GE Arctica PSS 23 Series, Arctica PSS 25 Series, Arctica PSS 27 Series, Arctica PSS 29 Series Technical Service Manual

Page 1

C

GE Consumer Home Services Training

TECHNICAL SERVICE GUIDE

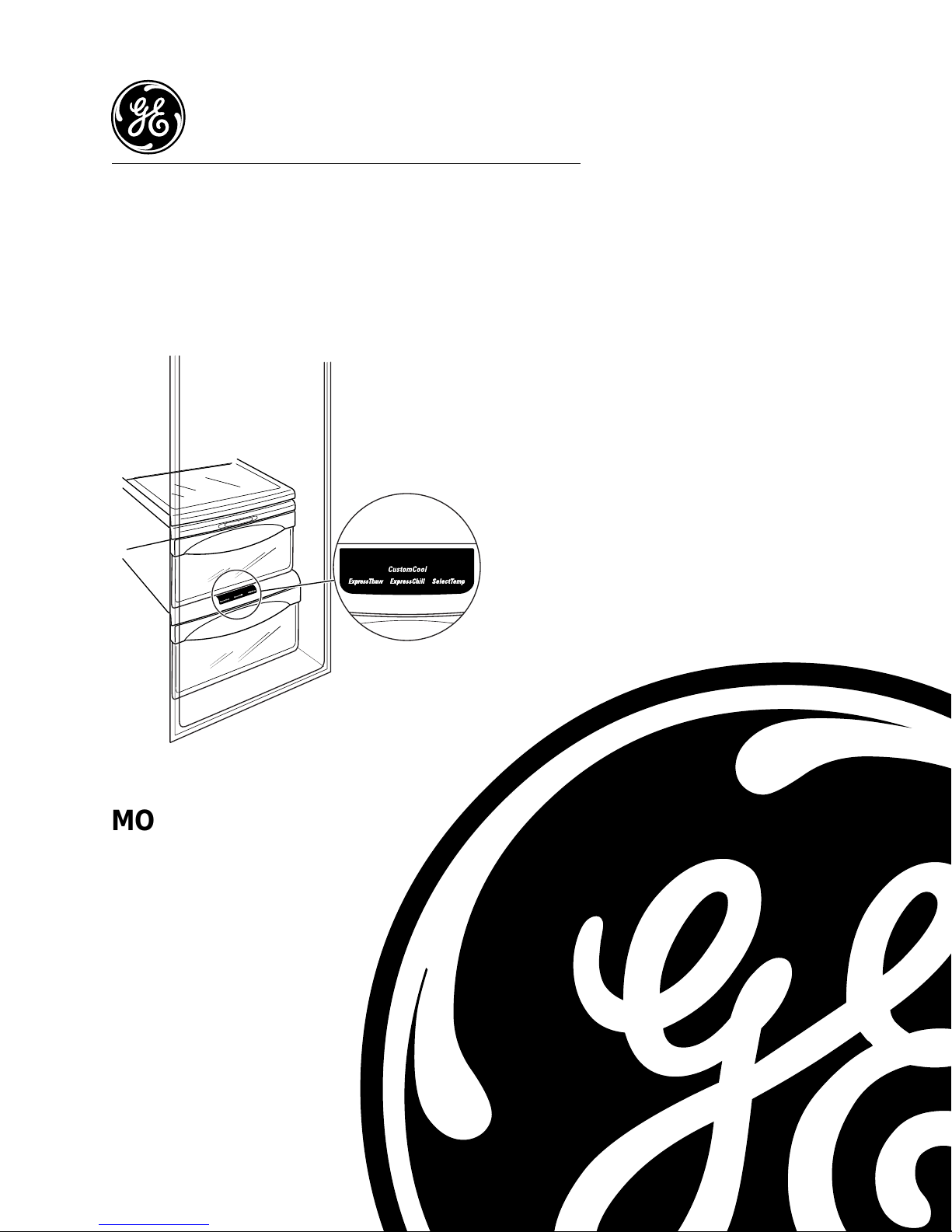

“CustomCoolTM”

MODEL SERIES:

Arctica Side by Side

PSS 23, 25, 27,

29 Cu. Ft.

PUB # 31-9075 06/01

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2001

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Use and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Mechanical Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Diagnosis Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Temperature Resistance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Strip Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Control Board Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Schematic Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Illustrated Parts/Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-20

– 1 –

Page 4

Introduction

2001 Arctica SxS models are being introduced in

response to the requirement for more energy-efficient

refrigerators by mid year 2001, along with having

feature and operation enhancements.

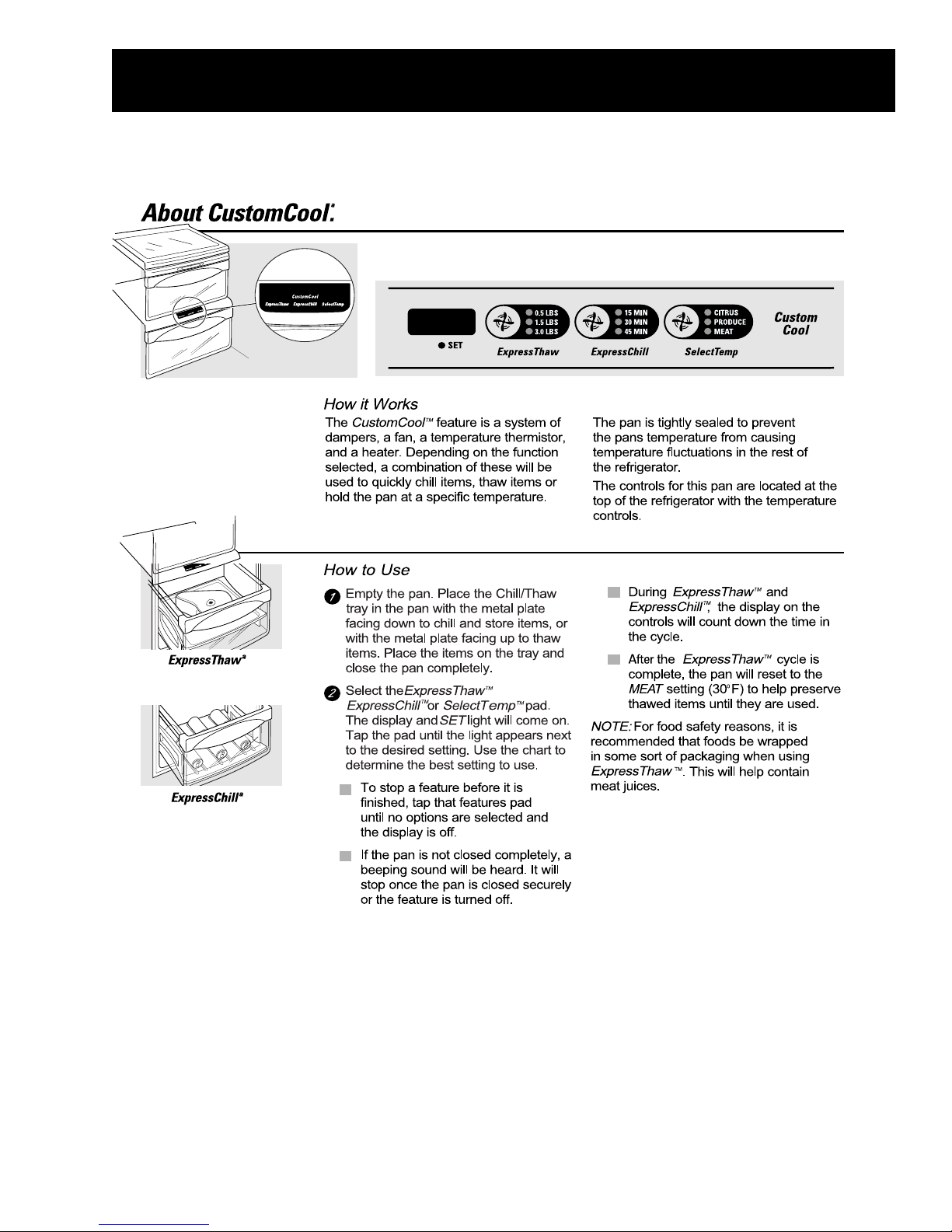

One of the innovative features is the “CustomCool

TM

bin. The system will provide optimum rapid cooling,

(ExpressChillTM) , and safely thaw frozen foods

(ExpressThawTM).

The main system components consist of two air

dampers, a DC exhaust fan, reed switch, control

board with buzzer, 3 color light diodes, a heater, and

a thermistor. These components provide feedback

to the main refrigerator processor board, and control

the temperature and air flow in the “CustomCool

TM

pan at the bottom of the fresh food compartment. A

tray, which has a metal surface on one side is

provided to place the foods on for chill or thaw.

The consumer sets the temperature from the

touchpad controls at the top of the fresh food

compartment, and selects mode of operation, and

length of cycle. Air circulates from the freezer and is

heated or maintained by the thermistor and control

settings.

The CustomCool

TM

pan is tightly sealed and has a

tray which when placed in the metal plate facing

down position, helps provide the chill, and in the metal

plate up position helps to provide thaw. It also

provides a method of catching liquid when thawing

”

and defrosting. The seals in their orginal position are

extremely important in maintaining fresh food and

feature temperatures.

”

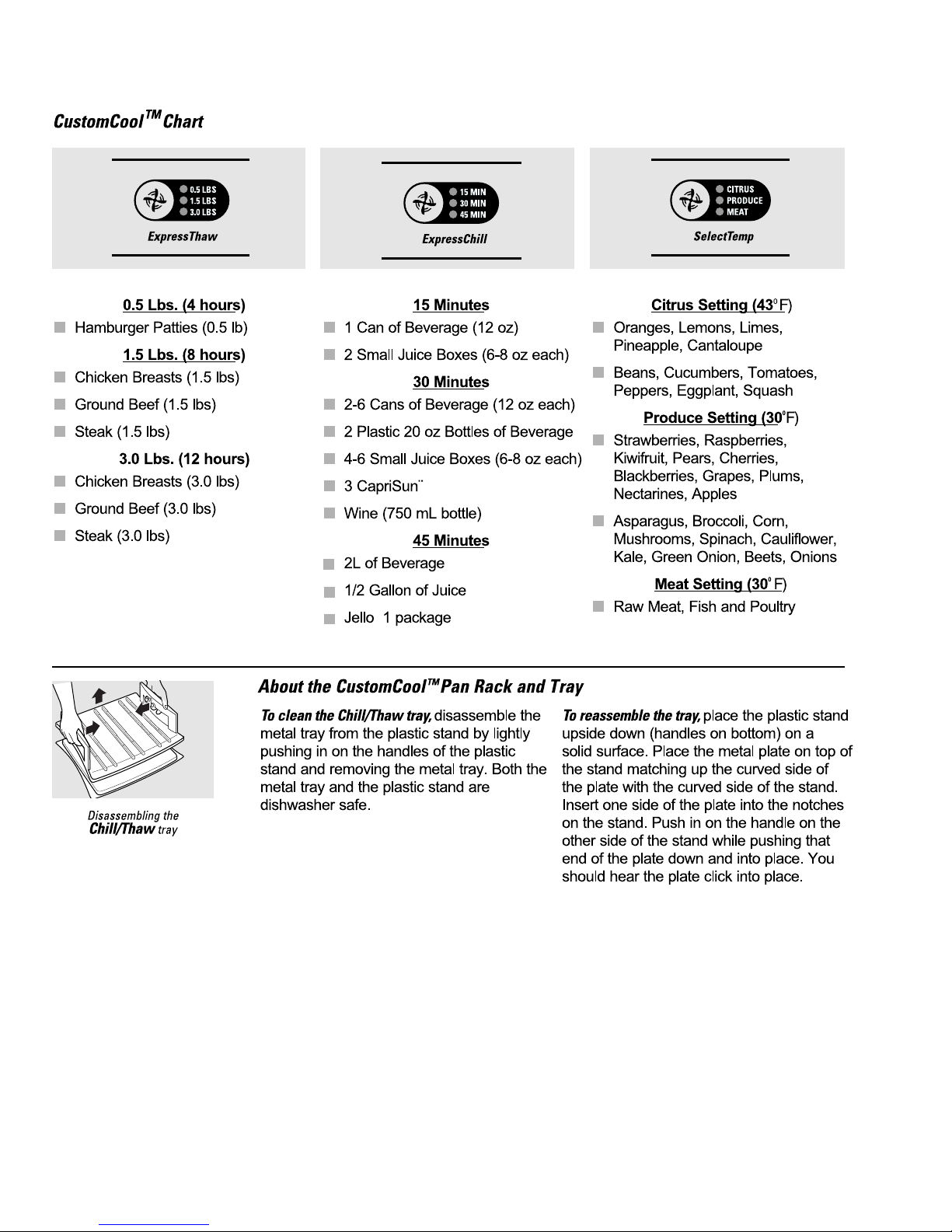

Three selection choices are provided for the

consumer:

• ExpressThaw

(maintains 41

TM

Selection in lbs.

0

)

.5 lbs.(4 hours)

1.5 lbs.(8 hours)

3.0 lbs.(12 hours)

• ExpressChill

TM

Selection in 15 minute

increments

15 Minutes

30 Minutes

45 Minutes

TM

• SelectTemp

Selection in preset

temperatures

Citrus (43

0

43

)

Produce (34

0

F) (Heater/Fan on to maintain

0

F)(Double damper open, no

fan)

Meat (30

0

F) (Double damper open, no fan)

– 2 –

Page 5

Customer Use and Care

– 3 –

Page 6

– 4 –

Page 7

Operation

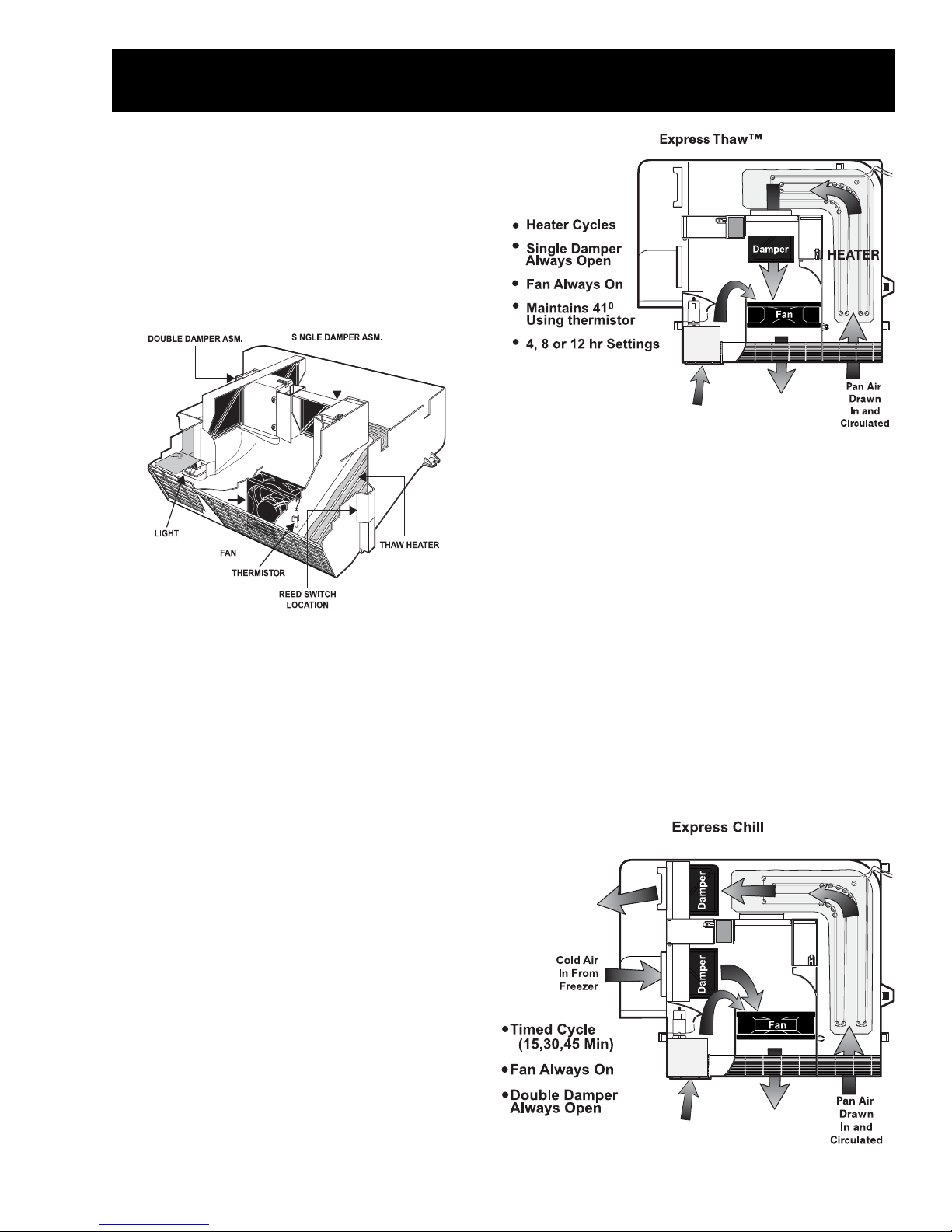

Operation is initated by the consumer when the

selection is made using the touch control at the top

of the fresh food section. The user will have placed

the chill/thaw tray in the proper position, metal

plate facing down for chill, and up for thaw, and

pan closed. A reed switch is mounted on the right

side of the pan to provide a completed circuit when

the pan is tightly closed. Open reed switch

initiates a “beep” from the processor located in the

CustomCool

TM

pan assembly.

The warmed air is circulated through the pan to

satisfy the temperature setting. Response to drastic

temperature change is limited between two and ten

minutes. The main control board located in the rear

of the refrigerator will only respond to 8 degrees of

temperature change per minute as determined by

the resistance of the thermistor.

NOTE: DO NOT MANUALLY FORCE DAMPER

DOORS OPEN, IT WILL DAMAGE THE ASSEMBLY

Based on users input one of the three selections is

selected, with multiple inputs indexing to provide

TIME, WEIGHT, or TEMPERATURE and

countdown LED. One of three leds will light the

selection portion of the touchpad to provide

feedback and selection information to the user.

The signal is then sent to the main processor and

uses preset software parameters to provide DC

inputs to the CustomCoolTM processor board

mounted in the cover assembly.

When the selection is made a thermistor located in

the side of the lower cover sends temperature

information (resistance) to the main processor. The

processor software determines what combination

of dampers or heater need to be used to achieve

the desired setting. (See thermistor temp chart on

page 8).

A double door damper 12VDC operates in the

TM

ExpressChill

mode, and both sides open to allow

cold air to be drawn in and circulated within the lower

cover. The single damper door is also closed to

prevent loss of cold air and it is returned through the

other side of the diverter back to the freezer

compartment. The double door is cycled open and

shut to maintain the temperature selection selected

by the user, based on thermistor resistance

feedback to the main processor board.

TM

Airflow is directed from a diverter in the freezer

side wall to provide cold air or drawn from fresh

food compartment, and is circulated by a 12VDC

fan in the front of the lower cover. When the

thermistor is calling for warmer air the single

damper motor is energized (12VDC) to open and

the 30 watt strip heater is turned on.

– 5 –

Page 8

CustomCoolTM feature has a third temperature preset selection which is SelectTempTM. It shows on the

control panel as Citrus (43

0

F), Produce (340 F) and Meat (300 F). Note airflow, damper, and fan

operation as described below.

SelectTempTM-Citrus Setting

SelectTemp

TM

-Produce Setting

SelectTempTM-Meat Setting

NOTE: After

ExpressThaw

cycle is complete,

the pan will reset to

the MEAT setting

(300 F) to help

preserve thawed

items until they are

used.

TM

– 6 –

Page 9

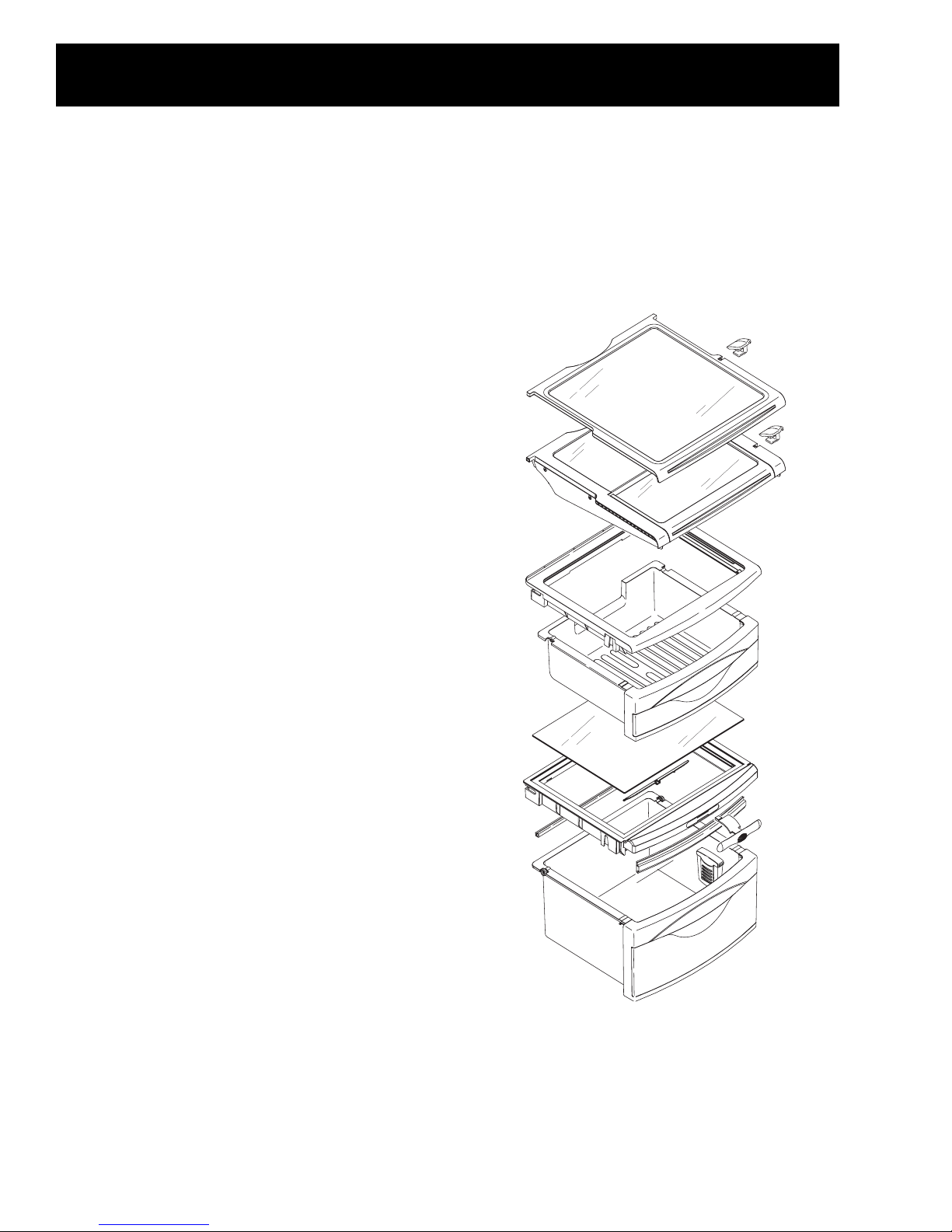

Mechanical Assembly and Disassembly

To Service complete

TM

CustomCool

pan and

Component access.

WARNING: MAKE SURE POWER IS

DISCONNECTED!

To Service Components:

st

1. Remove 1

fresh food section.

2. Lift up and out to remove the CustomCool

front chill cover (WR17X10915).

3. Remove two screws in front of CustomCool

lower cover (WR31X10006), two screws on

either side of the pan, and one screw in the

back of the housing.

and 2nd bin from bottom of

TM

7. Remove the freezer grill mullion (must be

removed prior to CustomCool

(WR02X10829) from the freezer side, by

inserting a #2 Phillips screwdriver into the

center of the diverter and turning the screw

counterclockwise. (See illustration below)

TM

TM

service),

4. Remove two screws holding chill water

reservoir assembly to back of refrigerator, and

plastic deflector cover.

5. In the freezer compartment lift up on freezer

baskets to remove (no need to remove rails),

to completely provide access to the lower air

duct cover.

6. Push in on the plastic lower freezer air tower,

and then push up to remove. It is attached by

two tabs one located on the backside of the

freezer and the other rest on the air diverter

asm.

TM

8. The CustomCool

assembly to the right to free from refrigerator

wall. A large StyrofoamTM insert is located in

the raised end of the upper cover housing,

note position for replacement, it must be

repositioned correctly to reassemble. The

upper cover can be removed, components

exposed.

9. Slots molded into the lower pan hold the fan,

single damper assembly, and dual damper

assembly. Pull up to release and push back

into slot to reassemble.

assembly is now free, slide

– 7 –

Page 10

NOTE: It is critical that all seals be replaced to

maintain proper temperatures in the

CustomCoolTM pan and in the refrigerator.

Several variations in the lighting components at

TM

the CustomCool

bin have been used in limited

numbers. You may encounter a version that has

light tubes, colored diodes on the pan PC board,

or a colored insert. Service is obvious on each

system. The terms CustomCoolTM has been

referred to as QuickChillTM on some models.

– 8 –

Page 11

Diagnostics and Problem Solving

MELBORP NOITULOS

MT

looCmotsuC

MT

wahTsserpxE

.gnikrowton

.wahtt'nseod

tcerrocerusekamotstupniremotsuckcehC.1

.tesneebsahemitdnanoitcnuf

eritnerofsruoh42deen-etadnoitallatsnikcehC.2

MT

looCmotsuCtceffalliw,ezilibatsottinu

.ecnamrofrep

sarevocpotevomerdetcennocsidrewophtiW.3

dna,slaes,kcehcdna6egapnodebircsed

MT

.nib

looCmotsuCtasnoitcennocssenrah

niegakcap-erroemitesaercnI-gnigakcaP.1

.citsalp

tceles-tcudorprofdetcelesthgiewgnorW.2

.thgiewtcerroc

.thgiewregralatceles-tnetnoctafhgihsahmetI.3

.puedislatemhtiwyartwahTehtgnisutoN.4

MT

nib

looCmotsuCfosedishtobnoslaeskcehC.5

.egakaelriarofkooldna

,rotcennocniptaecnatsiserretaehkcehC.6

.ecalpernepo,yakosetacidniecnatsiserssenrah

MT

looCmotsuCninafDCV21kcehC.7

swohstifi,

.nepowohsdluohs,ecalpersgnidaerecnatsiser

niegakcap-erroemitesaercnI-gnigakcaP.1

.citsalp

tceles-tcudorprofdetcelesthgiewgnorW.2

.thgiewtcerroc

.thgiewregralatceles-tnetnoctafhgihsahmetI.3

.nwodedislatemhtiwyartwahTehtgnisutoN.4

MT

nib

looCmotsuCfosedishtobnoslaeskcehC.5

.egakaelriarofkooldna

gnicapsreporpgnisusiremotsucerusekaM.6

.wolfriarof

MT

llihCsserpxE

.llihct'nseod

tcerrocerusekamotstupniremotsuckcehC.7

.tesneebsahemitdnanoitcnuf

eritnerofsruoh42deen-etadnoitallatsnikcehC.8

MT

looCmotsuCtceffalliw,ezilibatsottinu

.ecnamrofrep

sarevocpotevomerdetcennocsidrewophtiW.9

egapnodebircsed

7

dna,slaes,kcehcdna

MT

looCmotsuCtasnoitcennocssenrah

.nib

nepogniwohssiylbmessarepmadtahtkcehC.01

fi,)CDV21(sgnidaerecnatsiserlaminimhtiw

.repmadecalperecnatsisergniwohs

– 9 –

Page 12

MELBORP NOITULOS

.1

potst'nowgnipeeB

deertaht,desolcyllufsinaptahtkcehC

denoitisopyltcerroceratengamdnahctiws

.gnikrowdna

noitcennocssenrahkcehc,blubehtkcehC.1

krowt'nseodnapnithgiL

ecalper,esabnowercsasibluB.tekcosot

.21801X20RWhtiw

nehwysionsitifienimreteddnanetsiL.1

.gninnur

MT

looCmotsuCniysionsinaF

nap

evomer6egapnosnoitcurtsnigniwolloF.2

dnagniriwesoolrofkool,naFtaeserdna

.yrassecenfisserder

– 10 –

Page 13

Thermistor Temperature/Resistance Chart

NOTE: The thermistor’s resistance has a negative coefficient. As the temperature

increases the thermistor’s resistance decreases.

– 11 –

Page 14

Strip Circuits

– 12 –

Page 15

Control Board Connections/Location

– 13 –

Page 16

Schematic Wiring Diagram

NOTE: The feature named CustomCoolTM is

called QuickChillTM on some diagrams.

– 14 –

Page 17

NOTE: The feature named CustomCoolTM is

called QuickChillTM on some schematics.

– 15 –

Page 18

Illustrated Parts Catalog

– 16 –

Page 19

927

920

915

926

946

932

924

921

923

945

925

931

937

929

930

938

947

943

928

940

944

933

939

– 17 –

941

935

934

936

Page 20

View # Cat# Description Usage

216 WR32X10150 BUCKET EGG 1

400 WR01X10209 WHEEL PAN COVER 6

401 WRO1X10214 SCR 10-16 PL PNP 5/8 SZN 6

407 WR32X10190 PAN MIDDLE CHILL ASM 1

409 WR32X10156 GLASS PAN COVR 1

410 WR32X10151 COVER MIDDLE PAN 1

411 GFSFR02 FRESHSAVER FILTER 2PK 1

412 WR02X10684 HOLDER FRESHSAVER 1

413 WR02X10650 HUMIDITY CONTROL 1

414 WR14X10059 GASKET PAN CRV FRONT 1

417 WR021X10633 SLIDE MIDDLE PAN COVER 1

440 WWR17X10793 WINE RACK 1

470 WR32X10149 COVER TOP PAN ASM 1

471 WR32X10147 PAN ASM TOP 1

477 WR17X10921 TRAY DRIP CHILL 1

478 WR17X10922 RACK CHILL 1

487 WR32X10189 PAN ASM CHILL 1

488 WR02X10815 BOSS SPACER 1

489 WR04X10084 NAME PLATE CHILL 1

490 WR17X10914 FRAME CHILL 1

491 WR17X10915 COVER FRONT CHILL 1

492 WR14X10101 SEAL FRONT CHILL 1

493 WR02X10807 WHEEL AND RING ASM 4

– 18 –

Page 21

View # Cat# Description Usage

494 WR02X10813 MAGNETCHILL 1

495 WR14X10098 SEAL SIDES CHILL 2

496 WR14X10097 SEAL AHU CHILL 1

497 WR14X10100 SEAL FRAME & AHU 1

498 WR14X10099 SEAL REAR CHILL 2

499 WR17X10918 PLATE SEAL CHILL 1

501 WR71X10249 SHELF SLIDEOUT ASM 1

503 WR02X10818 LINKAGE PAN CHILL L.H. 1

504 WR02X10819 LINKAGE PAN CHILL R.H. 1

505 WR02X10662 STOP SHELF 3

530 WR71X10247 SHELF TUCKAWAY ASM 1

915 WR02X10829 GRILL MULLION 1

920 WR31X10008 COVER UPPER 1

921 WR31X10006 COVER LOWER 1

922 WR60X10064 FAN CHILL

1

923 WR60X10063 DAMPER ASM DESUPPLY 1

924 WR60X10062 DAMPER ASM SUPPLY 1

925 WR31X10007 PLENUM TOP 1

926 WR31X10009 DUCT CAVITY CHILL 1

927 WR14X10095 GASKET MULLION DUCT 1

928 WR31X10011 GRILL VANES CHILL 1

929 WR02X10820 COVER LED CHILL 1

930 WR51X10049 HEATER THAW 1

931 WR02X10809 RELECTOR 1

932 WR14X10096 GASKET DAMPER CHILL 1

933 WR31X10012 LIGH T SOCKET CHILL 1

– 19 –

Page 22

VIEW # Cat# Description Usage

934 WR02X10812 LAMP 40W CHILL 1

935 WR31X10010 GRILL BULB CHILL 1

936 WR14X10092 SEAL AHU CHILL 1

937 WR23X10203 HARNESS CHILL AC 1

938 WR23X10202 HARNESS CHILL AC 1

939 WR14X10090 SEAL AHU CHILL 1

940 WR23X10204 SWITCH REED CHILL 1

941 WR14X10091 SEAL AHU CHILL 1

942 WR01X10239 WASHER RETAINER CHILL 4

943 WR55X10066 BOARD ASM PAN LED 2

944 WR14X10093 GASKET LC 1

945 WR14X10094 GASKET UC 1

946 WR31X10013 NOISE WALL CHILL 1

947 WR55X10030 SENSOR TEMPERATURE 1

– 20 –

Loading...

Loading...