Page 1

GE Fanuc Automation

Programmable Control Products

GE Fanuc

Micro PLC

Programmer’s Guide

GFK-0804B April 1994

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL–002

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding

and operating the equipment.

This document is based on information available at the time of its publication. While

efforts have been made to be accurate, the information contained herein does not

purport to cover all details or variations in hardware or software, nor to provide for

every possible contingency in connection with installation, operation, or maintenance.

Features may be described herein which are not present in all hardware and software

systems. GE Fanuc Automation assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or

statutory with respect to, and assumes no responsibility for the accuracy, completeness,

sufficiency, or usefulness of the information contained herein. No warranties of

merchantability or fitness for purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alar m Master CIMST AR Helpmate PROMA CRO Series Six

CIMPLICITY Field Control GEnet Logicmaster Series One

Series 90 CIMPLICITY 90–ADS Genius Modelmaster Series Three

VuMaster CIMPLICITY PowerTRA C Genius PowerTRA C ProLoop Series Five

Workmaster

Copyright 1994 GE F anuc A utomation North America, Inc.

All Rights Reserved

Page 3

This book is the reference guide to programming the GE Fanuc Micro PLC.

Content of this Manual

Chapter 1. Programming for the Micro PLC: describes programming basics, the Micro

PLC instruction set, programming devices and formats, memory types and addresses,

constants and register values in a program, and special coils.

Chapter 2. Programming with the Programming Software: explains how to create and

edit programs using the programming software.

Chapter 3. Programming with a Hand-held Programmer: explains how to create and

edit programs using a Hand-held Programmer.

Chapter 4. The Micro PLC Instruction Set: explains in detail the instructions that can be

incorporated into an application program for the Micro PLC.

Appendix A. Using Directories: gives advice on organizing the Micro PLC directory structure

on your hard disk.

Pr eface

Appendix B. Micro PLC Protocol: the information in this appendix is for advanced users

only. It explains programming to set up communications between the Micro PLC and a

host system.

Appendix C. RTU Protocol: describes the Remote Terminal Unit (RTU) serial

communications protocol, which can be used to provide communications between the

Micro PLC or other remote device and a host computer.

Appendix D. Communications Using Windows DDE: describes an available software

product that can be used to connect DDE-compliant Microsoftt Windows programs

with data in a Micro PLC.

Appendix E. Data Acquisition, Logging, and Display Program: describes the Data

Acquisition, Logging, and Display Program software, which is provided on the Micro

PLC software diskettes.

Appendix F . Programming Applications: describes simple programming for: a flip-flop,

a powerup one-shot, cascading counters, and an industrial “starting circuit”.

Related Publications

GE Fanuc Micro PLC User’s Guide (GFK-0803): contains product specifications,

installation instructions, and general information needed to set up and use a Micro PLC.

GE Fanuc Micro PLC Self- T each Manual (GFK–0811): a quick-start guide to

understanding and using the Micro PLC.

GFK-0804

iii

Page 4

Preface

Technical Assistance

If you should have a problem installing or programming your GE Fanuc Micro PLC, and the

information you need is not in this book or the Micro PLC User’s Guide, you can call GE

Fanuc Field Service at 1-800-828-5747.

We Welcome Your Comments and Suggestions

At GE F anuc automation, we strive to produce quality technical documentation. A fter

you have used this manual, please take a few moments to complete and return the

Reader’s Comment Card located on the next page.

Jeanne L. Grimsby

Senior Technical Writer

iv

Micro PLC Programmer ’s Guide – April 1994

GFK–0804B

Page 5

Chapter 1 Programming for the Micro PLC 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Basics 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Programs 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Micro PLC Instruction Set 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Devices and Formats 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Types and A ddresses 1-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Constants and Register Values in a Program 1-6 . . . . . . . . . . . . . . . . . . . . . . . .

Special Coils 1-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming for an Analog Expander Unit 1-8 . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Programming with the Programming Software 2-1 . . . . . . . . . . . . . . . .

Using the Programming Functions 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Program Rung 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Programming Software 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Basics 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horizontal and Vertical Lines in a Rung 2-7 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Element Labels and Rung Labels 2-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing a Completed Rung 2-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting Rungs 2-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moving Rungs 2-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying Rungs 2-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Searching for a Rung or Program Element 2-15 . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Chapter 3 Programming with a Hand-held Programmer 3-1 . . . . . . . . . . . . . . . . . .

Program Listing 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Transfer 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Program Logic 3-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inserting a Rung Element 3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting a Rung Element, Rung or Program In Memory 3-5 . . . . . . . . . . . . .

Searching 3-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Examples Using the HHP 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 The Micro PLC Instruction Set 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instruction Set Summary 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacts 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normally-Open Contact 4-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normally-Closed Contact 4-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P ositive T ransition Contact 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Negative Transition Contact 4-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-0804B Micro PLC Programmer’s Guide - April 1994

v

Page 6

Coils 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Coil 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set/Reset Coil Pair 4-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Control Relay/End Coil Pair 4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Skip/End Coil Pair 4-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timers 4-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On Timer 4-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Off Timer 4-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Counters 4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Up Counter 4-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Down Counter 4-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Math Functions 4-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A ddition (ADD) 4-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subtraction (SUB) 4-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiplication (MUL) 4-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Division (DIV) 4-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Move Functions 4-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move 4-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Move 4-34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indirect Move 4-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compare Functions 4-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Operations 4-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W ord AND 4-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inclusive OR (IOR) 4-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exclusive OR (XOR) 4-43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

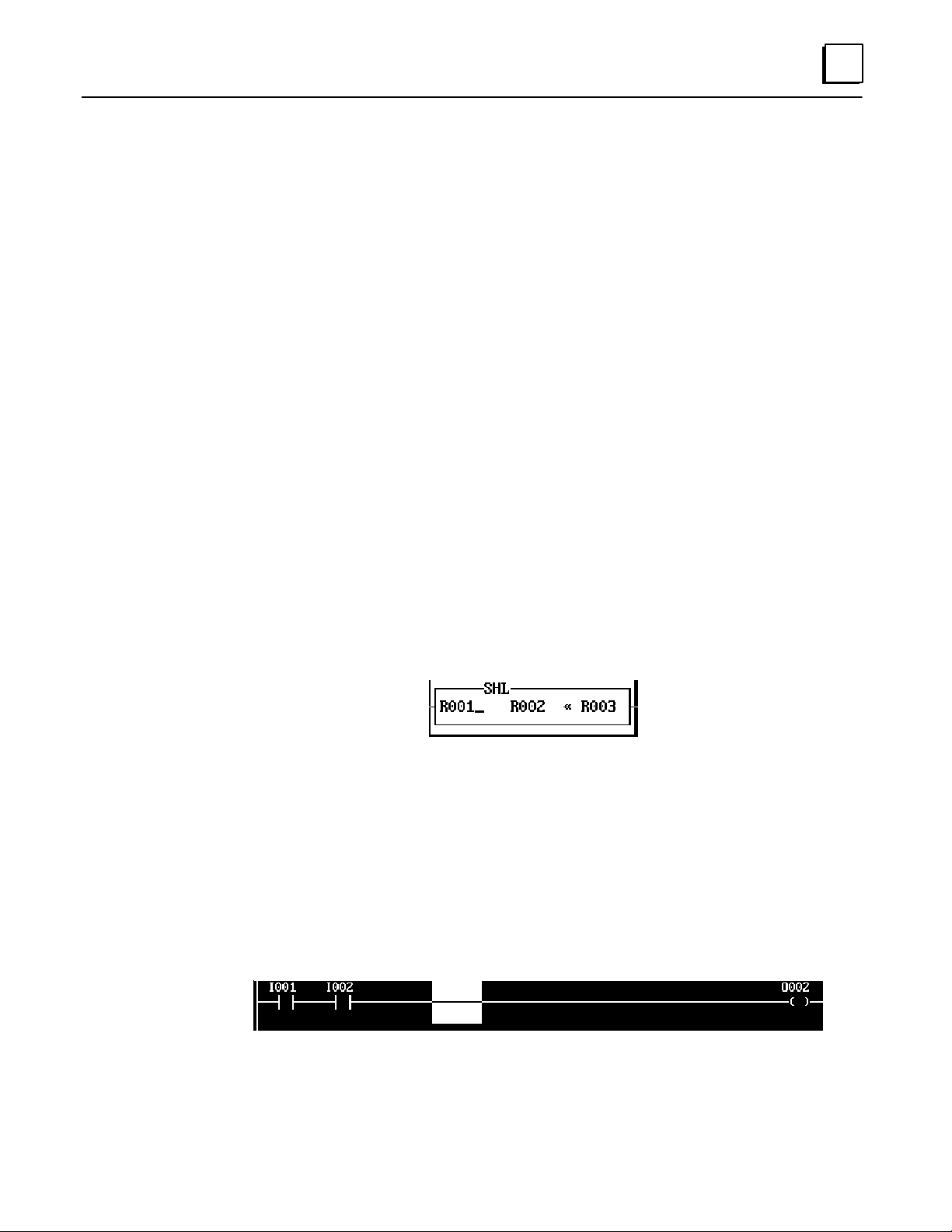

Shift Register Right 4-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Register Left 4-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NOT 4-46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-0804B Micro PLC Programmer’s Guide - April 1994

vi

Page 7

Appendix A Using Directories A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B Micro PLC Protocol B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Files B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Memory Types and Addresses B-3 . . . . . . . . . . . . . . . . . . . .

Communications Parameters B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Protocol B-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Format B-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Functions B-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C R TU Protocol C-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction C-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Types C-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Sequence C-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Fields C-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Format C-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Termination C-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timeout Usage C-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cyclic Redundancy Check (CRC) C-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RTU Message Length C-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Descriptions C-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (01): Read Output Table C-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (02): Read Input Table C-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (03): Read Registers C-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (04): Read Analog Inputs C-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (05): Force Single Output C-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (06): Preset Single Register C-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (07): Read Exception Status C-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (16): Preset Multiple Registers C-16 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message (17): Report Device Type C-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Errors C-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Invalid Query Message C-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Link Timeout C-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Invalid T ransactions C-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Appendix D Communications Using Windows DDE D-1 . . . . . . . . . . . . . . . . . . . . . . .

Features of the Micro PLC DDE Driver Software D-2 . . . . . . . . . . . . . . . . . . . . . .

Simple Demonstration using Microsoft Word D-3 . . . . . . . . . . . . . . . . . . . . . . . . .

Demonstration using Microsoft Excel D-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing PLC Data in Windows D-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing PLC Data in another DDE-compliant Application D-5 . . . . . . . . . . . . . .

Writing Values to the PLC from another Application D-5 . . . . . . . . . . . . . . . . . . .

Ordering Information D-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-0804B Micro PLC Programmer’s Guide - April 1994

vii

Page 8

Appendix E Data Acquisition, Logging, and Display Program E-1 . . . . . . . . . . . . . .

Features E-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Display Software with Micro PLC Net E-1 . . . . . . . . . . . . . . . . . . . . . .

Overview E-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required E-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup E-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Screen Colors E-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Summary E-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Mode E-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating or Editing Autopolling Screens E-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Messages E-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto-Polling During System Operation E-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Logging E-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages During Operation E-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Appendix F Programming Applications F-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application #1: FLIP / FLOP (Toggle Operation) F-2 . . . . . . . . . . . . . . . . . . . .

Application #2: Power Up One Shot (Start–up Protection) F-3 . . . . . . . . . . .

Application #3: Cascading Counters F-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application #4: Industrial “Starting Circuit” F-5 . . . . . . . . . . . . . . . . . . . . . . .

GFK-0804B Micro PLC Programmer’s Guide - April 1994

viii

Page 9

restart lowapp ARestart oddapp: ARestarts for autonumbers that do not restart in

each chapter . figure bi level 1, reset table_big level 1, reset chap_big level 1, reset1

Lowapp Alwbox restart evenap:A1app_big level 1, resetA figure_ap level 1, reset

table_ap level 1, reset figure level 1, reset table level 1, reset these restarts

oddbox reset: 1evenbox reset: 1must be in the header frame of chapter 1. a:ebx, l 1

resetA a:obx:l 1, resetA a:bigbx level 1 resetA a:ftr level 1 resetA c:ebx, l 1 reset1

c:obx:l 1, reset1 c:bigbx level 1 reset1 c:ftr level 1 reset1 Reminders for

autonumbers that need to be restarted manually (first instance will always be 4)

let_in level 1: A. B. C. letter level 1:A.B.C. num level 1: 1. 2. 3. num_in level 1: 1. 2.

3. rom_in level 1: I. II. III. roman level 1: I. II. III. steps level 1: 1. 2. 3.

Chapter 1 Programming for the Micro PLC

1

This chapter is an introduction to programming the Micro PLC.

H

Programming Basics

H

PLC Programs

h

P ower Flow in a Program

H

The Micro PLC Instruction Set

H

Programming Devices and F ormats

h

Programming with the Programming Software

h

Programming on a Hand-held Programmer

H

Memory T ypes and A ddresses

h

Memory Map

h

Non-retentive and Retentive Registers

h

Reserved Registers

h

Constants and Register Values in a Program

H

Special Coils

h

0.1 Sec Clock (C1018)

h

Start-up Scan Coil (C1019)

h

Hold Output Coil (C1021)

H

Programming for an Analog Expander Unit

h

Analog Scaling

h

Analog References

h

Programming Examples

GFK-0804B

1-1

Page 10

1

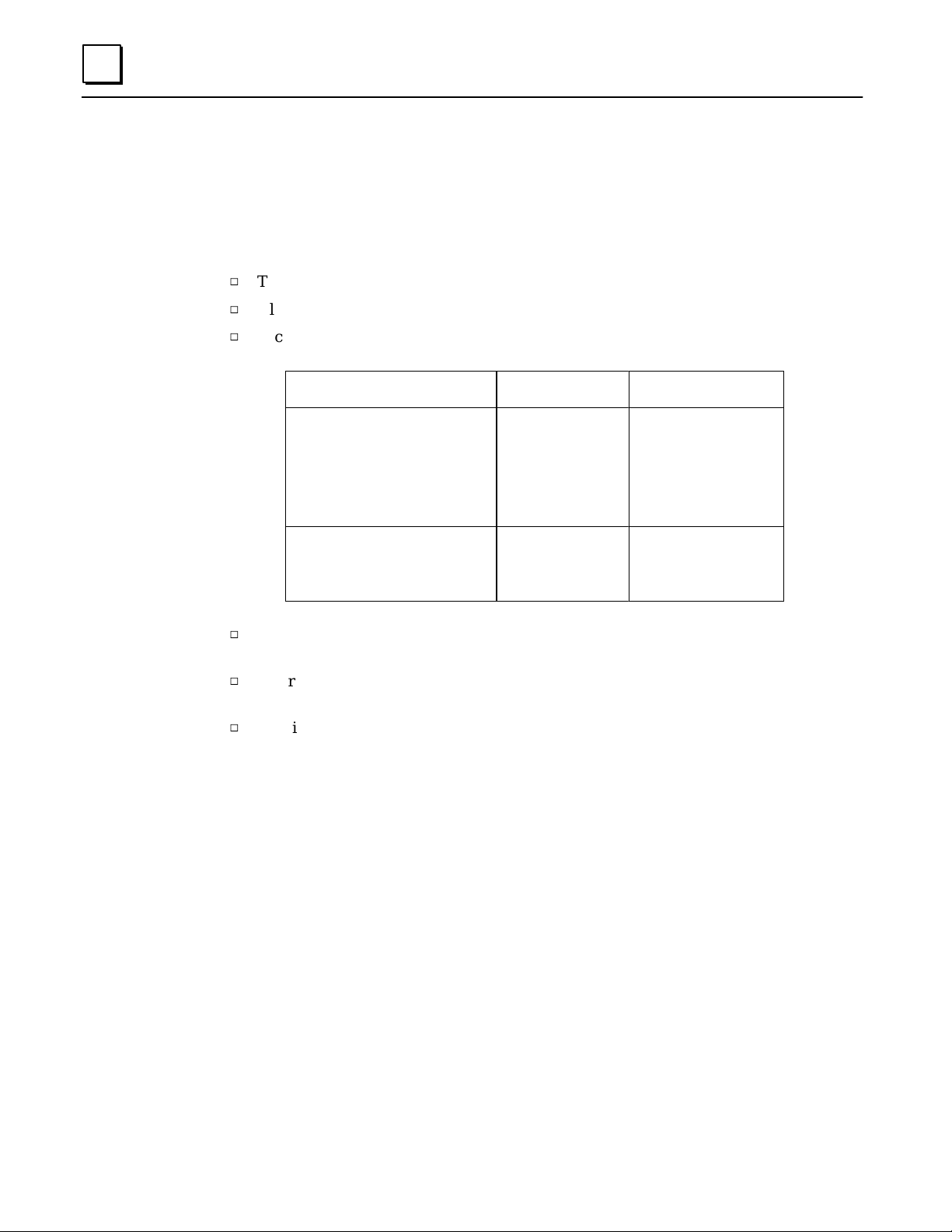

Programming Basics

The most important ingredients in creating a successful PLC program are a thorough

understanding of the application itself, and a good measure of common sense.

The first step in creating a PLC application program is planning.

h

The desired sequence of program actions is determined.

h

All of the required inputs and outputs are identified and listed.

h

Each input and output is associated with a PLC memory location. For example:

Device Designation Memory Location

Star t switch

Limit switch on conveyor line

Syrup tank #1, level detector

Syrup tank #2, level detector

Conveyor line optical sensor

Conveyor line motor star ter

Operator warning light

Signal to bottle capper

h

The program (like the short example program on the facing page) is created with a

Input 1

Input 2

Input 3

Input 4

Input 5

Output 1

Output 2

Output 3

Discrete Input Table 1

”2

”3

”4

”5

Discrete Output Table1

”2

”3

programming device and transferred to the PLC.

h

Before the system begins full operation, the program is tested and any corrections

that are needed are made.

h

The final version of the program is transferred to the PLC, and the application is

ready to go.

1-2 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 11

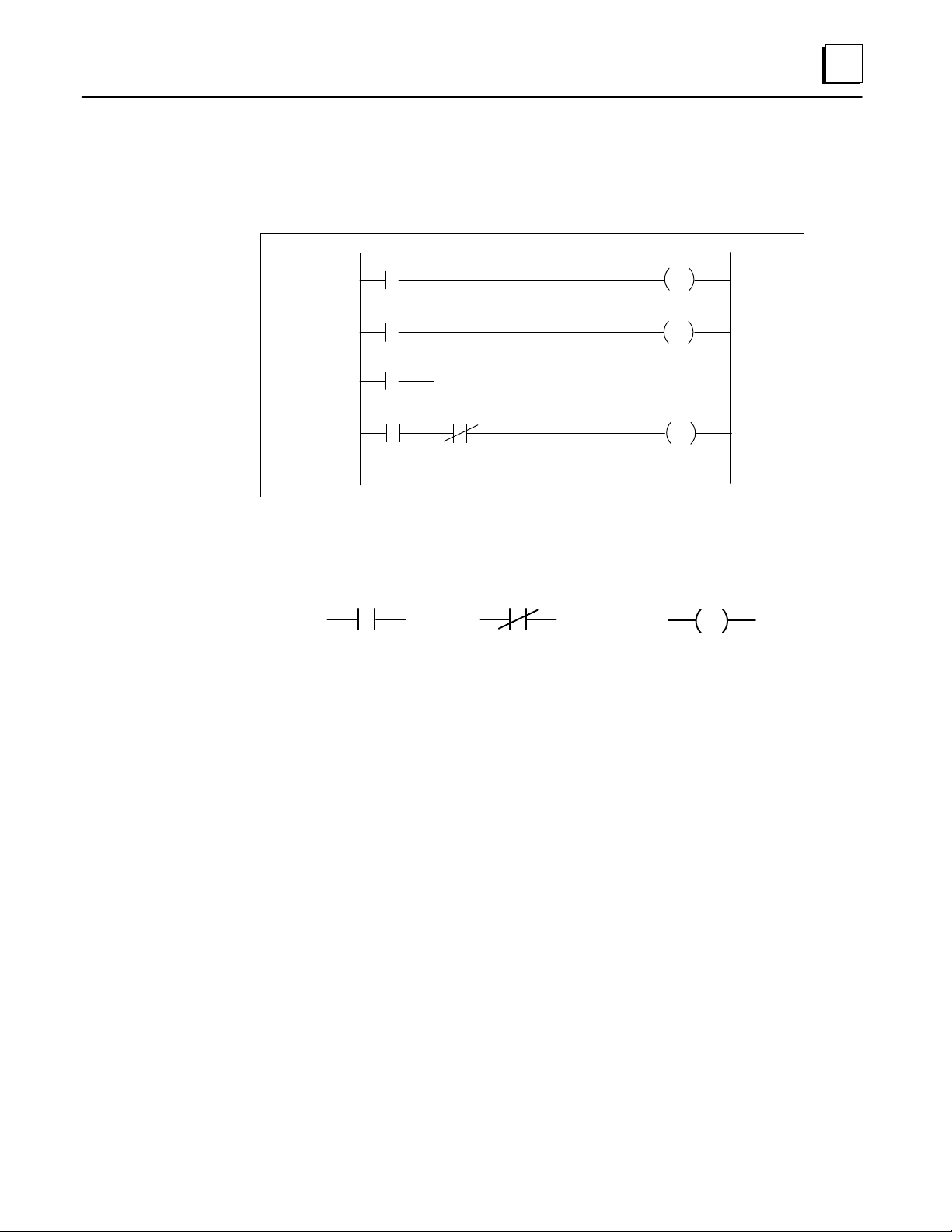

PLC Programs

A typical PLC application program is created in a format called ladder logic.

1

46101

Input 1

1

Input 2

2

Input 3

Input 4 Input 5

3

Output 1

Output 2

Output 3

Each symbol in the ladder logic represents a type of input, output, or other program

action. There are many types of symbols. The three symbols shown above are:

Inputs Output

normally–open

normally–open

contact

contact

normally–closed

contact

coil

46102

In the ladder logic, each line or group of lines that ends in an action being performed, such

as an output being sent, is called a rung. In the example above, there are three rungs.

Power Flow in a Program

The PLC executes the logic in the ladder from top to bottom, one rung at a time. Within

each rung, the execution flows from left to right. This movement of program execution

through the ladder can also be thought of as power flow. In the example:

Rung 1: Input 1 represents a switch. It is shown in the ladder logic program as a

“normally–open” contact. When the switch is turned on, the input 1 contact closes and power flows across rung 1 to the coil labelled Output 1.

Rung 2: Rung 2 begins at the left side with two lines of logic that lead to the same

output on the right. In this type of rung, which can have several lines

beginning on the left, the output is ON if any of the input lines can be

completed. In this rung, if either Input 2 or Input 3 is closed, Output 2 is

turned ON.

Rung 3: Rung 3 illustrates the use of multiple inputs in the same line of logic. All

of these inputs must be completed for the output to be ON. In this example, Input 4 must be closed (active), and Input 5 must be closed (inactive)

for Output 3 to be set to ON.

1-3GFK-0804B Chapter 1 Programming for the Micro PLC

Page 12

1

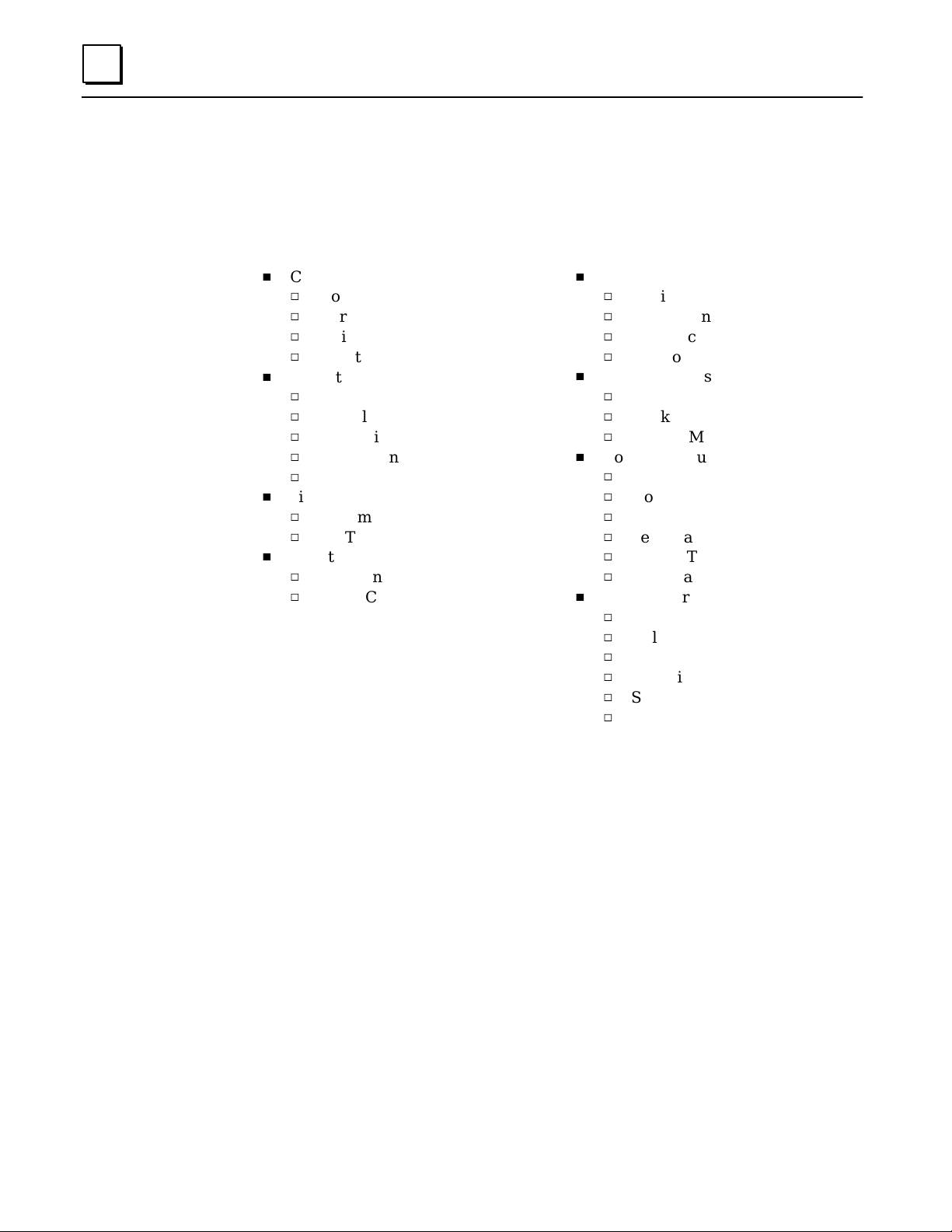

The Micro PLC Instruction Set

Programs for a PLC are created from the elements provided in its Instruction Set. The

Instruction Set for the GE Fanuc Micro PLC includes both basic relay-replacement

contacts and many advanced program functions:

H

Contacts

h

Normally-open Contact

h

Normally-closed Contact

h

P ositive T ransition Contact

h

Negative Transition Contact

H

Outputs

h

Output coil

h

Set coil

h

Reset coil

h

Master Control Relay

h

Skip/Jump

H

Timers

h

On Timer

h

Off Timer

H

Counters

h

Up Counter

h

Down Counter

H

Math functions

h

Addition

h

Subtraction

h

Multiplication

h

Division

H

Move functions

h

Move

h

Block Move

h

Indirect Move

H

Comparison functions

h

Equal

h

Not Equal

h

Greater Than

h

Less Than

h

Greater Than or Equal to

h

Less Than or Equal to

H

Logical operation functions

h

AND

h

Inclusive OR

h

Exclusive OR

h

Shift Right

h

Shift Left

h

Not

1-4 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 13

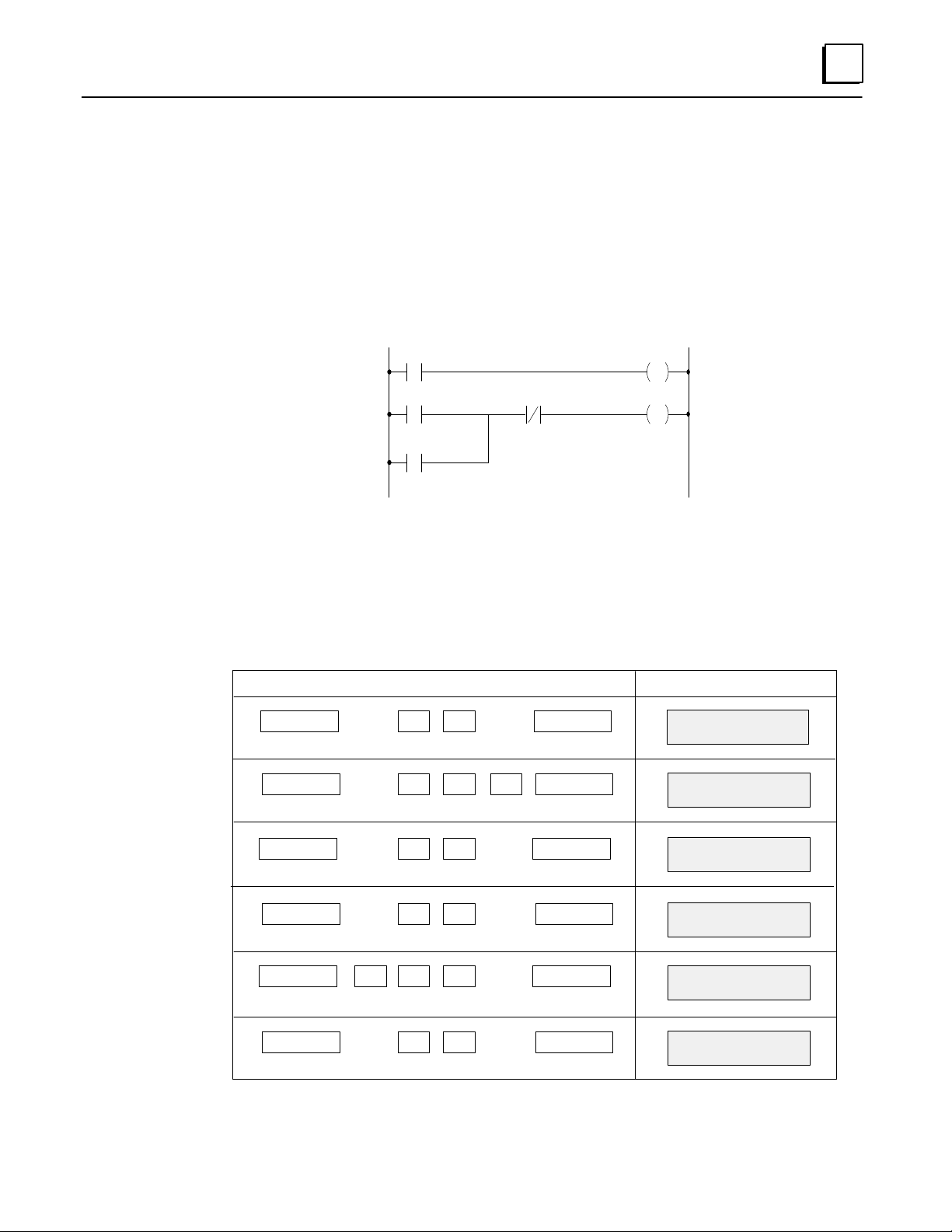

Programming Devices and Formats

Programs for the Micro PLC can be created using a computer that is equipped with the

programming software, or using a Hand-held Programmer.

Programming with the Programming Software

Programs created with the programming software are in traditional ladder logic format:

1

I0001

I0002

C0001

I0003 C0001

O0030

Chapter 2 describes programming with the programming software.

Programming on a Hand-held Programmer

Equivalent programs are easily created on the Hand-held Programmer. For example:

Key Operations HHP Displays

ISTART

OOUT

ENTER1

ENTER3 0

STA I001

Empty location

OUT O030

Empty location

46011

ISTART

COR

F3AND

COUT

ENTER2

ENTER1

ENTERI 3

ENTER1

Chapter 3 describes programming with a Hand-held Programmer.

ST A I002

Empty location

OR C0001

Empty location

AND NOT I003

Empty location

OUT C0001

Empty location

1-5GFK-0804B Chapter 1 Programming for the Micro PLC

Page 14

1

Memory Types and Addresses

Memor y Map

Type Total Non

Retentive

I

O

R

IR

OR

C

C

C

C

256 1 – 256 none no yes no no

256 1 – 256 none yes yes no no

512 1 – 384 385 – 512* no yes yes yes

256 1 – 256 no not applicable not applicable yes no

256 1 – 256 no not applicable not applicable yes no

1017 1 – 768 769 – 1017 yes yes no no

1 1018 0.1 sec clock for use as input in application program (read only).

1 1019 Startup scan coil for use as input in application program. (read only)

1 1021 Hold output coil for use in application program (read only).

Non-retentive and Retentive Registers

Data assigned to retentive memory is saved if power is removed from the Micro PLC.

Retentive

Use for Timer

or Counter

Coil?

General

Purpose

Internal Coil?

Use as

General

Purpose

Register?

Use as

Indirect

Register

Reference?

Non-retentive registers are cleared to zero when power is removed, and when the

Micro PLC is switched from Stop mode to Run mode.

* Reserved Registers

Retentive Registers 501 through 512 should not be used in your application program;

they are reserved.

Constants and Register Values in a Program

Many program functions for the Micro PLC use either constants, or variables in registers.

Constant values are limited to 32757 maximum. Single-register variables are limited to

65535 maximum.

1-6 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 15

Special Coils

The Micro PLC provides three special-purpose coils:

H

H

H

0.1 Sec Clock (C1018)

Coil C1018 is a pulse generator. The pulse width is shown below. This coil is a read-only

coil. It can only be used as a program input, not as an output.

1

0.1 sec clock

start–up scan coil

hold output coil

46103

Pulse

signal

50msec

0.1 sec

This coil should be used as a one-shot contact that feeds a regular coil.

Star t-up Scan Coil (C1019)

When the controller starts operating, this coil goes ON for one scan. It is a read-only coil.

It can only be used as a program input, not an output.

Run/power on

Stop/power off

1 Scan

46104

Hold Output Coil (C1021)

This coil can be used to control the state of the program outputs when the PLC is put in stop

mode. As a group, all of the outputs can either hold their last state, or be set to OFF.

If all outputs should hold their last state, set coil C1021 to ON (1).

If all outputs should be set to OFF, set coil C1021 to OFF (0).

Note: This function takes precedence over the Clear Data function of the programming

software (key F7 in the Online menu).

1-7GFK-0804B Chapter 1 Programming for the Micro PLC

Page 16

1

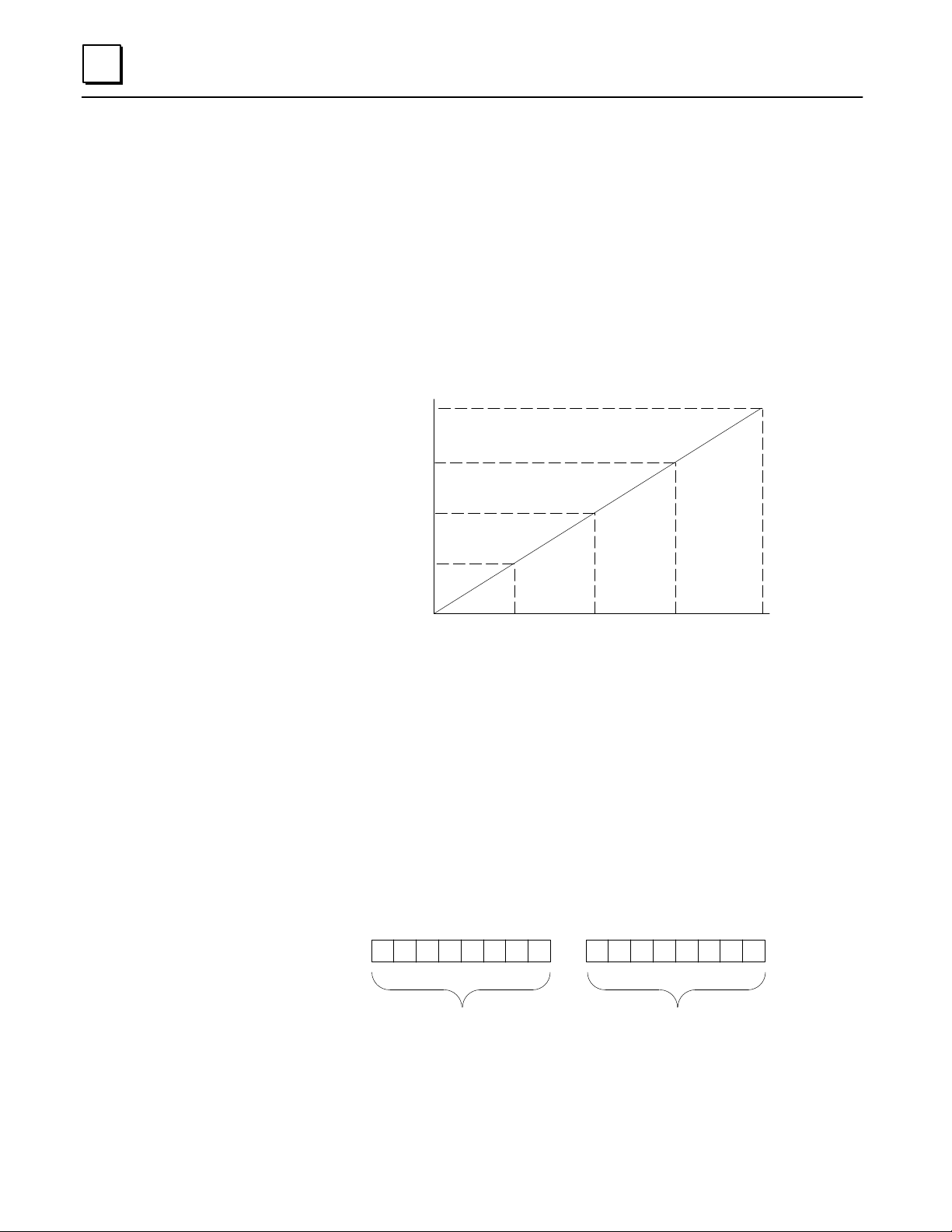

Programming for an Analog Expander Unit

Analog Scaling

The Analog Expander Unit provides two 8-bit analog inputs and one 8-bit analog output.

Scaling for an analog input or output is:

Minimum: 0 volts = 0mA = 0 bits

Maximum: 9.969 volts = 19.922mA = 255 bits

Some examples of equivalent values are:

V olts

9.969

7.5

2.5

5

0

0

12864 192

255 Bits

46190

Analog References

In a program, input 1 uses reference IR1. Input 2 uses reference IR2. The analog output

uses reference OR1.

Maximum Values

The program references (IR1, IR2, and OR) used to store analog data are 16 bits each.

However, the module utilizes only the lower 8 bits. Therefore, it is important not to

inadvertently program a value greater than 255, which would cause incorrect results.

For example, suppose you programmed an output value of 258. This is shown below in

bits. Because the module uses only the lower 8 bits, it would interpret the value

incorrectly.

00000001 00000010

Higher 8 bits not used

1-8 Micro PLC Programmer’s Guide – April 1994

Only these 8 bits are used

GFK-0804B

Page 17

Programming Examples

Two simple programming examples are shown below .

Example #1:

For an analog input, the program might read the input value and turn on a discrete

output when the analog input reaches a specific value. In this example, the program

compares the value of the first analog input (IR1) with a value stored in register R4. If

the analog input is greater than that value, then a discrete output (O18) is turned on.

O18

[IR1 > R4]

The output that is turned on might represent an actual output device such as a switch, or

a logical output that is used elsewhere in the program.

Example #2:

1

The logic below might be used for an analog output.

[R3 ! OR1]

In this example, each program scan, the Move function copies the content of register R3

to reference OR1, which is the reference used by the analog output.

1-9GFK-0804B Chapter 1 Programming for the Micro PLC

Page 18

Chapter 2 Programming with the Programming

2

Softwar e

This chapter explains how to create and edit a program using the Micro PLC

programming software.

H

Using the Programming Functions

H

Creating a Program Rung

H

Running the Programming Software

H

Editing Basics

H

Horizontal and Vertical Lines in a Rung

H

Element Labels and Rung Labels

H

Editing a Completed Rung

H

Deleting Rungs

section level 1 1

figure bi level 1

table_big level 1

H

Moving Rungs

H

Copying Rungs

H

Searching for a Rung or Program Element

See the Micro PLC User’s Guide if you need information about:

H

Software installation

H

Software functions

H

Changing to another directory

H

Loading a program file

H

Saving a Program File

H

Clearing a program from RAM memory

H

Printing an application program

H

Exiting the programming software

H

Setup parameters

H

Files and file-handling

H

Monitoring a program online in the PLC

GFK-0804B

2-1

Page 19

2

Using the Programming Functions

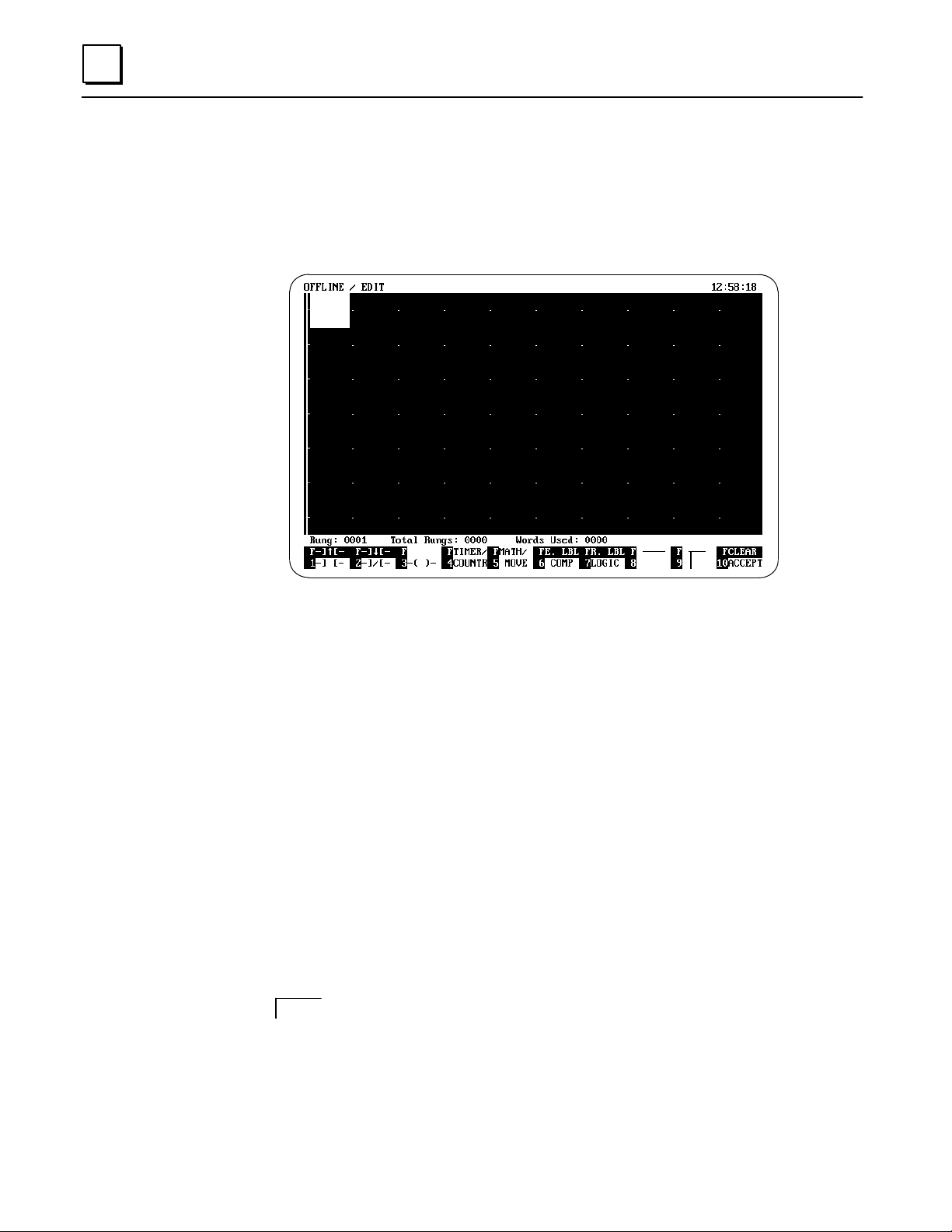

When you select Offline (F3) from the Main menu, the application program currently in

the computer’s RAM memory appears.

If there is no program currently in RAM memory, the screen looks lik e this:

The window shows the current rung, total number of rungs in the program, and

program size in words. If you want to quit the Programming window, use the ESC key.

Programming Operations

In the Offline window, use the function keys to select a programming operation.

Rung Create (F1) to create a new program rung

Rung Delete (F2) to delete a program rung

Search (F3) to search for a type of function or operand

Edit (F4) to edit the rung at the top of the screen. After pressing

F4, – moves the cursor within the rung. PgUp, PgDn

moves from rung to rung.

Rung Move (F5) to move a program rung

Rung Copy (F6) to duplicate a program rung

" Search (F7)

# Search (F8)

Label Display (F9) to toggle between absolute and symbolic display

Check (F10) to check program syntax.

to search previous rungs (search backward)

to search next program rungs (search forward)

2-2 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 20

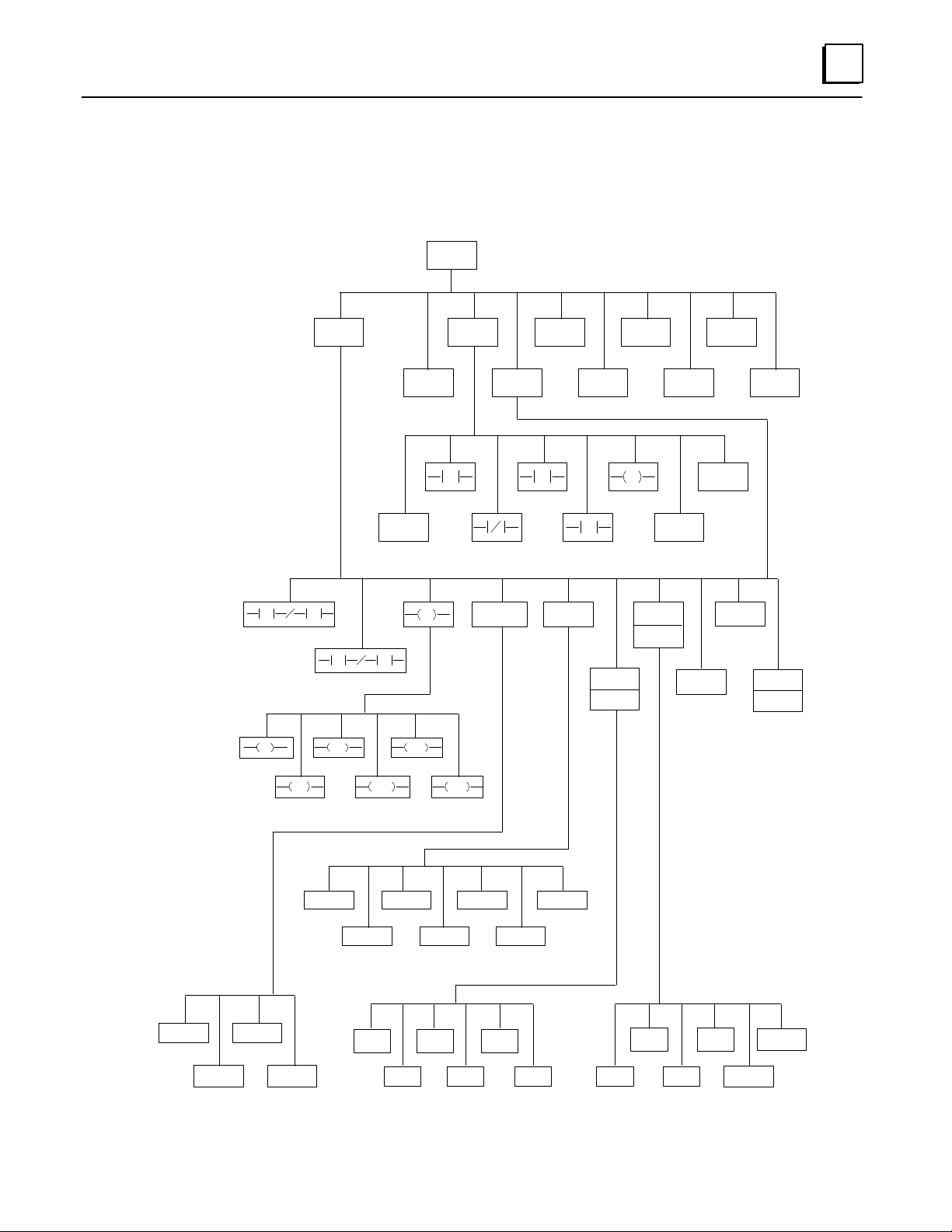

Programming Functions

2

46105

OFFLINE

RUNG

CREATE

RUNG

DELETE

SEARCH

RUNG MOVE SEARCH

EDIT RUNG COPY SEARCH CHECK

"

#

"

RUNG

"

#

MATH / MOVETIMER/COUNTER

REF

R LABEL

LOGIC

LABEL

DISPLAY

REF

VER T LINE

"

RST SKIP

E LABEL

COMP

HORI LINE

CLEAR

ACCEPT

ON TIMER

OFF TIMER

UP COUNTER

SET MCR END

( * ) MUL

( – ) SUB

.EQ.

DOWN

COUNTER

.NE.

MOVE

( / ) DIV B–MOVE

.GT .

.GE.

.LE.

I–MOVE( + ) ADD

SHIFT REG

LEFT

SHIFT REG

RIGHT

AND XOR

IOR.LT .

NOT

2-3GFK-0804B Chapter 2 Programming with the Programming Software

Page 21

2

Creating a Program Rung

Select Rung Create (F1) to create a new program rung. If there are already rungs in the

program, the new rung will appear at the top of the page.

You can now enter a program element in the highlighted location. Use the ESC key if

you want to return to a previous menu.

In the Edit window, use the function keys to select a program element.

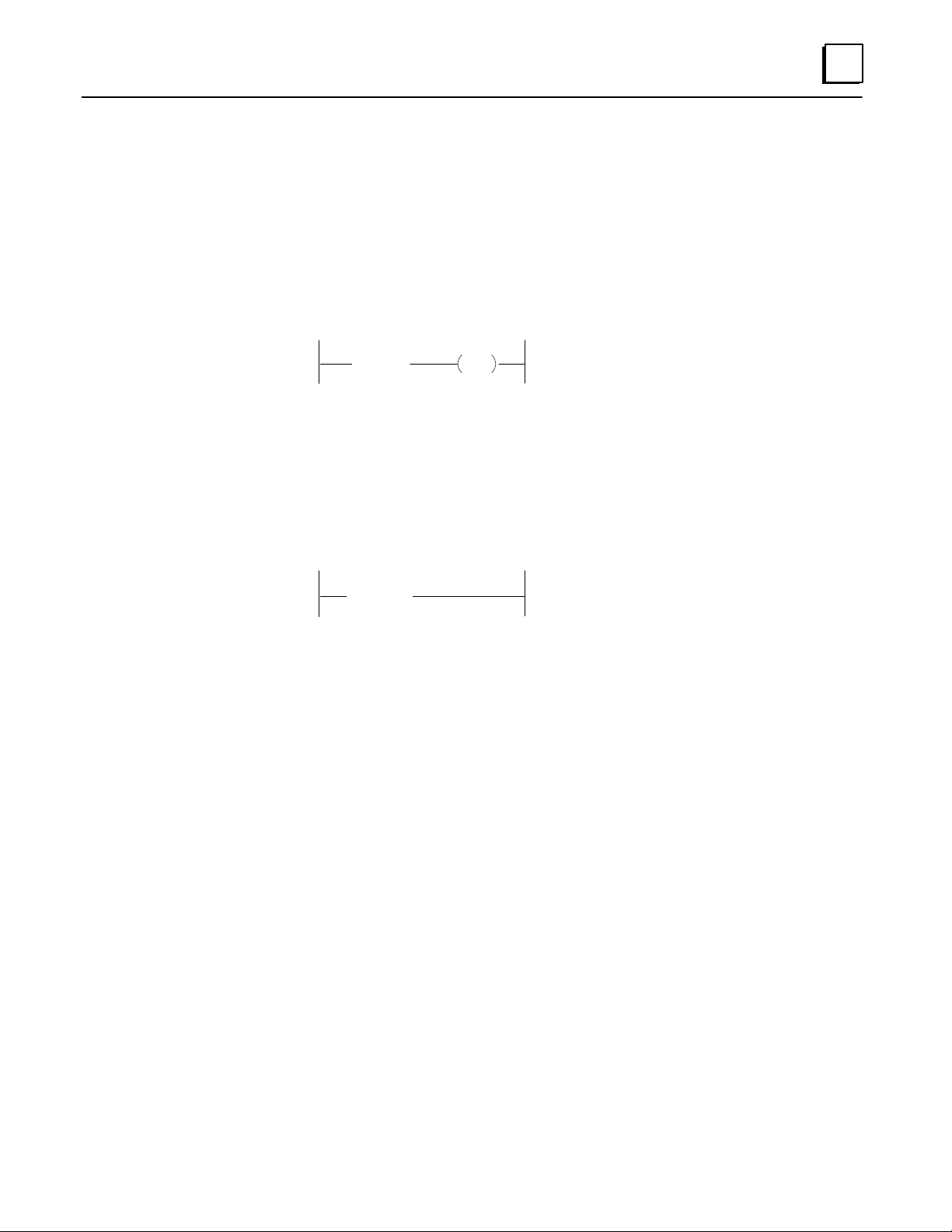

–| |– (F1) Normally-open contact. See page 4-4.

–| " |– (Shift, F1) Positive transition contact. See page 4-4.

–| / |– (F2) Normally-closed contact. See page 4-4.

–| #|– (Shift, F2) Negative transition contact. See page 4-4.

–( )– (F3) Output. See page 4-11.

Timer/Counter (F4) Timer or Counter. See pages 4-16 and 4-19.

Math/Move (F5) Math or Move function. See pages 4-22 and 4-30.

Comp (F6) Compare function. See page 4-36.

E. Lbl (Shift, F6) Element label. See page 2-8.

Logic (F7) Logic function. See page 4-38.

R. Lbl (Shift, F7) Rung label. See page 2-8.

________ (F8) Draw horizontal (serial) line. See page 2-7.

(F9) Draw or erase vertical (parallel) line. See page 2-7.

Accept (F10) Exit editing a rung. See page 2-6.

Clear (Shift, F10) Delete (clear) the rung being edited. Be careful.

Note: the Delete key on your keyboard will remove the

element at the current position in either Rung Edit or

Rung Create mode.

2-4 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 22

Running the Programming Softwar e

The programming software can be run from diskette, or installed on a hard disk. For

installation instructions and information about the files on the software diskette, refer to

the Micro PLC User’s Guide (GFK -0803).

Running the Programming Software from a Hard Disk

1. Go to the directory where you placed the MICRO.EXE file. For example:

C:>CD MICRO (Press the Enter key)

2. To run the programming software, type:

C:\MICRO>MICRO (Press the Enter key)

2

Running the Programming Software Directly from a Diskette

1. Go to the DOS prompt if it is not already displayed:

A:>

2. Place the diskette containing the programming software into the appropriate

disk ette drive (for e xample, drive A). To run the programming software, type:

A:>MICRO (Press the Enter key)

3. Place a formatted diskette into drive B. You can use this diskette for storing

configuration files.

2-5GFK-0804B Chapter 2 Programming with the Programming Software

Page 23

2

Editing Basics

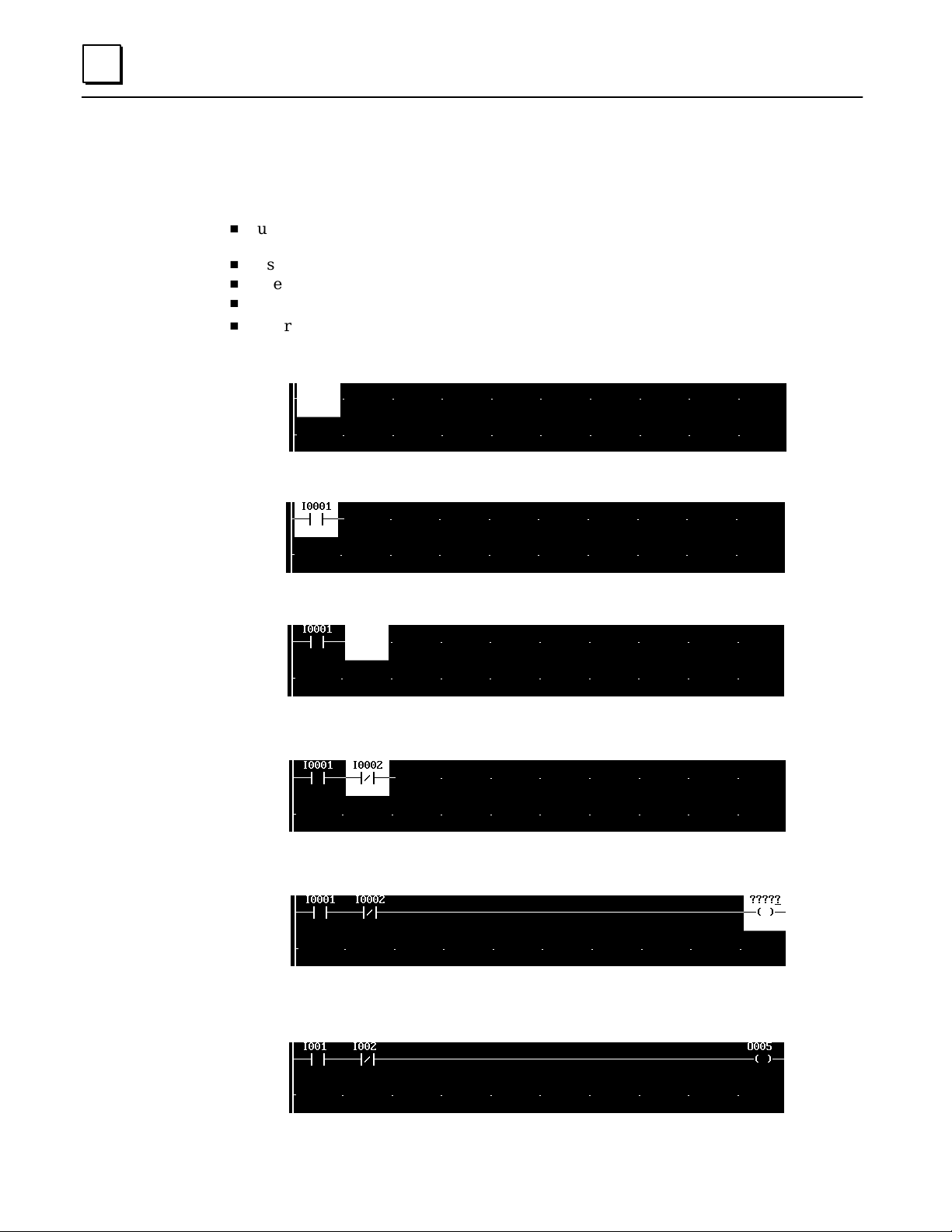

After selecting Rung Create (F1):

H

H

H

H

H

use the function keys to create an element and enter a reference value. For example,

“I2”. (Note that the element reference cannot be entered as “2I”).

use the cursor keys to move to another position in the rung being edited

use your keyboard Delete key to delete a rung element.

use your keyboard ESC key to quit a function or to return to the previous menu.

To create another r ung, press R ung Create (F1). The new rung appears.

Initial display:

Enter a function at the highlighted location. (Use the function keys)

Move the highlight box. (Use the cursor keys)

Enter the next function:

When you enter a coil, the highlight box automatically goes to the end of the rung:

After entering all the logic for the rung, use the Accept (F10) key to add it to the program. The

disappearance of the highlight box shows that the software is not presently in Edit mode.

2-6 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 24

Horizontal and Vertical Lines in a Rung

Horizontal and vertical lines are used to connect elements of a multi-line rung.

If a rung has more than one line of logic, move the highlight box down to the start

of the next line. Enter the first element on that line.

To add a horizontal line to the logic, move the highlight box to the location for the line.

2

Use the (F8) key to add the horizontal line.

Use the Delete key on your keyboard to remove a horizontal line.

To add a vertical line to the logic, move the highlight box to the end location for the line.

Use the (F9) key to add the vertical line.

Y ou must use the (F9) key to remove a vertical line.

2-7GFK-0804B Chapter 2 Programming with the Programming Software

Page 25

2

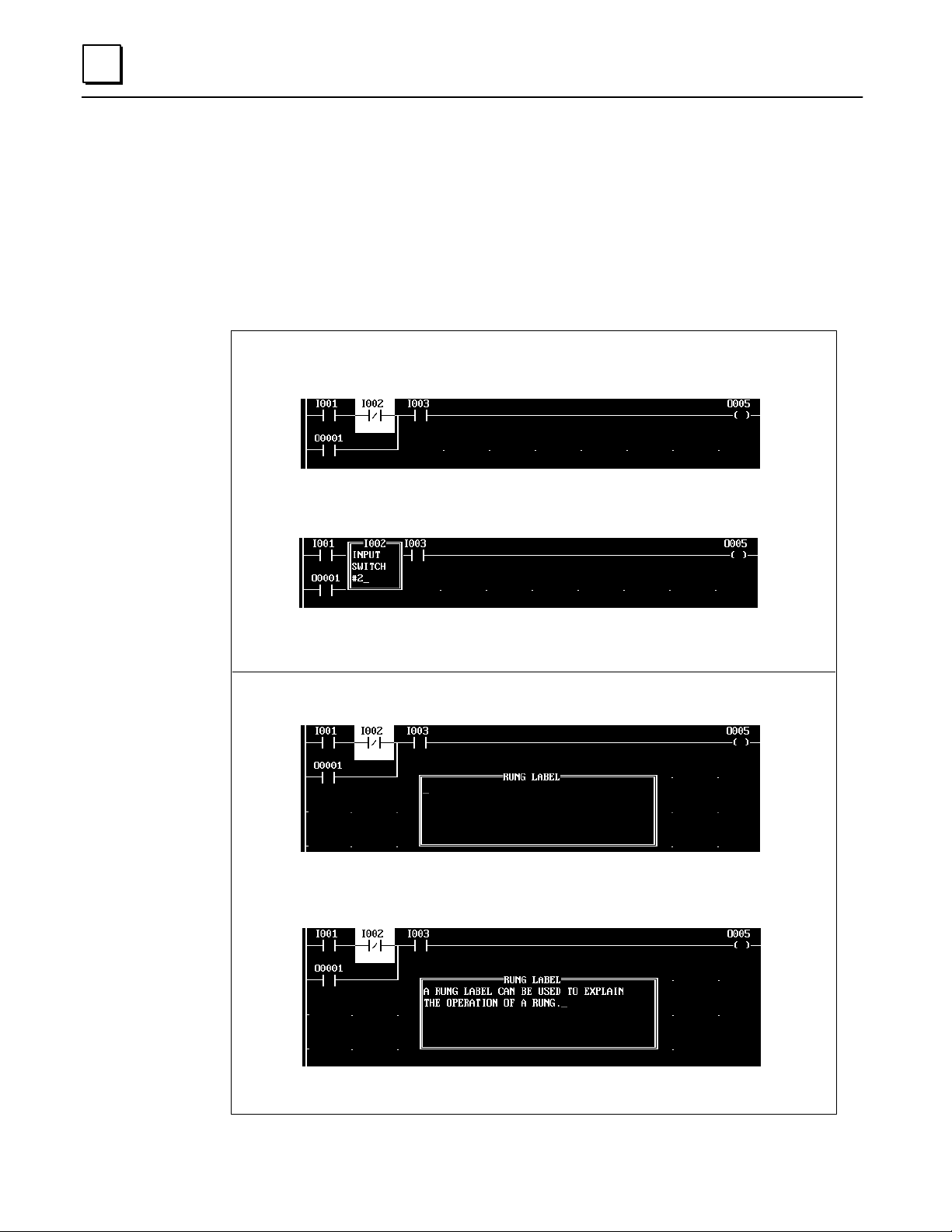

Element Labels and Rung Labels

Element labels and rung labels are text that can be added to a program and viewed in

Offline mode by selecting the Label Display function. Element and rung labels will also

appear in their entirety in a hard copy printout or a print to disk. The first 5 characters of

an element label can also be viewed in Online mode. (Think about this when selecting

the element label.) To create an element label or rung label, follow the instructions

below, in Edit or Create Rung mode.

To create a label for an individual element, move the highlight box to that

element. Press Enter to clear element edit. Then, press Shift, F6.

Enter the text for the element label. Pressing the Enter (return) key ends text

entry. Enter spaces if you want the label to have more than one line.

After you press the Enter key , the element label disappears.

To create a label for a rung, press Shift, F7.

Enter the text for the rung label. Pressing the Enter (return) key ends text

entry. Enter spaces if you want the label to have more than one line.

After you press the Enter key , the element label disappears.

2-8 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 26

Editing a Completed Rung

After using the Accept (F10) key to save a rung, the rung can be changed by selecting

Edit (F4) with the Offline function keys. The same basic programming features are

available in both Create mode and Edit mode. Refer to the previous descriptions of

program functions and editing techniques.

While editing a rung, you can delete, add, or change rung elements within the rung as

described below and on the following pages.

If you want to delete or move an entire rung, see page 2-13.

Selecting a Rung to Edit

To select a rung for display or editing, use the cursor keys to scroll the program up or

down on the screen. Or you can use the Search function to locate a specific rung,

element, or reference.

Bring the rung you want to edit to the top of the screen.

To edit the rung, use the Edit (F4) key. In Edit mode, you can add elements to the rung,

or edit the elements that are already there. You can then use the cursor keys to move

the cursor within a rung, and the PgUp, PgDn keys to move from rung to rung.

2

Editing a Rung Element

In Edit mode, the highlight box selects the rung element that can be edited.

Use the cursor keys to move to the highlighted box.

Enter the reference and address, then press the Enter key or a cursor key to go to the

next rung element.

Deleting a Rung Element

Delete the highlighted element by pressing the Delete key on your keyboard. (If the

small edit cursor is displayed in the highlight box, first press the Enter key to remove it).

This creates an empty space in the rung. If you do not want to add an element at that

location, insert a horizontal line (F8).

2-9GFK-0804B Chapter 2 Programming with the Programming Software

Page 27

2

Adding a Contact to a R ung

To add a contact to a rung, move the highlight box to the location for the new contact.

Add the contact using its function key. Enter a reference for the contact and press the

Enter key, or use the cursor keys to move to a new position.

Adding a Program Function to a Rung

If you want to add something other than a contact (for example, an Equal function) to a

rung, first create a space for it. Position the highlight box where the function should

begin, then press your keyboard Delete key. If the element to be added requires 2 or 3

consecutive spaces, move the highlight box, then press the Delete key again.

Move the highlight cursor back to the leftmost empty space:

Add the function using its function key. Edit the function as necessary.

2-10 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 28

2

Replacing a Rung Element with a Similar Element

To replace a rung element with a similar element (for example, to replace a normally-open

contact with a normally-closed contact), select the element with the highlight box.

Press the function key that corresponds to the new element type. Edit it if necessary.

Replacing a Rung Element with a Horizontal Line

To replace a rung element with a horizontal line, select it with the highlight box:

Then , select the horizontal line (F8).

2-11GFK-0804B Chapter 2 Programming with the Programming Software

Page 29

2

Replacing a Rung Element with a Dissimilar Element

To replace an element with an element of a different type (for example, to change a

normally-open contact to an Equals function), select the element with the highlight box.

First, delete the element by pressing the Delete key on your keyboard. (If the small edit

cursor is displayed in the highlight box, first press the Enter key to remove it).

This creates an empty space in the rung. If you do not want to add an element at that

location, insert a horizontal line (F8).

If you want to add an element at that location, use the appropriate function key to enter it.

You may need to delete more than one existing element to insert a new element if the

new element is wider than the element it is replacing.

2-12 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 30

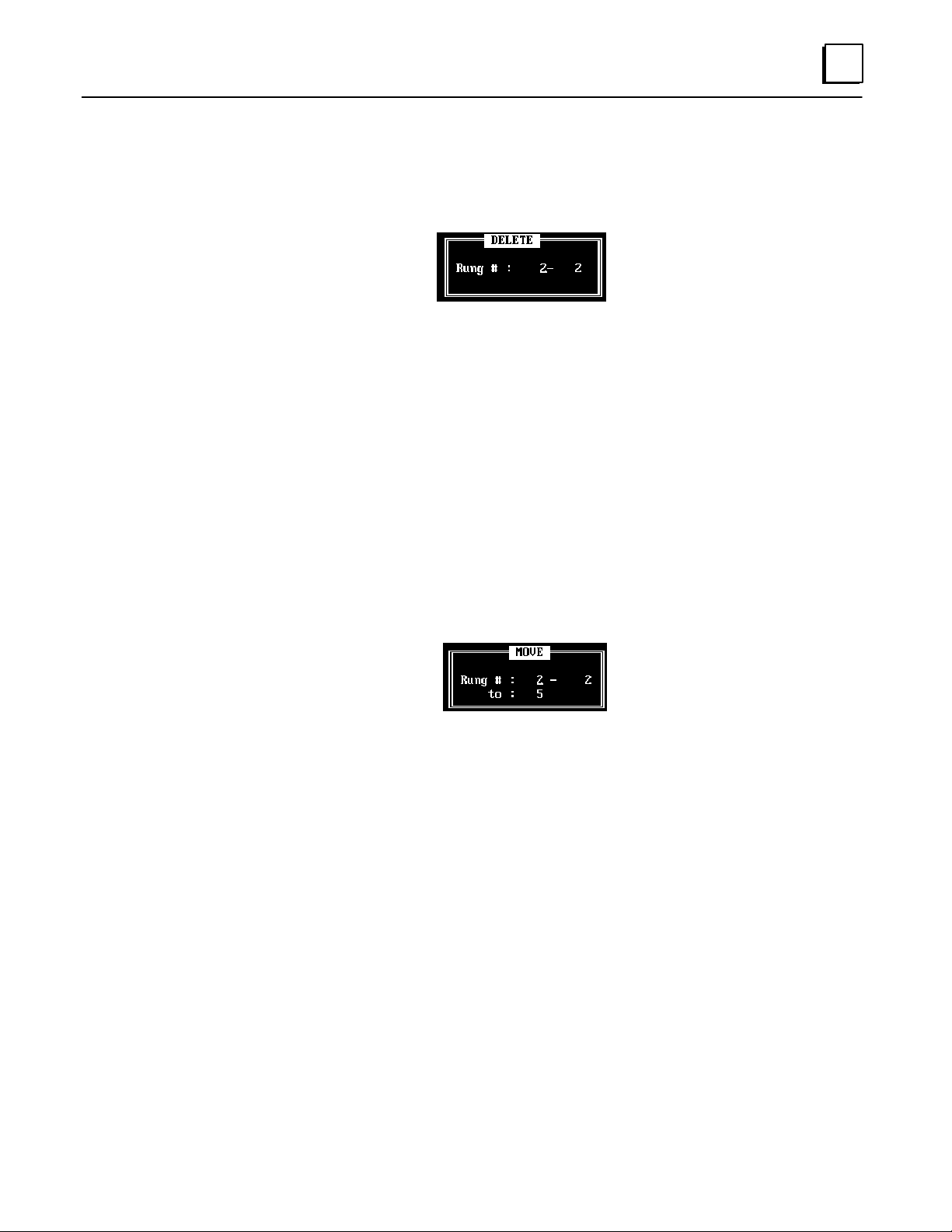

Deleting Rungs

To delete one or more rungs, use the Rung Delete (F2) key. The software prompts:

The first number that appears is the number of the rung that is now at the top of the

screen. If you want to delete just that rung, press the Enter key.

If you want to delete a different rung, or a group of rungs, enter their rung numbers

then press the Enter key.

If you want to quit the Delete function without deleting any rungs, press the ESC key.

2

Moving Rungs

You might want to move rungs to make a program more understandable, or to group

rungs together that work with each other.

To move one or more rungs, use the Rung Move (F5) key. The software prompts:

The first number that appears is the number of the rung that is now at the top of the screen.

Enter the numbers of the r ungs to be moved, and the number of the rung you want to

insert them in front of. Press the Enter key.

If you want to quit the Move function without moving any rungs, press the ESC key.

2-13GFK-0804B Chapter 2 Programming with the Programming Software

Page 31

2

Copying Rungs

You might want to copy rungs and then make simple changes to the rungs rather than

enter new rungs.

To copy one or more rungs, use the Rung Copy (F6) key. The software prompts:

The first number that appears is the number of the rung that is now at the top of the screen.

Enter the numbers of the rungs to be copied, and the number of the rung you want to

insert the copied rungs in front of. P ress the Enter key.

If you want to quit the Copy function without copying any rungs, press the ESC key.

2-14 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 32

Searching for a Rung or Program Element

You can search for a specific program rung, contact or coil, reference address, number , or

program function. Select Search (F3) in Offline mode, then use the function keys described

below to select the target of the search. Finally, use the " Search (F7) and # Search (F8) keys

to specify the search direction.

Rung (F1) rung number

Type in a rung number and

press the Enter key.

–] [– (F2) normally-open contact

–] / [– (F3) normally-closed contact

–] " [– (F4) positive transition contact

–] # [– (F5) negative transition contact

–( )– (F6) coil

2

Type in a reference address and

press the Enter key.

Ref (F7) reference

Type in a reference address and

press the Enter key.

Number (F8) number

Type in a number and

press the Enter key.

Func (F10) program function

Type in a number and

press the Enter key.

2-15GFK-0804B Chapter 2 Programming with the Programming Software

Page 33

Chapter 3 Programming with a Hand-held Programmer

section level 1 1

3

This chapter explains how use a Hand-held Programmer for programming the

GE F anuc Micro PLC.

H

Program Listing

H

Program Transfer

H

Entering Program Logic

H

Inserting a Rung Element

H

Deleting a Rung Element, Rung or Program In Memory

H

Searching

H

Programming Examples Using the HHP

figure bi level 1

table_big level 1

GFK-0804B

3-1

Page 34

3

Program Listing

To display the program listing, press the ENTER key from the powerup screen.

Program Transfer

To transfer a program, press the XFER key from the program listing screen.

PROGRAM START

Empty location

TRANSFER TO/FROM

PLC PROM PC

The Hand-held Programmer will transfer the program to or from the Micro PLC,

EEPROM, or the programming software in the computer.

3-2 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 35

Entering Program Logic

The steps below show how to create a simple example program.

Example Program

I0001

O0030

3

46011

I0002

C0001

I0003

C0001

Hand-Held Programmer Key Operation and Displays

h

use the ENTER key to accept a command.

h

On the display, “empty location” refers to the current unoccupied program line.

Key Operations HHP Displays

IST ART

OOUT

ENTER1

ENTER3 0

STA I001

Empty location

OUT O030

Empty location

ISTART

ENTER2

STA I002

Empty location

COR

ENTER1

OR C0001

Empty location

F3AND

ENTERI 3

AND NOT I003

Empty location

COUT

ENTER1

OUT C0001

Empty location

3-3GFK-0804B Chapter 3 Programming with a Hand-held Programmer

Page 36

3

Inserting a Rung Element

The steps below show how to insert an element in a simple example program.

Example Program

I1

O17

I5

"

In this example, the statement OR PTRAN I005 is inserted between the existing

statements:

AND NOT I003

OR PTRAN I005

OUT O017

I3

O17

I5

Element

added to the program as shown

"

46106

is to be

Hand-Held Programmer Key Operation and Displays

h

use the SRCH key to locate the ladder logic rung to be edited. The display selects the

last element in the selected rung.

h

Use the PREV key to select the previous element. In this example, it is:

AND NOT I003 (see below).

h

use the PREV key to scroll the program display backward.

h

use the NEXT key to scroll the program display forward.

Key Operations HHP Displays

SRCH

PREV

ENTER1

IOR

ENTER5F1

OUT O017

Empty location

AND NOT I003

OUT O017

OR PTRAN I005

OUT O017

3-4 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 37

Deleting a Rung Element, Rung or Program In Memory

The steps below show how to use the HHP’s delete function key to delete a program or

part of a program in memory.

Hand-Held Programmer Key Operation and Displays

h

use the SRCH key to locate the ladder logic rung to be edited. The display selects the

last element of the r ung. Use the PREV key to select a previous element.

h

use the PREV key to scroll the program display backward.

h

use the NEXT key to scroll the program display forward.

h

use the DEL key and F1 key to delete a program element.

h

use the DEL key and F2 key to delete a rung.

h

use the DEL key and F3 key to delete a program.

Key Operations HHP Displays

3

DEL

Delete the program element currently displayed.

DEL

Delete the program rung currently displayed.

DEL

Delete the current program.

F1

F2

F3

Elem Rung Prog

F1 F2 F3

DELETE

Elem Rung Prog

DELETE

Elem Rung Prog

DELETE PROGRAM

ENTER=YES, ESC=No

3-5GFK-0804B Chapter 3 Programming with a Hand-held Programmer

Page 38

3

Deleting a Rung Element

The steps below show how to delete an element of a simple example program.

Example Program

I5

I6

I3

I1

O17

I1

Element

removed from the program

as shown.

AND NOT I003

OR PTRAN I005

OUT O017

Hand-Held Programmer Key Operation and Displays

h

use the SRCH key to locate the ladder logic rung to be edited. The display selects the

last element of the r ung. Use the PREV key to select a previous element.

h

use the DEL key and F1 key to delete a program element.

h

use the PREV key to scroll the program display backward.

h

use the NEXT key to scroll the program display forward.

46107

is to be

Key Operations HHP Displays

SRCH

PREV

DEL

F1

3-6 Micro PLC Programmer’s Guide – April 1994

ENTER1

OUT O017

Empty location

AND I1

OUT O017

AND NOT I003

OUT O017

GFK-0804B

Page 39

Searching

3

Use the SRCH key to locate a rung, element, or operand in a program. The steps below

show how to search for an operand, element, or rung umber, or the start or end of the

program.

Hand-Held Programmer Key Operation and Displays

Key Operations HHP Displays

0

enter

number

or

ENTERI/O

ENTERF1

0

ENTER1

ENTER

SRCH

The search operand may be I, O, IR, OR, C, or R.

SRCH

This example searches for a counter (either up or down).

SRCH

This example searches for rung number 10.

SRCH

To locate the start of the program, search for rung 0.

SRCH

To locate the end of the program, search with no rung number.

CNTR F2

AND I001

OUT O017

C R001 T o 100

Empty location

OUT O040

Empty location

PROGRAM START

STA I001

OUT O040

Empty location

PLC TRANSFER

Open Rung

PLC TRANSFER

PLC in RUN Mode

An open rung or other program error was encountered.

The PLC was in Run mode when the transfer was attempted.

3-7GFK-0804B Chapter 3 Programming with a Hand-held Programmer

Page 40

3

Programming Examples Using the HHP

Example 1

Ladder Diagram Key Operations

46108

Example 2

I1

I3

I5

I2

I4

I6

C1

STAR T

AND

STAR T

AND

OR

STAR T

AND

OR

OUT

F3 (NOT)

Ladder Diagram Key Operations

I1

I3

I5

I2

I4

I6

C2

STAR T

OR

OR

STAR T

OR

OR

AND

OUT

F3 (NOT)

I1

I2

I3

I4

I5

I6

C1

I1

I3

I5

I2

I4

I6

C2

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

46109

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

Example 3

Ladder Diagram Key Operations

I6

"

C2 C21

O38

C51

C38

C51

3-8 Micro PLC Programmer’s Guide – April 1994

C1

C1

C4

C2

STAR T

STAR T

AND

OR

AND

STAR T

AND

STAR T

AND

OR

AND

OR

AND

OUT

F1 (PTRAN)

F3 (NOT)

F3 (NOT)

F3 (NOT)

F3 (NOT)

F3 (NOT)

I6

C2

C21

C1

O38

C51

C38

C51

C1

C4

C2

46110

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

GFK-0804B

Page 41

Example 4

I6

Ladder Diagram Key Operations

I1

I2

"

I4 I5

I9

I3

C5

I7

I8

I4

C2

STAR T

OR

STAR T

OR

AND

STAR T

OR

AND

OR

STAR T

OR

OR

AND

AND

OUT

F1 (PTRAN)

F3 (NOT)

F3 (NOT)

F3 (NOT)

F3 (NOT)

I1

I4

I2

I5

I6

I9

I7

I3

C5

I8

I4

C2

3

4611 1

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

Example 5

C1

C1

C2

C2

C3

C3

C4

Ladder Diagram Key Operations

RI

ONTMR

"

"

"

"

"

"

"

10

R2

UPCTR

60

R3

UPCTR

60

R4

UPCTR

24

C1

C2

C3

C4

STAR T

STAR T

TIMER

OUT

STAR T

STAR T

CNTR

OUT

STAR T

STAR T

CNTR

OUT

STAR T

STAR T

CNTR

OUT

F1 (PTRAN)

F1 (ONTIM)

F1 (PTRAN)

F1 (PTRAN)

F1 (UPCNT)

F1 (PTRAN)

F1 (PTRAN)

(F1 (UPCNT)

F1 (PTRAN)

F1 (PTRAN)

F1 (UPCNT)

C1

R1

10

C1

C1

C2

R2

60

C2

C2

C3

R3

60

C3

C3

C4

R4

24

C4

46112

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

3-9GFK-0804B Chapter 3 Programming with a Hand-held Programmer

Page 42

Chapter 4 The Micro PLC Instruction Set

Instruction Set Summary

Math Functions

section level 1 1

4

This chapter defines the individual logic elements that can be combined to make a

program for the Micro PLC.

figure bi level 1

table_big level 1

H

H

H

H

H

Contacts

h

Normally-Open Contact

h

Normally-Closed Contact

h

P ositive T ransition Contact

h

Negative Transition Contact

Coils

h

Output Coil

h

Set/Reset Coil Pair

h

Master Control Relay/End Coil

Pair

h

Skip/End Coil Pair

Timers

h

On Timer

h

Off Timer

Counters

h

Up Counter

H

h

A ddition (ADD)

h

Subtraction (SUB)

h

Multiplication (MUL)

h

Division (DIV)

H

Move Functions

h

Move

h

Block Move

h

Indirect Move

H

Compare Functions

H

Logic Operations

h

W ord AND

h

Inclusive OR (IOR)

h

Exclusive OR (XOR)

h

Shift Register Right

h

Shift Register Left

GFK-0804B

h

Down Counter

h

NOT

4-1

Page 43

4

Instruction Set Summary

Operation Ladder Symbol Description

Normally-open contact

Contact

Output

Timer

Counter

/

"

#

SET

RST

MCR

SKIP

END

ONTMR

R###

XXXX

OFTMR

R###

XXXX

UPCTR

R###

XXXX

Normally-closed contact

Positive transition

Negative transition

Output coil

Set coil

Reset coil

Master Control Relay

Skip/jump operation

Ending operation for a skip or jump

On Timer

V ariable Register R### (R1 – R500)

Timer Setting XXXX (Timebase 0.1S)

Off Timer

V ariable Register R### (R1 – R500)

Timer Setting XXXX (Timebase 0.1S)

Up Count

V ariable Register R### (R1 – R500)

Timer Setting XXXX

DNCTR

R###

XXXX

[???+???! ???]

Math

[???–???! ???]

Functions

[???x???! ???]

[???B ???! ???]

4-2 Micro PLC Programmer’s Guide – April 1994

Down Counter

V ariable Register R### (R1 – R500)

Timer Setting XXXX

Addition

Subtraction

Multiplication

Division

GFK-0804B

Page 44

Operation Ladder Symbol Description

4

Move

Operations

Compare

Function

[???! ???]

L

[???E???! ???]

N

[???! @???]

[S1 = S2]

[S1 > S2]

[S1 < S2]

[S1 > S2]

[S1 < S2]

[S1 0 S2]

A

[???N???! ???]

D

I

[???O???! ???]

R

Move

Block Move

Indirect Move

Continue when S1 = S2

Continue when S1 > S2

Continue when S1 < S2

Continue when S1 >

Continue when S1 < S2

Continue when S1 0 S2

AND

IOR

S2

XYO

111

100

010

000

XYO

111

101

011

000

Logic

Operation

X

[???O???! ???]

R

S

[???H???! ???]

R

S

[???H???! ???]

L

[??? ! ???]

XOR

Shift Right

Shift Left

Not

XYO

110

101

011

000

4-3GFK-0804B Chapter 4 The Micro PLC Instruction Set

Page 45

4

Contacts

The Micro PLC instruction set includes the following contacts:

–| |– Normally-open contact. Passes power flow to the right when its

associated reference is = 1.

–| " |– Positive transition contact. Passes power flow to the right for one

program cycle when its associated reference changes from 0 to 1.

–| / |– Normally-closed contact. Passes power flow to the right while its

associated reference is = 0.

–| # |– Negative transition contact. Passes power flow to the right for one

program cycle when its associated reference changes from 1 to 0.

Each of these contact types is described more fully on the pages that follow. If you are

using the programming software, refer to the programming instructions below. If you

are using the Hand-held Programmer, refer to the instructions for each contact type.

General Programming Software Instructions for Contacts

1. Select the contact type using the function keys:

–| |– (F1) Normally-open contact.

–| " |– (Shift, F1) Positive transition contact.

–| / |– (F2) Normally-closed contact.

–| #|– (Shift, F2) Negative transition contact.

The selected contact type is displayed:

2. Enter an appropriate address. For a contact, enter an address in input (I), output (O),

or internal (C) memory. For example: I4. You don’t need to enter leading zeros.

Note that you cannot enter the reference as “4I”.

3. Press the Enter key. The memory type and address appear:

If you want to change the memory type and address, press the Enter key . A cursor

appears next to the address. Type in the new memory type and address. Press the Enter

key again to accept the new entry.

4-4 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 46

Normally-Open Contact

A Normally-Open contact passes power flow to the right when the associated reference

is equal to 1.

Programming Software Instructions

If you are using the programming software, refer to the instructions on the opposite

page.

Examples and HHP Instructions

The HHP programming keystrokes to create a Normally-Open contact depend on its

position in a rung, as explained below.

Programming Normally-Open Contact at the Start of a R ung

4

When a Normally-Open contact is the first element of the rung, program a START, as

shown below.

46114

Ladder Diagram Hand-held Programmer

I1 O17

Timing Diagram

Input I1

Output O17

1

0

1

0

0

0

ST ART

OUT

I1

O17

The output O17 status follows the

signal of input I1, when I1–1,

output O17=1.

4-5GFK-0804B Chapter 4 The Micro PLC Instruction Set

Page 47

4

Programming a Normally-Open Contact in Series

When a Normally-Open contact is not the first element of the rung, program an AND

with the HHP, as shown below. The example shows how to use the HHP to program a

Normally-Open contact at the first and second positions in a rung.

46115

Ladder Diagram Hand-held Programmer

I1 O17

Timing Diagram

Input I1

Input I2

I2

START

AND

OUT

I1

I2

O17

AND operation of inputs I1 and I2;

output O17 is 1 when I1 and I2 are

both 1.

Output O17

Programming a Normally-Open Contact in Parallel

To enter a Normally-Open contact in parallel, as shown by I2 in the following example,

program an OR with the HHP.

46116

Ladder Diagram Hand-held Programmer

I1 O17

I2

ST ART

OR

OUT

I1

I2

O17

Timing Diagram

Input I1

Input I2

Output O17

4-6 Micro PLC Programmer’s Guide – April 1994

OR operation of inputs I1 and I2.

The output O17 is 1 when either I1

or I2 is 1.

GFK-0804B

Page 48

Normally-Closed Contact

A Normally-Closed contact passes power flow to the right when the associated reference

is equal to 0.

Programming Software Instructions

If you are using the programming software, refer to the instructions on page 4-4.

Examples and HHP Instructions

The HHP programming keystrokes to create a Normally-Closed contact depend on its

position in a rung, as explained below.

Programming Normally-Closed Contact at the Start of a R ung

4

When a Normally-Closed contact is the first element of the rung, program a

START NOT, as shown below.

Ladder Diagram Hand-held Programmer

I2 O18

Timing Diagram

Input I2

Output O18

ST ART

OUT

The output O18 status is the

reverse signal of input I2, when

I2=1, output O18=0.

F3 (NOT)

46017

II2

O18

4-7GFK-0804B Chapter 4 The Micro PLC Instruction Set

Page 49

4

Programming a Normally-Closed Contact in Series

When a Nor mally-Closed contact is not the first element of the rung, program an

AND NOT with the HHP, as shown below. The example shows how to use the HHP to

program a Normally-Closed contact at the first and second positions in a rung.

46018

Ladder Diagram Hand-held Programmer

I3 O18 START

Timing Diagram

Input I3

I4

AND

OUT

F3 (NOT)

F3 (NOT)

I3

I4

O18

NAND operation of inputs I3 and

Input I4

Output O18

I4; output O18 is 1 when I3 and I4

are both 0.

Programming a Normally-Closed Contact in Parallel

To enter a Normally-closed contact in parallel, as shown by I3 in the following example,

program an OR NOT with the HHP.

46019

Ladder Diagram Hand-held Programmer

I1 O17

I2

ST ART

OR

OR

OUT

F3 (NOT)

I1

I2

I3

O17

I3

Timing Diagram

Input I1

Input I2

Input I3

Output O17

4-8 Micro PLC Programmer’s Guide – April 1994

OR operation of inputs I1 and I2

and the reverse signal of I3. The

output O17 is 1 when either I1 or

I2 is 1 or I3 is 0.

GFK-0804B

Page 50

Positive Transition Contact

The Positive Transition contact passes power flow to the right for one program cycle

when its reference changes from 0 to 1.

Programming Software Instructions

If you are using the programming software, refer to the instructions on page 4-4.

Example and HHP Instructions

4

46020

Ladder Diagram Hand-held Programmer

I1 O17

"

Timing Diagram

Input I1

Output O17

! z

1 scan

START

OUT

Upon the rising edge signal of

input I1, output O17 is activated.

The status of O17 remains 1 for

only one program cycle.

F1 (PTRAN)

I1

O17

4-9GFK-0804B Chapter 4 The Micro PLC Instruction Set

Page 51

4

Negative Transition Contact

The Negative Transition contact passes power flow to the right for one program cycle

when its reference changes from 1 to 0.

Programming Software Instructions

If you are using the programming software, refer to the instructions on page 4-4.

Example and HHP Instructions

46021

Ladder Diagram Hand-held Programmer

I1 O17

#

Timing Diagram

Input I1

Output O17

! z

1 scan

START

OUT

Upon the falling edge signal of

input I1, output O17 is activated.

The status of O17 remains 1 for

only one program cycle.

F2 (NTRAN)

I1

O17

4-10 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 52

Coils

4

The Micro PLC instruction set includes the following coils:

–( )– Coil. The basic type of program output.

–(SET)– Set coil. Used to set a specified reference to 1.

–(RST)– Reset coil. Used to reset the same specified reference to 0.

–(MCR)– Master Control Relay . Used to set a group of outputs to 0.

–(SKIP)– Skip. Used to cause a group of outputs to hold last state.

–(END)– End of MCR or Skip

Using Coil Pairs

The following types of coils must always be used in pairs. If one of these instructions is

used in the program, the paired instruction must also exist somewhere in the program.

SET RST Set and Reset

MCR END Master Control Relay and End MCR

SKIP END Skip (rungs) to rung containing End

General Programming Software Instructions for Coils

1. Select –( )– (F3), then use the assigned function key(s) to select an output type:

–( )– (F1) Coil

–(SET)– (F2) Set coil

–(RST)– (F3) Reset coil

–(MCR)– (F4) Master Control Relay

–(SKIP)– (F5) Skip

–(END)– (F6) End of MCR or Skip

The selected coil type appears at the end of the rung:

2. Enter an appropriate address. For a coil, enter an address in output (O) or internal

coil (C) memory. For example, C0001. You don’t need to enter leading zeros.

3. Press the Enter key. The memory type and address appear:

If you want to change the memory type and address, press the Enter key . A cursor

appears next to the address. Type in the new memory type and address. Press the Enter

key again to accept the new entry.

4-11GFK-0804B Chapter 4 The Micro PLC Instruction Set

Page 53

4

Output Coil

The basic type of output coil is controlled by conditional logic within the same rung.

When the coil receives power flow from logic to its left in the rung, the reference

associated with that coil is set to 1. When no power flow is received, the reference is 0.

The state of output coils may also be affected if they are between an MCR/End MCR coil

pair or a Skip/End coil pair , as explained on the following pages.

Programming Software Instructions

If you are using the programming software, refer to the instructions on page 4-11.

Examples and HHP Instructions

46022

I1 O17

Timing Diagram

Input I1

Output O17

Output O18

Ladder Diagram Hand-held Programmer

START

OUT

O18

START

OUT

Output O17 follows the status of

input I1. Output O18 is

1

0

unconditional; it always remains 1.

I1

O17

O18

4-12 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 54

Set/Reset Coil Pair

Set Reset

The Set/Reset coil pair can be used to control the state of an associated reference. The Set

coil sets the reference to 1. The reference (O17 in the example below) STAYS set to 1 until

it is reset to 0 by the Reset coil. Notice that the Set and Reset coil are programmed with

the same associated reference; that of reference being controlled.

In the example below, the Set coil and Reset coil are shown in adjoining rungs of logic.

That is not necessary, however.

Programming Software Instructions

If you are using the programming software, refer to the instructions on page 4-11.

Example and HHP Instructions

4

I1 O17

I2 O17

Timing Diagram

Input I1

Input I2

Output O17

SET RST

Ladder Diagram Hand-held Programmer

SET

RST

START

OUT

START

OUT

F2 (SET)

F2 (RESET)

This is a flip-flop operation. Input I1 sets

output O17 to 1. Output O17 remains 1

even if I1 changes to 0. Output O17 is only

reset to 0 when I2 is activated.

When both I1 and I2 are ON, the last

occurrence in the scan (RST in this case)

takes precedence.

46023

I1

O17

I2

O17

4-13GFK-0804B Chapter 4 The Micro PLC Instruction Set

Page 55

4

MCR End

Master Control Relay/End Coil Pair

The MCR/End coil pair can be used to turn off one or more outputs in the program,

regar dless of the state of any inputs or other conditional logic to those outputs. The rungs with

the outputs to be controlled must be located between the Master Control Relay coil and

its paired End coil in the program.

In the example below, the MCR and End MCR coil control the states of outputs C1 and

O17. While the Master Control Relay coil receives power flow from its conditional logic

(in the example, it is contact I1), all output coils within the MCR/End MCR pair go to 0.

Programming Software Instructions

If you are using the programming software, refer to the instructions on page 4-11.

Example and HHP Instructions

Timing Diagram

Input I1

Coil C1

Input I2

Output O17

MCR

Ladder Diagram Hand-held Programmer

I1

I2 O17

MCR

C1

END

ST ART

OUT

ST ART

OUT

ST ART

OUT

OUT

END

More MENU

C1

I2

O17

More MENU

This is a Master Control Relay operation.

When I1 is 0, the program till the END

command operates normally.

When input I1 is 1, all outputs before the

END are disabled.

46024

I1

F1 (MCR)

F3 (END MCR)

4-14 Micro PLC Programmer’s Guide – April 1994

GFK-0804B

Page 56

Skip/End Coil Pair

)

)

Skip End

The Skip/End coil pair can be used to cause one or more outputs in the program to stay

in their current state (1 or 0), regardless of the state of any inputs or other conditional logic to

those outputs. The rungs with the outputs to be controlled must be located between the

Skip coil and its paired End coil in the program.

In the example below, the Skip and End coil control the states of outputs O17 and O18.

While the Skip coil receives power flow from its conditional logic (in the example, it is

contact I1), all output coils within the Skip/End pair hold their last states.

Programming Software Instructions

If you are using the programming software, refer to the instructions on page 4-11.

Example and HHP Instructions

4

Timing Diagram

Input I1

Input I2

Output O17

Input I3

Output O18

SKIP

Ladder Diagram Hand-held Programmer

I1

I2 O17

I3 O18

SKIP

END

START

OUT

START

OUT

START

OUT

START

OUT

END

F3 (NOT)

This is a Skip to END operation. When

input I1 is 0, the Skip command is not

performed.

When input I1 is 1, all outputs till END

are on hold, and are not affected by input

conditions.

46025

I1

More MENU F2 (SKIP

I2

O17

I3

O18

More MENU F3 (END

4-15GFK-0804B Chapter 4 The Micro PLC Instruction Set

Page 57

4

Timers

The Micro PLC instruction set provides two T imers:

On Timer Sets an output to 1 after a specified time period. See page 4-17.

Off Timer Sets an output to 0 after a specified time period. See page 4-18.

Programming Software Instructions for Timers