Page 1

GE Fanuc Automation

Field Control™

User’s Manual

Programmable Cont rol Products

Genius® Bus Interface Unit

GFK-0825F October 1999

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associate d with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

GFL-002

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alar m M aster Genius ProL oop Series Three

CIMPLICITY Helpmate PROMACRO VersaMax

CIM P LIC IT Y 90 – ADS Logicm aster Series Five VersaPro

CIMSTAR Modelmaster Series 90 VuMaster

Field Control Motion Mate Series One Workmaster

GEnet PowerTRAC Series Six

©Copyright 1996-1999 GE Fanuc Automation North America, Inc.

All Rights Reserved .

Page 3

Content of thi s M a nual

This manual describes the Field Control® Genius™ Bus Interface Unit (IC670GBI002). It explains

operation of the Bus Interface Unit as a Genius bus device. It also contains complete configuration

instructions for the Bus Interface Unit and all Field Control I/O modules.

Chapter 1. Introduction: Chapter 1 introduces Field Control systems, the Genius Bus Interface

Unit, and other equipment that may be used with the Bus Interface Unit. It will help you locate

more information about the components and operation of Field Control products.

Chapt er 2. Descrip tion : Chapter 2 describes the Genius Bus Interface Unit module, the Bus

Interface Unit Power Supply, and the Bus Interface Unit Terminal Block, and lists their

specifications.

Chapter 3. Installation: Chapter 3 describes Bus Interface Unit installation and gives system

installation guidelines.

Chapter 4. Operation: Chapter 4 explains how a Bus Interface Unit interacts with the modules in

its station, how it stores data, and how it exchanges data with a PLC or other type of system host.

Preface

Chapter 5. Station Configuration: Chapter 5 explains how to configure a Bus Interface Unit and

the modules in a station using a Hand-held Monitor.

Chapter 6. Diagnosti c s and Fault Cleari ng: Chapter 6 describes the diagnostics capabilities of

the Bus Interface Unit an d exp lains how faul ts are cleared.

Chapter 7. Monitoring and Controlling Field Control Data: Chapter 7 explains how to monitor

or control Field Control I/O data using Genius Hand-held Monitor or a programmer.

Chapter 8. Datagrams: Chapter 8 lists datagrams that can be sent to a Bus Interface Unit, and

shows the datagram format s for Fi el d Control modul es.

Appendix A. Scali ng Analog Channel s: Appendi x A ex pl ains how to select scal ing values when

configuring an analog input or output. (Configuration instructions are in chapter 5).

Appendix B. Install i ng Addit i onal Suppressi on: Appendix B describes some precautions that

can be taken in an installation to help assure proper operation.

Appendix C. The Genius Serial Bus: This appendix describes the selection and operating

chara cteristics of the bus cable that links Genius devices.

Appendix D. Configurati on Examples: Th is append ix includ es ex amples of di fferen t Field Control I/O

Station configurations.

GFK-0825F iii

Page 4

Preface

Relat e d Publi ca t ions

For more information, refer to these publications:

Field Control I/O Modules User's Manual (GFK-0826). This book desc ri bes Field C ontrol I/O

Modules and I/O Terminal Blocks and explains how to install them.

The Se rie s 90® Micro Fiel d Proce sso r User' s Manual (GFK-1171). This book describes the

Micro Field Processor (IC670MFP100) and provides installation procedures, operation

info rmation, and d iagnostic s infor mation.

Genius I/O System User' s Manual (GEK-90486-1). Reference manual for system designers,

programmers, and others involved in integrating Genius I/O products in a PLC or host co mputer

environmen t . T his book provides a syst e m overview, and des c ribes th e t ypes of systems that ca n be

created using Genius products. Datagrams, Global Data, and data formats are defined.

Series 90® −30 Bus Controller User's Manual (GFK-1034). Reference manual for the Bus

Controller, which interfaces a Genius bus to a Series 90-30 PLC. This book des c ribe s th e

inst allation and operation of the Bus C ontroll er .

Series Six® Bus Controlle r Use r's Manual (GFK-0171). Reference manual for the Bus Controller,

whi c h int e rfac e s a G e nius bus to a S eries Six PLC. This book d e scribes t he installation and

operation of the Bus Controller. It also contains the programming information needed to interface

Genius I/O devices to a Series Six PLC.

Series Five® Bus Controller User's Manual (GFK-0248). Reference manual for the Bus

Controller, which interfaces a Genius bus to a Series Five PLC. This book describes the installation

and operation of the Bus Controller. It also contains the programming information needed to

inter face Geni u s I/ O devi ces to a Series Five PLC.

Genius I/O PCIM User's Manual (GFK-0074). Reference manual for the PCIM, which interfaces

a Genius bu s to a suitable h ost com put e r. This book d escribes the installation and operation of t he

PCIM. It also contains the programming information needed to interface Genius I/O devices to a

host computer.

Installa ti on Re quire me nts for Conformance to Standards (GFK-1179)

Jeanne Grimsby

Lead Technical Writer for I/O Products

iv Field Control™ Genius® Bus Interface Unit User’s Manual– October 1999 GFK-0825F

Page 5

Contents

Chapter 1 Introduction..................................................................................................... 1-1

Overview......................................................................................................................1-1

Field Control Modules..................................................................................................1-2

Environmental Specifications........................................................................................1-5

Configuration for Field Control.....................................................................................1-6

Field Control in a Genius System..................................................................................1-7

Required Genius and Host System Equipment...............................................................1-9

Using Field Control in a CPU Redundancy System.....................................................1-10

Using Field Control in a Genius Bus Redundancy System...........................................1-11

Chapter 2 Description....................................................................................................... 2-1

Genius Bus Interface Unit.............................................................................................2-1

Bus Interface Unit Power Supply..................................................................................2-3

Backplane Current........................................................................................................2-4

Bus Interface Unit Power Dissipation............................................................................2-5

Load Requirements for Hardware Components.............................................................2-6

Bus Interface Unit Terminal Block................................................................................2-8

Functional Specifications..............................................................................................2-9

Chapter 3 Installation....................................................................................................... 3-1

Preinstallation Check....................................................................................................3-2

Static Protection............................................................................................................3-2

Hand-held Monitor Connector......................................................................................3-2

System Wiring Guidelines............................................................................................3-3

Installing Additional Suppression.................................................................................. 3-3

System Grounding ........................................................................................................3-4

Locations for Field Control ...........................................................................................3-5

Installing the DIN Rail..................................................................................................3-5

Installing the Bus Interface Unit Terminal Block on the DIN Rail.................................3-7

Installing the Cables Between Terminal Blocks.............................................................3-8

Power Wiring to the Bus Interface Unit.........................................................................3-9

Connecting the Communications Bus..........................................................................3-10

Bus Cables..................................................................................................................3-10

Making Bus Connections............................................................................................3-11

Installing the Bus Interface Unit on the Terminal Block..............................................3-14

Removing the Bus Interface Unit from the Terminal Block.........................................3-14

Removing/Replacing the Bus Interface Unit Fuse .......................................................3-15

Upgrading the BIU Firmware......................................................................................3-16

GFK-0825F v

Page 6

Contents

Chapter 4 Operation......................................................................................................... 4-1

BIU Data Handling at the I/O Station............................................................................4-2

I/O Data for Conventional Modules..............................................................................4-3

I/O Data, Status Data, and Control Data for Intelligent Modules....................................4-3

Group Data for Intelligent Modules...............................................................................4-4

The BIU Sweep............................................................................................................4-5

BIU Backplane Scan Time............................................................................................4-7

Data Transfer Between the BIU and the Host................................................................4-9

Data in the BIU's Network (Bus) Map...........................................................................4-9

Communications on the Genius Bus..............................................................................4-9

Input Data Sent by the Bus Interface Unit...................................................................4-10

Outputs from the Host to the BIU................................................................................4-11

Genius Bus Scan Time................................................................................................4-12

Operation of the BIU with a Micro Field Processor.....................................................4-14

MFP and BIU Synchronization................................................................................... 4-14

MFP I/O References ...................................................................................................4-14

MFP Operating Modes................................................................................................4-14

Overview of Synchronous Operation...........................................................................4-16

Backing Up Micro Field Processor Outputs................................................................4-17

How the Network Backs Up MFP Outputs..................................................................4-18

Backing Up BIU Outputs with a Micro Field Processor...............................................4-19

Example Ladder Logic................................................................................................4-20

Chapter 5 Station Configuration...................................................................................... 5-1

For Additional Information, Also See:..........................................................................5-1

Configuring the Serial Bus Address and Baud Rate.......................................................5-2

Special Instructions for Series 90-70 PLC Systems .......................................................5-2

Set Up the Hand-held Monitor......................................................................................5-3

Create a New Configuration..........................................................................................5-4

Assigning a Serial Bus Address to a New BIU..............................................................5-4

Configure the Bus Interface Unit................................................................................... 5-5

Field Control HHM Menu Overview.............................................................................5-6

Change the Serial Bus Address of the Bus Interface Unit ..............................................5-7

Select the Baud Rate.....................................................................................................5-8

Select a Series Six or Series Five PLC Reference Address............................................. 5-9

Configure Fault Reporting.......................................................................................... 5-10

Configure Genius Bus Redundancy.............................................................................5-11

Configure CPU Redundancy.......................................................................................5-12

Configure Field Control Modules................................................................................5-15

Enable/Disable the I/O Scan ....................................................................................... 5-15

vi Field Control™ Genius® Bus Interface Unit User’s Manual– October 1999 GFK-0825F

Page 7

Contents

Disable Network I/O Updates.....................................................................................5-15

Configure the Network Map for the Bus Interface Unit...............................................5-16

Configuring Extra References in the BIU I/O Map......................................................5-17

Add Modules and Assign References..........................................................................5-20

Configure a Discrete Input Module.............................................................................5-22

Configure a Discrete Output Module...........................................................................5-24

Configure a Discrete Input/Output Module..................................................................5-26

Configure a Conventional Analog Input Module.........................................................5-29

Configure a Conventional Analog Output Module.......................................................5-35

Configure a 16-Point Grouped Analog Input Module..................................................5-40

Configure an 8-Point Grouped Analog Voltage Input Module..................................... 5-48

Configure a 16-Point Grouped Analog Voltage Input Module..................................... 5-56

Circuit Configuration..................................................................................................5-60

Configure an RTD Input Module................................................................................5-64

Circuit Configuration..................................................................................................5-67

Configuring a Thermocouple Input Module.................................................................5-72

Configure an 8-Point Analog Voltage Output Module.................................................5-81

Configure an 8-Point Analog Current Output Module.................................................5-90

Configure a Micro Field Processor..............................................................................5-99

Chapter 6 Diagnostics and Fault Clearing....................................................................... 6-1

Diagnostics and Fault Clearing for Intelligent Modules.................................................6-1

Diagnostics and Fault Clearing for the BIU and Conventional Modules.........................6-2

Display and Clear Faults from a Genius Hand-held Monitor..........................................6-3

Display and Clear Faults from a PLC............................................................................6-5

Series 90 PLC: I/O Fault Table....................................................................................6-5

Series 90 PLC: PLC Fault Table...................................................................................6-5

Series Five or Series Six PLC.......................................................................................6-5

GFK-0825F Contents vii

Page 8

Contents

Chapter 7 Monitoring and Controlling Field Control Data............................................ 7-1

Overview......................................................................................................................7-2

Forcing Circuits ............................................................................................................7-2

Overriding I/O Circuits.................................................................................................7-2

Monitor/Control I/O Data: Genius Hand-held Monitor..................................................7-3

Forcing/Unforcing the Displayed Reference..................................................................7-5

Monitor/Control I/O Da ta: Series 90 PLC....................................................................7-6

Monitor/Control I/O Data: Series Six PLC or Series Five PLC.....................................7-6

Monitor/Control I/O Data: Computer............................................................................7-7

Chapter 8 Datagrams....................................................................................................... 8-1

Datagram Types............................................................................................................8-2

Read Map.....................................................................................................................8-3

Read Map Reply...........................................................................................................8-3

Write Map....................................................................................................................8-4

Report Fault Datagram Format......................................................................................8-5

Configuration Data.......................................................................................................8-7

Read Configuration Data ..............................................................................................8-7

Set Bus Interface Unit Operating Mode.......................................................................8-29

Set Micro Field Processor Operating Mode.................................................................8-29

Intelligent Analog Module Recalibration Datagram.....................................................8-30

Read I/O Forces.......................................................................................................... 8-32

Read I/O Forces Reply................................................................................................8-32

Read Slot Diagnostics ................................................................................................. 8-33

Read Slot Diagnostics Reply.......................................................................................8-33

viii Field Control™ Genius® Bus Interface Unit User’s Manual– October 1999 GFK-0825F

Page 9

Contents

Appendix A Scaling Analog Channels.................................................................................A-1

How Scaling Works..................................................................................................... A-1

Scaling Valu es for 1mV or 1µA Engineering Units: BIU Version 1.3........................... A-2

Scaling Valu es for 1mV or 1µA Engineering Units: BIU.............................................. A-3

Measuring Scaling Values............................................................................................A-4

Example of Scaling an Analog Input............................................................................ A-5

Appendix B Installing Additional Suppression .................................................................. B -1

Suppression at the Power Lines.................................................................................... B-1

Suppression for Devices in an Enclosure...................................................................... B-2

Suppression at the Communications Line..................................................................... B-2

Appendix C The Genius Serial Bus.....................................................................................C-1

Wiring Guidelines........................................................................................................C-1

Electrical Interface.......................................................................................................C-2

Genius Transceiver Electrical Specification................................................................. C-3

Selecting a Cable Type................................................................................................ C-4

Serial Bus Waveforms................................................................................................. C-5

Using Other Cable Types............................................................................................. C-6

Serial Data Format....................................................................................................... C-8

Bus Access.................................................................................................................. C-9

Bus Length................................................................................................................ C-10

Baud Rate Selection................................................................................................... C-10

Bus Ambient Electrical Information........................................................................... C-11

Lightning Transient Suppression................................................................................ C-11

Appendix D Configuration Examples.................................................................................D-1

Example 1: Discrete Data, Network Processing............................................................ D-1

Example 2: Discrete and Analog Data, Network Processing......................................... D-2

Example 3: Discrete and Analog Data, Network and Local Processing ......................... D-3

Example 4 : Discrete and A nalo g D ata, Netw ork a nd Local Proces sing and Gr oup Data

Moves...................................................................................................................... D-4

Example 5: Group Move.............................................................................................D-6

GFK-0825F Contents ix

Page 10

Chapter

1

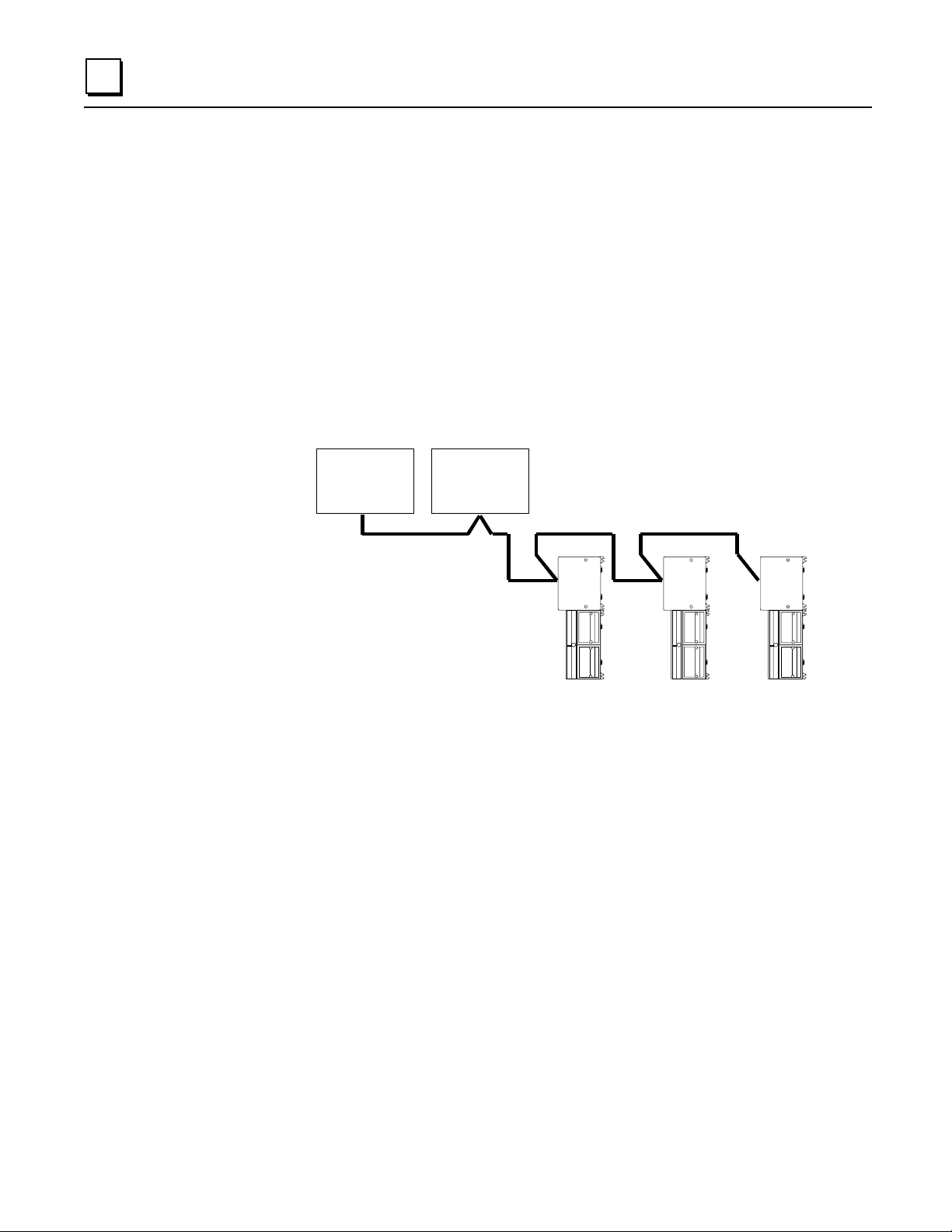

Overview

Bus

Interface

Unit

I/O

I/O

I/O

Introduction

This chapter introduces Field Control modules, the Genius Bus In terface Un it, and oth e r

equipment that may be used with the Bus Interface Unit. It will help you locate more information

in other Field Control and Genius documents.

Field Control is a family of highly modular distributed I/O and control products. They are suitable

for us e in a wid e range of host architectures.

The hear t of the Field Control system is th e Bu s Interface Unit. Th e Bus Interface Unit provid es

intelligent processing, I/O scanning, and feature configuration for a group of up to eight I/O

modules. Together, the Bus Interface Unit and its modules make up a Field Control station (see the

illustration, left).

The Bus Interface Unit and I/ O modu les are en closed in st urdy, compa ct aluminum housin g s. Bus

Interface Unit and I/O modules bolt securely to separate Terminal Blocks, which provide all field

wiring terminals. The I/O Terminal blocks are generic and allow different I/O module types to be

mounted on the same base. I/O Terminal Blocks are available with box-type terminals, barrier-type

terminals, or wire-to-board connectors. All Terminal Blocks must be mounted on a DIN rail. The

DIN rail, which serves as an integral part of the grounding system, can also be mounted on a panel.

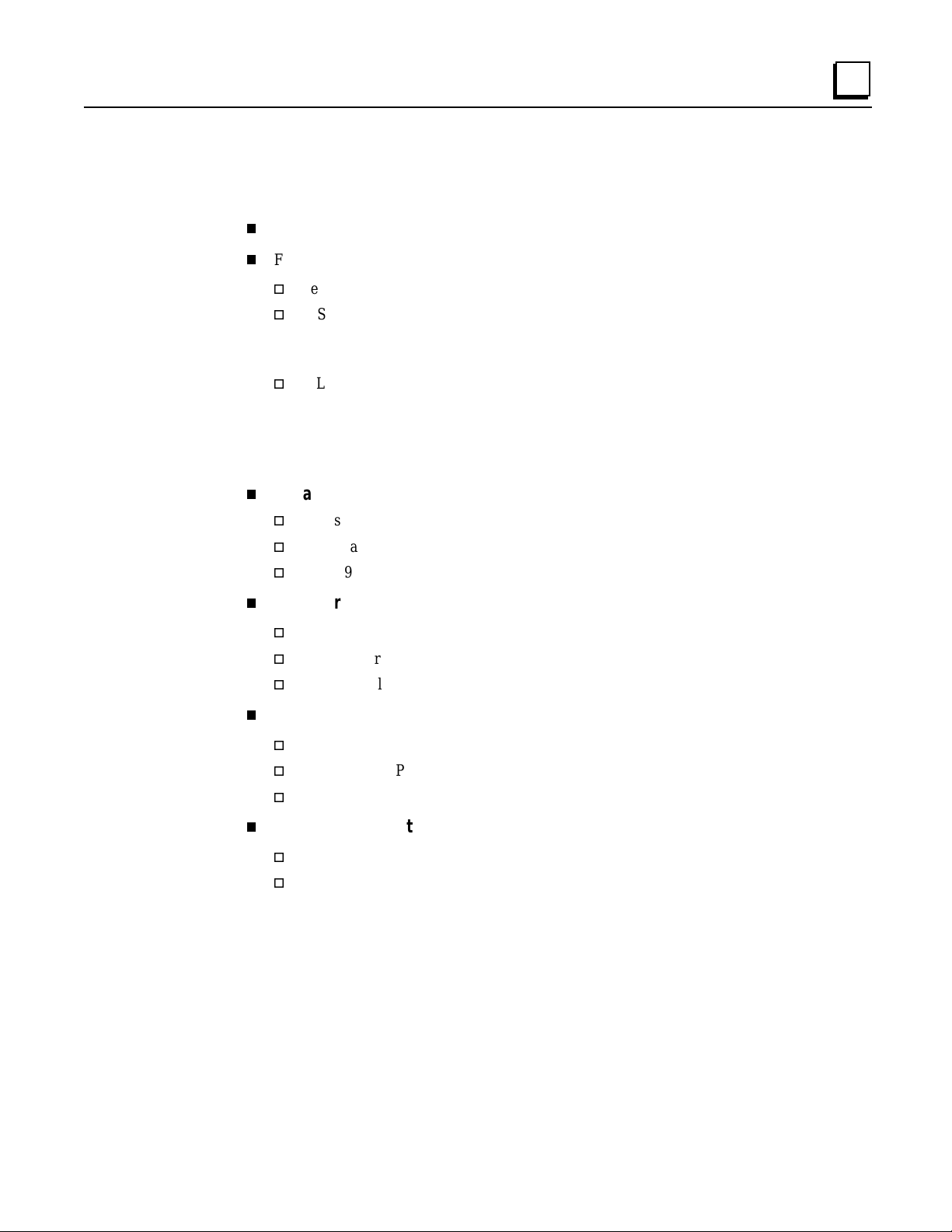

Field Control Features

I/O

I/O

I/O

I/O

I/O

GFK-0825F 1-1

Features and benefits of Field Control include:

wiring savings

better up time

easy installation and maintenance

spare parts savings

low cost

feature flexibility

open architect ure / adaptable to a var iety of networks

distributed I/O

small, compact I/O modules with generic terminal wiring bases.

DIN rail mounted

Page 11

1

Field Control Modules

Ther e are three basic types of Fi eld Control modul es:

Bus Interface Unit. The illustration below shows a Genius Bus Interface Unit.

I/O modules

Micro Field Pr ocessor

Terminal Blocks:

Bus Interface Unit Terminal Block.

I/O Terminal Blocks, each of which accommodates two I/O modules.

Auxiliary Term in al Blocks. These opti onal terminal strips can be connected t o the side of

an I/O Ter minal Block if extra common terminals ar e n eed ed .

Auxiliary

Terminal Blocks

Bus Interface Unit

Terminal Block

I/O Terminal

Block

Genius

Bus Interface Unit

Micro

Field Processor

I/O Modules

1-2 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 12

Genius Bus Interface Unit

The Genius Bus Interface Unit (IC670GBI002 or IC697GBI102) interfaces Field Control I/O

modules to a host PLC or computer via a Genius bus. It can exchange up to 128 bytes of input data

and 128 bytes of output data with the host, each Genius bus scan. It can also handle Genius

datagram communicati ons.

The intelligent processing capabilities of the Genius Bus Interface Unit allow the configuration of

features such as fault reporting, selectable input and output defaults, analog scaling and analog

range selection for the modules in the station. In addition, the Genius Bus Interface Unit performs

diagnostic checks on itself and its I/O modules, and relays diagnostic information to the host (if

configured for fault reporting) and to a Hand-held Monitor.

The Genius Bus Int erface Unit can be used on a bus controlled by redundant CPUs or Bus

Contr ol lers. It can also be used on a dual bus.

The Bus In terface Un it mounts on a Bus In terface Un it Termin a l Block. It c a n be re moved and

replaced if necessary without removing the wiring or reconfiguring the I/O station.

Bus Interface Unit Terminal Block

The Bus Interface Unit Terminal Block, which included with the BIU, has connections for power

wiring and single or dual communications cables. It has built-in bus switching circuitry, allowing

the Bus Interface Unit to be used on a dual (redundant) Genius bus (no external Bus Switching

Module is needed). The Bus Interface Unit Terminal Block stores the configuration parameters

selected f or the station.

1

I/O Modules

Field Control I/O Modules are available in many types to suit a wide range of application needs.

Modules can be installed and removed without disturbing field wiring. One or two I/O modules

may be mounted on an I/O Terminal Block.

Micro Field Processor

The Series 90 Micro Field Pr ocessor ( MFP) is a Micro PLC that provides local logic within a Field

Control stati on . The Micr o Fi eld Processor is the same size as a Fi eld Control I/ O module and

occupies one of the eight available I/O slots in a Field Control station.

MFP features in clude:

Compatible with Logicmaster 90-30/20/Micro programming software, revision 6.01 or later.

Alarm processor

Password protecti on

Built-in communications port that supports Series 90 protocols (SNP and SNPX)

The Micr o F ield P roces sor requires a G e nius Bus In ter face Un it revision 2. 0 or later.

GFK-0825F Chapter 1 Introduction 1-3

Page 13

1

I/O Terminal Blocks and Auxiliary I/O Terminal Blocks

An I/O Terminal Block provides mounting, electrical, and field wiring connections. Each half of

the I/ O T erm in al Block can be mechanically keyed to accept only an I/O module of a sp ecific type.

Auxiliary I/O Terminal Blocks can be easily attached to an I/O Terminal Block. They can be used

to provide additional common terminals if needed.

For more information, please refer to:

Chapter 3: Installation

inst all the Bus Interface Unit modul e on the Field T er minal Block.

Chapter 2: Description

Block in detail.

Chapter 4, Operation

Chapter 5: Hand-Held Monitor Configuration

The

Series 90 Micro Field Processor User's Manual

Field Processor (IC670MFP100) and provides installation procedures, operation information, and

diagnos tics inf ormation .

The

Field Control I/O Modules User' s Manual

Terminal Blocks. This manual also explains module installation and field wiring.

, which explains wiring to the Bus Interface Unit, and explains how to

, which describes the Bus Interface Unit and Bus Interface Unit Terminal

, which explains how the Genius Bus Interface Unit services I/O.

, which explains how to configure I/O modules.

(GFK-1171), which describes the Micro

(GFK-0826) which describes I/O modules and I/O

1-4 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 14

Environmental Specifications

Vibration Modules per form well wh ere vibrat ion is a factor. Designs are shock and

vibration tested to meet the following specifications when installed on a

panel-mounted DIN rail using the clamp supplied, and with the panelmount ing feet secured:

IEC68-2-6: 10 to 57 Hz 0.012 in displacement (peak to peak)

IEC68-2-27: Shock: 15G, 11 milliseconds, half sine wave

Noise Modules are resistant to noise levels found in most industrial applications

when in s talled according to accepted p r actices, inclu ding proper s ep aration

of wiring by voltage and power levels, on a conductive (unpainted) DIN rail.

The DIN ra i l is an in tegr al part of the grounding system.

Modules are tested to the specifications listed in the Conformance to

Standards document (GFK-1079).

1

57 to 500 Hz at 2 g (unless otherwise specified)

Temperature Modules operate reliably in ambient air temperatures from 0 deg. C (32 deg.

F) up to 55 deg. C (131 deg. F).

Storage temperatures are -40 deg. C (-40 deg. F) to +85 deg. C (185 deg. F).

Humidity 5% to 95%, non-condensing.

For information about installing Field Control modules, please see:

Chapter 2 of this manual. It describes installation and wiring for the Bus Interface Unit module and

terminal block.

Chapter 2 of the

for modules and terminal blocks.

The individual module datasheets included in the

which provide specific module wiring information.

Chapter 2 of the

instructions for selecting and installin g a Genius bus.

Field Control I/O Modules User's Manual

Field Control I/O Modules User's Manual

Genius I/O System and Communications User's Manual

. It summarizes installation instructions

, which includes detailed

,

GFK-0825F Chapter 1 Introduction 1-5

Page 15

1

Configuration for Field Control

Configuration is an important part of the process of setting up a Field Control station. It establishes

the following features:

For the Bus Interface Unit:

Genius serial bus address

Baud rate for Genius bus communications

Faul t r eportin g to the host

Use of the Bus Interface Unit as a bus switching device in a dual (redundant) bus system

Redundancy mode for CPU redundancy

Configuration protection

For I/O Modules:

I/O addressing

Wheth er faults wi ll be reported to the host

Hold Last State for inputs or outputs

Output defaults

Range selection for analog modules

Scaling for analog modules

Alarm limits for analog modules

For a Micro Field Processor:

Reference a ddress e s

Data Lengths

A Bus Interface Unit and I/O modules can be fully configured using a Hand-held Monitor.

Optionally, a previously-configured Bus Interface Unit can be reconfigured using datagrams.

For more information about configuration, please refer to:

Chapter 5 of this manual (

HHM Configuration

(IC660HHM501J ) or later, can be used to configure a Bus Interface Unit. HHM configuration

instructions are given in chapter 5.

In addition, chapter 8 of this manual (

Datagrams)

Interface Unit can be completed or changed by sending it Write Configuration datagrams.

The

Series 90 Micro Field Processor User's Manual

Field Processor (IC670MFP100), and provides installation procedures, operation information, and

diagnos tics inf ormation .

If the system host is a Seri es 90™70 PLC, the Geni u s Bus Inter face Uni t m u st be incl ud ed in th e

system configuration as a d evi ce on the bus . P lease see the programming soft wa re documentati on

for instructions.

). A Genius Hand-held Monitor, version 4.6

explains how the configuration of a Bus

(GFK-1171), which describes the Micro

1-6 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 16

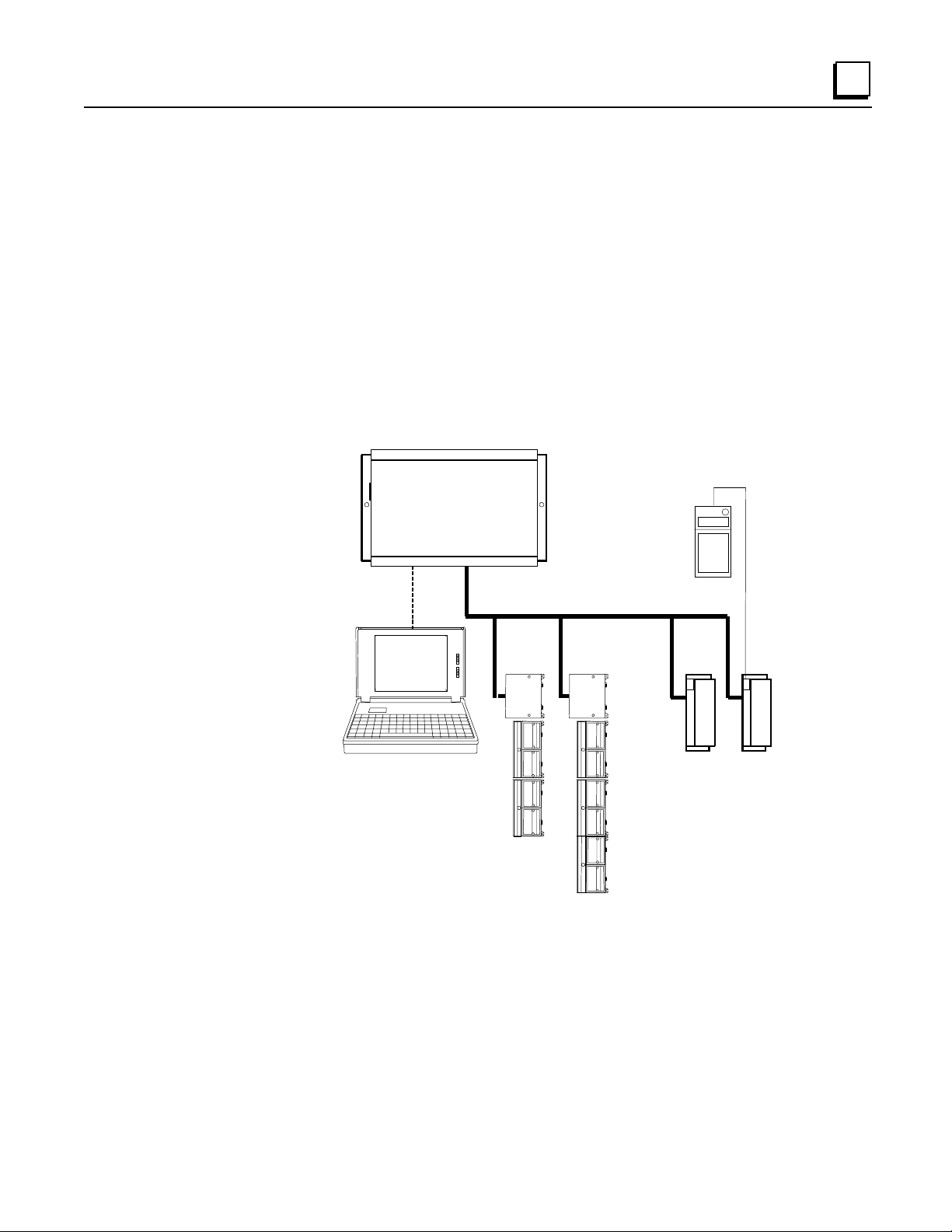

Field Control in a Genius System

Using Field Control modules on a Genius bus combines the low cost, small size, and flexibility of

Field Control with the versatility, power, and communications features of the Genius system.

The Genius bus is an industrially-hardened Local Area Network (LAN). It passes I/O (control)

data and background information (datagrams) between the Bus Interface Unit and a Genius bus

controller. A Genius bus can support up to 32 devices. Each Bus Interface Unit station counts as

one device on the bus, regard less of th e nu m ber or type of modul es present in the sta tion.

Oth e r devi c es on the sa me bus c a n be Field C ontr ol sta t ions , remote dr ops, I/O bloc ks, Bus

Controllers and Hand-held Monitors. Typical busses reserve one location for a Bus Controller and

one for a Hand-held Monitor, leaving 30 for additional devices. The illustration below shows a

Series 90-70 PLC connected to a Genius bus with I/O blocks and two Field Control stations.

Series 90-70 PLC

1

The Host CPU

The Genius Bus Inter face Unit is ideally suited for use with a Series 90-70 or Series 90-30 PLC.

However, any type of PLC or computer capabl e of c ontrolling a Genius bus can be us ed as the host .

Possible hosts in cl ud e Seri es Six PLCs, Seri es Fi ve PLCs, an d comput ers equip p ed with a PCIM

(Personal Computer Interface Module), QBIM (Q-Bus Interface Module), or a third-party GENIbased interfa ce modul e, in cluding several in DCS systems.

Hand-held

Monitor

Genius Bus

GFK-0825F Chapter 1 Introduction 1-7

Page 17

1

PCIM

A More Complex Field Control and Genius System

A more complex communications and control system is illustrated below. In this system, the Field

Control stations and Genius blocks on the lower left are controlled by a Series 90-70 PLC. The

Field Control stations and Gen i us blocks on the lower right are controlled by a host computer

equipped with a PCIM (Personal Computer Interface Module).

The PLC communicat es with a computer runn ing programming softwar e via an SNP (Serial

Network Protocol) link. And the PLC, host computer, and programmer computer exchange system

data vi a an Ethernet com munications link.

Series 90-70 PLC

SNP

Ethernet

Genius Bus

Genius Bus

For more information about Genius systems and communications, please refer to:

The

Genius I/O System and Communications User's Manual

operation, and communications formats.

, which describes Genius system

The

Bus Controller User's Manual

for the system host, wh ich inclu d es s p ecific system interfa ce

instructions.

1-8 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 18

Required Genius and Host System Equipment

The following system equipment is required:

Genius Hand-held Monit or version 4.6 (IC660HHM501J) or later.

For a Series 90-70 PLC

Series 90-70 CPU firmware, release 3.0 or later.

A Series 90-70 Genius Bus Contr oller, release 3.0 or later. The Bus Controller must be 4.0

or later for full diagnostics display from Logicmaster 90-70, or for redundancy

applications.

If Logicmaster 90-70 programming and configuration software is used, it must be

release 3.0 or later:

.

A

B

For a Series 90 30 PLC

Series 90 30 CPU firmware: any version.

Logicmaster 90-30 programming and configuration software: any version.

Series 90-30 Genius Bus Controller: any ver sion.

IC641SWP701F (3.5", 2DD, 5.25" 2S/HD)

.

IC641SWP704C (5.25" 2S/2D)

1

For a Series Six™ PLC

CPU: rev. 105 or later.

Logicmaster 6 Programming Software: release 4.02 or later.

Bus Controllers: IC660CBB902 or 903, version 1.7 or later.

For a Series Five™ PLC

CPU: rev. 3.2 (catalog number with E suffix) or later.

Logicmaster 5 Programming Software: release 2.01 or later.

Bus Controller: any version

For a Host Computer

PCIM: any version

QBIM: any version

GFK-0825F Chapter 1 I ntroduction 1- 9

Page 19

1

Using Field Control in a CPU Redund ancy System

Most systems use only one Bus Controller and CPU to control the I/O on the Genius bus. CPU

redundancy, which can be used for backup CPU/Bus Controller protection in critical applications,

is described in detail in the Genius documentation. The section that follows here summarizes how

Field Control product s can fit into a Genius CPU Redun dancy system.

CPU/Bus Controller Redundancy: Overview

In CPU redundancy, two Bus Controllers on the same bus can send control outputs at the same

time. Both Bus Controllers automatically receive i nputs an d fa u lt repor t s from all devi ces on the

bus that have been configured as being in “CPU Redundancy” mode. The Bus Controllers must

use serial bus addresses (devic e numbers) 30 and 31.

Field Control stations can be used on a bus controlled by redundant CPUs/Bus Controllers.

Bus

Controller

(Device 30)

How the two sets of outputs from the dual CPUs are handled by a Bus Interface Unit depen ds on

whether the Bus Interface Unit is set up for Hot Standby or Dupl ex redundancy.

contains any analog modules, the only form of CPU redundancy permitted is Hot Standby.

Bus

Controller

(Device 31)

If the station

46471

Hot Standby CPU Redundancy

A Bus Interface Unit con figured for Hot Stan dby mode is normally controlled by the Bus

Controller assigned to serial bus address 31. If no outputs are available from 31 for three bus

scan s, the Bus Inter face Unit accep ts outpu ts from the Bus Contr oller assigned to serial bus address

30. If outputs are not available fr om either Bus Controller, outputs go to th eir configur ed defaults

or hold their last state. In Hot Standby redundancy, Bus Controller -31 always has priority; when it

is on-line, it has control of the outputs.

Duplex CPU Redundancy

A Bus Int er face Unit configur ed for D u p lex mode compares outp uts it recei ve s from the two Bu s

Controllers, to determin e if they match. If corresponding outputs are th e same, th e Bus Interface

Unit set s the output to that state. If corres p onding outputs are not the same, the Bus Int erface Unit

sets the output to its config ur ed ON or OFF Duplex Default Stat e. If either Bus Controller stops

sending outputs to a Bus Interface Unit, its outputs are directly controlled by the r emaining Bus

Controller.

mode if the station contains any analog I/O modules.

1-10 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Only discret e I/O modules can operate in Duple x redundancy mode; do not use Duplex

Page 20

Using Field Control in a Genius Bus Redundancy System

In Geni u s bu s r edundancy, there ar e two bus cables ea ch connected to a Bus C ontroller. I/O

devices may be connected to either one bus of the pair, or to both. However, a device that is

connected to both busses actually communicates on only one bus at a time. Before the alternate

bus can be used for communication s, a bus switchover must occur and th e device must “log in”

with the Bus Controller (s) on the alternate bus.

The Bus Interface Unit Terminal Block contains a built-in bus switching r elay that is used to switch

busses in a dual bus system. Other types of devices with this capability ar e dedicated Bus

Switching Modules and Series 90-70 Remote I/O Scanner modul es. These are the only types of

devices that can be directl y connect ed to both redundant bus ca bl es .

A Bus Int er face Unit can not be used a s the BSM Contr ol ler for a bus stub. Other devices cannot be

located on a stub downstream of a BIU.

Also, the Bus Interface Unit should n ot be con nected to an externa l Bu s S wi t ching Mod u le.

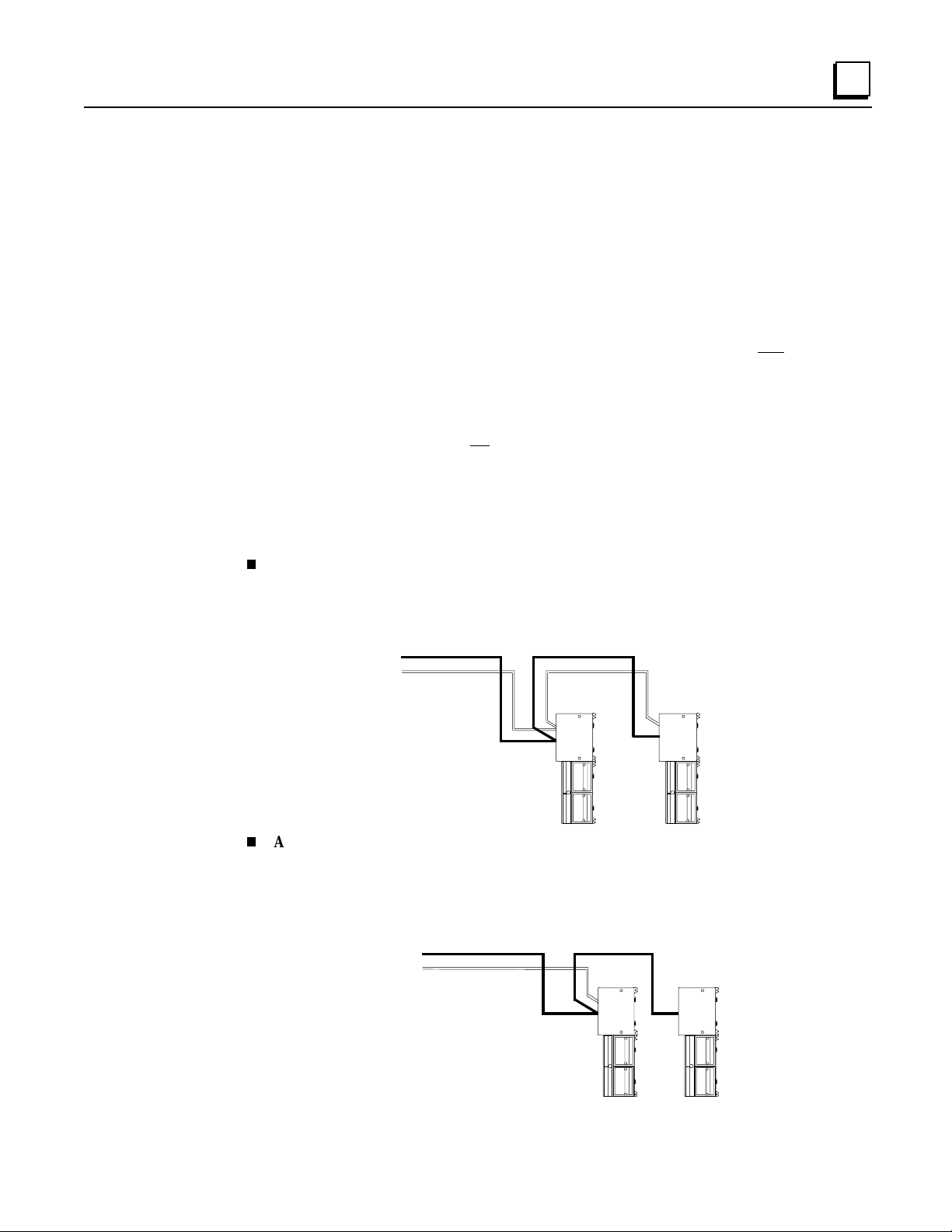

Redundant Bus Configurations

Many different redundant bus configurations are possible. T hree basic ways of using a Bus

Interface Unit wi th a r edundant bu s are descr i bed below.

1

A Bus Interface Unit can be installe d directly on both cables of the dual bus pair. The

Bus Interface Unit is configured to operate as a bus switching device in addition to perfor ming

its nor mal functions. Here, two Field Control stations ar e installed on a dual bus. Each Bus

Interface Unit would be set up as a bus switching devi ce.

Bus A

Bus B

A Bus Interface Unit can be located on just one bus of a redundant bus pair, i f bus

46472

redundancy is n ot needed for the modules in th at station . In this exam ple, the Bus Interface

Unit on th e left is connected to both Bus A and Bus B an d is configur ed as a bus swi tching

device. The Bus Interface Unit on the right, which serves non-critical I/O modules, is

conn ected to Bus A only, and is n ot configur ed as a bus switching device.

Bus A

Bus B

46473

GFK-0825F Chapter 1 I ntroduction 1-11

Page 21

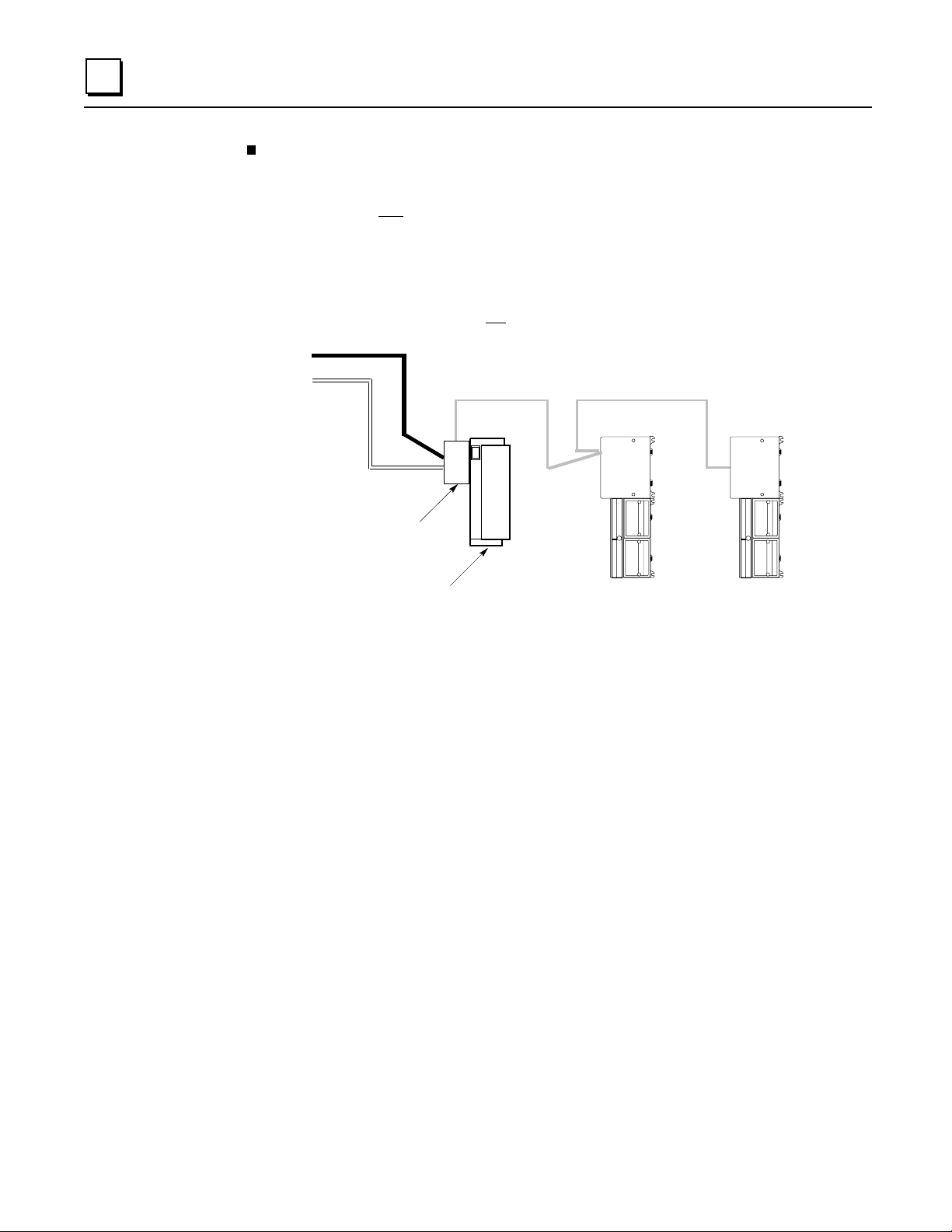

1

A Bus Interface Unit can be located on a bus stub.

A Bus Interface Unit can also be located

on a bus stub, which is a short length of unterminated cable downstream of either a Genius I/O

block/Bus Switching Module combination, or a Remote I/O Scanner connected to a dual bus.

Because the bus stub cable itself is not r edundant, this type of installation does not provide as

much protection as conn ecting directly to a dual bus. The bus switching device to which the

bus stub i s connected can be another Geni u s block wi th a Bus Swi tching Module atta ched, as

shown below, or a Series 90-70 Remote I/O Scanner.

In thi s ex ample, th er e are two Field Contr ol stations install ed on a bus stu b. Each is

configu red as “BSM Presen t” but not con fi g ured as a “BSM Controll er ”.

Bus A

Bus B

Bus

Switching

Module

Genius Block

Acting as a

BSM Controller

Up to 7 Additional Devices on the Bus Stub

46474

Up to seven device s (not counting th e BS M /block or Re mote I /O Sca nner to which the dua l bus is

connected) can be installed on a bus stub. Each device on a bus stub counts towar d the total of 32

devices on the Geniu s bus.

Restric tions on the number and length of bus st ubs that may be used on a dual bu s a re exp lained in

the

Genius I/O System and Communications User's Manual.

1-12 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 22

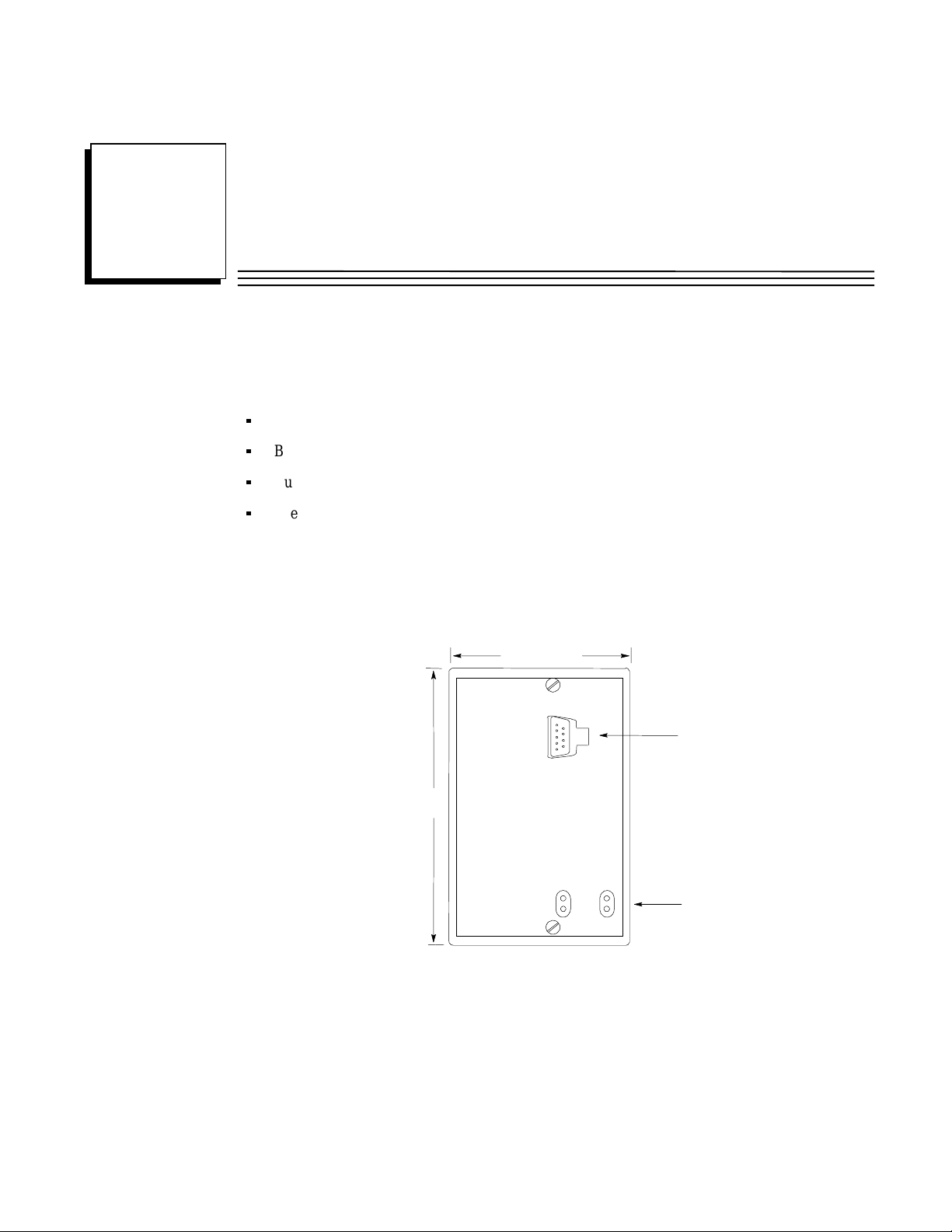

Chapter

2

Description

This chapter descr ibes:

Genius Bus Interface Unit

Bus Interface Unit Power Su pply

Bus Interface Unit Terminal Block

Specification s

Genius Bus Inter face Unit

The Genius Bus Interface Unit is a small, rugged, intelligent module with a sturdy aluminum

housing. The module has four status LEDs, described below, and a connector for attaching a

Genius Hand-held Monitor.

3.25" (8.2mm)

HHM

Connector

5.0" (12.7mm)

LEDs

The Bus Interface Unit contains th e logic power s u p pl y n eed ed to opera te the I/O modules

connected to it. It mounts on a separate terminal block, to wh ich it and all bus wiring are attached.

The configuration is stored in non-volatile memory located in the terminal block. Both the power

supply and terminal block a re described in this chapter.

The Bus Interface Unit has a replaceable 1A, 5x20mm 250VAC slow-blow fuse on the input power

lines. The fuse can be changed without disturbing the wiring of any other modules (instructions are

in chapter 3).

GFK-0825F 2-1

Page 23

2

LEDs

The LEDs on the Bus Interface Unit show its operating status.

BUS B PWR

RUN OK

ACTIVE

PWR

OK

lights to indicate that +5V power is available for logic oper ation.

lights to indicate that the module has passed its powerup diagnostic tests.

See the table below for more information.

RUN

lights only if output modules ar e in the BIU configuration and are written

to by the controlling bus controller . See the table below.

BUS B

if the Bus Interface Unit is installed on a dual (redundant) bus, this LED

lights if Bus B is the currently-active bus.

OK RUN Meaning

ON ON Module functioning, CPU communicating

ON OFF Modul e functioning, no CPU communications f or 3 bus scans

ON Blinking Module functioning, circuit forced

Blinking ON Circuit fault, CPU com m unic ati ng

Blinking OFF Circuit fault, no CPU communications for 3 bus scans

Alternate Bli nki ng Circuit fault, Circ ui t forced

Synchronous Blinki ng No CPU communications - block number conflic t

OFF Blinking Electronics/Terminal Assembly mismatch

OFF OFF No block power, or Block faulty

2-2 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 24

Bus Interface Unit Power Supply

The power supply in the Bus Interface Unit provides power for the Bus Interface Unit itself an d

logic power for all I/O modules that may potentially be installed at that station. External power

must be supplied for field wiring of input and output devices.

The power supply is not da maged by either of t he following:

Reversing input voltage on terminals 1 and 2.

Timing

Temporary

The Bus Interface Unit provides power to all I/O modules that are installed at the station. I/O

module operation is governed by a System Reset sign al to ensur e controlled operation during the

power up and sh ut down processes. As sh own in the timing diagram below, momentary power

losses of less than 10 mS (for 24VDC BIU) or 20mS (for 115VAC/125VDC BIU) do not affect I/O

module operation. Longer power losses generate a Reset for all system I/O modules.

overcurrent conditions on the 6.5 VDC output.

2

24VDC

Nominal

or 115 VAC

Nominal

6.5V Output

Input Power

On

RST*

Voltage

Overshoot

5% (max)

200mS

(min)

95% (min)

Minimum:

10mS for 24VDC BIU

20mS for 115VAC/12 5V DC BIU

Momentar y

Power

Loss

Hold

Up

Time

3mS

(min)

Voltage

Overshoot

5% (max)

200mS

(min)

Input Power

Off

Hold

Up

Time

10mS

(min)

3mS

(min)

GFK-0825F Chapter 2 Description 2-3

Page 25

2

Backplane Current

With a DC input voltage, the amount of current available to the backplane may be limited by lower

input voltage as indicated below.

Backplane

Current

Available

(Amps)

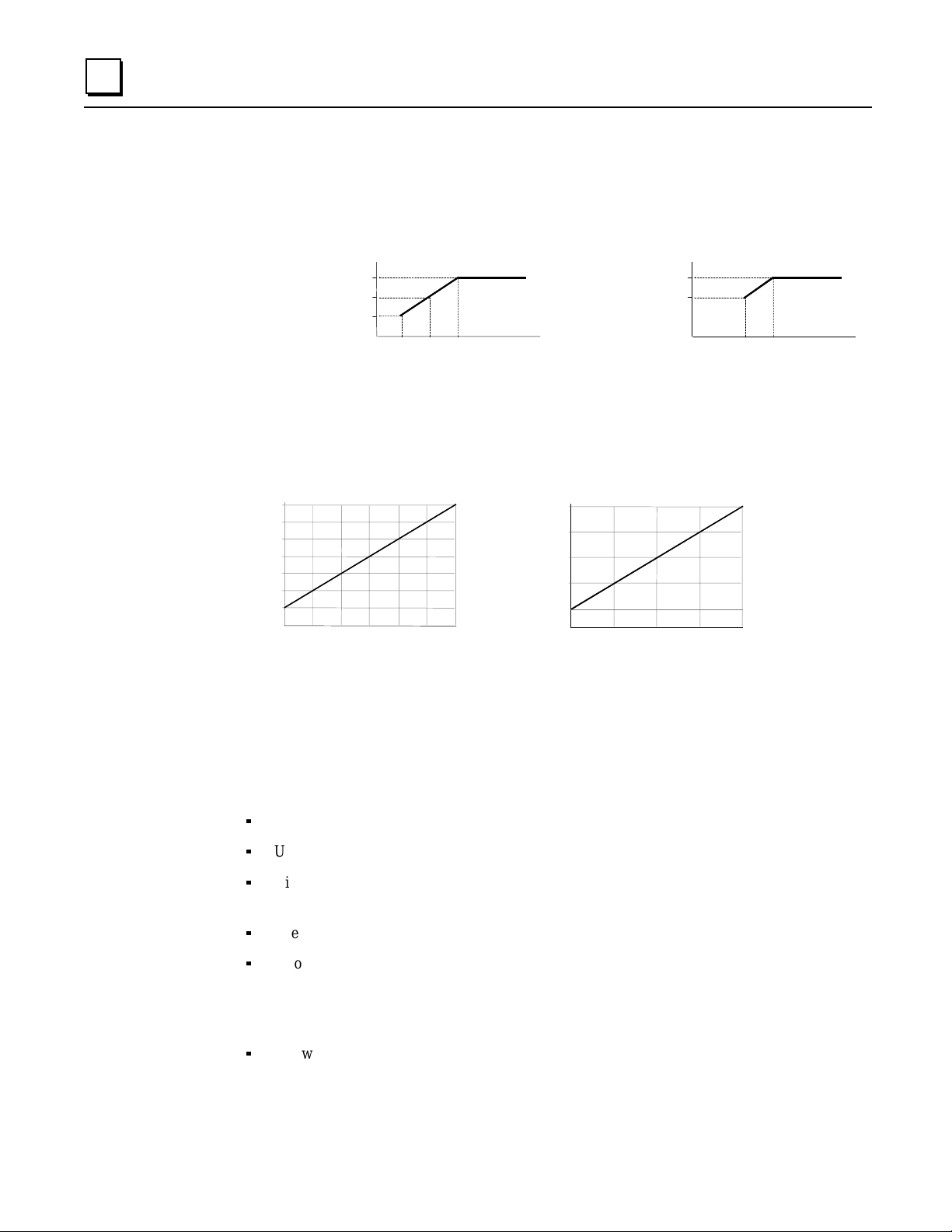

Calculating Input Power Requirements for a Bus Interface Unit

The charts below show typical input power requirements for a Bus Inter face Unit.

For 24VDC Bus Interface Unit

15.9

14.1

Typical

12.3

Input

10.0

Power

(Watts)

7.7

5.5

3.4

0.25 0.50 0.75 1.0 0 1.20 1.400

Total Backplane Cu r rent (Amps)

For 24VDC Supply

1.4

1.2

1.0

18

19

Voltage In

21

Typical

Input

Power

(Watts)

for DC

Inputs

For 125VDC Supply

Backplane

Current

Available

(Amps)

2.0

1.8

For 115VAC/125VDC Bus Interface Unit

24.0

18.75

13.5

8.25

3.0

0

0.50 1.501.00 2.0

Total Backplane Cu r rent (Volts)

105

110

Voltage In

48.0

37.75

27.5

17.25

7.0

Typical

Input

Power

(Volt/Amps)

for AC

Inputs

Note

For a 24VDC Bus Interface Unit, start-up surge at full load is 15-50 Amps for 3

milliseconds (maximum). For a 115VAC/125VDC Bus Interface Unit, startup

surge at full load is 20 Amps peak for 3mS.

To deter m ine speci fi c system requirem en ts:

Determine total output load from typical specifications listed for individual modules.

Use the appropriate graph of input power a bove to determine avera ge input power.

Divide the input power by the operating source voltage to determine the input curr ent

requirements.

Use the lowest input voltage to determine the maximum input current.

Allow for s t artup sur g e cur rent requirem en ts. Startu p surge curr ent levels are a function of

source impedance an d, therefore, are installation-dependent. Startup surge currents can vary

for approximately 3mS. For th e 24VDC Bus Interface Unit, variance is between 25A and 50A.

For the 115VAC/125VDC Bus Interface Un i t, startup surge current is 20A maximum peak.

Allow margins (10% to 20%) for variations.

2-4 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 26

Bus Interface Unit Power Dissipation

The Bus Interface Unit power dissip ation can be determined once th e ba ck p lane curr en t supplied to

the I/O modules is known.

The following equation can be used to calculate BIU power dissipation:

BIU Power Dissipat ion = Input P ower - (t otal back plane c ur r ent x 6.5 volts)

For exa mp le:

A. Total backplane cur rent = 0.5 Am ps

B. Typical Input power = 7.7 Watts

Therefore:

BIU Power Dissipat ion = 7.7 W - ( 0.5 x 6.5 ) = 4.45 Watts

2

GFK-0825F Chapter 2 Description 2-5

Page 27

2

Load Requirements for Hardware Components

The tabl e bel ow shows the DC load r eq u ired by each module an d har dware component. All r atings

are in milliamps. Input and Output module current ratings are with all inputs or outputs on. These

are maximum requirements, not typical.

Catalog Number Description Current (mAmps)

IC670MDD441 Mixed I/ O Module, 24 VDC 10 Inputs, 6 Outputs 110

IC670MDL233 Input Module, 120 VAC 8 Isolated Points 40

IC670MDL240 Input Module, 120 VAC 16 Grouped Points 77

IC670MDL241 Input Module, 16 Points, 2 groups 240 VAC 77

IC670MDL640 Input Module, 24 VDC 16 Grouped Pos/Neg Points 83

IC670MDL641 Input Module, 48 VDC 16 Grouped Pos/Neg Points 83

IC670MDL642 Input Module, 125 VDC 16 Grouped Pos/Neg Points 77

IC670MDL643 Input Module, 5/ 12 VDC 16 Point 80

IC670MDL644 Input Module, 12/24 VDC 16 Grouped Pos/Neg Fast Inputs 80

IC670MDL730 Output Module, 8 Pt 24 VDC Elect ronic Short Circuit Protection 125

IC670MDL740 Output Module, 12/24 VDC 0.5 Amp, 16 Grouped Pos. 111

IC670MDL742 Output Module, 5/12/24 VDC Negative Outputs 111

IC670MDL330 Output Module, 16 Point 12-120 VAC 16 Pt 1.0 Amp 285

IC670MDL331 Output Module, 120 VAC 2 Amp, 8 Isolated Points 154

IC670MDL930 Relay Output Module, 2 Amp, 6 Form A Points and 2 Isolated

Form C Points

IC670ALG230 Analog Current Input Module, 8 Grouped Points 51

IC670ALG240 Analog Input Module, 16 point Grouped 251

IC670ALG281 Analog Voltage Input Module, 8 Grouped Points 150

IC670ALG282 Analog Voltage Input Module, 16Grouped Points 150

HE670ACC100 Input Simulator Module, Horner 100

HE670ADC810 Analog Input Module, Horner, +/-10VDC, 0-10 VDC 131

IC670ALG620 RTD Input Module 190

IC670ALG630 Therm ocouple Input Module 195

IC670ALG320 Analog Current/Voltage Output M odul e, 4 Grp Points 51

IC670ALG330 Analog Current source Output Module, 8 Points 85

IC670MFP100 Micro Field Processor 111

IC693PRG300 Hand-held P rogram m er 170

313

IC660HHM501 Genius Hand-held Monitor 0

Hand-held Monitor and Hand-held Programmer

The Genius Hand-held Monitor (IC660HHM501), used for configuring and monitoring the BIU,

has it s own ba ttery and does not add to the load on the BI U.

However, if a Han d-held Programmer (IC693PRG300) will be attached to a Micro Field Processor

or other module in the I/O Station, it must be con sidered as a load component as listed above.

2-6 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 28

Hot Insertion/Removal of Modules

Bus Interface Un i ts IC670GBI002(F) and IC670GBI102A or later support Hot Insertion/Removal

of modules in the I/O Station.

Hot Insertion/Removal means that modules can be removed and replaced while I/O Station power

is applied without affecting the BIU or other modules in the I/O Station. Separate I/O module

power must be switched off to the module being inserted or removed.

Hot Insertion/Removal requires the use of specific modules and I/O terminal blocks:

• I/O modules having catalog num ber suffix J or above. These modules have a projecting

alignment tab that fits into a corresponding alignment tab on I/O Terminal Blocks listed below.

Note that modules with this tab can also be installed on older I/O Terminal Blocks that do not

have mating alignment tabs. However, Hot Insertion/Removal are not suppor t ed in such an

installation.

• I/O Term inal Blocks IC670CHS101, 102, or 103. These I/O Terminal Blocks have pr ojecting

alignment tabs designed to facilitate Hot Insertion/Removal of modules. Modules that are

earlier than r evi sion J cannot be mount ed on these ter minal blocks .

I/O Terminal Blocks IC670CHS001, 002, and 003, which lack alignment tabs, do not support

Hot Insertion/Removal of modules. With th ese terminal blocks, I/O Station power should be

off when installing or r emoving modules.

2

Mixing IC670CHS10x terminal blocks with IC670CHS00x terminal blocks in the same I/O

statio n is no t recommended.

Faults Reported During Hot Insertion/Removal

When using the recommended equipment listed above, Hot Insertion/Removal will cause the

expected fault reports r elated to the loss of or addition of the module and its I/O circuits. These

faults should be cleared in the normal manner. However, Hot Insertion/Removal of a r ev. J or later

module will NOT cause Configuration Mismatch errors that in some types of systems can sh ut

down the controller.

I/O Module Data During Hot Insertion/Removal

As men tioned, separate I/O module power must be turned off for Hot Insertion/Removal. When th e

module is installed and power is r eapplied, module data will quickly return to normal. For

intelligent I/O modules, there m a y be a delay of a few seconds while the m odule goes through its

powerup sequence.

Hot Insertion/Removal for a Micro Field Processor

A Micr o Field Processor that is r evision J or later may be removed/inserted as described above.

Note, however, that although the Micro Field Processor will start functioning upon reinstallation,

the MFP's applica ti on pr ogram must be rel oa ded . I/O data controlled by the Micr o Fiel d Processor

will be incorrect until that has been don e. (The BIU configuration of the Micro Field Processor is

not affected by Hot Insertion/Removal).

Hot Insertion/Removal Not Permitted in Hazardous Locations

In hazardous locations, I/O Station power must be turned off before inserting/removing module.

Failure to observe this precaution may result in personal injury, system malfunction and/or damage

to the eq u ipment.

GFK-0825F Chapter 2 Description 2-7

Page 29

2

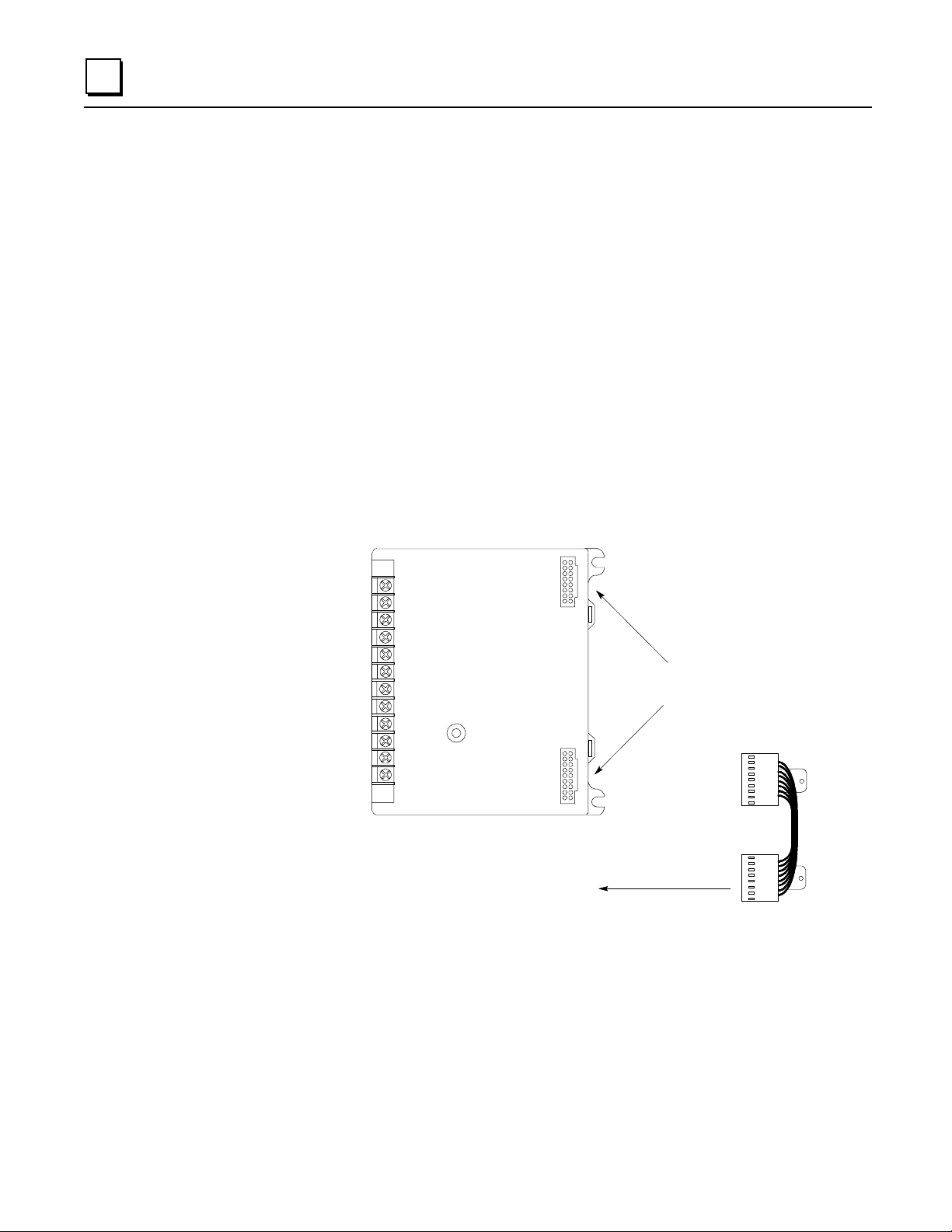

Bus Interface Unit Terminal Block

The Bus Interface Unit provides terminals for power and ground conn ections. Maximum wir e size

is AWG #14. (avg 2.0690mm2 cross-section).

The Bus Inter face Unit Terminal Block also has eight input terminals for connection to a single or

dual Genius bus. Th ese terminals accom modate up to two AWG #14 wires. The Bus Interface Unit

Terminal Block contains bus-switching circuitry per mitting it to be used

dual bus redundancy system.

A connect ing cable is provided wi th each I/ O Ter minal Block. It is used to connect th e Bus

Interface Unit Terminal Block t o the first I/O Terminal Block. The same type of cable

inter con nects su bseq uent I/O Terminal Blocks. The cable has molded connector s th at are keyed t o

assure prope r o rientation.

The Bus Interface Unit Terminal Block is designed to be extremely r eliable; it should not be

necessary to replace or rewire it after installation.

The Bus Interface Unit Terminal Block stores the configuration parameters for the station. The Bus

Interface Unit can be removed without removing the wiring or recon figuring the station.

as a BSM Controller

in a

Terminals for

power and

communications

wiring

I/O Terminal Block

Connectors

to next terminal block

46457

Connecting

Cable

2-8 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 30

Functi on a l Sp eci fi cations

Bus Interface Unit:

Reliability More than 183,000 hours operation MTBF, calculated

24VDC Power Supply Input

Nominal Rated Volt age 24 VDC

Voltage Range 18 VDC to 30 VDC

Power 16.8 Watts maximum at full load (nominal volt age)

Inrush Current 15-50 Amps peak, 3 mS maximum. Inrush current is installation

Power Supply Output

to I/O modules:

Holdup Time 10mS maximum from nominal input voltage.

115VAC/125VDC Power Supply Input

Nominal Rated Voltage 115 VAC, 125 VDC

Voltage Range 90 to 135 VAC, 105 to 150 VDC

Frequency (AC) 47 to 63 Hz

Power 115 VAC: 48VA maximum at full load (nominal volt age)

Inrush Current 20 Amps peak, 3 mS maximum.

Power Supply Output

to I/O modules:

Holdup Time 20mS maximum from nominal input voltage.

2

dependent. See page 2-4.

6.5 VDC ±5%

1.4 Amp maximum. See page 2-4.

125 VAC: 24W maximum at full load (nominal voltage)

6.5 VDC ±5%

2 Amp maximum. See page 2-4.

Bus Interface Unit Terminal Block:

Power Requirements 16mA maximum

Reliability More than 600,000 hours operation MTBF, calculated

For power requir ements of specific I/O modules, please see the

Manual

GFK-0825F Chapter 2 Description 2-9

, (GFK-0826).

Field Control I/ O Modules User's

Page 31

Chapter

3

Installation

This chapter descr ibes:

System Wi r ing Guid elines

System Grounding

Locations for Field Con trol Modules

Installing the Bus Interface Unit Terminal Block on a Panel

Installing the Bus Interface Unit Terminal Block on a DIN Rail

Installing the Cables Between Terminal Blocks

Power Wiring to the Bus Interface Unit

Connecting the Communications Bus

Installing/Removing the Bus Interface Unit

Removin g/Rep lacing the Bus Interface Unit Fuse

Upgrading the BIU firmware.

For more information, please refer to:

The Field Control I/O Modules User's Manual for information about in stalling I/O modules.

Appendix C, “The Genius Serial Bus” for a detailed description of the ch aracteristics of the Genius

bus.

GFK-0825F 3-1

Page 32

3

Preinstallation Check

Carefully inspect all shipping containers for damage during shipping. If any part of the system is

damaged, notify the carrier im mediately. The damaged sh ipping container should be saved as

eviden ce f or insp ection by the carrier .

As the consign ee, it is your res p onsibility to register a clai m wi th the carr ier for damage incurred

during shipment. However, GE Fanuc will fully cooper a t e with you, should such action be

necessary.

After unpacking the Field Control modules and other equipm ent, record all serial n umbers. Serial

numbers are required if you sh ould need to contact Product Service during the warranty period of

the equ ipment.

All shipping containers and all packing material sh ould be saved should it be necessary to transport

or shi p an y par t of the system.

Static Protection

The Bus Interface Unit ha s CMOS component s that ar e suscept i ble t o static dam age.

static handling techniques whe n handling this module.

Hand-held Monitor Connector

The connector on the Genius Bus Interface Unit is intended for use with a Genius Hand-held

Monitor only. It must be connected to a nonincendive circuit only.

Use proper

HHM (must be connected to

a nonincendive circuit only)

3-2 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 33

System Wiring Guidelines

Four types of wiring may be encountered in a typical factory installation:

1. Power wiring - the plant power distribution, and high power loads such as high

horsepower motors. These circuits may be rated from tens to thousands of KVA at 220

VAC or higher.

2. Control wiring - usually either low voltage DC or 120 VAC of limited energy rating.

Examples are wiring to start/stop switches, contactor coils, and machine limit switch es.

This is generally the interface level of the Genius discrete I/O.

3. Analog wiring - transducer outputs and analog con trol voltages. This is the in terface level

to Genius I/O ana log blocks.

4. Commun ications and signal wiring - the communications n etwork that ties everything

together, including computer LANs, MAP, and Geni us I/ O and commun ication s bus.

These four types of wiring should be sepa rat ed as much as possible to reduce the hazards from

insulation failure, miswiring, and interaction (noise) between signals. A typical PLC system with

Genius I/O may require some mixing of the latter three types of wiring, particularly in cramped

areas inside motor contr ol centers and on contr ol panels. In g en er al, it is accep table t o mi x the

communications bus cable with the I/O wiring from the blocks, as well as associated control level

wiring. All noise pickup is cumulative, depending on bot h the spacing between wires, and the

dist ance span th ey run together. I/O wires and comm unications bus cabl e can be placed random ly

in a wiring trough for lengths of up to 50 feet . If wiring is cord-tied (harnessed), do not include the

bus cable i n the harn es s, s ince bin ding wires tightly together increas es the coupling and mech an ical

stress that can damage th e relati vely soft insulation of some serial cable t ypes.

3

Wiring which is external to equipment, and in cable trays, should be separated following NEC

practices.

Installing Additional Suppression

It is possible some i nstall ations mi ght exceed the surge imm unity capa bilities specified in ch apter

1. This i s most likely in ou tdoor installations or where the powe r sou rce is from another bu ilding or

gr ound system. It is prud e nt to provide local transient prote c tion.

Appendix B describes installation of additional suppression at the power and communications

lines.

GFK-0825F Chapter 3 I nstallation 3-3

Page 34

3

System Grounding

All compone nts o f a control syste m and t he devices it contro ls must be properly

grounded.

central earth ground point as shown bel ow. This ensures that no ground conductor carries current

from any ot her bran ch.

Ground condu ct ors should be connected in a star fashion, with all bran ch es r ou t ed to a

Programming

Device

Each Terminal

Block

Motor Drives and

Other Electrical

Control

Equipment

Machinery

Earth

Ground

Central

Ground Point

connections not shown

NOTE

Signal and power

Each Field Control Terminal Block has a chassis ground terminal for safety and noise protection .

This terminal should be con n ected to th e conductive mounting panel with a 4-inch maximum

length of A W G #14 (avg 2. 1mm2) wire. Use ha rd wa re such as star washers t o ensur e ground

integrity.

The con trol panel and enclosu re shoul d al s o be bonded to the plant system ground per code.

Inadequate gr ounding may compromise system integrity in the presen ce of power switching

transients and surges.

3-4 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 35

Locations for Field Control

Field Control terminal blocks must be installed on a 35mm x 7.5mm DIN rail. Modules can be

loca ted on equipm ent, in junc tion box e s , insid e pa nel s , be hind operator stations, in NEMA

enclosures as little as 4" deep, and in other locations where space is limited. The area should be

clean an d free of airborne con taminants, with ad eq uate cooling air fl ow.

Modules can be mounted in any orientation without derating the temperature specification. They

can be installed in a linear stack as shown on the left in the following illustration, using the short

connection cables provided with each I/O Ter minal Block. An optional 21-inch (0.53 meter) cable

(IC670CBL002) is al so available. Only one 21" cable can be used per Field Control station.

All of the I/O Terminal Blocks in a group must be connected either at the top or the bottom of the

Bus Interface Unit (BIU in the illustration). A Bus Interface Unit may not be connected between

I/O Terminal Blocks.

BIU

3

46405

Install ing th e DI N Rai l

BIU

BIU

BIU

All Field Control Terminal Blocks must be mounted on a 7.5mm x 35mm DIN ra il. The rail must

have a conductive (unpainted) finish for proper grounding.

For best vibration resistance, the DIN rail sh ould be in stalled on a panel using screws spaced

approximately 6 inches (5.24cm) apart. When using multiple rail sections, be sure they are properly

aligned.

GFK-0825F Chapter 3 I nstallation 3-5

Page 36

3

Clamp

Screw

5.90in

4.25in

4.50in

5.00in

Wireway

4.31in

1.75in

Mount the DIN rail at least 4. 25 inches (10.80 cm) from any wireway or other obstruction

wiring side of the Bus Interface Unit.

Allow more space if th e wiring for I/O modules is very stiff.

on the

A wiring template is also provided in the instruction sheet included with each Bus Interface Unit

terminal block.

Drill mounting holes for the BIU Terminal Block as shown below. Allow a small tolerance

between the top and bottom of adjacent termin al blocks. After mounting the terminal blocks on the

DIN rail as descri bed on the followi ng pages, use #6 screws (not supplied) to attach them to the

panel. Length for all screws is 3/8 inch (9.525mm).

14.99cm

11.43cm

4.45cm

3-6 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

10.95cm

12.70cm

Page 37

Installing the Bus Interface Unit Terminal Block on the DIN Rail

1. Tilt the Bus Interface Unit Terminal Block and position it over the rail, as shown below left,

catching the rail behind the tabs in the terminal block.

2. Pivot the terminal bl ock downward until the spring-loaded DIN rail latches in the ter minal

block click into place.

12

DIN

tabs

3. Tighten the DIN rail clamp screw (see below left). Recommended torque is 4 to 6-in/lbs.

rail

3

Installing the BIU

Terminal Block

Tighten Loosen

Removing the BIU

Terminal Block

Removing the Bus Interface Uni t Term inal Block from the DIN Rail

1. Loosen the clamp scr ew.

Pry

Upper

latch

Pry

Lower

latch

2. Insert a small flat-blade screwdriver into the upper latch and pry it out ward. Then, pull up gen t ly

on the top of the terminal block to disengage the upper latch from the rail.

3. Keep gently pulling the top of the terminal bl ock away from the rail. Insert the screwdriver

into the lower latch and pry it outward to free the terminal block.

GFK-0825F Chapter 3 I nstallation 3-7

Page 38

3

Installing the Cables Between Terminal Blocks

Before instal ling modules on their terminal blocks, install th e con necting cable(s) bet w een terminal

blocks. A short connectin g ca bl e, as illustrated bel ow, is su p pl ied with ea ch I/O Termin al Block. A

set of three connecting cables is available as renewal part number IC670CBL001. Optional 21-inch

(0.53 meter) cabl e is also available (IC670CBL002) (only one 21" cable can be used per Field

Control station).

The illustration below shows cable connection between a Bus Interface Unit terminal block and an

I/O Terminal Block. Make connections between I/O Termina l Blocks in the same manner. The

conn ectors are k eyed to assur e proper in s tallati on .

Bus Interface

Unit Terminal

Block

I/O Term in a l

Block

Connector for Cable

to Next Device

After installing the cable, be sure it is firmly seated on both connectors.

Terminal

Block

Connection

Cable

3-8 Field Control™ Genius® Bus Interface Unit User’s Manual – October 1999 GFK-0825F

Page 39

Powe r Wiring to the Bus Interface Unit

Note: Do not apply power until the BIU module is in stalled on the Terminal Block.

1. Connect an appropriate power source as shown below.

3

Low Voltage

Connections

(IC670GBI002)

High Voltage

Connections

(IC670GBII02)

-

24 VDC

+

For BIU version IC670GBI102, if a DC supply is used the polarity is not important.

BIU version IC670GBI102 provides intern al overvoltage protection. Terminal 4 is normally

connected to frame groun d (terminal 3) by a factory-installed jumper. If overvoltage

protection is not required or is supplied upstream this feature can be disabled by removing the

jumper , leaving pin 4 unconnected.

2. Use one AWG #14 (2. 1mm2) or two AWG #16 (1. 3mm2) wires per t er minal. The wires into a

terminal should be the same type and size. Wires must be copper con ductors rated for

75 degrees C (167 degrees F) only. Suggested torque for the terminal screws is 9 in/l bs.

3. Connect the ground terminal to the conductive mounting panel with a 4-inch maximum length

of AWG #14 (a vg 2.1mm2) or larger wire. Use hardware such as star washers to ensure ground

integrity.

115VAC or

125VDC

GFK-0825F Chapter 3 I nstallation 3-9

Page 40

3

Connecting the Communications Bus

The Bus Interface Unit Terminal Block has a two sets of bus terminals. The terminals in the center

port ion of the ter min al block are for the main bus cable; they are always used.

The outermost set of bus te rminals is for an optiona l red undant (du al) bu s c able. The Bus Interface

Unit Terminal Block has built-in bus switching capability;

a dual bus application

.

do not attach a Bus Switching Module in

46462

Termin als accept one AWG #14 (2 .1mm2) or two AWG #14 (avg 2.1mm2 cross section) copper

75 deg. C

terminal should be the same t ype. The suggested torque is 9 in/lbs (1 Nm).

Bus Cables

Bus connections can be made using stan dard bus cables (cable specifications for the Genius bus are

detailed in Appendix C. Also see Appendix C for a discussion of the characteristics of the Genius

bus.

When making bus connections, the maximum exposed length of unshielded wires should be two inches

(5cm). For added protection, each shield drain wire should be insulated with spaghetti tubing to prevent

the Shield In and Shield Out wires from touching each other, or the signal wir es.

For applications using 150 ohm cables, prefabricated cables are availabl e in 15" (IC660BLC001)

and 36" (IC660BLC003) lengths. These cables terminate in mating connectors that simplify wiring

between I/O blocks. The 36" cable is recommended for Field Control installations.

Redundant Bus

Connections

(optional)

Main Bus

Connections

(167 deg. F) wires. Each ter minal can accept sol id or stranded wires . The wires on any

Serial 1

Serial 2

Shield In

Shield Out

Shield Out

Shield In

Serial 2

Serial 1

B1

B2

Bin

Bout

Aout

Ain

A2

A1

SHD

SHDINSER2SER

OUT

1

SHD

SHDINSER2SER

OUT

1