Page 1

GE Oil & Gas

Technical Specifications

07/2014

39003 Series

Masoneilan* High Performance Butterfly Valves

(HPBV)

Page 2

2 | GE Oil & Gas

Page 3

Table of Contents

Foreword ....................................................................................................................3

Features .....................................................................................................................4

Numbering System ...............................................................................................5

General Data ............................................................................................................ 7

Pressure/Temperature Ratings ........................................................................8

Body Assembly Data ......................................................................................... 10

Actuator Data ....................................................................................................... 11

Foreward

Rated Flow Coefficients (C

Standard Valve Components ......................................................................... 14

Allowable Pressure Drops ................................................................................16

Weights ................................................................................................................... 17

Dimensions ............................................................................................................ 19

GE Sales Offices ................................................................................. Back Cover

) and Pressure Recovery Coefficients (FL) ....... 12

V

GE’s Masoneilan 39003 Series High Performance Butterfly Valve

(HPBV) is a heavy duty automatic throttling control valve that

incorporates the two basic features of the HPBV types. These

features differentiate the the Masoneilan* 39003 Series HPBV

from the conventional swing-through butterfly valve in regards to

sealing method and operational characteristics. Specifically, the

two basic features are: (1) A PTFE, RTFE, or metal seal ring instead

of a liner, and (2) The employment of double offset (eccentric

operation). Each of these features contributes to the improved

performance of HPBV’s compared to conventional butterfly valves.

The use of a seal ring (PTFE, RTFE, or metal) eliminates the inherent

problems of high sealing forces, due to interference fit, and the

resultant high wear rates due to scraping and scuffing of liners.

Also, due to the design of the seal itself, which is a dynamic pressure-assisted member, ANSI Class VI shutoff rates are available

throughout the full range of ANSI Class 150, 300 and 600 ratings

(soft-sealed constructions only).

The double offset (eccentric) operating principles of both seal offset (the seal ring centerline is offset from the shaft centerline – see

Figure 1) and shaft offset (the shaft centerline is offset from the

valve centerline – see Figure 1) allows the disc to get off the seal

quickly due to the camming rotation with respect to the valve/seal

centerlines. This results in minimal sliding (friction producing) contact between the disc and the seal ring with complete separation

after only a few degrees of rotation.

The overall characteristics of the Masoneilan* 39003 Series Valve

are listed below:

• Long seal life – Offset (eccentric) operation gets the disc off the

seal quickly, minimizing sliding contact and friction, resulting

in reduced seal wear and lower breakaway and seating torque

requirements.

• Fast/dynamic operation – Offset (eccentric) operation elim-

inates disc-to-seal friction throughout the operating range

resulting in fast response to input signals. Also, the disc tends to

move in the direction of flow, assisting the valve and actuator to

maximize the allowable operating pressures.

• Excellent flow characteristics – the offset (eccentric) disc design

provides an approximate equal percentage flow characteristic

through its full travel of 90° rotation yielding a Cv ratio of 100:1.

• Extra heavy shafts with keyed ends for actuator mounting –

precise and accurate positioning without lost motion or back-

lash.

PTFE-lined low-friction bearing – Reduces operating torque and

promotes fast response to valve and actuator action. The triple

bearing support of the shaft prevents deflection of the shaft due

to side-loading.

Field replaceable components – Unlike most competitive valves,

shaft and disc need not be purchased as a set. The Masoneilan*

39003 Series Valve uses tapered pins to attach the shaft and disc

positively, yet provide component interchangeability.

Trade names noted throughout are for reference only. GE reserves

the right to supply trade named material or its equivalent.

39003 Series High Performance Butterfly Valves (HPBV) | 3

Page 4

Features

GE’s Masoneilan 39003 Series HPBV includes unique valve seal designs for

metal, soft seal, and fire-safe configurations.

Metal Seal Design

The metal seal design incorporates an Inconel seal for higher tensile strength,

a 300 series stainless steel back-up ring in the seal cavity for axial seal

support, and a disc that is case hardened by nitriding.

The Inconel seal, by its dynamic and flexible design, applies enough force per

linear inch against the disc edge (Rockwell Hardness of C66 to C70) to obtain

an optimum sealing characteristic while controlling the loads between the

metal surfaces.

The metal seal design can be utilized for temperatures up to 900˚F, in

compliance with ANSI B16.34 pressure/temperature specifications. Leakage

is rated at Class IV per ANSI FCI 70-2.

Soft Seal Design

The soft seal design provides a bi-directional bubble tight shutoff (zero

leakage) through the use of a patented seal. This unique seal design creates a

self-energized seal in vacuum-to-low pressure applications.

Under higher pressure conditions, the seal is also designed to confine and

direct movement of the soft seal against the disc edge, up to the full ANSI

Class 150, 300 and 600 Cold Working Pressures.

The soft seal is designed for high services with minimal wear and low torque.

Seal replacement is a simple procedure requiring no special tools.

Disc/Nitrided

300 Series Stainless

Steel Backup Ring

Inconel Seal

Disc

Seal

“O” Ring

Fire-Safe Seal Design

The fire-safe seal design incorporates two patented seals which function

together to seal off pipeline flow. In normal operation, the soft seal provides a

bi-directional “bubble tight” shutoff (zero leakage); the metal seal provides bidirectional shutoff in the event of a fire, in conformance to industry fire-safe

requirements.

With little or no pressure, the fire-safe seal creates a self-energized seal

against the disc. Higher line pressures act on the geometry of both seals

to dynamically load them against the disc, creating higher sealing forces in

either direction.

The metal seal is made of Inconel material which is shaped by a proprietary

hydroforming process into its unique, patented design. Stainless steel outer

bearings are included for post-fire disc and shaft alignment. Fireproof

packing is used to prevent external shaft leakage.

Disc

Metal Seal

Soft Seal

“O” Ring

Metal Seal Gasket

4 | GE Oil & Gas

Page 5

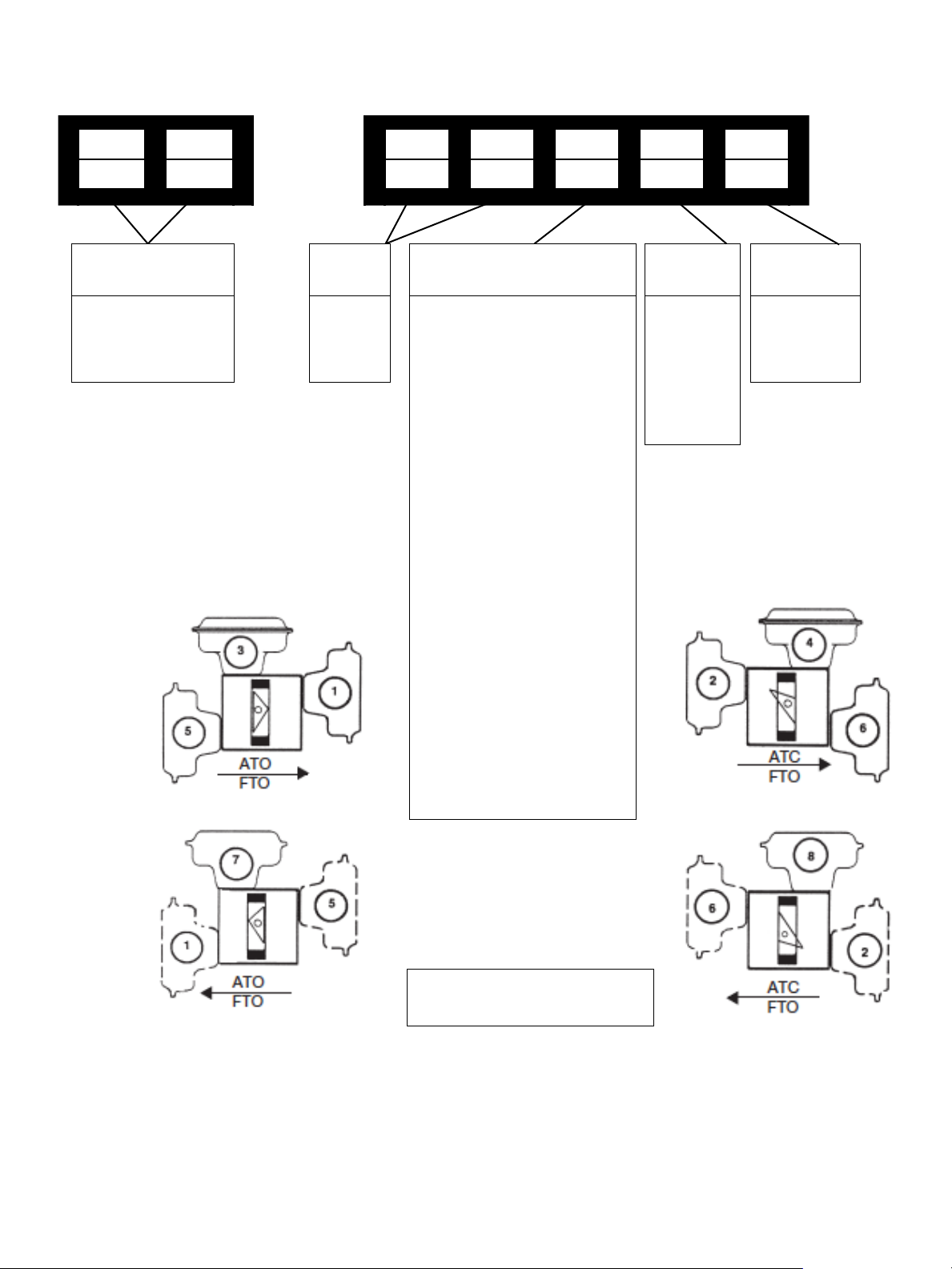

Numbering System

1st 2nd 1st 2nd 3rd 4th 5th

3 3 3 9 3

Actuator Type

33 Spring Diaphragm

(Air to extend action

only with or without

auxilliary handwheel)

—

—

Body

Series

39

Actuator Mounting

(Type 25 Only)

0. Undefined

1. Horizontal above center. Valve

opens on stem extension (airto-open action)

2. Horizontal above center. Valve

closes on stem extension (airto-close action)

*3. Vertical above center. Valve

opens on stem extension (airto-open action)

*4. Vertical above center. Valve

closes on stem extension (airto-close action)

5. Horizontal below center. Valve

opens on stem extension (airto-open action)

Seat

Material

1. PTFE or

RTFE Seal

Ring

2. Inconel

Seal Ring

3. Fire-Safe

Seal Ring

Not Assigned

3

6. Horizontal below center. Valve

closes on stem extension (airto-close action)

7. Vertical above center. Valve

opens on stem extension (airto-open action)

8. Vertical above center. Valve

closes on stem extension (airto-close action)

*Standard Actuator Mounting Arrangement

Note 1: Looking at valve from actuator and

bracket end, valve would not be visible.

Note 2: Positions 1, 2, 5 and 6 shown dotted

and obtained by rotating the valve 180° about

its shaft axis.

Caution: The valve must not be installed

with the actuator mounted vertically below

center.

Figure 2

39003 Series High Performance Butterfly Valves (HPBV) | 5

Page 6

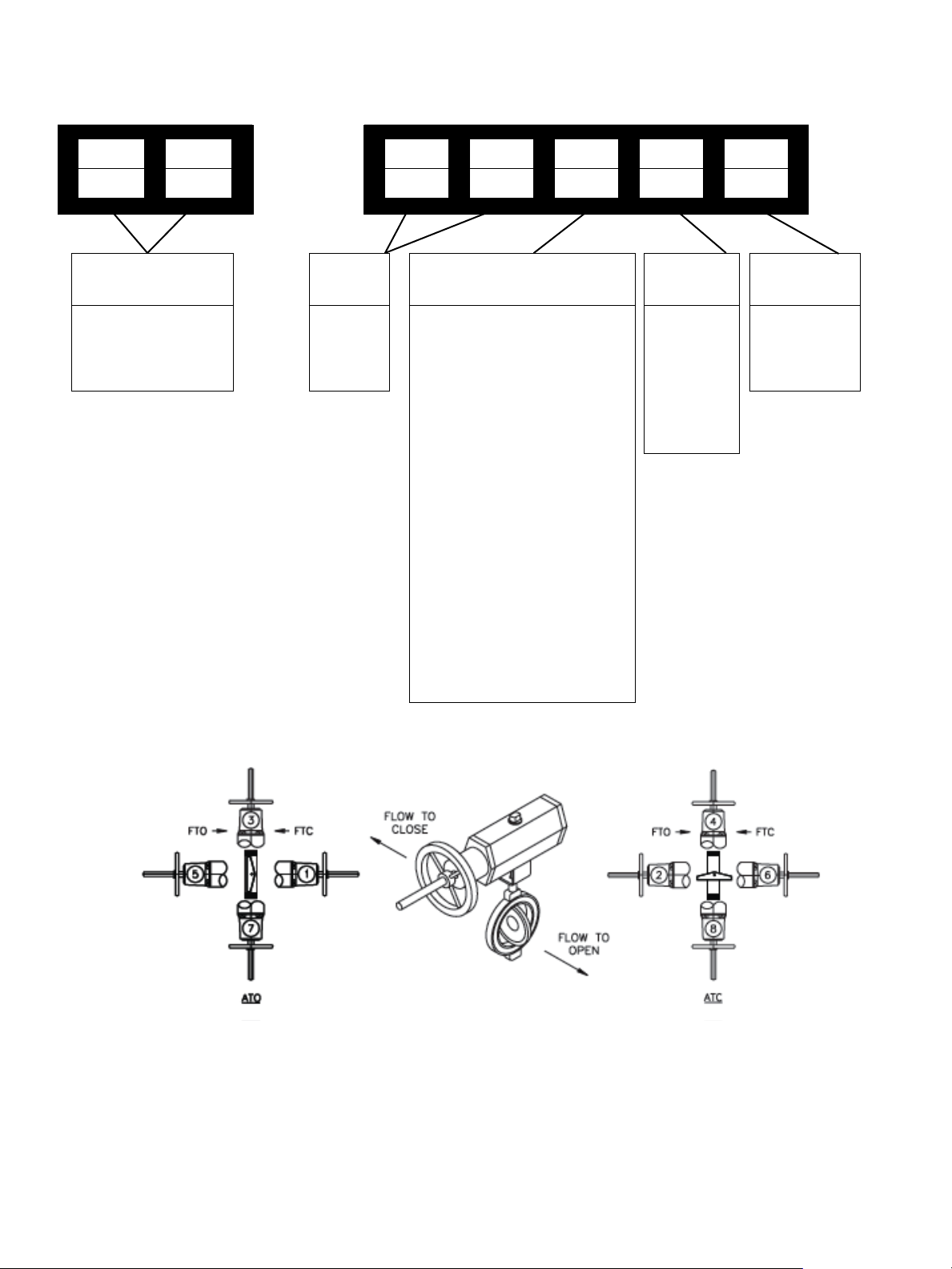

Numbering System

1st 2nd 1st 2nd 3rd 4th 5th

3 4 3 9 3

Actuator Type

34 Double acting or

spring return piston

actuator

—

—

Body

Series

39

Actuator Mounting

(Type 25 Only)

0. Undefined

*1. Parallel to pipe. Air to open

action.

*2. Parallel to pipe. Air to close

action.

3. Perpendicular to pipe. Air to

open action.

4. Perpendicular to pipe. Air to

close action.

5. Parallel to pipe. Air to open

action.

6. Parallel to pipe. Air to close

action.

7. Perpendicular to pipe. Air to

open action.

Seat

Material

1. PTFE or

RTFE Seal

Ring

2. Inconel

Seal Ring

3. Fire-Safe

Seal Ring

Not Assigned

3

8. Perpendicular to pipe. Air to

close action.

*Standard Actuator Mounting Arrangement

Figure 3

6 | GE Oil & Gas

Page 7

General Data

Flow Characteristic: equal percentage

Flow Direction: bi-directional

Seal Leakage: per ANSI FCI 70-2 Class VI,

PTFE, RTFE

Class IV, metal seals

C

Ratio: 100:1

v

Valve Sizes ANSI Class

inches mm 150 Carbon

& St. St.

2 50 • • •

3 80 • • •

4 100 • • •

6 150 • • •

8 200 • • •

10 250 • • •

12 300 • • •

14 350 • • •

16 400 • • •

18 450 • •

20 500 • •

24 600 • •

30 750 • •

36 900 •

42 1050 •

48 1200 •

300 Carbon

& St. St.

(1)

600

Carbon &

St. St.

1. ANSI Class 600 rating available in soft seat constructions only. Consult

GE for fire-safe or metal seat requirements.

39003 Series High Performance Butterfly Valves (HPBV) | 7

Page 8

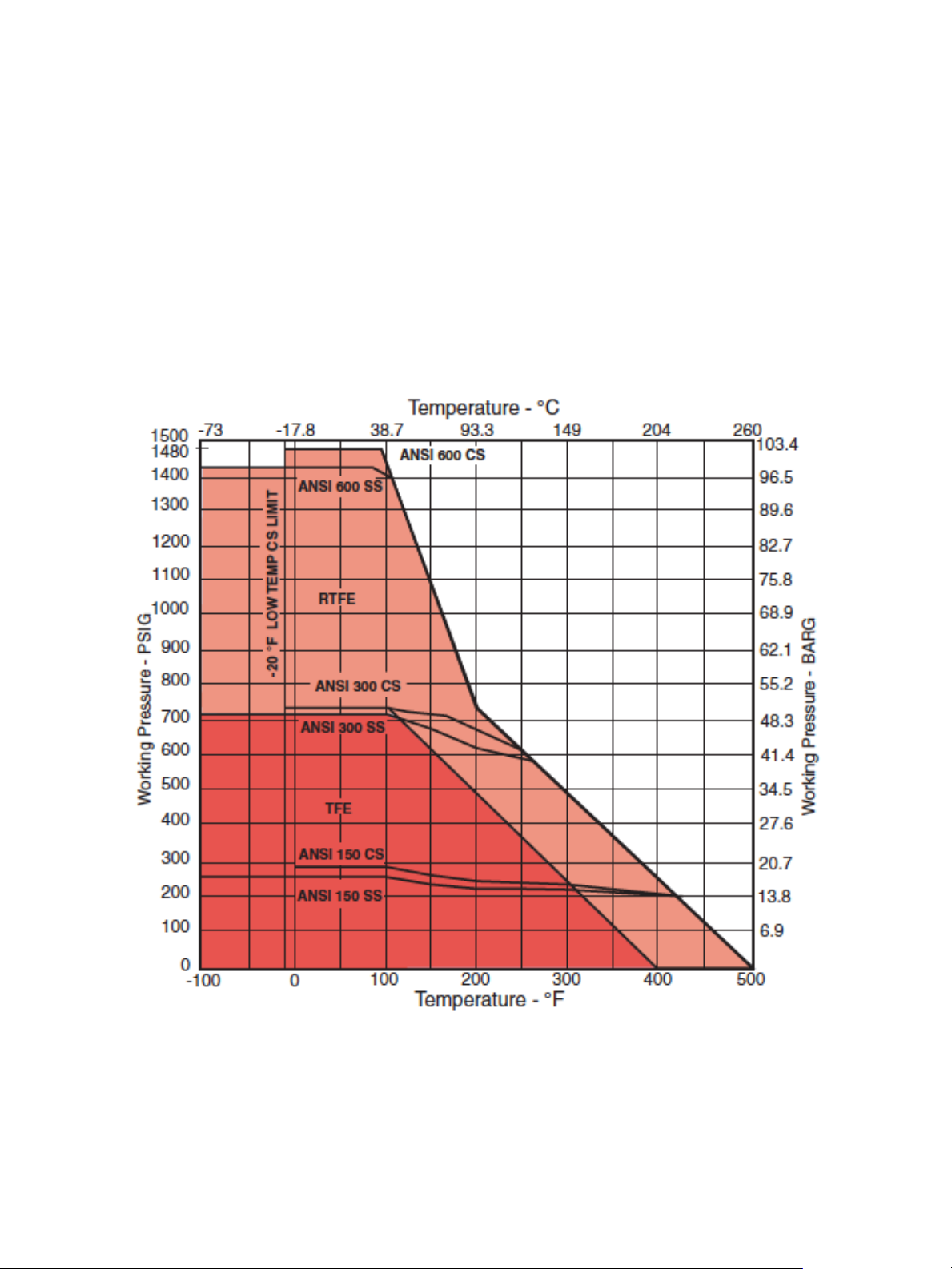

Pressure/Temperature Ratings

Soft and Fire-Safe Seal

As temperature increases, the pressure retaining capability of

materials decreases. The graph below illustrates the pressure/

temperature ratings for ANSI Class 150, Class 300 and Class 600.

The heavy lines define the ratings of the carbon steel and stainless

steel valve body (or “shell”) in conformance to ANSI B16.34. The

shaded areas define the ratings of the PTFE and RTFE Seal materials (Soft Seal).

Seal ratings are based on differential pressure with the disc in the

fully closed position.*

ANSI B16.34 Body and Flowseal Soft Seat Pressure - Temperature Ratings

Steam Service (Soft Seal only)

PTFE sealed valves are rated for 50 psi saturated steam.

Valves with “O” seal configuration (RTFE seal/AFLAS O-ring) are

rated to 100 psi steam service.

* Valves with 316SS shafts are rated for maximum pressure differentials of 150 psi for Class 150, 300 psi for Class 300, and 600 psi for

Class 600.

8 | GE Oil & Gas

Page 9

Pressure/Temperature Ratings

Metal Seal

As temperature increases, the pressure retaining capability of

materials decreases. The graph below illustrates the pressure/

temperature ratings for ANSI Class 150, Class 300 and Class 600.

The heavy lines define the ratings of the carbon steel and stainless

steel valve body (or “shell”) in conformance to ANSI B16.34. The

shaded areas define the ratings of the metal seal.

Seal ratings are based on differential pressure with the disc in the

fully closed position.*

ANSI B16.34 Body and Flowseal Metal Seat Pressure - Temperature Rating

* Valves with 316SS shafts are rated for maximum pressure differentials of 150 psi for Class 150, 300 psi for Class 300, and 600 psi for

Class 600.

39003 Series High Performance Butterfly Valves (HPBV) | 9

Page 10

Body Assembly Data

Body

Type:

wafer or lug with integral bonnet

Sizes:

2”, 3”, 4”, 6”, 8”, 10”, 12”, 14”, 16”, 18”, 20”, 24”, 30”, 36”, 42”,

48” (50 mm-1200 mm)

Materials:

carbon steel

ASTM A216 Gr WCB or ASTM A105

stainless steel

ASTM A351 Gr CF8M or ASTM A182-F316

Connections:

flangeless

clamped between ANSI Class 150, 300 or 600 line flanges

single flanged

bolts between ANSI Class 150, 300 or 600 line flanges

Ratings:

ANSI Class 150

carbon steel and stainless steel 2” - 48” sizes (50 mm-

1200 mm)

ANSI Class 300

carbon steel and stainless steel 2” - 30” sizes (50 mm-

750 mm)

ANSI Class 600

carbon steel and stainless steel 2” - 16” sizes (50 mm-

400 mm)

Seal:

PTFE, RTFE or Inconel with 304 stainless steel O-Ring

Disc

Type:

offset eccentric disc

Materials:

stainless steel ASTM A351 Gr CF8M or ASTM A182-F316

Nitrided

Shaft

Type:

Keyed on outboard end

Materials:

17-4 PH stainless steel A564 Gr 630 (others optional)

Valve Bearings:

PTFE-lined fiberglass

bronze (up to 750° F)

stainless steel (above 750° F)

Packing Box:

bolted

Packing

PTFE V-ring

graphite (optional)

10 | GE Oil & Gas

Page 11

Actuator Data

(Model 33) – Sizes 3” – 8”

(80mm – 200mm)

Type:

spring-diaphragm, floating stem pneumatic actuator

Action:

increasing air extends stem

Bench Range:

B size 7-16 psig (48-110 kPa) size 9-16 psig (62-110 kPa)

Connection:

1/4” NPT

Fail Safe Action:

field reversible

Yoke:

carbon steel

Bracket:

cast iron

Handwheel:

(optional) push type tilting, rising stem, permanently

lubricated materials: 17-4 PH and AISI 416 stainless steel

adjustable limit stops

Bracket Bearing:

a sealed, permanently lubricated ball bearing

(Model 34) – Sizes 3” – 48”

(80mm – 1200mm)

Type:

Spring-return, or double-acting scotch yoke piston

Body:

Extruded aluminum, anodized finish sizes 210 to 280 &

88

Ductile Iron sizes 90 and 100

Seals:

Buna-N

Pressure rating:

150 psi (1034 kPa) maximum working pressure

Manual Override:

Declutchable direct mount sizes 210 to 280

Hydraulic size 88

Bevel Gear sizes 90 and 100

Optional Construction:

Low temperature or high temperature seals, low

pressure hydraulic.

Actuator

Size

B

C

Valve Size Effective Area Travel

in. mm. sq. in. sq. cm in. mm

3 80 70 452 2.625 66.5

4 100 70 452 2.625 66.5

6 150 140 903 2.625 66.5

8 200 140 903 2.625 66.5

optional

3 80 140 903 2.625 66.5

4 100 140 903 2.625 66.5

39003 Series High Performance Butterfly Valves (HPBV) | 11

Page 12

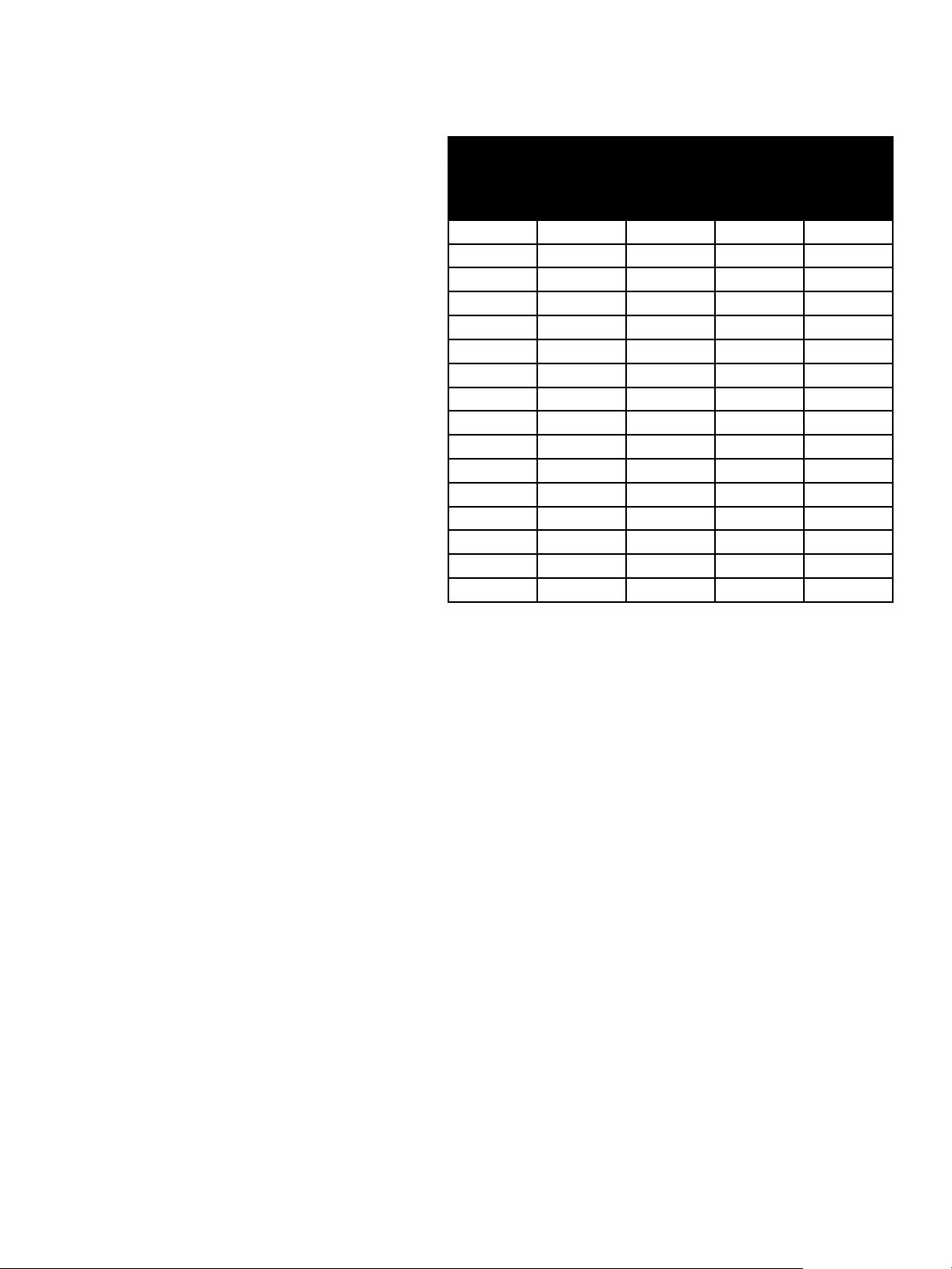

Rated Flow Coefficients (CV) and Pressure Recovery Coefficients (FL)

Rated Flow Coefficients (CV)

The values shown are for the valve installed in the seal upstream (“SUS”) position.

Degree Open/% Full C

Valve Size ANSI Class

150 1.5 6 14 25 39 56 76 99 102

2

3

4

6

8

10

12

14

16

18

20

24

30

36 150 707 2830 6602 1184 17920 25938 35370 45745 47160

42 150 963 3851

48 150 1258 5030 11738 21128 31859 46111 62881 81324 83840

300 1.4 6 13 24 36 52 71 95 100

600 1.4 5 13 23 35 51 70 90 93

150 3.4 14 32 57 87 125 141 221 228

300 3.2 13 30 53 81 117 159 212 223

600 3.1 12 29 52 79 114 156 202 208

150 6.8 27 63 114 171 248 338 437 451

300 6.2 25 58 104 157 228 310 414 435

600 5.8 23 54 98 147 213 290 375 387

150 15.5 66 154 278 419 607 827 1070 1103

300 14.9 60 139 250 377 546 744 992 1041

600 14.7 59 137 247 372 538 734 950 979

150 30.9 124 289 520 784 1135 1584 2002 1064

300 27.3 109 255 459 692 1001 1365 1820 1911

600 26.8 107 250 451 679 983 1341 1734 1788

150 52.8 211 492 886 1336 1934 2638 3411 3817

300 45.6 183 26 767 1156 1673 2282 3042 3194

600 41.2 165 384 692 1044 1511 2060 2665 2747

150 72.6 290 677 1219 1838 2660 3628 4690 4837

300 63.3 253 590 1063 1602 2319 3163 4217 4428

600 58.4 233 545 981 1479 5140 2918 3774 3891

150 90 392 914 1646 2481 3592 4898 6530 6857

300 81 326 760 1368 2063 2986 4072 4530 5702

600 73 292 682 1228 1838 2680 3655 4727 4873

150 132 531 1230 2229 3361 4865 6634 8845 9287

300 109 435 1015 1827 2755 3988 5438 7850 8243

600 96 385 899 1619 2423 3533 4818 6231 6424

150 171 684 1596 3873 4332 6270 8550 11270 11400

300 139 555 1295 2331 3515 5088 6938 9250 9712

150 207 828 1932 3478 3244 7590 10350 13800 14420

300 158 630 1470 2646 3990 5775 7875 10150 10658

150 315 1260 2940 5292 7890 11550 15750 21000 22050

300 242 966 2254 4057 6118 8855 12075 16100 16205

150 491 1965 4585 8253 12445 18012 24563 32750 34388

300 404 1614 3769 6779 10222 14795 20175 26900 28245

10° 20° 30° 40° 50° 60° 70° 80° 90°

1.5% 6% 14% 25.2% 38% 55% 75% 97% 100%

8987 16176 24392 35304 48143 62264 64190

V

Pressure Recovery Coefficients (FL)

Disc Degree Opening

o

15

20o25o30o35o40o45o50o55o60o65o70o75o80o85o90

Seal Upstream .95 .91 .84 .81 .78 .80 .77 .74 .74 .73 .70 .66 .63 .60 .57 .53

Seal Downstream .94 .89 .84 .82 .80 .77 .75 .72 .69 .66 .63 .30 .58 .55 .54 .53

12 | GE Oil & Gas

o

Page 13

Standard Valve Components

End Seal Variation

The ANSI 150 14” through 24” sizes feature a two-piece shaft

design. The lower shaft utilizes an end seal in the body to prevent

external leakage. The component parts include an end seal, an

end cap and end cap bolts.

Lower Packing Variation

The ANSI 150 30” through 48”; ANSI 300 14” through 30”; ANSI

600 10” through 16” sizes feature a two-piece shaft design which

utilizes a lower packing seal in the valve body to prevent external

leakage. The component parts are of the same design used in the

packing assembly in the top of the valve body neck.

39003 Series High Performance Butterfly Valves (HPBV) | 13

Page 14

Standard Materials of Construction

Metal Seal Design

Carbon Steel Construction

Item

Number

2 Shaft 17-4 PH Stainless Steel ASTM A564 Gr 630

5 Packing PTFE Graphite

6 Bearings Glass-Backed PTFE Bronze 316 Stainless Steel Nitrided

10 Body Carbon Steel A216 Gr WCB or A105

12 Disc 316 Stainless Steel A351 CF8M or A182 F316 Nitrided

14 Seal Inconel

Stainless Steel Construction

Item

Number

2 Shaft 17-4 PH Stainless Steel ASTM A564 Gr 630

5 Packing PTFE Graphite

6 Bearings Glass-Backed PTFE Bronze 316 Stainless Steel Nitrided

10 Body 316 Stainless Steel A351 CF8M or A182 F316

12 Disc 316 Stainless Steel A351 CF8M or A182 F316 Nitride

14 Seal Inconel

* Metal seal valves with 316 SS shafts have reduced pressure differential ratings. Monel, Nitronic 50 and Inconel (718 or X750) may be

substituted for higher differential pressures and elevated temperatures. Please consult GE for application assistance.

Description

Description

-20°F to +450°F

(-29°C to +232°C)

-100°F to +450°F

(-73°C to +232°C)

+451°F to +750°F

(+233°C to +399°C)

+451°F to +750°F

(+233°C to +399°C)

+751°F to +800°F

(+400°C to +427°C)

+751°F to +900°F

(+400°C to +482°C)

316 Stainless* Steel

ASTM A479 Gr 316

14 | GE Oil & Gas

Page 15

Standard Materials of Construction

Soft Seal Design

Item

Number

2 Shaft

5 Packing

6 Bearings

10 Body

12 Disc

14 Seal

Description

-100°F to +400°F

(-73°C to +204°C)

17-4 PH Stainless Steel ASTM A564 Gr 630

Optional: 316 SS, Inconel 718/750, Monel, Alloy 20, Nitronic 50, Hastelloy C, and Others

Optional: Graphite

Glass-Backed PTFE

Optional: 316 SS Backed TFE, Hastelloy C Backed TFE

Carbon Steel A216 Gr WCB or A105

Optional: 316 SS ASTM A351 CF8M or A182 F316, Monel,

Alloy 20, Aluminum Bronze, or Hastelloy C

316 Stainless Steel A351 CF8M or A182 F316

Optional: Monel, Alloy 20, Aluminum Bronze, or Hastelloy C

PTFE

Optional: RTFE, Polyethylene (UHMWPE)

Fire-Safe Design

Item

Number

2 Shaft

5 Packing Fire-Safe

6 Bearings Fire-Safe (Garfil & 316 SS)

10 Body

12 Disc

14 Seal

Description

Optional: 316 SS ASTM A351 CF8M or A182 F316, Monel, Alloy 20, or Hastelloy C, and Others

Optional: TFE & Monel, TFE & Hastelloy C RTFE & Monel, RTFE & Hastelloy C

-100°F to +400°F

(-73°C to +204°C)

17-4 PH Stainless Steel ASTM A564 Gr 630

Optional: 316 Stainless Steel

Carbon Steel A216 Gr WCB or A105

316 Stainless Steel A351 CF8M or A182 F316 - ENP

Consult Factory for Optional Materials

Fire-Safe (TFE & Inconel) RTFE & Inconel

+400°F to +500°F

(+204°C to +260°C)

TFE

+400°F to +500°F

(+204°C to +260°C)

39003 Series High Performance Butterfly Valves (HPBV) | 15

Page 16

Allowable Pressure Drops

GE has created a simple actuator sizing and selection program,

which allows for quick and accurate actuator sizing based on

the specific service conditions. This program is designed to run

in Microsoft® Excel®, and is available from your local GE sales

representative.

The opening screen of the sizing program is shown below.

Operating variables can be selected from a number of pulldown menus. The program will then provide an actuator

recommendation, along with calculations for the required torque

(with safety margins) for valve seating, unseating, and throttling

conditions.

This program covers standard product construction only. Please

consult with your local GE sales representative, or with the factory,

for applications and conditions not covered by this program.

16 | GE Oil & Gas

Page 17

Weights (lbs.)

150 Class Assemblies

Actuator Type Valve WtBrack-

Valve

Type DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR Yoke WtDA DA

Size

2 WAFER 8 12 23.1 24 24 25.85 28 30.4 30.4 35.5 24 64 117

LUG 11 12 26.1 27 2 28.85 31 33.4 33.4 38.5 24 67 120

3 WAFER 11 12 26.1 27 27 28.85 31 33.4 33.4 38.5 24 67 120

LUG 13 12 28.1 29 29 30.85 33 35.4 35.6 40.5 24 69 122

4 WAFER 17 12 32.1 33 33 34.85 37 39.4 39.6 44.5 24 73 126

LUG 25 2 40.1 41 41 42.85 45 47.4 47.6 52.5 24 81 134

6 WAFER 30 12 50 52.4 52.6 57.5 62.4 68.8 69 82 24 139

LUG 35 12 55 57.4 57.6 62.5 67.4 73.8 74 87 24 144

8 WAFER 44 12 72.5 76.4 82.8 83 96 125 125 24 153

LUG 48 12 75.5 80.4 86.8 87 100 129 129 24 157

10 WAFER 71 14 105.4 111.8 112 125 154 154 174 227

LUG 191 14 125.4 131.8 132 145 174 174 194 247

12 WAFER 110 14 157 170 199 199 219 272

LUG 127 14 174 187 216 216 236 289

14 WAFER 135 16 182 195 224 224 244 297

LUG 183 16 230 243 272 272 292 345

16 WAFER 182 20 271 271 291 344 364 532

LUG 250 20 339 339 359 412 432 600

18 WAFER 234 20 323 323 343 396 416 584 872 1026 938

LUG 305 20 394 394 414 467 487 655 943 1097 1009

20 WAFER 320 20 429 482 502 670 958 1112 1024

LUG 414 20 523 576 596 764 1052 1206 1118

24 WAFER 505 25 692 860 1148 1302 1214 1632

LUG 702 25 889 1057 1345 1499 1411 1829

30 WAFER 925 25 1112 1280 1568 1722 1634 2052

LUG 1130 25 1317 1485 1773 1927 1839 2257

36 WAFER 1630 25 1985 2273 2427 2339 2757

LUG 1890 25 2245 2533 2687 2599 3017

42 WAFER 2475 25 2830 3118 3272 3184 3602

LUG 2700 25 3055 3343 3497 3409 3827

48 WAFER 2815 25 3170 3458 3612 3524 3942

LUG 3085 25 3440 3728 3882 3794 4212

RC210 RC220 RC230 RC240 RC250 RC260 RC270 RC280 RC88 RCI90 RCG100 33 Actuator

et WT

3.1 4 4 5.85 8 10.4 10.6 15.5 20.4 26.8 27 40 69 69 89 142 162 330 618 772 684 1102 32 85

NOTES: 1. The weights of actuators are without handwheel

2. DA = Double Acting / SR = Spring Return

Handwheel Weights

Actuator Type

RC210

DA/SR

1.5 1.5 2.5 2.5 6.5 6.5 26 26 250 185 66 22

RC220

DA/SR

RC230

DA/SR

RC240

DA/SR

RC250

DA/SR

RC260

DA/SR

RC270

DA/SR

RC280

DA/SR

39003 Series High Performance Butterfly Valves (HPBV) | 17

RC88

DA/SR

RC90 &

100 DA

RC90 &

100 SR33Actuator

Page 18

Weights (lbs)

300 Class Assemblies

Actuator Type Valve WtBrack-

Valve

Type DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR Yoke WtDA DA

Size

2 WAFER 8 12 23.1 24 24 25.85 28 30.4 30.6 35.5 24 64 117

LUG 11 12 26.1 27 27 28.85 31 33.4 33.6 38.5 24 67 120

3 WAFER 11 12 27.1 28 28 29.85 32 34.4 34.6 39.5 24 68 121

LUG 13 12 32.1 33 33 34.85 37 39.4 39.6 44.5 24 73 126

4 WAFER 17 12 33 34.85 37 39.4 39.6 44.5 24 73 126

LUG 25 2 40 41.85 44 46.4 46.6 51.5 24 80 133

6 WAFER 30 12 50 52.4 52.6 57.5 62.4 68.8 69 82 24 139

LUG 35 12 69 71.4 71.4 76.5 81.4 87.8 88 101 24 158

8 WAFER 44 12 79.5 84.4 90.8 91 104 133 133 24 161

LUG 48 12 107.5 112.4118.8 119 132 161 161 24 189

10 WAFER 71 14 122.4 128.8 129 142 171 171 191 244

LUG 191 14 149.4 155.8 156 169 198 198 218 271

12 WAFER 110 14 194 207 236 236 256 309

LUG 127 14 240 253 282 282 302 355

14 WAFER 135 16 328 341 370 370 390 443 463 631

LUG 183 16 367 380 409 409 429 482 502 370

16 WAFER 182 20 425 425 445 498 518 686 974 1128 1040 1458

LUG 250 20 490 490 510 563 583 751 1039 1193 1105 1523

18 WAFER 234 20 482 482 502 555 575 743 1031 1185 1097 1515

LUG 305 20 606 606 626 679 699 867 1155 1309 1221 1639

20 WAFER 320 20 619 672 692 860 1148 1302 1214 1632

LUG 414 20 844 897 917 1085 1373 1527 1439 1857

24 WAFER 505 25 847 900 920 1088 1376 1530 1442 1860

LUG 702 25 1134 1187 1207 1375 1663 1817 1729 2147

30 WAFER 925 25 1932 2100 2388 2542 2454 2872

LUG 1130 25 2332 2500 2788 2942 2854 3272

RC210 RC220 RC230 RC240 RC250 RC260 RC270 RC280 RC88 RCI90 RCG100 33 Actuator

et WT

3.1 4 4 5.85 8 10.4 10.6 15.5 20.4 26.8 27 40 69 69 89 142 162 330 618 772 684 1102 32 85

600 Class Assemblies

Actuator Type Valve WtBrack-

Valve

Type DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR DA SR Yoke WtDA DA

Size

2 WAFER 8 12 26.1 27 27 28.85 31 33.4 33.6 38.5 24 67 120

LUG 11 12 28.1 29 29 30.85 33 35.4 35.6 40.5 24 69 122

3 WAFER 11 12 28.1 29 29 30.85 33 35.4 35.6 40.5 24 69 122

LUG 13 12 33.1 34 34 35.85 38 40.4 40.6 45.5 24 74 127

4 WAFER 17 12 46 47.85 50 52.4 52.6 57.5 24 86 139

LUG 25 2 68 69.85 72 74.4 74.6 79.5 24 108 161

6 WAFER 30 12 62 64.4 64.6 69.5 74.4 80.8 81 94 24 151

LUG 35 12 105 107.4 107.6 112.5 117.4123.8 1224 137 24 194

8 WAFER 44 12 99.5 104.4110.8 111 124 153 153 24 181

LUG 48 12 154.5 159.4165.8 166 197 208 208 24 236

10 WAFER 71 14 204.4 210.8 211 224 253 253 273 326 346 514 802 956 868 1286

LUG 191 14 267.4 273.8 274 274 316 315 336 389 409 577 865 1019 931 1349

12 WAFER 110 14 286 299 328 328 348 401 421 589 877 1031 943 1361

LUG 127 14 420 433 462 462 482 535 555 723 1011 1165 1077 1495

16 WAFER 182 20 1255 1255 1275 1328 1348 1516 1804 1958 1870 2288

LUG 250 20 1255 1255 1275 1328 1348 1516 1804 1958 1870 2288

NOTES: 1. The weights of actuators are without handwheel

2. DA = Double Acting / SR = Spring Return

RC210 RC220 RC230 RC240 RC250 RC260 RC270 RC280 RC88 RCI90 RCG100 33 Actuator

et WT

3.1 4 4 5.85 8 10.4 10.6 15.5 20.4 26.8 27 40 69 69 89 142 162 330 618 772 684 1102 32 85

18 | GE Oil & Gas

Page 19

Dimensions

Model 34 (RC) Actuators - Dimensional Dat

Double Acting

Sizes 210 thru 280

Double Acting

Size 100

Spring Return

Sizes 210/230/250/270

Spring Return

Spring Return

Sizes 220/240/260/280

Sizes 100

Double Acting

Size 88

Spring Return

Sizes 88

39003 Series High Performance Butterfly Valves (HPBV) | 19

Page 20

20 | GE Oil & Gas

Page 21

Dimensions

Model 33 Actuator - Dimensional Data

Model 39003 Butterfly Valve Table

Wafer Lug

Valve

Size

ANSI Class 150

ANSI Class 300

ANSI Class 600

A* A** E F G**

2 3.00 3.00 10.25 1.75 1.06 5/8-11 4 4.75

3 3.00 3.38 11.00 1.92 1.20 5/8-11 4 6.00

4 3.50 4.13 11.75 2.13 1.26 5/8-11 8 7.50

6 4.88 5.12 13.00 2..31 1.38 5/8-11 8 9.50

8 5.88 6.01 14.13 2.50 1.49 5/8-11 8 11.75

10 6.88 7.88 14.88 2.81 1.70 3/4-10 12 14.25

12 9.50 9.50 16.63 3.23 1.86 3/4-10 12 17.00

14 11.07 11.07 17.25 3.62 2.19 7/8-9 12 18.75

16 12.05 12.05 22.69 4.00 2.31 7/8-9 16 21.25

18 13.18 13.18 24.00 4.50 2.45 1-8 16 22.75

20 13.94 13.94 25.13 5.00 2.94 1-8 20 25.00

24 16.44 16.44 27.25 6.06 3.12 11/8-8 20 29.50

30 22.73 22.73 3.62 6.75 3.53 11/8-8 28 36.00

36 32.11 32.11 38.50 8.38 4.34 11/4-8 32 42.75

42 35.62 35.62 44.00 9.25 5.03 11/4-8 36 49.50

48 38.25 38.25 47.25 10.62 5.62 11/4-8 44 56.00

2 3.00 3.00 1025 1.75 1.06 5/8-11 8 5.00

3 3.00 3.38 11.00 1.92 1.20 3/4-10 8 6.63

4 3.50 4.12 11.75 2.13 1.25 3/4-10 8 7.88

6 5.12 5.50 13.00 2.29 1.38 3/4-10 12 10.63

8 5.88 7.28 14.14 2.88 1.54 7/8-9 12 13.00

10 7.38 7.88 15.38 3.25 1.70 1-8 16 15.25

12 10.50 10.50 21.00 3.62 1.86 11/8-8 16 17.75

14 14.57 14.57 22.38 4.62 2.48 11/8-8 20 20.25

16 16.32 16.32 24.00 5.25 2.59 11/4-8 20 22.50

18 17.26 17.26 25.13 5.88 3.03 11/4-8 24 24.75

20 18.49 18.49 26.39 6.31 3.24 11/4-8 24 27.00

24 21.67 21.67 29.38 7.19 3.62 11/2-8 24 32.00

30 30.50 30.50 38.88 8.88 4.39 13/4-8 28 39.25

3 3.00 3.00 11.00 2.12 1.20 3/4-10 8 6.63

4 4.62 4.62 12.00 2.50 1.40 7/8-9 8 8.50

6 5.56 6.75 13.62 3.06 1.66 1-8 12 11.50

8 7.38 8.03 15.13 4.00 1.85 11/8-8 12 13.75

10 13.25 13.25 19.00 4.62 2.00 11/4-8 16 17.00

12 14.67 14.67 22.63 5.50 2.53 11/4-8 20 19.25

16 - 18.87 30.00 7.00 3.50 11/2-8 20 23.75

B C D

Thread

Size

# of

Holes

Bolt

Circle

Model 34 (RC) Actuator Table

Size H J K L M N P Q

RC210 1.8 5.7 3.7 11.4 7.1 2.3 2.9 1.3

RC220 5.7 5.7 3.7 11.4 7.1 2.3 2.9 1.3

RC230 2.6 7.7 5.0 13.4 7.9 2.9 4.1 1.9

RC240 7.7 7.7 5.0 13.4 7.9 2.9 4.1 1.9

RC250 3.5 11.2 6.9 19.7 12.6 3.8 5.7 2.7

RC260 11.2 11.2 6.9 19.7 12.6 3.8 5.7 2.7

Spring Return

RC270 5.7 20.1 10.9 31.5 15.7 6.1 8.7 4.3

RC280 20.5 20.5 10.9 31.5 15.7 6.1 8.7 4.3

RC88 20.5 37.9 19.5 9.1 19.5 39.8 8.7 4.3

RC100 33.5 33.5 19.0 58.0 31.5 10.7 13.8 6.9

RC210

RC220 3.9 3.9 3.7 11.4 7.1 2.3 2.9 1.3

RC230 2.6 5.3 5.0 13.4 7.9 2.9 4.1 1.9

RC240 5.3 5.3 5.0 13.4 7.9 2.9 4.1 1.9

RC250 3.5 7.5 6.9 19.7 12.6 3.8 5.7 2.7

RC260 7.5 7.5 6.9 19.7 12.6 3.8 5.7 2.7

Double Acting

RC270 5.7 11.8 10.9 31.5 15.7 6.1 8.7 4.3

RC280 12.2 12.2 10.9 31.5 23.6 6.1 8.7 4.3

RC88 12.2 29.6 19.5 9.1 19.5 39.8 8.7 4.6

RC100 20.5 20.5 19.0 58.0 31.5 10.7 13.8 6.9

CL 150

CL 300

1.8 3.9 3.7 11.4 7.1 2.3 2.9 1.3

Model 33 Actuator Table

Size H J K L M N P Q

3 13.00 11.50 - - - - - -

4 13.00 11.50 - - - - - -

6 17.50 15.20 - - - - - -

8 17.50 15.20 - - - - - -

3

13.00 11.50 - - - - - -

4 13.00 11.50 - - - - - -

6 17.50 15.20 - - - - - -

8 17.50 15.20 - - - - - -

* - Dimensions apply to wafer valves only

** - Dimensions apply to lugged valves only

39003 Series High Performance Butterfly Valves (HPBV) | 21

Page 22

Notes

22 | GE Oil & Gas

Page 23

Notes

39003 Series High Performance Butterfly Valves (HPBV) | 23

Page 24

DIRECT SALES OFFICE LOCATIONS

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-5689-3600

Fax: +86-10-5689-3800

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-55-3640-5060

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH and CENTRAL

AMERICA and the CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Trademark of G eneral Elect ric Company

Other company names and product names used in this document are the registered trademarks

or trademarks of their respective owners.

© 2014 General Ele ctric Compa ny. All rights res erved.

GEA20238A 07/2014

Loading...

Loading...