Page 1

GE Fanuc Automation

Programmable Control Products

TCP/IP Ethernet Communications

for the Series 90™ PLC

User's Manual

GFK-1541B May 2002

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

GFL-002

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Master Genius PowerTRAC Series Six

CIMPLICITY Helpmate ProLoop Series Three

CIMPLICITY 90–ADS Logicmaster PROMACRO VersaMax

CIMSTAR Modelmaster Series Five VersaPoint

Field Control Motion Mate Series 90 VersaPro

GEnet PowerMotion Series One VuMaster

Workmaster

©Copyright 2002 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

Contents

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Introduction .........................................................................................................1-1

The Ethernet Interface.......................................................................................................1-2

Ethernet Interface Ports.....................................................................................................1-4

The Station Manager Software .........................................................................................1-7

Installation ...........................................................................................................2-1

Installing an IC693CMM321 Ethernet Interface Module................................................. 2-2

Installing an IC693CPU364 with Embedded TCP/IP Ethernet Interface .......................2-16

Installing an IC693 CPU374 with Embedded TCP/IP Ethernet Interface ......................2-30

Installing the IC697CMM742 Ethernet Interface ........................................................... 2-41

Programming SRTP Channel Commands........................................................3-1

The Communications Request .......................................................................................... 3-2

COMMREQ Function Block and Command Block .........................................................3-6

Channel Commands.......................................................................................................... 3-9

Status Data ......................................................................................................................3-31

Controlling Communications in the Ladder Program..................................................... 3-43

Programming Modbus/TCP Channel Commands...........................................4-1

Chapter 5

Chapter 6

The Communications Request .......................................................................................... 4-2

COMMREQ Function Block and Command Block .........................................................4-5

Modbus TCP Channel Commands.................................................................................... 4-8

Status Data ...................................................................................................................... 4-20

Controlling Communications in the Ladder Program..................................................... 4-26

Ethernet Global Data .......................................................................................... 5-1

Overview of EGD ............................................................................................................. 5-2

Configuring EGD............................................................................................................ 5-12

Adapter Names, Aliases, and Groups .............................................................................5-21

Exchange Status Word.................................................................................................... 5-23

Simple Network Time Protocol (SNTP)......................................................................... 5-25

Network Administration Support......................................................................6-1

IP Addressing.................................................................................................................... 6-2

Gateways........................................................................................................................... 6-4

Subnets and Multiple Gateways........................................................................................ 6-5

Configuring Multiple Gateways........................................................................................ 6-7

Network Address Naming Architecture............................................................................ 6-9

GFK-1541B iii

Page 4

Contents

Chapter 7

Troubleshooting...................................................................................................7-1

Diagnostic Tools Available for Troubleshooting.............................................................. 7-2

What to do if you Cannot Solve the Problem ...................................................................7-3

PLC Fault Table................................................................................................................ 7-4

Appendix A Glossary............................................................................................................... A-1

Appendix B Communications Port Characteristics ............................................................. B-1

RS-232, RJ-11 Serial Port................................................................................................ B-2

RS-485, 15-Pin, D-Type Port........................................................................................... B-4

10Base-T Port .................................................................................................................. B-6

10Base-T/100Base Tx Port .............................................................................................. B-8

10Base2 Port .................................................................................................................. B-11

AAUI Port...................................................................................................................... B-13

AUI Port......................................................................................................................... B-19

Appendix C PC Software Loader........................................................................................... C-1

Updating Firmware Under Windows............................................................................... C-2

Updating Firmware Under DOS and Windows 3.xx ....................................................... C-4

Appendix D Using the IC697CMM742 with PLC CPU Versions 4.12 - 5.50 ..................... D-1

Ethernet Interface Operational Restrictions..................................................................... D-6

Appendix E Translating PLC CPU Reference Addresses to Modbus Register Addresses

for the IC693CMM321....................................................................................... E-1

iv TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual– May 2002 GFK-1541B

Page 5

Contents

GFK-1541B Contents v

Page 6

Chapter

1

Introduction

This manual describes the following

Series 90-30 PLC TCP/IP Ethernet Interface (IC693CMM321)

Series 90-30 PLC CPU364 with embedded TCP/IP Ethernet Interface (IC693CPU364)

Series 90-30 PLC CPU374 with embedded TCP/IP Ethernet Interface (IC693CPU374)

Series 90-70 PLC TCP/IP Ethernet Interface (Type 2) (IC697CMM742)

The general term,

Interfaces require the more specific terms.

The Series 90-30 PLC CPU 364 and CPU374 are both modules that contain a PLC CPU and an

embedded Ethernet Interface. The general term Embedded Ethernet Interface will be used in this

manual to refer to these modules.

This chapter provides an overview of the Ethernet Interface and covers the following topics:

The Ethernet Interface

How to Make the System Work

Quick Guide to the Manual

Ethernet Interface

Ethernet Interfaces

, will be used in this manual except when differences in the

for the Series 90 PLC:

GFK-1541B 1-1

Page 7

1

g

The Ethernet Interface

The Ethernet Interface enables Series 90 PLCs to communicate with other Series 90 PLCs, with

with GE Fanuc PLC programming software, and with applications developed using the SRTP

protocol, such as CIMPLICITY® HMI.

The Ethernet Interfaces described in this manual have “client/server” capability. As a “client” the

Interfaces can initiate communications with other Series 90 PLCs containing Ethernet Interfaces.

This is done from the PLC ladder program using the COMMREQ function. As a “server” the

Interfaces respond to requests from other devices such as PLC programming software, a Host

computer running an SRTP application, or another Series 90 PLC acting as a “client”. No PLC

programming is required for server operation.

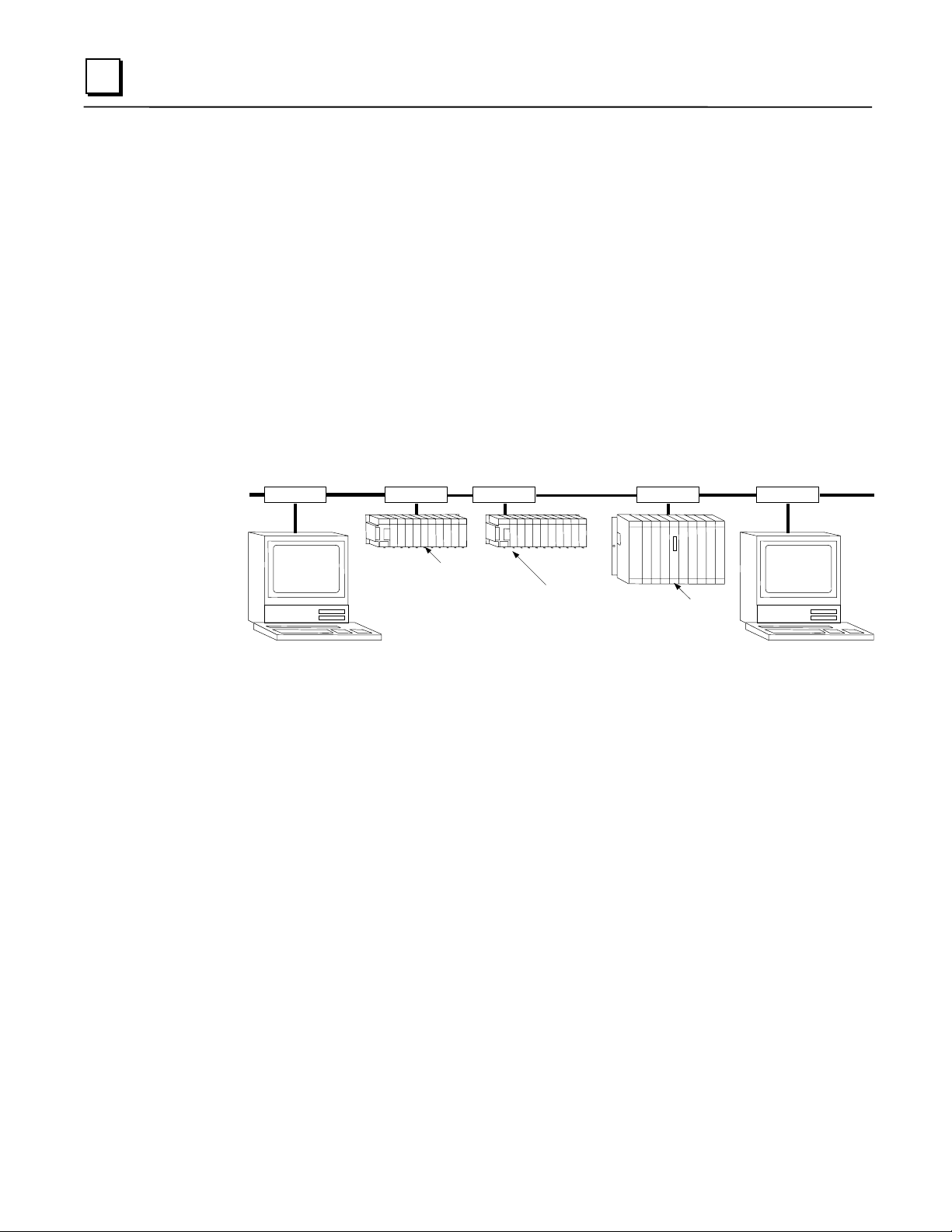

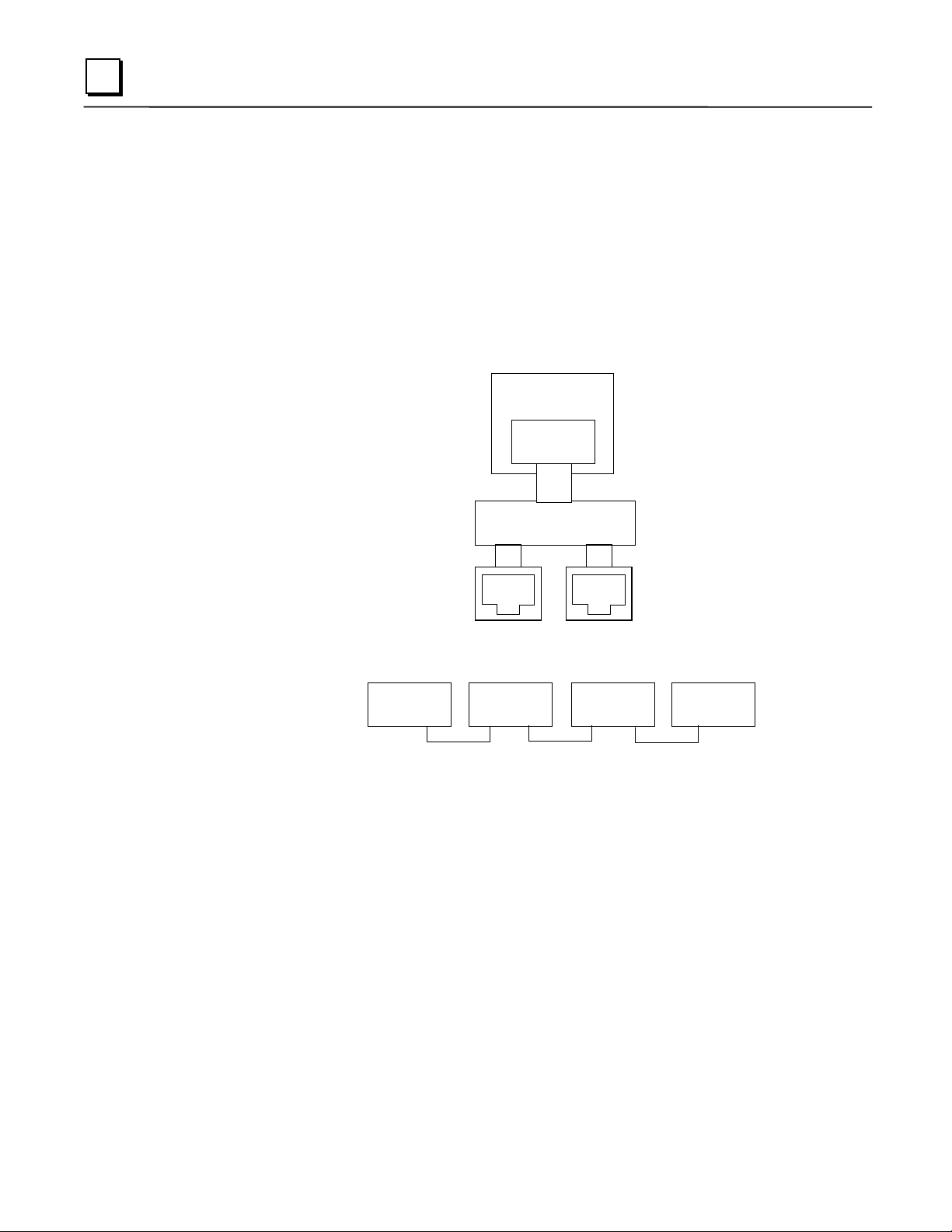

Ethernet Communications System

The diagram below represents a basic Ethernet Communications system.

Ethernet

Transceiver

Network

Connection

Cable

Transceiver

TransceiverTransceiver

Transceiver

Network

Connection

Series 90-30

CPU 364 or 374

with Embedded

Ethernet Interface

Host Computer or

Control Device Running an

SRTP Application

Series 90-30

PLC

Ethernet

Interface

® Windows is a registered trademark of Microsoft Corporation.

PLC

Series 90-70

PLC

Ethernet

Interface

Pro

rammer

1-2 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 8

Capabilities of the Ethernet Interface

The Ethernet Interface brings to your PLC a great deal of capability. It will allow you to:

Become operational quickly. The Ethernet Interface is made operational with very little effort.

You need only install the Interface in the PLC rack or baseplate and use the PLC

programming software to store basic configuration information to the module to make the

basic SRTP server capability functional. SRTP Client capability, the capability to initiate

communications, can be added using the COMMREQ function in the ladder program. For

Series 90-30 Ethernet Interface IC693CMM321-FH and later, basic Modbus/TCP server

capability is available as soon you supply basic configuration information to the module, and

you can use COMMREQs to initiate Modbus/TCP communications.

Directly attach your PLC to an Ethernet network. The Ethernet Interface allows you to directly

attach the Series 90 PLC to an Ethernet LAN via the built-in network ports or via a usersupplied transceiver and AUI or AAUI cable, and to communicate with host computers and

other Series 90 PLCs on the local network.

Ethernet Global Data. (Series 90-30 CPU364 and CPU374 and Series 90-70 Ethernet

Interface (Type 2) only.) When used with the latest Series 90 CPUs, the Ethernet Interface

provides highly efficient periodic data transfer between PLCs using Ethernet Global Data

exchanges.

Transfer data between PLCs.

to initiate communications to other Series 90 Ethernet Interfaces, using COMMREQ

functions in the ladder program.

Access data using a Host computer.

access data within the Series 90 PLC through the server capability of the Ethernet Interface. .

Communicate simultaneously to multiple devices. The multiplexing capabilities of the

Ethernet Interface, along with Ethernet network’s high capacity, allow the PLC to

communicate with several other devices at the same time.

Maintain compatibility with other GE Fanuc devices and devices from other vendors. The

Series 90-30 Ethernet Interface, Series 90-30 CPU364 Embedded Ethernet Interface, Series

90-30 CPU374 Embedded Ethernet Interface, and Series 90-70 Ethernet Interface (Type 2)

are compatible with each other. They are also compatible with GE Fanuc programming

packages supporting TCP/IP Ethernet communications.

Diagnose and maintain your system, using diagnostic and station management tools. You can

find problems before they become serious. In the event that communications software

upgrades are needed, you can use a built-in serial port to download the software to the

Ethernet Interface.

Indirectly attach to other Local Area Networks and/or wide area networks via third party IP

routers.

When configured to use an IP gateway (router), the Ethernet Interface can

communicate with remote PLCs and other nodes reachable through the router.

Communicate with remote computers via Serial Line Protocol (SLIP) using modems and/or

serial lines. Using third party SLIP software, a remote host computer can be attached to a

TCP/IP network.

Communicate with other Series 90 PLCs using symbolic names as well as IP addresses.

COMMREQs can be programmed to communicate with PLCs using IP addresses or Network

Address names (Series 90-30 Ethernet Interface, Series 90-30 CPU364 Embedded Ethernet

Interface, and Series 90-70 Ethernet Interface (Type 2)).

The Ethernet Interface provides client capability, the capability

Computer applications which use the SRTP protocol can

1

®Windows and Windows NT are registered trademarks of Microsoft Corporation.

GFK-1541B Chapter 1 Introduction 1-3

Page 9

1

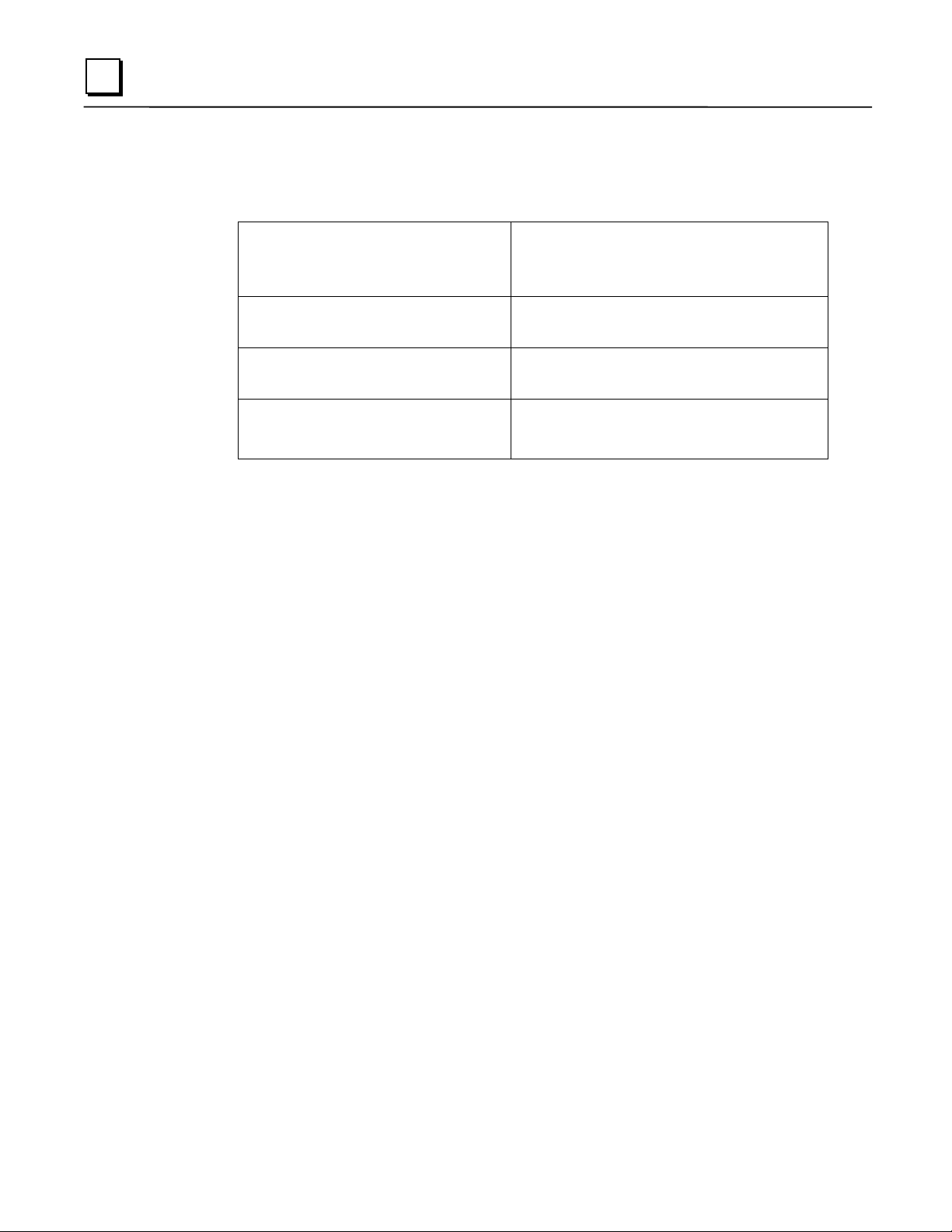

Ethernet Interface Ports

The Ethernet Interfaces provide ports for connection to the Ethernet network as listed below.

IC693CMM321 Series 90-30 TCP/IP

Ethernet Interface

IC693CPU364 Series 90-30 CPU with

Embedded TCP/IP Ethernet Interface

IC693CPU374 Series 90-30 CPU with

Embedded TCP/IP Ethernet Interface

IC697CMM742 Series 90-70 TCP/IP

Ethernet Interface (Type 2)

Port Descriptions

AAUI Port

10Base-T Port (RJ-45) (Module version

FG or later)

AAUI Port

10Base-T Port (RJ-45)

Auto-sensing 10Base-T Port (RJ-45)

10Base-T Port (RJ-45)

AUI Port

10Base2 Port (BNC)

10Base-T, RJ-45 port

and Series 90-70 IC697CMM742 Ethernet Interface (Type 2))

The 10Base-T port uses a twisted pair cable of up to 100 meters in length between each node and

a hub or repeater. Typical hubs or repeaters support 6 to 12 nodes connected in a star wiring

topology.

Auto-sensing 10 Base T / 100 Base TX, RJ-45 Port

The auto-sensing 10 Base T / 100Base TX ports are connected to a switch device embedded in the

Ethernet Interface. They use a twisted pair cable (unshielded or shielded) of up to 100 meters in

length between the node and another node, a hub, a repeater, or a switch. The port automatically

senses the speed (10Mbps or 100Mbps), duplex mode (half duplex or full duplex) and cable

(straight-through or crossover) attached to it with no intervention required.

10Base2, BNC port

The 10Base2 port uses a 0.2 inch diameter 50-ohm coaxial cable and is commonly called “thin

wire”. The maximum length of a cable segment is 185 meters. A maximum of 30 stations is

allowed on a 10Base2 Ethernet segment.

AUI Port

AAUI Port

The AUI and AAUI ports provide the electrical and mechanical interface to the user-provided

Ethernet transceiver cable, which connects the AUI or AAUI port to an external user-provided

transceiver. (The transceiver cable may be separate or built-in to the transceiver.) The external

transceiver is directly connected to the Ethernet cable.

(

Series 90-70 Ethernet Interface (Type 2))

(

Series 90-30 Ethernet Interface (AAUI-only Type) and Series 90-30 CPU364)

(Series 90-30 Ethernet Interface (10Base-T Type), Series 90-30 CPU364,

(Series 90-30 CPU374 only)

(Series 90-70 Ethernet Interface (Type 2))

and

1-4 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 10

Ethernet Media

Various Ethernet baseband media (10Base...) can be interconnected by appropriate hubs or

repeaters. Capabilities and limitations are defined in IEEE 802.3 Chapter 13, “System

Considerations for Multi-Segment Networks”. This document is published by the Institute of

Electrical and Electronics Engineers, Inc., 345 East 47th Street, New York, NY 10017-2394 USA.

The Ethernet Interface can operate on any of the following media with the appropriate usersupplied transceiver cable and transceiver. IEEE 802.3 specifies the definitive requirements of

each medium.

1

10Base5 Coax:

“thick wire”. The maximum length of a cable segment is 500 meters. The distance between any

two stations must be a multiple of 2.5 meters. A maximum of 100 stations is allowed on a

10Base5 Ethernet segment.

10Base2 Coax:

10Base-T:

10Base-F:

10Base-FP can support up to 33 nodes at distances of up to 500 meters from a passive star;

10Base-FL supports up to 2000 meters between a node and a repeater (a multi-port repeater

would thus constitute a star). Additionally, 10Base-FB provides a means of interconnecting

(only) repeaters by up to 2000 meters of (the same) fiber-optic cable.

10Broad36:

amplifiers, headend translators, etc.) to support hundreds of nodes at distances of up to 2800

meters. Broadband cannot be connected to baseband via repeaters. Broadband cable plant design

and installation must be in accordance with IEEE 802.7 and requires special expertise. GE Fanuc

recommends you contract professional specialists for these services. Consult your GE Fanuc

sales representative or field service office for help in identifying local specialists.

10Base5 uses a 0.4 inch diameter 50-ohm coaxial cable and is commonly called

10Base2 is described above.

10Base-T is described above.

10Base-F has two variations that both use the same type of fiber-optic cable.

10Broad36 uses 75-ohm coaxial cable and CATV-like media components (taps,

GFK-1541B Chapter 1 Introduction 1-5

Page 11

1

Special Considerations for Ethernet Interfaces with Embedded Switches

Ethernet Interfaces that incorporate embedded switches (only the Series 90-30 CPU374) provide

some additional connection options and have some additional installation and operation

considerations.

These Ethernet Interfaces provide two RJ-45 connectors on the front of the module. It is

important to realize that there is only one interface to the network (only one Ethernet address and

only one IP address) provided by these Ethernet Interfaces. The two connectors allow up to two

Ethernet devices (hubs, switches, other PLCs, PCs) to be connected to the Ethernet Interface. This

arrangement is diagrammed below.

90-30 CPU374

Ethernet

Processor

Ethernet

MAC

10/100 Network

Switch

Port 1 Port 2

For simple installations, the embedded switch allows PLCs and other devices to be connected

together without requiring any additional components.

Operator

Interface

PLC PLC

Personal

Computer

It is also possible to daisy-chain PLCs together without additional components, but that should be

done with great care. In designing a system, remember that a loss of power or reset on any

Ethernet Interface in a daisy chain will cause loss of communications with all devices

downstream from the lost module.

The second port, if left unused, can be used to plug in a programmer over Ethernet.

Caution

The two ports on the Ethernet Interface must not be connected, either directly or indirectly,

to the same device. The hub or switch connections in an Ethernet network must form a tree,

otherwise duplication of packets may result.

1-6 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 12

The Station Manager Software

The built-in Station Manager software provides on-line supervisory access to the Ethernet

Interface, through either the Station Manager port or over the Ethernet cable. The Station

Manager services on the Ethernet Interface include:

An interactive set of commands for interrogating and controlling the station.

Unrestricted access to observe internal statistics, an exception log, and configuration

parameters.

Password security for commands that change station parameters or operation.

Access to the Station Manager is attained through a user-provided computer terminal or terminal

emulator. See GFK-1186,

Manager Manual

, for more information on the Station Manager.

The PC Software Loader

The PC Software Loader is a separate software utility which runs on a PC in order to update the

communications software stored in flash memory in the Ethernet Interface. This utility is

supplied with any updates to the Ethernet Interface software.

TCP/IP Ethernet Communications for the Series 90 PLC Station

1

How to Make the System Work

There are only a few simple tasks required to get your Ethernet communications system working.

These tasks are addressed in detail later in this manual.

1. Install the Ethernet Interface into the Series 90 rack or baseplate and connect it to the

network.

2. Power-up the PLC.

3. Configure the Ethernet Interface using the PLC programming software and store to the PLC.

4. To add optional SRTP client capability, refer to Chapter 3 “Programming SRTP Channel

Commands” . To add optional Modbus/TCP client capability (Series 90-30 Ethernet

Interface IC693CMM321-FH or later only), refer to Chapter 4 “Programming Modbus/TCP

Channel Commands”. To configure or program Ethernet Global Data, refer to Chapter 6,

“Ethernet Global Data”.

GFK-1541B Chapter 1 Introduction 1-7

Page 13

1

1-8 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 14

Chapter

2

Installation

This chapter contains installation instructions for each Series 90 module that includes an Ethernet

Interface.

Section 1: IC693CMM321 Series 90-30 TCP/IP Ethernet Interface (10Base-T type)

Section 2: IC693CPU364 Series 90-30 CPU with Embedded TCP/IP Ethernet Interface

Section 3: IC693CPU374 Series 90-30 CPU with Embedded TCP/IP Ethernet Interface

Section 4: IC697CMM742 Series 90-70 TCP/IP Ethernet Interface

Each section covers the basic features of the Ethernet Interface, its installation, configuration, and

a procedure for its initial checkout on your Ethernet cable. Each section first provides a hardware

overview of the Ethernet Interface and is then divided into four Installation Procedures, each

providing an overview of the procedure and then explaining the detailed steps to be performed.

The installation procedures described for each Ethernet Interface are:

Installing the Ethernet Interface in the PLC - Required

Configuring the Ethernet Interface - Required

Verifying Proper Power-Up of the Ethernet Interface - Required

“Pinging” the Ethernet Interfaces on the Network - Optional

Some of the procedures require prior Ethernet cable plant design and installation.

GFK-1541B 2-1

Page 15

2

Installing an IC693CMM321 Ethernet Interface Module

The IC693CMM321Ethernet Interface mounts in a Series 90-30 PLC baseplate. It connects to an

Ethernet network either directly through its 10Base-T port (10Base-T Type only), or through its

AAUI port, which requires a user-provided transceiver and cable. If using the AAUI port, you

may order a transceiver from GE Fanuc (see Appendix B for information) or supply your own

equivalent transceiver. .

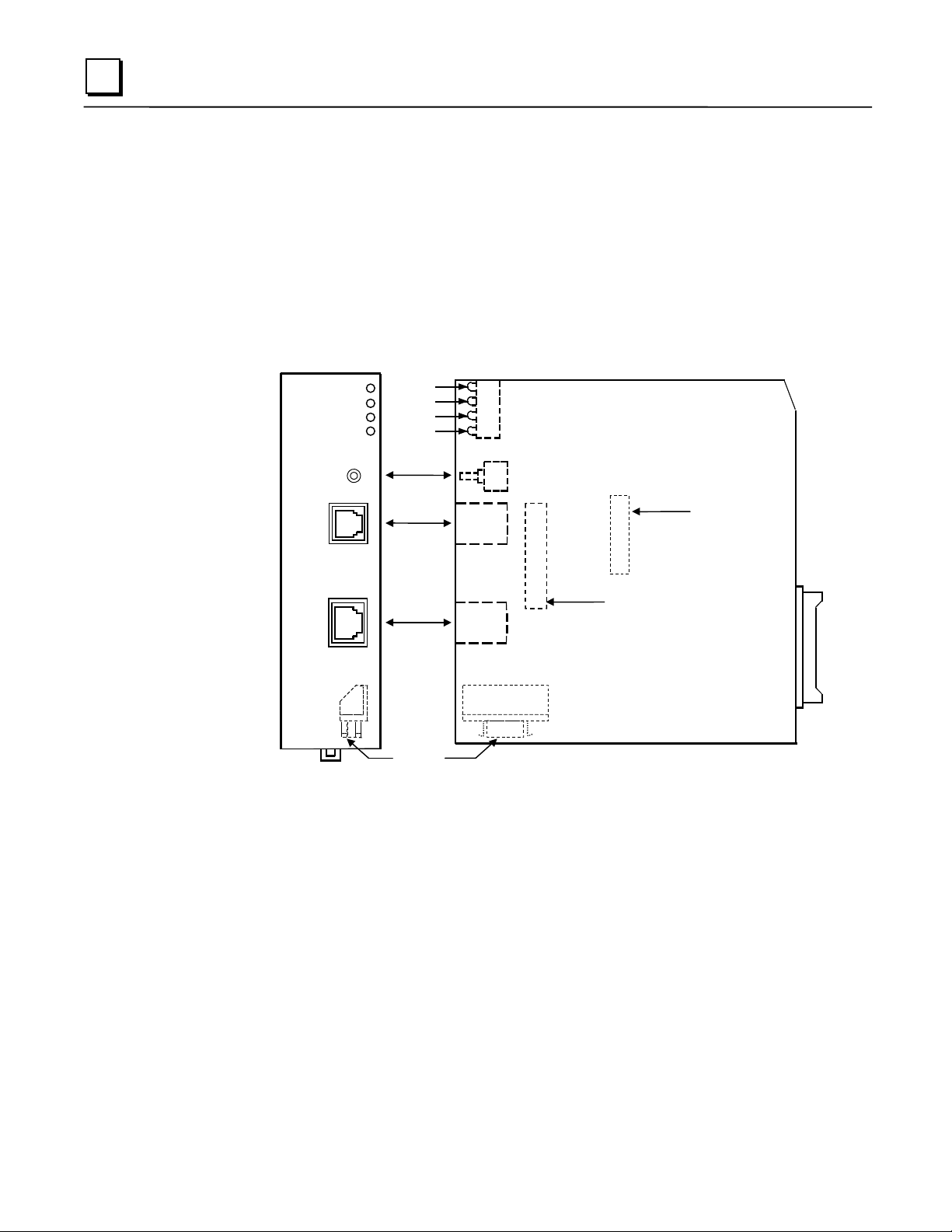

IC693CMM321 Series 90-30 TCP/IP Ethernet Interface (10Base-T Type)

CMM321 versions EF or earlier do not have a 10Base T port.

CMM321

ETHERNET

INTERFACE

ETHERNET

RESTART

STATION

MGR

RS-232

10BASE-T

OK

LAN

FDX

STAT

OK

LAN

FDX

STAT

RESTART

PUSHBUTTON

RS-232 STATION

MANAGER

PORT (RJ-11)

10BASE-T

PORT (RJ-45)

AAUI PORT

Serial Number

Label (Internal)

Default Station

Address Label

(Internal)

This module has several user-accessible features:

Four LEDs are located at the top of the board.

The Restart pushbutton is located immediately below the LEDs.

The Station Manager port (RS-232 serial port with an RJ-11 connector) is located on the front

of the module.

The 10Base-T Ethernet port (RJ-45 connector) is located on the front of the module. It does

not require an external transceiver.

The AAUI port (14-pin AAUI connector) is accessible through an opening in the bottom of

the module. It requires an external transceiver.

The Default Station Address label lists the MAC address to be used by this Interface. It is

located by removing the module’s front cover and looking on the circuit board.

The module’s serial number is on the silver label on the left side of the module.

2-2 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 16

LEDs

There are four LEDs on the CMM321 module. Each of these LEDs can be ON, OFF, or

BLINKING.

LED Indication Function

OK State of the Ethernet Interface

LAN Traffic on the network port

FDX Configuration of Full Duplex mode.

STAT An exception event has occurred

All LEDs are briefly turned ON whenever a restart is performed in the Operational state by

pressing and releasing the Restart pushbutton (described below). This allows you to verify that all

LEDs are operational. (On module versions EF or earlier, the FDX LED is labeled "SER".)

Restart Pushbutton

The Restart pushbutton serves four functions: LED test, Restart, Restart and enter Software Load

state, and Restart and enter Maintenance state. These four functions behave similarly in all states

except for the Software Load state. While in this state, pressing the pushbutton will cause an

immediate restart into the Operational state (without performing the LED test) if the software in

the Ethernet Interface has not been corrupted or erased. If the software has been corrupted or

erased, pressing the pushbutton will cause an immediate restart back into the Software Load state.

The following text describes Restart pushbutton behavior while not in the Software Load state.

2

Pressing the Restart pushbutton will disrupt Ethernet communications.

LED Test:

visually verify that all the LEDs go OFF and then ON at this time. Then the Interface performs

either a restart, a restart and enter Software Load state, or a restart and enter Maintenance state,

depending on the duration that you press the pushbutton.

Restart:

the Ethernet Interface. When the Restart pushbutton is pressed, all LEDs go out. When it is

released, all LEDs flash ON, then power-up diagnostics run, and the software on the Interface is

restarted into the Operational state.

Any time the Restart pushbutton is released,

Pressing the Restart pushbutton momentarily (less than 5 seconds) requests a restart of

the LEDs flash ON. You should

all

GFK-1541B Chapter 2 Installation 2-3

Page 17

2

Restart and Enter Software Load State:

bottom LED (STAT) turns ON (between 5 and 10 seconds) forces a restart and requests entrance

to the Software Load state. A reload is used to install a software update into the module and is

not part of normal operation. When the Restart pushbutton is pressed, all LEDs go out. After

approximately 5 seconds have elapsed, the STAT LED (bottom LED) comes ON, to indicate that

the Ethernet Interface will request a reload. After the Restart pushbutton is released, all LEDs

flash ON, then power-up diagnostics run, and the Ethernet Interface waits for the software load

with all LEDs blinking in unison.

Pressing and holding the Restart pushbutton until the

Notes

Reloading the Ethernet Interface requires the attachment of the PC Software

Loader to the Software Loader port and initiating a load with the PC Software

Loader. The PC Software Loader is a separate software utility that updates the

communications software in the Ethernet Interface. This utility is supplied with

any updates to the Ethernet Interface software.

At any time before you initiate a load with the PC Software Loader when the

Ethernet Interface is in the Software Load State, you can restart the Ethernet

Interface by pressing the Restart pushbutton. Pressing this pushbutton will

immediately cause the board to restart. If the reload has been initiated, see

Appendix C, “Upgrading the Ethernet Interface Firmware,” for more

information.

Restart and Enter Maintenance State:

bottom two LEDs turn ON (approximately 10 seconds) forces a restart and requests entrance to

the Maintenance state. Maintenance state must be invoked to change Advanced Parameters.

While in Maintenance state, all Advanced Parameters revert to their default value. When the

Restart pushbutton is pressed, all LEDs go out. After approximately 5 seconds, the STAT LED

comes ON, then after approximately a total of 10 seconds have elapsed, the FDX LED also comes

ON, to indicate that the Ethernet Interface will request entry to the Maintenance state. After the

Restart pushbutton is released, all LEDs flash ON then power-up diagnostics run and the Ethernet

Interface enters the Maintenance state.

Pressing and holding the Restart pushbutton until the

Notes

If a Restart is performed, any data being transferred by the Ethernet Interface at

that time will be lost.

The Restart pushbutton is not operable during the diagnostic phase of power-up.

The Ethernet Interface is in diagnostic phase when the OK LED is BLINKING

fast and other LEDs are OFF.

2-4 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 18

Ports on the CMM321

RS-232, RJ-11 Port (Station Manager Port)

The RS-232, 6-pin, RJ-11 “phone jack” port is used to connect a terminal or terminal emulator to

access the Station Manager software on the Ethernet Interface. A cable is needed to connect the

terminal or emulator to the Ethernet Interface (see Appendix B, “Communications Ports

Characteristics”). This port is also used to update the module’s firmware.

Ethernet Ports

The CMM321 has just one Ethernet interface. Connection to the Ethernet network can be made

either through the 10Base-T connector or the AAUI connector. You must connect to just one or

the other connector; you cannot use both at the same time. Note that module versions EF and

earlier do not have a 10Base T port, and can only be connected through their AAUI port.

10Base-T Port

This port is located on the front of the module and it can be directly connected to a 10Base-T

network (no external transceiver is needed). It uses a standard RJ-45 jack. See Appendix B for

port details.

2

AAUI (Transceiver) Port

This port uses a standard 14-pin AAUI connector to provide the electrical and mechanical

interface to a user-provided IEEE 802.3 transceiver. See Appendix B for Port details.

Caution

Do not connect or disconnect a transceiver cable at the AAUI port while

power is applied to the PLC. This may blow the AAUI port fuse and/or

cause permanent damage to the Ethernet Interface.

CMM321 Labels

Default Station Address Label

The Default Station Address label lists the MAC address to be used by this Interface.

Serial Number Label

The Serial Number Label indicates the serial number of this Interface.

Non-Replaceable AAUI Fuse

A non-replaceable fuse is provided on the DC power that is supplied by the Ethernet Interface to

the AAUI network port for use by an external transceiver. If this fuse blows, you must return the

Ethernet Interface to GE Fanuc for repair.

GFK-1541B Chapter 2 Installation 2-5

Page 19

2

Installing the CMM321 in the PLC

For general information about module and system installation, refer to GFK-0356,

Programmable Controller Installation Manual

.

Equipment Required to Perform the Installation Procedures

Make sure you have the items listed below before you begin.

A Series 90-30 PLC CPU baseplate, or any Series 90-30 baseplate and a Series 90-30 CPU

with power supply.

The CMM321 requires CPU version 6.50 or higher for full functionality. CPU versions

5.03 to 6.04 permit Ethernet operation with only 1 SRTP server connection.

The CMM321 requires PLC power supply IC693PWR321 (Revision K or later),

IC693PWR322, or IC693PWR330.

PLC programming software: Logic Developer (all versions), Control Version 2.01 or higher,

VersaPro version 1.0 or higher, or Logicmaster 90-30 version 6.01 or higher. (And a

compatible PC-compatible personal computer.)

If you are using the AAUI port instead of the 10Base-T port, you will need an Ethernetcompatible AAUI transceiver and Ethernet cables. (See Appendix B for more information on

the ports and transceivers.) Optional

IC693CBL316

An

Appendix B). Optional

A terminal or IBM-compatible personal computer equipped with terminal emulation

software. Optional

serial cable for the Station Manager port on the Ethernet Interface (see

Series 90-30

Notes

If your installation requires CE Mark compliance, please refer to GFK-1179,

Installation Requirements for Conformance to Standards

programming software, for additional guidelines.

A CMM321 can be mounted on a CPU baseplate, an expansion baseplate, or a

remote baseplate. However, due to power requirements, only two Ethernet

Interface modules are permitted per baseplate using a standard power supply.

Up to four Ethernet Interface modules are permitted per baseplate using a high

capacity power supply.

, shipped with the PLC

2-6 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 20

CMM321 Installation

Use the following instructions as a guide when inserting a module into a slot in a baseplate.

These instructions assume that the power supply on the baseplate is to your left.

Warning

Do not insert or remove modules with power applied. This could cause the

PLC to Stop, damage the module, or result in personal injury.

1. Be sure the Series 90-30 PLC baseplate power is OFF.

2. Align the module with the desired base slot and connector. Tilt the module upwards so that

the top rear hook of the module engages the slot on baseplate.

3. Swing the module downward until the connectors mate and the lock-lever on the bottom of

the module snaps into place engaging the baseplate notch.

4. Visually inspect the module to be sure that it is properly seated.

5. Connect the cable using one of the two following methods:

• If using a 10Base-T connection, plug the cable into the 10Base-T port on the front of the

module.

2

• If using the AAUI connection, connect the transceiver cable into the 14-pin AAUI port

on the bottom of the module, secure the cable, and connect the other end of the cable to

an external IEEE 802.3 compatible transceiver that is attached to the Ethernet network.

SQE must be enabled on the transceiver. (Note: The transceiver cable may be either

built-in to the transceiver or removable.)

Caution

Do not connect or disconnect a transceiver cable to the AAUI port while

power is applied to the PLC. This may blow the AAUI port fuse and/or

cause permanent damage to the Ethernet Interface.

6. Use the PLC programming software or a Hand Held Programmer to make sure the PLC CPU

is in Stop mode.

GFK-1541B Chapter 2 Installation 2-7

Page 21

2

CMM321 Configuration

Before you can use the Ethernet Interface you must configure the module using the PLC

programming software. The PLC programming software allows you to specify the modules and

I/O that will reside in your Series 90-30 PLC rack(s). The Hand Held Programmer can

used to configure the Ethernet Interface.

For the Ethernet Interface specifically, the configuration software allows you to:

Define the Status address of the Ethernet Interface.

Assign the IP address for the Ethernet Interface, and optionally the subnet mask and the

gateway address.

Configure the serial ports (optional).

Configuring the Interface Using Windows-Based Programming Software

To configure theCMM321 using Control, VersaPro or Logic Developer programming software,

do the following:

Control and VersaPro, from the Browser, double-click the 90-30 Rack System–Local

1

.In

Rack icon. The Local Rack Window will appear. In Logic Developer, expand the hardware

configuration and the desired rack in the browser.

not

be

Control and VersaPro, click the tab corresponding to the desired rack.

2

.In

Click the desired slot, press the right mouse button, and choose Add Module from the menu.

3

.

(If the slot already contains a module, choose Replace Module.) The Module Catalog dialog

box will then appear.

In the Module Catalog dialog box, click the Communications tab, select IC693CMM321

4

.

Ethernet Interface, and then click the OK button. The Parameters dialog box will then appear.

5

This dialog box will allow you to edit the module’s Ethernet parameters. To edit a parameter

.

value, click in the appropriate Values field. Refer to the topic “Configuration Parameters”

that follows for more information on these fields.

Optionally, after you have completed the Settings tab, you can then change the default

6

.

settings of the Station Manager and Software Loader ports by clicking the appropriate tab.

We recommend leaving the serial port parameters at default settings.

If you want to assign variable names to specific status points on the Ethernet card, click the

7

.

Point Reference tab. To assign a variable to a point, double-click the reference address you

want. The Insert Variable dialog box will appear, which will allow you to fill in a variable

name and description.

If you want to view the power consumption of this module, click the Power Consumption tab.

8

.

After you have configured all of the module’s applicable parameters, click the OK button.

The module will now appear in the selected slot.

Store the configuration to the PLC so these settings can take effect.

9

.

For more information, refer to Online Help in the PLC programming software.

2-8 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 22

Configuring the Interface Using the Logicmaster 90-30 Configuration Software

To configure the CMM321, access the I/O Configuration rack screen in the Logicmaster 90-30

Configuration Package, and do the following:

1. Move the cursor to the desired rack and slot location. The slot may be either unconfigured or

previously configured.

2. Press the Communications softkey, i.e., Comm (F6).

3. Press Ethernet (F2).

4. Press Enter to select the Ethernet Interface.

5. Configure the Ethernet parameters. Refer to the topic “Configuration Parameters” that

follows for more information on these fields.

6. Optionally, after you have assigned the Ethernet parameters, press Page Down to display the

serial port parameters. You can then change the default settings of the serial ports (optional).

Refer to the topic “Configuration Parameters” that follows for more information on these

fields. We recommend leaving the serial port parameters at default settings.

7. After you have completed the configuration, press the Escape key to return to the rack

display. Press Escape again to save the configuration to disk.

2

8. Store the configuration to the PLC so these settings can take effect.

Refer to GFK-0466,

Manual

software.

for more information on configuring the Ethernet Interface using Logicmaster 90-30

Logicmaster 90 Series 90-30/20/Micro Programming Software User’s

CMM321 Configuration Parameters

Ethernet Parameters

Configuration Mode:

Status Address:

bits) and the Channel Status bits (64 bits). The Channel Status bits are always located

immediately following the LAN Interface Status bits. The Status address must be assigned to %I

memory only. The default value is the next available %I address.

Note: Do not use the 80-bits assigned to the LIS bits and Channel Status bits for

other purposes or your data will be overwritten.

Status Length:

IP Address, Subnet Mask, Gateway IP Address, and Name Server IP Address:

should be assigned by the person in charge of your network (the network administrator). TCP/IP

network administrators are familiar with these parameters. It is important that these parameters

are correct, otherwise the Ethernet Interface may be unable to communicate on the network and/or

network operation may be corrupted. It is especially important that each node on the network is

assigned a

unique

This is fixed as TCP/IP.

The Status address is the location of the LAN Interface Status (LIS) bits (16

This is fixed at 80 bits (the sum of the LIS bits and the Channel Status bits).

These values

IP address.

However, if you have no network administrator and are configuring a simple,

with no gateways, you can use the following range of values for the assignment of local IP

addresses:

GFK-1541B Chapter 2 Installation 2-9

isolated network

Page 23

2

10.0.0.1 First PLC

10.0.0.2 Second PLC

10.0.0.3 Third PLC

..

..

10.0.0.255 PLC Programmer TCP or host

Also, in this case, set the subnet mask, gateway IP address, and name server IP address to 0.0.0.0.

Note

If the isolated network is ever connected to another network, the IP addresses

10.0.0.1 through 10.0.0.255 must not be used and the subnet mask, gateway IP

address, and name server IP address must be assigned by the network

administrator. The IP addresses must be assigned so that they are compatible

with the connected network. Refer to Chapter 6, “Network Administration

Support”, for more information on addressing.

See also “Determining If an IP Address Has Already Been Used”.

Converter:

(measured in Watts). Choices are 0, 0.50, and 0.60.

AAUI Transceiver (Watts):

that the transceiver draws from the port (measured in Watts). The valid range is 0.25 to 2.00.

The default value is 0.50.

Allows you to account for the power consumption added by a serial port converter

If you use an AAUI transceiver, allows you to account for the power

Station Manager PortParameters

Data Rate (bps):

4800, 9600‡, or 19200*.

Parity:

Type of parity to be used for the port. Choices are None‡, Even, or Odd*.

Stop Bits:

Flow Control:

parameter has no effect.

Turnaround Delay:

are None*‡, 10 ms, 100 ms, or 500 ms.

Timeout:

parameter has no effect.

* Default selection for the Software Loader Port.

‡ Default selection for the Station Manager Port.

This parameter is currently not used by the Ethernet Interface. Changing this

Data rate (bits per second) for the port. Choices are 300, 600, 1200, 2400,

Enter the number of stop bits. Choices are 1*‡ or 2.

This parameter is currently not used by the Ethernet Interface. Changing this

Turnaround delay time (in milliseconds) to be used for the port. Choices

2-10 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 24

Configuring Full-Duplex Operation

Before setting the module to Full-Duplex operation, be certain that it is connected directly to a

managed hub or switch that is manually configured for full-duplex operation on the port

connected to the IC693CMM321.

The default setting for the module is Half-Duplex. The Full Duplex parameter is an “advanced

user parameter” that can only be changed by using the CHPARM (Change Parameter) command

in the Station Manager softwar. Refer to GFK-1186, the

Station Manager Manual

, for additional information on using Station Manager.

TCP/IP Ethernet Communications

Warning

Contrary to the recommendation of IEEE Std. 802.3, this Ethernet Interface

module does NOT support autonegotiation of half/full-duplex. Attempting fullduplex operation of this interface with a repeater or half-duplex network

(including auto-negotiating hubs and switches) can cause severe network

performance degradation, increased collisions, late collisions, CRC errors, and

undetected data corruption.

If the module is configured in the Full-Duplex mode (see above), you can change it back to its

default value of Half-Duplex by using the Station Manager CHPARM command.

2

GFK-1541B Chapter 2 Installation 2-11

Page 25

2

Verifying Proper Power-Up of the CMM321

Powering-up the Ethernet Interface

After configuring the CMM321, follow the procedure below to be sure it is operating correctly.

1. Turn power OFF to the PLC for 3–5 seconds, then turn the power back ON. This will initiate

a series of diagnostic tests.

The OK LED will blink indicating the progress of power-up.

2. The LEDs will have the following pattern upon successful power-up. At this time the

Ethernet Interface is fully operational and on-line.

LED Ethernet Interface Online

OK ON

LAN ON or blinking

FDX ON Solid if Full Duplex mode is active OFF

if Full Duplex mode is not active

STAT ON

If STAT LED is OFF, check the PLC Fault Table. Alternatively, use the Station

Manager LOG command as explained in GFK-1186,

for the Series 90 PLC Station Manager Manual

TCP/IP Ethernet Communications

.

Problems During Power-up

If a problem is detected during power-up, the CMM321 may not transition directly to the

Operational State. If the Interface does not transition to Operational, check the LED pattern on

the Interface and refer to the following diagram and table for suggestions.

2-12 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 26

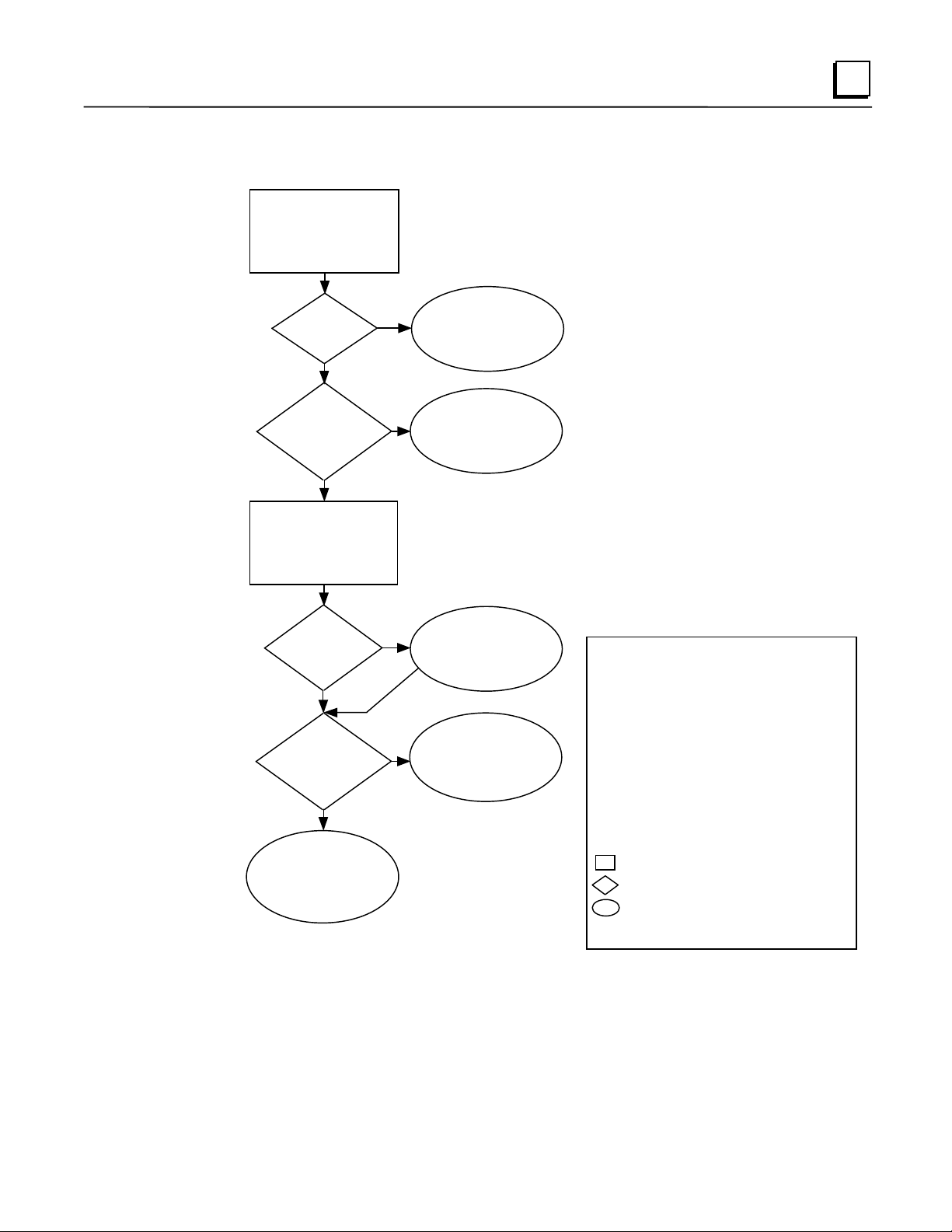

States of the Series 90-30 CMM321 Ethernet Interface

1

The Ethernet Interface is initialized by

- Powering-up the PLC

Ethernet Interf ace

Initializing

(approx. 2-10

seconds)

Diagnostics

Pass?

1

No

Yes

- S tori ng a new c onf igur ation to the P LC wi th c han ges f or t he Et her net In ter fac e

- Pressing the Restart pushbutton

- Issuing a Station Manager

- Internal System Error occurring when Interface is Operational

A

Hardware

Failu re

RESTART, LOAD

, or

MAINT

2

command

Load

Request or

Software

Corrupted?

No

Operati onal

- Full support for client and server

capability

- Uses user defined Advanced Parameters

C

Waiting for

Conf iguration from

PLC CPU

(max. 2 minutes)

Done

IP address =

0.0.0.0

No

Maintenance

Request or

Fatal System

Error?

No

F

Operational

z

/

/

∗

z

z

/

/

z

2

Ye

s

3

Yes

IP Address

Received

5

Yes

Maintenance

- Client and server capability disabled

- Uses default Advanced Parameters

- Permits changes to Advanced Parameters

Software

Load

/ ∗/

D

Waiting for

IP Address

z

4

E

Maintenance

z

/ ∗/

/

z

B

2

Software Load Caused by

- Rest ar t pushbu tton pu shed un til bot tom LED tur ns ON

- Station Manager

- Detection of corrupt software

3

Waiti ng for IP Address Caused by

- Not configuring Interface using configuration software

- Configuring Interface with IP address = 0.0.0.0

- New CPU wit h no configuration

- C PU f ailur e t o comm unica te wi th Int erfa ce

4

Continue to Maint enance or Operationa l Caused by

- IP address received from network BOOTP server

- IP address entered by

5

Ma inte nanc e Re ques t C aus ed by

- Restart pushbutton pushed until bottom two LEDs tu rn ON

- Station M anager

- Fatal System Error while in Operational State forced a restart

The LEDs are labeled from top to bottom as follows:

OK

LAN

SER

STAT

The symbols used for th e LEDs are defi ned as follows:

= OFF

= ON

z

= Slow Blink; multiple slow blinking LEDs blink in unison

= Fast Blink

= Traffic (blinks when there is traff ic on the line)

∗

The process symbols are defined as follows:

= Temporary condition; requires no intervention

= Decision point during power-up

= Interface State; normally the Interface remains

in a State unless there is user intervention

command issued

LOAD

BOOTP

command issued

MAINT

Symbols

Station Manager command

GFK-1541B Chapter 2 Installation 2-13

Page 27

2

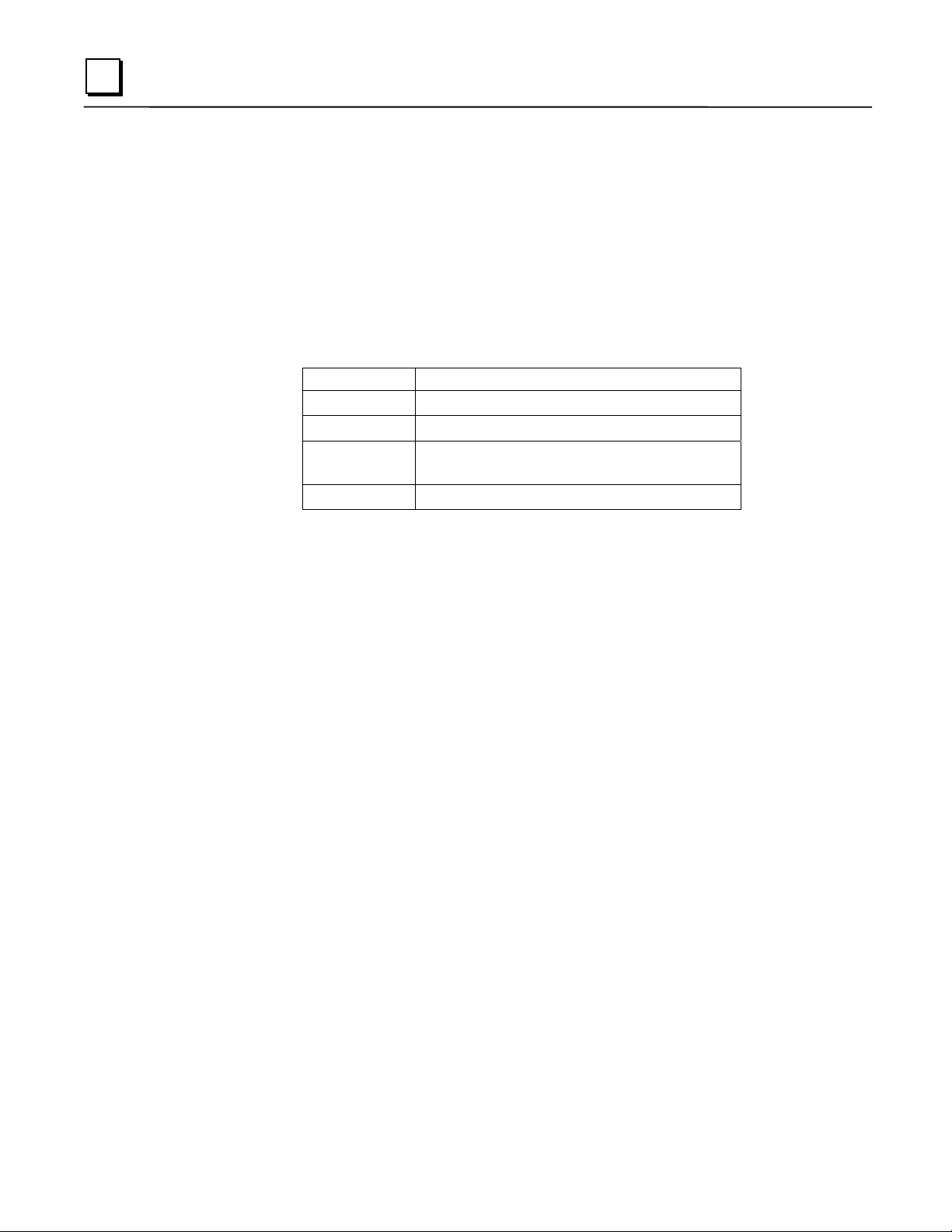

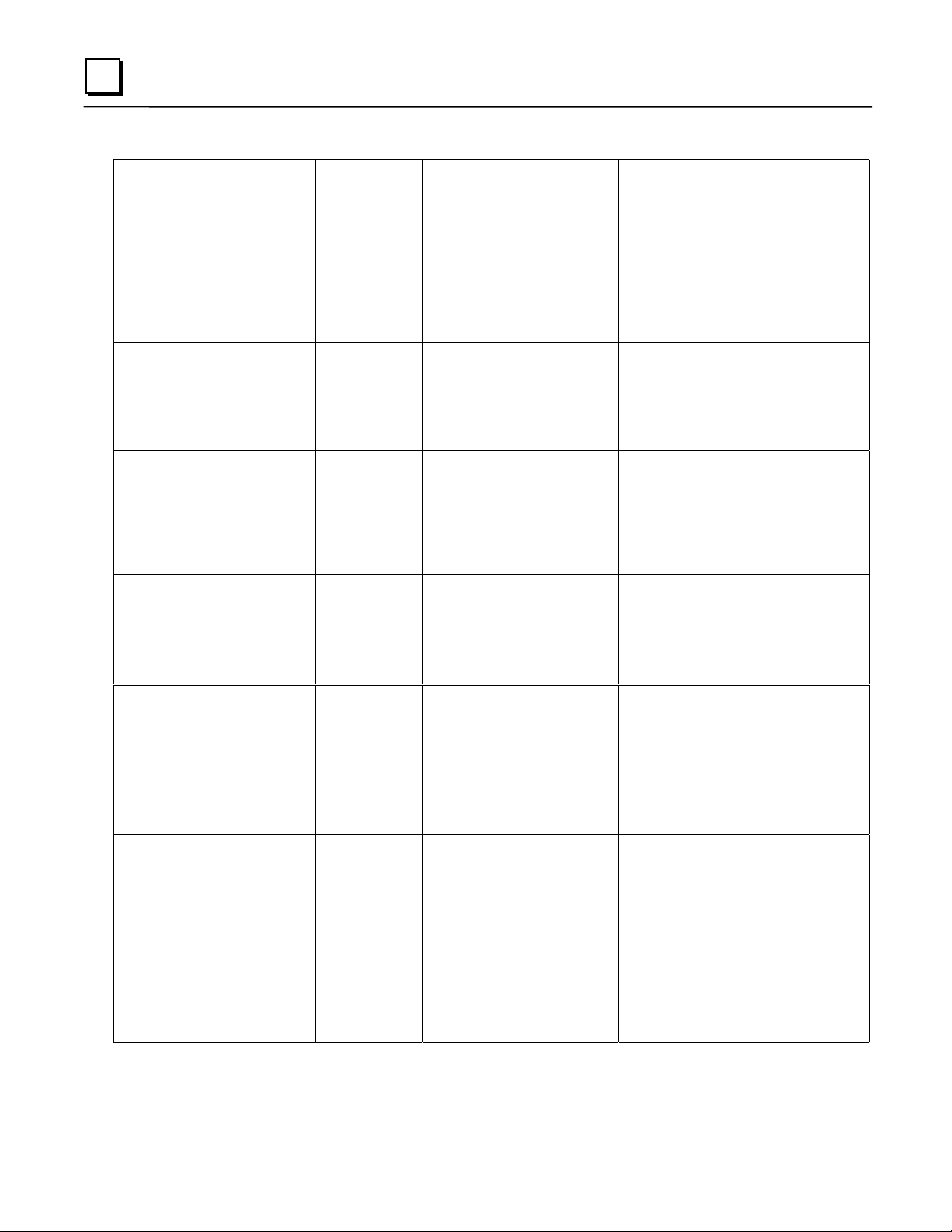

LED Pattern Where Stopped Possible Cause Corrective Actions

❍ OK

❍

❍

❍

✫ OK

✫

✫

✫

All LEDs blink in unison.

✫

❍

❍

❍

✫

●

❍

✫

(OFF)

LAN (OFF)

FDX (OFF)

STAT (OFF)

(Slowblink)

LAN (Slowblink)

FDX (Slowblink)

STAT (Slowblink)

OK (Slowblink)

LAN (OFF)

FDX (OFF)

STAT (OFF)

OK (Slowblink)

LAN (ON/Traffic/OFF)

❍

/∗/

FDX (OFF/Slowblink)

STAT (Slowblink)

A

Hardware

Failure

B

Software

Loader

C

Waiting for

Configuration

from PLC

D

Waiting for IP

Address

Fatal Hardware Error.

Restart pushbutton until

bottom LED turns ON.

Station Manager

command issued.

Software corrupt.

Did not configure slot using

PLC Programmer.

New CPU with no

configuration.

CPU not communicating

with Ethernet Interface

(Condition can last a

maximum of 2 minutes.)

Interface’s IP address has not

been configured or has been

configured as 0.0.0.0.

LOAD

Make sure the PLC has power.

Examine PLC Fault Table for clues.*

Recheck PLC Programmer

configuration.

Power off baseplate, inspect the

Interface for loose components,

reseat the Interface, and Restart.

Try a different slot.

If the problem persists, replace the

Interface or PLC hardware.

Connect a PC Software Loader and

load new software. See Appendix C.

Cycle power or press Restart

pushbutton again for less than 5

seconds to restart the Interface and

clear the load request.

Use PLC Programmer configuration

software to configure the Interface

then store the configuration to the

PLC CPU.

Make sure Interface is in the correct

slot on the baseplate.

Power cycle the PLC.

Clear faults and Restart Interface.

Use PLC Programmer to configure

the Interface with a non-zero IP

address.

Use a BOOTP server to provide

Interface with a non-zero IP address.

OK and STAT blink in unison.

Restart pushbutton pressed

OK (Slowblink)

✫

(ON/Traffic/O FF)

LAN

/∗/

●

❍

FDX (Slowblink)

✫

STAT (ON/OFF)

●/❍

OK and SER blink in unison.

● OK

/

●

∗

●/❍

●/❍

1

FDX should be ON if Full

Duplex mode is activated;

otherwise, it should be OFF.

(ON)

/❍ LAN

* Identify the PLC fault message using the PLC Programmer, then refer to Table 8-1 in Chapter 8 for corrective actions.

(ON/Traffic/OFF)

FDX (ON/OFF)

STAT (ON/OFF)

1

E

Maintenance

F

Operational

until bottom two LEDs turn

ON.

Station Manager MAINT

command issued.

Internal System Error when

Interface was Operational

caused a restart and

entrance into Maintenance.

If the LAN LED is OFF,

the problem may be:

Network cable or

transceiver not connected to

Interface or bad transceiver.

Network cable not

terminated properly.

SQE not enabled on

transceiver.

If the STAT LED is OFF,

an exception condition has

occurred.

If you did not intend to enter

Maintenance press the Restart

pushbutton for less than 5 seconds.

This clears the Maintenance request.

Examine PLC Fault Table for clues.*

If you need to use the Station

Manager to troubleshoot a problem,

see GFK-1186, TCP/IP Ethernet

Communications for the Series 90

PLC Station Manager Manual.

Connect cable and transceiver

properly. Replace transceiver.

Terminate network cable properly.

Set SQE ON on transceiver in accord

with manufacturer’s instructions.

Examine PLC Fault Table to find out

why the STAT LED is OFF. *

2-14 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 28

Pinging TCP/IP Ethernet Interfaces on the Network

PING (Packet InterNet Grouper) is the name of a program used on TCP/IP networks to test

reachability of destinations by sending them an ICMP echo request message and waiting for a

reply. Most nodes on TCP/IP networks, including the CMM321, implement a

PING

2

command.

You should

it verifies that the interface is operational and configured properly. Specifically, it verifies

ping,

that acceptable TCP/IP configuration information has been stored to the Interface.

each installed Ethernet Interface. When the Ethernet Interface responds to the

ping

Pinging the Interface from a UNIX® host or a PC Running TCP/IP Software

A

command can be executed from a UNIX host or PC running TCP/IP (since most TCP/IP

ping

communications software provides a

using a PC or UNIX host, the user can refer to the documentation for the

general all that is required is the IP address of the remote host as a parameter to the

For example, at the command prompt type:

ping 10.0.0.1

command) or from another Ethernet Interface.* When

ping

command, but in

ping

Determining If an IP Address Has Already Been Used

It is very important not to duplicate IP addresses.

Ethernet Interface with the same IP address as another node:

1. Disconnect your Interface from the LAN.

2. Ping the disconnected Interface’s IP address. If you get an answer to the ping, then the

chosen IP address is already in use by another node. You

assigning unique IP addresses.

To determine if you have configured your

correct this situation by

must

command.

ping

* To use another GE Fanuc Ethernet Interface, refer to the

Ethernet Communications for the Series 90 PLC Station Manager Manual.

® UNIX is a registered trademark exclusively licensed through X/Open Company LTD.

GFK-1541B Chapter 2 Installation 2-15

command in GFK-1186,

PING

TCP/IP

Page 29

2

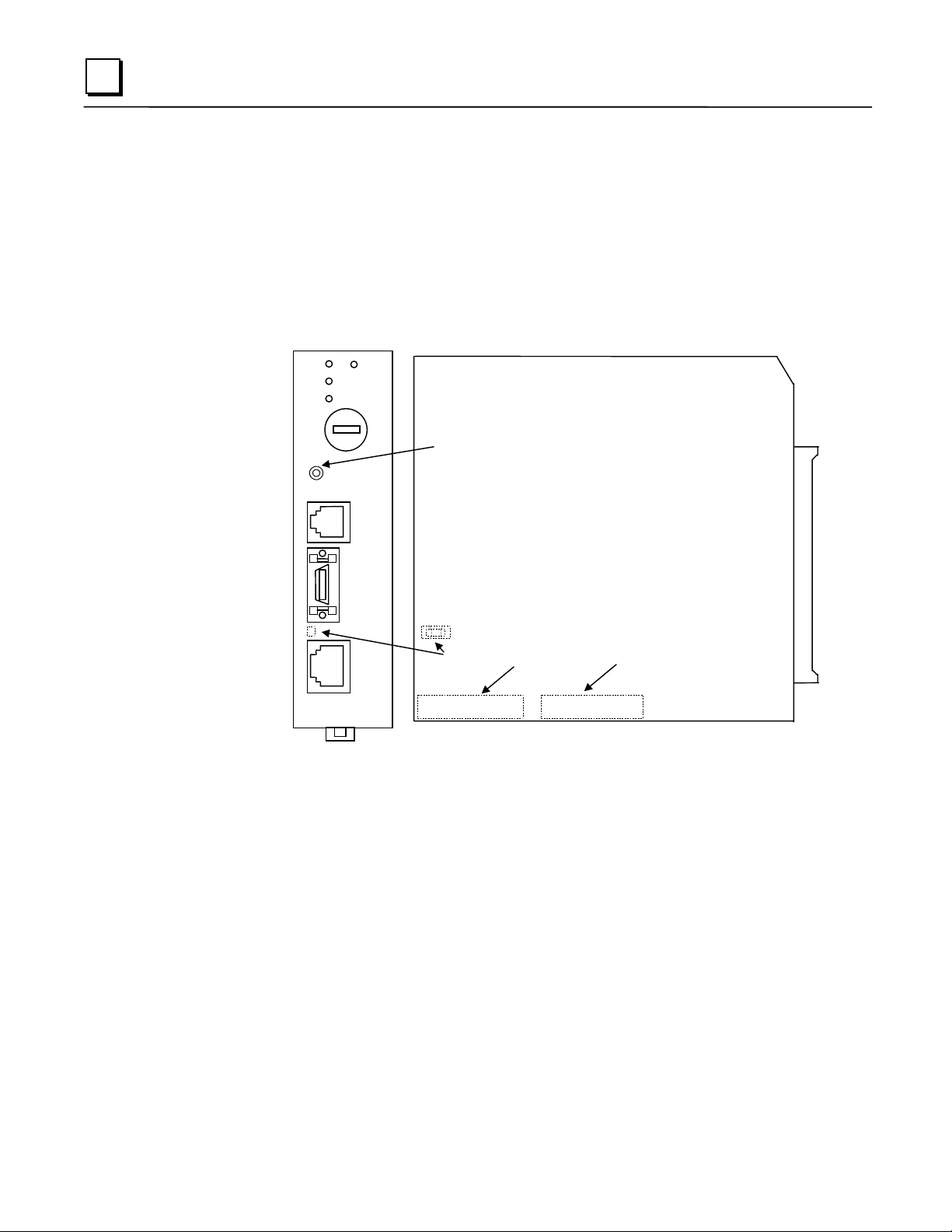

Installing an IC693CPU364 with Embedded TCP/IP Ethernet Interface

The CPU364 with Embedded Ethernet Interface is mounted on the Series 90-30 PLC baseplate. It

is connected to an Ethernet network via a 10Base-T port or a user-provided transceiver cable and

transceiver via an AAUI port.

IC693CPU364 Series 90-30 CPU Module with Ethernet Interface

EOK

LAN

STAT

CPU364

ON

ETHERNET

RESTART

STATION

MGR

RS-232

AAUI

10BASET

PS

PORT

OFF

RESTART

PUSHBUTTON

FUSE

DEFAULT

STATION

ADDRESS

LABEL

SERIAL

NUMBER

LABEL

The Series 90-30 CPU364 has several user-accessible elements (only the Ethernet Interface

elements are discussed here.)

Three Ethernet LEDs are located at the top left of the board. The Ethernet Restart pushbutton is

located below the LEDs. The RS-232 serial port with the RJ-11 connector (similar to a modular

telephone connector) is used to connect to Station Manager and to load software updates. Below

the serial port are two ports, either one of which can be used to connect to the Ethernet network:

the 14-pin AAUI connector (Transceiver port) and the 10Base-T, RJ-45 network port.

The default station address (MAC address) label, serial number label, and replaceable AAUI port

fuse are concealed by the front cover. The front cover must be removed to access these items.

2-16 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 30

LEDs

There are four LEDs on the CPU364: EOK, LAN, STAT, and PS PORT (on some early models

of the CPU364, the PS PORT LED is labeled “SNP”). The PS (Power Supply) PORT LED is not

Ethernet related; it indicates the presence of serial traffic through the serial port of the PLC’s

power supply. Each of the three Ethernet LEDs (EOK, LAN, and STAT) can be ON, OFF,

BLINKING slow, or BLINKING fast. They indicate the state of the Ethernet Interface, traffic on

the network port (LAN LED), and that an exception event has occurred.

The three Ethernet LEDs are briefly turned ON whenever a restart is performed in the Operational

state by pressing and releasing the Restart pushbutton (described below). This allows you to

verify that the Ethernet LEDs are operational.

Ethernet Restart Pushbutton

The Ethernet Restart pushbutton serves four functions: LED test, Restart, Restart and enter

Software Load state, and Restart and enter Maintenance state. These four functions behave

similarly in all states except for the Software Load state. While in this state, pressing the

pushbutton will cause an immediate restart into the Operational state (without performing the

LED test) if the software in the Ethernet Interface has not been corrupted or erased. If the

software has been corrupted or erased, pressing the pushbutton will cause an immediate restart

back into the Software Load state. The following text describes Restart pushbutton behavior

while not in the Software Load state.

2

Pressing the Ethernet Restart pushbutton will disrupt Ethernet communications.

LED Test:

ON. The operator should visually verify that the three LEDs go OFF and then ON at this time.

Then the Interface performs either a restart, a restart and enter Software Load state, or a restart

and enter Maintenance state, depending on the duration that you press the pushbutton.

Restart:

restart of the Ethernet Interface. When the Restart pushbutton is pressed, the three Ethernet LEDs

go out. When it is released, the three Ethernet LEDs flash ON, then power-up diagnostics run,

and the software on the Interface is restarted into the Operational state.

Any time the Ethernet Restart pushbutton is released, the three Ethernet LEDs flash

Pressing the Ethernet Restart pushbutton momentarily (less than 5 seconds) requests a

GFK-1541B Chapter 2 Installation 2-17

Page 31

2

Restart and Enter Software Load State:

bottom LED (STAT) turns ON (between 5 and 10 seconds) forces a restart and requests entrance

to the Software Load state. A reload is used to install a software update into the module and is

not part of normal operation. When the Restart pushbutton is pressed, all LEDs go out. After

approximately 5 seconds have elapsed, the STAT LED (bottom LED) comes ON, to indicate that

the Ethernet Interface will request a reload. After the Restart pushbutton is released, the three

Ethernet LEDs flash ON, then power-up diagnostics run, and the Ethernet Interface waits for the

software load with the three Ethernet LEDs blinking in unison.

Pressing and holding the Restart pushbutton until the

Notes

Reloading the Ethernet Interface requires the attachment of the PC Software

Loader to the RS-232, RJ-11 port and initiating a load with the PC Software

Loader. The PC Software Loader is a separate software utility that updates the

communications software in the Ethernet Interface. This utility is supplied with

any updates to the Ethernet Interface software. See Appendix C, “Upgrading

the Ethernet Interface Firmware”, for more information.

At any time before you initiate a load with the PC Software Loader when the

Ethernet Interface is in the Software Load State, you can restart the Ethernet

Interface by pressing the Restart pushbutton. Pressing this pushbutton will

immediately cause the board to restart. If the reload has been initiated, see

Appendix C, “Upgrading the Ethernet Interface Firmware”, for more

information.

Restart and Enter Maintenance State:

bottom two LEDs turn ON (approximately 10 seconds) forces a restart and requests entrance to

the Maintenance state. Maintenance state must be invoked to change Advanced Parameters.

While in Maintenance state, all Advanced Parameters revert to their default value. When the

Restart pushbutton is pressed, all LEDs go out. After approximately 5 seconds, the STAT LED

comes ON, then after approximately a total of 10 seconds have elapsed, the LAN LED also comes

ON, to indicate that the Ethernet Interface will request entry to the Maintenance state. After the

Restart pushbutton is released, the three Ethernet LEDs flash ON then power-up diagnostics run

and the Ethernet Interface enters the Maintenance state.

Pressing and holding the Restart pushbutton until the

Notes

In any case, any data being transferred by the Ethernet Interface at the time of

the Restart will be lost.

The Restart pushbutton is not operable during the diagnostic phase of power-up.

The Ethernet Interface is in diagnostic phase when the EOK LED is

BLINKING fast and the other Ethernet LEDs are OFF.

2-18 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 32

Ports on the CPU364

RS-232, RJ-11 Port (Station Manager Port)

The Station Manager port uses a 6-pin, RJ-11 “phone jack” connector. This port is used to

connect a terminal or terminal emulator to access the Station Manager software on the Ethernet

Interface. It is also used to connect to the PC Software Loader in case the communications

software in the Ethernet Interface needs to be updated. An IC693CBL316 cable (or equivalent) is

needed to connect the terminal, emulator, or Software Loader to the Ethernet Interface (see

Appendix B, “Communications Ports Characteristics”). On earlier versions of the CPU364

module, this port was labeled “Port 1 RS-232.”

Ethernet Ports

There are two Ethernet ports on the CPU364. Only one port can be used at a time. The Ethernet

Interface automatically detects the Ethernet port in use; special configuration is not required.

AAUI (Transceiver) Port

The 14-pin AAUI port provides the electrical and mechanical interface to a user-provided IEEE

802.3 transceiver cable, which connects the AAUI Port to an external Ethernet-compatible

transceiver (see Appendix B, “Communications Ports Characteristics”, for the characteristics of

the AAUI Port and suggested transceivers). The external transceiver is directly connected to the

Ethernet cable.

2

Caution

Do not connect or disconnect a transceiver cable to the AAUI port while

power is applied to the PLC. This may blow the AAUI port fuse and/or

cause permanent damage to the Ethernet Interface.

10Base-T, RJ-45 Port

This 8-pin, RJ-45 port provides a direct connection to a 10Base-T (twisted pair) Ethernet network

without an external transceiver.

GFK-1541B Chapter 2 Installation 2-19

Page 33

2

CPU364 Labels

Default Station Address Label

The Default Station Address label lists the MAC address to be used by this Interface.

Serial Number Label

The Serial Number Label indicates the serial number of this Interface.

Replaceable Surface Mount Fuse

A user-replaceable fuse is provided on the DC power that is supplied by the Ethernet Interface to

the AAUI network port for use by an external transceiver. Replace only with a surface mount

2.69x2.69x6.1mm, 125V, 1A, fast-acting fuse (such as catalog number R454 001 made by

LittelFuse; http://www.littelfuse.com). You may order this fuse from GE Fanuc. The part

number is 44A725214-001.

Removing and Installing the Fuse

1.Be sure the Series 90-30 PLC baseplate power is OFF.

Remove the CPU364 module from the baseplate.

2

.

Remove the front shroud. The CPU364 is a two-board module, the fuse is located between

3

.

the AAUI port and the 10Base-T port. See Figure 3-1.

Remove the blown fuse using a pair of small, bent-nose pliers.

4

.

Insert the new fuse. Make sure the fuse is seated properly.

5

.

Replace the front shroud and re-insert the CPU364 module.

6

.

Restore power to the baseplate.

7

.

2-20 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 34

Installing the CPU364 in the PLC

For general information about module and system installation, refer to GFK-0356,

Programmable Controller Installation Manual

.

Equipment Required to Perform the Installation Procedures

Make sure you have the items listed below before you begin.

A Series 90-30 PLC CPU baseplate with power supply. The Series 90-30 CPU364 requires

PLC power supply IC693PWR321 (Revision K or later), IC693PWR322, or IC693PWR330.

PLC programming software: Logic Developer (all versions), Control Version 2.01 or higher,

VersaPro version 1.0 or higher, or Logicmaster 90-30 version 6.01 or higher. (And a

compatible PC-compatible personal computer.)

Ethernet cables and, if using the AAUI port, an Ethernet-compatible AAUI transceiver. (See

Appendix B, “Communications Port Characteristics”, for more information.)

A serial cable for the Station Manager port on the Ethernet Interface (see Appendix B).

Optional

A terminal or IBM-compatible personal computer equipped with terminal emulation

software. Optional

Note: If your installation requires CE Mark compliance, please refer to GFK-1179,

Installation Requirements for Conformance to Standards

, for additional guidelines.

2

Series 90-30

CPU364 Installation

Use the following instructions as a guide when inserting a module into a slot in a baseplate.

These instructions assume that the power supply on the baseplate is to your left.

Warning

Do not insert or remove modules with power applied. This could cause the

PLC to Stop, damage the module, or result in personal injury.

1

Be sure the Series 90-30 PLC baseplate power is OFF.

.

Align the module with the CPU’s base slot (slot 1) and connector. Tilt the module upwards

2

.

so that the top rear hook of the module engages the slot on baseplate.

Swing the module downward until the connectors mate and the lock-lever on the bottom of

3

.

the module snaps into place engaging the baseplate notch.

Visually inspect the module to be sure that it is properly seated.

4

.

Connect

5

.

an external transceiver, connect the transceiver cable to the 14-pin AAUI port of the Ethernet

Interface. Secure the cable. The other end of the transceiver cable should be connected to an

external IEEE 802.3 compatible transceiver which is attached to the Ethernet network. SQE

must be enabled on the transceiver. (Note: The transceiver cable may be built-in to the

transceiver or removable.)

of the Ethernet ports on the Ethernet Interface to the network. If you are using

one

Caution

Do not connect or disconnect a transceiver cable to the AAUI port while

power is applied to the PLC. This may blow the AAUI port fuse and/or

cause permanent damage to the Ethernet Interface.

6

Restore power to the baseplate.

.

Use the PLC programming software or a Hand Held Programmer to make sure the PLC CPU

7

.

is in Stop mode.

GFK-1541B Chapter 2 Installation 2-21

Page 35

2

CPU364 Configuration

Before you can use the Ethernet Interface with the Series 90-30 PLC, you must configure the

Interface using the PLC programming software. The PLC programming software allows you to

specify the modules and I/O that will reside in your Series 90-30 PLC rack(s). The Hand Held

Programmer can

For the Ethernet Interface specifically, the configuration software allows you to:

Define the Status address of the Ethernet Interface.

Assign the IP address for the Ethernet Interface, and optionally the subnet mask, the gateway

address, and the name server address.

Configure the serial ports (optional).

be used to configure the Ethernet Interface.

not

Configuring the Interface Using Windows-Based Programming Software.

To configure the Ethernet Interface using Logic Developer, Control or VersaPro programming

software, do the following:

1

Control and VersaPro, from the Browser, double-click Hardware Configuration icon.

.In

The Local Rack Window will appear. In Logic Developer, expand the hardware

configuration and the main rack in the browser.

Control and VersaPro, click the Main tab.

2

.In

Click the CPU slot, press the right mouse button, and choose Replace Module. The Module

3

.

Catalog dialog box will appear.

In the Module Catalog dialog box, select CPU model IC693CPU364, then click the OK

4

.

button. Follow the instructions on the screen until the Parameters dialog box appears.

The Parameters dialog box will allow you to edit the module’s parameters. To edit a

5

.

parameter value, click the desired tab, then click in the appropriate Values field. The

Settings, Scan, and Memory tabs contain parameters that pertain directly to CPU operation.

Refer to Online Help for more information.

The Ethernet and RS-232 tabs contain parameters directly related to the embedded Ethernet

6

.

Interface’s functionality. Some fields in the Ethernet tab must be filled in. The default

settings for the RS-232 tabs can be used. Refer to the topic “Configuration Parameters” that

follows for information on these fields. We recommend leaving the serial port parameters at

default settings.

If you want to view the power consumption of this module, click the Power Consumption tab.

7

.

After you have configured all of the module’s applicable parameters, click the OK button.

The module will now appear in the selected slot.

Store the configuration to the PLC so these settings can take effect.

8

.

For more information, refer to Online Help in the PLC programming software.

2-22 TCP/IP Ethernet Communications for the Series 90™ PLC User's Manual – May 2002 GFK-1541B

Page 36

Configuring the Interface Using the Logicmaster 90-30 Configuration Software

To configure the Ethernet Interface, access the I/O Configuration rack screen in the Logicmaster

90-30 Configuration Package, and do the following:

1

Move the cursor to the CPU slot (slot1) and press Zoom (F10) to access the CPU

.

configuration screen.

If the current CPU is the CPU364, continue to step 3. Otherwise, press CPU (F1) to access

2

.

the CPU selection menu. Use the arrow keys to highlight the CPU364 (IC693CPU364),

press Enter to select it, and then press Y to replace the module.

The initial configuration screen contains the actual CPU configuration parameters. Press

3

.

Page Down to access the configuration screens for the Ethernet Interface (Ethernet

parameters and RS-232 serial port parameters).

4

Configure the Ethernet parameters. Refer to the topic “Configuration Parameters” that

.

follows for more information on these fields.

Optionally, after you have assigned the Ethernet parameters, press Page Down to display the

5

.

serial port parameters. You can then change the default settings of the serial ports (optional).

Refer to the topic “Configuration Parameters” that follows for more information on these

fields. We recommend leaving the serial port parameters at default settings.

2

After you have completed the configuration, press the Escape key to return to the rack

6

.

display. Press Escape again to save the configuration to disk.

Store the configuration to the PLC so these settings can take effect.

7

.

Refer to GFK-0466,

Manual

software.

for more information on configuring the Ethernet Interface using Logicmaster 90-30

Logicmaster 90 Series 90-30/20/Micro Programming Software User’s

CPU364 Configuration Parameters

Ethernet Parameters

Configuration Mode:

Adapter Name:

is listed in Chapter 6, “Network Administration Support”. The Adapter Name is associated with

the IP address used in Ethernet Global Data. If supported in the PLC programming software,

view all adapter names in Hardware Configuration by going to the Edit menu, choosing Rack

Operations, and selecting Name Resolution. Adapter names are listed in the Adapter Names tab.

Status Address:

bits (16 bits) and the Channel Status bits (64 bits). The Channel Status bits are always located

immediately following the LAN Interface Status bits. The Status address can be assigned to %I,

%Q, %R, %AI or %AQ memory. The default value is the next available %I address.

This is fixed as TCP/IP.

A symbolic name representation of the associated IP address. The character set

The Status Reference Type is the location of the LAN Interface Status (LIS)

Note