Page 1

GXSS17Z01

GE Appliances

Water Softening System

Part No. 215C1044P003–1 Pub. No. 49-50007–1

8–98 CG

7196674

Installation and

Owner’s Manual

GE Answer Center ®800.626.2000

Page 2

Congratulations!

You are Now Part of the GE Family.

Safety Information

. . . . . . . . . . . . . 3

Installation Instructions

. . . .4–11

Important Recommendations . . . . . . . . . . . .4

Tools/Materials Required . . . . . . . . . . . . . . .5

Step-by-Step Instructions . . . . . . . . . . .7–11

Drain Connections . . . . . . . . . . . . . . . . . . .8

Sanitize . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Program the Timer . . . . . . . . . . . . . . . . . .10

Specifications/Dimensions . . . . . . . . . . .11

Troubleshooting Tips

Before You Call For Service

. . . . . . . . . . . . .18

Operating Instructions

. . . .12–17

About the System . . . . . . . . . . . . . . . . . . .12

Service . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Water Bypass . . . . . . . . . . . . . . . . . . . . .12

Breaking a Salt Bridge . . . . . . . . . . . . . .13

Cleaning the Nozzle

and Venturi Assembly . . . . . . . . . . . . . . .14

Features . . . . . . . . . . . . . . . . . . . . . . . . . .15

Regeneration . . . . . . . . . . . . . . . . . . . .16, 17

Customer Service

Product Registration . . . . . . . . . . . . . . .19, 20

Parts List . . . . . . . . . . . . . . . . . . . . . . .21–24

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . .27

Service Telephone Numbers . . . . . . . . . . .28

2

Welcome to the GE family. We’re proud of our quality products and we are

committed to providing dependable service. You’ll see it in this easy-to-use Owner’s

Manual and you’ll hear it in the friendly voices of our customer service department.

Best of all, you’ll experience these values each time you use the water system. That’s

important, because your new system will be part of your family for many years. And

we hope you will be part of ours for a long time to come.

We thank you for buying GE. We appreciate your purchase, and hope you will

continue to rely on us whenever you need quality appliances for your home.

FOR YOUR RECORDS

Write the model and serial numbers here:

#

#

You can find them on the sump bracket.

Staple sales slip or cancelled check here.

Proof of the original purchase date is needed to obtain service under

the warranty.

Inside you will find many helpful hints on how to use and maintain

your water system properly. Just a little preventive care on your part

can save you a great deal of time and money over the life of your

system. A video has been included with the product containing

important use and care instructions.

You’ll find many answers to common problems in the

Before You Call

For Service

section. If you review our chart of

Troubleshooting Tips

first,

you may not need to call for service at all.

READ THIS MANUAL

IF YOU NEED SERVICE

If you do need service, you can relax knowing help is only a phone

call away. A list of toll-free customer service numbers is included in

the back section.

IMPORT ANT!

Fill out and return the Consumer Product Registration Card that is

packed with this product. If you cannot find it, please send in the

duplicate card printed in the back of this manual.

Customer Service Troubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

Page 3

3

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of

electric shock, property damage or personal injury.

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

SAFETY PRECAUTIONS

■ Check and comply with your state and local

codes. You must follow these guidelines.

■Use care when handling the water softening

system. Do not turn upside down, drop, drag,

or set on sharp protrusions.

■Water softening systems using sodium chloride

(salt) for regeneration add sodium to the water.

Persons on sodium restricted diets should consider

the added sodium as part of their overall intake.

Potassium chloride can be used as an alternative to

sodium chloride.

■

The water softening system works on 24 volt-60 Hz

electrical power only.

Be sure to use only the

included transformer.

■Keep the salt hole cover in place on the softener

unless servicing the unit or refilling with salt.

WARNING:

Do not

use with water that is

microbiologically unsafe or of unknown quality

without adequate disinfection before or after the

system.

Read and follow this Safety Information carefully.

SA VE THESE INSTRUCTIONS

PROPER INSTALLATION

■Install or store where it will not be exposed to

temperatures below freezing or exposed to any

type of weather. Water freezing in the system will

break it. Do not attempt to treat water over 100°F.

■

Do not

install in direct sunlight. Excessive sun heat

may cause distortion or other damage to nonmetallic parts.

■Properly ground to conform with all governing

codes and ordinances.

■Use only

lead-free solder and flux

for all sweatsolder connections, as required by state and

federal codes.

■

Maximum allowable inlet water pressure is 125 psi.

If daytime pressure is over 80 psi, nighttime

pressure may exceed the maximum. Use a pressure

reducing valve to reduce the flow if necessary.

WARNING:

Discard all unused parts and

packaging material after installation. Small parts

remaining after the installation could be a choke

hazard.

This water softening system must be properly installed and located in accordance with the Installation

Instructions before it is used.

Page 4

Read entire manual. Failure to follow all guidelines and rules could cause personal injury or property

damage.

•Before you begin installation, read these Installation Instructions completely. Then, obtain all the

materials and tools you will need to make the installation. Failure to properly install the softener

voids the warranty.

•Check local codes. The installation must conform to them.

•Use only lead-free solder and flux for all sweat-solder connections, as required by state and federal

codes.

•Connect the softener to the main water supply pipe

before

or

ahead of the

water heater.

DO NOT RUN

HOT WATER THROUGH THE SOFTENER.

Temperature of water passing through the softener must be

less than 120° F.

•Use care when handling the softener. Do not turn upside down, drop, drag, or set on sharp

protrusions.

•Maximum allowable inlet water pressure is 125 psi. If daytime pressure is over 80 psi, nighttime

pressure may exceed the maximum. Use a pressure reducing valve if necessary. (Adding a pressure

reducing valve may reduce the flow.)

•The softener works on 24 volt-60 Hz electrical power only. Be sure to use the included transformer.

Be sure the electric outlet and transformer are in an inside location to protect from wet weather.

•See

Where to Install the Softener

section for more details.

WARNING:

Do not use with water that is microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system. The water should be tested periodically to

verify that the system is performing satisfactorily.

Small parts remaining after the installation could be a choke hazard. Discard safely.

4

Installation instructions.

Customer Service Troubleshooting Tips

Operating Instructions

Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Safety Instructions

Installation Instructions

CAUTION:

Certain plumbing skills are needed for installation. If you are unsure about any part

of the installation of this product, consult a professional plumber.

Unpacking and Inspection

The softener is shipped in one master carton. The softener is completely assembled at the factory,

except as required at installation.

Be sure to check the entire softener for any shipping damage or parts loss. Also note damage to the

shipping cartons. Contact the transportation company for all damage and loss claims. The

manufacturer is not responsible for damages in transit.

Small parts, needed to install the softener, are on a skin-packed cardboard piece. To avoid loss of the

small parts, keep them on the skin-pack until you are ready to use them.

Important Installation Recommendations

Page 5

5

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

•Place the softener as close as possible to a sewer drain, or other acceptable drain point or standpipe.

•It is recommended to keep outside faucets on hard water to save soft water and salt.

•Do not install the softener in a place where it could freeze.

Freeze damage is not covered by the warranty.

•Do not install the softener where it would block access to the water heater or access to the main water

shutoff.

•Put the softener in a place where water damage is least likely to occur if a leak develops. The

manufacturer will not repair or pay for water damage.

•A 120 volt electric outlet is needed to plug in the included transformer. The softener has a 10 foot

power cable. If the outlet is remote (up to 100 feet), use 18 gauge wire to connect.

Be sure the

electric outlet and transformer are in an inside location, to protect from wet weather.

Be sure the outlet

is unswitched to prevent accidental shutoff.

•If installing in an outside location, you must take the steps necessary to assure the softener,

installation plumbing, wiring, etc., are as well protected from the elements (sunlight, rain, wind,

heat, cold), contamination, vandalism, etc., as when installed indoors.

•

Keep the softener out of direct sunlight.

The sun’s heat may distort non-metallic parts and may damage

the electronics.

Where to Install the Softener

•In and out pipes to the softener must be at least 3/4″size. Some local codes require a minimum of

1″pipe size. To plumb with 1″pipes, buy adapters to fit the 1″pipe threads on the bypass valve (see

Fig. 1 and Fig. 2).

• Use copper, brass or galvanized pipe and fittings. Some codes may also allow CPVC plastic pipes.

• Use the included bypass valve to install the softener. The bypass valve allows you to turn off water to

the softener for servicing, but still have water in the house pipes.

• Drain hose is needed for valve and salt tank drains. A 20′length of drain tubing is included. If a

longer length is needed, it can be ordered from GE Parts at 800.626.2002.

• If a rigid valve drain is needed to comply with plumbing codes, you can buy the parts needed (Fig. 4A)

to connect a 1/2″copper tubing or plastic pipe drain.

• Clean nugget or pellet water softener salt is needed to fill the brine tank, see

Step 9.

in the

Step-by-

Step Installation Instructions.

Tools and Materials Required for Installation

You must first decide how to run in and out pipes to the softener. Look at the house main water pipe

at the point where you will connect the softener. Is the pipe soldered copper, glued plastic, or

threaded galvanized? What is the pipe size?

WARNING:

Use only lead-free solder and flux to prevent lead poisoning.

See

T ypical Installation Illustration,

Fig.1. Use this as a guide when planning your particular installation.

Be sure to direct the incoming hard water supply to the softener valve inlet fitting.

The valve

is marked INand

OUT.

See below to help you prepare.

NOTE:

The state of Massachusetts requires a licensed plumber to perform the installation.

Plan How You Will Install the Softener

Page 6

Installation instructions.

Customer Service Troubleshooting Tips

Installation Instructions

Safety InstructionsCustomer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

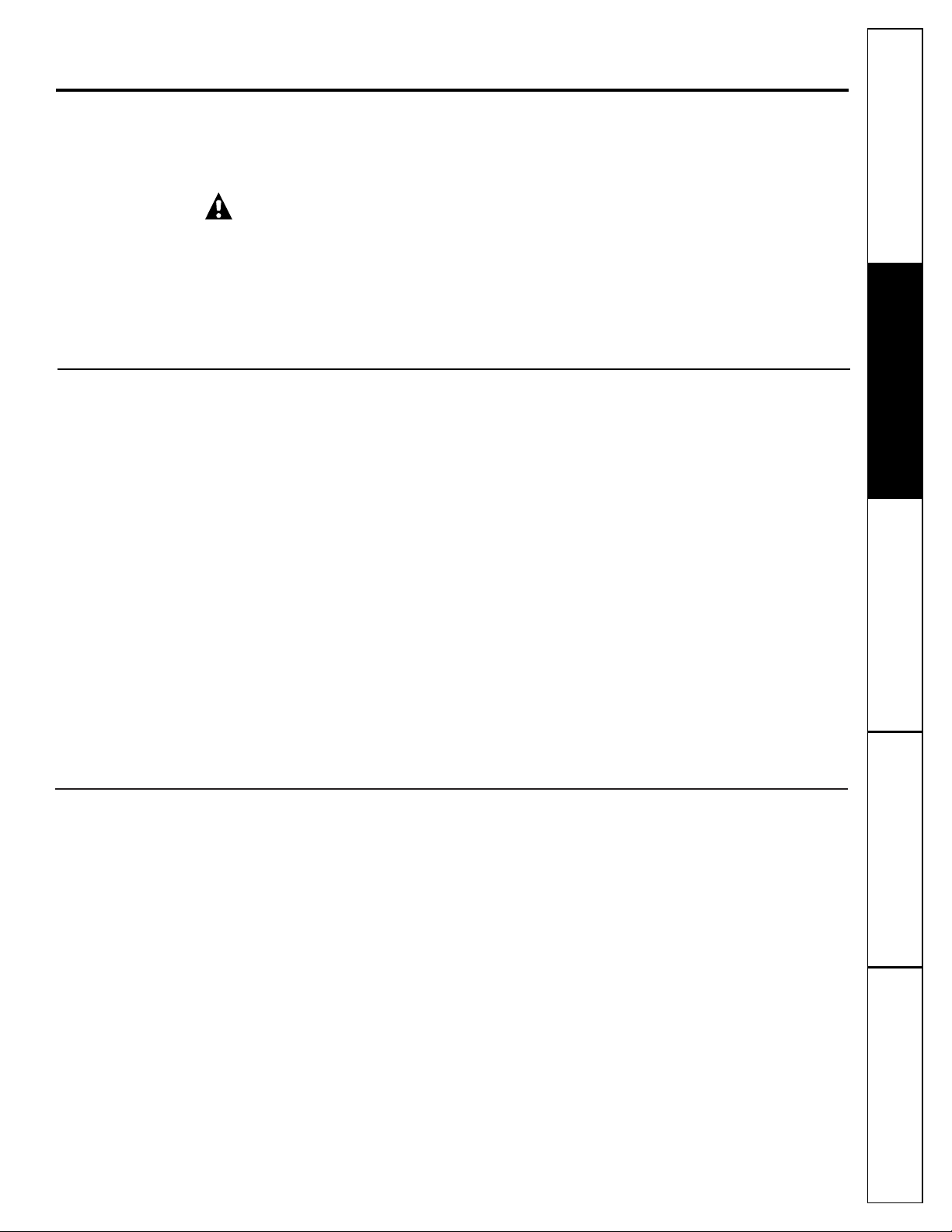

Typical Installation Illustration

Fig 1.

Optional 3-Valve Bypass Installation Illustration

Fig 2.

6

Adapters for this installation are not supplied with the softener. To order these adapters, call

GE Parts 800.626.2000.

Soft water

Hard water to

outside faucets

MAIN WATER PIPE

Hard water

Installation nut (2)

Copper tube, 3/4″(2)

Washer (2)

Bypass Valve

• Pull out for service

• Push in for bypass

NOTE:

Threads on the bypass

valve are 1″ male pipe. If 1″

pipes are needed, do not use the

copper tubes and nuts included.

Buy adapters and plumb directly

to the 1″ threads.

INLET

Brinewell

NOTE:

See

Drain Hose

Connections

section.

SALT

GOES HERE

Salt hole

cover

removed

24V transformer

120-volt outlet

Hard water

Soft water

From softener outlet

To softener inlet

CROSS-OVER

Use if water supply flows from the left.

Include single or 3-valve bypass.

Hard water

Soft water

From softener outlet

To softener inlet

CROSS-OVER

Use if water supply flows from the left.

Include single or 3-valve bypass.

MAIN WATER PIPE

Soft water

Hard water

Copper tube, 3/4″ (2)

Washer (2)

Installation adapter (2)

INLET

NOTE:

Threads on the installation adapters are 1″ male pipe.

If 1″ pipes are needed, do not use the copper tubes and nuts

included. Buy adapters and plumb directly to the 1″ threads.

24V transformer

120-volt outlet

Bypass valve

Hard water to outside faucets

Inlet valve

Outlet valve

Nut (2)

3-valve bypass system

For soft water service:

• Open the inlet and outlet valves

• Close the bypass valve

For bypass hard water:

• Close the inlet and outlet valves

• Open the bypass valve

Page 7

Step-by-step installation instructions.

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

7

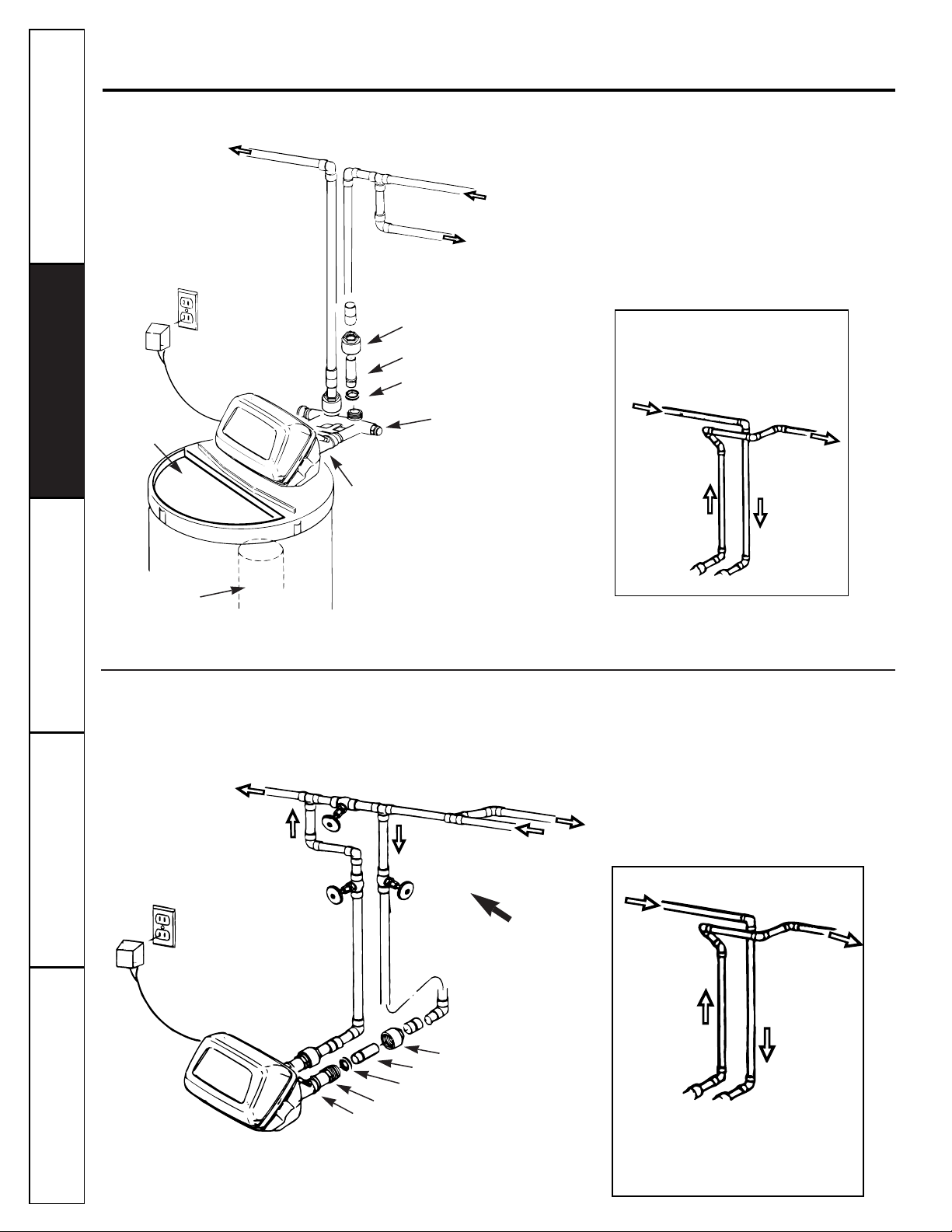

Turn off the water supply to pipes to be cut and drain the

house water pipes. Open both hot and cold faucets.

Install bypass valve:

•Push the bypass valve (lubricate o-ring seals with silicone

grease) into both ports of the valve as shown in Fig. 3A.

•Snap the 2 large plastic clips in place, from the top, down

as shown in Fig. 3A and Fig. 3B. Be sure they snap into

place. Pull on the bypass valve to make sure it is held

securely in place.

Move the softener assembly into installation position:

•Be sure the installation surface is level and smooth. Sharp

objects under the tank may puncture it. If needed, place

the tank on a section of 3/4″thick (minimum) plywood.

Then, place shims under the plywood as needed to level

the softener.

Plumb IN and OUT pipes to and from softener:

CAUTION:

Observe all of the following cautions as you

connect inlet and outlet plumbing.

•Turn off the water heater.

•Be sure incoming hard water supply is directed to the

softener valve inlet port. If house water flow is from the

left, use a plumbing cross-over as shown in Fig. 1.

•If making a soldered copper installation,

do all sweat

soldering before

connecting pipes to the bypass valve.

Torch

heat will damage plastic parts.

•When turning threaded pipe fittings onto plastic fittings,

use care not to cross-thread.

•Use pipe joint compound on all external pipe threads.

•Support inlet and outlet plumbing in some manner (use

pipe hangers) to keep the weight off of the valve fittings.

Install the brine tank overflow fittings:

•Insert the rubber grommet into the 3/4″diameter hole in

the brine tank sidewall as shown in Fig. 5.

•Push the end of the hose adapter elbow into the grommet

as shown in Fig. 5.

4

3

2

1

Fig. 3A.

Fig. 3B.

Fig. 3C.

Fig. 4.

Drain

fitting on

valve

Valve

drain

hose

To sewer drain

IN

OUT

Turn bypass valve upside down to connect

to floor level plumbing

Valve body inlet or

outlet

Bypass valve

(push all the way in)

Clip

END

VIEW

Clip

Outlet

Inlet

O-ring seal goes into the outer groove

only. The clip snaps into the inner

groove (see below).

Bypass valve

NOTE:

Threads on

the valve are 1″

male pipe. If 1″

pipe is needed, buy

adapters and plumb

to the 1″ threads.

SIDE

VIEW

Page 8

Step-by-step installation instructions.

Customer Service Troubleshooting Tips

Installation Instructions

Safety InstructionsCustomer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

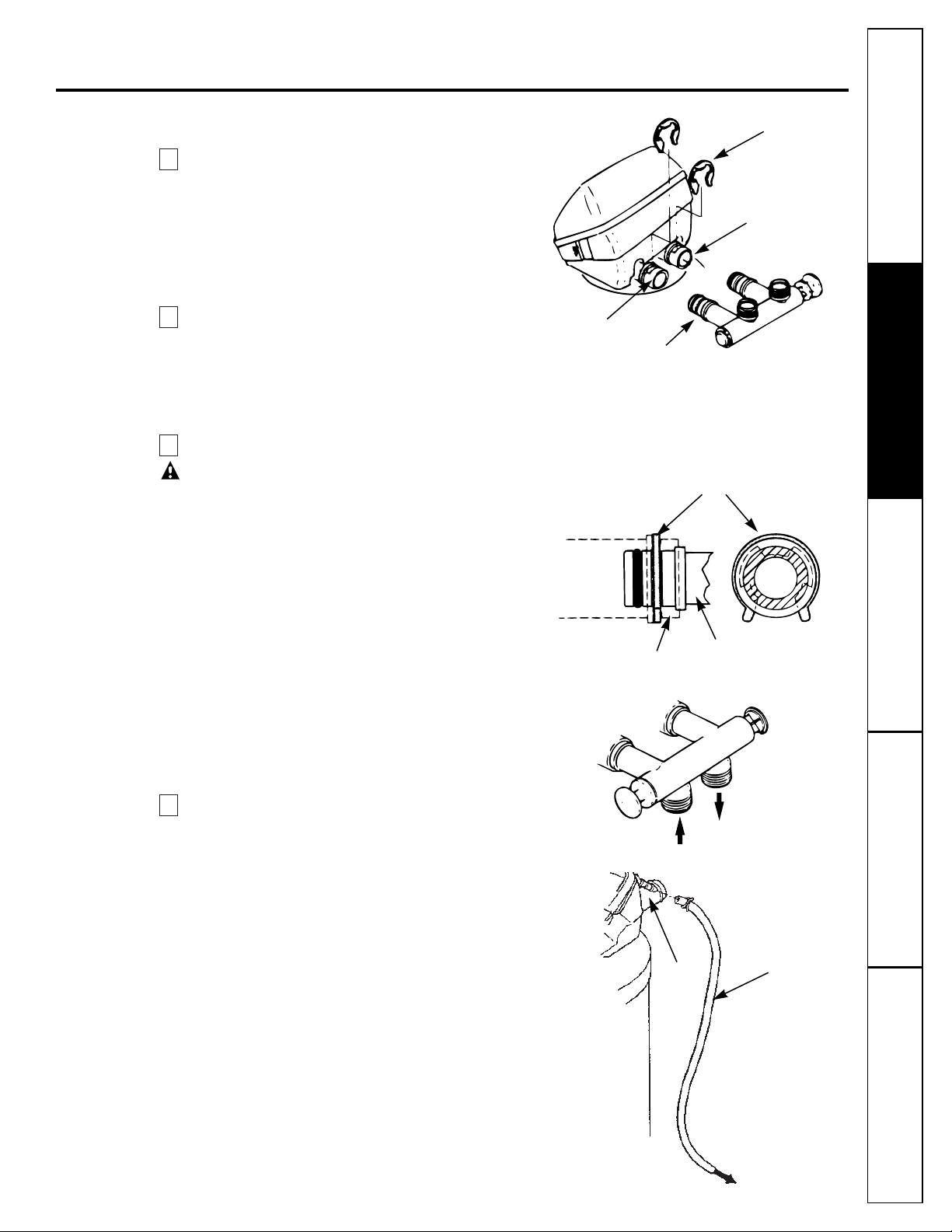

Connect and run the valve drain hose:

•Use the provided drain hose (20′length included) to attach

to the valve drain fitting. To keep water pressure from

blowing the hose off, use a hose clamp to secure in place.

•Locate the other end of the hose at a suitable drain point

(floor drain, sump, laundry tub, etc.) that terminates at the

sewer.

Check and comply with local codes.

IMPORTANT:

If more drain hose is needed, it should be

ordered from GE Parts at 800.626.2002.

The water softener will

not work if water cannot exit this hose during regenerations.

•Tie or wire the hose in place at the drain point. High water

pressure will cause it to whip during the back-wash and fast

rinse cycles of regeneration.

Also provide an air gap of at least

1–1/2″between the end of the hose and the drain point.

An air

gap prevents possible siphoning of sewer water into the

softener, if the sewer should back-up.

•If raising the drain hose overhead is required to get to the

drain point,

do not raise higher than 8´above the floor.

Elevating the hose may cause a back-pressure that could

reduce brine draw during regenerations.

Connect a rigid valve drain tube:

•To adapt a copper drain tube to the softener, use a hacksaw to

cut the barbed end from the drain fitting as shown in Fig. 4A.

Rotate the drain fitting so the cutting blade clears the valve

housing to prevent damage to valve. Buy a compression fitting

(1/4″female pipe thread x 1/2″O.D. tube) and needed

tubing from your local hardware store.

Connect and run the cabinet (brine tank) overflow hose

•

Attach a length of hose (use remaining hose from

Step 5

) to

the drain elbow installed in

Step 4.

Use a hose clamp to hold

it in place.

•

Locate the other end of the hose at the drain point.

DO NOT

ELEVATE

this hose higher than the elbow on the brine tank.

DO NOTTEE

this hose to the valve drain hose.

NOTE:

This drain is for safety only. If the cabinet (brine tank)

should over-fill with water, the excess is carried to the drain.

Install grounding clamps and wire:

DANGER:

Failure to properly attach ground wire could

result in electrical shock.

•If plumbing is metal, to

maintain electrical ground continuity

in the house cold water piping, install the included ground

clamps as shown in Fig. 6. Be sure the pipes are clean under

the clamps to assure good contact.

Flush pipes, expel air from softener, and test your

installation for water leaks:

CAUTION: To avoid water or air pressure damage to softener

inner parts, be sure to do the following steps in exact order.

A.

Fully open 2 cold soft water faucets nearby the softener.

B.

Place bypass valve in bypass position by pushing the stem

inward.

C.

Fully open the house main water pipe shutoff valve. Observe

a steady flow from both faucets opened in

Step A

above.

8

7

6

5A

5

8

Fig. 4A

Fig. 5

Fig. 6

Clamp (2)

Ground

wire

From valve outlet

To valve

inlet

To sewer

drain

Overflow drain hose

Hose clamp

Grommet

Clip

1/4″ NPT threads

Barbs

1/2″ O.D. copper

tube (not furnished)

Cut barbs

from drain

fitting

Compression fitting,

1/4″ NPT X 1/2″O.D.

tube (not furnished)

Page 9

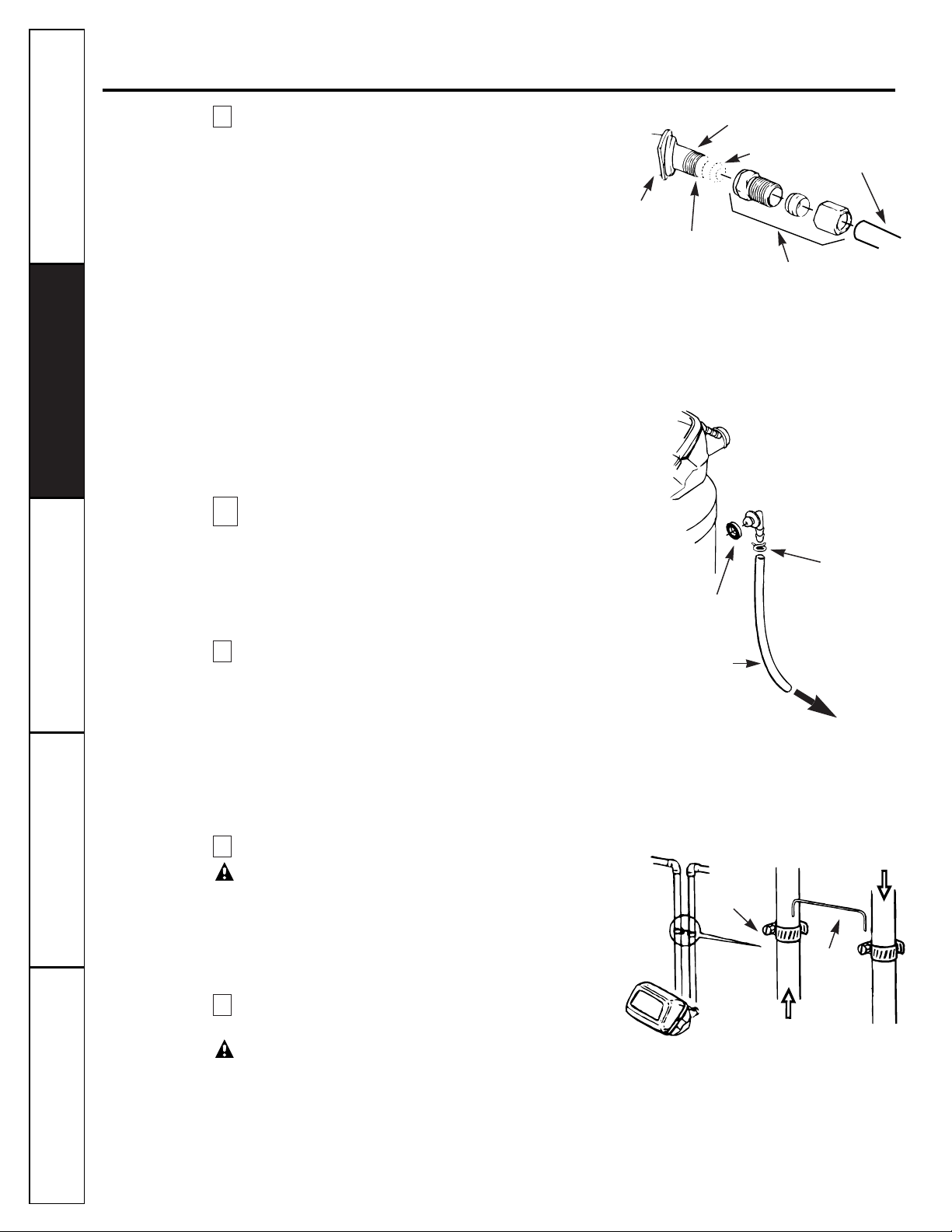

Add water and salt to the brine tank:

•Remove the cabinet (brine tank) cover. Add about 3 gallons of water into the tank. Do not add

into the brinewell.

•Fill tank with

NUGGET, PELLET

or coarse

SOLAR

water softener salt with a purity of 99.5% or higher.

Do not use rock, block, granulated, or ice cream-making salts. Salt storage capacity is

approximately 200 lbs. for model GXSS17. Keep the salt hole cover in place on the softener

unless servicing the unit or refilling with salt.

NOTE:

If the softener is installed in a humid basement or other damp area, it is better to fill the tank

with less salt, more frequently. Eighty to 100 lbs. of salt will last for several months, depending on

water hardness and family size.

Connect to electrical power:

•If transformer wiring is not visible at the back of the control head, remove control cover.

DO NOT

PULL ON OR DISCONNECT WIRING.

Locate the long wire with U shaped connectors on one end.

Route this wire through the rear of the control housing. Replace the control cover.

•Fasten the 2 power cable lugs (U shaped connectors) to the 2 screws on the transformer, and

tighten the screws. Then, plug the transformer into the electrical outlet.

Program the CONTROL.

11

10

9

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

9

D.

Place bypass valve in the service position

EXACTLY

as follows.

KEEP SOFT WATER FAUCETS OPEN.

SLOWLY

pull or slide the valve stem toward service, pausing several times to allow the softener to

pressurize slowly. This initial flow of water may be rusty colored. This is normal and will disappear

quickly.

E.

After about 3 minutes, open a

HOT

water faucet for 1 minute, or until all air is expelled, then close.

F.

Close all water faucets.

G.

Check your plumbing work for leaks and fix right away if any are found. Be sure to observe

previous caution notes.

H.

Turn on the gas or electric supply to the water heater. Light the pilot, if applicable.

I.

Sanitize the softener.

Care is taken at the factory to keep your softener clean

and sanitary. Materials used to make the softener will

not infect or contaminate your water supply and will

not cause bacteria to form or grow. However, during

shipping, storage, installing and operating, bacteria

could get into the softener. For is reason, sanitizing

as follows is suggested when installing.

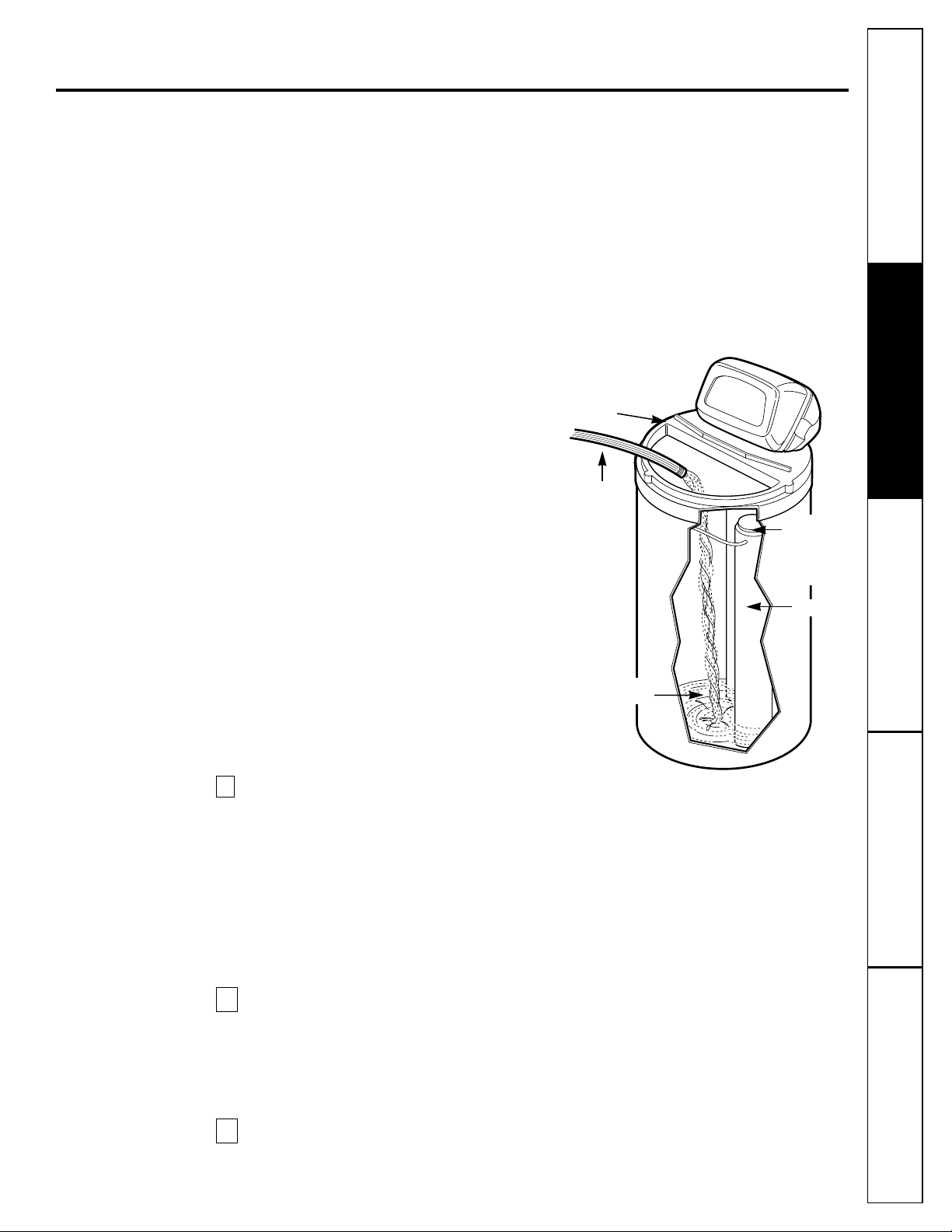

•Lift the salt hole cover and use a pail or hose to

fill the salt storage tank with at least 3 gallons

of water.

•

Remove the brinewell cover, see Fig. 7 and pour

about 3/4 ounce of common 5.25% household

bleach (Clorox, Linco, BoPeep, White Sail, Eagle,

etc.) in the softener brinewell.

•Press the

TOUCH/HOLD

button and hold for 3

seconds to start a recharge. This first recharge

does

several things: fills the salt tank to the water

level needed,

gets all the air out of the resin tank,

makes the resin bed ready for service. See the

Recharging

section.

NOTE: This recharge takes about 2 hours.

Fig. 7

Salt hole cover

removed

Hose

Brinewell

Brinewell

cover (remove

and add about

3/4 oz. bleach)

Water, about

3 gallons

Page 10

Step-by-step installation instructions.

Customer Service Troubleshooting Tips

Installation Instructions

Safety InstructionsCustomer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

10

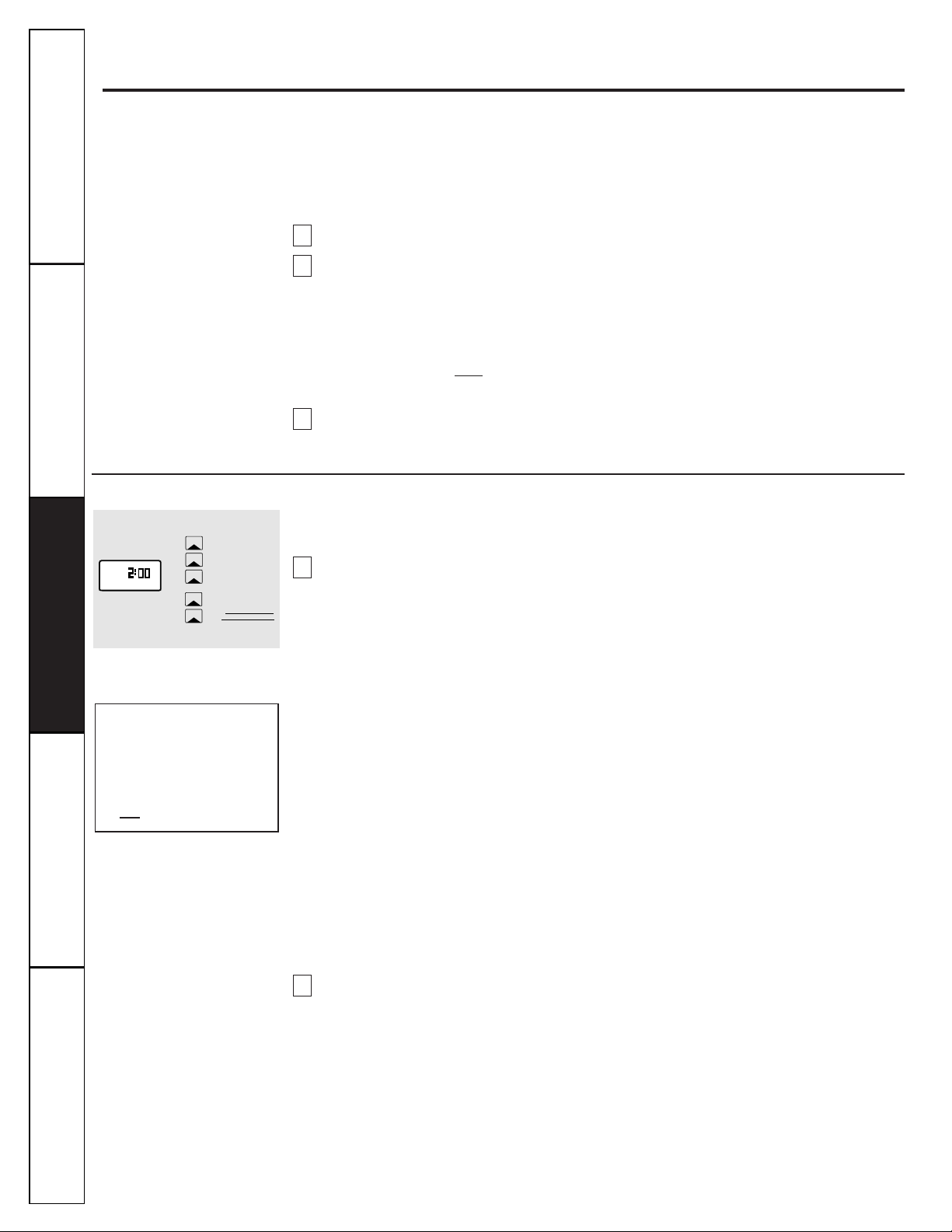

Program the Timer

Set the timer:

When the transformer is plugged into electrical outlet, 12:00AM, SUnday will begin to flash in the time display.

Set the time of day and present day of week as follows:

A.

Set the time of day:

Press the

TIME/DAY

b

utton once and the hour display will begin to flash.

Press the

SET/CLEAR

b

utton until the present hour of the day shows in the display. Be sure AMfor

morning hours, or PMfor afternoon and evening hours shows.

NOTE:

Press

SET/CLEAR

button and quickly release to move the hour display ahead 1 at a time to the

correct hour. Or, hold the

SET/CLEAR

button to move the display ahead 2 hours each second, to the

correct hour.

Press the

TIME/DAY

b

utton once to steady the hour display, and minutes begin to flash.

Repeat

Step A. 2

to set the correct minutes.

Press the

TIME/DAY

b

utton again to steady the minute display (day will begin flashing). Fig. 9 shows

the timer set at 3:30 PM.

B.

Set the present day of the week:

Press the

SET/CLEAR

b

utton to set the present day of the week in the display.

NOTE:

Press

SET/CLEAR

b

utton and quickly release to move the day display 1 at a time. Or hold the

SET/CLEAR

button to move the day display ahead 2 days each second.

Press the

TIME/DAY

button again to steady the entire display. Fig. 9 shows the timer set at

TUesday.

No other settings are needed

after installing your water softener. The softener is factory set to regenerate every

Monday, Wednesday and Saturday (beginning at 2:00 AM). For most families, this gives enough soft water

for their needs. However, if you want the softener to regenerate at a different time, or on different days, or to

set for the most efficiency, see

About the Water Softener System

section.

2

1

4

3

2

1

Solid State Timer

SmartWater Softening System

REGENERATE NOW

VACATION ON/OFF

TOUCH

HOLD

SET/CLEAR

TIME/DAY

REGENERATION

DAY

REGENERATION

TIME

Fig. 8

See the

Operating

section for other timer controls and features.

REGENERATE NOW

VACATION ON/OFF

TOUCH

HOLD

SET/CLEAR

TIME/DAY

REGENERATION

DAY

REGENERATION

TIME

PM

TU

E

E

Fig. 9

EXAMPLE: This drawing shows the

present time of day at 3:30 PM,

and the present day on TUesday.

Page 11

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

11

Specifications/Dimensions

Rated Capacity

Amount of high capacity resin (lbs/cu. ft)

Resin tank nominal size (in., dia. x height)

Service flow rate (gpm)

Water supply maximum hardness (gpg)

➄

Water supply maximum clear water iron (ppm) ➄

Water pressure limits (min.-max. psi)

Pressure drop at rated service flow (psig)

Water temperature maximum (°F)

Water supply minimum flow rate (gpm)

Regeneration cycle flow rates (gpm)

Fill (flow to brine tank)

Brining

Brine Rinse

Backwash

Fast Rinse

GXSS17Z

31.2/.6

8 x 40

8

50

3

20-125

15

120

3

.3

.19

.12

1.8

1.8

See rating decal, located on

the Softener

➄Determined by water analysis from a qualified water testing laboratory.

}

(flow to drain)

GXSS17

11–1/2″

3–3/8″

OUT

INLET

INLET-OUTLET

48–3/4″

41–1/4″

18–1/4″

40–1/2″

Page 12

Service

When the

water softening system

is providing soft water, it is called “Service.” During

service, hard water flows from the house main water pipe into the

water softening system

.

Inside the

water softening system

resin tank is a bed made up of thousands of tiny, plastic

resin beads. As hard water passes through the bed, each bead attracts and holds the hard

minerals. This is called ion-exchanging. It is much like a magnet attracting and holding

metals. Water without hard minerals (soft water) flows from the

water softening system

and

to the house pipes.

After a period of time, the resin beads become coated with hard minerals and they have to

be cleaned. This cleaning is called regeneration, or recharge. Regeneration is started at

2:00 AM (factory setting) by the

water softening system

control, and consists of five stages or

cycles. These are

FILL, BRINING, BRINE RINSE, BACKWASH

and

FASTRINSE

.

About the water softener system.

Customer Service Troubleshooting Tips

Installation Instructions

Safety InstructionsCustomer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

12

Automatic Hard Water Bypass During Regeneration

For emergency needs, hard water is available

to the home during the regeneration cycles.

However, you should avoid using HOT water

because the water heater will fill with the

hard water.

Fill Backwash

Salt dissolved in water is called brine. Brine

is needed to clean the hard minerals from

resin beads. To make the brine, water flows

into the salt storage area during the fill stage

as shown.

Brining

During brining, brine travels from the salt

storage area into the resin tank. Brine is the

cleaning agent needed to remove hard

minerals from the resin beads. The hard

minerals and brine are discharged to the

drain.

The nozzle and venturi create a suction to

move the brine, maintaining a very slow rate

to get the best resin cleaning with the least

salt.

Brine Rinse

After a pre-measured amount of brine is

used, the brine valve closes. Water

continues to flow in the same path as during

brining, except for the discontinued brine

flow. Hard minerals and brine flush from

the resin tank to the drain.

During backwash, water travels upthrough

the resin tank at a fast flow rate, flushing

accumulated iron, dirt, and sediments from

the resin bed and to drain.

Fast Rinse

Backwash is followed by a fast flow of water

down

through the resin tank. The fast flow

flushes brine from the bottom of tank, and

packs the resin bed.

After fast rinse, the

water softening system

returns to soft water service.

Soft water

OUT

Salt storage

tank (salt

not shown)

Brine

valve

Hard water

IN

Resin

tank

Resin

bed

Soft water

OUT

Hard water

IN

Salt

storage

tank

Fill

water

Brine

valve

Hard water

bypass OUT

Nozzle &

venturi

Hard water

IN

Brine

valve

Brine

Drain

Drain

Hard water

bypass OUT

Hard water

IN

Drain

Soft water

OUT

Hard water

IN

Page 13

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

13

Breaking a Salt Bridge

Sometimes, a hard crust or salt bridge forms in the salt storage area. It is usually caused

by high humidity or the wrong kind of salt. When the salt bridges, an empty space forms

between the water and salt. Then salt will not dissolve in the water to make brine.

If the brine tank is full of salt, it is hard to tell if you have a salt bridge. Salt is loose on top,

but the bridge is under it. The following is the best way to check for a salt bridge.

Salt should be loose all the way to the bottom of the tank. Take a broom handle or like

tool, and carefully push it down into the salt, working it up and down. If the tool strikes a

hard object (be sure it’s not the bottom or sides of the tank), it’s most likely a salt bridge.

Carefully break the bridge with the tool.

Do not

pound on the walls of the tank.

If the wrong kind of salt made the bridge, take it out. Then fill the tank with nugget or

pellet salt only. In humid areas, it is best to fill with less salt, more often.

Push tool into salt

bridge to break

Pencil

mark

Broom

handle

Salt

Salt

bridge

Water level

1

² – 2²

Page 14

About the water softener system.

Customer Service Troubleshooting Tips

Installation Instructions

Safety InstructionsCustomer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

14

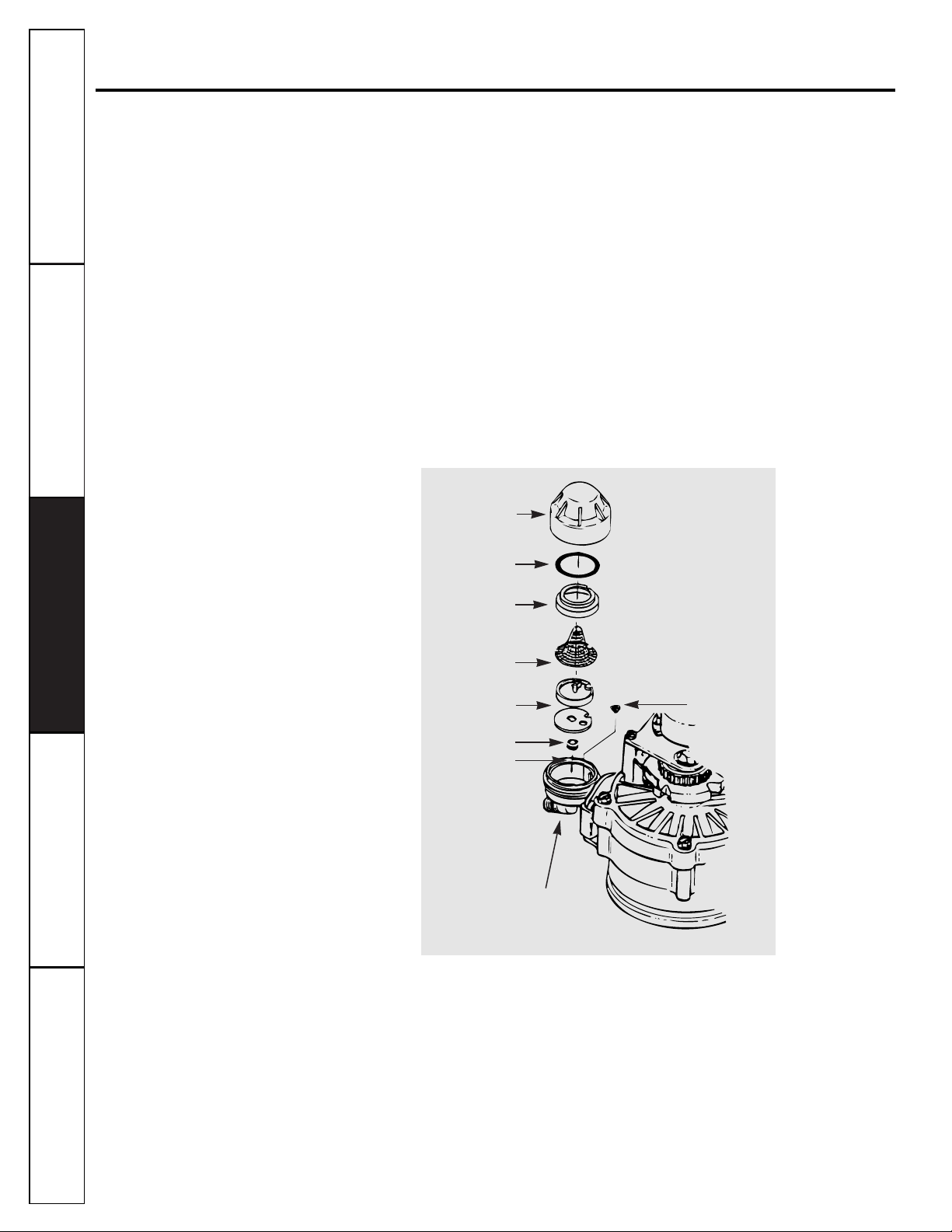

Cleaning the Nozzle and Venturi Assembly

A clean nozzle and venturi is needed for the water softening system to work properly.

This small

unit makes the suction to move brine from the salt storage area to the resin tank during

regeneration. If it becomes plugged with sand, dirt, etc., the water softening system will not

work and you will get hard water.

To get to the nozzle and venturi, remove the water softening system top cover. Be sure the

water softening system is in service cycle (no water pressure at nozzle and venturi). Then,

while holding the nozzle and venturi housing with one hand, remove the cap. Lift out the

screen support and screen, then the nozzle and venturi. Wash and rinse the parts in warm

water until clean. If needed, use a small brush to remove iron or dirt. Also check and clean

the gasket.

NOTE:

Some models have a small flow plug located in the nozzle and venturi, and/or a

small cone shaped screen in the housing. Be sure to check and clean these parts, if your

model is so equipped.

Carefully replace all parts in the correct order. Lightly lubricate the o-ring seal with clean

silicone grease or petroleum jelly and place in position.

Install and tighten the cap, by hand

only. Do not over-tighten the cap or housing.

IMPORTANT: Be sure small holes in the gasket are centered directly

over the small holes in the nozzle and venturi housing.

*Install with numbered side up, concave side down.

Cap

O-ring seal

Screen support

Screen

Screen

Nozzle & Venturi

Nozzle & Venturi housing

Gasket

*Fill Flow plug

Page 15

If electrical power to the timer goes off, the

memory built into the timer circuitry keeps

all settings for six hours (minimum) or

more. The display is blank and softener will

not regenerate.

When electrical power comes on… one of two

things will happen.

The present time of day will show,

meaning the timer memory has kept all

settings.

NOTE:

If the softener was in a

regeneration when the power was lost, it

will now finish the cycle.

OR

The display will show a flashing time.

The timer memory did not keep the

time settings and they must be reset.

See the

Program the Timer

section.

NOTE:

When the power comes on, the

flashing display returns to a time of

12:00 AM Sunday, then begins to keep

time again. If you do not reset all time

settings, the softener will regenerate

three days each week. However,

regeneration will most likely be on the

wrong days and at the wrong time.

If the softener was in a regeneration when

the power went off, the valve will return to

service position without finishing the

regeneration cycle.

If your water tastes salty:

—use

RECHARGENOW

to start another

regeneration. See the

Recharging

section.

—open one or more soft water faucets and

allow to run until the salt taste is gone.

2

1

About the face plate timer features.

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

15

Recharging

If you have guests visiting, or other times when you use more water than usual, you could

begin to run out of soft water. If the softener is not scheduled to regenerate for another day

or two, you would get hard water until then. If this happens, or you think it might happen,

press and hold in the

TOUCH HOLD

button for three seconds until

RCHG

shows.

RCHG

will

flash in the display during the regeneration, which lasts under two hours.

NOTE:

Avoid using

HOT

water while the softener regenerates, because bypass hard water will

refill the water heater, see the

Automatic Bypass

section.

REGENERATE NOW

VACATION ON/OFF

TOUCH

HOLD

SET/CLEAR

TIME/DAY

REGENERATION

DAY

REGENERATION

TIME

PM

RCHG

Going on Vacation?

The day you leave on vacation, or for a long

absence, press (do not hold) the

TOUCH

HOLD

button

VAC

begins to flash in the

display. The timer will keep time, but the

softener will not regenerate.

NOTE:

While on vacation, the softener will

go through a regeneration if the

RECHARGE

NOW

feature is used.

To shut off the water supply to the softener,

use the plumbing bypass valve.

When you return, press the

VACATION

button again to return the softener to

service and also returning the softener to

the correct time of day in the display.

WARNING:

Remember to do this or the

softener will not regenerate and you will

soon have hard water.

Error Code

An error code could appear in the face plate display if a problem occurs in the softener

electronics. If you see an error code instead of the present time of day, see the

Trouble

ShootingTips

section or call the GE Answer Center 800.626.2000 for service.

What to do When a Power Outage Occurs.

TIME/DAY

REGENERATION

PM

RCHG

TIME

REGENERATION

DAY

SET/CLEAR

TOUCH

HOLD

VACATION ON/OFF

REGENERATE NOW

E

E

Page 16

It is not hard to fine-tune your softener, but it does take a few minutes of your time to do it right.

Read the following carefully.

To have soft water all the time, the softener must regenerate, or recharge a certain number of

times in each seven day period. How many times to regenerate (set the timer) depends on three

things:

The number of people in your home tells you how much water is used.

The grains per gallon (GPG) hardness of your water supply.

NOTE:

If your water supply contains iron, compensate for it by adding to the water hardness

number.

For example, assume your water is 15 gpg hard and contains 2 ppm iron. Add 5 to

the

hardness number for each 1 ppm of iron thus, making the example water hardness number 25 .

15 gpg hardness

2 ppm iron x 5 = 10 +10

(times) 25 HARDNESS NUMBER

How much salt used in each regeneration is determined by the length of the fill cycle. See

the

Regeneration Chart

section.

3

2

1

About regenerating the system.

Customer Service Troubleshooting Tips

Installation Instructions

Safety InstructionsCustomer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

16

Setting the Timer for Days and Fill Minutes of Regeneration

NOTE:

The timer is factory set for Monday, Wednesday and Saturday with regenerations starting

at 2:00 AM. Fill time is factory set for 16 minutes.

Set days and time of regeneration or recharge.

Step 1—

Press the

REGENERATION TIME

button once to display the factory set regeneration days

and starting time (flashing). To change the regeneration start time, do

Step 2

following

this. Otherwise go to

Step 3.

NOTE:

See

Automatic Bypass

section, when choosing a regeneration starting time other

than 2:00 AM.

Step 2—

Press the

SET/CLEAR

button until the desired regeneration starting time shows in the

display.

NOTE:

Press

SET/CLEAR

and quickly release to move the display ahead 1 hour at a

time.

Or, hold the

SET/CLEAR

button to move display ahead 2 hours each

second.

Step 3—

Press the

REGENERATION DAY

button and

SUnday

begins to flash.

—

If you do want regenerations on Sunday, see the

Regeneration Chart

, press the

SET/CLEAR

button to display

ON.

—

If you do

NOT

want regenerations on Sunday, press

SET/CLEAR

button to display

OFF.

Step 4—

Press

REGENERATION DAY

button again to display a flashing

MOnday

and

ON

(factory set

recharge). Use the

SET/CLEAR

button to change display from ONto

OFF

or from

OFF

to

ON.

Step 5—

Press

RECHARGE DAY

button to display a flashing

TUesday, WEdnesday,

etc., each time

using the

SET/CLEAR

button to display either ONor

OFF

as needed.

Set the Fill Cycle Minutes

Step 1—

Press and hold the

REGENERATION TIME

button until

FILL

shows in the display, then

release button. After a few seconds, the fill cycle minutes (factory setting…16) will flash.

Step 2—

Press the

SET/CLEAR

button to set the minutes of fill cycle needed, as shown in the

Regeneration Chart

section.

NOTE:

You may get hard water between regenerations if you set the timer for fewer fill

minutes than the

Regeneration Chart

shows you to set. A higher setting than needed will

waste salt.

NOTE:

Press

SET/CLEAR

and quickly release to move the display ahead 1 minute at a time.

Or, hold the

SET/CLEAR

button to move the display ahead 2 minutes each second.

The

display begins over at 0 after passing 59.

2

1

AM

MO

WE SA

REGENERATE NOW

VACATION ON/OFF

TOUCH

HOLD

SET/CLEAR

TIME/DAY

REGENERATION

DAY

REGENERATION

TIME

Write in your results here.

1. M T W TH F S SU

—circle suggested days—

Suggested days to regenerate

2.

Fill Cycle minutes needed

Page 17

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

Regeneration Chart

This makes it easy for you to pick the best regeneration and fill time setting to use.

Step 1—

Go down the side of the chart to the number of persons in your family, or the

number of people in the house using water.

Step 2—

Across the top of the chart, find the column listing the grains per gallon hardness

of your water, or hardness number for iron water.

Step 3—

Read across and down the chart to find the point where

Steps 1

and 2meet. At this

point, suggested days to regenerate, and fill cycle minutes needed are shown.

Up to 5 6 to 10 11 to 15 16 tp 20 21 to 25 26 to 30 31 tp 35 36 to 40 41 to 45 46 to 50

M

2 min.

M

2 min.

M

2 min.

M

2 min.

M

3 min.

M

3 min.

M

4 min.

M

5 min.

M TH

2 min.

M TH

3 min.

M

2 min.

M

2 min.

M

3 min.

M

5 min.

M TH

3 min.

M TH

3 min.

M W S

2 min.

M W S

3 min.

M W S

3 min.

M T TH

F S

2 min.

M

2 min.

M

3 min.

M TH

2 min.

M TH

3 min.

M W S

3 min.

M W S

3 min.

M W S

3 min.

M T TH

S

3 min.

M T TH

F S SU

2 min.

M T TH

F S

3 min.

M

2 min.

M

5 min.

M TH

3 min.

M W S

3 min.

M T TH

F S

2 min.

M W S

2 min.

M T TH

F S SU

2 min.

Every

Day

2 min.

M T TH

F S SU

3 min.

Every

Day

3 min.

M

3 min.

M TH

6 min.

M W S

3 min.

M T TH

F S

2 min.

M T TH

F S SU

2 min.

M T TH

S

3 min.

M T TH

F S SU

3 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

4 min.

M

3 min.

M TH

3 min.

M W S

3 min.

M T TH

S

3 min.

M T TH

F S

3 min.

M T TH

F S SU

3 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

5 min.

Every

Day

7 min.

M

4 min.

M W S

2 min.

M W S

3 min.

M T TH

F S SU

2 min.

M T TH

F S SU

3 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

5 min.

Every

Day

8 min.

M

5 min.

M W S

3 min.

M T TH

S

3 min.

Every

Day

2 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

5 min.

Every

Day

8 min.

M TH

2 min.

M W S

3 min.

M T TH

F S SU

2 min.

M T TH

F S SU

3 min.

Every

Day

4 min.

Every

Day

5 min.

Every

Day

8 min.

M TH

6 min.

M T TH

F S

2 min.

M T TH

F S

3 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

7 min.

Step 3—

Press

TIME/DAY

button to return the present time and day display.

To set the present time of day and day of week see

Program the Timer

section.

If you need help to program the timer, all the GE Answer Center 800.626.2000.

17

# in household

1

2

3

4

5

6

7

8

9

10

Water Hardness—Grains Per Gallon

Days to Regenerate:

M=Monday, T=Tuesday, W=Wednesday, TH=Thursday, F=Friday, S=Saturday, SU=Sunday

(factory set for Monday, Wednesday and Saturday)

Min.= length of fill cycle needed (factory set for 8 minutes)

Salt

usage

Time

1.8 pounds 2.7 pounds 3.6 pounds 4.5 pounds 5.4 pounds 6.3 pounds 7.2 pounds 8.1 pounds 9.0 pounds

2 minutes 3 minutes 4 minutes 5 minutes 6 minutes 7 minutes 8 minutes 9 minutes

10

minutes

Pounds of Salt Used Each Regeneration

Minutes of Fill is at 0.3 GPM

Page 18

18

Before you call for service…

Customer Service Troubleshooting Tips Safety InstructionsCustomer Service Troubleshooting Tips Safety InstructionsCustomer Service Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation Instructions

Problem Possible Causes What To Do

No soft water

No salt in the storage tank. •Refill with salt. See the

Step-by-Step Installation Instructions.

Use the

TOUCH HOLD

button to start a regeneration. See

the

About the Face Plate Timer

section.

Transformer unplugged • Check for loss of power and correct. Reset the times, then

at the wall outlet, or power use the

TOUCH HOLD

button to start a regeneration. See

cable disconnected. the

About the Face Plate Timer

section.

Fuse blown, circuit breaker

•

Replace the fuse, reset the circuit breaker, or switch breaker

tripped, or circuit switched

on. Reset the times and then use the

TOUCH HOLD

button

off. to start a regeneration. See the

About the Face Plate Timer

section.

Timer in the vacation • See

VACATION

feature to return the softener to service.

(VAC) position. See the

About the Face Plate Timer

section.

No regenerations set on • Select and program a schedule. See the

About the Water

the timer.

Softener System

section. Use the

TOUCH HOLD

button to

start a regeneration. See the

About the Face Plate Timer

section.

Manual bypass valve(s) in • Move stem in single bypass valve to

SERVICE.

bypass position.

Salt in storage tank bridged.

•

See the

Breaking a Salt Bridge

section.

Dirty, plugged or damaged

• Take apart and clean or replace damaged parts.

nozzle & venturi. See

Cleaning the Nozzle and Venturi Assembly

section.

Valve drain hose plugged. • Hose must not have kinks, sharp bends or any water flow

breakage. See the

Step-by-Step Installation Instructions.

Low or high system water pressure • If pressure is low, increase to a minimum of 20 psi. Add a

(Low pressure may disrupt brine pressure reducing valve, in the supply pipe to the softener,

draw during recharge. High if day time pressure is over 100 psi.

pressures may cause inner valve

parts failure.)

Water hard sometimes

Too few regenerations. • See the

Regeneration Chart

, for the correct setting.

More water being used. •See the

Regeneration Chart

, for the correct setting.

Hot water used when softener • Avoid using hot water as the water heater refills with hard

is regenerating. water. See the

Automatic Bypass

section.

Possible increase in water • Call GE Answer Center 800.626.2000 for a new water

hardness. analysis.

Leaking faucet or toilet valve. • A small leak will waste hundreds of gallons of water in a

few days. Fix all plumbing leaks and always fully close faucets.

Troubleshooting Tips

Save time and money! Review the chart on this

page first and you may not need to call for service.

Page 19

19

General Electric Company

Warranty Registration Department

P.O. Box 34070

Louisville, KY 40232-4070

GE Service Protection Plus

™

GE, a name recognized worldwide for quality and dependability, offers you Service

Protection Plus

™

—comprehensive protection on all your appliances—No Matter

What Brand!

Benefits Include:

•Backed by GE

•All brands covered

• Unlimited service calls

•All parts and labor costs included

•No out-of-pocket expenses

•No hidden deductibles

•One 800 number to call

You will be completely satisfied with our service protection or you may request your money back

on the remaining value of your contract. No questions asked. It’s that simple.

Protect your refrigerator, dishwasher, washer and dryer, range, TV, VCR and much more—any brand!

Plus there’s no extra charge for emergency service and low monthly financing is available. Even icemaker

coverage and food spoilage protection is offered. You can rest easy knowing that all your valuable

household products are protected against expensive repairs.

Place your confidence in GE and call us in the U.S. toll-free at 800-626-2224

for more information.

*All brands covered, up to 20 years old, in the continental U.S.

We’ll Cover Any Appliance.

Anywhere. Anytime.*

Please place in envelope and mail to:

✁

Cut here

Page 20

20

Consumer Product Ownership Registration

Model Number Serial Number

Important

Mail

Today!

GE Appliances

General Electric Company

Louisville, Kentucky 40225

First

Name

Mr. ■■ Ms. ■■ Mrs. ■■ Miss ■■

Street

Address

City

State

Date Placed

In Use

Month

Day

Year

Zip

Code

Apt. #

Last

Name

Phone

Number

_ _

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our product and thank you for placing your

confidence in us. We are proud to have you as a customer!

Follow these three steps to protect your new appliance investment:

Complete and mail

your Consumer

Product Ownership

Registration today.

Have the peace of

mind of knowing we

can contact you in

the unlikely event of

a safety modification.

After mailing

the registration

below, store this

document in a safe

place. It contains

information you

will need should

you require service.

Our service number

is 800-GE-CARES

(800-452-2737).

Read your Owner’s

Manual carefully.

It will help you

operate your new

appliance properly.

If you have questions,

or need more

information call the

GE Answer Center

®

800.626.2000.

Important: If you did not get a registration card with your product,

detach and return the form below to ensure that your

product is registered.

1

2 3

Model Number Serial Number

✁

Cut here

Page 21

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

21

Parts list.

Page 22

22

Parts catalog.

Customer Service Troubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

REF. NO. PART NO. PART DESCRIPTION

0003 WS35X10001 O-RING SEAL KIT 1

0004 DECAL 1

0005 WS07X10004 HOSE DRAIN, 20 FT. 1

0007 WS14X10002 DISTRIBUTOR TOP 1

0008 WS14X10001 DISTRIBUTOR BOTTOM 1

0009 WS01X10002 RESIN - 1 CU. FT. 1

0010 WS32X10001 TANK RESIN 1

0011 WS31X10001 COVER BOTTOM 1

0012 WS31X10002 COVER CONTROL

0013 CONTROL 1

0014 WS19X10003 HARNESS WIRE 1

0015 WS06X10003 POWER CORD 1

0016 WS26X10001 TRANSFORMER 1

0017 WS31X10010 COVER SALT HOLE 1

0018 WS33X10001 SEAL VAPOR BARRIER 1

0019 WS33X10002 RIM 1

WS31X10003 COVER BRINEWELL 1

0021 WS02X10009 WING NUT, 1/4 ″ - 20 1

0022 WS32X10002 TANK BRINEWELL, ROUND 1

0023 WS02X10011 SCREW, 1/4 ″ - 20 NYLON 1

0024 WS32X10003 TANK BRINE, ROUND 1

0025 WS18X10003 CLAMP HOSE 1

0026 WS22X10016 ADAPTER HOSE 1

0027 WS22X10017 GROMMET 1

0028 WS35X10002 GROUND CLAMP KIT 1

0029 WS15X10005 BRINE VALVE ASM. 1

0030 WS35X10003 FLOAT, STEM & GUIDE ASM. 1

0031 WS03X10006 CLIP 1

0032 WS15X10006 VALVE BODY, BRINE 1

0033 WS03X10007 CLIP 1

0034 WS03X10008 SCREEN 1

0035 WS07X10002 TUBING ASM. 1

0036 WS07X10003 TUBE BRINE 1

0055 WS28X10003 RETAINER CLAMP 2

0056 WS28X10004 CLAMP 2

0999 49-50007 PM MANUAL INSTALLATION/

USE & CARE

Page 23

Parts list.

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

23

Page 24

24

Parts catalog.

Customer Service Troubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

REF. NO. PART NO. PART DESCRIPTION

0025 WS18X10003 CLAMP HOSE 1

0101 WS02X10012 SCREW, #4 - 24 X 1-1/8″ 1

0102 WS02X10013 SPACER 1

0103 WS21X10003 SWITCH 1

0104 WS03X10009 PIN EXPANSION 1

0105 WS02X10014 SCREW, #10 - 14 X 2″ 5

0106 WS31X10006 COVER VALVE 1

0107 WS03X10010 WASHER WAVE 1

0108 WS26X10002 ROTOR & DISC 1

0109 WS19X10004 CAP 1

0110 WS03X10011 SEAL O-RING 1.1″ X 1.4″ 1

0111 WS19X10005 SUPPORT SCREEN 1

0112 WS03X10013 SCREEN 1

0113 WS22X10020 FLOW PLUG, .1 GPM 1

0114 WS08X10005 GASKET, NOZZLE/VENT 1

0115 WS03X10015 CONE SCREEN 1

0116 WS22X10021 PLUG, FILL FLOW, .3 GPM 1

0117 WS03X10017 NUT FERRULE 1

0118 WS15X10009 NOZZLE/VENTURI ASM. 1

0119 WS03X10018 RETAINER 1

0120 WS03X10019 SEAL O-RING 1/4″ X 3/8″ 2

0121 WS15X10010 BODY VALVE 1

0122 WS03X10020 SPRING 1

0123 WS22X10022 PLUG, DRAIN SALT 1

0130 WS35X10005 SEAL KIT 1

0132 WS22X10023 ADAPTER DRAIN HOSE 1

0133 WS03X10021 O-RING 5/8″ X 13/16″ 1

0134 WS03X10022 PLUG FLOW, RINSE CONTROL 1

0135 WS03X10023 CLIP 1

0136 WS26X10003 CAM & GEAR 1

0137 WS26X10004 BEARING 1

0138 WS26X10005 PLATE MOTOR 1

0139 WS02X10015 SCREW, #6 - 20 X 3/8″ 2

0140 WS26X10006 MOTOR ASM. 1

0141 WS02X10016 SCREW, #6 - 20 X 7/8″ 2

0142 WS60X10001 NUT INSTALLATION 2

0143 WS60X10002 TUBE INSTALLATION 2

0144 WS60X10003 WASHER 2

0145 WS60X10004 CLIP 2

0146 WS28X10005 HOUSING SENSOR 1

0147 WS19X10006 TURBINE & SUPPORT ASM. 1

0150 WS03X10024 SEAL, O-RING 1

0151 WS15X10012 VALVE BYPASS ASM. 1

0152 WS03X10025 SEAL, O-RING 2

Page 25

Notes

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

25

Page 26

26

Notes

Customer Service Troubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

Page 27

Customer ServiceTroubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

27

GE Water Softening System Warranty

All warranty service provided by our Factory Service Centers, or an authorized Customer Care®technician.

For service, call 800-GE-CARES.

■ Service trips to your home to teach you how to use the

product.

■ Improper installation.

■ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■ Filters, membranes or batteries.

■ Replacement of house fuses or resetting of circuit

breakers.

■ Damage to the product caused by accident, fire, floods or

acts of God.

■ Incidental or consequential damage to personal property

caused by possible defects with this appliance.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your legal

rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

For The Period Of: GE Will Replace, At No Charge To You:

One Year Any part

of the Water Softening System which fails due to a defect in materials or workmanship.

From the date of the

During this

full one-year warranty,

GE will also provide,

free of charge,

all labor and in-home

original purchase

service to replace the defective part.

Three Years The electronic monitor,

if it fails due to a defect in materials or workmanship. During this

From the date of the three-year limited warranty,

you will be responsible for any labor or in-home service costs.

original purchase

Ten Years A replacement cabinet (brine tank) or resin tank,

if either fails due to a defect in materials or

From the date of the

workmanship. During this

ten-year limitedwarranty,

you will be responsible for any labor

original purchase

or in-home service costs.

Page 28

Printed in the United States

28

Service Telephone Numbers.

GE Answer Center

®

800.626.2000

The GE Answer Center® is open 24 hours a day, 7 days a week.

In-Home Repair Service

800-GE-CARES (800-432-2737)

Expert GE repair service is only a phone call away.

Special Needs Service

800.626.2000

800-TDD-GEAC (800-833-4322)

GE offers, free of charge, a brochure to assist in planning a barrier-free kitchen for persons

with limited mobility.

Service Contracts

800-626-2224

Purchase a GE service contract while your warranty is still in effect and you’ll receive a

substantial discount. GE Consumer Service will still be there after your warranty expires.

Parts and Accessories

800-626-2002

Individuals qualified to service their own appliances can have parts or accessories sent directly

to their homes (VISA, MasterCard and Discover cards are accepted).

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since

improper servicing may cause unsafe operation.

Service Satisfaction

If you are not satisfied with the service you receive from GE:

First,

contact the people who serviced your appliance.

Next,

if you are still not pleased, write all the details—including your phone number—to:

Manager, Consumer Relations

GE Appliances

Appliance Park

Louisville, KY 40225

Finally,

if your problem is still not resolved, write:

Major Appliance Consumer Action Program

20 North Wacker Drive

Chicago, IL 60606

Customer Service Troubleshooting Tips

Installation Instructions

Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Safety InstructionsCustomer Service Troubleshooting Tips Safety Instructions

Loading...

Loading...