Page 1

GEAppliances.com

Reverse Osmosis

215C1219P004 49-50237 07-09 JR

Filtration System

GXRM10RBL

Owner’s Manual

and Installation

Safety Instructions

Safety Instructions . . . . . . . . . . . . . . . . . .2

Specification Guidelines . . . . . . . . . . . . .3

Installation Instructions

Before Beginning Installation . . . . . . . .4

Faucet Drain Tubing and

Water Supply Tubing . . . . . . . . . . . . . . . .8

Faucet Installation . . . . . . . . . . . . . . . . . .7

Filtration Drain Connection . . . . . . . . . .8

System Assembly . . . . . . . . . . . . . . . . . . .9

Things to Check

Before Installation . . . . . . . . . . . . . . . . . . .5

Tools and Materials Required . . . . . . . .4

Water Supply . . . . . . . . . . . . . . . . . . . . . . .6

Care and Cleaning

Prefilter, Postfilter and

RO Cartridge Replacement . . . . .10, 11

Sanitization . . . . . . . . . . . . . . . . . . . . . . . .10

Water Test Kit . . . . . . . . . . . . . . . . . . . . .12

Operating Instructions

About the RO System . . . . . . . . . . .13, 14

Troubleshooting Tips . . . . . . . . . .15

Consumer Support

Consumer Support . . . . . . . .Back Cover

Parts List/Catalog . . . . . . . . . . . . . .16, 17

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . .20

Manuel d’utilisation

et d’installation

Manual del propietario

y instalación

La section française commence à la page 21

Osmose Inversée

Système de Filtration

La sección en español empieza en la página 41

Ósmosis Inversa

Sistema de Filtración

GXRM10RBL is Tested and

Certified by NSF International

against NSF/ANSI Standard 58

and CSA B483.1 for reduction

of the claims specified on the

Performance Data Sheet.

Write the model and serial

numbers here:

Model # __________________

Serial # __________________

You can find them on the bracket.

C U.S.

Page 2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

■ Check with your state and local public works

department for plumbing and sanitation codes.

You must follow these guidelines as you install the

Reverse Osmosis system. Using a qualified installer

is recommended.

■ If house water pressure is over the maximum

(125 pounds per square inch), install a pressure

reducing valve in the water supply line to the Reverse

Osmosis system.

■

Be sure the water supply conforms with the

Specification Guidelines. If the water supply conditions

are unknown, contact your municipal water company

or your local health department for a list of

contaminants in your area and a list of laboratories

certified by your state to analyze drinking water.

WARNING: Before using the Reverse

Osmosis system for the first time, the system must be

purged. The Reverse Osmosis cartridge contains

a food grade preservative that must be purged

from the system. The preservative will give product

water an unpleasant taste and odor.

■ This product reduces fluoride in drinking water.

Please consult your dentist if you have questions.

WARNING: Do not use with water that is

microbiologically unsafe or of unknown quality

without adequate disinfection before the system.

Systems certified for cyst reduction may be used on

disinfected water that may contain filterable cysts.

This system has been tested for the treatment of

water containing pentavalent arsenic (also known

as As(V), As(+5) or arsenate) at concentrations of 0.050

mg/L or less. This system reduces pentavalent

arsenic, but may not reduce other forms of arsenic.

This system is to be used on water supplies

containing a detectable free chlorine residual or

on water supplies that have been demonstrated

to contain only pentavalent arsenic. Treatment

with chloramine (combined chlorine) is not sufficient

to ensure complete conversion of trivalent arsenic

to pentavalent arsenic. Please see the Arsenic Facts

section of the Performance Data Sheet for further

information.

This Reverse Osmosis system contains a replaceable

treatment membrane cartridge critical for effective

reduction of Total Dissolved Solids. The water should

be tested periodically to verify that the system is

performing satisfactorily. See the About the Water Test

Kit section. This system is acceptable for treatment of

influent concentrations of no more than 27 mg/L

nitrate and 3 mg/L nitrite in combination measured as

N and is certified for nitrate/nitrite reduction only for

water supplies with a pressure of 280kPa (40 psig)

or greater.

SAVE THESE INSTRUCTIONS

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

■ Install or store where it will not be exposed to

temperatures below freezing or exposed to any type

of weather. Water freezing in the system will damage

it. Do not attempt to treat water over 100°F.

■ Do not install on HOT WATER. The temperature

of the water supply to the Reverse Osmosis system

must be between the minimum of 40°F and the

maximum of 100°F. See the Specification Guidelines.

■ Extended non-use of the Reverse Osmosis system.

If the system has not been used for one week or

more, open the RO water faucet and allow the

system to drain. Close the RO water faucet and

allow the system to regenerate the water supply.

■ Recommended installation is under the sink. However,

the unit can be installed in a remote location, up to

20 feet away from the sink. Additional installation

materials may be required. If Reverse Osmosis

system is connected to a refrigerator icemaker, a

special icemaker connection kit is required (RVKIT).

Do not use copper tubing for the connection between

the Reverse Osmosis system and the refrigerator.

WARNING: Discard all unused parts and

packaging material after installation. Small parts

remaining after the installation could be a choke

hazard.

■

Sanitize upon installation of the Reverse Osmosis

system and after servicing inner parts, including

replacement of prefilter, postfilter and Reverse

Osmosis cartridge. It is important to have clean hands

while handling inner parts of the system. See the

Sanitization section.

■

This Reverse Osmosis system contains a replaceable

component critical to the efficiency of the system.

Replacement of the Reverse Osmosis component

should be with one of identical specifications, as

defined by the manufacturer, to assure the same

efficiency and contaminant reduction performance.

See Automatic Shutoff Valve section on page 13.

BE SURE TO FOLLOW ALL APPLICABLE STATE

AND LOCAL CODES.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk

of property damage or personal injury.

SAFETY PRECAUTIONS

PROPER INSTALLATION AND MAINTENANCE

This Reverse Osmosis system must be properly installed and located in accordance with the

Installation

Instructions before it is used.

Consumer Support Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

2

Page 3

Consumer Support

Troubleshooting Tips

Operating InstructionsSafety Instructions

Installation

Instructions

Specification guidelines. GEAppliances.com

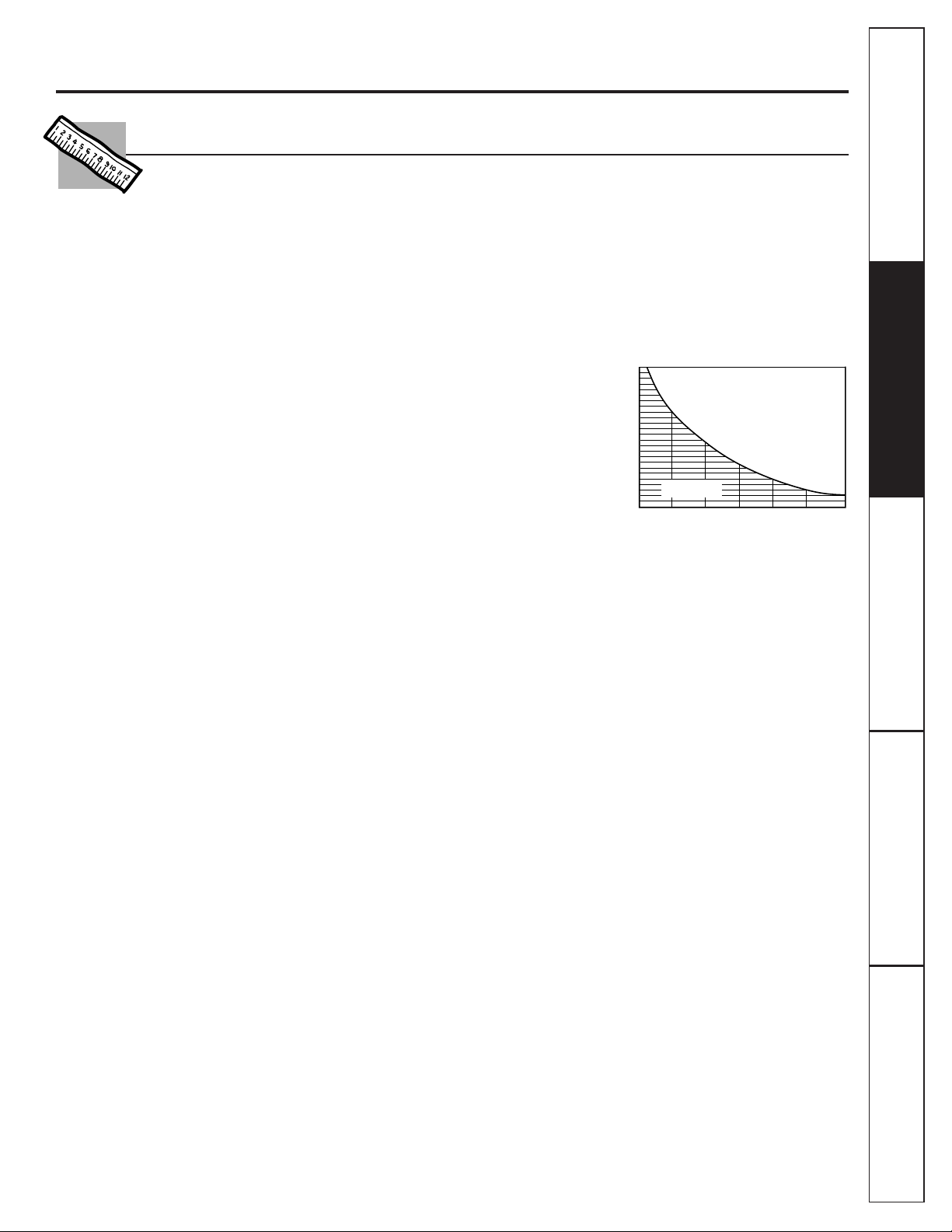

The system makes a good supply of drinking water each day.

How much it will make depends primarily on these things…

Product – height 15″ width 14″ depth 5.5″

Incoming Water pH

WATER SOFTENER RECOMMENDED

INCOMING WATER HARDNESS (GPG)

60

50

40

30

2010

8

6

7

7.5

6.5

Water Softener

not required

Maximum iron, manganese, hydrogen sulfide (ppm) . . . . . . . . . . . . . . . . . . . .<0.1

Chlorine in water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.0 ppm maximum allowable

b

Feed water pH limits (pH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–10

Product (quality) water, 24 hours—gallons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.83

a

Percent rejection of TDS (new membrane) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92.4%

a

Cyst reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99.99%

Storage tank capacity—gallons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

d

Efficiency rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.63%

e

Recovery rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18.77%

f

Automatic shutoff control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .yes

Prefilter and postfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(FX12P) Carbon Block

Reverse Osmosis membrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(FX12M) Thin Film Polyamide

Dimensions (inches) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .height 15″ width 14″ depth 5.5″

Feed water pressure limits—pounds per square inch (psi) . . . . . . . . . . . . . . . . . . . . . .40–125

c

Feed water temperature limits—minimum/maximum degrees F . . . . . . . . . . . . . . .40–100

Maximum Total Dissolved Solids (TDS)—parts per million (ppm) . . . . . . . . . . . . . . . .2000

Maximum water hardness at 6.9 pH recommended to optimize membrane

life—grains per gallon (gpg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

For water with hardness greater than 10 grains (at 6.9 pH), the use of a

softener is recommended. Failure to install a water softener will reduce

the life of the Reverse Osmosis membrane. See chart for additional

information on the possible need for a water softener.

a. Tested according to NSF/ANSI Standard 58. Source water test parameters are 50 psig, 77°F,

pH of 7.5 ± 0.5 and 750 ± 40 ppm total dissolved solids.

b. Reduced by the Reverse Osmosis prefilter. REGULAR MAINTENANCE IS REQUIRED. Chlorine will destroy

the Reverse Osmosis membrane.

c. If house water pressure is over 125 psi, install a pressure reducing valve in the water supply line.

If house water pressure is under 40 psi, install a Reverse Osmosis booster pump (contact your

local plumbing supply company).

d. Theoretical tank capacity. When tested according to NSF/ANSI Standard 58 at 50 psig inlet pressure,

tank capacity is 2.3 gallons.

e. Efficiency rating means the percentage of the influent water to the system that is available

to the user as Reverse Osmosis treated water under operating conditions that approximate typical

daily usage.

f. Recovery rating means the percentage of influent water to the membrane portion of the system

that is available to the user as Reverse Osmosis treated water when the system is operated

without a storage tank or when the storage tank is bypassed.

3

Page 4

Installation

Reverse Osmosis Filtration System

Instructions

Model GXRM10RBL

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: GEAppliances.com

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

•

IMPORTANT — Save these instructions

for local inspector’s use.

•

IMPORTANT — Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• Proper installation is the responsibility

of the installer.

• Product failure due to improper installation

is not covered under the Warranty.

• A shut-off valve must be available or added

near the installation point.

TOOLS AND MATERIALS REQUIRED

FOR INSTALLATION

• Drill with 1-1/2″ Drill Bit (type as required)

if mounting hole is needed for faucet

• Adjustable Open-End Wrenches

• Phillips and Flat-Blade Screwdrivers

• Utility Knife

CONTENTS INCLUDED

WITH PRODUCT

• Reverse Osmosis Assembly and Tubing

• Product Literature (Owner’s Manual and

Installation) and Performance Data Sheet

• Water Supply Inlet Parts Bag

• Drain Line Adapter

• Storage Tank

• Faucet

• Pipe Thread Tape

4

Page 5

5

Installation Instructions

Things to Check Before Beginning Installation

WATER SUPPLY

The water supply to the undercounter Reverse

Osmosis system must have the qualities listed in

the specifications (see the Specifications Guidelines

section). Municipal water supplies most often will

have these qualities. Well water may need

conditioning—have the water tested by a water

analysis laboratory and get their recommendations

for treatment.

CAUTION: For water with a hardness

greater than 10 grains (at 6.9 pH), the use of a

softener is recommended. Failure to install a

softener will reduce the life of the Reverse Osmosis

membrane. See the Specifications Guidelines

section for additional information on the possible

need for a softener.

DRAIN POINT

A suitable drain point and air gap (check your

local codes) are needed for reject water from the

Reverse Osmosis membrane cartridge.

BASEMENT INSTALLATION

If installing in a basement, leave enough tubing

in place during installation to be able to move the

unit to the floor for ease at servicing and making

filter/membrane changes. Additional tubing

and fittings required.

RO FAUCET

The RO product water faucet installs on the sink

or on the countertop next to the sink. Often, it is

installed in an existing sink spray attachment hole

or a hole may be drilled. Space is required

underneath for tubing to and from the faucet,

and for securing the faucet in place. All faucet

connections and installation procedures are done

on or above the sink or countertop. Refer to

illustration above.

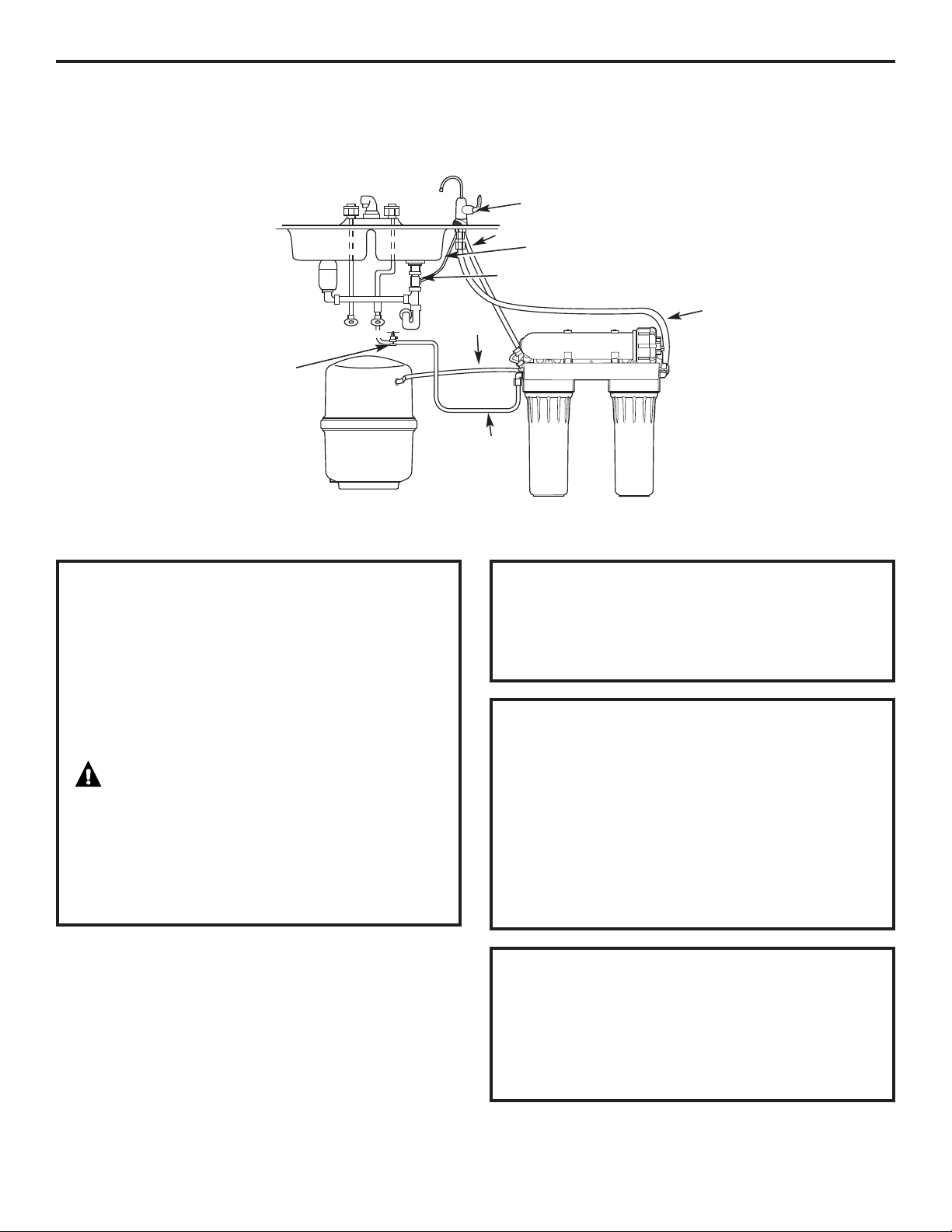

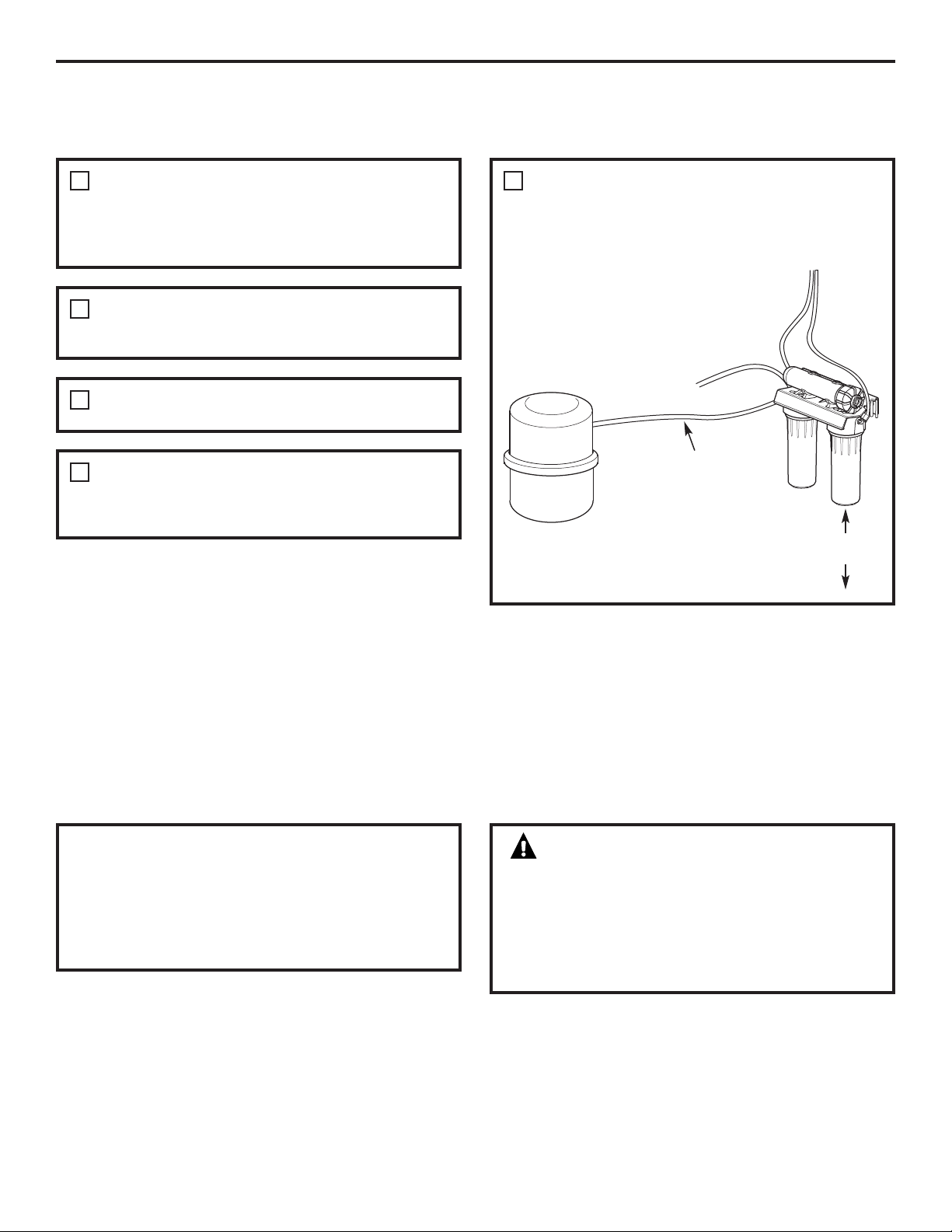

Storage tank

Saddle valve

HOT

Drain adapter

3/8″ black drain tubing

RO product water faucet mounted through sink

or countertop

Yellow

(inlet)

Orange

1/4″ black

Blue

(to faucet)

COLD

Page 6

Installation Instructions

WATER SUPPLY

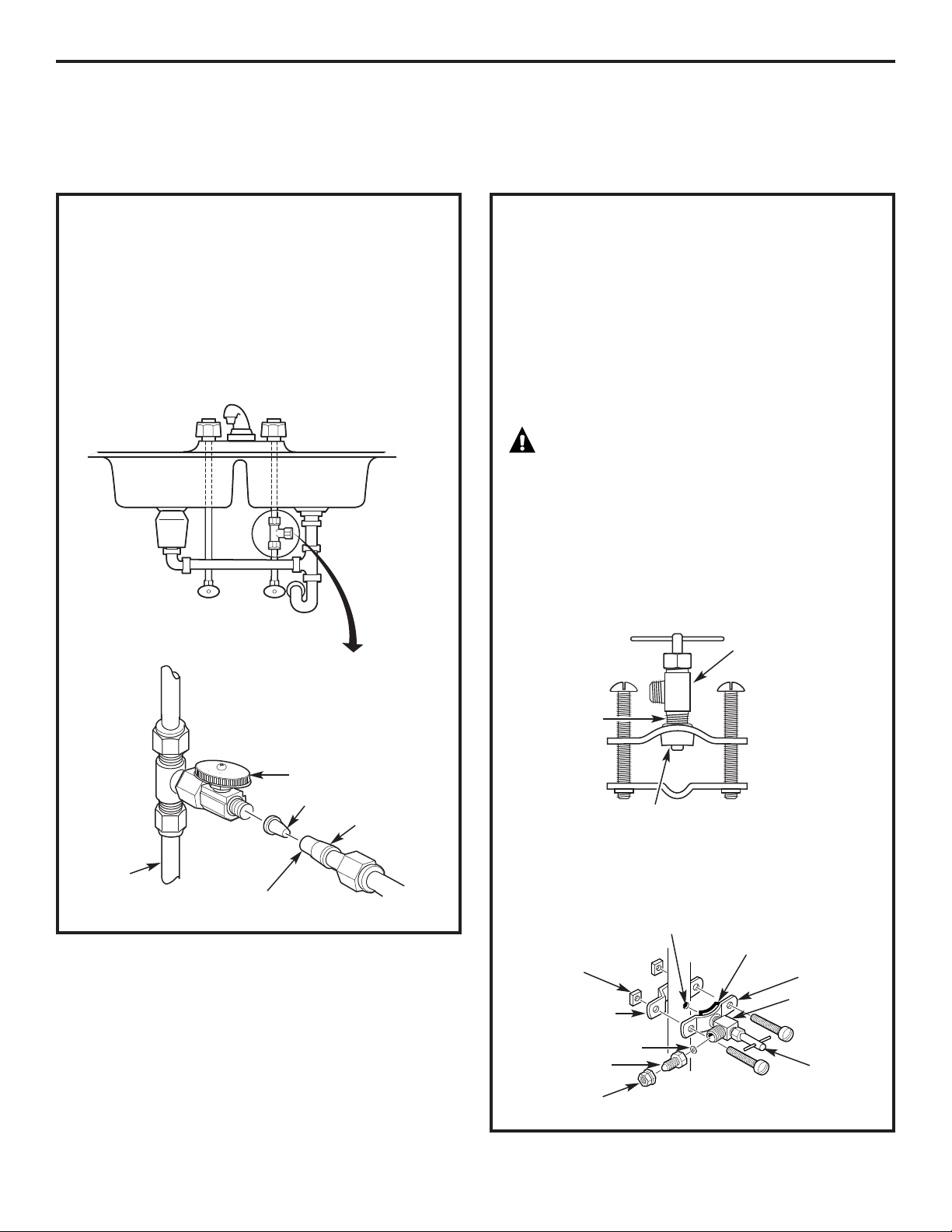

Check and comply with local plumbing codes as you plan, then install a cold water supply fitting. For new home

installation using standard plumbing fittings, see first two illustrations below. A typical installation for existing homes

using the saddle valve is shown in the third illustration below.

B. OPTIONAL HOME INSTALLATION

(Where codes permit)

*For 1/4″ OD or larger metal tubing only.

NOTE: Codes in the state of Massachusetts require

installation by a licensed plumber and do not

permit the use of the saddle valve. For installation,

use plumbing code 248-CMR of the Commonwealth

of Massachusetts.

1. Turn off the cold water supply and attach

saddle valve as shown in illustration below.

DANGER: To protect yourself from

serious injury or fatal shock, use a batterypowered hand drill only to make the hole.

DO NOT USE AN ELECTRIC DRILL.

2. Close the water supply valve by turning the

handle clockwise.

3. Open the main water supply valve and several

house faucets to purge air from the system.

Close faucets when water runs smoothly.

Optional water supply connection (using saddle valve)*

Pre-drill

1/4″ hole

Seal—make sure the seal

is in place

Clamp X

Nut (2)—not

required if holes

in clamp are

threaded

Valve

Handle

Tubing adapter

Washer

Compression nut

❵

Clamp Z

Use to connect the tubing

*For 1/4″ OD or larger metal tubing only.

6

WATER SUPPLY

A. PREFERRED INSTALLATION

1. Turn off the cold water supply.

2.

Complying with plumbing codes, install a fitting

on the cold water pipe to adapt 3/8

″

OD tubing.

A typical connection is shown in the illustrations

below (parts not included). Make sure a water

supply valve is used.

Preferred water supply connection (using

compression fitting)

Insert (not included)

Cold

water

pipe

3/8

″ Tubing to inlet

Ferrule

Water supply valve

(not included)

Typical location

Cold

water

Snug valve into bracket

DO NOT OVERTIGHTEN

Some threads

should be visible

Rubber gasket

Page 7

Installation Instructions

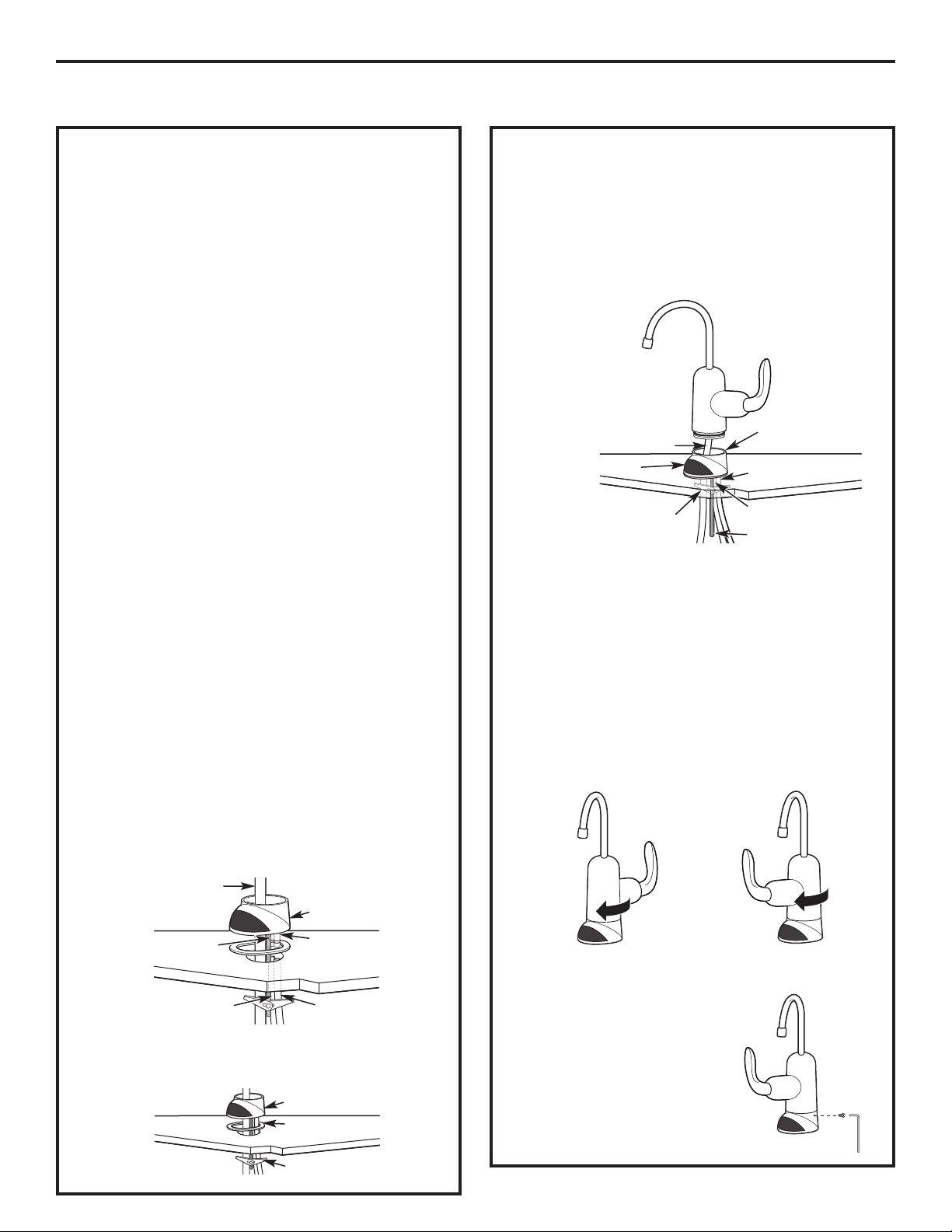

FAUCET INSTALLATION

INSTALL THE FAUCET (CONT.)

5. Tighten the toggle screw until the base is firmly

in place and does not wobble or turn.

6. Push the 3/8″ blue tube up to connect

it to the fitting on the bottom of the faucet body.

It should go in about 3/4″. Pull tube slightly to

make sure it is secure.

7. Push the faucet body down into the faucet base

and twist clockwise until it stops into place.

NOTE: You can install the faucet so the handle

is on the right or the left side.

If you want the faucet handle on the right,

position the handle at the back of the faucet

base before turning clockwise.

If you want the faucet handle on the left,

position the handle at the front of the faucet

base before turning clockwise.

8. Locate the hole at the rear

of the base. Insert set screw

and begin to tighten by

hand. Finish tightening

with the Allen wrench

provided in the packet.

DO NOT OVERTIGHTEN.

Faucet body

Faucet base

Sink

Gasket

Toggle screw

3/8″ Black tube

INSTALL THE FAUCET

Be sure there is room underneath and above

the sink to make the needed connections. Before

starting, make sure there is sufficient room for the

faucet base and unit. Select one of the following

places to install the faucet:

A. In an existing sink spray attachment or soap

dispenser hole.

B. In a hole to be drilled in the sink top.

C. In a hole to be drilled in the countertop, next

to the sink.

NOTES:

• Be sure the faucet base will fit flat against the

surface at the selected location so the bottom

gasket between the base and surface area

will seal.

• Make sure to leave enough clearance at the back

of the faucet in case you need to remove it.

Installation Steps (refer to illustration below

for clarification)

1. If drilling is needed, make a 11⁄2″ diameter hole.

Be sure to use the proper procedure for drilling

porcelain or stainless steel. Special drill bits

may be needed. Consult a qualified plumber

for the proper procedure.

NOTE: When drilling in stainless steel, the edges

may be sharp and could puncture the tube. Be

careful to not cut yourself or damage the tube.

2. Remove the faucet body and base by turning

the base counterclockwise.

3. Push the 1/4″ black tube and the 3/8″ black tube

onto the correct barb fittings on the faucet base.

Push the 3/8″ blue tube through the base.

4. Align the gasket to cover the hole completely. Then

place the toggle screw on the base into the hole.

Faucet base

Sink

Gasket

Toggle screw

1/4″ Black tube

Faucet base

1/4″ Barb fitting

1/4″ Black tube

3/8″ Barb fitting

3/8″ Black tube

3/8″ Blue tube

3/8″ Blue tube

Mounting screw

Faucet Faucet

Faucet handle on the RIGHT Faucet handle on the LEFT

7

Page 8

Installation Instructions

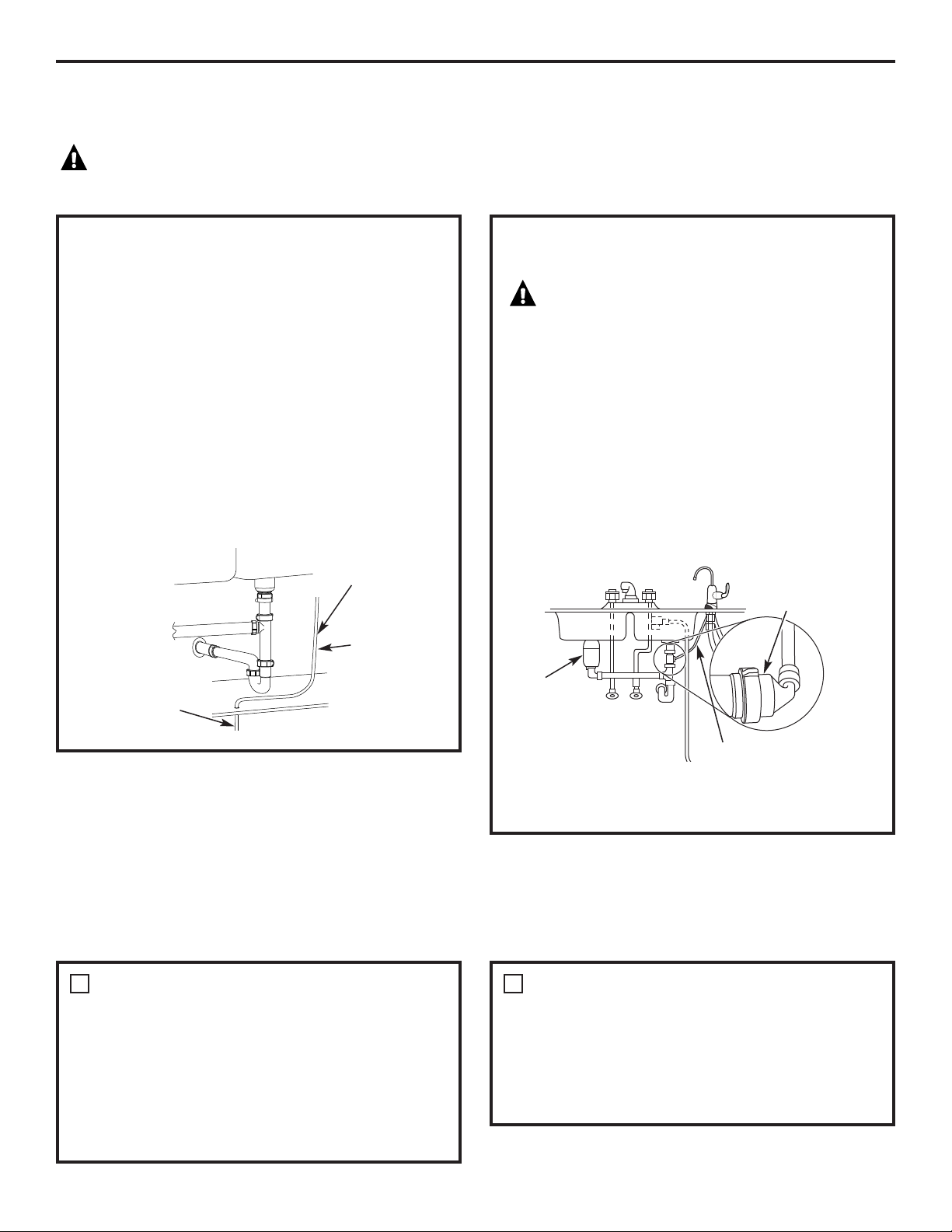

FILTRATION DRAIN CONNECTION INSTALLATION

Check and comply with all state and local plumbing codes as you plan.

CAUTION: The options detailed in this section are the ONLY approved installation configurations.

Do not use any drain saddle device.

OPTION A: BASEMENT ACCESS

INSTALLATION

Route the drain line (1/4″ black line) DIRECTLY from

the Reverse Osmosis system to a standpipe in the

basement, bypassing the air gap provided in the

faucet. The drain line may also be routed in the

basement to a floor drain or washtub, provided

that the air gap in the basement is maintained.

Avoid dips, loops or low spots in the drain line.

The basement air gap and drain installation

configuration must conform to all local codes.

Special air gap fittings are available from your

local hardware store to connect the drain line

to the top of the standpipe.

Drain line from Reverse

Osmosis bypassing

faucet air gap

Maintain air gap

at drain point

in basement

1/4″ Black

tubing

OPTION B: DRAIN LINE ADAPTER

INSTALLATION

CAUTION!

DO NOT INSTALL DRAIN LINE ADAPTER

DOWNSTREAM FROM DISPOSER.

Install the provided drain line adapter under the sink

as shown. The baffle-tee provided must be in place

(purchase and install if necessary) to prevent a clog

in the Reverse Osmosis drain line. Route the drain line

(3/8″ black) from the faucet air gap to the drain line

adapter, ensuring that there are no dips, loops or low

spots in the line that could result in a clogged

drain line.

The tubing must be cut to length to provide

a straight routing from the faucet to the drain.

Drain noise in the sink drain is normal when the

Reverse Osmosis system is operating.

FAUCET DRAIN TUBING AND WATER SUPPLY TUBING

If OPTION A: BASEMENT ACCESS INSTALLATION (see Filtration Drain Connection Installation section, above) was

used, go to Step 2.

If OPTION B: DRAIN LINE ADAPTER

INSTALLATION was used, connect the faucet

drain tubing by running the 3/8″ black tubing from the 3/8″ faucet barb to the drain fitting (installed in Filtration Drain Connection Installation section, above). Keep this tubing run as short and straight as possible, without loops, dips or low spots. Cut the tubing as needed and insert into the drain fitting.

1

To connect the water supply tubing:

Run the 1/4″ yellow tubing from the Reverse

Osmosis inlet to the water supply fitting

(on illustrations in the Water Supply section

on page 6). Connect the tubing as applies

(see Water Supply section) and tighten the

nut securely.

2

Drain line adapter

in different line

from disposer

HOT COLD

Disposer

Drain line is straight

8

Page 9

Installation Instructions

9

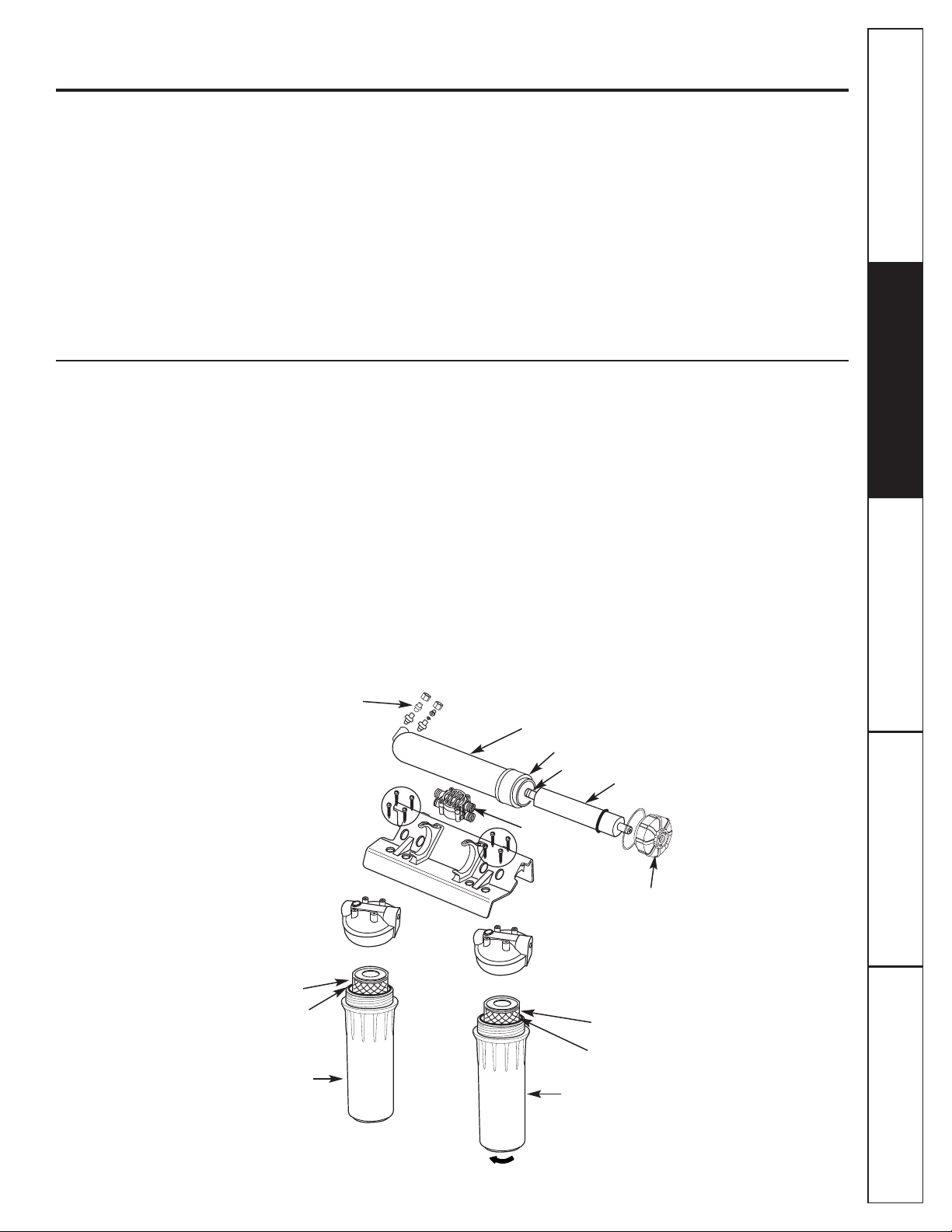

REVERSE OSMOSIS SYSTEM ASSEMBLY

AND STORAGE TANK INSTALLATION

NOW THAT YOUR REVERSE OSMOSIS SYSTEM

IS INSTALLED…SANITIZE!

Sanitize upon installation and after servicing inner

parts, including replacement of prefilter, postfilter

and the Reverse Osmosis cartridge. It is important

to wash hands with anti-bacterial soap before

handling inner parts of the system. See the

Sanitization section.

CAUTION: If installing unit in new

construction, ensure that house plumbing is

flushed thoroughly before opening the water

supply valve. Also, before sanitizing, be sure

to remove all cartridges as described in the

Sanitization section. Chlorine will destroy the

Reverse Osmosis cartridge.

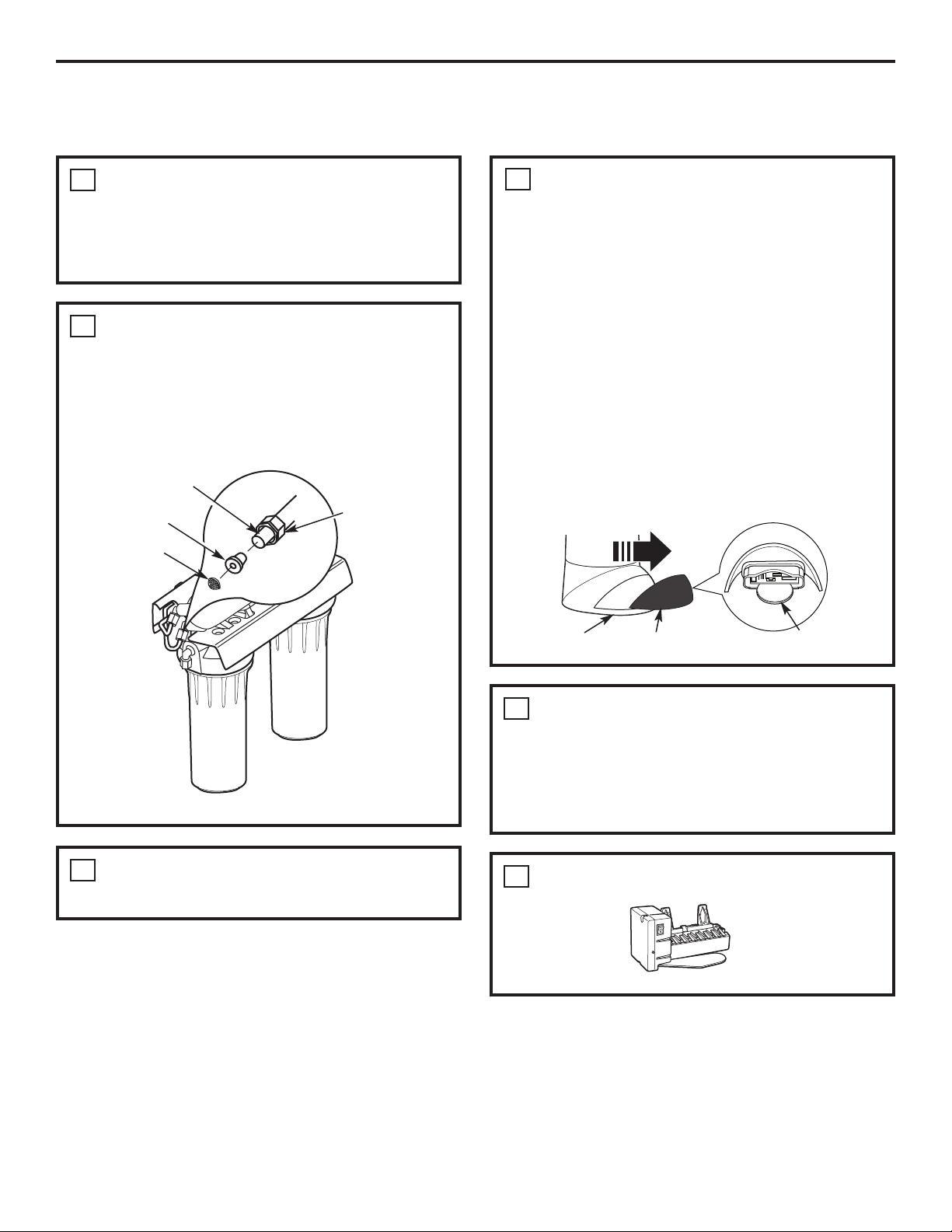

Hold the Reverse Osmosis assembly up

to the wall surface where you will install it. Mark

locations for the screws. The arrows on the top of

the bracket show the location of the screw holes.

1

Connect the tubing to the storage tank: Run the

length of 3/8″ orange tubing from the tee fitting

on the Reverse Osmosis module to the tank inlet

fitting.

5

Wood screws are included for fastening to a wood

surface. Provide other screws as needed.

2

Hang the Reverse Osmosis assembly on the screws.

3

Apply pipe thread sealing tape to the tank fitting.

Insert into tank threads. Tighten with a wrench.

4

Storage

tank

To faucet

Supply line

Orange tubing

2″ minimum clearance

for changing cartridges

Page 10

Installation Instructions

10

PREFILTER, POSTFILTER AND RO CARTRIDGE REPLACEMENT

PROCEDURE, INCLUDING SANITIZATION

Turn OFF the icemaker (if attached to the

RO system).

1

Wash your hands with anti-bacterial soap.

2

Turn off water supply

to RO system.

3

Remove cap from RO cartridge housing (unscrew

tubing first, on some models). Use pliers to remove

the RO cartridge. Place in a clean plastic bag or

discard if replacing. Thoroughly wipe inside of

housing and cap with a paper towel or dish brush

moistened with dish soap. Rinse well. Install RO

cartridge housing cap.

NOTE: Failure to

remove RO cartridge

during sanitization

will destroy the RO

cartridge.

6

Turn on RO faucet. Drain tank (may take several

minutes). Turn off RO faucet.

CAUTION: Failure to close the water

supply valve or tank shut-off valve will cause water

to spray or run when sumps are removed.

4

Remove the sumps.

Be careful—sumps will be full

of water.

Discard filters. Thoroughly

wash sumps with dish soap.

Thoroughly wipe inside of heads

with a paper towel moistened

with dish soap. Rinse well.

5

Install empty postfilter sump.

7

Fill prefilter sump with water to within 1″

of O-ring. Add 2 oz. (4 Tbsp.) ordinary household

bleach. Install prefilter sump.

8

Turn on water supply. Open RO faucet until water

begins to flow, then close. Allow system to fill for

1 minute.

9

Open faucet and allow water to flow for

10 minutes. Close faucet for one minute more,

then open and allow water to flow for another

10 minutes, or until bleach odor is gone. Turn

off water supply again. Drain RO.

10

Remove sumps. Insert filters.

Lubricate O-ring with food-grade

silicone grease, if necessary. (Do not

use petroleum jelly.) Tighten sumps

securely.

11

Page 11

Installation Instructions

11

Remove cap from RO cartridge housing. Install

RO cartridge, O-ring end first. Lubricate cover Oring with food-grade silicone grease, if necessary.

(DO NOT use petroleum jelly.) Tighten cap

securely.

12

If you only replaced the prefilter and postfilter,

allow faucet to run 5 minutes to remove

harmless carbon particles. If you replaced the

RO cartridge, fill and empty the storage tank

three times, until taste and odor from food-grade

membrane preservative is gone.

16

Once storage tank is full, turn on icemaker.

17

Turn on water supply. Allow to fill. (May take up to

four hours.) Check for leaks.

14

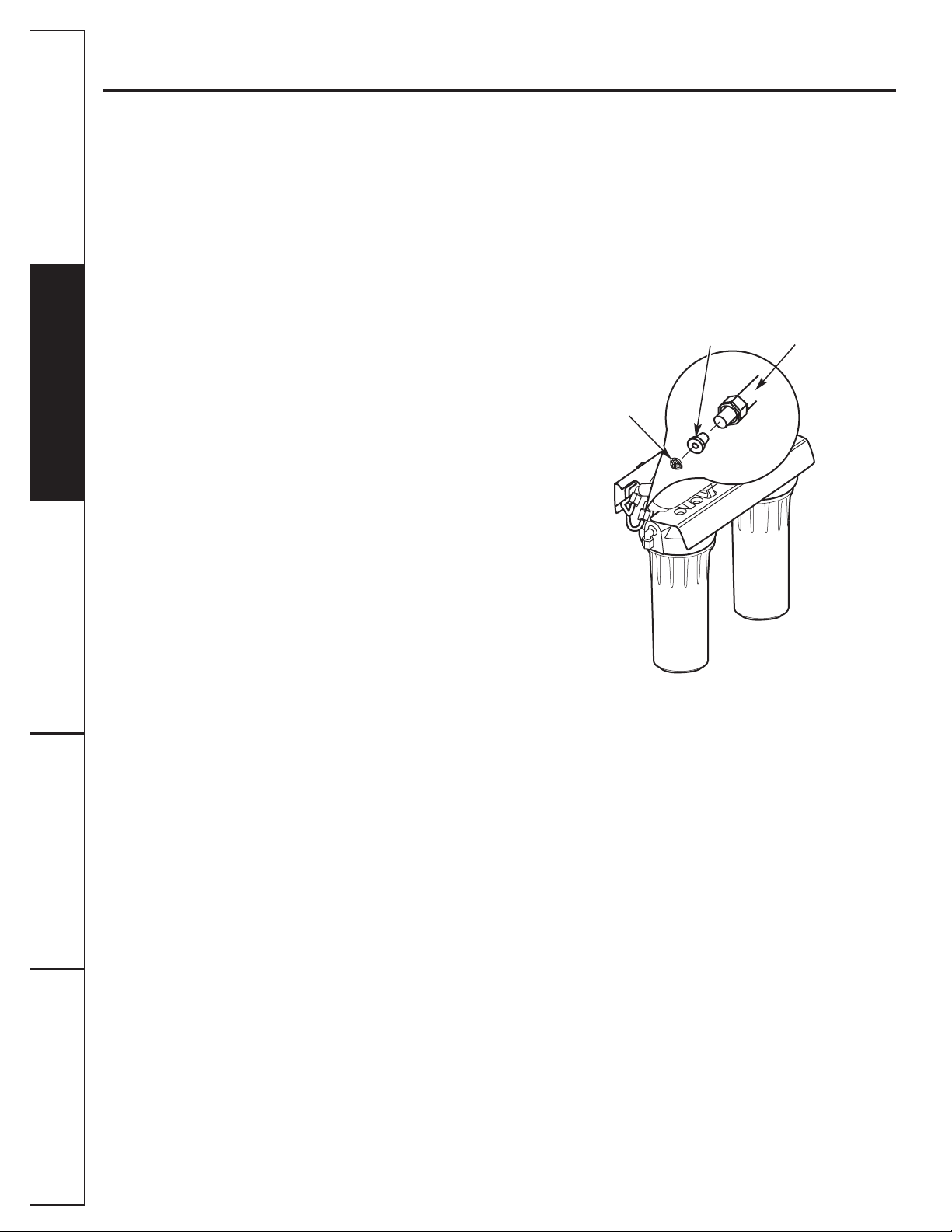

If you replaced the RO cartridge, also replace the

flow control and screen. (Unscrew the black 1/4″

line from the fitting. Remove flow control with

clean knife edge. Remove screen with a clean

toothpick.) Tighten the nut hand-tight and then

tighten 1/4 turn with pliers. DO NOT

OVERTIGHTEN.

13

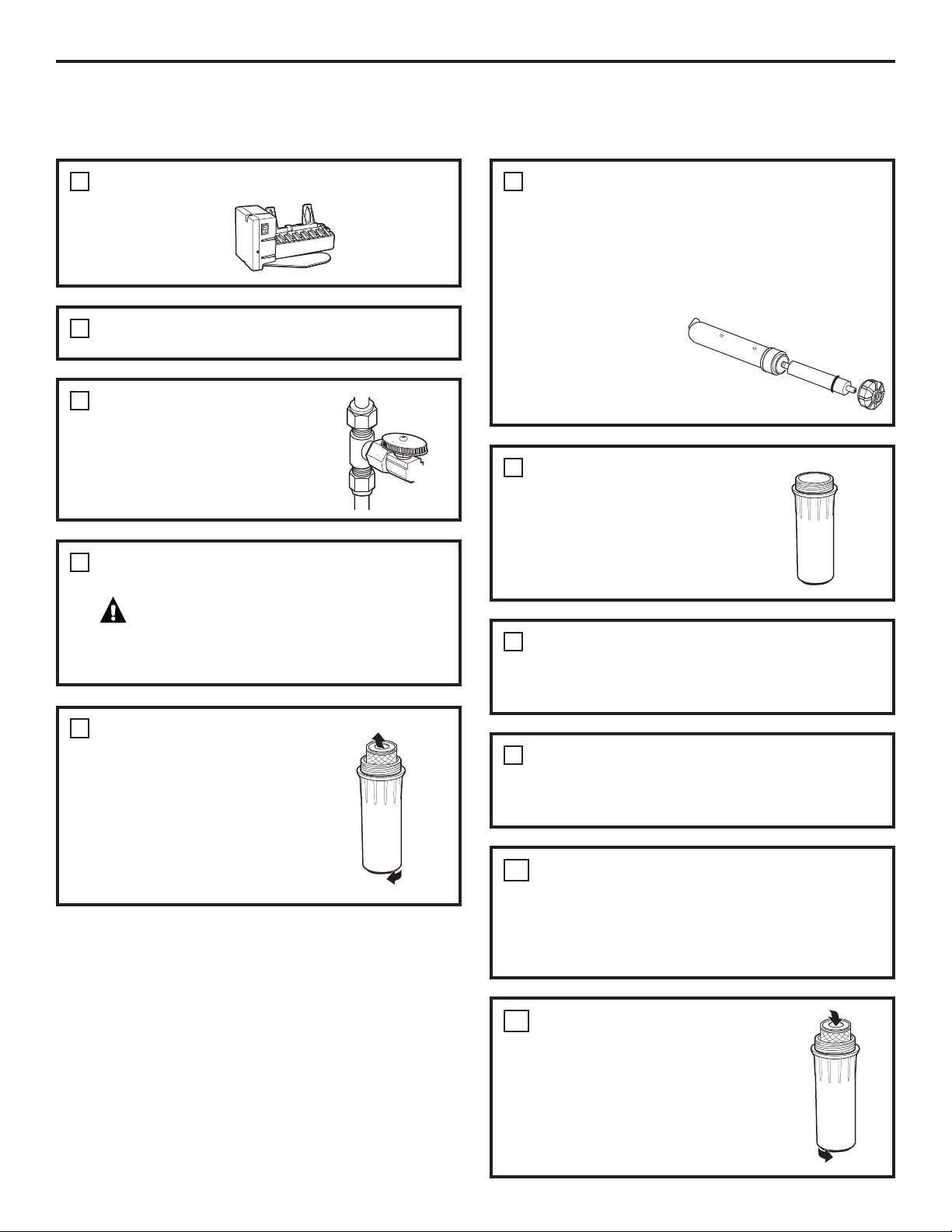

Flow control

Screen

Compression nut

1/4″ Black tubing

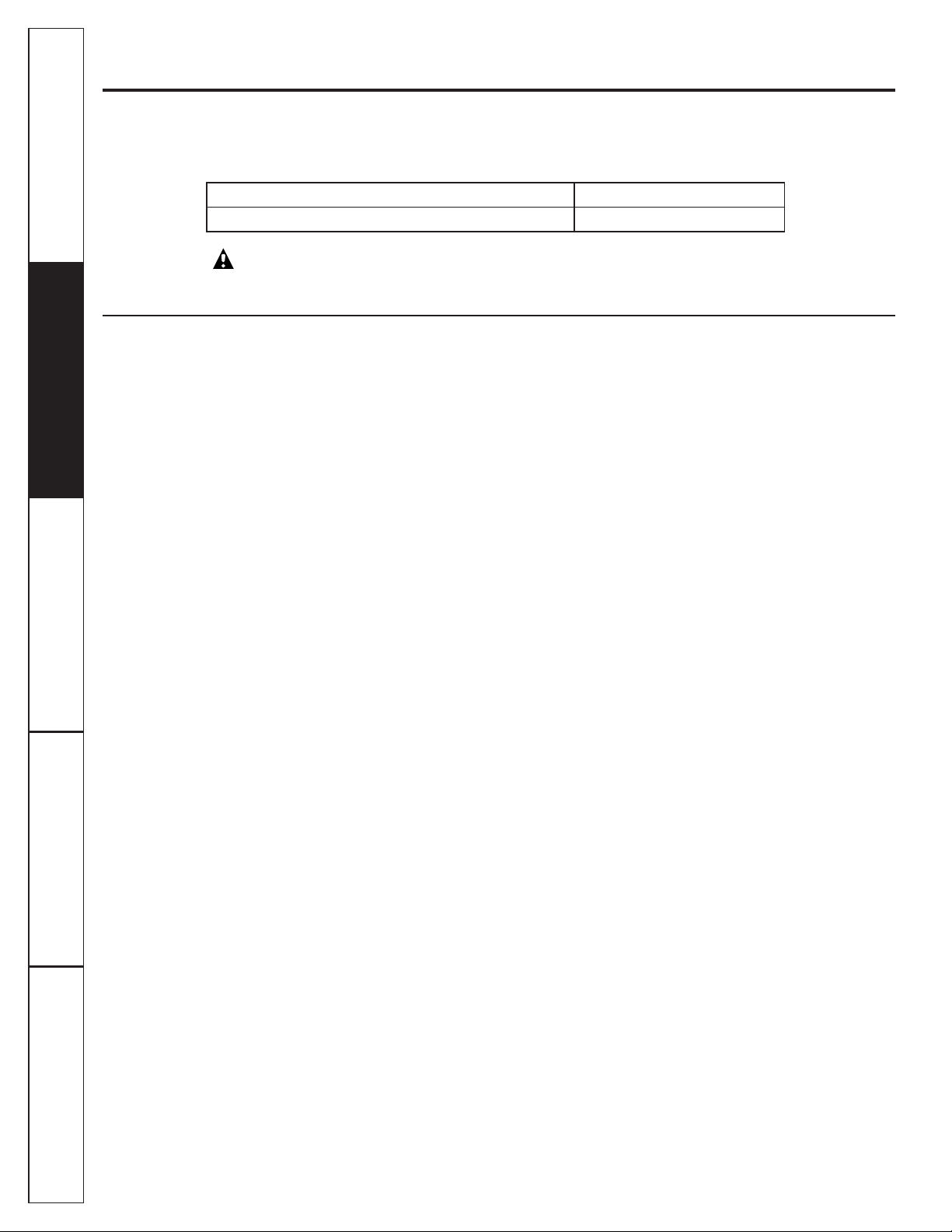

INSTALL THE BATTERY

1. Remove the lens cover from the faucet base.

Grip it from both sides and pull forward.

2. Install one CR2032 3V battery with the “+” side

down into the battery tray.

3. The amber LED light will flash 5 times, indicating

a proper installation and system reset.

4. Slide the lens cover back into the faucet base.

5. Normally, the light is off. After 6 months of use,

the amber LED light will flash every 30 seconds,

indicating the time to replace the filter canister.

NOTE: The amber LED light may stop blinking

if it is allowed to blink for an extended period

of time. To ensure proper operation, the battery

should be replaced with every filter change.

Faucet base

Lens cover

Battery “+”side down

15

Page 12

Care and cleaning of the reverse osmosis system.

To obtain replacement filters, call toll-free GE Appliance Parts at 800.626.2002 (U.S.),

800.663.6060 (Canada–English), 800.361.3869 (Canada–French) or visit the store

where you purchased your reverse osmosis system.

CAUTION: Before servicing the Reverse Osmosis system, close the water supply/saddle

valve and open the RO water faucet. Allow the system to drain.

Prefilter/Postfilter Cartridge Replacement FX12P Carbon Block

Reverse Osmosis Cartridge Replacement FX12M Thin Film Polyamide

The Water Test Kit

To obtain an independent laboratory water test kit, please call Legend Technical Services at

1.800.826.8553, ext. 47, and leave your contact details. They will contact you to find out what water

tests you are interested in and inform you of the cost of the testing. You will then receive a kit that will

include all necessary tests to properly indicate the performance level of your system. Product water

should be tested a minimum of every 6 months.

Troubleshooting TipsConsumer Support Troubleshooting Tips

Installation

Instructions

Safety Instructions

Operating Instructions

12

Page 13

Consumer SupportTroubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

13

Description of the Reverse Osmosis System

Prefilter—Water from the cold supply pipe is

directed to the prefilter cartridge, which is inside

the sump.

The prefilter is a replaceable sediment

cartridge containing activated carbon. The cartridge

reduces sand, silt, dirt, other sediments and up to

2.0 ppm of aesthetic chlorine from the water. The

prefilter reduces chlorine in the water because

CHLORINE DESTROYS THE REVERSE OSMOSIS

MEMBRANE. Filtered, clean, aesthetic chlorine-

reduced water flows from the prefilter to the

Reverse Osmosis cartridge.

Storage Tank—The storage area holds up to

3 gallons of product water. A diaphragm inside

the tank keeps water pressurized for fast flow

to the faucet when drinking water is needed.

Check Valve—A check valve is built into one end

of the Reverse Osmosis housing. The check valve

prevents a backward flow of product water from

the storage area. A backward flow could cause

the Reverse Osmosis membrane to rupture.

Automatic Shutoff Valve—To conserve water, the

drinking water system has an automatic shutoff.

When the storage tank has filled to capacity and the

drinking water faucet is closed, pressure closes the

shutoff. Water flow to the Reverse Osmosis housing

is shut off until drinking water is used again, and

pressure drops in the Reverse Osmosis system.

About the reverse osmosis system. GEAppliances.com

What the Reverse Osmosis System Does

Reverse Osmosis removes Total Dissolved Solids

(TDS) and other contaminates, as specified on page

3, from the water by diffusing it through a special

membrane. High-quality product water goes

directly to the drinking water faucet or to the

storage tank. The system makes a good supply

of drinking water each day; see Specification

Guidelines. How much it makes depends on the

water supply pressure, temperature and quality.

The carbon prefilter and postfilter are replaceable

cartridges. The prefilter reduces chlorine taste and

odor while also filtering sediments. The postfilter

reduces any other undesirable taste and odors

before you use the water.

Sump

Postfilter

cartridge

Prefilter cartridge

Reverse Osmosis cartridge

Reverse Osmosis housing

Turn sump this way to remove

O-ring housing

Reverse Osmosis

housing cap

Sump

O-ring on top lip of sump

O-ring on top lip of sump

O-ring end

Check valve

Automatic

shutoff valve

Page 14

Reverse Osmosis Cartridge—The cartridge, inside

the Reverse Osmosis housing, includes a tightly

wound, special membrane. Water is forced through

the cartridge where the membrane reduces the

dissolved solids and other contaminants, as specified

on page 3. High-quality product water exits the

Reverse Osmosis housing and goes to the storage

tank. Reject water, with the dissolved solids and

other contaminants, as specified on page 3, leaves

the housing and is discharged to the drain through

tubing.

Postfilter—After leaving the storage area,

but before going to the system faucet, product

water goes to the postfilter which is inside the

sump. The postfilter is also a replaceable sediment

cartridge that contains activated carbon. Any

remaining tastes, odors or sediments are reduced

from product water by the postfilter. Clean, highquality drinking water flows through the tubing

and to the system faucet.

System Monitor—

A timer is provided in the faucet

base to remind you when it is time to replace your

prefilter and postfilter. Replace the filters when the

amber light begins to flash in order to protect the

RO membrane and keep the system functioning

properly. Be sure to remove and replace the

battery at the same time to reset the timer.

Flow Control—The flow control regulates the flow

of water through the Reverse Osmosis cartridge at

the required rate to produce high-quality water.

The control is located in the Reverse Osmosis

housing drain port. A small, cone-shaped screen

fits over the front end of the flow control to prevent

clogging due to sediments in drain water. The flow

control and screen should be replaced each time

the Reverse Osmosis membrane cartridge is

changed.

About the reverse osmosis system.

Screen

Flow control

1/4″ black tubing

(to drain)

14

Troubleshooting TipsConsumer Support Troubleshooting Tips

Installation

Instructions

Safety InstructionsOperating Instructions

Page 15

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Before you call for service… GEAppliances.com

Problem Possible Causes What To Do

Sounds you might hear Running water from the unit • This is normal.

to a drain.

Water has air bubbles Air in system after installation. • Will go away after water runs for a while.

and is cloudy

Chlorine taste and/or The ppm of chlorine in your

• If the water supply contains more than 2.0 ppm of

odor in the Reverse water supply exceeds maximum aesthetic

chlorine,

additional filtering of the water supply to

Osmosis product water limits and has destroyed the the Reverse Osmosis is needed. Correct this condition

Reverse Osmosis membrane. before doing maintenance on the Reverse Osmosis system.

The prefilter is no longer • Replace the Reverse Osmosis membrane cartridge,

removing aesthetic chlorine flow control, screen, prefilter and postfilter.

from the water supply.

Other taste and/or odor High-quality product water • This is normal.

may have a different taste

than what you’re used to.

Low water usage. • Completely drain system and allow to refill.

Contamination in product

•

Use sanitizing procedures.

water storage.

Prefilter and postfilter

• Replace the prefilter and postfilter. If taste and odor

need to be changed and/or persists, replace the Reverse Osmosis cartridge, flow

the Reverse Osmosis cartridge control and screen.

needs to be changed.

Water leaking from Drain side of faucet air gap • Inspect and eliminate restriction or plug. It is important

faucet air gap hole (3/8″ tubing) plugged, restricted that there are no dips, loops or low spots in the drain line

or incorrectly connected to the from the faucet air gap to the drain pipe. Refer to the

drain point. Filtration Drain Connection section, for proper drain

connection. If drain line adapter was used as the

drain

point, periodic inspection/cleaning is recommended.

System makes product This is normal. • Water flow rate will be lower than your regular faucet.

water slowly

Water supply to the Reverse • Increase water pressure, precondition the water, etc.,

Osmosis system not within as needed to conform to specification guidelines before

specifications. doing maintenance on the Reverse Osmosis system.

Prefilter cartridge plugged • Replace the prefilter and postfilter.

If rate does not

with sediments and/or the

increase,

replace the Reverse Osmosis cartridge, flow

Reverse Osmosis cartridge control and screen.

plugged with sediments.

Faucet light blinking Prefilter and postfilter • Replace filters. Don’t forget to sanitize the system when

need replacing. replacing filters.

Timer was not reset when filters • Remove and replace battery in faucet base.

were replaced.

Six months have passed Battery may be dead. • Replace battery. NOTE: Replacing the battery resets the

and faucet light is not six-month timer, so be sure to replace

the prefilter and

blinking postfilter if it is time to do so.

Battery may have been • Any time the battery is removed and reinserted, the

removed recently. six-month timer starts over again. Do not remove

the battery unless you wish to restart the timer.

Troubleshooting Tips

Save time and money! Review the chart first and you

may not need to call for service.

15

Page 16

* NOTE: Codes in the State of Massachusetts require installation by a licensed plumber

and do not permit the use of the saddle valve. For installation, use plumbing code

248-CMR of the Commonwealth of Massachusetts.

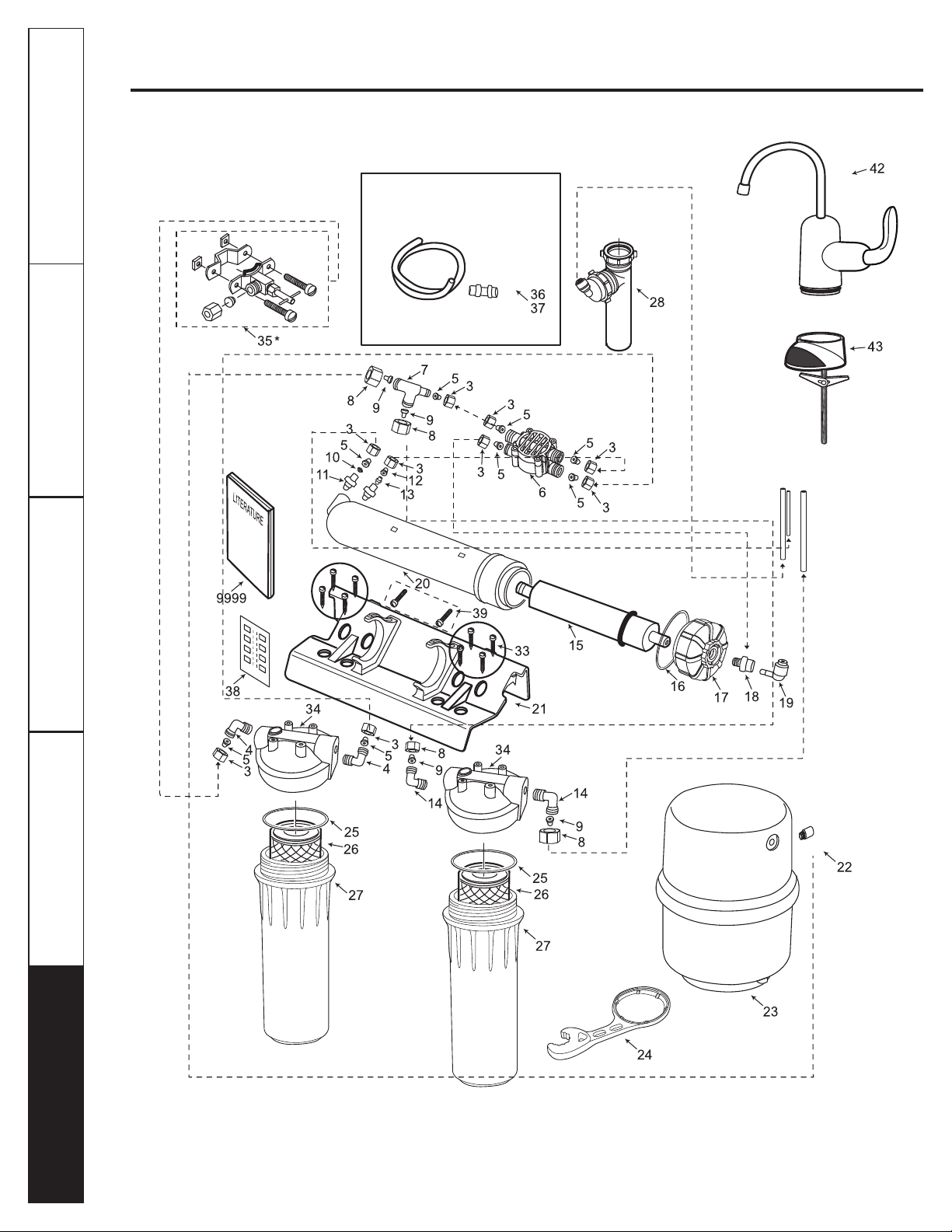

Parts list.

Consumer Support Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

16

Optional Accessories

Page 17

17

Consumer SupportTroubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

General Electric parts catalog. GEAppliances.com

REF. NO. PART NO. PART DESCRIPTION GXRM10RBL

0003 WS22X10005 1/4″ NUT 10

0004 WS22X10026 3/8″ NPT X 1/4″ NUT ELBOW 2

0005 WS22X10006 1/4″ TUBE INSERT 8

0006 WS22X10038 VALVE—AUTO SHUT OFF 1

0007 WS22X10039 1/4″ X 3/8″ X 3/8″ TUBE TEE 1

0008 WS22X10008 3/8″ NUT 4

0009 WS22X10007 3/8″ TUBE INSERT 4

0010 WS22X10040 CHECK VALVE—1/4″ INSERT 1

0011 WS22X10041 1/8″ NPT X 1/4″ FITTING 1

0012 WS03X10016 FLOW CONTROL 1

0013 WS03X10015 CONE SCREEN 1

0014 WS22X10002 3/8″ NPT X 3/8″ NUT ELBOW 2

0015 FX12M RO MEMBRANE 1

0016 WS03X10045 O-RING—RO MEMBRANE HSNG 1

0017 WS31X10025 CAP—RO MEMBRANE HSNG 1

0018 WS22X10042 1/8″ NPT X 1/4″ FITTING 1

0019 WS22X10043 ELBOW—1/4″ STEM X 1/4″ 1

0020 WS20X10006 HOUSING—RO MEMBRANE 1

0021 WS28X10039 BRACKET 1

0022 WS22X10044 CONNECTOR—3/8″ X 3/8″ MNPT 1

0023 WS32X10019 STORAGE TANK 1

0024 WX5X140 WRENCH 1

0025 WS03X10038 O-RING, SUMP HOUSING 2

0026 FX12P CARBON BLOCK CARTRIDGE 2

0027 WS20X10007 SUMP HOUSING 2

0028 WS18X10006 DRAIN LINE ADAPTER—DLA9 1

0033 WS02X10032 SCREWS, BRACKET 8

0034 WS31X10026 HOUSING HEAD 2

0035 WS15X10023 SADDLE VALVE 1

0036 WS07X10018 TUBING—1/4″ X 33′—WHITE 1

0037 WS07X10019 TUBING—3/8″ X 33′—WHITE 1

0038 WS01X10013 NITRATE TEST STRIP 1

0039 WS02X10033 MOUNTING SCREWS 2

0042 WS15X10070 FAUCET BODY AND SPOUT 1

0043 WS10X10041 3/8″ QUICK CONNECT BASE—FAUCET 1

9999 49-50237 OWNER’S MANUAL/INSTALLATION 1

INSTRUCTIONS

* NOTE: Codes in the State of Massachusetts require installation by a licensed plumber

and do not permit the use of the saddle valve. For installation, use plumbing code

248-CMR of the Commonwealth of Massachusetts.

To obtain replacement parts, call toll-free 800.626.2002 (U.S.), 800.663.6060

(Canada–English), 800.361.3869 (Canada–French).

Page 18

18

Notes.

Consumer Support Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Page 19

19

Consumer SupportTroubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Notes.

Page 20

GE Reverse Osmosis System Warranty.

For The Period Of: GE Will Replace:

One Year Any part of the Reverse Osmosis Filtration System which fails due to a defect in materials or

From the date of the workmanship. During this limited one-year warranty, GE will also provide, free of charge, all labor

original purchase and related service to replace the defective part.

All warranty service provided by our SmartWater™Authorized

Servicer Network. To schedule service on-line, contact us

at GEAppliances.com, or call toll-free 800.GE.CARES (U.S.), or

866.777.7627 (Canada). Please have serial number and model

number available when calling for service.

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused, used for

other than the intended purpose or used commercially.

■ Use of this product where water is microbiologically

unsafe or of unknown quality, without adequate

disinfection. Systems certified for cyst reduction

may be used on disinfected water that may contain

filterable cysts.

■ Filter cartridges, membrane cartridges and batteries

after 30 days from date of purchase.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

What GE Will Not Cover:

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. If the product is located in an area where service by a GE Authorized Servicer is not available, you may

be responsible for a trip charge or you may be required to bring the product to an Authorized GE Service location for

service. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in

this Limited Warranty. Any implied warranties, including the implied warranties of merchantability or

fitness for a particular purpose, are limited to one year or the shortest period allowed by law.

20

Consumer Support Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Page 21

21

Mesures de sécurité

Mesures de sécurité . . . . . . . . . . . . . . . . . . . . . . .22

Guide des spécifications . . . . . . . . . . . . . . . . . . .23

Instructions d’installation

Alimentation en eau . . . . . . . . . . . . . . . . . . . . . . .26

Avant de commencer l’installation . . . . . . . . .24

Conduite pour la vidange du robinet

et pour l’alimentation d’eau . . . . . . . . . . . . . . . .29

Installation de l’ensemble du système . . . . . .29

Installation du robinet . . . . . . . . . . . . . . . . . . . . .27

Outillage et matériel requis . . . . . . . . . . . . . . . .24

Points à vérifier avant de commencer

l’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Raccordements à la conduite

de vidange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Entretien et nettoyage

Désinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Remplacement des cartouches

pré-filtre, post-filtre et osmose inversée . . . .30, 31

Trousse pour le test d’eau . . . . . . . . . . . . . . . . .32

Fonctionnement

Au sujet du système de filtration

par osmose inversée . . . . . . . . . . . . . . . . . . .33, 34

Conseils de dépannage . . . . . . . . . . . . . . .35

Soutien au consommateur

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Liste des pièces/catalogue . . . . . . . . . . . . .36, 37

Soutien au consommateur . . . . . . . . . . . . . . . . .40

La section Française.

Écrivez ici les numéros de modèle et de série :

Numéro de modèle : __________________________

Numéro de série : ____________________________

Vous les trouverez sur le support du corps de filtre.

Soutien au

consommateur

Conseils de dépannageFonctionnement

Mesures de sécurité

Installation

Page 22

Soutien au

consommateur

Conseils de dépannage

Fonctionnement

Mesures de sécurité

Installation

22

MESURES DE SÉCURITÉ IMPORTANTES.

LISEZ D’ABORD TOUTES LES INSTRUCTIONS.

■ Vérifiez avec les travaux publics locaux ou de votre

état quels sont les codes régissant la plomberie et les

aménagements sanitaires. Vous devrez vous y conformer

lors de l’installation du système du système de filtration

par osmose inversée. Il est recommandé de faire appel

à un installateur qualifié.

■ Si la pression de l’eau arrivant à l’habitation dépasse la valeur

maximale de 125 livres/po2, montez un détendeur dans la

conduite d’arrivée de l’eau au système de filtration.

■

Assurez-vous que l’eau est conforme au Guide des

spécifications. Si les conditions de l’eau ne sont pas connues,

contactez votre compagnie municipale de fourniture d’eau

ou votre service de santé local pour obtenir une liste des

agents de contamination de votre région et une liste des

laboratoires homologués par votre état pour l’analyse

de l’eau de table.

AVERTISSEMENT : Avant la première

utilisation du système de filtration, celui-ci doit être purgé.

La cartouche du système de filtration par osmose inversée

contient un préservatif pour aliments qui doit être purgé

du système. Ce préservatif donne à l’eau un goût et

une odeur désagréables.

■ Cet appareil réduit la fluoration de l’eau de table. Veuillez

consulter votre dentiste pour toute question à ce sujet.

AVERTISSEMENT :

N’utilisez pas l’appareil avec de l’eau qui n’est pas sûre

microbiologiquement ou de qualité inconnue sans qu’elle

n’ait été désinfectée avant l’entrée ou la sortie de celui-ci.

Les appareils homologués pour la réduction des spores

peuvent être utilisés pour le filtrage de l’eau qui a été

désinfectée pouvant contenir des spores filtrables.

Ce système à été testé pour le traitement de l’eau

contenant de l’arsenic pentavalent (aussi appelé As(V),

As(+5) ou arséniate) à une concentration de 0,050 mg/L ou

moins. Ce système réduit l’arsenic pentavalent, mais peut

ne pas réduiser d’autres formes d’arsenic. Ce système doit

être utilisé dans les alimentations en eau contenant du

chlore libre résiduel détectable ou dans les alimentations

en eau qui se sont avérées contenir seulement de l’arsenic

pentavalent. Le traitement à la chloramine (chlore combiné)

n’est pas suffisant pour assurer la conversion complète de

l’arsenic trivalent en arsenic pentavalent. Veuillez lire la

section Faits sur l’arsenic de la fiche technique de

performance pour des renseignements supplémentaires.

Cet appareil comporte une cartouche avec membrane

remplaçable essentielle pour réduire efficacement les

matières solides totalement dissolvables. Il est nécessaire

de tester l’eau périodiquement afin de s’assurer que

l’appareil fonctionne de manière satisfaisante.

Voyez la

section Au sujet de la trousse de test de l’eau.

Cet appareil

est acceptable pour des concentrations maximum de

nitrates à 27 mg par litre et de nitre à 3 mg par litre en

combinaison appelée N. Il est acceptable pour la réduction

de nitrate/nitre dans de l’eau dont la pression est égale ou

supérieure à 280kPA (40psig).

CONSERVEZ CES INSTRUCTIONS

VEUILLEZ LIRE ET SUIVRE ATTENTIVEMENT

CES MESURES DE SÉCURITÉ.

■ Installez l’appareil ou entreposez-le de telle façon qu’il

ne soit pas exposé à des températures inférieures au point

de congélation ou non à l’abri de tout type de conditions

météorologique. Il sera endommagé par l’eau qui se

congèle. N’essayez pas de traiter de l’eau dont la

température est supérieure à 100 degrés F.

■ Ne branchez pas l’appareil sur une CONDUITE D’EAU

BOUILLANTE. La température de l’eau arrivant au

système doit se trouver entre 40°F au minimum et

100°F au maximum. Voyez le Guide des spécifications.

■ Période prolongée de non-utilisation du système de

filtration.

Si le système n’a pas été utilisé au cours d’une période

d’une semaine ou plus, ouvrez le robinet d’eau RO pour

permettre la vidange de celui-ci. Fermez le robinet pour

permettez au système de régénérer l’alimentation en eau.

■ L’installation recommandée est sous l’évier. Toutefois, l’unité

peut être installée dans un lieu éloigné, jusqu’à une distance

de 6 m (20 pi) de l’évier. Du matériau d’installation

supplémentaire peut être nécessaire. Si le système de filtration

par osmose inversée est raccordé à la machine à glaçons du

réfrigérateur, un kit spécial pour la connexion de la machine à

glaçons est nécessaire (RVKIT). N’utilisez pas de tubes en cuivre

pour la connexion entre le système de filtration par osmose

inversée et le réfrigérateur.

AVERTISSEMENT : Débarrassez-vous

de tous les composants non-utilisés ainsi que de

l’emballage après l’installation. Les petites pièces qui restent

après l’installation peuvent constituer un danger

d’étouffement si ingérées.

■

Désinfectez les éléments au cours de l’installation et

après l’entretien des composants internes. Ceci inclut

le remplacement de l’élément de pré-filtrage, l’élément

du post-filtrage et de la cartouche de l’appareil. Il est

important que les mains soient propres lors de la

manipulation des éléments internes du système.

Voyez la section Désinfection du système de filtration

par osmose inversée.

■

Ce système d’osmose inverse contient un élément

remplaçable essentiel à son efficience. Vous ne pouvez

remplacer l’élément d’osmose inverse que par un élément

ayant des caractéristiques techniques identiques, telles que

définies par le fabricant, pour assurer le même rendement

en matière d’efficience et de réduction de contaminants.

Consultez la section Robinet d’arrêt automatique, page 34.

ASSUREZ-VOUS QUE VOUS SUIVEZ TOUTS

DE VOS CODES D’ÉTAT ET LOCAUX.

AVERTISSEMENT!

Pour votre sécurité, suivez les instructions fournies dans le présent

manuel afin de minimiser les risques de dommages au matériel ou

de blessures corporelles.

PRÉCAUTIONS DE SÉCURITÉ

INSTALLATION ET ENTRETIEN DU SYSTÈME

Avant son utilisation, le système de filtration doit être correctement installé et positionné

conformément aux instructions d’installation.

Page 23

Guide des spécifications. www.electromenagersge.ca

L’appareil produit une bonne quantité d’eau potable quotidiennement.

Cette quantité est fonction des données suivantes…

Produit – hauteur 38,1 cm (15 po) largeur 35,6 cm

(14 po) profondeur 14 cm (5,5 po)

pH de l’eau d’admission

ADOUCISSEUR D’EAU RECOMMANDÉ

DURETÉ DE L’EAU D’ADMISSION (GPG)

60

50

40

30

2010

8

6

7

7,5

6,5

Adoucisseur

d’eau inutile

Quantité maximale de fer, de manganèse, d’hydrogène sulfuré (en ppm) . .<0,1

Chlore dans l’eau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,0 ppm admissible maximum

b

Limites pH de l’eau d’admission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–10

Production d’eau (de qualité) en gallons par 24 heures . . . . . . . . . . . . . . . . . . . .37,2 L (9,83 gallons)

a

Pourcentage de rejet des TDS (nouvelle membrane) . . . . . . . . . . . . . . . . . . . . . . .92,4%

a

Pourcentage de réduction des spores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99,99%

Capacité du réservoir—gallons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

d

Notation d’efficience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9,63%

e

Notation de recouvrement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18,77%

f

Commande d’arrêt automatique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .oui

Pré-filtre et post-filtre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(FX12P) Bloc de charbon

Membrane du système de filtration par osmose inversée . . . . . . . . . . . . . . . . . .(FX12M) Pellicule mince

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .en polyamide

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .hauteur 38,1 cm (15 po)

largeur 35,6 cm (14 po)

profondeur 14 cm (5,5 po)

Limites de pression de l’eau à l’admission—livres par pouce carré (psi) . . . . . . . . . . . . . . . . . . .40–125

c

Limites de température de l’eau à l’admission—min/max en degrés F . . . . . . . . . . . . . . . . . . . . .40–100

Maximum de matières solides totalement dissolvables (TDS)—parties par millions (ppm) . . . .2000

Dureté maximale de l’eau @ 6,9 pH conseillé pour optimiser la vie de membrane—

grains par gallon (gpg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Lorsque la dureté de l’eau est supérieure à 10 grains (à un pH de

6,9), il est recommandé d’utiliser un adoucisseur. Si un adoucisseur

n’est pas installé, la durée de vie de la membrane du système de

filtration par osmose inversée est réduite. Voyez le graphique pour

les informations complémentaires concernant la nécessité

d’installer un adoucisseur d’eau.

a. Lorsque testé conformément à la norme 58 de NSF/ANSI. Pour le test, les paramètres de l’eau d’origine sont

de 50 psig, 77°F, un pH de 7,5 ± 0,5 et une valeur ppm (parties par million) de 750 ± 40 de matières solides

totalement dissoutes.

b. Réduit par le pré-filtre du système de filtration par osmose inversée. UN ENTRETIEN RÉGULIER EST

NÉCESSAIRE. Le chlore détruira la membrane du système de filtration par osmose inversée.

c. Si la pression de l’eau arrivant à l’habitation dépasse 125 livres/po2, montez un détendeur dans la conduite

d’arrivée de l’eau au système de filtration. Si cette pression est inférieure à 40 livres/po2, installez une pompe

d’appoint sur l’appareil de filtration (contactez votre magasin de plomberie local).

d. Capacité théorique du réservoir. Essayé conformément à la norme 58 de NSF/ANSI à une pression

de 50 livres par pouce carré, le réservoir a une capacité de 2,3 gallons.

e. La notation d’efficience indique le pourcentage d’eau entrant dans le système, qui est disponible pour

l’utilisateur comme eau traitée par osmose inverse dans des conditions d’exploitation qui avoisinent celles

d’une utilisation quotidienne normale.

f. La notation de recouvrement indique le pourcentage d’eau entrant dans la partie membrane du système,

qui est disponible pour l’utilisateur comme eau traitée par osmose inverse quand le système

fonctionne sans réservoir de stockage ou quand l’eau ne passe pas par le réservoir de stockage.

Soutien au

consommateur

Conseils de dépannageFonctionnement

Mesures de sécurité

Installation

23

Page 24

Instructions

Système de filtration par osmose inversée

d’installation

Modèle GXRM10RBL

Si vous avez des questions, appelez le 1.800.561.3344 ou visitez notre site Web à l’adresse :

www.electromenagersge.ca

AVANT DE COMMENCER

Veuillez lire toutes les directives attentivement.

•

IMPORTANT — Conservez ces

instructions pour l’inspecteur local.

•

IMPORTANT — Respectez toutes

les ordonnances et les codes locaux.

• Avis à l’installateur – Assurez-vous de laisser

ces instructions au consommateur.

• Avis au consommateur – Conservez ces

instructions pour référence future.

• L’installateur est responsable de bien installer.

• Toute panne du produit due à une mauvaise

installation n’est pas couverte par la garantie.

• Un robinet d’arrêt doit être disponible ou ajouté

à côté du point d’installation.

OUTILLAGE ET MATÉRIEL REQUIS

POUR L’INSTALLATION

• Perceuse et mèche de perceuse de 1-1/2 po

(du type nécessaire) si un trou de montage est

requis pour le robinet

• Clefs à molette réglables

• Tournevis normaux et Phillips

• Couteau

LISTE DES COMPOSANTS

DE L’APPAREIL

• Ensemble de filtration par osmose inversée

et conduite

• Imprimés concernant l’appareil (manuel

d’utilisation et d’installation) et feuillet

de données relatives

• Sac contenant les éléments des robinets

d’alimentation

• Adaptateur de la conduite de vidange

• Réservoir

• Robinet

• Chatterton du filetage

24

Page 25

Instructions d’installation

Points à vérifier avant de commencer l’installation

EAU D’ALIMENTATION

L’eau alimentant le système de filtration par

osmose inversée monté sous le comptoir doit

présenter des qualités répertoriées dans les

spécifications (voyez la section Guide des

spécifications). Dans la plupart des cas, l’eau fournie

par les municipalités répond à ces spécifications.

L’eau de puits peut requérir un traitement—faites-la

tester par un laboratoire d’analyses et suivez leurs

recommandations pour traitement.

MISE EN GARDE : Lorsque la

dureté de l’eau est supérieure à 10 grains (à un pH

de 6,9), il est recommandé d’utiliser un adoucisseur.

Si un adoucisseur n’est pas utilisé, la durée de vie

de la membrane du système de filtration sera

réduite. Voyez la section Guide des spécifications

pour les informations complémentaires concernant

la nécessité de disposer d’un adoucisseur.

POINT DE VIDANGE

L’eau évacuée provenant de la membrane du

système de filtration nécessite un point de vidange

approprié et un espace d’air (vérifiez vos codes

locaux).

INSTALLATION DANS UN SOUS-SOL

Si l’installation est effectuée dans un sous-sol,

ménagez une longueur de conduite suffisante au

cours de l’installation afin de faciliter l’entretien et

d’assurer le remplacement des filtres/membrane.

Conduite et raccords supplémentaires sont

nécessaires.

ROBINET RO

Le robinet d’eau produite RO est monté sur l’évier

ou sur le comptoir à proximité de l’évier. Souvent, il

est monté dans l’orifice de l’arrosoir existant, ou un

trou peut être percé. Il est nécessaire de disposer

d’un espace suffisant sous l’évier ou le comptoir

pour la conduite reliée au robinet ou en provenance

de celui-ci et pour le montage du robinet. Tous les

raccordements de robinet, conformément aux

méthodes de montage, sont effectués sur ou au

dessus de l’évier ou du comptoir. Voyez l’illustration

ci-dessous.

Réservoir

Eau

chaude

Adaptateur de la conduite de vidange

Conduite noire de vidange de 3/8″ po

Robinet d’eau produite RO passant

au travers de l’évier ou le comptoir

Jaune

(entrée)

Orange

Conduite noire (1/4 po)

Bleu

(à robinet)

25

Soupape à bride

Eau

froide

Page 26

Instructions d’installation

ALIMENTATION EN EAU

Vérifiez et conformez-vous aux codes de plomberie lors de la planification puis installez un raccord d’alimentation

d’eau froide. Pour les installations effectuées dans des nouvelles habitations utilisant les raccords de plomberie

standards, examinez d’abord les deux schémas ci-dessous. Une installation type pour les habitations existantes

utilisant la soupape à étrier est illustrée sur le troisième schéma ci-dessous.

B. INSTALLATION OPTIONNELLE

EFFECTUÉE DANS UN DOMICILE

(Lorsque les codes l’autorisent)

*Pour OD de 1/4 po ou tube métallique de plus grandes

dimensions.

NOTE : Les codes de l’état du Massachusetts exigent que

l’installation soit effectuée par un plombier certifié et ne

permettent pas l’utilisation de soupapes à étrier. Pour

l’installation, utilisez le code 248-CMR du Commonwealth

du Massachusetts.

1. Fermez l’arrivée d’eau froide et montez

la soupape à étrier comme illustré ci-dessous.

DANGER :Pour vous mettre à l’abri de

blessures graves ou de choc électrique fatal, utilisez

une perceuse alimentée par batterie pour faire le trou.

N’UTILISEZ PAS DE PERCEUSE ÉLECTRIQUE.

2. Fermez le robinet d’alimentation d’eau en tournant

la commande dans le sens horaire.

3. Ouvrez le robinet principal d’alimentation et

plusieurs autres robinets de l’habitation afin

de purger l’air du système. Fermez les robinets

une fois que l’écoulement d’eau est régulier.

Raccordement optionnel à la source d’alimentation d’eau

(avec utilisation de la soupape à bride)*

Trou de 1/4 po

pré-percé

Joint—assurez-vous que

le joint est en place

Bride X

Écrou (2)–Non

nécessaire si les

trous de la bride

sont filetés

Soupage

Poignée

Adaptateur de la conduite

Rondelle

Écrou de

compression

❵

Bride Z

Utilisez pour raccorder la conduite

*Pour OD de 1/4 po ou tube métallique de plus grandes dimensions.

ALIMENTATION EN EAU

A. INSTALLATION PRÉFÉRENTIELLE

1. Fermez l’arrivée d’eau froide.

2.

Pour respecter les codes de plomberie, montez

un raccord sur le tuyau d’eau froide pour y

adapter un tube de 3/8 po OD. Un raccord type

est illustré sur le schéma ci-dessous (pièces non

incluses). Assurez-vous qu’un robinet

d’alimentation est fourni.

Raccord préférentiel d’alimentation d’eau

(utilisant un raccord à compression)

Raccord (non inclus)

Tuyau

d’eau

froide

Tube de raccordement à la

conduite d’admission 3/8 po

Bague

d’extrémité

Soupape d’alimentation

d’eau (non inclus)

Localisation type

Eau

froide

Montez la soupape dans

le support NE SERREZ

PAS EXCESSIVEMENT

Plusieurs filets

doivent être visibles

Joint en caoutchouc

26

Page 27

Instructions d’installation

INSTALLATION DU ROBINET

INSTALLATION DU ROBINET

Assurez-vous qu’il y ait suffisamment de place

au-dessous et au-dessus de l’évier pour faire les

branchements nécessaires. Avant de commencer,

assurez-vous qu’il y ait suffisamment de place pour

la base de robinet et l’unité. Choisissez l’un des

emplacements suivants pour installer le robinet :

A. Dans un trou existant de distributeur de savon

ou de douchette.

B. Dans un trou à percer en haut de l’évier.

C. Dans un trou à percer dans le comptoir, près de l’évier.

NOTES :

•

Assurez-vous que la base de robinet soit bien plate

contre la surface de l’emplacement choisi de

manière à ce que le joint placé entre la base et la

surface de l’emplacement choisi soit bien étanche.

• Laissez suffisamment d’espace à l’arrière du

robinet au cas où vous devriez l’enlever.

Étapes d’installation (voir l’illustration

ci-dessous pour plus de clarté)

1. Si vous devez faire un trou, faites un trou de 11/2 po

de diamètre. Assurez-vous d’utiliser la bonne

procédure pour percer la porcelaine ou l’acier

inoxydable. Vous pouvez avoir besoin d’une

mèche spéciale de perceuse. Consultez un

plombier qualifié pour trouver la bonne procédure.

NOTE :Le perçage de l’acier inoxydable engendre souvent

des rebords coupants qui peuvent percer le tube. Prenez

soin de ne pas vous couper ni endommager le tube.

2. Enlevez la corps et la base du robinet en tournant

la base dans le sens antihoraire.

3. Poussez les tubes noirs de 1/4 po et de 3/8 po dans

les raccords cannelés adéquats de la base du robinet.

Poussez le tube de 3/8 po bleu à travers la base.

4. Alignez le joint de façon à recouvrir le trou

entièrement. Placez ensuite le boulon à ailettes

de la base dans le trou.

Base de robinet

Évier

Joint

Boulon à ailettes

Base de robinet

Raccord cannelé

de 1/4 po

Tube noir de 1/4 po

Raccord cannelé de 3/8 po

Tube noir de 3/8 po

Tube bleu de 3/8 po

INSTALLATION DU ROBINET (SUITE)

5. Serrez le boulon à ailettes jusqu’à bien fixer la base

en place pour l’empêcher de branler ou de tourner.

6. Poussez le tube de 3/8 po bleu par en haut pour

le connecter au raccord dans le bas du corps

du robinet. Il devrait rentrer sur environ 3/4 po.

Tirez le tube légèrement pour vérifier qu’il est

solidement inséré.

7. Poussez le corps du robinet vers le bas dans sa

base puis tournez dans le sens horaire jusqu’à ce

qu’il arrive en bout de course.

NOTE : Vous pouvez installer le robinet pour que

sa poignée se trouve à droite ou à gauche.

Si vous la souhaitez à droite, placez la poignée

à l’arrière de la base avant de tourner dans le

sens horaire.

Pour la gauche, placez la poignée au devant

de la base avant de tourner dans le sens horaire.

8. Localisez le trou à l’arrière

de la base. Insérez la vis de

pression et commencez à

la visser à la main. Finissez

de la visser à l’aide de la clé

Allen fournie dans le paquet.

NE SERREZ PAS TROP FORT.

Corps du robinet

Base de robinet

Évier

Joint

Boulon à ailettes

Tube noir de 3/8 po

Tube noir

de 1/4 po

Tube bleu de 3/8 po

Vis de montage

Robinet Robinet

Poignée du robinet à DROITE Poignèe du robinet à GAUCHE

27

Page 28

Instructions d’installation

RACCORDEMENTS À LA CONDUITE DE VIDANGE

Vérifiez et conformez-vous aux codes de plomberie lors de la planification.

MISE EN GARDE : Les options décrites ci-dessous représentent UNIQUEMENT les configurations

d’installation homologuées. N’utilisez pas de systèmes comportant des soupapes à étrier.

OPTION A : INSTALLATION

DU SYSTÈME AU SOUS-SOL

Acheminez DIRECTEMENT la conduite de vidange

(noire, de 1/4 po) du système de filtration par

osmose inversée à un évent du sous-sol, en

dérivant l’espace d’air ménagé dans le robinet. Il

est aussi possible de diriger la conduite de vidange

sur un orifice d’évacuation du sol ou encore dans

une baignoire sous réserve que l’espace d’air du

sous-sol est respecté. Évitez de faire des boucles

et autres formes non rectilignes avec la conduite.

L’espace d’air dans le sous-sol et la configuration

de l’installation de vidange doivent être conformes

à tous les codes locaux. Des raccords spéciaux

pour l’espace d’air sont disponibles pour le

raccordement de la conduite à l’évent.

Conduite de vidange du

système de filtration par

osmose inversée en

dérivation de l’espace d’air.

Maintenez

l’espace d’air au point de

vidange dans le sous-sol

Conduite noire

de 1/4 po

OPTION B : INSTALLATION

D’ADAPTATEUR DE LA CONDUITE

DE VIDANGE

MISE EN GARDE!

N’INSTALLEZ PAS L’ADAPTATEUR DE

LA CONDUITE DE VIDANGE EN AVAL

DU BROYEUR À DÉCHETS.

Installez l’adaptateur de conduite de vidange fourni

sous l’évier, conformément à l’illustration. Le tédéflecteur fourni doit être en place (achetez et

installez-le si nécessaire) pour empêcher la conduite

de vidange de l’osmose inversée de se boucher.

Acheminez la conduite de vidange (noire, de 3/8 po) de

l’espace d’air du robinet à l’adaptateur de la conduite

de vidange, en vous assurant qu’il n’y a pas

d’inclinaison, boucle ou de point bas dans la conduite

qui pourrait résulter en une conduite de vidange

bouchée.

La conduite doit être coupé à la bonne longueur

pour fournir un acheminement droit du robinet

à l’évacuation.

Du bruit de vidange dans le trou d’évacuation de

l’évier est normal lorsque le système de filtration

par osmose inversée fonctionne.

Adaptateur de conduite

de vidange dans une

conduite différente

de celle

du broyeur

de déchets

CHAUD FROID

Broyeur

La conduite de vidange est droite

28

Page 29

Instructions d’installation

INSTALLATION DE L’ENSEMBLE DU SYSTÈME DE FILTRATION PAR

OSMOSE INVERSÉE ET DU RÉSERVOIR

À PRESENT QUE VOTRE SYSTÈME DE FILTRATION PAR OSMOSE

INVERSÉE EST INSTALLÉ…DÉSINFECTEZ!

Désinfectez au cours de l’installation et après

l’entretien des composants internes, incluant

le remplacement du pré-filtre, du post-filtre

et la cartouche du système de filtration par

osmose inversée. Il est important que vous vous

laviez les mains avec du savon anti-bactéries

avant de manipuler les composants internes du

système. Référez-vous à la section Désinfection.

MISE EN GARDE : Si le système est

installé dans une nouvelle habitation, assurez-vous

que les tuyaux ont été complètement rincés avant

d’ouvrir le robinet d’alimentation d’eau. Et avant la

désinfection, assurez-vous de retirer toutes les

cartouches comme décrit à la section Désinfection.

Le chlore détruira la cartouche du système.

Tenez l’équipement de filtration par osmose

inversée contre la surface du mur où il va être

installé. Marquez les emplacements des vis.

Les flèches au-dessus du support montrent

l’emplacement des trous de vis.

1

Branchez la conduite sur le réservoir

de stockage : Acheminez la longueur de

conduite orange de 3/8 po du raccord en té

sur le module de filtration par osmose inversée

au raccord d’entrée du réservoir.

5

Des vis à bois sont fournies pour fixation sur

une surface de bois. Procurez-vous d’autres vis

si besoin est.

2

Accrochez l’ensemble de filtration par osmose

inversée sur les vis.

3

Mettez du chatterton d’étanchéïté pour filetage

sur le raccord et les filetages du réservoir.

Serrez avec une clé anglaise.

4

Réservoir

Au robinet

Conduite d’alimentation

Conduite orange

Jeu de 2 po minimum

pour changer les cartouches

CONDUITE DE VIDANGE DU ROBINET ET CONDUITE

D’ALIMENTATION D’EAU

Si OPTION A : INSTALLATION DU SYSTÈME AU SOUS-SOL (consultez la section Raccordements à la conduite de

vidange, page 29) est utilisée, passez à l’étape 2.

Si OPTION B : INSTALLATION D’ADAPTATEUR DE LA

CONDUITE DE VIDANGE est utilisée, branchez la

conduite de vidange de robinet en acheminant la

conduite noire de 3/8 po du raccord cannelé de 3/8

po au raccord de vidange (installé dans la section

Raccordements à la conduite de vidange, page 28).

Gardez la conduite aussi courte et droite que

possible, sans boucle, creux ou point bas. Coupez la

conduite comme nécessaire et insérez-la dans le

raccord de vidange.

1

Pour brancher la conduite d’alimentation d’eau :

Acheminez la conduite jaune de 1/4 po de l’entrée

du système de filtration par osmose inversée

au raccord de l’alimentation en eau (voir les

illustrations dans la section Alimentation en eau

à la page 26). Branchez la conduite de la manière

appropriée (voir la section Alimentation en eau) et

serrez l’écrou fortement.

2

29

Page 30

Instructions d’installation

PROCÉDURE DE REMPLACEMENT POUR PRÉ-FILTRE, POSTFILTRE ET CARTOUCHE DE FILTRATION PAR OSMOSE INVERSÉE,

COMPRIS DÉSINFECTION

COUPEZ la machine à glaçons (s’il est connecté au

système de filtration par

osmose inversée).

1

Lavez vos mains avec du savon antibactérien.

2

Coupez l’alimentation d’eau au

système de filtration par osmose

inversée.

3

Retirez le capuchon du logement de cartouche

de filtration par osmose inversée (dévissez la conduite

en premier, sur certains

modèles). Utilisez des pinces

pour retirer la cartouche de

filtration par osmose inversée.

Placez-la dans un sac en

plastique propre ou jetez-la si vous la remplacez.

Essuyez complètement l’intérieur du logement et du

capuchon avec un essuie-tout ou une brosse à vaisselle

imbibée de produit vaisselle. Rincez soigneusement.

Installez le capuchon du logement de cartouche de

filtration par osmose inversée.

NOTE : Si la cartouche à osmose inversée n’est pas

retirée pendant la désinfection, elle risque d’être

détruite.

6

Ouvrez le robinet de filtration par osmose

inversée. Vidangez le réservoir (cela peut prendre

quelques minutes). Coupez le robinet de filtration

par osmose inversée.

MISE EN GARDE : Ne pas fermer

le robinet d’alimentation d’eau ou le robinet d’arrêt

du réservoir causera des pulvéristations ou des

écoulements d’eau lorsque les corps de filtre sont

enlevés.

4

Enlevez les corps de filtre.

Faites attention—les corps

de filtre seront pleins d’eau.

Jetez les filtres. Nettoyez

soigneusement les corps de filtre

avec du produit-vaisselle. Essuyez

soigneusement l’intérieur des têtes

avec un essuie-tout imbibé de

produit-vaisselle. Rincez soigneusement.

5

Installez le collecteur vide

du post-filtre.

7

Remplissez le corps de pré-filtre avec de l’eau

jusqu’à 2,5 cm (1 po) du joint torique. Ajoutez 50 ml

(4 cuiller à soupe) d’eau de javel ordinaire. Installez le

collecteur du pré-filtre.

8

Rétablissez l’alimentation d’eau. Ouvrez le robinet

de filtration par osmose inversée jusqu’à ce que