GE GFWN1100, GFWN1200, GFWH1200, GMAN1200, GFWH1300 Owner’s Manual & Installation Instructions

...

GEAppliances.com

Safety Instructions .............. 2, 3

Operating Instructions

Control Panels ...................... 4-7

Features ............................8–9

Loading and Using the Washer ....10, 11

Cleaning the Washer ..............12–14

Installation Instructions ......15–20

Preparing to Install Your Washer ......15

Rough-In Dimensions .................16

Location of Your Washer .............16

Unpacking Your Washer ..............17

Drain Requirements ..................18

Electrical Requirements ..............18

Water Supply Requirements ..........18

Installing the Washer ..............19, 20

Replacement Parts ...................20

Troubleshooting Tips .........21–24

Consumer Support

Warranty ............................ 25

Service Telephone Numbers .......... 26

Owner’s Manual &

Installation Instructions

GFWN1100

GFWN1200

GFWH1200

GMAN1200

GFWH1300

GFWN1300

GFWH1400

GFWH1405

GFWS1500

GFWS1505

English/Français/Español

Printed in China

As an ENERGY STAR® partner,

GE has determined that this

Washers

product meets the ENERGY STAR®

guidelines for energy efficiency.

Write the model and serial

numbers here:

Model # _________________

Serial # __________________

You can find them on a label on the

side of the washer.

49-90454-3 12-13 GE

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill you or hurt you and others. All

safety messages will follow the safety alert symbol and the word “DANGER”, “WARNING”, or “CAUTION”. These words are

defined as:

IMPORTANT SAFETY INSTRUCTIONS

Read all instructions before using the appliance.

DO NOT wash or dry articles that have been previously cleaned in, washed in, soaked in or spotted with gasoline,

dry-cleaning solvents, or other flammable or explosive substances, as they give off vapors that could ignite or

explode.

DO NOT add gasoline, dry-cleaning solvents, or other flammable or explosive substances to the wash water. These

substances give off vapors that could ignite or explode.

Under certain conditions, hydrogen gas may be produced in a hot-water system that has not been used for 2

weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has not been used for such a period, before

using a washing machine, turn on all hot-water faucets and let the water flow from each for several minutes. This

will release any accumulated hydrogen gas. As the gas is flammable, DO NOT smoke or use an open flame during

this time.

DO NOT allow children to play on or in this appliance. Close supervision of children is necessary when this appliance

is used near children. Before the washer is removed from service or discarded, remove the door or lid. Failure to

Installation

Instructions

follow these instructions may result in death or injury to persons.

DO NOT reach into the appliance if the tub or agitator is moving to prevent accidental entanglement.

DANGER

WARNING

CAUTION

WARNING

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

To reduce the risk of death, fire, explosion, electric shock, or injury to persons when using your

appliance, follow basic precautions, including the following:

DO NOT install or store this appliance where it will be exposed to the weather.

DO NOT tamper with controls, repair or replace any part of this appliance or attempt any servicing unless

specifically recommended in the user maintenance instructions or in published user repair instructions that you

understand and have the skills to carry out.

Keep the area around your appliance clean and dry to reduce the possibility of slipping.

DO NOT operate this appliance if it is damaged, malfunctioning, partially disassembled, or has missing or broken parts

including a damaged cord or plug.

Unplug the appliance or turn off the circuit breaker before servicing. Pressing the Power button DOES NOT disconnect

power.

See “Electrical Requirements” located in the Installation Instructions for grounding instructions.

SAVE THESE INSTRUCTIONS

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

2

GEAppliances.com

PROPER INSTALLATION

This washer must be properly installed and located in accordance with the Installation Instructions before it is used.

If you did not receive an Installation Instructions, you can receive one by visiting GEAppliances.com or by calling

800.GE.CARES (800.432.2737).

Ensure that the hot water hose is connected to the “H”

(internal red screened) valve and the cold water hose is

connected to the “C” (internal blue screened) valve.

Install or store where it will not be exposed to

temperatures below freezing or exposed to the weather,

which could cause permanent damage and invalidate

the warranty.

Properly ground washer to conform with all

governing codes and ordinances. Follow details

in Installation Instructions.

This washer does not include water supply hoses.

GE strongly recommends the use of factory specified

parts. A list of factory hoses available for purchase are

listed below. These hoses are manufactured and tested

to meet GE specifications.

GE strongly recommends the use of new water supply

hoses. Hoses degrade over time and need to be

replaced every 5 years to reduce the risk of hose failures

and water damage.

Parts and Accessories

WARNING

Plug into a grounded 3 prong outlet.

DO NOT remove ground prong.

DO NOT use an adapter.

DO NOT use an extension cord.

Failure to do so can result in death, fire or electrical

shock.

- Electrical Shock Hazard

WHEN NOT IN USE

Turn off water faucets to minimize leakage if a break

or rupture should occur. Check the condition of the fill

hoses; GE recommends changing the hoses every 5

years.

Order on-line at GEApplianceparts.com today, 24 hours a

day or by phone at 800.626.2002 during normal business

hours.

Part Number Accessory

PM14X10002 4 ft Rubber Water Supply Hoses

Or

PM14X10005 4 ft Braided Metal Water Supply Hoses

WX10X10011 Tide® Washing Machine Cleaner*

WX7X1 Washer Floor Tray

SAVE THESE INSTRUCTIONS

Instructions

Installation

* Tide® is a registered trademark of Procter & Gamble

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

3

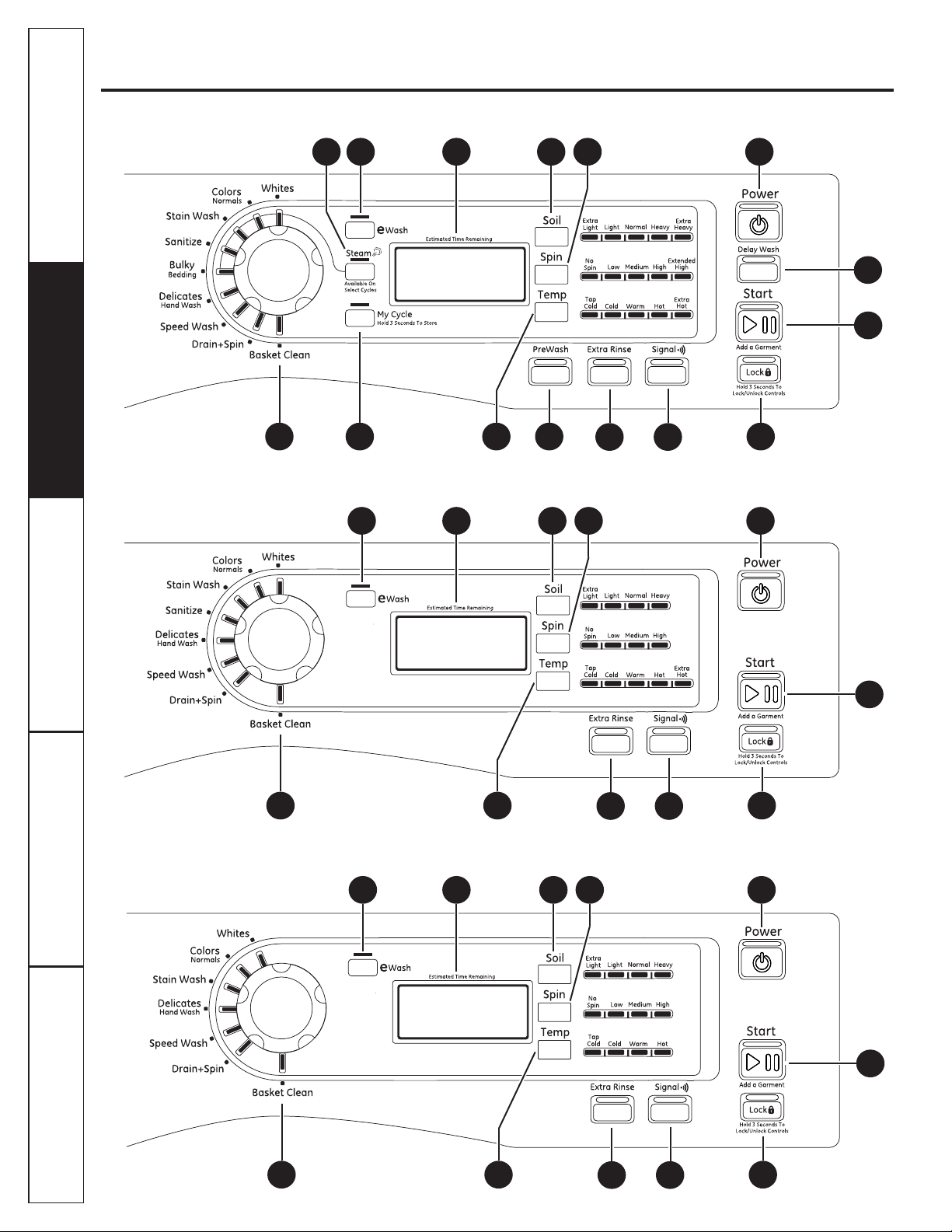

About the washer control panel.

Find the illustration that closely matches your model and see the descriptions for details.

1314 15

13 15

3 4

1

10

6

512

82

79

3 4

11

1

Installation

Instructions

6

2

13 15

5

79

3 4

11

1

6

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

4

2

5

79

11

GEAppliances.com

Power

1

Press to “wake up” the display. If the display is active, press to put the washer into standby mode.

NOTE: Pressing Power does not disconnect the appliance from the power supply.

Wash Cycles

The wash cycles are optimized for specific types of wash loads. The chart below will help you match

2

the wash setting with the loads. The GentleClean™ lifters lightly tumble the clothes into the water and

detergent solution to clean the load.

Whites For heavily to lightly soiled white laundry.

Colors/Normals For heavily to lightly soiled colorfast cottons, household linens, work and play

clothes.

Stain Wash For heavily soiled colorfast laundry.

Sanitize When selecting sanitize, the washer increases the water temperature to sanitize

(on some models) and remove 99.9% of bacteria found in home laundry. For best results, select the

heavy soil setting when using the sanitize cycle.

NSF Protocol P172

Sanitization Performance of Residential and

Commercial, Family-Sized Clothes Washers

Bulky Bedding For large coats, bed spreads, mattress covers, sleeping bags and similar large and

(on some models) bulky items. Large items such as blankets, comforters, jackets and small rugs.

Delicates For lingerie and special-care fabrics with light to normal soil. Provides gentle

Hand Wash

Speed Wash For lightly soiled items that are needed in a hurry. Cycle time is approximately

30 minutes, depending on selected options.

Drain & Spin Drain and spin at any time.

Basket Clean Use for cleaning the basket of residue and odor. Recommended use of once per month.

NOTE: Never load laundry while using Basket Clean. The laundry may become

damaged or contaminated. See the Care and Cleaning section.

Soil Level

3

Changing the Soil level increases or decreases the wash time to remove different amounts of soil.

To change the Soil level, press the Soil level pad until you have reached the desired setting.

tumbling and soak during wash and rinse.

Instructions

Installation

Spin Speed

4

Changing the Spin speed changes the final spin speed of the cycles. Always follow the fabric

manufacturer’s care label when changing the spin speed.

To change the spin speed, press the Spin speed pad until you have reached the desired setting. Higher

spin speeds are not available on certain cycles, such as Delicates.

Higher spin speeds remove more water from the clothes and will help reduce dry time, but may also

increase the possibility of setting wrinkles on some fabrics.

Wash Temp

5

Adjust to select the proper water temperature for the wash cycle. The prewash and rinse water is

always cold to help reduce energy usage and reduce setting of stains and wrinkles.

Follow the fabric manufacturer’s care label when selecting the wash temperature.

To change the wash temperature, press the Wash Temp pad until you have reached the desired

setting.

NOTE: The first 10 seconds of the wash fill is always cold. This feature assists in conditioning the fabric

and preventing stains from setting on garments.

Start/Add a Garment

6

Press to start a wash cycle. If the washer is running, pressing it once will pause the washer and unlock

the door. Press again to restart the wash cycle.

NOTE: If the washer is paused and the cycle is not restarted within 2 hours, the current wash cycle will

be cancelled.

NOTE: The washer performs automatic system checks after pressing the Start pad. Water will flow

in 45 seconds or less. You may hear the door lock and unlock before water flows; this is normal.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

5

About the washer control panel.

Installation

Instructions

7

8

9

10

Cycle Signal

Use the Signal pad to change

the volume of the end of cycle signal.

Prewash (on some models)

Prewash is an extra wash before

the main wash. Use it for heavily soiled

clothes or for clothes with a care label

that recommends prewashing before

washing. Be sure to add high-efficiency

Extra Rinse

Use an extra rinse when additional rinsing

is desired to remove excess dirt and

detergent from soiled loads.

Delay Wash (on some models)

You can delay the start of a wash cycle

for 10–18 hours, depending on the model.

Press the Delay Wash pad to choose the

number of hours you want to delay

the start of the cycle, then press the Start

pad. The machine will count down and

start automatically at the correct time.

Press the pad until you reach

the desired volume.

detergent, or the proper wash additive

to the prewash dispenser.

NOTE: When selecting prewash,

it is recommended to use powder

detergent in the main wash (detergent)

compartment.

NOTE: If you forget to fully close the door,

a reminder signal will beep reminding you

to do so.

NOTE: If you open the door when the delay

is counting down, the machine will enter

the pause state. You must close the door

and press Start again in order to restart

the countdown.

11

12

Lock

You can lock the controls to prevent any

selections from being made. Or you can

lock the controls after you have started

a cycle.

Children cannot accidentally start

the washer by touching pads with

this option selected.

My Cycle (on some models)

To save a favorite cycle, set the desired

settings for wash cycle, soil level, spin speed

and wash temp settings and hold down

the My Cycle pad for 3 seconds. A beep will

sound to indicate the cycle has been saved.

To use your custom cycle, press the

My Cycle pad before washing a load.

To change the saved cycle, set the desired

settings and hold down the My Cycle pad

for 3 seconds.

To lock the washer controls, press and

hold the Lock pad for 3 seconds.

To unlock the washer controls, press

and hold the Lock pad for 3 seconds.

The control lock icon on the display will

light up when it is on.

NOTE: The Power pad can still be used

when the machine is locked.

NOTE: When using My Cycle, wash

options cannot be modified after the

cycle has been started.

NOTE: If you change wash options with

My Cycle before starting the cycle, the

My CycleOLJKWZLOOWXUQRȺDQG\RXZLOO

be returned to the base cycle.

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

6

GEAppliances.com

13

14

15

eWash (Energy Saving Wash)

Use eWASH to save energy on specified

wash cycles. eWASH cannot be used

with Steam Refresh, Stain Wash or

Basket Clean.

Steam

Steam adds steam into the washer

during Whites, Colors/Normals, Stain

Wash, Sanitize or Bulky Bedding

cycles.

(on some models)

To use:

1. Turn Power on and select a wash

cycle.

Display

The display shows the approximate time

remaining until the end of the cycle.

The Steam option is only available

on Whites, Colors/Normals, Stain

Wash, Sanitize or Bulky Bedding

cycles.

2. Press Steam pad to activate.

3. Press the Start pad.

NOTE: The cycle time is affected by how long

it takes the washer to fill. This depends on the

water pressure in your home.

Instructions

Installation

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

7

About the washer features.

O

NOTE: Features may not be available on all washer models.

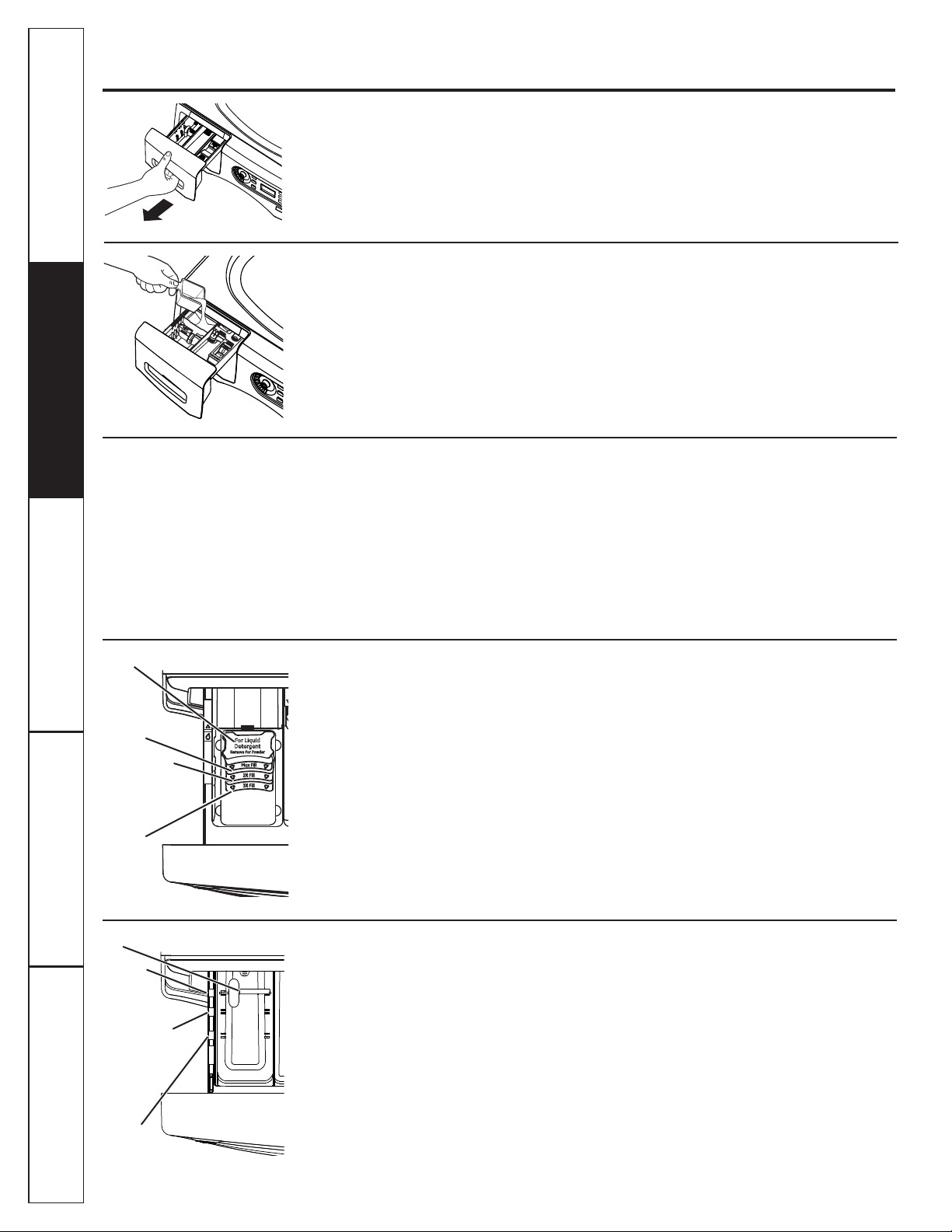

The Dispenser Drawer

Slowly open the dispenser drawer by pulling

it out until it stops.

After adding laundry products, slowly close

the dispenser drawer. Closing the drawer too

quickly could result in early dispensing of the

bleach, fabric softener or detergent.

The Prewash Compartment (on some models)

Only use the Prewash Compartment if

you are selecting the Prewash cycle for

heavily soiled clothes. Add measured

detergent or prewash additive to the

back left prewash compartment of the

dispenser drawer.

Detergent or prewash additive is flushed

from the dispenser in the prewash cycle

(if selected).

The Detergent Compartment

High-efficiency detergent is required

for this washer. Use the detergent

manufacturer’s recommended amount.

Add measured detergent to the front left

detergent compartment of the dispenser

drawer.

Detergent is flushed from the dispenser

at the beginning of the wash cycle. Either

powdered or liquid detergent can be used.

You may see water in the bleach and fabric

softener compartments at the end of the cycle.

This is a result of the flushing/siphoning action

and is part of the normal operation of the

washer.

NOTE: Liquid detergent will drain into the

washer drum as it is added.

Detergent usage may need to be adjusted

for water temperature, water hardness, size

and soil level of the load. Avoid using too

much detergent in your washer as it can

lead to over sudsing and detergent residue

being left on the clothes.

Detergent usage may need to be adjusted

for water temperature, water hardness,

size and soil level of the load. Avoid using too

much detergent in your washer as it can lead

to oversudsing and detergent residue being

left on the clothes.

Using more detergent than the

recommended quantity can cause residue

buildup on your washer.

Installation

Remove for powder detergent

Instructions

Max HE

Liquid

Detergent

Setting

2X HE Liquid

Detergent Setting

(most common

setting)

3X HE

Liquid

Detergent

Setting

Appearance may vary

Remove for powder detergent

Normal

HE Liquid

Detergent

Setting

2X HE Liquid

Detergent Setting

(most common

setting)

3X HE

Liquid

Detergent

Setting

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

Appearance may vary

8

EWASH

PR

Remove For Powder

1X

2X

3X

LIQUID

DETERGENT

For Liquid

Detergent

Max Fill

2X Fill

3X Fill

remove for powder

On models with a removable detergent cup

Powder Detergent – Remove the

liquid detergent cup and place it in a

safe location outside of the washer.

Follow the detergent manufacturer’s

instructions when measuring the

amount of powder to use.

On models with a selection insert

The detergent selection insert must be placed

in the detergent compartment in a specific

position according to what type of detergent

you are using.

Powder Detergent – Remove the

detergent selection insert and place it in

a safe location outside of the washer.

S

Liquid Detergent – You will need to adjust

the insert according to the type of Liquid

Detergent you are using. The Icons on the

side of the detergent compartment must

line up on the center when the insert is in

position.

Liquid Detergent – Locate the

concentration of your detergent on the

bottle. Do not fill above the Max Fill line

in the detergent cup for your detergent

concentration type.

NOTE: Not all models have the 2x and 3x

detergent settings. Some have only regular

HE detergent settings. You must reduce the

amount of detergent for 2x or 3x detergent

per bottle instructions.

Move the insert by pulling it up and replace

it by sliding it down between either the rear

or front detergent compartment molded

rails,

as desired, for liquid detergent.

Remove for powder detergent.

GEAppliances.com

On some models:

On some models:

On some models:

On some models:

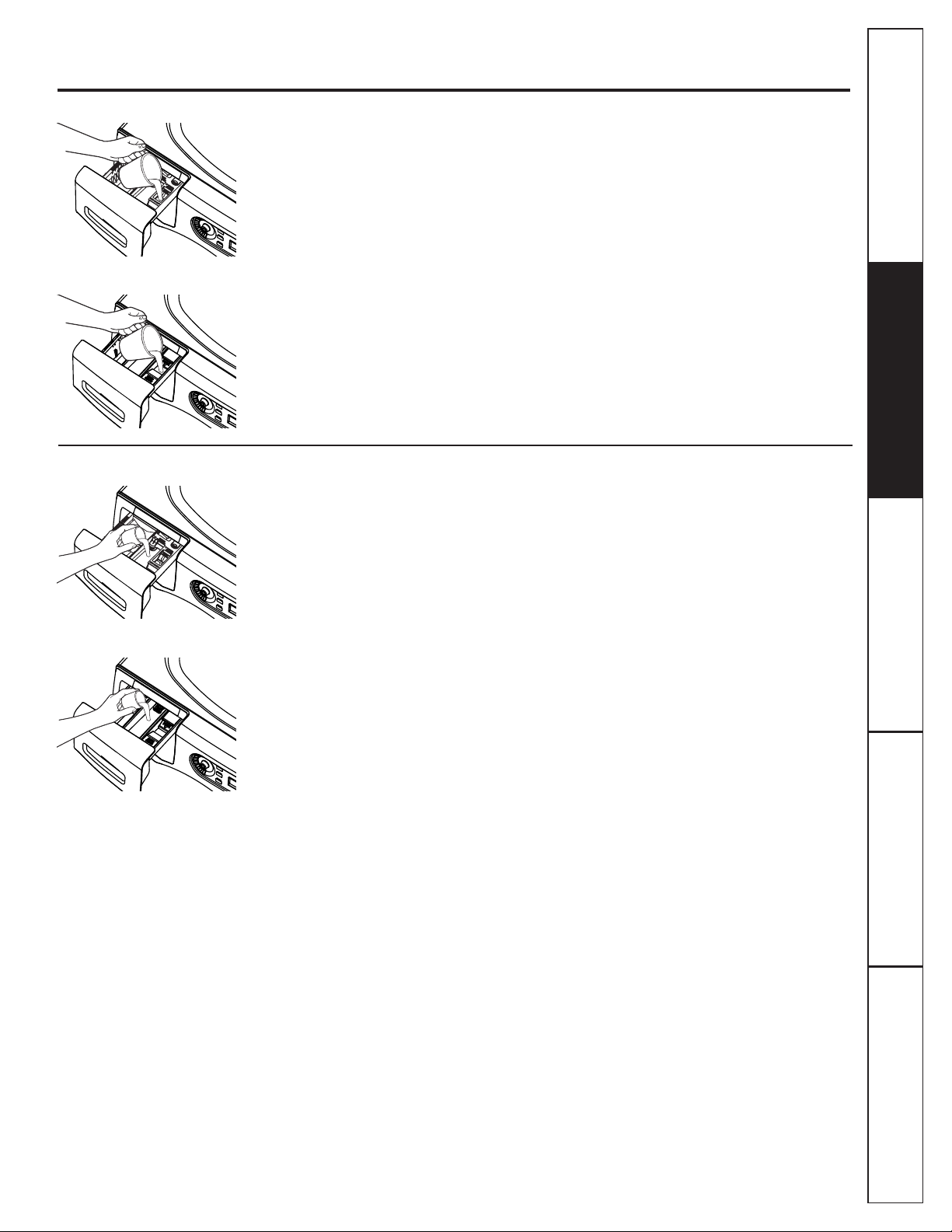

The Liquid Bleach Compartment

IMPORTANT: The bleach compartment

position varies by model. Be sure to identify

the correct compartment for bleach before

using.

If desired, measure out the recommended

amount of liquid bleach, not to exceed

1/3 cup (80 ml), and pour into the right

compartment labeled “LIQUID BLEACH”.

The Fabric Softener Compartment

IMPORTANT: The fabric softener compartment

position varies by model. Be sure to identify

the correct compartment for fabric softener

before using.

If desired, pour the recommended amount

of liquid fabric softener into the compartment

labeled “FABRIC SOFTENER.”

Use only liquid fabric softener in the dispenser.

Dilute with water to the maximum fill line.

Do not exceed the maximum fill line. Overfilling

can cause early dispensing of the fabric softener

which could stain clothes.

NOTE: Do not pour fabric softener directly

on the wash load.

Do not exceed the maximum fill line. Overfilling

can cause early dispensing of the bleach which

could result in damaged clothes.

NOTE: Do not use powdered bleach in the

dispenser.

Instructions

Installation

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

9

Loading and using the washer.

Always follow fabric manufacturer’s care label when laundering.

Sorting Wash Loads

Sort laundry into loads that can be washed together.

Installation

Instructions

Colors

Whites

Lights

Darks

Combine large and small items in a load. Load large items first. Large items should not be more than half

the total wash load.

Washing single items is not recommended. This may cause an out-of-balance load. Add one or two

similar items.

Pillows and comforters should not be mixed with other items. This may cause an out-of-balance load.

WARNING

Never place items in the washer that are dampened with gasoline or other flammable liquids.

No washer can completely remove oil.

Do not dry anything that has ever had any type of oil on it (including cooking oils).

Doing so so can result in death, explosion, or fire.

Soil

Heavy

Normal

Light

- Fire Hazard

Fabric

Delicates

Easy Care

Sturdy Cottons

Lint

Lint Producers

Lint Collectors

Preparing Clothes

To avoid snags during washing:

Follow these steps to maximize garment care.

• Close garment zippers, snaps, buttons and hooks.

• Mend seams, hems, tears.

• Empty all items from pockets.

• Remove nonwashable garment accessories such as ornaments and nonwashable trim materials.

To avoid tangling, tie strings, draw ties and belt-like materials.

Brush away surface dirt and lint; treat spots and stains.

Promptly wash wet or stained garments to maximize results.

Mix garments using recommended maximum load sizes on page 11.

Use nylon mesh garment bags to wash small items.

Wash multiple garments at one time for best results.

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

10

GEAppliances.com

Loading the Washer

Wash drum may be fully loaded with loosely added

items. Do not wash fabrics containing flammable

materials (waxes, cleaning fluids, etc.).

Maximum Loading Sizes*

WORKWEAR

4 Jeans

5 Workwear Shirts

5 Workwear Pants

10 Bath Towels/

12 Washcloths

7 Hand Towels/

2 Flat Queen-Sized

LINENS

2 Bath Sheets

2 Terrycloth

Bath Mats

OR

Sheets

2 Fitted

Queen-Sized

Sheets

4 Pillowcases

MIXED LOAD

4 Pillowcases

2 Hand Towels

2 Flat Sheets/

2 Fitted Sheets

2 Bath Towels/

4 Washcloths

6 Shirts (Men’s

or Women’s)

4 Pair Pants

(Khakis

or Twills)

5 T-Shirts

7 Pairs of Boxers

4 Pairs of Shorts

6 T-Shirts

4 Pairs of

Sweatpants

4 Sweatshirts

2 Hoodies

7 Pairs of Socks

To add items after washer has started, press Start

and wait until the door is unlatched. The washer

may take up to 30 seconds to unlock the door

after pressing Start depending on the machine

conditions. Do not try to force open the door when

it is locked. After the door unlocks, open gently. Add

items, close the door and press Start to restart.

OR

OR

DELICATES**

7 Bras

7 Panties

3 Slips

2 Camisoles

4 Nightgowns

SPEED WASH

(2–4 GARMENTS)

2 Casual Wear

Work Shirts

1 Pair Casual Wear

Work Pants

OR

3 Soccer Uniforms

Instructions

Installation

*Exceeding maximum recommended load sizes may affect cleaning performance and garment care.

**Using a nylon mesh bag for small items is recommended.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

11

Cleaning the washer.

Care and Cleaning

Exterior: Immediately wipe off any spills. Wipe with damp cloth. Do not hit surface with sharp objects.

Moving and Storage: Ask the service technician to remove water from drain pump and hoses.

Do not store the washer where it will be exposed to the weather. When moving the washer,

the tub should be kept stationary by using the shipping bolts removed during installation.

See Installation Instructions in this book. If these parts are not available, they can be ordered

by visiting our Website at GEAppliances.com or by calling 800.GE.CARES. In Canada, call 800.561.3344.

Long Vacations: Be sure the water supply is shut off at the faucets. Drain all water from the hoses if the

weather will be below freezing.

Installation

Instructions

Cleaning the Interior

of the Washer

To clean the interior of the washer, select

the Basket Clean feature on the control

panel. The cycle will use more water,

in addition to bleach, to refresh your

washer.

NOTE: Read the instructions below

completely before starting the Basket

Clean cycle.

1. Remove any garments or objects from

the washer and ensure the washer

basket is empty.

2. Open the washer door and pour

one cup or 250 ml of liquid bleach

or other washing machine cleaner

into the basket.

3. Close the door and select the Basket

Clean cycle. Push the Start pad.

4. When the Basket Clean cycle is

working, you will see CLn on the

display. The cycle will complete in

about 90 minutes. Do not interrupt

the cycle.

5. After the cycle is complete, leave

the door open slightly for better

ventilation.

If for any reason the cycle needs to

be interrupted, the door will not open

immediately. Forcing open the door at

this stage may cause water to flood.

The door will open after the water is

drained to a level where it would not

flood the floor.

Basket Clean may be interrupted

by pressing the Start pad in between

cycles. A power outage in the house might

also interrupt the cycle. When the power

supply is back, the Basket Clean cycle

resumes where it had stopped. When

interrupted, be sure to run a complete

Basket Clean cycle before using the

washer. If the Power pad is pressed during

BasketClean, the cycle will be lost.

IMPORTANT:

Run Basket Clean with 1 Cup (250 ml) of

bleach once a month.

After the completion of a Basket Clean

cycle, the interior of your washer may

have a bleach smell.

It is recommended to run a light color

load after the Basket Clean cycle.

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

12

GEAppliances.com

Cleaning the Pump Filter

Due to the nature of the front-load washer,

it is sometimes possible for small articles

to pass to the pump. The washer has a

filter to capture lost items so they are not

dumped to the drain. To retrieve lost items,

clean out the pump filter.

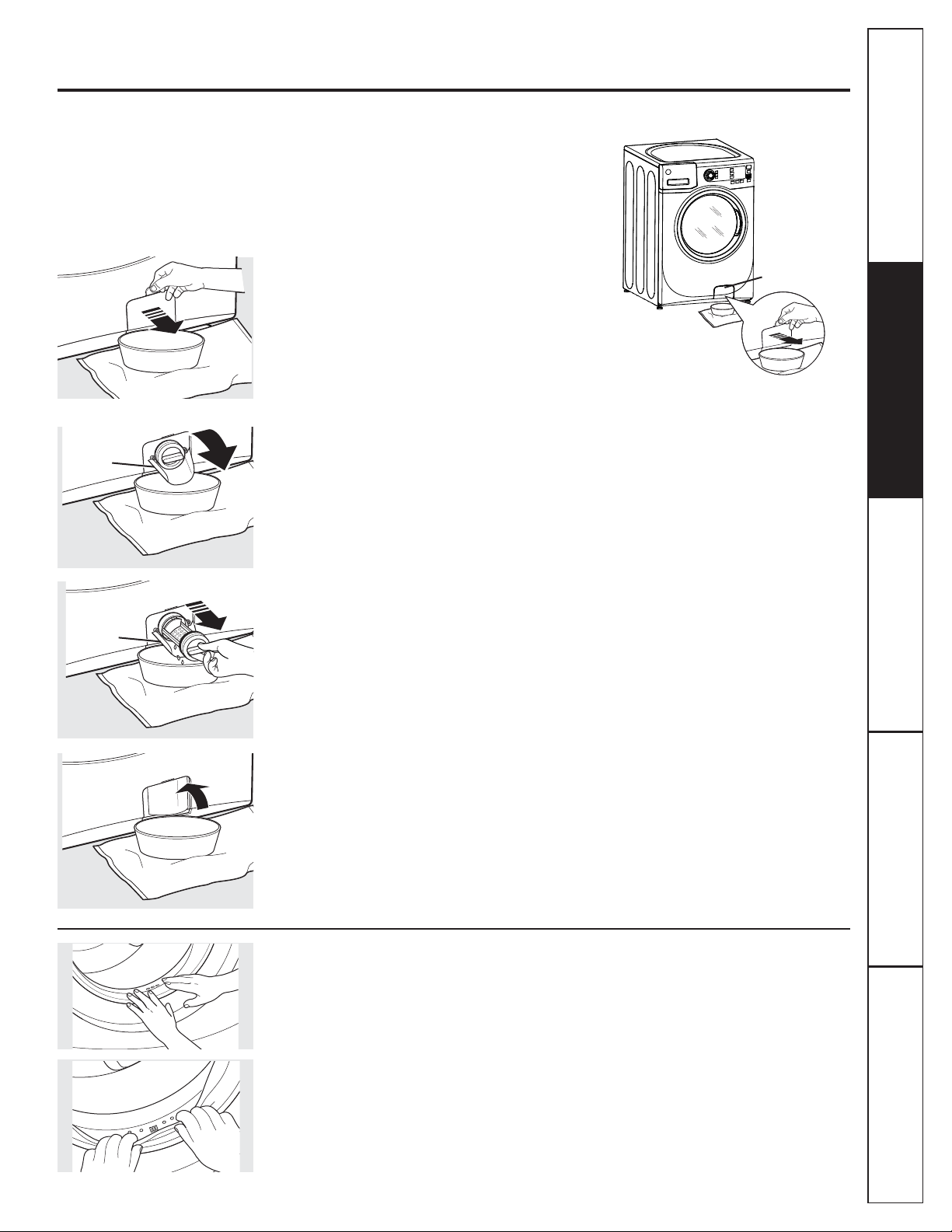

1. Using a coin or flat screwdriver

in the notch on the door, open

the access door.

2. Place a shallow pan or dish under

the pump access door and towels

on the floor in front of the washer to

protect the floor. It is normal to catch

about a cup of water when the filter

is removed.

3. Pull down the pour spout.

Pour

spout

Pump filter

Pour

spout

4. Turn the pump filter counterclockwise

and remove the filter. Open slowly to

allow the water to drain.

5. Clean the debris from the filter.

6. Replace the filter and turn clockwise.

Tighten securely.

7. Flip up the pour spout.

8. Close the access door.

Cleaning the Door Gasket

Open the washer door. Using both hands,

press down the door gasket. Remove any

foreign objects if found trapped inside

the gasket. Make sure there is nothing

blocking the holes behind the gasket.

While holding down the door gasket,

inspect the interior gasket by pulling it

down with your fingers. Remove any

foreign objects if found trapped inside

this gasket. Make sure there is nothing

blocking the holes behind the gasket.

When you are finished cleaning

the door gasket, remove your

hands and the gasket will return

to the operating position.

Instructions

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

13

Installation

Cleaning the washer.

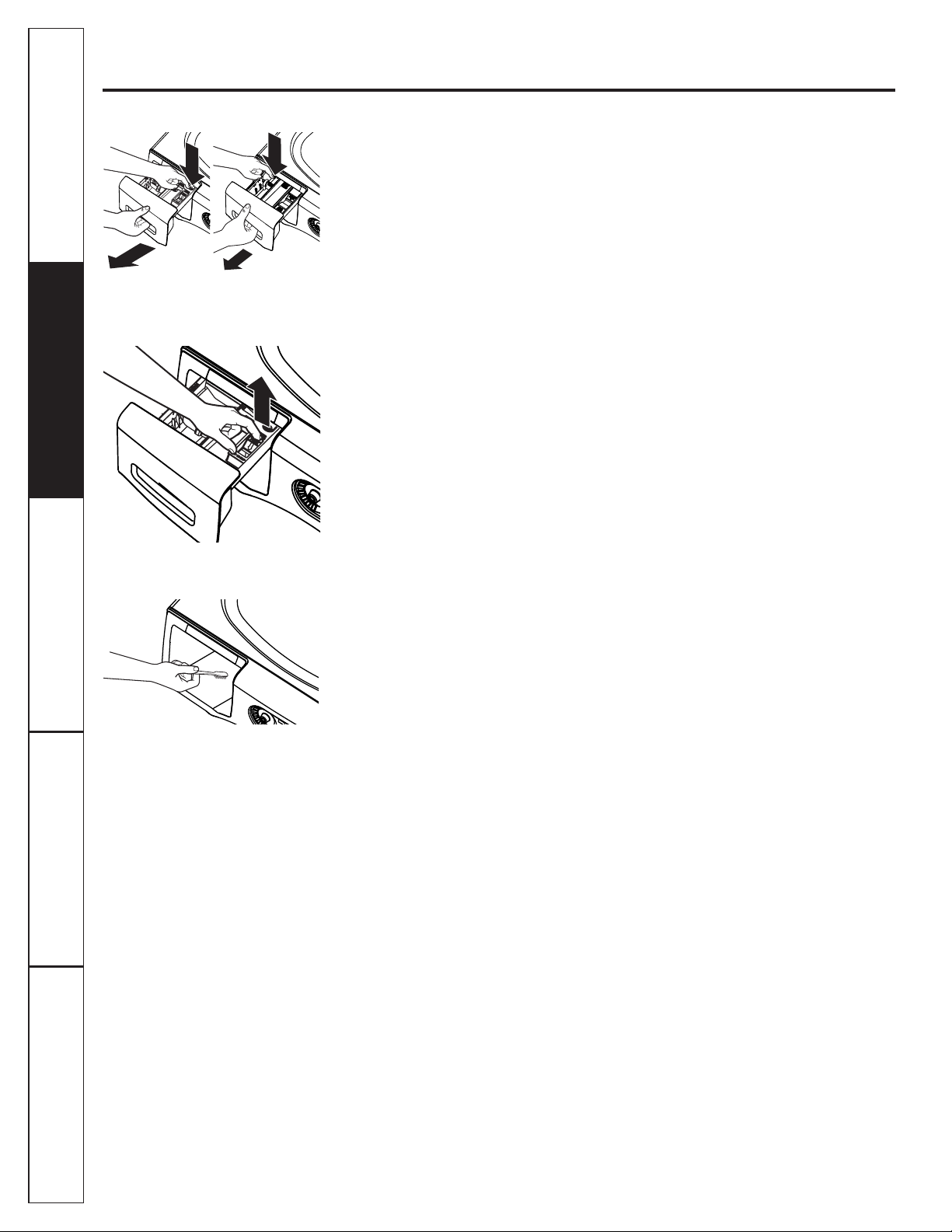

Tab on back right or left depending on model

Lock tab is visible only after drawer

has been pulled open

Dispenser Drawer Area: Detergent and fabric softener may build up

in the dispenser drawer. Residue should be removed once or twice a month.

Remove the drawer by first pulling it out until it stops. Then reach back into

the left or right rear corner (depending on model) of the drawer cavity and

press down firmly on the lock tab, pulling out the drawer.

Remove the inserts from the bleach and fabric softener compartments and

the detergent insert. Rinse the inserts and the drawer with hot water to

remove traces of accumulated laundry products.

Installation

Instructions

To clean the drawer opening, use a small brush to clean the recess. Remove

all residue from the upper and lower parts of the recess.

Return inserts to the proper compartments. Replace the dispenser drawer.

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

14

Installation

Washer

Instructions

If you have any questions, call 800.GE.CARES (800.432.2737) or visit our Website at: GEAppliances.com

In Canada, call 800.561.3344 or visit GEAppliances.ca

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these instructions

for local inspector’s use.

•

IMPORTANT – Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• Skill level – Installation of this appliance requires

basic mechanical and electrical skills.

• Completion time – 1-3 hours

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

FOR YOUR SAFETY:

WARNING

TOOLS REQUIRED

Adjustable wrench or 1/2” socket with ratchet

Adjustable wrench or 9/16” open-end wrench

Channel-lock adjustable pliers

Carpenter’s level

PARTS REQUIRED (Obtain locally)

Water Hoses (2)

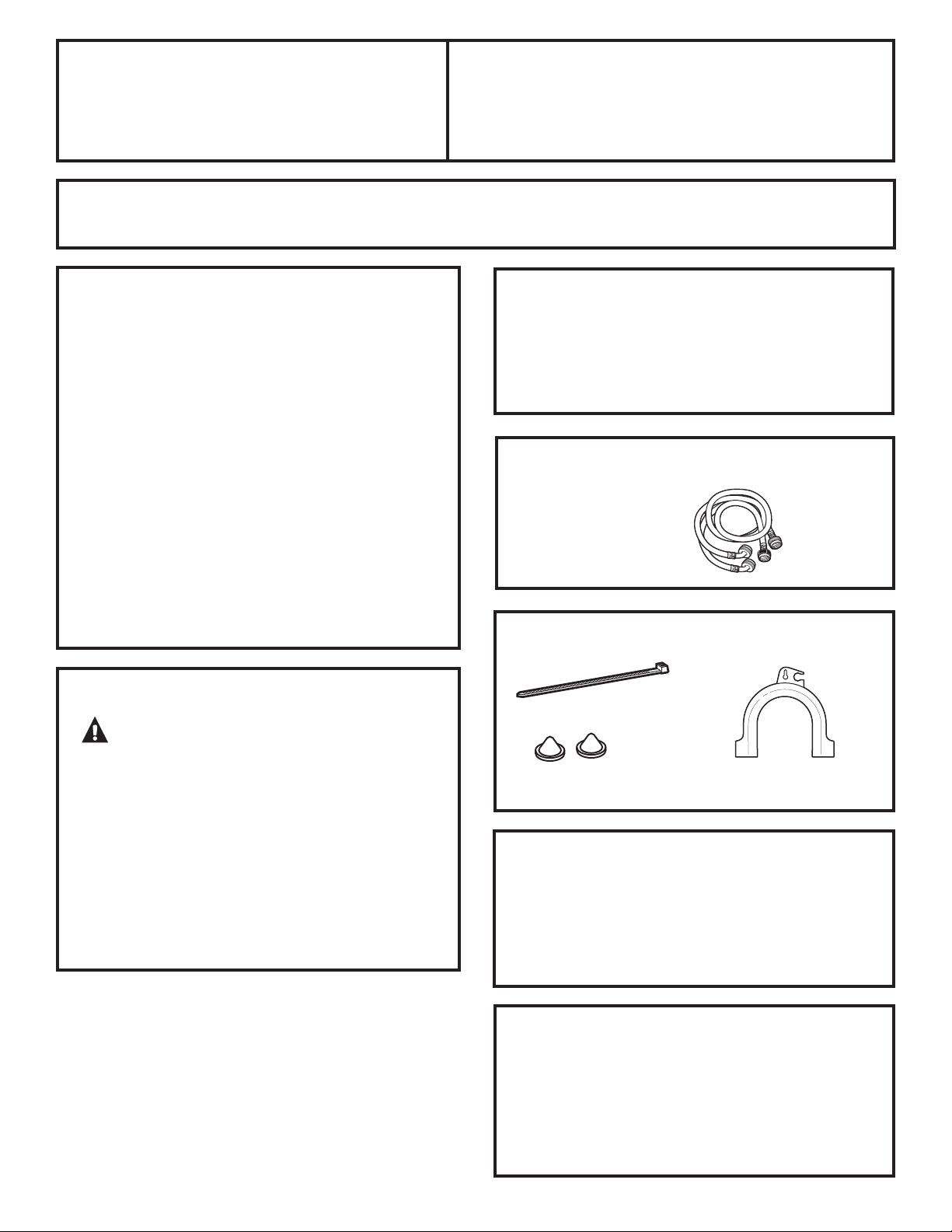

PARTS SUPPLIED

Cable Tie

• This appliance must be properly grounded and

installed as described in these Installation Instructions.

• Do not install or store the appliance in an area where

it will be exposed to water/weather. See the Location

of Your Washer section.

• NOTE: This appliance must be properly

grounded, and electrical service to the washer

must conform with local codes and ordinances

and the latest edition of the National Electrical

Code, ANSI/NFPA 70.

Inlet Hose Screen

Washers (2)

Hose Guide

STACK BRACKET KIT

A stack bracket kit is available at additional cost.

It can be ordered in the United States by visiting

our Web site at GEAppliances.com or calling 800.

GE.CARES. In Canada, call 800.661.1616 or visit your

local GE Appliances dealer. Order kit # WE25X10018 or

GEFLSTACK.

OPTIONAL PEDESTAL ACCESSORY

A pedestal is available at additional cost. It can be

ordered in the United States by visiting our Web site at

GEAppliances.com or calling 800.GE.CARES. In Canada,

visit your local GE Appliances dealer. This product

should be used with the pedestal # SBSD137HXX

and SBSD227FXX. Follow the pedestal Installation

Instructions.

15

Installation Instructions

LOCATION OF YOUR WASHER

Do Not Install the Washer:

1. In an area exposed to dripping water or outside

weather conditions. The ambient temperature should

never be below 60°F (15.6°C) for proper washer

operation.

2. In an area where it will come in contact with curtains

or drapes.

3. On carpet. The floor MUST be a hard surface with

a maximum slope of 1/2” per foot (1.27 cm per

30 cm). To make sure the washer does not vibrate

or move, you may have to reinforce the floor.

NOTE: If floor is in poor condition, use 3/4” impregnated

plywood sheet solidly attached to the existing floor

covering.

IMPORTANT:

Minimum Installation Clearances

• When installed in alcove: Sides, Rear,

Top = 0” (0 cm)

• When installed in closet: Sides, Rear,

Top = 0” (0 cm), Front = 1” (2.54 cm)

ROUGH-IN DIMENSIONS

FRONT

27.0”

(68.6 cm)

39.8”

(101.09 cm)

• Closet door ventilation openings required:

2 louvers each 60 square in. (387 cm), located 3”

(7.6 cm) from top and bottom of door

SIDE

33.6”

(85.3 cm)

39.8”

(101.09 cm)

*NOTE: With pedestal, 52.6”

Stacked, 84”

16

Installation Instructions

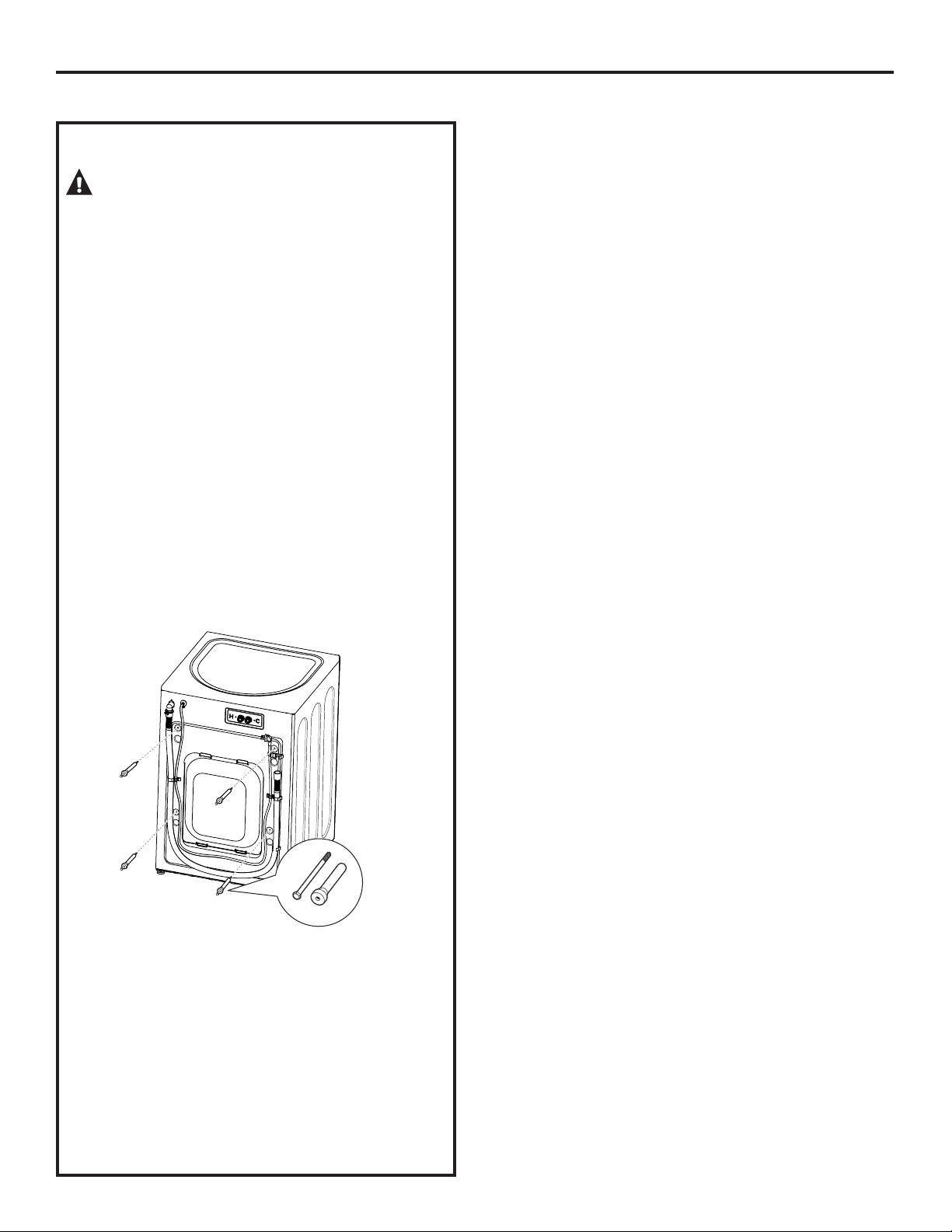

UNPACKING THE WASHER

WARNING: Recycle or destroy the carton

and plastic bags after the washer is unpacked. Make

materials inaccessible to children. Children might use

them for play. Cartons covered with rugs, bedspreads

or plastic sheets can become airtight chambers causing

suffocation.

1. Cut and remove the top and bottom packaging straps.

2. While it is in the carton, carefully lay the washer on its

side. DO NOT lay the washer on its front or back.

3. 7XUQGRZQWKHERWWRPIODSV³UHPRYHDOOEDVHSDFNDJLQJ

including the cardboard, styrofoam base and styrofoam

tub support (inserted in center of base).

NOTE: If you are installing a pedestal, proceed to

the installation instructions that come with the pedestal.

4. Carefully return the washer to an upright position and

remove the carton.

5. Carefully move the washer to within 4 feet (122 cm)

of the final location.

6. Remove the following from the back side of the washer:

4 bolts

4 plastic spacers (including rubber grommets)

4 power cord retainers

NOTE: Failure to remove the shipping braces can cause

the washer to become severely unbalanced.

Save all bolts for future use.

NOTE: If you must transport the washer at a later date,

you must reinstall the shipping support hardware to prevent

shipping damage. Keep the hardware in the plastic bag

provided.

In case you misplace your shipping bolts, replacements

are available at additional cost. They can be ordered in the

United States by visiting our website at GEAppliances.com

or calling 800.GE.CARES. In Canada, call 800.661.1616. Order

kit #WH49X10039.

17

Installation Instructions

ELECTRICAL REQUIREMENTS

Read these instructions completely and carefully.

WARNING:

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK AND

PERSONAL INJURY:

• DO NOT USE AN EXTENSION CORD OR AN ADAPTER

PLUG WITH THIS APPLIANCE.

Washer must be electrically grounded in accordance

with local codes and ordinances, or in the absence

of local codes, in accordance with the NATIONAL

ELECTRICAL CODE, ANSI/NFPA NO. 70.

CIRCUIT – Individual, properly polarized and grounded

15-amp branch circuit fused with 15-amp time-delay fuse

or circuit breaker.

POWER SUPPLY – 2-wire, with ground, 120-volt,

single-phase, 60-Hz, alternating current.

OUTLET RECEPTACLE – Properly

grounded 3-prong receptacle to be

located so the power supply cord

is accessible when the washer is

in an installed position.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within

42 inches (107 cm) of your washer’s water inlet. The faucets

MUST be 3/4” (1.9 cm) garden hose-type so inlet hoses can

be connected. Water pressure MUST be between 10 and 120

pounds per square inch. Your water department can advise

you of your water pressure. The hot water temperature

should be set to deliver water at 120° to 140°F (48°–60°C).

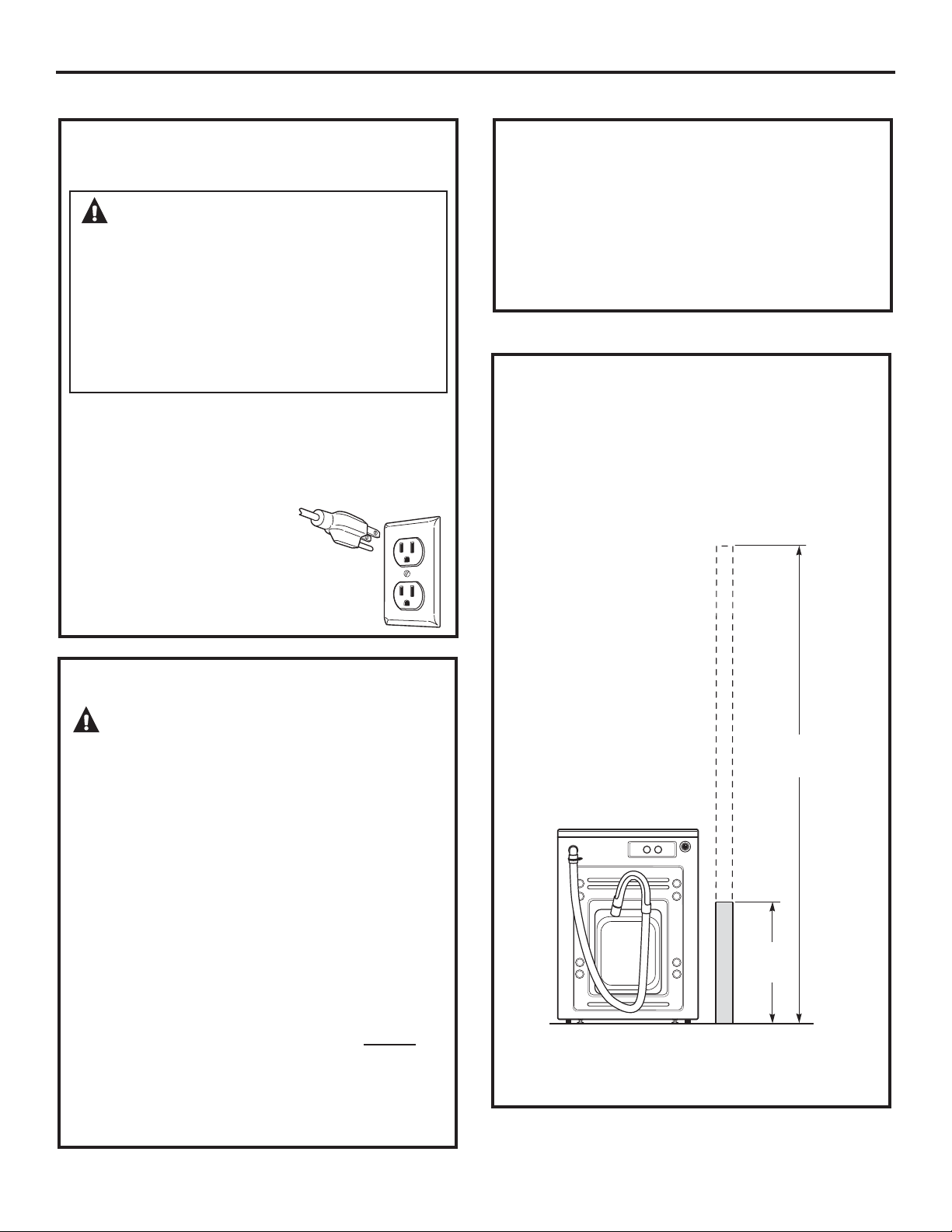

DRAIN REQUIREMENTS

1. Drain capable of eliminating 17 gals (64.3 L)

per minute.

2. A standpipe diameter of 1–1/4” (3.18 cm) minimum.

3. The standpipe height above the floor should be:

Minimum height: 24” (61 cm)

Maximum height: 96” (244 cm)

GROUNDING REQUIREMENTS

WARNING:

Improper connection of the equipment grounding conductor

can result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is

properly grounded.

1. The washer MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce

the risk of electrical shock by providing a path of least

resistance for electrical current.

2. Since your washer is equipped with a power supply

cord having an equipment-grounding conductor and

a grounding plug, the plug MUST be plugged into an

appropriate, copper-wired receptacle that is properly

installed and grounded in accordance with all local

codes and ordinances or in the absence of local codes,

with the National Electrical Codes, ANSI/NFPA 70 (latest

edition). If in doubt, call a licensed electrician. DO NOT

cut off or alter the grounding prong on the power

supply cord. In situations where a two-slot receptacle is

present, it is the owner’s responsibility to have a licensed

electrician replace it with a properly grounded

three-prong grounding-type receptacle.

96”

(244 cm)

Max.

BACK

24”

(61 cm)

Min.

NOTE: The drain hose attached to the washer can reach

a 58” (147 cm) high standpipe. For a higher standpipe,

contact an authorized parts distributor.

18

Installation Instructions

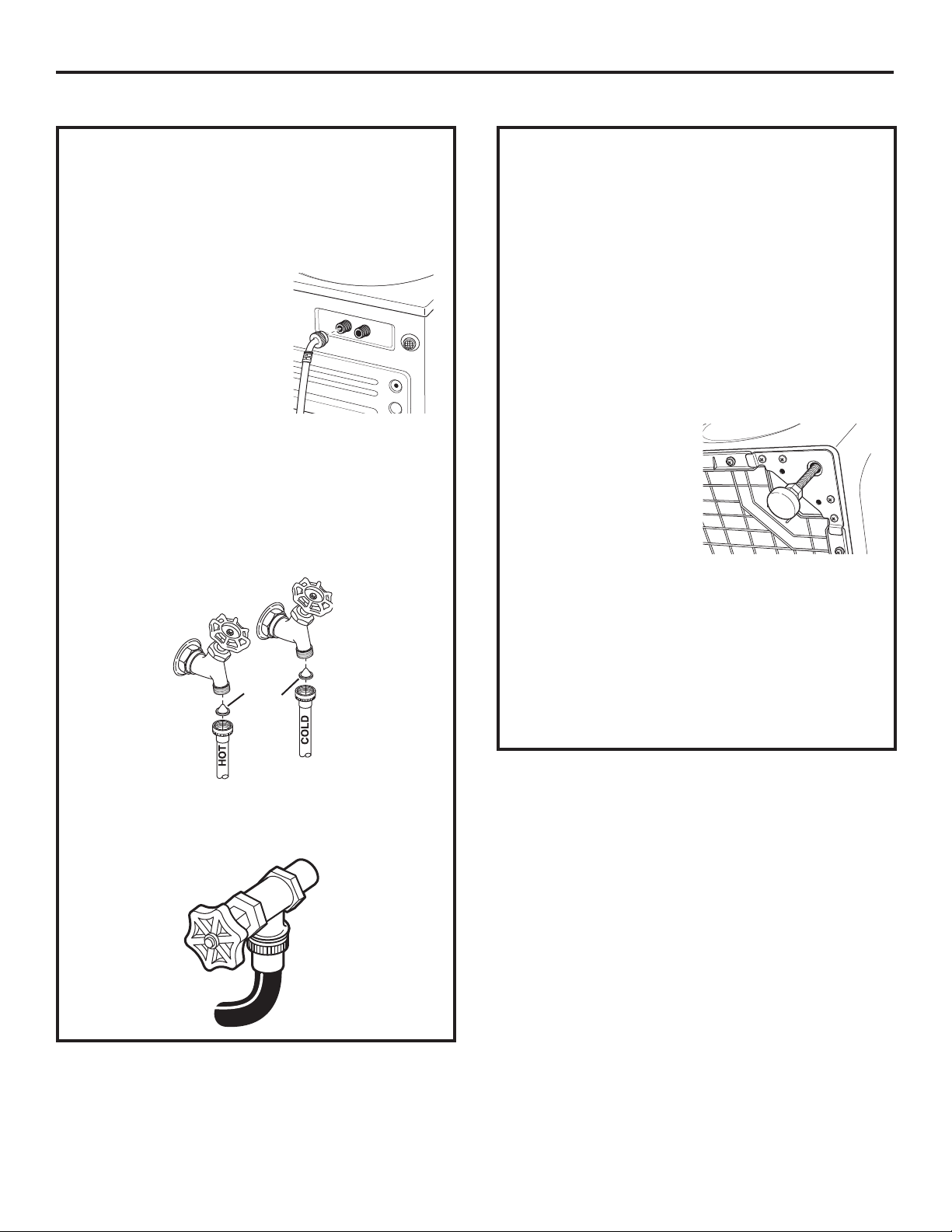

INSTALLING THE WASHER

1. Run some water from the hot and cold faucets to flush

the water lines and remove particles that might clog up

the inlet hoses and water valve screens.

2. Obtain inlet hoses locally.

3. Ensure there is a rubber

washer in the hoses. Reinstall

the rubber washer into the

hose fitting if it has fallen out

during shipment. Carefully

connect an inlet hose to

the outside “H” outlet of the

water valve. Tighten by hand,

then tighten another 2/3 turn

with pliers. Carefully connect

the other inlet hose to the inside “C” outlet of the water

valve. Tighten by hand; then tighten another 2/3 turn

with pliers. Do not crossthread or over-tighten these

connections.

4. Install the screen washers by inserting them into the free

ends of the inlet hoses with protruded side facing the

faucet.

C

H

6. Carefully move the washer to its final location. Gently

rock the washer into position ensuring inlet hoses do

not become kinked. It is important not to damage the

rubber leveling legs when moving your washer to its final

location. Damaged legs can increase washer vibration. It

may be helpful to spray window cleaner on the floor to

help move your washer into its final position. NOTE: To

reduce vibration, ensure that all four rubber leveling legs

are firmly touching the floor. Push and pull on the back

right and then back left of your washer.

NOTE: Do not use the dispenser drawer or door to lift

the washer.

NOTE: If you are installing into a drain pan, you can use

a 24-inch long 2x4 to lever the washer into place.

7. With the washer in its

final position, place

a level on top of the

washer (if the washer

is installed under a

counter, the washer

should not be able to

rock). Adjust the front

leveling legs up or down

to ensure the washer is resting solid. Turn the lock

nuts on each leg up towards the base of the washer

and snug with a wrench.

Inlet Hose

Screen

Washers

5. Connect the inlet hose ends to the HOT and COLD water

faucets tightly by hand, then tighten another 2/3 turn

with pliers. Turn the water on and check for leaks.

NOTE: Keep the leg extension at a minimum to prevent

excessive vibration. The farther out the legs are extended,

the more the washer will vibrate.

If the floor is not level or is damaged, you may have

to extend the rear leveling legs.

19

Installation Instructions

INSTALLING THE WASHER

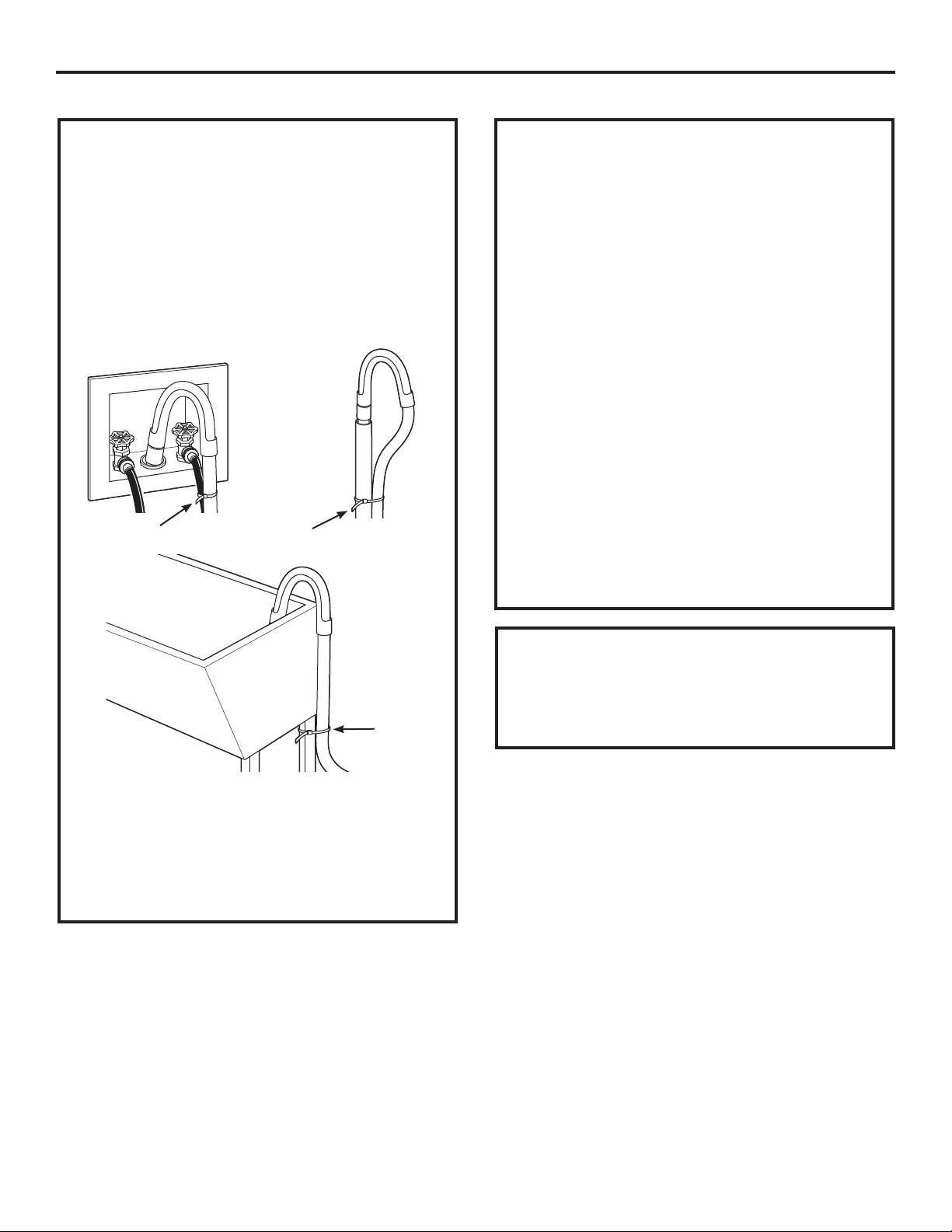

8. Attach the U-shaped hose guide to the end of

the drain hose. Place the hose in a laundry tub or

standpipe and secure it with the cable tie provided in

the enclosure package.

NOTE: Placing the drain hose too far down the drain pipe

can cause a siphoning action. No more than 7 inches of

hose should be in the drain pipe. There must be an air

gap around the drain hose. A snug fit can also cause a

siphoning action.

Cable Tie

Cable Tie

(cont.)

10. Turn on the power at the circuit breaker/fuse box.

11. Read the rest of this Owner’s Manual. It contains

valuable and helpful information that will save you

time and money.

12. Before starting the washer, check to make sure:

Main power is turned on.

The washer is plugged in.

The water faucets are turned on.

The unit is level and all four leveling legs are firmly

on the floor.

The shipping support hardware is removed

and saved.

The drain hose is properly tied up.

There are no leaks at the faucet, drain line

or washer.

13. Run the washer through a complete cycle.

Check for water leaks and proper operation.

14. If your washer does not operate, please review

the Before You Call For Service section before

calling for service.

15. Place these instructions in a location near the washer

for future reference.

Cable Tie

9. Plug the power cord into a grounded outlet.

NOTE: Check to be sure the power is off at the circuit

breaker/fuse box before plugging the power cord into

an outlet.

REPLACEMENT PARTS

If replacement parts are needed for your washer, they

can be ordered in the United States by visiting our Web

site at GEAppliances.com or by calling 800.GE.CARES. In

Canada, call 800.661.1616.

20

Before you call for service… GEAppliances.com

Troubleshooting Tips

Save time and money! Review the charts on the

following pages first and you may not need to call for

service.

Problem Possible Cause What To Do

Not draining

Not spinning

Not agitating

Pump clogged • See page 13 on how to clean the Pump Filter.

be clogged a plumber.

Drain hose siphoning; drain hose • Ensure there is an air gap between hose and drain.

pushed too far down the drain

Leaking water Door gasket is damaged • Check to see if gasket is seated and not torn. Objects

left in pockets may cause damage to the washer (nails,

screws, pens, pencils).

Door gasket not damaged • Water may drip from the door when the door is opened.

This is a normal operation.

• Carefully wipe off rubber door seal. Sometimes dirt or

clothing is left in this seal and can cause a small leak.

Check back left of washer • If this area is wet, you have oversudsing condition.

for water Use less detergent.

Fill hoses or drain hose is • Make sure hose connections are tight at washer and

improperly connected faucets and make sure end of drain hose is correctly

inserted in and secured to drain facility.

Household drain may • Check household plumbing. You may need to call

be clogged a plumber.

Dispenser clogged • Powder soap may cause clogs inside the dispenser and

cause water to leak out the front of the dispenser. Remove

drawer and clean both drawer and inside of dispenser box.

Please refer to Cleaning the Washer section.

Incorrect use of detergent • Use HE and correct amount of detergent.

Dispenser box crack • If new installation, check for crack on inside of dispenser box.

Clothes too wet Load is out of balance • Redistribute clothes and run drain & spin or rinse & spin.

• Increase load size if washing small load containing heavy

and light items.

• The machine will slow the spin speed down to 410 rpm if

it has a hard time balancing the load. This speed is normal.

Pump clogged • See page 13 on how to clean the Pump Filter.

Overloading • The dry weight of the load should be less then 16 lb.

Drain hose is kinked or • Straighten drain hose and make sure washer is not

improperly connected sitting on it.

Household drain may • Check household plumbing. You may need to call

be clogged a plumber.

Drain hose siphoning; drain hose • Ensure there is an air gap between hose and drain.

pushed too far down the drain

Load is out of balance • Redistribute clothes and run drain & spin or rinse & spin.

and light items.

Drain hose is kinked or • Straighten drain hose and make sure washer is not

improperly connected sitting on it.

Household drain may • Check household plumbing. You may need to call

• Increase load size if washing small load containing heavy

Instructions

Installation

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

21

Before you call for service…

Problem Possible Cause What To Do

Incomplete cycle or timer Automatic load redistribution • Timer adds 3 minutes to cycle for each rebalance.

not advancing 11 or 15 rebalances may be done. This is normal operation.

Do nothing; the machine will finish the wash cycle.

Pump clogged • See page 13 on how to clean the Pump Filter.

Drain hose is kinked or • Straighten drain hose and make sure washer is not

improperly connected sitting on it.

Household drain may • Check household plumbing. You may need to call

be clogged a plumber.

Drain hose siphoning; drain hose • Ensure there is an air gap between hose and drain.

pushed too far down the drain

Loud or unusual noise; Cabinet moving • Washer is designed to move 1/4” to reduce forces

vibration or shaking transmitted to the floor. This movement is normal.

All rubber leveling legs are not • Push and pull on the back right and then back left of your

firmly touching the floor washer to check if it is level. If the washer is uneven, adjust

the rubber leveling legs so they are all firmly touching the

floor and locked in place. Your installer should correct this

problem.

Unbalanced load • Open door and manually redistribute load. To check

machine, run rinse and spin with no load. If normal,

unbalance was caused by load.

Pump clogged • See page 13 on how to clean the Pump Filter.

No power/washer not Washer is unplugged • Make sure cord is plugged securely into a working outlet.

working or dead

Circuit breaker/fuse is • Check house circuit breakers/fuses. Replace fuses or

tripped/blown reset breaker. Washer should have separate outlet.

Automatic self system checks • First time the washer is plugged in, automatic checks

occur. It may take up to 20 seconds before you can use

Installation

your washer. This is normal operation.

Instructions

Snags, holes, tears, rips Overloaded • Do not exceed maximum recommended load sizes.

or excessive wear See recommended maximum load sizes on page 11.

other objects left in pockets

Pins, snaps, hooks, sharp • Fasten snaps, hooks, buttons and zippers.

buttons, belt buckles, zippers

and sharp objects left in pockets

Control time wrong This is normal • During spin the washer may need to rebalance the load

or changes sometimes to reduce vibrations. When this happens,

the estimated time is increased causing time left to

increase or jump.

Not enough water This is normal • Horizontal washers do not require the tub to fill with water

like top-load washers.

Washer pauses or has Pump clogged • See page 13 on how to clean the Pump Filter.

to be restarted, or washer

door is locked and will

not open

Door unlocks or This is normal • Front-load washers start up differently than top-load

press Start and machine washers, and it takes 30 seconds to check the system.

doesn’t operate The door will lock and unlock.

Incorrect operation • Simply open and close the door firmly; then press Start.

Water supply is turned off • Turn both hot and cold faucets fully on.

Pens, pencils, nails, screws or • Remove loose items from pockets.

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

22

GEAppliances.com

Problem Possible Cause What To Do

Water does not enter Automatic self system checks • After Start is pressed, the washer does several system

washer or enters slowly

Water supply is turned off • Turn on both hot and cold faucets fully.

toothpick to clean the screens in the machine. Reconnect

the hoses and turn the water back

Inlet hose screen washers are •

screen washers in the end of the hoses. Reconnect the

hoses and turn the water back

Wrinkling Improper sorting • Avoid mixing heavy items (like work clothes) with

light items (like blouses).

Overloading • Load your washer so clothes have enough room

to move freely.

Incorrect wash cycle • Match cycle selection to the type of fabric you are

washing (especially for easy care loads).

Repeated washing in • Wash in warm or cold water.

water that is too hot

Grayed or yellowed Not enough detergent • Use correct amount of detergent.

clothes

detergent

• Use a water conditioner like Calgon brand or install

a water softener.

Water is not hot enough • Make sure water heater is delivering water at

120°–140°F (48°–60°C).

Detergent is not • Try a liquid detergent.

dissolving

Dye transfer • Sort clothes by color. If fabric label states wash separately,

unstable dyes may be indicated.

Colored spots Incorrect use of fabric • Check fabric softener package for instructions and follow

softener directions for using dispenser.

Dye transfer • Sort whites or lightly colored items from dark colors.

• Promptly remove wash load from washer.

Water temperature Water supply is improperly • Make sure hoses are connected to correct faucets.

is incorrect connected

House water heater is • Make sure house water heater is delivering water

not set properly at 120°–140°F (48°–60°C).

Slight variation This is normal • Due to the metallic properties of paint used for this unique

in metallic color product, slight variations of color may occur due to viewing

angles and lighting conditions.

Bad odor inside Washer unused for a long time, • Run a Basket Clean cycle.

your washer

detergent container.

• Use only HE (high-efficiency) detergent.

• Always remove wet items from the washer promptly after

machine stops running.

• Leave the door slightly open for the water to air dry. Close

supervision is necessary if this appliance is used by or

near children. Do not allow children to play on, with or

inside this or any other appliance.

Water valve screens are •

stopped up

stopped up

Hard water • Use hottest water safe for fabric.

Not using HE (high-efficiency) • Use HE detergent.

not using recommended

quality of HE detergent

or used too much detergent

hoses from the upper back of the washer. Use a brush or

the wall faucets. Use a brush or toothpick to clean the

• In the case of strong odor, you may need to run

the Basket Clean cycle more than once.

• Use only the amount of detergent recommended on the

checks. Water will flow 60 seconds after

Turn off the water source and remove the water connection

Turn off the water source and remove the inlet hoses from

on.

on.

Start

is pressed.

23

Instructions

Installation

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

Before you call for service…

Problem Possible Cause What To Do

Detergent leak Incorrect placement of • Make sure detergent insert is properly located and fully

detergent insert seated. Never put detergent above max line.

Improper dispensing of Dispenser clogged • Monthly clean the dispenser drawer to remove buildup

softener or bleach

Softener or bleach is filled above • Make sure to have the correct amount of softener or bleach.

the max line

or they will not work

Softener or bleach cap issue •

of chemicals.

Make sure softener and bleach cap for dispenser are seated

.

Installation

Instructions

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

24

Loading...

Loading...