Page 1

GE Oil & Gas

Masoneilan* Valves

37/38 Pneumatic Spring

Diaphragm Actuator

The 37/38 Series actuator is designed to

provide high performance, reliability and

long service life.

Technical Specifications

05/2013

Page 2

Features

GE's Masoneilan Type 37 direct acting and Type 38 reverse acting

pneumatic spring diaphragm actuators are designed to provide

high performance. Their features include:

Heavy One-piece Yoke

Provides maximum strength and rigidity

Diaphragm Cases

Pressed steel upper and lower cases combine lightness, high mechanical strength and adequate protection in the event of severe

over-pressurization

Thrust Capability

Two actuator types and seven sizes provide a wide range of applications

Diaphragm

Molded elastomer with fabric insert for strength, long life and

high sensitivity

Linearity

The molded diaphragm and deep cases minimize area change

and produce a linear relationship between travel and air pressure

Numbering System

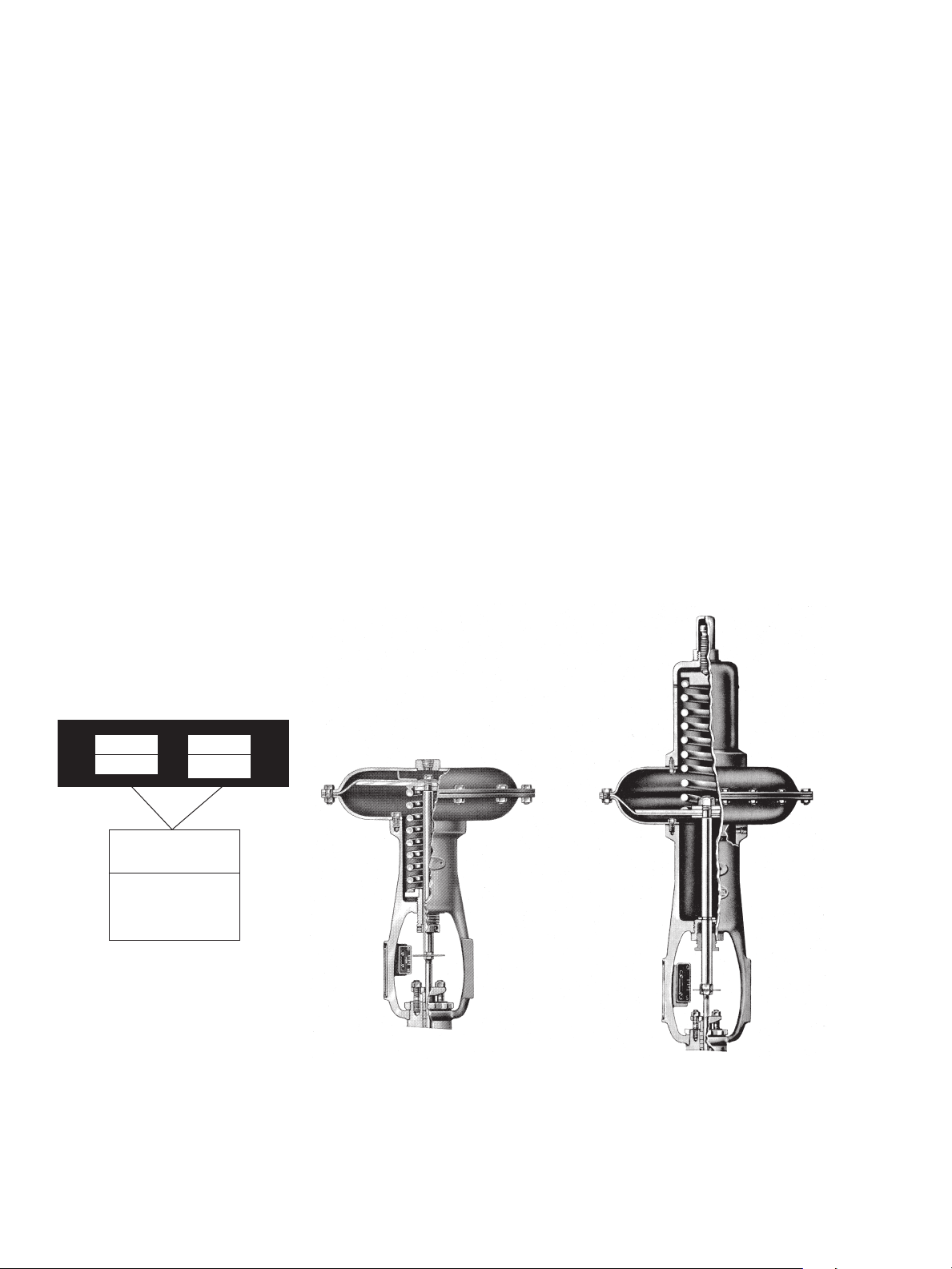

2nd1st

3

Actuator

Types

37 Air to Close

38 Air to Open

2 | GE Oil & Gas

Direct: air to extend stem

Type 37

Reverse: air to retract stem

Type 38

Page 3

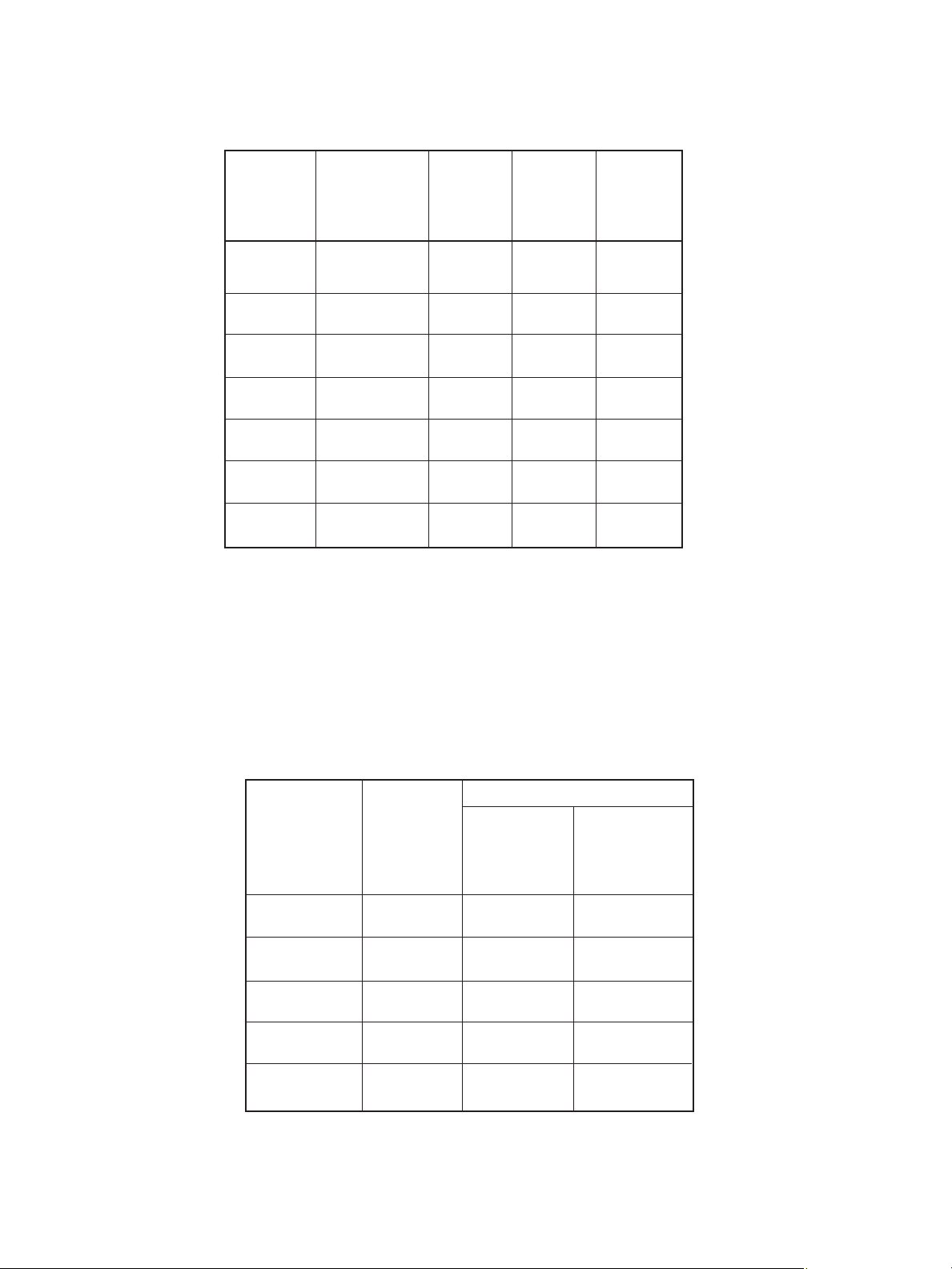

Specifications

Nominal

Diaphragm Max. Bench Max.

Actuator Effective Travel Range Supply

Size Area (sq. in.) (in.) psi psi

11 71 1.0 3-15 60

6-30

13 105 1.5 3-15 60

6-30

15 145 2.0 3-15 60

6-30

18 200 2.5 3-15 60

6-30

18 (16") 200 4.0

6-30

18 (20") 200 4.0 6-30 60

Rev. only

24 330 4.0

6-30

NOTE: Additional travels and spring ranges available.

3-15 60

3-15

55

Travel Time - Typical Bench Values

8012

Electro- 7400

Actuator Travel pneumatic Pneumatic

Size (inches) Positioner Positioner

1.5 6.3 13

2.0 11.4 20

2.5 21 34

4.0 32 48

¨

3-15 psi bench range and 20 psi supply. For 6-30 psi bench range,

increase travel time by 15%.

11 1.0 3.3 7

1.0 4.9 11

13

1.5 9.4 17

15

2.0 19 30

18

18 (16")

3.5 29 44

Time (seconds)¨

Model 37/38 Pneumatic Spring Diaphragm Actuator | 3

Page 4

Materials of Construction

Direct: air to extend stem

4 | GE Oil & Gas

Type 37 Actuator *

* Size 11 view shown

Type 38 Actuator

Reverse: air to retract stem

Page 5

Materials of Construction

Reverse - Type 38Direct - Type 37

Ref.

No. Description Materials

17 Yoke Cast Iron

18 Cap Screw Carbon Steel

22 Actuator Spring Spring Steel

26 Actuator Stem Steel

30 Hex Nut Carbon Steel

33 Spring Guide Carbon Steel

34 Spring Button Nickel Copper Alloy

35 Pipe Plug Plastic

36 Spring Adjuster Steel

37 Bushing Steel

39 Diaphragm

Insert

40 Diaphragm Plate Carbon Steel

41 Diaphragm Washer Carbon Steel

43 Diaphragm Case Carbon Steel

44 Diaphragm Case Carbon Steel

45 Cap Screw Carbon Steel

46 Hex Nut Carbon Steel

56 Travel Indicator Scale Aluminum

57 Machine Screw Stainless Steel

70 Ball & Retainer¨ Stainless Steel

¨

Size 13, 15, 18 and 24 only.

Elastomer w/Fabric

Ref.

No. Description Materials

15 Gasket (Packing Box) Copper

17 Yoke Cast Iron

18 Cap Screw Carbon Steel

19 Gasket Acrylic Fiber

20 Packing Nut Brass

21 Snap Ring Carbon Steel

22 Actuator Spring Spring Steel

22A Actuator Spring Spring Steel

26 Actuator Stem Stainless Steel

30 Hex Nut Carbon Steel

31 Packing Box Brass

32 Yoke Packing Braided PTFE

33 Spring Guide Carbon Steel

34 Spring Button Nickel Copper Alloy

36 Spring Adjuster Carbon Steel

39 Diaphragm

Insert

40 Diaphragm Plate Carbon Steel

41 Diaphragm Washer Carbon Steel

43 Diaphragm Case Carbon Steel

44 Diaphragm Case Carbon Steel

45 Cap Screw Carbon Steel

46 Hex Nut Carbon Steel

56 Travel Indicator Scale Aluminum

57 Machine Screw Stainless Steel

70 Ball & Retainer Stainless Steel

71 Spring Barrel Cast Iron

72 Spring Barrell Cap Cast Iron

73 Ball Bearing Race Steel

74 Cap Screw Carbon Steel

Elastomer w/Fabric

Model 37/38 Pneumatic Spring Diaphragm Actuator | 5

Page 6

Handwheels

6A Series Side Mounted

8A Series Side Mounted

Side Mounted

Max. Max.

H/W Actuator Travel Air Supply

Type Size Action (in.) psi

6A1

Reverse

6A2

Reverse

Reverse

Direct &

6A3

Reverse

Direct &

Reverse

18 (20") Reverse 2.5 35

Reverse

8A Reverse

18 (20") Reverse 4.0 60

Reverse

Direct &

11

Direct &

13

Direct &

15

18

18 (16") Reverse 2.5 35

Direct &

18

18 (16")

Direct &

Direct &

24

1.0 60

1.5 60

2.0 60

2.0 40

2.5 35

2.5 60

4.0 60

4.0 55

Case Mounted

Case Mounted

Max. Turns

H/W Actuator Travel for Rated

Type Size (in.) Travel

Direct Actuator

2-11 11 1.0 14.0

2-13 13 1.5 28.0

3-15 15 2.0 16.0

4-18 18 2.5 20.0

6-18 18 (16") 4.0 32.0

7-24 24 4.0 32.0

Reverse Actuator

9-11 11 1.0 14.0

9-13 13 1.5 21.0

6 | GE Oil & Gas

Page 7

Dimensions (in.)

Type 6A

Side Mounted

* 1/2" NPT for No. 24 Actuators

Direct (Type 37)

Air to close

Direct (37) Reverse (38)

Air to close Air to open

Type 8A

Side Mounted

Reverse (Type 38)

Air to open

Types 3-15,

4-18, 6-18,

Case Mounted

Case Mounted Handwheels

Type J K

2-11 9.00 9.50

2-13 9.00 9.50

3-15 12.00 12.75

4-18 18.00 12.75

6-18 18.00 15.50

9-11 9.00 13.00

9-13 9.00 16.25

Direct Actuator

Reverse Actuator

Actuator Spud

Actuator Removal Dia. Type G H

Size Clearance A B C D E F Dir. Rev.

Actuator

Side Mounted Handwheels

11 5.6 13.00 24.1 16.4 2.25 6A1 9 8.75 ------ -- 13 5.6 15.00 29.6 20.1 2.25 6A2 12 10.88 ------ ----- 15 5.6 17.50 35.3 25.4 3.31 6A3 18 15.00 ------ ----- 18 5.6 20.75 36.8 26.8 3.31

18 (16") 5.6 20.75 42.1 33.2 3.75 8A 8 ------ 53 53

18 (20") 5.6 20.75 52.0 N/A 3.75 8A 8 ------ N/A 53

24 5.0 27.50 45.5 34.7 3.75 8A 12 ------ 53 58

Model 37/38 Pneumatic Spring Diaphragm Actuator | 7

Page 8

Weights (lbs.)

Actuator

Size

Direct

Type 37

Reverse

Type 38

Side Mounted

Handwheel

Type Weight

11 45 55 6A1 19

13 70 87 6A2 45

15 120 140

18 180 250

18 (16*) 190 370

18 (20*) N/A 450

6A3 75

8A 40

24 325 540 8A 70

DIRECT SALES OFFICE LOCATIONS

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

Case Mounted Handwheel

Type

Actuator

Direct Actuator

2-11 11 25

2-13 13 25

3-15 15

4-18 18

6-18 18 (16*) 45

Reverse Actuator

9-11 11 20

9-13 13 25

SOUTH and CENTRAL

AMERICA and the CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

Size

Weight

40

* Trademark of G eneral Elect ric Company

Other company names and product names used in this document are the registered trademarks or trademarks of their respective owners.

GEA19531 05/2013

Loading...

Loading...