Page 1

GE

Measurement & Control

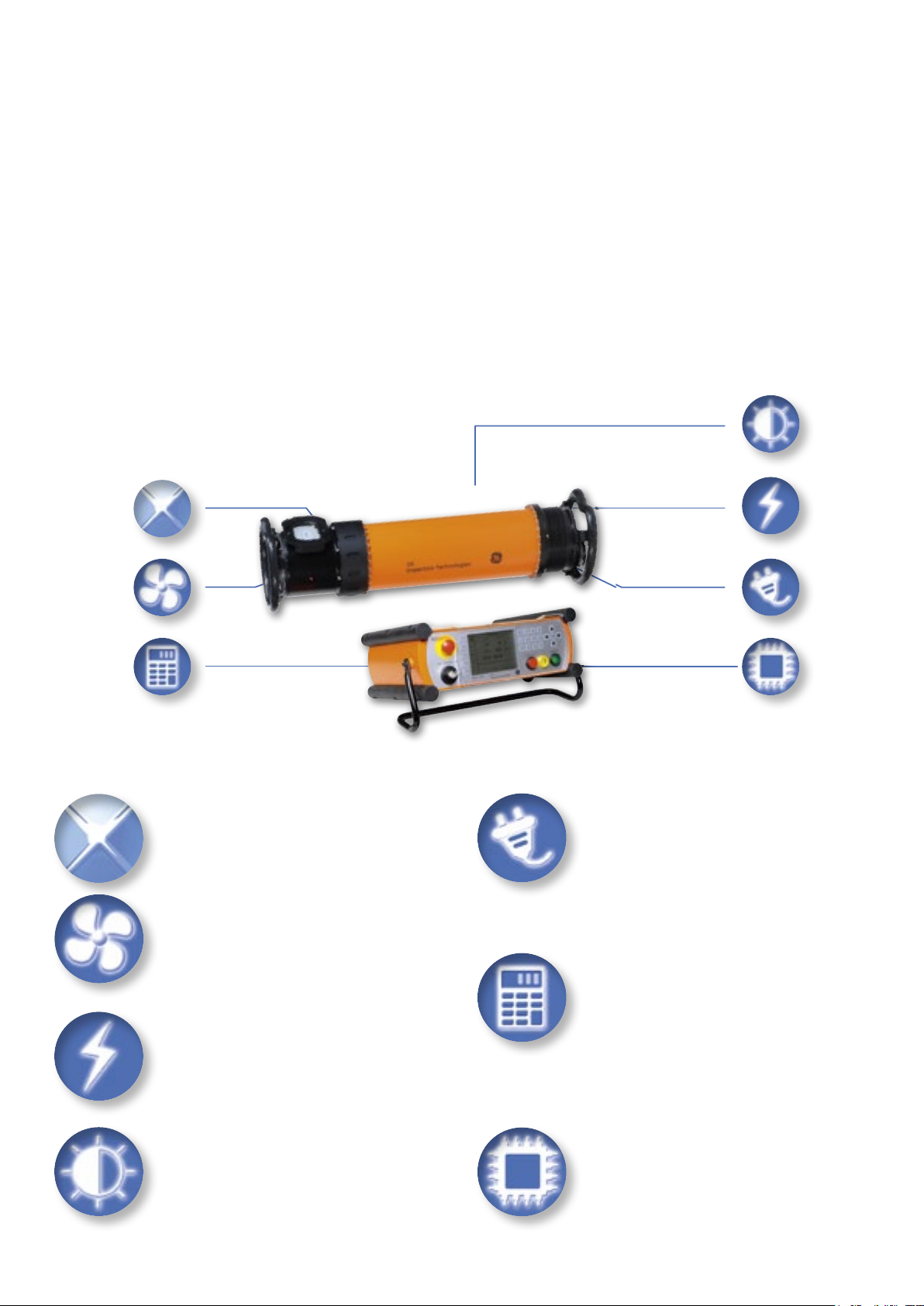

ERESCO MF4

Reliable, Lightweight, Portable X-ray Generator

Page 2

Microprocessor platform enables fast and

safe unit control providing intelligent features,

such as automatic tube head identication,

autonomous operation with event recording,

multi-lingual user interface and different

exposure programs.

Full graphic display and intuitive user

interface for simple and guided operation.

On-Board exposure calculator for

determination of the optimum exposure

settings and further exposure time reduction

through unique ERESCO power mode.

Several programming and reporting features

to shorten X-ray setup and evaluation times.

The power electronics of ERESCO units

provide

extremely low power consumption between 1

to 2 kW/h.

operation with portable power supplies are made easier.

Special power electronics allow for an alternative operation in

the eld as well as integration in crawlers. Even with reduced

weight, the new tube heads comply with the strict

requirements of the European X-ray regulations.

Using modern compact electronics to minimize weight and

provide a high power output with extremely low ripple, together

with a sturdy metal ceramic X-ray tube, the ERESCO MF4

generates a high X-ray dose which allows the shortest

exposure time, resulting in higher productivity.

ERESCO MF4 – For the toughest of tasks

A glance at the benets

The metal/ceramic technology ensures both

continuous operation and a long operating life.

The MF4 cooling system also assists in

prolonging long trouble-free operation as its

specially designed copper cooler optimises the

air ow for maximum cooling effect.

The ERESCO MF technology allows the X-ray

generator to be operated in power mode,

because, unlike competitive generators, it

can drive high tube currents. As a result,

continuous power ratings of up to 900 W and

high currents ensure that the ERESCO MF4 range

of X-ray generators offer the best image

denition in the 200 kV to 300 kV class.

Operation starts from 5 kV to enable optimized

exposure of low-density materials, such as

aluminum, composites and plastics resulting in

high-contrast images.

Microprocessor platform enables fast and

safe unit control providing intelligent features,

such as automatic tube head identication,

autonomous operation with event recording,

multi-lingual user interface and different

exposure programs.

Full graphic display and intuitive user

interface for simple and guided operation.

On-Board exposure calculator for

determination of the optimum exposure

settings and further exposure time reduction

through unique ERESCO power mode.

Several programming and reporting features

to shorten X-ray setup and evaluation times.

The power electronics of ERESCO units

provide

extremely low power consumption between 1

to 2 kW/h.

The ERESCO MF4 portable X-ray units are designed for

reliability in some of the world’s toughest conditions. With the

ERESCO MF4 line, mobile X-ray inspection becomes lighter in

the true sense of the word. By using the latest display

technology, the new user interface to control and monitor the

X-ray setup, has been fully utilized and features graphic

visualization and menu driven operation to optimize

productivity.

The robust construction of the control and the tube heads

make them suitable for hostile environments. Due to its low

power consumption, not only is energy cost reduced, but

operation with portable power supplies are made easier.

Special power electronics allow for an alternative operation in

the eld as well as integration in crawlers. Even with reduced

weight, the new tube heads comply with the strict

requirements of the European X-ray regulations.

Using modern compact electronics to minimize weight and

provide a high power output with extremely low ripple, together

with a sturdy metal ceramic X-ray tube, the ERESCO MF4

generates a high X-ray dose which allows the shortest

exposure time, resulting in higher productivity.

ERESCO MF4 – For the toughest of tasks

The ERESCO MF4 portable X-ray units are designed for

reliability in some of the world’s toughest conditions. With the

ERESCO MF4 line, mobile X-ray inspection becomes lighter in

the true sense of the word. By using the latest display

technology, the new user interface to control and monitor the

X-ray setup, has been fully utilized and features graphic

visualization and menu driven operation to optimize

productivity.

The robust construction of the control and the tube heads

make them suitable for hostile environments. Due to its low

power consumption, not only is energy cost reduced, but

operation with portable power supplies are made easier.

Special power electronics allow for an alternative operation in

the eld as well as integration in crawlers. Even with reduced

weight, the new tube heads comply with the strict

requirements of the European X-ray regulations.

Using modern compact electronics to minimize weight and

provide a high power output with extremely low ripple, together

with a sturdy metal ceramic X-ray tube, the ERESCO MF4

generates a high X-ray dose which allows the shortest

exposure time, resulting in higher productivity.

ERESCO MF4 – For the toughest of tasks

The ERESCO MF4 portable X-ray units are designed for

reliability in some of the world’s toughest conditions. With

the ERESCO MF4 line, mobile X-ray inspection becomes lighter

in the true sense of the word.

The robust construction of the control and the tube heads

make them suitable for hostile environments. Due to its low

power consumption, not only is energy cost reduced, but

operation with portable power supplies are made easier.

Special power electronics allow for an alternative operation

A glance at the benets

in the field as well as integration in crawlers. Even with

reduced weight, the new tube heads comply with the strict

requirements of the European X-ray regulations.

Using modern compact electronics to minimize weight and

provide a high power output with extremely low ripple,

together with a sturdy metal ceramic X-ray tube, the ERESCO

MF4 generates a high X-ray dose rate which allows the

shortest exposure time, resulting in higher productivity.

The metal/ceramic technology ensures both

continuous operation and a long operating life.

2 ERESCO MF4

The MF4 cooling system also assists in

prolonging long trouble-free operation as its

specially designed copper cooler optimises

the air flow for maximum cooling effect.

The ERESCO MF technology allows the X-ray

generator to be operated in power mode,

because, unlike competitive generators, it can

drive high tube currents. As a result, continuous

power ratings of up to 900 W and high currents

ensure that the ERESCO MF4 range of X-ray

generators offer the best image definition in the

200 kV to 300 kV class.

Operation starts from 5 kV to enable optimized

exposure of low-density materials, such as

aluminum, composites and plastics resulting

in high-contrast images.

The power electronics of ERESCO units provide

extremely low power consumption between

1 to 2 kW.

Full graphic display and intuitive user interface

for simple and guided operation.

On-Board exposure calculator for determination

of the optimum exposure settings and further

exposure time reduction through unique ERESCO

power mode.

Several programming and reporting features to

shorten X-ray setup and evaluation times.

Microprocessor platform enables fast and safe

unit control providing intelligent features, such as

automatic tube head identification, autonomous

operation with event recording, multi-lingual user

interface and different exposure programs.

Page 3

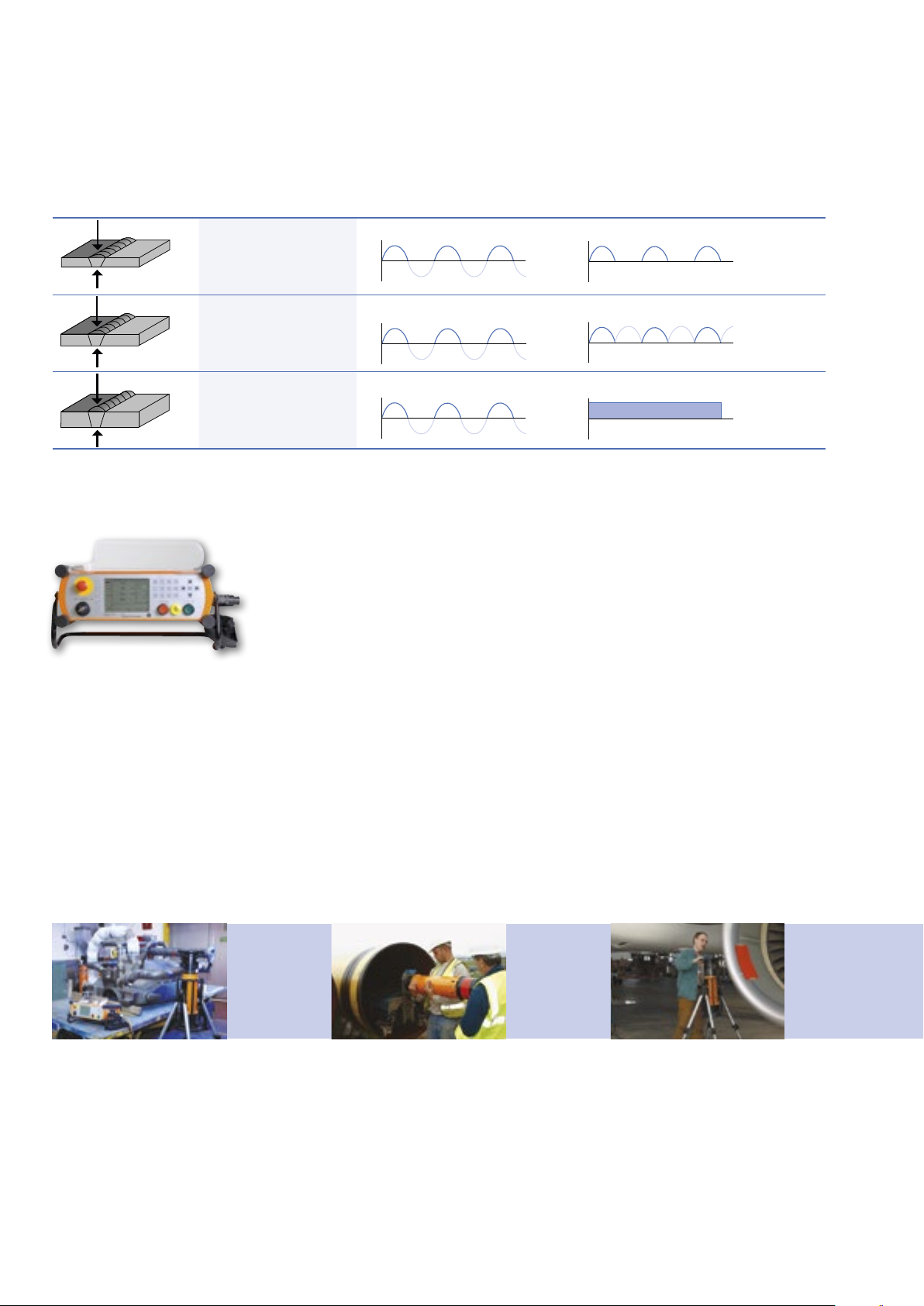

MF Technology for constant potential high dose output

Control Unit

Applications

A medium frequency output (around 20 kHz) can be used to produce a high power output with extremely low ripple.

The portable ERESCO X-ray digital

control can operate any X-ray

generator in the MF4 range. It

features modern, power

electronics and is ruggedly

constructed to with-

stand heavy use in the eld.

The MF4 Control faciliates a ergonomical interaction concept for

safe and efcient operation unit operation. Several on-board

features, such as Exposure Calculator, Parameter Monitoring or

Programming / Reporting tools are simplying inspections.

A large, back-lit, full graphic, transreective display allows easy

viewing even in very strong sunlight and provides details of the

system status in up to 19 languages supporting different

character-sets. All operating and setup parameters can be

entered by means of function keys, an alphanumeric keypad

and cursor keys. Menu driven interfaces complete the ease of

use. Alternatively setup parameters can be retrieved from a

bank of 250, pre-entered exposure programmes, stored in a

non-volatile memory. In addition, these programs can be

uniquely named or commented and can be downloaded,

modied, uploaded and archieved. In power operation, the

maximum tube current is calculated and set, so minimising

exposure times. Besides interfaces for warning lamps, interlocks

and pumps, the MF4 control also offers a serial interface for

external control or communication with PC based tools.

The ERESCO MF4 range of X-ray generators nds application throughout the industrial spectrum in the inspection of welds and in the

examinations for structural integrity.

32 mm

Simple X-Ray Unit

6

38 mm

Basic CP Unit

6

42 mm

ERESCO MF High

Performance Unit

6

Output Power of the ERESCO MF Units

-

+

o

+

o

-

+

o

-

+

o

-

+

o

High Voltage Out

High Voltage Out

-

+

o

-

+

o

-

+

o

-

+

o

-

+

o

-

+

o

+

o

-

+

o

-

+

o

-

+

o

Mains Power In

Mains Power In

AC Waveform

-

+

o

-

+

o

-

+

o

MF Technology for constant potential high dose output

A medium frequency output (around 20 kHz) can be used to produce a high power output with extremely low ripple.

-

+

o

+

o

-

+

o

-

+

o

-

+

o

-

+

o

-

+

o

-

+

o

-

+

o

-

+

o

-

+

o

-

+

o

MF Technology for constant potential high dose output

A medium frequency output (around 20 kHz) can be used to produce a high power output with extremely low ripple.

Mains Power In

Simple X-Ray Unit

32 mm

+

o

-

Mains Power In

Basic CP Unit

38 mm

+

o

-

AC Waveform

42 mm

ERESCO MF High

Performance Unit

Control Unit

The MF4 Control faciliates an ergonomical interaction concept

for safe and efficient unit operation. Several on-board

features, such as Exposure Calculator, Parameter Monitoring

or Programming / Reporting tools are simplifying inspections.

The portable ERESCO X-ray digital

control can operate any X-ray

generator in the MF4 range.

It features modern power

electronics and is ruggedly

constructed to withstand

heavy use in the field.

+

o

-

A large, back-lit, full graphic, transreflective display allows easy

viewing even in very strong sunlight and provides details of

the system status in up to 19 languages supporting different

character-sets. All operating and setup parameters can be

entered by means of function keys, an alphanumeric keypad

and cursor keys. Menu driven interfaces complete the ease

of use. Alternatively setup parameters can be retrieved from

a bank of 250 pre-entered exposure programmes, stored in

a non-volatile memory. In addition, these programs can be

uniquely named or commented and can be downloaded,

modified, uploaded and archived. In power operation, the

maximum tube current is calculated and set, so minimizing

High Voltage Out

+

6

o

-

High Voltage Out

+

6

o

-

Output Power of the ERESCO MF Units

+

6

o

exposure times. Besides interfaces for warning lamps, interlocks

Applications

The ERESCO MF4 range of X-ray generators finds application throughout the industrial spectrum in the inspection of welds

and in the examinations for structural integrity.

• Standard radiographic inspections, such

as those carried out in fabrication yards

in the oil and gas segment, in power

plants, in the automotive sector and in

general engineering.

With direct emission and panoramic emission models as well as small focal spot radioscopy units, the ERESCO MF4

range offers a comprehensive solution to meet virtually all customer portable X-ray generation needs.

• Oil and Gas segments require inspections

in extreme conditions, such as pipeline

inspections — both off-shore and land-based

applications — where equipment have to

withstand hostile environment like very low or

very high ambient temperature or permanent

exposure to salt-water, sand or dirt.

and pumps, the MF4 control also offers a serial interface for

external control or communication with PC based tools.

• Structural integrity testing in the

aerospace segment, where special

materials, honeycomb sections and

composites demand exceptional

tube performance.

ERESCO MF4 3

Page 4

Features Summary

ERESCO MF4 Generators

• Highest power output, with best image definition in

its class

• High X-ray dose permitting short exposure times with

associated increases in productivity

• Operation with 100% Duty Cycle at 30°C at 1 hour

operation time

• Light weighted and compact design

• Robust construction of control and tube heads allowing

operation in hostile environments (IP65)

• Lower power consumption meaning low energy costs

• Range of designs, including panoramic output and small

focal spot, suitable for radioscopy

• Wide range of accessories, including stands and carriages

to facilitate positioning during exposure set-up

ERESCO MF4 Control Unit

• Intuitive and menu driven user interface with

multifunction-, numeric- and cursor keys input

• Transreflective, backlit, graphic display for contrast

optimized indoor and outdoor operation exposure

calculator

• Integrated, real time clock, enabling intelligent and

automatic warm-up of the generating unit, taking past

operational intervals into account

• Robust and ergonomic design for operation in different

working position

• Automatic recognition of the type and serial number of the

connected X-ray tube head

• Free configurable exposure programming mode

• Off-line report generation and programming

• Multi-lingual graphical user interface

• Easily adapts to different main supplies, including portable

generators and batteries

• Built-in fail-safe warning lamp

• Emergency stop button, in compliance with international

standards

4 ERESCO MF4

Page 5

Accessories

Exchangeable lead diaphragms Aluminium transport boxes

Four legged stands for tube heads to ensure

stability

Lead plug for the tube window

Remote warning ash lamp

Laser centring device

A wide range of accessories complements the ERESCO MF4 generators.

Accessories

Four legged stands for tube heads to ensure

stability

Lead plug for the tube window

Laser centring device

A wide range of accessories complements the ERESCO MF4 generators.

Accessories

A wide range of accessories complements the ERESCO MF4 generators.

Accessories

Accessories

Other available accessories

• Caster extensions for the pipe carriage

• Portable power generator

• Carrying cradle for the MF3 tube

• Door contact cable

• Bracing belts

• Interface cables

• Diaphragm caps for panoramic units

• 20 m extension cable

• PC based exposure calculator

• MF4 Administrator Kit (Serial Interface cable and SW CD-ROM)

• Crawler integration kit

• Pipe inspection carriage to facilitate transport and set-up

Adapter cables

Telescope centering device

Exchangeable lead diaphragms Aluminium transport boxes

Four legged stands for tube heads to ensure

stability

Lead plug for the tube window

Remote warning ash lamp

Laser centring device

Remote control

A wide range of accessories complements the ERESCO MF4 generators.

A wide range of accessories complements the ERESCO MF4 generators.

Four legged stands for tube heads to ensure

stability

Laser centring device Lead plug for the tube window

Remote warning flash lamp Exchangeable lead diaphragms Aluminium transport boxes

Remote control Telescope centering device Adapter cables

Other available accessories

Transport and Positioning Cart

• Portable power generator

• Carrying cradle for the MF3 tube

• Door contact cable

• Bracing belts

• Interface cables

• Diaphragm caps for panoramic units

• 20 m extension cable

• PC based exposure calculator

• MF4 Administrator Kit (Serial Interface cable and SW CD-ROM)

• Pipe inspection carriage to facilitate transport and set-up

ERESCO MF4 5

Page 6

Technical Specifications

ERESCO MF4 – Serie

ERESCO-Typ 200 MF4-R 280 MF4-R 300 MF4-R

Description A real time imaging

Emergent Beam Direct Emission Direct Emission Direct Emission

Penetration of Steel in 10 min - - 65 mm (2.55”)

High Voltage Range 10 - 200 kV 10 - 280 kV 5 - 300 kV

Tube Current Range 0.5 – 10 mA 0.5 - 4.5 mA 0.5 - 6 mA

Tube Current at U max 3.0 mA / 200 kV 1.2 mA /280 kV 3.0 mA / 300 kV

Continous Rating 600 W 340 W 900 W

Nominal Focus Spot Value

Anode Material Tungsten (W) Tungsten (W) Tungsten (W)

Target Angle 20° 15° 15°

Emergent Beam Range Elliptical, 40° x 60° Elliptical, 30° x 60° Elliptical, 30° x 60°

Inherent Filtration 0.8 ± 0.1 mm, Be 0.8 mm ± 0.1 mm Be 0.8 mm ± 0.1 mm, Be

Cooling Air-cooled

Duty Cycle (1 h operation time) 100%

Current and Voltage Stability ± 1 %

Power Supply Requirements 160 V - 253 V AC, 80 V - 127 V AC, 50/60 Hz *

Weight of Tube Head 26.8 kg (59.1 lbs) 40 kg (88,2 lbs) 40 kg (88,2 lbs)

Certifications CE Conformity, NFC 74100 **, BfS Certification (PTB Approval) **

device, with small

focal spot (EN12543),

for applications

requiring geometric

enlargement

1.0 mm (EN 12 543)

0.5 (IEC 336)

A real time imaging

device, with small

focal spot (EN12543),

for applications

requiring geometric

enlargement

0.5 mm (EN 12543) 1 mm ( EN 12543)

A real time imaging

device, with small

focal spot (EN12543),

for applications

requiring geometric

enlargement or fast

exposure time

* Operation with reduced output is possible at main voltages below 205 V and 108 V respectively

** Available for selected models

6 ERESCO MF4

Page 7

32 MF4-C 42 MF4 52 MF4-CL 65 MF4

Panoramic-Beam unit

designed for pipeline and

butt-weld inspection

Panoramic Emission Direct Emission Panoramic Emission Direct Emission

32 mm (1.26”) 42 mm (1.65”) 52 mm (2.04”) 65 mm (2.55”)

5 - 200 kV 5 - 200 kV 5 - 300 kV 5 - 300 kV

0.5 – 10 mA 0.5 – 10 mA 0.5 - 6 mA 0.5 - 6 mA

3.0 mA / 200 kV 4.5 mA / 200 kV 2.0 mA / 300 kV 3.0 mA / 300 kV

600 W 900 W 600 W 900 W

0.4 x 4 mm

(EN 12543)

Tungsten (W) Tungsten (W) Tungsten (W) Tungsten (W)

22° 20° 20° 20°

40° x 360° Elliptical, 40° x 60° 38° x 360° Elliptical, 40° x 60°

0.4 mm Fe/Ni/Co + 2 mm, Al 0.8 mm ± 0.1 mm, Be 0.4 mm Fe/Ni/Co + 3 mm, Al 0.8 mm ± 0.1 mm, Be

31 kg (68,3 lbs) 26,8 kg (59,1 lbs) 36 kg (79 lbs) 40 kg (88,2 lbs)

Air-cooled unit, for a wide

range of applications in

weld inspection, aluminum

casting and also composite

materials

3.0 mm (EN 12543)

1.5 (IEC 336)

160 V - 253 V AC, 80 V - 127 V AC, 50/60 Hz *

CE Conformity, NFC 74100 **, BfS Certification (PTB Approval) **

Panoramic unit designed

for pipeline

and butt-weld inspection

where high penetration

power is demanded

0.5 x 5.5 mm (EN 12543) 3.0 mm (EN 12543)

Air-cooled

100%

± 1 %

Air-Cooled unit for a wide

range of applications in

weld inspection, Al casting

and composite materials,

especially where high

penetration power is

demanded

1.5 (IEC 336)

ERESCO MF4 7

Page 8

Regional Offices

Europe Americas Asia

Germany

Robert Bosch Str. 3

50354 Huerth

+49 2233 6010

Niels-Bohr-Str. 7

31515 Wunstorf

P.O. Box 6241

(RT only)

31510 Wunstorf

+49 5031 172 0

Bogenstr. 41

22926 Ahrensburg

(RT only)

+49 4102 807 117

United Kingdom

892 Charter Avenue Canley

Coventry CV4 8AF

+44 845 130 3925

France

68, Chemin des Ormeaux

Limonest 69760

+33 47 217 9216

Spain

San Maximo, 31, Planta 4A, Nave 6

Madrid 28041

+34 915 500 59 90

United States

50 Industrial Park Road

Lewistown, PA 17044

+1 866 243 2638 (toll-free)

+1 717 242 0327

721 Visions Drive

Skaneateles, NY 13152

(RVI only)

+1 888 332 3848 (toll-free)

+1 315 554 2000 ext. 1

Brazil

Av. Maria Coelho Aguiar, 215

Building C, 6th floor

Jd. Sao Luiz - Sao Paulo - SP

CEP 05804-900 - Brazil

+ 55 11 3614-1840

GE has sales and service offices all over the world.

Below are some of our locations. Visit www.ge-mcs.com for a complete listing.

• Berchem, Belgium

• Alzenau, Germany

• Burford, United Kingdom

• Moscow, Russia

• Bucharest, Romania

• Prague, Czech Republic

• Stockholm, Sweden

• Milan, Italy

China

5F, Building 1, No.1 Huatuo Road,

Zhangjiang High-Tech Park,

Shanghai 201203

+86 800 915 9966 (toll-free)

+86 (0) 21-3877 7888

Unit 1602, 16/F Sing Pao Building

101 King’s Road

North Point

Hong Kong

+852 2877 0801

Japan

Harumi Island Triton Square Office Tower X

1-8-10, Harumi, Chuo-ku, Tokyo 104-6023

Tel: +81 3 6890 4567

Fax: +81 3 6864 1738

• East Perth, Australia

• Singapore

• Dubai, UAE

• Buenos Aires, Argentina

• Mexico City, Mexico

• Airdrie, Alberta, Canada

• Toronto, Ontario, Canada

• Montreal, Quebec, Canada

www.ge-mcs.com/x-ray

xray.info@ge.com

GEIT-30002EN (02/15)

© 2015 General Electric Company. All Rights Reserved. Specifications are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product names

mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affiliated with GE.

Loading...

Loading...