuer. For this reason, sanitizing as

tollows is suggested when installing.

NOTE: Smfitizing is recommended by the

Water Quality Association for disinfecting.

I. Be sm'e to complete all installation steps,

including programming the control.

2. Pour about 3/4 oz. (1 ½ tablespoons) of

common 5.25% unscented household bleach

(Clorox, I,inco, Be Peel), White Sail, Eagle,

etc.) into the brinewell. Refer to illustration

on page 5.

3. IMPORTANT." Press and hold lot 3 seconds

the taceplate RECHARGE@ button to start

an immediate recharge. RECHARGEbegins

to flash in the displa> The bleach will be

drawn through the water softener, and out

the drain. This process rakes approximately

2 hours.

4. If, after sanitization, water fl'om the house

fimcet tastes salty or has a slight col(n; this is

a preservative ti'om the resin tank. Tm'n on

the cold sott water fimcets and drain tin" a

tew minutes or until clear.

NOTE:When the sanitizing recharge is ovex,

all remaining bleach is flushed from the

conditioner and veto" house COlD water supply

is hilly soft im m ediatel> However, yam" water

heater is filled with hard water and as hot water

is used, it will refill with soft water. When all the

hard water is replaced in the water heater, hot

only and mixed hot and cold water will be hilly

soil If you want totally salt water imm ediatel>

after the above recharge, drain the water heater

tmtil the water runs cold.

A WARNING:,,,,(),,dod,aiuthe

water heater, rise extreme care as the hot

water could catlse burus. Turu the water

heater off prior to draining.

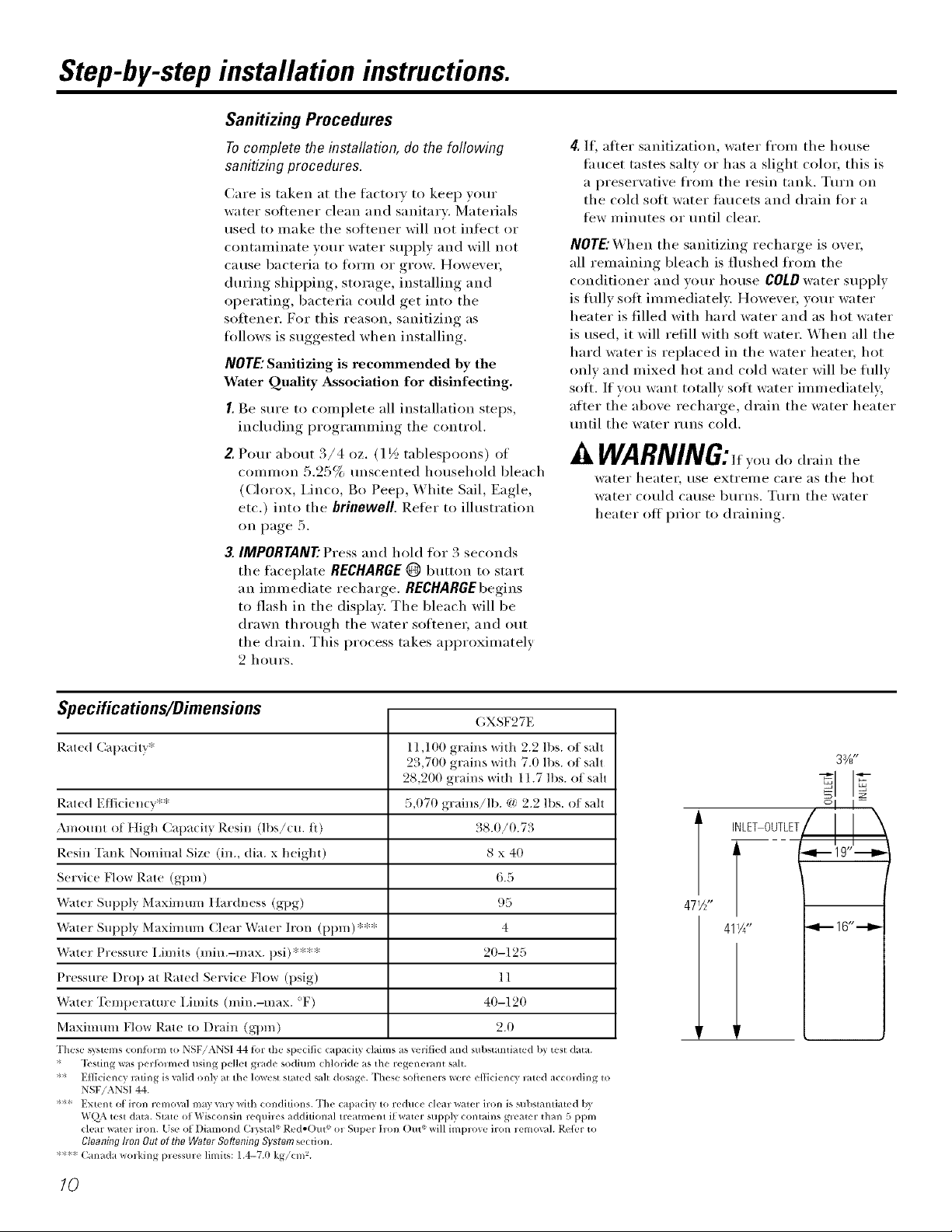

Specifications/Dimensions

Rated Cat)acity* 11,100 grains with 2.2 lbs. oI sah

23,700 grains with 7.0 lbs. of salt

28,900 grains widl 11.7 lbs. of salt

Rated E/l]ciencv':* 5,070 grains!lb. @ 2.2 lbs. of salt

Amotmt of tligh Cat)acity Resin (lbs!cu./1) 38.0/0.73

Resin Tank Nominal Size (in., dia. x heigh0 8 x 40

Service Flow Rate (gt)m) 6.5

\rater Supply Maximmn IIardness (gpg) {)5

\rater Supply Maximmn Clear Water Iron (t)pm)':** 4

\rater Pressure 15mils (min.-max. psi)**** 20-125

Pressure Drop at Rated Service Iqow (psig) 11

Water Temt)eratm:e limits (min.-max. OF) 40-120

Maximum Flow Rate to Drain (glint) 2.0

These b}btems con[oll// to NSFiANSI 44 for the specific capacity claims as xs.rified and substantiated b_ test data.

* _l_sting was performed using pellet grade sadiron chlolide as the regene_ant salt.

** E_ciency rating is valid only at the lowest sta_d salt dosage. These softeners were e_cien(_ l_t_(1 acco_ling to

NSF/ANS144.

_'_"*: Extel/t of h'Oll rl.ml)\_ll ma} \_1 i_ith COllditil)ns. The _apa(ity to r(,t-hlce deal !_at(,l" ill)n is stlbstantiated 1)_

_'(_\ test data. State of Wis(onsin lequiles additional treatmellt if _att,r supply contains gl_atel" tha]l 5 ppm

(lear watel iron. [se of Diamond (;i _tal _ Red-()/It _ o_ Stlper hen ()tit _ _dll implmv iron lenlo_al. Reler to

Cleaning Iron Out of the Water Softening System section.

***:*: Canada _o_;ing p_ essm'e limits: ] .4-7.0 kg/tm _.

(;XSF27E

3 3/8"

,NLETOOTLET/°-\

477:"

411/4" .,_._ 16"--_,-

i

10

Page 11

About the water softener system. GEAppliances.com

Service

When tile water softening s):stem is providing

sott water, it is called "Service." During service,

hard water flows fl'om the house main water

pipe into the water sottening system. Inside the

water sottening system resin tank is a bed made

up of thousands of tiny; plastic resin beads. As

hard water passes through the bed, each bead

attracts and holds tile hard minerals. This is

called ion-exchanging. ]t is much like a magnet

attracting and holding metals. _hter without

hard minerals (soft water) flows fl'om tile water

softening system and to the house pipes.

_Mter a period of time, tile resin beads become

coated with hard minerals and they have to be

cleaned. This cleaning is called recharge.

Recharge is started at 2:00 AM (Iactory setting)

by tile water softening system control, and

consists of five stages or cycles. These are

FILL, BRINING, BRINE RINSE BACKWASH and

FAST RINSE.

Automatic Hard Water Bypass During Recharge

For emexgency needs, hard water is awfilable

to tile home dm'ing tile recharge cycles.

Fill

Salt dissolved in water is called brine. Brine is

needed to clean tile hard minerals fl'om resin

beads. To make tile brine, water flows into tile

salt storage area during tile fill stage.

However,youshouldavoid usingHOTwater

becausethe water heater will fill with the

hardwater.

Backwash

Dm'ing backwash, water travels up through

the resin tank at a tast flow rate, flushing

accumulated iron, dirt and sediments fl'om

tile resin bed and to tile drain.

Brining

During brining, brine travels from tile salt

storage area into tile resin tank. Brine is tile

cleaning agent needed to remove hard minerals

fl'om tile resin beads. Tile hard minerals and

brine are discharged to tile drain.

The nozzle and venturi create a suction to

move the brine, maintaining a very slow rate

to get the best resin cleaning with the least salt.

Brine Rinse

After a pre-measured amount of brine is used,

the brine wdve closes. _'Ker continues to flow

in tile same path as dm'ing brining, except fin.

tile discontinued brine flow. Hard minerals and

brine flush fl'om tile resin tank to tile drain.

Fast Rinse

Backwash is tollowed by a last flow of water

down through the resin tank. The tast flow

flushes brine fl'om tile bottom of tile tank,

and packs the resin bed.

_Mter thst rinse, tile water sottening system

rettlrns to sott water selwice.

11

Page 12

About the water softener system.

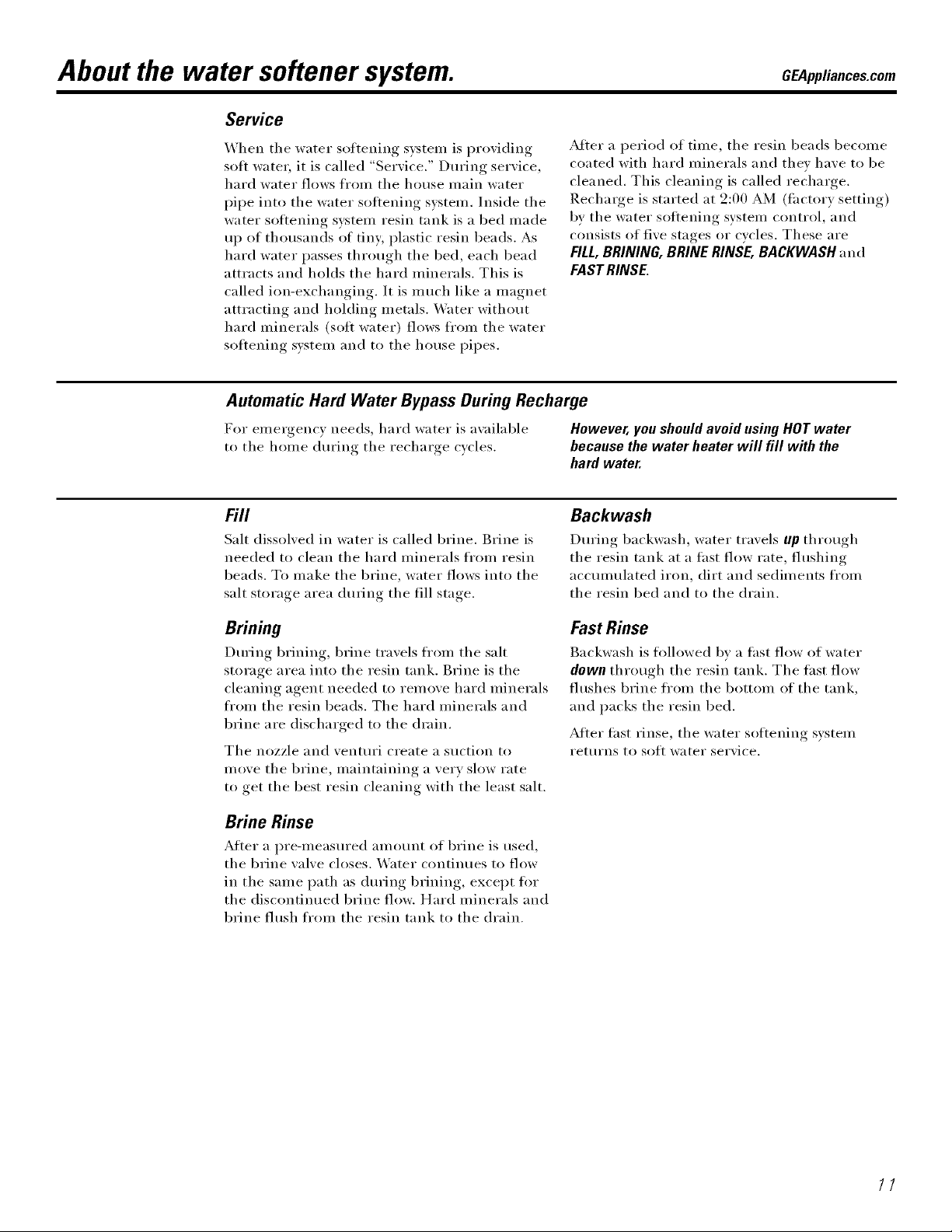

Breaking a Salt Bridge

Sometimes, a hard crest or salt bridge forn_s in

the salt storage area. It is usually caused by high

humidity or the wrong kind of salt. When the

salt bridges, an empty space torms between tile

water and salt. Then salt will not dissolve in the

water to make brine.

If tile brine tank is full of salt, it is hard to tell

if wm have a salt bridge. Salt is loose on top,

but the bridge is under it. The following is the

best way to check tot a salt bridge.

Salt should be loose all the way to the bottom

of tile tank. Take a broom handle or like tool,

and carefully push it down into the salt,

working it up and down. If tile tool strikes

a hard object (be s/tt'e it's not tile bottom or

sides of the tank), it's most likely a salt bridge.

Carefltllv break the bridge with the tool.

Do notpound on tile walls of tile tank.

If the wrong kind of salt made the bridge, take

it out. Then fill the tank with nugget or pellet

salt only: In lmmid areas, it is best to fill with

less salt, inore often to prevent a salt bridge

fl'om limning.

Pushtool intosalt

bridgeto break

/

Pencil

mark

Broom

handle

bridge

Waterlevel

12

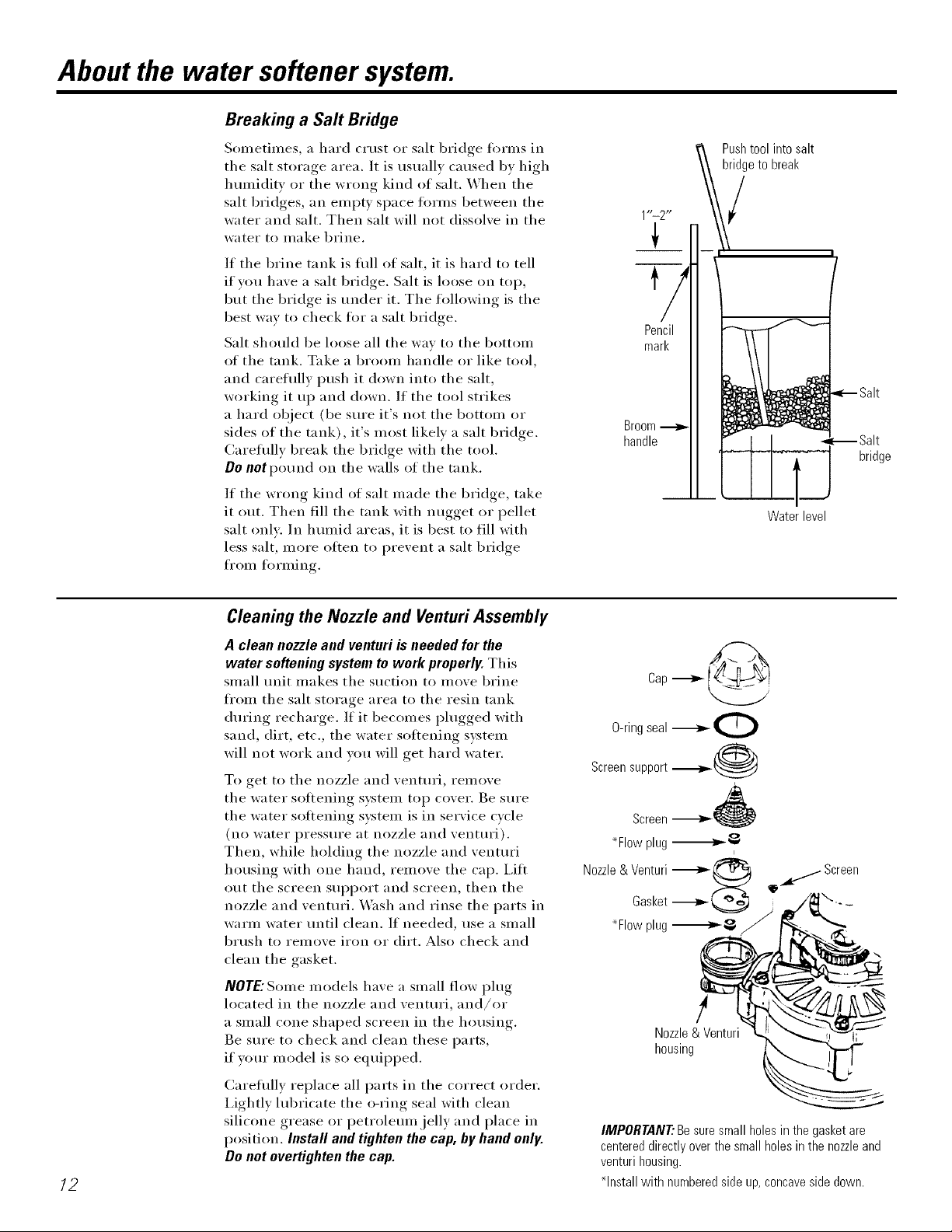

Cleaning the Nozzle and Venturi Assembly

A clean nozzle and venturi is needed for the

water softening system to work properly. This

small trait makes tile suction to move brine

fl'om tile salt storage area to tile resin tank

dm'ing recharge. If it becomes plugged with

sand, dirt, etc., tile water softening s):stem

will not work and you will get hard water.

To get to tile nozzle and venturi, remove

the water softening system top covet'. Be sure

the water softening system is in service cycle

(no water pressure at nozzle and venturi).

Then, while holding the nozzle and venmri

housing with one hand, remove tile cap. i,ifl

out tile screen sui)port and screen, then tile

nozzle and venturi. Wash and rinse tile parts in

warm water tmtil clean. If needed, use a small

brush to remove iron or dirt. Also check and

clean the gasket.

NOTE: Some models have a small flow plug

located in tile nozzle and venmri, and/or

a small cone shaped screen in the housing.

Be sure to check and clean these parts,

if vo m" model is so eq uiI)ped.

Carefltlly replace all parts in tile correct order.

I,ightly lubricate the o-ring seal with clean

silicone grease or petroleum.jelly and place in

position. Install and tighten the cap, by hand only.

Do not overtighten the cap.

Cap

9/Screen

Nozzle& Venturi

housing

IMPORTANT"Besuresmallholesin the gasketare

centereddirectlyoverthe smallholesinthe nozzleand

venturihousing.

*Install with numberedsideup,concavesidedown.

Page 13

Normal Operation, Control Displays

During normal operation, tile present time of

dav and AM or PM show in the control display

area. When tile demand comlmter determines

a recharge is needed, RECHARGE TONIGHT

begins to flash in tile display ahmg with tile

present time. RECHARGETONIGHTflashesuntil

tile next recharge start time, then changes to

RECHARGE, which flashes until the recharge

is {)vex',

Feature: Optional Recharge Controls

Sometimes, a manually started recharge may

be desired or needed. Two examples:

::_)::YOIX have txse(1 XlXOX'e wateI" than txstxal

(house guests, extra washing, etc.) and

VO/X may xxxxl otxt of sott water befi)l'e tile

next recharge.

_: Tile system ran o/xt of salt.

Use one of tile fl)llowing teatures to start

a recharge immediately, or at the next preset

recharge start time,

GEAppliances.com

RECHARGETONIGHT

Toud/ (do not hold) tile RECHARGE @ button.

RECHARGE TONlGHT flashes in tile control

display area. A recharge will occur at tile next

preset recharge start time. If you decide to

cancel this recharge, touch tile same button

once XllOl'e.

RECHARGENO W

Press and hold tile RECHARGE 0 button until

RECHARGE NOWstarts to flash in tile control

display area. Tile water sottening system begins

an immediate recharge and, when ()vex"in

about two hours, you will have a new suI)ply of

soft water. Once started, you cannot cancel this

rechaxge.

Feature: Memory

It electrical power to tile water soltening system

is interrupted, tile control display is blank, and

tile blue indicator light is off; but tile control

keeps correct time fin" about 6 hours. When

power is restored, you have to reset tile present

time only if tile display is flashing. All other

settings are maintained and never require

resetting unless a change is desired.

If tile time is flashing after a long power outage,

tile water softening system continues to work

as it should to provide you with sott watex:

However, rechaxge may occm" at the wrong time

of day/mtil you reset tile control to tile correct

tim e of (lay

Feature/Service: Automatic Electronic Diagnostics

Tile control computer has a sell=diagnostic

flmction for tile electrical system (except

input power and water xl/etex'). Tile computer

monitors tile electronic components and

circuits fin" correct operation. If a malflmction

OCC/XIN_ aXl ex'x'ox" code al)l)eax's ixl tile

control display.

Tile chart on Error Codes shows tile error codes

that could appear and possible reasons fi)r each

code. See Manually Initiated Electronic Diagnostics

to flu'tiler isolate tile deflect.

13

Page 14

About the water softener system.

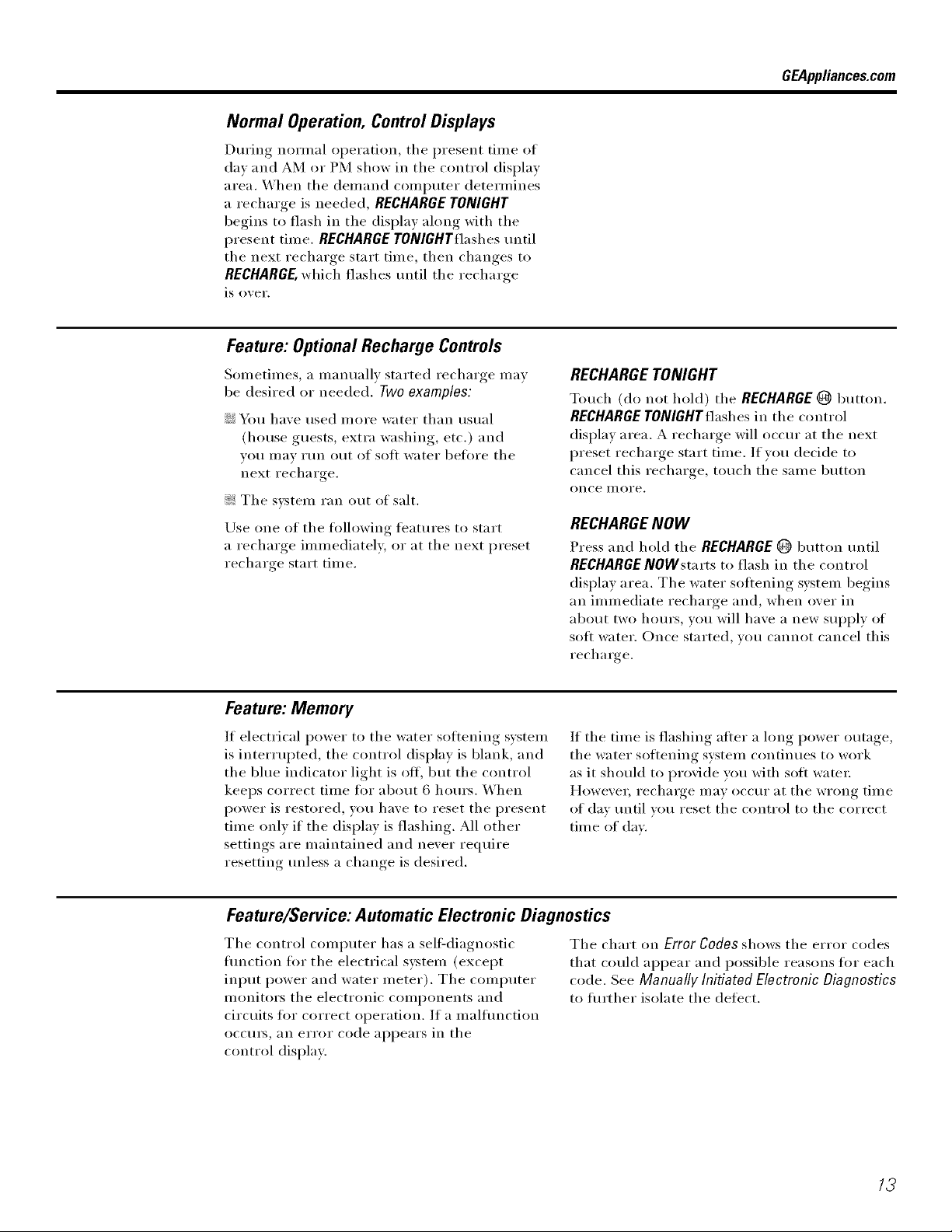

Service: Electronic Demand Time Features and Service

ERRORCODEDISPLAYED ERR05

POSSIBLEDEFECT • Control

Toremove an error code:

Service: Timer/Softener, Service Checkout Procedure

If you are not getting soft water; and an error

code is not displayed, use the procedures below

to find the problem. First make the tollowing

visual checks.

VISUALCHECKS:

I. Is there electrical power to the outlet the

water softening system transformer is

plugged into?

ERR01

• Motor

inoperative

• Wiring harness

or connection

to switch

• Positionswitch

• Control

Unplugtransformer

Z Correctdefect.

3.Plugtransformerin.

4. Waitfor at least6minutes.Theerror code will return if the reasonfor

theerror codewas not corrected.

ERR02

•Position

switch

• Control

ERR03

• Motor

inoperative

orwiring

harness

• Control

2. Is there sufticient salt in the storage tank?

3. Is the sottener bypass wove directing water

for sott water service?

4 Is the valve drain hose open to the drain,

not more than 8' above the sottener, and

unobstructed? If hose is above 8', see page 6,

section 4.

If you do not find a problem with the visual checks,

continue below

ERR04

•Position

switch or

wiring

harness

• Control

14

CONTROLSHOWS I Electricalpowerwasoff.

WRONGTIMEANDDAY, _ Resetthecorrecttimeof

AND/ORSFLASHNG. day.

CONTROL_ powerto control [ NEEDED

DISPLAY (outlet,transformer, I POWEROKI___ I CONTROL

BLANK. powercable,all

CONTROLDISPLAYSHOWSI

CORRECTTIMEANDDAY

AND SSTEADY

l Checkelectrical I__.C NOPOWER].__ REPAIRAS

connections). I DEFECTIVE

Domanual

diagnostics.

Investigatereasonfor I

powerloss.

Domanual

diagnosticsto

verifyproper

I functon.

I

I

Page 15

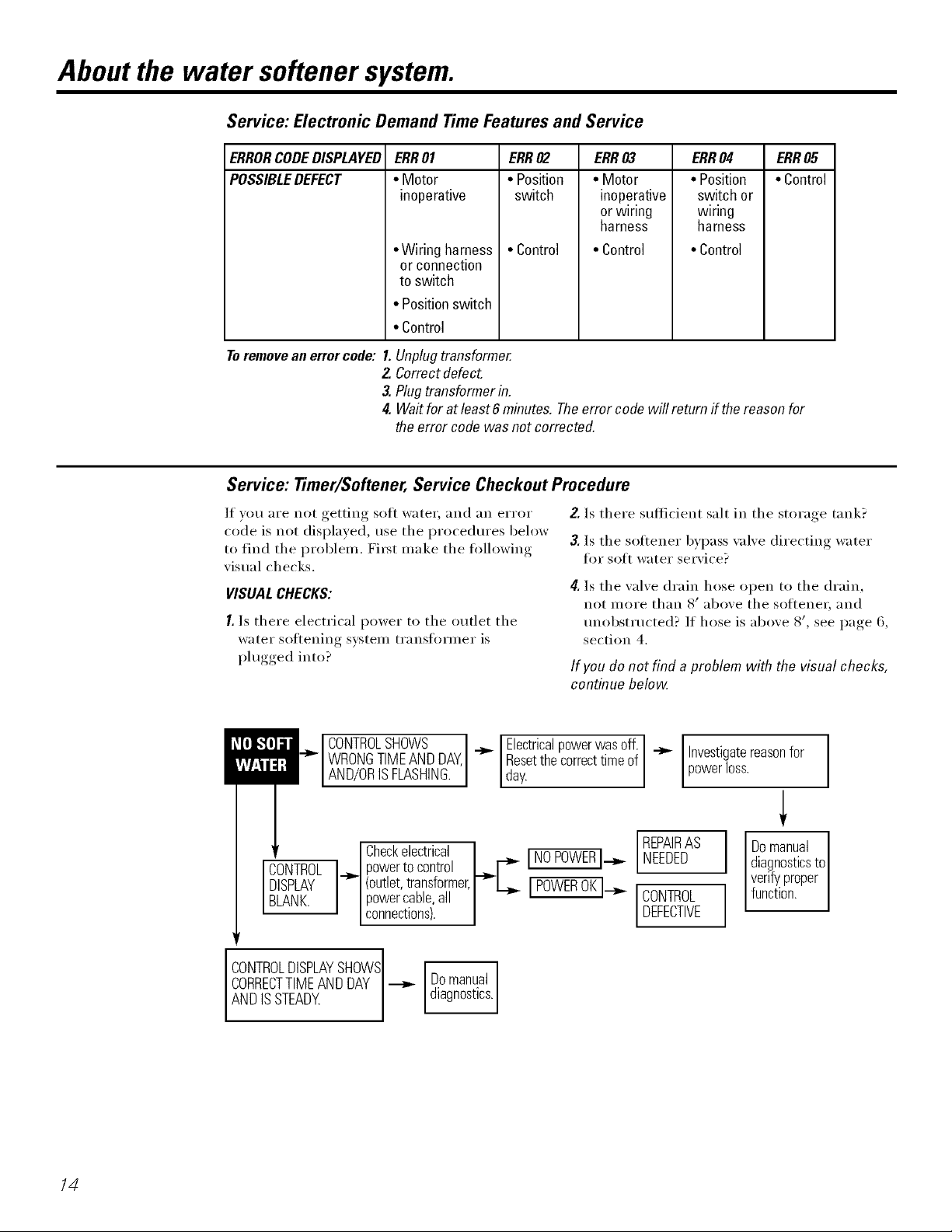

Service: Manually Initiated Electronics Diagnostics

I. To enter diagnostics, press and hold the

MODE button until (000 --) shows in the

display.

A The fixst 3 digits indicate water meter

operation as fi)llo_:s:

_: 000 (steady) = soft water not in

use...no flow through the metei:

--OPEN A NEARBYSOFTWATERFAUCET--

?_:000 to 199 (continual) = repeats display fin" each

gallon of water passing through the Ineter

switch

..Sensor

l':neSitchesOR

Water Switch(B)

Meter(A)

housing

GEAppliances.com

C

_._lfile in this diagnostic screen, the following infi)m_ation

is available and may be benefidal for wuious reasons.

This inlom_afion is retained by the computer fl'om the

fi_t time electrical power is applied to the control.

::Ji::Press and hold the UP button to display the mmg)er

of days this control has had electrical power applied.

?_:Press and hokl the DOWN button to display the

number cff regenerations initiated by this control

since the SR code number was entered.

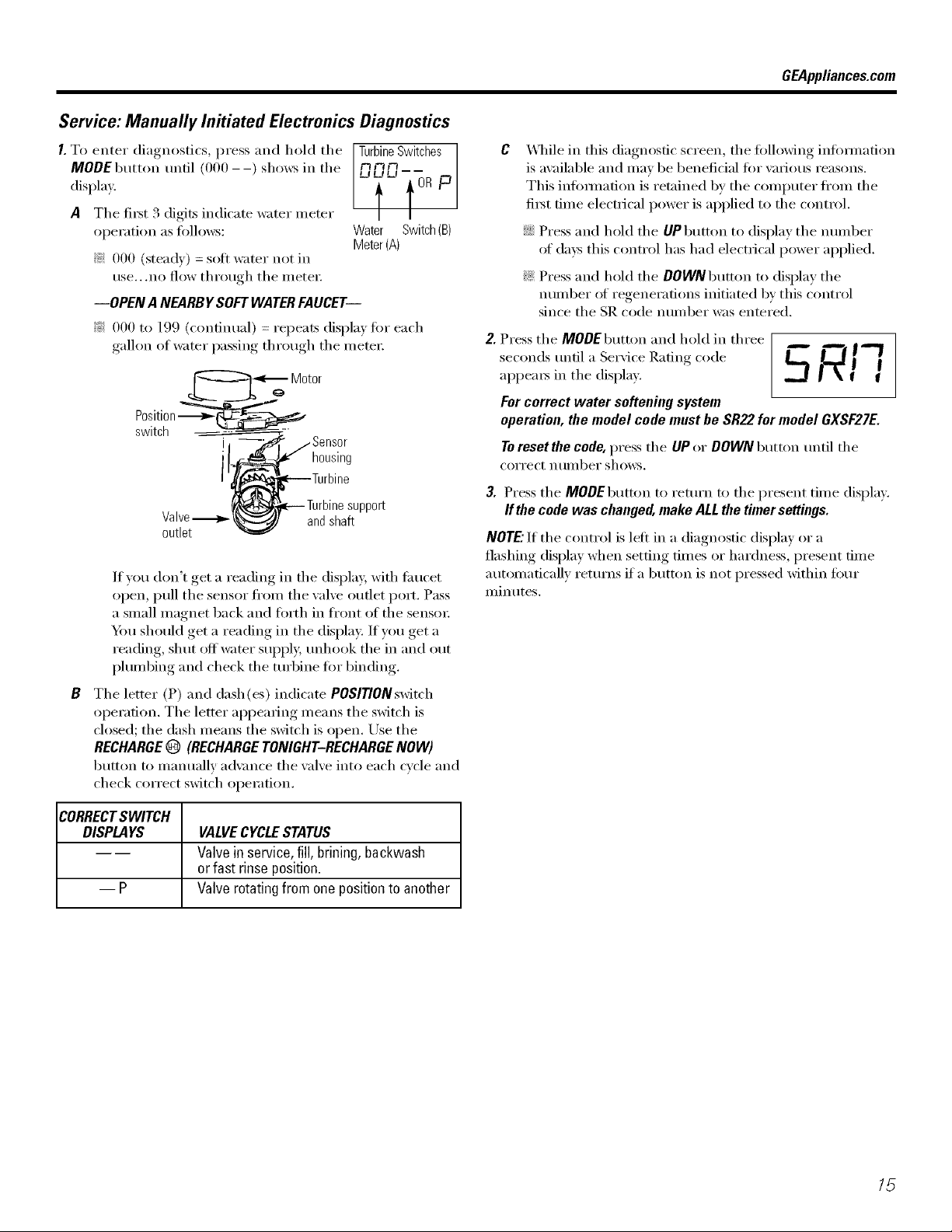

2. Press the MOOEbutton and hold in three

se('on(ls until a SelM('e ]_atino (-o(le_ 5R ' ''_| |

appea_ in the display, f f

Forcorrect water softeningsystem

operation,the modelcodemustbeSR22formodel GXSF27E.

Toreset the code, press the UP or DOWN button until the

COITeCt ntllIlbeF shows.

Valye-_

outlet

If you don't get a reading in the display; with fimcet

open, pull the sensor fl'om the wflve outlet port. Pass

a small magnet back and fi)rth in front of the sensm:

You should get a reading in the displa> If you get a

reading, shut off' water suppl B tmhook the in and Grit

plumbing and check the turbine fin" binding.

B

The letter (P) and dash (es) indicate POSITION switch

operation. The letter appearing ineans the switch is

closed; the dash means the switch is open. Use the

RECHARGE@ (RECHARGETONIGHT-RECHARGENOW)

button to manually ad\ance the valve into each cycle and

check correct switch operation.

CORRECTSWITCH

DISPLAYS

Ep

VALVECYCLESTATUS

Valvein service,fill, brining,backwash

orfast rinseposition.

Valverotatingfrom one positionto another

support

andshaft

3. Press the MODEbutton to return m the present time display,

If the code was changed, make ALL the timer settings.

NOTE"It the c(>ntrol is left in a diagnostic display (>ra

flashing display when setting times or hardness, present time

automatically retm'ns if a button is not pressed within fi)m"

minutes.

15

Page 16

About the water softener system.

Service: Manually Advance Recharge Check

NOTE:The control display must show a steady

time (not flashing).

I. Press the RECHARGE @ button and hold in

fin" three seconds. RECHARGE NOWbegins to

flash as tile water soDening system enters tile

fill cycle of recharge. Remove the brinewell

cover and, using a flashlight, observe fill

water entering tile brine tank. If water does

not enter tile tank, look fl)r an obstructed

nozzle, venturi, fill flow plug or brine tubing.

See Care and Cleaning of the Water Softener

System section.

2.ADer obser\ing fill, press tile RECHARGE @

button to move tile water softening system

into brining. A slow flow of water to the drain

will begin. Veritk' brine draw fl'om tile brine

tank by shining a flashlight into the brinewell

and observing a noticeable drop in the liquid

level over an extended period of time.

NOTE: Be sm'e a salt bridge is not preventing

water fl'om contacting salt. See Care and

cleaning of the water softening system section.

If the water softening system does not draw brine,

check:

i_i' nozzle and/or venttlri dirty or deflective.

N defective nozzle and venmri seal.

_: nozzle and venturi not seated propedy

on gasket.

_: other inner wdve defect (rotor seal, rotor

and disc, wave washe_; etc.).

::Ji::restricted drain (check drain fitting and

hose).

NOTE:If water system pressure is low, an

elevated drain hose may cause back pressure,

stopping brine draw.

3.Again, press tile RECHARGE@ button to ino_,e

tile water soDening system into backwash.

I,ook for a fhst flow of water fl'om tile drain

hose. A slow flow indicates a plugged top

distributor, backwash flow i_lug or drain hose.

4. Press tile RECHARGE@ button to Inove tile

water soDening s):stem into tast rinse. Again

look for a tast drain flow. Allow the water

soDening system to rinse for a few minutes

to flush out any brine that mav remain in

the resin tank fl'om the brining cycle test.

5. To return tile water soDening system to

set\ice, press tile RECHARGE @ button.

16

Page 17

Care and cleaning of the water softening system. CEappliancescem

Checking the Salt Storage Level and Refilfing

Brine (salt dissolved in water) is needed fin"

each and every recharge. Tile water for making

brine is metered into tile salt storage area by

tile water softening system wflve and control.

However, you must keep the tank supplied

with salt.

When to refill with salt: Check tile salt level a

tew weeks after you install tile water softening

system and periodically after that. Refill when

tile tank gets less than 1/3 flfll. In hmnid areas

it is best to refill with less salt and more often,

to avoid torming a salt bridge (see page 12).

Never allow the softening system to use all the

salt befi_re you refill it. X4]thout salt, you will

soon have hard water.

Cleaning Iron Out of the Water Softening System

Your water softening system takes hardness

minerals (calcimn and magnesimn) out of

the water. Also, it can control some (see the

Specification Guidelinessection) "clear water"

iron. With clear water iron, water from a fimcet

is clear when fi_t put into a glass. After 15 to

30 minutes, tile water begins to chmd or turn

ItlSt colored. A water softening s):stem will not

remove any iron that makes tile water chmdv

or rusty as it comes fl'om tile fimcet (called red

water iron). To take red water iron out of water;

or over tile IllaxiIlltlIll of clear watei" ii'on,

an iron filter or other equipment is needed.

Use clean water softening salts only; at least

99.5% pure. NUGGET, PEI,I,ET or coarse

SOI,AR salts are recommended. Do not use rock,

block, granulated or ice cream making salts.

They contain dirt and sediments, or mush and

cake, and will create maintenance problems.

A CAUTION:Waterso,teningsa,twith

ironremovingadditives:Some salts may have

an additive to hel I) tile water softening

system handle iron in tile water SUl)l)ly.

Although this additive may hel I) to kee I) the

water softening system resin clean, it may

also release corrosive tirades that weaken

and shorten tile lift _ of some water softening

systeln parts. GE recomn/ends using only

Dianmnd Crx:stal <': Red*O/W: brand salt.

IMPORTANT"It is important to mix tile resin bed

cleaner with water (tollowing tile manufacturer's

instructions), pour it into tile brinewell tube

(see page 5) and recharge tile softener

immediately. Do not pour tile resin bed cleaner

in with the salt, as it will not be as efli_cdve in

cleaning tile resin, and can catlse damage to

tile softener if it is left in tile brine tank ,fi:,r an

extended period due to tile corrosive gases that

are fl)rmed.

GE recommends using only Diamond Crystal '_

Red*Out e_brand salts with h'on Fighter '_

additive to hel I) kee I) the resin bed clean of

clear iron. If vour water SUl)ply has clear water

iron, periodic resin bed cleaning is needed.

GE reconllnends using Super Iron Out '_brand

resin bed cleaner to thoroughly clean veto"

resin bed if veto" iron content is high. Clean

tile bed at least every six months, or more

often if iron appears in tile soft water between

cleanings.

17

Page 18

Before you call for service...

Troubleshooting -tips

Save time and money! Review the charts on the

following pages first andyou may not need to carl

for service.

NO SOFF WATER--Most Common Problems:

Check the following before calling for service:

• Not enough salt--should be at least 1/3 fifll.

• Bypass valve in "Bypass" position--lmob should be in the "OUT" (service) position.

• Hardness setting mo low. Check hardness setting and adjust. Verify hardness of

supply wamr fiom local wamr company, wamr test or call the (;E Answer Cenmr

• Salt Bridge--salt solidifies above wamr level so that brine wamr is not in contact

with salt. See the Breaking a Salt Bridgesection.

Problem Possible Causes What To Do

No soft water Faucet or fixture where smnple was

taken not plumbed to soft water

NOTE"Be sure sample is from a faucet

that does not mix soft and hard water.

For example, a single lever kitchen faucet,

if the cold side is plumbed to hard water.

No salt in the brine taafl¢ or

salt bridged

Transformer unplugged at wall outlet or

power cable to softener not com_ected.

Fuse blown or circuit breaker popped

on circuit to electrical outlet.

Electrical outlet on a circuit that can

be switched off

Mmmal bypass valve ha bypass position " Be sure tile b)])ass xalxe stein is positioned propelty, with tile

Valve drain hose pinched, plugged,

elevated too high or otherwise

restricted

" To couselwe salt, tile installer Ina) have isolated sonle fixtures

(outside timcets, toilets, etc.) fl'om soft _ter From the outlet

of tile water sottening s}stem, trace tile water flow path,

in house phunbiI_g. If sod water is not directed to a tilucet

or tixmre where wanted, consult a phunber

Check fin" a salt bridge oi, if tile tank is elnpt); refill with

recoullneuded salt. Press (fi)r 3 secouds) tile RECHARGE

button to staxt an immediate recharge and restore

sod water suppl}:

" Check fi)r a loss of electrical power to tile water soflelfing

system, due to any ot these conditions and correct as needed.

With tile power supply restored, observe tile ti_ceplate tilne

display and read Programmingthe Controlsection.

NOTE:Theelectricaloutletfor thesoftenershouldbe continuously

liveso# cannotbe accidentally switched of_

knob in tile OUT position. Obserxe instrucfioi_s on tile decal

at the end of the stein.

" An} restliction in this drain hose ma) prevellt proper

operation of tile nozzle aud xeutulJ aud reduce or prexent

blJue draw duriug rechar ,e

Nozzle mid venturi dirty, incorrectly

assembled or dmnaged

• Reter to Cleaningthe Nozzle and VentudAssemblyinstructions.

_]th water pressure to tile water sottelfiug s)'stem off', take

tile nozzle assembly apart. Inspect, clean and replace as

needed. Any toreigu particle(s), scratches, nicks, etc., in the

passages can preveI_t operatk)I_. Be sure holes in file gasket are

centered O\reI" holes in file housing,

/8

Page 19

GEAppliances.com

Problem Possible Causes What ToDo

Water hard sometimes Using hot water while the water • Avoid using hot water during water s()ftening system

softeathag system is regenerating recharge, because tile water heater will refill with hard water:

See Automatic Hard Water Bypass During Recharge section,

page 11.

Control HARDNESSnumber setting • Press tile MODEbutton tmfil HARDNESSappeax_ in tile

too low displa): Be sure tile iaUlaaber showla is the same as tile actual

grains per gallon hardness of your water supply. See the

Programming the Controlsection if a change in tile setting

is needed.

Grains of haardamss in your water • _'\_ater hardness can change over tim e, espedally in well water:

supply have increased To check, have the water tested bx a water analysis laboratm_'

or call your local water department. A(!just tile HARDNESS

number setting as needed.

Water feels slippery Absence of hardness mhaeraJs • This is nomml. Hardness in water gives it tile abrasive feel

after installation of you may have been accustomed to. Tile slippe U teel is tile

water softening system clean teel of soft water:

Water softening system Water softening system is a • Does not use much salt to regenerate--\'e_ T efficient.

not using any salt "demmad" unit

Possible salt bridge • See tile About the Water Softener System section, page 19.

Possible plugged nozzle mad venturi • See tile About the Water Softener System section, page 1_2.

Water is blue color Acidic water in copper plttmbhag • Have tile water tested at ()lace.

after water softening

system was installed

Water softening system Meter tttrbhae stuck • See tile Service." Manually Initiated Electronics Diagnostics

notregenerating section for troubleshootilag l)rocedtlres, [)age 15.

• Call fi)r service.

Sensor wire not plugged • See tile Service: Manually Initiated Electronics Diagnostics

into the control section for troubleshooting l)roce(hu'es, page 15.

• Call tot service.

No power to unit • Check the drcuit breaker or fllses.

MechmficaJ defect • Call fi)r se_Mce.

Cloudiness on glassware Combhmtion of soft water mad • Tiffs is called etching and is pexmanent. To prevent this

(automatic dishwashers) too much detergent fl'om hal)pening, use less detergent if you have soft watex:

X._hsh glassware in tile shortest cycle that will get them clean.

Excessive/high level VaJve daraJn hose pinched, • Any restriction in this drain hose may prevent proper

of water in brine tank plugged, elevated too high operation of tile nozzle and ventulJ and reduce or prevent

or otherwise restricted brine draw during rechmge.

Nozzle mad venturi dirty, incorrectly • See tile Cleaning the Nozzle and VenturiAssemblgsection,

assembled or dmnaged page 12. With water pressure to tile water softening system

off, take tile nozzle assembly apart. Inspect, clean and

replace as needed. Any fi)reign particle(s), scratches, nicks,

etc., in tile passages can I)revent operation. Be sure holes

in the gasket are centered over holes in the housing.

19

Page 20

Before you call for service...

_ Troubleshooting -tips

Problem Possible Causes What To Do

Salty tasting or Unit not sanitized • Conq)lete the Sanitization Procedures on page 10.

brown/yellow colored • At ('(nnl)lefion of recharge, cycle, (approx, _2hLO,_run water

waterafter installation from timcets to purge the salty water:

Low water pressure Check pI'esstlI'e,

• Drain height 8' or less, pressure shotfld be minimum of 20 psi.

• Drain height above 8', pressure should be minimum ot 50 psi.

Restricted drain hose • Clean and reconnect hose.

• Check fin" ]6nks in drain line.

Brown/yellow Unit was idle for a period of time • Complete the Sanitization Procedures on page 10.

colored water

Resin beads showing Cracked distributor • Call fin" sexsice.

up in drinking water

and sink

Sounds you might hear Rmmhag water from the refit • This is noIIllal.

into a drain dulhag recharge

Water has air bubbles Air ha system after installation • _,_]11go away alter it runs fin" a while.

and is cloudy

Error Code on control Wiring may have worked loose • See page 14 fin" details.

ha the control

• Unl)lug transfin3ne_:

• Remove control covex, release clips on side.

• Check fin" loose/incorrect wiring connections to electronic

board or switch. Reconnect as required.

• Reassemble control cove_:

• Plug in Transfin3ner

• X,Vaitsix minutes fin" Error Code to real)pea_;

• If Error Code reappeaI_, call fin" service.

2O

Page 21

Notes. GEAppliances com

21

Page 22

Parts lisL

11

4

\

\

28

j18

\

19

55

10

22

38

23

29

/

"--"--- 24

36

,,.-30

22

35

33

31

25

26

/

32

Page 23

106

GEAppliances.com

152

\

151

135

25

124 115

,/

\

134 133

-- 130

132

145

144

\

143

146 147

117

118

150

119

120

121

23

Page 24

Parts catalog.

GENERAL ELECTRIC PARTS CATALOG

G

X

S

F

2

7

E

REE NO. GE PART NO. PART DESCRIPTION

0003 WS35X10001 O-RING SEAI, KIT

0004 WS34X10014 DECAl,, FACEPLATE

0005 WS07X10004 HOSE, DRAIN, 20 FT.

0007 WS14X10002 DISTRIBUTOR, TOP

0008 WS14X10001 DISTRIBUTOR, BOTTOM

0009 WS01X10002 RESIN, 1 CU. FT.

0010 WS32X10001 RESIN TANK, 8 X 40

0011 WS31X10019 COVER, TOP

0012 WS31X10020 FACEPH__TE

0013 WS21X10012 CONTROl,

0016 WS26X10013 TIUkNSFOI_JlER WITH PO_'ER CORD

0017 WS31X10021 COVER, SAlT HOLE, _4]TH LABEI,S

0018 WS33X10001 VAPOR BARRIER

0019 WS33X10007 RIM

0020 WS31X10003 COVER, BRINEWEI,I,

0021 WS02X10009 NUT

0022 WS32X10002 BRINEWEI,I,

0023 WS02X10027 SCREW

0024 WS32X10016 TANK, BRINE, ROUND

0025 WS18X10003 CLAMP, HOSE

0026 WS22X10016 ADAPTER, HOSE

0027 WS22X10017 GROMMET

0028 WS35X10035 GROUND CLAMP KIT

0029 WS15X10005 BRINE VAI,VE ASM.

0030 WS35X10003 FI,OAT, STEM & GUIDE

0031 WS03X10006 CI,IP

0032 WS15X10006 VAI,VE BODY, BRINE

0033 WS03X10007 CI,IP

0034 WS03X10008 SCREEN

0035 WS07X10002 TUBING ASM.

0036 WS07X10003 BRINE TUBE ASM.

0037 WS31X10018 BACK COVER, EI,ECTRONICS

0038 WS02X10029 SPACER

0039 WS02N10030 FACEPI,ATE SUPPORT

0055 WS28X10003 RETAINER CI,AMP

0056 WS28X10004 CLAMP

0101 WS02X10012 SCREW

0102 WS02X10013 SPACER

0103 WS21X10003 SWITCH

0104 WS03X10009 PIN, EXPANSION

0105 WS02X10014 SCREW

0106 WS31X10006 COVER, VAI,VE

0107 WS03X10010 WAVE SPRING

0108 WS26X10002 ROTOR & DIS(] ASM.

0109 WS19X10004 CAP, VENTUI?d

0110 WS03X10011 SEAl,, O-RING

(01)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

5

1

1

1

1

1

24

Page 25

GENERAL ELECTRIC PARTS CATALOG

GEAppliances.com

G

X

S

F

2

7

E

REE NO. GE PART NO.

0111 WS19X10005

0112 WS03X10013

0113 WS22X10020

0114 WS08X10005

0115 WS03X10015

0116 WS22X10021

0117 WS03X10017

0118 WS15X10034

0119 WS03X10018

0120 WS03X10019

0121 WS15X10010

0122 WS03X10020

0123 WS22X10022

0124 WS15X10009

0130 WS35X10005

0132 WS22X10023

0133 WS03X10021

0134 WS03X10022

0135 WS03X10023

0136 WS26X10003

0137 WS26X10004

0138 WS26X10005

0139 WS02X10015

0140 WS26X10011

0141 WS02X10016

0142 WS60X10001

0143 WS60X10002

0144 WS60X 10003

0145 WS60X 10004

0146 WS28X10017

0147 WS19X10006

0150 WS03X10024

0151 WS15X10012

0152 WS03X10025

0153 WS60X10006

0999 49-50150

WS35X10034

PART DESCRIPTION

SUPPORT SCREEN

SCREEN

FI,OW PI,UG, .10 GPM

GASKET & ASPIRATOR

(;ONE SCREEN

PLUG, FILL FLOW, .30 GPM

FERRUI,E NUT

NOZZLE/VENTURI BODY

RETAI NEll

SEAl,, O-RING, 1/4" X 3/8"

BODY, VALVE

SPRING

PI,UG, DRAIN SEA1,

NOZZI,E/VENTURI ASM.

SEAl, KIT, 3/4"

ADAPTER, DRAIN HOSE

O-RING, 5/8" X 13/16"

PLUG, FI_O_4, RINSE CONTROL

CI,IP

CAM 8.: GEAR

BEARING

PLATE, MOTOR, 3/4"

SCREW4. #6-20 X 3/8"

MOTOR ASM.

SCREX4. #6-20 X 7/8"

NUT, INSTAI,I,ATION

TUBE, INSTAI,I,ATION

_A_tSHER

CI,IP

HARNESS WIRE, SENSOR ASSY., 3/4"

TURBINE & SUPPORT ASM.

SEAl,, O-RING

BYPASS ASM.

SEAl,, O-RING

ADAPTER

OWNER'S MANUAl,

INSTAI,I,ATION KIT

(01)

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

2

2

2

1

1

1

1

2

2

1

1

25

Page 26

GEWater Softening System Warranty. (For Customers in the United States)

Aft warranty service provided by our SmartWateF MAuthorized

Servicer Network. To schedule service, on-line, 24 hours a day, vis#

us at GEAppfiances.com, or call 800.GE.CARES (800.432.2737)(U.S),

or 866.777.7627 (Canada).

For The Period Of."

OneYear

Fromthedate ofthe

originalpurchase

ThreeYears

Fromthedate ofthe

We Will Replace:

Anypartof the _hter Softening S}'stem which tifils due to a dete('t in materials or workmanship.

During this full one-year warranty,GE will also provide, free ofcharge,all labor and in-home service

to replace the (lelecti\'e part. M1 warranty service will be provided by a GE Smart_,Vater'" Authorized

Service agent,

Theelectronic monitor,if it fails due to a (lefect in materials or workananship. During this three-year

limitedwarranty,you will be responsil)le tor any labor or in-home servicecosts.

originalpurchase

TenYears

Fromthedate ofthe

A replacement brine tank or cabinet, if either tifils due to a defect in materials or workananship.

During this ten-year limited warranty, you will be responsible fl)r any labor or in-home selMce costs.

originalpurchase

What Is Not Covered'.

• Service trips to your home to teach you how to use

the product.

• Improper installation, delivery or ma2mtenaa_ce.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warrantg

• Products that axe used for commercial or h_dustrial

applications.

• Filters, membrmles or batteries.

• Failure of the product if it is abused, misttsed, or used for

other thml the intended purpose or used commercially.

• Defects that result from improper installation or dmnage

not caused by GE.

• Liability on the part of GE under this or may other warrmaty

for any hldJrect or consequential dmnage.

• Replacement of house fuses or resetting of circuit breakers.

• Damage to the product caused by accident, fire, floods or

acts of God.

• h_cidentaJ or consequential damage caused by possible

defects with this applimace, its hlstallation or repair.

• Damage caused after delivery.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state. Toknow what your legal rights

are, consult your local or state consumer affairs office or your state's Attorney General THIS WARRANTY IS INTENDED

TOBE IN LIEU OF ALL OTHER WARRANTIES, WHETHER EXPRESS ORIMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FORA PARTICULAR PURPOSE.

Warrantor: General Electric Company.Louisville, KY 40225

26

Page 27

GEWater Softening System Warranty. (ForCustomersinCanada)

All warranty service provided by our Factory Service Centers or an authorized technician.

For service, call toll free 1.866.777.7627.

For ThePeriod Of." We Will Replace:

One Year Any part of the _,_ater Softening S,_;stem whi(h fifils due to a (lefect in materials or workmanship.

Fromthedate ofthe During this fullone-yearwarranty,GE will also provide, free ofcharge,all labor and in-home service

original purchase to replace the defective part.

Three Years The electronic monitor, if it fifils due to a (lefect in materials or workmanship. During this three-year

Fromthedate ofthe limitedwarranty,you will be responsible fin" any labor or in-home service costs.

originalpurchase

Ten Years A replacement brine tank or cabinet, if either fifils due to a defe(t in materials or workmanship.

Fromthedate ofthe During this ten-yearlimitedwarranty,you will be responsible for any labor or in-home service costs.

originalpurchase

What Is Not Covered:

• Service trips to your home to teach you how to use

the product.

• hnproper installation.

If you have an installation problem, contact your dealer

or installer. You are responsible for providing adequate

electrical, exhausting and other cmmecting facilities.

I WARRANT()R IS NOT RESPONSIBLE FOR CONSE(_UENTIAI, DAMAGES. ]

Wari_ntor: CAMCO IN(:. ]

• Replacement of house fuses or resetting of circuit

breakers.

• Failure of the product if it is misused, or used for other

than the intended purpose or used commercially.

• Dmnage to product caused by accident, fire, floods or

acts of God.

27

Page 28

Notes.

28

Page 29

Informaci6n de seguridad ..... 30

Instrucciones para la

instalaci6n ............... 31-39

Instrucciones paso pot paso ...34-39

Instrucciones para la operaci6n

C6mo limpiar la ensambladura

de la boquilla y el Venturi ....... 49

C6mo romper un puente de sal . . .41

Funciones ................... 43

Servicio ................ 40, 44-46

Sistema de descalcificaci6n

de agua .................. 40-46

Cuidado y limpieza ........... 47

Consejos para la soluci6n

de averias ................ 48-50

Soporte al cliente

Garantfa ..................... 58

Lista de partes/catfilogo ..... 54-57

Soporte al consumidor . ........ 59

Escriba aqui el modelo y los nfimeros

de la serie:

Modelo No.

Serie No.

PaI'a en('onti'ai" estos II(lIlleYos_

levante la cubierta v mire en la

borde debajo del panel del control.

29

Page 30

INFORMACIONIMPORTANTEDESEGURIDAD.

LEATODASLASINSTRUCCIONESANTESDELUSO.

ADVERTENCIA

Per su seguridad, se debe seguir la informaciSn en este manual con el fin de reducir el riesgo de una

descarga el#ctrica, dafios a la propiedad o dafios personales.

PRECAUCIONESDESEGURIDAD

_: Revise y cumpla con to(los los c6digos estatales v

locales. Observe las pautas aquf presentadas.

_: Tenga cuidado al manipular el sistema de

descalcificacidn de agua. No lo voltee, deje cae_;

_IITilStI'e o coloque en prottlbei'ancias exti'eiilas.

::J?::Ix_s sistemas de descalcificacidn de agua que utilicen

cloruro de sodio (sal) para la reca_ga agregan sodio

al agua. Los personas que siguen dietas con

restricciones de sadie deben considerar el sadie

adicional come parte de su consume general El cloruro

de potash) puede servir come una altemativa para el

cloruro de sadie de su descalcificador

E1 sistema de descalcificacidn de agua flmciona

solamente con 24 xoltio_60 Hz. Cercidrese de usar

exclusivamente el transformador incluido.

E1 transtmmador se debe conectar finicamente

a tin toii/acoFiJente inteiJor con conexi(Sn a tieiTa

de 120 xoltios.

_: Utilice finicamente sales para descaldficaci6n

del agua, al menos con 99.5% de pm'eza. Se

recomiendan las sales en PEPITAS, BOI,ITAS

o SAI, GRUESA SOLAR. No utilice sales en roca,

bloque, granuladas o sales para la elaboraddn

de helados, t_stas pueden contener suciedad v

sedimentos, o pasta y masa y podrfan crear

problemas de mantenimiento.

_: Mantenga la tapa del orifido de la sal en su lugar

en el descalcificador a menos que est(_ realizando

i/lantenii/liento o i'eponiendo 1;:1sal.

A ADVERTENCIA:No.,ec,,,,._,,,que

sea microbioldgicamente insegm'a o de calidad

desconocida sin llevar a cabo la desintecci6n

adecuada antes o despu_s del sistema.

INSTALACIONCORRECTA

Este sistema de descalcificaciOn de agua debe instalarse correctamente y colocarse de acuerdo a los

instrucciones de instalaciOn antes de su use.

_: lnstale o ahnacene donde no quede expuesto a

temperaturas pot deb@) del ptmto de congelaci6n

ni est(_ eN)uesto a ningOn tipo de inclemencias

atmosl>ficas. Si el agua llega a congela_se dentro

del sismma, (_ste pod6a rompe_se. No interim dar

ti'atailliento al agtla si se enctlenti'a a tlil}l

temperamra pot encima de 38 °C (l O0 °F).

::Ji::No instale expuesto a los mvos directos del sol.

EN)osiddn al sol o calor excisivos podrfan causar

disto_idn u otros dafios a las partes no met;ilicas.

::Ji::Conecte a fierra de nmnera apropiada segfin los

cddigos y ordenanzas aplicables.

::J?::Use solam ente fundente y soldadura sin plomo para

todas las cone_ones de condensaddn soldadas,

segfin los c6digos estatales y federales aplicables.

_: E1 sistema de descalcificacidn de agt_ requiere tm

flt!jo de agua inhlilno de tres g_dones por ininuto en

la entmda, ia presidn de entmda m;ixima pemfitida

es de 125 psi. Si la presidn dm_mte el dia es pot

encima de 80 psi, la presidn noctm'na pod6a exceder

el m:_ximo. Use tma v;il\'ula reductora de presi6n

pare reducir el flt{jo si es necesario.

::Ji::i_s msinas de descalcificacidn pod6an degmdarse

ante la presencia de cloro pot encima de 1 ppm.

Si usted fiene una canfidad de cloro mayor a (_sta,

quiz:is expefimente tma \ida menor de la resina.

En estas condiciones, es posible que quiem

considemr la compm de tm sistema de filtmcidn

del I)tmto de admisidn pare casas (;E con un filtro

reductor de cloro.

A ADVERTENCIA:Desechetodaslas

partes y los matedales de embal_!ie no utilizados

despu(_s de la instalaci6n. Paltes pequefias

restantes despu(_s de la instalad6n podrfan

representar tm peligro de asfixia.

LEAYSIGAESTAINFORMACIONDESEGURIDADCUIDADOSAMENTE.

GUARDEESTASINSTRUCCIONES

30

Page 31

Instrucciones de instalacion.

!

--_PRECAUCION:sonocositaciertahabiliUaU lomerra lainstalaci6n

Si usted no est4 seguro acerca de la instalaci6n de alguna de/as partes de este producto,

consulte a un plomero profesional.

Desempacado e inspeccion

Cercidrese de inspeccionar completan/ente el

descalcificador en busca de dafios durante el

envfo o partes que puedan haberse perdido.

Tambi&_ revise en busca de dafios en la caja

de envfo. P6ngase en contacto con la compafifa

de transporte para cualquier reclamo per dafio

o p&'dida. E1 thbricante no es responsable per

dafios sufl'idos din'ante el trfinsito.

Recomendaciones importantes para la instalacion

Lea el manual completo. Ignorar las directrices y reglas podria causar lesiones personales o

dafios a la prop&dad.

::Ji::Antes de comenzar la instalacidn, lea estas

lnstrucciones de instalaci6n completamente.

i,uego, obtenga todos los materiales y

herramientas que necesita para llew_r a cabo

la instalaci6n. No instalar correctai//ente el

descalcificador invalida la garantfa.

_: Revise los cddigos locales. I,a instalaci6n

debe cumplir tales requisites.

::J_::En el estado de Massachusetts, la instalaciOn

debe ajustarseal C6digode Plomeria 248 CMR.

CensuRe a su plemem certificade.

?_: Use solamente flmdente v sol(ladura sin

ploillo p}lI'}l todas las conexiones de

condensacidn soldadas, segfin los cddigos

estatales v tederales aplicables.

_: Conecte el descalcificador en la tuberfa

de smninistro principal antes del calentador

de agua: NO HAGAPASARAGUA CALIENTE

A TRAVESDELDESCALCIFICADOR.I,a

temperatura del agua que pase a trav0s

del descalcificador debe set menor de

49 °C (120 °F).

Tenga cuidado cuan(lo manipule el

descalcificador. No lo coh)que boca arriba,

ni lo deje caer, ni h) arrastre, nilo apoye

en protuberancias.

I,as partes pequeflas necesarias para instalar el

descalcificador se encuentran en una pieza de

cart6n termoconflwmada. Para evitar la p&'dida

de las partes pequefias, mant0ngalas en el

paquete termoconfi)rmado hasta que usted

est0 listo para usarlas. Cerci6rese de no

descartar COil/ponentes qtle podrlan estar

escondidos en el embalage.

::Ji::i,a presi6n de entrada mfixima permitida

es de 125 psi. Si la presi6n durante el dfa es

pot encima de 80 psi, la presi6n noctm'na

podrfa exceder el mfiximo. Use tma vfilvula

reductora de presidn para reducir el fltljo si

es necesario. (Agregar tma vfilvula reductora

de presi6n podrfa reducir el fltljo.)

_: E1 sistema de descalcificacidn flmciona

solamente con 94 voltios-60 Hz. Cerci6rese

de usar exclusivamente el transformador

inchfido. Cerci6rese de que el tomacorriente

el0ctrico y el transfl)rmador estfin en el

interior de tm recinto para protegerlos

de la hmnedad.