Page 1

SAFETY INFORMATION ...........4

USING THE UNIT

Getting Started ...................... 6

Loading .............................15

OWNER’S MANUAL &

INSTALLATION

INSTRUCTIONS

CARE AND CLEANING ........... 16

INSTALLATION

INSTRUCTIONS .....................18

TROUBLESHOOTING TIPS ......23

LIMITED WARRANTY ............31

CONSUMER SUPPORT .......... 32

GFQ14

ENGLISH/FRANÇAIS/

ESPAÑOL

Write the model and serial

numbers here:

Model # _________________

Serial # _________________

Front Load Steam Washer & Condenser Dryer

GE is a trademark of the General Electric Company. Manufactured under trademark license.

COMBINATION

You can find them on a label

inside the door.

0020507767YB 49-3000230 Rev 2 12-19 GEA

Page 2

THANK YOU FOR MAKING GE APPLIANCES A PART OF YOUR HOME.

Whether you grew up with GE Appliances, or this is your first, we’re happy to have you in the family.

We take pride in the craftsmanship, innovation and design that goes into every GE Appliances

product, and we think you will too. Among other things, registration of your appliance ensures that we

can deliver important product information and warranty details when you need them.

Register your GE appliance now online. Helpful websites and phone numbers are available in the

Consumer Support section of this Owner’s Manual. You may also mail in the pre-printed registration

card included in the packing material.

2 49-3000230 Rev 2

Page 3

Introduction

• This unit allows: wash only; dry only; wash and dry cycles.

• Fill the drum 2/3 full with laundry for best wash and dry performance. This allows air movement and proper drying.

A fully loaded drum will lead to longer dry times.

NOTE: During Dry cycles temperatures in the unit can get very hot. For this reason, the door will lock during the dry

cycle and remain locked, after pausing or at the end of the cycle, until temperatures cool down. Forcing the door

open will result in a broken door mechanism.

• This unit uses condenser drying technology. This enables installation and use without a vent, but loads take

approximately 1.5 times longer to dry than a traditional vented dryer.

INTRODUCTION

49-3000230 Rev 2 3

Page 4

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

SAFETY INFORMATION

WARNING

Ŷ

Read all instructions before using the appliance.

Ŷ

Follow all fabric care instructions and warnings to prevent melting of garments or damage to the appliance.

Ŷ

DO NOT wash or dry articles that have been previously cleaned in, washed in, soaked in or spotted with

gasoline, dry-cleaning solvents, or other flammable or explosive substances, as they give off vapors that could

ignite or explode.

Ŷ

DO NOT add gasoline, dry-cleaning solvents, or other flammable or explosive substances to the wash water.

These substances give off vapors that could ignite or explode.

Ŷ

DO NOT place items exposed to cooking oils in your unit. Items contaminated with cooking oils may contribute

to a chemical reaction that could cause a load to catch fire. To reduce the risk of fire due to contaminated loads,

the final part of the tumble dryer cycle occurs without heat (cool down period). At the end of the cycle the door

remains locked during the cool down period to protect from surfaces that get hot during drying. The cool down

period will be approximately 10 minutes before the door is unlocked.

Ŷ

DO NOT dry articles containing foam rubber or similarly textured rubber-like materials.

Ŷ

DO NOT store combustible materials, gasoline or other flammable liquids near the unit. Keep area around the

air intake vent on the front of the unit and adjacent surrounding areas free from the accumulation of lint, dust

and dirt.

Ŷ

The interior of the appliance should be cleaned periodically by qualified service personnel.

Ŷ

DO NOT add dryer lint sheet in the unit when washing.

To reduce the risk of death, fire, explosion, electric shock, or injury to persons when using

your appliance, follow basic precautions, including the following:

Ŷ

DO NOT spray any type of aerosol into, on or near the unit at any time. DO NOT use any type of spray

cleaner when cleaning the interior. Hazardous fumes or electrical shock could occur.

Ŷ

Under certain conditions, hydrogen gas may be produced in a hot-water system that has not been used for

2 weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has not been used for such a

period, before using a washing machine, turn on all hot-water faucets and let the water flow from each for

several minutes. This will release any accumulated hydrogen gas. As the gas is flammable, DO NOT smoke

or use an open flame during this time.

Ŷ

DO NOT allow children to play on or in this appliance. Close supervision of children is necessary when this

appliance is used near children. Before the appliance is removed from service or discarded, remove the door

or lid. Failure to follow these instructions may result in death or injury to persons.

Ŷ

DO NOT reach into the appliance if the drum is moving to prevent accidental entanglement.

Ŷ

DO NOT install or store this appliance where it will be exposed to the weather.

Ŷ

DO NOT tamper with controls, repair or replace any part of this appliance or attempt any servicing unless

specifically recommended in the user maintenance instructions or in published user repair instructions that you

understand and have the skills to carry out.

Ŷ

DO NOT climb or stand on this unit.

Ŷ

DO NOT operate this appliance if it is damaged, malfunctioning, partially disassembled, or has missing or

broken parts including a damaged cord or plug.

Ŷ

Unplug the appliance or turn off the circuit breaker before servicing. Pressing the Power button DOES NOT

disconnect power.

Ŷ

See “ELECTRICAL REQUIREMENTS” located in the Installation Instructions for grounding instructions.

READ AND SAVE THESE INSTRUCTIONS

4 49-3000230 Rev 2

Page 5

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

PROPER INSTALLATION

This unit must be properly installed and located in accordance with the Installation Instructions before it is used.

Ŷ

Ensure that the hot water hose is connected to the “H” valve and the cold water hose is connected to the “C”

valve.

Ŷ

Install or store where it will not be exposed to temperatures below freezing or exposed to the weather, which

could cause permanent damage and invalidate the warranty.

Ŷ

Properly ground unit to conform with all governing codes and ordinances. Follow details in the Installation

Instructions.

Ŷ

Ensure unit is properly leveled and unit legs are adjusted such that unit is stable.

Ŷ

GE Appliances strongly recommends the use of factory specified parts. A list of factory hoses available for

purchase are listed. These hoses are manufactured and tested to meet GE Appliances specifications.

Ŷ

GE Appliances strongly recommends the use of new water supply hoses. Hoses degrade over time and need

to be replaced every 5 years to reduce the risk of hose failures and water damage.

WHEN NOT IN USE

Ŷ

Turn off water faucets to minimize leakage if a break or rupture should occur. Check the condition of the fill

hoses; GE Appliances recommends changing the hoses every 5 years.

SAFETY INFORMATION

PARTS AND ACCESSORIES

Order on-line at GEApplianceparts.com today,

24 hours a day or by phone at 877.959.8688 during

normal business hours. In Canada, visit your local

GE Appliances parts distributor or call 800.661.1616

GEAppliances.ca/en/products/parts-filters-accessories.

or

Part Number Accessory

PM14X10002 4 ft rubber water supply hoses

Or

PM14X10005 4 ft braided water supply hoses

WX10X10011 Tide® Washing Machine Cleaner*

PM7X1 Washer Floor Tray

GFA140SS 24” Front load riser - ADA compliant

with plumbable drip pan

*Tide® is a registered trademark of Procter & Gamble

READ AND SAVE THESE INSTRUCTIONS

49-3000230 Rev 2 5

Page 6

Getting started

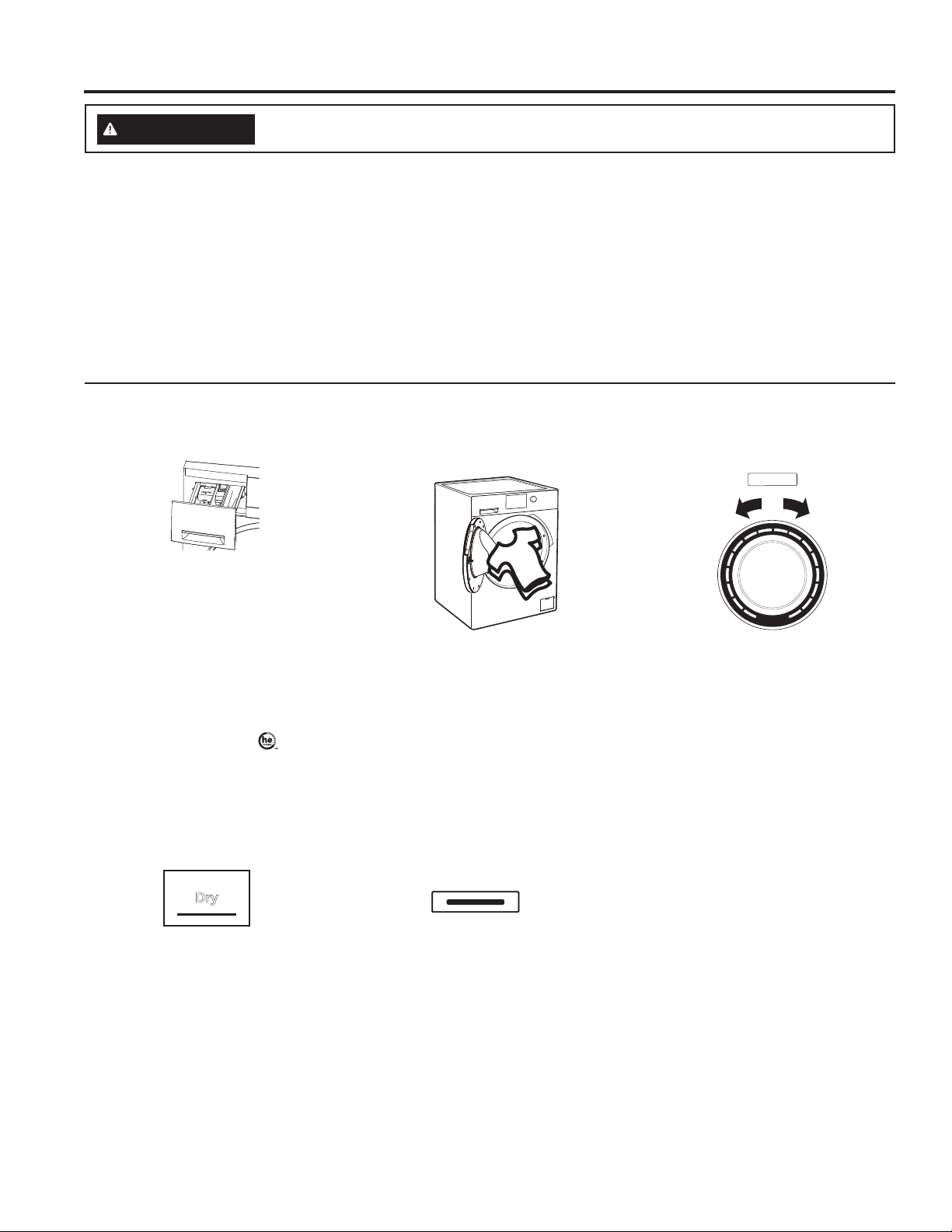

WARNING

To reduce the risk of fire, electric shock, or injury to persons, read the IMPORTANT SAFETY

INFORMATION before operating this appliance.

Introduction

• This unit allows: wash only; dry only; wash and dry cycles.

• Fill the drum 2/3 full with laundry for best wash and dry performance. This allows air movement and proper drying.

A fully loaded drum will lead to longer dry times.

NOTE: During Dry cycles temperatures in the unit can get very hot. For this reason, the door will lock during the dry

cycle and remain locked, after pausing or at the end of the cycle, until temperatures cool down. Forcing the door

open will result in a broken door mechanism.

• This unit uses condenser drying technology. This enables installation and use without a vent, but loads take

approximately 1.5 times longer to dry than a traditional vented dryer.

Throughout this manual, features and appearance may vary from your model.

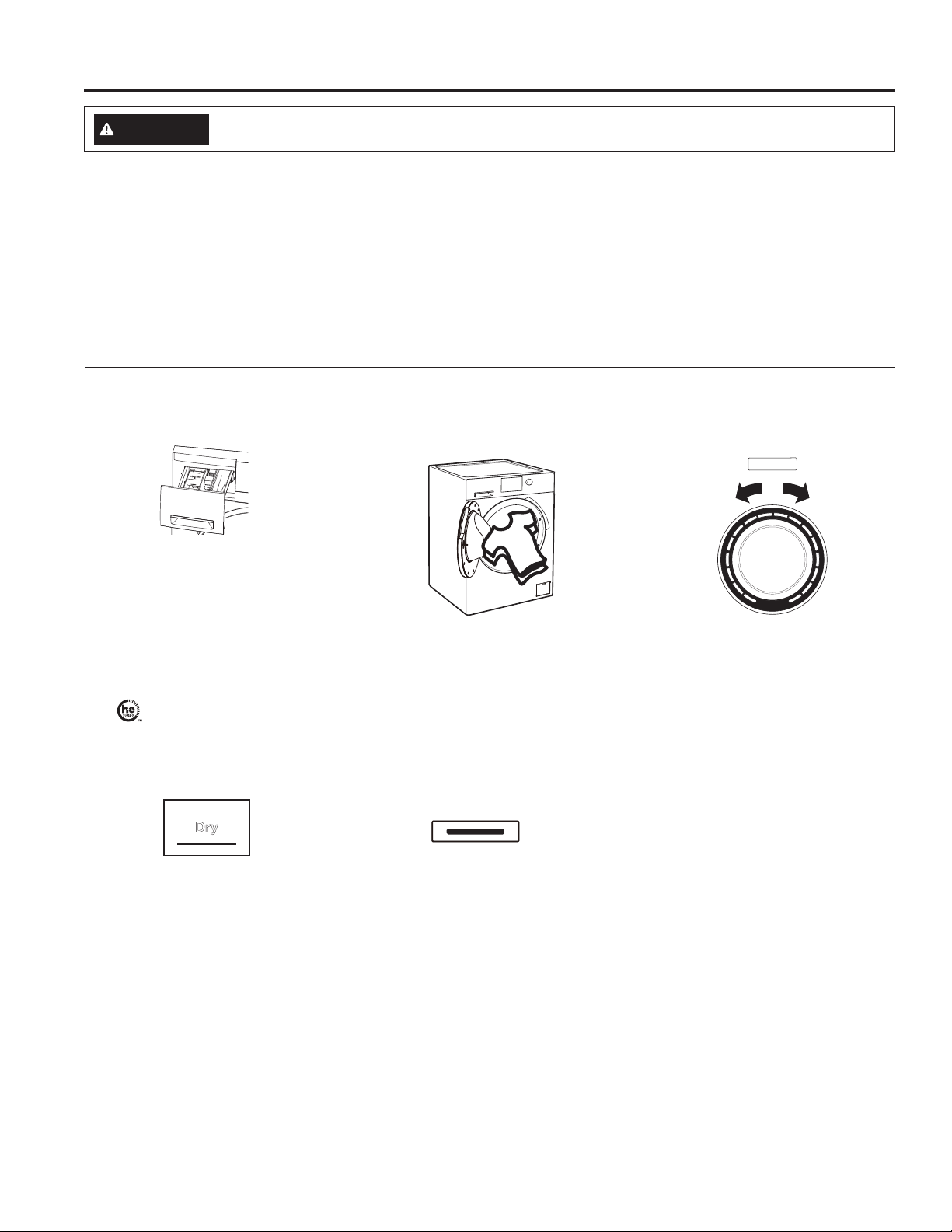

Quick Start

Step 1

(Appearance

will vary)

• Add fabric softener to the

fabric softener dispenser; see

page 14.

USING THE COMBO WASHER/DRYER

• Add the manufacturer’s

recommended amount of

detergent. GE Appliances

recommends the use of High

Efficiency detergents such

as in your energy efficient

unit. Place detergent pods in

the bottom of the wash basket

before adding clothes.

Liquid Only

MAX

MAX

Step 4

Dry

• Set the dry cycle by pressing

the Dry pad. The unit will

automatically run Auto

Dry after the wash cycle is

complete.

• Set Dry pad to Off to run a

wash only cycle.

Step 2 Step 3

• Loosely add items. Overloading

may negatively impact wash and

dry performance. See page 15 for

suggested loading examples.

• Close door.

NOTE: Unit will not start with door

open.

Step 5

• Press the Start/Pause button.

Start

Pause

• If the screen is dark, press the

Power button to “wake up” the

display.

• Select a wash cycle. (Defaults are

set for each wash cycle. These

default settings can be changed.

See Control settings for more

information.)

• The unit can be used as a dryer

only by turning the selector knob

to one of the red dry cycles.

Power

6 49-3000230 Rev 2

Page 7

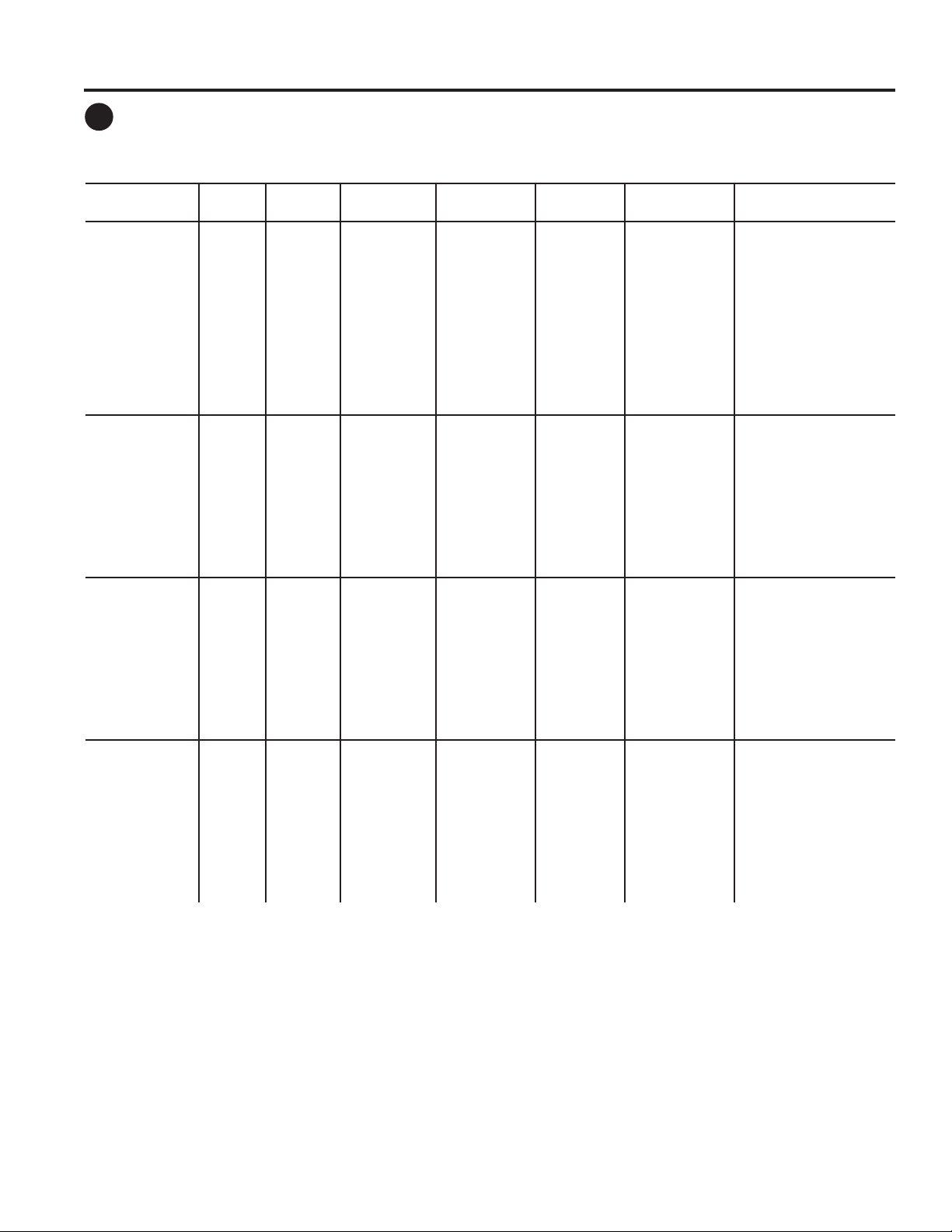

Getting started

Doo

O

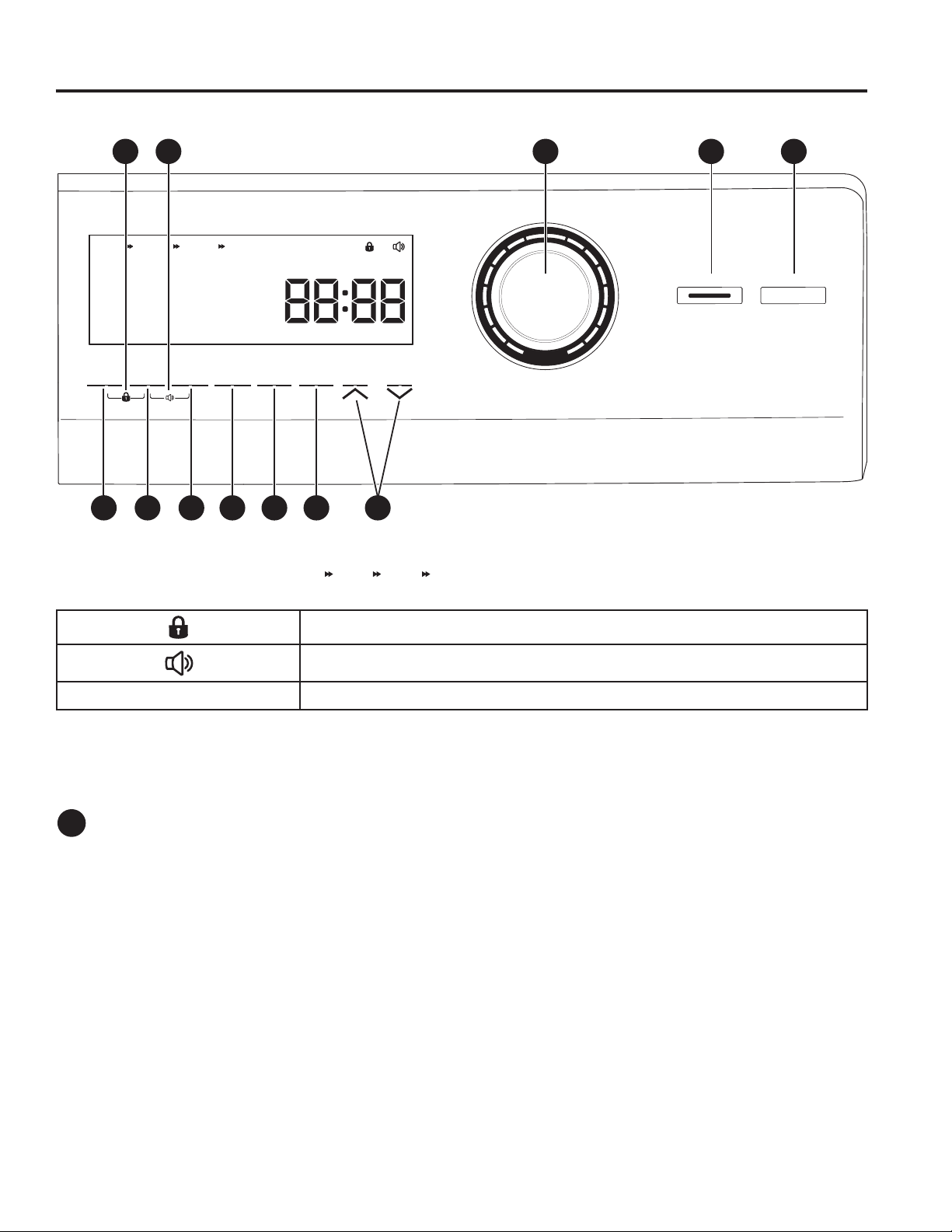

Controls

J AIBK

WASH SPIN DRY COOL

Ex Hot

Ex Heavy

Ex Heavy

Heavy

Heavy

Normal

Normal

Light

Light

Ex Light

Ex Light

Soil

Max

Ex Hot

Max

Hot

High

Hot

High

Warm

Medium

Warm

Medium

Cool

Low

Cool

Low

Cold

No Spin

Cold

No Spin

Spin Add Dry Time

r Lock

Tumble

Low

Normal

DryTemp

Options

Time

Saver

Extra

Rinse

Est Time Remaining

Est Time Remaining

Delay Ex Tumble

Delay

Wash

Auto Damp DryNormal

Auto DryDelicates

Casuals Auto Extra Dry

Whites Timed Dry

Heavy

Duty

Quick

Wash

Stain Wash

With Steam

Soak

Rinse + Spin

Spin Only

Tub CleanSanitize

Pause

add a garment

USING THE COMBO WASHER/DRYER

PowerStart

C

D E F H LG

Display and Status Lights

The display shows cycle status (

DRY COOLWASH SPIN

cycle and the options selected. In addition, the display will show:

Controls locked on.

End of cycle signal on.

Door Lock Door will lock from the start of the cycle until the end of the cool down phase.

NOTE: If an out-of-balance condition is detected by the unit, the SPIN light will blink during the remaining portion of

the cycle and will stay illuminated for a short time after cycle completion. When this occurs, the unit is taking actions

to correct the out-of-balance condition and complete the cycle normally. In some cases, the unit may not be able to

balance the load and spin up to full speed. Run a Spin Only cycle.

Power

A

Press to “wake up” the display. If the display is active, press to put the unit into standby mode.

NOTE: Pressing Power does not disconnect the appliance from the power supply.

), the Estimated Time Remaining until the end of the

49-3000230 Rev 2 7

Page 8

Getting started

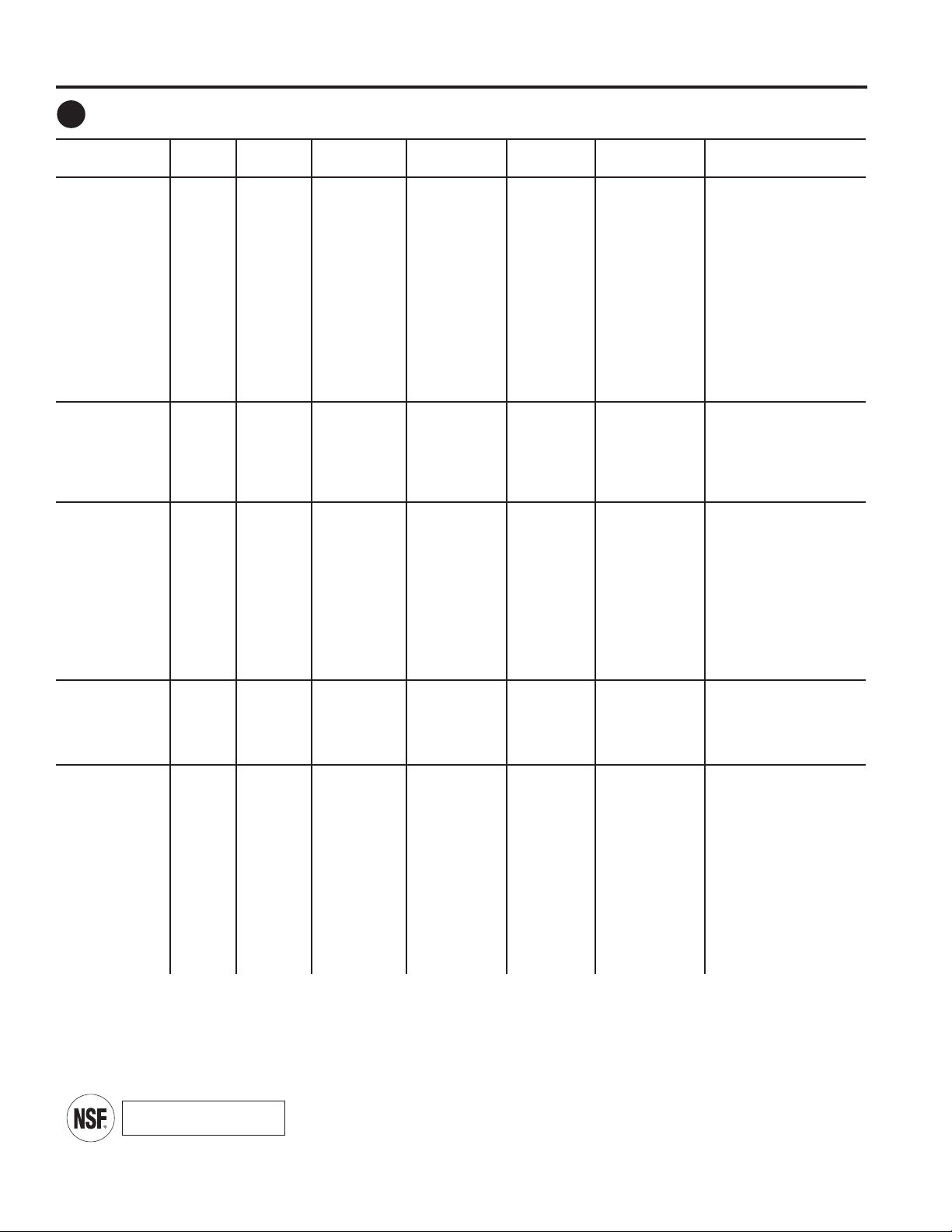

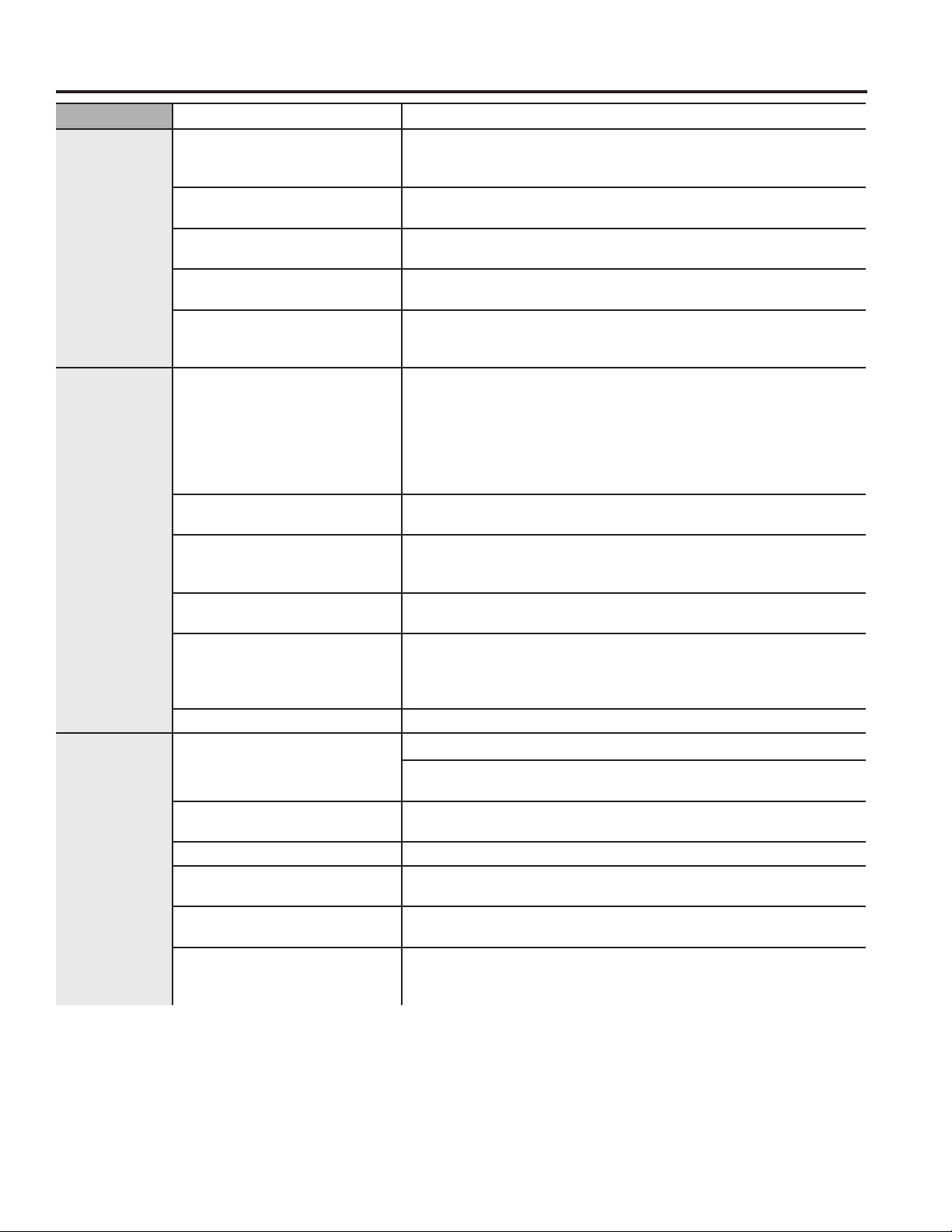

Cycles - Wash, Soak, Spin and Clean

B

The cycles are optimized for specific types of loads. The chart below will help you match the setting with the

loads. The Gentle Wash™ lifters lightly tumble the clothes into the water and detergent solution to clean the

load.

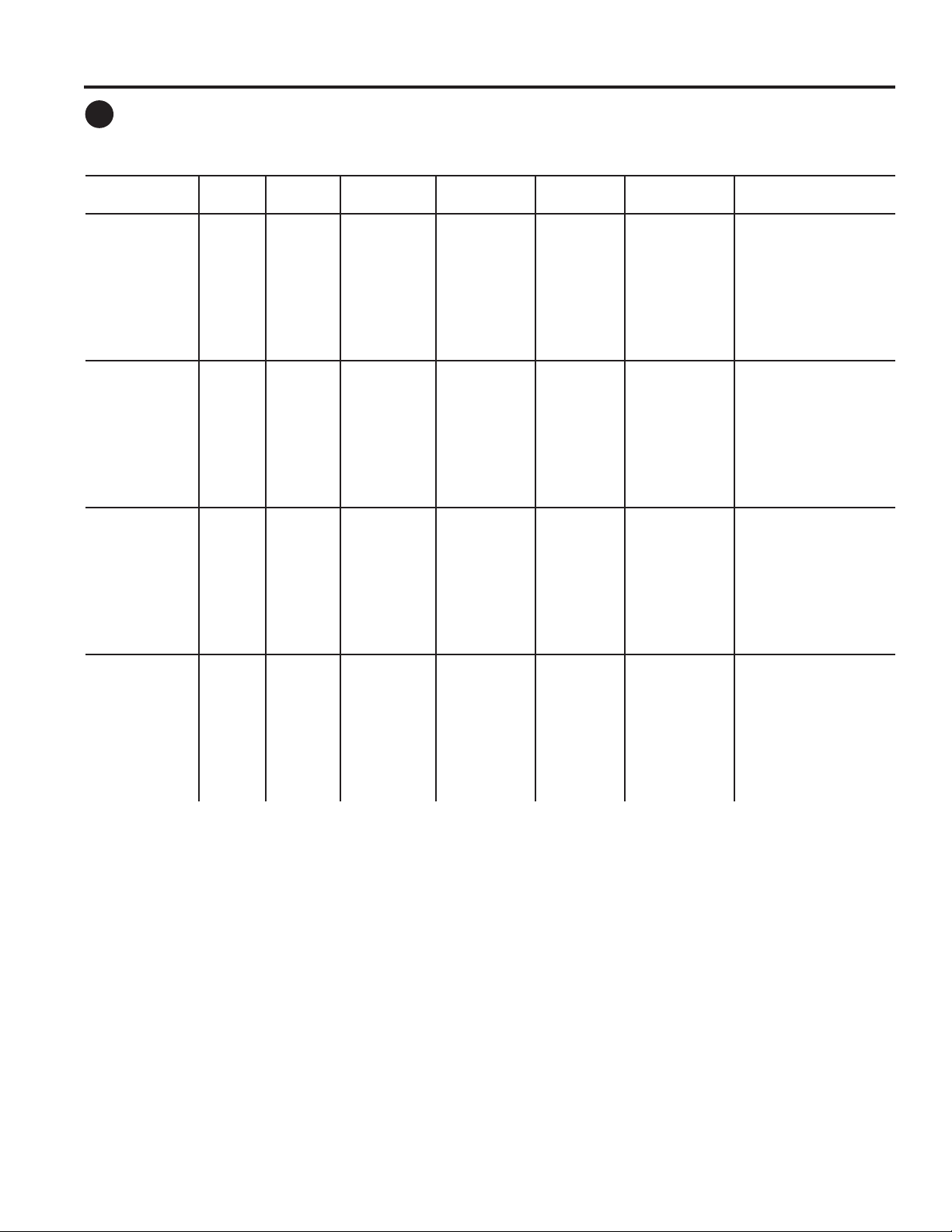

Items to Wash Cycle Soil

Cycle for

normal, regular,

or typical use

for washing up

to a full load of

normally soiled

cotton clothing.

Lingerie and

special care

fabrics with

light soil.

Casual clothes,

lightly soiled

office wear.

Normal Ex. Heavy

Delicates

Casuals Ex. Heavy

USING THE COMBO WASHER/DRYER

Whites and

household

linens.

Sturdy fabrics

with heavy to

medium soil.

Small loads of

lightly soiled

items that are

needed in a

hurry.

Cycle for

heavily soiled

colorfast

laundry.

Whites Ex. Heavy

Heavy

Duty

Quick

Wash

Stain

Wash

with

Steam

Level

Heavy

Normal

Light

Ex. Light

Ex. Heavy

Heavy

Normal

Light

Ex. Light

Heavy

Normal

Light

Ex. Light

Heavy

Normal

Light

Ex. Light

Ex. Heavy

Heavy

Normal

Light

Ex. Light

Ex. Heavy

Heavy

Normal

Light

Ex. Light

Ex. Heavy

Heavy

Normal

Light

Ex. Light

Wash Temp Spin

Ex. Hot

Hot

Warm

Cool

Cold

Warm

Cool

Cold

Ex. Hot

Hot

Warm

Cool

Cold

Ex. Hot

Hot

Warm

Cool

Cold

Ex. Hot

Hot

Warm

Cool

Cold

Hot

Warm

Cool

Cold

Ex. Hot

Hot

Warm

Cool

Cold

Selection

Max

High

Medium

No Spin

High

Medium

Low

No Spin

Max

High

Medium

Low

No Spin

Max

High

Medium

Low

No Spin

Max

High

Medium

Low

No Spin

Max

High

Medium

Low

No Spin

Max

High

Medium

No Spin

Dry Options

Off

Tumble

Low

Normal

Off

Tumble

Low

Normal

Off

Tumble

Low

Normal

Off

Tumble

Low

Normal

Off

Tumble

Low

Normal

Off

Tumble

Low

Normal

Off

Tumble

Low

Normal

Available

Time Saver

Extra Rinse

Extended

Tumble

Delay

Time Saver

Extra Rinse

Extended

Tumble

Delay

Time Saver

Extra Rinse

Extended

Tumble

Delay

Time Saver

Extra Rinse

Extended

Tumble

Delay

Time Saver

Extra Rinse

Extended

Tumble

Delay

Extra Rinse

Extended

Tumble

Delay

Time Saver

Extra Rinse

Extended

Tumble

Delay

Cycle Details

Cycle for normal,

regular, or typical use

for washing up to a

full load of normally

soiled cotton clothing.

Choose the Heavy or

Extra Heavy soil level

selection and Warm or

Hot water temperature

selection as appropriate

for your clothes load

for a higher degree of

cleaning.

For lighty soiled items

labeled hand-washable.

Provides gentle

tumbling and soak

during wash and rinse.

Wash cycle tailored to

care for casual clothes

and office wear items.

Cycle tailored to clean

and brighten your

whites.

Incorporates multi-step

wash and soak periods

combined with extended

wash periods to

effectively clean heavily

to medium soiled sturdy

fabrics.

For cleaning lightly soiled

loads in the fastest time

possible. Cycle time

is approximately 33

minutes, depending on

selected options.

Add steam to the unit

to assist with stain

removal for heavily

soiled colorfast laundry.

8 49-3000230 Rev 2

Page 9

Getting started

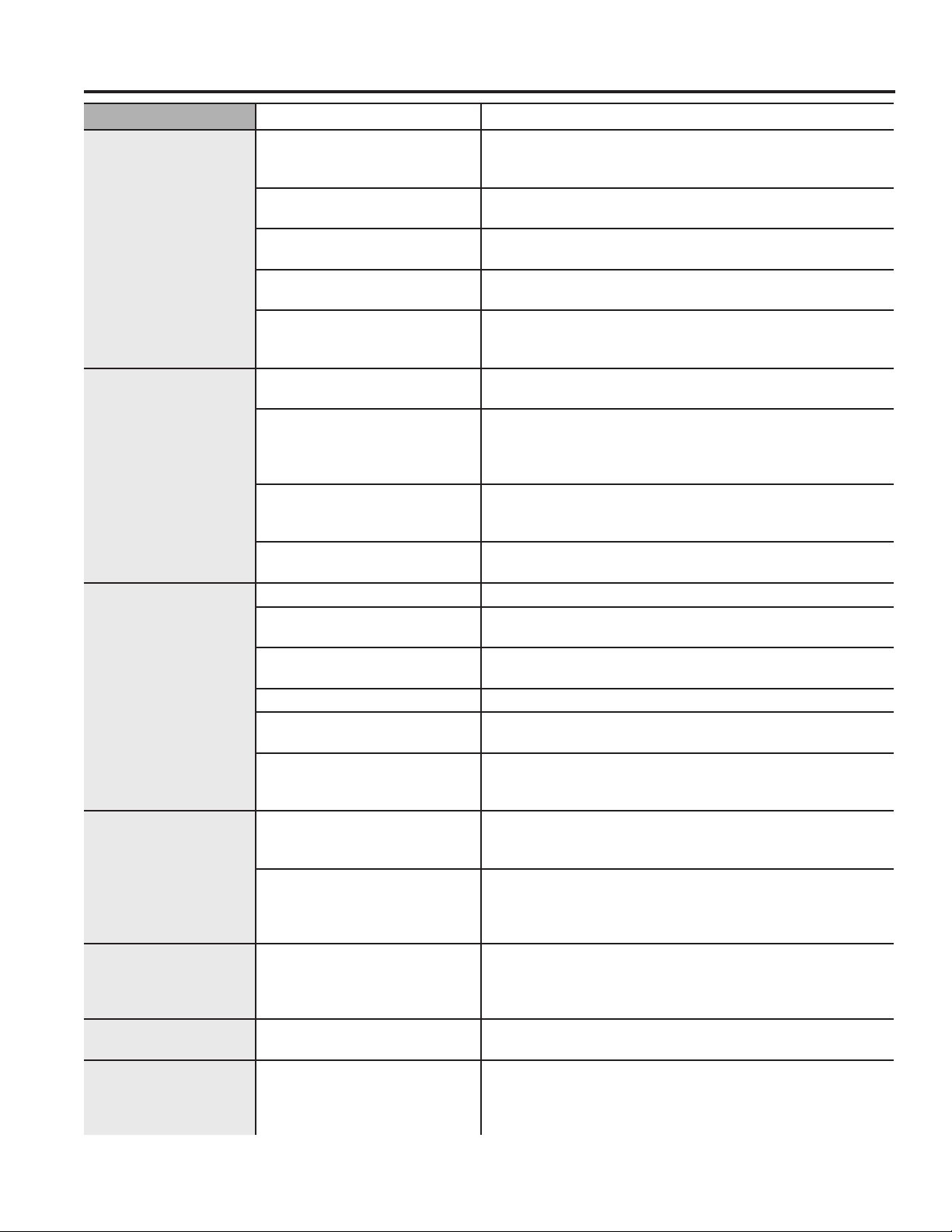

Cycles - Wash, Soak, Spin and Clean (Continued)

B

USING THE COMBO WASHER/DRYER

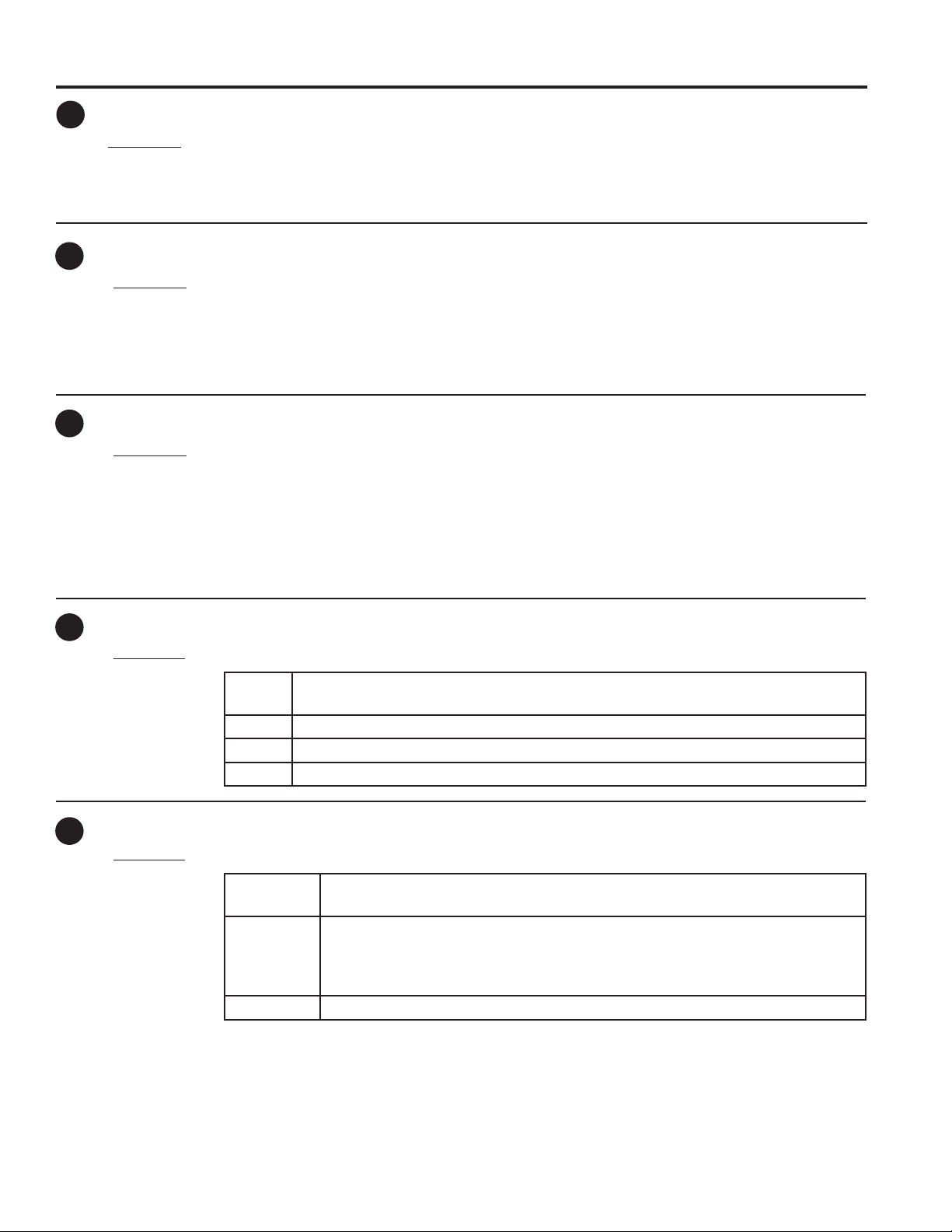

Items to Wash Cycle Soil

Heavily soiled

colorfast items

with the need

for sanitization.

Use to soak

clothes.

For items that

need only to be

rinsed, use this

cycle.

Use to spin dry

clothes that have

already been

washed.

Cleaning the

tub of residue

and odor. No

clothes to be

washed using

this cycle.

Sanitize Ex. Heavy

Soak Ex. Heavy

Rinse +

Spin

Spin

Only

Tub

Clean

Level

Heavy

Normal

Heavy

Normal

Light

Ex. Light

Wash Temp Spin

Selection

Ex. Hot Max

High

Medium

Low

No Spin

Ex. Hot

Hot

Warm

Cool

Cold

Max

High

Medium

Low

No Spin

Max

High

Medium

Low

No Spin

Dry Options

Off

Tumble

Low

Normal

Off

Tumble

Low

Normal

Off

Tumble

Low

Normal

Available

Extra Rinse

Extended

Tumble

Delay

Time Saver

Extended

Tumble

Delay

Extra Rinse

Extended

Tumble

Delay

Delay

Delay Recommended use

Cycle Details

Use this cycle to

eliminate 99.9% of

bacteria from fabrics.

Cycle uses an increased

water temperature and

a longer wash cycle to

provide the sanitization

benefit. A longer rinse is

incorporated to remove

contaminates. For best

results, select the Extra

Heavy soil selection if

available. See NOTE

below.

The basket will fill with

water to soak and

gently agitate the load.

At the end of the cycle

the remaining water will

be drained.

To quickly rinse and

spin out any items at

any time. Utilizes a high

speed spin to extract

water from wet items.

To achieve a drain and

spin, delselect the Extra

Rinse option. This cycle

will dispense prewash

detergent and fabric

softener.

Utilizes a high-speed

spin to extract water

from wet items.

of at least once per

month to clean the

basket of residue

and odor. Never load

laundry when using

this cycle; laundry may

become damaged.

Cycle incorporates a

hot extended wash,

intense agitation action

and a flush out of the

pump.

NOTE: The Sanitize cycle water temperatures CANNOT be changed. The Sanitize cycle is certified by NSF

International, an independent third party testing and certification organization.

The Sanitize certification verifies that the cycle reduced 99.9% of bacteria typically found in residential laundry

and that no significant contamination is transferred to subsequent washer loads. Only the Sanitize cycle has been

designed to meet the requirements of NSF Protocol P172 for sanitizing effectiveness.

NSF Protocol P172

Sanitization Performance of Residential and

Commercial, Family-Sized Clothes Washers

49-3000230 Rev 2 9

Page 10

Getting started

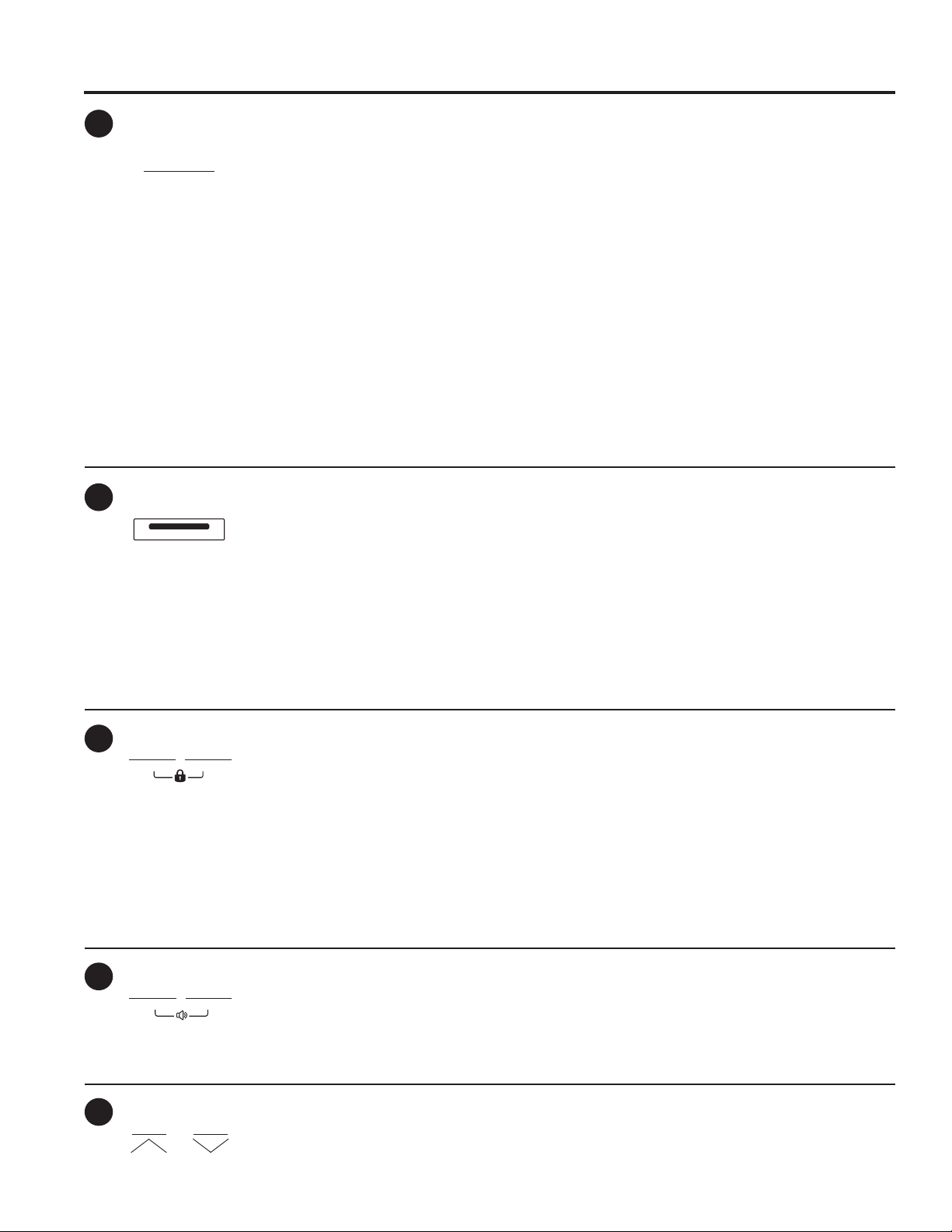

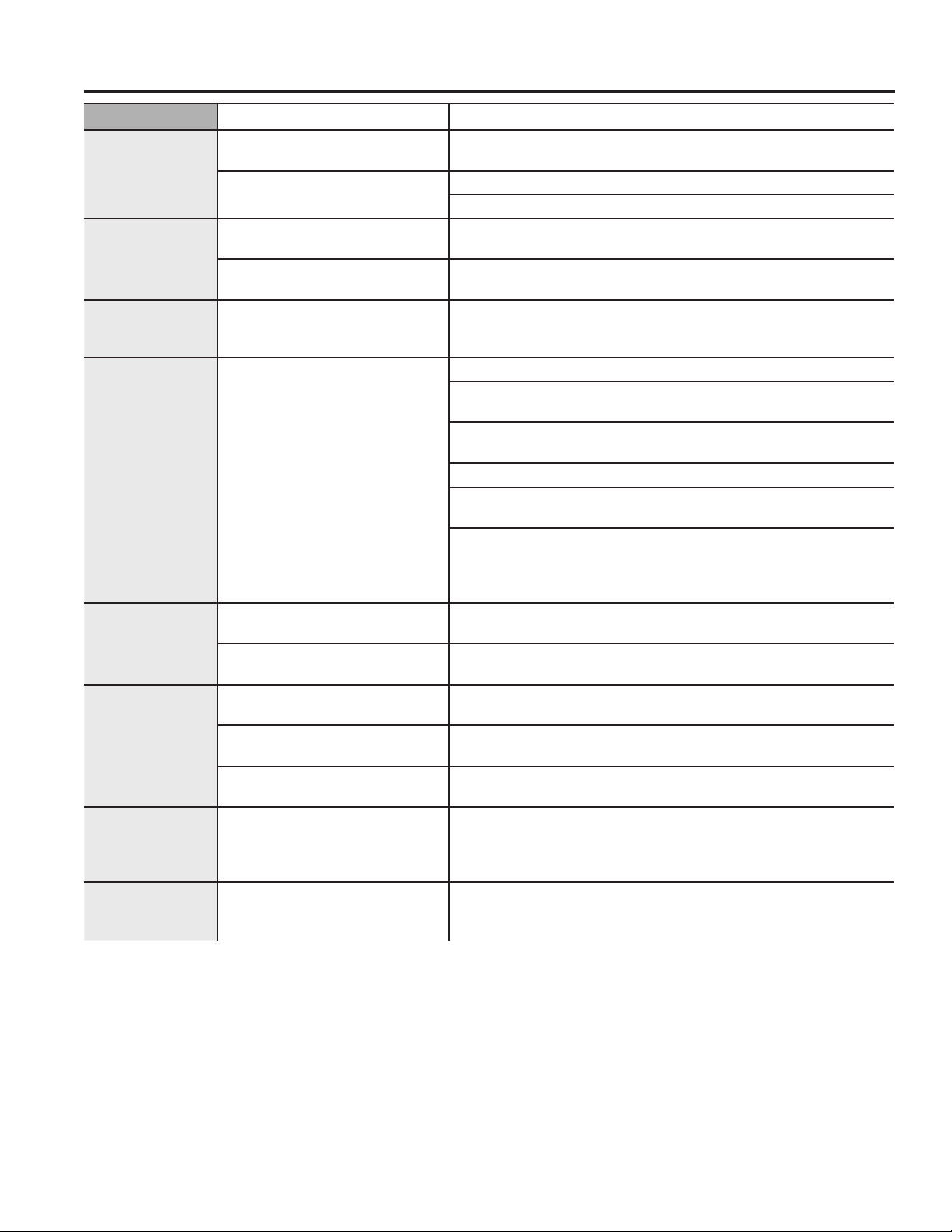

Cycles - Dry

B

The cycles are optimized for specific types of loads. The chart below will help you match the setting with the

loads.

Items to Dry Cycle Soil

Use to dry

clothes for a

specific amount

of time.

Use for drying

heavy-duty

fabrics or items

that should be

very dry, such

as towels.

Use for normal

dryness level

suitable for

most loads. This

is the preferred

cycle for energy

USING THE COMBO WASHER/DRYER

saving.

For leaving

items partially

damp.

Timed

Damp

Dry

Auto

Extra

Dry

Auto

Dry

Auto

Dry

Level

Wash Temp Spin

Selection

Dry Options

Tumble

Low

Normal

Tumble

Low

Normal

Tumble

Low

Normal

Tumble

Low

Normal

Available

Extended

Tumble

Delay

Extended

Tumble

Delay

Extended

Tumble

Delay

Extended

Tumble

Delay

Cycle Details

Once the Timed Dry

1.

cycle is selected,

press the arrow

pads to increase or

decrease the dry

time.

2.

Select the dry Temp.

3.

Close the door.

4.

Press Start/Pause.

The sensor

continuously monitors

the amount of moisture

in the load by detecting

temperature in the

drum. The cycle ends

when the moisture

reaches the selected

dry level.

The sensor

continuously monitors

the amount of moisture

in the load by detecting

temperature in the

drum. The cycle ends

when the moisture

reaches the selected

dry level.

The sensor

continuously monitors

the amount of moisture

in the load by detecting

temperature in the

drum. The cycle ends

when the moisture

reaches the selected

dry level.

10 49-3000230 Rev 2

Page 11

Getting started

USING THE COMBO WASHER/DRYER

C

D

E

Soil

Temp

Spin

Soil

Changing the Soil level increases or decreases the wash time to remove different amounts

of soil.

To change the Soil level, press the Soil level pad until you have reached the desired setting.

You can choose between Extra Light, Light, Normal, Heavy or Extra Heavy soil.

Temp

Adjust to select the proper water temperature for the wash cycle. The rinse water is always

cold to help reduce energy usage and reduce setting of stains and wrinkles.

Follow the fabric manufacturer’s care label when selecting the wash temperature.

To change the wash temperature, press the Temp pad until you have reached the desired

setting. You can choose between Cold, Cool, Warm, Hot or Extra Hot.

Spin

Changing the Spin setting changes the final spin speed of the cycles. Always follow the

garment manufacturer’s care label when changing the Spin setting.

To change the Spin setting, press the Spin setting pad until you have reached the desired

setting. You can choose between No Spin, Low, Medium, High or Max. Higher spin speeds

are not available on certain cycles, such as Delicates.

Higher spin speeds remove more water from the clothes and will help reduce dry time, but

may also increase the possibility of setting wrinkles on some fabrics.

F

G

Dry

Options

Dry

Changing Dry will change the temperature for your dry cycle:

Normal For regular to heavy cottons, synthetics, blends, and items labeled permanent

press.

Low For delicates, synthetics, and items labeled Tumble Dry Low.

Tumble Items are continuously tumbled without heat.

Off Unit will skip dry cycle and wash only.

Options

Press to select your desired options:

Time

Saver

Extra

Rinse

Ex Tumble Add more tumbling time by selecting this option.

Choose your own timing and save it for the chosen cycle.

Extra rinse is the extra wash before the main wash. Use it for heavily soiled

clothes or for clothes with a care label that recommends prewashing before

washing. Be sure to add liquid or powder high-efficiency detergent, or the

proper wash additive, to the prewash dispenser.

49-3000230 Rev 2 11

Page 12

Getting started

H

I

USING THE COMBO WASHER/DRYER

Delay

Wash

Start

Pause

Delay Wash

Use to delay the start of your unit.

1. Choose your wash cycle and any options.

2. Press Delay Wash pad. You can change the delay time in 1-hour increments (up to

24 hours) each time you press the Delay Wash pad. Stop pressing the pad when your

desired time is displayed.

3. Press the Start/Pause button to start the countdown.

The countdown time will be shown in the Est Time Remaining (Estimated Time Remaining)

display.

NOTES:

• If the door is opened while the unit is in Delay Wash, the countdown time will stop the

count down and the display will show “door”. The door must be closed and the Start/Pause

button must be pressed to continue the delay time count down.

• You can delay the start of a wash cycle up to 24 hours.

The light on the pad will light up when Delay Wash is on.

Start/Pause

Press to start a wash cycle. If the unit is running, pressing it once will pause the unit and

unlock the door. This function can be used to add garments during a cycle. Press again to

restart the wash cycle.

NOTE: If the unit is paused and the cycle is not restarted within 15 minutes, the current

wash cycle will be cancelled.

NOTE: In some cases the unit will drain first, then unlock the door when it is paused.

NOTE: The unit performs automatic system checks after pressing the Start/Pause button.

Water will flow in 45 seconds or less. You may hear the door lock and unlock before water

flows; this is normal.

J

K

L

Soil

Temp Spin

Add Dry Time

Temp

Lock

You can lock the controls to prevent any selections from being made. Or you can lock or

unlock the controls after you have started a cycle.

Children cannot accidentally start the unit by touching pads with this option selected.

To lock the unit, press and hold the Soil and Temp pads together for 3 seconds.

To unlock the unit controls, press and hold the Soil and Temp pads together for 3 seconds.

A sound is made to indicate the lock/unlock status.

The control lock icon on the display will light up when it is on.

NOTE: The Power button can still be used when the unit is locked.

Signal

When the light is on, the unit will beep at the end of the cycle and every time you press a

pad on the control panel.

To turn the signal off, press and hold the Temp and Spin pads together for 3 seconds.

A sound is made to indicate the lock/unlock status.

Add Dry Time

Press the up and down arrow pads to increase or decrease the Dry cycle time as desired.

12 49-3000230 Rev 2

Page 13

Notes

NOTES

49-3000230 Rev 2 13

Page 14

Getting started

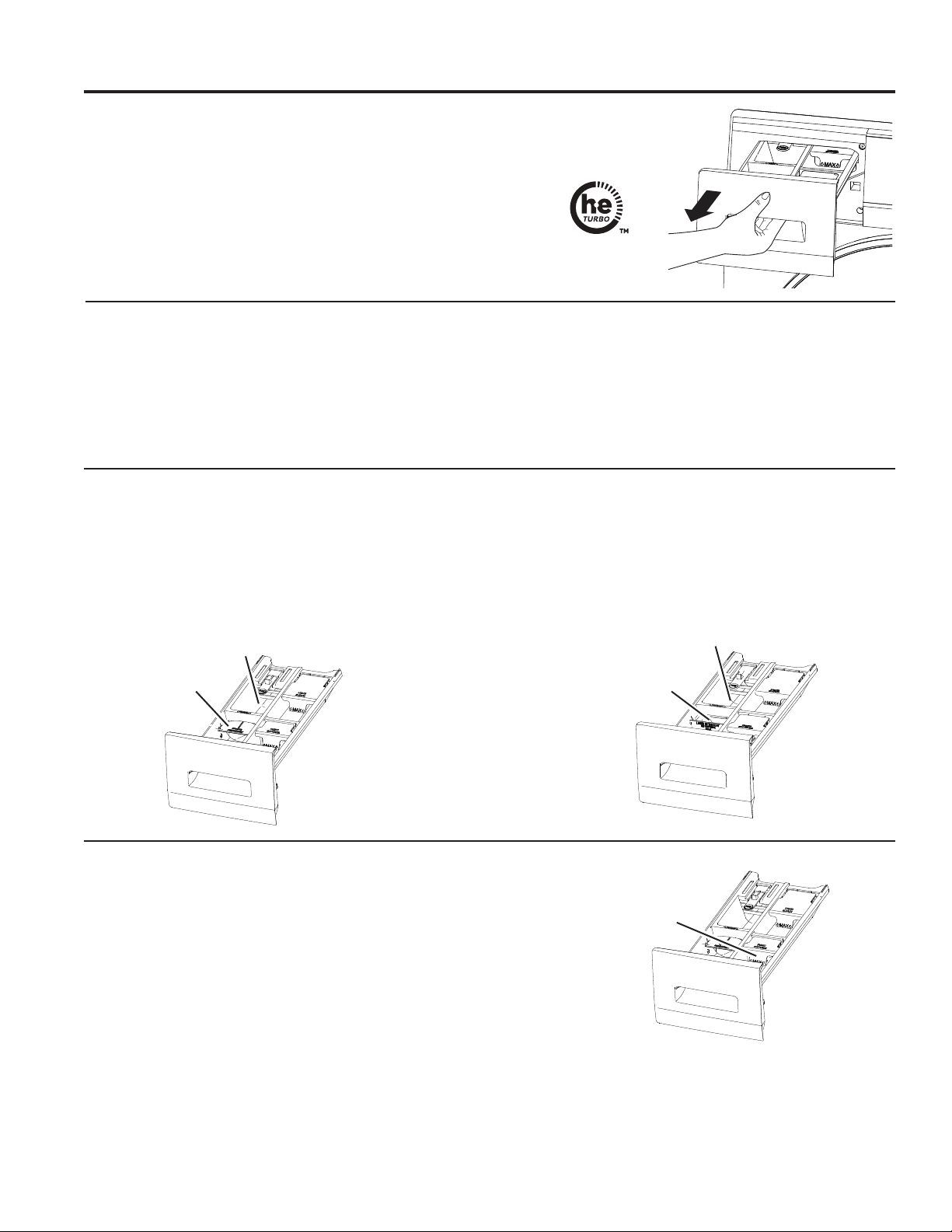

Dispenser Drawer

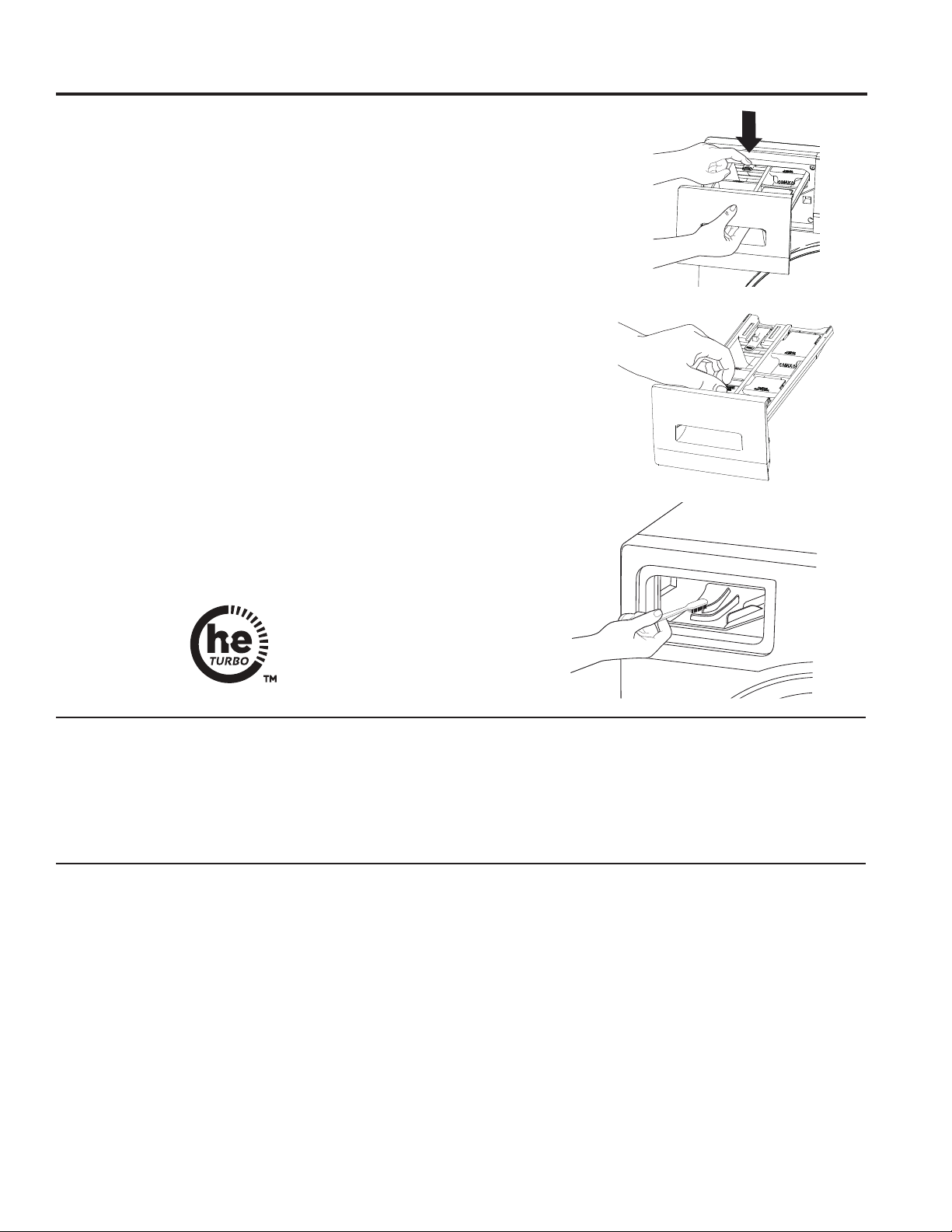

Slowly open the dispenser drawer by pulling it out until it

stops.

After adding laundry products, slowly close the dispenser

drawer. Closing the drawer too quickly could result in early

dispensing of the fabric softener or detergent.

You may see water in the fabric softener compartment at

the end of the cycle. This is a result of the flushing/siphoning

action and is part of the normal operation of the unit.

Use only HE

High-Efficiency

detergent

Detergent Compartment

• Only use high-efficiency detergent in this unit. Use the detergent manufacturer’s recommended amount.

DO NOT fill above the MAX line.

• Detergent is flushed from the dispenser at the beginning of the wash cycle. Either powdered or liquid high-efficiency

detergent can be used.

• Detergent usage may need to be adjusted for water temperature, water hardness, size and soil level of the load. Avoid

using too much detergent in your unit since it can lead to oversudsing and detergent residue being left on the clothes.

Divider Drawer System

The detergent compartment is in the front left of the dispenser drawer.

• Powder Detergent – Lock the detergent card flat into

its top position in the compartment. Make sure the card

is locked, then pour the suggested amount of powder

detergent into the detergent dispenser.

USING THE COMBO WASHER/DRYER

Locked FLAT

Position

for Powder

Detergent

PreWash Compartment

(no cup) – Use for Liquid

and Powder Detergent

• Liquid Detergent – Lock the detergent card vertically

into its center position in the compartment. Make sure the

card is locked, then pour the suggested amount of liquid

detergent into the detergent dispenser.

PreWash Compartment (no cup)

– Use for Liquid and Powder Detergent

Locked VERTICAL

Position for Liquid

Detergent

Fabric Softener Compartment

If desired, pour the recommended amount of liquid fabric softener into the

compartment labeled “Fabric Softener.”

Use only liquid fabric softener in the dispenser.

Dilute with water to the maximum fill line.

Do not exceed the maximum fill line. Overfilling can cause early dispensing

of the fabric softener, which could stain clothes.

NOTE: Do not pour fabric softener directly on the wash load.

14 49-3000230 Rev 2

Fabric

Softener

Compartment

Page 15

Loading

Always follow fabric manufacturer’s care label when laundering.

Sorting and Loading

Sort by color (whites, lights, colors), soil level, fabric type (sturdy cottons, easy care, delicates) and whether the

fabric produces lint (terry cloth, chenille) or collects lint (velveteen, corduroy). Wash lint producers such as cotton

towels and socks separate from lint collectors including synthetic garments and dress pants.

USING THE COMBO WASHER/DRYER

WARNING

DO NOT wash fabrics soiled with flammable liquids or cleaning solvents.

No washer can completely remove oil.

DO NOT wash or dry anything that has been soaked in or spotted with any type of oil (including cooking oils).

DO NOT reach into the unit until all moving parts have stopped.

Keep flammable materials and vapors, such as gasoline, away from the unit.

Items containing foam, rubber, or plastic must be dried on a clothesline.

Failure to do so can result in death, explosion, fire or amputation.

- Fire Hazard

Loading to Wash

The drum may be fully loaded with loosely added items.

To add items after the unit has started, press Start/Pause and wait until the door is unlatched. The unit may take

up to 30 seconds to unlock the door after pressing Start/Pause, depending on the machine conditions. Do not try to

force open the door when it is locked. After the door unlocks, open gently. Add items, close the door and press Start/

Pause to restart.

Loading Examples

WORKWEAR LINENS MIXED LOAD DELICATES* QUICK WASH

3 Jeans

3 Work Wear

Shirts

2 Work Wear

Pants

1 Bath Sheet

6 Bath

Towels/

8 Washcloths

4 Hand

Towels/

1 Terrycloth

Bath Mat

OR

1 Flat

Queen-Sized

Sheet

1 Fitted

Queen-Sized

Sheet

2

Pillowcases

2 Pillowcases

1 Hand Towel

1 Flat Sheet/

1 Fitted Sheet

2 Bath Towels/

2 Washcloths

OR

4 Shirts (Men’s or

Women’s)

3 Pair Pants (Khakis or

Twills)

3 T-shirts

4 Pairs of Boxers

2 Pairs of Shorts

OR

4 T-shirts

2 Pairs of Sweatpants

2 Sweatshirts

1 Hoodie

5 Pairs of Socks

4 Bras

4 panties

2 Slips

1 Camisole

3 Nightgowns

* Using a nylon mesh

bag for small items is

recommended.

(2–3 GARMENTS)

2 Casual Wear Work Shirts

1 Pair Casual Wear Work Pants

OR

3 Soccer Uniforms

Loading to Dry

As a general rule, if clothes are sorted properly for the wash, they are sorted properly for the dry cycle. Try also to

sort items according to size. For example, do not dry a sheet with socks or other small items.

®

Do not add fabric softener sheets once the load has become warm. They may cause fabric softener stains. Bounce

Fabric Conditioner Dryer Sheets have been approved for use in this unit when used in accordance with the

manufacturer’s instructions.

Do not overload. This wastes energy and causes wrinkling.

49-3000230 Rev 2 15

Page 16

Care and cleaning

Water Supply Hoses

Hoses connecting unit to faucet should be replaced every 5 years.

Exterior

Immediately wipe off any spills. Wipe with damp cloth. Wipe or dust spills or washing compounds with a damp cloth.

Unit control panel and finishes may be damaged by some laundry pretreatment and stain remover products. Apply

these products away from the unit. The fabric may then be washed and dried normally. Damage to your unit caused

by these products is not covered by your warranty. Do not hit surface with sharp objects.

Interior

Dry around the door opening, flexible gasket (including attached hoses) and door glass. These areas should always

be clean to ensure a watertight seal.

It is recommended to rinse the unit at least once per month with 1 cup of bleach (or other commercially available

product manufactured for this purpose, such as Tide® Washing Machine Cleaner) poured directly into the basket

CARE AND CLEANING

without clothes and using the Tub Clean Cycle.

The interior of the appliance should be cleaned once a year by qualified service personnel.

Stainless Steel

To clean stainless steel surfaces use a damp cloth with a mild, non-abrasive cleaner suitable for stainless steel

surfaces. Remove the cleaner residue and then dry with a clean cloth.

The stainless steel used to make the drum provides the highest reliability available in a GE Appliances unit. If the

drum should be scratched or dented during normal use, the drum will not rust or corrode. These surface blemishes

will not affect the function or durability of the drum.

Door Gasket

Open the door. Using both hands, press down the door gasket. Remove any foreign

objects if found trapped inside the gasket. Make sure there is nothing blocking the holes

behind the gasket.

While holding down the door gasket, inspect the interior of the gasket by pulling it down

with your fingers. Remove any foreign objects if found trapped inside this gasket. Make

sure there is nothing blocking the holes behind the gasket.

When you are finished cleaning the door gasket, remove your hands and the gaskets will

return to the operating position.

Pump Filter

Clean EVERY MONTH to remove any items that may have been caught in

the filter or housing.

Due to the nature of the front-load unit, it is sometimes possible for small articles

to pass to the pump. The unit has a filter to capture lost items so they are not

dumped to the drain. To retrieve lost items, clean out the pump filter.

Open the door on the bottom right of the front of the unit.

1

Twist the small white cap counterclockwise a quarter turn and unhook the small

2

rubber hose. Pull the hose out of the hole and remove the white drain hose

plug above a small pan to capture any water that may drain. Drain the excess

water. Replace.

Unscrew the pump filter. Rinse off any debris. Replace.

3

Close the access door.

4

Drain Hose

Drain Plug

Pump Filter

Door

(appearance

will vary)

Pump Filter

16 49-3000230 Rev 2

Page 17

Care and cleaning

Dispenser Drawer Area

Detergent and fabric softener may build up in the dispenser drawer. Residue

should be removed once or twice a month.

• Remove the drawer by first pulling it out until it stops. Then reach back into

the rear of the drawer cavity and press down firmly on the lock tab, pulling

out the drawer.

• Remove the insert from the dispenser drawer. Rinse the insert and drawer

with hot water to remove traces of accumulated laundry products.

• To clean the drawer opening, use a small brush to clean the recess. Remove

all residue from the upper and lower parts of the recess.

CARE AND CLEANING

• Return inserts to the proper compartments. Replace the dispenser drawer.

• To reduce buildup in the Dispenser Drawer area:

Use only HE

High-Efficiency

detergent.

Moving and Storage

Ask the service technician to remove water from drain pump and hoses. Do not store the unit where it will be exposed

to the weather. When moving the unit, the tub should be kept stationary by using the shipping bolts removed during

installation. See Installation Instructions in this manual. If these parts are not available, they can be ordered by visiting

our Website at GEApplianceparts.com or by calling GE Appliances at 877.959.8688. In Canada, visit your local

GE Appliances parts distributor or call 800.661.1616 or GEAppliances.ca/en/products/parts-filters-accessories.

Long Vacations

Be sure water supply is shut off at faucets. Drain all water from hoses and water filter pump area if weather will be

below freezing.

49-3000230 Rev 2 17

Page 18

Installation Combo

Ŷ

Ŷ

Ŷ

Ŷ

Ŷ

Ŷ

Washer/Dryer

Instructions

If you have any questions, call GE Appliances at 800.GE.CARES

(800.432.2737) or visit our Website at: GEAppliances.com

In Canada, call 800.561.3344 or visit GEAppliances.ca

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these

instructions for local inspector’s use.

•

IMPORTANT – Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• Skill level – Installation of this appliance requires

basic mechanical and electrical skills.

• Completion time – 1-3 hours

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is not

covered under the Warranty.

LOCATION OF YOUR UNIT

DO NOT Install the Unit:

TOOLS REQUIRED FOR

UNIT INSTALLATION

Safety Glasses

Level ŶWrench (provided)

Channel-lock adjustable pliers

Gloves

PARTS SUPPLIED

Water Hoses (2)

(Flat washers

pre-installed)

IMPORTANT:

Drain Hose

Guide

1. In an area exposed to dripping water or outside weather

conditions. The ambient temperature should never be

below 60°F (15.6°C) for proper unit operation.

2. In an area where it will come in contact with curtains or

drapes.

3. On carpet. The floor MUST be a hard surface with a

PD[LPXPVORSHRIƎSHUIRRWFPSHUFP

To make sure the unit does not vibrate or move, you

may have to reinforce the floor.

NOTE:,IIORRULVLQSRRUFRQGLWLRQXVHƎLPSUHJQDWHG

plywood sheet solidly attached to existing floor covering.

Minimum Installation Clearances

• :KHQLQVWDOOHGLQDOFRYH6LGHV5HDU ´DQG7RS Ǝ

• When installed in closet: Sides/Rear = 0” and Top/Front =

ƎFP

• Consideration must be given to provide adequate

clearance for installation and service.

• Closet doors must be louvered or otherwise ventilated

and have at least 60 square inches (387.1 cm2) of open

area. If the closet contains a second laundry unit, doors

must contain a minimum of 120 square inches (774.2

cm2) of open area.

MOBILE HOME INSTALLATION:

Installation must conform to Standard for Mobile Homes, ANSI A119.1 and National Mobile Home Construction and

Safety Standards Act of 1974 (PL93-383).

18 49-3000230 Rev 2

Page 19

Installation Instructions

CONNECTION DIMENSIONS ROUGH-IN DIMENSIONS

BACK

21-3/4”

(55.25 cm)

4-3/4”

(12 cm)

2-1/16”

(5.24 cm)

31-1/32”

(78.82 cm)

29-3/4”

(75.57 cm)

FRONT

23-7/16”

(59.5 cm)

*33-1/4”

(84.5 cm)

SIDE

25-5/8”

(65 cm)

*NOTE:

Leveling legs retracted = 33-1/4” (84.5 cm)

Leveling legs extended = 33-3/4” (85.5 cm)

Stacked = 66-1/2” (169.0 cm)

*33-1/4”

(84.5 cm)

49-3000230 Rev 2 19

Page 20

Installation Instructions

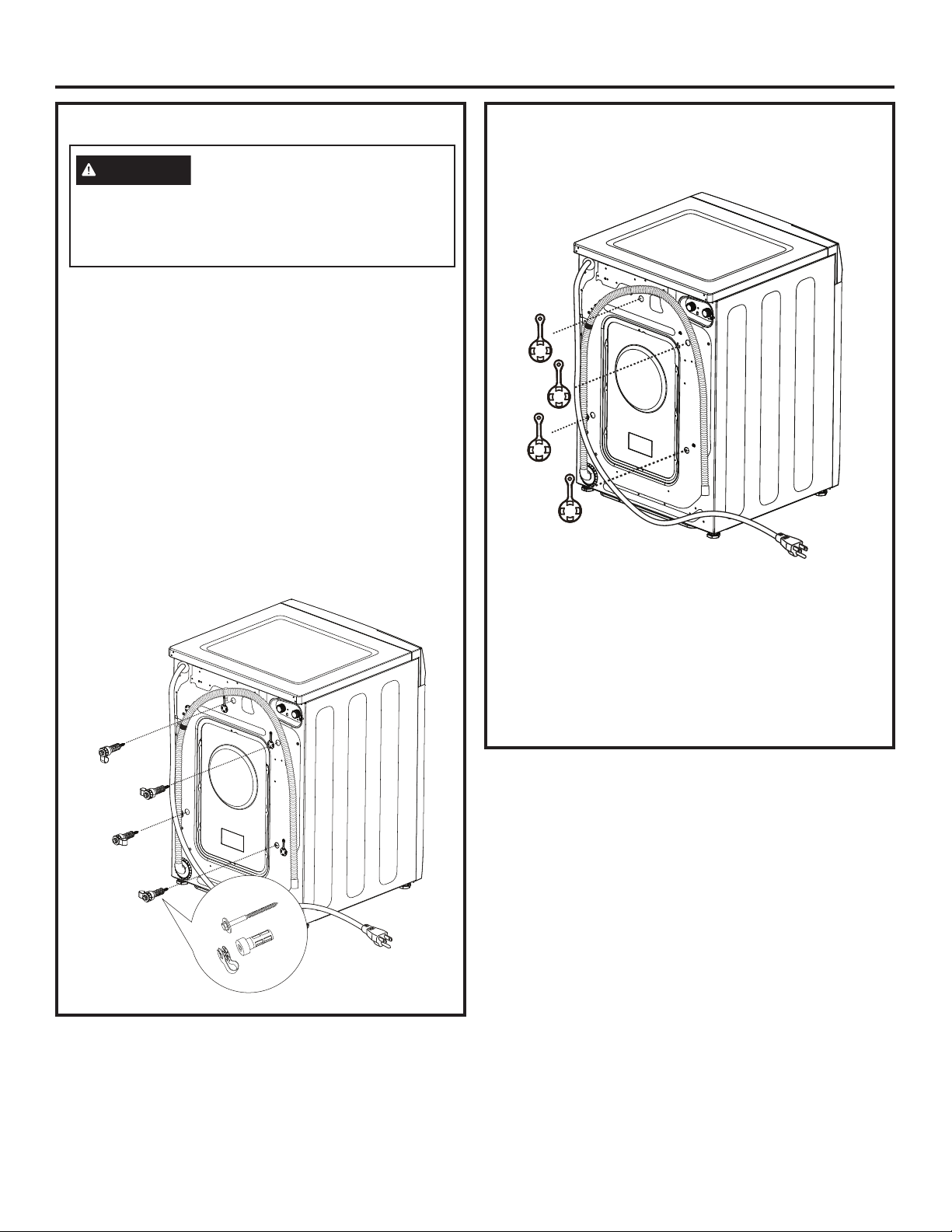

UNPACKING THE UNIT UNPACKING THE UNIT (cont.)

WARNING

unpacked. Make materials inaccessible to children.

Children might use them for play. Cartons covered

with rugs, bedspreads or plastic sheets can become

airtight chambers causing suffocation.

1. Cut and remove all packaging straps.

2. While it is in the carton, carefully lay the unit on its

side. DO NOT lay the unit on its front or back.

3. Turn down the bottom flaps. Remove all base packaging

including the styrofoam base.

4. Carefully return the unit to an upright position and

remove the carton by lifting it upward.

5. Carefully move the unit to within 4 feet (122 cm) of

the final location.

6. Remove the following from the back side of the unit:

4 bolts

4 plastic spacers (including rubber grommets)

Recycle or destroy the carton

and plastic bags after the unit is

7. Insert shipping bolt hole covers into shipping bolt

holes.

NOTE: Do NOT remove the screw or clip holding the

hose.

NOTES:

• Failure to remove the shipping braces can cause

the unit to become severely unbalanced.

• IMPORTANT: Save all bolts for future use.

If you must transport the unit at a later date, you must

reinstall the shipping support hardware to prevent

shipping damage. Keep the hardware in the plastic

bag provided.

20 49-3000230 Rev 2

Page 21

Installation Instructions

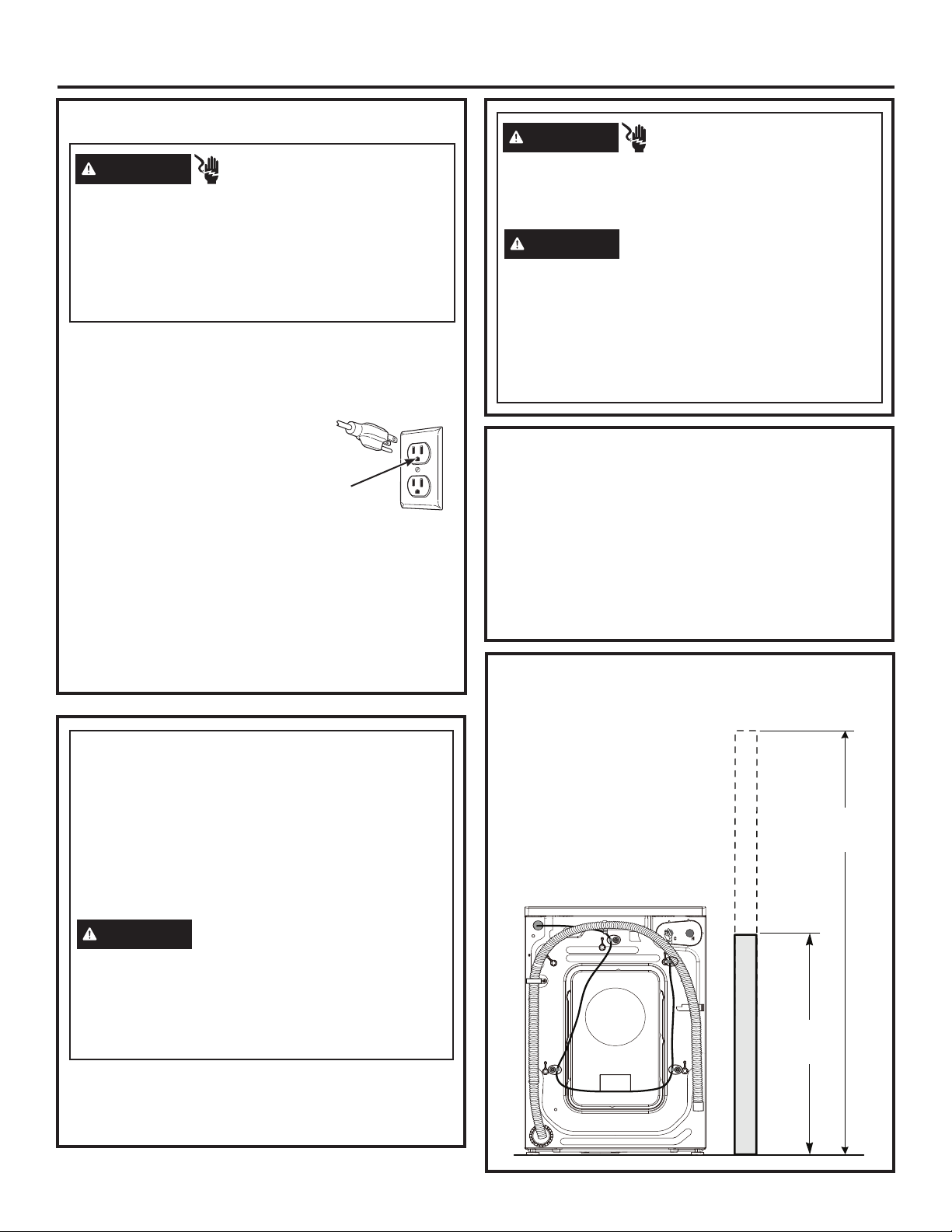

ELECTRICAL REQUIREMENTS

WARNING

Plug into a grounded 3-prong outlet.

DO NOT remove ground prong.

DO NOT use an adapter.

DO NOT use an extension cord.

Failure to follow these instructions can result in death,

fire or electrical shock.

CIRCUIT – Individual, properly polarized and grounded

15 or 20 amp circuit breaker or time-delay fuse.

POWER SUPPLY – 2 wire plus ground, 120 Volt, single

phase, 60 Hz, alternating current.

Outlet Receptacle – Properly

grounded 3-prong receptacle to

be located so the power cord is

accessible when the unit is in an

installed position. If a 2-prong

receptacle is present, it is the

owner’s responsibility to have a

licensed electrician replace it with

a properly grounded 3-prong grounding type receptacle.

Unit must be electrically grounded in accordance with

local codes and ordinances, or in the absence of local

codes, with latest edition of the NATIONAL ELECTRICAL

CODE, ANSI/NFPA NO. 70 or CANADIAN ELECTRICAL

CODE, CSA C22.1. Check with a licensed electrician if you

are not sure that the unit is properly grounded.

- Electrical Shock Hazard

Ensure proper

ground exists

before use.

WARNING

Disconnect power supply before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Certain internal parts are intentionally not grounded

and may present a risk of electric shock only during

servicing.

Service personnel – DO NOT contact the following

parts while the appliance is energized: water valve,

drain pump, NTC, motor, fan capacitor, fan motor,

heater,

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within

42 inches (107 cm) of your unit’s water inlet. The

faucets MUST be 3/4” (1.9 cm) garden hose-type so

inlet hoses can be connected. Water pressure MUST be

between 10 and 120 pounds per square inch. Your water

department can advise you of your water pressure. The

hot water temperature should be set to deliver water at

120° to 140°F (48°–60°C) to provide proper Automatic

Temperature Control (ATC) performance.

DRAIN REQUIREMENTS

1. Drain capable of eliminating 9.5

door lock, inverter board and MC board.

gals (36 L) per minute.

- Electrical Shock Hazard

- Shock Hazard

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk

of electric shock by providing a path of least resistance

for electric current. This appliance is equipped with a

cord having an equipment- grounding conductor and

a grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

WARNING

risk of electrical shock. Check with a qualified electrician,

or service representative or personnel, if you are in

doubt as to whether the appliance is properly grounded.

DO NOT modify the plug on the power supply cord. If it

will not fit the outlet, have a proper outlet installed by a

qualified electrician.

If required by local codes, an external 18 gauge or larger

copper ground wire (not provided) may be added. Attach

to unit cabinet with a #10-16 x

(available at any hardware store) to rear of unit.

49-3000230 Rev 2 21

Improper connection of the equipmentgrounding conductor can result in a

1/2

” sheet metal screw

2. A standpipe diameter of 1-1/4”

(3.18 cm) minimum.

3. The standpipe height above the

floor should be:

Minimum height: 36” (91.4 cm)

Maximum height: 58” (147 cm)

BACK

(147 cm)

Max.

36”

(91.4 cm)

Min.

58”

Page 22

Installation Instructions

Ŷ

Ŷ

Ŷ

Ŷ

Ŷ

Ŷ

Ŷ

INSTALLING THE UNIT

1. Run some water from the hot and cold faucets to

flush the water lines and remove particles that might

clog the water valve screens.

2. Remove the inlet hoses from the plastic bag. Remove

black rubber washers from bag and insert into hose

fitting before connecting to unit.

3. (90° elbow end)

Carefully connect the inlet hose

marked HOT to the outside “H”

outlet of the water valve. Tighten

by hand; then tighten another

2/3 turn with pliers. Carefully

connect the other inlet hose to

the inside “C” outlet of the water

valve. Tighten by hand; then

tighten another 2/3 turn with pliers. Do not cross-

thread or overtighten these connections.

4. Connect the inlet hose ends to the HOT

and COLD water faucets tightly by hand;

then tighten another 2/3 turn with pliers.

Turn the water on and check for leaks.

5. Carefully move the unit to its final location.

Gently rock the unit into position. It is important not to

damage the rubber leveling legs when moving your

unit to its final location. Damaged legs can increase

appliance vibration. It may be helpful to spray window

cleaner on the floor to help move your unit into its final

position. NOTE: To reduce vibration, ensure that

all four rubber leveling legs are firmly touching

the floor. Push and pull on the back right and then

back left of your unit.

NOTE: Do not use the dispenser drawer or door to

lift the unit.

NOTE: If you are installing into a drain pan, you can

use a 24-inch-long 2x4 to lever the unit into place.

6. With the unit in its final position, place a level on top

of the unit (if the unit is

installed under a counter,

the unit should not be

able to rock). Adjust the

front leveling legs up or

down to ensure the unit

is resting solidly and level

front-to-back and leftto-right. It may also be

necessary to adjust the rear legs. Turn the locknuts

on each leg up toward the base of the unit and snug

with a wrench.

NOTE: Keep the leg extension at a minimum to

prevent excessive vibration. The farther out the

legs are extended, the more the unit will vibrate.

If the floor is not level or is damaged, you may have

to extend the rear leveling legs.

INSTALLING THE UNIT (cont.)

7. Attach U-shaped hose guide to the end of the drain

hose. Place the hose in a laundry tub or standpipe.

Drain hose should be secured to the home or

adjacent faucet with a zip-tie to keep it from coming

free during operation.

NOTE: If the drain hose is placed in a standpipe

without forming a U shape, a siphoning action could

occur. There must be an air gap around the drain hose.

A snug hose fit can also cause a siphoning action.

NOTE: Do not place drain hose deeper than 7” into

the drain. 4” - 7” is suggested. Deeper than 7” can

cause a siphoning action.

8. Plug the power cord into a grounded outlet.

NOTE: Check to be sure the power is off at the circuit

breaker/fuse box before plugging the power cord into

an outlet.

9. Turn on the power at the circuit breaker/fuse box.

10. Read the rest of this Owner’s Manual. It contains

valuable and helpful information that will save you

time and money.

11. Before starting the unit, check to make sure:

Main power is turned on.

The unit is plugged in.

The water faucets are turned on.

The unit is level and all four leveling legs are firmly

on the floor.

The shipping support hardware is removed and

saved.

The drain hose is properly tied up.

There are no leaks at the faucet, drain line or unit.

12. Run the unit through a complete cycle. Check for

water leaks and proper operation.

13. If your unit does not operate, please review the

Troubleshooting Tips section before calling for

service.

14. Place these instructions in a location near the unit

for future reference.

REPLACEMENT PARTS

If replacement parts are needed for your unit, they can be

ordered in the United States by visiting our Website at

GEApplianceparts.com or by calling GE Appliances at

877.959.8688. In Canada, visit GEAppliances.ca/en/

products/parts-filters-accessories or call 800.661.1616.

22 49-3000230 Rev 2

Page 23

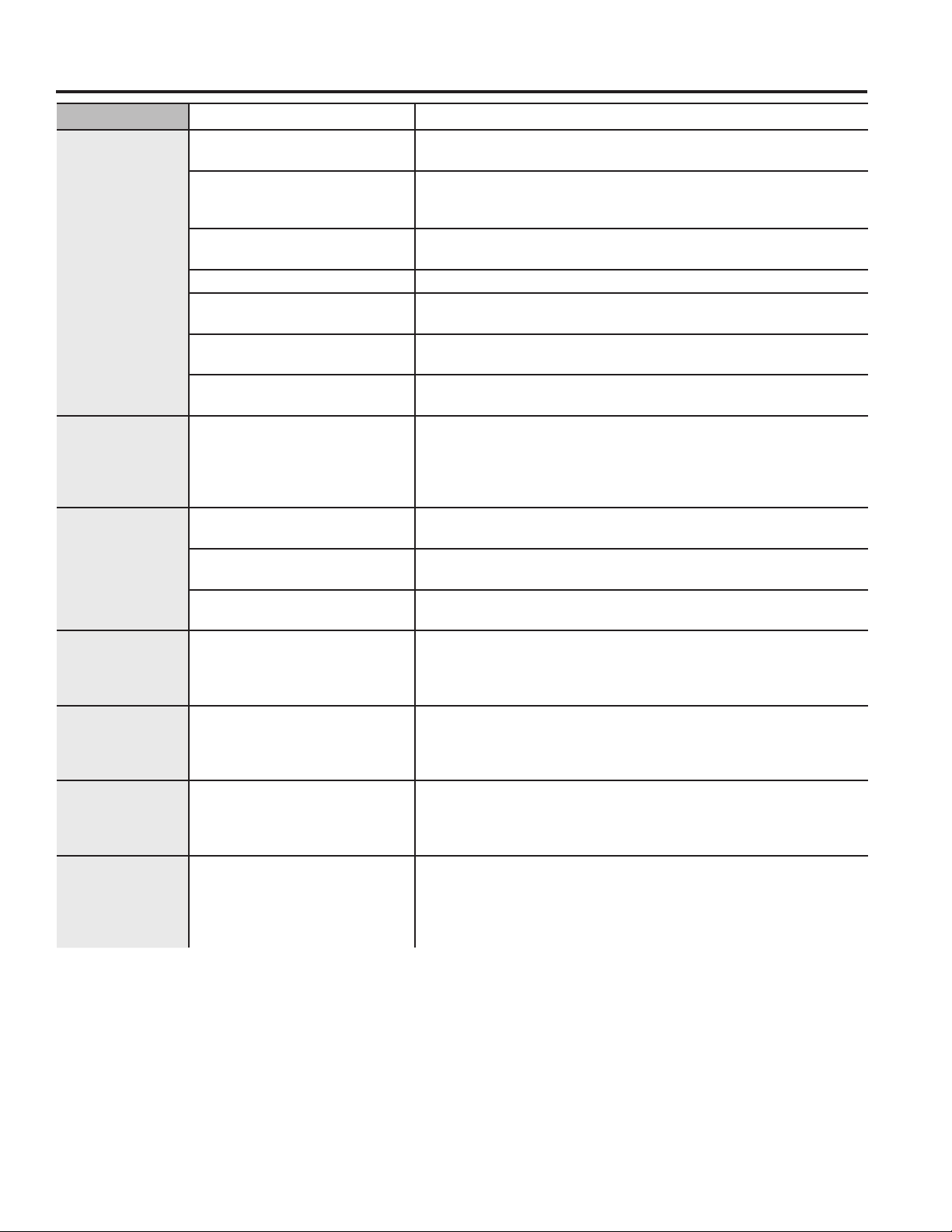

Troubleshooting Tips... Before you call for service

Problem Possible Cause What To Do

Not draining

Not spinning

Not tumbling

Leaking water Door gasket is damaged Check to see if gasket is seated and not torn. Objects left in

Clothes too

wet

Load is out of balance Redistribute clothes and run Rinse+Spin.

Increase load size if washing small load containing heavy and

light items.

Pump filter may be clogged See the Care and Cleaning section on how to clean the Pump

Filter.

Drain hose is kinked or

improperly connected

Household drain may be

clogged

Drain hose siphoning; drain

hose pushed too far down

the drain

Check back left of the unit

for water

Fill hoses or drain hose is

improperly connected

Household drain may be

clogged

Dispenser clogged Powder soap may cause clogs inside the dispenser and cause

Incorrect use of detergent Use only HE and correct amount of detergent.

Load is out of balance Redistribute clothes and run Rinse+Spin.

Pump filter may be clogged See the Care and Cleaning section on how to clean the Pump

Overloading Load your unit so clothes have enough room to move freely.

Drain hose is kinked or

improperly connected

Household drain may be

clogged

Drain hose siphoning; drain

hose pushed too far down

the drain

Straighten drain hose and make sure unit is not sitting on it.

Check household plumbing. You may need to call a plumber.

Ensure there is an air gap between hose and drain.

pockets may cause damage to the unit (nails, screws, pens,

pencils)

Water may drip from the door when the door is opened. This is a

normal operation.

Carefully wipe off rubber door seal. Sometimes dirt or clothing is

left in this seal and can cause a small leak

If this area is wet, you have oversudsing condition. Use less

detergent.

Make sure hose connections are tight at unit and faucets and

make sure end of drain hose is correctly inserted in and secured

to drain facility.

Check household plumbing. You may need to call a plumber.

water to leak out the front of the dispenser. Remove drawer and

clean both drawer and inside of dispenser box. Please refer to

Care and Cleaning section.

Increase load size if washing small load containing heavy and

light items.

Filter.

Straighten drain hose and make sure unit is not sitting on it.

Check household plumbing. You may need to call a plumber.

Ensure there is an air gap between hose and drain.

TROUBLESHOOTING TIPS

49-3000230 Rev 2 23

Page 24

Troubleshooting Tips... Before you call for service

Problem Possible Cause What To Do

Incomplete cycle or

timer not advancing

Loud or unusual

noise; vibration or

shaking

TROUBLESHOOTING TIPS

No power/unit not

working or dead

Snags, holes, tears,

rips or excessive

wear

Control time wrong

or changes

Not enough water This is normal Horizontal machines do not require the tub to fill with

Unit pauses or has

to be restarted, or its

door is locked and

will not open

Automatic load

redistribution

Pump filter may be clogged See the Care and Cleaning section on how to clean the

Drain hose is kinked or

improperly connected

Household drain may be

clogged

Drain hose siphoning; drain

hose pushed too far down

the drain

Cabinet moving Unit is designed to move 1/4” to reduce forces transmitted

All rubber leveling legs are

not firmly touching the floor

Unbalanced load Pause unit, open door and manually redistribute load. To

Pump filter may be clogged See the Care and Cleaning section on how to clean the

Unit is unplugged Make sure cord is plugged securely into a working outlet.

This is normal. Control

panel is “asleep”.

Unit was accidentally paused

when starting Delay Dry

Water supply is turned off Turn both hot and cold faucets fully on.

Circuit breaker/fuse is

tripped/blown

Automatic self system

checks

Pens, pencils, nails, screws

or other objects left in

pockets

Pins, snaps, hooks, sharp

buttons, belt buckles, zippers

and sharp objects left in

pockets

This is normal During spin the unit may need to rebalance the load

Pump filter may be clogged See the Care and Cleaning section on how to clean the

Timer stops at 1 minute; machine has redistributed the load once or

twice.

This is normal operation.

Do nothing; the machine will finish the wash cycle.

Pump Filter.

Straighten drain hose and make sure unit is not sitting on

it.

Check household plumbing. You may need to call a

plumber.

Ensure there is an air gap between hose and drain.

to the floor. This movement is normal.

Push and pull on the back right and then back left of your

unit to check if it is level. If the unit is uneven, adjust the

rubber leveling legs so they are all firmly touching the

floor and locked in place.

check machine, run rinse and spin with no load. If normal,

unbalance was caused by load.

Pump Filter.

Press the Power button to “wake up” the display.

If the light on the Start/Pause button is flashing, the unit is

paused. Press Start/Pause button to restart the countdown.

Check house circuit breakers/fuses. Replace fuses or

reset breaker. Unit should have separate outlet.

First time the unit is plugged in, automatic checks occur. It

may take up to 20 seconds before you can use your unit.

This is normal operation.

Remove loose items from pockets.

Fasten snaps, hooks, buttons and zippers.

sometimes to reduce vibrations. When this happens, the

estimated time is increased causing time left to increase

or jump.

water like top-load machines.

Pump Filter.

24 49-3000230 Rev 2

Page 25

Troubleshooting Tips... Before you call for service

Problem Possible Cause What To Do

Door unlocks

or press Start

and machine

doesn’t operate

Water does not

enter unit or

enters slowly

Wrinkling Improper sorting Avoid mixing heavy items (like work clothes) with light items

Grayed or

yellowed

clothes

This is normal

Incorrect operation Simply open and close the door firmly; then press Start.

Automatic self system

checks

Water valve screens are

stopped up

Inlet hose screen washers

are stopped up

Pump filter may be clogged See the Care and Cleaning section on how to clean the

Fill hoses may be kinked Check that fill hoses are not kinked or clogged.

Water supply is turned off Turn on both hot and cold faucets fully.

Energy efficiency This is an energy-efficient unit. As a result, the temperature

Insufficient water supply Make sure that the water supply is turned on. Make sure that

The door is open The door must be closed for all cycle operations. If the door is

Incorrect fill hose connection Make sure that the fill hoses connect the hot water supply to

Overloading Load your unit so clothes have enough room to move freely.

Incorrect wash cycle Match cycle selection to the type of fabric you arewashing

Repeated washing in water

that is too hot

Not enough detergent Use correct amount of detergent.

Not using HE (high

efficiency) detergent

Hard water Use hottest water safe for fabric.

Water is not hot enough Make sure water heater is delivering water at 120°–140°F

Detergent is not dissolving Try a liquid HE detergent.

Dye transfer Sort clothes by color. If fabric label states wash separately,

Front-load machines start up differently than top-load machines,

and it takes several seconds to check the system. The door will

lock and unlock.

After Start is pressed, the unit does several system checks.

Water will flow

Turn off the water source and remove the water connection

hoses from the upper back of the unit. Use a brush or

toothpick to clean the screens in the machine. Reconnect the

hoses and turn the water back on.

Turn off the water source and remove the inlet hoses from

the wall faucets. Use a brush or toothpick to clean the screen

washers in the end of the hoses. Reconnect the hoses and

turn the water back on.

Pump Filter.

settings for this unit may be different than for a non-energyefficient unit.

the water faucets are turned to their completely open position.

opened during operation, all functions will stop, including water

filling.

the hot inlet on the unit and the cold water supply to the cold

inlet on the unit (hot to hot, cold to cold).

(like blouses).

For best drying results, load the unit 2/3 full.

(especially for easy care loads).

Wash in warm or cold water.

Use only HE detergent.

Use a water conditioner like Calgon brand or install a water

softener.

(48°–60°C).

unstable dyes may be indicated.

several

seconds after Start is pressed.

TROUBLESHOOTING TIPS

49-3000230 Rev 2 25

Page 26

Troubleshooting Tips... Before you call for service

Problem Possible Cause What To Do

Colored spots Incorrect use of fabric

softener

Dye transfer Sort whites or lightly colored items from dark colors.

Water

temperature is

incorrect

Slight variation

in metallic color

Bad odor inside

your machine

Water supply is improperly

connected

House water heater is not set

properly

This is normal Due to the metallic properties of paint used for this unique

Unit unused for a long time,

not using recommended

quality of HE detergent or

used too much detergent

TROUBLESHOOTING TIPS

Detergent leak Incorrect placement of

detergent insert

This is normal It is normal operation to see detergent leak on door gasket

Improper

dispensing

of softener

Dispenser

drawer not

dispensing

properly

Pump running

while unit is not

in use

Dispenser clogged Monthly clean the dispenser drawer to remove buildup of

Softener is filled above the

max line

Softener cap issue Make sure softener cap for dispenser is seated or it will not

Laundry detergent packet

placed in dispenser drawer

Clog in sump drain This is normal. Drain sump is detecting an undesired water

Check fabric softener package for instructions and follow

directions for using dispenser.

Promptly remove wash load from unit.

Make sure hoses are connected to correct faucets.

Make sure house water heater is delivering water at 120°–

140°F (48°–60°C).

product, slight variations of color may occur due to viewing

angles and lighting conditions.

Run a Tub Clean cycle.

In case of strong odor, you may need to run the Tub Clean

cycle more than once.

Use only the amount of detergent recommended on the

detergent container.

Use only HE (high efficiency) detergent.

Always remove wet items from the unit promptly after machine

stops running.

Leave the door slightly open for the water to air dry. Close

supervision is necessary if this appliance is used by or near

children. Do not allow children to play on or in this or any other

appliance.

Make sure detergent insert is properly located and fully seated.

Never put detergent above max line.

about 20 seconds after filling the dispenser.

chemicals.

Make sure to have the correct amount of softener.

work.

Laundry detergent packets should not be used in the

dispenser. They should only be added directly to the wash tub

following the manufacturer's directions.

fill level from a potential open faucet. Shut off water valve and

inspect water valve for blockage.

26 49-3000230 Rev 2

Page 27

Troubleshooting Tips... Before you call for service

Problem Possible Cause What To Do

Clothes take

too long to dry

The Dry

dryness level

was chosen

but load is still

damp

Control

buttons not

responding

No numbers

displayed

during cycle,

only lights

Time

Remaining

jumped to a

lower number

Cannot make a

selection and

the unit beeps

twice

Unit is running

but 00 is

displayed

in Time

Remaining

Improper sorting Separate heavy items from lightweight items (generally, a

well-sorted washer load is a well-sorted dryer load).

Large loads of heavy

fabrics (like beach towels)

Non-venting unit Condensing dryers usually take longer to dry than a vented

Controls improperly set Match control settings to the load you are drying.

Blown fuses or tripped

circuit breaker

Overloading/combining

loads

Underloading If you are drying only one or two items, add a few items to

Load consists of a mixture

of heavy and light fabrics

Controls accidentally put in

service mode

Controls accidentally put in

lock mode

Controls performed an

incorrect operation

Unit is continuously

monitoring the amount of

moisture in the clothes

The estimated time may

change when a smaller load

than usual is drying

The dryness Level, Temp or

option that you are trying to

select is incompatible with

the chosen dry cycle

The Ext Tumble option was

chosen

Large, heavy fabrics contain more moisture and take longer to

dry. Separate large, heavy fabrics into smaller loads to speed

drying time.

dryer.

Replace fuses or reset circuit breakers. Since most dryers use

2 fuses/breakers, make sure both are operating.

Do not put more than one washer load in the unit at a time.

ensure proper tumbling.

When combining heavy and light fabrics in a load, choose

Auto Extra Dry.

Press Start/Pause.

Hold the Soil and Temp buttons for 3 seconds to unlock the

unit.

Reset the in-house breaker.

This is normal. When the unit senses a low level of moisture in

the load, the unit will display the dry time remaining.

This is normal.

This is normal.

This is normal. During extended tumbling, the time remaining

is not displayed. The extended tumbling option lasts

approximately 60 minutes.

TROUBLESHOOTING TIPS

49-3000230 Rev 2 27

Page 28

Troubleshooting Tips... Before you call for service

Problem Possible Causes What To Do

Unit doesn’t

heat

Inconsistent

drying times

Clothes are

still wet and

unit shuts off

after a short

time

TROUBLESHOOTING TIPS

Clothes are

wrinkled

Clothes shrink Some fabrics will naturally

Greasy spots

on clothes

Lint on clothes Improper sorting Sort lint producers (like chenille) from lint collectors (like

Static occurs No fabric softener was used Try a fabric softener.

Fuse is blown/circuit

breaker is tripped; the unit

may tumble but not heat

Type of load and drying

conditions

Excess debris has collected

on the fan preventing

proper airflow

The door was opened

mid-cycle. The load was

then removed from the

unit and a new load put in

without selecting a new

cycle

Load was already dry

except for collars and

waistbands

Unit is not level Move unit to an even floor space or adjust leveling legs as

Letting items sit in unit

after cycle ends

Overloading Separate large loads into smaller ones.

shrink when washed.

Others can be safely

washed, but will shrink

while drying in the unit.

Improper use of fabric

softener

Drying dirty items with

clean ones

Clothes were not

completely clean

Static electricity can attract

lint

Overloading Separate large loads into smaller ones.

Paper, tissue, etc., left in

pockets

Synthetics, permanent

press and blends can cause

static

Check the building’s fuse/circuit breaker box and replace both

fuses or reset both breakers. Your unit may tumble if only one

fuse is blown or one breaker tripped.

The load size, types of fabric, wetness of clothes and/or air

intake vent located on the front of the unit will affect drying

times.

Refer to the Care and Cleaning section.

A dry cycle must be reselected each time a new load is put in.

Choose Timed Dry to dry damp collars and waistbands. In the

future, when drying a load with collars and waistbands, choose

Auto Extra Dry.

necessary until even.

Remove items when cycle ends and fold or hang immediately,

or use the Ext Tumble option.

To avoid shrinkage, follow garment care labels exactly.

Some items may be pressed back into shape after drying.

If you are concerned about shrinkage in a particular

item, do not machine wash or tumble dry it.

Follow directions on fabric softener package.

Use your unit to dry only clean items. Dirty items can stain

clean items and the unit.

Sometimes stains which cannot be seen when the clothes

are wet appear after drying. Use proper washing procedures

before drying.

corduroy).

See suggestions in this section under Static occurs.

Empty all pockets before laundering clothes.

Try a fabric softener.

28 49-3000230 Rev 2

Page 29

Troubleshooting Tips... Before you call for service

Problem Possible Causes What To Do

Collars and

waistbands

still wet at end

of cycle

Unit continues

to tumble after

display says

Complete

The dryness monitor

senses that the body of the

clothes is dry

Ext Tumble was selected Ensure Ext Tumble option is not selected.

Choose Timed Dry to dry damp collars and waistbands. In the

future, when drying a load with collars and waistbands, choose

Auto Extra Dry.

TROUBLESHOOTING TIPS

49-3000230 Rev 2 29

Page 30

Notes

NOTES

30 49-3000230 Rev 2

Page 31

GE Appliances Washer/Dryer Limited Warranty

GEAppliances.com

All warranty service is provided by our Factory Service Centers, or an authorized Customer Care® technician. To schedule

service online, visit us at GEAppliances.com/service, or call GE Appliances at 800.GE.CARES (800.432.2737). Please

have your serial number and your model number available when calling for service.

Servicing your appliance may require the use of the onboard data port for diagnostics. This gives a GE Appliances factory

service technician the ability to quickly diagnose any issues with your appliance and helps GE Appliances improve its

products by providing GE Appliances with information on your appliance. If you do not want your appliance data to be

sent to GE Appliances, please advise your technician not to submit the data to GE Appliances at the time of service.

For the period of: We will replace:

One year

From the date of the

original purchase

What is not covered:

Ŷ

Service trips to your home to teach you how to use

the product.

Ŷ

Improper installation, delivery or maintenance.

Ŷ

Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

Ŷ

Replacement of house fuses or resetting of circuit

breakers.

Ŷ

Products which are not defective or broken, or which

are working as described in the Owner’s Manual.

Any part of the washer/dryer which fails due to a defect in materials or workmanship.

During this limited one-year warranty, we will also provide, free of charge, all labor

and related service to replace the defective part.

Ŷ

Damage to the product caused by accident, fire,

floods or acts of God.

Ŷ

Incidental or consequential damage caused by

possible defects with this appliance.

Ŷ

Defects or damage due to operation in freezing

temperatures.

Ŷ

Damage caused after delivery.

Ŷ

Product not accessible to provide required service.

Ŷ

Cleaning of condenser to restore product drying

performance.

LIMITED WARRANTY

Staple your receipt here. Proof of the original purchase

date is needed to obtain service under the warranty.

EXCLUSION OF IMPLIED WARRANTIES

Your sole and exclusive remedy is product repair as provided in this Limited Warranty. Any implied warranties,

including the implied warranties of merchantability or fitness for a particular purpose, are limited to one year or the

shortest period allowed by law.

In the United States:

This limited warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. If the product is located in an area where service by a GE Appliances Authorized Servicer is not available,

you may be responsible for a trip charge or you may be required to bring the product to an Authorized GE Appliances

Service location for service. In Alaska, the limited warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This limited warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: GE Appliances, a Haier Company

Louisville, KY 40225

In Canada:

This limited warranty is extended to the original purchaser and any succeeding owner for products purchased in Canada

for home use within Canada. If the product is located in an area where service by a GE Appliances Authorized Servicer is

not available, you may be responsible for a trip charge or you may be required to bring the product to an Authorized

GE Appliances Service location.

Some provinces do not allow the exclusion or limitation of incidental or consequential damages. This limited warranty

gives you specific legal rights, and you may also have other rights which vary from province to province. To know what

your legal rights are, consult your local or provincial consumer affairs office.

Warrantor: MC Commercial Inc., Burlington, ON, L7R 5B6

Extended Warranties: Purchase a GE Appliances extended warranty and learn about special discounts that are

available while your warranty is still in effect. You can purchase it online anytime at

GEAppliances.com/extended-warranty

or call 800.626.2224 during normal business hours. GE Appliances Service will still be there after your warranty expires.

49-3000230 Rev 2 31

Page 32

Consumer Support

GE Appliances Website

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day, any day

of the year! You can also shop for more great GE Appliances products and take advantage of all our on-line support

services designed for your convenience. In the US: GEAppliances.com.

In Canada: GEAppliances.ca.

Register Your Appliance

Register your new appliance on-line at your convenience! Timely product registration will allow for enhanced

communication and prompt service under the terms of your warranty, should the need arise. You may also mail in the

pre-printed registration card included in the packing material. In the US: GEAppliances.com/register.

In Canada: Prodsupport.mabe.ca/crm/Products/ProductRegistration.aspx.

CONSUMER SUPPORT

Schedule Service

Expert GE Appliances repair service is only one step away from your door. Get on-line and schedule your service at

your convenience any day of the year. In the US: GEAppliances.com/service or call 800.432.2737 during normal

business hours.

In Canada: GEAppliances.ca/en/support/service-request or call 800.561.3344.

Extended Warranties

Purchase a GE Appliances extended warranty and learn about special discounts that are available while your

warranty is still in effect. You can purchase it on-line anytime. GE Appliances Services will still be there after your

warranty expires. In the US: GEAppliances.com/extended-warranty or call 800.626.2224 during normal business

hours.

In Canada: GEAppliances.ca/en/support/purchase-extended-warranty or call 866.277.9842.

Remote Connectivity