Page 1

GE Consumer & Industrial

ISO9001:2000

Multilin

EPM 6000 Multi-function Power

Metering System

Chapter 1:

EPM 6000

Instruction Manual

Software Revision: 4.5

Manual P/N: 1601-0215-A4

Manual Order Code: GEK-106558C

Copyright © 2007 GE Multilin

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet:

*1601-0215-A4*

http://www.GEmultilin.com

LISTED

T

E

S

I

R

E

G

D

E

R

G

E

GE Multilin's Quality

Management System is

registered to ISO9001:2000

QMI # 005094

N

I

M

L

I

U

T

L

Page 2

Page 3

Table of Contents

1: OVERVIEW INTRODUCTION ................................................................................................................................ 1-1

D

ESCRIPTION ........................................................................................................................ 1-1

H

IGHLIGHTS ......................................................................................................................... 1-1

FEATURES ............................................................................................................................................ 1-3

U

NIVERSAL VOLTAGE INPUTS ............................................................................................ 1-3

C

URRENT INPUTS ................................................................................................................. 1-3

U

TILITY PEAK DEMAND .......................................................................................................1-3

M

EASURED VALUES ............................................................................................................ 1-4

ORDERING ........................................................................................................................................... 1-5

O

RDER CODES ..................................................................................................................... 1-5

SPECIFICATIONS ............................................................................................................................... 1-6

I

NPUTS/OUTPUTS ................................................................................................................ 1-6

M

ETERING ............................................................................................................................. 1-6

E

NVIRONMENTAL ................................................................................................................. 1-7

C

OMMUNICATIONS .............................................................................................................. 1-7

M

ECHANICAL PARAMETERS ................................................................................................ 1-7

A

PPROVALS ........................................................................................................................... 1-8

2: ELECTRICAL

BACKGROUND

THREE-PHASE POWER MEASUREMENT .................................................................................2-1

ESCRIPTION ........................................................................................................................ 2-1

D

THREE-PHASE SYSTEM CONFIGURATIONS ........................................................................... 2-2

D

ESCRIPTION ........................................................................................................................ 2-2

W

YE CONNECTION .............................................................................................................. 2-2

D

ELTA CONNECTION ........................................................................................................... 2-4

B

LONDELL'S THEOREM AND THREE-PHASE MEASUREMENT ........................................2-5

POWER, ENERGY, AND DEMAND .............................................................................................. 2-8

D

ESCRIPTION ........................................................................................................................ 2-8

P

OWER .................................................................................................................................. 2-8

E

NERGY ................................................................................................................................. 2-8

D

EMAND ...............................................................................................................................2-10

REACTIVE ENERGY AND POWER FACTOR ............................................................................. 2-12

R

EAL, REACTIVE, AND APPARENT POWER ........................................................................ 2-12

P

OWER FACTOR ................................................................................................................... 2-13

HARMONIC DISTORTION ..............................................................................................................2-14

H

ARMONICS OF A NON-SINUSOIDAL WAVEFORM ......................................................... 2-14

I

NDUCTIVE AND CAPACITIVE IMPEDANCE ......................................................................... 2-15

V

OLTAGE AND CURRENT MONITORING ............................................................................ 2-15

W

AVEFORM CAPTURE .........................................................................................................2-16

POWER QUALITY .............................................................................................................................. 2-17

D

ESCRIPTION ........................................................................................................................ 2-17

3: INSTALLATION MECHANICAL INSTALLATION .....................................................................................................3-1

IMENSIONS ......................................................................................................................... 3-1

D

ANSI I

NSTALLATION STEPS ............................................................................................... 3-2

DIN I

NSTALLATION STEPS .................................................................................................. 3-3

ELECTRICAL INSTALLATION ......................................................................................................... 3-5

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE TOC–1

Page 4

INSTALLATION CONSIDERATIONS ....................................................................................... 3-5

CT L

EADS TERMINATED TO METER ...................................................................................3-6

CT L

EADS PASS-THROUGH (NO METER TERMINATION) ................................................ 3-6

Q

UICK CONNECT CRIMP CT TERMINATIONS ................................................................... 3-7

V

OLTAGE AND POWER SUPPLY CONNECTIONS .............................................................. 3-7

G

ROUND CONNECTIONS ....................................................................................................3-8

WIRING DIAGRAMS .........................................................................................................................3-9

D

ESCRIPTION ........................................................................................................................ 3-9

W

YE, 4-WIRE WITH NO PTS AND 3 CTS, 3 ELEMENT ..................................................3-10

W

YE, 4-WIRE WITH NO PTS AND 3 CTS, 2.5 ELEMENT .............................................. 3-11

W

YE, 4-WIRE WITH 3 PTS AND 3 CTS, 3 ELEMENT .................................................... 3-12

W

YE, 4-WIRE WITH 2 PTS AND 3 CTS, 2.5 ELEMENT ................................................. 3-13

D

ELTA, 3-WIRE WITH NO PTS AND 2 CTS ..................................................................... 3-14

D

ELTA, 3-WIRE WITH 2 PTS AND 2 CTS ........................................................................ 3-15

C

URRENT-ONLY MEASUREMENT (THREE-PHASE) .......................................................... 3-16

C

URRENT-ONLY MEASUREMENT (DUAL-PHASE) ............................................................ 3-17

C

URRENT-ONLY MEASUREMENT (SINGLE-PHASE) ......................................................... 3-18

COMMUNICATIONS SETUP .......................................................................................................... 3-19

D

ESCRIPTION ........................................................................................................................ 3-19

I

RDA COM1 PORT .............................................................................................................3-19

RS485 COM2 P

ORT ......................................................................................................... 3-19

4: USING THE METER FRONT PANEL INTERFACE ............................................................................................................ 4-1

ESCRIPTION ........................................................................................................................ 4-1

D

F

ACEPLATE ELEMENTS ........................................................................................................ 4-1

F

ACEPLATE BUTTONS .......................................................................................................... 4-2

P

ERCENTAGE OF LOAD BAR ...............................................................................................4-3

W

ATT-HOUR ACCURACY TESTING (VERIFICATION) ........................................................ 4-4

CONFIGURING THE METER VIA THE FRONT PANEL .......................................................... 4-5

O

VERVIEW ............................................................................................................................ 4-5

S

TART UP .............................................................................................................................. 4-5

M

AIN MENU ......................................................................................................................... 4-6

R

ESET MODE AND PASSWORD ENTRY .............................................................................4-6

CHANGING SETTINGS IN CONFIGURATION MODE ...........................................................4-9

D

ESCRIPTION ........................................................................................................................ 4-9

C

ONFIGURING THE SCROLL FEATURE ............................................................................... 4-9

P

ROGRAMMING THE CONFIGURATION MODE SCREENS ................................................ 4-10

C

ONFIGURING THE CT SETTING ........................................................................................ 4-11

C

ONFIGURING THE PT SETTING ........................................................................................4-12

C

ONFIGURING THE CONNECTION SETTING ...................................................................... 4-13

C

ONFIGURING THE COMMUNICATION PORT SETTING .................................................... 4-14

OPERATING MODE ...........................................................................................................................4-17

D

ESCRIPTION ........................................................................................................................ 4-17

5: COMMUNICATIONS MODBUS COMMUNICATIONS ..................................................................................................... 5-1

EMORY MAP DESCRIPTION ............................................................................................. 5-1

M

M

EMORY MAP ......................................................................................................................5-1

M

ODBUS MEMORY MAP NOTES .......................................................................................5-7

M

ODBUS MEMORY MAP DATA FORMATS ........................................................................5-9

DNP POINT MAPPING ..................................................................................................................... 5-10

DNP P

OINT MAPS ..............................................................................................................5-10

DNP P

OINT MAP NOTES ...................................................................................................5-12

TOC–2 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 5

DNP IMPLEMENTATION ................................................................................................................. 5-13

O

VERVIEW ............................................................................................................................ 5-13

D

ATA LINK LAYER ................................................................................................................ 5-13

T

RANSPORT LAYER .............................................................................................................. 5-13

A

PPLICATION LAYER ............................................................................................................5-14

DNP OBJECTS AND VARIATIONS ............................................................................................... 5-15

D

ESCRIPTION ........................................................................................................................ 5-15

B

INARY OUTPUT STATUS (OBJECT 10, VARIATION 2) ...................................................5-15

C

ONTROL RELAY OUTPUT (OBJECT 12, VARIATION 1) .................................................. 5-15

32-B

IT BINARY COUNTER WITHOUT FLAG (OBJECT 20, VARIATION 4) .................... 5-16

16-B

IT ANALOG INPUT WITHOUT FLAG (OBJECT 30, VARIATION 5) ......................... 5-16

C

LASS 0 DATA (OBJECT 60, VARIATION 1) ..................................................................... 5-17

I

NTERNAL INDICATIONS (OBJECT 80, VARIATION 1) ...................................................... 5-17

6: MISCELLANEOUS NAVIGATION MAPS .........................................................................................................................6-1

NTRODUCTION .....................................................................................................................6-1

I

M

AIN MENU SCREENS ........................................................................................................ 6-2

O

PERATING MODE SCREENS ............................................................................................. 6-3

R

ESET MODE SCREENS ....................................................................................................... 6-4

C

ONFIGURATION MODE SCREENS .................................................................................... 6-5

REVISION HISTORY .......................................................................................................................... 6-6

R

ELEASE DATES ...................................................................................................................6-6

C

HANGES TO THE MANUAL ............................................................................................... 6-6

WARRANTY ......................................................................................................................................... 6-8

GE M

ULTILIN WARRANTY .................................................................................................. 6-8

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE TOC–3

Page 6

TOC–4 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 7

GE Consumer & Industrial

Multilin

1.1 Introduction

EPM 6000 Multi-function Power

Metering System

Chapter 1: Overview

Overview

1.1.1 Description

1.1.2 Highlights

The EPM 6000 is a multifunction power meter designed to be used in electrical substations,

panel boards and as a power meter for OEM equipment. The unit provides multifunction

measurement of electrical parameters.

The unit is designed with advanced measurement capabilities, allowing it to achieve high

performance accuracy. The EPM 6000 is specified as a 0.2% class energy meter for billing

applications as well as a highly accurate panel indication meter.

The EPM 6000 provides a host of additional capabilities, including standard RS485 Modbus

Protocol and an IrDA port remote interrogation.

The following EPM 6000 features are detailed in this manual:

• 0.2% class revenue certifiable energy and demand metering

• Meets ANSI C12.20 (0.2%) and IEC 687 (0.2%) classes

• Multifunction measurement including voltage, current, power, frequency, energy

• Percentage of load bar for analog meter perception

• Easy-to-use faceplate programming

• IrDA port for PDA remote read

• RS485 Modbus communications

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 1–1

Page 8

FIGURE 1–1: EPM 6000 Highlights

CHAPTER 1: OVERVIEW

1–2 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 9

CHAPTER 1: OVERVIEW

1.2 Features

1.2.1 Universal Voltage Inputs

1.2.2 Current Inputs

Voltage Inputs allow measurement to 416 V line-to-neutral and 721 V line-to-line. This

insures proper meter safety when wiring directly to high voltage systems. One unit will

perform to specification on 69 V, 120 V, 230 V, 277 V, and 347 V systems.

The EPM 6000 current inputs use a unique dual input method.

• Method 1 – CT Pass Through: The CT passes directly through the meter without

any physical termination on the meter. This insures that the meter cannot be a

point of failure on the CT circuit. This is preferable for utility users when sharing

relay class CTs. No burden is added to the secondary CT circuit.

• Method 2 – Current “Gills”: This unit additionally provides ultra-rugged

termination pass-through bars that allow CT leads to be terminated on the meter.

This, too, eliminates any possible point of failure at the meter. This is a preferred

technique for insuring that relay class CT integrity is not compromised (the CT will

not open in a fault condition).

FIGURE 1–2: Current Input Connections

1.2.3 Utility Peak Demand

The EPM 6000 provides user-configured Block (fixed) or Rolling window demand. This

feature allows you to set up a customized demand profile. Block window demand is

demand used over a user-defined demand period (usually 5, 15, or 30 minutes). Rolling

window demand is a fixed window demand that moves for a user-specified subinterval

period. For example, a 15-minute demand using 3 subintervals and providing a new

demand reading every 5 minutes, based on the last 15 minutes.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 1–3

Page 10

Utility demand features can be used to calculate kW, kvar, kVA and PF readings. All other

parameters offer maximum and minimum capability over the user-selectable averaging

period. Voltage provides an instantaneous maximum and minimum reading which

displays the highest surge and lowest sag seen by the meter.

1.2.4 Measured Values

The EPM 6000 provides the following measured values all in real time and some

additionally as average, maximum, and minimum values.

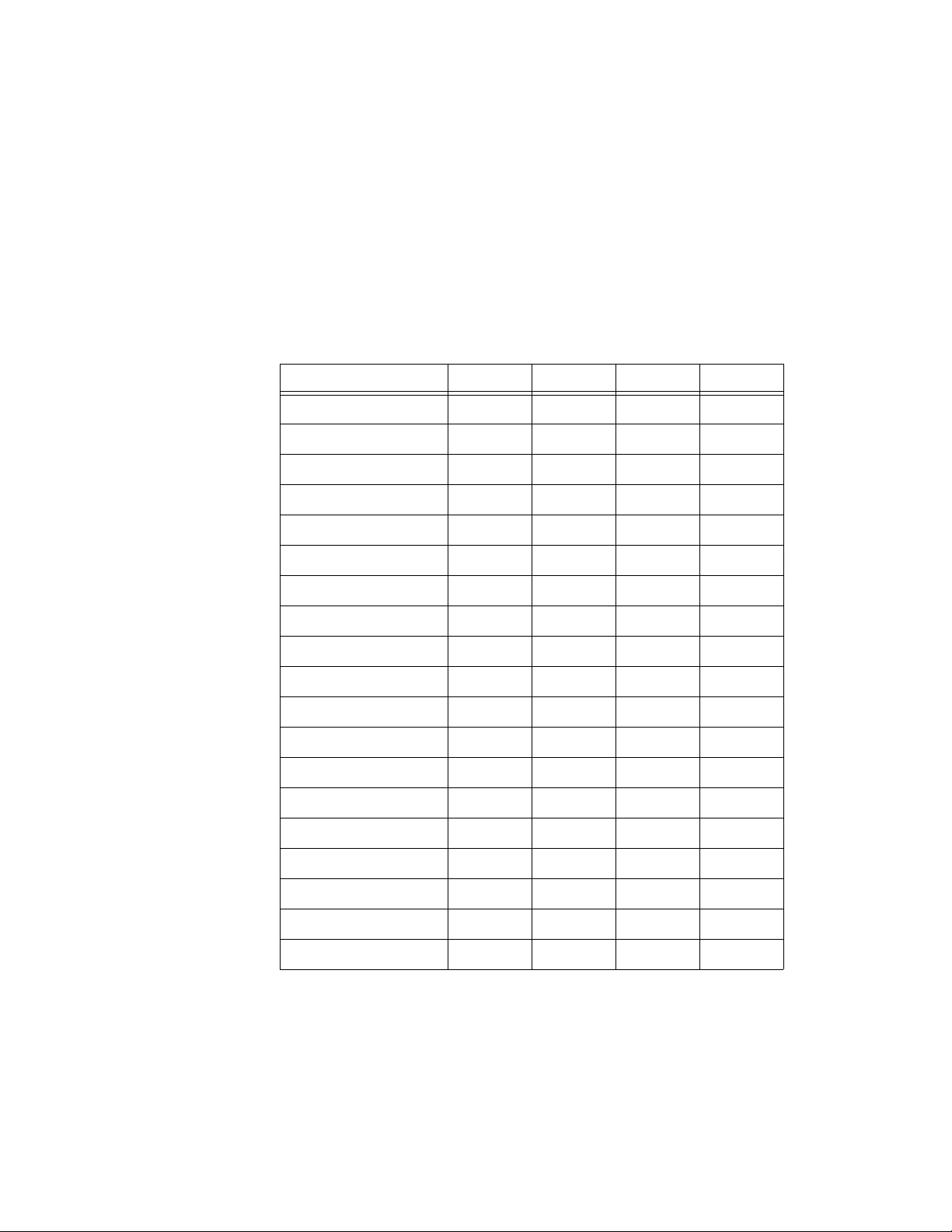

Measured Values Real Time Average Maximum Minimum

Voltage L-N XXX

Voltage L-L XXX

Current per phase XXXX

Watts XXXX

CHAPTER 1: OVERVIEW

Table 1–1: EPM 6000 Measured Values

vars XXXX

VA XXXX

Power Factor (PF) XXXX

Positive watt-hours X

Negative watt-hours X

Net watt-hours X

Positive var-hours X

Negative var-hours X

Net var-hours X

VA-hours X

Frequency XXX

%THD XXX

Voltage angles X

Current angles X

% of load bar X

1–4 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 11

CHAPTER 1: OVERVIEW

1.3 Ordering

1.3.1 Order Codes

The order codes for the EPM 6000 are indicated below.

Table 1–2: EPM 6000 Order Codes

PL6000 – * – * – *

Base Unit

System

Frequency

Current Input

THD and Pulse Output

For example, to order an EPM 6000 for 60 Hz system with a 1 A secondary CT input and no

THD or pulse output option, select order code PL6000-6-1A-0. The standard unit includes

display, all current/voltage/power/frequency/energy counters, percent load bar, RS485,

and IrDA communication ports.

PL6000 || |

5 | |

6 | |

1A |

5A |

EPM 6000 Power Metering System

50 Hz AC frequency system

60 Hz AC frequency system

1 A secondary CT

5 A secondary CT

No THD or pulse output option

0

THD, limit alarms, and 1 KYZ pulse output

THD

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 1–5

Page 12

1.4 Specifications

1.4.1 Inputs/Outputs

CHAPTER 1: OVERVIEW

POWER SUPPLY

Range:..................................................................D2 Option: Universal, 90 to 265 V AC at 50/60Hz, or 100 to

370 V DC

D Option: 18 to 60 V DC

Power consumption:.....................................5 VA, 3.5 W

VOLTAGE INPUTS (MEASUREMENT CATEGORY III)

Range:..................................................................Universal, Auto-ranging up to 416 V AC L-N, 721 V AC L-L

Supported hookups:......................................3-element Wye, 2.5-element Wye, 2-element Delta,

4-wire Delta

Input impedance:...........................................1 MOhm/phase

Burden:................................................................0.0144 VA/phase at 120 Volts

Pickup voltage: ................................................10 V AC

Connection:.......................................................Screw terminal (see Voltage Connection on page 3–8)

Maximum input wire gauge: ....................AWG #12 / 2.5 mm

Fault withstand: ..............................................Meets IEEE C37.90.1

Reading:..............................................................Programmable full-scale to any PT ratio

2

1.4.2 Metering

CURRENT INPUTS

Class 10:..............................................................5 A nominal, 10 A maximum

Class 2: ................................................................1 A nominal, 2 A maximum

Burden:................................................................0.005 VA per phase maximum at 11 A

Pickup current:.................................................0.1% of nominal

Connections:.....................................................O or U lug (see CT Leads Terminated to Meter on page 3–

6);

Pass-through wire, 0.177" / 4.5 mm maximum diameter

(see Pass-Through Wire Electrical Connection on page

3–7);

Quick connect, 0.25" male tab

(see Quick Connect Electrical Connection on page 3–7)

Fault Withstand:..............................................100 A / 10 seconds, 300 A / 3 seconds, 500 A / 1 second

Reading:..............................................................Programmable full-scale to any CT ratio

MEASUREMENT METHODS

Voltage and current:.....................................true RMS

Power:..................................................................sampling at 400+ samples/cycle on all channels

measured; readings simultaneously

A/D conversion:...............................................6 simultaneous 24-bit analog-to-digital converters

UPDATE RATE

Watts, vars, and VA: ......................................100 ms (10 times per second)

All other parameters:....................................1 second

1–6 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 13

CHAPTER 1: OVERVIEW

ACCURACY

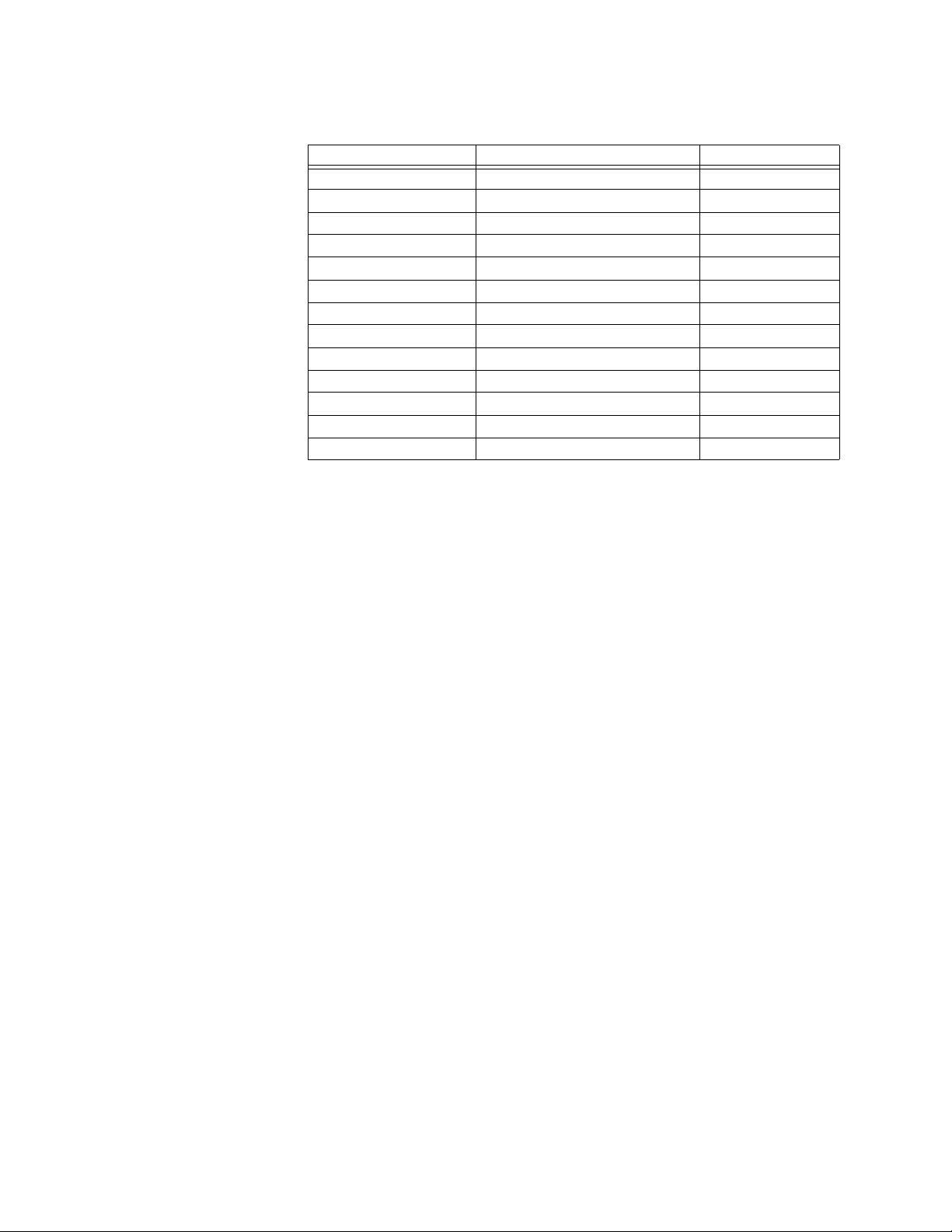

Measured Parameters Display Range Accuracy

Voltage L-N 0 to 9999 kV or scalable 0.1% of reading

Voltage L-L 0 to 9999 V or kV scalable 0.1% of reading

Current 0 to 9999 A or kA 0.1% of reading

+/– Watts 0 to 9999 W, kW, or MW 0.2% of reading

+/– Wh 5 to 8 digits (programmable) 0.2% of reading

+/– vars 0 to 9999 vars, kvars, Mvars 0.2% of reading

+/– varh 5 to 8 digits (programmable) 0.2% of reading

VA 0 to 9999 VA, kVA, MVA 0.2% of reading

VAh 5 to 8 digits (programmable) 0.2% of reading

Power Factor (PF) ±0.5 to 1.0 0.2% of reading

Frequency 45 to 65 Hz 0.01 Hz

% THD 0 to 100% 2.0% F.S.

% Load Bar 10 digit resolution scalable 1 to 120% of reading

NOTE: Typical results are more accurate.

1.4.3 Environmental

TEMPERATURE AND HUMIDITY

Storage:...............................................................–40 to 85°C

Operating:..........................................................–30 to 70°C

Humidity:............................................................up to 95% RH, non-condensing

Faceplate rating: ............................................NEMA 12 (water resistant), mounting gasket included

1.4.4 Communications

COMMUNICATIONS FORMAT

Types:...................................................................RS485 port through back plate

COMMUNICATIONS PORTS

Protocol:..............................................................Modbus RTU, Modbus ASCII, DNP 3.0

Baud rate: ..........................................................9600 to 57600 bps

Port address: ....................................................001 to 247

Data format:.....................................................8 bits, no parity

1.4.5 Mechanical Parameters

DIMENSIONS

Size:.......................................................................4.25" × 4.82" × 4.85" (L × W × H)

Mounting:...........................................................mounts in 92 mm square DIN or ANSI C39.1 4-inch round

Weight:................................................................2 pounds / 0.907 kg

Shipping..............................................................ships in 6-inch / 152.4 mm cube container

IrDA port through face plate

105.4 mm × 123.2 mm × 123.2 mm (L × W × H)

cut-out

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 1–7

Page 14

1.4.6 Approvals

CHAPTER 1: OVERVIEW

TYPE TESTING

IEC 687 (0.2% accuracy)

ANSI C12.20 (0.2% accuracy)

ANSI (IEEE) C37.90.1: ....................................Surge Withstand

ANSI C62.41 (burst)

IEC 1999-4-2: ...................................................ESD

IEC 1000-4-3: ...................................................Radiated Immunity

IEC 1000-4-4: ...................................................Fast Transient

IEC 1000-4-5: ...................................................Surge Immunity

COMPLIANCE

ISO: ........................................................................manufactured to an ISO9001 registered program

UL:..........................................................................UL listed (file E250818)

CSA:.......................................................................Certified per: C22.2 No.1010.1 Electrical and Electronic

Measuring and Testing Equipment

CE:..........................................................................conforms to EN 55011 / EN 50082

1–8 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 15

GE Consumer & Industrial

Multilin

EPM 6000 Multi-function Power

Metering System

Chapter 2: Electrical Background

Electrical Background

2.1 Three-Phase Power Measurement

2.1.1 Description

This introduction to three-phase power and power measurement is intended to provide

only a brief overview of the subject. The professional meter engineer or meter technician

should refer to more advanced documents such as the EEI Handbook for Electricity

Metering and the application standards for more in-depth and technical coverage of the

subject.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–1

Page 16

2.2 Three-Phase System Configurations

2.2.1 Description

Three-phase power is most commonly used in situations where large amounts of power

will be used because it is a more effective way to transmit the power and because it

provides a smoother delivery of power to the end load. There are two commonly used

connections for three-phase power, a wye connection or a delta connection. Each

connection has several different manifestations in actual use. When attempting to

determine the type of connection in use, it is a good practice to follow the circuit back to

the transformer that is serving the circuit. It is often not possible to conclusively determine

the correct circuit connection simply by counting the wires in the service or checking

voltages. Checking the transformer connection will provide conclusive evidence of the

circuit connection and the relationships between the phase voltages and ground.

2.2.2 Wye Connection

The wye connection is so called because when you look at the phase relationships and the

winding relationships between the phases it looks like a wye (Y). The following figure

depicts the winding relationships for a wye-connected service. In a wye service the neutral

(or center point of the wye) is typically grounded. This leads to common voltages of 208/

120 and 480/277 (where the first number represents the phase-to-phase voltage and the

second number represents the phase-to-ground voltage).

CHAPTER 2: ELECTRICAL BACKGROUND

Ia

A

Van

B

C

FIGURE 2–1: Three-Phase Wye Winding

Vbn

N

Vcn

The three voltages are electrically separated by 120°. Under balanced load conditions with

unity power factor, the currents are also separated by 120°. However, unbalanced loads

and other conditions can cause the currents to depart from the ideal 120° separation.

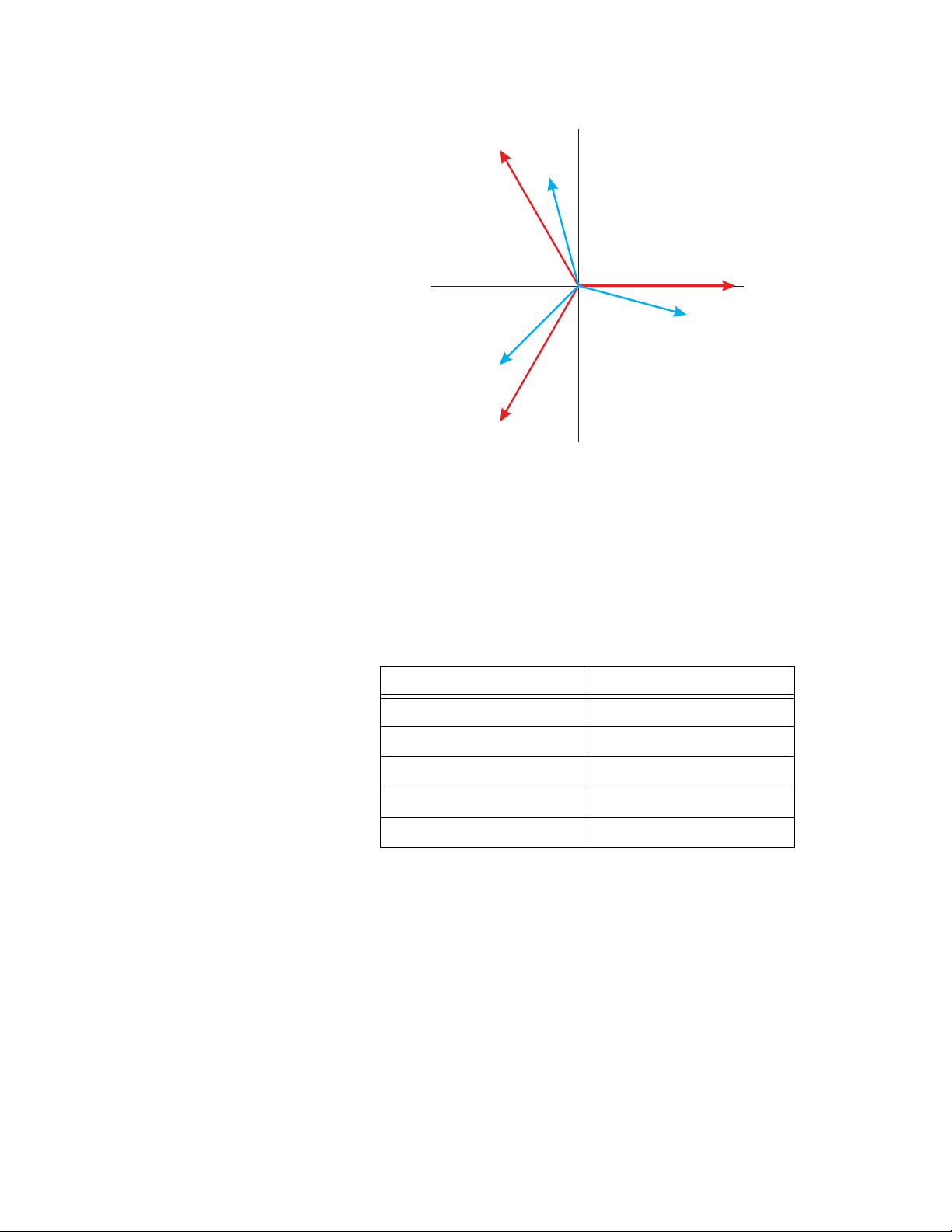

Three-phase voltages and currents are usually represented with a phasor diagram. A

phasor diagram for the typical connected voltages and currents is shown below.

2–2 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 17

CHAPTER 2: ELECTRICAL BACKGROUND

The phasor diagram shows the 120° angular separation between the phase voltages. The

phase-to-phase voltage in a balanced three-phase wye system is 1.732 times the phaseto-neutral voltage. The center point of the wye is tied together and is typically grounded.

The following table indicates the common voltages used in the United States for wyeconnected systems.

Vcn

Ic

Van

Ia

Ib

Vbn

FIGURE 2–2: Three-Phase Voltage and Current Phasors for Wye Winding

Table 2–1: Common Phase Voltages on Wye Services

Phase-to-Ground Voltage Phase-to-Phase Voltage

120 volts 208 volts

277 volts 480 volts

2400 volts 4160 volts

7200 volts 12470 volts

7620 volts 13200 volts

Usually, a wye-connected service will have four wires: three wires for the phases and one

for the neutral. The three-phase wires connect to the three phases. The neutral wire is

typically tied to the ground or center point of the wye (refer to the Three-Phase Wye

Winding diagram above).

In many industrial applications the facility will be fed with a four-wire wye service but only

three wires will be run to individual loads. The load is then often referred to as a deltaconnected load but the service to the facility is still a wye service; it contains four wires if

you trace the circuit back to its source (usually a transformer). In this type of connection

the phase to ground voltage will be the phase-to-ground voltage indicated in the table

above, even though a neutral or ground wire is not physically present at the load. The

transformer is the best place to determine the circuit connection type because this is a

location where the voltage reference to ground can be conclusively identified.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–3

Page 18

2.2.3 Delta Connection

Delta connected services may be fed with either three wires or four wires. In a three-phase

delta service the load windings are connected from phase-to-phase rather than from

phase-to-ground. The following figure shows the physical load connections for a delta

service.

CHAPTER 2: ELECTRICAL BACKGROUND

A

Ia

Iab

Vab

Vca

B

Vbc

Ib

Ica

Ibc

Ic

C

FIGURE 2–3: Three-Phase Delta Winding Relationship

In this example of a delta service, three wires will transmit the power to the load. In a true

delta service, the phase-to-ground voltage will usually not be balanced because the

ground is not at the center of the delta.

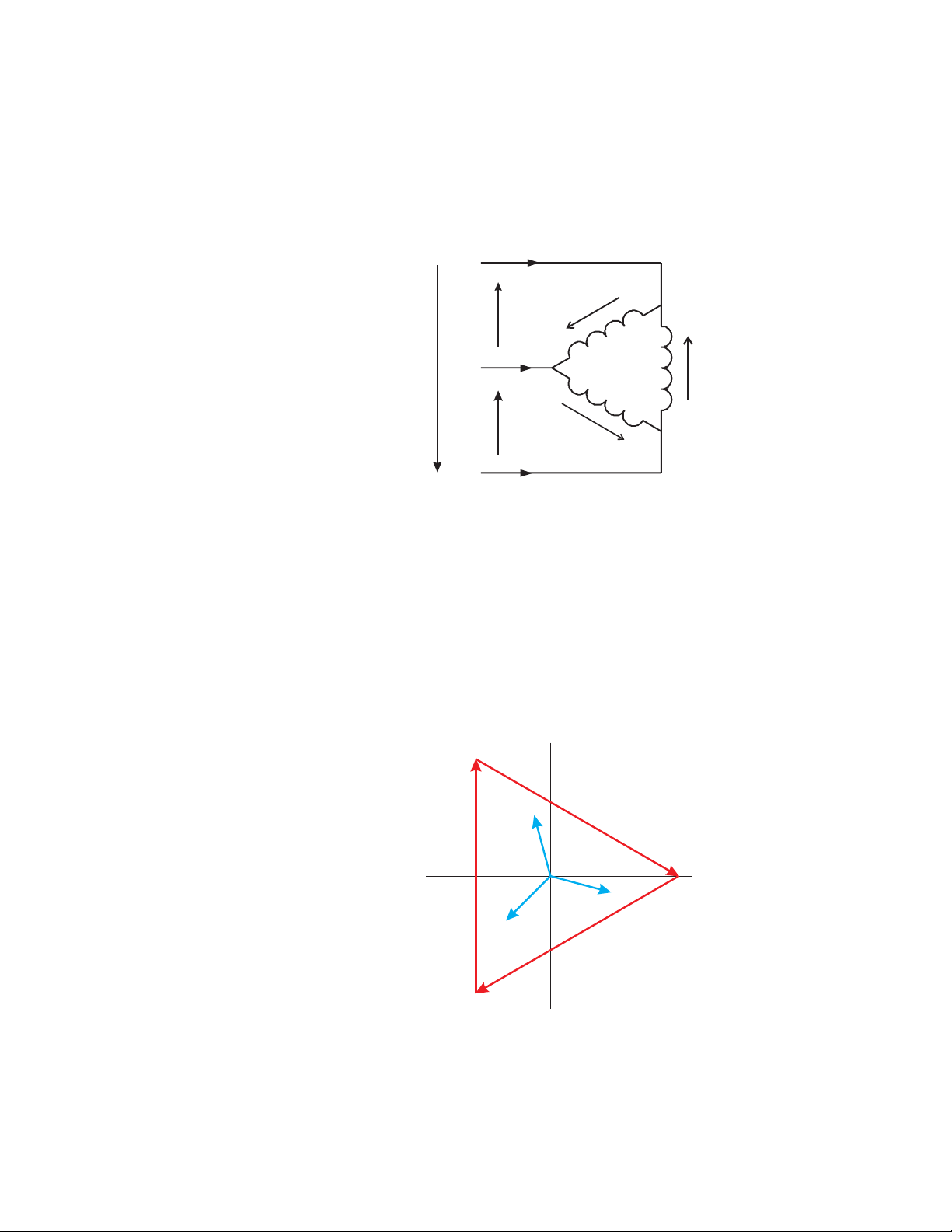

The following diagram shows the phasor relationships between voltage and current on a

three-phase delta circuit.

In many delta services, one corner of the delta is grounded. This means the phase to

ground voltage will be zero for one phase and will be full phase-to-phase voltage for the

other two phases. This is done for protective purposes.

Vca

Ic

Vbc

Ia

Ib

Vab

FIGURE 2–4: Three-Phase Voltage and Current Phasors for Delta Winding

2–4 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 19

CHAPTER 2: ELECTRICAL BACKGROUND

Another common delta connection is the four-wire, grounded delta used for lighting loads.

In this connection the center point of one winding is grounded. On a 120/240 volt, fourwire, grounded delta service the phase-to-ground voltage would be 120 volts on two

phases and 208 volts on the third phase. The phasor diagram for the voltages in a threephase, four-wire delta system is shown below.

120 V

Vbc

120 V

FIGURE 2–5: Three-Phase, Four-Wire Delta Phasors

Vnc

Vbn

2.2.4 Blondell's Theorem and Three-Phase Measurement

In 1893 an engineer and mathematician named Andre E. Blondell set forth the first

scientific basis for poly phase metering. His theorem states:

If energy is supplied to any system of conductors through N wires, the total power in the

system is given by the algebraic sum of the readings of N watt-meters so arranged that

each of the N wires contains one current coil, the corresponding potential coil being

connected between that wire and some common point. If this common point is on one

of the N wires, the measurement may be made by the use of N-1 wattmeters.

Vca

Vab

The theorem may be stated more simply, in modern language:

In a system of N conductors, N – 1 meter elements will measure the power or energy

taken provided that all the potential coils have a common tie to the conductor in which

there is no current coil.

Three-phase power measurement is accomplished by measuring the three individual

phases and adding them together to obtain the total three phase value. In older analog

meters, this measurement was made using up to three separate elements. Each element

combined the single-phase voltage and current to produce a torque on the meter disk. All

three elements were arranged around the disk so that the disk was subjected to the

combined torque of the three elements. As a result the disk would turn at a higher speed

and register power supplied by each of the three wires.

According to Blondell's Theorem, it was possible to reduce the number of elements under

certain conditions. For example, a three-phase, three-wire delta system could be correctly

measured with two elements (two potential coils and two current coils) if the potential coils

were connected between the three phases with one phase in common.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–5

Page 20

CHAPTER 2: ELECTRICAL BACKGROUND

In a three-phase, four-wire wye system it is necessary to use three elements. Three voltage

coils are connected between the three phases and the common neutral conductor. A

current coil is required in each of the three phases.

In modern digital meters, Blondell's Theorem is still applied to obtain proper metering. The

difference in modern meters is that the digital meter measures each phase voltage and

current and calculates the single-phase power for each phase. The meter then sums the

three phase powers to a single three-phase reading.

Some digital meters calculate the individual phase power values one phase at a time. This

means the meter samples the voltage and current on one phase and calculates a power

value. Then it samples the second phase and calculates the power for the second phase.

Finally, it samples the third phase and calculates that phase power. After sampling all three

phases, the meter combines the three readings to create the equivalent three-phase

power value. Using mathematical averaging techniques, this method can derive a quite

accurate measurement of three-phase power.

More advanced meters actually sample all three phases of voltage and current

simultaneously and calculate the individual phase and three-phase power values. The

advantage of simultaneous sampling is the reduction of error introduced due to the

difference in time when the samples were taken.

Blondell's Theorem is a derivation that results from Kirchhoff's Law. Kirchhoff's Law states

that the sum of the currents into a node is zero. Another way of stating the same thing is

that the current into a node (connection point) must equal the current out of the node. The

law can be applied to measuring three-phase loads. The figure below shows a typical

connection of a three-phase load applied to a three-phase, four-wire service. Kirchhoff's

Laws hold that the sum of currents A, B, C and N must equal zero or that the sum of

currents into Node “n” must equal zero.

C

B

Phase B

Phase C

Node "n"

Phase A

A

N

FIGURE 2–6: Three-Phase Load Illustrating Kirchhoff’s Law and Blondell’s Theorem

2–6 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 21

CHAPTER 2: ELECTRICAL BACKGROUND

If we measure the currents in wires A, B and C, we then know the current in wire N by

Kirchhoff's Law and it is not necessary to measure it. This fact leads us to the conclusion of

Blondell's Theorem that we only need to measure the power in three of the four wires if

they are connected by a common node. In the circuit of Figure 1.6 we must measure the

power flow in three wires. This will require three voltage coils and three current coils (a

three element meter). Similar figures and conclusions could be reached for other circuit

configurations involving delta-connected loads.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–7

Page 22

2.3 Power, Energy, and Demand

2.3.1 Description

It is quite common to exchange power, energy, and demand without differentiating

between the three. Because this practice can lead to confusion, the differences between

these three measurements will be discussed.

2.3.2 Power

Power is an instantaneous reading. The power reading provided by a meter is the present

flow of watts. Power is measured immediately just like current. In many digital meters, the

power value is actually measured and calculated over a one-second interval, since it takes

some amount of time to calculate the RMS values of voltage and current. However, this

time interval is kept small to preserve the instantaneous nature of power.

2.3.3 Energy

CHAPTER 2: ELECTRICAL BACKGROUND

Energy is always based upon some time increment – it is the integration of power over a

defined time increment. Energy is an important value because almost all electric bills are

based, in part, on the amount of energy consumed.

Typically, electrical energy is measured in units of kilowatt-hours (kWh). A kilowatt-hour

represents a constant load of 1000 watts (1 kW) for 1 hour. Stated another way, if the

power delivered (instantaneous watts) is measured as 1000 W, and the load was served for

a one-hour time interval, then the load would have absorbed 1 kWh of energy. A different

load may have a constant power requirement of 4000 W. If this load were served for one

hour, it would absorb 4 kWh of energy. Likewise, if it were served for 15 minutes, it would

absorb ¼ of that total, or 1 kWh.

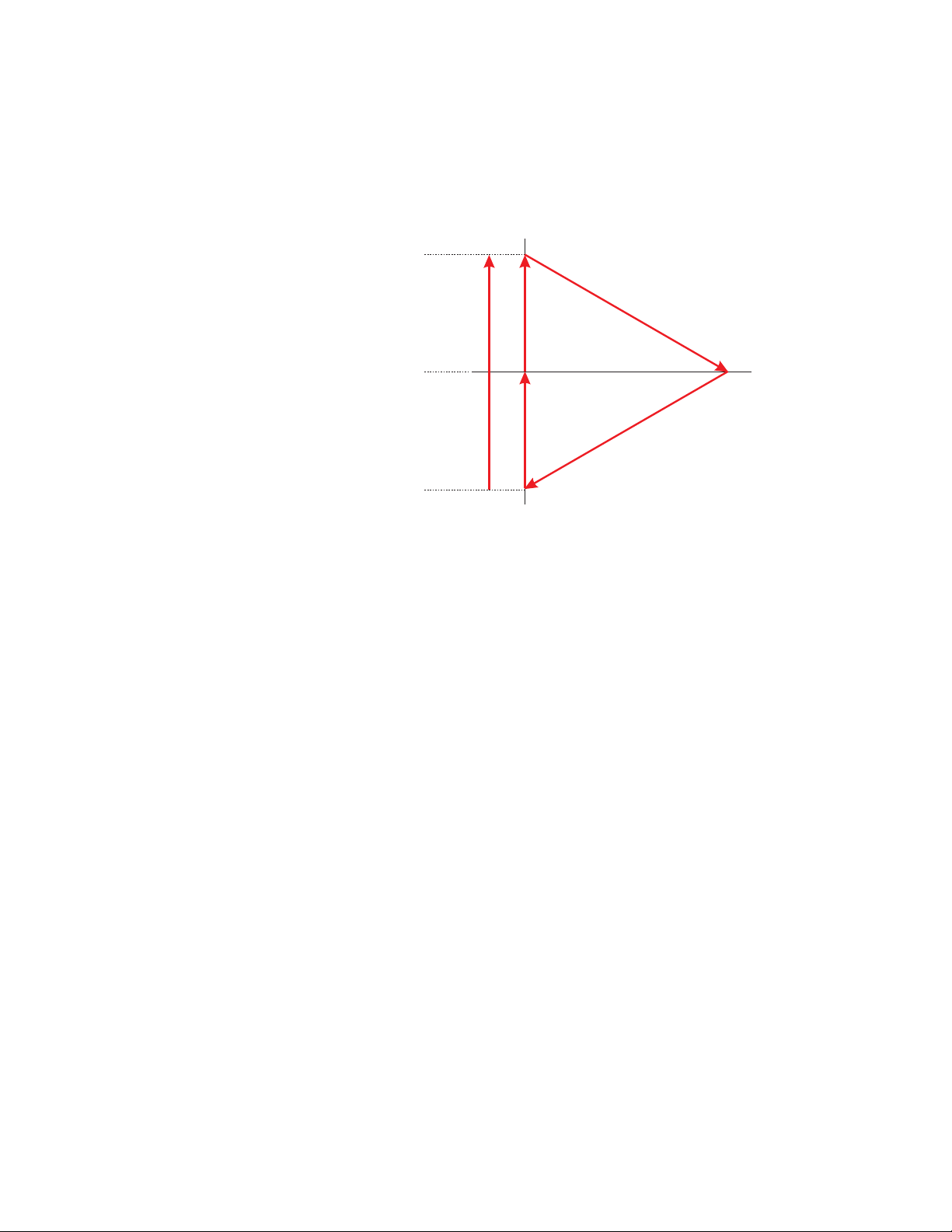

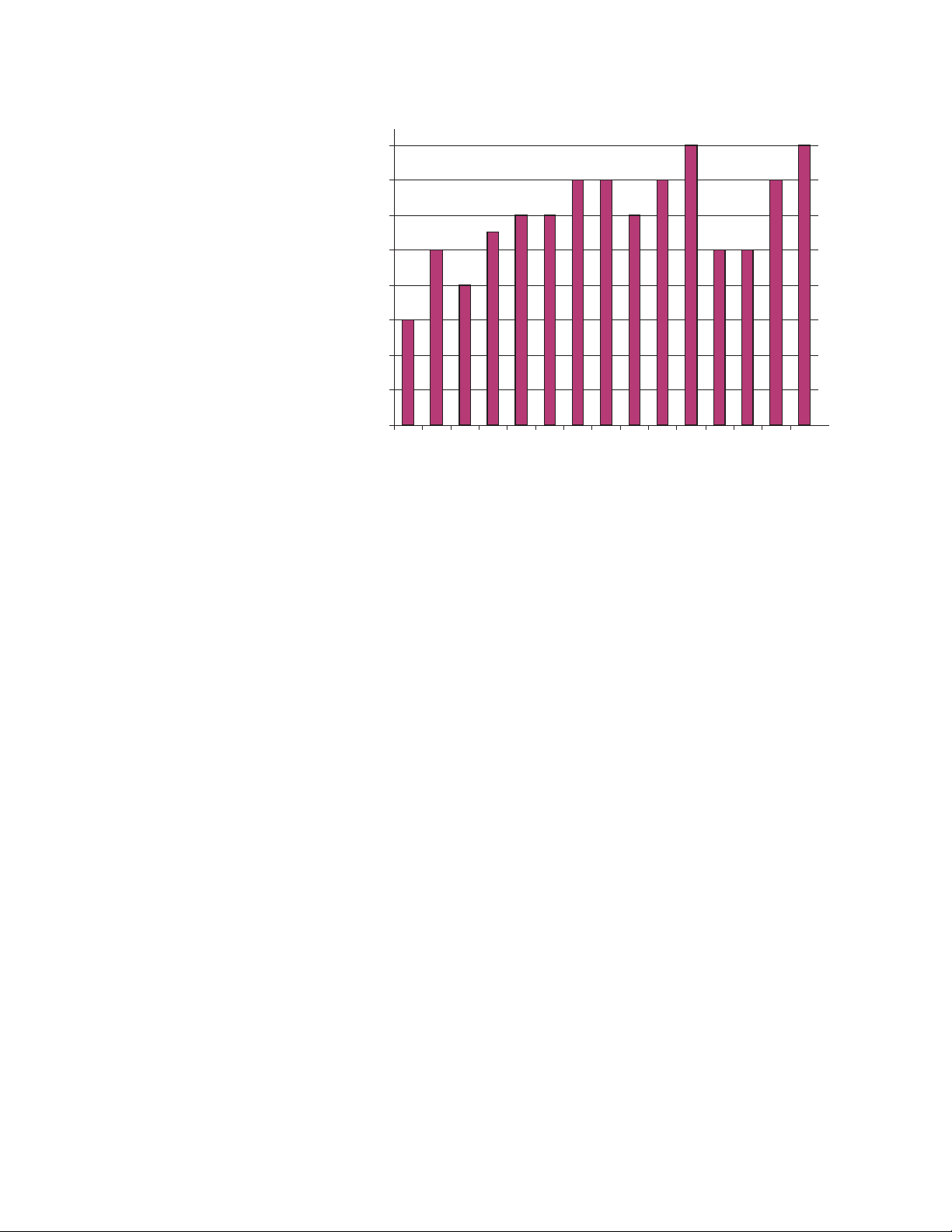

The following figure shows a graph of power and the resulting energy that would be

transmitted as a result of the illustrated power values. For this illustration, it is assumed

that the power level is held constant for each minute when a measurement is taken. Each

bar in the graph represents the power load for the one-minute increment of time. In real

life, the power values are continually moving.

2–8 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 23

CHAPTER 2: ELECTRICAL BACKGROUND

kilowatts

80

70

60

50

40

30

20

10

0

123456789101112131415

Time (minutes)

FIGURE 2–7: Power Use Over Time

The data in the above figure is reproduced in the following table to illustrate the

calculation of energy. Since the time increment of the measurement is one minute, and

since we specified a constant load over that minute, the power reading can be converted

to an equivalent consumed energy reading by multiplying the power reading by 1/60

(converting the time base from minutes to hours).

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–9

Page 24

CHAPTER 2: ELECTRICAL BACKGROUND

Table 2–2: Power and Energy Relationship Over Time

Time Interval Power Energy Accumulated

Energy

1 minute 30 kW 0.50 kWh 0.50 kWh

2 minutes 50 kW 0.83 kWh 1.33 kWh

3 minutes 40 kW 0.67 kWh 2.00 kWh

4 minutes 55 kW 0.92 kWh 2.92 kWh

5 minutes 60 kW 1.00 kWh 3.92 kWh

6 minutes 60 kW 1.00 kWh 4.92 kWh

7 minutes 70 kW 1.17 kWh 6.09 kWh

8 minutes 70 kW 1.17 kWh 7.26 kWh

9 minutes 60 kW 1.00 kWh 8.26 kWh

10 minutes 70 kW 1.17 kWh 9.43 kWh

11 minutes 80 kW 1.33 kWh 10.76 kWh

12 minutes 50 kW 0.83 kWh 12.42 kWh

13 minutes 50 kW 0.83 kWh 12.42 kWh

14 minutes 70 kW 1.17 kWh 13.59 kWh

2.3.4 Demand

15 minutes 80 kW 1.33 kWh 14.92 kWh

As shown in the above table, the accumulated energy for the power load profile of the

data in Power Use Over Time on page 2–9 is 14.92 kWh.

Demand is also a time-based value. The demand is the average rate of energy use over

time. The actual label for demand is kilowatt-hours/hour but this is normally reduced to

kilowatts. This makes it easy to confuse demand with power. But demand is not an

instantaneous value. To calculate demand it is necessary to accumulate the energy

readings (as illustrated in Power Use Over Time on page 2–9) and adjust the energy reading

to an hourly value that constitutes the demand.

In the example, the accumulated energy is 14.92 kWh. But this measurement was made

over a 15-minute interval. To convert the reading to a demand value, it must be

normalized to a 60-minute interval. If the pattern were repeated for an additional three 15minute intervals the total energy would be four times the measured value or 59.68 kWh.

The same process is applied to calculate the 15-minute demand value. The demand value

associated with the example load is 59.68 kWh/hour or 59.68 kWd. Note that the peak

instantaneous value of power is 80 kW, significantly more than the demand value.

2–10 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 25

CHAPTER 2: ELECTRICAL BACKGROUND

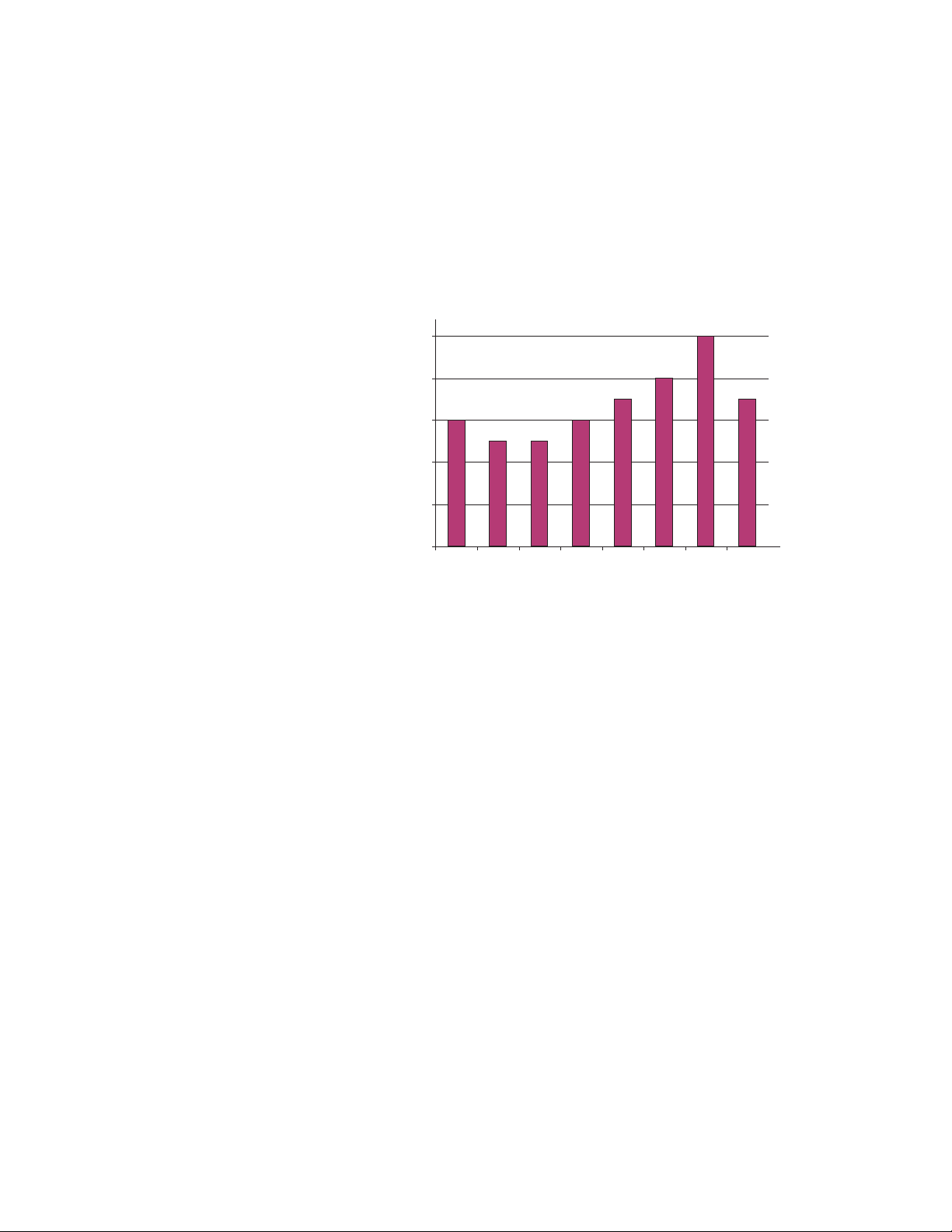

The following figure illustrates another example of energy and demand. In this case, each

bar represents the energy consumed in a 15-minute interval. The energy use in each

interval typically falls between 50 and 70 kWh. However, during two intervals the energy

rises sharply and peaks at 100 kWh in interval #7. This peak of usage will result in setting a

high demand reading. For each interval shown the demand value would be four times the

indicated energy reading. So interval 1 would have an associated demand of 240 kWh/hr.

Interval #7 will have a demand value of 400 kWh/hr. In the data shown, this is the peak

demand value and would be the number that would set the demand charge on the utility

bill.

100

80

60

40

kilowatt-hours

20

0

12345678

FIGURE 2–8: Energy Use and Demand Intervals

Intervals (15 mins.)

As seen in this example, it is important to recognize the relationships between power,

energy and demand in order to effectively control loads or to correctly monitor use.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–11

Page 26

2.4 Reactive Energy and Power Factor

2.4.1 Real, Reactive, and Apparent Power

The real power and energy measurements discussed in the previous section relate to the

quantities that are most used in electrical systems. But it is often not sufficient to only

measure real power and energy. Reactive power is a critical component of the total power

picture because almost all real-life applications have an impact on reactive power.

Reactive power and power factor concepts relate to both load and generation

applications. However, this discussion will be limited to analysis of reactive power and

power factor as they relate to loads. To simplify the discussion, generation will not be

considered.

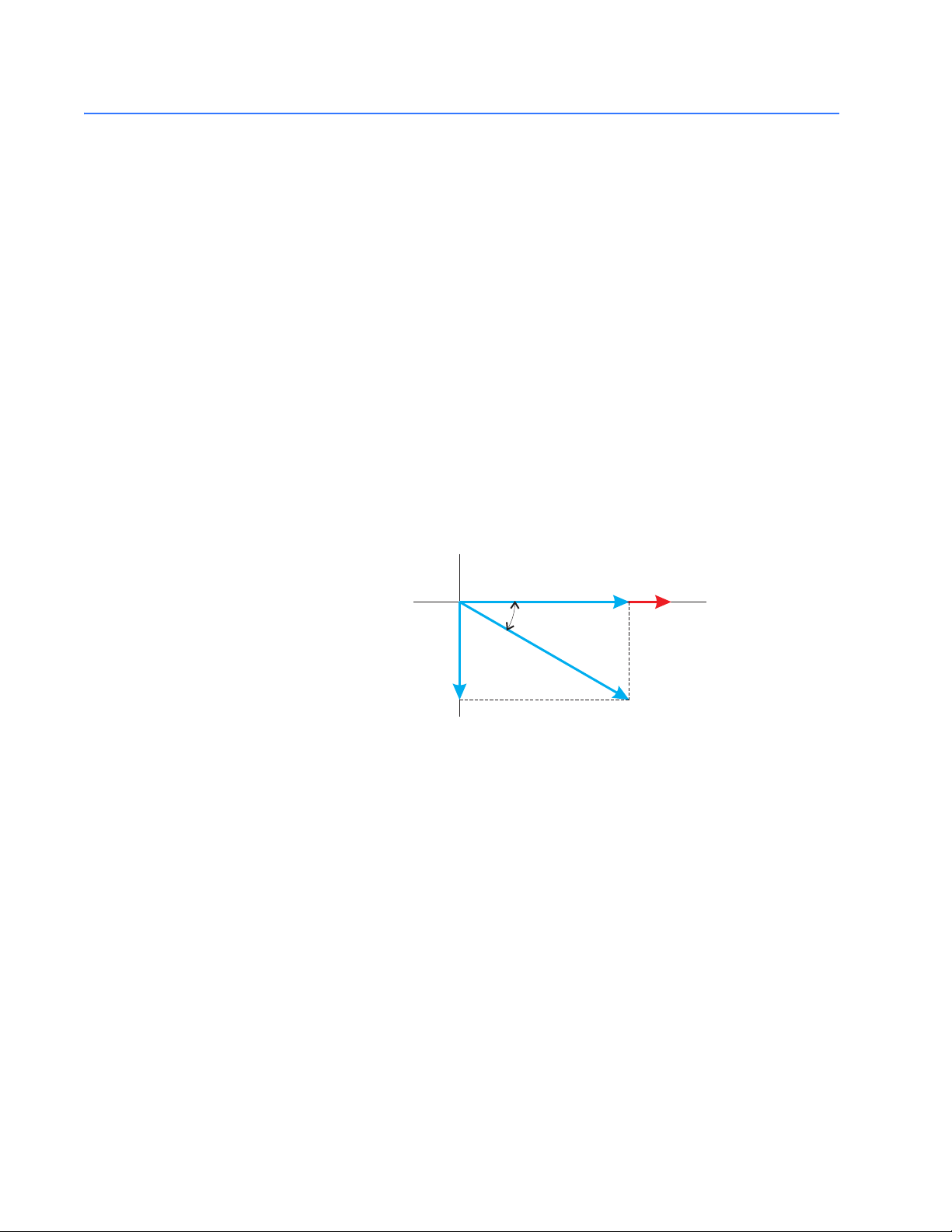

Real power (and energy) is the component of power that is the combination of the voltage

and the value of corresponding current that is directly in phase with the voltage. However,

in actual practice the total current is almost never in phase with the voltage. Since the

current is not in phase with the voltage, it is necessary to consider both the in-phase

component and the component that is at quadrature (angularly rotated 90° or

perpendicular) to the voltage. The following figure shows a single-phase voltage and

current and breaks the current into its in-phase and quadrature components.

CHAPTER 2: ELECTRICAL BACKGROUND

I

V

R

θ

I

X

FIGURE 2–9: Voltage and Complex Current

I

The voltage (V) and the total current (I) can be combined to calculate the apparent power

or VA. The voltage and the in-phase current (I

watts. The voltage and the quadrature current (I

) are combined to produce the real power or

R

) are combined to calculate the reactive

X

power.

The quadrature current may be lagging the voltage (as shown above) or it may lead the

voltage. When the quadrature current lags the voltage the load is requiring both real

power (watts) and reactive power (vars). When the quadrature current leads the voltage

the load is requiring real power (watts) but is delivering reactive power (vars) back into the

system; that is VARs are flowing in the opposite direction of the real power flow.

Reactive power (vars) is required in all power systems. Any equipment that uses

magnetization to operate requires vars. Usually the magnitude of vars is relatively low

compared to the real power quantities. Utilities have an interest in maintaining VAR

requirements at the customer to a low value in order to maximize the return on plant

invested to deliver energy. When lines are carrying vars, they cannot carry as many watts.

2–12 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 27

CHAPTER 2: ELECTRICAL BACKGROUND

So keeping the var content low allows a line to carry its full capacity of watts. In order to

encourage customers to keep VAR requirements low, most utilities impose a penalty if the

var content of the load rises above a specified value.

2.4.2 Power Factor

A common method of measuring reactive power requirements is power factor. Power

factor can be defined in two different ways. The more common method of calculating

power factor is the ratio of the real power to the apparent power. This relationship is

expressed in the following formula:

Total PF

real power

----------------------------------------

apparent power

watts

------------- -==

VA

(EQ 2.1)

This formula calculates a power factor quantity known as Total Power Factor. It is called

Total PF because it is based on the ratios of the power delivered. The delivered power

quantities will include the impacts of any existing harmonic content. If the voltage or

current includes high levels of harmonic distortion the power values will be affected. By

calculating power factor from the power values, the power factor will include the impact of

harmonic distortion. In many cases this is the preferred method of calculation because the

entire impact of the actual voltage and current are included.

A second type of power factor is Displacement Power Factor. Displacement PF is based on

the angular relationship between the voltage and current. Displacement power factor

does not consider the magnitudes of voltage, current or power. It is solely based on the

phase angle differences. As a result, it does not include the impact of harmonic distortion.

Displacement power factor is calculated using the following equation:

Displacement PF θcos=

(EQ 2.2)

where θ is the angle between the voltage and the current (see FIGURE 2–9: Voltage and

Complex Current on page 2–12).

In applications where the voltage and current are not distorted, the Total Power Factor will

equal the Displacement Power Factor. But if harmonic distortion is present, the two power

factors will not be equal.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–13

Page 28

2.5 Harmonic Distortion

2.5.1 Harmonics of a Non-Sinusoidal Waveform

Harmonic distortion is primarily the result of high concentrations of non-linear loads.

Devices such as computer power supplies, variable speed drives and fluorescent light

ballasts make current demands that do not match the sinusoidal waveform of AC

electricity. As a result, the current waveform feeding these loads is periodic but not

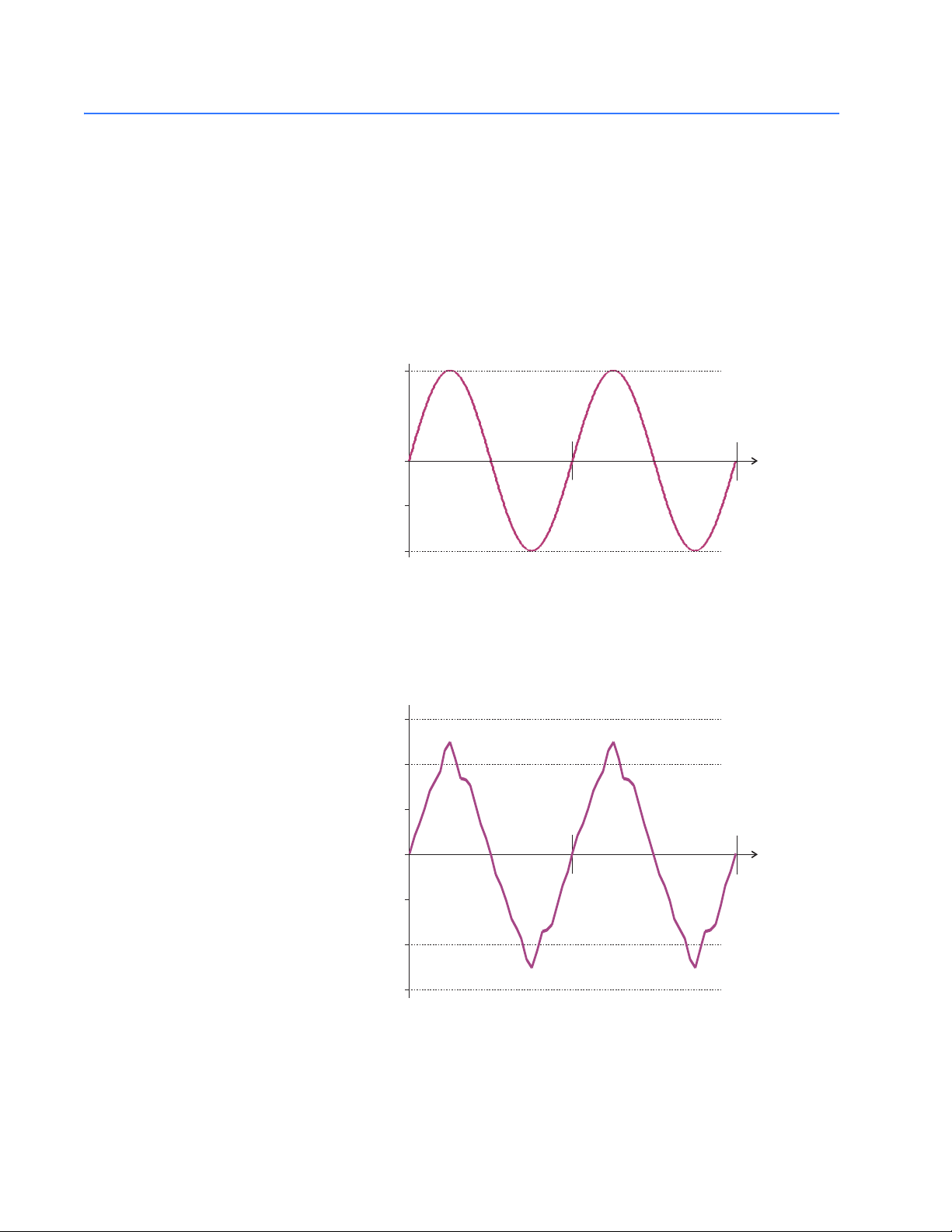

sinusoidal. The following figure shows a normal, sinusoidal current waveform with a period

of a. This example has no distortion.

CHAPTER 2: ELECTRICAL BACKGROUND

1000

500

0

Current (amps)

–500

–1000

a

FIGURE 2–10: Non-Distorted Current Waveform

t

2a

The figure below shows a current waveform with a slight amount of harmonic distortion.

The waveform is still periodic and is fluctuating at the normal 60 Hz frequency (a = 1/60

second). However, the waveform is not the smooth sinusoidal form seen above.

1500

1000

500

0

Current (amps)

–500

a

t

2a

–1000

–1500

FIGURE 2–11: Distorted Current Waveform

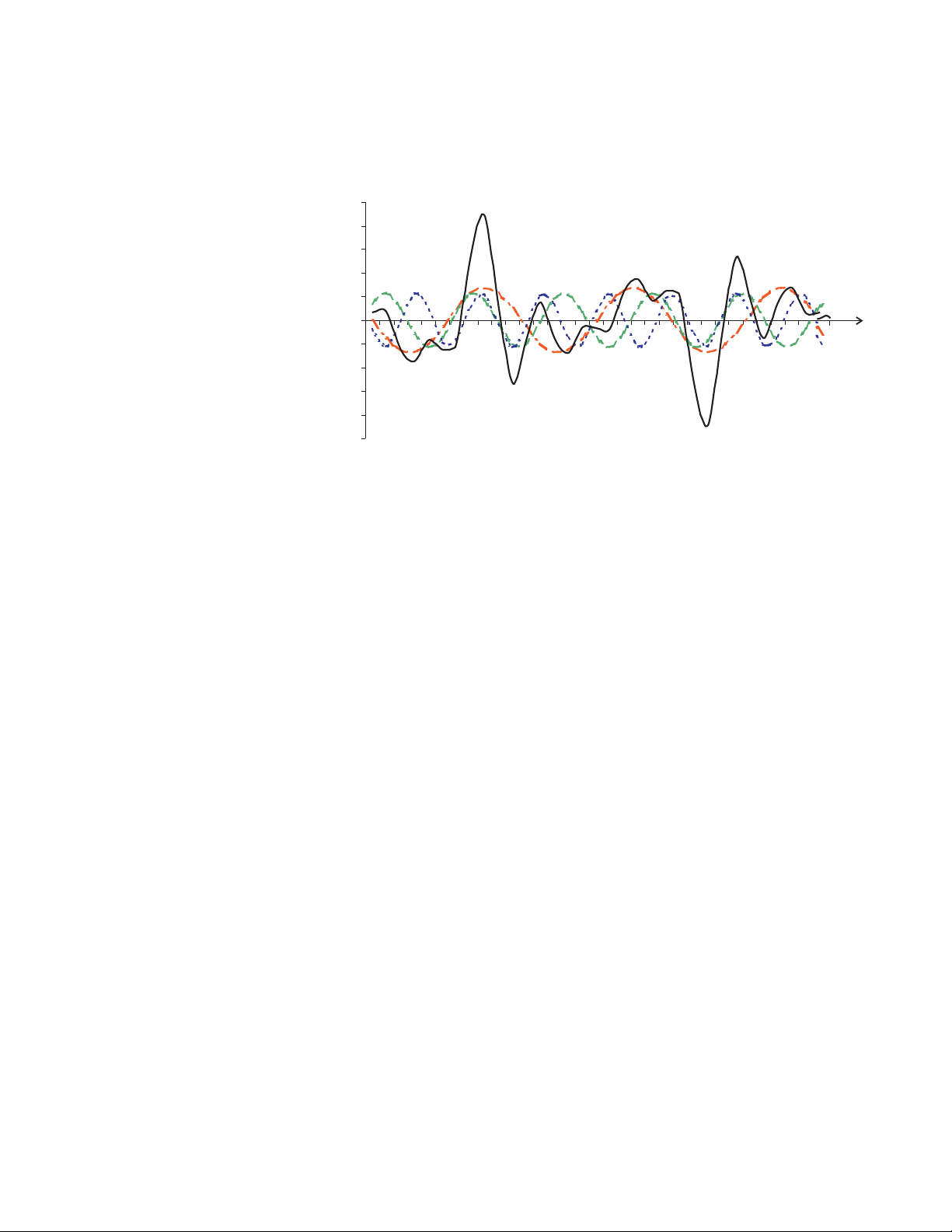

The distortion above can be modeled as the sum of several sinusoidal waveforms of

frequencies that are multiples of the fundamental 60 Hz frequency. This modeling is

performed by mathematically reducing the distorted waveform into a collection of higher

2–14 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 29

CHAPTER 2: ELECTRICAL BACKGROUND

frequency waveforms. These higher frequency waveforms are referred to as harmonics.

The following figure shows the content of the harmonic frequencies that comprise one

cycle of the distorted portion of the above waveform.

250

200

150

100

50

0

-50

Current (amps)

-100

-150

-200

-250

t

a

FIGURE 2–12: Harmonics for Distorted Current Waveform

The waveforms above provide an indication of the impact of combining multiple harmonic

frequencies together. The broken lines represent the 3rd, 5th, and 7th current harmonics.

The solid line represents the sum of the three harmonics.

When harmonics are present, it is important to remember that they are operating at

higher frequencies. As such, they do not always respond in the same manner as 60 Hz

values.

2.5.2 Inductive and Capacitive Impedance

Inductive and capacitive impedance are present in all power systems. We are accustomed

to thinking about these impedances as they perform at 60 Hz. However, these impedances

are subject to frequency variation.

XLjω L and XC1 jωC⁄==

At 60 Hz, ω = 377; but at 300 Hz (5th harmonic) ω = 1885. As frequency changes, the

impedance changes and system impedance characteristics that are normal at 60 Hz may

be entirely different in the presence of higher order harmonic waves.

Traditionally, the most common harmonics have been the low order odd frequencies, such

as the 3rd, 5th, 7th, and 9th. However newer, new-linear loads are introducing significant

quantities of higher order harmonics.

(EQ 2.3)

2.5.3 Voltage and Current Monitoring

Since much voltage monitoring and almost all current monitoring is performed using

instrument transformers, the higher order harmonics are often not visible. Instrument

transformers are designed to pass 60 Hz quantities with high accuracy. These devices,

when designed for accuracy at low frequency, do not pass high frequencies with high

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–15

Page 30

accuracy; at frequencies above about 1200 Hz they pass almost no information. So when

instrument transformers are used, they effectively filter out higher frequency harmonic

distortion making it impossible to see.

However, when monitors can be connected directly to the measured circuit (such as direct

connection to 480 V bus) the user may often see higher order harmonic distortion. An

important rule in any harmonics study is to evaluate the type of equipment and

connections before drawing a conclusion. Not being able to see harmonic distortion is not

the same as not having harmonic distortion.

2.5.4 Waveform Capture

It is common in advanced meters to perform a function commonly referred to as

waveform capture. Waveform capture is the ability of a meter to capture a present picture

of the voltage or current waveform for viewing and harmonic analysis. Typically a

waveform capture will be one or two cycles in duration and can be viewed as the actual

waveform, as a spectral view of the harmonic content, or a tabular view showing the

magnitude and phase shift of each harmonic value. Data collected with waveform capture

is typically not saved to memory. Waveform capture is a real-time data collection event.

Waveform capture should not be confused with waveform recording that is used to record

multiple cycles of all voltage and current waveforms in response to a transient condition.

CHAPTER 2: ELECTRICAL BACKGROUND

2–16 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 31

CHAPTER 2: ELECTRICAL BACKGROUND

2.6 Power Quality

2.6.1 Description

Power quality can mean several different things. The terms power quality and power

quality problem have been applied to all types of conditions. A simple definition of power

quality problem is any voltage, current or frequency deviation that results in misoperation

or failure of customer equipment or systems. The causes of power quality problems vary

widely and may originate in the customer equipment, in an adjacent customer facility or

with the utility.

In his book Power Quality Primer, Barry Kennedy provided information on different types of

power quality problems. Some of that information is summarized in the following table.

Table 2–3: Typical Power Quality Problems

Cause Disturbance Type Source(s)

Impulse

transient

Oscillatory

transient with

decay

Sag/swell

Interruptions

Undervoltage/

Overvoltage

Voltage flicker

Harmonic

distortion

It is often assumed that power quality problems originate with the utility. While it is true

that may power quality problems can originate with the utility system, many problems

originate with customer equipment. Customer-caused problems may manifest themselves

inside the customer location or they may be transported by the utility system to another

adjacent customer. Often, equipment that is sensitive to power quality problems may in

fact also be the cause of the problem.

Transient voltage disturbance,

sub-cycle duration

Transient voltage, sub-cycle

duration

RMS voltage, multiple cycle

duration

RMS voltage, multiple second or

longer duration

RMS voltage, steady state,

multiple second or longer

duration

RMS voltage, steady state,

repetitive condition

Steady-state current or voltage,

long term duration

Lightning;

Electrostatic discharge;

Load switching;

Capacitor switching

Line/cable switching;

Capacitor switching;

Load switching

Remote system faults

System protection;

Circuit breakers;

Fuses;

Maintenance

Motor starting;

Load variations;

Load dropping

Intermittent loads;

Motor starting;

Arc furnaces

Non-linear loads;

System resonance

If a power quality problem is suspected, it is generally wise to consult a power quality

professional for assistance in defining the cause and possible solutions to the problem.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 2–17

Page 32

CHAPTER 2: ELECTRICAL BACKGROUND

2–18 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 33

GE Consumer & Industrial

Multilin

EPM 6000 Multi-function Power

Chapter 3: Installation

Installation

3.1 Mechanical Installation

Metering System

3.1.1 Dimensions

The EPM 6000 meter can be installed using a standard ANSI C39.1 (4" round) or an IEC

92 mm DIN (square) form. In new installations, simply use existing DIN or ANSI punches. For

existing panels, pull out old analog meters and replace with the EPM 6000. The various

models use the same installation. See Wiring Diagrams on page 3–9 for various Wye and

Delta wiring diagrams.

FIGURE 3–1: Bezel, Side, and Back Dimensions

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–1

Page 34

3.1.2 ANSI Installation Steps

Mount the meter in a dry location free from dirt and corrosive substances. The meter is

designed to withstand harsh environmental conditions (see the Environmental

specifications in Chapter 2 for additional details).

CHAPTER 3: INSTALLATION

FIGURE 3–2: ANSI and DIN Mounting Panel Cutouts

Use the following steps to install the meter:

Z Insert the four threaded rods by hand into the back of the meter.

Twist until secure.

Z Slide the ANSI 12 mounting gasket onto the back of the meter with

the rods in place.

Z Slide the meter with the mounting gasket into the panel.

Z Secure from the back of the panel with a lock washer and nut on

each threaded rod.

Use a small wrench to tighten – do not overtighten.

3–2 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 35

CHAPTER 3: INSTALLATION

NEMA12 mounting

gasket

threaded rods

lock washer

and nut

FIGURE 3–3: ANSI Mounting Procedure

3.1.3 DIN Installation Steps

Mount the meter in a dry location free from dirt and corrosive substances. The meter is

designed to withstand harsh environmental conditions (see the Environmental

specifications in Chapter 2 for additional details).

Use the following steps to install the meter:

Z Slide the meter with NEMA 12 mounting gasket into panel.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–3

Page 36

CHAPTER 3: INSTALLATION

Z From back of the panel, slide 2 DIN mounting brackets into the

grooves on the top and bottom of the meter housing, then snap

into place.

Z Secure meter to panel with a lock washer and #8 screw through

each of the two mounting brackets.

Tighten with a #2 Phillips screwdriver – do not overtighten.

DIN mounting

bracket

top-mounting

bracket groove

bottom mounting

bracket groove

#8 screw

EPM 6000 meter

with NEMA 12

mounting gasket

FIGURE 3–4: DIN Mounting Procedure

3–4 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 37

CHAPTER 3: INSTALLATION

3.2 Electrical Installation

3.2.1 Installation Considerations

Installation of the EPM 6000 Power Metering System must be performed by only qualified

personnel who follow standard safety precautions during all procedures. Those personnel

should have appropriate training and experience with high voltage devices. Appropriate

safety gloves, safety glasses and protective clothing is recommended.

During normal operation of the EPM 6000, dangerous voltages flow through many parts of

the meter, including: Terminals and any connected CTs (current transformers) and PTs

(potential transformers), all input/output modules and their circuits. All primary and

secondary circuits can, at times, produce lethal voltages and currents. Avoid contact with

any current-carrying surfaces.

Do not use the meter or any I/O output device for primary protection or in an energylimiting capacity. The meter can only be used as secondary protection. Do not use the

meter for applications where failure of the meter may cause harm or death. Do not use the

meter for any application where there may be a risk of fire.

All meter terminals should be inaccessible after installation.

Do not apply more than the maximum voltage the meter or any attached device can

withstand. Refer to meter and/or device labels and to the Specifications for all devices

before applying voltages. Do not hi-pot/dielectric test any outputs, inputs or

communications terminals.

GE recommends the use of shorting blocks and fuses for voltage leads and power supply

to prevent hazardous voltage conditions or damage to CTs, if the meter needs to be

removed from service. CT grounding is optional.

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Note

There is no required preventive maintenance or inspection necessary for safety. however,

any repair or maintenance should be performed by the factory.

DISCONNECT DEVICE: The following part is considered the equipment disconnect

device.

A switch or circuit-breaker must be included in the end-use equipment or building

installation. The switch shall be in close proximity to the equipment and within easy

reach of the operator. The switch shall be marked as the disconnecting device for the

equipment.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–5

Page 38

3.2.2 CT Leads Terminated to Meter

The EPM 6000 is designed to have current inputs wired in one of three ways. The figure

below shows the most typical connection, where CT Leads are terminated to the meter at

the current gills. This connection uses nickel-plated brass studs (current gills) with screws

at each end. This connection allows the CT wires to be terminated using either an “O” or a

“U” lug. Tighten the screws with a #2 Phillips screwdriver.

Current gills

(nickel-plated

brass stud)

CHAPTER 3: INSTALLATION

FIGURE 3–5: CT Leads Terminated to Meter

Wiring diagrams are detailed in Wiring Diagrams on page 3–9. Communications

connections are detailed in Communications Setup on page 3–19.

3.2.3 CT Leads Pass-Through (No Meter Termination)

The second method allows the CT wires to pass through the CT Inputs without terminating

at the meter. In this case, remove the current gills and place the CT wire directly through

the CT opening. The opening will accommodate up to 0.177" / 4.5 mm maximum diameter

CT wire.

3–6 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 39

CHAPTER 3: INSTALLATION

3.2.4 Quick Connect Crimp CT Terminations

CT wire passing

through the meter

Current gills

removed

FIGURE 3–6: Pass-Through Wire Electrical Connection

For quick termination or for portable applications, a quick connect crimp CT connection

can also be used.

Crimp CT

terminations

FIGURE 3–7: Quick Connect Electrical Connection

3.2.5 Voltage and Power Supply Connections

Voltage Inputs are connected to the back of the unit via a optional wire connectors. The

connectors accommodate up to AWG#12 / 2.5 mm wire.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–7

Page 40

3.2.6 Ground Connections

The EPM 6000 ground terminals ( ) should be connected directly to the installation's

protective earth ground. Use 2.5 mm wire for this connection.

Power supply

inputs

Voltage

inputs

CHAPTER 3: INSTALLATION

RS485 outputs

(do not place voltage

on these terminals!)

FIGURE 3–8: Voltage Connection

GE recommends the use of fuses on each of the sense voltages and on the control power,

even though the wiring diagrams in this chapter do not show them.

• Use a 0.1 A fuse on each voltage input.

• Use a 3 A fuse on the power supply.

3–8 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 41

CHAPTER 3: INSTALLATION

3.3 Wiring Diagrams

3.3.1 Description

Choose the diagram that best suits your application and maintains the CT polarity.

These diagrams are indicated in the sections following.

1. Three-phase, four-wire system Wye with direct voltage, 3 element.

2. Three-phase, four-wire system Wye with direct voltage, 2.5 element.

3. Three-phase, four-wire Wye with PTs, 3 element.

4. Three-phase, four-wire Wye with PTs, 2.5 element.

5. Three-phase, three-wire Delta with direct voltage.

6. Three-phase, three-wire Delta with PTs.

7. Current-only measurement (three-phase).

8. Current-only measurement (dual-phase).

9. Current-only measurement (single-phase).

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–9

Page 42

3.3.2 Wye, 4-Wire with no PTs and 3 CTs, 3 Element

For this wiring type, select 3ELWYE (3-element Wye) in the meter programming setup.

CHAPTER 3: INSTALLATION

FIGURE 3–9: 4-Wire Wye with no PTs and 3 CTs, 3 Element

3–10 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 43

CHAPTER 3: INSTALLATION

3.3.3 Wye, 4-Wire with no PTs and 3 CTs, 2.5 Element

For this wiring type, select 2.5EL WYE (2.5-element Wye) in the meter programming setup.

FIGURE 3–10: 4-Wire Wye with no PTs and 3 CTs, 2.5 Element

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–11

Page 44

3.3.4 Wye, 4-Wire with 3 PTs and 3 CTs, 3 Element

For this wiring type, select 3ELWYE (3-element Wye) in the meter programming setup.

CHAPTER 3: INSTALLATION

FIGURE 3–11: 4-Wire Wye with 3 PTs and 3 CTs, 3 Element

3–12 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 45

CHAPTER 3: INSTALLATION

3.3.5 Wye, 4-Wire with 2 PTs and 3 CTs, 2.5 Element

For this wiring type, select 2.5EL WYE (2.5-element Wye) in the meter programming setup.

FIGURE 3–12: 4-Wire Wye with 2 PTs and 3 CTs, 2.5 Element

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–13

Page 46

3.3.6 Delta, 3-Wire with no PTs and 2 CTs

For this wiring type, select 2CtdEL (2 CT Delta) in the meter programming setup.

CHAPTER 3: INSTALLATION

FIGURE 3–13: 3-Wire Delta with no PTs and 2 CTs

3–14 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 47

CHAPTER 3: INSTALLATION

3.3.7 Delta, 3-Wire with 2 PTs and 2 CTs

For this wiring type, select 2CtdEL (2 CT Delta) in the meter programming setup.

FIGURE 3–14: 3-Wire Delta with 2 PTs and 2 CTs

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–15

Page 48

3.3.8 Current-Only Measurement (Three-Phase)

For this wiring type, select 3ELWYE (3 Element Wye) in the meter programming setup.

CHAPTER 3: INSTALLATION

Note

Even if the meter is used only for current measurement, the unit requires a AN volts

reference. Please ensure that the voltage input is attached to the meter. AC control power

can be used to provide the reference signal.

3–16 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 49

CHAPTER 3: INSTALLATION

3.3.9 Current-Only Measurement (Dual-Phase)

For this wiring type, select 3ELWYE (3 Element Wye) in the meter programming setup.

Note

Even if the meter is used only for current measurement, the unit requires a AN volts

reference. Please ensure that the voltage input is attached to the meter. AC control power

can be used to provide the reference signal.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–17

Page 50

3.3.10 Current-Only Measurement (Single-Phase)

For this wiring type, select 3ELWYE (3 Element Wye) in the meter programming setup.

CHAPTER 3: INSTALLATION

Note

Even if the meter is used only for current measurement, the unit requires a AN volts

reference. Please ensure that the voltage input is attached to the meter. AC control power

can be used to provide the reference signal.

3–18 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 51

CHAPTER 3: INSTALLATION

3.4 Communications Setup

3.4.1 Description

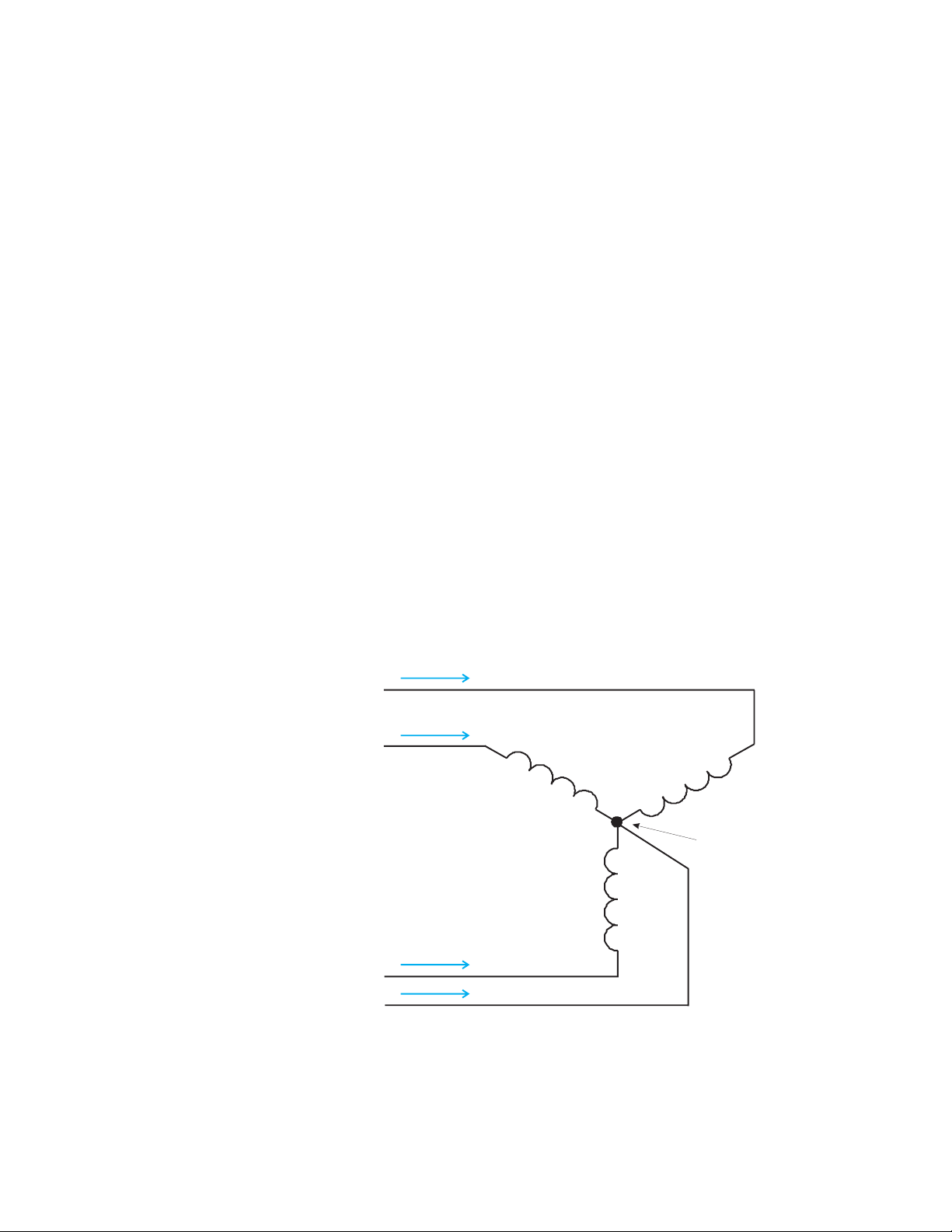

The EPM 6000 Power Metering System provides two independent communication ports.

The first port, COM1, is an optical IrDA port . The second port, COM2, provides RS485

communication via the Modbus protocol.

3.4.2 IrDA COM1 Port

The COM1 IrDA port is located on the meter faceplate. The IrDA port allows the unit to be

set up and programmed using a remote laptop without the need for a communication

cable. Just point at the meter with an IrDA-equipped computer to configure it.

Use the GE Communicator software package that works with the EPM 6000 IrDA port to

configure the port and poll readings. Refer to the GE Communicator User Manual for details

on programming and accessing readings.

Wireless Communication

Settings for the COM1 IrDA port are configured using GE Communicator software. This port

communicates via the Modbus ASCII protocol only.

3.4.3 RS485 COM2 Port

The EPM 6000 COM2 port uses standard 2-wire, half-duplex RS485 communications. The

RS485 connector is located on the back face of the meter. A connection can easily be

established to a master device or to other slave devices, as indicated below.

Direct PC Interface

FIGURE 3–15: Simultaneous Dual Communications Paths

Modbus

Serial RS485

Master Host

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 3–19

Page 52

CHAPTER 3: INSTALLATION

FIGURE 3–16: RS485 Communications Installation

The EPM 6000 COM2 port can be programmed through the faceplate or with software.

The standard RS485 port settings are:

Address: 001 to 247

Baud rate: 9.6, 19.2, 38.4, or 57.6 kbps

Protocol: Modbus RTU, Modbus ASCII, or DNP 3.0

3–20 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 53

GE Consumer & Industrial

Multilin

EPM 6000 Multi-function Power

Chapter 4: Using the Meter

Using the Meter

4.1 Front Panel Interface

Metering System

4.1.1 Description

The EPM 6000 Power Metering System can be configured and a variety of functions can be

accomplished simply by using the elements and the buttons on the meter faceplate. This

chapter will review front panel navigation. Complete navigation maps can be found in

Navigation Maps on page 6–1.

4.1.2 Faceplate Elements

The meter faceplate elements are described below.

• Reading Type Designator: indicates type of reading.

• IrDA Communication Port: COM1 port for wireless communications.

• % of Load Bar: graphic display of current as a percentage of the load.

• Parameter Designator: indicates the reading displayed.

• Watt-Hour Pulse: energy pulse output to test accuracy.

• Scale Selector: “kilo” or “mega” multiplier of displayed readings.

EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE 4–1

Page 54

CHAPTER 4: USING THE METER

4.1.3 Faceplate Buttons

The following functions can be performed using the MENU, ENTER, DOWN and RIGHT

buttons:

• View meter information

•Enter display modes

• Configure parameters (password protected)

• Perform resets

• Perform LED checks

• Change settings

• View parameter values

• Scroll parameter values

•View limit states

Reading

type indicator

IRDA communications

port

% of Load Bar

Parameter

designator

Watt-hour

pulse

FIGURE 4–1: EPM 6000 Faceplate Elements

The faceplate buttons function as follows:

• Enter button: Press and release the ENTER button to select one of four display

modes: operating mode (default), reset mode (press ENTER once, followed by

DOWN), settings mode (press ENTER twice, followed by DOWN), and configuration

mode (press ENTER three times, followed by DOWN).

• Menu button: Press and release to navigate the configuration menu and again to

return to the main menu.

• Right button: Press the RIGHT button to enter the menus for the operate, reset ,

settings, and configuration mode.

• Down button: Press the DOWN button to scroll through the menus for each of the

modes.

In operating mode (default), the faceplate buttons are used to view parameter values. In

reset mode, the buttons are used to restore maximum and minimum values. In settings

mode, the buttons are used to view settings parameters and change the scroll setting. In

configuration mode, the buttons are used to change meter configuration (in this case, they

can be password protected).

4–2 EPM 6000 MULTI-FUNCTION POWER METERING SYSTEM – USER GUIDE

Page 55

CHAPTER 4: USING THE METER

4.1.4 Percentage of Load Bar

The 10-segment LED bar graph at the bottom of the EPM 6000 front panel provides a

graphic representation of current. The segments illuminate according to the load shown in

the table below. When the load is greater than 120% of full-load, all segments flash “ON”

for 1.5 seconds and “OFF” for 0.5 seconds.

MENU

button

DOWN

button

ENTER

button

RIGHT

button

FIGURE 4–2: EPM 6000 Faceplate Buttons

Table 4–1: % of Load Bar Segments

Segments Load ≥ % Full Load

none no load

11%

1 to 2 15%

1 to 3 30%

1 to 4 45%

1 to 5 60%

1 to 6 72%

1 to 7 84%

1 to 8 96%

1 to 9 108%

1 to 10 120%