Page 1

1

Gardner

Bender

Powered Cable Pullers

CP800, CP8000, CP8000D

CP8003, CP8006

Instruction

Sheet

IMPORTANT: RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

If any shipping damage is found, notify carrier at once.

Shipping damage is NOT covered by warranty. The

carrier is responsible for all repair or replacement

costs resulting from damage in shipment.

Do not use broken or damaged cable puller component parts.

Damaged parts can cause structural weakness resulting in failures

at loads below rated capacity.

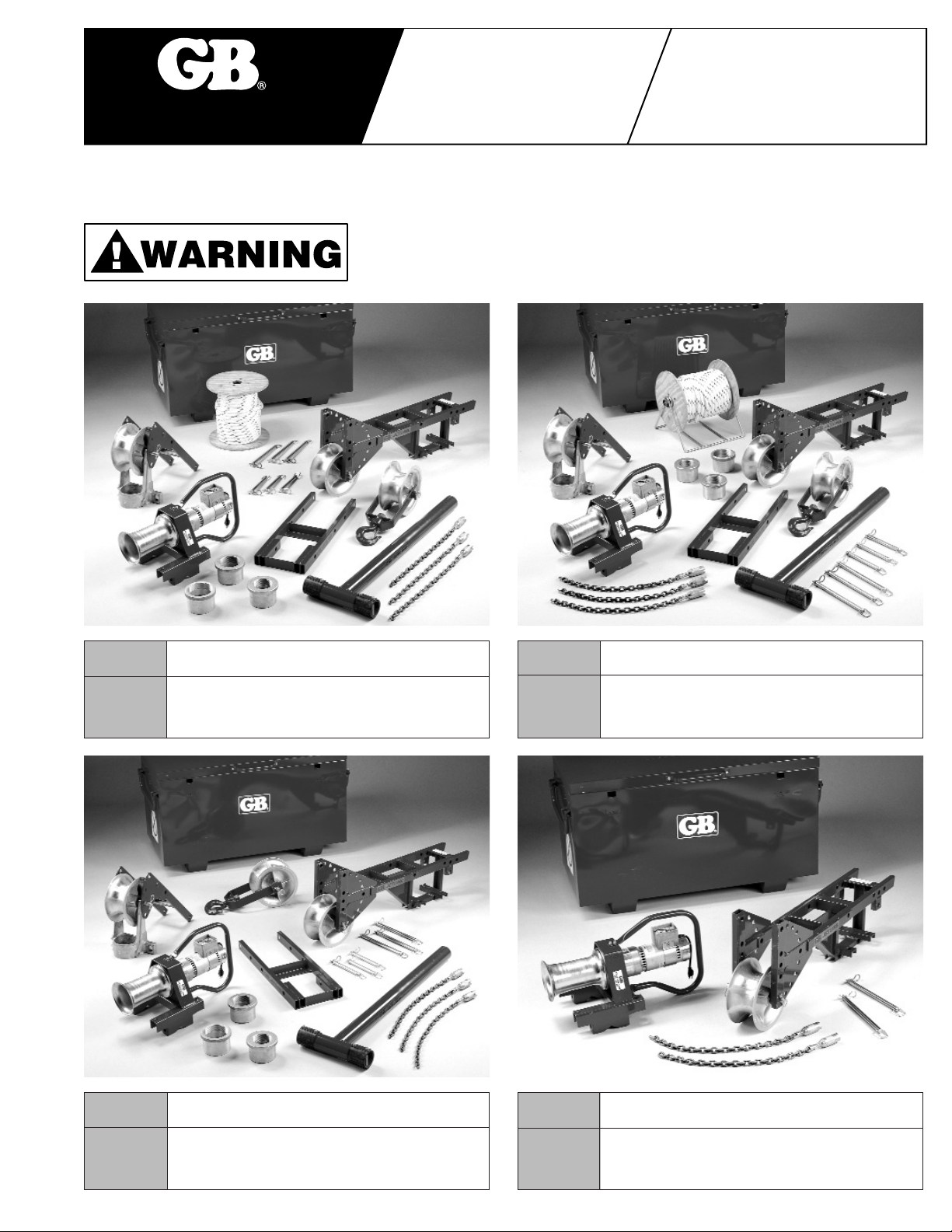

CATALOG

NUMBER DESCRIPTION

CP8006 Brutus™ Power Puller – with 600’ rope; for

exposed or concealed conduit (Wt: 495 lbs.).

Includes metal case with casters (Cat. #CM16).

CATALOG

NUMBER DESCRIPTION

CP8003 Brutus™ Power Puller – with 300’ rope; for

exposed or concealed conduit (Wt: 440 lbs.).

Includes metal case with casters (Cat. #CM16).

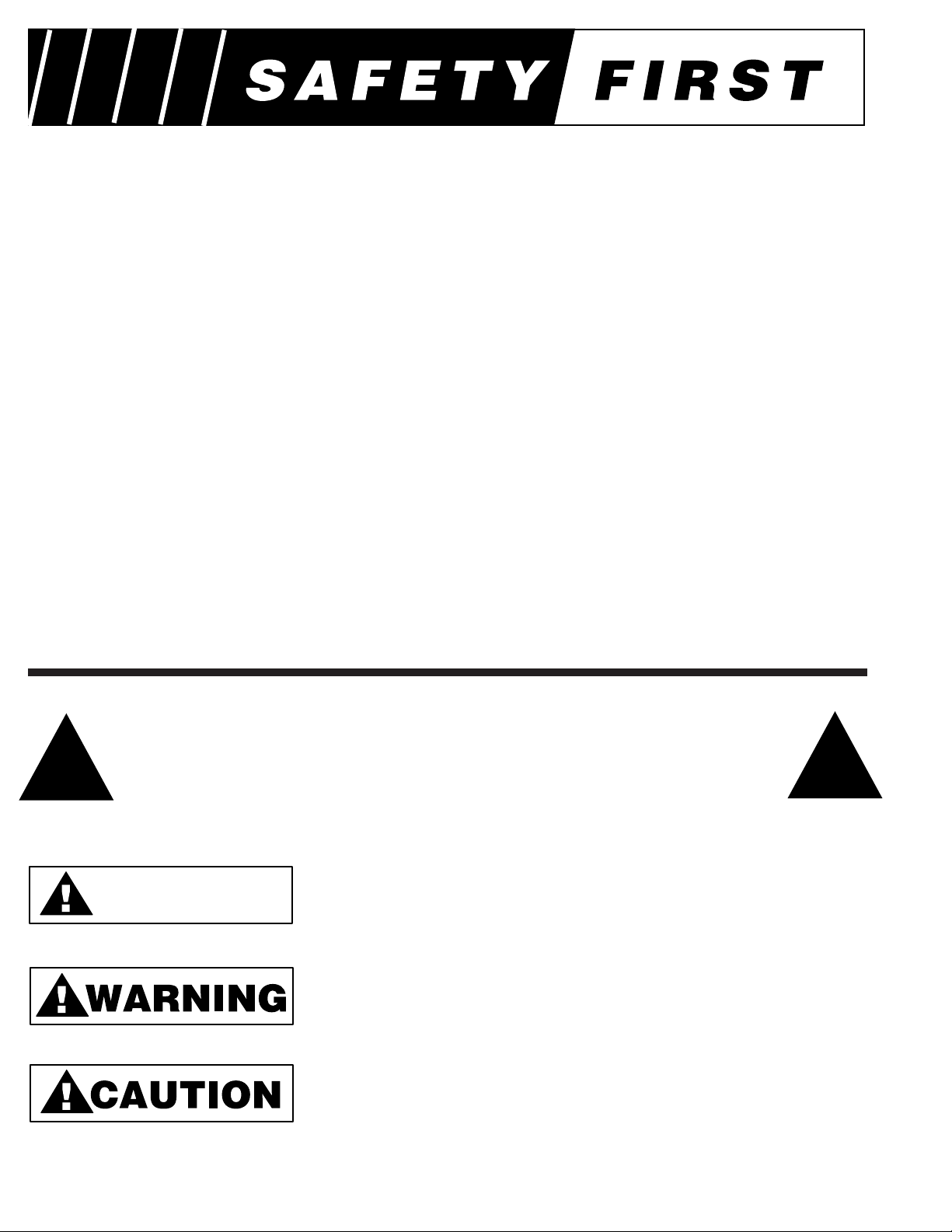

CATALOG

NUMBER DESCRIPTION

CP8000 Brutus™ Power Puller – for exposed or

concealed conduit (Wt: 235 lbs.).

Includes metal case with casters (Cat. #CM16).

CATALOG

NUMBER DESCRIPTION

CP8000D Brutus™ Power Puller – for exposed conduit

(Wt: 355 lbs.). Includes metal case with casters

(Cat. #CM16).

Page 2

2

!

!

DANGER

IMPORTANT - USER SAFETY AND PROTECTION: In setting up systems, take care to select the

proper components and design to insure appropriate integration with your operations and

existing equipment. Observe all safety measures to avoid the risk of personal injury and

property damage from your application or system.

GB ELECTRICAL CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY

UNSAFE USE, MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact GB

Electrical for guidance when you are in doubt as to the proper safety precautions to be taken

in designing and setting up your particular application.

INTRODUCTION

GB Electrical produces three different models of cable pullers. Each version uses the CP800 power

head assembly. Differences between models are based on the accessories included with each model

or the length of rope provided with the cable puller. Since the same CP800 power head is part of

each model, the instructions and safety information apply to all uses of GB powered cable pullers.

Cable pulling encounters a wide variety of situations and materials. Because of that variety, it is not

possible to provide instruction that applies to each unique situation. Principles presented here provide

as much general assistance as possible. Assembly instructions are specific. Follow them precisely to

ensure safe, reliable and effective cable puller installations.

All instructions are important, but safety is paramount during pulling. Safety alert symbols are located

throughout this manual, and a separate section is included to identify specific safety concepts.

Before operating the GB cable puller, read and understand this entire manual. If you do not

understand any area or subject, contact GB Electrical, Inc. at 1-414-352-4160 or 1-800-624-4320.

Ask for Technical Services.

SAFETY ALERT SYMBOLS

The symbol to the left is used in conjunction with a danger, warning or caution

statement. It alerts operators, supervisors and all personnel that safety

precautions are required during specific situations and under specific conditions.

Failure to comply with safety data could result in serious injury or death.

This symbol indicates a high probability that death, severe injury or

major property damage could result.

This symbol indicates serious but less probability that death,

severe bodily injury or major property damage could result.

This is a less serious alert but still demands attention to detail. It

indicates a hazard that may cause minor injuries.

Page 3

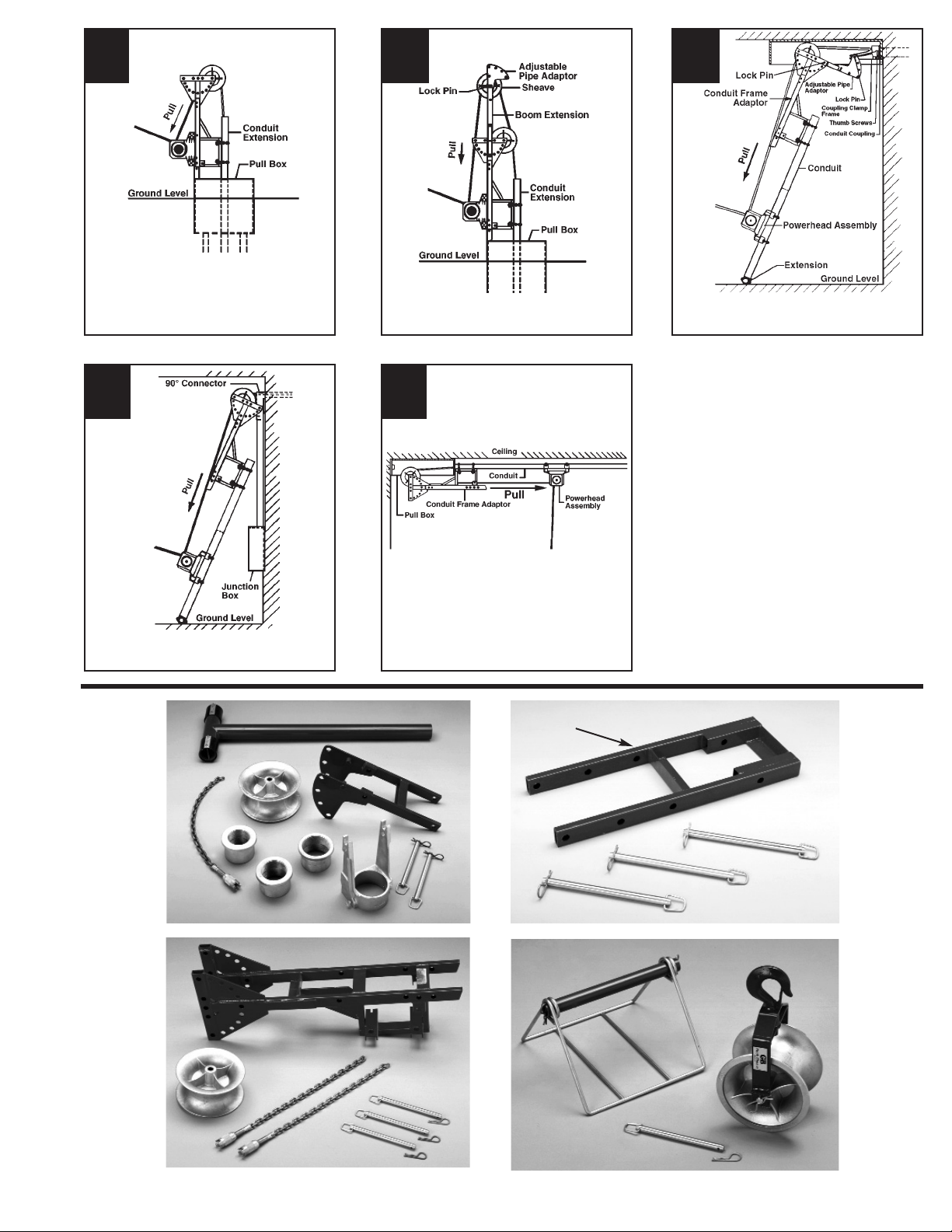

15

21 22 23

24 25

Conduit frame adaptor chained to conduit

extension in pull box-- pulling vertically

from underground.

Use boom extension to obtain

extra cable length for splicing

Conduit frame adaptor and power head

assembly chained to conduit (over

extension) pulling down from box on ceiling.

Pulling from 90° connector to obtain

leads long enough to complete

connection in junction box

Conduit frame adaptor and power head

assembly chained separately to conduit,

pulling from a ceiling pull box for

additional cable.

CP1002

CP505

HS8512

CP601

CP505 (3)

CP701

S8512

CP703

CP505 (2)

CP708

CP601

CP505 (3)

CP503

S8512

CP600

CP702

CP707

CP503

Refer to Contents Chart on page 16 for puller set components.

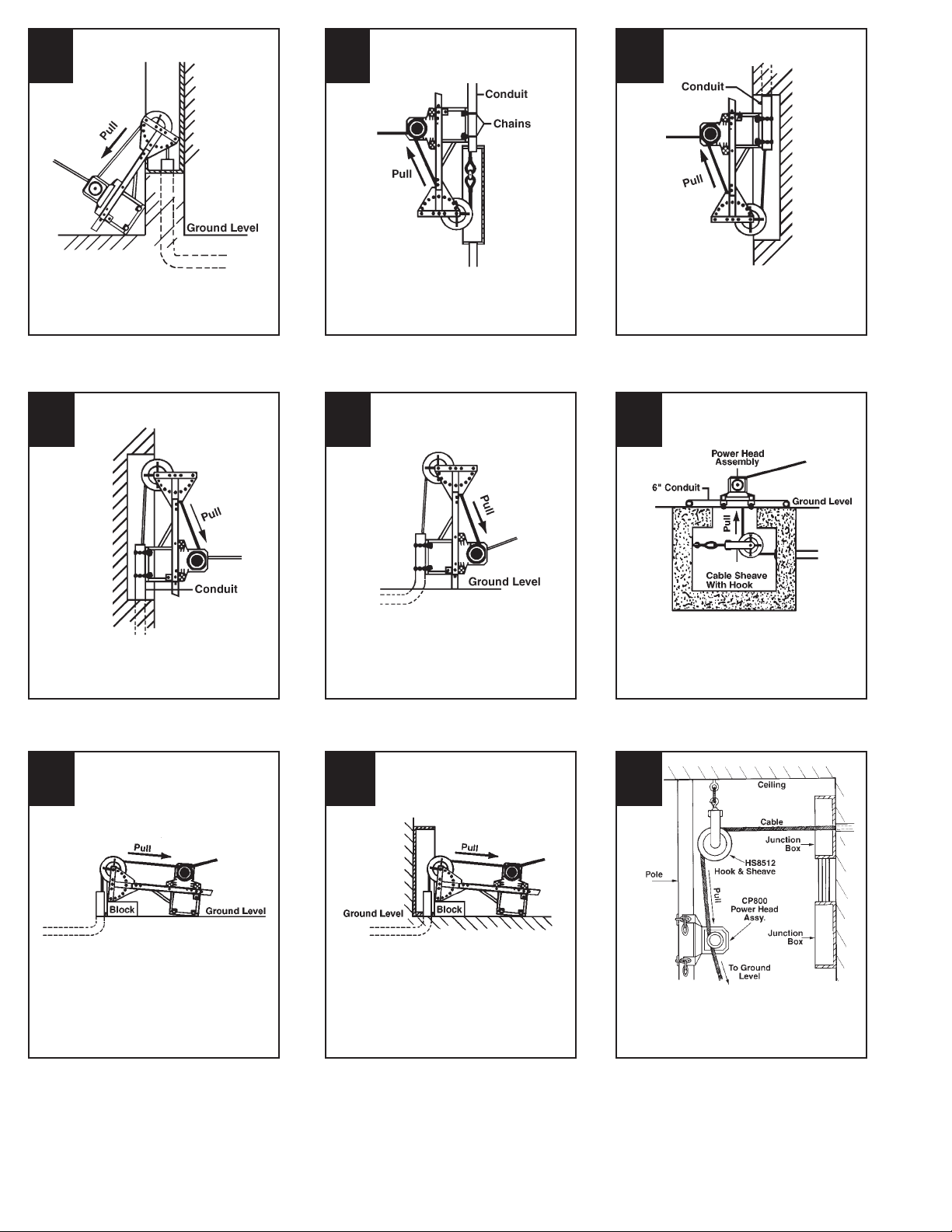

Page 4

14

12 13 14

15 16 17

18 19 20

Conduit frame adapter resting on floor

and on back of box -- pulling up

Conduit frame adapter chained to

exposed conduit -- pulling down

Downward pull -- conduit frame adapter

chained to conduit extension

Upward pull -- conduit frame adapter

chained to conduit extension

Conduit frame adapter chained to conduit

-- pulling up

Resting conduit frame adaptor on floor

over conduit and pulling up

Resting conduit frame adaptor on floor

and blocks over conduit and pulling up

Pulling additional cable from junction box

(1) down to junction box (2) using cable

sheave with hook and power head

assembly chained to pole.

Power head assembly chained to 6”

conduit with two 90° bends pulling from

underground conduit using cable

sheave with hook

Page 5

3

DANGER

DANGER

DANGER

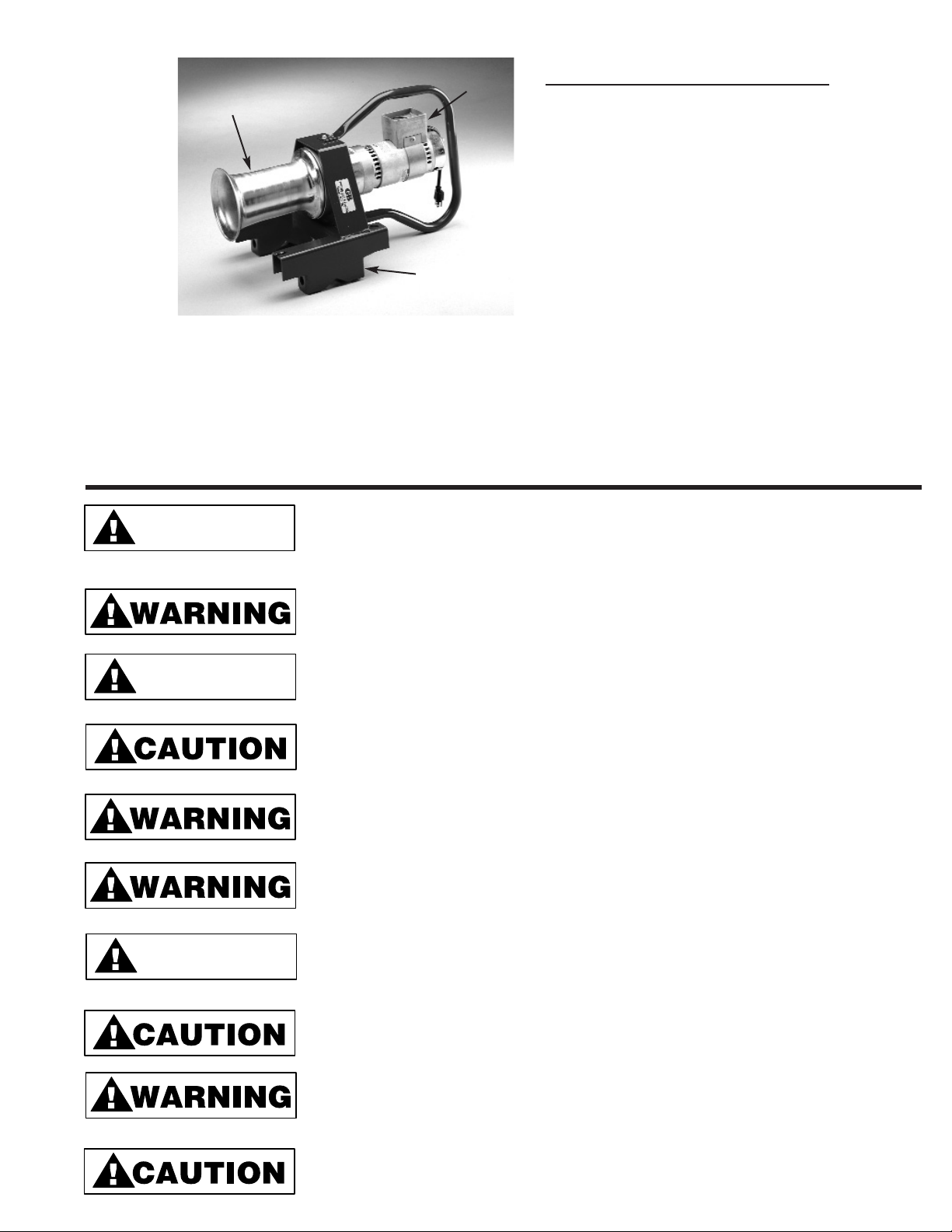

CP800 Power Head with Bracket

• 120 VAC 50/60 HZ rectified to D. C.

• 15 AMP - Start Up

• 5 AMPS @ No Load

• 5.5 AMPS per 1,000 lbs.

• Max. 20 AMPS @ 8,000 lbs.

• Permanent Magnet Motor

• Weight 65 lbs.

• Maximum Pulling Capacity - 8,000 lbs.

• Capstan - 12 R.P.M.

• On-Off Toggle Switch

• 3-Prong Grounded Power Cord

• Non-Reversing Capstan

• Load Meter

The powered cable puller CP800 and its accessories are designed specifically

for pulling electrical cable through conduit or across cable trays. GB does not

recommend pulling any other objects or materials. Using this unit for any other

pulling or lifting activity could result in serious injury or death.

Operate the Cable Puller only in well lighted areas.

All pull set-ups must be approved by qualified supervisors. Follow all safety

precautions and wear appropriate safety clothing.

Keep the pull rope away from the operator’s feet. Coil the tailing rope in an area

where the operator cannot become entangled.

Never stand directly under a vertical pull. Do not stand directly in front of a pull

rope under tension. The operator must stand at an angle to the capstan. Keep all

other personnel away from the cable puller.

Inspect all cable puller components prior to pulling cable. Never use worn or

damaged parts or accessories.

Never use general purpose rope. Use only GB double braided polyester, 3/4”

diameter rope. All rope must have a working load of 8,000 lbs. minimum.

Rope that breaks under tension may recoil, causing serious injuries and property

damage.

After each pull, inspect the rope for abrasion and cuts in the strands. Do not use

damaged rope for pulling cable.

SPECIFICATIONS

Power Cable Puller CP800

Figure 1

SAFETY PRECAUTIONS

Do not allow pull rope to wrap around the legs, arms or torso of anyone. A quick

release of the rope will cause severe injuries.

Cable puller models CP800, CP8003, CP8006 and CP8000D plus accessory

items are rated at 8,000 lbs. maximum pulling force. Attempts to exceed 8,000

lbs. could result in severe injury, death and major property damage.

CP806

CP10

CP802

Page 6

4

Always choose a strong, durable rope

with limited elasticity and long service life.

When selecting and using a rope it is

essential to choose the proper size and

type for each job need. The material,

tensile strength and recommended

working load are critical factors.

Polyester ropes such as Tuff Pull™ and

Super Tuff Pull™ are preferred for cable

pulling because of their low elasticity, high

strength and endurance as compared to

other types of rope.

• Working load rating represents the

maximum pulling load to which the rope

should be subjected. It increases with rope

diameter and is calculated for rope in good

condition with appropriate splices under

normal service. Note that working load

guidelines are void under conditions of rapid

or sudden load changes.

• Tensile strength is the average breaking

point of new, unused rope. While it gives

some indication of the rope’s ability to

withstand sudden or shock loads, tensile

strength decreases over time as the rope is

used and should

not

be relied upon as an

indication of working strength.

All synthetic rope under load will recoil if it, or a fitting

(chain, hook, bolt, etc.) fails. The snap-back action will

propel the rope – and any still-attached metal fittings –

at high speed. Serious injury to persons or property in

the vicinity is possible.

Always check all fittings, splices, connectors,

etc. before using rope.

Do not allow anyone to stand directly in line with

rope under tension!

Avoid using rope that shows signs of wear, such as

frayed ends, broken yarns or pulled strands. Open the

strands of braided rope and look for powdered fiber, a

sign of internal wear. When fibers show wear, the rope

should be respliced or downgraded. A heavily-used

rope will often become compacted or hard, a sign of

reduced strength. If in doubt, destroy the used rope

and replace it.

Do Not Overload the Rope

Reverse the rope, end-for-end, between uses. Also,

alternate the lay of the rope around capstan and

sheaves from job to job.

Repeated hauling of a line over a capstan in a

counterclockwise direction changes the twist of each

strand, causing hockles or backturning that cannot be

removed. Repeated clockwise hauling stiffens the rope

and causes it to kink easily.

Rough surfaces and sharp edges can severely damage

rope. Do not pull rope over sharp bends or angles.

Make sure chocks, capstans, sheaves and pulleys are

free of burrs and rust and rotate freely.

Keep the rope surface clean. Do not drag it over rough

ground; dirt and grit will work into and cut inner fibers.

Line of Pull

Avoid damaging storage and use conditions that can

weaken rope:

• Store rope in a clean, dry area. Keep coils off

dirt or concrete floors. Instead, store it in wellventilated racks.

• Keep rope away from chemical contact or fumes.

Solvents, acids and alkalis can damage rope,

especially natural fibers.

• Avoid exposing rope to excessive heat (in

excess of 140° F) in either use or storage. Heat

weakens rope, even after it has cooled. Also, avoid

friction heating caused by slippage around winches

or sheaves.

Observe Recommended Practices for Safe

Handling and Proper Care of Pulling Rope.

Handle loads slowly and smoothly to avoid sudden

strains or shock loads, which can exceed the rope’s

breaking strength. Such “dynamic loading” occurs

when a load is picked up, stopped, moved or swung,

and may subject the rope to two or three times its

normal working load. The affect is greater on lowelongation types of rope and on shorter lengths of

rope, although high-elongation ropes can recoil

dangerously if broken.

Vary Rope Application to Distribute Wear Evenly

Avoid Abrasive Conditions

IMPORTANT!

Store Rope Properly

If a Rope Breaks Under Tension,

it Can Recoil Causing Serious Injury!

Inspect Rope Thoroughly Before Use

Strength

Elasticity

Super Tuff™

and Tuff Pull™

PolyPro

Nylon

Super Tuff™

and Tuff Pull™

PolyPro

Nylon

Select the Right Rope

for the Job.

Danger Zone

Page 7

13

3 4 5

6 7 8

9 10 11

Puller suspended using horizontal pull

Puller suspended using vertical pull

Vertical - pulling up

Underground pulling

Conduit frame adapter with sheave

chained to exposed conduit

Power head assembly being attached to

conduit frame adapter using two lock pins.

Pulling up cable with conduit frame

adapter chained to exposed conduit --

mounted flush

Conduit frame adapter chained to conduit

(over the extension resting on floor)

pulling down

Coupling slipped into conduit. Coupling

clamp locked to coupling with two

thumb screws

Page 8

12

The Power Head capstan rotates in one direction only and

is non-reversing; it will not reverse under load or when the

power is off.To make your pulls easier, it is recommended

that you fully wrap the capstan with rope.

Figure 16

Do not stand directly in line with rope under tension. The

operator must be positioned far enough to one side that

injury will not occur if rope or other components should

break.

Before actually using your puller, review the following 26

pictures showing the versatility of and suggested

applications for the GB Electrical Powered Cable Puller.

These same pictures are also on the inside cover of the

metal storage case for ready reference in the field.

If the Power Head is used in other than its normal installed

position (See figure 16) the rope must be wound on the

capstan in the opposite direction.

Rope:

The use of a 3/4” diameter double braid 100% polyester

rope is recommended – such as GB’s 300’ reel of 3/4”

diameter polyester rope (RST7530 -- white rope with a

red streamer). For assistance in pay out of the rope, use

a CP1002 Rope Reel Stand.

1

2

Different positions

Pulling horizontally

Page 9

The chains are also used for mounting the CP800 and CP601 to another object.

5

OPERATION

Cable Puller Components

I. CP800 Power Head

The power head consists of an electric DC motor rectified for AC current. The motor is mated to a

3-stage planetary gear drive system. Attached to the motor are the on/off switch, load meter and power cord.

At the gear drive output end is a capstan for rope.The entire power head assembly is bolted to a steel

bracket assembly. Maximum pulling capacity is 8,000 lbs. Power source requires 120VAC, 50/60 HZ and a

20 AMP circuit.

Avoid motor overheating during cable pulls. For pulls in excess of

4,000 lbs., stop motor, tie off rope, and let motor cool for five to seven

minutes. Use load meter to constantly monitor pulls. Sudden spikes or

jumps in pull forces indicate increased friction. The load meter is

calibrated in 1,000 lb. increments. Color coding provides a quick

reference of what pull range is being shown. Green 0 - 4,000 lbs;

Yellow 4,000 - 8,000 lbs; Red 8,000 - 10,000 lbs.

Immediately stop any cable pull during which the load meter registers in

the red zone. Do not operate puller when pull requires more than

8,000 lbs. of pulling force. Cable puller and accessories are rated for a

maximum of 8,000 lbs. pull force.

The CP800 power head assembly can be used alone or in conjunction with a variety of accessories. For

recommended set-ups, refer to the illustrations at the end of this instruction manual.Virtually every cable pull

has unique differences. Due to the differences, it is not possible to show every set-up. However, the principles

of cable pulling will be explained and each set-up must apply the principles correctly to avoid dangerous

situations.

Use only the mounting chains CP503 or CP504 to attach the power head

to accessories and fixed supports. Using any other chain could cause the

power head to stretch the chain, loosen or move. A loose or stretched

chain could cause injury, death or property damage.

Mounting the power head to another accessory is accomplished using two chains (CP503 or CP504) or

two CP505 eight-inch anchor pins. The pins are designed for mounting CP800 to the CP601 frame adaptor.

See figure 2.

DANGER

II. Power Head Installation

CP601

CP800

CP800

CP601

CP503

Figure 2

CP505

Fixed

Support

Page 10

1.

Secure the power head to a fixed support

that is capable of withstanding 8,000 lbs. of

pulling forces in the direction of the pull line

on the capstan. See figure 4.

2.

Position the puller using a supporting

structure that directs the forces of the pull

parallel to or into the supporting structure.

Do not pull directly against the mounting

chains.

3.

Mounting chains are limited to obstacles

from a minimum of 2” diameter to a

maximum of 10” diameter.

6

Tighten chains securely. The hand grips are slotted to accept a

screwdriver shank, wrench handle or flat steel bar. Make certain the chain

stays straight. Avoid side loading the adjusting screw pins. See figure 3.

CP503 Hand Grip Wrenching Slots - Tighten with screwdriver shank, adjustable wrench handle, a piece of flat

steel, or hex socket wrench (allen wrench).

Figure 3

Make sure that the links A are straight

during installation. Avoid side loading

conditions on the pins that connect the chain

to the adjusting screw. This can occur when

directly connecting the CP800 (without puller

frame) to a large column or I-beam.

Wrenching slots:

Tighten with screwdriver shank,

adjustable wrench handle, piece

of flat steel, or hex socket wrench

(allen wrench).

Figure 4

SCREW ADJUSTABLE FLAT

DRIVER WRENCH STEEL

Make sure that the links A are straight during installation. Avoid side

loading conditions on the pins that connect the chain to the adjusting

screw. This can occur when directly connecting the CP800 (without

puller frame) to a large column or I-beam.

Correct position

Incorrect position

Power Head

Frame

Adaptor

CP503

Chains

Page 11

11

Basic Frame to Extension for

Elevated Use. See figure 13.

For elevated pulls, attach the basic frame to the

CP701 extension using 2 (CP503) 2-foot chains.

III. Extension Boom to Basic Puller Frame

Attach the CP631 Extension Boom to the

CP601 Conduit Frame Adapter along with the

S8512 Sheave using a CP622 ten-inch Lock

Pin. Insert (1) CP622 ten-inch Lock Pin thru

CP631 Boom and into the hole pattern of the

CP601 Conduit Frame Adapter to position

the angle of the CP631 Extension Boom.

See figure 12.

IV. Operating Instructions:

The Cable Puller frame is rated for a maximum pull of

8000 pounds.

DO NOT make pulls on the frame in

excess of 8000 pounds.

The CP800 Power Head comes equipped with a load

meter to monitor the actual pulling force. To further

assist monitoring of the load, the load meter is color

coded as follows:

0 to 4,000 lbs. Green Band - Most Average Pulls

4,000 to 8,000 lbs. Yellow Band - Heavy Pulls

To avoid overheating the motor

when making pulls in excess of

4,000 lbs., stop the motor every five

to seven minutes and let it cool or

provide external cooling (i.e. fan).

8,000 to 10,000 lbs. Red Band Do not operate power head in this

load range

.

CP800 Power Head Electrical Specifications

120 V.A.C. 50/60 Hz

Amperes: 15 AMPS for 3500 lbs. Maximum Pulls

20 AMPS for 5000 lbs. Maximum Pulls

30 AMPS for 8000 lbs. Maximum Pulls

ON/OFF Toggle Switch

3-Prong Grounded Power Cord

Non-reversing Capstan

The Power Head is normally attached to the CP601

Conduit Adapter Frame by (2) CP505 Lock Pins.

Note: If Power Head is to be attached to a large

member, such as a utility pole, 2 (CP504) 6 foot chains

are required.

Figure 14

Figure 15

Do not make pulls directly away

from power head. See figure 15.

For correct pulling applications,

see illustrations on pages 12

through 15.

Figure 12

Figure 13

Page 12

B

A

d. Conduit Couplers CP704, CP705, CP706, CP707 and CP708

1). Conduit couplers are used to secure a location for attaching the CP702 adjustable pipe

adaptor. Couplers are threaded onto rigid or I.M.C. conduit with the external flange facing

toward the conduit. See figure 11.

2). The flexible pipe adaptor is to be placed over the coupler until it bottoms against the flange.

Tighten adaptor thumb screws to secure it to the conduit coupler.

3). Two versions of flanges were manufactured. From 1976 to 1988, couplers were long

enough to be inserted into conduit A . A flange separated the larger and smaller sections.

See figure 11. From 1988 to 1996 couplers were manufactured without a threaded section

below the flange B .

10

To avoid injury and damage to equipment, place the coupling clamp over

conduit couplers CP704, CP705, CP706, CP707 or CP708. Do not

attach the coupling clamp to the outside of the conduit using chains or

similar devices.

2). The slots in the coupling frame are designed to engage the trunion studs on CP703 frame

adaptor.To use other angles or gain height, a CP505 8-inch lock pin may be installed

through holes in the frame adaptor.The coupling frame slots can rest under the pin instead

of the trunion studs. See figure 10.

The CP702 Coupling Clamp Frame may be used

two ways on the CP703 Adjustable Pipe Adaptor. It

may be mounted freely against the trunion studs on

the CP703 Adjustable Pipe Adaptor. Or...

It may be pinned securely to any of the location

holes of the CP703 Adjustable Pipe Adaptor, using a

(CP505) 8-inch Lock Pin.

Figure 10

1976-1988

Coupling Design

1988 - 1996

Coupling Design

Figure 11

NOTE: CP702 coupling clamp must always be used with CP703 frame adaptor.

NOTE: CP702 coupling clamp must always be used with CP705 frame adaptor.

CP704 2”

CP705 21⁄2”

CP706 3”

CP707 31⁄2”

4”

CP704 2”

CP705 21⁄2”

CP706 3”

CP707 31⁄2”

4”

Page 13

7

Mounting the cable puller with the mounting chains requires that both

chains be fully tightened in order to have maximum holding power. Loose

chains could cause components to break under load. Broken

components will fly out of control and can cause severe injury, death or

major property damage.

III. Assembling Cable Puller Accessories

The following illustrations are requirements when using various accessories. Follow these procedures prior

to the pull set-ups shown in the diagrams on pages 12-15.

a. Conduit Frame Adaptor - CP601

1) All pull set-ups require the CP601 frame adaptor. The adaptor is used to mount the power head and

pulling sheaves. Some set-ups will also require the CP703 - Adjustable Pipe Adaptor.

2) Position the power head CP800 on the conduit frame adaptor (CP601). Position the power head on

the frame and secure using two 8-inch long pins (CP505). See figure 5.

DANGER

Figure 5

Be sure the mounting pins (CP505) pass through the power head frame

and the CP601 frame. Insert retaining clips in the end of each pin.

3) The combination conduit frame adaptor and power head assembly can be mounted to exposed

conduit or attached to other accessory pieces.

4) For all cable pulls, a 10-inch sheave (S8512) or two sheaves must be installed to direct the pull rope

out of the conduit to the power head. The sheaves can be installed in any of the five holes along the

top of the CP601 frame. One CP505, 8-inch lock pin is required for each sheave.

Do not use exposed conduit as a mounting anchor to pull in opposing

directions. See figure 6. Resulting forces could cause conduit damage

and injuries to operators.

CP800

Power Head

CP505

Pins

CP601

Adaptor

Page 14

5). The CP800 power head can be mounted to the CP601 frame in two ways. The position is

dependent on space constraints. See figure 7.

Capstan rotation is always clockwise (as viewed from end of capstan). If

power head is rotated, pull rope must always be wound from narrow end

toward wide end of capstan to prevent overlap.

Optional Mounting Position of CP800Normal Mounting Position of CP800

8

Figure 6

Rope Conduit

CP800 CP601

Figure 7: In this position, the capstan rotates in the opposite direction; therefore, the rope must be wound in

the opposite direction.

Figure 7

Incorrect Setup Correct Setup

Page 15

9

b. Adjustable Pipe Adaptor CP703.

1) The adjustable pipe adaptor is used with the CP601 conduit frame adaptor. Install by inserting the

CP703 pipe adaptor into the conduit frame adaptor.The legs must be inserted until end hole is

aligned with the hole closest to the frame adaptor cross member. See figure 8.

To avoid damage to the CP703 pipe adaptor, do not mount to the frame

adaptor using the first hole. The two pieces require support by using the

entire length of the frame adaptor opening.

Figure 8

2) Use of the CP703 pipe adaptor also requires the S8512 10-inch sheave for the rope to travel

across. The sheave must be mounted with one CP505 8-inch pin as shown in figure 9. (See figure

12 for optional method.)

To avoid damage to equipment, do not mount sheaves to CP703 using

the holes along the curved frame. The holes on the curvature are used

as alternate locations to attach the frame to the conduit coupler

adaptor CP702 with CP505 pins.

Figure 9

c. Coupling clamp frame CP702

1) Coupling clamp frame CP702 is used to provide a connection between the conduit and the puller

frame. See figure 10.

Page 16

ZRPS-0026 Rev. A 03/07

Model

Quantity Included in Puller Sets

No. Description

CP8006 CP8003 CP8000 CP8000D

CP800 Power Head Assembly 1 1 1 1

CP802 Base Mounting Bracket Included in CP800

CP10 Load Readout Meter & Switch Assembly * * * *

CP15 Foot Switch for Remote Operation * * * *

CP503 2” Chain Assembly 3 3 3 2

CP504 6” Chain Assembly * * * *

CP505 8” Lock Pins 5 5 5 3

CP601 Conduit Frame Adaptor 1 1 1 1

S8512 12” Sheave 2 2 2 1

CP622 10” Lock Pins 3 3 3 *

CP631 Boom Extension 1 1 1 *

CP701 Puller Base Extension 1 1 1 *

CP702 Coupling Clamp 1 1 1 *

CP703 Adjustable Pipe Adaptor 1 1 1 *

CP704 2” Conduit Coupling * * * *

CP705 2 1/2” Conduit Coupling * * * *

CP706 3” Conduit Coupling 1 1 1 *

CP707 3 1/2” Conduit Coupling 1 1 1 *

CP708 4” Conduit Coupling 1 1 1 *

CP709 6” Lock Pin 1 1 1 *

CP806 Capstan * * * *

CP1002 Rope Reel Stand * 1 *

HS8512 12” Cable Sheave with Hook 1 1 1 *

CM-16 Metal Case with CM44 Casters 1 1 1 1

RST7530 Double Braided Rope (3/4” x 300’ Spool) * 1 * *

RST7560 Double Braided Rope (3/4” x 600’ Spool) 1 * * *

Contents of Powered Cable Puller Sets

In order to guarantee maximum performance and safety, use only original GB rope.

* Optional accessories not included in puller sets – can be ordered individually.

WARRANTY: GB ELECTRICAL, INC. warrants its

products against defects in workmanship and

materials for 1 year from date of delivery to user.

Chain is not warranted. Warranty does not cover

ordinary wear and tear, abuse, misuse, overloading,

altered products or use of improper fluid.

WARRANTY RETURN PROCEDURE: When

question of warranty claim arises, send the unit to the

nearest GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our

warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact GB Electrical

(414) 352-4160 for the name of the nearest GB

Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL

Service Center. The Service Center will provide complete and prompt service on all GB ELECTRICAL products.

GB Electrical, Inc.

An Applied Power Company

6101 N. Baker Road, Milwaukee, WI 53209

Phone: (414) 352-4160 FAX (414) 352-2377

Loading...

Loading...