Page 1

Getting Started

Logic Developer - PLC

PLC Programming Software

Version 4.00

May 2003

GFK-1918D

Page 2

All rights reserved. No part of this publication may be reproduced in any form or by

any electronic or mechanical means, including photocopying and recording,

without permission in writing from GE Fanuc Automation Americas, Inc..

Disclaimer of Warranties and Liability

The information contained in this manual is believed to be accurate and reliable.

However, GE Fanuc Automation Americas, Inc. assumes no responsibilities for any

errors, omissions or inaccuracies whatsoever. Without limiting the foregoing, GE

Fanuc Automation Americas, Inc. disclaims any and all warranties, expressed or

implied, including the warranty of merchantability and fitness for a particular

purpose, with respect to the information contained in this manual and the

equipment or software described herein. The entire risk as to the quality and

performance of such information, equipment and software, is upon the buyer or

user. GE Fanuc Automation Americas, Inc. shall not be liable for any damages,

including special or consequential damages, arising out of the use of such

information, equipment and software, even if GE Fanuc Automation Americas, Inc.

has been advised in advance of the possibility of such damages. The use of the

information contained in the manual and the software described herein is subject to

GE Fanuc Automation Americas, Inc. standard license agreement, which must be

executed by the buyer or user before the use of such information, equipment or

software.

Notice

GE Fanuc Automation Americas, Inc. reserves the right to make improvements to the

products described in this publication at any time and without notice.

© 2003 GE Fanuc Automation Americas, Inc. All rights reserved. CIMPLICITY is a

registered trademark of GE Fanuc Automation. Any other trademarks referenced

herein are used solely for purposes of identifying compatibility with the products of

GE Fanuc Automation Americas, Inc.

We want to hear from you. If you have any comments, questions, or suggestions

about our documentation, send them to the following email address:

doc@gefanuc.com

Page 3

Contents

1 Welcome 1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Product Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2 CIMPLICITY Machine Edition 9

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Machine Edition Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Companion Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

InfoViewer Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3 GE Fanuc PLC Targets 23

Addinging, Configuring and Converting Targets . . . . . . . . . . . . . .24

Adding Targets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Configuring Targets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Converting Targets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Configuring Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Configuring Communication for PACSystems™ . . . . . . . . . . . .28

Configuring Communication for non-PACSystems™ PLCs . . . .30

Interacting with the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Validating a Target . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Online/Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Upload/Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Run/Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Fault Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Reference View Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

CIMPLICITY Logic Developer - PLC Version 4.00 i

Page 4

4 Hardware Configuration (HWC) 43

PACSystems™ RX7i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Configuring PACSystems™ RX7i Hardware . . . . . . . . . . . . . . 44

Redundancy (Series 90™-70 and PACSystems™ RX7i only) . . 50

Configuring Redundant Systems . . . . . . . . . . . . . . . . . . . . . . . 52

Series 90™-30: DSM314 Motion Module . . . . . . . . . . . . . . . . 55

Series 90™-70 Genius Remote I/O Scanner . . . . . . . . . . . . . . 57

VersaMax Remote I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5 Logic Editors 63

LD Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Working with the LD Editor Offline . . . . . . . . . . . . . . . . . . . . 67

Editing Logic as Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Working with the LD Editor Online . . . . . . . . . . . . . . . . . . . . 72

Word-for-Word Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Writing Changes to a Target PLC . . . . . . . . . . . . . . . . . . . . . . 74

LD Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

IL Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Working with the IL Editor Offline . . . . . . . . . . . . . . . . . . . . . 80

Working with the IL Editor Online . . . . . . . . . . . . . . . . . . . . . 82

Writing Changes to a Target PLC . . . . . . . . . . . . . . . . . . . . . . 83

IL Instructions and Functions . . . . . . . . . . . . . . . . . . . . . . . . . 84

C Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Working with C blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

C Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

User Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Working with User Programs . . . . . . . . . . . . . . . . . . . . . . . . . 89

6 Motion Programming 91

PLC Motion Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Working with the Motion Editor . . . . . . . . . . . . . . . . . . . . . . . 93

Motion Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Local Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Working with Local Logic Editor . . . . . . . . . . . . . . . . . . . . . . . 96

Local Logic Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Local Logic Commands and Operators . . . . . . . . . . . . . . . . . . 99

ii CIMPLICITY Logic Developer - PLC Version 4.00

Page 5

CAM Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Working with the CAM Editor . . . . . . . . . . . . . . . . . . . . . . . .101

CIMPLICITY Logic Developer - PLC Version 4.00 iii

Page 6

Page 7

1

Welcome

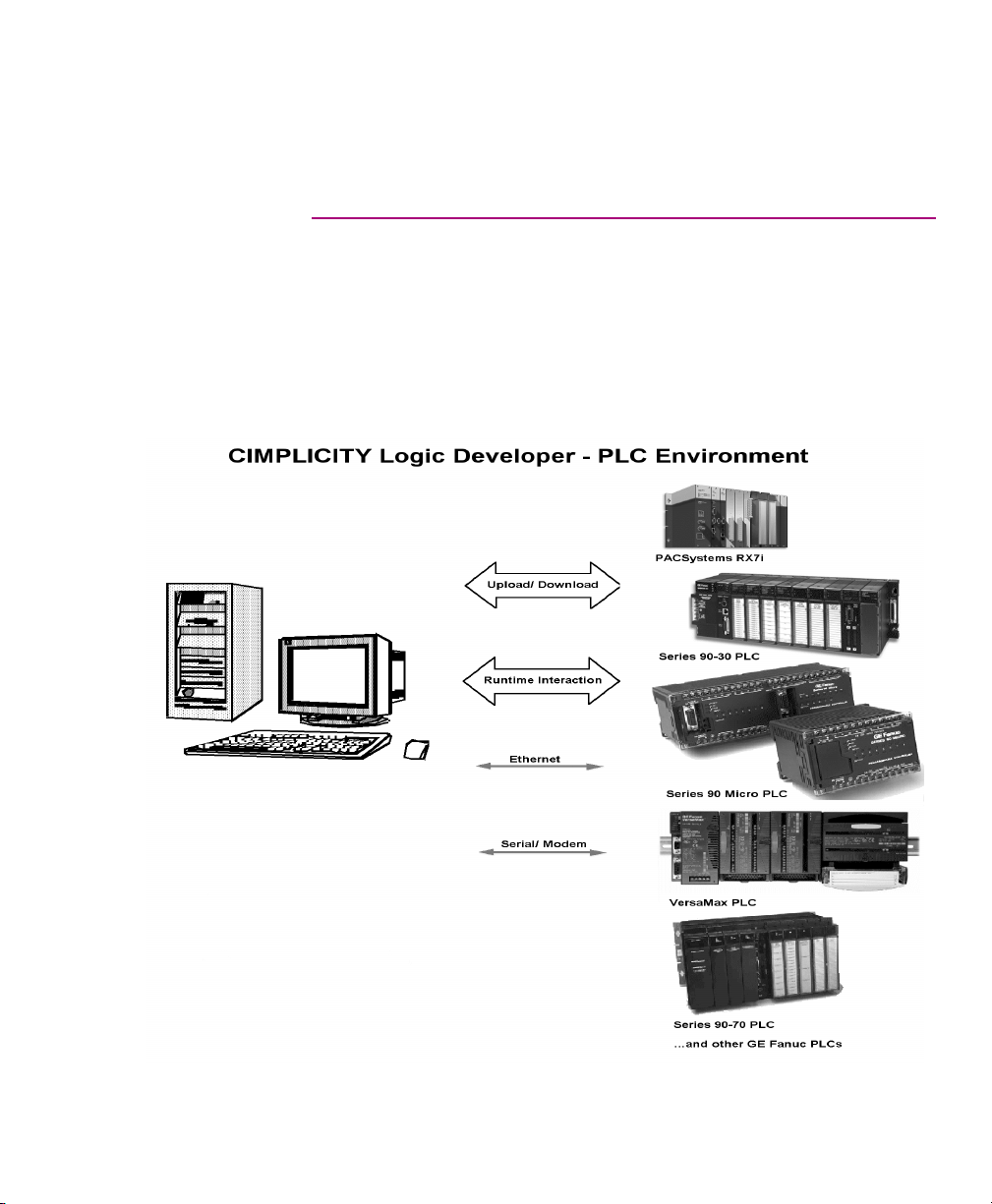

Congratulations on your purchase of Logic Developer - PLC, the GE Fanuc PLC

programming component of Machine Edition automation software. This software

package provides all the tools necessary to create powerful control applications.

Logic Developer - PLC provides a way to configure your PLC hardware or remote

I/O, create and edit PLC logic, upload and download projects, and monitor and

debug the execution of control programs. Projects can be imported from

Logicmaster, VersaPro, and CimplicityControl folders.

CIMPLICITY Logic Developer - PLC Version 4.00 1

Page 8

1

Welc ome

Logic Developer - PLC makes it possible to develop control applications on a

personal computer and download them to a PLC via Ethernet or serial/modem

connection.

Hosted in the Machine Edition environment, Logic Developer - PLC takes

advantage of a powerful set of common programming tools (see page 14). The

same tools can be applied to Logic Developer - PC (PC Control), Logic Developer State, CIMPLICITY View and CIMPLICITY Motion components, providing a single

programming environment. The Machine Edition environment unites and

organizes components, providing data sharing and networked operation.

The following features are included in this version of Logic Developer - PLC:

■

Hardware Configuration (HWC): a comprehensive tool for configuring and

customizing GE Fanuc PLCs or racks of Remote I/O for your specific operating

needs. For more information on Hardware Configuration, see page 43.

■

LD Editor: an intelligent, cell-based, graphical editor for developing LD (Ladder

Diagram) logic. You can customize the look and feel of the LD Editor. For more

information on the LD Editor, see page 63.

■

IL Editor: an easy-to-use, free-form text editor for creating Instruction List logic.

Configurable formatting rules and color coding make your scripts easy to read.

For more information on the IL editor, see page 79.

■

C Blocks and C Programs: independent sections of executable code, written in

C language, that are developed outside of Logic Developer - PLC. Precompiled

C blocks and C programs are imported into your project. For more information

on C blocks, see page 86. For more information on C programs, see page 88.

■

PLC Motion Editor: a free-form text editor that enables you to enter the program

in your preferred style. The PLC Motion editor is specifically designed for

support of the IC693DSM314 motion module. For more information on the

Motion editor, see page 91.

■

Local Logic Editor: a text-based editor used for developing logic that executes

locally on a IC693DSM314 motion module. Local Logic runs synchronously

with the PLC Motion program, but is independent of the PLC’s CPU. For more

information on the Local Logic editor, see page 95.

■

CAM Editor: an accessory for the Logic Developer - PLC Motion editor

specifically designed for support of the IC693DSM314 motion module. It

provides a graphical means to create, edit, and manage electronic CAM

profiles. For more information on the CAM editor, see page 100.

2 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 9

System Requirements

SYSTEM REQUIREMENTS

To use Logic Developer - PLC and its tools, you require the following:

■

Windows® NT version 4.0 with service pack 6.0 or later

OR

Windows 2000 Professional

OR

Windows XP Professional

OR

Windows ME

OR

Windows 98 SE.

■

Internet Explorer version 5.5 with Service Pack 2 or later. (You must install

IE5.5 SP2 before installing Machine Edition.)

■

500 MHz Pentium-based computer. (1 GHz recommended.)

■

128 MB RAM (256 MB recommended).

■

TCP/IP Network protocol-based computer.

■

150-750 MB free hard disk space depending on the selected products.

■

200 MB hard disk space for sample projects (optional).

■

Additional hard disk space for projects and temporary files.

Welcome

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 3

Page 10

1

Welc ome

Installation

INSTALLATION

For last-minute information, release notes, and supported hardware lists for

Machine Edition products, see the Important Product Information (IPI) document

on the CD. There are several ways to view this document

■

When installing Machine Edition, select Important Product Information on the

initial Launcher screen.

■

From the Machine Edition Help menu, choose Important Product Information.

■

When running Machine Edition, click the InfoView tab in the Navigator, then

double-click the Important Product Information page under Getting Started in

the Table of Contents.

■

When running Machine Edition, click the Home button on the InfoViewer

toolbar, then click the What’s New link under Get Started on the left hand side.

If you have a previous version of Machine Edition installed on your workstation,

you must uninstall it before installing the latest version. You can do so by selecting

the “Uninstall CIMPLICITY Machine Edition” option from the CIMPLICITY

Machine Edition Start menu group. All projects, settings, and authorizations will

remain intact during an uninstall operation.

To install Logic Developer - PLC

1. Insert the CIMPLICITY Machine Edition CD into your CD-ROM drive.

By default, the setup program will automatically start. If the setup program does

not automatically start, run Setup.exe in the root directory of the CD.

2. Click Install to start the install process.

3. Follow the instructions as they appear on the screen.

4 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 11

PRODUCT AUTHORIZATION

Before you can start developing projects with Logic Developer - PLC, you must

authorize the software with a program called Product Authorization. If you don’t

authorize the software, you can use it for only a four-day trial period. This

procedure takes only a few minutes and enables you to take advantage of any

product support for which you qualify. You will need to contact us by telephone,

fax, or e-mail as part of the authorization process.

To authorize a copy of Machine Edition

1. Have your serial numbers ready.

The serial numbers can be found on the License Key sheet that came with your

product.

2. Run the Product Authorization program from the Start menu > Programs > Product Authorization.

The Product Authorization dialog box appears.

3. Click Add.

4. Select the medium with which you are authorizing: Internet, Phone/Fax/E-mail, or Floppy Disk Transfer. Click Next.

If you choose the Internet option, proceed to step 5.

If you choose the Phone/ Fax/E-mail option, proceed to step 5.

If you choose the Floppy Disk Transfer option, ensure you have an authorization

disk before proceeding.

5. Fill in the fields in the dialog box.

Fields that are identified with an asterisk (*) must be filled in.

6. If authorizing by:

■

Internet, click Submit Authorization. We will reply by e-mail with your new

key code(s).

■

Phone, click Phone/Fax and call the number on the screen to receive a new key

code(s).

■

Fax, click Phone/Fax. In the dialog box that appears, click Print FAX. Fax the

Product Authorization Request to us, using our fax number on the printout. We

will reply by fax with your new key code(s).

■

E-mail, click Send E-mail. In the dialog box that appears, click Authorize to email us. We will reply by e-mail with your new key code(s).

Product Authorization is complete after you enter the new key code and it has

been accepted. Depending on the product you have purchased, you may need to

run the Product Authorization program a number of times.

Welcome

Product Authorization

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 5

Page 12

1

Welc ome

Product Authorization

To move the authorization to another computer

You can run the software on only the computer that the Product Authorization was

run on. If you want to develop your projects on a different computer, you need to

complete the following steps to move the authorization from one computer to

another.

1. Install Logic Developer - PLC on the computer that the authorization will be moved to. Run the Product Authorization

program from the Start menu > Programs > CIMPLICITY Machine Edition > Product Authorization.

The Product Authorization dialog box appears.

2. Click Software.

There is a Target Site Code on the top right-hand side of the screen. Write down

this site code carefully. It must be accurate for the move to work. You will need the

Target Site Code when you move the authorized software from the source

computer.

3. Click Add.

The Product Authorization wizard appears.

4. Click Authorize by disk.

At this point, you need to go to the source computer that has the authorized

software, and move the authorization to a disk.

5. From the source computer, run the Product Authorization program and click Software.

6. Click Move, and then click OK. Enter the Target Site Code that you wrote down from Step 3 and click Next. Verify

that the site code is correct and click OK.

7. Insert a blank formatted floppy disk into the floppy drive and click Next.

The authorization code will be moved to the disk and a dialog box should appear

telling you it was successful.

8. Click OK.

9. Go back to the computer to which you are moving the authorization and insert the floppy disk.

The screen that is asking for an authorization disk should be displayed.

10. Click Next.

11. Click Finish.

A screen should appear telling you the move was successful.

12. Click OK.

The authorization has now been moved to the new computer.

6 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 13

Welcome

Technical Support

TECHNICAL SUPPORT

Support is available to registered users at no charge for 90 days after purchase. A

support agreement can be purchased from your local GE Fanuc distributor if

extended support is required.

If problems arise that can’t be solved using the information in your product

manual, online Help system, or the GE Fanuc Technical Advisor knowledge base,

contact us by telephone, fax, or mail.

When contacting us, call from a telephone near your computer and have your

CIMPLICITY Machine Edition software running. Have the following information

handy to help us assist you as quickly as possible:

■

The serial number from your installation CD case, and the Product name and

version number from the Help>About dialog box.

■

The brand and model of any hardware in your system.

■

Operating system and version number.

■

The steps you performed prior to the problem occurring.

North America

Support Hotline: 1-800-GEFANUC (1-800-433-2682) Fax: (780) 420-2049

Internet: http://www.gefanuc.com Email: support@gefanuc.com

Comments about our manuals and help: doc@gefanuc.com

Mailing Address: GE Fanuc

2700 Oxford Tower, 10235 - 101 St.

Edmonton, AB, Canada, T5J 3G1

South America

Te le ph o ne : +58 (261) 760 2862 Fax: +58 (261) 765 0909

Internet: http://www.gefanuc.com (visit our Portuguese web site at www.gefanuc.com.br)

E-Mail: luis.wilhelm@gefanuc.com

Mailing Address: GE Fanuc Automation Latin America

Calle 120 con Av. 17, Los Haticos -GE Turbimeca

Maracaibo, Venezuela

Europe

Internet: For up-to-date contact information, visit www.gefanuc-europe.com and click on “Offices and Services”.

For up-to-date technical information visit www.gefanuc.com/support.

E-mail: plc_europe@gefanuceur.ge.com

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 7

Page 14

Page 15

2

Help I ndex

CIMPLICITY Machine Edition

Machine Edition offers you a complete solution for the development of automation

applications in one package. Machine Edition features an integrated development

environment and tools that enable you to spend more time building applications

and less time learning the software. All Machine Edition products are fully

integrated into the environment and interact with each other.

■

They share the same set of tools providing a consistent interface throughout the

development process.

■

They feature full drag-and-drop capabilities between tools and editors.

■

They feature a true scalable solution. You have the choice of what type of

machine your projects run on.

■

They automatically display Help in the Companion for what you click on.

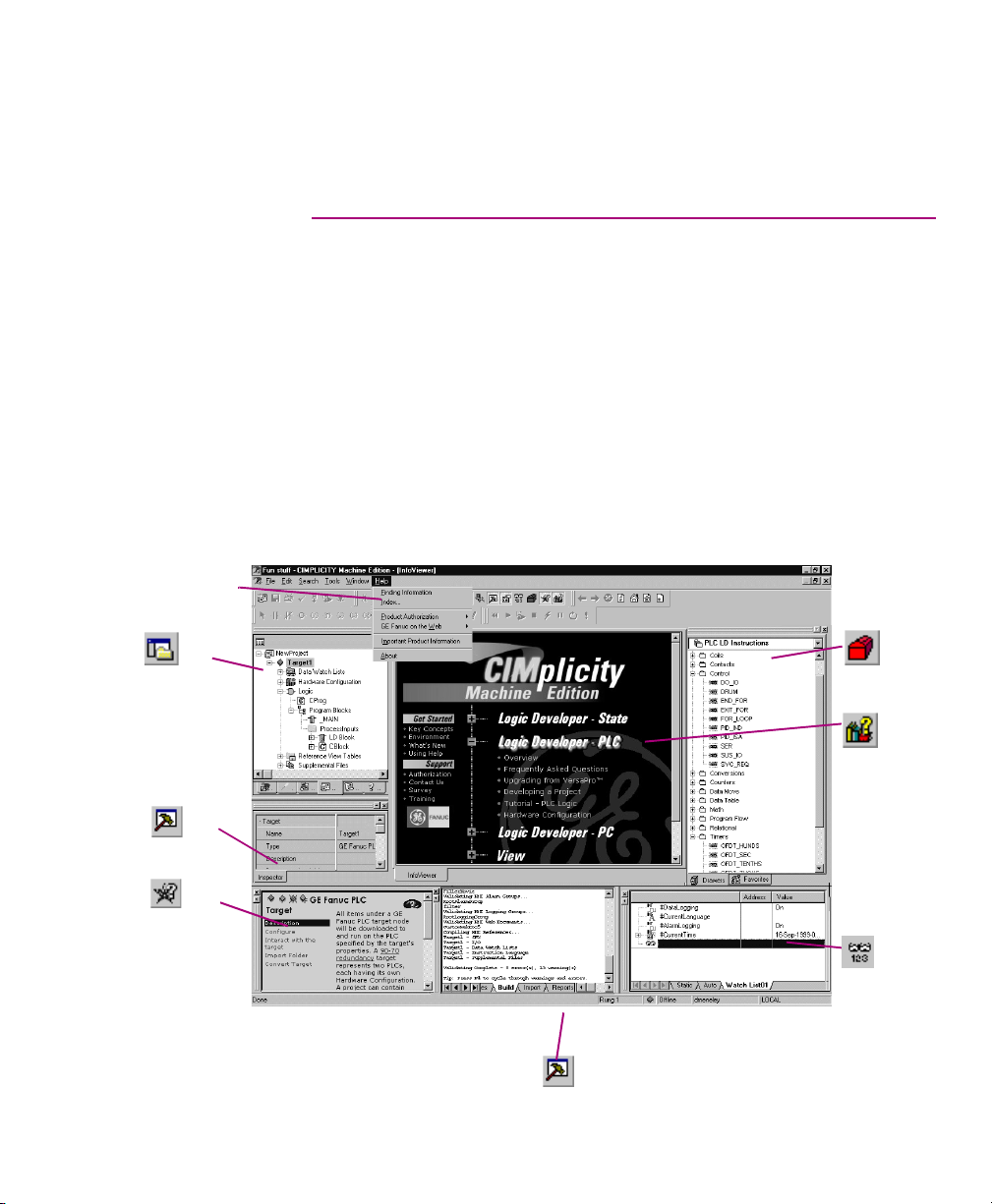

The following illustrates a Machine Edition project:

Navig ator

Inspector

Companion

Toolchest

InfoViewer

Data Watch

Feedback Zone

CIMPLICITY Logic Developer - PLC Version 4.00 9

Page 16

2

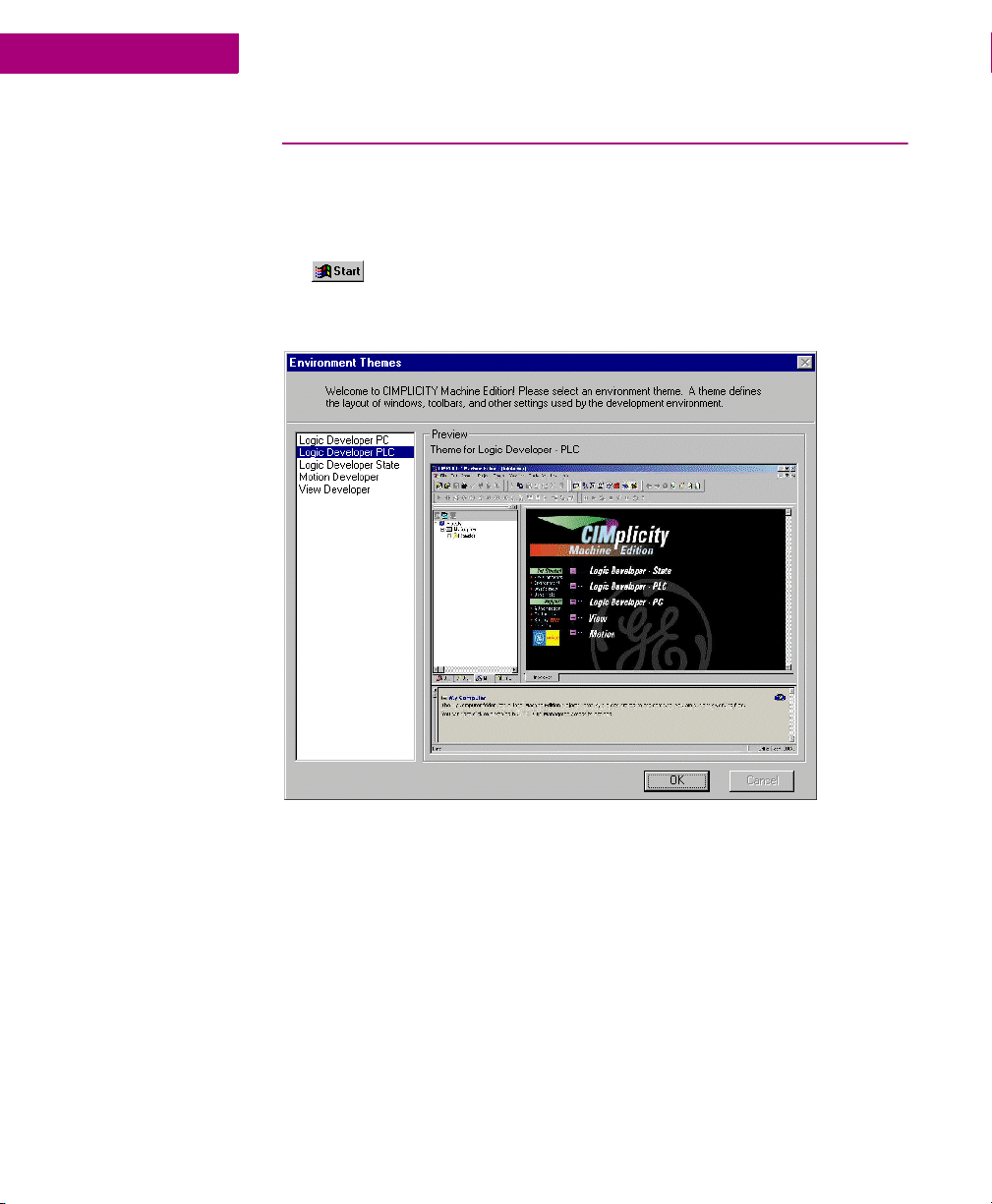

To start Machine Edition

CIMPLICITY Machine Edition

Quick Start

QUICK START

Machine Edition makes it easy to get started developing a project.

1. Click Start, point to Programs, point to CIMPLICITY Machine Edition and then choose CIMPLICITY

Machine Edition.

After Machine Edition initializes, the Environment Themes dialog box appears.

Note: The Environment Themes dialog box appears automatically the first time you

start Machine Edition. To change the theme later, choose Apply Theme from the

Windows menu.

2. Choose the Logic Developer - PLC theme.

3. Click OK.

When you open a project, the appearance of your Machine Edition screen will

match the preview in the Environment Themes dialog box.

10 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 17

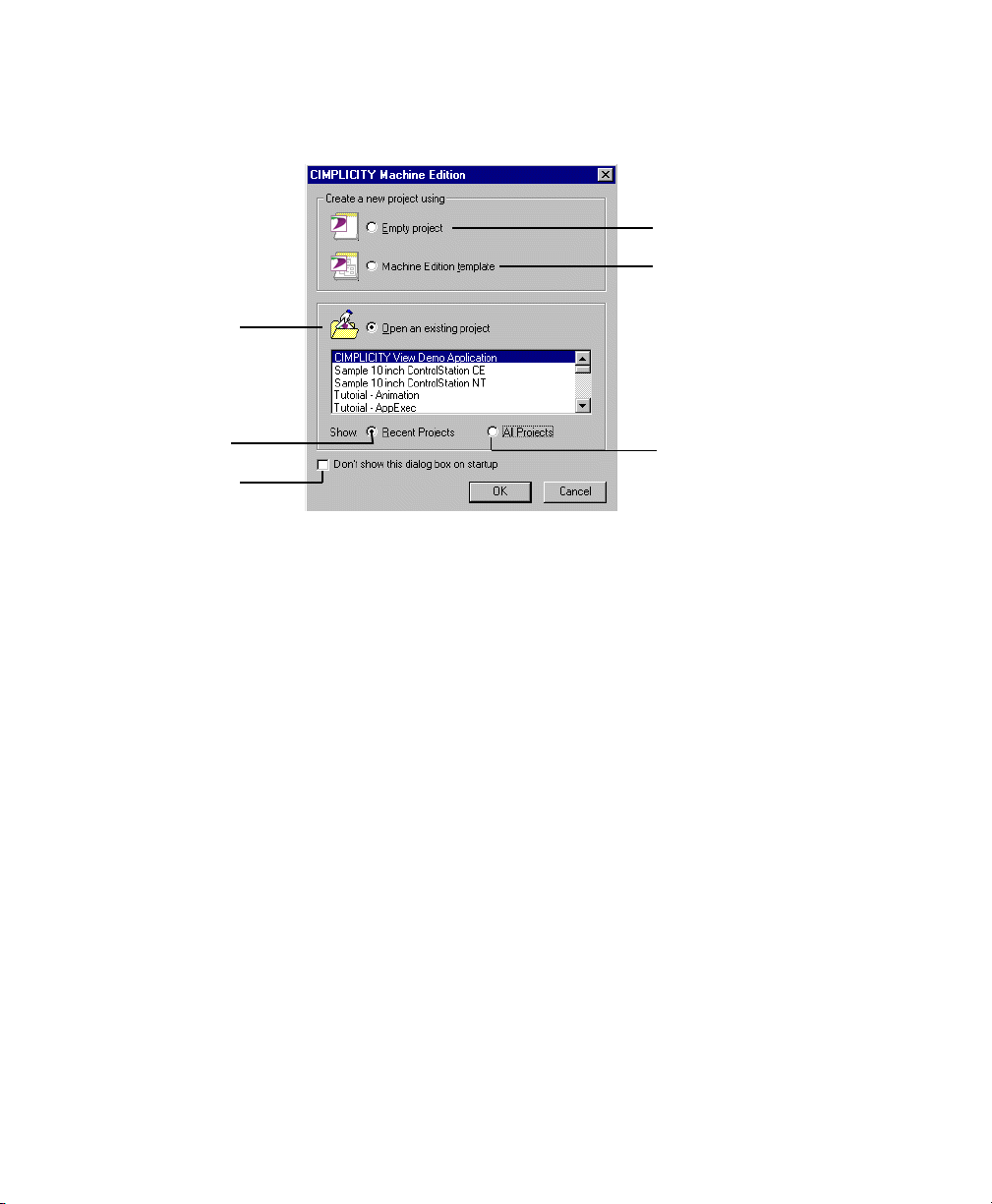

Select this option if you want

to select an existing project.

Select th is option to displ ay only

the projects that have been

used recently.

Select this che ck box if you

do not want to see this dialog

box again.

CIMPLICITY Machine Edition

Quick Start

The CIMPLICITY Machine Edition dialog box appears.

Select this option if you

want to create a new project

from scratch.

Select this option if you

want to use a Mach ine Edition

template to create your project.

Select th is option to displ ay

all existing projects.

4. Select the appropriate option to open a project. The Open an existing project option is selected by default.

Notes:

■

If you select either the Empty project option or the Machine Edition template

option, the New Project dialog box appears and you can continue creating a

new project (see page 12).

■

If you select the Open an existing project option, you can also select either the

Recent Projects option or the All Projects option. The Recent Projects option is

selected by default.

5. If you selected the Open an existing project option, select from the list the project that you want to open.

The existing projects include samples and tutorials that you can open and use to

familiarize yourself with Machine Edition.

6. If you want, select the Don’t show this dialog box on startup option.

7. Click OK.

Your project opens in the Machine Edition environment that you specified in the

Environment Themes dialog box.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 11

Page 18

2

CIMPLICITY Machine Edition

Projects

PROJECTS

You can create and edit Machine Edition projects using products such as

CIMPLICITY View, Logic Developer - PC, CIMPLICITY Motion, Logic Developer State, and Logic Developer - PLC. These products share Machine Edition tools to

provide a high level of integration between the various parts of your project.

You can import folders created with Logicmaster, CimplicityControl, or VersaPro.

Using Logic Developer - PLC, you can build multiple projects to suit your specific

requirements.

To create a new project using a template

Before creating a project, there are some things you should know:

■

The primary components your project will contain.

■

The PLC you project will run on.

1. From the File menu, choose New Project, or click on the File toolbar.

The New Project dialog box appears.

Enter the name of

Choose your project

template from the

Project Template

list.

A sample description of the

project appears on the

screen.

2. Choose a Project Template that suits your needs.

3. Enter a descriptive Project Name.

4. Click OK.

your project in the

Project Name box.

You can set th e selected

project template as the

default template by

clicking the S et as default

button.

Your project opens in the Machine Edition environment.

12 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 19

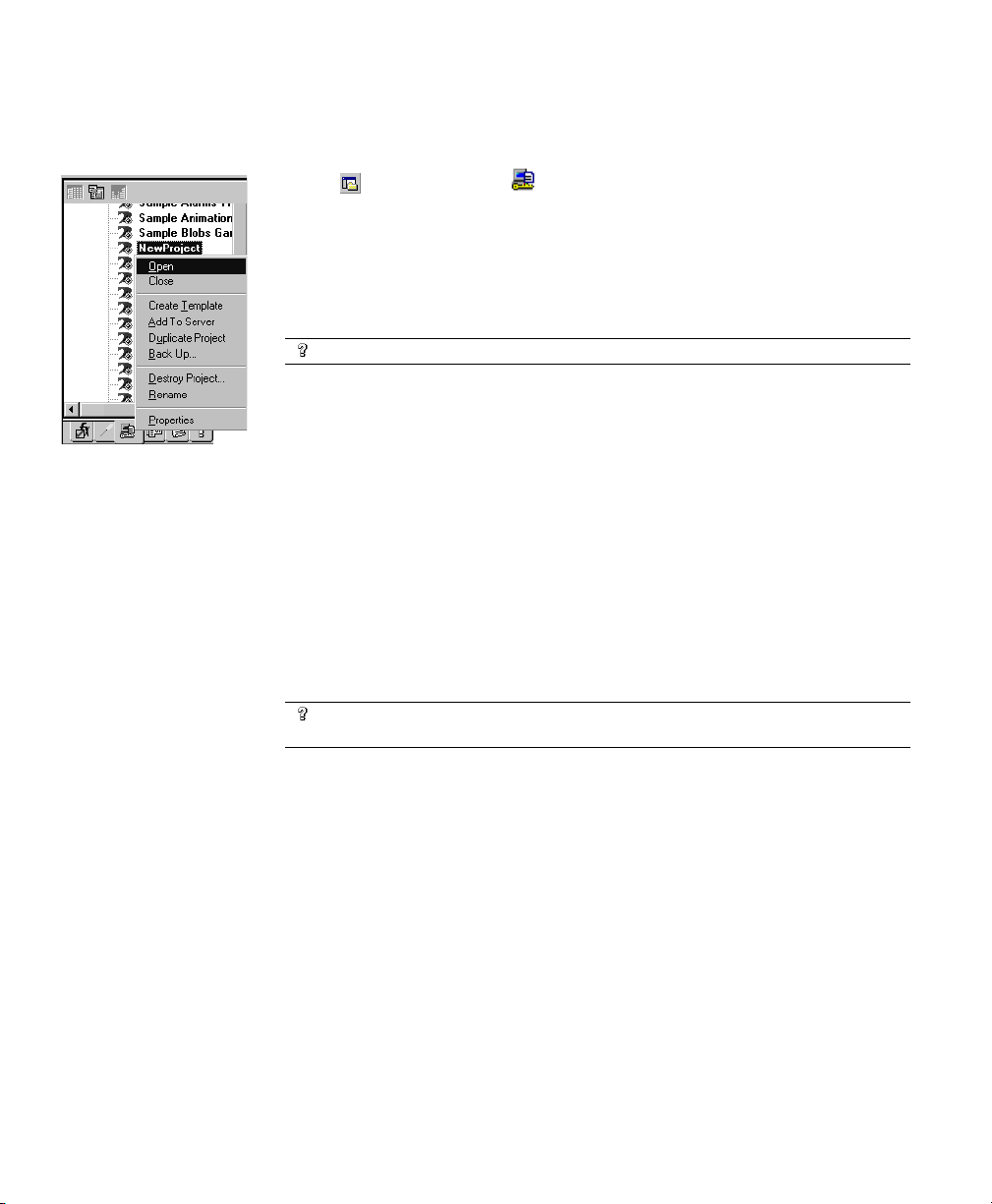

To open an existing project for editing

1. Open the Navigator and choose the Manager tab.

A list of projects is displayed.

2. Right-click a project and choose Open.

Your project loads and is ready for editing.

CIMPLICITY Machine Edition

Projects

Navigator: Manager tab

To import a folder

Want to know more?

1. Open the Navigator and choose the Project tab.

2. Select the target that you want to import the folder into.

3. Right-click the target, point to Import, and choose the folder type.

4. In the dialog box that appears, navigate to and double-click the folder you want to import.

Want to know more?

In the Help Index, look up “Projects”.

In the Help Index, look up “import a CimplicityControl folder”, “import

a Logicmaster folder”, or “import a VersaPro folder”.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 13

Page 20

2

CIMPLICITY Machine Edition

Tools

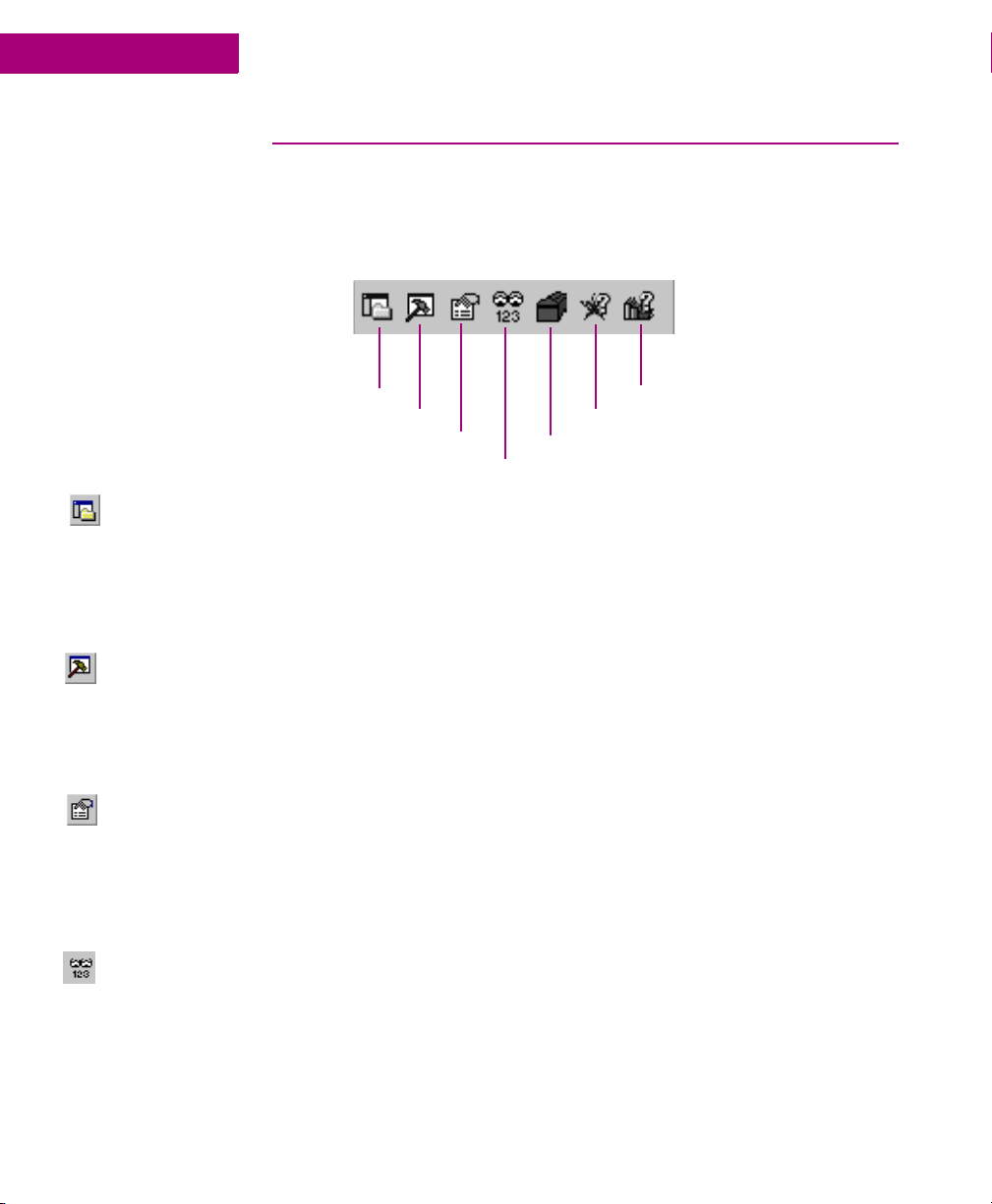

TOOLS

Project development is supported by the Machine Edition tools. Each tool is

opened and closed by means of a button on the Tools toolbar.

A description of each tool’s function is provided below.

Navigator

Feedback Zone

Inspector

Navigator

Feedback Zone

Inspect or

Toolchest

Data Watch

Infoviewer

Companion

The Navigator is a docking tool window containing a set of tabs. Each tab displays

information about your development system in a hierarchical tree structure similar

to Windows Explorer. The available tabs depend on which Machine Edition

products you have installed and what kind of work you are developing or

managing. The Project tab shows the overall organization of your application.

The Feedback Zone window is a docking window used to display several types of

output information generated by Machine Edition components. This interactive

window uses category tabs to organize the output generated from the Machine

Edition products you have installed.

The Inspector lists the properties and current settings for a selected object or

element. You can edit these properties directly in the Inspector. When you select

several objects, the Inspector window lists the properties commom to all of them.

The Inspector window provides a simple method of viewing and setting properties

for all objects.

Data Watch

The Data Watch tool is a runtime debugging tool that enables you to monitor and

edit the values of variables. This tool is useful while working online to a target.

With the Data Watch tool, you can monitor individual variables or user-defined

lists of variables. Data Watch lists can be imported, exported, or saved with a

project.

14 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 21

CIMPLICITY Machine Edition

Too ls

Toolchest

Companion

InfoViewer

The Toolchest is a powerful storehouse of objects you can add to your project. You

can drag most items directly from the Toolchest into Machine Edition editors. You

can choose from predefined objects or create your own reusable fxClasses. The

Toolchest adds true object-oriented capability to Machine Edition.

The Companion provides useful tips and information while you work. While the

Companion is open, it tracks your moves and displays help on whatever item is

currently selected in the Machine Edition environment. It is context-sensitive and

displays a description of whatever you click on the Machine Edition screen.

The InfoViewer is an embedded Web browser used mainly to display

■

Machine Edition help.

■

Machine Edition reports.

■

The documentation associated with a project or target.

If you are familiar with Internet Explorer or Netscape Navigator, then you are

already familiar with the basic InfoViewer interface. Like the Companion, the

InfoViewer is context-sensitive. Press F1 to get help on any item you select in the

Machine Edition environment. A table of contents is found in the InfoView tab of

the Navigator.

Want to know more?

In the Help Index, look up “Tools: an Overview”.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 15

Page 22

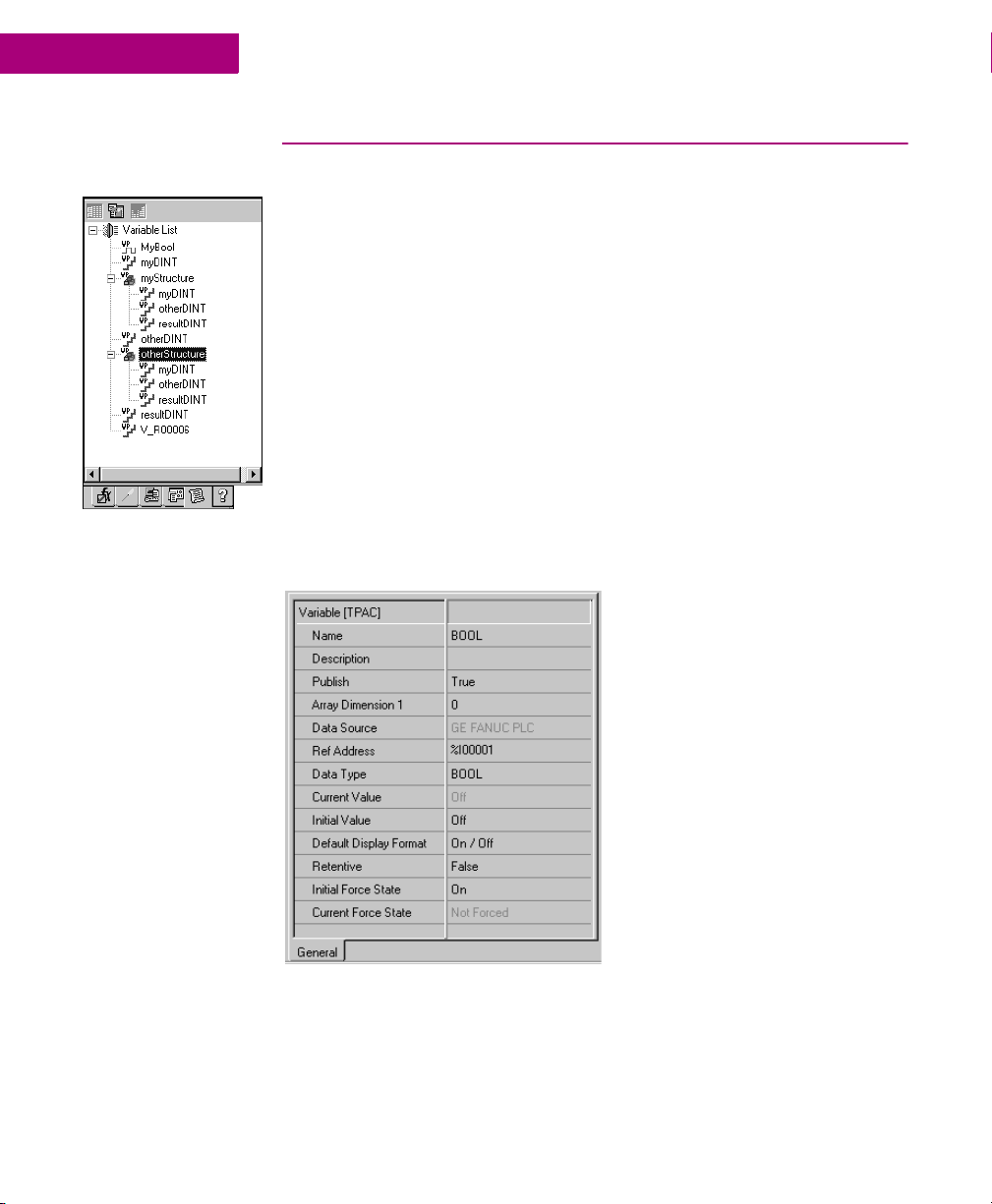

Navigator: Variables tab

2

CIMPLICITY Machine Edition

Variables

VARIABLES

A variable (sometimes called a tag) is a named storage space for data values.

All variables in a project are displayed in the Variables tab of the Navigator. A

variable represents a memory location in the target PLC. Each variable must be

mapped to a reference address (for example, %R00001) for all PLC families except

PACSystems™ RX7i. On a PACSystems™ RX7i, if you don’t map to a specific

reference address, it is considered a symbolic variable. Machine Edition handles

all the mapping for you in a special portion of PACSystems™ user space memory.

The reference address and other properties of a variable, such as data type, are

configured in the Inspector.

Arrays and compound structure variables are supported by Machine Edition.

Variable definitions can be imported from and exported to a variety of file types.

You can edit your variables in a spreadsheet and then import them. Logic

Developer - PLC variables, that is, variables used on GE Fanuc PLC and

PACSystems™ targets, can be viewed in CIMPLICITY View.

shows the Inspector displaying a typical set of variable properties.

The following diagram

16 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 23

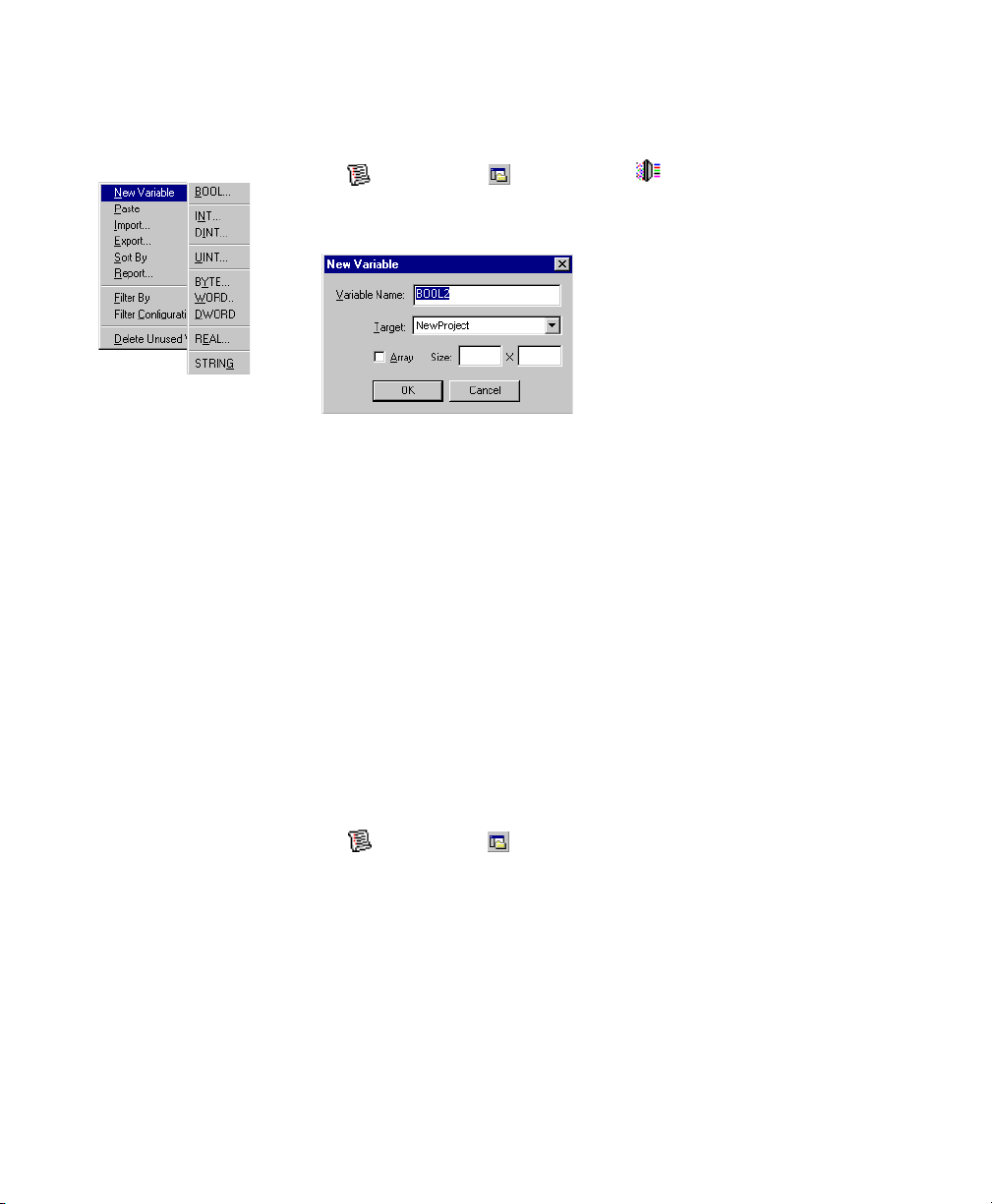

To create a variable

New Variable menu

CIMPLICITY Machine Edition

Variables

1. In the Variables tab of the Navigator, right-click Variable List, point to New Variable and then

choose the data type of the variable.

The New Variable dialog box appears.

2. Type a name for the variable and press ENTER.

Variable names can range from 1 to 32 characters, begin with a letter, contain

upper or lower case letters, use numbers between zero and nine, and use the

underscore character (“_”).

3. Select the target the variable will be used in.

4. If the new variable is an array, select the Array check box and enter the size(s).

5. Click OK.

A new variable with a default name appears in the list.

To map a variable to PLC memory

In order to successfully download a project to the PLC, variables must be properly

mapped to the PLC’s memory, unless they are symbolic variables, which a

PACSystems™ RX7i will automatically map for you. There are two ways to map a

non-symbolic variable.

First method:

1. In the Variables tab of the Navigator, right-click a variable and choose Properties.

The Inspector displays the properties of the variable.

2. In the Ref Address field, enter an address. You can:

■

Spell out the exact address, for example, %R00123 or 123R. In either case this

maps the variable to %R00123.

■

Enter only the memory area, for example %R. This maps the variable to the next

highest available address. For example, if %R00122 was the last address used,

entering %R maps the variable to %R00123.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 17

Page 24

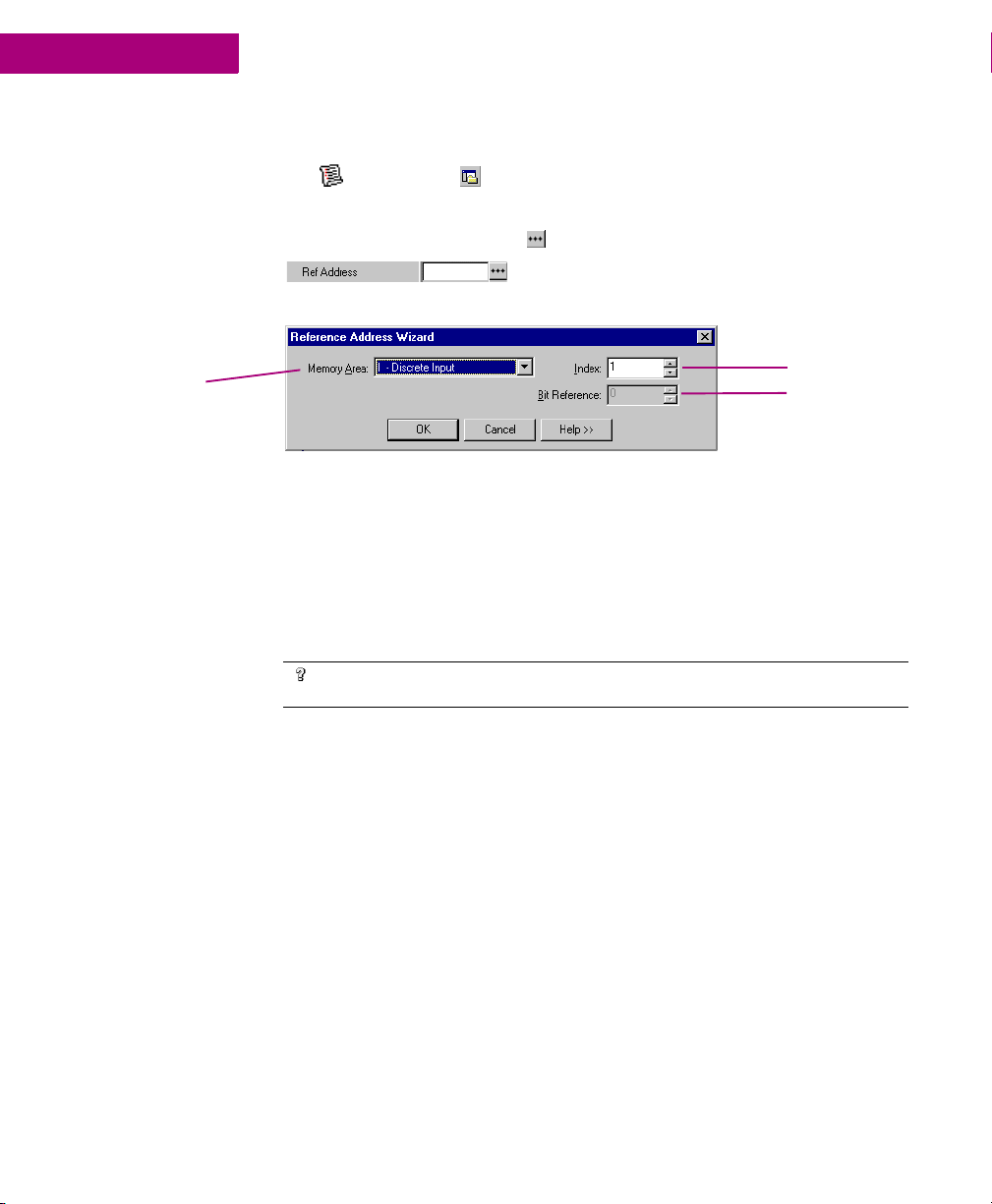

2

CIMPLICITY Machine Edition

Variables

Second method:

1. In the Variables tab of the Navigator, right-click a variable and choose Properties.

The Inspector displays the properties of the variable.

2. Click the Ref Address field and then click the button.

The Reference Address Wizard appears.

Select a region of

Select an index

Select a bit reference

for a BOOL variable in

16-bit memory.

3. From the Memory Area list, choose a region of PLC memory.

4. In the Index box, enter an index from the beginning of the region.

5. Select a bit reference.

The Bit Reference box is available only if you're mapping a BOOL variable to 16bit memory area on a PACSystems™ PLC.

6. Click OK.

Your variable is mapped to the Reference Address.

Want to know more?

In the Help Index, look up “Variables”, “Importing variables from a file”,

“Symbolic Variable”, and “Bit addressing in 16-bit memory”.

18 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 25

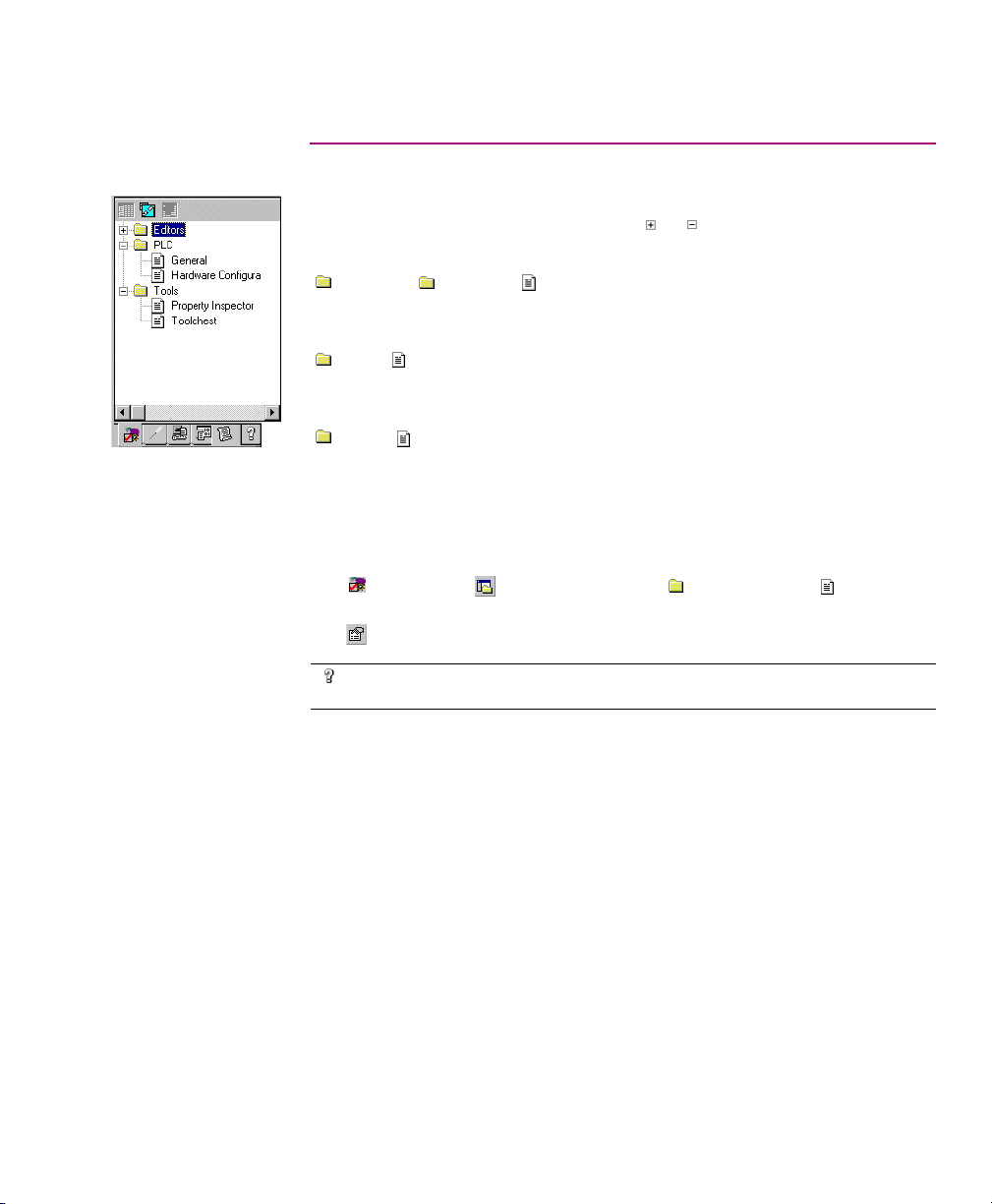

Navigator: Options tab

To set options and preferences

1. In the Options tab of the Navigator, expand an options folder and right-click a page within the

2. In the Inspector, edit the option’s settings as needed..

CIMPLICITY Machine Edition

Options

OPTIONS

The Options tab of the Navigator contains option and preference settings. Options

are organized into folders and pages. Click or to expand or collapse folders.

Examples:

Editors > Ladder > View >Coil Justification: The leftmost column in

which coils can be placed; also the column where the right power rail resides. The

default is 10.

PLC> General > Duplicate Addresses: Indicates whether to prevent, warn

about, or ignore mapping two variables of the same data size (1, 8, 16, 32, or 64

bits) and length (array size) to the same reference address.

PLC > Hardware Configuration >New Reference Assignment: The way in

which default reference addresses will be assigned when modules are added to the

Hardware Configuration.

folder to display the option’s properties in the Inspector.

Want to know more?

and “General Options”.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 19

In the Help Index, look up “Options”, “Confirmations”, “PLC Options”,

Page 26

To use Companion help

2

CIMPLICITY Machine Edition

Machine Edition Help

MACHINE EDITION HELP

CIMPLICITY Machine Edition includes a comprehensive online help system that

enables you to access specific help topics while working with Machine Edition.

Use the InfoViewer or Companion to access help.

Companion Help

The Companion is a Machine Edition help system that provides useful tips and

information while you work. While the Companion is open, it displays help on

whatever item is currently selected in the Machine Edition environment, tracking

your movements while you work.

1. Ensure the Companion window is open. To open it, press Shift+F11.

2. Click on any item on the screen.

A description of the item you clicked appears in the Companion.

InfoViewer Help

The InfoViewer, another Machine Edition help system, provides detailed

information. The InfoViewer has its own toolbar for navigating the help system, a

Table of Contents (in the InfoView tab of the Navigator), and a searchable index. As

with the Companion, InfoViewer help is context-sensitive. Click an item on the

screen and press F1 to display the appropriate topic in the InfoViewer.

20 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 27

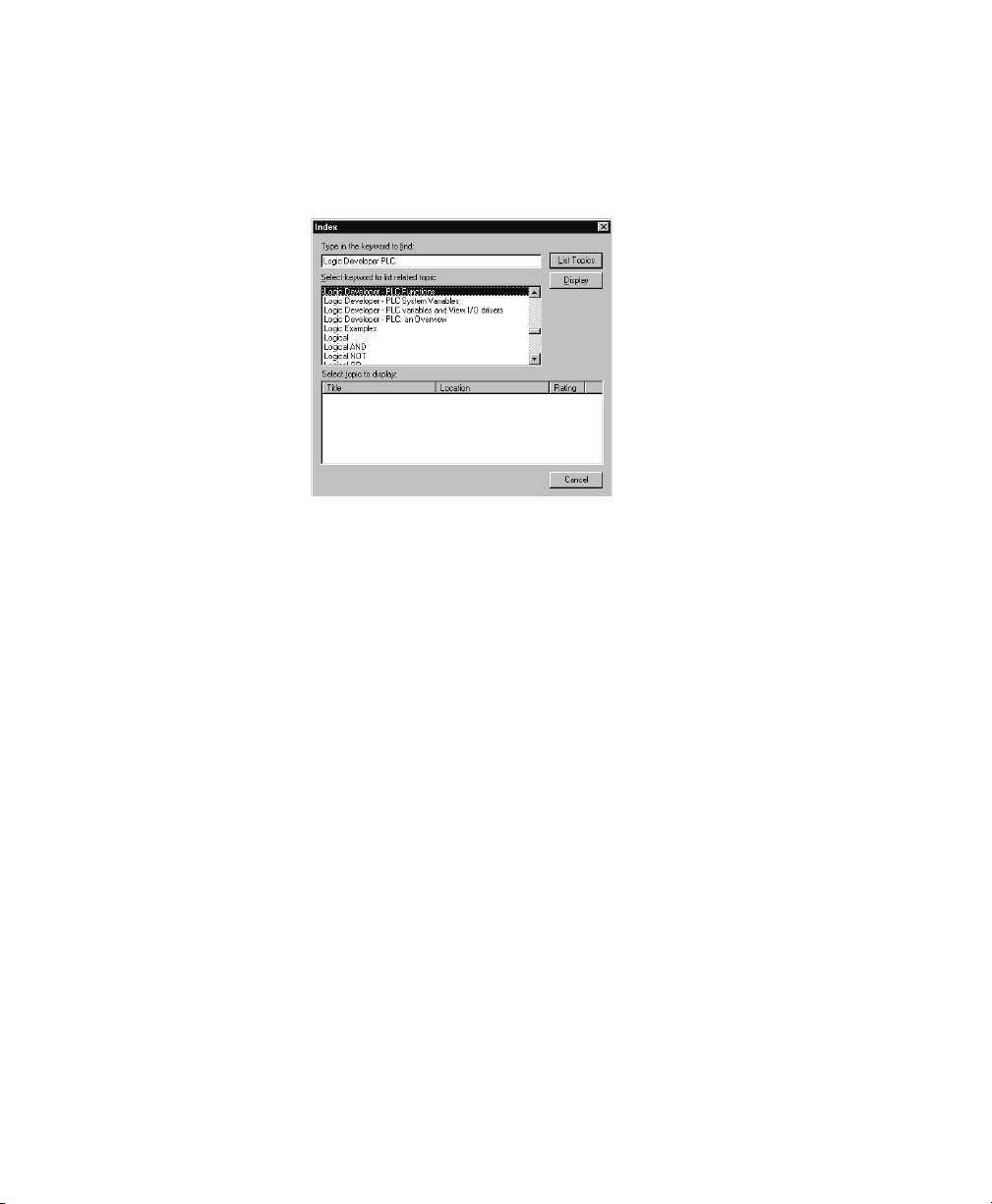

To use the Help index

CIMPLICITY Machine Edition

Machine Edition Help

1. From the Help menu, choose Index.

The Index dialog box appears.

2. Enter a keyword in the top text box or select one in the middle text box.

3. Click List Topics.

A list of topics appears in the bottom text box. The topics are sorted by their rating

or likelihood of containing the correct information.

4. In the bottom text box, select a topic to display.

5. Click Display.

The selected Help topic is displayed in the InfoViewer.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 21

Page 28

2

CIMPLICITY Machine Edition

Machine Edition Help

To look up topics in the Help Table of Contents

1. Open the InfoView tab of the Navigator.

A table of contents for the entire help system appears.

2. Expand Libraries and Books to locate a topic of interest

3. Double-click a topic.

The topic is displayed in the InfoViewer.

Navigator: InfoView Tab

22 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 29

3

Navigator: New PACSystems™ Project

GE Fanuc PLC Targets

A target represents a run-time destination of the programs you develop with

Logic Developer - PLC. Each target contains all of the components that will

download to it. Logic Developer - PLC supports the following GE Fanuc PLC target

families:

■

PACSystems™ RX7i

■

Series 90™-70 PLC

■

Series 90™-30 PLC

■

VersaMax® PLC

■

VersaMax® Nano/Micro PLC

■

Series 90™ Micro PLC

and the following remote I/O interface targets:

■

GE Fanuc Series 90™-70 Genius Remote I/O Scanner

■

GE Fanuc VersaMax® Ethernet

■

GE Fanuc VersaMax® Genius

■

GE Fanuc VersaMax® Profibus

CIMPLICITY Logic Developer - PLC Version 4.00 23

Page 30

3

To add a target to a project

GE Fanuc PLC Targets

Addinging, Configuring and Converting Targets

ADDINGING, CONFIGURING AND CONVERTING

TARGETS

Adding Targets

Normally a target is present in a project when you use a template to create the

project (see page 12). A project can contain multiple targets. The actual largest

number possible may vary, depending on the available memory on your computer,

the operating system you are using, or the available disk space, etc.

One target is required for each PLC or remote I/O adapter your project accesses,

except when you are using CPU redundancy. In this case, one target contains a

Primary Hardware Configuration and a Secondary Hardware Configuration, which

respectively correspond to the primary PLC and the redundant PLC. For more

information, see page 50.

Existing targets can be converted from one GE Fanuc PLC family to another. For

more information, see page 26.

1. In the Project tab of the Navigator, right-click the Project node and point to Add Target.

2. Point to GE Fanuc PLC or GE Fanuc Remote I/O and then respectively choose the PLC family or the Remote

I/O.

Project right-click menu

24 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 31

GE Fanuc PLC Targets

Addinging, Configuring and Converting Targets

Configuring Targets

The properties of a target specify the PLC family, the communication connections

between your computer and the PLC, and various other settings. All properties are

edited in the Inspector. The following table describes a PLC target’s properties:

To configure a PLC target

Name

Type

Edit the name for your target in this field.

The type of target is set by default to GE Fanuc PLC. Note:

Logic Developer - PLC is operational with GE Fanuc PLCs only.

Description

Enter a description of your project in this field. The maximum

characters is 255.

Documentation Address

Family

PLC Target Name

Update Rate (ms)

Sweep Time (ms)

Enter the URL where your project documentation is stored.

By changing the PLC type in this field, you initiate a target

conversion.

Caution: Changes are irreversible.

The name of the target as stored on the PLC target.

Set the rate at which the screen is updated while online.

The sweep time of the PLC when online is also displayed on

the status bar.

PLC Status

Dual HWC

The online/offline, run/stop status of the PLC.

(Series 90™-70 only.) Indicates whether HWC redundancy is

set up. Change the field to False to delete the secondary HWC.

Selected HWC

(Displayed only if Dual HWC is set to True.) Change the

selected HWC in this field.

Physical Port

Choose the type of connection to the PLC (Ethernet, COM, or

modem).

IP Address

Additional Configuration

(Ethernet protocol only.) Set the IP address of the PLC.

Group of properties used for the detailed configuration of your

communication connection.

1. In the Project tab of the Navigator, right-click a target and choose Properties.

The properties of the target appear in the Inspector.

2. In the Inspector, configure the properties as needed.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 25

Page 32

To convert a target

3

GE Fanuc PLC Targets

Addinging, Configuring and Converting Targets

Converting Targets

With Logic Developer - PLC, you can convert targets from one GE Fanuc PLC

family type to another. This enables you, for example, to take logic written for a

Series 90™-70 PLC and convert it for use on a PACSystems™ RX7i. However,

target conversions are irreversible; when logic blocks are deleted during a

conversion, they cannot be restored. It is recommended that you make a backup of

your project before converting a target in it. There may also be execution

differences when converting an application from one GE Fanuc PLC family type to

another. You must validate the application execution prior to deployment into a

production environment.

1. In the Project tab of the Navigator, right-click an existing target and choose Properties.

The Inspector displays the target’s properties.

2. In the Inspector, click Family.

3. From the list, choose the new PLC Family you want to convert the target to.

Target conversion involves the following changes:

■

Stripping all the configured modules from the original Hardware Configuration

(HWC) and setting up the destination family’s default HWC, with a single

power supply and a CPU.

Note: PACSystems™ RX7i supports many Series 90™-70 modules and some

Series 90™-70 expansion racks. When converting a Series 90™-70 target to a

PACSystems™ RX7i target, the supported modules and expansion racks are

retained (with rare exceptions). The modules’ parameters are also retained or

26 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 33

GE Fanuc PLC Targets

Addinging, Configuring and Converting Targets

converted to the nearest equivalent. Unsupported expansion racks are

converted to the nearest equivalent. which retains the supported modules. All

Hardware Configuration changes made during the conversion are documented

in a target conversion report.

■

Deleting or adding target components, blocks, and/or programs.

■

Updating the system variables, including the fault locating references.

■

Displaying a conversion report in the InfoViewer when converting to

PACSystems™ targets only

Warning: Changing the PLC Family can result in logic in your project becoming

invalid.

Note: PLC hardware must be configured before it will be operational. For detailed

information on hardware configuration, see page 46..

Want to know more?

In the Help Index, look up “Target Conversions (GE Fanuc PLC Targets)”.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 27

Page 34

3

GE Fanuc PLC Targets

Configuring Communication

CONFIGURING COMMUNICATION

In order for Logic Developer - PLC to communicate with a target PLC, a

connection must be properly configured. The properties of a target are adjustable

to accommodate your connection(s).

To configure an Ethernet or serial connection

1. In the Project tab of the Navigator, right-click a target and choose Properties.

The Inspector opens showing the target’s properties.

2. In the Inspector, set the Physical Port property to Ethernet or a COM port (or a modem if one is installed).

3. If the Physical Port is Ethernet, enter the IP Address of the target PLC.

Note: You can connect to a GE Fanuc PACSystems™ RX7i by means of Ethernet

only.

4. Double-click Additional Configuration to access the detailed settings for your connection.

Note: Serial communication with a non-PACSystems™ PLC is always available if it

is the only device connected and an SNP_ID is not specified. An IP address must

be set in the PLC before an Ethernet link can be established.

Want to know more?

In the Help Index, look up “Configuring a direct connection”.

Configuring Communication for PACSystems™

The only communication method supported by a PACSystems™ is Ethernet. This

ensures fast communication, because every PACSystems™ has an embedded

Ethernet adapter.

To configure communication with a PACSystems™ RX7i

1. Physically connect the PACSystems™ RX7i to the Ethernet network.

2. Set up a temporary IP address. For more information, see “To set a temporary IP address for a PACSystems™ RX7i”.

The temporary IP address enables you to communicate with the PACSystems™

RX7i the first time.

3. Do one of the following:

If there is already a hardware configuration stored on the PACSystems™ RX7i

target, it contains a permanent IP address. To obtain this permanent IP address

from the PACSystems™, upload the hardware configuration from the

PACSystems™ RX7i.

- OR -

28 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 35

Set up a permanent IP address. For more information, see “To set a permanent IP

address for a PACSystems™ RX7i”.

To set a temporary IP address for a PACSystems™ RX7i

1. In the Utilities tab of the Navigator, double-click Set Temporary IP Address.

The Set Temporary IP Address dialog box appears.

GE Fanuc PLC Targets

Configuring Communication

2. In the MAC Address field, specify the MAC address for the PACSystems™ RX7i.

3. In the IP Address to Set field, specify the temporary IP address you want to set on the PACSystems™ RX7i.

4. If required, select the Network Interface Selection check box and specify the network interface the PACSystems™

RX7i is located on.

5. Click the Set IP button.

The IP address of the specified PLC or device is temporarily set to the indicated

address.

Warning: The IP address set by the Set Temporary IP Address utility will not be

retained through a power cycle. If you want to set a permanent IP address, you

must do so by other methods.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 29

Page 36

3

GE Fanuc PLC Targets

Configuring Communication

To set a permanent IP address for a PACSystems™ RX7i

1. In the Project tab of the Navigator, right-click the target and choose Properties.

The Inspector displays the target’s properties.

2. In the IP Address property, enter an IP address.

3. Download the hardware configuration to the PACSystems™ RX7i. For more information, see page 35.

Note: Ensure that you have configured the rest of the hardware configuration

before downloading it.

Want to know more?

PACSystems™ RX7i” and “Set Temporary IP Address utility”.

Configuring Communication for non-PACSystems™ PLCs

To set an IP address for Series 90™-70 PLCs

1. In the Project tab of the Navigator, expand the Hardware Configuration node.

2. Expand the Main Rack and double-click the slot where you want to add a communications module.

The Module Catalog appears.

3. Choose the Communications tab and select the communications module you want to add.

Select either IC697CMM741 or IC697CMM742.

4. Click OK.

The Parameter editor opens showing the configuration settings for the module.

5. In the Settings tab, double-click the IP Address parameter.

In the Help Index, look up “Configuring communication with a

30 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 37

The IP Address dialog box appears..

6. Enter the IP Address and click OK.

To set an IP address for a Series 90™-30 CPU364 or CPU374

Note: For CPU364 and higher-end Series 90™-30 CPUs, the Ethernet adapter is

built into the CPU. For other Series 90™-30 CPUs, the Ethernet connects through

an optional expansion slot on the rack.

1. Obtain an IP address, perhaps from your network administrator.

2. In the Project tab of the Navigator, expand the Hardware Configuration node to reveal the rack and

slot containing a CPU364 or CPU374.

3. Right-click the slot containing the CPU364 or CPU374 and choose Configure.

The Parameter editor appears.

4. In the Parameter editor, click the Ethernet tab.

The Parameter editor displays the contents of the Ethernet tab.

GE Fanuc PLC Targets

Configuring Communication

5. Double- click the IP address parameter.

The IP Address dialog box appears

6. Enter the IP address in the box and click OK.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 31

Page 38

3

GE Fanuc PLC Targets

Configuring Communication

To set an IP address for other Series 90™-30 CPUs (not CPU364 or CPU374)

1. In the Project tab of the Navigator, expand the Hardware Configuration node.

2. Right-click the slot containing an Ethernet Interface Module (IC693CMM321)and choose Configure.

The Parameter editor opens showing the configuration settings for the module.

3. In the Settings tab, double-click the IP Address field.

The IP Address dialog box appears.

4. Enter the IP address and click OK.

To download an IP address to a non-PACSystems™ target

1. Configure a CPU or Ethernet COM Module with an IP address using Hardware Configuration.

2. Right-click the target and choose Properties.

The Inspector displays the target’s properties.

3. In the Physical Port property, select a serial connection.

4. Right-click the target and choose Go Online.

5. Right-click the target and choose Download to PLC.

The Download to PLC dialog box appears.

6. Select Hardware Configuration and click OK.

The IP address is assigned to the PLC.

7. Right-click the target anch choose Go Offline.

8. Right-click the target and choose Properties.

9. In the Physical Port property, select Ethernet.

The next time you go online, Machine Edition will use an Ethernet connection with

the specified IP address.

32 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 39

To validate a target

GE Fanuc PLC Targets

Interacting with the PLC

INTERACTING WITH THE PLC

Communicating with the PLC is necessary to perform such operations as storing

and loading programs or monitoring data values and PLC status information. You

can connect to a PLC from Logic Developer - PLC over a serial, Ethernet or modem

connection, depending on the capabilities of the PLC.

All interactions with a target are available from the target’s right-click menu.

Validating a Target

Validating your project detects any syntax errors that may be present. Error

messages are generated for each error and displayed in the Feedback Zone. A

project containing errors cannot be downloaded. For that reason, whenever you

initiate a download, the logic is automatically validated.

• In the Project tab of the Navigator, right-click a target and choose Validate.

Logic Developer - PLC checks all items under the target for syntax errors. Any

errors detected are noted with messages in the Build tab of the Feedback Zone.

Tip: Double-click an error message to locate the noted error in your project. The

appropriate editor or tool opens automatically with the item in question selected.

Tips showing you how to proceed are displayed in the Companion. To open the

Companion, press

SHIFT + F11.

Online/Offline

When offline from a target PLC, there is no ongoing communication between the

PLC and your development computer. When offline from the target PLC the

number and type of interactions available are limited, and the actual

communication link is not required as long as you only edit logic. If a

communication link has been configured and the Offline PLC Operations option is

enabled, you can:

■

Download to the PLC .

■

Upload from the PLC.

■

Start the PLC.

■

Stop the PLC.

■

Clear the PLC.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 33

Page 40

3

GE Fanuc PLC Targets

Interacting with the PLC

When you issue such commands, the communication link becomes active while

performing the operation and then returns to an idle state. When the Offline PLC

Operations option is disabled, the only PLC operation you can perform while

offline is to go online.

Note: You enable or disable the PLC Offline Operations option in the Options tab

of the Navigator. For more information, see page 19.

While online to a target PLC, a communication link exists and is active and you

have an ongoing real-time communication with the PLC. You can perform

commands to monitor and control the PLC’s action and memory including the

commands available when offline. Also, while online, the LD editor displays a

graphical representation of LD logic as it executes, if the PLC’s project is equal to

the current project. You can edit LD logic while online; you are prompted to

download your word-for-word changes. For more information on word-for-word

changes, see page 73.

To go online to a PLC

To go offline from a PLC

Want to know more?

• In the Project tab of the Navigator, right-click a target PLC and choose Go Online.

Logic Developer - PLC connects your project to the PLC. The online status is

indicated by the target icon in the Project tab and on the status bar.

Note: When online to a PLC, the target icon in the Project tab of the Navigator

appears as (equal), (not equal), or (stop faulted).

• In the Project tab of the Navigator, right-click a target PLC and choose Go Offline.

Logic Developer - PLC goes offline.

Want to know more?

from a PLC”.

In the Help Index, look up “Offline versus Online”.

In the Help Index, look up “going online with a PLC” and “going offline

34 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 41

To download to a target PLC

1. In the Project tab of the Navigator, right-click the target to which you want to download files and

GE Fanuc PLC Targets

Interacting with the PLC

Upload/Download

The download process creates (or builds) and validates all runtime files necessary

for a target to perform its role in a completed project. The compiled project is then

transferred to the target hardware via the communication connection previously

configured. For more information, see page 28.

The upload process acquires a project from an active PLC target and transfers it to

Logic Developer - PLC for editing.

choose Download to PLC.

The Download to PLC dialog box appears.

Note: If the PLC is running, you can download only logic that is not equal to the

PLC’s current logic and the Download to PLC dialog box does not appear.

2. Choose the items you want to download and click OK.

Tip: To download files for all targets in a project, right-click the project node and

choose Download All. If you want to download files to the active target, choose

Download Active Target.

Note: Only one project can be downloaded to a target at a time. If you download

to a target machine that already has a project on it, the existing project is

overwritten.

For each target that you download to, Machine Edition saves the project, performs

a validation, builds the runtime files and attempts to establish a connection to the

target. Any errors that occur are displayed in the Build tab of the Feedback

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 35

Page 42

3

GE Fanuc PLC Targets

Interacting with the PLC

Zone. If connection to a target is successful, Machine Edition sends all the

necessary runtime files to the PLC.

To upload files from a PLC

Want to know more?

1. In the Project tab of the Navigator, right-click the target PLC from which you want to upload

information and choose Upload from PLC.

The Upload from PLC dialog box appears.

Note: If you are uploading from Logic Developer - State, only the Hardware

Configuration can be uploaded.

2. Choose the item(s) you want to upload and click OK.

Logic Developer - PLC connects to the PLC and uploads the selected item(s) to

Logic Developer - PLC. If you already had a version of the PLC’s project open, the

uploaded project merges with the existing project. This ensures that all variable

names are retained throughout the uploading process. If you upload to an empty

target, all variables are assigned default names. For example, %R00001 is named

R00001.

Want to know more?

In the Help Index, look up “downloading to PLC”.

In the Help Index, look up “uploading from PLC”.

Run/Stop

You can set a target PLC to Run or Stop mode. In Stop mode, you can choose to

enable or disable the outputs.

If you are starting a PACSystems™ RX7i or Series 90™-70 PLC, you can choose to

have outputs enabled or disabled.

36 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 43

To start a PLC

To stop a PLC

GE Fanuc PLC Targets

Interacting with the PLC

• In the Project tab of the Navigator, right-click a target, point to Online Commands or to Offline

Commands, and then choose Start PLC.

The target PLC begins executing its program.

1. In the Project tab of the Navigator, right-click a target, point to Online Commands or to Offline

Commands, and choose Stop PLC.

The Stop PLC dialog box appears, prompting you to enable or disable the PLC’s

outputs.

2. Select an option.

3. Click OK.

The target PLC stops executing its program.

Want to know more?

In the Help Index, look up “starting the PLC” and “stopping the PLC”.

Fault Tables

The PLC and I/O Fault Tables display fault information logged by the CPU or

modules in the PLC. This information is used to determine if there are problems

with the PLC hardware or software running in the PLC’s CPU. To view the PLC and

I/O fault tables, your computer must be online to the PLC.

To view the fault table reports

• In the Project tab of the Navigator, right-click the target you want to report on and choose

Diagnostics.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 37

Page 44

3

Choose the type of

fault information you

require.

Print fault table by

clicking here .

Select the format of

fault data.

Sort fault

information.

Clear fault

informat ion by

clicking here.

GE Fanuc PLC Targets

Interacting with the PLC

The fault table appears in the InfoViewer window.

Indicates on line

status of PLC.

View the date and

time of the faults.

Double-click a row to

view details of faults.

Want to know more?

In the Help Index, look up “fault”, then select “Working with the Fault

Tables”.

Reference View Tables

The Reference View Tables (RVTs) are tables of reference addresses that can be

monitored and changed in real-time. In the Project tab of the Navigator the

Reference View Tables folder contains a Default Tables folder and you can

add user-defined tables to the Reference View Tables folder. A target can have

zero or more user-defined RVTs.

The number of entries contained in an RVT does not affect performance.

Performance is affected only by the number of entries that are displayed and have

to be updated in the view.

An RVT displays data when the parent GE Fanuc PLC target is active and online.

You can configure the appearance of your RVTs in the Options tab of the

Navigator.

38 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 45

Format of selected address

GE Fanuc PLC Targets

Interacting with the PLC

Data values at sequential addresses are displayed, by default, from right to left,

starting at the reference address specified. Both default and user-defined RVTs

display rows of 8 cells for discrete memory and rows of 10 cells for register

memory. The amount of data displayed in the columns depends on the data

display format.

Starting AddressSelected address

Subsequent addresses

are displayed right to

left by defaul t.

This is the data at the

starting address.

Display format can be

selected for individual

cells or the entire

table.

To create a user-defined Reference View Table

• In the Project tab of the Navigator, right-click on the Reference View Tables folder and choose New.

A new Reference View Table with a default name is added to the folder.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 39

Page 46

3

GE Fanuc PLC Targets

Interacting with the PLC

To work with a Reference View Table

1. n the Project tab of the Navigator, expand the Reference View Tables folder and double-click the

table you want to view.

The Reference View Table appears in the Machine Edition main window.

2. Add reference addresses to the table as required.

Note: You cannot add reference addresses to a default RVT.

3. Format the table entries as desired.

Navigator: Project Tab

Reference View Table node

Want to know more?

In the Help Index, look up “RVT”, then select “Working with Reference

View Tables.

Reports

Reports provide summaries and tables of information about your project. Most

reports are displayed in the InfoViewer window (see page 20). The Reports tab of

the Feedback Zone contains a list of all reports generated since the last

Machine Edition project was opened. The following list shows the types of reports

and logic printouts available in Logic Developer - PLC:

Address Use report C block report* Online Force Report

Hardware Configuration report IL block report*

Variables report(s) Local Logic block report *

CAM profile report Motion block report*

Notes

■

An asterisk (*) indicates a logic printout.

■

Reports are not generated for LD blocks. Rather, these blocks are printed

directly from the Program Blocks node.

To generate reports

• In the Project tab of the Navigator, right-click a node and choose Report to generate a report on that

node.

A report is automatically generated and displayed in the InfoViewer.

40 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 47

Note: To generate an Online Force report for a target, you must be online to the

target. Right-click the target, point to Online Commands, and then choose Online

Force Report.

To redisplay a previously generated report

1. In the Feedback Zone, double-click the Reports tab.

A list of previously generated reports appears in the Feedback Zone.

2. From the list choose the report you want to view.

The report displays in the Infoviewer.

Many items in a report contain hyperlinks. Click a hyperlinked item to jump to that

item in the project. For example, if a variable's name appears hyperlinked in a

report, clicking it selects that variable in the Variables tab of the Navigator.

Large reports are often separated into several pages. To view a different page of the

report, scroll to the bottom of the report in the InfoViewer and click the number of

the page you want to view.

To print a report displayed in the InfoViewer

1. Do one of the following:

■

Generate the report you want to print.

- OR -

■

Redisplay a previously generated report.

2. When the report is displayed, right-click the InfoViewer window and select Print.

GE Fanuc PLC Targets

Interacting with the PLC

Want to know more?

In the Help Index, look up “Reports”.

To print LD Blocks

1. In the Project tab of the Navigator, expand the Logic node.

2. Right-click the Program Blocks node and choose Print LD Blocks.

The Print dialog box appears.

3. Select the blocks to print.

■

To print all of the target's LD blocks, select the All option.

■

To print only some of the target's LD blocks, select the Selection option, then

select the check box in front of each block you want to print.

4. Select options as required and click OK.

Want to know more?

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 41

In the Help Index, look up “printing LD logic”.

Page 48

Page 49

4

Power Supply

Hardware Configuration (HWC)

Logic Developer - PLC supports six GE Fanuc PLC families and various remote I/O

interfaces (see page 59) with a variety of CPUs, racks and modules for each. In

order to operate, PLC hardware must be configured with Logic Developer - PLC or

some other GE Fanuc tool. The HWC component of Logic Developer - PLC

provides a way to completely configure your target equipment. This chapter details

specifics on configuring PLC hardware for your operational needs.

The first step in configuring PLC hardware is to select the PLC you want to

configure (see page 24). When creating a new project, you can use a project

template containing default hardware configuration, or you can create an empty

project and configure it manually.

PACSystems™ RX7i

The PACSystems™ RX7i, pictured below, is the newest family of GE Fanuc PLCs.

Most of its features are based on the features of the Series 90™-70 PLC family. The

PACSystems™ RX7i’s Ethernet capabilities are based on the Series 90™-30

CPU364.

Rack

CPU

The PACSystems™ RX7i consists of a main rack and up to seven expansion racks.

The PACSystems™ RX7i supports two types of main racks, IC698CHS017 and

IC698CHS117. It supports five types of expansion racks, all of them Series 90™-70

racks. All main racks and expansion racks support three non-intelligent Series

90™-70 fan kits.

I/O Modul es

CIMPLICITY Logic Developer - PLC Version 4.00 43

Page 50

4

Hardware Configuration (HWC)

The PACSystems™ RX7i main racks have 18 single-width VME slots. Slot 0

supports two power supply modules: IC698PSA100 and IC698PSA350. Slots 1 and

2 are used to house a double-width CPU. PACSystems™ RX7i supports two CPUs

IC698CPE010 (300 mHz) and IC698CPE020 (700 mHz). The PACSystems™ RX7i

communicates through Ethernet only and the CPU has an embedded Ethernet

adapter. In addition to the Ethernet adapter, up to three IC698ETM001 Ethernet

modules can be installed in a PACSystems™ RX7i main rack. The Ethernet

modules occupy only one slot. All of the IC698 modules are supported only on the

main racks.

PACSystems™ RX7i supports several Series 90™-70 modules. Each one is doublewidth, that is, it occupies two slots on the main rack, but it occupies only one slot

on a Series 90™-70 expansion rack. You can plug double-width modules into any

two adjacent slots of the main rack except slots 0, 1, or 2. Because slot 17 is a

double-width slot, any module in slot 17 occupies only slot 17. Slot 17 can also

accept a single-width module.

PACSystems™ RX7i supports the following Series 90™-70 bus expansion

modules:

■

IC697BEM711

■

IC697BEM713

In addition to the Series 90™-70 support, PACSystems™ also supports numerous

Genius devices.

Configuring PACSystems™ RX7i Hardware

When you create a target with a PACSystems™ RX7i rack system, the default HWC

consists of the main rack, with a power supply in slot 0 and a single CPU in slots 1

and 2. You can change the default power supply and CPU, and add single-width

or double-width modules. You can add up to seven secondary racks, and on each

of these, you can add Series 90™-70 modules.

Note: On PACSystems™ RX7i targets, only one rack is added by default. On Series

90™-70 and Series 90™-30 PLCs, seven secondary racks are added by default to

the HWC. You do not need to add them.

The configuration of the PACSystems™ RX7i is detailed in the following

procedures. Configuration procedures for the other PLC types supported by Logic

Developer - PLC are almost identical.

Navigator: Project Tab displaying the

HWC node of a PACSystems™ RX7i

44 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 51

To choose a power supply

Hardware Configuration (HWC)

The default power supply for the PACSystems™ RX7i is the PSA100. To change the

power supply:

1. In the Project tab of the Navigator, right-click Slot 0 and choose Replace Module.

A list of available power supplies appears.

Note: For other GE Fanuc PLC families, there is no Slot 0. Right-click the PWR

node instead.

2. Select the power supply you have installed in your rack and click OK.

To choose a CPU

The default CPU specified in all project templates for a PACSystems™ RX7i is the

CPE010. To change the CPU:

1. In the Project tab of the Navigator, expand the Hardware Configuration folder.

All racks are revealed.

2. Expand the Main rack.

3. Right-click Slot 1 and choose Replace Module.

HWC right-click menu

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 45

Page 52

4

Hardware Configuration (HWC)

The Module Catalog dialog box appears.

4. From the list, select a CPU.

5. Click OK.

A dialog box appears asking if you want to retain the settings from the existing

CPU.

6. Click Yes or No.

Note: On targets other than PACSystems™, you are prompted to confirm the

replacement.

The target is configured with the selected CPU.

To configure a CPU

1. In the Project tab of the Navigator, right-click a slot containing a CPU and choose Configure.

The Parameter editor appears showing all configurable settings for the CPU.

46 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 53

2. Modify the settings as required. For information on any parameter, select the parameter.

Help is displayed in the Companion.

Tip: To open the Companion, press S

To add a secondary rack (PACSystems™ RX7i only)

Note: On Series 90™-70 and Series 90™-30 PLCs, seven secondary racks are

added by default to the HWC. You do not need to add them.

1. In the Project tab of the Navigator, right-click the HWC node and choose Add Rack.

The Module Catalog dialog box appears listing available rack types.

Hardware Configuration (HWC)

HIFT+F11.

Navigator: Project tab

PACSystems™ HWC configuration

2. Select a rack and click OK.

The Series 90™-70 expansion rack is added to the PACSystems™ RX7i rack

system. It is assigned an available number in the range of 1 through 7, excluding

numbers already assigned to other expansion racks.

To replace a rack

1. In the Project tab of the Navigator, right-click a rack node and choose Replace Rack.

The Module Catalog dialog box appears listing available rack types.

2. Select a rack and click OK.

Navigator: Project tab

HWC configuration

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 47

Page 54

4

Hardware Configuration (HWC)

To add a fan kit to a rack (PACSystems™ RX7i only)

1. In the Project tab of the Navigator, expand the Hardware Configuration folder.

2. Right-click a rack and choose Properties.

The rack’s properties are displayed in the Inspector.

3. In the Inspector, to the right of the Fan Catalog Number property, click .

The Fan Kits catalog opens.

4. Select the fan kit you want to add and click OK.

The fan kit is added to the rack.

To configure the Ethernet daughterboard (PACSystems™ RX7i only)

1. In the Project tab of the Navigator, expand the Hardware Configuration folder, then Rack 0 (the

Main rack), and then Slot 1.

2. Double-click Ethernet adapter.

The Parameter Editor window opens.

3. Configure the Ethernet adapter’s parameters as needed.

Navigator: Project tab PACSystems™

Ethernet Daughterboard

48 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Page 55

To add an Ethernet module (PACSystems™ RX7i only)

1. In the Project tab of the Navigator, expand the Hardware Configuration folder and then Rack 0

(the Main rack).

2. Right-click the slot you want to add an Ethernet module to and choose Add Module.

The Module Catalog opens.

3. In the Communications tab of the Module Catalog, select the Ethernet Module and click OK.

The Ethernet module is added to the slot.

4. Double-click the Ethernet module (IC698ETM001).

The Parameter Editor opens.

5. Configure the Ethernet module’s parameters as needed.

Hardware Configuration (HWC)

Want to know more? In the Help Index, look up “configuring a PACSystems™ RX7i Rack

System”.

GFK-1918D CIMPLICITY Logic Developer - PLC Version 4.00 49

Page 56

Basic CPU Redundancy

4

Hardware Configuration (HWC)

Redundancy (Series 90™-70 and PACSystems™ RX7i only)

In redundant systems, two units are set up and configured to share the

responsibility of a single unit. If one unit fails or is taken offline, the other unit

assumes responsibility without interrupting operation of the entire system.

There are three types of redundant systems:

■

Basic CPU Redundancy (Series 90™-70 only)

■

Genius Redundancy

■

CPU Redundancy Over Genius (Series 90™-70 only)

(Series 90™-70 CPUs CGR772 and CGR935 only.) To implement CPU

redundancy, a single target is associated with two physical PLCs, a Primary and

a Secondary. Both PLCs share the same logic, but each has its own Hardware

Configuration (HWC): Primary or Secondary. The selected HWC is the HWC that

you can go online with, download to, upload from, and so on.

Series 90™-70 rack systems support three types of basic CPU redundancy. These

redundant systems can be used in combination with Genius redundancy schemes.

■

Single Bus with Preferred Master - uses a single Genius bus with one or more

bus controllers in each PLC. The primary unit is always chosen as the active

unit when the units initially synchronize.

■

Single Bus with Floating Master - uses a single Genius bus with one or more bus

controllers in each PLC. No switchover occurs on initial synchronization to

make the primary unit the active unit.

■

Dual Bus with Floating Master - uses dual busses with one or more bus

controllers in each PLC. No switchover occurs on initial synchronization. Bus

Navigation: Project Tab

HWC Node

CPU Redundancy

(Series 90™-70 only)

50 CIMPLICITY Logic Developer - PLC Version 4.00 GFK-1918D

Switching Modules (BSMs) are required in accordance with configuration of a

dual bus network. This option provides redundancy of both the PLC and the I/O

bus.

Page 57

Genius Redundancy

CPU Redundancy Over Genius