GE GTUN275EM0WW, GTUN275EM1WW, GTUN275EM2WW, GTUN275GM0WW, GTUN275GM1WW Installation Guide

...Page 1

Installation

Unitized Gas

Instructions

Questions on installation? Call: 1-800-GECARES (US}or Visit our Web site at: www.GEAppliunces.com (US).

In Canada, call 800-561-3344 or visit www.GEAppliunces.cu.

BEFOREYOU BEGIN

Readtheseinstructions completely and

carefully.

•IMPORTANT-Save these instructionsfor

localinspector'suse.

•IMPORTANT- Observe all governing

codesandordinances.

• Note to Installer - Be sure to leave these

instructionswith thecustomer.

• Note to Customer - Keepthese instructions

with your Use and Care Book for future

reference.

• Beforethe appliance isremovedfrom service

or discarded, remove the washer and dryer

door.

•inspectthedryerexhaustoutletandstraighten

theoutlet walls if they are bent.

• Service information and the wiring diagram

are locatedat the accesspanel.

• Do not allow childrenon or in the appliance.

Close supervision of children is necessary

whentheappliance isusednearchildren.

• Install the dryer where the temperature is

above50°F(].O°C)for satisfactory operationof

thedryercontrol system.

WARNING RISK OF FIRE

, Toreducethe riskofsevereinjuryordeath,followallinstallationinstructions.

. Applianceinstallationmustbeperformedbyaqualifiedinstaller.

. Installtheclothesapplianceaccordingtotheseinstructionsandinaccordancewithlocal

codes.In theabsenceof localcodes,installationmustcomplywith NationalFuelGas

Code,ANSIZ223.1/NFPA54ortheCanadianNaturalGasandPropaneInstallationCode,

CSAB149,1,

,CalifomiaSafeOnnkingWaterandToxicEnforcementAct.

Thisact requiresthegovernorofCaliforniato publisha listofsubstancesknowntothe

statetocausecancer,birthdefectsorotherreproductiveharmandrequiresbusinesses

to warn customersof potentialexposureto suchsubstances.Gasappliancescan

causeminorexposureto fourof thesesubstances,namelybenzene,carbonmonoxide,

formaldehydeandsoot,causedprimarilybytheincompletecombustionof naturalgas

or LPfuels.Properlyadjusteddryerswillminimizeincompletecombustion.Exposureto

thesesubstancescanbeminimizedfurtherbyproperlyventingthedryertotheoutdoors.

, Thisappliancemustbeexhaustedtotheoutdoors.

, Useonly4"rigidmetalductingforexhaustingtheappliancetotheoutdoors.

, DONOTinstalla clothesdryerwithflexibleplasticductingmaterials.Ifflexiblemetal

(semi-rigidorfoiFtype)ductisinstalled,it mustbeULlistedandinstalledinaccordance

withtheinstructionsfoundin"ConnectingTheDryerTo HouseVent"onpage8 ofthis

manual.Flexibleventingmaterialsareknowntocollapse,beeasilycrushed,andtraplint.

Theseconditionswillobstructdryerairflowandincreasetheriskoffire.

, Donotinstallorstorethisapplianceinanylocationwhereitcouldbeexposedtowater

andorweather.

, Savetheseinstructions.(Installers:Besuretoleavetheseinstructionswiththecustomer).

--i@

Washer/Dryer

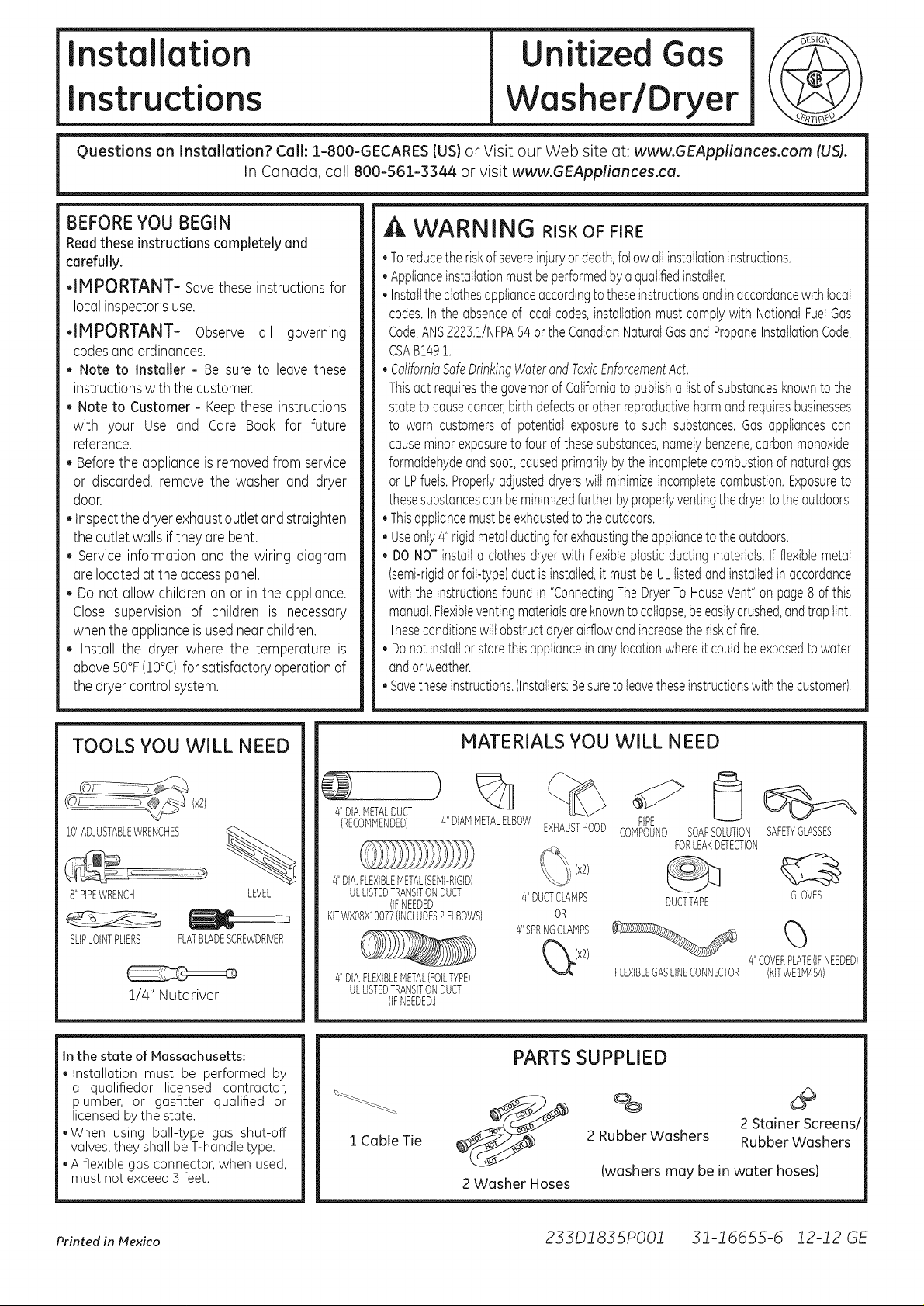

TOOLS YOU WILL NEED

{x2I

i0" ADJUSTABLEWRENCHES _._

8"PIPEWRENCH LEVEL

SUPJOINTPUERS FLATBLADESCREWDRIVER

1/4" Nutdriver

In the state of Massachusetts:

• Installation must be performed by

e qualifledor licensed contractor,

plumber, or gesfltter qualified or

licensed by the state.

• When using bell-type gas shut-off

valves, they shell be T-handle type.

• A flexible gas connector, when used,

must not exceed 3 feet.

MATERIALS YOU WILL NEED

4'IDIA.METALDUCT

(RECOMMENDED) 4'IDIAMMETALELBOW

4"DIA.FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

KITWXO8XlO077(INCLUDES2ELBOWS)

4"DIA.FLEXIBLEMETAL(FOILTYPE)

(IFNEEDED)

ULLISTEDTRANSITIONDUCT

(IFNEEDED.)

1.Cable Tie

2 Washer Hoses

EXHAUSTHOOD

(x2)

4"DUCTCLAMPS

OR

4"SPRINGCLAMPS

PIPE

COMPOUND SOAPSOLUTION

FLEXIBLEGASLINECONNECTOR

PARTS SUPPLIED

% O

2 Rubber Washers Rubber Washers

(washers may be in water hoses)

FORLEAKDETECTION

DUCTTAPE

2 Stainer Screens

SAFETYGLASSES

GLOVES

<5

4"COVERPLATE(IFNEEDED)

(KITWEIM454)

Printedinlexico 233D1835PO01 31-16655-6 12-12 GE

Page 2

Installation

nstructions

INSTALLATION REQUIREMENTS LOCATION

Thisappliance must beinstalled on firm flooring to minimize

vibration during spin cycle. Concrete flooring is best, but

wood base is sufficient, provided floor support meets FHA

standards. This appliance should not be installed on rugs

or exposed to weather.

PLUMBING

WATERPRESSURE- Must be 20 psi minimum to 120 psi

maximum.

WATERTEIVlPERATURE- Household water heater should be

set to deliver water at 120° to 150°F (50° to 66°C) IN THE

WASHERwhen hot wash is selected.

SHUTOFFVALVES-Bothhot and cold shutoffvalves (faucets)

should be supplied.

DRAIN- Water may be drained into standpipe or set tub.

Discharge height MUSTNOT BE LESSTHAN 30 INCHES,

and no more than 6 feet above the base of the washer.

Standpipe must be 1-!/2 inches minimum inside diameter

and must be open to atmosphere.

Verify Your Gas Installation (see section 2).

Step 1

Prepare the Area and Exhaust for Installation of

Step 2

appliance (seesection 1).

Check and Insure the Existing External Exhaust

Step 3

is Clean (seesection 1)and Meets Attached

Installation Specifications (see section 6).

Remove the Foam Shipping Pads (seesection 1).

Step 4

Move the appliance to the Desired Location.

Step 5

Levelyour appliance (seesection 8).

Step 6

Connect the Gas Supply (seesection 3) and check

Step 7

for leaks (seesection 4).

Connect the External Exhaust (seesection 7).

Step 8

Connect to plumbing facilities (seesection 11).

Step 9

ELECTRICAL REQUIREMENTS

CAUTION: Before plugging in washer, read the following

electrical requirements.

CAUTION: For personal safety, do not use an extension

cord or adapter plug with this appliance. Do not, under any

circumstances, cut or remove the third grounding prong

from the power cord. Follow national electrical codes and

ordinances. Thisappliance must besupplied with the voltage

and frequency indicated on the rating plate (located at the

top of the dryer front panel),and connected to an individual,

properly grounded branch circuit, protected by a 15- or 20-

amp circuit breaker or time-delay fuse. If the electric supply

provided does not meet the above requirements, call a

licensed electrician.

Step 10 Connect the Power Supply (seesection 5).

Step 11 Check the Operation of the Power Supply, Gas

Connections, and Venting.

Step 12 Place the Owners Manual and the Installation

Instructions in a Location Where They Will Be

Noticed Bythe Owner.

For Alcove or Closet Installation see section 1:3.

For Bathroom or Bedroom Installation see section 14.

For Mobile or Manufactured Home see section 12.

ADJUSTING FOR ELEVATION

. Gas clothes dryers input ratings are based on sea level

operation and need not be adjusted for operation at

or below 2000 ft. elevation. For operation at elevations

above 2000 ft., input ratings should be reduced at a rate

of 4 percent for each 1000 ft. above sea level.

. Installation must conform to local codes and ordinances

or, in their absence with the National Fuel Gas Code,

ANSI Z22:3.1/NFPA54, or the Natural Gas and Propane

Installation Code,CSAB149.1.

2

Page 3

L5

Installation Instructions

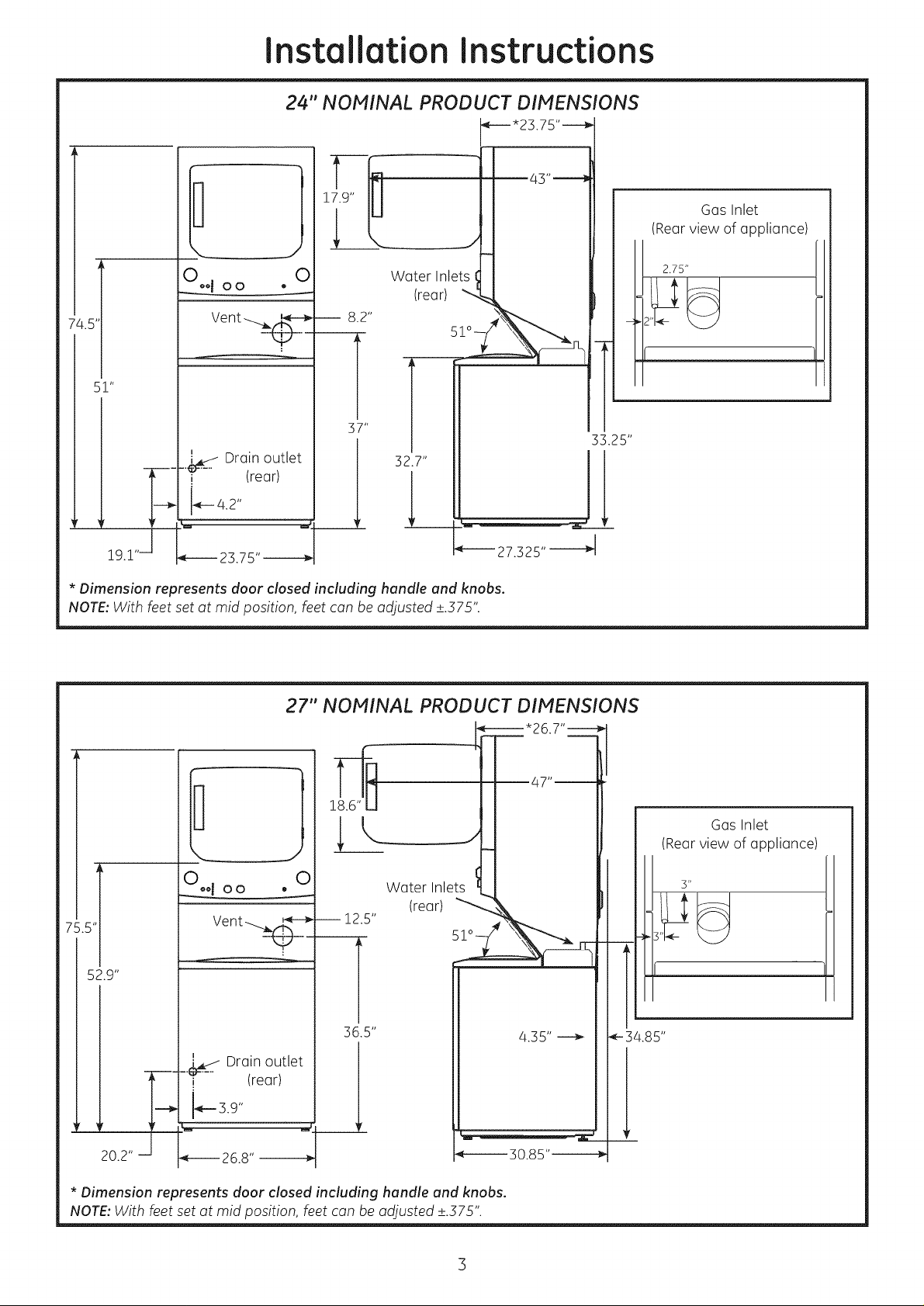

24" NOMINAL PRODUCT DIMENSIONS

_---'23.75"----_

Gas Inlet

(Rearview of appliance)

W(]ter Inlets

(reor)

51"

* Dimension represents door closed including handle and knobs.

NOTE:With feet set at mid position, feet can be adjusted +_.575".

27" NOMINAL PRODUCT DIMENSIONS

_------'26.7"-----_

0oolo o O

--12.5"

52.9"

W(]ter Inlets

]

36.5"

_47"_

Gas Inlet

(Rec]rview of appliance)

4.35"

_._ Drc]in outlet

i (rec]r)

_-- 3.9"

F

_--- 26.8"

* Dimension represents door closed including handle and knobs.

NOTE:With feet set at mid position, feet can be adjusted +_.575".

L

_------ 30.85"------_

3

Page 4

Installation Instructions

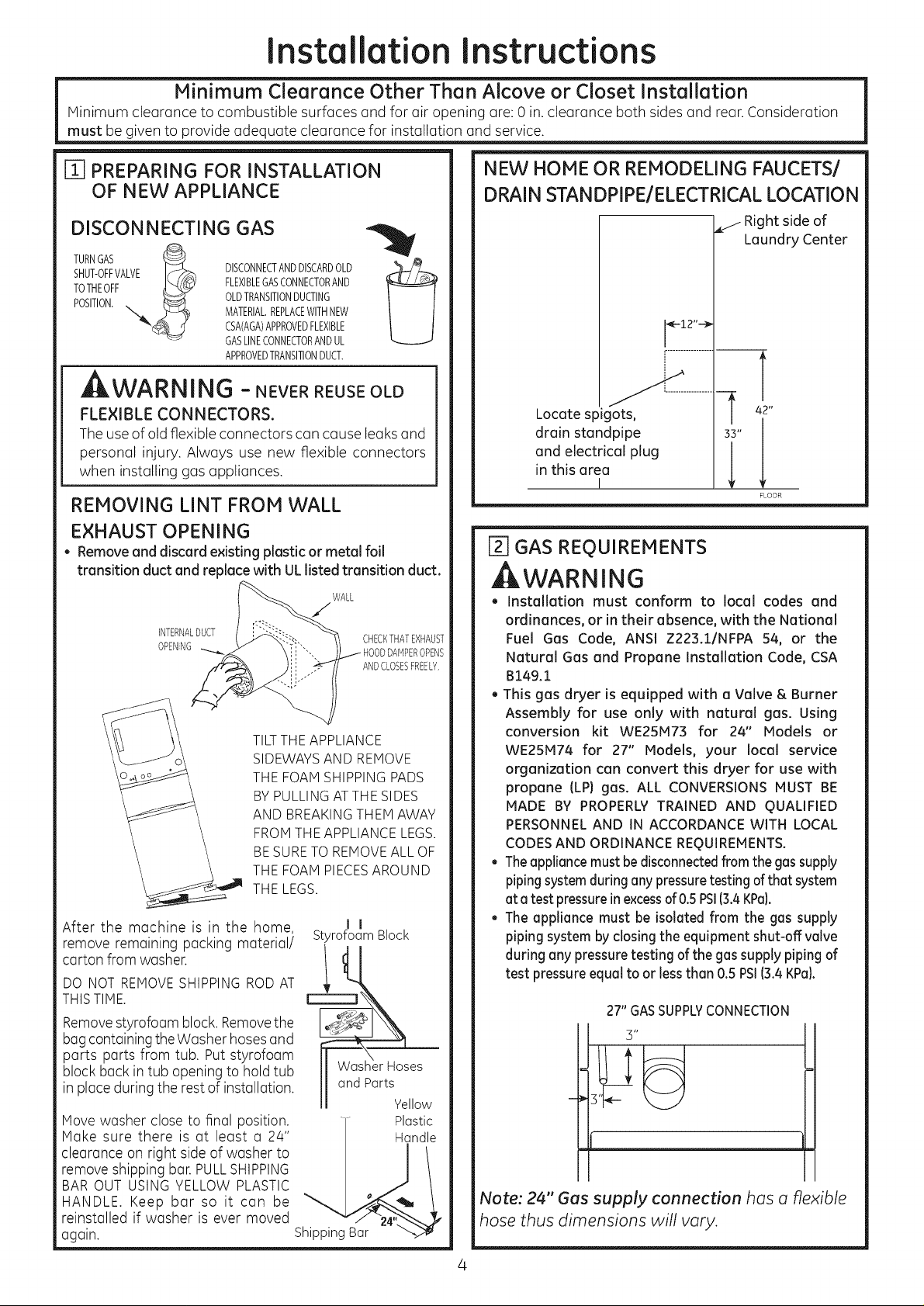

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and rear.Consideration

must be given to provide adequate clearance for installation and service.

I-_ PREPARING FOR INSTALLATION

OF NEW APPLIANCE

NEW HONE OR REMODELING FAUCETS/

DRAIN STANDPIPE/ELECTRICAL LOCATIO N

DISCONNECTING GAS

TURNGAS

SHUT-OFFVALVEI_ DISCONNECTANDDISCARDOLD,_._,

TOTHEOFF ___ FLEXIBLEGASCONNECTORAND

POS,T,ON OLDTRANS,T,ONDUCT,NG

MATERIAL.REPLACEWITHNEW

CSA(AGA)APPROVEDFLEXIBLE

GASLINECONNECTORANDUL

APPROVEDTRANSITIONDUCT.

WARNING - NEVERREUSEOLD

FLE×IBLE CONN ECTORS.

Theuse of old flexible connectors can cause leaks and

personal injury. Always use new flexible connectors

when installing gas appliances.

REMOVING LINT FROM WALL

EXHAUST OPENING

• Removeand discard existing plastic or metal foil

transition duct and replace with ULlisted transition duct.

_j WALL

INTERNAL_t_,].DUCT _ CHECKTHATEXHAUST

OPENING -'_-_ \ G "'.. HOODDAPIPEROPENS

TILTTHEAPPLIANCE

SIDEWAYSAND REMOVE

THE FOAMSHIPPINGPADS

BYPULLINGATTHESIDES

AND BREAKINGTHEMAWAY

FROMTHEAPPLIANCELEGS.

BESURETOREMOVEALL OF

THE FOAMPIECESAROUND

THE LEGS.

After the machine is in the home,

remove remaining packing material/

carton from washer.

DO NOT REMOVE SHIPPING ROD AT

THISTIME.

Removestyrofoam block. Removethe

bag containing theWasher hosesand

parts parts from tub. Put styrofoam

block back in tub opening to hold tub

in placeduring the rest of installation.

Hove washer close to final position.

Make sure there is at least a 24"

clearance on right side of washer to

remove shipping bar.PULLSHIPPING

BAROUT USINGYELLOWPLASTIC

HANDLE. Keep bar so it can be

reinstalled if washer is ever moved

again.

StyrofoamBlock

ANDCLOSESFREELY.

II

and Parts

Yellow

" Plastic

/ Handle

I-_ GAS REQUIREMENTS

WARNING

, Installation must conform to local codes and

ordinances, or in their absence, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the

Natural Gas and Propane Installation Code, CSA

B1491

. Thisgas dryerisequippedwitha Valve& Burner

Assembly foruse onlywith naturalgas Using

conversion kit WE25M73 for 24" Models or

WE25M74 for 27" Models,your localservice

organizationcan convertthisdryerforuse with

propane (LP)gas ALL CONVERSIONS MUST BE

MADE BY PROPERLY TRAINED AND QUALIFIED

PERSONNEL AND IN ACCORDANCE WITH LOCAL

CODES AND ORDINANCE REQUIREMENTS

• Theappliancemustbedisconnectedfromthegassupply

pipingsystemduringanypressuretestingofthatsystem

ata testpressureinexcessof05 PSI(34KPa)

• The appliancemustbe isolatedfromthegassupply

pipingsystembyclosingtheequipmentshutoffvalve

duringanypressuretestingofthegassupplypipingof

testpressureequaltoorlessthan05 PSI(34KPa)

Note: 24" Gas supply connection has a flexible

hose thus dimensions will vary.

Right side of

Laundry Center

12"--_

Locate spigots, "

drain standpipe s3" |

and electrical plug |

in this area

!

27" GASSUPPLYCONNECTION

_ .................. _|

!

FLOOR

3"

4

Page 5

Installation Instructions

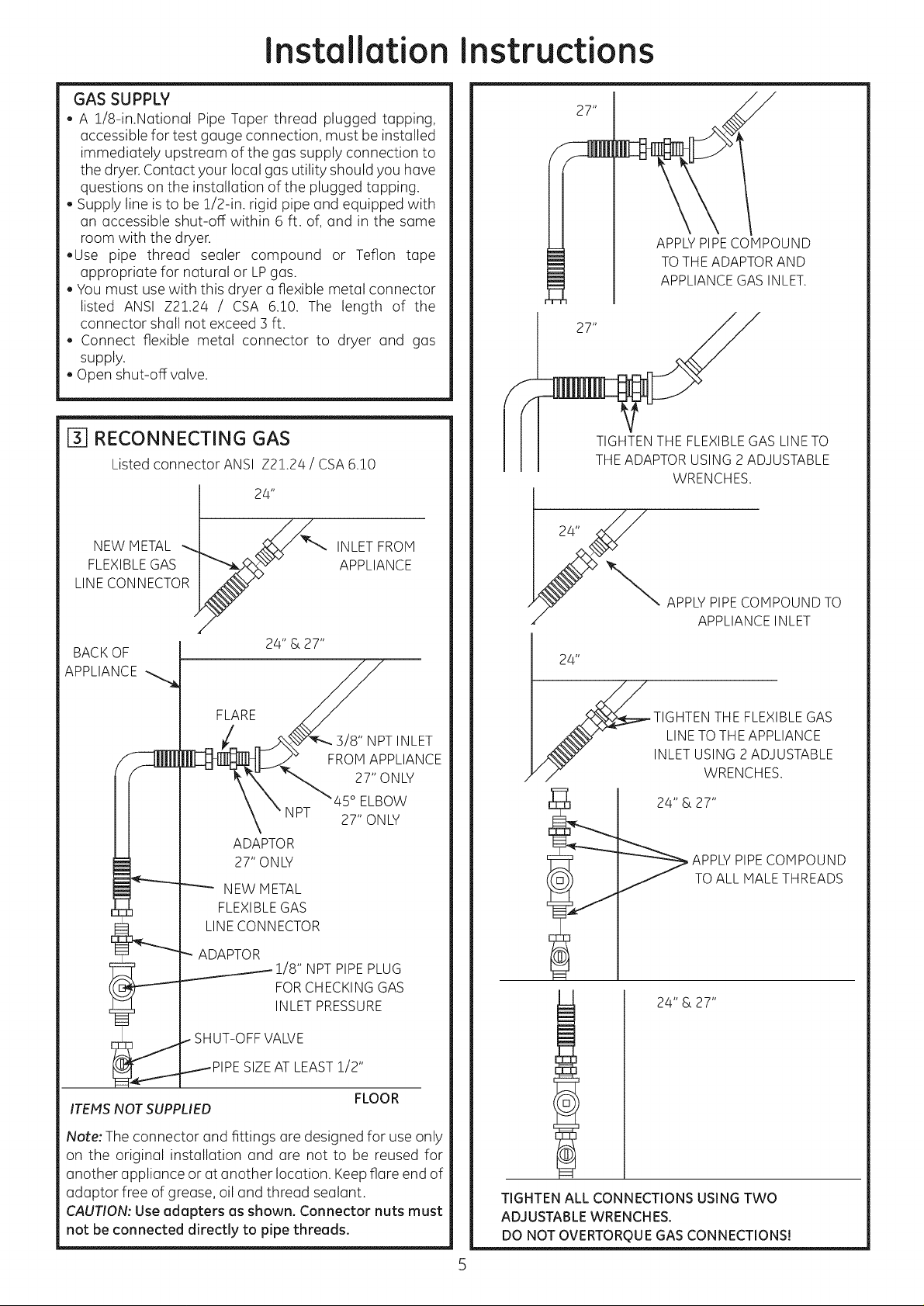

GAS SUPPLY

, A 1/8-in.National Pipe Taper thread plugged tapping,

accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to

the dryer, Contact your local gas utility should you have

questions on the installation of the plugged tapping.

. Supply line isto be 1/2-in. rigid pipe and equipped with

an accessible shut-off within 6 ft. of, and in the same

room with the dryer.

,Use pipe thread sealer compound or Teflon tape

appropriate for natural or LPgas.

, You must usewith this dryer a flexible metal connector

listed ANSI Z21.24 / CSA 6.10. The length of the

connector shall not exceed 3 ft.

, Connect flexible metal connector to dryer and gas

supply.

, Open shut-off valve.

RECONNECTING GAS

Listed connector ANSI Z21.24 / CSA6.10

24"

NEW METAL _.. _ _k_>4/ '_

FLEXIBLEGAS

INLET FROM

APPLIANCE

LINECONNECTOR

/

BACK OF

APPLIANCE

2a" & 27"

27"

APPLYPIPECOMPOUND

TOTHEADAPTORAND

APPLIANCEGASINLET.

TIGHTENTHEFLEXIBLEGASLINETO

THEADAPTORUSING2ADJUSTABLE

WRENCHES.

APPLY PIPE COMPOUND TO

APPLIANCE INLET

24"

FLARE

/8" NPT INLET

FROM APPLIANCE

27"ONLY

ELBOW

27" ONLY

ADAPTOR

27" ONLY

NEW METAL

FLEXIBLE GAS

LINE CONNECTOR

ADAPTOR

SHUT-OFF VALVE

ITEHS NOT SUPPLIED

NPT PIPE PLUG

FOR CHECKING GAS

INLET PRESSURE

AT LEAST 1/2"

FLOOR

Note: The connector and fittings are designed for use only

on the original installation and are not to be reused for

another appliance or at another location. Keepflare end of

adaptor free of grease, oil and thread sealant.

CAUTION: Use adopters as shown. Connector nuts must

not be connected directly to pipe threads.

;HTEN THE FLEXIBLE GAS

LINE TO THE APPLIANCE

INLET USING 2 ADJUSTABLE

WRENCHES.

24" & 27"

_ APPLY PIPECOMPOUND

TIGHTEN ALL CONNECTIONS USING TWO

ADJUSTABLE WRENCHES.

DO NOT OVERTORQUE GAS CONNECTIONS!

TO ALL MALE THREADS

24" & 27"

5

Page 6

Installation Instructions

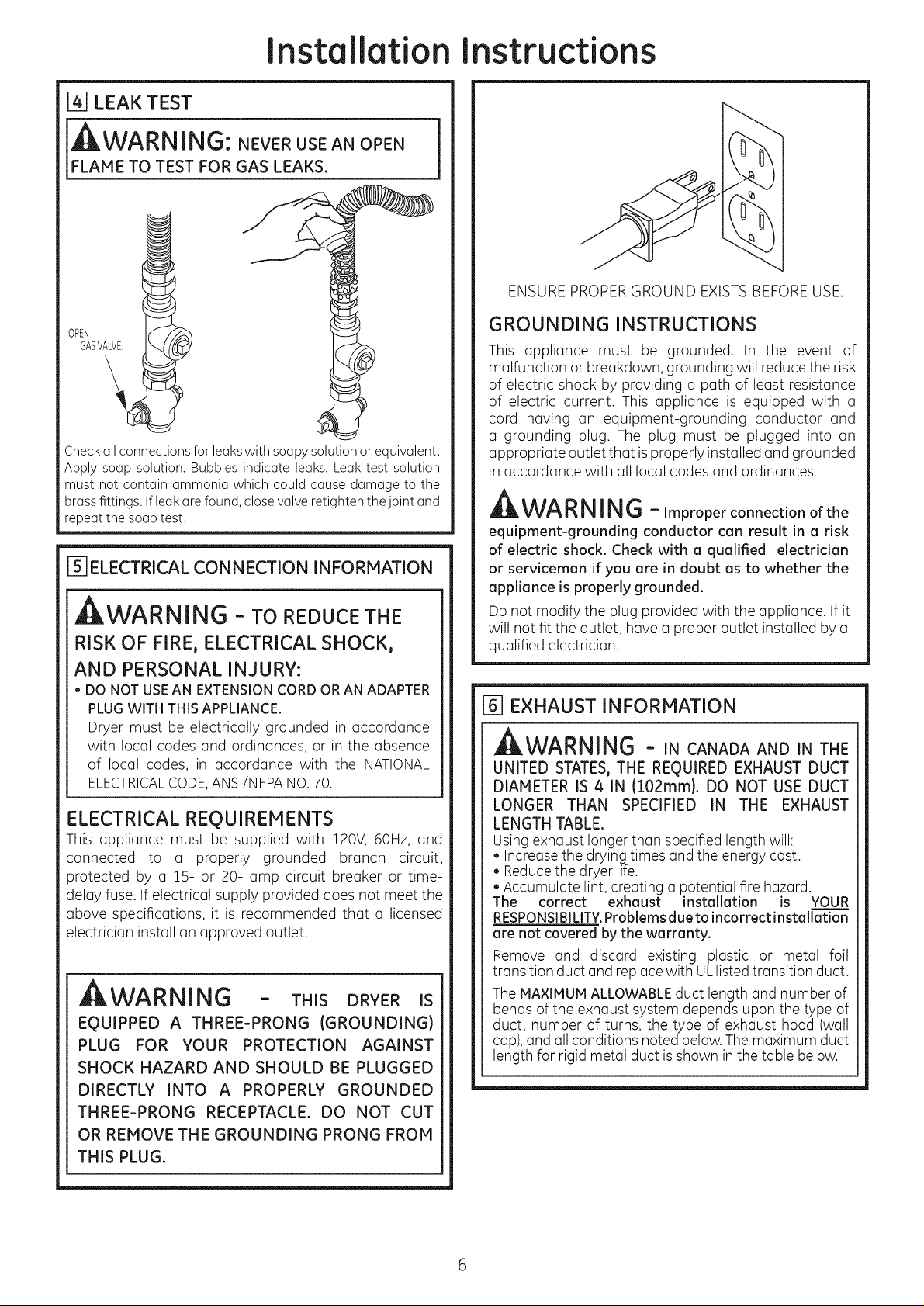

[-4]LEAK TEST

I WARNING: NEVER USE AN OPEN

FLAME TO TEST FOR GAS LEAKS.

ENSURE PROPERGROUND EXISTSBEFOREUSE.

OPEN

GASVALVE.

Check oil connections for leaks with soapy solution or equivalent.

Apply soap solution. Bubbles indicate leaks. Leak test solution

must not contain ammonia which could cause damage to the

brass fittings, tfleak are found, close valve retighten thejaint and

repeat the soap test.

[_ELECTRICAL CONNECTION INFORMATION

WARNING - TO REDUCE THE

RISK OF FIRE, ELECTRICAL SHOCK,

AND PERSONAL INJURY:

. DO NOT USEAN EXTENSIONCORDOR AN ADAPTER

PLUGWITH THISAPPLIANCE.

Dryer must be electrically grounded in accordance

with local codes and ordinances, or in the absence

of local codes, in accordance with the NATIONAL

ELECTRICALCODE,ANSI/NFPANO.70.

ELECTRICAL REQUIREMENTS

This appliance must be supplied with 120V, 60Hz, and

connected to u properly grounded brunch circuit,

protected by u 15- or 20- amp circuit breaker or time-

delay fuse. If electrical supply provided does not meet the

above specifications, it is recommended that a licensed

electrician install an approved outlet.

, WARNING - THIS DRYER IS

EQUIPPED A THREE-PRONG (GROUNDING)

PLUG FOR 'fOUR PROTECTION AGAINST

SHOCK HAZARD AND SHOULD BE PLUGGED

DIRECTLY INTO A PROPERLY GROUNDED

THREE-PRONG RECEPTACLE. DO NOT CUT

OR REMOVE THE GROUNDING PRONG FROM

THIS PLUG.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk

of electric shock by providing u path of least resistance

of electric current. This appliance is equipped with a

cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into an

appropriate outlet that isproperly installed and grounded

in accordance with all local codes and ordinances.

WARN IN G - Improper connectionofthe

equipment-grounding conductor can result in a risk

of electric shock. Check with a qualified electrician

or serviceman if you are in doubt as to whether the

appliance is properly grounded.

Do not modify the plug provided with the appliance. If it

will not fit the outlet, have a proper outlet installed by a

qualified electrician.

_-I EXHAUST INFORMATION

I WARNING - IN CANADA AND IN THE

UNITED STATES,THE REQUIRED EXHAUST DUCT

DIAMETER IS 4 IN (102ram). DO NOT USE DUCT

LONGER THAN SPECIFIED IN THE EXHAUST

LENGTH TABLE.

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

Reducethe dryer life.

Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR

RESPONSIBILITYoProblems due to incorrect installation

are not covered by the warranty.

Remove and discard existing plastic or metal foil

transition duct and replace with ULlisted transition duct.

The MAXIMUM ALLOWABLEduct length and number of

bends of the exhaust system depends upon the type of

duct, number of turns, the type of exhaust hood (wall

cap), and all conditions noted below. The maximum duct

length for rigid metal duct isshown in the table below.

6

Page 7

Installation instructions

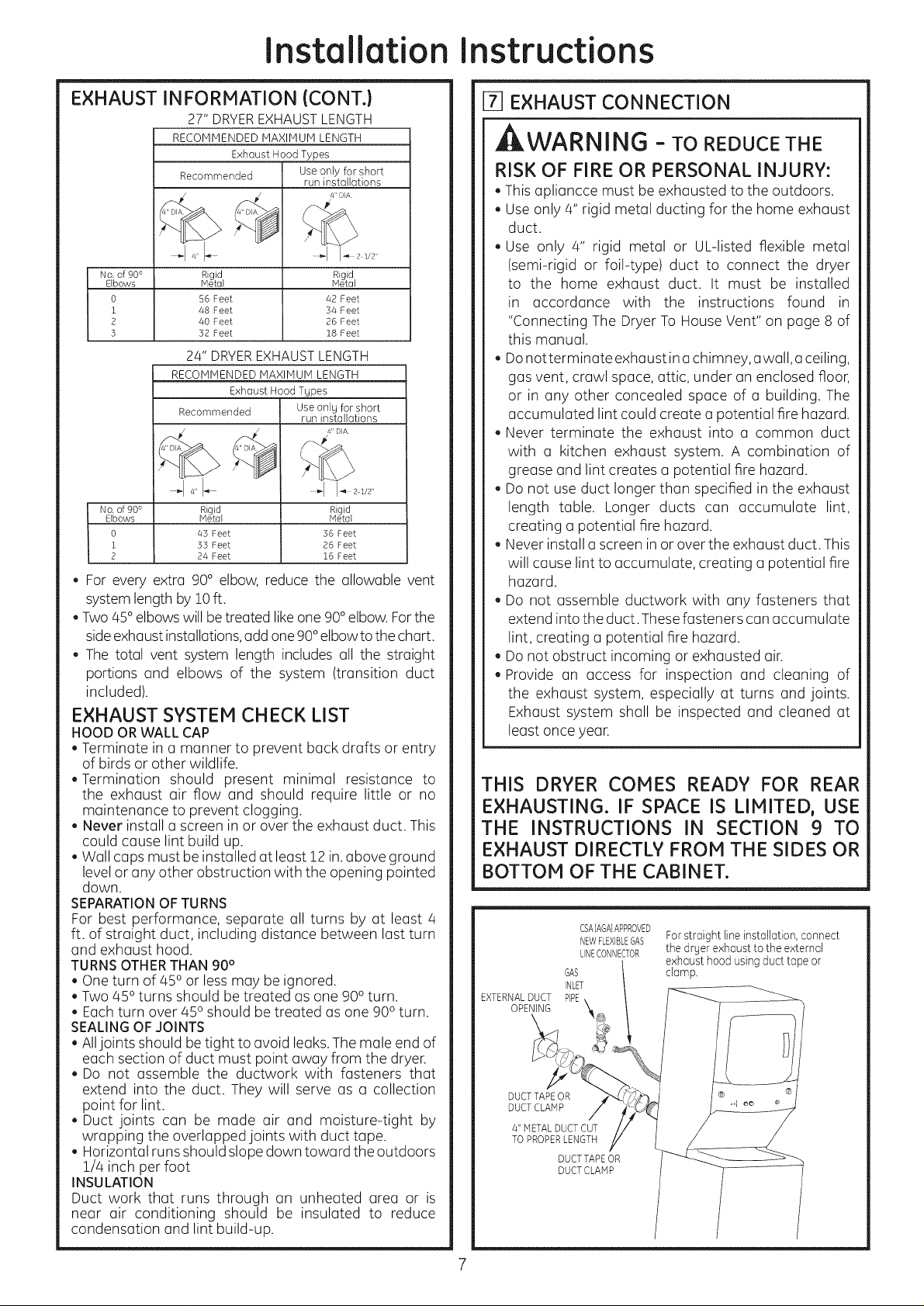

EXHAUST INFORMATION (CONT.)

27" DRYEREXHAUSTLENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended

No. of 900 Rigid Rigid

Elbows Metal Metal

O 56 Feet 42 Feet

i 48 Feet 34 Feet

2 40 Feet 26 Feet

3 32 Feet 18 Feet

Use only for short

run installations

24" DRYEREXHAUSTLENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended Use only for short

No. of 900 Rigid Rigid

Elbows Metal Metal

O 45 Feet 56 Feet

i 53 Feet 26 Feet

2 24 Feet 16 Feet

run installations

, For every extra 90° elbow, reduce the allowable vent

system length by 10ft.

, Two 45°elbows will be treated likeone 90°elbow. Forthe

sideexhaust installations,add one 90° elbow to the chart.

, The total vent system length includes all the straight

portions and elbows of the system (transition duct

included).

EXHAUST SYSTEM CHECK LIST

HOOD ORWALL CAP

, Terminate in a manner to prevent back drafts or entry

of birds or other wildlife.

, Termination should present minimal resistance to

the exhaust air flow and should require little or no

maintenance to prevent clogging.

, Never install u screen in or over the exhaust duct. This

could cause lint build up.

, Wall cups must be installed at least 12 in.above ground

level or any other obstruction with the opening pointed

down.

SEPARATIONOFTURNS

For best performance, separate all turns by at least 4

ft. of straight duct, including distance between lust turn

and exhaust hood.

TURNS OTHERTHAN 90°

, One turn of 450 or less may be ignored.

, Two 450 turns should be treated us one 900 turn.

, Each turn over 450 should be treated as one 900 turn.

SEALINGOFJOINTS

, Alljoints should be tight to avoid leaks. The mule end of

each section of duct must point away from the dryer.

, Do not assemble the ductwork with fasteners that

extend into the duct. They will serve as a collection

point for lint.

, Duct joints can be made air and moisture-tight by

wrapping the overlapped joints with duct tape.

, Horizontal runs should slope down toward the outdoors

1/4 inch per foot

INSULATION

Duct work that runs through an unheated urea or is

near air conditioning should be insulated to reduce

condensation and lint build-up.

P-JEXHAUST CONNECTION

, WARNING - TO REDUCE THE

RISK OF FIRE OR PERSONAL INJURY:

, This apliancce must be exhausted to the outdoors.

, Use only 4" rigid metal ducting for the home exhaust

duct.

, Use only 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer

to the home exhaust duct. It must be installed

in accordance with the instructions found in

"Connecting The Dryer To House Vent" on page 8 of

this manual.

, Donot terminate exhaust inu chimney, uwall, uceiling,

gas vent, crawl space, attic, under an enclosed floor,

or in any other concealed space of u building. The

accumulated lint could create a potential fire hazard.

, Never terminate the exhaust into a common duct

with u kitchen exhaust system. A combination of

grease and lint creates mpotential fire hazard.

, Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating u potential fire hazard.

, Never install u screen in or over the exhaust duct. This

will cause lint to accumulate, creating mpotential fire

hazard.

, Do not assemble ductwork with any fasteners that

extend into the duct. Thesefasteners can accumulate

lint, creating mpotential fire hazard.

, Do not obstruct incoming or exhausted air.

, Provide an access for inspection and cleaning of

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once year.

THIS DRYER COMES READY FOR REAR

EXHAUSTING. IF SPACE IS LIMITED, USE

THE INSTRUCTIONS IN SECTION 9 TO

EXHAUST DIRECTLY FROM THE SIDES OR

BOTTOM OF THE CABINET.

CSA(AGA}APPROVED

NEWFLEXIBLEGAS For straight line installation, connect

EXTERNALDUCT

OPENING

DUCTTAPEOR

DUCTCLAMP

4" METALDUCTCUT

TO PROPERLENGTH

LINECONNECTOR the drger exhaust to the external

GAS clamp.

INLET

PIPE

DUCTTAPEOR

DUCTCLAMP

exhaust hood using duct tape or

7

Page 8

Installation Instructions

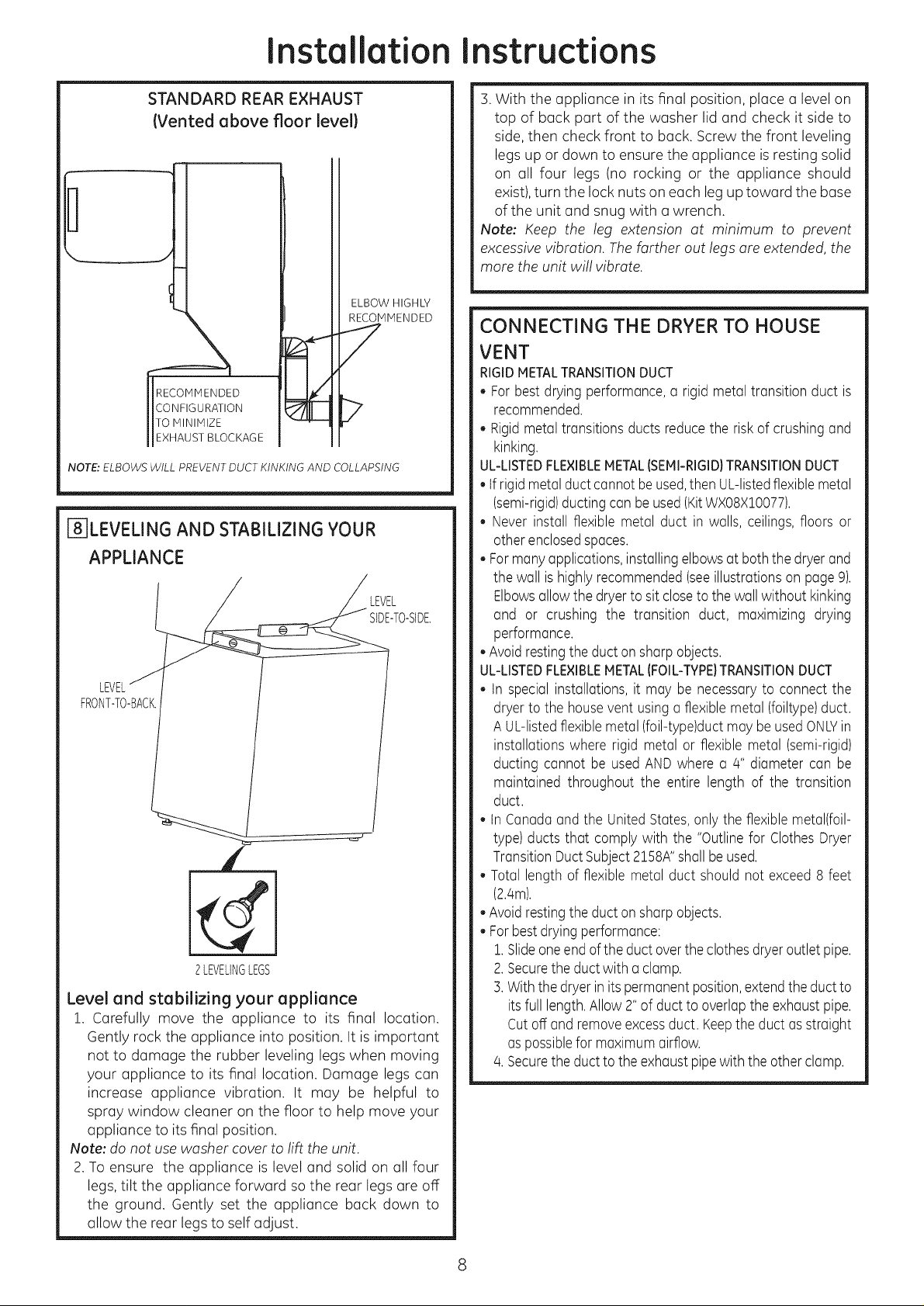

STANDARD REAR EXHAUST

(Vented above floor level}

U

ELBOW HIGHLY

RECOMMENDED

ECOMMENDED

ONFIGURATION

O MINIMIZE

XHAUSTBLOCKAGE

NOTE: ELBOWS WILL PREVENT DUCT KINKING AND COLLAPSING

[8]LEVELING AND STABILIZING YOUR

APPLIANCE

_.__E LEVEL

LEVEL

FRONT-TO-BACK.

2LEVELINGLEGS

Level and stabilizing your appliance

1. Carefully move the appliance to its final location.

Gently rock the appliance into position. It is important

not to damage the rubber leveling legs when moving

your appliance to its final location. Damage legs can

increase appliance vibration. It may be helpful to

spray window cleaner on the floor to help move your

appliance to its final position.

Note: do not usewasher cover to lift the unit.

2. To ensure the appliance is level and solid on all four

legs, tilt the appliance forward so the rear legs are off

the ground. Gently set the appliance back down to

allow the rear legs to self adjust.

2

-TO-SIDE

3.With the appliance in its final position, place a level on

top of back part of the washer lid and check it side to

side, then check front to back. Screw the front leveling

legs up or down to ensure the appliance is resting solid

on all four legs (no rocking or the appliance should

exist), turn the lock nuts on each leg up toward the base

of the unit and snug with a wrench.

Note: Keep the leg extension at minimum to prevent

excessive vibration. The farther out legs are extended, the

more the unit will vibrate.

CONNECTING THE DRYER TO HOUSE

VENT

RIGIDMETALTRANSITIONDUCT

• Forbest drying performance,a rigid metal transition duct is

recommended.

• Rigidmetaltransitions ducts reducethe risk of crushing and

kinking.

UL-LISTEDFLEXIBLEMETAL(SEMI-RIGID)TRANSITIONDUCT

• tf rigidmetal ductcannotbeused,thenUL-listedflexiblemetal

(semi-rigid)ductingcan beused(KitWX08X10077).

• Never install flexible metal duct in walls, ceilings, floors or

otherenclosedspaces.

Formanyapplications,installingelbowsat boththe dryer and

thewall ishighly recommended(seeillustrationsonpage 9).

Elbowsallowthe dryerto sit closeto the wallwithout kinking

and or crushing the transition duct, maximizing drying

performance.

Avoidrestingthe duct on sharpobjects.

UL-LISTEDFLEXIBLEMETAL(FOIL-TYPE}TRANSITIONDUCT

• tn special installations,it may be necessaryto connect the

dryerto the housevent usinga flexiblemetal (foiltype)duct.

AUL-listedflexiblemetal (foil-type)ductmaybe usedONLYin

installations where rigid metal or flexible metal (semi-rigid)

ducting cannot be usedAND where a 4" diameter can be

maintained throughout the entire length of the transition

duct.

tn Canadaand the United States,onlythe flexible metal(foil-

type) ducts that comply with the "Outline for ClothesDryer

TransitionDuctSubject2158A"shallbeused.

Total length of flexible metal duct should not exceed 8 feet

(2.4m).

• Avoidrestingthe duct on sharpobjects.

• Forbestdryingperformance:

1.Slideoneendof the duct overthe clothesdryeroutletpipe.

2.Securetheduct with a clamp.

3.Withthe dryerinits permanentposition,extendthe ductto

its full length.Allow 2" of ductto overlap the exhaustpipe.

Cutoffand removeexcessduct. Keepthe duct asstraight

aspossiblefor maximumairflow.

/4.Securetheductto the exhaustpipewith the otherclamp.

8

Page 9

DO NOT _

EXCESSIVE

EXHAUST

USE

Installation instructions

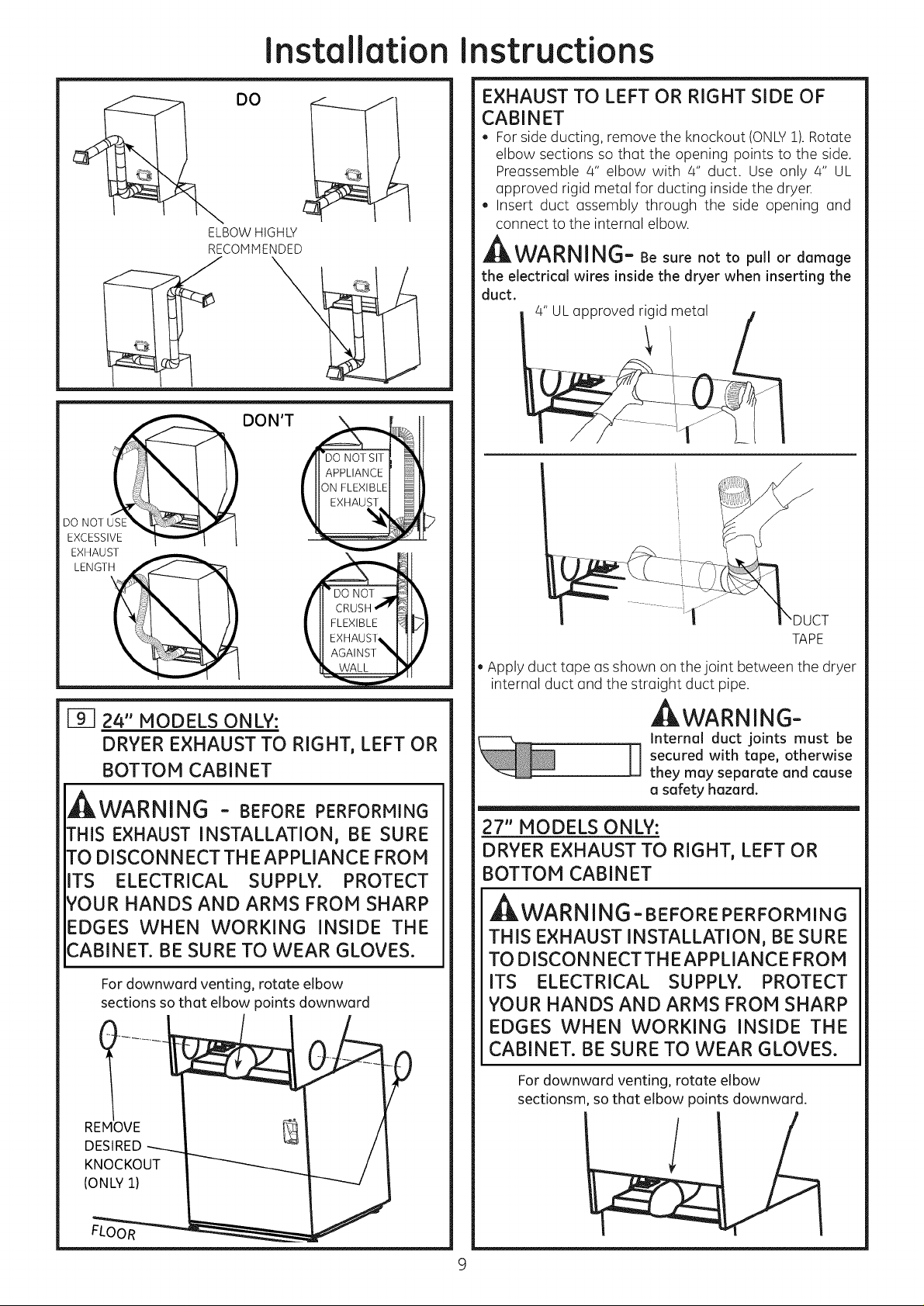

DO

ELBOW HIGHLY

RECOMMENDED

DON'T

EXHAUST TO LEFT OR RIGHT SIDE OF

CABINET

, For side ducting, remove the knockout (ONLY1).Rotate

elbow sections so that the opening points to the side.

Preassemble 4" elbow with 4" duct. Use only 4" UL

approved rigid metal for ducting inside the dryer.

, Insert duct assembly through the side opening and

connect to the internal elbow.

WARNING- Be sure not to pullor damage

the electrical wires inside the dryer when inserting the

duct.

4" ULapproved rigid metal

I IIAPPLIANCE

I II°NFLEXIBLE

o

[-_ 24" MODELS ONLY:

DRYER EXHAUST TO RIGHT, LEFT OR

BOTTOM CABINET

_WARNING - BEFOREPERFORMING

THIS EXHAUST INSTALLATION, BE SURE

TO DISCON NECTTH EAPPLIANCE FROM

ITS ELECTRICAL SUPPLY. PROTECT

YOUR HANDS AND ARMS FROM SHARP

EDGES WHEN WORKING INSIDE THE

CABINET. BE SURE TO WEAR GLOVES.

For downward venting, rotate elbow

sections so that elbow points downward

DUCT

TAPE

Apply duct tape as shown on the joint between the dryer

internal duct and the straight duct pipe.

WARNING-

Internal duct joints must be

R secured with tape, otherwise

they may separate and cause

a safety hazard.

27" MODELS ONLY:

DRYER EXHAUST TO RIGHT, LEFT OR

BOTTOM CABINET

WARNING -BEFOREPERFORMING

THIS EXHAUST INSTALLATION, BE SURE

TO DISCON NECTTH EAPPLIANCE FROM

ITS ELECTRICAL SUPPLY. PROTECT

YOUR HANDS AND ARMS FROM SHARP

EDGES WHEN WORKING INSIDE THE

CABINET. BE SURE TO WEAR GLOVES.

i

REMOVE

DESIRED

KNOCKOUT

(ONLY1)

FLO0

JJ

!

For downward venting, rotate elbow

sectionsm, so that elbow points downward.

9

Page 10

Installation instructions

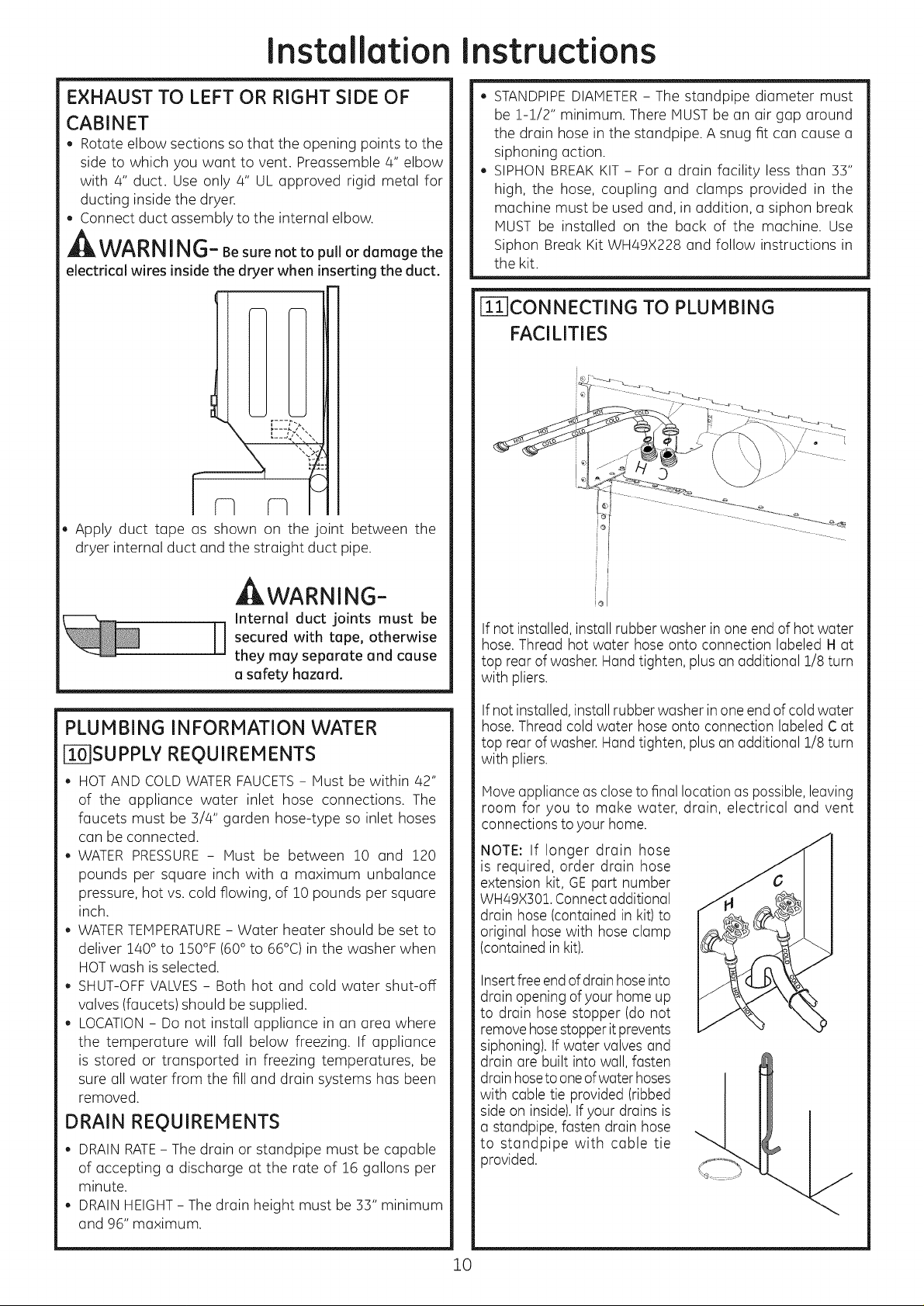

EXHAUST TO LEFT OR RIGHT SIDE OF

CABINET

, Rotate elbow sections so that the opening points to the

side to which you want to vent. Preassemble 4" elbow

with 4" duct, Use only 4" UL approved rigid metal for

ducting inside the dryer.

, Connect duct assembly to the internal elbow.

WARNING- Besure not to pull or damage the

electrical wires inside the dryer when inserting the duct.

, Apply duct tape as shown on the joint between the

dryer internal duct and the straight duct pipe.

, STANDPIPEDIAMETER- The standpipe diameter must

be 1-1/2" minimum. There MUST be an air gap around

the drain hose in the standpipe. A snug fit can cause a

siphoning action.

SIPHON BREAKKIT- For a drain facility less than 33"

high, the hose, coupling and clamps provided in the

machine must be used and, in addition, a siphon break

MUST be installed on the back of the machine. Use

Siphon Break Kit WH/49X228 and follow instructions in

the kit.

[ ]CONNECTING TO PLUMBING

FACILITIES

WARNING-

Internal duct joints must be

H secured with tape, otherwise

they may separate and cause

a safety hazard.

PLUMBING INFORMATION WATER

[ -ISU PPL¥ REQUIREMENTS

, HOTAND COLD WATERFAUCETS- Must be within 42"

of the appliance water inlet hose connections. The

faucets must be 3/4" garden hose-type so inlet hoses

can be connected.

WATER PRESSURE- Must be between 10 and 120

pounds per square inch with a maximum unbalance

pressure, hot vs. cold flowing, of 10 pounds per square

inch.

WATERTEMPERATURE- Water heater should be set to

deliver 140° to 150°F (60° to 66°C) in the washer when

HOTwash is selected.

, SHUT-OFFVALVES- Both hot and cold water shut-off

valves (faucets) should be supplied.

LOCATION- Do not install appliance in an area where

the temperature will fall below freezing. If appliance

is stored or transported in freezing temperatures, be

sure all water from the fill and drain systems has been

removed.

DRAIN REQUIREMENTS

, DRAINRATE- The drain or standpipe must be capable

of accepting a discharge at the rate of 16 gallons per

minute.

, DRAINHEIGHT- The drain height must be 33" minimum

and 96" maximum.

If not installed, install rubber washer in one end of hot water

hose. Thread hot water hose onto connection labeled H at

top rear of washer. Handtighten, plus an additional 1/8 turn

with pliers.

Ifnot installed, install rubber washer in one end of coldwater

hose. Thread cold water hoseonto connection labeled Cat

top rear of washer. Handtighten, plus an additional 1/8 turn

with pliers.

Moveappliance as closeto final location as possible,leaving

room for you to make water, drain, electrical and vent

connections to your home.

NOTE: If longer drain hose

is required, order drain hose

extension kit, GE part number

WH/49X301.Connectadditional

drain hose (contained in kit) to

original hose with hose clamp

(contained in kit).

Insertfree endofdrain hoseinto

drain opening ofyour home up

to drain hose stopper (do not

removehosestopperitprevents

siphoning). If water valves and

drain are built into wall, fasten

drain hoseto oneofwater hoses

with cable tie provided (ribbed

side on inside).Ifyour drains is

a standpipe, fasten drain hose

to standpipe with cable tie

provided.

10

Page 11

Installation instructions

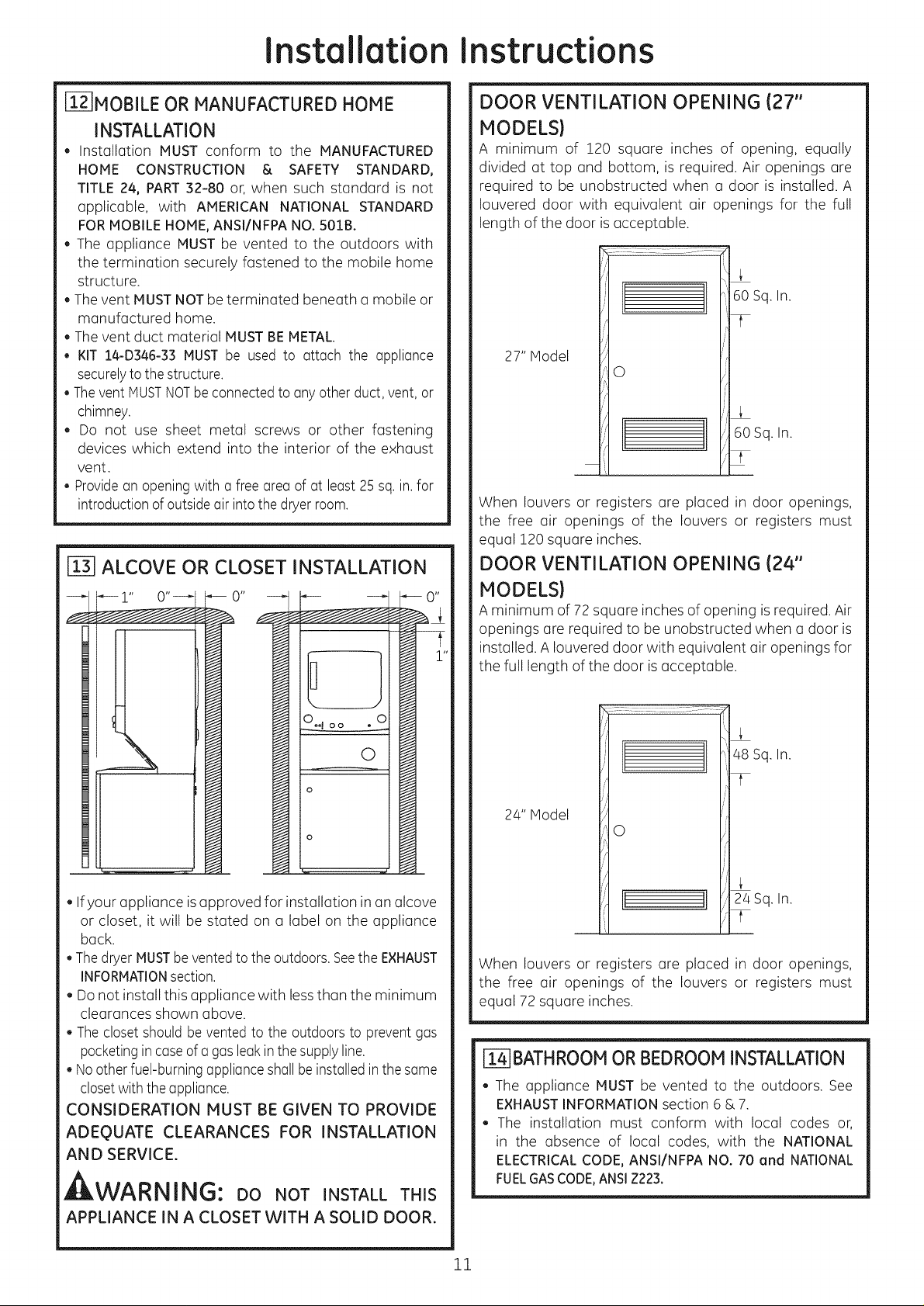

_-2]MOBILE OR MANUFACTURED HOME

INSTALLATION

, Installation MUST conform to the MANUFACTURED

HOME CONSTRUCTION & SAFETY STANDARD,

TITLE 24, PART 32-80 or, when such standard is not

applicable, with AMERICAN NATIONAL STANDARD

FORMOBILEHOME, ANSi/NFPA NO. 501B.

, The appliance MUST be vented to the outdoors with

the termination securely fastened to the mobile home

structure.

, Thevent MUSTNOTbe terminated beneath a mobile or

manufactured home.

, Thevent duct material MUSTBEMETAL.

• KIT 14-D346-33 MUST be used to attach the appliance

securelyto the structure.

• Thevent MUSTNOTbeconnected to anyother duct, vent,or

chimney.

, Do not use sheet metal screws or other fastening

devices which extend into the interior of the exhaust

vent.

• Provideanopening with a freearea of at least 25 sq.in.for

introductionof outsideairinto thedryer room.

ALCOVE OR CLOSET INSTALLATION

DOOR VENTILATION OPENING (27"

MODELS)

A minimum of 120 square inches of opening, equally

divided at top and bottom, is required. Air openings are

required to be unobstructed when a door is installed. A

Iouvered door with equivalent air openings for the full

length of the door is acceptable.

z: :::n::

Sq.In.

27" Model

Mli i o%.,n.

When louvers or registers are placed in door openings,

the free air openings of the louvers or registers must

equal 120 square inches.

DOOR VENTILATION OPENING (24"

MODELS)

A minimum of 72 square inches of opening is required. Air

openings are required to be unobstructed when a door is

installed. A Iouvered door with equivalent air openings for

the full length of the door is acceptable.

, If your appliance isapproved for installation in an alcove

or closet, it will be stated on a label on the appliance

back.

•Thedryer MUSTbevented to theoutdoors.Seethe EXHAUST

INFORMATIONsection.

Donot install this appliance with less than the minimum

clearances shown above.

Thecloset shouldbe vented to the outdoors to prevent gas

pocketingin caseofa gasleakinthe supplyline.

Nootherfuel-burning applianceshall beinstalledinthesame

closetwith the appliance.

CONSIDERATION MUST BE GIVEN TO PROVIDE

ADEQUATE CLEARANCES FOR INSTALLATION

AND SERVICE.

, WARNING: DONOTINSTALLTHIS

APPLIANCE IN A CLOSET WITH A SOLID DOOR.

24" Model

/o/

H II J'ii'J;4 Sq. In.

I'l HT

When louvers or registers are placed in door openings,

the free air openings of the louvers or registers must

equal 72 square inches.

[Z4]BATHROOM OR BEDROOM INSTALLATION

, The appliance MUST be vented to the outdoors. See

EXHAUSTINFORMATIONsection 6 & 7.

, The installation must conform with local codes or,

in the absence of local codes, with the NATIONAL

ELECTRICALCODE,ANSI/NFPA NO. 70 and NATIONAL

FUELGASCODE,ANSIZ223.

11

Page 12

Installation instructions

SERVICING

ILWARNING- LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING

CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION

AFTER SERVICING/INSTALLATION.

Forreplacement parts and other information, refer to Owner's Manual for servicing phone numbers.

REGISTERYOUR NEW APPLIANCE TO RECEIVEANY

IIvlPORTANTPRODUCT NOTIFICATIONS.

Please go to www.GEAppliances.com or mail in your

Product Registration Card.

For questions on installation, call: 800.626.2000 (US)or

800-561-3344 (Canada).

12

Page 13

Instructions

Laveuse/S cheuse

D'Installation

Question sur l'installation? Appelez au 800.561.3344 (Canada)

Ou visitez notre site web: www.electromenagersge.ca.

AVANT DE COMMENCER

Lisezles instructions compl_tement et avec

attention.

•IMPORTANT- Gardezcesinstructionspour

uneutilisationpossiblepar un r@arateur local.

•IMPORTANT- Respecter les normes en

vigueuret ordonnances.

•Note pour I'instaltateur - Assurez-vous de

laissercesinstructionsavec leclient.

•Note pour le client - Gardezces instructions

avec votre manuel d'utilisation et d'entretien

pour uneconsultationfuturepossible.

•Avant que I'appareil soit d@lac@ apres

r@aration ou pour @trejet@,enlevezlesportes

delalaveuseet de las@cheuse.

•Contr61ezlessortiesd'@chappementet redressez

I'installationsurlemur sielleesttordue.

•Lesinformationsder@aration et lediagramme

desconduits sont situ@ssur letableaud'acces.

•Emp@chezles enfants d'@tre sur ou dans

I'appareil.Une supervisionproche des enfants

estn@cessaireIorsqueI'appareilestutilis@.

•tnstallez I'appareil o0 la temp@ature est en-

dessousde50°F(!0°C)pour un fonctionnement

satisfaisantdu systemede contr61e.

Gaz Unifi s

, AVERTISSEMENT- RIESQUED'INCENDIE

•Pourr@duireJesrisquesde blessuresgravesou de mort, suiveziesinstructions

d'instaltation.

•L'installationdeI'appareildolt@refaiteparunepersonnequalifi@.

•Instatlezt'appareilsetoncesinstructionset conform@mentauxnormeslocales.Dans

I'absencede normeslocales,I'instatlationdolt@treconformea taNormeNationale

surleGazetleCombustible,ANSIZ223.Z/NFPA54outaNormeNationateCanadienne

surleGazNaturetetlePropane,CSIBZ49.Z.

•Lesappareilsa gazpeuventcausesuneexpositionmineur@quatredecessubstances,

benz@ne,monoxydede carbone,formaldehydeet suie,caus@principalementpar

la combustionincompl@tedu gaz natureloudesfuelsLRProprementajust@s,les

s_cheusesminimiserontlacombustionincompl@te.L'exposition(_cessubstancespeut

@treminimis@enventilantcorrectementlas_cheuseversI'ext@ieur.

•Cettes@heusedoltavoirunsystemed'@happementversI'ext@ieur.

•Utilisezseulementdesconduitsrigidesen m@talde 4" pour la canalisationde la

s@cheuseversI'ext@ieur.

•NEPASinstallerunes_cheuseavecdesconduitsflexiblesenplastique.Silesconduits

flexiblesde m@al(semi-rigideou en aluminium)sont install_s,ils doivent_treUL

et install@sconform@mentaux instructionstrouv@sdans<<BranchezLaS@heuse

AuxConduitsdela Haison>>dela page8decemanuel.Lesmat@iauxdesconduits

flexiblessontconnuspoursefendre,s'_cras_set_tredespi_ges6 peluches.Ces

conditionsferont obstacleaufluxd'airde las_cheuseet augmenterontles risques

d'incendie.

•N'installezpaset n'entreposezpascet appareitdansun endroitoOil pourrait@tre

expos@a l'eauouau dimat.

•Gardezlesinstructions.(l'installateurdolts'assurerdelaissercesinstructionschez

le client).

OUTILS A UTILISER

(×2)

CLE A PIPE 8"

PINCE TOURNE-VIS PLAT

TOURNE-VIS A DOUILLE _,"

MATERIAL NECESSAIRE

}

TUYAU EN METAL DE

DIAM 4" (RECOMMEN DE)

TUYAU FLEXIBLE EN METAL (SEMIRIGIDE)

UL DE DIAM 4" (SI NECESSAIRE) KIT

WXO8XlO077 (2 COUDES INCLUS)

TUYAU FLEXIBLE EN METAL

(SEMIRIGIDE) UL DE DIAIVi

4" (SI NECESSAIRE)

%

COUDE DE

METAL DE

PIECES FOURNISES

1 COLLIER EN

PLASTIQUE

2 TUYAUX DE LA LAVEUSE

CAPUCHON COMPOSE

D'ECHAPPEMENT TUYAU

2 PINCES DE

TUYAU 4"

OU 2 PINCES

TENDEUR 4"

ROULEAU ADHESIF GANTS

POUR TUYAU

__CHE DE FR_CTECTION

BRANCHEMENT (SI NECESSAIRE) DE 4"

FLEXIBLE A GAZ (KIT WE:Ilvi454)

% oo

2 RONDELLES EN RONDELLES

CAOUTCHOUC ENCAOUTCHOUC

(LES JOINTS PEUVENT ETRE

DANS LES TUYAUX A EAU)

SOLUTION DE SAVON POUR

LA DETECTION DES FUITES

LUNETTES DE

SECURITE

233DI835PO01 31-16655-6 12-12 GE

Page 14

Instructions d'Installation

CONDITIONS D'INSTALLATION DE

L'EMPLACEMENT

Cet appareil doit @reinstall6 sur un solsolidepour minimiser

lesvibrations durant le cycle d'essorage. Lesol en b6ton est

meilleur, mais une base en bois est suffisante. Cet appareil

nedevrait pas 6tre install6 sur un tapis ou e×pos6au climat.

PLOMBERIE

PRESSIONDE UEAU- Elledolt 6tre de 20 psi minimum et

120 psi maximum.

TEMPERATUREDEL'EAU- le chauffe-eau de votre maison

dolt 6tre configur6 pour distribuer uneeau de 120o6!50°F

(50° 6 66o Ct DANS LA LAVEUSEIorsque I'eau chaude est

s61ectionn6e.

VALVESDE FERMETURE- La valve de fermeture d'eau

froide et celle d'eau chaude (robinet) doivent @trefournies.

DRAINAGE- L'eau peut 6tre drain6e par letuyau derejet a

1'6goutou par lebac configur6. La hauteur de 1'6coulement.

NEDOlTPASETREINFERIEUREA 30 POUCES,et pas plusde

6pieds audessusde labase de la laveuse. Letuyau de rejeta

I'@goutdoit mesurer 1-!/2 pouce minimum 6 I'int@ieur du

diam6tre et doit @treouverte vers I'ext@ieur.

CONDITIONS ELECTRIQUES

PRUDENCE: Avant de brancher la laveuse, lisez les

conditions @lectriquessuivantes.

PRUDENCE: Pour votre propre s_curit6, n'utilisez

pas de rallonge ou d'adaptateur avec cet appareil.

Ne coupez pas ni enlevez la troisi_me dent de la prise

61ectrique correspondant (3la masse. Suivez les normes

61ectriques nationales pour le voltage et la fr_quence

indiqu_s sur la plaque de conversion (situ6e au-dessus de

la s6cheuse surle tableau avant), et branchez (_une prise

individuelle,correctement connect6e (3laterre, prot6g6e par

disjoncteur de 15- ou 20-amp ou un fusible (_retardement.

SiI'installation 61ectrique ne r6pond pas aux condition sci-

dessus,appelez un61ectricien qualifi6.

Etape ! V6rifiez votre Installation de Gaz (voir section 2).

Etape 2 Pr6parez la Zone et I'Echappement pour

I'lnstallation de I'Nouvelle Appareil (voir section !).

Etape 3 V@ifiez et Assurez I'Echappement Existant

Externe qu'il soit Propre (voir section 1)et les

Sp6cifications d'lnstallation Ci-jointes (voir

section 6).

Etape 4 Enlevez la Mousse de Rembourrage de Transport

(voir section 1).

Etape 5 D6placez I'appareil au Lieu D6sir6.

Etape 6 Nivelez I'appareil (voir section 8).

Etape 7 Branchez le gaz (voir section 3)et v@ifiez les

fuites (section 4).

Etape 8 Branchez I'Echappement Externe (voir section 7).

Etape 9 Raccordezausyst@mede plomberie (voirsection !1)

Etape10Branchez I'appareil au Courant Electrique (voir

section 5).

AJUSTEMENT POURL'ALTITUDE

. Les classifications du gaz d'entr6e d'une s6cheuse

(3 gaz sont bas6es sur le fonctionnement au niveau

de la met et aucun ajustement n'est n6cessaire pour

fonctionner (3 une altitude de 2000 pieds ou moins.

Pour un fonctionnement aux altitudes plus 61ev6esque

2000 pieds, les classifications d'entr6e doivent _tre

r6duites de 4% pour chaque 1000 pieds au-dessus du

niveau de la met.

. L'installation doit _tre conforme aux normes ou

ordonnances Iocaux, ou, dans I'absence de ceux-

ci, conforme (3 la Norme Nationale sur le Gaz et le

Combustible, ANSIZ223.1/NFPA 5/4 ou la Norme

Nationale Canadienne sur le Gaz Naturel et le Propane,

CSIB!49.1.

Etape11V@ifiez le Fonctionnement du Courant Electrique,

du Branchement du Gazet la Ventilation.

Etape12Placez le Manuel de I'Utilisateur et les Instructions

d'lnstallation dans un Lieu O_ IIsSeront Trouv6s

Par le Propri@aire

Pour le Renfoncement ou I'lnstallation dans un iVleuble,

voir section 13.

Pour I'installation dans une salle de bain ou une

chambre, voir section 1/4.

Pour I'installation dans un mobile home, voir section 12.

2

Page 15

.5'

Instructions d'Installation

DIMENSIONS NOMINALES DU PRODUIT 24"

'_--'23.75"---_

- -- 43"'-'--_

Entr6e du gc]z

Arriv#e d'emu

arri_re

51"

, Sortie drainage

-.W arri@re

Vue de I'orri_re de I'opporeil)

2.75"

_--4.2"

* Dimensions Iorsque les portes sont ferrules incluant les poign_es et les boutons.

NOTE: Dimensions en pieds, correspond(]nt 5 _+375".

DIIVlENSiONES NOMINALES DU PRODUIT 27"

_------'26.7"----_

47"

18.6" H

Arriv_e d'eau

Ooolo o , O

Ventilation

--12.5"

Entr6e du gc]z

(rue de I'orri_re de I'opporeil)

52.9"

36.5"

Sortie drainage

_._ orri@re

i_-- 3.9"

_---26.8"

30.85

* Dimensions Iorsque les portes sont ferrules incluant les poign6es et les boutons

NOTE:Dimensions en pieds, correspondant a _+375".

3

Page 16

Instructions d'Installation

Espace Minimum Autre Oue le Renfoncement ou l'installation Dans un Meuble

Uespace minimum pour les surfaces combustibles et I'ouverture d'air sont: 0 in.d'espace de chaque cot# et 6 I'arri_re. Les

consid@ations doivent @redonn@espour fournir un espace ad@quatpour I'installation et la r@paration.

[Tl SE PREPARER POUR L'INSTALLATION

D'UN NOUVEL APPAREIL

DEBRANCHEZ LE GAZ

TOURNEZ DEBRANCHEZETDEBARRASSEZ-_IIf

LAVALVE DE _ VOUS DES ANCIENSTUYAUXA 4qW

FERMETURE _ GAZ FLEXIBLESET LESANCIENS

AGAZA LA JL_/_ HATERIAUX DE TRANBISTION.

POSITIONFERME _--_ REMPLACEZ-LES AVEC UN

BRANCHEMENTA GAZ FLEXIBLE

APPROUVECSA (AGA) NEUF ET

UN TUYAU DE TRANSITION UL

AUSSIAPPROUVE.

i AVERTISSEMENT - NE JAMAm

REUTILISER DES BRANCHEMENTS FLEXIBLES

ANCIENS Uutilisation de branchements flexibles anciens

peut causer desfuites et des blessures personnelles.

Toujours utiliser desbranchements flexibles neufs lorsque

vous installezdesappareils6 gaz.

ENLEVER LES PELUCHES DE

L'OUVERTURE D'ECHAPPEMENT DU

MUR

• Enlevezet d6barrassez-vous des feuilles de m@taletde

plastique du tuyau de transition et remplacez-le avec un

tuyau de transition UL.

/MUR

OUVERTURE VERIFIEZQUELACLE

INTERNEDU ECHAPPEMENT

TUYAU OUVRE ET FERME

PENCHER L'UNITE VERS

LE COTE ET ENLEVER LES

PROTECTIONS DE TRANSPORT

DE STVROMOUSSE EN LES

BRISANT VERS L'EXTERtEUR

DES PATTES DE L'UNITE.

S'ASSURER D'ENLEVER

TOUS LES MORCEAUX DE

DES PATTES.

Apr#s que la machine salt dans votre

maison, enlevez les mat@iaux restants

et cartons de la laveuse.

N'ENLEVEZ PAS LES BARRES DE

TRANSPORT POUR LE MOMENT.

Enlevez le bloc de mousse de

potystyr#ne.Enlevezlesaccontenanties

Tuyauxdejonction et lespi@cesdubac.

Mettezleblocdemoussedepolystyrene

danst'ouverturedu bacpourtenirlebac

enplacedurant lerestedeI'instaltation.

Blocdemousse

i_ncC_°n et i

LIBREMENT

AUTOURS

NOUVELLE MAISON OU NOUVEAU×

ROBINETSICANALISATION D'EVACUATION/

EMPLACEMENT ELECTRIQUE

C6t# droite

du centre de

lavage (laveuse/

s6cheuse)

l 2"---_

i...................

T

Placez la robinetterie, le ..........

connexion @lectriqu6 cet

tuyau d'@vacuation et la i"

endroit.

!

r2]CONDITIONS CONCERNANT LE GAZ

AVERTISSEMENT

, L'installation dolt @reconforme aux normes locales et

ordonnances, ou en absence de ces derniers, conforme

6 la Norme Nationale sur le Gaz et le Combustible,

ANSIZ223.1/NFPA54ou laNorme NationaleCanadienne

sur leGazNaturel et le Propane,CSIBZ49.1.

, Cette s#cheuse 6 gaz est #quip6e d'une Valve et

d'un Bruleur Assembl#s pour I'utilisation unique de

gaz naturel. Utilisant le kit de conversion WE251v173

- 24"/WE25M74 - 27", votre organisation locale

de r#paration pourra convertir cette s6cheuse (3

I'utilisation du propane (LP). TOUTE CONVERSION

DOlT ETREREALISEEPARUNE PERSONNEQUALIFIEE

CONFORMEMENT AUX NORMES LOCALES ET

ORDONNANCESREQUISES.

• La s@cheusedolt @tred@branch@edu systemed'arriv@ede

gazdurant lestests depressiondece m@mesystemepour

untest de pressionsup@ieur60.5 PSi(3.4Kpa).

• Las@cheusedolt @treisol@edeI'arriv@degaz enfermantles

robinets durant tout test de pressiondu gaz d'un test de

pression@galeouinferieur60.5PSi(3.4Kpa).

27" CONNEXION D'ALIMENTATION EN GAZ.

- 3"<--

42"

1

sot --

D_ptacez la laveuse vers la position

finale.Assurez-vousqu'ilyait au mains

24" d'espace 6 droite de la laveuse

pour eniever les barresde transport.

TIREZLESBARRESDETRANSPORT

VERS L'EXTERIEUR UTILISANT LA

POIGNEE JAUNE EN PLASTIQUE.

Gardezlesbarresau cos at]vous

devriezlar_instatl_ou sila taveuseest

d@ptac_eplustard.

REPIARQUE:24" a une connexion d'alimentation en

gaz avec conduit flexible donc lesdimensions vont _tre

differentes.

transport

4

Page 17

Instructions d'Installation

ALIMENTATION DE GAZ

. Un rouleau adh6sif pour branchement a gaz de 1/8 in.,

accessible pour des tests de calibrage du branchement,

doit _tre install6 immadiatement en amont du

branchement d'alimentation en gaz _ la s@cheuse.

Contactez I'entreprise de gaz la plus proche si vous avez

des questions sur I'installation du rouleau adh@sif pour

prise.

. Le branchement d'alimentation doit _tre un tuyau

rigide de 1/2in. et 6quip6 avec une valve de fermeture

accessible a 6 ft. de distance, et dans la m_me piece

que la s_cheuse.

Utilisez le compos6 pour tuyau ou le scotch Taflon

appropri_ pour le gaz naturel et LR

Vous devez utiliser avec cette s@cheuse un

branchement flexible en matal list6 comme

branchement ANSI Z21.24 / CSA6.!0. La Iongueur de

ce branchement ne devrait pas excader 3 ft.

Connectez le branchement flexible en matal 5 la

sacheuse et (3I'alimentation en gaz.

Ouvrez la valve de fermeture.

REBRANCHER LE GAZ

Branchement list6 ANSI Z2!.24 / CSA 6.10

24"

27"

APPLIQUEZLECOMPOSED'

ETANCHEtTEDESTUYAUTERIESA

L'ADAPTATEURETLEENTREEDU GAZ

DELA SECHEUSE

SERRERLA LIGNE DE BRANCHEMENT A

GAZ FLEXIBLE A L'ENTREEA GAZDE LA

SECHEUSE EN UTILISANT 2 CLES/_ MOLETTE

24"

NEUF FLEXIBLEA,

BRANCHEMENT

GAZ EN METAL ENTREEA GAZ

DE LA SECHEUSE

/

RETOUR DE

L'APPAREIL

FLARE

27" SEULEMENT

BRANCHEMENT NEUF

ADAPTATEUR

VALVE DE FERMETURE

TAILLE DU BRANCHEMENT D'AU

MOINS 1/2"

N'EST PAS FOURNI

24" & 27"

NPT ENTREE

DE L'APPAREIL 27"

SEULEMENT

45 ° COUDE

27" SEULEMENT

ADAPTATEUR

FLEXIBLE A GAZ EN

METAL

1/8" POUR VERIFIER

LA PRESSION DU GAZ A

ENTRANT

PLANCHER

J NPT

24"

D' ETANCHEITE DES

/_ APPLIQUEZ LE COMPOSE

TUYAUTERIES A L' ENTREEA

GAZ DE LA SECHEUSE

SERRERLA LIGNE DE

BRANCHEMENT A GAZ

FLEXIBLE A L'ENTREEA GAZ DE

LA SECHEUSE EN UTILISANT 2

CLES/_ MOLETTE

24" & 27"

COMPOSED' ETANCHEITE

APPLIQUEZ LE

DESTUYAUTERIES

SURTOUS LES FILETS

DESPARTIESM/_LE

24" & 27"

Note: Le connecteur et les raccords sont congus pour 6tre

utilisas uniquement sur I'installation d'origine et ne doivent

pas 6tre rautilisas pour un autre appareil ou a un autre endroit.

Gardez fusae fin de I'adaptateur sans graisse, huile et un produit

d'6tanch6it6.

ATTENTION:Utiliser des adaptateurs, comme i!lustr@. Ecrous

connecteur dolt ne pas 6tre connect6 directement (] filetages.

SERRER TOUS LES CONNECTEURS EN UTILISANT

2 CLt]S A MOLETTE. NE PAS SUR-SERREZ PAS LES

CONNECTEURS DE GAZ.

5

Page 18

Instructions d'Installation

[-4-]TEST DE LA FUITE

AVERTISSEMENT: NE3AMAIS

UTILISERUNE FLAMME POUR TESTER S'IL¥ A

DES FUITESDE GAZ.

OUVRIR

A GAZ

LA VALVE

V@ifiez s'il y a des fuites 6 tousles branchements avec

du savon ou un produit 6quivalent. Appliquez la solution

de savon. Des bulles indiquent une fuite. Le test de la

fuite ne dolt pas contenir d'ammoniac car ceci pourrait

causer des d@g6ts au× accessoires en cuivre. Si des

fuites sont rencontr6es, resserrez les joints, et r6p6tez le

test du savon.

FS]INFORMATION CONCERNANT LE

iSlINFORMATION CONCERNANT LE

BRANCHEMENT ELECTRIQUE

ASSUREZ-VOUS QU'IL EXISTE UNE PRISE A LA

TERRE AVANT UTILISATION

INSTRUCTIONS DE MASSE

Cet appareil dolt @tremis (_la terre. En cas de d@faillance

ou de punne, luterre r@duirale risque de choc @lectriqueen

fournissant un chemin de moindre r@sistancedu courant

@lectrique.Cetappareil est @quip@d'un cordon comportant

un conducteur deterre et unefichedeterre. Lafichedoit @tre

branch@edans une priseappropri@e0correctement install@e

et raise en conformit@avec tousles codes locaux unedes

ordonnances.

AVERTISSEMENT - UnemuuvuJse

connexion du conducteur de terre peut entra_'nerun risque

dechoc@lectrique.Consultezun_lectricien ouunr@puruteur

qualifi_ si vous @tesdunsledoute quant 6 savoir si l'appareil

est correctementmise6 la terre.

Nepasmodifier lafichefournie avec I'appareil- sielle n'entre

pas dans la prise,faites installer une prise ad@quatepar un

_lectricienqualifi_.

BRANCHEMENT ELECTRIQUE

AVERTISSEMENT- POUR

REDUIRE LES RISQUES D'INCENDIE,

DE DECHARGE ELECTRIQUE ET DE

BLESSURE PERSONNELLE :

. N'UTILISEZPASDERALONGEELECTRIQUEOU

D'ADAPTATEURAVECCETAPPAREIL.

Cet appareil doit _tre branch_ 6 la terre

conform6ment aux normes locales et ordonnances,

ou dons I'absencede normes locales, conform6ment

AUXNORMESELECTRIQUESNATIONALES,ANSI/NFPA

NO.70.

CONDITIONS ELECTRIQUES

Cet appareil doit @trebranch6 6 une prise 61ectrique 120V,

60Hz, et correctement connect@e@la terre, prot@g6epar

disjoncteur de 15- ou 20-amp ou un fusible 6 retardement.

Si I'installation 61ectriquene r_pond pas aux sp6cifications

ci-dessus, alors appelez un 61ectricien qualifi6.

AVERTISSEMENT - LASECHEUSE

EST EQUIPPEE D'UNE PRISE TRIPHASEE

(MASSE} POUR VOTRE PROTECTION CONTRE

LES RISQUES DE DECHARGES ELECTRIQUES

ET DEVRAIT ETRE BRANCHEE DIRECTEMENT

AU RECEPTAVLETRIPHASE. NE COUPEZ PAS ET

N'ENLEVEZ PAS LA DENT CORRESPONDANT A

LA MASSE SUR LA PRISE.

[] INFORMATION D'ECHAPPEMENT

AVERTISSEMENT -AUCANADAETAU×

USA,LEDIAMETREDU TUYAUD'ECHAPPEMENTREQUISEST4"

(102ram).N'UTILISEZPASDETUYAUPLUSGRANDQUELATAILLE

SPECIFIEEDANSLETABLEAUDELONGUEURD'ECHAPPEMENT.

En utilisantun tuyaud'@chappementplusgrandque

la Iongueur sp#cifi#e, cela :

, Aug.menterale temps de s@chageetles d@enses en

energ_e.

. R6duira la dur_e de vie de la s6cheuse.

. Accumulera lespeluches, cr6ant un risque potentiel

d'incendie.

L'installation correcte d'_chuppement est VOTRE

RESPONSABILITE.Lesprobl_mes dus 6 une installation

incorrecte ne sont pus couverts per la garantie.

Enlevez et d6barrassez-vous des plastiques

existants ou du tuyau detransition en feuilles de

m6tal et remplacez-le par un tuyau de transition

UL. La Iongueur de tuyau MAXIMUM AUTORISEEet

le nombre de coudes du syst_me d'6chappement

d6pend du type de tuyau, du nombre decourbes, du

type du capuchon d'6chappement (bouchon du mur)

etdes conditions pr6sent6es ci-dessous. La Iongueur

maximum du tuyau pour les tuyaux rigide en m@al

est montr6e dans le tableau cidessous.

6

Page 19

Instructions d'Instollotion

INFORMATION D'ECHAPPEMENT ccom.l

27" LONGUEUR D'ECHAPPEMENT

LONGUEUR MAXIMUM RECOMMANDEE

RECOM MAN DEE Utiliseseulement pour les

N°de coudes

9o° M6talrigide M6tal rigide

Instollations de petites distonces

0 56 Feet 42 Feet

i 48 Feet 34Feet

2 40 Feet 26 Feet

3 32 Feet 18 Feet

24" LONGUEUR D'ECHAPPEMENT

LONGUEUR MAXIMUM RECOMMANDEE

RECOMMANDEE

Utilise seulement pour les

Installations de petites distances

....14"1.....

N9dooecoudes M@alrigide M@alrigide

0 43 Feet 36 Feet

1 33 Feet 26 Feet

•Pour chaque coude additionnel de 90°, r_duire de 10 pieds la

Iongueur totale permise du syst_me de ventilation.

•Deux coudes de 45° devront @treconsid@@scomme un coude de

90°

•Pour la ventilation lat@ale,ajouter un coude de 90° au tableau.

•LaIongueurtotale dusyst@medeventilation incluttoutes lesportions

droites et toes lescoudes du syst@me(letuyau detransition inclus).

LISTE DE CONTROLE DU SYSTEME D'ECHAPPEMENT

CAPUCHONOUGRILLEDUMUR

• Prot#gez la sortie de votre canalisation dans le but d'#viter les

appels d'air ou I'entr#ed'un oiseau et autres animaux sauvages.

• Cette protection devrait pr@senteruner@sistanceminimum au flux

d'air #chappement et devrait exiger peu ou pas de maintenance

pour #viter I'encrassement.

• Ne gamais installezd'#cran dans ou sur letuyau d'#chappement.

Cecipourrait conduire 6 la creation de peluches.Lesgrilles du mur

doivent @treinstall#esau moins _ 12 in.Au-dessus du niveau du

sol ou (_cette distance au-dessus de n'importe quel autre objet

pouvant faire obstruction a cette sortie.

SEPARATIONDESCOUDES

Pour une meilleure performance, s_pareztoes lescoudesd'au moins

4ft. Detuyauterie droite, incluant ladistance entre ledernier coude et

le capuchon du syst_me d'_chappement.

COUDESAUTRESQUE90°

• Un coude de 45° ou moins peut @reignor_

• Deuxcoudes de45° devraient _tre trait_s comme uncoude de 90°.

• Cheque coude de plus de 45° devrait _tre trait_ comme un coude

de 90°.

SCELLAGEDESJOINTS

• Toeslesjoints devraient @treserr@spour@viterlesfuites.L'extr@mit@

male de chaque section de tuyau doit @tredirig@evers I'ext@ieur

de la s@cheuse.

• N'assemblezpas la canalisation avec desagrafes qui entrent dans

le tuyau. Ellesserviront 6 lacreation de peluches.

• Lesjoints de tuyaux peuvent @trefaits d'air et de moisissures en

emballant lechevauchement dejoints avec le rouleau adh@sifde

tuyau.

• Lestrajets horizontaux devraient descendre vers I'ext@ieurde 1/2

pouce par pied.

ISOLATION

La canalisation qui court (_ travers une zone non chauff@e ou

qui est pr@sde I'air conditionn@devrait @treisol@epour r@duirela

condensation et la creation de peluches.

[-7]BRANCHEMENT DE L'ECHAPPEMENT

AVERTISSEMENT-POURREDUIRE

LES RISOUES D'INCENDIE OU DE BLESSURES

PERSONNELLES •

• Cet appareil doit avoir un syst_me d'#chappement

versl'ext@rieur.

Utilisez seulement de la tuyauterie rigide en m_tal de

4" pour letuyau d'_chappement de la maison.

• Utilisezseulement un tuyau rigide en m@talou untuyau

flexible UL(semi-rigideou en aluminium) pour brancher

la s@cheuseau tuyau d'@chappementde la maison. II

doit @treinstall@conform@mentaux instructions trouv@

en page 7 de ce manuel sous "Brancher La S@cheuse

au Conduit d'A@ation de la Maison'.

, Ne mettez pas fin a I'@chappementpar une chemin@e,

un mur, un toit, un conduit de gaz,un petit espace, un

grenier,sees un plancher nonfermi, ou dans n'importe

quelautre espacedissimul@devotre b@timent.Lacharpie

accumul@epourrait crier un risquepotentiel d'incendie.

, Nejamais mettre fin (_I'_chappement par un tuyau

commun avec le syst_me d'_chappement de la

cuisine. Unecombinaison de graisses et de peluches

cr#er un risque potentiel d'incendie.

N'utilisez pas de tuyau plus grand que ce qui est

sp_cifi_ dans letableau de grandeur d'_chappement.

Des tuyaux plus grands peuvent permettre

I'accumulation de peluches et cr#er unrisque

d'incendie potentiel.

Ne jamais installer un #cran dans ou sur le tuyau

d'_chappement. Ceci causera I'accumulation de

peluches,cr#ant un risque potentiel d'incendie.

N'assemblez pas la canalisation avec des agrafes

qui entrent dans le tuyau. Ces agrafes peuvent cr##s

I'accumulation depeluches,cr#ant un risqued'incendie.

N'obstruez pas I'air entrant et sortant.

Mettez6disposition un acc_spour inspecteret nettoyer

le syst_me d'#chappement, sp_cialement aux coudes

et aux joints. Le syst_me d'#chappement devrait @re

inspects et nettoy# aumoins une lois par an.

L'ECHAPPEMENT ARRIERE FAIT PARTIE DE CETTE SECHEUSE,

SI VOTRE ESPACE EST LIMITE, UTILISEZ LES INSTRUCTIONS

DE LA SECTION 9 POUR AVOIR UN SYSTEME D'ECHAPPEMENT

LATERAL OU PAR LE BAS DU COFFRAGE DE LA MACHINE,

BRANCHEMENT NEUF

FLEXIBLE A GAZ EN METAL

APPROUVE CSA(AGA) /

OU E TU EIU2 'E, EE

SCOTCH DE TUYAU

OU PINCE

TUYAUEN METAL

4" COUPE A LA

LONGUEUR

7

APPROPRIEE

SCOTCH

DETUYAU OU

PINCE

Pour une installation en ligne drake,

branchez lesyst_me d'_chappement de la

s_cheuse au conduit externed'_chappement

en utilisant du scotch ouune pince.

® @

Page 20

Instructions d'Installation

ECHAPPEMENT ARRIERE STANDARD

(Ventil_ au-dessous du niveau du sol)

U

COUDE

HAUTEMENT

COMMANDE

ONFIGU RATION

ECOMMANDEE POUR

INIMISERLESBLOCAGE _E_ _

E CANALISATION

NOTE : LES COUDES EMPECHERONT LES NOEUDS ET LES

EFFONDREMENT5 DU CONDUIT.

[_]METTRE A NIVEAU ET STABILISER

VOTRE APPAREIL

/.,,,EAu

/D'U N COTEA

NIVEAU DE j_TRE

L'AVA NT A

L'ARRIERE

__Z_

di

PIEDS DE NIVELEMENT

Mettre 6 niveau et stabiliser votre appareil

!. D@lacez prudemment I'appareil vers sa position finale.

Balancez avec douceur I'appareil en position. II est

important de ne pas endommager les pieds de niv@lement

en caoutchouc Iorsque vous d@lacez votre appareil vers sa

position finale. Les pieds endommag@s peuvent augmenter

les vibrations de I'appareil. II peut @tre utile de pulv@iser

un nettoyeur de vitre sur le sol pour aider 6 d@placer votre

appareil vers sa position finale.

Note : N'utilisez pas la protection de la laveusepour porter I'unitd.

2. Pour assurer que I'appareil est 6 niveau et stable sur ses

quatre pieds, inclinez I'appareil vers I'avant pour que les

pieds arri@e soient hors du sol. Redescendez en douceur

I'appareil pour permettre aux pieds arri@resde s'ajusteront

seuls.

3. Ayant I'appareil 6 sa position finale, placez un niveau

au-dessus au fond du couvercle de la laveuse et v@ifiez

de chaque cot@,puis v@ifiez I'avant et I'arri@re.Vissezles

pieds de niv_lement avant pour assurer que I'appareil

reste stable sur ses quatre pieds (ne balancez pas

I'appareil pour v@ifier sa stabilit@),relevez les@crousde

verrou sur chaque pied vers la base de I'unit6 et assurez

avec un tourne-a-gauche.

Note: Gardez I'extension de pied au minimum pour dviterles

vibrations excessives. Plusles pieds sont agrandis, plus'unitd a de

chance de vibren

BRANCHER LA SECHEUSE A UAERATION

DE LA MAISON

TUYAU RIGIDEDETRANSITION EN METAL

• Pourlesmeitteuresperformancesdes_chagepossibles,le tuyau de

transitionrigide en m_talestrecommand_.

• Les tuyaux de transition rigides en m_tal r_duisent le risque

d'_crasementet de noeuds.

TUYAU DETRANSITION UL FLEXIBLEENMETAL(SEMI-RIGIDE)

• Siletuyaurigide en m_tal ne peutpas_tre utilis_, alors tetuyau UL

flexibteen m@al(semi-rigide)peut_tre utilis_(KitWX08X!0077).

• Nejamais installerde tuyau flexibleen m@alau murs,au plafond,

auxsotsou autresespacesfarm,s.

• LaIongueurdutuyauflexibleenm@alnedevrait pasexc6d68 pieds

(2,4m).

• Pour ptusieurs applications, installer des coudes 6 la fois 6 la

s6cheuseet au tour est fortement recommand6 (voir illustration

cidessous).Les coudes permettent 6 I'appareit d'etre ptac6 pros

du mur sans fake de noeuds et/ou _craser letuyau de transition,

maximisantlesperformancesdes_chage.

• Evitezde pauser letuyaudur desobjetscoupants.

LETUYAUDETRANSITIONUL FLEXIBLEENMETAL(ALUMINIUM)

• Pourdesinstallationssp_ciales,itpeut _tre n_cessairede brancher

la s_cheuse6 I'a@ationde la maison utitisant un tuyau flexible en

m@al(aluminium).Un tuyau UL flexible en m@al (semi-rigide)ne

peutpas@reutitis@ETceci or]un diam_trede4"peut @tremaintenu

toutau long du tuyau.

• Au Canada et aux USA,seulement lestuyaux flexibtes en m@al

(aluminium) qui se plient 6 "Description G6n6rale du Tuyau de

Transition dela Laveusede V@ementsdu Sujet 2158A"devrait @re

utitis@.

Ne jamais installer de tuyau flexible en m@al sur les murs,les

ptafonds,lessotsou autresespacesfarm,s.

• La longueur du tuyau flexible en m@alne devrait pas exc6d6e 8

pieds(2,4m).

• Evitezde pauser letuyaudur desobjetscoupants.

• Pourlesmeitteuresperformancespossibles:

1. Faitesgiisserune extr_mit@dutuyau sur leconduit ext@ieurdela

s@cheusedev@tements

2. Fixezletuyau avecune pince.

3. Ayant la s@cheusedans sa position permanente, protongez

le tuyau vers sa Iongueur maximum. Laissez 2" de tuyau se

chevaucheravec le conduit d'_chappement. Coupezet enlevez

I'exc_sde tuyau. Gardezle tuyau aussi droit qua possiblepour

maximiserle flux d'air.

4. Fixezletuyau auconduit d'_chappementavec I'autrepince.

8

Page 21

NE PA

UTILISER UN

CONDUIT

TRO.'ONG

Instructions

FA___IRE

UDES FORTEMENT

RECOiVtiVtANDES

\

NE PAS FAIR_

_, MACHINE

d' nstallation

AJOUTER LE COUDE ETLE TUYAU POU

L'ECHAPPEMENT PAR LA GAUCHE OU PAR LA

DROITE DY COFFRAGE

. Pour la canulisation de cot6, enlevez le cache

(SEULEMENT1).Faites pivoter les sections du coude Grin

qu'il soit duns ludirection d6sir6e. Pr6parez I'assemblage

du coude de 4" avec le tuyau de 4". Utilisez seulement le

tuyau UL rigide en m6tal approuv6 pour la canalisation

de la s6cheuse.

Ins6rez I'assemblage du tuyau par I'ouverture et

branchez le coude interne.

AVERTISSEMENT - Assurez-vousdene

pus tirer ou endommager les ills @lectriques 6 i'int_rieur

de la s@cheuselorsque vous Jns_rezle tuyau.

Tuyau rigide UL en m6tal

autoris6 de 4"

/

i //J//

L[

Appliquez le rouleau adh6sif comme il est montr6 sur le

joint entre le tyuyau interne de la s6cheuse et le conduit.

SCOTCHA

[9-1UNIQUEMENT POUR MODELES DE 24 PO

ECHAPPEMENT DE LA SECHEUSE PAR LA DROITE,

PAR LA GAUCHE OU PAR LE HAUT DE COFFRAGE

AVERTISSEMENT - AVANT DE

REALISER L'INSTALLATION DE L'ECHAPPEMENT,

ASSUREZ-VOUS DE DEBRANCHER LA SECHEUSE

DE L'ALIMENTATION ELECTRIQUE. PROTEGEZ VOS

MAINS ET VOS BRAS DESPARTIES COUPANTES

LORSQUE VOUS TRAVAILLEZ DANS LE COFFRAGE.

ASSUREZVOUS DE PORTER DES GANTS.

Pourune a_ratJonverslebus,fuitespivoterles

sectionsdu coude pourque ce m_me coude

penche vers le bas.

DEPLACEZ LES

CACHES DESIRES

(SEULEMENT 1)

_ILAVERTISSEM ENT -

Les joints du tuyau interne

doivent @tre bien attach@s

_ avecdu scotch, sinon ils

pourraient ses@pareroucauser

un risque pour la s@curit@des

personnes et de la machine.

UNIQUEMENT POUR MODELES DE 27 PO

ECHAPPEMENT DE LA SECHEUSE PAR LA DROITE,

PAR LA GAUCHE OU PAR LE HAUT DE COFFRAGE

AVERTISSEMENT- AVANT DE

REALISER L'INSTALLATION DE L'ECHAPPEMENT,

ASSUREZ-VOUS DE DEBRANCHER LA SECHEUSE

DE L'ALIMENTATION ELECTRIQUE. PROTEGEZ VOS

MAINS ET VOS BRAS DESPARTIES COUPANTES

LORSQUE VOUS TRAVAILLEZ DANS LE COFFRAGE.

ASSUREZVOUS DE PORTER DESGANTS.

Pour une a6ration vers le bas, faites pivoter les

sections du coude pour que ce m6me coude

penche vers le bas.

9

Page 22

Instructions d'Installation

AJOUTER LE COUDE ETLE TUYAU POU

L'ECHAPPEMENT PAR LA GAUCHE OU PAR LA

DROITE DY COFFRAGE

. Faites pivoter les sections du coude Grin qu'il penche

vers le c6t6 que vous desirez a@er. Faites pivoter les

sections du coude afin qu'il soit duns ladirection d6sir6e.

Pr6parez I'assemblage du coude de 4" avec le tuyau

de 4". Utilisez seulement le tuyau UL rigide en m6tal

approuv6 pour la canalisation de la s6cheuse.

. Connectez I'assemblage de tuyau au coude interne.

AVERTISSEM ENT- Assurez-vo.sde

ne pus tirer ou endommager les ills _lectriques a

l'int_rieur de la s_cheuse lorsque vous ins_rez le

tuyau.

CONDITIONS DE DRAINAGE

. RAPPORTDEDRAINAGE- Ledrainage et le tuyau de rejet

(31'6goutdoivent _tre capable d'accepter un 6coulement

d'un rapport de 16 gallons par minute.

. TAILLEDU DRAINAGE- Lataille du drainage doit _tre de

33" minimum et de 96" maximum.

. DIAMETREDUTUYAUDEREJETA L'EGOUT- Le diam_tre

du tuyau de rejet (_1'6goutdoit _tre de 1-1/4"minimum.

II DOlT y avoir un espace d'air autour duconduit de

drainage dans le tuyau de rejet (31'6gout. Une coupure

peut causer un effet de siphon.

, KIT BRISE-SIPHON- Pour une installation de drainage

inferieure (333" de hauteur, le tuyau, la connexion et les

pinces fournies dans I'appareil doivent _tre utilis6s et,

de plus, un brise-siphon DOlT _tre install_ au dos de la

machine. Utilisez le Kit Brise-Siphon WH49X228 et suivez

les instructions du kit.

[Yi]BRANCHER LA PLOMBERIE

. Appliquez le rouleau adh6sif comme il est montr6 sur le

joint entre le tyuyau interne de la s6cheuse et le conduit.

AVERTISSEMENT -

Les joints du tuyau interne

doivent _tre bien attaches

avecdu scotch, sinon ils

hi pourraient se s_parer ou

causer un risque pour la

s_curit_ des personnes et de la

machine,

INFORMATION SUR LA PLOMBERIE

CONDITIONS DE L'APPROVISIONEMENT EN EAU

. ROBINETS D'EAU CHAUDE ET FROIDE - IIs doivent

@re 6 moins de 42" des branchements de I'appareil

pour I'arriv6e d'eau. Les robinets doivent _tre sA"de

la tuyauterie du jardin afin que les tuyaux internes

puissent _tre branch6s.

. PRESSIONDE L'EAU - Elle doit _tre entre 10 et 120psi

avec un maximum de pression d_s6quilibr6e, un flux

d'eau chaude et un flux d'eau froide, de 10 psi.

, TEMPERATUREDE L'EAU- Le chauffe-eau devrait _tre

configur6 pour distribuer une eau de 1400(_150°F (600

a 66°C) (_la laveuse Iorsque I'option de lavage CHAUD

est s61ectionn6e.

. VALVESDEFERIVlETURE- Lesvalves de fermeture d'eau

chaude et d'eau froide devraient _tre fournies.

. EMPLACEMENT-N'installez pas I'appareil dans une zone

o_ la temp@ature sera en-dessous dez@o.Si I'appareil

est gard6 ou transport6 avec des temp@atures en-

dessous de z@o, assurez-vous que toute I'eau depuis

le remplissage jusqu'au syst_me de drainage a 6t6

enlev6e.

I

J_

Installez si n@cessairelesjoints en caoutchouc 6 I'extr@mit@

de I'arriv@ed'eau chaude sur la machine. Introduisezle tuyau

d'eau sur le branchement marqu@de la lettre Cdans le coin

en haut de la machine.Serrez6 lamain, et ajouter 1/8 de tour

avec une pince.

Installez si n@cessairelesjoints en caoutchouc 6 I'extr@mit@

de I'arriv@ed'eau froide sur la machine. Introduisez le tuyau

d'eau sur le branchement marqu@de la lettre H dans le coin

en haut de la machine.Serrez6 lamain, et ajouter 1/8 de tour

avec une pince.

D_placez I'appareil au plus proche de sa potion finale si

possible,laissantde la place pour que vous puissiezfake les

branchements d'eau,dedrainage, @lectriqueetde ventilation

dansvotre maison.

NOTE:Siun conduit dedrainage plus

grand est requis, commandez le kit

d'extension de conduit de drainage,

num@ode produit GEWH49X301.

Branchez un conduit additionnel

de drainage (inclut dons le kit) au

conduit original avec des pinces de

conduit (inclut dans le kit).lnc@ezun

tuyau devidange 6 lacanalisation de

drainage devotremaisonpourfermer

letuyau de drainage (nepas assurer

I'6tanch6it@destuyaux pour 6viterde

crier un effet de siphon).Silesvalves

d'eau et le drainage construit dans le

tour, attachez le tuyau de drainage

61'undestuyaux d'eau avec le collier

en plastique inclut (fix6face 6 face).Si

votre drainage estun tuyau de rejet6

I'6gout,attachezletuyau dedrainage

aut uyau de rejet 6 I'6gout avec un

collier en plastique inclut

10

Page 23

Instructions d'Installation

[f2]INSTALLATION POUR LESMOBILES

HOMES

• L'installation DOIT _tre conforme aux STANDARDS DE

CONSTRUCTION ET DE SECURtTE DU MOBILE HOME, TITRE

24, PARTtE 32-80 ou, Iorsque de tels standards ne sont

pas applicables, il faut alors consid@er LES STANDARDS

NATIONAUX AMERICAINS POUR LES MOBILES HOMES, ANSI/

NFPA NO. 50lB.

• L'appareil DOlT @re ventil_ vers I'ext@ieur avec une sortie

s_curis_e fix_e (3 la structure du mobile home.

La ventilation NE DOIT PAS sortir par le dessous du mobile

home.

Le mat@iel du conduit d'a@ation DOIT ETRE DE METAL.

• Kit !4-D346-33 dolt _tre utilis_ pour attacher la s_cheuse 6 la

structure de faqon s_curitaire.

Lo ventilation NE DOIT PAS _tre connect_e _] aucun autre

conduit d'_vacuotion des goz brGl_s ou (_ une chemin_e.

N'utilisez pas de vises pour le m_tal en feuille ou qui

d_passent _]I'int@ieur du conduit d'_vacuation.

• Pr_voyez une ouverture de minimum 25 pouces carr_s ou

I'introduction de I'air de I'ext@ieur dans la chambre o_ se

trouve la s_cheuse.

[13]RENFONCEMENT OU INSTALLATION

DANS UN MEUBLE

ooi,

JT31VENTILATION DE L'OUVERTURE DE

PORTE {MODELES 27")

Un minimum de 120 Sq. In. d'ouverture, divis6 6 part 6gale en haut et

en bas, est requis. Les ouvertures d'air sont tenues d'@re d6gag6es

Iorsqu'une porte est install6e. Une porte persienne avec d'ouvertures

d'air 6quivalentes sur toute la Iongueur de la porte est acceptable.

I1............I1

! 60sq.,o.

, _

27" Model / /_

/I O

Lorsque les persiennes ou les gonds sont plac6s sur les ouvertures de la

porte, les ouvertures d'air des persiennes ou des gonds doit @tre 6gale 6

120 Sq. In.

VENTILATION DE L'OUVERTURE DE

PORTE {MODELES 24")

Un minimum de 72 Sq. In. d'ouverture est requis. Les

ouvertures d'air sont tenues d'etre d_gug6es Iorsqu'une

porte est instull6e. Une porte persienne uvec des

ouvertures d'uir 6quivulentes sur toute lu Iongueur de lu

porte est acceptable.

Si votre appareil est autons_ pour une installation dans un

emplacement ou un meuble, cela sera indiqu_ sur la plaque

au dos de I'appareil.

POUR EVITER UN GRAND NOMBRE DE PELUCHES ET

D'HUMIDITE CAUSES PAR L'ACCUMULATION ET POUR

MAINTENIR L'EFFICACITE DE SECHAGE, CETTE MACHINE

DOlT AVOIR UN SYSTEME D'ECHAPPEMENT VERS

UEXTERIEUR.

N'installez pas cet appareil s'il vous manque I'espace

minimum tel qu'il est montr_ ci-dessus.

UNE ATTENTION PARTICULIERE DOIT ETREPRISE

POUR ASSURER DES ESPACES ADEQUATS POUR

L'INSTALLATION ET LA REPARATION

AVERTISSEMENT: N'INSTALLEZPAS

CET APPAREIL DANS UN MEUBLE AYANT UNE

PORTE.

II 1! 24 Sq. In.

Lorsque les persiennes ou les gonds sont pluc6s duns les

ouvertures de lu porte, lesouvertures d'uir des persiennes

ou des gonds doivent _tre 6gale (372 sq. in.

[1-4-]INSTALLATION POUR SALLE DE BAIN OU

CHAMBRE

o

L'appareil DOlT _tre ventil@vers I'ext@ieur.Voir INFORMATION

D'ECHAPPEMENTdes sections 3 & 4.

o

L'installation dolt _tre conforme aux names locales ou, dans

I'absence de ces normes locales, aux NORMESNATIONALES

ELECTRIQUES,ANSI/NFPA NO.70.

11

Page 24

Instructions d'Installation

i_-IREPARATION

AVERTISSEMENT - MARQUEZ TOUSLES FILS AVANT LE DEBRANCHEMENT

LORSQUE VOUS EFFECTUEZ UN CONTROLE POUR REPARATION. LES ERREURS DE

BRANCHEMENT PEUVENT CAUSEES DES PROBLEMES DE FONCTIONEMENT APRES

REPARATION ET D'INSTALLATION.

Pour les pisces de rech(]nge et (]utres inform(]tions, veuillez reporter (]u Manuel de I'Utilis(]teur pour les num6ros de

t616phone du service (]prOsvente.

ENREGISTREZVOTRE NOUVEL APPAREIL POUR q)UE

VOUS RECEVIEZ DESINFORMATIONS IMPORTANTES

SUR LE PRODUIT.

Allez, SVP,sur notre site www.GffAppliances.com ou

envoyez par la poste votre Carte d'inscription du produit.

Pour des questions sur I'inst(]ll(]tion, composez:

800.626.2000 (E.U.)ou 800.56!.334/4 (CGnGdG)

12

Page 25

Instrucciones de

Secadora Unificada

Instalaci6n

zPreguntas sabre la Instalaci6n? Llame al: 1-800-GECARES (US)

0 visite nuestro sitio web en: www.GEAppliances.com (US)

ANTES DE COHENZAR

Lea estas instrucciones en su totalidad y

atentamente.

,IMPORTANTE- Conserve est(]s

instruccionespar(]usadelinspectorlocal.

,IMPORTANTE- Cumpl(]con todoslos

c6digosy orden(]nz(]sgubern(]ment(]les.