Page 1

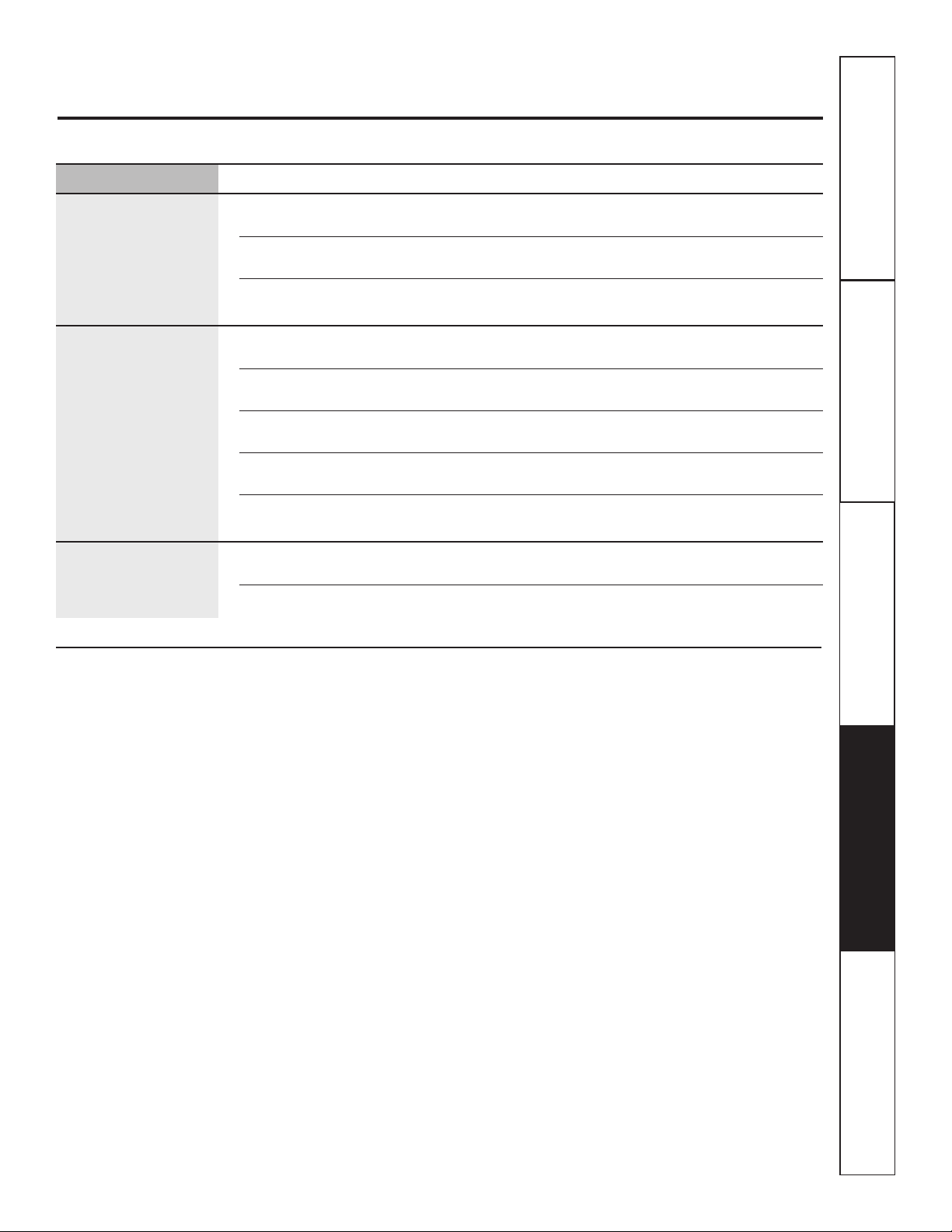

Cool Only Models

AE1CD10AM / AE0CD10AM

AE1CD14DM / AE0CD14DM

AE1CD20DM / AE0CD20DM

Heat/Cool Models

AE1RD10AM / AE0RD10AM

AE1RD14DM / AE0RD14DM

AE1RD20DM / AE0RD20DM

Write the model and serial numbers here

for the indoor and outdoor units:

Indoor Model # __________________

Indoor Serial # ____________________

Outdoor Model #

____________________

Outdoor Serial # ____________________

Find these numbers on a label on the side of

each unit.

Air Conditioners

Mini Split-System

49-7600 05-09 JR

Safety Instructions . . . . . . . . . . . . 2

Operating Instructions

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Care and Cleaning . . . . . . . . . . . . . . .6, 7

Remote Control Features . . . . . . . . 4, 5

Installation Instructions

Air Purging and Leakage Test . . . . . 15

Before You Begin . . . . . . . . . . . . . . . . . . .8

Connection Tubing . . . . . . . . . . . . . . . 11

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 9

Drainage Hose . . . . . . . . . . . . . . . . . . . 11

Electrical Requirements . . . . . . . . . . . . .8

Electrical Wiring . . . . . . . . . . . . . . 12–14

Indoor Unit . . . . . . . . . . . . . . . . . . . . 12, 13

Location . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Outdoor Unit . . . . . . . . . . . . . . . . . . 14, 15

Tubing Hole . . . . . . . . . . . . . . . . . . . . . . . 11

Power Line . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting Plate . . . . . . . . . . . . . . . . . . . 11

Test Operation . . . . . . . . . . . . . . . . . . . . 16

Wiring Indoor Unit . . . . . . . . . . . . . . . . 12

Wiring Outdoor Unit . . . . . . . . . . . . . . 14

Troubleshooting Tips . . . . . . . . 17

Normal Operating Sounds . . . . . . . . 17

Consumer Support

Consumer Support . . . . . . Back Cover

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 18

Owner’s Manual and

Installation Instructions

Climatiseurs

Minibloc

Acondicionador de aire

de sistema mini split

Manuel d’utilisation et

instructions d’installation

Manual del propietario

e instrucciones de

instalación

La section française commence à la page 19

La sección en español empieza en la página 37

Page 2

2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of fire, electric

shock or personal injury.

Use this equipment only for its intended

purpose as described in this Owner’s

Manual.

This system must be properly installed

in accordance with the Installation

Instructions before it is used.

All wiring should be rated appropriate for

the current value listed on the rating plate.

Use only copper wiring.

WARNING!Risk of electric

shock. Can cause injury or death: Earth

connection is essential before connecting

the power supply.

WARNING!Risk of electric

shock. Can cause injury or death: Disconnect

all remote electric power supplies before

servicing.

WARNING!Risk of electric

shock. Can cause injury or death: Repair or

replace immediately all electrical wiring

that has become frayed or otherwise

damaged. Do not use wiring that shows

cracks or abrasion damage along its

length or at either end.

All electrical work must be completed by a

qualified electrician and completed to local

and national building codes and regulations.

Any servicing must be performed by a

qualified individual.

WARNING!Risk of fire. Can

cause injury or death: Do not store or use

combustible materials, gasoline or other

flammable vapors or liquids in the vicinity

of this or any other appliance.

All air conditioners contain refrigerants,

which under federal law must be removed

prior to product disposal. If you are getting

rid of an old product with refrigerants, check

with the company handling disposal.

R410A air conditioning systems require

contractors and technicians to use tools,

equipment and safety standards approved

for use with this refrigerant. DO NOT use

equipment certified for R22 refrigerant only.

SAFETY PRECAUTIONS

READ AND FOLLOW THIS SAFETY INFORMATION

CAREFULLY.

SAVE THESE INSTRUCTIONS

For any service which requires entry

into the refrigerant sealed system,

Federal regulations require the work

be performed by a technician having

a Class II or Universal certification.

Consumer Support Troubleshooting Tips

Operating

Instructions

Safety Instructions

Installation

Instructions

Page 3

3

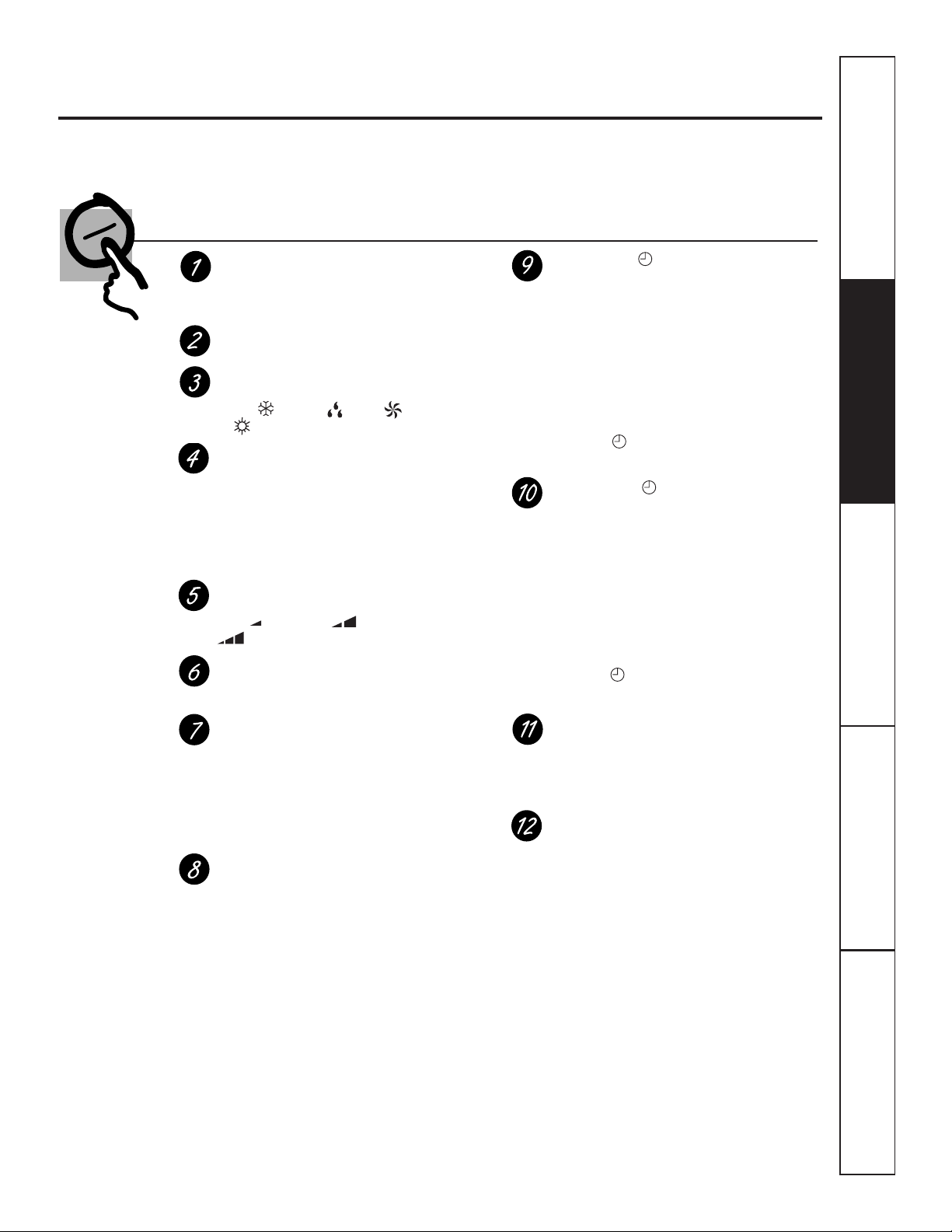

Operating the air conditioner.

GEAppliances.com

General Procedure

NOTE: For best results, point the remote control

at the indoor unit.

Make sure power is connected and press the

ON/OFF pad to start the system.

Press the MODE pad to select the desired

operation mode.

Press the SWING pad for automatic rotation of

the louvers. Press again to stop the rotation.

Press the FAN pad to set the desired fan speed

(AUTO/Low/Medium/High).

Press the TEMP +/– pads to set the desired

temperature

.

NOTE: For detailed remote control instructions, see

About the remote control section.

5

4

3

2

1

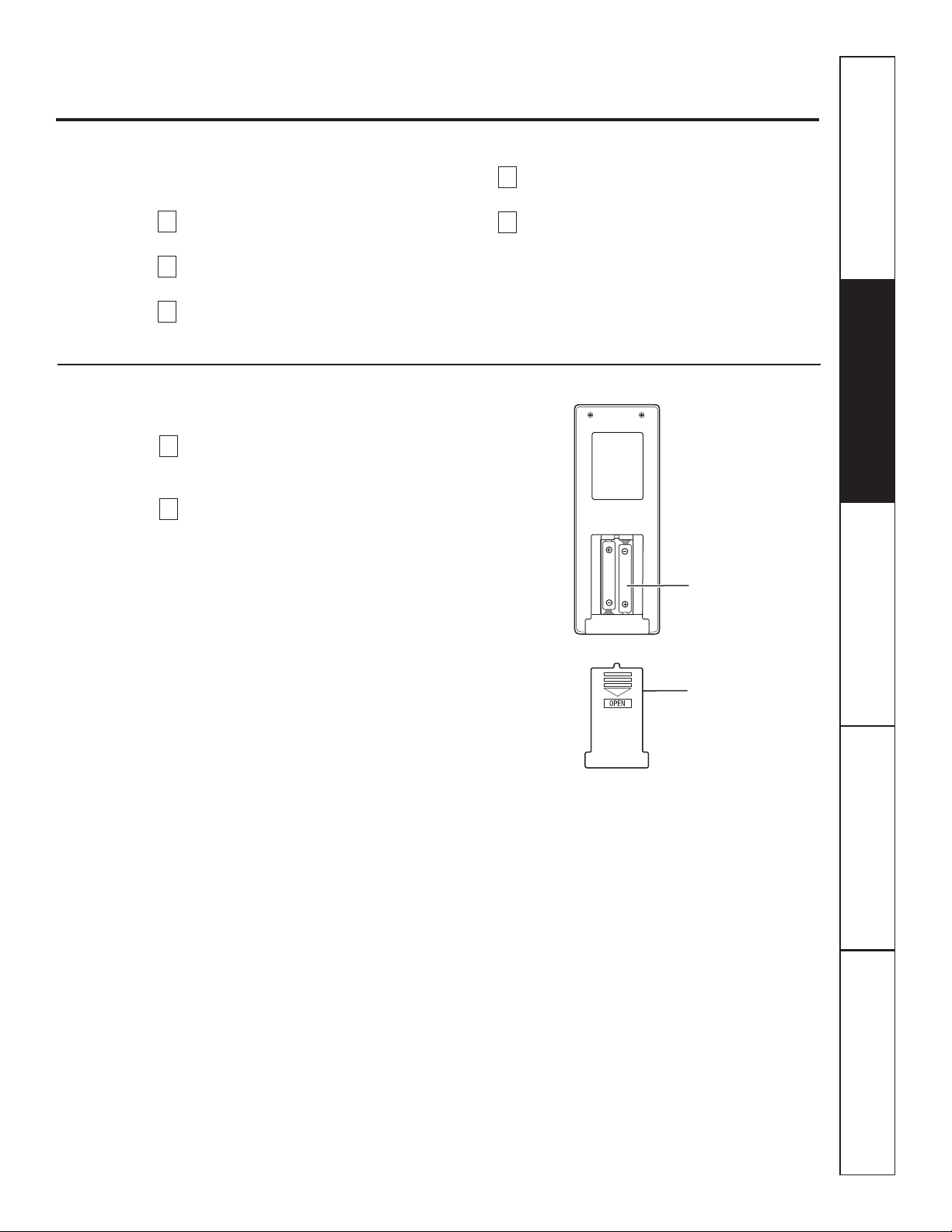

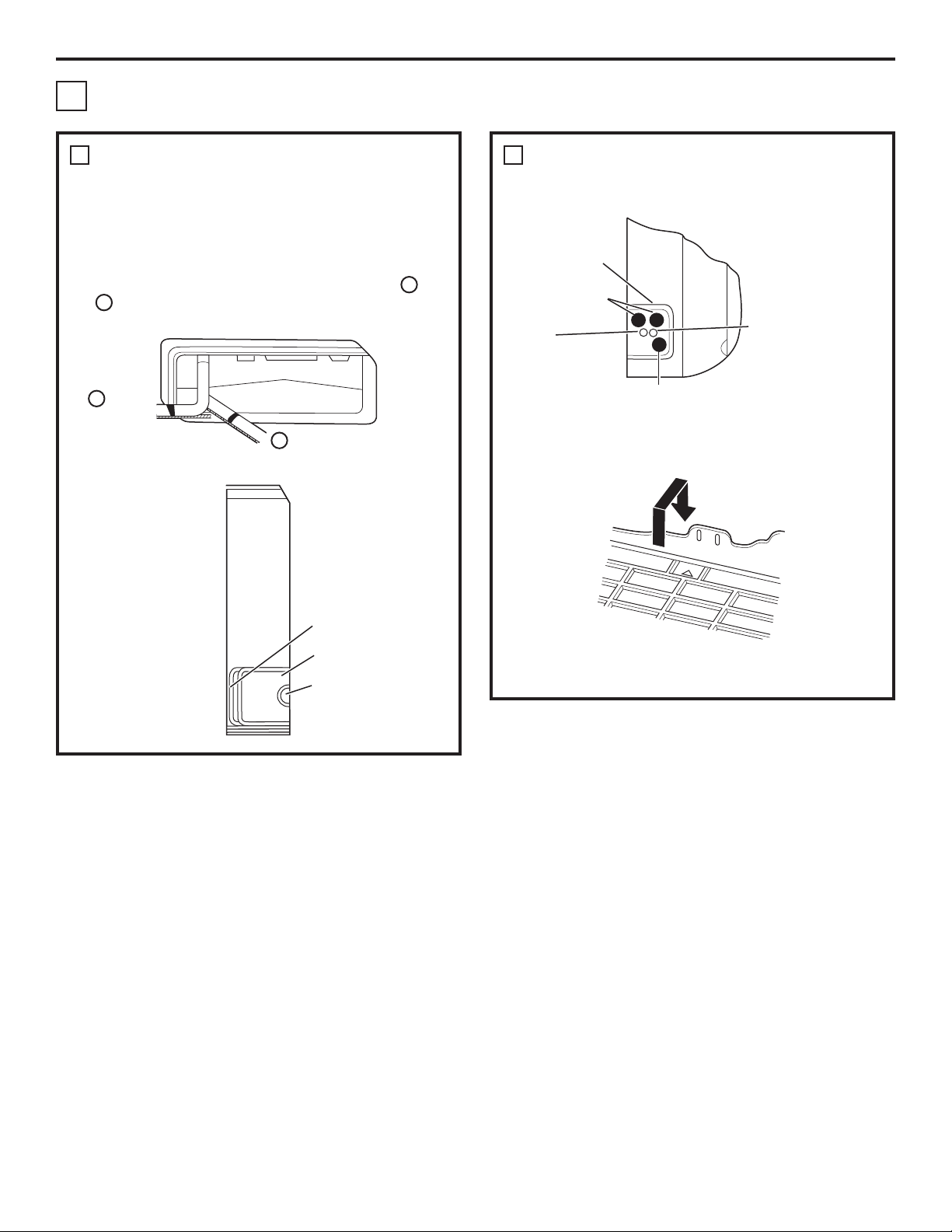

How to Insert Batteries

The remote control uses two AAA batteries.

Remove the cover from the back of the remote

control and insert two new batteries (pay

attention to the polarity).

Reattach the cover.

NOTES:

Do not mix new and used batteries or different

types of batteries.

Remove batteries when the remote control is not

in use for an extended time.

The remote control signal can only be received

within a range of 20 ft.

The remote control should be placed about

3 feet or more away from TV sets or any other

electrical appliances.

2

1

Battery type: AAA

Battery cover

Consumer Support

Troubleshooting Tips

Operating

Instructions

Safety Instructions

Installation

Instructions

Page 4

4

Consumer Support Troubleshooting Tips

Operating

Instructions

Safety Instructions

Installation

Instructions

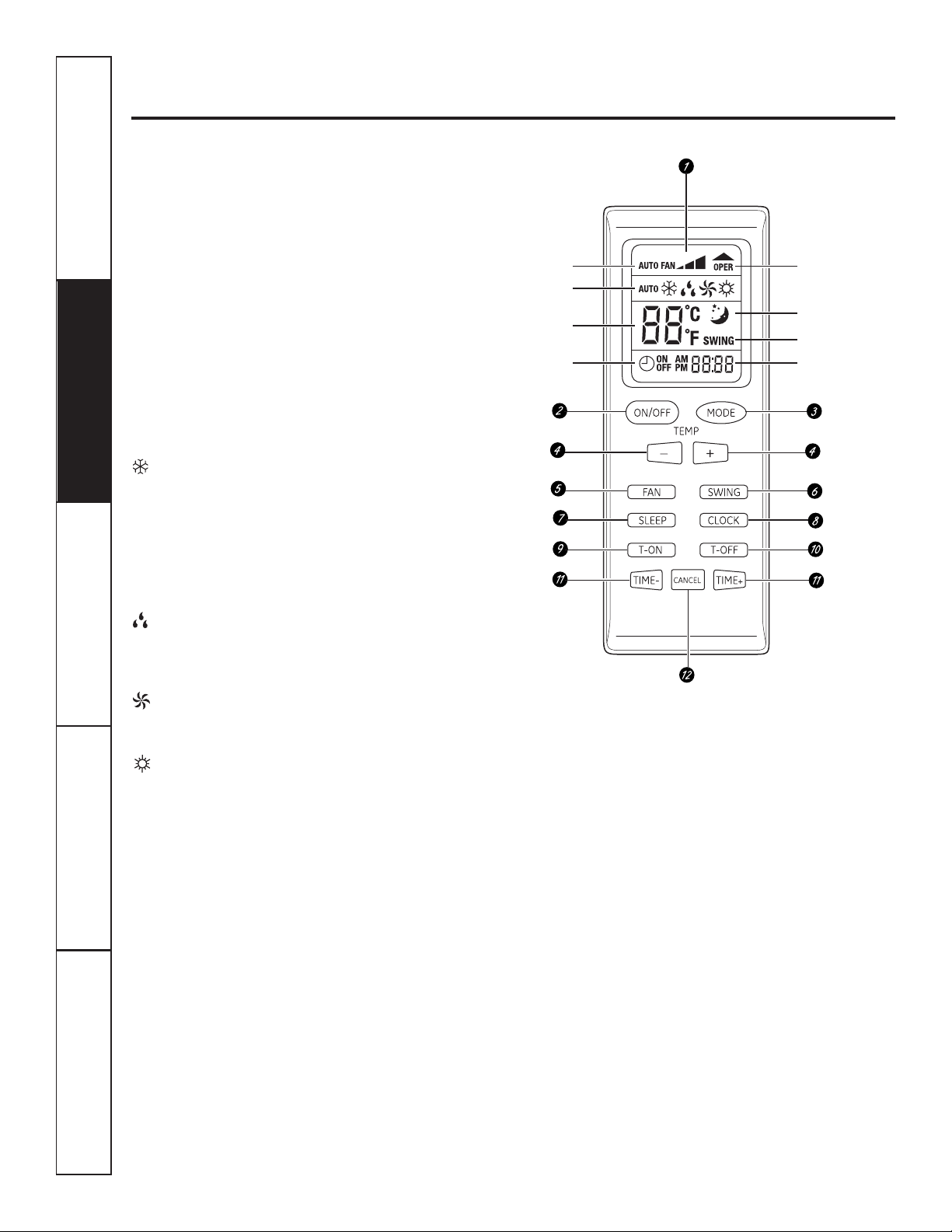

About the remote control

.

The remote control transmits the signals to the system.

Features and appearance may vary.

Fan setting

Mode

Temperature

Timer set

ON and OFF

Operation

Sleep on

Swing on

Clock and timer

AUTO—In this mode, the unit automatically

controls the room temperature within the

range of 77ºF and 68ºF. The fan will run

continuously while the unit is in AUTO mode.

When the room temperature exceeds 77ºF, the

unit will go into COOL Mode. When the room

temperature drops to 73ºF, the fan will

continue to run but COOL Mode will turn off.

When the temperature drops below 68ºF, the

unit will go into HEAT Mode. When the

temperature reaches 73ºF, the fan will

continue to run but HEAT Mode turns off.

NOTE: This temperature range setting cannot

be adjusted and will not be displayed.

COOL—Use to cool the room to the desired

temperature set between 61ºF and 86ºF.

NOTE: The unit will not provide optimum

cooling if the outside temperature is below

60ºF. Under certain conditions, the unit may

activate the antifreeze protection cycle for

approximately 5 minutes to remove ice from

the indoor coil.

DRY—Use to dehumidify the room. The fan will

run at a fixed low speed to provide maximum

dehumidification. The temperature can be set

between 61ºF and 86ºF.

FAN—Use to turn ON and OFF the fan-only

operation. COOL, HEAT or DRY mode will not

be provided.

HEAT (on models so equipped)—Use to warm

the room to the desired temperature set

between 61ºF and 86ºF.

NOTE: The unit will not provide optimum

heating if the outside temperature is below

14ºF. Under certain conditions, the unit may

activate the antifreeze protection cycle for

approximately 8 minutes to remove ice from

the outdoor coil. During this cycle, it is normal

to hear operating sounds such as refrigerant

flowing inside the system.

Page 5

About the remote control.(cont.)

GEAppliances.com

The remote control transmits the signals to the system.

Display

Displays all set contents when turned on.

Displays only the set temperature and time

when turned off.

ON/OFF Pad

Press to turn the system on and off.

MODE Pad

Press to change the operation mode to

AUTO, (COOL), (DRY), (FAN ONLY)

or (HEAT).

TEMP Pads

Press + to increase the set temperature in

1ºF increments. Press – to decrease the set

temperature in 1ºF increments. In the COOL

and HEAT modes, the set temperature can

be selected from 61ºF to 86ºF. The set

temperature will not be displayed in the

AUTO mode.

FAN Pad

Press to change the fan speed to AUTO

FAN, (Low Fan), (Medium Fan) or

(High Fan).

SWING Pad

Press for automatic rotation of the louvers.

Press again to stop them from rotating.

SLEEP Pad

Press to turn the sleep mode on and off.

When in the cooling mode and the sleep

timer is set, the set temperature will

automatically increase 2ºF after the first

hour and 2°F after the second hour. SLEEP

Mode is compatible with COOL, HEAT and

DRY.

CLOCK Pad

Press to set the time of day. Press TIME- or

TIME+ pads to set the time in 1-minute

increments. Press and hold the TIME- or

TIME+ pads to set the time in 10-minute

increments.

T-ON (Timer ON) Pad

When the air conditioner is off, press T-ON

(timer on) to set it to turn on automatically

(using its previous settings) at the time you

set.

Press TIME- or TIME+ pads to set the start

time in 1-minute increments.

Press and hold the TIME- or TIME+ pads to

set the start time in 10-minute increments.

To cancel ON (T-ON), press the CANCEL

pad.

T-OFF (Timer OFF) Pad

When the air conditioner is on, press T-OFF

(timer off) to set it to automatically turn off

at the time you set.

Press TIME- or TIME+ pads to set the turnoff time in 1-minute increments.

Press and hold the TIME- or TIME+ pads to

set the turn-off time in 10-minute

increments.

To cancel OFF (T-OFF), press the

CANCEL pad.

TIME Pads

Use when setting the CLOCK and timers

(T-ON and T-OFF). Press to set in 1-minute

increments. Press and hold to set in

10-minute increments.

CANCEL Pad

Press to cancel the timer(s).

Features of the Remote Control

5

Consumer Support

Troubleshooting Tips

Operating

Instructions

Safety Instructions

Installation

Instructions

Page 6

6

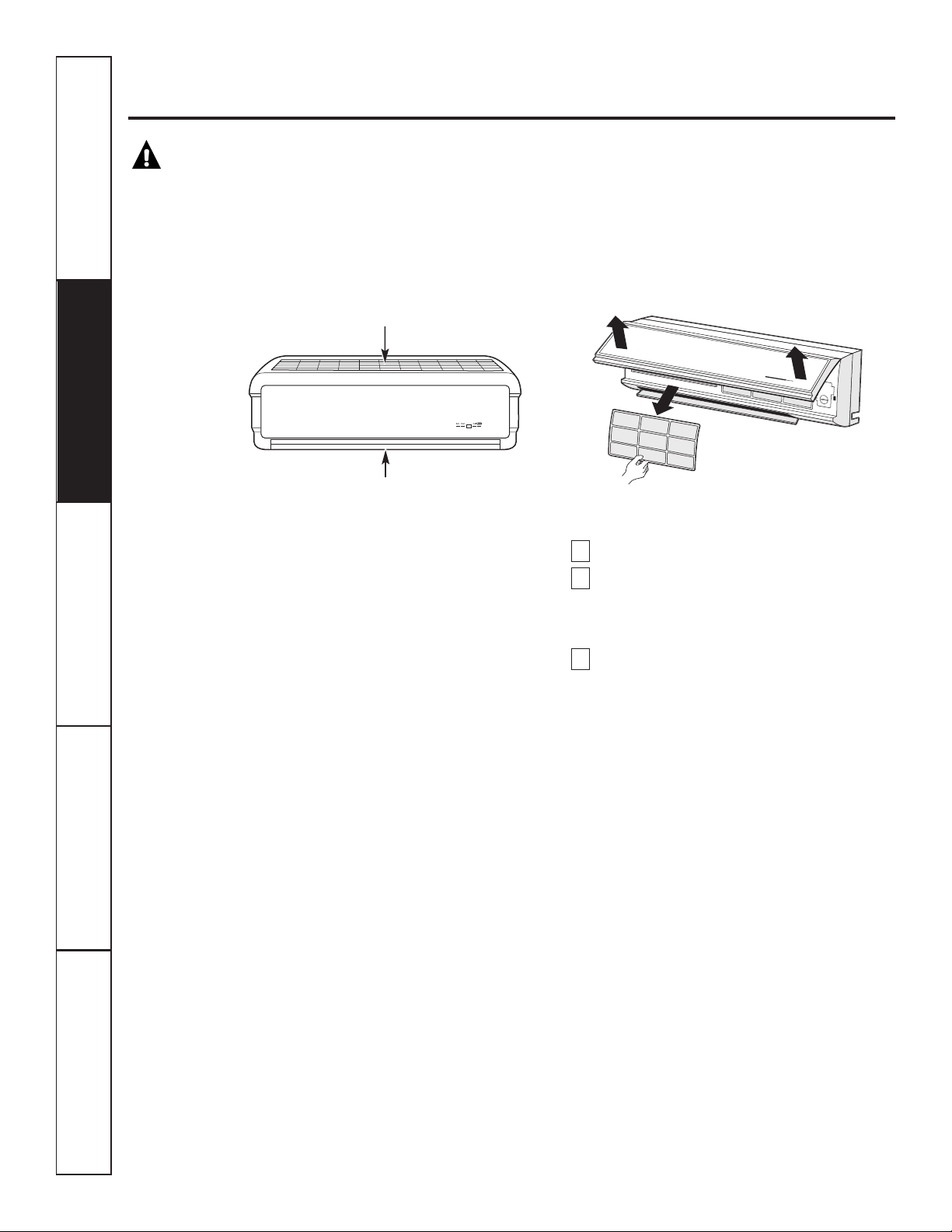

Indoor Unit

Grille, Case and Remote Control

Turn the system off before cleaning. To clean,

wipe with a soft, dry cloth. Do not use bleach

or abrasives.

Air Filters

The two air filters behind the front grille should be

checked and cleaned at least every 30 days or

more often, if necessary.

Open the front access panel.

Pull the filter tab slightly forward to remove the

filter. Clean the filter with a vacuum or warm,

soapy water. Rinse and allow the filter to dry

before replacing it.

Reinsert the filters and close the front access

panel.

NOTE: DO NOT operate the system without a filter

because dirt and lint will clog it and reduce

performance.

3

2

1

Air intake vent

Air outlet vent

Care and cleaning of the air conditioner.

CAUTION:

Before performing any maintenance, turn off the main power to the system.

Consumer Support Troubleshooting Tips

Operating

Instructions

Safety Instructions

Installation

Instructions

Page 7

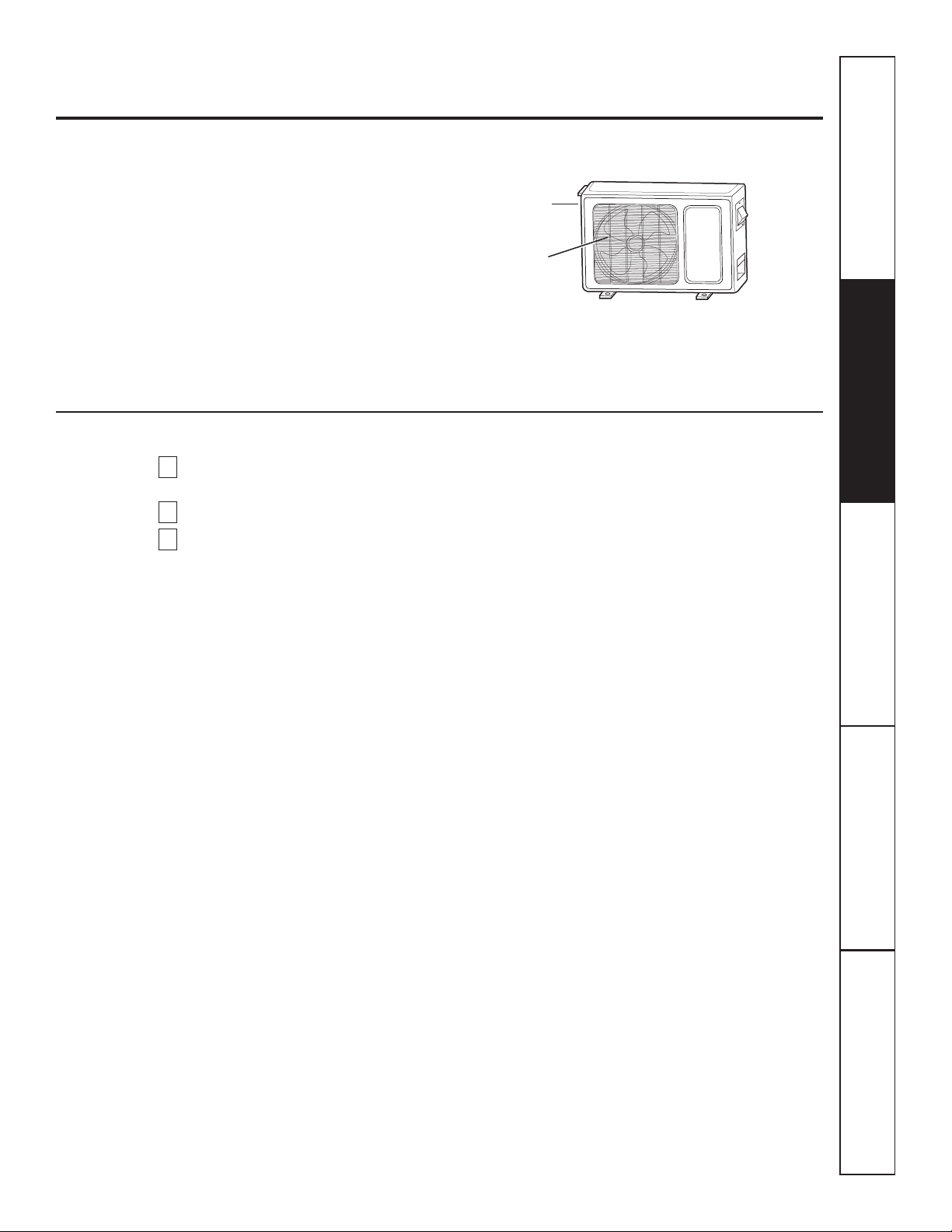

Outdoor Unit

The heat exchanger coils and panel vents of

the outdoor unit should be checked regularly.

If clogged with dirt or debris, the heat exchanger

and panel vents should be professionally

cleaned.

NOTES:

Power supply must be disconnected before

cleaning the outdoor unit.

Dirty or clogged coils will reduce the operating

efficiency of the system and cause higher

operating costs.

Air intake

vents

Air outlet

vent

If you’re closing up for the season…

Operate the system in the fan mode for 2

hours. This will dry out the system.

Remove the batteries from the remote control.

Cover the outdoor unit with a protective cover.

NOTE: Next season make sure to remove the

protective cover from the outdoor unit before

restarting the system.

3

2

1

7

Consumer Support

Troubleshooting Tips

Operating

Instructions

Safety Instructions

Installation

Instructions

GEAppliances.com

Page 8

ELECTRICAL REQUIREMENTS

• Be certain all wiring complies with local building codes and

NEC and that the supply voltage for this system is correct.

The system supply voltage is connected to the outdoor

unit only.

• Check the rating nameplate on the side panel of outdoor

unit for required circuit protection rating and required supply

voltage.

• Use UL-approved electrical branch circuit disconnect

for providing supply voltage to split system indoor and

outdoor units. Locate disconnect within sight and readily

accessible per NEC and local codes.

• All wiring should be rated appropriate for the current value

listed on the rating plate.

• Be certain there is an uninterrupted, unbroken electrical

ground connection.

• Wiring should be encased in liquid-tight tubing with

connections sealed with liquid-tight connectors.

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•

IMPORTANT

— Save these instructions for local

inspector’s use.

•

IMPORTANT —

Observe all governing codes

and ordinances.

• Note to Installer – Be sure to leave these instructions

with the Consumer.

• Note to Consumer – Keep these instructions for future

reference.

• Skill level – A licensed, certified (to handle refrigerant-

R410A, recovery, etc.) technician and a qualified

electrician are required for installation of this split

air conditioning system.

• Completion time – Approximately 2

1

⁄2 hours

• Two people are required to install this unit due to

the weight of the product.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

• For personal safety, this system must be properly

grounded.

• Protective devices (fuses or circuit breakers)

acceptable for installation are specified on the

nameplate of each unit.

• Servicing and installation of the refrigerant system

must be performed only by a licensed, HVAC-certified

technician.

• Make sure to avoid wiring or plumbing inside the wall

when installing.

• For any service which requires entry into the refrigerant

sealed system, Federal regulations require the work be

performed by a technician having a Class II or Universal

certification.

Installation

Instructions

8

CAUTION:

• Do not use an extension cord with this system.

• Aluminum building wiring may present special

problems—consult a qualified electrician.

• When the unit is in the STOP position, there is still

voltage to the electrical controls.

• Disconnect the power to the system before

servicing by removing the branch circuit fuses

or turning the circuit breakers off at the panel.

• DO NOT use equipment certified for R22 refrigerant

only.

Mini Split-System

Air Conditioners

Page 9

9

Installation Instructions

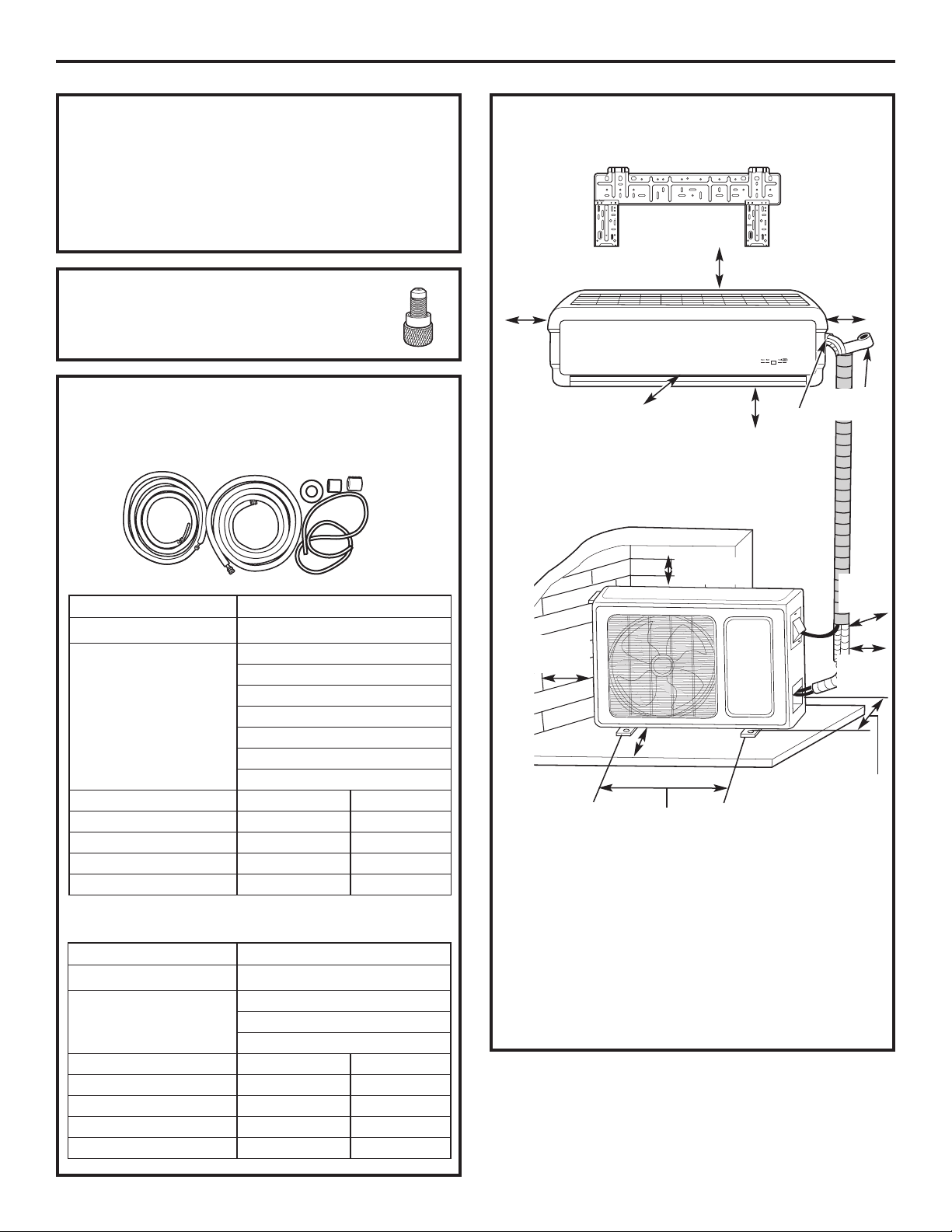

PARTS INCLUDED INSTALLATION DIMENSIONS

IMPORTANT NOTES:

• The installation must be done by a trained

and qualified electrician and technician with

Class II or Universal certification.

• When picking up and moving the units,

you must be guided by trained and qualified

personnel

.

6” or more space

to the ceiling

Wrapping

tape

Tubing hole

sleeve

211⁄4”–10K and 14K BTU models

227⁄16”–20K BTU models

111⁄4”–10K and 14K BTU models

117⁄8”–20K BTU models

6” or more

space to

the wall

79” or more

space to the

floor

118” or more

air outlet side

6” or more

space to

the wall

20” or more space

to the cover

12” or

more air

intake side

20” or more

space to the

wall

12” or more

space to the

wall

79” or more air

outlet side

• Mounting plate

• Sealer

• Screws (5 for 10,000 and

14,000 BTU models/10 for

20,000 BTU models)

• Remote control

• Batteries AAA (2)

• Drainage hose

• Insulation hose

• Two (2) filters

OPTIONAL ACCESSORY KITS

To aid installation, the following tubing kits may be

ordered:

GE Kit TUE1650 TUE3250

For use on models AE1CD10AM

AE0CD10AM

AE1RD10AM

AE0RD10AM

AE1CD14DM

AE0CD14DM

AE1RD14DM

AE0RD14DM

Suction line dia. and length 1/2″ x 16 ft. 1/2″ x 32 ft.

Liquid line dia. and length 1/4″ x 16 ft. 1/4″ x 32 ft.

Tube insulation length 16 ft. 32 ft.

Wall hole sleeves (2) included included

PVC wrapping tape included included

GE Kit TUE1662 TUE3262

For use on models AE1CD20DM

AE0CD20DM

AE1RD20DM

AE0RD20DM

Suction line dia. and length 5/8″ x 16 ft. 5/8″ x 32 ft.

Liquid line dia. and length 3/8″ x 16 ft. 3/8″ x 32 ft.

Tube insulation length 16 ft. 32 ft.

Wall hole sleeves (2) included included

PVC wrapping tape included included

SUPPLIED BY INSTALLER

Adapter: 1/4″ male flare with Schrader

valve x 5/16″ female (1/2″-20UN)

Page 10

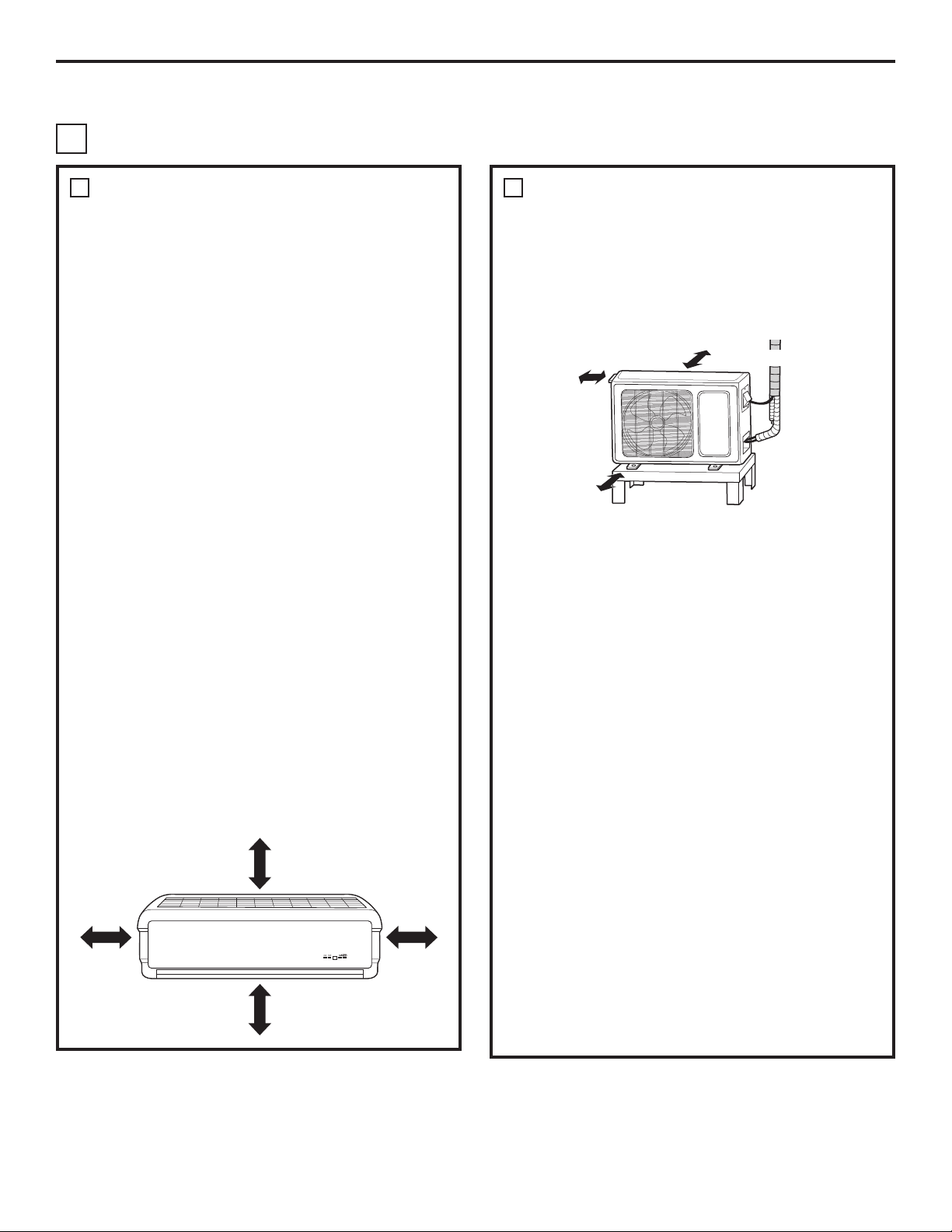

OUTDOOR UNIT

• If an awning is built over the unit to prevent direct

sunlight or rain exposure, make sure that heat

radiation from the condenser is not restricted.

• Ensure that the space around the back and sides

is more than 12″. The front of the unit should have

more than 79″ of space.

• Install in a location that is strong enough to permit

safe installation and to withstand the full weight

and vibration of the unit.

• Construct and anchor a strong and level mounting

base or pad for the outdoor unit.

• Anchor the outdoor unit through its four mounts,

using bolts.

• Select a location from which noise and outflow

air emitted by the unit will not inconvenience

neighbors.

• In humid locations, the unit may sweat and

condensation (water) may drip from it. Take this

into consideration when choosing the location.

• Select a location that has sufficient ventilation.

• Do not cover the inlet and outlet.

• Install unit away from flammable gas or corrosive

gas leaks.

• Be sure the installation conforms to the installation

dimension diagram.

•

Rooftop Installations:

If the outdoor unit is installed on a roof structure,

be sure to level the unit. Ensure the roof structure

and anchoring method are adequate for the unit

location. Consult local codes regarding rooftop

mounting.

B

INDOOR UNIT

• Do not allow any heat or steam near the unit.

• Select a location where there are no obstacles

in front of the unit.

• Make sure that condensate drainage can be

conveniently routed away.

• Do not install near a doorway.

• Ensure that the space around the left and right

of the unit is more than 6″. The unit should be

installed as high on the wall as possible, allowing

a minimum of 6″ from ceiling.

• Use a stud finder to locate studs for mounting and

to prevent unnecessary damage to the wall.

• Install on studs and in a location from which

the condensation water can be drained out

conveniently and that permits easy connection

with the outdoor unit.

• Do not cover the inlet and outlet so that the

outflow air can reach all parts of the room.

• Install in a location that is strong enough to

withstand the full weight and vibration of the unit.

• Be sure that the installation conforms to the

installation dimension diagram.

• Leave enough space to allow access for routine

maintenance. The height of the installed location

should be 79″ or more away from the floor.

• Install in a location that is 3 ft. or more away from

other electrical appliances, such as televisions and

audio devices.

• Select a location that gives you easy access to

remove and clean the filter.

A

Read these instructions completely and carefully; then follow step by step.

More than 6”

More

than 6”

More than 79”

More

than 6”

More than 12”

More than 79”

More than 12”

The platform must

support a minimum of

200 lbs. See Installation

Dimensions for mounting

hole spacing.

SELECT THE BEST LOCATION

1

10

Installation Instructions

Page 11

INSTALL THE CONNECTION TUBING

• Connect the copper tubing with the relevant union

tubes of the indoor unit and tighten the flare nut

of the connection tubes.

NOTE: Be careful when bending the connection

tubes to avoid damaging them.

1. Align the center of the tube flare with the relevant

valve.

2. Screw in the flare nut by hand and then tighten

the nut with spanner and torque wrench. See the

table below for the correct torque.

3. Connecting tube specifications are shown below:

NOTE: Exceeding tightening torque will damage

the copper tubing.

Installation Instructions

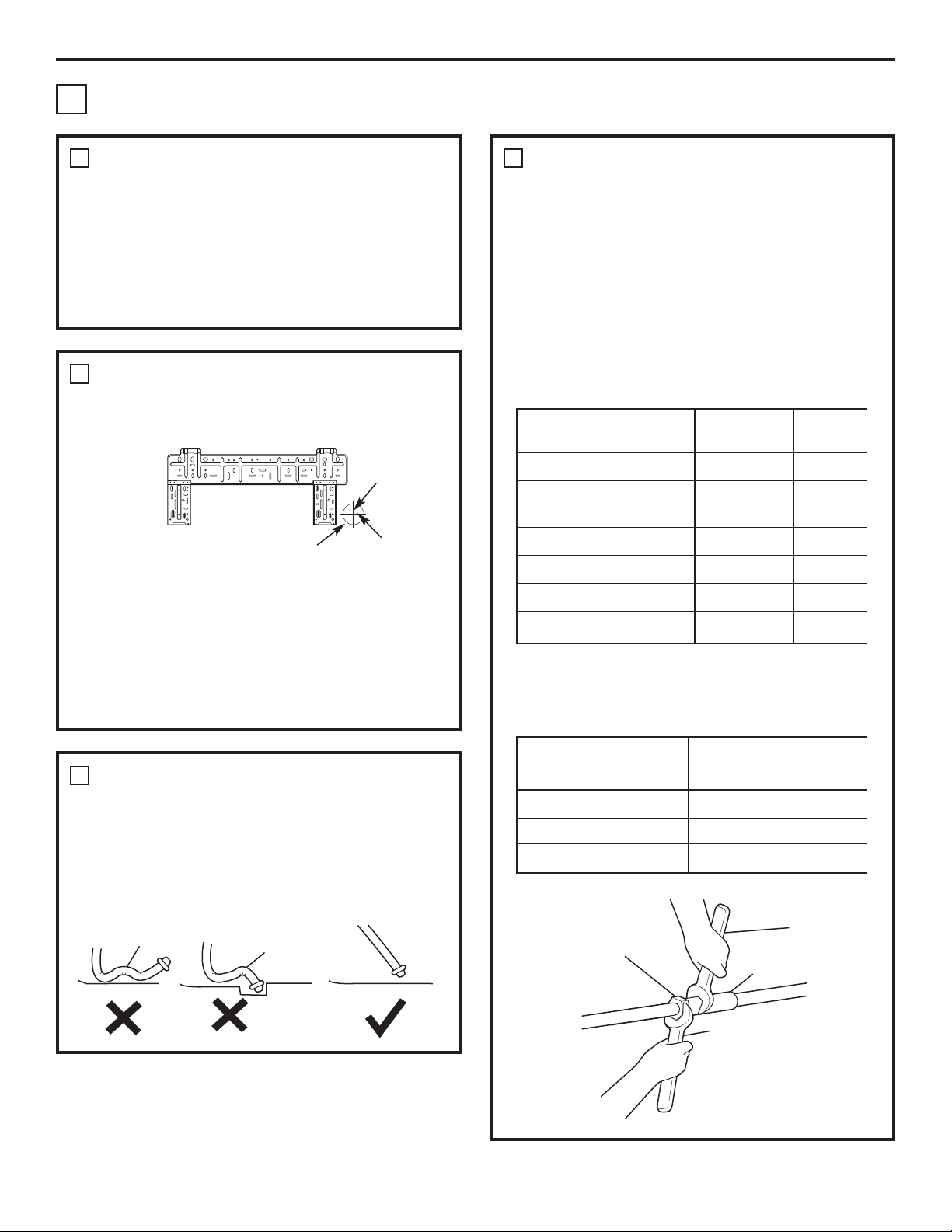

INSTALL THE MOUNTING PLATE

• Always mount the mounting plate horizontally.

• Attach the mounting plate at the selected location

with screws supplied with the unit.

• Be sure that the mounting plate has been

attached firmly enough to withstand the weight

of an adult of 130 lbs. Also, the weight should be

evenly shared by each screw.

1

INSTALLATION

2

INSTALL THE TUBING HOLE

• Make the tubing hole in the wall at a slight

downward slant to the outdoor side.

• To let water drain and prevent damage to wiring

and tubing, insert a 2

1

⁄2″ plastic pipe, cut to a

length equal to the wall depth. Insert the tubing

and wiring through the pipe.

• Copper tubing should be capped until ready to

install flare fitting, to prevent contamination.

2

INSTALL THE DRAINAGE HOSE

• For good drainage, the drain hose should be

placed at a downward slant.

• Do not wrench or bend the drain hose or allow

it to contact standing water.

• The extended drainage tube in the room should

be wrapped with the insulating materials.

3

Bend

Wrenched

Flooded

4

Torque wrench

Flare nut

Joint

Spanner

Tubing OD Tightening torque (in./lb.)

1/4″ 140–170

3/8″ 270–310

1/2″ 440–480

5/8″ 530–570

Tightening torque table

11

11⁄2” from bottom

edge to center of

right tubing hole

3” from right

edge to center of

right tubing hole

Hole is 2” diameter for 10K and 14K BTU

models and 2

1

⁄2” diameter for

20K BTU models.

10,000/14,000 20,000

Specifications BTU Units BTU Units

Design Length 20 ft. 26.2 ft.

Extra Refrigerant Charge 0.16 oz./ft. 0.54 oz./ft.

Per Ft. Above Design Length

Outer Diameter Liquid Pipe 1/4″ 3/8″

Outer Diameter Gas Pipe 1/2″ 5/8″

Max. Distance Height 33 ft. 33 ft.

Max. Distance Length 68 ft. 98 ft.

Page 12

Installation Instructions

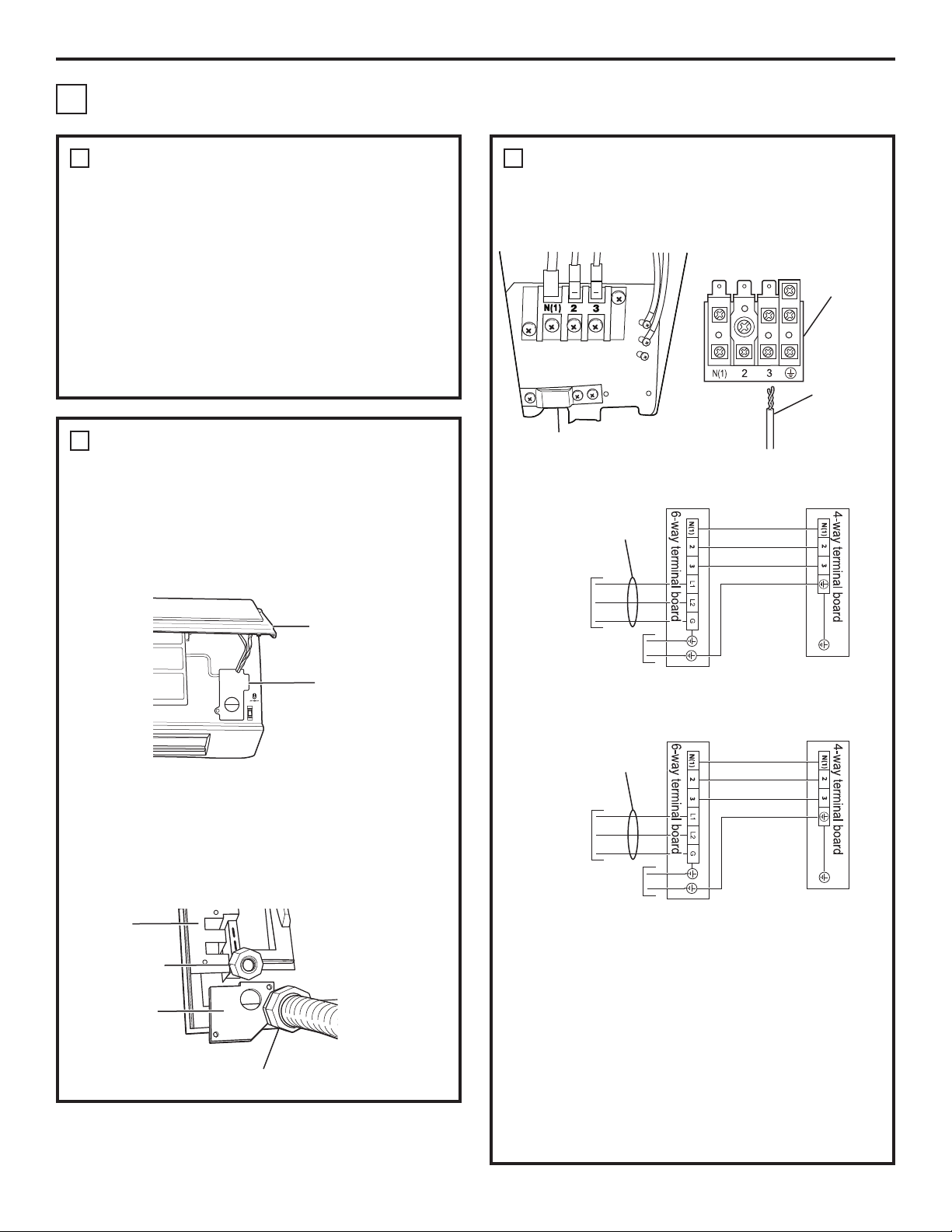

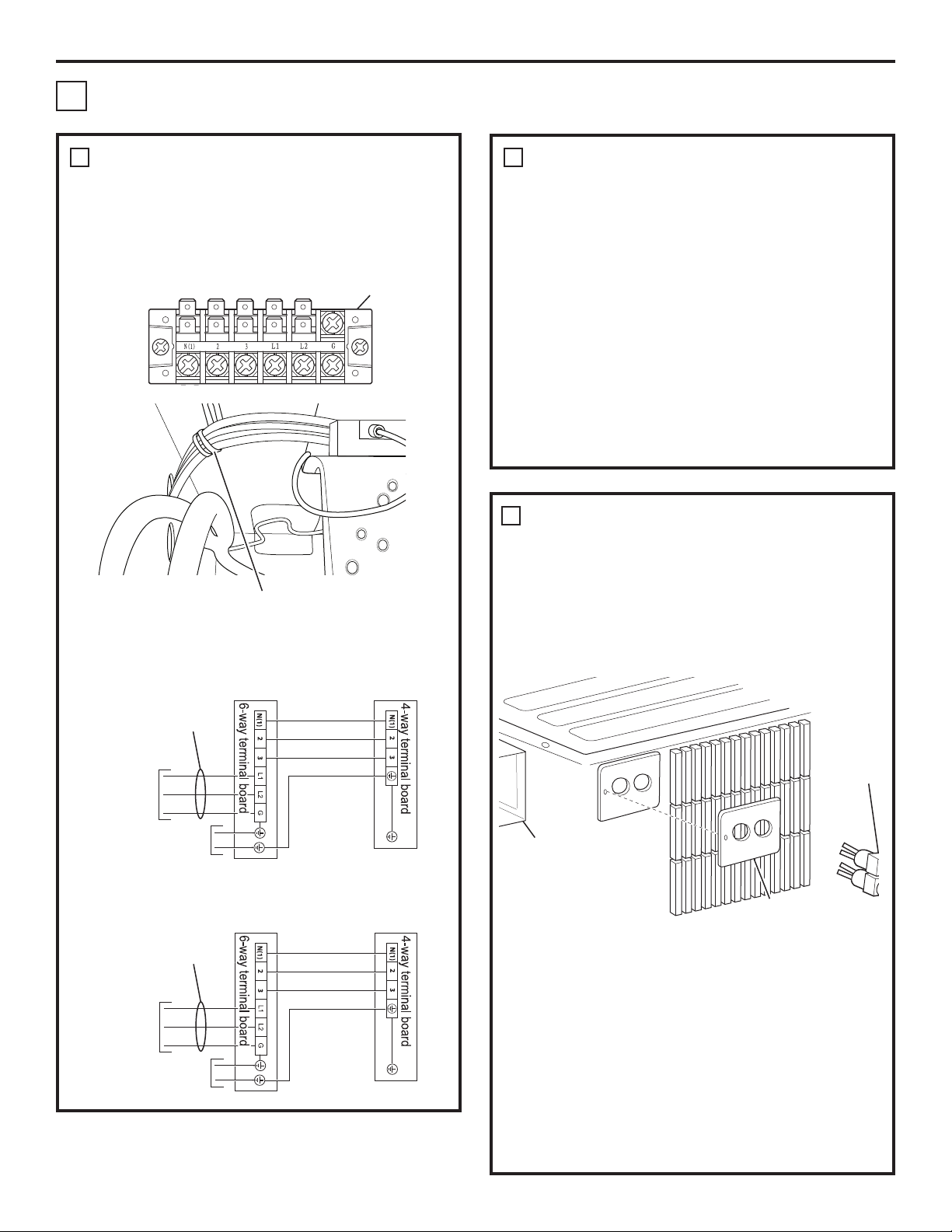

CONNECT ELECTRICAL WIRING

BETWEEN INDOOR AND OUTDOOR

UNITS

• All wiring should be rated appropriately for the

current value listed on the rating plate.

• The power supply should accommodate the rated

voltage.

• Wiring must be done by a qualified electrician

according to local codes, regulations and this

manual.

• All wiring connections should be tightened securely.

5

WIRE THE INDOOR UNIT

NOTE:

Use UL-approved electrical branch circuit

disconnect for providing supply voltage to split system

indoor and outdoor units. Locate disconnect within sight

and readily accessible per NEC and local codes

.

1. Open the front access panel.

2. Remove the cover plate of the electrical box.

3. On the back of the indoor unit, remove the

conduit connecting cover. Using the fixing nut,

connect the conduit to the connecting cover.

Route the wire leads through the unit to the

electrical box area. Reinstall the connecting cover.

6

Cover plate

Access panel

WIRE THE INDOOR UNIT (cont.)

NOTE: Wiring must be done by a qualified electrician

according to the local codes and regulations and

this manual. The connecting wire should be correctly

connected to the circuit interface.

NOTES:

• Wiring should be consistent with the wiring

diagrams above.

• Tighten the nut of the terminal board to keep

the board secured.

• After tightening, the wire cannot be removed

if pulled.

• Incorrect wiring will cause the air conditioner

to work abnormally.

• Incorrect grounding will cause a short circuit.

4. Replace the cover plate over the electrical box

and lower the access panel into position.

6

Conduit

INSTALLATION (cont.)

2

Indoor unit

*L1 will be used for neutral

in 115V models.

Outdoor unit

To branch

circuit

Ground

Power supply

115V Models

4-way

terminal

board

Power

connection

cord

Fixing nut

Back of unit

Connecting cover

12

Electrical wires must be secured

with attached strain reliefs.

Indoor unit

Outdoor unit

To branch

circuit

Ground

Power supply

230/208V Models

Page 13

INSTALL THE INDOOR UNIT

• Route the tubes and wiring from the right side of

the indoor unit. Cut off the tailings from the

chassis as necessary.

1. Cut off tailings 1 when routing the wiring only.

2. Cut off tailings 1 and 2 (or tailings 1, 2 and 3)

when routing both the wiring and tubing. 1 and

2 below are the recommended tubing.

Installation Instructions

13

INSTALLATION (cont.)

2

7

INSTALL THE INDOOR UNIT (cont.)

• Wrap the tubes and wiring and pull them through

the cut-off-tailings hole.

• Hang the mounting slots of the indoor unit on

the upper tabs of the mounting plate and make

sure it is firm enough.

• The height of the installed location should be

79″ or more from the floor.

7

2 Right rear tube

Tailings 2

1 Right

tube

Tailings 1

Tailings 3

Control cord (for

cooling/heating

type only)

Wrapping tape

Connection tubes

Power

connection cord

Drainage hose

Page 14

WIRE THE OUTDOOR UNIT

1. Open the cover of the outdoor unit.

2. The connecting wire lead from the terminal board

of the indoor unit must be connected correctly.

3. The connecting wire should be a little longer so

that it can be maintained easily.

Installation Instructions

14

8

WIRE THE OUTDOOR UNIT (cont.)

NOTES:

• Wiring should be consistent with the above wiring

diagrams.

• Wiring must be correct.

• Tighten the nut of the terminal board to keep the

board secured.

• After tightening, the wire cannot be removed if

pulled.

• Incorrect wiring will cause the air conditioner to

work abnormally.

• Incorrect grounding will cause a short circuit.

• Electrical connections must be made by a qualified

electrician.

• All electrical work must be completed according to

local codes and regulations.

8

INSTALL THE POWER LINE

1. Open the wiring cover and remove the knockouts.

2. The connector should be secured by the nut, and

the wiring cover should be replaced and secured

with the included screw.

3. All wiring should be protected by liquid-tight

tubing, and connections to the wiring cover

should be with liquid-tight connectors.

NOTES:

• The connecting wire and connection tube cannot

touch each other.

• The top cover of the outdoor unit and the electrical

box assembly should be fixed by the screw.

Otherwise, it can cause a fire or a short circuit

caused by water or dust.

• Use a UL-approved electrical branch circuit

disconnect for providing supply voltage to the split

system outdoor unit. Locate the disconnect within

sight and readily accessible per NEC and local

codes.

Connector

Electrical box

assembly

Wiring cover

6-way terminal board

Wrap electrical cords with attached

metal tie to provide strain relief.

10,000 and 14,000 BTU Models

9

Indoor unit

*L1 will be used for neutral

in 115V models.

Outdoor unit

To branch

circuit

Ground

Power supply

115V Models

Indoor unit

Outdoor unit

To branch

circuit

Ground

Power supply

230/208V Models

INSTALLATION (cont.)

2

Page 15

15

Installation Instructions

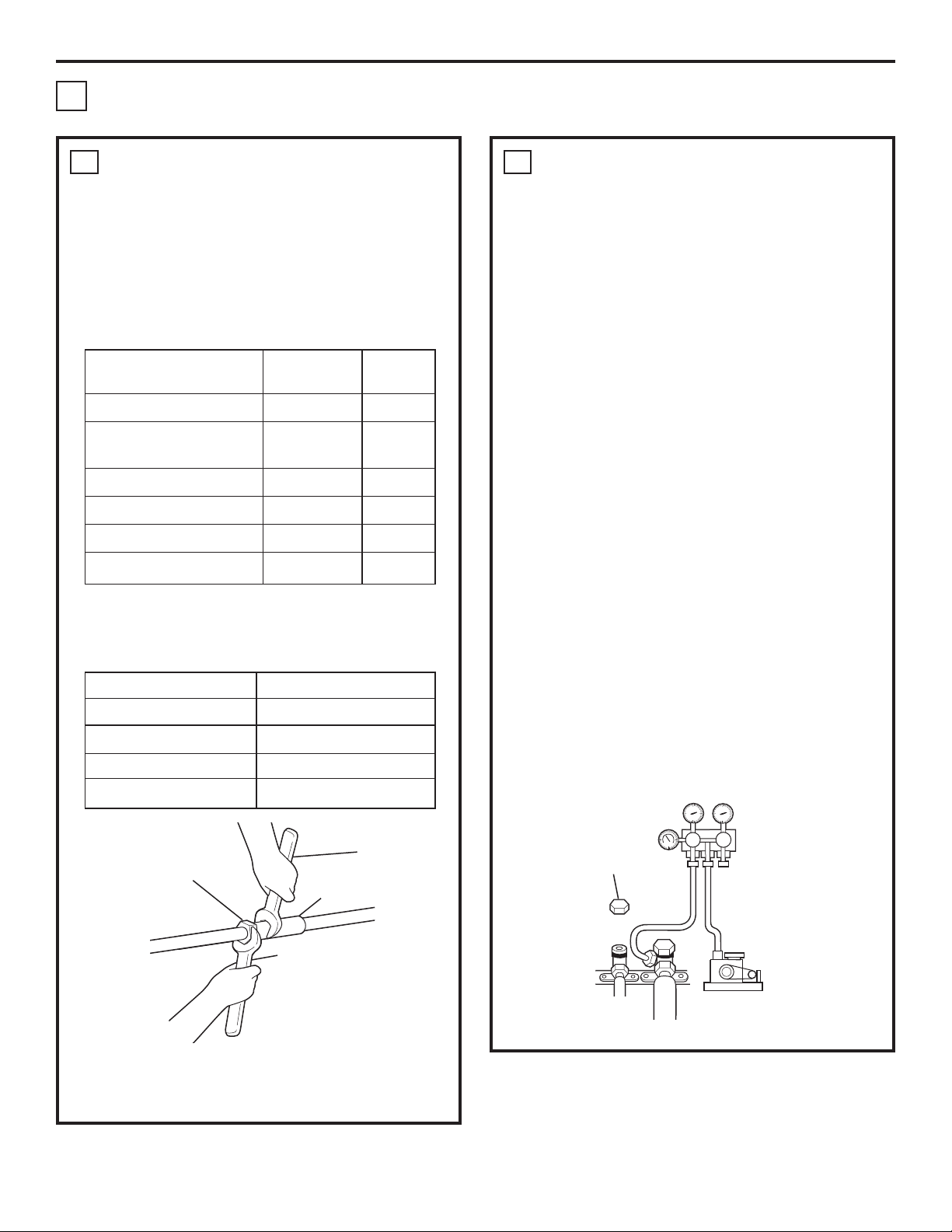

INSTALL THE OUTDOOR UNIT

• Install the connection tube

1. Align the center of the tubing flare with the

relevant valve.

2. Screw in the flare nut by hand and then tighten

the nut with spanner and torque wrench. See

the table below for the correct torque.

3. Connecting tube specifications are shown

below:

NOTE: Exceeding tightening torque will damage

the copper tubing.

NOTE: To prevent wind and pest infiltration,

seal holes around the tubing and wiring with

the supplied sealer.

10

PURGE THE AIR AND

TEST FOR LEAKAGE

1. Install the connecting tubes of the

indoor/outdoor unit.

2. DO NOT OPEN THE GAS VALVES UNTIL THE

EVACUATION PROCESS IS COMPLETE.

3. Remove the gas line service port cap and

connect the gas valves of the vacuum gauge,

vacuum pump and outdoor unit.

NOTE: Connect by using a 1/4″ Female x

1/2″ Male Adapter Access Fitting (obtain locally).

4. Start the vacuum pump. (Running time should

be more than 15 minutes.)

5. Check the vacuum with the vacuum gauge. The

gauge should read -30 in. Hg. After evacuation,

fully close the handle on the manifold valve

(on the vacuum pump device). Then stop the

vacuum pump and disconnect it.

6. The pressure should be kept for 1–2 minutes

to confirm that the reading of the vacuum

gauge does not change. The pressure should

be -30 in. Hg.

7. Remove the vacuum line and replace the service

port cap.

8. Remove both the liquid and gas valve caps.

9. Open the gas and liquid valve entirely, using

the 5 mm Allen wrench. If this is not done, the

performance will be reduced, or an error will

occur.

10. Replace the caps and tighten securely.

11

Cap

Liquid tube

Gas tube

Vacuum pump

Vacuum gauge

INSTALLATION (cont.)

2

Tubing OD Tightening torque (in./lb.)

1/4″ 140–170

3/8″ 270–310

1/2″ 440–480

5/8″ 530–570

Tightening torque table

Torque wrench

Flare nut

Joint

Spanner

10,000/14,000 20,000

Specifications BTU Units BTU Units

Design Length 20 ft. 26.2 ft.

Extra Refrigerant Charge 0.16 oz./ft. 0.54 oz./ft.

Per Ft. Above Design Length

Outer Diameter Liquid Pipe 1/4″ 3/8″

Outer Diameter Gas Pipe 1/2″ 5/8″

Max. Distance Height 33 ft. 33 ft.

Max. Distance Length 68 ft. 98 ft.

Page 16

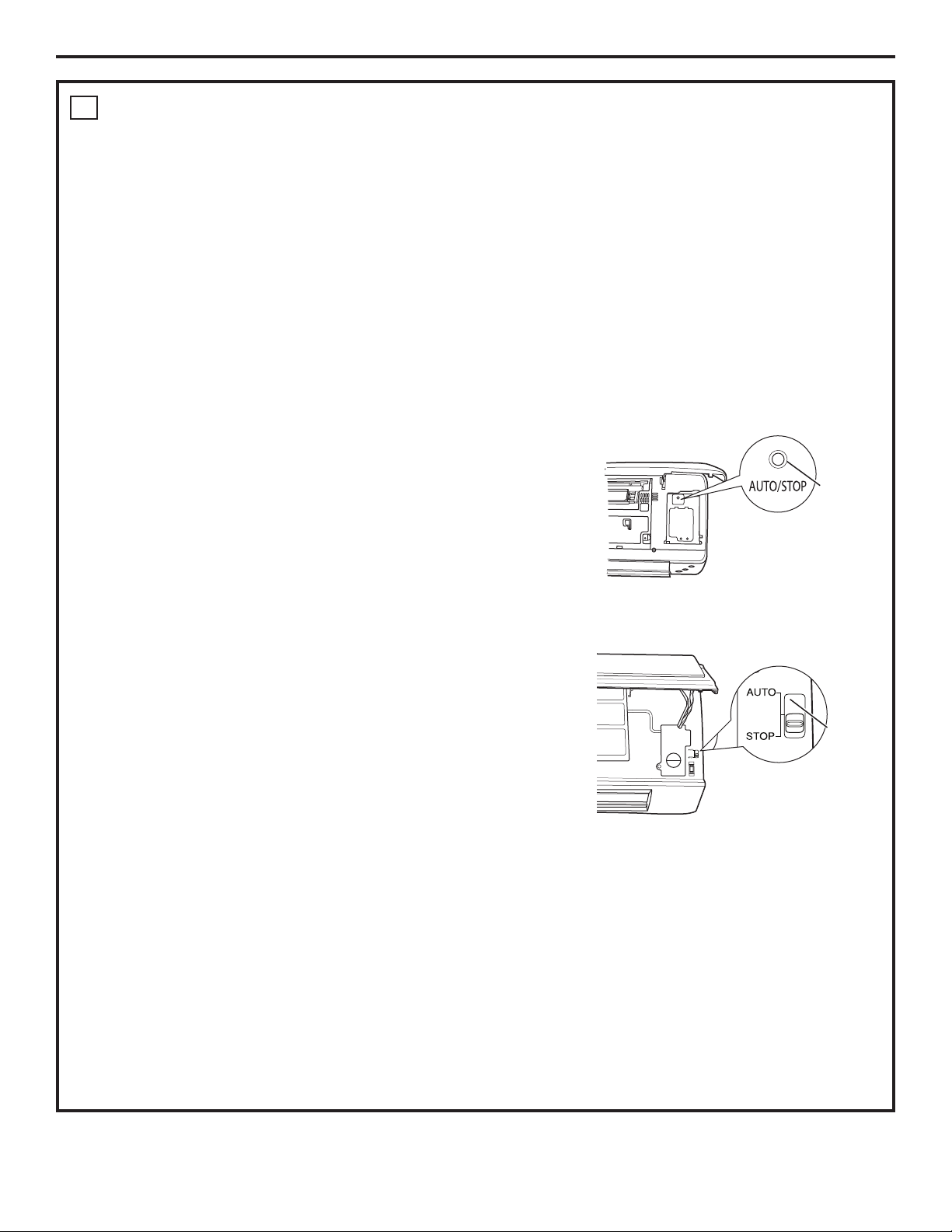

TEST OPERATION AND CHECK AFTER INSTALLATION

Test operation

1. Before test operation

• Do not switch on power before installation is finished completely.

• Electrical wiring must be connected correctly and securely.

• Shut-off valves of the connection tubes should be opened.

• All impurities such as scraps and particulates must be cleared from the unit.

2. Test operation method

• Switch on power and press the ON/OFF pad on the remote control to turn on the air conditioner.

• Press the MODE pad and check the operation conditions of each of the modes.

10,000 and 14,000 BTU models only:

• If the remote control is lost, the emergency run operation can be performed with a ballpoint pen

or similar object.

a. When the unit is off, set the handling switch to the AUTO mode.

The unit will then automatically run in the mode selected by

the microcomputer system according to the surrounding

temperature. If you want to turn the unit off, press the

handling switch again.

b. When the unit is on, set the handling switch to the STOP mode to

turn off the unit.

20,000 BTU models only:

• If the remote control is lost, open the front access panel and

perform the following:

a. Set the handling switch to the AUTO position to operate in the

AUTO mode. Once there is a remote control signal, the unit will

again be controlled by that signal.

b. Set the handling switch to the STOP position to turn off the unit.

Installation Checklist

16

Installation Instructions

13

Handling

switch

10,000 and 14,000 BTU Models

20,000 BTU Models

Has the unit been securely installed? If not, the unit may fall, shake or make noises.

Has the refrigerant leak test been performed? Leakage may cause insufficient cooling capacity.

Does the unit drain well? Poor drainage can cause condensation and dripping.

Is the voltage correct according to the nameplate? Incorrect voltage may cause electrical malfunction. Diagnostic

information is available for this unit. Contact your service technician.

Is the unit properly grounded? A nonsecure ground connection can cause damage.

Are the air inlet and outlet completely free of cover? Covering the air inlet or outlet may cause insufficient cooling

capacity.

Have the length of the connection tubing and refrigerant capacity been recorded? It is important to know these

things for future reference.

Handling

switch

Page 17

17

Before you call for service… GEAppliances.com

Troubleshooting Tips: Save time and money! Review the chart below first and you may not need to call for service.

Normal Operating Sounds

These sounds are common during the

antifreeze cooling or heating modes.

You may hear a sound like water flowing. This

is the sound of refrigerant flowing inside the

system.

A noise that sounds like air being released is a

design feature of dehumidifying water being

processed inside the system.

You may hear a clicking noise when you start

or stop the unit. This sound is the expansion

or contraction of the unit due to changes in

the temperature.

Problem Possible Causes What To Do

The system The fuse is blown/circuit • Check the house fuse/circuit breaker box and

does not start breaker is tripped. replace the fuse or reset the breaker.

The Timer operation is not set •Check the Timer functions and make sure they are

correctly. set to the desired settings.

The unit does not operate when •This is normal. Wait about 3 minutes and the unit

restarted. will restart.

The system does not Airflow is restricted. •Make sure there are no curtains, blinds or furniture

cool as it should blocking the front of the system.

The temperature control may •Turn to a lower or higher setting. The lowest setting

not be set high or low enough. provides maximum cooling.

The air filter is dirty. •Clean the filter at least every 30 days.

See the Operating Instructions section.

The room may have been hot. •When the system is first turned on, you need

to allow time for the room to cool down.

Cold air is escaping. • Check for open furnace floor registers and cold air

returns.

The remote control The batteries are inserted •Check the position of the batteries. They should be

display is faint or incorrectly. inserted in the opposite (+) and (–) direction.

shows no display

The batteries may be dead. •Replace the batteries

.

at all

Consumer Support

Troubleshooting Tips

Operating

Instructions

Safety Instructions

Installation

Instructions

Page 18

18

Split System Warranty.

All warranty service provided by our designated service network.

To schedule service, call 866.404.5245. For service in Canada, contact

Gordon Williams Corp. at 1.888.209.0999. Please have serial number

and model number availa ble when calling for service.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

Consumer Support Troubleshooting Tips

Operating

Instructions

Safety Instructions

Installation

Instructions

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for home use within the USA and Canada. If the product is located in an area where service by a GE

Authorized Servicer is not available, you may be responsible for a trip charge or you may be required

to bring the product to an Authorized GE Service location for service. In Alaska, the warranty excludes

the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney

General.

Warrantor: General Electric Company. Louisville, KY 40225

Service trips to your home to teach you how to use

the product.

Improper installation, delivery or maintenance. If you

have an installation problem, or if the air conditioner is

of improper cooling capacity for the intended use,

contact your dealer or installer. You are responsible for

providing adequate electrical connecting facilities.

Failure of the product resulting from modifications to

the product or due to unreasonable use including

failure to provide reasonable and necessary

maintenance.

In commercial locations labor necessary to move the

unit to a location where it is accessible for service by

an individual technician.

Replacement of house fuses or resetting of circuit

breakers.

Failure due to corrosion on models not corrosion-

protected.

Damage to the product caused by improper power

supply voltage, accident, fire, floods or acts of God.

Incidental or consequential damage caused by possible

defects with this air conditioner.

Damage caused after delivery.

Product not accessible to provide required service.

What GE Will Not Cover:

For The Period Of: GE Will Replace:

One Year Any part of the air conditioner which fails due to a defect in materials or workmanship.

From the date of the During this limited one-year warranty, GE will also provide, free of charge, all labor

original purchase and related service to replace the defective part.

Five Years Any part of the sealed refrigerating system (the compressor, condenser, evaporator

From the date of the and all connecting tubing) which fails due to a defect in materials or workmanship.

original purchase During this four-year limited additional warranty, GE will also provide, free of charge,

all labor and related service to replace the defective part.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this Limited

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by law.

Page 19

Modèles de Refroidissement

AE1CD10AM / AE0CD10AM

AE1CD14DM / AE0CD14DM

AE1CD20DM / AE0CD20DM

Modèles de Chauffage/Refroidissement

AE1RD10AM / AE0RD10AM

AE1RD14DM / AE0RD14DM

AE1RD20DM / AE0RD20DM

Inscrivez ici le numéro de modèle et le numéro de série des unités

extérieures et intérieures:

Numéro de modèle de l’unité intérieure __________________

Numéro de série de l’unité intérieure ____________________

Numéro de modèle de l’unité extérieure

__________________

Numéro de série de l’unité extérieure ______________________

Vous trouverez ces numéros sur l’étiquette apposée sur le côté

de chaque appareil.

Consignes de sécurité . . . . . . . . . . . 20

Consignes d’utilisation

Entretien et nettoyage . . . . . . . . . . . . . . . . .24

Fonctions de la télécommande . . . . 22, 23

Piles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Instructions de montage

Avant de commencer . . . . . . . . . . . . . . . . .25

Branchements . . . . . . . . . . . . . . . . . . . . . . . . 28

Branchement électrique

de l’unité extérieure . . . . . . . . . . . . . . . . . . . 31

Branchement électrique

de l’unité intérieure . . . . . . . . . . . . . . . . . . . . 29

Câblage électrique . . . . . . . . . . . . . . . . 29–31

Câble électrique . . . . . . . . . . . . . . . . . . . . . . . 31

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Emplacement . . . . . . . . . . . . . . . . . . . . . . . . . 27

Essai de fonctionnement . . . . . . . . . . . . . . 33

Exigences electriques . . . . . . . . . . . . . . . . . .25

Plaque de montage . . . . . . . . . . . . . . . . . . . 28

Purge de l’air et test de fuite . . . . . . . . . . 32

Trou pour les tuyauteries . . . . . . . . . . . . . 28

Tuyau de vidange . . . . . . . . . . . . . . . . . . . . . 28

Unité extérieure . . . . . . . . . . . . . . . . . . . 31, 32

Unit intérieure . . . . . . . . . . . . . . . . . . . . . 29, 30

Conseils de dépannage . . . . . . . . . . 34

Bruits normaux de fonctionnement . . . 34

Assistance à la clientèle

Assistance à la clientèle . . . . . . . . . . . . . . . 36

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Assistance

à la clientèle

Conseils de

dépannage

Consignes

d’Utilisation

Consignes

de sécurité

Instructions

de montage

19

Page 20

20

IMPORTANTES CONSIGNES DE SÉCURITÉ.

VEUILLEZ LIRE TOUTES LES CONSIGNES AVANT UTILISATION.

AVERTISSEMENT!

Pour votre sécurité, les informations contenues dans ce manuel doivent être suivies afin

de minimiser les risques d’incendie, de chocs électriques ou de blessures corporelles.

N’utilisez cet appareil qu’aux fins prévues

décrites dans le manuel d’utilisation.

Ce système doit être correctement installé

conformément aux Consignes de Montage

avant toute utilisation.

Tous les câblages devraient être adaptés à

la valeur donnée sur la plaque signalétique.

Utilisez uniquement des câbles en cuivre.

AVERTISSEMENT!

Risque de choc électrique. Peut provoquer

des blessures voire la mort. Il est important

que l’appareil soit branché à la terre avant

de le connecter à l’alimentation électrique.

AVERTISSEMENT!

Risque de choc électrique. Peut provoquer

des blessures voire la mort. Débranchez

toutes les alimentations électriques avant

d’effectuer l’entretien de l’appareil.

AVERTISSEMENT!

Risque de choc électrique. Peut provoquer

des blessures voire la mort. Réparez ou

remplacez immédiatement tout cordon

électrique usé ou endommagé. N’utilisez

pas un cordon fissuré ou présentant des

dommages dus aux frottements soit sur

sa longueur ou aux extrémités.

Tous les travaux électriques doivent

être effectués par un électricien qualifié

conformément aux codes de construction

locaux et nationaux et à la législation en

vigueur.

La maintenance doit être effectuée par

un technicien qualifié.

AVERTISSEMENT!

Risque d’incendie. Peut provoquer des

blessures voire la mort. Ne stockez pas et

n’utilisez pas d’essence ou d’autres vapeurs

et liquides inflammables dans les parages

de cet appareil ou de tout autre appareil.

Tous les climatiseurs contiennent des

fluides frigorigènes qui conformément à la

législation fédérale doivent être retirés avant

la mise au rebut de l’appareil. Si vous mettez

au rebus un ancien appareil contenant des

fluides frigorigènes, vérifiez la procédure à

suivre auprès de la compagnie responsable

de l’élimination.

Pour les systèmes de climatisation

au R410A, il est nécessaire que les

entrepreneurs et les techniciens utilisent

des outils, un équipement et des normes de

sécurité autorisés pour ce fluide frigorigène.

N’utilisez PAS d’équipement certifié pour

le fluide frigorigène R22.

CONSIGNES DE SÉCURITÉ

LISEZ ET SUIVEZ SOIGNEUSEMENT CES CONSIGNES

DE SÉCURITÉ.

CONSERVEZ CES INSTRUCTIONS

Pour tout entretien demandant

l’ouverture du système de réfrigération

étanche, il est requis par la législation

fédérale que les travaux soient

effectués par un technicien certifié

Class II ou Universal.

Assistance

à la clientèle

Conseils de

dépannage

Consignes

d’Utilisation

Consignes

de sécurité

Instructions

de montage

Page 21

21

Utilisation du climatiseur.

www.electromenagersge.ca

Procédure générale

REMARQUE : Pour obtenir de meilleurs résultats,

pointez la télécommande en direction de l’unité

intérieure.

Assurez-vous que l’appareil est branché à

l’alimentation électrique puis appuyez sur la

touche ON/OFF (Marche/arrêt) pour mettre

l’appareil en marche.

Appuyez sur la touche MODE (Mode) pour

sélectionnez le mode de fonctionnement

approprié.

Appuyez sur la touche SWING (Orienter) pour

une orientation automatique des persiennes.

Appuyez de nouveau sur cette touche pour

arrêter le mouvement des persiennes.

Appuyez sur la touche FAN (Ventilation) pour

régler la vitesse souhaitée du ventilateur

(Automatique/Douce/Moyenne/Forte).

Appuyez sur la touche TEMP +/– (Température)

pour régler l’appareil à la température désirée

.

REMARQUE : Pour des instructions détaillées sur la

télécommande, voir la section A propos de la

télécommande.

5

4

3

2

1

Comment insérer les piles

Deux piles AAA sont nécessaires au fonctionnement

de la télécommande.

Enlevez le couvercle du logement au dos de la

télécommande et insérez deux nouvelles piles

(attention aux polarités).

Remettez le couvercle.

REMARQUES :

Ne mélangez pas des piles neuves et des piles

usagées et n’utilisez pas des piles différentes.

Retirez les piles de la télécommande si vous

prévoyez de ne pas utiliser le système pendant

une longue durée.

Le rayon d’action de la télécommande s’étend

jusqu’à 6,1 m (20 pieds).

La télécommande doit être placée à 1 m (3 pieds)

ou plus d’un téléviseur ou de tout autre appareil

électrique.

2

1

Type de piles : AAA

Couvercle du logement

de batterie

Assistance

à la clientèle

Conseils de

dépannage

Consignes

d’Utilisation

Consignes

de sécurité

Instructions

de montage

Page 22

22

Assistance

à la clientèle

Conseils de

dépannage

Consignes

d’Utilisation

Consignes

de sécurité

Instructions

de montage

A propos de la télécommande

.

La télécommande transmet les signaux au système. Les fonctions et l’apparence peuvent varier.

Réglage du

ventilateur

Mode

Température

Marche et arrêt

de la minuterie

Marche

Fonction nuit

activée

Fonction Swing

(Orienter) activée

Horloge et

minuterie

AUTO (Automatique)—Dans ce mode, l’unité

maintient la température de la pièce entre

25 °C (77°F) et 20 °C (68 °F). Le ventilateur fonctionne

en continu pendant que l’unité est en mode AUTO.

Lorsque la température de la pièce dépasse

25 °C (77 °F), l’unité passe au mode COOL

(Refroidissement). Lorsque la température de

la pièce descend en dessous de 23 °C (73 °F),

le ventilateur continue à fonctionner mais

le mode COOL (Refroidissement) s’éteint. Lorsque

la température de la pièce descend en dessous

de 20 °C (68 °F), l’unité passe en mode HEAT

(Chauffage). Lorsque la température de la pièce

atteint 23 °C (73 °F), le ventilateur continue à

fonctionner mais le mode HEAT (Chauffage) s’éteint.

REMARQUE : Le réglage de cette gamme de

température ne peut être modifié et ne sera

pas affiché.

COOL (Refroidissement)—Est utilisé pour

refroidir la pièce à des températures variant

de 16 °C (61 ºF) à 30 °C (86 ºF).

REMARQUE : L’unité ne donnera pas un

refroidissement optimal si la température

extérieure est inférieure à 15 °C (60 °F). Dans

certaines conditions, il est possible que l’unité

lance le cycle de protection contre le gel

pendant environ 5 minutes pour retirer

la glace formée sur le serpentin intérieur.

DRY (Déshumidification)—Est utilisé pour

déshumidifier la pièce. Le ventilateur fonctionne

à une vitesse faible et fixe pour donner une

déshumidification maximale. Les températures

peuvent être réglées entre 16 °C (61 °F) et

30 °C (86 °F).

FAN (Ventilation)—Est utilisé pour éteindre ou

mettre en marche la fonction n’utilisant que le

ventilateur. Les modes COOL (Refroidissement),

HEAT (Chauffage) et DRY (Déshumidification) ne

pourront être utilisés.

HEAT (Chauffage) (pour les modèles équipés de

cette fonction)—Est utilisé pour réchauffer la

pièce à des températures variant de 16 °C (61 ºF)

à 30 °C (86 ºF).

REMARQUE : Est utilisé pour éteindre ou

mettre en marche la fonction n’utilisant que

le ventilateur. L’unité ne donnera pas un

chauffage optimal si la température extérieure

est inférieure à -10 °C (14 °F). Dans certaines

conditions, il est possible que l’unité lance

le cycle de protection contre le gel pendant

environ 8 minutes pour retirer la glace formée

sur le serpentin extérieur. Pendant ce cycle, il est

normal d’entendre des bruits de fonctionnement

tels que le fluide frigorigène circulant dans

le système.

Page 23

A propos de la télécommande (suite)

. www.electromenagersge.ca

La télécommande transmet les signaux au système.

Affichage

Affiche les réglages lorsque l’appareil est mis en

marche. Affiche seulement le réglage de la

température et de l’heure lorsque l’appareil est éteint.

Touche ON/OFF (Marche/Arrêt)

Appuyez sur cette touche pour allumer ou éteindre

l’appareil.

Touche MODE (Mode)

Appuyez sur cette touche pour passer à différents

modes de fonctionnement AUTO (Automatique),

(COOL) (Refroidissement), (DRY)

(Déshumidification), (FAN ONLY) (Ventilation

uniquement) ou (HEAT) (Chauffage).

Touches TEMP (Température)

Appuyez sur +pour augmenter la température de

réglage par incrément d’1 °F. Appuyez sur –pour

réduire la température de réglage par incrément d’1 °F.

En mode COOL (Refroidissement) et HEAT (Chauffage),

il est possible de sélectionner le réglage de la

température entre 16 °C (61 ºF) à 30 °C (86 ºF).

La le réglage de température ne sera pas affichée

en mode AUTO (Automatique).

Touche FAN (Ventilation)

Appuyez sur cette touche pour modifier

la vitesse du ventilateur à AUTO FAN (Ventilation

automatique), (Low Fan) (Ventilation douce),

(Medium Fan) (Ventilation moyenne) ou

(High Fan) (Forte ventilation).

Touche SWING (Orienter)

Appuyez sur cette touche pour orienter

automatiquement les persiennes. Appuyez

de nouveau sur cette touche pour arrêter

le mouvement des persiennes.

Touche SLEEP (Fonction nuit)

Appuyez pour activer ou désactiver le mode SLEEP

(Fonction nuit). Lorsque le climatiseur est en mode

refroidissement et que la minuterie de nuit est

activée, la température fixée augmentera

automatiquement de 2 °F après la première heure

et de 2 °F après la deuxième heure. Le mode SLEEP

(Fonction nuit) est compatible avec les modes COOL

(Refroidissement), HEAT (Chauffage) et DRY

(Déshumidification).

Touche HORLOGE

Appuyez sur cette touche pour régler l’heure.

Appuyer sur TIME + ou TIME – pour régler l’heure

par incrément d’une minute. Appuyez et maintenez

appuyées les touches TIME + ou TIME – pour régler

l’heure par incrément de 10 minutes.

Touche T-ON (Minuterie activée)

Lorsque le climatiseur est éteint, appuyez

sur la touche T-ON (Minuterie activée) pour

le programmer pour qu’il se mette en marche

automatiquement (en utilisant les réglages

précédents) à l’heure programmée.

Appuyer sur les touches TIME- ou TIME+ pour

régler l’heure de mise en marche par incrément

d’une minute.

Appuyez et maintenez appuyées les touches

TIME- ou TIME+ – pour régler l’heure de mise

en marche par incrément de 10 minutes.

Pour annuler ON (T-ON) (Minuterie activée),

appuyez sur la touche CANCEL (Annuler).

Touche T-OFF (Minuterie désactivée)

Lorsque le climatiseur est allumé, appuyez

sur la touche T-OFF (Minuterie désactivée)

pour le programmer pour qu’il s’arrête

automatiquement à l’heure programmée.

Appuyer sur les touches TIME- ou TIME+

pour régler l’heure d’arrêt par incrément

d’une minute.

Appuyez et maintenez appuyées les touches TIME-

ou TIME+ pour régler l’heure d’arrêt par incrément

de 10 minutes.

Pour annuler OFF (Minuterie désactivée),

appuyez sur la touche CANCEL (Annuler).

Touches TIME (Heure)

Utilisez ces touches pour réglez l’heure de la

pendule (CLOCK) et des minuteries de mises en

marche et d’arrêt (T-ON et T-OFF). Appuyez sur

ces touches pour régler l’heure par incrément

d’1 minute. Appuyez et maintenez appuyées

ces touches pour régler l’heure par incrément

de 10 minutes.

Touche CANCEL (Annulation)

Appuyez sur cette touche pour annuler la/les

minuterie(s).

Fonctions de la télécommande

23

Assistance

à la clientèle

Conseils de

dépannage

Consignes

d’Utilisation

Consignes

de sécurité

Instructions

de montage

Page 24

Unité extérieure

Les serpentins échangeurs de chaleur et les

évents de l’unité extérieure doivent être examinés

régulièrement. S’ils sont bouchés par des saletés ou

des débris, les serpentins échangeurs de chaleur et

les évents doivent être nettoyés par un spécialiste.

REMARQUES :

L’alimentation électrique doit être débranché avant

de procéder à l’entretien de l’unité extérieure.

Les serpentins sales ou bouchés réduiront

l’efficacité de votre système et augmenteront

les coûts de fonctionnement.

Event de

prise d’air

Event de

sortie d’air

Si vous envisagez de ne pas utiliser votre

climatiseur pendant une longue durée…

Faites fonctionner votre appareil dans

le mode de ventilateur pendant 2 heures.

Ce processus assèchera votre système.

Retirez les piles de la télécommande.

Couvrez l’unité extérieure avec une housse

de protection.

REMARQUE : A la saison suivante, assurez-vous

d’avoir retirer la housse de protection de l’unité

extérieure avant de remettre le système en marche.

3

2

1

24

Unité intérieure

Grille, Logement et Télécommande

Eteignez le système avant de le nettoyer. Pour le

nettoyer, essuyez-le avec un chiffon doux et sec.

N’utilisez pas d’eau de Javel ou de nettoyants

abrasifs.

Filtres à Air

Les deux filtres à air derrière la grille frontale doivent

être inspectés et nettoyés au bout de 30 jours de

fonctionnement ou plus souvent si nécessaire.

Ouvrez le panneau frontal d’accès ainsi.

Tirez légèrement la languette du filtre vers

l’avant pour retirer le filtre. Nettoyez le filtre

à l’aide d’un aspirateur ou avec de l’eau

savonneuse tiède. Rincez le filtre et laissez-le

sécher avant de le remettre dans le climatiseur.

Réinsérez les filtres et fermez le panneau frontal

d’accès.

REMARQUE : NE faites PAS fonctionner le système

sans un filtre sous peine de le boucher avec de la

poussière et de la charpie et de réduire son efficacité.

3

2

1

Event d’arrivée d’air

Event de sortie d’air

Entretien et nettoyage du climatiseur.

MISE EN GARDE :

Avant d’effectuer l’entretien de votre appareil, débranchez l’alimentation électrique.

Assistance

à la clientèle

Conseils de

dépannage

Consignes

d’Utilisation

Consignes

de sécurité

Instructions

de montage

Page 25

EXIGENCES ÉLECTRIQUES

• Assurez-vous que le câblage soit conforme aux codes de

construction locaux et au NEC et que la tension d’alimentation

pour ce système soit correcte. La tension d’alimentation du

système est uniquement branchée à l’unité extérieure.

• Vérifiez la plaque signalétique sur le côté de l’unité extérieure

pour connaître la protection et la tension d’alimentation

requise.

• Utilisez un sectionneur de circuit dérivé homologué UL pour

la tension d’alimentation aux unités extérieures et intérieures

du système à blocs. Placez ce sectionneur à portée de vue

et facilement accessible selon les codes locaux et le NEC.

• Tous les câblages devraient être adaptés aux valeurs

données sur le plaque signalétique.

• Assurez-vous que le branchement à la terre est continu et

non endommagé.

• Le câblage doit être protégé dans des tubes étanches

équipés de connecteurs également étanches.

AVANT DE COMMENCER

Lisez ces instructions entièrement et

attentivement.

•

IMPORTANT

— Conservez ces instructions pour

l’inspecteur électrique local.

•

IMPORTANT —

Respectez tous les codes et

règlements en vigueur.

• Remarque pour l’installateur – Assurez–vous de

remettre ces instructions au client.

• Remarque pour le client – Conservez ces instructions

pour toute référence future.

• Niveau de compétence – Un technicien agréé et certifié

(pour manipuler les frigorigènes R410A, récupération,

etc.) et un électricien qualifié sont requis pour

l’installation de ce système de climatisation à blocs.

• Délai d’exécution – Environ 2 heures

1

⁄2.

• A cause du poids du produit, deux personnes sont

requises pour installer cet appareil.

• L’installateur est responsable de l’installation correcte

de l’appareil.

• La panne de l’appareil due à une mauvaise installation

n’est pas couverte par la garantie.

• Pour des raisons de sécurité, cet appareil doit être

correctement mis à la terre.

• Les dispositifs de protection (fusibles ou disjoncteurs)

acceptables pour cette installation sont spécifiés sur

la fiche signalétique de chaque unité.

• L’entretien et l’installation de ce système de climatisation

doivent être effectués par un technicien qualifié, certifié

pour l’installation de chauffage, de ventilation et de

climatisation.

• Evitez d’avoir à effectuer des travaux de câblage et

de plomberie dans le mur au moment de l’installation.

• Pour tout entretien demandant l’ouverture du système

de réfrigération étanche, il est requis par la législation

fédérale que les travaux soient effectués par un

technicien certifié Class II ou Universal.

Instructions

de montage

25

MISE EN GARDE :

• N’utilisez pas de rallonges avec cet appareil.

• Un câblage en aluminium dans le domicile peut

occasionner des problèmes particuliers—consultez

un électricien qualifié.

• Lorsque l’unité est en position STOP (Arrêt),

les commandes sont toujours sous tension.

• Débranchez le système de l’alimentation électrique

avant d’effectuer l’entretien en retirant les fusibles

du circuit dérivé ou en déclenchant le disjoncteur

au niveau du tableau électrique.

• N’utilisez PAS d’équipement certifié pour le fluide

frigorigène R22.

Climatiseurs

Minibloc

Page 26

26

Instructions de montage

PIÈCES INCLUSES DIMENSIONS DE L’INSTALLATION

REMARQUES IMPORTANTES :

• L’installation doit être effectuée par un

électricien qualifié et par un technicien certifié

Class II ou Universal.

• Lorsque vous soulevez et déplacez des unités,

vous devez être guidé par une personne formée

et qualifiée

.

6 po ou plus entre le

climatiseur et le plafond

Bande de

protection

Trou pour les

manchons de

tuyauterie

211⁄4 po–Modèles à 10000 et 14000 BTU

227⁄16 po–Modèles à 20000 BTU

111⁄4 po–Modèles à 10000 et 14000 BTU

11

7

⁄8 po–Modèles à 20000 BTU

6 po ou plus

entre le

climatiseur

et le mur

79 po ou plus

entre le

climatiseur

et le sol

118 po ou plus

du côté sortie

d’air

6 po ou plus

entre le

climatiseur

et le mur

20 po ou plus entre le

climatiseur et la protection

12 po ou

plus du côté

prise d’air

20 po ou plus

entre le climatiseur

et le mur

12 po ou plus entre le

climatiseur et le mur

79 po ou plus du

côté sortie d’air

• Plaque de montage

• Enduit

• Vis (5 pour les modèles à

10 000 et 14 000 BTU et

10 pour les modèles à

20 000 BTU)

• Télécommande

• Piles AAA (2)

• Tuyau de vidange

• Tuyau d’isolation

• Deux filtres (2)

ACCESSOIRES EN OPTION

Pour faciliter le montage, les accessoires suivants

peuvent être commandés :

Trousse GE TUE1650 TUE3250

Pour une utilisation avec les modèles AE1CD10AM

AE0CD10AM

AE1RD10AM

AE0RD10AM

AE1CD14DM

AE0CD14DM

AE1RD14DM

AE0RD14DM

Diamètre et longueur 1/2 po x 16 pi. 1/2 po x 32 pi.

du conduit d’aspiration

Diamètre et longueur 1/4 po x 16 pi. 1/4 po x 32 pi.

du conduit de liquide

Longueur du tube d’isolation 16 pi. 32 pi.

Manchons pour trous dans le mur (2) inclus inclus

Bande de protection en PVC inclus inclus

Trousse GE TUE1662 TUE3262

Pour une utilisation avec les modèles AE1CD20DM

AE0CD20DM

AE1RD20DM

AE0RD20DM

Diamètre et longueur 5/8 po x 16 pi. 5/8 po x 32 pi.

du conduit d’aspiration

Diamètre et longueur 3/8 po x 16 pi. 3/8 po x 32 pi.

du conduit de liquide

Longueur du tube d’isolation 16 pi. 32 pi.

Manchons pour trous dans le mur (2) inclus inclus

Bande de protection en PVC inclus inclus

FOURNIS PAR L’INSTALLATEUR

Adaptateur : Soupape Schrader

femelle 5/16 po, filetage male

1/4 po (1/2 po-20UN)

Page 27

UNITÉ EXTÉRIEURE

• Si une marquise est construite au dessus de l’unité

pour la protéger d’une exposition directe au soleil

ou à la pluie, assurez-vous que le rayonnement de

chaleur en provenance du condenseur ne soit pas

restreint.

• Prévoyez un espace d’au moins 12 po à l’arrière et

sur les côtés de l’unité. Le devant de l’unité doit

avoir un espace de 79 po.

• Installez l’unité dans un emplacement suffisamment

solide pour permettre une installation sûre qui puisse

supporter le poids et les vibrations de l’appareil.

• Construisez et ancrez une base solide et de niveau

pour l’unité extérieure.

• Ancrez l’unité grâce à ses quatre montants, en

utilisant les boulons.

• Choisissez un emplacement où le bruit et l’air émis

par l’unité ne dérangeront pas les voisins.

• Dans les endroits humides, l’unité risque de suinter

et l’eau de condensation peut s’en écouler. Tenez

compte de ce point lorsque vous choisissez

l’emplacement.

• Choisissez un emplacement suffisamment ventilé.

• Ne couvrez pas l’entrée et la sortie.

• Installez l’unité à l’écart des gaz inflammables ou

des fuites de gaz corrosifs.

• Assurez-vous que l’installation soit conforme aux

dimensions indiquées sur le diagramme de

montage.

•

Installation sur un toit :

Si l’unité extérieure doit être installée sur un toit,

assurez-vous que l’unité est de niveau. Assurezvous que la structure du toit et la méthode

d’ancrage soit adéquate pour l’unité. Consultez

les codes locaux concernant une installation

sur un toit.

B

UNITÉ INTÉRIEURE

• N’exposez pas votre unité à la chaleur ou la vapeur.

• Choisissez un emplacement sans obstacle devant

l’unité.

• Assurez-vous que le condensat puisse être

facilement évacué.

• N’installez pas l’appareil près d’une ouverture.

• Prévoyez un espace d’au moins 6 po à gauche

et à droite de l’unité. Cette unité doit être installée

le plus haut possible sur le mur, en prévoyant un

espace d’au moins 6 po entre l’unité et le plafond.

• Utilisez un détecteur de montant pour localiser les

montants et éviter tout dommage inutile au mur.

• Installez l’unité sur le montants et dans un

emplacement d’où l’eau de condensation peut être

facilement évacuée et qui permette une connexion

facile à l’unité extérieure.

• Ne recouvrez pas l’entrée et la sortie pour ainsi

permettre à l’air d’atteindre toutes les parties de

la pièce.

• Installez l’unité dans un emplacement suffisamment

solide pour supporter le poids et les vibrations de

l’appareil.

• Assurez-vous que l’installation soit conforme aux

dimensions indiquées sur le diagramme de

montage.

• Laissez suffisamment de place pour permettre

d’accéder à l’unité pour effectuer l’entretien de

routine. L’unité doit être installée à une hauteur

minimale de 79 po du sol.

• Installez dans un emplacement éloigné d’au poins

3 pi de tout autre appareil électrique tel qu’un

téléviseur et des appareils audio.

• Choisissez un emplacement vous permettant un

accès facile pour retirer et nettoyer le filtre.

A

Lisez ces instructions entièrement et attentivement, puis suivez-les étape par étape.

Plus de 6 po

Plus de

6 po

Plus de 79 po

Plus de 6 po

Plus de 12 po

Plus de 79 po

Plus de 12 po

CHOISISSEZ L’EMPLACEMENT LE PLUS APPROPRIÉ

1

27

Instructions de montage

La plateforme doit pouvoir

supporter une charge

minimale de 91 kg (200

livres). Voir Dimensions de

l’Installation pour

l’espacement des trous

de montage

Page 28

Instructions de montage

INSTALLATION DU PLAQUE

DE MONTAGE

• Installez toujours le plaque de montage

horizontalement.

• Fixez le plaque de montage à l’emplacement choisi

avec les vis fournies avec l’unité.

• Assurez-vous que le plaque de montage est

correctement fixé pour soutenir le poids d’un adulte

d’environ 60 Kg (130 livres). De plus, tout le poids

doit être uniformément réparti sur chaque vis.

1

INSTALLATION

2

INSTALLATION DU TROU POUR

LES CONDUITES

• Le trou pour les conduites doit être incliné vers

l’extérieur.

• Pour permettre à l’eau de s’évacuer et pour éviter

tout dommage au câblage et aux conduites, insérez

un tuyau en plastique de 2

1

⁄2 po de diamètre, coupé

à une longueur égale à la profondeur du mur.

Insérez les conduites et le câblage par ce tuyau.

• Les tubes en cuivre doivent être bouchés jusqu’à ce

que vous soyez prêt à installez le raccord conique,

pour éviter toute contamination.

2

INSTALLATION DU TUYAU

D’ÉVACUATION

• Pour une bonne évacuation, le tuyau d’évacuation

doit être incliné vers le bas.

• Ne vrillez pas ou ne tordez pas le tuyau

d’évacuation, ne le laissez pas dans l’eau stagnante.

• Le tuyau d’évacuation allongé dans la pièce doit

être enveloppé de matériau isolant.

3

To rd u

Vrillé

Inondé

INSTALLATION DES TUYAUX

DE CONNEXION

• Branchez les tuyaux de cuivre de connexion avec

les raccords union de l’unité intérieure et resserrez

le raccord conique des tuyaux de connexion.

REMARQUE : Courbez délicatement les tuyaux

de connexion pour éviter de les endommager.

1. Alignez le centre de l’évasement du tuyau avec

le robinet correspondant.

2. Vissez le raccord conique à la main, puis serrez-le

à l’aide d’une clé et d’une clé dynamométrique.

Référez-vous au tableau ci-dessous pour obtenir

le couple de serrage approprié.

3. Le spécification du tuyau de connection est

indiquée ci-dessous :

REMARQUE : Si vous dépassez le couple de

serrage, vous endommagerez les tubes en cuivre.

4

Clé dynamométrique

Raccord conique

Joint

Clé

Diamètre extérieur Couple de serrage

du tuyau en cuivre (po/livre)

1/4 po 140–170

3/8 po 270–310

1/2 po 440–480

5/8 po 530–570

Tableau de couple de serrage

28

11⁄2 po du bord

inférieur au centre

du trou pour les

conduites à droite

3 po du bord droit

au centre du trou

pour les conduites

à droite

Trous est 2 po de diamètres pour les modèles

à 10K et 14K BTU et 2

1

⁄2 po pour les modèles

à 20K BTU.

Modèles Modèles

Spécifications 10 000/14 000 BTU 20 000 BTU

Longueur designee (pieds) 20 26,2

Extra Charge Refrigerant 0,16 0,54

par pieds par-dessus

longueur designee (oz/ft)

Diamètre extérieur du 1/4 3/8

tuyau de liquide (pouces)

Diamètre extérieur des 1/2 5/8

tuyaus de gaz (pouces)

Max Distance Hauteur (pieds)

33 33

Distance Max Longueur (pieds)

68 98

Page 29

Instructions de montage

BRANCHEMENT DU CÂBLAGE

ÉLECTRIQUE ENTRE LES UNITÉS

EXTÉRIEURE ET INTÉRIEURE

• Tous les câblages devraient être adaptés à la valeur

donnée sur la plaque signalétique.

• L’alimentation électrique doit pouvoir accommoder

la tension nominale.

• Le câblage doit être effectué par un électricien qualifié

conformément aux codes locaux, aux législations et à

cette notice.

• Toutes les connexions de câblage doivent être serrées

adéquatement.

5

CÂBLAGE DE L’UNITÉ INTÉRIEURE

REMARQUE : Utilisez un sectionneur de circuit dérivé

homologué UL pour la tension d’alimentation aux unités

extérieures et intérieures du système à blocs. Placez ce

sectionneur à portée de vue et facilement accessible selon

les codes locaux et le NEC.

1. Ouvrez le panneau d’accès frontal.

2. Retirez le couvercle du coffret de branchement.

3. Au dos de l’unité intérieure, retirez le couvercle

de connexion du conduit. A l’aide de l’écrou

de fixation, branchez le conduit au couvercle

de connexion. Faites passer les câbles à travers l’unité

jusqu’au coffret de branchement. Réinstallez le couvercle

de connexion.

6

Couvercle

Panneau d’accès

CÂBLAGE DE L’UNITÉ INTÉRIEURE (suite)

REMARQUE : Le câblage doit être effectué par un électricien

qualifié conformément aux codes locaux, aux législations et

à cette notice. Le fil de branchement doit être correctement

branché à l’interface du circuit.

REMARQUES :

• Le câblage doit suivre les schémas de câblage ci-dessus.

• Serrez l’écrou du bornier pour s’assurer que ce dernier

est bien fixé.

• Après serrage, le fil ne doit pas pouvoir est enlevé en tirant.

• Le climatiseur fonctionnera de façon anormale si les fils

ne sont pas branchés correctement.

• Une mauvaise mise à la terre provoquera des courts-circuits.

4. Remettez le couvercle sur le coffret de branchement et

abaissez le panneau d’accès en position fermée.

6

Conduit

Ecrou de fixation

Dos de l’unité

Couvercle de

connexion

29

Unité intérieure

*L1 sera utilisé pour le neutre

sur les modèles à 115V.

Unité extérieure

Vers le

circuit de

dérivation

Terre

Alimentation

électrique

Modèles 115V

Bornier à

4 pôles

Cordon

d’alimentation

Les fils électriques doivent être sécurisés

avec des réducteurs de tension.

Unité intérieure

Unité extérieure

Vers le

circuit de

dérivation

Terre

Alimentation

électrique

Modèles 230/208V

Bornier à 4 pôles

Bornier à 6 pôles

Bornier à 4 pôles

Bornier à 6 pôles

Page 30

INSTALLATION DE L’UNITÉ INTÉRIEURE

• Faites passer les tuyaux et le câblage sur la droite

de l’unité intérieure. Découpez les parties en excès

du châssis si nécessaire.

1. Découpez le rejet 1 lorsque vous faites

seulement passer le câblage.

2. Découpez les rejets 1 et 2 (ou rejets 1, 2 et 3)

lorsque vous faites passer le câblage et les

tuyauteries. 1 et 2 ci-dessous sont les

tuyauteries recommandées.

Instructions de montage

30

INSTALLATION (suite)

2

7

INSTALLATION DE L’UNITÉ

INTÉRIEURE (suite)

• Enveloppez les tuyauteries et le câblage et tirez-les

au travers du trou découpé.

• Accrochez les fentes de montage de l’unité

intérieure aux languettes supérieures de la plaque

de montage et assurez-vous que le système soit

résistant.

• L’unité doit être installée à une hauteur minimale

de 79 po du sol.

7

2 Tuyauterie arrière droite

Rejet 2

1 Tuyauterie

droite

Rejet 1

Rejet 3

Cordon de commande

(seulement pour

les modèles chauffage/

refroidissement)

Bande de

protection

Tuyaux de

connexion

Cordon

d’alimentation

Tuyau d’évacuation

Page 31