Page 1

GE Fanuc Automation

Programmable Control Products

GeniustModular Redundancy

Flexible Triple Modular

Redundant (TMR) System

User’s Manual

GFK-0787B March 1995

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL–002

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding

and operating the equipment.

This document is based on information available at the time of its publication. While efforts have been made to be accurate, the information contained herein does not purport

to cover all details or variations in hardware or software, nor to provide for every possible contingency in connection with installation, operation, or maintenance. Features

may be described herein which are not present in all hardware and software systems.

GE Fanuc Automation assumes no obligation of notice to holders of this document with

respect to changes subsequently made.

GE Fanuc A utomation makes no representation or warranty, expressed, implied, or statutory with respect to, and assumes no responsibility for the accuracy , completeness, sufficiency, or usefulness of the information contained herein. No warranties of merchantability or fitness for purpose shall apply .

The following are trademarks of GE Fanuc Automation North America, Inc.

Alar m Master

CIMPLICITY

CIMPLICITY 90-ADS

CIMPLICITY PowerTRAC

CIMST AR

GEnet

Genius

Genius PowerTRAC

GMR

Field Control

Helpmate

Logicmaster

Modelmaster

ProLoop

PROMA CRO

Series One

Series Three

Series Five

Series Six

Series 90

V uMaster

W orkmaster

Copyright 1995 GE Fanuc Automation North America, Inc.

All Rights Reserved

Page 3

This manual is a reference to planning, configuring and programming a Series 90t-70 PLC

system that utilizes Genius Modular Redundancy (GMR).

The information in this manual is intended to supplement the basic system installation,

programming, and configuration instructions located in the manuals listed on the next page.

Content of this Manual

Chapter 1. Introduction: describes the concept of GMR, and gives an overview of

system components, configuration, and programming.

Chapter 2. Input Subsystem: provides information about the inputs to a GMR system.

Chapter 3. Output Subsystem: describes GMR output groups, output handling, manual

output controls, and load sharing.

Chapter 4. PLC Operation: describes system startup, the CPU sweep in a GMR system,

PLC operation, I/O processing, and communications between redundant PLCs

Preface

Chapter 5. Diagnostics: chapter 5 describes the various types of diagnostics available in

a GMR system.

Chapter 6. Configuration: desc rib es configuration for a S eries 90-70 /Genius GMR system.

Chapter 7. Programming Information : describes the application program interface to

the GMR software.

Chapter 8. Installation Information: provides supplementary installation information

for GMR.

Appendix A. TÜV Certification: describes restrictions placed on the design,

configuration, installation and use of a GMR system that will be applied in an

Emergency Shut Down (ESD) application, for which for a TÜV site application approval

will be sought.

Appendix B. Maintenance Override: The information in this appendix is reprinted by

permission of TÜV. Suggestions are made about the use of maintenance override of

safety relevant sensors and actuators. Ways are shown to overcome the safety problems

and the inconvenience of hardwired solutions. A checklist is given.

Changes for this Version of the Manual

This manual describes a group of features and product enhancements that are

collectively referred to as “GMR Phase II”:

GFK–0787B

H

Programming can now be done online. This capability is intended for use during

debug and commissioning.

H

32-circuit DC Genius I/O blocks can now be used in ”H-pattern” output subsystems.

iii

Page 4

Preface

H

The GMR configuration software now allows selection of memory addresses for

external write access. Serial and network communication ports are restricted; the

Genius bus is not. A GMR Genius bus must not be used for communications.

H

Input autotest is enhanced. External isolation diodes are required.

H

The method used for input voting adaptation can now be configured to suit the

application.

H

New diagnostics including parity checks and checksums are provided.

H

Fault text displayed by the Logicmaster software is improved.

Related Publications

For more information, refer to these publications:

Genius I/O System User’s Manual (GEK-90486-1). Reference manual for system

designers, programmers, and others involved in integrating Genius I/O products in a

PLC or host computer environment. This book provides a system overview, and

describes the types of systems that can be created using Genius products. Datagrams,

Global Data, and data formats are defined.

Genius Discrete and Analog Blocks User’s Manual (GEK-90486-2). Reference manual for

system designers, operators, maintenance personnel, and others using Genius discrete

and analog I/O blocks. This book contains a detailed description, specifications,

installation instructions, and configuration instructions for all currently–available

discrete and analog blocks.

Series 90t-70 PLC Installation and Operation Manual (GFK-0262). This book describes

the modules of a Series 90–70 PLC system, and explains system setup and operation.

Logicmaster 90t-70 User’s Manual (GFK-0263). Reference manual for system operators

and others using the Logicmaster 90–70 software to program, configure, monitor, or

control a Series 90–70 PLC and/or a remote drop.

Logicmaster 90 Software Reference Manual (GFK-0265). Reference manual which

describes program str ucture and defines program instructions for the Series 90–70 PLC.

Series 90-70 Bus Controller User’s Manual (GFK–0398). Reference manual for the Bus

Controller, which interfaces a Genius bus to a Series 90-70 PLC. This book describes the

installation and operation of the Bus Controller. It also contains the programming

information needed to interface Genius I/O devices to a Series 90-70 PLC.

We Welcome Your Comments and Suggestions

At GE Fanuc automation, we strive to produce quality technical documentation. After

you have used this manual, please take a few moments to complete and return the

Reader’s Comment Card located on the next page.

Jeanne L. Grimsby

Senior Technical Writer

iv

Geniust Modular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK–0787B

Page 5

Chapter 1 Introduction 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Components of a GMR System 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series 90-70 PLCs 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Busses and Bus Controllers 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Overview 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius I/O Blocks 1-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration and Programming 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Input Subsystem 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GMR Input Groups 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-Voted I/O in the Input Subsystem 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Discrete Inputs 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs 2-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Output Subsystem 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GMR Output Handling 3-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Fault Reporting 3-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-Block Output Groups 3-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Output Controls and Diagnostics 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy Modes for Output Blocks 3-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 PLC Subsystem 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Startup 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Sweep in a GMR System 4-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Estimating CPU Sweep Time 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Processing 4-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Processing 4-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Shutdown 4-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Between PLCs 4-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Diagnostics 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming for Diagnostics 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-0787B Genius

t

Modular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

v

Page 6

Diagnostics in a GMR System 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up Blocks to Report Genius Faults 5-3 . . . . . . . . . . . . . . . . . . . . . . . . .

GMR Autotesting 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GMR Discrepancy Reporting 5-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Line Fault Detection in a GMR Application 5-14 . . . . . . . . . . . . . . . . . . .

The PLC and I/O Fault Tables in a GMR System 5-15 . . . . . . . . . . . . . . . . . . . . .

Manual Output Controls and Diagnostics 5-23 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault, No Fault, and Alarm Contacts 5-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Configuration 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Overview 6-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the GMR Configuration Software 6-4 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Completing the Logicmaster 90 Configuration 6-45 . . . . . . . . . . . . . . . . . . . . . .

Configuring Genius I/O Blocks 6-50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 Programming Information 7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Overview 7-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Instruction Set for GMR 7-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Estimating Memory Usage 7-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Estimating Bus Scan Time 7-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reserved References 7-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input and Output Addressing for GMR 7-5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Register (%R) Memory Assignment for GMR 7-9 . . . . . . . . . . . . . . . . . . . . . . .

System Status (%S) References 7-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GMR Status and Control (%M) References 7-11 . . . . . . . . . . . . . . . . . . . . . . . . .

Programming for Startup 7-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Point Faults 7-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming for I/O Shutdown 7-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming for Fault and Alarm Contacts 7-21 . . . . . . . . . . . . . . . . . . . . . . .

Reading GMR Diagnostics 7-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming for Global Data 7-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding the GMR System Software to a New Application Program Folder 7-28

Adding the GMR Configuration to the Application Program Folder 7-29 . . .

Storing a Program to the PLC 7-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-0787B Genius

User’s Manual – March 1995

t

Modular Redundancy Flexible Triple Modular Redundant (TMR) System

vi

Page 7

Chapter 8 Installation Information 8-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus Connections 8-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination Boards 8-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Wiring 8-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Wiring for a 16-Circuit, 4-Block Group 8-10 . . . . . . . . . . . . . . . . . . . . . .

Output Wiring for a 32-Circuit, 4-Block Group 8-14 . . . . . . . . . . . . . . . . . . . . . .

Appendix A TÜV Certification A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B Maintenance Override B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abstract B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Override Procedures B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommendations B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Version History B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

GFK-0787B Genius

User’s Manual – March 1995

t

Modular Redundancy Flexible Triple Modular Redundant (TMR) System

vii

Page 8

restart lowapp ARestart oddapp: ARestarts for autonumbers that do not restart in

each chapter . figure bi level 1, reset table_big level 1, reset chap_big level 1, reset1

Lowapp Alwbox restart evenap:A1app_big level 1, resetA figure_ap level 1, reset

table_ap level 1, reset figure level 1, reset Figure 1. table level 1, reset Table 1.

these restarts oddbox reset: 1evenbox reset: 1must be in the header frame of

chapter 1. a:ebx, l 1 resetA a:obx:l 1, resetA a:bigbx level 1 resetA a:ftr level 1 resetA

c:ebx, l 1 reset1 c:obx:l 1, reset1 c:bigbx level 1 reset1 c:ftr level 1 reset1

Reminders for autonumbers that need to be restarted manually (first instance will

always be 4) let_in level 1: A. B. C. letter level 1:A.B.C. num level 1: 1. 2. 3.

num_in level 1: 1. 2. 3. rom_in level 1: I. II. III. roman level 1: I. II. III. steps level 1:

1. 2. 3.

Chapter 1 Introduction

section level 1 1

1

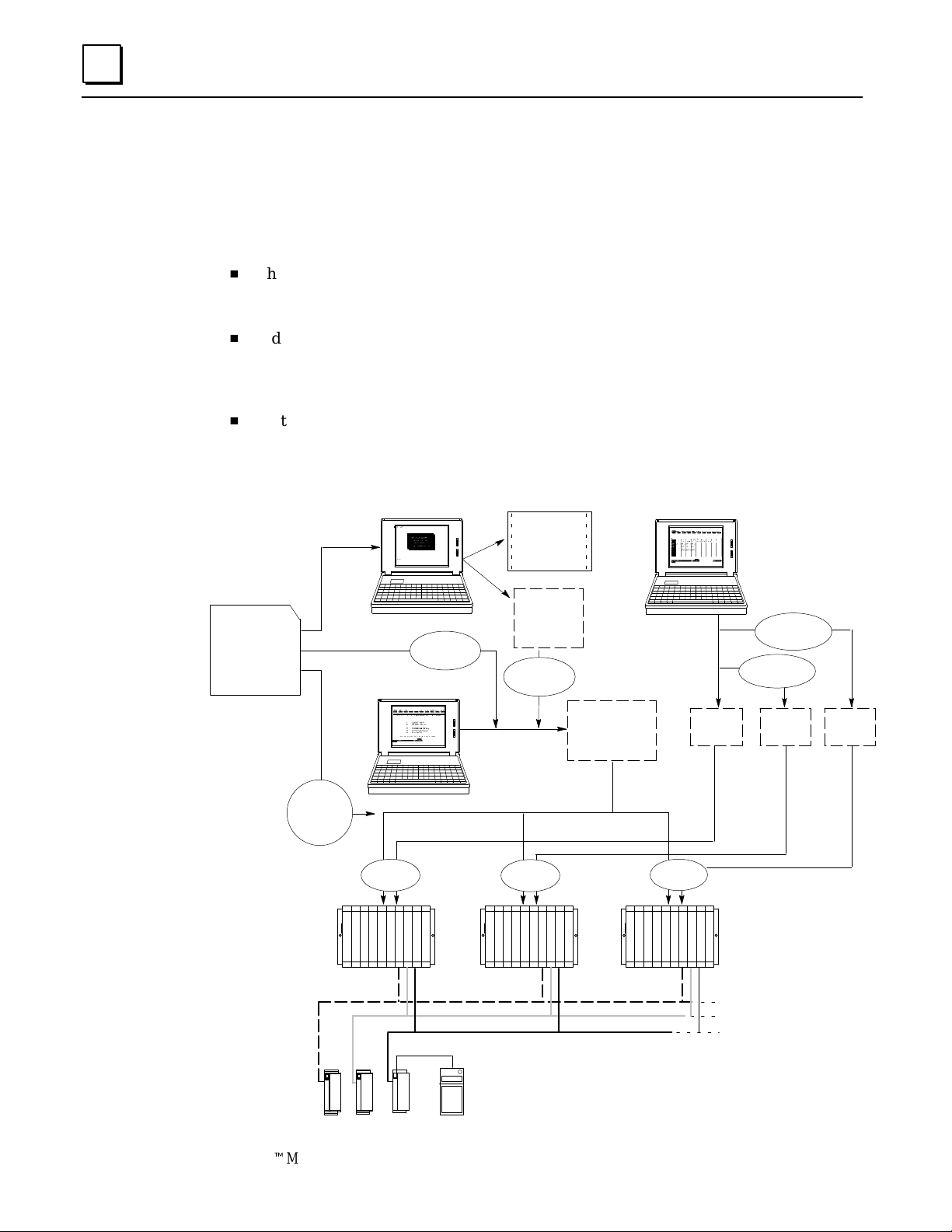

Genius Modular Redundancy (GMRt) has been developed by GE Fanuc Automation and Silvertech

Limited of the United Kingdom. Silvertech has many years experience applying GE Fanuc products to

high-integrity safety system applications such as Emergency Shutdown and Fire & Gas Detection in the

petrochemical / oil and gas industries. They have captured this expertise in the GMR system software.

GMR is a high-reliability, high-availability redundancy system that provides a scalable solution for many

types of redundancy applications, incl ud i ng cri ti cal TMR (Triple Modular Redundancy) applications.

figure bi level 1

table_big level 1

restart lowapp ARestart oddapp: ARestarts for autonumbers that do not restart in

each chapter . figure bi level 1, reset table_big level 1, reset chap_big level 1, reset1

Lowapp Alwbox restart evenap:A1app_big level 1, resetA figure_ap level 1, reset

table_ap level 1, reset figure level 1, reset Figure 1. table level 1, reset Table 1.

these restarts oddbox reset: 1evenbox reset: 1must be in the header frame of

chapter 1. a:ebx, l 1 resetA a:obx:l 1, resetA a:bigbx level 1 resetA a:ftr level 1 resetA

c:ebx, l 1 reset1 c:obx:l 1, reset1 c:bigbx level 1 reset1 c:ftr level 1 reset1

Reminders for autonumbers that need to be restarted manually (first instance will

always be 4) let_in level 1: A. B. C. letter level 1:A.B.C. num level 1: 1. 2. 3.

num_in level 1: 1. 2. 3. rom_in level 1: I. II. III. roman level 1: I. II. III. steps level 1:

1. 2. 3.

TÜV has certified GMR for class ification to these requirements: triplex Class 5, duplex Cl as s 4 and 5,

and simplex Cl as s 4 accord ing to the DIN V19250/DIN V VDE 08 1 s t a nd a rds . For use of the GMR

system in a TÜV approved safety critical installation, refer to information in Appendix A.

The GMR system is based on standard, off-the-shelf hardware. It utilizes field-proven Series 90-70

PLC and Genius I/O products. Enhancements have been incorporated into the standard PLC CPU,

bus controller, and several Genius I/O blocks specifically for use in GMR systems. These enhanced

products, together with GMR system software, provide input voting by the PLCs, output voting,

support for both discrete and analog I/O, automatic testing of discrete inputs and outputs, and

extensive fault-monitoring capabilities for the application program.

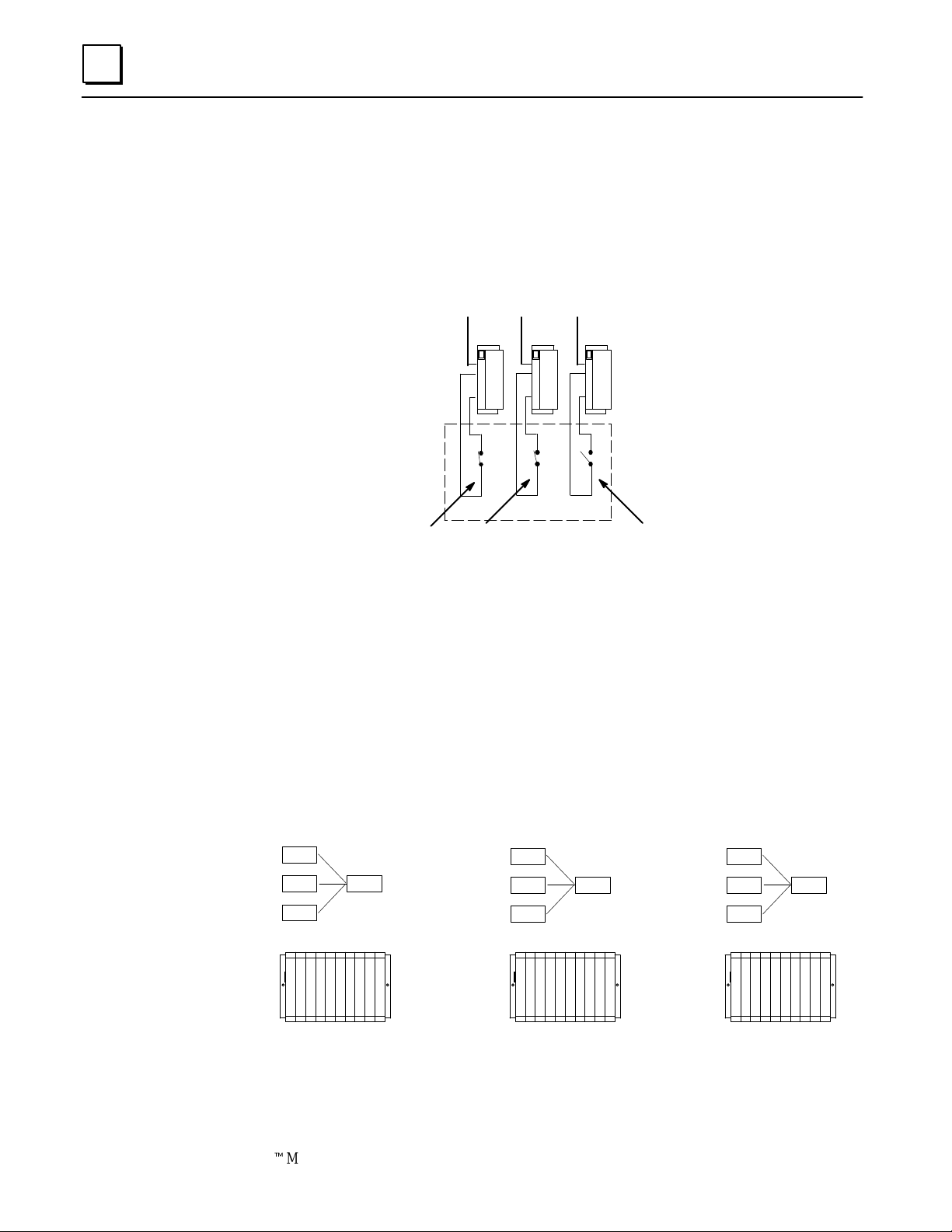

A basic GMR system consists of groups of Genius blocks gathering data from multiple or single

sensors, multiple PLCs running the same application program, and groups of Genius blocks

controlling shared output loads. Communications between the blocks and PLCs and among the

PLCs is provided by the Genius bus.

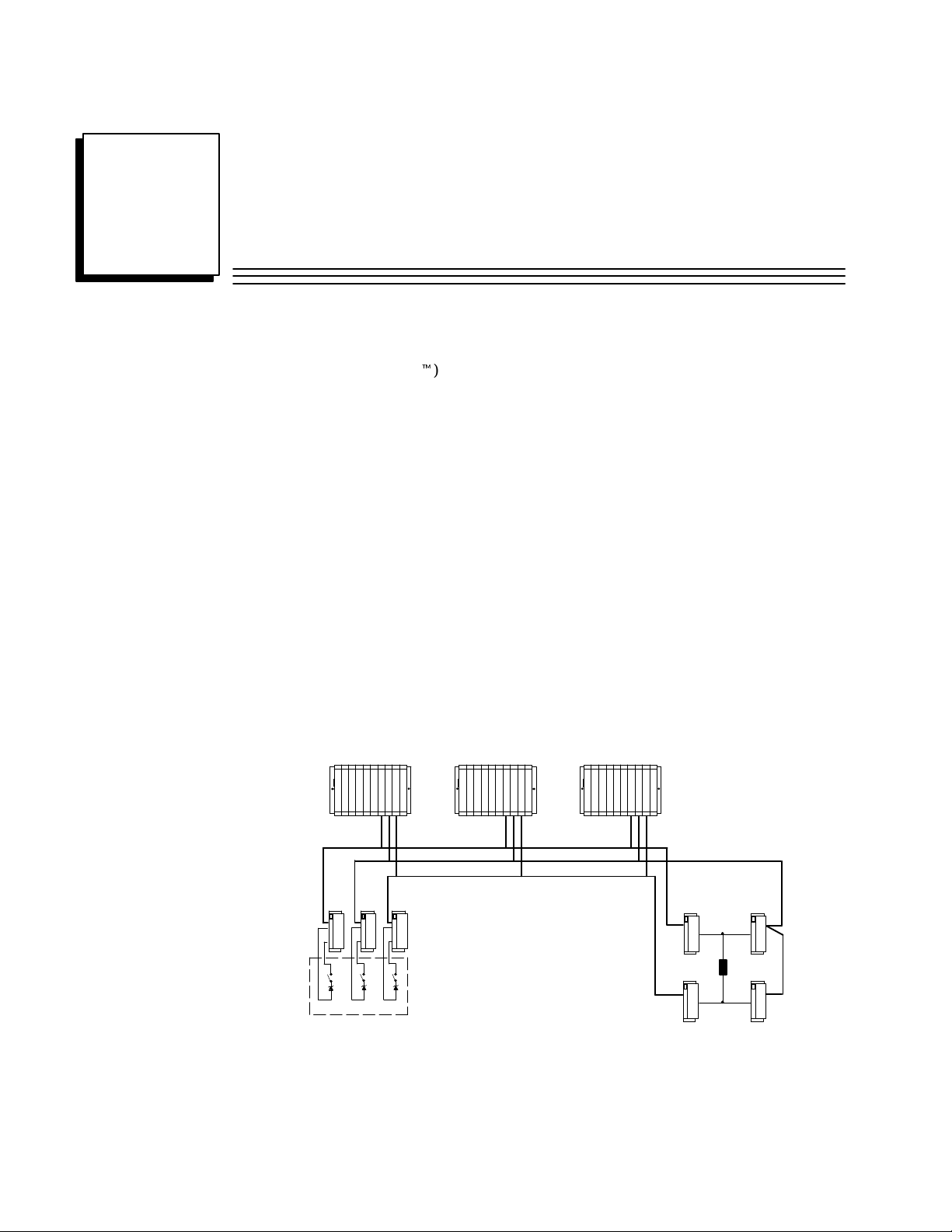

Triple PLCs

Triple Genius Busses

GFK-0787B

Load

Triple Input Sensors

GMR provides great configuration flexibility. A system can include 1, 2, or 3 PLCs. There can be just one

I/O subsystem, as represented above, or more than one. Each I/O subsystem can include 1, 2, or 3 busses.

A bus can serve up to a total of 32 devices (I/O blocks, P LCs , a nd a Ha nd - h eld Monitor ) . T he system c an

include both non-redundant I/O blocks and individual non-redundant points on redundant blocks.

1-1

Page 9

1

Series 90-70 PLC CPU

IC697CPU788

DA

Series 90-70 PLC CPU

IC697CPU788

DA

Components of a GMR System

GMR Software

GMR software version 2.06 (catalog number IC641SWP714B) provided on diskette

consists of:

H

Easy-to-use GMR configuration software.

H

GMR system software, which automatically processes, monitors, and tests redundant I/O.

H

A download utility for updating programs in systems with SNP multidrop communications.

Series 90-70 PLCs

Two models of the Series 90-70 PLC CPU support GMR, CPU 788 and CPU 789. If the

GMR system includes either two or three PLC CPUs, they must be the same model.

Each PLC requires one to three Bus Controllers per bus. Minimum suffixes for GMR

version 2.06 are:

CPUs and Bus Controllers Catalog Number Minimum Suffix

IC697CPU789

Series 90-70 PLC CPU Memory IC697BEM735 D

Series 90-70 Bus Controller IC697BEM731 N

DA

Genius I/O Blocks

H

The following standard Genius blocks are supported by the GMR system. These

blocks contain GMR modifications for version 2.06 beginning with the “minimum

suffix” listed:

Block Type Catalog Number Minimum Suffix

24/48 VDC 16-Circuit Source block IC660BBD020 M

24/48 VDC 16-Circuit Sink block IC660BBD021 M

12/24 VDC 32-Circuit Source block IC660BBD024 N

5/12/24 VDC 32-Circuit Sink block IC660BBD025 N

Analog, R TD, and Thermocouple blocks no specific suffix required

H

Other types of Genius blocks can be used as non-redundant blocks in the same

system.

Additional Items

H

“SPECIAL SAFETY SYSTEM” red I/O block labels (package of 20 of the same type)

are available: IC660SLA020, A021, A023, A024, A026, A100, A101, A103, A104, A106,

D020, D021, D024, D025. These numbers correspond to the numbers of the blocks.

For example, order label IC660SLA021 for block IC660BBA021.

H

Logicmaster 90-70 Software: release 4.02 or later.

H

Hand–held Monitor (optional): IC660HHM501H (version 4.5) or later.

H

SNP Programming Cable and RS 232/RS 485 adapter . (IC690A CC901)

H

Multidrop Cable (IC690CBL714) (Two required for connecting 3 CPUs.)

1-2 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

Incompatible Products

H

Graphics Display System (GDS): GMR is incompatible with Cimplicity 70 GDS.

User’s Manual – March 1995

GFK-0787B

Page 10

Series 90-70 PLCs

A GMR system normally consists of one to three identical CPUs running identical

application software. Each CPU is connected to the same input and output subsystems.

Each CPU receives all inputs and performs voting for discrete inputs and mid-value

selection for analog inputs. Each CPU computes the required outputs as a function of the

inputs and the application program logic.

Inter-processor Communications

The PLCs exchange initialization data at startup, then operate asynchronously. They

communicate regularly using Global Data. Each Genius bus scan, each PLC broadcasts up to

64 words of Global Data. This includes 8 words of system information. An additional 56

words of Global Data are available for use by the application program. Redundancy is also

built into Global Data communications. Each message is sent twice, using different busses.

The PLCs may also be joined in a multidrop Series Ninety Protocol (SNP) network. A host

computer on the network can be used for gathering data from the system. In addition, the

SNP network permits convenient program updates using the Logicmaster 90 programming

software and the Program Download utility included on the GMR software diskette.

1

PLC A

C

P

U

All other normal Series 90-70 communications interfaces are also available. If required

for the application, the host software should collect data from each CPU and perform

the necessary voting.

C

P

U

Multidrop Cable

RS–232/422

Converter

Multidrop cable is catalog number

IC690CBL714 (1 cable). Two cables

are needed for 3 CPUs.

PLC CPLC B

C

P

U

1-3GFK-0787B Chapter 1 Introduction

Page 11

1

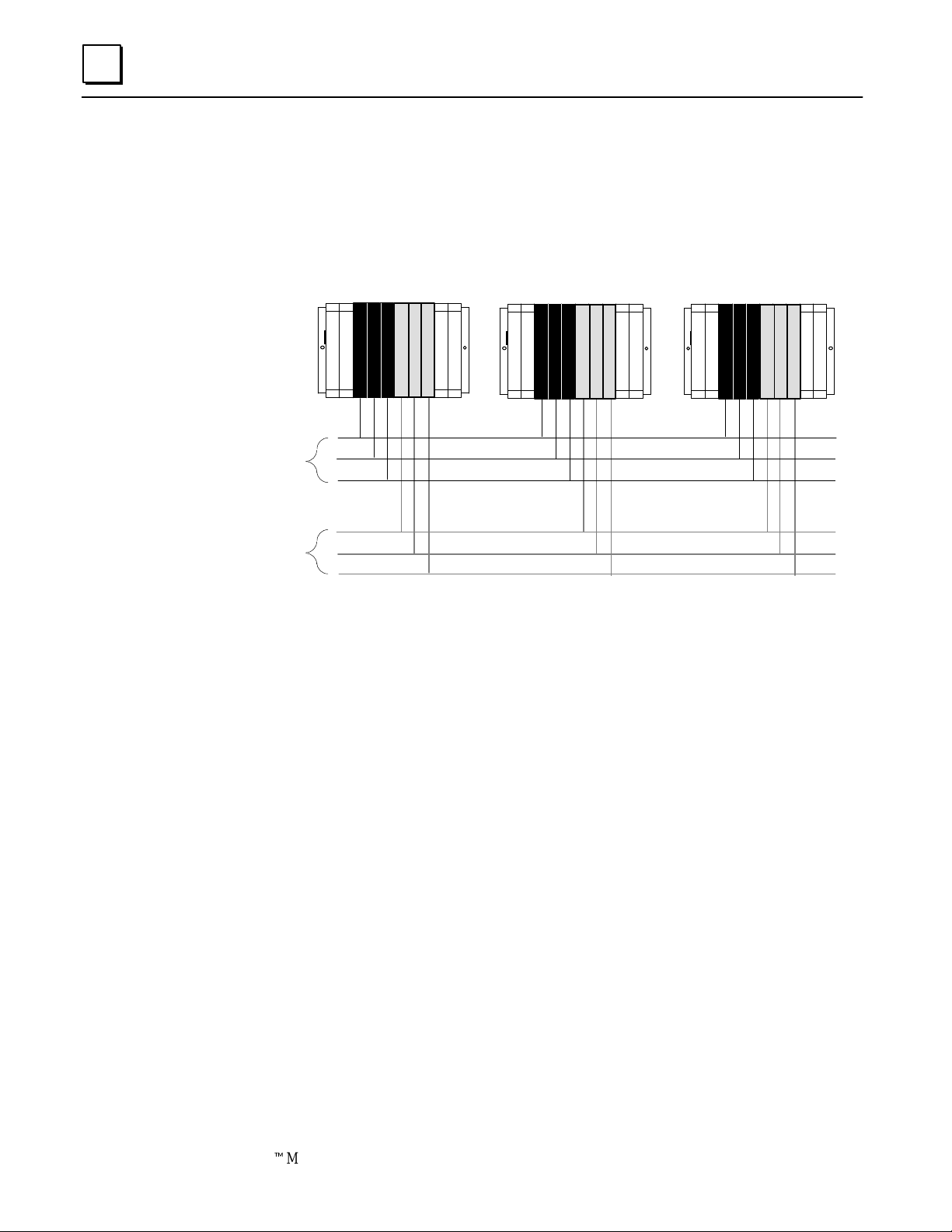

Busses and Bus Controllers

In a GMR system, there can be one to three bus controllers per bus, per PLC. Larger systems

may require more than one I/O subsystem. For example, the GMR system represented below

has two I/O subsystems for a total of six independent Genius busses and 18 bus controllers.

PLC A PLC CPLC B

ABCABC

Bus A

I/O Sub–

system

I/O Sub–

system

Each Genius bus uses a single twinax cable over distances of up to 7500 feet and data

rates of up to 153.6K baud.

Each PLC may have up to 31 Genius bus controllers, in multiple racks.

Bus B

Bus C

Bus A

Bus B

Bus C

ABCABC ABCABC

Additional Bus Controllers for Communications

The Genius busses that support GMR input/output groups are also used for internal

communications between PLCs, as explained on the previous page. They should not be

used for datagram communications. Separate busses for communications can be used for

datagrams or additional global data in the application program.

The Bus baud rate should be selected on the basis of the calculations in the Genius I/O

System and Communications User’s Manual (GFK-90486). For correct autotesting in a GMR

system, the Genius bus scan time should not be be more than 60mS.

1-4 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 12

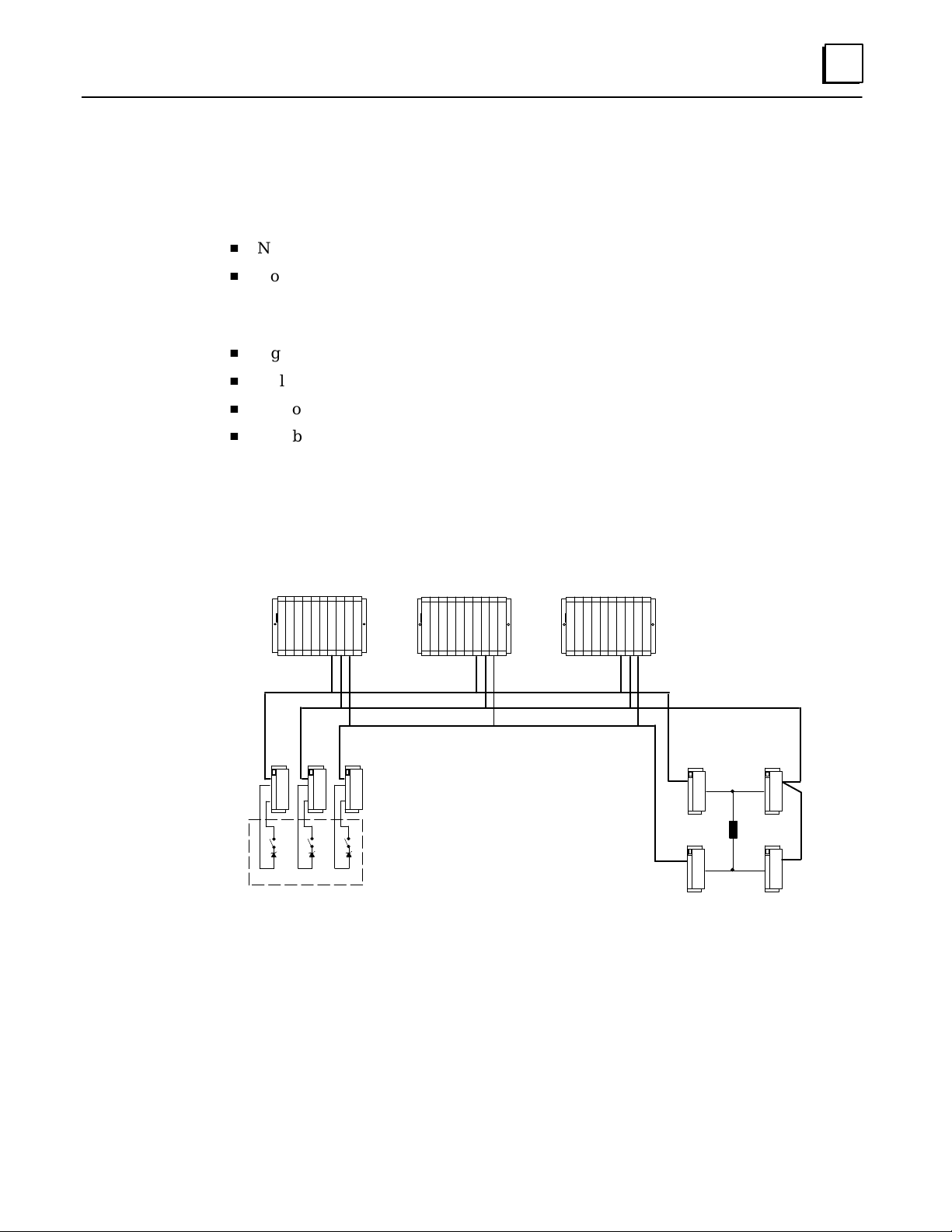

Operation Overview

Genius Modular Redundancy has been developed for use in systems that have static or nearly

static I/O under normal operating conditions. The system may have:

H

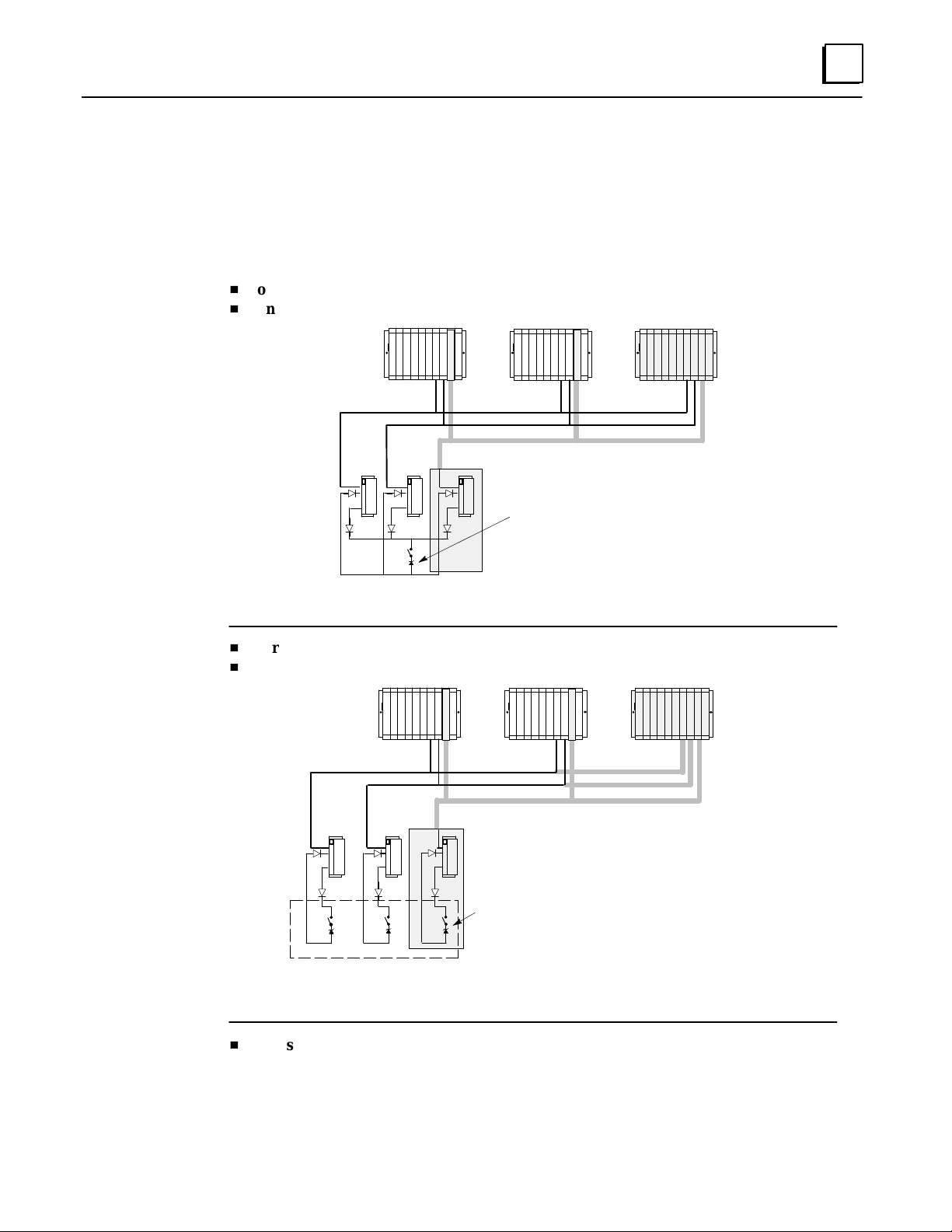

Normally-on inputs with normally-energized outputs, as in emergency shutdown systems.

H

Normally-off inputs with normally-deenergized outputs, as in fire and gas detection

systems.

Genius Modular Redundancy provides:

H

high degree of self-test and monitoring with diagnostics

H

fault tolerance.

H

support for centralized or fully distributed systems.

H

Scalable voting: 2-out-of-3, 2-out-of-2, 1-out-of-2, or simplex.

The example that follows illustrates how the GMR input subsystem, PLC subsystem, and

output subsystem combine to provide a high-availability , high-reliability system.

1

PLC A PLC CPLC B

Input Subsystem

PLC Subsystem

Load

Output Subsystem

1-5GFK-0787B Chapter 1 Introduction

Page 13

1

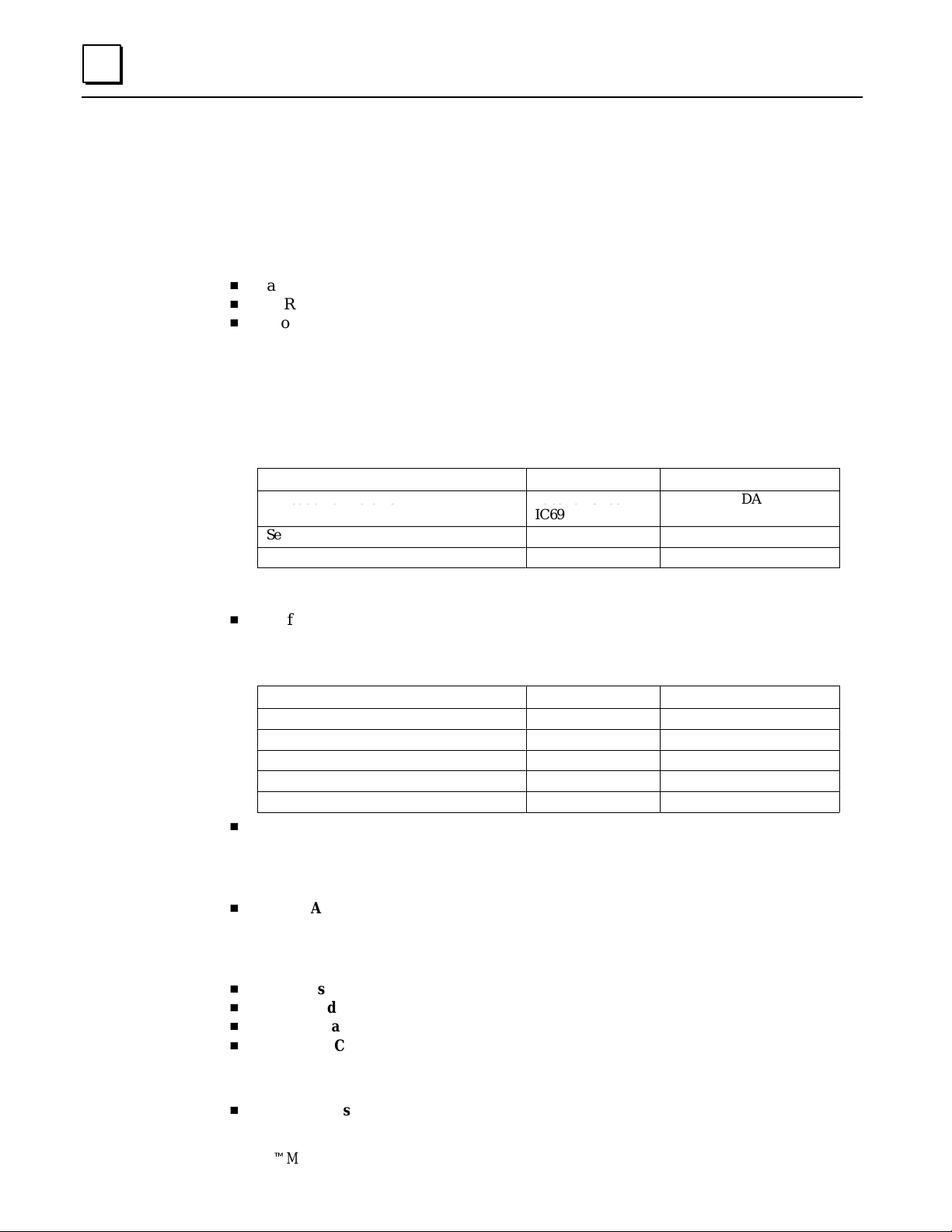

Input Subsystem

In a GMR system, the basic elements of an input subsystem are single or triple sensors

connected to triple Genius blocks. Each block is on a different communications bus

(shown below as A, B, and C).

For this example, there are triple input sensors which are normally-on. However, one of

these input sensors is off:

ABC

Closed (1)

Open (0)

Each PLC in the example system votes on the input data received from these three

sensors as summarized below. For a more detailed description of input processing, see

chapter 2.

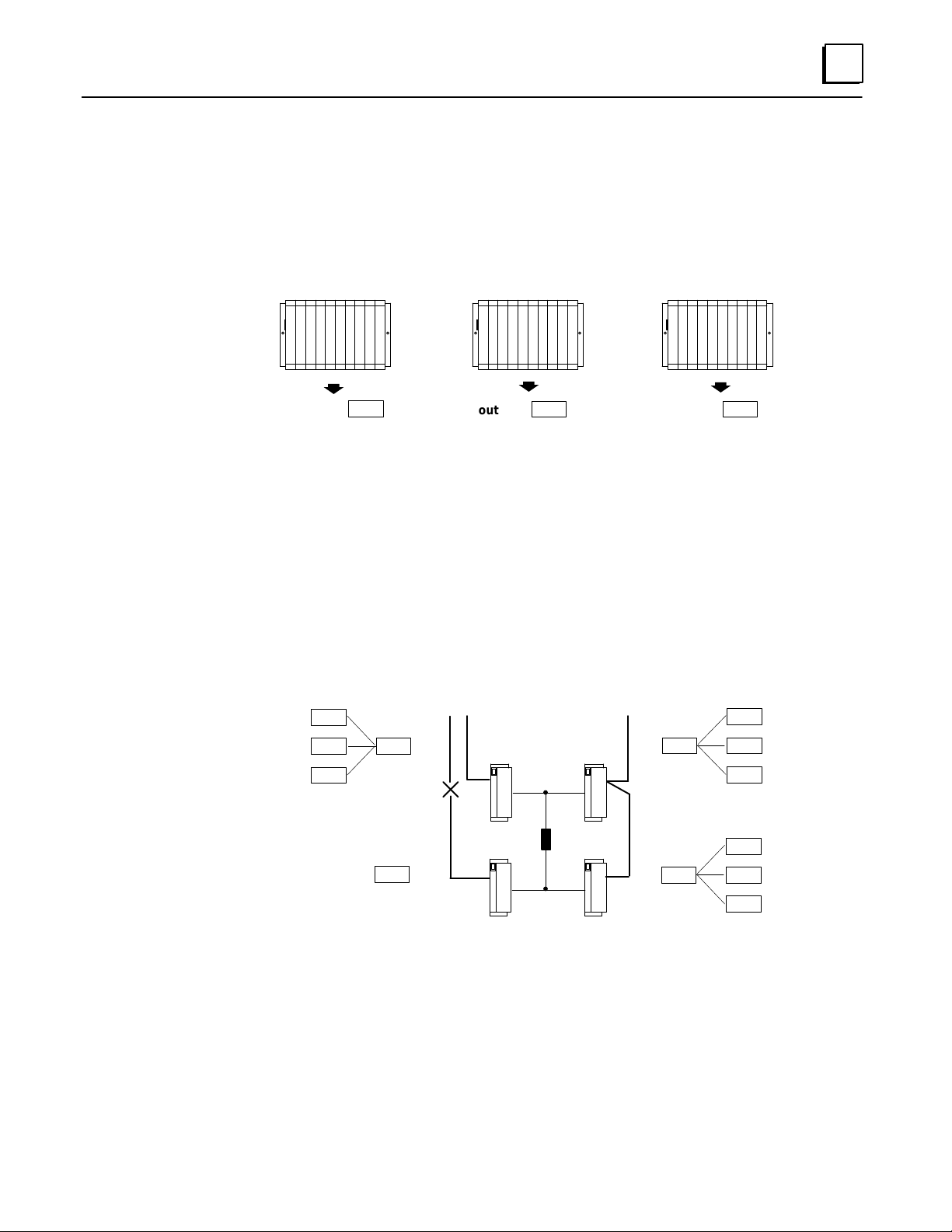

PLC Subsystem: Voting on Input Data

The example system uses three PLCs. Each PLC receives corresponding inputs from all

three blocks in the input group.

The GMR software in each PLC automatically votes on the input data and provides the

voted input to the application program (the program can also access the unvoted input

data). Each of these example voted inputs represents the same input sensors.

input A

input B

input C

1

1

0

voted

input

1

input A

input B

input C

1

1

0

voted

input

1

input A

input B

input C

1

1

0

voted

input

1

PLC A PLC CPLC B

If an input is faulty, the PLC(s) follow a configurable, predetermined voting scheme

based on the remaining input data.

1-6 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 14

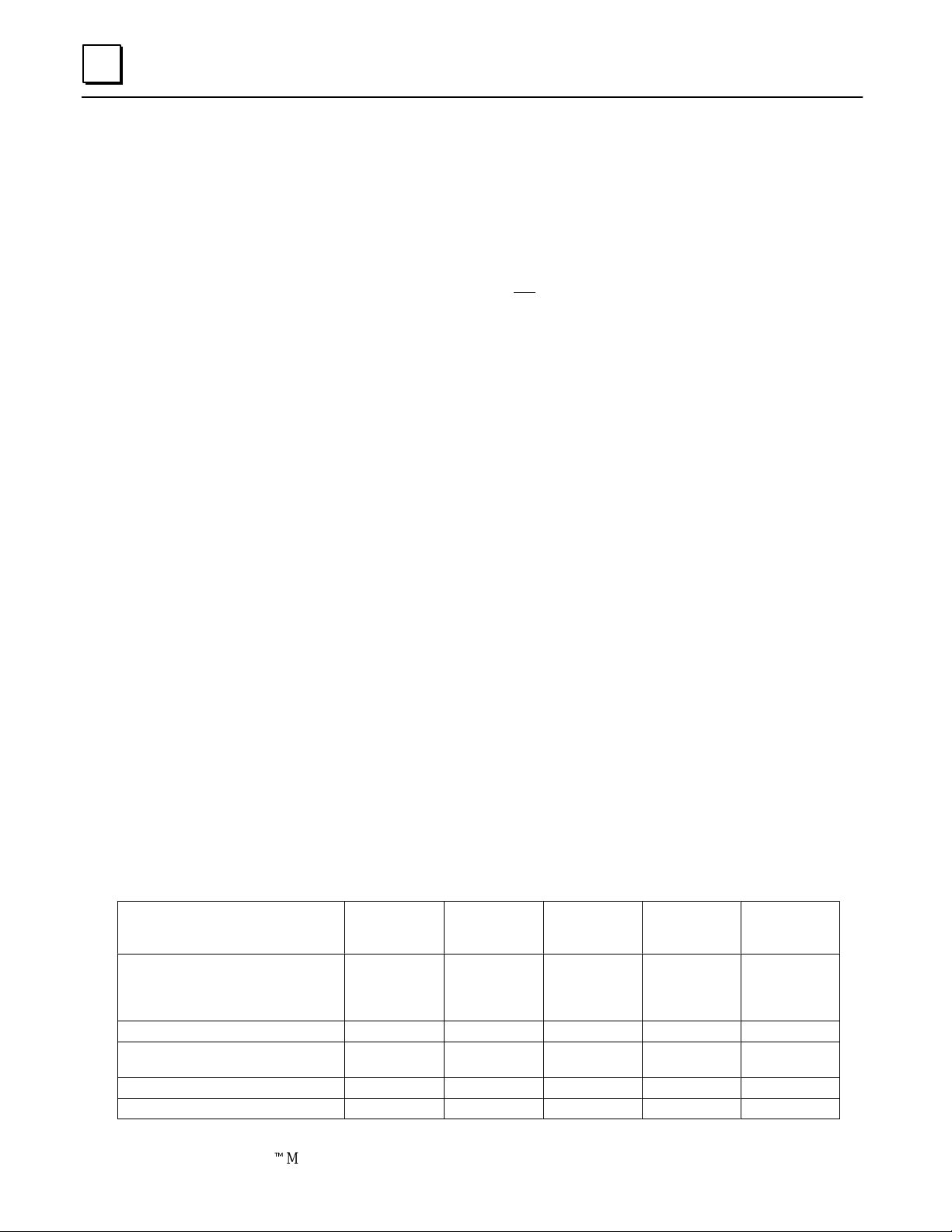

PLC Subsystem: Providing Output Data

Running the same application program, each PLC (referred to here by Genius Bus

Controller (GBC) serial bus addresses: 31, 30, and 29) processes the voted input data and

produces appropriate outputs. Because each of the three PLCs is running the same

program, they produce three copies of the same output data.

Each PLC then sends this triplicated output data on the bus.

PLC A PLC CPLC B

GBC 31

GBC 31

GBC 31

GBC 30

GBC 30

GBC 30

GBC 29

GBC 29

GBC 29

1

b

output 1

b

output 1 output 1

b

Output Subsystem

The basic element of an output subsystem is the output group. Each block in the group

has the same reference address in the application program, so each block receives the

same output data.

The output group votes on the three outputs and uses the result as the physical output.

In this example, communications are lost on bus C. Upon losing communications, the

block on bus C follows its configuration instructions, which are to default its outputs to 0.

However, the remaining blocks in the group continue to receive valid output data from

all three PLCs over busses A and B, and the actual state of the output load is controlled

properly. The loss of block or loss of bus diagnostic would be recorded, providing an aid

to troubleshooting and annunciating the problem.

C

output 31

output 30

output 29

1

1

1

voted

output

1

default

output

0

AB

AB

Load

CD

voted

output

1 output 30

voted

output

1

1

1

1

1

1

1

output 31

output 29

output 31

output 30

output 29

In a 4-block output group, each field output is supported by two Genius source outputs

connected in parallel on one side of the actuator and two Genius sink outputs connected

in parallel on the other. Each block in the group receives outputs from each of the three

separate processors.

Automatic System Test

Optional autotest routines test the complete system from input modules through to

output modules, including failures in the I/O wiring. Autotesting does not affect the

normal state of field devices.

1-7GFK-0787B Chapter 1 Introduction

Page 15

1

Genius I/O Blocks

Inputs and outputs in a GMR system are provided by Genius I/O blocks. Some types of

Genius blocks are now enhanced for GMR operation. In addition, these and other types

of blocks can be included in a GMR system as “ non-voted” blocks. Non-voted blocks are

individual blocks that are present on GMR busses in the system; they are not part of any

GMR input group or output group. They are included in the GMR configuration and

they may be autotested.

Discrete Blocks

All types of discrete blocks can be used as non-voted blocks in a GMR system.

The discrete blocks listed on page 1-2 are standard Genius blocks that are now

enhanced to include GMR functions. These blocks can be used in either GMR or

non-GMR systems. When configured for GMR operation (only), they perform output voting,

support GMR autotesting, and provide diagnostic reports to up to three PLCs. In

addition, certain of their operating parameters are changed when they are in GMR

mode.

Analog, RTD, and Thermocouple Blocks

Analog blocks can be included in the GMR configuration and used in GMR input groups,

as either voted or non-voted inputs. However , analog blocks in GMR input groups are

not autotested by the GMR software.

Analog blocks do not provide output voting, so they cannot be used in GMR output

block groups. However, they can be used as non-voted blocks in a GMR system, and

support standard Hot Standby Redundancy.

Analog, RTD, and Thermocouple blocks operate the same way in either GMR or non-GMR

systems. No specific versions of these blocks are required for GMR use.

I/O Block Summary

The following table summarizes how different types of blocks can be used in a GMR system.

Basic Block Types Can be GMR

Input Block

24/48 VDC 16-Circuit Source block

24/48 VDC 16-Circuit Sink block

12/24 VDC 32-Circuit Source block

5/12/24 VDC 32-Circuit Sink block

Any other discrete block no no yes no yes

Analog, R TD, and Thermocouple

blocks

High-speed Counter block no no no no yes

P ower Trac block no no no no yes

yes yes yes yes yes

yes no yes no yes

Can be GMR

Output Block

Can be

“ non-voted”

GMR block

Can be

A utotested

Can be

non-GMR

block

1-8 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 16

Number of

Voted GMR

Number

of V oted

1

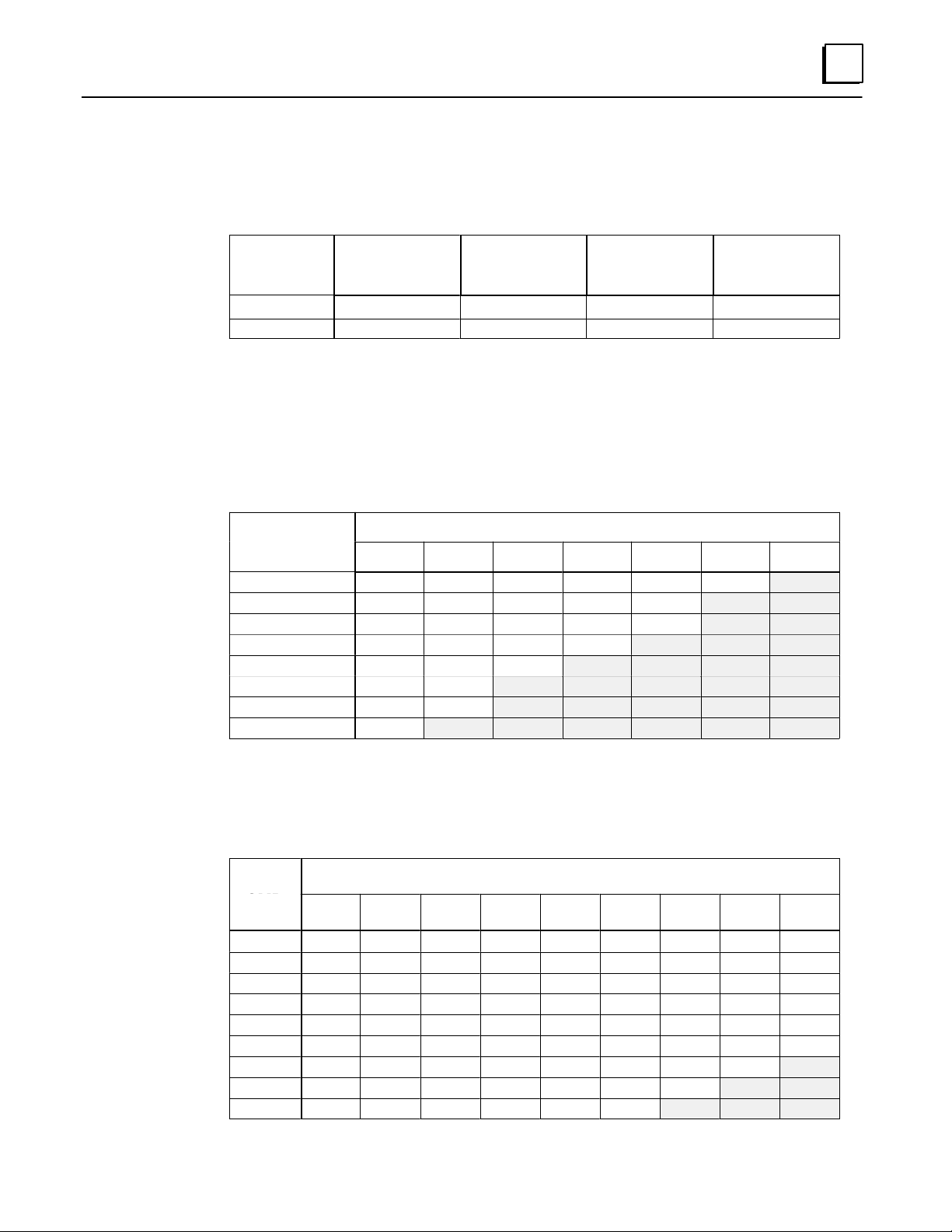

Number of I/O Points in a GMR System

The I/O capacity of the system depends on whether the CPU is a model 788 or model 789. For

most applications, these limits will not be reached. If you need help estimating I/O sizes for a

large application, contact GE Fanuc at 1-800-828-5747.

CPU Model Total Discrete

Physical I/O

788 352 112 80 100

798

Non-GMR I/O: Non-GMR I/O is I/O that is not included in the GMR configuration. The

amount of non-GMR I/O that can be used depends on the amount of GMR I/O present and

the CPU memory capacity. The tables below show how much memory is available for

non-GMR I/O (main part of tables) for given numbers of GMR inputs and GMR outputs. In

the equations, the GMR Inputs and GMR Outputs are the actual number of I/O configured

with the programming software.

12288 2048 2048 4096

Maximum

Number of

V oted Inputs

Maximum

Number of

Voted Outputs

Maximum Total

Voted I//O

Number of Non-GMR I/O Available for the 788 CPU

Number of Redundant GMR Outputs

Inputs

0 352 288 224 160 96 32

16

32

48

64

80

96

112

0 16 32 48 64 80 96

304 240 176 112 48

256 192 128 64 0

208 144 80 16

160 96 32

112 48

64 0

16

Number of Non-GMR I/O Available for the 789 CPU

These numbers are determined by the limits of physical I/O based on the Logicmaster

configuration and table size limitations based on the manner in which GMR maps I/O into

multiple locations in the I/O tables (this is explained in chapter 4).

of Voted

GMR

Inputs

0

256

512

768

1024

1280

1536

1792

2048

0 256 512 768 1024 1280 1536 1792 2048

12288 11264 10240 9216 8192 7168 6144 5120 4096

11264 10496 9472 8448 7424 6400 5376 4352 3328

10240 9728 8704 7680 6656 5632 4608 3584 2560

9216 8960 7936 6912 5888 4864 3840 2816 1792

8192 7936 7168 6144 5120 4096 3072 2048 1024

7168 6912 6400 5376 4352 3328 2304 1280 256

6144 5888 5632 4608 3584 2560 1536 512

5120 4864 4608 3840 2816 1792 768

4096 3840 3584 3072 2048 1024

Number of Redundant GMR Outputs

1-9GFK-0787B Chapter 1 Introduction

Page 17

1

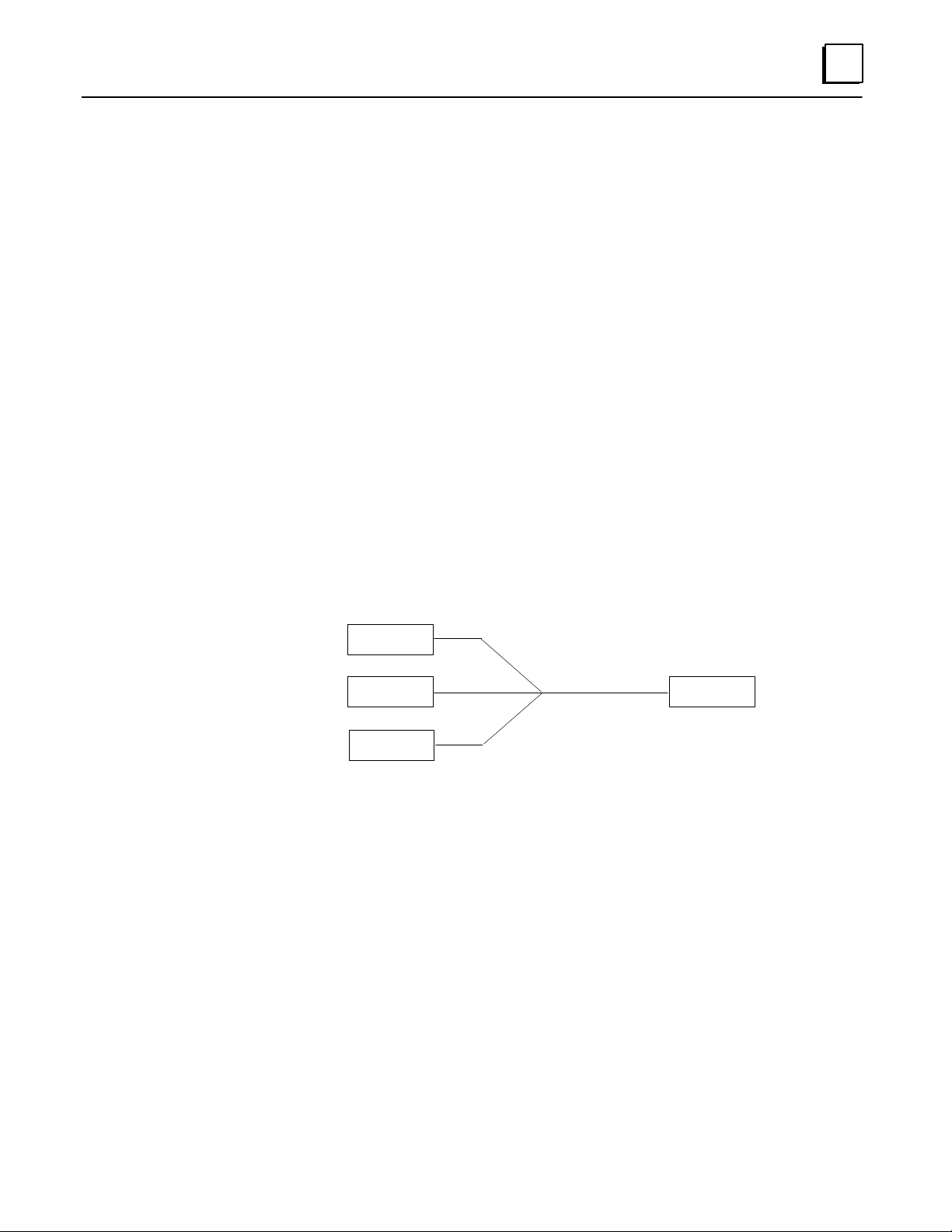

Configuration and Programming

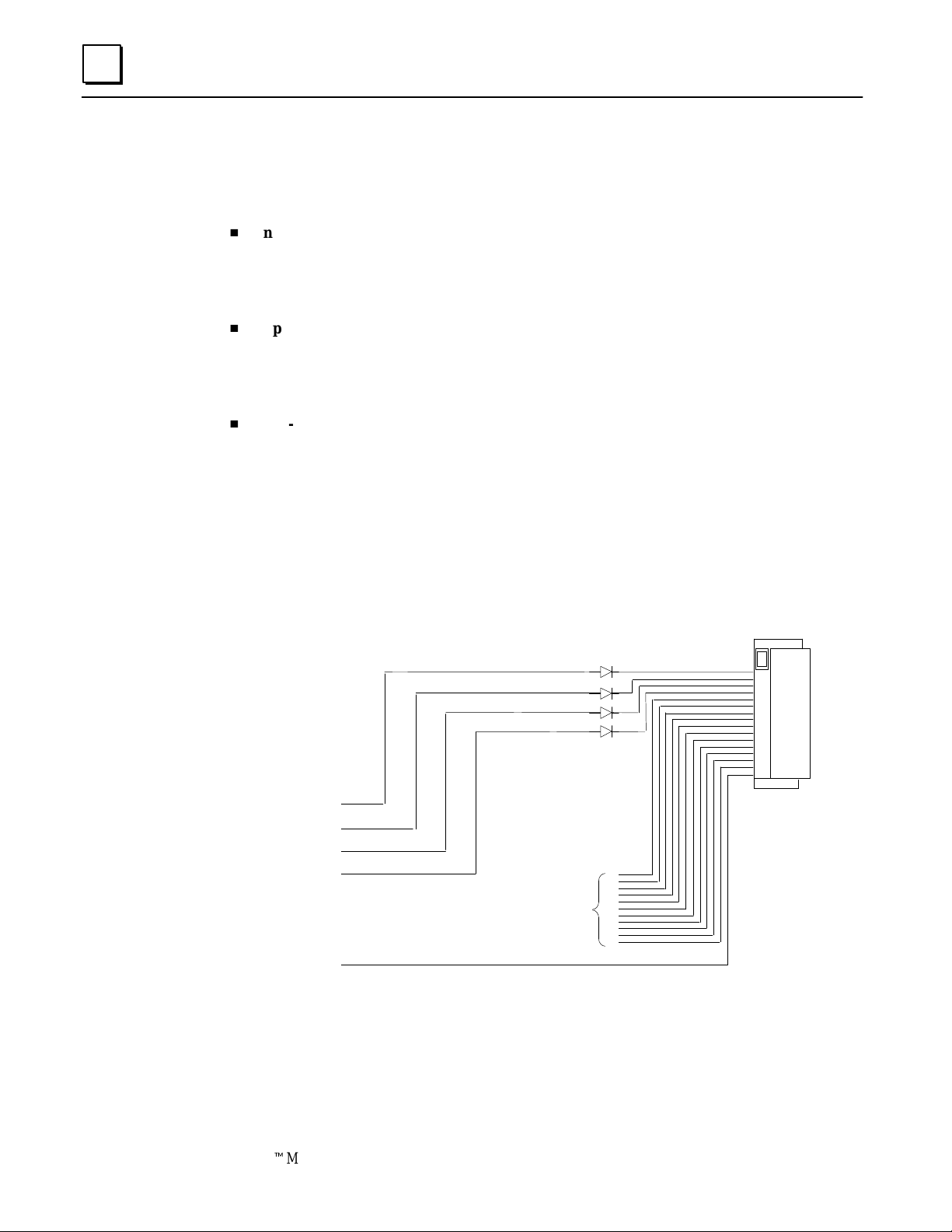

The GMR Software

The GMR software consists of:

H

The GMR configuration software file, CONFIG.EXE. This file, which runs under DOS, is

used to enter the system parameters that will be used by the GMR system software. When

the GMR configuration is completed, it produces a Program Block named G_M_R10.

H

A directory named GMRxxyy containing the GMR system software files, to which

the application program will be added. In the directory name GMRxxyy, xx is two

digits representing the major revision level of the GMR software. The last two digits

(yy) represent the minor software revision level.

H

A “teach” file named KEY0.DEF for use in future application program updates.

Subsequent chapters of this book explain configuration steps and programming

guidelines for a GMR system. The basic steps are illustrated below.

GMR

Diskette

CONFIG.EXE

GMRxxyy

KEY0.DEF

future

program

updates

GMR CONFIGURATION

LM90

Copy Folder

LM90 PROGRAMMING

LM90

Store

GMR

Configuration

Printout

G_M_R10

Program

Block

LM90

Librarian

LM90

Store

The

Application

Program

LM90 CONFIGURATION

Copy Folder

LM90

Store

LM90

Copy Folder

LM90

CONFIGBCONFIGA

CONFIGC

PLC A

PLC B PLC C

I/O Block Configuration with

Hand-held Monitor

1-10 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 18

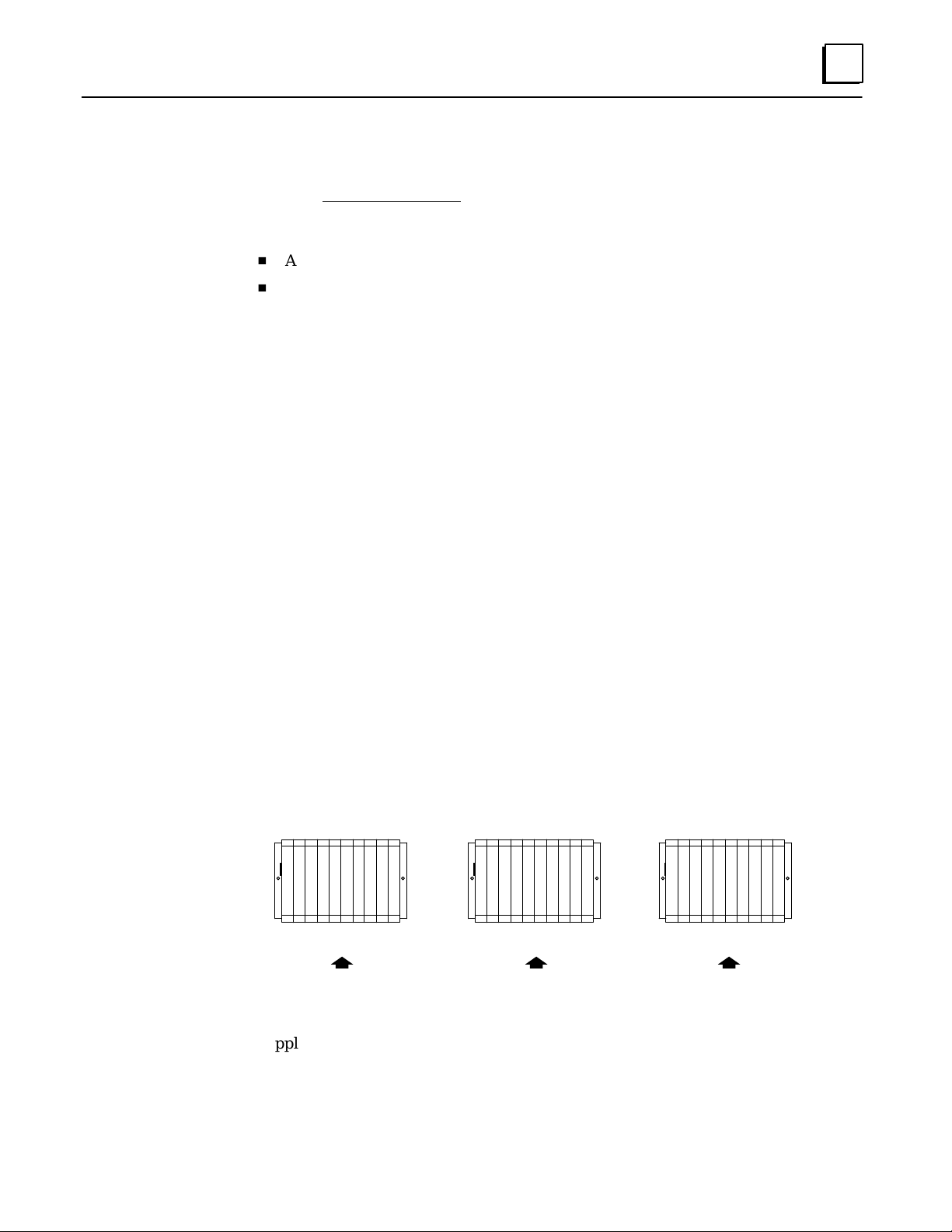

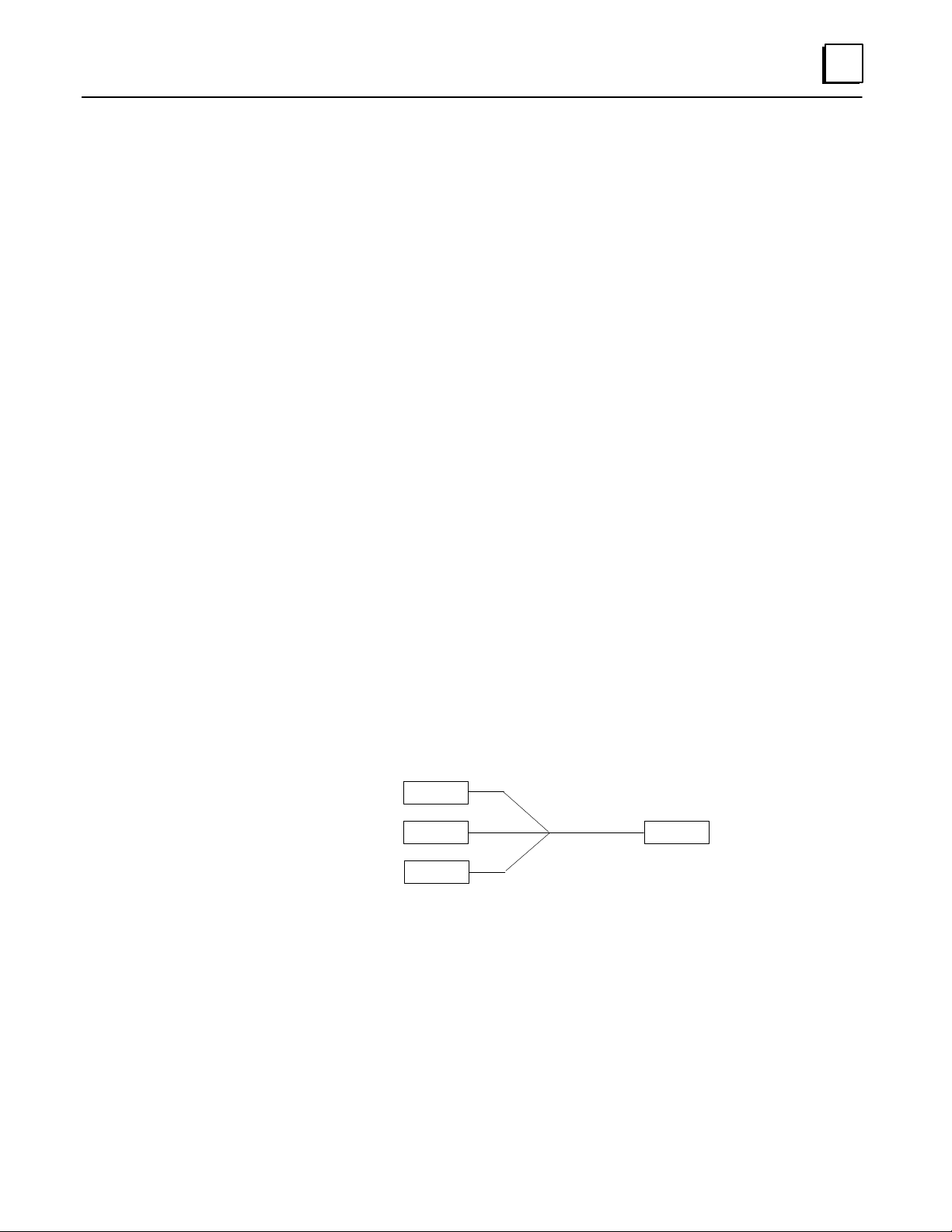

The Basic Steps of Configuration and Programming

1. Use the GMR configuration software to complete the GMR configuration. There is

only one GMR configuration needed for the system. GMR configuration sets up the

parameters that will be used by the system, including refer ence addr esses. The GMR

configuration software produces:

H

A printout of the GMR Configuration.

H

A program block named G_M_R10. This is later added to the application program.

2. Using the LM90 configuration software, create a Logicmaster configuration for

each PLC. The easiest way to do that is to:

A. Create a Program Folder for PLC A. W ith the GMR configuration printout as a

reference, complete its Logicmaster configuration.

B. Use the Copy Folder feature of the Logicmaster 90 programming software to

copy the configuration of PLC A to additional folders for PLC B and PLC C.

C. Edit the configurations for PLC B and PLC C as necessary .

3. Using a Hand-held Monitor , complete the Genius block configuration. Genius block

configuration sets up the operating characteristics of each block in the GMR system.

1

4. Using the Logicmaster 90 programming software, create the application program.

While there can be up to three PLCs in a GMR system, each of which has a slightly

different configuration, there is normally only one application program.

A. Using Logicmaster 90, copy the folder named GMRxxyy (for example,

GMR0101) from the GMR software diskette to a program folder with your

application program name (such as GMRPROG).

B. Using Logicmaster 90, add program block G_M_R10 (created with the

configuration utility) to the application program folder.

C. Create or add the application program logic in this folder.

5. After completing the application program and the configuration(s), store them to

the PLCs. As explained above, all redundant PLCs in the GMR system normally use

the same application program, but different configurations:

PLC A

PLC B PLC C

yyy

Program: GMRPROG

Configuration: CONFIGA

Supplying the configuration and program as separate files, as shown, makes it easier

to perform program updates in the future.

The GMR Configuration Software allows the system to be set up for online program

changes. Online changes are intended for system debug and commissioning.

Program: GMRPROG

Configuration: CONFIGB

Program: GMRPROG

Configuration: CONFIGC

1-11GFK-0787B Chapter 1 Introduction

Page 19

Chapter 2 Input Subsystem

section level 1 1

2

This chapter provides information about the inputs to a GMR system.

H

H

H

H

figure bi level 1

table_big level 1

Overview

GMR Input Groups

Non-Voted I/O in the Input Subsystem

Discrete Inputs

h

Types of Blocks in the Input Subsystem

h

Discrete Input Processing

h

Discrepancy Reporting for GMR Inputs

h

Input Autotest for GMR Inputs

h

Line Monitoring for Discrete Inputs

h

Manual Input Controls

H

Analog Inputs

h

Voted Analog Inputs

h

Analog Discrepancy Reporting

h

Non-Voted Analog Inputs in GMR Input Groups

h

Non-GMR Analog Blocks

GFK-0787B

2-1

Page 20

2

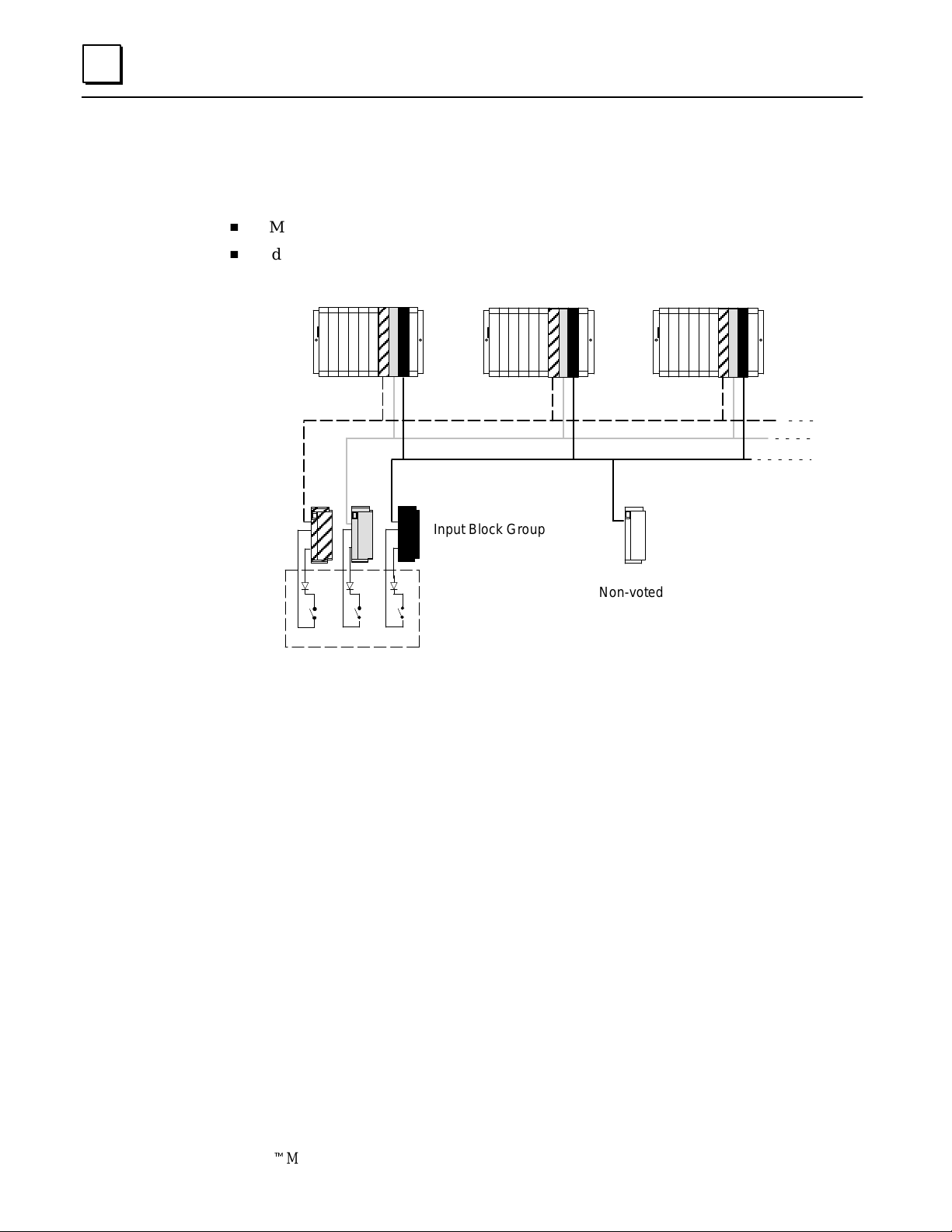

Overview

The input subsystem is the part of a GMR system that gathers input data. It may consist of:

H

GMR Input groups of 1 to 3 discrete or analog blocks

H

Individual non-voted discrete and analog blocks

The following illustration represents basic elements of an input subsystem.

Triple PLCs

Triple Genius Busses

Input Block Group

Non-voted

(non-redundant)

ABC

Triple Input Sensors

GMR blocks are arranged in “groups” of 1, 2, or 3 blocks. Within a group, all the blocks must be

the same type. The input group shown above consists of three Genius blocks. Each has its own

input sensors monitoring the same parts of the applic ati on process. Each block sends the input

data from its sensors to three Series 90-70 PLCs. F or si mpl i fication, the illus trati on only shows one

input circuit on each block. However , each group can serve multiple GMR inputs. In additi on,

circuits that are not needed for GMR inputs can be used for non-voted inputs or outputs.

Genius blocks broadcast their inputs. So each block’s input data is received by all PLCs on the

bus. The GMR system software in each PLC then performs input voting and provides the results

to its application program. If all input data is not availabl e, the software follows a configured

voting adaptation scheme. Details of both discrete and analog input voting are in the PLC

chapter.

In addition to the diagnostics capabilities of the Series 90-70 PLC and Genius I/O blocks,

the GMR system provides autotesting and discrepancy reporting for GMR inputs.

Input Block

Genius blocks configured for GMR operation automatically generate three copies of

their standard Genius fault report messages. They send one copy to the PLC Bus

Controller configured with serial bus address 31, one to 30, and one to 29. So all of the

GMR PLCs are able to monitor the blocks for Genius diagnostics.

2-2 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 21

GMR Input Groups

The configuration can include as many as 128 16-circuit voted discrete and 256 four-input analog

input groups. (The actual I/O capacity of the system depends on the CPU type. See page 1-9).

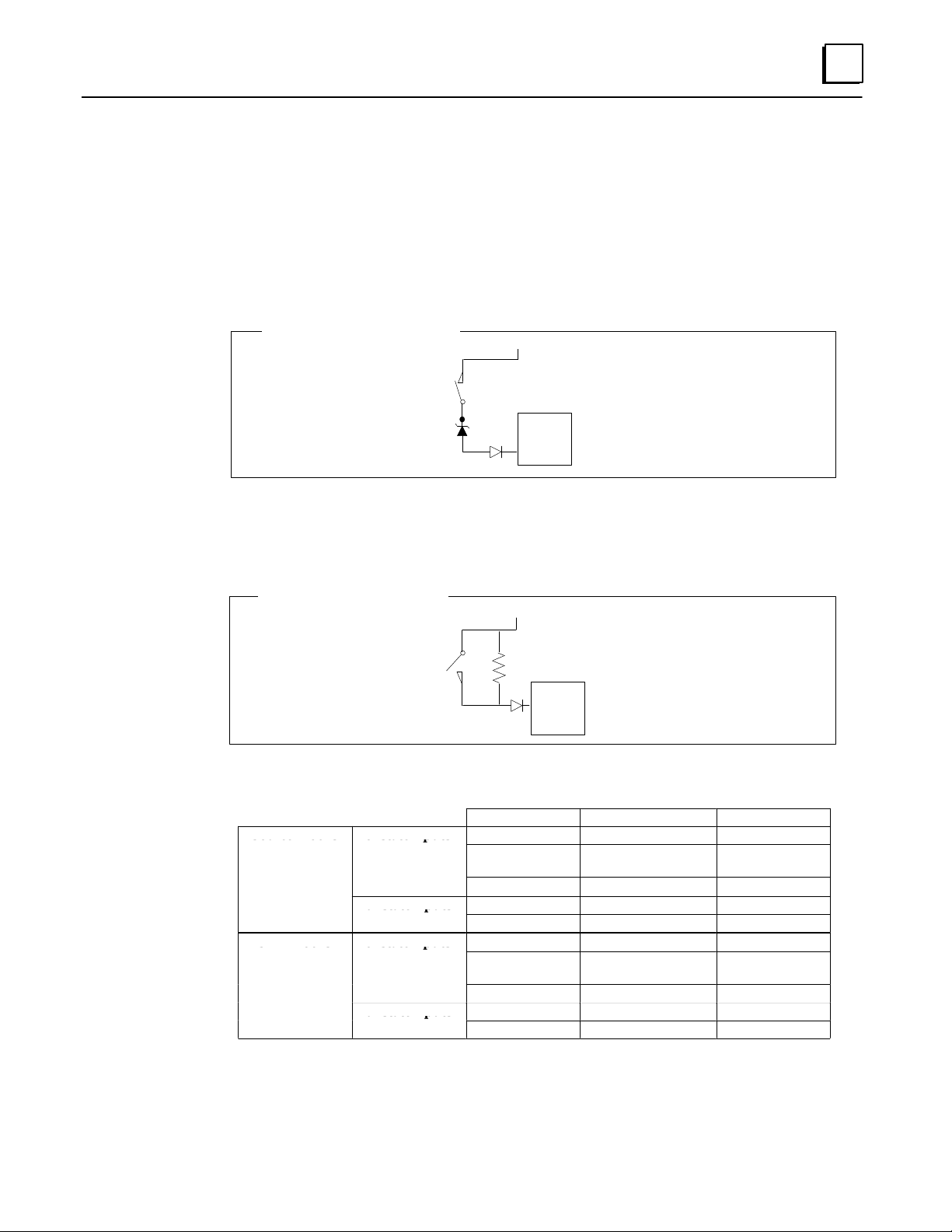

In an system that has normally-energized discrete inputs, the following combinations of

sensors and Genius inputs can be used with Genius Modular Redundancy.

H

one sensor to three Genius inputs, three busses, three PLCs

H

one sensor to two Genius inputs, two busses, two PLCs

2

Triple PLCs

Triple Genius Busses

Shaded items omitted

for duplex operation

Optional Zener

diode for line

monitoring

One Input Sensor

H

three sensors to three Genius inputs, three busses, three PLCs

H

two sensors to two Genius inputs, two busses, two PLCs

Triple PLCs

Triple Genius Busses

Shaded items omitted

for duplex operation

Optional Zener

diodes for line

monitoring

Triple Input Sensors

H

one sensor to one Genius input

Single blocks can be configured as non-voted GMR blocks, allowing them to take

advantage of the GMR autotest feature. Both discrete and analog blocks can be used;

however, analog blocks cannot be autotested.

2-3GFK-0787B Chapter 2 Input Subsystem

Page 22

2

Non-Voted I/O in the Input Subsystem

The input subsystem can also include three types of non-voted inputs:

H

Inputs from single-block (simple x) GMR input groups

Individual blocks can be included in the GMR configuration as “simplex groups”,

and can utilize the GMR features such as autotesting. Inputs from simplex blocks are

placed into the area of the Input Table used for GMR inputs.

H

Inputs from non-GMR I/O blocks

“Non-voted” blocks are individual blocks that are present on a GMR bus and are

included in the GMR configuration. However, their inputs are not voted on by the

PLC(s), and are located in a different area of the Input Table.

H

Non-voted points on individual blocks in a multiple-block GMR input group

Non-voted I/O points may be placed within a voted input group, to take advantage

of unused circuits. These extra circuits can be used as either inputs or outputs. If the

group utilizes GMR autotesting of inputs, circuit 16 on each block, which is required

for autotest, cannot be used for non-GMR I/O.

Example: a discrete input group consisting of three 16-circuit blocks has only four

voted inputs. That leaves circuits 5 through 15 on each block for use as non-GMR

inputs or outputs. Circuit 16 is used for the autotest feature.

Block A

1st GMR input

2nd GMR input

3rd GMR input

4th GMR input

Can be used as

non-GMR inputs

and outputs

GMR Autotest

Blocks B and C are the same

Individual input points used in this way can be autotested if autotesting is set up as

part of their GMR configuration.

2-4 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 23

Discr ete Inputs

Types of Blocks in the Input Subsystem

The following discrete block versions can be configured for GMR version 2.06 operation

and used as GMR input blocks:

All types of Genius blocks can be used as non-GMR blocks in a GMR system.

Note that the GMR Input Autotest feature requires point 16, so if the system uses Input

Autotest, point 16 is not available as an I/O point for the application (leaving either 15 or 31

points available on the blocks listed above).

24/48 VDC 16-Circuit Source block: IC660BBD020M or later

24/48 VDC 16-Circuit Sink block: IC660BBD021M or later

12/24 VDC 32-Circuit Source block: IC660BBD024N or later

5/12/24 VDC 32-Circuit Sink block: IC660BBD025N or later

2

Discrete Input Processing

Discrete input processing is handled in each PLC, by the GMR system software. The

manner in which inputs are handled depends upon whether a block is included in the

GMR configuration, and if it is, upon whether it is part of a 3-block, 2-block, or 1-block

group. Input processing by the PLC is explained in detail in the PLC chapter. In general,

the GMR system software compares input data from all corresponding inputs (3, 2, or 1)

for each point, and provides a voted input result for use by the application program. If

all the input data is not available, the GMR system software follows a configured voting

adaptation scheme. The application program can also access the original, unvoted input

data, along with any non-GMR inputs that have been included in the input subsystem.

Field Input Data

Input A

Input B

Input C

0

0

1

GMR Software Performs

2 out of 3 V oting

Single Input Provided to Applica-

tion Logic

0

Discrepancy Reporting for GMR Inputs

For GMR inputs, if there is a discrepancy between the original input data for an input

and the voted input state, the GMR software automatically places a message in the I/O

Fault Table, where it is available to the Logicmaster 90 software and the application

program logic. This is also described in more detail in the PLC chapter. Fault bits are also

set for input discrepancies. These fault bits are available for use in the application

program, for further annunciation or corrective action.

Discrepant signals are filtered for a configurable time period, to eliminate transient

discrepancies caused by timing differences.

2-5GFK-0787B Chapter 2 Input Subsystem

Page 24

2

Input Autotest for GMR Inputs

During GMR configuration, input autotesting can be individually turned on or off for each

input in an input group. The GMR software will automatical l y test the selected inputs for the

ability to reach the alarm state. The ability to diagnose short circuits on inputs depends on

whether the circuit is set up as a bistate or tristate input, and on whether the block itself is

configured for GMR mode (using the Hand-held Monitor).

H

Autotesting checks the ability of the input electronics to recognize both the On and

the Off state. During each Input Autotest, some inputs are forced to the Off state by

de-energizing the power feed output, and some are forced to the On state via the

Genius block electronics. See page 5-6 for more detailed information.

H

Input autotesting also detects circuit-to-circuit shorts.

H

Note: blocking diodes are required to use the Input Autotest feature. These diodes

are in addition to a Zener diode that may be added for line monitoring.

+24V

Optional Zener diode

for line monitoring

Source

Genius

Block

See page 5-6 for more detailed information about input autotesting. Also see pages 8-3

through 8-9 for Autotest wiring information.

Calculating Voltage Drops on Tristate Inputs

It is important to consider the field wiring runs required for devices configured as

tristate inputs. Devices that are powered by 24V DC will have a voltage-reducing

component inserted at the field device to provide an input threshold range for three

states. The table on the next page shows appropriate ranges. Wiring r uns can reduce the

voltage at the input block terminal further, to an inoperable level, depending on the

length, conductor, and gauge. Isolation diodes placed before the terminal on the input

will also drop the voltage.

Most applications do not have limitations created by these factors. However, to ensure

that all input state operations are indicated correctly, calculations should include the field

signal voltage, the wire resistance times the length and the voltage drop in any barriers

or isolation devices, to determine the actual voltage present at the input terminal.

Additional information about input blocks is located in the Genius I/O Discrete and Analog

Blocks User’s Manual (GEK-90486-2).

2-6 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 25

Source Blocks

tristate inputs

Source Blocks

tristate inputs

bi-state inputs

bi-state inputs

Sink Blocks

tristate inputs

Sink Blocks

tristate inputs

bi-state inputs

bi-state inputs

2

Line Monitoring for Discrete Inputs

Normally-closed inputs on GMR -configured blocks can be monitored for short circuit

faults. Normally-open inputs on blocks which are not configured in GMR mode can be

monitored for open circuit faults.

Normally-closed Inputs

For applications such as Emergency Shutdown (ESD), normally-closed inputs are generally

monitored for short circuits across the lines, since that represents a fail to danger condition

(that is: trip is not detected). In general, these inputs are powered from +24V, and a field

short to ground is interpreted as a trip condition.

Typical Normally-closed Input

Normally-open Inputs

For applications such as Fire and Gas Detection, normally-open inputs are generally

monitored for open circuits on the lines, since that represents a fail to danger condition

(that is: trip is not detected). In general, these inputs are powered from +24V, and a field

short to +24V is interpreted as a trip condition.

Typical Normally-open Input

+24V

Source

Genius

Block

+24V

Source

Genius

Block

When a block is configured (with a Hand-held Monitor) as a GMR block, its input thresholds

change to those listed below.

Input Voltage Input Status Input State

<30% V

>50% V

< Vdc–7V

dc

dc

< Vdc–4V

<30 V

dc

>50% V

<50% V

>70% V

<50% V

>70% V

dc

<4V short circuit fault 1

>7V

dc

dc

dc

dc

off 0

on 1

short circuit fault 1

off 0

on 1

on 1

off 0

on 1

off 0

Input Filter Time

For any circuit configured as a tristate input, the Input F ilter Time configured for the block

(using a Hand-held Monitor) must be at least 30mS.

2-7GFK-0787B Chapter 2 Input Subsystem

Page 26

2

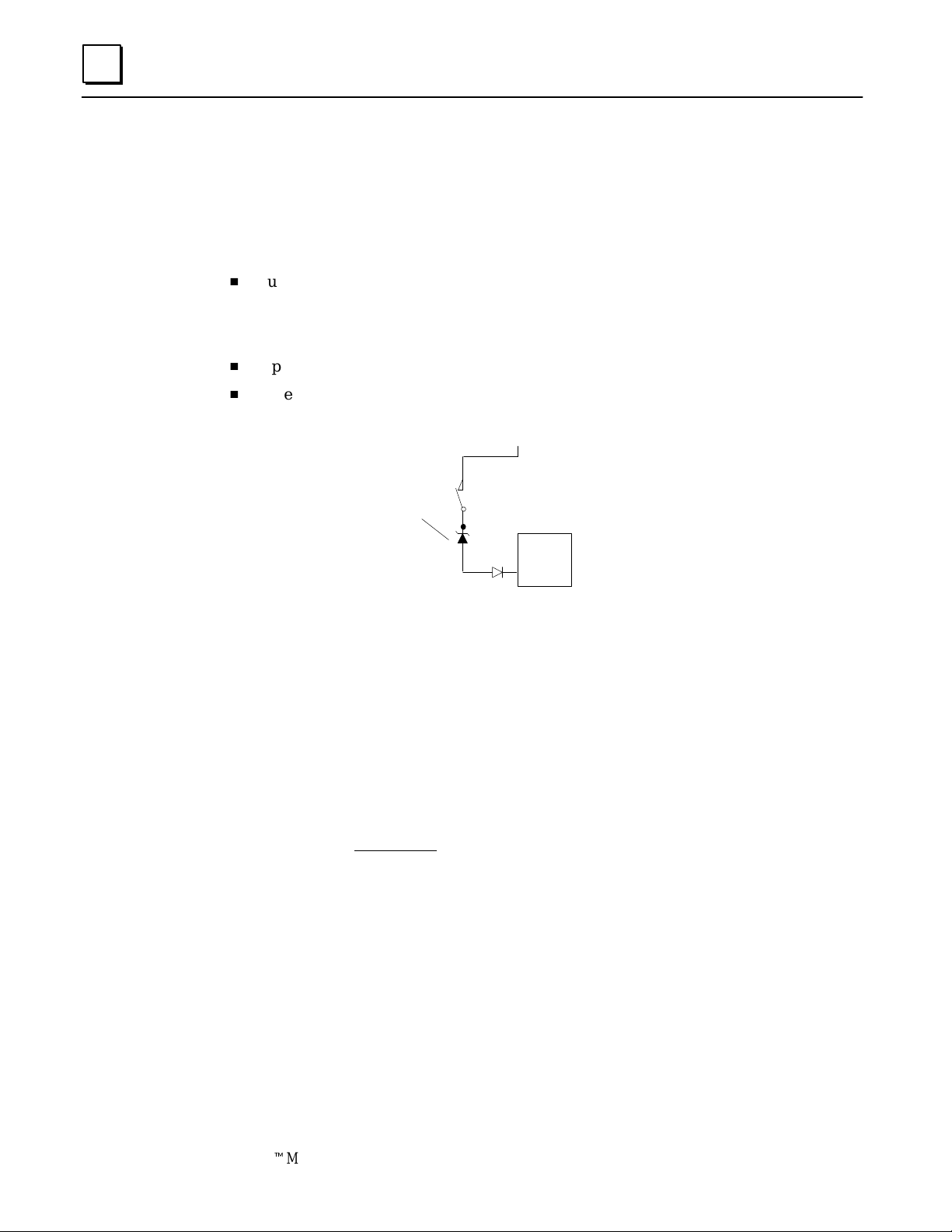

Manual Input Controls

Safety systems often use controls for manual trip and manual inhibit. The GMR autotest and

fault processing operations are unaffected by such controls.

H

A manual trip causes the input to assume the alarm condition. For example, for a

normally-energized input, the input is open circuit.

H

A manual inhibit causes the input to remain in the normal condition. F or e xample,

for a normally-energized input, the input is held high even if the device is in the Off

state.

These manual controls can be implemented either in hardware or in software.

Hardware control usually consists of switch contacts applied to the input circuit, as shown

below for a normally-energized input. Repeat contacts of the control switches are often input

into the system for reporting purposes.

Field

Circuit

System Input

Manual Inhibit

System Input

Manual Trip

point 1

Source

Genius

Block

point 16

point 1

Source

Genius

Block

point 16

point 1

Source

Genius

Block

point 16

2-8 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 27

Analog Inputs

Like discrete blocks, analog blocks can be used in the input subsystem as members of

GMR input groups of 1 to 3 blocks, or as non-voted blocks. Also like discrete blocks,

individual circuits of analog blocks in multiple-block GMR input groups can be used as

non-voted analog inputs.

Analog blocks in GMR input groups are not autotested by the GMR software.

All of the available types of analog blocks can be used, including the Thermocouple and

RTD blocks. See the Genius I/O Discrete and Analog Blocks User’s Manual for information

about the various analog Genius blocks.

The application program can reference all analog inputs directly, whether they are

located in the non-voted analog inputs area or not.

V oted Analog Inputs

For voted analog inputs, analog blocks must be set up as 2-block or 3-block input groups.

The input values are in engineering units.

2

For a 3-block group, the GMR software compares the three corresponding inputs for

each channel and selects the intermediate value. This value is made available to the

application program. The application program can also access the original input values.

Field Input Data

Input A

Input B

Input C

For example, in the illustration above, inputs A, B, and C might represent the first

channel on each block in a three-block group. The PLC would place the selected input

value into the first voted input word for that group.

152

150

110

PLC Selects the

Intermediate Value

Single Input Provided

to Application Logic

150

Number of Input Sensors per Voted Channel

For each voted input channel in a 3-block group, either single or triple input sensors that

are compatible with the input drive requirements of the Genius blocks can be used.

Current-loop (4-20mA) devices must be converted to voltage when a single sensor is

used.

Analog Voting Adaptation

If a failure (discrepancy fault, or Genius fault) occurs, the GMR software rejects the

faulty data. Depending on the configuration of the input group, input voting may go

from three inputs to two inputs to one input, or from three inputs to two inputs to the

configured default value.

2-9GFK-0787B Chapter 2 Input Subsystem

Page 28

2

Analog Discrepancy Reporting

When the GMR software compares analog input data, it checks each channel against

discrepancy limits provided as a part of the configuration for that input group. Any

channel that varies by more than a configurable percentage from the intermediate value

is reported.

Discrepancy signals are filtered for a configurable time period, to eliminate transient

discrepancies caused by timing differences.

Non-Voted Analog Inputs in GMR Input Groups

If a system includes analog inputs that do not require redundancy, they are usually

located on individual analog blocks. However, they can also be located on channels of

blocks in a GMR analog input group that do not require redundancy. For e xample, a

group of three 6-channel analog input blocks might use only four voted inputs on each

block. That would leave inputs 5 and 6 available for connection to other sensors not

requiring voting.

Non-GMR Analog Blocks

Individual analog blocks can be used as input blocks or combination input/output blocks.

All of the operating features of these blocks are available.

Individual non-voted analog blocks can be included in the GMR configuration.

2-10 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 29

Chapter 3 Output Subsystem

section level 1 1

3

This chapter describes GMR output subsystem.

H

H

H

figure bi level 1

table_big level 1

Overview

Types of Blocks in the Output Subsystem

GMR Output Handling

h

Output Voting

h

Duplex Default for Outputs

h

Output Forces and Overrides

h

Output Fault Reporting

H

4-Block Output Groups

h

Output Load Sharing

H

Manual Output Controls and Diagnostics

H

Redundancy Modes for Output Blocks

h

GMR Mode

h

Hot Standby Mode

GFK-0787B

3-1

Page 30

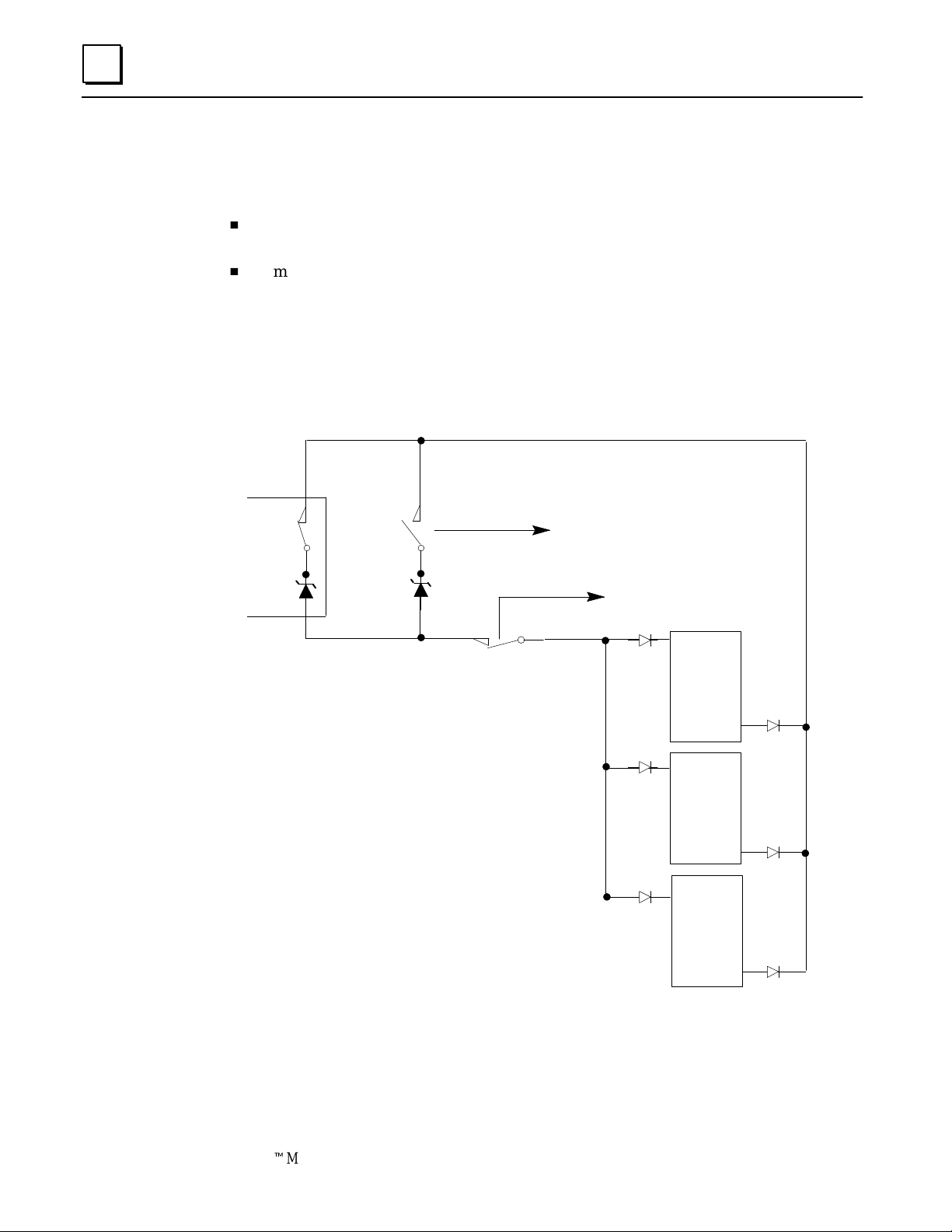

3

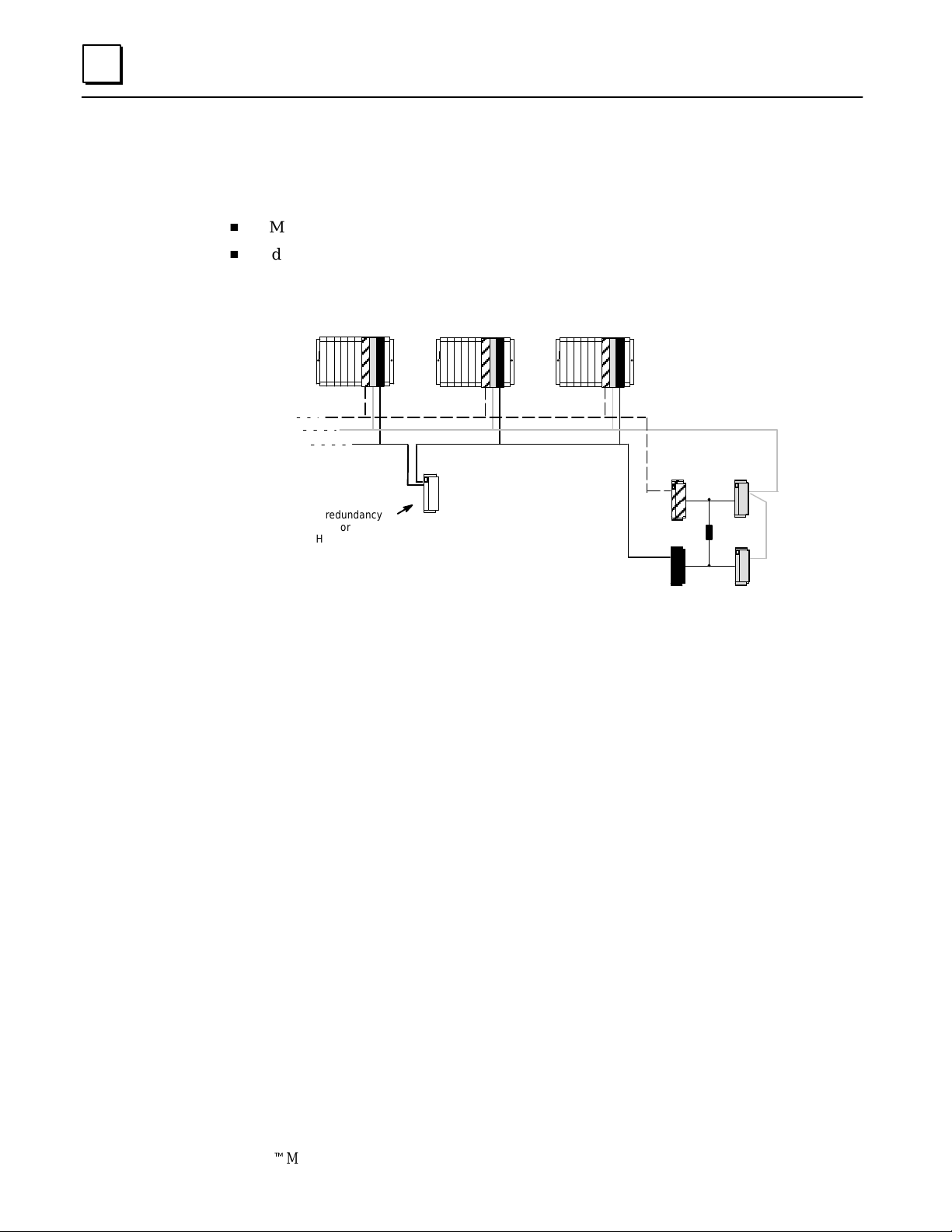

Overview

The output subsystem is the part of a GMR system that provides output data. It may consist of:

H

GMR Output groups of 4 discrete blocks

H

Individual non-GMR discrete and analog blocks

The following illustration represents basic elements of an output subsystem.

ABC

No redundancy

or

Hot Standby

or

Duplex

In a 4-block output group, each field output is supported by two Genius source outputs

connected in parallel on one side of the actuator and two Genius sink outputs connected

in parallel on the other. Each block in the group receives outputs from each of the three

separate processors. Three Genius busses are used.

Individual Genius blocks can also be connected to the system. These blocks may be

configured for either hot standby or duplex CPU redundancy if desired.

ABC ABC

A

Load

DC

4-Block Output Group

B

Types of Blocks in the Output Subsystem

The following discrete block versions can be configured for GMR operation. They will

perform output voting and autotesting when used in GMR mode:

24/48 VDC 16-Circuit Source block:

24/48 VDC 16-Circuit Sink block:

12/24 VDC 32-Circuit Source block.

5/12/24 VDC 32-Circuit Sink block:

3-2 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

IC660BBD020M

IC660BBD021M

IC660BBD024N

IC660BBD025N

GFK-0787B

Page 31

GMR Output Handling

Unlik e GMR input voting, which is done by the GMR software in the PLCs, output voting is

performed at the output block groups. To perform output voting, the blocks must be one of the

listed types, and they must be configured (with a Hand-held Monitor) to be in GMR mode.

Output Voting

A GMR output block group compares corresponding output data for each point as

received from each of the three PLCs. If all three PLCs are online, the data from at least

two must match. The block group sets each output load to match the state commanded

by at least two of the PLCs.

Outputs from 3 PLCs

PLC A

3

Single Output

0

Provided to

Field Device

PLC B

PLC C

If only two of the three PLCs are communicating on the bus and they send matching

output data for a point, the block group sets the output to that state.

If only two PLCs are communicating, the block group performs 2 out of 3 voting using

the data from the two online PLCs and the block’s configured duplex default state in

place of the offline PLC data.

If only one of the three bus controllers is present on the bus, the block group sets output

states to match the output data sent by that PLC.

If the Simplex Shutdown feature is enabled, a PLC will shut down if it determines that it

is the only PLC still operating. The timeout period before it shuts down is configured as

the next item. When the PLC shuts down and a block group is no longer receiving

output data, outputs will go to their default state or last state, as configured at each block

group.

If all PLCs are offline, the block group forces its outputs to the block’s configured default state.

The voted state of the output is available to the GMR system for monitoring purposes to

determine output discrepancies. However, the voted output state is not available to the

application program.

0

1

GMR Block Performs

2 out of 3 V oting

0

Duplex Default for Outputs

As mentioned, the duplex default state is used when a block determines that only two PLCs

are online. The Duplex Default state of On or Off is used by the 2 out of 3 voting algorithm

in the block group, instead of the state that would have been supplied by the third PLC.

The Duplex Default state determines whether voting will be 1 out of 2 or 2 out of 2 when

only two PLCs are providing outputs. This is explained on the next page.

3-3GFK-0787B Chapter 3 Output Subsystem

Page 32

3

The following three tables compare voting results for a block group receiving outputs

from all three PLCs with results when one of the three PLCs is offline.

Results of Block Group Voting with Three PLCs Online

For comparison, this table shows how a block group votes on outputs received from

three PLCs when all three are online. The block group doesn’t use the Duplex Default, so

it is shown as an X (don’t care).

PLC A Output

State

0 0 0 X 0

0 0 1 X 0

0 1 0 X 0

0 1 1 X 1

1 0 0 X 0

1 0 1 X 1

1 1 0 X 1

1 1 1 X 1

PLC B Output

State

PLC C Output

State

Duple x Default

Setting in Block

Output State

Results of Block Group Voting with Two PLCs Online, and Duplex Default Set to 1

If one PLC is offline, the outputs from both online PLCs must be 0 for the voted output

state to be 0. The voted output is 1 if either of the online PLCs outputs a 1.

PLC A Output

State

0 0 1 0

0 0 1 0

0 1 1 1

0 1 1 1

1 0 1 1

1 0 1 1

1 1 1 1

1 1 1 1

PLC B Output

State

PLC C Output

State

Duple x Default

Setting in Block

Output State

Results of Block Group Voting with Two PLCs Online, and Duplex Default Set to 0

If one PLC is offline, the inputs from both online PLCS must be 1 for the voted output to

be 1. The voted output is 0 if either of the online PLCs outputs a 0.

PLC A Output

State

0 0 0 0

0 0 0 0

0 1 0 0

0 1 0 0

1 0 0 0

1 0 0 0

1 1 0 1

1 1 0 1

PLC B Output

State

PLC C Output

State

Duple x Default

Setting in Block

3-4 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

Output State

GFK-0787B

Page 33

Results of Block Group Voting with One PLC Online

If two PLCs are offline, the “voted” outputs are the same as the outputs from the PLC

which is still online (x = don’t care).

3

PLC A Output

State

0 x 0

0 x 0

0 x 0

0 x 0

1 x 1

1 x 1

1 x 1

1 x 1

PLC B Output

State

PLC C Output

State

Duple x Default

Setting in Block

Output State

PLC Logon Control

To prevent untripping of tripped block outputs, blocks do not use output data from a

PLC that has previously been offline until one of the following occurs:

A. all of the output data received from the newly-online PLC agrees with the voted

output data of the block.

B. the user forces the PLC to log onto the output block(s) by turning on the GMR

control bit FORCLOG (Force Logon).

For more information about PLC Logon control, please see page 7-17.

Output Fault Reporting

On detection of any block or circuit fault, a directed fault message is transferred to the

three PLCs on an event-driven basis.

The PLC currently operating as the Autotest Master also monitors output blocks for

discrepancies between the output values commanded by the PLCs. If a PLC is offline, its

data is not considered “discrepant”. But if a PLC is online and its data is discrepant, the

GMR software logs a fault into the I/O Fault Table of the PLC that detects the

discrepancy which is copied to the other PLCs. The appropriate fault references are also

set in each PLC.

3-5GFK-0787B Chapter 3 Output Subsystem

Page 34

3

4-Block Output Groups

All four blocks in a group must be either 16-circuit or 32-circuit blocks. In a group, two

source-type Genius blocks are connected in parallel on one side of each load, and two

sink-type Genius blocks are connected in parallel on the other side.

Bus A

There are three busses. One source block and one sink block are connected to either bus

A or bus B (see blocks B and D on bus B in the illustration above). The other two blocks

are connected to the remaining two busses (A and C above).

Bus C

Bus B

Source Blocks

(IC660BBD020

or

IC660BBD024)

A

Load

CD

Sink Blocks

(IC660BBD022

or

IC660BBD025)

B

The illustration shows just one load for a group of four blocks. However, up to 16 loads

could be controlled by the same group of four blocks (using 16-circuit blocks).

When the blocks are configured, each is assigned the same output reference addresses

using Logicmaster 90. Then, the blocks are configured for GMR mode using the Genius

Hand-held Monitor.

Output circuits that are to be autotested must be able to withstand the On and Off pulse

times used by the test. Check each output device’s characteristics against the

specifications listed on page 8-12 (for 16-point blocks) and page 8-17 (for 32-point blocks)

to verify that it can be autotested and/or used in a 4-block output group.

Output Load Sharing

In a 4-block output group, current to output loads is shared. Therefore, it is not possible

to be sure exactly how much power is being provided by each block. If 16-circuit blocks

in a GMR output group are configured for No Load fault reporting, the minimum

connected load that can be used is 100mA. If blocks in a 4-block output group are

configured for No Load reporting, a system output No Load fault will only be reported if

both of the source blocks or both of the sink blocks report No Load faults.

3-6 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 35

Operation of a 4-Block Output Group

Each GMR output state is sent to four blocks set up in an H-pattern as shown on the

opposite page. This type of grouping creates a fault-tolerant system where any single

point of failure does not cause the system to lose control of a critical load. This is

achieved by:

H

output voting (which is explained on page 3-3), and

H

the electrical characteristics of sink and source blocks, and

H

redundant busses.

Electrical Characteristics of Sink and Source Blocks

If a load is wired between a sink and source block, both the sink output and the source

output must be active to control the load. If either the sink output or the source output

fails On, turning the other Off, turns the load Off. Doubling the number of blocks to

four and putting them in an H pattern means that if any single point of failure occurs,

the system can still control the load.

The following chart shows how the GMR system uses the 4-block H-pattern output

group to maintain control of critical loads following certain types of failures. All

operating blocks receive the same I/O data, because within a fault-tolerant 4-block

H-pattern group, all four blocks are configured at the same output address. The chart

indicates which blocks actually affect the state of the load under different fault scenarios.

All operating blocks act on the I/O data received.

3

Other Blocks Used Other Blocks Used

Fault To Turn the Load Off To Turn the Load On

output at block A fails On turn outputs at block C and D Off turn output at block C or D On

output at block A fails Off turn output at block B off turn output at block B and either C or D On

output at block B fails On turn outputs at block C and D Off turn output at block C or D On

output at block B fails Off turn output at block A off turn output at block B and either C or D On

output at block C fails On turn outputs at block A and B Off turn output at block A or B On

output at block C fails Off turn output at block D off turn output at block D and either A or B On

output at block D fails On turn outputs at block A and B Off turn output at block A or B On

output at block D fails Off turn output at block C off turn output at block C and either A or B On

Bus Redundancy in a 4-Block Output Group

If one of the three busses in an output group is damaged or cut, there is still I/O data

communicated to at least one sink output and one source output to control the load.

When a block loses communication with all the PLCs, its outputs go to a default state. If

the default state is Off, the system is fault-tolerant as shown in the following chart.

Fault To Turn the Load Off or On

bus A fails busses B and C still provide I/O communications to blocks B, C, and D;

turning outputs at those blocks On or Off turns the load On or Off.

bus B fails busses A and C still provide I/O communications to blocks A and C; if the

block B and D outputs are configured to default Off, turning output at

blocks A and C On or Off turns the load On or Off.

bus C fails busses A and B still provide I/O communications to blocks A, B, and D;

turning outputs at those blocks On or Off turns the load On or Off.

3-7GFK-0787B Chapter 3 Output Subsystem

Page 36

3

Manual Output Controls and Diagnostics

Safety systems are often provided with controls for manual trip and manual override.

H

A manual trip causes the output to assume the alarm condition. For example, a

normally-energized output would be de-energized.

H

A manual override causes the output to remain in the normal condition. For

example, a normally-energized output is held energized.

These manual controls can be implemented either in hardware, as represented below, or in

software. If the software method is used, GMR autotest and fault processing operations are

unaffected.

Hardware control usually consists of switch contacts applied to the output circuit, as shown

below (for a normally-energized output).

+24V

Manual

Source

Genius

Block

System Input

Sink

Genius

Block

System Input

In this circuit, operation of either the trip or override switch can cause no-load faults, state

faults, and autotest faults to be generated. In the GMR system, fault reporting can be

modified to suppress no-load faults and state faults by wiring additional inputs that reflect

the states of the manual override and manual trip input switch to the GMR system. The GMR

system then takes these into account before reporting faults. Use of manual controls does not

affect fault reporting for Short Circuit, Overtemperature, Overload, or Discrepancy faults.

(see chapter 5, “Monitoring Manual Output Controls”).

Override

Manual Trip

LOAD

Manual

Override

+0 VDC

Source

Genius

Block

Sink

Genius

Block

3-8 GeniustModular Redundancy Flexible Triple Modular Redundant (TMR) System

User’s Manual – March 1995

GFK-0787B

Page 37

Redundancy Modes for Output Blocks

There are three separate configuration processes for a GMR system:

H

GMR configuration, which supplies parameters used by the GMR system software.

H

PLC configuration, which is performed as usual for a Series 90-70 PLC system using

the Logicmaster 90 software.

H

Genius block configuration, which sets up the operating characteristics of the blocks

themselves.

It is during Genius block configuration that the redundancy mode of blocks is selected.

This is particularly relevant to the operation of output blocks. The four possible choices

for redundancy mode are:

A. GMR

B. Hot Standby PLC Redundancy

C. Duplex PLC Redundancy

3

D. No PLC Redundancy

Blocks in an output group must be set up for GMR mode. This changes the operating

characteristics of the block as described.

Individual output blocks (or combination I/O blocks) can be set to any of the latter three

modes (above). Block operation in these modes is described in the Genius I/O System User’s

Manual and in the Genius Discrete and Analog Blocks User’s Manual.

If an individual block is configured for Hot Standby redundancy mode, it can be included in

the GMR configuration as a Non-voted Discrete Group.

Blocks that are set up for Duplex PLC redundancy or no redundancy are not autotested.

They operate in the same manner as Duplex blocks in a non-GMR system.

GMR Mode

Configuring a block for GMR mode changes its operating characteristics as described below.

H

GMR mode supports non-redundant outputs with or without pulse test, and

redundant outputs with or without output autotest.

H

To prevent false Failed Switch diagnostics during switching transitions, detection of

Failed Switches is delayed for one second.

H

For the 16-circuit DC block, detection of No-load faults is delayed for one second.

This prevents No-load faults being falsely reported during switching transitions.

H

Operation of Block OK LED is modified. For the 16-circuit DC block, the Unit OK

LED does not indicate No-load faults when the block is in GMR mode. This is

necessary, since blocks may share output loads.

H

Modified fault reporting. In GMR mode, blocks automatically report faults to bus

controllers at serial bus addresses 29, 30, and 31.

3-9GFK-0787B Chapter 3 Output Subsystem

Page 38

3

Hot Standby Mode

Individual blocks can be included in the output subsystem as GMR blocks, Hot Standby

blocks, or non-GMR blocks. There are significant differences in block operation between