Page 1

The Mini-Eegor™ bender was designed with personal safety in mind. Nevertheless, when a

machine is powered with ten tons of force, certain precautions must be exercised to keep that force under control at

all times.

Fully Assemble All Load-bearing Pins:

Unless all pins are fully engaged in their respective sockets, the resulting misapplied loads can deform and destroy

the bender, with associated danger to attending personnel.

1. All four axles of the compression roller plate assembly must project through, or be flush with, both plates.

2. The top aluminum load arm must be fully seated so that three pins project through it with the chamfered roller

engaging the slot.

3. The U-strap pin must seat on its handle.

Do Not Attempt to Use Damaged Components:

Should any part of the Mini-Eegor™ bender become

damaged for any reason, replace it before resuming

bending operations. Failure to do so may jeopardize other

components and personal safety as well.

Keep Clear of Possible Pinch Points:

Relative motion between bender components could severely

pinch fingers or cut any objects wedged in between.

Use Standard Precautions with Hydraulic Hoses:

Couplings must be fully engaged to permit free flow of oil.

Be alert to avoid developing sharp bends or pinching

of hose.

Bend Only Conduit that Fits Freely into Shoe Grooves:

Oversize pipe that hangs up on the groove edges can

sometimes split a shoe.

Gardner

Bender

IMPORTANT RECEIVING INSTRUCTIONS: Visually inspect all components for shipping damage. If any shipping

damage is found, notify carrier at once. Shipping damage is NOT covered by warranty. The carrier is responsible for

all repair or replacement costs resulting from damage in shipment.

Instruction

Sheet

Mini-Eegor™

Hydraulic Bender

IMPORTANT USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken

to select the proper components and design to insure appropriate integration with your operations and existing

equipment and that all safety measures have been taken to avoid the risk of personal injury and property damage

from your application or system.

GB ELECTRICAL CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE,

MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact GB Electrical for guidance when you are

in doubt as to the proper safety precautions to be taken in designing and setting up your particular application.

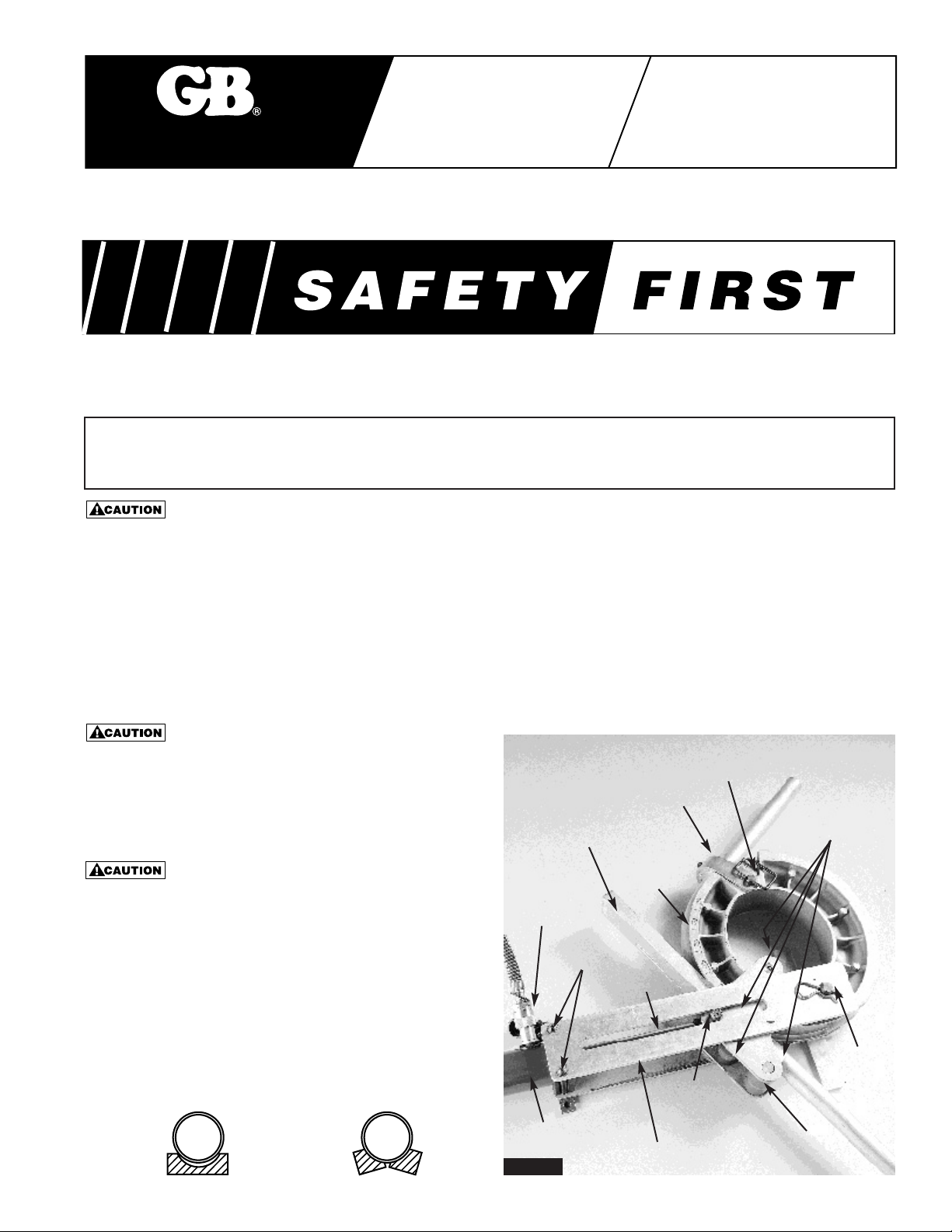

To Protect Your Warranty, Use Only Enerpac Hydraulic Oil

Hydraulic

Coupling

Follow Bar

Load Arm Pins

Hydaulic Cylinder

Rod Eye

Chamfered

Roller

U-strap

Top

Load Arm

Top Compression

Roller Plate

U-strap Pin

Load

Arm Pin

4 Compression

Roller Axles

Bending

Shoe

Mini-Eegor™ Bender

Figure 1

This: Results in this:

Page 2

2

Instructions

Description

The Mini-Eegor™ conduit bender hydraulically bends

Electrical Metallic Tubing (i.e., Thinwall or EMT),

Intermediate Metal Conduit (IMC), Rigid Aluminum and

Rigid Steel Conduit, all with the same shoe, in sizes 1”,

11⁄4”, 11⁄2”, and 2”. Any angle up to and including 90°

can be quickly bent in one set-up. Upon completion of

the operation, the bent pipe is hydraulically stripped

from the bending shoe. The Mini-Eegor™ is available

with a variety of hydraulic pumps, and can be purchased

without the 1” bending capability at a reduced cost.

Operation

1. Select a work location with a reasonably flat surface

and, preferably, free of sand, gravel, or other debris

that might interfere with the bending operation.

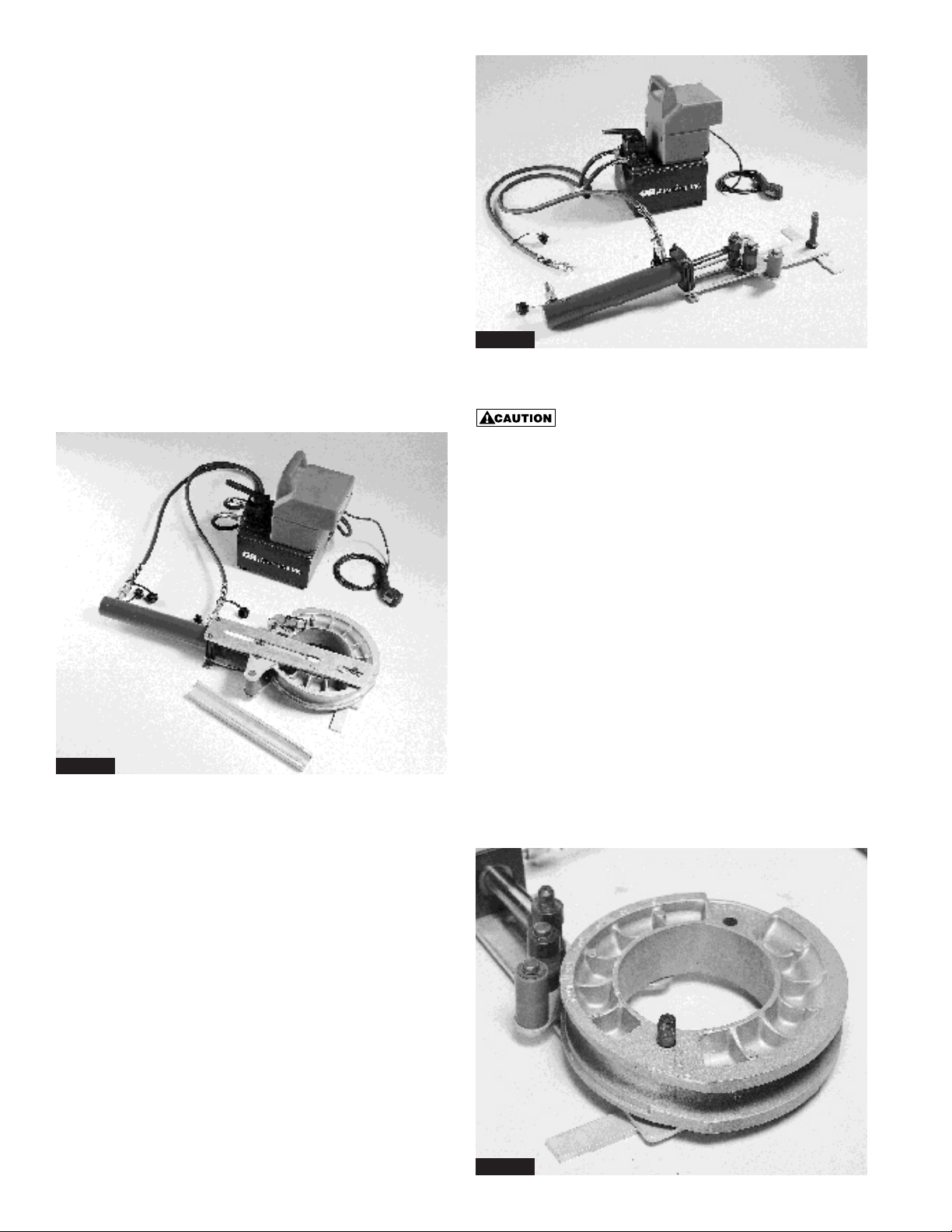

(See Figure 2.)

2. Select a bending shoe and follower shoe (or follow

bar), if required, for the size pipe to be bent. Follow

bars are required for 2” IMC and rigid conduit and for

2”, 1

1

⁄2” and 11⁄4” EMT. All shoes are identified with

the nominal conduit size marked on the shoe. It is

recommended, particularly when preparing to bend

unfamiliar brands of conduit, to first lay the pipe in

the groove of the shoe and follow bar to ensure that

the pipe fits without hanging up on the edges.

Note that each Mini-Eegor™ bending shoe has two

grooves, one for EMT and the other for IMC and rigid

conduit. The conduit type is engraved in its

corresponding shoe side to indicate the side you will use

when bending EMT, or IMC and rigid conduit. The

appropriate shoe side will make contact with the conduit

during bending. For bending the other type of conduit,

just flip the shoe over.

3. Connect the hydraulic hoses between the pump and

cylinder ports (see Figure 3).

Fully engage the couplers, and then be sure that the

threaded coupler sleeves bottom against their seats.

Failure to fully engage the couplers could result in oil

entrapment in one end of the cylinder which could

seriously over-pressurize the cylinder, resulting in

reduced product life and safety.

4. Lift off the top aluminum load arm and the top plate

of the roller assembly. The bending shoe must

swivel on the pivot pin and rest on the lower roller

plate close to the steel rollers.

5. Extend the cylinder plunger hydraulically until the

lower roller plate approaches the pivot pin closely

enough to support one end of the bending shoe.

6. Engage the bending shoe over the pivot pin (see

Figure 4).

Note: The 1” bending shoe (BZ259) has two pivot

holes. Be sure the pivot pin engages the hole

marked for the type conduit to be bent.

Otherwise, the shoe will not bend a full 90° bend.

Figure 2

Figure 3

Figure 4

Page 3

3

7. The bending shoe must swivel in a clockwise

direction about the pivot pin when bending pipe.

Therefore, when assembling the bender, swivel the

shoe counter clockwise to bring it into contact with

the steel rollers so that the top roller plate can be

assembled (see Figure 5).

8. Assemble the top roller plate sub-assembly (see

Figure 6). For easy assembly of the top roller plate

sub-assembly, first loosely engage the chamfered

roller atop the cylinder rod eye pin in its socket; then

engage the axle of the large steel roller into its

socket in the lower roller plate. The remaining axles

will then readily engage their respective sockets to

seat flush with the top plate surface.

Figure 7 illustrates the wrong way to assemble the

roller plates. The axle of the large steel roller inside of

the bending shoe (at right) is not seated in the lower

roller plate, as the gap under the roller indicates. Any

attempt to bend pipe with the roller plates in this position

will destroy the bender.

9. The top aluminum load arm can then be assembled

over the three projecting support pins and the

chamfered roller. Engage the pivot pin and

chamfered roller first, then lift lightly under the end

of the cylinder and the load arm will slip down over

the remaining pins in the cylinder support block

(see Figure 8).

Figure 8

Figure 5

Figure 6

Figure 7

The gap here indicates that the

axle is not seated in the lower

roller plate. Do not proceed with

bending until all axles are

properly engaged.

Do not attempt to bend pipe until all load bearing pins

are fully engaged in their respective sockets, or serious

damage may result.

10. Insert the pipe to be bent into the groove between

the rollers and the bending shoe (see Figure 9).

Page 4

4

4

12. The follow bar is next inserted between the pipe

and the rollers. The cylinder plunger should be fully

retracted, but not to the extent of locking up the

assembly. If a little slack is allowed so that the

bending shoe and frame components are loose, the

“start” end of the follow bar (with the ramp) can be

readily inserted until it contacts the U-strap.

11. The U-strap must now be assembled to clamp the

pipe to the bending shoe. Hydraulically retract the

cylinder plunger until the U-strap hole in the shoe

approaches the edge of the aluminum load arm

(bender frame). The greatest clearance for easiest

assembly exists when the U-strap hole is right next

to the load arm edge. Assemble the correct size

insert into the U-strap for the size pipe to be bent.

(No insert is required for the 2” size.) Assemble the

U-strap assembly over the conduit onto the shoe,

and insert the U-strap into the aligned holes until it

bottoms on the handle. Lay the handle flat against

the U-strap and oriented away from the bender

frame so that it will not contact the frame while

bending (see Figure 10).

13. The end of the follow bar must be inserted at least

as far as the rollers at the cylinder rod eye so that

all of the short steel rollers can ride on the follow

bar pressure surface (see Figure 11).

14. You are now ready to bend pipe. Actuate the

cylinder, and observe that the follow bar moves

together with the pipe as it passes through the roller

assembly (see Figure 12). If the follow bar does not

move, it has not been inserted far enough.

Immediately retract the cylinder plunger and re-seat

the follow bar so that it will move with the pipe.

15. Actuate the cylinder until the desired angle of bend

is achieved, as indicated by the bend angle scale

on the bending shoe as it emerges from under the

edge of the upper roller plate. A maximum 90°

bend is obtainable on all sizes and types of conduit

in one set-up with the Mini-Eegor™ (see Figure 13).

Figure 9

Figure 10

Figure 11

Figure 12

Insert pipe here

To prevent U-strap from damaging

conduit, be sure U-strap is completely

against the shoe prior to bending.

The end of the follow bar

must project past the contact

line of the short steel rollers.

Page 5

5

Note: Because electrical conduit varies somewhat from

lot to lot in size, material composition, hardness,

wall thickness, etc..., a general-purpose bend

angle scale cannot be established with any great

precision. Preparatory to doing any precision

bending, it is recommended that a trial bend be

made on each lot of conduit to establish a

correction value to be made to the bend angle

scale. The precise angle can then be marked on

the bending shoe at the leading edge of the

roller plate.

Maintenance of the Mini-Eegor™ Bender

Aside from conventional care of the hydraulic

components, very little maintenance of the Mini-Eegor™

bender is required. Removing sand and dirt from

grooves and moving parts will extend the bender life

and facilitate ease of operation. Lubricate rollers, when

needed, with molybdenum disulfide paste only (such as

Dow Corning’s Molykote No. G-n paste, or equivalent).

Note:

Graphite formulations are not equivalent lubrication.

Figure 13

Picture of a Finished Bend

Figure 14

16. To remove bent conduit from the Mini-Eegor™

upon completion of the bend, retract the cylinder

plunger, pull out the follow bar, and lift out the pipe (see

Figure 14).

Make sure follow bar doesn’t slide forward during

retraction.

Note: Removal of bent pipe may be easier if the

U-strap is first removed. Just pull the pin.

17. Offsets or other more complicated bends may

justify lifting off the top aluminum load arm and the

top roller plate before removing the pipe. Then,

just swivel the shoe away from the pipe for

easiest removal.

90° Stub-up and Kick Bend Instructions

Diagonal Distance (D) Chart

Rise

Bend Angle

(H) 15° 30° 45° 60° 90°

27

3

⁄4 42

13

⁄16 25⁄16 2

415

7

⁄16 85

11

⁄16 45⁄8 4

623

3

⁄16 12 81⁄2 615⁄16 6

830

15

⁄16 16 115⁄16 91⁄4 8

10 38

5

⁄8 20 141⁄8 119⁄16 10

12 46

3

⁄8 24 17 137⁄8 12

14 54

1

⁄16 28 1913⁄16 163⁄16 14

16 61

13

⁄16 32 225⁄8 181⁄2 16

18 69

9

⁄16 36 257⁄16 2013⁄16 18

20 77

1

⁄4 40 285⁄16 231⁄8 20

22 85 44 31

1

⁄8 253⁄8 22

24 92

3

⁄4 48 3315⁄16 2711⁄16 24

26 100

7

⁄16 52 363⁄4 30 26

28 108

3

⁄16 56 395⁄8 325⁄16 28

30 115

15

⁄16 60 427⁄16 345⁄8 30

Conduit “S” Set-back Dimension (inches)

Nominal Stub-ups Kick Bends

Type Size 90° 75° 60° 45° 30° 15°

1" 9

5

⁄16 713⁄16 69⁄16 51⁄2 41⁄2 35⁄8

11⁄4"11

1

⁄16 91⁄8 71⁄2 63⁄16 415⁄16 313⁄16

11⁄2"12

5

⁄8 107⁄16 85⁄8 71⁄8 53⁄4 41⁄2

2" 141⁄4 113⁄4 93⁄4 86

1

⁄2 51⁄16

1" 95⁄16 713⁄16 69⁄16 51⁄2 49⁄16 35⁄8

11⁄4"11

1

⁄4 95⁄16 73⁄4 67⁄16 53⁄16 41⁄16

11⁄2"12

5

⁄16 103⁄16 83⁄8 67⁄8 51⁄2 41⁄4

2" 1315⁄16 111⁄2 91⁄2 77⁄8 61⁄4 47⁄8

Mini-Eegor™ Set-back Chart

Rigid

&

IMC

EMT

(Thinwall)

Page 6

WARRANTY: GB ELECTRICAL, INC. warrants its

products against defects in workmanship and

materials for 1 year from date of delivery to user.

Chain is not warranted. Warranty does not cover

ordinary wear and tear, abuse, misuse, overloading,

altered products or use of improper fluid.

WARRANTY RETURN PROCEDURE: When

question of warranty claim arises, send the unit to the

nearest GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our

warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact GB Electrical

(414) 352-4160 for the name of the nearest GB

Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL

Service Center. The Service Center will provide complete and prompt service on all GB ELECTRICAL products.

GB Electrical, Inc.

An Applied Power Company

6101 N. Baker Road, Milwaukee, WI 53209

Phone: (414) 352-4160 FAX (414) 352-2377

RPS-0034 Rev. A 03/07

6

6

To Make a Stub-up or Kick Bend

1. Determine “H” dimension by measuring rise or

height needed. From “Diagonal Distance

Chart” on page 5, determine straight length of

pipe (D) needed to reach to desired turn-up

height (H) at desired bend angle.

2. Lay off this distance (D) from end of conduit

and make first mark.

3. From “Set-back Chart”, select proper set-back

dimension (S) corresponding to conduit size

and bend angle desired.

4. Measure distance (S) back from the first mark and make second mark (see figure above).

5. Place conduit in bender with second mark aligned with leading edge of U-strap (see figure above) and bend

conduit to desired angle.

D

D

S

1st Mark

2nd Mark (Position leading edge of U-Strap at this mark.)

Turn-up

or

Rise (H)

Angle

To Make an Offset Bend:

1. Make first mark at location determined either by edge of obstacle or by following “Kick Bend Instructions for

Mini-Eegor™ Benders” (page 5).

2. From the “Offset Chart” for the size of conduit to be bent, obtain measurement (B) for offset height (H) and bend

angle desired.

3. Make second mark at distance (B) beyond first mark and on opposite side of conduit as

illustrated below.

4. Place conduit in Mini-Eegor™ bender with first mark aligned with leading edge of U-strap (see figure below) and

make first bend to the desired angle.

5. Advance the bent conduit through the frame assembly of

the Mini-Eegor™ bender and rotate the conduit 180°, so

the second mark aligns with the leading edge of

the U-strap.

6. Complete offset by making second bend to the exact

same angle as the first bend.

Offset

or

Rise (H)

Angle

B

B

2nd Mark

1st Mark (on other side of conduit)

Measurement (B) (Inches)

Desired Offset

Offset Angle

➤

15° 30° 45° 60°

(H) Conduit

(Inches) Size

➤

1”, 11⁄4”, 11⁄2”, & 2" 1” 11⁄4”11⁄2”2”

27

11

⁄16 ––––––

415

3

⁄8 713⁄16 –––––

623

1

⁄8 1113⁄16 85⁄16 ––––

830

13

⁄16 1513⁄16 111⁄8 87⁄16 –––

10 38

9

⁄16 1913⁄16 1315⁄16 103⁄4 109⁄16 107⁄16 –

12 46

5

⁄16 2313⁄16 163⁄4 131⁄16 127⁄8 123⁄4 129⁄16

14 54 2713⁄16 199⁄16 153⁄8 153⁄16 151⁄16 147⁄8

16 613⁄4 3113⁄16 227⁄16 1711⁄16 171⁄2 173⁄8 173⁄16

18 691⁄2 3513⁄16 251⁄4 20 1913⁄16 1911⁄16 191⁄2

20 773⁄16 3913⁄16 281⁄16 225⁄16 221⁄16 22 2113⁄16

22 8415⁄16 4313⁄16 307⁄8 245⁄8 243⁄8 241⁄4 241⁄8

24 9211⁄16 4713⁄16 333⁄4 2615⁄16 2611⁄16 269⁄16 267⁄16

26 1003⁄8 5113⁄16 369⁄16 291⁄4 29 287⁄8 283⁄4

28 1081⁄8 5513⁄16 393⁄8 319⁄16 315⁄16 313⁄16 311⁄16

30 11513⁄16 5913⁄16 423⁄16 337⁄8 335⁄8 331⁄2 333⁄8

Loading...

Loading...