Page 1

GE Fanuc Automation

Programmable Control Products

TCP/IP Ethernet Communications

for the Series 90t-70 PLC

User’s Manual

GFK-1004B January 1996

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that

hazardous voltages, currents, temperatures, or other conditions that

could cause personal injury exist in this equipment or may be

associated with its use.

In situations where inattention could cause either personal injury or

damage to equipment, a Warning notice is used.

Caution notices are used where equipment might be damaged if care is

not taken.

GFL–002

Warning

Caution

Note

Notes merely call attention to information that is especially significant to

understanding and operating the equipment.

This document is based on information available at the time of its publication. While

efforts have been made to be accurate, the information contained herein does not

purport to cover all details or variations in hardware or software, nor to provide for

every possible contingency in connection with installation, operation, or maintenance.

Features may be described herein which are not present in all hardware and software

systems. GE Fanuc Automation assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or

statutory with respect to, and assumes no responsibility for the accuracy, completeness,

sufficiency, or usefulness of the information contained herein. No warranties of

merchantability or fitness for purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alar m Master

CIMPLICITY

CIMPLICITY PowerTRAC

CIMPLICITY 90–ADS

CIMST AR

Field Control

GEnet

Genius

Genius PowerTRA C

Helpmate

Logicmaster

Copyright 1994-1996 GE Fanuc Automation North America, Inc.

All Rights Reserved

Modelmaster

ProLoop

PROMA CRO

Series Five

Series 90

Series One

Series Six

Series Three

V uMaster

W orkmaster

Page 3

Content of this Manual

Chapter 1. Introduction: Discusses the TCP/IP Ethernet Interface, the communica-

tions software, and the GEnet System Manager.

Chapter 2. Installing the TCP/IP Ethernet Interface: Describes the basic features of

the TCP/IP Ethernet Interface, the installation and power-up of the Interface, and a procedure for the initial checkout of the Interface on your Ethernet cable.

Chapter 3. The GEnet System Manager-Station Configuration: Describes the instal-

lation and operation of the GEnet System Manager and how to configure a

Series 90-70 PLC Ethernet Station.

Chapter 4. Programming Communications Requests: Describes the ladder program-

ming necessary for communications between PLCs.

Chapter 5. The Station Manager: Describes how to use the Station Manager to pro-

vide on-line supervisory access to the TCP/IP Ethernet Interface.

Preface

Chapter 6. T roubleshooting: Describes troubleshooting and problem isolation for the

TCP/IP Ethernet Interface.

Appendix A. Glossary of Terms

Appendix B. Communications P ort Characteristics

Appendix C. Soft Switch Parameters

Appendix D. DOS System Files

Appendix E. Data Link Error Codes

Appendix F . Forms

Appendix G. Assigning IP and MAC Addresses

Appendix H Sample Ladder Program

GFK-1004B

TCP/IP Ethernet Communications User’s Manual – Januar y 1996 iii

Page 4

Preface

Related Publications

GFK -0262 Series 90t-70 Programmable Controller Installation and Operation

GFK -0263 Logicmaster 90t Programming Software User’s Manual

GFK -0265 Logicmaster 90t Programming Software Reference Manual

GFK -1029 Logicmaster 90t -70-Ethernet TCP/IP User’s Manual

GFK -0870 Host Communications Toolkit for C/C++ Applications User’s Manual

GFK-1026 Host Communications Drivers for Microsoft Windowst User’s Manual

GFK -1063 Host Communications Toolkit for Visual Basict Applications User’s Manual

GFK -1186 TCP/IP Ethernet Communications for the Series 90t-30 PLC Station Manager

GFK -1084 T CP/IP Ethernet Communications for the Series 90t-30 PLC User’s Manual

Manual

We Welcome Your Comments and Suggestions

At GE Fanuc automation, we strive to produce quality technical documentation. After

you have used this manual, please take a few moments to complete and return the

Reader’s Comment Card located on the next page.

iv GFK-1004B

TCP/IP Ethernet Communications User’s Manual – Januar y 1996

Page 5

Contents

Chapter 1 Introduction 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Ethernet Communications System 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Ethernet Inter face 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The GEnet System Manager (GSM) 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Make it Work 1-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Guide to the Manual 1-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Installing the Ethernet Interface 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Interface Hardware Over view 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board Indicators 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restart Button 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial P ort 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUI (Transceiver) Port 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Station Address Label 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Label 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 1: Installing the Ethernet Controller Board in the PLC 2-5

Equipment Required to Perform the Installation Procedures 2-5 . . . . . . . . . . . .

Ethernet Controller Board Installation 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 2: V erif ying Proper P ower-Up of the Ethernet Interface 2-7

Using the GSM “Access Station Manager” Function 2-7 . . . . . . . . . . . . . . . . . . . .

States of the Ethernet Interface 2-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powering-Up the Ethernet Inter face 2-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problems During P ower -Up 2-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 3: Configuring the Ethernet Interface with

Logicmaster 90-70 (PLC Module Configuration) 2-11 . . . . . . . . .

PLC Systems with CPU Firmware Version 5.03 or Later 2-12 . . . . . . . . . . . . .

PLC Systems with CPU Firmware Versions Prior to 5.03 2-16 . . . . . . . . . . . . .

Procedure 4: Configuring and Downloading a Station 2-20 . . . . . . . . .

Configuring a Station 2-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading a Station 2-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initiating the Download 2-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problems During the Download 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Issue the LOAD Command from the Station Manager 2-23 . . . . . . .

Procedure 5: Testing the Ethernet Interfaces on the Network 2-24 . . .

Field Network Test Utility 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Invoking the Field Network Test Utility 2-25 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running Field Network Test 2-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-1004B TCP/IP Ether net Communications User’s Manual – Januar y 1996

v

Page 6

Contents

Procedure 6: Pinging the TCP/IP Interfaces on the Network 2-30 . . . .

Chapter 3 The GEnet System Manager–Station Configuration 3-1 . . . . . . . . . . . . .

What is the GSM? 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Why Does a Station Have to be Configured and Downloaded? 3-2 . . . . . . . . . .

Connecting the GSM to the LAN Interface 3-3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 1: Installing and Starting-Up the GSM 3-4 . . . . . . . . . . . . . . . .

Hardware Requirements 3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the PC Network Card (for Network GSM Operation) 3-5 . . . . . . . . .

Installing the GEnet System Manager (GSM) Software 3-6 . . . . . . . . . . . . . . . . .

Setting-Up DOS System Files 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local GSM Operation (Exclusively) 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network GSM Operation (or Both Local and Network) 3-8 . . . . . . . . . . . . .

Unusual Procedures 3-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Updating or Adding to Existing GSM Software 3-12 . . . . . . . . . . . . . . . . . . . . .

Changing the PC Network Card 3-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting-Up the GSM 3-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Working Your Way through the GSM Menus 3-14 . . . . . . . . . . . . . . . . . . . . . .

GSM Keyboard Functions 3-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GSM Menu Structure 3-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2: Configuring a Station 3-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Information Needed to Configure a TCP/IP Ethernet Interface Station 3-17 . . .

Configure a Station Screen 3-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Station Configuration File 3-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Station Configuration File 3-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting a Station Configuration File 3-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Structure of the MAC Address 3-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Editor Menu for Series 90-70 PLCs 3-21 . . . . . . . . . . . . . . . . . . . . .

Saving Changes Before Exiting the Configuration Editor Main Menu 3-21 . .

TCP/IP Parameters Screen 3-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced Parameters Menu 3-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Link Parameters Screen 3-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Parameters Screen 3-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3: Downloading a Station 3-29 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download Station Screen 3-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Locally (Over the Serial P ort) 3-29 . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Over the Network 3-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

TCP/IP Ethernet Communications User’s Manual – January 1996 GFK-1004B

Page 7

Contents

Section 4: Accessing the Station Manager 3-32 . . . . . . . . . . . . . . . . . . . .

Access Station Manager Screen 3-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5: Using the GSM Support F unctions 3-33 . . . . . . . . . . . . . . . . .

List All Stations Screen 3-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup GSM Menu 3-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the GSM Password Screen 3-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Download Mode Screen 3-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Station Manager Mode Screen 3-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exit to DOS 3-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Programming Communications Requests 4-1 . . . . . . . . . . . . . . . . . . . . . .

Section 1: The Communications Request 4-2 . . . . . . . . . . . . . . . . . . . . .

Structure of the Communications Request 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMMREQ Function Block 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMMREQ Command Block 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Commands 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Data 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Logic Program Controlling Execution of the

COMMREQ Function Block 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation of the Communications Request 4-5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2: The COMMREQ Function Block and Command Block 4-6

The COMMREQ Function Block 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The COMMREQ Command Block 4-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3: Channel Commands 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Establishing a Channel 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aborting and Re-tasking a Channel 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Retrieving Detailed Status on the Channel 4-10 . . . . . . . . . . . . . . . . . . . . . . . .

Specifying the Location of the Channel Status 4-10 . . . . . . . . . . . . . . . . . . . . .

Establish Read Channel (2003) 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Establish Write Channel (2004) 4-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Send Information Report (2010) 4-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abort Channel (2001) 4-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Retrieve Detailed Channel Status (2002) 4-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assign Channel Status Vector (2000) 4-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4: Status Data 4-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Status Data 4-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of the Status Data 4-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OK Output of the COMMREQ Function Block 4-26 . . . . . . . . . . . . . . . . . . . . .

FT Output of the COMMREQ Function Block 4-26 . . . . . . . . . . . . . . . . . . . . . .

Status Bits 4-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Status Words 4-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minor Error Codes 4-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-1004B TCP/IP Ether net Communications User’s Manual – Januar y 1996

vii

Page 8

Contents

Section 5: Controlling Communications in the Ladder Program 4-34 .

Essential Elements of the Ladder Program 4-34 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Your Ladder P rogram 4-37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring the Communications Channel 4-38 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequencing Communications Requests 4-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transfers with One Repetition 4-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 The Station Manager 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Station Manager Services 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 1: Accessing the Station Manager 5-2 . . . . . . . . . . . . . . . . . . . .

Accessing the Station Manager Using the GSM 5-3 . . . . . . . . . . . . . . . . . . . . . . . .

Accessing the Station Manager Using an ASCII Terminal 5-4 . . . . . . . . . . . . . . .

Remote Operation of the Station Manager 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2: Using the Station Manager 5-5 . . . . . . . . . . . . . . . . . . . . . . . .

Using the Monitor Commands 5-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Modify Commands 5-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Station Manager Command Syntax 5-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Task Identification 5-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Data Representation 5-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Numeric Values 5-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Byte String Values 5-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IP Address 5-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Station Manager in Utility Programs 5-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Soft Switch Entry Utility 5-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Network Test Utility 5-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

TCP/IP Ethernet Communications User’s Manual – January 1996 GFK-1004B

Page 9

Section 3: Command Descriptions 5-15 . . . . . . . . . . . . . . . . . . . . . . . . . .

CHANNEL Command 5-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BPS Command 5-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHBPS Command 5-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHDATE Command 5-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHLTIME Command 5-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHSOSW Command 5-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHTIME Command 5-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEAR Command 5-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLSOSW Command 5-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATE Command 5-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXS Command 5-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HELP Command 5-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

LOAD Command 5-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOG Command 5-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOGIN Command 5-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOGOUT Command 5-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LTIME Command 5-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NET Command 5-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NODE Command 5-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OK Command 5-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PING Command 5-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROG Command 5-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REM Command 5-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPORT Command 5-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPP Command 5-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RESTART Command 5-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHOW Command 5-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SOSW Command 5-34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STAT Command 5-34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPP Command 5-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPT Command 5-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TALLY Command 5-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Command 5-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIME Command 5-43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACE Command 5-43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-1004B TCP/IP Ether net Communications User’s Manual – Januar y 1996

ix

Page 10

Contents

Chapter 6 Troubleshooting 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using this Chapter 6-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What to do if you Cannot Solve the Problem 6-4 . . . . . . . . . . . . . . . . . . . . . . . . .

The Power-Up State 6-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Soft Switch Entry State 6-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Field Network Test State 6-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Loader State 6-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Operational State 6-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting When STATUS OK LED is OFF 6-8 . . . . . . . . . . . . . . . . . . . .

Troubleshooting When the STATUS OK LED is ON 6-9 . . . . . . . . . . . . . . . . .

Exception Log Event Error Codes 6-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Glossary A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commonly Used Acronyms and Abbreviations A-1 . . . . . . . . . . . . . . . . . . . . . . .

Glossary of Terms A-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B Communications Ports Characteristics B-1 . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Port for Local GSM Communications B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial P ort Settings B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial P ort Pinouts B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Cable B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display T erminal Settings B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The AUI Port for the Ether net Inter face B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet AUI Port Pinouts B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUI (Transceiver Cable) B-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ransceiver Description B-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C Soft Switch Parameters C-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Config Mode C-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Station Address C-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Source C-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LAN Online C-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backplane Online C-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Load Address C-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modify Soft Switch Settings C-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Soft Switch Parameters C-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Soft Switch Parameters Using the GSM C-5 . . . . . . . . . . . . . . . .

Correct Results of Soft Switch Configuration C-7 . . . . . . . . . . . . . . . . . . . . . . .

x

TCP/IP Ethernet Communications User’s Manual – January 1996 GFK-1004B

Page 11

Contents

Appendix D Sample DOS System Files D-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3Com Etherlink II D-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3Com Etherlink 3 D-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3Com Etherlink 16 D-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3Com Etherlink /MC D-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W estern Digital EtherCard PLUS, EtherCard PL US Elite 16,

EtherCard PLUS/A D-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intel 82593 D-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Xircom P ocket Adapter (PE2) D-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Xircom P ocket Adapter (PE3) D-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SMC EtherCard PLUS, EtherCard PLUS Elite 16, EtherCard PLUS/A D-10 . . .

IBM PCMCIA D-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optimizing the GSM for Network Operation D-12 . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E GEnet System Manager Data Link Error Codes E-1 . . . . . . . . . . . . . . . . .

Appendix F Network Test Form F -1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Form F-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix G Advanced Information About IP and MAC Addresses G-1 . . . . . . . . . . .

IP Addresses G-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gateways G-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subnets G-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MA C Addresses G-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix H Sample Ladder P rogram H-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-1004B TCP/IP Ether net Communications User’s Manual – Januar y 1996

xi

Page 12

Contents

Figure 1-1. Major Components of the TCP/IP LAN 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-2. The Main Tasks for Installing the TCP/IP Ethernet Communications System 1-6 . . . . . . . . . .

Figure 2-1. Ethernet Controller Board 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-2. Ethernet Controller Installation in the Series 90-70 PLC 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-3. States of the Ethernet Interface 2-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-1. GEnet System Manager (GSM) on 802.3 LAN 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-2. GSM Main Menu 3-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-3. GSM Menu Structure 3-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-4. Configure a Station Screen 3-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-5. Configuration Editor Menu 3-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-6. TCP/IP P arameters Screen 3-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-7. Advanced P arameters Menu 3-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-8. Data Link P arameters Screen 3-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-9. System P arameters Screen 3-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-10. Download Station Screen 3-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-11. Access Station Manager Screen 3-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-12. List All Stations Screen 3-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-13. Setup GSM Menu 3-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-1. Elements of the Communications Request 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-2. Operation of the Communications Request for an Establish Read ChannelCommand 4-5 . .

Figure 4-3. Format of the COMMREQ Status Word (CRS Word) 4-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-4. Format of the Detailed Channel Status Words (DC S Words) 4-29 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5-1. Station Manager Accessed Locally through the 9–pin Serial Port by a GSM in

Local Station Manager Mode (or an ASCII Terminal) 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5-2. Station Manager Accessed Directly over the Network by a GSM in Network

Station Manager Mode 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5-3. Station Manager Accessed Remotely over the Network by a GSM in Local

Station Manager Mode using the REM (Remote) Command 5-3 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-1. Determining the State of the Ethernet Inter face 6-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-1. Serial Cable to Connect GSM (25–Pin Connector) to Ethernet Interface B-2 . . . . . . . . . . . . . .

Figure B-2. Serial Cable to Connect GSM (9–Pin Connector) to Ethernet Interface B-2 . . . . . . . . . . . . . . .

Figure B-3. Transceiver Cable Connection B-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-4. 10Base2 Transceiver Configuration B-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-1. IP A ddress F ormat for Network Classes A, B, C G-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-2. Connecting Two Networks with a Gateway G-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-3. Network Configuration Using a Subnet Mask G-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

TCP/IP Ethernet Communications User’s Manual – January 1996 GFK-1004B

Page 13

Table 2-1. Ethernet Controller Board Indicators 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-1. 802.3/Ethernet Cards for the PC 3-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-2. Default PC Hardware Settings for 802.3/Ethernet Cards 3-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-3. GSM Keyboard Functions (Alt-K) 3-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-1. Time Unit Values for Read/Write Repetition Period 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-2. Series 90-70 PLC Memory Types 4-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-3. Status Bits (LIS Bits and Channel Status Bits) 4-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-4. Major Error Codes 4-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-5. Minor Error Codes for Major Error Codes 05H (at Remote Server PLC) and

85H (at Client PLC) 4-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-5. Minor Error Codes for Major Error Codes 5H and 85H (Continued) 4-32 . . . . . . . . . . . . . . . . . .

Table 4-6. Minor Error Codes for Major Error Code 11H (at Remote Server PLC) 4-32 . . . . . . . . . . . . . . . .

Table 4-7. Minor Error Codes for Major Error Code 90H (at Client PLC) 4-33 . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-1. Monitor Commands 5-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Table 5-2. Modify Commands 5-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-3. Task Identifiers 5-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-4. Soft Switch Entry Utility Commands 5-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-5. Field Network Test Utility Commands 5-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-6. Control Characters 5-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-7. Load Source Parameters 5-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-8. Soft Switch Default Values for the Ethernet Interface 5-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-9. Log Event Definitions 5-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-10. Configuration Parameters 5-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-11. PLC Driver Tallies (Tally c) 5-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-12. Address Resolution Protocol (ARP) Driver Tallies (Tally f) 5-37 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-13. Channel API Tallies (Tally h) 5-37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-14. Internet Protocol (IP) Tallies (Tally i) 5-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-15. Internet Control Message Protocol (ICMP) Tallies (Tally j) 5-39 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-16. Data Link Tallies (part of Tally l) 5-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-17. MAC Layer Tallies (part of T ally l) 5-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-18. Service Request Transfer Protocol (SRTP) Server Tallies (Tally v) 5-41 . . . . . . . . . . . . . . . . . . . . .

Table 5-19. Transmission Control Protocol (TCP) Tallies (Tally w) 5-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-1. Ethernet Interface Diagnostic Tools 6-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-2. Power -Up State 6-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-3. Soft Switch Entry State 6-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-4. Field Network Test State 6-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-5. Loader State 6-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-6. Operational State 6-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-1004B TCP/IP Ether net Communications User’s Manual – Januar y 1996

xiii

Page 14

Contents

Table 6-7. Troubleshooting with ONLINE LED OFF 6-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-8. Troubleshooting with ONLINE LED ON 6-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-9. Exception Log Event Definitions 6-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-10. Exception Log Event Codes 6-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-1. Pinouts of the Serial Port B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-2. Pinouts of the AUI Port B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-3. 10Base5 T ransceiver Configuration B-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table C-1. Soft Switch Settings C-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table E-1. GEnet System Manager Data Link Error Codes E-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table E-2. NDIS Error Codes E-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiv

TCP/IP Ethernet Communications User’s Manual – January 1996 GFK-1004B

Page 15

Restarts for autonumbers that do not restart in each

chapter.

figure bi level 1, reset

table_big level 1, reset

chap_big level 1, reset1

app_big level 1, resetA

figure_ap level 1, reset

table_ap level 1, reset

figure level 1, reset

table level 1, reset Table 1.

these restarts must be in the header frame of chapter 1.

a:ebx, l 1 resetA

a:obx:l 1, resetA

a:bigbx level 1 resetA

a:ftr level 1 resetA

c:ebx, l 1 reset1

c:obx:l 1, reset1

c:bigbx level 1 reset1

c:ftr level 1 reset1

Chapter 1 Introduction

section level 1

figure bi level 1

1

This manual describes the Series 90-70 Ethernet Interface and the GEnett System Manager

Software (GSM).

The Series 90-70 Ethernet Interface and the GSM, together with applications running on

other Series 90-70 or 90-30 PLCs and host computers, form a complete TCP/IP Communications System for the Series 90-70 PLC. The host application can be Logicmaster

90-70-TCP/IP Software or an application developed using the Host Communications

Toolkit (HCT). GE Fanuc offers the Logicmaster 90-70-TCP/IP software product and the

Host Communications Toolkit product separate from the Ethernet Interface and GSM.

table_big level 1

Reminders for autonumbers that need to be restarted

manually (first instance will always be 4)

let_in level 1: A. B. C.

letter level 1:A.B.C.

num level 1: 1. 2. 3.

num_in level 1: 1. 2. 3.

rom_in level 1: I. II. III.

roman level 1: I. II. III.

steps level 1: 1. 2. 3.

This chapter provides an overview of the product and covers the following topics.

H

The Ethernet Communications System,

H

How to Make the System Work,

H

Quick Guide to the Manual.

The Ethernet Communications System

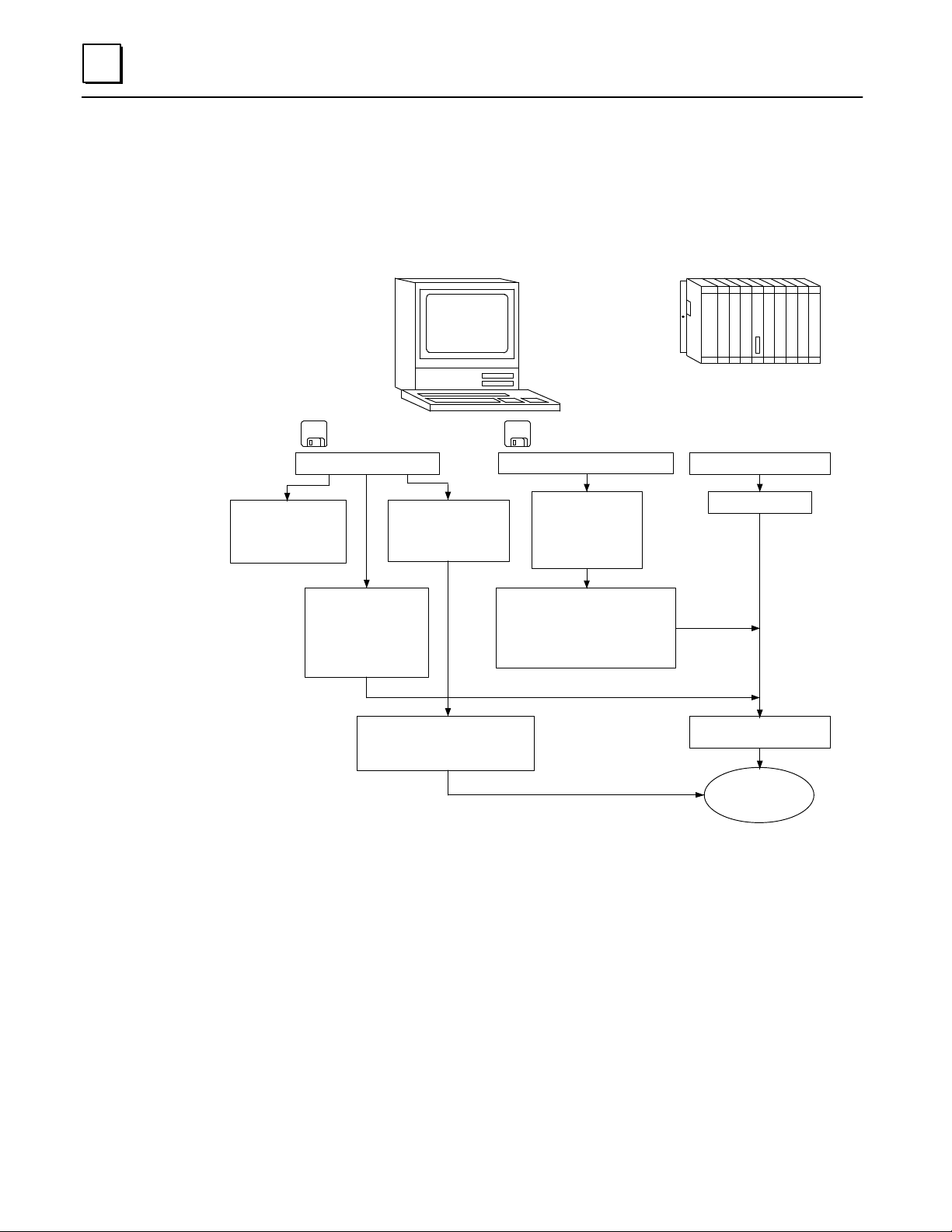

The Figure 1-1 shows the major components of the Ethernet Communications System,

along with a third- party compatible device, together on one Ethernet cable. Note especially the two main parts of the Ethernet Communications system, the Ethernet Interface

and the GEnet System Manager Software, and the separation of functions between them.

Ethernet

Cable

Network

Connection

IBM PC

Compatible

Series 90–70

PLC

GEnet SYSTEM MANAGER Software

– Creates Configuration Files

for Stations on the Network

– Downloads Configuration

Files and Executive Software

to the TCP/IP Ethernet Interface

– Accesses Station Manager

Software on Interface

– Network and Local Connections

TCP/IP

Ethernet

Interface

Local RS–232 Connection

TransceiverTransceiver TransceiverTransceiverTransceiver

TCP/IP

Ethernet

Interface

– Direct Network Attachment

of PLC

– On–board Diagnostics and

Communication Software

Downloaded from GSM

Series 90–70

Series 90–30

PLC

Ethernet

PLC

Interface

Other Ethernet DevicesTCP/IP Ethernet InterfaceGEnet SYSTEM MANAGER (GSM)

– User Applications

– Logicmaster 90

Programming Software

a45401

Host Computer or

Control Device

GFK -1004B

Figure 1-1. Major Components of the TCP/IP LAN

1-1

Page 16

1

The Ethernet Interface allows you to directly attach the Series 90-70 PLC to an Ethernet

LAN via a user-supplied transceiver and AUI cable, and to communicate with other

PLCs, hosts, and other control devices on the network.

The Ethernet Interface for the Series 90-70 PLC has “client/server” capability. As a “client” it can initiate communications with other Series 90 PLCs containing Ethernet Interfaces. This is done from the PLC ladder program using the COMMREQ function. As a

“server” it responds to requests from other devices such as Logicmaster 90-70 TCP/IP

Ethernet, a Host computer running a Host Communications Toolkit application, or

another Series 90 PLC acting as a “client”. No PLC programming is required for server

operation.

The Ethernet Interface

An operational Ethernet Interface consists of the Ethernet controller board with resident

firmware and the Ethernet Interface software downloaded from the GEnet System Manager .

(It is the TCP/IP-Ethernet software that distinguishes this product from the similar MMSEthernet product.) The Ethernet controller board provides a physical connection from

the PLC to the Ethernet LAN. It also is shipped with on–board diagnostics, a download

program to complement the downloader on the GEnet System Manager , and a utility program that permits testing the cable plant. The controller board becomes a fully functional communications interface only after downloading additional software from the GEnet

System Manager .

Capabilities of the Ethernet Interface

The Ethernet Interface brings to your PLC a great deal of capability . It will allow you to:

H

Directly attach your PLC to an Ethernet network. The Ethernet Interface allows

you to directly attach the Series 90-70 PLC to an Ethernet LAN via a user-supplied

transceiver and AUI cable, and to communicate with host computers and other

Series 90 PLCs on the local network.

H

Transfer data between PLCs. The Ethernet Interface provides client capability, the

capability to initiate communications to other Series 90 Ethernet Interfaces, using

COMMREQ functions in the ladder program.

H

Access data using a Host Computer. Computer applications which use the GE

Fanuc Host Communications Toolkit can access data within the Series 90-70 PLC

through the server capability of the Ethernet Interface. Supported computer

operating systems include Windowst for Workgroups, Windows NTt, HP -UX

9000, DEC VAX/VMSt, and DEC Alpha AXP/VMSt.

H

Communicate simultaneously to multiple devices. The multiplexing capabilities of

the Ethernet Interface, along with Ethernet network’s high capacity, allow the PLC

to communicate with several other devices at the same time.

t

Windows, and Windows NT are trademarks of Microsoft Corporation.

t

DEC, VAX, Alpha AXP, and VMS are trademarks of Digital Equipment Corporation.

1-2 TCP/IP Ethernet Communications User’s Manual – Januar y 1996

GFK-1004B

Page 17

H

Maintain Compatibility with other GE F anuc devices, as well as with devices from

other vendors. The GE Fanuc Series 90–70 PLC with TCP/IP Ethernet Interface is

compatible with the Series 90-30 PLC with TCP/IP Ethernet Interface.

It is also compatible with GE Fanuc Logicmaster 90-70 TCP/IP Ethernet and GE

Fanuc HCT Ethernet products available on DEC, HP, IBM, and other computer

platforms running TCP/IP.

H

Diagnose and maintain your system, using diagnostic and station management

tools. You can find problems before they become serious. In the event that

communications software upgrades are needed, you can use the network or the

built-in serial port to download the software to the interface.

H

Indirectly attach to other Local Area Networks and/or wide area networks via third

party IP routers. When configured to use an IP gateway (router), the Ethernet

Interface can communicate with remote PLCs and other nodes reachable through

the router.

H

Communicate with remote computers via Serial Line Internet Protocol (SLIP)

using modems and/or serial lines. Using third party SLIP software, a remote host

computer can be attached to a TCP/IP network thus allowing it to communicate to

the Series 90 PLC via the Ethernet Interface.

1

Attachment of the Ethernet Interface to the LAN

The A UI port provides the electrical and mechanical interface to the user-provided

Ethernet transceiver cable, which connects the AUI port to an external user-provided

transceiver. The external transceiver is directly connected to the Ethernet cable.

Various Ethernet baseband media (10Base...) can be interconnected by appropriate repeaters. Capabilities and limitations are defined in IEEE 802.3 Chapter 13, “System Considerations for Multi-Segment Networks”.

The Ether net Controller can operate on any of the following media with the appropriate

user-supplied transceiver cable and transceiver. IEEE 802.3 specifies the definitive requirements of each medium.

10Base5 Coax: 10Base5 uses a 0.4 inch diameter 50–ohm coaxial cable. The maximum

length of a cable segment is 500 meters. The distance between any two stations must be

a multiple of 2.5 meters. A maximum of 100 stations is allowed on a thickwire Ethernet

segment.

10Base2 Coax: 10Base2 uses a 0.2 inch diameter 50–ohm coaxial cable. The maximum

length of a cable segment is 185 meters. A maximum of 30 stations is allowed on a thinwire Ethernet segment.

10BaseT: 10BaseT uses a twisted pair cable of up to 100 meters in length between each

node and a hub or repeater. Typical hubs or repeaters support 6 to 12 nodes connected

in a star wiring topology.

GFK-1004B

10BaseF: 10BaseF has two variations that both use the same type of fiberoptic cable:

10BaseFP can support up to 33 nodes at distances of up to 500 meters from a passive

star; 10BaseFL supports up to 2000 meters between a node and a repeater (a multi-port

repeater would thus constitute a star). Additionally, 10BaseFB provides a means of interconnecting (only) repeaters by up to 2000 meters of (the same) fiber optic cable.

Chapter 1 Introduction

1-3

Page 18

1

10Broad36: 10Broad36 uses 75-ohm coaxial cable and CATV-like media components

(taps, amplifiers, headend translators, etc.) to support hundreds of nodes at distances of

up to 2800 meters. Broadband cannot be connected to baseband via repeaters. Broadband cable plant design and installation must be in accordance with IEEE 802.7 and requires special expertise. GE Fanuc recommends you contract professional specialists for

these services. Consult your GE Fanuc sales representative or field service office for help

in identifying local specialists.

The Ethernet Software

A s stated above, the Ethernet Interface becomes fully functional only after additional software

is download ed from the GEnet System Manager. The downloaded software consists of:

The Station Manager . The Station Manager provides On–Line supervisory access to the

Ethernet Interface, through either the serial port on the controller board or over the

Ethernet cable. These Station Manager services on the Ethernet Interface include:

H

An interactive set of commands for interrogating and controlling the station.

H

Unrestricted access to observe internal statistics, an ex ception log, and configuration

parameters.

H

Password security for commands that change station parameters or operation.

The Ethernet Interface firmware provides some Station Manager

functions. Downloaded software adds commands to provide more

functionality.

Communications Software. This software consists of the TCP/IP protocol stack and interface software interfacing the protocol stack with the PLC.

Configuration File. This configuration data consists of an IP address for the Interface, a

subnet mask, and the IP address of a gateway. This data is overridden by any TCP mode

configuration configured for the Ethernet Interface in the LM90 configurator.

The GEnet System Manager (GSM)

The GEnet System Manager is a menu–driven software package that runs on a user–provided Workmaster or IBM PC. The GSM provides various management and configuration tools. The GSM can be connected to the Ethernet Interface either with a serial RS–232

cable, or over the Ethernet cable. When used over Ethernet, one GSM can conveniently

access any of the Ethernet Interfaces on that cable.

The most essential GSM tools are:

H

The Configuration Editor

Note

H

The Downloader

H

Access to the Station Manager on the Ethernet Interface

In addition, the GSM has the following functions:

H

Examine the list of configured Ethernet Interfaces.

H

Examine and modify network–wide configuration parameters.

1-4 TCP/IP Ethernet Communications User’s Manual – Januar y 1996

GFK-1004B

Page 19

1

Note

Typically, there will be only one GSM on the network. It will contain

configuration information and communications software for all the

GEnet stations on the network.

The Configuration Editor

The Configuration Editor is a menu–driven software package that is part of the GSM.

It is used offline to examine and modify configuration parameters for the GE Fanuc Series

90-70 Ethernet Interfaces on your network. These configuration parameters are stored in files

on the PC hard disk and subsequently downloaded to the interface using the GSM

Downloader.

The Downloader

The Downloader is a utility which transfers the Communications Software and the Configuration File to the Ethernet Interface. The Downloader operates in two modes, local (RS232)

and network. The Downloader and the download mode are selected in the main screen of

the GSM.

Access to the Station Manager on the Ethernet Interface

The Ethernet Interface provides an interactive maintenance interface called the Station Manager (described in Chapter 5). The Station Manager allows you to view current and historical information about the operation of the Ethernet Inter face. The GSM provides access to

the Ethernet Interface and Station Manager in both local and network modes. A ccess to the

Station Manager and the access mode are selected in the main screen of the GSM.

GFK-1004B

Chapter 1 Introduction

1-5

Page 20

1

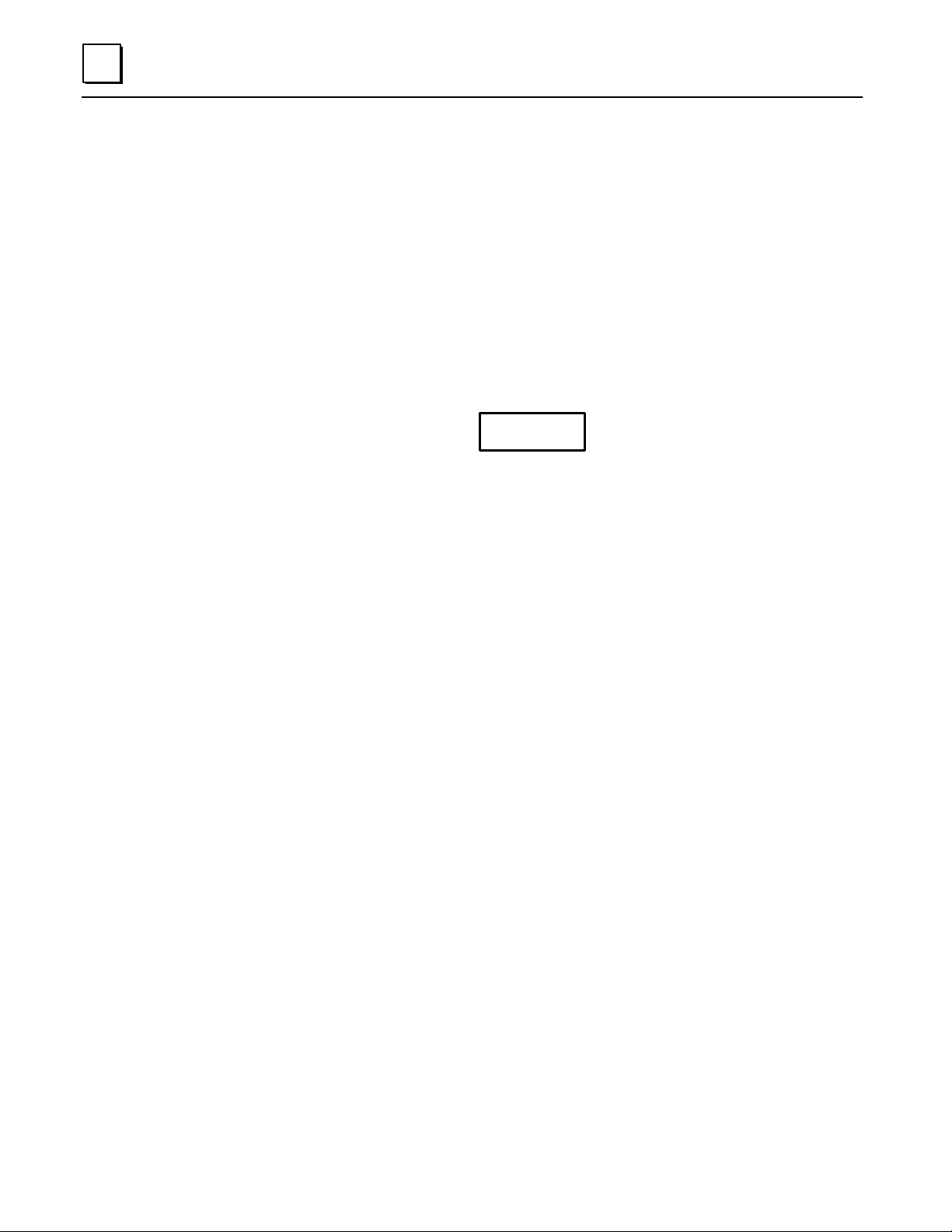

How to Make it Work

There are a number of tasks required to get your Ethernet Communications System

working. These tasks involve not only the Ethernet Interface and the GEnet System Manag-

er Software, but also Logicmaster Configuration and Programming Software. The figure below

illustrates what the tasks are for each part of the system.

a45402

User supplied

compatible

Install GSM software

Use Configuration

Editor to create

configuration

files for stations

Use Downloader

executive software

IBM PC

GSM software

Station Manager

Field Network Test

to download

configuration

files and

to Interface

Access Station Manager on

Interface to monitor

and manage network

Logicmaster software

Install Logicmaster software

Access

to run

Optional if client capability is needed

*

Use Logicmaster

configuration

package to

configure

Interface

Use Logicmaster 90

programmer package to

program COMMREQs to

initiate communications from

your Series 90–70 PLC

Series 90–70

PLC

Ethernet Interface

Install Interface in PLC

Power–up PLC

*

Power–up PLC again

or restart Interface

Fully

Operational

Interface

Figure 1-2. The Main Tasks for Installing the TCP/IP Ethernet Communications System

1-6 TCP/IP Ethernet Communications User’s Manual – Januar y 1996

GFK-1004B

Page 21

Quick Guide to the Manual

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

As you can see from Figure 1–2, the tasks to install the TCP/IP Communications System

fall into three categories:

1. GEnet System Manager (GSM) Tasks

2. Ethernet Inter face Tasks

3. Logicmaster Configuration and possibly Programming Tasks

The table below breaks down these tasks and identifies where in the manual they are

described.

1

Tasks

GEnet System Manager (GSM)

Installing, Starting Up, and

Using the GSM

БББББББББББ

Configuring Stations

БББББББББББ

Downloading a Station

Accessing the Station Manager

БББББББББББ

(T erminal Emulation Mode)

БББББББББББ

Ethernet Interface

Installing the Interface

БББББББББББ

Powering–Up the Interface

БББББББББББ

Configuring the Module

(Setting Soft Switch Configuration)

БББББББББББ

Field Network T ests

БББББББББББ

PING Application Connection T ests

Monitoring the Station and

БББББББББББ

Managing the Network

Troubleshooting the Interface on

the Network

БББББББББББ

Logicmaster Configuration/Programming

Configuring the Module

БББББББББББ

БББББББББББ

PLC Ladder Programming (COMMREQ)

Where to go in the Manual

Chapter 3. The GEnet System Manager

БББББББББББББББ

Starting–Up the GSM

Chapter 3. The GEnet System Manager

БББББББББББББББ

Chapter 3. The GEnet System Manager

Chapter 3. The GEnet System Manager

БББББББББББББББ

Chapter 5. The Station Manager

БББББББББББББББ

Chapter 2. Installing the Ethernet Interface

БББББББББББББББ

Procedure 2. Verifying Proper Power–

БББББББББББББББ

БББББББББББББББ

БББББББББББББББ

Chapter 5. The Station Manager

БББББББББББББББ

Chapter 6. Troubleshooting

БББББББББББББББ

Chapter 2. Procedure 3. Configuring the Interface

БББББББББББББББ

БББББББББББББББ

Chapter 4. Programming Communications Requests

Section 1. Installing and

Section 2. Configuring Stations

Section 3. Downloading a Station

Section 4. Accessing the Station Manager

Procedure 1. Installing the Interface

Up of the Interface

Procedure 3. Configuring the Interface

with the Logicmaster 90-70

Configurator

Procedure 5. T esting the TCP/IP Interfaces on

the Network

Procedure 6. Pinging the TCP/IP Interfaces on

the Network

with the Logicmaster 90-70

Configurator

GFK-1004B

Chapter 1 Introduction

1-7

Page 22

Chapter 2 Installing the Ethernet Interface

section level 1

figure bi level 1

2

This chapter describes the basic features of the Ethernet Interface, its installation, and a

procedure for its initial checkout on your Ethernet cable. The chapter first provides an

overview of the Ether net Controller Board, which is the hardware component of the

Ethernet Interface. It is then divided into six sequential Installation Procedures, each

providing an overview of the procedure, explaining the steps to be performed, and describing the expected results.

As you work through a procedure you may encounter references to the appendices and

other chapters in this manual. These references provide more detailed information

about the subject under discussion.

The installation procedures described in this chapter are listed below:

H

table_big level 1

Procedure 1: Installing the TCP/IP Ethernet Controller Board in the PLC Rack -

Required

H

Procedure 2: Verifying Proper Power-Up of the Ethernet Interface - Required

H

Procedure 3: Configuring the Ethernet Interface with the Logicmaster 90-70

Configurator - Required

H

Procedure 4: Configuring and Downloading a Station - Required

H

Procedure 5: Testing the Ethernet Interfaces on the Network - Optional

H

Procedure 6: Pinging the Ethernet Inter faces on the Network - Optional

Some of the procedures require prior cable plant design and installation.

After completing the Installation Procedures you will gain an understanding of the parts

of the network and how they fit together. You will also have confidence that your equipment is working properly.

Ethernet Interface Hardware Overview

The Ethernet Controller board is mounted in the Series 90-70 PLC rack. It is connected to

an external transceiver via a user-provided transceiver cable. The external transceiver is

then connected to the Ethernet cable. The figure below shows the layout of the Ethernet

Controller board.

GFK -1004B

2-1

Page 23

2

a44663

LEDS

RESTART

PUSHBUTTON

OPEN

REPLACEMENT

BATTERY

CONNECTOR

CURRENTLY

INSTALLED

BATTERY

CONNECTOR

9–PIN

SERIAL

PORT

15–PIN

ETHERNET

CONNECTOR

DEFAULT

STATION

ADDRESS

LABEL

B

A

T

T

E

R

Y

MODEL 70

CMM 741

MODULE OK

ONLINE

STA TUS OK

ON OR BLINK= OK

PUSH TO RESTART

LAN INTERFACE.

PUSH AND HOLD

TO REQUEST

LAN INTERFACE

DOWNLOAD. INOP

WHEN RUNNING

DIAGNOSTICS

BATTERY

CONNECTIONS

INSTALL NEW

BATTERY BEFORE

UNPLUGGING OLD

BATTERY. USE

IC697ACC701

SERIAL

PORT

RS–232

DTE

2 TX (OUT)

3 RX (IN)

7 GND

PUSH

SLIDE FROM

FRONT TO

LOCK: FROM

BACK TO

RELEASE

TRANSCEIVER

CABLE

MODULE

IC697CCM741

LABEL

44A726758–117R01

GROUND

WIRE

SERIAL

NUMBER

LABEL

Figure 2-1. Ethernet Controller Board

The Ethernet Controller board has several user-accessible elements.

Three LEDs are located at the top of the board. The Restart pushbutton is located immediately below the LEDs. The battery and battery holder is located to the right of the

LEDs. The battery connectors are located on the controller board between the Restart

button and the 9-pin connector to the serial port. The 15-pin connector, located beneath

the serial port and facing downward, is the transceiver port. The Default Station Address label is affixed on the outside of the plastic housing.

2-2 TCP/IP Ethernet Communications User’s Manual – Januar y 1996

GFK-1004B

Page 24

Board Indicators

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

There are three LEDs on the Ethernet Controller board. The table below describes the

meaning of the LED patterns for all possible states.

Table 2-1. Ethernet Controller Board Indicators

2

Indicator

MODULE OK

ÁÁÁÁ

Status

ON

ÁÁÁÁ

OFF

BLINKING

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ONLINE

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ON

OFF

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

BLINKING

ST ATUS OK

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ON

ÁÁÁÁ

OFF

ÁÁÁÁ

ÁÁÁÁ

BLINKING

ÁÁÁÁÁÁÁÁÁ

Description

MODULE OK is ON if the Ethernet Interface has passed

ББББББББББББББ

diagnostics and its hardware is operating properly .

It is OFF if the module fails a diagnostic test or if a fatal

failure is detected while the board is running.

This LED is blinking if the module is running

diagnostics or is in Soft Switch Entry state.

ББББББББББББББ

If this LED and the ST ATUS OK LED are blinking

ББББББББББББББ

together , diagnostics have completed and the operator

is being given a chance to enter Field Network Test.

ББББББББББББББ

ONLINE is ON when the Ethernet Interface is

connected to and ready to communicate on the network.

This LED is OFF when:

H

the station is not communicating on the network

ББББББББББББББ

due to disconnection or a disruption of the cable.

ББББББББББББББ

H

the local station has malfunctioned, or the

Ethernet Interface has been commanded not to enter

ББББББББББББББ

the network, or is in a state where network operation

ББББББББББББББ

is inappropriate, such as Soft Switch Entry state or

local loading.

ББББББББББББББ

It is BLINKING when the module is transferring data

on the network or loading over the network.

ST ATUS OK is ON if the module is running without

exception conditions.

ББББББББББББББ

This LED is OFF if the module is running and detects an

ББББББББББББББ

event that calls for supervisor y attention. In this case

you should connect the GSM and follow the instructions

ББББББББББББББ

in Chapter 5 to obtain further information.

This LED is BLINKING if the module is loading or look-

ББББББББББББББ

ing for a load source for the Ethernet Interface software.

GFK-1004B

Restart Button

The Restart button serves two functions: Restart, and Restart and Reload. The Restart

button is inaccessible when the door to the Ethernet Controller board is closed.

Restart: Pressing the Restart button (for fewer than 5 seconds) forces a restart of the

Ethernet Interface. The power-up diagnostics run and the software on the module is

restarted when the pushbutton is released.

Restart and Reload: Pressing and holding the Restart button for 5 seconds or more

forces a restart and requests a reload of the Ethernet Interface. When the Restart button

is pressed, all LEDs go out. After 5 seconds have elapsed, the STATUS OK LED comes

ON, to indicate that the Ethernet Inter face will request a reload. After the Restart pushbutton is released, the power-up diagnostics run and the Ethernet Interface requests to

be loaded.

Chapter 2 Installing the Ethernet Interface

2-3

Page 25

2

Battery

Notes

In either case, any data being transferred by the Ethernet Interface at

the time of the Restart will be lost.

The Restart Pushbutton will not be operable during the Ethernet

Controller board diagnostic phase. The Ethernet Controller board is in

diagnostic phase when the BOARD OK LED is BLINKING and the

ONLINE and STATUS OK LEDs are off.

When connected, the battery preserves the contents of RAM when there is no power to

the board. The battery will maintain RAM contents for a minimum of six months.

Warning

The lithium battery presents a fire, explosion, or severe burn risk. Do

NOT: recharge it, remove its polarized connector, disassemble it, heat

it above 100C (212F), incinerate it, or expose its cell contents to water.

Dispose of the battery as required by applicable ordinances or

regulations. When replacing the battery, use only Catalog No.

IC697ACC701. Use of another battery could result in ignition or

explosion of the battery. Replacement batteries can be ordered from

GE Fanuc Automation - NA or any GE Fanuc Authorized Distributor.

Serial Port

The 9-pin serial port (RS-232 interface) is used to connect to the GEnet System Manager

(GSM). The communication software on the distribution diskette may be loaded

through this port. A cable is needed to connect the GSM to the Ethernet Interface (see

Appendix B, Communications Ports Characteristics). The faceplate of the Ethernet Interface must be open to connect the cable. The serial port may also be used with a serial

terminal for local Station Management.

AUI (Transceiver) Port

The 15-pin AUI port provides the electrical and mechanical interface to the user-provided IEEE 802.3 transceiver cable, which connects the AUI Port to an external Ethernetcompatible transceiver (see Appendix B for the characteristics of the AUI Port). The external transceiver is directly connected to the Ethernet cable.

Default Station Address Label

The Default Station Address label lists the station address to be used by this module, unless changed by the user via soft switches.

Serial Number Label

The Serial Number Label indicates the serial number of this controller board.

2-4 TCP/IP Ethernet Communications User’s Manual – Januar y 1996

GFK-1004B

Page 26

Procedure 1: Installing the Ethernet Controller Board in the PLC

This section describes the physical installation of the Ethernet Controller board into the

Series 90-70 PLC rack. For information on the installation procedures for the rack, 90-70

CPU, Power Supply, and other Series 90-70 modules, refer to GFK-0262, Series 90-70 Pro-

grammable Controller Installation and Operation User’s Manual.

Equipment Required to Perform the Installation Procedures

In addition to the Ethernet Controller board, make sure you have the items listed below

before you begin.

H

A Series 90-70 PLC rack.

H

A Series 90-70 power supply.

Note

2

The Ethernet Inter face requires a power supply that can provide +5

Vdc and +12 Vdc. Use one of the following power supplies:

IC697PWR711 IC697PWR724

IC697PWR721 IC697PWR748

IC697PWR731

H

A Series 90-70 CPU.

H

An operating Logicmastert 90-70 system (serial, parallel, or network version).

H

A W orkmaster, or IBM-compatible personal computer.

H

The Ethernet Interface software diskette.

H

A copy of the data sheet applicable to your Ethernet Controller board and cable plant.

H

A certified Ether net-compatible transceiver and Ethernet cables.

H

A serial cable for the RS-232 connector on the Ethernet Controller board (see

Appendix B).

Ethernet Controller Board Installation

The Ethernet Controller board installation is summarized here.

1. Read and record the 12-digit default station address (MAC address) from the printed

label on the Ethernet Controller board. A Station Configuration Data Form is

provided in Appendix F for your convenience in recording the station configuration

information.

GFK-1004B

2. Be sure the Series 90-70 PLC rack power is OFF.

3. Connect the batter y to either of the battery connectors on the controller board.

4. Slide the Ethernet Controller into the Series 90-70 PLC slot for which it was

configured in the system - normally the first available slot to the right of the CPU.

The controller must be placed in the main rack.

Chapter 2 Installing the Ethernet Interface

2-5

Page 27

2

Press firmly to lock the board in place, but do not force the board.

Note

The Ethernet Controller board will not operate properly if there are

empty slots to the left of the slot you select.

5. Connect the free end of the safety wire (18 inch long green wire attached to the

Ethernet Controller board) to the ground lug at the side of the Series 90-70 PLC rack.

(See Figure 2-2).

Warning

The ground wire must be securely fastened to the chassis of the Series

90-70 PLC rack and the rack must be properly grounded. Failure to do

so may cause personal injury and/or improper operation of the LAN.

6. Connect the transceiver cable into the 15-pin AUI Port of the Ethernet Controller

board. Secure the cable with the slide latch mechanism. The other end of the

transceiver cable should be connected to an external IEEE 802.3 compatible

transceiver which is attached to the Ethernet network. SQE must be enabled on the

transceiver.

7. Set the CPU Run/Stop switch to STOP.

8. Continue with Procedure 2: Verifying Ethernet Interface Power-Up.

Ethernet Controller Board Installed in Series 90-70 PLC Rack

a45349

P

S

GROUND

WIRE

B

E

C

T

T

P

M

U

H

E

R

N

E

T

TRANSCEIVER

CABLE

TO

802.3

TRANSCEIVER

Figure 2-2. Ethernet Controller Installation in the Series 90-70 PLC

Note

The Ethernet Controller board must be installed in the main rack;

installation in an expansion rack is not supported.

2-6 TCP/IP Ethernet Communications User’s Manual – Januar y 1996

GFK-1004B

Page 28

Procedure 2: Verifying Proper Power-Up of the Ethernet Interface

Before powering–up the Ethernet Interface, you may wish to connect the GEnet System

Manager (GSM) locally to the Ethernet Interface, and select the “Station Manager” func-

tion from the GSM Main menu. This allows you to observe the progress of the power–

up diagnostics via the Station Manager software on the Ethernet Interface. The GSM is

also used to perform other operations in subsequent Installation Procedures.

Refer to Chapter 3, “The GEnet System Manager”, for instructions on installing the GSM

software on a user-supplied PC-compatible computer .

Note

Alternately, you can use a dumb terminal, or another terminal

emulation product on a PC. However, you will probably find it most

convenient to use the GSM since you will be using the GSM for other

configuration purposes in subsequent steps.

2

If you do not use the GSM, configure the terminal for 9600 bps, 8 bits, no

parity, and 1 stop bit. See Appendix B, for instructions on making the

serial cable.

Using the GSM “Access Station Manager” Function

The Station Manager software on the Ethernet Inter face is accessed by connecting the

Ethernet Interface to a Workmaster or other computer running the GSM software and

selecting the “Station Manager” function from the GSM main menu.

1. There are two ways the GSM can be physically connected to an Ethernet Interface:

Local Connection and Network Connection.

Note

To observe the progress of Power–Up Diagnostics described in this

procedure and to invoke the Field Network Test Utility described in

Installation Procedure 5, the GSM must be connected locally and put in

the Local Station Manager Mode.

A. GSM Using Local Connection. Connect the COM1 RS–232 serial port on the

device running the GSM to the 9–pin connector on the Ethernet Inter face. Refer

to Appendix B, for instructions on how to make the RS–232 cable.

GFK-1004B

B. GSM Using Network Connection. Connect the Ethernet card on the device

running the GSM to the Ethernet Network.

C. For now, use the Local connection.

2. Power–up the computer (on which you have previously installed the GSM software)

into DOS. Refer to Chapter 3 for the GSM installation procedure.

Chapter 2 Installing the Ethernet Interface

2-7

Page 29

2

3. Set the PC default directory to the GSM directory, by typing:

C:\> cd \gsm

4. Start–up the GSM by typing:

C:\GSM> gsm

5. At the password screen, type in the password. The default password is “gsm”.

6. Once the GSM Main Menu appears, go into the Setup GSM functions to set the

Station Manager communications mode to Local, exiting with <ALT-U>.