GE GFK-2892F User Manual

GE

Automation & Controls

For Public Disclosure

Programmable Control Products

PACSystems RX3i Genius Communications Gateway User Manual GFK-2892F

PACSystems RX3i Genius

Communications

Gateway

User Manual

GFK-2892F

March 2019

Legal Information

Warnings, Cautions, and Notes as Used in this Publication GFL-002

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in

this equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note: Notes merely call attention to information that is especially significant to understanding

and operating the equipment.

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met during installation, operation, and maintenance. The information is supplied for

informational purposes only, and GE makes no warranty as to the accuracy of the information included herein.

Changes, modifications, and/or improvements to equipment and specifications are made periodically and

these changes may or may not be reflected herein. It is understood that GE may make changes, modifications,

or improvements to the equipment referenced herein or to the document itself at any time. This document is

intended for trained personnel familiar with the GE products referenced herein.

GE may have patents or pending patent applications covering subject matter in this document. The furnishing

of this document does not provide any license whatsoever to any of these patents.

GE PROVIDES THE FOLLOWING DOCUMENT AND THE INFORMATION INCLUDED THEREIN AS-IS AND

WITHOUT WARRANTY OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

STATUTORY WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

* indicates a trademark of General Electric Company and/or its subsidiaries.

All other trademarks are the property of their respective owners.

©Copyright 2014-2019 General Electric Company.

All Rights Reserved

Contact Information

If you purchased this product through an Authorized Channel Partner, please contact the seller directly.

General Contact Information

Online technical support and GlobalCare

www.geautomation.com/support

Additional information

www.geautomation.com

Solution Provider

solutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this manual, please contact us

by telephone or email, or on the web at www.geautomation.com/support

Americas

Phone

1-800-433-2682

International Americas Direct Dial

1-780-420-2010 (if toll free 800 option is unavailable)

Customer Care Email

digitalsupport@ge.com

Primary language of support

English

Europe, the Middle East, and Africa

Phone

+800-1-433-2682

EMEA Direct Dial

+ 420-296-183-331 (if toll free 800 option is unavailable or

if dialing from a mobile telephone)

Customer Care Email

digitalsupport.emea@ge.com

Primary languages of support

English, French, German, Italian, Spanish

Asia Pacific

Phone

+86-21-3877-7006 (India, Indonesia, and Pakistan)

+86-400-820-8208 (rest of Asia)

Customer Care Email

digitalsupport.apac@ge.com

Primary languages of support

Chinese, English

GFK-2892F March 2019 i

Table of Contents

PACSystems RX3i Genius Communications Gateway User Manual GFK-2892F

Table of Contents ............................................................................................................................................................. i

Table of Figures ............................................................................................................................................................... iv

Chapter 1 Introduction ............................................................................................................................................... 1

1.1 Revisions in this Manual .......................................................................................................................... 2

1.2 Acronyms and Abbreviations ................................................................................................................ 3

1.3 PACSystems Documentation................................................................................................................. 4

1.4 Description ................................................................................................................................................. 5

1.5 Product Overview ..................................................................................................................................... 6

1.6 Specifications ............................................................................................................................................ 7

1.7 Controls and Indicators ........................................................................................................................... 8

Mounting ................................................................................................................................................................ 9

1.8 PROFINET Operation Overview........................................................................................................... 10

1.9 System Limits .......................................................................................................................................... 14

1.10 Operational Differences vs. Genius Bus Controller ........................................................................ 15

1.11 Supported Genius Devices.................................................................................................................... 16

Chapter 2 Installation ............................................................................................................................................... 17

2.1 Pre-Installation Check ........................................................................................................................... 17

2.2 Installation Location .............................................................................................................................. 17

2.3 Installation in Hazardous Areas .......................................................................................................... 18

ATEX Zone 2 ....................................................................................................................................................... 18

ATEX Marking ..................................................................................................................................................... 18

2.4 Module Installation ................................................................................................................................ 19

Install SD Card ................................................................................................................................................... 19

Mounting the GCG001 ................................................................................................................................... 19

GCG001 Module Removal ............................................................................................................................. 21

Light-Emitting Diode (LED) Indications ................................................................................................... 22

Fault Notifications ........................................................................................................................................... 23

Contents

ii PACSystems RX3i Genius Communications Gateway GFK-2892F

2.5 Configuring the Genius Gateway to Operate with the RX3i CPU ............................................... 24

2.6 Ethernet Port Connections .................................................................................................................. 25

RJ-45 Port Connections ................................................................................................................................. 25

2.7 Firmware Updates .................................................................................................................................. 26

2.8 Spare Parts ............................................................................................................................................... 26

Chapter 3 Configuration ........................................................................................................................................... 27

3.1 Configuration Tools ................................................................................................................................ 27

3.2 Configuration Overview ........................................................................................................................ 27

GCG001 in Simplex Genius Bus Configuration ..................................................................................... 27

Genius Hot-Standby Redundancy Configuration ................................................................................ 33

Genius Duplex Configuration ...................................................................................................................... 34

Genius Dual Bus Configuration ................................................................................................................... 34

Genius Hot Standby Dual Bus Configuration ........................................................................................ 35

Chapter 4 System Operation ................................................................................................................................... 37

4.1 System Overview .................................................................................................................................... 37

Communications .............................................................................................................................................. 37

Redundancy ........................................................................................................................................................ 38

I/O Scans .............................................................................................................................................................. 39

Alarms................................................................................................................................................................... 40

Chapter 5 Diagnostics ............................................................................................................................................... 41

5.1 Status Data ............................................................................................................................................... 42

Gateway Status Data ...................................................................................................................................... 42

Genius Status Data.......................................................................................................................................... 43

Fault Status Data ............................................................................................................................................. 43

5.2 Module LED Indicators .......................................................................................................................... 43

5.3 Power-Up .................................................................................................................................................. 44

Problems during Power-up .......................................................................................................................... 44

Transitioning from Firmware Update Mode to Operational Mode .............................................. 44

5.4 Module Faults in the RX3i I/O Fault Tables ....................................................................................... 45

Fault Types Reported to the RX3i Controller I/O Fault Table ......................................................... 46

Clearing the RX3i Fault Tables .................................................................................................................... 47

Chapter 6 COMMREQ/Data_Init_Comm Programming ..................................................................................... 49

6.1 COMMREQs and Passwords ................................................................................................................. 50

6.2 Programming for a COMMREQ Communication Request ............................................................. 50

6.3 COMMREQ Command Block Format .................................................................................................. 51

COMMREQ Command Block Contents .................................................................................................... 52

Contents

GFK-2892F March 2019 iii

COMMREQ Commands Supported by the Genius Gateway (GCG001) ..................................... 53

COMMREQ Command Block Quick Reference ..................................................................................... 54

Mechanics of the COMMREQ Instruction ............................................................................................... 55

Comparison: COMMREQ vs Data_Init_Comm ...................................................................................... 60

COMMREQ Differences: Genius Bus Controllers and Genius Gateway ..................................... 61

6.4 COMMREQ Descriptions and Formats ............................................................................................... 62

COMMREQ #1: Pulse Test Command....................................................................................................... 62

COMMREQ #2: Read Configuration Command .................................................................................... 63

COMMREQ #3: Write Configuration Command ................................................................................... 64

COMMREQ #4: Read Diagnostics Command ........................................................................................ 65

COMMREQ #5: Clear Circuit Fault Command ....................................................................................... 66

COMMREQ #6: Clear All Circuit Faults Command .............................................................................. 67

COMMREQ #7: Assign Monitor Command ............................................................................................. 68

COMMREQ #8: Enable/Disable Outputs Command ........................................................................... 69

COMMREQ #10: Switch BSM Command ................................................................................................. 70

COMMREQ #11: Read Device Command ................................................................................................ 71

COMMREQ #12: Write Device Command .............................................................................................. 72

COMMREQ #19: Read Identification ......................................................................................................... 73

COMMREQ #20: Write Point Command ................................................................................................. 75

COMMREQ #21: Read Block I/O Command ........................................................................................... 76

COMMREQ #22: Read Map Command ..................................................................................................... 80

COMMREQ #23: Write Map Command ................................................................................................... 81

COMMREQ #24: Read Data Command .................................................................................................... 82

COMMREQ #25: Write Data Command .................................................................................................. 83

Contents

iv PACSystems RX3i Genius Communications Gateway GFK-2892F

Table of Figures

Figure 1: Simplex PLC System Using Genius Gateway GCG001 .................................................................................................. 5

Figure 2: GCG001 Module ............................................................................................................................................................................ 6

Figure 3: Genius Gateway GCG001 Front Panel View ...................................................................................................................... 8

Figure 4: GCG001 Panel Mount Diagram .............................................................................................................................................. 9

Figure 5: Application Relationships between PROFINET Controller & Genius Gateway .................................................... 10

Figure 6: Real-Time & Non-Real-Time Data Types ........................................................................................................................... 11

Figure 7: PLC - GCG - Genius Scan Cycles ........................................................................................................................................... 12

Figure 8: Rear View of GCG001 ............................................................................................................................................................... 19

Figure 9: GCG001 Power Connector ...................................................................................................................................................... 19

Figure 10: Daisy Chain Genius Bus Wiring ......................................................................................................................................... 20

Figure 11: Genius Bus Wiring for Bus Termination .......................................................................................................................... 20

Figure 12: PROFINET Discovery Screenshot ....................................................................................................................................... 21

Figure 13: GCG001 Firmware Upgrade ZIP File UnZIPped to SD Card ..................................................................................... 26

Figure 14: Hardware Configuration Expanded Tree ........................................................................................................................ 28

Figure 15 - GCG Data Reference Addresses ........................................................................................................................................ 28

Figure 16: Genius Gateway Parameters .............................................................................................................................................. 28

Figure 17: Change Module List for Genius Gateway GCG001 ..................................................................................................... 29

Figure 18: Populating the Genius IO Devices to be Controlled by the Genius Gateway .................................................... 30

Figure 19: Populating Slots in S90-70 Rack Controlled by Remote I/O Scanner (BEM733) ............................................. 30

Figure 20: PME Display of Complete Genius Gateway Configuration ...................................................................................... 32

Figure 21: GCG001 Units Deployed in Genius Hot Standby Dual Bus Redundancy ........................................................... 36

Figure 22: Genius Hot Standby Redundancy ..................................................................................................................................... 38

Figure 23: PROFINET Media Redundancy ............................................................................................................................................ 39

Figure 24: Gateway Status Data ............................................................................................................................................................. 42

Figure 25: Genius Status Data ................................................................................................................................................................. 43

Figure 26: Fault Status Data ..................................................................................................................................................................... 43

Figure 27 - I/O Fault Table Message Identifiers ................................................................................................................................. 46

Figure 28: Genius Discrete Block Failed Switch Fault Display (Example) ............................................................................... 47

Figure 29: Genius Analog Block Over Range Fault Display (Example) ..................................................................................... 47

Figure 30: Ladder Logic to Clear Circuit Fault .................................................................................................................................... 59

Figure 31: Data_Init_Comm to Clear Circuit Fault ............................................................................................................................ 60

GFK-2892F March 2019 1

Chapter 1 Introduction

This manual describes the RX3i Genius Communications Gateway, which acts as a gateway between

PROFINET and Genius I/O. Introductory material may be found in this chapter. Chapter 2 provides installation

and set-up information. Chapter 3 provides configuration instructions. Chapter 4 describes system operation.

Chapter 5 provides diagnostic information. Chapter 6 covers the use and format of ladder logic COMMREQ

instructions.

Chapter 1. Introduction

2 PACSystems RX3i Genius Communications Gateway GFK-2892F

1.1 Revisions in this Manual

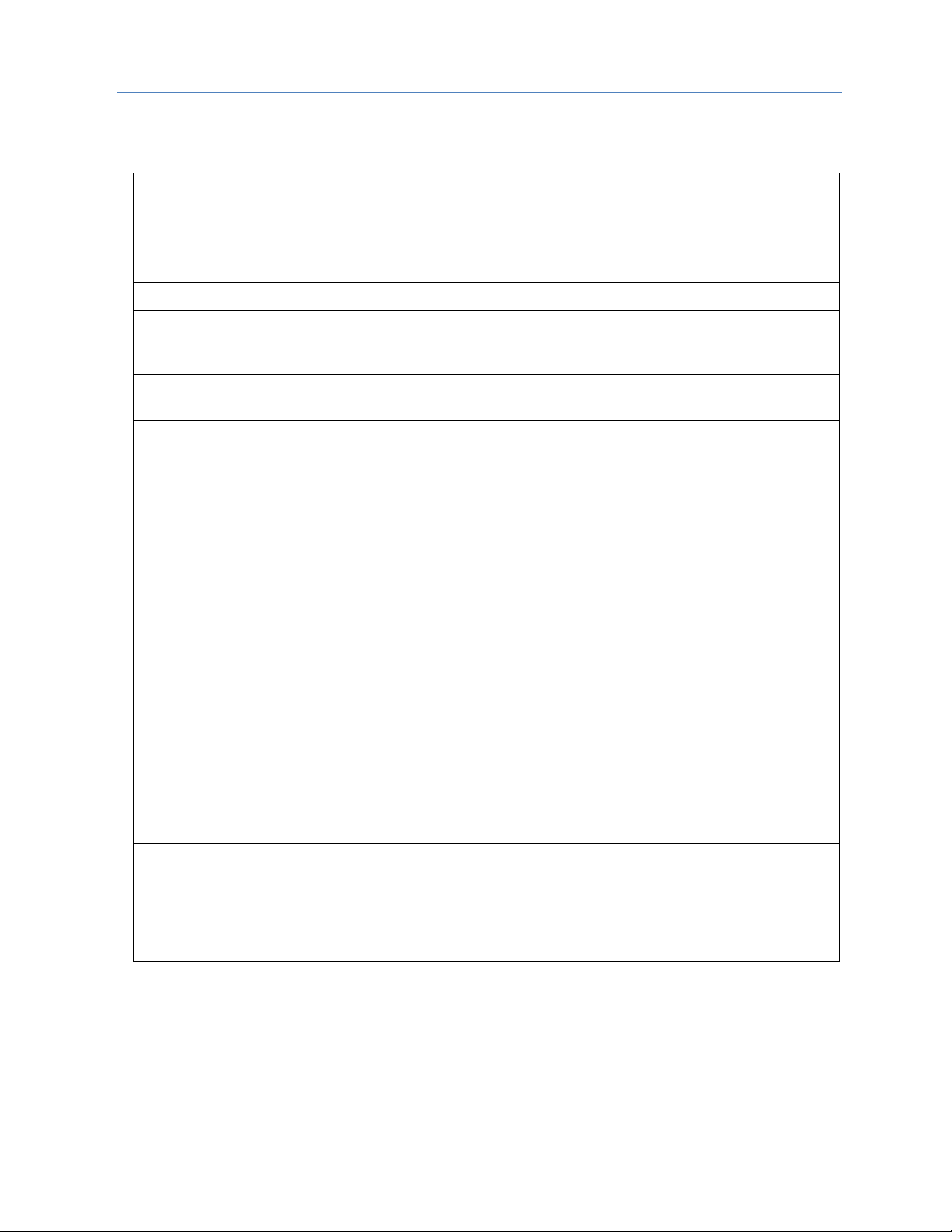

Rev

Date

Description

F

Mar

2019

• In Section 5.1.3, added Fault Status Data.

E

Oct

2018

• Added note 3.2.2 concerning PNC001 Critical Network Ports feature with GCGs.

D

Mar

2018

• Added compatibility with CPE302.

C

Dec

2017

• Added support for Field Control Bus Interface Unit.

• Added Outputs at Startup hardware configuration parameter.

• Added Enable/Disable Outputs and Switch BSM COMMREQs.

• Documented GCG001 Units deployed in Genius Hot Standby Dual Bus Redundancy

(Section 3.2.5).

B

Aug

2016

• Added support for VersaMax Genius Network Interface (GNIU)

• Added support for IC660BSS101 isolated I/O block

• Added support for additional Genius baud rates

A

Mar

2015

• Behavior of GCG001 with respect to input references associated with a faulted block

is described in Section 1.10, with workaround in Section 4.1.4.

• Correction to Figure 22: Genius Hot Standby Redundancy to indicate CPU type is CRU

and RMX modules are required.

• Clear All Faults can now be dispatched to all blocks on the bus in a single command.

See Section 6.4.6.

-

Jun

2014

Initial release

Chapter 1. Introduction

GFK-2892F March 2019 3

1.2 Acronyms and Abbreviations

AR

PROFINET Application Relationship

CR

PROFINET Communication Relationship

DCP

PROFINET Discovery & Configuration Protocol

GBIU

Genius Bus Interface Unit

GCG

Genius Communications Gateway (specifically GCG001)

GENA

Genius Network Adaptor

GENI

Genius Network Interface

GNIU

Genius Network Interface Unit

GR7

Series 90-70 Remote I/O Scanner (IC697BEM733)

GSDML

General Station Description Markup Language

HHM

Genius Hand-Held Monitor

HWC

Hardware Configuration (in PME)

LAN

Local Area Network

LED

Light Emitting Diode

MRC

Ethernet Media Redundancy Client

MRM

Ethernet Media Redundancy Manager

MRP

Ethernet Media Redundancy Protocol

NRT

Non-Real-Time PROFINET Communication

PCIM

Personal Computer Interface Module

PME

Proficy® Machine Edition

PNC

PROFINET Controller

PPV

PLC Protocol Variables

RT

Real-Time PROFINET Communication

SBA

Genius Serial Bus Address

SD

Secure Digital Card Slot

STP

Shielded Twisted Pair

UTP

Unshielded Twisted Pair

Chapter 1. Introduction

4 PACSystems RX3i Genius Communications Gateway GFK-2892F

1.3 PACSystems Documentation

PACSystems Manuals

PACSystems RX7i, RX3i and RSTi-EP CPU Reference Manual

GFK-2222

PACSystems RX7i, RX3i and RSTi-EP CPU Programmer’s Reference Manual

GFK-2950

PACSystems RX7i, RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual

GFK-2224

PACSystems TCP/IP Ethernet Communications Station Manager User Manual

GFK-2225

C Programmer’s Toolkit for PACSystems

GFK-2259

PACSystems Memory Xchange Modules User’s Manual

GFK-2300

PACSystems Hot Standby CPU Redundancy User Manual

GFK-2308

PACSystems Battery and Energy Pack Manual

GFK-2741

Proficy Machine Edition Logic Developer Getting Started

GFK-1918

Proficy Process Systems Getting Started Guide

GFK-2487

PACSystems RXi, RX3i, RX7i and RSTi-EP Controller Secure Deployment Guide

GFK-2830

PACSystems RX3i & RSTi-EP PROFINET I/O Controller Manual

GFK-2571

PACSystems RX3i Genius Communications Gateway

GFK-2928

RX3i Manuals

PACSystems RX3i System Manual

GFK-2314

PACSystems RX3i PROFINET Scanner Manual

GFK-2737

PACSystems RX3i CEP PROFINET Scanner User Manual

GFK-2883

Distributed I/O Systems Manuals

Genius I/O System and Communications User’s Manual

GEK-90486-1

Genius I/O Analog and Discrete Blocks User’s Manual

GEK-90486-2

Genius Hand-Held Monitor User’s Guide

GFK-0121

Series 90-70 Remote I/O Scanner User’s Manual

GFK–0579

VersaMax Systems Manuals

VersaMax System Genius Network Interface Unit User’s Manual

GFK-1535

In addition to these manuals, datasheets and product update documents describe individual modules and

product revisions. The most recent PACSystems documentation is available on the GE Automation & Controls

support website www.geautomation.com/support.

Chapter 1. Introduction

GFK-2892F March 2019 5

1.4 Description

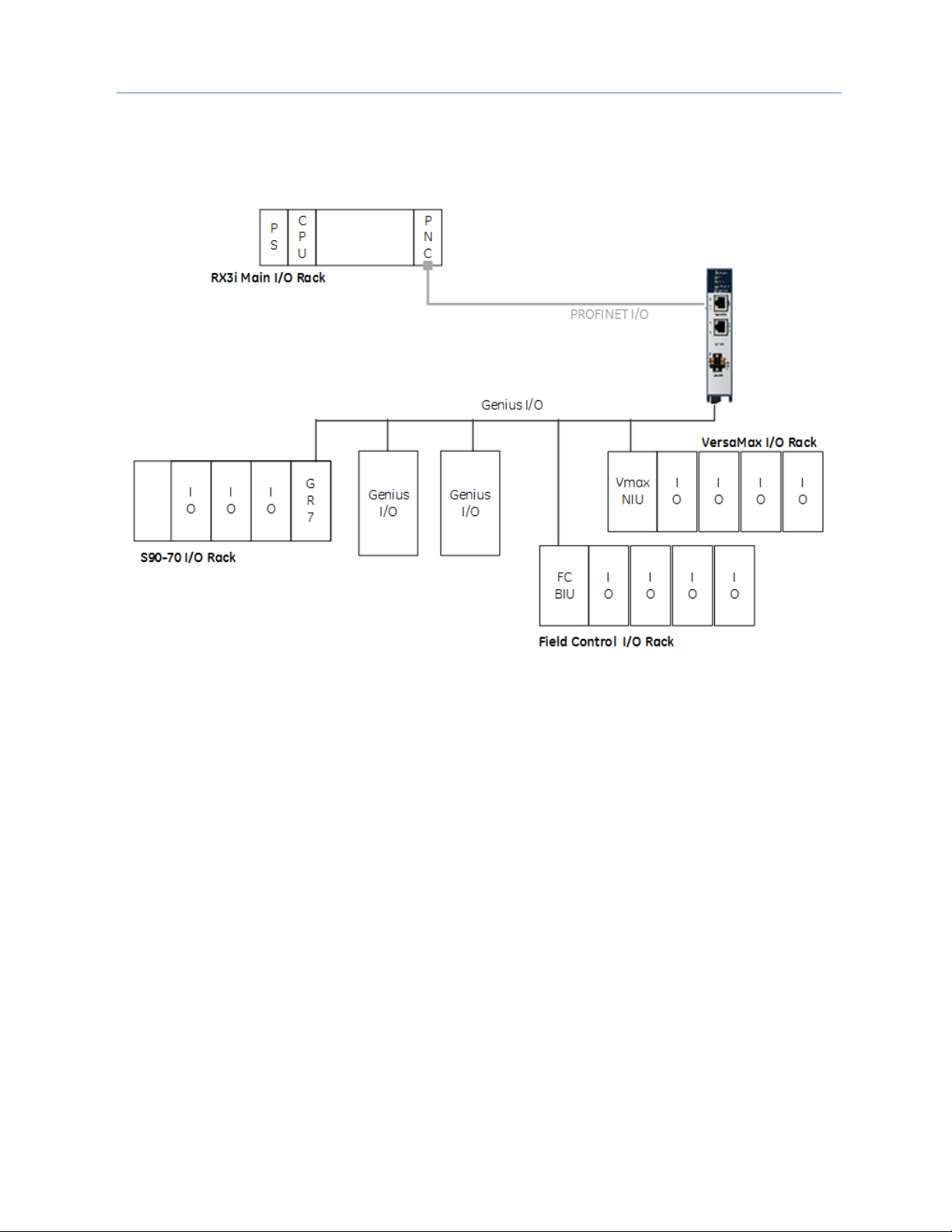

The RX3i Genius Communications Gateway, IC695GCG001 (or GCG001), interfaces Genius IO devices on a

Simplex Genius Serial Bus to a GE PROFINET IO Controller.

Figure 1: Simplex PLC System Using Genius Gateway GCG001

The GCG001 operates as a Genius Bus Controller on a Genius network. It scans the Genius IO devices

configured to it, retrieving input data and providing output data. It then exchanges that data with its configured

PROFINET IO Controller over its Ethernet interfaces at the configured production rate. The GCG001 can

manage communications for up to 31 Genius IO devices on a single Genius Serial Bus.

The GCG001 also operates as an IO Device on PROFINET. It may be controlled by any of the following PROFINET

IO Controllers:

• PNC001 (the RX3i rack-mounted PNC module), or by

• CPE330 LAN 2 when configured as a PROFINET LAN, or by

• CPE400 LAN 2 when configured as a PROFINET LAN.

Thus, when correctly configured, the entire Genius Bus, including the GCG001 itself, becomes visible to the

controlling PLC. Note that the GCG001 operates only with GE PLC PROFINET IO Controllers.

PROFINET operates on an Ethernet network. If the Ethernet network or Genius serial bus communications are

lost, the GCG001 manages I/O states according to the individual module configurations.

Both PROFINET and Genius may be set up in Redundant configurations. These are discussed later in this

manual.

Chapter 1. Introduction

6 PACSystems RX3i Genius Communications Gateway GFK-2892F

1.5 Product Overview

Features of the GCG001 module include:

• Attachment of two RJ-45 Ethernet connections (Ports 1 & 2)

• Support for both star (switched) and linear (daisy-chained) network

topologies

• Supports Ethernet Media Redundancy Protocol (MRP)

• LEDs to indicate Ethernet status (ACT & LINK)

• Genius bus terminal block attachment

• Supports Genius Redundancy consisting of a single Genius bus with two

GCG001 Gateways, one at SBA #30 and the other at SBA #31.

• LED to indicate Genius Communications Status (COM)

• LEDs to indicate module status (refer to module header)

• Panel-mount (typical)

• Optional mounting in RX3i expansion slot

• Cable tie-down loop on underside of module (at front)

• 24Vdc power connector on underside of module

• 0.2A maximum current draw

• Secure Digital (SD) Card Slot, accessible at rear of module

• Firmware load pushbutton, accessible at rear of module

ETHERNET

ACT

LINK

PORT 1

PORT 2

COM

POWER

FAULT

CONNECT

OK

GCG001

LINK

ACT

GENIUS A

SER 1

SER 2

SHLD

IN

GENIUS

SHLD

OUT

Figure 2: GCG001

Module

Note: Although the hardware supports the 10/100BASE TX Ethernet standard, PROFINET I/O

over wired infrastructure must be 100Mbps full-duplex or faster. 10Mbps should not be

used for PROFINET.

Chapter 1. Introduction

GFK-2892F March 2019 7

1.6 Specifications

RX3i Genius Communications Gateway Specifications

PROFINET Support

PROFINET version 2.3 Class A IO-Device

CPU Compatibility

RX3i CPE330

RX3i CPE302/CPE305/CPE310 with firmware version 8.15 or later

RX3i CPU315/CPU320/CRU320 with firmware version 8.15 or later

Rx3i CPE302 (any firmware version)

PNC001 Compatibility

Firmware version 2.05 or later

Embedded PROFINET

Compatibility

RX3i CPE400 embedded PROFINET

RX3i CPE330 embedded PROFINET with firmware version 8.90 or

later

Proficy* Machine Edition

Compatibility

PME 8.0 or later

Power Requirements

External 24Vdc: (±10%) 0.2A

Operating Temperature Range

0 to 60°C

Number of Port Connectors

Two RJ-45

Local Area Network (LAN)

IEEE 802.2 Logical Link Control Class I

IEEE 802.3 CSMA/CD Medium Access Control 10/100 Mbps

Status Data

64 (two banks of 32 bits)

Genius Bus Support

Supports One Genius Bus.

Serial 1, Serial 2, Shield In and Shield Out, as marked.

Up to 29 additional devices supported per Genius Bus.

Selectable Baud Rate, per Genius specifications.

Genius Hot Standby and Duplex Redundancy supported.

HHM Compatibility

IC660HHM501

Other Genius Compatibility

See table in Section 1.11

SD Card

2GB or smaller. Not compatible with SDHC or SDXC cards.

Configuration

GSDML file is available on the Support website for download and

import into PME. The GSDML supporting a firmware release is part

of the firmware upgrade kit available on the Support website.

Hot Swappable

The Genius Gateway requires an external 24Vdc power supply

and does not draw power from the Rx3i backplane. Swapping out

the GCG001 will therefore not impact the PLC. However, this

cannot be performed without disconnecting its power supply. If

configured to support Genius Hot Standby, the loss of a single

GCG001 will be tolerated; otherwise not.

For system standards, general operating specifications, and installation requirements, refer to the PACSystems

RX3i System Manual, GFK-2314.

Chapter 1. Introduction

8 PACSystems RX3i Genius Communications Gateway GFK-2892F

1.7 Controls and Indicators

The following figure shows the front of the module and identifies the controls and indicators.

ETHERNET

ACT

LINK

PORT 1

PORT 2

COM

POWER

FAULT

CONNECT

OK

GCG001

LINK

ACT

GENIUS A

SER 1

SER 2

SHLD

IN

GENIUS

SHLD

OUT

Module Status

Indicator LEDs:

POWER, OK,

FAULT,

CONNECT

Ethernet Port

Indicator LEDs:

LINK,

ACT

24 V dc

Power

Connector

Genius Bus

Indicator LEDs:

COM

PROFINET

Ports

Genius Bus

Connector

Figure 3: Genius Gateway GCG001 Front Panel View

Chapter 1. Introduction

GFK-2892F March 2019 9

Mounting

The GCG001 may either be panel-mounted or be mounted in the rightmost slot (expansion slot) of an RX3i

rack (IC695CHS012 or IC695CHS016).

Note: The SD Card supplied with the GCG001 will have been installed at the factory. See

section 2.4.1 for instructions for installing the SD Card when doing a retrofit. The

presence of the SD Card should be checked before mounting the module.

Note: Clearance of 3 inches (75mm) must be provided above and below the module for proper

ventilation and to permit cable access.

Note: External power must always be supplied to the module, regardless of which mounting

arrangement is chosen. When rack-mounted, the GCG001 does not draw power from the

RX3i Universal Backplane.

RX3i Backplane Mounting

The GCG001 may be mounted in the rightmost slot

(expansion slot) of an RX3i Universal Backplane.

The two captive M3.5 screws at the rear of the GCG001

align with mating tapped holes on the right side of the

backplane, providing a convenient mounting location.

When rack-mounted, the module does not make contact

with the backplane connector.

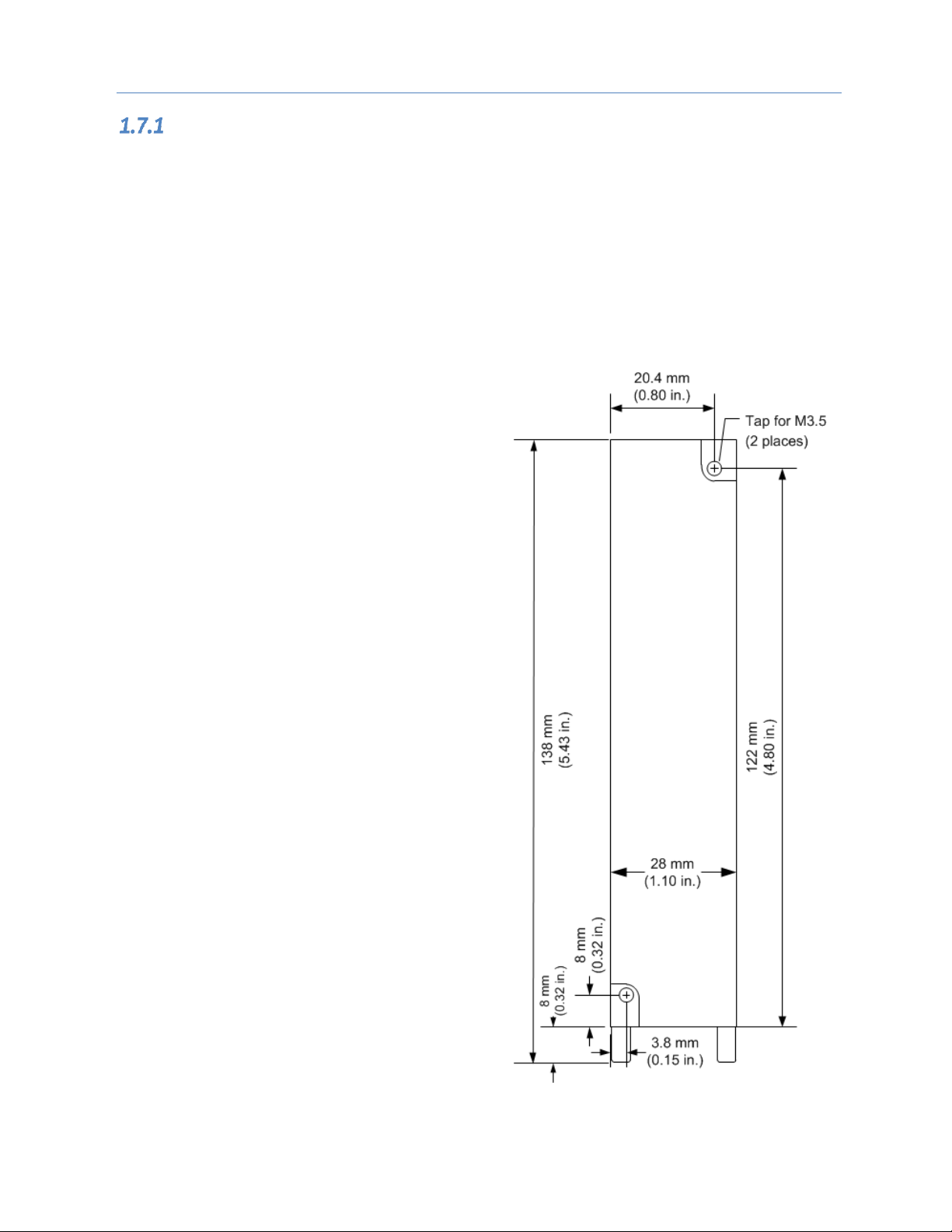

Panel-Mounting

Panel-mounting allows for mounting where no RX3i

backplane slot is available. The two captive M3.5 machine

screws on the GCG001 can be used for attaching the unit

to a panel.

Note: The panel must have a minimum

thickness of 2.4mm (0.094in).

1. Drill two mounting holes using the spacing

shown in the drawing (at right) and tap for

M3.5 (3.5 x 0.6mm).

2. Align the two mounting screws of the module

with the mounting holes in the panel.

3. Using a Philips screwdriver, tighten the two

screws to a maximum torque of 0.5 Nm

(4.4 in-lbs).

Figure 4: GCG001 Panel Mount Diagram

Chapter 1. Introduction

10 PACSystems RX3i Genius Communications Gateway GFK-2892F

1.8 PROFINET Operation Overview

An RX3i Genius Communications Gateway (GCG001) uses PROFINET communications for data exchange with

the PLC. As noted above, the data rate must be 100Mbps full-duplex or faster. The same network may be used

for basic Ethernet communications, but use of a separate Ethernet network and RX3i Ethernet interface is

recommended.

PROFINET Communications

Communications on an RX3i PROFINET network use the standard PROFINET communications described in this

section. Note, however, that the Genius Gateway GCG001 is constrained to work only with GE PROFINET PLC

products.

Application Relationships

Before a PROFINET IO-Controller can exchange data with a PROFINET IO-Device such as the GCG001, an

Application Relationship (connection) must be established between the devices. The PROFINET IO-Controller

automatically sets up the correct number and types of Application Relationship and Communication

Relationship channels (see below) based on its PME configuration. Usually, only one Application Relationship is

established per IO-Device.

Communication Relationships within an Application Relationship

Within each Application Relationship, the PROFINET IO-Controller establishes the following types of

Communication Relationships (CRs):

Record Data CRs – always the first to be established within an Application Relationship. Record Data

Communication Relationships are used for non-real-time transfers of data records such as startup parameter

data, diagnostics data, identification data, and configuration data.

IO CRs – used for the real-time, cyclic transfer of IO data

Alarm CR – used for real-time, acyclic transfer of alarms and events

The following illustration represents an Application Relationship between an RX3i PROFINET Controller and an

RX3i Genius Gateway GCG001.

Record Data Communication Relationship

I/O Data Communication Relationship

Alarm Communication Relationship

Application Relationship

Genius Gateway (GCG001)

1

2

3

4

PNS001

ACTIVE

USB

OK

LAN

STATUS

CONN

USB

IP ADDRESS

MAC ADDRESS

PORTS

TO INSTALL,

TORQUE TO

6 IN-LB.

IO DEVICE

FRONT

3 4

1 2

SD CARD

!

RX3i with PROFINET Controller (PNC)

Figure 5: Application Relationships between PROFINET Controller & Genius Gateway

Chapter 1. Introduction

GFK-2892F March 2019 11

Types of PROFINET Communications

Genius Communications Gateways use two types of PROFINET communication transfers: real-time and nonreal-time. The illustration below shows real-time communications as solid lines and non-real-time

communications as dashed lines.

1

2

3

4

PNS001

ACTIVE

USB

OK

LAN

STATUS

CONN

USB

IP ADDRESS

MAC ADDRESS

PORTS

TO INSTALL,

TORQUE TO

6 IN-LB.

IO DEVICE

FRONT

3 4

1 2

SD CARD

!

RX3i with PROFINET Controller (PNC)

Real-Time Data

Inputs

Outputs

Alarms

Non Real-Time

Data

Parameters

Configuration Data

Figure 6: Real-Time & Non-Real-Time Data Types

Real-Time (RT) communication: PROFINET real-time communication is used for time-sensitive data. A

PROFINET IO-Controller (PROFINET Controller) and PROFINET IO-Device use two types of real-time

communications to exchange data: cyclic communication and acyclic communication:

Real-time Cyclic communication is used to periodically transfer the application’s input and output data. Cyclic

communication occurs each PROFINET IO production cycle.

Real-time Acyclic communication is used to transfer non-periodic data such as alarms. Acyclic communication

occurs only when needed.

Non-Real-Time (NRT) communication: PROFINET non-real-time communication is used for less timesensitive data such as configuration, parameterization, diagnostics, and identification data.

Operations of the Genius Communications Gateway

The Genius Communications Gateway performs the following operations:

Consumes PROFINET IO-Device configuration from the PROFINET IO-Controller over the PROFINET network.

Scans input data from each Genius device it manages and produces that data to the PROFINET IO-Controller.

Consumes the output data that it receives from the PROFINET IO-Controller and applies it to each Genius

device it manages.

Where needed, translates Genius Datagrams (background traffic) into PROFINET packages that are sent to the

PROFINET Controller. This includes Datagrams that originated at the Genius Devices, such as Fault Reports.

Translates PROFINET packages that are sent by the PROFINET Controller into Genius Datagrams. This includes

Datagrams that originated at the PLC through use of COMMREQ or Data_Init_Comm instructions. For example,

a COMMREQ is used to generate a Clear Fault Report datagram.

Chapter 1. Introduction

12 PACSystems RX3i Genius Communications Gateway GFK-2892F

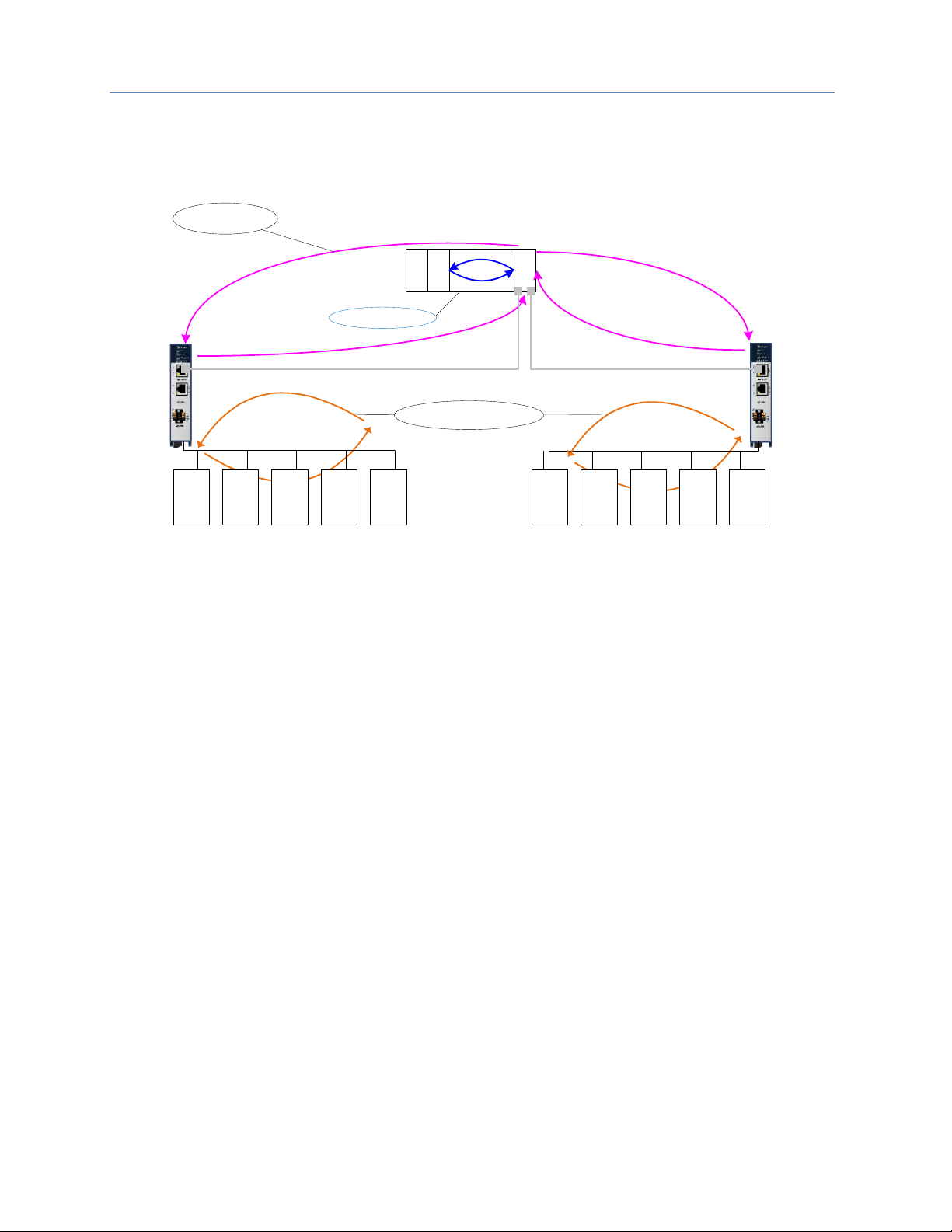

IO Scanning

In the PACSystems RX3i PROFINET network, multiple IO cycles run asynchronously and independently. Figure 7

illustrates typical cycles in a system with an RX3i CPU with a PROFINET Controller module communicating with

a Genius Communications Gateway. Cycles may be different for third-party devices.

Genius

I/O

Genius

I/O

Genius

I/O

Genius

I/O

Genius

I/O

PROFINET I/O

Genius

I/O

Genius

I/O

Genius

I/O

Genius

I/O

Genius

I/O

Genius Bus Scans

P

S

C

P

U

P

N

C

PROFINET IO

Production Cycle

RX3i CPU Sweep

Figure 7: PLC - GCG - Genius Scan Cycles

Genius IO-Device Scan: In this example, each GCG scans all of its Genius devices. The GCG stores the devices’

input data into its internal memory. Every time the GCG gets a turn on the Genius bus, it transmits the output

data from its internal memory to each of the Genius devices.

3rd party devices: The transfer of IO data between an IO module and the PROFINET IO network is device

dependent. Refer to the third-party manufacturer documentation for specifics for a particular device.

PROFINET IO Production Cycle: Each PROFINET Controller and IO-Device publishes data from its internal

memory onto the network at its scheduled PROFINET production cycle (Note: Production cycles between

IO-Controllers and IO-Devices are not synchronized; each publishes at its configured update rate

independently). The PROFINET Controller publishes output data received from the RX3i CPU to each IO-Device,

and the IO-Device publishes input data from its memory to the PROFINET Controller.

RX3i CPU Sweep: The RX3i CPU Sweep includes both an input scan and an output scan. The CPU input scan

retrieves the current input data being stored within the PROFINET Controller module. This input data is then

available for use by the application logic. After the logic solution, the CPU output scan writes the outputs to the

PROFINET Controller.

Chapter 1. Introduction

GFK-2892F March 2019 13

Media Redundancy Protocol Support

PROFINET Media Redundancy Protocol (MRP) supports devices configured in a ring topology. MRP is specified

as part of IEC62439 and has been adopted by the PROFINET specification, which provides for convenient

configuration of the ring topology and necessary parameters. Like PROFINET IO data, Media Redundancy

Protocol operations are not routable between different IP subnets.

Each device within an MRP ring has two physical pathways to the IO-Controller. To connect to the ring, each

device requires an integrated switch with at least two external ports (ring ports) that support MRP. Devices

that are not MRP-capable can be connected to a device in the ring (i.e., an MRP-capable switch in the ring), but

they should not be in the ring themselves. The redundancy capability offered by the ring topology only extends

to the devices on the ring that are MRP-capable and enabled.

One of the devices on the ring must be configured as the Media Redundancy Manager (MRM), and all the other

devices must be configured as Media Redundancy Clients (MRCs). The GCG001 can be configured as an MRC.

Configuring the GCG as an MRC alters how the Ethernet ports connect to the network. They attempt to

indicate their state to the MRM before allowing traffic to flow between the ports and close the ring topology

through the internal switch. They also send out notifications to the MRM when a port is lost. Operation of the

GCG001 is otherwise unchanged.

The MRP configuration is stored in non-volatile storage in the GCG001 and activated immediately upon

powering up. Non-volatile storage is updated as part of a connection with the IO-Controller. A PROFINET

Discovery & Configuration Protocol (DCP) Reset disables MRP Client operation and updates non-volatile

storage. The current state of the MRP configuration is provided as part of the GCG’s Gateway Status Bits which

are accessible to user application logic. Refer to the description of Gateway Status Bits in Section 5.1.1 for

further details.

Fast ring-break detection is not fully functional until all MRP clients have received their MRP configuration. For

a discussion of ring-break detection and bumpless operation with MRP, refer to sections 6.1.1 and 6.1.2 in the

PACSystems RX3i & RSTi-EP PROFINET I/O Controller Manual, GFK-2571K or later.

Chapter 1. Introduction

14 PACSystems RX3i Genius Communications Gateway GFK-2892F

1.9 System Limits

IO-Controllers have limitations on the size of the system they support. One of these limits is the number of

PROFINET sub-modules supported. The GCG001 uses four sub-modules: two for basic operation and two builtin port sub-modules that are always configured. Each Genius device attached to a GCG001 uses one additional

sub-module.

Other limitations, such as the configuration and IO sizes are specific to the configuration options chosen. Note

that not every combination of options is supported in every system. If the configuration uses all Genius bus

slots with a corresponding large device count, the memory of the IO-Controller system will be a limiting

resource.

Refer to the PACSystems RX3i & RSTi-EP PROFINET I/O Controller Manual, GFK-2571, for actual limits in the

RX3i PROFINET Controller (PNC001) and the embedded PROFINET controllers.

Refer to the Genius I/O System and Communications User's Manual, GEK-90486-1 for information on how

much I/O, and which type of I/O, need to be allocated to Genius devices.

PME (v8.0 or later) takes into account both system limits and I/O allocation.

Chapter 1. Introduction

GFK-2892F March 2019 15

1.10 Operational Differences vs. Genius Bus Controller

Persons migrating from a Genius environment where the Genius Bus Controller performs functions similar to

those of the GCG001 will want to be aware of the following differences:

1. COMMREQ function block SYSID and Task parameters change. SYSID is now the rack & slot of the

PNC connected to the GCG001. Task is now 132.

2. COMMREQ data blocks are different, mainly due to added PROFINET Device Number and

expansion of memory address fields from one word to two words. See COMMREQ summary in

Section 6.3.3.

3. Pulse Test and Assign Monitor COMMREQs do not support Genius bus address of 255 to send

messages to all blocks.

4. COMMREQ commands: GCG001 does not support all datagrams. See section 6.3.2 for a

corresponding list of supported COMMREQs.

5. GCG001 supports hot-standby, duplex, and dual-bus redundancy modes

1

. Dual-bus requires

additional application code.

6. GCG001 can be assigned to bus addresses 30 and 31 only.

7. GCG001 does not support GENI, GENA, or PCIM.

8. Prior to V1.1.1, fault contact operation has changed. Whenever there is a fault on a single channel

of a Genius block, all fault contacts associated with that Genius block will become active. All faults

on that device must be cleared before any of the fault contacts will de-energize. Beginning with

V1.1.1, when there is a fault on a single channel, none of the fault contacts will become active.

9. Genius faults routed through a GCG001 appear as PROFINET faults to the CPU. The same fault

routed through a Genius Bus Controller will present a different error code.

10. Circuit Fault Behavior:

• Prior to GCG firmware release V1.1.1, when a Genius block encounters a circuit fault on

one or more points or channels, the GCG001 causes all of the input references associated

with that block to either hold last state or go to default values until such time as the fault

is cleared. See the Alarms discussion in section 4.1.4 for a work-around to this behavior.

• Beginning with V1.1.1, when a Genius block encounters a circuit fault on one or more

points or channels, the GCG will cause only the faulted input references to hold the last

state or go to default values. The other points or channels on the block will continue to

operate normally.

11. Beginning with V2.2.2, Addition of Module and Loss of Module faults will not be logged when

Genius devices change their online status with the Genius bus. The user must monitor the 32 bits

of Genius Status Data to determine if Genius devices are operational or not.

12. Beginning with V2.2.4.1 Fault Status Bits are available to monitor each device on the bus. Refer to

Section 5.1.3 for additional information.

1

For Dual Bus Redundancy, GCG001 firmware version 2.2.0 or later is required; for all other redundancy modes, version

1.1.0 (minimum) is required.

Chapter 1. Introduction

16 PACSystems RX3i Genius Communications Gateway GFK-2892F

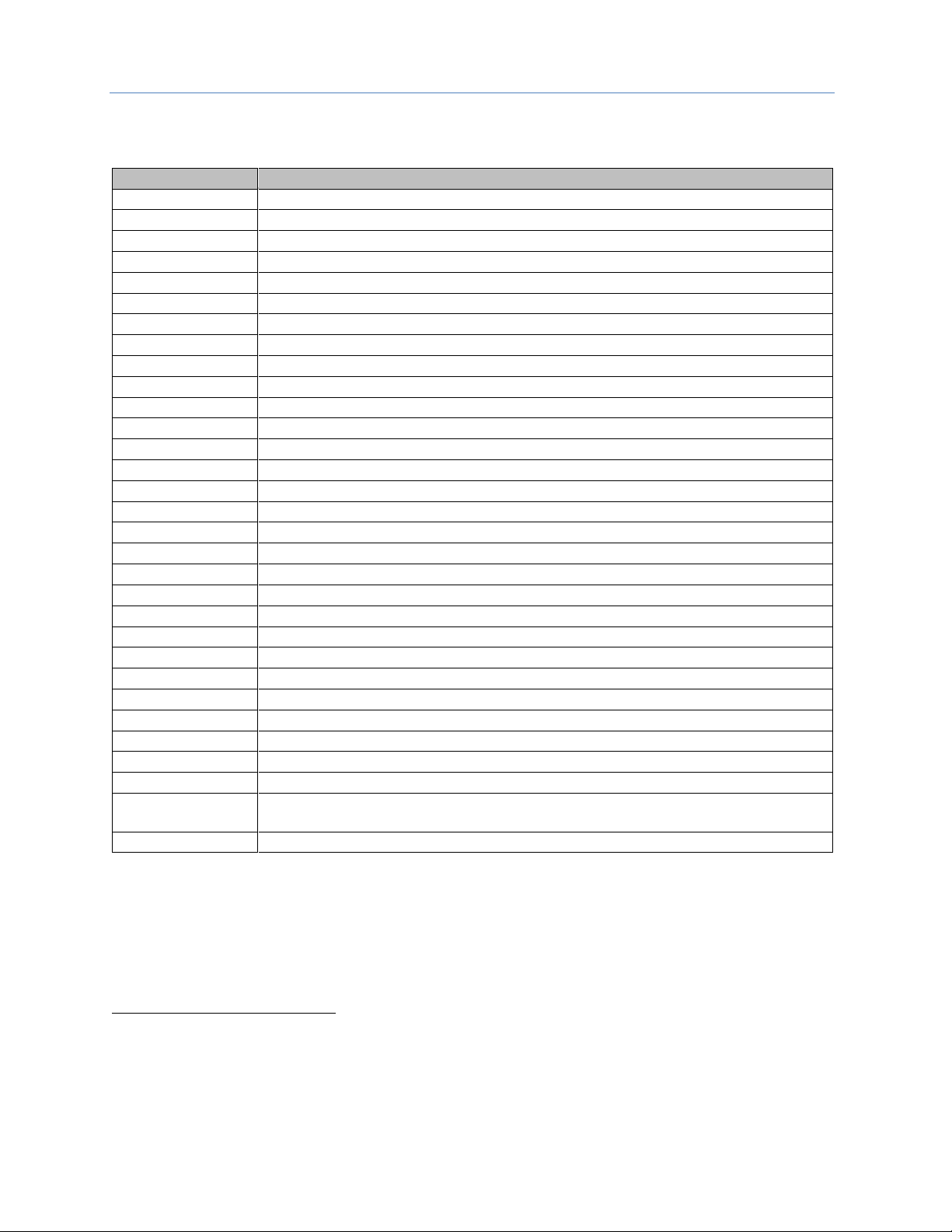

1.11 Supported Genius Devices

The following Genius devices are compatible with the GCG001 Genius Communications Gateway.

Catalog Number

Description

IC200GBI0012

VersaMax Genius Network Interface Unit (GNIU)

IC660BBA020

24/48Vdc 4-Input/2-Output Analog Block

IC660BBA021

24/48Vdc RTD Input Block

IC660BBA023

24/48Vdc Thermocouple Input Block

IC660BBA024

24/48Vdc Current–Source Analog Block

IC660BBA025

24/48Vdc Current–Source Output Block

IC660BBA026

24/48Vdc Current–Source Input Block

IC660BBA100

115Vac 4-Input/2-Output Analog Block

IC660BBA101

115Vac RTD Input Block

IC660BBA103

115Vac/125Vdc Thermocouple Input Block

IC660BBA104

115Vac/125Vdc Current–Source Analog Block

IC660BBA105

115Vac/125Vdc Current–Source Output Block

IC660BBA106

115Vac/125Vdc Current–Source Input Block

IC660BBD020

24/48Vdc 16-Circuit Source I/O Block

IC660BBD021

24/48Vdc 16-Circuit Sink I/O Block

IC660BBD022

24Vdc 16-Circuit Source I/O Block

IC660BBD023

24Vdc 16-Circuit Sink I/O Block

IC660BBD024

12/24Vdc 32-Circuit Source I/O Block

IC660BBD025

5/12/24Vdc 32-Circuit Sink I/O Block

IC660BBD1003

115Vac 8-Circuit Grouped Block

IC660BBD101

115Vac Low–Leakage 8-Circuit Grouped Block

IC660BBD110

115Vac 16-Circuit Input Block

IC660BBD120

High–Speed Counter Block

IC660BBR100

16-Circuit Relay Block, Normally–Closed

IC660BBR101

16-Circuit Relay Block, Normally–Open

IC660BBS100

115Vac/125Vdc 8-Circuit Isolated I/O Block

IC660BBS101

115Vac/125Vdc 8-Circuit Isolated I/O Block Without Failed Switch Diagnostic

IC660BBS102

115Vac/125Vdc 8-Circuit Isolated I/O Block

IC660BBS103

115Vac/125Vdc 8-Circuit Isolated I/O Block Without Failed Switch Diagnostic

IC670GBI002

IC670GBI102

Field Control Genius Bus Interface Unit (GBIU)

IC697BEM733 4

Series 90-70 Remote I/O Scanner (GR7)

2

Refer to VersaMax System Genius Network Interface Unit User’s Manual, GFK-1535, Chapter 1 for a list of VersaMax

modules supported by GBI001

3

Prior to GCG version 2.2.4.2, in PME Hardware Configuration, configure the BBD100 as a BBD101.

4

Refer to Series 90-70 Remote I/O Scanner User’s Manual, GFK–0579, Chapter 1 for a list of S90-70 modules supported by

BEM733.

GFK-2892F March 2019 17

Chapter 2 Installation

This chapter provides instructions for installing the module. The following topics are covered.

• Pre-Installation check

• Module installation and removal

• Port connections

• LED indications

• Firmware updates

For additional information about RX3i system installation, see the PACSystems RX3i System Manual, catalog

number GFK-2314.

For additional information about PROFINET installation and configuration, refer to the PACSystems RX3i &

RSTi-EP PROFINET I/O Controller Manual, GFK-2571. You will also need Proficy Machine Edition (PME)

configuration and programming software, version 8.0 or later.

2.1 Pre-Installation Check

Upon receiving your RX3i equipment, carefully inspect all shipping containers for damage. If any part of the

system is damaged, notify the carrier immediately. The damaged shipping container should be saved as

evidence for inspection by the carrier.

As the consignee, it is your responsibility to register a claim with the carrier for damage incurred during

shipment. GE Automation & Controls will cooperate fully with you, however, should such action be necessary.

After unpacking the RX3i equipment, record all serial numbers. Serial numbers are required if you should need

to contact Customer Care during the warranty period. All shipping containers and all packing material should

be saved should it be necessary to transport or ship any part of the system.

Verify that all components of the system have been received and that they agree with your order. If the system

received does not agree with your order, contact Customer Care.

If you need technical help, contact Technical Support. For phone numbers and email addresses, see the

Contact Information page in the front of this manual.

2.2 Installation Location

This product is primarily intended for use with the RX3i system. Its components are considered open

equipment (having live electrical parts that may be accessible to users) and must be installed in an ultimate

enclosure that is manufactured to provide safety. At a minimum, the enclosure shall provide a degree of

protection against solid objects as small as 12mm (e.g. fingers). This equates to a NEMA/UL Type 1 enclosure or

an IP20 rating (IEC 60529) providing at least a pollution degree 2 environment. For details about installing RX3i

rack systems, refer to the PACSystems RX3i System Manual, GFK-2314.

Chapter 2. Installation

18 PACSystems RX3i Genius Communications Gateway GFK-2892F

2.3 Installation in Hazardous Areas

The following information is for products bearing the UL marking for Hazardous Areas or ATEX marking for

explosive atmospheres:

CLASS 1 DIVISION 2 GROUPS ABCD

• This equipment is an open-type device and is meant to be installed in an enclosure

suitable for the environment that is only accessible with the use of a tool.

• Suitable for use in Class I, Division 2, Groups A, B, C and D Hazardous Locations, or

nonhazardous locations only.

Warning

EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR CLASS I, DIVISION 2.

WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES; AND

DO NOT CONNECT OR DISCONNECT EQUIPMENT UNLESS

POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO

BE NONHAZARDOUS.

Warning

EXPLOSION HAZARD - USB PORT IS ONLY FOR USE IN

NONHAZARDOUS LOCATIONS, DO NOT USE UNLESS AREA IS

KNOWN TO BE NON-HAZARDOUS.

ATEX Zone 2

The module must be mounted in an enclosure certified in accordance with EN60079-15 for use in Zone 2,

Group IIC and rated IP54. The enclosure shall only be able to be opened with the use of a tool.

ATEX Marking

II 3 G Ex nA IIC T4 X Ta: 0 - 60C

Chapter 2. Installation

GFK-2892F March 2019 19

2.4 Module Installation

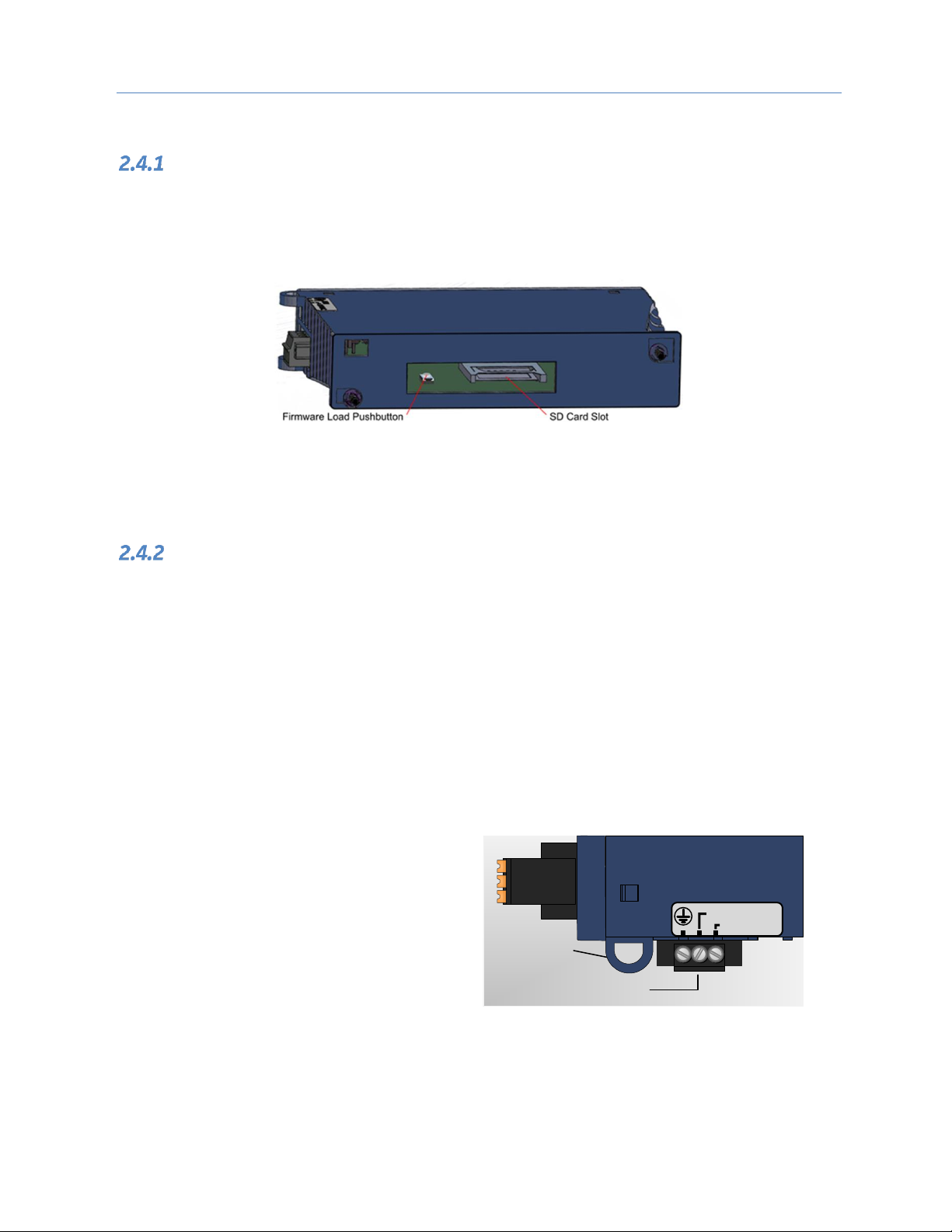

Install SD Card

The SD card slot is designed to support a Secure Digital (SD) non-volatile memory card in standard capacity

format. This optional card has two distinct uses: (1) backup storage of some key PROFINET configuration data

and (2) loading new GCG001 module firmware. Insert the SD Card into its slot at the rear of the GCG001 before

mounting the module, as shown in Figure 8.

Figure 8: Rear View of GCG001

When shipped from the factory, the SD card will have been pre-installed. It will have been programmed with

the then-current version of the firmware for the GCG001. In the event the firmware on the SD card needs to be

updated, see section 2.7. Note that the firmware upgrade should be performed before mounting the module.

Mounting the GCG001

The GCG001 is designed to mounted in one of the following ways:

a. In the expansion slot of an RX3i Universal Backplane

b. Panel-mounted

In both cases, at least 75 mm (3 in.) must remain clear above and below the module to allow for convection

cooling. See section 1.7.1 for mounting details.

Once the module has been mounted, connect 24Vdc power via the connector on the underside of the module,

connect PROFINET via the RJ-45 connectors and the Genius bus via twisted pair cable. Each connection is

described in the following section.

Once all connections are in place, it will be necessary to configure PROFINET. This is also discussed in the

following sections

Power Connection

The module requires a user-supplied 24Vdc

(±10%) power source wired to the removable

screw-terminal block located on the bottom of

the module. Connector pin-outs are identified

on the module, as indicated at right. The

module draws 0.2 A maximum current.

+24 VDC

RTN

24 Vdc Power

Connector

(Use for cable

tie-downs)

Figure 9: GCG001 Power Connector

Chapter 2. Installation

20 PACSystems RX3i Genius Communications Gateway GFK-2892F

Grounding

For proper operation, always connect the GCG001 ground terminal (see Figure 9, above) to earth ground. The

panel to which the GCG001 module is mounted, or the RX3i Universal Backplane to which it is mounted, must

have a safety ground connection to protective earth. This ground wire must be at least 1.5 mm2 (16 AWG).

• Connect the frame ground connection on the power plug to protective earth.

• Terminate all ground wires at the same grounding point.

• Make all ground wires as short as possible.

• Where the grounding terminal contacts a painted enclosure panel, scrape the paint away down to

clean, bare metal to ensure good contact.

PROFINET Connection

Attach the PROFINET via one or both of the RJ-45 connectors provided (Port 1 & Port 2). Various configurations

are possible. Refer to the manual for the PROFINET controller used in the application (PACSystems RX3i &

RSTi-EP PROFINET I/O Controller Manual, GFK-2571 for the RX3i PROFINET Controller Module).

Genius Bus Connection

The GCG module is equipped with one active six-terminal Genius Serial Bus connector.

Two terminals each are provided on a removable terminal block for Serial 1, Serial 2, and Shield connections.

The figure (above left) shows the Genius connection continuing through the connector block (daisy chain).

Whenever the Genius bus is terminated at the GCG001, a bus termination resistor should connect Serial 1 to

Serial 2, with SHLD IN unterminated, (as shown above right). The value of the termination resistor must match

the impedance of the Genius Bus cable.

Note: Whenever the GCG001 Genius terminal blocks are removed from the faceplate, the

continuity of the Genius Bus is disrupted.

COM

GENIUS A

SER 1

SER 2

SHLD

IN

GENIUS

SHLD

OUT

Figure 10: Daisy Chain Genius Bus Wiring

COM

GENIUS A

SER 1

SER 2

SHLD

IN

GENIUS

SHLD

OUT

Bus

termination

resistor

Figure 11: Genius Bus Wiring for Bus

Termination

Chapter 2. Installation

GFK-2892F March 2019 21

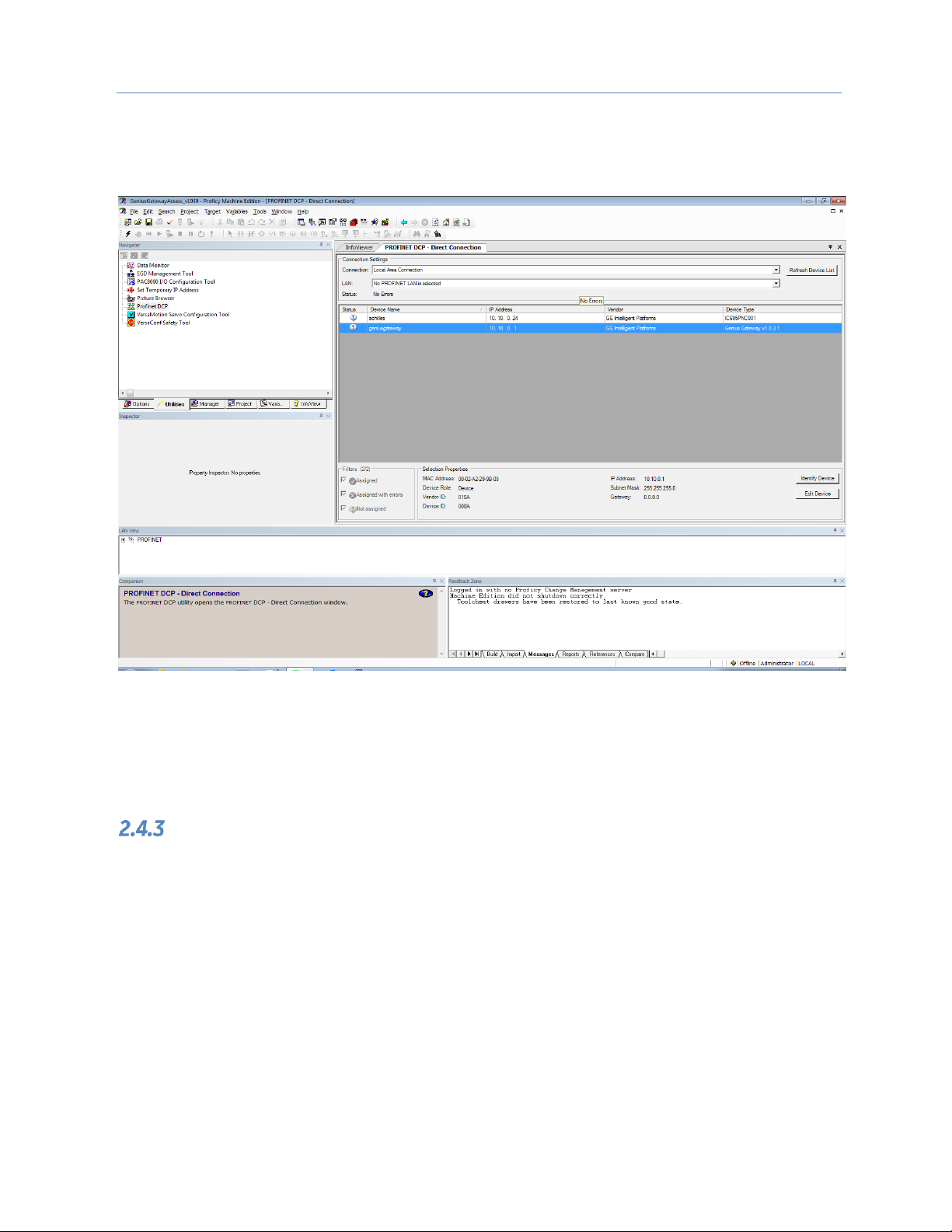

PROFINET Configuration

Once all connections are in place, it will be necessary to set up the PROFINET configuration. This requires use

of the PC-based PROFINET Discovery tool. Be sure your PC is connected to the same PROFINET network and

interrogate the network to discover what is connected, as shown in the following screen-shot.

Figure 12: PROFINET Discovery Screenshot

Initially, the out-of-the box GCG001 will not have a name assigned. Select the row containing the GCG001, then

click on the Edit Device button in order to assign a unique name.

Configuration tools and procedures are discussed in detail in Chapter 3.

GCG001 Module Removal

• Power down the external 24Vdc source

• Remove the Power connector from the underside of the GCG001 module

• Disconnect the RJ-45 PROFNET connector(s)

• Remove the Genius terminal block

• While holding the GCG001, loosen the two captive M3.5 screws that hold the module

in place, then pull away from the mounting surface. Note that, if mounted to an RX3i

rack, there is no pivot attachment or backplane connection to the rack.

• The SD Card may be transferred from the removed GCG001 to another (successor)

GCG001. This permits the PROFINET configuration of the removed module to be

transferred to the successor module.

• Once the successor module has been mounted, the original Power, PROFINET and

Genius connections may be restored to it.

Loading...

Loading...