GE ARITECH FP1500 Series, ARITECH DI1552, ARITECH DP1551, ARITECH 1500 Series, ARITECH DP1551T Installation And Maintenance Manual

...Page 1

Series 1500 Analogue Addressable Detectors

Installation and Maintenance Guide

X

Y

Z

[

\

© 2003 GE Interlogix B.V.. All rights reserved.

Version 1.0 / July 2003

1044999

Page 2

Installation and Maintenance

Guide

DESCRIPTION

For general guidelines on system planning, design,

installation, commissioning, use and maintenance,

refer to the EN54-14 (2001) standard and local

regulations.

DI1552 Analogue addressable ionisation smoke detector

DP1551 Analogue addressable optical smoke detector

DT1553 Analogue addressable rate of rise heat detector

DB304 Detector mounting base

S700 Mounting supplement

The S1500 series detectors are designed specifically for use with

the ARITECH FP1500 series of analogue addressable fire

detection control panels. On these systems the control panel

communicates with the individual detectors using a unique data

transmission protocol. The detectors continuously monitor the

environment where they are installed and report any changes in

smoke or heat concentration to the control panel. In turn, the

control panel generates the alarm condition if applicable.

The detectors have indicators that flash in a “pre-alarm” condition

and light continuously in a ”full” alarm condition. The system is

reset at the control panel.

An optional remote indicator (part no. AI300) may be connected

from the mounting base connections and will mimic the detector

indicator.

The DP1551 and DI1552 comply with EN54-7 (2000).

I

NSTALLATION

The detectors must not be exposed to dusty or dirty environments.

During building works or repairs, the detectors must be removed.

Smoke detectors should not be installed in environments where

condensation may be present.

The surface of the detector must not be painted.

Positioning

Smoke and temperature detectors are designed to be positioned

on the ceiling and should be well away from ventilation inlets and

air extractors. Once the location is decided, the detector base

should be fitted first either to the pre-wired mounting box or direct

to the ceiling through the S700 mounting supplement.

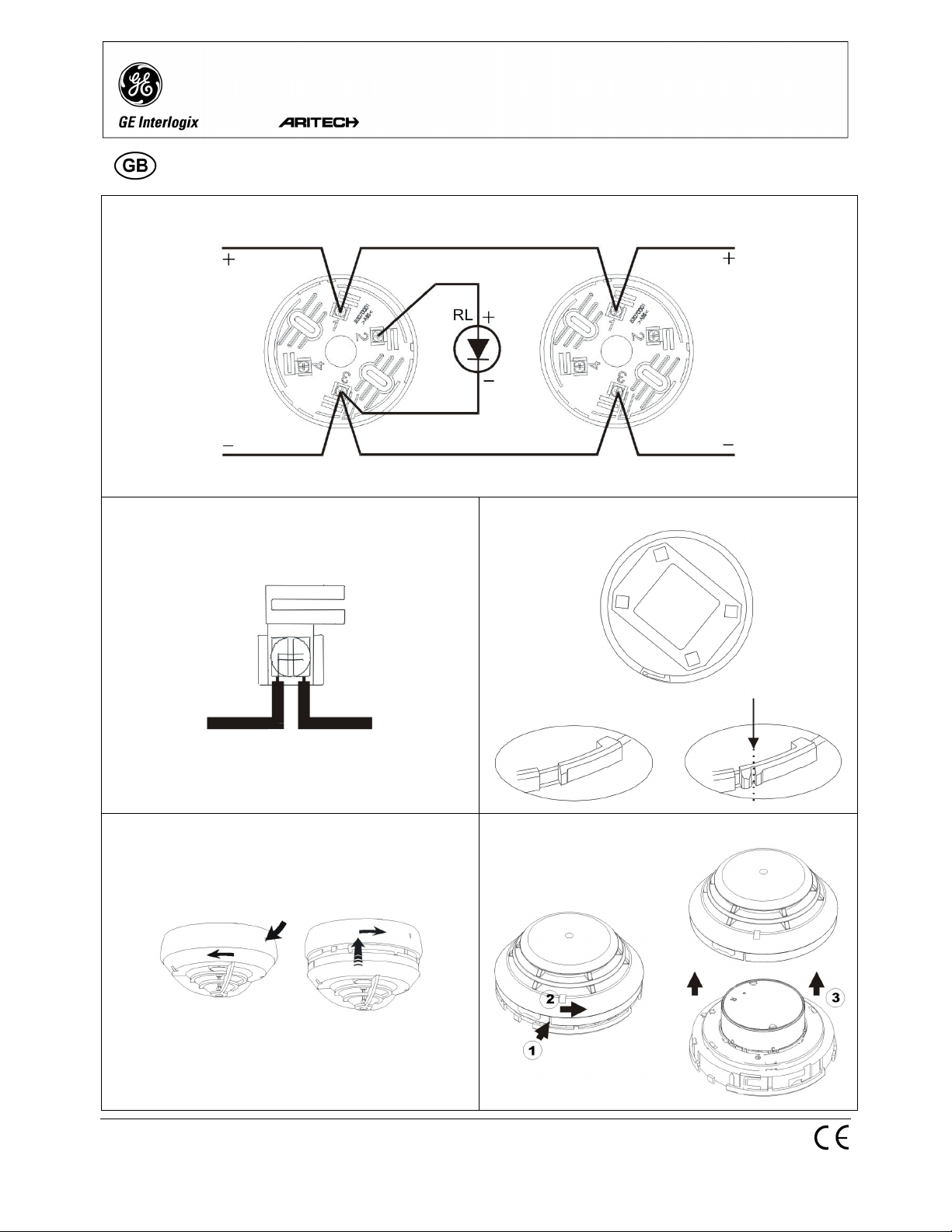

Connections

The detectors must be connected as shown in figure X. The cable

from the last detector on the loop should return to the control panel

to close the loop.

The positive line cable (+) must be connected to terminal 1, and

the negative line (-) to terminal 3. If a remote indicator is used, its

positive line cable (+) must be connected to terminal 2 in the

mounting base and the negative to terminal 3.

To connect the cables in the mounting base, remove a piece of

insulation (about 1 cm in length), pass the cables through the hole

and connect each cable in its proper location. To lock each cable,

unscrew each mounting base connection. Slide the un-insulated tip

of the cable under the metal piece and screw down (figure Y).

Check cable continuity before connecting.

Addressing

Each detector requires a numeric address between 1 and 125 for

identification purposes. The address may be set using the PG700

portable address programmer or the fire system control panel.

Consult the handset or fire panel manual for more full instructions.

Connecting the detector to the mounting base

Once the mounting base is in position, the detector is connected

by inserting it and turning. To remove the detector, turn it in the

opposite direction (figure [).

Locking catch

All of the detector heads have a locking catch to prevent

unauthorised removal.

To enable locking, the locking catch must be broken (figure Z).

After connecting the detector, it will be locked in place.

To remove a locked detector, press through the hole (figure \)

using a screwdriver or similar, and turn.

Testing

• Check that all detectors are properly assembled in their

mounting bases.

• Activate the control panel and check for correct operation.

• Check that all of the installed detectors are recognised by the

control panel. If any detector is not recognised, check that no

duplicate addresses have been assigned, check the correct

assembly of the detector and its connection.

• To test smoke detectors, apply smoke or approved aerosol

and verify alarm condition.

• To test heat detectors apply temperature using for example a

hair dryer and verify that the detector goes into alarm.

Consult the fire panel manual for further test procedures.

M

AINTEN ANCE

In normal environments cleaning should be done at least every

three or four years. It is recommended that random functional tests

be carried out every six months.

DP1551, DI1552

1. Remove the detector form the mounting base

2. Remove the detector cover by pressing the catch with a

screwdriver and turning (see figure 6)

3. Use a vacuum cleaner or clean compressed air to remove the

dust from the chamber.

4. Re-install the detector cover

5. Assemble again the detector in its mounting base and test it.

DT1553

These detectors do not require special maintenance or cleaning.

Only authorised personnel must carry out adjustments.

S

ECURITY CERTIFICATE (DI1552)

KILSEN S.A. radioactive facilities....................................IR-B/197/97

The DI1552 has been approved by Spanish Industry and Energy

Ministry, as EXEMPT from authorisation as radioactive installation.

Approval code .................................................................. NHM-D161

The detector corresponds exactly with approved sample.

Quality system........................................................ ISO9001 certified

Source manufacturer............................. Amersham International plc.

NRPB and CIEMAT laboratories measures done, (following

European Nuclear Energy Agency):

Radioactive source..................................................... Americium 241

Average activity............................... 0.33 ± 0.04 µCi (12.1 ± 1.5 kBq)

Radiation level at 0.1m......................................................0.01 µSv/h

Contamination .................................................................<0.1 Bq/cm

Valid use period is for 10 years. It is forbidden to tamper with the

workings of the unit or to remove any labels or signs. If radioactive

source is suspected of being faulty, please contact KILSEN S.A.

This certificate covers all devices with referred approval code.

2

Page 3

ECHNICAL CHARACTERISTICS

T

DI1552 DP1551 DP1551T DT1553 DB304 S700

Supply Voltage 22-38V 22-38V 22-38V 22-38V

Standby current 200 µA @ 38 V 350 µA @ 38 V 350 µA @ 38 V 250 µA @ 38 V

Alarm current < 11 mA < 11 mA < 5 mA < 11 mA

EMC Standards EN 50130-4, EN

50081-2

Operating

-10 a 60ºC -10 a 60ºC -10 a 70ºC -10 a 70ºC

EN 50130-4, EN

50081-2

EN 50130-4, EN

50081-2

EN-50130-4, EN

50081-2

temperature

Storage

-10 a 70ºC -10 a 70ºC -10 a 70ºC -10 a 80ºC

Temperature

Maximum relative

95% 95% 95% 95%

humidity

Remote indicator AI300 AI300 AI300 AI300

Dimensions 45 x Ø 99 mm 45 x Ø 99 mm 51 x Ø 99 mm 45 x Ø 99 mm Ø 103 x 23

Mounting base DB304 DB304 DB304 DB304

Accessories S700 S700 S700 S700

Terminals 4 screws, washer

Wire cross

1.5 mm²

section

Type of cable Twisted pair Twisted pair Twisted pair Twisted pair

Protection Index IP205 IP205 IP42 IP205

Coverage See EN54-14

(2001) 60-80 m²

Fixing screws Depending on the

See EN54-14

(2001) 60-80 m²

See EN54-14

(2001) 60-80 m²

See EN54-14

(2001) 60-80 m²

Depending on the

type of ceiling 2 x

type of ceiling

35 mm

Installation piping Ø 20 mm

Colour White White White White White White

Weight 116g 109g 78g 43g 23g

Loading...

Loading...