Page 1

vvvvw.GEAppliances.com

Safety Information .......... 2

Installation Instructions . ._3-1_2

Step-by-step instructions . . .6-12

Operating Instructions

Breaking a sah bridg_ ....... 14

Cleaning the nozzle and

venturi assembly ........... 14

Features .................. ] 5

Service ............. 13, 16-18

V_'ater softener system .... 1,9,-18

Care and Cleaning ........ 19

Troubleshooting Tips .... 20-22

Consumer Support

Consumer Support . .Back Cover

Parts list/catalog ........ 24-27

V_'arranty (U.S.) ............ 98

_'arrantv (Canada) ......... 99

Water

Softening

System

ModelGXSF18G

Sistema Suavizante

de Agua

Mode/o GXSF18G

La secci6n en espafiol empieza en la pagina 31

©

System tested and certified by NSF International

against NSF/ANSI Standard 44 for the chemical

reduction claims specified on the performance data.

Write the model and serial numbers here:

Model #

Serial #

To lind these numbers, lift the cover and

look on the rim below the control panel.

7270321 215Cl173P007 49-50140-1 12-04JR

Page 2

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of electric shock,

property damage or personal injury.

SAFETYPRECAUtiONS

_: Check and conq)ly with vour state and local

codes. You must fl)llow ti_ese guidelines.

::Ji::Use care when handling the water sotiening

s_:stem. Do not tm'n upside down, drop, drag

or set on sharp protrusions.

_: Water sotiening systems using sodimn chloride

(salt) for recharge add sodimn to the water.

Persons on sodium restricted diets should consider

the added sodium as part of their overall intake.

Potassium chloride can be used as an alternative

to sodium chloride in your softener

Tile _sater softening system _sorks on 24 _olt,60 Hz

electrical power only. Be sure to use onlythe

included transformer

iJi::Transformer must be )luo,_ed into indoor

120 "_olt, grotmded outlet only.

_: Use clean water softening salts only, at least

99.5% pm'e. NUGGET, PEI,I,ET or coarse

SOLAR salts are recommended. Do not tlse rock,

block, granulated or ice cream making salts.

They contain dirt and sediments, or mush and

cake, and will create maintenance problems.

::Ji::Kee I) the salt hole cover in place on the softener

tmless servicing the trait or refilling with salt.

_, WARNING:Do.o, use with water that is

microbiologically tmsat_" or el unknown quality

without adequate disinfection beti)re or atier

tile system.

PROPERINSTALLAtiON

This water softening system must be properly installed and located in accordance with the Installation

Instructions before it is used.

?_: Install or store where it will not be exposed to

temperatures beh)w fl'eezing or exposed to any

type of weather: Water fl'eezing in tile system will

break it. Do not attempt to treat water over I O0°E

::Ji::O0 n0tinstall in direct s/mlight, Excessive sun or

heat may catlse distortion or other damage to

non-metallic parts.

Properly ground to cent)tin with all governing

codes and ordinances.

Use only lead-free solder and flux for all sweat-

solder connections, as required by state and

federal codes.

_: Softener resins may degrade in tile presence

of chlorine above 1 ppm. If you have chlorine

in excess of this alnount, you inay experience

reduced life of tile resin. In these conditions,

you may wish to consider pro'chasing a (;E

i)oint-ofent_y household filtration system with

a chlorine reducing filte_:

A WARNING:Disc.,d.lluilusedpax'ts

and packaging material alter installation.

Small parts remaining after the installation

could be a choke hazard.

The water softening s}:stem requires a minimmn

water flow of three galhms per minute at the inlet.

Maximum allowable inlet water pressm'e is 125 psi.

]f daytime pressure is over 80 psi, nighttime

pressm'e may exceed the maximmn. Use a pressm'e

reducing wdve to reduce the flow if necessarx:

READANDFOLLOWTHISSAFETYINFORMAtiONCAREFULLY.

SAVETHESEINSTRUCTIONS

2

Page 3

Installation instructions. GEA,,,,liancescam

A_ CAUTION: Certain plumbing skills are needed for installation. If you are unsure about

any part of the installation of this product, consult a professional plumber.

Unpacking and Inspection

Be sure to check the entire softener for any

shii)ping damage or parts loss. Also note

dmnage to the shii)ping cartons. Contact the

transportation company for all damage and

loss claims. The ii/antlf;iCttli'ei" is not

responsible fl)r damages in transit.

Important Installation Recommendations

Read entire manual. Failure to follow aft guidelines and rules could cause personal injury or

properly damage.

Small parts needed to install the softener are

packaged either in a bag or on a cardboard

sheet. To avoid loss of the small parts, kee I)

them packaged until you are ready to use them.

Be StlYe not to discard components hidden in

packaging.

::Ji::Before you begin installation, read these

Installation Instructions completely. Then,

obtain all the materials and tools you will

need to make the installation. Failm'e to

properly install the softener voids the

W_I I'I'_l n IV;

Check local codes. The installati(m must

COIl[OI'Ill 10 thenL

In the Commonwealth of Massachusetts,

Plumbing Code 248 CMR shall be adhered to.

Consult with your ficensed plumber.

Use only lead-h'ee solder and flux for all

sweat-solder connections, as required bv

state and federal codes.

(_onnect the softener to the main water

SUl)ply pipe before or ahead of the water

heater. DO NOT RUN HOT WATER THROUGH

THESOFTENER.Temi)erature at water

passing through the softener illtlSt be

less than 120°F.

::Ji::Use care when handling the softener.

Do not turn upside down, drop, drag

or set on sharp protrusions.

Maximmn allowable inlet water pressure is

12,5 psi. If daytime pressm'e is over 80 psi,

nighttime pressm'e may exceed the

inaxilnum. Use a pressure reducing valve

if necessary. (Adding a pressm'e reducing

valve Inav reduce the flow.)

::Ji::The softener works on 24 volt-60 Hz

electrical power only: Be sure to use the

included transfl)rmer. Be sure the electric

outlet and transflmner are in an inside

location to protect ]VI'OII/ ii/oisttlre.

N See Where to Install the Softenersection fi)r

more details.

A WARNING:Do.,it.sewithwater

that is microbiologically tmsafe or of

tmknown quality without adequate

disinfection before or alier the system.

The water should be tested periodically

to verifk' that the system is i)erforming

satisla ctorilv.

::Ji::Small parts remaining after the installation

could be a choke hazard. Discard saflqv.

Page 4

Installation instructions.

Plan How You Will Install the Softener

You must first decide how to mm in and out

pipes to the softener. I,ook at the house

main water pipe at the point where you will

connect the soiiener. Is the pipe soldered

coppe_; glued plastic or threaded galwmized?

What is the pipe size?

.4,WARNING:Use..l, le,,d.,ee

solder and flux to prevent lead poisoning.

Where to Install the Softener

::Ji::Place the sottener as close as possible to a

sewer drain, or other acceptable drain point

or standpipe.

::Ji::It is recommended to kee I) outside thucets

on hard water to save sott water and salt.

_: Do not install the softener in a place where it

could fi'eeze. Freeze damage is not covered by

the warranty.

_: Do not install the softener where it would

block access to the water heater or access to

the main water shutott.

Put the softener in a place where water

damage is least likely to occur if a leak

develops. The manufacturer will not repair

or pay for water damage.

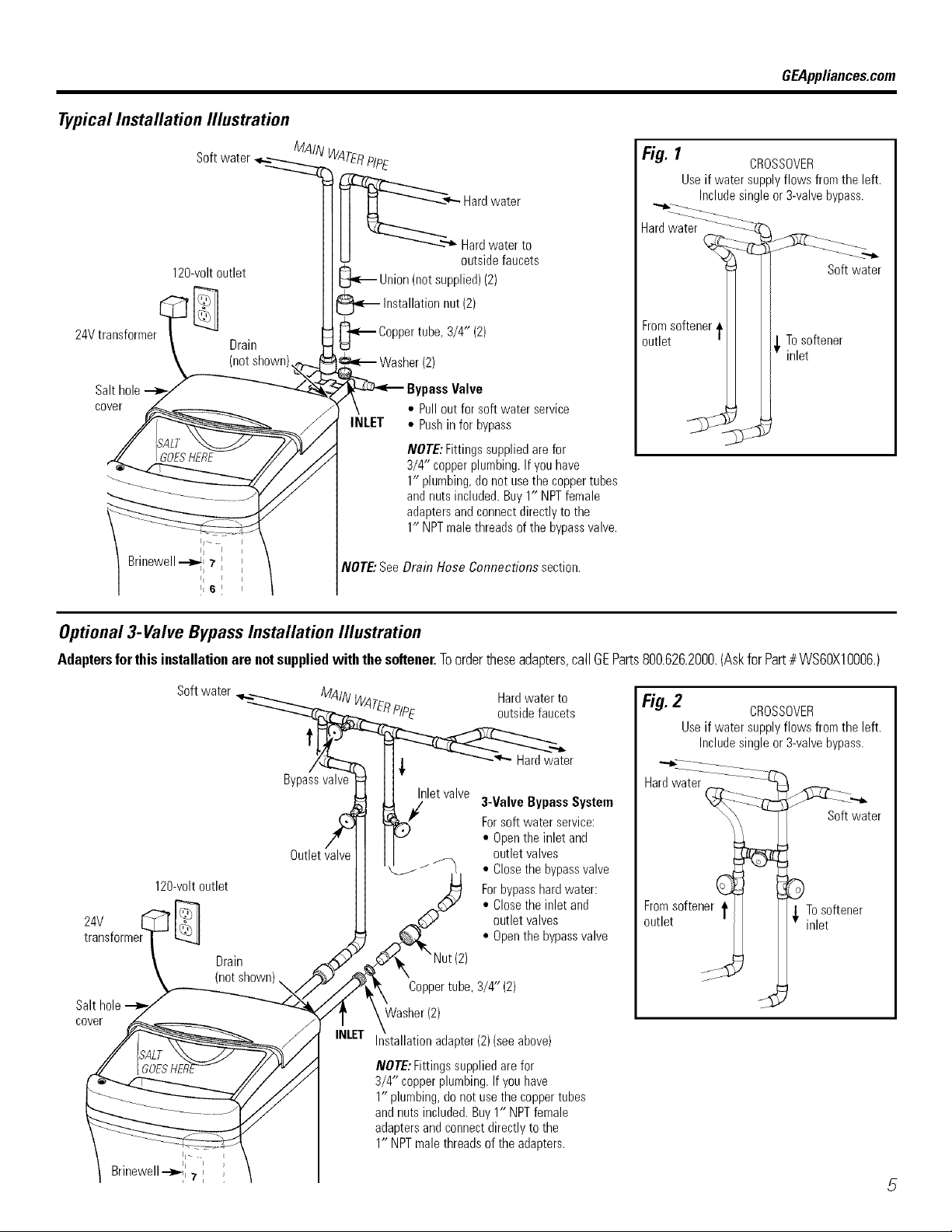

See Yypical Installation Illustration, Fig. 1. Use

this as a guide when planning yore" particular

installation. Be sure to direct the incoming hard

water supply to the softener valve inlet fitting.

The valve is marked IN and OUT See illustration

on page 5 to help you prepare.

_: A 120 volt electric outlet is needed to plug

in the included transtormer. The sottener

has a 10 toot power cable. If the outlet is

remote (up to 100 filet), use 18 gauge wire

to connect. Be sure the electric outlet and

transformer are in an inside location, toprotect

from wet weather. Be sure the outlet is

unswit('hed to prevent accidental shutolt.

_: If installing in an outside location, you must

take the steps necessary to assure the sotiene_;

installation plumbing, wiring, etc., are as

well protecmd ti'om the elements (stmlight,

rain, wind, heat, cold), contamination,

wmdalism, etc., as when installed indoors.

Outdoor installation is not recommended and

voids the warranty.

_: Keep the softener out of direct sunlight.

The sun's heat may distort non-metallic

parts and may damage the electronics.

Toolsand Materials Required for Installation

_: In and out fittings included with the softener

are 3/4" (nominal) Col)per sweat tubes.

You should maintain the same, or larger,

pipe size as the water supply pipe, up to the

sottener inlet and outlet.

Use the included bypass wdve to install the

sottener. The bypass valve allows you to mrn

off water to the sottener fin" servicing, but

still have water in the house pipes. The in

and out fittings referred to above connect to

the bypass valve with the included nuts and

wash ers.

::Ji::Use coppex; brass or galwmized pipe and

fittings. Some codes may also allow CPVC

plastic pipes.

4

If additi(mal drain hose is needed tot wove

and salt tank drains, it can be ordered from

GE Parts at 800.626.2002.

::Ji::If a rigid wdve drain is needed to comply

with plmnbing codes, you can buy the parts

needed to connect a 1/2" copper tubing or

plastic pipe drain.

::Ji::Clean nugget or pellet water sottener salt is

needed to fill the brine tank, see Step 8 in

the Step-by-Step Installation Instructions.

Page 5

Typical Installation Illustration

Softwater

MAIN

V47_f_P/RE

- Hardwater

GEAppliances.com

Fig. 1 CROSSOVER

Useifwater supplyflows fromthe left.

Includesingleor3-valvebypass.

Hard water

24V transformer

Salthole

cover

120-voltoutlet

Drain

(notshown)

_a_ddwa_e_t°ts

_ Union(notsupplied)(2)

_ Installationnut(2)

_ oppertube,3/4" (2)

Washer(2)

_assValve

INLET

NOTE:SeeDrainHose Connections section.

• Pullout for softwater service

• Pushinfor bypass

NOTE:Fittingssuppliedare for

3/4" copperplumbing.Ifyouhave

1" plumbing,do notusethecoppertubes

andnutsincluded.Buy1" NPTfemale

adaptersandconnectdirectlytothe

1" NPTmalethreadsof thebypassvalve.

From softener,

)utlet

,_ To softener

Softwater

inlet

Optional 3-Valve Bypass Installation Illustration

Adapters for this installation are notsupplied with the softener.Toordertheseadapters,call GEParts800.626.2000.(Askfor Part# WS60X100O6.)

24V

transf,

Salt h(

cover

Softwater "_---_N

120-volt outlet

D ii__

Drlneweu-.J_ 7

Drain

Bypassvalve

/

Outletvalve

4 P/pE

Inlet valve

d

Hardwaterto

outsidefaucets

3-Valve BypassSystem

Forsoft waterservice:

• Openthe inlet and

outletvalves

• Closethe bypassvalve

Forbypasshardwater:

• Closethe inletand

outletvalves

• Openthe bypassvalve

(2)

Coppertube,3/4"(2)

Washer(2)

Installation adapter (2) (see above)

NOTE:Fittingssuppliedarefor

3/4" copperplumbing.Ifyouhave

1" plumbing,donot usethe coppertubes

andnutsincluded.Buy1" NPTfemale

adaptersandconnectdirectlytothe

1" NPTmalethreadsof the adapters.

Fig. 2 CROSSOVER

Useifwater supplyflows fromthe left.

Includesingleor3-valvebypass.

"___-__::_-_--_:-:_:::___

Hardwater

(_ Softwater

C 9

Fromsoftenert _, Tosoftener

outlet inlet

d

5

Page 6

Step-by-step installation instructions.

::Ji::Turn off the gas or electric supply to the water heater) in the possibility

that the water heater may be drained while draining pipes.

::Ji::Turn off the water supply to pipes to be cut and drain the house

water pipes.

_: Open both hot and cold taucets at the lowest location possible.

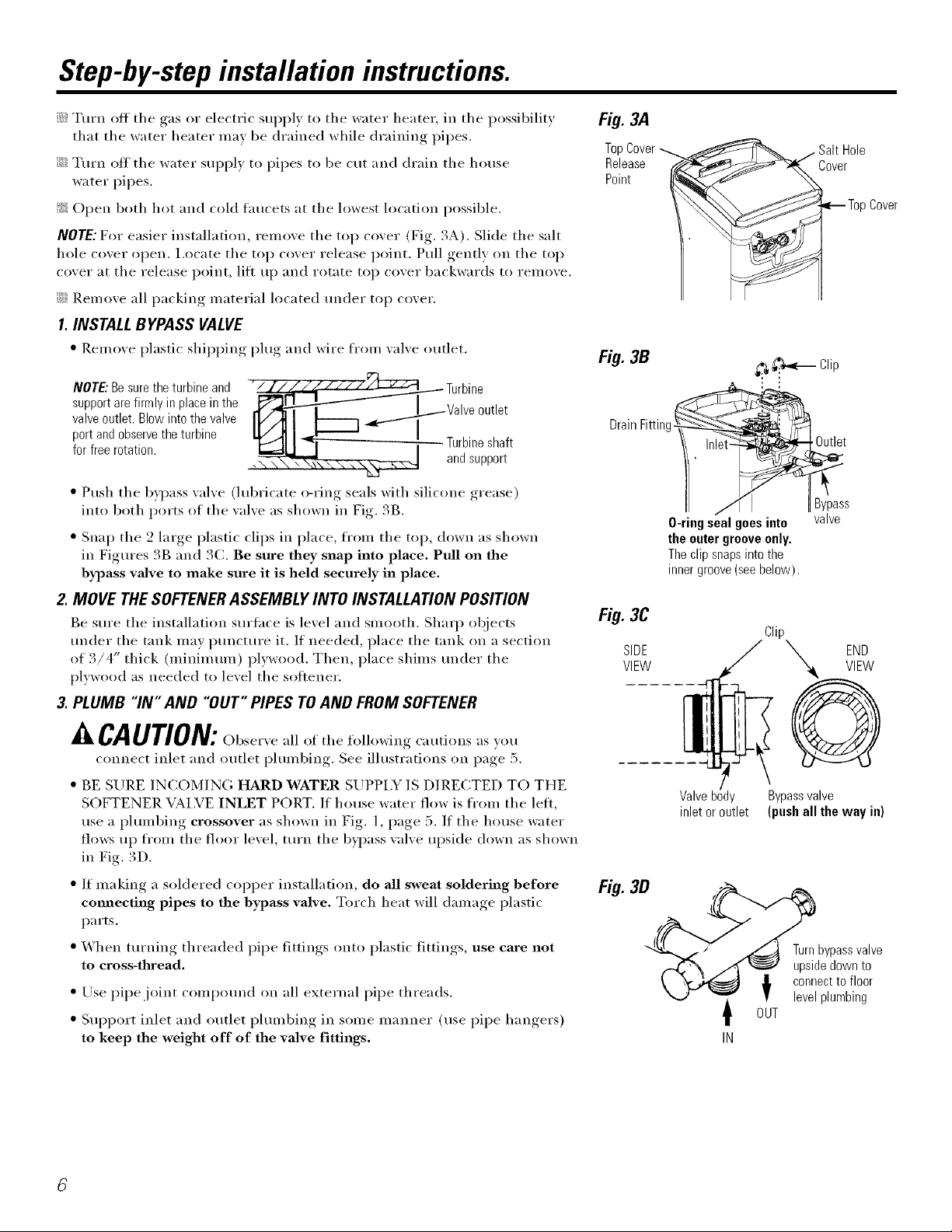

NOTE: For easier installation, remove the top cover (Fig. 3A). Slide the salt

hole cover open. i,ocate the top cover release point. Pull gently on the top

cover at the release point, lilt up and rotate top cover backwards to remove.

::Ji::Remove all packing material located under top cover.

1.INSTALL BYPASS VALVE

* Remove plastic shii_ping plug and wire ti'om valve outlet.

supportare firraly in placeinthe __1 _u£1 utlet

NOTE:Besuretheturbine and " " bv__

port andobservethe turbine

for free rotation, t

valveoutlet. Blowinto the valve _TaUn_lsn:p Sp_/

• Push the byl)ass valve (lubricate o-ring seals with silicone grease)

into both ports of the valve as shown in Fig. 3B.

• Snap the 2 large plastic clips in place, from the top, down as shown

in Figures 3B and 3(:. Be sure they snap into place. Pull on the

bypass valve to make sure it is held securely in place.

2. MOVE THE SOFTENERASSEMBLY INTO INSTALLATION POSITION

Be sure the installation surtace is level and smooth. Shaq_ objects

under the tank may i)uncture it. If needed, place the tank on a section

of 3/4" thick (minimum) plywood. Then, place shims under the

plywood as needed to level the sottener.

3. PLUMB "IN" AND "OUT" PIPES TO AND FROM SOFTENER

Rg3A

TopCover_

Release

Point

Rg3B

DrainFitting!

Fig. 3C

SIDE

VIEW

Salt Hole

Cover

EmTop Cover

_ _'._<-i Clip

Inl

J IBypass

O-ring sealgoes into valve

the outergrooveonly.

Theclipsnapsinto the

innergroove(seebelow).

Clip

END

CAUTION:(-)bser\e all of the following cautions as you

connect inlet and outlet i)lumbing. See illustrations on page 5.

• BE SURE INCOMING HARD WATER SUPPI,Y IS DIRECTED TO THE

SOFTENER VAI,VE INLET PORT. If house water flow is fi'om the left,

use a I)lumbing crossover as shown in Fig. 1, page 5. If the house water

flows up from the floor level, turn the bypass valve upside down as shown

in Fig. 3D,

" If making a soldered copper installation, do all sweat soldering before

comlecting pipes to the bypass valve, Torch heat will damage i)lastic

parts.

• When turning threaded pipe fittings onto plastic fittings, use care not

to cross-thread,

" Use pipe joint compound on all external pipe threads.

• Sul)port inlet and outlet I)hunbing, in some manner (use pipe hangers)

to keep the weight off of the valve fittings.

Rg3B

Valve body Bypassvalve

inlet or outlet (push all the way in)

Turnbypassvalve

upsidedownto

O_U connectto floor

T

levelplumbing

IN

Page 7

GEAppliances.com

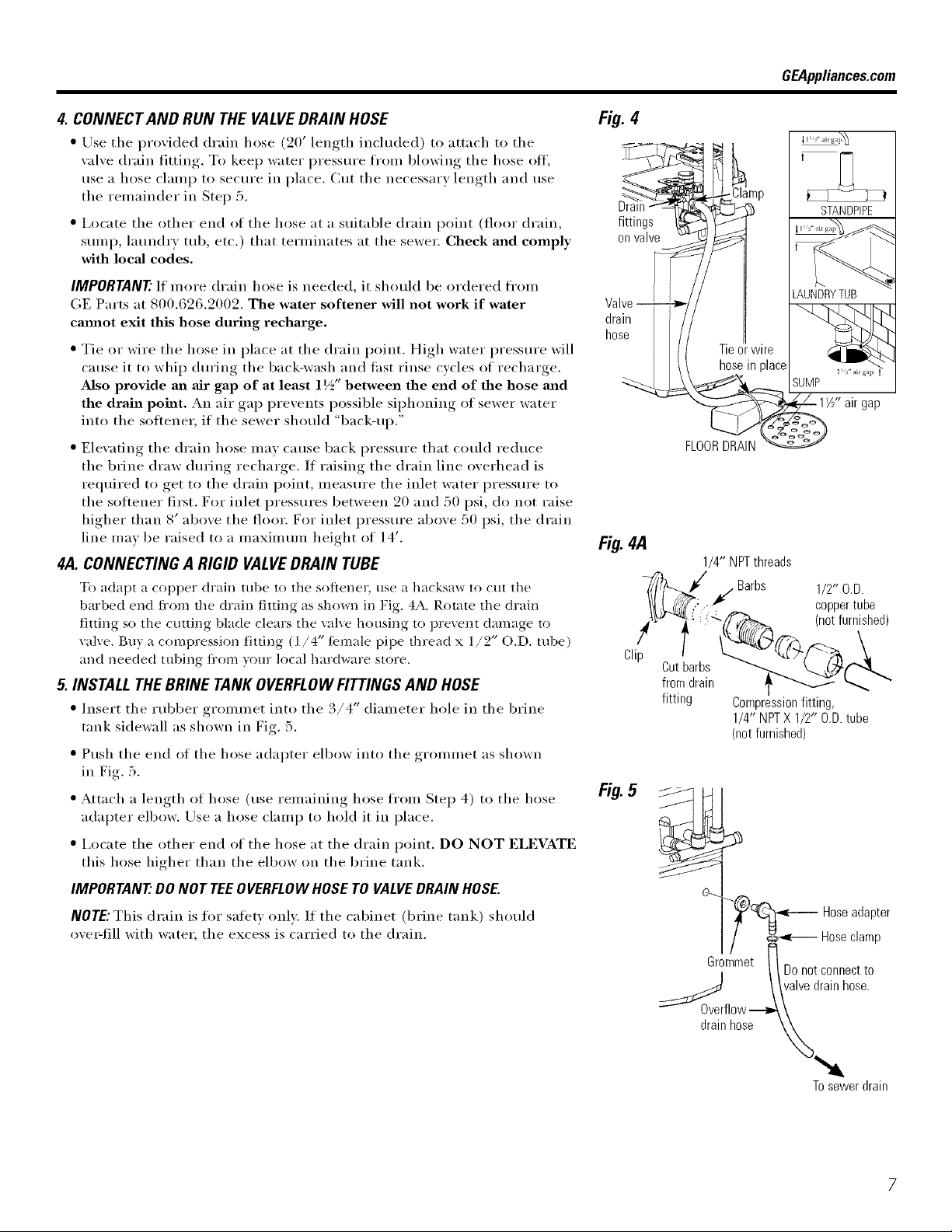

4. CONNECT AND RUN THE VALVEDRAIN HOSE

• Use the provided drain hose (20' length included) to attach to the

valve drain fitting. To kee I) water pressure fl'om blowing the hose off,

use a hose clamp to secure in place. Cut the necessary length and use

the remainder in Step 5.

• i,ocate the other end of the hose at a suitable drain point (floor drain,

sump, latm(h T tub, etc.) that terminates at the sewer. Check and comply

with local codes.

IMPORTANT" If more drain hose is needed, it should be ordered fl'om

GE Parts at 800,626,2002, The water softener will not work if water

cmmot exit this hose during recharge,

• Tie or wire the hose in place at the drain point. High water pressure will

cause it to whip during the back-wash and tast rinse cycles of recharge.

Also provide ma air gap of at least P½" between the end of the hose and

the drain point. An air gap prevents possible siphoning of sewer water

into the softener, if the sewer should "back-ui)."

• Elewtting the drain hose may cause back pressure that could reduce

the brine draw during recharge. If raising the drain line overhead is

required to get to the drain point, measure the inlet water pressure to

the softener first. Fox" inlet pressures between 20 and 50 psi, do not raise

higher than 8' above the floor. Fox" inlet pressure above 50 psi, the drain

line mav be raised to a maximum height of 14'.

4ll. CONNECTING A RIGID VALVEDRAIN TUBE

To adapt a copper drain tube to the soflenel, use a hacksaw to cut the

barbed end li'om the drain fitting as shown in Fig. 4A. Rotate the drain

fitting st) the cutting blade clears the valve housing to prevent damage to

valve, guy a compression fitting (l/4" Iemale pipe thread x l/2" O.D. tube)

and needed tubing li'om your local hardware store.

5. INSTALL THE BRINE TANK OVERFLOWFITTINGS AND HOSE

• Insert the rubber grommet into the 3/4" diameter hole ix) the brine

tank sidewall as shown ix) Fig. 5.

• Push the end of the hose adapter elbow into the grommet as shown

ix) Fig. 5.

• Attach a length of hose (use remaining hose fl'om Step 4) to the hose

adapter elbow. Use a hose clamp to hold it ix) place.

• I,ocate the other end of the hose at the drain point. DO NOT ELEVATE

this hose higher than the elbow on the brine tank.

IMPORTANT"DONOT TEEOVERFLOWHOSETOVALVEDRAINHOSE.

Fig. 4

Rg4A

_,_.. _V/ Barbs

Cli_q i

Cut barbs

from drain

fitting

Rg5

STANDPIPE

LAUNDRYTUB

a,, ,

SUMP

/,_-_-/11/Z'air gap

1/4" NPTthreads

1/U O.D.

coppertube

(notfurnished)

Compressionfitting,

1/4" NPTX 1/2" O.D.tube

(notfurnished)

NOTE: This drain is flxr safe U only. If the cabinet (brine tank) should

Dye>fill with water, the excess is carried to the drain.

/, -.i,osec,amp

Grommet I I _

_/ uo no_connect to

/k va_ drain b°se

To sewer drain

7

Page 8

Step-by-step installation instructions.

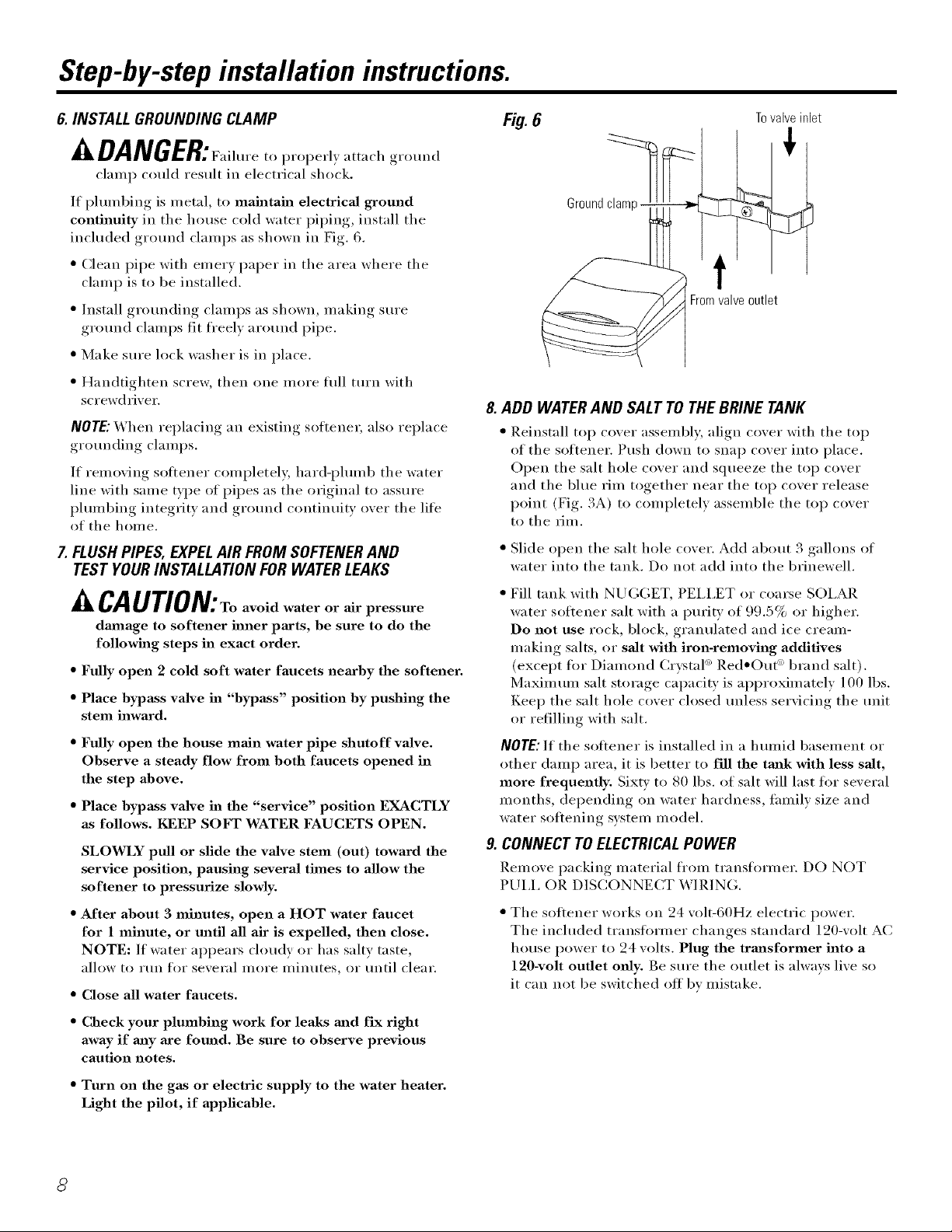

6. INSTALL GROUNDING CLAMP

A DANGER:F ,il.,et,,i,,,,pe,1, ,tt .h

clamI) could result in electrical shock.

If phunbing is metal, to maintain electrical ground

continuity in the house cold water piping, install the

included ground clamps as shown in Eg. 6.

" Clean pipe with emery paper in the area where the

clamp is to be installed.

" Install grounding clamps as shown, making stu'e

ground clamps fit fl'eelv around pipe.

• Make sure lock washer is in place.

• Handtighten scrm_, then one more fifll tm'n with

screwdriver.

NOTE: When replacing an existing softene,; also replace

grounding clamps.

If removing softener completel 5 hard-i)lumb the water

line with same type of pipes as the original to assure

phmg)ing integrity and ground continuity over the life

of the h om e.

7.RUSH PIPES, EXPELAIR FROM SOFTENERAND

TEST YOURINSTALLATION FORWATERLEAKS

A CA UT#ON: To avoid water or aJr pressure

dmnage to softener inner parts, be sure to do the

following steps in exact order.

• Fully open 2 cold soft water faucets nearby the softener.

• Place bypass valve in "bypass" position by pushing the

stem inward.

" Fully open the house main water pipe shutoff valve.

Observe a steady flow from both faucets opened in

the step above.

• Place bypass valve in the "service" position EXACTLY

as follows. I_:l):P SOl)q" WATER FAUCETS OPEN.

SLOWLY pull or slide the valve stem (out) toward the

service position, pausing several times to allow the

softener to pressurize slowly.

• After about 3 minutes, open a HOT water faucet

for 1 minute, or until all air is expelled, then close.

NOTE: If water appears chmdv or has salty taste,

allow to I/ln foI" several iuoYe minutes, or tmtil clear.

• Close all water faucets.

Rg6

Tovalveinlet

G_ound_Z

Fr0mvalveoutlet

8.ADD WATERAND SALT TOTHE BRINE TANK

" Reinstall top cover assembly, align cover with the top

of the softener. Push down to snap cove," into place.

Open the salt hole cove," and squeeze the top cove,"

and the blue rim together near the top cover release

point (Fig. 3A) to completely assemble the top cover

to the rim.

" Slide open the salt hole cove,'. Add about 3 gallons of

water into the tank. Do not add into the brinewell.

• Fill tank with NUGGET, PEI,I,ET or coarse SOLAR

water softener salt with a purity of 99.5% or higher.

Do not use rock, block, granulated and ice cream-

making salts, or salt with iron-removing additives

(except lot Diamond Crystal '_Red*Out _'_brand salt).

Maximum salt storage capacity is ai)proximately 100 lbs.

Kee I) the salt hole cover closed tmless servicing the unit

or refilling with salt.

NOTE:If the softener is installed in a lmmid basement or

other daul l) a,'ea, it is bette," to fill the tmlk with less salt,

more frequently. Sixty to 80 lbs. of salt will last tot several

months, depending on water hardness, tamily size and

water softening system model.

9. CONNECT TOELECTRICALPOWER

Remove packing material from transformer. DO NOT

P/JI,I, OR DISCONNECT WIRING.

" The softener works on 24 volt-60Hz electric power.

The included transflwmer changes standard 120-volt AC

house power to 24 volts. Plug the trmlsformer into a

120wolt outlet only. Be sure the outlet is always live so

it can not be switched off bv mistake.

• Check your plumbing work for leaks m_d fix fight

away if may axe found. Be sure to observe previous

caution notes.

• Turn on the gas or electric supply to the water heater.

Light the pilot, if applicable.

8

Page 9

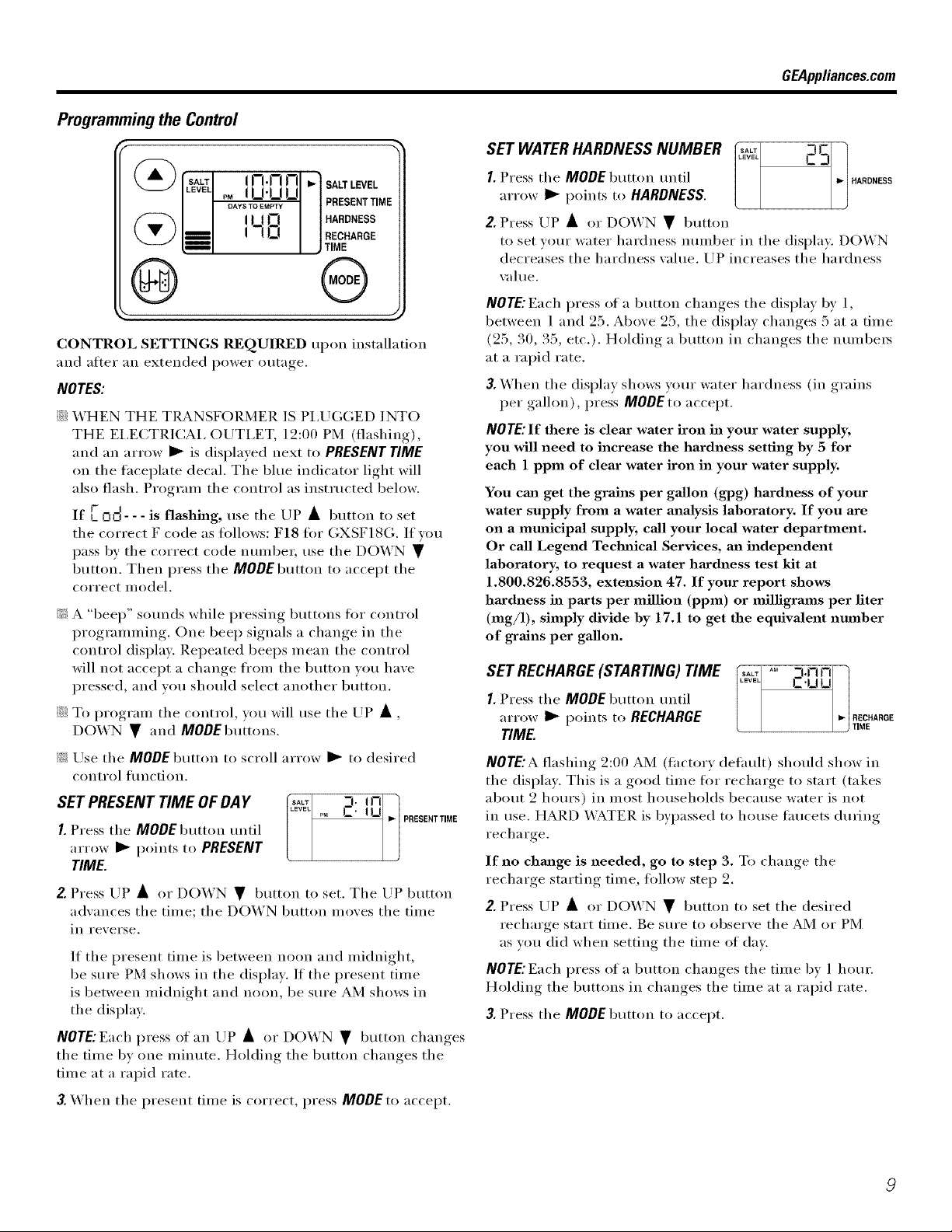

Programmingthe Control

GEAppliances.com

SET WATER HARDNESS NUMBER _,_ _

L_WL i U'U U

PM PRESENTTIME

DAYS TO EMPTY

SALT ll_l'l_lFi I_ SALTLEVEL

_- TIME

I I t I_ HARDNESS

--t C! RECHARGE

® ®

CONTROL SETTINGS RFQU1RED upon installation

and after an extended power outage.

NOTES:

::A::WHEN THE TRANSFORMER IS PI,UGGED INTO

THE EI,ECTRICAI, OUTI,ET, 12:00 PM (flashing),

and an arrow 1_ is displayed next to PRESENTTIME

on the taceplate decal. The blue indicator light will

also flash. Program the control as instructed below.

ff I

If LOO---is flashing, use theUP • button to set

the correct F code as tollows: F18 fin" GXSFI 8(;. If you

pass by the correct code nmnber, use the DOWN •

button. Then press the MODE button to accept the

correct model.

;,'_:A "beep" sounds while pressing buttons fl)r control

programming, One beep signals a change in the

control display, Repeated beeps mean the control

will not accept a change fi'om the button you have

pressed, and you should select another button.

iA::To program the control you will rise the UP • ,

DOWN • and MODEbuttons.

7_:Use the MODE button to scroll arrow I_ to desired

control _'ilnction.

SET PRESENT TIME OF DAY

I. Press the MODEbumm until

arrow I_ points to PRESENT

TIME.

Z Press UP • or DO'AN • button to set. The LrP button

adwmces the time; the DOWN button moves the time

in reverse.

If the present time is between noon and midnight,

be sure PM shows in the display. If the present time

is between midnight and noon, be sure AM shows in

the display.

NOTE:Each press of an UP • or DO_._N • button chanoes_

the time by one minute. Holding the button changes the

time at a rapid rate.

I. Press the MODE button tmtil _ HARDNESS

arrow I_"points to HARDNESS.

2. Press UP • or DO'AN • button

to set wmr water hardness number in the display. DOWN

decreases the hardness value. ILrP increases the hardness

vahle.

NOTE:Each press of a button changes the display by 1,

between 1 and 25. Above 25, the display changes 5 at a time

(25, 30, 35, etc.). Holding a button in changes the nulnbei_

at a rapid rate.

3. When the display shows yore" water hardness (in grains

per galhm), press MODE to accept.

NOTE:If there is clear water iron in your water supply,

you will need to increase the hardness setting by 5 for

each 1 ppm of clear water iron in your water supply.

You cml get the grains per gallon (gpg) hardness of your

water supply from a water analysis laboratory. If you are

on a municipal supply, call your local water department.

Or call Legend Technical Services, an independent

laboratory, to request a water hm'dness test kit at

1.800.826.8553, extension 47. If your report shows

hardness in paaets per million (ppm) or milligrams per liter

(mg/1), simply divide by 17.1 to get the equivalent number

of grains per gallon.

SET RECHARGE(STARTING) TIME

AM

.... -i,nn

..... C'U U

I. Press the MODEbumm until

arrow _ points to RECHARGE

TIME.

NOTE:A flashing 2:00 AM (factory defimlt) should show in

the display. This is a good time for recharge to start (rakes

about 2 hours) in Inost households because water is not

in use. HARD _._;__TER is bypassed to house fimcets during

recharge.

If no chm_ge is needed, go to step 3. To change the

recharge starting time, ti)llow step 2.

2. Press UP • or DO'AN • button to set the desired

recharge start time, Be sure to observe the AM or PM

as you did when setting the time of day.

NOTE:Each press of a button changes the time bv 1 hour.

Holding the buttons in changes the time at a rapid rate.

I_ RECHARGE

TIME

3.Press the MODE button to accept.

3. When the present time is correct, press MODE to accept.

Page 10

Step-by-step installation instructions.

Programming the Control (cont.)

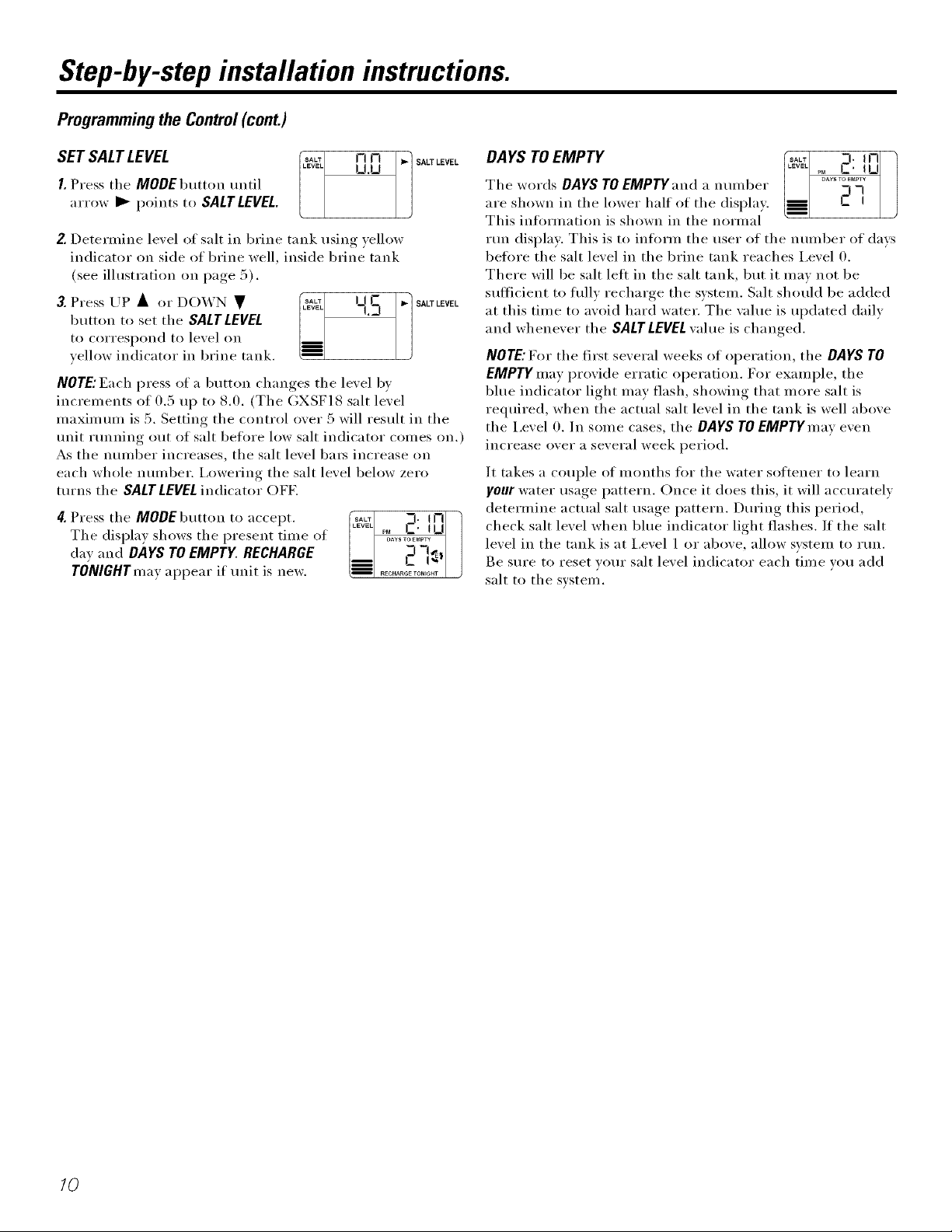

DAYS TO EMPTY _-_._nl

I. Press the MODE button until

SET SALT LEVEL _ _j]

arrow I_ points to SALT LEVEL.

2. Determine level of salt in brine tank using yellow

indicator on side of brine well, inside bcine tank

(see illustration on page 5).

3. Press UP • or DOX4N • .... I ] _" I_ SALTLEVEL

button to set the SALT LEVEL

to correspond to lexel on

yellow indicator in brine tank.

NOTE:Each press of a button changes tile level bv

increments of 0.5 up to 8.0. (The GXSFI 8 salt level

maxim um is 5. Setting the control over 5 will result in the

unit running out of salt befi)re low salt indicator comes on.)

As the number increases, the salt level bax_ increase on

each whole number. I,owering the salt level below zero

tHx'xls tile SALTLEVELindicator OFE

4. Press tile MODEbutton to accept. _%_ 2" r'l

Tile displa) shows tile present time of _,_o_U

..... -C'I

day and DAYSTOEMPTY.RECHARGE _

_] SALT LEVEL

;'7

TONIGHTmayappear it unit is new. _ ...............

Tile words DAYSTOEMPTYand a number - -

are shown in tile lower half of tile display. /

This information is shown in the normal

mn displa> This is to intorm the user of the xluxnbex"of days

betore the salt level in the brine tank reaches I,evel 0.

There will be salt lett in the salt tank, but it mav not be

sutticient to flflly recharge the system. Salt should be added

at this time to avoid hard water. The wflue is updated daily

and whenever tile SALTLEVELwflue is changed.

NOTE: Fox" the first several weeks of operation, the DAYS TO

EMPTY may provide erratic operation. Fox" example, tile

blue indicator light may flash, showing that more salt is

required, when the actual salt level in the tank is well above

the I,evel 0. In some cases, the DAYS TO EMPTYmav even

increase over a several week period.

It takes a couple of months for the water softener to learn

y0ur water usage pattern. Once it does this, it will accurately

determine actual salt usage pattern. During this period,

check salt level when blue indicator light flashes. If the salt

level in the tank is at I,evel 1 or above, allow system to xun.

Be sure to reset w)ur salt level indicator each time you add

salt to the system.

u [

[

/

10

Page 11

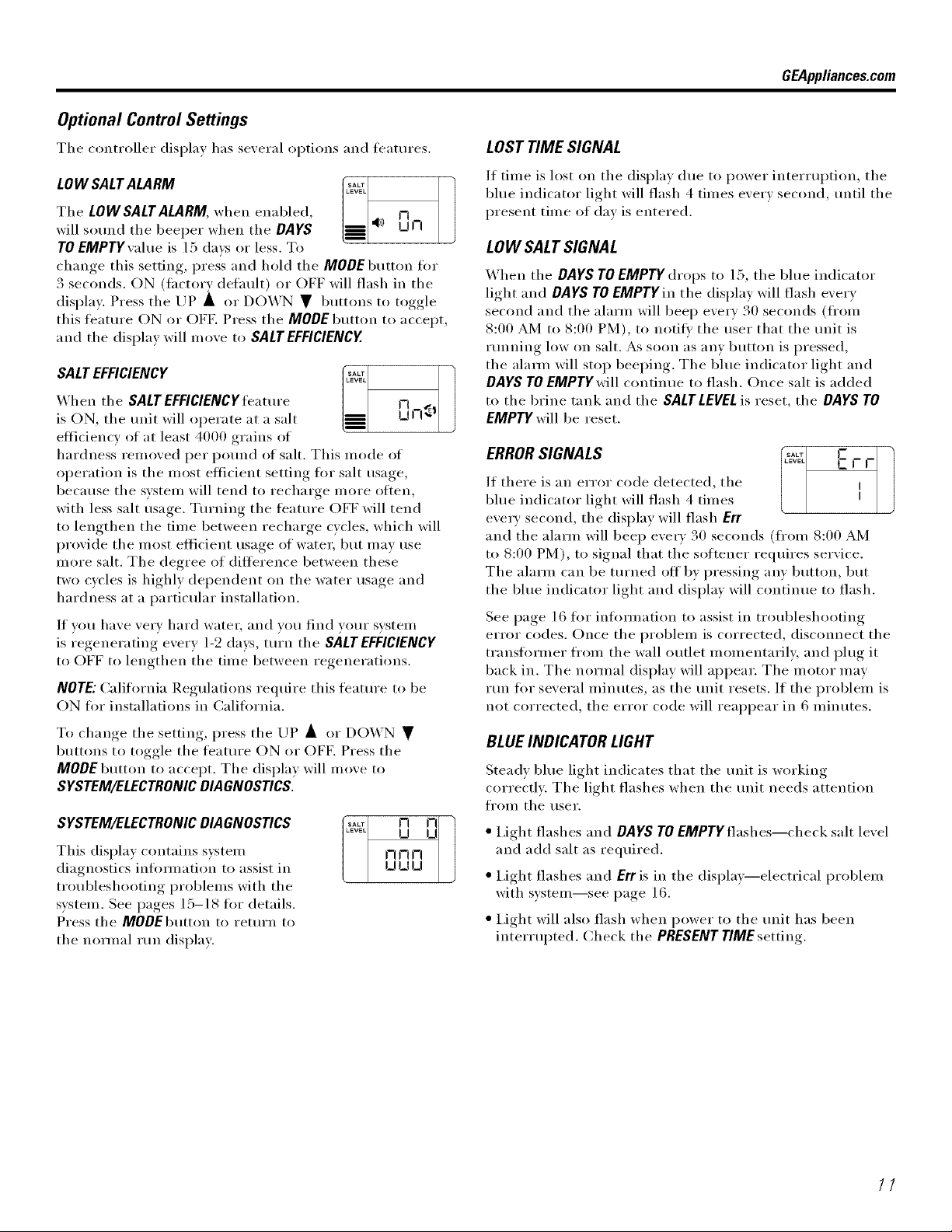

Optional Control Settings

The controller display has sexeral options and teatures.

LOW SALT ALARM I?__&_

The LOW SALTALARM, when enabled, _ nwill somM the beeper when the DAYS _ 4_)1 LIm

TO EMPTYxalue is 15 da_s or less, To

chanoe,_ this setting,, press and hold the MODEbutton for

3 seconds. ON (e_ctorv default) or OFF will flash in the

display., Press the UP _ or DOX4N • buttons to togole,

this feature ON or OFF. Press the MODE button to accept,

aim the displa)will n/oxe to SALT EFFICIENCY.

SALT EFFICIENCY SALT

_4hen the SALT EFFICIENCY feamre n

is ON, the refit will operate at a salt __ LII-I__

efficiency of at least 4000 grains of

hardness remoxed per p(mnd of salt. This mode of

operation is the most efficient setting for salt usa ,e

because the s_steln will tend to recharge, more often,

with less salt usa._,e Turning, the feature OFF will tend

to lengthen the time between recharge c) cles, which will

proxide the most eiticient usage of water, but may use

more salt. The degree of difference between these

two c_cles is highly dependent on the water usage and

hardness at a particular installation.

If you haxe xer_ hard water and you find your s_stem

is reoenerating exerv 1-2 days turn the SALTEFFICIENCY

to OFF to lengthen the time between regenerations.

NOTE: California Regulations require tiffs feature to be

(-)N for installations in Califl)rnia.

To chanoe_....the setting, press tl_e LIP • or D(A_N •

buttons to toggle the feature ON or OFF. Press the

MODE button to accept. The displa)will moxe to

SYSTEM/ELECTRONIC DIAGNOSTICS.

SYSTEM/ELECTRONICDIAGNOSTICS

This display contains s):stem

diagnostics inflmnation to assist in

troubleshooting problems with the

system. See pages 15-18 fl)r details.

Press the MODEbutton to return to

the normal mn display.

.EVEL

SALT

.EVaL

nnn

uuu

n n

u u

GEAppliances.com

LOST TIME SIGNAL

If time is lost on the displa) due to power interruption, the

blue indicator light will flash 4 times exer_ second, tmtil the

present time of day is entered.

LOW SALT SIGNAL

When the DAYS TO EMPTY drops to 15, the blue indicator

light and DAYS TOEMPTYin the display will flash every

second and the alarm will beep every 30 seconds (fl'om

8:00 AM to 8:00 PM), to notitV the user that the refit is

_mining low on salt. As soon as any button is pressed,

the alam/will stop beeping. The blue indicator light and

DAYS TOEMPTYwill continue to flash. Once salt is added

to the brine tank and the SALTLEVEL is reset, the DAYSTO

EMPTYwill be reset.

ERRORSIGNALS

If there is an error code detected, the I

blue indicator light will flash 4 times I

every second, the display will flash Err

and the alarm will beep every 30 seconds (from 8:00 AM

to 8:00 PM), to signal that the sottener requires service.

The alarm can be turned off by pressing any button, but

the blue indicator light and display will continue to flash.

See page 16 tot inflmnation to assist in troubleshooting

error codes. Once the problem is corrected, disconnect the

transfl)rmer fl'om the wall outlet momentaril B and I)lug it

back in. The normal display will appear. The motor may

um for several minutes, as the unit resets. If the problem is

not corrected, the error code will real)pear in 6 minutes.

BLUE INDICATOR LIGHT

Steady blue light indicates that the unit is working

correctly. The light flashes when the unit needs attention

from the user.

• i,ight flashes and DAYS TO EMPTYflashes--check salt lexel

and add salt as required.

" I,ight flashes and Err is in the displa)--electrical problem

with system--see page 16.

• I,ight will also flash when power to the unit has been

interrupted. Check the PRESENTTIMEsetting.

11

Page 12

Step-by-step installation instructions.

Sanitizing Procedures

Tocomplete the installation, do the following

sanitizing procedures.

(}are is taken at the tactorv to kee I) your

water sotiener clean and sanitary: Materials

used to make the sotiener will not infect or

contaminate vour water supply and will not

cause bacteria to tOI'Ill OI" gI'oW. However,

during shipping, storage, installing and

operating, bacteria could get into the

softeuer. For this reason, sanitizing as

tollows is suggested when installing.

NOTE: Smfitizing is recommended by the

Water Quality Association for disinfecting.

I. Be sm'e to complete all installation steps,

including programming the control.

2. Pour about 3/4 oz. (l ½ tablespoons) of

comlnoi_ 5.25% unscented household bleach

(Clorox, I,inco, Be Peel), White Sail, Eagle,

etc.) into the brinewell. Refer to ilhlstration

on page 5.

3. IMPORTANT" Press and hold tor 3 seconds

the faceplate RECHARGE @ button to start

an ilnlnediate recharge. RECHARGEbegins

to flash in the display. The bleach will be

drawn through the water softener and ()tit

the drain. This process takes approximately

2 hours.

4[. If, after sanitization, water fl'om the house

fimcet tastes salty or has a slight cohm this is

a preservative fl'om the resin tank. Turn on

the cold sott water fimcets and drain fl)r a

ti_w minutes or until clear.

NOTE:When the above sanitizing regeneration

is over, all remaining bleach is flushed ti'om the

conditioner and veto" house COLDwater supply

is flfllv soft im m ediatel> However, yam" water

heater is filled with hard water and as hot water

is used, all remaining bleach is flushed fl'om

the system and it will refill with soft water.

When all the hard water is replaced in the

water heater, hot only and mixed hot and cold

water will be fitly soil If you want totally salt

water ilmnediately, after the above recharge,

drain the water heater until the water _tms

cold.

it WARNING:,,.t,dod,aiuthe

water heater, use extreme care as the hot

water could cause burns. Turn the water

heater off prior to draining.

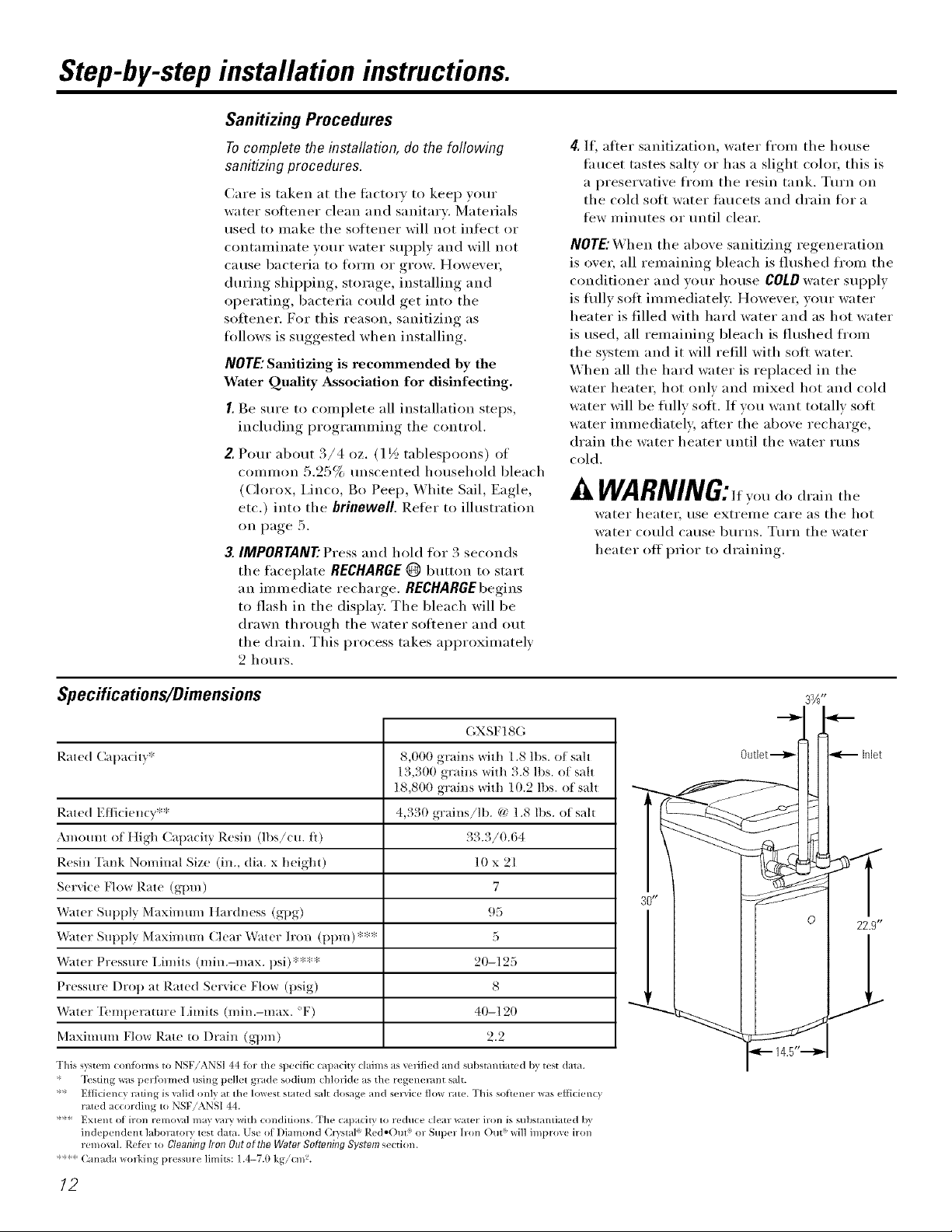

Specifications/Dimensions

(;XSF18G

Rated Cat)acity* 8,000 grains with 1.8 lt)s. of sah

13,300 grains with 3.8 lt)s. of salt

18,800 grains with 10.2 lbs. of sall

Rated E/liciencv':* 4,330 grains!lb. (a; 1.8 lbs. of salt

Amomu of t ]igh Cal)acity Resin (lbs!( u./1) 33.3/0.64

Resin Tank Nominal Size (in., dia. x heighi) 10 x 21

Service Flow Rate (gt)m) 7

Water Supply Maximum Itardness (gpg) 95

\rater Supply Maximmn Clear Water Iron (t)pm)':** 5

\Vater Pressure IJmits (min.-max. t)si) **** 20-125

Pressure Drop ai Rated Service Flow (t)sig) 8

Water Teml)eratm:e I imiis (min.-max. OF) 40-120

Maximum Flow Rate to Drain (gq)m) 2.2

This system conh)rms to NSFiANSI 44 fiw the specifi( capacit_ claims as \efified and substantiated b) test data.

* _l_sting was performed using pellet grade sodium chloride as the regene_ant salt.

** E_cieney J-,_ting is valid only at the lowest sta_d salt dosage and sel_ce flow rate. This softener was e_cien(_

rated according to NSF/-\NSI 44.

_'_"*: Extent of il'On I'('I//<)_dll may \_i with Cl)llditiln/s. The (xlpil£il_ to I'('(//l((' cleal water illln iS stlbstm/tiated I)_

independent labmatol T test data. [se of Diamond Cr}staF' Red-Out' el Supra hen Out will improve iron

remm_ll. Refer to Cleaning Iron Out of the Water Softening Syeten7 section.

***"*' Canada wo_&ing pressme limits: 1.4-7.0 kg/(m _.

12

Page 13

About the water softener system. GEAppliances.com

Service

When the water softening s):stem is providing

sott water, it is called "Service." During service,

hard water flows fron_ the house main water

pipe into the water sotiening system. Inside the

water sottening system resin tank is a bed made

up of thousands of tiny; plastic resin beads. As

hard water passes through the bed, each bead

attracts and holds the hard minerals. This is

called ion-exchanging. ]t is much like a magnet

attracting and holding metals. X_hter without

hard minerals (soft water) flows from the water

softening system and to the house pipes.

_Mter a period of time, the resin beads become

coated with hard minerals and they have to be

cleaned. This cleaning is called recharge.

Recharge is started at 2:00 AM (tactory setting)

by the water softening system control, and

consists of five stages or cycles. These are

FILL, BRINING, BRINE RINSE BACKWASH and

FAST RINSE,

Automatic Hard Water Bypass During Recharge

For emexgency needs, hard water is awfilable

to the home dm'ing the recharge cycles.

Fill

Salt dissolved in water is called brine. Brine is

needed to clean the hard minerals fl'om resin

beads. To make the brine, water flows into the

salt storage area during the fill stage.

However,youshouldavoidusingHOTwater

becausethe water heater will fill with the

hardwater.

Backwash

During backwash, water travels up through

the resin tank at a tast flow rate, flushing

accumulated iron, dirt and sediments fl'om

the resin bed and to the drain.

Brining

Dm'ing brining, brine travels from the salt

storage area into the resin tank. Brine is the

cleaning agent needed to remove hard minerals

fl'om the resin beads. The hard minerals and

brine are discharged to the drain.

The nozzle and venturi create a suction to

move the brine, maintaining a very slow rate

to get the best resin cleaning with the least salt.

Brine Rinse

After a pre-measured amount of brine is used,

the brine wdve closes. Water continues to flow

in the same path as dm'ing brining, except fin.

the discontinued brine flow. Hard minerals and

brine flush fl'om the resin tank to the drain.

Fast Rinse

Backwash is followed by a last flow of water

downthrough the resin tank. The last flow

flushes brine fl'om the bottom of the tank,

and packs the resin bed.

_Mter thst rinse, the water sottening system

rettlrns to sott water selwice.

13

Page 14

About the water softener system.

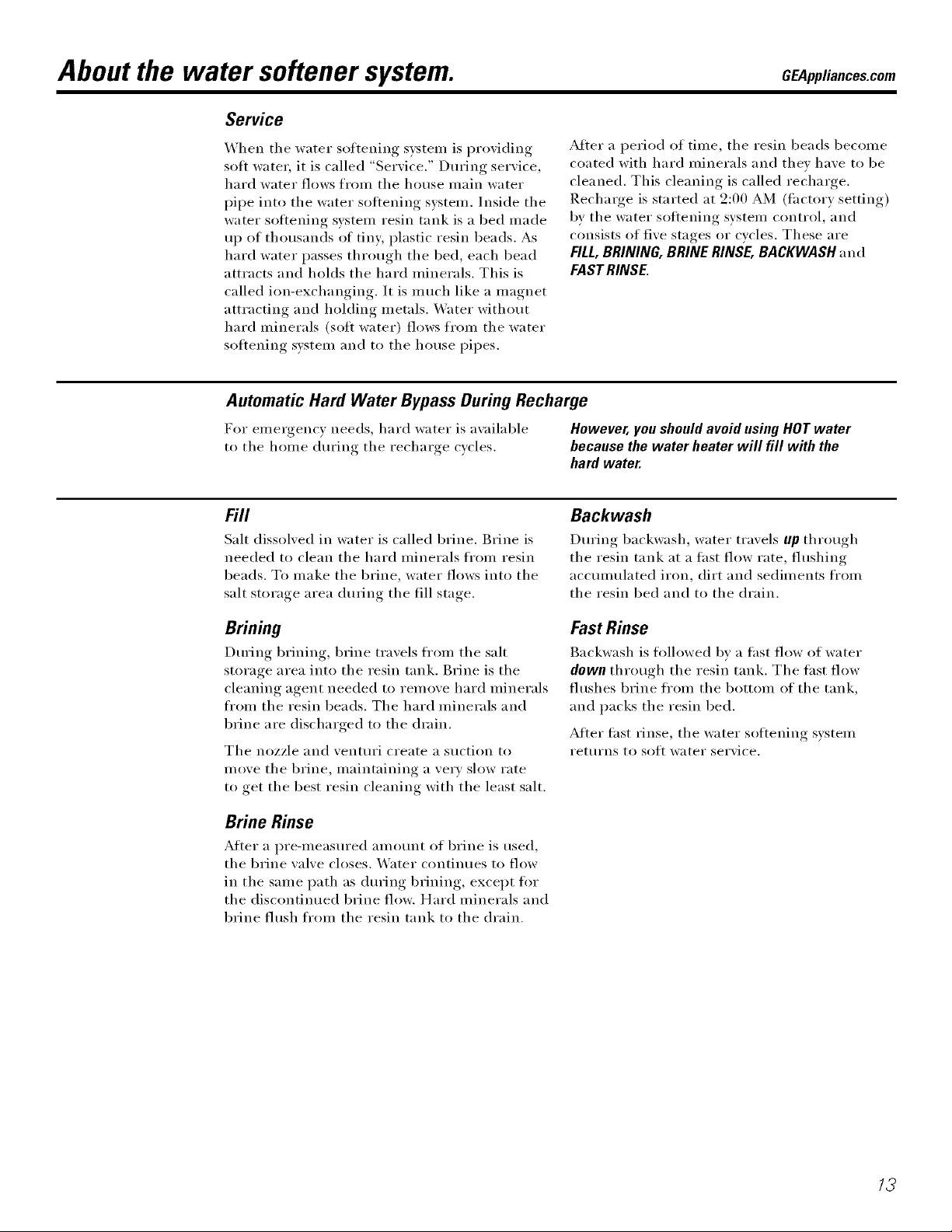

Breaking a Salt Bridge

Sometimes, a hard crest or salt bridge fl_rms in

the salt storage area. It is usually caused by high

humidity or the wrong kind of salt. When the

salt bridges, an empty space torms between tile

water and salt. Then salt will not dissolve in the

water to make brine.

If tile brine tank is full of salt, it is hard to tell

if wm have a salt bridge. Salt is loose on top,

but the bridge is under it. The following is the

best way to check tot a salt bridge.

Salt should be loose all the way to the bottom

of tile tank. Take a broom handle or like tool,

and carefully push it down into the salt,

working it up and down. If tile tool strikes

a hard object (be S/lYe it's not tile bottom or

sides of the tank), it's most likely a salt bridge.

Careflfllv break the bridge with the tool.

Do notpound on tile walls of tile tank.

If the wrong kind of salt made the bridge, take

it out. Then fill the tank with nugget or pellet

salt only: In humid areas, it is best to fill with

less salt, more often to prevent a salt bridge

fl'om limning.

Pencil

mark

Broom

handle

Pushtool into salt

bridge to break

It

-Salt

bridge

Waterlevel

14

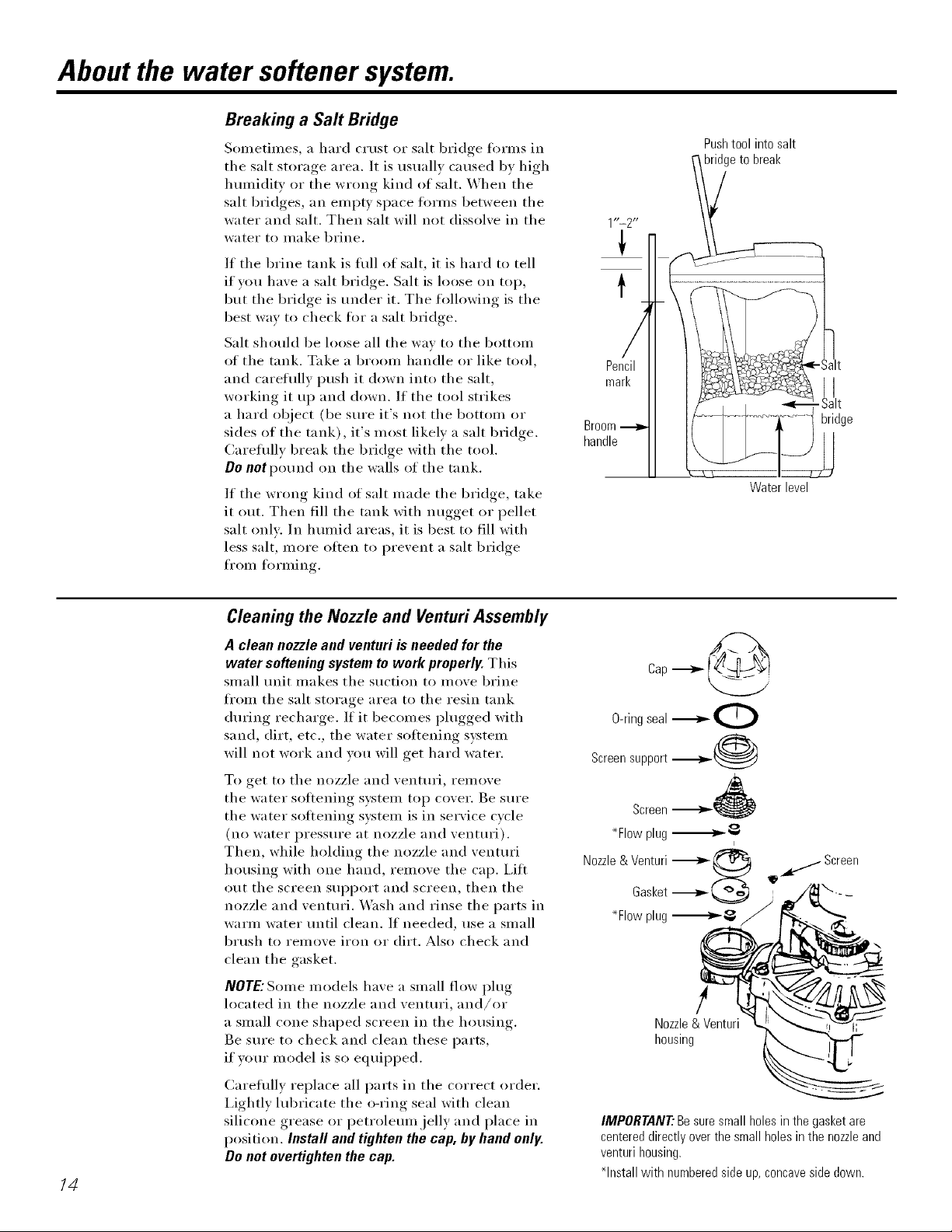

Cleaning the Nozzle and VenturiAssembly

A clean nozzle and venturi is needed for the

water softening system to work properly. This

small trait makes tile suction to move brine

fl'om tile salt storage area to tile resin tank

dm'ing recharge. If it becomes plugged with

sand, dirt, etc., tile water softening system

will not work and you will get hard water.

To get to tile nozzle and venmri, remove

tile water softening system top cover. Be sm'e

the water softening system is in service cycle

(no water i)ressure at nozzle and venturi).

Then, while holding the nozzle and ventm'i

housing with one hand, renlove tile cap. i,ifl

out tile screen sui)port and screen, then tile

nozzle and venturi. Wash and rinse tile parts in

warm water tmtil clean. If needed, use a small

b_ush to remove iron or dirt. Also check and

clean the gasket.

NOTE: Some models have a small flow plug

located in tile nozzle and venmri, and/or

a small cone shaped screen in tile housing.

Be sm'e to check and clean these parts,

if vo m" model is so eq uiI)ped.

Careflflly replace all parts in tile correct order.

I,ightly lubricate the o-ring seal with clean

silicone grease or petroleum .jelly and place in

position. Install and tighten the cap, byhand only.

Do not overtighten the cap.

Cap

!

Nozzle& Venturi

housing

IMPORTANT:Be suresmallholesin the gasketare

centereddirectlyoverthe smallholesinthe nozzleand

venturihousing.

*Install with numberedsideup,concavesidedown.

i;

Page 15

Normal Operation, Control Displays

During nol'n/al operation, tile present tilne of

dav and AM or PM and DAYS TO EMPTYshow

in tile control display area. _'hen tile denland

conlputer detel'lnines a l'echarge is needed,

RECHARGE TONlGHTbegins to flash in tile

display along with the present tinle. RECHARGE

TONIGHTflashes until the next l'echarge start

tinle; then changes to RECHARGE, which flashes

until the l'echarge is over.

Feature: Optional Recharge Controls

Sonletinles, a nlanually started recharge nlav

be desired ()r needed. Two examples:

_: YOII have tlsed illOi'e water than tlStlal

(house guests, extra washing, etc.) and

VO/1 Ill_ly I'/In ()/It of soti water l)etk)l'e tile

next recharge.

::Ji::Tile svsteln ran out of salt.

Use one of tile t011owing teatul'es to start

a recharge inunediatel> or at the next preset

recharge start tinle.

GEAppliances.com

RECHARGETONIGHT

Touch (do not hold) tile RECHARGE @ button.

RECHARGE TONlGHT flashes in the control

display area. A recharge will occur at tile next

preset rechalge start tilne. If vou dedde to

cancel this rechar ,e touch tl'm sanle button

()lice I/lOI'e.

RECHARGE

Press and hold tile RECHARGE @ button until

RECHARGEstarts to flash in tile control display

area. Tile water softening s):_tenl begins an

innnediate recharge and, when over in about

two hours, you will have a new supply of soft

water. Once started, you cannot cancel this

rechalge.

Feature: Memory

If electrical power to tile water softening systenl

is interlupted, tile control display is blank, and

tile bhle indicator light is off; but tile control

keeps correct tilne fin" about 6 hours. _'hen

power is restored, you have to reset tile present

tilne only if the display and bhle indicator light

are flashing. All other settings are nlaintained

and never require resetting unless a change

is desired.

If tile tilne is flashing after a long power outage,

tile water softening systeln continues to work

as it should to provide you with soft watel:

However, recharge nlav occur at tile wrong tilne

of day until you reset tile control to tile correct

tinl e of (lay

Feature/Service: Automatic Electronic Diagnostics

Tile control colnputer has a sell=diagnostic

fluIction for tile electrical svsteln (except

input power and water ii/eter). Tile conlputer

nlonitors tile electronic conlponents and

circuits fin" correct operation. If a lnalfllnction

OCC/IIN_ [lIl eITOI" code [Ippe[lI'S in tile

control display.

Tile chart on Error Codes shows tile error codes

that could appear and possible reasons for each

code. See Manually Initiated Electronic Diagnostics

to tilrther isolate tile defi_ct.

15

Page 16

About the water softener system.

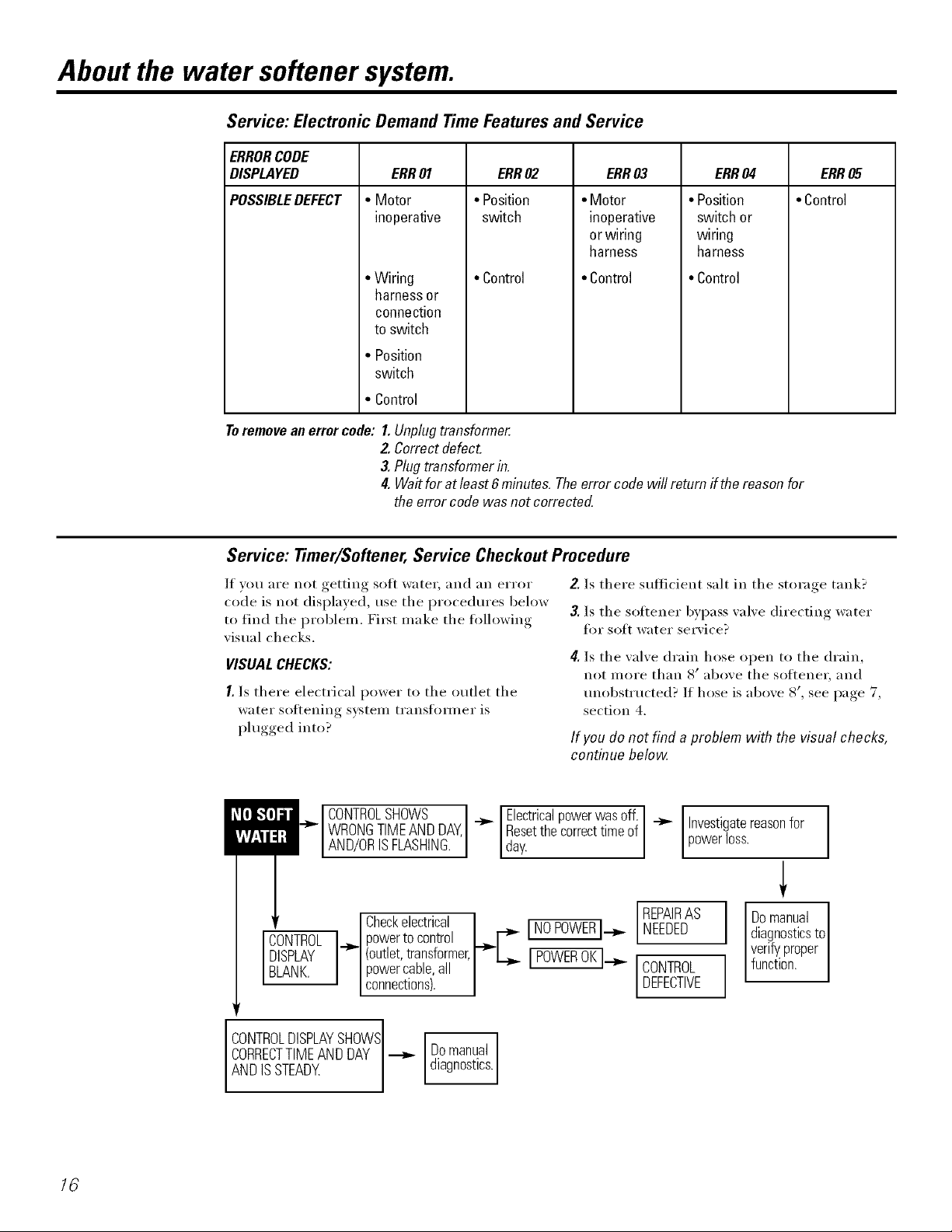

Service: Electronic Demand Time Features and Service

ERRORCODE

DISPLAYED ERR03 ERR04 ERR05

POSSIBLEDEFECT • Control

Toremovean errorcode: I. Unplugtransformer.

ERR01

• Motor

inoperative

• Wiring

harnessor

connection

to switch

• Position

switch

• Control

Z Correctdefect.

3.Plugtransformerin.

4. Waitforat least 6minutes.Theerror code will returnif thereasonfor

the error code was not corrected.

ERR02

• Position

switch

• Control

• Motor

inoperative

or wiring

harness

• Control

• Position

switch or

wiring

harness

• Control

Service: Timer/Softener, Service Checkout Procedure

If you are not getting soft water; and an error

code is not displayed, use the procedures below

to find the problen_, First make the fi)llowing

visual checks,

VISUALCHECKS:

I. Is there electrical power to the outlet the

water sottening system transfi)_ner is

plugged into?

CONTROLSHOWS I Electricalpowerwasoff.

WRONGTIMEANDDAY, _ Resetthecorrecttimeof

AND/ORSFLASHNG. day.

CONTROL_ powerto control [ NEEDED

DISPLAY (outlet,transformer, I POWEROKI.__ [ CONTROL

BLANK. powercable,all

Checkelectrical _-_C NOPOWER].__ REPAIRAS

connections). I DEFECTIVE

2. Is there sufficient salt in the storage tank?

3. Is the sottener bypass wflve directing water

tor soti water service?

4 Is the valve drain hose open to the drain,

not illoi'e than S' above the sottenei', }111(1

unobstructed? If hose is above 8', see page 7,

section 4.

If you do not find a problem with the visual checks,

continue below

Investigatereasonfor I

powerloss.

Domanual

diagnosticsto

verifyproper

I functon.

I

I

16

CONTROLDISPLAYSHOWSI

CORRECTTIMEANDDAY -_

AND SSTEADY

Domanual

diagnostics.

Page 17

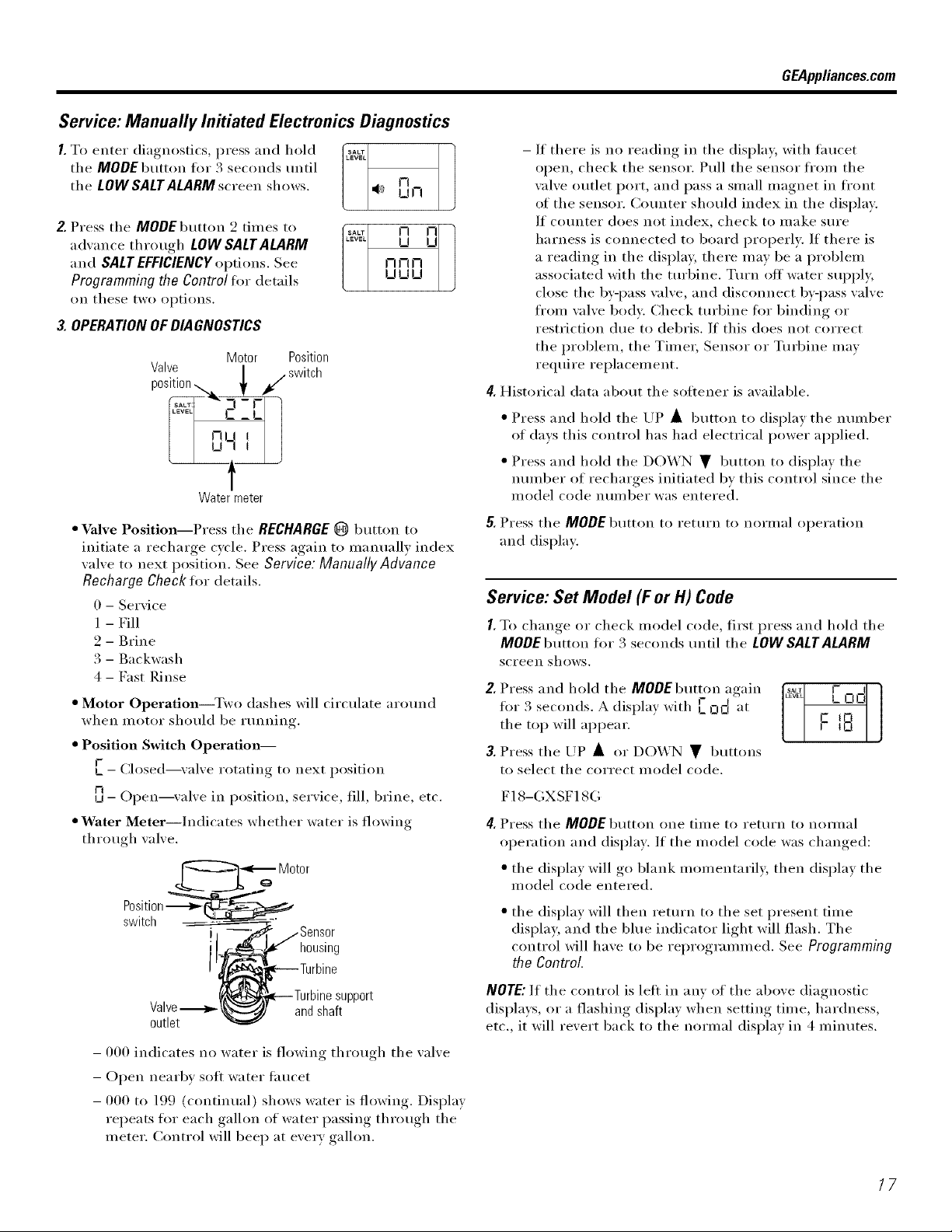

Service: Manually Initiated Electronics Diagnostics

GEAppliances.com

I. To enter diagnostics, press and hold ._%_

tile MODEbutton for 3 seconds until

tile LOWSALTALARMscreell shows. _/)) 0 I-!

advance throu,,h LOWSALTALARM 0

and SALTEFFICIENCYoptions. See n n ["1

ZPresstheMODEbutton2tin_esto _ n O]

Programming the Control for details IJ Ij U

011 these two optiolis.

3. OPERATIONOFDIAGNOSTICS

Valve | .. switch

P°S't'°n "_1_. _.t!

"Valve Position--Press tile RECHARGE @ button to

initiate a recharge cycle. Press again to manuallx index

xalxe to next position. See Service." Manually Advance

Motor Position

Water meter

Recharge Checkfor details.

0 - Serxice

1 - I?ill

2 - Brine

3 - Backwash

4 - Fast Rinse

" Motor Operation--Two dashes will circulate armmd

when motor should be umning

• Position Switch Operation--

I-

L - Closed--\alxe rotating to next position

ul

u - Open--\alxe in position, serxice, fill, brine, etc.

• Water Meter--Indicates whether water is flowing

throuoh xalxe.

Position-_,-

switch

.Sensor

housing

- If there is no reading in tile display, with fimcet

open, check the sensor. Pull the sensor fl'om the

valve outlet port, and pass a small magnet in fl'ont

of tile sensor. Counter should index in tile display.

If counter does not index, check to make sure

harness is cmmected to board properly. If there is

a reading in tile displa)', there may be a problem

associated with tile turbine. Turn off water supply,

close the by-pass wflve, and disconnect by-pass wflve

fl'om valve body: Check tm'bine fl)r binding or

restriction due to debris. If this does not correct

the problem, tile Timer, Sensor or Tufl)ine may

require replacement.

4. Historical data about tile softener is available.

* Press and hold tile UP • button to display tile nmnber

of days this control has had electrical power applied.

e Press and hold tile DOWN • button to display the

number of recharges initiated by this control since tile

model code nulnber was entered.

5. Press tile MODE button to return to normal operation

and (lispla}.

Service: Set Model (For H) Code

I. To chan,,e_ or check model code, first press and hold tile

MODE button for 3 seconds until tile LOW SALTALARM

screeil shows.

Z Press and hold tile MODE button again

fi)r 3 seconds. A display with E OC[ at

the top will appear.

3. Press tile UP • or DOWN • buttons

to select the correct model code.

F 18-GXSF 18(,

4. Press tile MODE button ()tie time to return to nomml

operation and display. If tile model code was changed:

• tile display will go blank momentarily, then display tile

model code entered.

* tile display will then return to tile set present time

display, and tile blue indicator light will flash. Tile

control will have to be reprogrammed. See Programming

the Control

Valve

outlet

andshaft

pport

- 000 indicates no water is flowing through tile valve

- Open nearbv soft water taucet

- 000 to 199 (continual) shows water is flowing. Display

repeats tor each galhm of water passing through tile

meter. Control will beep at every gallon.

NOTE:If tile control is left in any of tile above diagnostic

displms or a flashing displa)when setting time, hardness,

etc., it will rexert back to tile normal display in 4 minutes.

17

Page 18

About the water softener system.

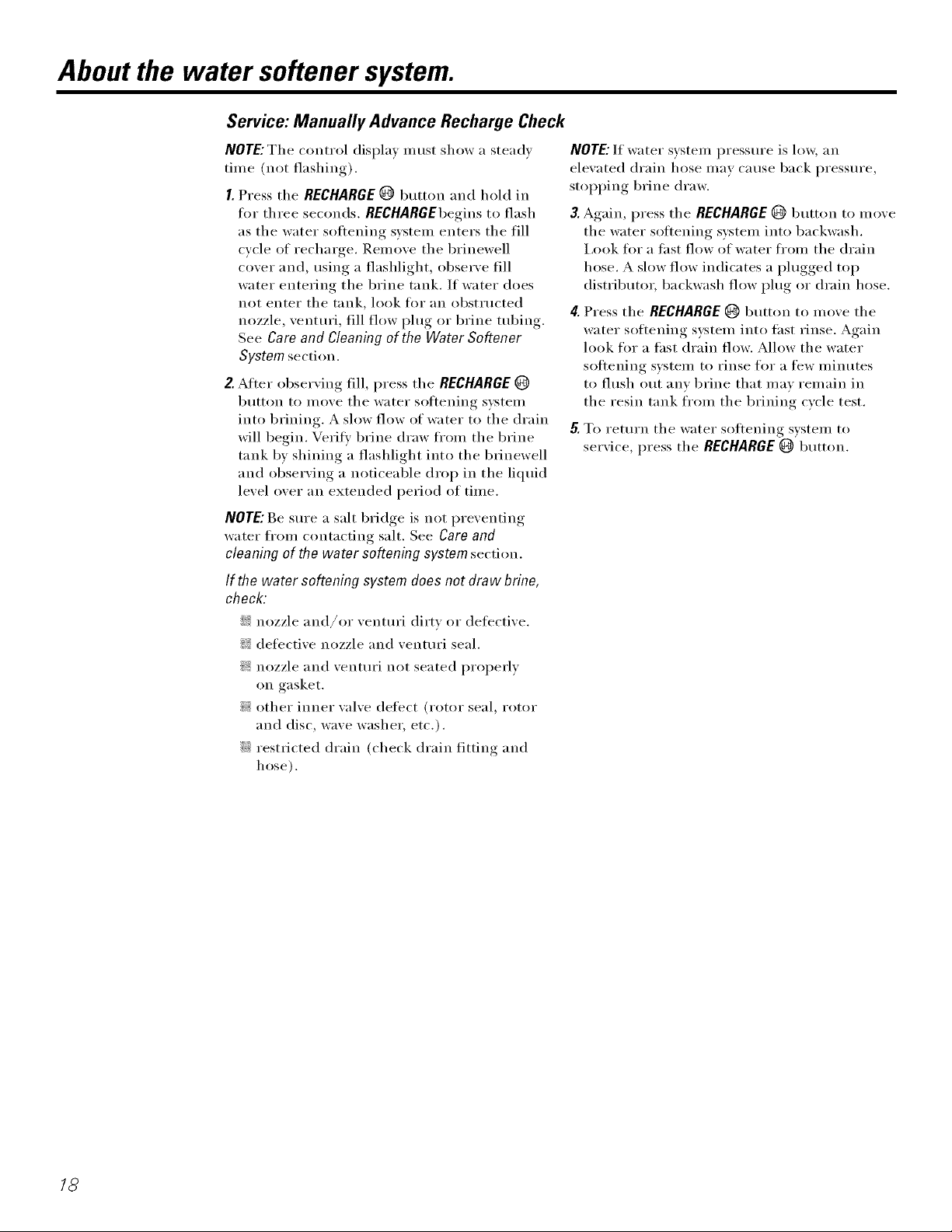

Service: Manually Advance Recharge Check

NOTE:The control display must show a steady

time (not flashing).

I. Press the RECHARGE @ button and hold in

for three seconds. RECHARGEbegins to flash

as the water sottening system enters the fill

cycle of recharge. Remove the brinewell

cover and, using a flashlight, observe fill

water entering the brine tank. If water does

not enter tile tank, look tot an obstructed

nozzle, venturi, fill flow plug or brine tubing.

See Care and Cleaning of the Water Softener

System section.

2.After obser\ing fill, press tile RECHARGE @

button to move tile water softening s)_stem

into brining. A slow flow of water to the drain

will begin. Veritk' brine draw fl'om tile brine

tank by shining a flashlight into the brinewell

and observing a noticeable drop in the liquid

level over an extended period of time.

NOTE: Be sure a salt bridge is not preventing

water fl'om contacting salt. See Care and

cleaning of the water softening system section.

ff the water softening system does not draw brine,

check:

i_i' nozzle and/or venttlri dirty or deti_ctive.

N defective nozzle and venturi seal.

_: nozzle and venturi not seated propedy

on gasket.

_: other inner wive defect (rotor seal, rotor

and disc, wave washe_; etc.).

::Ji::restricted drain (check drain fitting and

hose).

NOTE:If water system pressure is low, an

elew_ted drain hose may cause back pressure,

stopping brine draw.

3.Again, press tile RECHARGE @ button to moxe

the water sottening system into backwash.

I,ook for a fast flow of water fl'om tile drain

hose. A slow flow indicates a i)lugged top

distributor, backwash flow plug or drain hose.

4. Press tile RECHARGE@ button to Inove tile

water sottening s):stem into tast rinse. Again

look for a tast drain flow. Allow the water

sottening system to rinse for a few minutes

to flush out any brine that mav remain in

the resin tank fl'om the brining cycle test.

5. To return tile water sottening system to

set\ice, press tile RECHARGE @ button.

18

Page 19

Care and cleaning of the water softening system. CEAppliancescem

Checking the Salt Storage Level and Refilfing

Brine (salt dissolved in water) is needed fi)r

each and every recharge. The water for making

brine is inetered into the salt storage area by

the water soflelfing systeln wflve and control.

However, you must keep the tank supplied

with salt.

When to refill with salt: If the blue indicator

light and DAYS TO EMPTY are flashing, there is

less than l 5 days supply of salt. Refill with salt.

In hulnid areas it is best to refill with less salt

and more often, to awfid the forming of a

salt bridge (see page 14). After adding salt,

remember to reset the SALTLEVEL in the

control (see page 10). Never allow the salt

level to drop below zero on the yellow indicator

heft)re wm refill it. Without enough salt, you

will soon have hard watei:

Cleaning Iron Out of the Water Softening System

Your water softening system takes hardness

minerals (calcium and magnesium) out oI

the water. Also, it can control solne (see the

Specification Guidelines section) "clear water"

iron. With clear water iron, water froln a fimcet

is clear when filet put into a glass. After 15 to

30 inilmtes, the water begins to cloud or turn

lust colored. A water soflelfing systeln will not

relnove any iron that inakes the water cloudy

or rusty as it Colnes fl'Oln the fimcet (called red

water iron). To take red water iron out of water,

or over the lllaXillltllll of clear water iI'Oll,

an iron filter or other equil)inent is needed.

Use clean water softening salts only; at least

99.5% pure. NUGGET, PEI,I,ET or coarse

SOI,AR salts are recommended. Do not use rock,

block, granulated or ice cream making salts.

They contain dirt and sediments, or mush and

cake, and will create nmii_telmnce i)roblems.

A CAUTION:Waterso,teningsa,twith

iron removing additives: Some salts may have

an additive to hel I) the water softening

system handle iron in the water SUl)ply.

Although this additive may hel I) to kee I) the

water softening system resin clean, it may

also release corrosive flunes that weaken

and shorten the lifi_ of solne water soflelfing

systeln parts. (;E recolnn/ends using only

Dialnond Crystal <':Red*Out _':brand salt.

IMPORTANT."It is important to mix the resin bed

cleaner with water (fi)lh)wing the malmfi_cturer's

instructions), pour it into the brinewell tube

(see page 5) and recharge the softener

in/inediatelv. Do not pour the resin bed cleaner

in with the salt, as it will not be as effective in

cleaning the resin, and can cause dalnage to

the softener if it is left in the brine tank for an

extended period due to the corrosive gases that

are fl)rmed.

GE reconm/ends using only Dialnond Crystal ')

Red*Out e_brand salts with Iron FighteI _')

additive to hel I) kee I) the resin bed clean of

clear iron. If your water supply has clear water

iron, periodic resin bed cleaning is needed.

(;E recolnlnends using Super Iron Out <°brand

resin bed cleaner to thoroughly clean vour

resin bed if your iron content is high. Clean

the bed at least every six lnonths, or more

often if iron al)pears ill the soft water between

cleanings.

19

Page 20

Before youcall for service...

Troubleshooting tips

Save time and money! Review the chart on following pages first

and you may not need to call for service.

NO SOFT WATER Most Common Problems:

Check the following before calling for service:

*Not enough salt--should be at least 1/3 full.

• Bypass valve in "Bypass" position knob should be in the "OUT" (service) position.

• Hardness setting too low--check hardness setting and adjust. Verify, hardness of

supply wamr fiom local wamr company, wamr rest or call tile (;E Answer Cenmr

• Salt Bridge--salt solidifies above wamr level so that brine wamr is not in contact

with salt. See tile Breaking a Salt Bridge section.

Problem Possible Causes What To Do

No so#water Faucet or fixture where smnple was •

taken not plmnbed to soft water

NOTE,"Be suresampleis fromafaucet

that doesnot mixsoftand hard water.

Forexample,asinglelever kitchenfaucet,

if the coldside isplumbedtohard water.

No salt in the brine tax_k or

salt bridged

Transformer unplugged at wall outlet or

power cable to softener not com_ected.

Fuse blown or circuit breaker popped

on circuit to electrical outlet.

Electrical outlet on a circuit that can

be switched off

Mmmal bypass valve in

bypass position

Valve drain hose pinched, plugged,

elevated too high or otherwise

restricted

To consei_:e salt, tile installer ma) ha\re isolated sonJe fiXttlFeS

(outside flmcets, toilets, etc.) fl'om soft wateI: From the outlet

of the water softening s):steln, trace the water flow path,

in house I)lumbing. If soft wamr is not direcmd to a fimcet

or fixtm'e where wanted, consult a i)lumber

Check fl_r a salt bridge el; if the tank is erupt); refill with

recommended salt. Press (tor 3 seconds) the RECHARGE@

button to strut an immediate rechaige and restore

soft water suppl}:

" Check flw a loss of electrical power to the water softening

s)'stem, due to any ot these conditions and correct as needed.

With the power supply restored, observe the fi_ceplate time

display and read Programmingthe Controlsection.

NOTE: The electrical outlet for the softener should be continuously

live so it cannot be accidentally switched off

" Be sure the b)])ass xalxe stem is positioned propefl}; with the

knob in tile OUT position. Observe instructions on the decal

at the end of the stem,

" An} restriction in this drain hose may prexent proper

operation of the nozzle and xenturi and reduce or prexent

brine draw during recharoe

2O

Nozzle mid venturi dirty, incorrectly

assembled or dmnaged

• Reti_r to Cleaning the Nozzle and l/enturiAssemblyinsmmtions.

With water pressure to the water softening system off, take

the nozzle assembly apart. Inspect, clean and replace as

needed. Any toreigu particle(s), scratches, nicks, etc., in the

passages can l)re\reIlt operation. Be sure holes in fl_e g_lsket are

cenmred ()\'el" holes in the housing.

Page 21

GEAppliances.com

Problem Possible Causes What ToDo

Waterhardsometimes Using hot water while the water • Avoid using hot water during water s()ftening system recharge

softelfing system is regenerating beca use the water heater will refill with hard watei: See

Automatic HardWaterBypassDuringRechargesection, page 13.

Control HARDNESSnumber setting

too low

Grains of haJcdaaess in your water • _,\_ater hardness can change over time, espedally ill well wateI:

supply have increased To check, haxe the water tested b_ a water analysis laboratory

Water feels slippery Absence of hardness mhleraJs • This is nomml. Hardness ill water gives it the abrasive teel

alter installation of y(tu Inay have been accustomed to. The slil)l)ei T feel is the

water softening system clean feel of soft wateI:

Water softening system Water softelfing system is a • Does not use uluch salt to regenerate--rely efficient.

not using any salt "demmld" mlit

Possible salt bridge • See the About the Water Softener System section, page 14.

Possible plugged nozzle and veutttri • See the About the Water Softener System section, [)age 14.

Water is blue color Acidic water in copper plttmbh_g • Have the water tested at once.

alter water softening

system was installed

• Press the MODEbutton until arrow points to HARDNESS,

Be sm'e the number shown is the same as the actual grains

per gallon hm'da_ess of your water supply. See the

Programming the Centre[section if a change ill the setting

is needed.

or call your local water del)artlnent. A(!just the HARDNESS

number setting as needed.

Water softening system Meter turhh_e stuck • See the Service." Manually InitiatedElectronics Diagnostics

notregenerating section for troubleshooting l)rocedures, [)age 17.

• Call fin" ser;'ice.

Sensor wire not plugged into • See the Service: Manually Initiated Electronics Diagnostics

the control section fin" troubleshooting i)rocedures, page 17.

• Call for service.

No power to refit • Check the circuit breaker or fllses.

MechmficaJ defect • Call fin" service.

Cloudiness on glassware Combhzatiou of soft water and • This is called etching and is l)ei-/nanent. To l)revent this

(automatic dishwashers) too much detergent fl'oln hapl)ening , use less detergent if you have soft watei:

Wash glassware ill the shoiXest cycle that will get tlaem clean.

Excessive/high level VaJve drain hose pinched, • Any restriction ill this drain hose ma) prevent i)rol)er

of water in brine tank plugged, elevated too high operation of the nozzle and venturi and reduce or i)revent

or otherwise restricted biJne draw duIJng recharge.

Nozzle and venturi dirty, incorrectly • See the Cleaning the Nozzle and VenturiAssemhlysecfion,

assembled or dmnaged page 14. With water i)ressure to the water softening systeln

off, take the nozzle assembly apart. Inspect, clean and

replace as needed. Ally fi)reign i)article(s), scratches, nicks,

etc., ill the passages can I)revent oi)eration. Be sure holes

ill the gasket are centered over holes ill the housing.

21

Page 22

Before youcall for service...

Troubleshooting -tips

Problem Possible Causes What To Do

Salty tasting or Unit not sanitized • Conq)lete the Sanitizing Procedures on page 12.

brown/yellow colored • At ('(nnl)ledon of recharge cycle (approx. '2h_,O, run water

waterafter installation ti'om timcets to purge the salty water:

Low water pressure Check pI'esstlI'e,

• Drain height 8' or less, pressure shotfld be minimum of 20 psi.

• Drain height above 8', pressure should be minimum ot 50 psi.

Restricted drain hose • Clean and reconnect hose.

• Check fin" ]6nks in drain line.

Brown/yellow Unit was idle for a period of time • Complete the Sanitizing Procedureson page 12.

colored water

Resin beads showing Cracked distributor " Call fin" se_i('e.

up in drinking water

and sink

Sounds you might hear Rmmhag water from the unit • This is IlOIIllal.

into a drain durhag rechmge

Water has air bubbles Air ha system after installation " _'_]11go away alter it runs fin" a while.

and is cloudy

Error Code on control Wiring may have worked loose " See page 1(3fin" details.

Blue light flashing

When power applied Control needs to be pmgrmnmed • See the Programming the Controlsection, page 9-10.

to the system (a power outage may have occurred)

ha the control

• Unl)lug transfin3ne_:

• Remove control cove_; release clips on side.

• Check fin" loose/incorrect wiring connections to electronic

board or swit('h. Reconnect as required.

• Reassemble control cove_:

• Plug in Transfin3ne_:

• X_'aitsix minutes fin" Error Code to real)pea_;

• If Error Code reappeaI_, call fin" service.

If "DAYS TOEMPTY" Low salt level, less thma 15 days • Ell with salt.

is flashing • Reset salt level.

If "Err"in display Electrical problem with system • See page 16 fin" details.

• See l)rocedtlre above, EITOI" code oi1 control.

22

Page 23

Notes.

23

Page 24

Parts list. GXSF18GO1

999

4

28

11

146

19

29

/

24

33

38

23

24

31

32

Page 25

152

GEAppliances.com

\

151

_/25

124 --

153

134 133

107_

130

115

132

144

\

143

146 147

/

/

117

118

150

119

120

121

25

Page 26

Parts catalog.

GENERAL ELECTRIC PARTS CATALOG

REE NO. PART NO.

0003 WS35X10001

0004 WS34X10017

0005 WS07X10004

0007 WS14X10002

0008 WS14X10001

0009 WS01X10002

0010 WS32X10008

0011 WS31 X10027

0012 WS31 X10028

0013 WS21X10016

0014 WS31X10029

0016 WS26X10013

0017 WS31X10030

0018 WS33X10008

0019 WS33X10009

0020 WS31X10024

0021 WS02X10009

0022 WS32X10022

0023 WS02X10027

0024 WS32X10023

0025 WS18X10003

0026 WS22X10016

0027 WS22X10017

0028 WS35X10035

0029 WS15X10045

0030 WS35X10036

0031 WS03X10006

0032 WS15X10006

0033 WS03X10007

0034 WS03X10008

0035 WS07X10002

0036 WS07X10021

0037 WS31X10031

0038 WS02X10029

0039 WS02X10035

0055 WS28X10003

0056 WS28X10007

0101 WS02X10012

0102 WS02X10013

0103 WS21X10003

0104 WS03X10009

0105 WS02X10014

0106 WS31 X10006

0107 WS03X10010

0108 WS26X10002

0109 WS19X10010

0110 WS03X10011

G

X

S

F

1

8

G

PART DESCRIPTION (01)

O-RING SEAI, KIT 1

DECAL, FACEPI A,TE 1

HOSE, DRAIN, 20 FT. 1

DISTRIBUTOR, TOP 1

DISTRIBUTOR, BOTTOM 1

RESIN, 1 CU. FT. 1

RESIN TANK, 10 X 21 1

COVER, TOP ASM

W/ I,ENS & IABEI, 1

FACEPIATE 1

CONTROI, 1

LID EI,ECTRONIC 1

TILCNSFORMER WITH

POWER CORD 1

LID, SALT HOLE 1

VAPOR BARRIER 1

RIM 1

COVER, BRINEWELL W/ DECAL 1

NUT 1

BRINEWEI,I, W/ DECAI, 1

SCREW 1

TANK, BRINE, COMPACT 1

CIAMP, HOSE 2

ADAPTER, HOSE 1

GROMMET 1

GROUND (;1AMP KIT 1

BRINE VAI,VE ASM. 1

FLOAT, STEM 8.:GUIDE 1

CI,IP 1

VALVE BODY, BRINE 1

CI,IP 1

SCREEN 1

TLrBING ASM. 1

BRINE TUBE ASM. 1

EI,ECTRONICS 1

SPACER 1

SUPPORT I,ED 1

RETAI NEll CI,AMP 2

C i AM P 2

SCREW 1

SPACER 1

SWITCH 1

PIN, EXPANSION 1

SCREW 5

C(-)VER, VAI iVE 1

_2__VE SPRING 1

ROTOR & DISC ASM. 1

CAP, VENTURI 1

SEAl,, O-RING 1

26

Page 27

GENERAL ELECTRIC PARTS CATALOG

REE NO. PART NO.

0111 WSI 9X10005

0112 WS03X10013

0113 WS22X10036

0114 WS08X10008

0115 WS03X10015

0116 WS22X10021

0117 WS03X10017

0118 WS15X10034

0119 WS03X10018

0120 WS03X10019

0121 WS15X10010

0122 WS03X10020

0123 WS22X10022

0124 WS15X10046

0130 WS35X10005

0132 WS22X10023

0133 WS03X10032

0134 WS03X10022

0135 WS03X10023

0136 WS26X10003

0137 WS26X10004

0138 WS26X10005

0139 WS02X10015

0140 WS26X10011

0141 WS02X10016

0142 WS60X10001

0143 WS60X10002

0144 WS60X10003

0145 WS60X 10004

0146 WS28X10017

0147 WS19X10006

0150 WS03X10024

0151 WS15X10012

0152 WS03X10025

0153 WS60X 10006

0998 WS35X10042

0999 49-50140

PART DESCRIPTION (01)

SUPPORT SCREEN 1

SCREEN 1

FI,OW PIJUG, .15 GPM 1

GASKET & ASPIRATOR 1

CONE SCREEN 1

PIJ.JG, FILL FLOW, .30 GPM 1

FERRIJI,E NUT 1

NOZZLE/VENTLrRI BODY 1

RETAI NEll 1

SEAl,, O-RING, 1/4" X 3/8" 2

BODY, VALVE 1

SPRING 1

PI,UG, DRAIN SEA1, 1

NOZZI,E/VENTURI ASM. 1

SEAl, K/T, 3/4" 1

ADAPTER, DRAIN HOSE 1

O-RING, 5/8" X 13/1{;" 1

PI,UG, FI,OXM RINSE CONTROl, 1

CI,IP 1

CAM & GEAR 1

BEARING 1

PI,ATE, MOTOR, 3/4" 1

SCREAM #6-20 X 3/8" 2

MOTOR ASM. 1

SCREXM #6-20 X 7/8" 2

NLTT, INSTAI,I,ATION 2

TLrBE, INSTAI,I,ATION 2

WASHER 2

CI,IP 2

HARNESS WIRE, SENSOR ASS¥., 3/4" 1

TURBINE 8.: SUPPORT ASM. 1

SEM,, O-RING 1

BYPASS ASM. 1

SEAl,, O-RING 2

ADAPTER 2

INSTAI,I,ATION KIT 1

OWNER'S MANUAI, 1

GEAppliances.com

G

X

S

F

1

8

G

27

Page 28

GEWater Softening System Warranty. (For Customers in the United States)

All warranty service provided by our SmartWateF MAuthorized

Servicer Network. Toschedule service, on-line, 24 hours a day, visit

us at GEAppliances.com, or call 800.GE.CARES(800.432.2737) (U.S),

or 866.777.7627(Canada).

For The Period Of."

OneYear

Fromthe date ofthe

originalpurchase

ThreeYears

Fromthe date ofthe

We Will Replace:

Any part of the _,V_ter Softening System which fifils due to a defect in materials or workmanship.

During this full one-year warranty,GE will also provide, free of charge,all labor and in-home se_a'ice

to rel)lace the defective part. _M1 warranP,' service will be provided b v a (;E Smart_,V_ter _ Authorized

Service agent,

The electronic monitor, if it tifils due to a (lefect in materials or workmanship. During this three-year

limited warranty, you will be rcsponsible fin" any labor or in-home service costs.

originalpurchase

TenYears

Fromthe date ofthe

A replacement brine tank or cabinet if either tifils due to a (letect in matedals or workmanship,

L)twing this ten-year limited warranty, you will be responsible for any labor or in-home service costs.

originalpurchase

What Is Not Covered:

• Service trips to your home to teach you how to use

the product.

• hnproper h_stallation, delivery or maintenance.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warrantg

• Products that are used for commercial or industrial

applications.

• Filters, membrmles or batteries.

• Failure of the product if it is abused, misused, or used for

other thin1 the intended purpose or used commercially.

• Defects that result from improper h_staUation or damage

not caused by GE.

• Liability on the part of GE under this or may other warranty

for rely indirect or consequential dmnage.

• Replacement of house fuses or resetting of circuit breakers.

• Dmnage to the product caused by accident, fin'e, floods or

acts of God.

• h_cidental or consequential dmnage caused by possible

defects with this appliance, its installation or repair.

• Dmnage caused after delivery.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state. Toknow what your legal rights

are, consult your local or state consumer affairs office or your state's Attorney General THIS WARRANTY IS INTENDED

TOBE IN LIEU OFALL OTHER WARRANTIES, WHETHER EXPRESSOR IMPLIED, INCLUBIN6 THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FORA PARTICULAR PURPOSE.

Warrantor: General Electric Company.Louisville, KY40225

28

Page 29

GEWater Softening System Warranty. (ForCustomersinCanada)

All warranty service provided by our Factory Service Centers or an authorized technician.

For service, call toll free 1.866.777.7627.

For The Period Of." We Will Replace:

One Year Any part of the _\'ater Softening S}'stem which fifils due to a defect in materials or workananship.

Fromthe date ofthe During this fullone-yearwarranty,GE will also provide, freeof charge,all labor and in-home service

originalpurchase t(> replace the detective part.

Three Years Theelectronic monitor,if it tifils (hie tO a (lelect iIl inaterials or workinailshil). OtliJilg this three-year

Fromthe date ofthe limitedwarranty,y(>uwill be responsible tot any labor or in-home service costs.

originalpurchase

Ten Years A replacement brine tank or cabinet if either tifils due to a defect in materials or workananship.

Fromthe date ofthe During this ten-yearlimitedwarranty,y(>uwill be responsible tot any labor or in-home service costs.

originalpurchase

What Is Not Covered:

• Service trips to your home to teach you how to use

the product.

• hnproper installation.

If you have an installation problem, contact your dealer

or installer. You are responsible for providing adequate

electrical, exhausting and other cmmecting facilities.

I WARRANTOR IS NOT RESPONSIBLE FOR CONSEQUENTIAI, DAMAGES. I

VCarrantor: (;AM(;() IN(;. [

• Replacement of house fuses or resetting of circuit

breakers.

• Failure of the product if it is misused, or used for other

than the intended purpose or used commercially.

• Dmnage to product caused by accident, fire, floods or

acts of God.

29

Page 30

Notes.

30

Page 31

Informaci6n de sequridad ..... 32

Instrucciones para la

instalaci6n ............... 33-42

Instrucciones paso por paso ...36-49

Instrucciones para la operaci6n

C6mo limpiar la ensambladura

de la boquilla y el Venturi ....... 45

C6mo romper un puente de sal . . .44

Funciones ................... 46

Servicio ................ 43, 47-49

Sistema de descalcificaci6n

de agua .................. 43-49

Cuidado y limpieza ........... 50

Consejos para la soluci6n

de averias ................ 51-54

Soporte al cliente

Garantfa ..................... 62

Lista de partes/catfilogo ..... 56-59

Soporte al consumidor . ........ 63

Este sistema ha sido probado y cerfificado por la

NSF International contra el Estfindar 44 NSF / ANSI

pot la reducci6n de productos qufmicos, reclamos

especificados en la hoja de desarrol]o.

Escriba aqui el modelo It los nfimeros

de la serie:

Modelo No.

Serie No.

Para en('onti'ai" estos n(lIlleI'os_ levante

la c/ibierta v illire en el borde, debajo

del panel del control.

31

Page 32

INFORMACIONIMPORTANTEDESEGURIDAD.

LEATODASLASINSTRUCCIONESANTESDELUSO.

AADVERTENCIA

Per su seguridad, se debe seguir la informaci6n en este manual con el fin de reducir el riesgo de una

descarga el#ctrica, dafios a la propiedad o dafios personales.

PRECAUCIONESDESEGURIDAD

_: Revise y ctunpla con to(los los c6digos estatales v

locales. Observe las pautas aquf presentadas.

_: Tenga cuidado al manipular el sistema de

descalcificacidn de agua. No lo voltee, deje cae_;

_IITilStI'e o coloque en prottlbei'ancias exti'eiilas.