Page 1

GB

Gas Hobs

THG40

THG41

THG42

THG50

INSTALLATION AND USER INSTRUCTIONS

Note: This appliance is supplied for use with Natural Gas

and can be converted to LPG by a suitably qualified

engineer with the kit supplied

COD. 208084 03.02.2005

Page 2

Contents

1. Introduction 3

2. Your Servis Hob 4

3. Cleaning 4

4. Safety Instructions 5

5. Installation Instructions 6-9

6. User Instructions 10

7. Fault Finding Guide 11

8. Calling for Service Back Cover

This appliance conforms to the following EEC Directives:

Low Voltage Equipment

73/23/EEC

93/68/EEC

Electromagnetic Compatibility

89/336/EEC

92/31/EEC

93/68/EEC

EN30

Page 3

1. Introduction

Thank you for purchasing a new Servis Gas Hob.

This instruction book applies to the following models:

THG40

THG41

THG42

THG50

Even if you have used a gas hob before, it is important that you read these

instructions thoroughly before starting to cook, paying particular attention to the

installation and safety instructions.

If you have any problems with installing, operating, or cooking with your Servis

hob, please check through these instructions thoroughly to make sure that you

have not missed anything. If you still need help, then please contact (including a

daytime telephone number if possible):

CUSTOMER CARE LINE: 0990 168299

Please quote the model and serial number with all enquiries.

This can be found on the rating plate on the underside of the hob.

WARNING! For your own safety, make sure that these instructions on

installation, use and maintenance are followed.

We advise you to keep these instructions in a safe place for future reference.

If you sell or transfer ownership of this product, please pass on these instructions

to the new owner.

Page 4

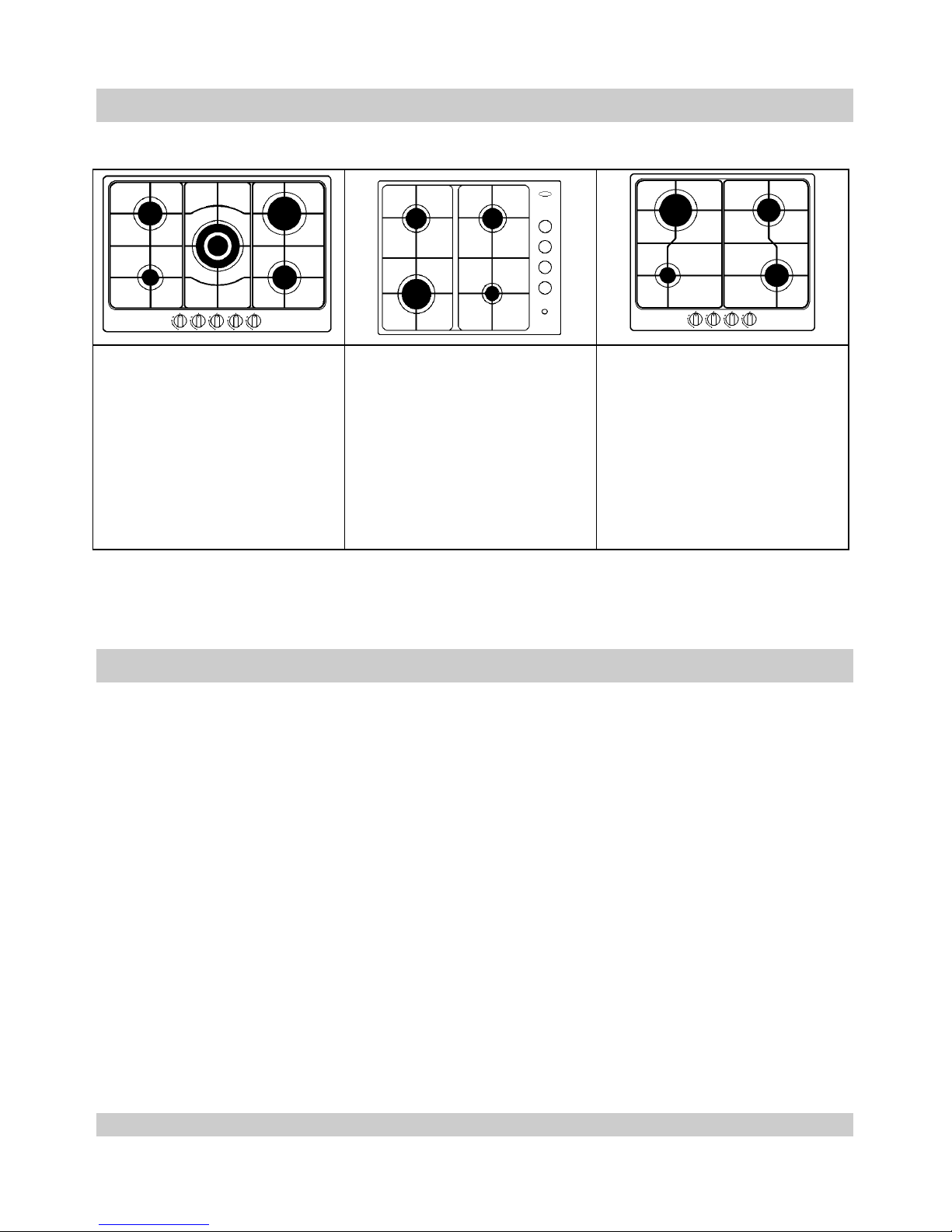

2. Your Servis Hob

THG50

Rapid gas burner Rear Right 3000 W

Semirapid gas burner Rear Left and

Front Right 1750 W

Auxil i a r y g a s b ur n e r F r o nt Le f t 1000 W

Triple ring gas burner Central 3800 W

THG40

THG41

Rapid gas burner Front Left 2900 W

Semirapid gas burner Rear Left and

Rear Right 1650 W

Auxiliary gas burner Front Right 1000 W

THG42

Rapid gas burner Rear Left 3000 W

Semirapid gas burner Rear Right and

Front Right 1750 W

Auxiliary gas burner Front Left 1000 W

3. Cleaning

VITREOUS ENAMEL

Hotplate, burner caps, pan supports

Cloth wrung out in hot soapy water. Stubborn stains can be removed with a cream paste

approved by the Vitreous Enamel Development Council, liquid cleaner or by rubbing with

fine steel wool soap pads.

NOTE: The pan supports can also be cleaned in the dish washer

.

ALUMINIUM

Hotplate burner bodies

Similar to paint cleaning above. Use a nylon brush to remove any cleaning materials, water

or dirt from the hotplate burner bodies. After cleaning, wipe dry and refit to the hob

ensuring they are correctly seated.

Check parts are reassembled correctly by lighting the burners and allowing to dry out

.

PLASTIC

Control knobs: Wipe with a cloth wrung out in hot soapy water.

STAINLESS STEEL

Cloth wrung out in hot soapy water. Alternatively use a propriety stainless steel cleaner

obtainable from Servis Cares; call 0990168299.

Page 5

4. Safety Instructions

Ensure that these notes and that the whole of this instruction book are thoroughly

read and understood before installation or operation of the hob.

The instructions are provided in the interest of your safety.

GAS SAFETY (INSTALLATION & USE) REGULATIONS

1. It is the law that all gas appliances are installed by competent persons in

accordance with the current edition of the above regulations. It is in your

interest and that of safety to ensure compliance with the law.

2. Repairs or servicing of this product must only be carried out by an authorised

service agent using only approved parts.

3. No attempt must be made to modify this appliance.

4. Cooking appliances become very hot in use, therefore ensure children and

pets are kept away. The use of oven gloves is recommended when during

use.

5. Do not allow children to operate or play with any part of the appliance.

6. Do not use unstable pans and position handle away from the edge of the hob.

The use of a suitable hob guard is recommended.

7. In the interests of safety and hygiene, ensure the hob is kept clean as a build

up of grease could cause fire.

8. This appliance is designed for domestic cooking only, commercial catering

may invalidate the warranty.

9. Do not cover the hob or place combustible materials on or near the surface

even when the hob is not in use.

10. Do not fill deep fat frying pans more than one third full of oil. Do not leave

unattended.

11. Before cleaning the hob, switch off at the mains.

12. Never use steam cleaners on this appliance.

13. When finished cooking, switch all controls off and allow to cool.

14. If you sell or transfer ownership of this product, please pass on these

instructions to the new owner.

15. If uncertain of any points, please telephone Servis Cares.

Page 6

5. Installation Instructions

TECHNICAL INFORMATION

• The installation, the adjustments, conversions and maintenance listed in this

part must only be carried out by qualified persons

• The safety and automatic adjustment devices of th e appliance may only be

modified by an authorised service agent.

• The installation of this gas hob must comply with the standards in fo rce.

• This appliance is not connected to a flue for discharge of the combustion

products; therefore, it must be connected in compliance with the above

mentioned installation rules. Particular attention must be paid to the

instructions given below for ventilation and aeration.

LOCATION

The cooker may be located in a kitchen, kitchen/diner or a bed-sitting room, but not in a

room containing a bath or shower. The hob must not be installed in a bed-sitting room of

less than 20m

3

.

LPG models shall not be installed in a room or internal space below ground level, e.g. in a

basement.

PROVISION FOR VENTILATION

The room containing the cooker should have an air supply in accord ance with BS 5440:

Part 2.

The room must have an opening window or equivale nt; some rooms may also require a

permanent vent. If the room has a volume between 5 and 10 m

3

, it will require an air vent

of 50cm

2

effective area unless it has a door which opens directly to outside. If the room has

a volume of less than 5m

3

, it will require an air vent of 100cm2 effective area (fig. 1). If there

are other fuel burning appliances in the same room, BS 5440: Part 2 should be consulted

to determine air vent requirements.

NOTE: The use of a gas cooking appliance results in the producti on of heat and moisture

in the room in which it is installed. Always ensure that the kitchen is well ventilated; keep

natural ventilation holes open or install a mechanical ve ntilation device (fig 2).

In particular, when using the grill or more than one hotplate burner, ope n a window if a

mechanical ventilation device is not operating (fig. 3).

Page 7

5. Installation Instructions

UNPACKING THE APPLIANCE

Remove all packaging before use and check to make sure that the appliance is in perfect

condition. If you have any doubts do not use the appliance and call your supplier.

Some parts on the appliance are protected by a plastic film. This protective film must be

removed before the appliance is used. We recommend carefully slitting the pl astic film along the

edges with a sharp knife or pin.

The packaging materials shou ld carefully d iscarded an d no t left within eas y reach of

children as they are a potential safety hazard.

INSTALLING AND FIXING THE HOB

Your hob can be fitted to any worktop w ith a thi ckness of 30 to 40 mm.

It is advisable to isolate the appliance from the pi ece of furniture below with a separator, leaving

a depression space of at least 10 mm (fig. 4)

No overhanging surface or cooker hood should be closer to the hotplate than 750 mm (29½”).

Fix in position in accordance with fig. 5. If fitting a 600 mm bridging unit above the 700mm hob

unit, the sides of adjacent cabinets may be lower than 760 mm dow n to 334 mm pro vided they

are resistant to heat and steam.

The hob has a special seal which prevents liquid from entering the cabinet. Follow these

instructions in order to correctly apply this seal:

- Detach the seals from their backing, checking that the transparent protection still

adheres to the seal itself.

- Turn over the hob and correctly position seal (S) (fig. 6) under the edge of the hob

itself, so that the outer part of the seal itself perfectly matches the outer edge of the

hob. The ends of the strips must fit together without overlapping.

- Evenly and securely fix the seal to the hob, pressing it firmly in place.

- Remove the strip of protective paper from the seal. Insert the hooks (G) fig.7 or (C)

fig. 8) into their relative housings on the hob and place into the prepared ho le in the

cabinet. Lock in place with the relative fixing screws (see fig. 7/8).

Fig. 4 Fig. 5

Fig. 6

APPLIANCE

DIMENSIONS

(mm)

L P

THG42

THG50

560 490

THG40

THG41

558 478

Fig. 8 Fig. 7

Page 8

5. Installation Instructions

ELECTRICAL CONNECTION

This appliance must be connected by a competent person, using fixed wiring via a double

pole switched fused spur outlet with a fuse rating of 3amps, and with a contact separation

of at least 3mm in all poles.

We recommend that the appliance is connected by a qualified electricia n who will comply

with I.E.E. regulations.

The wires in the mains lead are coloured in accordance with the follo wing code: Green &

Yellow = Earth, Blue = Neutral, Brown = Live.

GAS CONNECTION

The appliance’s gas inlet fitting is a 1/2” male threaded cylindrical gas type in accordance

with the ISO 228-1 standards. Make the connection using rigid pipe.

This appliance is adjusted for NATURAL GAS at 20mbar ONLY.

The hob is suitable for conversion to Liquid Petroleum Gas BUTANE (G30) at 2830 mbar and PROPANE (G31) at 37 mbar by the following procedure using the kit

supplied.

• Replace the injectors with the corresponding injector from the table

below. First remove the burner caps and rings and with a socket sp anner

(B), unscrew injector (A) (see fig. 9).

• The adjustment of the reduced rate position is as follows:

Light the burner and turn the knob to reduced rate position.

Remove the knob (M) which is simply inserted onto tap stem.

Insert a small screwdriver (D) into the top shaft (C) and turn the bypass

screw left or right until flame of the burner is conveniently regulated to the

low position (see fig.10).

• Make sure that when turning quickly from “Full on” position to reduced rate

position that the burner does not extinguish.

Page 9

5. Installation Instructions

INJECTOR REPLACEMENT TABLE: MODELS THG42 - THG50

BURNERS

NORMAL

PRESSURE

NOMINAL

RATE

INJECTOR

DIAMETER

BY- PASS

DIAMETER

NOMINAL

HEAT

INPUT (W)

Nº

DESCRIPTION

GAS

mbar g/h L/h 1/100 mm 1/100 mm Max. Min.

G30/G31 28/30 218 - 85 42 3000 950

1 RAPID

G20 20 - 286 115Y Reg. 3000 950

G30/G31 28/30 127 - 65 31 1750 600

2 SEMI-RAPID

G20 20 - 167 97Z Reg. 1750 600

G30/G31 28/30 73 - 50 27 1000 450

3 AUXILIARY

G20 20 - 95 72X Reg. 1000 450

G30/G31 28/30 277 - 98 60

4 TRIPLE RING

G20 20 - 362 135K Reg.

3800

3800

2100

2100

INJECTOR REPLACEMENT TABLE: MODELS THG40 - THG41

BURNERS

NORMAL

PRESSURE

NOMINAL

RATE

INJECTOR

DIAMETER

BY- PASS

DIAMETER

NOMINAL

HEAT

INPUT (W)

Nº

DESCRIPTION

GAS

mbar g/h L/h 1/100 mm 1/100 mm Max. Min.

G30/G31 28/30 218 - 85 40 2900 950

1 RAPID

G20 20 - 274 128 Reg. 2900 950

G30/G31 28/30 120 - 65 29 1650 600

2 SEMI-RAPID

G20 20 - 154 94 Reg. 1650 600

G30/G31 28/30 73 - 50 27 1000 450

3 AUXILIARY

G20 20 - 95 76 Reg. 1000 450

Page 10

6. User Instructions

1. To light the hotplate push in the appropriate control knob and turn anti-

clockwise to the large flame symbol (fig. 11).

2. Keep the knob depressed until the burner lights.

3. Turn the tap to the required setting.

NOTE: Matches can be used to light the burners in the event of a power failure.

SELECT THE RIGHT BURNER

Use an appropriately sized pan and with flat bottom for each burner (see the table

below and fig. 12).

When the contents of the pan start to boil, turn the knob down to reduced rate

position.

Always put a lid on the pan.

Burners

Ultra Rapid Triple ring Rapid Semirapid Auxiliary

Ø pans in cm 24-26 24-26 20-22 16-18 10-14

Page 11

Fault Finding Guide

Check the guide below if there is a problem with your hob.

UNEVEN OR YELLOW FLAME RATHER THAN BLUE.

Switch off and check the following points:

1. Are the burners fitted correctly?

2. Are the holes in the burner clear?

3. Check that no dust has fallen into the flame turning it yellow.

BURNER FAILING TO IGNITE?

Check that the power is turned on or that the fuse has not blown.

Make sure that the ignitor isn’t coated with food spillage.

SPARK BUT NO GAS?

Make sure the gas is turned on.

Check that the burner holes are not blocked.

SMELL GAS?

Check to see if any gas tap has been left on.

If they are off, switch off gas at mains and call a service agent.

DO NOT search with a naked flame, strike any matches or press ignitor.

STILL NOT WORKING?

Call the service agent.

Page 12

7. Calling for Service

Please consult your retailer in the first instance. If you experience difficulty

contact Customer Care Line.

Remember that you may be charged for the visit (even during the guarantee

period) if nothing is found to be wrong with your appliance, so always check to

make sure that you have not missed anything.

Service Cares:

Tel.: 0990 168299 (all calls will be charged at local rate)

Before contacting a service agent, please note the following details about

your appliance.

Date of Purchase _____________

Also note your Postcode _______

Model number ________________

Serial Number _______________

Loading...

Loading...