Page 1

GE

Measurement & Control

High Resolution Weld Inspection and All-Purpose

Computed Radiography Scanner

Inspection Technologies:

CRxVision

Packed with innovative features to increase throughput, extend plate life

and provide excellent image quality, the CRxVision is designed specifically

for the inspection of welds. The scanner is developed to cover the stringent

ISO 17636-2 Class A and B requirements, as well as ASTM, ASME and EN

weld standards. Because of its versatility, it can also be used for many

other applications across the NDT industry.

Page 2

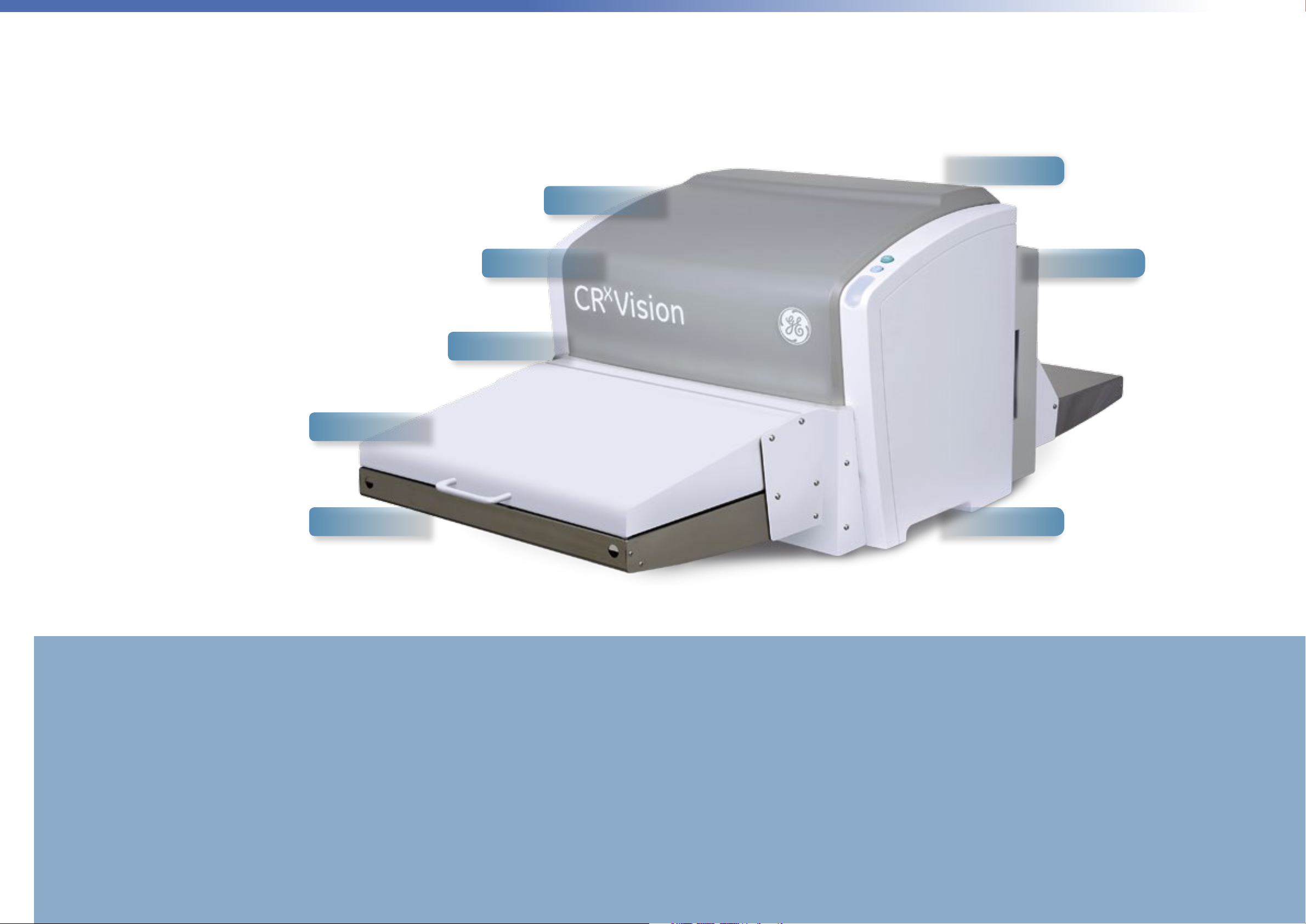

CRxVision: the versatile, new tabletop scanner from GE.

Flexible

accepting a wide range of sizes, shapes and classes of imaging plates

Intuitive

no gain setting or photomultiplier adjustments required when

exposing various thicknesses

Fast

multiple plate scanning option: side-by-side and back-to-back

with a flat transport path

High Resolution

new laser optics for profound reading and

higher data extraction

4

3

2

1

6

ASTM DICONDE Compliant

fully compatible with GE´s existing

Rhythm Software Platform

7

Ambient Operation

cover protects the imaging plate

from light exposure

Extended Plate Life

no mechanical handling of the imaging

plate during scanning and erasing

Your Benefits:

— Compliant to ISO 17636-2 Class A

and B, ASME, ASTM and EN weld

inspection standards.

— The CRxVision has an extremely wide

latitude eliminating the need for multiple

gain settings when exposing over a wide

range of thicknesses. This is the result of a

16 bit image processing at selectable

35 or 70 microns resolution.

— Exposure times for welds are equal or

better than existing film exposure times

(to comply with Code Standards like EN

and ASME) and can be reduced by up to

ten times for non-code type applications

like erosion/corrosion or valve placement.

5

— Designed for extremely high throughput:

90 plates/hr at 70 microns or 28 plates/hr

at 35 microns for a 10 x 40 cm (4.5 x 17”)

plate. The scanner allows multiple imaging

plates to be scanned simultaneously …

side-by-side and back-to-back as well as

various lengths to be scanned together.

This is a result of the straight and flat,

in-line scan and erase transport path.

— Ability to scan any shape or size of

imaging plate from from 20 to 1500 mm

(0.75 to 60”) in length. Imaging plates can

be exposed in any type of cassette, then

simply removed and inserted directly

into the scanner without the need of

any type of adapter, template or leader.

— A new innovative imaging plate design

now provides the GE CRxVision imaging

plates with more flexibility. This new

design allows each imaging plate the

ability to return to a flat state after being

constantly bent around pipes for the

inspection of welds. This feature also helps

improve productivity by allowing the

imaging plates to be easily extracted and

reinserted into cassettes.

— Plate transport through the scanners

is achieved by a magnetic transportation

system. This new combination of scanner

and imaging plate design allows the

imaging plate to be transported through

the scanner without any mechanical

handling of the phosphor ultimately

extending the overall life of the plate.

— The updated Rhythm RT software

simplifies inspection workflow. It now has

the ability to automatically crop the images

by detecting the physical edges of each

individual plate when they are processed.

Consequently, each individual plate can be

separately identified and saved or grouped

together and saved as one file.

— The new scanner enjoys all the

functionality offered by GE´s Rhythm

Software giving the inspector the ability

to view, enhance, measure, annotate and

comment on the images. The CRxVision

8

system is completely DICONDE compliant

and compatible with all existing modules in

GE´s Rhythm Software platform.

— The CRxVision can be used in ambient

light conditions with suitable handling as

the light cover protects the plates from light

exposure during the scan cycle. The cover

can be removed for work in darkrooms if

required.

— The scanner weighs less than 45 kg

(99 lbs) and has a footprint of 560 x 560 mm

(22 x 22 inches). It extends to 560 x 1280 mm

(22 x 50 inches) when the feed and exit

tables are attached.

Direct Laser Contact

the laser beam is in direct contact

with the imaging plate (no glass to

obscure data collection)

— The light guide can be easily cleaned

with an internal brush which is operated

by simply turning a set screw. The eraser

section of the scanner is completely sealed

from the optics section to prevent migration

of any dust particles into the machine.

Page 3

Applications

Even though the CRxVision was designed for the inspection of welds, it also has the

ability to cover a wide range of industrial radiography applications, from Oil & Gas

to Aerospace, and from Power Generation to General NDT.

• Weld inspection

• Erosion/Corrosion inspection (CUI, FAC, etc.)

• Castings (In-process and final)

• Valve positioning

• Concrete and Structure inspection

• Government (Arsenals, National Laboratories, Proving Grounds)

• Military (in-service aircraft, ships, etc.)

In all applications the CRxVision offers the following significant benefits of digital

radiography:

• No darkroom facilities/trucks needed

• Eliminate processing chemicals and chemical disposal/silver recovery

• Improved image interpretation and inspection quality level with Flash!Filters

• Consistent & operator–independent results with the Automated WT Measurement tool

• High reduction in retakes due to the wide dynamic range of the imaging plates

• No development time, as images are immediately available after scanning

• High reduction in storage space when archiving digital images

• Data management (trending) and data sharing advantages

• Fully DICONDE compliant

TM

Rhythm RT for Workflow Optimization

Both GE´s Rhythm RT and Rhythm RT Lite provide a powerful, ASTM DICONDE Compliant operational software platform, which

simplifies the overall inspection workflow.

After entering the component and technique data, select the

required scan resolution and then the scanner will prompt you to

insert the imaging plate. Once the imaging plate is scanned, the

image will appear and any Region of Interest (ROI) may then be

identified on the computer screen and enhancements,

annotations and measurements applied. The image can then be

saved for further review and/or storage. The files can be saved in

TIFF, BMP, JPEG, and/or DICONDE formats.

Rhythm RT workflow

Select the required

1

resolution

Enter the component

2

and technique

information

3

plate(s) to start the cycle

Press scanInsert the imaging

4

Send image to review

6

Select a specific ROI

5

(if desired)

Page 4

Imaging Plates

Technical Specifications of CRxVision

Four different types of imaging plates with a ferromagnetic

back layer have been developed specifically for the CRxVision.

This allows the imaging plates to be magnetically transported

through the scanner with no phosphor touch points. In addition,

this new design helps reduce backscatter which improves the

overall quality of the image as well as allows the imaging plate

the ability to return to a flat position after being constantly bent

around curved objects.

GE´s four imaging plate types are as follows:

• IPC2: Standard Resolution & High Speed - for general purpose

• IPS: High Resolution & Medium Speed - for inspection of welds

• IPS2: High Resolution & Medium Speed – for inspection of welds

Excellent for very low contrast, homogeneity type applications

and premium weld quality inspections.

• IPU: Extreme High Resolution & Slow Speed - for extremely high

resolution applications when very low micron range sensitivity

is required.

Plates are available in various size formats ranging from 70 mm

(2.76”) wide to 1500 mm (60”) in length.

Protective Cassettes

A range of flexible and hard cassettes are also available. Both

versions may be supplied with or without lead, depending on

the application.

Functional Data

Principle High performance table-top flatbed scanner with

Eraser Inline

Resolution Standard resolution (SR) 70 µm

Maximum basic Standard resolution (SR) 80 µm (6,25 LP / mm)

Spatial resolution High resolution (HR) 40 µm (12,5 LP / mm)

Scan width 35 cm (14 inch)

Throughput

(10 x 40 cm

4.5 x 17”)

Time to image

(in Rhythm RT)

LUT

(look up table)

Bit depth 16 Bit

Dimensions Scanner 56 x 56 x 47 cm

Weight Scanner 45 kg (99 lbs)

Interfaces Ethernet, RJ45

Certifications CE, UL (NRTLus), cUL (cNRTLus), C-Tick, Customs

contactless plate transport

High resolution (HR) 35 µm

Standard resolution (SR) 90 plates/hour

High resolution (HR) 28 plates/hour

Standard resolution (SR) 40 sec

High resolution (HR) 147 sec

Linear

(native Square root)

(22” x 22” x 19”)

Scanner including I/O

table and light cover

Scanner including I/O

table and light cover

DC voltage, coded 8-pin, female

Union Mark

128 x 56 x 47 cm

(52” x 22” x 19”)

50 kg (110 lbs)

Environmental Conditions

Operation Temp. allowed 15 °C to 35 °C

Relative humidity 15% to 80%

Magnetic field Compliant with

Transport IEC721-3-2 (1997): class 2K2 and 2M3, with

Mechanical

conditions for

transport

Shock

specifications

following restrictions

Temperature -25 °C to +55 °C

Vibration 5 to 200 Hz

In packaging IEC 721-3-2 (1997):

In packaging IEC TR 60721-4-5 (1997):

(59 °F to 95 °F)

(non condensed)

EN 61000-4-8, Level 2

(-13 °F to 131 °F)

(vertical, longitudinal,

transversal axis)

class 2M2

class 5M2

Electrical Data

Operating voltage Auto-ranging external power supply from

Mains frequency 50/60 Hz

Mains fuse protection Europe min. 10 A, max. 16 A

Power

consumption

100 V to 240 V, DC Output 24V

USA & Japan min. 10 A, max. 15 A

Standby

110 V - 240 V / 50-60 Hz

During operation

110 V - 240 V / 50-60 Hz

max. 22 W

max. 140 W

(absolute peak)

Application Compliance

ASME ASME Code Section V Article 2

ISO 17636-2 Class A / Class B

(in defined exposure

conditions)

EN14784-1 IPS, IPS-2: 1/80,

IPU: 1/40

EN2446-06 IPS, IPS-2: S/80,

IPU: S/40

Verified with X-ray,

Ir-192, Se-75, Co-60

Certified by BAM

Certified by BAM

Accessories

I/O Table with light cover Quick mountable, stainless steel, input/output

Long I/O table Input/output extension for long plates scanning

Flight Case Robust Flight Case with shock-absorbers, wheel,

table set with 43 cm (17”) tray length and light

cover for input side

150 cm (59”)

ruggedized handles and compartments for I/O

tables, laptop, accessories

Imaging Plates

IPC2 High speed plate Use: CRxVision can scan

IPS High resolution

IPS2 High resolution

IPU Extremely high

resolution (X-ray)

any shape or size

imaging plate from 20

to 1500 mm (0.75 to 60”)

in length.

Cassettes

Flexible cassettes PVC or vinyl envelopes different sizes

Hard cassettes

(for defined exposure conditions)

35 x 43 cm, 20 x 24 cm, 24 x 30 cm, 15 x 30 cm

14” x 17”, 8” x 10”, 10” x 12”, 6” x 12”

Page 5

Regional Offices

Europe Americas Asia

Germany

Niels-Bohr-Str. 7

31515 Wunstorf

P.O. Box 6241

31510 Wunstorf

+49 5031 172 0

Bogenstr. 41

22926 Ahrensburg

+49 4102 807 117

Belgium

Roderveldlaan 5

2600 Berchem

+32 3 456 2820

United Kingdom

Fir Tree Lane

Groby LE6 0FH

+44 845 601 5771

France

68, Chemin des Ormeaux

Limonest 69760

+33 47 217 9216

Spain

San Maximo, 31, Planta 4A, Nave 6

Madrid 28041

+34 915 500 59 90

United States

50 Industrial Park Road

Lewistown, PA 17044

+1 866 243 2638 (toll free)

+1 717 242 0327

201 Beltway Green

Pasadena, Texas 77503

+1 855 232 7470

Brazil

Av. Maria Coelho Aguiar, 215

Building C, 6th floor

Jd. Sao Luiz - Sao Paulo - SP

CEP 05804-900 – Brazil

+55 11 3614-1840

GE has sales and service offices all over the world.

Below are some of our locations. Visit www.ge-mcs.com for a complete listing.

• Alzenau, Germany

• Burford, United Kingdom

• Moscow, Russia

• Bucharest, Romania

• Prague, Czech Republic

• Stockholm, Sweden

• Milan, Italy

China

5F, Building 1, No.1 Huatuo Road,

Zhangjiang High-Tech Park,

Shanghai 201203

+86 800 915 9966 (toll-free)

+86 (0) 21-3877 7888

Unit 1602, 16/F Sing Pao Building

101 King’s Road

North Point

Hong Kong

+852 2877 0801

Japan

Harumi Island Triton Square Office Tower X

1-8-10, Harumi, Chuo-ku, Tokyo 104-6023

Tel: +81 3 6890 4567

Fax: +81 3 6864 1738

• East Perth, Australia

• Singapore

• Dubai, UAE

• Buenos Aires, Argentina

• Mexico City, Mexico

• Airdrie, Alberta, Canada

• Toronto, Ontario, Canada

• Montreal, Quebec, Canada

www.ge-mcs.com/x-ray

GEIT-40058EN (06/14)

© 2014 General Electric Company. All Rights Reserved. Specifications are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product names

mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affiliated with GE.

Loading...

Loading...