Page 1

A

GE Fanuc Automation

Programmable Control Products

Series 90™-30

PROFIBUS Slave Module

User's Manual

GFK-2193A

ugust 2004

Page 2

GFL-002

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous

voltages, currents, temperatures, or other conditions that could cause

personal injury exist in this equipment or may be associated with its use.

In situations where inattention could cause either personal injury or

damage to equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not

taken.

Note: Notes merely call attention to information that is especially significant to understanding

and operating the equipment.

This document is based on information available at the time of its publication. While efforts have

been made to be accurate, the information contained herein does not purport to cover all details

or variations in hardware or software, nor to provide for every possible contingency in connection

with installation, operation, or maintenance. Features may be described herein which are not

present in all hardware and software systems. GE Fanuc Automation assumes no obligation of

notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Master Genius PowerMotion VersaMax

CIMPLICITY Helpmate PowerTRAC VersaPro

CIMPLICITY 90–ADS Logicmaster Series 90 VuMaster

CIMSTAR Modelmaster Series Five Workmaster

Field Control Motion Mate Series One

FrameworX ProLoop Series Six

GEnet PROMACRO Series Three

©Copyright 2002—2004 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

Contents

Overview and Specifications........................................................................................ 1-1

PROFIBUS Information ................................................................................................... 1-1

Related Publications....................................................................................................... 1-1

IC693PBS201 Slave Module Specifications.................................................................. 1-2

PROFIBUS Basics ........................................................................................................... 1-3

PROFIBUS Network Overview.......................................................................................... 1-3

Bus Communication ..........................................................................................................1-3

Network Topology ............................................................................................................. 1-4

Network Connectors.......................................................................................................... 1-5

Installation ..................................................................................................................... 2-1

Reviewing System Power Requirements...................................................................... 2-1

Installing the PROFIBUS Module in the PLC Rack ...................................................... 2-1

Connecting the Slave to the PROFIBUS Network........................................................ 2-2

Network Segment Length.................................................................................................. 2-2

PROFIBUS Cable Types................................................................................................... 2-3

Network Termination ......................................................................................................... 2-3

Network Baud Rate ........................................................................................................... 2-4

Removing the Module from the Rack............................................................................ 2-4

Configuration................................................................................................................. 3-1

Adding a PROFIBUS Slave Module to the Hardware Configuration.......................... 3-1

Configuring a PROFIBUS Slave Module ....................................................................... 3-2

Settings Tab ...................................................................................................................... 3-2

Input Data Area Tab ..........................................................................................................3-3

Output Data Area Tab ....................................................................................................... 3-4

Power Consumption Tab................................................................................................... 3-4

Status and Diagnostics................................................................................................. 4-1

PROFIBUS Slave Module LED Indicators ..................................................................... 4-1

Status/Firmware ID Array ............................................................................................... 4-2

Word 1 – Slave Status Word............................................................................................. 4-2

Network Parameter Errors ................................................................................................ 4-2

Communication Requests.............................................................................................. 4-3

COMMREQ Ladder Instruction ......................................................................................... 4-3

Operation of the Communications Request ............................................................... 4-4

COMMREQ Programming Requirements and Recommendations ............................4-5

Error Detection and Handling ..................................................................................... 4-5

Corrective Actions for COMMREQ Errors ..................................................... 4-5

COMMREQ Status Word............................................................................... 4-6

PROFIBUS Slave Module COMMREQ Reference......................................................... 4-7

Get Slave Status COMMREQ (3)...................................................................................... 4-7

Memory Types ............................................................................................................ 4-7

GFK-2193A iii

Page 4

Contents

Get Slave Status Command Block – Basic Example ................................................. 4-7

Get Slave Status - Reply Data Format ....................................................................... 4-8

Network Parameter Errors ..........................................................................................4-9

Read Module Header (5)................................................................................................. 4-10

Read Module Header Command Block – Basic Example ........................................4-10

Read Module Header Reply Data Format for Slave................................................. 4-11

Clear Counters (6)........................................................................................................... 4-12

Clear Counters Command Block – Basic Example .................................................. 4-12

Clear Counters Reply Data Format .......................................................................... 4-12

iv Series 90™-30 PROFIBUS Slave Module User's Manual –August 2004 GFK-2193A

Page 5

Chapter

1

Overview and Specifications

This manual provides instructions for installing, programming, and troubleshooting control

systems that use the Series 90-30 PROFIBUS slave module, IC693PBS201. It is

assumed that you have a basic understanding of Series 90-30 PLCs and are familiar with

PROFIBUS-DP protocol.

The Series 90-30 PROFIBUS Slave module enables a Series 90-30 CPU to be a slave on

a PROFIBUS DP network and to communicate with a PROFIBUS DP master. It operates

as a slave on the network, automatically exchanging data with a master device. The slave

module has no bus access rights. It can only acknowledge received messages or transmit

messages to a master upon request. Its features include:

ability to read up to 244 bytes of input data from the network, and send up to 244

bytes of output data

support for all standard PROFIBUS data rates

PROFIBUS-compliant Module and Network Status LEDs

an RS-232 serial port (the Service port) for upgrading the firmware

PROFIBUS Information

Please refer to the following sources for PROFIBUS information:

PROFIBUS standard DIN 19245 parts 1 (low-level protocol and electrical

characteristics) and 3 (DP protocol)

European standard EN 50170

ET 200 Distributed I/O system, 6ES5 998-3ES22

IEEE 518 Guide for the Installation of Electrical Equipment to Minimize Electrical

Noise Input to Controllers

Related Publications

Series 90-30 PROFIBUS Master Module User’s Manual, GFK-2121

Series 90-30 Installation and Hardware Manual, GFK-0356.

Series 90-30/20/Micro PLC CPU Instruction Set Reference Manual, GFK-0467

Proficy™ Machine Edition Getting Started, GFK-1868

Proficy Machine Edition Logic Developer-PLC Getting Started Guide, GFK-1918

GFK-2121A 1-1

Page 6

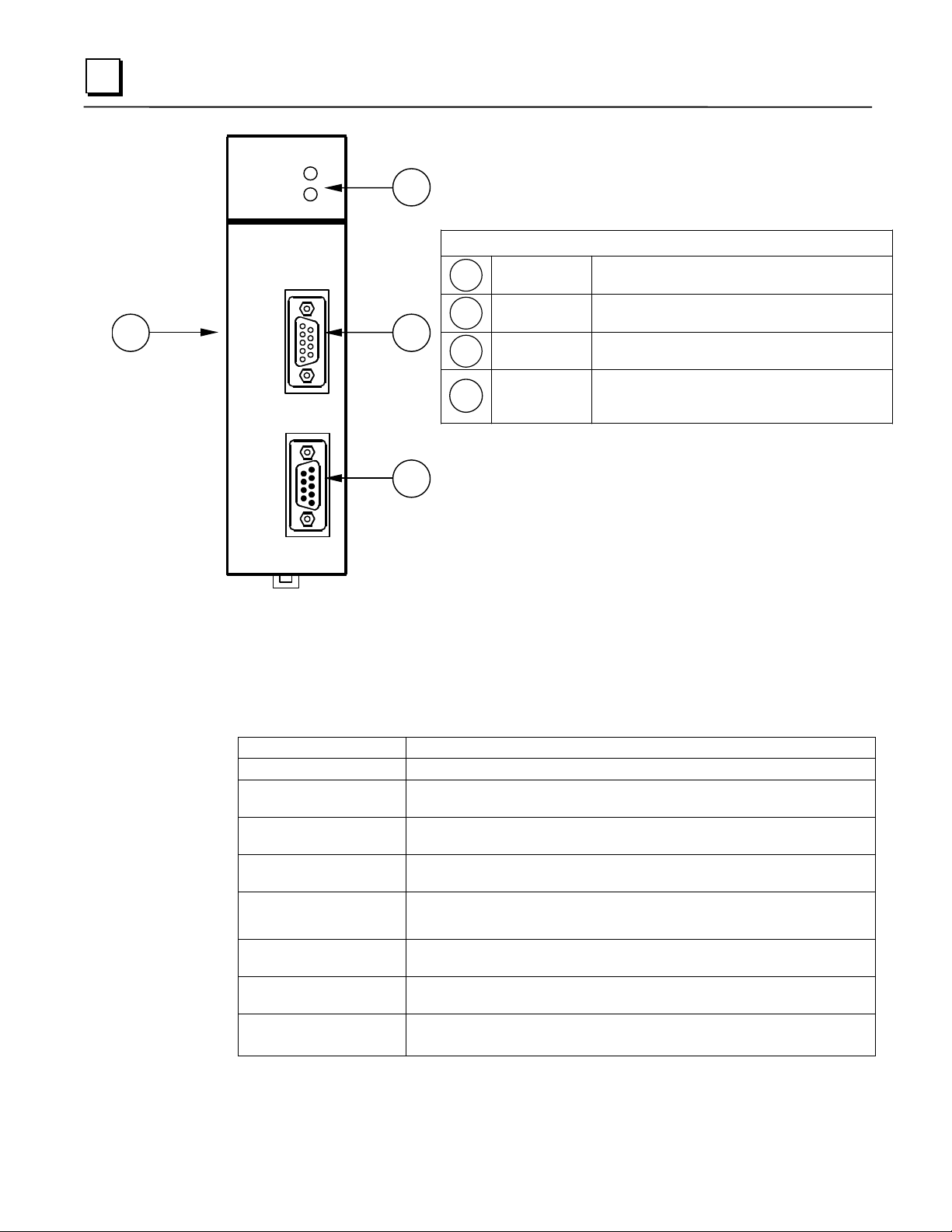

1

SYS

COM

1

PROFIBUS DP

SLAVE

SERVICE RS232

4

5-IGND

3-TxD

2-RxD

5-IGND

8-A

3-B

1-SHLD

PROFIBUS

IC693PBS201

PROFIBUS

Slave Module

Figure 1-1. PROFIBUS Slave Module

Key

1

LEDs

2

2

3

4

Service Port

PROFIBUS

Port

Label (not

shown)

System (SYS) and Communications (COM)

indicators

RS232, 9-pin male, D-Shell Connector. Used

for module firmware upgrades.

9-pin female D-Shell Connector. Used for

connecting to a PROFIBUS network.

Label on side of module contains catalog

number, description, standard conformance,

and serial number information

3

IC693PBS201 Slave Module Specifications

Catalog number IC693PBS201

Description Series 90-30 Slave module for PROFIBUS DP networks

Configuration software

requirement

CPU version

requirement

Mounting location Can reside in any Series 90-30 baseplate (CPU, expansion, or remote)

Environment

Backplane current

consumption

Data rates Supports all standard Data Rates (9.6KBps, 19.2KBps, 93.75KBps,

Status information Slave Status Word

Note: The PROFIBUS Slave module does not support Sync and Freeze modes

1-2 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2121A

Requires Proficy Machine Edition Logic Developer version 2.6 or later

Requires CPU firmware version 8.00 or later

slot except for slot 1 of a modular CPU baseplate

Storage temperature = –40°C to 85°C

Operating temperature = 0°C to 60°C

450 mA at 5VDC (typical)

187.5KBps, 500KBps, 1.5Mbps, 3MBps, 6MBps and 12MBps)

Firmware module revision

Page 7

PROFIBUS Basics

PROFIBUS Network Overview

• PROFIBUS is an open, vendor independent FieldBus standard for a wide range of

applications in industrial automation, including motion control.

• PROFIBUS is a dynamic technology that grows functionally while complying with the

European FieldBus Standard EN 50 170.

• PROFIBUS Guidelines and Profiles provide the means for further technical

development based on the ever-changing communication requirements of the

networks, systems, and devices used in today's industrial automation applications.

PROFIBUS specifications reference three different protocols to cover a range of industrial

requirements:

• PROFIBUS-DP High speed data communication. DP stands for Decentralized

Periphery. In practice, the majority of slave applications are DP applications.

• PROFIBUS-FMS Object oriented general-purpose data communication. FMS

stands for FieldBus Message Specification. FMS protocol devices may exchange data

on the same bus used for DP devices.

1

• PROFIBUS-PA Meets requirements for intrinsic safety and non-intrinsic safety

areas and includes bus powered field devices.

Note: The PROFIBUS logo is a registered trademark of the PROFIBUS International

Organization. Membership in the organization is open to all individuals,

companies and organizations. More information about the organization and the

protocol is available at http://www.profibus.com

Bus Communication

The PROFIBUS specification defines the technical characteristics of a serial field bus

system that links distributed digital controllers on the network, from field level to cell level.

PROFIBUS is a multi-master system that allows the joint operation of several automation,

engineering or visualization systems with their distributed peripherals on one bus.

PROFIBUS distinguishes between the following types of devices:

• Master devices determine the data communication on the bus. A master can send

messages without an external request when it holds the bus access rights (the token).

Masters are also called active stations.

• Slave devices include motion controllers, drives, I/O devices, valves, and

transducers. Slaves do not have bus access rights and can only acknowledge

received messages or send messages to the master when requested to do so. Slave

devices are passive stations and require only small portions of the bus protocol.

The majority of PROFIBUS-DP applications are located at the field level. The field level

typically includes slave devices such as the S2K motion controller station and host

devices like PLC or PC control systems for the PROFIBUS-DP master station. Operator

interfaces and DCS type systems usually operate at the cell level.

GFK-2121A Chapter 1 Overview and Specifications 1-3

Page 8

1

Data bandwidth Demands on PROFIBUS Communications Systems

Management level Mbytes Hours/Minutes Day/Shift

Cell level Kbytes Seconds Hours/Minutes

Field Level Bytes Several 100

Actuator sensor level Bits Microseconds to

Network Topology

A PROFIBUS-DP network may have up to 127 stations (address 0-126), however address

126 is reserved for commissioning purposes. The bus system must be sub-divided into

individual segments to handle this many participants. These segments are linked by

repeaters. The function of a repeater is to condition the serial signal to allow connection of

segments. In practice, both regenerating and non-regenerating repeaters may be used.

Regenerating repeaters actually condition the signal to allow increased range of the bus.

Up to 32 stations are allowed per segment and the repeater counts as a station address.

A specialized “link” segment consisting only of optical fiber modem repeaters may be used

to span long distances. Plastic fiber optic segments are typically 50 meters or less while

glass fiber, optic segments may extend several kilometers.

The user assigns a unique PROFIBUS station address to identify each master, slave, or

repeater in the entire network. Each participant on the bus must have a unique station

address.

Amount of Data Transmission

Duration

microseconds to 100

milliseconds

milliseconds

Transmission

Frequency

10 to 100 milliseconds

Milliseconds

1-4 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2121A

Page 9

p

Participant Participant

Termination

Termination

Figure 1-2. Repeaters and bus termination

ParticipantParticipant

Repeater

Connecting

Segments

Branch

Segment

Participant

Participant

1

Remote

Repeate

Link Segment

(No Participants)

Remote

Repeater

To additional

articipants

Network Connectors

PROFIBUS connections are created with a 9 pin sub-D connector. A minimum connection

consists of a shielded twisted-pair cable (shield to pin 1 and twisted-pair wires to pins 3

and 8) with terminating connections in the appropriate bus plugs. The pin to signal

conventions are described below.

Pin-out Listing for the PROFIBUS Bus Plug Connector

Pin No. Signal Designation

1 Shield Shield / Protective Ground

2 M24 Ground / Common of the 24V output voltage

3 RxD/TxD-P Receive data / transmission data plus

4 CNTR-P Control signal for repeaters (direction control)

5 DGND Data transmission potential (ground to 5V)

6 VP Supply voltage of the terminating resistance (+ 5V)

7 P24 Output voltage (+ 24V)

8 RxD/TxD-N Receive data / transmission data negative

9 CNTR-N Control signal for repeaters (direction control)

Note: For information on network segment length, network connectors and network

termination, and network baud rate, refer to Chapter 2, “Installation.”

GFK-2121A Chapter 1 Overview and Specifications 1-5

Page 10

Chapter

Installation

2

This chapter contains information on the following procedures:

Reviewing system power requirements

Installing the PROFIBUS module in the PLC rack

Installing PROFIBUS wiring

Connecting the Slave to the PROFIBUS network

Selecting the proper line type

PROFIBUS cable types

Installing bus termination

Reviewing System Power Requirements

Review the power requirements of your system to ensure that your power supply has

sufficient capacity to support the PROFIBUS Slave module. Power supply load is

automatically calculated by the CIMPLICITY Machine Edition configuration software.

Details on manually calculating power supply load can be found in the Series 90-30

Installation and Hardware Manual, GFK-0356.

Note: High capacity Series 90-30 power supplies IC693PWR330 or IC693PWR331 are

recommended, particularly for systems with CPU350 or higher, or that have

Ethernet adapters and/or multiple PROFIBUS modules. The Series 90-30

PROFIBUS Slave module consumes 450mA at 5VDC (typical).

Installing the PROFIBUS Module in the PLC Rack

1. Remove power from Series 90-30 rack.

2. Turn off power to rack.

3. Place the module into slot 1 or higher in the rack (slot 2 or higher in the Main

rack) by hooking the top of the module on the notch above the slot and slowly

lowering the module until it snaps into place.

4. Attach the PROFIBUS cable and terminate as required.

Note: For details about installing Series 90-30 rack systems and modules, refer to the

Series 90-30 Installation Manual and Hardware Manual, GFK-0356.

GFK-2193A 2-1

Page 11

2

Connecting the Slave to the PROFIBUS Network

Network Segment Length

A PROFIBUS network uses either fiber optic or RS-485 copper media. The copper bus

line specified in EN 50 170 is “Line Type A” and is the recommended cable type. A more

economical copper cable “Line Type B” is commonly used for smaller installations;

however, it is not specified in EN 50 170. It is extremely important to use cable rated to

PROFIBUS specifications. The higher the baud rate selected and the longer the distances

involved, the more critical cable selection becomes. (PROFIBUS cable has a distinctive

purple color.)

Stub or “T” type branch connections are supported if the total stub (branch) lengths do not

exceed 6.6 meters. Do not use stubs at all on 12 Mbaud networks.

The data rates for network communication with maximum segment trunk length per cable

type are provided below. Multiple segments may be connected via repeater stations to

extend the total bus length.

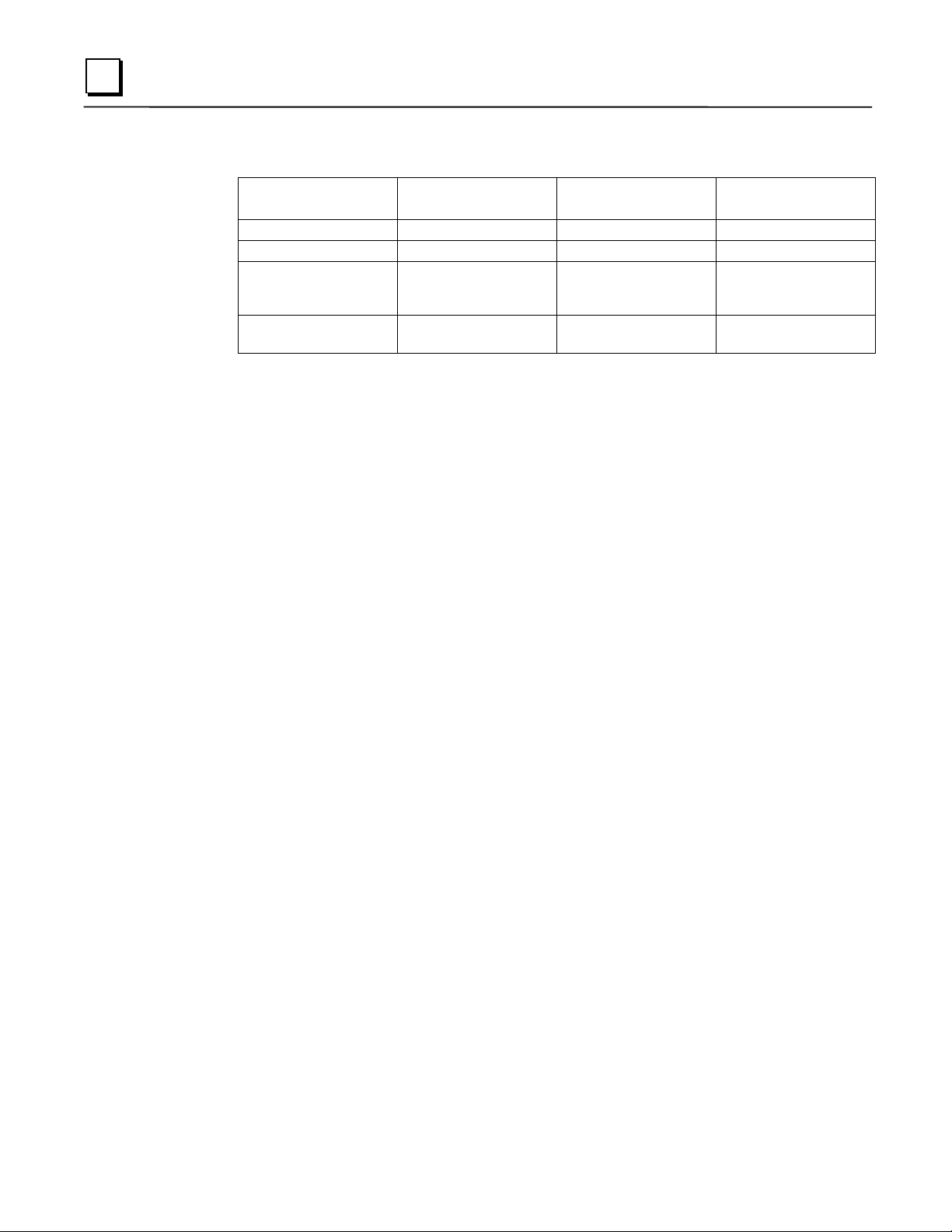

Line Types

Baud Rate Line A

Distance (Max) 1, 2

9.6KBps, 19.2KBps and 93.75KBps 1200 m 1200 m 6Km

187.5KBps 1000 m 600 m 6Km

500KBps 400 m 200 m 6Km

1.5MBps 200 m NA 6Km

3, 6 and 12MBps 100 m NA 6Km

1

If using a combination of both line types, divide the lengths shown by two.

2

Values shown are the sum of all bus segment and drop cable lengths.

NA = Not Applicable

Note: The two physical ends of the PROFIBUS network should be terminated. There

should be two, and only two, terminators on a network.

Line B

Distance (Max) 1, 2

Glass Fiber

2-2 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 12

PROFIBUS Cable Types

The recommended cable is

Belden 3079A PROFIBUS Cable

This is a shielded, 150 ohm twinaxial (single twisted pair) cable. It has 22 AWG

conductors and a mutual capacitance of 9.0 pF per foot, nominal. For complete

specifications on this cable, please contact your Belden dealer or visit their website at

www.belden.com.

Alternate cable types are:

Siemens 6XV1 830-OAH10 Two Core shielded

Siemens 6XV1 830-OBH10 w/PE Sheath

Siemens 6XV1 830-3AH10 for underground burial

Siemens 6XV1 830-3BH10 trailing cable

Bosch Comnet DP #913 548 Flexible PROFIBUS cable

Bosch Comnet DP #917 201 Trailing PROFIBUS Cable

Bosch Comnet DP #917 202 Massive PROFIBUS Cable

2

Note: Allen Bradley “blue hose,” which has an impedance of 78 ohms, is not

recommended for this application.

Network Termination

Termination resistors are needed, as defined in DIN 19245 Part 1 section 3.1.2.5.

Master Slave Slave Slave SlaveSlave

One terminator must be applied at each end of a network segment.

Master Slave Slave Slave SlaveSlave

Generally, termination is provided in commercially-available PROFIBUS standard network

connectors. Some connector vendors provide termination capability in the connector and

a switch on the connector to enable/disable termination. Some connector vendors provide

both terminated and unterminated connectors.

Termination Required

(Segment 1)

Termination Required

(Segment 1)

Repeater

Termination Re quired

(Segment 2)

GFK-2193A Chapter 2 Installation 2-3

Page 13

2

Note: For proper network termination, it is essential that the terminating devices

maintain power. Power is provided by the device on Pin 6 and Ground on Pin 5. If power

is lost to either terminating device, the network may not operate correctly. Generally, the

lone network master device is one of the terminating devices. Therefore, a loss of power

to the network master renders the network inoperable anyway. The other terminating

device may be a critical slave device, which must maintain power, or a separately

powered, stand-alone terminator. These stand-alone devices are commercially available.

RxD/TxD-P (3)

RxD/TxD-N (8)

Figure 2-1. Bus Termination for Type A Cable in Accordance to PROFIBUS Specifications

In addition to the termination shown above, the following compensation should be added

for 12 Mbit bus technology:

To/from

another

node

VP (6)

DGND (5)

110nH

110nH

Ru = 390 Ohms

Rt = 220 Ohms

Rd = 390 Ohms

5

9

8

7

6

110nH

4

3

2

110nH

1

To/from

another

node

Network Baud Rate

The master configures the appropriate network baud rate for each station on the network.

Typical baud rate values are: 9.6KBps; 19.2KBps; 45.45KBps; 93.75KBps; 187.5KBps;

500KBps; 1.5MBps; 3MBps; 6MBps; or 12MBps. For details on using the configuration

software, refer to chapter 3.

Removing the Module from the Rack

The following procedure describes how to remove the GE Fanuc Series 90-30 master:

1. Turn off power to rack.

2. Remove all cabling from the module.

3. Press the release latch located on the bottom of the module and slowly raise the

module from the bottom until it comes out of the slot.

2-4 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 14

Chapter

Configuration

3

These configuration procedures are intended for users with at least a basic knowledge of

the CIMPLICITY Machine Edition Logic Developer software and the Series 90-30 PLC.

For help with using the software, please see the software’s built-in help system.

Note: The PROFIBUS Slave is supported only in Machine Edition Logic Developer-PLC.

Adding a PROFIBUS Slave Module to the Hardware Configuration

Add the IC693PBS201 module to the PLC rack configuration.

1. In the

folder.

2. In the Hardware Configuration folder, right click the PLC Slot where you wish to install

the PROFIBUS Slave module. Note that a PROFIBUS module is not a valid choice for

slot 1 of a modular CPU rack.

Project tab of the Navigator, expand the Hardware Configuration

3. Select Add Module from the shortcut menu. The Module Catalog dialog box appears.

Note: To edit a module that already appears in the rack, right click the module and

select Configure. The module’s Parameter Editor window opens.

4. Click the Communications tab. The Communications module list appears.

5. Select the IC693PBS201 PROFIBUS Slave and click the OK button. The module is

added to the PLC configuration in the Navigator window, and the module’s Parameter

Editor window appears in the InfoViewer window space.

GFK-2193A 3-1

Page 15

3

Configuring a PROFIBUS Slave Module

The PROFIBUS Slave module has four Parameters tabs: Settings, Input Data Area,

Output Data Area, and Power Consumption.

Settings Tab

Station

Baud Rate

Note: The Horner PROFIBUS Slave module, HE693PBS105, does not have this setting. If you are converting from a

Horner module to a Series 90-30 IC693PBS201 PROFIBUS Slave module, you will need to set this parameter.

Status/Firmware

ID Address

Tip: Use the Communication Request (COMMREQ) task 3 (GetSlaveStatus) to retrieve the information that is

reported in this memory area. (This COMMREQ is sent from the CPU of the PLC where the Slave module

resides.)

Length

Inputs on Loss of

Master

The Slave module’s station number that is used on the PROFIBUS network. Can be in the range

from 1 to 125. Each module on a network should be given a unique station number. Default is 1.

Note that the Master is commonly assigned to Station 0 (zero).

Specifies the data transmission rate for the PROFIBUS Slave module in bits/second (bps).

Values: 9.6Kbps, 19.2KBps, 93.75KBps, 187.5KBps, 500KBps, 1.5MBps, 3MBps, 6Mbps,

12MBps

Default: 1.5MBps

This is the starting address for this two-word array. Status/Firmware ID Address is a consumed

range and as such must be a non-overlapping range in %AI, %I, %Q, %G, %AQ, %R, %T, or

%M. Defaults to %AI memory.

The Status word provides information about the status of the PBS201 module to the PLC

CPU. For more information, see “Get Slave Status Reply Data Format” in chapter 4.

The Firmware ID word contains the current firmware version running on the PBS201. The

Major Revision number resides in the upper byte and the Minor Revision number resides in

the lower byte of this word.

Always two words. (A value of 2 for register memories and 32 for discrete memories.)

Determines what values are used for the data received by the module from the master (inputs to

the Slave module/outputs from the master) if communication with the master is lost.

Choices are:

Hold Last State (default) – Until communication resumes and new values are received, each

input will have the value that it had when communication was lost.

Clear – Until communication resumes and new values are received, each input will have a

value of 0.

3-2 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 16

Input Data Area Tab

The input data area describes data received over the network by the Slave module from

the PROFIBUS Master. These inputs are mapped, using the Input Data Area tab, into

specific memory locations in the PLC where the Slave module resides.

3

PROFIBUS Slave Module’s Input Data Area Parameters

Area

Type

Size

Notes: The total number of input bytes for all entries cannot exceed 244.

A value of 0 sets Type to Empty.

Units

Ref

Address

Length

Note: If an input data area is defined (Type and Size are specified) but Length is set to 0, data received by the Slave

A read-only identifier for the row. Valid range: 1 to 32.

Data type of area being defined. Valid types are Digital In, Analog In, and Empty. The default value is

Empty.

Describes the size of the data area on the network. Set to 0 and read-only if Type is set to Empty. Valid

ranges:

If Type is set to Analog In (Word): 1—122

If Type is set to Digital In (Byte): 1—244

This read-only field gives the units for the Type specified.

If Type is set to Empty or Digital In: Byte

If Type is set to Analog In: Word

Location in PLC memory where the received data is mapped. This field is read-only if Size is set to 0. This

is a consumed range and must be a non-overlapping range in %AI, %I, %Q, %G, %AQ, %R, %T or %M. If

Type is set to Digital In and the number of bytes (Size) is odd, an address in discrete memory must be

used: %I, %Q, %G, %M, or %T.

Default:

For Digital In, next available address in %I

For Analog In, next available address in %AI

The length of the reference mapped to the area. Allowable ranges:

For discrete memories (in bits), 0, 8, 16 ... X

For register memories (in words), 0, 1, 2 ... X

where X is the required length to hold the entire data area. The default value is the space required to map

bytes specified by the entries in Type and Size.

is ignored.

GFK-2193A Chapter 3 Configuration 3-3

Page 17

3

Output Data Area Tab

The output data area describes data sent over the network by the Slave module to the

PROFIBUS Master. These outputs are mapped, using the Output Data Area tab, from

specific memory locations in the PLC where the Slave module resides.

Area

Type

Size

Note: The total number of output bytes for all entries cannot exceed 244.

Units

Ref

Address

Length

Note: If an output data area is defined (Type and Size are specified) but Length is set to 0, a value of 0 is sent to the

Read-only identifier for the row. Valid range: 1-32.

Data type of area being defined. Valid types are Digital Out, Analog Out, and Empty. The default value is

Empty.

Describes the size of the data area on the network. Set to 0 and read-only if Type is set to Empty. Valid

ranges:

If Type is set to Digital Out (Byte): 0—244

If Type is set to Analog Out (Word): 0—122

This read-only field gives the units for the Type specified.

If Type is set to Empty or Digital Out: Byte

If Type is set to Analog Out: Word

Location in PLC memory where the data to be sent is mapped. This field is read-only if Size is set to 0.

This is a produced range and can be any range in %AI, %I, %Q, %G, %AQ, %R, %T, or %M. If Type is

Digital Out and the number of bytes (Size) is odd, an address in discrete memory must be used: %I, %Q,

%G, %M, or %T. Overlaps with another produced range are not considered fatal and can be included in a

valid configuration.

Default: For Digital Out, next available address in %Q

For Analog Out, next available address in %AQ

The length of the reference mapped to the area.

Allowable ranges: For discrete memories: 0, 8, 16 ... X

For register memories: 0, 1, 2 ... X

where X is the required length to hold the entire data area. The default value is the space required to map

bytes specified by the entries in Type and Size.

Master for that data area.

Power Consumption Tab

The information in this tab is read-only. It displays the power consumed by the module

from the PLC backplane.

3-4 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 18

Chapter

Status and Diagnostics

4

The following methods can be used to obtain status and diagnostic data:

Observing and interpreting the LED indicators on the PROFIBUS module, described

below

Monitoring the Status/Firmware ID Array, page 4-2

Using Communications Request (COMMREQ) ladder logic instructions to instruct the

PROFIBUS module to gather diagnostic or status data and report it to the PLC CPU,

page 4-3

Note: The PROFIBUS Slave Module does not generate faults for the Fault Table.

PROFIBUS Slave Module LED Indicators

SYS

COM

PROFIBUS DP

SLAVE

SERVICE RS232

5-IGND

3-TxD

2-RxD

PROFIBUS

5-IGND

8-A

3-B

1-SHLD

LED

Indicators

Red The Slave is not being scanned or is faulted.

Amber

Green

Flashing Green This LED flashes green for two seconds at system

Off PROFIBUS Slave is not configured

The PROFIBUS slave does not use the COM LED, except when loading firmware.

This LED is normally off.

Flashing Green – PROFIBUS Slave is not configured

Color Indication

The Slave is being scanned in Stop mode.

The Slave is being scanned in Run mode.

startup

Note: When loading firmware, the module is placed in the System Configuration mode.

When in this mode, the COM and SYS LEDs flash red alternately.

SYS LED

COM LED

GFK-2193A 4-1

Page 19

4

Status/Firmware ID Array

The starting reference address for this two-word array is set in the PROFIBUS Slave

software configuration. For details, see “Parameters” in chapter 3.

Word Name Description

1 Slave Status This word contains the slave status code. The status can be read using the

2 Firmware ID Current firmware version running on the Slave module. The Major Revision

Word 1 – Slave Status Word

Bits Meaning Value

Get Slave Status COMMREQ (task 3), described on page 4-7. .

number resides in the upper byte and the Minor Revision number resides

in the lower byte of this word.

15—12 Baud Rate

(bps)

11—10 Module State 0=Module is waiting for parameters from Master

9 On-line 1=Online module firmware is running

8 PLC Cfg 0= Module configuration from PLC CPU is bad

7 Run/Stop 0=Stop, 1=Run. This is the state of the PROFIBUS module; it is not the

6—0 Error Info See “Network Parameter Errors”

Network Parameter Errors

The following errors codes may be returned in bits 0—6 in the Slave Status word.

Note: The error code is the numerical value of the bits.

Error

Code

0 No error

1 ID from master does not match Slave ID

2 Ready Time from Master does not match Slave Ready time

3 Master is requesting Freeze or Sync, which is not supported

4 Length of data from master to slave is incorrect

5 Length of data from slave to master is incorrect

6 One of the watchdog factors (SlvWdFact1 or SlvWdFact2)

7 Slave watchdog time out (check response timeout)

8 Slave timeout watchdog disabled from master

0=12MBps, 1=6MBps, 2=3MBps, 3=1.5MBps, 4=500KBps,

5=187.5KBps, 6=93.75Bps, 8=19.2KBps, 9=9.6KBps

1=Module is waiting for configuration from Master

2=Data Exchange is occurring – normal operation

3=Error (either configuration error or module watchdog timeout)

0=Offline

1=Module configuration from PLC CPU is good

status of the PLC CPU. If the SYS LED is Green the bit=1, if the SYS

LED is Red or Amber the bit=0

Meaning

by the slave

from the master was 0.

4-2 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 20

r

Communication Requests

The Communications Request uses the parameters of the COMMREQ Ladder Instruction

and an associated Command Block to define the characteristics of the request. An

associated Status Word reports the results of each request.

The Communication Request function (COMMREQ) allows the program to communicate

with a GE Fanuc intelligent module, such as a PROFIBUS slave module.

The COMMREQ function uses a command block that contains the data to be

communicated to the other device, plus information related to the execution of the

COMMREQ. The command block must be placed in the designated memory area using

data move instructions, such as MOVE or BLKMOV (Block Move).

The CPU reports the result of the COMMREQ in the status word, which is a single

location in PLC data memory. The status word address is specified in the command block.

For a list of status codes reported in the status word, see “COMMREQ Status Word” on

page 4-6.

The PROFIBUS slave module supports one COMMREQ, described on page 4-7.

4

COMMREQ Ladder Instruction

This discussion provides an overview of

the COMMREQ instruction. For details

of the COMMREQ ladder instruction,

refer to the online help provided with the

programming software. The

Communications Request begins when

the COMMREQ Ladder Instruction is

activated. The COMMREQ ladder

instruction has four inputs and one

output:

Enable Input: Must be Logic 1 to enable the COMMREQ Instruction. It is recommended that

the enabling logic be a contact from a transition (“one-shot”) coil.

IN: The memory location of the first word of the Command Block. It can be any valid

address in word-type memory (%R, %AI, or %AQ). For example, %R00100 at IN would

indicate that the starting address of the Command Block is %R00100.

SYSID: The rack and slot location of the module that the COMMREQ is targeting. The high

byte contains the rack number, and the low byte contains the slot number. The table

below shows some examples of SYSIDs:

Rack Slot Word Value

0 4 0004

3 4 0304

2 9 0209

TASK: Must be set to 1.

Command Block Pointe

SYSID Examples

Enable Input

Rack/Slot Location

Task #

Figure 4-1. COMMREQ Ladder Instruction

COMM_

REQ

IN FT

SYSID

TASK

Fault Output

GFK-2193A Chapter 4 Status and Diagnostics 4-3

Page 21

4

y

p

k

FT Output: The function’s FT (fault) output can provide an output to optional logic that can

verify successful completion of the Communications Request. The FT output can have

these states:

FT Output Truth Table

Enable Input Status Does an Error Exist? FT output

Active No Low

Active Yes High

Not active No execution Low

The FT output is set High if:

The specified target address is not present (for example, specifying Rack

1 when the system only uses Rack 0).

The specified task number is not valid for the device.

Data length is set to 0.

The FT output can either be connected to another device, such as a set coil, or

can be left open.

Operation of the Communications Request

The figure below illustrates the flow of information between the PLC CPU and the

PROFIBUS Slave module:

PLC CPU

Ladder

program

COMMREQ

•

CPU

memory

Data

•

Status word

•

Figure 4-2. Operation of the PROFIBUS Communications Request

A Communications Request is initiated when a COMMREQ ladder instruction is activated

during the PLC scan. At this time, a command from the PLC via the Communications

Request is sent to the PROFIBUS Master module (PBM).

At the conclusion of every request, the PLC CPU reports the status of the request to the

Status Word, which is a location in PLC memory that is designated by the Status Word

Pointer in the Command Block.

In Figure 4-2, the PBM is shown in the CPU rack and communications occur over the PLC

backplane. If the PBM is located in an expansion or remote rack, the commands and data

are sent over the CPU rack’s backplane, through the expansion or remote cable to the

rack containing the PBM, and across that rack’s backplane to the PBM.

PLC

Back

Command

Requested data

Status bits

lane

PROFIBUS Slave

Module

Firmware

instructions

On-board

memor

PROFIBUS

networ

to Master

4-4 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 22

COMMREQ Programming Requirements and Recommendations

COMMREQ instructions should be enabled by a contact from a transition coil.

If using more than one COMMREQ in a ladder program, verify that a previous

COMMREQ executed successfully before executing another one. This can be done

by checking the Status Word and the FT (Fault) output.

The FT output is held False if the Enable Input is not active. This means that if the

COMMREQ is enabled by a transitional (one-shot) contact and a fault occurs, the FT

output is High for only one PLC scan. To capture the fact that a fault occurred, you

can program the fault output as a Set coil, which would not be automatically reset at

the end of a scan. Additional logic would then be needed to reset the fault output coil

after the fault is acknowledged and before the next execution of the COMMREQ.

Programming a device, such as a Set Coil, on the FT output of the COMMREQ is

optional; this output may be left open if desired.

It is necessary to initialize the data in the Command Block before executing the

COMMREQ instruction. Since the normal PLC sweep order is from top to bottom,

initializing the Command Block in an earlier rung (or rungs) than the rung that contains

the COMMREQ will satisfy this requirement.

4

Error Detection and Handling

As shown in “COMMREQ Status Word”, a value of 1 is returned to the Status Word if

communications proceed normally, but if any error condition is detected, a value greater

than 1 is returned. If you require error detection in your ladder program, you can use a

Greater Than (GT) compare instruction to determine if the value in the Status Word is

negative (less than zero). If an error occurs, the GT instruction’s output (Q) will go high. A

coil driven by the output can be used to enable fault handling or error reporting logic.

The FT output of the COMMREQ, described on page 4-4, goes high for certain faults and

can be used for fault detection also. Additionally, the first Status Word can be monitored

by error message logic for display on an Operator Interface device, in which case, Status

Word codes would correspond to appropriate error messages that would display on the

operator screen.

To dynamically check the Status Word, write a non-significant positive number (0 or 99

are typically used) into the Status Word each time before its associated COMMREQ is

executed. If the instruction executes successfully, the CPU will write the number 1 there.

This method lets you know that if the number 1 is present, the last COMMREQ executed

successfully, and that the 1 was not just left over from a previous execution.

When multiple COMMREQs are used, it is recommended that each be verified for

successful communications before the next is enabled. Monitoring the Status Word is one

way to accomplish this.

Corrective Actions for COMMREQ Errors

The type of corrective action to take depends upon the application. If an error occurs

during the startup or debugging stage of ladder development, you should verify the

COMMREQ parameters. The same is true if an error occurs right after a program is

modified. But, if an error occurs in a proven application that has been running

successfully, the problem is more likely to be hardware-related. The PLC fault tables

should be checked for possible additional information when troubleshooting Status Word

errors.

GFK-2193A Chapter 4 Status and Diagnostics 4-5

Page 23

4

COMMREQ Status Word

The following table defines the format of the Status Block used during the COMMREQ

handshake.

Status Word Format

Word Name Description

1 State

(See “Status Word State

Codes” below.)

2 LostCommand Command code of the last command lost when

3 ErrorCode Not Used

4 AdditionalCode Additional code for error reporting

Status Word State Codes

Value Description

0 Module has not yet processed the COMMREQ

1 Command Complete

Note: This status does not necessarily mean success. Some commands have

reply data that must also be checked.

2 Command Terminated – module busy

3 Command Terminated – invalid command

4 Command Terminated – invalid command data

5 Command Terminated – not enough data

6 Command Terminated – command collision

An identical command, which has already reported completion, is currently being

processed and has not replied yet.

7 Command Terminated – not enough memory in reply area

The command did not specify sufficient PLC memory for the reply. Command will

be ignored.

8 Command Terminated – command-specific error. See ErrorCode and

AdditionalCode in the Status Block for more information.

9–255 Reserved

The state of the current COMMREQ request

the CRL bit is set in Flags.

4-6 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 24

PROFIBUS Slave Module COMMREQ Reference

The PROFIBUS Slave module supports the following COMMREQ tasks and responses.

Task Name Description Page No.

3 Get Slave Status Retrieves detailed status information for the Slave. 4-7

5 Read Module Header Retrieves module header information. 4-10

6 Clear Counters Clears counters in ReadModuleHeader 4-12

Get Slave Status COMMREQ (3)

The Get Slave Status COMMREQ retrieves detailed status information for the slave

module from the 16-bit slave status word. The starting address of this word is configured

as Status/Firmware ID Address in the PROFIBUS Slave module software configuration.

For details, refer to “Parameters” in chapter 3.

Memory Types

The following table lists the memory types that can be used for the Status Block and

Reply Data areas.

4

COMMREQ Status Word Memory Type Codes

Memory Type

Abbreviation

%I Discrete input table (BYTE mode) 16

%Q Discrete output table (BYTE mode) 18

%R Register memory 8

%AI Analog input table 10

%AQ Analog output table 12

%T Discrete temporary memory (BYTE) 20

%M Discrete internal memory (BYTE) 22

Memory Type

Get Slave Status Command Block – Basic Example

Get Slave status for Device

Return the COMMREQ status words to %R10—%R13.

Return the Slave status to %R251-%R259.

Word Dec (Hex) Definition

Word 1 4 (0004) Length of command Data Block

Word 2 0 (0000) Always 0 (no-wait mode request)

Word 3 8 (0008) Memory type of COMMREQ status word (%R)

Word 4 9 (0009) COMMREQ status word address minus 1 (%R10)

Word 5 0 (0000) Reserved

Word 6 0 (0000) Reserved

Word 7 3 (0003) Get Module Status command code.

Word 8 8 (0008) Memory type to write response (%R)

Word 9 250 (00FA) Starting Address to write response (response written to %R251)

Word 10 5 (0005) Maximum size of response area. Must be 2 words or more, or an error

will be reported in the COMMREQ status and the Get Slave Status

request will be ignored.

Decimal

code to enter

GFK-2193A Chapter 4 Status and Diagnostics 4-7

Page 25

4

(Word 7) Command Code: Word 7 specifies the Command code for the COMMREQ to

be executed. Get Slave Status = 3.

(Word 8) Local PLC - Memory Type: Words 8—9 specify the location in the PLC where

the response will be written. Valid values for Word 8 are listed on page 4-7.

(Word 9) Local PLC - Memory Starting Address: Word 9 determines the starting

address in the local PLC in which the response is to be written. The value entered is the

offset (0-based) from the beginning of PLC memory for the memory type and mode

specified in Word 8. This offset will be either in bits, bytes, or words depending on the

mode specified (for example, if Word 8=16 and Word 9=2, the starting address will be

%I9). Valid ranges of values depend on the PLC’s memory ranges.

(Word 10) Response Memory Size: Words 10 specifies the size of the memory block for

the response. (Must be at least 2 words.)

Get Slave Status - Reply Data Format

Word Name Description

Word 1 Command Code Echo of Command code that this data block is replying

Word 2 Status Code See Word 2 formats in table below

Word 3—10 Reserved for Future

Use

Note: The reply from Get Slave Status contains the same information that is provided to

the PLC CPU in the Status/Firmware ID Address. This parameter is defined when

the module is configured in the PLC hardware configuration.

to. (0x0003)

Word 10 of the command block should specify a

minimum of 5 words to accommodate possible future

use of this space.

Word 2 – Status Code

Bit Meaning Value

15—12 Baud Rate (bps) 0=12MBps, 1=6MBps, 2=3MBps, 3=1.5MBps,

4=500KBps, 5=187.5KBps, 6=93.75Bps, 8=19.2KBps,

9=9.6KBps

11—10 Module State 0=Module is waiting for parameters from Master

1=Module is waiting for config from Master

2=Data Exchange is occurring – normal operation

3=Error (either config error or module watchdog

timeout)

9 On-line 1=Online module firmware is running

0=Offline

8 PLC Cfg 0= Module config from PLC CPU is bad

1=Module config from PLC CPU is good

7 Run/Stop 0=Stop, 1=Run This is the State of the PROFIBUS

Module, it is not the status of the PLC CPU. If the SYS

LED is Green the bit=1, if the SYS LED is Red or

Amber the bit=0

6—0 Error Info See “Network Parameter Errors”

4-8 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 26

Network Parameter Errors

The following errors codes may be returned in bits 0—6 in the Get Slave Status reply.

Note: The error code is the numerical value of the bits.

0 No error

1 ID from master does not match Slave ID

2 Ready Time from Master does not match Slave Ready time

3 Master is requesting Freeze or Sync, which is not supported

4 Length of data from master to slave is incorrect

5 Length of data from slave to master is incorrect

6 One of the watchdog factors (SlvWdFact1 or SlvWdFact2)

7 Slave watchdog time out (check response timeout)

8 Slave timeout watchdog disabled from master

Error

Code

by the slave

from the master was 0.

4

Meaning

GFK-2193A Chapter 4 Status and Diagnostics 4-9

Page 27

4

Read Module Header (5)

The Read Module Header command retrieves Network Diagnostic Information for the

Device.

Read Module Header Command Block – Basic Example

The following command block accomplishes the following:

Get Module Header Data

Return the COMMREQ Status Word to %R10—%R13.

Return the Device Status to %R251—%R275.

Word Dec (Hex) Definition

Word 1 4 (0004) Length of command Data Block

Word 2 0 (0000) Always 0 (no-wait mode request)

Word 3 8 (0008) Memory type of COMMREQ status word (%R)

Word 4 9 (0009) COMMREQ status word address minus 1 (%R10)

Word 5 0 (0000) Reserved

Word 6 0 (0000) Reserved

Word 7 5 (0005) Read Module Header command number

Word 8 8 (0008) Memory type to write response (%R)

Word 9 250 (00FA) Starting Address to write response(response written to %R251)

Word 10 25 (0019) Size of response area, 25 for slave

(Word 7) Command Code: Word 7 specifies the Command code for the COMMREQ to

be executed . Read Module Header = 5

(Word 8) Local PLC - Memory Type: Words 8—9 specify the location in the PLC where

the response will be written. Valid values for Word 8 are listed below:

Type

%R 8 (0008) Register memory (word mode)

%AI 10 (000A) Analog input memory (word mode)

%AQ 12 (000C) Analog output memory (word mode)

%I 16 (0010) Discrete input memory (byte mode)

%Q 18 (0012) Discrete output memory (byte mode)

%T 20 (0014) Discrete temporary memory (byte mode)

%M 22 (0016) Discrete momentary internal memory (byte mode)

Value

Dec (Hex)

Description

4-10 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 28

(Word 9) Local PLC - Memory Starting Address: Word 9 determines the starting

address in the local PLC in which the response is to be written. The value entered is the

offset (0-based) from the beginning of PLC memory for the memory type and mode

specified in Word 8. This offset will be either in bits, bytes, or words depending on the

mode specified (for example, if Word 8=16 and Word 9=2, the starting address will be

%I9). Valid ranges of values depend on the PLC’s memory ranges.

(Word 10) Response Memory Size: Word 10 specifies the size of the memory block for

the response. The Response Memory Size is 25 words. If the Response Memory Size is

set smaller than 25, the COMMREQ will fail with a 7 in the COMMREQ Status Word. The

user is responsible for assuring that this area is large enough to contain the requested

data without overwriting other application data

Read Module Header Reply Data Format for Slave

Word Name Description

Word 1 Command Code Echo of the Command Code that this data block is replying to

(0x0005).

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 8

Word 9

Word 10

Word 11

Word 9

Word 10

Word 11

Word 12

Word 13

Word 14

Word 15

Word 16

Word 17

Word 18

Word 19

Word 20

Word 21

Word 22

Note: If the Name starts with Err the value stops at the maximum. If the Name starts

ModuleType Contains 1 if the module is a Slave and a 2 if the module is a

Master.

PfbStatus PROFIBUS Status register, also can be read using the Get

Device Status COMMREQ. For definitions, see page 4-8.

ModuleVersion Module firmware version.

0122h = 1.22

ErrLanOffline Counter. LAN went offline due to errors.

DiagConf Total confirmations.

DiagInd Total indications.

ErrNotOk Total not OK confirmations and indications.

DiagSlaveUpdate Number of updates the Slave has received from the Master

ErrSlvErr Count of Slave Configuration Errors

ErrSlvTout Count of Slave Watchdog timeouts (update not received in time)

ErrInvReqLen Invalid request length error counter.

ErrFifo FIFO overflow error counter.

ErrRxOverun Receive overrun error counter.

ErrDblTok Double token error counter.

ErrRespErr Response error counter.

ErrSynErr General network error counter.

ErrNetTout Network timeout error counter.

ErrHsa Station higher than HAS was heard counter.

ErrStn Duplicate station detected counter.

ErrPasTok Unable to pass token counter.

ErrLasBad Active station list is invalid.

ErrInternal Internal errors.

ErrArg Argument errors.

ErrEventOverun A new event occurred before the last one was cleared.

with Diag the count rolls over to zero.

4

GFK-2193A Chapter 4 Status and Diagnostics 4-11

Page 29

4

Clear Counters (6)

The Clear Counters Command sets the counters in the PROFIBUS module to zero.

Clear Counters Command Block – Basic Example

In the following command block, Status is returned in %R251—%R252 (words 8 and 9).

Word Dec (Hex) Definition

Word 1 4 (0004) Length of command Data Block

Word 2 0 (0000) Always 0 (no-wait mode request)

Word 3 8 (0008) Memory type of COMMREQ status word (%R)

Word 4 9 (0009) COMMREQ status word address minus 1 (%R10)

Word 5 0 (0000) Reserved

Word 6 0 (0000) Reserved

Word 7 6 (0006) Clear Counters command number

Word 8 8 (0008) Memory type to write response (%R)

Word 9 250 (00FA) Starting Address to write response (response written to %R251)

Word 10 2 (0002) Maximum size of response area

(Word 7) Command Code: Word 7 specifies the Command code for the COMMREQ to

be executed . Clear Counters = 6

(Word 8) Local PLC - Memory Type: Words 8—9 specify the location in the PLC where

the response will be written. Valid values for Word 8 are listed below

Type

%R 8 (0008) Register memory (word mode)

%AI 10 (000A) Analog input memory (word mode)

%AQ 12 (000C) Analog output memory (word mode)

%I 16 (0010) Discrete input memory (byte mode)

%Q 18 (0012) Discrete output memory (byte mode)

%T 20 (0014) Discrete temporary memory (byte mode)

%M 22 (0016) Discrete momentary internal memory (byte mode)

Value

Dec (Hex)

(Word 9) Local PLC - Memory Starting Address: Word 9 determines the starting

address in the local PLC in which the response is to be written. The value entered is the

offset (0-based) from the beginning of PLC memory for the memory type and mode

specified in Word 8. This offset will be either in bits, bytes, or words depending on the

mode specified (for example, if Word 8=16 and Word 9=2, the starting address will be

%I9). Valid ranges of values depend on the PLC’s memory ranges.

(Word 10) Response Memory Size: Words 10 specifies the size of the memory block for

the response. The Response Memory Size is 2 words. If the Response Memory Size

(word 10 in the Clear Counters command block) is set greater than 2, the COMMREQ will

succeed. The unneeded memory locations are not written.

Clear Counters Reply Data Format

Description

Word Name Description

Word 1 CommandCode Echo of Command code that this data block is replying to. (0x0006)

Word 2 StatusCode Reports 1 for success and 0 for failure.

4-12 Series 90™-30 PROFIBUS Slave Module User's Manual – August 2004 GFK-2193A

Page 30

C

Clear Counters (6), 4-12

COMMREQs

Clear Counters (6), 4-12

Get Slave Status

details, 4-7

memory types, 4-7

PROFIBUS Master, 4-7

Read Module Header (5), 4-10

COMMREQs, general information, 4-3

error detection and handling, 4-5

ladder instruction, 4-3

operation, 4-4

programming recommendations, 4-5

status word, 4-6

Configuration, 3-1

software, 1-2

CPU version, 1-2

F

Features, 1-2

G

Index

network connectors, 1-5

network overview, 1-3

network topology, 1-4

standards, 1-1

R

Read Module Header, 4-10

Reviewing system power requirements,

2-1

S

Selecting the proper line type, 2-2

Specifications, 1-2

environment, 1-2

power consumption, 1-2

Standards

PROFIBUS, 1-1

Status and diagnostic methods, 4-1

Status information, 1-2

Status Word codes, 4-6

Status/firmware ID array, 4-2

Get Slave Status

details, 4-7

memory types, 4-7

I

Indicators, 4-1

Installation procedures

installing bus termination, 2-3

installing the module in the rack, 2-1

reviewing system power requirements, 2-1

L

LEDs, 4-1

M

Mounting location, 1-2

P

Pin-out

PROFIBUS bus plug connector, 1-5

Power consumption, 1-2

Power supplies, 2-1

PROFIBUS

baud rate, 2-4

bus communication, 1-3

GFK-2193A Index-1

Loading...

Loading...