Page 1

GE Fanuc Automation

Programmable Control Products

Series 90t-70

Remote I/O

Scanner

User’s Manual

GFK–0579B July 1992

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL–002

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding

and operating the equipment.

This document is based on information available at the time of its publication. While

efforts have been made to be accurate, the information contained herein does not

purport to cover all details or variations in hardware or software, nor to provide for

every possible contingency in connection with installation, operation, or maintenance.

Features may be described herein which are not present in all hardware and software

systems. GE Fanuc Automation assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or

statutory with respect to, and assumes no responsibility for the accuracy, completeness,

sufficiency, or usefulness of the information contained herein. No warranties of

merchantability or fitness for purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alar m Master CIMST AR Helpmate PROMA CRO Series Six

CIMPLICITY GEnet Logicmaster Series One Series 90

CIMPLICITY 90–ADS Genius Modelmaster Series Three VuMaster

CIMPLICITY PowerTRA C Genius PowerTRA C ProLoop Series Five Workmaster

Copyright 1992 GE F anuc A utomation North America, Inc.

All Rights Reserved

Page 3

Content of this Manual

This book is a reference to installing, configuring, and using a GE Fanuc Series 90t–70

Remote I/O Scanner (IC697BEM733).

Chapter 1. Introduction: This chapter describes the Remote I/O Scanner and other

equipment that may be used with it. It discusses Geniust bus operation as it relates to

the Remote I/O Scanner, and describes how the Remote I/O Scanner can be used in

redundancy systems. Chapter 1 also describes configurable features of a remote drop,

and explains configuration methods.

Chapter 2. Installation: Explains how to properly install the components of a remote

drop, including Series 90–70 racks, a Remote I/O Scanner, and other Series 90–70

modules. Chapter 2 also explains how to complete the Genius bus connections and how

to connect a programmer to the Remote I/O Scanner.

Chapter 3. Remote I/O Scanner Operation: Describes the memory and operating

modes of the Remote I/O Scanner, and explains its operation. This chapter also explains

how option modules such as the Programmable Coprocessor Module (PCM) could be

used in a remote drop.

Preface

Chapter 4. Configuration with Logicmastert 90–70: Explains configuration steps

using Release 4 of the Logicmaster 90–70 configuration software.

Chapter 5. Logicmaster 90 Operation with a Remote Drop: Explains how to set up a

Logicmaster 90 programmer to communicate with a remote drop. This chapter also

describes functional differences in LM90 when it communicates with a remote drop.

Chapter 6. Remote Drop Configuration with a Hand–held Monitor: Explains how to

configure a remote drop using a Genius Hand–held Monitor.

Chapter 7. Monitoring and Controlling Remote Drop Data: Explains how the I/O data

for a remote drop can be displayed on a Hand–held Monitor or programmer. Chapter 7

also describes how I/O circuits can be forced, toggled, or overwritten.

Chapter 8. Diagnostics and Fault Clearing: Explains how diagnostic information from a

remote drop can be displayed on a Hand–held Monitor or programmer, and how faults

can be cleared.

Chapter 9. Remote I/O Scanner Datagrams: Describes datagrams that can be sent to a

Remote I/O Scanner. Chapter 9 also shows the format of the Remote I/O Scanner’s

Report Fault datagrams.

Appendix A. Estimating the Maximum Number of Remote Drops for a Bus: Shows

how to roughly estimate how many remote drops can be on a bus with one Bus

Controller, one Hand–held Monitor, no Genius blocks, and no programmed

communications.

Appendix B. Finding the I/O Configuration Data Total of a Remote Drop: Gives

instructions for finding the amount of configuration data needed for the I/O modules in

a remote drop.

iii

Page 4

Preface

Appendix C. Logicmaster 90–70, Release 3, Series 90–70 PLC Configuration

Instructions: Explains how to complete the PLC portion of the configuration if you are

using Release 3 of the Logicmaster 90–70 software.

Appendix D. Logicmaster 90–70, Release 3, Remote Drop Configuration Instructions:

Explains how to configure a remote drop if you are using Release 3 of the Logicmaster

90–70 software.

Related Publications

For more information, refer to these publications:

Genius I/O System User’s Manual (GEK–90486–1). Reference manual for system

designers, programmers, and others involved in integrating Genius I/O products in a

PLC or host computer environment. This book provides a system overview, and

describes the types of systems that can be created using Genius products. Datagrams,

Global Data, and data formats are defined.

Series 90–70 PLC Installation and Operation Manual (GFK–0262). This book describes

the modules of a Series 90–70 PLC system, and explains system setup and operation.

Logicmaster 90–70 User’s Manual (GFK–0263). Reference manual for system operators

and others using the Logicmaster 90–70 software to program, configure, monitor, or

control a Series 90–70 PLC and/or a remote drop.

Logicmaster 90 Software Reference Manual (GFK–0265). Reference manual which

describes program str ucture and defines program instructions for the Series 90–70 PLC.

Series Sixt

Controller, which interfaces a Genius bus to a Series Six PLC. This book describes the

installation and operation of the Bus Controller. It also contains the programming

information needed to interface Genius I/O devices to a Series Six PLC.

Series Five Bus Controller User’s Manual (GFK–0248). Reference manual for the Bus

Controller, which interfaces a Genius bus to a Series Five PLC. This book describes the

installation and operation of the Bus Controller. It also contains the programming

information needed to interface Genius I/O devices to a Series Five PLC.

Genius I/O PCIM User’s Manual (GFK–0074). Reference manual for the PCIM, which

interfaces a Genius bus to a suitable host computer. This book describes the installation

and operation of the PCIM. It also contains the programming information needed to

interface Genius I/O devices to a host computer.

Bus Controller User’s Manual (GFK–0171). Reference manual for the Bus

We Welcome Your Comments and Suggestions

At GE Fanuc automation, we strive to produce quality technical documentation. After

you have used this manual, please take a few moments to complete and return the

Reader’s Comment Card located on the next page.

Jeanne Grimsby

Senior technical writer

Series 90–70 Genius Bus Controller User’s Manual – July 1992iv

Page 5

Contents

Chapter 1 Introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Description 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts of a Remote Drop 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redundancy 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Installation 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Packaging 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preinstallation Check 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Grounding Procedures 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Installation 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P ower Supply Installation 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Locations 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Installation and Removal 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Wiring to I/O Modules 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Racks in a Remote Drop 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus Connections: Single Bus Cable 32 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genius Bus Connections: Dual Bus Cables 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programmer Connection at the Remote I/O Scanner 35 . . . . . . . . . . . . . . . . . . .

Multidrop Connections 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Remote I/O Scanner Operation 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Scan 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Scanner Memory 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transfer with the Host 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Option Modules in a Remote Drop 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Configuration with Logicmaster 90–70 53 . . . . . . . . . . . . . . . . . . . . . . .

Configuration Limits 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filenames for Configuration Files 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Release 3 Configuration Files with Release 4 Software 54 . . . . . . . . . . . .

“Attaching” Configuration Files 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Remote Drop 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Modules in the Remote Drop 65 . . . . . . . . . . . . . . . . . . . . . . . . . .

Completing the Remote Drop Configuration 68 . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Configured References 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying, Deleting, and Undeleting 73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting an Existing Configuration File 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storing the Configuration 75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK–0579B Series 90–70 Remote I?O Scanner User ’s Manual – July 1992

v

Page 6

Contents

Chapter 5 Logicmaster 90 Operation with a Remote Drop 77 . . . . . . . . . . . . . . . .

Overview 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up Programmer Communications with a Remote Drop 78 . . . . . . . . .

Status Display for a Remote Drop 79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logicmaster 90 Software,

Programmer Differences for a Remote Drop 80 . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Remote Drop Configuration

with a Hand–held Monitor 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Up the Hand–held Monitor 86 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display the Configuration Main Menu 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select the Device Number 88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select a Series Six or Series Five PLC Reference Address 89 . . . . . . . . . . . . . . . .

Select the Baud Rate 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Series 90–70 Data Lengths 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select the Remote Drop ID 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display I/O Modules in Remote Drop 94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Genius Bus Redundancy 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select BSM Control 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select CPU Redundancy 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Configuration Protection 97 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 Monitoring and Controlling

Remote Drop Data 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring/Controlling I/O Data:

Genius Hand–held Monitor 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring/Controlling I/O Data:

Logicmaster 90–70 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring/Controlling I/O Data:

Series Six PLC or Series Five PLC 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring/Controlling I/O Data:

Computer 112 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Diagnostics and Fault Clearing 113 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 113 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display and Clear Faults from a Genius Hand–held Monitor 114 . . . . . . . . . . .

Display and Clear Faults from Logicmaster 90–70 116 . . . . . . . . . . . . . . . . . . . . .

Display and Clear Faults from Logicmaster 5 or Logicmaster 6 121 . . . . . . . . . .

GFK–0579B Series 90–70 Remote I?O Scanner User ’s Manual – July 1992

vi

Page 7

Contents

Chapter 9 Remote I/O Scanner Datagrams 123 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Datagram Types 124 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Map 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Map Reply 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write Map 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Report Fault Datagram Format 126 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Estimating the Number of Remote Drops for a Bus 129 . . . . . . . . . . . . .

Appendix B Finding the I/O Configuration Data Total

for a Remote Drop 131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C Logicmaster 90–70, Release 3:

Series 90–70 PLC Configuration

for Remote Drops 133 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 133 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 1: Create or Select a PLC Program Folder 134 . . . . . . . . . . . . . . . . . . . . . . . .

Step 2: Add the Remote I/O Scanner to the Genius Bus 134 . . . . . . . . . . . . . . . . .

Step 3: Configure the Remote I/O Scanner 137 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 4: Store the Configuration to the PLC 140 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D Logicmaster 90–70, Release 3:

Remote Drop Configuration Instructions 141 . . . . . . . . . . . . . . . . . .

Overview 141 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Drop Configuration Summary 142 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 1: Create a Folder 143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 2: Configure the Remote I/O Scanner 144 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 3: Configure the Modules in the Remote Drop 148 . . . . . . . . . . . . . . . . . . . .

Step 4: Store the Configuration to the Remote Drop 150 . . . . . . . . . . . . . . . . . . .

GFK–0579B Series 90–70 Remote I?O Scanner User ’s Manual – July 1992

vii

Page 8

restart lowapp ARestart oddapp: ARestarts for autonumbers that do not restart in

Î

Î

Î

Î

Î

each chapter . figure bi level 1, reset table_big level 1, reset chap_big level 1, reset1

Lowapp Alwbox restart evenap:A1app_big level 1, resetA figure_ap level 1, reset

table_ap level 1, reset figure level 1, reset Figure 1. table level 1, reset Table 1.

these restarts oddbox reset: 1evenbox reset: 1must be in the header frame of

chapter 1. a:ebx, l 1 resetA a:obx:l 1, resetA a:bigbx level 1 resetA a:ftr level 1 resetA

c:ebx, l 1 reset1 c:obx:l 1, reset1 c:bigbx level 1 reset1 c:ftr level 1 reset1

Reminders for autonumbers that need to be restarted manually (first instance will

always be 4) let_in level 1: A. B. C. letter level 1:A.B.C. num level 1: 1. 2. 3.

num_in level 1: 1. 2. 3. rom_in level 1: I. II. III. roman level 1: I. II. III. steps level 1:

1. 2. 3.

Chapter 1 Introduction

section level 1 1

1

This chapter describes the Series 90t–70 Remote I/O Scanner (IC697BEM733) and

other equipment that may be used with it. It discusses Genius bus operation as it

relates to the Remote I/O Scanner, and describes how the Remote I/O Scanner can be

used in Genius redundancy systems.

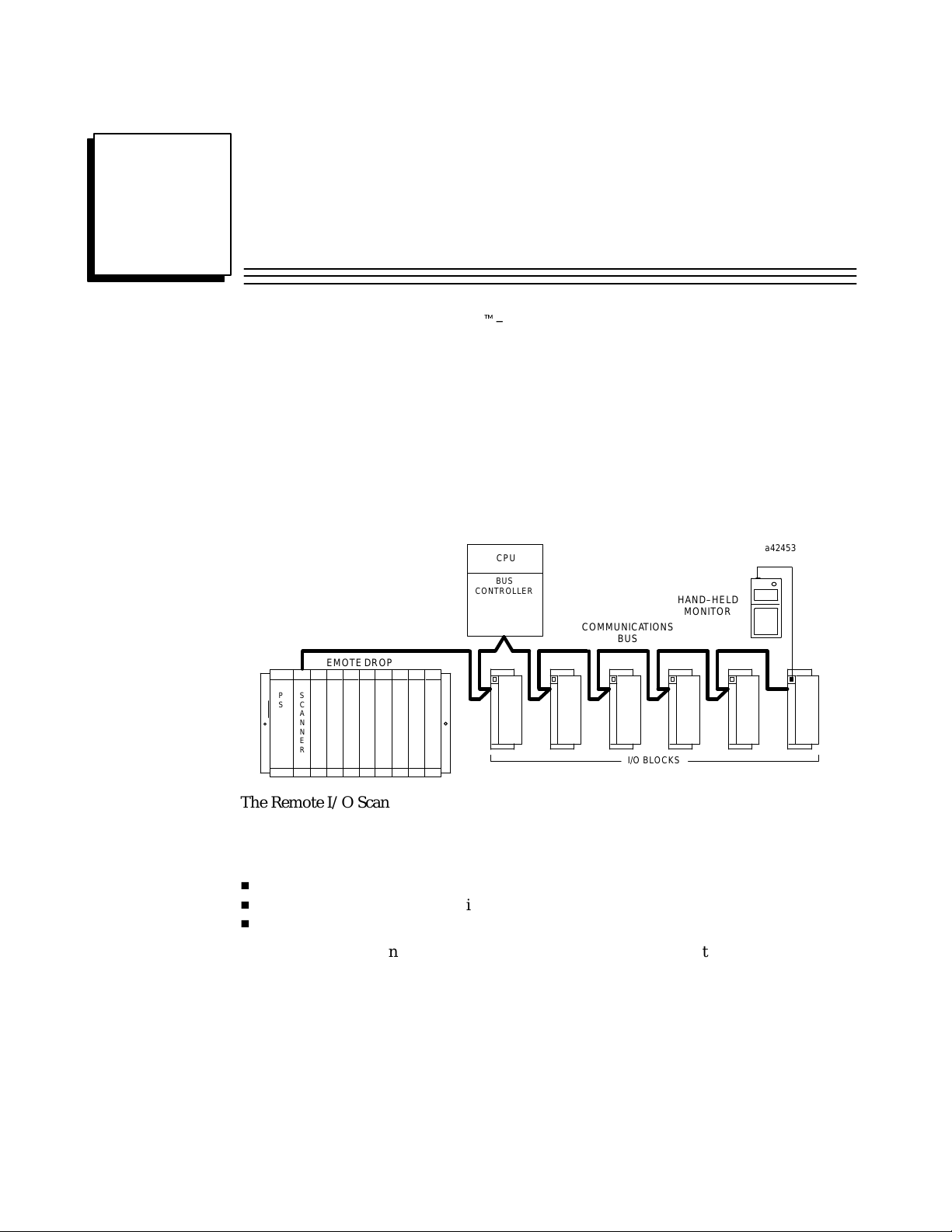

Overview

The Remote I/O Scanner is an intelligent module which mounts in a remote Series

90–70 rack, and inter faces Series 90–70 modules to a Genius bus.

figure bi level 1

table_big level 1

The Genius bus connects the Remote I/O Scanner to a Bus Controller in the host PLC

or computer. A dditional remote drops, Genius blocks, Bus Controllers, and

Hand–held Monitors can be attached to the same bus.

a42453

S

P

C

S

A

N

N

E

R

REMOTE DROP

CPU

BUS

CONTROLLER

COMMUNICATIONS

BUS

I/O BLOCKS

HAND–HELD

MONITOR

The Remote I/O Scanner can send up to 128 bytes of inputs from input boards in its

remote drop to the CPU, and can provide up to 128 bytes of outputs from the CPU to

output boards in the remote drop. The amount of data transferred is configurable.

Individual I/O circuits in the remote drop can be:

H

Forced and unforced from a Hand–held Monitor or the application program logic.

H

Overridden from a PLC application program.

H

Toggled from a Logicmaster 90–70 programmer.

The Remote I/O Scanner can be used in CPU redundancy (dual controller) and bus

redundancy (dual bus) systems.

The Host CPU

The Remote I/O Scanner is ideally suited for use in a Series 90–70 PLC system.

However, any type of PLC or computer capable of controlling a Genius bus can be

used as the host. Suitable hosts include Series Six PLCs, Series Five PLCs, and

computers equipped with a PCIM (P ersonal Computer Interface Module), QBIM

(Q–Bus Interface Module), or a third–party GENI–based interface.

1

Page 9

1

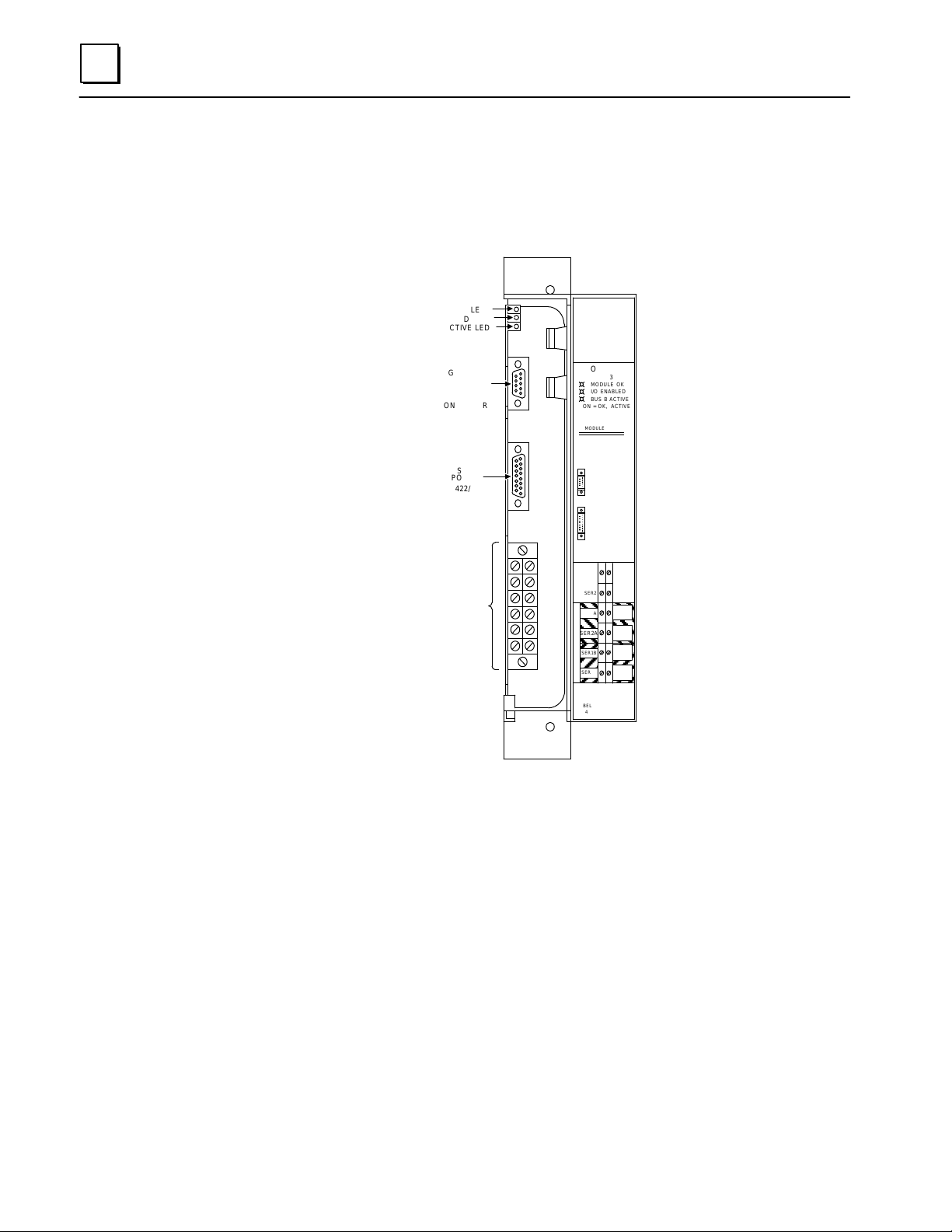

Module Description

The Series 90–70 Remote I/O Scanner consists of a single circuit board, with a hinged

door which serves as a faceplate. It occupies one slot in a Series 90–70 I/O rack.

MODULE OK LED

I/O ENABLED LED

BUS B ACTIVE LED

a44761

GENIUS

HAND HELD

MONITOR

CONNECTOR

SERIAL

PORT

RS–422/485

COMPATIBLE

GENIUS

BUS

TERMINALS

MODEL 70

BEM 733

MODULE OK

I/O ENABLED

BUS B ACTIVE

ON = OK, ACTIVE

MODULE FUNCTION

SERIES 90–70

GENIUS BUS

REMOTE I/O

SCANNER

GENIUS

HAND HELD

MONITOR

SERIAL PORT

RS–422/485

COMPA TIBLE

SER1

SER2

SER1A

R

E

D

SER2A

U

N

D

A

SER1B

N

C

Y

SER2B

MODULE

IC697BEM733

LABEL

44A726758–110R02

SHIELD

SHIELD

OUT

SHIELD

IN A

SHIELD

OUT A

SHIELD

IN B

SHIELD

OUT B

IN

BEM 733

The Remote I/O Scanner does not require batteries; the battery holder in the faceplate

is not used.

Series 90–70 Remote I/O Scanner User’s Manual – July 19922

Page 10

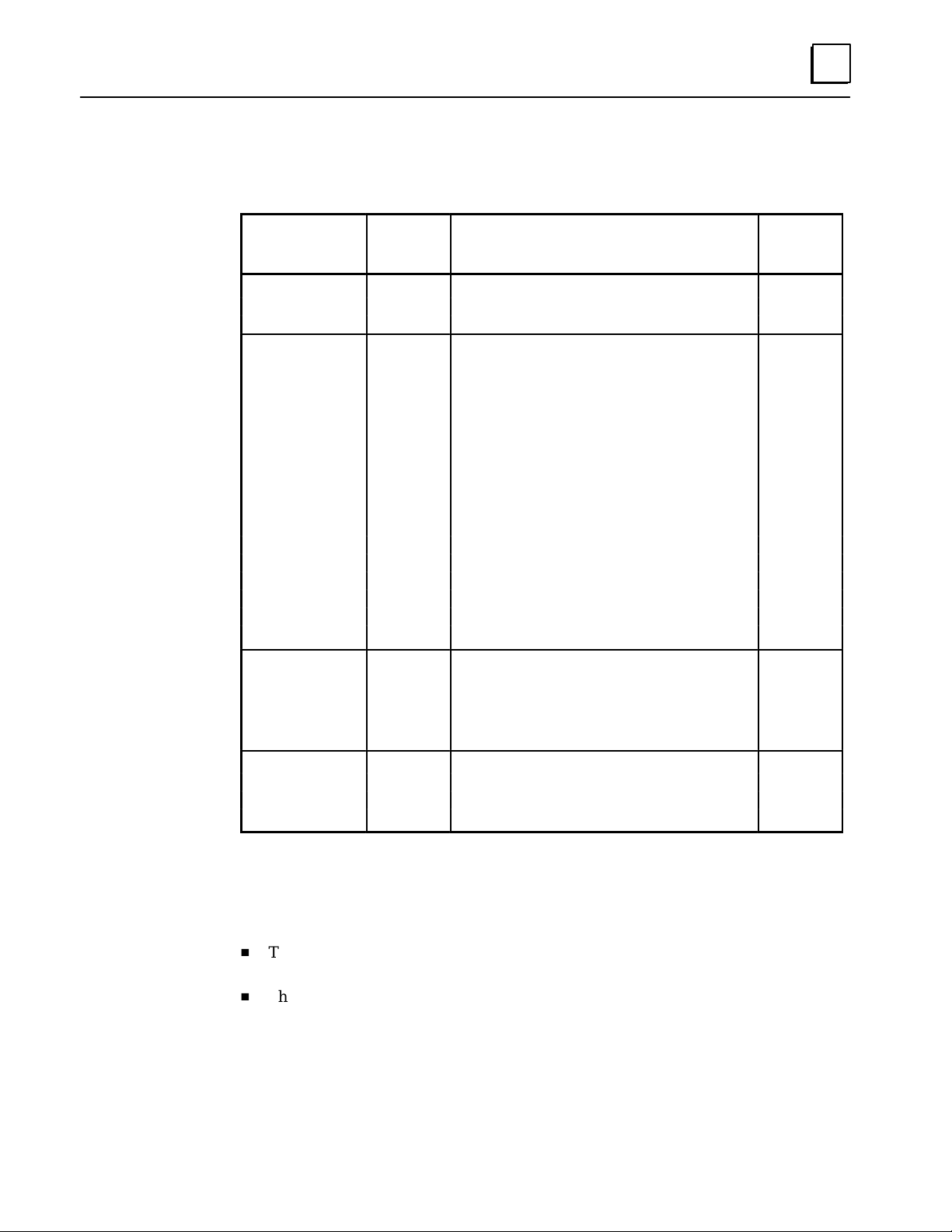

LEDs

Module OK

I/O Enabled

Bus B Active

The Remote I/O Scanner has three LEDs that show through the transparent portion at

the top of the door.

lights to indicate that the module has passed its powerup diagnostic

tests. If this LED flashes, it indicates a problem, as shown in the table

below . If this LED is off, there is a fatal error, which causes the Remote

I/O Scanner to go to stop/faulted mode.

lights when the Remote I/O Scanner is receiving the expected output

data from the CPU. If this LED flashes, it indicates either I/O data is

forced, or a Device Number conflict.

if the Remote I/O Scanner is installed on a dual (redundant) bus, this

LED lights if Bus B of the dual bus pair is the currently–active bus.

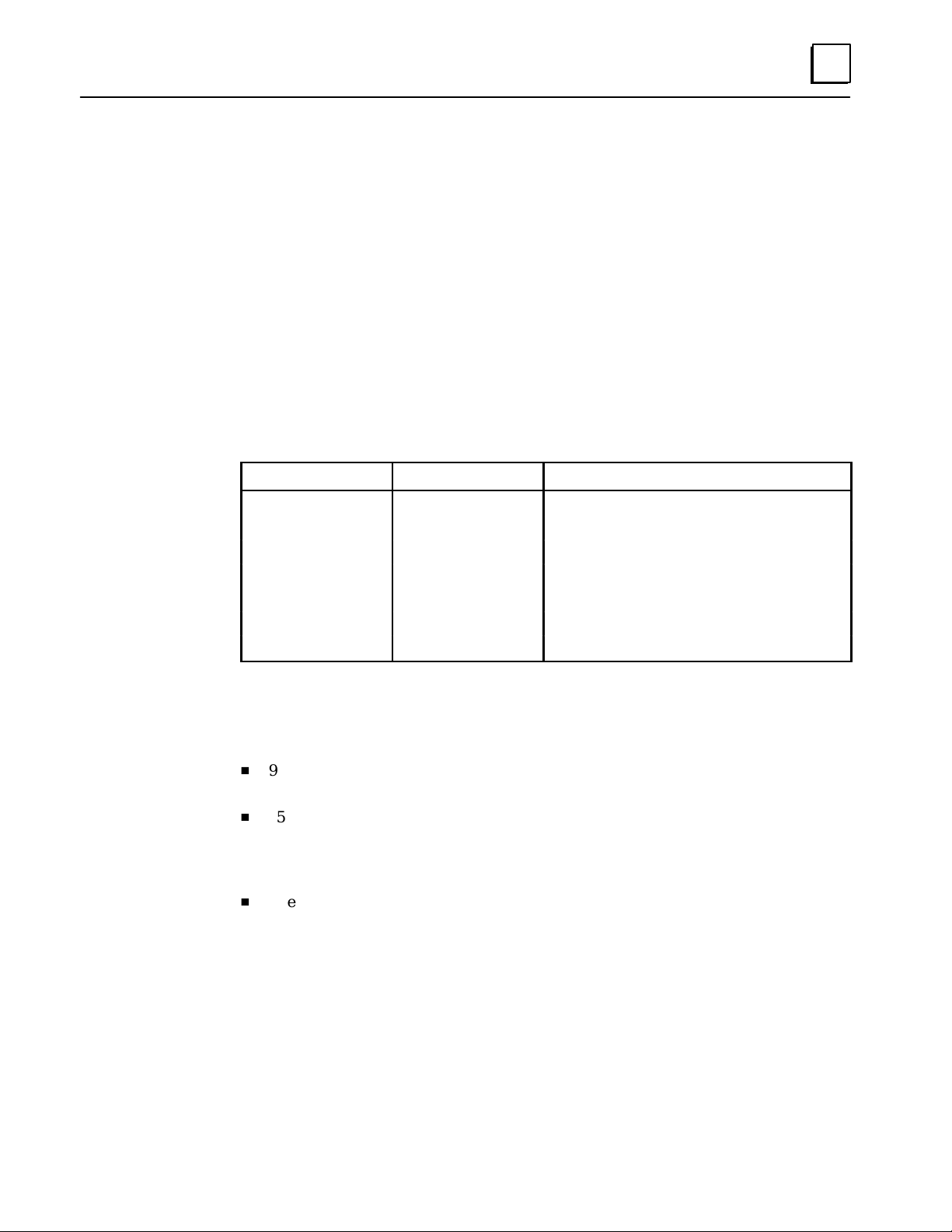

The following table summarizes the LED indications.

Module OK I/O Enabled Meaning

On On Normal operation

Blinking On Fault detected

On Blinking I/O data forced

Alter nate blinking Alternate blinking F ault detected, and I/O data forced

Synchronous blinking Synchronous blinking Device Number conflict

On Off Outputs not being updated from CPU

Off Off No power or fatal error

1

Connectors

The front of the module has three connectors:

H

9–pin male D Connector: the upper connector. Used for attaching a Genius

Hand–held Monitor.

H

15–pin female D Connector: the center connector. This connector is an RS–422

compatible RS–485 serial port. It can be used for communicating with a

programmer equipped with the serial version of Logicmaster 90–70, or for

connection to a multidrop communications network.

H

The connector at the bottom of the module attaches the Genius bus terminal strip.

Because the terminal strip is removable, it is possible to service or replace the

Remote I/O Scanner while the rest of the system is operating, without disrupting

bus communications.

3Chapter 1 Introduction

Page 11

1

Required Equipment

The following equipment is required to use a Remote I/O Scanner.

H

At least one Series 90–70 5–slot or 9–slot remote rack with Power Supply. A

remote drop may include multiple racks and power supplies.

H

If a Genius Hand–held Monitor will be used to configure or monitor a remote

drop, it must be version 4.0 (IC660HHM501G) or later.

H

If Logicmaster 90–70 configuration software will be used to configure the remote

drop, it must be release 3.0 or later:

A. IC641SWP701F (3.5”, 2DD, 5.25” 2S/HD)

B. IC641SWP704C (5.25” 2S/2D)

H

If the parallel version of Logicmaster 90–70 will be used with a remote drop, the

remote drop must include a Bus Transmitter Module (IC697BEM713) for

connection to the programmer.

H

If the remote drop will include more than one rack of modules, a Bus Transmitter

Module (IC697BEM713) one or more Bus Receiver Modules (IC697BEM711), and

appropriate cables are required.

H

For a Series 90–70 PLC

h

The Series 90–70 CPU firmware must be release 2.0 or later.

h

The Logicmastert 90–70 programming and configuration software must be

release 3.0 or later. Catalog numbers are given above.

h

A Series 90–70 Genius Bus Controller, release 3.0 or later. The Bus Controller

must be 4.0 or later for full diagnostics display from Logicmaster 90–70 (see

chapter 8), or for redundancy applications.

H

For a Series Sixt PLC

h

CPU: rev. 105 or later.

h

Logicmaster 6 Programming Software: release 4.02 or later.

h

Bus Controllers: IC660CBB902 or 903, version 1.7 or later.

H

For a Series Fivet PLC

h

CPU: rev . 3.2 (catalog number with E suffix) or later.

h

Logicmaster 5 Programming Software: release 2.01 or later.

h

Bus Controller: any version

H

For a Host Computer

h

PCIM: any version

h

QBIM: any version

Series 90–70 Remote I/O Scanner User’s Manual – July 19924

Page 12

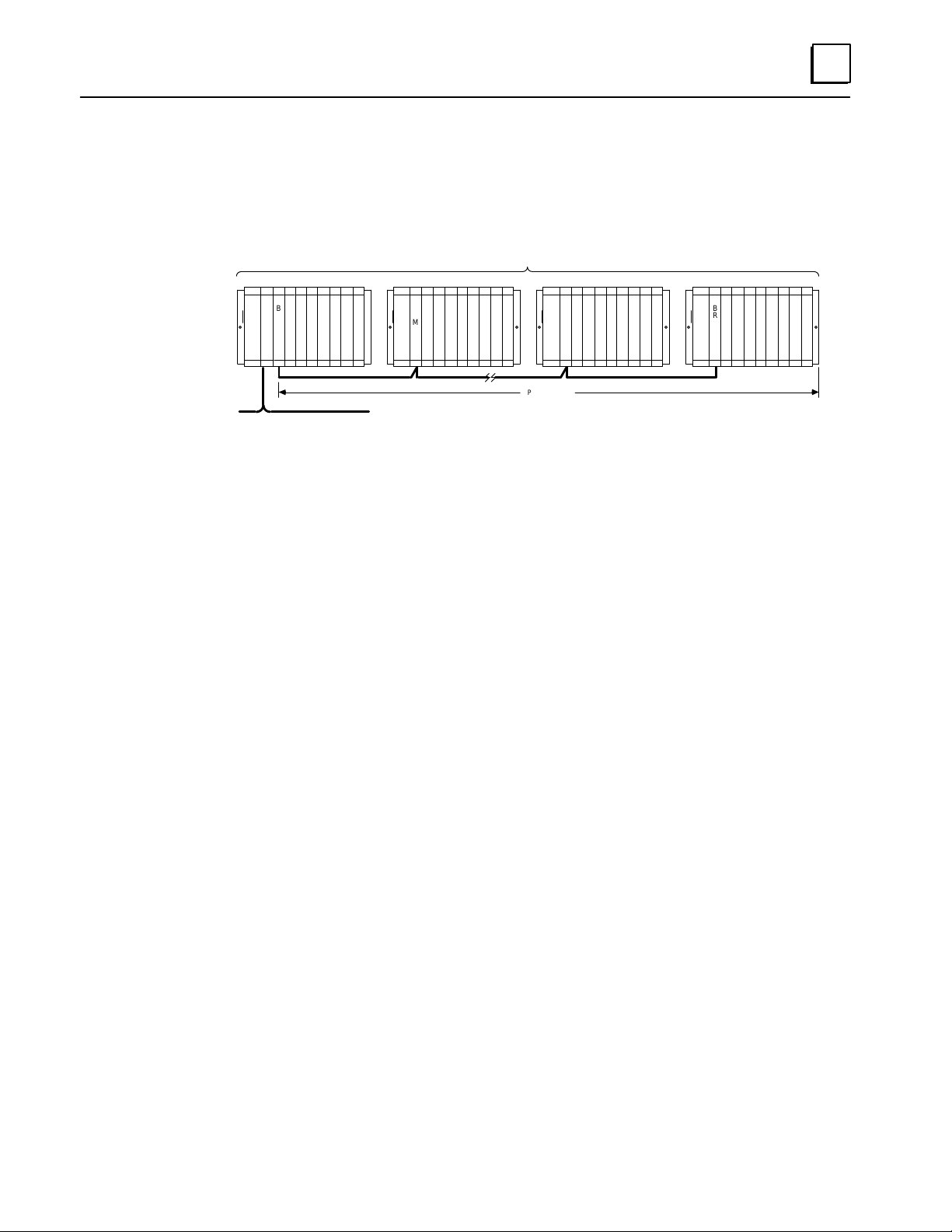

Parts of a Remote Drop

Together, a Remote I/O Scanner and the modules it serves make up a remote drop on

the Genius bus. The remote drop may consist of one to eight Series 90–70 racks.

1

P

S

S

B

C

T

A

M

N

N

E

R

GENIUS BUS

RACK 0

REMOTE DROP

PSB

RACK 7

R

M

RACK 1

P

B

S

R

M

UP TO 50 FEET

NOTE:

ALL RACKS MUST BE AT THE SAME GROUND POTENTIAL

PSB

RACK 6

R

M

a44875

Multiple R acks

When there are multiple racks, the Remote I/O Scanner must be located in the first

rack (rack 0). To link multiple racks in a remote drop, a Bus T ransmitter (IC697BEM713)

Module in rack 0 is connected to a Bus Receiver Module (IC697BEM711) in the first

expansion rack. Additional racks are also linked via Bus Receiver Modules.

All racks in a remote drop must be at the same ground potential.

Distance Between R acks in a Remote Drop

The maximum total cable length from the first Bus Transmitter to the last Bus Receiver

in a remote drop is 50 feet (15 meters). Since none of the daisy–chained signals (all at

the same ground potential) are broken at a rack, any rack can be independently

powered–down without affecting the operation of the rest of the system.

Data Quantities

Regardless of the number of racks used for a remote drop, the maximum amount of

data for a remote drop is 128 bytes of inputs and 128 bytes of outputs (8 discrete points

represent one byte and 1 analog channel uses 2 bytes).

5Chapter 1 Introduction

Page 13

1

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

Î

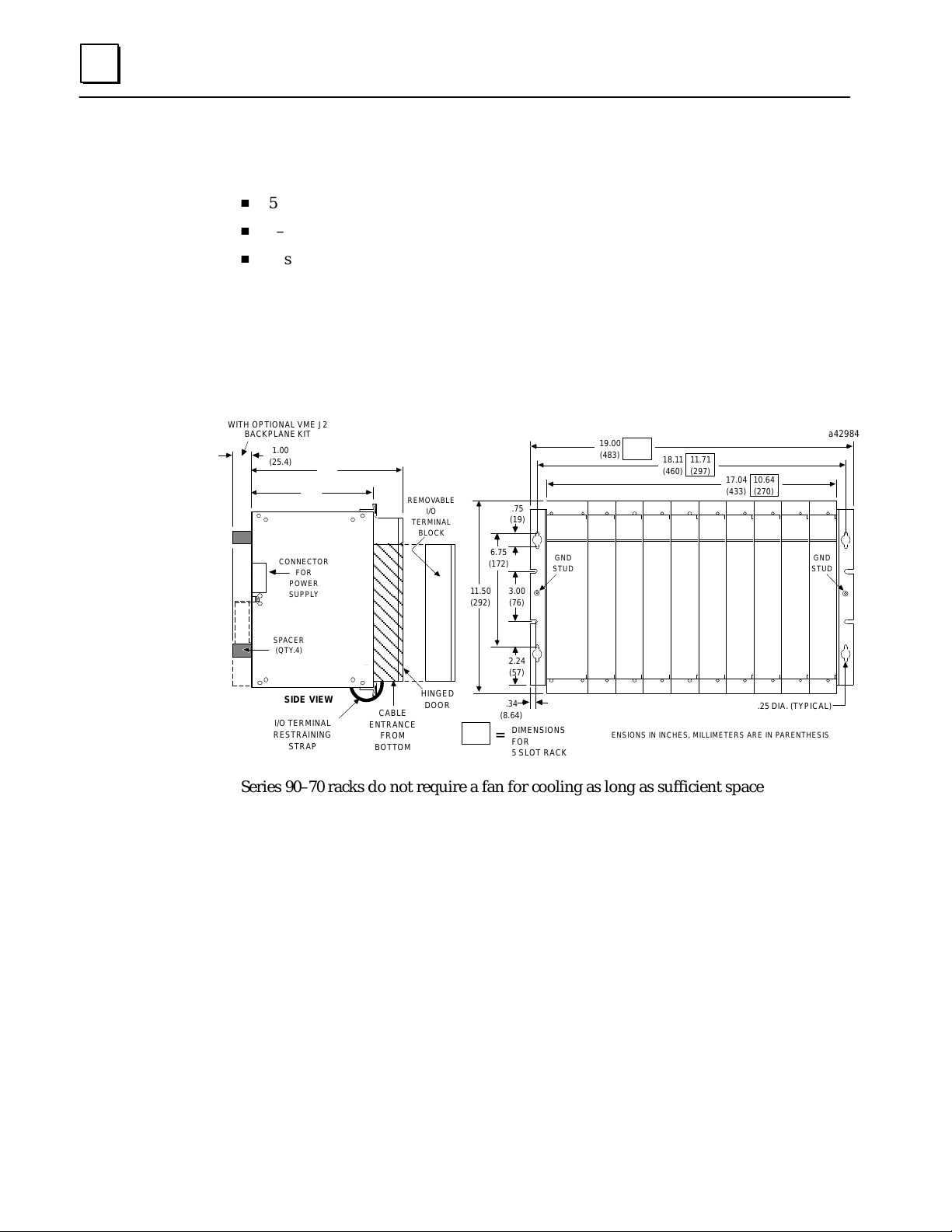

Series 90–70 Racks

Any of the following racks can be used in a remote drop:

H

5–slot, panel mount rack (IC697CHS750).

H

9–slot, panel mount rack (IC697CHS790).

H

9–slot, rack mount rack (IC697CHS791).

Each of these racks has an additional, wider slot for a P ower Supply. Rack sizes may be

mixed in a system installation to suit the requirements of your application.

The rack–mount Series 90–70 rack has flanges on the front for mounting on 19–inch

standard instrument rack hardware. The panel–mount racks have rear flanges for

mounting on electrical panels.

WITH OPTIONAL VME J2

BACKPLANE KIT

1.00

(25.4)

CONNECTOR

FOR

POWER

SUPPLY

SPACER

(QTY.4)

SIDE VIEW

I/O TERMINAL

RESTRAINING

STRAP

7.25

(184)

9.14

(232)

CABLE

ENTRANCE

FROM

BOTTOM

REMOVABLE

I/O

TERMINAL

BLOCK

Î

Î

Î

Î

Î

HINGED

DOOR

11.50

(292)

6.75

(172)

=

(19)

3.00

(76)

1.50

(38)

2.24

(57)

.34

(8.64)

.75

ОООООООООООО

ОООООООООООО

Î

GND

STUD

ОООООООООООО

Î

ОООООООООООО

Î

ОООООООООООО

Î

ОООООООООООО

Î

ОООООООООООО

Î

ОООООООООООО

DIMENSIONS

FOR

5 SLOT RACK

12.60

19.00

(320)

(483)

18.11

(460)

Î

Î

Î

Î

Î

Î

FRONT VIEW

11.71

(297)

17.04

(433)

10.64

(270)

.25 DIA. (TYPICAL)

DIMENSIONS IN INCHES, MILLIMETERS ARE IN PARENTHESIS

Series 90–70 racks do not require a fan for cooling as long as sufficient space is left

around the rack when it is mounted.

GND

STUD

a42984

Series 90–70 Remote I/O Scanner User’s Manual – July 19926

Page 14

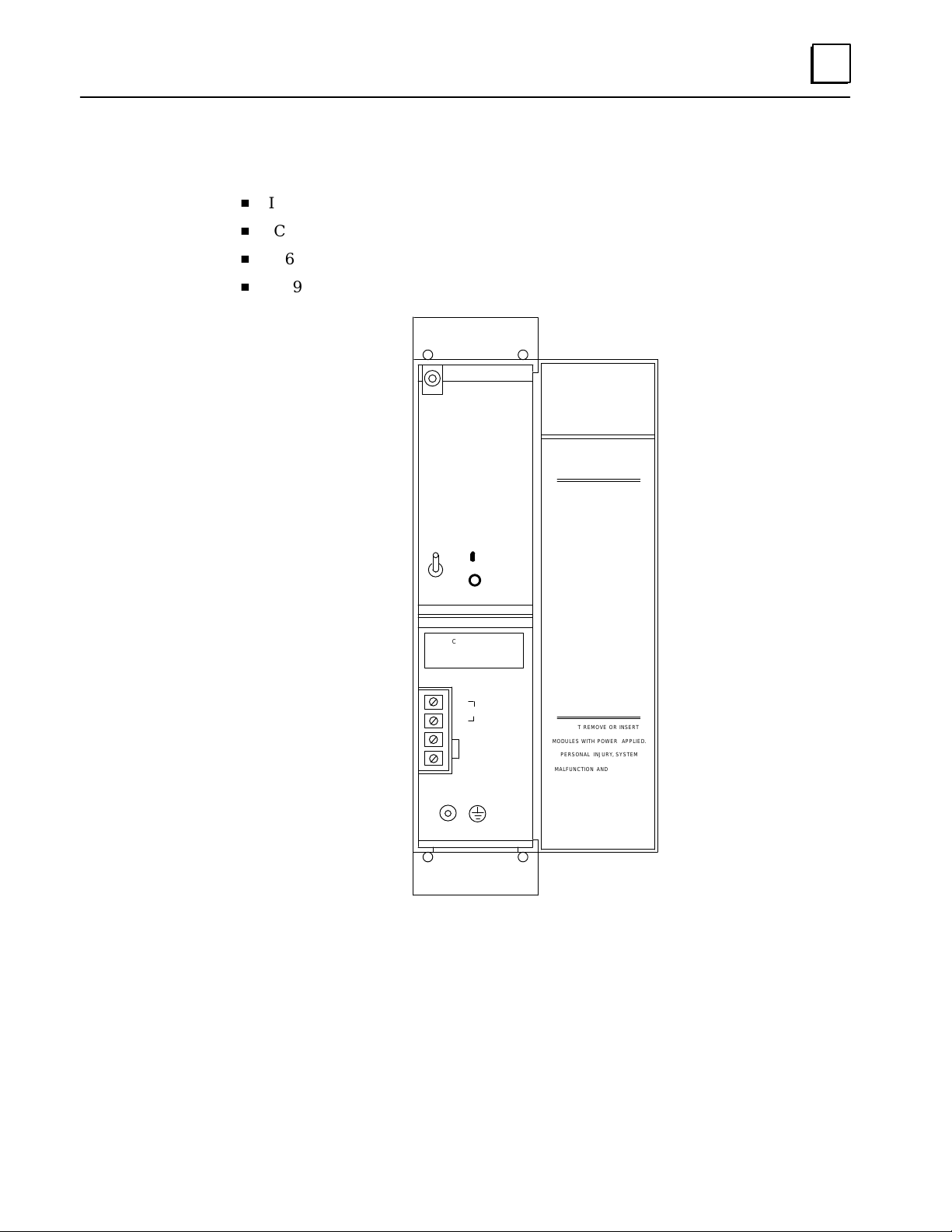

Series 90–70 Power Supplies

These Series 90–70 Power Supplies can be used in a remote drop:

H

IC697PWR710, 120/240 VAC input, +5 VDC output, 55 Watts (shown below)

H

IC697PWR711, 120/240 VAC input, +5 VDC, +12 VDC, –12 VDC output, 100 Watts

H

IC697PWR721, 24VDC input, +5 VDC, +12 VDC, –12 VDC output, 90 Watts

H

IC697PWR731, 125VDC input, +5 VDC, +12 VDC, –12 VDC output, 60 Watts

a42818

LED

MODEL 70

PWR 710

POWER SUPPLY MODULE

INPUT

OUTPUT

BRANCH CIRCUIT FUSING

MUST BE PROVIDED

EXTERNALLY

RECOMMENDED TIGHTENING

TORQUE 1,5Nm (15kg cm)

ON

OFF

L1

N

SHORT FOR 120

OPEN FOR 240

120/240VAC

50/60HZ

1.5/0.8A

5V

11A

120

SELECT

INPUT

L1

240

L2

WARNING

EVEN IF THE POWER SUPPLY

IS SWITCHED OFF, HAZARDOUS

VOLTAGES FROM USER FIELD

WIRING MAY STILL BE PRESENT

ON THE I/O TERMINAL BOARDS

AS WELL AS THE POWER

SUPPLY TERMINAL BOARD.

CARE SHOULD BE TAKEN WHEN

HANDLING THE POWER SUPPLY

AND I/O MODULES AS WELL AS

ANY WIRING CONNECTED TO

THEM IN ORDER TO PREVENT

PERSONAL INJURY.

WARNING

DO NOT REMOVE OR INSERT

MODULES WITH POWER APPLIED.

PERSONAL INJURY, SYSTEM

MALFUNCTION AND/OR DAMAGE

TO THE EQUIPMENT MAY OCCUR.

1

MODULE IC697PWR710

LABEL 44A726758–501

Power supply selection will depend on the input power and load requirements of the

application. Load specifications for Series 90–70 modules are listed on page 9.

AC power supplies mount in the leftmost slot of a Series 90–70 rack. DC power

supplies can be mounted on the side of the rack or used as freestanding modules. The

DC power supplies require a power supply adapter, which installs in the power supply

slot and is connected to the power supply by a short cable.

7Chapter 1 Introduction

Page 15

1

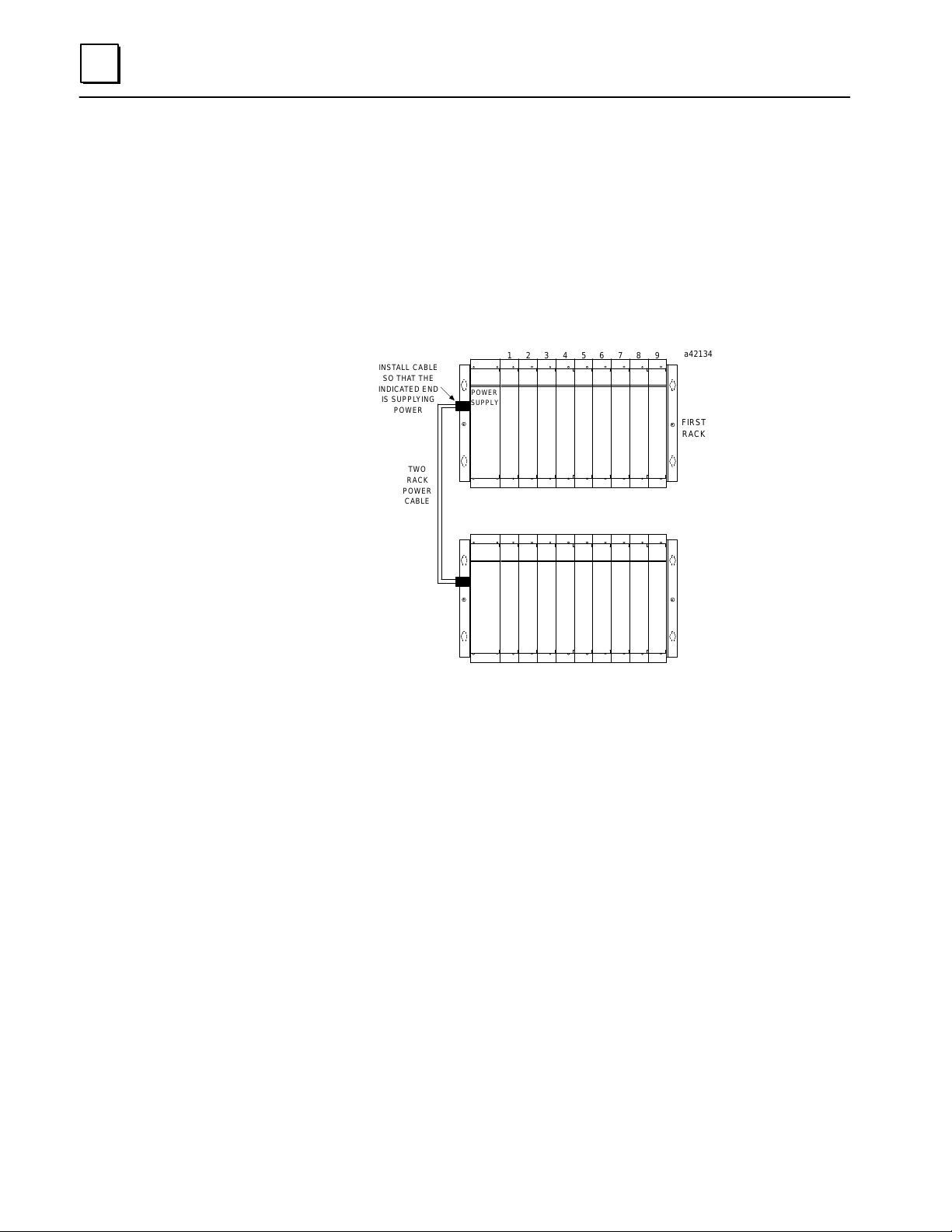

Powering Two Racks from a Single Power Source

Except for the 125VDC supply, each of these power supplies can be used to power two

racks if the total current requirement for both racks does not exceed the power

supply’s load capacity. The rack that does not contain the Power Supply must not have

a load greater than 5.2 amps.

Connection from the rack with the power supply to the second rack is made through a

cable (catalog number IC697CBL700) three feet (one meter) in length, which is

terminated at both ends with 9–pin D–connectors. This cable car ries both +5 volt

power and control signals (power sequencing signals only) to the second rack.

INSTALL CABLE

SO THAT THE

INDICATED END

IS SUPPLYING

POWER

TWO

RACK

POWER

CABLE

123456789

POWER

SUPPLY

FACE

PLATE

a42134

FIRST

RACK

SECOND

RACK

Series 90–70 Remote I/O Scanner User’s Manual – July 19928

Page 16

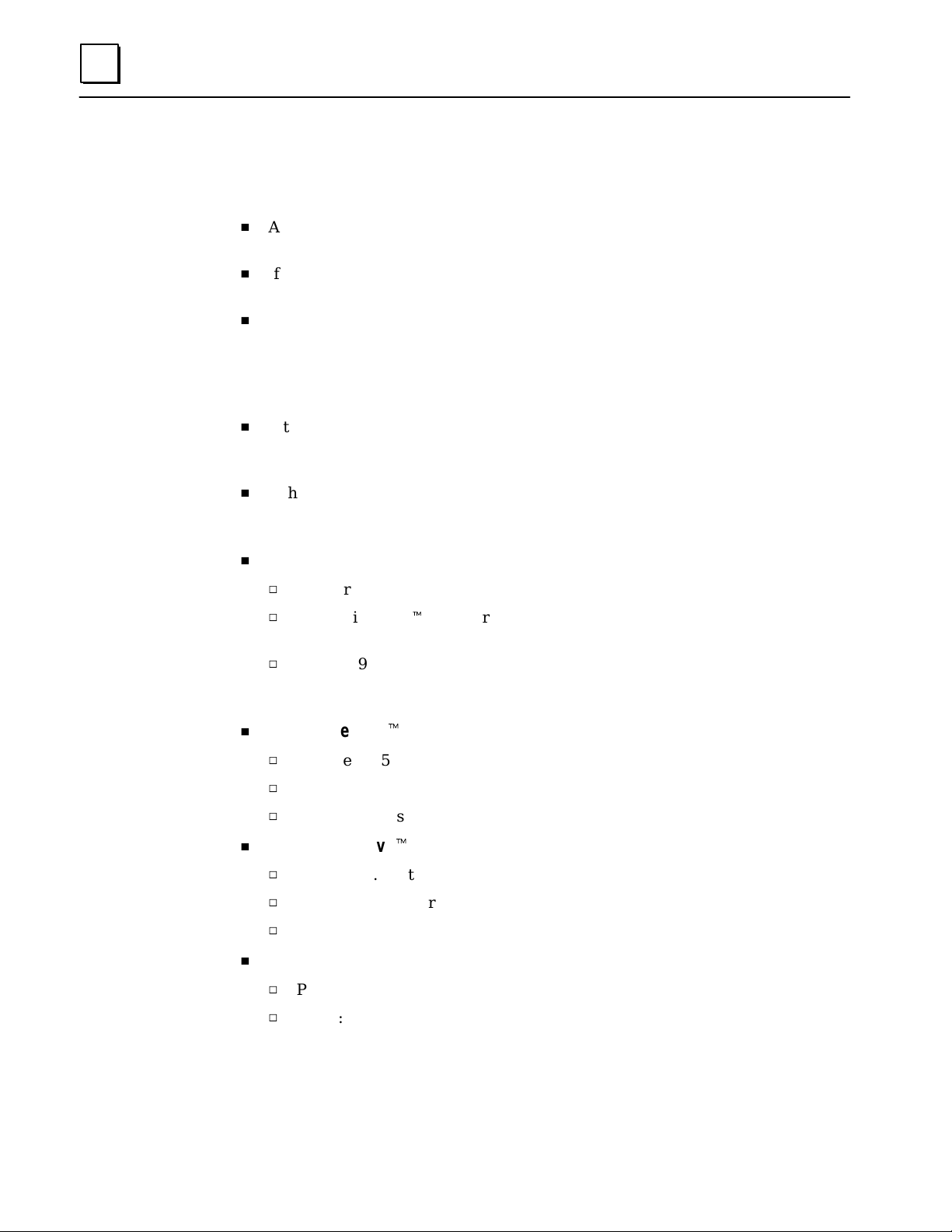

Series 90–70 Modules for a Remote Drop

The table below lists modules that can be placed in a remote drop, and gives their

catalog numbers, I/O capacities, and loads.

1

Module

Catalog

Number

IC697BEM733 Remote I/O Scanner 0.80

IC697BEM713 Bus T ransmitter Module 1.40

IC697BEM711 Bus Receiver Module 0.80

IC697MDL240 16 120 V A C Isolated, Input, 16 points 0.25

IC697MDL241 16 240 V A C Isolated, Input, 16 points 0.25

IC697MDL250 32 120 VAC Input, 32 point 0.35

IC697MDL650 32 24 VDC Input, 32 point 0.30

IC697MDL651 32 Input module, negative logic, TTL 0.525

IC697MDL652 32 12 VDC Pos/Neg Logic Input, 32 points 0.30

IC697MDL653 32 24 VDC Pos/Neg Logic Input, 32 points 0.30

IC697MDL654 32 48 VDC Pos/Neg Logic Input, 32 points 0.30

IC697MDL340 16 120 VAC Output, 16 point 0.25

IC697MDL341 16 120/240 V A C Isolated 2A Output, 16 points 0.25

IC697MDL350 32 120 VAC Output, 32 point 0.50

IC697MDL740 16 24/48 VDC Output, 16 point 0.25

IC697MDL750 32 24/48 VDC Output, 32 point 0.15

IC697MDL752 32 12 VDC 0.5A Output, 32 points 0.50

IC697MDL753 32 5/48 VDC 0.5A Neg Logic Output, 32 points 0.50

IC697MDL940 16 Relay Output 16 points 0.75

IC697ALG230 8 Analog Input Base Converter 0.80

IC697ALG440 16 Analog Input Current Expander 0.40

IC697ALG441 16 Analog Input Voltage Expander 0.40

IC697ALG320 4 High Level Analog Output, V oltage/Current 1.66

I/O Points

or

Channels

Module Description

Discrete Modules

Analog Modules

Load in

Amps at

+5 VDC

Option Modules

IC697PCM711 Programmable Coprocessor Module 1.00

IC697GDC701 Graphics Display Coprocessor Module 1.20

IC697ADC701 Alphanumeric Display Coprocessor Module 1.00

Remote Drop Capacity

The maximum number of I/O and option modules that can be installed in a remote

drop is 63, which requires eight 9–slot racks. There are two limits that cannot be

exceeded when locating modules in a remote drop:

H

There must not be too many option modules in a remote drop. See “Option

Modules”, below .

H

The configuration data for all the I/O modules in a remote drop must not add up to

more than 4500 bytes. This amount of configuration data will not be reached in

any remote drop where all I/O modules are included in the Remote I/O Scanner’s

configured I/O map. However, it is possible to have I/O modules in a remote drop

configured to use references outside the I/O map, as explained in chapter 3. If the

drop will have some modules configured outside the Remote I/O Scanner’s I/O

map, refer to appendix B.

9Chapter 1 Introduction

Page 17

1

Analog Modules: The maximum number of analog input modules that can provide

input data to the host is 8; however, there may be additional modules in the remote

drop configured outside the Remote I/O Scanner’s I/O map. The maximum number of

analog input modules that can be configured for a remote drop is 29. Similarly, while

the maximum number of analog output modules that can receive output data from the

host is 16, as many as 54 can be configured for a remote drop.

Option Modules: A remote drop with seven or fewer racks can contain up to 18 GDS

(Graphics Display Coprocessor), or ADS (Alphanumeric Display Coprocessor) modules,

or up to 9 PCM (Programmable Coprocessor) modules with daughterboards. Each

PCM/daughterboard combination counts as two option modules against the total of 18.

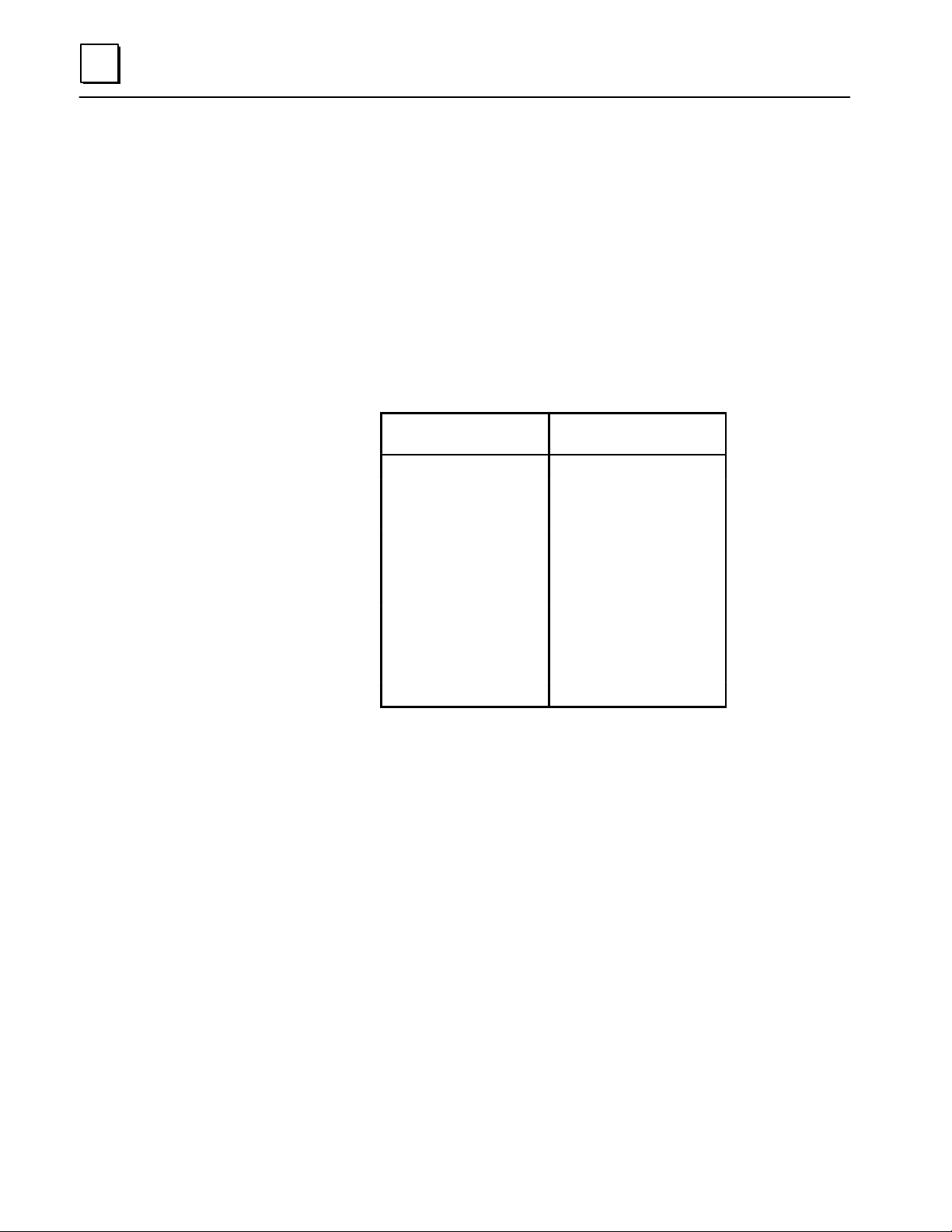

The following table shows how many GDS and/or ADS modules can be used with 0 to

9 PCMs.

Total Option Modules in a Remote Drop

Number of PCMs and

Daughterboards

0 18

1 16

2 14

3 12

4 10

5 8

6 6

7 4

8 2

9 0

Number of GDS and/

or ADS Modules

If there are 8 racks in the remote drop, one less PCM with daughterboard, or two less GDS or

ADS modules are permitted.

Analog Expanders: A remote drop can accommodate up to one analog input module

with eight expander modules. However, the maximum number of expanders that can

pass inputs to the CPU is three, due to the Remote I/O Scanner’s 128–byte input data

limit. If an analog module and three expanders were used, no additional input

modules (either analog or discrete) could communicate with the host from the remote

drop.

Modules Not Supported: A remote drop cannot have any I/O module interrupts, or

bus controllers or other modules that depend on COMREQ instructions for their

operations.

Third–party VME modules cannot be used in a remote drop.

Series 90–70 Remote I/O Scanner User’s Manual – July 199210

Page 18

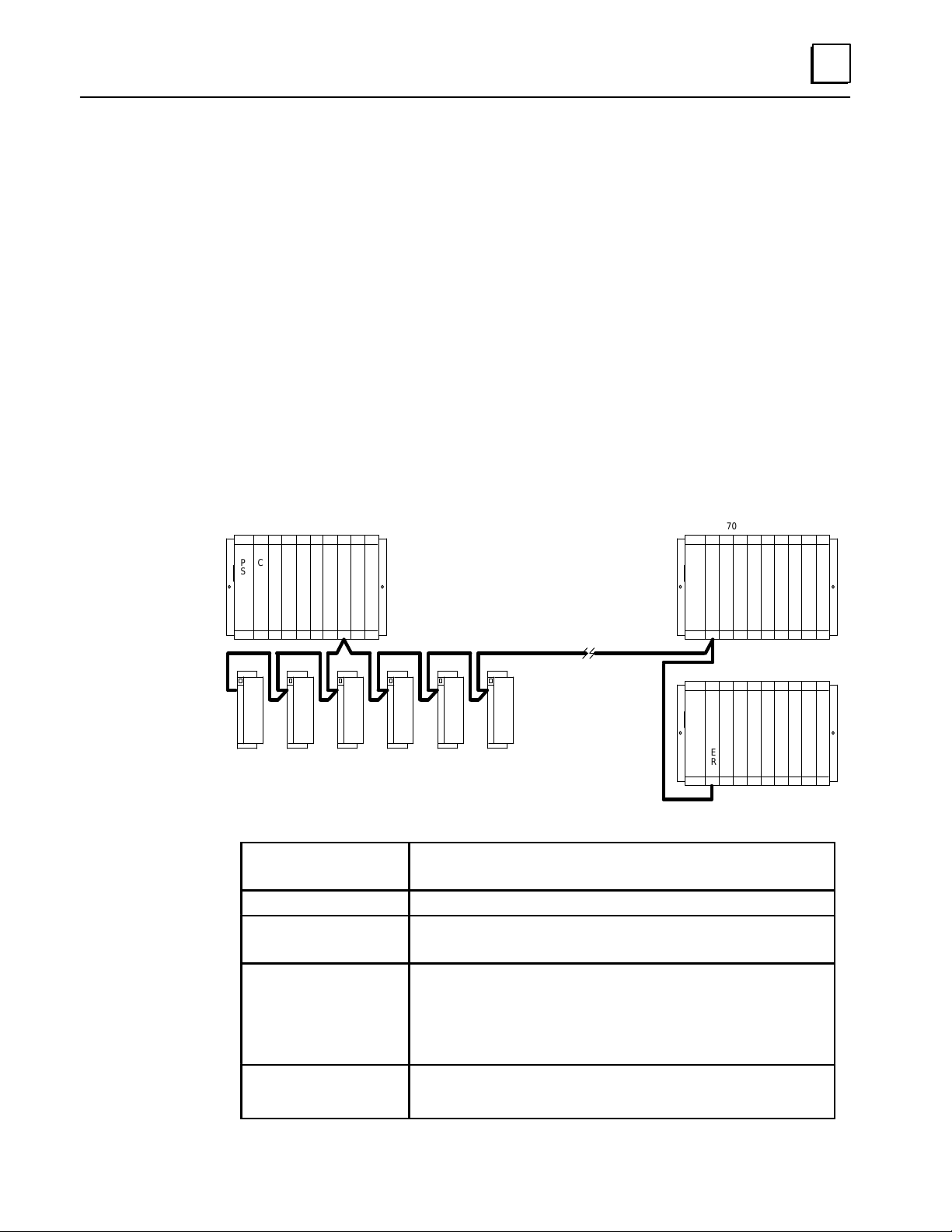

Genius Bus

1

The Genius bus is an industrially–hardened Local–Area–Network (LAN). It passes

I/O (control) data and background information (datagrams) between the Remote I/O

Scanner and a Genius bus controller. The communicated data is protected from

environmental interference and corruption in several ways. Each byte is

triply–encoded during transmission, and each message is checksummed with a cyclic

redundancy check (CRC). Embedded intelligence at either end also checks for correct

message length and type.

A Genius bus can support up to 32 devices. Each remote drop counts as one device on

the bus, regardless of the number or type of modules it includes. A bus can serve any

mix of remote drops, I/O blocks, Bus Controllers and Hand–held Monitors, provided

the bus scan time does not exceed 400mS. Typical busses reserve one location for a Bus

Controller and one for a Hand–held Monitor, leaving 30 for additional devices. The

illustration below shows a Bus Controller in a Series 90–70 PLC connected to a Genius

bus with I/O blocks and two single–rack remote drops.

PSC

P

U

Bus Type

Bus Termination

Baud Rate

7500 FEET WITH 16 DEVICES, AT 38.6K BAUD

B

C

3500 FEET WITH 32 DEVICES, AT 153.6K BAUD EXT.

MAXIMUM BUS LENGTH

90–70 REMOTE RACK

S

I

I

I

C

/

/

/

A

O

O

O

N

N

E

R

90–70 REMOTE RACK

S

I

I

I

C

/

/

/

A

O

O

O

N

N

E

R

a44669

I

I

I

I

/

/

/

/

O

O

O

O

I

I

I

I

/

/

/

/

O

O

O

O

Daisy–chained bus cable; single twisted pair plus shield or Twinax.

Fiber optics cable and modems can also be used.

75, 100, 120, or 150 ohm resistor at both ends of electrical bus cable.

Configurable. 153.6 Kbaud standard, 153.6 Kbaud extended,

76.8Kbaud, or 38.4 Kbaud.

Maximum Bus

Length

Maximum Number of

Devices

7500 feet at 38.4 Kbaud, 4500 feet at 76.8 Kbaud, 3500feet at 153.6

Kbaud extended, 2000 feet at 153.6 Kbaud, standard. Maximum

length at each baud rate also depends on cable type. The Genius I/O

System User’s Manual pro vides a complete list of cable types, showing corresponding bus lengths and baud rates. Greater bus lengths

are possible using sections of fiber optics cable with modems.

32 devices at 153.6 Kbaud standard, 153.6 Kbaud extended, or 76.8

Kbaud. 16 devices at 38.4 Kbaud. Includes Bus Controller and

Hand– held Monitor.

11Chapter 1 Introduction

Page 19

1

Total Amount of Input and

Total Amount of Input and

Output Data for

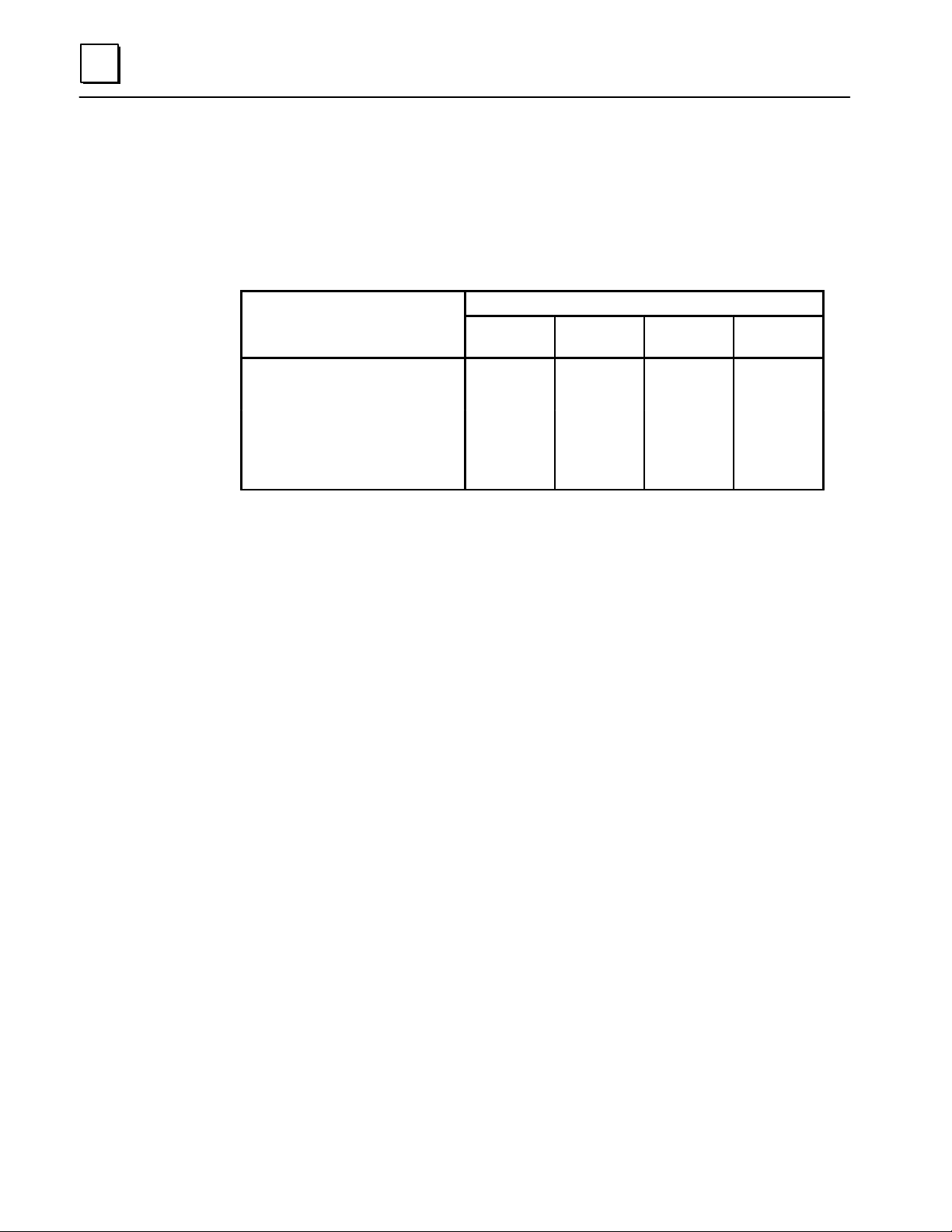

Timing

A fully–loaded (128 input bytes and 128 output bytes) remote drop adds at least 20mS

to the bus scan. The table below shows the bus scan time contribution, at each baud

rate, for remote drops with a total of 16, 32, 64, 128, and 256 bytes (fully–loaded),

when the Remote I/O Scanner receives outputs from only one bus controller at a time.

Contribution time in mS at each baud rate *

Remote Drop

16 bytes 2.09 2.16 3.83 7.16

32 bytes 3.24 3.31 6.12 11.74

64 bytes 5.52 5.60 10.69 20.89

128 bytes 10.10 10.17 19.85 39.20

256 bytes (fully–loaded) 19.25 19.32 38.15 75.80

* See below to calculate the exact scan time contribution for the application.

153.6 Kb

std

153.6 Kb

ext

76.8 Kb 38.4 Kb

Estimating Bus Scan Time for Remote I/O Drops

The scan time contribution for a remote drop depends on its I/O data usage. Follow

the procedure below to estimate the the scan time contribution of a remote drop.

(Each analog channels is 2 bytes. Eight discrete points are one byte).

1. Find the total number of input bytes and output bytes.

number of input bytes = ________

number of output bytes = ________

total bytes = ________

2. With this total, calculate a scan time contribution using the formula below that

corresponds to the Genius bus baud rate.

Formula for 153.6 Kbaud Standar d:

0.943mS + (0.0715 x total bytes) = ________ mS

Formula for 153.6 Kbaud Extended:

1.015mS + (0.0715 x total bytes) = ________ mS

Formula for 76.8 Kbaud:

1.538mS + (0.143 x total bytes) = ________ mS

Formula for 38.4 Kbaud:

2.583mS + (0.286 x total bytes) = ________ mS

Other devices on the bus, including the Bus Controller, Hand–held Monitor, and I/O

blocks also add to the bus scan time. The Genius I/O System Manual (Volume 1) shows

how to calculate bus scan time based on the devices actually present.

Series 90–70 Remote I/O Scanner User’s Manual – July 199212

Page 20

Number of R emote Drops on a Bus

The number of remote drops on a bus depends on the baud rate and the total number

of I/O points in the remote drops.

Since the maximum Genius bus scan time is 400mS, and the bus scan time contribution

of one fully–loaded remote drop is 20mS, only twenty fully–loaded remote drops are

supported on a single bus that operates at 153.6 Kbaud. If remote drops are not

fully–loaded, more may be used on a bus operating at these baud rates.

If some remote drops are not fully–loaded, more than the maximum number given

below can be used. The table in appendix A will help you estimate the total number of

remote drops and data bytes that can be accommodated on a bus that has one Bus

Controller, one Genius Hand–held Monitor, no datagrams or Global Data

communications, and no Genius I/O blocks. The Genius I/O System User’s Manual

explains how to calculate the bus scan time for a specific bus.

Maximum Number of Drops per Baud Rate

153.6K baud extended: Up to 20 fully–loaded drops, or up to 30 drops with the total

number of I/O bytes less than the limits listed in the table.

1

153.6K baud standard: Up to 20 fully–loaded drops, or up to 30 drops with the total

number of I/O bytes less than the limits listed in the table.

76.8K baud: Up to 10 fully–loaded drops, or up to 30 drops with the total number of

I/O bytes less than the limits listed in the table.

38.4K baud: Up to 5 fully–loaded drops, or up to 14 drops with the total number of

I/O bytes less than the limits listed in the table.

13Chapter 1 Introduction

Page 21

1

Redundancy

The Remote I/O Scanner can be used with CPU redundancy, bus redundancy, or both.

The suitability of redundancy features for any system depends on the requirements of

the application. For Series 90–70 PLC CPUs that are release 3 and earlier, some types

of redundancy are not supported.

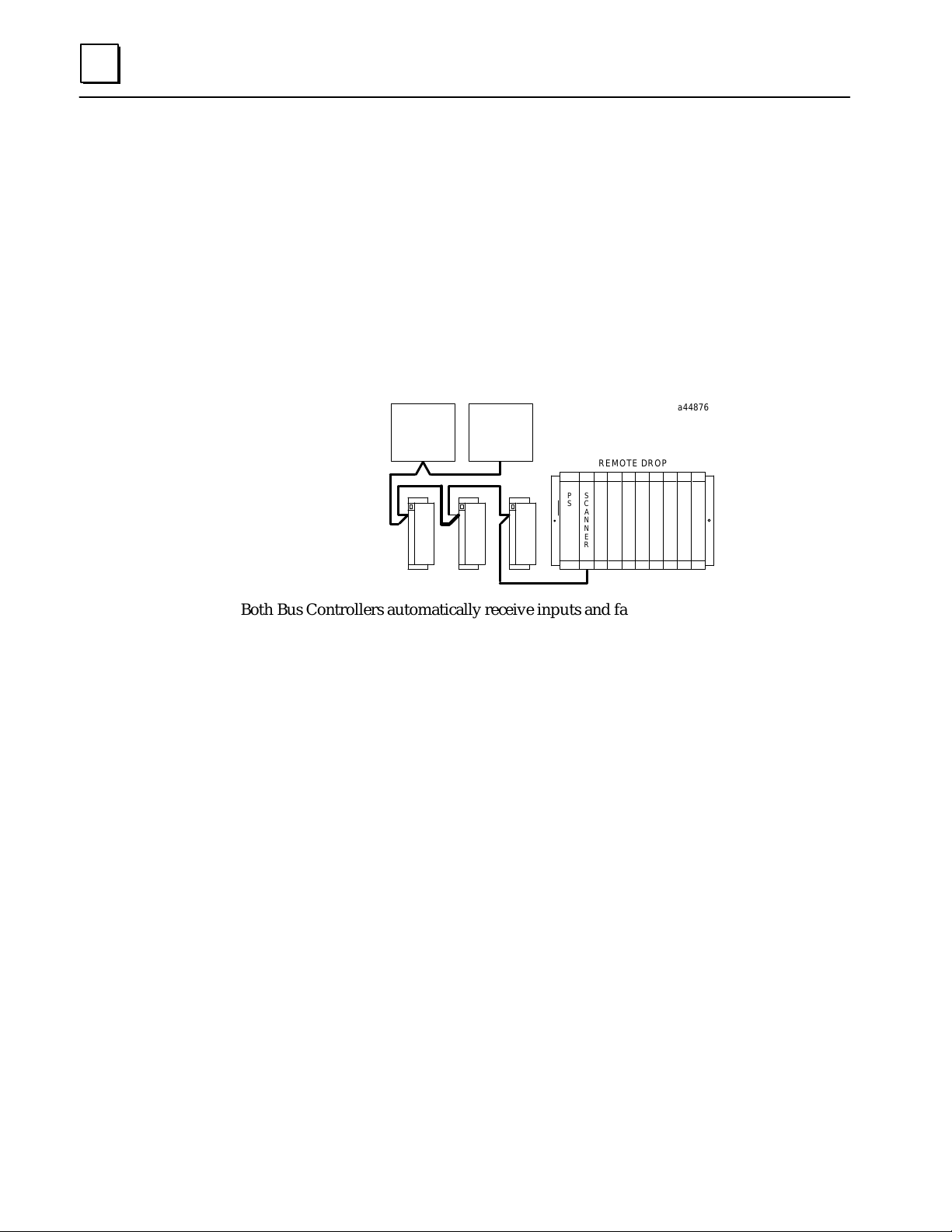

CPU Redundancy

Genius devices are considered to be controlled by the Bus Controller that sends them

outputs. In CPU redundancy, two Bus Controllers on the same bus can send control

outputs at the same time. The Bus Controllers must use Device Numbers 30 and 31.

BUS

CONTROLLER

(DEVICE 30)

BUS

CONTROLLER

(DEVICE 31)

S

P

C

S

A

N

N

E

R

REMOTE DROP

a44876

Both Bus Controllers automatically receive inputs and fault reports from all devices on

the bus that have been configured as being in “CPU Redundancy“ mode.

How the two sets of outputs are handled by devices that receive them depends on

whether the devices are set up for Hot Standby or Duplex redundancy. Both are

explained below . If the remote drop contains any analog modules, the only form of CPU

redundancy permitted is Hot Standby .

Hot Standby CPU Redundancy

A device configured to be in Hot Standby redundancy mode is normally controlled by

the Bus Controller assigned to Device Number 31. If no outputs are available from that

Bus Controller for a period of three bus scans, the device accepts outputs from the Bus

Controller assigned to Device Number 30. If outputs are not available from either Bus

Controller, outputs go to their configured defaults or hold their last state. In Hot

Standby redundancy, Device Number 31 always has priority, so that when that Bus

Controller is on–line, it has control of the outputs.

Duplex CPU Redundancy

A device configured to be in Duplex redundancy mode compares the outputs it

receives from the two bus controllers, to determine whether they match. If

corresponding outputs are the same, the device sets the output to that state. If

corresponding outputs are not the same, the device sets the output to its configured

ON or OFF Duplex Default State. If either Bus Controller stops sending outputs to a

device, its outputs are directly controlled by the remaining device. Only discrete devices

can operate in Duplex redundancy mode; do not use Duplex mode if the analog drop contains

any analog modules.

Series 90–70 Remote I/O Scanner User’s Manual – July 199214

Page 22

1

Genius Bus Redundancy

In Genius bus redundancy, there are two bus cables each connected to a Bus Controller.

The device communicates on only one bus at a time. Before the alternate bus can be

use for communications, a bus switchover must occur and the device must “log in“

with the Bus Controller(s) on the alternate bus. Bus switching can be handled by a Bus

Switching Module attached to a Genius block, or by a Remote I/O Scanner

(IC697BEM733 rev. B or later) which contains a built–in bus switching relay. Bus

Switching Modules and Remote I/O Scanners are the only devices that can be directly

connected to redundant bus cables.

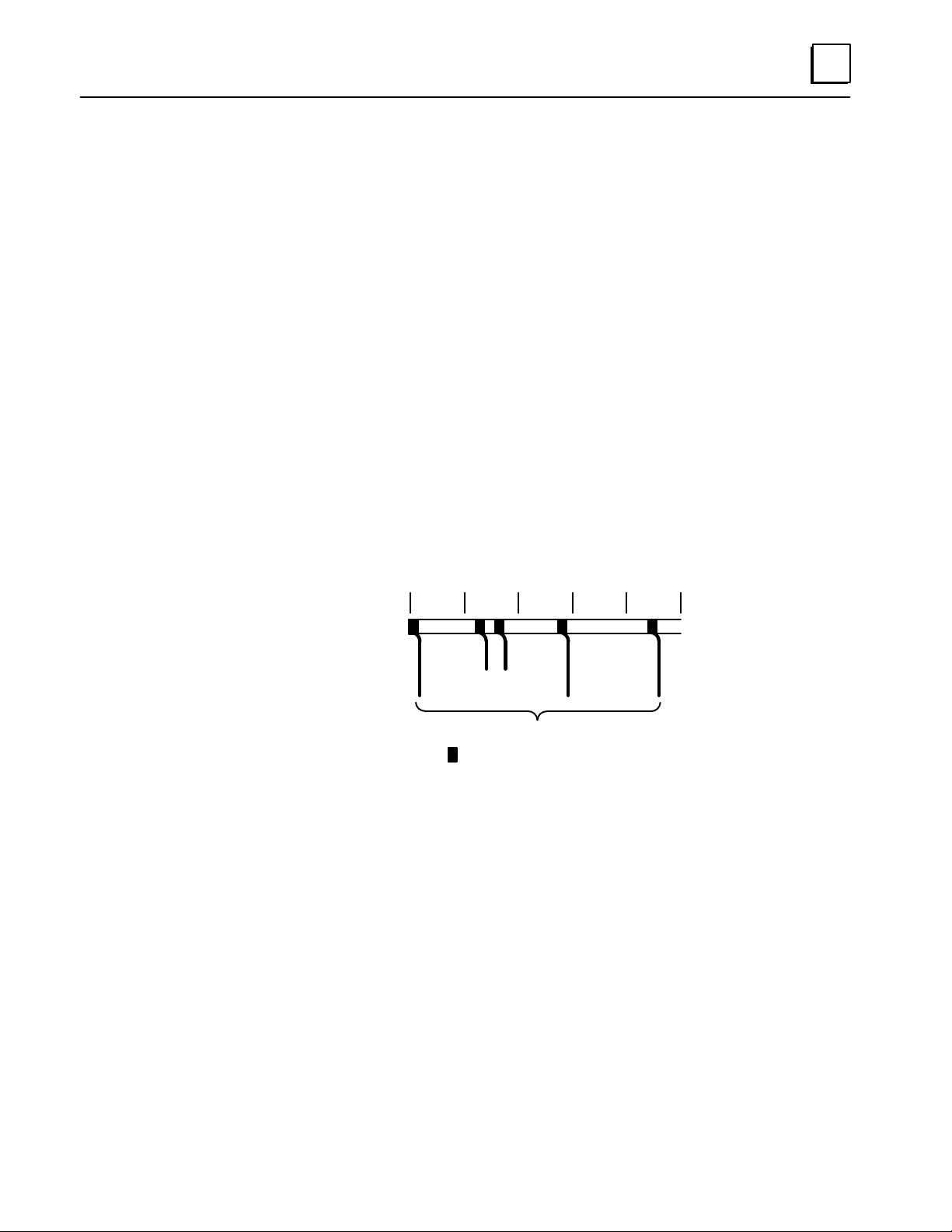

Bus Stubs Connect Other Devices to a Dual Bus

Other Genius devices, such as I/O blocks and additional Remote I/O Scanners, can be

interfaced to a dual bus by short lengths of unterminated cable called a bus stubs.

Typical arrangements are shown on the following pages. Up to seven devices can be

installed on a bus stub (plus the device that is connected to the dual bus). Each device

on a bus stub counts toward the total of 32 devices on the Genius bus.

The total length of all bus stubs on a bus should be 100 feet or less. Within each 20%

section of the actual bus length, the total maximum stub length is 20 feet. This can be

divided into shorter stubs, provided that the total length in each 20% of the bus is 20 ft.

or less.

a44976

20% 20% 20% 20% 20%

10’ 10’

20’

COMBINED = 100 FEET MAXIMUM

= REMOTE I/O SCANNER OR

BUS SWITCHING MODULE

20’

20’

For example, for a trunk cable 3000 ft. long, 20% of the trunk cable length is 600 ft.

Therefore, 20 ft. of bus stub cable can be located within any 600 ft. section of the bus.

There might be two 10 ft. stubs with up to 8 devices each, or four 5 ft. stubs, with fewer

devices on each.

15Chapter 1 Introduction

Page 23

1

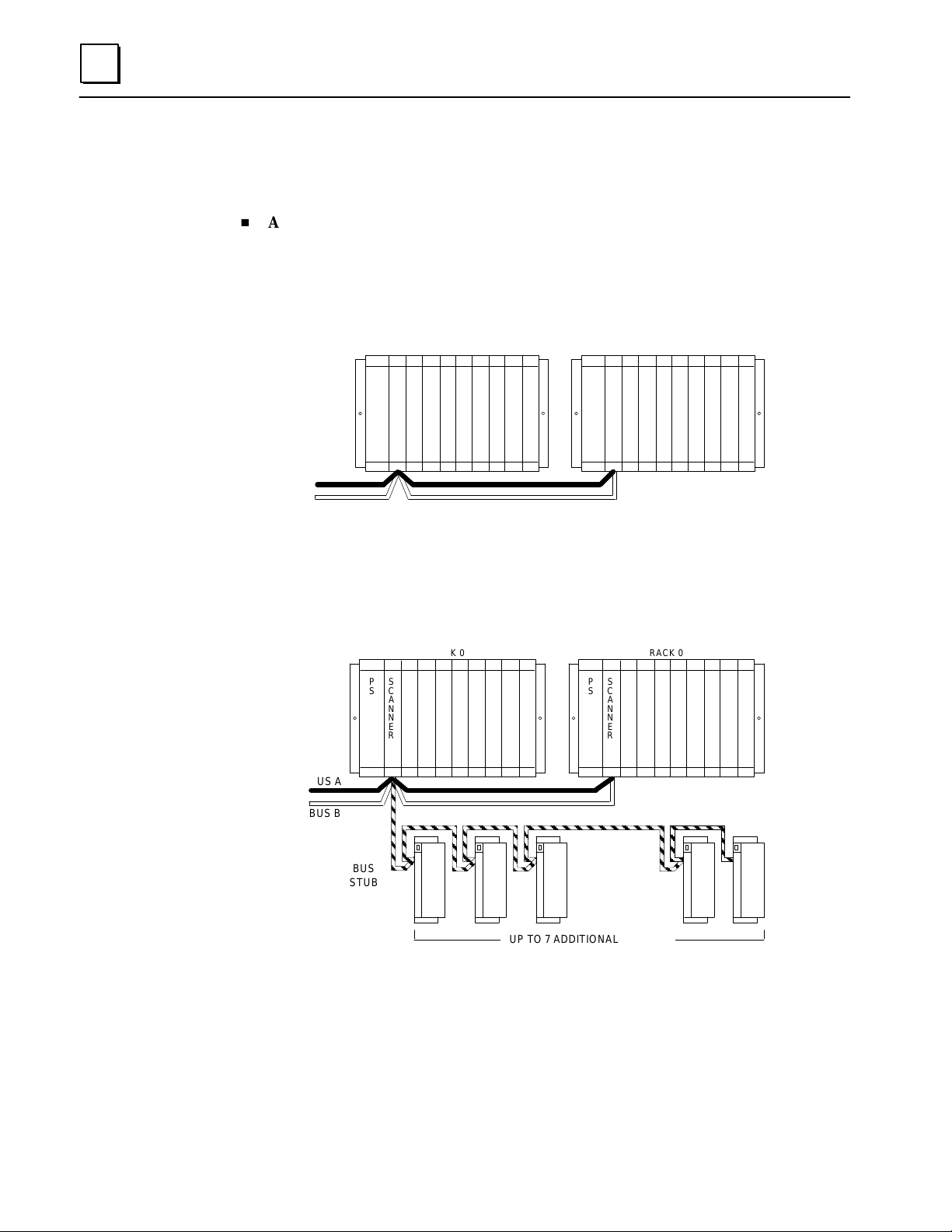

Redundant Bus Configuations

Many different redundant bus configurations are possible. Three basic ways of using a

Remote I/O Scanner with a redundant bus are described below.

H

A Remote I/O Scanner can be installed directly on both cables of the dual bus

pair. The Remote I/O Scanner is configured to operate as a bus switching device in

addition to performing its normal remote drop functions.

Here, two single–rack remote drops are installed on a dual bus. The Remote I/O

Scanner in each remote drop would be set up as a bus switching device.

a44974

BUS A

BUS B

RACK 0

P

S

S

C

A

N

N

E

R

P

S

RACK 0

S

C

A

N

N

E

R

A bus stub may be connected to a Remote I/O Scanner that is configured as a bus

switching device, allowing up to seven additional devices to utilize its bus

switching action. Devices on a bus stub are independent Genius devices. When

bus switching is controlled by a Remote I/O Scanner , as shown below, the devices

on the bus stub are not part of the remote drop. Their data does not count toward

the remote drop’s data total.

a44878 RACK 0 RACK 0

P

BUS A

S

S

C

A

N

N

E

R

P

S

S

C

A

N

N

E

R

BUS B

BUS

STUB

UP TO 7 ADDITIONAL DEVICES

Series 90–70 Remote I/O Scanner User’s Manual – July 199216

Page 24

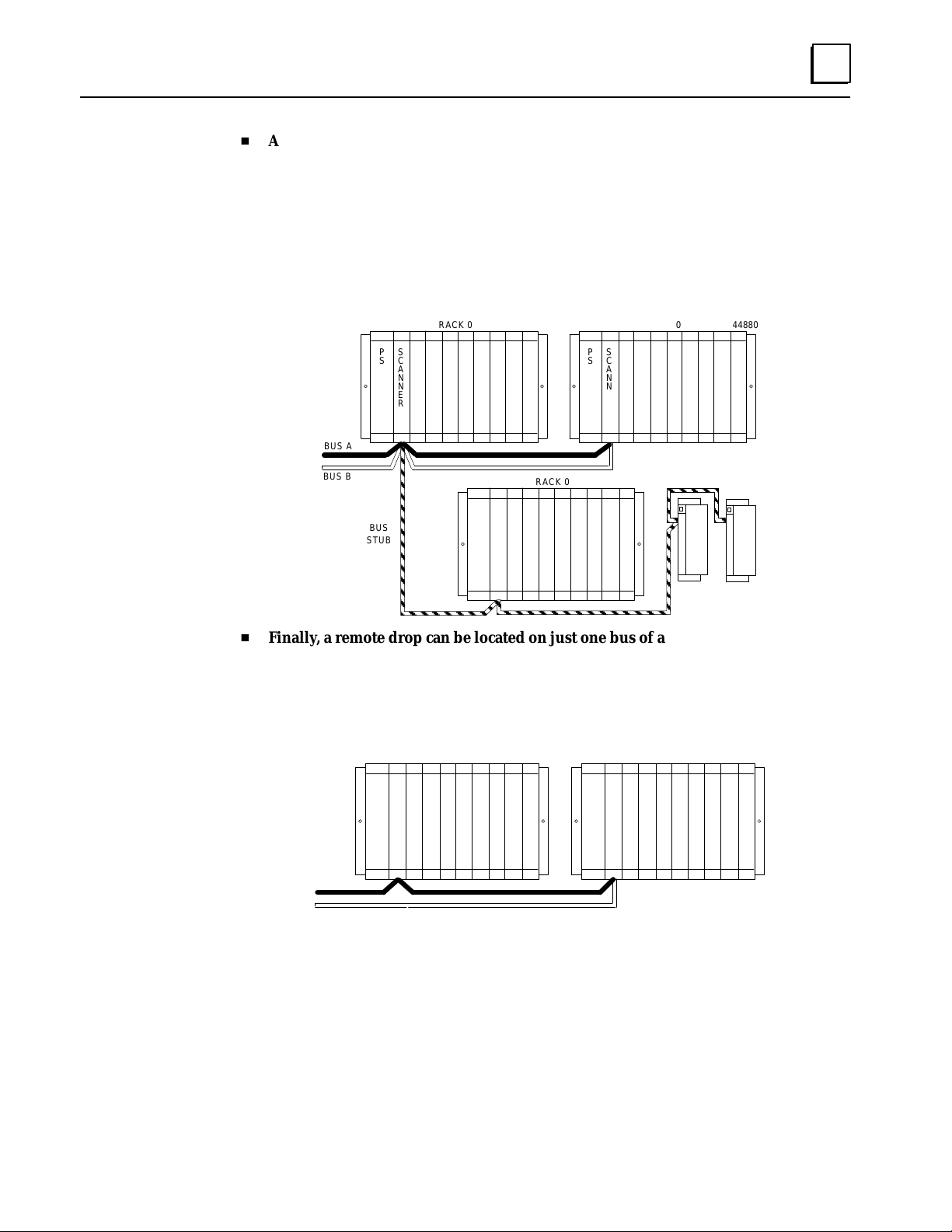

H

A Remote I/O Scanner can be located on a bus stub. The bus switching device to

which the bus stub is connected can be another Remote I/O Scanner, as shown

below, or a Genius block with a Bus Switching Module attached.

In this example, there are two remote drops installed directly on a dual bus. A

third remote drop and some Genius blocks are installed on a bus stub connected to

one of the Remote I/O Scanners. That Remote I/O Scanner acts as the bus

switching device. A remote drop on a bus stub can accommodate up to 128 bytes

of inputs and 128 bytes of outputs, and may include expansion racks.

1

RACK 0

P

S

S

C

A

N

N

E

R

BUS A

BUS B

P

BUS

STUB

H

Finally, a remote drop can be located on just one bus of a redundant bus pair, if

S

RACK 0

S

C

A

N

N

E

R

P

S

RACK 0

S

C

A

N

N

E

R

a44880

bus redundancy is not needed for the modules in that remote drop.

In this example, the remote drop on the right is connected to both Bus A and Bus

B; the remote drop on the left, which contains non–critical I/O modules, is

connected to Bus A only.

RACK 0

RACK 0

a44877

BUS A

BUS B

P

S

S

C

A

N

N

E

R

P

S

S

C

A

N

N

E

R

17Chapter 1 Introduction

Page 25

1

Configuration

A remote drop can be fully configured using Logicmaster 90–70, or automatically

configured using a Genius Hand–held Monitor. Differences between the two

methods are explained below. Optionally, a previously–configured remote drop can

be reconfigured using datagrams.

Remote Drop Configuration with Logicmaster 90–70

Logicmaster 90–70, release 3.0 or later can be used to configure a remote drop for any

type of host. Either serial or parallel Logicmaster can be used. For serial Logicmaster,

the connection to the remote drop can be direct, or via a multidrop network. Direct

connection or a Hand–held Monitor is needed to configure the SNP ID of the remote drop, before

multidrop communications with it are possible.

Logicmaster 90–70 release 4.01 or later, which provides reference checking through

the use of a common folder, is preferred for configuring a Series 90–70 PLC with

remote drops. Chapter 4 explains how to configure a remote drop using Logicmaster

90–70 software which is Release 4 or later.

Appendixes C and D give instructions for configuration using Release 3 Logicmaster

90–70 software.

Remote Drop Configuration with a Genius Hand–held Monitor

A Genius Hand–held Monitor , version 4.0 (IC660HHM501G) or later, can be used to

configure a remote drop that does not include Analog Expander modules. If Analog

Expanders are present, Logicmaster 90 must be used for configuration.

The I/O modules in the remote drop cannot be individually configured with a

Hand–held Monitor; they will operate in default mode. HHM configuration

instructions are given in chapter 6.

Configuring a Remote Drop using Datagrams

The configuration of a remote drop can be completed or changed by sending it

datagrams, as shown in the table on the following page. The Write Map datagram will

supply Series 90–70 data types and lengths, and a Series 90–70 SNP ID for the remote

drop.

Series 90–70 Remote I/O Scanner User’s Manual – July 199218

Page 26

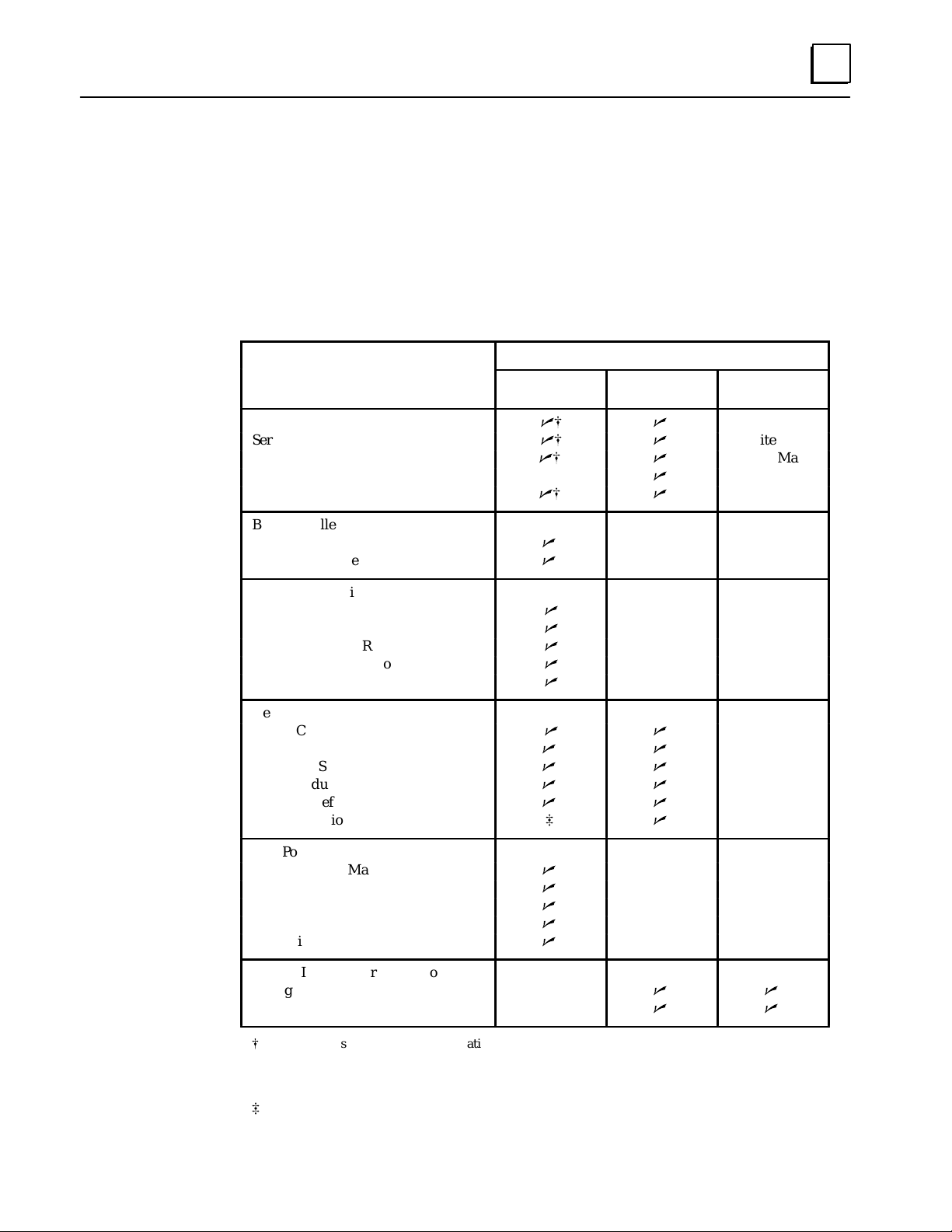

Configurable Features

The following table summarizes configuration options for a remote drop, and

compares them to the PLC configuration required with a remote drop. The remote

drop can be configured, or reconfigured, using Logicmaster 90–70 or a Genius

Hand–held Monitor, or datagrams. If the configuration is not protected, as explained

on the next page, a reconfiguration will replace part or all of an existing configuration,

regardless of the configuration method originally used.

Remote Drop Configuration

Configuration Item

Logicmaster

90–70

Hand–held

Monitor

Datagrams

1

Device Number (SBA)

Series 90–70 References

Data Lengths

Series Six/Series Five References •

Baud Rate

Bus Controller Options:

Input Default

Outputs Enabled

I/O Module Options:

Input Filter Time

Outputs Default

V oltage/Current Range

Analog Expander Modules

PCM*, GDS*, ADS*

Genius Options:

BSM Controller *

BSM Present *

Timeout Select *

CPU Redundancy *

Duple x Default *

Configuration Protection

SNP P ort Options:

SNP ID W rite Map

Baud Rate

Stop Bits

Modem TT

Idle Time

n[ n

n[ n

n[ n

n[ n

n

n

n

n

n

n

n

n

n n

n n

n n

n n

n n

] n

n

n

n

n

n

W rite Map

W rite Map

Remote I/O Scanner Sweep Control:

Programmer Window

Communications Window

[

with release 3 software, PLC configuration must match the remote drop configuration.

• Only for a new Remote I/O Scanner , for which no Series Six/Series Five reference has been entered.

* Not approved for use with Remote I/O Scanner version IC697BEM733A;

upgrade to IC697BEM733B or later .

]

Automatically supplied.

n n

n n

19Chapter 1 Introduction

Page 27

1

Configuration Protection

After configuring a Remote Drop, it is important to prevent inadvertent change while

the system is in operation. For this reason, Logicmaster 90–70 automatically protects

any configuration you download to a Remote I/O Scanner.

A configuration done with a Hand–held Monitor should be protected as described in

chapter 6.

Any Hand–held Monitor used with the system while it is operating should be set up

to prevent undesirable configuration changes:

Protect These Remote Drop Fea -

tures

Device Number (SBA) Change Block ID Disabled

Reference Address

Data Lengths (%I, %Q, %AI, %AQ)

Remote Drop ID

Module Options: Output Defaults

Input Filter T ime V oltage Range

Baud Rate Change Block Baud Disabled

Configuration Protection

Redundancy Options *

By Setting this HHM Option

Change Block Config Disabled

* Not available with Remote I/O Scanner version IC697BEM733A.

To prevent access to restricted HHM configuration options, remove the HHM key.

Caution

If configuration protection is removed from the Remote I/O Scanner

and the Hand–held Monitor’s Change Block ID option is

ENABLED, the HHM’s automatic configuration capability can

overwrite any existing I/O configuration, including one created using

Logicmaster 90–70, or downloaded using a Write Map datagram.

This automatic reconfiguration will also set any module options (see

the table above) back to their defaults.

Series 90–70 Remote I/O Scanner User’s Manual – July 199220

Page 28

Chapter 2 Installation

section level 1 1

2

This chapter describes procedures for installing the racks and modules in a remote

drop, grounding equipment, connecting the Genius bus, completing SNP connections,

and attaching a programmer.

Hardware Packaging

Each Series 90–70 rack is shipped in its own carton, without a power supply. The

power supply and all of the Series 90–70 modules are shipped in individual boxes.

When multiple modules are included in one shipment, individual module boxes are

packaged either two, five or ten boxes to a carton.

Verify that all components of the system have been received and that they agree with

your order. If the items received do not agree with your order, call Programmable

Control Customer Service, toll free, in Charlottesville, V A at 1–800–432–7521. A

Customer Service representative will assist you.

figure bi level 1

table_big level 1

Preinstallation Check

Carefully inspect all shipping containers for damage during shipping. If any part of

the system is damaged, notify the carrier immediately. The damaged shipping

container should be saved as evidence for inspection by the carrier.

As the consignee, it is your responsibility to register a claim with the carrier for damage

incurred during shipment. However , GE F anuc will fully cooperate with you, should

such action be necessary.

After unpacking the Series 90–70 PLC racks, modules, and other equipment, record all

serial numbers. Serial numbers are required if you should need to contact Product

Service during the warranty period of the equipment. Complete all software product

registration cards, and return them to to GE Fanuc.

All shipping containers and all packing material be saved should it be necessary to

transport or ship any part of the system.

21

Page 29

2

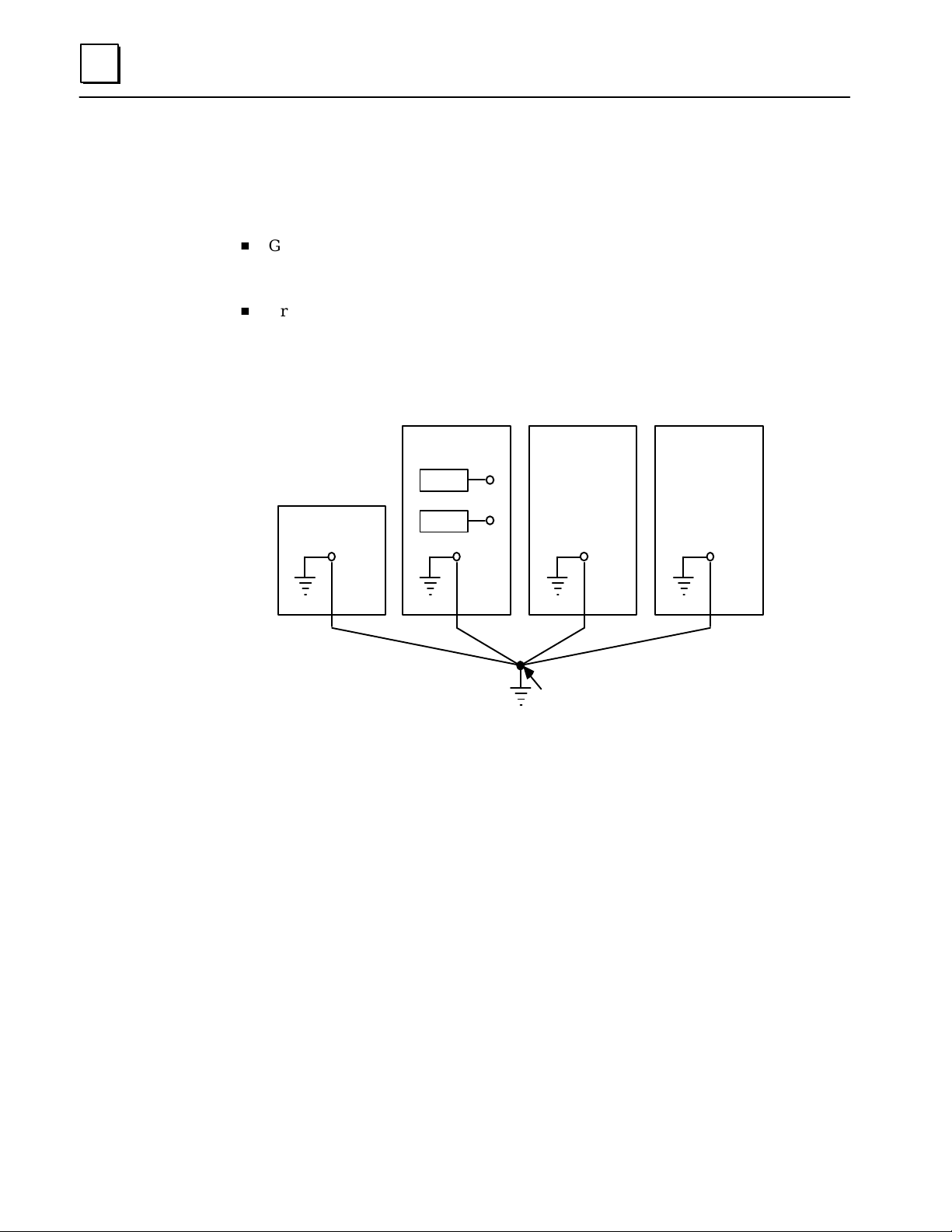

System Grounding Procedures

All components of a control system and the devices it is controlling must be properly

grounded.

H

Ground conductors should be connected in a tree fashion with branches routed to

a central earth ground point. This ensures that no ground conductor carries

current from any other branch. This method is shown in the figure shown below.

H

Ground conductors should be as short and as large in size as possible. Braided

straps or ground cables (typically green insulation with a yellow tracer – AWG

#12 or larger) can be used to minimize resistance. Conductors must always be

large enough to carry the maximum short circuit current of the path being

considered.

SERIES 90–70

PLC CABINET

PROGRAMMING

DEVICE

RACK

RACK

MOTOR DRIVES

AND

OTHER

ELECTRICAL

CONTROL

EQUIPMENT

a42942

MACHINERY

EARTH

GROUND

CENTRAL

GROUND POINT

NOTE

SIGNAL AND POWER

CONNECTIONS

NOT SHOWN

Series 90–70 Remote I/O Scanner User’s Manual – July 199222

Page 30

Rack Installation

Î

Î

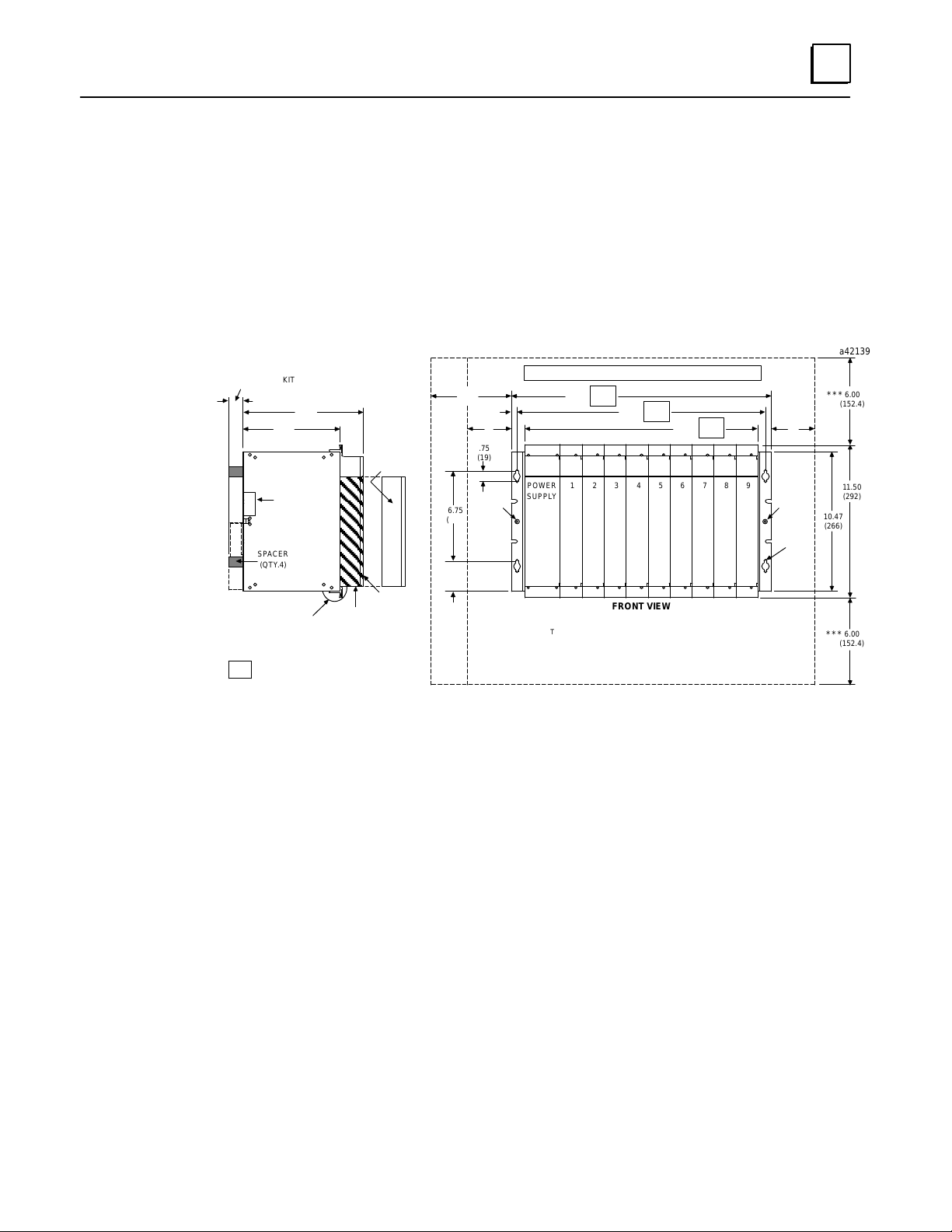

Install the rack(s) in the orientation shown below. The illustration shows a 9–slot rack,

but a 5–slot rack could be used.

Series 90–70 PLC racks may be rack or panel mounted, depending on version

ordered. Rack dimensions for installation purposes are shown below.

The Series 90–70 rack does not require a fan as long as sufficient space is left around

the rack for cooling airflow .

WITH OPTIONAL VME J2

BACKPLANE KIT

1.00

(25.4)

SPACER

(QTY.4)

=

9.14

(232)

7.25

(184)

CONNECTOR

FOR

POWER

SUPPLY

SIDE VIEW

I/O TERMINAL

RESTRAINING

STRAP

DIMENSIONS FOR 5 SLOT RACK

CABLE

ENTRANCE

FROM

BOTTOM

REMOVABLE

I/O

TERMINAL

BLOCK

Î

Î

Î

Î

HINGED

DOOR

DIMENSIONS IN INCHES, MILLIMETERS ARE IN PARENTHESIS

12.60

6.75

(172)

2.24

(57)

6.00

**

(152.4)

.45

(11)

*

.75

(19)

GROUND

STUD

SUPPLY

19.00

(483)

123456789POWER

(320)

18.11

(460)

11.71

(297)

17.04

(433)

FRONT VIEW

ALLOW SUFFICIENT HORIZONTAL CLEARANCE FOR ACCESS TO GROUND STUDS

*

AT EACH END OF THE RACK.

IF THE EXTENSION CABLE IS USED, ALLOW APPROXIMATELY 6 INCH HORIZONTAL

**

CLEARANCE ON THE LEFT SIDE OF THE RACK FOR ACCESS TO THE CONNECTOR.

ALLOWANCE FOR COOLING ( If REQUIRED FOR ADDITIONAL COOLING, RACK FAN

***

ASSEMBLY (IC697ACC721 IS AVAILABLE. )

10.64

(264)

*

GROUND

STUD

.25 DIA.

(TYPICAL)

2

10.47

(266)

a42139

6.00

***

(152.4)

11.50

(292)

6.00

***

(152.4)

23Chapter 2 Installation

Page 31

2

Rack Grounding

H

Complete safety and reference ground connections from the GND terminal on the

rack to earth ground using minimum AWG #12 wire and a ring terminal. Use of a

nut and star washer for each wire on the GND lug is recommended to ensure

adequate grounding.

Warning

If the ground lug on the rack is not connected, the rack is not

grounded. The rack must be grounded to minimize electrical shock

hazard which may result in severe personal injury or may be fatal.

H

All racks that are grouped together MUST have a common ground connection.

This is especially important for racks which are not mounted in the same cabinet.

H

Connect the rack frame directly to the control panel or rack on which it is

mounted. Attach a ground strap from one of the ground lugs on either side of the

rack to the control panel or cabinet following applicable electrical safety codes.

H

Use the bottom rail of the rack for module shield grounding. Some modules have

a ground clip that contacts the conductive bottom rail when the module is fully

inserted. Shield connections in the user connector are routed to this ground clip

through conductors on the module.

Rack Number Selection

Before installing the power supply or power supply adapter in the rack, set the

rack–number jumpers. Each rack in a remote drop must have a rack number

between 0 and 7. Rack number 0 must always be present; in the remote drop, it is the

rack that contains the Remote I/O Scanner.

To select a rack number, move jumpers X1, X2, and X4 so that the sum of the numbers

in the 1 (right) position equals the desired rack number. Jumper X8 must always be in the

0 (left) position. The jumper plug connects the middle post under the 1 or 0 column as

shown in the following example, which shows jumper positions for rack 2.

a42823

01

8

4

RACK NUMBER =2

2

1

Series 90–70 Remote I/O Scanner User’s Manual – July 199224

Page 32

Do not confuse this rack number with the Device Number used by a Remote I/O

Scanner. Rack number refers to a rack’s position within a remote drop. A Device

Number is a Remote I/O Scanner’s assigned ID on the Genius bus. These two

numbers are not related. The following example shows rack numbering for three

remote drops. The Remote I/O Scanners for those remote drops are configured to use

Device Numbers 7, 8, and 9.

Do not select duplicate rack numbers in the same remote drop. After selecting the rack

number, record it on the inside of the Power Supply hinged door.

2

DEVICE

#7

GENIUS

BUS

DEVICE

#8

GENIUS

BUS

DEVICE

#9

GENIUS

BUS

a44879 RACK 3

PSB

RACK 1

R

M

RACK 0

P

S

B

S

C

T

A

M

N

N

E

R

PSB

RACK 2

PSB

R

M

R

M

RACK CONNECTION CABLE

RACK 0

P

S

S

C

A

N

N

E

R

PSB

RACK 1

R

M

RACK 0

P

S

B

S

C

T

A

M

N

N

E

R

PSB

RACK 2

R

M

RACK CONNECTION CABLE

25Chapter 2 Installation

Page 33

2

Î

Power Supply Installation

After setting the rack number selection jumpers, install the power supply as instructed

in its datasheet. An AC power supply installs directly in the leftmost slot of the rack.

For DC power supplies, a Power Supply Adapter installs in the leftmost slot. The DC

power supply itself can either be installed on the side of the rack or used as a

freestanding module up to 20 inches from the adapter module.

Power Supply Switch

On an AC power supply, the switch on the front of the power supply controls power to

the rack. With the switch in the up (ON) position, the power supply is on and power

flows to the rack. With the switch down (OFF), power is disconnected from the rack.

With a DC power supply, an external switch must be installed to control input power.

Power must be off when installing or removing modules.

Caution

Power Supplied to Two Racks

The 120/240VAC 55–Watt, 24VDC 90–Watt, and 120/240VAC 100–Watt power

supplies can be used to supply power to two racks. The 125VDC, 60–Watt supply

cannot provide power for two racks.

Connect the rack with the power supply to the second rack using the two–rack power

extension cable (catalog number IC697CBL700). Plug the cable into the connectors on

the left side of each rack. When using a DC power supply mounted on the side of the

rack, the power extension cable must be installed first; the DC power supply will block

access to the connector on the side of the rack.

Maximum cable length between two racks that share a power supply is 3 feet (1 meter).

INSTALL CABLE

SO THAT THE

INDICATED END

IS SUPPLYING

POWER

TWO

RACK

POWER

CABLE

123456789

POWER

SUPPLY

FACE

PLATE

a42134

FIRST

RACK

SECOND

RACK

Series 90–70 Remote I/O Scanner User’s Manual – July 199226

Page 34

Module Locations

Follow the guidelines below when planning module locations in a remote drop.

Remote I/O Scanner

Locate the Remote I/O Scanner in rack 0, slot 1, next to the power supply .

Bus Transmitter Module

A Bus Transmitter Module (BTM) can be located in any slot of rack 0; however, there

must be no empty slots between the Bus Transmitter and the Remote I/O Scanner. It is

recommended that the Bus T ransmitter be located in slot 2, next to the Remote I/O

Scanner.

Bus Receiver Module

In a multiple–rack remote drop, locate a Bus Receiver Module (BRM) in slot 1 of each

expansion rack, next to the power supply slot.

I/O and Option Modules

Generally , I/O and option modules can be installed in any slot. Some exceptions are

noted below.

2

Analog Expanders

A high–level analog input module and its associated expander modules must be

installed in the same rack of a remote drop. Locate the high–level analog input

module in the lowest slot position of the group. Locate the expander modules to its

right. A second high–level analog input module cannot be located between a

high–level analog module and its expander modules. It must either be placed to the

left of the first analog module, or to the right of the last expander module.

Analog output modules, discrete I/O modules, and/or special–function modules may

be located between the analog input module and any of its expander modules.

Empty Slots in the Rack

Empty slots are permitted between modules, with two exceptions:

A. There can be no empty slots to the left of a Bus Transmitter, analog, PCM, GDS, or

ADS module.

B. If, in the future, modules will be placed in the empty slots and a Hand–held

Monitor will be used to automatically reconfigure the remote drop, locate empty

slots to the right in the rack. Otherwise, automatic reconfiguration will change the

I/O references assigned to the boards already there.

P

S

REMOTE DROP

I/I

SCI

A

N

N

E

R

/

/

OOOOO

I/I

a44753

/

EMPTY

27Chapter 2 Installation

Page 35

2

Module Installation and Removal

Always be careful working near the power supply and the wiring to

I/O boards in the rack. Be sure a protective faceplate cover is

installed on each board. Voltages present on I/O wiring and power

supply could cause severe or fatal injury to personnel.

Do not insert or remove a module when power is applied to the rack.

This could cause the system to stop. Use care when inserting or

removing a module so that the printed circuit board or its

components are not damaged.

Warning

Caution

Installing a Module

Install each module with its component side to the right. The LEDs will be at the top

front.

1. Be sure the rack in which the module is to be inserted is powered–down.

2. Grasp the module firmly with your hand and insert it into the card guide.

3. Align the module’s printed circuit board with the connector on the rack backplane

and slide it towards the connector until it has started to seat.

4. Place one thumb on the left side of the top plastic flange and the other thumb on

the left side of the bottom plastic flange. Push the board into the connector until

the top and bottom latches click onto the rack rails.

5. Visually inspect the board to be sure it has seated properly.

6. If the rack is in a high–vibration area, use screws to secure the module in the rack.

Removing a Module

1. Be sure the rack is powered–down.

2. Grasp the module firmly at the top and bottom of the board cover with your

thumbs on the front of the cover and your fingers on the plastic clips on the back

of the cover.

3. Squeeze the rack clips on the back of the cover with your fingers to disengage the

clip from the rack rail and pull the board firmly to remove it from the backplane

connector.

4. Slide the printed circuit board along the card guide and remove it from the rack.

Series 90–70 Remote I/O Scanner User’s Manual – July 199228

Page 36

Field Wiring to I/O Modules

Basic procedures for completing module wiring are given on the next page. For

additional information about installing a specific module, please read the module

datasheet.

2

JACKSCREW JACKSCREW

TERMINAL

BOARD

CORD

TIE

CORD

TIE

CLEAT

STRAP

HINGED

DOOR

CORD

TIE

STRAP

CORD

TIE

CLEAT

STRAP

CLEAT

a43855

29Chapter 2 Installation

Page 37

2

1. Open the hinged door on the module to access the jackscrew which holds the

terminal board securely in place. Remove the terminal board by turning the

jackscrew counter–clockwise until it is fully disengaged.

2. Remove the terminal board by grasping the top and swinging it outward.

JACKSCREW

DO NOT

PULL

ON DOOR

a43747

WIRE BUNDLE CABLE TIE CLEAT

Caution

Do not use the hinged door to remove the terminal board. The

hinged door could be damaged if this is done.

3. Referring to the wiring information on the module door, complete the field wiring.

Use AWG #22 (0.324 mm) through AWG #14 (2.08 mm) wire. When using AWG

#14 wire and wiring all points, do not exceed a maximum insulation diameter of

.135 inch. To ensure proper connection, two wires may be ter minated on any one

terminal only if both wires are the same size.

4. After completing connections to all modules in a rack, secure the wire bundle.

Wrap a cable tie around the wire bundle and secure it tightly through the cable tie

cleat at the lower right corner of the terminal board. For large wire bundles, use

additional cable ties.

5. Record circuit wiring identification on the door label. Insert the label in the door’s

slot (crease the scored edge of the label if necessary).

6. Fasten the terminal board to the rack securely . Insert the terminal board strap into

the small rectangular slots in the bottom card guide grill on the rack.

7. Leave a ventilation space of at least 6 inches above and below the rack grill. Do

not obstruct the grill with wire bundles.

Warning

Ensure that the protective cover is installed over all terminal boards.

The cover protects against accidental shock hazard which could

cause severe or fatal injury to the operator or maintenance personnel.

Series 90–70 Remote I/O Scanner User’s Manual – July 199230

Page 38

Multiple Racks in a Remote Drop

If the remote drop has more than one rack, rack 0 must contain a Bus Transmitter

Module. The Bus T ransmitter should be installed in slot 2, ne xt to the Remote I/O

Scanner. Using the appropriate cable (see the table below), attach the bottom connector

of the Bus Transmitter to the top connector of a Bus Receiver Module in the next rack.

Continue this process to connect all of the racks in the drop. The maximum total cable

length from the Bus T ransmitter to the last Bus Receiver is 50 feet (15 meters).

Catalog Number Length

IC600WD005 5 feet (1.5 meters)

IC600WD010 10 feet (3.0 meters)

IC600WD025 25 feet (7.5 meters)

IC600WD050 50 feet (15.0 meters)

Terminator Plug

2

Each Bus Receiver Module is shipped with a termination resistor pack installed in the

lower connector. Only the last Bus Receiver in a remote drop may have the terminator

plug installed. If the remote drop has three or more racks, remove the terminator

plugs from the intermediate Bus Receivers.