Page 1

GE

GE Proprietary and Confidential Information

Transportation

1150 HP AC Drilling Motor,

Model 5GEB22

Document No. GEK-91696, Rev. D

Page 2

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

ing Motor, Model 5GEB22

© {2009} Genera

General Electric Company and is disclosed in confidence. This publication is intended for use by GE customers solely

for purposes of operating and performing routine maintenance of purchased or licensed GE products, and it shall not

be reproduced

any form, in whole or in part, or used for any other purpose, or disclosed to third parties, without the express written

consent of GE.

GE and Customer agree that the information contained herein does not purport to cover all details or variations in GE

products or

mation be desired or should particular problems arise that are not covered sufficiently for the user’s purposes, the matter

should be referred to Gene ral Electric Company. Any applicable Federal, State or local regulations or company safety or

operating r

has no obliga tion to keep the material up to date after the original publication.

GENERAL ELECTRIC COMPANYEXPLICITLY DISCLAIMS ALL WARRANTIES OFACCURACY, MERCHANTABILITY OR FITNESS FOR

ANY PURPOSE IN CONNECTION WITH THIS PUBLICATION AND USE THEREOF.

If you are not an authorized recipient of this publication, you are hereby notified that any perusal, use, distribution, copy-

ing or dis

following address: GE Transportation, Technical Publications Department, Building 14, 2901 East Lake Rd., Erie, PA 16531.

closure is strictly prohibited. If you have received this publication in error, please immediately return to GE at the

l Electric Company. All rights reserved. The information contained in this publication is the property of

, redistributed, retransmitted, translated, abridged, adapted, condensed, revised or otherwise modified, in

to provide for ever y possible contingency with installation, operation or maintenance. Should further infor-

ules must take precedence over any information or instructions given in the Technical Documentation. GE

2

Page 3

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drilling Motor, Model 5GEB22

CONTENTS

Page

1. GENERAL INFORMATION.......................................................................................................................................................................................... 4

1.1. INTRODUCTION........................................................................................................................................................................................................... 4

1.2. SAFETY INFOR

1.3. ATEX CERTIFICATION.................................................................................................................................................................................................. 4

1.4. INSTALLATION AND OPERATIONAL INSTRUCTIONS..................................................................................................................................... 5

1.5. MODEL DIFFE

2. CONTROLS AND INDICATORS................................................................................................................................................................................ 13

3. FUNCTIONAL DESCRIPTION................................................................................................................................................................................... 13

4. SCHEDULED M

4.1. MONTHLY SCHEDULED MAINTENANCEPROCEDURE..................................................................................................... ............................ 14

4.2. CLEANING THE MOTOR ............................................................................................................................................................................................ 16

5. REMOVAL AN

5.1. MOTORPREPARATION FOR SHIPMENT.............................................................................................................................................................. 16

5.2. DISASSEMBLY PROCEDURES............................................................................................................................................ ...................................... 19

5.3. INSPECTI

5.4. STEAM CLEANING.......................................................................................................................................................................................................28

5.5. STATIC ELECTRICAL TESTING.................................................................................................................................................................................. 29

5.6. ROTOR SUB

5.7. ROTOR INSTALLATION INTO THE STATOR FRAME .........................................................................................................................................35

5.8. MOTORBEARING CHECKS AFTER ASSEMBLY.................................................................................................................................................37

5.9. FINAL AS

5.10.FINAL ASSEMBLY OF ROTOR CONNECTION END (CE) COMPONENTS.................................................................................................. 39

5.11. ELECTRICAL RUNNING TESTS.... .............. .............. .............. .............. .............. .............. ........................................................................................ 39

5.12. HUB INS

6. SUMMARY DATA........................................................................................................................................................................................................... 44

6.1. DRILL MOTOR DATA....................................................................................................................................................................................................44

6.2. DRILL M

6.3. INSPECTIONDATA....................................................................................................................................................................................................... 47

6.4. SPECIAL TOOLS AND MATERIALS......................................................................................................................................................................... 47

MATION..............................................................................................................................................................................................

RENCES ...............................................................................................................................................................................................

AINTENANCE..................................................................................................................................................................................

D REPLACEMENT PROCEDURES ...............................................................................................................................................

ON AND REPAIR PROCEDURES ..........................................................................................................................................................

ASSEMBLY PROCEDURES...................... .............. .............. .............. .............. .............. .............. ......................................................

SEMBLY OF ROTOR DRIVE END (DE) COMPONENTS ................................................................................................................

TALLATION....................................................................................................................................................................................................

OTOR COMPONENT IDENTIFICATION................................................................................................................................................

4

13

13

16

25

30

39

40

46

3

Page 4

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

ing Motor, Model 5GEB22

1. GENERAL INFORM

1.1. INTRODUCTION

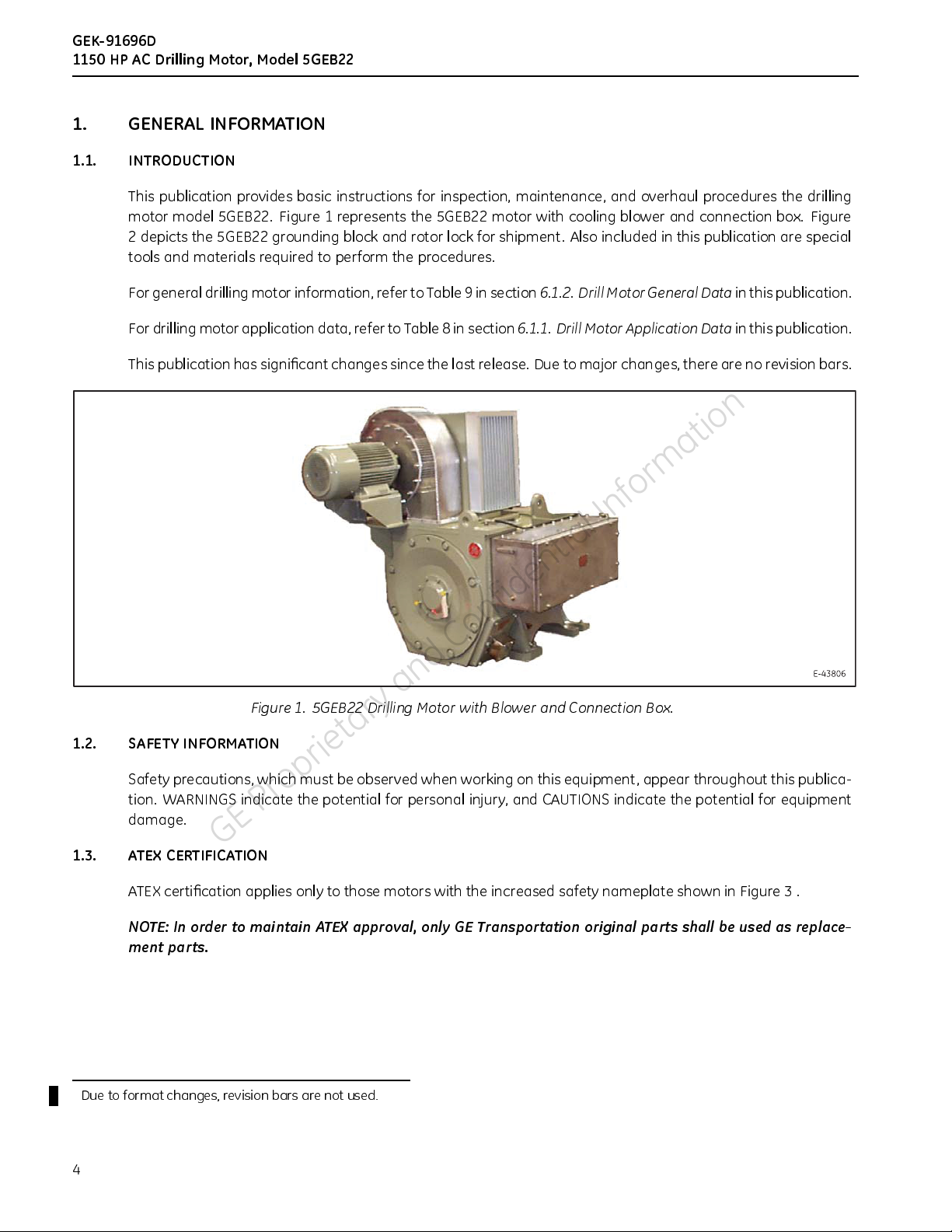

This publication provides basic instructions for inspection, maintenance, and overhaul procedures the drilling

motor model 5GEB22. Figure 1 represents the 5GEB22 motor with cooling blower and connection box. Figure

2depictsthe

tools and materials required to perform the procedures.

For general

For drilling motor application da ta, refer to Table 8insection

This publication has significant changes since the last release. Due to major changes, there are no revision bars.

5GEB22 grounding block and rotor lock for shipment. Also included in this publication are special

drilling motor information, refer to Table 9 in section

ATION

6.1.2. Drill Motor General Data

6.1.1. Drill Motor Application Data

in this publication.

in this publication.

Figure 1. 5GEB22 Drilling Motor with Blower and Connection Box.

1.2. SAFETY INFORMATION

Safety precautions, which must be observed when working on this equipment, appear throughout this publica-

tion. WARNINGS indicate the potential for personal injury, and CAUTIONS indicate the potential for equipment

damage.

1.3. ATEX CERTIFICATION

ATEX certification applies only to those motors with the increased safety nameplate shown in Figure 3 .

NOTE: In order to maintain ATEX approval, only GE Transportation ori ginal parts shall be used as replace-

ment parts.

Due to format changes, revision bars are not used.

4

Page 5

1150HPACDrill

GE Proprietary and Confidential Information

GEK-91696D

ing Motor, Model 5GEB22

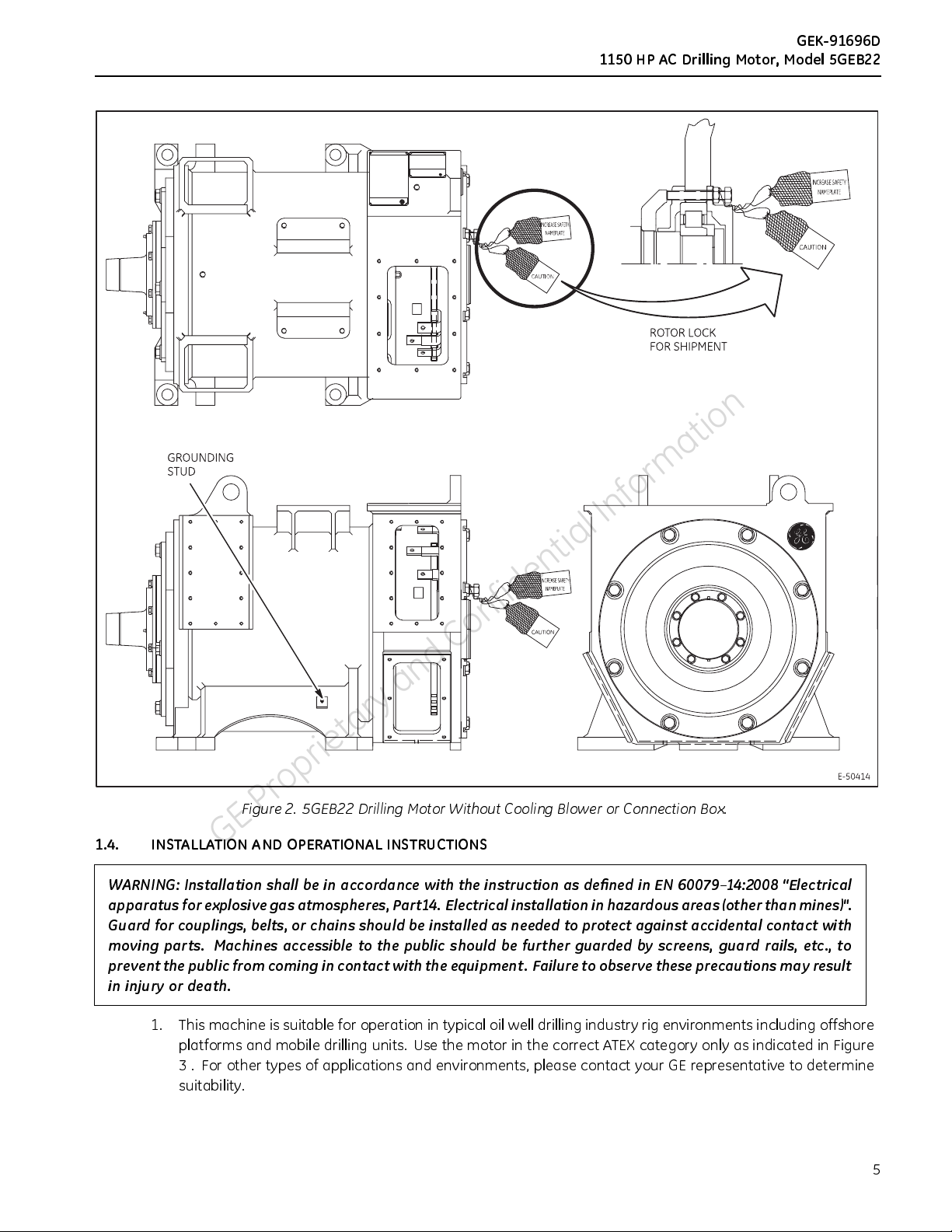

Figure 2. 5GEB22 Drilling Motor Without Cooling Blower or Connection Box.

1.4. INSTALLATION AND OPERATIONAL INSTRUCTIONS

ING: Installation shall be in accordance with the instruction as defined in E N 60079–14:2008 “Electrical

WARN

apparatus for explosive gas atmospheres,Part14. Electrical installation in hazardous areas(otherthanmines)".

Guard for couplings, belts, o r chains should be installed as needed to protect against accidental contact with

ing parts. Machines accessible to the public should be further guarded by screens, guard rails, etc., to

mov

prevent the public from coming in contact with the equipment. Failure to observe these precautions may result

in injury or death.

1. This machine is suitable for operation in typical oil well drilling industry rig environments including offshore

platforms and mobile drilling units. Use the motor in the correct ATEX categor y only as indicated in Figure

3 . For other types of applications and environments, please contact your GE representative to determine

suitability.

5

Page 6

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

ing Motor, Model 5GEB22

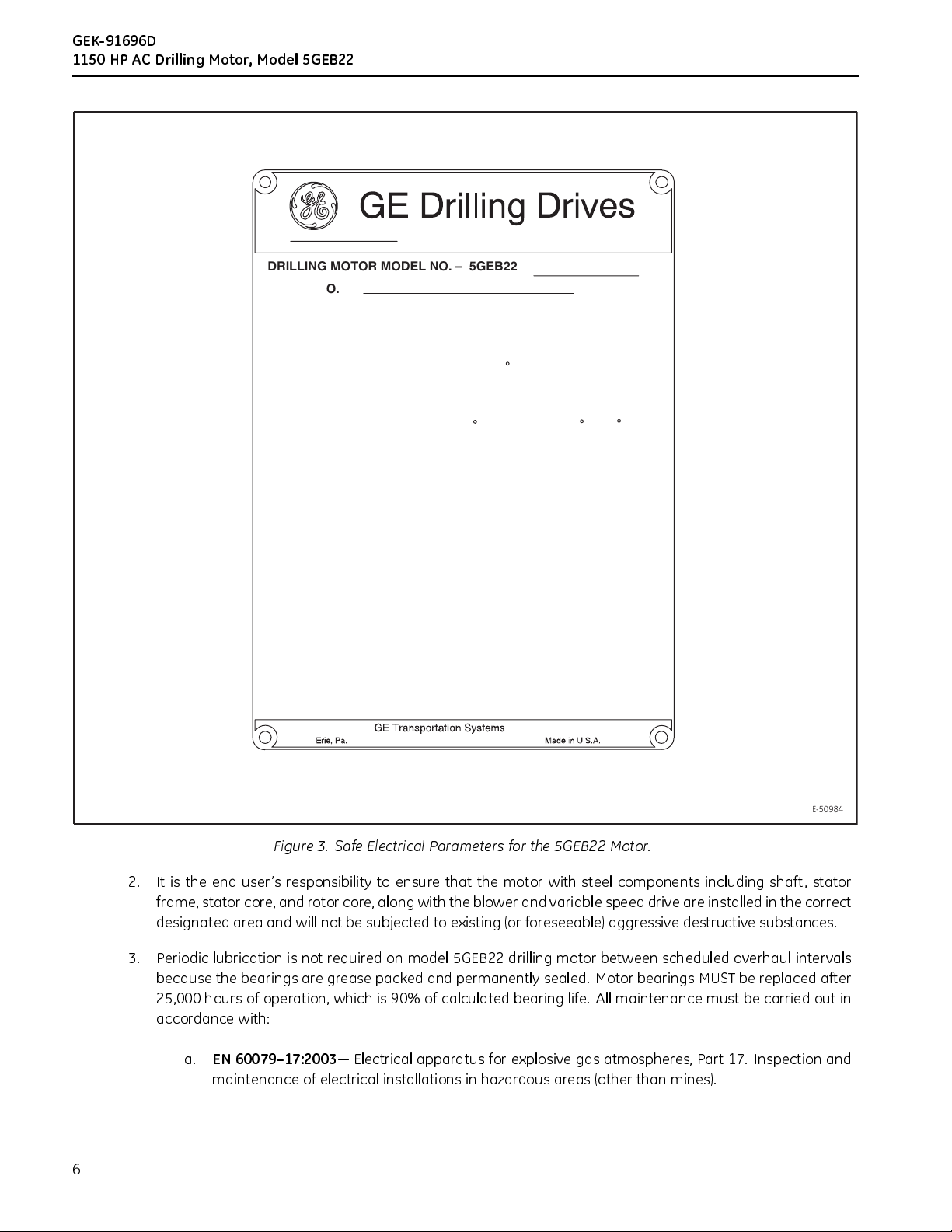

DRILLING MOTOR MODEL NO. – 5GEB22

.ON LAIRES

COOLING–3000 SCFM AIR SUPPLIED

BY BLOWER UNIT

CLOSED COOLING SYSTEM, IP56, TO MAINTAIN MAX.

INTERNAL AIR TEMPERATURE OF 45 C

RATINGS S9 CONTINUOUS

PHASE 3

AC VOLTS (L-L) 587

AMPS AC 1380 1120 / 1048

RATER RPM 800

SHAFT HP 1400 1150 / 1075

MAX. FREQUENCY HERTZ 153

MAX OPERATING RPM 3000

CONSTANT HP 800–1800 RPM (600 VOLT L–LINE SUPPLY)

CONSTANT HP 800–2400 RPM (690 VOLT L–LINE SUPPLY)

INSULATING CLASS H

INGRESS PROTECTION

WITH 600 VOLTS MAINTAINED ABOVE 820 RPM

WITH 690 VOLTS MAINTAINED ABOVE 940 RPM

AMBIENT AIR MAX 45 C 45 C / 55 C

N WYEOITCENNOC

IP44 / 6424 LBS (2914 Kg)

IP56 / 7124 LBS (3238 Kg)

Figure 3. Safe Electrical Parameters for the 5GEB22 Motor.

2. It is the end user’s responsibility to ensure that the motor with steel components including shaft, stator

frame, stator core, and rotor core, along with the blower and variable speed drive are installed in the correct

gnated area and will not be subjected to existing (or foreseeable) aggressive destructive substances.

desi

3. Periodic lubrication is not required on model 5GEB22 drilling motor between scheduled overhaul intervals

ause the bearings are grease packed and permanently sealed. Motor bearings MUST be replaced after

bec

25,000 hours of operation, which is 90% of calculated bearing life. All maintenance must be carried out in

accordance with:

a.

EN 60079–17:2003

— Electrical apparatus for expl osive gas atmospheres, Part 17. Inspection and

maintenance of electrical installations in hazardous areas (other than mines).

6

E-

50984

Page 7

GEK-91696D

GE Proprietary and Confidential Information

ing Motor, Model 5GEB22

b.

IEC 60079–19:2006

haul for appara

1150HPACDrill

— Electrical apparatus for explosive gas atmospheres, Part 19. Repair and over-

tus used in explosive atmospheres (other than mines or explosive industry).

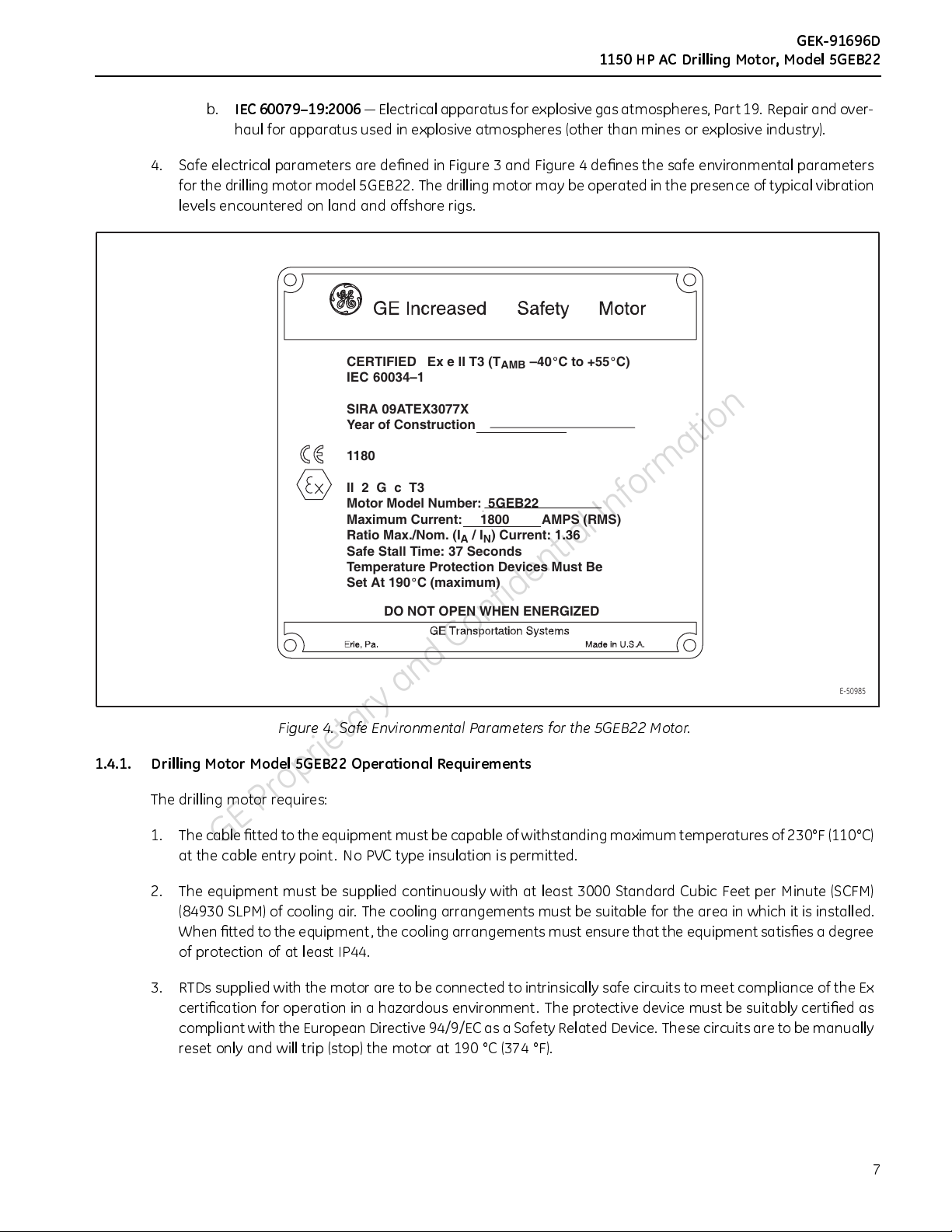

4. Safe electrical parameters are defined in Figure 3 and Figure 4 defines the safe environmental parameters

for the drilli

ng motor model 5GEB22. The drilling motor may be operated in the presence of typical vibrat ion

levels encountered on land and offshore rigs.

CERTIFIED Ex e II T3 (T

IEC 60034–1

SIRA 09ATEX3077X

Year of Construction

1180

II 2 G c T3

Motor Model Number: 5GEB22

Maximum Current: 1800 AMPS (RMS)

Ratio Max./Nom. (IA / IN) Current: 1.36

Safe Stall Time: 37 Seconds

Temperature Protection Devices Must Be

Set At 190

C (maximum)

DO NOT OPEN WHEN ENERGIZED

AMB

Figure 4. Safe Environmental Parameters for the 5GEB22 Motor.

1.4.1. Drilling Motor Model 5GEB22 Operational Requirements

The drilling motor requires:

–40 C to +55 C)

E-50985

1. The cable fitted to the equipment must be capable of withstanding maximum temperatures of 230°F (110°C)

at the cable entry point. No PVC type insulation is permitted.

2. The equipment must be supplied continuously with at least 3000 Standard Cubic Feet per Minute (SCFM)

(84930 SLPM) of cooling air. The cooling arrangements must be suitable for the area in which it is installed.

When fitted to the equipment, the cooling arrangements must ensure that the equipment satisfies a degree

of protection of at least IP44.

3. RTDs suppli ed with the motor are to be connected to intrinsically safe circuits to meet compliance of the Ex

certification for operation in a hazardous environment. The protective device must be suitably certified as

compliant with the European Directive 94/9/EC as a Safety Relate d Device. These circuits are to be manually

reset only and will trip (stop) the motor at 190 °C (374 °F).

7

Page 8

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

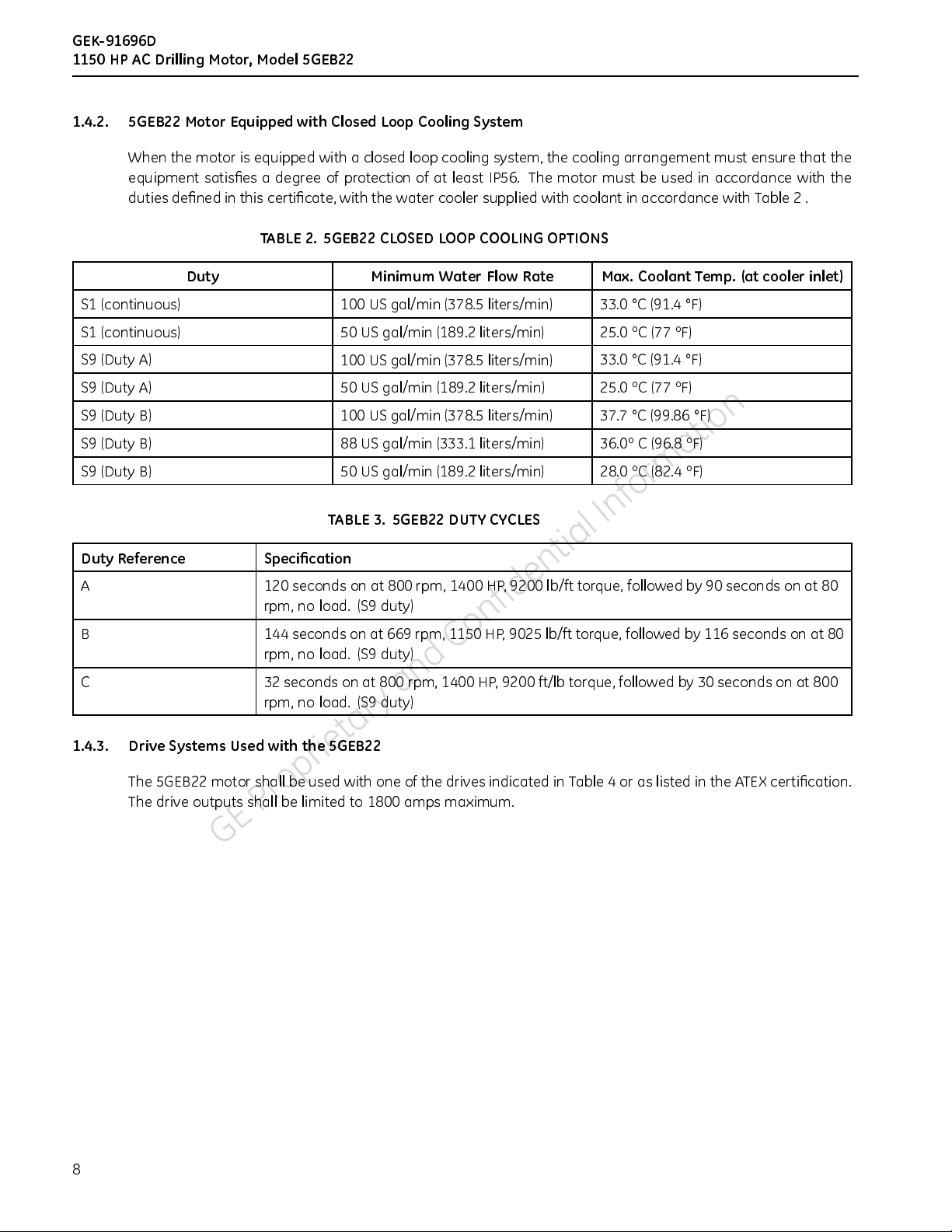

1.4.2. 5GEB22MotorEquippedwithClosedLoopCoolingSystem

When the motor is equippe d with a closed loop cooling system, the cooling arrangement must ensure that the

equipment satisfies a degree of protection of at least IP56. The motor must be used in accordance with the

duties defined in this certificate, with the water cooler supplied with coolant in accordance with Table 2 .

ing Motor, Model 5GEB22

TABLE 2. 5GEB22 CLOSED LOOP COOLING OPTIONS

Duty Minimum Water Flow Rate Max. Coolant Temp. (at cooler inlet)

S1 (continuous)

S1 (continuous)

S9 (Duty A)

S9 (Duty A) 50 US gal/min (189.2 liters/min) 25.0 ºC (77

S9 (Duty B)

S9 (Duty B)

S9 (Duty B)

Duty Reference Specification

A

B

C

1.4.3. Drive Systems Used with the 5GEB22

120 seconds on at 800 rpm, 1400 HP, 9200 lb/ft torque, followed by 90 seconds on at 80

rpm, no load. (S9 duty)

144 se

rpm, no load. (S9 duty)

32 seconds on at 800 rpm, 1400 HP, 9200 ft/lb torque, followed by 30 seconds on at 800

rpm, no load. (S9 duty)

100 US gal/min (378.5 liters/min)

50 US gal/min (189. 2 liters/min)

100 US gal/min (378.5 liters/min)

100USgal/

88 US gal/min (333. 1 liters/min)

50 US gal/min (189. 2 liters/min)

TABLE 3. 5GEB22 DUTY CYCLES

conds on at 669 rpm, 1150 HP, 9025 lb/ft torque, followed by 116 seconds on at 80

min (378.5 liters/min) 37.7 °C (99.86 °F)

33.0 °C (91.4 °F)

25.0 ºC (77 ºF)

33.0 °C (91.4 °F)

36.0º C (96.8 ºF)

28.0 ºC (82.4 ºF)

ºF)

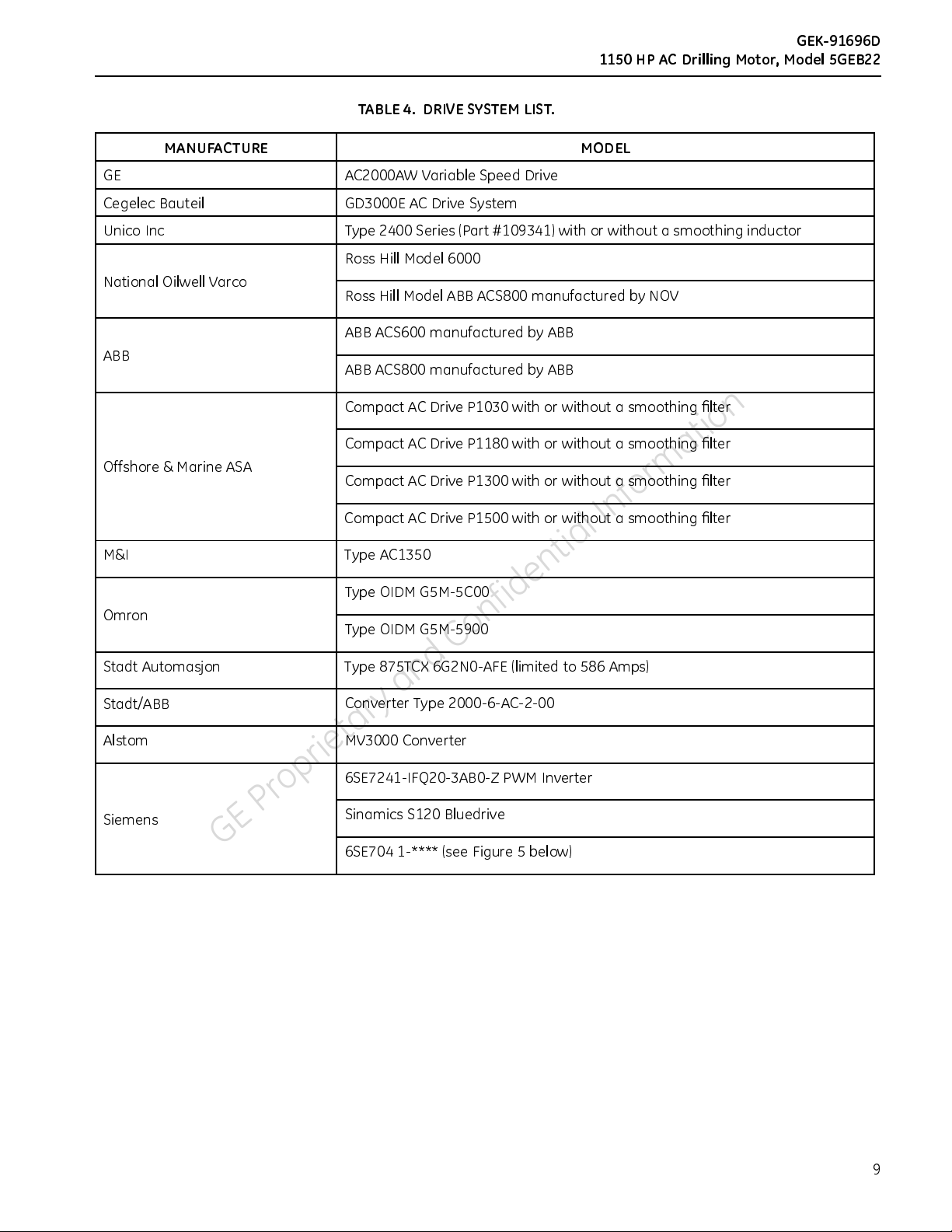

The 5GEB22 motor shall be used w ith one of the drives indicated in Table 4 or as listed in the ATEX certification.

The drive outputs shall be limited to 1800 amps maximum .

8

Page 9

TABLE 4. DRIVE SYSTEM LIST.

GE Proprietary and Confidential Information

MANUFACTURE MODEL

GE AC2000AW Variable Speed Drive

1150HPACDrill

GEK-91696D

ing Motor, Model 5GEB22

Cegelec Baut

Unico Inc Type 2400 Series (Part #109341) with or w ithout a smoothing inductor

National Oilwell Varco

ABB

Offshore

M&I Type AC1350

Omron

eil

&MarineASA

GD3000E AC Dr

Ross Hill Model 6000

Ross Hill Model ABB ACS800 manufactured by NOV

ABB ACS600 manufactured by ABB

ABB ACS800 manufactured by ABB

Compact AC Dri ve P1030 with or without a smoothing filter

Compact AC Dri ve P1180 with or without a smoothing filter

Compact AC Dri ve P1300 with or without a smoothing filter

Compact AC Dri ve P1500 with or without a smoothing filter

Type OIDM G5M-5C00

Type OIDM G5M-5900

ive System

Stadt Automasjon Type 875TCX 6G2N0-AFE (limited to 586 Amps)

Stadt/ABB

Alstom MV3000 Converter

Siemens

Converter Type 2000-6-AC-2-00

6SE7241-IFQ20-3AB0-Z PWM Inverter

Sinamics S120 Bluedrive

6SE704 1-**** (see Figure 5 below)

9

Page 10

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

ing Motor, Model 5GEB22

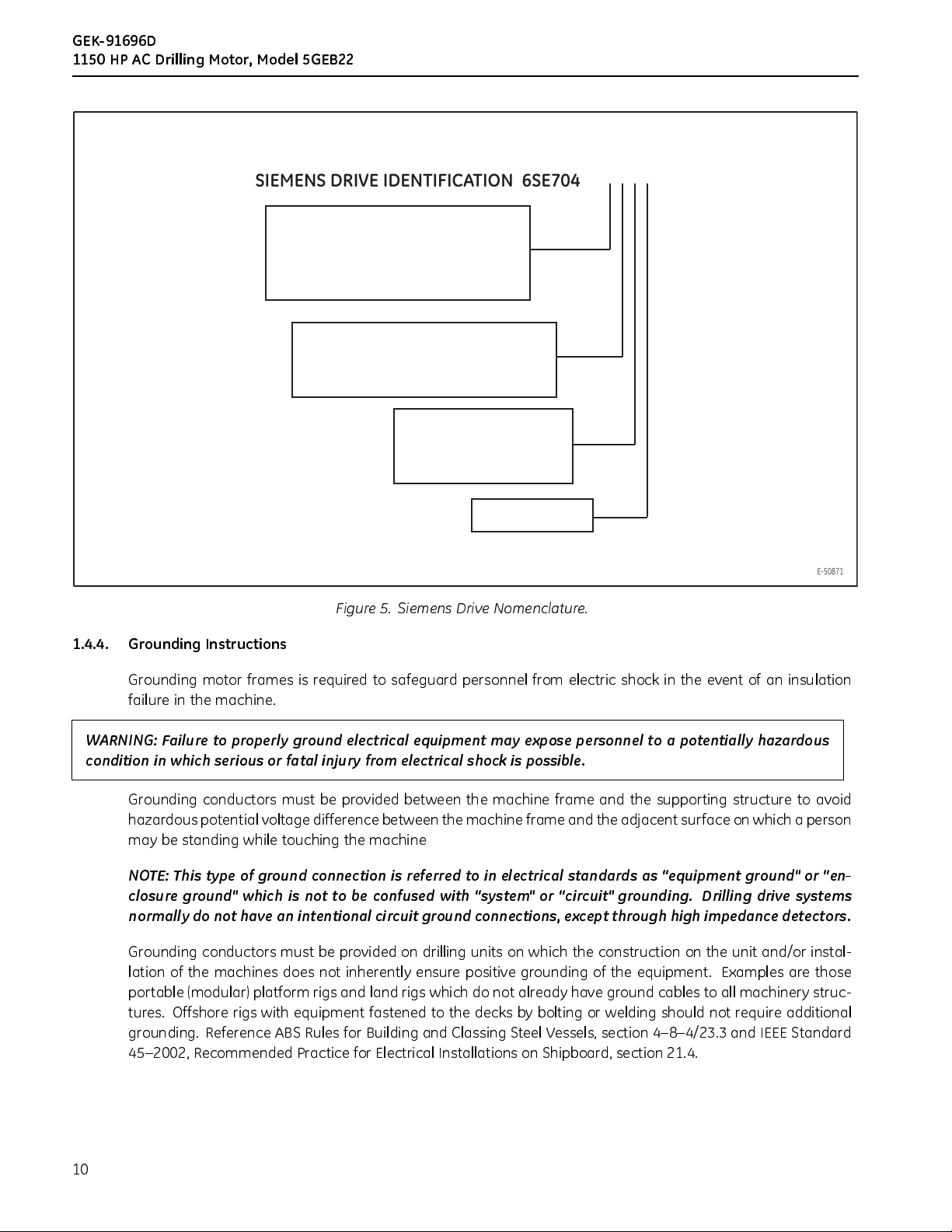

SIEMENS DRIVE IDENTIFICATION 6SE7041 - * * * *

RATED CURRENT INDICATOR:

0 = 1000A (M CHASSIS)

2 = 1200A (L OR M CHASSIS)

5 = 1500A (M CHASSIS)

DC LINK VOLTAGE INDICATOR:

V = 930V (690V LINE-LINE)

U = 780V (600V LINE-LINE)

CHASSIS INDICATOR:

M

L

DIGIT 2 OR 6

Figure 5. Siemens Drive Nomenclature.

1.4.4. Grounding Instructions

Ground

failure in the machine.

WARNI

condition in which serious or fatal injury from electrical shock is possible.

Grounding conductors must be provided between the machine frame a nd th e sup porting structure to avoid

hazardous potential voltage difference between the machine frame and the adjacent surface on which a person

may be standing while touching the machine

NOTE: This type of ground connection is referred to in electrical standards as “equipment ground" or “en-

closure ground" which is not to be confu sed with “system" or “circuit" grounding. Drilling drive systems

normally do not have an intentional circuit ground connections, except through high impedance detectors.

Grounding conductors must be provided on drilling units on which the construction on the unit and/or instal-

lation of the machines does not inherently ensure positive grounding of the equipment. Examples are those

portable (modular) platform rigs and land rigs which do not already have ground cables to all machinery struc-

tures. Offshore rigs with equipment fastened to the decks by bolting or welding should not require additional

grounding. Reference ABS Rules for Building and Classing Steel Vessels, section 4−8−4/23.3 and IEEE Standard

45−2002, Recommended Practice for El ectrical Installations on Shipboard, section 21.4.

ing motor frames is required to safeguard personnel from electric shock in the event of an insulation

NG: Failure to properly ground electrical equipment may expose personnel to a potentially hazardous

E-50871

10

Page 11

1.4.5. Grounding Procedures

GE Proprietary and Confidential Information

The 5GEB22 has a ground blockattached totheframeasshowninFigure2 . The mounting stud is 3/8–16 thread.

To attach a ground cable to the ground block:

1. Obtain a 3/8–16 nut and a lockwasher. Also required is a cable lug to fit the ground cable and terminal hole

clearance for the 0.375 diameter stud.

2. Prepare a ground conductor (use appropriate size cable per National Electrical Code) long enough to run

from the motor frame to an existing ground conductor system or to a suitable equipment ground point as

defined by the National Electrical Code Article 250 or other applicable regulation. Check that the system

ground detector is a lso connected to the Common ground point for the rig and make connection if neces-

sary.

3. Install terminal lugs on cable. Remove paint, rust and oil from all surfaces to which the cables are to be

attached and bolt the lugs securely to t hese surfaces. Torque the nut to 25 lb-ft (34 Nm).

4. After installation, protect the ground stud, nut, and cable lug connection from corrosion by applying a rust

inhibitor on the exposed components.

1150HPACDrill

GEK-91696D

ing Motor, Model 5GEB22

1.4.6. Motor Coupling and Alignment

CAUTION: Be sure to align, or check alignment carefully on either motors or MG sets. Misalignment can cause

excessive vibration and damaging forces on shaft and bearings.

Time taken to assure good alignment will be returned in reduced downtime.

1

.4.6.1.Coupled

On coupled drives, when a motor and adriven unit together have fourormorebearings, flexible couplings should

be used

CAUTION: Careful alignment of machines, when using either solid (rigid) or flexible couplings, is essential to

nt excessive vibration, hot bearings, or shaft failures.

preve

Couplings must be properly sized to be capable of driving maximum machine t orque. Interference fits should be

used between motor shaft and coupling.

1

.4.6.2. V-Belt Drives

On V−beltdrives, thedrivinganddriven shafts shouldbelocated so that they areparallelandthe sheaves aligned.

If properly aligned, there is minimum wear on the belts and no excessive thrust on the machine bearings. The

sheave should be mounted as close as possible to the motor bearings. The following recommendations should

be followed concerning the minimum sheave pitch diameter which can be used for the particular motor. The

belt manufacturer should be consulted for the maximum speed ratio and belt for the particular application.

Drives

to facilitate alignment. Three−bearing construction requires a rigid coupling.

The following formula and dat a can be used to select the MINIMUM allowable sheave diameter from the stand-

point of bearing life and shaft stress. A larger s heave will further reduce the shaft stress and bearing loading.

This data is based upon the belts being tightened to a maximum total pull of 1.5 times the required transmission

load used in the sheave diameter calculation. Belts should never be tightened more than necessary to transmit

this torque.

D = HP/RPM X 189000/W

11

Page 12

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

Where D = Minimum sheave pitch diameter in inches for V-belt application.

HP/RPM = Maximum ratio of hors epower, including overloads, to the speed which that power occurs.

W = Maximum allowable radial load.

Belt−driven machines may be equipped with sliding rails. Proper and constant belt tension is easily maintained

and the replacement of belts is simplified. This reduces the operating cost a nd increases the efficiency. Sliding

rails are to be used for floor mounting only.

Belt idlers reduce the life of the belts and should not be used if any other method is available. The belts should

never be forced over the sheaves. W hen the drive is started and operating at full speed and full load, the take−up

should be adjusted until only a slight bow appears in the slack side. If slippage occu rs after the belt tension has

been correctly adjusted, the belts and p ulleys have not been chosen properly for the job.

CAUTION: Over−tightening to avoid this slippage may result in early failures of belts, shafts, and bearings.

Belt tension s hould be checked and adjusted following the belt manufacturer’s recommendations.

ing Motor, Model 5GEB22

There is n

belts seat themselves in the sheave grooves and initial stretch is removed. Belt tension should be rechecked

after a day or two of operation.

Matched belts run smoother,look better, and last longer. Longer belt life results if the belts and sheaves are kept

clean and the belts are prevented from rubbing against the belt guards or other obstructions.

1

.4.6.3. Grouting

On conc

A rich, non−shrink grout should be used. High− grade grout mixtures are available commercially. If the grout

is to be

to give a stiff mixture. The clean, but rough surface of the foundation should be wet and the grout rammed or

puddled under the base.

1

.4.6.4. Flexible Coupling Alignment Procedure

Leve

should be checked as follows :

1. Remo

2. Check the coupling hub spacing is in accordance with the outline dimensions with the units in the mechan-

ormally a drop in tension during the first 24 to 48 hours of operation. During this "run in" period, the

rete foundations, a minim um of one inch (25 mm) should be allowed for grouting.

prepared at the site, a cement−sand ratio of 1:2 is recommended. Just enough water should be used

l all mounting base supports before setting the base in position. Before grouting the base, the alignment

ve all coupling bolts a nd slide the shells back so the hub faces are exposed.

l center of their end play.

ica

3. Start with the coupling next to the largest unit (usually the motor) or near the middle of multiple units. Check

radial alignment by using a straightedge across the two hubs at vertical and hori zontal. Or, clamp a dial

the

indicator to one hub and use the outside diameter of the other member to give indication of the misalign-

ment. Be sure the dial indicator supports do not bend or sag, since this will give inaccurate readings. The

ximum variation should not exceed 0.002 inches (0.05 mm).

ma

4. Insert a feeler gage or use the dia l indicator at hub faces. Measure the gap between hub faces at 0, 90, 180

d 270 degrees and record. Rotate both shafts together 90 degrees and repeat the gap readings. Continue

an

rotation in 90 degree inc rem ents until five sets of readings are taken. The fifth set of readings is a check on

12

Page 13

the first set of readings to assure that data is reliable. The readings should not vary by more than 0.002

GE Proprietary and Confidential Information

inches (0.05 mm

5. Correct the horizontal alignment by shifting frames on the base and the vertical alignment by shimming

between the ma

6. Repeat Steps 2, 3 and 4 on each coupling, working away from the motor or center unit.

7. Recheck the coupli ngs on long sets after completing the above checks, because shimming when checking

subsequent units may affect those already checked. After the set has been aligned within the specified

limits, the

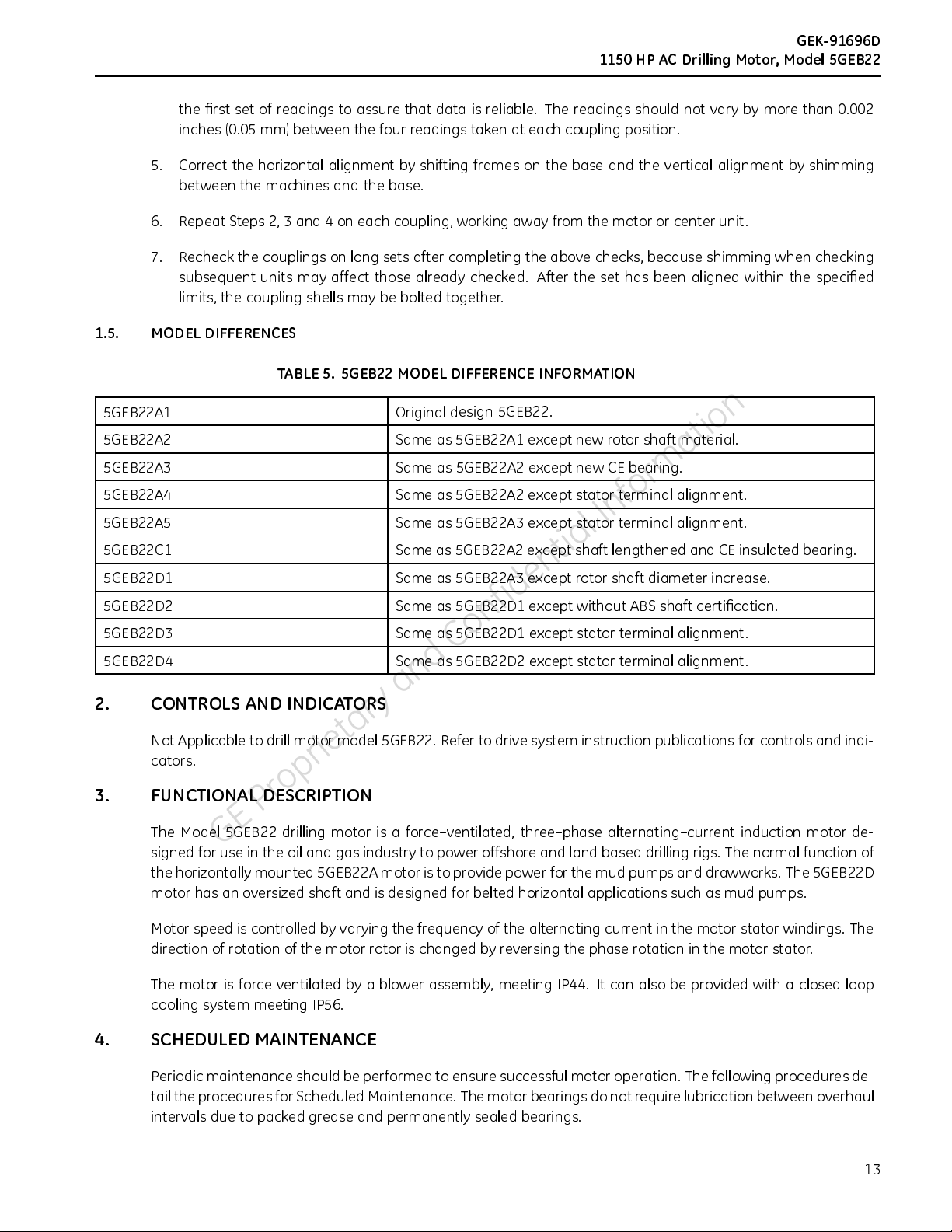

1.5. MODEL DIFFERENCES

coupling shells may be bolted together.

TABLE 5. 5GEB22 MODEL DIFFERENCE INFORMATION

1150HPACDrill

) between the four readings taken at each coupling position.

chines and the base.

GEK-91696D

ing Motor, Model 5GEB22

5GEB22A1 Original d

5GEB22A2 Same as 5GEB22A1 except new rotor shaft material.

5GEB22A3 Same as 5GEB22A2 except new CE bearing.

2D1

B22D4

4

Same as 5

Same a

Sam

5GEB22A

5GEB22A5 Same as 5GEB22A3 except stator t erminal alignment.

5GEB22C1 Same as 5GEB22A2 except shaft lengthened and CE insulated bearing.

5GEB2

5GEB22D2 Same as 5GEB22D1 except without ABS sha ft certification.

5GEB22D3 Same as 5GEB22D1 except stator terminal alignment.

5GE

esign 5GEB22.

GEB22A2 except stator t erminal alignment.

s 5GEB22A3 except rotor shaft diameter increase.

e as 5GEB22D2 except stator terminal alignment.

2. CONTROLS AND INDICATORS

t Appli cable to drill motor model 5GEB22. Refer to drive system instruction publications for controls and indi-

No

cators.

3. FU

NCTIONAL DESCRIPTION

The Model 5GEB22 drilling motor is a force–ventilated, three–phase alternating–current induction motor de-

igned for use in the oil and gas industry to power offshore and land based drilling rigs. The normal function of

s

the horizontally mounted 5GEB22A motor is to provide power for the mud pumps and drawworks. The 5GEB22D

motor has an oversized shaft and is designed for belted horizontal applications such as mud pumps.

Motor speed is controlle d by varying the frequency of the alternating current in the motor stator windings. The

direction of rotation of the motor rotor is changed by reversing the phase rotation in the motor stator.

The motor is force ventilated by a blower assembly, meeting IP44. It can also be provided with a closed loop

cooling system meeting IP56.

4. SCHEDULED MAINTENANCE

Periodic mainten ance should be performed to ensure successful motor operation. The following procedures de-

tail the procedures for Scheduled Ma intenance. The motor bearings do not require lubrication between overhaul

intervals due to packed grease and permanently sealed bearings.

13

Page 14

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

NOTE: In order to maintain ATEX approval, only GE Transportation ori ginal parts shall be used as replace-

ment parts.

4.1. MONTHLY SCHEDULED MAINTENANCE PROCEDURE

4.1.1. Covers, Seals, and Latches

WARNING: Hazardous voltages are present in this equipment. Follow shutdown procedures to ensure power

is not applied to the machine before performing any maintenance procedures. Failure to do so may result in

injury or death.

1. Remove all power from the machine before attempting maintenance procedures.

2. Clean the outside of the mach ine and remove the inspection covers.

ing Motor, Model 5GEB22

WARNING: W

to personnel in the immediate area. Personnel should be provided with, and trained in the use of, protective

equipment as specified by applicable federal or state safety regulations. Failure to do so may result in injury or

death.

4.1.2. Power Cable Inspection

hen using compressed air for cleaning pu rposes, flying debris and particles may present a hazard

3. Use clean, dry compressed air and blow the dirt and dust from the interior of the machine.

4. Check exterior covers to ensure the felt seals are intact. Replace seals if missing, broken, deformed or hard-

ened.

5. Install the covers into position on the machine. Torque the cover bolts to 58 ±2 lb.–ft. (79 ±2,7 Nm).

During inspection of the power cables and associated hardware, replace any components that are damaged.

Inspect the power cables for:

1. Inspect the cable terminals for discoloration from heat, arc damage, cracks or fractures. Replace terminals

and/or cable if damage is found.

2. Ensure terminal connections are tight and arcing is not present.

3. Inspect cable insulation for cracked, worn, cut, bubbled or burnt insulation. Replace the cable if damage is

found.

4. Check cable connection bushings and mounting hardware (such as cable cleats). Replace damaged or miss-

ing hardware.

5. Check the ground cable connection to the motor frame. Ensure the connection is tight on the ground stud.

4.1.3. Megohmmeter Test

The insulation condition of the motor and cables can be determined by a megohmmeter test. When the high

voltage of the megohmmeter test instrument is applied to the power components of the motor circuit, a high

ohm reading i ndicates good insulation quality. Low ohm readings indicate insulation breakdown, moisture/de-

bris contamination, or carbon tracking. To test the power circuit insulation with a megohmmeter:

1. Ensure all the components in the power circuit are not affecte d by a megohmmeter test. Check the drive

system for megohmmeter test procedures or disconnect power cables from the drive system. If cables are

14

Page 15

GEK-91696D

GE Proprietary and Confidential Information

1150HPACDrill

disconnected for the megohmmeter, make sure the cables are insulated from touching any surrounding

surfaces.

2. Connect a le ad from the megohmmeter instr ument to th e motor TA lead.

3. Connect the second lead of the megohmmeter to a cleaned ground connection.

ing Motor, Model 5GEB22

4. Apply a 500 vo

5. If the reading is above 2 megohms, the power circuit insulation is satisfactory and proceed to Step 7.

6. If the reading is below 2 megohms, the power circuit insulation is degraded or bad. Perform the following

procedures to attempt to raise the ohm reading:

a. Check the power cables for cracks, scuffed or open insulation. Repair or replace the cables if dam-

b. Water or dirt/debris contamination may be adversel y affecting the ohm reading. Disconnect the

7. Connect o

8. Connect the second lead of the megohmm eter to one of the RTD leads (red, white, or white).

9. Apply a 500V megohmmeter test to the circuit.

10. If the re

the RTD cable for cracked, scuffed, or open insulation. Repair or replace the cable if damage is found. If no

cable damage is found, then the RTD is defective and should not be used.

ading is greater than 2 megohms, proceed to Step 11. If the reading is less than 2 megohms, check

lt megohmmeter test to the power circuit.

age is found.

power cables from themotorandretestjustthe stator leads. If the reading is still below 2 megohms,

the motor w

publication for cleaning instructions.

ne lead of the megohmmeter to the motor lead TA.

ill have to be removedfor cleaning or repair. Refer to

4.2. CLEANING THE MOTOR

in this

4.1

11. Move the first lead of the megohm meter from the motor TA lead to a cleaned motor frame ground while

leaving the second lead of the megohmmete r connected to one of the RTD leads (red, white, or white).

12. Apply a 500V megohmmeter test to the circuit.

13. If the

14. Repeat Steps 7 through 13 until all the RTD cables have been checked against the stator motor leads and

15. Remove the megohmmeter leads and return all components to operating condition.

.4.

Mot

Check the motor mounting bolts, nuts, and associated hardware. Ensure the hardware is not missing or loose.

Rep

reading is greater than 2 megohms, proceed to Step 14. If the reading is less than 2 megohms, check

the RTD cable for cracked, scuffed, or open insulation. Repair or replace the cable if damage is found. If no

cable damage is found, then the RTD is defective and should not be used.

the motor frame.

or Mounting Hardware

lace missing hardware and tighten loose bolts.

15

Page 16

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

4.2. CLEANING THE MOTOR

Cleaning the motor is essential to long–term motor life. When the drilling motor is removed from its machinery,

accumulated dirt a nd oil buildup can be removed. The external motor surfaces can be cleaned by steam clean-

ing. The i nternal motor components should not be sprayed with a steam cleaner. To clean the motor:

1. Clean the motor only when the drilling motor is removed from its machinery and power is removed from the

WARNING: Personnel performing cleaning procedures must wear protective clothing, gloves and eye protec-

tion. Follow local practices and procedures for cleaning. Failure to do so may result in injury or death.

ing Motor, Model 5GEB22

motor.

CAUTION: Al

due to theadverseaffects on motor insulation. Use of thesesolutionsmaycause motor failure or reducedmotor

life.

CAUTION: Do not spray the internal components of the motor with a steam cleaner. Moisture contamination

may cause motor failure or reduced motor life.

WARNIN

to personnel in the immediate area. Personnel should be provided with, and trained in the use of, protective

equipment as specified by applicable federal or state regulators. Failure to do so may result in injury or death.

kali and chlorinated hydrocarbon cleaning solutions arenot recommended forcleaningdrillmotors

2. Cover the motor air inlet and outlet with heavy plastic and tape. Ensure the interior motor components are

protect

3. Steam clean the external surfaces of the motor. Do not direct the spray at mot or openings or the plastic

covers.

4. When steam cleaning is complete, let excess fluid drain from the motor.

5. Remove the plastic covers or protecti ve covers and tape from the motor.

G: When using compressed air for cleaning purposes, flying debris and particles may present a hazard

6. Using compressed air, blow out the interior of the motor to remove all dirt, dust and moi sture. If necessary,

apply heat to dry the motor thoroughly.

ed from spray during cleaning

Recommended cleaning solutions are: CHEMICAL METHODS, INC., 809 or GE BETZ KLEEN SBC120.

5. REMOVAL AND REPLACEMENT PROCEDURES

The following procedures outl ine the overhaul process. All procedures may not be required even though all are

described. Inspection of the components will determine the procedures necessary to return the motor to oper-

ation.

Do not order replacement parts from this publication. Refer to the PARTS CATALOG for the motor for the correct

replacement part number.

5.1. MOTOR PREPARATION FOR SHIPMENT

The drill motor must be prepared for shipment to prevent damage to components during shipping. The following

sections detail rotor locking procedures and packaging for shipment.

16

Page 17

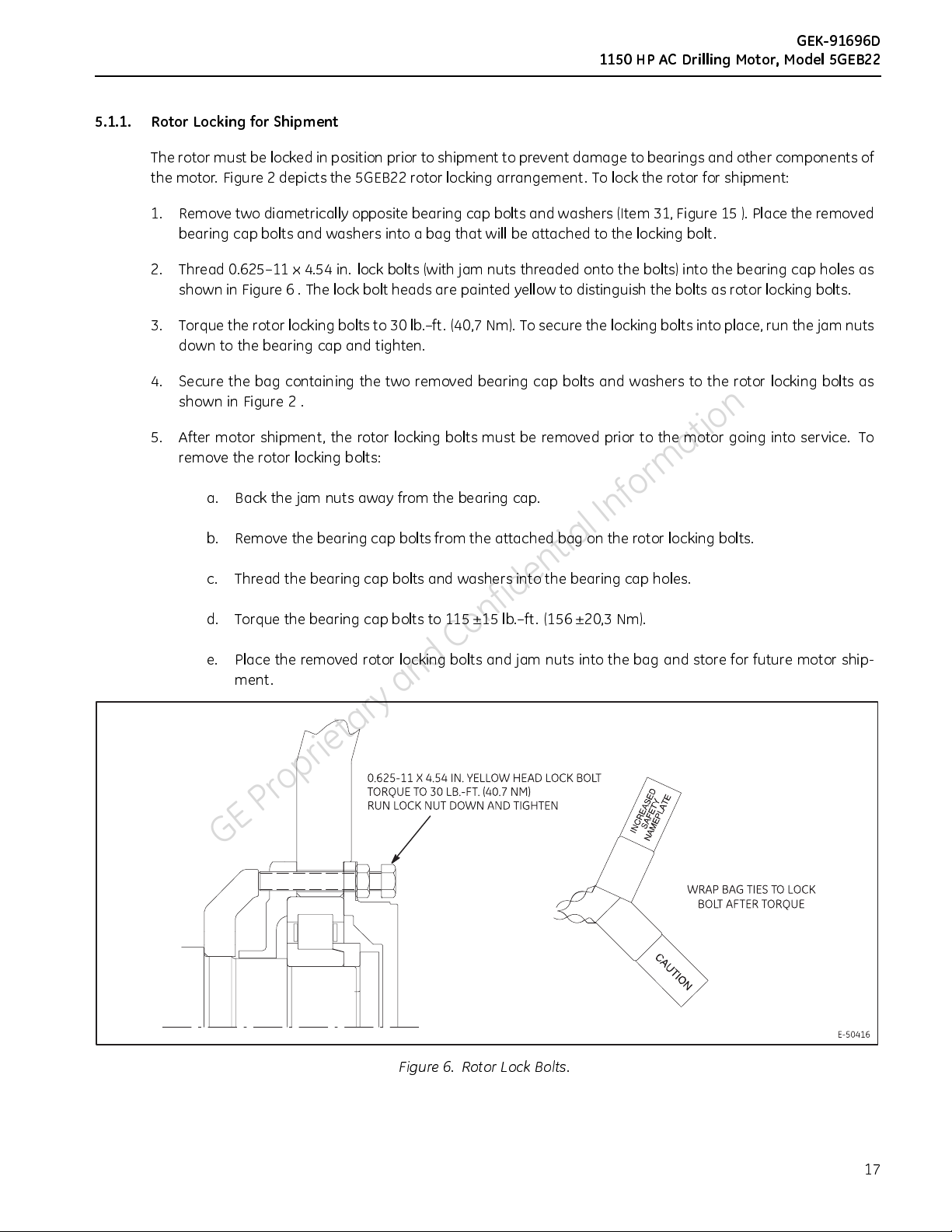

5.1.1. Rotor Locking for Shipment

GE Proprietary and Confidential Information

The rotor must be locked in position prior to shipm ent to prevent damage to bearings and othe r components of

the motor. Figure 2 depicts the 5GEB22 rotor locking arrangement. To lock the rotor for shipment:

1. Remove two diametrically opposite bearing cap b olts and washers (Item 31, Figure 15 ). Place the rem oved

bearing cap bolts and washers into a bag that will be attached to the locking bolt.

2. Thread 0.625–11 x 4.54 in. lock bolts (with jam nuts threaded onto the bolts) into the bearing cap holes as

shown in Figure 6 . The lock bolt heads are painted yellow to distinguish the bolts as rotor locking bolts.

3. Torque the rotor locking bolts to 30 lb.–ft. (40,7 Nm). To secure the locking bolts into place, run the jam nuts

down to the bearing cap and tighten.

4. Secure the bag containing the two removed bearing cap bolts and washers to the rotor locking bolts as

showninFigure2.

5. After motor shipment, the rotor locking bolts m ust be removed prior to the motor going into service. To

remove the rotor locking bolts:

1150HPACDrill

GEK-91696D

ing Motor, Model 5GEB22

a. Back the jam nuts away from the bea ring cap.

b. Remove the bearing cap bolts from the attached bag on the rotor locking bolts.

c. Thread the bearing cap bolts and washers into the bearing cap holes.

d. Torque the bearing cap bolts to 115 ±15 lb.–ft. (156 ±20,3 Nm).

e. Place the removed rotor locking bolts and jam nuts into the bag and store for future motor ship-

ment.

gure 6. Rotor Lock Bolts.

Fi

17

Page 18

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

5.1.2. Motor Packaging for Shipment

After locking the rotor for shipment, the motor should be securely packaged to avoid damage during s hipment.

To package the motor for shipment:

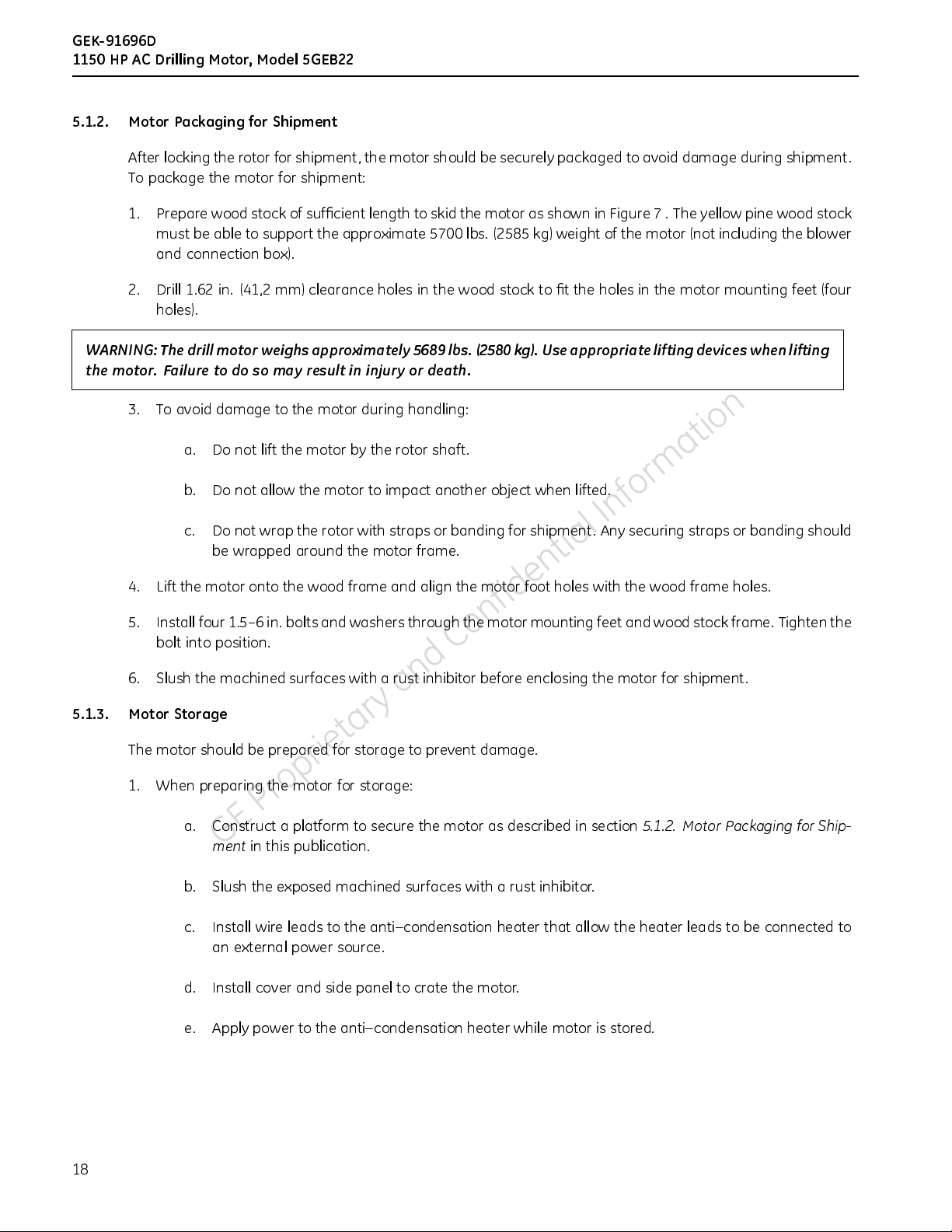

1. Prepare wood stock of sufficient length to skid the motor as shown in Figure 7 . The yellow pine wood stock

2. Drill 1.62 in. (41,2 mm) clearance holes in the wood stock to fit the holes in the motor mounting feet (four

WARNING: The drill motor weighs approximately 5689 lbs. (2580 kg). Use appropriat e lifting devices when lifting

the motor. Failure to do so may result in injury or death.

ing Motor, Model 5GEB22

must be able to support the approximate 5700 lbs. (2585 kg) weight of the motor (not including the blower

and connection box).

holes).

3. To avoid da

a. Do not lift the motor by the rotor shaft.

b. Do not allow the motor to impact another object when lifted.

c. Do not wra

be wrapped around the motor frame.

4. Lift the

5. Install four 1.5–6 in. bolts and washers through the motor mounting feet an d wood stock frame. Tighten the

bolt int

6. Slush the machined surfaces with a rust inhibitor before enclosing the motor for shipment.

5.1.3. Motor Storage

The mo

1. When preparing the motor for storage:

motor onto the wood frame and align the motor foot holes with the wood frame holes.

o position.

tor should be prepared for storage to prevent damage.

a. Construct a platform to secure the motor as described in section

ment

mage to the motor during handling:

p the rotor with straps or banding for shipment. Any securing straps or banding should

5.1.2. Motor Packaging for Ship-

in this publication.

b. Slush the exposed machined surfaces with a rust inhibitor.

c. Inst

d. Ins

e. Apply power to the anti−condensation heater while motor is stored.

18

all wire leads to the anti−condensation heater that allow the heater leads to be connected to

an external power source.

tall cover and side panel to crate the motor.

Page 19

ALLOW CONTAINER

GE Proprietary and Confidential Information

CLEARANCE FROM

MOTOR ON BOTH ENDS

1150HPACDrill

GEK-91696D

ing Motor, Model 5GEB22

Figure 7. Shipment Preparation for the 5GEB22 Motor.

2. When removing the motor from storage:

a. Disco

nnect power from the anti−condensation heater.

b. Remove the crating material from the motor.

c. Remove the rust inhibitor from the machined surfaces.

d. Visu

ally inspect the motor for excessive rust or other defects.

e. Megger the stator lea ds as described in section

f. If the motor has been in extended storage, the grease in the bearing should be replaced. Follow the

overhaul instructions in the following sections to disassemble the motor for bearing access.

5.2. DISASSEMBLY PROCEDURES

5.2

.1.

Hub

Removal

1.5-6 BOLTS, NUTS, AND

WASHERS, 4 PLACES

APPROXIMATE WEIGHT OF MOTOR 5689 LBS (2580 KG)

4.1.3. Megohmmeter Test

in this publication.

E-50540

When removing a hub, use a suitable puller, similar to Part 41B535703G1, Figure 32 . This is a simple, efficient

draulic puller employing the float method of removal. A complete unit consists of a pump kit, a backing pla te,

hy

anadapter,afeltringandabolt.

19

Page 20

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

NOTE: Do not heat the hub before pulling it, and do not use steel wedges between the hub and bearing cap.

1. Remove the set−screw plug from the tapped hole in the end of the shaft.

2. Screw the backing plate, with felt ring in place, to the end of the shaft as tight as possible by hand. Back off

the backing plate to line up the slot with the tapped hole in the end of the shaft. This is to provide sufficient

clearance for the hub to pop off.

3. Screw the pressure−fitting adapter into the hole in the shaft until it seats at the bottom.

4. Attach the pump by screwing the connector on one end of the pressure tube into the adapter, and the other

end into the pump.

5. Close the hand relief valve and work the pump handle to force oil into thegrooveinthearmatureshaftunder

the hub. When sufficient pressure has been built up, the hub will pop off the shaft and be stopped by the

felt washer and backing plate.

NOTE: Capacity of the pump is 40,000 psi (275800 kPa). It holds sufficient oil to remove eight to ten hubs;

check at each use. Periodically, remove the filling plug and refill with SAE−10 lubricating oil.

ing Motor, Model 5GEB22

6. Open the relief valve, disconnect the pump from adapter, remove the adapter and backin g plate from the

shaft, and lift off the hub. Rein sert the plug to prevent clogging the hole.

5.2.2. Rotor Removal

To remove the rotor from the motor assembly:

CAUTION: Special precautions should be taken to avoid damage to the rotor, bearings, or bearing fits when

lifting the rotor in the vertical position or turning the rotor to a horizontal position.

NOTE: N

COMPONENT IDENTIFICATION of this publication, unless otherwise noted.

1. Place

2. Remove the eight bolts and flat washers (31) securing the connection−end bearing housing to the connec-

3. Screw two long guide studs (.625–11 X 10) through the frame head and into the connection−end bearing

4. Plac

umbers in parenthesis () refer to item numbers in Figure 15 located in section 6.2. DRILL MOTOR

the motor in a horizontal positi on.

end frame head. Remove the connection−end bearing cap

tion−

r cap (35) in opposite holes of the six just emptied. These studs will help to guide the rotor out of the

inne

motor frame.

e the motor on a heavy−duty stand with the drive−end up. Level the mot or so that the rotor can be lifted

vertically with a hoist without damaging the bearing or bus rings.

5. Rem

6. Screw a 1 in.−8 steel lifting eyebolt into the threaded hole in the drive−end of the rotor shaft (5).

7. Align the hoist cable with the center line of the rotor and attach the hoist hook to the lifting eye.

NO

removed with the rotor as an assembly.

20

ove the eight bolts (10) and flat washers holding the drive−end frame head to the motor frame.

TE: The connection−end bearing and housing and the drive−end frame head, bearing and housing are

Page 21

GEK-91696D

GE Proprietary and Confidential Information

1150HPACDrill

CAUTION: Use extreme care when turning the rotor to the horizontal position to avoid damage to the core and

the bearing and

8. Carefully lift the rotor assembly out of the motor stator and p lace the rotor in a horizontal position on a

9. With the rotor in t he horizontal position, remove the two long guide studs (.625–11 X 10) from the connec-

frame head fits. Use two hoists when positioning the rotor horizontally.

wooden cradle supporting the core assembly.

tion−end bearing housing.

ing Motor, Model 5GEB22

10. Remove and service the rotor bearings according to instruction in section

Assembly Removal

5.2.3. Connection End (CE) Bearing Assembly Removal

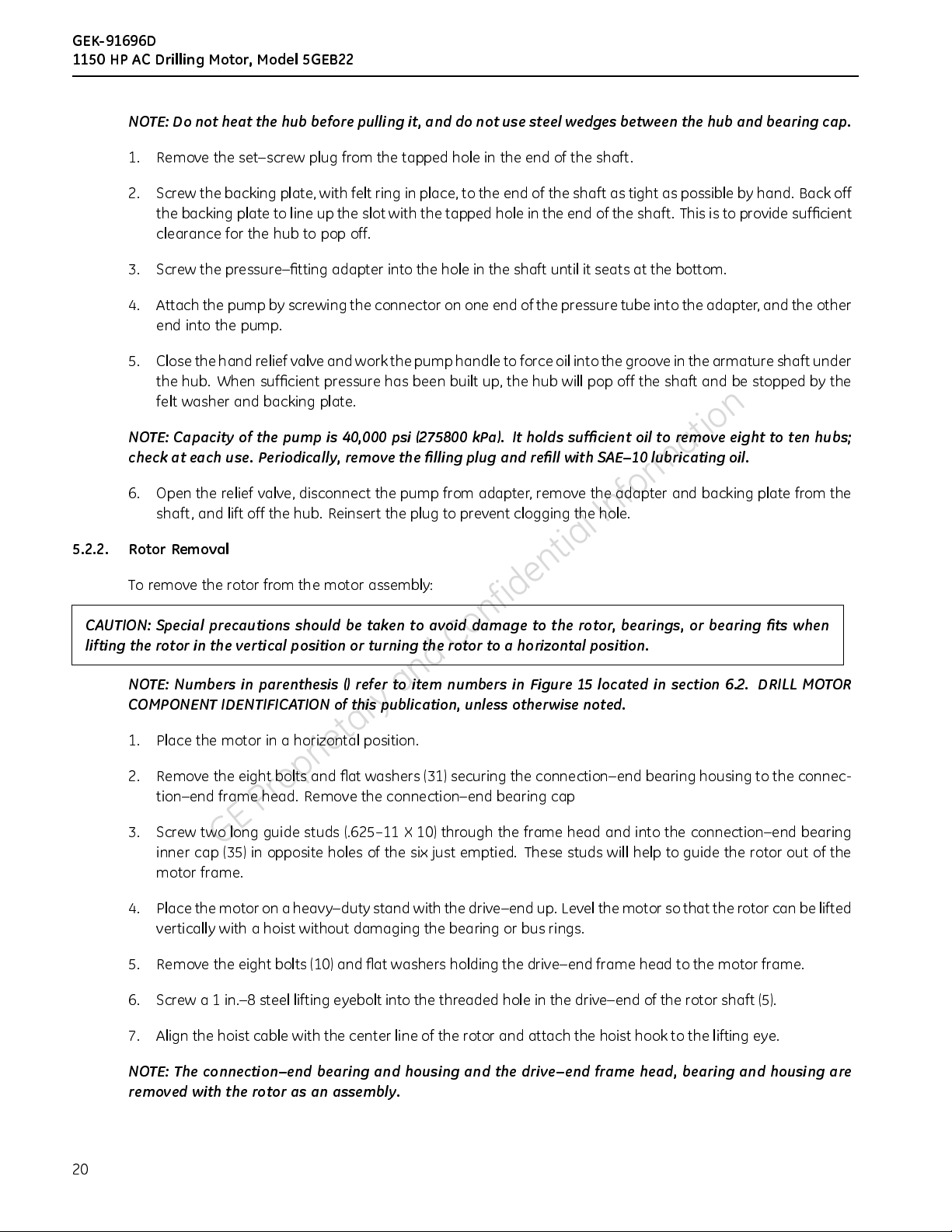

There are two Connection End (CE) bearing assemblies used for the 5GEB22 models. Models of the 5GEB22 man-

ufactured prior to October, 2001 use the original design CE bearing assembly as shown in Figure 8 . 5GEB22

models manufactured after September, 2001 ( Figure 9 ) use an enhanced p erformance CE bearing assembly.

Refer to section

the CE bearing designs. The following sections describe the CE bearing removal for both designs of CE bearings.

Select the removal procedure appropriate for the bearing design on the drill motor.

5

.2.3.1. Connection End Bearing Assembly Removal Procedure for 5GEB22 Models Manufactured Prior to October,

2001

The following procedure details the removal procedure for 5GEB22 drill motor models manufactured prior to

October, 2001. To remove the CE bearing assembly:

NOTE: Numbers in parenthesis () refer to item numbers in Figure 15 located in section 6.2. DRILL MOTOR

COMPONENT IDENTIFICATION of this publication, unless otherwise noted.

1. Remove the twosetscrews(40) from the rotorbearingnut(33). Attach the spanner wrench (GE Tool9945228)

to the rotor beari ng nut. Using a dead blow hammer, tap the wrench handle in a counter clockwise (CCW)

direction t o loosen the nut. Remove the spanner wrench, and remove the bearing nut from the rotor.

of this publication.

6.2. DRILL MOTOR COMPONENT IDENTIFICATION

in this publication for details of differences in

5.2.3. Connection End (CE) Bearing

2. Assemble the bearing puller (GE Tool 41D736059G3), and use the hydraulic jack to pull the connection–end

bearing housing (35) and bearing (34) from the rotor shaft.

3. Position the bearing housing – with the bearing down – on a flat surface. Reassemble the be aring puller (to

GE Tool 41D736059G4), and use the hydraulic jack to push the bearing from the bearing housing.

21

Page 22

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

ing Motor, Model 5GEB22

± ±

± ±

Figure 8. Connection End (CE) Bearing Assembly for Models Manufactured Prior to September 2001.

22

Page 23

1150HPACDrill

GE Proprietary and Confidential Information

±

±

GEK-91696D

ing Motor, Model 5GEB22

± ±

Figure 9. Connection End (CE) Bearing Assembly for Models Manufactured After September 2001.

5

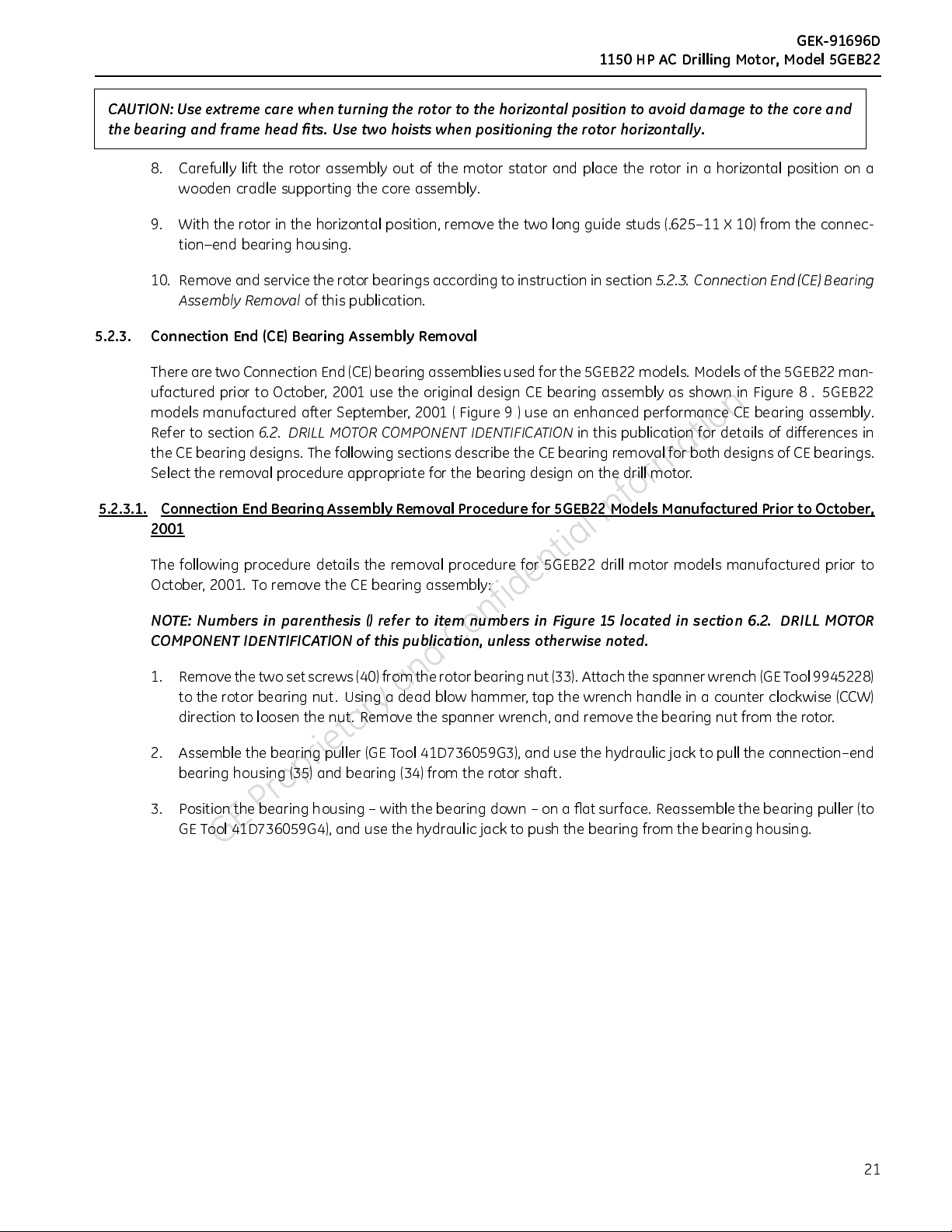

.2.3.2. Connection End Bearing Assembly Removal Procedure for 5GEB22 Models Manufactured After September,

2001

The following procedure details the removal procedure for 5GEB22 drill motor models manufactured after to

September, 2001. To remove the CE bearing assembly:

NOTE: Numbers in parenthesis () refer to item numbers in Figure 15 located in section 6.2. DRILL MOTOR

COMPONENT IDENTIFICATION of this publication, unless otherwise noted.

1. Remove the four bearing clamp (41) retaining bolts and hardened washers (42).

2. Thr

3. Assemble the bearing puller (GE Tool 41D736059G3), and use the hydraulic jack to pull the connection–end

4. Position the bearing housing – with the bearing down – on a flat surface. Reassemble the be aring puller (to

ead two bolts into the bearing clamp (41) jack out holes. Tighten the bolts alternately until the bearing

clamp (41) is free of the rotor shaft fit. Remove the bearing clamp and remove the jack out bolts from the

bearing clamp.

bearing housing (35) and bearing (34) from the rotor shaft.

GE Tool 41D736059G4), and use the hydraulic jack to push the bearing from the bearing housing.

23

Page 24

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

5.2.4. Drive End Bearing Assembly Removal

The following procedures details the drive end (DE) bearing assembly ( Figure 10 ) removal. To remove the DE

bearing assembly:

NOTE: Numbers in parenthesis () refer to item numbers in Figure 15 located in section 6.2. DRILL MOTOR

COMPONENT IDENTIFICATION of this publication, unless otherwise noted.

1. Remove the eight bolts and the flat washers (8) from the outer bearing cap (7).

2. Support the weight of the DE frame head (11) with a hoist, taking care not to lift the rotor off its support.

3. Use an arbor press and fixtures to separate the bearing assembly (3) from the DE frame head (11).

4. Remove the inner shaft collar (1) only if damaged, if outside of inspection limits, or if the shaft must be re-

5.2.5. Connection End Frame Head Removal

ing Motor, Model 5GEB22

Assemble the bearing puller and use the hydraulic jack to pull the frame head (11), roller bearing (3), and

inner bearing cap (12) from the rotor.

moved from the rotor. If necessary, use a pulle r to remove the sleeve.

Removal of the connection end frame head may be required to gai n acce ss t o the bus rings and stator coil

connections. To remove the CE frame head:

NOTE: Numbers in parenthesis () refer to item numbers in Figure 15 located in section 6.2. DRILL MOTOR

COMPONENT IDENTIFICATION of this publication, unless otherwise noted.

1. Remove the eight bolts and flat washers (28) holding the frame head (27) to the stator fram e (21).

2. Thread three 1–8x3 jack out bolts into the threaded holes of the CE frame head (27). Evenly tighten the jack

out bolts until the frame head is free of the stator frame (21) fit.

WARNING: The CE frame head weighs approximately 220 lbs. (100 kg). Use appropriate lifting devices for this

weith. Failure to do so may result in injury or death.

3. Lift the frame head (27) from the stator frame (21).

24

Page 25

GEK-91696D

GE Proprietary and Confidential Information

1150HPACDrill

±

±

ing Motor, Model 5GEB22

Figure 10. 5GEB22 Drive End (DE) Bearing Assembly.

5.3. INSPECTION AND REPAIR PROCEDURES

1.

5.3.

5.3.2. Stator Coils and Bus Rings Connection Inspection

r Shaft Inspection

Roto

Check dime nsions as shown in Figure 16 located in section

pect the stator coils and bus rings as follows:

Ins

1. Examine the bus rings for damaged or loose connections.

2. Observe the condition of the coil insulation and varnish. Evidence of burned or charred insulation or varnish

may indicate an overheating condition from a defective connection or defective coils.

6.3.1. Rotor Shaft Inspection Data

in this publication.

25

Page 26

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

5.3.2.1. Repairing Stator Coils to Bus Ring Connection, Cleaning and Breaking the Connection

The connection of the stator coils to the bus ring can be repaired when the connection shows signs of overheat-

ing. The connections are exposed by cutting and stripping the insulation around the connection requiring the

use of a hammer, knife, chisel, screwdriver, pry bar, and slip joint pliers. To expose the connections for repair:

NOTE: Read this entire procedure first to become familiar with these steps.

1. Position the stator frame to obtain the best working position for the connections to be cleaned.

2. Remove any mount ing hardware (bolts, nuts, insulating blocks, etc.) from the area of the brazed connection.

3. Use the knife, chisel, and hammer to cut the insulation. Cut the insulation down to the copper the full length

4. After cutting the insulation the full le ngth, pry the i nsulation away from the connection using the slip joint

5. Brazing tool heat can be used to soften the insulation for final cleaning. Alternately heat the insulation, and

ing Motor, Model 5GEB22

of the connection.

pliers, pry bar, screwdriver, or knife.

scrape off all material until reaching bare copper.

NOTE: Use the resistance brazing machine (GE Tool 41D780746–1 or equivalent) and tongs (GE Tool

41D780746–11 or equivalent) to produce the heat necessary to separate the connection. Passing current

through the brazing tongs carbons and the metal to be separated produces heat.

6. The area of the joint to be disconnected must be clean and free of dirt, oil and insulating material such as

varnish and tape.

WARNING: Observe all government and shop safety regulations when using compressed air. Failure to do so

may result in injury.

7. Position the brazing tong on the connection that is to be opened. Keep an air supply nozzle on hand to cool

parts after separation occurs. The air supply also is used to cool the surrounding area by dissi pating heat

he area being heated.

from t

CAUTION: Power is to be applied in pulses ONLY. This enables the heat to spread out gradually, providing a more

eating of the connection area, and eliminating any intense hot spots that may damage the ring or coil

even h

material.

8. Apply power to the brazin g tongs in pulses ONLY until the heat melts the brazing material in the joint, then

shut off the power.

9. Quickly remove the brazing tongs, and using the screwdriver or pry bar, spread the connection joints before

the solder cools and resolidifies.

10. When the bus ring and stator coil connections are sepa rated, repair or replace damaged bus rings, straps,

or stator coil leads prior to brazing the connection together.

11. Before brazing together, ensure the material is clean, parts being brazed are flat against each other to pre-

vent voids.

5

.3.2.2. Repairing Stator Coils to Bus Ring Connection, Brazing and Insulating

To braze and insulate the connection after repairs have been made:

26

Page 27

GEK-91696D

GE Proprietary and Confidential Information

1150HPACDrill

NOTE: The brazing median can be used in strip form (GE Part 41A231281P46) or rod form (GE P art

41A330300P2). It is recommended that strips 0.010 in (0.25 mm) thick cut into squares or rectangles 0.06 in.

(1.6 mm) larger than the conductors, beused for the initial connection. Use the brazing rod to fill voids after

the initial co nnection. Use of this m aterial eliminates the need for flux.

1. The connection area of the material to be brazed must be clean and free of dirt, oil, and insulating materials.

2. If necessary, bend the soft copper connecting straps to align the connection.

NOTE: When using brazing material in strip form, the strip should be sandwiched between the two pieces

being brazed, which must be flat along the entire length of the joint.

3. Insert a brazing strip between the two c onnecting straps being brazed.

4. Position the b razing tongs on the area to be brazed, and clamp in place.

WARNING: Observe all government and shop safety regulations when using compressed air. Failure to do so

may result in injury.

CAUTION: Power is to be applied in pulses ONLY. This enables the heat to spread out gradually, providing a more

even heating of the connection area, and eliminating any intense hot spots that may damage the ring or coil

material

.

ing Motor, Model 5GEB22

5. Apply p owe r to the brazing tongs in pulses ONLY, and heat until t he brazing solder flows freely. Using an air

nozzle, blow air on the surrounding area while heating to dissipate heat from the area being brazed.

NOTE: When brazing,silver solder in rod form will be required to fill areaswhere the strip may have dripped

outortofillvoids.

6. Remove power from the tongs, but do NOT release the tongs until the silver solder has cooled enough to

hold the connection. Blowing compressed air on the brazed area will speed the cooling.

7. Insulate the connection area using Micamat (part number 41A239176P215) and half lap insulating tape (part

number 41A239176P15) or other appropriate insulation material specific to the connection area.

8. Varnish application over the new insulation is required either by P5D-EP25 VPI process or hand application.

5.3.3. Stator / Rotor Reconditioning

The stator and rotor must be reconditioned during the overhaul procedures before bein g returned to service.

These process help ensure long operating life for the components.

The stator assembly should be treated by Vacuum Pressure Impregnation (VPI) with an approved varnish. VPI

will seal and secure the stator coils. VPI only after cleaning, inspection and testing of the stator assembly. The

VPI process is GE Process P5D–EP25.

The rotor assembly should be treated by a powder coating process. Powder coat the rotor after cleaning and

inspecting. The powder coat treating is GE Process P6C– EP45.

Due to changing technology, contact your local GE representative or Drill Product Service Center for current

instruction processes at time of overhaul. Drill product Service Center contact information as follows:

27

Page 28

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

GE Transportation

Attention Drill Product Service

2901 East Lake Road

Erie, PA 16531

www.GEtransportation.com

5.4. STEAM CLEANING

5.4.1. Steam Cleaning Introduction

WARNING: Cleanin g agents may be toxic and/or flammable. Cleaning agents can cause serous or fatal injury

if used without proper precautions. For safety; do not inhale fumes, use only in adequately ventilated areas,

avoid contact of cleaning agents with the skin, do not expose cleaning agent to flame or sparks, and observe

cautions and warnings issued by the manufacture of the cleaning agent.

Care must betakeninthe selection and strength of cleaning agents ordetergents usedinconjunctionwithsteam

cleaning. Typical cleaning agents pH (alkalinity) are alkaline and not chemically neutral. Check the pH level with

a pH monit

is used, Table 6 depicts the pH test paper color and corresponding alkalinity level.

ing Motor, Model 5GEB22

or or pH test paper strips to ensure of the cleaning solution is in an acceptable range. If pH test paper

TABLE 6.

Acid Neutral Base−Alkaline

5 — 6 7 8 9 10 11

Orange Yellow Green Ivy—Green Blue Purple

Cleaning processes in which heavy, dirty, greasy mechanical equipment is cleaned should not be used to clean

rical eq uipment. Due to chemical make up and high concentrations of cleaning agents in solution, utilizing

elect

the mechanical equipment cleaning processes on electrical equipment can have a significant impact on the life

of the electrical insulation systems used in motors

A suggested cleaning agent for use in steam cleaning processes for electrical equipment is CM−809−S (or equiv-

alent). This cleaning agent is available at Chem Methods, Inc., 12703 Trisket Road, Cleveland, OH 44111. Chem

ods, Inc. telephone number is (216) 476−8400. This cleaning agent is Potassium Phosphate based and does

Meth

not contain caustic materials or silicate.

mixed steam cleaning solution should be heated to 158 °F to 194 °F (70 °C to 90 °C) and have a pH of 10.5

The

to 11.0. Approximately a 10% solution of the cleaning agent and heated water should achievethe pH level. The

10% solution should be used on the rotor and stator of the motor. If needed, a 50% solution of the cleaning

ent and heated water can be used on the motor frame externally. Do not allow the stronger solution to leak

ag

internally to the motor.

control the cleaning agent in solution, a steam cleaner with an adjustable soap (cleaning agent) valve should

To

be used.

CLEANING AGENT PH DATA.

28

Page 29

GEK-91696D

GE Proprietary and Confidential Information

1150HPACDrill

To clean the motor:

1. Using the 50% solution, spray the external motor frame with the cleaning solution. Let the cleaning solution

soak the motor frame five to t w enty minutes (depending on the contaminant) to penetrate the accumulated

contaminants.

2. If deposits of contaminants are too heavy to be steam cleaned off, manually scrap the debris off and steam

clean.

3. Rinse the cleaning solution off motor with steam and hot water.

4. Blow the motor frame dry with clean, dry compressed air.

5. After motor disassembly during the overhaul process, clean the internal motor components using a 10%

cleaning solution.

6. Rinse of the cleaning solution off with hot water heated to a minimum 194ºF (90ºC).

NOTE: The internalmotor componentsmust be thoroughly rinsed. Cleaningsolutions mayform a crystalline

compound if left on the motor components. The motor insulation systems may be affected by the crystalline

deposits which may shorten the insulation life.

ing Motor, Model 5GEB22

WARNING: When using compressed air, loosened debris may make the surrounding area dangerous for per-

sonnel. Ensure all personnel are clear and wear appropriate safety equipment. Follow all local regulations and

procedures for compressed air use. Failure to d o may result in injury or death.

7. Using clean, dry compressed air, blow excess water off internal motor components.

8. Bake th

9. Allow parts to cool to room temperature and visually inspect for defects.

10. Perform the Megohmmet er and High−Potential tests described in section

troduction

11. If the stator assembly does not meet specifications in tests, bake an additional two hours in the oven and

retest.

5.5. STATIC ELECTRICAL TESTING

5.5.

1.

ic Electrical Testing Introduction

Stat

Static electrical tests include a Megohmmeter tes t and High−Potential (Hi−Pot) test. Both tests check motor insu-

on systems. Always perform the Megohmmeter test prior to the Hi−Pot test. High voltage used in the Hi−Pot

lati

test may be destructive to insulation if water or debris is present. If the Megohmmeter test indicates moisture or

debris is present, clean the stator as described in section

e th e Megohmmeter test specification is met, proceed to the Hi−Pot test.

Onc

e motor electrical parts in a ventilated oven at 257ºF to 320ºF (125ºC to 160ºC) for 8 to 12 hours.

5.5.1. Static Electrical Testing In-

of this publication.

5.4.1. Steam Cleaning Introduction

of this publication.

5

.5.1.1. Megohmmeter Test

Perform the Megohmmeter test as described in section

4.1.3. Megohmmeter Test

in this publication.

29

Page 30

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

5.5.1.2. High–Potential (Hi–Pot) Test

WARNING: High−Potential (Hi−Pot) testing is performed with high voltage electrical power. Follow safety regu-

lations and local practices for high voltage testing. Failure to do so may result in injury or death.

Hi−Pot te sts evaluate the insulation dielectric strength (ability to insulate) of the motor insulation systems. High

voltage is ap

CAUTION: Always perform the Megohmmet er test before Hi−Pot test. Damage may occur to insulation during

Hi−Pot test

damage to the stator windings requi ring replacement of the stator.

1. Ground one lead of the RTD temperature sensor for sensor protection. Do not Hi−Pot the RTD during testing.

2. Apply the specified high voltage at 60 Hz to each motor lead for one minute with the other lead of the Hi−Pot

ing Motor, Model 5GEB22

plied to each motor phase to test insulation to ground during the test. To perform the Hi−Pot test:

ing if moisture or debris is present in the coils of the stator. Failure to do so may result in permanen t

connected to ground. There should not be any significant current (amperage) leakage to ground during

testing. The voltage applied should be:

a. New or recoiled stator − apply 3500 VAC rms.

b. Reconditioned stator − apply 2500 VAC rms.

c. In−service or used stator − apply 2250 VAC rms.

3. If the stator windings show significant current leakage to ground, clean the stator as described in section

5.4.1. Steam Cleaning Introduction

5.6. ROTOR SUBASSEMBLY PROCEDURES

5.6.1. Rotor Balancing

Dynamic balance of the rotor assembly is required for smooth operation and low vibration. If not corrected, an

out−of−balance rotor will lead to complete motor failure.

The rotor must be balanced to within 50 gram−in. at both ends of the rotor.

These instructions pertain only to the location and method of attaching the balance weights. The set−up, fixtures

to hold components in the balance machine, and the procedures required to obtain a balance within specified

limits is dependent on the type of balance machine. Therefore, follow the operating procedures for the balance

machine used.

CAUTION: Use ONLY the specified welding rod. Use of other types may result in poor welds leading to motor

failure.

in this publication. After cleaning, retest the stator windings.

E: Keep weld splatter out of the rotor core vent holes when welding balance weights to the end pla te.

NOT

Attach the balance weights as needed by welding to the rotor end plates at a diameter of 13.75 in. (276,9 mm).

e welding rod GE Spec. G50E37, BRON ZE (AWS−E−Cu−Sn−C). Weld the balance weights using GE weld process

Us

P8B−EP35.

30

Page 31

GEK-91696D

GE Proprietary and Confidential Information

1150HPACDrill

5.6.2. Connection–End (CE) Frame Head Installation

NOTE: Numbers in parenthesis () refer to item numbers in Figure 15 located in section 6.2. DRILL MOTOR

COMPONENT IDENTIFICATION of this publication, unless otherwise noted.

WARNING: The CE frame head weighs approximately 220 lbs. (100 kg). Use appropriate lifting devices for this

weith. Failure to do so may result in injury or death.

To assemble the connection–end frame head (27), align the frame head on the motor frame. Install and

hand–tighten the eight bolts and hardened flat washers (28) holding the frame head (27) to the motor frame

(21). Then t

5.6.3. Connection−End (CE) Bearing Assembly

To assemble the CE bearing onto the 5GEB22 rotor:

orque the bolts evenly in a diametrically opposite sequence to 468 ±28 lb–ft (634 ±38 Nm).

ing Motor, Model 5GEB22

NOTE: Numb

COMPONENT IDENTIFICATION of this publication, unless otherwise noted.

WARNING:

sonnel. Ensure all personnel are clear and wear appropriate safety equipment. Follow all local regulations and

procedures for compressed air use. Failure to d o may result in injury or death.

WARNING: Components heat in ovens may be hot enough to cause injury. Use appropriate safety equipment

and follow shop procedures for handling heat ed compon ents. Failure to do so may result in injury.

When using compressed air, loosened debris may make the surrounding area dangerous for per-

1. Using clean, dr y, com pressed a ir, blow debris from CE bearing mounting area on the rotor shaft (5).

2. Inspect all CE bearing assembly components to ensure parts are clean and free of damage or burrs.

3. The rotor assembly must be in the horizontal position and blocked to prevent rotation or movement during

the assembly procedure.

4. If removed, install the rotor locking collar (36). To install the collar:

ers in parenthesis () refer to item numbers in Figure 15 located in section 6.2. DRILL MOTOR

a. Heat the rotor locking collar (36) to 212°F (100°C) in an oven.

b. Remo

ve the locking collar (36) from the oven and place onto the rotor shaft. Press the collar into

position against the shoulder of the rotor shaft (5).

c. Sec

5. Fill th e cavity of the CE inner bearing cap (35) with 2.2 oz. (62.4 g) of GE specification D6A2C10 grease.

6. Pack the CE bearing (34) with 5 oz. (142 g) of GE specification D6A2C10 grease.

enly heat the CE inner bearing cap (35) to 212°F (100°C) in an oven to expand the cap’s bearing fit for the

7. Ev

CE bearing (34). Remove the inner bearing cap (35) from the oven and place onto a flat surface. Press the

CE bearing (34) (rotor side of the bearing as shown in Figure 15 ) into the inner bearing cap (35) bearing fit.

8. Cover or coat the CE rotor shaft (5) running surfaces with 0.25 oz. (7 g) of GE specification D6A2C10 grease.

ure the collar into position until it cools.

31

Page 32

GEK-91696D

GE Proprietary and Confidential Information

1150 HP AC Drill

9. Heat the CEinnerbearingcap,withthe CE bearing, to 212°F (100°C) inanove n. Remove the heated assembly

from the oven and immediately slide the assembly onto the CE end of the rotor shaft. Press the assembly

tightly against the shaft shoulder. Secure the assembly in position until cool.

10. Securing the CE bearing assembly on the rotor shaft (5) depends on the 5GEB22 model. Select the app ro-

priate process for the 5GEB22 model.

ing Motor, Model 5GEB22

a. For 5GEB22 models manufactured prior to September, 2001, the CE bearing assembly is secured

on the rotor shaft with a bearing retaining nut (33). Refer to Figure 8 for grease application during

assembly process. To secure thebearing assembly ontherotor shaft, thread the nut into thetapped

end of the rotor shaft until hand tight. Insert a spanner wrench (tool number 9945228) into the

holes on the outside flat of the bearing nut. Using a brass sledgehammer, strike two or three sharp

blows, driving the n ut clockwise, approximately one quarter turn from hand tightened. Thread the

two locking set screws (40) into the bearing retaining nut (33) and torque the set screws to 40 ±2

lb—ft (54 ±3Nm). Using a heavy center punch, stake or peen each set screw intwoplaces to prevent

loosing.

b. For 5GEB22 models manufactured after September, 2001, the CE bear ing assembly is secured on

the rotor shaft with a bearing clamp (41). Refer to Figure 9 for grease applications during assembly

process. To secure the bearing assembly on the rotor shaft, Inspect the rotor shaft bore (5) and

clamp (41) to ensure the components are free of damage and burrs. Lightly coat the rotor shaft

bore with GE specification D6A2C10 grease to facilitate assembly. Insert the bearing clamp into the

rotor shaft b ore. Thread the clamp bolts (42) through the clamp into the tapped holes of the rotor

shaft. Tighten the clamp bolts alternately to evenly to draw the clamp into the rotor shaft bore.

When the clamp is fully seated in the rotor shaft, torque the clamp bolts to 58 ±2 lb—ft (78 ±3 Nm).

11. Apply the gasket and assemble the dummy CE bearing cap 41C689896 ( Figure 36 ) with four bearing cap

bolts and hardened washers (31). Thread the bolts through the dummy bearing cap into the inner bearing

cap (35) to secure the bearing assembly.

5.6.4. Drive End (DE) Bearing Assembly

NOTE: Numbers in parenthesis () refer to item numbers in Figure 15 located in section 6.2. DRILL MOTOR

COMPONENT IDENTIFICATION of this publication, unless otherwise noted.

ToassembletheDEbearing:

WARNING: When using compressed air, loosened debris may make the surrounding area dangerous for per-

sonnel. Ensure allpersonnel are clearand wear appropriate safety equipment. Follow alllocal regulations and

procedures for compressed air use. Failure to do may result in injury or death.

1. Using clean, dry compressed air, blow any loose debris clear of the DE rotor shaft (5).

2. Inspect the DE bearing assembly and rotor shaft to ensure parts are free of damage and burrs.

3. The

WARNING: Componentsheated in ovens maybehot enough to cause injury. Use appropriate safety equipment

d follow shop procedures for handling heated components. Failure to do so may result in injury.

an

rotor should be in the horizontal position and blocked to prevent movement and rotation.

4. If removed, install th e inboard DE shaft collar (1) onto the rotor shaft (5). to install the rotor shaft:

32

Page 33

a. Heat the shaft collar (1) to 212°F (100°C) in an oven.

GE Proprietary and Confidential Information

b. With the rotor in a horizontal position, remove the collar from the oven and press onto the rotor

shaft (5) drive end until seated against the rotor shaft shoulder. Secure the collar in place until cool.

c. After the collar has cooled, coat the rotor shaft collar’s running surfaces with GE specification

D6A2C10 grease as shown in Figure 10 .

d. Pack approximately 8 oz. (227 g) with GE specification D6A2C10 grease into the DE inner bearing

cap (12) as shown in Figure 10 . Coat the inner bearing cap running surfaces with the same grease.

5. Place the inner bearing cap in position over the DE shaft collar (1).

1150HPACDrill

GEK-91696D

ing Motor, Model 5GEB22

6. Install the

7. Install

8. Fill the DE bearing (rollers and outer race) with 16 oz. (454 g) with GE specification D6A2C 10 grease as shown

inFigure10.

flinger (2) onto the rotor shaft drive end. To install the flinger:

a. Heat the flinger to 212°F (100°C) in an oven.

b. Ensure the inner bearing cap (12) is in position on the rotor shaft drive end.

c. With the r