Page 1

Installation Dryers

Instructions

Questions? Call GE Appliances at 800.GE.CARES (800.432.2737) or visit our Web site at: GEAppliances.com

BEFORE YOU BEGIN

Read these instructions completely and carefully.

IMPORTANT – Save these instructions for local

•

electrical inspector’s use.

•

IMPORTANT – Observe all governing codes and

ordinances.

Install the clothes dryer according to the manufacturer’s

•

instructions and local codes.

Note to Installer – Be sure to leave these instructions

•

with the Consumer.

Note to Consumer – Keep these instructions for future

•

reference.

Clothes dryer installation must be performed by a

•

qualified installer.

This dryer must be exhausted to the outdoors.

•

Before the old dryer is removed from service or

•

discarded, remove the dryer door.

Service information and the wiring diagram are located

•

in the control console.

Do not allow children on or in the appliance. Close

•

supervision of children is necessary when the appliance

is used near children.

Proper installation is the responsibility of the installer.

•

Product failure due to improper installation is not

•

covered under the Warranty

• Install the dryer where the temperature is above 50°F

for satisfactory operation of the dryer control system.

• Remove and discard existing plastic or metal foil duct

and replace with UL-listed duct.

.

WARNING

• Clothes dryer installation must be performed by a

qualified installer.

Install the clothes dryer according to these

•

instructions and local codes.

DO NOT install a clothes dryer with flexible plastic

•

venting materials. If flexible metal (semi-rigid or

foil-type) duct is installed, it must be UL-listed and

installed in accordance with the instructions found

in “Connecting the Dryer to House Vent” later in

this manual. Flexible venting materials are known

to collapse, be easily crushed and trap lint. These

conditions will obstruct dryer airflow and increase

the risk of fire.

DO NOT install or store this appliance in any

•

location where it could be exposed to water or

weather.

To reduce the risk of severe injury or death, follow

•

all installation instructions.

Save these instructions. (Installers: Be sure to leave

•

these instructions with the customer.)

FOR GAS DRYERS ONLY

IN THE COMMONWEALTH OF

MASSACHUSETTS, THE FOLLOWING

INSTALLATION INSTRUCTIONS APPLY:

• Installation must be performed by a qualified

or licensed contractor, plumber, or gasfitter

qualified or licensed by the State.

•

If using a ball valve, it shall be a T-handle type.

•

A flexible gas connector, when used, must not

exceed 3 feet.

- Fire Hazard

04

Printed in Mexico

234D2274P004

31-16769-3 08-16 GEA

Page 2

Installation Instructions

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam

shipping pads by pulling at the sides and breaking

them away from the dryer legs. Be sure to remove all

of the foam pieces around the legs.

Remove the bag containing the literature.

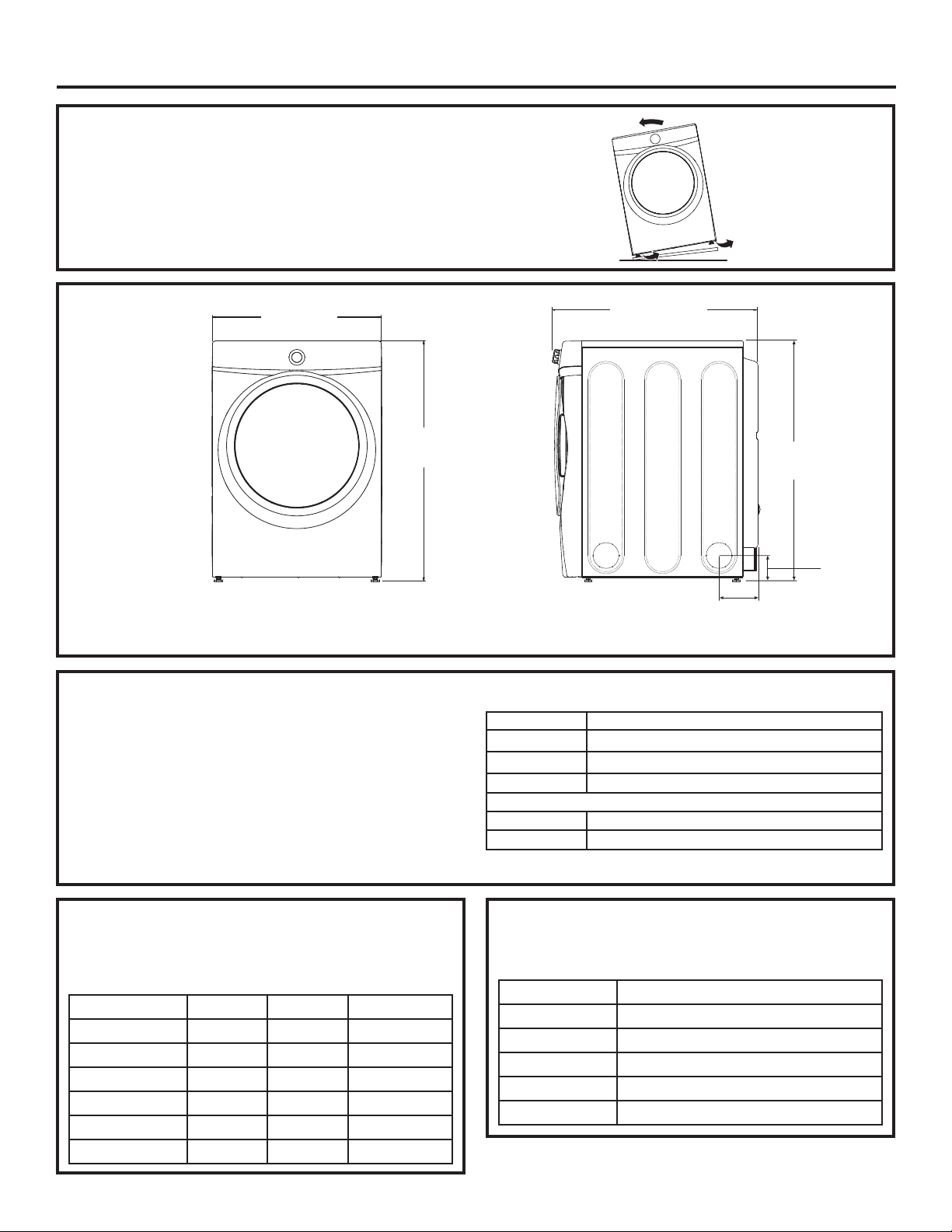

ROUGH-IN

DIMENSIONS

Front View

NOTE:

Dryer height can be adjusted to match washer height

With Pedestal: 52.1” (132.33 cm)

Stacked: 84” (213.36 cm)

27”

(68.6 cm)

39.3”

(99.8cm)

STEAM WATER HOSES (for steam dryer models only):

GE Appliances strongly recommends the use of factory

specified parts. These hoses are manufactured and tested to

meet GE Appliances specifications.

GE Appliances strongly recommends the use of new water supply

hoses. Hoses degrade over time and need to be replaced every 5

years to reduce the risk of hose failures and water damage.

Parts and Accessories

Order on-line at GEApplianceParts.com, 24 hours a day or

by phone at 800.626.2002 during normal business hours.

Part Number

WE25X20060

WE49X25794

WE1M847

OR SEPARATELY

WE1M847

WE1M848 Short Hose

33” (83.8 cm)

39.3”

(99.8 cm)

4.4”

Side View

5.4”

(13.7 cm)

Accessory

Complete Kit (hoses, Y-adapter, washers) or

Kit (Short hose, Y-adapter, washers) and

Long Hose

Long Hose and

(11.2 cm)

POWER CORDS:

GE Appliances strongly recommends the use of factory

specified parts. Select the power cord to fit your installation

requirements.

Part Number Type Length Amperage

WX9X2 3-Prong 4 Feet 30

WX9X3 3-Prong 5 Feet 30

WX9X4 3-Prong 6 Feet 30

WX9X18 4-Prong 4 Feet 30

WX9X19 4-Prong 5 Feet 30

WX9X20 4-Prong 6 Feet 30

ACCESSORIES:

Order on-line at GEApplianceParts.com, 24 hours a day or

by phone at 800.626.2002 during normal business hours.

Part Number Accessory

SBSD137HWW

SBSC137HDG

GEFLSTACK Stacking Kit for Dryer over Washer

PM08X10085

WE01X20677

2

27” width White Pedestal

27” width Diamond Gray Pedestal

Flexible Metal Dryer Transition Duct

Clothes Dryer Shoe Rack

Page 3

Installation Instructions

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

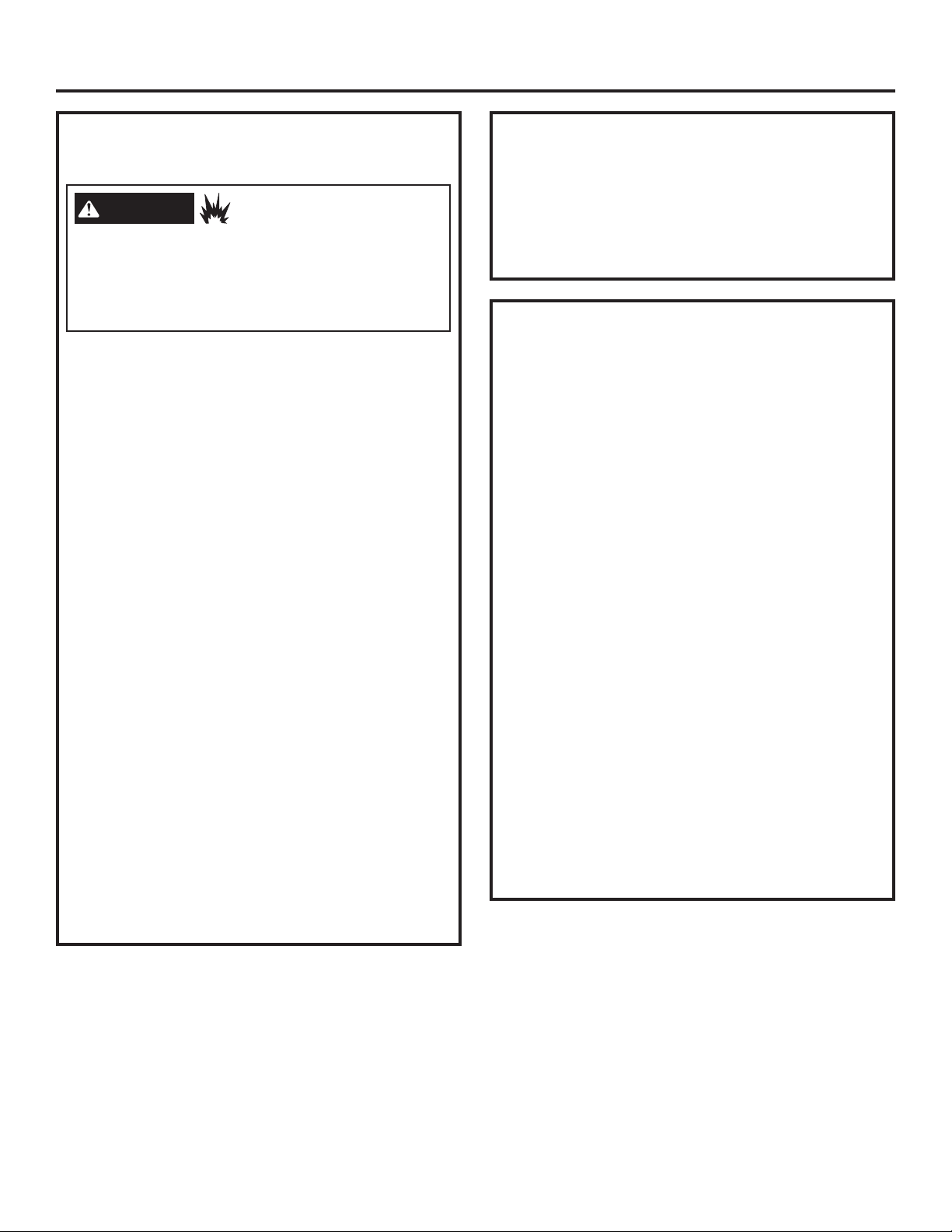

WARNING

Keep flammable materials and vapors, such as gasoline,

away from dryer.

Place dryer at least 18” (46 cm) above the floor for a

garage installation.

Failure to do so can result in death, explosion, or fire.

• The dryer MUST be vented to the outdoors. See

the EXHAUSTING THE DRYER section.

•

Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0” either side

1” front

1” rear

1” top

•

Consideration must be given to provide adequate

clearance for installation and service.

•

Closet doors must be louvered or otherwise

ventilated and have at least 60 square inches of

open area. If the closet contains both a washer

and a dryer, doors must contain a minimum of

120 square inches of open area.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED IN

THE REAR OF THE DRYER, THE CONFIGURATION OF

THE DUCTING MAY REQUIRE GREATER THAN 1” OF

REAR CLEARANCE.

Gas Dryers Only:

•

No other fuel burning appliance shall be installed

in the same closet as a gas dryer.

•

The dryer must be disconnected from the gas

supply piping during pressure testing at pressures

greater than ½ psi (3.5 kPa).

•

A 1/8 inch NPT minimum plugged tapping,

accessible for test gauge connection, must be

installed immediately upstream of the gas supply

connection to the dryer.

- Explosion Hazard

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and

for air opening are:

Consideration must be given to provide adequate

clearance for installation and service.

0” both sides; 1” rear; 1” top

.

MOBILE OR MANUFACTURED HOME

INSTALLATION

• Installation MUST conform to the

MANUFACTURED HOME CONSTRUCTION AND

SAFETY STANDARD, TITLE 24, PART 32–80 or

Standard CAN/CSA-Z240 MH, or, when such

standard is not applicable, with AMERICAN

NATIONAL STANDARD FOR MOBILE HOME,

ANSI/NFPA NO. 501B.

•

The dryer MUST be vented to the outdoors.

•

The exhaust vent MUST be securely fastened to

a non-combustible portion of the mobile home.

•

The vent MUST NOT be terminated beneath a

mobile or manufactured home.

•

The vent duct material MUST BE METAL.

•

KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

•

The vent MUST NOT be connected to any other

duct, vent or chimney.

•

DO NOT use sheet metal screws or other

fastening devices which extend into the interior

of the exhaust vent.

•

Provide an opening with a free area of at least

25 square inches for introduction of outside air

into the dryer room.

•

See the sections for electrical connection

information.

3

Page 4

Installation Instructions

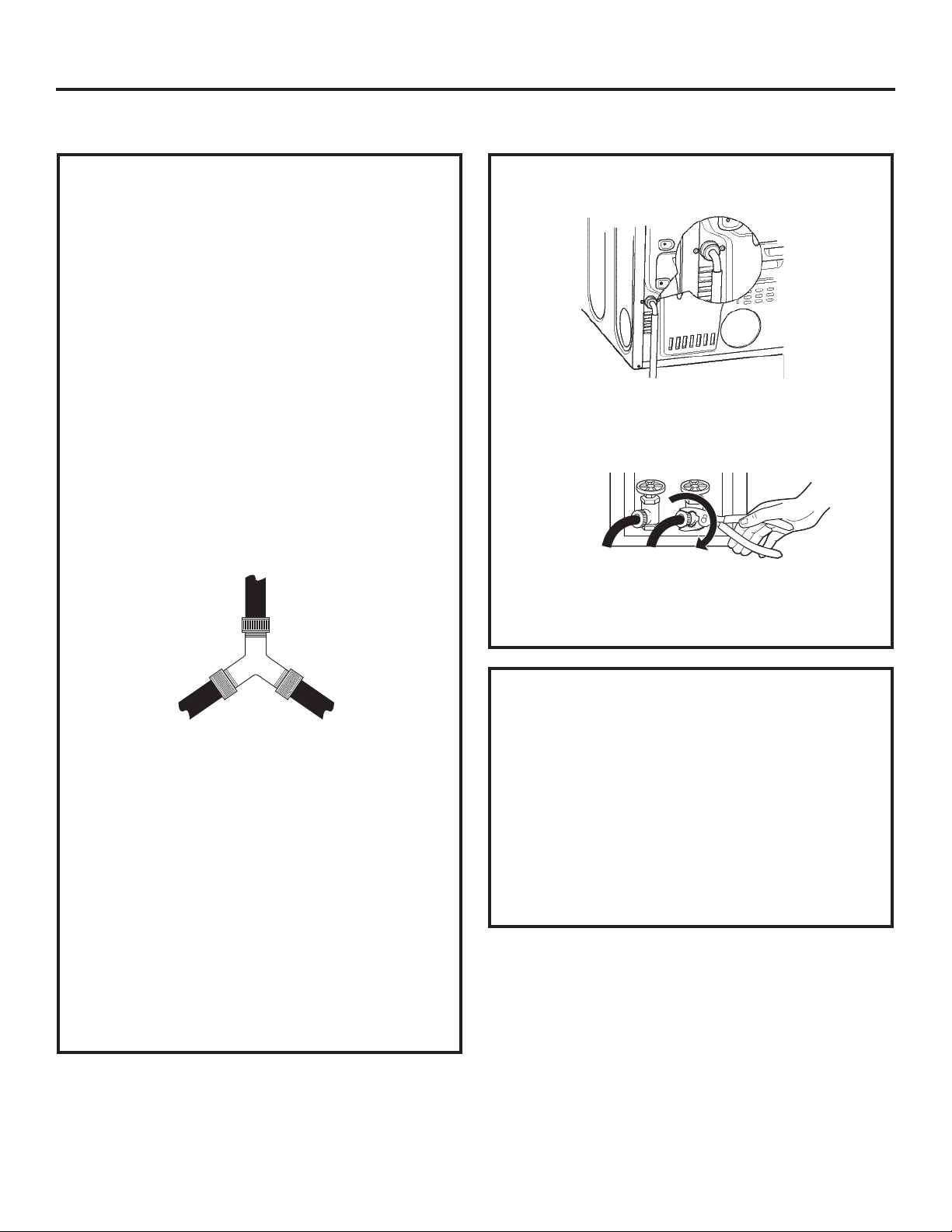

CONNECTING INLET HOSES (for steam dryer models only)

CONNECTING INLET HOSES

To produce steam, the dryer must connect to

the cold water supply. Since the washer must

also connect to the cold water, a “Y” connector

is inserted to allow both inlet hoses to make that

connection at the same time.

NOTE: Use new inlet hoses; never use old hoses.

1. Turn the cold water faucet off. Remove the

washer inlet hose from the washer fill valve

connector (cold).

2. Ensure the rubber flat washer is in place and

attach one female coupling of the short hose

provided onto the washer fill valve connector.

Tighten by hand until firmly seated.

3. Attach one male end of the “Y” connector to the

other female coupling of the short hose. Ensure

the rubber flat washer is in place. Tighten by

hand until firmly seated.

CONNECTING INLET HOSES (cont.)

7. Using pliers, tighten all the couplings with an

additional two–thirds turn.

NOTE: Do not overtighten. Damage to the couplings

may result.

8. Turn the water faucet on.

9. Check for leaks around the ‘’Y’’ connector, faucet

and hose couplings.

4. Insert the filter screen in the coupling of the

washer’s inlet hose. If a rubber flat washer is

already in place remove it before installing the

filter screen. Attach this coupling to one male end

of the ‘’Y’’ connector. Tighten by hand until firmly

seated.

5. Ensure the rubber flat washer is in place and

attach a 4 ft. to 6 ft. long water inlet hose (may

need to be purchased separately) to one male

end of the ‘’Y’’ connector. Tighten by hand until

firmly seated.

6. Ensure the rubber flat washer is in place and

attach the other end of the dryer’s long inlet

hose to the fill valve connector at the bottom of

the dryer back panel. Tighten by hand until firmly

seated.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed

within 42 in. (107 cm) of your washer’s water

inlet. The faucets MUST be 3/4 in. (1.9 cm) garden

hose-type so inlet hoses can be connected. Water

pressure MUST be between 10 and 120 pounds

per square inch. Your water department can

advise you of your water pressure.

NOTE: A water softener is recommended to reduce

buildup of scale inside the steam generator if the

home water supply is very hard.

4

Page 5

Installation Instructions

CONNECTING A GAS DRYER (skip for electric dryers)

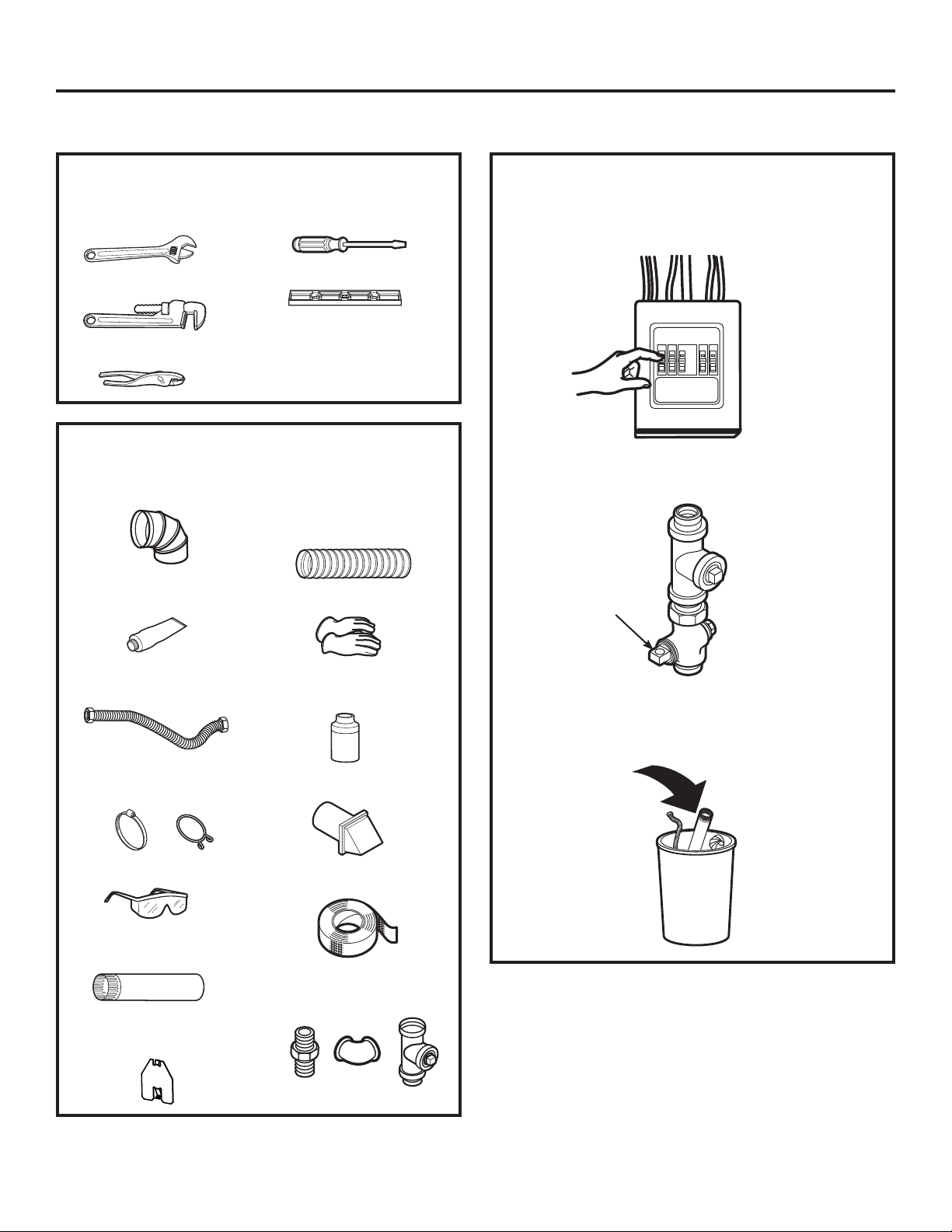

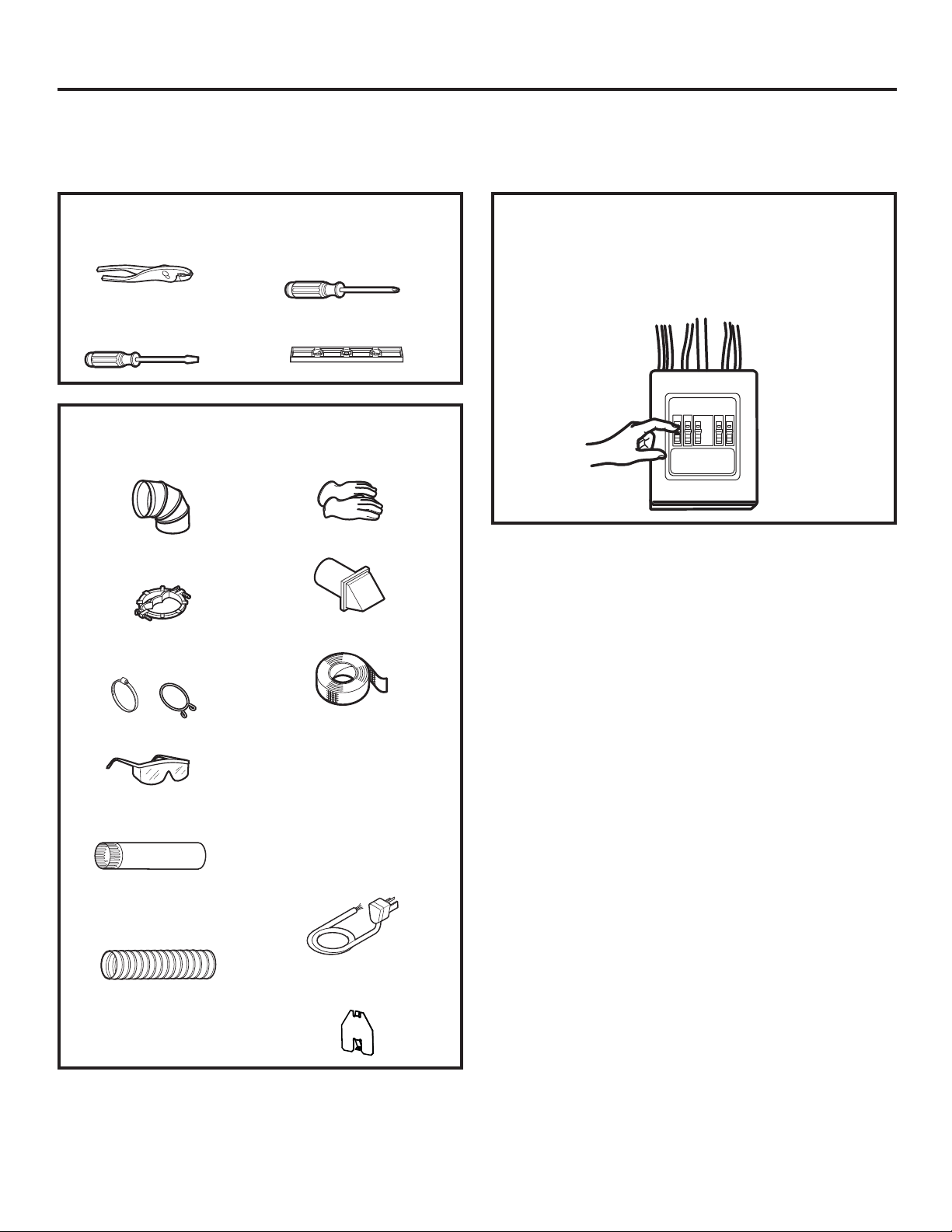

TOOLS YOU WILL NEED

10” Adjustable

wrenches (2)

8” Pipe wrench

Slip-joint pliers

Flat-blade

screwdriver

Level

MATERIALS YOU WILL NEED

4” dia. metal elbow

Pipe compound or

PTFE tape

4” dia., UL-listed

flexible metal duct

(if needed)

Gloves

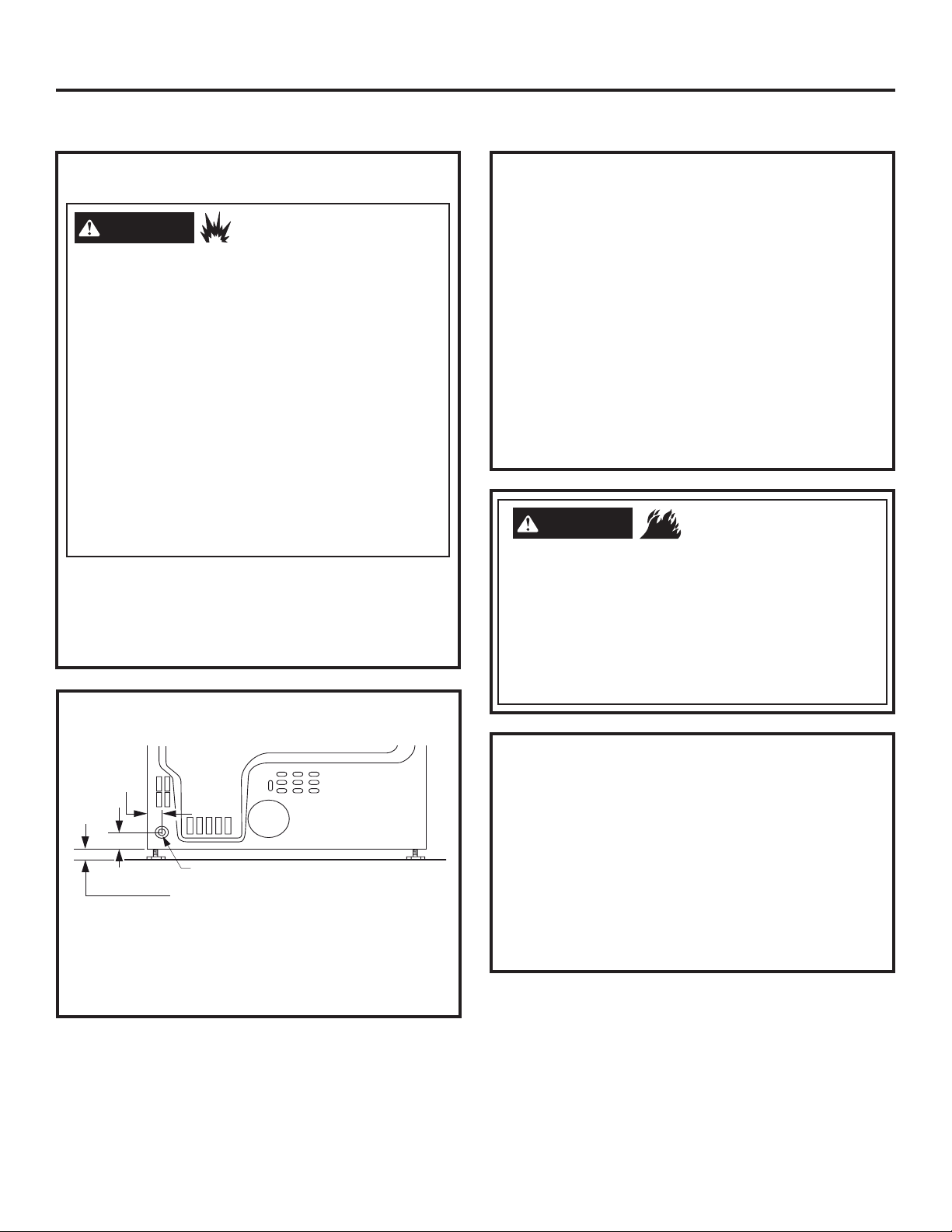

• Before beginning the installation, turn off

the circuit breaker(s) or remove the dryer’s circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall.

•

Turn the dryer’s gas shut-off valve in the supply

line to the OFF position.

Shut-off

Valve

Flexible gas line

connector

Duct clamps (2) or

Spring clamps (2)

Safety glasses

4” dia. metal duct

(recommended)

4” Cover Plate (Kit

WE49X22606)

Soap solution for

leak detection

Exhaust hood

Duct tape

Gas pipe adapters (2),

elbow and pipe plug

•

Disconnect and discard old flexible gas connector

and ducting material.

5

Page 6

Installation Instructions

CONNECTING A GAS DRYER (cont.)

GAS REQUIREMENTS

WARNING

• Use a new CSA International approved flexible

gas supply line. Never reuse old flexible

connectors.

• Install an individual manual shut-off valve

within 6ft. of the dryer in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

• Securely tighten all gas connections.

• If connected to LP gas, have a qualified person

make sure gas pressure DOES NOT exceed 13”

water column.

• Examples of a qualified person include: licensed

heating personnel, authorized gas company

personnel, and authorized service personnel.

• Failure to do so can result in death, explosion,

or fire.

• The installation must conform with local codes,

or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54,

or the Natural Gas and Propane Installation

Code, CSA B149.1.

- Explosion Hazard

GAS SUPPLY

• A 1/8” National Pipe Taper thread plugged

tapping, accessible for test gauge connection,

must be installed immediately upstream of the

gas supply connection to the dryer. Contact

your local gas utility should you have questions

on the installation of the plugged tapping.

•

Supply line is to be 1/2” rigid pipe and equipped

with an accessible shutoff within 6 feet of, and

in the same room with, the dryer.

•

Use pipe thread compound appropriate for

natural or LP gas or use PTFE tape.

•

Connect flexible metal connector to dryer and

gas supply.

WARNING

FOR USE WITH NATURAL GAS ONLY

Dryer as produced by manufacturer is to be used only

with a natural gas supply. A manufacturer-supplied

conversion kit is required to convert this dryer for

propane gas supply. Use propane gas conversion

kit WE25X217. Conversion must be made by properly

trained and qualified personnel in accordance with

local codes and ordinances.

- Fire Hazard

DRYER GAS SUPPLY CONNECTION

2"

2-5/8"

• You must use with this dryer a flexible metal

connector (listed connector ANSI Z21.24/CSA 6.10).

The length of the connect shall not exceed 3 ft.

3/8" NPT MALE THREAD GAS SUPPLY

NOTE: Add to vertical dimension

the distance between cabinet

bottom to floor.

ADJUSTING FOR ELEVATION

• Gas clothes dryers input ratings are based on

sea level operation and need not be adjusted

for operation at or below 2000 ft. elevation. For

operation at elevations above 2000 ft., input

ratings should be reduced at a rate of 4 percent

for each 1000 ft. above sea level.

•

Installation must conform to local codes and

ordinances or, in their absence, the NATIONAL

FUEL GAS CODE, ANSI Z223.

6

Page 7

Installation Instructions

CONNECTING THE DRYER TO THE GAS

SUPPLY

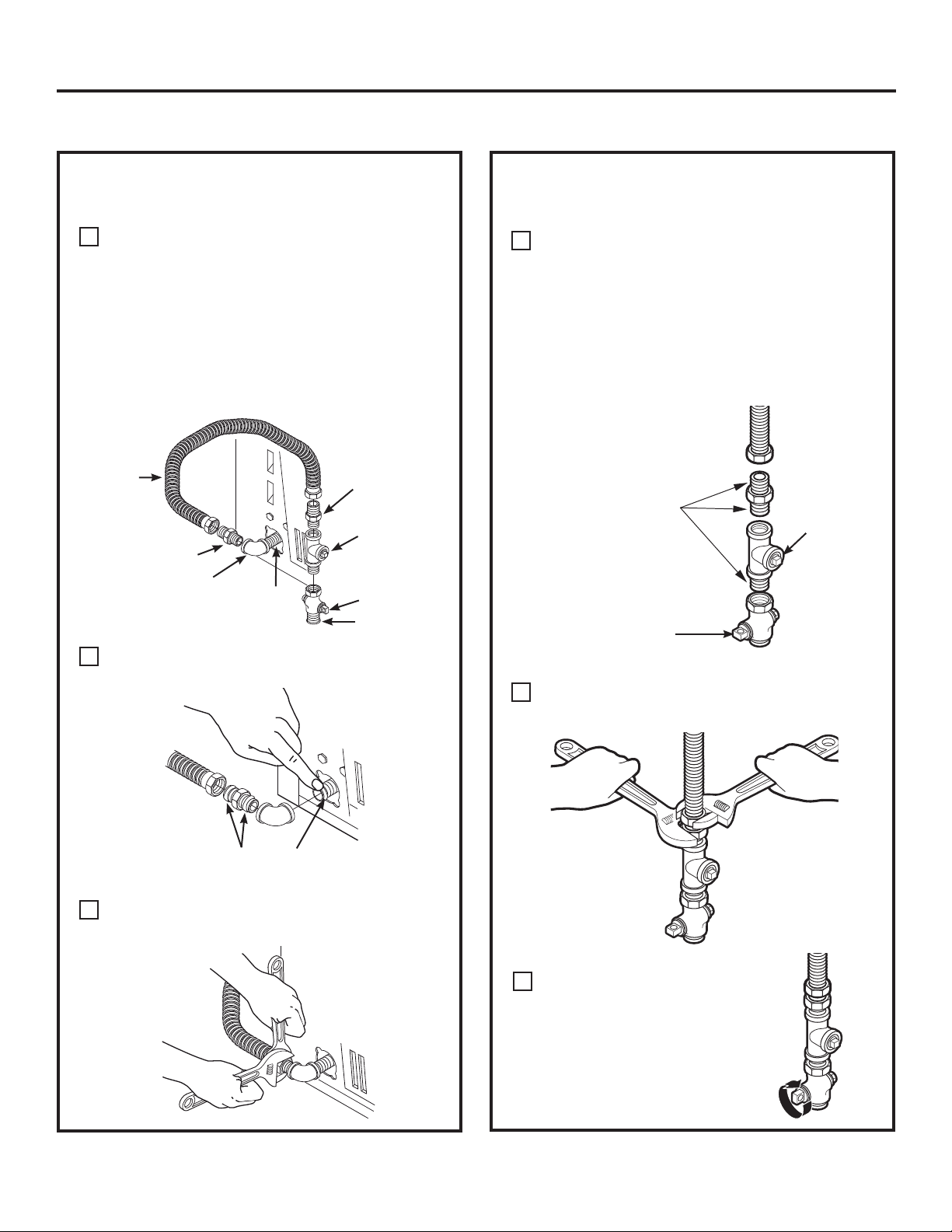

Install a female 3/8” NPT elbow at the end of the

A

dryer gas inlet.

Install a 3/8” flare union adapter to the female

elbow.

IMPORTANT: Use a pipe wrench to securely hold

on to the end of the dryer gas inlet to prevent

twisting the inlet.

NOTE: Apply pipe compound or PTFE tape to the

threads of the adapter and dryer gas inlet.

New Metal

Flexible Gas

Line Connector

Adapter

Elbow

3/8” NPT

Items not supplied

Attach the flexible metal gas line connector to

B

the adapter.

Adapter

1/8” NPT

Pipe Plug for

Checking Gas

Inlet Pressure

Shut-Off Valve

Pipe size at

least 1/2”

CONNECTING THE DRYER TO THE GAS

SUPPLY (cont.)

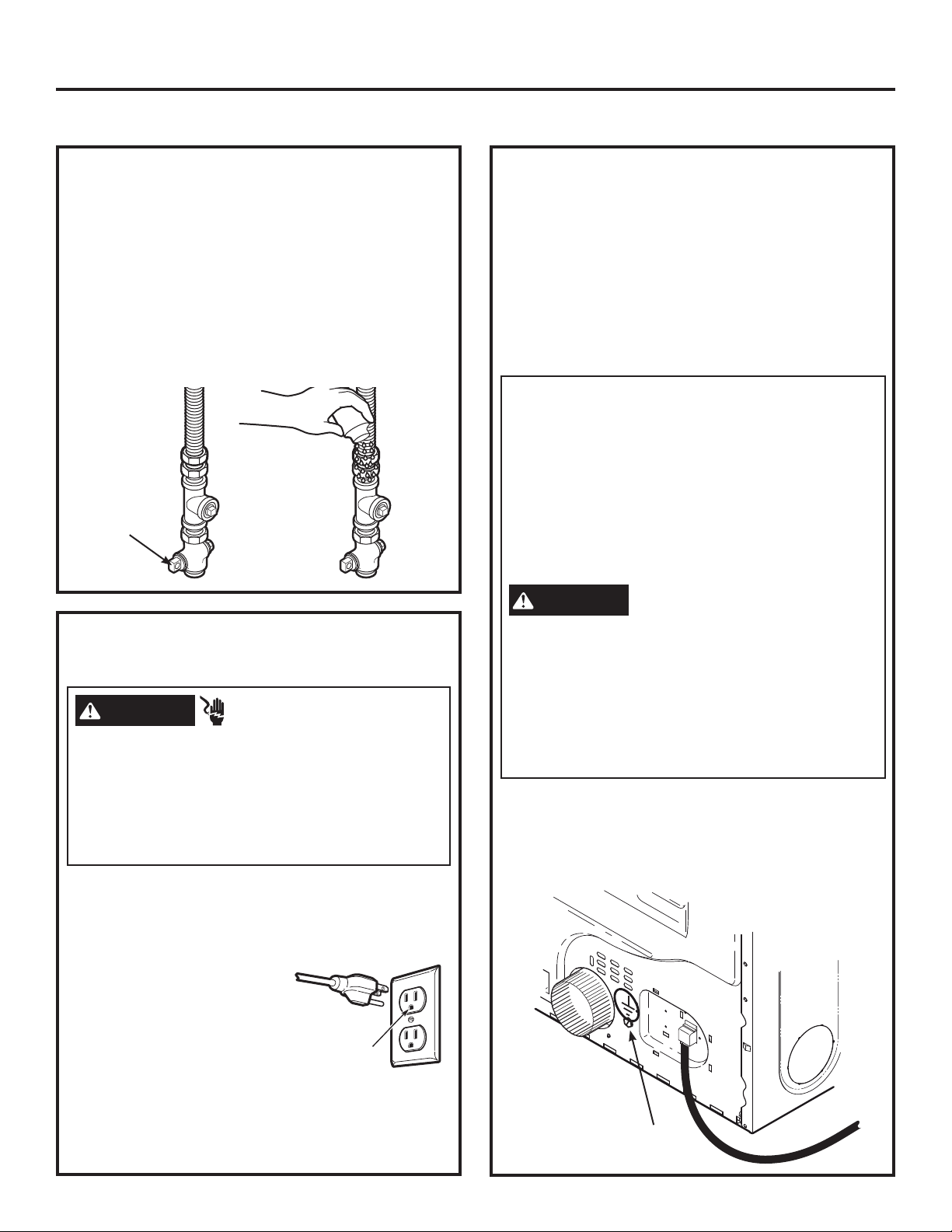

Install a 1/8” NPT plugged tapping to the dryer

D

gas line shut-off valve for checking gas inlet

pressure.

Install a flare union adapter to the plugged

tapping.

NOTE: Apply pipe compound or PTFE tape

to the threads of the adapter and plugged

tapping.

Apply pipe compound

or PTFE tape to all

male threads.

Shut-Off

Valve

Tighten all connections, using two adjustable

E

wrenches. Do not overtighten.

Plugged

Tapping

Apply pipe compound to the

adapter and dryer gas inlet.

Tighten the flexible gas line connection, using

C

two adjustable wrenches.

Tighten the flexible

gas line using two

adjustable wrenches.

Open the gas shut-off valve.

F

7

Page 8

Installation Instructions

CONNECTING A GAS DRYER (cont.)

TEST FOR LEAKS

Never use an open flame to test for gas leaks.

Check all connections for leaks with soapy solution

or equivalent.

Apply a soap solution. The leak test solution must

not contain ammonia, which could cause damage

to the brass fittings.

If leaks are found, close the valve, retighten the

joint and repeat the soap test.

Open Gas

Valve

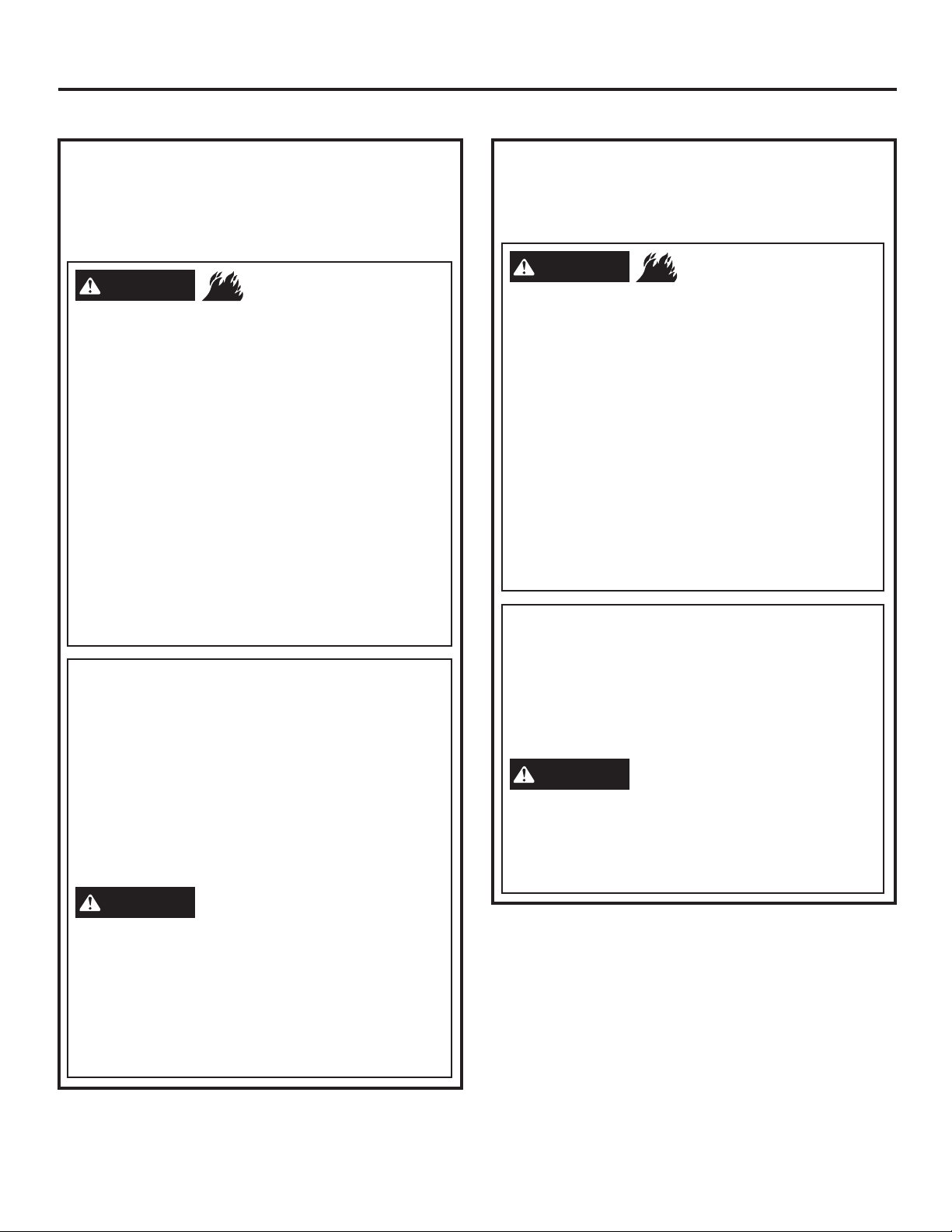

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS

WARNING

Plug into a grounded 3 prong outlet.

DO NOT remove ground prong.

DO NOT use an adapter.

DO NOT use an extension cord.

Failure to do so can result in death, fire or electrical

shock.

• Circuit – Individual properly polarized and grounded

15 or 20 amp circuit breaker or time-delay fuse.

•

Power Supply – 2-wire plus ground, 120 Volt,

single phase, 60 Hz, alternating current.

•

Outlet Receptacle –

Properly grounded

3-prong receptacle to

be located so the power

cord is accessible when

the dryer is in an installed

position. If a 2-prong

receptacle is present, it

is the owner’s responsibility to have a licensed

electrician replace it with a properly grounded

3-prong grounding type receptacle.

- Electrical Shock Hazard

Ensure proper

ground exists

before use.

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS (cont.)

• Dryer must be electrically grounded in

accordance with local codes and ordinances,

or in the absence of local codes, with the latest

edition of the NATIONAL ELECTRICAL CODE,

ANSI/NFPA NO. 70 or CANADIAN ELECTRICAL

CODE, CSA C22.1. Check with a licensed

electrician if you are not sure that the dryer is

properly grounded.

GROUNDING INSTRUCTIONS

This dryer must be grounded. In the event of a

malfunction or breakdown, grounding will reduce

the risk of electric shock by providing a path of

least resistance for electric current. This dryer uses

a cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed

and grounded in accordance with all local codes

and ordinances.

WARNING

can result in a risk of electric shock. Check with a

qualified electrician, or service representative or

personnel, if you are in doubt as to whether the

appliance is properly grounded. DO NOT modify the

plug on the power supply cord. If it will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

SAVE THESE INSTRUCTIONS

•

If required by local codes, an external 18 gauge

or larger copper ground wire (not provided)

may be added. Attach to dryer cabinet with a

#8-18 x ½” sheet metal screw (available at any

hardware store) to rear of dryer as illustrated.

8

Improper connection of the

equipment-grounding conductor

Ground

Screw

Page 9

Installation Instructions

CONNECTING AN ELECTRIC DRYER

(Skip for gas dryers and if your dryer already has a power cord attached)

TOOLS YOU WILL NEED

Slip-joint pliers

Flat-blade

screwdriver

Phillips

screwdriver

Level

MATERIALS YOU WILL NEED

4” dia. metal elbow

3/4” Strain relief

(UL recognized)

4” Duct clamps (2) or

4” spring clamps (2)

Gloves

Exhaust hood

Duct tape

Before making the electrical connection, turn off

the circuit breaker(s) or remove the dryer’s circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall.

NEVER LEAVE THE

ACCESS COVER OFF THE TERMINAL BLOCK.

Safety glasses

4” dia. metal duct

(recommended)

4” dia., UL-listed

flexible metal duct (if

needed)

Dryer power cord kit

(not provided with

dryer)

UL rated 120/240V,

30A with 3 or 4 prongs.

Identify the plug type

as per the house

receptacle before

purchasing line cord.

4” Cover plate (Kit

WE49X22606)

9

Page 10

Installation Instructions

CONNECTING AN ELECTRIC DRYER (cont.)

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC DRYERS

For electrical connections using a

power cord:

WARNING

Use a new UL-listed 240V 30 amp dryer power supply

cord with closed ring terminals or spade terminals with

upturned ends.

Use a UL-listed strain relief.

Disconnect power before making electrical

connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining two supply wires to remaining two

terminals.

Securely tighten all electrical connections.

Replace the terminal block cover.

Failure to do so can result in death, fire or electrical

shock.

- Fire Hazard

GROUNDING INSTRUCTIONS

For a grounded, cord-connected dryer: This dryer

must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk

of electric shock by providing a path of least

resistance for electric current. This dryer uses a

cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed

and grounded in accordance with all local codes

and ordinances.

WARNING

can result in a risk of electric shock. Check with a

qualified electrician, or service representative or

personnel, if you are in doubt as to whether the

appliance is properly grounded. DO NOT modify the

plug on the power supply cord. If it will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

SAVE THESE INSTRUCTIONS

Improper connection of the

equipment-grounding conductor

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC DRYERS

For direct wire connections:

WARNING

Use 10 gauge copper wire.

Use a UL-listed strain relief.

Disconnect power before making electrical

connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining two supply wires to remaining two

terminals.

Securely tighten all electrical connections.

Replace the terminal block cover.

Failure to do so can result in death, fire or electrical

shock.

- Fire Hazard

GROUNDING INSTRUCTIONS

For a permanently connected dryer: This

dryer must be connected to a grounded metal,

permanent wiring system, or an equipmentgrounding conductor must be run with the circuit

conductors and connected to the equipmentgrounding terminal on the appliance.

WARNING

can result in a risk of electric shock. Check with a

qualified electrician, or service representative or

personnel, if you are in doubt as to whether the

appliance is properly grounded.

SAVE THESE INSTRUCTIONS

Improper connection of the

equipment-grounding conductor

10

Page 11

Installation Instructions

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION)

NOTE: Since January 1, 1996, the National Electrical

Code requires that new constructions use a 4-wire

connection to an electric dryer. A 4-wire cord must

also be used where local codes do not permit

grounding through the neutral.

3-wire connection is NOT for use on new construction.

REMOVE GROUND STRAP

AND DISCARD. KEEP GREEN

GROUND SCREW

SCREWS

(3)

COVER

1. Turn off the circuit breaker(s) (30 amp) or remove

the dryer’s circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall

receptacle.

3. Remove the power cord cover located at the lower

back.

4. Remove and discard ground strap. Keep the green

ground screw for Step 7.

5. Install 3/4 in. UL-recognized strain relief to power

cord entry hole. Bring power cord through strain

relief.

6. Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of the

terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

7. Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket).

Tighten all terminal block screws (3) securely.

8. Properly secure power cord to strain relief.

9. Reinstall the cover.

NEVER LEAVE THE COVER OFF OF THE TERMINAL

BLOCK.

HOT

RELOCATE GREEN

WIRE

GROUND SCREW

HERE

L1

N

L2

NEUTRAL

(White)

3/4", UL

RECOGNIZED

HOT

STRAIN RELIEF

WIRE

4 #10 AWG MINIMUM COPPER

CONDUCTORS OR 120/240V 30A POWER

SUPPLY CORD KIT MARKED FOR USE

WITH DR YERS & PROVIDED WITH

CLOSED LOOP OR SPADE TERMINALS

WITH UPTURNED ENDS (NOT SUPPLIED).

GREEN OR

YELLOW WIRE

STRAIN

RELIEF

BRACKET

CONNECTING DRYER USING 3-WIRE

CONNECTION

If required, by local code, install external ground (not

provided) to grounded metal, cold water pipe, or

other established ground determined by a qualified

electrician.

IF REQUIRED, BY LOCAL CODE,

INSTALL EXTERNAL GROUND

(NOT PROVIDED) TO GROUNDED

METAL, COLD WATER PIPE, OR

OTHER ESTABLISHED GROUND

DETERMINED BY A QUALIFIED

ELECTRICIAN.

COVER

GREEN

GROUND

SCREW

SCREWS

(3)

3-wire Connection

Not for use in Canada.

DO NOT use for Mobile Home Installations.

NOT for use on new construction.

NOT for use on recreational vehicles.

NOT for use in areas where local codes prohibit

grounding through the neutral conduction.

1. Turn off the circuit breaker(s) (30 amp) or remove

the dryer’s circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall

receptacle.

3. Remove the power cord cover located at the lower

back.

4. Install 3/4-in. UL-recognized strain relief to power cord

entry hole. Bring power cord through strain relief.

5. Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of the

terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

6. Be sure ground strap is connected to neutral

(center) terminal of block and to green ground

screw on cabinet rear. Tighten all terminal block

screws (3) securely.

7. Properly secure power cord to strain relief.

8. Reinstall the cover.

NEVER LEAVE THE COVER OFF OF THE TERMINAL

BLOCK.

11

GROUND

STRAP

HOT

WIRE

L1

L2

NEUTRAL

(White)

3 #10 AWG MINIMUM COPPER

CONDUCTORS OR 120/240V 30A POWER

SUPPLY CORD KIT MARKED FOR USE

WITH DRYERS & PROVIDED WITH CLOSED

LOOP OR SPADE TERMINALS WITH

UPTURNED ENDS (NOT SUPPLIED).

HOT

WIRE

STRAIN RELIEF

BRACKET

3/4", UL

RECOGNIZED

STRAIN RELIEF

Page 12

Installation Instructions

EXHAUSTING THE DRYER

WARNING

This dryer MUST be vented to the outdoors.

Use only 4” rigid metal ducting for the home

exhaust vent.

Use only 4” rigid metal or UL-LISTED transition duct

to connect the dryer to the home exhaust duct.

DO NOT use a plastic vent.

DO NOT exhaust into a chimney, kitchen exhaust,

gas vent, wall, ceiling, attic, crawl space, or

concealed space of a building.

DO NOT install a screen in or over the exhaust duct.

DO NOT install a booster fan in the exhaust duct.

DO NOT use duct longer than specified in the

exhaust length table.

Failure to follow these instructions can result in

death or fire.

TOOLS AND MATERIALS YOU WILL

NEED TO INSTALL EXHAUST DUCT

- Fire Hazard

CONNECTING THE DRYER TO HOUSE

VENT

RIGID METAL TRANSITION DUCT

•

For best drying performance, a rigid metal transition

duct is recommended.

•

Rigid metal transition ducts reduce the risk of crushing

and kinking.

UL-LISTED FLEXIBLE METAL CLOTHES DRYER

TRANSITION DUCT

If rigid metal cannot be used, then UL-LISTED flexible

•

metal clothes dryer transition duct (GE Appliances

parts –

•

Never install transition duct in walls, ceilings, floors or

other enclosed spaces.

• Total length of transition duct should not exceed

8’ (2.4 m).

• For many applications, installing elbows at both

the dryer and the wall is highly recommended (see

illustrations at right). Elbows allow the dryer to sit

close to the wall without kinking and/or crushing the

transition duct, maximizing drying performance.

•

Avoid resting the duct on sharp objects.

PM08X10085) can be used.

Phillips-head

screwdriver

Duct tape or

duct clamp

Rigid or UL-listed

flexible metal 4”

(10.2 cm) duct

PARTS AVAILABLE FROM GEAPPLIANCES.COM

Drill with 1/8” drill bit

(for bottom venting)

Hacksaw

Vent hood

OR LOCAL SERVICE ORGANIZATIONS

PM8X85

PM08X10085

WX08X10130

WE49X22606

Outdoor exhaust hood

8’ Flexible metal clothes dryer

transition duct with 2 clamps

4” Dryer exhaust clamp

Rear exhaust opening cover, for side

or bottom vented dryers

UL-LISTED FLEXIBLE METAL (FOIL-TYPE) TRANSITION

DUCT

In special installations, it may be necessary to connect the

•

dryer to the home exhaust vent using flexible metal (foil-type)

transition duct. UL–LISTED universal flexible dryer transition

duct (GE Appliances parts – PM8X73 or WX8X73) may be

used ONLY in

metal transition ducting cannot be used AND where a 4”

diameter can be

the transition duct

•

In Canada and the United States, only transition ducts

that comply with “UL 2158A STANDARD FOR CLOTHES

DRYER TRANSITION DUCT” shall be used.

•

Avoid resting the duct on sharp objects.

•

For best drying performance:

1. Slide one end of the duct over the clothes dryer

2. Secure the duct with a clamp.

3. With the dryer in its permanent position, extend

4. Secure the duct to the exhaust pipe with the

installations where rigid metal or flexible

maintained throughout the entire length of

.

outlet pipe.

the duct to its full length. Allow 2

overlap the exhaust pipe. Cut off and remove

excess duct. Keep the duct as straight as

possible for maximum airflow.

other clamp.

”

of duct to

12

Page 13

Installation Instructions

• DO cut duct as short

as possible and install

straight into wall.

•

DO use elbows when

turns are necessary.

Elbows

• DO NOT bend

or collapse

ducting. Use

elbows if turns

are necessary.

• DO NOT use

excessive

exhaust

length. Cut

duct as short

as possible.

EXHAUST LENGTH

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

• Reduce the dryer life.

• Accumulate lint, creating a potential fire

hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.

Problems due to incorrect installation are not

covered by the warranty.

The MAXIMUM ALLOWABLE length of the exhaust

system depends upon the type of duct, number of

turns, the type of exhaust hood (wall cap) and all

conditions noted on the chart.

• Internal elbows added for side or bottom vent

conversions must be included in the total elbow

count.

• Any elbow greater than 45° should be treated as

a 90° elbow.

• Two 45° elbows will be treated like one 90°

elbow.

• For every additional 90° elbow, reduce the

allowable vent system length by 10 feet.

• When calculating the total vent system length,

you must add all the straight portions and elbows

of the system (including the transition duct).

No. of 90°

Elbows

0

1

2

3

4

• DO NOT

crush duct

against the

.

wall

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended

4" DIA.

4"

Rigid

Metal

90 Feet

60 Feet

45 Feet

35 Feet

25 Feet

4" DIA.

Use only for short

run installations

• DO NOT

set dryer

on duct

4" DIA.

Rigid

Metal

60 Feet

45 Feet

35 Feet

25 Feet

15 Feet

.

2-1/2"

13

Page 14

Installation Instructions

EXHAUSTING THE DRYER (cont.)

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

Terminate in a manner to prevent back drafts or entry

•

of birds or other wildlife.

Termination should present minimal resistance to

•

the exhaust airflow and should require little or no

maintenance to prevent clogging.

Wall caps must be installed at least 12” above ground

•

level or any other obstruction with the opening

pointed down.

SEPARATION OF TURNS

For best performance, separate all turns by at least

•

4 ft. of straight duct, including distance between last

turn and dampened wall cap.

SEALING OF JOINTS

All joints should be tight to avoid leaks. The male end

•

of each section of duct must point away from the

dryer.

Duct joints should be made air- and moisture-tight

•

by wrapping the overlapped joints with duct tape or

aluminum tape.

Do not assemble ductwork with any fasteners

•

that extend into the duct. These fasteners can

accumulate lint, creating a potential fire hazard.

• Horizontal runs should slope down towards the

outdoors 1/4” per foot.

•

Provide an access for inspection and cleaning of

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

INSULATION

Ductwork that runs through an unheated area or is

•

near air conditioning should be insulated to reduce

condensation and lint buildup.

STANDARD REAR EXHAUST

We recommend that you install your dryer before

installing your washer. This will permit direct

access for easier exhaust connection.

Slide the end of the exhaust duct on the back of the

dryer and secure with duct tape or a hose clamp.

Duct

NOTE: We strongly recommend using rigid metal

exhaust duct.

For straight-line installation, connect the dryer

•

exhaust to the wall, using duct tape.

Wall Side

Dryer

Side

RECOMMENDED CONFIGURATION TO

MINIMIZE EXHAUST BLOCKAGE

BEFORE YOU BEGIN

• Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

•

Remove any lint from the wall exhaust opening.

Wall

Internal

Duct

Opening

Check that exhaust

hood damper opens

and closes freely.

Using duct elbows will prevent duct kinking and

collapsing.

Transition

Ducting

14

Page 15

Installation Instructions

SIDE OR BOTTOM VENTING

Dryer Exhaust to right of cabinet for Electric

models only.

Dryer Exhaust to left of cabinet for Gas and

Electric models.

Dryer Exhaust to the bottom of cabinet for

Gas and Electric models.

WARNING

Close the back opening with cover plate (Kit

WE49X22606).

Disconnect dryer from electrical supply.

Wear gloves and arm guards.

Failure to do so may result in fire, electrical shock

or lacerations.

Remove

screw

and save

Detach and remove the right (electric models only),

left or bottom knockout as desired. Remove the

screw inside the dryer exhaust duct and save. Pull

the duct out of the dryer.

Right

(electric

models

only)

- Fire Hazard

Bottom

Remove desired

knockout (one only)

Fixing hole

A

Left

TAB LOCATION

Bend tab

up 45°

Not for gas

Through the rear opening, locate the tab in the

middle of the appliance base. Lift the tab to about

45°,

using a flat-blade screwdriver.

ADDING A NEW DUCT

Portion “A”

Fixing hole

Right

Right (electric

models only)

or left side

exhaust

Left

Reconnect the cut portion (A) of the duct to the

blower housing. Make sure that the shortened

duct is aligned with the tab in the base. Use the

screw saved previously to secure the duct in place

through the tab on the appliance base.

ADDING ELBOW AND DUCT FOR EXHAUST TO

LEFT OR RIGHT SIDE OF CABINET

Right

Exhaust can be

added to left or

right (electric

models only) side

Left

Duct

tape

13 1ø2” (34.29cm)

Cut the duct as shown and keep portion A.

• Preassemble 4” elbow with 4” duct. Wrap duct

tape around joint.

•

Insert duct assembly, elbow first, through the

side opening and connect the elbow to the dryer

internal duct.

Be sure not to pull or damage the electrical wires

inside the dryer when inserting the duct.

15

Page 16

Installation Instructions

EXHAUSTING THE DRYER (cont.)

SIDE OR BOTTOM VENTING (cont.)

ADDING ELBOW AND DUCT FOR EXHAUST TO

LEFT OR RIGHT SIDE OF CABINET (cont.)

• Apply duct tape as

shown on the joint

between the dryer

internal duct and the

elbow, and also the joint

between the elbow and

the side duct.

Use 4” rigid metal ducting only inside the dryer.

Internal duct joints must be secured with tape,

otherwise they may separate and cause a safety

hazard.

ADDING ELBOW FOR EXHAUST THROUGH

BOTTOM OF CABINET

• Insert the elbow through the rear opening and

connect it to the dryer internal duct.

Apply duct tape as

•

shown on the joint

between the dryer

internal duct and the

elbow, and also the

joint between the

elbow and the bottom

duct.

Internal duct joints must be secured with tape;

otherwise, they may separate and cause a safety

hazard.

Duct tape

DUCT

TAPE

FINAL SETUP

1

LEVEL THE DRYER

Stand the dryer upright near the final location and

adjust the four leveling legs at the corners to ensure

that the dryer is level from side to side and front to

rear.

Raise

2

PLUG DRYER IN

Lower

Ensure proper

ground exists

before use.

ADDING COVER PLATE TO REAR OF CABINET

Plate

(Kit WE49X22606)

Connect standard metal elbows and ducts to

complete the exhaust system. Cover back opening

with the plate (kit WE49X22606) which can be

purchased from GEApplianceparts.com or a local

service provider. Place dryer in final location.

NEVER LEAVE THE BACK OPENING WITHOUT THE

PLATE.

3

DRYER START-UP

Press the Power button.

NOTE: If the dryer has been exposed to

temperatures below freezing for an extended

period of time, allow it to warm up before pressing

Power. Otherwise, the display will not come on.

The dryer is now ready for use.

16

Page 17

Instrucciones Secadora

de instalación

Si tiene alguna pregunta, llame GE Appliances a 800.GE.CARES (800.432.2737) o visite nuestro sitio Web en: GEAppliances.com

ANTES DE COMENZAR

Lea estas instrucciones por completo y con

detenimiento.

IMPORTANTE – Guarde estas instrucciones

•

para el uso de inspectores eléctricos locales.

IMPORTANTE – Cumpla con todos los

•

códigos y ordenanzas vigentes.

•

Instale la secadora de acuerdo con las instrucciones

del fabricante y los códigos locales.

• Nota al instalador – Asegúrese de dejar estas

instrucciones con el consumidor.

• Nota al usuario – Conserve estas instrucciones para

referencia futura.

•

La instalación de la secadora debe efectuarla un

instalador calificado.

•

Esta secadora debe tener una salida al exterior.

•

Antes de que la secadora antigua sea retirada del

servicio o eliminada, quítele la puerta.

•

La información sobre reparaciones y el diagrama del

cableado se encuentran en la consola de control.

•

No permita que niños se suban o se metan dentro

del artefacto. Se requiere una supervisión estricta

cuando el aparato es utilizado cerca de niños.

•

El instalador tiene la responsabilidad de efectuar una

instalación adecuada.

•

La garantía no cubre las fallas del producto debido a

una instalación incorrecta. .

• Instale la secadora en lugares donde la temperatura

sea mayor a 50°F para un funcionamiento

satisfactorio del sistema de control de la secadora.

• Quite y descarte el conducto existente de plástico

o de papel de aluminio y coloque un conducto

aprobado por UL.

ADVERTENCIA

La instalación de la secadora debe efectuarla

•

un instalador calificado.

•

Instale la secadora de ropa de acuerdo con estas

instrucciones y en cumplimiento con los códigos

locales

•

NO instale una secadora de ropa con conductos

de plástico flexible. Si se instala un conducto

flexible de metal (semi rígido o de tipo papel de

aluminio), debe estar aprobado por UL e instalarse

de acuerdo con las instrucciones de “Cómo

conectar la secadora a la ventilación doméstica”

de este manual. Los materiales de los conductos

flexibles a menudo se desploman, se aplastan y

atrapan pelusas. Estas condiciones obstruyen la

corriente de aire de la secadora e incrementan el

riesgo de incendio.

•

NO instale o almacene este aparato en un

lugar donde se vea expuesto al agua o a las

inclemencias del tiempo.

•

Para reducir el riesgo de una lesión grave o de

muerte, cumpla con todas las instrucciones de

instalación.

• Guarde estas instrucciones. (Instaladores: Asegúrense

de dejar estas instrucciones al consumidor).

SECADORAS A GAS ÚNICAMENTE

EN LA MANCOMUNIDAD DE

MASSACHUSETTS, SE APLICAN LAS

INSTRUCCIONES DE INSTALACIÓN

SIGUIENTES:

• Este producto debe instalarlo un plomero

matriculado o un instalador de gas.

•

Cuando use válvulas esféricas de apagado de

gas, deberán ser del tipo de manija en T.

•

Si se usa una conexión flexible para gas, ésta

no debe superar 1 m (3 pies).

- Riesgo de incendio

04

234D2274P004

31-16769-3 08-16 GEA

Page 18

Instrucciones de instalación

CÓMO DESEMPACAR LA SECADORA

Incline la secadora de costado y saque los soportes de espuma de

embalaje tirando de los costados y quitándolos de las patas de la secadora.

Asegúrese de quitar todas las piezas de espuma de las patas.

Saque la bolsa que contiene la información.

DIMENSIONES

APROXIMADAS

Visión frontal

NOTE :

La altura de la secadora puede ser ajustada para quedar a la misma a altura

de la lavadora

Con pedestal: 52.1” (132.33 cm)

Apilada: 84” (213.36 cm)

27”

(68,6 cm)

39.3”

(99,8cm)

33” (83,8 cm)

39,3”

(99,8 cm)

Visión lateral

5.4”

(13,7 cm)

MANGUERA DE VAPOR Y AGUA (sólo para los modelos de secadoras de vapor):

GE Appliances recomienda enfáticamente el uso de

piezas específicas de fábrica. A continuación figura una

lista de mangueras de fábrica que podrá adquirir. Dichas

mangueras son fabricadas y probadas de modo que se

cubran las especificaciones de GE Appliances.

GE Appliances recomienda enfáticamente el uso de nuevas

mangueras de suministro de agua. Con el paso del tiempo, las

mangueras se degradan y deben ser reemplazadas cada 5 años, a fin

de reducir el riesgo de fallas sobre las mismas y daños con el agua.

Piezas y Accesorios

Ordene hoy a través de Internet en GEAppliancesparts.com,

las 24 horas del día o en forma telefónica llamando al

800.626.2002, durante el horario comercial habitual.

Número de Pieza Accesorio

WE25X20060 Kit Completo (mangueras, adaptador

en Y, arandelas) o

WE49X25794 Kit (Manguera corta, adaptador en Y,

arandelas) y

WE1M847

O POR SEPARADO

WE1M847

WE1M848

Manguera Larga

Manguera Larga y

Manguera Corta

4,4”

(11,2 cm)

CABLES DE CORRIENTE:

GE Appliances recomienda enfáticamente el uso de piezas

específicas de fábrica. Seleccione el cable de corriente que se

adecúe a sus requisitos de instalación.

Pieza Nº Tipo Longitud Amperios

WX9X2 3-Clavijas 4 Pies 30

WX9X3 3-Clavijas 5 Pies 30

WX9X4 3-Clavijas 6 Pies 30

WX9X18 4-Clavijas 4 Pies 30

WX9X19 4-Clavijas 5 Pies 30

WX9X20 4-Clavijas 6 Pies 30

ACCESORIOS:

Ordene hoy a través de Internet en GEAppliancesparts.com,

las 24 horas del día o en forma telefónica llamando al

800.626.2002, durante el horario comercial habitual.

Accesorio

2

Pieza Nº

SBSD137HWW

SBSC137HDG

GEFLSTACK Kit para apilar Secadora sobre Lavadora

PM08X10085

WE01X20677

Pedestal blanco 27” de ancho

Pedestal gris diamante 27” de ancho

Ducto de transición de metal flexible

Estante de secadora para zapatos

Page 19

Instrucciones de instalación

REQUERIMIENTOS PARA INSTALACIÓN

EN NICHOS O ARMARIOS

ADVERTENCIA

Mantenga cualquier material y vapores inflamables,

tales como gasolina, alejados de la secadora.

Coloque la secadora a por lo menos 18” (46 cm.) del

piso cuando sea instalada en un garaje.

Si no se cumple con esto, se podrá producir una

explosión, incendio o la muerte.

• Esta secadora DEBE tener una ventilación

al exterior. Ver la sección SALIDA AL EXTERIOR

DE LA SECADORA.

•

El espacio libre mínimo entre la secadora y las

paredes adyacentes u otras superficies es:

0” en ambos lados

1” en el frente

1” en la parte trasera

1” en la parte superior

•

Se deberá considerar que se debe brindar el

despeje adecuado para la instalación y el servicio

técnico.

•

Las puertas del armario deben contar con rejillas

u otro tipo de ventilación y tener por lo menos

60 pulgadas cuadradas de espacio abierto. Si el

armario incluye una lavadora y una secadora,

las puertas deben

pulgadas cuadradas

NOTA: CUANDO EL CONDUCTO DE ESCAPE SE

ENCUENTRA EN LA PARTE TRASERA DE LA SECADORA,

LA CONFIGURACIÓN DEL DUCTO DE ESCAPE PUEDE

REQUERIR MAS DE 1” DE ESPACIO EN LA PARTE

TRASERA.

Secadoras a Gas Únicamente:

• No se deberá instalar ningún otro electrodoméstico

que consuma combustible en el mismo armario

donde haya una secadora a gas.

• La secadora se deberá desconectar de la tubería de

suministro de gas durante la prueba de presión en

presiones superiores a ½ psi (3.5 kPa).

• Una rosca cubierta NPT de 1/8”, accesible para

la conexión de un dispositivo de calibración,

deberá ser instalada inmediatamente arriba de la

conexión del suministro de gas a la secadora.

- Riesgo de

contener un mínimo de 120

de espacio abierto.

explosión

ESPACIO LIBRE MÍNIMO EN OTROS

ESPACIOS QUE NO SEAN INSTALACIONES

EN NICHOS O ARMARIOS

Los espacios libres mínimos respecto de superficies

combustibles y de aberturas de aire son: 0” a ambos

lados; 1” (7,62 cm) en la parte trasera; 1” (2,54 cm)

en la parte superior. Debe tenerse en cuenta un

espacio libre adecuado para un funcionamiento y

reparación correctos.

INSTALACIÓN EN CASAS MÓVILES

O PREFABRICADAS

• Instalación debe cumplir con la NORMA

SOBRE CONSTRUCCIÓN Y SEGURIDAD DE CASAS

PREFABRICADAS, TÍTULO 24, PARTE 32-80 o

Norma CAN/CSA-Z240 MH, o, cuando dicha

norma no sea aplicable, con la NORMA NACIONAL

ESTADOUNIDENSE PARA CASAS MÓVILES, ANSI/

NFPA Nº 501B.

•

La secadora DEBE tener ventilación al exterior.

•

La ventilación del escape DEBERÁ estar ajustado

de forma segura a una parte no combustible de

la casa rodante.

•

La ventilación NO DEBE terminar debajo de una

casa móvil o prefabricada.

•

El material del conducto de ventilación DEBE SER

METAL.

•

DEBE utilizarse el KIT 14-D346-33 para conectar

bien la secadora a la estructura.

•

La ventilación NO DEBE conectarse a ningún otro

conducto, ventilación o chimenea.

•

NO utilice tornillos para placas de metal u otros

dispositivos de sujeción que se extiendan

al interior de la ventilación de salida.

•

Debe contar con una abertura con un espacio

libre de por lo menos 25 pulgadas cuadradas

para el ingreso de aire exterior dentro de la

secadora habitación.

•

Para acceder a información sobre la conexión

eléctrica, consulte la section.

3

Page 20

Instrucciones de instalación

CÓMO CONECTAR MANGUERAS DE ENTRADA

(sólo para los modelos de secadoras de vapor)

CÓMO CONECTAR MANGUERAS

DE ENTRADA

Para producir vapor, la secadora debe conectarse

al suministro de agua fría. Ya que la lavadora

también debe conectarse al agua fría, debe

introducirse un conector en “Y” para permitir

que ambas mangueras de entrada puedan

utilizarse al mismo tiempo.

NOTA: Utilice nuevas mangueras de entrada; nunca

utilice mangueras viejas.

1. Cierre el grifo de agua fría. Quite la manguera

de entrada de la lavadora del conector de la

válvula de llenado (fría).

2. Asegúrese de que la arandela plana de goma se

encuentre en su lugar y sujete una unión hembra

de la manguera corta provistas en el conector

de la válvula de llenado de la lavadora. Ajuste a

mano hasta que esté firmemente asentada.

3. Sujete un extremo macho del conector en “Y” a la

unión hembra de la manguera corta. Asegúrese

de que la arandela plana de goma se encuentre

en su lugar. Ajuste a mano hasta que esté

firmemente asentada.

CÓMO CONECTAR MANGUERAS

DE ENTRADA (cont.)

7. Utilizando alicates, ajuste todas las uniones con

un giro adicional de dos tercios.

NOTA: No ajuste de más. Pueden dañarse las

uniones.

8. Abra el grifo de agua.

9. Controle la presencia de pérdidas alrededor

del conector en “Y”, el grifo y las uniones

de las mangueras.

4. Introduzca el filtro en la unión de la manguera

de entrada de la lavadora. Si la arandela plana

de goma ya se encuentra en su lugar, quítela

antes de instalar el filtro. Sujete esta unión

a un extremo macho del conector en “Y”. Ajuste

a mano hasta que esté firmemente asentada.

5. Asegúrese de que la arandela de goma plana se

encuentra en su posición y coloque una manguera

de entrada de agua de 4 a 6 pies de largo (puede

ser necesario comprarla por separado) a un

extremo macho del conector ‘’Y‘’. Apriete con la

mano hasta que quede firmemente asentado.

6. Asegúrese de que la arandela plana de goma

se encuentre en su lugar y sujete el otro extremo

de la manguera larga de entrada al conector

de la válvula de llenado en la parte inferior del

panel trasero de la secadora. Ajuste a mano

hasta que esté firmemente asentada.

REQUISITOS DE SUMINISTRO DE AGUA

Los grifos de agua caliente y fría DEBEN instalarse

dentro de las 42 pulg. (107 cm) de la entrada de

agua de la lavadora. Los grifos DEBEN ser del tipo

de manguera de jardín de 3/4 pulg. (1.9 cm) para

que las mangueras de entrada puedan conectarse.

La presión de agua DEBE hallarse entre 10 y 120

libras por pulgada cuadrada. La compañía de agua

puede informarle sobre la presión de agua.

NOTA: Se recomienda el uso de un suavizante de

agua para reducir la acumulación de sarro dentro

del generador de vapor si el suministro doméstico

contiene agua muy dura.

4

Page 21

Instrucciones de instalación

CÓMO CONECTAR UNA SECADORA A GAS

(si se cuenta con una secadora eléctrica, saltear este paso)

HERRAMIENTAS NECESARIAS

Llaves ajustables

de 10” (2)

Llave para tubos de

8”

Pinzas

Destornillador

de lados planos

Nivel

MATERIALES NECESARIOS

Codo de metal de

4” diámetro

Conducto de metal

flexible de 4”

diámetro (si fuese

necesario)

• Antes de comenzar la instalación, apague

el disyuntor o quite los fusibles de la secadora

de la caja eléctrica. Verifique que el cable

de la secadora esté desenchufado

del tomacorriente.

•

Gire a la posición OFF (apagado) la válvula de gas

de la secadora de la línea de suministro.

Compuesto o PTFE

cinta para tuberías

Conector de tubería

de gas flexible

Abrazaderas de tubería

(2) o abrazaderas de

resorte (2)

Gafas de seguridad

Conducto de metal de 4”

diámetro (recomendado)

4” Placa de cubierta

(Kit WE49X22606)

Guantes

Solución jabonosa

para detección de

pérdidas

Campana de salida

Cinta aislante

Gas adaptador (2),

codo, y tapón de

tubería

Válvula

de cierre

•

Desconecte y elimine el conector flexible de gas

y el material del conducto.

5

Page 22

Instrucciones de instalación

CÓMO CONECTAR UNA SECADORA A GAS (cont.)

REQUERIMIENTOS DE GAS

ADVERTENCIA

• Use una línea nueva de suministro de gas flexible

que esté aprobada por CSA International. Nunca

vuelva a usar conectores flexibles viejos.

• Instale una válvula de cierre manual individual

dentro de 6 pies de la secadora en acuerdo

con el Código Nacional de Gas Combustible,

ANSI Z223.1 / NFPA 54.

• De forma segura ajuste todas las conexiones de

gas.

• Si la conexión fue realizada a gas LP, solicite a

una persona calificada que le asegure que la

presión del gas NO supera una columna de agua

de 13”.

• Ejemplos de una persona calificada incluyen:

Personal de calefacción calificado, personal

autorizado de una compañía de gas, y personal

autorizado del servicio técnico.

• Si no se cumple con esto, se podrá producir la

muerte, una explosión o incendio.

• La instalación deberá ser conforme con los códigos

locales, o en ausencia de los códigos locales, con

el Código Nacional de Gas Combustible (National

Fuel Gas Code), ANSI Z223.1/NFPA 54, o el Código de

Instalación de Gas Natural o Propano (Natural Gas

and Propane Installation Code), CSA B149.1.

- Riesgo de

explosión

SUMINISTRO DE GAS

• Debe instalarse una toma a rosca de 1/8” NPT,

accesible para una conexión del manómetro de

prueba, inmediatamente en sentido ascendente

de la conexión de suministro de gas hacia

la secadora. Si tiene dudas sobre la instalación

de la toma, comuníquese con su empresa

proveedora de gas local.

•

La línea de suministro debe ser de tubería rígida

de 1/2” y debe contar con un cierre accesible

dentro de los 6 pies de la secadora, dentro

de la misma habitación donde se encuentra

la misma.

•

Utilice compuesto para rosca de tubería apropiado

para gas natural o LP o utilice cinta de PTFE.

•

Una el conector de metal flexible a la secadora

y al suministro de gas.

ADVERTENCIA

SOLAMENTE PARA USO CON GAS NATURAL

Esta secadora a gas está equipada con un montaje

de válvula y quemador para utilizar sólo con gas

natural. Mediante el kit de conversión WE25X217, la

organización de atención local puede convertir esta

secadora para su uso con gas propano (LP). Todas

las conversiones deben llevarlas a cabo personal

capacitado y calificado en cumplimiento con

códigos locales y requerimientos de ordenanzas.

- Riesgo de incendio

CONEXIÓN DE SUMINISTRO DE GAS

DE LA SECADORA

2"

2-5/8"

• Debe utilizar un conector flexible metálico

listado por ANSI Z21.24/CSA 6.10. La longitud del

conector no excederá 3 pies.

SUMINISTRO DE GAS ROSCA MACHO NPT DE 3/8"

NOTA: Agregue a la dimensión vertical la distancia

entre la parte inferior del gabinete y el piso.

AJUSTE PARA ELEVACIÓN

• Los niveles de entrada de las secadoras de ropa

a gas están basados en el funcionamiento al nivel

de mar y no necesitan ajustes para funcionar

en o por debajo de los 2000 pies de elevación.

Para un funcionamiento a más de 2000 pies de

elevación, los niveles de entrada se deberían

reducir a un promedio del 4 por ciento por cada

1000 pies sobre el nivel del mar.

•

La instalación debe cumplir con los códigos

y ordenanzas locales, o en su ausencia, con

el CÓDIGO NACIONAL DE GAS COMBUSTIBLE

(NATIONAL FUEL GAS CODE), ANSI Z223.

6

Page 23

Instrucciones de instalación

CÓMO CONECTAR LA SECADORA

AL SUMINISTRO DE GAS

Instale un codo hembra NPT de 3/8” al final

A

de la entrada de gas de la secadora.

Instale un adaptador de unión cónica

de 3/8” al codo hembra.

IMPORTANTE: Utilice una llave para tubos para

sostener bien el extremo de la entrada de gas

de la secadora para no doblar la entrada.

NOTA: Aplique compuesto para tubería o cinta

PTFE a las roscas del adaptador y la entrada de

gas de la secadora.

EXTREMO

ABOCINADO

CONECTOR NUEVO

DE LÍNEA DE GAS

DE METAL FLEXIBLE

ADAPTADOR

ITEMS NOT SUPPLIED

Una el conector de tubería de gas de metal

B

flexible al adaptador.

NPT

CODO

NPT DE 3/8”

ADAPTADOR

TAPÓN DE TUBERÍA

NPT DE 1/8” PARA

CONTROLAR LA

PRESIÓN DE ENTRADA

DE GAS

VÁLVULA DE CIERRE

TAMAÑO DE TUBERÍA

AL MENOS 1/2"

CÓMO CONECTAR LA SECADORA

AL SUMINISTRO DE GAS (cont.)

Instale una toma a rosca de 1/8” NPT

D

en la válvula de apagado de la tubería de gas

de la secadora para controlar la presión

de gas en la entrada.

Instale un adaptador de unión cónica

en la toma a rosca.

NOTA: Aplique compuesto para tubería o cinta

PTFE a las roscas del adaptador y a la toma.

Aplique compuesto para

tubería o cinta PTFE en

todas las roscas macho.

Válvula de apagado

Ajuste todas las conexiones mediante

E

dos llaves ajustables. No ajuste de más.

Toma a

rosca

Aplique compuesto para tubería al

adaptador y a la entrada de gas de la

secadora.

Ajuste la conexión de tubería flexible de gas,

C

utilizando dos llaves ajustables.

Tighten the flexible

gas line using two

adjustable wrenches.

Cierre la válvula de apagado del gas.

F

7

Page 24

Instrucciones de instalación

CÓMO CONECTAR UNA SECADORA A GAS (cont.)

PRUEBA DE PÉRDIDAS

Nunca utilice una llama abierta para detectar

pérdidas de gas.

Controle todas las conexiones con una solución

jabonosa o un elemento equivalente.

Aplique una solución jabonosa. La solución para

controlar pérdidas no debe contener amoníaco,

ya que este producto puede dañar los accesorios

de bronce.

Si se detectan

pérdidas, cierre la

válvula, vuelva

a ajustar la junta y

repita la prueba de

la solución jabonosa

and repeat the soap

test.

Abra la

válvula

de gas

CONEXIÓN ELÉCTRICA INFORMACIÓN

SOBRE LAS SECADORAS A GAS

ADVERTENCIA

Enchufe en un tomacorriente con conexión a tierra

de 3 cables.

NO retire la conexión a tierra.

NO UTILICE un cable de extensión.

NO UTILICE un enchufe adaptador con este

artefacto.

Si no cumple con esto, se podrá producir la muerte,

incendio o descarga eléctrica.

• Circuito - individual, correctamente polarizado y

conectado a tierra, interruptor de 15 o 20 amperios

o un fusible de retardo.

•

Potencia - 2 hilos más la tierra, 120 voltios,

monofásica, 60 Hz,

corriente alterna.

- Riesgo de Descarga Eléctrica

CONEXIÓN ELÉCTRICA INFORMACIÓN

SOBRE LAS SECADORAS A GAS (cont.)

• La secadora debe estar conectada a tierra según

los códigos y ordenanzas locales, o, en ausencia

de tales códigos, según la última edición del

Código Eléctrico Nacional, ANSI/NFPA NO. 70

o del Código Eléctrico Canadiense, CSA C22.1.

Consulte con un electricista calificado si no está

seguro de que la secadora esté correctamente

conectada a la tierra.

INSTRUCCIONES DE CONEXIÓN A TIERRA

Esta secadora deberá estar conectado a tierra. En

caso de mal funcionamiento o avería, la conexión a

tierra reducirá el riesgo de descargas eléctricas al

brindar un camino con una resistencia menor para

la corriente eléctrica. Esta secadora está equipada

con un cable con un conductor para la conexión

a tierra del equipo y un enchufe con conexión a

tierra. El enchufe deberá estar conectado a un

tomacorriente instalado en forma adecuada y con

conexión a tierra de acuerdo con todos los códigos

y ordenanzas locales.

ADVERTENCIA

equipo puede provocar riesgos de descargas eléctricas.

Consulte a un electricista calificado o personal o

representantes del servicio técnico si tiene dudas de que

el electrodoméstico se encuentre conectado a tierra

apropiadamente. NO modifique el enchufe en el cable

de suministro de corriente. Si no coincide con la toma de

corriente, contrate a un electricista calificado para que

instale una toma de corriente en forma adecuada.

GUARDE ESTAS INSTRUCCIONES

•

Si los códigos locales lo requieren, se puede

añadir un hilo de cobre externo de conexión a

tierra de calibre 18 o más. Conecte el cable a la

parte posterior del gabinete de la secadora con

tornillos de plancha # 8-18 x ½ “(disponible en

cualquier ferretería) como se ilustra.

Una conexión inapropiada del

conductor de conexión a tierra del

•

Tomacorriente de

salida - Receptáculo de

3 clavijas debidamente

conectado a tierra,

deberán colocarse

de modo que el

cable de alimentación esté accesible cuando la

secadora está instalada en su posición final. Si

el circuito tiene un receptáculo de 2 clavijas, es

responsabilidad del propietario de reemplazarlo

con un receptáculo de 3 clavijas debidamente

conectado a tierra por un electricista autorizado.

Assurez-vous au

préalable qu’une

mise à la terre

existe bien et

qu’elle fonctionne

correctement.

Tornillo de

conexión a tierra

8

Page 25

Instrucciones de instalación

CÓMO CONECTAR UNA SECADORA ELECTRICA

(Sáltese si se trata de las secadoras a gas o si su secadora ya tiene un cable de alimentación conectado)

HERRAMIENTAS NECESARIAS

Pinzas

Destornillador

de lados planos

Destornillador

Phillips

Nivel

MATERIALES NECESARIOS

Codo de metal de

4” de diámetro

Alivio de tensión de

3/4” (reconocido por

UL)

Guantes

Campana de salida

Cinta aislante

Antes de efectuar la conexión eléctrica, desactive

los disyuntores o quite los fusibles del circuito

de la secadora de la caja eléctrica. Verifique

que el cable de la secadora esté desenchufado

del tomacorriente. NUNCA OLVIDE DE VOLVER

A COLOCAR LA TAPA DE ACCESO DEL BLOQUE

TERMINAL.

Abrazaderas de

tubería de 4” (2)

o abrazaderas de

resorte de 4” (2)

Gafas de seguridad

Conducto de metal

de 4” de diámetro

(recomendado)

Conducto de metal

flexible de 4” de

diámetro (si fuese

necesario)

Kit de cable de

energía de la

secadora (no incluido

con la secadora)

Clasificado UL, de

120/240V, 30A con

3 o 4 patas. Identifique

el tipo de enchufe

según el tomacorriente

de la vivienda antes de

comprar el cable.

4” Placa de cubierta

(Kit WE49X22606)

9

Page 26

Instrucciones de instalación

CÓMO CONECTAR UNA SECADORA ELECTRICA (cont.)

CONEXIÓN ELÉCTRICA INFORMACIÓN

SOBRE LAS SECADORAS ELÉCTRICAS

Para realizar conexiones eléctricas con

un cable de corriente:

ADVERTENCIA

Use un cable de suministro de corriente de la secadora

de 30 amperes y 240V de la lista de UL, con terminales

de anillo cerradas o terminales de espada con

extremos al revés.

Use un amortiguador con refuerzo de la lista de UL.

Desconecte la corriente antes de realizar conexiones

eléctricas.

Conecte el cable neutro (el blanco o el cable central) a

la terminal central.

El cable a tierra (verde o pelado) se deberá conectar al

conector a tierra verde.

Conecte los dos cables de suministro restantes a las

dos terminales restantes.

De forma segura ajuste todas las conexiones eléctricas.

Reemplace la tapa del bloque terminal.

Si no cumple con esto, se podrá producir la muerte,

incendio o descarga eléctrica.

- Riesgo de incendio

INSTRUCCIONES DE CONEXIÓN A TIERRA

Para una secadora conectada con cable con

conexión a tierra: Esta secadora deberá estar

conectado a tierra. En caso de mal funcionamiento

o avería, la conexión a tierra reducirá el riesgo

de descargas eléctricas al brindar un camino con

una resistencia menor para la corriente eléctrica.

Esta secadora está equipada con un cable con un

conductor para la conexión a tierra del equipo y un

enchufe con conexión a tierra. El enchufe deberá

estar conectado a un tomacorriente instalado

en forma adecuada y con conexión a tierra de

acuerdo con todos los códigos y ordenanzas

locales.

ADVERTENCIA

del equipo puede provocar riesgos de descargas

eléctricas. Consulte a un electricista calificado o

personal o representantes del servicio técnico si

tiene dudas de que el electrodoméstico se encuentre

conectado a tierra apropiadamente. NO modifique

el enchufe en el cable de suministro de corriente. Si

no coincide con la toma de corriente, contrate a un

electricista calificado para que instale una toma de

corriente en forma adecuada.

GUARDE ESTAS INSTRUCCIONES

Una conexión inapropiada del

conductor de conexión a tierra

CONEXIÓN ELÉCTRICA INFORMACIÓN

SOBRE LAS SECADORAS ELÉCTRICAS

Para conexiones directas de cables:

ADVERTENCIA

Use un cable de cobre con calibre de 10

Use un amortiguador con refuerzo de la lista de UL.

Desconecte la corriente antes de realizar conexiones

eléctricas.

Conecte el cable neutro (el blanco o el cable central) a

la terminal central.

El cable a tierra (verde o pelado) se deberá conectar al

conector a tierra verde.

Conecte los dos cables de suministro restantes a las

dos terminales restantes.

De forma segura ajuste todas las conexiones eléctricas.

Reemplace la tapa del bloque terminal.

Si no cumple con esto, se podrá producir la muerte,

incendio o descarga eléctrica.

- Riesgo de incendio

INSTRUCCIONES DE CONEXIÓN A TIERRA

Para una secadora conectada de forma

permanente: Esta secadora debe estar conectada

a un sistema de cableado de metal permanente

con conexión a tierra o se debe tender un

conductor para la conexión a tierra del equipo con

los conductores del circuito y ser conectado al

terminal de tierra del electrodoméstico.

Una conexión inapropiada del

ADVERTENCIA

del equipo puede provocar riesgos de descargas

eléctricas. Consulte a un electricista calificado

o personal o representantes del servicio técnico

si tiene dudas de que el electrodoméstico se

encuentre conectado a tierra apropiadamente.

GUARDE ESTAS INSTRUCCIONES

conducto de conexión a tierra

10

Page 27

Instrucciones de instalación

CÓMO CONECTAR LA SECADORA

USANDO UNA CONEXIÓN DE 4 CABLES

(DEBE UTILIZARSE EN INSTALACIONES

DE CASAS RODANTES)

NOTA:

Desde el 1 de enero de 1996, el Código Eléctrico

Nacional exige que las nuevas construcciones utilicen una

conexión de 4 cables a una secadora eléctrica. También debe

usarse un cable de 4 alambres cuando los códigos locales no

permiten una conexión a tierra a través de cable neutral.

NO debe usarse una conexión de tres cables en una

construcción nueva.

QUITE LA CINTA DE

CONEXIÓN A TIERRA

Y DESCÁRTELA. CONSERVE

EL TORNILLO VERDE

DE CONEXIÓN A TIERRA

TORNILLOS

(3)

TAPA

1. Desactive el disyuntor (30 amperios) o quite el fusible

del circuito de la secadora de la caja eléctrica.

2. Verifique que el cable de la secadora esté

desenchufado del tomacorriente.

3. Quite la tapa del cable de energía ubicada en la parte

trasera inferior.

4. Quite y descarte la cinta de conexión a tierra. Conserve

el tornillo verde de conexión a tierra para el paso 7.

5. Instale un alivio de tensión de 3/4 pulgadas reconocido

por UL en el orificio de entrada del cable de energía.

Pase el cable de energía a través del alivio de tensión.

6. Conecte el cable de energía de la siguiente manera:

A. Conecte los dos cables vivos a los tornillos externos

del bloque terminal (marcado L1 y L2).

B. Conecte el cable neutral (blanco) al centro del

bloque terminal (marcado N).

7. Conecte el cable a tierra del cable de energía con el

tornillo verde de conexión a tierra (orificio sobre el

soporte de alivio de tensión). Ajuste por firmemente

todos los tornillos (3) del bloque terminal.

8. Ajuste bien el cable de energía al alivio de tensión.

9. Vuelva a instalar la tapa.

NUNCA OLVIDE DE VOLVER A COLOCAR LA TAPA

DEL BLOQUE TERMINAL.

CABLE

VIVO

VUELVA A COLOCAR

EL TORNILLO VERDE

DE CONEXIÓN A TIERRA AQUÍ

L1

N

L2

NEUTRAL

(blanco)

ALIVIO DE TENSIÓN

DE ¾” RECONOCIDO

CABLE

POR UL

VIVO

4 CONDUCTORES DE COBRE #10 AWG

MÍNIMO O KIT DE CABLE DE SUMINISTRO

DE ENERGÍA DE 120/240V 30A MARCADO

PARA USO EN SECADORAS Y PROVISTO

CON TERMINALES DE BUCLE CERRADO O

DE PALA CON EXTREMOS HACIA ARRIBA

(NO PROVISTOS).

CABLE VERDE

O AMARILLO

SOPORTE

DE ALIVIO

BRACKET

CÓMO CONECTAR LA SECADORA

UTILIZANDO UNA CONEXIÓN DE 3 CABLES

Si así lo requirieran los códigos locales, instale una conexión

a tierra externa (no provista) a metal con conexión a tierra,

tuberías de agua fría con conexión a tierra u otra conexión

a tierra establecida por un electricista calificado.

TORNILLOS

(3)

TORNILLO

VERDE

DE CONEXIÓN

A TIERRA

CINTA DE CONEXIÓN

A TIERRA

CABLE VIVO

SOPORTE

DE ALIVIO

DE TENSIÓN

ALIVIO DE TENSIÓN

DE ¾” RECONOCIDO

POR UL

CABLE VIVO

L1

L2

NEUTRAL

(blanco)

3 CONDUCTORES DE COBRE #10 AWG

MÍNIMO O KIT DE CABLE DE SUMINISTRO

DE ENERGÍA DE 120/240V 30A MARCADO

PARA USO EN SECADORAS Y PROVISTO

CON TERMINALES DE BUCLE CERRADO O

DE PALA CON EXTREMOS HACIA ARRIBA

(NO PROVISTOS).

SI ASÍ LO REQUIRIERAN LOS CÓDIGOS

LOCALES, INSTALE UNA CONEXIÓN

A TIERRA EXTERNA (NO PROVISTA)

A METAL CON CONEXIÓN A TIERRA,

TUBERÍAS DE AGUA FRÍA CON CONEXIÓN

A TIERRA U OTRA CONEXIÓN A TIERRA

ESTABLECIDA POR UN ELECTRICISTA

CALIFICADO.

TAPA

Conexión de 3 cables

NO usar en Canadá.

NO usar en instalaciones en casas móviles.

NO usar en casas nuevas.

NO usar en vehículos recreativos.

NO usar en áreas donde los códigos locales prohíben

la connexión eléctrica a tierra por el medio del cable

neutral.

1. Desactive el disyuntor (30 amperios) o quite el fusible

del circuito de la secadora de la caja eléctrica.

2. Verifique que el cable de la secadora esté

desenchufado del tomacorriente.

3. Quite la tapa del cable de energía ubicada en la parte

trasera inferior.

4. Instale un alivio de tensión de 3/4 pulgadas reconocido

por UL en el orificio de entrada del cable de energía.

Pase el cable de energía a través del alivio de tensión.

5. Conecte el cable de energía de la siguiente manera:

A. Conecte los dos cables vivos a los tornillos externos

del bloque terminal (marcado L1 y L2).

B. Conecte el cable neutral (blanco) al centro del

bloque terminal (marcado N).

6. Asegúrese de que la cinta de conexión a tierra esté

conectada a la terminal neutral (central) del bloque

y al tornillo verde de conexión a tierra de la parte

trasera del gabinete. Ajuste por firmemente todos los

tornillos (3) del bloque terminal.

7. Ajuste bien el cable de energía al alivio de tensión.

8. Vuelva a instalar la tapa.

NUNCA OLVIDE DE VOLVER A COLOCAR LA TAPA

DEL BLOQUE TERMINAL.

11

Page 28

Instrucciones de instalación

SALIDA AL EXTERIOR DE LA SECADORA

CONEXIÓN DE LA SECADORA A LA

ADVERTENCIA

Esta secadora DEBE tener una ventilación al exterior.

Utilice sólo un conducto de metal rígido de 4” para la

ventilación de salida doméstico.

Utilice

sólo un conducto de transición de metal rígido

de 4” o de la lista de UL para conectar la secadora a la

salida del hogar conducto.

NO use una ventilación del plástico.

NO use la salida de una chimenea, la salida de la

cocina, ventilación de gas, pared, cielo raso, ático,

espacio de rastreo, o espacio escondido de una

edificación.

NO instale una pantalla en o sobre el conducto de

salida.

NO instale un ventilador de refuerzo en el ducto de

ventilación.

NO use un conducto más largo que aquél especificado

en la tabla de longitud de salida.

Si no se siguen estas instrucciones se podrá producir la

muerte o un incendio.

HERRAMIENTAS Y MATERIALES NECESARIOS

PARA INSTALAR UN CONDUCTO DE SALIDA

Destornillador phillips

Cinta aislante o

abrazaderas de tubería