Page 1

GE Fanuc Automation

Programmable Control Products

Series 90™

Micro PLC

User's Manual

GFK-1065F June 1998

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment,

a Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

GFL-002

Warning

Caution

Note

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Master Field Control Modelmaster Series One

CIMPLICITY GEnet PowerMotion Series Six

CIMPLICITY Control Genius ProLoop Series Three

CIMPLICITY PowerTRAC Genius PowerTRAC PROMACRO VuMaster

CIMPLICITY 90–ADS Helpmate Series Five Workmaster

CIMSTAR Logicmaster Series 90

©Copyright 1994—1998 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

RFI Standards

The Series 90 Micro PLCs have been tested and found to meet or exceed the requirements of FCC Rule, Part 15,

Subpart J. The Federal Communications Commission (FCC) requires the following note to be published according to

FCC guidelines.

Note

This equipment generates, uses, and can radiate radio frequency energy and if not installed in

It has been tested and found to comply with the limits for a Class A digital device pursuant to Part

15 of the FCC Rules, which are designed to provide reasonable protection against harmful

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at his own expense.

The following note is required to be published by the Canadian Department of Communications.

Note

apparatus set out in the radio interference regulations of the Canadian Department of

Communications.

GFK-1065F iii

Page 4

This page was intentionally left blank for pagination purposes . . .

replace with a BLANK SHEET

iv

Page 5

The following markings are required to appear in the Series 90 Micro PLC User’s for Class I Div 2

1.

IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A,B,C,D

OR NON-HAZARDOUS LOCATIONS ONLY.

Preface

2. WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2:

and

ADVERTISSEMENT - RISQUE D’EXPLOSION - LA

SUBSTITUTION DE COMPOSANTS PEUT RENDRE

CE MATERIEL INACCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I, DIVISION 2.

3. WARNING - EXPLOSION HAZARD - DO NOT

DISCONNECT EQUIPMENT UNLESS POWER HAS

BEEN SWITCHED OFF OR THE AREA IS KNOWN

TO BE NON-HAZARDOUS.

ADVERTISSEMENT - RISQUE D’EXPLOSION AVANT DE DECONNECTER L‘EQUIPEMENT,

COUPER LE COURANT OU S‘ASSURER QUE

L‘EMPLACEMENT EST DESIGNE NON DANGEREUX.

v

Page 6

replace with a BLANK SHEET

vi

Page 7

Content of This Manual

This manual provides information necessary to enable you to integrate a Series 90 Micro

Programmable Logic Controller (PLC) into a wide variety of control applications. This manual

contains descriptions of hardware components, installation procedures, system operation

information, and maintenance information for the Series 90 Micro PLC.

Revisions to This Manual

This manual revision (GFK-1065E) incorporates the following changes:

Preface

• A new 14-point Micro PLC, IC693UDD104, is now available. Technical information

pertaining to this unit has been added where appropriate.

• Additional corrections have been made as needed.

Content of This Manual

Chapter 1. Quick Start. Brief procedures for getting the Micro PLC up and running. Includes

“Frequently Asked Questions” and “Programming Examples.”

Chapter 2. Introduction. An overview of the Micro PLC functional and physical characteristics.

Describes compatibility with other Series 90 PLCs and lists model specifications.

Chapter 3. Installation. Procedures for installing the Micro PLC and preparing the system for use.

Included in this chapter are instructions for unpacking, inspecting, and installing the Micro PLC.

Instructions are also provided for connecting cables to programming devices.

Chapter 4. Field Wiring. Power and I/O specifications, and wiring information for the Micro PLC.

Chapter 5. Configuration. Configuration and programming using the Logicmaster 90 Micro

software or the Hand-Held Programmer.

Chapter 6. High Speed Counters. Features, operation, and configuration of the High Speed

Counter function.

Chapter 7. Analog I/O. Features, operation, and configuration of the Analog I/O function, a

feature of the 23-point Micro PLC.

Chapter 8. System Operation. System operation of the Micro PLC. Includes a discussion of the

PLC system sweep sequences, the power-up and power-down sequences, clocks and timers, security

through password assignment, and the I/O system.

GFK-1065F vii

Page 8

Preface

Chapter 9. Diagnostics. A guide to troubleshooting the Micro PLC system. Section 1 describes

how to use the self-diagnostic LED blink codes. Section 2 describes how the Micro PLC handles

system faults.

Appendix A. Instruction Timing. Tables showing the memory size and execution time required

for each function.

Appendix B. Reference Types. Listing of user references and references for fault reporting. Also

contains tables listing memory locations that are reserved for I/O functions.

Appendix C. PLC/Software Cross Reference. A comparative listing of the instructions and

function blocks supported by the Series 90 Micro PLC and the Series 90-20 PLC.

Appendix D. Serial Port and Cables. Description of the serial port, converter, and cables used to

connect Series 90 PLCs for Series 90 Protocol (SNP).

Appendix E. Converters. Detailed description of the RS-422/RS-485 to RS-232 Converter for the

Series 90 PLCs. Describes the Miniconverter Kit for and the Isolated Repeater/Converter with

Series 90 PLCs.

Appendix F. Cable Data Sheets. Data sheets describing each of the Series 90 PLC cable types that

are commonly used with the Micro PLC.

Appendix G. Sample Application for PWM and Pulse Outputs. An example of the use of analog

I/O through a signal conditioning unit.

Appendix H. Case Histories. Brief summaries of applications that use the Micro PLC.

viii Series 90™ Micro PLC User's Manual–June 1998 GFK-1065F

Page 9

Related Publications

Logicmaster™ 90 Series 90-30/20/Micro Programming Software User’s Manual (GFK-0466)

Series 90™-30/20/Micro Programmable Controllers Reference Manual (GFK-0467)

Workmaster® II PLC Programming Unit Guide to Operation (GFK-0401)

Workmaster Programmable Control Information Center Guide to Operation (GEK-25373)

Hand-Held Programmer, Series 90™-30/20/Micro Programmable Controllers User’s Manual

(GFK-0402)

Series 90™-30 Programmable Controller Installation Manual (GFK-0356)

Series 90™-70 Programmable Controller Installation Manual (GFK-0262)

Series 90™ PLC Serial Communications User’s Manual (GFK-0582)

Series 90™ Micro Field Processor User’s Manual (GFK-0711)

Important Product Information, Micro PLC (GFK-1094)

Preface

Important Product Information, Micro Expansion Unit (GFK-1474)

Data Sheet, 14-Point Micro PLCs (GFK-1087)

Data Sheet, 28-Point Micro PLCs (GFK-1222)

Data Sheet, 23-Point Micro PLC (GFK-1459)

Data Sheet, Micro Expansion Unit (GFK-1460)

At GE Fanuc Automation, we strive to produce quality technical documentation. After you have

used this manual, please take a few moments to complete and return the Reader's Comment Card

located on the next page.

Dave Bruton

Senior Technical Writer

GFK-1065F Preface ix

Page 10

Page 11

Contents

Chapter 1 Quick Start...........................................................................................................1-1

What You Will Need ........................................................................................................1-1

Getting Started ..................................................................................................................1-2

Frequently Asked Questions.............................................................................................1-4

Programming Examples....................................................................................................1-6

Chapter 2 Introduction.........................................................................................................2-1

Compatibility ....................................................................................................................2-3

Functional Description......................................................................................................2-4

CPU Board..................................................................................................................2-4

High Speed Counters (IC693UDR011/002/005, IC693UAL006, IC693UDR010)...2-6

Type A Counters.................................................................................................2-6

Type B Counter...................................................................................................2-6

DC Output (IC693UDR005/010, UAL006)...............................................................2-6

PWM Output.......................................................................................................2-6

Pulse Output........................................................................................................2-7

ASCII Output (IC693UDR005/010, UAL006)..........................................................2-7

I/O Board....................................................................................................................2-7

Input Circuits..............................................................................................................2-7

DC Input Circuits (IC693UDR001/002/005/010, UAL006)...............................2-7

AC Input Circuits (IC693UAA003/007).............................................................2-7

Potentiometer Inputs (All Models)......................................................................2-7

Output Circuits...........................................................................................................2-8

Relay Output Circuits (IC693UDR001/002/005/010, UEX011, UAL006)........2-8

AC Output Circuits (IC693UAA003/007)..........................................................2-8

DC Output (IC693UDR005/010, IC693UAL006)..............................................2-8

Analog I/O (IC693UAL006)......................................................................................2-8

Input/Output Connectors............................................................................................2-9

Serial Ports.................................................................................................................2-9

Serial Communications Protocols.......................................................................2-9

Port 1 (All Models)...........................................................................................2-10

Port 2 (23 and 28-Point Models).......................................................................2-11

Expansion Port (23 and 28-Point Models)...............................................................2-11

Terminal Strips.........................................................................................................2-12

Status Indicators .......................................................................................................2-13

Power Supply Board.................................................................................................2-13

Configuration and Programming.....................................................................................2-14

Fault Reporting ...............................................................................................................2-14

Specifications..................................................................................................................2-15

Chapter 3 Installation........................................................................................................... 3-1

Minimum Hardware Requirements...................................................................................3-1

Unpacking.........................................................................................................................3-1

Installation Requirements .................................................................................................3-2

Installation.........................................................................................................................3-2

Mounting a Unit on a DIN Rail..................................................................................3-4

GFK-1065F xi

Page 12

Contents

Removing a Unit From a DIN Rail.............................................................................3-4

Grounding Procedures................................................................................................3-5

Logicmaster Programming Device Grounding...........................................................3-5

I/O Installation and Wiring.........................................................................................3-5

Powerup Self-test..............................................................................................................3-6

Normal Powerup Sequence........................................................................................3-6

Fast Powerup..............................................................................................................3-7

Error Detection And Correction.................................................................................3-7

Connecting a Programming Device ..................................................................................3-8

Connecting the Hand-Held Programmer....................................................................3-8

Connections for Using Logicmaster 90-30/20/Micro Software...............................3-10

Workmaster II Computer with WSI.........................................................................3-10

lBM-PC Compatible Computer................................................................................3-10

Multidrop Serial Data Configuration to Series 90 PLCs..........................................3-12

Replacing Fuses (AC In/AC Out Models Only).............................................................3-13

Expansion Unit Installation.............................................................................................3-16

Micro Expansion Unit ..............................................................................................3-16

Micro Expansion Unit Orientation...........................................................................3-17

Electromagnetic Compatibility.................................................................................3-18

Physical Order of Different Types of Expansion Units ...........................................3-18

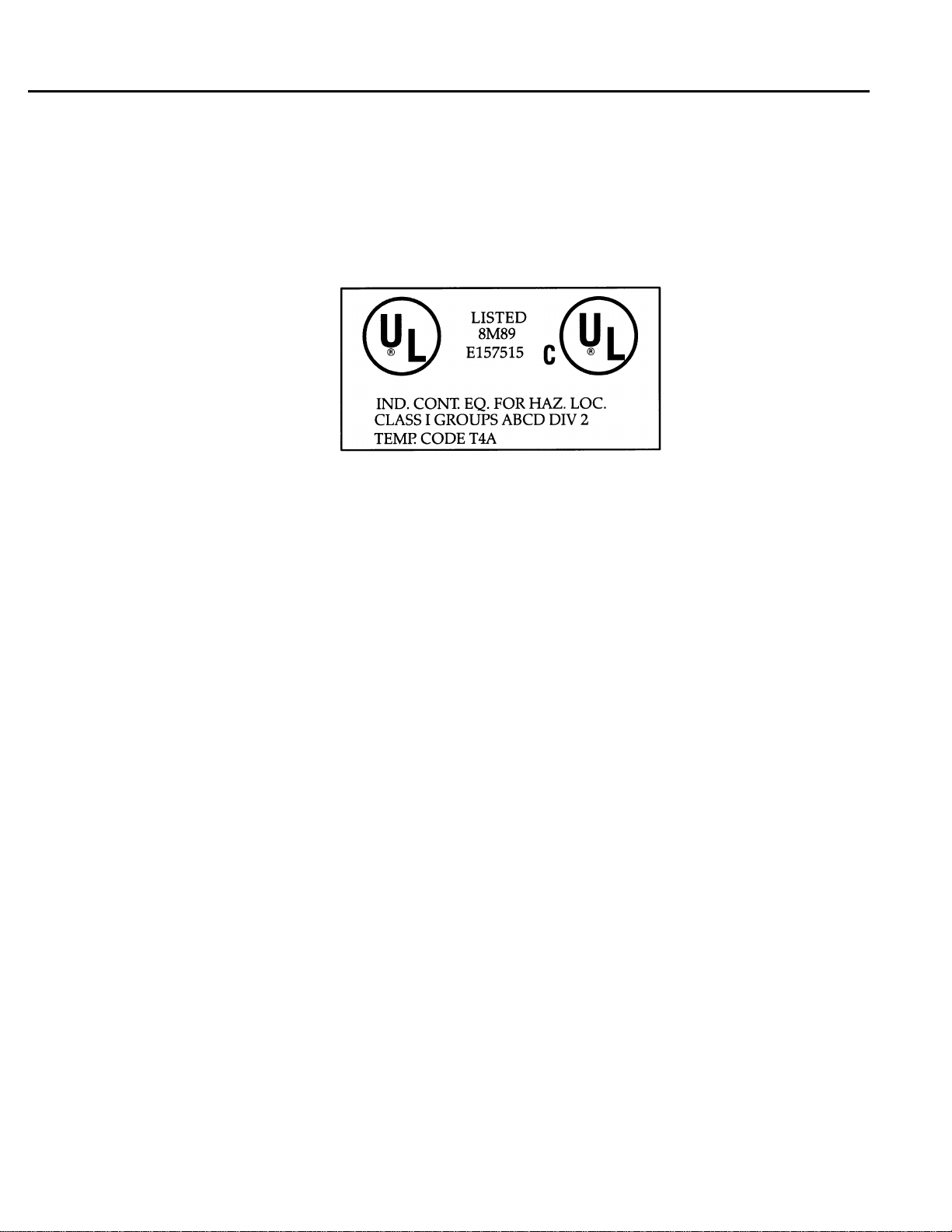

Agency Approvals, Standards, and General Specifications for Series 90 Micro PLC..3-20

CE Mark Installation Requirements................................................................................3-22

Chapter 4 Field Wiring.........................................................................................................4-1

Positive and Negative Logic Definitions..........................................................................4-1

Interface Specifications.....................................................................................................4-3

Model Summaries.......................................................................................................4-3

14-Point DC In/Relay Out/AC Power (IC693UDR001/UEX011).............................4-3

14-Point DC In/Relay Out/DC Power (IC693UDR002), 14 Point DC In/DC Out/DC

Power (IC693UDD104)............................................................................................4-4

14-Point AC In/AC Out/AC Power (IC693UAA003)................................................4-4

28-Point DC In/DC & Relay Out/AC Power (IC693UDR005)..................................4-5

23-Point DC In/DC & Relay Out/Analog I/O/AC Power (IC693UAL006)...............4-5

28-Point AC In/AC Out/AC Power (IC693UAA007)................................................4-6

28-Point DC/DC & Relay Out/DC Power (IC693UDR010)......................................4-6

Positive/Negative Logic Inputs (IC693UDR001/002/005/010, UDD00104, UAL006,

UEX011).....................................................................................................................4-7

Potentiometer Analog Inputs (All Models)................................................................4-8

High Speed Counter Inputs (IC693UDR001/002/005/010, UAL006).......................4-9

Relay Outputs (IC693UDR001/002/005/010, UAL006, UEX011) .........................4-10

Output Circuit Protection.........................................................................................4-11

High Speed Counter Outputs (IC693UDR001/002/005, IC693UAL006) ...............4-12

DC Outputs (IC693UDR005/010 and IC693UAL006)............................................4-12

Transistor Outputs 24VDC (IC693UDD104) ..........................................................4-12

xii Series 90™ Micro PLC User's Manual–June 1998 GFK-1065F

Page 13

Contents

24 VDC Output Power Supply (IC693UDR001/002/005/010, IC693UDD104,

IC693UAL006, IC693UEX011)...............................................................................4-14

Analog Inputs (IC693UAL006)................................................................................4-15

Analog Output (IC693UAL006) ..............................................................................4-16

AC Inputs (IC693UAA003/007) ..............................................................................4-17

AC Outputs (IC693UAA003/007)............................................................................4-18

Field Wiring Installation.................................................................................................4-20

Wire Connection Information...................................................................................4-20

Power Supply and I/O Connections..........................................................................4-20

General Wiring Procedures ......................................................................................4-21

Chapter 5 Configuration ...................................................................................................... 5-1

Micro PLC Parameters......................................................................................................5-1

Configuration and Programming Using the HHP.............................................................5-4

HHP Configuration Screens.......................................................................................5-4

Storing the User Program Using the HHP..................................................................5-7

Storing Configuration and Register Data Using the HHP..........................................5-8

Other HHP Functions.................................................................................................5-8

Clearing User Memory Using the HHP......................................................................5-8

Booting up in Stop Mode Without Clearing Memory................................................5-9

Setting the Time of Day Clock (23 and 28-Point PLCs)............................................5-9

Configuration and Programming Using Logicmaster 90 Software.................................5-10

Configuring Serial Ports .................................................................................................5-12

Logicmaster 90 Configuration of Serial Port 2 ........................................................5-13

Configuring Serial Ports Using the COMM_REQ Function....................................5-15

Command Block.......................................................................................................5-15

Example ...................................................................................................................5-18

Programmer Attach Feature (14-Point Micro PLCs) ...............................................5-20

Configuring ASCII Output..............................................................................................5-21

Autodial Command Block........................................................................................5-21

Put String Command Block......................................................................................5-23

Status Word for Custom Protocol COMM_REQs ...................................................5-25

Configuring Expansion Units (23 and 28-Point Micro PLCs)........................................5-26

Logicmaster Screens for Configuring Expansion Units...........................................5-27

Series 90 Micro 14-Point Expansion Unit................................................................5-28

14-Point Generic Expansion Unit.............................................................................5-28

Generic Expansion Unit...........................................................................................5-29

I/O Link Interface Expansion Unit...........................................................................5-30

HHP Screens for Configuring Expansion Units.......................................................5-31

Configuring Generic Expansion Units .....................................................................5-31

Configuring Standard Expansion Units....................................................................5-32

Configuring I/O Link Interface Expansion Units .....................................................5-33

Reference Error Checking........................................................................................5-34

Configuring Q1 for PWM or Pulse Output (IC693UDR005/010 and IC693UAL006)..5-35

GFK-1065F Contents xiii

Page 14

Contents

PWM Output ............................................................................................................5-36

Pulse Train Output....................................................................................................5-38

Configuring of Outputs Q1 to Q5 (IC693UDD104) ................................................5-39

PWM Output (IC693UDD104)................................................................................5-40

Sample Calculation for PWM Output...............................................................5-42

Pulse Output (IC693UDD104).................................................................................5-43

Chapter 6 High Speed Counters..........................................................................................6-1

High Speed Counter/CPU Interface..................................................................................6-3

Registers.....................................................................................................................6-3

Counts per Timebase Register....................................................................................6-3

Preload Register.........................................................................................................6-3

Strobe Register...........................................................................................................6-4

Data Automatically Sent by the HSC.........................................................................6-4

Analog Input (%AI) Data...........................................................................................6-4

High Speed Counter Status Codes..............................................................................6-5

Status Bits (%I)..........................................................................................................6-5

Data Automatically Sent to the HSC (%Q)................................................................6-6

Output Failure Mode.........................................................................................................6-7

Type A Counter Operation................................................................................................6-8

Type A Counter Overview .........................................................................................6-8

Type A Operating Parameters ....................................................................................6-9

Counter Enable/Disable .............................................................................................6-9

Counter Output Enable/Disable..................................................................................6-9

Preload/Strobe............................................................................................................6-9

Count Mode .............................................................................................................6-10

Count Direction........................................................................................................6-10

Strobe/Count Edge...................................................................................................6-10

Counter Time Base...................................................................................................6-10

Count Limits.............................................................................................................6-11

Output Preset Points.................................................................................................6-11

Preload Value...........................................................................................................6-13

Type B Counter Operation..............................................................................................6-14

A-Quad-B Counting..................................................................................................6-14

Type B Counter Overview........................................................................................6-15

Type B Operating Parameters ..................................................................................6-16

Counter Enable/Disable ...........................................................................................6-16

Counter Output Enable/Disable................................................................................6-16

Preload/Strobe..........................................................................................................6-16

Count Mode .............................................................................................................6-16

Strobe Edge..............................................................................................................6-17

Counter Time Base...................................................................................................6-17

Count Limits.............................................................................................................6-17

Output Preset Points.................................................................................................6-18

Preload Value...........................................................................................................6-19

Configuration..................................................................................................................6-20

Logicmaster 90 Software..........................................................................................6-24

xiv Series 90™ Micro PLC User's Manual–June 1998 GFK-1065F

Page 15

I/O Scanner and Counter Type Configuration..........................................................6-24

Counter-specific Configuration................................................................................6-25

Type A Counter.................................................................................................6-25

Type B Counter.................................................................................................6-26

Contents

Hand-Held Programmer............................................................................................6-27

Configuration Screens Common to A4 and B1-3A4 Configurations .......................6-27

A4 Counter Specific Screens....................................................................................6-28

Type B Counter Specific Screens.............................................................................6-31

COMM_REQ Function ............................................................................................6-34

Command Block.......................................................................................................6-34

Example ...................................................................................................................6-38

Application Examples–RPM Indicator...........................................................................6-40

Example 1.................................................................................................................6-40

Example 2.................................................................................................................6-40

Application Example — Input Capture ..........................................................................6-41

Chapter 7 Analog I/O............................................................................................................ 7-1

Overview...........................................................................................................................7-2

Configuration....................................................................................................................7-5

Logicmaster 90 Screens..............................................................................................7-6

Analog Input ..............................................................................................................7-6

Analog Output............................................................................................................7-6

HHP Screens...............................................................................................................7-7

Calibration.........................................................................................................................7-9

Default Gains and Offsets ..........................................................................................7-9

Calibration Procedure...............................................................................................7-10

Calibration of Input Channels ..................................................................................7-10

Calibration of Output Channels................................................................................7-11

Storing Calibration Constants ..................................................................................7-12

Chapter 8 System Operation................................................................................................8-1

PLC Sweep Summary .......................................................................................................8-1

Sweep Time Contribution...........................................................................................8-3

Housekeeping.............................................................................................................8-3

Input Scan ..................................................................................................................8-3

Program Execution.....................................................................................................8-4

Output Scan................................................................................................................8-4

Programmer Service...................................................................................................8-4

Deviations from the Standard Program Sweep...........................................................8-5

Constant Sweep Time Mode ......................................................................................8-5

PLC Sweep When in STOP Mode.............................................................................8-5

Software Structure ............................................................................................................8-6

Program Structure.......................................................................................................8-6

Data Structure.............................................................................................................8-6

Powerup and Power-Down Sequence...............................................................................8-8

Powerup Sequence......................................................................................................8-8

GFK-1065F Contents xv

Page 16

Contents

Power-Down Conditions ............................................................................................8-8

Power Cycle................................................................................................................8-9

Clocks and Timers ..........................................................................................................8-11

Elapsed Time Clock .................................................................................................8-11

Time of Day Clock (23 and 28-Point Micro PLCs) .................................................8-11

Watchdog Timer.......................................................................................................8-11

Constant Sweep Timer .............................................................................................8-11

Timer Function Blocks.............................................................................................8-12

Timed Contacts.........................................................................................................8-12

System Security...............................................................................................................8-13

Overview ..................................................................................................................8-13

Password Protection .................................................................................................8-13

Privilege Levels........................................................................................................8-13

Privilege Level Change Requests.............................................................................8-14

OEM Protection.......................................................................................................8-14

I/O System for the Series 90 Micro PLC........................................................................8-15

I/O Scan Sequence....................................................................................................8-15

Default Conditions for Micro PLC Output Points ...................................................8-15

Software Filters ........................................................................................................8-16

Discrete Input Filtering ............................................................................................8-16

Discrete Input Filtering Control........................................................................8-16

Limitations of Discrete Input Filtering..............................................................8-16

Analog Potentiometer Input Filtering.......................................................................8-17

Input Settings....................................................................................................8-17

Limitations of Analog Potentiometer Input Filtering........................................8-17

Diagnostic Data...............................................................................................................8-18

Flash Memory .................................................................................................................8-18

Chapter 9 Diagnostics........................................................................................................... 9-1

Powerup Diagnostics.........................................................................................................9-2

Faults and Fault Handling.................................................................................................9-3

Fault Handling............................................................................................................9-3

Classes of Faults.........................................................................................................9-3

System Response to Faults.........................................................................................9-4

Fault Summary References.........................................................................................9-6

Fault Reference Definitions........................................................................................9-6

Fault Results...............................................................................................................9-8

Accessing Additional Fault Information ....................................................................9-8

Special Operational Notes.................................................................................................9-9

Technical Help..................................................................................................................9-9

Appendix A Instruction Timing................................................................... A-1

Appendix B Reference Types........................................................................B-1

xvi Series 90™ Micro PLC User's Manual–June 1998 GFK-1065F

Page 17

Contents

User References ............................................................................................................... B-1

References for Fault Reporting........................................................................................ B-2

Fixed I/O Map Locations................................................................................................. B-3

Appendix C PLC/Software Cross Reference.............................................. C-1

Appendix D Serial Port and Cables............................................................. D-1

RS-422 Interface ..............................................................................................................D-1

Cable and Connector Specifications................................................................................D-2

Port Configurations..........................................................................................................D-3

Series 90 PLC Serial Port..........................................................................................D-3

Workmaster Serial Port .............................................................................................D-5

IBM-AT Serial Port...................................................................................................D-6

RS-232/RS-485 Converter......................................................................................... D-6

Serial Cable Diagrams .....................................................................................................D-7

Point-to-Point Connections .......................................................................................D-7

RS-232 Point-to-Point Connections..........................................................................D-7

RS-422 Point-to-Point Connection..........................................................................D-11

Multidrop Connections............................................................................................D-12

Programmer-to-Series 90 PLC Connections ...........................................................D-12

PLC-to-PLC Master/Slave Connections..................................................................D-18

Appendix E Converters.................................................................................E-1

RS-422/RS-485 to RS-232 Converter.............................................................................. E-2

Features...................................................................................................................... E-2

Functions ................................................................................................................... E-2

Location in System.................................................................................................... E-2

Installation................................................................................................................. E-3

Cable Description...................................................................................................... E-4

Pin Assignments........................................................................................................ E-5

Logic Diagram........................................................................................................... E-6

Jumper Configuration................................................................................................ E-7

Specifications ............................................................................................................ E-8

Miniconverter Kit............................................................................................................. E-9

Description of Miniconverter.................................................................................... E-9

Pin Assignments......................................................................................................E-10

System Configurations ............................................................................................ E-11

Cable Diagrams (Point-To-Point) ...........................................................................E-11

Isolated Repeater/Converter........................................................................................... E-13

Logic Diagram of the Isolated Repeater/Converter................................................. E-15

Pin Assignments for the Isolated Repeater/Converter.............................................E-16

System Configurations ............................................................................................ E-18

Simple Multidrop Configuration............................................................................. E-18

GFK-1065F Contents xvii

Page 18

Contents

Complex Multidrop Configuration.......................................................................... E-19

Rules for Using Repeater/Converters in Complex Networks..................................E-19

Cable Diagrams ....................................................................................................... E-20

Appendix F Cable Data Sheets.....................................................................F-1

IC693CBL303: Hand-Hand Programmer Cable...............................................................F-2

IC690CBL701: Workmaster (PC-XT) to RS-485/RS-232 Converter Cable....................F-4

IC690CBL702: PC-AT to RS-485/RS-232 Converter Cable............................................F-5

IC647CBL704: Workstation Interface to SNP Port Cable ...............................................F-6

IC690CBL705: Workmaster II (PS/2) to RS-485/RS-232 Converter Cable ....................F-7

2-Wire Cable Diagrams.....................................................................................................F-8

Appendix G Sample Application or PWM and Pulse Outputs.................G-1

Series 90 Micro PLC Analog I/O Through CALEX Signal Conditioners.......................G-1

Application.......................................................................................................................G-1

Solution............................................................................................................................G-3

Example 1..................................................................................................................G-3

Example 2..................................................................................................................G-4

Benefits ............................................................................................................................ G-4

Sample Ladder Logic Diagram........................................................................................G-5

Appendix H Case Histories...........................................................................H-1

Automotive Industry ........................................................................................................H-2

Fluid Pumping Control..............................................................................................H-2

Bakery Industry................................................................................................................H-3

Pastry Line Conveyor Control...................................................................................H-3

Chemical Industry............................................................................................................H-4

Chemical Pumping Station........................................................................................H-4

Commercial Agriculture Industry....................................................................................H-5

Grain Processing.......................................................................................................H-5

Commercial Laundry Industry.........................................................................................H-6

Garment Storage Rail Control...................................................................................H-6

Construction Equipment Industry....................................................................................H-7

Pipe Measuring System.............................................................................................H-7

Entertainment Industry.....................................................................................................H-8

Nightclub Entertainment ...........................................................................................H-8

General Purpose Machinery.............................................................................................H-9

Automated Picture Frame Stapler .............................................................................H-9

Lumber Industry.............................................................................................................H-10

Pallet Rebuilding.....................................................................................................H-10

Material Handling Industry............................................................................................H-11

Automated Guided Vehicles ...................................................................................H-11

Paper Industry ................................................................................................................ H-12

Gear Pumping Machinery .......................................................................................H-12

xviii Series 90™ Micro PLC User's Manual–June 1998 GFK-1065F

Page 19

Contents

Petroleum Industry.........................................................................................................H-12

Lease Acquisition Control Transfer ........................................................................H-12

Packaging Industry.........................................................................................................H-13

Shrink Wrapping Machine ......................................................................................H-13

Videocassette Packaging.........................................................................................H-14

Plastics Industry.............................................................................................................H-15

Injection Molding....................................................................................................H-15

Plastic Parts Manufacturing.....................................................................................H-16

Public Emergency Services Industry .............................................................................H-17

Storm Warning Systems..........................................................................................H-17

Sports Equipment Industry.............................................................................................H-18

Boxing Partner ........................................................................................................H-18

Tubing Manufacturing Industry..................................................................................... H-19

Tube Bending..........................................................................................................H-19

Water and Wastewater Industry.....................................................................................H-20

Flood Control Monitoring ....................................................................................... H-20

Sewage/Wastewater Lift Stations............................................................................H-21

Wastewater Treatment.............................................................................................H-22

Water Flow Control.................................................................................................H-23

Wire Manufacturing Industry.........................................................................................H-24

Quality Control........................................................................................................H-24

Woodworking Industry ..................................................................................................H-25

Conveyor Chain Lubricator.....................................................................................H-25

GFK-1065F Contents xix

Page 20

Chapter

Quick Start

1

This chapter provides an overview of the steps required to get your Micro PLC set up and running.

The Series 90 Micro PLC product line offers models with different capabilities and special features

to meet the needs of a wide range of applications. For this reason, you will need to refer to other

chapters in this manual for details pertaining to the specific Micro PLC that you have. For

summaries of Micro PLC features and specifications for each model, refer to Chapter 2.

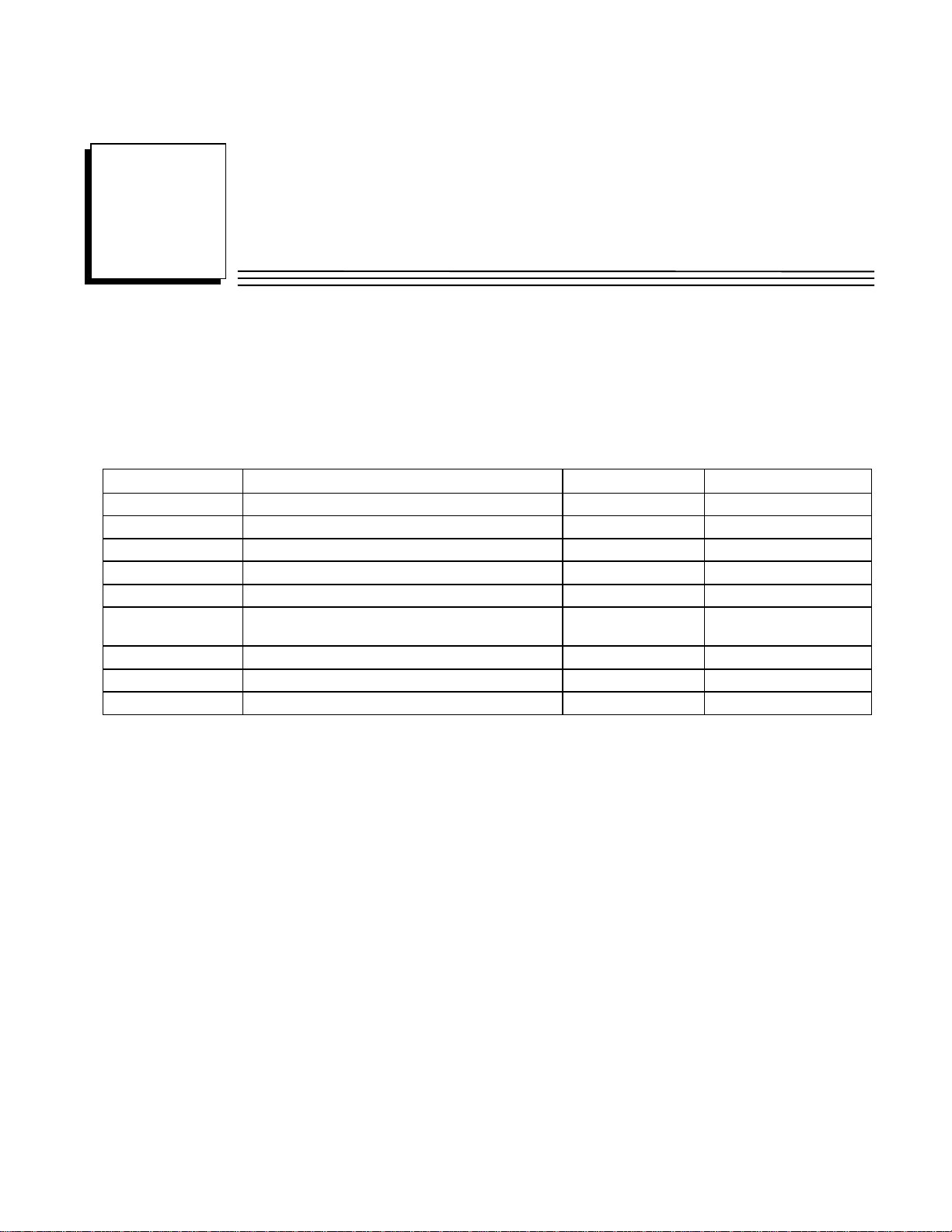

No. of I/O Points I/O Configuration Power Supply Catalog Numbers

14 8 DC inputs, 6 relay outputs

14 8 DC inputs, 6 relay outputs

14 8 AC inputs, 6 AC outputs 100 to 240 VAC IC693UAA003

14 8 DC inputs, 6 DC outputs

14 8 DC inputs, 6 relay outputs (expansion unit)

23 13 DC inputs, 1 DC output, 9 relay outputs,

2 ana log in, 1 anal og out

28 16 DC inputs, 1 DC output, 11 relay outputs 100 to 240 VAC IC693UDR005

28 16 AC inputs, 12 AC outputs 100 to 240 VAC IC693UAA007

28 16 DC inputs, 1 DC output, 11 relay outputs 24 VDC IC693UDR010

100 to 240 VAC

12 to 24 VDC

12 to 24 VDC

100 to 240 VAC

100 to 240 VAC IC693UAL006

IC693UDR001

IC693UDR002

IC693UDD104

IC693UEX011

What You Will Need

• One of th e M icro P L Cs listed above.

• Logicmaster 90-30/20/Micro software (or Logicmaster 90 Micro software).

• Programming device and appropriate cables: Workmaster® II or CIMSTAR I industrial

computer, an I BM® AT, PS/2® or other MS-DOS comp at i ble Personal Computer (with 386 or

higher microprocessor and 2 MB memory), or a Hand-Held Programmer and cable.

• RS-422 to RS-232 Interface. Logicmaster 90 software can use a Work Station Interface (WSI)

board, an RS-422 port, or a standard RS-232 interface with an RS-422 to RS-232 converter.

The WSI board is in stalled in th e Workmaster II compu ter at th e fact ory.

• Tools for mounting the Micro PLC and connectin g field wiring ca bles.

To run Logicmaster 90-30/20/Micro software, the programmer (computer) will need:

• At least 4MB of free disk space.

• At least 520KB (532,480 bytes) of available DOS application memory for the WSI version; at

least 564KB (577,536 bytes) of available DOS application memory, or 520 KB and 42 KB of

available High Memory Area, Upper Memory Block, or Expanded Memory. For details, see

Logicmaster™ 90-30/30/Micro Programming Software User’s Manual

the

GFK-1065F 1-1

, GFK-0466.

Page 21

1

Getting Started

The following procedure outlines the steps required to put your Micro PLC into operation.

Step 1.Unpack the Micro PLC

First, carefully inspect all shipping containers for damage. Unpack the shipping container and

verify the contents. Record all serial numbers. For details, see “Unpacking” in Chapter 3.

Step 2.Install the Micro PLC

Mount the Micro PLC on a vertical surface: a wall or panel using screws or on a 35mm DIN rail.

The Micro PLC requires a minimum clearance of 1.99 inches (50mm) on each side for cooling.

For details, see “Installation Requirements” and “Installation” in Chapter 3.

Step 3.Connect Ground and Power Wiring

• For safe operation of your Micro PLC, the installation must meet the requirements of

“Grounding Procedures” in Chapter 3.

• For power connections, refer to the wiring diagram for the Micro PLC model that you have.

(See “Field Wiring Installation” in Chapter 4.)

Step 4. Power-up Test

Warning

Ensure that the protective cover is installed over terminals on the terminal

board when power is applied to the unit. The cover protects against

accidental shock hazard which could cause severe or fatal injury to

personnel.

Apply the required power to the system. The Micro PLC should perform a self-diagnostic test. The

OK indicator will blink during power-up diagnostics. When self-diagnostics have been successfully

completed, the OK indicator will remain lighted. For details, refer to “Powerup Self-test” in

Chapter 3.

Step 5. Connect a Programmer to the PLC

Connect a programming device to the RS-422 serial port (Port 1) on the Micro PLC. (Port 2 on 28

and 23-point Micro PLCs does not support configuration and programming.) For cabling diagrams,

refer t o “ Connecti ng a Progra mming Devi ce ” in Chapter 3.

If Logicmaster 90 software is not installed on your programmer, install it according to the

procedures in the

GFK-0466.

Logicmaster™ 90-30/20/Micro Programming Software User’s Manual

,

1-2 Series 90™ Micro PLC User's Manual – June 1998 GFK-1065F

Page 22

Step 6.Configure the Micro PLC

The Logicmaster 90 configuration function is used to select Micro PLC operating parameters to

meet the requir ements of your system.

.

A

Start up your computer in DOS mode.

.

B

At the DOS prompt, type CD LM90 and press th e E

.

C

Type LM90 and press E

NTER

.

NTER

key.

1

D. When th e main menu for th e Log icmaster 90 software app ears, pr es s S

PLCs will appear.

E. From the list, select the type of Micro PLC that you have and press E

F. Pr ess F2. The Software Configuration menu will appear.

For deta ils on con figur ation, r e fer to Chapters 5, 6, and 7. When you have fini shed c onfi guring the

Micro PLC, press E

Step 7.Enter a Ladder Program

A.In the Logicmaster 90 main menu, press F2. The Programming Software menu will appear.

.

B

Press F1, Program Display Edit. An empty program folder will appear. For details on using the

programming software, refer to the

User’s Manual

Series 90™ Micro Programmable Logic Controller Self-Teach Manual

Turn off power to the Micro PLC before connecting field wiring.

Step 8.Connect Field Wiring

Refer to “Field Wiring Installation” in Chapter 4 for general wiring information and wiring

diagrams for each Micro PLC model.

to return to the main me nu .

SC

Logicmaster 90-30/20/Micro Programming Software

, GFK-0466. A sample program for the Micro PLC is provided in the

Warning

+ F1. A list of

HIFT

.

NTER

, GFK-1104.

GFK-1065F Chapter 1 Quick Start 1-3

Page 23

1

Frequently Asked Questions

1. What causes a “No Communications” message when I toggle to MONITOR or ONLINE?

Following are a few possible causes:

• Insufficient conventional memory (at least 545Kbytes) in your personal computer to load the

Logicmaster 90 communications driver.

Make sure the config.sys file in your computer is properly configured. For details on configuring

your config.sys file, refer to “Software Installation” in the

30/20/Micro Programming Software User’s Manual

your personal computer help line or GE Fanuc PLC Technical Support at 1-800-GEFANUC.

• Configuration mismatch between Logicmaster 90 in your computer and the PLC configuration.

Make sure that the computer and the PLC are using the same baud rate and parity. From the main

menu in Logicmaster 90, press F2 to enter the configuration software. To check the computer

settings, press F7, Pr ogra mmer M ode and Setup, and th en F4, PLC Communicati on s Ser ia l Port

Setup. To check th e PLC settin gs, press F1, I/O Configuration. The PLC baud rate and parity will

be displayed in the Software Configuration Screen.

Logicmaster™ 90 Series 90™-

, GFK-0466. For additional assistance, call

• Broken cable between your computer and PLC or broken or missing RS-232/RS-422

converter.

For information on installing the converter, refer to Appendix E in this manual.

2. How do you set up the High Speed Counters (HSCs)?

Using the Logicmaster 90 configuration software or a Hand-Held Programmer (HHP), enable each

HSC that you want to use. If you want the HSC to drive an output, you must enable its output in the

software configuration and set its Enable Output bit in your program or in the data tables. For

example, if HSC 1 is configured with its output enabled and its Output Enable bit, %Q505 is set, it

will control Q1. (HSC 1 will continually report to the CPU memory location %AI06.) A sample

rung that sets the Output Enable bit for HSC 1 is shown below.

|

|FST SCN

|%S0001 +—————+

+——] [———————+MOVE_|

| | BIT |

| | |

| | |

| +IN Q+——————————————————————%Q0505

| | LEN |

| |00003|

| +—————+

For more information, refer to “High Speed Counter/CPU Interface” in Chapter 6 of this manual.

Simple (A-type) counters and A-Quad-B (B-type) HSCs count

continuously

by default, resetting

themselves automatically when a high or low limit is reached. A-type HSCs can also be configured

for

one-shot

counting, in which the HSC counts to one past the limit and then stops.

In one-shot mode, the HSC can be reset by the program using a Communications Request

(COMM_REQ) functi on to write a z ero to th e Accumul at or. The HSC can also be reset by the

Preload input . If th e count er’ s Pr el oad / Strobe parameter is set to PRELOAD (default ) , the

configured preload value will be loaded to the Accumulator when the Preload/Strobe signal goes

1-4 Series 90™ Micro PLC User's Manual – June 1998 GFK-1065F

Page 24

active. For exam ple, if PRELOAD is configured and the defau l t Prel oa d Val u e of 0 is used, an

input on I2 will reset the Accumulator for HSC 1.

For wiring information, refer to the diagrams in “High Speed Counter Inputs” and the wiring

diagr am s provided in “Genera l Wiring Pr oced u res” in Chapter 4.

Warning

When the Micro PLC goes from RUN to STOP mode, the HSCs will

continue to operate. Al so, t he HSCs will remain i n run mode through a

power cycle. Therefore, if an HSC is running when power is lost, it will run

when power is restored.

3. How do I program the Micro PLC?

You can use a Hand Held Programmer (IC693PRG300) or Logicmaster 90 software

(IC640HWP300, includes a 2-meter programming cable) loaded into a DOS-based personal

computer. The personal computer must have at least a 386 processor and at least 2 megabytes of

RAM.

1

For a new-user programming lesson, refer to Appendix A of the

GFK-0466. Chapter 4 of the

Manual,

PLC.

4. What should I do when I get a “Password disabled” or “insufficient privilege” message?

There are two possible causes for these messages:

• Passwor d i s set to DISABLE in th e Software Con fig ura tion screen for the Micro PLC.

The default config ur at ion for password is ENABLE. When chan g ed to DISABLE an d stored t o th e

Micr o PLC , the setting is perm anent. If the confi g uration i s ch anged back to E NA BLE and stored ,

the “password disabled” error message will be generated and the store will not be allowed. You can

either change th e configuration back to DISABLE, or use an HHP to eras e th e program and

configuration, thereby restoring the default configuration.

• Insufficient privilege has been set in the Software Configuration and stored to the PLC.

The OEM password cannot be overwritten. To remove the OEM password, you must use the HHP

to clear the PLC memory.

If a password has been set from the level 4 menu and then forgotten, you can override it. This

procedure is documented in Chapter 5 in the

program disks are required.)

5. What does it mean when OK LED is blinking or the Run LED is not lighted?

GFK-0467 provides descriptions and examples of programming commands for the Micro

Series 90™-30/20/Micro Programmable Controllers Reference

Software User’s Manual

Software User’s Manual

, GFK-0466. (The original

,

Each time power is applied, the CPU performs a self check for several seconds. The OK LED

blinks during the self-test and then changes to a steady on state.

If the Run LED does not light when you go to run mode, the cause could be invalid configuration

or a fata l er ror in the C P U fau lt table.

GFK-1065F Chapter 1 Quick Start 1-5

Page 25

1

Programming Examples

Test Rung

In the following test rung, an input on I1 will turn on output Q1.

%I1 %Q1

|—————————| |—————————————————( )—|

On-Delay Timer

In the following LD, the set coil, M0001, turns on the timer, which counts to 5 seconds (00050 x

0.10s) and then activates %M0002. %M0002 turns on the output, %Q0001, activates %M0003 to

reset the timer, and resets M0001.

|[ START OF LD PROGRAM EXAMPLE ]

|

|[ VARIABLE DECLARATIONS ]

|

|[ BLOCK DECLARATIONS ]

|

|[ START OF PROGRAM LOGIC ]

|

|FST_SCN %M0001

+——] [——————————————————————————————————-(S)——|

|

| M0001 +—————-+ %M0002

+——] [———————+ONDTR_+————————————————————( )——|

| |0.10s |

| | |

|%M0003 | |

+——] [———————+R |

| | |

| CONST —+PV |

| 00050 +——————+

| %R0001

|

|%M0002 %Q0001

+——] [——————————————————————————————————( )———|

|

|%M0002 %M0003

+——] [——————————————————————————————————( )———|

+%M0002 %M0001

+——] [——————————————————————————————————(R)——|

|

[ END OF PROGRAM LOGIC ]

1-6 Series 90™ Micro PLC User's Manual – June 1998 GFK-1065F

Page 26

Chapter

2

Introduction

Series 90 Micro PLCs offer an a rray of useful features, including:

• Compatibility with Logicmaster 90-30/20/Micro programming software

• Support for the 90-30 Hand-Held Programmer (HHP)

• An alarm processor function

• Password protection to limit access to PLC content s

• A built-in High Speed Counter (HSC) function that can be configured as four type A counters

or as one type B counter and one type A counter (DC in/relay out Micro PLCs only)

• Two potentiometers that pr ovide selectable analog inputs to %AI16 and %AI17 (with

configurable filtering)

• Configurable software filtering of discrete inputs

• Series 90 (SNP) a nd SNP Ext ended (SNPX), a nd RTU slave communication protocols

pulse catch input

• A

microseconds in width

function, selectable on up to four inputs, that detects pulses at least 100

• Pulse train and Pulse Width Modulation (PWM) outputs (Micro PLCs with DC output only)

• Compatibility with 14-point expansion unit (23 and 28-point Micro PLCs)

• Pager Enunciation function that can be configured to send a specified byte string from Serial

Port 2 (23 and 28-point Micro PLCs)

• Two analog inputs and one anal og output (23-point Micro PLC)

GFK-1065F 2-1

Page 27

2

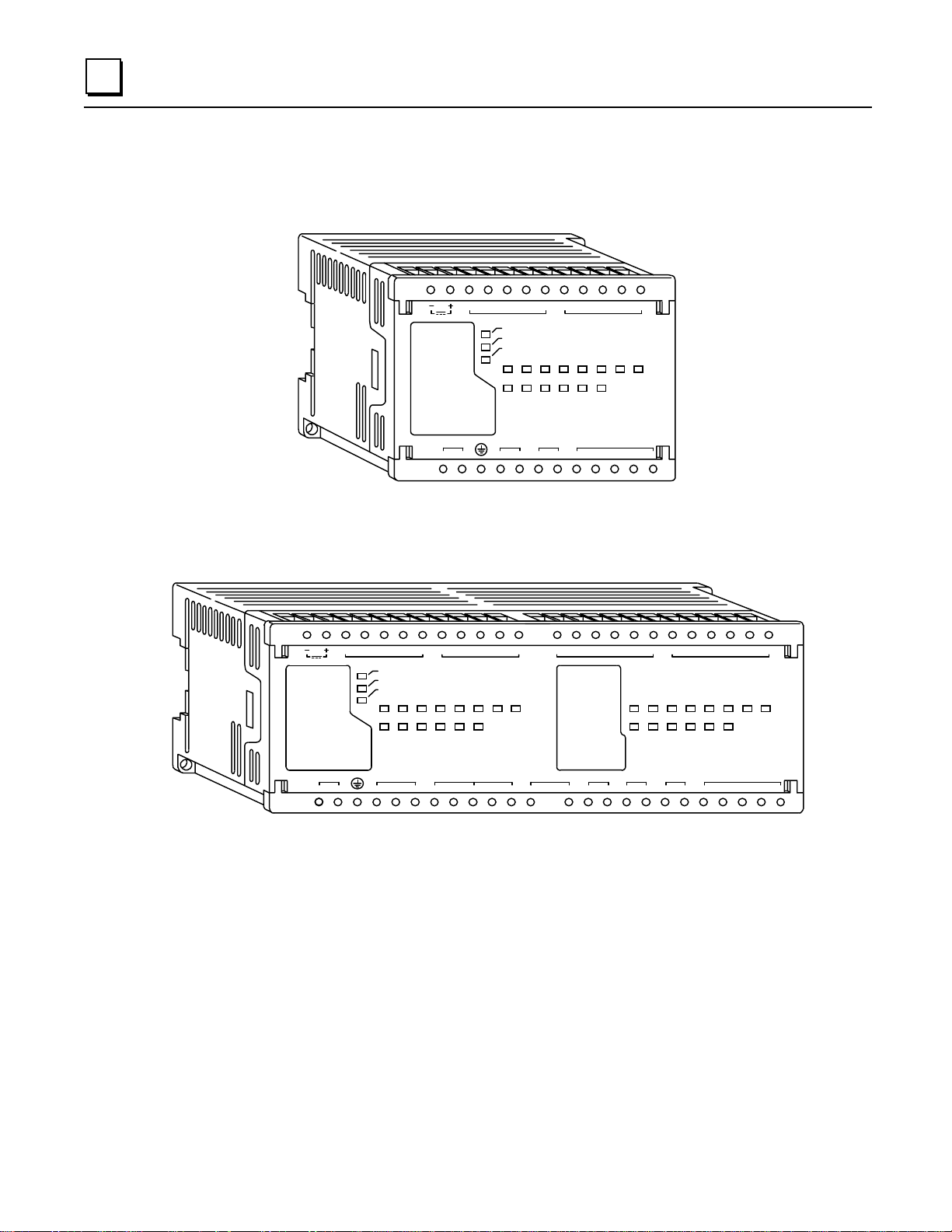

The Micro PLC hardware consists of a single module that includes CPU, I/O, and power supply

functions (Figure 2-1). The compact, lightweight unit is designed for 35mm DIN rail or panel

mounting.

a45452

24 VDC OUT

100-240VAC

LH

Typical 14-Point Mi cro PLC

24 VDC OUT

100-240VAC

PWR

OK

RUN

INPUT

12345678

OUTPUT

~

Q1 C OM 1 VC Q2 Q3 Q4

I1 I2 I3 I4 COM1

PWR

OK

RUN

INPUT

1

OUTPUT

~

Q1 COM1 Q2 COM2 Q3 Q4

COM2I5 I6 I7 I 8I1 I2 I3 I4 CO M1

COM2LH

Q5

INPUT

COM2I5 I6 I7 I8

Se rie s 9 0 Mi cro

2345678

PROGRAMMAB LE CONTROLLER

INPUT

OUTPUT

OUTPUT

COM3Q6

Q6

Q5

INPUT

910111213141516

789101112

OUTPUT

COM4Q7

Q8 COM5 Q9 COM6 Q10 Q11 CO M7

COM3

Series 90 Micro

PROGRAMMABLE CONTRO LLER

a45499

COM4I15 I16 COM4I11 I12 CO M3 I14I9 I10 I13COM3

COM7

Q12

Typical 28-Point Mi cro PLC

Figure 2-1. Series 90 Micro Programmable Logic Controll ers

2-2 Series 90™ Micro PLC User's Manual – June 1998 GFK-1065F

Page 28

Compatibility

• Logicmaster 90-30/20/Micro software(IC641SWP301, 304, 306, 307), release 8.01 or later

• Series 90-30 firmware release 5.0 and later

• Series 90-30 Hand-Held Programmer (IC693PRG300)

• Series 90 Protocol (SNP and SNPX) a nd RTU Slave protocol

• Series 90-20 PLCs (Micro PLCs with relay output – IC693UDR005/010 and UAL006 – only)

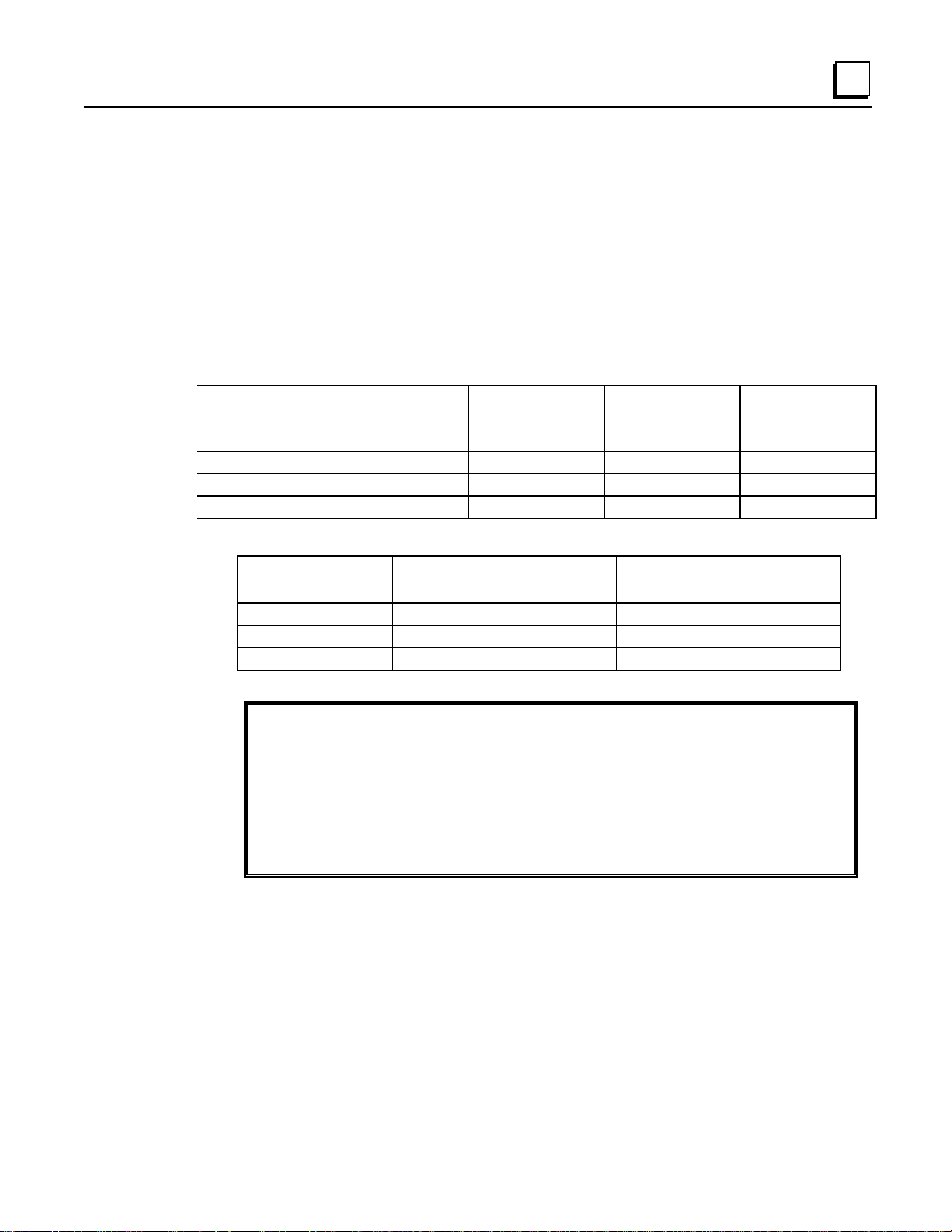

Table 2-1. Configuration/Programming Software Versions for Partial Compatibility

2

Store to

Logicmaster 90

Software Version

8.00 or later No Yes Yes Yes

5.01 or later Yes Yes Yes No

6.01 or later Yes Yes Yes No

Table 2-2. Micro to Micro Compatibility

Component Rel. 3 reads from Memcard

Program Yes Yes

Registers Yes No

Configuration Yes No

Micro Rel. 2

or Earlier

Written by a Rel. 2 Micro

Store to

Micro Rel. 3

or Later

Load from

Micro Rel. 2

or Earlier

Rel. 2 reads from Memcard

Written by a Rel. 3 Micro

Load from

Micro Rel. 3

or Later

Instructions and Function Blocks

The Series 90 Micro PLC supports most 90-30 instr uction functions and function blocks.

Detailed descriptions and examples of the use of these instructions can be found in the

Logicmaster 90-30/20/Micro Programming Software User’s Manual

30/20 Programmable Controllers Reference Manual

Programmer, Series 90-30/20/Micro Programmable Controllers User’s Manual (

(GFK-0467), and

(GFK-0466),

Hand-Held

Series 90-

GFK-0402).

See Appendix A for a list of instructions supported by the Series 90 Micro PLC.

GFK-1065F Chapter 2 Introduction 2-3

Page 29

2

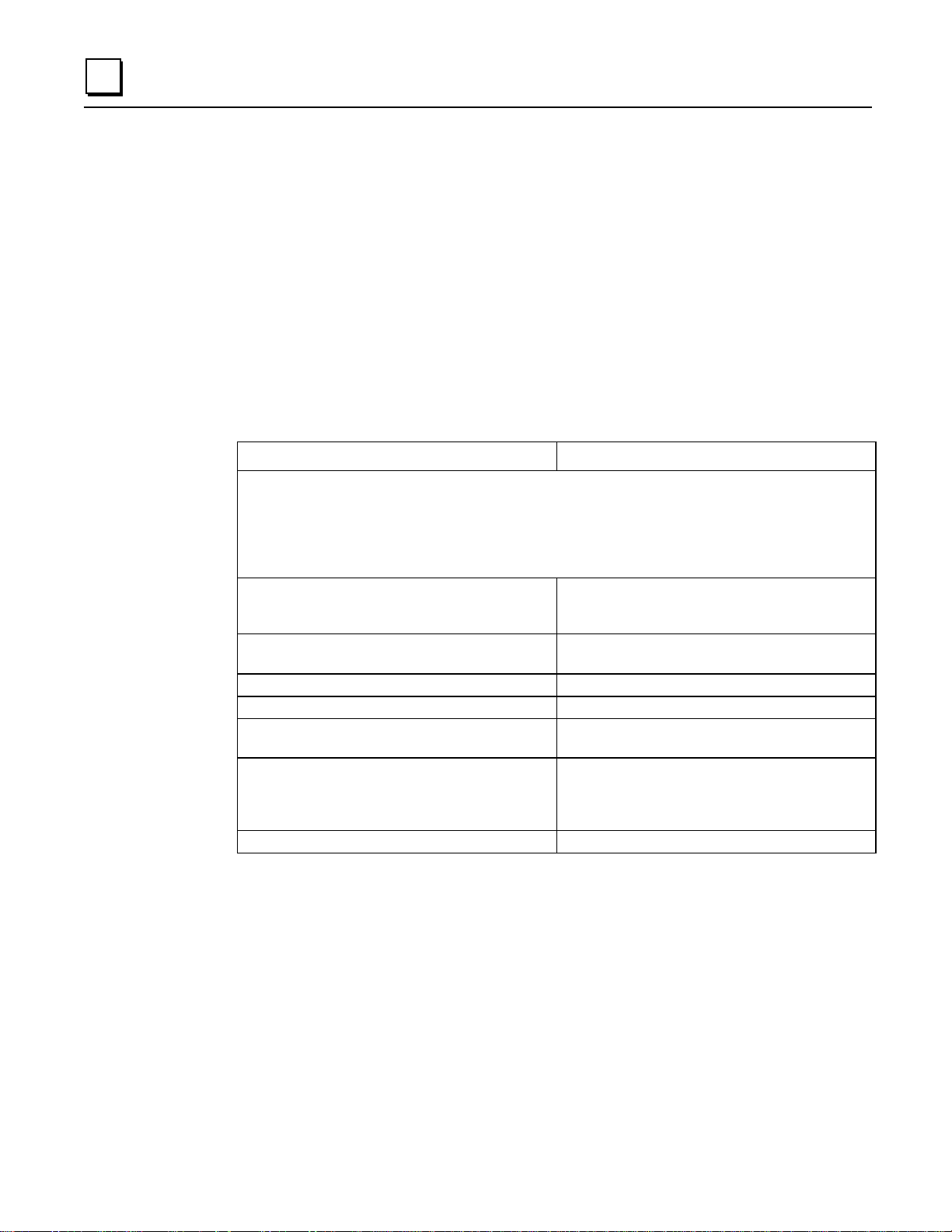

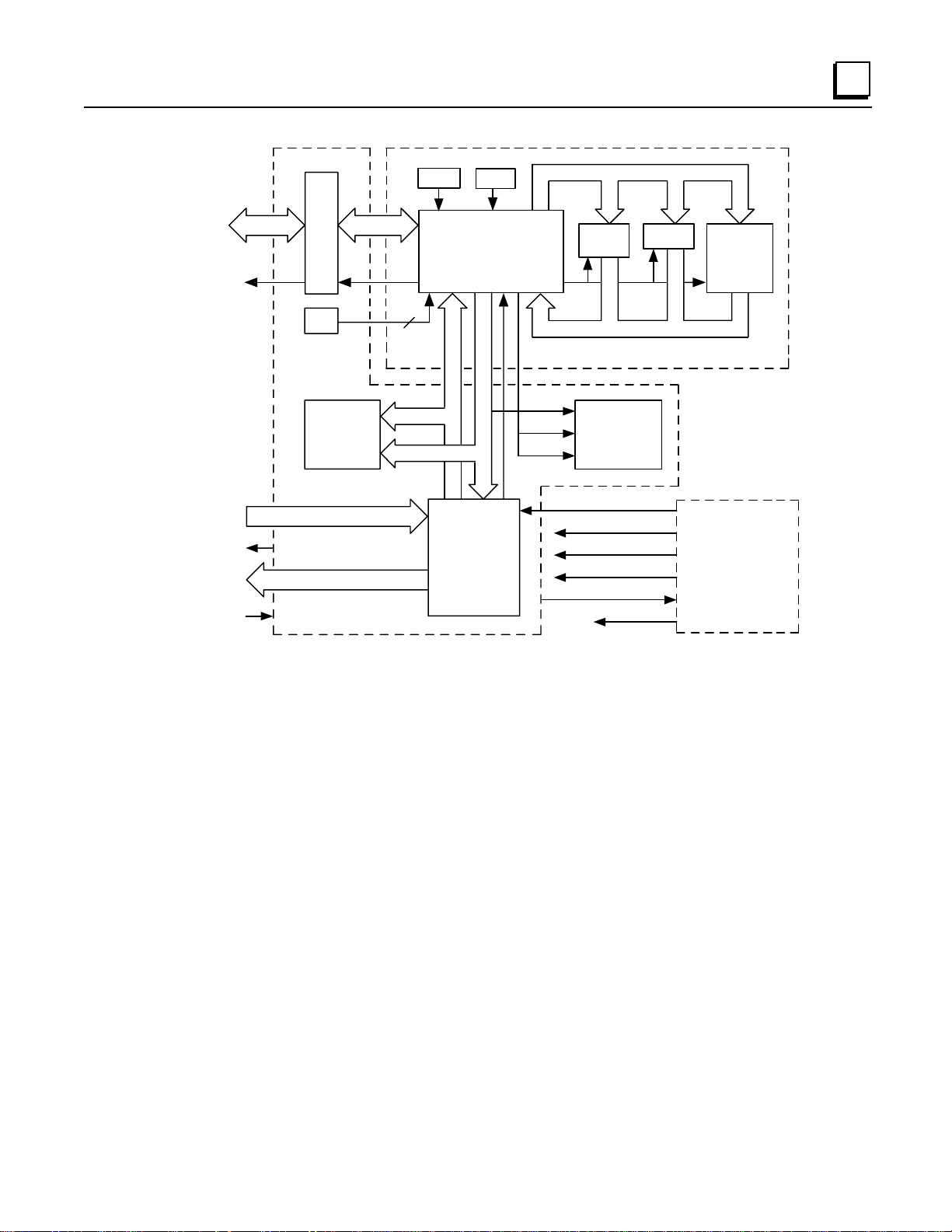

Functional Description

The Micro PLC contains a CPU circuit board, an I/O board, and a Power Supply board. Figure 2-2

provides an overview of Micro PLC inputs and outputs and of the functions performed by each

circuit board.

CPU Board

The CPU contains and executes the user program and communicates with the programmer (HHP

or computer runn in g Logicmaster 90-30/90-20/Micro software). The primary capabilities of the

Micro PLC CPU h ardware are listed in Table 2-3

Table 2-3. CPU Capabilities

512K x 8 sectored flash memory for operating

system and nonvolatile user program storage (3K

words of user flash memory)

32 Kbyte RAM backed by super cap (provides data

retention for 3–4 days with the power off at 25°C)

Maximum User Program - 3K words Maximum User Program – 6K words

Registers - 256 words Registers – 2K words

Typica l Sca n Rate: 1. 8 ms/K of l ogic (Boolea n

contacts)

An RS-422 serial port that supports SNP, SNPX and

RTU S lave prot ocols

14-Point Micro PLCs 23 and 28-Point Micro PLCs

H8/3003 microprocessor running at 9.84Mhz

Powerup reset circuit

Interrupt for power fail warning (2.0 ms)

Internal Coils - 1024

Four configurable 5Khz HSCs

256K x 16 sectored flash memory for operating

system and nonvolatile user program storage (6K

words of user flash memory)

64 Kbyte RAM backed by lithium battery

Real time clock backed up by lithium battery

Typica l Sca n Rate: 1. 0 ms/K of l ogic (Boolea n

contacts)

Two RS-422 serial ports: Port 1 supports SNP/SNPX

slave protocols; Port 2 supports SNP/SNPX Slave

and Mas ter pr otocols and RTU S lave protocol. (P ort

2 does not support the HHP.)

Ability to support up to four expansion units

2-4 Series 90™ Micro PLC User's Manual – June 1998 GFK-1065F

Page 30

Hand-held

Program mer

SNP

Port

Clock Reset

Microprocessor

Flash

Memory

control

RAM

2

a45683

Parallel

Expansion

Port

24 V DC

In put Powe r

Pots.

INPU T

LEDs

OUTPUT

IN P U T

OUTPUT

2

Inp uts

Outputs

PSOK

RUN

I/O C irc uits

Figure 2-2. Micro PLC Functional Block D i agram

OK

PWR

RUN

OK

24 VD C for O utp uts

24 V D C for Inp uts

CPU Board

LEDs

PSOK

5 VDC

In p u t P o w e r

5.14 VD C

Power Supply Boar dI/O Board

GFK-1065F Chapter 2 Introduction 2-5

Page 31

2

High Speed Counters

(IC693UDR011/002/005,

IC693UAL006, IC693UDR010)

The high speed counter (HSC) function consists of four built-in counters. Each counter provides

direct processing of rapid pulse signals up to 5Khz for industrial control applications such as:

meter proving, turbine flowmeter, velocity measurement, material handling, motion control, and

process control. Because it u s es dir ect process ing, the HSC can s ense input s , count, and respond

with outputs without needing to communicate with the CPU.

The HSC function can be configured to operate in one of two modes:

A4 – four identical, independent, simple (type A) counters that can count up or down

B1–3, A4 – counters 1–3 configured as one type B counter; counter 4 as one type A counter.

In ei ther mode, each counter can be enabled independently. Type A counters can be configu red for

up or down counting (default is up) and for positive or negative edge detection (default is

positive).

The HSC function is configured using the Series 90-30 and 90-20 Hand-Held Programmer or the

Logicmaster 90-30/20/Micro software configurator function. Many features can also be configured

from an application program using the COMM_REQ functi on block.

Type A Counters

A type A counter a ccepts a cou nt i nput th at increment s a 16 bit accumulator. It also accepts a

preload/strobe input that can either preload the counter accumulator with a user-defined value

(PRELOAD mode) or str obe th e a ccumu lator (STROBE mode) into a 16-bit register.

The four type A counters provide 15 words of %AI data or 16 bits of %I data to the PLC. They

receive 1 6 bi ts of %Q data from the PLC. Each counter has two discrete inputs and one discrete

output.

Type B Counter

The type B counter provides an AQUADB counting function. An AQUADB input consists of two

signals (designated A and B). A count occurs for each transition of

the phase relationship between A and B to determine count direction.

either A or B

. The counter u ses

DC Output (IC693UDR005/010, UAL006)

The high -speed DC output (%Q1) can be configured for PWM, pulse train, or HSC output.

Counter channel 1 can be configured for only one of these outputs at a time. Because AQUADB

counting uses channels 1–3, the PWM and pulse train outputs are not available when a type B

count er is configured.

PWM Output

The frequency of the PWM output (19hz to 2Khz) is selected by writing a value to memory

location %AQ2. A PWM duty ratio (the amount of time that the signal is active compared to the

signal period) within the range of 0 to 100% can be selected by writing a value to memory

location %AQ3.

2-6 Series 90™ Micro PLC User's Manual – June 1998 GFK-1065F

Page 32

I/O Board

2

Pulse Output

The frequency (10h z to 2Khz) of the pulse train is selected by writing a value to memory location

%AQ123. The number of pulses to be output (0 to 32767) is selected by writing a value to memory

location %AQ124.

ASCII Output (IC693UDR005/010, UAL006)

This feature allows you to send a specified byte string out the serial port by including a

COMM_REQ (Communications Request) instruction in a ladder diagram. The Micro PLC can

automatically send a message to a remote location that has the ability to display an ASCII string,

such as a pager. As an example of how pager enunciation could be used, when a specific alarm

condition is detected by the PLC, the PLC would execute a COMM_REQ instru ct i on to autodial

the modem attached to the serial port. If the autodial COMM_REQ is successful, a second

COMM_REQ would be executed to send an informative ASCII string to the pager where it can be

viewed by the user. Finally, a third COMM_REQ would be sent to hang up the pager .

The I/O board provides the interface to the front panel input, output, a nd power supply