Page 1

GE Oil & Gas

Technical Specifications

12/2012

Masoneilan* 36005 Series

V-Max* Rotary Control Valves

These high-capacity V-ported control ball valves offer automatic throttling

capability with flexible shutoff options, simplified maintenance needs, and

enhanced operational reliability.

Page 2

Table of Contents

Features and Benefits .................................................................................................................................................................................................................................. 2

Numbering System ........................................................................................................................................................................................................................................ 3

Actuator Mounting Guide .......................................................................................................................................................................................................................4-5

General Data .................................................................................................................................................................................................................................................6-7

Temperature/Seat Leakage ....................................................................................................................................................................................................................... 8

C

and FL versus Travel ............................................................................................................................................................................................................................... 9

V

Materials of Construction ................................................................................................................................................................................................................ 10 -13

Dimensions ............................................................................................................................................................................................................................................... 14 -17

Assembly Weights .........................................................................................................................................................................................................................................18

Features and Benefits

The V-Max* rotary control valve offers high-capacity, heavy-duty

automatic throttling capability. The valve’s advanced design features

offer substantial benefits, including:

• Simplified alignment. The valve’s integrally cast raised face flanges

(in compliance with ASME 150 or 300 Class standards) eliminate the

need for long tie rods, significantly simplifying the alignment process.

• Installation flexibility. To meet a variety of application needs,

the valve is available with two different face-to-face dimensions:

standard construction complies with ISA S75.04 and IEC 534-3-2

standards and a short pattern complies with the ANSI B16.10

standard (ANSI class 150 only).

• Enhanced flow capacities. A straight-through flow pattern provides

exceptional capacities, while the patented dual-characterized

V-port ball combines an equal percentage flow characteristic with

high capacities and greater than 500:1 rangeability.

• Excellentleakagecontrol.AstandardEF(emissionfree)seal

packingsystemprovideslong-term,zeroleakage

performance.

†

shaft sealing

• Flexible,reliableshutoffoptions.Threedifferentsealtypesprovide

flexible solutions for a variety of applications.

— MN-7 Seal Ring – This low-friction polymeric seal ring provides

reliable Class VI shutoff capability.

— 316 Stainless Steel Seal Ring – This unique seal ring design does

not require shims. It achieves Class IV shutoff and higher tem-

perature capability when combined with satellite bearings and

exiblegraphitepacking.

— Optional Heavy-duty Metal Seal Ring – This optional (NPS1-6)

heavy-duty seal ring provides long service life in harsh applica-

tions. The wiping action of the seal ring against the ball prevents

buildup of contaminants, helping maintain long-term perfor-

mance and reliable Class IV shutoff.

• Reliable operation, simplified maintenance.Fullinvolutespline

connections on plug, shaft, and actuator connections virtually

eliminatebacklash,enhancingoperationalreliabilityand

simplifying maintenance needs. Changing the ring seal requires

only the simple removal of two machine screws on the inlet flange.

†FactoryMutualcertiedreport

2 | GE Oil & Gas

Page 3

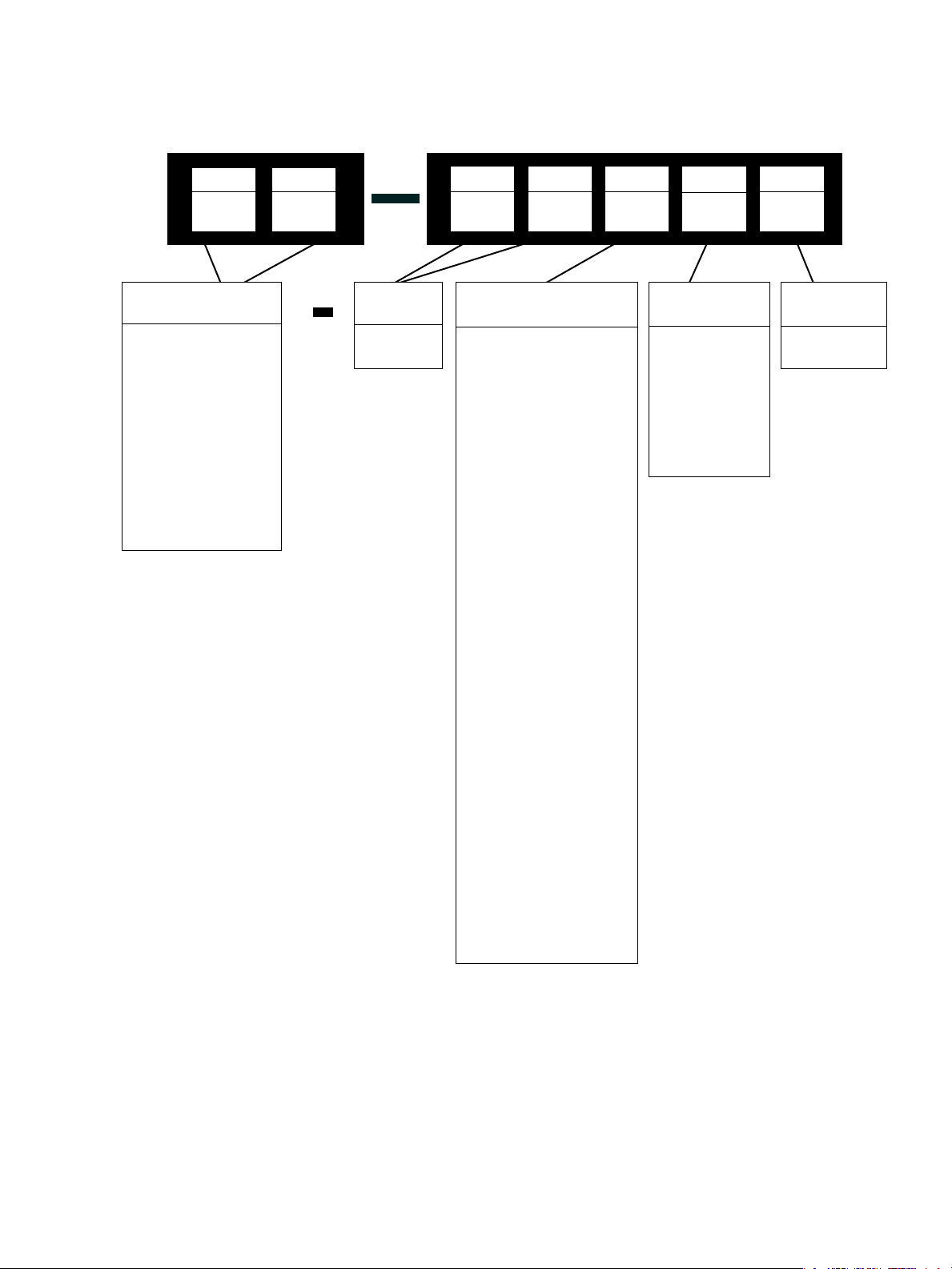

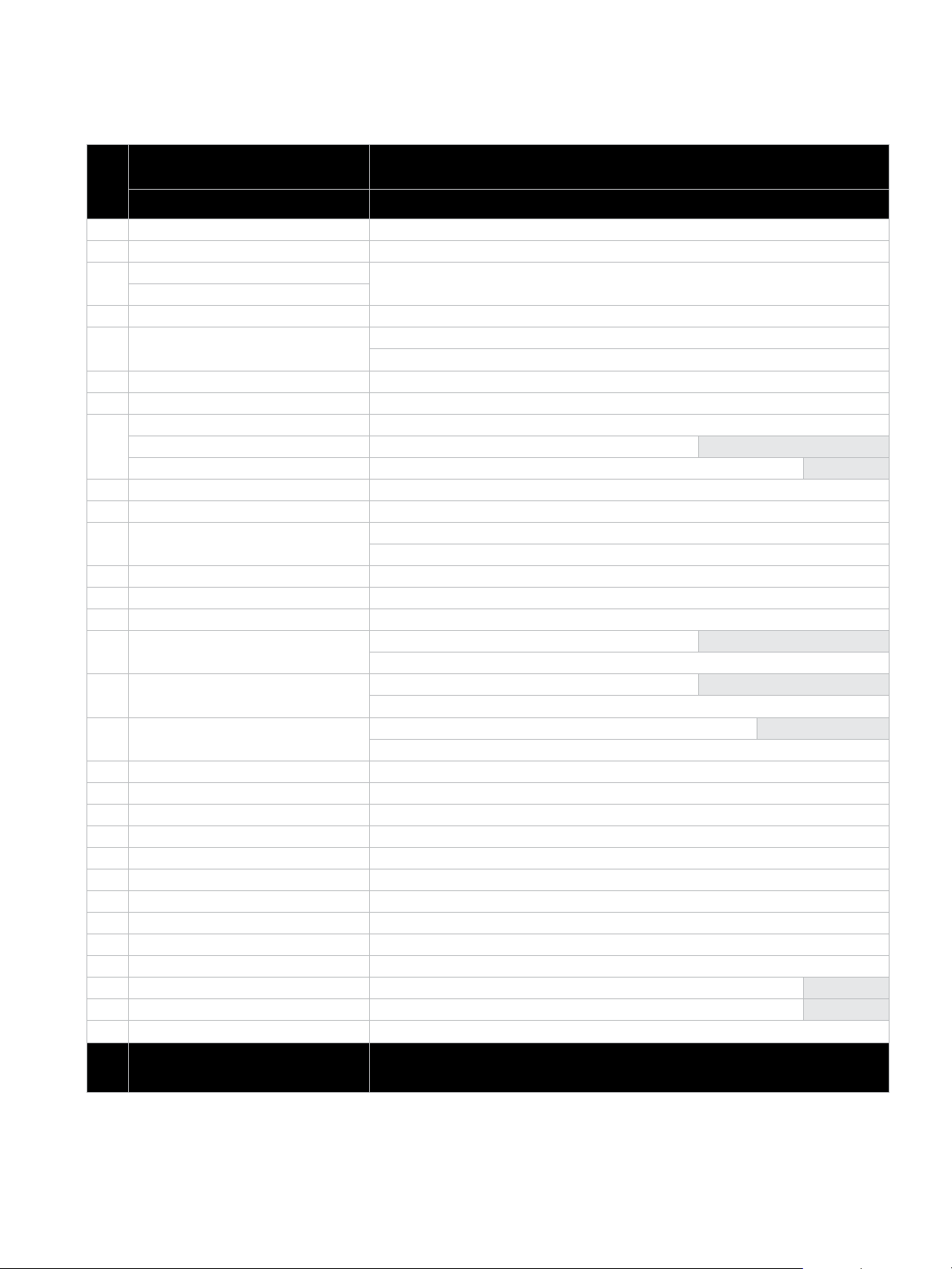

Numbering System

1st

Actuator Type

31 Spring opposed,

rolling diaphragm.

Air to close, fail

open action

32 Spring opposed,

rolling diaphragm,

Air to open, fail

closed action

33 Spring Diaphragm.

Air to extend action

only

2nd 3rd 4th 5th2nd

Body

Series

36

1st

3

6

Actuator Mounting

0 Undefined

1 Parallel to pipeline;

valve closes on stem

extension (air to close,

fail open)

2 Parallel to pipeline;

valve opens on stem

extension (air to open,

fail closed)

3 Vertical above

center; valve closes on

stem extension (air to

close, fail open)

4 Vertical above center;

valve opens on stem

extension (air to open,

fail closed)

5 Parallel to pipeline;

valve closes on stem

extension (air to close,

fail open)

6 Parallel to pipeline;

valve opens on stem

extension (air to open,

fail closed)

7 Vertical below

center; valve closes on

stem extension (air to

close, fail open)

8 Vertical below center;

valve opens on stem

extension (air to open,

fail closed)

Seal Type

1 MN-7 Seal Ring

2 316 SS Seal Ring

3 Heavy-Duty

Metal Seal Ring

(Optional)

Design

Series

5

Note:

Actuator sizes B and C are only supplied in positions 3, 4, 7 or 8.

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 3

Page 4

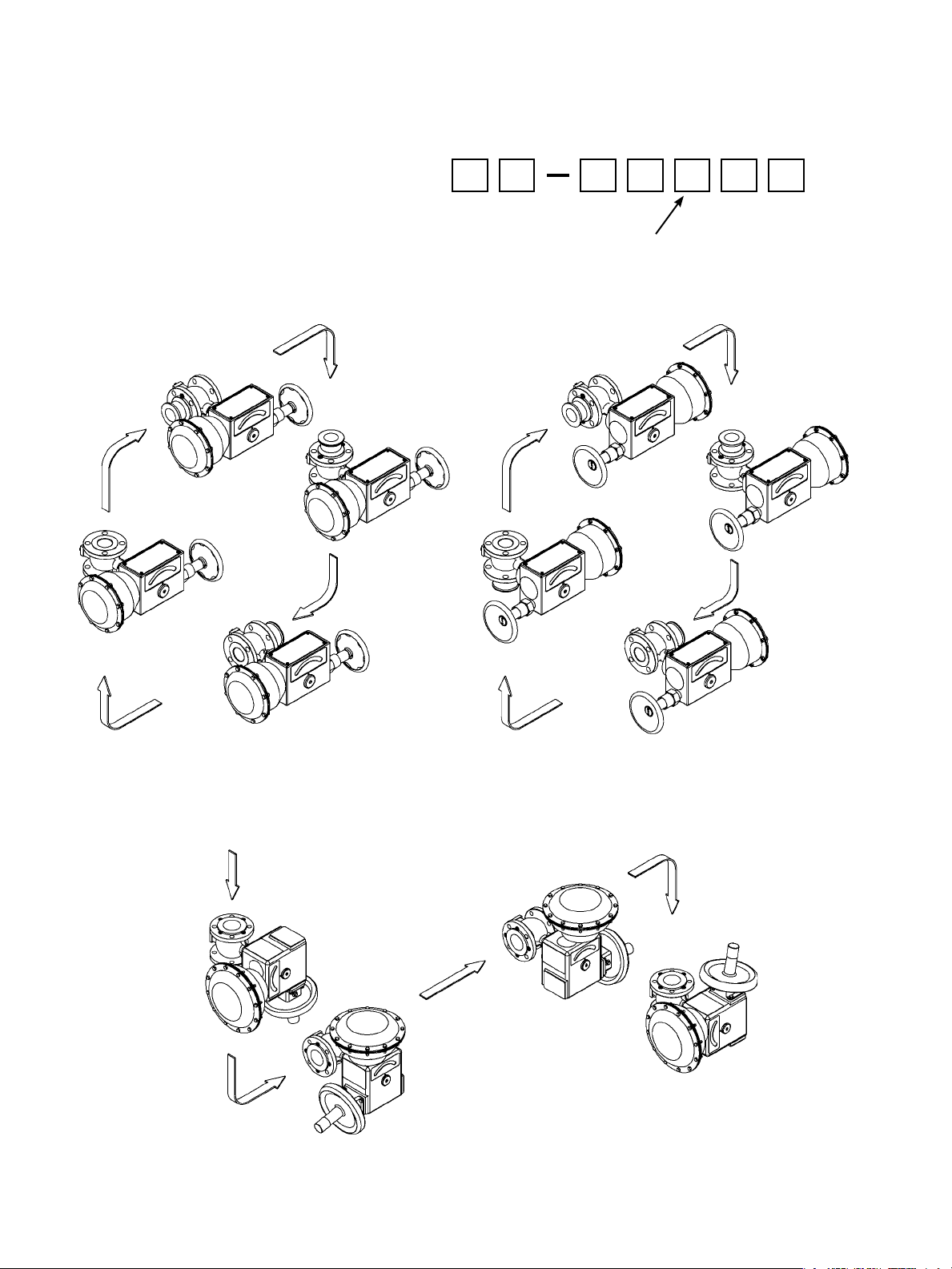

Actuator Mounting Guide

V-Max Valves

Actuator Model 33, Size AC

POS. 2

ATO

AIR TO

OPEN

POS. 4

ATO

POS. 8

ATO

3 X 3 6 X 0 5

Actuator position in relation to valve body

numbering system: 1 to 8.

POS. 1

ATC

POS. 3

POS. 7

POS. 7

ATO

ATC

AIR TO

CLOSE

ATC

POS. 6

ATO

Actuator Model 33, Sizes B and C

POS. 7

ATC

AIR TO

CLOSE

POS. 5

ATC

POS. 4

ATO

AIR TO

OPEN

POS. 3

ATC

POS. 8

ATO

4 | GE Oil & Gas

Page 5

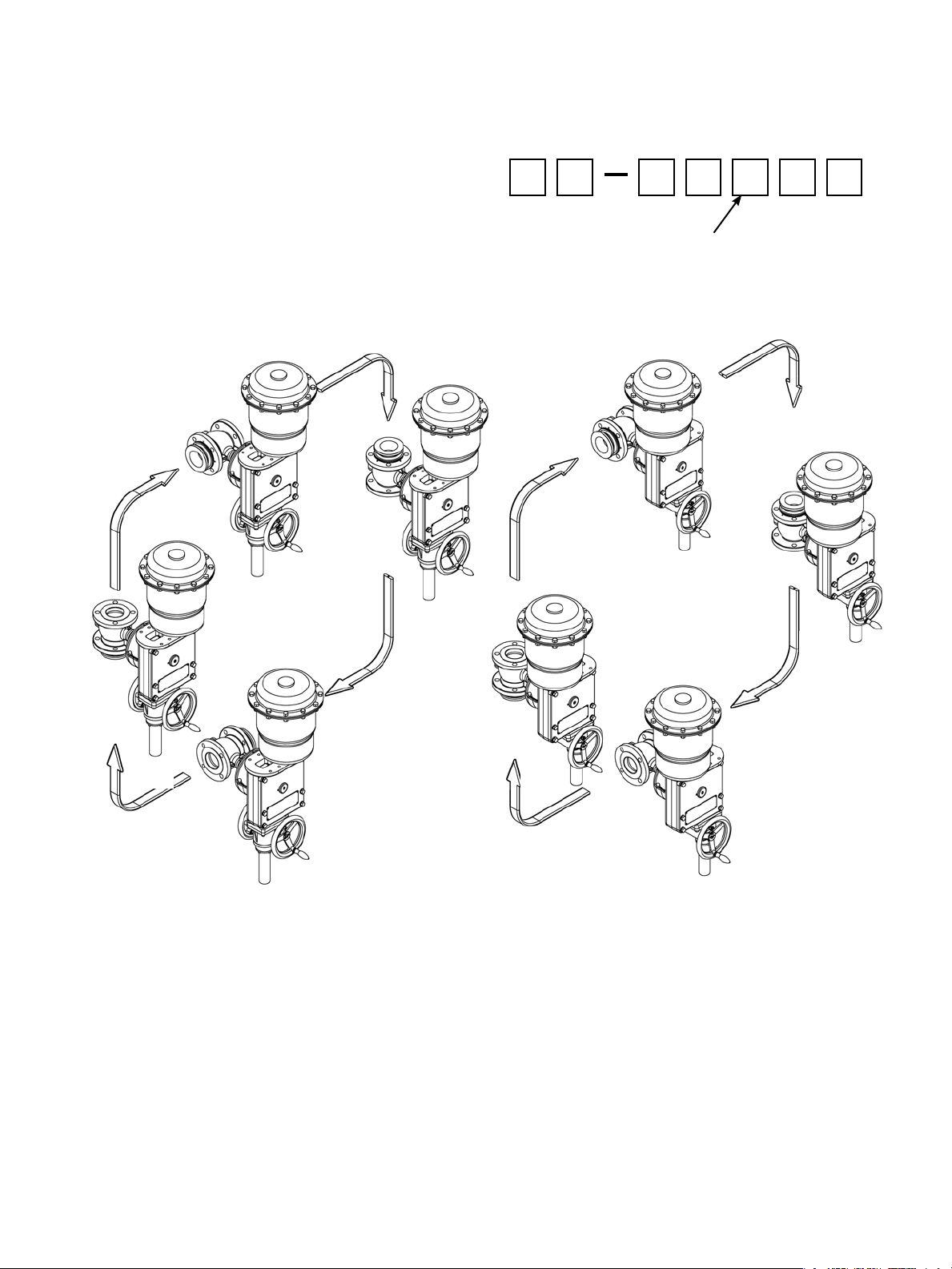

Actuator Mounting Guide

V-Max Valves

Actuator Models 31 and 32 (Size D)

POS. 4

ATO

AIR-TO-OPEN

ACTUATOR MODEL 32

SIZE D

POS. 2

ATO

3 X 3 6 X 0 5

Actuator position in relation to valve body

numbering system: 1 to 8.

POS. 3

ATC

AIR-TO-CLOSE

ACTUATOR MODEL 31

SIZE D

POS. 5

ATC

POS. 6

ATO

POS. 8

ATO

POS. 1

ATC

POS. 7

ATC

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 5

Page 6

General Data

n Body

Type: Cast with integral bonnet

FlowDirection: Flowtoopen

Materials: Carbon steel

317 Stainless steel

Body Pressure

Rating:

EndConnections: F

n Trim

PlugType: D

Material: 317 Stainless steel, hard chrome plated

Seat Ring:

Materials:

Retainer: 317 Stainless steel

Capacity:

FlowCharacteristic:

Cv Ratio:

ANSI150or300Dependingonangerating

langed – bolts to ANSI Class 150 or 300 rated

flanges (1-inch to 12-inch)(DN25–300)

ual characterized, high capacity “V” contoured

segmented ball

MN-7,StandardMetalandHeavyDutyMetal

MN-7PolymericreinforcedPTFE

316 Stainless steel Standard Metal

Nitronic60HeavyDutymetal(OptionalNPS1-6)

High capacity ball valve

Equal percentage

Greater than 500:1

n Actuators

Spring-Opposed Diaphragm – Model 33

Size

AC:

B:

C:

Range

AC:

B:

C:

Air Connection:

Yoke: Castiron

Bearing: Sealed radial ball

Auxiliary Handwheel

AC:

B:

C:

Spring-Opposed Rolling Diaphragm – Model 31/32

SizeD:

RangeD:

Air Connection:

Yoke:

Bearing:

Manual Override:

30 in2 (194 cm2)

2.25-inch(57.2mm)Stroke

1-inch to 2-inchValves(DN25-50)

70 in2 (452 cm2)

2.625-inch(66.5mm)Stroke

2-inch to 4-inchValves(DN50-100)

140 in2 (903 cm2)

2.625-inch(66.5mm)Stroke

3-inch to 12-inch Valves(DN80-300)

7-15 psi

7-16 psi

9-16 psi

1/4 NPT

Optionalsoliddiskwithlockingnut

Optional rising stem push type

Optional rising stem push type

60 in2 (387 cm2)

4.00-inch(101.6mm)Stroke

6-inch to 12-inchValves(DN150-300)

12-28 psi

17-40 psi

29-68 psi

1/4 NPT

Cast iron

Sealed radial ball

Optionjackscrewgear

6 | GE Oil & Gas

Page 7

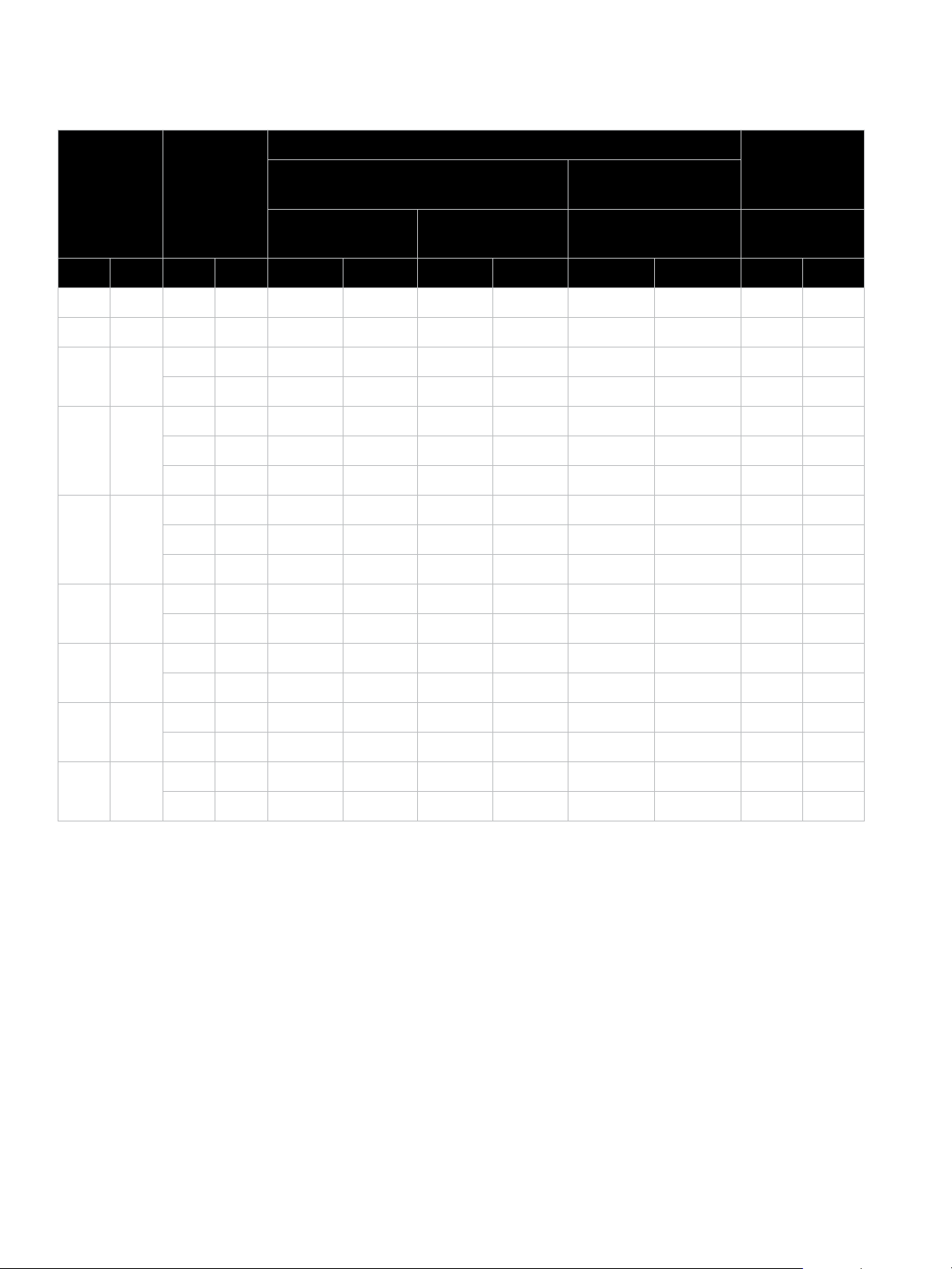

General Data

Standard Actuator Characteristics

Valve Size

in. DN in. mm

Shaft

Diameter

Model

Size Spring Range Effective Area

Standard Oversized

psi bar Sq. in. Sq. cm in. mm

Actuator

Stroke

1 25 0.62 15.7 33 AC 7-15 .48-1.03 30 194 2.250 57.2

1-1/2 40 0.62 15.7 33 AC 7-15 .48-1.03 30 194 2.250 57.2

Actuator

2 50

3 80

4 100

0.62 15.7 33 AC 7-15 .48-1.03 30 194 2.250 57.2

0.62 23.7 33 B 7-16 .48-1.10 70 452 2.625 66.5

0.93 23.7 33 B 7-16 .48-1.10 70 452 2.625 66.5

0.93 23.7 33 C 9-16 .62-1.10 140 903 2.625 66.5

0.93 23.7 33 B 7-16 .48-1.10 70 452 2.625 66.5

0.93 23.7 33 C 9-16 .62-1.10 140 903 2.625 66.5

1.2 30.5 33 C 9-16 .62-1.10 140 903 2.625 66.5

6 150

1.2 30.5 31/32 D 12-28 .83-1.93 60 387 4.000 101.6

1.2 30.5 31/32 D 17-40 1.17-2.76 60 387 4.000 101.6

1.2 30.5 31/32 D 29-68 2.00-4.69 60 387 4.000 101.6

1.2 30.5 33 C 9-16 .62-1.10 140 903 2.625 66.5

8 200

1.2 30.5 31/32 D 12-28 .83-1.93 60 387 4.000 101.6

1.2 30.5 31/32 D 17-40 1.17-2.76 60 387 4.000 101.6

1.2 30.5 31/32 D 29-68 2.00-4.69 60 387 4.000 101.6

1.37 34.8 33 C 9-16 .62-1.10 140 903 2.625 66.5

10 250

1.37 34.8 31/32 D 12-28 .83-1.93 60 387 4.000 101.6

1.37 34.8 31/32 D 17-40 1.17-2.76 60 387 4.000 101.6

1.37 34.8 31/32 D 29-68 2.00-4.69 60 387 4.000 101.6

1.37 34.8 33 C 9-16 .62-1.10 140 903 2.625 66.5

12 300

1.37 34.8 31/32 D 12-28 .83-1.93 60 387 4.000 101.6

1.37 34.8 31/32 D 17-40 1.17-2.76 60 387 4.000 101.6

1.37 34.8 31/32 D 29-68 2.00-4.69 60 387 4.000 101.6

Handwheel

Diameter

in.

mm

6.5

6.5

6.5

10

10

10

10

10

10

10

10

10

165

165

165

254

254

254

254

254

254

8

203

8

203

8

203

254

8

203

8

203

8

203

254

8

203

8

203

8

203

254

8

203

8

203

8

203

O-RING

Fugitive Emission Containment Package for

† Factory Mutual certified report

Zero Leakage

11

O-RING

Standard V-Max Packing Arrangement

EF Seal (Emission Free) Double O-Ring Seal

Packing Follower

Suitable for use in environmentally

sensitive applications, this economical

shaft seal solution to fugitive emissions

provides long-term, reliable, extremely low

emission performance without compromising control performance.

†

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 7

Page 8

Temperature/Seat Leakage

Standard Metal Seal Ring Temperature Limitations

A strain hardened 316 stainless steel seal ring is an available

option when the MN-7 Seal is not suitable. Seat leakage is per

ANSI /FCI 70.2 Class IV. The metal seal ring can be used with

either MN-7 lined bearings or the optional solid metal bearings.

The fluid temperature is limited to 425°F (218°C) when using the

MN-7 lined. A high temperature package consisting of metal seal

ring, bearings and flexible graphite packing

elevates fluid temperature limitations to 600°F (316°C)

maximum or ANSI working pressure and temperature

limitations. For use in lubricated service only.

MN-7 Seal Ring Temperature Limitations

The standard MN-7 seal ring provides tight, ANSI/FCI 70.2

Class VI seat leakage. Pressure and temperature ratings of this

design are limited as shown in the chart below as well as those

shown in the corresponding pressure drop tables.

(Optional) Heavy Duty Metal Seal Ring (Bi-directional Flow)

A solid Heavy Duty Metal seat ring is available (NPS 1-6) when

the MN-7 or Standard Metal Seal ring is not suitable. The Heavy

Duty Seat ring must be used with solid metal bearings. Fluid

temperature is limited to 500°F (260°C) due to the material of

the radial seal. Seat leakage is per ANSI/FCI 70.2 Class IV.

400

300

200

Temperature °F

100

0

-50

100 200 300 400 500 600 700 800

(6.89) (13.79) (20.68) (27.58) (34.47) (41.37) (48.26) (55.16)

Temperature °F

1

3

2

Pressure Drop psi (bar)

1

1 Zone of maximum temperature limits

2

2 Zone of maximum pressure limits

3

3 Zone of maximum interactive pressure/temperature limits

200

150

100

50

0

-45

Temperature °C

8 | GE Oil & Gas

Page 9

CV and FL versus Travel

Flow Direction: Flow to Open

Flow Characteristics: Equal Percentage

ANSI Class 150 and 300

Valve Sizes: 1 to 12-inch (DN 25-300)

Percent (%) of Max.

Opening

Percent (%) of Max.

C

V

F

L

Valve Size

in DN

1 25 0.11 0.54 1.2 2.9 5.2 8.3 12.1 17 26 40 55

1-1/2 40 0.25 1.2 2.7 6.5 12 19 28 39 58 90 125

2 50 0.34 1.7 3.7 8.8 16 26 37 54 79 122 170

3 80 0.88 4.3 9.5 23 42 66 97 139 205 317 440

4 100 1.48 7.3 16 38 70 111 163 233 344 533 740

6 150 2.50 12 27 65 119 188 275 394 581 900 1250

8 200 3.72 18 40 97 177 279 409 586 865 1339 1860

10 250 6.0 30 65 157 287 453 664 951 1404 2174 3020

12 300 8.8 43 95 229 418 660 968 1386 2046 3168 4400

10 15 20 30 40 50 60 70 80 90 100

0.20% 0.98% 2.15% 5.2% 9.5% 15.0% 22.0% 31.5% 46.5% 72.0% 100.0%

0.92 0.91 0.90 0.89 0.87 0.83 0.80 0.76 0.72 0.67 0.60

Rated C

V

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 9

Page 10

Materials of Construction

27

5

28

12

25 24 23 22 20 21 28 29

5

8

30

26 19 17

31

3

3

3

32

32

8

6

8

7

16

15

11

14

12

2

1

4

10

3

9

10 | GE Oil & Gas

Page 11

Materials of Construction

Carbon Steel Construction

Ref.

No

1 Body Flanged ASTM A216 Gr WCB Carbon Steel

2 Ball Plug ASTM A351 Gr CG8M Type 317, Hard Chromium Plated

Retainer Standard (ISA S75.04)

3

Retainer Extended (ANSI B16.10)

4 Gasket (retainer body) Flexible Graphite

5 Stem Shaft

6 Backup Ring (flat metal seat) ASTM A240 Type 317L Stainless Steel

7 Gasket (flat metal seat) 316 Stainless Steel/Flexible Graphite

Seat Ring Flexible Metal ASTM A66 1/4 Hard Strain Hardened 316 Stainless Steel Sheet

8

Seat Ring MN-7

Seat Ring Heavy Duty Rigid Nitronic 60 Stainless Steel

9 Slot Button Head Screw Carbon Steel Plated

10 Flat Washer Carbon Steel Plated

11 Pin Shaft

12 Cap Screw, End Flange ASTM A193 Gr B8

14 End Flange ASTM A36 Plated

15 Gasket Pin Shaft Nitrile Bound Acrylic

16 Lower Bushing

17 Upper Bushing

19 Packing Set

20 Packing Follower ASTM A582 Type 303 St. St.

21 O-Ring Viton

22 O-Ring Viton

23 Packing Box Flange ASTM A216 Gr WCC Plated

24 Nut, Packing Flange Stud ASTM A194 Gr 8

25 Stud, Packing Flange Alloy Steel ASTM A193 Gr B8

26 Stud, Bonnet Alloy Steel ASTM A193 Gr B8

Safety Pin ASTM A479 Type 316

27

Packing Adapter ASTM A479 Type 316

28

Shaft Ring ASTM A564 Gr 632

29

Radial Seal, HD Seat GFP Graphite Fiber Reinforced PTFE Seal, Hastelloy C276 Spring

30

Wave Spring, HD Seat Inconel X-750 Material (AM-5699) Precipitation Hardened

31

Seat Support Ring, Downstream ASTM A240 Type 317L Stainless Steel

32

Ref.

No

Temperature Range

Description Standard Materials

Temperature Range

-20oF +425oF +450oF +500oF +600oF

-29°C +218°C +232°C +260°C +316°C

∆∆ ∆∆∆

ASTM A351 Gr CG8M Type 317

ASTM A564 Gr 630 H1075

(NACE) Nitronic 50

ASTM A564 Gr 630 H1075

Nitronic 50

316 Stainless Steel/MN-7 Lined

Stellite

316 Stainless Steel/MN-7 Lined

Stellite

Crane 285K - TFE Aramid Core

Flexible Graphite

∆

-20oF +425oF +450oF +500oF +600oF

-29°C +218°C +232°C +260°C +316°C

∆ ∆ ∆

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 11

Page 12

Materials of Construction

Stainless Steel Construction

Ref.

No

1 Body Flanged ASTM A351 Gr CG8M Type 317

2 Ball Plug ASTM A351 Gr CG8M Type 317, Hard Chromium Plated

Retainer Standard (ISA S75.04)

3

Retainer Extended (ANSI B16.10)

4 Gasket (retainer body) Flexible Graphite

5 Stem Shaft

6 Backup Ring (flat metal seat) ASTM A240 Type 317L Stainless Steel

7 Gasket (flat metal seat) 316 Stainless Steel/Flexible Graphite

Seat Ring Flexible Metal ASTM A66 1/4 Hard Strain Hardened 316 Stainless Steel Sheet

8

Seat Ring MN-7

Seat Ring Heavy Duty Rigid Nitronic 60 Stainless Steel

9 Slot Button Head Screw Carbon Steel Plated

10 Flat Washer Carbon Steel Plated

11 Pin Shaft

12 Cap Screw, End Flange ASTM A193 Gr B8

14 End Flange ASTM A36 Plated

15 Gasket Pin Shaft Nitrile Bound Acrylic

16 Lower Bushing

17 Upper Bushing

19 Packing Set

20 Packing Follower ASTM A582 Type 303 St. St.

21 O-Ring Viton

22 O-Ring Viton

23 Packing Box Flange ASTM A216 Gr WCC Plated

24 Nut, Packing Flange Stud ASTM A194 Gr 8

25 Stud, Packing Flange Alloy Steel ASTM A193 Gr B8

26 Stud, Bonnet Alloy Steel ASTM A193 Gr B8

Safety Pin ASTM A479 Type 316

27

Packing Adapter ASTM A479 Type 316

28

Shaft Ring ASTM A564 Gr 632

29

Radial Seal, HD Seat GFP Graphite Fiber Reinforced PTFE Seal, Hastelloy C276 Spring

30

Wave Spring, HD Seat Inconel X-750 Material (AMS 5699) Precipitation Hardened

31

Seat Support Ring, Downstream 317 Stainless Steel

32

Ref.

No

Temperature Range

Description Standard Materials

Temperature Range

-50oF +425oF +450oF +500oF +600oF

-46°C +218°C +232°C +260°C +316°C

∆∆ ∆∆∆

ASTM A351 Gr CG8M Type 317

Nitronic 50 (Standard)

ASTM A564 Gr 630 H1075 (Optional)

Nitronic 50 (Standard)

ASTM A564 Gr 630 H1075 (Optional)

316 Stainless Steel/MN-7 Lined

Stellite

316 Stainless Steel/MN-7 Lined

Stellite

Crane 285K - TFE Aramid Core

Flexible Graphite

∆

-50oF +425oF +450oF +500oF +600oF

-46°C +218°C +232°C +260°C +316°C

∆ ∆ ∆

12 | GE Oil & Gas

Page 13

Materials of Construction

Carbon Steel NACE Construction — Complies with NACE MR0103-2003

Ref.

No

1 Body Flanged

2 Ball Plug ASTM A351 Gr CG8M Type 317, Hard Chromium Plated

Retainer Standard (ISA S75.04)

3

Retainer Extended (ANSI B16.10)

4 Gasket (retainer body) Flexible Graphite

5 Stem Shaft Nitronic 50

6 Backup Ring (flat metal seat) ASTM A240 Type 317L Stainless Steel

7 Gasket (flat metal seat) 316 Stainless Steel/Flexible Graphite

Seat Ring Flexible Metal ASTM A66 1/4 Hard Strain Hardened 316 Stainless Steel Sheet

Seat Ring MN-7

8

Seat Ring Heavy Duty Rigid Nitronic 60 Stainless Steel

9 Slot Button Head Screw Carbon Steel Plated

10 Flat Washer Carbon Steel Plated

11 Pin Shaft Nitronic 50

12 Cap Screw, End Flange ASTM A193 Gr B8

14 End Flange ASTM A36 Plated

15 Gasket Pin Shaft Nitrile Bound Acrylic

16 Lower Bushing

17 Upper Bushing

19 Packing Set

20 Packing Follower ASTM A582 Type 303 St. St.

21 O-Ring Viton

22 O-Ring Viton

23 Packing Box Flange ASTM A216 Gr WCC Plated

24 Nut, Packing Flange Stud ASTM A194 Gr 8

25 Stud, Packing Flange Alloy Steel ASTM A193 Gr B8

26 Stud, Bonnet Alloy Steel ASTM A193 Gr B8

Safety Pin ASTM A479 Type 316

27

Packing Adapter ASTM A479 Type 316

28

Shaft Ring ASTM A564 Gr 632

29

Radial Seal, HD Seat GFP Graphite Fiber Reinforced PTFE Seal, Hastelloy C276 Spring

30

Wave Spring, HD Seat Inconel X-750 Material (AMS 5699) Precipitation Hardened

31

Seat Support Ring, Downstream ASTM A240 Type 317L Stainless Steel

32

Ref.

No

Temperature Range

Description Standard Materials

Temperature Range

-50oF -20oF +425oF +450oF +500oF +600oF

-46°C -29°C +218°C +232°C +260°C +316°C

∆∆∆ ∆∆∆

ASTM A216 Gr WCB Carbon Steel

ASTM A351 Gr CG8M Type 317

ASTM A351 Gr CG8M Type 317

316 Stainless Steel/MN-7 Lined

Stellite

316 Stainless Steel/MN-7 Lined

Stellite

Crane 285K - TFE Aramid Core

Flexible Graphite

∆ ∆ ∆ ∆ ∆

-50oF -20oF +425oF +450oF +500oF +600oF

-46°C -29°C +218°C +232°C +260°C +316°C

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 13

Page 14

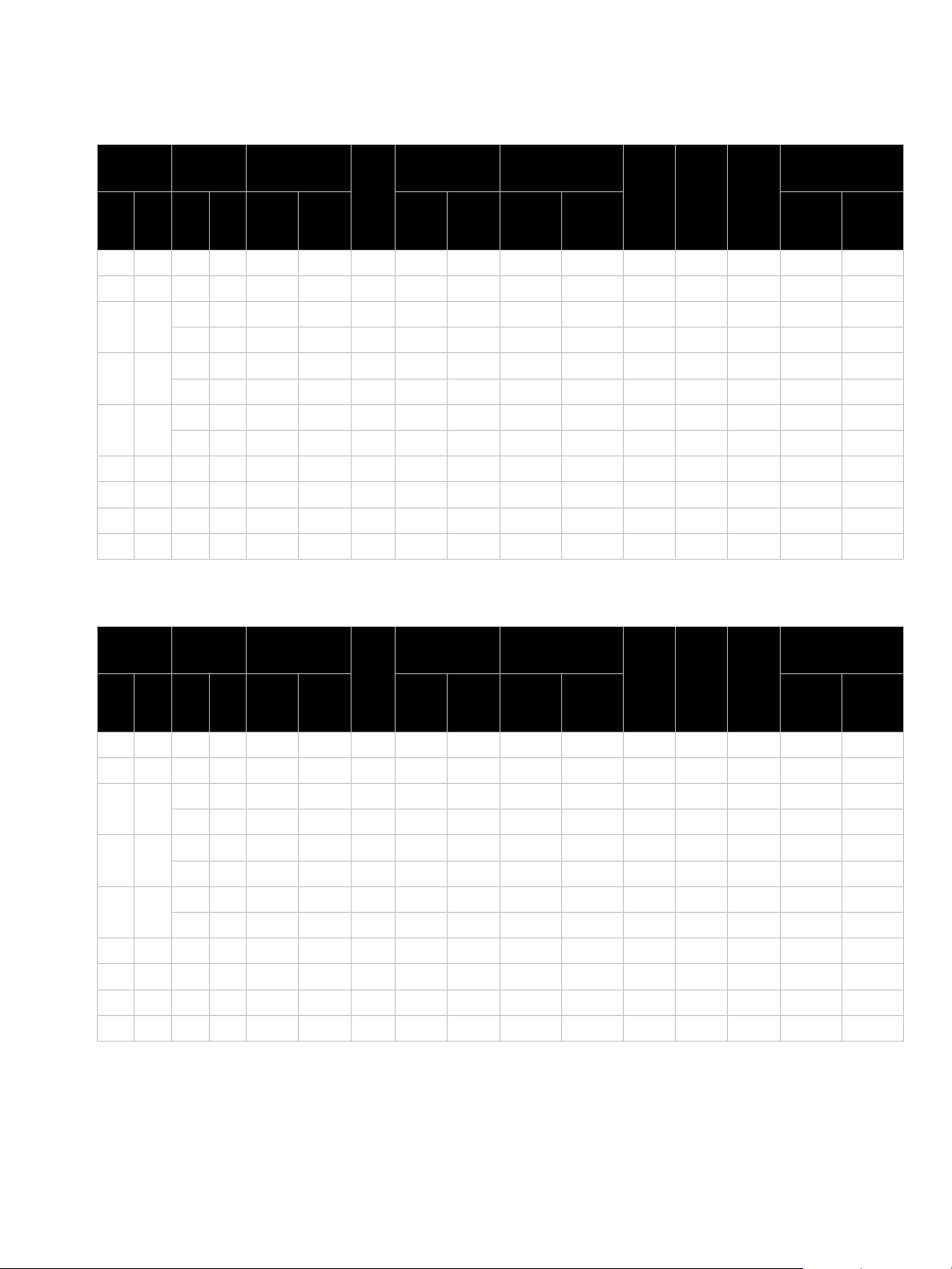

Dimensions

Actuator Model 33, Size AC – inches [millimeters]

Actuator Model 33, Size B and C – inches [millimeters]

14 | GE Oil & Gas

Page 15

Dimensions

Actuator Model 33, Sizes AC, B and C (inches)

Valve

Size

in. DN Size

Actuator

Size

Sq.

In.

ANSI

150

A

ANSI

300

(1)

C

B

ANSI

150

ANSI

300

Face-to-Face

D

Standard

ISA

(2)

S75.04

Optional

ASME

(3)

B16.10

E F G

Center-to-Face

H

Standard

S75.04

ISA

(2)

Optional

ASME

B16.10

1 25 AC 30 2.74 2.74 8.06 4.25 4.88 4.00 5.00 10.70 8.50 10.53 2.12 3.12

1.5 40 AC 30 3.13 4.08 8.33 5.00 6.12 4.47 6.49 10.70 8.50 10.80 2.43 4.46

AC 30 3.92 5.05 8.74 6.00 6.50 4.93 7.01 10.70 8.50 11.21 2.56 4.64

2 50

B 70 3.92 5.05 8.52 6.00 6.50 4.93 7.01 11.45 13.00 11.21 2.56 4.64

B 70 4.64 4.64 10.24 7.50 8.25 6.54 8.00 11.45 13.00 12.93 3.59 5.06

3 80

C 140 4.64 4.64 10.24 7.50 8.25 6.54 8.00 15.07 17.50 12.93 3.59 5.06

B 70 5.48 5.48 10.87 9.00 10.00 7.61 9.00 11.45 13.00 13.56 3.95 5.50

4 100

C 140 5.48 5.48 10.87 9.00 10.00 7.61 9.00 15.07 17.50 13.56 3.95 5.50

6 150 C 140 6.76 6.76 12.09 11.00 12.50 8.99 10.52 15.07 17.50 14.78 4.85 6.37

8 200 C 140 7.88 7.88 13.81 13.50 15.00 9.59 11.50 15.07 17.50 16.50 5.03 6.95

10 250 C 140 9.46 9.46 15.75 16.00 17.50 11.69 13.02 15.07 17.50 18.44 6.09 7.42

12 300 C 140 10.63 10.63 16.92 19.00 20.50 13.33 14.00 15.07 17.50 19.61 7.52 8.19

Actuator Model 33, Sizes AC, B and C (millimeters)

(3)

Valve

Size

Actuator

Size

A

(1)

C

B

in. DN Size

1 25 AC

1.5 40 AC

AC

Sq. cmANSI

150

194 69.60 69.60 204.72 107.95 123.95 101.60 127.00 271.78 215.90 267.46 53.85 79.25

194 79.50 103.63 211.58 127.00 155.45 113.54 164.85 271.78 215.90 274.32 61.72 113.28

194 99.57 128.27 222.00 152.40 165.10 125.22 178.05 271.78 215.90 284.73 65.02 117.86

ANSI

300

ANSI

150

ANSI

300

2 50

B

452 99.57 128.27 216.41 152.40 165.10 125.22 178.05 290.83 330.20 284.73 65.02 117.86

452 117.86 117.86 260.10 190.50 209.55 166.12 203.20 290.83 330.20 328.42 91.19 128.52

B

3 80

C

903 117.86 117.86 260.10 190.50 209.55 166.12 203.20 382.78 444.50 328.42 91.19 128.52

452 139.19 139.19 276.10 228.60 254.00 193.29 228.60 290.83 330.20 344.42 100.33 139.70

B

4 100

C

903 139.19 139.19 276.10 228.60 254.00 193.29 228.60 382.78 444.50 344.42 100.33 139.70

6 150 C

8 200 C

10 250 C

12 300 C

Notes:

1. Conforms to ASME/ANSI Standard B16.5 - 1996 “Pipe Flanges and Flange Fittings.”

2. Conforms to ISA Standard S75.04.

3. Conforms to ASME Standard B16.10 - 1992 (formerly ANSI Standard B16.10 - 1973)

Short Pattern Ball. Available for ANSI 150 Class Valves ONLY.

903 171.70 171.70 307.09 279.40 317.50 228.35 267.21 382.78 444.50 375.41 123.19 161.80

903 200.15 200.15 350.77 342.90 381.00 243.59 292.10 382.78 444.50 419.10 127.76 176.53

903 240.28 240.28 400.05 406.40 444.50 296.93 330.71 382.78 444.50 468.38 154.69 188.47

903 270.00 270.00 429.77 482.60 520.70 338.58 355.60 382.78 444.50 498.09 191.01 208.03

Face-to-Face

D

Standard

ISA

(2)

S75.04

Optional

ASME

(3)

B16.10

E F G

Center-to-Face

H

Standard

S75.04

ISA

(2)

Optional

ASME

B16.10

(3)

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 15

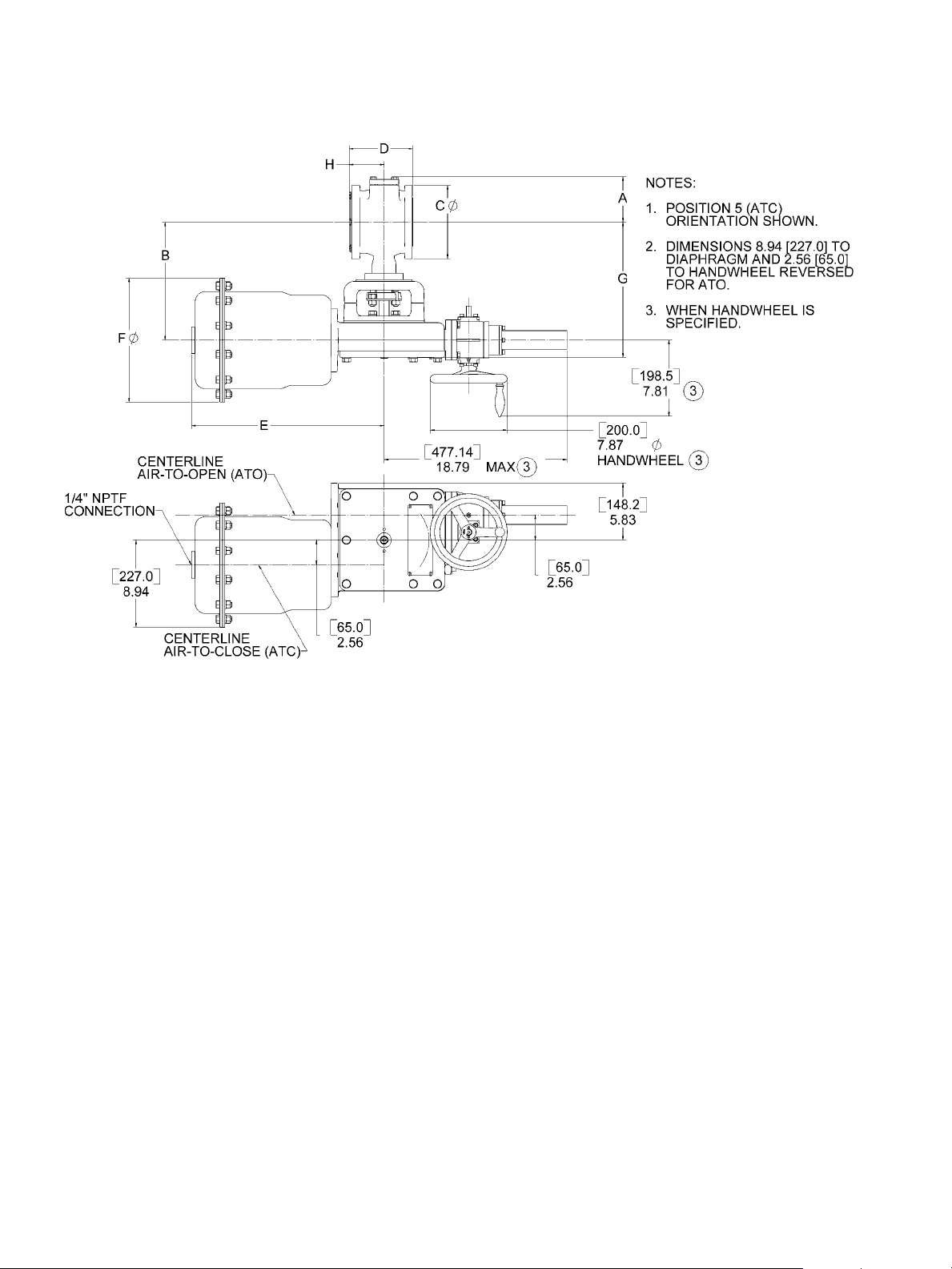

Page 16

Dimensions

Actuator Model 31/32, Size D – inches [millimeters]

16 | GE Oil & Gas

Page 17

Dimensions

Actuator Model 31/32, Size D (inches)

Valve

Size

in. DN Size

Actuator

Size

Sq.

In.

ANSI

150

A

ANSI

300

(1)

C

B

ANSI

150

ANSI

300

Face-to-Face

D

Standard

ISA

(2)

S75.04

Optional

ASME

(3)

B16.10

E F G

Center-to-Face

H

Standard

S75.04

ISA

(2)

Optional

ASME

B16.10

3 80 D 60 4.64 4.64 12.12 7.50 8.25 6.54 8.00 19.78 12.75 13.88 3.59 5.06

4 100 D 60 5.48 5.48 12.75 9.00 10.00 7.61 9.00 19.78 12.75 14.51 3.95 5.50

6 150 D 60 6.76 6.76 14.06 11.00 12.50 8.99 10.52 19.78 12.75 15.82 4.85 6.37

8 200 D 60 7.88 7.88 15.69 13.50 15.00 9.59 11.50 19.78 12.75 17.45 5.03 6.95

10 250 D 60 9.46 9.46 17.63 16.00 17.50 11.69 13.02 19.78 12.75 19.39 6.09 7.42

12 300 D 60 10.63 10.63 18.80 19.00 20.50 13.33 14.00 19.78 12.75 20.56 7.52 8.19

Actuator Model 31/32, Size D (millimeters)

Valve

Size

in. DN Size

3 80

4 100

6 150

8 200

10 250

12 300

Actuator

Size

Sq. cmANSI

150

A

ANSI

300

(1)

C

B

ANSI

150

ANSI

300

Face-to-Face

D

Standard

ISA

(2)

S75.04

Optional

ASME

(3)

B16.10

E F G

Center-to-Face

H

Standard

S75.04

ISA

(2)

Optional

ASME

B16.10

D 387 117.86 117.86 307.85 190.50 209.55 166.12 203.20 502.41 323.85 352.55 91.19 128.52

D 387 139.19 139.19 323.85 228.60 254.00 193.29 228.60 502.41 323.85 368.55 100.33 139.70

D 387 171.70 171.70 357.12 279.40 317.50 228.35 267.21 502.41 323.85 401.83 123.19 161.80

D 387 200.15 200.15 398.53 342.90 381.00 243.59 292.10 502.41 323.85 443.23 127.76 176.53

D 387 240.28 240.28 447.80 406.40 444.50 296.93 330.71 502.41 323.85 492.51 154.69 188.47

D 387 270.00 270.00 477.52 482.60 520.70 338.58 355.60 502.41 323.85 522.22 191.01 208.03

(3)

(3)

Notes:

1. Conforms to ASME/ANSI Standard B16.5 - 1996 “Pipe Flanges and Flange Fittings.”

2. Conforms to ISA Standard S75.04.

3. Conforms to ASME Standard B16.10 - 1992 (formerly ANSI Standard B16.10 - 1973)

Short Pattern Ball. Available for ANSI 150 Class Valves ONLY.

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 17

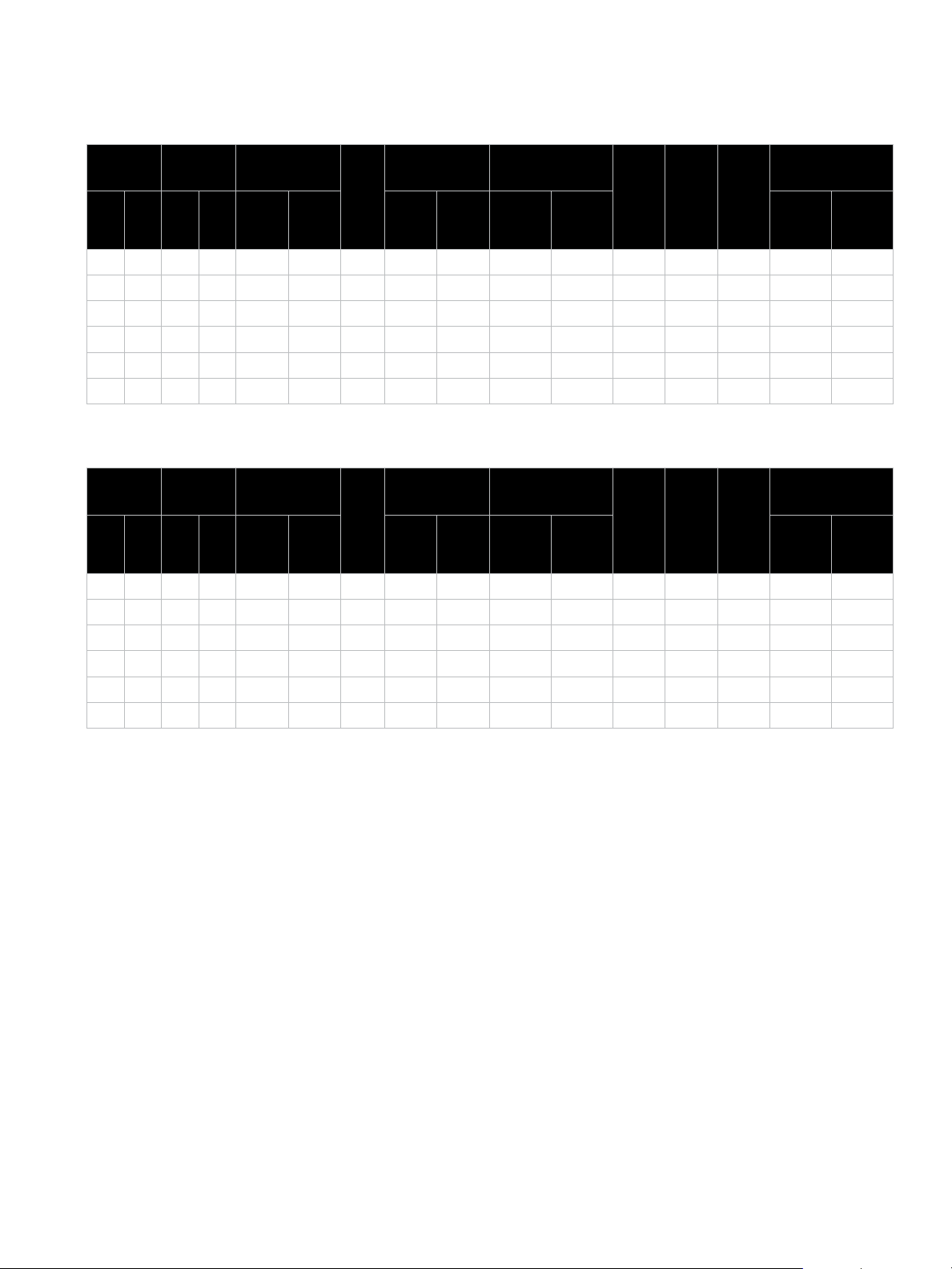

Page 18

Assembly Weights

Valve and Actuator Assembly Weights (without Manual Override)

Valve Size Actuator

in. DN Model Size lbs Kg lbs Kg lbs Kg lbs Kg

1 25 33 AC 50 22 53 24 50 23 7 3

1.5 40 33 AC 54 24 61 27 56 25 7 3

2 50

3 80

4 100

6 150

33 AC 60 27 81 37 63 29 7 3

33 B 101 46 122 55 103 47 27 12

33 B 124 56 134 61 128 58 27 12

33 C 182 82 192 87 186 84 27 12

31/32 D 227 103 237 107 231 105 12 5

33 B 147 67 166 75 152 69 27 12

33 C 205 93 224 101 210 95 27 12

31/32 D 250 113 269 122 255 116 12 5

33 C 250 114 288 131 260 118 27 12

31/32 D 295 134 333 151 305 138 12 5

Standard ISA S75.04 Face-to-Face

ANSI Class 150 Flanged ANSI Class 300 Flanged

Optional ASME B16.10

Face-to-Face

ANSI Class 150

Flanged ONLY

Manual

Override

Add to Valve /

Actuator Weight

8 200

10 250

12 300

33 C 303 137 359 163 326 148 27 12

31/32 D 348 158 404 183 371 168 12 5

33 C 393 178 416 189 480 217 27 12

31/32 D 438 199 461 209 525 238 12 5

33 C 520 236 540 245 642 291 27 12

31/32 D 565 256 585 265 687 312 12 5

18 | GE Oil & Gas

Page 19

36005 Series V-Max High Capacity V-Ported Control Ball Valve | 19

Page 20

DIRECT SALES OFFICE LOCATIONS

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH and CENTRAL

AMERICA and the CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Trademark of G eneral Elect ric Company

Other company names and product names used in this document are the registered trademarks

or trademarks of their respective owners.

© 2012 General El ectric Comp any. All rights re served.

GEA19375 12/2012

Loading...

Loading...