Page 1

GE Fanuc Automation

Programmable Cont rol Product s

PANELWA RE™ MMI A pplication Manual

for GE Fanuc Genius™ Pr otocol

User's Manual

GFK - 1115 June 1995

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-002

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts have been

made to be accurate, the information contained herein does not purport to cover all details or variations in

hardware or software, nor to provide or every possible contingency in connection with installation,

operation, or maintenance. Features may be described herein which are not present in all hardware and

software systems. GE Fanuc Automation assumes no obligation of notice to holders of this document with

respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with respect

to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of the

information contained herein. No warranties of merchantability or fitness for purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Master Field Control Modelmaster Series One

CIMPLICITY GEnet ProLoop Series Six

CIMPLICITY Genius PROMACRO Series Three

PowerTRAC Genius PowerTRAC Series Five VuMaster

CIMPLI C I TY 90–A DS Helpmate Series 90 Workmaster

CIMSTAR Logicmaster

©Copyright 1995 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

This manual provides a quick guide to installing and operating PANELWARE™ Panels,

describes configuration techniques, and outlines general use of the PANELWARE Configuration

Software (PCS) with GE Fanuc Genius Protocol.

Some of the products mentioned or illustrated in this manual may not be released when this

document is published. Please do not rely on any references made to these units. Your local

GE Fanuc distributor will inform you of any new product releases.

Content of This Manual

Chapter 1. Overview provides a short description of the PCS and outlines the prerequisites for

PCS operation with the PC and the PLC.

Chapter 2. C400 Panel Controller Hardware provides specifications, descriptions of

connections and operational elements, and operating instructions for the C400 Controller.

Chapter 3. Quick Start provides installation instructions and introduces the operation and

functionality of the PCS by means of several easy-to-follow examples.

Preface

Chapter 4. Configuring Communication with the PLC contains information on Panel

Controller and PLC interface configurations and describes how to make the connection between

the Panel and PLC.

Chapter 5. Connection Editor describes the PCS function that performs the organization of

variables in the Panel (symbolic names) and addresses in the PLC.

Chapter 6. Demo Project briefly explains how to run the demo projects that are delivered with

the software.

Appendix A. Cabling Information describes the required PCS to PLC and PC interface cables

and provides several cabling diagrams.

Appendix B. Errors / Troubleshooting provides an overview of possible system errors and

explains their causes and possible solutions.

GFK-1115 iii

Page 4

Preface

Related Publications

PANELWARE Manuals

GFK-0848 PANELWARE™ Hardware Installation User's Manual

Describes the PANELWARE Operator Panels and contains technical data, hardware installation

instructions, and the general information required for putting the Panels into operation.

GFK-0849 PANELWARE™ Configuration Software Reference Manual

Describes the PANELWARE Configuration Software and provides the program setups for Panels

that are equipped with a programmable controller.

GFK-0850 PANELWARE™ MMI Application Manual for GE Fanuc Series 90™

Protocol (SNP)

Contains specific information on the configuration of PANELWARE Panels that communicate by

means of GE Fanuc Series 90 Protocol.

GFK-1112 PANELWARE™ Application Manual for Siemens SINEC L1 Driver

Contains specific information on the configuration of PANELWARE Panels that communicate

with Siemens controllers by means of the SINEC L1 protocol.

GFK-1113 PANELWARE™ Application Manual for the Modicon MODBUS

Contains specific information on the configuration of PANELWARE Panels that communicate

with MODICON controllers by means of the MODBUS protocol.

GFK-1142 PANELWARE™ Configuration Software Quick Start Guide

This guide, a companion to the PANELWARE Configuration Software Reference Manual (GFK-

0849), provides basic information for configuring and using PCS.

Other Documents

GEK-90486-1 Genius™ I/O System and Communications User’s Manual

Reference manual for systems designers, programmers, and others involved in integrating Genius

I/O products in a PLC or host computer environment. This book provides a system overview, and

describes the types of systems that can be created using Genius products. Datagrams, global data,

and data formats are defined.

GFK-0398 Series 90™-70 Genius™- Bus Controller User’s Manual

Describes the features and operation of the Series 90-70 Genius Bus Controller. Provides

configuration and programming information needed to complete the interface between a Series

90-30 PLC and a Genius I/O Bus.

(RTU/ASCII) Driver

GFK-0585 Series 90 PLC SNP Communications Driver User’s Manual

Describes the software installation, operation, and programming of the GE Fanuc Series 90

Protocol Driver. The SNP is used to retrieve/store data or issue commands to a given Series 90

PLC via the serial port.

iv PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 5

GFK-0852 Series 90™ PLC Serial Communications User's Manual

This manual describes serial communications products for the Series 90 Programmable Logic

Controller. Information is provided to implement a serial communications link between the Series

90 PLC, a host computer, peripheral device, or another PLC.

GFK-0898 Series 90-30 Programmable Controller I/O Module Specifications

Describes the discrete and analog I/O modules for the GE Fanuc Series 90-30 PLC. Contains

descriptions of each I/O module and provides specifications and wiring information for each

module.

GFK-1034 Series 90™-30 Genius™ Bus Controller User’s Manual

Describes the features and operation of the Series 90-30 Genius Bus Controller. Provides

configuration and programming information needed to complete the interface between a Series

90-30 PLC and a Genius I/O Bus.

We Welcome Your Comments and Suggestions

At GE Fanuc Automation, we strive to produce quality technical documentation. After you have

used this manual, please take a few moments to complete and return the Reader's Comment Card

located on the next page.

Preface

Libby Allen

Senior Technical Writer

GFK-1115 Preface v

Page 6

Contents

Chapter 1 Overview ............................................................................................................... 1-1

PANELWARE Configuration Software..............................................................................1-2

Hardware and Software Requirements................................................................................1-3

PLC Requirements.............................................................................................................1-4

Document Conventions.......................................................................................................1-5

Key Symbols ...............................................................................................................1-5

Menu Functions...........................................................................................................1-5

Chapter 2 C400 Panel Controller Hardware.........................................................................2-1

General Information...........................................................................................................2-2

Power Requirement......................................................................................................2-2

Connecting Power to the Controller..............................................................................2-2

Setting Number Switches.............................................................................................2-2

Genius Panel Controller (C400)..........................................................................................2-3

Specifications ..............................................................................................................2-3

Overview of Connections and Operational Elements .....................................................2-5

Operating the C400 Controller ...........................................................................................2-9

FlashPROM ................................................................................................................2-9

RESET Modes............................................................................................................. 2-9

Loading and Starting Panel Programs.........................................................................2-10

Update Mode/Reloading the Operating System...........................................................2-10

Chapter 3 Quick Start............................................................................................................ 3-1

Section 1 Software Installation............................................................................ 3-2

Calling the Setup Program..................................................................................................3-2

Language Selection ............................................................................................................3-2

Installation Menu............................................................................................................... 3-3

Changing the Destination Path .....................................................................................3-3

Start Installation..........................................................................................................3-3

Screen Configuration ...................................................................................................3-4

Exiting the Installation.................................................................................................3-4

Section 2 Starting PCS......................................................................................... 3-5

Section 3 General Operation ............................................................................... 3-6

Pull-Down Menus (Main Menu)......................................................................................... 3-6

Window Name...................................................................................................................3-6

Selection Windows.............................................................................................................3-7

Context-Sensitive Help Screens..........................................................................................3-7

Screen Elements................................................................................................................. 3-8

Section 4 PCS Configuration............................................................................... 3-9

GFK-1115 vii

Page 7

Contents

Section 5 Creating a New Project.......................................................................3-10

Section 6 Defining Connections..........................................................................3-13

Connection to a GE Fanuc PLC via Genius ......................................................................3-14

Internal Connection..........................................................................................................3-17

Genius Internal Connection ..............................................................................................3-18

Section 7 Key Assignments.................................................................................3-19

Section 8 Creating Pictures ................................................................................3-21

Picture 1..........................................................................................................................3-21

Picture 2..........................................................................................................................3-25

Picture 3..........................................................................................................................3-27

Section 9 Defining the Project Variables............................................................3-28

Genius Device Connection................................................................................................3-29

Genius Internal Connection ..............................................................................................3-30

Internal Connection..........................................................................................................3-31

Section 10 Binding Pictures in the Project.........................................................3-32

Picture for a Communications Error.................................................................................3-33

Picture Binding Overview.................................................................................................3-34

Error Picture..............................................................................................................3-35

Start-up Picture .........................................................................................................3-36

Pict_1........................................................................................................................3-37

Picture List Organization .................................................................................................3-38

Section 11 Compiling the Project.......................................................................3-39

Section 12 Downloading the Project to the Panel..............................................3-40

Section 13 Connecting the PLC and the Panel..................................................3-42

Section 14 Starting the Project...........................................................................3-43

Section 15 Exiting PCS.......................................................................................3-44

Chapter 4 Configuring Communication with the PLC......................................................... 4-1

Genius Protocol Parameters (Definition in PCS).................................................................4-2

PLC Types..................................................................................................................4-3

PLC Node Parameter Definitions .................................................................................4-5

PLC Network Parameter Definitions ............................................................................4-7

SNP 90 Protocol Parameters (Definition in PCS)................................................................4-9

Settings on the Panel ........................................................................................................4-10

Panel Interface.................................................................................................................4-10

Configuration of the PLC Interface...................................................................................4-10

Chapter 5 PCS Connection Editor ........................................................................................ 5-1

General Information...........................................................................................................5-2

Accessing the Connection List............................................................................................5-2

viii PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 8

Contents

Elements of the Connection List .........................................................................................5-3

Using Function Keys in the Connection List........................................................................5-3

Overview.....................................................................................................................5-3

Editing/Inserting Connections.......................................................................................5-4

Defining/Changing an ID .............................................................................................5-4

Defining/Changing a Connection..................................................................................5-4

Deleting Connections ...................................................................................................5-5

Editing PLC Node Parameters of a Connection.............................................................5-5

Editing the Variable Assignment Table...............................................................................5-6

Elements of the VAT ...................................................................................................5-6

Function Keys of the VAT ...........................................................................................5-7

Editing/Inserting Variable Assignments........................................................................5-8

Entering/Changing the Tagname...................................................................................5-8

Entering/Changing PLC Addresses...............................................................................5-8

Entering/Changing PLC Variable Types....................................................................... 5-9

Deleting Variable Assignments...................................................................................5-10

Marking Unused Variables.........................................................................................5-10

Global Data Format.........................................................................................................5-11

Data Type Conversions....................................................................................................5-12

Chapter 6 Demo Project......................................................................................................... 6-1

Section 1 General Information............................................................................ 6-2

Section 2 Required Hardware............................................................................. 6-3

Section 3 Downloading the Demo Project........................................................... 6-4

Defining the User Path .......................................................................................................6-4

Loading the Project............................................................................................................6-5

Downloading and Starting the Project.................................................................................6-6

Section 4 Description of the Demo Project.......................................................... 6-7

General Information...........................................................................................................6-7

Main Menu........................................................................................................................6-8

Value Entries.....................................................................................................................6-9

INPUT VALUES Picture.............................................................................................6-9

CLOCK Picture.........................................................................................................6-10

Entering a Password.........................................................................................................6-11

INPUT PASSWORD Picture.....................................................................................6-11

LOCKED INPUT Picture..........................................................................................6-12

Key Functions..................................................................................................................6-13

Alarm List .......................................................................................................................6-14

Error Picture....................................................................................................................6-15

Section 5 Creating the Demo Project.................................................................6-16

General Information.........................................................................................................6-16

GFK-1115 Table of Contents ix

Page 9

Contents

Creating a Project ............................................................................................................6-16

Preparing a Concept...................................................................................................6-17

Creating a New Project..............................................................................................6-18

Selecting the Connections...........................................................................................6-19

Defining Key Assignments.........................................................................................6-22

Creating the Pictures..................................................................................................6-23

Defining the Text Groups...........................................................................................6-51

Binding Pictures to the Project ...................................................................................6-52

Editing the Alarm System...........................................................................................6-58

Activating the Alarm System......................................................................................6-60

Editing the Connections..............................................................................................6-61

Compiling the Project.......................................................................................................6-64

Errors..............................................................................................................................6-64

Appendix A Cabling Information............................................................................................A-1

Genius Communications....................................................................................................A-2

Selecting a Cable Type ...............................................................................................A-2

Using Other Cable Types............................................................................................ A-2

Bus Length.................................................................................................................A-4

Baud Rate Selection....................................................................................................A-4

Connecting Devices to the Bus ....................................................................................A-5

SNP Communications.......................................................................................................A-5

Cable Diagrams................................................................................................................A-6

Appendix B Errors/Troubleshooting ....................................................................................... B-1

Errors During Installation.................................................................................................. B-2

Errors During Program Start............................................................................................. B-3

Errors While Working in PCS........................................................................................... B-4

Error Numbers in Internal USER Variable......................................................................... B-6

x PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 10

Chapter

1

Overview

This chapter provides a short overview/description of the PANELWARE Configuration Software

(PCS) and outlines the requirements for PCS operation with the PC and PLC. It includes the

following information:

■ PANELWARE Configuration Software (PCS) ............................................................1-2

■ Hardware and Software Requirements ........................................................................1-3

■ PLC Requirements......................................................................................................1-4

■ Document Conventions...............................................................................................1-5

GFK-1115 1 - 1

Page 11

1

PANELWARE Configuration Software

PANELWARE Configuration Software allows complex projects to be created, using easy-tofollow, menu-controlled instructions. These projects are actually programs that are transferred to a

Panel and started there via a Panel power-on or Reset. The PCS-created Panel program (project)

then takes over communication with the PLC and performs the following:

■ Reads data from the PLC and displays it on the screen in the specified format (values,

text, bar-graphs, graphics)

■ Writes data to the PLC and executes PLC functions

■ Displays static data, such as text masks and lines

Using PCS, projects can be created for the C400 Panel Controller.

Every project consists of at least the following components:

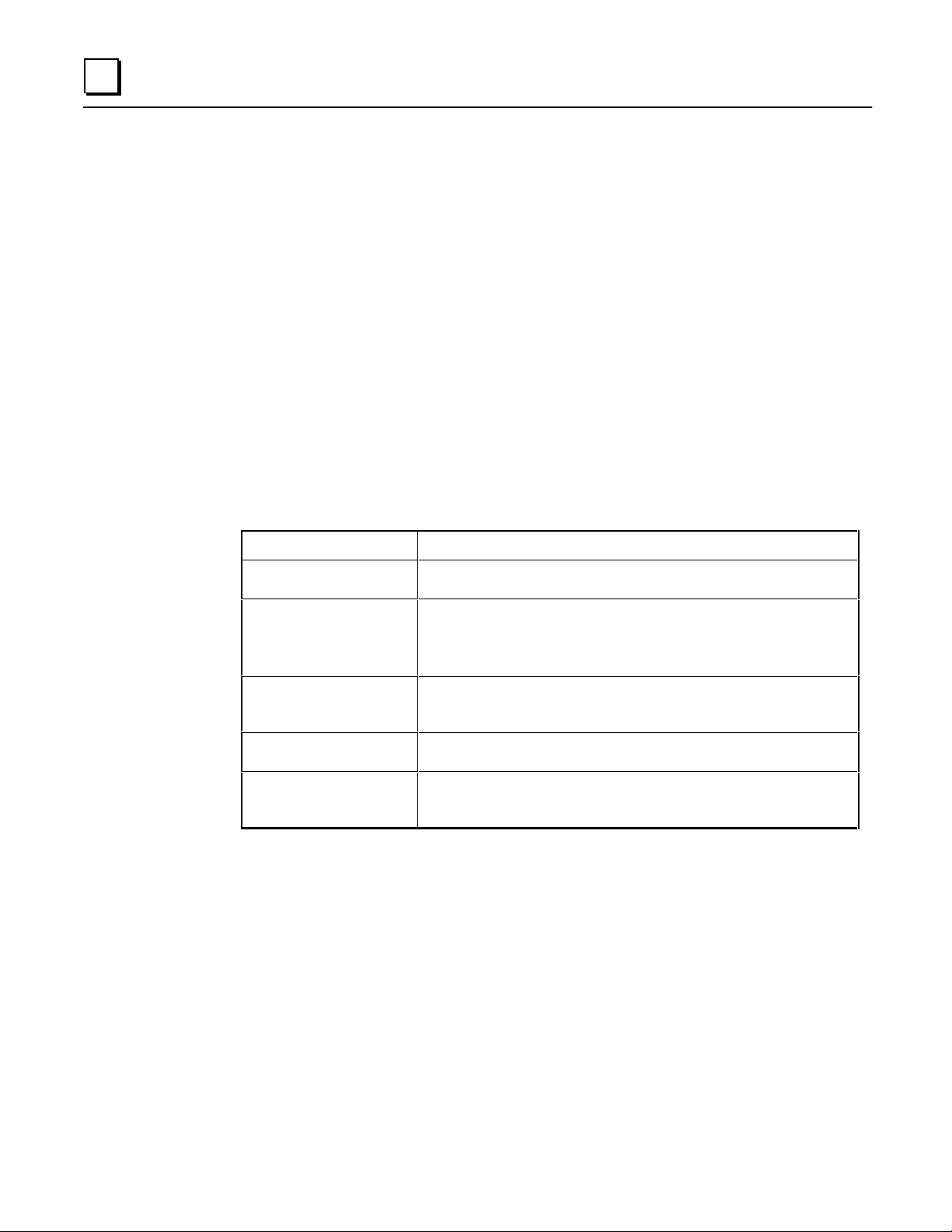

Table 1 - 1. PCS Project Component Descriptions

Project Component Definition

Project Definition Consists mainly of the hardware configuration of the Panel and the picture

directory.

Picture Directory A list of all pictures used in the project; also contains information on

switching to other pictures.

A picture change (making a different picture appear on the screen) can be

performed either by pressing a defined key or via the direction of the PLC.

Pictures Contains all information about what is to be displayed on the display

module. Text, in/output fields, and on graphics-capable displays, lines, and

bars, can all be components of a picture.

Keyboard Definition Defines the keyboard function assignments (function keys, numeric, or

alphanumeric keys can be defined).

Connection List Lists all connections that the Panel can access. A connection defines the

type of connection (protocol), the interface, and the location where the

Panel can find the data (e.g., which CPU in a network).

1 - 2 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 12

1

Hardware and Software Requirements

PCS is delivered on two 3½-inch disks in 2DD (720K) format and on one 5¼-inch disk in 2S/HD

(1.2M) format. The diskette(s) you use to install the PCS depends on your PC configuration.

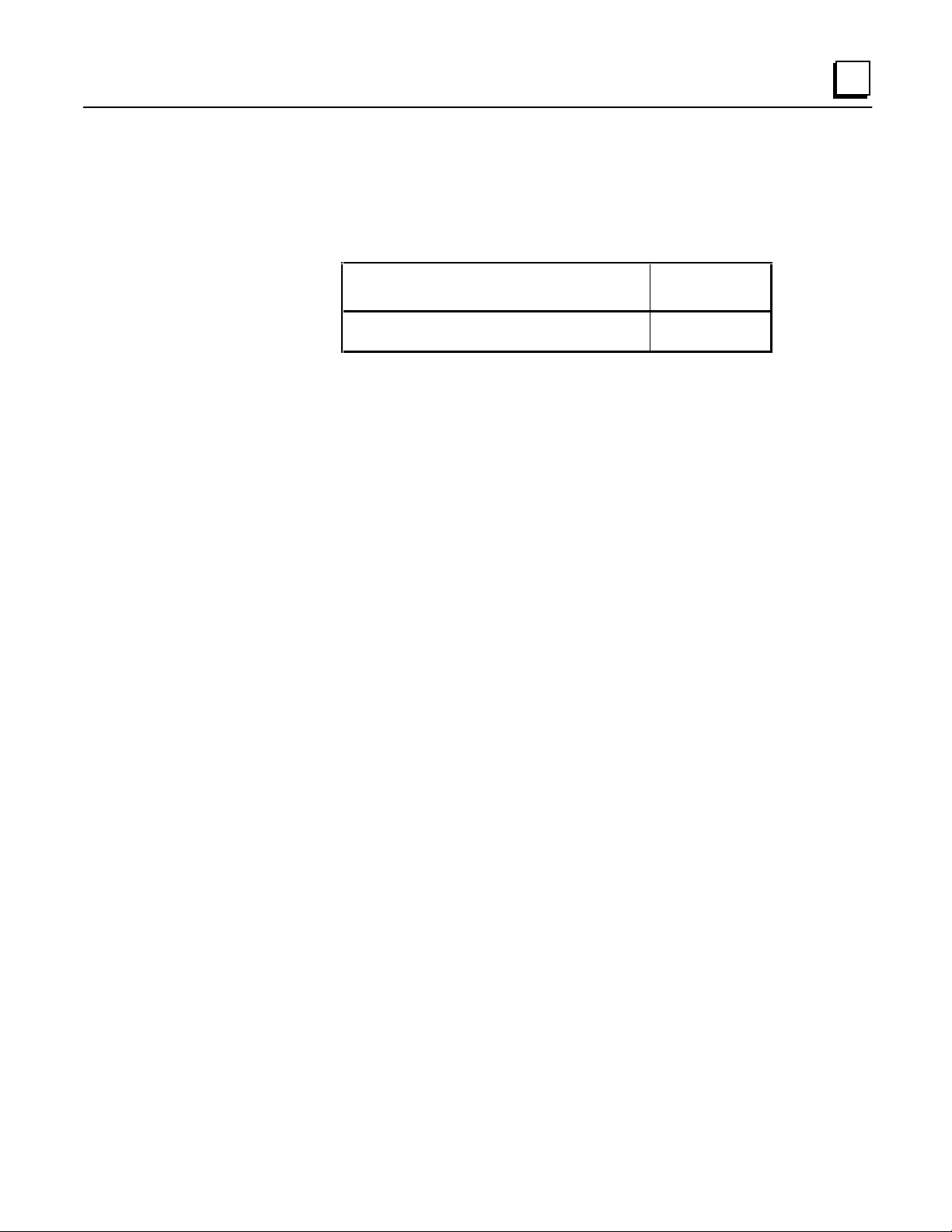

Description Catalog

PANELWARE Configuration Software

(includes cable assembly)

Before starting the software installation, make sure the following requirements are met:

■ Complete IBM PC compatibility (processor types: 80286 and higher)

■ IBM compatible monochrome or color adapter

■ One 3½ inch (720 Kbyte) or 5¼ inch (1.2 Mbyte) floppy disk drive

■ For the installation, approximately 3 Mbytes must be free on the hard disk.

■ 640 KB RAM, of which at least 512 KB must be available. Memory-resident programs

should be removed if necessary to free up the RAM.

■ Minimum 1 serial interface (COM1 or COM2)

■ MS-DOS version 3.30 or higher

Number

IC641SWP950

■ The CONFIG.SYS file settings for FILES and BUFFERS must be set to a minimum of:

FILES=40; BUFFERS=10.

Note

PCS can be executed in a DOS box under Windows 3.1 only in offline mode. To

either download or upload a project to/from a Panel, you must exit Windows and

run PCS from the DOS prompt.

GFK-1115 Chapter 1 Overview 1 - 3

Page 13

1

PLC Requirements

To communicate with the C400 Genius Panel Controller, the PLC must meet the following

requirements:

■ Series 90-70 PLC

❏ Genius Bus Controller (GBC), IC697BEM731

■ Series 90-30 PLC

❏ Genius Communications Module (GCM), IC693CMM301

❏ Enhanced Genius Communications Module (GCM+), IC693CMM302

❏ Genius Bus Controller, IC693BEM331

■ Series Six

❏ Genius Bus Controller with diagnostics, IC660CBB902

❏ Genius Bus Controller without diagnostics, IC660CBB903

■ Series Five

❏ Genius Bus Controller, IC655BEM510

1 - 4 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 14

1

Document Conventions

Key Symbols

All keys used to operate PCS are shown in bold in this manual:

Table 1 - 2. Key Symbols

Key

German English

↑↑↑↑

↓↓↓↓

←←←←

→→→→

↵↵↵↵

Bild↑↑

Bild↓↓

Einfg Ins

Entf Del

Esc Esc

Space Space

Strg Ctrl

Shift Shift

Alt Alt

⇐⇐⇐⇐

PgUp

PgDn

Description

Cursor up

Cursor down

Cursor left

Cursor right

Enter (Return)

Cursor one page up

Cursor one page down

Switches between insert and overwrite modes

The character in the cursor position is deleted

Exits from the current function; exits the editor or a menu

Space (Blank character)

Control key

SHIFT key

Alternate key

The character to the left of the cursor position is deleted (Back Space)

If two keys are to be pressed simultaneously in order to execute a function, the keys will be

connected by the plus (+) character. Example:

Ctrl

+ Ins

Text that is to be entered directly using the keyboard is shown in bold and italic. Example:

panel

Menu Functions

The names of pull-down menus and menu functions are shown in bold. Example:

Edit menu

GFK-1115 Chapter 1 Overview 1 - 5

Page 15

Chapter

2

C400 Panel Controller Hardware

This chapter describes the C400 PANELWARE Panel Controller (IC750CTR400), its connections

(interfaces) and all operational elements for which hardware must be configured on the modular

Panel. The following sections of information are included:

■ General Information ...................................................................................................2-2

❏ Power Requirement..............................................................................................2-2

❏ Connecting Power to the Controller.....................................................................2-2

❏ Setting Number Switches.....................................................................................2-2

■ Genius Panel Controller (C400)..................................................................................2-3

❏ Specifications ......................................................................................................2-3

❏ Overview of Connections and Operational Elements............................................2-5

■ Operating the C400 Controller ...................................................................................2-7

❏ FlashPROM.........................................................................................................2-9

❏ RESET Modes.....................................................................................................2-9

❏ Loading and Starting Panel Programs................................................................2-10

❏ Update Mode/Reloading the Operating System ..................................................2-10

GFK-1115 2 - 1

Page 16

2

General Information

Power Requirement

24 VDC power must be supplied to the PANELWARE Controller unit. The Controller, in turn,

supplies the Keyblock and Display modules with power.

When estimating the total 24 VDC power consumption for a system, add up the 24 VDC power

supply requirements for all of the PANELWARE components being used, then add an additional

30% to allow for power on surge currents. Refer to the PANELWARE™ Hardware Installation

User’s Guide (GFK-0848) for details on displays and Keyblocks.

Connecting Power to the Controller

The 24 VDC power connector on the Controller is located on the top left corner of the unit. The

mating connector is supplied with each Controller.

Do not try to run PANELWARE off a Series 90-30 power supply revision M

or earlier. Although some configurations might function under this setup, it

is not recommended. Damage to the 90-30 power supply could result.

The suitability of a Series 90-30, revision N or later power supply depends

on the +24VDC isolated load requirements of the modules in your PLC.

Refer to the Series 90-30 Programmable Controller I/O Module

Specifications (GFK-0898) to determine additional load requirements of

your system.

All components of a PLC and the devices it is controlling must be properly grounded. This is

particularly important for the reasons listed below:

■ A low-resistance path from all parts of a system to ground minimizes exposure to shock

in the event of short circuits or equipment malfunction.

■ PANELWARE Operator Panels require proper grounding for correct operation.

The importance of grounding can not be over emphasized.

Setting Number Switches

Number switch settings on the Panel Controller can be set using a small flathead screwdriver to

turn the switch dial to the desired setting (so that the arrow points at the desired setting).

Caution

The assembled Panel configuration provides minimal space to reach the number switches once the

Panel is installed. If possible, these settings should be made before the Controller is installed.

2 - 2 PANELWARE MMI Application Manual for Genius Protocol - June 1995 GFK-1115

Page 17

2

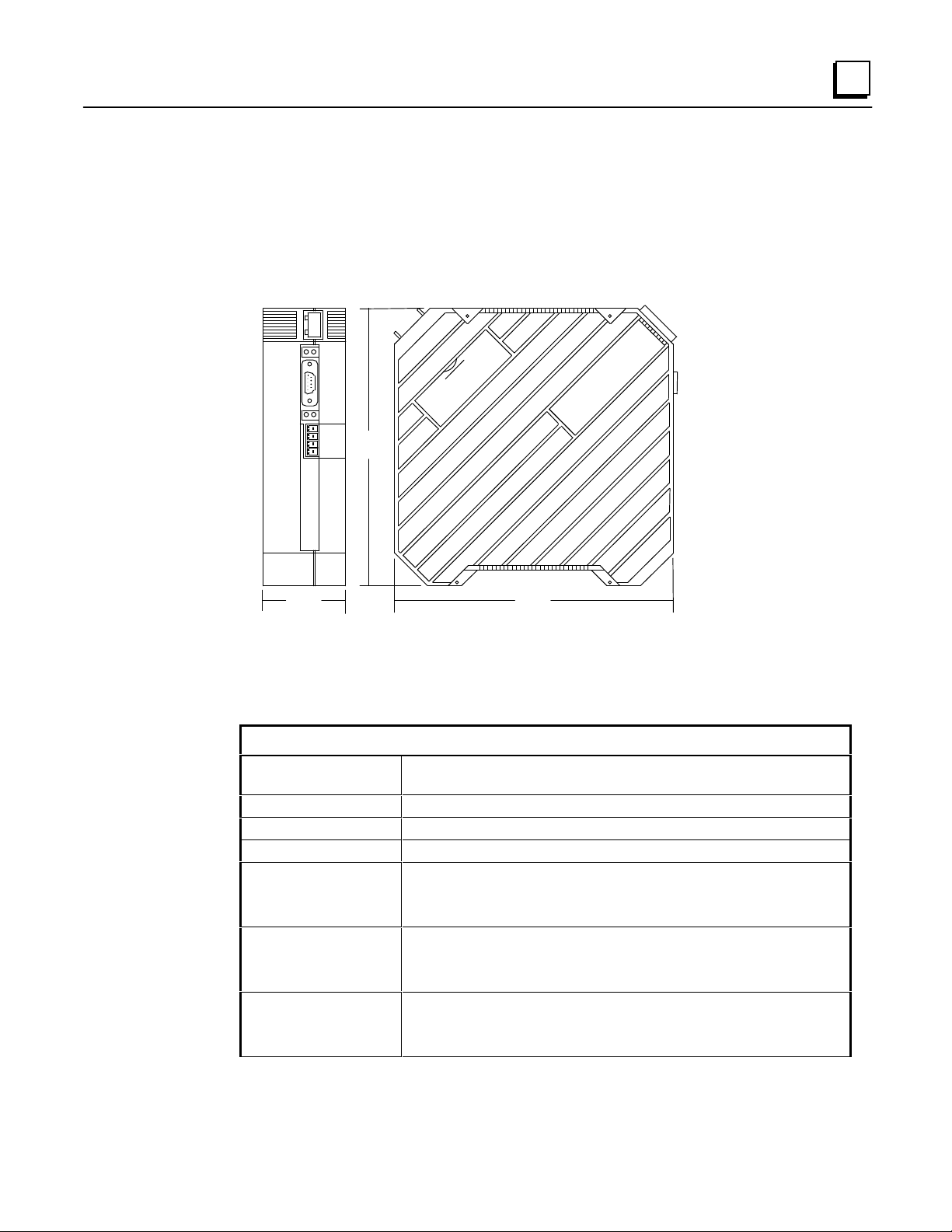

Genius Panel Controller (C400)

Specifications

GENIUS

SHLD OUT

SHLD IN

7.165"

X2

(182mm)

X1

a45517

2.165"

(55mm)

7.165"

(182mm)

Figure 2 - 1. Genius Panel Controller (C400)

Table 2 - 1. Specifications for Genius Panel Controller (C400)

Technical Data

Interfaces

Programming

Power supply

Real-time clock

Connection of ....

Display modules

Keyblock modules

Temperature

Operating

Storage

Relative humidity

Operating

Storage

IF0: RS-232 (not galvanically isolated)

Genius: (isolated)

PANELWARE Configuration Software

24 VDC (min. 18 VDC, max. 30 VDC)

YES with battery installed (non-volatile)

1

maximum of 7

0 to 50 °C (32 to 122 °F)

-20 to 60 °C (-4 to 140 °F)

10 to 95 % (non-condensing)

10 to 95 % (non-condensing)

GFK-1115 Chapter 2 C400 Panel Controller Hardware 2 - 3

Page 18

2

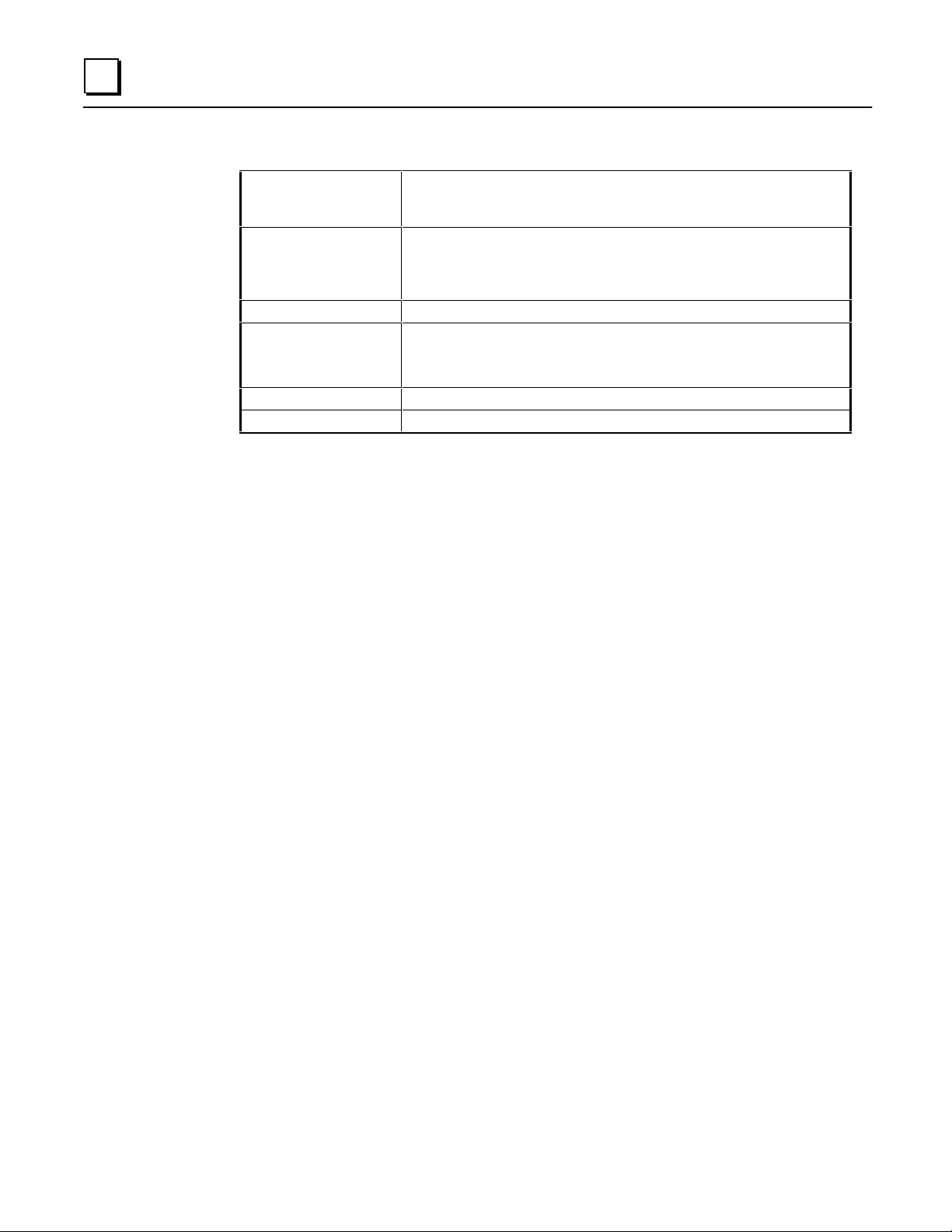

Table 2 - 1. - Continued

Shock

Vibration

Processor

24 VDC power

requirements

(typical)

Sealing

Noise immunity

conforms to IEC 68-2-27

15g equivalent, 150 m/sec

2

, 11 msec, 3 axes (positive and

negative)

conforms to IEC 68-2-6

1g equivalent, 10-58 Hz; 0.075 mm

58-150 Hz; 9.8m/sec

2

20 cycles per axis

Motorola 68302 @ 16 MHz

185 mA, 24 VDC

260 mA, 18 VDC (minimum power voltage)

150 mA, 30 VDC (maximum power voltage)

NEMA 12 and IP54 when properly mounted in a Panel

conforms to IEC 801.2; IEC 801.3; IEC 801.4

2 - 4 PANELWARE MMI Application Manual for Genius Protocol - June 1995 GFK-1115

Page 19

2

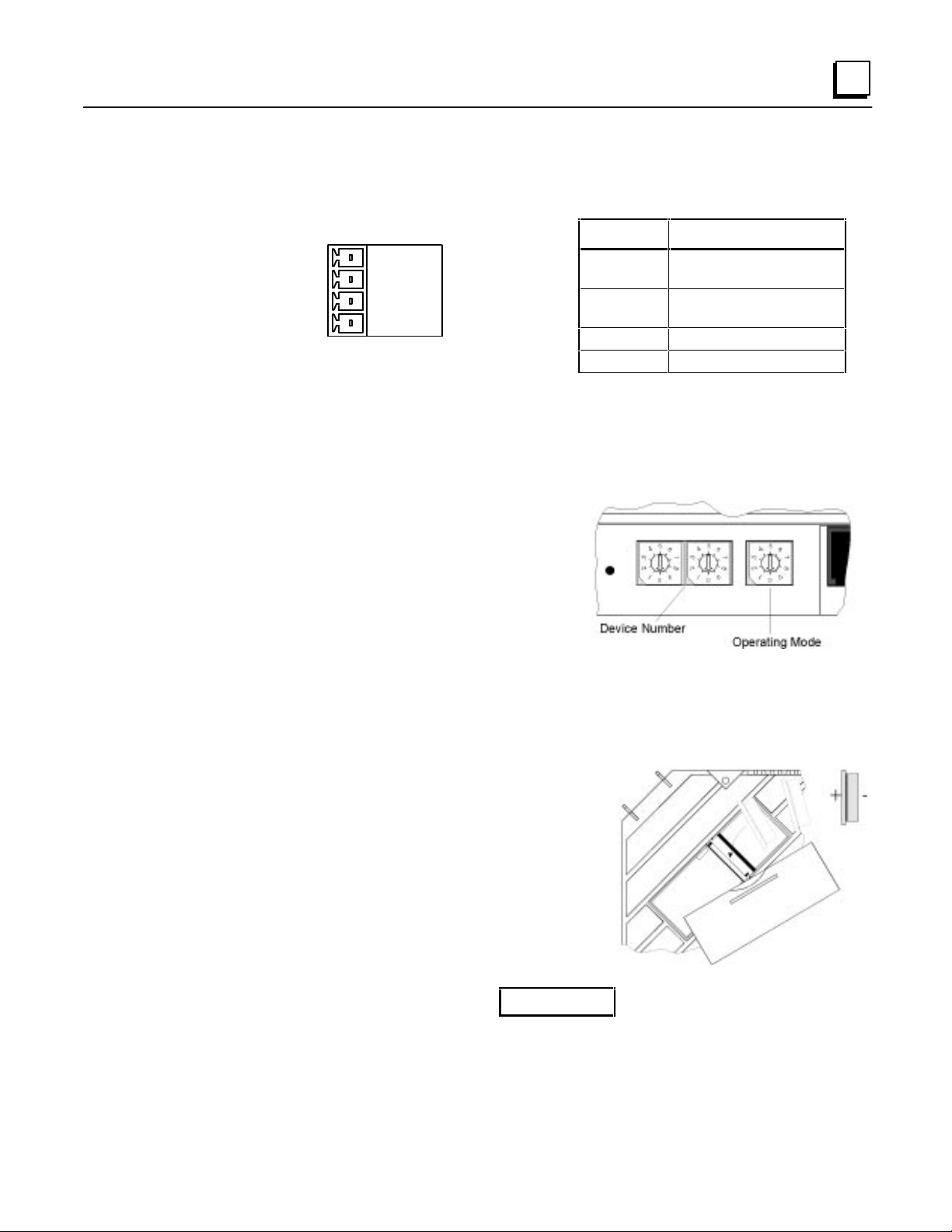

Overview of Connections and Operational Elements

1

9

8

7

6

5

Figure 2 - 2. Genius Panel Controller (C400) Elements/Connections

. Display Module Connector (ribbon

1

cable)

2

. 24 VDC Power Supply Connector

3

. IF0: RS-232 (to PC), labeled 0

4

. Genius Bus Connector

6

. Mode Switch - Operating Mode

7

. Cover for Lithium Battery

8

. Device Number Switches

9

. Reset Button

a45516

2

3

4

5

. Keyblock Module Connector

GFK-1115 Chapter 2 C400 Panel Controller Hardware 2 - 5

Page 20

2

Description

+24 V

0 V

Ground

Ground

24 VDC Power Supply (item 2, Figure 2-2)

Pin

+

-

The pins are to be connected using as short a cable as is possible. If the Panel is mounted in a

cabinet, the connecting cable should be as short as possible.

IF0 - RS-232, Non-isolated (item 3, Figure 2-2)

Pin Description

1NC

2 RxD Receive Data (Input)

3 TxD Transmit Data (Output)

9 pin D-Type (M)

LED Meaning

TxD Send data over interface

RxD Receive data over interface

4 + 5 V Power Supply

5 GND Signal Ground

6NC

7 RTS Request To Send (Input)

8 CTS Clear To Send (Output)

9NC

(200 mA available to user)

2 - 6 PANELWARE MMI Application Manual for Genius Protocol - June 1995 GFK-1115

Page 21

2

Genius Bus Connector, Isolated (item 4, Figure 2-2)

a45318

SHLD OUT

SHLD IN

GENIUS

X2

X1

Pin Description

SHLD OUT Shield Out (to next physical

device on bus)

SHLD IN Shield In (from previous

physical device on bus)

X2 Serial 2

X1 Serial 1

Mode Switch (item 6, Figure 2-2)

The mode of operation for the Panel Controller is

selected by setting the Operating Mode switch (see

Table 2-2 for operating modes).

Device Number Switches (item 8, Figure 2-2)

The Genius bus address for the C400 Controller is set using the Device Number switches. Valid

device numbers are 00 to 31, inclusive.

Lithium Battery (item 7, Figure 2-2)

The lithium battery is stored in its own compartment in

the Controller and covered for its own and the user's

protection. It should be replaced every two years, or

whenever the software indicates that the battery is low.

Warning

Lithium batteries are considered harmful waste. Dispose of them in

accordance with the instructions in the Material Safety Data Sheet (MSDS)

that accompany the battery, and in accordance with local regulations.

GFK-1115 Chapter 2 C400 Panel Controller Hardware 2 - 7

Page 22

2

Reset Button (item 9, Figure 2-2)

A hardware reset can be executed by pressing this button.

Depending on the setting of the mode selection switch,

different functions can be executed. These functions are

explained in the descriptions of the connections and

operational elements that follow.

2 - 8 PANELWARE MMI Application Manual for Genius Protocol - June 1995 GFK-1115

Page 23

2

Operating the C400 Controller

FlashPROM

The Panel Controller has non-volatile memory called FlashPROM, which is split into two separate

areas (banks) as follows:

System Bank contains the operating system, which is necessary for the Panel program created by

the user to be processed. The system bank can not be deleted by the user.

Routine operating system updates to a higher revision level are performed with PCS in Update-

Mode.

User Bank contains the Panel program that controls and is used by the display and Keyblock

modules. The Panel program is created with PCS on a standard PC and downloaded in Teach-

Mode.

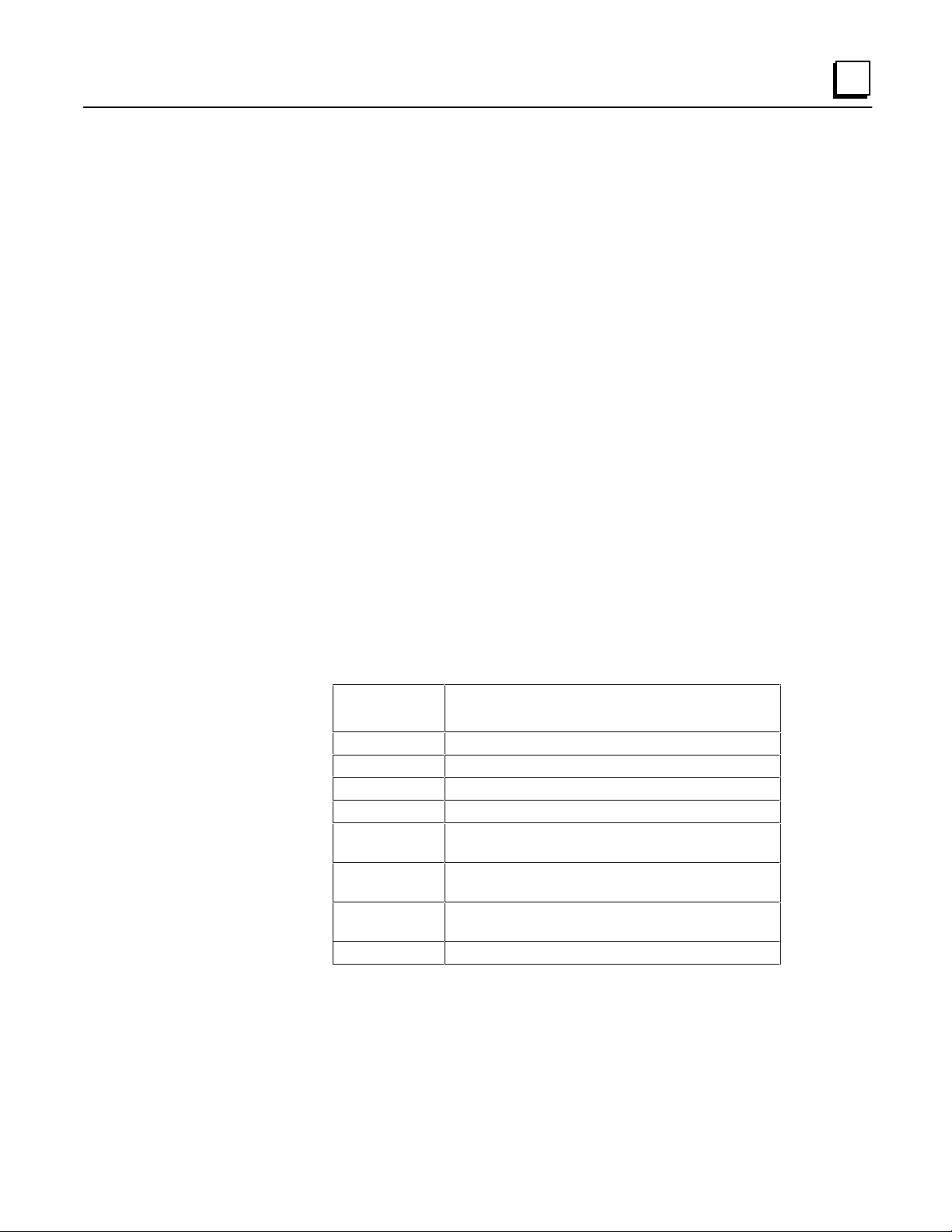

RESET Modes

After a Reset or power-on, different operating modes can be activated depending on the settings of

the mode switch (operating mode). The mode swi tch is us ed t o select run, update, or teach mode. In

addition, se ttings 1 — 5 selec t the baudrate in run mode.

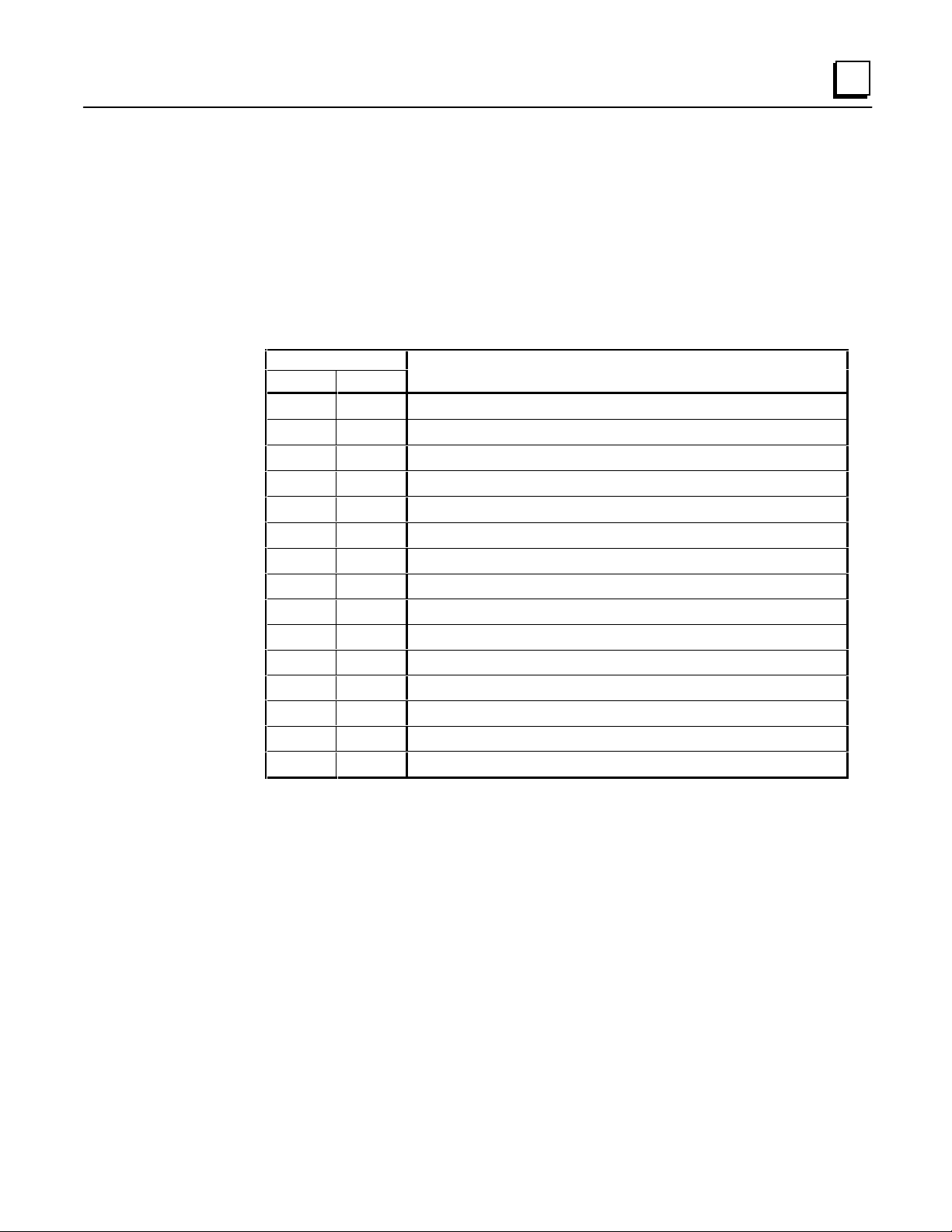

Table 2 - 2. C400 Controller Mode Switch Settings

Switch

Setting

1

2

3

4

5

6

7

8-9

Run Mode: The Panel Controller starts the operating system from the FlashPROM (Bank

0). Existing Panel programs (in FlashPROM User Bank) are started automatically.

Run Mode, 153.6 kBaud extended

Run Mode, 76.8 kBaud

Run Mode, 38.4 kBaud

Run Mode, 153.6 kBaud standard

Run Mode, 153.6 kBaud standard, or the baudrate set in

PCS

Update Mode: An update of the operating system can be

performed with PCS.

Teach Mode: Panel programs that are created by means

of PCS are transferred to the FlashPROM (User Bank)

Not allowed

Description

GFK-1115 Chapter 2 C400 Panel Controller Hardware 2 - 9

Page 24

2

Loading and Starting Panel Programs

A Panel program is created using PCS and then transferred (loaded) to the Panel through the

serial interface when Teach Mode is selected. To start an application, RUN Mode must be

selected. The following sections outline how to load, start, and reload the operating system.

Loading the Panel Program

1. Connect the PC (COM1 or COM2) to the Panel Controller (always IF0) using the

appropriate serial cable (see Appendix A).

If you are using a printer with the C400, the printer must be disconnected while

the Panel program is loaded.

2

. Select Teach Mode (position 7).

. Press the Reset button.

3

. Wait until Teach-Mode is displayed.

4

Note

. Start the transfer from PCS.

5

. Wait until PCS acknowledges that the entire Panel program has been transferred.

6

Starting the Panel Program

1. Select Run Mode (position 5, or 1 — 4, as appropriate).

. Connect the PLC to the Panel Controller.

2

. Press the Reset button.

3

Update Mode/Reloading the Operating System

The Panel Controller's operating system can be reloaded from PCS. The steps for accomplishing

this transfer are identical to those in the section, “Loading the Panel Program,” except that

Update Mode (position 6) is selected. The Update Mode is only required to support future

operating system upgrades.

To update in this mode, proceed as follows:

1. Select Update Mode (position 6).

2. Press the Reset button.

3. Begin the update operation with PCS.

4. Wait until PCS acknowledges that the update is complete.

5. Select Run Mode (position 5, or 1 — 4, as appropriate).

6. Press the Reset button to start the existing Panel program.

2 - 10 PANELWARE MMI Application Manual for Genius Protocol - June 1995 GFK-1115

Page 25

Chapter

3

Quick Start

This chapter provides a quick guide to installing and using PCS and, using step-by-step

instructions, explains how to create a project. It includes the following information:

■ Software Installation........................3-2

❏ Calling the Setup Program........3-2

❏ Language Selection................... 3-2

❏ Installation Menu .... ............. ....3-3

■ Starting PCS ...................................3-5

■ General Operation...........................3-6

❏ Pull-down Menus...............3-6

❏ Window Name...................3-6

❏ Selection Windows ............3-7

❏ Context-Sensitive Help ......3-7

❏ Screen Elements................3-8

■ PCS Configuration ..........................3-9

■ Creating a New Project..................3-10

■ Defining Connections....................3-14

❏ PLC ↔ Panel Connection.......3-15

❏ Connection to a GE Fanuc PLC

via Genius.............................. 3-15

❏ Internal Connection ............... 3-18

❏ Genius Internal Connection.... 3-19

■ Key Assignments .......................... 3-20

■ Creating Pictures .......................... 3-22

■ Defining the Project Variables ...... 3-29

■ Binding Pictures in the Project...... 3-33

❏ Communications Error Picture 3-34

❏ Picture Binding Overview...... 3-35

❏ Picture List Organization....... 3-39

■ Compiling the Project ................... 3-40

■ Downloading the Project............... 3-41

■ Starting the Project ....................... 3-44

■ Exiting the PCS ............................ 3-45

GFK-1115 3 - 1

Page 26

3

Section 1 Software Installation

The Genius protocol driver is copied to your computer as part of the standard PCS installation

(PCS version 1.8 or later). The PCS should be installed according to the instructions in the

following sections.

Calling the Setup Program

Insert the PCS distribution diskette into the appropriate floppy disk drive. If you are using the two

3 1/2” diskettes, install the #1 disk first (the system will prompt you when it is time to insert disk

#2).

Depending on the floppy drive designation (a or b), type one of the following commands at the

DOS prompt, then press the ↵↵ (Enter) key:

C:\>

a:setup

or

After you press ↵↵ , the setup program is called and the menu for language selection appears on the

screen.

Language Selection

The Language Selection menu is used to select the language (English or German/Deutsch) in

which you wish to configure the PCS during the installation procedure. This language is used as

the default selection for the PCS.

Press the function key that corresponds to the desired language. When it has been selected, the

Install Program menu is displayed on the screen.

C:\>

b:setup

3 - 2 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 27

3

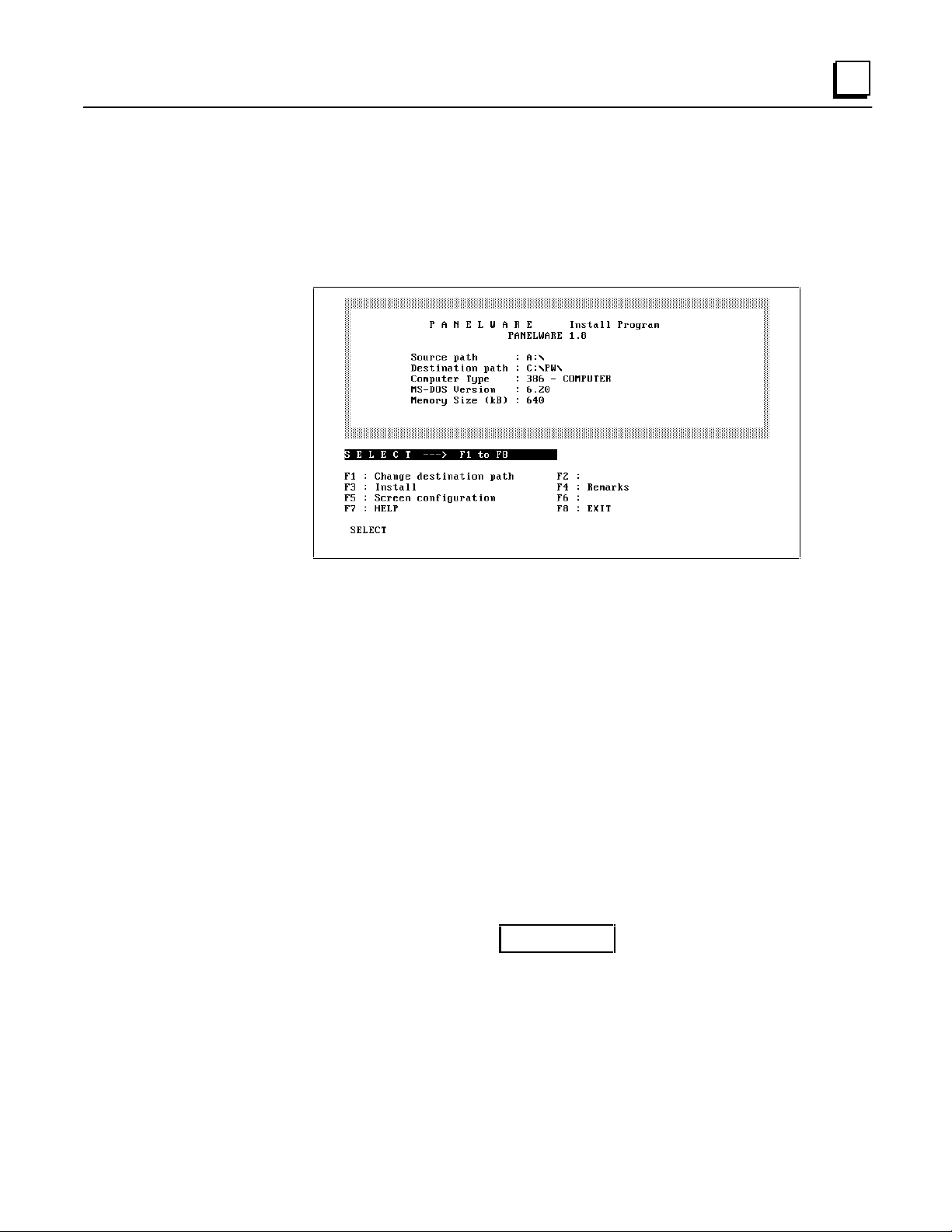

Installation Menu

All system information that the software requires is entered or displayed in the Install Program

menu. Computer type, DOS version, source path and memory size are entered automatically. You

must enter the desired destination path.

From the Install Program menu, you can change destination paths, start the installation,

configure the screen, and exit the installation.

Changing the Destination Path

The destination path (the directory in which the software is to be installed) is set to C:\PW\ by

default. By pressing F1 Change destination path, you can specify a different disk drive and/or

path into which the PCS will be installed.

Start Installation

Once the system information is correct in the Install Program menu, start the installation process

by pressing F3 Install.

The setup program may recommend changes to the CONFIG.SYS file. These changes are only

made if you confirm them at the prompt.

The PCS requires the minimum values recommended for FILES and

BUFFERS. If you enter smaller values in the CONFIG.SYS file, problems

could arise while running the PCS.

Caution

GFK-1115 Chapter 3 Quick Start 3 - 3

Page 28

3

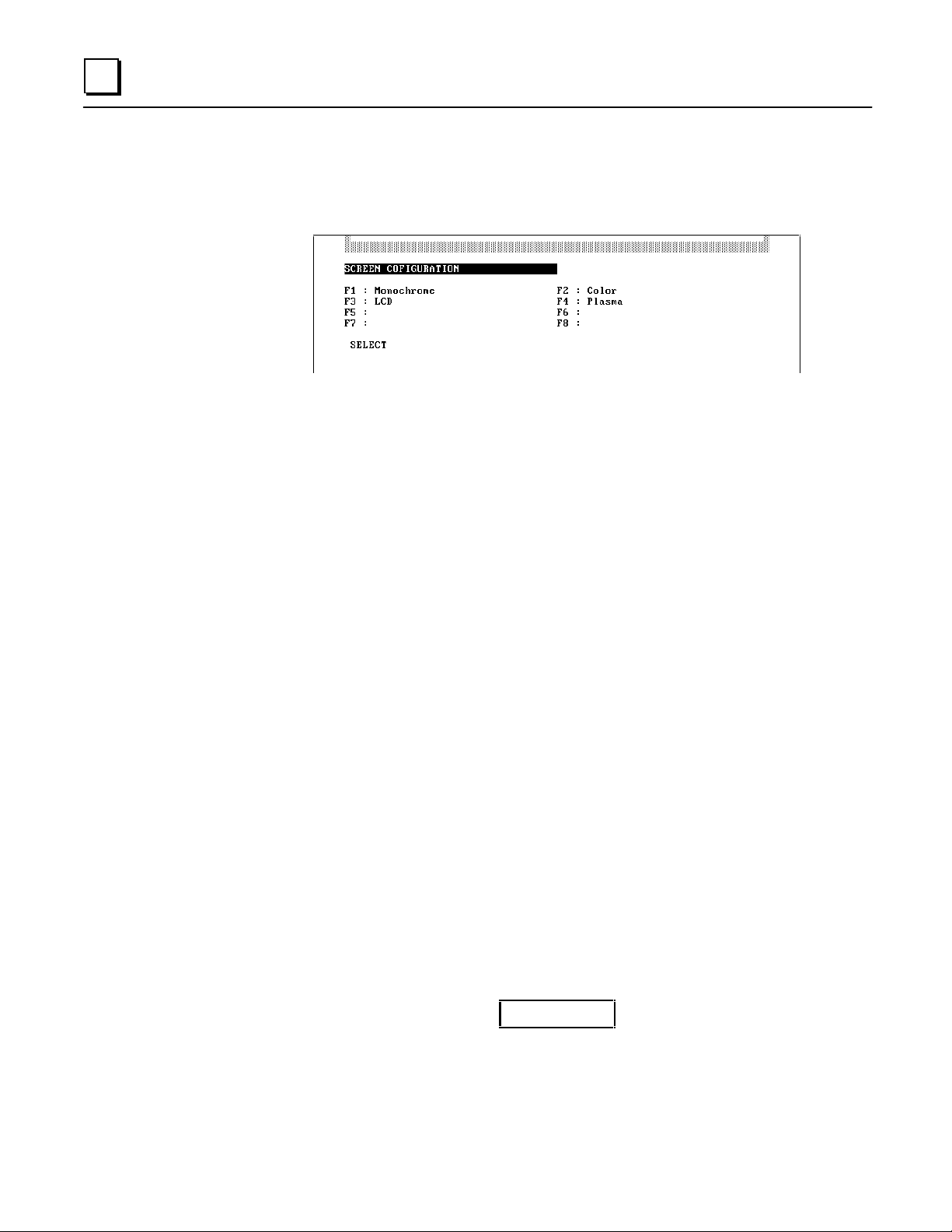

Screen Configuration

The Screen Configuration menu is displayed once the CONFIG.SYS file changes are made.

This screen allows you to set up the appropriate PCS screen type by pressing the function key that

corresponds to your computer's display. When you select a display type, the system begins copying

the PCS files to the destination directory you selected.

After all PCS installation files are copied to the destination directory, the following message is

displayed:

Installation completed. Press any key to continue _

The Install Program menu reappears on the screen when any key is pressed.

If the screen type that was selected during installation must be changed after

installation, you can access the Screen Configuration menu again by pressing

F5 Screen configuration from the Install Program menu and selecting the

desired screen type.

Exiting the Installation

The setup (installation) program is exited when you press F8 EXIT from any of the menus. Before

exiting, the following message will appear on the screen if changes were made to the

CONFIG.SYS file:

System file modified: RE-BOOT (Y/N)?

To start the PCS properly, it is necessary to reboot the computer after installation when changes

have been made to the CONFIG.SYS file.

Remove the distribution diskette from the floppy drive and press

to put the changes to the CONFIG.SYS file into immediate effect. If you do not remove the

diskette from the floppy drive, the system will reboot from the floppy drive rather than the hard

drive.

Note

Y

to reboot the computer in order

Caution

During the installation process, a batch file called PANEL.BAT is created

in the root directory of your hard disk. This file should never be deleted,

because it is used to access the PCS.

3 - 4 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 29

3

Section 2 Starting PCS

To start PCS, type the following command at the C: prompt, then press ↵↵ (if you installed the

software on a drive other than C, substitute the correct drive ID for C:):

C:\>panel

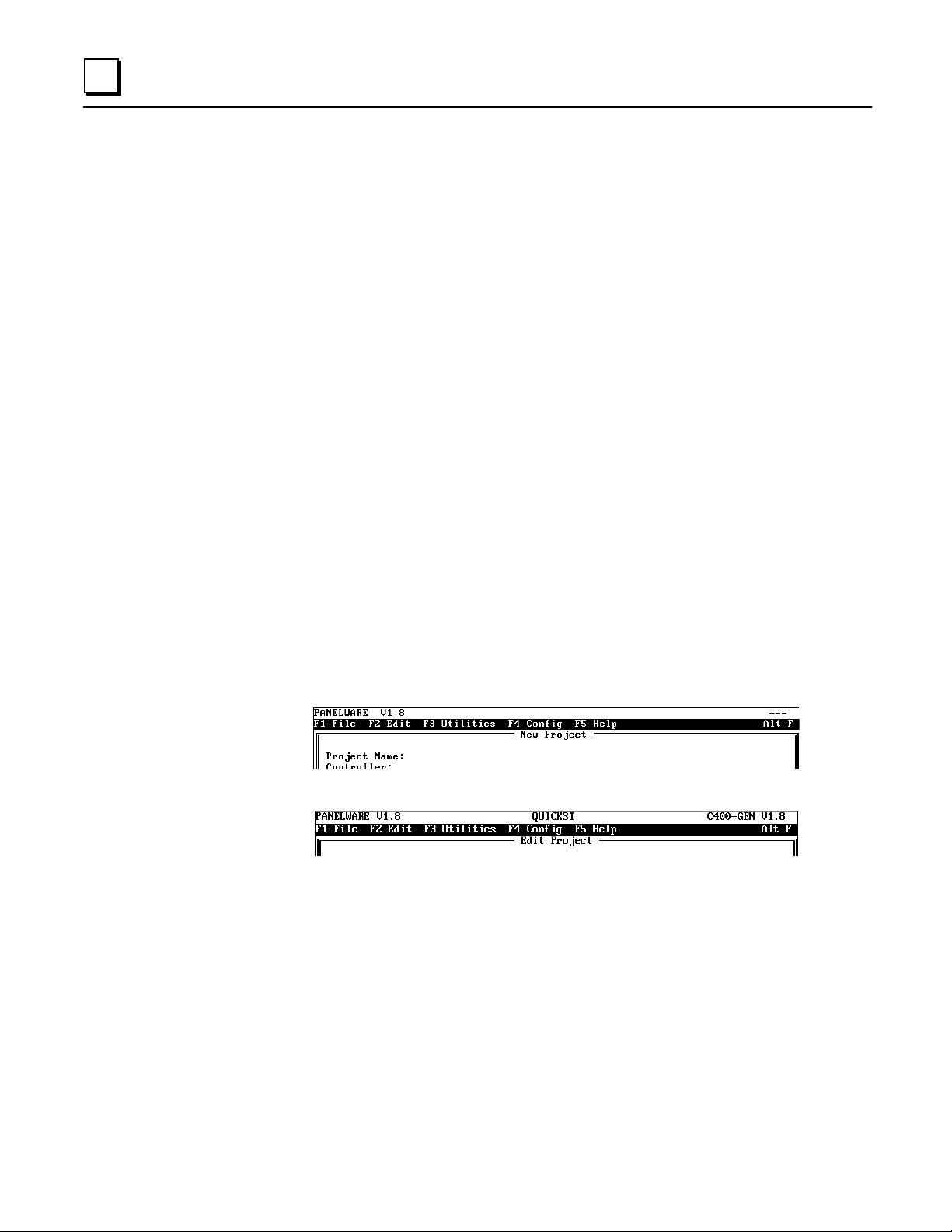

The PCS is called up and the following copyright information is displayed on the screen:

After a delay, the Main menu, with its pull-down menu line and messages, is displayed:

GFK-1115 Chapter 3 Quick Start 3 - 5

Page 30

3

Section 3 General Operation

Pull-Down Menus (Main Menu)

The pull-down menus of the Main menu can be opened at any time using two different methods:

■ By pressing the alternate (Alt) key simultaneously with the desired function key (F1 to

F5)

■ By pressing the Alt key simultaneously with the first letter of the desired menu name

For example, the F1 File menu can be opened by pressing either Alt + F1 or Alt + F.

Once a menu is open, select the desired option by highlighting it using the cursor keys and

pressing ↵↵. Any resulting window that the option calls up will be displayed in the blank window

of the Main menu, with its associated function key line displayed below.

Key shortcuts (hot keys) for specific menu entries are displayed on the menu next to the associated

entry.

Window Name

Every window that can be displayed within the Main menu has a name that is centered inside the

top line margin of the window. For example:

■ Window name New Project

■ Window name Edit Project

3 - 6 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 31

3

Selection Windows

If the ↵↵ character is displayed in the bottom line of a screen, a selection window can be opened by

pressing the enter (↵↵) key. A selection can be made from these windows by moving through the

list using the cursor keys until the desired entry is highlighted, then pressing ↵↵.

Context-Sensitive Help Screens

While using the PCS, context-sensitive help screens can be accessed at any time. If you press

Alt + F5 or ALT + H while working in the PCS environment, a help screen that corresponds to

the current PCS function/activity is displayed. Using the PgUp or PgDn keys, you can flip forward

or backward through the help screens. If all of the help text in a Help screen can not be seen, the ↑↑

and ↓↓ (Cursor Up/Down) keys can be used to scroll through to the end.

On some Help screens, related (cross-referenced) help may be signaled by the presence of one or

more Help screen numbers. These cross-references are indicated with the respective Help screen

number displayed between the < and > characters (e.g., Help Screen <0000>). The first of these

numbers will be highlighted. The Tab and BackTab keys can be used to highlight a different

screen number, then when you press ↵↵, that highlighted Help screen will be displayed. The Alt +

F1 key returns you to the previous Help screen level. Pressing F10 returns you to the first Help

screen <0000> at any time. The following example shows a typical Help screen:

To exit any Help screen, press Esc.

GFK-1115 Chapter 3 Quick Start 3 - 7

Page 32

3

Screen Elements

The PCS display contains a few basic elements that are displayed at all times:

Figure 3 - 1. Basic PCS Screen Elements

■ In the top line (title line) of the screen, the software version number is displayed at the left,

the name of the current project is in the middle, and the Panel Controller description (type

and operating system version) is on the right.

■ The next line down (menu line) contains the headings of the pull-down menus.

■ The second to the last line (function line) of the screen displays the current function key

assignments.

■ The bottom line (message line) contains any error messages, important notices that relate to

the project, or the character ↵↵, which indicates that a selection window can be accessed.

3 - 8 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 33

3

Section 4 PCS Configuration

Before you can begin creating projects using the PCS, the appropriate interface to be used to

connect your PC to the PANELWARE controller must be defined. The F4 Config. pull-down

menu shown below can be opened by pressing Alt + F4 or Alt + C:

To set up the interface, select the Channel #2 command by highlighting the entry and pressing ↵↵

. This opens a window that allows you to choose from several options. At this point, you are only

concerned with selecting an interface. When you highlight the Interface option, it is displayed

inversely in the window and is selected by pressing ↵↵.

In a selection window, you can choose whether you want to use COM1 or COM2 as the PC

interface to be used for programming the C400 Panel Controller. The Network setting is for

future expansion.

Once a serial interface, e.g., COM2, is selected, the Panel Controller can be connected to this

interface using a serial interface cable (see the PANELWARE Hardware Installation User's

Manual — GFK-0848).

Note

The remaining Channel #2 options should be left at their default settings until

you have successfully downloaded a project to the Panel Controller. See the

PANELWARE Configuration Software Reference Manual (GFK-0849) for

details on all of the Channel #2 configuration items.

GFK-1115 Chapter 3 Quick Start 3 - 9

Page 34

3

Section 5 Creating a New Project

Throughout the remainder of this chapter, you will create an example project (named QUICKST)

by following the steps that are outlined in the text. This sample project is designed to provide an

overview of how the PCS works.

The following minimum hardware setup is required to execute the sample project you will create:

❏ one C400 Panel Controller

❏ one 4 x 20 LCD display module

❏ one 16-key Keyblock module

❏ one numeric (12+4) Keyblock module

❏ one PLC capable of Genius communications

Assemble the modules according to the instructions in the PANELWARE™ Hardware Installation

User's Manual (GFK-0848) so that the numeric Keyblock module is the one to be connected to the

Panel Controller.

Note

Although your hardware configuration may be different than that specified

above, creating the example project is still recommended as it will introduce you

to the basic techniques you will need to use for any hardware configuration.

To create a new project, access the F1 File menu by pressing either the Alt + F1 or Alt + F key

combination. Select the New Project menu option using the cursor keys:

When the New Project option is highlighted inversely within the menu, press ↵↵ to open the New

Project window, in which the project name and the type of Panel Controller to be used are

entered.

Use the keyboard to type the desired name of the project (QUICKST) in the current cursor

position. Press ↵↵ to accept the name and the cursor moves to the next line, where the type of

controller can be defined.

3 - 10 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 35

3

Press ↵↵ again to open a selection window that contains a list of the available Controllers.

Note

The available Controllers are listed in the form <type>.#<OS version>, where

<type> is the basic controller model (e.g., C400) and <OS version> is the

operating system version number (e.g., V1.8).

When you press ↵↵, the controller selection (C400-GEN.#18 in the example above) is confirmed.

Another window appears on the screen from which the display and Keyblock module types can be

configured.

Caution

Both the controller and the display type must be defined when creating a

new project. Once selected, you CAN NOT change them. You should know

which controller and display type will be used before the project creation

process is started.

GFK-1115 Chapter 3 Quick Start 3 - 11

Page 36

3

Select the Display Type entry and press ↵↵ to display a window

that lists all display types. Select one of the display types (in the

example, LCD 4x20) and press ↵↵.

The cursor jumps to the next line, Number of Keyblock

Modules. Enter a number (1 through 7) and press ↵↵ to confirm

the number of Keyblock modules in your configuration (e.g., 2).

The next step is to define the individual Keyblock modules (not all of the

modules in the list have to be defined). When the cursor is in one of the

Type Keyblock Module x lines, you can access a selection window that

lists the Keyblock modules by pressing ↵↵.

For this example, select the numeric (12+4) and the 16-key Keyblock modules as Keyblocks 1 and

2, respectively. The following table defines the numbers in the Keyblock Module selection

window:

Table 3 - 1. Keyblock Module Definitions

List Entry Keyblock Module

16 16-key Keyblock module

12+4 Numeric Keyblock module

8 8-key Keyblock module

4 4-key Keyblock module

3 - 12 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 37

3

The new project definition can be saved and closed by pressing the F4 Accept function key. While

the system is saving the project, the following screen is displayed:

After the project is saved, the New Project window is closed and the project name (QUICKST) is

displayed in the title line.

GFK-1115 Chapter 3 Quick Start 3 - 13

Page 38

3

Section 6 Defining Connections

The next step after creating a new project is to define the connections. All PLCs and other devices

that are to communicate with the Panel must be entered in the connection editor. To change or

insert connections, select the Connection option from the Edit menu.

The following window, Connection List displays all entered connections:

When creating a new project for the C400-Genius Controller, a default entry with the ID, DD, is

made automatically (connection to a GE Fanuc PLC via the Genius bus). However, the associated

PLC type is not defaulted and must be specified.

3 - 14 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 39

3

Connection to a GE Fanuc PLC via Genius

Press F1 Edit to edit the connection DD Genius:

Move the cursor to the PLC Type line using the →→ or ↵↵ key:

The PLC type to communicate with can be chosen from this selection window. For this example,

use the cursor keys to highlight the entry GBC Series 90-70 and press the ↵↵ key, closing the

selection window.

GFK-1115 Chapter 3 Quick Start 3 - 15

Page 40

3

The Connection Definition window containing the new connection is displayed.

By pressing F4 Accept, the change is confirmed and shown in the Connection List window:

To configure the Genius bus aspects of the connection, press the F4 PLC Node Parameters Key.

3 - 16 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 41

3

Here, the Target device number, or Genius bus address, of the connection is specified. Enter the

bus address of your GBC (typically bus address 31) in the Target device number field.

No other data needs to be entered into the PLC Node Parameter Definition screen for this

example. Pressing F4 Accept completes the entry

GFK-1115 Chapter 3 Quick Start 3 - 17

Page 42

3

Internal Connection

Now insert an internal connection into the connection list. This is done by first pressing the F2

Ins key and then specifying the ID DI in the window that appears.

Choose Internal as the connection. Press F4 to confirm this definition and see it displayed in the

Connection List window.

3 - 18 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 43

3

Genius Internal Connection

As a final connection, insert a Genius internal connection into the connection list. this is done by

first pressing the F2 Ins key and then specifying the ID GI in the window that appears. Choose

Genius as the Connection and Genius Internal as the PLC Type. This definition is now

confirmed and the new connection displayed in the connection list upon pressing the F4 Accept

key.

GFK-1115 Chapter 3 Quick Start 3 - 19

Page 44

3

Section 7 Key Assignments

Every key on every Keyblock module can be defined according to the project's unique needs. You

can also assign keys for numbers, letters, and the Next and Previous functions.

In order to assign functions to the keys, the Edit Keycode Table window must be accessed by

selecting the Keyboard option from the F2 Edit pull-down menu or by pressing Ctrl + K:

The Edit Keycode Table window shown below is displayed (the default keycode settings that are

shown will work for this example project):

Save the key assignments by pressing the F10 Exit function key.

3 - 20 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 45

3

The abbreviations on the Keyblock module keys have the following meanings:

Table 3 - 2. Keyblock Abbreviation Definitions

Abbr. Description

F1 ... F4 Function keys 1 through 4 (used for commands and picture changes)

+p+ Moves cursor to the previous INPUT field

+n+ Moves cursor to the next INPUT field

+P+ Changes to the previous picture

+N+ Changes to the next picture

+G+ Global alarm acknowledgment

+B+ Backspace; deletes the character before the cursor in an INPUT field

+S+ Changes the sign in a numerical INPUT field

+E+

+C+

. Decimal point

0 ... 9 Numbers 0 - 9 for the entry of numbers

Enter key; transmits the value entered in an INPUT field; labeled as ↵↵ on

actual Keyblock

Cancels (deletes) an INPUT field; labeled as ← on actual Keyblock

GFK-1115 Chapter 3 Quick Start 3 - 21

Page 46

3

Section 8 Creating Pictures

Picture 1

Pictures make up the basic elements of every Panel project. They include static elements such as

text and lines

information, such as temperature, RPM, etc., to be updated and displayed for the user. Input fields

can be used to display entries given to the process that you enter using the keyboard.

A project must contain at least two pictures—one picture that displays when the Panel powers up,

and another that displays in the event of a communications failure. This example project will

contain three pictures, as follows:

1. Picture 1 is the picture where values will be entered using the keyboard, transmitted to the

PLC and output in another field.

2. Picture 2 is the start-up picture that is to be displayed when the Panel and PLC are switched

on. Only the Panel’s date and time, and the scan rate of the Genius bus will be displayed.

3. Picture 3 is displayed if there is a communications failure between the PLC and the Panel.

Only text providing notice of a communications error will be displayed in this picture.

To edit or create a picture using the picture editor, select the Picture option from the F2 Edit

pull-down menu or press Ctrl + B.

1

, and/or dynamic elements like input and output fields. Output fields allow

1

Lines can only be inserted in a picture if a graphic display has been selected in the project

definition. See the PANELWARE™ Hardware Installation User's Manual (GFK-0848) for a

list of available graphic displays.

3 - 22 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 47

3

The blank Edit Picture window shown below is displayed:

The size of the dark rectangle (picture) at the bottom of the screen corresponds to the selected

display type (display type LCD 4x20 is shown above, i.e., the rectangle consists of 4 lines and 20

characters per line). Text or fields can now be entered into this rectangle.

In the first line, enter the text

Move the cursor to position (3,0) (the current cursor position is indicated in the lower right-hand

corner of the screen as Column/Row). A text field can now be created simply by typing in the

desired text (

function key and then entering the desired text.

As long as the cursor is within this text field, the field is displayed inversely (on color monitors it

has a red background). Press ↵↵ to complete the text field. The inverse display is switched off and

the text is displayed normally.

Move down to lines 2 and 3, and enter the following text:

Next to the Output: text, begin creating an output field by moving the cursor to the following

position (8,2):

Input / Output

Input / Output

). It is also possible to start a text field by pressing the F1 Text

as follows:

GFK-1115 Chapter 3 Quick Start 3 - 23

Page 48

3

Press the F2 Field function key to open the Field Class selection window.

Select the Output Field entry from the list and press ↵↵ to access the Select Field Type window.

Several output field types can be chosen from this widow:

For this example, select the Output Word (signed) field type. This results in a data entry form

(with default entries) being opened on the screen.

In the Output Word window, change the following entries as shown by highlighting them using

the cursor keys, then typing the new text:

Places after dec. point:

Tagname:

2

VALUE1

Note

To complete an entry, you must press ↵↵. If you change an entry and then press a

cursor key instead, your entry will be ignored and the previous contents of the

entry will be restored.

VALUE1 is a symbolic name for a memory location in the PLC. Assigning symbolic names to the

actual PLC addresses is accomplished using the connection editor.

Press the F4 Accept function key to close the field and confirm it as part of the picture. The field

should be displayed within the picture:

3 - 24 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 49

3

Move the cursor to the Input: text line and press the F2 Field function key. Select the Input

field option from the Field Class window that is displayed:

The Select Field Type window containing all of the input field types is displayed.

For this example, select the Input Word (signed) field type:

In the Input Word window that is displayed, change the following entries as shown by

highlighting them using the cursor keys, then typing the new text:

Places after dec. point:

Tagname:

Press the F4 Accept function key to close the field and confirm it as part of the picture. The field

should be displayed within the picture as shown below:

2

VALUE1

GFK-1115 Chapter 3 Quick Start 3 - 25

Page 50

3

Press the F10 Exit function key to end this picture editing session. Because this is a new picture, a

window will open to confirm whether or not the picture should be saved:

Type Y to request that the picture be saved, and a prompt will request you to enter the filename

under which the picture will be saved:

Type the desired filename using the keyboard (e.g., PICT_1). PCS saves the picture under the

filename you type and assigns a .BIL extension (e.g., PICT_1.BIL) automatically when you

press ↵↵.

Picture 2

Picture 2 will serve as the start-up picture for the project.

Access the picture editor by selecting the Picture option from the F2 Edit pull-down menu or by

pressing Ctrl + B.

In line 1 of the rectangle, type the text

Move the cursor to position (1,2) and press the F2 Field function key, then select the Output

Field option from the Field Class window:

*** Start-up Pict ***

and press ↵↵.

3 - 26 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 51

3

From the Select field type window that is displayed, select the Output Date/Time option:

The output format for the date and time is selected from the following window that is displayed:

Do not make any changes in this window and press the F4 Accept function key. The Date/Time

field will be displayed in the start-up picture:

Move the cursor to position (1,3), type the text

to position (16,3), type the text

Using the same process detailed above for creating the Output Date/Time field, position the cursor

at (11,3), and create an Output Word (unsigned) field with the following definition:

GFK-1115 Chapter 3 Quick Start 3 - 27

ms

, and again press ↵↵.

Bus Scan:

, and press ↵↵. Next, move the cursor

Page 52

3

Picture 3

Press the F4 Accept key to close the field and confirm it as part of the picture. The field should be

displayed within the picture as shown below:

Press the F10 Exit function key to end this picture editing session. Because this is a new picture, a

window will open to confirm whether or not the picture should be saved.

Type

Y

to request that the picture be saved, then type the desired filename (START-UP) using the

keyboard. The picture is saved under the name you type and assigned a .BIL extension

automatically when you press ↵↵.

An error picture that will display on any communication error is created in exactly the same way

as any other picture. Input or output fields that would access variables from the PLC are of no use,

however, because the error picture is supposed to show an error in communications. Internal

variables can be shown (e.g., error variables that are used to display the type of communications

error). See the PANELWARE™ Configuration Software Reference Manual (GFK-0849) for

details.

Using the steps followed to create the first two pictures, create the following error picture and save

it under the name ERROR:

The Output Bit/Byte field in the picture is defined as follows:

3 - 28 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 53

3

Section 9 Defining the Project Variables

All variables used in the project (symbolic variable names) must be connected to specific

addresses in the PLC CPU.

In order to define these connections, access the connection list by selecting the Connection option

from the F2 Edit pull-down menu or by pressing Ctrl + C.

The Connection List window shown below is opened:

GFK-1115 Chapter 3 Quick Start 3 - 29

Page 54

3

Genius Device Connection

Use the cursor keys to highlight connection DD Genius, and then press the F5 VAT function key

to display the associated variable assignment table (VAT) on the screen.

All variables that have been used in a picture's input or output fields in the project are listed in the

Variable Assignment Table window. In this example project, only one name, VALUE1, is

displayed:

To assign an address in the PLC CPU to the VALUE1 variable, press the F1 Edit function key.

The VAT Definition window shown below is opened:

The PLC address can be entered directly at the PLC Address line using the keyboard (e.g.,

%R0100

If the cursor is in the PLC Variable Type line, a variable type selection

window that shows all valid variable types can be opened by pressing ↵↵.

Select DINT from the selection window.

).

3 - 30 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 55

3

The definition that is entered can be saved by pressing the F4 Accept function key. Once saved,

the newly selected variable is shown in the VAT.

Pressing the F10 Exit function key causes the connection list to appear on the screen again.

Genius Internal Connection

Select the GE Genius Internal connection from the connection list and press either F5 VAT or ↵↵

to display the connection in the Variable Assignment Table:

Press the F1 Edit function key to open the VAT Definition window for the GENIUS_BUS

tagname. Edit the definition for GENIUS_BUS as shown below (Follow the same procedure that

was used for editing the tagname VALUE1 in the DD connection

After accepting the entry (by pressing F4), press F10 Exit to return to the Connection List

window.

GFK-1115 Chapter 3 Quick Start 3 - 31

— see page 30):

Page 56

3

Internal Connection

Select the DI Internal connection from the connection list and press F5 or ↵↵ to view its VAT:

This is the variable that will be output in the error picture. The internal variables cannot be edited.

You can close the VAT by pressing F10 Exit, which calls the connection list once again. Press the

F10 Exit key again to close the connection list and return to the main menu.

3 - 32 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115

Page 57

3

Section 10 Binding Pictures in the Project

The pictures that you have created for this project still have to be bound into the project definition.

To begin the binding process, select the Project option from the F2 Edit pull-down menu or press

Ctrl + P.

The Edit Project window shown below is opened:

The picture binding process for this project consists of the following three steps:

1. Entering the filename of the ERROR picture

2. Binding the three project pictures

3. Organizing the picture directory

These processes are explained in the sections that follow.

GFK-1115 Chapter 3 Quick Start 3 - 33

Page 58

3

Picture for a Communications Error

From the Edit Project window, press the F1 Project Def. function key to move the cursor to the

Picture for Communications Error line in the window. The function line options are changed as

shown below:

The file name of the error picture can be entered directly using the keyboard or the following

selection window can be accessed by pressing the F5 Pictures function key.

Highlight the desired filename (ERROR.BIL) and press ↵↵, then confirm the project definition by

pressing the F4 Accept function key.

3 - 34 PANELWARE MMI Application Manual for GE Fanuc Genius Protocol - June 1995 GFK-1115