Page 1

Specification Created 7/01

DCD330EYAC/ WC - GE Commercial Front Loading Electric Dryer

GE Appliances

For answers to your Monogram,® GE Profile™or

GE appliance questions, visit our website at

GEAppliances.com or call

GE Answer Center®service, 800.626.2000.

R

Listed by

Underwriters

Laboratories

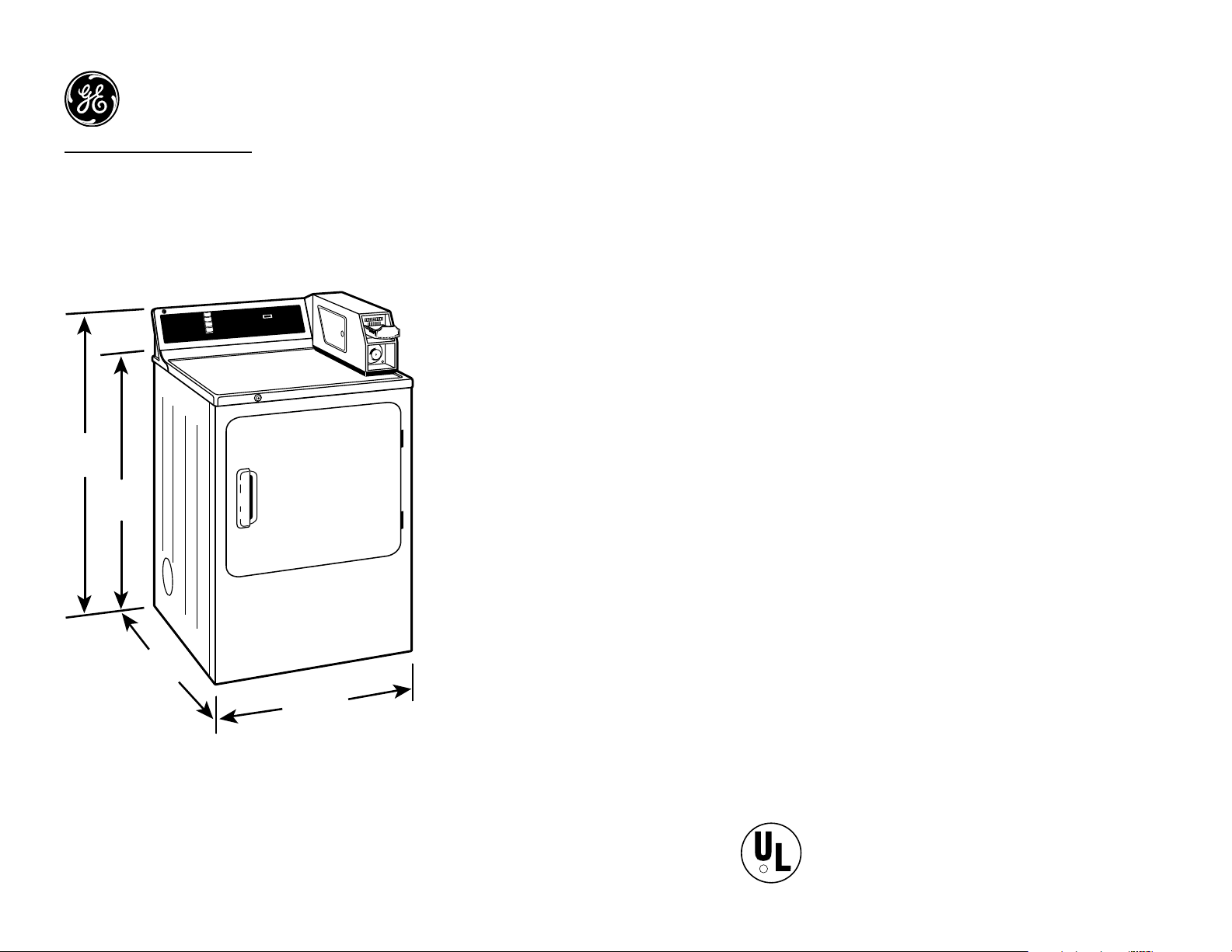

Dryer Dimensions (in inches)

Exhaust Options: Shipped with exhaust to the rear.

Electric model offers 4-way venting: left, right, bottom or rear. Maximum recommended exhaust

duct length is 45 feet of 4" rigid ducting with two 90° elbows and 4" dampered wall cap.

Requirements:

Electric—120/240 Volts, 60 Hertz, 120/208* Volts, 60 Hertz, 5600 Watts at 240 Volts,

4400 Watts at 208 Volts. An individual branch circuit fused for 30-amps is required for each dryer.

*A special 208 Volt heater, part number WE11X0101 is available to reduce drying time in

208 Volt installations.

Dryer Note: Dryer wall outlet must be located within 36” of service cord entry and accessible

when dryer is mounted in position.

Installation Information: For complete installation information see installation

instructions packed with product.

PERMAMENT PRESS

HIGH HEA

T WITH

COOL DOWN CYCLE

LOW HEA

RESUME HEA

1.

2.

Add coins for extra dry time.

If dryer door is opened during

cycle, push PRESS TO ST

ART

button again to resume cycle.

SYNTHETIC KNITS

PRESS TO ST

ART

OPERA

TING

COTTONS

HEA

T W

ASH

42"

36"

25-1/2"

Commerical Dryer

N

W

O

D

L

S

O

S

O

E

C

R

P

T

N

E

M

A

M

R

E

P

T

A

E

H

W

O

L

S

T

I

N

K

C

I

T

E

H

T

N

Y

S

T

A

E

H

E

M

U

S

E

R

T

R

A

T

S

O

T

S

S

E

R

P

.

e

m

i

t

y

r

d

a

r

t

x

e

r

o

f

s

n

i

o

c

d

d

A

.

1

g

n

i

r

u

d

d

e

n

e

p

o

s

i

r

o

o

d

r

e

y

r

d

f

I

.

2

T

R

A

T

S

O

T

S

S

E

R

P

h

s

u

p

,

e

l

c

y

c

.

e

l

c

y

c

e

m

u

s

e

r

o

t

n

i

a

g

a

n

o

t

t

u

b

TING

OPERA

H

S

A

W

T

A

E

H

S

N

O

T

T

O

C

H

T

I

W

T

A

E

H

H

G

I

H

E

L

C

Y

C

27"

Page 2

Specification Created 7/01

DCD330EYAC/ WC - GE Commercial Front Loading Electric Dryer

GE Appliances

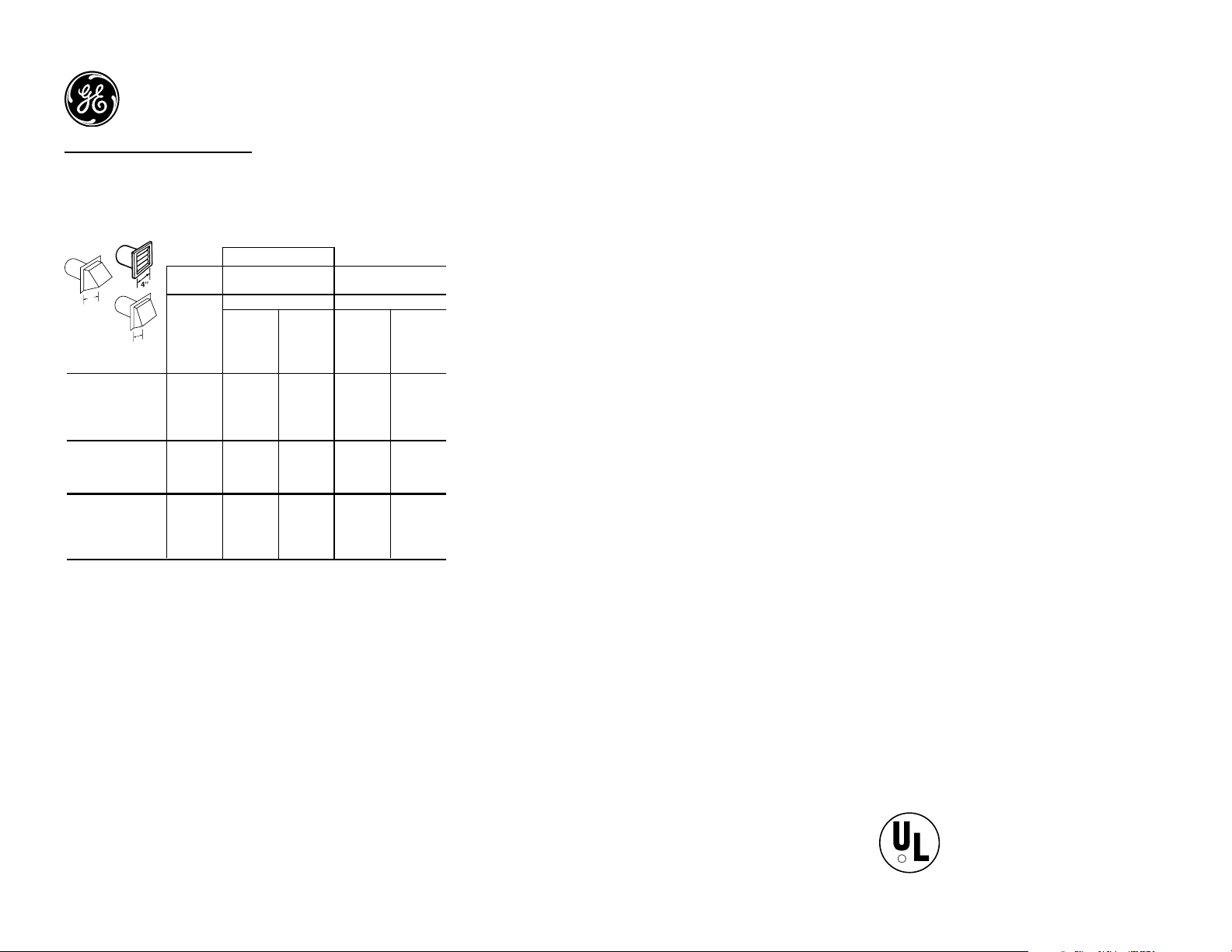

Dryer Exhausting Information—Use Metal Duct Only

For complete information, see installation instructions packed with your dryer.

Important Note:

GE Kit Number WE14X70 needed when converting rear exhaust to bottom or side. (On large capacity models.)

Ducting Materials:

For best performance, this dryer should be vented with 4” diameter all rigid metal exhaust duct. If “all rigid metal”

duct cannot be used, then “flexible all metal” venting can be used, but it will reduce the maximum recommended

duct length.

Exhaust Length Calculation:

1. Determine the number of 90° turns needed for your installation. If you exhaust to the side

or bottom of dryer, add one turn.

2. The maximum length of 4’ rigid (aluminum or galvanized) duct which can be tolerated is shown

in the table. The maximum length for flexible ducts are less than for rigid duct.

A turn of 45° or less may be ignored. Two 45° turns within the duct length should be treated as a 90° elbow. A

turn over 45° should be treated as a 90° elbow.

Exhausting the dryer to the outside is strongly recommended to prevent large amounts of moisture and

lint from being blown into the room. Gas dryers or any dryer located in a closet

must be exhausted to the outside.

Caution: For personal safety do not terminate exhaust into a chimney, under any enclosed

house floor (crawl space), or into an attic, since the accumulated lint could create a fire hazard

or moisture could cause damage. Never terminate the exhaust into a common duct or plenum with a kitchen

exhaust, since the combination of lint and grease could create a fire hazard.

Exhaust ducts should be terminated in a dampered wall cap to prevent back drafts, bird nesting, etc. The wall

cap must also be located at least 12” above the ground or any other obstruction with the opening pointed Down.

Other terminations, such as louvered wall boxes, are acceptable provided they are equivalent to a 4” opening

dampered wall cap.

Special Installation Requirements

Alcove or Closet Installation:

• If your dryer is approved for installation in an alcove or closet, it will be stated on a label on the dryer back.

• The dryer MUST be exhausted to the outside.

• Minimum clearances between dryer cabinet and adjacent walls or other surfaces are:

0” either side

3” front and rear

• Minimum vertical space from floor to overhead cabinets, ceilings, etc. is 52”.

• Closet doors must be louvered or otherwise ventilated and must contain a minimum of 60 sq. in. of open area

equally distributed. If this closet contains both a washer and a dryer, doors must contain a minimum of 120 sq. in.

of open area equally distributed.

• The closet should be vented to the outdoors to prevent gas pocketing in case of a gas leak in the supply line.

• No other fuel-burning appliance shall be installed in the same closet with the dryer.

Bathroom or Bedroom Installation:

• The dryer MUST be exhausted to the outdoors.

• The installation must conform with the local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.

Minimum Clearances other than Alcove or Closet Installation:

•Minimum clearances to combustible surfaces

0” both sides

3” rear

For answers to your Monogram,® GE Profile™or

GE appliance questions, visit our website at

GEAppliances.com or call

GE Answer Center®service, 800.626.2000.

R

Listed by

Underwriters

Laboratories

A

4

B

2-1/2

A

0 90 ft. 60 ft. 55 ft. 45 ft.

1 60 ft. 45 ft. 40 ft. 30 ft.

Super & Extra-Large 2 45 ft. 35 ft. 30 ft. 20 ft.

6.0 Capacity Models 3 35 ft. 25 ft. 20 ft. 15 ft.

All Electric Dryers 4 25 ft. 15 ft. 15 ft. 10 ft.

0 45 ft. 30 ft. 30 ft. 15 ft.

Super & Extra-Large 1 35 ft. 20 ft. 20 ft. 10 ft.

6.0 Capacity Models 2 25 ft. 10 ft. 10 ft. —

All Gas Dryers 3 15 ft. — — —

0 60 ft. 48 ft. 30 ft. 18 ft.

1 52 ft. 40 ft. 22 ft. 14 ft.

Extra-Large 5.7 2 44 ft. 32 ft. 14 ft. 10 ft.

Capacity Electric 3 32 ft. 24 ft. — —

and Gas Dryers 4 28 ft. 16 ft. — —

Number

of

90°

Turns

Maximum Length of 4"

Dia.

Rigid Metal Duct

Maximum Length of 4"

Dia. Flexible Metal Duct

Exhaust Hood Type

Exhaust Hood Type

Domestic

Dryer Models

A

4" OpeningB2-1/2"

Opening

A

4" OpeningB2-1/2"

Opening

Best Performance

Page 3

Specification Created 7/01

GE Appliances

DCD330EYAC/ WC - GE Commercial Front Loading Electric Dryer

Features and Benefits

• Extra-Large 5.7 cu. ft. Capacity

• LED Cycle Countdown

• Automatic Dry Control

• 3 Cycles:

- Cottons; Permanent Press; Synthetic Knits

• 3 Heat Selections

• Up-Front Lint Filter

• Reverse-A-Door

• 100% Front Serviceable

• Porcelain Drum Interior

• Model DCD330EYWC - White

• Model DCD330EYAC - Almond

• Model DCD330GYWC - White

• Model DCD330GYAC - Almond

Loading...

Loading...