Page 1

GE Zoneline® packaged

terminal air conditioners

2010 contract sales architects and engineers data manual

Page 2

Quick Reference

Full Specs on pages 52 and 53

ALL UNITS REQUIRE POWER CONNECTION KIT

Power Connection Kit determines resistance heat output

7000 Btuh units are not offered with 4.7 KW resistance heater

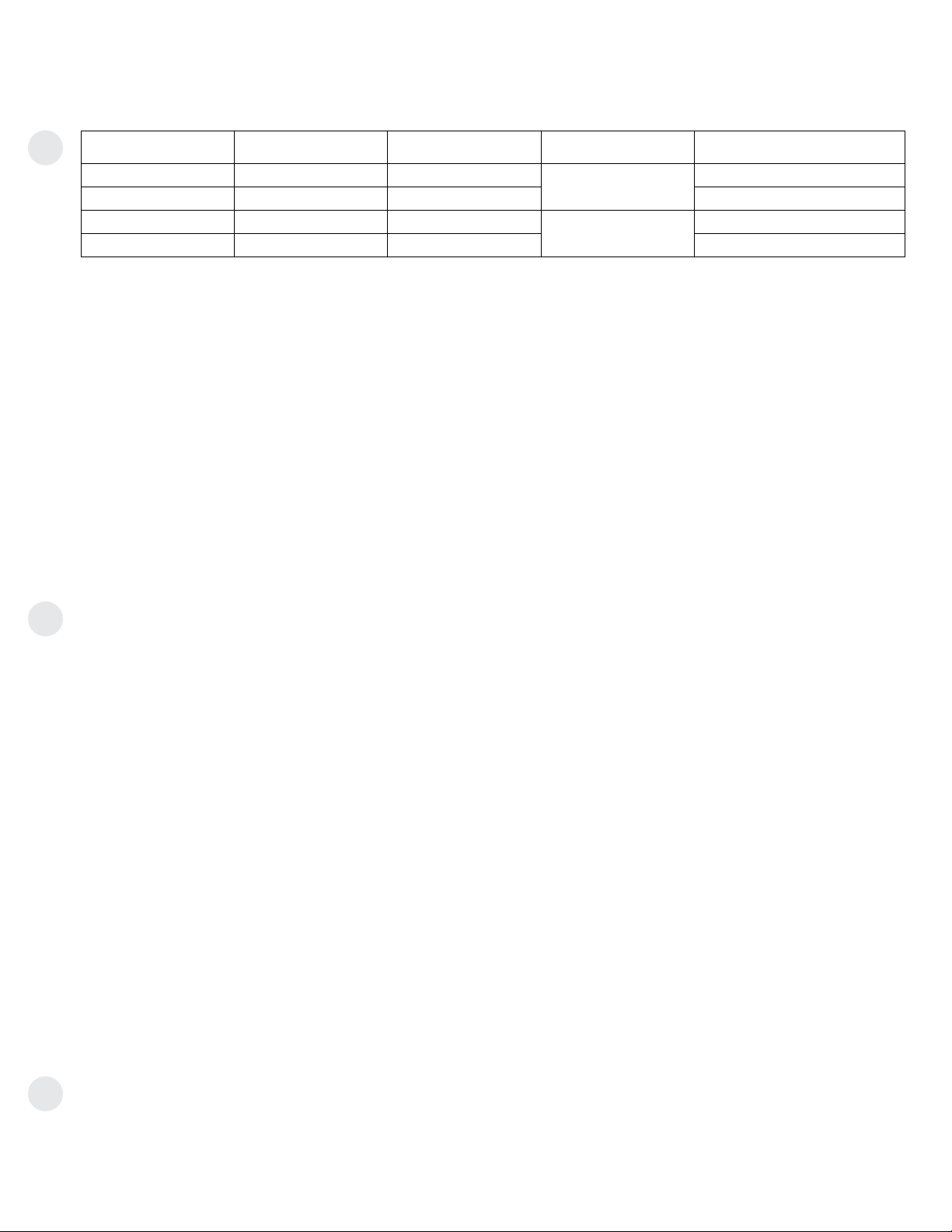

4100 Series Cooling with Electric Heat

MODEL

NUMBER

AZ41E07DA* 7300/7100 12.8/12.8

AZ 41E09 DA* 9450/9250 12.3/12.3

AZ41E12DA* 11800/11600 11.8/11.8

AZ41E15DA* 1470 0/1450 0 10.6/10.6

AZ41E07EA* 7300 12.8

AZ 41E09 EA* 9450 12.3

AZ41E12EA* 11800 11.8

AZ41E15EA* 1470 0 10.6

COOLING

(Btuh)

EER

Dry Air 25

4100 Series Cooling with Electric Heat

6100 Series Heat Pump with Backup Electric Heat

MODEL

NUMBER

AZ61H07DA* 7200/7000 13.2/13.2 6400/6200 4.0/4.0

AZ 61H09 DA* 9400/9200 12.7/12.7 8300/8100 3.8/3.8

AZ 61H12DA* 11800/11600 12.1/12.1 1060 0/10400 3.7/3.7

AZ 61H15DA* 14800/14 600 11.2/11.2 14000/13900 3.3/3.3

AZ61H07EA* 7200 13.2 6400 4.0

AZ 61H09 EA* 9400 12.7 8300 3.8

AZ 61H12E A* 118 00 12.1 10600 3.7

AZ 61H15E A* 14 800 11.2 14000 3.3

COOLING

(Btuh)

EER

REVERSE CYCLE

BTUH

MODEL

NUMBER

AZ41E07DAP 6800/6600 12.2/12.2

AZ 41E09 DAP 9000/8800 11.8/11.8

AZ41E12DAP 11200/11000 11.3/11.3

AZ41E07EAP 6800 12.2

AZ 41E09 EAP 9000 11.8

AZ41E12EAP 11200 11.3

COP

COOLING

(Btuh)

EER

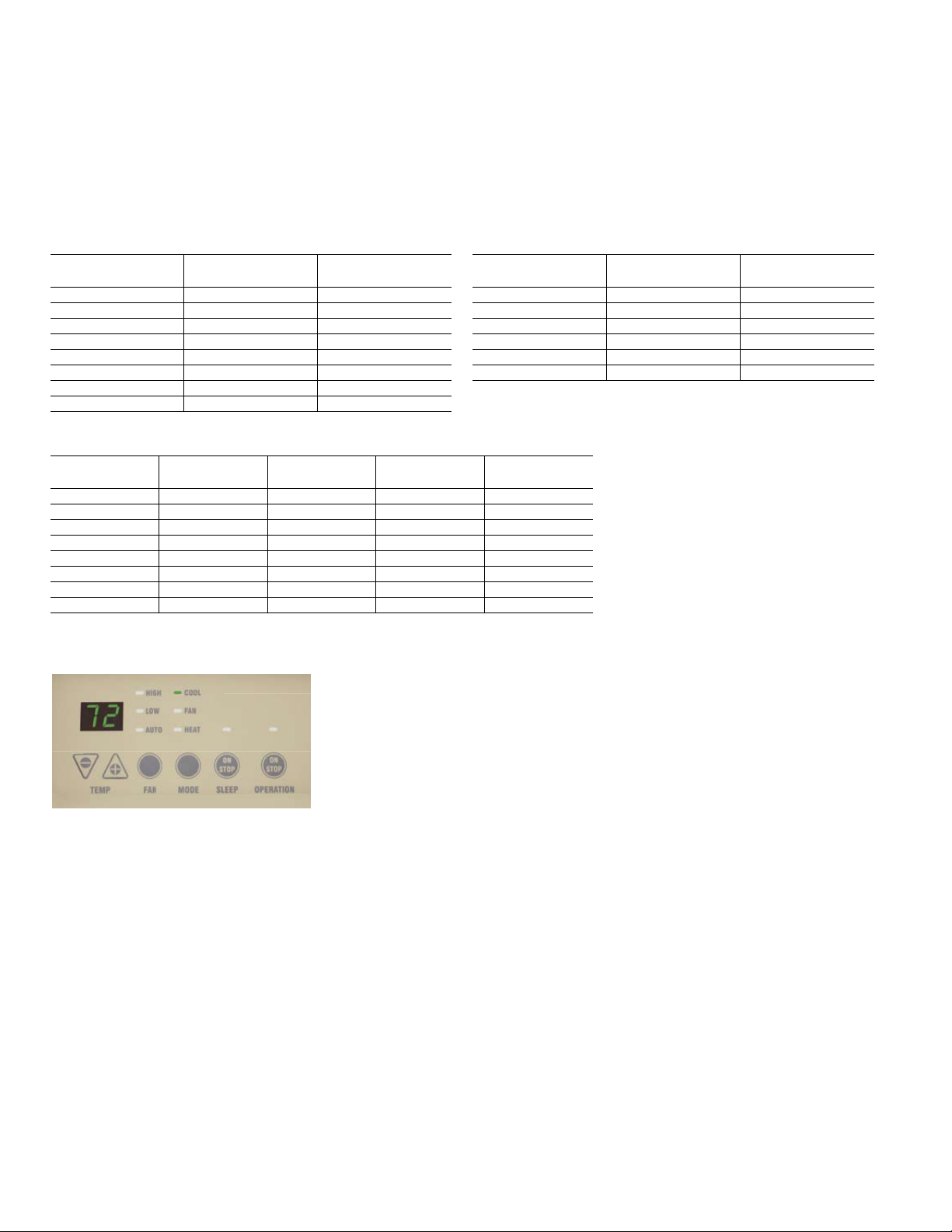

4100 and 6100 Series Control Panel

*Dual-rated 230/208-volt units are shown with ratings separated by “/”.

Units with single rating are 265-volt units.

2

Page 3

Power Connection Kits

geappliances.com

230/208-Volt Line Cord Connection Units

Line Cord

Kit

RA K3153A 8150/7900 240 0/2320 11.0/11.6 15

RAK 3203A 11200/10900 3300/3200 15.1/16.0 20

RAK3303A 16000/15450 4700/4530 21.2/22.4 30

Electric Heat Amps include electric heater and fan motor current draw.

Each Line Cord Kit has an integral Leakage Current Detection and Interruption (LCDI) or Arc Fa ult

Current Interr upter (AFCI) device as required by National Ele ctrical Code (NEC) and Underwriter s

Laboratories (UL) for units m anufactured after August 1, 2004.

Electric

Heat

BTUH

Electric

Heater

Watts

Electric

Heat

Amps

Min. Circuit

Protection

(Amps)

230/208-Volt Sub-Base and Direct Connected Units

Heat

Min. Circuit

Protection

Sub-Base

Connection

Kit

RA K204D1 5P RA K4157 8150/7900 240 0/2320 11.0/11.6 15

RAK204D20P R AK4207 11200/10900 3300/3200 15.1/16.0 20

RAK204D30P RAK43 07 16000/15450 4700/4530 21.2/22.4 30

Electric Heat Amps include electric heater and fan motor cu rrent draw.

Units connected through sub-base do not require an LCDI or AFCI device since they are not

considered to be line-cord connected. Each 230/208-volt sub-base kit consists of sub-base wit h

appropriate receptacle for minimum circuit amperage, chaseway to route power connector from

sub-base to chassis, wiring to connect sub-base to building wiring and a short line cord with 9-pin

connector to connect to chas sis and plug into receptacle in sub-base.

Short sub -base line cord may not be u sed without sub-base.

Junction box for 230/208-volt chassis must be purchased separate ly.

RAK4002A for 2900, 3900, 4100, and 6100 series units, RAK4002B for 5800 series units.

Direct

Electric

Heat

BTUH

Electric

Heater

Watts

Electric

Amps

265-Volt Sub-Base and Direct Connected Units

Sub-Base

RAK204E15 RA K5172 RA K5157 8150 240 0 9.6 15

RAK204E20 RAK5202 RA K5207 11550 3400 13.3 20

RAK204E30 RAK5302 RA K5307 16350 4800 18.6 30

Electric Heat Amps include electric heater and fan motor current draw.

265-volt units are to be permanently connected in compliance with National Electrical Code and local codes and have a factory-installed junction box on the chassis.

Each 265-volt sub-base kit consists of sub-base with appropriate receptacle fo r minimum circuit amperage, chaseway to route power connector from sub-base to chassis

and wiring to connect sub-base to building wiring.

265-Volt Power Connection Kit must be ordered separately.

Power

Connection Kit

Direct

Connection Kit

Electric Heat

BTUH

Electric Heater

Watts

Electric Heat

Amps

Min. Circuit Protection

(Amps)

Important

(Amps)

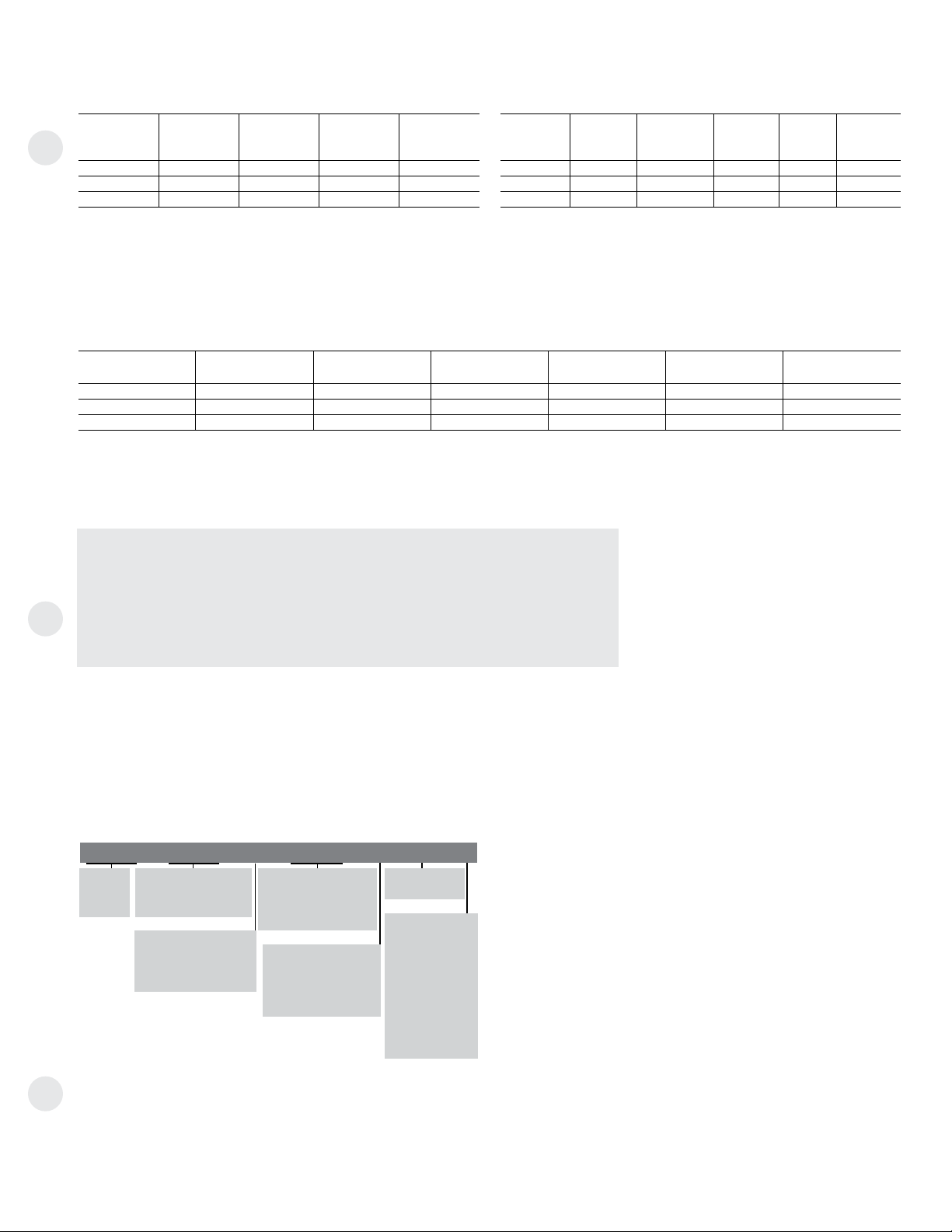

Essential Elements Ordering Overview

230/208-volt line cord connected units — order line cord kit

230/208-volt sub-base connected units — order sub-base

265-volt units — order sub-base and power connection kit

®

Zoneline

Chassis Nomenclature

The Zoneline chassis is identified by a model number defining the type of unit, cooling capacity, electrical information and

optional features included on the unit. When specifying or ordering the Zoneline chassis, the use of this nomenclature will

assure receiving the correct unit.

EXAMPLE

AZ61H12DAD

Zoneline

packaged

terminal

chassis

Chassis series

41= deluxe line cool/

electric heat

61=deluxe line heat pump

Unit type

E= cooling with electric

resistance heat

H= heat pump with electric

resistance heat

Nominal cooling capacity

07=7,000 BTUH cooling

09=9,000 BTUH cooling

12=12,000 BTUH cooling

15=15,000 BTUH cooling

Voltage/Phase/

Frequency

D= 230/208-Volt,

single-phase, 60 Hz

E= 265-Volt, single-phase,

60 Hz

Universal

power connection

Special Features

B=base unit

C=corrosion treated

D= internal

condensate

removal (ICR)

system (heat

pump models

only) (not for

coastal areas)

P= Dry Air 25 (4100

Series only)

3

Page 4

The Zoneline® 4100 and 6100 Series have incorporated changes suggested by customers, along with

enhancements by GE’s Technology Team and changes necessary to meet new UL and NEC requirements.

“L” shaped condenser coil.

Cross flow blower across the product line for quieter operation.

The “Partial Open Vent Air” feature was a specific request by a customer.

“Heat Sentinel” is an enhancement developed by GE’s Technology Team to help lodging professionals welcome their

guests with a moderate-temperature room and to help lower cooling costs.

Devices have been added on cord-connected units to protect against injury from unsafe power cords.

See the “Features and Benefits” section for in-depth explanation of these changes and the industry-leading features

of GE Zoneline retained from the previous series.

The Deluxe 4100 Series Zoneline models include The “Dry Air 25” models

which remove 25% more moisture than other Zoneline models.

As warm, humid air is pulled through the pre-cool (front)

section of the heat pipe, the heat removed from the air is

absorbed by the refrigerant, causing the refrigerant to change

to a gas and flow to the re-heat (rear) section of the heat

pipe. The air leaving the pre-cool section of the heat pipe is

cooler and at a higher relative humidity level than the room

air. The pre-cooled air is further cooled as it passes through

the evaporator; consequently allowing the evaporator coil to

remove more moisture.

When the cold air from the evaporator comes in contact

with the re-heat section of the heat pipe, the heat that was

removed by the pre-cool section is added back to the air

Deluxe Dry Air 25 Models

Cooling With Resistance Heat

• Removes25%moremoisturethanstandardZonelinemodels.

• CoolsanddriesairinlesstimethanstandardZonelinemodels

• DryAirisaseparatesealedrefrigerantsystem

— No mechanical parts — No special maintenance required

• Helpsmaintainlowerrelativehumidityinrooms

• Maintainscomfortatslightlyhigherroomtemperatures

— Reduces operating costs — Provides comfort without

overcooling

• Corrosiontreatmentisstandard

• Excellentchoiceforhumidclimates

• Availablein7000,9000and12000BTUsizes

The Dry Air 25 system, a heat pipe, is a hermetically sealed

heat transfer surface installed in a “saddlebag” configuration

around the indoor (evaporator) coil of the Zoneline unit. This

coil arrangement will transfer heat from the front coil of the

saddlebag to the rear coil without power consumption.

This assembly uses R-410A as the refrigerant and is not

connected to the regular Zoneline refrigerant circuit.

and the refrigerant in the heat pipe condenses and flows

back to the pre-cool (front) section. The air discharged into

the room by this process is much drier, creating a more

comfortable room condition.

The Dry Air 25 models center around GE’s exclusive use of

the patented Dinh® Dehumidifier Heat Pipe from Heat Pipe

Technology, Inc. This innovative NASA spin-off technology

enables Dry Air 25 to remove 25% more moisture from the

air than other leading manufacturers’ packaged terminal air

conditioners. This helps maintain room comfort at a higher

room temperature, reducing operating costs.

The Dry Air 25 keeps a room cool and dry, and this is the

most important benefit when it comes to the occupant of

the room—hotel guests, apartment residents, students. In a

hot, humid climate, getting away from the humidity is just

as important as getting away from the heat, and the Dry Air

25 is the perfect solution. The dehumidification of the Dry

Air 25 has been verified by the same ARI test conditions that

standard units are rated under.

4

Page 5

Table of Contents

Front Cover 1

Mini Specs 4100 and 6100 Series 2

Mini Specs Power Connection Kits and Nomenclature 3

The 4100/6100 and Dry 25 4

Table of Contents 5

Introduction 6

The Zoneline System 7

Features and Benefits

Features Table 8

Features and Benefits 9–11

Auxiliary Control Settings 12–13

Central Desk Control 14

Remote Thermostat Control 15–17

Heat Pumps and Energy Savings 18–19

Installation and Dimensions

Application Comments 20

Case Dimensions 21

Wall Case/Sub-Base Installation 22–33

Condensate Disposal Systems 34–36

Ducted Installations 37–39

Exterior Grilles 40–41

geappliances.com

Product Data

Electrical Connection 42

Essential Elements Ordering Overview 43

Maximum Connected Load 44

Latent System Capacity 44

Normal Yearly Operating Data 45

Schematics 46–49

Product Specifications

Suggested Bid Form Specifications 50–51

Zoneline Chassis Nomenclature/Receptacles/Sub-Bases 52

Installation Specifications 53

Complete Accessory List 54

General Installation Suggestions 55–56

Warranty 56

Notes 57-58

Alphabetical Index 59

Back Cover 60

Important Notice

Equipment used as a primary source for

heating or cooling is an integral part of

the building in which it is installed. Proper

application is essential for satisfactory

performance over a wide range of

operating conditions. It is strongly

recommended that a professional

engineer determine proper application.

If the unit is a replacement unit, its

specifications and performance

may differ from those of the unit it is

replacing. For that reason, we again

strongly recommend that a professional

engineer determine proper application.

5

Page 6

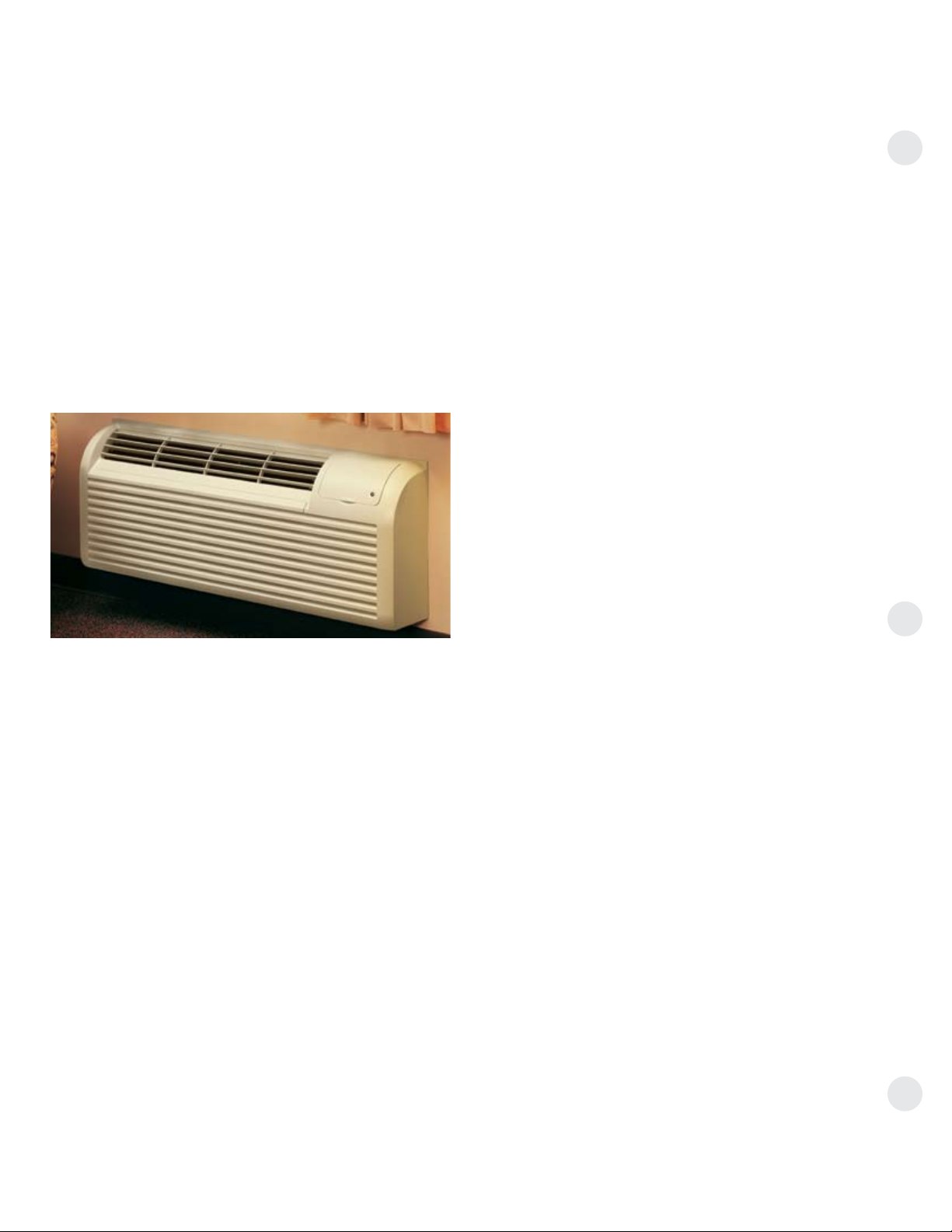

Introduction

This manual is designed to provide product, performance

and application information to our customers and their

architects and engineers for use in selection and design

of a zonal comfort control system utilizing GE Zoneline®

Packaged Terminal Air Conditioners (PTAC) and Packaged

Terminal Heat Pumps (PTHP). GE Zoneline PTACs and PTHPs

are self-contained units designed for through-the-wall

installations in hotels, motels, apartments, hospitals,

nursing homes, add-on rooms and many other installations.

Zoneline units provide individual room or zone control in both

cooling and heating operation. There is a model for practically

every application, ranging in cooling capacity from 7,200 to

14,800 BTUH and heating capacity from 6,400 to 14,000 BTUH

in heat pump operation. See pages 42 and 54 for resistance

heaters available.

Zoneline offers a two-tier lineup: The Deluxe Line consists of

the 4100 Series with electric resistance heat, the 4100 Series

Dry Air 25 Models with enhanced dehumidification for hot

and humid climates and the 6100 Series heat pump. The

6100 Series heat pump features reverse cycle defrost and

simultaneous supplemental resistance heat, when needed,

to maintain room comfort. Both offer tactile touch controls

with digital display and optional corrosion protection.

Deluxe Line Standard Features:

• Two-fan-motorsystemwithIndoorCross-Flow

Blower for quieter operation

• DigitalControls

—LED Temperature Display

—Easy Temperature Selection

—Tactile Touch Pad

• UniversalHeaters

• HeatSentinel

• “L”CoilDesignCondenser

• 3-PositionVentDoor

• FreezeSentinel™

• IndoorCoilFrostControl

• CentralDeskControlInterface

• RemoteThermostatControlInterface

• RandomRestart

• ElectronicTemperatureLimiting

• “SmartFan”FanCycle/ContinuousControl

• TransferFanInterface

• ReverseCycleDefrostandSimultaneous

Supplemental Resistance Heat on Heat Pumps

• QuickHeatRecovery

Deluxe Line Optional Features:

• CorrosionProtection

• InternalCondensateRemoval(on6100Series

Heat Pump without Corrosion Protection)

NOTE: Dry Air 25 models include all the standard features of the

4100 Series plus standard corrosion protection.

Advantages of the GE Zoneline System:

• FlexibleApplication

— May be installed from flush to finished floor to

3" from the ceiling

— 7,200 to 14,800 BTUH units in same physical size

— Deluxe 4100 and 6100 Series may be ducted to

condition more than one room

— Compatible with Class 2 remote thermostat control

— Compatible with 2-wire CDC or many Energy

Management Systems

• EconomicalInstallation

— No ductwork necessary

— No mechanical equipment rooms or pipes required

for heating/cooling units

— Replacement units fit existing 42"-wide by 16"-high

wall cases

• QuietOperation

— Indoor cross-flow blower

• Energy-SavingOperation

— Units in unoccupied areas may be turned off

— Designed for efficient cooling operation — EERs from

10.6 to 13.2

— Efficient heat pump units — COPs from 3.3 to 4.0

— Extended heat pump operation without sacrificing

room comfort

• EaseofMaintenance

— Permanently lubricated fan motors

— Upfront lift-out interchangeable filters

— Slide-out chassis for easy access for cleaning or if

service is required

• ReverseCycleHeatPumpOperation

The 6100 Series heat pumps utilize the unique GE PTAC

heat pump operation to ensure a comfortable room.

The logic used by the units is the same logic used by

central system heat pumps to provide greater savings.

6

Page 7

geappliances.com

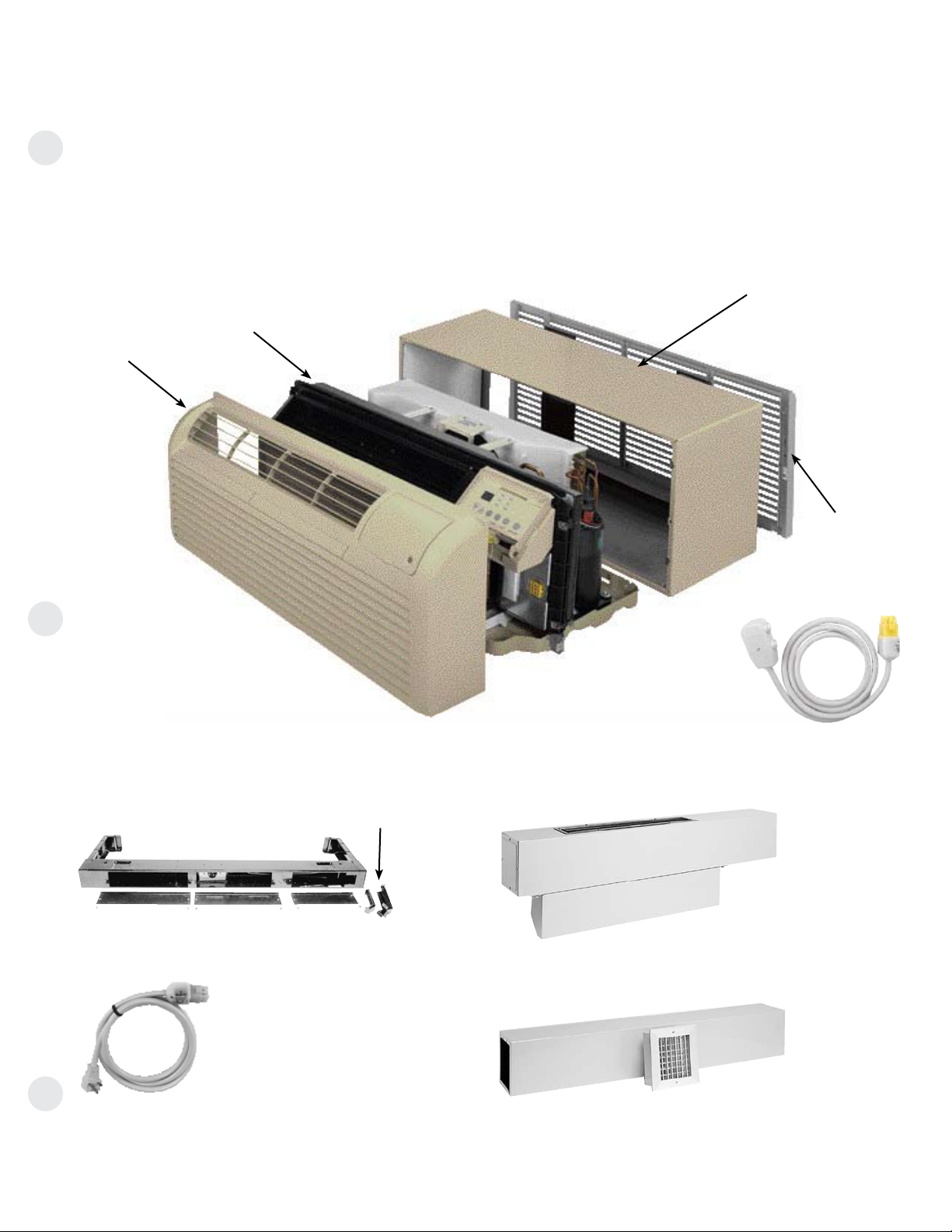

The Zoneline System

The typical Zoneline installation consists of the wall case (or sleeve), chassis, power cord and exterior grille. Some installations may

use a sub-base for support of the unit or for ease of electrical connections. Each of the components should be the standard

products offered by GE or, in the case of the exterior grille, approved by GE Applications Engineering. Use of components not

specifically designed or approved for use with the Zoneline unit can result in unsatisfactory operation

and can be the cause of failure not covered by the warranty.

Components of the Zoneline System

Typical Installation

Chassis

Room Cabinet

(Deluxe Series shown)

Wall Case

RAB71A (Steel-Insulated)

RAB77A4 (SMC — Molded)

Wall Case Options

(See page 22)

RAG67 (shown)

Grille Options

(See page 40)

Power Connection Kit (required on all units)

Line Cord Kit shown

See pages 42-43

Power Supply Cord

Optional Accessories of the Zoneline System

Chaseway

RAK204D20P Sub-Base (shown)

Power Supply Cord (included with 208V/230V

sub-bases)

See pages 22 and 32 for information on electrical sub-bases and chaseway.

See pages 37-39 for information on ducted installations.

RAK6052 Duct Adapter

RAK601/602

Duct Extension, Register and Trim Flange

7

Page 8

Zoneline® Features

Resistance heat Heat pump

AZ

41 Series

Cooling EER Range (230 Volts/265 Volts) 10.6 - 12.8 11.3 - 12.2 11.2 - 13.2

Heating COP Range (230 Volts/265 Volts) N/A N/A 3.3 - 4.0

Refrigerant type R- 410A R- 410A R- 410A

Cross-flow (tangential) blower Standard Standard Standard

Enhanced Dehumidification Optional Standard —

Heat pump with resistance heat back-up — — Standard

Heat pump with supplemental resistance heat — — Standard

Staged Heating — — 3-Stage***

Universal heaters - UPC** Standard Standard Standard

Tactile touch pad controls with LED Standard Standard Standard

Touch control set-up features Standard Standard Standard

Highly featured microcomputer controls Standard Standard Standard

Electric resistance heat lock-out (above 46°F) — — Standard

Automatic emergency heat Standard Standard Standard

Heat pump defrost system — — Reverse cycle

High-Temperature Operation Protection — — Standard

Quickheatrecovery — — Standard

Temperature Boost — — Selectable

Separate Indoor & Outdoor

Motors — Permanently Lubricated

2-Speed Outdoor Fan Standard Standard Standard

Indoor fan speed settings Hi/Low Hi/Low Hi/Low

Fan Only setting—2-speed Hi/Low Hi/Low Hi/Low

Cool & heat only settings Hi/Low/Auto Hi/Low/Auto Hi/Low/Auto

“SmartFan” Fan Cycle Control Standard Standard Standard

Auto power recovery Standard Standard Standard

Automatic Compressor Restart Delay Standard Standard Standard

Freeze Sentinel

Heat Sentinel (85F) Standard Standard Standard

Automatic indoor frost control Standard Standard Standard

Temperature limiting Electronic 7-step Electronic 7-step Electronic 7-step

Solid-state thermostat Standard Standard Standard

Remote thermostat compatibility Standard Standard Standard

Central desk control compatibility Standard Standard Standard

2-position discharge grille 50º/40º Standard Standard Standard

Upfront filter (interchangeable) Standard Standard Standard

3-position manual air vent control Standard Standard Standard

Sleep function Standard Standard Standard

Transfer Fan Connections Standard Standard Standard

Ducted Installation Capability Optional Optional Optional

Corrosion-treated chassis Optional Standard Optional

Internal condensate removal (ICR)* — — Optional

*Not for use in corrosive environments

**UPC — Universal Power Cord Connection (see pages 42 and 54).

*** Two stage heating if using remote thermostat

265-volt units must be connected in a manner to meet National Electrical Code and all local codes.

™

( 41F) Standard Standard Standard

AC AC DC

AZ

41 Dry Air 25

AZ

61 Series

8

Page 9

Features and Benefits

geappliances.com

Standard Physical Dimensions

GE has maintained the same dimensions since 1961 —

42" wide x 16" high x 13-3/4" deep

Replacement of older units is made easy.

Weather-Protected Electrical Components

Vital electrical components are protected from the weather

by locating them on the indoor side of the weather barrier.

Weather-Resistant “Superseal”

Properly installed unit in undistorted case keeps air leakage

to a minimum.

7 CFM air infiltration with 25 MPH wind on ICR

units — even less on units without ICR.

Industry specification is 19 CFM of air infiltration.

Heater Sizes to Meet Room Requirements

All units are equipped with a universal heater —

the resistance heat output is determined by power

connection kit.

230/208-volt — Line-Cord Connected Units — 2.4/2.32 KW

with RAK3153A — 15-amp circuit; 3.3/3.20 KW with

RAK3203A — 20-amp circuit; 4.7/4.53 KW with RAK3303A —

30-amp circuit.

230/208-volt - Sub-Base Connected Units — 2.4/2.32 KW

with RAK204D15P — 15-amp circuit; 3.3/3.20 KW with

RAK204D20P — 20-amp circuit; 4.7/4.53 KW with RAK204D30P

— 30-amp circuit.

265-volt — 2.4 KW with RAK5172 — 15-amp circuit; 3.4 KW

with RAK5202 — 20-amp circuit; 4.8 KW with RAK5302 —

30-amp circuit.

Unit Controls

4100 and 6100 Series — touch pad controls with digital

readout of temperature set point.

Highly Featured Microprocessor Controls

Microprocessor controls are programmed to interface with

the temperature sensors to maximize comfort conditions

for the room occupant and provide outstanding features.

Thermistors are used to sense small changes in temperature

to give excellent room control and allow the microprocessor

to monitor and react to changing conditions.

Automatic Emergency Heat

Automatically uses electric resistance heat if the heat

pump output is not sufficient to maintain selected

room temperature.

Reverse Cycle Heat Pump Defrost System

Standard on all Zoneline 6100 Series heat pumps.

Enables heat pump to operate at lower temperatures

when other systems switch to more expensive electric

resistance heat.

See pages 18 and 19 for discussion of heat pump operation

and defrost systems.

High-Temperature Heat Pump Operation Protection

Automatically protects the compressor if heat pump is

operated with high outdoor temperatures.

Power to the outdoor fan is turned off if the indoor coil

gets too hot during heat pump operation to prevent

damage to the compressor.

Quick Heat Recovery – Heat Pump Units

When the unit operation is changed from STOP or COOL to

HEAT, the electric resistance heaters are used to warm the

room to the thermostat set point. This provides faster room

temperature increase for greater guest comfort.

Fan Motors – Permanently Lubricated

All units have two fan motors for quiet operation and

maximum operating efficiency.

Motors are permanently lubricated to reduce maintenance

and totally enclosed to keep dirt and water out of the

motor windings.

Outdoor Fan

The unit automatically selects the most efficient speed

for the outdoor fan. The operating sound level is lower

when the outdoor fan can operate in low speed yet

there are situations where it must operate in high

speed. The unit changes the fan speed automatically.

Indoor Fan Speed Selections – HIGH/LOW

Unit may be operated in HIGH HEAT or LOW HEAT or

HIGH COOL or LOW COOL.

Electric Resistance Heat Lock-Out

To maximize the savings of the heat pump operation, the

Zoneline heat pumps do not utilize the resistance heater

when the outdoor temperature is above 46°F during normal

operation.TheresistanceheatisusedintheQuickHeat

Recovery feature.

9

Page 10

Features and Benefits

Fan-Only Setting – HIGH/LOW

The unit provides the option of selecting either HIGH or LOW

speed for Fan-Only operation.

Fan-Cycle Switch – “SmartFan”

Unique “SmartFan” allows unit to operate fan continuously

in cooling operation and fan cycle in heating to provide better

guest comfort. Eliminates complaint of cold air draft during

heating operation.

Eliminates need of changing fan-cycle switch seasonally.

“SmartFan” settings are controlled via the auxiliary control

setting push button.

Compressor Random Restart

In the event of a power failure, all compressors attempting

to restart immediately when power is restored can result

in a power surge that can cause another power interruption.

The microprocessors in the Zoneline® units have a random

restart logic system that prevents all units from starting at

the same time.

Rotary Compressor

Smoother operation for quiet, dependable service. GE has

used rotary compressors since 1961.

Compressor Restart Delay

Zoneline units are designed to provide a minimum of three

minutes of compressor off time to allow refrigerant pressures

to equalize before restarting to prevent compressor damage.

Zoneline units are also designed to provide a minimum

of three minutes of compressor run time to prevent room

occupant disturbance due to short-cycling of the air

conditioner.

Freeze Sentinel

Detects low room temperature and turns on heater to

help protect against damage caused by freezing room

temperature.

Heater turns on at 41°F and warms indoor thermistor

temperature to 46°F and shuts off.

Freeze Sentinel may be turned off by dip switch on

auxiliary control.

™

Heat Sentinel

The property owner may choose to activate the Heat Sentinel

feature on the Zoneline unit. If the Heat Sentinel is activated

and room temperature reaches 85°F while the

unit is in the “STOP” setting, the unit will automatically start

in air conditioning operation and will shut off when the room

temperature reaches 80°F. This will help dehumidify the air

and lower high temperatures so the guest will not be entering

an extremely hot room.

Indoor Coil Frost Control

Prevents indoor coil from freezing

and causing complaints due to lack

of cooling. Frost can form on the

indoor coil when the unit is operated

in cooling when outdoor temperatures

are low. The unit automatically shuts

the compressor off until the indoor coil

temperature warms to the point where

frosting will no longer occur.

Transfer Fan Interface

24 VAC terminals are provided to operate a relay to control

a fan mounted in a wall to move conditioned air into another

space. The electrical power for the operation of the transfer

fan itself is not provided by the Zoneline unit. Transfer fans

and their controlling relays are field supplied.

Electronic Temperature Limiting

Seven independent programmable heating temperature

limits and seven independent programmable cooling

temperature limits.

Heating Temperature Limits

65 70 72 74 76 78 80 85

Lowest

Cool

60 64 66 68 70 72 74 76

Limits are set via the auxiliary control setting push button.

Cooling Temperature Limits

Highest

Heat

Remote Control Capability with Wall-Mounted

Thermostat

See pages 15–17.

Central Desk Control Capability

See page 14.

Energy Management System Interface with

Load-Shedding Option

All units have a switch via the auxiliary control setting to

allow the indoor fan to continue operating if the unit is

connected to an energy management system that shuts off

compressor or heater operation. By allowing the indoor fan to

run when the heater or compressor is shut off by the energy

management system, the guest is less likely to realize the

operation of the unit has been altered. This helps reduce peak

energy demand loads without disturbing the room occupant.

Reversible Indoor Air Louvers

Allows air to be directed into room at 40º or 50º angle to

provide better air distribution.

Angle is changed by removing room front and screws

holding louver in place, and rotating louver section.

10

Page 11

Features and Benefits

geappliances.com

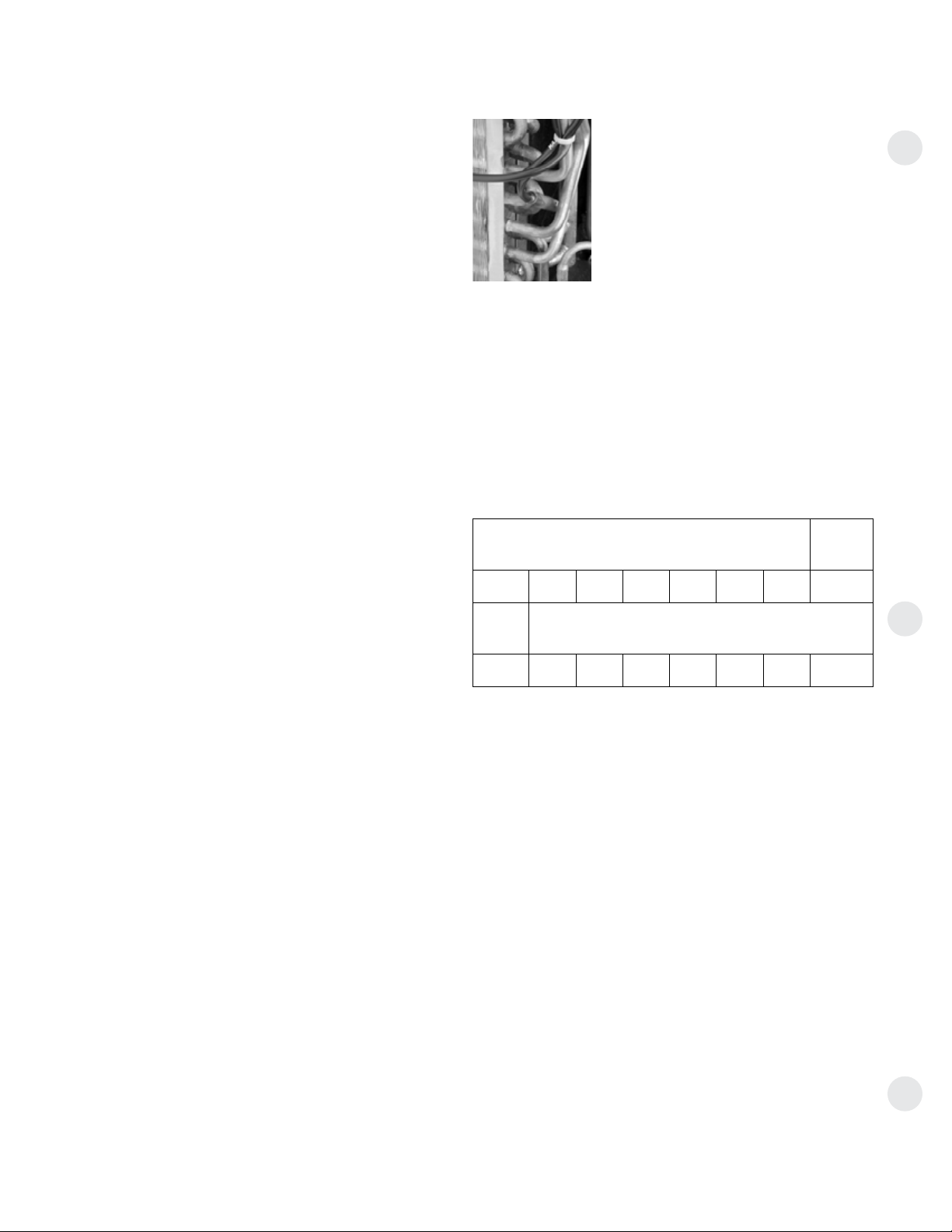

Up-Front Air Filters

Two interchangeable

up-front filters, easy

to remove and reinstall,

may be cleaned without

opening or removing

the room front.

Clean filters by brushing,

vacuuming or backflushing under faucet

or shower head.

Concealed Manual

Vent Control

Open ventilation doors on

GE Zoneline® Packaged

Terminal Air Conditioners

and Heat Pumps allow

outside air to enter the room through a screen-covered

opening in the weather barrier that separates the indoor

and outdoor sections of the unit.

A concealed lever is located along the left side of the unit

under the front cover is used to open and close the vent door.

The 3-position manual vent door control may be closed,

partially open or fully open. Positive vent door closure

prevents accidental opening and unwanted air infiltration.

Vent CFM High Speed

U n i t F u l l O p e n P a r t i a l O p e n

7000 50 40

9000 70 45

12000 75 45

15000 75 45

CFM ratings at 230 and 265 volts.

For each CFM of air to enter the room, an equal amount of

air must be removed through exhaust fans in the bathroom

or roof tops. Greater amounts of air will be introduced (from

chart shown above) depending on the size of the exhaust fan.

Outside ambient air entering the room through this screened

vent opening is not conditioned. This unconditioned air

becomes mixed with the conditioned air that is circulated by

the indoor fan. This air mixture generates an additional heat

load/heat loss that causes the unit to run longer and may

translate into higher operating costs.

Zoneline vent openings are not intended to be the source

of make-up air for building ventilation systems due to the

additional heating or cooling loads generated.

Corrosion Protection (Optional)

4100 and 6100 Series units may be ordered with special

protection to better withstand damage from salt air and

salt water in seacoast areas.

Corrosion protection is standard on the Dry Air 25 models.

Heat pump units with ICR are not available with corrosion

protection and should not be installed in seacoast or

corrosive environments.

Units installed in corrosive areas should use the RAB77 wall

sleeve and be examined/cleaned more frequently than

normal installations.

Internal Condensate Removal (ICR)

See page 34 for a discussion of the Internal Condensate

Removal system available on 6100 Series heat pumps.

Enhanced Dehumidification

Moisture removal is an important function of an air

conditioner. People are more comfortable at higher

temperatures when the humidity level is relatively low.

Air conditioners operate with less energy consumption

when the room temperatures are set higher.

The GE Zoneline 4100 Series with the Dry Air 25 heat pipe

application removes 25% more moisture than the base

4100 Series unit.

The GE Zoneline Dry Air 25 chassis is the only PTAC available

with the application of the patented Dinh® Dehumidifier

Heat Pipe under license from Heat Pipe Technology, Inc.

Customers who are using the Dry Air 25 report a freshersmelling room as a result of the lower humidity levels, as

well as lower operating costs.

Locking Door Kit

RAK8023 — A door with a lock that replaces the standard

control cover door to prevent unauthorized changing of

control setting is offered as an accessory.

11

Page 12

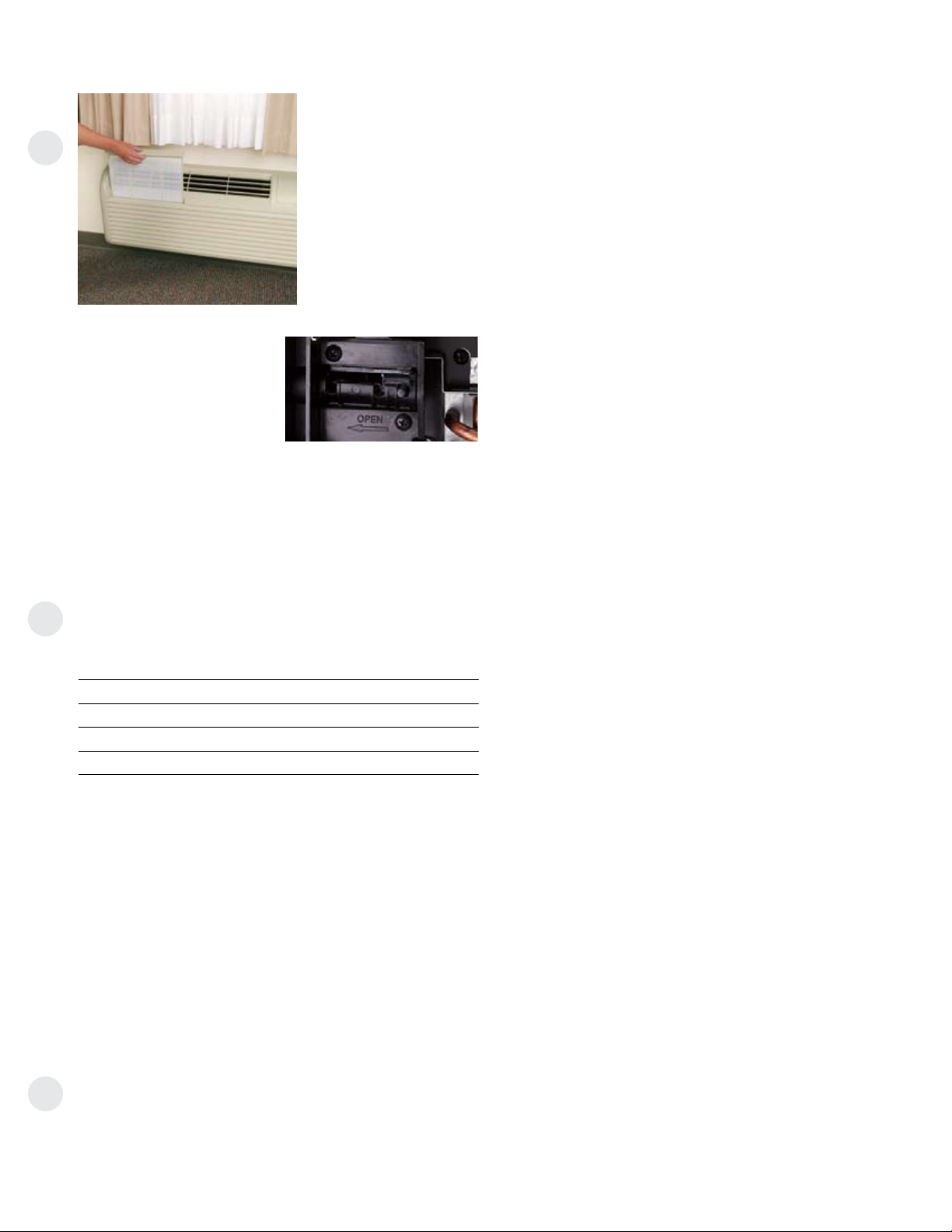

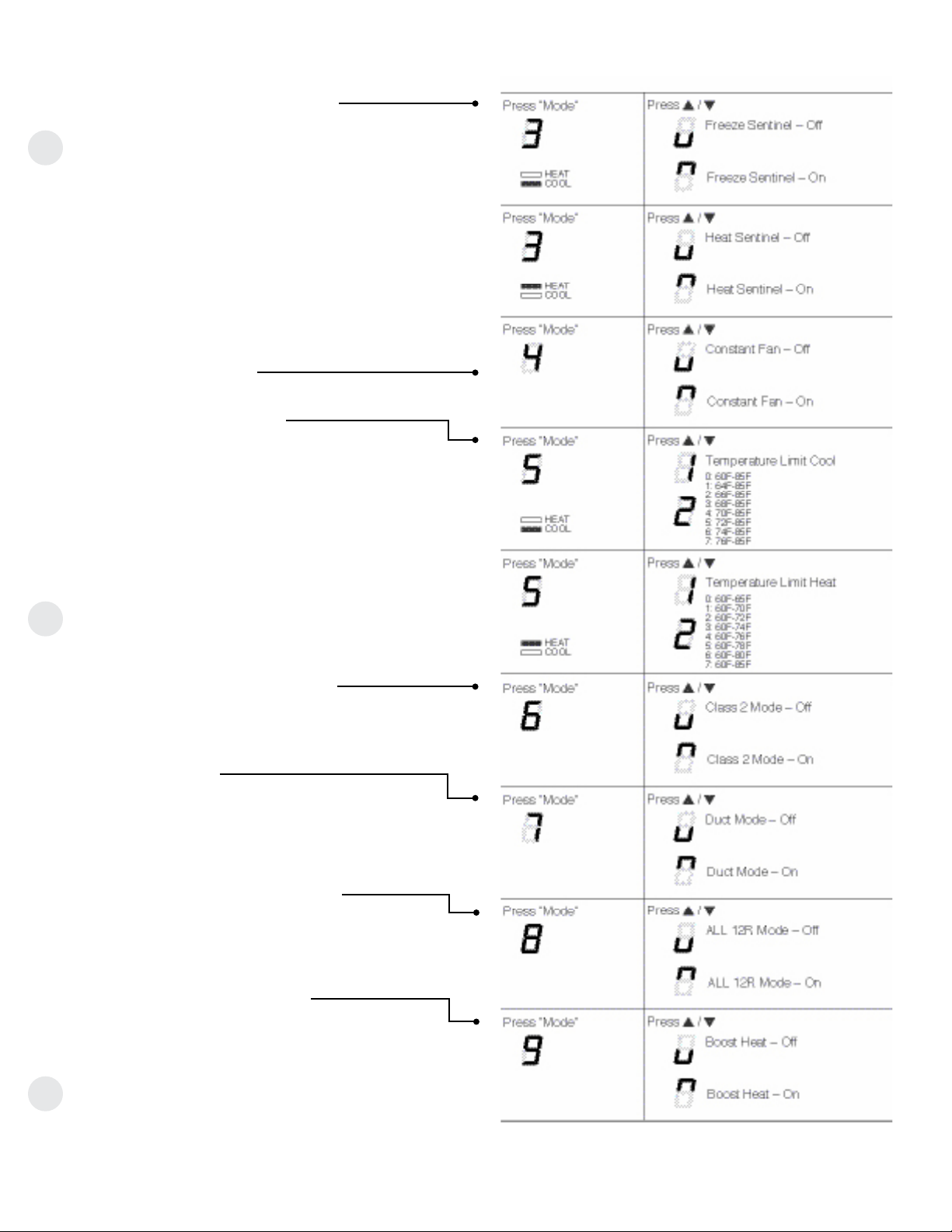

Auxiliary Control—Aux Set Button

The auxiliary control push button is located behind the room

cabinet, below the control panel. The auxiliary controls come

preset to the modes most desired by customers. However,

the owner is responsible for ensuring the auxiliary controls

are set to the desired function. There are 9 different modes

that can be set using the auxiliary set button.

To change modes:

•PressAUXSET(“AU”appearsonthedisplay).

•PresstheMODEbuttononthecontrolpaduntil

the first digit in the display shows the number

corresponding to the mode you are choosing

and the correct HEAT/COOL LED is lit.

•Presstheupordownarrowtochangethemode

setting selection (second digit in the display).

•PresstheMODEbuttontomovetothenextfeature

or the AUX SET button to exit the set up process.

Auxiliary Set Button

Access

Cover

Auxiliary Control Settings

Mode 1—Smart Fan—Cooling/Heating

The default setting for Mode 1 is as follows:

Cooling: Continuous (ON)

Heating: Cycle (OFF)

Mode 2—Load Shedding (Central Desk Control)

The default setting for Mode 2 is OFF.

This feature is active only if the unit is connected to a

CDC and the CDC has control. When this mode is on,

only the indoor fan can be turned ON or OFF with the

unit controls. When this mode is off, all operation is

disabled except Heat/Freeze Sentinel (Mode 3).

12

Page 13

Auxiliary Control Settings (cont)

Mode 3—Freeze Sentinel/Heat Sentinel

The default settings for Mode 3 are:

Heat Sentinel is off

Freeze Sentinel is on.

When Freeze Sentinel is activated, it automatically provides

heat without user interface. This helps to prevent plumbing

damage by turning the heater and indoor fan ON at 41ºF and

OFF at 46ºF.

When Heat Sentinel is activated, it automatically provides

cooling without user interface. This helps to prevent an

excessively hot room by turning the air conditioner ON at 85ºF

and OFF at 80ºF.

NOTE: These functions are active whenever the unit is plugged

in, even if the unit is in the STOP position.

Mode 4—Constant ON Fan

The default setting for Mode 4 is OFF.

Mode 5—Temperature Limiting

The default setting for Mode 5 is as follows:

Cool: 0 (60ºF to 85ºF)

Heat: 7 (60ºF to 85ºF)

geappliances.com

Temperature limits—Cool Temperature limits—Heat

0 = 60°F to 85°F 0 = 60°F to 65°F

1 = 64°F to 85°F 1 = 60°F to 70°F

2 = 66°F to 85°F 2 = 60°F to 72°F

3 = 68°F to 85°F 3 = 60°F to 74°F

4 = 70°F to 85°F 4 = 60°F to 76°F

5 = 72°F to 85°F 5 = 60°F to 78°F

6 = 74°F to 85°F 6 = 60°F to 80°F

7 = 76°F to 85°F 7 = 60°F to 85°F

Mode 6—Remote Thermostat – Class 2

The default setting for Mode 6 is OFF.

Setting this mode to ON will allow the unit to operate

with a Class 2 Remote Control Wall Thermostat.

Mode 7—Duct Mode

The default setting for Mode 7 is OFF.

This setting is used when the unit is installed using a duct

adapter kit. If the unit is ducted, the Duct Mode needs to

be set to ON. This increases the fan speed to ensure proper

circulation.

Mode 8—All-Electric Heat (AZ6100 only)

The default setting for Mode 8 is OFF.

This electric heat option functions only on the 6100 model.

When this option is ON, heat pump operation is locked out,

causing the unit to provide only electric resistance heat.

Mode 9—Heat Boost (AZ6100 only)

The default setting for Mode 9 is OFF.

When Heat Boost is ON and outer temperatures are between

25ºF and 46ºF, heat pump only operation is locked out. This

setting is used to provide supplementary heat to the heat

pump operation by electric resistance heat in conditions

where the heat pump-only operation is not sufficient to

maintain a consistent, comfortable room temperature. NOTE:

Temperature Boost option should NOT be used with remote

thermostat operation. This will cause the unit to switch to

resistance heat when the outdoor temperature is 46ºF.

13

Page 14

Central Desk Control

Unit #2

Unit #1

Unit #3

CDC Terminals

on Zoneline unit

Some installations may want to govern the ability of the unit

to operate from a control device remote to the unit or even

remote to the room in which the unit is located. The general

term given to systems such as this is Central Desk Control.

The most common installation of this type of system is a

switch mounted at the registration desk and, upon guest

check-in, a button is pushed or a switch is moved to allow

the air conditioner to operate. Likewise, when the guest

checks out the device is put into the “OFF” position so the

unit will not operate while the room is vacant.

It is not necessary that the controlling device be located

at a central desk to employ a device that will control the

unit operation. For instance, in some resort areas devices

are connected to sliding glass doors and opening the door

causes a contact to close, turning the air conditioner off.

This prevents energy being wasted by operating the air

conditioner when warm, humid air is entering the room.

Some systems operate by motion sensors or heat-sensing

detectors mounted in the room. These types of systems

determine occupant presence in the room and allow the

unit to operate; if no one is in the room the device signals

the air conditioner to turn off.

Zoneline® models offer load-shedding capabilities on

units connected to Central Desk Control systems. For

more information on the models’ load-shedding feature,

see page 10.

There is a wide variety of devices available, each with

its own benefits and constraints. While GE does not offer

components that are external to the unit for a Central Desk

Control (CDC) system, GE Zoneline units are compatible with

most CDC and energy management systems. Zoneline units

provide a 24 VAC circuit that powers the Central Desk

Control system and no external power is needed.

All Zoneline 4100 and 6100 Series units are compatible with

simple on/off 2-wire Central Desk Control systems. Consult

with the provider of the energy management system to be

sure it is compatible with GE Zoneline units. Zoneline units

have standard connectors factory-installed to provide a

CDC interface that permits the unit to be connected to most

of the energy management systems. The devices connected

to the Zoneline units require no power supply or transformers

external to the unit.

Important CDC Comments (all series applicable)

4. Recommended wire size must be followed as a minimum

requirement.

Wire Size #AWG Maximum Allowable Length

#22 600 Ft.

#20 900 Ft.

#18 1500 Ft.

#16 2000 Ft.

Freeze Sentinel™ and Heat Sentinel remains operational when

the unit is connected to a CDC system. Even if the unit is

turned “OFF” at the central location, if the sensor at the unit

detects the low or high limit temperature, the unit will

automatically turn on until it reaches the preset shutdown

temperature (46°F heating, 80°F cooling).

Connecting the Zoneline unit to a CDC system does not

eliminate the ability to connect the unit to a remote thermostat.

Once the circuit is “opened,” and control of the unit removed

from the CDC system, the selected controls—either the unit—

mounted control or the remote thermostat—govern the

operation of the unit.

Please see page 55 for installation recommendations

for the Central Desk Control wiring.

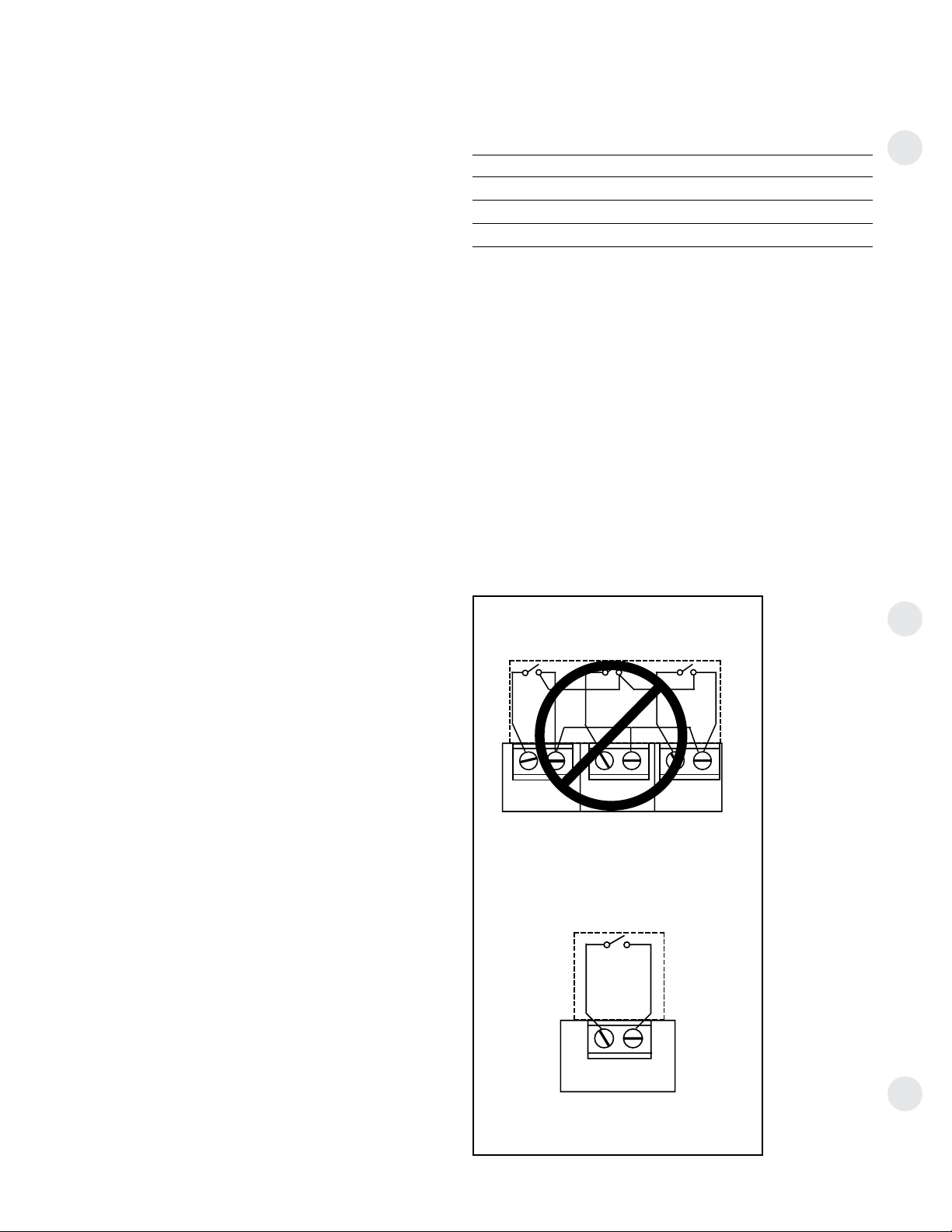

CDC Terminal Location and Typical Wiring

See page 15 for location of CDC terminals on unit.

Example of Common Busing

NOT PERMITTED

INCORRECT Common Busing

Normally Open

Switch -

Unit Operational

1. When the switching device closes the circuit of the CDC

conductors, the unit operation stops.

2. Do not use a common bus (at the unit or at the switch

panel) in the wiring. Both wires comprising the circuit

must connect to the unit connectors and to the controlling

switch. Running one wire from one unit to another unit is

common busing and may damage internal components

or cause erratic operation of the system.

3. A 24-volt transformer is contained within the Zoneline unit.

No external voltage may be applied to the unit through

the CDC terminals. (Voltage on the CDC conductors is

24 volts AC.)

14

Typical Wiring

(All Wiring Shown Is Field Supplied)

Page 15

Remote Thermostat Control

R

GL

GH

B

Y

W

C

Common

White — Heater

Yellow — Compressor

Black — Not Used On 4100

Green — High-Speed Fan

Green — Low-Speed Fan

Red — 24V AC

CDC Terminal

CDC

geappliances.com

In some installations, control of the operation of the unit at

a location remote from the unit itself may be desired. A unit

mounted high in the wall or over a door, for instance, where

the unit-mounted controls are inaccessible, can be connected

to a wall-mounted thermostat. Other installations may use

remote thermostat control for design or performance

enhancement. The unit is connected to the thermostat by

low-voltage wiring which permits the operation of the unit to

be selected and the temperature sensed at the thermostat.

Important Notes: Remote thermostat wiring should NOT be

run through wall case. Thermostat wiring should exit the

wall below the unit and enter the unit between room cabinet

and chassis. Wire molding may be used to hide thermostat

wiring. If a sub-base is used, the thermostat wiring may be

concealed by the sub-base. Thermostat wiring should NOT be

run parallel to line voltage wires since induced current may

cause erratic operation.

All Zoneline 4100 and 6100 Series units are adaptable to Class

2 remote low-voltage thermostat. The only additional fieldsupplied components are the remote thermostat and wiring

necessary to connect it.

The controls on the unit are not functional when the remote

control function is used.

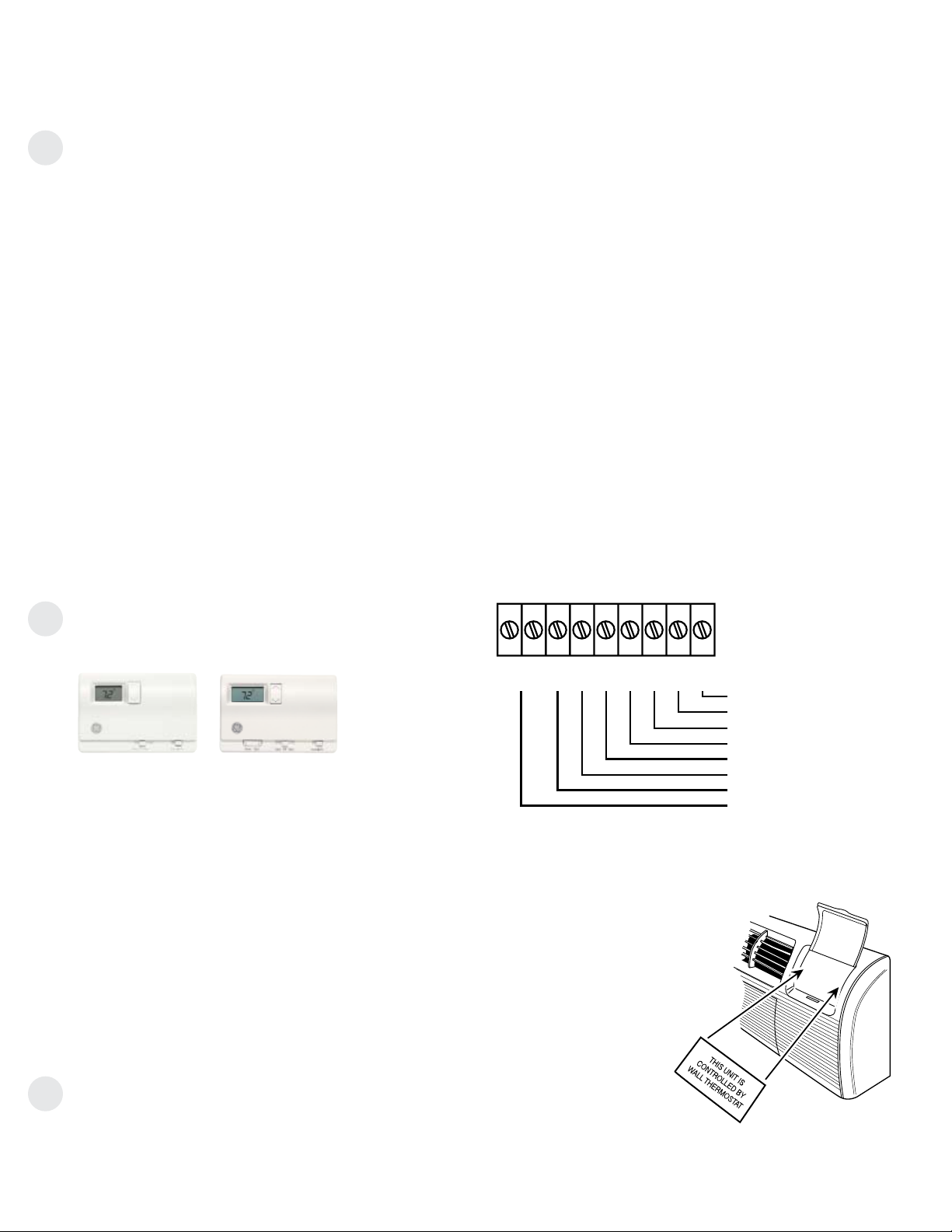

Resistance Heat Models

The Zoneline 4100 resistance heat units may be connected

to a single-stage thermostat designed for use with cooling

with electric heat systems. GE offers two thermostats

compatible with the 4100 Series unit.

The fan speed for the 4100 Series in remote thermostat

operation is selected by the connection of the fan wire from

the thermostat to either the HIGH or LOW terminal on the unit.

See the sketch of the unit terminals below for the location of

the HIGH and LOW fan-speed terminals. Operating the unit in

low fan speed reduces the operating sound level of the unit.

Freeze Sentinel™ and Heat Sentinal remain operational if the

unit is connected to a remote thermostat. The unit may be

connected to a Central Desk Control (CDC) system and

controlled with a remote thermostat when the CDC system has

the unit in operation. See page 14 for additional information on

the CDC system.

Unit temperature limiting settings are not functional when unit

is connected to a remote thermostat.

Field Wiring Terminal

R — 24V AC

GL — Low-Speed Fan

GH — High-Speed Fan

B — Not Used on 4100

Y — Compressor

W — Heater

C — Common

RAK806 Universal Control Cover Label

RAK164D1 —

a solid-state

digital thermostat

requiring five

connection wires.

RAK164P1 —

a solid-state digital

programmable

thermostat

requiring five

connection wires.

The remote thermostat-Class 2 option (Mode 6 in the auxiliary

control setting) must be turned ON to enable remote

thermostat control. Refer to installation instructions packaged

with the chassis.

Please see page 55 for installation recommendations for

the remote thermostat wiring.

Compatibility of other thermostats considered for use with

GE Zoneline units is the responsibility of the customer. The

control voltage on the remote control conductors is 24 volts

AC. The AC voltage may not be compatible with some

solid-state thermostats.

When a Zoneline unit is using a remote thermostat control,

the RAK806 Universal

Control Cover Label is

recommended. The

RAK806 is only

available in a

package of 10 labels.

The label is placed

over the control panel

to direct the user to

the wall thermostat

for operation of the

Zoneline unit.

15

Page 16

Remote Thermostat Control

R

GL

GH

B

Y

W

C

Common

White — Heater

Yellow — Compressor

Black — Reversing Valve

Green — High-Speed Fan

Green — Low-Speed Fan

Red — 24V AC

CDC Terminal

CDC

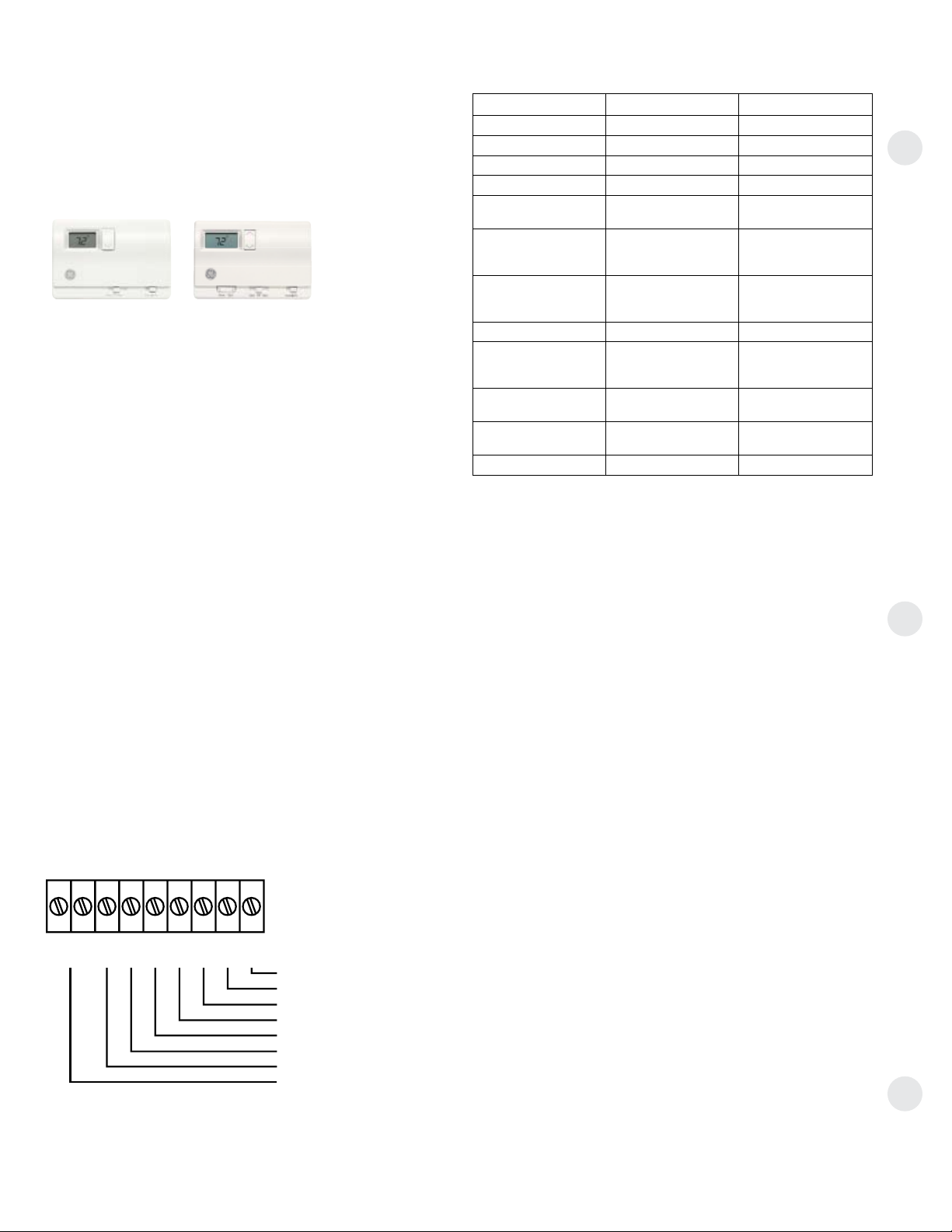

Heat Pump Models

The Zoneline® 6100 Series heat pump units may be

connected to a single-stage cooling/two-stage heating

thermostat designed for use with heat pump systems.

GE offers two thermostats compatible with the

6100 series units:

RAK148D1 —

solid-state digital

thermostat

requiring six

connection wires.

Please see page 55 for installation recommendations

for the remote thermostat wiring. Compatibility of other

thermostats considered for use with the GE Zoneline

unit is the responsibility of the customer.

The control voltage on the remote control conductors is 24 VAC.

The remote thermostat-Class 2 option (Mode 6 in the

auxiliary control setting) must be turned ON to enable remote

thermostat control. Refer to installation instructions packaged

with the chassis.

The fan speed for the 6100 Series in remote thermostat

operation is selected by the connection of the fan wire from

the thermostat to either the HIGH or LOW terminal on the

unit. See the sketch of the unit terminals for the location of

the HIGH and LOW fan speed terminals. Operating the unit in

low fan speed reduces the operating sound level of the unit.

RAK148P1 —

solid-state digital

programmable

thermostat

requiring six

connection wires.

Feature Heat Pump Electric Heat

Indoor Frost Control Yes Yes

Freeze Sentinel

Heat Sentinel Yes Yes

Auto Fan Speed No No

Electronic

Temperature Limiting No No

Switch to Resistance

Heat Based on Indoor

Temperature

Switch to Resistance

Heat Based on

Outdoor Temperature Yes N/A

Reverse Cycle Defrost Yes N/A

Simultaneous

Resistance Heat

with Heat Pump No N/A

Resistance Heat

Lockout Ye s N/A

“Smart Fan”

Fan Cycle

Central Desk Control Yes Yes

™

Yes Yes

Determined by

Remote Thermostat N /A

Fan ON/AUTO Set On

Remote Thermostat

Fan ON/AUTO Set On

Remote Thermostat

When connected to a remote thermostat, the indoor-airtemperature sensing is shifted from the unit to the remote

thermostat. For this reason, the units will operate slightly

differently when connected to a remote thermostat. The

above chart shows the unit operation when connected

to a remote thermostat.

Boost heat option should NOT be used with remote

thermostat operation since this will cause the unit to

switch to resistance heat when outdoor temperatures

are below 46ºF.

Field Wiring Terminal

R — 24V A C GL — Lo w- Sp ee d Fa n

GH — High-Speed Fan B — Reversing Valve

Y — Compressor W — Heater

C — Common

16

Page 17

geappliances.com

Remote Thermostat Control Selection Chart For Zoneline Packaged Terminal Units

Zoneline Series Thermostat Model Ty pe Function Low-Voltage Conductors

4100 RAK164D1 Digital

RAK164P1 Digital Programmable 5

6100 RAK148D1 Digital

RA K148P1 Digital Programmable 6

Thermostat wire size – up to 60 feet AWG20 – up to 66 feet AWG18

For remote thermostat operation follow the steps below:

1. Turn on the unit and ensure it is working properly

BEFORE proceeding.

2. Unplug the unit or disconnect power and remove

the room cover.

3. Connect the thermostat wiring per the appropriate

diagram/colors for your model.

4. Plug the unit back in or reconnect power.

5. Press the Aux Set button once. The letters AU will

appear in the display.

6. Press the mode button until the number “6” appears

in the left hand digit.

7. Press the up arrow once so the top half of the right

hand digit is lit.

8. Press the Aux Set button to exit the setup function.

9. Replace the room cover.

Cooling and Heating

Single-Stage Cooling –

2-Stage Heating

5

6

See pages 12 and 13 for full instructions on using the

Auxiliary Controls Feature.

17

Page 18

Heat Pumps and Energy Savings

• GEZoneline® heat pumps are designed to provide

cost-efficient heat pump operation while monitoring

room conditions to maintain comfort.

The units employ a logic system monitoring both outdoor

and indoor temperatures to determine the heat source, thus

increasing energy savings by operating longer in the heat

pump mode.

Heat pumps save energy and cost less to operate than

units with electric resistance heaters as the only heat source.

Just as the EER of an air conditioner is an indication of the

efficiency of the unit, COP (Coefficient of Performance) is the

indication of the efficiency of the heat pump. This relative

efficiency of a heat pump compares the unit to electric

resistance heat. If a unit has a COP of 3.0, it means the

unit will produce three times as much heat at rating

conditions for the same electrical input wattage used

for electric resistance heat.

The compressor is used in heat pump operation just as

in air conditioning operation. In heat pump operation,

the hot refrigerant gas is directed to the indoor coil rather

than to the outdoor coil. Room air that circulates over the

indoor coil gains heat from the coil rather than losing heat

to the coil as during cooling operation.

As the outdoor temperature falls, the heat pump is able to

extract less heat from the outdoor air to raise the temperature

of the indoor air. For this reason, all packaged terminal heat

pumps also have electric resistance heaters as backup to heat

pump operation. At some point, the heat pump is unable to

provide sufficient heat to adequately warm the room. Many

Packaged Terminal Heat Pumps cease heat pump operation

and change to more expensive resistance heat at some

pre-determined outdoor temperature to compensate for

the inability of the heat pump to maintain room temperature.

This point, called the “switchover point,” is usually at an outdoor

temperature where savings from heat pump operation may

still be realized if the unit is designed to maintain room comfort

at the lower outdoor temperatures.

Balance Point

An important consideration in the selection of a heat pump

unit is the “balance point” of the installation. Virtually every

room is unique—with different insulation, different sizes

and types of windows, different types of construction,

different directional exposures. All these variables, as well

as geographical location, must be considered in order to

determine the balance point, the point at which the heat pump

is unable to produce enough heat to compensate for the heat

loss of the room or area being heated. For these reasons a

consulting engineer should be engaged to calculate the heat

loss and specify the heat pump unit required.

GE offers the 6100 series of Zoneline heat pump units—with

highly featured microprocessor controls—react to the

indoor temperature as well as the outdoor temperature in

determining the heat source to provide comfortable room

conditions and energy savings. This determination of the heat

source based on the indoor temperature helps provide a more

comfortable room.

18

Page 19

Heat Pumps and Energy Savings

geappliances.com

Heat Pump Operation — Zoneline 6100 Series

Heat sources: Heat pump, heat pump and simultaneous

electric resistance heat or electric resistance heat.

Zoneline heat pumps employ a highly featured microprocessor

control system interfaced with thermistors to accurately

measure indoor air temperature, outdoor air temperature,

indoor coil temperature and outdoor coil temperature. This

system allows the microprocessor to precisely and predictably

react to changing conditions in order to provide a very

advanced packaged terminal heat pump operating system.

The Zoneline heat pumps are designed to help ensure a

comfortable room. When “HEAT” is selected, the unit will

determine if the room air is warm enough to satisfy the

thermostat setting. If the temperature at the unit sensor

is below the desired temperature, the electric resistance

heater will be utilized to warm the room to the point where

the thermostat is satisfied. This feature is designed to allow

the temperature of an unoccupied room to be maintained

at an energy-saving level without inconveniencing the room

occupant. Once the thermostat has been satisfied, the

resistance heater will turn off and the heat pump will operate

as shown in the Heat Source Logic chart until the thermostat

calls for heat again. The unit will operate in this manner even

if connected to a Central Desk Control.

Zoneline Heat Pump Heat Source Logic

ROOM

TEMPERATURE

VS. THERMOSTAT

SET POINT

Less Than

1.8°F Below

1.8°F to 2.7°F

Below

More than 2.7°F

Below

Above

46°F

Heat Pump Heat Pump*

Heat Pump

Heat Pump

Between 46°F

and 25°F

Heat Pump +

Supplemental

Heater

Full Resistance

Heat

Below

25°F

Full Resistance

Heat

Full Resistance

Heat

Full Resistance

Heat

An option is provided in the auxiliary controls (Mode 8) to

allow the unit to operate only in resistance heat. The use of

this option significantly increases the cost for heating.

Heat pump defrost — Zoneline 6100 Series

Zoneline heat pumps utilize a reverse-cycle demand defrost

system to extend heat pump operation and increase

savings from extended operation. The microprocessor

determines the need for defrosting by criteria based

on continuous compressor running time, outdoor air

temperature, outdoor coil temperature and the rate of

temperature change of the outdoor coil. When defrosting

is required, the unit reverses the flow of refrigerant to direct

the hot gas into the outdoor coil to melt the frost buildup.

Before and after the reverse-cycle defrosting, the unit shuts

off the compressor to allow the refrigerant pressures

to equalize throughout the system. This eliminates the

possibility of a loud reversing noise. During these periods

of pressure equalization, the full resistance heat capacity

of the unit is activated to help ensure room comfort

conditions during the defrost cycle. The unit remains in

the defrost cycle for a minimum of two minutes up to a

maximum of nine minutes. The defrost cycle terminates

when the outdoor coil reaches a temperature of 68°F or

the maximum time has been reached.

Heat pump condensate

See page 34 for information on heat pump condensate.

The Zoneline 6100 Series heat pumps may be ordered with

a factory-installed Internal Condensate Removal (ICR) system

to minimize the amount of condensate water draining from

the unit during heat pump operation. The ICR system has

proven to be an effective means of minimizing the amount of

heat pump condensate dripping from the unit. However, if the

requirements of a particular installation will allow no dripping

of condensate water from the wall case, the installation of an

internal or external drain system is recommended.

Units with ICR may not be installed in seacoast or corrosive

environment applications.

The Boost Heat option utilizes the supplemental

simultaneous heater at the same time as heat pump

operation when the outdoor temperature is below 46°F

regardless of the indoor air temperature**. The chart above

indicates the heat source of the heat pump under various

indoor and outdoor conditions. The unit is designed to

provide heat pump savings without sacrificing room comfort.

TheQuickHeatRecoveryfeatureisnotaffectedbytheHeat

Source Logic shown in the chart below. For more information

abouttheQuickHeatRecoveryFeature,seepage9.The

full heat output of the resistance heater is dependent upon

circuit amperage and the power connection kit used. See

pages 3 and 42–43 for information on power connection kits

and available heater capacities.

* If the Boost Heat switch (auxiliary setting #9) is “ON”, the supplemental

simultaneous heater will be used with heat pump operation.

Simultaneous supplemental heater: 1.0 KW @ 230 V; 0.8 KW @ 208V;

1.0 KW @ 265V.

** Boost Heat option only applies to systems controlled at the unit. Boost Heat

option should NOT be used with remote thermostat operation since this will

cause the unit to switch to resistance heat when outdoor temperatures are

below 46°F.

19

Page 20

OVER 40 FT.

CORRECT

Application Comments

OVER 40 FT.

INCORRECT

Use and Care Manual and installation instructions are

shipped with Zoneline® units. It is important that any air

conditioning system be properly sized and applied in order

to achieve the desired temperature and humidity levels in

the space to be conditioned. Zoneline units are designed

primarily to provide heating and cooling with the additional

benefit that during operation in the cooling mode, the units

also remove some moisture from the conditioned space.

The following are some brief application comments on

undersizing, oversizing, heating, wall coverings, and air

infiltration: all are important in the proper matching of the

heating/air conditioning system to the building structure.

Undersizing: If an air conditioner is undersized (cooling

capacity is less than required for a specific application), the

unit will typically not be able to cool the space down to the

desired temperature (thermostat set point), nor be able to

remove enough moisture from the air. A result could be a

warm and humid or warm and dry conditioned space.

Oversizing: If an air conditioner is oversized (cooling capacity

is greater than required for the specific application), the unit

will typically cool the space down to the desired temperature

(thermostat set point) too quickly. The compressor then

begins to cycle on and off. Dehumidification only takes place

when the compressor is operating. A typical result in a hot/

humid climate could be a cool but excessively humid space.

Heating: Undersizing can result in not being able to maintain

the desired temperature level within the conditioned space.

Wall Covering: Use of a non-permeable wall covering (some

paints, some wallpapers, and other types of coverings) which

severely restricts passage of air or water vapor can cause a

severe moisture problem. Typical results could be staining of

room surfaces, wall damage, as well as mold and mildew

growth in hot/humid climates.

Air Infiltration: Excessive air infiltration can magnify

problems associated with undersizing or oversizing of an

air conditioner unit and can be the root cause of insufficient

cooling, dehumidification, or heating. Some sources of air

infiltration include vents, gaps around windows and doors,

and improperly sealed floor, ceiling and wall joints.

Recommendation: For the above reasons it is strongly

recommended that a professional engineer be retained

to match the Zoneline unit with the building structure.

High Wall Mount — For units

mounted high in the wall, the

discharge louvers should be

at a setting that provides the

most horizontal air discharge.

Recommended installation is

at least 3" below the ceiling. In

installations where units are close to the ceiling, the greatest

horizontal discharge angle can be obtained by removing

the discharge grille from the room cabinet.

Supply Air Throw — One Zoneline unit should not be required

to do a job obviously requiring two or more units. Units

should be located around large rooms according to

calculated loads or in such fashion as to achieve balanced

air distribution in all parts of the room. The single unit in

the “Incorrect” illustration below obviously cannot condition

the entire room. Add a second unit as shown in the

“Correct” illustration.

Air Distribution

Zoneline packaged terminal air conditioners and heat pumps

discharge air from the top of the unit through reversible

two-position discharge louvers. Unit discharge louvers are

reversed by removing the room cabinet from the unit,

removing seven screws that hold the louver section in

place, removing the louver section and rotating it end for

end, reinstalling the louver section in the room cabinet with

the seven screws, and reinstalling the room cabinet on the

unit. The unit is shipped from the factory with the discharge

louvers at an angle of 50° off vertical. In the alternate

position, the louvers will be at an angle of 40° off vertical.

All room cabinets return air through the front of the unit.

20

50°

40°

Page 21

Dimensions

RAB71A WALL CASE

16"

geappliances.com

Additional

Wall Case Depths

42"

A

13-

3/4"

1-1/2" TYP

1/2" SQ. HOLE (2 REQ'D.)

1/2"

2-3/4"

5-5/8"

RAB7116 - 16"

RAB7124 - 24"

RAB7128 - 28"

RAB7131 - 31"

4"

WALL OPENING

16-1/4" MIN. x 42-1/4" MIN.

RAB77 WALL CASE

WALL OPENING

16-1/2" MIN. x 42-3/8" MIN.

WALL CASE WITH

CHASSIS INSTALLED

13-7/8"

16-1/4"

RAB71 = 13-3/4"

RAB77 = 13-7/8"

1-1/2"

36"

1/2" SQ. HOLE

(2 REQ'D.)

36"

RAB71 = 42"

RAB77 = 42-1/8"

TOP VIEW

21"

19"

6"

6"

42-1/8"

9/16"

GRILLE

INSIDE

1/2" DIA.

HOLE (3 REQ'D.)

2-7/8"

1/2" DIA.

(3 REQ'D.)

RAB71 = 20-7/8"

RAB77 = 21"

7-1/8"

5-5/8"

4"

SIDE

VIEW

GRILLE

RAB71 = 16"

RAB77 = 16-1/4"

OUTSIDE

42"

ROOM

CABINET

ROOM

CABINET

WALL CASE WITH

SUB-BASE

3-1/2"

*SHOWN WITH ACCESS COVERS REMOVED.

NOTE: CAUTION - REMOVE KNOCKOUTS FROM INSIDE OUT.

12-3/4" 12" 9-3/8"

FRONT VIEW*

13"

KNOCKOUTS (ENCLOSURE)

4 REAR; 4 BOTTOM

SEE PAGE 32 FOR KNOCKOUT LOCATION DIMENSIONS.

LEVELING SCREW

1-7/16"

2-1/2"

3" MIN.

ADJUSTABLE

TO 5" MAX.

1-5/16"

Installation instructions packed with wall case. See page 25 for additional information concerning outdoor

weather panel and case stiffener.

SIDE VIEW

FINISHED FLOOR

2-3/8" MIN.

INTERIOR

WALL

21

Page 22

Wall Case

A choice of wall cases is available for Zoneline® units.

RAB71A — This insulated case is constructed of heavy-

gauge galvanized steel and finished with a baked-enamel

finish for protection and appearance. Design of the case

provides for support of the chassis and free draining of any

water entering the wall case. A petroleum microcrystalline

wax is applied at critical points of fabrication to seal against

moisture. The dimensions of the RAB71A wall case are 42"

wide by 16" high by 13-3/4" deep, the same dimensions as

the original wall case for GE Zoneline units built in 1961. The

RAB71A wall case is also available in depths other than the

standard depth. It is available on special order as: RAB7116

– 16" deep; RAB7124 – 24" deep; RAB7128 – 28" deep; and

RAB7131 – 31" deep. All these special-order deep wall cases

are insulated and have sheet-metal dividers, or splitters, to

prevent the recirculation of condenser discharge air.

RAB77 — This non-insulated wall case is molded from

fiberglass-reinforced polyester compound. This SMC

(Sheet-Molded Compound) wall case offers outstanding

strength, durability, color retention, water integrity and

corrosion resistance. The dimensions of the RAB77 wall

case are 42-1/8" wide by 16-1/4" high by 13-7/8" deep.

• Bothwallcasesareofuniversaldesign,acceptingall

Zoneline chassis of current design as well as all GE Zoneline

chassis produced since 1961.

• Drainholesareprovidedintherearofthewallcaseto

permit excessive cooling condensate water, heat pump

condensate or precipitation entering the wall case to drain

freely. A drain kit may be connected to the wall case to

control any water draining from the wall case. See page

35 for information on RAD10 Drain Kit.

RAK901L — For installations where the wall case extends into

room, RAK901L is an insulation kit that can be used with the

RAB77 or any existing non-insulated wall case to minimize

the possibility of condensation forming on the indoor side of

the case during the winter.

Sub-Base

The sub-base is an optional accessory for the Zoneline unit

and is presented with the wall case information since the

decision to use or not use a sub-base in the installation

is a factor in the location of the wall opening for the unit.

National Electrical Code® requires that air conditioning units

connected to voltages in excess of 250 volts be “permanently

connected.” There are also some installations where units

connected to voltage sources under 250 volts may also

need to be “permanently connected.” If you are in doubt

about the requirements for a particular installation, consult

Article 440 of the NEC or the local electrical inspector. These

requirements are designed to protect personal safety and

should be strictly followed. Although NEC is cited here as a

reference, all electrical wiring and installations must conform

to any and all local electrical codes and regulations.

“Permanent connection” generally means wiring to the unit

must be contained in an enclosed “chaseway,” where access

to the wiring connections is more restrictive than a normal

line cord plugged into a receptacle. NEC requirements may

be met by using flexible or rigid conduit to contain the wiring

between the unit and a junction box that contains the wiring

connections. The conduit is connected to the unit and to the

junction box with connectors to hold the conduit in place.

The junction box may be located in the floor or the wall of the

structure but only approved connectors may be used outside

the unit or the junction box. The sub-base is UL® listed as a

junction box for permanent connection of a Zoneline unit.

Using a sub-base in an installation requiring permanent

connection provides a convenient, consistent location for

unit wiring to be connected to building wiring. The use of

a sub-base is not required, but the convenience and the

improved aesthetics it offers makes the use of a sub-base

a viable means of permanent connection.

RAK204U — The RAK204U Series of sub-bases provides a

variety of designs that fit the site needs and are available

for use with Zoneline PTAC/PTHP units. The RAK204U will

most likely be used for support of the wall case and unit.

The RAK204U is the same physically as the other sub-bases

except there is no receptacle installed. Receptacles and

wiring can be field installed and, by using the RAK205CW

chaseway and the RAK4002A junction box perform the same

function as any of the other sub-base kits by selecting the

correct receptacle and installing it in the interior mounting

plate inside the RAK204U.

208/230-volt receptacles can also be mounted in the cover

plate for easy access when direct connect wiring is not

required. 265-volt units are to be “Permanently (or Direct)

Connected” and the external receptacle (when wiring is not

enclosed in a chaseway) does not meet this requirement.

A knockout for a fuseholder or a disconnect is also provided

in the cover plate.

RAK204U — No receptacle, no wiring; will accept any

15-, 20-, 30-amp receptacle and wiring. No chaseway is

included. RAK205CW chaseway must be ordered separately.

The 230/208-volt sub-bases below include a short,

sub-base power connection kit. Since sub-base connected

units are not considered to be line-cord connected, a

Leakage Current Detection and Interruption or Arc Fault

Current Interrupter device is not necessary.

The junction box (RAK4002A for 4100 and 6100 Series

units) that mounts on the chassis of 230/208-volt sub-base

connected units must be purchased separately.

RAK204D15P 208/230-volt 15-amp receptacle. Receptacle

is NEMA6-20R with 18" of #12AWG wires attached to

the receptacle. Short power connection kit included.

Chaseway included.

RAK204D20P 208/230-volt 20-amp receptacle. Receptacle

is NEMA6-20R with 18" of #12AWG wires attached to

the receptacle. Short power connection kit included.

Chaseway included.

22

Page 23

Sub-Base (Continued)

geappliances.com

RAK204D30P 208/230 volt 30-amp receptacle. Receptacle

is NEMA6-30R with 18" of #12AWG wires attached to the

receptacle. Short power connection kit included.

Chaseway included.

The junction box (RAK4002A for 4100 and 6100 Series

units) that mounts on the chassis of 230/208 volt sub-base

connected units must be purchased separately.

Sub-bases for the 265-volt units:

RAK204E15 265-volt 15-amp receptacle. Receptacle is

NEMA7-15R with 18" of #12AWG wires attached to the

receptacle. Chaseway included.

RAK204E20 265-volt 20-amp receptacle. Receptacle is

NEMA7-20R with 18" of #12AWG wires attached to the

receptacle. Chaseway included.

RAK204E30 265-volt 30-amp receptacle. Receptacle is

NEMA7-30R with 18" of #12AWG wires attached to the

receptacle. Chaseway included.

The junction box for 265-volt units is shipped with the

chassis since all 265-volt units are to be “permanently

(or direct) connected.”

The power connection kit is not included

There are separate internal compartments to permit

separation of low-voltage (Class 2) connections from linevoltage connections as required by NEC. Conduit containing

building wiring enters the sub-base through knockouts

located in the rear or bottom of the sub-base and is not

accessible when the wall case is installed.

The sub-base attaches to the RAB71 wall case with two clips

(field-assembled) that are screwed into pre-drilled holes in the

bottom front flange of the wall case. It attaches to the RAB77

wall case with clips that fit over molded ribs without requiring

the use of screws into the wall case. See page 33 for illustration.

Since the sub-base extends under the wall case, clearance

from the inner edge of the wall case to the finished wall must

be 2-3/8" or greater. The sub-base has four leveling legs and

adjustable side channels to enable the area under the wall

case to be enclosed. Clearance from the bottom edge of the

wall case to the finished floor must be between 3" and 5".

The sub-base may be used as support for the chassis and

wall case in installations where the wall is of insufficient

thickness to provide secure mounting of the wall case.

Wall Case Installation Data

General

of installation. The unit may be installed high in the wall and

these installations usually require a remote thermostat and

are discussed on pages 15 and 16.

Regardless of the installation, there are several things to

consider when selecting a location for installing the unit.

For instance, drapery location could interfere with air

discharge, and placement of furniture may have an impact

on the performance of the unit. The following information

is intended to minimize installation problems and assure

you of trouble-free installation.

Refer to page 21 for required wall opening dimensions.

Minimum recommended interior and exterior case projections

for standard wall thicknesses are shown in the drawings in

this manual. The case may be installed flush with the finished

indoor wall. Special attention must be paid to room-side case

projection when the unit is installed in a ducted application

as shown on pages 38 and 39.

In walls thicker than 13-1/2" for line-cord-connected units

and 11-1/8" for sub-base installations, it may be necessary

to install a field-fabricated case extension or use one of the

special- order RAB71 deep wall cases. Such extensions must

be carefully flashed and sealed both to the wall case and to

the wall to ensure water integrity. This is necessary to ensure

that any water entering the wall case, either from operation

of the unit or from other sources, such as rain storms or from

washing the exterior of the building, will drain from the case

without the possibility of capillary action drawing the water

into either the room or the wall cavity. In an installation where

the case is recessed less than 3" from the outside surface,

flashing and sealing may be all the modification necessary.

In such an installation, the sides and top of the wall opening

must be waterproof to prevent moisture from seeping into

and damaging the walls. See pages 30 and 31 for suggested

detail. Since the installation of a case extension requires a

considerable amount of attention, we recommend using

one of the deep wall cases if the standard case is not of

sufficient depth.

Mounting an outdoor grille or louver section to the building

face may cause a space between the outdoor coil and the

louver section. Air splitters, aligned with the ends of the

outdoor coil, must be installed between the outdoor coil inlet

and outlet air streams. Gaps between the outdoor coil and

the louver section may allow condenser air recirculation and

affect the operation of the unit. See page 41 for requirements

for custom louvers.

Generally, Zoneline units are installed 3" to 5" above the

floor (flush to finished floor installation is possible) as near

to the center of the room as possible; underneath a window

or a glass panel is typical. Normal installation of the wall

case allows installation flexibility; from flush with the

finished interior wall to a minimum of 1/4" of the wall case

extending beyond the finished exterior of the building. Special

consideration must be given to installations where the wall

case does not extend a minimum of 1/4" beyond the finished

exterior wall. See pages 30 and 31 for information on this type

The wall case should be level from side to side and

from level to 1/4 bubble tilt to the outdoors. The

condensate disposal system in the unit is designed

to dissipate the condensate water generated

during cooling operation in accordance with ARI

standards and actually uses this water for maximum

unit efficiency. A level unit will also ensure proper

performance of the Internal Condensate Removal (ICR)

system optional on heat pump units.

23

Page 24