Page 1

EPM 3000P

THREE-PHASE DIGITAL VOLT/AMPS MONITOR

EPM 3000P –F

THREE-PHASE VOLTS/AMPS/FREQUENCY MONITOR

Instruction Manual

NORTH AMERICA

GE Industrial Systems, 41 Woodford Avenue, Plainville, CT 06062

Internet: http: www.geindustrial.com

g

GE Industrial System

Page 2

All Rights Reserved.

Printed in the United States of America.

NORTH AMERICA

GE Industrial Systems, 41 Woodford Avenue, Plainville, CT 06062

Internet: http: www.geindustrial.com

Page 3

Customer Service and Support

Customer service and support is available 24 hours a day, 7 days a week.

Please have the model, serial number and a detailed problem description available. If the

problem concerns a particular reading, please have all meter readings available.

For customer or technical assistance, call: 1-888-GE4SERVICE (1-888-434-7378).

Product Warranty

GE warrants all products to be free from defects in material, workmanship and title and will be of

the kind and quality specified in GE’s written description in the manual. The foregoing shall

apply only to failures to meet said warranties which appear within one year from the date of

shipping. During the warranty period, GE will, at its option, either repair or replace any product

that proves to be defective.

Limitation of Warranty

This warranty does not apply to defects resulting from unauthorized modification, misuse or use

for any reason other than electrical power monitoring.

OUR PRODUCTS ARE NOT TO BE USED FOR PRIMARY OVER-CURRENT

PROTECTION. ANY PROTECTION FEATURE IN OUR PRODUCTS IS TO BE

USED FOR ALARM OR SECONDARY PROTECTION ONLY.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANABILITY OR FITNESS FOR A PARTICULAR PURPOSE. GE

SHALL NOT BE LIABLE FOR ANY PENAL, INDIRECT, SPECIAL OR

CONSEQUENTIAL DAMAGES ARISING FROM ANY AUTHORIZED OR

UNAUTHORIZED USE OF ANY GE PRODUCT. LIABILITY SHALL BE

LIMITED TO THE ORIGINAL COST OF THE PRODUCT SOLD.

Statement of Calibration

Our instruments are inspected and tested in accordance with specifications published by an

independent testing facility. The accuracy and a calibration of our instruments are traceable to

the National Institute of Standards and Technology through equipment that is calibrated at

planned intervals by comparison to certified standards.

Disclaimer

The information presented in this publication has been carefully checked for reliability; however,

no responsibility is assumed for inaccuracies. The information contained in this document is

subject to change without notice.

GE Industrial Systems

i

Page 4

TABLE OF CONTENTS

I N S T A L L A T I O N & O P E R A T I O N

CHAPTER 1 M

ECHANICAL INSTALLATION

1

Installation of the EPM3000P with K-110 Option for limited space

conditions

Standard Installation of the EPM3000P 1

Standard Cutout of EPM3000P 2

Communication Converter Installation or DC Output

CHAPTER 2 E

LECTRICAL INSTALLATION

3

Section 2.1 Connecting the Current Circuit 3

2.2 Connecting Voltage Circuit of Potential Transformer 3

2.3 Selecting the Voltage Fuses 3

2.4 Connection to the Main Power Supply 3

2.5 Electrical Connection Installation 4

3-Phase, 3-Wire Delta with Direct Voltage and CTs 5

3-Phase, 3-Wire Open Delta with 2 CTs and 2 PTs 5

3-Phase, 3-Wire Open Delta with 3 CTs and 2 PTs 6

3-Phase, 4-Wire Wye with Direct Voltage and CTs 6

3-Phase, 4-Wire Wye with CTs and PTs 7

Single Phase System 7

Dual Phase System 8

2.6 Relays and Protection

CHAPTER 3 C

OMMUNICATION INSTALLATION

10

Section 3.1 RS-232C 10

3.2 RS-485 10

CHAPTER 4 EPM3000P: O

VERVIEW

13

Section 4.1 Accessing Max/Min Values 13

4.2 Resetting Values 14

4.3 Accessing the LM1/LM2 Set Limits 15

4.4 Voltage Phase Reversal and Imbalance 15

4.5 Printing Operating Data 16

4.6 Printing Programming Data 17

4.7 Accessing LED Test 18

4.8 Accessing Firmware Versions 18

1

2

8

GE Industrial Systems

ii

Page 5

TABLE OF CONTENTS

P R O G R A M M I N G

CHAPTER 5 G

Section 5.1 How to Use This Portion of the Manual 19

5.2 Switch Packs 19

5.3 Programming Mode Entry 20

5.4 Standard Numeric Data Entry

CHAPTER 6 E

Section 6.1 Checksum Error - Protective Mechanism 21

6.2 Password Entry 21

CHAPTER 7 PROGRAMMING GROUP 0: G

Section 7.1 The Integration Interval 22

7.2 The Meter Address 23

7.3 Communication Baud Rate 23

7.4 System Configuration 24

7.5 Programming Procedure 26

7.6 Time Delay For Relays 1 & 2

CHAPTER 8 PROGRAMMING GROUP 1 29

Section 8.1 Scale Selections & Full Scale Settings 29

8.2 Full Scale Settings, Volt & Amp Channels, Volt & Amp Decimal

CHAPTER 9 PROGRAMMING GROUP 2: M

Section 9.1 Standard Calibration 31

9.2 High End Calibration of Voltage Channels, High & Low End

CHAPTER 10 PROGRAMMING GROUP 4: S

Section 10.1 Trip Relay

CHAPTER 11 PROGRAMMING GROUP 7: P

Section 11.1 Voltage Phase Reversal & Phase Imbalance 38

11.2 Trip Relay 38

11.3 Voltage Phase Reversal Detection 39

11.4 Percentage Voltage Phase Imbalance

CHAPTER 12 E

ENERAL PROCEDURE OVERVIEW

NTERING THE PROGRAMMING MODE

Placement

Calibration of Amperage Channels

MBALANCE SET LIMITS/RELAYS

I

XITING THE PROGRAMMING MODE

19

20

21

LOBAL METER SETUP

ETER CALIBRATION

ET LIMITS

HASE REVERSAL

& R

ELAYS

22

26

29

31

32

34

34

HASE

& P

38

40

41

GE Industrial Systems

iii

Page 6

INSTALLATION & OPERATION

CHAPTER 1

ECHANICAL INSTALLATION

M

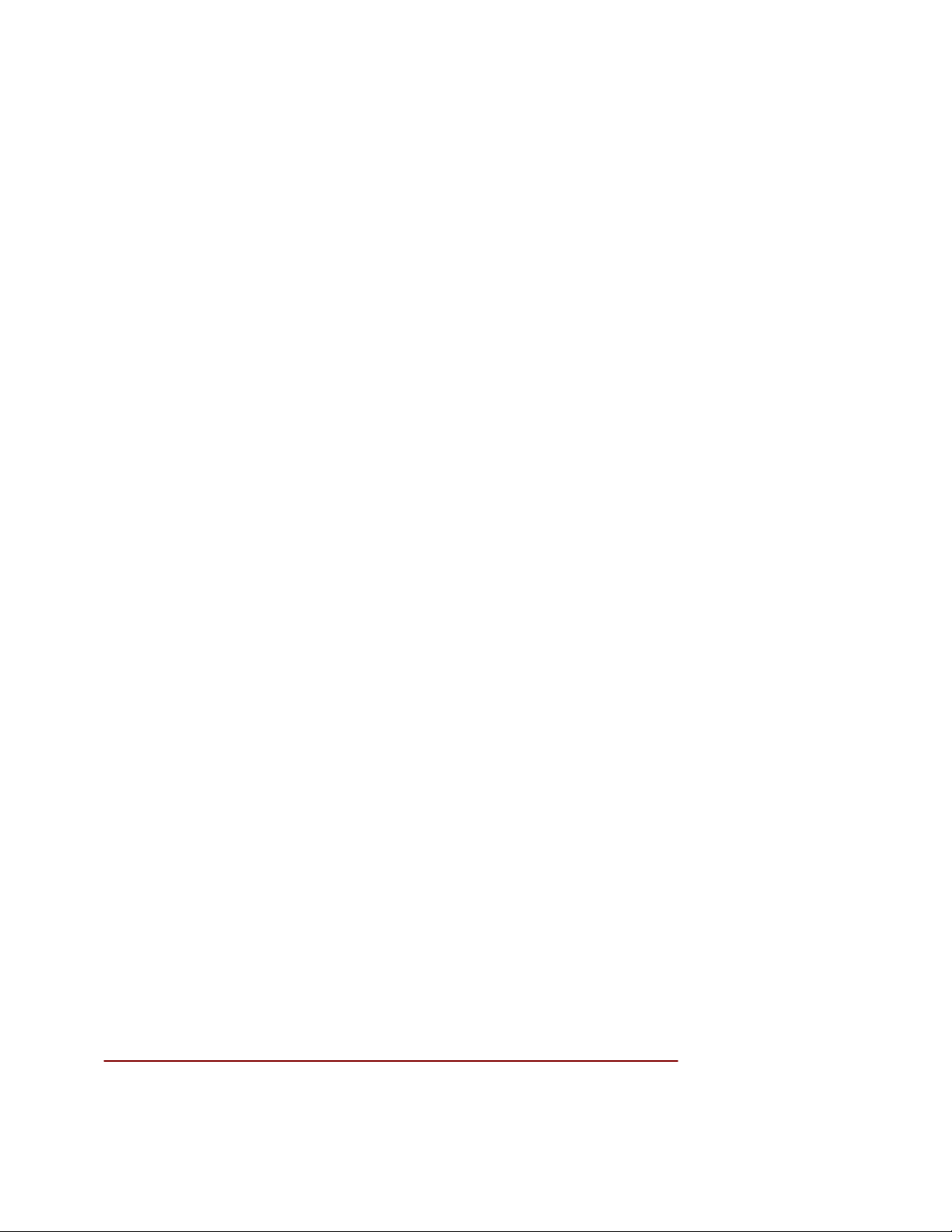

The following diagrams display the various possible EPM3000P and EPM3000P-F mechanical installations and

Communication Converter installation. All illustrations are of the EPM3000P with notes on the F Model.

ALL MEASUREMENTS ARE IN INCHES

NOTE:

.

3.00

0.80

AC VOLTS

C

B

ANB

A

C

N

C

N

B

A

AC AMPS

NCBA

MIN

MAX

MAX/MIN

PRINT

PROG

VOLTS

4.375

SQ.

LIMITS

AMPS

PHASE

NEXT

LM2LM1

2.425

0.890

4.50

SQ.

(4) 8-32 SCREWS

5.00

36" CABLE

0.336

2.45

0.714

Diagram 1.1 Installation of the EPM3000P with K-110 Option for limited space conditions.

4.50

SQ.

MAX MIN LM2LM1

MAX/MIN

PRINT

PROG

VOLTS

LIMITS

4.375

SQ.

Diagram 1.2

GE Industrial Systems

AC VOLTS

B

A

CNA

C

C

NBN

B

A

AC AMPS

AMPS

PHASE

NEXT

NCBA

3.0

2.0

0.890

Standard Installation of the EPM3000P.

1

Page 7

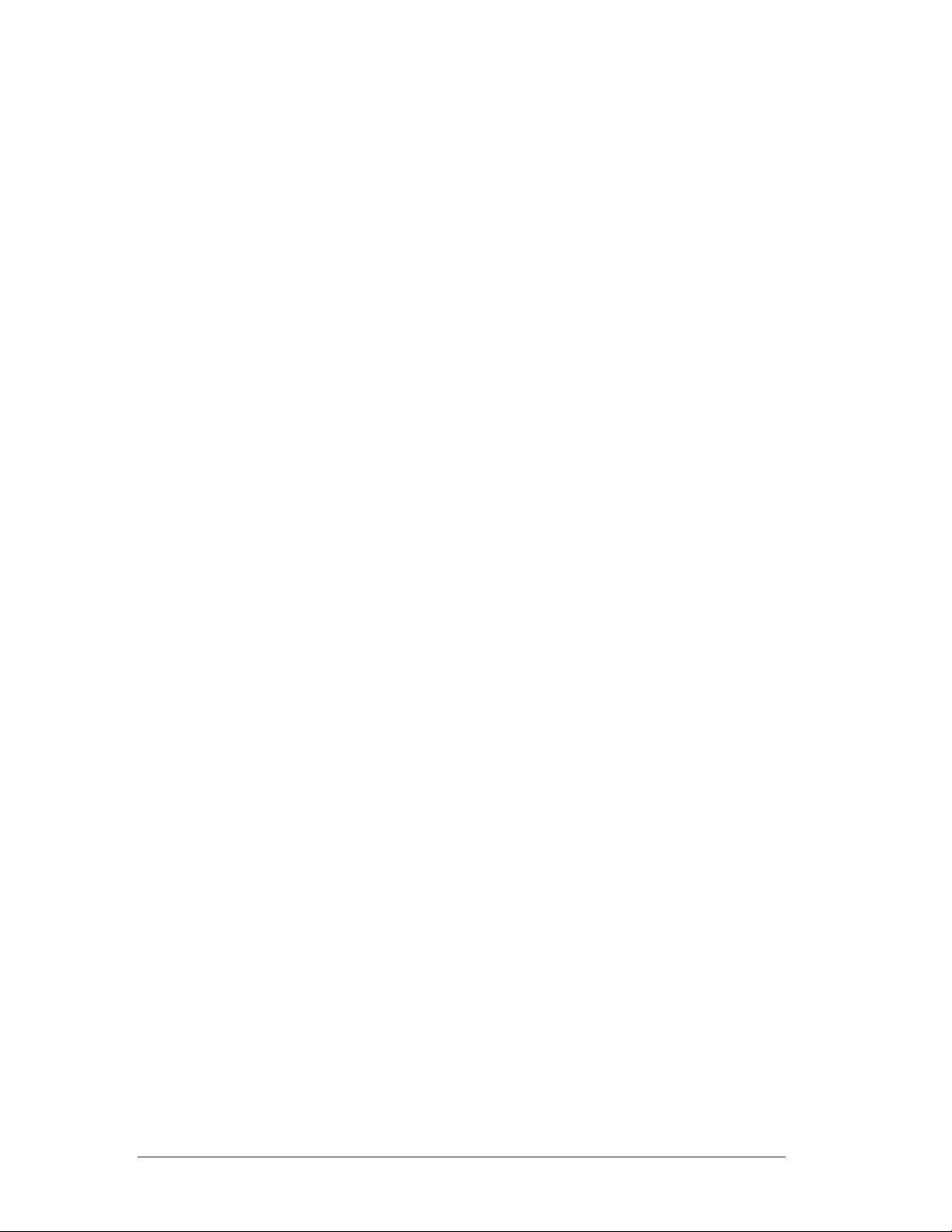

Chapter 1 Mechanical Installation

1.6875

SIDE VIEW

RECOMMENDED

CUTOUT

4.0 DIA.

1.6875

(4) 8-32 SCREWS

0.80

0.198 DIA.

3.375

FIRST PUT (16) PIN

CONNECTOR TOGETHER.

(2) 8-32 SCREWS WILL

LINE UP WITH 2 PEMS

ON THE BACK PLATE.

3.375

Diagram 1.3

Standard cutout for EPM3000P.

BACK VIEW

W Port

Diagram 1.4

CAREFULLY LINE UP THE GUIDE SCREW AND

NOTE:

Optional Communication Converter or DC Output Module Installation

PIN PORT CONNECTOR TO PREVENT PINS FROM BREAKING

8

GE Industrial Systems

.

2

Page 8

CHAPTER 2

E

LECTRICAL INSTALLATION

2.1 C

ONNECTING THE CURRENT CIRCUIT

The cable used for the current should be installed at 600V AC minimum. The cable connector should be rated at 6

Amps or greater, and it should have a cross-sectional area of 16 AWG.

The current transformers should be mounted as close as possible to the meter. The following table gives the

maximum recommended distances for various CT sizes, assuming the connection is made via 16 AWG cable.

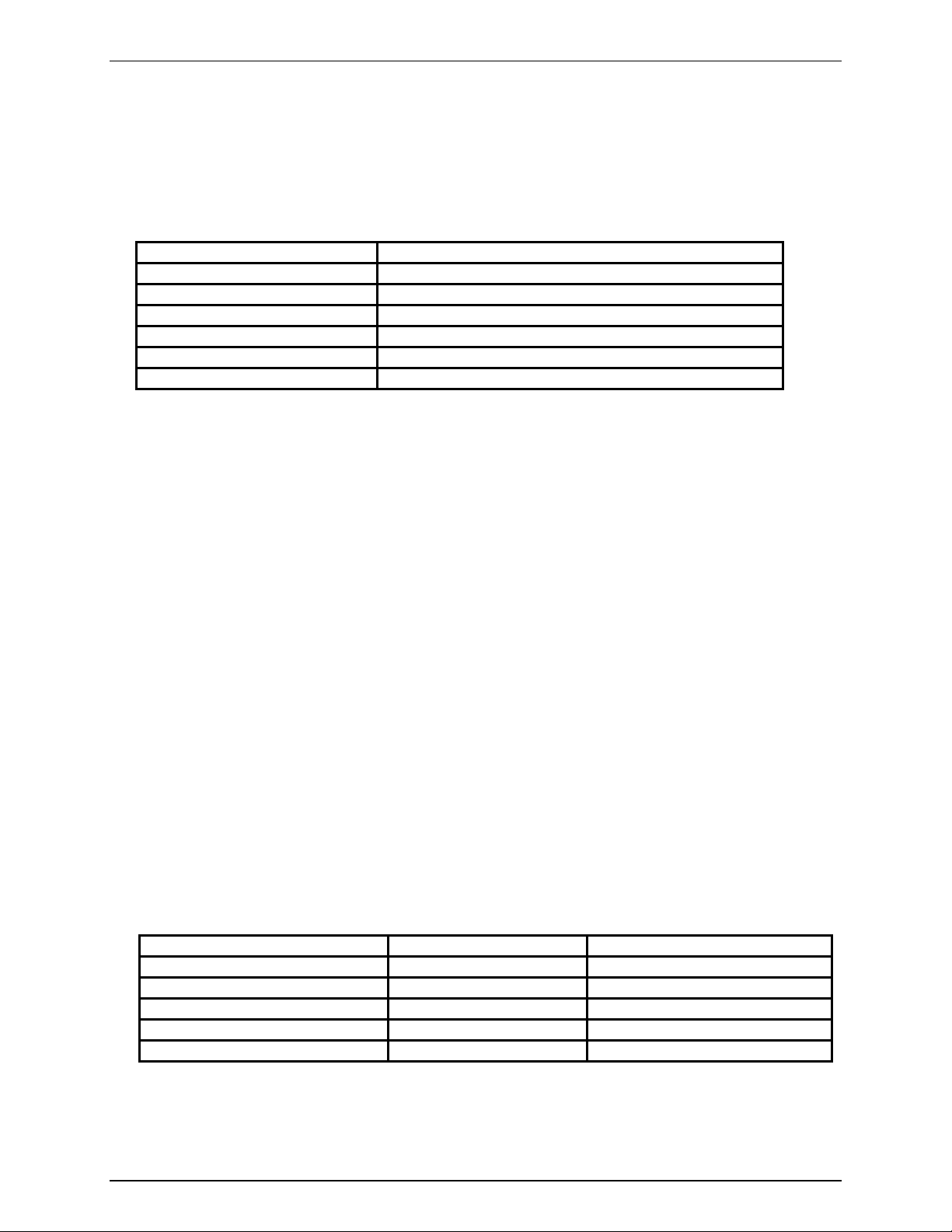

CT SIZE (VA) MAXIMUM DISTANCE (CT TO EPM3000P)

2.5 VA 10 F

5.0 VA 15 F

7.5 VA 30 F

10.0 VA 40 F

15.0 VA 60 F

30.0 VA 120 F

WARNING:

WHICH OVERHEATS THE SECONDARY OF THE

SECONDARY OF THE

DO NOT

CT.

LEAVE SECONDARY OF

CT. I

EET

EET

EET

EET

EET

EET

CT

WHEN PRIMARY CURRENT IS FLOWING

CT

F THE

IS NOT CONNECTED, PROVIDE A SHORTING BLOCK ON THE

. T

HIS MAY CAUSE HIGH VOLTAGE

,

2.2 C

ONNECTING VOLTAGE CIRCUIT OF POTENTIAL TRANSFORMER

For proper operation, the voltage connection must be maintained. If an error occurs, such as mistaking Line A for

Line B, a PH message appears, indicating a Phase Reversal (see Phase Imbalance and Reversal).

The cable required to terminate the voltage sense circuit should have an insulation rating greater than 600V AC and a

current rating greater than 0.1 A.

2.3 S

ELECTING THE VOLTAGE FUSES

We recommend using fuses, although connection diagrams do not show them. Slow blow, 200 mA rating fuses

should be used.

The maximum voltage EPM3000P can handle 150V phase to neutral. If Suffix -G is added to the model number, the

maximum voltage to be used is 300V phase to neutral.

2.4 C

ONNECTION TO THE MAIN POWER SUPPLY

The EPM3000P requires a separate power supply connection. Listed are the 5 different power supply options and

corresponding.

: F

DC-

OR

NOTE

MANDATORY FOR NORMAL OPERATION

S

EPARATE GROUNDING IS REQUIRED

POWERED UNITS POLARITY MUST BE OBSERVED

(

TERMINAL

.

3). D

O NOT GROUND THE UNIT THROUGH THE NEGATIVE OF THE

. A

N EARTH TO GROUND CONNECTION TO CHASSIS IS

POWER SUPPLY OPTIONS SUFFIXES CURRENT

120V AC NO S

240V AC A .05 AAC

24V DC D .5 ADC

48V DC D1 .25 ADC

125V DC D2 .1 ADC

.1 AAC

UFFIX

DC

SUPPLY

.

GE Industrial Systems

3

Page 9

Chapter 2 Electrical Installation

2.5 E

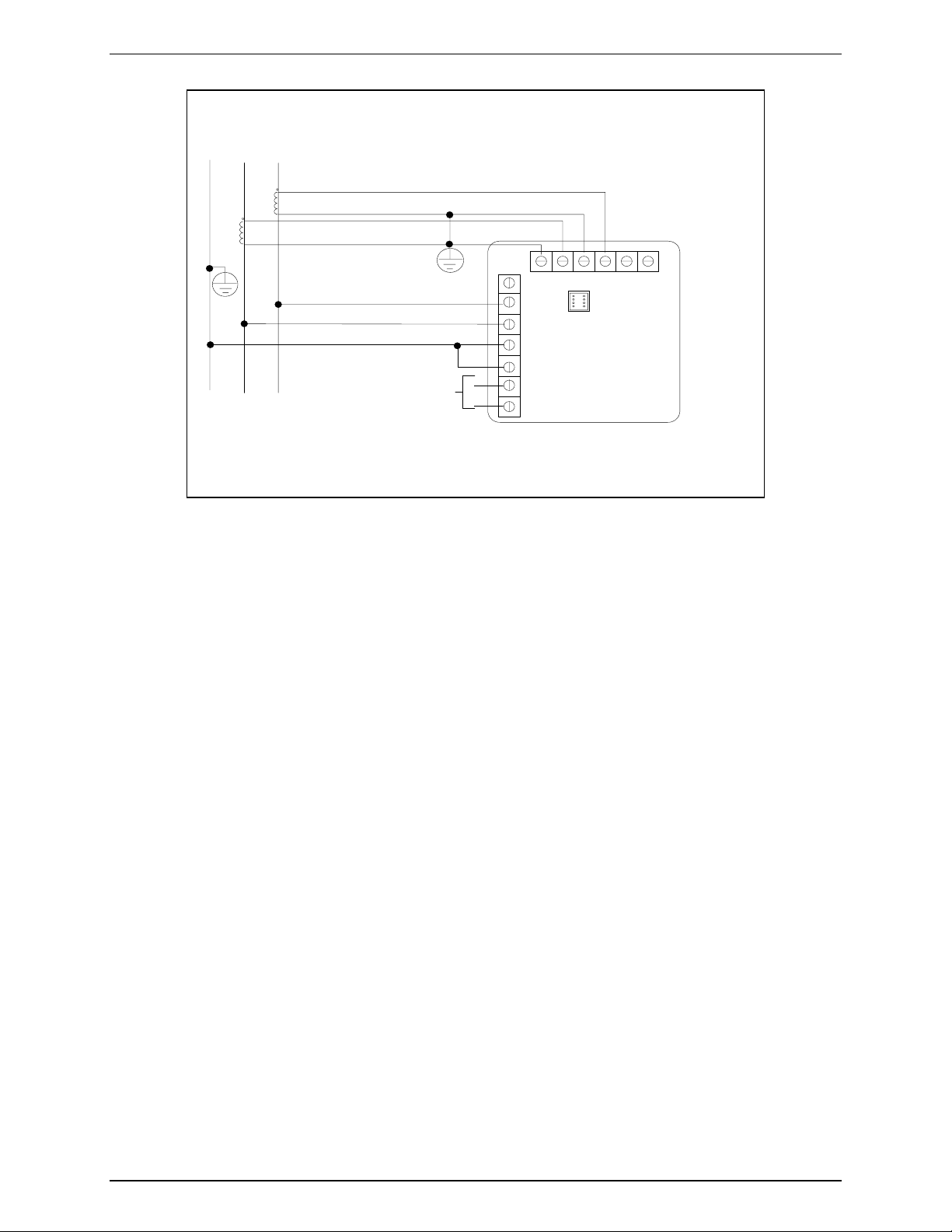

LECTRICAL CONNECTION INSTALLATION

Choose the diagram that best suits your application and maintain the polarity. Follow the outlined

procedure to verify correct connection.

NOTE: T

CURRENT INDICATES REVERSE

HE NEUTRAL READING IS CALCULATED FROM THE SUM OF THE 3 PHASES OF CURRENT

CT

POLARITY

.

. H

IGH NEUTRAL

LISTING OF CONNECTION DIAGRAMS

NOTE:

S

EE PHASE REVERSAL IF A MESSAGE OF

PH

APPEARS AFTER INSTALLATION

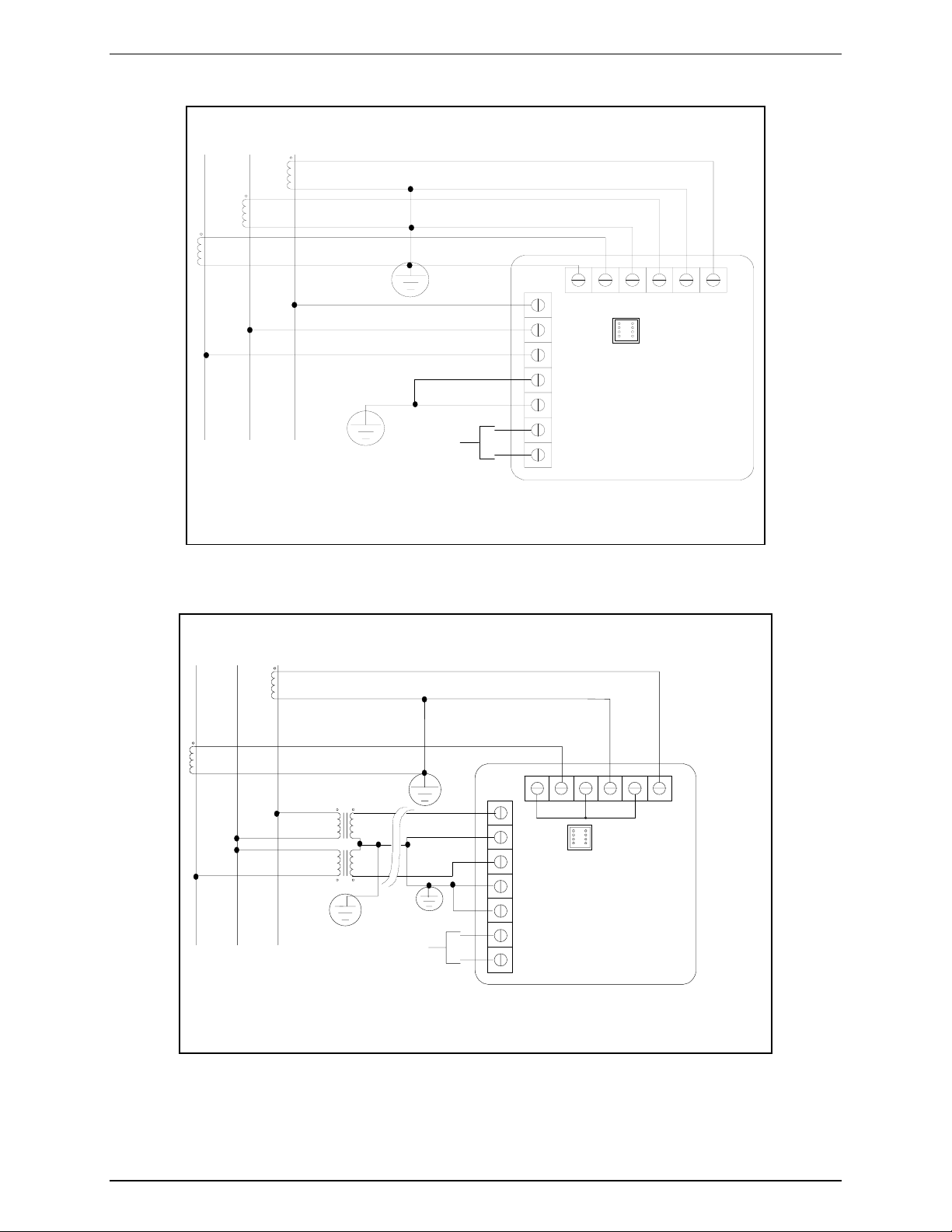

I Three-Phase, Three-Wire System Delta with Direct Voltage and CTs.

II Three-Phase, Three-Wire Open Delta with two CTs and two PTs.

(Open Delta System Installation should only be used if the electrical system is a 3-wire OPEN

DELTA. Open Delta can be enabled or disabled in Programming Group 0, Function 3.)

III Three-Phase, Three-Wire Open Delta with three CTs and two PTs.

(Open Delta System Installation should only be used if the electrical system is a 3-wire OPEN

DELTA. Open Delta can be enabled or disabled in Programming Group 0, Function 3.)

IV Three-Phase, Four-Wire System Wye with Direct Voltage and CTs.

V Three-Phase, Four-Wire System Wye with CTs and PTs.

VI Single Phase System

VII Dual Phase System

.

GE Industrial Systems

4

Page 10

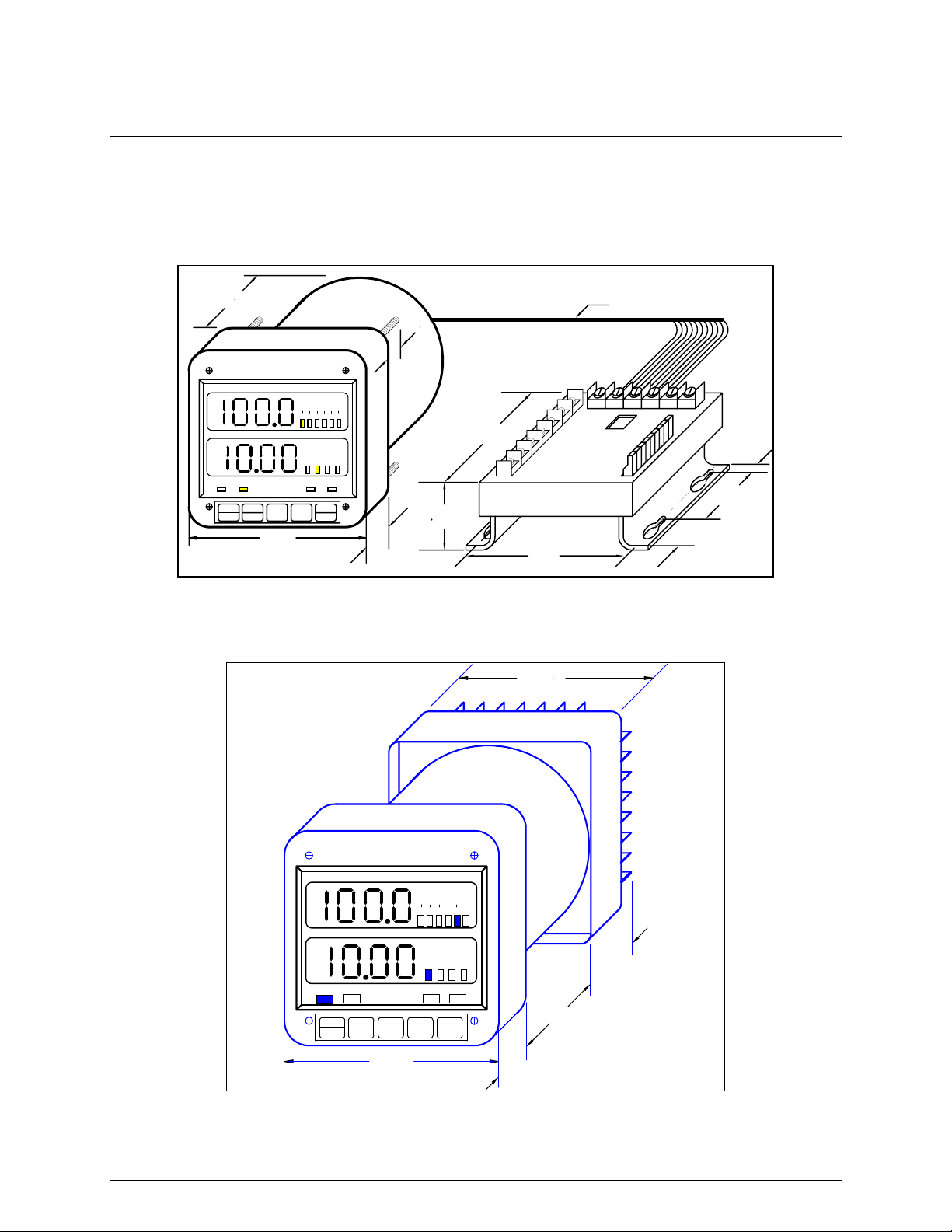

Chapter 2 Electrical Installation

LINE

BC

A

BACK VIEW

LOAD

I. Three Phase System

LINE

BC

A

CONTROL

POWER

8

9

7

6

5

4

3

+

-

L1

2

L

1

10

PORT

11

12

13

3-PHASE, 3-WIRE DELTA

WITH DIRECT VOLTAGE AND CTs

BACK VIEW

LOAD

II. Open Delta PT Connection

CONTROL

POWER

8

7

6

5

4

3

+

-

L1

2

1

L

910

PORT

11 12 13

3-PHASE, 3-WIRE OPEN DELTA

WITH 2 CTs AND 2 PTs

Special programming required.

GE Industrial Systems

5

Page 11

Chapter 2 Electrical Installation

LINE

BC

A

LOAD

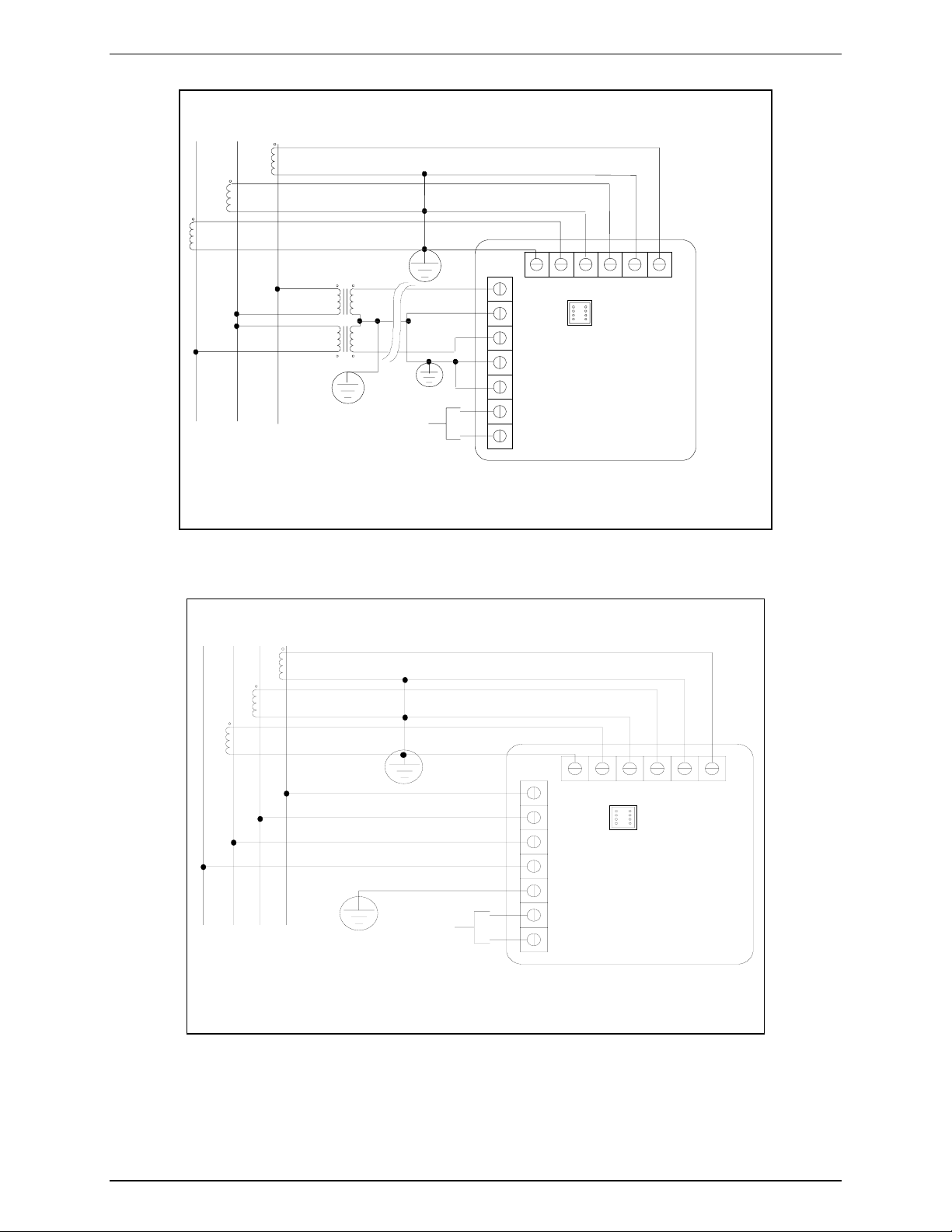

III. Open Delta PT Connection

LINE

NA

BC

BACK VIEW

POWER

8

7

6

5

4

3

+

-

L1

2

1

L

910

PORT

11 12 13

3-PHASE, 3-WIRE OPEN DELTA

WITH 3 CTs AND 2 PTs

Special programming required.

BACK VIEW

LOAD

IV. Three Phase System

CONTROL

POWER

8

9

7

6

5

4

3

+

-

L1

2

L

1

10

PORT

11

12

13

3-PHASE, 4-WIRE WYE

WITH DIRECT VOLTAGE AND CTs

6

GE Industrial Systems

Page 12

Chapter 2 Electrical Installation

LINE

NA

BC

BACK VIEW

POWER

LOAD

3-PHASE, 4-WIRE WYE

V. Three Phase System Wye System with PTs

LINE

A

8

7

6

5

4

3

+

-

2

L2

1

L1

WITH CTs AND PTs

BACK VIEW

910

PORT

11

12 13

LOAD

VI. Single-Phase System

POWER

8

7

6

5

4

3

L2

+

-

2

1

L1

910

PORT

11 12 13

SINGLE-PHASE

WITH CT AND PT CONNECTION

7

GE Industrial Systems

Page 13

Chapter 2 Electrical Installation

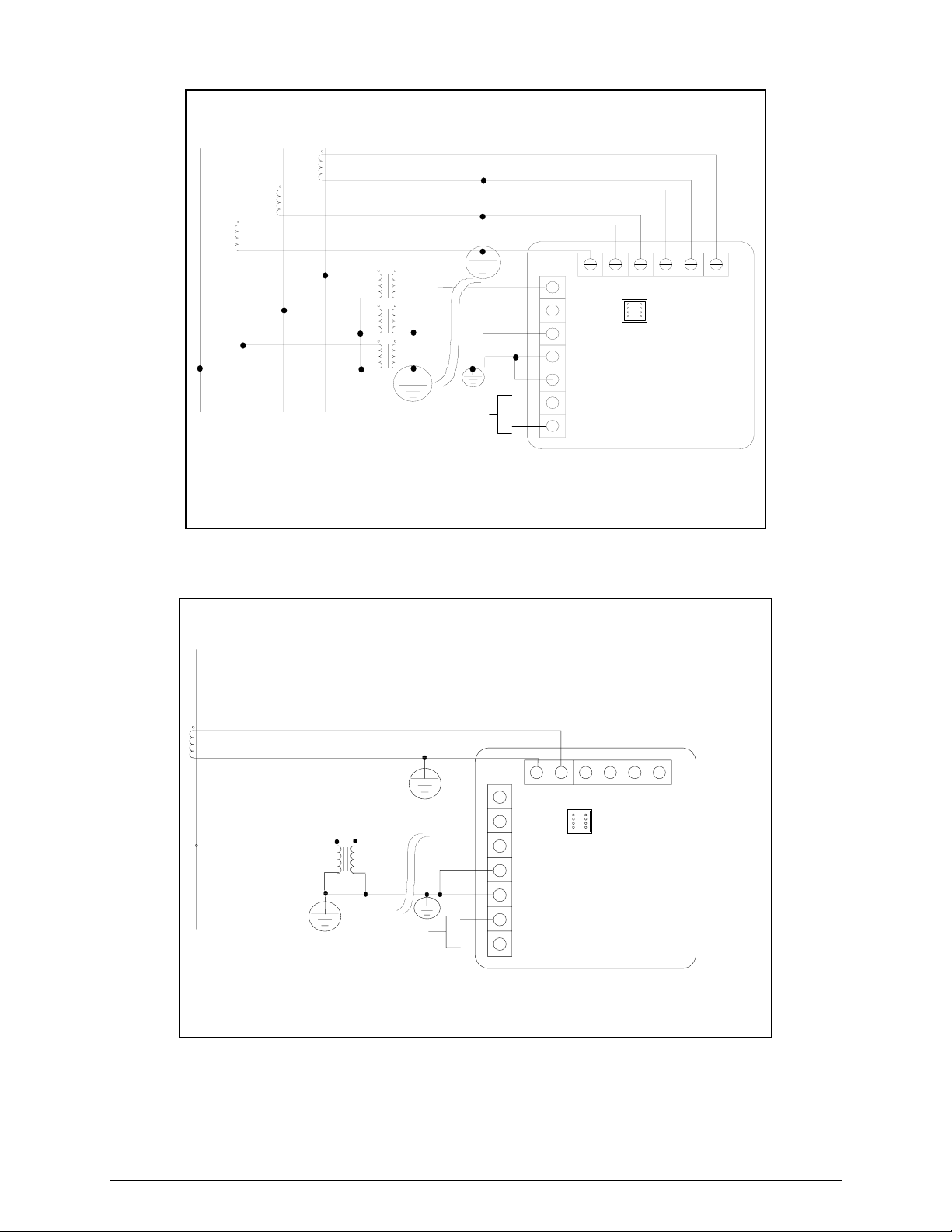

BACK VIEW

POWER

8

9 10

7

6

PORT

5

4

3

+

-

2

L2

1

L1

11

12 13

LINE

N

LOAD

A

B

DUAL-PHASE

WITH CTs AND Direct Voltage

VII. Dual-Phase System

2.6 R

NOTE:

The EPM3000P allows the user to access a variety of relay options through the programming mode. The relay option

package consists of two relays, which can be dedicated to alarm or communication (or both).

TIME DELAY

limit. The time delay can be programmed for any desirable duration.

If the relays are dedicated to communication, there are two different modes:

Lock ON Relay will not be affected by any alarm condition.

Lock OFF Relay will not be affected by any alarm condition.

If the relays are used for communication and alarm, there are four different modes:

Lock ON Relay stays on regardless of any alarm condition.

Lock OFF Relay stays off regardless of any alarm condition.

Free ON Relay turns on unless other conditions force it off.

Free OFF Relay turns off unless other conditions force it on.

ELAYS AND PROTECTION

T

HIS SECTION IS APPLICABLE ONLY IF THE

: Sets off the alarm, alerting the user that an out-of-limits condition occurred during the defined time

-NL R

ELAY OPTION WAS ORDERED

.

GE Industrial Systems

8

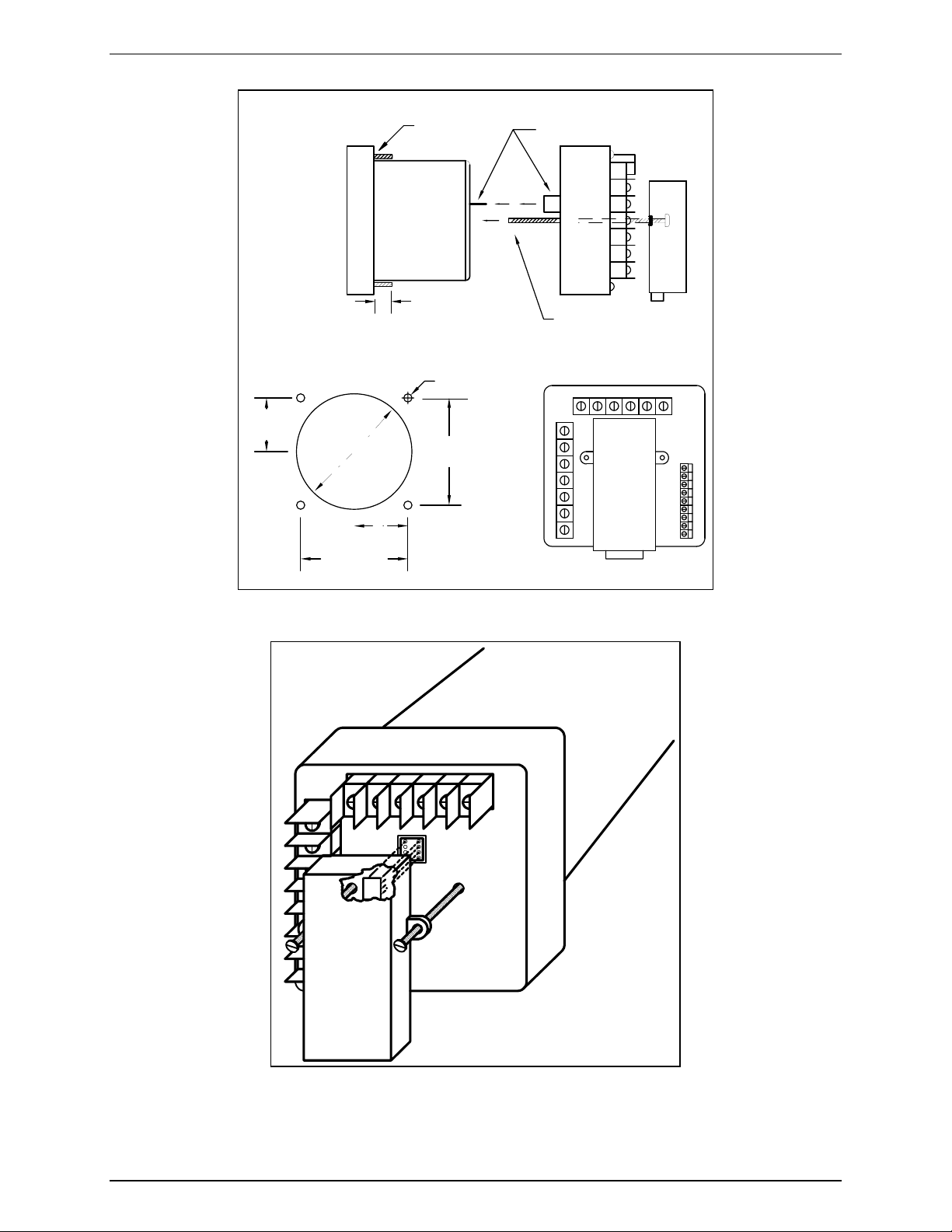

Page 14

Chapter 2 Electrical Installation

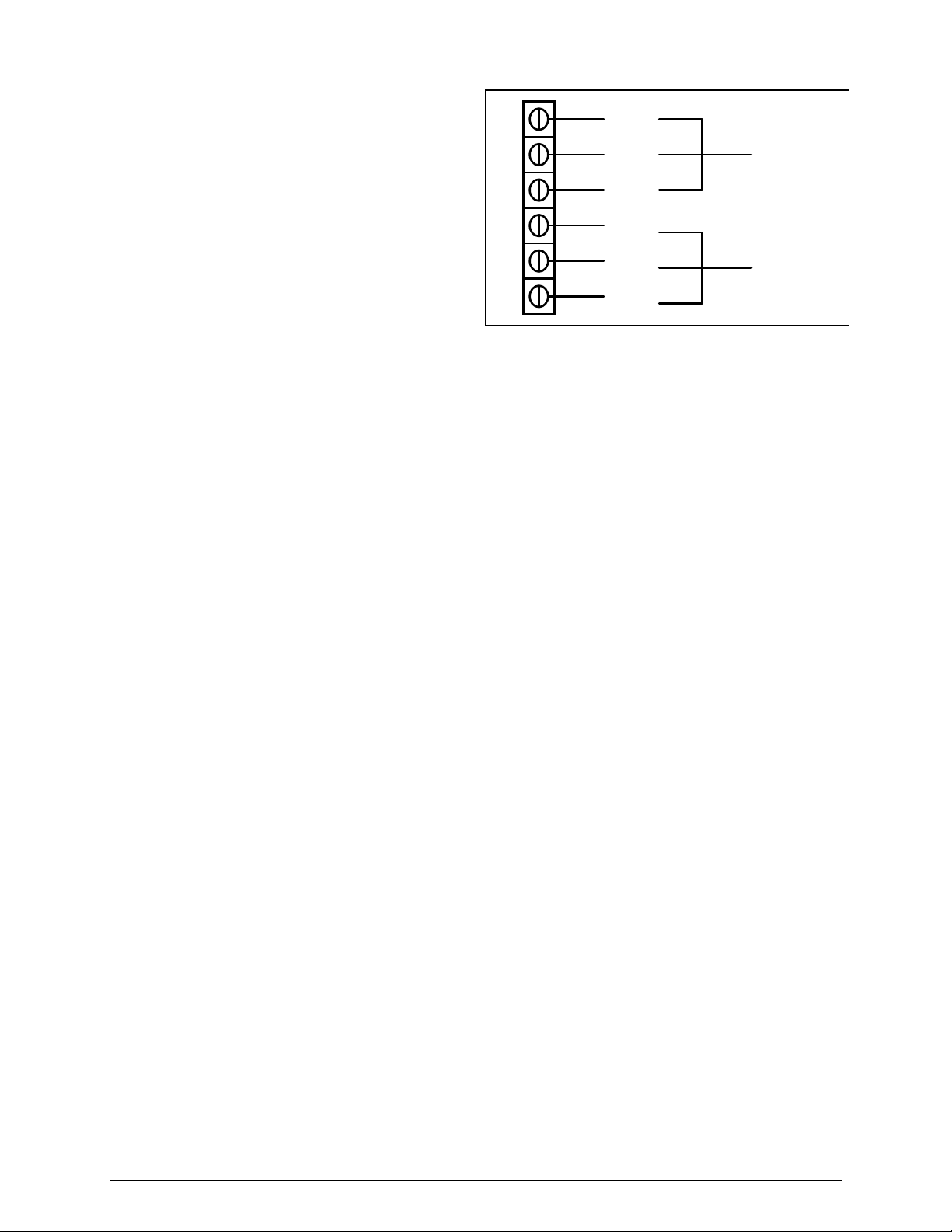

1

2

Figure 2.1 - Relay Connection

Close-up of the relays on the rear panel. The relays

shown are in the NOT energized state. (Form C relays,

rated 250V, 5A, 2 each)

20

21

22

N.O.

N.C.

COM

ALARM #

23

24

25

N.O.

N.C.

COM

T

HE INSTRUMENT CAN BE PROGRAMMED TO DETECT TWO ALARM LEVELS FOR THE FOLLOWING FUNCTIONS

LM1/LM2 Voltage AN, BN, CN, AB, BC, CA

LM1/LM2 Current A, B, C, N

Voltage Imbalance (One level only)

Voltage Phase Reversals (One level only)

ALARM #

:

9

GE Industrial Systems

Page 15

CHAPTER 3

C

OMMUNICATION INSTALLATION

3.1 RS-232C

All EPM3000P and EPM300P-F instruments can be equipped with: the EIA RS-232C or the EIA RS-485.

RS-232C communication links a single instrument with a computer or device such as an RTU or PLC. Its

capability is up to 100 feet. A standard 9-pin female serial port connector mounts on the instrument for

direct connection to a computer with a 9-pin cable.

NOTE:

O

NLY THREE PINS ARE USED IN

RS-232C. (See

Figure 3.1

).

BACK VIEW

RS-232 COMMUNICATION CONNECTION

8 9 10 11 12 13

7

6

COMMUNICATION

5

4

3

2

1

DB-9 CONNECTOR

CONVERTER

Model

SF-232DB3

A DIRECT PIN-TO-PIN CABLE CAN BE USED.

NO NULL MODEM IS REQUIRED.

20

21

22

23

24

25

26

27

28

Figure 3.1 RS-232C Communication Connection Installation

NOTE: T

TOGETHER AT ONLY ONE POINT

O AVOID GROUND LOOPS, THE NEUTRAL AND SAFETY GROUND (PIN

.

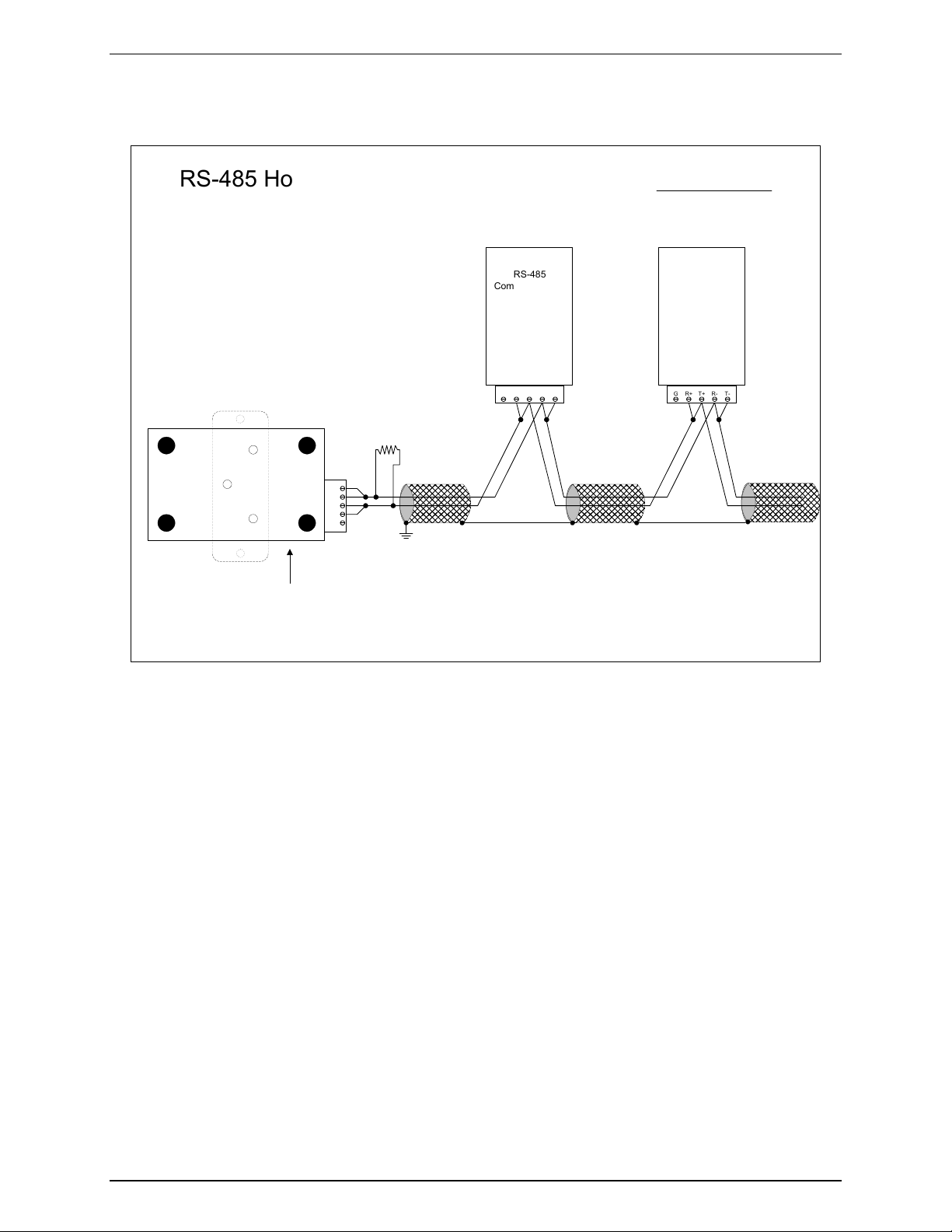

3.2 RS-485

NOTE: T

HIS SECTION APPLIES ONLY IF A COMMUNICATION OPTION WAS ORDERED

Each EPM3000P has an unique address up to four digits long. This allows the user to communicate with

up to 10,000 instruments. Standard baud rates are available up to 4800 baud. To select the proper baud

rate, apply the following rules:

The unit operates up to 4800. For a smaller number of instruments over a long distance,

use a lower baud. Optimal recommended baud rate is 1200 baud if noisy conditions

exist.

CONNECTION FOR DB-9 FEMALE

PIN 2 - RECEIVE OF THE HOST/COMPUTER

PIN 3 - TRANSMIT OF THE HOST/COMPUTER

PIN 5 - GROUND OF THE HOST/COMPUTER

54321

DETAIL OF DB-9

7

98 6

LAPTOP

3)

SHOULD BE CONNECTED

.

GE Industrial Systems

10

Page 16

Chapter 3 Communication Installation

RS-485 is used to parallel multiple instruments on the same link. Its operating capability is up to 4000

feet.

• When only 2 wires are used (on the RS-485), the link can include up to 30 instruments, (Figure 3.2).

• When using all 4 wires, the link can include up to 60 instruments, (Figure 3.3).

RS-485 Hookup Diagram (2 wire) Half Duplex

3000P Instruments (rear view)

RS-485

Communications Port

Model#SF485DB

R

T

RS-485

R

T

UNICOM 2500

(Bottom View Shown)

RS-232

PC

Figure 3.2 2-Wire RS-485 Communication Connection Installation Half Duplex

NOTE: Communication is supported over Belden 3074F and Belden 9841 cable types.

GE Industrial Systems

11

Page 17

Chapter 3 Communication Installation

RS-485 Hookup Diagram (2 wire) Half Duplex: Detail View

RS-232

RS-485

RS-485

Communications

Port

Model#

SF485DB

GR+T+R-T- GR+T+R-T-

R

T

T-

R-

T+

R+

Gnd

RS-485

Communications

Port

Model#

SF485DB

UNICOM 2500

(Bottom View Shown)

Figure 3.3 2-Wire RS-485 Communication Connection Installation Half Duplex Detailed View

NOTE: Communication is supported over Belden 3074F and Belden 9841 cable types.

GE Industrial Systems

12

Page 18

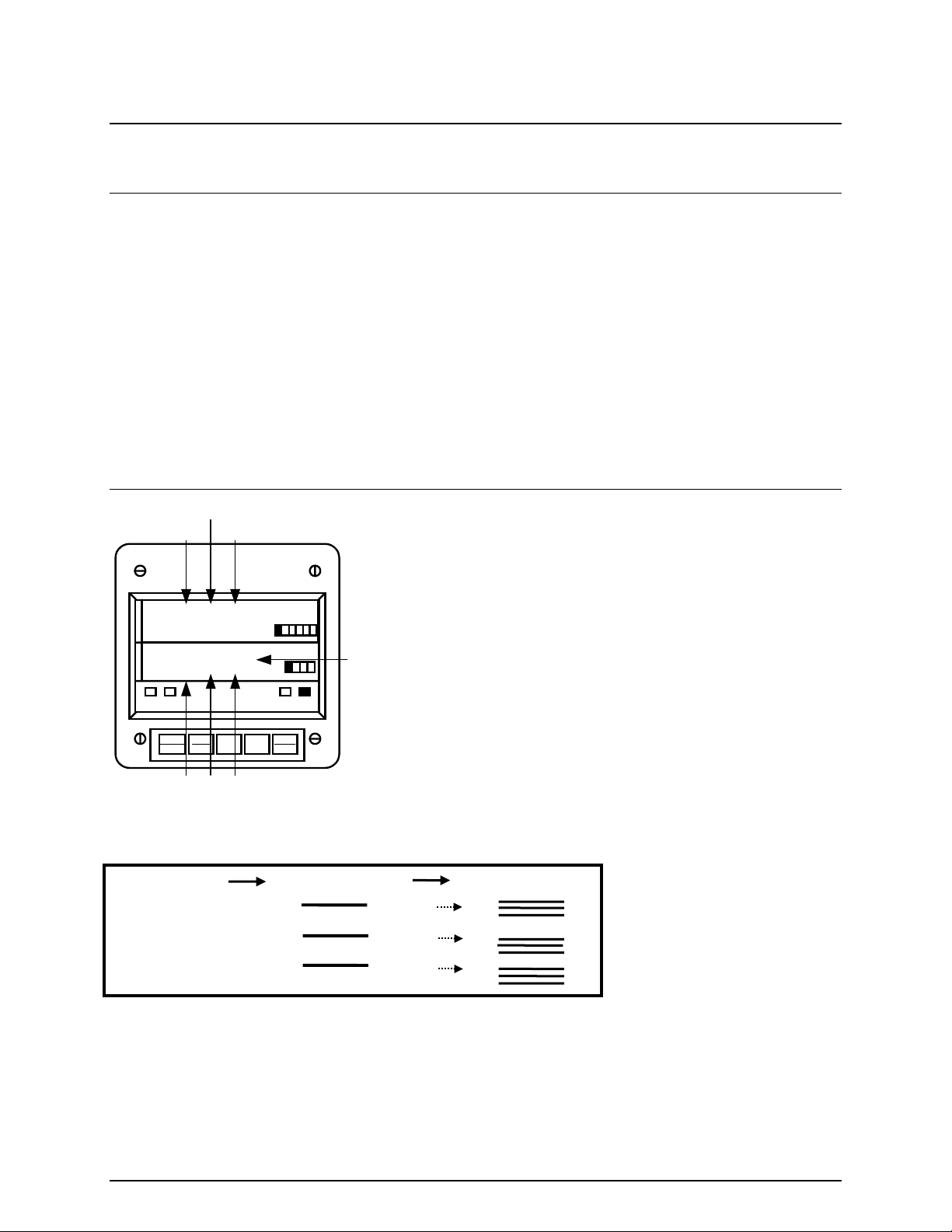

CHAPTER 4

EPM3000P O

VERVIEW

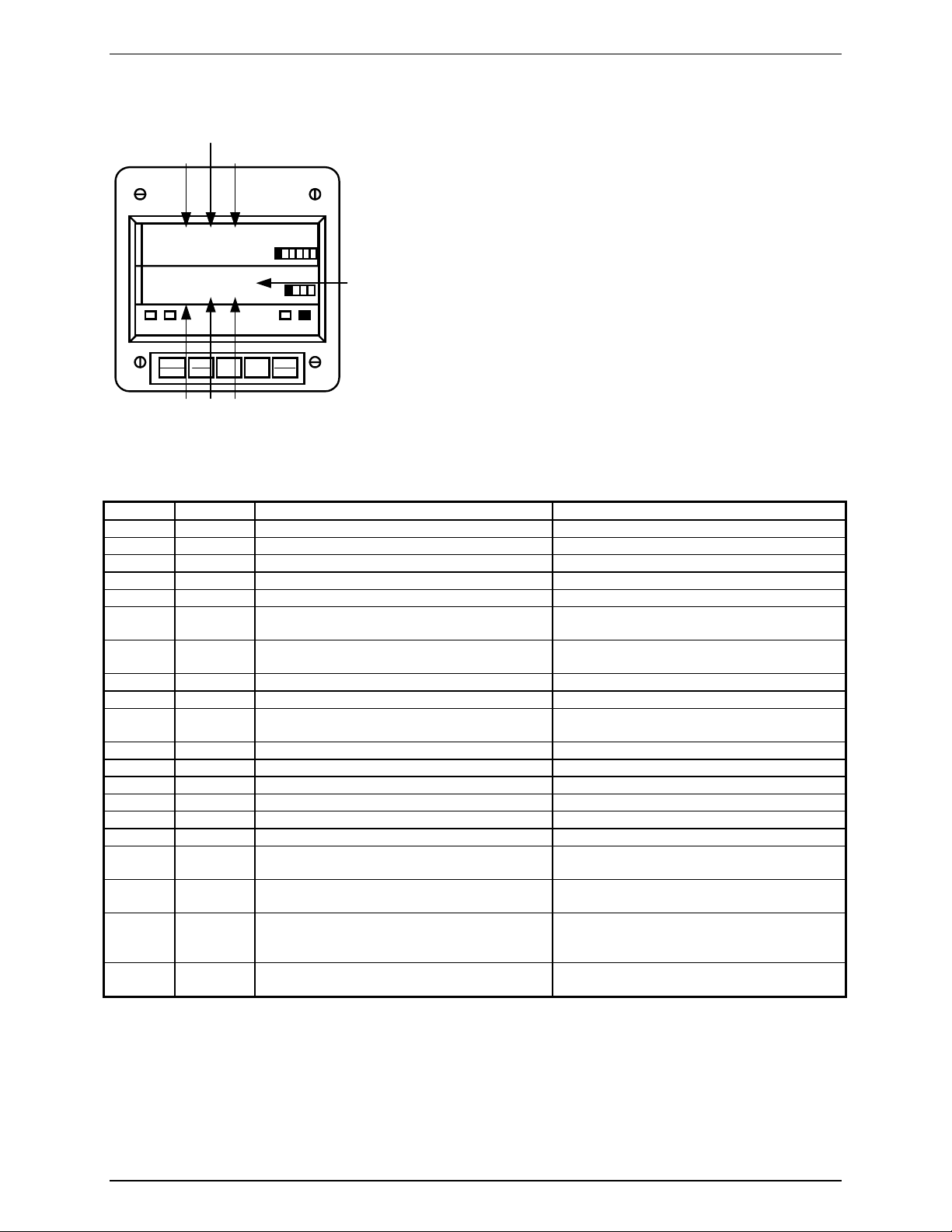

The EPM3000P and EPM3000P-F measure 10 electrical parameters. Values for each parameter are accessed

through the keypad on the meter's front panel (See

Figure 4.1

). The meters illustrated throughout the manual are

EPM3000P except for Figure 4.1 below. The EPM3000P-F (Frequency Option) displays the Frequency measurement

on the face of the meter. Max, Min and Limits indicators are on the left side of the face.

VOLTS AMPS

A-N A

B-N B

C-N C

A-B N

B-C

C-A

PRESS THE MAX/MIN/LIMITS

BUTTON TO ACCESS

MAXIMUM, MINIMUM, LIMIT 1

OR LIMIT 2 VALUES.

FREQUENCY

MEASUREMENT

AVAILABLE WHEN

ORDERED WITH

OPTION -F.

MAX

MIN

I20

LM1

LM2

I000

60.0

MAX/MIN

PRINT

LIMITS

PROG

VOLTS

AMPS

AC VOLTS

A B C

A B C

I I I

B C A

N N N

AC AMPS

A B C N

FREQUENCY

PHASE

NEXT

I I I

A GLOWING

ANNUNCIATOR INDICATES

THE VALUE CURRENTLY

DISPLAYED

WHEN THE DESIRED

FUNCTION IS CHOSEN, THE

PHASE/NEXT BUTTON

SELECTS THE VOLT AND

AMP PHASES.

THE VOLTAGE AND AMPERAGE

FUNCTIONS ARE ACCESSED BY PRESSING

THE APPROPRIATE BUTTON.

Figure 4.1 : EPM3000P –F (FREQUENCY OPTION)

4.1 A

CCESSING MAX/MIN VALUES FROM OPERATING MODE

The max/min values represent the highest and lowest average demand over a user programmable time period, know

as the

INTEGRATION INTERVAL

. The readings are calculated using a rolling average technique. Each second, a

new reading is used to calculate the max/min and the last reading of the interval is dropped.

ÖTo

ACCESS MAX/MIN VALUES

, follow these steps:

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

A B C N

AMPS

LM1MIN

PHASE

NEXT

LM2

MAX

Step 1:

MAX/MIN

LIMITS

PRINT

VOLTS

PROG

a. Press VOLTS to select the VOLTS

category.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

MAX

MAX/MIN

LIMITS

i20

i000

PRINT

PROG

Step 2:

a. Press PHASE/ NEXT until the

desired phase is selected.

GE Industrial Systems

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

MAX

MAX/MIN

i24

i000

PRINT

LIMITS

PROG

Step 3:

a. Press MAX/MIN/ LIMITS:

ÖONCE for max of VOLT A-N

ÖTWICE for min of VOLTS A-N

13

Page 19

Chapter 4 EPM3000P Overview

4.2 R

ESETTING VALUES FROM OPERATING MODE

Use the reset function if a new value is desired. It is available in two different modes:

1. UNPROTECTED MODE: allows quick and easy resetting of max/min values.

2. PROTECTED MODE: prevents unauthorized personnel from resetting the max/min.

UNPROTECTED RESET

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

i020

MAX

MAX/MIN

LIMITS

i24

PRINT

PROG

i000

MAX

MAX/MIN

LIMITS

i20

PRINT

PROG

Step 1:

a.

desired phase.

Press PHASE/NEXT to select the

Step 2:

Press MAX/MIN/LIMITS:

a.

ÖONCE for max

ÖTWICE for min

PROTECTED RESET

IF THE METER WAS PROGRAMMED TO HAVE A PROTECTED RESET

NOTE:

READINGS MAY BE RESET

. T

HE PASSWORD IS

005.

VOLTS

AMPS

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

MAX

MAX/MIN

LIMITS

_

_

_

_

PRINT

AMPS

VOLTS

PROG

Step 3:

a.

ÖThe display blanks and a

Press PHASE/NEXT to reset.

checkmark appears, confirming

successful reset.

,

A PASSWORD MUST BE ENTERED BEFORE ANY

AC VOLTS

A B C

A B C

I I I

I I I

_

B C A

N N N

AC AMPS

A B C N

LM2

LM1MIN

PHASE

NEXT

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

N N N

AC AMPS

A B C N

LM2

LM1MIN

PHASE

AMPS

NEXT

i000

MAX

MAX/MIN

LIMITS

i20

PRINT

PROG

Step 1:

a.

Press PHASE/NEXT to select the desired phase.

Press MAX/MIN/LIMITS:

b.

ÖONCE for max

ÖTWICE for min

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

N N N

AC AMPS

A B C N

LM2

LM1MIN

PHASE

AMPS

NEXT

0

___

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 2:

a.

Press PHASE/NEXT to commence the Protected

reset.

ÖThe display blanks, three dashes appear in lower

display and digits begin scrolling in upper display.

ÖThe password required is 005.

GE Industrial Systems

14

Page 20

Chapter 4 EPM3000P Overview

_

VOLTS

AC VOLTS

A B C

A B C

I I I

I I I

_

B C A

N N N

_

AC AMPS

A B C N

LM2

LM1MIN

PHASE

AMPS

NEXT

MAX

MAX/MIN

005

PRINT

LIMITS

PROG

VOLTS

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

_

_

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 3:

a.

password number appears.

Press PHASE/NEXT each time the appropriate

Step 4:

ÖUpon entering the correct password, the display blanks

and a checkmark appears, confirming successful reset.

4.3 A

CCESSING THE

The DMVA100 is designed with two manual set limits. The set limits monitor the instantaneous readings, warning the

user of abnormal conditions. Each limit can detect readings above or below the set level.

the relay changes position, if the DMVA100 is equipped with the Relay Option (Suffix -NL).

If a limit is exceeded, the annunciator LM1 and/or LM2 indicator glow and the display flashes, alternating between the

instantaneous reading.

ÖTo

VIEW THE SETUP OF THE LM1/LM2 SET LIMITS OF THE FUNCTIONS

I25.0

MAX

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

A B C

I I I

B C A

LM2

LM1/LM2 S

ET LIMITS FROM OPERATING MODE

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

l i

MAX

LM1MIN

A B C N

LM2

SET LIMITS:

, follow these steps:

l i

MAX

the point when

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

A B C N

LM2

LM1MIN

MAX/MIN

PRINT

LIMITS

PROG

Step 1:

a.

To access the set limit, press

MAX/MIN/ LIMITS:

ÖTHREE times for LM1

ÖFOUR times for LM2

VOLTS

AMPS

PHASE

NEXT

MAX/MIN

LIMITS

PRINT

PROG

VOLTS

AMPS

PHASE

NEXT

Step 2:

Press PHASE/NEXT when the

a.

LM1 annunciator glows.

ÖThe annunciators that glow are

out-of-limits in LM1.

MAX/MIN

LIMITS

PRINT

PROG

VOLTS

AMPS

PHASE

NEXT

Step 3:

a.

Press PHASE/NEXT when the

LM2 annunciator glows.

ÖThe annunciators that glow are

out-of-limits in LM2.

4.4 V

OLTAGE PHASE REVERSAL AND IMBALANCE FROM OPERATING MODE

In a three phase power distribution system, the normal phase shift between each line is 120°. The EPM3000P

detects an abnormality and displays a PH message every six seconds.

VOLTAGE PHASE REVERSAL:

If there is an incorrect connection, such as mistaking line A for line B, a PH message appears. The correct sequence

is a-b-c.

VOLTAGE PHASE IMBALANCE LIMIT:

Can be detected using the phase imbalance limit in the Programming Mode. The phase imbalance is expressed in a

percentage with 0% indicating a 120° phase shift between each line. A PH message appears if the limit is exceeded.

GE Industrial Systems

15

Page 21

Chapter 4 EPM3000P Overview

VOLTS

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

ph

i000

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

Step 1:

a.

Press AMPS and PHASE/NEXT simultaneously to

MAX/MIN

LIMITS

PRINT

PROG

0

MAX

Step 2:

a.

Press PHASE/NEXT to select zero.

access the display.

PH

NOTE:

AND VOLTAGE PHASE IMBALANCES

INDICATES BOTH VOLTAGE PHASE REVERSALS

.

_

MAX

MAX/MIN

LIMITS

_

_

_

_

_

___

___

PRINT

VOLTS

PROG

_

_

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

ÖUpper display indicates a Voltage Phase Reversal of B

and C.

i00.0

MAX

MAX/MIN

PRINT

LIMITS

PROG

ÖUpper display indicates a Voltage Phase Imbalance.

Limit has been exceeded.

VOLTS

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

In the event Voltage Phase Reversal and Voltage Phase Imbalance occur simultaneously, the display alternates

between the incorrect phase sequence and the exceeded limit percentage. After six seconds the display returns to the

normal operating mode.

ACCESS MODE

Sections

NOTE:

WHEN USING THE MULITMETER CONNECTION

4.6, 4.7

ACCESS OPERATION

1

2

3

4

P

RINT COMMANDS 1 AND 2 ARE ONLY AVAILABLE IF ENABLED IN THE PROGRAMMING MODE AND ARE NOT RECOMMENDED

and

allow the user to access specific operation tasks (see table below).

4.8

Print Operating Data

Print Programming Data

Enter Programming Mode (see Programming Manual)

LED Test

RS485.

4.5 P

NOTE:

C

OMMUNICATION CONVERTER

RINTING OPERATING DATA FROM OPERATING MODE

T

HIS FUNCTION APPLIES ONLY IF A SERIAL PRINTER IS CONNECTED TO THE

.

DMVA 100

VIA AN

RS232C

This function sends the data to a serial printer. This allows hard copy of the instantaneous and max/min data of all the

functions to compile without manually copying the data.

GE Industrial Systems

16

Page 22

Chapter 4 EPM3000P Overview

ÖTo PRINT THE OPERATING DATA, follow these steps:

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

i20

i000

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 1:

a.

Press PRINT/PROG to begin the

special printing sequence.

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 2:

The display blanks and 1 appears.

a.

Press PHASE/NEXT to select.

b.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

i

VOLTS

i i i

MAX

MAX/MIN

PRINT

LIMITS

PROG

VOLTS

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

B C A

I I I

LM2

Ö111 appears confirming a

successful print command.

4.6 P

RINTING PROGRAMMING DATA FROM OPERATING MODE

T

NOTE:

C

OMMUNICATION CONVERTER

HIS FUNCTION APPLIES ONLY IF A SERIAL PRINTER IS CONNECTED TO THE

.

EPM3000P

VIA AN

RS232C

This function sends the programming data (or the meter setup) to a serial printer for verification and quick

reference.

ÖTo PRINT THE PROGRAMMING DATA, follow these steps:

AC VOLTS

A B C

A B C

I I I

I I I

N N N

AMPS

AC AMPS

LM1MIN

PHASE

NEXT

B C A

A B C N

LM2

i20

i000

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

Step 1:

a.

Press PRINT/PROG to enter the

access mode.

AC VOLTS

A B C

A B C

I I I

I I I

N N N

B C A

AC AMPS

MAX/MIN

LIMITS

PRINT

PROG

2

VOLTS

MAX

AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

Step 2:

ÖThe display blanks.

Press PRINT/PROG until 2

a.

appears.

Press PHASE/NEXT to select.

b.

AC VOLTS

A B C

I I I

N N N

AC AMPS

222

MAX

MAX/MIN

PRINT

LIMITS

PROG

VOLTS

AMPS

LM1MIN

PHASE

NEXT

Ö222 appears confirming a

successful print command.

A B C

B C A

A B C N

I I I

LM2

GE Industrial Systems

17

Page 23

Chapter 4 EPM3000P Overview

4.7 LED T

EST FROM OPERATING MODE

The EPM3000P is equipped with an LED test to check if the LEDs and annunciators are functioning

properly.

VOLTS

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

B C A

I I I

LM2

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

i i9. !

300.0

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 1:

a.

Press PRINT/PROG to enter the

Access Mode.

MAX/MIN

LIMITS

PRINT

PROG

4

VOLTS

AMPS

MAX

Step 2:

ÖThe display blanks.

Press PRINT/PROG until 4

a.

appears.

AC VOLTS

A B C

I I I

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

A B C N

LM2

8.8.8.8.

8.8.8.8.

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 3:

a.

test.

ÖAll segments and annunciators

glow.

Press PHASE/NEXT for the LED

4.8 A

CCESSING FIRMWARE VERSION FROM OPERATING MODE

The EPM3000P is equipped with a function to access the firmware version.

Step 1:

a.

AC VOLTS

A B C

A B C

I I I

I I I

N N N

i.0

MAX

AC AMPS

A B C N

LM1MIN

B C A

LM2

b.

ÖUpper display indicates the version number.

Disconnect power to the meter.

Press MAX/MIN/LIMITS upon power up.

MAX/MIN

LIMITS

PRINT

PROG

VOLTS

AMPS

PHASE

NEXT

GE Industrial Systems

18

Page 24

PROGRAMMING YOUR EPM3000P

CHAPTER 5

ENERAL PROCEDURE OVERVIEW

G

5.1 H

OW TO USE THIS PORTION OF THE MANUAL

This manual contains programming for basic operation, available options and parameters. Using the Table of

Contents or “Quick Reference Guide”, find the programming feature location and read that chapter.

Programming tasks are arranged into nine major GROUPS. Within each GROUP are the specific meter

FUNCTIONS. Outlined is the general approach to alter programming mode values.

1. Enter the Programming Mode.

2. Select the desired GROUP.

3. Select a FUNCTION within the GROUP.

4. After the FUNCTION selection, proceed with DATA ENTRY of the new value for the desired parameter.

5. Proceed to program another location and/or exit the programming mode.

IMPORTANT

: T

HE FULL EXITING PROCEDURE MUST BE FOLLOWED TO STORE ANY NEW PROGRAMMING

5.2 S

WITCH PACKS

FUNCTION

PACKGROUP

AC VOLTS

A B C

I I I

N N N

A B C

I I I

B C A

03.P

AC AMPS

_ _

_

MAX

A B C N

LM1MIN

LM2

NEW

ENTRY

.

GROUPS, Functions, and Switch PACKS

• GROUPS are the main category.

• Functions are sub categories of GROUPS.

• Switch PACKS are sub categories of Functions.

:

MAX/MIN

PRINT

LIMITS

VOLTS

PROG

ABC

AMPS

PHASE

NEXT

HE DIAGRAM BELOW ILLUSTRATES THE ARRANGEMENT OF THE THREE CATEGORIES

T

GROUPS

FUNCTIONS

S

WITCH PACKS

NOTE

HESE ARE VERY SIMILAR TO DIP SWITCH CONCEPT

: T

.

GE Industrial Systems

:

19

Page 25

Chapter 5 General Procedure Overview

5.3 P

MAX/MIN

LIMITS

SED FOR PROGRAMMING

U

ROGRAMMING MODE ENTRY

PR IN T

PROG

VOLTS

AMPS

PHASE

NEXT

U

SED FOR

ASSWORD

P

E

NTRY

BUTTON FUNCTION DESCRIPTION

MAX/MIN/LIMITS ADVANCE Scrolls groups, functions, and advances to exit point from function and

group level.

PRINT/PROG CHANGE

VALUE

VOLTS STORE Activates new data entry, stores digits, and enters or exits from group or

Scrolls packs, digit counters, and changes Switch PACK position UP or

DOWN.

function level.

5.4 S

TANDARD NUMERIC DATA ENTRY

Programmable FUNCTION values are always three digit numeric fields designed to accept any value

between 000 and 1999. When entering the value of a function enter all three digits, leading zero's

included. For instance, to enter 25, enter: 025.

When activating the Data Entry Sequence, certain Functions allow for a four digit entry. The display

indicates a blank followed by three dashes (see diagram). The first digit may only be a 1 or a blank (the

blank signifying 0). Press PRINT/PROG ONCE for 0, TWICE for 1.

GE Industrial Systems

20

Page 26

CHAPTER 6

E

NTERING THE PROGRAMMING MODE

6.1 C

HECKSUM ERROR

- P

ROTECTIVE MECHANISM

If the control power is interrupted while in Programming Mode or the user does not fully exit, the meter enters a

checksum mode. The display blanks, except for the max LED. Press PRINT/PROG for several seconds and the unit

recovers. Follow the procedure to enter the Programming Mode to check program data, then exit.

6.2 P

ASSWORD ENTRY

The EPM3000P is password protected. To enter the programming mode, key in the following password. The

password is 555.

NOTE

: T

HE METER WILL NOT STORE ANY PROGRAMMING UNLESS PROPERLY EXITED. (SEE CHAPTER

11

TO EXIT

).

NTERING THE PROGRAMMING MODE

E

:

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

PRINT

PROG

3

VOLTS

AMPS

LM1MIN

PHASE

NEXT

MAX

MAX/MIN

LIMITS

:

Step 1

Press PRINT/PROG until 3

a.

appears in lower display.

Press PHASE/NEXT to select.

b.

333 appears in lower display.

c.

A B C

I I I

B C A

LM2

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

FREQUENCY

PHASE

NEXT

A B C

I I I

B C A

MAX

MIN

LM1

LM2

555

MAX/MIN

PRINT

LIMITS

PROG

VOLTS

:

Step 2

Digits begin scrolling in upper

display.

⌦The password is

555

.

Press PHASE/NEXT each time

a.

appears.

The selected digits appear in

lower display.

0.

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

Display blanks and

upper display, confirming a correctly

entered password.

is replaced by 0. and the

PPP

meter is now in the Programming

5

Mode, GROUP 0.

AMPS

PPP

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

A B C N

LM1MIN

LM2

PHASE

NEXT

flashes in

21

GE Industrial Systems

Page 27

CHAPTER 7

P

ROGRAMMING GROUP

0: G

LOBAL METER SETUP

The Global Meter Setup includes Functions 0 through 5 that control configuration and basic operation. Below is an

outline of GROUP 0 to assist in locating a feature. FUNCTION 3 System Configuration contains Switch PACKS with

various options, including open delta installation and communications.

T

7-1: GROUP 0 P

ABLE

ROGRAMMING FORMAT

FUNCTION NUMBER FUNCTION

0. Integration Interval

1. Meter Address for Communication

2. Baud Rate for Communication

3. System Configuration

4. Relay 1 Set-up/Time Delay

5. Relay 2 Set-up/Time Delay

E. Exit Programming GROUP 0

7.1 G

INTEGRATION INTERVAL:

minimum demand. The Integration Interval is entered in seconds. When entering 15 minutes, enter: 0900 seconds.

Ö

To change the

PRESS MAX/MIN/LIMITS, AT ANY TIME, TO CANCEL BEFORE STORING THE LAST DIGIT OR SWITCH.

NOTE:

0, F

ROUP

UNCTION

The time over which all instantaneous readings are averaged to obtain a maximum and

INTEGRATION INTERVAL

0.

MAX

0 - T

HE INTEGRATION INTERVAL

, follow these steps:

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

A B C N

LM1MIN

LM2

AC VOLTS

A B C

A B C

I I I

I I I

B C A

00.

0 I0

MAX

N N N

AC AMPS

LM1MIN

A B C N

LM2

MAX/MIN

PRINT

LIMITS

PROG

Step 1:

a

. Enter Group Level of Programming Mode,

VOLTS

AMPS

PHASE

NEXT

(see Chapter 6).

Press MAX/MIN/LIMITS until 0. appears in upper

b.

display.

Press VOLTS to activate the GROUP.

c.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

LM2

00

_ _

3

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 2:

a.

Press VOLTS to begin Data Entry Sequence.

Ö

Three dashes appear in lower display.

Press PRINT/PROG for desired number.

b.

Press PRINT/PROG once and the blank signifies zero.

Press PRINT/PROG twice and 1 appears.

Press VOLTS to store.

c.

MAX/MIN

LIMITS

PRINT

PROG

VOLTS

AMPS

PHASE

NEXT

Ö 00. appears in upper display, indicating current Group

and Function number.

Ö

Lower display indicates current Interval setting.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

LM2

MAX

MAX/MIN

LIMITS

00.

300

PRINT

PROG

Ö

Repeat this procedure until new Integration Interval is

entered.

Ö

When complete, lower display indicates new

Integration Interval.

See Chapter 12 to Exit.

22

GE Industrial Systems

Page 28

Chapter 7 Global Meter Setup

7.2 G

METER ADDRESS:

numerous meters are at one site, it is essential that each meter have its own address.

Ö

To change the

NOTE:

PRESS MAX/MIN/LIMITS, AT ANY TIME, TO CANCEL BEFORE STORING THE LAST DIGIT OR SWITCH

0, F

ROUP

Identifies the meter when communicating with a computer system or an RS485 bus. When

METER ADDRESS

UNCTION 1

- T

HE METER ADDRESS

, follow these steps:

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

LM2

0.

MAX

MAX/MIN

PRINT

LIMITS

PROG

:

Step 1

Enter Group Level of Programming Mode,

a.

(see Chapter 10).

Press MAX/MIN/LIMITS until 0. appears in upper

b.

display.

Press VOLTS to activate the GROUP.

c.

Ö 01. appears in upper display.

Ö

Lower display indicates the current Meter Address.

0 I.

00 I

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

AMPS

.

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

B C A

I I I

LM2

VOLTS

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

LM2

0 I

_

02

MAX

MAX/MIN

PRINT

LIMITS

PROG

:

Step 2

Press VOLTS to activate Data Entry Sequence.

a.

Ö

Three dashes appear in lower display.

Press PRINT/PROG for desired number.

b.

• Press PRINT/PROG once and the blank signifies a

0 I.

020

MAX

MAX/MIN

PRINT

LIMITS

PROG

Ö

Repeat this procedure until new Address is entered.

Ö

When complete, lower display indicates new Address.

See Chapter 12 to Exit.

zero.

• Press PRINT/PROG twice and 1 appears.

Press VOLTS to store.

c.

7.3 G

ROUP

UNCTION 2

0, F

BAUD RATE:

Speed at which data is transmitted between device and remote computer. The rate programmed into

the meter must match the rate used by the remote polling device.

Valid Baud Rates are 1200, 2400 and 4800. When entering a baud rate, the last zero is omitted. Therefore, three

digits and a leading zero (or blank) must be entered. Example: To enter a baud rate of 2400, enter 0240.

Ö

To change the

COMMUNICATION BAUD RATE

NOTE:

PRESS MAX/MIN/LIMITS, AT ANY TIME, TO CANCEL BEFORE STORING THE LAST DIGIT OR SWITCH.

- C

OMMUNICATION BAUD RATE

, follow these steps:

GE Industrial Services

23

Page 29

Chapter 7 Global Meter Setup

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

02.

LM2

I20

MAX

MAX/MIN

PRINT

LIMITS

PROG

0.

MAX

MAX/MIN

PRINT

LIMITS

PROG

VOLTS

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

Step 1:

Enter Group Level of Programming Mode

a.

(see Chapter 6).

Press MAX/MIN/LIMITS until 0. appears in upper

b.

Ö 02. appears in upper display.

Ö

Lower display indicates current Baud Rate.

display.

Press VOLTS to activate the Group.

c.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

02.

LM2

MAX

MAX/MIN

LIMITS

240

PRINT

PROG

02

_

24

MAX

MAX/MIN

PRINT

LIMITS

PROG

VOLTS

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

:

Step 2

Press VOLTS to begin Data Entry Sequence.

a.

Three dashes appear in lower display.

b.

Press VOLTS to select.

c.

Ö

Repeat this procedure until new Communication Baud

Rate is entered.

Ö

When complete, lower display indicates new Baud

Rate.

See Chapter 12 to Exit.

7.4 G

The System Configuration Function is used to set basic meter operational parameters. (This Function

utilizes Switch PACKS).

FUNCTION 3 contains six Switch PACKS, 0 - 5. Each PACK contains three individual UP/DOWN (toggle)

switches.

• Toggling the segment UP and DOWN, toggles the switch ON and OFF respectively, or chooses

between two options.

• The meter displays one Switch PACK at a time.

ROUP

0, F

UNCTION 3

- S

YSTEM CONFIGURATION

24

GE Industrial Services

Page 30

Chapter 7 Global Meter Setup

ÖPress PRINT/PROG to scroll from PACK to PACK.

FUNCTION

PACKGROUP

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

03.P

AC AMPS

AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

MAX

MAX/MIN

LIMITS

_ _

_

PRINT

VOLTS

PROG

ABC

T

ABLE

7-2: S

WITCH FEATURES

PACK SWITCH FEATURE SEGMENT POSITION

0 A Reserved -

B Reserved C Reserved -

1 A Reserved -

B Blank non-significant leading zero(s) UP Ö Enable

C Reset Protection

(See User’s Installation & Operation Section)

2 A Reserved -

B Open Delta Installation UP Ö Enable

C Reserved -

3 A Reserved -

B Reserved C Reserved -

4 A Relay Control I UP Ö Alarm Only

B Relay Control II UP Ö Alarm Only

C

5 A

NOTE:

T

O PRINT

: PACK 4, S

WITCH C MUST BE IN THE

NEW

ENTRY

DOWN Ö Disable

UP Ö Enable

DOWN Ö Disable

DOWN Ö Disable

DOWN Ö Computer Control & Alarm

DOWN Ö Computer Control & Alarm

UP Ö Comm.

-

DOWN Ö Disable Comm. and Print

UP Ö Print

-

UP

POSITION

.

DOWN Ö Disable Print

GE Industrial Services

25

Page 31

Chapter 7 Global Meter Setup

7.5 G

ROUP

0, F

UNCTION

3 - P

ROGRAMMING PROCEDURE

ÖTo change the SYSTEM CONFIGURATION SWITCH settings, follow these steps:

NOTE: PRESS

Step 1:

a. Enter Group Level of Programming Mode,

(see Chapter 6).

b. Press MAX/MIN/ LIMITS until 0. appears in

upper display.

MAX/MIN/LIMITS

0.

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

, AT ANY TIME, BEFORE STORING THE LAST DIGIT OR SWITCH.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

03.0 appears in upper display.

Ö

MAX

MAX/MIN

LIMITS

03.0

_

PRINT

PROG

Ö Lower display indicates current PACK 0 Switch

Settings.

c. Press VOLTS to activate the Group.

_

VOLTS

_

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

_

VOLTS

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

A B C N

_

LM2

LM1MIN

PHASE

AMPS

NEXT

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

Step 2:

MAX

MAX/MIN

LIMITS

03 I

_

_ _

PRINT

PROG

a. Press PRINT/PROG until desired PACK appears.

b. Press VOLTS to begin Data Entry Sequence.

ÖThree dashes appear in lower display.

03. I

_

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 3:

a. Press PRINT/PROG to toggle the segments UP or

DOWN for desired setting.

b. Press VOLTS to store

See Chapter 12 to Exit.

7.6 G

ROUP

0, F

UNCTIONS

4-5 - T

IME DELAY FOR RELAYS

1 & 2 (O

PTION

NL)

The EPM3000P can be equipped with a relay option. Two relays are included in this option. The relays can be used in

computer controlled or dedicated alarm options.

COMPUTER

CONTROLLED

DEDICATED ALARM

The relays can be locked or unlocked through a computer

option).

The relays can be locked or unlocked using the meter's keypad or its measured inputs.

(must have communication

The computer cannot change the state of the relay.

Under GROUP 0, FUNCTIONS 4-5, time delay for the Relays 1 or 2 can be set between 0 - 255 seconds. This allows

conditions to exist for a specified time period before the relay or alarm activates. If a time greater than 255 seconds is

entered, the meter defaults to the maximum value of 255 seconds.

GE Industrial Systems

26

Page 32

Chapter 7 Global Meter Setup

EXAMPLE 1:

Relay 1 will be “SET” once the reading exceeds 5.00 amps. Relay 1 will be “RESET” once the reading

falls below 5.00 amps.

SET

5.00 A

L 1

RESET

0 A

1. Enter in GROUP 0, FUNCTION 4, Segment C and D: UP, DOWN

2. Enter in GROUP 4, FUNCTION 2, LIMIT 1, Segments B, C, and D: UP, UP, DOWN

EXAMPLE 2: NORMALLY RESET - NON-EVENT CONDITION WILL RESET RELAY

Relay 1 will be “SET” if the instantaneous reading for amps is below 4.00 amps or above 5.00 amps.

Under all other conditions the relay will be “RESET”.

NOTE: U

NO POW ER TO THE UNIT

NDER THIS SETUP THE RELAY WILL

RESET

NOT

ACT AS A PROTECTIVE SWITCH

.

SET

LM1

5.00 A

RESET

4.00 A

0.00 A

SET

NO POW ER TO THE UNIT

LM2

RESET

P

ROGRAMMING STEPS

1. Enter in GROUP 0, FUNCTION 4, Segments C and D: UP, UP

2. Enter in GROUP 4, FUNCTION 2, LIMIT 1, Segments: B, C, and D: UP, UP, DOWN. Value: 5.00

3. Enter in GROUP 4, FUNCTION 2, LIMIT 2, Segments: DOWN, UP, DOWN. Value: 4.00

:

27

GE Industrial Systems

Page 33

Chapter 7 Global Meter Setup

ÖTo change the TIME DELAY FOR RELAY 1 OR RELAY 2, follow these steps:

MAX/MIN/LIMITS

PRESS

, AT ANY TIME, TO CANCEL BEFORE STORING THE LAST DIGIT OR SWITCH.

AC VOLTS

A B C

A B C

I I I

I I I

N N N

AMPS

AC AMPS

LM1MIN

PHASE

NEXT

B C A

A B C N

LM2

0.

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

Step 1:

a. Enter Group Level of Programming Mode

(see Chapter 6).

b. Press MAX/MIN/LIMITS until 0. appears.

c. Press VOLTS to activate the Group.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

_

N N N

AC AMPS

A B C N

LM1MIN

LM2

04

MAX

I2

AC VOLTS

A B C

A B C

I I I

I I I

B C A

VOLTS

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

04.

060

MAX

MAX/MIN

PRINT

LIMITS

PROG

Step 2:

To program Relay 1:

a. Press MAX/MIN/LIMITS until 04. appears in upper

display.

To program Relay 2:

a. Press MAX/MIN/LIMITS until 05. appears in upper

display.

ÖLower display indicates current Time Delays.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

04.

MAX

I25

N N N

AC AMPS

A B C N

LM1MIN

LM2

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

Step 3:

a. Press VOLTS and two dashes appear in lower

display.

b. Press MAX/MIN/LIMITS and three dashes appear in

lower display.

AMPS

PHASE

NEXT

ÖRepeat this procedure until desired value is entered.

ÖLower display indicates the current Time Delay.

See Chapter 12 to Exit.

c. Press PRINT/PROG for desired number.

• Press PRINT/PROG once and the blank signifies a

zero.

• Press PRINT/PROG twice and 1 appears.

d. Press VOLTS to store.

GE Industrial Systems

MAX/MIN

LIMITS

PRINT

PROG

VOLTS

AMPS

PHASE

NEXT

28

Page 34

CHAPTER 8

P

ROGRAMMING

GROUP 1

8.1 S

CALE SELECTIONS AND FULL SCALE SETTINGS

Programming GROUP 1 functions provide a selection of Full Scale Settings to accommodate the different CT’s and

PT’s. The decimal point may be positioned for maximum resolution. The user can perform Scale Selection in each

function. The site technician has a choice of Full Scale selection between volts and kilovolts or amps and kiloamps.

: D

NOTE

ÖTables

T

ABLE

UE TO THE RESOLUTION CAPABILITY, READINGS OVER

8-0

8-0

and

contain Full Scale settings for typical voltages and currents (PT and CT arrangements):

8-1

INPUT VOLTAGE PT RATIO FULL SCALE

120/208V 1:1 (D

) 120V

IRECT

120/208V 4:1 480V

120/208V 12:1 1.44KV

277/480V (S

G) 1:1 (D

UFFIX

) 300V

IRECT

2000

COUNTS RESULT IN A LESS STABLE MEASUREMENT

.

T

8-1

ABLE

INPUT CURRENT CT TYPE FULL SCALE

0 - 5A N

5.00A

ONE

0 - 1000A 1000/5 1000A

0 - 5000 A 5000/5 5.00KA

T

8.2 G

P

ÖTo change the

NOTE: PRESS

ABLE

8-2: G

ROUP

1 P

ROGRAMMING FORMAT

FUNCTION NUMBER FUNCTION

0. Full Scale Selection for Volts

1. Full Scale Selection for Amps

E. Exit Programming GROUP 1

1, F

ROUP

LACEMENT

VOLT OR AMP FULL SCALE

MAX/MIN/LIMITS

UNCTIONS

0-1: F

ULL SCALE SETTINGS

settings (Function 0 and 1, respectively), follow these steps:

, AT ANY TIME, TO CANCEL BEFORE STORING THE LAST DIGIT OR SWITCH.

, V

OLT

& A

MP CHANNELS

, V

OLT

& A

MP DECIMAL

AC VOLTS

A B C

A B C

I I I

I I I

N N N

AMPS

AC AMPS

LM1MIN

PHASE

NEXT

B C A

A B C N

LM2

I.

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

Step 1:

a.

Enter Group Level of Programming Mode,

(see Chapter 6).

Press MAX/MIN/LIMITS until 1. appears in upper

b.

display.

Press VOLTS to activate the Group.

c.

Step 2:

Ö 10. appears in upper display.

Ö

Lower display indicates Full Scale setting.

Ö

A segment appears in upper display.

Ö

UP signifies - Kilovolts.

Ö

DOWN signifies - Volts.

Press VOLTS to begin Data Entry Sequence.

a.

GE Industrial Systems

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

_

I0.

MAX/MIN

LIMITS

I20

PRINT

PROG

VOLTS

MAX

AMPS

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

29

Page 35

Chapter 8 Programming GROUP 1

AC VOLTS

A B C

A B C

I I I

I I I

B C A

_

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

LM2

I0

MAX

MAX/MIN

PRINT

PROG

VOLTS

LIMITS

NTERING THE FULL SCALE FACTOR

E

:

Step 3

ÖA dash appears in lower display.

Press PRINT/PROG to move the segment UP or

a.

DOWN.

Press VOLTS to store.

b.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

I0

AC AMPS

LM1MIN

A B C N

LM2

___

MAX

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

A B C N

.

LM2

LM1MIN

PHASE

NEXT

I0

MAX

MAX/MIN

PRINT

PROG

VOLTS

LIMITS

ECIMAL POINT SELECTION

D

Step 4:

a.

Press PRINT/PROG to begin decimal placement.

Press VOLTS to store

b.

Ö

NOTE

ON THE DISPLAY

THE DECIMAL POINT FOR

:

.

1999.

DOES NOT APPEAR

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

_

AC AMPS

A B C N

LM1MIN

LM2

MAX

I0.

I50

MAX/MIN

PRINT

PROG

VOLTS

LIMITS

Step 5:

Ö

Three dashes appear in lower display.

AMPS

PHASE

NEXT

Press PRINT/PROG for desired number.

a.

• Press PRINT/PROG once and the blank

signifies a zero.

• Press PRINT/PROG twice and 1 appears.

Press VOLTS to store.

b.

GE Industrial Systems

Ö

Repeat this procedure until desired value is entered

Ö

When complete, lower display indicates new Full Scale

setting.

See Chapter 12 to Exit.

MAX/MIN

LIMITS

PRINT

PROG

VOLTS

AMPS

PHASE

NEXT

30

Page 36

CHAPTER 9

PROGRAMMING GROUP 2: METER CALIBRATION

9.1 S

TANDARD CALIBRATION

WARNING - R

⌦ Calibration does not need to be accomplished to change CT or PT ratios. (See GROUP 1).

⌦ Meter calibration cannot be performed if the meter is installed for service. The sensing must be

connected to a power supply with variable voltage and separate current outputs.

⌦ The calibration procedure requires highly accurate and stable input signals. Incorrect

readings result from improper calibration procedures. If unsure, return unit to the factory for

calibration.

⌦ BEFORE calibrating any channel, make note of its Full Scale Setting (see Ch. 8). Set the Full

Scale in accordance with Table 9-1 for calibration. Restore original Full Scale Setting when

calibration is completed.

⌦ The first function in GROUP 2 (STD.CORR) is NOT to be changed by the user. Please make

note of the value here () before using any other function in this Group. If the STD.CORR

value is inadvertently lost or changed, contact the factory for assistance.

All sensitive electronic measuring devices drift slightly over time, requiring periodic calibration. We recommend

returning the meter to the factory on a yearly basis.

T

The Full Scale and Calibration values should be equal during the calibration procedure. The meter may be rescaled

without calibrating by changing the full scale in GROUP 1, FUNCTION 0 or 1. (See Table

T

9-0: G

ABLE

FUNCTION NUMBER FUNCTION

P. Standard Correction. Factory Procedure only.

0. High End Calibration, VOLTS AN

1. High End Calibration, VOLTS BN

2. High End Calibration, VOLTS CN

3. High End Calibration, AMPS A

4. High End Calibration, AMPS B

5. High End Calibration, AMPS C

6. Low End Calibration, AMPS A

7. Low End Calibration, AMPS B

8. Low End Calibration, AMPS C

E. Exit Programming GROUP 2

9-1: S

ABLE

CALIBRATION TYPE/

RANGES

VOLTS 120/208V 120V 120V 120

VOLTS 277/480V 300V 300V 300

VOLTS 4/1 PT 120V 480V 480

VOLTS 60/1 PT 120V 7.20KV 7.20

AMPS Hi End 1000/5 CT 5A 1000A 1000

AMPS Hi End 5000/5 CT 5A 5.00KA 5.00

AMPS Lo End 1000/5 CT 2.5A 500

AMPS Lo End 5000/5 CT 2.5A 2.50

ROUP

OURCE

2 P

ROGRAMMING FORMAT

, F

ULL SCALE AND VALUE SETTINGS FOR CALIBRATION

EAD THIS SECTION CAREFULLY BEFORE PROCEEDING

9-1

CALIB. SOURCE

NECESSARY

FULL SCALE SETTING CALIBRATION VALUE

)

GE Industrial Systems

31

Page 37

Chapter 9 Programming GROUP 2: Meter Calibration

9.2 G

C

ROUP

2, F

UNCTIONS

0-8: H

IGH END CALIBRATION OF VOLTAGE CHANNELS

ALIBRATION OF AMPERAGE CHANNELS

, H

To change the

CALIBRATION

, follow these steps:

PRESS MAX/MIN/LIMITS, AT ANY TIME, TO CANCEL BEFORE STORING THE LAST DIGIT OR SWITCH.

NOTE:

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

2 I.

MAX/MIN

LIMITS

I20

PRINT

PROG

VOLTS

MAX

2.

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

AMPS

AC VOLTS

PHASE

:

Step 1

Enter Group Level of Programming Mode,

a.

(see Chapter 6).

Press MAX/MIN/LIMITS until 2. appears in upper

b.

display.

Press VOLTS activate the Group.

c.

A one-digit password is required to continue.

:

Step 2

Refer to Table

for Function Number that

9-0

corresponds to channel requiring calibration.

Press MAX/MIN/LIMITS (to calibrate VOLTS BN) until

a.

21. appears in upper display.

(2P is pre-calibrated. This is a factory set value and

should not be altered).

Press PRINT/PROG until 5 appears.

d.

Press VOLTS to select.

e.

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

NEXT

IGH

A B C

I I I

B C A

LM2

& L

OW END

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

2 I

_ _

MAX/MIN

LIMITS

PRINT

PROG

I

VOLTS

MAX

:

Step 3

Apply the calibration to the appropriate channel.

Press VOLTS to activate calibration.

a.

Press PRINT/PROG for desired number.

b.

Press PRINT/PROG once and the blank signifies a zero.

Press PRINT/PROG twice and 1 appears.

Press VOLTS to store.

c.

When complete, lower display indicates the calibrated

reading after

10-15 seconds

.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

2 I.

MAX/MIN

LIMITS

I20

PRINT

PROG

VOLTS

MAX

:

Step 4

Press MAX/MIN/LIMITS to exit calibration sequence.

a.

Proceed to calibrate another function, or exit.

See Chapter 12 to Exit.

0

EPEAT THIS PROCEDURE FOR

R

FUNCTIONS

5

-

.

GE Industrial Systems

32

Page 38

Chapter 9 Programming GROUP 2: Meter Calibration

F

FUNCTIONS 6 THROUGH 8,

OR

FOLLOW THESE STEPS

:

PRESS MAX/MIN/LIMITS, AT ANY TIME, TO CANCEL BEFORE STORING THE LAST DIGIT OR SWITCH.

NOTE:

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

26.

250

MAX

MAX/MIN

PRINT

PROG

VOLTS

LIMITS

2.

MAX

MAX/MIN

PRINT

PROG

VOLTS

LIMITS

AMPS

AC VOLTS

PHASE

:

Step 1

Enter Group Level of Programming Mode,

a.

(see Chapter 6).

Press MAX/MIN/LIMITS until 2. appears in

b.

upper display.

Press VOLTS to activate the Group.

c.

A single dash appears indicating a one-digit

password is required to continue.

Press PRINT/PROG until 5 appears.

d.

Step 2:

Press MAX/MIN/LIMITS until 26. appears in upper

a.

display.

Press VOLTS to activate.

b.

Lower display blanks.

After

10 seconds

, three dashes appear in lower

display.

Press VOLTS to select.

e.

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

NEXT

A B C

I I I

B C A

LM2

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

LM1MIN

PHASE

NEXT

A B C N

LM2

26

_ _

MAX/MIN

LIMITS

PRINT

PROG

I

VOLTS

MAX

Step 3:

a.

Press PRINT/PROG for desired number.

Press VOLTS to store.

b.

When complete, lower display indicates the

calibrated reading after

10-15 seconds

.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

LM2

26.

MAX

MAX/MIN

PRINT

PROG

VOLTS

LIMITS

Step 4:

a.

Press MAX/MIN/LIMITS at exit calibration sequence.

Proceed to calibrate another function, or exit.

See Chapter 12 to Exit.

GE Industrial Systems

33

Page 39

CHAPTER 10

P

ROGRAMMING GROUP

4: S

ET LIMITS

& R

ELAYS

GROUP 4

the limits for the following Groups: VOLTS phase-to-neutral, VOLTS phase-to-phase, AMPS A, B, C, and AMPS

neutral.

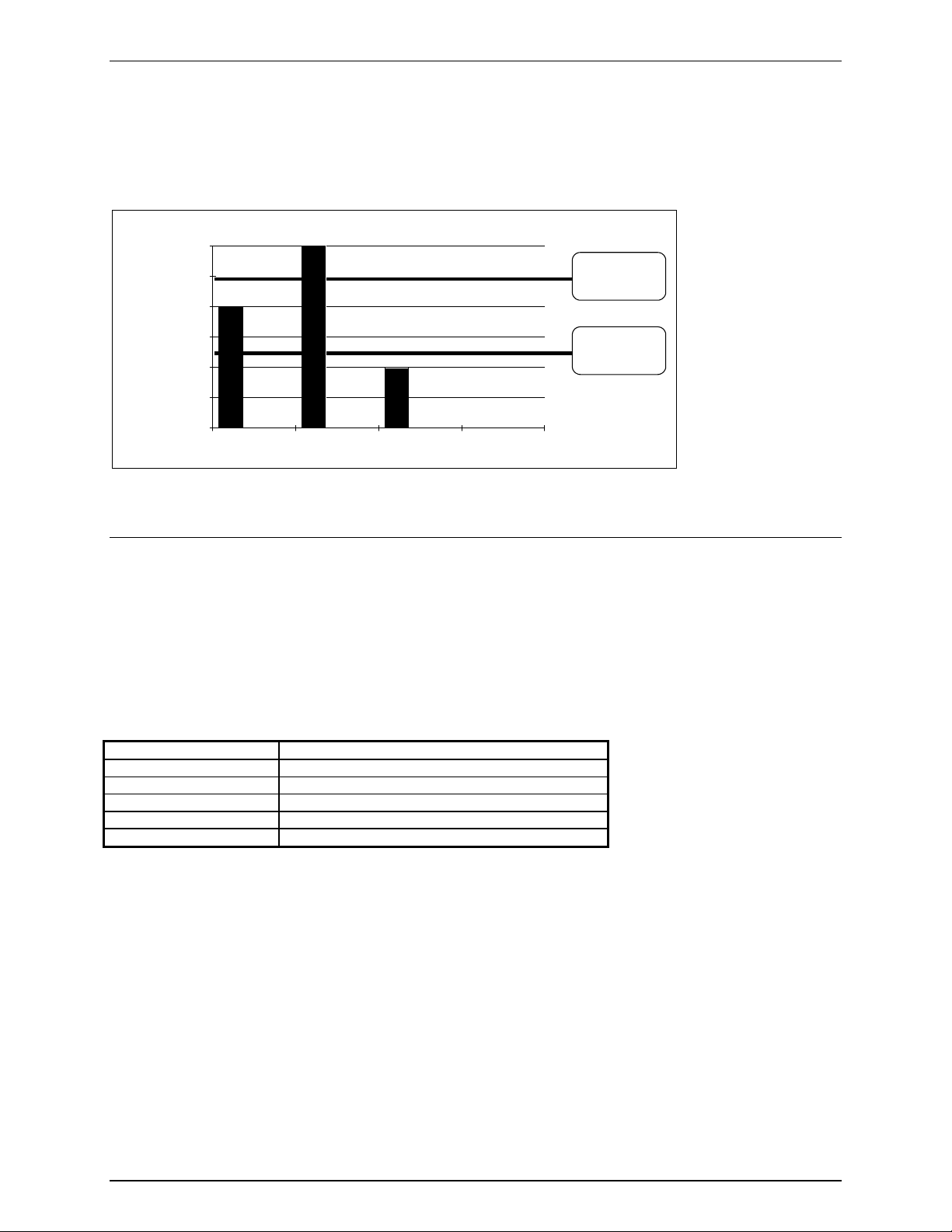

D

IAGRAM

CURRENT

10.1 T

The EPM3000P has two Relays. These relays are linked through the program to Set Limits LM1 and LM2. The user

can program above or below set limits for every reading. When a measurement exceeds a particular value, the set

limit triggers and alerts the user. Each relay is programmed to a separate delay time (see Chapter 8).

NOTE:

SECONDARY PROTECTION

GROUP 4: SET LIMITS FOR VOLTS/AMPS

T

ABLE

FUNCTION NUMBER FUNCTION

NOTE:

Part 1

The second switch sets whether Relay 1 will trip when the condition occurs.

The third switch sets whether Relay 2 will trip when the condition occurs.

Part 2

contains LM1 and LM2 set limit values for the voltage and amperage scale allowing the user to program

10.1: E

(AMPS)

RIP RELAY

E

ACH LIMIT CAN BE PROGRAMMED TO TRIGGER THE TWO INTERNAL FORM C DRY CONTACT RELAYS FOR ALARM OR

10-0: G

I

N TABLE

: The first switch sets the limit to trip either above or below the limit value.

: The second part is the Limit Value.

XAMPLE OF

120

100

80

80

60

50

40

20

0

A B C

.

4 P

ROUP

0. LM1/LM2 Set Limits for Volts AN,BN,CN

1. LM1/LM2 Set Limits for Volts AB,CB,CA

2. LM1/LM2 Set Limits for Amps A,B,C

3. LM1/LM2 Set Limits for Amps Neutral

E. Exit Programming GROUP 4

,

ALL FUNCTIONS HAVE A TWO PART ENTRY

10-0

LM1/LM2 S

120

LM1 is triggered

ROGRAMMING FORMAT

ET LIMITS

40

PHASES

, V

OLTS AND AMPS

LM2 is triggered

LM1 AND LM2 SET LIMITS

.

LM1 SET TO

TRIGGER ABOVE

100 AMPS.

LM2 SET TO

TRIGGER BELOW

50 AMPS.

GE Industrial Systems

34

Page 40

Chapter 10 Set Limits & Relays

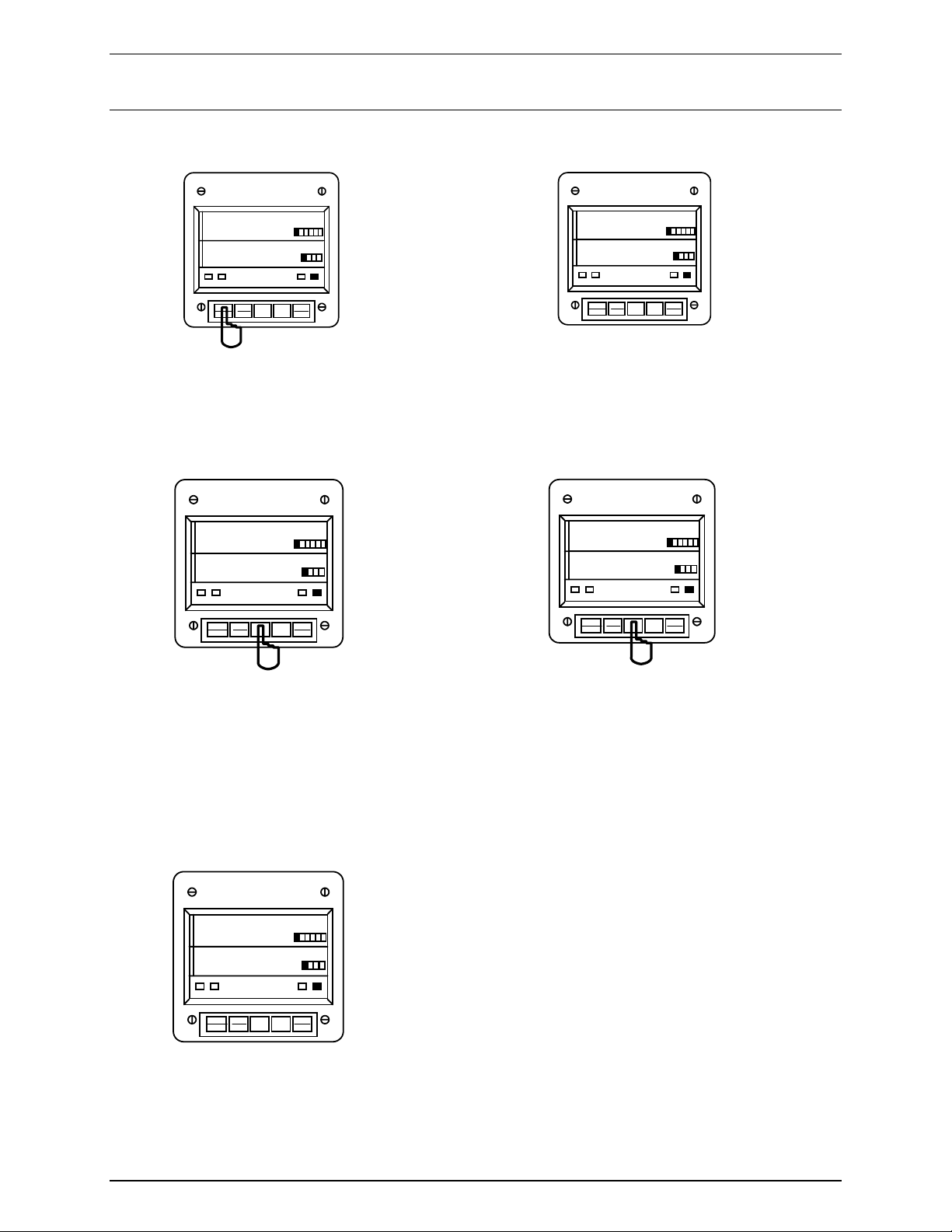

G

ROUP

4, F

UNCTIONS

0 - 3: LM1/LM2 S

ET LIMITS

_

AMPS

AC VOLTS

A B C

I I I

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

A B C

I I I

B C A

LM2

AC VOLTS

A B C

A B C

I I I

I I I

B C A

40

I

LIMITS

25

PRINT

PROG

VOLTS

MAX

MAX/MIN

LIMIT VALUE USE PRINT/PROG BUTTON TO

N N N

AC AMPS

A B C N

LM2

LM1MIN

PHASE

AMPS

NEXT

TOGGLE BETWEEN LM1 AND LM2

FROM LEFT TO RIGHT:

SET LIMIT ABOVE OR

BELOW, TRIP RELAY I

AND TRIP RELAY II

40.

_

MAX/MIN

LIMITS

PRINT

PROG

_

VOLTS

MAX

USE PHASE/NEXT TO TOGGLE

BETWEEN SEGMENT AND LIMIT VALUE

E

XAMPLE

: F

UNCTION

0

LM1 LED LM2 LED ABOVE/BELOW RELAY 1 RELAY 2 VALUE

ON OFF Digit Up Digit Up Digit Down 120

OFF ON Digit Down Digit Down Digit Up 090

T

LM1 LED LM2 LED ABOVE/ BELOW RELAY 1 RELAY 2 LEVEL

NOTE:

TRIGGERED AND RELAY

ABLE

10-1: F

UNCTION

0

ON OFF Digit Up-trigger above level

Digit Down- trigger below level

OFF ON Digit Up-trigger above level

Digit Down-trigger below level

2

IS ENABLED

120V, LM1

.

IS TRIGGERED AND RELAY 1 IS ENABLED

I

F VOLTAGES EXCEED

Digit Up - enabled

Digit Down-disabled

Digit Up- enabled

Digit Down-disabled

. I

F VOLTAGES DO NOT EXCEED

Digit Up- enabled

Digit Down- disabled

Digit Up-enabled

Digit Down-disabled

90V, LM2

0-1999

0-1999

IS

GE Industrial Systems

35

Page 41

Chapter 10 Set Limits and Relays

ÖTo program

LIMITS OR RELAYS

, follow these steps:

MAX

MAX/MIN

MAX/MIN/LIMITS

4.

PRINT

VOLTS

PROG

AMPS

LIMITS

, AT ANY TIME, BEFORE STORING THE LAST DIGIT OR SWITCH.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

N N N

AC AMPS

A B C N

LM2

LM1MIN

PHASE

NEXT

NOTE: PRESS

Step 1:

Enter Group Level of Programming Mode,

a.

(see Chapter 2).

Press MAX/MIN/LIMITS until 4. appears in upper

b.

display.

Press VOLTS to activate the Group.

c.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

_

_

AMPS

N N N

AC AMPS

A B C N

LM1MIN

PHASE

NEXT

LM2

40.

_

MAX

MAX/MIN

PRINT

VOLTS

LIMITS

PROG

Step 2:

Press MAX/MIN/LIMITS to select desired

a.

Function (0-3).

Ö

Lower display provides the currently selected value for

whether to trip above or below on Relay 1 and Relay 2.

LEFT SWITCH

: UP position indicates above tripping

value for lower display’s value. DOWN position indicates

below tripping value for lower display’s value.

MIDDLE SWITCH

: UP position sets Relay 1 to trip.

DOWN position doesn’t activate Relay 1 when limit

condition exists.

RIGHT SWITCH

: Same as Middle Switch, regarding

Relay 2.

Press PRINT/PROG to toggle between LM1 and LM2

b.

setting.

Ö

The LM1 or LM2 annunciator indicates the limit being

displayed.

AC VOLTS

A B C

A B C

I I I

I I I

B C A

40

_

_

MAX

MAX/MIN

PRINT