Page 1

• Read this owners manual

thoroughly before use and save.

• Lea completamente este manual

del propietario antes del uso y

consérvelo como referencia.

• Avant de se servir du multimetre,

lire attentivement le present

manuel d’utilisation, et le

conserver.

GMT-318

Analog Multimeter

Owners Manual

Multímetro análoga

Manual del propietario

Multimètre analogue

Manuel d’utilisation

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 1

Page 2

2

1. Introduction

The GMT-318 is an Analog Multimeter

capable of measuring 6 functions on 14

ranges. A mirror scale is provided to

reduce the possibility of parallax errors.

Small lightweight and rugged construction.

This meter was designed for the

homeowner, hobbyist and professional

needing to make electrical and electronic

equipment measurements.

1.1 Meter Functions

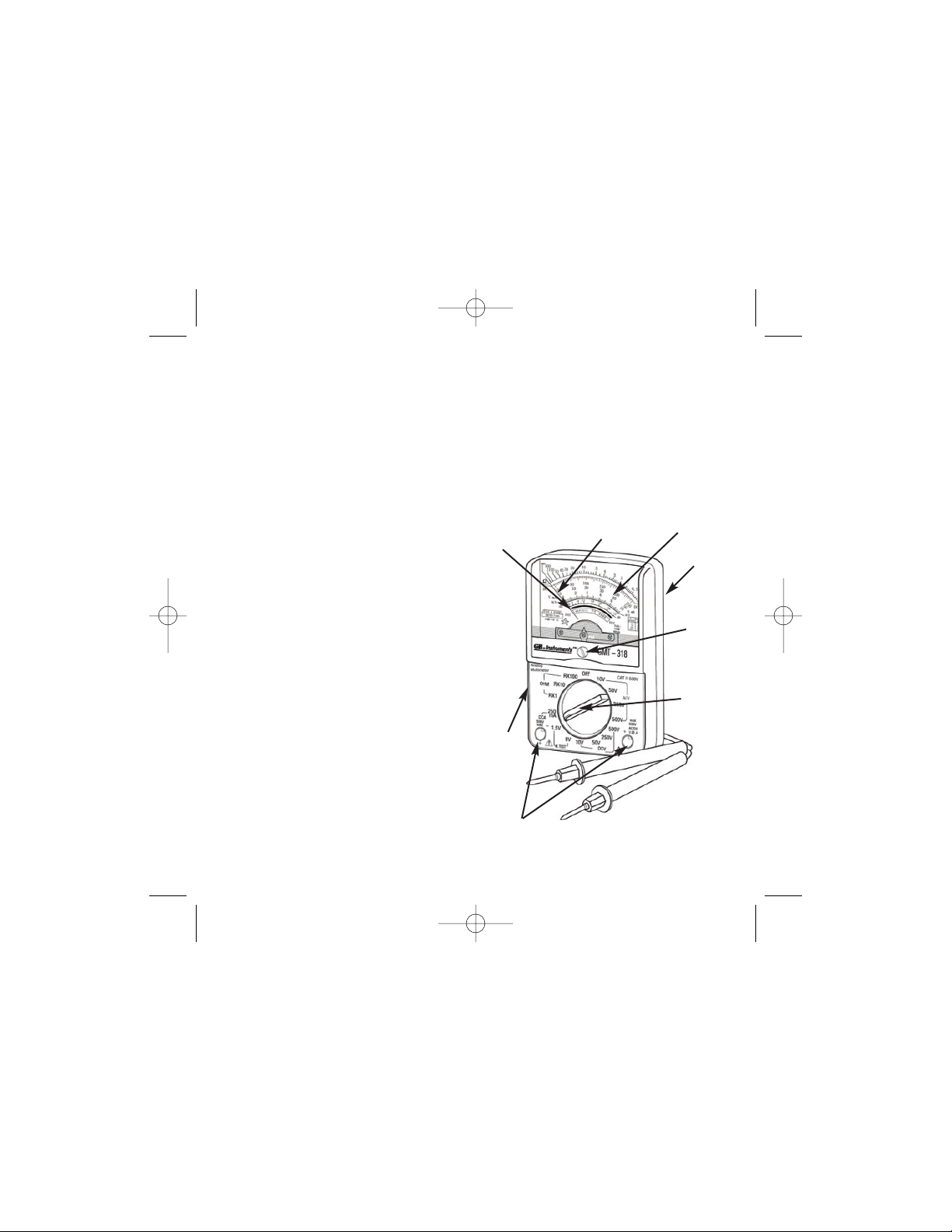

Needle

Analog

Scale

Mechanical

Zero

Adjust

Screw

Zero

Ohms

Adjust

ment

Input Jacks

Function/

Range

Selector

Switch

Contents

1. Introduction

1.1 Meter Functions

2. Specifications

2.1 For Your Safety

3. Operating Suggestions

3.1 Preliminary Adjustments

3.2 Internal Battery Condition

4. DC Voltage Measurement

5. DC Milliamp Measurement

6. AC Voltage Measurement

6.1 Wall Receptacles

7. Resistance/Continuity

Measurement

7.1 Extension Cords

7.2 Fuses

7.3 Switches

8. Decibel Measurement

(Transistor Gain)

9. Household Batteries

10. Battery and Fuse Replacement

11. Warranty

12. Disposal

1

Figure 1

Battery/

Fuse

Cover

Mirror

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 2

Page 3

Use extreme caution when

using this multimeter. Improper use of

this meter can result in severe damage to

property, severe personal injury or death.

Follow all instructions and suggestions in

this operators manual as well as normal

electrical safety precautions. Do not use

this multimeter if you are unfamiliar with

electrical circuits and proper test procedures.

2.1 For Your Safety

The marking “ ” on the multimeter represents

Caution, risk of electric shock.

The marking “ ” on the multimeter represents Caution,

risk of danger, important information, refer to the manual.

In order to find out the nature of the potential HAZARD

and any actions which have to be taken consult the

manual in all cases where “ ” is marked.

The marking “ ” on the multimeter represents

Functional earth terminal.

The marking “ ” on the multimeter represents

Equipment protected throughout by DOUBLE

INSULATION or REINFORCED INSULATION.

Measurement category II is for measurements

performed on circuits directly connected to the low

voltage installation. Examples are measurements

on household appliances, portable tools and

similar equipment.

1)Use extreme caution when checking

electrical circuits.

2)

Do not stand in wet or damp

work areas when working with electricity.

Wear rubber-soled boots or shoes.

3) Do not apply more voltage

4

2. Specifications

Ranges: 14 measuring ranges

DC Voltage: 10-50-250-500 Volts

AC Voltage: 10-50-250-500 Volts

DC Current (Milliamperes): 250mA

Resistance (Ohms): Rx1, Rx10, Rx100

Decibels: -20dB to +56dB on AC voltage ranges

Battery: 1.5, 9V

Accuracy: DC voltage, mA = ±4% full scale of range

AC voltage = ±5% full scale of range

Resistance = ±4° arc of scale length

Sensitivity: 2000 ohms per volt DC and AC

Function/Range Switch: 6 functions

15 positions

14 measuring ranges

Zero Ohms Adjustment Dial: Located on the left side of the housing;

adjustment dial is used to zero the needle

indicator on the ohms scale while

shorting the test leads together.

Mechanical Zero

Adjustment Screw: Located directly below the center of the

meter scale; adjust needle indicator to

read zero at the left side of the scale

before taking any measurement.

Mirrored Scale Plate: The mirror on the scale plate is used to

line up the needle with its reflection to

improve the reading accuracy by

preventing parallax error.

Recessed Input Jacks: Negative (-) input jack for black test lead,

positive (+) input jack for red test lead.

Fuse Type: F500mA, 250V, GB GF-0306

Power Source: One 1.5V AA size (non-rechargeable) battery

Test Lead Type: ETL, cETL, CE, CATII 500V 1A

Size (L X W X H): approx 109mm X 70mm X 33mm

Weight: approx 140g (including battery)

Agency Approvals: ETL cETL, CE, CATII 500V

Operating Temperature: 64F-77F (18°C-25°C)

Note: Accuracy is given for one year, at 23°C ±

2° RH<60%

This multimeter was designed to be safe at least under the following conditions

Indoor Use

Altitude: up to 2000m

Pollution degree: 2

Ingress Protection Degree: IP20

Important:

Read this operators manual thoroughly before

using this multimeter.This manual is intended

to provide basic information regarding this

multimeter and to describe common test

procedures which can be made with this unit.

Many types of appliance, machinery and

other electrical circuit measurements are

not addressed in this manual and should

be handled by experienced service

technicians.

3

!

WARNING

!

!

!

WARNING

!

WARNING

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 4

Page 4

or current than the set range of the

multimeter will allow.

4) Do not touch the metal

probes of the test leads when making a

measurement.

5) Replace worn test leads. Do not use test

leads with broken or tattered insulation. Only

test leads meeting ETL, cETL, CE CAT II

500V IA can be used in this multimeter.

6) Discharge a capacitor before measuring it.

7) Remove the test leads from the circuit being

measured as soon as the test is completed.

8) Do not measure voltage

when the function/range switch is set on

the resistance (ohms) or the current (mA)

settings. Never measure current when the

meter is set on the resistance range.

Never measure AC voltage when the

meter is set on DC voltage or DCmA.

Setting the meter on the incorrect function

may burn out some of the internal circuitry

and may pose a safety hazard.

3. Operating Suggestions

1) Set the function/range switch to the proper

position before making a measurement.

When the voltage or current is not known, it

MUST be determined that the capacity of

the selected range will handle the amount of

voltage or current in the circuit (see #3

under

For Your Safety

). Always start with the

highest range in the function. If the

reading falls within the range of a lower

setting, reset the function/range switch to

!

WARNING

!

WARNING

65

the appropriate setting for greater accuracy.

2) Avoid placing the meter in areas where

vibration, dust or dirt are present. Do not

store the meter in excessively hot, humid

or damp places. This meter is a sensitive

measuring device and should be treated

with the same regard as other electrical

and electronic devices.

3) Using the meter in areas with high magnetic

fields can result in inaccurate readings. For

greatest accuracy, lay the meter flat on a

non-metallic surface.

4) When the meter is not in use, keep the

function/range switch in the OFF position.

This keeps the needle indicator from

deflecting or ”bouncing” excessively.

5) When disconnecting the test leads from

the unit, always grasp the leads where the

input jacks meet the meter housing. Never

pull the leads out of the jacks by the

insulated wire or transport the meter using

the test leads as a carrying strap.

6) Never immerse the meter in water or

solvents. To clean the housing use a damp

cloth with a minimal amount of mild soap.

7) If the resistance (ohms) function of the

meter is not going to be used for a week or

more, remove the internal battery to avoid

potential leaks that may damage the unit.

3.1 Preliminary Adjustments

Fully seat the test leads in the correct input

jacks. If necessary, using a small flat tip

screwdriver, slowly turn the mechanical zero

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 6

Page 5

87

adjustment screw clockwise or counterclockwise until the needle indicator is directly over

the three black zeros at the left end of the scale.

Analog Meter:

Reading the Scale

General

The first step in reading the analog scale is to

align the needle with the scale. This is

achieved by locating the mirror on the scale.

Line the needle up with its reflection. When

the reflection is hidden by the needle, the

needle is properly aligned.

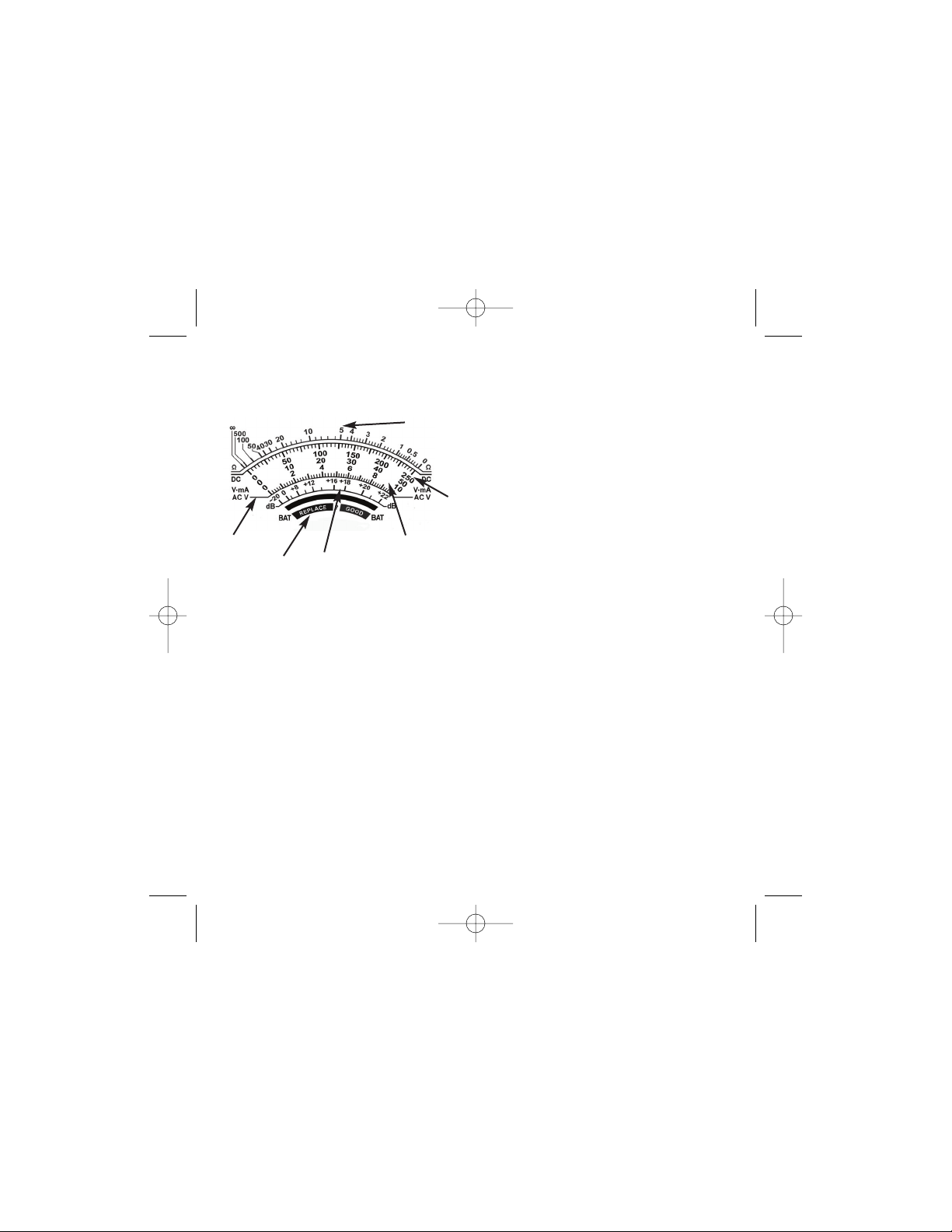

Resistance (Ohms - Ω)

Use the top scale for reading the resistance.

DC Voltage (V DC)

Use the middle scale directly below the

resistance scale. Match the dial setting to the

highest number on the scale. If the setting

does not match one of the numbers, use a

scale that can be easily multiplied to give the

setting (i.e. - for 500V, use the 50V scale and

multiply the reading by 10).

AC Voltage (V AC)

Use the same numbers and procedures as

used for the DC voltage setting, but use the

scale directly below the numbers.

DC Milliamps

Use the same scale and procedure as used

for the DC voltage setting.

Decibel Gain (dB) - see pg. 14

Use the scale marked dB to read decibels for

transistor gain. Use the chart at the right of

the scale for proper conversion.

3.2 Internal Battery Condition

Before making resistance or continuity tests,

check the condition of the internal battery. First

turn the function/range switch to the ohms Rx1

position. Short the test leads together and the

needle indicator should deflect to the right side

of the scale. Keep the test leads shorted

together while simultaneously turning the zero

ohms adjustment dial until the needle indicator

reads zero at the right side of the ohms

(green) scale. If the needle will not zero,

replace the battery with a new 1.5 volt AA size

non-rechargeable battery (see

Battery

Replacement

).

4. DC Voltage Measurement

1) Fully seat the test leads in the correct input

jacks, (-) black lead, (+) red lead.

2) Set the function/range switch to the

appropriate DC voltage range. If the voltage

is unknown, use the highest range. If the

Resistance

(Ohms)

Scale

DC Voltage

& Milliamps

Scale

Common Markings

for both the AC & DC

Voltage Scales

AC Voltage Scale

dB Scale for

Transistor Gain

Measurement

}

Battery Test Scale

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 8

Page 6

109

voltage applied falls within the range of a

lower setting, reset the function/range switch

to the appropriate setting for greater accuracy.

3) If the polarity of the circuit to be tested is

known, touch the black test lead to the

neutral side. If the polarity is unknown, touch

the test leads to opposite sides of the circuit.

If the needle indicator deflects to the left of

the scale, reverse the test leads.

Use the chart below as a guide to reading DC

voltage measurements:

DC V Read and

range following multiply

setting scale reading by:

10 0-10 1

50 0-50 1

250 0-250 1

500 0-50 10

5. DC Milliamp Measurement

1) Fully seat the test leads in the correct input

jacks, (-) black lead, (+) red lead.

2) Set the function/range switch to the 250

DCmA setting.

3) Touch the test leads to the circuit in series (in

line with the circuit) so that the circuit current

passes through the multimeter in order to

make the measurement. If the needle indicator

deflects to the left, reverse the test leads.

DC mA Read and

range following multiply

setting scale reading by:

250 0-250 1

Common DC Milliamperage

Measurements

It is important to point out that milliamps can

also be expressed as thousandths of an

Ampere; therefore 250 milliamps is 250

thousandths of one Amp.The 250mA function

of your multimeter is commonly used by

electronics repair technicians and hobbyists to

troubleshoot various low voltage circuits.

Although not normally used for electrical

troubleshooting around the home, this function

can be used to measure the milliamperage

draw of household items such as flashlights,

and other battery operated devices that do not

draw more than 250 mA. In fig. 2 the red (+)

test lead is hooked up to the (+) terminal of the

lantern battery while the black (-) test lead is

hooked up to the bulb.The meter will indicate

the milliamperage draw when the flashlight

switch is thrown in the ON position.

Do not apply voltage to the

test leads while the meter is set in the

milliamp range. See #8

For Your Safety.

6. AC Voltage Measurement

1) Fully seat the test leads in the correct input

jacks (-) black lead, (+) red lead.

2) Set the function/range switch to the

appropriate AC voltage range. If the

Figure 2

!

WARNING

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 10

Page 7

1211

voltage is unknown, use the highest range.

If the voltage applied falls within the range

of a lower setting, reset the function/range

switch to the appropriate setting for

greater accuracy.

3) Touch the test leads to the circuit under

test. With AC voltage, the polarity of the

test leads is not a factor.

Use the chart below as a guide to reading

AC voltage measurements:

AC V Read and

range following multiply

setting scale reading by:

10 0-10 1

50 0-50 1

250 0-250 1

500 0-50 10

Common AC Voltage Measurements

6.1 Wall Receptacles

If the receptacle is controlled by a switch, make

sure the switch is ON. Set the function/range

switch to 250V AC. Touch the test leads to the

“hot” and “neutral” slots of the receptacle (see

fig. 3A).The needle indicator should read 120V

AC on the 0-250 scale.To test for proper

grounding of the receptacle, touch one test lead

to the “hot” (narrow) side of the receptacle, and

the other test lead to the ground slot. The meter

should read 120V AC as before.

7. Resistance/Continuity Measurement

For resistance and continuity testing POWER

MUST BE OFF:

1) Fully seat the test leads in the input jacks (-)

black lead, (+) red lead.

2) Set the function/range switch to the desired

position and short the test leads together. Using

the zero ohms adjustment dial, slowly turn the

dial until the needle indicator reads -0- ohms at

the right end of the ohms scale. If the needle will

not zero, replace the internal battery with a new

1.5 volt AA size non-rechargeable battery (see

Battery Replacement

).

3) Touch the test leads to the resistance or nonenergized circuit to be measured. Measure the

value of the reading on the green ohms scale

and multiply the reading by 1/10/100. If you’re

making basic continuity tests, the needle

indicator should move all the way to the right

side of the ohms scale if continuity exists.

Note: When switching the unit back and forth

from ohms to other functions, always zero the

needle indicator before taking another reading.

Failure to zero the needle before taking

resistance/continuity measurements will result in

inaccurate readings.

Continuity tests are probably the most frequently

performed electrical troubleshooting procedures

around the home. ALWAYS REMEMBER THAT

CONTINUITY CHECKS ARE TO BE MADE

WITH THE POWER TO THE CIRCUIT

Figure 3

3A

3B

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 12

Page 8

1413

TURNED OFF. Polarity of the test leads is not a

factor in making continuity checks.

7.1 Extension Cords

Unplug the cord. Set the function/range switch to

the Rx1 position. Touch one of the test leads to

one of the metal prong ends of the cord, and

insert the other test lead in either one of the

receptacle slots on the other end of the cord,

making sure the test lead is making good contact

with the receptacle (see fig. 4). If the needle

indicator does not move to -0- ohms, insert the

test lead into the other receptacle slot, again

making sure of good contact. If the needle

indicator still does not move the cord has a break

and should be replaced.

7.2 Fuses

Note: With the power OFF, always remove a

fuse from its socket before testing it.With

cartridge fuses, touch the test leads to each

end of the fuse (see fig. 5). If the fuse is good,

the needle indicator will move to -0- ohms. If not,

replace the fuse. On plug-type fuses, touch the

the test leads on the bottom contact and the

other on the threaded metal contact (see fig. 6).

7.3 Switches

Cut off the power source to the switch. If

necessary, remove the switch.Turn the switch to

the ON position and touch the test leads to the

switch terminals (see fig. 7). If the switch is

good, the needle indicator will move to -0ohms. If not, replace the switch. On other

switches such as three-way light switches or

double pole double throw (ON-OFF-ON)

switches, each ON position will need to be

tested. Alternate the test leads between the

switch terminals to determine which two

terminals control that ON position.

8. Decibel Measurement

The decibel feature of this multimeter is for

transistor gain measurement in electronic circuits and should not be confused with audio

decibels. This function is used primarily by electronics technicians to measure the power gain

in transistors, and is rarely encountered in home

project applications.

1) Fully seat the test leads in the correct input

jacks, (-) black lead, (+) red lead.

Figure 4

Figure 6Figure 5

Figure 7

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 14

Page 9

1615

2) Set the function/range switch to any one of

the AC voltage ranges and read the decibel

measurement on the bottom (red) scale of

the faceplate. Based on the AC voltage range

you selected, you will need to compute the

actual measurement by using the decibel

conversion chart located at the bottom right

of the faceplate.

Important: For absolute decibel measurements,

circuit impedance must be at least 600 ohms. -0decibels = 1 milliwatt in a 600 ohm impedance

(equivalent to 0.775 volts across 600 ohms).

9. Household Batteries

Household batteries can be tested in either one

of two ways. For a good/bad check, set the

function/range switch to the 1.5V or 9V BAT

setting depending on which type of battery is to

be tested. Plug the red test lead into the jack

marked " V.Ω.A.". Touch the red (+) lead to the

(+) terminal of the battery and the black (-) lead

to the (-) terminal of the battery. Read the BAT

scale at the very bottom of the scale plate. The

scale will indicate if the battery is good,

questionable or should be replaced. To more

accurately measure the voltage value of

household batteries, set the function/range

switch to 10 VDC and touch the leads to the

battery as before. Read the 0-10 scale to

determine the condition of the battery.

10. Battery and Fuse Replacement

1) Remove the screw in the back cover of the

meter and carefully separate the back cover

from the front.

2) Note the polarity of the battery when

removing it from its compartment and replace.

3) Use F500mA 250V replacement fuses, GB

model GF-0306

4) Carefully replace the back cover and tighten

the screw. Do not overtighten, as this may

strip the threads in the meter housing.

11.Warranty

1 YEAR WARRANTY limited solely to repair

or replacement; no warranty of

merchantability or fitness for a particular

purpose. Product is warrantied to be free

of defects in materials and workmanship

for the normal life of the product. In no

event shall Gardner Bender be liable for

incidental or consequential damage.

12. Correct Disposal of this product

This marking indicates that this

product should not be disposed with

other household wastes throughout

the EU.To prevent possible harm to

the environment or human health

from uncontrolled waste disposal, recycle it

responsibly to promote the sustainable reuse

of material resources. To return your used

device, please use the return and collection

systems or contact the retailer where the

product was purchased. They can take this

product for environmental safe recycling.

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 16

Page 10

1817

Contenido

1. Introducción

1.1 Funciones del medidor

2. Especificaciones

2.1 Para su seguridad

3. Sugerencias de operación

3.1 Ajustes preliminares

3.2 Estado de la batería interna

4. Medición de voltaje DC

5. Medición de corriente continua

(mA)

6. Medición de voltaje AC

6.1 Receptáculos de pared

7. Medición de

resistencia/continuidad

7.1 Cables de extensión

7.2 Fusibles

7.3 Interruptores

8. Medición de decibeles

(ganancia del transistor)

9. Baterías (pilas) domésticas

10. Reemplazo de la batería y del

fusible

11. Garantía

12. Descarte correcto de este

producto

Aguja

Escala

analógica

Tornillo

de ajuste

mecánic

o a cero

Ajuste

a cero

ohmios

Enchufes

Selector

de

función/

escala

Figura 1

Tapa de

batería/

fusible

Espejo

1. Introducción

El GMT-318 es un multímetro analógico

capaz de medir 6 funciones en 14 rangos.

Se proporciona una escala de espejo para

reducir la posibilidad de errores de paralaje. Fabricación pequeña, liviana y robusta.

Este medidor fue diseñado para el dueño

de casa, aficionado y profesional que

necesita hacer mediciones eléctricas y de

equipo electrónico.

1.1 Funciones del medidor

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 18

Page 11

20

19

2. Especificaciones

Escalas: 14 escalas de medición

Voltaje DC: 10-50-250-500 voltios

Voltaje AC: 10-50-250-500 voltios

Corriente DC (miliamperios): 250mA

Resistencia (ohmios): Rx1, Rx10, Rx100

Decibeles: -20dB a +56dBb en escalas de voltaje AC

Batería: 1.5, 9V

Precisión: Voltaje DC, mA = ±4% de la escala completa

Voltaje AC = ±5% de la escala completa

Resistencia = ±4° grados de arco de longitud

de escala

Sensibilidad: 2000 ohmios por voltio de DC y AC

Selector de función/escala: 6 funciones

15 posiciones

14 escalas de medición

Perilla de ajuste a cero ohmios: Localizada en el lado izquierdo de la caja; la

perilla de ajuste se utiliza para poner a cero la

aguja en la escala de ohmios, mientras se pone

en cortocircuito los conductores de prueba.

Tornillo de ajuste mecánico a cero: Localizado directamente abajo del centro de la

escala del probador; ajuste la aguja a cero en el

lado izquierdo de la escala antes de tomar

cualquier medición.

Placa de escala con acabado El espejo en la placa de escala se utiliza para

de espejo: alinear la aguja con su reflejo para mejorar la

precisión de lectura al evitar el error de paralaje.

Enchufes empotrados: Enchufe negativo (-) para el conductor de

prueba negro, enchufe positivo (+) para el

conductor de prueba rojo.

Tipo de fusible: F500mA, 250V, GB GF-0306

Fuente de energía: Una batería de 1.5V tamaño AA (no recargable)

Tipos de conductores de prueba: ETL, cETL, CE, CATII 500V 1A

Tamaño (L X An X Al): aprox 109 mm X 70 mm X 33 mm

Peso: aprox 140 g (incluyendo la batería)

Aprobaciones de agencias: ETL cETL, CE, CATII 500V

Temperatura operativa: 18°C-25°C

Nota: La precisión se indica para un año, a

23°C ± 2° HR<60%

Este multímetro fue diseñado para ser seguro al menos bajo las siguientes condiciones

Para usar en interiores

Altitud: hasta 2000 m

Grado de contaminación: 2

Grado de protección de ingreso: IP20

Importante:

Lea este manual del operador completamente

antes de utilizar este multímetro. El fin de este

manual es proporcionar información básica

relacionada con este multímetro y describir

procedimientos básicos de prueba que pueden

realizarse con este probador. La medición de

muchos tipos de aparatos, maquinaria y

otros circuitos eléctricos no se menciona en

este manual y debe solicitarse la asesoría de

técnicos de servicio experimentados.

Sea sumamente precavido

cuando use este multímetro. El uso indebido

de este probador puede provocar daños

materiales graves, lesiones personales

graves o la muerte. Siga todas las

instrucciones y suger-encias de este manual

del operador, y observe además las

precauciones normales de seguridad

eléctrica. No utilice este multímetro si no está

familiarizado con los circuitos eléctricos y

procedimientos de prueba correctos.

2.1 Para su seguridad

La marca “ ” en el multímetro representa

Precaución, riesgo de choque eléctrico.

La marca “ ” en el multímetro representa

Precaución, peligro, información importante, consultar el manual. Con el fin de averiguar la naturaleza del RIESGO potencial y cualquier medida

que se deba tomar, consulte el manual en todos

los casos donde exista la marca “ ”.

La marca “ ” en el multímetro representa Terminal

de tierra funcional.

La marca “ ” en el multímetro representa Equipo

protegido totalmente mediante DOBLE AISLAMIENTO o AISLAMIENTO REFORZADO.

La categoría de medición II es para mediciones

realizadas en circuitos directamente conectados a la

instalación de bajo voltaje. Los ejemplos son

mediciones de electrodomésticos, herramientas

portátiles y equipo similar.

1) Sea sumamente precavido cuando revise

circuitos eléctricos.

2) Aléjese de las áreas

mojadas o húmedas cuando trabaje con

electricidad. Use botas o zapatos con

!

PRECAUCION

!

!

!

PRECAUCION

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 20

Page 12

22

21

suela de goma.

3) No aplique más voltaje o

corriente de lo permitido por la escala

seleccionada en el multímetro.

4) No toque las puntas

metálicas de los conductores de prueba

cuando realice mediciones.

5) Reemplace los conductores de prueba

desgastados. No use conductores de prueba

con aislamiento roto o agrietado. En este

multímetro solamente pueden usarse

conductores de prueba que cumplan con las

normas ETL, cETL, CE, CAT II 500V 1A .

6) Descargue un condensador antes de medirlo.

7) Retire los conductores de prueba del circuito

bajo prueba tan pronto como termine la prueba.

8) No mida el voltaje cuando

el selector de función/escala esté colocado en

una de las escalas de resistencia (ohmios) o

de corriente (mA). Nunca mida la corriente

cuando el selector de función/escala esté

colocado en la escala de resistencia (ohmios).

Nunca mida el voltaje de corriente alterna

cuando el selector de función/escala esté

colocado en la escala de voltaje de corriente

continua (DC V) o de corriente (mA).Colocar

el probador en la función incorrecta puede

fundir algunos de los circuitos internos, y

puede representar un riesgo de seguridad.

3. Sugerencias de operación

1) Coloque el selector de función/escala en la

posición correcta antes de efectuar una

medición. Cuando se desconozca el voltaje o

la corriente, DEBE determinarse que la

capacidad de la escala seleccionada acepte

la cantidad de voltaje o corriente del circuito

(vea el No.3 bajo la sección

Para su

seguridad

). Siempre empiece con la escala

más alta en la función. Si la lectura cae dentro

de la escala de una posición inferior, coloque

el selector de función/escala en la posición

correcta para obtener mayor precisión.

2) Evite colocar el probador en áreas donde exista

vibración, polvo o suciedad. No almacene

el probador en lugares excesivamente

calientes o húmedos. Este probador es un

dispositivo de medición sensible y debe

ser tratado con el mismo cuidado que otros

dispositivos eléctricos y electrónicos.

3) Utilizar el probador en zonas con campos

magnéticos altos puede dar lecturas

incorrectas. Para mayor precisión, coloque

el probador horizontalmente en una

superficie no metálica.

4) Cuando no use el probador, mantenga el

selector de función/escala en posición de

apagado (OFF). Esto protege la aguja contra

deflexión o “rebote” excesivo.

5) Cuando desconecte los conductores de

prueba del probador, siempre tómelos desde

donde los enchufes se encuentran con la caja

del probador.No tire de los conductores por el

cable aislado para sacarlos de los enchufes ni

lleve el probador utilizando los conductores

de prueba como tiras de transporte.

6) Nunca sumerja el probador en agua ni

solventes. Para limpiar la caja, utilice un

paño húmedo con una cantidad mínima de

jabón suave.

7) Si la función de resistencia (ohmios) del

probador no se va a utilizar por una semana o

!

PRECAUCION

!

PRECAUCION

!

PRECAUCION

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 22

Page 13

24

23

más, retire la batería interna para evitar fugas

potenciales que puedan dañar la unidad.

3.1 Ajustes preliminares

Asiente completamente los conductores de

prueba en los enchufes correctos. Si es

necesario, con un destornillador plano

pequeño, gire lentamente el tornillo de ajuste

mecánico a cero hacia la derecha o hacia la

izquierda, hasta que la aguja esté colocada

directamente sobre los tres ceros negros en

el extremo izquierdo de la escala.

Generalidades

El primer paso para leer la escala analógica es

alinear la aguja con la escala. Localice el espejo

y alinee la aguja con su reflejo. Cuando el reflejo

está tapado por la aguja, ésta está alineada

correctamente.

Resistencia (ohmios - Ω)

Utilice la escala superior para leer la resistencia.

Voltaje DC (“DC V”)

Utilice la escala de en medio directamente abajo

del escala de resistencia. Haga coincidir la

posición del selector con el número más alto de

la escala. Si la posición no coincide con uno de

los números, utilice una escala que se pueda

multiplicar fácilmente para dar la posición (por

ejemplo - para 500V, use la escala de 50V y

multiplique la lectura por 10).

Voltaje AC (“AC V”)

Utilice los mismos números y procedimientos que

los usados para la posición de voltaje DC, pero

use la escala que se encuentra directamente

abajo de los números.

Miliamperios DC

Utilice la misma escala y procedimientos que los

usados para la posición de voltaje DC.

Ganancia en decibeles (dB) (Ver la

pagina 30) Utilice la escala marcada dB para leer

decibeles de la ganancia del transistor.Utilice la

tabla del lado derecho de la escala para la

conversión correcta.

3.2 Estado de la batería interna

Antes de efectuar las pruebas de resistencia o

continuidad, revise el estado de la batería interna.

Primero coloque el selector de función/escala en

la posición de ohmios Rx1. Ponga en cortocircuito

los conductores de prueba uno con otro, y la

aguja debe desviarse al lado derecho de la

escala. Mantenga los conductores de prueba en

cortocircuito mientras gira simultáneamente la

perilla de ajuste a cero ohmios, hasta que la

lectura de la aguja sea cero en el lado derecho

de la escala de ohmios (verde). Si la aguja no se

pone en cero, reemplace la batería por otra nueva

de 1.5 voltios tamaño AA no recargable (vea

Reemplazo de la batería

).

4. Medición de voltaje DC

1) Asiente completamente los conductores de

prueba en los enchufes correctos: (-) conductor

Escala de

resistencia

(ohmios)

Escala de

voltaje DC y

miliamperios

Marcas comunes

para ambas escalas

de voltaje AC y DC

Escala de

voltaje AC

Escala de dB para

la medición de la

ganancia de transistores

}

Probador de

batería

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 24

Page 14

26

25

negro, (+) conductor rojo.

2) Coloque el selector de función/escala en la

escala de voltaje DC correcta. Si se desconoce

el voltaje, utilice la escala más alta.Si el voltaje

aplicado cae dentro de la escala de una

posición inferior, restablezca el selector de

función/escala a la posición correcta para

obtener mayor precisión.

3) Si se conoce la polaridad del circuito bajo

prueba, toque el conductor de prueba negro

con el lado neutro.Si se desconoce la

polaridad, toque los conductores de prueba

con los lados opuestos del circuito.Si la aguja

se desvía a la izquierda de la escala, invierta

los conductores de prueba.

Utilice la tabla siguiente como guía para leer las

mediciones de voltaje DC:

10 0-10 1

50 0-50 1

250 0-250 1

500 0-50 10

5.Medición de corriente continua

(mA)

1) Asiente plenamente los conductores de

prueba en las tomas de entrada correctas,

(-) conductor negro, (+) conductor rojo.

2) Ponga el interruptor de función/rango en la

posición 250 CCmA.

3) Toque el circuito con los conductores de

prueba en serie (en línea con el circuito) de

tal modo que pase la corriente del circuito por

el multímetro para efectuar la medición. Si el

indicador de aguja se desvía a la izquierda,

invierta los conductores de prueba.

250 0-250 1

Mediciones comunes de

corriente continua (en mA)

Es importante señalar que los miliamperios

también pueden expresarse como milésimas de

un amperio; por consiguiente, 250 miliamperios

son 250 milésimas de un amperio. La función

250 mA de su multímetro se utiliza comúnmente

por técnicos de reparaciones de aparatos

electrónicos y aficionados para resolver fallas de

varios circuitos de voltaje bajo.Aunque no lo

utilizan normalmente los que reparan

desperfectos eléctricos en el hogar, esta función

puede usarse para medir el consumo de corriente

(en miliamperios) de aparatos domésticos tales

como linternas, y otros aparatos que funcionan

con baterías que no consumen más de 250 mA.

En la figura 2, el conductor de prueba rojo (+)

está conectado al terminal (+) de la batería de la

linterna, mientras que el conductor de prueba

negro (-) está conectado al bulbo.El probador

indicará el consumo de corriente (en

miliamperios) cuando el interruptor de la linterna

se coloca en posición de encendido (ON).

Posición de

la escala

“DC V”

Lea la

siguiente

escala

y multiplique

la lectura por:

Posición

de rango

CC mA

Lea la

escala

siguiente

Y multiplique

la lectura por:

Figura 2

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 26

Page 15

2827

No aplique voltaje a los

conductores de prueba mientras el

probador esté colocado en la escala de

miliamperios. Vea el punto No. 8 bajo

Para

su seguridad

.

6. Medición de voltaje AC

1) Asiente plenamente los conductores de

prueba en las tomas de entrada correctas,

(-) conductor negro , (+) conductor rojo.

2) Coloque el selector de función/escala en la

escala de voltaje AC correcta. Si se

desconoce el voltaje, utilice la escala más

alta. Si el voltaje aplicado cae dentro de la

escala de una posición inferior, restablezca

el selector de función/escala a la posición

correcta para obtener mayor precisión.

3) Toque los conductores de prueba con el circuito

bajo prueba. Con el voltaje AC, la polaridad de

los conductores de prueba no es importante.

Utilice la tabla siguiente como una guía para

la lectura de las mediciones de voltaje AC:

10 0-10 1

50 0-50 1

250 0-250 1

500 0-50 10

Mediciones comunes de voltaje AC

6.1 Receptáculos de pared

Si el receptáculo se controla por un interruptor,

asegúrese de que el interruptor esté en posición

de encendido (ON). Coloque el selector de

función/escala en la posición de 250 “AC V”.

Toque los conductores de prueba con las ranuras

“energizada” y “neutral”del receptáculo (vea la fig.

3A). La lectura de la aguja debe ser de 120 voltios

AC en la escala de 0-250. Para probar que el

receptáculo esté debidamente conectado a tierra,

toque uno de los conductores de prueba con el

lado “energizado” (angosto) del receptáculo, y el

otro conductor de prueba con la ranura

conectada a tierra. La lectura del probador debe

ser de 120 voltios AC, como antes.

7. Medición de

resistencia/continuidad

Para las pruebas de resistencia y continuidad,

LA CORRIENTE ELECTRICA DEBE ESTAR

APAGADA.

1) Asiente plenamente los conductores de

prueba en las tomas de entrada correctas,

(-) conductor negro, (+) conductor rojo.

2) Coloque el selector de función/escala en la

posición adecuada de ohmios y ponga en

cortocircuito los conductores de prueba

uno con otro. Con la perilla de ajuste a

cero ohmios, gire lentamente la perilla

hasta que la lectura de la aguja sea de -0ohmios en el extremo derecho de la escala

de ohmios. Si la aguja no se pone en cero,

reemplace la batería por otra nueva de 1.5

voltios tamaño AA no recargable (vea

Reemplazo de la batería

).

3) Toque los conductores de prueba con la

resistencia o el circuito no energizado bajo

prueba. Mida el valor de la lectura en la

escala verde de ohmios y multiplique la

lectura por 1/10/100. Si efectúa pruebas

!

PRECAUCION

Posición de

la escala

“AC V”

Lea la

siguiente

escala

y multiplique

la lectura por:

Figura 3

3A

3B

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 28

Page 16

30

29

básicas de continuidad, la aguja debe

moverse hasta el extremo del lado derecho

de la escala de ohmios si existe continuidad.

Nota: Cuando cambie el probador de ohmios a

otras funciones o viceversa, siempre coloque la

aguja en cero antes de tomar otra lectura. Si no

se coloca la aguja en cero antes de tomar las

mediciones de resistencia/continuidad, la lectura

será imprecisa.

Las pruebas de continuidad son los

procedimientos de resolución de fallas que

probablemente se efectúan con más frecuencia

en el hogar. RECUERDE SIEMPRE QUE LAS

PRUEBAS DE CONTINUIDAD DEBEN

EFECTUARSE CON LA CORRIENTE

ELECTRICA APAGADA. Cuando se efectúan

pruebas de continuidad, la polaridad de los

conductores de prueba no es importante.

7.1 Cables de extensión

Desenchufe el cable.Coloque el selector de

función/escala en la posición de ohmios Rx1.

Toque uno de los conductores de prueba con uno

de los extremos de las espigas metálicas del cable,

e inserte el otro conductor de prueba en cualquiera

de las ranuras del receptáculo en el otro extremo

del cable, asegurándose de que el conductor de

prueba haga buen contacto con el receptáculo (vea

la fig. 4).Si la aguja no se mueve a -0- ohmios,

introduzca el conductor de prueba en la otra ranura

del receptáculo, de nuevo asegúrese de que haga

buen contacto. Si la aguja aún no se mueve,

el cable está roto y deberá reemplazarse.

7.2 Fusibles

Nota: Con el suministro eléctrico apagado (OFF),

siempre retire un fusible del zócalo antes de

probarlo. Con los fusibles de cartucho, toque los

conductores de prueba con cada extremo del

fusible (vea la fig. 5). Si el fusible está en buen

estado, la aguja se moverá a -0- ohmios. De lo

contrario, reemplace el fusible.En los fusibles de

tipo tapón, toque uno de los conductores de prueba

con el contacto inferior y el otro conductor de prueba

con el contacto metálico roscado (vea la fig.6).

7.3 Interruptores

Corte el suministro eléctrico al interruptor. Si es

necesario, retire el interruptor.Coloque el interruptor

en la posición de encendido (ON), y toque los

conductores de prueba con los terminales del

interruptor (vea la fig. 7).Si el interruptor está en

buen estado, la aguja se moverá a -0- ohmios.

De lo contrario, reemplace el interruptor.

8. Medición de decibeles

La función de decibeles de este multímetro es

para la medición de la ganancia del transistor

en circuitos electrónicos, y no debe confundirse

con decibeles auditivos. Esta función la utilizan

principalmente los técnicos en electrónica para

medir la ganancia de energía en transistores, y

raramente se utiliza en el hogar.

1) Asiente plenamente los conductores de

prueba en las tomas de entrada correctas,

(-) conductor negro , (+) conductor rojo.

Figura 4

Figura 6

Figura 5

Figura 7

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 30

Page 17

32

31

2) Coloque el interruptor de función/escala en

cualquiera de las escalas de voltaje AC y lea

la medición de decibeles en la escala inferior

(roja) de la carátula. Según la escala del

voltaje AC que seleccionó, necesitará

calcular el valor real utilizando la tabla de

conversión de decibeles localizada en el lado

inferior derecho de la carátula.

Importante: Para obtener las medidas absolutas

de decibeles, la impedancia del circuito debe ser

al menos de 600 ohmios. -0- decibeles = 1

milivatio en una impedancia de 600 ohmios

(equivalente a 0.775 voltios, 600 ohmios).

9. Baterías (pilas) domésticas

Las baterías caseras pueden probarse usando

uno de dos métodos. Para revisar si están

buenas o malas, ponga el interruptor de

función/rango en la posición 1.5V o 9V BAT

dependiendo de cuál tipo de batería se vaya a

probar.Inserte el conductor de prueba rojo en la

toma marcada " V.Ω.A.". Toque con el

conductor rojo (+) el terminal (+) de la batería y

con el conductor negro (-) el terminal (-) de la

batería. Lea la escala BAT en la parte inferior de

la placa de escala. La escala debe indicar si la

batería está buena, dudosa o si debe

cambiarse. Para medir más precisamente el

valor de voltaje de las baterías caseras, ponga

el interruptor de función/rango en 10 VCC y

toque la batería con los conductores como

antes. Lea la escala de 0-10 para determinar el

estado de la batería.

10. Reemplazo de la batería y del

fusible

1) Retire el tornillo en la tapa posterior del

probador, y separe cuidadosamente la

tapa posterior de la delantera.

2) Observe la polaridad de la batería cuando la

retire de su compartimiento y reemplácela.

3) Use los fusibles de recambio con núm

ero

de catálogo GB GF-0306.

4) Reemplace cuidadosamente la tapa

posterior y apriete el tornillo. No apriete el

tornillo de más, porque esto puede dañar

las roscas de la caja del probador.

11. Garantía

GARANTÍA LIMITADA DE 1 AÑO limitada

exclusivamente a la reparación o reemplazo;no

se ofrece garantía de comerciabilidad ni id

oneidad para ningún fin en particular. El

producto está garantizado como exento de

defectos en materiales y mano de obra durante

la vida útil normal del mismo. Bajo ninguna

circunstancia será Gardner Bender responsable

de daños fortuitos o consecuentes.

12. Descarte correcto de este

producto

Esta marca indica que este producto no

debe descartarse con otros desechos

domésticos en ninguna parte de la UE.

Para prevenir posible daño al medio

ambiente o a la salud humana con

motivo del descarte descontrolado de

desechos, recíclelo de manera responsable

para promover la reutilización sustentable de los

recursos materiales. Para devolver su

dispositivo usado, utilice los sistemas de

devolución y recolección o póngase en contacto

con la tienda donde compró el producto.

Pueden recibir este producto para reciclarlo de

manera segura para el medio ambiente.

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 32

Page 18

34

33

Table des Matières

1. Présentation

1.1 Fonctions du multimètre

2. Caractéristiques

2.1 Sécurité

3. Conseils d’utilisation

3.1 Réglages préliminaires

3.2 Etat de la pile interne

4. Mesure de tension c.c.

5. Mesure d’intensité c.c. (mA)

6. Mesures de tension c.a.

6.1 Prises murales

7. Mesures de

résistance/continuité

7.1 Rallonges

7.2 Fusibles

7.3 Commutateurs

8. Mesure des décibels

(gain des transistors)

9. Piles d’usage domestique

10. Remplacement de la pile et du

fusible

11. Garantie

12. Façon appropriée de jeter ce

produit

1. Présentation

Le GMT-318 est un multimètre analogique

capable de mesurer 6 fonctions sur 14 plages.

Une échelle à miroir est fournie afin de réduire

la possibilité d'erreurs de parallaxe. Compact,

léger et résistant. Ce multimètre a été conçu

pour les propriétaires de maison, les

hobbyistes et les professionnels ayant besoin

d'effectuer des mesures d'équipement

électrique et électronique.

1.1 Fonctions du multimètre

Aiguille

Echelle

analogique

Vis de

réglage

mécaniq

ue du

zéro

Réglage

du zéro

de

gamme

d'ohms

Jacks d'entrée

Sélecteur

fonctions/

gammes

Couvercle

de pile/

fusible

Miroir

Figure 1

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 34

Page 19

36

35

2. Caractéristiques

Gammes : 14 gammes de mesure

Tension c.c.: 10-50-250-500 V

Tension c.a.: 10-50-250-500 V

Intensité c.c. (milliampères) : 250 mA

Résistance(ohms) : Rx1, Rx10, Rx100

Décibels : -20 dB à +56 dB sur gammes de tension c.a.

Pile : 1.5, 9V

Précision : Tension c.c., mA = ±4 % du total de

l’échelle de gamme

Tension c.a.= ±5 % du total de l’échelle

de gamme

Résistance = arc de ±4° de l’échelle totale

Sensibilité : 2000 ohms par volt c.c.et c.a.

Sélecteur fonctions/gamme : 6 fonctions

15 positions

14 gammes de mesure

Molette de réglage du zéro Situé sur le côté gauche du boîtier, cette molette

de gamme d’ohms : permet de mettre l’aiguille sur le zéro d’une

gamme d’ohms lorsque les deux sondes sont

mises en contact l’une avec l’autre.

Vis de réglage mécanique du zéro : Située au-dessous de l’échelle, au centre,

cette vis permet de mettre l’aiguille sur le

zéro de la gauche de l’échelle avant de

prendre toute mesure.

Miroir d’échelle : Le miroir de l’échelle permet d’aligner

l’aiguille sur sa propre réflexion afin

d’obtenir des mesures plus précises en

évitant les erreurs de parallaxe.

Jacks d’entrée en retrait : Jacks d’entrée négative (-) pour la sonde noire

et d’entrée positive (+) pour la sonde rouge.

Format de fusible : F500mA, 250V, GB GF-0306

Source d'alimentation : Une pile de format AA de 1,5V

(non rechargeable)

Type de fil d'essai : ETL, cETL, CE, CATII 500V 1A

Dimensions (Lo X La X H) : environ 109 mm X 70 mm X 33 mm

Poids : environ 140 g (pile comprise)

Approbations d’organismes : ETL cETL, CE, CATII 500V

Température de fonctionnement : 18 °C à 25 °C

Remarque : La précision et donnée pour un an,

à 23 °C ± 2 ° HR<60 %

Le multimètre a été conçu pour être sécuritaire tout au moins dans les conditions suivantes

Pour utilisation à l'intérieur

Altitude : jusqu'à 2000 m

Degré de pollution : 2

Indice de protection d'entrée : IP20

Important:

Avant d'utiliser le multimètre, lire

attentivement ce manuel. Il contient les

caractéristiques de l'instrument et les

contrôles courants qu'il permet d'effectuer. Le

contrôle d'appareils électroménagers, de

machines et autres circuits électriques

dont ne traite pas ce manuel doit être

confié à des techniciens d'entretien

expérimentés.

Utiliser ce

multimètre avec la plus grande prudence.

Un usage incorrect pourrait résulter en

des dommages matériels importants et

des blessures graves ou mortelles. Suivre

toutes les instructions et recommandations

de ce manuel d’utilisation et prendre toutes

les précautions normales concernant

l’électricité. Ne pas utiliser ce multimètre

sans être familiarisé avec les circuits

électriques et les méthodes de test

appropriées.

2.1 Sécurité

La marque « » sur le multimètre représente

Avertissement, risque de choc électrique.

La marque « » sur le multimètre représente

Avertissement, risque de danger, information

importante, reportez-vous au manuel. Pour

connaître la nature du DANGER potentiel et les

actions qui doivent être prises, consulter le manuel

dans tous les cas où « » apparaît.

La marque « » sur le multimètre représente

Borne de mise à la terre fonctionnelle.

La marque « » sur le multimètre représente

Équipment protégé de bout en bout par une DOUBLE ISOLATION ou une ISOLATION RENFORCÉE.

La catégorie de mesure II est pour les mesures

effectuées sur les circuits directement branchés à

une installation de basse tension. Par exemple, les

mesures prises sur des appareils domestiques, des

outils portatifs et de l'équipement semblable.

1) Faire preuve d'une prudence extrême lors

de la vérification des circuits électriques.

2) Eviter tout contact

!

AVERTISSEMENT

!

!

!

AVERTISSEMENT

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 36

Page 20

38

37

avec de l'eau ou une surface humide lors du

travail sur un circuit électrique.Porter des bottes

ou des chaussures à semelle de caoutchouc.

3) N'appliquer ni tension

ni courant supérieurs à la limite de la gamme

de mesure permise par le multimètre.

4) Ne pas toucher les

sondes d'essai métalliques pendant une

mesure.

5) Remplacer les sondes d'essai usées. Ne

pas utiliser de fils d'essai dont l'isolation est

coupée ou déchiquetée. Seuls les fils d'essai

ETL, cETL, CE CAT II 500V IA peuvent

être utilisés sur ce multimètre.

6) Décharger un condensateur avant de le

contrôler.

7) Retirer les sondes d’essai du circuit testé

dès que la mesure est terminée.

8) Ne pas mesurer la

tension lorsque le sélecteur

fonctions/gammes est sur une gamme de

résistance (ohms) ou d’intensité (mA). Ne

pas mesurer l'intensité lorsque le sélecteur

fonctions/gammes est sur une gamme de

résistance (ohms). Ne pas mesurer une

tension c.a. lorsque le sélecteur

fonctions/gammes est sur une gamme de

tension c.c. (DC V) ou intensité (mA). Un

réglage incorrect de l’appareil peut griller

certains circuits internes et être dangereux.

3. Conseils d’utilisation

1) Avant de procéder à toute mesure, régler le

sélecteur fonctions/gammes sur la position

voulue. Si la tension ou l'intensité du courant

est inconnue, S'ASSURER que la gamme

choisie a une limite nominale suffisante pour

permettre de mesurer la tension ou

l'intensité du circuit (voir Sécurité n° 3).

Toujours commencer avec la gamme la plus

élevée d’une fonction.Si la valeur mesurée

appartient à une gamme inférieure, mettre le

sélecteur fonctions/gammes sur la position

permettant une plus grande précision.

2) Eviter d'exposer le multimètre aux vibrations,

à la poussière et à la saleté. Le ranger à l'abri

de la chaleur et de l'humidité excessives.Cet

instrument de mesure délicat doit être traité

avec le même soin que les autres appareils

électriques ou electroniques.

3) L’utilisation du multimètre en présence de

champs magnétiques puissants peut

fausser les mesures. Pour un maximum de

précision, poser l’appareil à plat sur une

surface non métallique.

4) Lorsque le multimètre n’est pas en usage,

laisser le sélecteur fonctions/gammes sur

la position OFF (arrêt). Ceci empêche

l’aiguille d’osciller ou de “fouetter”

excessivement.

5) Pour débrancher les sondes d'essai du

multimètre, toujours les saisir au point de

contact avec le boîtier du multimètre. Ne

jamais tirer sur les fils pour les débrancher des

jacks d’entrée et ne jamais transporter le

multimètre en le tenant par les sondes d'essai.

6) Ne jamais immerger le multimètre dans de

l’eau ou des solvants. Nettoyer le boîtier

avec un chiffon humide et un minimum de

savon doux.

7) Si la fonction de résistance (ohms) du

multimètre ne doit pas être utilisée

pendant une semaine ou plus, retirer la

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 38

Page 21

40

39

pile interne pour éviter les risques de fuites

qui pourraient endommager l’appareil.

3.1 Réglages préliminaires

Insérer les connecteurs des fils de sonde à

fond dans les jacks d’entrée appropriés. Si le

réglage du zéro est nécessaire, tourner lentement la vis de réglage mécanique dans un

sens ou dans l’autre, de façon à placer l’aiguille exactement au-dessus des trois zéros noirs

de l’extrémité gauche de l’échelle.

Multimètre analogique : lecture de

l’échelle

Généralités

La première étape d’utilisation d’un

multimètre analogique est d’aligner l’aiguille

sur l’échelle de mesure. Localiser le miroir et

aligner l’aiguille sur sa propre réflexion.

Lorsque la réflexion est cachée par l’aiguille,

cette dernière est correctement alignée.

Résistance (Ohms - Ω)

Utiliser l’échelle du haut pour mesurer la

résistance.

Tension c.c. (“DC V”)

Utiliser l’échelle du milieu, qui se trouve juste audessous du echelle de résistance. Mettre le

sélecteur sur la position correspondant au

nombre le plus élevé de l’échelle. Si le réglage

ne correspond à aucun des nombres, utiliser

une échelle pouvant être facilement multipliée

(par ex., pour 500 V utiliser l’échelle 50 V, puis

multiplier la mesure par 10).

Tension c.a. (“AC V”)

Utiliser les mêmes nombres et procédures que

pour la tension c.c., mais consulter l’échelle qui

se trouve directement au-dessous des nombres.

Milliampères c.c.

Utiliser la même échelle et les mêmes

procédures que pour la mesure de tension c.c.

Gain en décibels (dB) (Voir page 46)

Utiliser l’échelle marquée dB pour la mesure

des décibel le gain des transistors. Consulter

le tableau à la droite de l’échelle pour la

conversion correcte.

3.2 Etat de la pile interne

Avant d’effectuer des contrôles de résistance ou

de continuité, vérifier l’état de la pile interne. Tout

d’abord, mettre le sélecteur fonctions/gammes

sur la gamme d’ohms Rx1.Toucher l’une des

sondes avec l’autre : l’aiguille doit basculer vers la

droite de l’échelle. Garder les sondes en contact

et tourner la molette de réglage du zéro jusqu’à

ce que l’aiguille se trouve sur le zéro du côté droit

de l’échelle des ohms (verte). Lorsqu'une aiguille

ne se centre pas sur le zéro, remplacer la pile par

une pile neuve 1,5 volt de format AA non

rechargeable (voir

Remplacement de la pile

).

Echelle de

résistance

(ohms)

Echelle de

tension c.c. et

de milliampères

Graduations

communes des

gammes de

tension c.a. et c.c

Echelle de

tension c.a.

Echelle dB pour

mesure de gain

de transistor

}

Testeur de pile

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 40

Page 22

42

41

4. Mesure de tension c.c.

1) Insérer les connecteurs des fils de sonde à

fond dans les jacks d’entrée appropriés : (-)

fil noir, (+) fil rouge.

2) Mettre le sélecteur fonctions/gammes sur

la gamme de tension c.c. voulue. Si la

tension est inconnue, utiliser la gamme la

plus élevée. Si la tension appliquée se

trouve dans une gamme inférieure, mettre

le sélecteur fonctions/gammes sur la

valeur permettant la plus grande précision.

3) Si la polarité du circuit à tester est connue,

toucher le côté neutre avec la sonde noire.

Si elle est inconnue, mettre les sondes

d’essai en contact avec les côtés opposés

du circuit. Si l’aiguille oscille vers la gauche

de l’échelle, inverser les sondes d’essai.

Utiliser le tableau ci-dessous comme guide pour

l’interprétation des mesures de tension c.c. :

10 0-10 1

50 0-50 1

250 0-250 1

500 0-50 10

4.1 Piles d’usage domestique

Pour tester les piles d’usage domestique de

1,5 à 9 volts, mettre le sélecteur

fonctions/gammes sur 10 “DC V”. Mettre la

sonde d'essai rouge (+) en contact avec la

borne (+) de la pile, et la sonde d'essai noire

(-) en contact avec la borne (-) de la pile.

Consulter l’échelle de 0 à 10 V pour

déterminer l’état de la pile.

5. Mesure d’intensité c.c. (mA)

1) Enfoncer les fils d'essai entièrement dans

les prises d'entrée appropriées, (-) fil noir,

(+) fil rouge.

2) Régler le commutateur fonction/plage au

réglage 250 CC mA.

3) Appliquer les fils d'essai au circuit en

séries (en ligne avec le circuit) afin que le

courant passe par le multimètre pour que

la mesure soit prise. Si l'aiguille de

l'indicateur fléchit vers la gauche, inverser

les fils d'essai.

250 0-250 1

Mesures courantes d’intensité c.c.

(en mA)

Un milliampère est un millième d’ampère, par

conséquent, 250 milliampères représentent

250 millièmes d’ampère. La fonction 250 mA

du multimètre est couramment utilisée par les

techniciens en électronique et les bricoleurs

pour contrôler divers circuits à basse tension.

Bien qu’elle ne soit pas normalement utilisée

pour le contrôle des circuits électriques

résidentiels, cette fonction permet de

mesurer l’appel de courant (en milliampères)

d’articles ménagers tels que des lampes de

poche et autres appareils fonctionnant sur

piles ne consommant pas plus de 250 mA.

Dans la figure 2, la sonde rouge (+) est

connectée sur la borne (+) de la pile de la

lampe et la sonde noire (-) sur l’ampoule. Le

multimètre indique alors l’appel de courant

Gamme de

tension V

Lire l’échelle

suivante

et multiplier la

mesure par :

Réglage de la

plage CC mA

Lire l’échelle

suivante

et multiplier la

mesure par :

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 42

Page 23

44

43

lorsque l’interrupteur de la lampe est en

position de MARCHE.

Ne pas appliquer de

tension sur les sondes lorsque le multimètre est

en gamme de milliampères.

Voir Sécurité

n° 8.

6. Mesures de tension c.a.

1) Enfoncer les fils d'essai entièrement dans

les prises d'entrée appropriées, (-) fil noir,

(+) fil rouge.

2) Mettre le sélecteur fonctions/gammes sur la

gamme de tension c.a. appropriée. Si la tension est inconnue, utiliser la gamme la plus

élevée. Si la tension appliquée tombe dans

une gamme inférieure, mettre le sélecteur sur

la position appropriée afin d’obtenir une

précision maximum.

3) Mettre les sondes en contact avec le circuit

testé. Avec la tension c.a. la polarité des sondes est sans importance.

Utiliser le tableau ci-dessous comme guide pour

l’interprétation des mesures de tension c.a. :

10 0-10 1

50 0-50 1

250 0-250 1

500 0-50 10

Mesures courantes de tension c.a.

6.1 Prises murales

Si la prise est commandée par un

commutateur, s’assurer que ce dernier est en

position MARCHE. Régler le sélecteur

fonctions/gammes sur 250 “AC V”. Mettre les

sondes d'essai en contact avec les fentes

“sous tension” et “neutre” de la prise (voir fig.

3A). L’aiguille doit indiquer 120 V c.a. sur

l’échelle de 0 à 250. Pour s'assurer que la prise

est correctement mise à la terre : mettre une

sonde d'essai en contact avec la fente “sous

tension” (étroite) de la prise, et l'autre en

contact avec la fente de terre. Le multimètre

doit indiquer 120 V c.a., comme

précédemment.

7. Mesures de

résistance/continuité

Pour les mesures de résistance et de continuité,

l’appareil testé DOIT ETRE HORS TENSION.

1) Enfoncer les fils d'essai entièrement dans

les prises d'entrée appropriées, (-) fil noir,

(+) fil rouge.

2) Mettre le sélecteur fonctions/gammes sur la

gamme d’ohms appropríe et mettre les

sondes en contact l’une avec l’autre.Tourner

lentement la molette de réglage du zéro

jusqu’à ce que l’aiguille se trouve sur le zéro

à l’extrémité droite de la gamme d’ohms.

Lorsqu'une aiguille ne se centre pas sur le

zéro, remplacer la pile par une pile neuve

1,5 volt de format AA non rechargeable (voir

Remplacement de la pile

).

3) Mettre les sondes d’essai en contact avec la

résistance ou le circuit hors tension à tester.

Relever la valeur mesurée sur l’échelle

d’ohms verte et la multiplier par 1/10/100.

Figure 2

!

AVERTISSEMENT

Gamme de

tension c.a.

Lire l’échelle

suivante

et multiplier la

mesure par :

Figure 3

3A

3B

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 44

Page 24

46

45

Dans le cas de tests de continuité

élémentaires, l’aiguille doit aller jusqu’à

l’extrémité droite de l’échelle d’ohms si la

continuité existe.

Remarque : lors du passage de la gamme

d’ohms à une autre fonction ou vice versa,

toujours régler l’aiguille sur le zéro avant de

prendre une autre mesure. Si l’aiguille n’est pas

remise au zéro avant de prendre une mesure

de résistance/continuité, le résultat sera inexact.

Le contrôle de la continuité de circuits

électriques est probablement la plus courante

des opérations de dépannage domestique. NE

JAMAIS OUBLIER QU'UN TEL CONTROLE

NE DOIT ETRE EFFECTUE QU'APRES MISE

HORS TENSION DU CIRCUIT. Pour les

contrôles de continuité, la polarité des sondes

d'essai n'entre pas en ligne de compte.

7.1 Rallonges

Débrancher la rallonge. Mettre le sélecteur

fonctions/gammes sur la gamme d’ohms Rx1.

Mettre une des sondes d'essai en contact avec

l'une des broches de la rallonge et insérer

l'autre dans une des fentes de la prise, à l'autre

bout de la rallonge, en s'assurant que les deux

fils soient bien en contact (voir fig. 4). Si l’aiguille

ne se met pas sur -0- ohm, insérer la sonde

dans l’autre fente en veillant à nouveau à

obtenir un bon contact. Si l’aiguille ne bouge

toujours pas, il existe une rupture dans la

rallonge et celle-ci doit être remplacée.

7.2 Fusibles

Remarque : après avoir coupé l'alimentation,

toujours retirer un fusible de sa douille avant

de le vérifier. Pour les fusibles à cartouche,

mettre les sondes d'essai en contact avec

chaque extrémité du fusible (voir fig.5). Si le

fusible est en bon état, l’aiguille doit indiquer -0ohms. Si ce n’est pas le cas, remplacer le fusible.

Pour les fusibles bouchon, mettre une sonde

d'essai sur le contact inférieur et l'autre, sur le

contact fileté métallique (voir fig. 6).

7.3 Commutateurs

Couper l'alimentation du circuit que commande

le commutateur.Au besoin, retirer le

commutateur.Le mettre en position de

MARCHE et mettre les sondes d'essai en

contact avec ses bornes (voir fig. 7). Si le

commutateur est en bon état, l’aiguille doit

indiquer -0- ohms. Si ce n’est pas le cas,

remplacer le commutateur.

8. Mesure des décibels

La fonction de décibels de ce multimètre

permet de mesurer le gain des transistors de

circuits électronique, ce qui n’a rien à voir

avec la mesure de niveau acoustique. Cette

fonction est principalement utilisée par les

techniciens en électronique pour mesurer le

gain des transistors et elle est rarement

utilisée pour les projets domestiques.

Figure 4

Figure 6Figure 5

Figure 7

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 46

Page 25

48

47

1) Enfoncer les fils d'essai entièrement dans

les prises d'entrée appropriées, (-) fil noir,

(+) fil rouge.

2) Mettre le sélecteur fonctions/gammes sur

l’une quelconque des gammes de tension

c.a. et lire la valeur en décibels sur

l’échelle (rouge) du bas du cadran. Selon

la gamme de tension c.a. choisie, il sera

nécessaire de calculer la valeur réelle en

utilisant le tableau de conversion se

trouvant en bas et à droite du cadran.

Important : pour les mesures absolues de

décibels, l’impédance du circuit doit être d’au

moins 600 ohms. -0- décibels = 1 milliwatt à

une impédance de 600 ohms (équivalente à

0,775 volts sur 600 ohms).

9. Piles d’usage domestique

Les piles pour usage domestique peuvent être

vérifiées l'une de deux façons. Pour vérifier l'état

de la pile, régler l'interrupteur fonction/champ au

réglage 1,5 V ou 9 V BAT selon le type de pile à

vérifier. Enficher le fil d'essai rouge dans la prise

marquée " V.Ω.A.". Appliquer le fil d'essai

rouge (+) sur la borne (+) de la pile et le fil noir (-)

sur la borne (-) de la pile. Lire l'échelle BAT tout

au bas de la plaque d'échelle. L'échelle indiquera

si la pile est bonne, douteuse ou à remplacer.

Afin de mesurer la valeur de la tension de piles

pour usage domestique, régler l'interrupteur de

fonction/champ à 10 VCC et appliquer les fils

sur la pile comme indiqué ci-haut. Lire l'échelle 0

à 10 afin de déterminer l'état de la pile.

10. Remplacement de la pile et du

fusible

1) Retirer la vis du couvercle arrière et le

séparer avec précaution du devant du boîtier.

2) Noter la polarité de la pile avant de la retirer

de son logement et de la remplacer.

3) Utiliser les fusibles de rechange num

éro de

catalogue GB GF-0306

.

4) Remettre le couvercle arrière en place, avec

précaution. Ne pas trop serrer la vis pour ne

pas abîmer le filetage du boîtier du multimètre.

11. Garantie

GARANTIE_DE_UN_AN

limitée seulement à la

réparation ou au remplacement; aucune

garantie d’aptitude à la commercialisation ni à

un usage particulier. Ce produit est garanti être

exempt de défaut de matériau et de fabrication

pour sa durée de vie normale. Gardner Bender

n'assume aucune responsabilité pour les dommages indirects ou accessoires.

12. Façon appropriée de jeter ce

produit

Cette marque indique que ce produit

ne doit pas être jeté avec les autres

ordures ménagères dans les pays de

l’UE. Afin de prévenir les dommages à

l'environnement et la santé humaine

causés par une mise aux rebuts incorrecte,

veuillez le recycler de manière responsable

afin de promouvoir l’utilisation durable des

ressources matérielles. Pour retourner l’appareil usagé, veuillez utiliser le système de

retour et de ramassage ou contactez le détaillant de qui vous avez acheté le produit. Il sera

en mesure de reprendre ce produit et de le

recycler de façon écologique et sécuritaire.

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 48

Page 26

Gardner

Bender

Milwaukee, WI 53209

Questions or comments 800.624.4320

www.gardnerbender.com

Made in China/Hecho en China/

Fabriqué en Chine

GMT-318 6-09 manual.qxp 6/8/09 2:03 PM Page 50

Loading...

Loading...