Page 1

GE Fanuc Automation

Series 90™-70

CPU Redundancy User' s Guide

Programmable Cont rol Products

Enhanced Hot Standby

GFK-1527A May 2000

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associate d with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

GFL-002

Warning

Caution

Note

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Master Genius PROMACRO Series Six

CIMPLICITY Helpmate PowerMotion Series Three

CIM P LIC IT Y 90 – ADS Logicm aster PowerTRA C VersaMax

CIMSTAR Modelmaster Series 90 VersaPro

Field Control Motion Mate Series Five VuMaster

GEnet ProL oop Series One Workm aster

©Copyr ight 1998 - 2 000 GE Fanuc Autom ation N orth Am erica, In c.

All Rights Reserved .

Page 3

This manual is a reference to the hardware components, configuration and operation of Enhanced

Hot Standby CPU Redundancy for the Series 90-70 Programmable Logic Controller. This revision

adds information about new redundancy CPUs IC697CGR772 and IC697CGR935, as well as new

features available with Release 7.85 of the product. Also, corrections have been made where

necessary.

The information in this manual is intended to supplement the information contained in the system

installation, programming, and configuration information found in the manuals listed below under

Related Publications.

Content of This Ma nual

Chapter 1. Introduction: introduces a method of CPU Redundancy for the Series 90-70

Programmable Logic Controller, which is referred to as Enhanced Hot Standby CPU Redundancy.

Preface

Chapter 2. System Components: describes th e h ar d wa re compon en ts for an Enhanced Hot

Standby CPU Redundancy system.

Chapter 3. Configuration Requirements: defines the special configuration requirements of an

Enhanced Hot Standby CPU Redundancy system.

Chapter 4. Normal Operation: describes the operation of an Enhanced Hot Standby CPU

Redundancy system.

Chapter 5. Fault Detection: describes how faults are handled in an Enhanced Hot Standby CPU

Redundancy system.

Appendix A. Cabling: provides a description and diagram of the Series 90-70 multidrop cable for

use in redundancy systems.

Relat e d Publi ca t ions

For more information, refer to these publications:

Genius I/O System User' s Manual (GEK-90486-1). Reference manual for system designers,

programmers, and others involved in integrating Genius I/O products in a PLC or host co mputer

environ ment. This book provides a syste m overvie w, and describes t he type s of syst ems that can be

created using Genius products. Datagrams, Global Data, and data formats are defined.

Genius Discrete and Analo g Bl ocks User' s Ma nual (GEK-90486-2). Reference manual for system

designers, operators, mai ntenance pe rso nnel, a nd others usi ng Genius disc rete a nd analog I/O

blocks. This book contains a detailed description, specifications, installation instructions, and

conf i gura tion i nstructions for dis cre t e a nd an alo g blocks .

Series 90-70 PLC Installation Manual (GFK-0262). This book describes the hardware

components in a Series 90-70 PLC system, and provides the details of system installation.

GFK-1527A iii

Page 4

Preface

Logicmaster 90-70 Programming Software User's Manual (GFK-0263). A programming software

user's manual for system operators and others using the Logicmaster 90-70 software to program,

configure, monitor, or control a Series 90-70 PLC system.

Series 90-70 PLC CPU Instruction Set Reference Manual (GFK-0265). Reference manual which

describes operation, fault handling, and programming instructions for the Series 90-70 PLC.

Series 90-70 System Manual for Control Software Users (GFK-1192). Provides an overview of

hardware and software features of the Series 90-70 PLC.

Series 90-70 Remote I/O Scanner User's Manual (GFK-0579). Reference manual for the Remote

I/O Scanner, which interfaces a drop containing Series 90-70 modules to a Genius bus. Any CPU

capable of controlling t he bus can be used as the hos t. This book d e s c ribes the Re mote I /O Scanner

features, configuration, and operation.

Series 90-70 Bus Controller User's Manual (GFK-0398). Reference manual for the bus

controller, which interfaces a Genius bus to a Series 90-70 PLC. This manual describes the

ins tallation and op erat ion of the Bus Controller. It also contai ns the progr am min g infor m ation

needed to interface Genius I/O devices to a S er ies 90-70 P LC.

Control User’s Gui de (GFK-1295). Describes configuration and programming software using

Control Programming. Control software, release 2.1 or later is required to configure Ethernet

Global Data as described in this manual.

iv Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide–May 2000 GFK-1527A

Page 5

Contents

Chapter 1 Introduction..................................................................................................... 1-1

Enhanced Hot Standby CPU Redundancy.....................................................................1-2

Features of Enhanced Hot Standby CPU Redundancy...................................................1-3

Using the Redundancy CPU for Non-Redundant Operation ....................................1-3

Compatibility with CPU780...................................................................................1-3

Redundancy CPUs as Compared to Other Series 90-70 CPUs.......................................1-4

Features not Available with Redundancy CPUs......................................................1-4

Differences in Operation for Redundancy CPUs.....................................................1-4

Components of the Enhanced Hot Standby Redundancy System...................................1-5

Enhanced Redundancy CPU Module......................................................................1-5

Redundancy Communications Module....................................................................1-5

Redundant Racks....................................................................................................1-5

I/O Systems for Enhanced Hot Standby CPU Redundancy......................................1-5

Genius I/O............................................................................................................1-6

Local I/O..............................................................................................................1-6

Cable Connections................................................................................................1-6

Enhanced Hot Standby CPU Redundancy System with Local I/O ..........................1-7

Control Strategies.........................................................................................................1-8

GHS Control Strategy........................................................................................... 1-8

GDB Control Strategy...........................................................................................1-8

Basic Enhanced Hot Standby Operation ........................................................................1-9

Output Control with GHS......................................................................................1-9

Output Control with GDB.....................................................................................1-9

Basic CPU Redundancy Setups...................................................................................1-10

Single Bus with Preferred Master: GHS Control Strategy.....................................1-10

Single Bus with Floating Master: GDB Control Strategy......................................1-11

Dual Bus with Floating Master: GDB Control Strategy........................................ 1-12

Duplex CPU Redundancy.................................................................................... 1-13

Online Programming...................................................................................................1-13

On-Line Repair...........................................................................................................1-13

Chapter 2 System Components........................................................................................ 2-1

System Racks...............................................................................................................2-1

Redundancy CPU.........................................................................................................2-2

Features................................................................................................................2-2

CPU Architecture .........................................................................................................2-3

Expansion Memory Board.....................................................................................2-3

Watchdog Timer...................................................................................................2-3

CPU Features ...............................................................................................................2-4

Memory Protect Keyswitch...................................................................................2-4

CPU LEDs............................................................................................................2-4

Battery Connectors................................................................................................2-4

CPU Mode Switch................................................................................................2-5

Run/Outputs Enabled Mode............................................................................2-5

Run/Outputs Disabled Mode...........................................................................2-5

Stop Mode .....................................................................................................2-5

Port 1....................................................................................................................2-5

GFK-1527A v

Page 6

Contents

Port 2....................................................................................................................2-5

Port 3....................................................................................................................2-5

Redundancy Communications Module..........................................................................2-6

Unit Select Pushbutton.......................................................................................... 2-6

Connector............................................................................................................. 2-7

RCM Status LEDS................................................................................................2-7

Bus Transmitter Module...............................................................................................2-8

Connectors............................................................................................................2-8

Bus Transmitter Module Status LEDs....................................................................2-8

Bus Receiver Module....................................................................................................2-9

Connectors............................................................................................................2-9

Cables and Termination ........................................................................................2-9

Genius Bus Controller ................................................................................................ 2-10

Location of GBCs and Blocks .............................................................................2-10

Single Bus Genius Networks ............................................................................... 2-11

Dual Bus Genius Networks .................................................................................2-11

Connectors..........................................................................................................2-12

Bus Controller LEDs...........................................................................................2-12

Chapter 3 Configuration Requirements.......................................................................... 3-1

Programmer Connection for Configuration...................................................................3-1

One Application Program in Both PLCs........................................................................3-1

Program Folders in Control Programming Software...............................................3-1

Program Folders in Logicmaster 90.......................................................................3-2

CPU Configuration Parameters.....................................................................................3-2

Configuring Shared I/O References ........................................................................ 3-3

Finding the Memory Available for Application Program Storage............................3-4

System Communications Window Considerations ..................................................3-4

Configuring the Redundancy CPU for Non-redundant Operation..................................3-5

Rack Module Configuration Parameters........................................................................3-5

Bus Controller Configuration Parameters......................................................................3-5

Genius I/O Block Configuration Parameters..................................................................3-6

Chapter 4 Normal Operation........................................................................................... 4-1

Powerup of a Redundant CPU.......................................................................................4-2

Incompatible Configurations.........................................................................................4-3

Resynchronization of a Redundant CPU........................................................................4-3

GHS Control Strategy...................................................................................................4-4

GDB Control Strategy................................................................................................... 4-4

%S References for CPU Redundancy............................................................................4-5

OVR_PRE %S Reference Not Available...............................................................4-5

Scan Synchronization...................................................................................................4-6

Input Data and Synchronization Data Transfer to the Backup Unit................................4-6

Sweep Time Synchronization................................................................................4-6

Output Data Transfer to the Backup Unit......................................................................4-7

Data Transfer Time.......................................................................................................4-8

vi Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide–May 2000 GFK-1527A

Page 7

Contents

Fail Wait Time......................................................................................................4-8

Programming a Data Transfer from Backup Unit to Active Unit..................................4-10

Data Transfer Example................................................................................. 4-10

Disabling Data Transfer Copy in Backup Unit (SVCREQ #43)...................................4-11

Command Block for SVCREQ #43..................................................................... 4-12

Backup Qualification with SVCREQ #43............................................................4-13

Validating the Backup PLC's Input Scan ............................................................. 4-13

Validating the Backup PLC's Logic Solution....................................................... 4-13

Switching Control to the Backup Unit.........................................................................4-14

Switching Times ................................................................................................. 4-14

Commanding a Role Switch from the Application Program (SVCREQ #26)........4-14

Example.......................................................................................................4-14

RUN Disabled Mode..................................................................................................4-15

RUN Disabled Mode for GHS Control Strategy....................................................4-15

Example 1: Role switches allowed on both units.................................................. 4-15

Example 2: Role switches allowed on both units.................................................. 4-16

Example 3: Role switches not allowed on either unit............................................4-16

Example 4: Role switches allowed on both units.................................................. 4-16

Example 5: Role switches allowed on both units Secondary Unit Active.............. 4-17

Example 6: Role switches not allowed on either unit, Secondary Unit Active.......4-17

Example 7: Role switches allowed on both units, Secondary Unit Active............. 4-17

Example 8: Invalid..............................................................................................4-18

RUN Disabled Mode for GDB Control Strategy...................................................4-18

Background User Checksum and Background Window Timing Instructions................4-19

Finding the Words to Checksum Each Sweep...................................................... 4-19

Finding the Background Window Time...............................................................4-20

Finding the Total Sweep Time.............................................................................4-20

Miscellaneous Operation Information.........................................................................4-21

Timer and PID Function Blocks.......................................................................... 4-21

Timed Contacts...................................................................................................4-21

Multiple I/O Scan Sets........................................................................................4-21

C Debugger ........................................................................................................4-22

STOP to RUN Mode Transition ..........................................................................4-22

Background Window Time.................................................................................4-22

Sequential Function Chart Programming (SFC)...................................................4-22

Genius Bus Controller Switching................................................................................4-23

Ethernet Global Data in a Redundancy CPU............................................................... 4-24

Ethernet Global Data Consumption..................................................................... 4-24

Ethernet Global Data Production.........................................................................4-25

SNTP Timestamping...........................................................................................4-25

Chapter 5 Fault Detection................................................................................................ 5-1

Configuration of Fault Actions......................................................................................5-1

Fault Detection.............................................................................................................5-2

PLC Fault Table Messages for Redundancy..................................................................5-3

Fault Response .............................................................................................................5-5

Faulting RCMs, Losing Links, and Terminating Communications.................................5-6

Faulting the Redundancy Communications Module...............................................5-6

Losing a Link........................................................................................................5-6

GFK-1527A Contents vii

Page 8

Contents

Fault Actions in a CPU Redundancy System.................................................................5-7

Configurable Faults...............................................................................................5-8

Non-Configurable Fault Group..............................................................................5-9

Fatal Faults on Both Units in the Same Sweep.......................................................5-9

On-Line Repair...........................................................................................................5-10

Maintaining Parallel Bus Termination...................................................................5-11

On-Line Repair Recommendations....................................................................... 5-11

Power Supply.......................................................................................................5-11

Racks...................................................................................................................5-11

Central Processor Unit..........................................................................................5-12

Redundancy Communications Module and Cables................................................5-12

Redundancy Communications Link Failures.........................................................5-12

Bus Transmitter Module.......................................................................................5-13

Genius Bus Controller..........................................................................................5-13

Genius Bus ........................................................................................................... 5-13

Single Bus Networks Bus faults .......................................................................... 5-13

Dual Bus Networks ............................................................................................. 5-14

Genius Blocks......................................................................................................5-14

Appendix A Cabling Information .......................................................................................A-1

IC690CBL714A Multi-drop Cable............................................................................... A-1

Purpose.................................................................................................................A-1

Specifications........................................................................................................ A-1

viii Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide–May 2000 GFK-1527A

Page 9

Chapter

Introduction

1

This chapter introduces the method of CPU Redundancy for the Series 90-70 Programmable Logic

Controller, which is referred to as Enhanced Hot Standby CPU Redundancy. The contents of this

chapter describe:

Enhanced Hot Standby CPU Redundancy

Components of the Enhanced Hot Standby Redundancy System

Control Strategies

Basic Enhanced Hot Standby Operation

Basic CPU Redundancy Systems

Definition of Terms

Active Unit

Backup Unit

CPU Redundancy

Critical Component

Hot Standby

Primary Unit

Redundancy

Secondary Unit

Synchronized

Dual Bus

Local System

Remote System

The unit that is currently contr oll in g the pr o cess .

That unit that is synchron ized with the active unit and able to take over the process.

A system with two PLC CPU units cooperating to control the same process.

A component whose failure causes the PLC (either active o r b ac kup) where it res ides to stop.

A featu re of Ge ni us devi c e s w hereb y the device pre f ers outp u t da t a from the Bus Cont roller at Ser i a l Bus

Address 31. When outputs from that Bus Contr oller are not avai lable, the devi ce takes output data from the

Bus Contro ller at Serial B us Address 30. If outputs from neither Controlle r are available, the device places its

outputs in the designate d default state .

The unit in which the externally redundant Bus Controllers' Serial Bus Address is 31.

The us e of multi ple ele m ents control ling th e same proces s to provid e alterna te fun ct ional channels in case of

failure.

The unit in which the externally redundant Bus Controllers' Serial Bus Address is 30.

A unit is considered to be synchronized when it has received the latest status information from the Active unit

and is running the PLC program in parallel.

The use of two Genius busses to control the same I/O devices. The busses are linked to the I/O devices by one

or more Bus Switch ing Modu les (BSMs) . A BSM will automatically switch to the other bus if the active bus

has a failure.

(LE Ds on RCM) - The system where the RCM resides. LEDs indicate whethe r the lo cal u n it is ready to

become the active unit or is the act ive unit in a redundancy system.

(LEDs on RCM) - The system to which the RCM is connected via the communications cable. LEDs indicate

whethe r the remote unit is ready to become the active unit or is th e active unit in a red undancy system.

GFK-1527A 1-1

Page 10

1

Enhanced Hot Standby CPU Redundancy

CPU Redundancy allows a critical application or process to continue operating if a failure occurs in

any sin g le component. An Enhanced Hot Stand by CP U Redundan cy syst em consis ts of two CPUs

conn ected to one or more Geniu s I/ O networks. One P LC is the Primary PLC and the other is the

Secondary PLC. The Primary PLC contains all externally redundant Genius Bus Controllers at

Seri al Bus Addres s 31 ; the Secondary PLC contains all externall y r ed undant Genius Bus

Controllers at Serial Bus Address 30.

Each PLC

Redundancy Communications module and a Bus Transmitter Module

Communications module provides the synchronizing link between the two units. The scanning

process of both CPUs is synchronized to minimize bumpless switching from one PLC to the other.

The CPU that currently controls the system is called the active unit, the other CPU is the backup

unit. Control automatically switches to the backup unit if certain system failures are detected in the

active unit. Control can also be switched manually by pressing a pushbutton on the Redundancy

Communications Module, or through the application program. When a manual switch of control

occurs, the CPUs switch roles; the active unit becomes the backup unit and the backup unit

becomes active.

The system runs synchronously with a transfer of all control data that defines machine status and

any in ternal data n eeded to keep the two CPUs operating in s ync. The transfer of data from the

acti ve un it to the standby unit occurs twice per sweep. These CPU to CPU tr ansfers ar e checked

for data integrity.

must have a Redundancy CPU module (IC697CGR772 or IC697CGR935), a

. The Redundancy

1-2 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 11

Features of Enhanced Hot Standby CPU R edundancy

Bumpless switching

Synchronized CPUs

4.7 ms (CGR935), 5.9 ms (CGR772) base sweep time in Run mode

One scan switching (in most ca ses)

Configurable backup data size

No single point of failure (excluding Genius I/O blocks and bus stubs)

Redundant backup communications

Online repair of failed component

Onl i ne pr ogramming

Same or di ff erent programs in Primary and S econdary uni ts

Redundancy Communications Module

Manual pushbutton for switching control between active and backup CPUs

Five Status LEDs

1

Status Bits (%S) reflect redundancy status of Primary/Secondary units

Program control switching

Memory parity and checksums

Common I/O on Genius bus

Genius Dual Bus support

Background Diagnostics

Memory Protect Keyswitch

Using the Redundancy CPU for Non-Redundant Operation

The Redundancy CPU can be used for both redundant and non-redundant applications. The

functionality and performance of a Redundancy CPU configured for standalone operation is the

same as for a unit that is configured for redundant operation which has no backup currently

available. This includes the redundancy informational messages such as those generated when a

unit goes to Run mode. Refer to Chapter 3, "Configuring the Redundancy CPU for Non-redundant

Operation."

Compatibility with CPU780

Note that the IC697CGR772 is not compatible with the CPU780. Also, mixing of IC697CGR935

and IC697CGR772 CPUs is not allowed in the same redundant system, since there are several

differences betw een the t wo models.

GFK-1527A Chapter 1 Introduction 1-3

Page 12

1

Redundancy CPUs as Compared to Other Series 90-70 CPUs

The Redundancy CPU has several differences in operation compared to other Series 90-70 CPUs.

Features not Available with Redundancy CPUs

The following features are not available:

I/O Interrupts:

modules, the high alarm and low alarm interrupts from the analog input modules, and

interrupts from third party VME modules. A program that declares I/O Interrupt triggers

cannot be store d to a Red undancy CP U.

Timed Interrupts

VME Integrator Racks.

This includes the single edge triggered interrupts from the discrete input

Stop I/O Scan mode:

the sel ection and r eturn an error .

Flash operation: User Flash (Store/Load, Verify) as opposed to Flash firmware upgrade

FBCs and FIP I/O

Timed and Event-triggered Programs:

cannot be store d.

Microcycle Mode and Periodic Programs

14-point interrupt module

OVR_PRE %S reference which indicates whether one or more overrides is active

If an attempt is made to place the PLC in this mode, the PLC will reject

Differences in Operation for Redundancy CPUs

The following features operate differently with the CGR772 or CGR935 than they do with other

Series 90-70 CPUs:

RUN/DISABLED mode. This is explained in chapter 4,

Configuration of Fault Actions

STOP to RUN mode transition

Background Window Time (default is different)

Logic that contains Timed or Event-triggered programs

Operation

.

C Debugger

Ethernet Global Data operation is enhanced

Rack 7 is not available

1-4 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 13

Components of the Enhanced Hot Standby Redundancy System

Enhanced Redundancy CPU Module

To utilize the features described in this manual, an Enhanced Redundancy CPU Module

(IC697CGR935 or IC697CGR772) must be installed rack 0, slot 1 of both the Primary and

Second ary PLCs. Fea tures of the redundancy CPU that ar e different from conven tional C P US are

listed on the previous page.

Redundancy Co mmunications Modul e

Two Redundancy Communications Modules (RCM) are available that provide a path for sharing

data between the two CPUs in the redundant system. Catalog number IC697RCM711 is for use in

standard Series 90-70 racks and IC687R CM 711, whic h is for use in dual redundant racks

(described below).

The RCM module has a pushbutton switch that can be used to manually switch control from the

active unit to the backup unit. The switch between units can also be controlled through the

application p ro g ram logic.

1

In a synchronized system, I/O data is controlled by only one unit (the active unit) but is shared

between both units (active and backup units). The Redundancy Communications Module provides

a communications path to synchronize the two CPUs. It also provides the communications path for

the transfer of I/ O da ta. An RCM must be located in th e main rack of both the Primar y PLC and

the Secon dary PLC, or in both sections of a dua l r edundant r ack.

Redundant Ra ck s

Redundant racks; IC697CHS770 (rear mount) and IC697CHS771 (front mount) have two power

supply slots and 12 backplane slots divided into two separate sections, each having a power supply

slot and 6 backplane slots. The redundant rack is designed for easy integration of third-party VME

modules into a Series 90-70 PLC system. These racks accept all standar d Ser ies 90-70 modules

and ½ slot VME mod u les. VME modul es r eq uire 0.8” spa cing and use one slot, while standard

Series 90-70 modules use two of the available slots. Cable connection between the required ½ slot

RCM modules and the required ½ slot BTM modules (catalog number IC687BEM713) in a

redundant rack is through an available 3 foot (0.9 meter) cable, IC697CBL803.

I/O Systems for Enhanced Hot Standby CPU Redundancy

Both Series 90-70 Local I/O and Genius I/O systems can be present in an Enhanced Hot Standby

CPU Redundancy system. The two PLCs need not have matching I/O systems -- they may have

different numbers of I/O racks, different I/O modules and different option modules.

GFK-1527A Chapter 1 Introduction 1-5

Page 14

1

Genius I/O

The redundant portion of the system is based on Genius I/O. A system using standard Series 90-70

racks can have multiple Genius I/O bus networks. A system using the ½ slot redundant racks may

have only one bus in the CPU ra c k. Any Geniu s de vice ca n be placed on the bus (Genius blocks,

Field Control, Remote I/O Scanner, VersaMax I/O, etc.). The Genius devices are under control of

the active unit in the Redund ancy system. The Genius Bus C ontroller in the Primar y Un it has a

Serial Bus Address of 31; the Geni us Bus Controller in the Secondary Unit has a Serial Bus

Address of 30. Data from S e ria l Bus Address 31 is th e prefer red data when dat a is being sent from

both units to devices on the Genius bus.

Local I/O

Local I/O can be included in the overall PLC system; however,

CPU Redundancy system. Control of Local I/O is done normally through the application program.

Transfer of this data between the redundan cy CPUs is optional. A failure in the Local I/O system

will affect the system as described in GFK-0265, the

Reference Manual

.

Series 90-70 Programmable Controller

it is not

part of t he Hot S tan dby

Cable Connections

In an Enhanced Hot Standby CPU Redundancy system that requires expansion racks, a Bus

Tran sm itter Module in rack 0 is connected by a p ar allel I/O cable to a Bus Receiver Module in the

next r ack. The link is con tinued fr om this Bus Receiv er Module to a Bus Receiver M odu le in the

next rack. This link is continued with a maximum of six expansion racks. The last Bus Receiver is

connected via an I/O cable with built-in termination (catalog number IC697CBL803 (3 feet (0.9m))

catalog IC697CBL811 (10 feet (3m)) or IC697CBL826 (25 feet (7.5m)). The last module in the

parallel I/O bus link must be a Redundancy Communications Module (RCM). This terminated I/O

cable allows replacement of the RCM without interrupting the running system. If no expansion

racks are used, th e terminat ed I/O cable is connected directly from the Bus Transmitter Mod u le to

the Redundancy Communications Module.

1-6 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 15

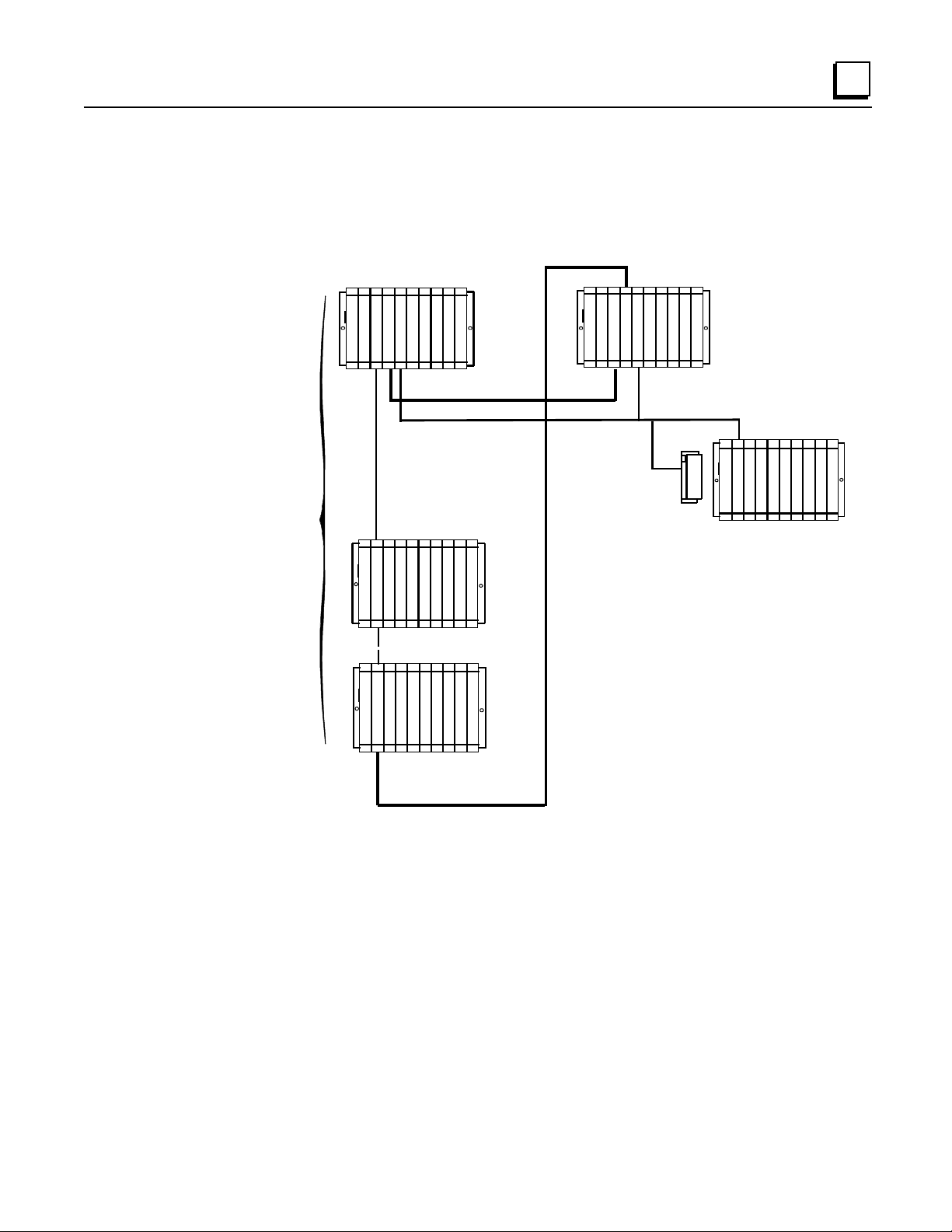

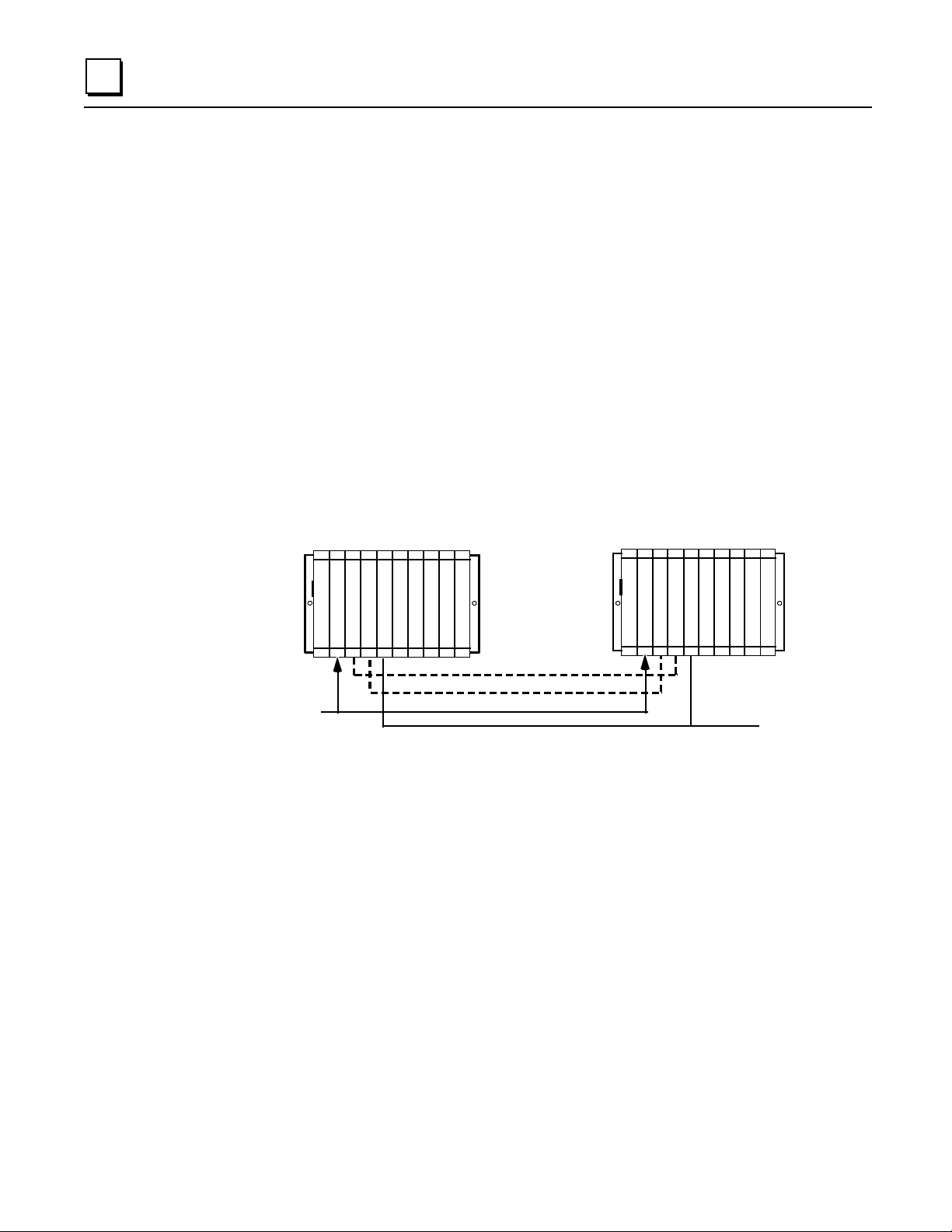

Enhanced Hot Standby CPU Redundancy System with Local I/O

The following illustration is an example of an Enhanced Hot Standby CPU Redundancy system

with Local I/O in standard Series 90-70 expansion racks.

1

LOCAL I/0

CAN BE IN

RACKS

0 - 6

Secondary Unit

RACK 0

C

P

B

R

S

T

P

C

M

U

M

RACK 1

IOIOI

B

P

R

S

M

---

---

RACK 6

IOIOIOIOI

P

B

S

R

M

G

IOIOIOI

B

C

30

OIO

TERMINATED I/O CABLE

*

I

I

I

I

O

OIO

O

O

I

IOI

O

O

O

O

P

S

B

C

P

T

U

M

Primary Unit

RACK 0

I

R

G

IOIOIOI

C

B

O

M

C

31

O

REMOTE DROP

I

I

S

P

B

L

O

C

K

OIO

C

S

A

N

N

E

R

IOIOIOI

I

O

O

O

I/O CABLE WITH BUILT-IN TERMINATION

*

IC697CBL803 (3 FEET (0.9m))

TERMINATED I/O CABLE

*

IC697CBL811 (10 FEET (3m))

IC697CBL826 (25 FEET (7.5m))

Note

Rack 7 is not available for I/O modules in an Enhanced Hot Standby CPU

Redundancy system.

GFK-1527A Chapter 1 Introduction 1-7

Page 16

1

Control St rategies

There are two different Control Strategies for Enhanced Hot Standby CPU Redundancy: GHS and

GDB.

GHS Control Strategy

The GHS control strategy has the following features:

Multiple single bus Genius I/O networks with redundant controller in each synchronized PLC

Multiple local single bus Genius I/O networks

Redundant Genius I/O driven exclusively by the active unit

Primary Unit is always the Active Unit in synchronized system unless explicitly overridden by

user or application; switchover from secondary active to primary active may not be bumpless

in certain failure conditions

Only critical control data must be transferred from Active to Backup CPU

Compatible with the release 4 based Hot Standby Redundancy Product (CPU780)

GDB Cont rol Strategy

The GDB control strategy has the following features:

Multiple dual bus Genius I/O Networks with redundant controllers in each synchronized PLC

Multiple single bus Genius I/O networks with redundant controller in each synchronized PLC

Multiple local Genius I/O networks with single or dual buses or controllers

Active unit does not automatically switch to Primary on resynchronization

Bumpless switchover with either PLC active

Critical control data plus all redundant outputs must be transferred from Active to Backup

CPU

1-8 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 17

Basic Enhanced Hot Standby Operation

In an Enhanced Hot Standby CPU Redundant system, Genius I/O Blocks are normally configured

for Hot Standby operation. Genius I/O Blocks can also be configured for the less frequently used

Duplex operation, but only with the GDB Control Strategy. When configured for Hot Standby

operation, the blocks must choose between outputs from the Genius Bus Controller at serial bus

address 31 and the Genius Bus Controller at serial bus address 30. If outputs from both Genius Bus

Controllers are available, then the blocks will prefer the outputs from bus address 31. If there are

no outputs from bus address 31 for three consecutive Genius I/O bus scans, the blocks will use the

outputs from bus address 30. If out puts are not available from ei t her bus address 3 1 or 30, t he

outputs go to their configured default (OFF or hold last state).

For Hot Standby CPU Redundant systems, the Genius Bus Controllers in the Primary Unit are

normally configured at serial bus address 31 and the Genius Bus Controllers in the Secondary Unit

are normally configured at serial bus address 30.

It is possible to configure Genius I/O networks in which there is not a redundant bus controller in

the synchronized PLC. It i s not necessar y for th e serial bus addresses to be 31 in the Prim ary unit

and 30 in the secondary for such networks.

1

In an Enhanced Hot Standby CPU Redundancy system, only the active unit may control the

redundant Genius outputs. This is accomplished differently in the two control strategies:

Output Control with GHS

In the GHS control strategy, the PLC CPU allows only the active unit to control the outputs. When

the Primary Unit is active (GBCs at bus address 31), the PLC CPU allows both units to send

outputs to the blocks. The result is a bumpless switchover if the Primary Unit fails while it is the

active unit.

If the Secondary Unit is active, the PLC CPU automatically disables outputs from the redundant

GBCs in the Primary Unit. That means the Genius I/O blocks will only receive out p u ts from th e

Secondary Unit (bus controllers at serial bus address 30).

Output Control with GDB

In the GDB control strategy, both the Primary and Secondary Units send outputs regardless of

which one is active. The user is resp onsible for ensurin g tha t all redundant outpu ts are tran s ferred

from the active unit to the backup unit. Because the same output values will then be present in both

units, the blocks will receive the same outputs (regar dl es s of wheth er the Primary or the Secondary

Unit is active). There is no output glitch (data interruption) on switchover since both units are

always sending outputs.

GFK-1527A Chapter 1 Introduction 1-9

Page 18

1

B

R

B

Basic CPU Redundancy Setups

Ther e are three basi c C P U Redundan cy setu p s :

Singl e Bus with Preferred Master

Single Bus with Floating Master

Dual Bus with Floating Master

Single Bus with Preferred Master: GHS Control Strategy

This type of system uses a single Genius bus with bus controllers in each PLC. The Primary Unit

is always chosen as the active unit when the units initially synchronize.

Secondary Uni t Prima r y Uni t

C

P

B

R

G

P

S

T

C

B

U

M

M

C

30

C

B

R

P

S

G

P

T

C

B

U

M

M

C

31

Only Critical Data Transferred

PS.............. Power Supply..

CPU........... Central Processor Unit.

TM............ Bus Transmitter Module

CM........... Redundancy Communications Module

GBC............ Genius Bus Controller

LOCK....... Genius I/O Block (or Field Control)

B

L

O

C

K

B

L

O

C

K

B

L

O

C

K

The single bus with preferred master setup is suitable if:

A. The application does not require redundant I/O buses, AND

B. It is desirable to minimize the amount of data transferred between units, OR It is desirable

that the Primary Unit always becomes active at synchronization.

Single Bus with Preferr ed Ma ster requ ires selection of the GHS control strategy.

The GBCs must be config u red with the followin g s ettings. Note that the GBC s can also be

configured with Redundant Mode = NONE but RED CTRL provides more diagnostic s a nd will be

preferred in most installations.

Redundant Mode = RED CTRL

Paired GBC = External

Serial Bu s Addr = 31 (Primary Unit) or 30 (Secondar y Uni t)

Assuming that Redundant Mode is set to RED CTRL, the redundant I/O blocks mu st be

configured with the following settings:

(Hand-Held Monitor) CPU Redundancy = HOT STBY MODE

(Hand-Held Monitor) BSM Present = NO

(Programmin g Tool) Redundancy = YE S

1-10 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 19

Single Bus with Floating Master: GDB Control Strategy

p

P

B

R

B

This type of system also uses a single bus with bus controllers in each PLC. However, no

switchover occurs on initial synchronization to make the Primary Unit the active unit.

Secondary Unit Prima r y U ni t

1

C

P

B

R

G

P

S

T

C

B

U

M

M

C

30

C

B

R

P

S

G

P

T

C

B

U

M

M

C

31

Critical Data + Redundant

uts Transferred

Out

S.............. Power Supply..

CPU........... Central Processor Unit.

TM............ Bus Transmitter Module

CM........... Redundancy Communications

GBC............ Genius Bus Controller

B

L

O

C

K

B

L

O

C

K

B

L

O

C

K

LOCK....... Genius or Field Control I/O Block.

The single bus with floating master setup is suitable if:

A. The application does not require redundant I/O buses, AND

B. It is desirable that the active unit not switch on initial synchronization, AND/OR

The system cannot tolerate the potential for a bump in the outputs when switching from

the secon dary acti ve t o t he primary active in fa ilure condi tions.

Single Bus with Floating Mast er r equ ires selection of the GDB control strategy.

The GBCs must be config u red with the followin g s ettings. Note that the GBC s can also be

configured with Redundant Mode = NONE but RED CTRL provides more diagnostic s a nd will be

preferred in most installations.

Redundant Mode = RED CTRL

Paired GBC = External

Serial Bu s Addr = 31 (Primary Unit) or 30 (Secondar y Uni t)

Assuming that Redundant Mode is set to RED CTRL, the redundant I/O blocks mu st be

configured with the following settings:

(Hand-Held Monitor) CPU Redundancy = HOT STBY MODE*

(Hand-Held Monitor) BSM Present = NO

(Programmin g Tool) Redundancy = YE S

* Configuration as Duplex mode is also permitted; duplex default also needs to be properly

selected. (See “Duplex CPU Redundancy” on page 1-13.)

GFK-1527A Chapter 1 Introduction 1-11

Page 20

1

Dual Bus with Floating Master: GDB Control Strategy

This type of system uses dual buses with bus controllers in each PLC. No switchover occurs on

initial synchronization to make the Primary Unit the Active Unit. Bus Switch ing Modules (BSMs)

are required in accordance with the traditional configuration of a Dual Bus network. This option

pr ovides redundan c y of both the P L C and the I/O bus.

Secondary Unit Prima r y U ni t

C

P

B

R

G

P

S

U

G

T

C

B

B

M

M

C

C

30

30

Critical Data + Redundant

Outputs Transferred

C

B

R

P

S

G

P

U

Bus Switching Module

G

T

C

B

B

M

M

C

C

31

31

B

L

O

C

K

The Dual Bus with floating master setup is suitable if:

A. The application requires redundancy of the PLC and I/O bus, AND

B. The Active unit should not switch when the Primary Unit is returned to service.

Dual Bus with Floating Mast er r equires sel ecti on of the GDB contr ol stra t egy.

The GBCs must be confi g ured with the following settings

Redundant Mode = DB/RC (Dual Bus/Redundant Controlle r)

Paired GBC = INT/EXT (Internal External)

Serial Bu s Addr = 31 (Primary Unit) or 30 (Secondar y Uni t)

The I/ O block s must be con fi g u red with th e fol l owing settings:

(Hand-Held Monitor) CPU Redundancy = HOT STBY MODE*

(Hand-Held Monitor) BSM Present = YES

(Hand-Held Monitor) BSM Controller = YES or NO (depending on the block)

(Programmin g Tool) Redundancy = YE S

B

L

O

C

K

B

L

O

C

K

* Configuration as Duplex mode is also permitted; duplex default also needs to be properly

selected. . (See “Duplex CPU Redundancy” on page 1-13.)

1-12 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 21

Duplex CPU Redundancy

Only discrete blocks (or Remote I/O Scanners with only discrete modules) can be

configured for Duplex CPU Redundancy mode. Blocks or I/O Scanners configured for

Duplex mod e receive outputs from BOTH bus controller s 30 and 31, and com p are them.

If devices 30 and 31 a gree on an outp ut state, the ou tput goes to th a t s tate. If devices 30

and 31 send different states for an output, the block or I/O Scanner defaults that output

to its pre- s elected Dup lex Defaul t State. F or ex ample:

1

Commanded State

from D evic e

Number 31

On On Don’ Care On

Off On Off Off

Off Off Don’t Care Off

On Off On On

If either device 30 or 31 stop s sending outputs to the block or I/O Sc a nner, outputs wi ll be direct ly

controlled by the remaining device.

Online Programming

On-line changes to the application program are permitted in both the active unit and the backup

unit. The programming device mu s t be connected to the system in which changes are to be made

in order to make any on-line changes. Note that all precautions regarding power source and

groun d ing for connecting the programming device mu st be followed in accordance with

instructions in the

A connect ion and di s connecti on of t he parallel programm er cable should only be ma d e wi th the

programmer proper ly grounded, and programming software proper l y booted up and in OFF-LINE

mode. For more information, refer to the

Manual

, GFK-0262.

Commanded State

from D evic e

Number 30

Series 90-70 Programmable Controller Installation Manual

Duplex Default

State in the Block

or I/O Scanner

Series 90-70 Programmable Controller Installation

Actual Output

State

, GFK-0262.

On-Line Repair

An Enhanced Hot Standby CPU Redundancy system permits online repair of failed components

with out disrupt ing the process under control. Control stat u s of both the Prim ary and the Secondary

units can be monitored by the LEDs on the Redundancy Communications Module in each system.

When a component of the active unit fails, control switches to the backup unit. The failed

component can then be replaced after first removing power from the rack in which it is installed.

After r eplacement of the failed compon en t and return ing power to the rack, th e ba ck u p unit

resynchronizes with the currently active unit. The unit that had failed, which was previously the

active unit, determines its role in the system based on configured control strategy.

Online repair is described in more detail in chapter 5.

GFK-1527A Chapter 1 Introduction 1-13

Page 22

Chapter

2

2

System Components

This chapter describes the hardware components for an Enhanced Hot Standby CPU Redundancy

system.

System Rack s

Redundancy CPU

Redundancy Communications Module

Bus Transmitter Module

Bus Receiver Module

Genius Bus Controller

For Installation Instructions

For detailed installation instructions for the Series 90-70 PLC, refer to GFK-0262, the Series 90-70

Programmable Controller Ins tal lation Manual.

System Racks

The following Series 90-70 I/O racks may be used in a Hot Standby CPU Redundancy System:

Use of Series 90-70 VME Integrator racks (IC697CHS782 and IC697CHS783) in a Hot Standby

CPU Redundancy System is not supported.

IC697CHS750, 5-slot rear mount - standard rack

IC697CHS790, 9-slot rear mount - standard rack

IC697CHS791, 9-slot front mount - standard rack

IC697CHS770, redunda nt rack - rear mount

IC697CHS771, redundant rack - fro nt mount

GFK-1527A 2-1

Page 23

2

y C

Redundanc y CPU

The redundancy CPUs have been designed specifically for Series 90-70 Hot Standby CPU

Redundancy applications.

Features

The Enhanced Hot Standby CPU supports floating point calculations, offers remote programmer

keyswitch memory protection, and has seven status LEDs. Operation of the CPU may be

controlled by the three-position RUN/STOP switch on the module, or remotely by an attached

programmer. Program and configuration data can be locked through software passwords or

manually by the memory protect keyswitch. When the key is in the protected position, a

progr ammer connected to th e Bus Tr ansmitt er M odu le can only change progr am and config uration

data.

In a Hot Standby CPU Redundancy system, one CPU is configured as the Primary CPU and the

other as the Secondary CPU. The Primary unit an d the Secondary unit must each have a

Redundancy CPU installed in slot 1 of rack 0.

Secondary Unit Primary Unit

P

S

CGR935

or

CGR772

in these slots

C

B

R

P

U

G

T

C

B

M

M

C

30

Redundancy Communications Link

Redundanc

ommunications Link

C

B

R

T

M

G

C

B

M

C

31

Genius Bus

P

P

S

U

Not all features of other Series 90-70 CPUs are available in redundancy models. See chapter 4 for

details.

2-2 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 24

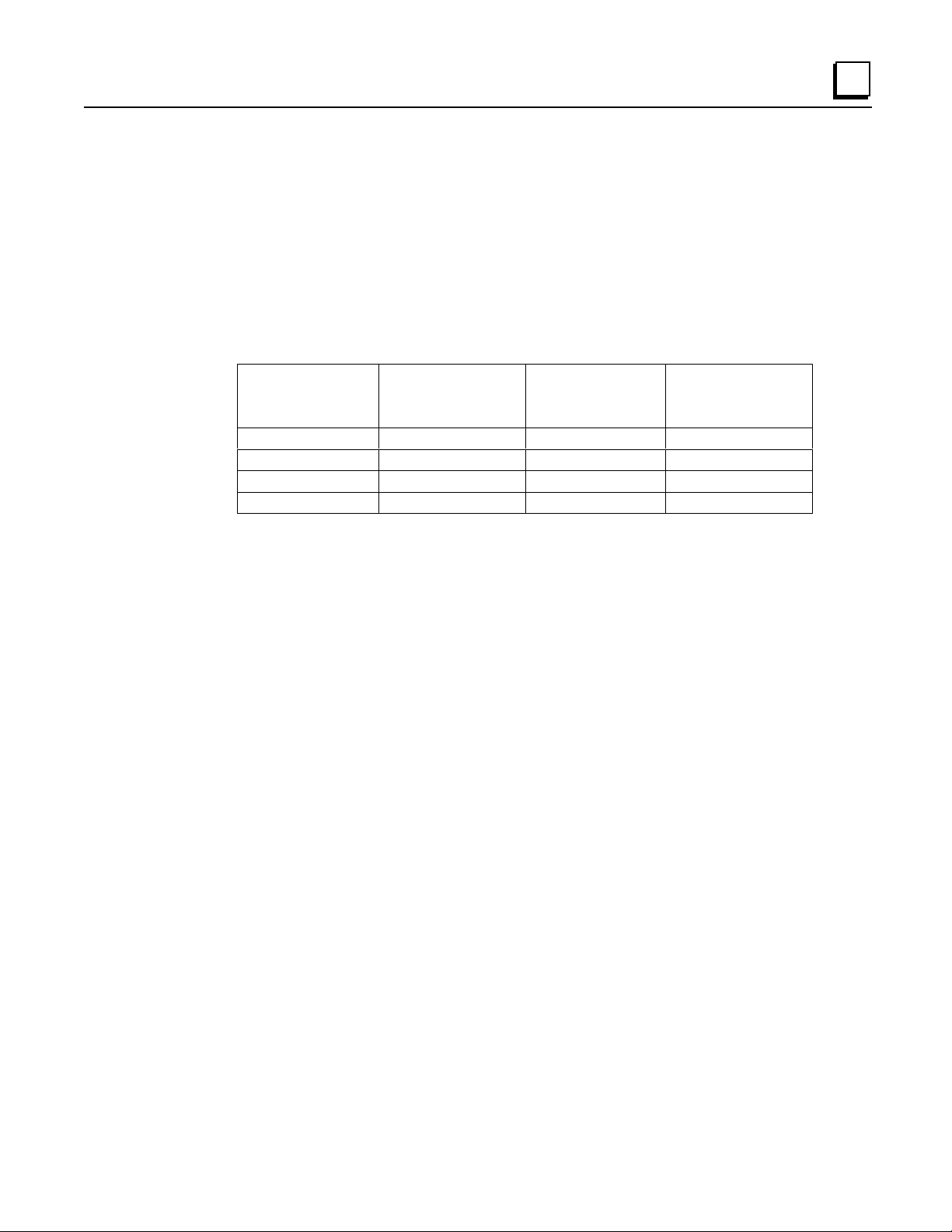

CPU Architecture

The CGR772 and CGR935 have an 80486DX4 microprocessor, on-board memory, and a dedicated

VLSI proce s sor for per f orming Boolean opera tions. The CG R772 and CGR935 interface to serial

ports and the system bus. The microprocessor provides all fundamental sweep and operation

control, plu s e xecut ion of non- Boolean func tions. Bool ean functi ons ar e ha ndled by the dedi c ated

VLSI, Boolean Coprocessor (BCP).

2

Model

CGR772 96 80486DX4 2048 2048 512K Bytes Yes

CGR935 96 80486DX4 12288 12288 1 Megabyte Yes

Speed

(MHz)

Processor

Input

Points

Output

Points

Expansion

Memory

Floating

Point Math

Expansion Memory Board

Program and data memory are provided by an attached expansion memory board with 512K Bytes

of user memory for CGR772 and 1 Megabyte of user memory for CGR935. The expansion

mem ory board pr ovides RA M memory for program and data stor age. Error check ing is provid e d by

a CPU ch eck sum routine. Logic progr am memory is continual ly error- ch eck ed by the CPU a s a

background task. Memory pari ty errors ar e reported to the microprocessor when they occur.

The RAM memory on the expansion memory board is backed-up by the Lithium battery mounted

on the CPU module.

Watchdog Timer

The CPU provides a watchdog timer to catch certain failure conditions. The value of this timer can

be set from 10 milliseconds to 1000 milliseconds. The default is 200 milliseconds. The watchdog

timer resets at the beginning of each sweep. The watchdog timer should be set to allow for the

expected scan

two fail wait times.

plus

GFK-1527A Chapter 2 System Components 2-3

Page 25

2

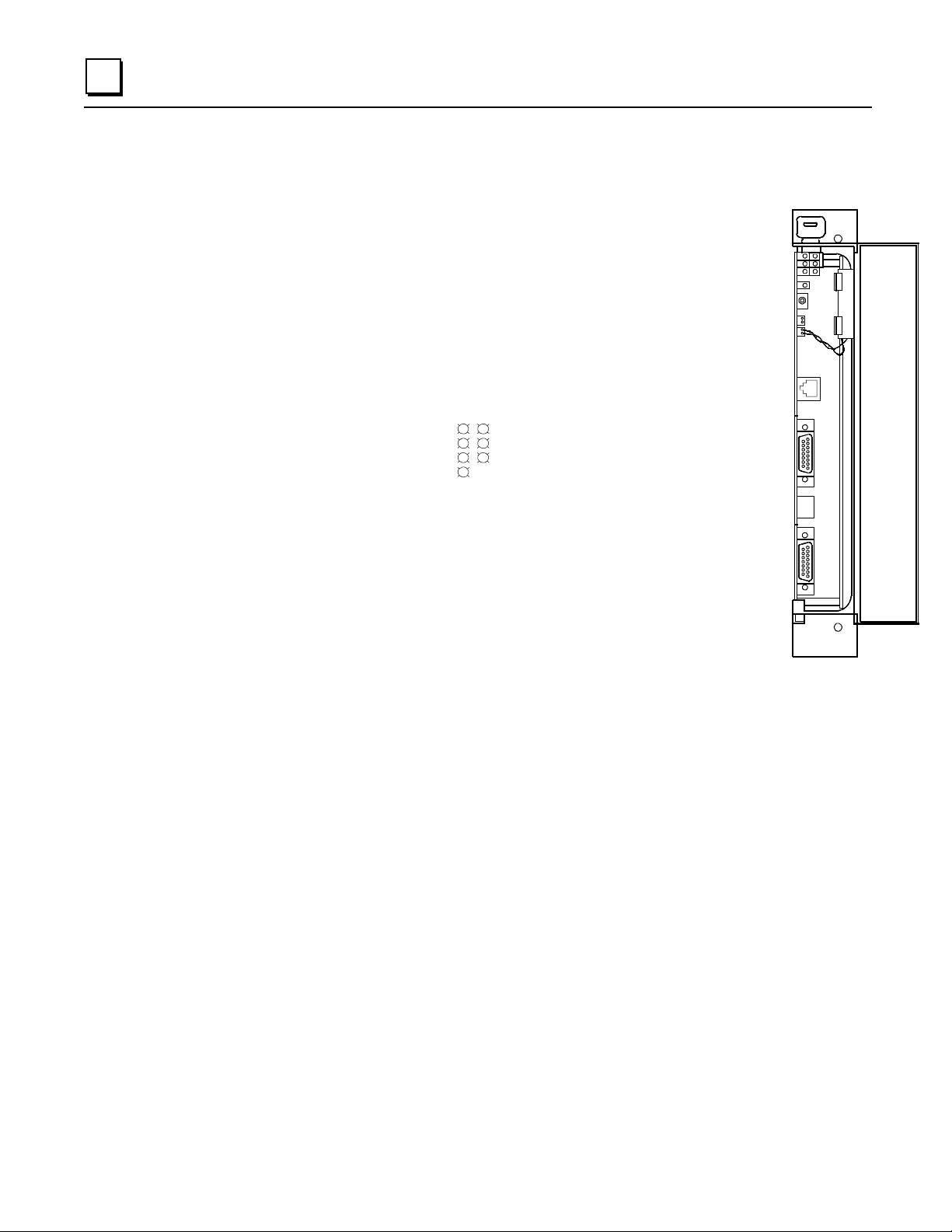

CPU Features

Memory Pro tect Keyswitch

The Memory Protect keyswitch can be used to manually

lock program and configuration data from access by a

remote programmer (serial or Ethernet). When the key is

in the ON p os ition , program and con figurati on data

only be changed

by a programmer connected to the Bu s

Tran sm itter Module.

CPU LEDs

OK:

The OK LED is ON when the CPU is functioning properly. The

OK

RUN

EN

P1

P2

P3

MEM PROTECT

OK LED blinks when the CPU executes power-up diagnostics, when

the remote unit is powered-up, or if the system has failed. If the system

has failed and the OK LED is blinking, the CPU can still communicate

with the programm er (the CPU cannot commun i cate with the

programmer during power-up diagnostics). If the OK LED is OFF, the

system has failed and the CPU cannot communicate with the

programmer.

can

Memory

Protect

Keyswitch

LEDs

CPU Mode

Switch

Battery

Connectors

Port 1

RS-232

Port 2

RS-485

Port 3

RS-422/485

B

A

T

T

E

R

Y

RUN:

This LED is ON when the CPU is in the RUN/ENABLE or RUN/DISABLE mode. It is

OFF when the CPU is in STOP mode.

ENabled

MEMory PROTECT:

:

This LED is ON when outputs are enabled and OFF when outputs are disabled.

This LED indicates the status of the memory protect keyswitch. It is ON

when the keyswitch is in the ON position. It is OFF when the keyswitch is in the OFF position.

P1, P2, P3:

LED blinks intermittently when there is serial communications on the indicated serial

port (Port 1, Port 2, or Port 3).

Batter y Co nnector s

There are two identical battery connectors. The battery currently installed can remain connected

while a new battery is being installed, minimizing the risk of data loss. A Low Battery Warning

occurs when the battery needs replacement.

When the CPU is in storage, the battery can be disconnected if there is no application program

stored in memory. If a program is stor ed in memory, the battery sh ould not be disconnect ed , or the

data will be lost.

2-4 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 26

CPU Mode Switch

2

The CPU Mode switch selects the op eratin g mode o f the CPU:

or

switch position restricts the ability of the programmer to put the CPU into certain modes, as shown

in the fo llo wing table.

. The CPU mode can also be controlled from the programmer. However, the CPU Mode

STOP

CPU Mode Switch Position Allowable Programmer

Mode Command

Run/Outputs Enabled Run/Enabled

Run/Disabled

Stop

Run/Outputs Disabled Run/Disabled

Stop

Stop Stop

RUN/ENABLED , RUN/DIS ABLED

Run/Outputs Enabled Mode

In this mode, the CPU executes all portions of the sweep normally.

Run/Outputs Disabled Mode

In this mode, the CPU executes all portions of the sweep normally, but physical outputs are held in

their default state and remain unchanged. Refer to Chapter 4 for important information about

Run/Disabled mode in a Hot Standby CPU Redundancy system.

,

Stop Mode

In Stop mod e, the CPU commu n icates with the programmer and th e d evices conn ected to th e ser ial

port , com municat es with other communications modul es such as the eth ernet modul e, and recover s

fault ed modules. Values in the I/ O ta bl es can be changed using the programm ing comput er .

The STOP/IOSCAN mode

detailed information.

is not a valid mode

in a redun dancy system. Refer to Chap ter 4 for

Port 1

The RJ-11 connector provides an RS-232 compatible serial port.

Port 2

The 15-pin D-connector is an RS-485 compatible serial port.

Port 3

The 15-pin D-connector at the bottom of the module provides an RS-422/RS-485 serial port. For

applications requiring RS-232 communications, an RS-232 to RS-422 converter (IC690ACC900)

or RS-232 to RS422 miniconverter (IC690ACC901) is available.

Note

An RS-422 Isolated Repeater/RS-232 Converter (IC655CCM590) is available for

applications requiring ground isolation where a common ground cannot be

established between components.

GFK-1527A Chapter 2 System Components 2-5

Page 27

2

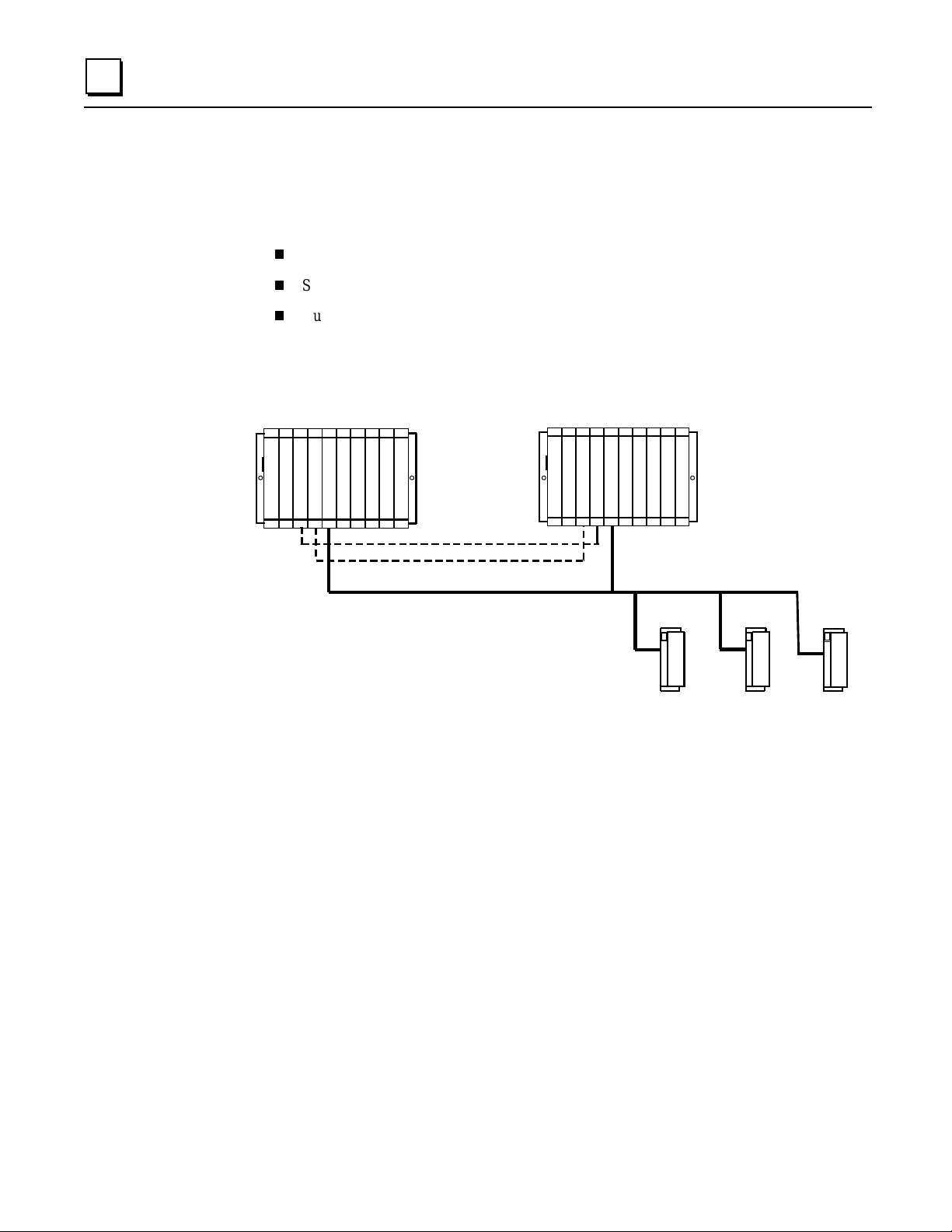

Redundanc y Communications Module

The Redundancy Communications Module (RCM), catalog number IC697RCM711 or

IC687RCM711 (½ slot version), provides a communications path for sharing data between the two

CPUs in the redundant system. In a synchronized system, I/O data is controlled by one unit (the

active unit) but is shared between both units (active and backup units).

An RCM must be in both the Primary PLC and the Secondary PLC. The RCM must reside in

rack 0. Th er e can be no empty slot between the RCM and th e C P U (there can be other modules).

Primary Unit Secondary Unit

( RACK 0 )

R

C B

P

B

G

C

S

T

B

P

M

M

C

U

31

Redundancy Communications Link

Redundancy Communications Link

If the other PLC has only one rack, the Redundancy Communications Module connects directly to

the Bus Transmitter Module. If the other PLC has expansion racks, the RCM connects to a Bus

Receiver Module in the last rack. The termination plug at the end of the bus is not required since

the I/O cables for redundancy systems have termination built-in to the cables.

Primary Unit Secondary Unit

( RACK 0 )

( RACK 0 )

C

R

P

U

C

T

M

M

( RACK 0 )

G

B

C

30

P

S

C

R

C B

P

B

G

C

S

T

B

P

M

M

C

U

31

Redundancy Communicatio ns Link

PSB

R

M

Redundancy Communicatio ns Link

P

S

PSB

R

G

C

B

P

T

U

M

C

M

30

R

M

Unit Select Pushbutton

The Redundancy Communications Module's pushbutton can be used to manually switch control

from the

1 second and released. Switching between units can also be controlled from the application

program with a SVC_REQ function.

The pushbutton status is checked by the PLC CPU software. After a switch has been requested,

you must wait 10 seconds before requesting another switch.

acti v e

unit to the

unit if the backup unit is

backup

READY. T

he switch must be pressed for

2-6 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 28

2

Connector

LEDs

BOARD OK

The top connector on the Redundancy Communications Module

must be connected vi a an I/O cable t o the last rack of t he

other

PLC. If n o expansion rack is used, it is connected t o the lower

conn ector on the Bus Tr ansmitt er M odu le of the other system. The

LOCAL SYSTEM READY

LOCAL SYSTEM ACTIVE

REMOTE SYSTEM RE ADY

REMOTE SYSTEM ACT IVE

Unit Select

Pushbutton

I/O cable with built-in termination is available in three lengths:

IC697CBL803, 3 feet (0.9 meters)

IC697CBL811, 10 feet (3 meters)

IC697CBL826, 25 feet (7.5 meters)

Connector

Communications

for

Cable

The lower con nector is not used.

RCM Status LEDS

The RCM's five status LEDs are always updated by the appropriate system.

The module automatically turns off four of the LEDs (not the board OK LED)

if they are not updated within 500ms.

These LE D s report the status of t he health of the RCM and control status of

the Hot Standby CPU Redundancy system. The status provided by these

LEDs can also be read from the application program logic in an area of %S

memory (%S33 - %S39). These status bits are read-only.

The term

Local System

system t o wh ich the RCM i s con nected via the communications cable. Each RCM h as an

associated local and remote sy s tem.

below means the system where the RCM resides.

Remote System

is the

Board OK:

This LED lights when diagnostics are complete and the RCM has been determined to

be operat i ng nor mall y. It sta ys on unless the RCM fails .

Local System Ready

:

Indicates whether the local system is ready to become the active system

in a redundant PLC configuration. If this LED is on, the local system has been configured for

redundancy, is in RUN mode, and is able to take control of the redundant system if selected as the

active system. The local system MUST set the state of this LED at least once each sweep; if it

doesn't, the hardware forces the LED off after the timer expires.

Local System Active

:

Indica tes whether the local system is the controlling (a ctive) system in a

redundancy system. The local system MUST set the state of this LED at least once during each

sweep; if the local system fails to set the state of the LED, the hardware forces the LED off after

the timer expires .

Remote System Ready

:

Indicates whether the remote system is ready to become the active

system i n a redundant PLC system. If the LED is on, th e r emote system h as been config ured for

redundancy, is in RUN mode, and is able to take control of the redundant system if selected as the

active system. The remote system MUST set the state of this LED at least once during each sweep;

if the remote system fails to set the state of the LED, the hardware forces the LED off after the

timer expires.

Remote System Acti ve

:

Indicat es whether th e r emote system is the control ling (act ive) system

in a redundancy scheme. The remote system MUST set the state of this LED at least once during

each sweep; if the remote system fails to set the state of the LED, the hardware forces the LED off

after the timer expires.

GFK-1527A Chapter 2 System Components 2-7

Page 29

2

Bus Transmitter Module

A Bus Transmitter Module (BTM), catalog number IC697BEM713 or IC687BEM713 (½ slot

version), must be in r ack 0 of both th e Primary PLC and the Secondary PLC in a Hot St andby CPU

Redundancy system. The Bus Transmitter Module provides a path for Redundancy

communications when connected to the Redundancy Communications Module as described

previously. Each PLC in the redundancy system (Primary and Secondary) must have a BTM and

an RCM in ra ck 0.

P

S

B

C

P

T

M

U

Primary Unit

( RACK 0 )

R

G

C

B

M

C

Secondary Unit

( RACK 0 )

B

P

C

T

S

P

M

U

R

G

C

B

M

C

31

Redundancy Communications Link

Redundancy Communications Link

30

When included as a bus communications module in an I/O expansion system, the BTM is a high

speed parallel interface wh ich propa ga tes the I/O bus s i gn als through a cable to a Bus Recei ver

Module located in the first I/O expansion rack. The BTM also provides a high speed parallel

connection to the programmer.

Connectors

The lower con nector on the BTM is used to connect t o a

Redundancy Communicatio ns Module i n the othe r

Redund ancy system or to a Bus Recei ver Module in the first

expansion rack. Standard parallel I/O cables are used to

PROG RA MMER P ORT EN A BL E D

EXPANSION PORT ENABLED

LEDs

MODULE OK

make th e con nection to a Bus Receiver M odule. Cabl es with

built-in termination are used to make the connection to a

Redundancy Communications Module.

The upper connector provides a parallel connection to a Work

Station Interface (WSI) board installed in the programmer for

the Series 90-70 PLC.

Connector for

Programmer

(Programm e r Port)

Bus Transmitter Module Status LEDs

Module OK:

completed its power-up configuration of the BTM, and has

polled (or attempted to poll) each expansion rack in the

system. It is OFF when any of these condit ions are not met.

Programmer Port Enabled

or ON when th e pr ogrammer an d the PLC are

communicating. It is

Expansion Port Enabled:

The top LED is ON when the CPU software has

:

The middle LED is either

when th ey are not comm un icating .

OFF

blinking

The bot tom LED shows the stat u s of

Connector for

Redundancy

Communications

or Bus Re ce iver

Module

(Expansion Port)

the exp ansion bus . This LED is ei ther blinking or ON wh en

the BTM is communi cating.

2-8 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 30

Bus Receiver Module

The Bus Receiver Module (BRM), catalog number IC697BEM711, is the expansion rack interface

to the I /O bus. The Bus Receiv er Modul e connects t o a Bus Transmitter Modul e in ra ck 0 or to a

Bus Recei ver Module in the previ ou s rack via a par allel I/ O bus ca bl e.

In a CPU Redundancy system with expansion racks, the last bus connection is to a Redundancy

Communicati ons Mod u le, as explained previ ou s ly.

Connectors

2

The top connector on the Bus Receiver M od u le is for connection

to the previous Bus Transmitter or Bus Receiver Module.

The lower con nector on the Bus Receiver Module is for

connection to the upper connector of a Bus Receiver Module in

the next expansion rack or to the upper connector of a

Redundancy Communications Module.

Cables and Termin ation

In an expansion I/O system, th e cable between Bu s

Tran sm itter/Receiver m odu les is an 18 twi sted-pair cable with a

ground shield. The total maximum cable length from the CPU

rack to the most distant expansion rack (at the same ground

poten tial) is 50 feet. Standard parallel I/O bus cabl es th at meet

this specification are available

in lengths of 5, 10, 25, and 50 feet.

In a non-redundant PLC system, thi s bus must be

terminated using terminator plug (IC697ACC702) on the

bottom con nector of the last Bus Receiver. All BRMs are

shi pped from the factory with a terminator plug installed.

For a red undant PLC system, thes e terminat or plugs must

be removed from all BRMs.

LEDs

BOARD OK

LAST RACK

BUS ACTIVE

Connector to

Previous BTM

or BRM

Connector to

Redundancy

Communications

Module or Bus

Receiver Module

In a Hot Standby CPU Redundancy system a special I/O cable with

built-in termination is used. Do not use the resistor plug with the

terminat ed cable.

Bus Receiver Module Status LEDs

:

Board OK

the expansion rack and at least one module in that rack respo nds to the CPU reque sts for

info rma tion. It is

Last Rack

conn ector of thi s Bus Rec eiver Module and is

Expansion Bus Active

the last 500 ms. Otherwise it is off and I/O modules in the rack are held in their default state.

GFK-1527A Chapter 2 System Components 2-9

The top LED is ON when the CPU completes its power-up configuration of

when an y of th es e conditions are not met.

OFF

:

The middle LED is ON when the terminator plug is installed in the bottom

when it is not installed.

Off

:

The bottom LED ON indicates activity on the expansion bus in

Page 31

2

)

Genius Bus Controller

The Genius Bus Controller (IC697BEM731) interfaces the Series 90-70 PLC to a Genius I/O bus.

The bus controll er s cans bus devices asynchronousl y an d ex ch anges I/O dat a wi th the CPU once

per scan .

Location of GBCs and Blocks

For dual bus Genius networks, the Genius bus controllers should be placed at the same end of the

bus, as pi ctured belo w. In p ar ticular , the Secondary Unit must be placed at one en d of the bus an d

the Primary Unit m u st be placed between the Secon d ary Unit and th e G en ius I/O blocks. N o I/O

blocks or other devices should be locat e d on the bus between the bus con t rollers. Placing th e bus

controllers and blocks in this manner minimizes the risk of a bus break between the two CPUs. A

bus break between the CPUs could result in only some blocks switching busses, and make the other

blocks inaccessible to one of the CPUs. It also allows the Primary Unit to continue to control the

I/O in bus failure conditions that might otherwise result in loss of inputs and unsynchronized

control of outputs.

Since the recommended configuration still has the possibility of a bus breaking between the two

CPUs, you may want to program the application to monitor the status of the buses from the unit

configured at the end of the buses and request a role switch or bus switch if the bus is determined to

be broken. Locating singl e bu s n etworks in th e same manner h as similar advantages.

Secondary Unit Primary Unit

C

P

B

R

G

P

S

U

PS........ Power Supply..

CPU...... Central Processor Unit.

BTM..... Bus Transmitter Module

RCM...... Redundancy Communications Module

GBC.... . Genius Bus Controller

BLOCK.. Genius I/O Block (or Field Control

G

T

C

B

B

M

M

C

C

30

30

C

B

R

P

S

Bus Switching Module

G

P

U

G

T

C

B

B

M

M

C

C

31

31

B

L

O

C

K

B

L

O

C

K

B

L

O

C

K

For fastest switching, all Genius Bus Controllers in the Hot Standby CPU Redundancy system

shoul d be in the main rack, or in a rack driven by the main rack's power supply. Th is will cau s e th e

Genius Bus Controller to lose power at the same time that the CPU loses power and allow the

backup unit to gain full control of the I/O as soon as possible. Each GBC has an output timer,

which it resets during every output scan. If the GBC determines that the CPU in its PLC has failed,

it will stop sending outputs to its Genius I/O block. This allows the other GBC to take control of

the I/O.

2-10 Series 90™-70 Enhanced Hot Standby CPU Redundancy User's Guide – May 2000 GFK-1527A

Page 32

Single Bus Genius Networks

When using single-bus Genius networks in a Hot Standby CPU Redundancy system, one Genius

Bus Controller for the bus mu st be l ocated in the Primary PLC and one in the S econdary PLC.

There can be multiple Geni u s busses in the system.

The bus controll er s in th e Primar y PLC are assigned Serial Bus Ad dress 31. Th e bus controllers in

the Secondary PLC are assign ed Ser ial Bus Addr ess 30. Data from Seria l Bus Address 31 in the

Prim ary PLC is the "preferred" data. If the GHS Control Str ategy is used, the Primary PLC is

normally the active unit in the redundancy system.

Each bus can have up to 30 Genius devices connected to it. One Serial Bus Address m ust be