GE CV936M3SS, CV936M2SS, CV936M1SS Owner’s Manual

GEPppliances.com

=3

0

Safety Instructions ......... 2, 3

Operating Instructions

Fan Control .................. 4

light Control ................ 4

Care and Cleaning

Grease Filters ................ 5

Hood Lights ................. 6

Stainless Steel Surfhces ......... 5

Installation Instructions ...7-18

Troubleshooting Tips ........ 19

Consumer Support

Consumer Support .......... 24

Owner Registration ....... 21, 22

Warranty ................... 23

CV936

Write the model and serial

numbers here:

Model #

Serial #

You can find them on a label

on the inside of the hood°

LI1275A 49-80521-2 08-09Jfl

iMPORTANTSAFETYiNFORMATiON.

READALLiNSTRUCTiONSBEFOREUSING.

SAFETYPRECAUTIONS

,i_ WARNING- TOREBUCETHERiSK

OFFIRE,ELECTRICSHOCKORiNJURYTOPERSONS,

OBSERVETHEFOLLOWING:

A.

Use this unit only in the manner intended

by the manufacturer. If you have quesuons,

contact tile manufhcturer.

B. Before servicing or cleaning unit, sxdtch

power offal service panel and lock tile service

disconnecting means to prevent power fiom

being switched on accidentalb: _\_len tile

service disconnecting means cannot be locked,

securely fasten a prominent warning dedce,

such as a tag, to tile service panel.

C. Do not use this unit xdth any solid-state speed

control device.

D. This unit nmst be grounded.

X_,CAUTION-Forgeneralventilatinguse

only. Donot use to exhausthazardousor explosive

materials and vapors.

XILCAUTION-rereducerisko_ireand

to properly exhaustair,besure to duct air outside.

Donot vent exhaustair intospaces within walls

or ceilingsorinto attics, crawl spaces or garages.

,_ WARNING- ToREBUCETHERiSK

OFiNJURYTOPERSONSiN THEEVENTOFA RANGE

TOPGREASEFiRE,OBSERVETHEFOLLOWING*:

A. SMOTHER FIAMES _dth a close4itting

lid, cookie sheet or metal tray, then turn off

tile burner. BE CAREFUL TO PRE\%NT

BURNS. If tile flames do not go out

immediatel}; E_ACUATE AND CMI_

THE FIRE DEPARTMENT.

B. NEVER PICK UP A FLAMING PAN--

You rnW be burned.

C. DO NOT USE _\ATER, including wet

dishcloths or mwels--a x4olent steam

explosion will result.

D. Use an extinguisher ONLY if".

1. You know you have a Class Agc

extinguishei; and you already know how

to operate it.

2. Tile fire is small and contained in tile

area where it started.

3. Tile fire department is being called.

4. You can fight tile fire x_dthyour back to

an e_t.

* Based on "Kitchen Fire Safety Tips" published

by NFPA.

2

SAFETYPRECAUTIONS

GEAppliances.com

WARNING- TOREBUCETHERISK

OFA RANGETOPGREASEFIRE:

A. Never leave surface units unattended at high

settings, goilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on

low or medium settings.

B. Always turn hood ON when cooldng on high

heat or when flamb_ing fbod (i.e. Crepes

S_tzette, CherfiesJubilee, Peppercorn Beef

Idamb_).

C_

Clean ventilating fans flequen@ Grease

should not be allowed to accumulate on fan

or filter.

D. Use proper pan size. Always use cookware

appropriate fbr tile size of tile surface element.

WARNING- TOREBUCETHERISK

OFFIRE,ELECTRICSHOCKORINJURYTOPERSONS,

OBSERVETHEFOLLOWING:

A_

Installation work and electrical _dring must be

done by qualified person(s) in accor<tance

_dth all applicable codes and start<lards,

including fire-rated construction.

Sufficient air is needed fbr proper

combustion and exhausting of gases through

tile flue (chimney) of fuel burning equipment

to prevent back drafting. Follow tile heating

equipment mam_hcmrer's gtfidelines and

safety standards such as those published by

tile National Fire Protection Association

(NFPA), tile American Society fbr Heating,

Refrigeration and Air Conditioning Enfneers

(ASHRAE) and tile local code authorities.

C_

V_llen cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

WARNING- TOREBUCETHERISK

OFFIRE,USEONLYMETALDUCTWORK

Do not attempt to repair or replace an},

part of your hood unless it is specifically

recommended in this manual. All other

ser_4cing should be referred to a qualified

technician.

D. Ducted fans must alwaysbe vented to tile

outdoors.

READANDFOLLOWTHISSAFETYINFORMATIONCAREFULLY.

READAND SAVETHESEiNSTRUCTiONS

3

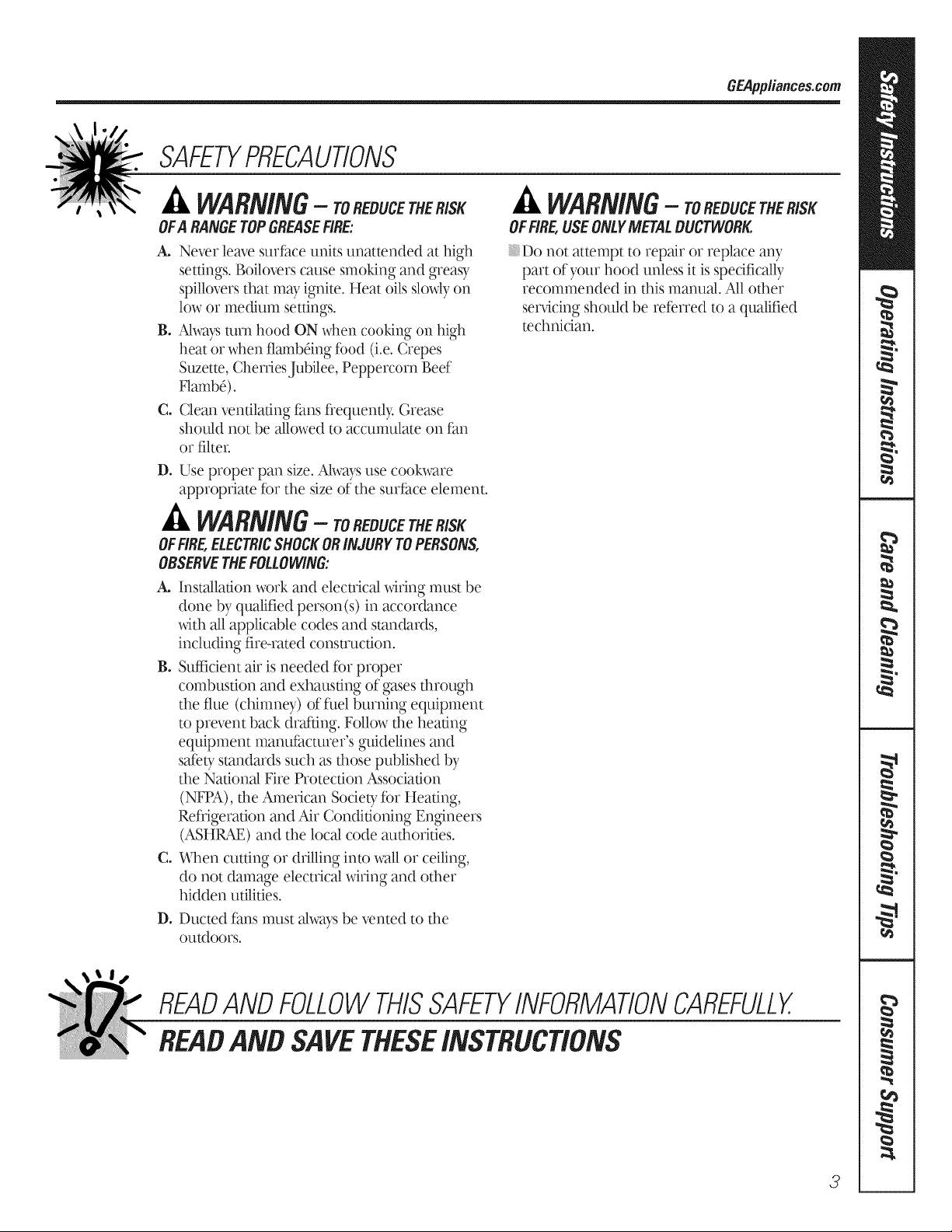

Usingthehoodcontrols.

Throughout this manual, features and appearance may vary from your model.

OFF_ LO LIGHT OFF

NED LO

] NITE

, @'

MED HI

/

HI

,j

0 FAN Control

Turn the FANspeed conQol to tO, MEOtO,

MEB H/ or H/,;_sneeded°

Continuous use of the f_m system while cooking

helps keep the kitchen comKnmble and less

humid. It also reduces cooking odors and soiling

moisture that c_eate a flequent need K)r

cleaning.

NOTE:Whenthe fan is operating on the LOsetting,

it will be very quiet. Always make sure that the fan

is turned OFFwhen you are finished in the kitchen.

0 tIGHT Control

Turn die tlGHYconuol to HI for bright light while

cooking. Turn m NITEK_r use as a night light.

4

Care and cleaning of the vent hood. aappliancescom

Be sure electrical power is off and all surfaces are cool before cleaning or servicing any part of the

vent hood.

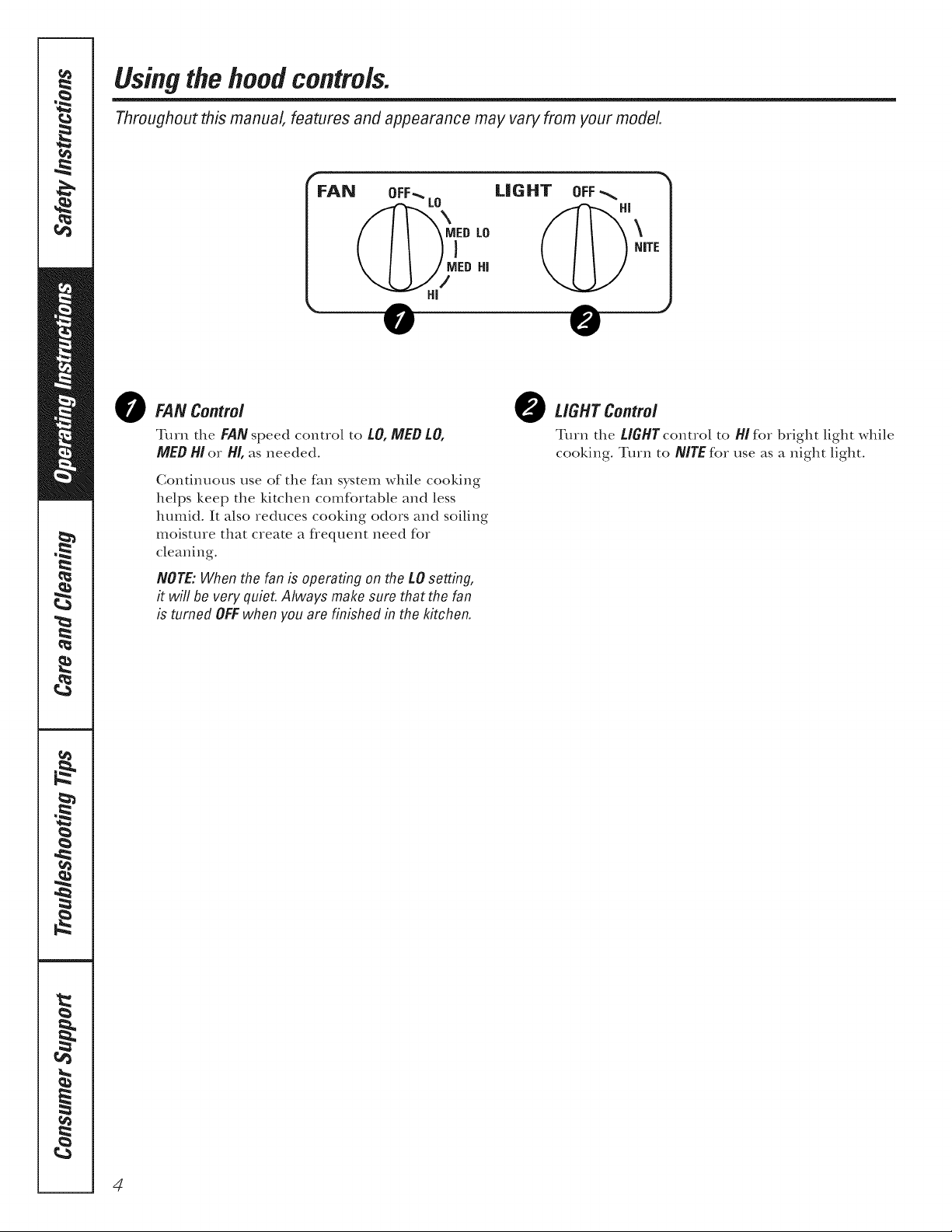

Reusable Metal Grease Filters

The hood has 2 metal reusable

grease filters.

The metal filters trap grease

released by foods on the cooktop.

They also help prevent flaming

foods on the cooktop flom

damaging the inside of the hood.

For this reason, the filters must

ALWAYS be in place when the

hood is used. The grease filters

should be cleaned once a month,

or as needed.

Toclean the grease filters, soak

them and then swish them around

in hot water and detergent.

Don't use ammonia or ammonia

products because they will darken

the metal. Do not use abrasives or

oven cleaners, i,ight brushing can

be used to remove embedded dirt.

Rinse, shake and let them dry

before replacing.

To remove:

Grasp the filter handle and pull it

up, fbrward and out.

Toreplace:

[_ Hold the filter at the bottom

with the handle.

[_ Place the top end of the filter

against the inside flont of the

hood.

[_ Slide it up until it stops and

push the bottom end back

until it snaps into place.

Stainless Steel Surfaces

Oo notuse a steel wool pa& # will

scratchthesurface.

To clean the stainless steel

stlIf_ce, tlse warIIl sudsy water or

a stainless steel cleaner or polish.

Always wipe the surfime in the

direction of the grain. Follow the

cleaner instructions for cleaning

the stainless steel smface.

To inquire about prochasing

stainless steel appliance cleaner or

polish, or to find the location of a

dealer nearest you, please call our

toll-flee nmnber:

NationalParts Center

800.626.2002

GEAppliances.com

5

Care and cleaning of the vent hood.

Be sure electrical power is off and aft surfaces are cool before cleaning or servicing any part of

the vent hood.

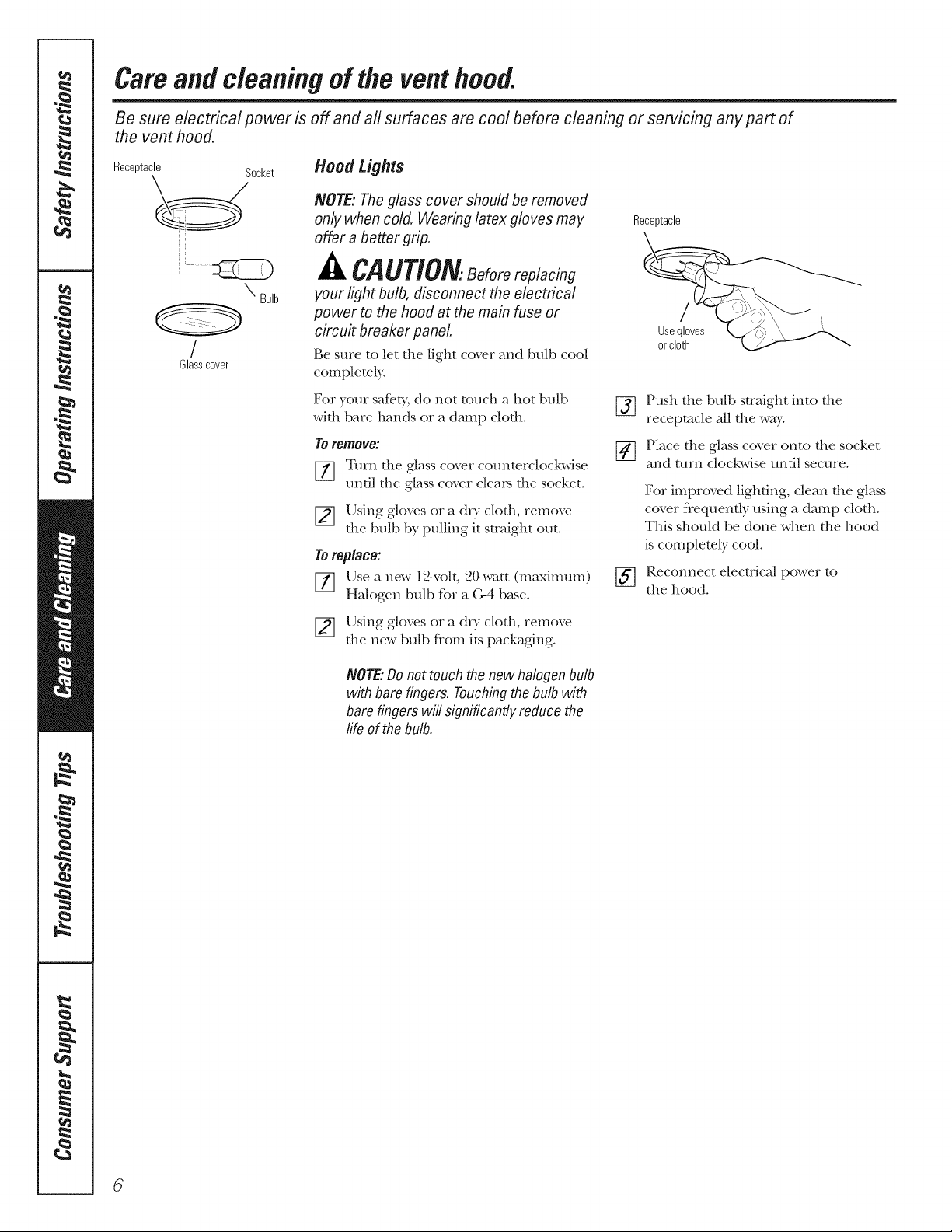

Receptacle Socket Hood Lights

/

NOTE:The glass cover should be removed

ii

/

Glasscover

\ Bulb

only when cold. Wearing latex gloves may

offer a better grip.

A CAUT/O_V.. Before replacing

your light bulb, disconnect the electrical

power to the hood at the main fuse or

circuit breaker panel.

Be sure to let file light cover and bulb cool

completely.

For your safeb,, do not touch a hot bulb

with bare hands or a damp cloth.

TO remove:

[_ Turn the glass cover counterclockwise

until the glass cover clea_ the socket.

[_ Using gloves or a (h T cloth, remove

the bulb by pulling it straight out.

Toreplace:

S c ) c •

[y] U_e a new 12w(lt, 20-watt (maxmmm)

Halogen bulb for a (;-4 base.

Receptacle

/

orcloth _

Push the bulb straight into the

receptacle all the way.

Place the gl_kss cover onto the socket

and mrn clockwise undl secure.

For improved lighting, clean file glass

cover fiequently using a damp cloth.

This should be done when the hood

is complemly cool.

[_ Reconnect electrical power to

the hood.

[_ Using gloves or a (h T cloth, remove

the new bulb flom its packaging.

NOTE:Donot touch thenewhalogenbulb

with barefingers.Touchingthe bulbwith

bare fingerswill significantlyreduce the

life of thebulb.

6

Installation

instructions

RangeHoods

m

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•IMPORTANT- S.ve_hesei.s_,uc_io.s

for local inspector's use.

•IMPORTANT- Obse,ve.ll,_ove,.i._

codes and ordinances.

• Note to Installer - Be sure to leave these instruc-

tions with the Consmner.

• Note to Consumer - Keep these instructions for

furore reference.

• Skill Level - Installation of this vent hood requires

basic mechanical and electrical skills.

•Completion time - 1 to 3 hours.

• Proper installation is the responsibiliD_ of the installer.

• Product failure due to improper installation is not

covered under the _uranty.

ACAUTION:

Due to the weight and size of these vent hoods and to

reduce the risk of personal i_j ury or damage to the

product, TWO PEOPLE ARE REQUIRED FOR

PROPER INSTALLATION.

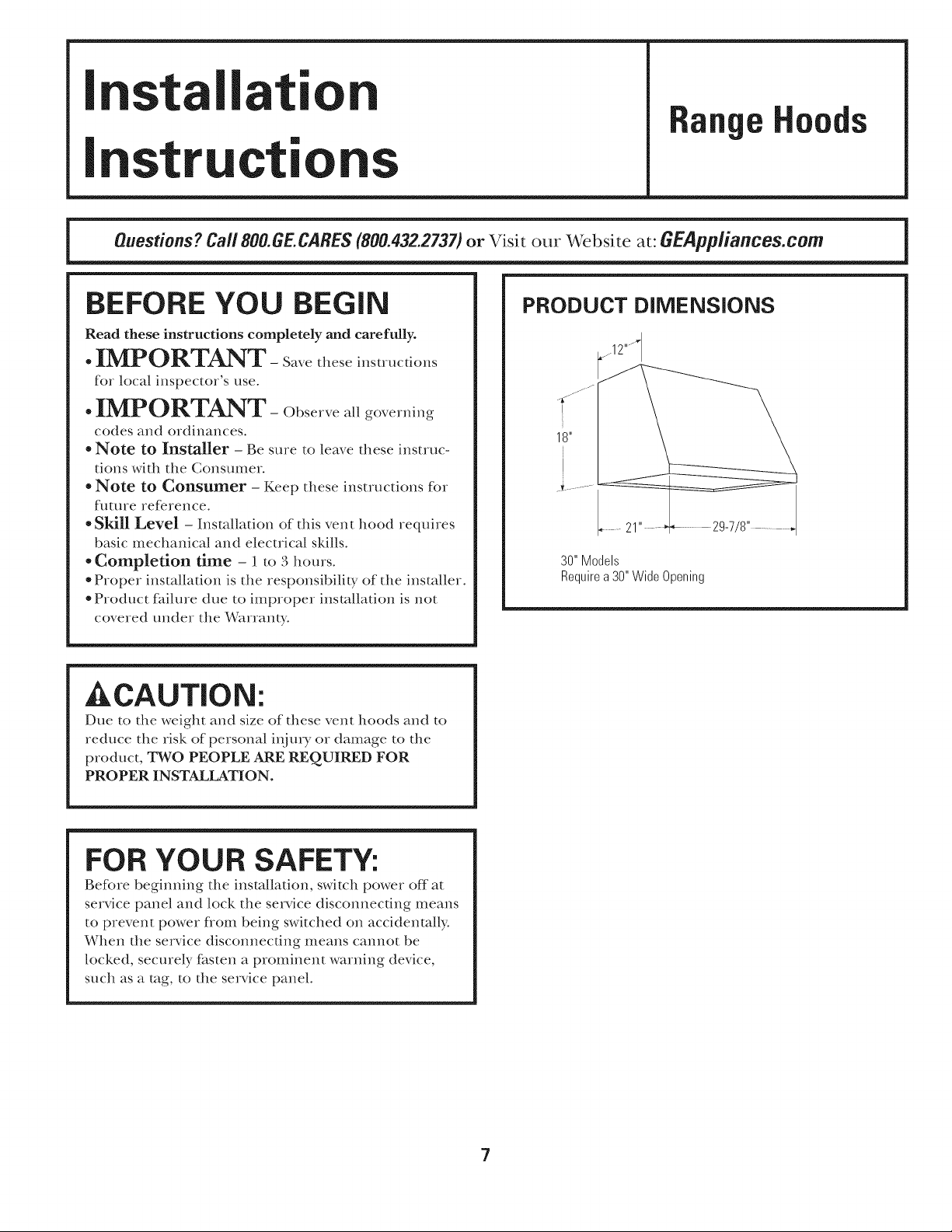

PRODUCT DIMENSIONS

18

i

30" Models

Requirea30"Wide Opening

FOR YOUR SAFETY:

Before beginning the installation, switch power off at

service panel and lock the smMce disconnecting means

to prevent power fiom being switched on accidentally.

When the se_wice disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a rag, to the service panel.

Installation instructions

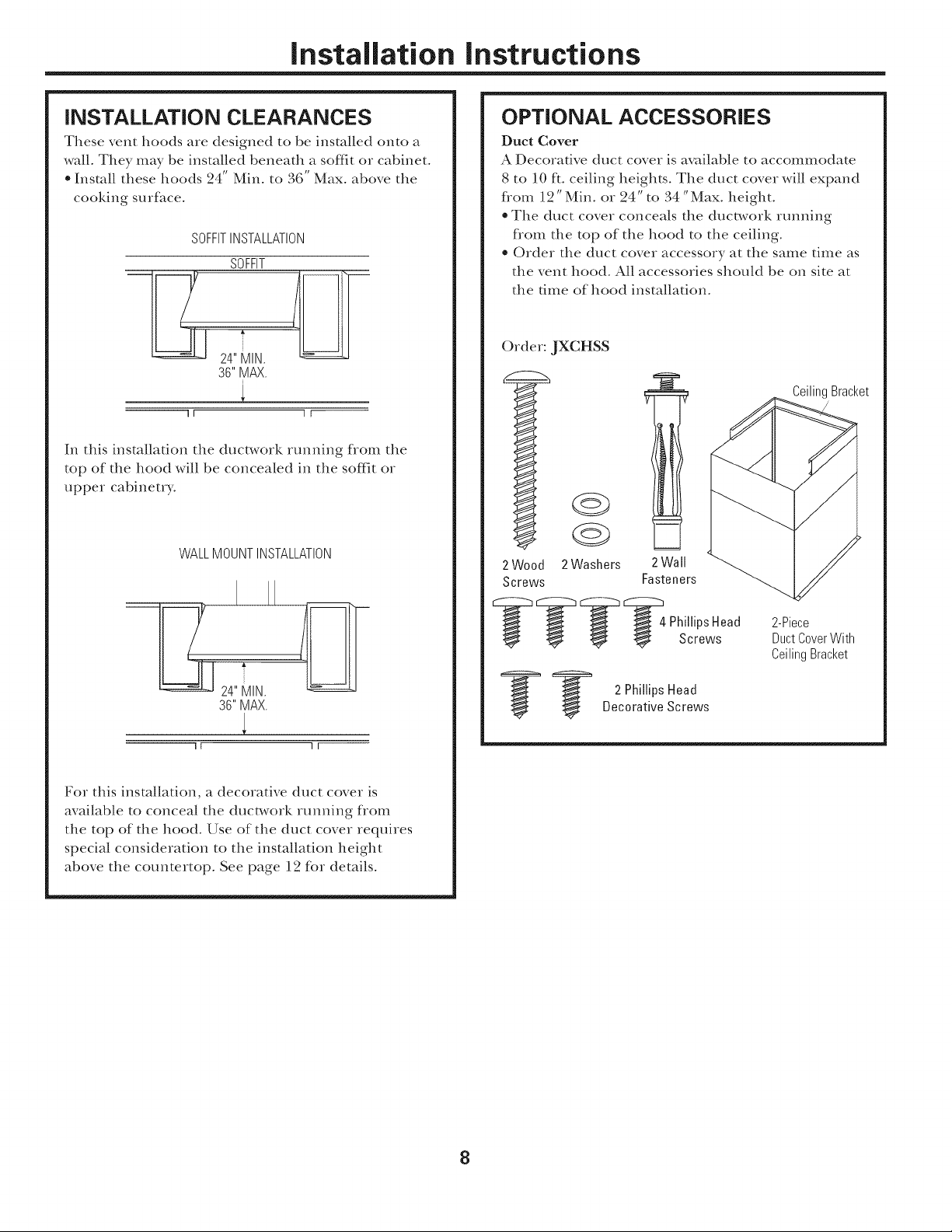

iNSTALLATiON CLEARANCES

These vent hoods are designed to be installed onto a

wall. They may be installed beneath a soffit or cabinet.

* Install these hoods 24" Min. to 36" Max. above the

cooking surface.

SOFFITINSTALLATION

SOFFIT

24"MIN.

36" MAX.

it--

In this installation the ductwork running from the

top of the hood will be concealed in the soffit or

upper cabinet_ T.

WALLMOUNTINSTALLATION

OPTIONAL ACCESSORIES

Duct Cover

A Decorative duct cover is available to accommodate

8 to 10 ft. ceiling heights. The duct cover will expand

flom 12" Min. or 24" to 34 "Max. height.

* The duct cover conceals the ductwork running

flom the top of the hood to the ceiling.

* Order the duct cover accessory at the same time as

the vent hood. All accessories should be on site at

the dine of hood installation.

Order: JXCHSS

CeilingBracket

2 Wood

Screws

2Washers

2WaII

Fasteners

For this installation, a decorative duct cover is

available to conceal the duct_,vork running flom

the top of the hood. Use of the duct cover requires

special consideration to the installation height

above the countertop. See page 12 for details.

g T 2 Phillips Head

Decorative Screws

2-Piece

DuctCoverWith

CeilingBracket

8

Installation instructions

ADVANCE PLANNING

Ductwork Planning

. This hood may be vented vertically through upper

cabinets, soffit or ceiling. A duct transition piece is

supplied for vertical exhaust. Use locally supplied

elbows to vent horizontally through the rear wall.

See page 13.

* Determine the exact location of the vent hood.

* Plan the route for venting exhaust to the outdoors°

* Use the shortest and straightest duct rotlte possible.

For safisfhctory peffbrmance, duct run should not

exceed 100 R. equivalent length for any duct

configurations.

* Refer to "Duct Fittings" chart to compute the maximum

permissible length for duct runs to the outdoors.

* Use metal duct_,vork only.

* A transition piece for 7" round duct is supplied. Use

7" rotuxd duct or you may use 3-1/4" x 12" rectangular.

* Install a wall cap or roof cap with damper at the

exterior opening. Order the wall or roof cap and

any transition needed in advance.

Kit -JXDW1

Order kitJXDW1 if your installation requires horizon ml

ducfing fi'om the top of the hood through the back _vtll and:

* You have an 8 fL ceiling and need to use aJXCH

Series Chimney Corm; or

* You have a 12" cabinet or 12" soffit that the hood is to

be mounted beneath.

This kit provides a duct transition fiom 7" round to

3¼" x 10" rectangular for through-the-wall venting.

Wall Framing for Adequate Support

* This vent hood is heavy. Adequate structural support

must be provided. The hood must be secured to

vertical studs in the wall. See page 14.

* We strongly recommend that the vent hood with

duct cover be on site before final f]aming and wall

finishing. This will also help to accurately locate the

ductwork and electrical service.

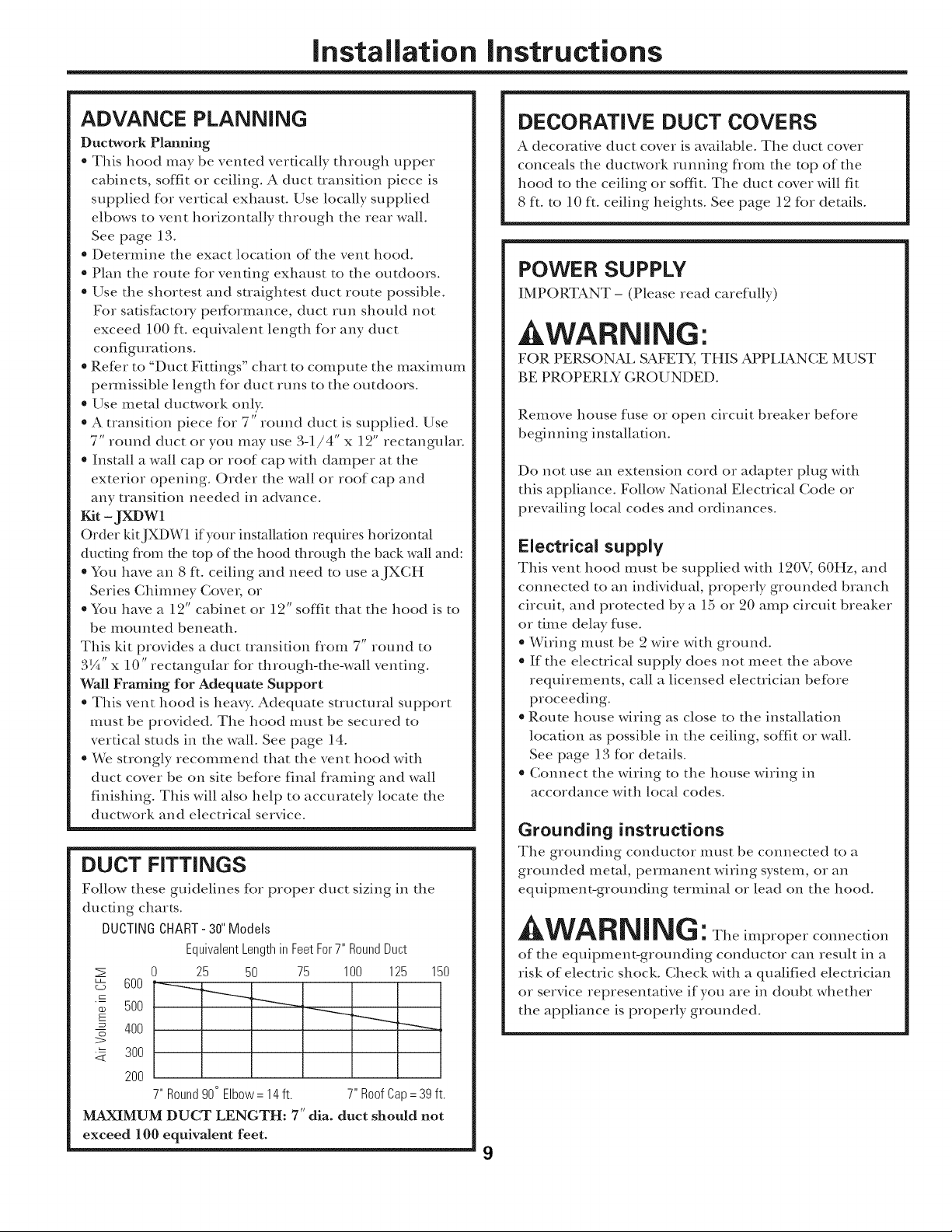

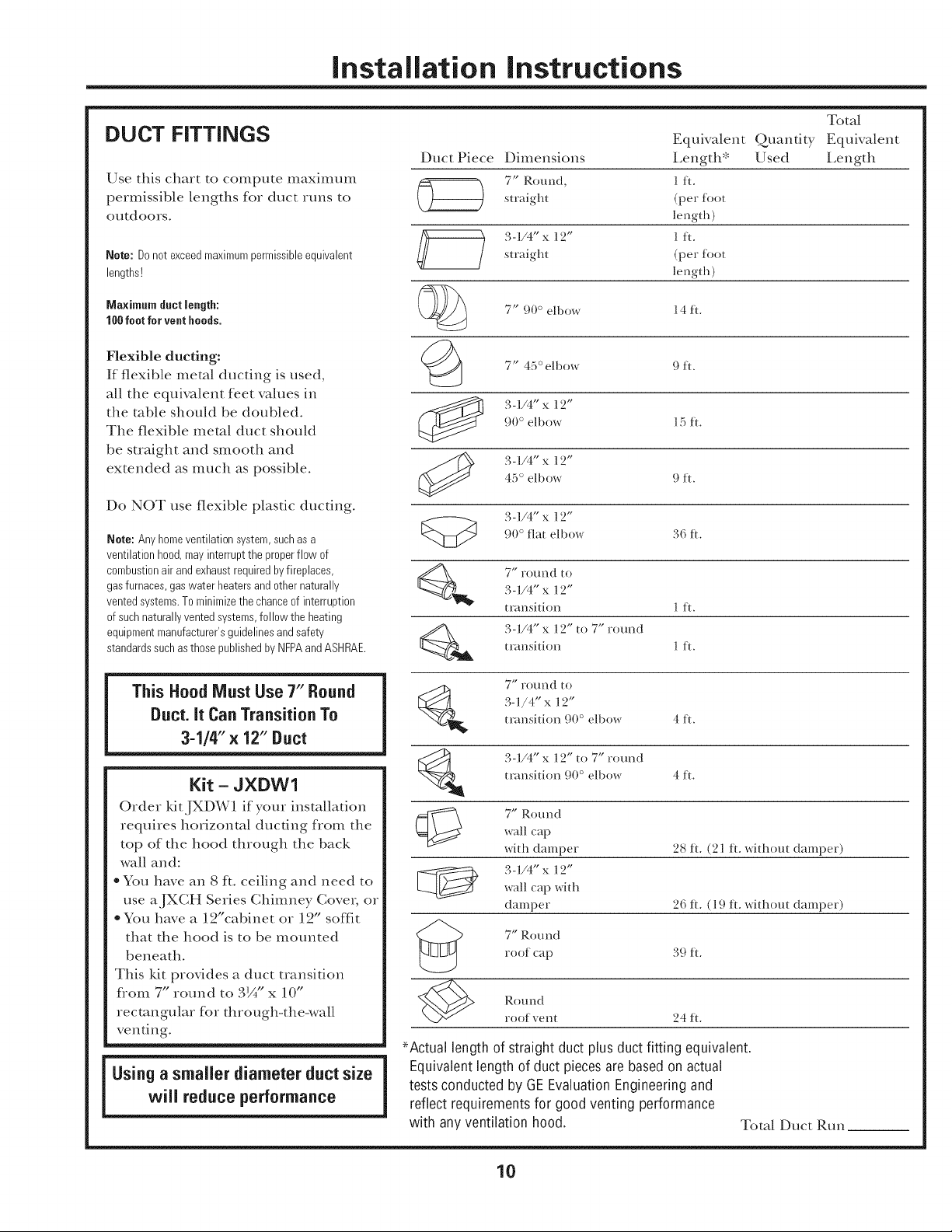

DUCT FiTTiNGS

Follow these guidelines fin proper duct sizing in the

ducting charts.

DUCTIN6CHART- 30"Models

EquivalentLengthinFeetFor7" RoundDuct

Z 0 25 50 75 100 125 150

600

500

E

400

>

300

200

7" Round90° Elbow= 14ft. 7" RoofCap=39ft.

MAXIMUM DUCT LENGTH: 7" dia. duct should not

exceed 100 equivalent feet.

DECORATIVE DUCT COVERS

A decorative duct cover is available. The duct cover

conceals the ductwork running f?om the top of the

hood to the ceiling or soffit. The duct cover will fit

8 R. to 10 R. ceiling heights. See page 12 for details.

POWER SUPPLY

IMPORTANT- (Please read carefully)

,&WARNING'.

FOR PERSONAL SAFETY, THIS APPLIANCE MUST

BE PROPERIX GROU NDED.

Remove house fl_se or open circuit breaker before

beginning installation.

Do not use an extension cord or adapter plug with

this appliance. Follow National Electrical Code or

prevailing local codes and ordinances.

Electrical supply

This vent hood must be supplied with 120V, 60Hz, and

connected to an individual, properly grounded branch

circuit, and protected by a 15 or 20 amp circuit breaker

or time delay fl_se.

* Wiring must be 2 wire with ground.

* If the electrical supply does not meet the above

requirements, call a licensed electrician before

proceeding.

* Route house wiring as close to the installation

location as possible in the ceiling, soffit or wall.

See page 13 for details.

* Connect the wiring to the house wiring in

accordance with local codes.

Grounding instructions

The grounding conductor must be connected to a

grounded metal, permanent wiring system, or an

equipment-grounding terminal or lead on the hood.

AWARNING"

of the equipment-grounding conductor can result in a

risk of electric shock. Check with a qualified electrician

or service representative if you are in doubt whether

the appliance is properly grounded.

9

[]The improper connection

Installation instructions

DUCT FiTTiNGS

Use this chart to compute maximum

permissible lengths for duct runs to

Outdoors.

Note: Donot exceedmaximumpermissibleequivalent

lengths!

Duct Piece Dimensions

7" Round,straight

• -1/4 x 12"

straight

Total

Equivalent Quandty Equivalent

Length* Used Length

ltt.

(per %ot

length)

lit.

(per foot

length)

Maximum duct length:

100 foot for vent hoods•

Flexible ducting:

If flexible metal ducting is used,

all the equivalent feet values in

the ruble should be doubled.

The flexible metal duct should

be straight and smooth and

extended as much as possible.

Do NOT use flexible plastic ducting.

Note: Anyhomeventilationsystem,suchasa

ventilation hood,mayinterruptthe properflow of

combustionair and exhaustrequiredbyfireplaces,

gasfurnaces,gaswater heatersand othernaturally

ventedsystems.Tominimizethechanceof interruption

ofsuchnaturallyventedsystems,follow the heating

equipmentmanufacturer'sguidelinesandsafety

standardssuchasthosepublishedby NFPAandASHRAE.

This HoodMust Use 7" Round

Duct. It CanTransition To

3=1/4,, × 12" Duct

Kit - JXDWI

Order ldtJXDW1 if your installation

requires horizontal ducfing f)om the

top of the hood through the back

wall and:

*You have an 8 fk. ceiling and need to

use aJXCH Series Chimney Corm; or

* You have a 12"cabinet or 12" soflit

that the hood is to be mounted

beneath.

This ldt provides a duct transition

f}'oIIl 7** rotlnd to 31/4 " X 10"

rectangular for through-the-wall

venting.

Using a smaller diameter duct size

will reduce performance

7" 90° elb(m

7" 45 °elbox_

14it.

9it.

• -1/4 x 12"

90 ° elbo_

15 ft.

• -1/4 x 12"

45 ° elb o_,_

:_ p*• -I/4 x 12"

90 ° fiat elbo_

@_11_ 7 p' i'Ot/lld to

p,• -1/4 x12"

transition

• -1/4 xl2"to / rmnd

transition

7 p* I'Ot/lld to

9it.

36fl.

lit.

lit.

•-1/4 x 12"

transition 90° elb(m

4it.

• -1/4 x12 t_ / rmnd

transition 90° elb(m

wall cap

7" Round

with damper

4it.

28 it. (21 it. x_ithout damper)

• -1/4 x 12"

_all cap _ith

damper

26 it. (19 it. x_ithout damper)

7" Round

roof cap 39 fk

Round

roof vent 24 ft.

*Actual length of straight duct plusductfitting equivalent.

Equivalentlength of duct piecesare basedon actual

testsconductedby GEEvaluationEngineeringand

reflectrequirementsfor good venting performance

with any ventilation hood. Total Duct Run

10

Installation instructions

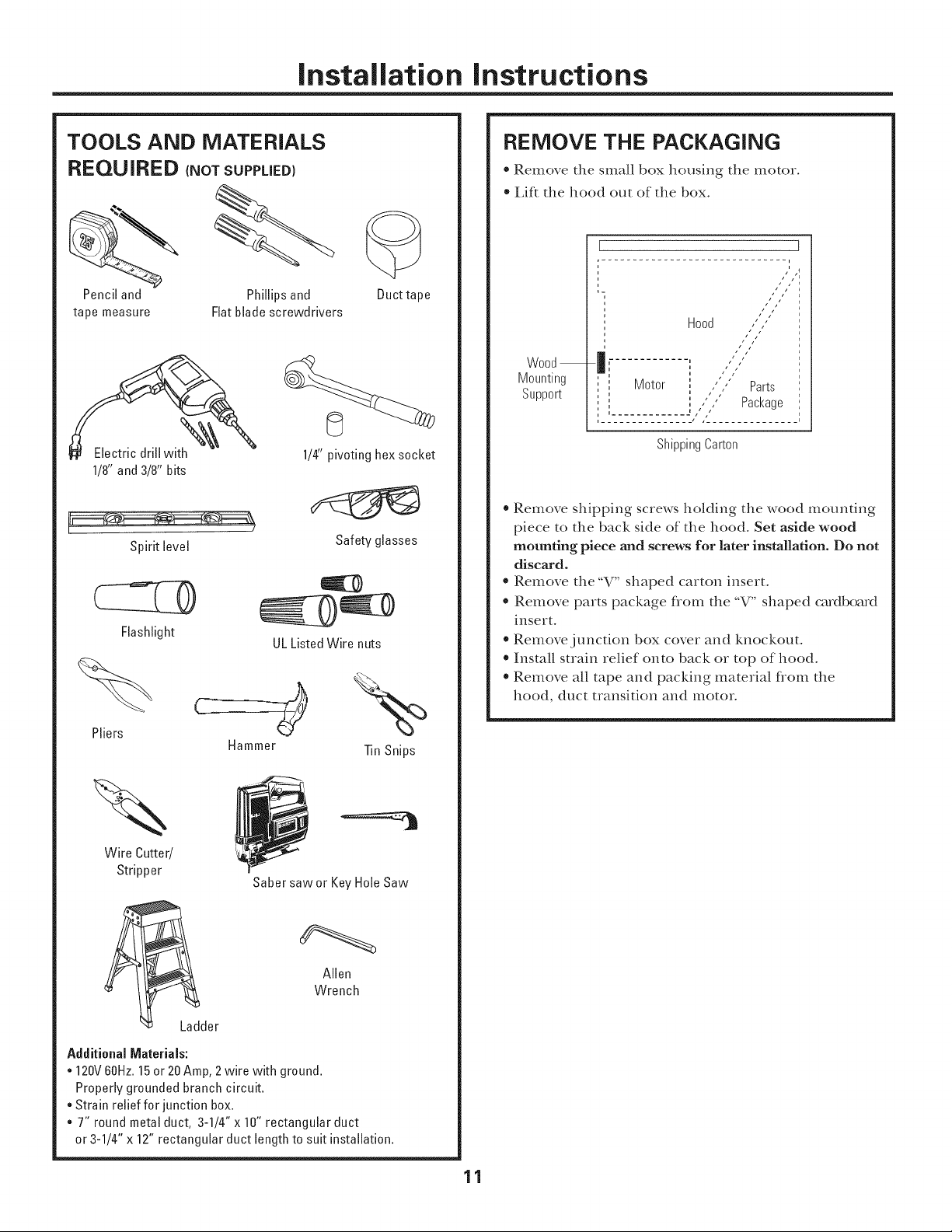

TOOLS AND MATERIALS

REQU iRED INOTSUPPUEDI

Pencil and Phillipsand

tape measure Hat blade screwdrivers

1/4"pivoting hex socket

1/8"and 3/8" bits

Spirit level

Flashlight

Pliers

UL ListedWire nuts

Ducttape

Safety glasses

REMOVE THE PACKAGING

= Remove the small box housing the motor.

* i,iff the hood out of the box.

i

/ ,/

Hood,:::7

i I /

Wood

Mounting

Support

* Remove shipping screws holding tile wood mounting

piece to tile back side of tile hood. Set aside wood

mounting piece and screws for later installation. Do not

discard.

* Remove tlle"V" shaped carton insert.

* Remove parts package flom tile "V" shaped cardboard

insert.

* Removej unction box cover and knockout.

* Install strain relief onto back or top of hood.

* Remove all tape and packing material flom tile

hood, duct transition and motor.

Motor I ,",'" Parts

,__2............. ",t ...............

! ,,:7

,/

' ' '* Package

I II /

Shipping Carton

Hammer Tin Snips

Wire Cutter/

Stripper

Ladder

AdditioaalMaterials:

,120V 60Hz.15or 20 Amp,2wire with ground.

Properly grounded branch circuit.

, Strain relief for junction box.

,7" round metal duct, 3-1/4" x 10" rectangular duct

or 3-1/4" x 12" rectangular duct length to suit installation.

Saber saw or Key Hole Saw

Allen

Wrench

11

Installation instructions

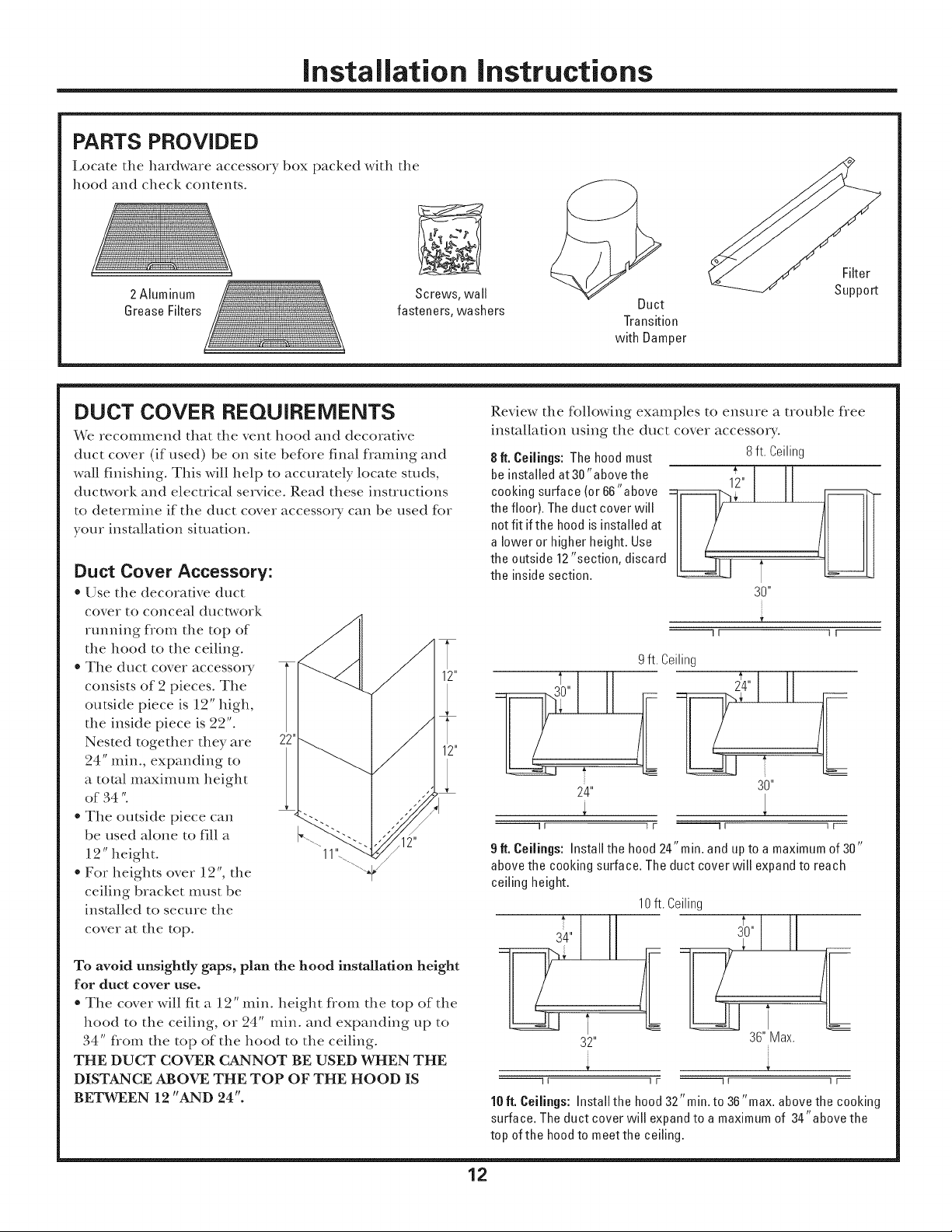

PARTS PROVIDED

i,ocate the hardware accessory box packed with the

hood and check contents.

2Aluminum Screws, wall

Grease Filters fasteners, washers

@

Duct

Transition

with Damper

Filter

Support

DUCT COVER REQUIREMENTS

We recommend that the vent hood and decorative

duct cover (if used) be on site before final flaming and

wall finishing. This will help to accurately locate studs,

ductwork and electrical service. Read these instructions

to determine if the duct cover accesso_ T can be used for

your installation situation.

Duct Cover Accessory:

* Use the decorative duct

cover to conceal duct_,vork

running flom the top of

the hood to the ceiling°

* The duct cover accessory

consists of 2 pieces. The

outside piece is 12" high,

the inside piece is 22".

Nested together they are

24" rain., expanding to

a total maximum height

of 34 ".

* The outside piece can

be used alone to fill a

12" height.

* For heights over 12", the

ceiling bracket must be

installed to secure the

cover at the top.

Review the ff_llowing examples to ensure a trouble flee

installation using the duct cover accesso_ T.

8R. Ceilings: The hood must 8ft. Ceiling

beinstalled at30"above the

cooking surface (or 66"above

the floor). The duct cover will

notfit ifthe hood is installed at

a lower or higher height. Use

the outside 12"section, discard

the inside section.

--11 1 I--

9ft. Ceiling

24"

f

30"

30"

24"

--1 r

9R. Ceifings: Install the hood 24"min. and up to a maximum of 30"

above the cooking surface. The duct cover will expand to reach

ceiling height,

3_"

1F il IF--

10ft. Ceiling

To avoid unsightly gaps, plan the hood installation height

for duct cover use.

* The cover will fit a 12" rain. height flom the top of the

hood to the ceiling, or 24" rain. and expanding up to

34" flom the top of the hood to the ceiling.

THE DUCT COVER CANNOT BE USED WHEN THE

DISTANCE ABOVE THE TOP OF THE HOOD IS

BETWEEN 12 "AND 24".

L

32"

--1[ 1F --7t II--

10ft. Ceilings: Install the hood32" min.to 36"max. above the cooking

surface. Theduct cover will expandto a maximum of 34"above the

top ofthe hoodto meet the ceiling.

12

36" Max.

Installation instructions

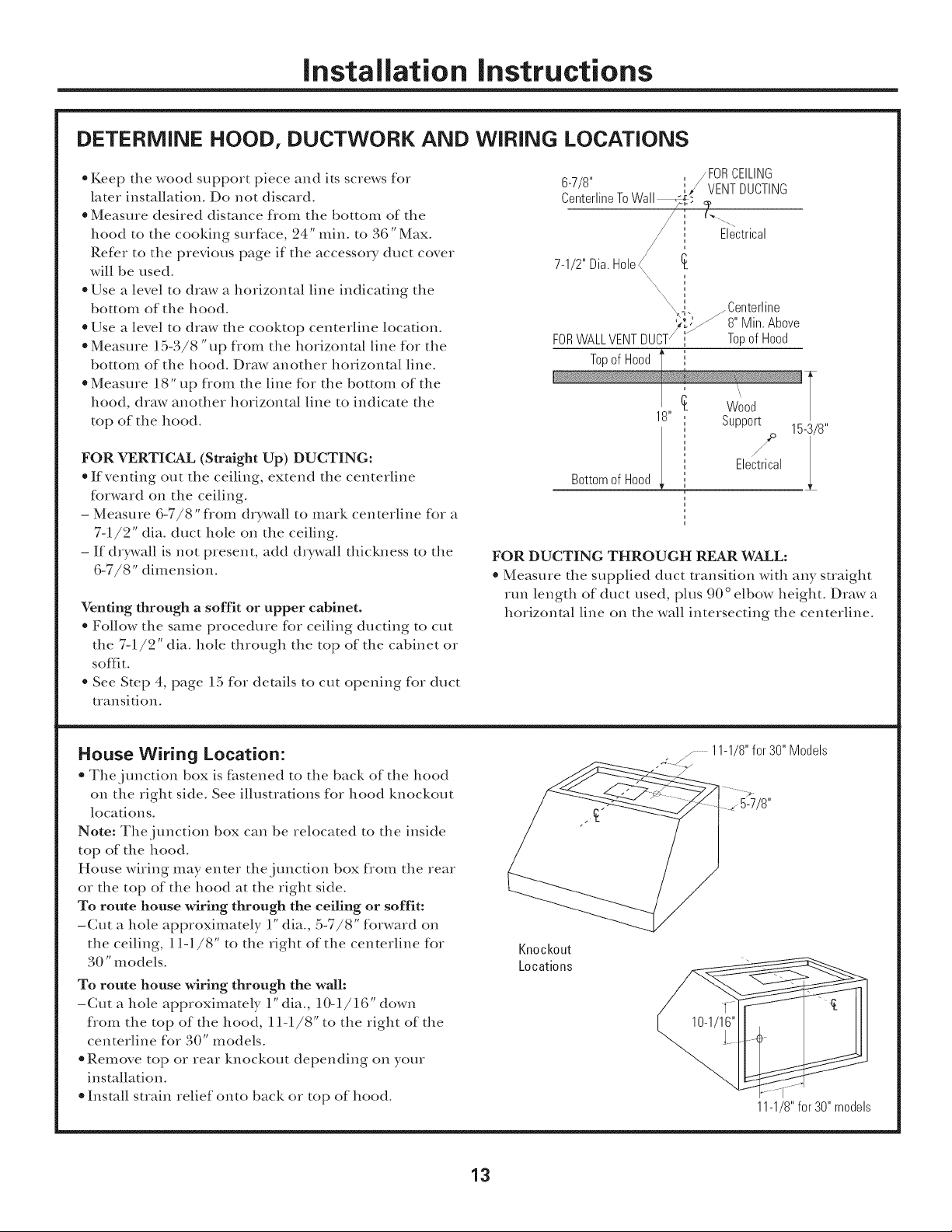

DETERMINE HOOD, DUCTWORK AND WIRING LOCATIONS

• Keep the wood support piece and its screws for

later h_stallation. Do not discard.

• Measure desired distance flom the bottom of the

hood to the cooking surf_ce, 24" rain. to 36 "Max.

Refer to the previous page if the access<n T duct cover

will be used.

• Use a level to draw a horizontal line indicating the

bottom of the hood.

• Use a level to draw the cooktop centerline location.

• Measure 15-3/8 "up flom the horizontal line fin the

bottom of the hood. Draw another horizontal line.

• Measure 18" up flom the line for the botton_ of the

hood, draw another horizontal line to indicate the

top of the hood.

FOR VERTICAL (Straight Up) DUCTING:

*If venting out the ceiling, extend the centerline

fbrward on the ceiling.

- Measure 6-7/8" flom drywall to mark centerline fin a

7-1/2" dia. duct hole on the ceiling.

- If drywall is not present, add drywall thickness to the

6-7/8" dimension.

Venting through a soffit or upper cabinet.

* Follow the same procedure ff_r ceiling ducting to cut

the 7-1/2" dia. hole through the top of the cabinet or

soffit.

* See Step 4, page 15 fin derails to cut opening fin duct

transition.

,, , _FOR CEILING

6-7/,8.... ',,/VENT DUCTING

benterllne/o vvall_X_- _

F== E,ectrica,

/

7-1/2" Dia.Hole

X

\ ,

i

"\\ =

,

"\\ i

"\,4, _Centerline

8" Min.Above

FOR , Topof Hood

Topof Hood

Wood

18" , Support

II 15-3/8"

| i Electrical

Bottomof Hood ,r II

,

i

,

,

i

FOR DUCTING THROUGH REAR WALL:

* Measure the supplied duct transition with any straight

run length of duct used, plus 90 oelbow height. Draw a

horizontal line on the wall intersecting the centerline.

House Wiring Location:

* Thej unction box is fastened to the back of the hood

on the right side. See illustrations fin hood knockout

locations.

Note: The j unction box can be relocated to the inside

top of the hood.

House wiring may enter thejtmcdon box fYom the rear

or the top of the hood at the right side.

To route house wiring through the ceiling or soffit:

- Cut a hole approximately 1" dia., 5-7/8" finward on

the ceiling, 11-1/8" to the right of the centerline fin.

30" models.

To route house wiring through the wall:

- Cut a hole approximately 1" dia., 10-1 / 16" down

fYom the top of the hood, 11-1/S" to the right of the

centerline fin 30" models.

* Remove top or rear knockout depending on your

installation.

* Install strain relief onto back or top of hood.

, j ............11-1/8"for30" Models

Knockout

Locations

11-1/8"for30"models

13

Installation instructions

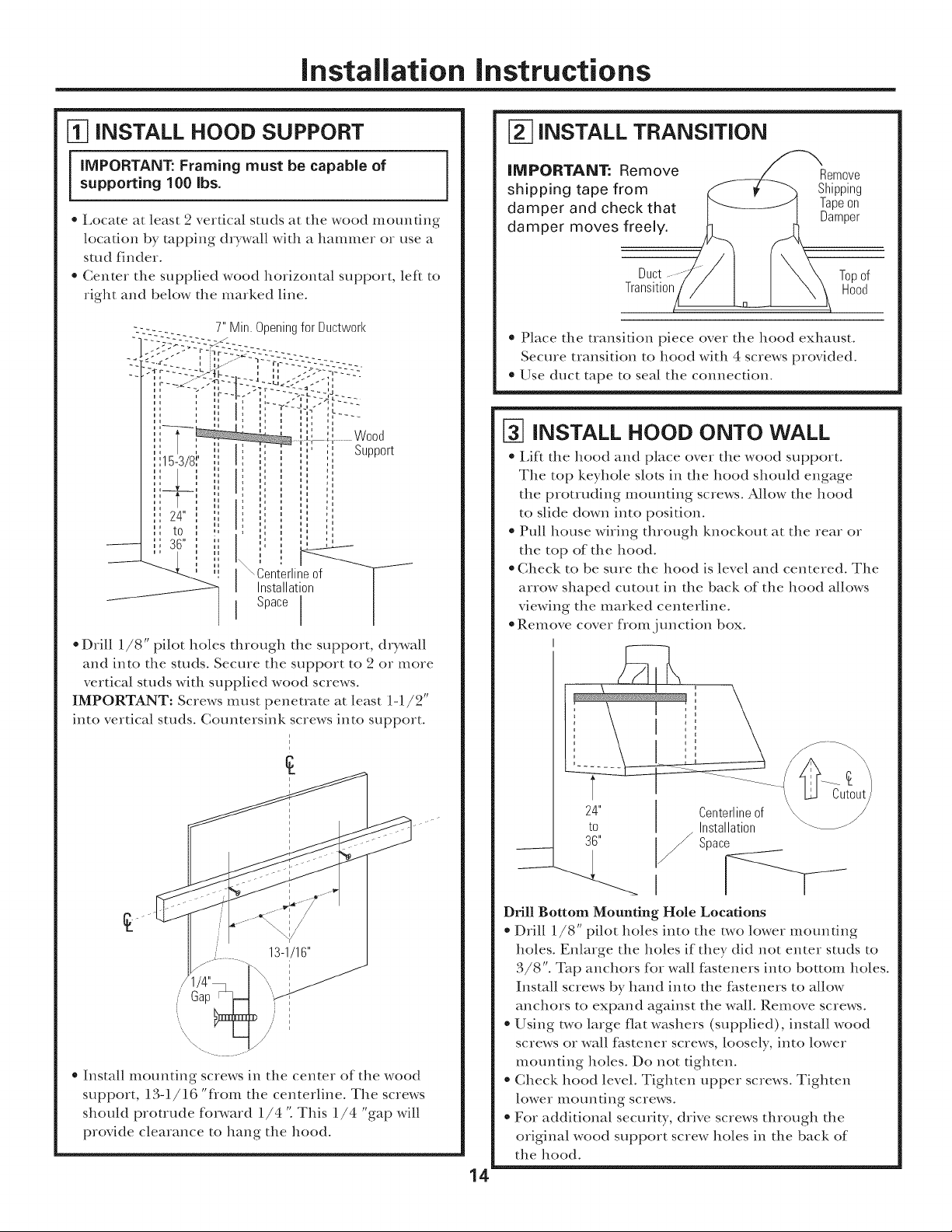

iNSTALL HOOD SUPPORT

IMPORTANT: Framing must be capable of

supporting 100 Ibs.

. i.ocate at least 2 vertical studs at the wood mounting

location by tapping drywall with a lmmmer or use a

stud finder.

* Center the supplied wood horizontal support, left to

right and below the marked line.

7" Min.Openingfor Ductworl<

Support

',,

,',

,',

\ Centerlineof

Installation

Space

*Drill 1/8" pilot holes thro ugh the support, drywall

and into the studs. Secure the support to 2 or more

vertical studs with supplied wood screws.

IMPORTANT: Screws must penetrate at least 1-1/2"

into vertical studs. Countersink screws into support.

i

i

i

/

l

INSTALL TRANSITION

IMPORTANT: Remove

shipping tape from

damper and check that

damper moves freely.

Duct -- Topof

Transition Hood

* Place the transition piece over the hood exhaust.

Secure transition to hood with 4 screws provided.

e Use duct tape to seal the connection.

Remove

Shipping

Tapeon

Damper

iNSTALL HOOD ONTO WALL

* Lif_ the hood and place over the wood support.

The top keyhole slots in the hood should engage

the protruding mounting screws. Allow the hood

to slide down into position.

* Pull house wiring through knockout at the rear or

the top of the hood.

. Check to be sure the hood is level and centered. The

arrow shaped c!ltotlt in the back of the hood allows

viewing the marked centerline.

*Remove cover flomj unction box.

/

/

Gap

* Install mounting screws in the center of the wood

support, 13-1/16 "fl'om the centerlin e. The screws

should protrude forward 1/4 'i This 1/4 "gap will

provide clearance to hang the hood.

24"

to

36"

Drill Bottom Mounting Hole Locations

* Drill 1/8" pilot boles into the two lower mounting

boles. Enlarge the holes if they did not enter studs to

3/8". Tap anchors for wall fasteners into bottom boles.

Install screws by band into the fasteners to allow

anchors to expand against the wall. Remove screws.

* Using two large fiat washers (supplied), install wood

screws or wall fastener screws, loosely, into lower

mounting boles. Do not tighten.

* Check hood level. Tighten upper screws. Tighten

lower IIlotlnting sciews.

* For additional securiv, drive screws through the

original wood support screw boles in the back of

the hood.

Centerlineof \ _ __

Installation

Space

14

Installation instructions

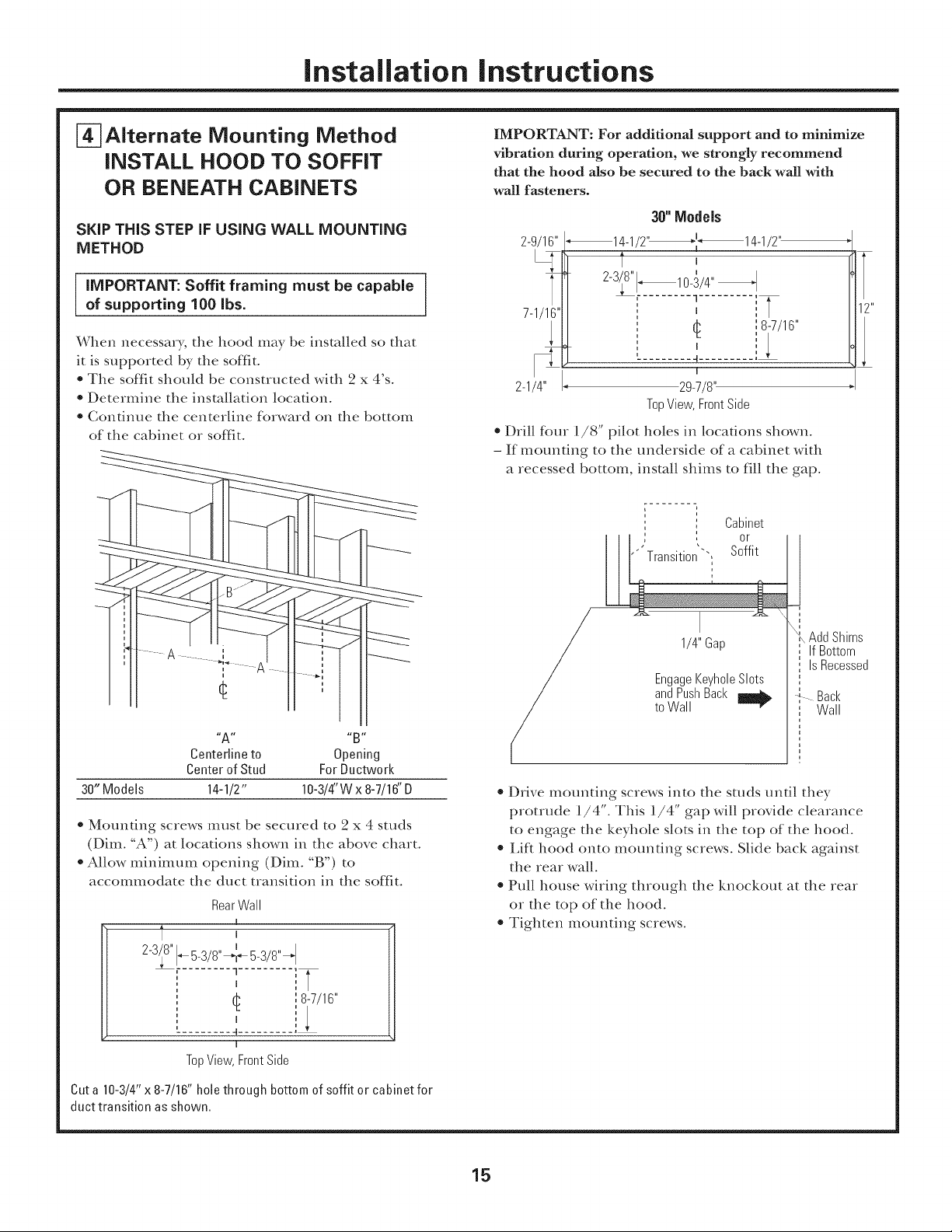

_Alternate Mounting Method

iNSTALL HOOD TO SOFFIT

OR BENEATH CABINETS

SKIP THiS STEP IF USING WALL MOUNTING

METHOD

IMPORTANT: Soffit framing must be capable

of supporting 100 Ibs.

When necessary, the hood may be installed so that

it is supported by the soffit.

* The soft=it should be constructed with 2 x 4's.

* Determine the installation location.

* Continue the centerline forward on the bottom

of the cabinet or soffit.

IMPORTANT: For additional support and to minimize

vibration during operation, we strongly recommend

that the hood also be secured to the back wall with

wall fasteners.

30"Models

2-9/16"

_14-1/2'_1R_14-1/2 '_

t

2-3/8" 10-3/4"_

7-1/16"

',8#/16"

f

......... 4......... i ;

2-1/4"

TopView, FrontSide

I "

I

29-7/8"

*Drill four 1/8" pilot boles in locations shown.

- If mounting to the underside of a cabinet with

a recessed bottom, install shims to fill the gap.

i.........

: Cabinet

/

or

Soffit

"A" "B"

Centerline to Opening

Centerof Stud For Ductwork

30" Models

Mounting screws must be secured to 2 x 4 studs

(Dim. "A") at locations shown in the above chart.

* Allow minimum opening (Dim. "B") to

accommodate the duct transition in the sofIlt.

t

24/8"

14-1/2" 10-3/4"W x 8-7/16"D

RearWall

I

I

4 3/8

' :T

(_ ',8-7/16"

......... _......... ] 1

I

TopView, FrontSide

]

1/4"Gap

EngageKeyholeSlots

andPushBack

to Wall

* Drive mounting screws into the studs until they

protrude 1/4". Tiffs 1/4" gap will provide clearance

to engage the keyhole slots in the top of the hood.

* i,if_ hood onto mounting screws. Slide back against

the rear wall.

* Pull house wiring through the knockout at the rear

or the top of the hood.

* Tighten mounting screws.

AddShims

If Bottom

Is Recessed

Back

Wall

Cuta 10-3/4"x 8-7/16"hole through bottomof soffit or cabinet for

duct transition as shown.

15

Loading...

Loading...