GB Hydraulic Knockout Sets User Manual

To prevent injury, keep hands away from the punch

and die while punching holes. NOTE: To ensure ease

of assembly, keep all threads clean and lightly oiled.

Do not drop objects on hydraulic hoses. An impact on

the hose will weaken internal strands and lead to

premature failure.

Avoid dropping the cylinder. During punch operation,

support the cylinder to prevent it from falling after

punching is completed.

To prevent thread damage, be sure punch is threaded

onto the stud until the stud extends beyond the punch.

The following general instructions and guides will be

helpful in determining if you have properly connected

your hydraulic circuit:

1. Be sure all hydraulic connections, hoses, fittings, etc.,

are of the proper pressure rating and are fully

tightened. Always use hoses and fittings specified by

the manufacturer to insure correct pressure rated

connections. Seal all NPT pipe connections with a

high-grade pipe thread sealer.

Teflon tape is an excellent thread sealer; however, if

not properly applied, pieces may enter the hydraulic

system and cause malfunctioning or damage.

2. DO NOT over-tighten connections. Connections need

only be snug and leak free. Over-tightening can cause

premature thread failure and may cause high pressure

fittings or castings to split at lower than-rated-capacity.

3. Tighten all hydraulic couplers fully. Loose coupler

connections will cause complete or partial blockage of

oil flow from the pump to the cylinder.

4. Be sure all hydraulic hoses and fittings are connected

to the proper inlet and outlet ports of the pump

and cylinders.

Gardner

Bender

IMPORTANT: RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

If any shipping damage is found, notify carrier at once.

Shipping damage is NOT covered by warranty. The carrier

is responsible for all repair or replacement costs resulting

from damage in shipment.

Instruction

Sheet

Hydraulic

Knockout Sets

IMPORTANT — USER SAFETY AND PROTECTION: In setting up systems to fit your operations, take care to select the

proper components and design to insure appropriate integration with your operations and existing equipment. Observe

safety measures to avoid the risk of personal injury and property damage from your application or system.

GB ELECTRICAL CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE, MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact GB ELECTRICAL for guidance when you are in

doubt as to the proper safety precautions to be taken in designing and setting up your particular application.

NOTE: The hydraulic cylinder in the knockout punch set

is built and tested in compliance with ANSI B30.1. Use

the cylinder to this specification.

To protect your warranty, use only Enerpac Hydraulic Oil.

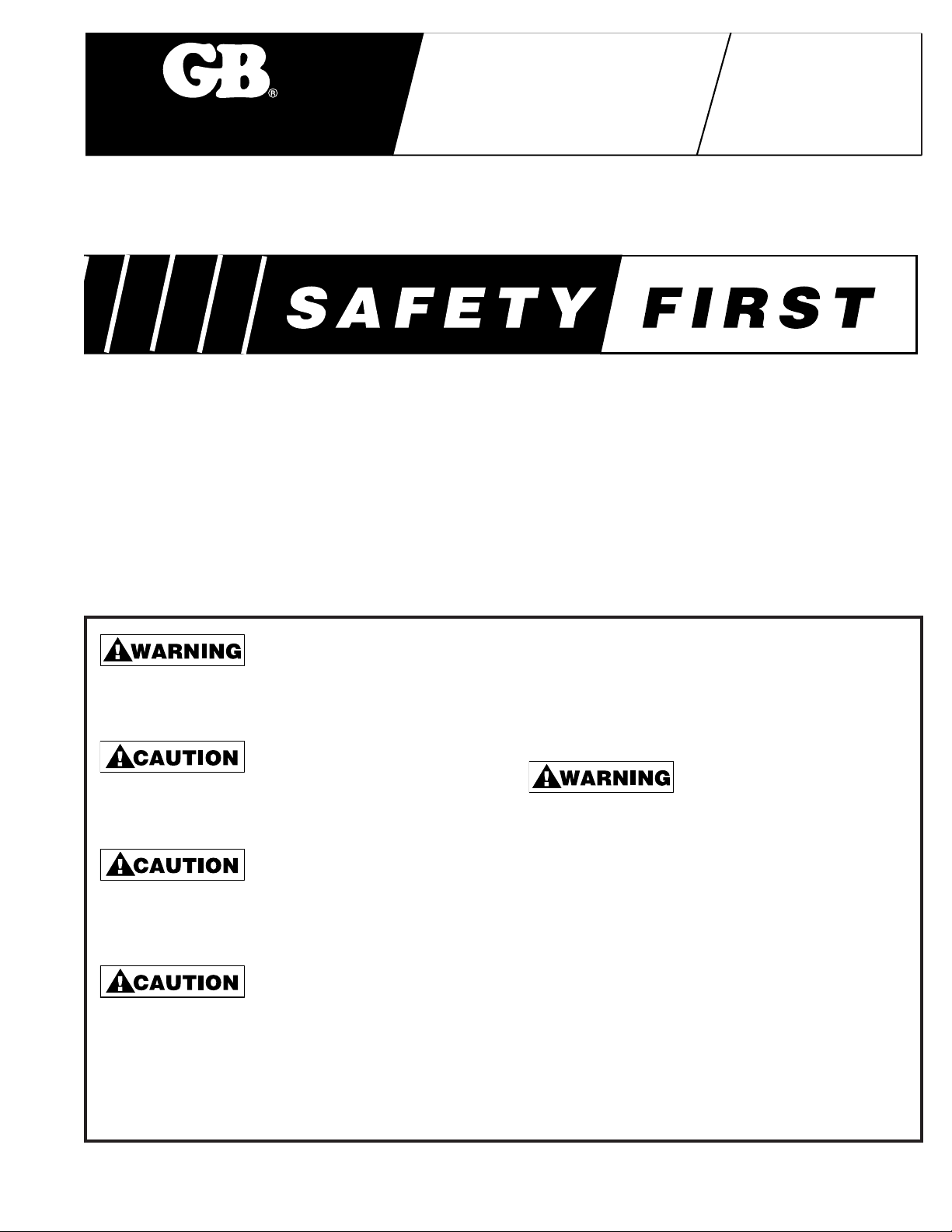

Lines on

die line up

with

cross lines

Center

Cross Lines

6" Long

Dotted line

indicates

knock-out

die

Drilling Guide Holes

1. Mark the center position; drill a 1⁄8” pilot hole. Enlarge

the hole with a 7⁄16” drill to provide pull rod clearance.

a. If working to close tolerances, mark the center

position by scribing cross lines shown in figure 1.

b. When assembling the punch to the pull rod, align

the cross marks with the four marks on the outer

die surface.

NOTE: If pre-punched knockouts are already in the

desired location, drilling a guide hole is not required.

2. For larger holes 3⁄4” to 3”, the 1⁄2” punch is used to

make the guide hole.

Punching 1⁄2" Holes

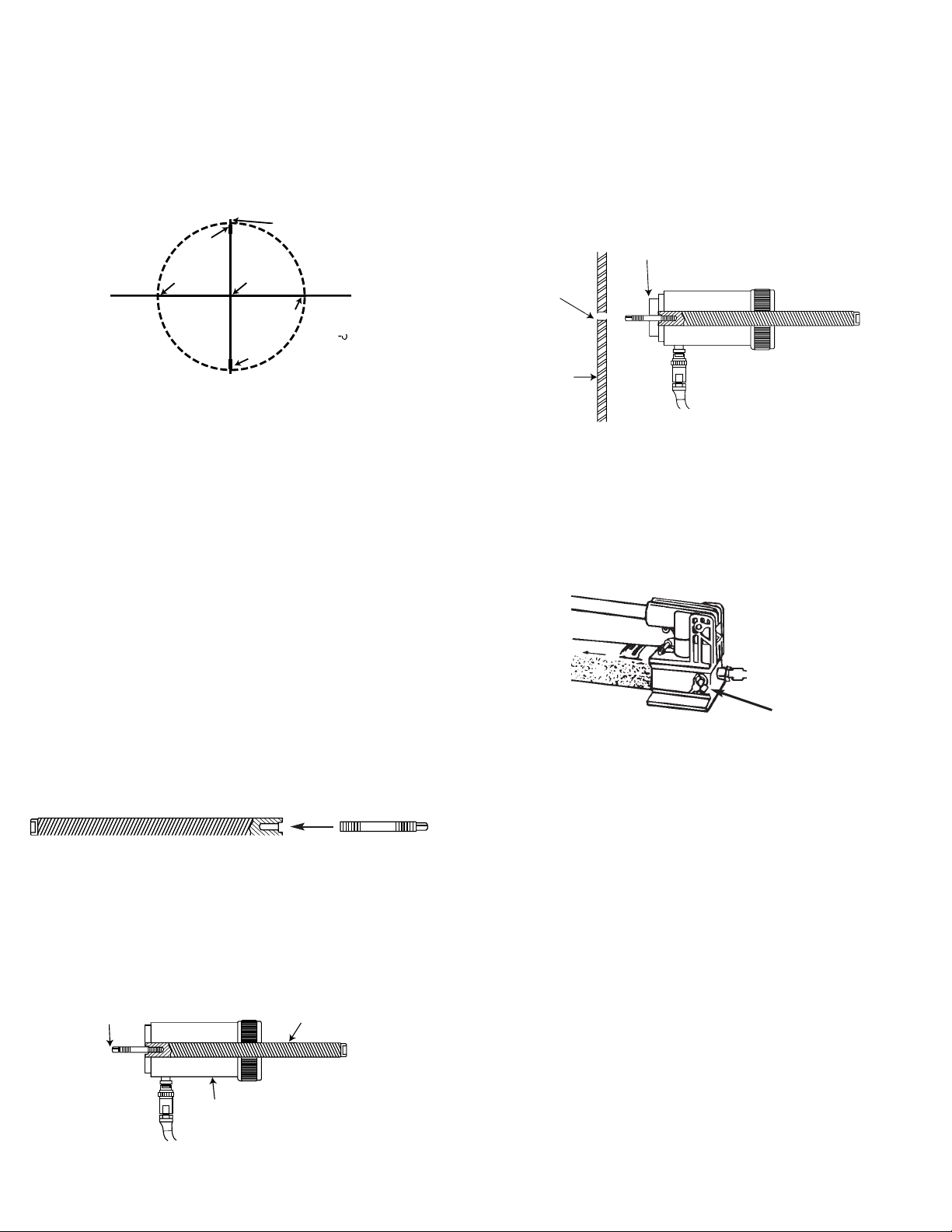

1. Thread the pull stud into the pull rod end until firmly

seated. (Figure 2)

NOTE: The pull stud is only used with the 1⁄2” punch.

The 1⁄2” punch is used to make guide holes for larger

punch sizes.

2. Attach the pull rod to the cylinder by inserting the pull

stud into the plunger opening and threading until the

pull stud extends beyond the coupler end of the

cylinder. (Figure 3)

Figure 2

Figure 3

3. Attach the hydraulic hose to the hand pump and to

the hydraulic cylinder.

4. Slide the 1⁄2” die over the pull stud, flat side toward

the cylinder.

5. Insert the pull stud through the guide hole (Figure 4).

Attach the 1⁄2” punch to the pull stud. Turn the punch

until it is completely threaded onto the pull stud.

6 Close the pump release valve by turning it clockwise

(Figure 5). Holding the punch set in position, work the

pump handle until the punch completely penetrates

the metal.

NOTE: When you use the hand pump it must sit level or

with the hose end down.

7. Remove the punch set from the hole. Turn pump

release valve counterclockwise to open. Remove punch

from pull stud. Slide the die off the pull stud. To remove

the slug, turn die over and tap lightly on a solid object.

Punching Holes 3⁄4" Through 3"

1. Drill a 7⁄16” or 1⁄2” pilot hole; install the 1⁄2” punch and

make guide hole. See “Punching 1/2” holes”.

2. Remove the 1⁄2” punch and die. Also remove the

pull stud.

3 Select the punch set needed. Slide the die over the

pull rod (Figure 6).

4. Place the pull rod into the 1⁄2” guide hole; thread the

punch onto the pull rod. Be sure the pull rod extends

beyond the punch.

5. Operate the hand pump until the punch penetrates

the metal. Open the pump release valve. Remove the

punch and die from the pull stud. Remove the slug.

Pump Release Valve

Figure 5

Drilling of Guide Hole

Figure 1

Thread through center hole of cylinder

Figure 4

Release Valve

2

Pull Rod

Cylinder

Pre-drill

7

⁄16” or 1⁄2”

Hole

Metal

Box

Die

Loading...

Loading...