Page 1

GE

Inspection Technologies

CL5

g

Ultrasonic Precision Thickness Gauge

Micrometer Precision in a Rugged Package

The CL5 is an easy-to-use precision thickness measuring

solution for components used in the automotive and

aerospace industries, such as:

• Cast and stamped metal components made of

aluminum, steel, copper, bronze

• Machined workpieces

• Chemically milled components

• Metal strips, metal plates

• Plastics and composites

• Glass

The instrument can be held in one hand or placed on

flat workpieces, making the CL5 a compact way to test

your material for the required thickness or checking for

sheet corrosion.

Page 2

Compact Solution With a Full Range of Functionality

The CL5 precision thickness gauge offers a full range of

functionality in an easy to use, compact and rugged package.

Three soft keys directly under the display activate the functions

shown on the display menus. Four directional keys help make

menu changes and navigation of the text entry screen simple

and efficient .

The graphical display presents the user with seven different

operation modes. The user can select Normal, Minimum Scan,

Maximum Scan, Differential/Rate of Reduction, Thk+A-Scan

(option), Velocity (option) or Quality View. The CL5 uses a

programmable data recorder for easy set up of data files from

the PC. The SD Card memory system places all the data

recording and set-up information on a removable SD memory

card. The files are formatted allowing drag and drop files when

plugged directly into the PC. Other data such as digital

photographs can also be stored on the same SD card. The CL5

allows direct connection to the PC, using a serial or USB port

(with optional cable).

Simple Operation

The CL5 is a very straightforward instrument to operate. The

MODE key progresses the user through a series of selection and

set-up menus and back to the measurement mode. One press of

the MODE key displays a table of standard probes and up to five

special set-ups. Another press of the MODE key displays a set-up

menu where the user can easily scroll through the menu, see the

current settings and make fast changes to any of the displayed

settings.

A supervisor lock-out function enables a knowledgeable user to

set up all the specific measuring functions and settings of the

CL5 and lock the settings so critical settings cannot be changed

by a subordinate user.

Additional advantages offered by this compact, multifunctional

instrument include:

• Enhanced measurement performance produces stable and

repeatable thickness values

• Seven measurement and display modes: Normal, Minimum

Capture, Maximum Capture, Differential and Rate of Reduction,

Velocity (with CL5 VL option), Thickness+A-Scan (with Live A-Scan

Option) and Quality View Mode (with Data Recorder option).

• Snapshot A-Scan on all models

• Hollow/Fill thickness digits showing coupling or non-coupling

status

• Visual LED alarm to alert user when measurements are

exceeding the user selectable limit values

• Customer parameter set-ups for special configurations and

quick instrument set-up

• Flexible power system via standard AA batteries or

rechargeable battery pack system (standard)

• Multi-language user interface

• Automatic ultrasonic performance (gain and gate controls)

• Wide variety of standard probes (sold separately)

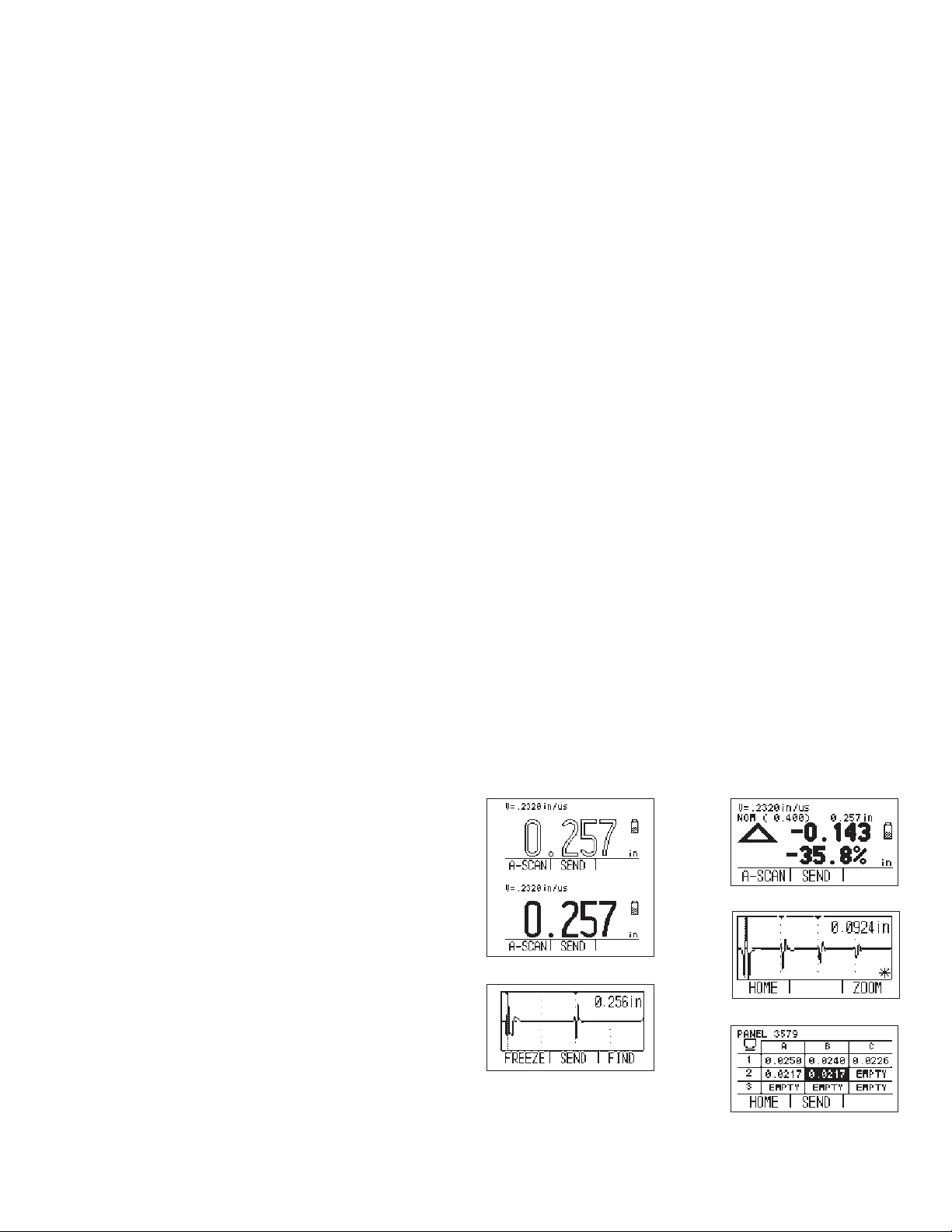

Filled digits indicate successful coupling

Live A-Scan for more precise evaluations

Rate of reduction

Data recorder

Snapshot A-Scan

CL5––Simply reliable, reliably

simple

The Velocity Option: Performance and Flexibility

The CL5 Velocity option gives the user an added measurement

mode used for determining the velocity of a known thickness of

material. Material thickness can be entered manually via the CL5

keyboard or a digital caliper can be connected, allowing the

thickness value to be sent electronically from the caliper to the

CL5. The user simply places the probe on the part, and the CL5

displays the material velocity of the test object. Both the thickness

and the velocity value can be stored in the Data Recorder and

downloaded to the PC.

The Live A-Scan Option

The optional Live A-Scan feature gives the user a real time view of

the echoes being digitally measured by the CL5.

Viewing the Live A-Scan can aid users when attempting to

properly align the probe and the test object to achieve the best

measurement values. Viewing the Live A-Scan enables the user to

ensure the proper echoes are being measured and the digital

value is correct.

The Data Recorder Option

The Data Recorder option permits the quick and easy storage of

thickness values in file form. Fully user-programmable, it stores up

to 10,000 measured values or as many as 500 values with

attached A-Scan.

The programmable data recorder allows creation of data recorder

files directly from the CL5 keypad, or from the PC using the

flexible UltraMATE

®

or UltraMATE®Lite software program. The

Data Recorder supports the use of alphanumeric file names,

standard linear and grid files and custom linear files.

Extended file types store the thickness values, velocity settings

and other critical data for each measurement point, making the

CL5 and UltraMATE

®

ideal for test data management.

Page 3

Achieve More Precision With

Quality View

Quality View Mode permits Data Recorder-driven control and

capture of thickness measurements. It is ideal for singular parts

or structures with numerous measurement points that have

different target thicknesses and/or varying upper and lower limits

or tolerances.

Uses of Quality View Mode include:

1. Fast collection of thickness measurement data for statistical

analysis during variation control and quality assurance.

2. Digitally capturing thickness measurement data for quality

records and traceability.

3. Variation control of work in progress on the manufacturing or

workshop floor.

Quality View Mode displays the current measurement location

name, a bar graphic of the thickness measurement that shows

the lower specified limit value, the nominal/target value, the

upper specified limit and a numerical readout of the

measurement.

Selection of Quality View Mode displays

To work in Quality View Mode, custom four-point linear files are created in either Microsoft®Excel or UltraMate®software applications

on a PC and downloaded to the CL5 using the optional serial or USB cable. Measurements can also be uploaded into a PC for

processing and analysis using Microsoft

®

Excel, UltraMate®or a third party statistics and/or quality software application.

Quality View Mode Out of tolerance dialogue Measurement Review Mode

Numerical value of thickness is filled when

probe is coupled to the location of measurement

Page 4

Model Probe Type Nominal Frequency Contact Diameter Measuring Range (in Mild Steel Unless Noted)

Alpha 2 DFR/CLF4 Standard Delay Line 15 MHz 0.30 in (7.6 mm) 0.007 to 1.0 in (0.18 to 25.4 mm)

Alpha 2 F/CLF5 Fingertip Contact 10 MHz 0.38 in (9.5 mm) 0.060 to 10.0 in (1.52 to 254 mm)

Mini DFR Thin Range Delay Line 20 MHz 0.19 in (4.8 mm) 0.006 to 0.2 in (0.16 to 5.1 mm)

Alpha DFR-P Delay Line for Plastic Materials 22 MHz 0.30 in (7.6 mm) 0.005 to 0.15 in (0.13 to 3.8 mm) in plastic materials

K-Pen Delay Line Pencil Probe 20 MHz 0.065 or 0.090 in (1.7 or 2.3 mm) 0.008 to 0.175 in (0.20 to 4.4 mm)

CA211A Standard Contact 5 MHz 0.75 in (19.1 mm) 0.060 to 20.0 in (1.52 to 508 mm)

g

GE Inspection Technologies: productivity through inspection solutions

GE Inspection Technologies provides technology-driven inspection solutions that deliver productivity, quality and safety. We design,

manufacture and service ultrasonic, remote visual, radiographic and eddy current equipment and systems. We offer

specialized solutions that will help you improve productivity in your applications in the aerospace, power generation, oil & gas,

automotive or metals Industries.

www.ge.com/inspectiontechnologies

© 2007 General Electric Company. All Rights Reserved. We reserve the right to technical modifications without prior notice. GE®is a registered trademark of General Electric Co. Other company or product names

mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affiliated with GE.

GEIT-20206EN (09/07)

CL5 Compatible Transducer Specifications

Environmental Sealing Impact resistant, dust and splash proof, gasket-

sealed, case-tested to IP54

Weight 0.92 lb (420 g) with batteries

Size 7.1 in H × 3.7 in W × 1.8 in D

(180 mm × 94 mm × 46 mm)

Temperature Range Operating: –10 ºC to +60 ºC

Storage: –20 ºC to +70 ºC

Operating Languages English, German, French, Spanish, Italian, Russian,

Japanese, Chinese

Application Software UltraMATE®Lite and UltraMATE

®

Base Instrument Package CL5 precision thickness gauge

Lithium poly battery pack

AC power supply

Plastic carry case

Wire stand

XL couplant sample, 4 oz

Firmware upgrade CD-ROM

Operating manual

Operating instruction card

Certificate of Conformity

Options CL5 AS OPT – Live A-Scan option

CL5 DR OPT – Data Recorder option

CL5 VL – Velocity option

Accessories PCCBL-690 USB PC cable

PCCBL-419 serial PC cable

Li-135 lithium poly battery pack

AC-296 AC power supply

UltraMATE

®

Lite or UltraMATE

®

Data Management software

Measuring Range .005 in to 20.00 in (0.13 mm to 500 mm): depends

on material, probe, surface condition and

temperature

Units and Measuring Resolution Inch – 0.0001, 0.001, 0.01 Millimeter – 0.001, 0.01, 0.1

Material Velocity Range 0.03937 to 0.78736 in/μs 1000 to 19999 m/s

Receiver Bandwidth of 1.0 to 16 MHz at –6 dB

Update Rate User selectable 4 or 8 Hz, up to 32 Hz in Min Cap or

Max Cap mode

Display Type Graphical LCD 64 × 128 pixels

2.25 in × 2.56 in (40 mm × 57 mm) with backlight

and adjustable contrast

Thickness Display Five-digit display with 0.75 in (19.5 mm) height digits

in standard mode and 0.25 in (6.35 mm) height digits

in Thickness + A-Scan mode, solid or hollow digits

coupling indicator, A-Scan view – R.F. mode only

Display Modes Thickness (includes Snapshot A-Scan), Thickness +

Live A-Scan (optional), Minimum Capture, Maximum

Capture, Differential and Rate of Reduction, Velocity

Mode (optional), Quality View Mode (optional)

Supervisor Lockout Alphanumeric password lockout for calibrations,

set-up and Data Recorder

I/O Port Bi-directional serial RS-232: baud rate 1200, 9600,

57600 and 115200

Data Recorder Programmable Data Recorder, 120 files max. on

each 64 MB SD card

File Formats Grid created from instrument keypad. Grid and

Custom Linear files accepted from UltraMATE

®

software.

Power Supply Three AA batteries (Alkaline, NiMH or NiCad) or

custom rechargeable battery pack

Technical Data

Loading...

Loading...