GE GUD37EEMNDG, GUD27EEMNWW Installation Instructions

WARNING

WARNING

Installation

WARNING

Unitized Washer/Dryer

Instructions

Questions? Call GE Appliances at 800.GE.CARES (800.432.2737) or visit our Web site at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca

BEFORE YOU BEGIN

Read these instructions completely and carefully.

IMPORTANT – Save these instructions for local electrical

inspector’s use.

IMPORTANT –

ordinances.

• Install the appliance according to the manufacturer’s

instructions and local codes.

• Note to Installer – Be sure to leave these instructions

with the Consumer.

• Note to Consumer – Keep these instructions for future

reference.

• Appliance installation must be performed by a qualified

installer.

• This dryer must be exhausted to the outdoors.

• Before the old appliance is removed from service or

discarded, remove the washer and dryer doors.

• Do not allow children on or in the appliance. Close

supervision of children is necessary when the appliance

is used near children.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

• Install the appliance where the temperature is above 50°F

for satisfactory operation of the appliance control system.

• Remove and discard existing plastic or metal foil duct

and replace with UL-listed duct.

• Service information and the wiring diagram are located

at the access panel.

Observe all governing codes and

- Fire Hazard

• Appliance installation must be performed by a qualified

installer.

• Install the appliance according to these instructions

and local codes.

• DO NOT install a clothes dryer with flexible plastic venting

materials. If flexible metal (semi-rigid or foil-type) duct is

installed, it must be UL-listed and installed in accordance

with the instructions found in “Connecting the Dryer

to House Vent” later in this manual. Flexible venting

materials are known to collapse, be easily crushed and

trap lint. These conditions will obstruct dryer airflow and

increase the risk of fire.

• DO NOT install or store this appliance in any location

where it could be exposed to water or weather.

• To reduce the risk of severe injury or death, follow all

installation instructions.

• Save these instructions. (Installers: Be sure to leave

these instructions with the customer.)

FOR GAS DRYERS ONLY

In the Commonwealth of Massachusetts,

the following installation instructions apply:

• Installation must be performed by a qualified or

licensed contractor, plumber, or gasfitter qualified

or licensed by the State.

• If using a ball valve, it shall be a T-handle type.

• A flexible gas connector, when used, must not

exceed 3 feet.

01

FOR GAS DRYERS ONLY

State of California Proposition 65 Warnings

Gas appliances can cause low-level exposure to some of these substances, including benzene, carbon monoxide,

formaldehyde and soot, caused primarily by the incomplete combustion of natural gas or LP fuels. Exposure to these

substances can be minimized by properly venting the dryer to the outdoors.

PARTS SUPPLIED

This product contains one or more chemicals known to the State of California to cause cancer, and birth

defects or other reproductive harm.

1 Cable Tie

2 Washer Hoses

2 Strainer Screens/

Rubber Washers

NOTE: The Rubber

Washers may be in

the water hoses

234D2665P001

31-16781-2 05-18 GEA

Installation Instructions

UNPACKING YOUR APPLIANCE

Tilt the appliance sideways and remove the

foam shipping pads by pulling at the sides

and breaking them away from the appliance

legs. Be sure to remove all of the foam pieces

around the legs.

After the machine is in the home, remove

remaining packing material/carton from the

appliance.

Remove the bag containing the washer

hoses and parts from tub.

Washer

hoses

and parts

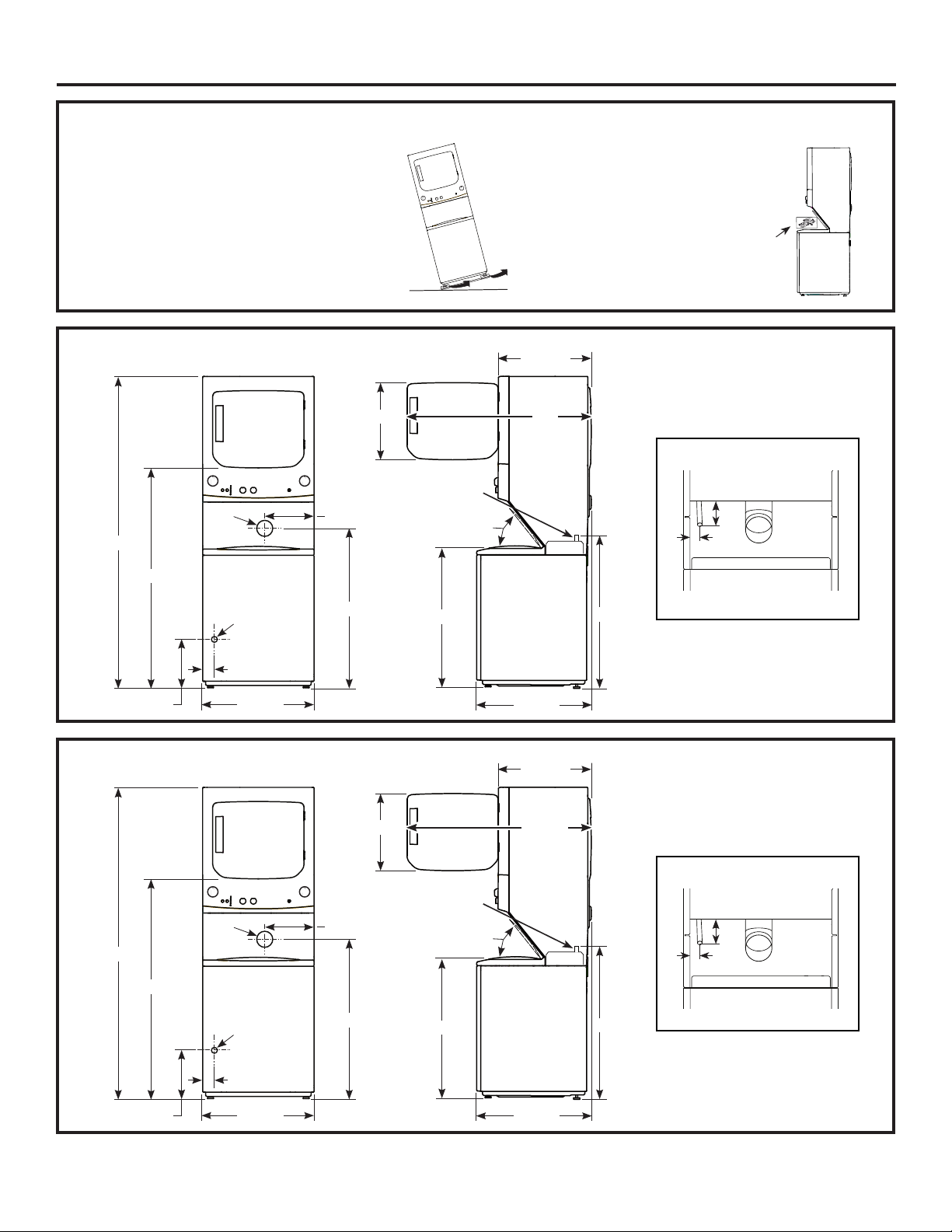

24” NOMINAL PRODUCT DIMENSIONS

18”

Water Inlets

(rear)

32-3/4”

74-7/8”

51-3/8”

21-1/8”

Vent

Drain outlet

(rear)

4-1/4”

23-3/4”

8-5/8”

37-1/4”

27” NOMINAL PRODUCT DIMENSIONS

51

*24-5/8”

* Dimension represents door closed

including handle and knobs.

43”

NOTE: All dimensions are within ± 1/8”.

FOR GAS DRYERS ONLY

Gas Inlet

2-3/4”

°

33-7/8”

2”

Rear View of Appliance

NOTE: With feet set at mid position,

27-3/8”

*26-1/8”

feet can be adjusted ± 3/8”.

* Dimension represents door closed

including handle and knobs.

75-7/8”

53-1/4”

22-1/4”

Vent

Drain outlet

(rear)

3-7/8”

26-3/4”

18-5/8”

13-1/4”

36-7/8”

Water Inlets

(rear)

34-3/8”

2

51

47-1/2”

NOTE: All dimensions are within ± 1/8”.

FOR GAS DRYERS ONLY

Gas Inlet

3”

°

3”

34-7/8”

Rear View of Appliance

NOTE: With feet set at mid position,

30-7/8”

feet can be adjusted ± 3/8”.

Installation Instructions

WARNING

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

- Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Failure to do so can result in death, explosion, or fire.

• The dryer MUST be vented to the outdoors.

• Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0” either side

0” rear

1” front

1” top

• Consideration must be given to provide adequate

clearance for installation and service.

• Closet doors must be louvered or otherwise ventilated

and doors must contain a minimum of:

72 square inches of open area for GUD24 series

models

120 square inches of open area for GUD27 and

GUV27 series models

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, THE CONFIGURATION

OF THE DUCTING MAY REQUIRE GREATER THAN

3” OF REAR CLEARANCE.

Gas Dryers Only:

• No other fuel burning appliance shall be installed in

the same closet as a gas dryer.

• The dryer must be disconnected from the gas

supply piping during pressure testing at pressures

greater than ½ psi (3.5 kPa).

• A 1/8 inch NPT minimum plugged tapping,

accessible for test gauge connection, must be

installed immediately upstream of the gas supply

connection to the dryer.

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and

for air opening are: 0” both sides, 0” rear and 1” top.

Consideration must be given to provide adequate

clearance for installation and service.

INSTALLATION REQUIREMENTS

LOCATION

This appliance must be installed on firm flooring to minimize

vibration during spin cycle. Concrete flooring is best, but

wood base is sufficient, provided floor support meets FHA

standards. This appliance should not be installed on rugs.

DO NOT Install the Appliance:

1. In an area exposed to dripping water or outside

weather conditions. The ambient temperature should

never be below 60°F (15.6°C) for proper operation.

2. In an area where it will come in contact with curtains

or drapes.

3. On carpet. The floor MUST be a hard surface with

a maximum slope of 1/2″ per foot (1.27 cm per 30

cm). To make sure the appliance does not vibrate or

move, you may have to reinforce the floor.

NOTE: If floor is in poor condition, use 3/4″ impregnated

plywood sheet solidly attached to existing floor covering.

MOBILE OR MANUFACTURED

HOME INSTALLATION

• Installation MUST conform to the MANUFACTURED

HOME CONSTRUCTION AND SAFETY

STANDARD, TITLE 24, PART 3280 or STANDARD

FOR MOBILE HOMES CAN/CSA-Z240 MH, or,

when such standards are not applicable, with

AMERICAN NATIONAL STANDARD FOR MOBILE

HOME, ANSI/NFPA NO. 501B.

• The dryer MUST be vented to the outdoors.

• The exhaust vent MUST be securely fastened to a

non-combustible portion of the mobile home.

• The vent MUST NOT be terminated beneath a

mobile or manufactured home.

• The vent duct material MUST BE METAL.

• KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

• The vent MUST NOT be connected to any other

duct, vent or chimney.

• DO NOT use sheet metal screws or other

fastening devices which extend into the interior of

the exhaust vent.

• Provide an opening with a free area of at least 25

square inches for introduction of outside air into

the dryer room.

• See the sections for electrical connection information.

3

Installation Instructions

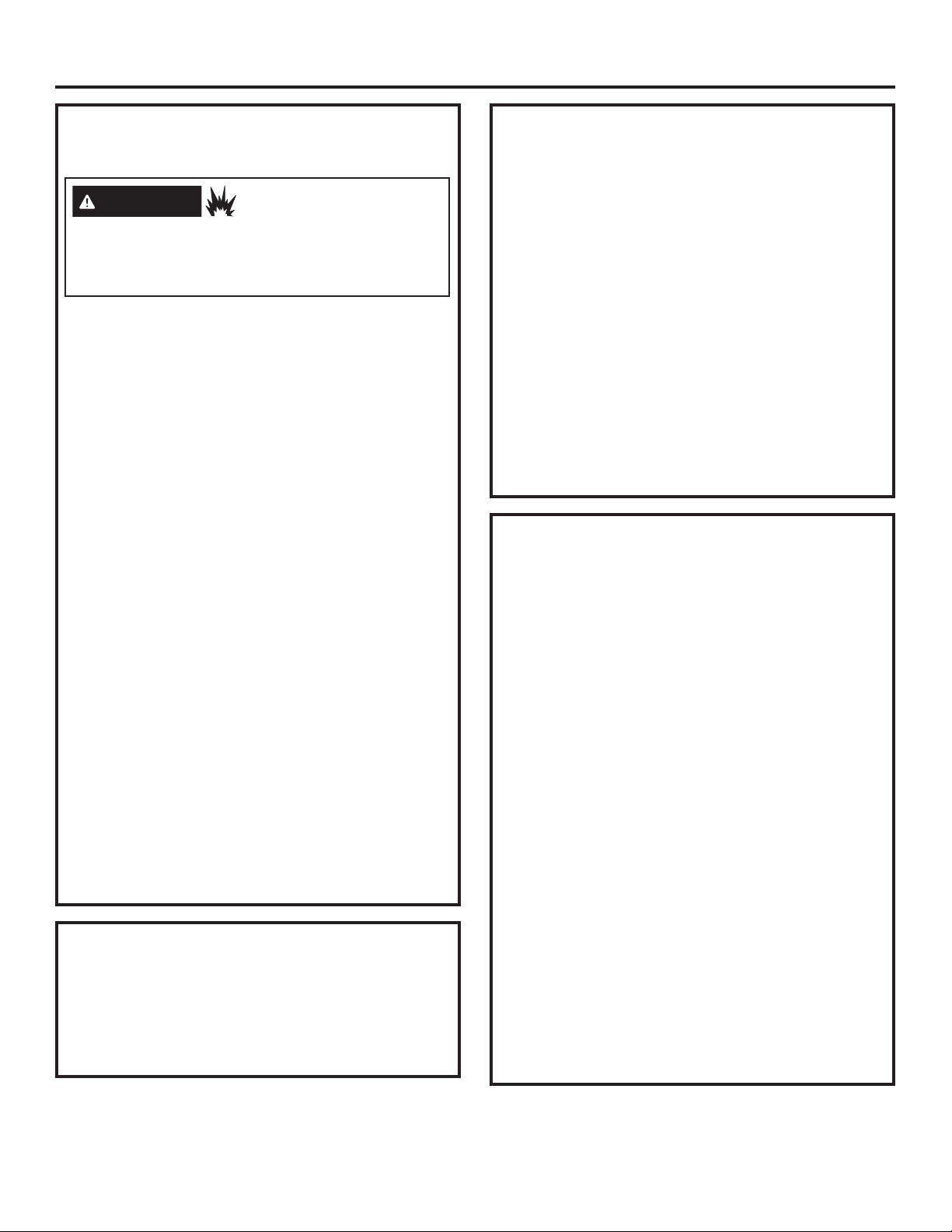

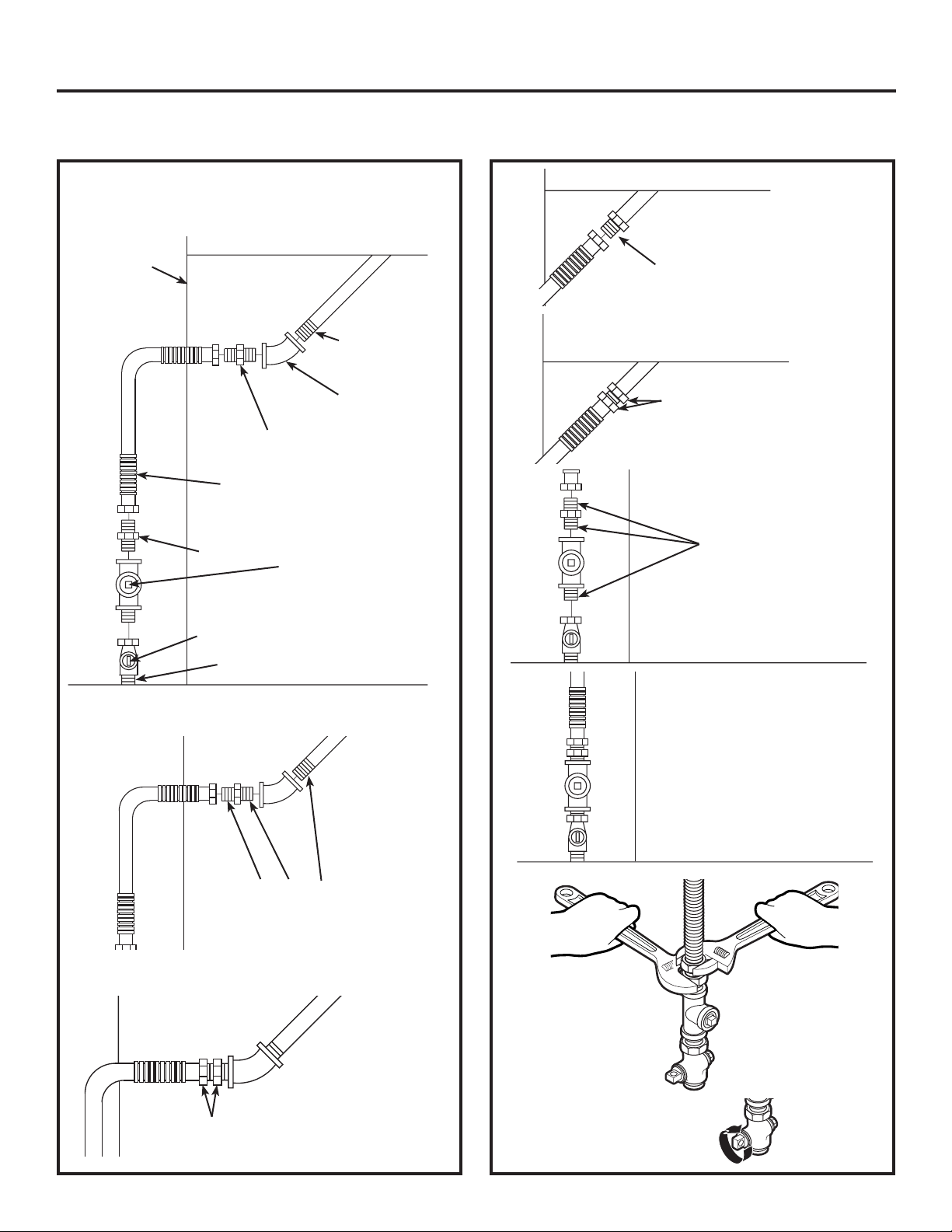

CONNECTING A GAS DRYER (skip for electric dryers)

TOOLS YOU WILL NEED

■

10” Adjustable

wrenches (2)

■

8” Pipe wrench

■

Slip-joint pliers

■

Flat-blade

screwdriver

■

1/4” Nutdriver

■

Level

MATERIALS YOU WILL NEED

■

4” dia. metal elbow

■

Pipe compound or

PTFE tape

■

Gloves

■

Soap solution for

leak detection

• Before beginning the installation, turn off the circuit

breaker(s) or remove the dryer’s circuit fuse(s) at

the electrical box. Be sure the dryer

cord is unplugged from the wall.

• Turn the dryer’s gas shut-off valve in the supply line

to the OFF position.

Shut-off

Valve

■

Flexible gas line

connector

■

Duct clamps (2) or

Spring clamps (2)

■

Safety glasses

■

4” dia. metal duct

(recommended)

■

4” dia., UL-listed

flexible metal duct

(if needed)

■

Exhaust hood

■

Duct tape

■

Gas pipe adapters (2)

(for 27” dryers only),

elbow (for 27” dryers

only) and pipe plug

• Disconnect and discard old flexible gas connector

and ducting material.

4

Installation Instructions

WARNING

WARNING

GAS REQUIREMENTS

WARNING

• Use a new CSA International approved flexible

gas supply line. Never reuse old flexible

connectors.

• Install an individual manual shut-off valve

within 6ft. of the dryer in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA

54.

• Securely tighten all gas connections.

• If connected to LP gas, have a qualified

person make sure gas pressure DOES NOT

exceed 13” water column.

• Examples of a qualified person include:

licensed heating personnel, authorized gas

company personnel, and authorized service

personnel.

• Failure to do so can result in death,

explosion, or fire.

• The installation must conform with local

codes, or in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1.

- Explosion Hazard

GAS SUPPLY

• A 1/8” National Pipe Taper thread plugged

tapping, accessible for test gauge connection,

must be installed immediately upstream of the

gas supply connection to the dryer. Contact your

local gas utility should you have questions on the

installation of the plugged tapping.

• Supply line is to be 1/2” rigid pipe and equipped

with an accessible shutoff within 6 feet of, and in

the same room with, the dryer.

• Use pipe thread compound appropriate for

natural or LP gas or use PTFE tape.

• Connect flexible metal connector to dryer and

gas supply.

- Fire Hazard

FOR USE WITH NATURAL GAS ONLY

Dryer as produced by manufacturer is to be used

only with a natural gas supply. A manufacturersupplied conversion kit is required to convert

this dryer for propane gas supply. Use propane

gas conversion kit WE25M73 for 24” models or

WE25M74 for 27” models. Conversion must be

made by properly trained and qualified personnel

in accordance with local codes and ordinances.

DRYER GAS SUPPLY CONNECTION

You must use with this dryer a flexible metal connector

(listed connector ANSI Z21.24 / CSA 6.10). The length

of the connect shall not exceed 3 ft.

ADJUSTING FOR ELEVATION

• Gas clothes dryers input ratings are based on

sea level operation and need not be adjusted

for operation at or below 2000 ft. elevation. For

operation at elevations above 2000 ft., input

ratings should be reduced at a rate of 4 percent

for each 1000 ft. above sea level.

• Installation must conform to local codes and

ordinances or, in their absence, the NATIONAL

FUEL GAS CODE, ANSI Z223.

5

Installation Instructions

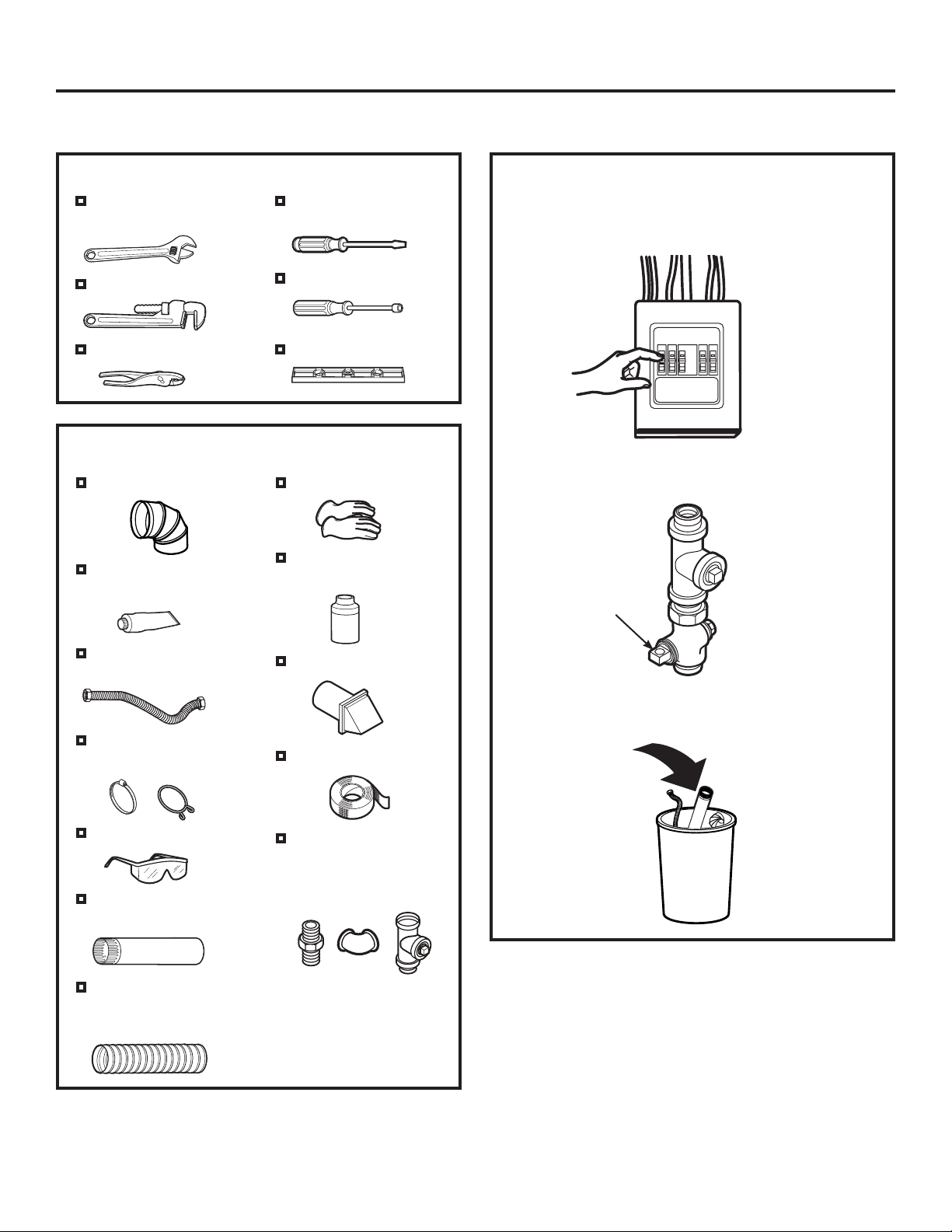

CONNECTING A GAS DRYER (cont.)

CONNECTING THE DRYER TO THE

GAS SUPPLY

Back of

Appliance

24” & 27”

24”

Apply pipe compound to

appliance inlet

27”

Adaptor

27” ONLY

New metal

flexible gas

line connector

Adaptor

1/8” NPT pipe plug

for checking gas

inlet pressure

Shut-O valve

Pipe size at least 1/2”

3/8” NPT inlet

from appliance

27” only

45° Elbow

27” ONLY

Floor

24”

Tighten the flexible gas line

to the appliance inlet using

2 adjustable wrenches.

24” & 27”

Apply pipe compound

to all male threads

24” & 27”

Apply pipe compound

to the adaptor and

appliance gas inlet.

27”

Tighten the flexible gas line to the

adaptor using 2 adjustable wrenches.

Tighten all

connections, using

two adjustable

wrenches. Do not

overtighten.

Open the gas shut-off valve.

6

Loading...

Loading...